Page 1

Type BBS-03, BBS-05, BBS-06, BBS-25

Sterile connection elements

Sterile Verbindungselemente

Raccords union stériles

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

www.burkert.com

International address

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet: www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet : www.buerkert.fr

© 2013 Bürkert Werke GmbH

Operating Instr uctions 1402/01_EU-ML _00810203 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 2

2

1. THE OPERATING INSTRUCTIONS

The operating instructions contain important information.

• Read the instructions carefully and follow the safety instructions in

particular.

• Keep the instructions in a location where they are available to every

user.

• The liability and warranty for types BBS-03, BBS-05, BBS-06 and

BBS-25 do not apply if the procedures in the instructions are not

observed.

1.1. Symbols

→ designates a procedure which you must carry out.

Warning of injuries:

DANGER!

Immediate danger! Serious or fatal injuries.

WARNING!

Possible danger! Serious or fatal injuries.

CAUTION!

Danger! Moderate or minor injuries.

Warning of damage:

NOTE!

2. INTENDED USE

Non-authorized use of Type BBS-03, BBS-05, BBS-06 and

BBS-25 may be dangerous to people, nearby equipment and

the environment.

• Type BBS-03, BBS-05, BBS-06 or BBS-25 has been designed

as a connection between pipelines for the flow of gases and

liquids in the sterile area.

• Use according to the authorized data, operating conditions, and

conditions of use specified in the contract documents and operating instructions.

• Correct transportation, storage and installation, as well as careful

use and maintenance are essential for reliable and faultless

operation.

• Use the connection elements only as intended.

2.1. Restrictions

If exporting the products, observe any existing restrictions.

2.2. Definitions of terms

The term "connection element" used in these instructions always stands

for Type BBS-03, BBS-05, BBS-06 and BBS-25.

english

3

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Germany

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

Email: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions. And also on the Internet at: www.burkert.com

4.2. Warranty

The warranty is only valid if the connection elements are used as

intended in accordance with the specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Types BBS-03, BBS-05,

BBS-06 and BBS-25 can be found on the Internet at: www.burkert.com

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not take into account any contingencies and

events which may arise during the installation, operation and maintenance

of the connection elements.

Danger – high pressure and discharge of medium!

• Before loosening the lock nut or locking clamp, always turn off the

pressure and vent the lines.

• Wear protective equipment if media is hazardous.

General hazardous situations

• Do not make any internal or external changes to the connection

element.

• Ensure that the system cannot be activated unintentionally.

• Installation and maintenance work may be carried out only by

authorized technicians with the appropriate tools.

• The connection elements may be operated only when in perfect

condition and in consideration of the operating instructions.

• As far as inspection, maintenance and repairs are concerned,

observe national provisions of the country in which the connection

elements are installed.

• The general rules of technology apply to application planning and

operation of the connection elements.

english

4

5. TECHNICAL DATA

5.1. Conformity

The connection elements of Type BBS-03, BBS-05, BBS-06 and

BBS-25 comply with EC Directives in accordance with the

EC Declaration of Conformity.

5.2. Standards (if applicable)

The applied standards which are used to demonstrate compliance with

the EC Directives are listed in the EC type test certificate and/or the

EC Declaration of Conformity.

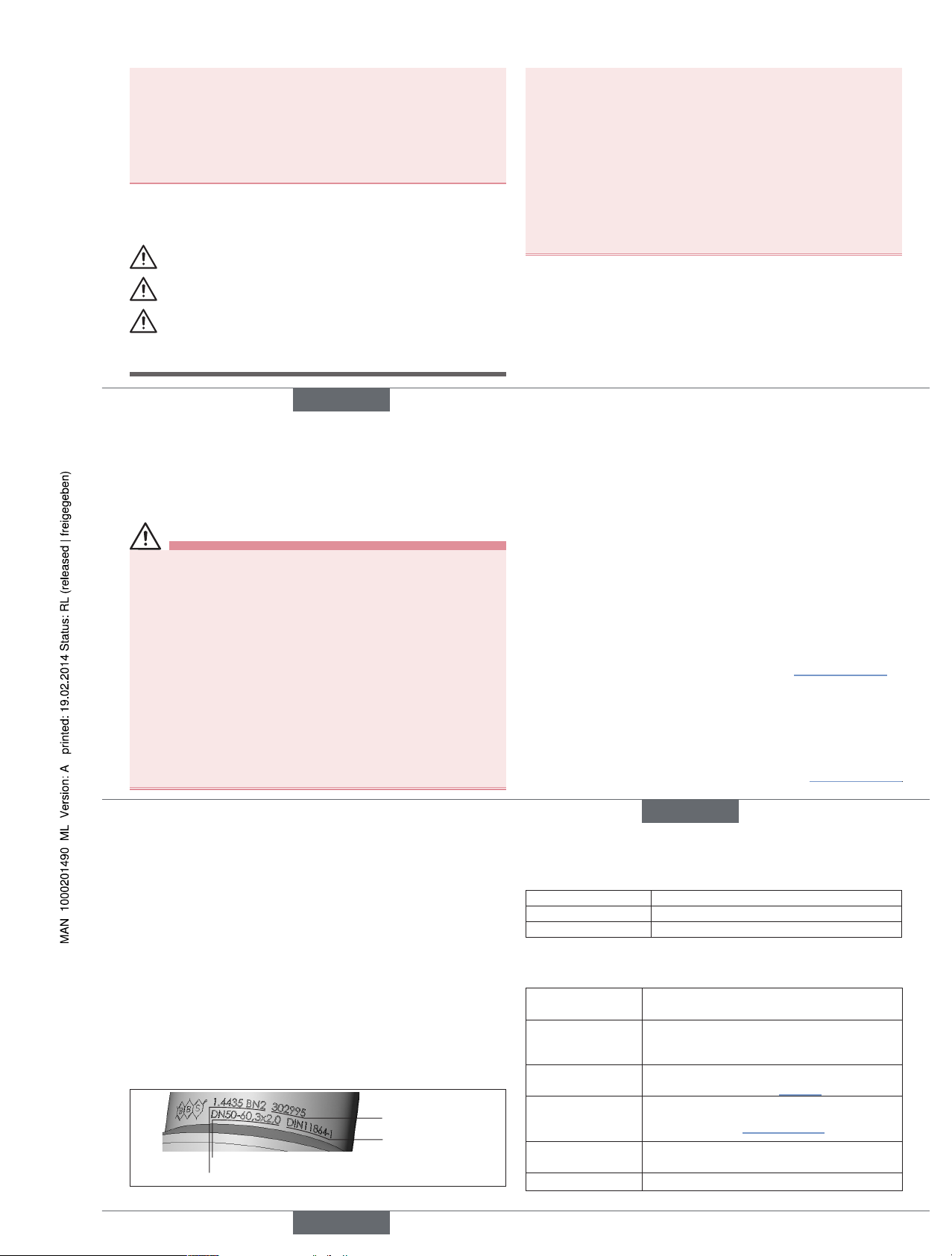

5.3. Identification

Information on material and pipe dimensions can be found on the

stamping on the connection element. The identification number of the

connection element can be found on the supplied 3.1 certificate.

Material

Pipe dimension

Batch number

Standard

Fig. 1: Example of identification of the connection element

5.4. Sealing materials

Seal material Operating temperature

EPDM –40 °C to 90 °C, briefly up 140 °C

FEP -60 °C to 160 °C, briefly up 205 °C

Tab. 1: Material of O-rings (BBS-03, -05, -06) or clamp seal (BBS-25).

5.5. General technical data

Material comes into

contact with medium

Stainless steel 1.4435 BN2 (316L)

Material does not

comes into contact

with medium

Stainless steel 1.4305 or equivalent

Pipe dimensions

See label on connection element

(Example: "Fig. 1")

Permitted

application

temperature

Depending on sealing material,

see "Tab. 1" page 4

Ambient

temperature

–20 °C to +80 °C

Media Gases or liquids

english

Type BBS-03, -05, -06, -25

Page 3

5

5.5.1. Operating pressure

BBS-03, BBS-05 and BBS-06 as sterile orbital connection:

–1 to +16 bar (depending on the temperature).

BBS-03 and BBS-05

according to DIN 11864

BBS-06 according to DIN

11864

ISO DN08 to DN25 = 40 bar

ISO DN32 to DN80 = 25 bar

DIN DN10 to DN40 = 40 bar

DIN DN50 to DN100 = 25 bar

BS-OD DN½" to DN1½" = 40 bar

BS-OD DN2" to DN4" = 25 bar

ISO DN08 to DN25 = 25 bar

ISO DN32 to DN80 = 16 bar

ISO DN100 = 10 bar

DIN DN10 to DN40 = 25 bar

DIN DN50 to DN100 = 16 bar

DIN DN125 to DN150 = 10 bar

BS-OD DN½" to DN1½" = 25 bar

BS-OD DN2" to DN4" = 16 bar

BBS-25 according to DIN 11864

ISO DN08 to DN32 = 25bar

ISO DN40 to DN65 = 16bar

ISO DN80 to DN150 = 10bar

DIN DN04 to DN40 = 25bar

DIN DN50 to DN65 = 16bar

DIN DN80 to DN150 = 10bar

BS-OD DN¼" to DN1½" = 25bar

BS-OD DN2" to DN3" = 16bar

BS-OD DN4" to DN8" = 10bar

SMS DN06 to DN40 = 25bar

SMS DN50 to DN65 = 16bar

SMS DN80 to DN100 = 10bar

6. ASSEMBLY

WARNING!

Risk of injury from improper assembly!

• Installation must only be carried out by authorized technicians and

with the appropriate tools!

• Secure system from unintentional activation.

6.1. Welding in the pipe connection

NOTE!

Damage to the welding ends!

• Remove end protection just before welding.

Leak due to damaged sealing contour!

• To ensure the sealing function, protect the sealing contour during

installation, welding and cleaning procedures.

Leak due to damaged seal!

• It is essential to remove the seal before welding and protect it

from dust, flying sparks and other influences!

Before welding:

→ Connect the parts positively in a protective gas shield.

english

6

→ For type BBS-03: Unscrew pipe connection!

Pull union nut on the liner side over the area to be welded onto

the pipe part to be welded on.

Welding

We recommend welding the connections using orbital welding

machines.

→ Always supply the weld with an inert gas.

→ Always form root seam welds.

→ Carefully clean welded joint.

→ Manual welding is possible. In doing so, use a higher-alloy filler

metal than the base material of the connection.

After welding:

When cleaning the weld seam by grinding or acid cleaning, observe

the following before assembling the connection:

• Carefully remove all grinding dust and acid-cleaning residue.

• Do not damage the label.

• There must be no material abrasion on the sealing edges. Material

abrasion will result in sharp-edged sealing contours and a damaged

seal.

• Check sealing contour for damage.

We recommend preparing a welding report.

6.2. Installing the seal

NOTE!

Damage to the EPDM and FEP seal!

• Sealing contours and contact areas must be free of contaminants.

• Do not use any pointed metallic objects.

• Never install FEP seals by force – e.g. by kinking. Even the slightest damage will result in leaks!

Damaged seals must be replaced!

→ Remove protective caps from sealing contours (protective caps

only for small delivery quantities or per order)

Type BBS-03, BBS-05 and BBS-06:

→ Insert O-ring before assembling the connection element into the

threaded connection or liner.

EPDM seals: Do not install using grease or oil!

If required, glycerin can be used as an installation aid.

FEP seals: Install by lubricating the surface with silicone grease

(FDA-compliant).

O-ring must be located firmly and tightly in the designated groove and

must not protrude into the pipe connection.

english

7

Type BBS-25:

→ Insert clamp seal into the threaded connection before screwing the

connection element together.

EPDM seals: Do not install using grease or oil!

If required, glycerin can be used as an installation aid.

Clamp seal must be located centrically and firmly and tightly in the

designated groove and must not protrude into the pipe connection.

6.3. Installing the pipe connection

→ Ensure that the seal is located correctly in the sealing contour.

→ Assemble both connection parts so that they are in alignment

(concentric deviation and angular offset of the pipe ends

max. +/–0.5 % of the outer pipe diameter)

Type BBS-03

→ Pull union nut over the liner.

→ We recommend lubricating the thread with suitable grease.

→ Manually turn union nut clockwise on the threaded connection.

Ensure that the connection turns freely, do not use force.

→ Tighten union nut using a suitable tool.

We recommend using flanges from DN 40.

Type BBS-06

→ Insert hexagon bolts through the screw holes in the flange.

→ Push circlip over the ends of the bolts.

→ Turn nuts on to the bolt threads, tighten by hand.

→ Tighten bolts crosswise using a suitable tool until flange sheets are

firmly situated one on top of the other.

Type BBS-05 and BBS-25

NOTE!

Damage to the connection element!

• Do not use any tools to install the clamp.

→ Manually place clamp over the connection.

→ Insert clamp screw into the designated slot, but do not use force.

→ Check that the clamp is seated correctly.

→ Carefully and evenly tighten the wing nut by hand until both pipe

components are firmly situated one on top of the other.

english

Type BBS-03, -05, -06, -25

Page 4

8

7. START-UP

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the

connection element and the surrounding area.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

• Observe the safety instructions and intended use.

• Only adequately trained personnel may start up the equipment/the

connection element.

• Following assembly, ensure a controlled restart.

• When starting up the equipment, ensure that no unauthorized voltage increases and pressure surges can occur.

NOTE!

Dama

ge to the seals when cleaning the pipelin

e systems.

• Clean the pipeline systems preferably with a cleaning agent which

does not damage the seals.

• Do not clean the connection elements with wire brushes or

machines which cause abrasion of the surface.

• When using mechanical pipeline monitoring devices, ensure

that they do not damage the sealing elements (also the sealing

contour).

Damaged seals must be replaced!

english

9

8. MAINTENANCE

WARNING!

Danger – high pressure and discharge of medium!

• Before loosening the lock nut or locking clamp, always turn off the

pressure and vent the lines.

• Wear protective equipment if media is hazardous.

• Lock nuts or locking clamps of the connection elements on pressurized lines may be retightened only by technicians in consideration of special precautions.

• When shutting down the equipment, ensure that no unauthorized

voltage increases and pressure surges can occur.

• Following maintenance, ensure a controlled restart.

Have the connection elements serviced regularly by technicians!

We recommend a maintenance interval of 6 months.

Inspection and maintenance work includes in particular monitoring and

ensuring the

• leak-tightness,

• identification,

• proper mode of operation of the safety and warning devices.

Opening the screw connection Types BBS-03 and BBS-06

→ Follow safety instructions!

→ Slacken lock nut or lock screws until they can still hold the pipe

ends.

→ Vent the pipe ends slightly and slacken them until they no longer

stick to each other.

→ Remove lock nut or lock screws.

→ Loosen pipe connection.

Opening the clamp connection Types BBS-05 and BBS-25

→ Follow safety instructions!

→ Open wing nut until the locking clamp still holds the pipe

ends.

→ Vent the pipe ends slightly and slacken them until they no longer

stick to each other.

→ Remove locking clamp.

→ Loosen pipe connection.

english

10

9. TRANSPORTATION, STORAGE,

DISPOSAL

NOTE!

Transport damage!

Inadequately protected connection elements may be damaged during

transportation.

• Transport the connection element in a firmly assembled state, protected against moisture and dirt, in shock-resistant packaging.

• The welding ends must be protected by end caps.

Incorrect storage may damage the connection element.

• Prevent the temperature from exceeding or dropping below the

permitted storage temperature.

• Store the connection element in a dry and dust-free location!

• Store EPDM O-rings and FEP O-rings dry and protected from

UV radiation and for not longer than 3 years.

• Storage temperature -40 to +80°C.

Damage to the environment caused by device components contaminated with media.

• Dispose of the device and packaging in an environmentally friendly

manner!

• Observe applicable disposal and environmental regulations.

english

Type BBS-03, -05, -06, -25

Page 5

Type BBS-03, BBS-05, BBS-06, BBS-25

Sterile connection elements

Sterile Verbindungselemente

Raccords union stériles

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

www.burkert.com

International address

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet: www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet : www.buerkert.fr

© 2013 Bürkert Werke GmbH

Operating Instr uctions 1402/01_EU-ML _00810203 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 6

12

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

• Anleitung sorgfältig lesen und besonders die Hinweise zur Sicherheit

beachten.

• Anleitung so aufbewahren, dass sie jedem Benutzer zur Verfügung

steht.

• Haftung und Gewährleistung für Typ BBS-03, BBS-05, BBS-06 und

BBS-25 entfällt, wenn die Anweisungen der Anleitung nicht beachtet

werden.

1.1. Darstellungsmittel

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

Warnung vor Verletzungen:

GEFAHR!

Unmittelbare Gefahr! Schwere oder tödliche Verletzungen.

WARNUNG!

Mögliche Gefahr! Schwere oder tödliche Verletzungen.

VORSICHT!

Gefahr! Mittelschwere oder leichte Verletzungen.

Warnung vor Sachschäden:

HINWEIS!

2. BESTIMMUNGSGEMÄSSER

GEBRAUCH

Bei nicht bestimmungsgemäßem Gebrauch des Typs BBS-03,

BBS-05, BBS-06 und BBS-25 können Gefahren für Personen,

Anlagen in der Umgebung und die Umwelt entstehen.

• Typ BBS-03, BBS-05, BBS-06 bzw. BBS-25 ist als Verbindung

von Rohrleitungen zum Durchfluss von Gasen und Flüssigkeiten im

sterilen Bereich konzipiert.

• Für den Einsatz die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs- und Einsatzbedingungen beachten.

• Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instandhaltung.

• Setzen Sie die Verbindungselemente nur bestimmungsgemäß ein.

2.1. Beschränkungen

Bei der Ausfuhr der Produkte gegebenenfalls bestehende Beschränkungen beachten.

2.2. Begriffsdefinition

Der in dieser Anleitung verwendete Begriff „Verbindungselement“ steht

immer für den Typ BBS-03, BBS-05, BBS-06 und BBS-25.

deutsch

13

4. ALLGEMEINE HINWEISE

4.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten

Bedienungsanleitung. Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch der Verbindungselemente unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ BBS-03, BBS-05,

BBS-06 und BBS-25 finden Sie im Internet unter: www.buerkert.de

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung der Verbindungselemente

auftreten können.

Gefahr durch hohen Druck und Mediumsaustritt!

• Vor dem Lösen von Verschlussmutter bzw. Verschlussklammer unbedingt den Druck abschalten und Leitungen entlasten.

• Bei gefährlichen Medien Schutzausrüstung tragen.

Allgemeine Gefahrensituationen

• Am Verbindungselement keine inneren oder äußeren Veränderungen

vornehmen.

• Beachten, dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt werden.

• Die Verbindungselemente nur in einwandfreiem Zustand und unter

Beachtung der Bedienungsanleitung betreiben.

• Bei Inspektion, Wartung und Instandsetzung nationale Bestimmungen

des Aufstellungslands beachten.

• Für die Einsatzplanung und den Betrieb der Verbindungselemente

die allgemeinen Regeln der Technik einhalten.

deutsch

14

5. TECHNISCHE DATEN

5.1. Konformität

Die Verbindungselemente Typ BBS-03, BBS-05, BBS-06 und

BBS-25 sind konform zu den EG-Richtlinien entsprechend der

EG-Konformitätserklärung.

5.2. Normen (soweit anwendbar)

Die angewandten Normen, mit denen die Konformität mit den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformitätserklärung nachzulesen.

5.3. Kennzeichnung

Angaben zu Material und Rohrmaß sind der Prägung auf dem

Verbindungselement zu entnehmen. Die Identnummer des Verbindungselements entnehmen Sie bitte dem mitgelieferten 3.1-Zeugnis.

Material

Rohrmaß

Chargennummer

Norm

Bild 1: Beispiel für die Kennzeichnung des Verbindungselements

5.4. Dichtungsmaterialien

Dichtwerkstoff Betriebstemperatur

EPDM –40 °C bis 90 °C, kurzzeitig bis 140 °C

FEP –60 °C bis 160 °C, kurzzeitig bis 205 °C

Tab. 1: Material O-Ringe (BBS-03, -05, -06) bzw. Clamp-Dichtung (BBS-25).

5.5. Allgemeine technische Daten

Material

mediumberührt

Edelstahl 1.4435 BN2 (316L)

Material

nicht mediumberührt

Edelstahl 1.4305 oder gleichwertig

Rohrmaße

siehe Beschriftung Verbindungselement

(Beispiel: „Bild 1“)

zulässige

Einsatztemperatur

je nach Dichtungsmaterial,

siehe „Tab. 1“ auf Seite 14

Umgebungs-

temperatur

–20 °C bis +80 °C

Medien Gase oder Flüssigkeiten

deutsch

Typ BBS-03, -05, -06, -25

Page 7

15

5.5.1. Betriebsdruck

BBS-03, BBS-05 und BBS-06 als Steril-Orbital-Verbindung:

–1 bis +16 bar (in Abhängigkeit der Temperatur).

BBS-03 und BBS-05

nach DIN 11864

BBS-06 nach DIN 11864

ISO DN08 bis DN25 = 40 bar

ISO DN32 bis DN80 = 25 bar

DIN DN10 bis DN40 = 40 bar

DIN DN50 bis DN100 = 25 bar

BS-OD DN½” bis DN1½” = 40 bar

BS-OD DN2” bis DN4” = 25 bar

ISO DN08 bis DN25 = 25 bar

ISO DN32 bis DN80 = 16 bar

ISO DN100 = 10 bar

DIN DN10 bis DN40 = 25 bar

DIN DN50 bis DN100 = 16 bar

DIN DN125 bis DN150 = 10 bar

BS-OD DN½” bis DN1½” = 25 bar

BS-OD DN2” bis DN4” = 16 bar

BBS-25 nach DIN 11864

ISO DN08 bis DN32 = 25bar

ISO DN40 bis DN65 = 16bar

ISO DN80 bis DN150 = 10bar

DIN DN04 bis DN40 = 25bar

DIN DN50 bis DN65 = 16bar

DIN DN80 bis DN150 = 10bar

BS-OD DN¼“ bis DN1½“ = 25bar

BS-OD DN2“ bis DN3“ = 16bar

BS-OD DN4“ bis DN8“ = 10bar

SMS DN06 bis DN40 = 25bar

SMS DN50 bis DN65 = 16bar

SMS DN80 bis DN100 = 10bar

6. MONTAGE

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage!

• Die Montage darf nur autorisiertes Fachpersonal mit geeignetem

Werkzeug durchführen!

• Anlage vor unbeabsichtigtem Betätigen sichern.

6.1. Einschweißen der Rohrverbindung

HINWEIS!

Beschädigung der Schweiß-Enden!

• Endenschutz erst unmittelbar vor dem Verschweißen entfernen.

Undichtheit durch beschädigte Dichtkontur!

• Zur Sicherstellung der Dichtfunktion die Dichtkontur während

Montage, Schweißen und Reinigungsverfahren schützen.

Undichtheit durch beschädigte Dichtung!

• Dichtung vor dem Schweißen unbedingt entfernen und vor Staub,

Funkenflug und anderen Einflüssen schützen!

Vor dem Schweißen:

→ Verbindung formschlüssig unter Schutzgas heften.

deutsch

16

→ Bei Typ BBS-03: Rohrverbindung auseinanderschrauben!

Überwurfmutter auf der Bundstutzenseite über die zu verschweißenden Stelle auf das anzuschweißende Rohrteil ziehen.

Schweißen

Wir empfehlen, die Verbindungen mit Orbitalschweißmaschinen zu

schweißen.

→ Zur Schweißung immer ein Edelgas zuführen.

→ Wurzelnahtschweißungen immer formieren.

→ Schweißstelle sorgfältig reinigen.

→ Manuelle Schweißung ist möglich. Dabei höher legierten Schweiß-

zusatz verwenden als das Grundmaterial der Verbindung aufweist.

Nach dem Schweißen:

Bei Schweißnahtreinigung mittels Schleifen oder Beizen vor dem

Zusammenbau der Verbindung beachten:

• Alle Schleifstaub- und Beizereste sorgfältig entfernen.

• Beschriftung nicht beschädigen.

• An den Dichtkanten darf kein Materialabtrag vorgenommen werden.

Materialabtrag führt zu scharfkantigen Dichtkonturen und damit zur

Verletzung der Dichtung.

• Dichtkontur auf Beschädigung kontrollieren.

Wir empfehlen die Erstellung eines Schweißprotokolls.

6.2. Einbau der Dichtung

HINWEIS!

Beschädigung der EPDM- und FEP-Dichtung!

• Dichtkonturen und Kontaktflächen müssen frei von Verunreinigungen

sein.

• Keine spitzen metallischen Gegenstände benützen.

• FEP-Dichtungen keinesfalls gewaltsam – z. B. durch Knicken –

montieren. Selbst kleinste Verletzungen führen zu Undichtheit!

Verletzte Dichtungen müssen ersetzt werden!

→ Schutzkappen auf Dichtkonturen entfernen (Schutzkappen nur bei

kleinen Liefermengen oder auf Bestellung)

Typ BBS-03, BBS-05 und BBS-06:

→ O-Ring vor dem Zusammenfügen des Verbindungselements in den

Gewinde- bzw. Bundstutzen einlegen.

EPDM-Dichtungen: zur Montage kein Fett oder Öl benützen!

Wenn nötig, kann Glyzerin als Hilfsmittel verwendet werden.

FEP-Dichtungen: zur Montage Oberfläche mit Silikonfett (FDA-

konform) fetten.

O-Ring muss in der dafür vorgesehenen Nut fest und eng anliegen und

darf nicht in die Rohrverbindung ragen.

deutsch

17

Typ BBS-25:

→ Clamp-Dichtung vor dem Zusammenschrauben des Verbindungs-

elements in den Gewindestutzen einlegen.

EPDM-Dichtungen: zur Montage kein Fett oder Öl benützen!

Wenn nötig, kann Glyzerin als Hilfsmittel verwendet werden.

Clamp-Dichtung muss zentrisch und in der dafür vorgesehenen Nut fest

und eng anliegen und darf nicht in die Rohrverbindung ragen.

6.3. Montage der Rohrverbindung

→ Sicherstellen, dass die Dichtung richtig in der Dichtkontur liegt.

→ beide Verbindungsteile zusammenfügen, so dass sie fluchtend auf-

einandertreffen (konzentrische Abweichung und Winkelversatz der

Rohr-Enden max. +/–0,5 % des Rohr-Aussendurchmessers)

Typ BBS-03

→ Überwurfmutter über den Bundstutzen ziehen.

→ Wir empfehlen, das Gewinde mit einem geeignetem Fett einzufetten.

→ Überwurfmutter von Hand im Uhrzeigersinn auf Gewindestutzen

drehen. Auf leichtgängige Verschraubung achten, keine Gewalt

anwenden.

→ Überwurfmutter mit geeignetem Werkzeug anziehen.

Wir empfehlen ab DN 40 Flansche einzusetzen.

Typ BBS-06

→ Sechskantschrauben durch die Schraubenlöcher des Flansches

stecken.

→ Federring über die Schrauben-Enden schieben.

→ Muttern auf die Schraubengewinde drehen, von Hand festziehen.

→ Schrauben mit geeignetem Werkzeug über Kreuz anziehen, bis

Flanschblätter fest aufeinander liegen.

Typ BBS-05 und BBS-25

HINWEIS!

Beschädigung des Verbindungselements!

• Zur Klammermontage keine Werkzeuge verwenden.

→ Klammer von Hand über die Verbindung legen.

→ Klammerschraube in dafür vorgesehenen Schlitz einfädeln, dabei

keine Gewalt anwenden.

→ Richtigen Sitz der Klammer kontrollieren.

→ Flügelmutter von Hand vorsichtig und gleichmäßig anziehen, so dass

beide Rohrbauteile fest aufeinander liegen.

deutsch

Typ BBS-03, -05, -06, -25

Page 8

18

7. INBETRIEBNAHME

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen sowie Schäden am

Verbindungselement und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist und

vollständig verstanden wurde.

• Die Sicherheitshinweise und der bestimmungsgemäße Gebrauch

müssen beachtet werden.

• Nur ausreichend geschultes Personal darf die Anlage/das Verbindungselement in Betrieb nehmen.

• Nach der Montage einen kontrollierten Wiederanlauf gewährleisten.

• Anlage so in Betrieb nehmen, dass sich keine unzulässigen Spannungserhöhungen und Druckschläge ergeben können.

HINWEIS!

Beschä

digung der Dichtungen beim Reinigen der

Rohrleitun

gssysteme.

• Zur Reinigung der Rohrleitungssysteme möglichst Reinigungsmittel

verwenden, welche die Dichtungen nicht beschädigen.

• Zur Reinigung der Verbindungselemente keine Drahtbürsten oder

Maschinen benützen, die einen Oberflächenabtrag zur Folge haben.

• Bei Verwendung mechanischer Rohrleitungs-Kontrollgeräte beachten, dass diese keine Beschädigung der Dichtelemente (auch der

Dichtkontur) verursachen.

Beschädigte Dichtungen müssen ausgetauscht werden!

deutsch

19

8. WARTUNG

WARNUNG!

Gefahr durch hohen Druck und Mediumsaustritt!

• Vor dem Lösen von Verschlussmutter bzw. Verschlussklammer

unbedingt den Druck abschalten und Leitungen entlasten.

• Bei gefährlichen Medien Schutzausrüstung tragen.

• An unter Druck stehenden Leitungen dürfen Verschlussmuttern bzw.

Verschlussklammer der Verbindungselemente nur von Fachpersonal

unter Beachtung besonderer Vorsichtsmaßnahmen nachgezogen

werden.

• Anlage so abfahren, dass sich keine unzulässigen Spannungserhöhungen und Druckschläge ergeben können.

• Nach der Wartung einen kontrollierten Wiederanlauf gewährleisten.

Verbindungselemente regelmäßig durch fachkundiges Personal

warten! Wir empfehlen einen Wartungsintervall von 6 Monaten.

Zu den Inspektions- und Wartungsarbeiten gehören insbesondere die

Überwachung und Sicherstellung der

• Dichtheit,

• Kennzeichnung,

• ordnungsgemäßen Funktionsweise der Sicherheits- und

Warneinrichtungen.

Öffnen der Verschraubung Typ BBS-03 und BBS-06

→ Sicherheitshinweise beachten!

→ Verschlussmutter bzw. Verschlussschrauben so weit lockern, dass

sie die Rohrenden noch halten können.

→ Rohrenden leicht anlüften und lockern, dass sie nicht mehr anein-

ander haften.

→ Verschlussmutter bzw. Verschlussschrauben entfernen.

→ Rohrverbindung lösen.

Öffnen der Clamp-Verbindung Typ BBS-05 und BBS-25

→ Sicherheitshinweise beachten!

→ Flügelmutter so weit öffnen, dass die Verschlussklammer die Rohr-

enden noch hält.

→ Rohrenden leicht anlüften und lockern, dass sie nicht mehr anein-

ander haften.

→ Verschlussklammer entfernen.

→ Rohrverbindung lösen.

deutsch

20

9. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Verbindungselemente können durch den

Transport beschädigt werden.

• Verbindungselement in fest zusammengesetztem Zustand vor

Nässe und Schmutz geschützt in einer stoßfesten Verpackung

transportieren.

• Die Schweißenden müssen durch Endkappen geschützt sein.

Falsche Lagerung kann Schäden am Verbindungselement

verursachen.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur

vermeiden.

• Verbindungselement trocken und staubfrei lagern!

• EPDM-O-Ringe und FEP-O-Ringe trocken und vor UV-Strahlung

geschützt und nicht länger als 3 Jahre lagern.

• Lagertemperatur –40 … +80 °C.

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

deutsch

Typ BBS-03, -05, -06, -25

Page 9

Type BBS-03, BBS-05, BBS-06, BBS-25

Sterile connection elements

Sterile Verbindungselemente

Raccords union stériles

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

www.burkert.com

International address

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet: www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet : www.buerkert.fr

© 2013 Bürkert Werke GmbH

Operating Instr uctions 1402/01_EU-ML _00810203 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 10

22

1. MANUEL

Le manuel contient des informations importantes.

• Lire attentivement le manuel et tenir particulièrement compte des

consignes de sécurité.

• Conserver le manuel afin qu'il soit accessible à tous les utilisateurs.

• La responsabilité et la garantie légale concernant les types

BBS-03, BBS-05, BBS-06 et BBS-25 sont exclues en cas de

non-respect des instructions contenues dans le manuel.

1.1. Symboles

→ Identifie une opération que vous devez effectuer.

Mise en garde contre les blessures :

DANGER !

Danger imminent ! Blessures graves ou mortelles.

AVERTISSEMENT !

Danger potentiel ! Blessures graves ou mortelles.

ATTENTION !

Danger ! Blessures légères ou de moyenne gravité.

Mise en garde contre les dommages matériels :

REMARQUE !

2. UTILISATION CONFORME

L'utilisation non conforme des types BBS-03, BBS-05, BBS-06

et BBS-25 peut présenter des dangers pour les personnes, les

installations avoisinantes et l'environnement.

• Le type BBS-03, BBS-05, BBS-06 ou BBS-25 est conçu pour

raccorder des tuyauteries assurant le débit de gaz et de liquides

en milieu stérile.

• Lors de l'utilisation, il convient de respecter les données et conditions d'utilisation et d'exploitation admissibles spécifiées dans le

manuel et dans les documents contractuels.

• Les conditions pour l'utilisation sûre et parfaite sont un transport,

un stockage et une installation dans les règles ainsi qu'une utilisation et une maintenance parfaites.

• N'utilisez jamais les raccords union pour un usage autre que celui

prévu.

2.1. Limitations

Lors de l'exportation des produits, veuillez respecter les limitations éventuelles existantes.

2.2. Définition des termes

Le terme « raccord union » utilisé dans ce manuel désigne toujours les

types BBS-03, BBS-05, BBS-06 et BBS-25.

français

23

4. INDICATIONS GÉNÉRALES

4.1. Adresse

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tél. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages du manuel imprimé.

Également sur internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie légale est l'utilisation conforme

des raccords union dans le respect des conditions d'utilisation spécifiées.

4.3. Informations sur Internet

Vous trouverez les manuels et les fiches techniques concernant les

types BBS-03, BBS-05, BBS-06 et BBS-25 sur Internet sous :

www.burkert.fr

3. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte des hasards et des

événements pouvant survenir lors du montage, de l'exploitation et de

l'entretien des raccords union.

Danger dû à la pression élevée et à la sortie de fluide !

• Avant de desserrer l'écrou-raccord et la bride de fermeture, il faut

absolument couper la pression et purger l'air des conduites.

• En cas d'utilisation de fluides toxiques, porter l'équipement de protection.

Situations dangereuses d'ordre général

• N'apportez pas de modifications internes ou externes au raccord union.

• L'actionnement par inadvertance de l'installation ne doit pas être possible.

• Les travaux d'installation et de maintenance doivent être effectués

uniquement par des techniciens qualifiés et habilités disposant de

l'outillage approprié.

• Les raccords union doivent être utilisés uniquement en parfait état et en

respectant le manuel.

• Respecter les dispositions nationales en vigueur dans le pays d'installation lors de l'inspection, de l'entretien et de la réparation.

• Les règles générales de la technique sont d'application pour planifier

l'utilisation des raccords union.

français

24

5. CARACTÉRISTIQUES TECHNIQUES

5.1. Conformité

Les raccords union de types BBS-03, BBS-05, BBS-06 et BBS-25

satisfont aux directives CE conformément à la déclaration de

conformité CE.

5.2. Normes (si applicables)

Les normes utilisées attestant de la conformité avec les directives CE

figurent dans l'attestation CE de type et/ou la déclaration de

conformité CE.

5.3. Identification

Les informations concernant le matériau et la dimension du tube sont

gravées sur le raccord union. Vous trouverez le numéro d'identification

du raccord union dans le certificat 3.1 fourni.

Matériau

Dimension du tube

Numéro de lot

Norme

Fig. 1: Exemple d'identification du raccord union

5.4. Matériaux d'étanchéité

Matériau du joint Température de service

EPDM -40 à 90 °C, brièvement jusqu'à 140 °C

FEP -60 à 160 °C, brièvement jusqu'à 205 °C

Tab. 1: Matériau des joints toriques (BBS-03, -05, -06) et du joint clamp

(BBS-25).

5.5. Caractéristiques techniques générales

Matériau en contact

avec le fluide

Acier inoxydable 1.4435 BN2 (316L)

Matériau pas en

contact avec le fluide

Acier inoxydable 1.4305 ou similaire

Dimensions du tube

Voir les informations sur le raccord union

(exemple : « Fig. 1 »)

Température

d'utilisation

admissible

selon le matériau d'étanchéité,

voir « Tab. 1 » page 24

Température

ambiante

-20 °C à +80 °C)

Fluides Gaz ou liquides

français

Type BBS-03, -05, -06, -25

Page 11

25

5.5.1. Pression de service

BBS-03, BBS-05 et BBS-06 comme raccord orbital stérile :

-1 à +16 bar (en fonction de la température).

BBS-03 et BBS-05

selon DIN 11864

BBS-06 selon DIN 11864

ISO DN08 à DN25 = 40 bar

ISO DN32 à DN80 = 25 bar

DIN DN10 à DN40 = 40 bar

DIN DN50 à DN100 = 25 bar

BS-OD DN½" à DN1½" = 40 bar

BS-OD DN2" à DN4" = 25 bar

ISO DN08 à DN25 = 25 bar

ISO DN32 à DN80 = 16 bar

ISO DN100 = 10 bar

DIN DN10 à DN40 = 25 bar

DIN DN50 à DN100 = 16 bar

DIN DN125 à DN150 = 10 bar

BS-OD DN½" à DN1½" = 25 bar

BS-OD DN2" à DN4" = 16 bar

BBS-25 selon DIN 11864

ISO DN08 à DN32 = 25 bar

ISO DN40 à DN65 = 16 bar

ISO DN80 à DN150 = 10 bar

DIN DN04 à DN40 = 25 bar

DIN DN50 à DN65 = 16 bar

DIN DN80 à DN150 = 10 bar

BS-OD DN¼" à DN1½" = 25 bar

BS-OD DN2" à DN3" = 16 bar

BS-OD DN4" à DN8" = 10 bar

SMS DN06 àDN40 = 25 bar

SMS DN50 à DN65 = 16 bar

SMS DN80 à DN100 = 10 bar

6. MONTAGE

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme !

• Le montage doit être effectué uniquement par des techniciens qualifiés et habilités disposant de l'outillage approprié !

• Empêcher tout actionnement involontaire de l'installation.

6.1. Soudage du raccord de tuyauterie

REMARQUE !

Endommagement des extrémités à souder !

• Enlever la protection des extrémités juste avant de procéder au

soudage.

Fuites dues à un contour d'étanchéité endommagé !

• Pour garantir la fonction d'étanchéité, protéger le contour d'étanchéité pendant le montage, le soudage et le nettoyage.

Fuites dues à un joint endommagé !

• Toujours retirer le joint avant de procéder au soudage et le protéger de la poussière, des étincelles et d'autres influences !

Avant le soudage :

→ Pointer le raccord union sur toute sa surface sous gaz protecteur.

français

26

→ Avec le type BBS-03 dévisser le raccord de tuyauterie !

Positionner l'écrou raccord du côté de l'embout à collerette sur

l'endroit de la partie de tube à souder.

Soudage

Nous recommandons d'utiliser des soudeuses orbitales pour souder

les raccords.

→ Toujours utiliser un gaz rare pour souder.

→ Toujours former les soudures de passe de fond.

→ Nettoyer minutieusement la soudure.

→ Le soudage manuel est possible. Dans ce cas, utiliser un apport de

soudage plus fortement allié que le matériau de base du raccord.

Après le soudage :

Lors du nettoyage de la soudure par meulage ou décapage avant

assemblage du raccord :

• Retirer soigneusement tous les résidus de poussière de meulage et

de décapage.

• Ne pas endommager les informations.

• Aucun enlèvement de matière ne doit être effectué au niveau des

bords d'étanchéité. L'enlèvement de matière génère des contours

d'étanchéité à arêtes vives endommageant le joint.

• Contrôler la présence de dommages sur le contour d'étanchéité.

Nous recommandons d'établir un rapport de soudage.

6.2. Montage du joint

REMARQUE !

Endommagement du joint EPDM et du joint FEP !

• Les contours d'étanchéité et les surfaces de contact doivent être

parfaitement propres.

• Ne pas utiliser d'objets métalliques pointus.

• Ne jamais effectuer le montage des joints FEP en forçant, par ex.

en les pliant. Le moindre dommage peut être à l'origine de fuites !

Les joints endommagés doivent être remplacés !

→ Retirer les capuchons de protection des contours d'étanchéité

(capuchons de protection uniquement pour des livraisons de

petites quantités ou sur commande)

Types BBS-03, BBS-05 et BBS-06 :

→ Mettre le joint torique en place dans la tubulure filetée ou l'embout

à collerette avant d'assembler le raccord union.

Joints EPDM : ne pas utiliser de graisse ou d'huile pour

effectuer le montage !

Si nécessaire, utiliser de la glycérine.

Joints FEP : appliquer de la graisse silicone (conforme FDA) sur la

surface pour effectuer le montage.

français

27

Le joint torique doit être étroitement en contact dans la rainure prévue

à cet effet et ne doit pas dépasser dans le raccord de tuyauterie.

Type BBS-25 :

→ Mettre le joint clamp en place dans la tubulure filetée avant de

visser le raccord union.

Joints EPDM : ne pas utiliser de graisse ou d'huile pour

effectuer le montage !

Si nécessaire, utiliser de la glycérine.

Le joint clamp doit être étroitement en contact dans la rainure prévue à

cet effet et ne doit pas dépasser dans le raccord de tuyauterie.

6.3. Montage du raccord de tuyauterie

→ Assurez-vous que le joint est correctement en place dans le

contour d'étanchéité.

→ Assembler les deux parties du raccord de sorte qu'elles se

rejoignent parfaitement (écart concentrique et écart angulaire maxi

des extrémités de tube +/–0,5 % du diamètre extérieur du tube)

Type BBS-03

→ Positionner l'écrou-raccord sur l'embout à collerette.

→ Nous recommandons d'appliquer une graisse appropriée sur le

filetage.

→ Visser l'écrou-raccord à la main sur la tubulure filetée dans le sens

des aiguilles d'une montre. Veiller à la souplesse du vissage, ne

pas forcer.

→ Serrer l'écrou-raccord avec un outil approprié.

Nous recommandons d'utiliser des brides à partir du DN 40.

Type BBS-06

→ Faire passer les vis à tête hexagonale à travers les trous de vis de

la bride.

→ Glisser la rondelle Grower sur les extrémités de vis.

→ Visser les écrous sur les pas de vis, serrer à fond à la main.

→ Serrer les vis en croix avec un outil approprié jusqu'à ce que les

faces de bride soient parfaitement solidaires.

Types BBS-05 et BBS-25

REMARQUE !

Endommagement du raccord union !

• Ne pas utiliser d'outils pour le montage des brides.

→ Positionner la bride à la main sur le raccord.

français

Type BBS-03, -05, -06, -25

Page 12

28

→ Introduire la vis à tête rectangulaire dans la fente prévue à cet effet

sans forcer.

→ Vérifier le bon positionnement de la bride.

→ Serrer l'écrou à oreilles avec précaution et régulièrement à la

main de sorte que les deux parties de tube soient parfaitement

solidaires.

7. MISE EN SERVICE

AVERTISSEMENT !

Risque de blessures en cas d'utilisation non conforme !

Une utilisation non conforme peut entraîner des blessures et endommager le raccord union et son environnement.

• Avant la mise en service, il faut s'assurer que le contenu du manuel

est connu et parfaitement compris par les opérateurs.

• Respecter les consignes de sécurité et l'utilisation conforme.

• L'installation/le raccord union doit être mis(e) en service uniquement par un personnel suffisamment formé.

• Garantir un redémarrage contrôlé après le montage.

• Mettre l'installation en service en veillant à empêcher les augmentations de tension et les coups de bélier inadmissibles.

français

29

REMARQUE !

Endom

magement des joints lors du nettoyage des systèmes de

tuyauterie.

• Pour nettoyer les systèmes de tuyauterie, utiliser dans la mesure du

possible des produits de nettoyage n'endommageant pas les joints.

• Pour nettoyer les raccords union, ne pas utiliser de brosses métalliques ou de machines attaquant la surface.

• Si vous utilisez des appareils de contrôle mécaniques pour tuyauteries, veiller à ce que ceux-ci n'endommagent pas les éléments

d'étanchéité (ni le contour d'étanchéité).

Les joints endommagés doivent être remplacés !

8. ENTRETIEN

AVERTISSEMENT !

Danger dû à la pression élevée et à la sortie de fluide !

• Avant de desserrer l'écrou-raccord et la bride de fermeture, il faut

absolument couper la pression et purger l'air des conduites.

• En cas d'utilisation de fluides toxiques, porter l'équipement de

protection.

• Seuls les techniciens qualifiés sont autorisés à resserrer les

écrous-raccords et les brides de fermeture des raccords union sur

les conduites sous pression en respectant les mesures de sécurité

spécifiques.

• Mettre l'installation hors service en veillant à empêcher les augmentations de tension et les coups de bélier inadmissibles.

• Garantir un redémarrage contrôlé après l'entretien.

Faire effectuer régulièrement l'entretien des raccords union par

un personnel spécialisé. Nous recommandons de respecter une

périodicité d'entretien de 6 mois.

Font notamment partie des travaux d'inspection et d'entretien, la sur-

veillance et la garantie de

• l'étanchéité,

• l'identification

français

30

• et le parfait fonctionnement des dispositifs de sécurité et

d'avertissement.

Ouverture des raccords union, types BBS-03 et BBS-06

→ Respecter les consignes de sécurité !

→ Desserrer les écrous-raccords et les bouchons filetés juste ce qu'il

faut pour qu'ils puissent encore maintenir les extrémités de tube.

→ Soulever et desserrer légèrement les extrémités de tube de sorte

qu'elles soient désolidarisées.

→ Retirer les écrous-raccords et les bouchons filetés.

→ Desserrer le raccord de tuyauterie.

Ouverture du raccord clamp, types BBS-05 et BBS-25

→ Respecter les consignes de sécurité !

→ Desserrer l'écrou à oreilles juste ce qu'il faut pour que la bride de

fermeture puisse encore maintenir les extrémités de tube.

→ Soulever et desserrer légèrement les extrémités de tube de sorte

qu'elles soient désolidarisées.

→ Retirer la bride de fermeture.

→ Desserrer le raccord de tuyauterie.

9. TRANSPORT, STOCKAGE,

ÉLIMINATION

REMARQUE !

Dommages dus au transport !

Les raccords union insuffisamment protégés peuvent être endommagés pendant le transport.

• Transporter le raccord union, bien assemblé, à l'abri de l'humidité et

des impuretés et dans un emballage résistant aux chocs.

• Les extrémités à souder doivent être protégées par des capuchons.

Un mauvais stockage peut endommager le raccord union.

• Éviter le dépassement vers le haut ou le bas de la température de

stockage admissible.

• Stocker le raccord union au sec et à l'abri des poussières !

• Stocker les joints toriques EPDM et FEP au sec et à l'abri des UV,

la durée de stockage ne devant pas dépasser 3 ans.

• Température de stockage -40 à +80 °C.

Dommages à l'environnement causés par des pièces d'appareil

contaminées par des fluides.

• Éliminer l'appareil et l'emballage dans le respect de l'environnement !

• Respecter les prescriptions en matière d'élimination des déchets et

de protection de l'environnement en vigueur.

français

Type BBS-03, -05, -06, -25

Loading...

Loading...