Page 1

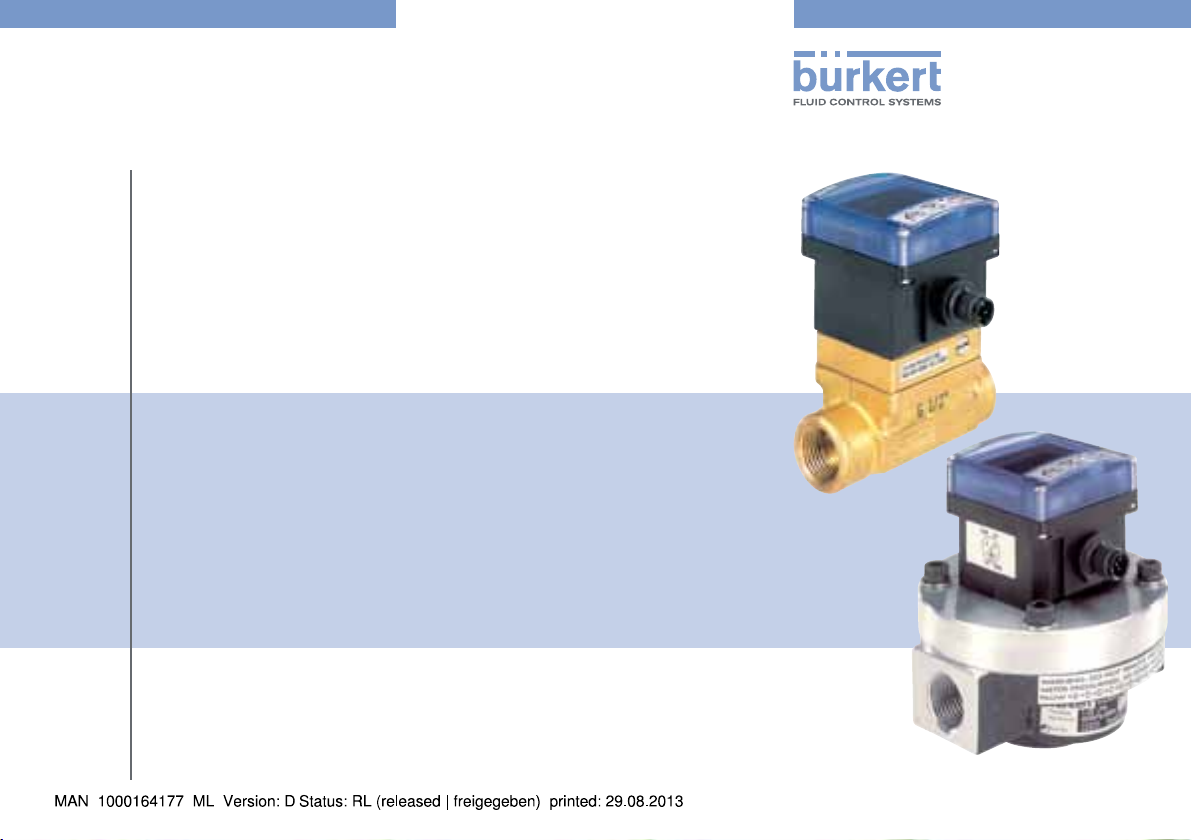

Type 8032 / 8072

Flowmeter / Flow threshold detector

Durchfluss-Messgerät / -Schwellendetektor

Débitmètre / Détecteur à seuil du débit

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2011-2013 Bürkert SAS

Operating Instructions 1304/1_EU-ML 00560375 / Original_FR

Page 3

Type 8032 / 8072

1. ABOUT THIS MANUAL .................................................................................3

1.1. Symbols used .......................................................................................3

1.2. Definition of the word "device" ....................................................3

2. INTENDED USE ................................................................................................4

3. BASIC SAFETY INFORMATION ...............................................................4

4. GENERAL INFORMATION ...........................................................................6

4.1. Manufacturer's address and international contacts .........6

4.2. Warranty conditions ...........................................................................6

4.3. Information on the Internet ............................................................6

5. DESCRIPTION ...................................................................................................6

5.1. Construction ..........................................................................................6

5.2. Measuring element ............................................................................6

5.3. Available versions of the SE32 electronic module ...........7

5.4. Description of the name plate .....................................................8

6. TECHNICAL DATA ...........................................................................................8

6.1. Conditions of use ................................................................................8

6.2. Compliance to standards and directives ................................8

6.3. General technical data .....................................................................9

6.3.1. Mechanical data ....................................................................9

6.3.2. General data .........................................................................10

6.3.3. Electrical data.......................................................................12

6.3.4. Data of the cables and wires ............................................13

7. INSTALLATION AND WIRING .................................................................14

7.1. Safety information ........................................................................... 14

7.2. Installation onto the pipe ............................................................. 15

7.2.1. Diagrams ...............................................................................15

7.2.2. Assembly of the 8032 / 8072 ..........................................16

7.3. Wiring ...................................................................................................... 17

7.3.1. Assembling the connectors ..............................................17

7.3.2. Wiring a version with transistor output and

EN175301-803 male fixed connector ...........................18

7.3.3. Wiring a version with 2 transistor outputs and a

5-pin M12 male fixed connector ......................................19

7.3.4. Wiring of the version with a single relay output ............. 21

7.3.5. Wiring of the version with a single current output ......... 22

7.3.6. Wiring the version with both relay and current

outputs (5-pin M12 fixed connector) ................................ 23

7.3.7. Wiring the version with relay and current out-

puts (8-pin M12 fixed connector) ...................................24

8. COMMISSIONING ........................................................................................ 27

8.1. Safety information ........................................................................... 27

English

1

Page 4

9. ADJUSTMENT AND FUNCTIONS .........................................................27

9.1. Safety information ........................................................................... 27

9.2. Operating levels ................................................................................28

9.3. Description of the display and the operating keys ........ 29

9.4. Process level ...................................................................................... 29

9.5. Configuration level - Parameters menu ...............................31

9.5.1. Selecting the unit of the flow rate ...................................32

9.5.2. Entering the K factor or having it determined by

teach-in ..................................................................................33

9.5.3. Configuring the relay or transistor output ......................34

9.5.4. Setting the flow rate range associated to the

4-20 mA output ...................................................................36

9.5.5. Choosing the filter of the flow rate ..................................36

9.5.6. entering the flow rate range related to the bar graph . 37

9.5.7. Adjusting the brightness of the backlight or

deactivating the backlight .................................................37

9.5.8. Activating and defining the access code to the

Configuration level ..............................................................38

9.5.9. Saving the modified parameters ......................................38

9.6. Configuration level - Test menu ...............................................39

9.6.1. Adjusting the 4-20 mA output .........................................40

9.7. Default settings ................................................................................. 41

9.8. Your settings for the 8032 / 8072 ...........................................41

10. MAINTENANCE AND TROUBLESHOOTING ................................42

10.1. Safety information ........................................................................... 42

10.2. Maintenance and cleaning ..........................................................42

10.3. If you encounter problems ..........................................................43

11. SPARE PARTS AND ACCESSORIES ............................................... 44

12. PACKAGING, TRANSPORT ...................................................................45

13. STORAGE ....................................................................................................... 45

14. DISPOSAL OF THE DEVICE ................................................................. 45

2

English

Page 5

About this manual

About this manual

1. ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please keep

this manual in a safe place, accessible to all users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations.

• This manual must be read and understood.

1.1. Symbols used

DANGER

Warns against an imminent danger.

• Failure to observe this warning can result in death or in serious

injury.

WARNING

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or

even death.

CAUTION

Warns against a possible risk.

• Failure to observe this warning can result in substantial or minor

injuries.

NOTE

Warns against material damage.

• Failure to observe this warning may result in damage to the

device or system.

Indicates additional information, advice or important

recommendations.

refers to information contained in this manual or in other

documents.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

The word "device" used within these operating instructions refers to

the flowmeter or the flow threshold detector type 8032 or 8072.

English

3

Page 6

Intended use

Intended use

2. INTENDED USE

Use of the Flow Threshold Detector / Flowmeter that does

not comply with the instructions could present risks to

people, nearby installations and the environment.

• The flow Threshold detector / Flowmeter is intended solely to

measure the flow rate of liquids.

• Protect the device from electromagnetic perturbations, ultraviolet radiations and, when installed outside, from the effects of

climatic conditions.

• Use this device in compliance with the characteristics and

commissioning and use conditions specified in the contractual

documents and in the instruction manual.

• Requirements for safe and proper operation are proper transport, storage and installation as well as careful operation and

maintenance.

• Only use the device as intended.

• Observe any existing restraints when the device is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during assembly,

use and maintenance of the devices.

• the local safety regulations that the operator must ensure the staff

in charge of assembly observe.

Danger due to high pressure in the installation.

Danger due to electrical voltage.

Danger due to high temperatures of the fluid.

Danger due to the nature of the fluid.

Various dangerous situations

To avoid injury take care:

• to prevent any accidental power supply switch-on.

• to carry out installation and maintenance by qualified and skilled

staff with the appropriate tools.

• to guarantee a defined or controlled restarting of the process,

after a power supply interruption.

4

English

Page 7

Basic safety information

Basic safety information

Various dangerous situations

To avoid injury take care:

• to use the device only if in perfect working order and in compliance with the instructions provided in the operating instructions.

• to observe the general technical rules during the planning and

use of the device.

• not to use the device in explosive atmospheres.

• not to use the device to measure the flow rate of a gas.

• not to use the device in an environment that is incompatible with

the materials of which the device is made.

• not to subject the device to mechanical loads (e.g. by placing

objects on top of it or by using it as a step).

• not to make any external or internal modifications to the device.

NOTE

The device may be damaged by the fluid in contact with.

• Systematically check the chemical compatibility of the component materials of the device and the fluids likely to come into

contact with it (for example: alcohols, strong or concentrated

acids, aldehydes, alkaline compounds, esters, aliphatic compounds, ketones, halogenated aromatics or hydrocarbons,

oxidants and chlorinated agents).

NOTE

Elements / Components sensitive to electrostatic discharges

• This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they are touched by

an electrostatically charged person or object. In the worst case

scenario, these components are instantly destroyed or go out of

order as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 and 5-2 norms.

• Also ensure that you do not touch any of the energized electrical components.

English

5

Page 8

General information

General information

4. GENERAL INFORMATION

4.1. Manufacturer's address and

international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

The addresses of our international branches can be found on the

last pages of this manual.

They can also be found on the Internet under:

www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of

the device in observance of the operating conditions specified in this

manual.

4.3. Information on the Internet

You can find the operating instructions and technical datasheets

regarding types 8032 and 8072 on the internet at:

www.burkert.com

5. DESCRIPTION

The device is intended for measuring the flow rate of liquids.

The threshold detector can be used to control a valve or activate an

alarm. A flowmeter version can also be used to establish a control loop.

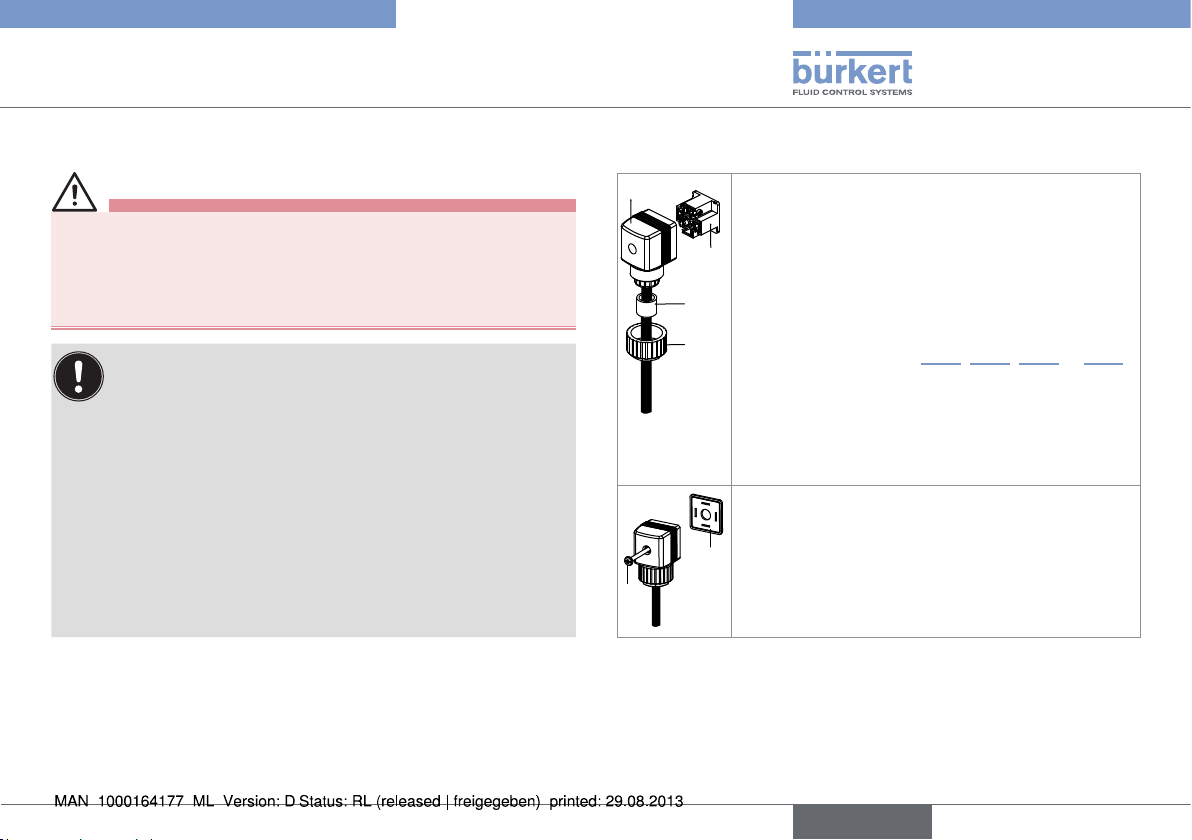

5.1. Construction

The flow threshold detector / flowmeter is made up of an SE32 electronic module and a fitting, either a fitting S030 for the 8032 or a fitting

S070 for the 8072, integrating the measuring element. The position of

the electronic module can be adjusted by 180°.

• The electrical connection of the 8032/8072 threshold detector

is made via a 5-pin M12 fixed male adjustable connector and,

depending on the version, an EN 175301-803 fixed connector.

• Depending on the version, the electrical connection of the

8032/8072 flowmeter is made via an EN 175301-803 fixed connector and/or a male 8-pin or a male 5-pin M12 fixed connector,

the latter being adjustable.

The device requires a 12-36 V DC power supply.

• Depending on the version, a threshold detector has 1 or 2 transistor outputs, NPN and/or PNP, or 1 relay output.

• A flowmeter has either one 4-20 mA current output or one current

output and one relay output.

5.2. Measuring element

• The device 8032 detects the rotation of the paddle-wheel from

the S030 fitting. The paddle-wheel generates pulses with a

6

English

Page 9

Description

Description

frequency proportional to the flow rate (f = KxQ, f is the frequency in Hz, K the proportionality factor, called K factor, in pulse/litre, which is

specific to each S030 fitting, and Q is the flow rate in l/s).

• The device 8072 detects the rotation of the oval gears of the S070 fitting. The oval gears generate a measuring signal with a frequency

proportional to the flow rate. The proportionality factor, called K factor, is specific to each S070 fitting.

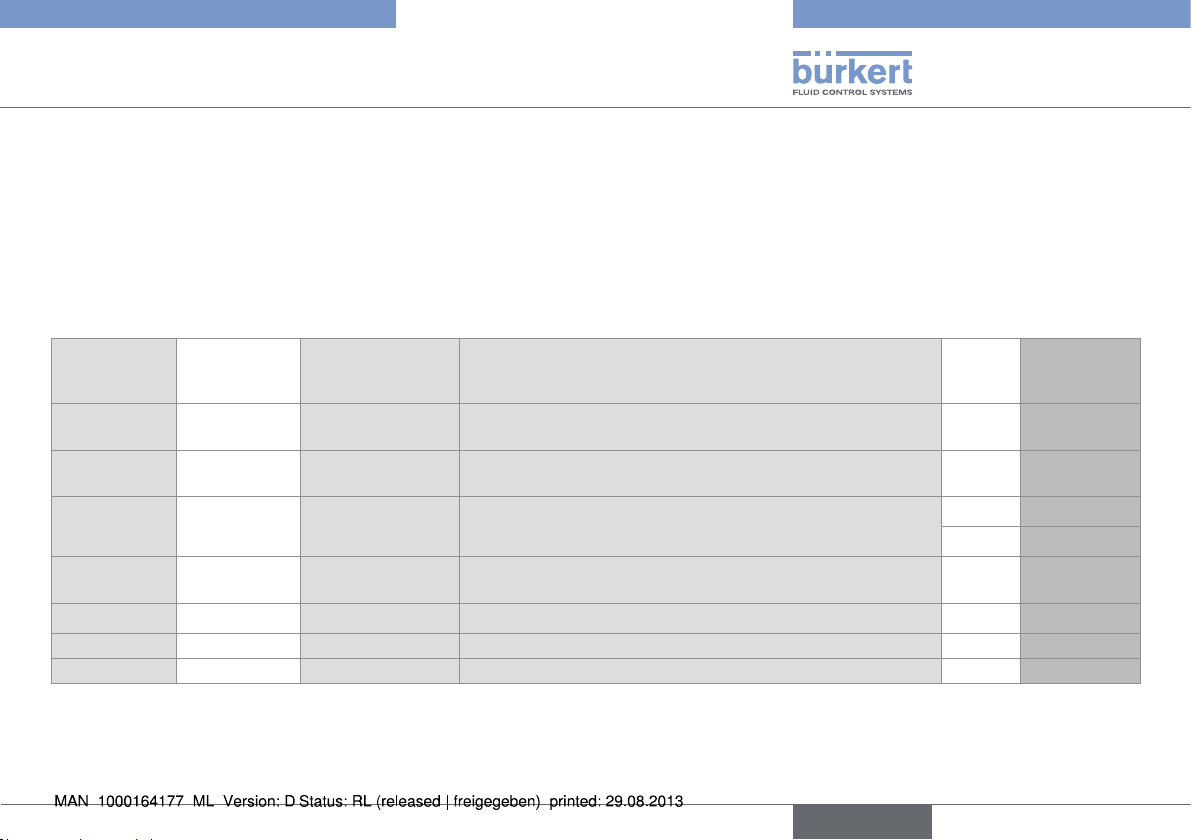

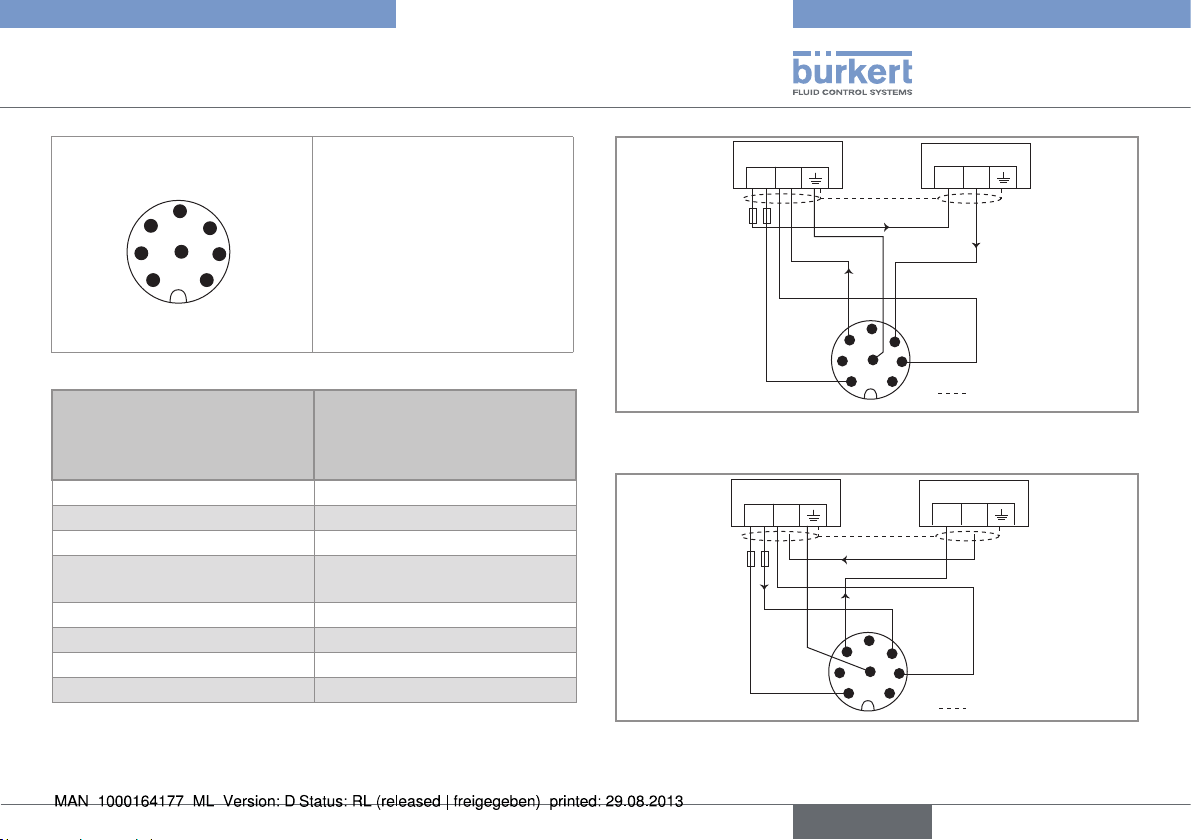

5.3. Available versions of the SE32 electronic module

The order codes of the S030 or S070 fittings can be taken from the related data sheet: refer to the data sheets to select the fitting suited to

your application.

SE32 version

Threshold

detector

Threshold

detector

Threshold

detector

Threshold

detector

Flowmeter 12-36 V DC 4-20 mA + Relay Male 8-pin M12 and male EN 175301-803 fixed connectors

Flowmeter 12-36 V DC 4-20 mA + Relay Male 5-pin M12 and male EN 175301-803 fixed connectors no 560402

Flowmeter 12-36 V DC 4-20 mA Male 5-pin M12 fixed connector no 560403

Supply

voltage

12-36 V DC Transistor, NPN EN 175301-803 male fixed connector

12-36 V DC Transistor, PNP EN 175301-803 male fixed connector

12-36 V DC Transistor, NPN

12-36 V DC Relay Male 5-pin M12 and male EN 175301-803 fixed connectors

Output Electrical connection UL Order code

Male 5-pin M12 fixed connector

and PNP

no 436474

no 434871

no 436473

yes 553431

no 436475

no 560547

English

7

Page 10

Technical data

Technical data

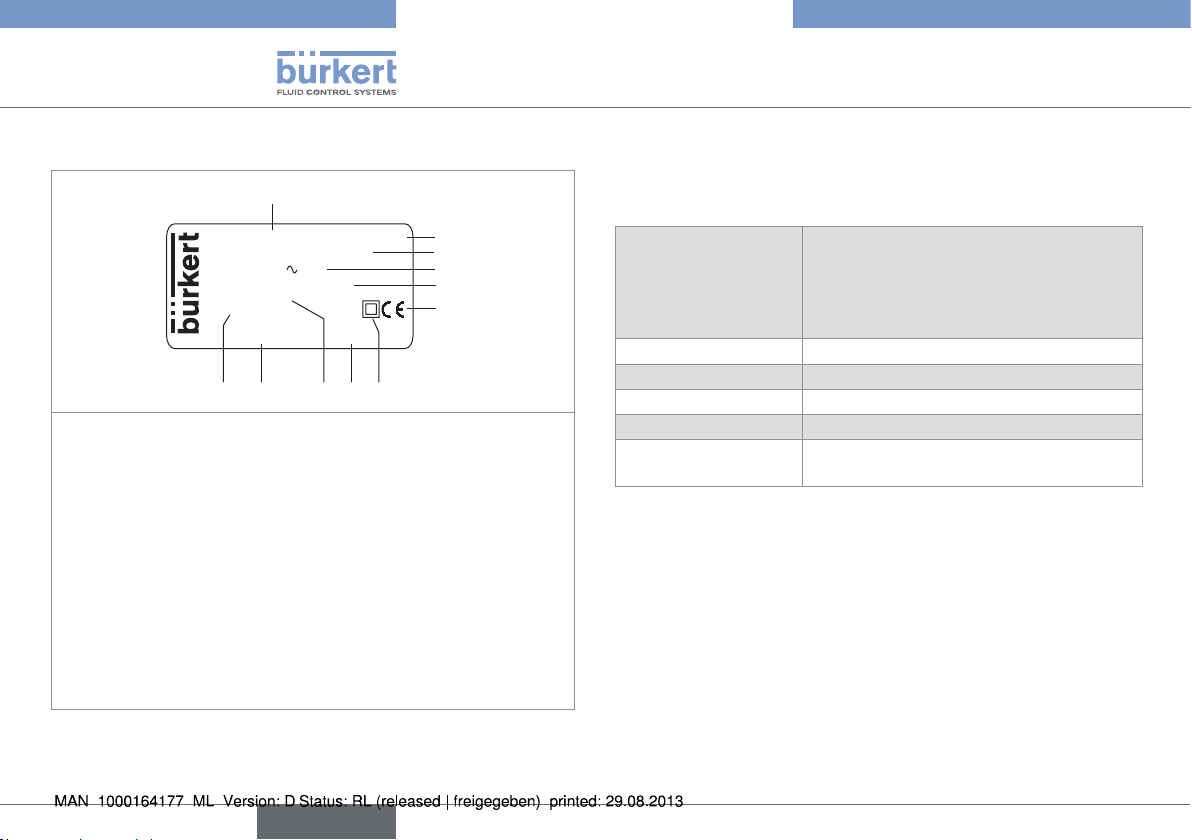

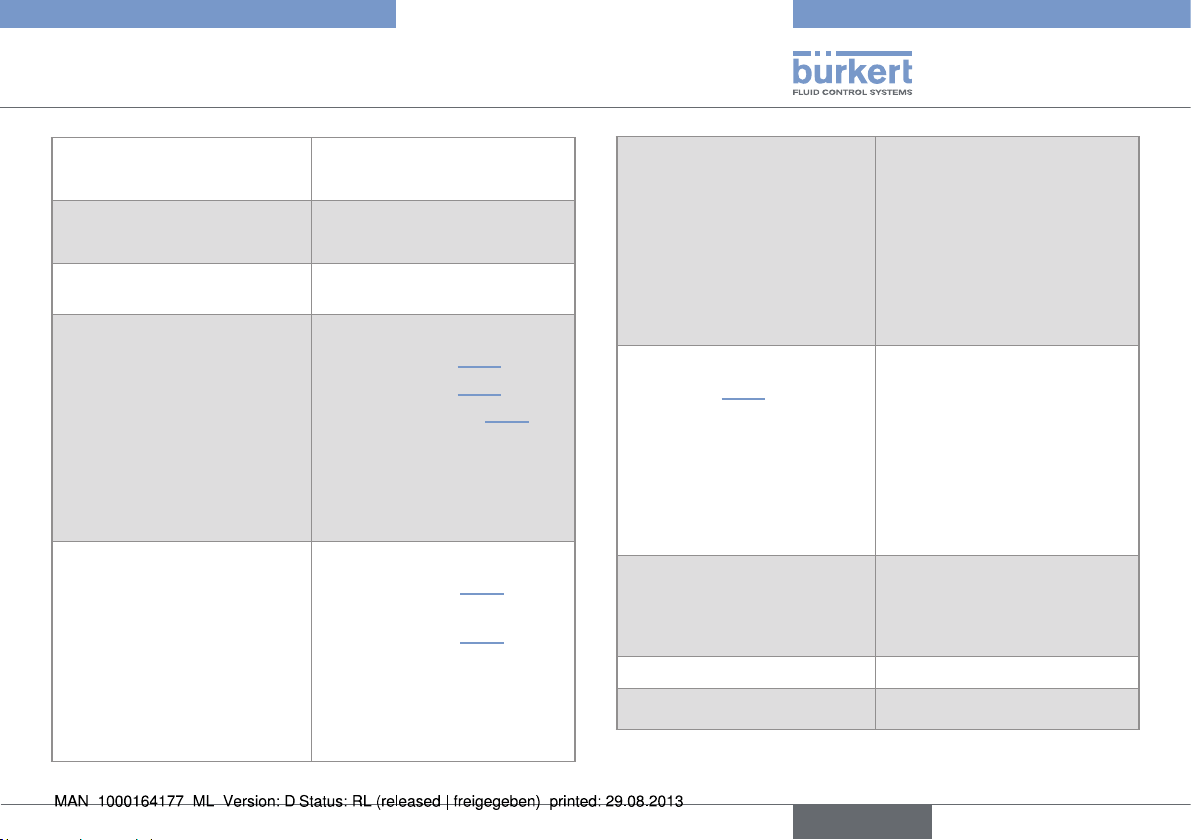

5.4. Description of the name plate

1

FLOW : SE32 HALL

SUPPLY:12-36V= 90mA

REL:230V 3A

PV:12-36V / 4-20mA

0.3-10m/s

S-N:1110

Made in France

00560547 W45LP

10 7

911

8

1. Measured process value and type of the electronic module

2. Type of sensor

3. Power supply; Max. current consumption

4. Data of the on/off output

5. Data of the current output

6. Conformity logo

7. Electrical protection class: double insulation

8. Manufacturing code

9. Measurement range of the flow rate

10. Order code

11. Serial number

Fig. 1: Name plate (example)

2

3

4

5

6

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature

• 8032

• 8072

• UL device

Air humidity < 80%, non condensated

Height above sea level 2000 m max. (UL device)

Degree of pollution Degee 2 acc. to EN 61010-1 (UL device)

Installation class Class I acc. to UL 61010-1 (UL device)

Protection rating IP65 acc. to EN 60529, with connectors

6.2. Compliance to standards and

directives

The device conforms to the EC directives through the following

standards:

• EMC: EN 61000-6-2, EN 61000-6-3

• LVD: EN 61010-1

• Environnemental testing: Vibration: EN 60068-2-6, Shock:

EN 60068-2-27.

• Pressure: The S030 fitting complies with article 3 of §3 from

97/23/CE directive.

(in operation)

• -10°C...60°C

• 0°C...60°C

• 0°C...40°C

plugged-in and tightened or sealed

8

English

Page 11

Technical data

Technical data

Acc. to the 97/23/CE pressure directive, the fitting S030 can only

be used in the following cases (depending on max. pressure, pipe

diameter and fluid):

Type of fluid Conditions

Fluid group 1, par. 1.3.a only DN ≤ 25

Fluid group 2 par. 1.3.a DN ≤ 32

or DN > 32 and PNxDN ≤ 1000

Fluid group 1 par. 1.3.b PNxDN ≤ 2000

Fluid group 2 par. 1.3.b DN ≤ 200

The UL device, with order code 553431, for the United States of

America and Canada complies with the following standards:

• UL 61010-1

• CAN/CSA-C22.2 n° 61010-1.

6.3. General technical data

6.3.1. Mechanical data

Parts not exposed to the

fluid

Housing, cover Fibre glass reinforced polycarbonate

Fixed connectors PA

Material

Parts not exposed to the

fluid

Screws Stainless steel

O-ring seals FKM as standard (EDPM optional)

DN H with S070 fitting

15 85

25 100

40 117

50 135

80 175

100 176

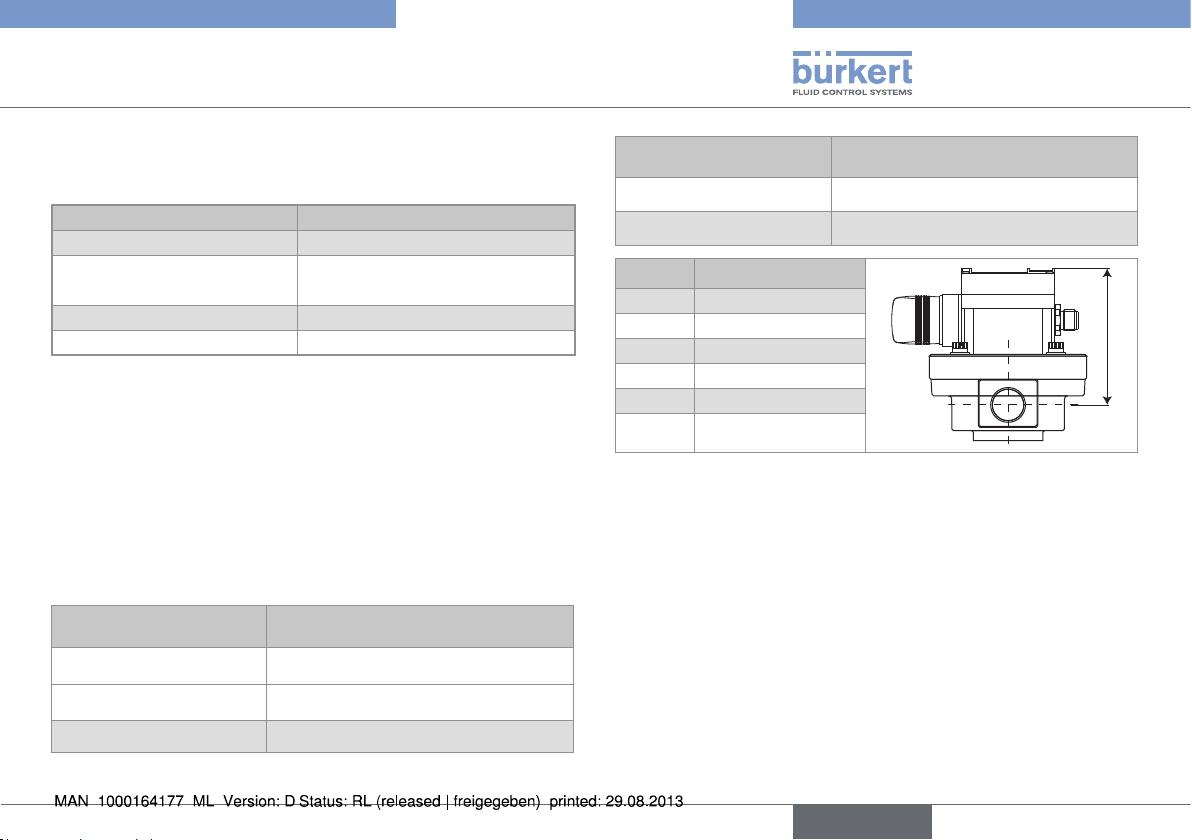

Fig. 2: Dimension H [mm] of the 8072 depending on the S070

fitting diameter

Material

H

Front panel Polyester

English

9

Page 12

Technical data

Technical data

DN H with S030 fitting

06 80

08 80

15 85

20 82

H

25 83

32 86

40 90

50 96

65 96

Fig. 3: Dimension H [mm] of the 8032 depending on the S030

fitting diameter

54 40

22

SW 22

50

76

5-pin M12

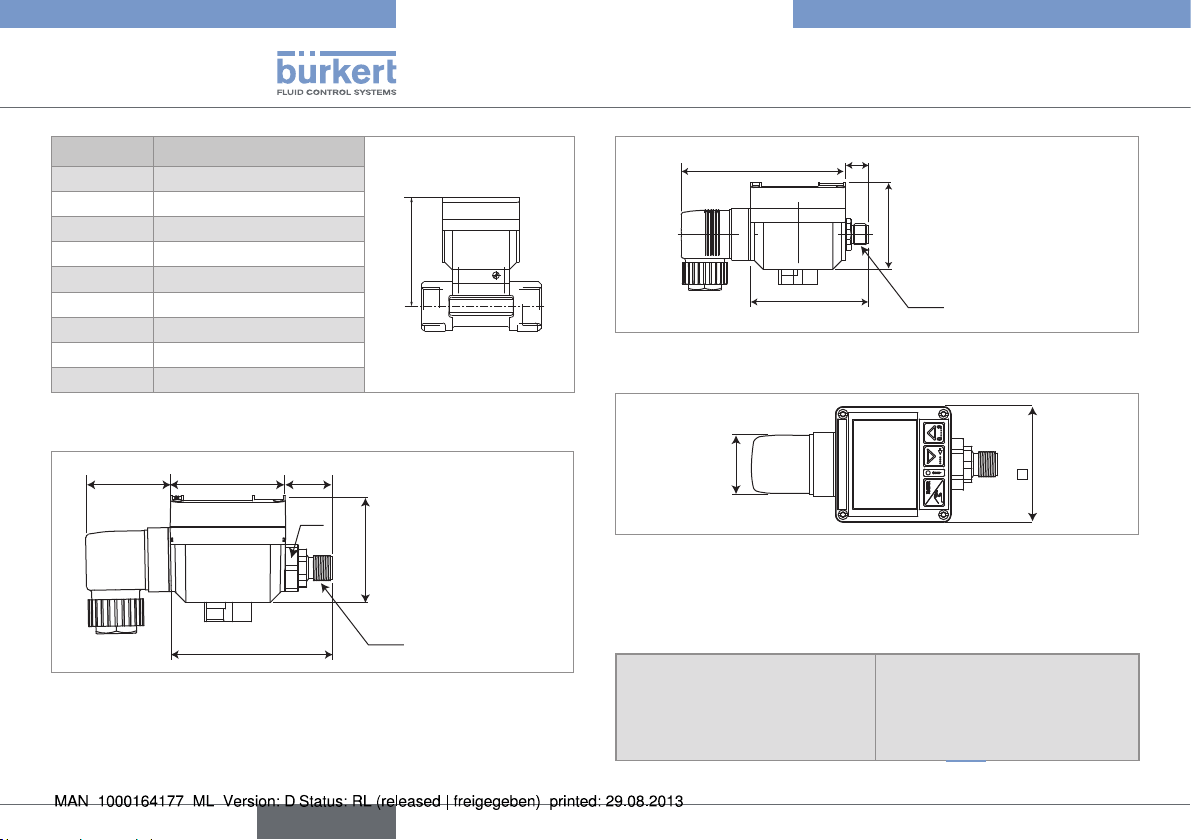

Fig. 4: Dimensions [mm] of the SE32 electronic module with a

5-pin M12 fixed connector

67.5

13.5

50

8-pin M12

94

Fig. 5: Dimensions [mm] of the SE32 electronic module with an

8-pin M12 fixed connector

30

54

Fig. 6: Dimensions [mm] of the SE32 electronic module, top

view

6.3.2. General data

Pipe diameter depends on the fitting used; The

appropriate diameter of an S030

fitting is determined using the

flow/DN/fluid velocity diagrams

in chap. 7.2.1).

10

English

Page 13

Technical data

Technical data

Type of fluid depends on the fitting used

(refer to the operating instructions of the fitting used)

Fluid viscosity depends on the fitting used

(refer to the operating instructions of the fitting used)

Rate of solid particles (8032

max. 1%

only)

Fluid temperature

• with fitting S030 in PVC

• with fitting S030 in PP

• with fitting S030 in stainless

• 0 to 50 °C (see Fig. 8)

• 0 to 80 °C (see Fig. 8)

• -15 to 100 °C (see Fig. 8)

steel, PVDF, or brass

• with S070 fitting, housing in

• max. 80 °C

aluminium

• with S070 fitting, housing in

• max. 100 °C

stainless steel

Fluid pressure

• 8032 with S030 fitting in

• PN16 max. (see Fig. 8)

metal

• 8032 with S030 fitting in

• PN10 max. (see Fig. 8)

plastic

• 8072 with fitting S070 with

• PN10 max.

flanges

• 8072 with any fitting S070

• PN55 max.

except S070 with flanges

Measurement range

• 8032

• 0.3 m/s to 10 m/s,

0.3 m/s corrresponds to a flow

rate of 0.5 l/min in a DN06

fitting

• 8072

• 2 to 1200 l/min, with a viscosity > 5 cps;

3 to 616 l/min, with a viscosity

< 5 cps;

Accuracy

• 8032 (see

Fig. 7)

• ±1 % of the full scale1), with

on site calibration or when

using the teach-in feature

or

± (1 % of the full scale1) + 3%

of the measured value), when

using the standard K factor

• 8072

• ±1% of the measured value

Repeatability

• 8032

• 8072

Linearity (8032 only) ±0.5 % of the full scale

• ±0.4% of the measured value

• ±0.03% of the measured

value

1)

Measuring element paddle-wheel of the S030 fitting

or oval gears of the S070 fitting

1)

Full scale = 10 m/s

English

11

Page 14

Technical data

Technical data

Max error %

20

16

12

8

4

-4

-8

-12

-16

-20

Measuring error - % of the

measurement

1 9

2 3 4 5 6 7 8 10

Fluid velocity in m/s

with a Teach-in procedure

With standard K factor of

the S030 fitting

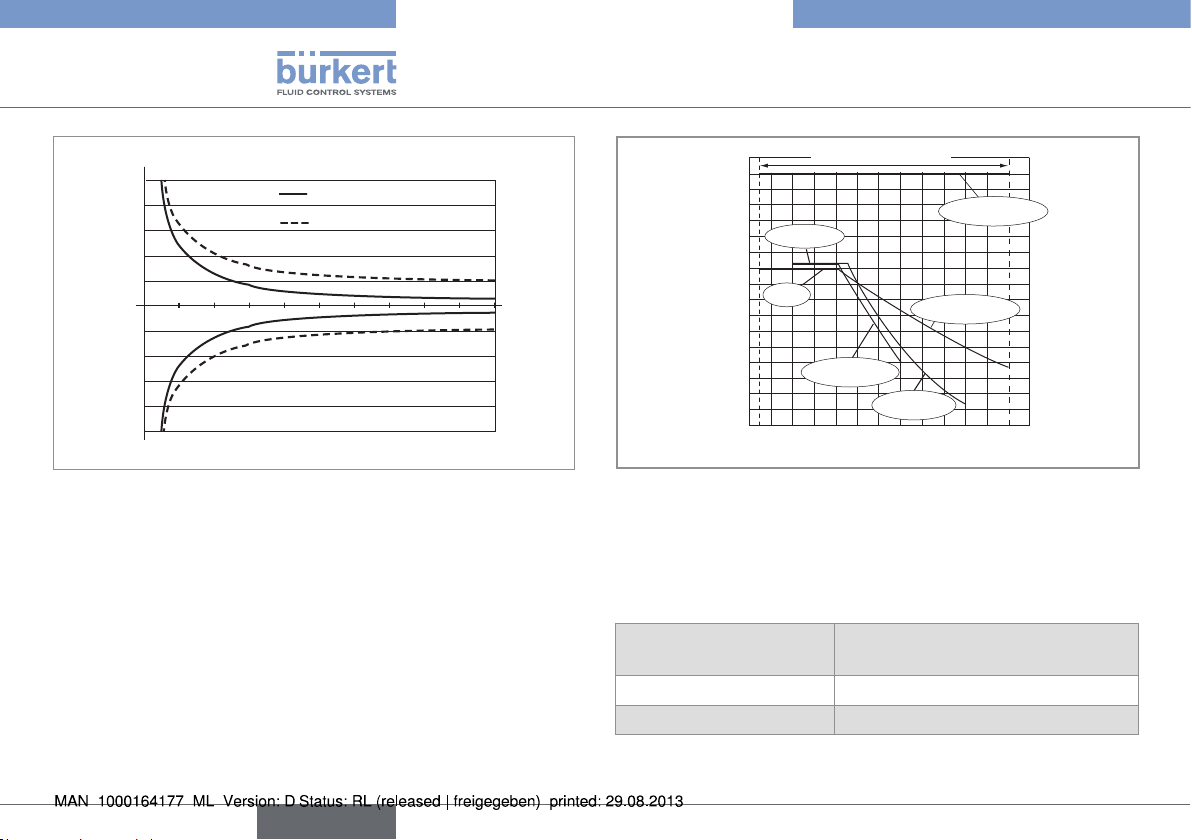

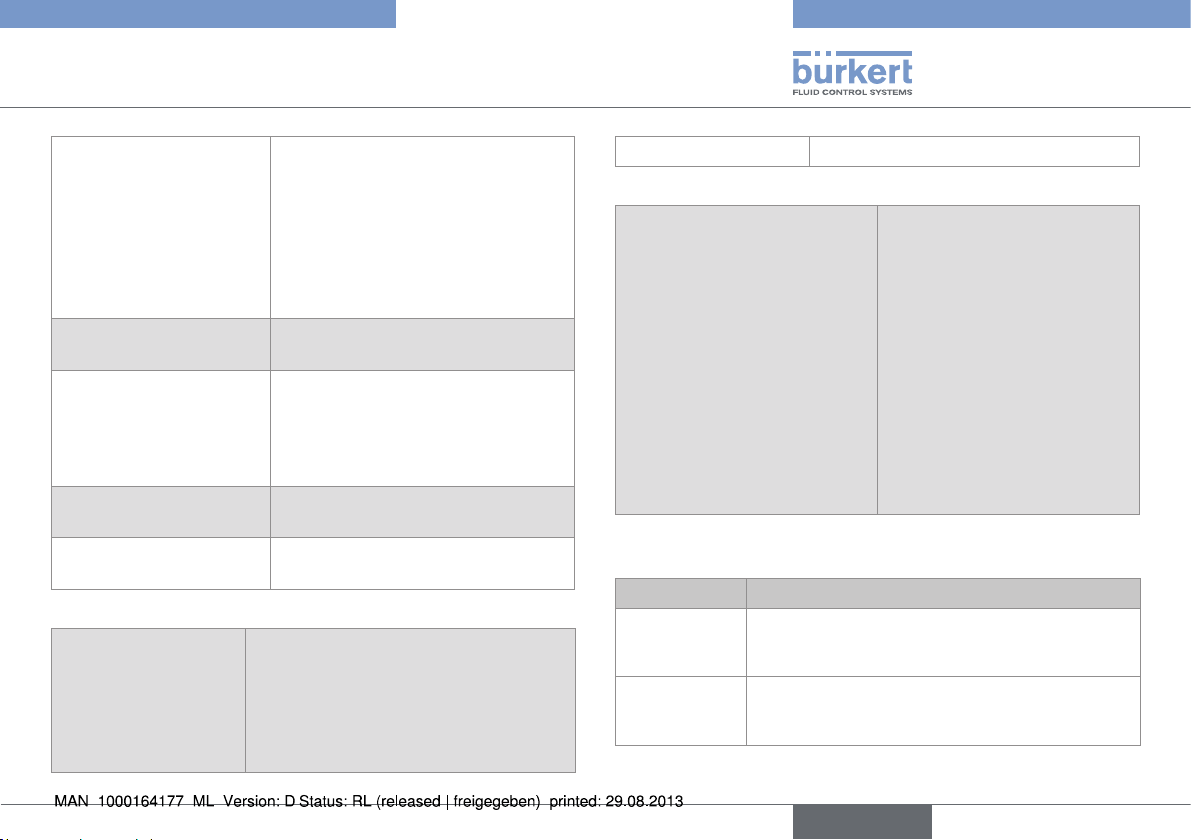

Fig. 7: Accuracy of the measurements made by a 8032, when

using or not the Teach-in feature.

These values were determined in the following reference conditions:

medium = water, water and ambient temperatures 20 °C, min. upstream and

downstream distances respected, appropriate pipe dimensions

P [bar]

16

15

14

13

12

PVC + PP

11

10

9

PVDF

8

7

6

5

4

3

2

1

0

-15 0 +20 +40 +60 +80 +100

PVC (PN10)

A

Metal (PN16)

PVDF (PN10)

PP (PN10)

T [°C]

Fig. 8: Fluid temperature / pressure dependency of the 8032,

depending on the material the S030 fitting is made of

6.3.3. Electrical data

Table 1: Electrical data for threshold detectors

Installation class (overvoltage class)

Supply voltage 12-36 V DC

Dielectric strength 2300 V AC

2

12

English

Page 15

Technical data

Technical data

Current consumption

• Version with transistor

output

• Version with 1 single

output, relay or current

• version with 1 relay and

1 current outputs

Protection against polarity

reversal

Transistor output NPN and/or PNP, 700 mA max.,

Relay output 250 V AC, 3 A max, operation and

Protection against short

circuits

Table 2: Electrical data specific to the UL threshold detector

Characteristics of the

power source (not

supplied)

• 50 mA max.

• 70 mA max.

• 90 mA max.

yes

operation and thresholds can be

parametered

NPN output: 0,2-36 V DC,

PNP output: supply voltage

thresholds can be parametered

yes, for the transistor output

• Limited power source (in accordance

with § 9.3 of the UL 61010-1

standard)

• or class 2 type power source

(according to the 1310/1585 and

60950-1 standards)

Drain current 30-50 mA

Table 3: Electrical data for flowmeters

4-20 mA output

• Accuracy

• Wiring

• Loop resistance

• Galvanically insulated

• 4 mA adjustment

• 20 mA adjustment

• Response time (10% up to

90%)

• ±0.5%

• 4 wires

• 1300W at 36 V DC, 1000W at

30 V DC, 700 W at 24 V DC,

450 W at 18 V DC, 200W at

12 V DC

• yes

• between 3 and 5 mA

• between 18.5 and 21.5 mA

• 3 s with filter 2 (default setting)

6.3.4. Data of the cables and wires

Version Type of connector

Detector with

NPN transistor

output

Detector with

PNP transistor

output

EN 175301-803 female connector (type 2508,

supplied)

EN 175301-803 female connector (type 2508,

supplied)

English

13

Page 16

Installation and wiring

Installation and wiring

Version Type of connector

Detector with

Female 5-pin M12 connector (not supplied)

NPN/PNP transistor output

Detector with

relay output

Flowmeter with

relay output

EN175301-803 (type 2508 supplied) and 5-pin

M12 (not supplied) female connectors

EN 175301-803 (type 2508 supplied) and 8-pin

M12 (not supplied) or 5-pin M12 (not supplied)

female connectors

Flowmeter

Female 5-pin M12 connector (not supplied)

without relay

output

Type of connector Cable type

M12 with order code

917116

• shielded

• 3 to 6.5 mm in diameter

• with wires with a max. cross section

of 0,75 mm

2508 with order code

438811

• shielded

• 6 to 7 mm in diameter

• with wires with a cross section of

between 0.14 and 0.5 mm

7. INSTALLATION AND WIRING

7.1. Safety information

DANGER

Risk of injury due to high pressure in the installation

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to the nature of the fluid.

• Respect the regulations on accident prevention and safety relating to the use of aggressive fluids.

Risk of injury due to electrical voltage.

2

2

• Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

• Do not unscrew the cover of a powered device.

• Observe all applicable accident protection and safety guidelines

for electrical equipment.

14

English

Page 17

Installation and wiring

Installation and wiring

WARNING

Risk of injury due to nonconforming installation.

• The electrical and fluid installation can only be carried out by

qualified and skilled staff with the appropriate tools.

• Install appropriate safety devices (correctly rated fuse and/or

circuit-breaker).

• Respect the assembly instructions for the fitting used.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

• Take appropriate measures to avoid unintentional activation of

the installation.

• Guarantee a set or controlled restarting of the process subsequent to any intervention on the device.

To ensure that the device runs correctly, plug in and tighten

the connectors.

7.2. Installation onto the pipe

7.2.1. Diagrams

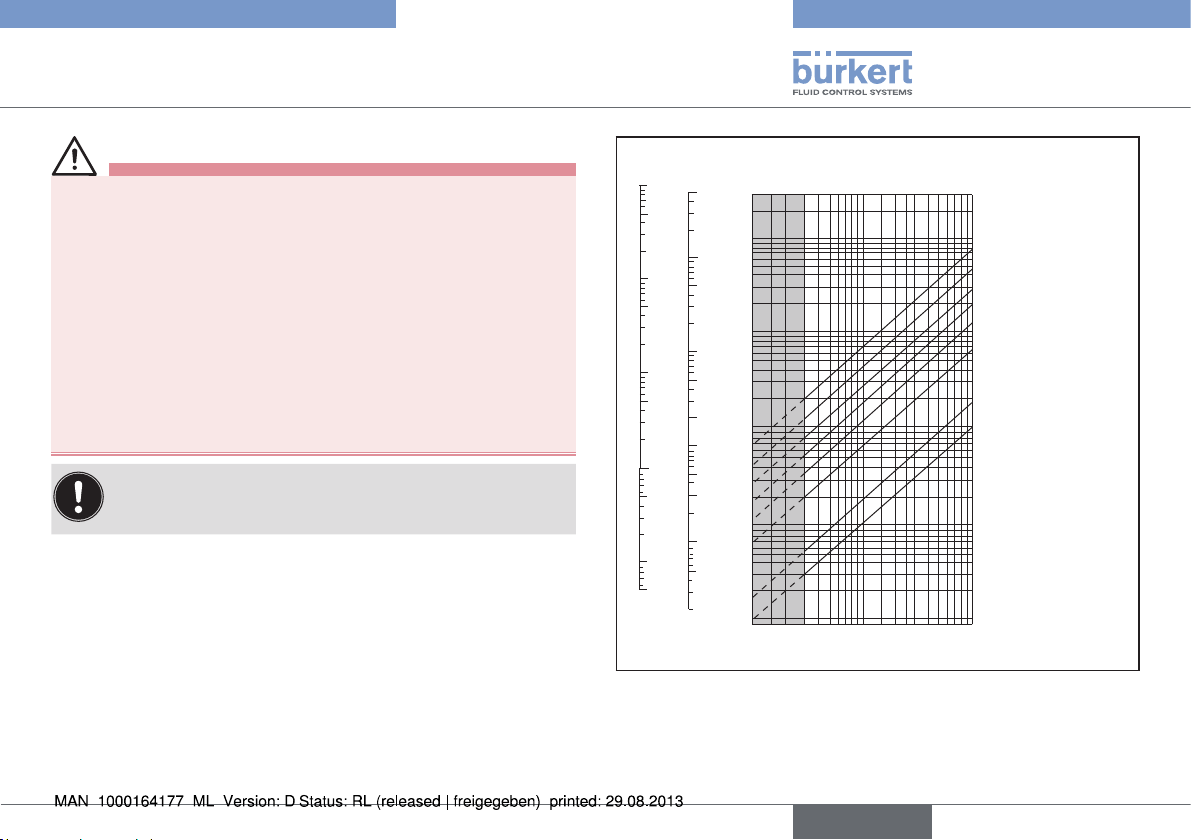

These diagrams are used to determine the DN of the fitting (only

for a threshold detector / flowmeter 8032) appropriate to the application, according to the fluid velocity and the flow rate.

Flow rate

l/s

100

50

10

5

1

0.5

0.1

0.05

0.01

0.005

l/min

5000

1000

500

100

50

20

10

5

3

2

1

0.5

0.3

0.2

m

200

100

50

20

10

0.5

0.2

0.1

0.05

0.02

0.01

3

/h

5

2

1

0.1 0.3 0.5 1 2 3 5 100.2

Flow velocity

DN 50 (DN65)*

DN 40 (DN50)*

DN 32 (DN40)*

DN 25 (DN32)*

DN 20 (DN25)*

DN 15 (DN15 / DN20)*

DN 08

DN 06

m/s

English

15

Page 18

Installation and wiring

Installation and wiring

gpm

1000

Flow rate

500

200

100

50

20

10

5

2

1

0.5

0.2

0.1

0.05

0.02

0.01

DN50 (DN65)*

DN40 (DN50)*

DN32 (DN40)*

DN25 (DN32)*

DN20 (DN25)*

DN15 (DN15 / DN20)*

DN08

DN06

fps

30200.3 0.5 1 2 3 5 10

Flow velocity

* for the following fittings:

- with external threads acc. to SMS 1145.

- with weld ends acc. to SMS 3008, BS 4825 / ASME BPE or

DIN 11850 Rg2.

- with clamp connections acc. to SMS 3017 / ISO 2852 or

BS 4825 / ASME BPE or DIN 32676.

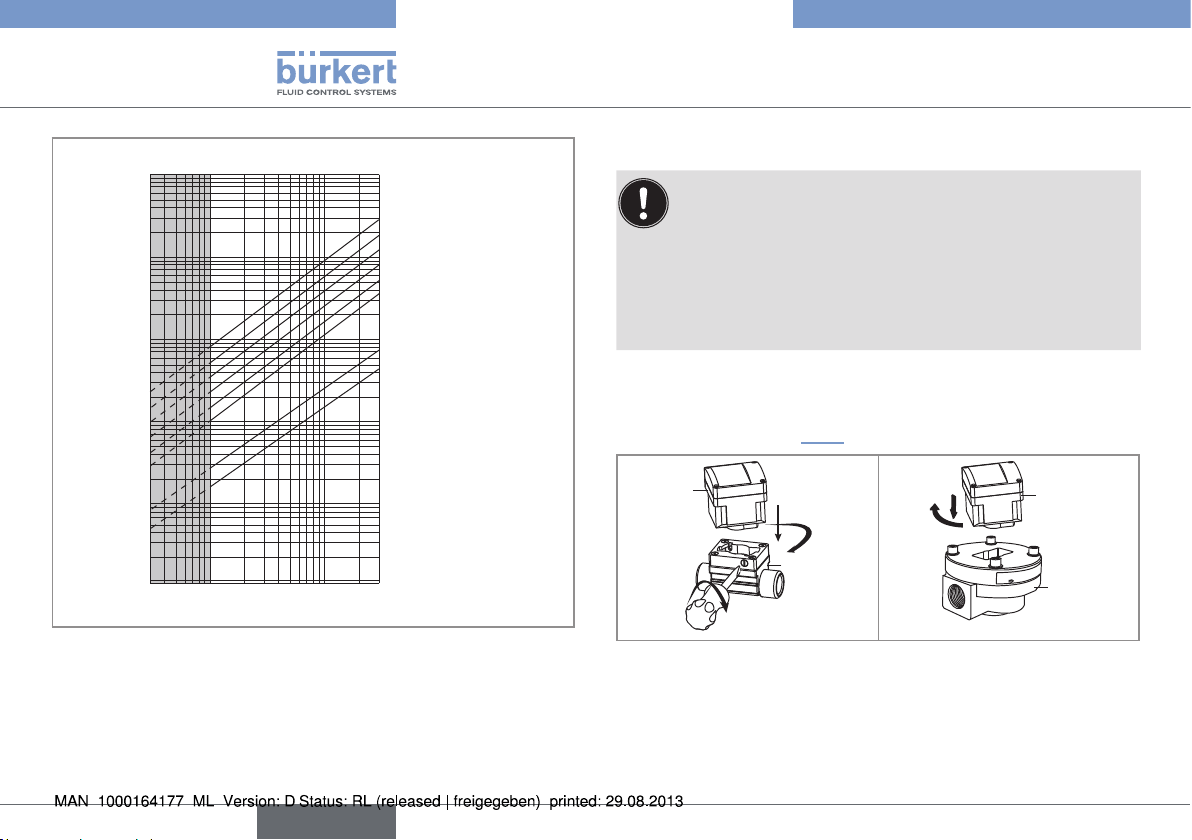

7.2.2. Assembly of the 8032 / 8072

The electronic module SE32 only detects one rotation

direction of the oval gears of a fitting S070.

• If the 8072 does not run properly, once assembled and

energized, do the following:

→ remove the SE32 from the S070,

→ turn the electronic module SE32 by 180°,

→ insert the SE32 back into the S070.

→ Install the fitting in the pipe according to the installation instruc-

tions provided with the fitting.

→ To assemble the electronic module with the fitting, follow the

instructions given in Fig. 9.

SE32

1

2

S030

3

Fig. 9: Assembling the SE32 with the fitting S030 or S070

1

2

SE32

FLOW

S070

16

English

Page 19

Installation and wiring

Installation and wiring

7.3. Wiring

DANGER

Risk of injury due to electrical voltage

• Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

• Observe all applicable accident protection and safety guidelines

for electrical equipment.

• Use shielded cables with a temperature limit of 80 °C

minimum.

• Use a high quality electrical power supply, filtered and

regulated.

• Protect the power supply by means of a 1 A fuse and a

switch.

• Protect the power supply of each transistor by means of a

125 mA fuse.

• Protect the relays by means of a max. 3 A fuse and a

circuit breaker (depending on the process).

• Do not apply both a dangerous voltage and a safety extralow voltage to the relays.

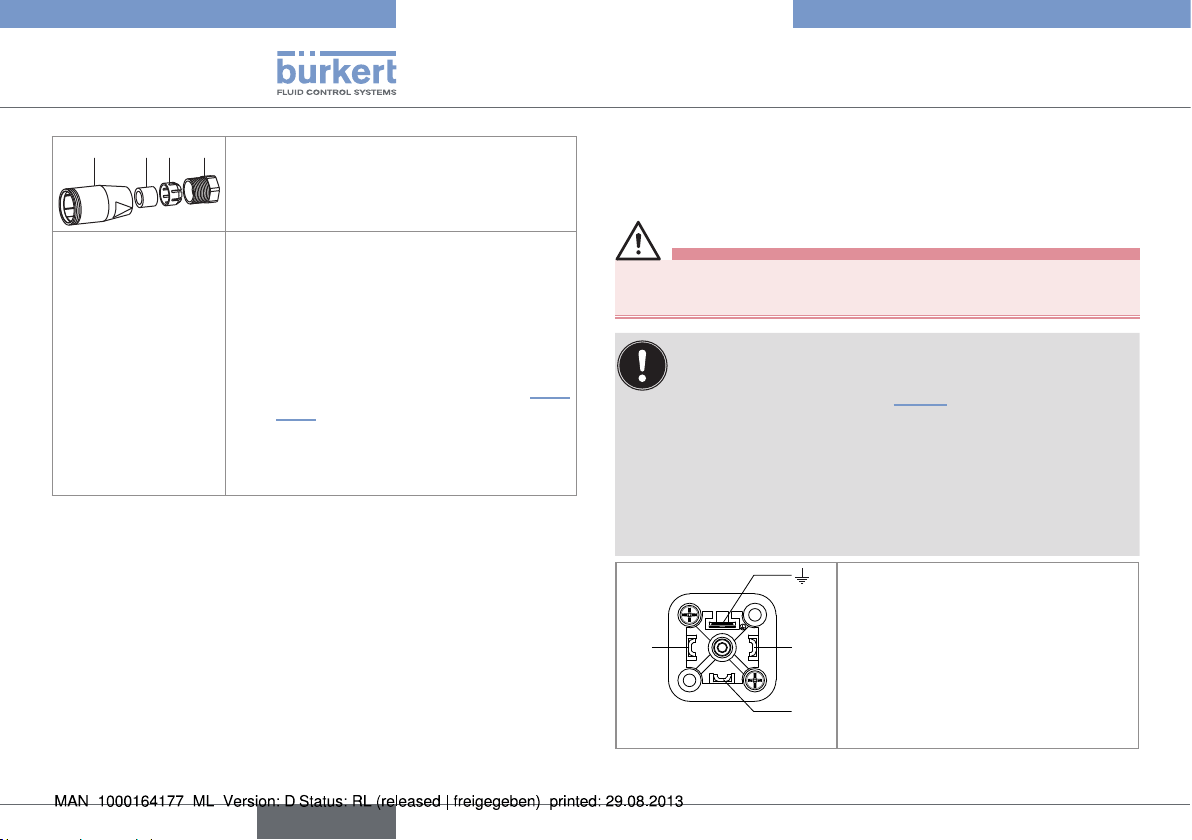

7.3.1. Assembling the connectors

2

→ Unscrew the nut [1] of the cable gland.

→ Remove the terminal block [3] from the housing

[2].

3

→ Insert the cable through the nut [1] then through

the gasket [4], through the cable gland and

4

1

finally through the housing [2].

→ Make the connections to the screw terminal

block [3] (see chap. 7.3.2, 7.3.4, 7.3.6 or 7.3.7).

→ Position the terminal block [3] in steps of 90°

then put it back into the housing [2], pulling

gently on the cable so that the wires do not

clutter the housing.

→ Tighten the nut [1] of the cable gland.

→ Place the seal [5] between the connector and

the EN175301-803 fixed connector on the

device and then plug the 2508 connector into

5

the fixed connector.

6

Fig. 10: Assembling the female connector type 2508 (supplied)

→ Insert and then tighten the screw [6] to ensure

tightness and correct electrical contact.

English

17

Page 20

Installation and wiring

Installation and wiring

4 3 2 1

→ Unscrew the nut [1] on the body [4].

→ Insert the cable into the nut [1], the cable

clamp [2] and the seal [3], and then into

the body [4].

→ Strip 20 mm of the cable.

→ Cut the central wire (earth) so that its

length is equal to 11.5 mm.

→ Expose 5.5 mm of the wires on the

stripped cable.

→ Insert each wire into the appropriate pin

on the terminal block [5] (see chap. 7.3.3

to 7.3.7).

→ Screw the terminal block [5] once wired

to the body [4]

→ Tighten the connector nut [1].

Fig. 11: Assembling an M12 female connector (not supplied )

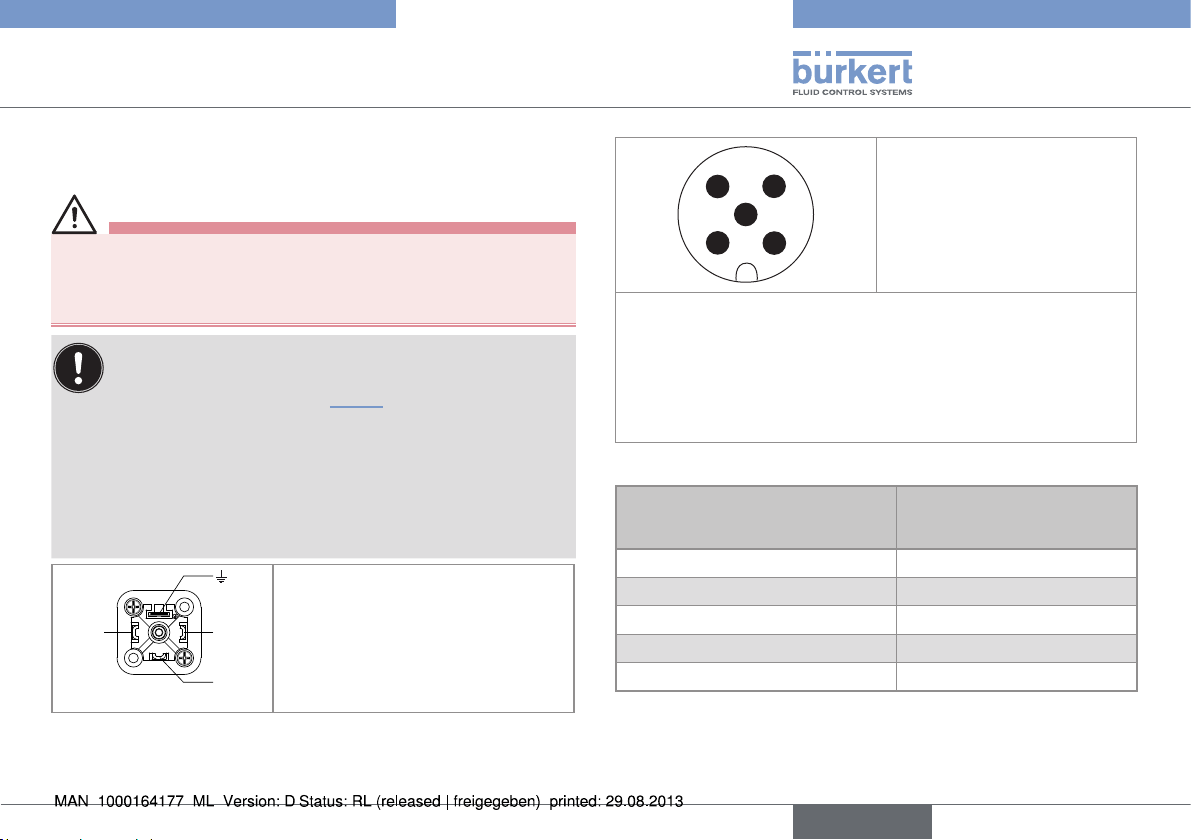

7.3.2. Wiring a version with transistor

output and EN175301-803 male fixed

connector

DANGER

Risk of injury due to electrical voltage

• Always plug in and tighten the connectors correctly.

The device is not tight when the EN 175301-803 fixed

connector is not wired:

→ Unscrew the nut [1] (see Fig. 10) on the 2508 female

connector supplied with the device.

→ Insert the plug with order code 444509, supplied with

the device, into the cable gland.

→ Screw the nut again.

→ Plug the sealed 2508 connector onto the

EN 175301-803 fixed connector.

1: V+ (12-36 V DC)

2

1

1

3

2: Transistor output (NPN or PNP)

2

3: 0 V DC

4: Functional earth

3

18

Fig. 12: Pin assignment of the EN175301-803 fixed connector

English

Page 21

Installation and wiring

Installation and wiring

Load

(solenoid valve,

for example)

+-

Power cable shield

(*)

1

V+

PNP transistor

2

output

+ -

12-36 V DC

3

0 V DC

Power supply

Fig. 13: NPN wiring of the transistor output of a version with

EN 175301-803 fixed connector

Load

(solenoid valve,

for example)

+-

+ -

12-36 V DC

Power supply

Power cable shield

V+

1

3

0 V DC

(*)

NPN transistor

output

2

Fig. 14: PNP wiring of the transistor output of a version with

EN 175301-803 fixed connector

(*) Functional earth

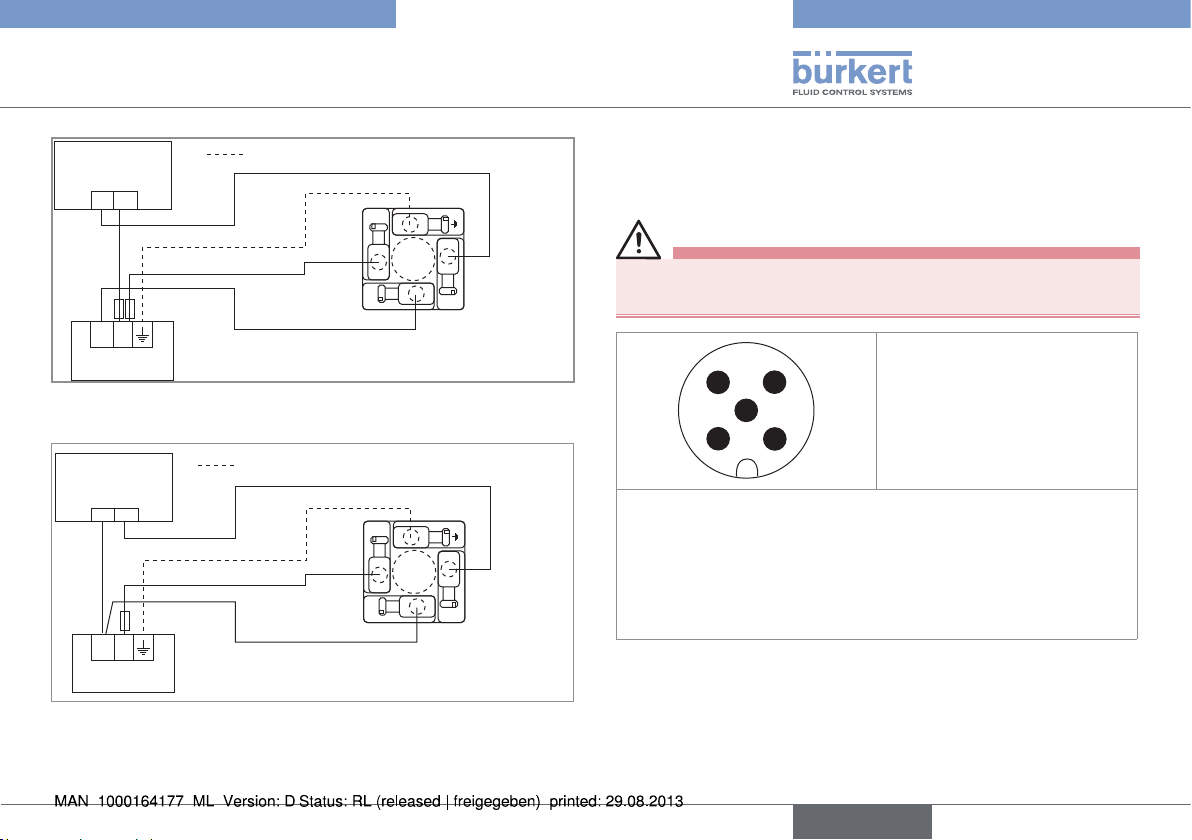

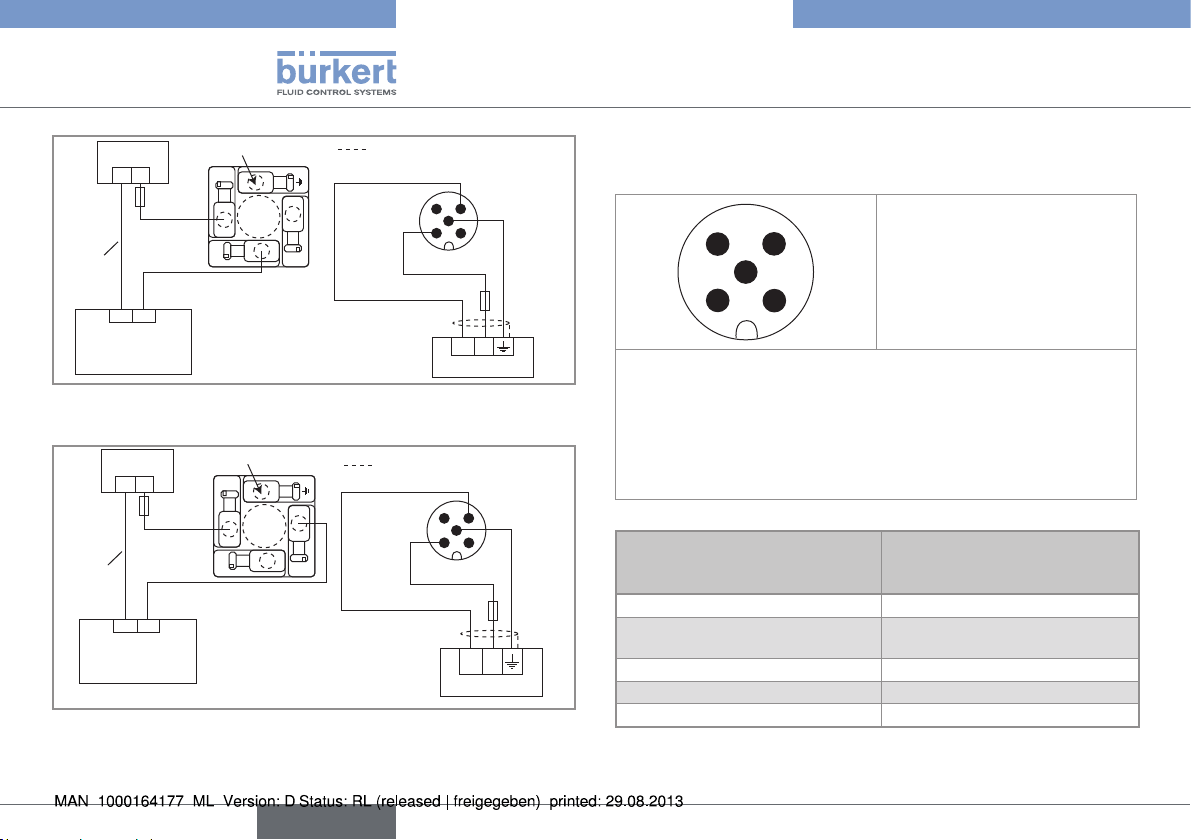

7.3.3. Wiring a version with 2 transistor

outputs and a 5-pin M12 male fixed

connector

DANGER

Risk of injury due to electrical voltage

• Always plug in and tighten the connectors correctly.

1: V+ (12-36 V DC)

4 3

5

1 2

2: NPN transistor output

3: 0 V DC

4: PNP transistor output

5: Functional earth

The position of the 5-pin M12 fixed connector is adjustable:

→ Unscrew the locknut.

→ Turn the fixed connector to the desired position, by 360° max. to

prevent the cables from twisting inside the housing.

→ Tighten the locknut using a spanner, while keeping the fixed

connector in the desired position.

Fig. 15: Allocation of the pins on the 5-pin M12 fixed connector

English

19

Page 22

12-36 V DC

Installation and wiring

Installation and wiring

Pin of the M12 female cable

available as accessory

Colour of the wire (signal)

equipment (order code 438680)

1 brown (12-36 V DC)

2 white (NPN transistor output)

3 blue (0 V DC)

4 black (PNP transistor output)

5 grey (functional earth)

When both transistor outputs are wired, they operate with

the same settings made within the OUT function.

Load 1

(wired in PNP

mode)

5

1 2

3 4

brown

blue

grey

+ -+ -

black

Load 2

(wired in NPN

mode)

white

(*)

Power cable shield

Power supply

+ -

12-36 V DC

Fig. 16: Wiring both transistor outputs on a version with a 5-pin

M12 fixed connector

Load

(solenoid valve,

for example)

+-

white

5

1 2

3 4

blue

grey

brown

(*)

Power cable shield

Power supply

+ -

Fig. 17: Wiring of the NPN transistor output of a version with a

5-pin M12 fixed connector

Load

(solenoid valve,

for example)

+-

black

5

1 2

3 4

blue

grey

brown

(*)

Power cable shield

Power supply

+ -

12-36 V DC

Fig. 18: Wiring of the NPN transistor output of a version with a

5-pin M12 fixed connector

(*) Functional earth

20

English

Page 23

Installation and wiring

Installation and wiring

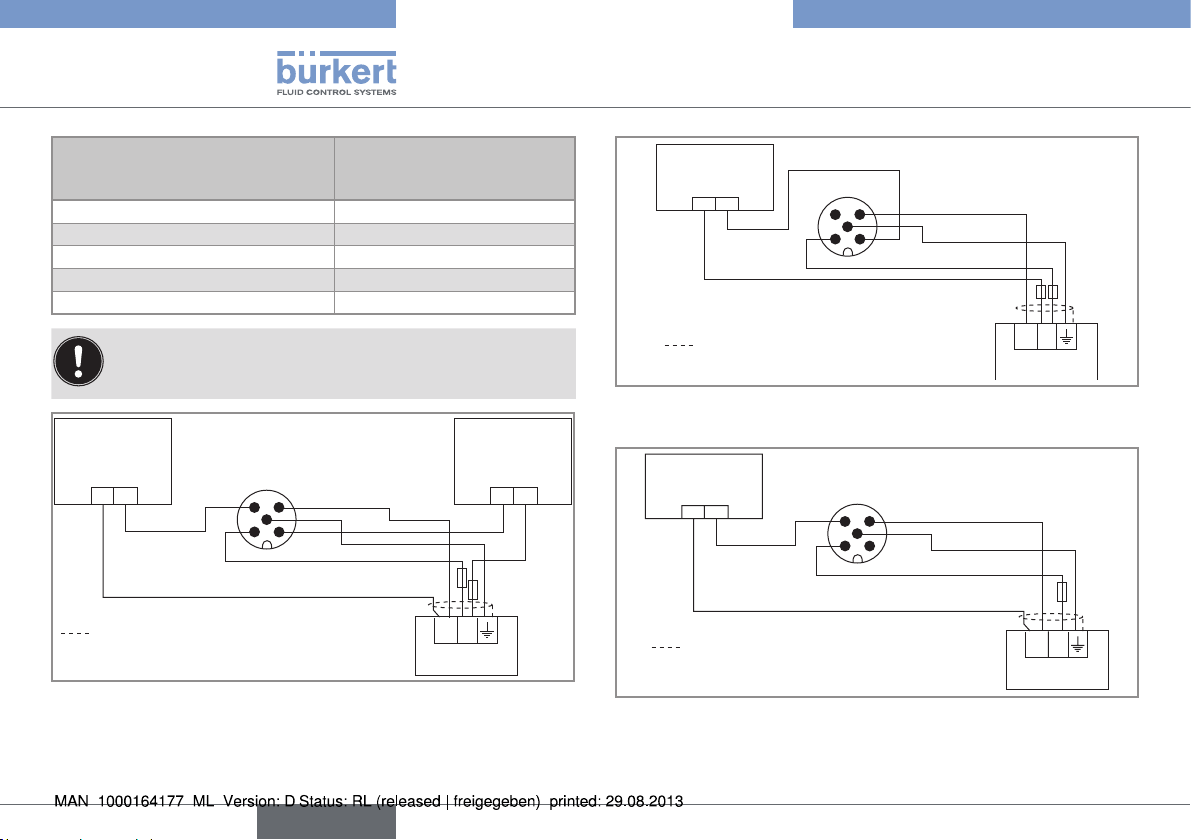

7.3.4. Wiring of the version with a single

relay output

WARNING

Shock hazard due to the voltage at the relay terminals, which

is higher than 48V.

• Before powering the device, always check that the connectors

are correctly plugged-in and tightened.

The device is not tight when the EN 175301-803 fixed

connector is not wired:

→ Unscrew the nut [1] (see Fig. 10) on the 2508 female

connector supplied with the device.

→ Insert the plug with order code 444509, supplied with

the device, into the cable gland.

→ Screw the nut back.

→ Plug the sealed 2508 connector onto the

EN 175301-803 fixed connector.

1: Common

2

1

1

3

2

3

Fig. 19: Pin assignment on the EN 175301-803 fixed connector

2: Relay, normally closed (NC)

3: Relay, normally open (NO)

4: Not connected

4 3

5

1 2

1: V+ (12-36 V DC)

2: not connected

3: 0 V DC

4: not connected

5: Functional earth

The position of the 5-pin M12 fixed connector is adjustable:

→ Unscrew the locknut.

→ Turn the fixed connector to the desired position, by 360° max. to

prevent the cables from twisting inside the housing.

→ Tighten the locknut using a spanner, while keeping the fixed

connector in the desired position.

Fig. 20: Pin assignment of the 5-pin M12 fixed connector

Pin of the M12 female cable

available as accessory

equipment (order code 438680)

1 brown (V+)

2 not connected

3 blue (0 V DC)

4 not connected

5 grey (functional earth)

(1) Use a voltage limiter depending on the load selected, e.g. for the solenoid

valve, an EN 175301-803 connector with integrated varistor.

(*) Functional earth

Colour of the wire (signal)

English

21

Page 24

Installation and wiring

Installation and wiring

250 V AC

L

N

(1)

Load

(solenoid valve,

for example)

not connected

1

3

Relay output, normally open

(NO)

2

Power cable shield

blue

Power supply

3 4

5

1 2

brown

12-36 V DC

grey

(*)

+ -

Fig. 21: NO wiring of the relay output of a version with one 5-pin

M12 and one EN 175301-803 fixed connectors

250 V AC

L

N

(1)

Load

(solenoid valve,

for example)

not connected

1

3

Relay output, normally

closed (NC)

2

Power cable shield

blue

1 2

Power supply

3 4

grey

5

brown

(*)

+-

12-36 V DC

Fig. 22: NC wiring of the relay output of a version with one 5-pin

M12 and one EN 175301-803 fixed connectors

7.3.5. Wiring of the version with a single

current output

4 3

5

1 2

The position of the 5-pin M12 fixed connector is adjustable:

1: V+ (12-36 V DC)

2: Negative 4-20 mA output

3: 0 V DC

4: Positive 4-20 mA output

5: Functional earth

→ Unscrew the locknut.

→ Turn the fixed connector to the desired position, by 360° max. to

prevent the cables from twisting inside the housing.

→ Tighten the locknut using a spanner, while keeping the fixed

connector in the desired position.

Fig. 23: Pin assignment of the 5-pin M12 fixed connector

Pin of the M12 female cable

available as accessory

equipment (order code 438680)

1 brown (V+)

2

3 blue (0 V DC)

4 black (positive 4-20 mA output)

5 grey (functional earth)

The current output can be connected in either sourcing or sinking

mode.

Colour of the wire (signal)

white (negative 4-20 mA

output)

22

English

Page 25

Installation and wiring

Installation and wiring

Power supply

12-36 V DC

+

+

(*)

-

4-20mA input

(at external

instrument)

i

brown

grey

white

blue

4

5

1 2

3

i

black

i

shield

Fig. 24: Wiring of the current output, in sinking mode, of a

version with a single 5-pin M12 fixed connector

Power supply

12-36 V DC

+

+

(*)

-

4-20mA input

(at external

instrument)

i

black

4

grey

1 2

blue

i

white

3

5

shield

i

brown

Fig. 25: Wiring of the current output, in sourcing mode, of a

version with a single 5-pin M12 fixed connector

(*) Functional earth

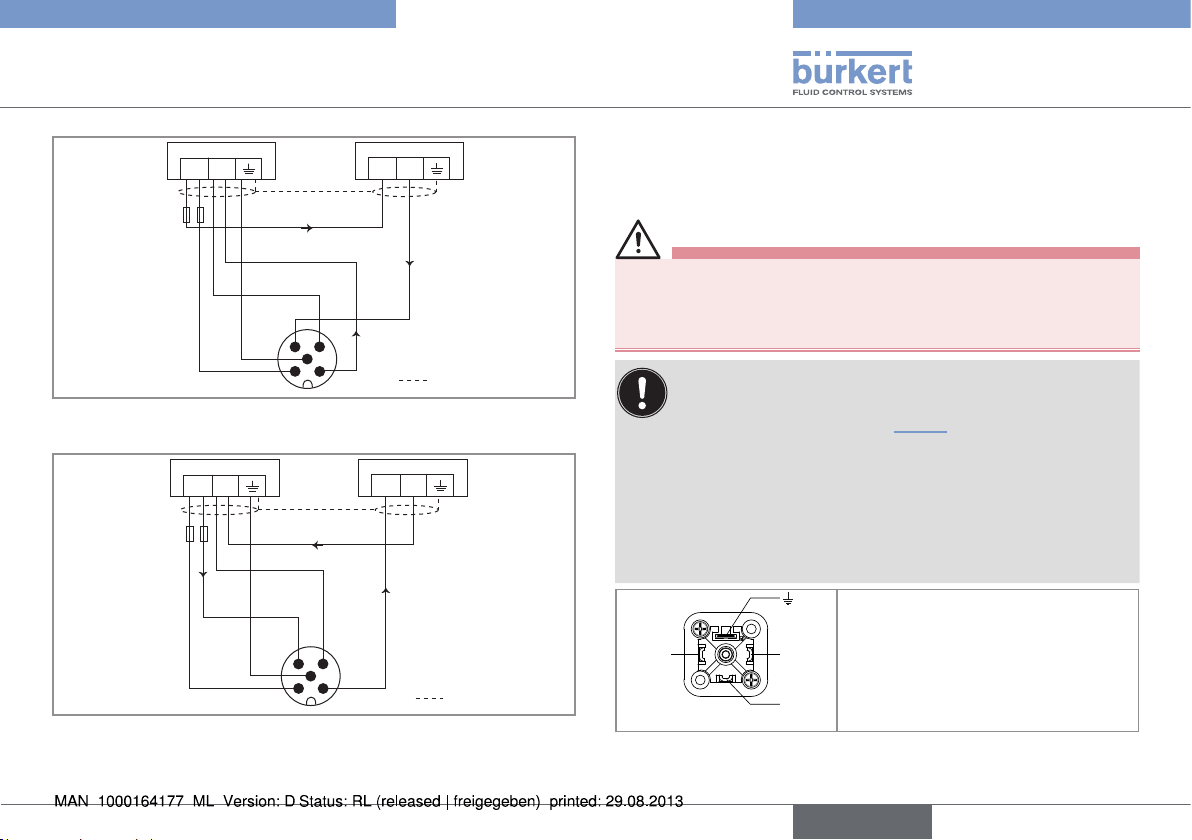

7.3.6. Wiring the version with both relay

and current outputs (5-pin M12 fixed

connector)

WARNING

Shock hazard due to the voltage at the relay terminals, which

is higher than 48V.

• Before powering the device, always check that the connectors

are correctly plugged-in and tightened.

The device is not tight when the EN 175301-803 fixed

connector is not wired:

→ Unscrew the nut [1] (see Fig. 10) on the 2508 female

connector supplied with the device.

→ Insert the plug with order code 444509, supplied with

the device, into the cable gland.

→ Screw the nut back.

→ Plug the sealed 2508 connector onto the

EN 175301-803 fixed connector.

1: Common

2

1

1

3

2

3

Fig. 26: Pin assignment on the EN 175301-803 fixed connector

2: Relay, normally closed (NC)

3: Relay, normally open (NO)

4: not connected

English

23

Page 26

Installation and wiring

Installation and wiring

1: V+ (12-36 V DC)

4 3

5

1 2

2: Negative 4-20 mA output

3: 0 V DC

4: Positive 4-20 mA output

5: Functional earth

The position of the 5-pin M12 fixed connector is adjustable:

→ Unscrew the locknut.

→ Turn the fixed connector to the desired position, by 360° max. to

prevent the cables from twisting inside the housing.

→ Tighten the locknut using a spanner, while keeping the fixed con-

nector in the desired position.

Fig. 27: Pin assignment of the 5-pin M12 fixed connector

The current output can be connected in either sourcing or

sinking mode. See Fig. 30 and Fig. 31 for the related wiring

charts.

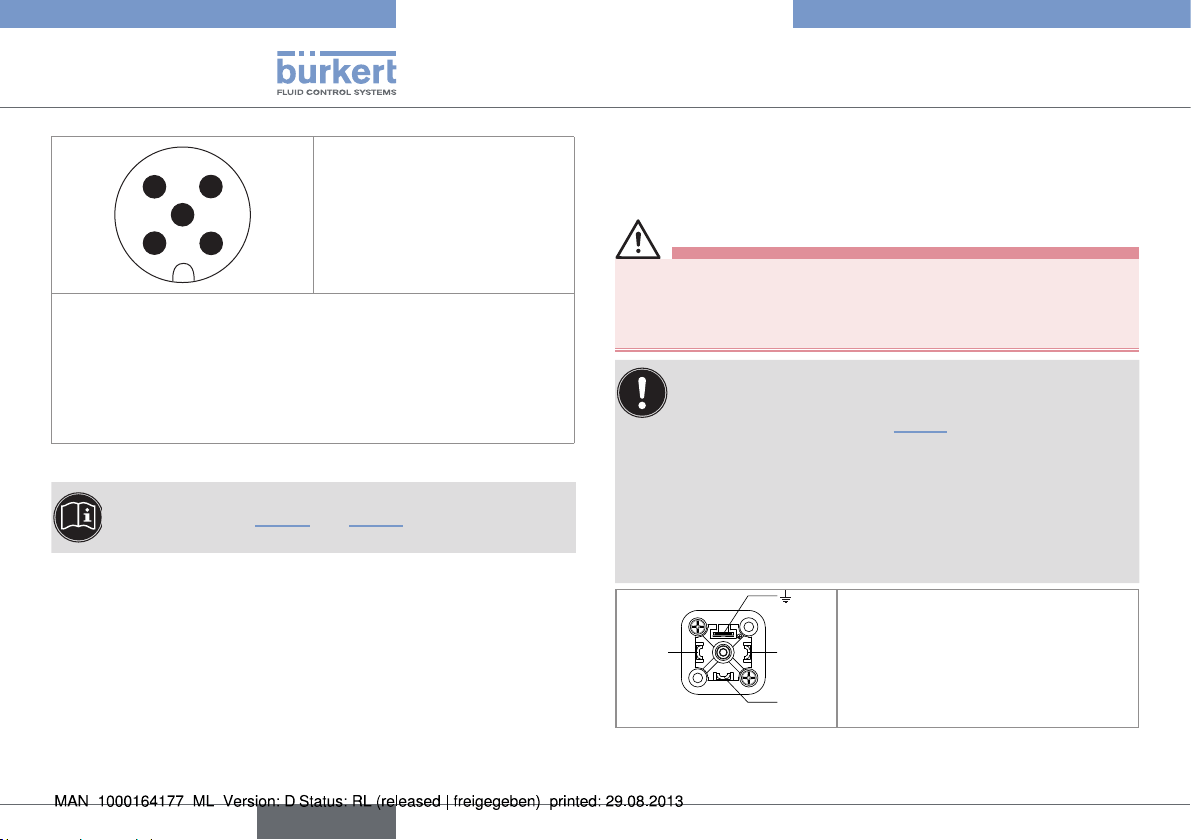

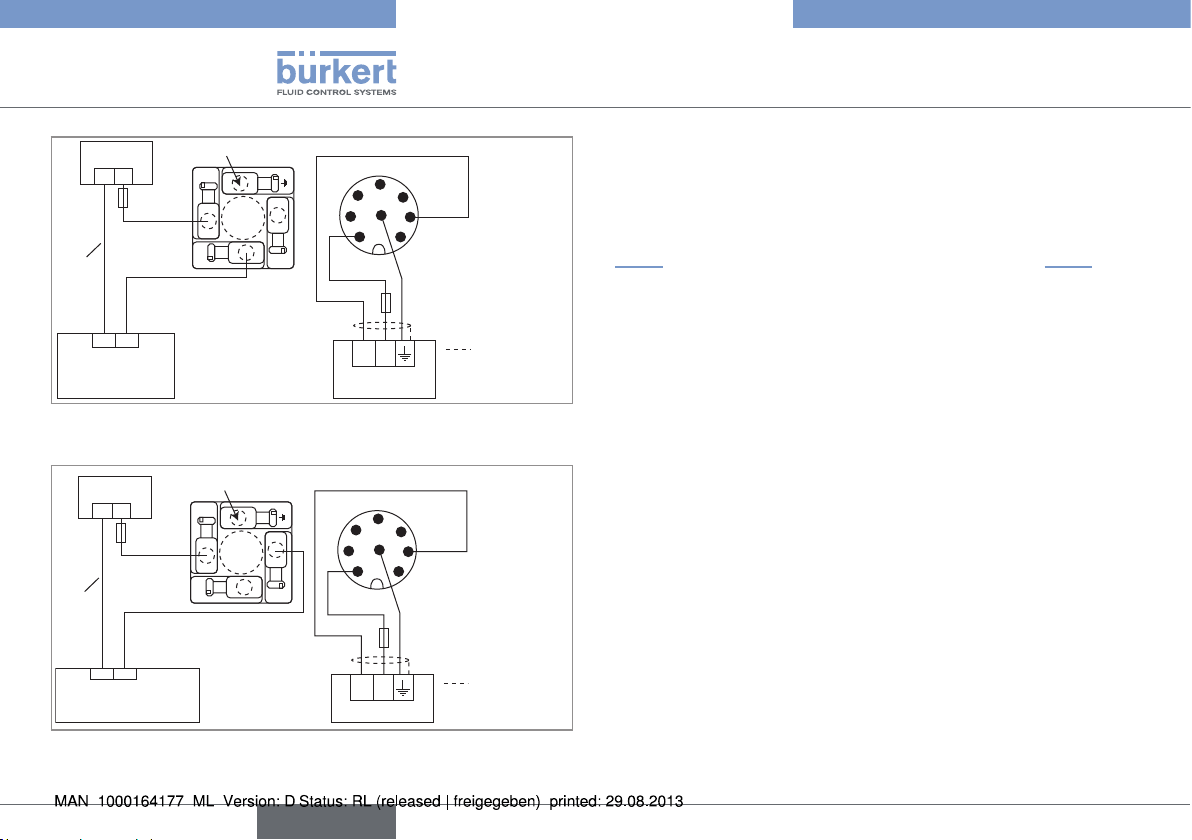

7.3.7. Wiring the version with relay and

current outputs (8-pin M12 fixed

connector)

WARNING

Shock hazard due to the voltage at the relay terminals, which

is higher than 48V.

• Before powering the device, always check that the connectors

are correctly plugged-in and tightened.

The device is not tight when the EN 175301-803 fixed

connector is not wired:

→ Unscrew the nut [1] (see Fig. 10) on the 2508 female

connector supplied with the device.

→ Insert the plug with order code 444509, supplied with

the device, into the cable gland.

→ Screw the nut back.

→ Plug the sealed 2508 connector onto the

EN 175301-803 fixed connector.

1: Common

2

1

1

3

2: Relay, normally closed (NC)

2

3: Relay, normally open (NO)

3

4: Not connected

24

Fig. 28: Pin assignment on the EN 175301-803 fixed connector

English

Page 27

Installation and wiring

Installation and wiring

1: V+ (12-36 V DC)

5

6

4

2: Not connected

3: 0 V DC

4: Positive 4-20 mA output

8

7

1

3

2

5: Not connected

6: Negative 4-20 mA output

7: Not connected

8: Functional earth

Fig. 29: Allocation of the pins on the M12, 8-pin fixed connector

Pin of the 8-pin M12 female

Colour of the wire (signal)

cable available as an

accessory equipment (order

code 444800)

1 white (12-36 V DC)

2 not connected

3 green (0 V DC)

4 yellow (positive 4-20 mA

output)

5 not connected

6 pink (negative 4-20 mA output)

7 not connected

8 grey (functional earth)

The current output can be connected in either sourcing or sinking mode.

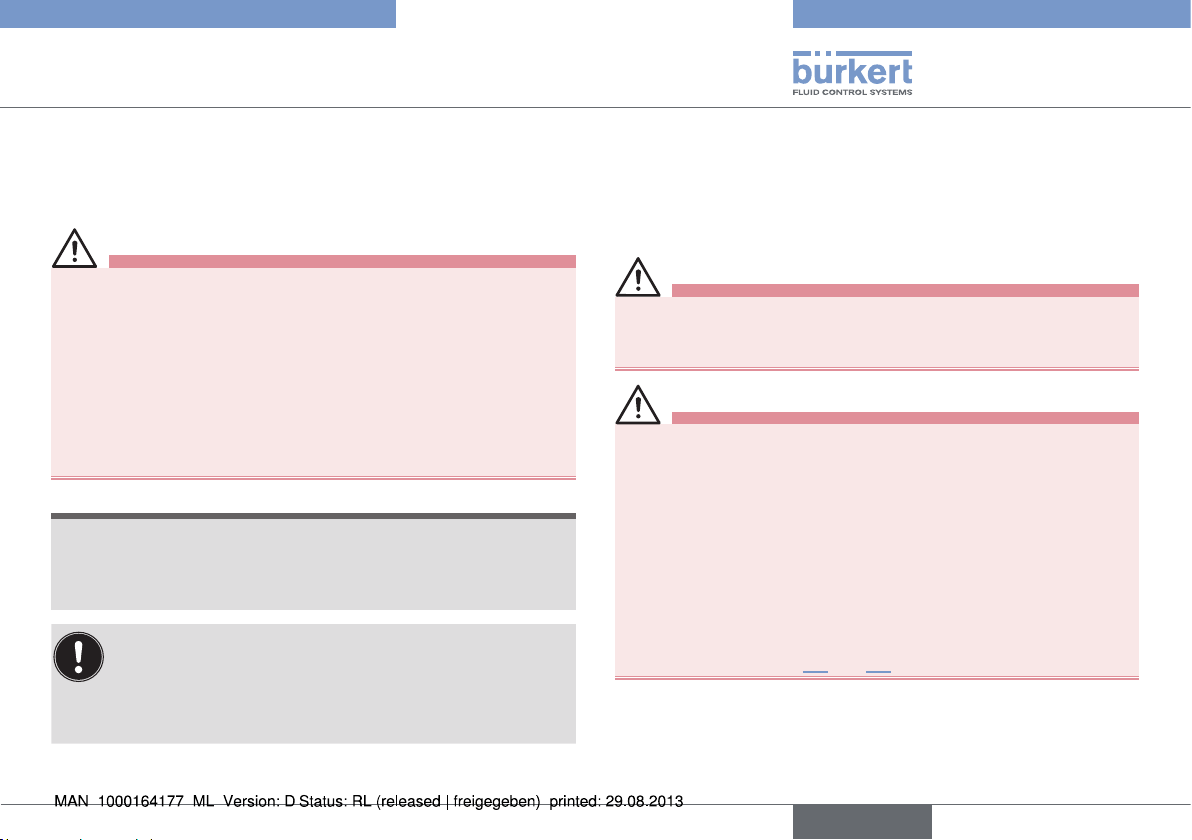

Power supply

12-36 V DC

+

(*)

+

-

4-20mA input

(at external

instrument)

i

i

green

shield

white

6

7

1 2

yellowpink

grey

i

5

4

3

8

Fig. 30: Wiring of the current output, in sinking mode, of a

version with an 8-pin M12 fixed connector

Power supply

12-36 V DC

+

(*)

+

-

4-20mA input

(at external

instrument)

i

6

7

1 2

pink

i

5

yellow

4

green

3

8

shield

i

grey

white

Fig. 31: Wiring of the current output, in sourcing mode, of a

version with an 8-pin M12 fixed connector

English

25

Page 28

Installation and wiring

Installation and wiring

250 V AC

L

N

(1)

Relay output, normally open

(NO)

Load (solenoid

valve, for example)

not connected

1

3

Power supply (2)

6

7

2

1 2

white

12-36 V DC

green

5

4

3

8

grey

(*)

+ -

Power cable

shield

Fig. 32: NO wiring of the relay output of a version with an 8-pin

M12 fixed connector

250 V AC

L

N

(1)

Relay output, normally

closed (NC)

Load (solenoid valve,

for example)

not connected

1

3

Power supply (2)

6

7

2

1 2

white

12-36 V DC

green

5

4

3

8

grey

(*)

+ -

Power cable

shield

Fig. 33: NC wiring of the relay output of a version with an 8-pin

M12 fixed connector

(*) Functional earth

(1) Use a voltage limiter depending on the load selected, e.g. for the solenoid

valve, an EN 175301-803 connector with integrated varistor.

(2) If the current output is needed, wire the 8-pin M12 connector acc. to

Fig. 30 if the current output is wired in sinking mode, or acc. to Fig. 31 if the

current ouput is wired in sourcing mode.

26

English

Page 29

Commissioning

Commissioning

8. COMMISSIONING

8.1. Safety information

WARNING

Danger due to nonconforming commissioning.

Nonconforming commissioning could lead to injuries and damage

the device and its surroundings.

• Before commissioning, make sure that the staff in charge have

read and fully understood the contents of the manual.

• In particular, observe the safety recommendations and intended

use.

• The device/installation must only be commissioned by suitably

trained staff.

NOTE

Risk of damage to the device due to the environment

• Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of the

climatic conditions.

• When the device is switched on and the cover is open,

protection against electric shock is no longer guaranteed.

• Check the chemical compatibility between the fluid to

be measured and the materials from which the device is

made exposed to it.

9. ADJUSTMENT AND

FUNCTIONS

9.1. Safety information

DANGER

Risk of injury due to electrical voltage

• Observe all applicable accident protection and safety guidelines

for electrical equipment.

WARNING

Risk of injury due to nonconforming adjustment.

Nonconforming adjustment could lead to injuries and damage the

device and its surroundings.

• The operators in charge of adjustment must have read and

understood the contents of this manual.

• In particular, observe the safety recommendations and intended

use.

• The device/installation must only be adjusted by suitably trained

staff.

• Before commissioning the device, enter the K factor of the fitting used. See chap. 9.4 and 9.5.

English

27

Page 30

Adjustment and functions

Adjustment and functions

9.2. Operating levels

All settings may influence the correct running of the

process.

• Note the values of the parameters set in the table at chap.

9.8.

The flow threshold detector / flowmeter 8032/8072 has 2 operating

levels: the Process level and the Configuration level.

The Configuration level comprises the Parameters and Test menus.

Operating level Functions

Process • To read out:

- the measured flow rate

- the switching thresholds

- the value of the 4-20 mA output (flowmeter

only)

• To access the Parameters and Test menus of

the Configuration level

Operating level Functions

Configuration

- Parameters

menu

Configuration Test menu

• To make the settings needed for operation:

- flow rate unit

- transistor or relay output

- filter

- bar graph

- K factor

- 4-20 mA current output (flowmeter only)

• To make the following additional settings:

- backlighting

- access code to the Parameters and Test

menus.

• To test the configuration made in the Parameters menu with entering of a theoretical value.

• To read the frequency of the measured signal.

• To adjust the 4-20 mA output.

28

English

Page 31

Adjustment and functions

Adjustment and functions

9.3. Description of the display and

the operating keys

The display is used to:

• read the value of certain parameters such as the measured flow

rate;

• parameterize the device by means of 3 keys;

• read the configuration of the device;

• get notification of some events.

• To change the value (0...9)

0......9

Back key

Next key

ENTER

Confirm key

of the selected digit.

• To go back to the previous

function.

• To select the digit at the

left;

• To go to the next function.

• To confirm the function

displayed;

• To confirm the parameters

set.

Bar graph running in each

mode, except during a

teach-in procedure.

O

U

T

Shows the status of the on/

off output (red LED).

Shows if the relay is open or

closed.

Means that the access to

the Parameters and Test

menus is protected through

a code.

Fig. 34: Description of the keys and icons

9.4. Process level

The use and setting of the access code to the Parameters

and Test menus are defined within the Parameters menu.

Display Displays...

Dispaly A ...the measured flow rate

Display B (only flowmeters) ...the value of the 4-20 mA output.

Display C ...the value of the low switching

threshold (

Display D ...the value of the high switching

threshold (

O LO).

O HI).

English

29

Page 32

Display A

Display B

Display C

Display D

0......9

Process level

1

0.615

l/s

12.56

MA

0.200

OLO

1.000

OHI

(by default)

Press the keys simultaneously

0......9

0......9

+

more than 5 s

ENTER

+

> 5 s

ENTER

+

> 5 s

> 5 s

+

ENTER

OFF

Status of

function

CODE?

Status of

function CODE?

OFF

(by default)

ON

ON

0000

0......9

0000

0......9

CODE

CODE

Adjustment and functions

Adjustment and functions

ENTER

ENTER

Code

OK?

Code

OK?

access to the Param-

2

eters menu (see chap.

9.5)

3

access to the Test

menu (see chap. 9.6)

30

English

Page 33

Adjustment and functions

Adjustment and functions

9.5. Configuration level - Parameters menu

All settings may influence the correct running of the process.

→ Note the values of the parameters set in the table at chap. 9.8.

Function Description of the function

UNIT (see chap. 9.5.1) To select the unit of the flow rate.

KFAC (see chap. 9.5.2) To enter the K factor of the fitting used or have it determined. The K factor is specific to each fitting. It is used by

the device to convert the measured signal into a flow rate.

OUT (see chap. 9.5.3) • To select:

- the operation of the transistor or relay output (Hysteresis or Window);

- whether the operation is inverted or not.

• To set:

- the high (

- the time delay before switching in seconds (

mA (see chap. 9.5.4) To set the flow rate range associated to the 4-20 mA output.

FILT (see chap. 9.5.5) • To choose the filter of the displayed flow rate.

Filter 0 means that flow rate variations are displayed.

Filter 9 means that flow rate variations are attenuated to the maximum.

BRGR (see chap. 9.5.6)

BKLG (see chap. 9.5.7) To deactivate the backlighting of the display, or adjust its intensity and set the time-out after which it goes off.

CODE (see chap. 9.5.8) To activate the use of the access code to the Parameters and Test menus. By default, the access code is not

END (see chap. 9.5.9) To go back to the Process level by saving or not the settings made.

To enter the flow rate range, minimum (

requested.

O HI) and low (O LO ) switching thresholds;

DEL).

BG LO) and maximum (B G HI) values, associated to the bar graph.

English

31

Page 34

9.5.1. Selecting the unit of the flow rate

WARNING

If the flow rate unit is modified, also modify the transistor or relay

switching thresholds (function OUT), the threshold values of the

bar graph (function BRGR) and the flow rate range associated to

the current output (function mA).

2

ENTER

UNIT

To function KFAC

0......9

GA/H

L/S

UNIT

ENTER

.

.

.

ENTER

2

Refer to chap. 9.4 to access

the Parameters menu.

→ Select the desired unit of the flow rate.

Adjustment and functions

Adjustment and functions

32

English

Page 35

Adjustment and functions

Adjustment and functions

9.5.2. Entering the K factor or having it determined by teach-in

During the whole teach-in procedure, the outputs are frozen to the status they had at the start of the teach-in.

• Entering the K factor of the fitting used:

KFAC

ENTER

0......9

NO

TEAC

YES

TEAC

ENTER

ENTER

TEAC

49.03

KFAC

0......9

ENTER

ENTER

*

200.0

0......9

VOL

→ select "NO TEAC",

→ press key "ENTER",

→ In the KFAC parameter, enter the K factor of the

ENTER

49.03

ENTER

KFAC

*

fitting used, in pulse/litre (value between 0,001 and

9999). Find the K factor within the operating instructions of the fitting.

• Determining the K factor by means of a teach-in

procedure:

To function OUT

→ install the 8032 / 8072 in series with a valve, for

instance, then

→ fill a tank with x litres capacity (200 litres for

* to move the decimal point, simultaneously press keys

0......9

and

example).

→ select "YES TEAC",

→ press key "ENTER",

→ open the valve: message "TEAC" blinks.

→ when the tank if full, press again key "ENTER".

→ enter the volume of liquid that has passed through

the circuit (in the unit displayed alternately with the

message "VOL"): the device calculates the K factor

and displays it.

English

33

Page 36

9.5.3. Configuring the relay or transistor output

Adjustment and functions

Adjustment and functions

0......9

01

DEL

* to move the decimal

point, simultaneously

press keys

0......9

and

OUT

ENTER

0......9

MODE

MODE

ENTER

ENTER

0.200

OLO

0......9

*

no

OHI>

OLO

1.000

0......9

*

OHI

ENTER ENTER

0......9

NO

ENTER ENTER

inv

ENTER

YES

inv

yes

To function "mA"

Hysteresis operation

The change of state is done when a threshold is detected (increasing flow rate:high threshold (OHI) to be detected, decreasing flow rate: low

threshold (OLO) to be detected).

Contact

ON

OFF

Not inverted

OLO OHI

Flow

rate

Contact

ON

OFF

Inverted

OLO OHI

Flow

rate

Fig. 35: Hysteresis operation of the transistor output

34

English

Page 37

Adjustment and functions

Adjustment and functions

Window operation

The change of state is done whenever one of the thresholds is

detected.

ON

OFF

Not invertedContact

OLO OHI

Flow

rate

Contact

ON

OFF

Inverted

OLO OHI

Flow

rate

Fig. 36: Window operation of the transistor output

The time delay (DEL) is valid for both output thresholds. switching

is only done if one of the thresholds (OHI - OLO) is exceeded for a

duration longer than this time delay.

Flow rate

OHI

OLO

2 s

2 s

2 s

OUT

Hysteresis operation

DEL = 0 s

DEL = 2 s

Window operation

DEL = 0 s

DEL = 2 s

Not inverted

Not inverted

Not inverted

Not inverted

Inverted

Inverted

Inverted

Inverted

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Fig. 37: Examples for the behaviour of the transistor or relay

output of a 8032 / 8072, depending on the flow rate and

the operation chosen.

t

English

35

Page 38

ENTER

0......9

*

0......9

*

ENTER

ENTER

Adjustment and functions

Adjustment and functions

9.5.4. Setting the flow rate range

associated to the 4-20 mA output

The 4-20 mA output provides an electrical current, the value of

which reflects the flow rate measured by the device.

• The signal may be inverted, i.e. the flow rate value associated to the

20-mA current is lower than the one associated to the 4-mA current.

• The current output gives a 22-mA current when the device shows

an operating error.

mA

20

4

20 180

Fig. 38: Example of relation between the measuring range and

the current output

MA

To function "FILT"

→ Enter the flow rate values, in the unit that has been chosen in the

0.200

4ma

1.000

UNIT parameter, related to the 4-20-mA current range.

20ma

l/min

* to move the

decimal point,

simultaneously

press keys

0......9

and

9.5.5. Choosing the filter of the flow rate

FILT

ENTER

ENTER

2

FILT

0......9

To function "BRGR"

The "Filter" function is used to attenuate the display and 4-20 mA

output, if any, fluctuations when the flow rate varies in the process.

Ten attenuation levels, from 0 (means no attenuation) to 9 (maximum

attenuation of the fluctuations) are available.

Table 4: Response times of the current output and the display

depending on the filter chosen

Filter N° Response time (10% up to 90%)

0 300 ms

1 1,5 s

2 3 s

3 (by default) 5 s

4 7 s

5 11 s

6 20 s

36

English

Page 39

ENTER

0......9

*

0......9

*

ENTER

ENTER

Adjustment and functions

Adjustment and functions

7 38 s

8 100 s

9 200 s

9.5.6. entering the flow rate range related

to the bar graph

BRGR

To function "BKLG"

* to move the decimal point, simultaneously press keys

0.200

BGLO

Set the min. and max. flow rate values, in the unit chosen within the

"UNIT" function, related to the bar graph:

• BGLO is related to the flow rate value for which all the bar graph

segments are out.

• BGHI is related to the flow rate value for which all the bar graph

segments are on.

1.000

BGHI

0......9

and

9.5.7. Adjusting the brightness of the

backlight or deactivating the

backlight

BKLG

To function "CODE"

ENTER

0......9 0......9

• Function "BKLG": to deactivate the backlight (choice "0") or to

choose its intensity (choice "1" to "9").

• Function "BDEL": to have the backlight permanently activated

(choice "00") or have it on for a constant duration (between "01"

and "99" seconds) after a key press.

ENTER ENTER

5

BKLG

0

BDEL

English

37

Page 40

Adjustment and functions

Adjustment and functions

9.5.8. Activating and defining the access

code to the Configuration level

CODE

ENTER

0......9

ON

CODE

OFF

ENTER

0000

0......9

CODE

ENTER

CODE

To function "END"

• Function "CODE ON": the access code to the Parameters and

Test menus is required. Enter a 4-digit code.

• Function "CODE OFF": the access code to the Parameters and

Test menus is not required.

9.5.9. Saving the modified parameters

END

ENTER

0......9

NO

save

YES

save

ENTER

ENTER

Back to the Process

1

level

Back to the Process

1

level

changed.

• Function "SAVE YES": the changes made within the Parameters

menu are saved. Is only displayed if any parameter has been

changed.

• Function "SAVE NO": the changes made within the Parameters

menu are not saved. Is only displayed if any parameter has been

38

English

Page 41

Adjustment and functions

Adjustment and functions

9.6. Configuration level - Test menu

3

FREQ

ENTER ENTER

123.4

HZ

ENTER ENTER

SIM

0......9

MA

see chap. 9.6.1

ENTER

END

* to move the decimal point, simultaneously press keys

0.600

SIM

0......9

*

1

1

and 3: see chap. 9.4, Process level

0......9

FREQ To read the frequency of the measured signal.

SIM To test the switching thresholds set for the transistor

output or the relay output and/or the conversion of the

flow rate into mA, by entering a flow rate value.

MA To adjust the 4-20 mA output.

END To go back to the Process level and display the flow

rate measured.

and

English

39

Page 42

9.6.1. Adjusting the 4-20 mA output

Adjustment and functions

Adjustment and functions

yes

ENTER ENTER

MA

3.95

OFFS

0......9

*

To the function "END" of the Test menu

20.50

span

0......9

ENTER

YES

MA

0......9

NO

*

MA

• When the function "OFFS" is displayed, the device gives a 4-mA current.

→ Measure the current given on the 4-20 mA output using a multimeter.

→ Enter this value in the function O FFS. The permitted offset range is 3 to 5 mA.

→ Press ENTER to confirm.

• When the function "SPAN" is displayed, the device gives a 20-mA current.

→ Measure the current given on the 4-20 mA output using a multimeter.

→ Enter this value in the function SPA N. The permitted span range is 18,5 to 21,5 mA.

• Confirm or do not confirm the values entered by choosing "

values entered is outside the permitted range: see chap. 10.3.

40

English

YES MA" or "NO MA". When the message "ERR11" is displayed, at least one of the

ENTER

ENTER

ERR 11 ?

no

* to move the decimal point, simultane-

ously press keys

0......9

and

Page 43

Adjustment and functions

Adjustment and functions

9.7. Default settings

At first power-up of the device, the configuration of the 8032 / 8072 is the following:

Flow rate

unit

UNIT KFAC Operation OLO

1)

In the unit set within the UNIT function (l/s, by default).

2)

By default, the access code is not requested (CODE=OFF).

K factor Relay or transistor output Current

OHI

threshold

l/s 1 imp./l Hysteresis, inverted 0

1)

threshold

1)

0

output

DEL 4mA 20mA FILTER BG LO BG HI BKLG BDEL CODE

0 s 0 1)100

9.8. Your settings for the 8032 / 8072

Filter Bar graph Backlighting Code

1)

2 0

1)

1)

0

5 0 s 0000

2)

Flow rate

K factor Relay or transistor output Current

unit

UNIT KFAC Operation OLO

threshold

ON

OFF

1)

Hysteresis operation:

OLO OHI

OHI

threshold

Filter Bar graph Backlighting Code

output

DEL 4mA 20mA FILTER BG LO BG HI BKLG BDEL CODE

ON

OFF

2)

Window operation:

OLO OHI

English

41

Page 44

Maintenance and troubleshooting

Maintenance and troubleshooting

10. MAINTENANCE AND

TROUBLESHOOTING

10.1. Safety information

DANGER

Risk of injury due to high pressure in the installation

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

• Observe all applicable accident protection and safety guidelines

for electrical equipment.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

• Keep all easily flammable material and fluid away from the device.

Risk of injury due to the nature of the fluid.

• Respect the regulations on accident prevention and safety relating to the use of aggressive fluids.

WARNING

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Guarantee a defined or controlled restarting of the process

subsequent to any intervention on the device.

10.2. Maintenance and cleaning

NOTE

The device may be damaged by the cleaning product.

• Clean the device with a cloth slightly dampened with water or a

cleaning liquid compatible with the materials the device is made

of.

Please feel free to contact your Bürkert supplier for any additional

information.

42

English

Page 45

Maintenance and troubleshooting

Maintenance and troubleshooting

10.3. If you encounter problems

Message

displayed

ERR 2 22 mA The Parameters menu cannot be accessed.

ERR 11 - The span and/or offset values entered during

4-20 mA output,

if present

Meaning Recommended actio

Read fault of the menu: the process is not stopped.

adjustment of the 4-20 mA output are out of range:

offset < 3 mA or > 5 mA

and/or span <18,5 mA or > 21,5 mA

→ Press the ENTER key to acknowledge the

message.

→ If the failure occurs regularly, contact your

retailer.

→ Press the ENTER key to go back to the Test

menu.

The device operates with the previous adjustment

values.

English

43

Page 46

Spare parts and accessories

Spare parts and accessories

11. SPARE PARTS AND

ACCESSORIES

CAUTION

Risk of injury and/or damage by the use of incorrect parts.

Incorrect accessories and unsuitable spare parts may cause

injuries and damage the device and the surrounding area.

• Use only original accessories and original spare parts from

Bürkert.

Spare part Order code

1)

Complete unit

with NPN and PNP transistor

outputs

1)

Complete unit

Complete unit

Complete unit

with a single relay output 563104

1)

with a single current output 563105

1)

with both relay and 4-20 mA

current outputs

1)

Complete unit = cover, display and electronic board

563103

563106

Accessory Order code

5-pin M12 female connector, to be wired 917116

5-pin M12 female connector, moulded on

438680

shielded cable (2 m)

EN175301-803 female connector (type

438811

2508) with cable gland

Plug for the cable gland of the type 2508

444509

female connector

EN175301-803 female connector (type

162673

2509) with NPT ½" reduction

8-pin M12 female connector, to be wired 444799

8-pin M12 female connector, moulded on

444800

shielded cable (2 m)

44

English

Page 47

Packaging, Transport

Packaging, Transport

12. PACKAGING, TRANSPORT

NOTE

Damage due to transport

Transport may damage an insufficiently protected device.

• Transport the device in shock-resistant packaging and away

from humidity and dirt.

• Avoid the effects of heat and cold, which could cause the storage temperature range to be exceeded.

• Protect the electrical interfaces using protective plugs.

13. STORAGE

NOTE

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Ambient storage temperature: -10 to +60 °C.

14. DISPOSAL OF THE DEVICE

→

Dispose of the device and its packaging in an environmentallyfriendly way.

NOTE

Damage to the environment caused by products contaminated by fluids.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

Note

Comply with the national and/or local regulations which

concern the area of waste disposal.

English

45

Page 48

46

English

Page 49

Typ 8032 / 8072

1. DIE BEDIENUNGSANLEITUNG ...............................................................3

1.1. Darstellungsmittel ..............................................................................3

1.2. Begriffsdefinition "Gerät" ................................................................3

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ......................................4

3. GRUNDLEGENDE SICHERHEITSHINWEISE ....................................4

4. ALLGEMEINE HINWEISE .............................................................................6

4.1. Herstelleradresse und internationale Kontaktadressen 6

4.2. Gewährleistung ....................................................................................6

4.3. Informationen im Internet ...............................................................6

5. BESCHREIBUNG .............................................................................................6

5.1. Aufbau .......................................................................................................6

5.2. Messelement .........................................................................................7

5.3. Verfügbare Versionen des Elektronikmoduls SE32 .........7

5.4. Beschreibung des Typenschilds .................................................8

6. TECHNISCHE DATEN ...................................................................................8

6.1. Betriebsbedingungen .......................................................................8

6.2. Einhaltung von Normen und Richtlinien .................................8

6.3. Allgemeine technische Daten ......................................................9

6.3.1. Mechanische Daten .............................................................. 9

6.3.2. Allgemeine Daten ................................................................11

6.3.3. Elektrische Daten ................................................................13

6.3.4. Daten der Steckverbinder und Kabel .............................14

7. INSTALLATION UND VERKABELUNG ...............................................15

7.1. Sicherheitshinweise ....................................................................... 15

7.2. Anschluss an die Rohrleitung ................................................... 15

7.2.1. Diagramme (8032) .............................................................15

7.2.2. Montage des 8032 / 8072 ...............................................17

7.3. Verkabelung ........................................................................................ 17

7.3.1. Montage der Buchsen .......................................................18

7.3.2. Verkabelung einer Version mit Transistoraus-

gang und EN175301-803-Gerätestecker ....................19

7.3.3. Verkabelung einer Version mit 2 Transistoraus-

gängen und einem 5-poligen M12-Gerätestecker......20

7.3.4. Verkabelung der Version mit einzelnem Relais-

ausgang ....................................................................................21

7.3.5. Verkabelung der Version mit einzelnem Strom-

ausgang ....................................................................................23

7.3.6. Verkabelung der Version mit Relais- und Strom-

ausgängen (5-poligem M12-Gerätestecker)..................24

7.3.7. Verkabelung der Version mit Relais- und Strom-

ausgängen (8-poligem M12-Gerätestecker) ................25

8. INBETRIEBNAHME ...................................................................................... 27

deutsch

1

Page 50

Typ 8032 / 8072

8.1. Sicherheitshinweise ....................................................................... 27

9. BEDIENUNG UND FUNKTION .............................................................. 28

9.1. Sicherheitshinweise ....................................................................... 28

9.2. Bedien-Ebenen ..................................................................................28

9.3. Beschreibung der Anzeige und der

Einstellungstasten ...........................................................................29

9.4. Prozess-Ebene ..................................................................................30

9.5. Einstellung - Parametriermenü ................................................32

9.5.1. Durchflusseinheit auswählen. ...........................................33

9.5.2. K-Faktor eingeben oder mittels Teach-in bestimmen . 34

9.5.3. Den Transistor- oder Relaisausgang parametrieren ....35

9.5.4. Durchflussbereich für den 4-20 mA-Ausgang

einstellen ...............................................................................37

9.5.5. Filterstufe des Durchflusses auswählen ........................37

9.5.6. Durchflussbereich für die Balkengrafik eingeben ........38

9.5.7. Stärke der Hintergrundbeleuchtung einstellen

oder deaktivieren .................................................................38

9.5.8. Zugriffscode auf die Einstellungs-Ebene aktivie-