Page 1

Type 8071

Flowmeter with oval rotors

Durchfluss-Messgerät mit Ovälradern

Débitmètre à roues ovales

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2010-2012 Bürkert SAS

Operating Instructions 1209/4 EU-ML_448739_ORIGINAL_FR

Page 3

Type 8071

Type 8071

1. ABOUT THIS MANUAL ................................................................................4

1.1. Symbols used ...................................................................................... 4

1.2. Definition of the word "device" ................................................... 4

2. INTENDED USE ...............................................................................................5

3. BASIC SAFETY INFORMATION .............................................................. 5

4. GENERAL INFORMATION ..........................................................................7

4.1. Contacts ..................................................................................................7

4.2. Warranty conditions .......................................................................... 7

4.3. Information on the Internet ...........................................................7

5. DESCRIPTION .................................................................................................. 7

5.1. Area of application ............................................................................ 7

5.2. General description .......................................................................... 7

5.3. Description of the name plate ....................................................8

5.4. Available versions .............................................................................. 9

6. TECHNICAL DATA ....................................................................................... 11

6.1. Conditions of use ............................................................................ 11

6.2. General data ...................................................................................... 11

6.3. Dimensions ........................................................................................ 12

6.4. K factors (in pulse/l) ..................................................................... 13

7. INSTALLATION AND WIRING ................................................................13

7.1. Safety instructions.......................................................................... 13

7.2. Installation instructions ............................................................... 14

7.3. Wiring ..................................................................................................... 15

8. COMMISIONING .......................................................................................... 16

8.1. Safety instructions.......................................................................... 16

9. MAINTENANCE AND TROUBLESHOOTING ................................. 16

9.1. Safety instructions.......................................................................... 16

9.2. Maintenance of the strainer ...................................................... 17

9.3. Maintenance of the device ......................................................... 17

9.4. Dismantle the device .................................................................... 17

9.5. Assemble the device ..................................................................... 18

9.6. If a problem occurs ........................................................................ 19

10. SPARE PARTS AND ACCESSORIES .............................................. 20

11. PACKAGING, TRANSPORT .................................................................. 21

12. STORAGE ...................................................................................................... 21

13. DISPOSAL OF THE DEVICE ................................................................ 21

English

Page 4

Type 8071

About this manual

1. ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please keep

this manual in a safe place, accessible to all users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations.

• This manual must be read and understood.

1.1. Symbols used

danger

Warns against an imminent danger.

• Failure to observe this warning can result in death or in serious

injury.

Warning

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or

even death.

attention

Warns against a possible risk.

• Failure to observe this warning can result in substantial or minor

injuries.

note

Warns against material damage.

• Failure to observe this warning may result in damage to the

device or system.

Indicates additional information, advice or important

recommendations.

refers to information contained in this manual or in other

documents.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

The word "device" used within this manual refers to the flowmeter

type 8071.

4

English

Page 5

Type 8071

Intended use

2. INTENDED USE

Use of the device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

• The device is intended to measure the flow rate of fluids, especially of viscous fluids.

• This device must be protected against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects

of climatic conditions.

• This device must be used in compliance with the characteristics

and commissioning and use conditions specified in the contrac-

tual documents and in the user manual.

• Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

• Only use the device as intended.

→ Observe any existing restraints when the device is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during installation,

use and maintenance of the devices.

• the local safety regulations that the operator must ensure the staff

in charge of installation and maintenance observe.

Danger due to high pressure in the installation.

Danger due to electrical voltage.

Danger due to high temperatures of the fluid.

Danger due to the nature of the fluid.

Various dangerous situations

To avoid injury take care to:

• Prevent any unintentional power supply switch-on.

• Ensure that installation and maintenance work are carried out by

qualified, authorised personnel in possession of the appropriate

tools.

English

5

Page 6

Various dangerous situations

To avoid injury take care:

• to guarantee a set or controlled restarting of the process, after a

power supply interruption.

• to use the device only if in perfect working order and in compliance with the instructions provided in the instruction manual.

• to observe the general technical rules when installing and using

the device.

• not to use the device in an explosive atmosphere.

• not to use this device in an environment incompatible with the

materials it is made of.

• not to use fluid that is incompatible with the materials the device

is made of.

• not to use the device for the measurement of gas flow rates.

• not to subject the device to mechanical loads (e.g. by placing

objects on top of it or by using it as a step).

• not to make any external modifications to the device. not to paint

or varnish any part of the device.

Type 8071

Basic safety information

note

The device may be damaged by the fluid in contact with.

• Systematically check the chemical compatibility of the component materials of the device and the fluids likely to come into

contact with it (for example: alcohols, strong or concentrated

acids, aldehydes, alkaline compounds, esters, aliphatic compounds, ketones, halogenated aromatics or hydrocarbons,

oxidants and chlorinated agents).

note

Elements / Components sensitive to electrostatic discharges

This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they are touched by an

electrostatically charged person or object. In the worst case scenario, these components are instantly destroyed or go out of order

as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 and 5-2 norms.

• Also ensure that you do not touch any of the live electrical

components.

6

English

Page 7

Type 8071

General information

4. GENERAL INFORMATION

4.1. Contacts

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the

internet at: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of

the device in observance of the operating conditions specified in this

manual.

4.3. Information on the Internet

You can find the user manuals and technical data sheets regarding the

type 8071 at: www.burkert.com

5. DESCRIPTION

5.1. Area of application

The device is intended to measure, thanks to its oval rotors, the flow

rate of viscous fluids. It must be combined with a remote instrument

(such as transmitter type 8025 Universal or batch controller type 8025

Batch) which converts the pulse frequency due to oval rotors rotation.

5.2. General description

5.2.1. Construction

The device is built of a fitting which includes oval rotors and of a cover

including the electronic module with Hall effect sensor and Reed switch.

The oval rotors of the fitting contain magnets.

All the device versions provide an NPN transistor output and a Reed

switch output.

The electrical connection is made by a 1 meter 5-wire cable.

5.2.2. Measuring principle

When the fluid flows through the pipe, the oval rotors which contain

magnets turn (see Fig. 1). The displacement of magnets lead to a

variation of magnetic field. The sensor measures the variation of the

magnetic field and converts the signal into a frequency. The frequency

is available at both the NPN transistor and Reed switch outputs.

English

7

Page 8

Fig. 1: Running/displacement of oval rotors

The remote instrument converts the frequency into a flow rate by

using the correct K factor.

5.3. Description of the name plate

Type 8071 Flow Sensor

1

Model

2

Flow Range

3

Max Pressure

4

Max Temp

Serial No

5

Fig. 2: Name plate of the device

1. Order code of the device

2. Flow rate measuring range

3. Max. pressure

4. Max. temperature

5. Serial number

433864N

2-100LPH

1000kPa/55Bar

120°C

D34128

Type 8071

Description

8

English

Page 9

Type 8071

Description

5.4. Available versions

Flow rate range Materials

Process

connection

Viscosity

> 1 mPa.s and

< 1000 mPa.s

Viscosity

< 1 mPa.s

Housing Rotors / axis Seal

G 1/8'' 0.5-50 l/h 5-50 l/h Aluminium Stainless steel FKM 5 bar

Stainless steel Stainless steel FFKM 55 bar

NPT 1/8'' 0.5-50 l/h 5-50 l/h Aluminium Stainless steel FKM 5 bar

Stainless steel Stainless steel FFKM 55 bar

Flow rate range Materials

Process

connection

Viscosity

> 5 mPa.s and

< 1000 mPa.s

Viscosity

< 5 mPa.s

Housing Rotors / axis Seal

G 1/4'' 2-100 l/h 12.5-100 l/h PPS PPS / Hastalloy C FFKM 5 bar

Stainless steel Stainless steel FFKM 55 bar

15-500 l/h 40-500 l/h PPS PPS / Hastalloy C FFKM 5 bar

Stainless steel Stainless steel FFKM 55 bar

NPT 1/4'' 2-100 l/h 12.5-100 l/h PPS PPS / Hastalloy C FFKM 5 bar

Stainless steel Stainless steel FFKM 55 bar

15-500 l/h 40-500 l/h PPS PPS / Hastalloy C FFKM 5 bar

Stainless steel Stainless steel FFKM 55 bar

Max.

pressure

Max.

pressure

Order code

1)

552818

552820

552819

552821

Order code

1)

432288

433864

430856

437518

448654

448656

448655

448657

English

9

Page 10

Type 8071

Description

Process

connection

Flow rate range Materials

Viscosity > 1000 mPa.s Housing Rotors / axis Seal

Max.

pressure

G 1/4'' 15-500 l/h Stainless steel Stainless steel FFKM 55 bar

NPT 1/4'' 15-500 l/h Stainless steel Stainless steel FFKM 55 bar

1)

High pressure versions available on request

2)

Other high viscosity versions available on request

Order code

1)

552426

553652

2)

10

English

Page 11

Type 8071

Technical data

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature

• Aluminium or PPS housing

• Stainless steel housing

Air humidity < 85%, non condensated

Protection rating IP54 (NEMA 13)

6.2. General data

6.2.1. Mechanical data

Part Material

Housing • Aluminium

Rotors • PPS

Axis • Hastalloy C

Seal FKM or FFKM

• max. 80 °C

• max. 120 °C

• PPS

• Stainless steel 316F (1.4401)

• Stainless steel 316F (1.4401)

• Stainless steel 316F (1.4401)

6.2.2. General data

Process connection Internal thread G 1/8" or G 1/4",

NPT 1/8’’or NPT 1/4’’

Max. fluid pressure

• PPS or aluminium housing

• Stainless steel housing

Viscosity

Flow rate measuring range

Accuracy ≤ ± 1 % of the measured value

Repeatability ≤ ± 0,03 % of the measured

Max. size of particles 75 µm

• 5 bar

• 55 bar (550 bar on request)

Depends on the version (see

chap. 5.4)

Depends on the version (see

chap. 5.4)

value

English

11

Page 12

Type 8071

Technical data

6.2.3. Electrical data

Supply voltage 4,5- 24 V DC

Tansistor output

• Type of output

• Hall sensor max. intensity

• Recommended load

Reed switch output

• Type

• Max. switching voltage

• Max. switching current

• Max. operating current

• Number of cycles (typical)

Electrical connection 5-wire cable, 1m long

• Frequency on open collector,

NPN, max. 25 mA, 4,5 to

24 V DC

• 25 mA

• 1,8 Kohm Pull up at 24 VDC

• Frequency

• 30 VDC

• 0,5 A

• 0,5 A

6

• 500 x 10

cycles (at 10 VDC

and 10 mA)

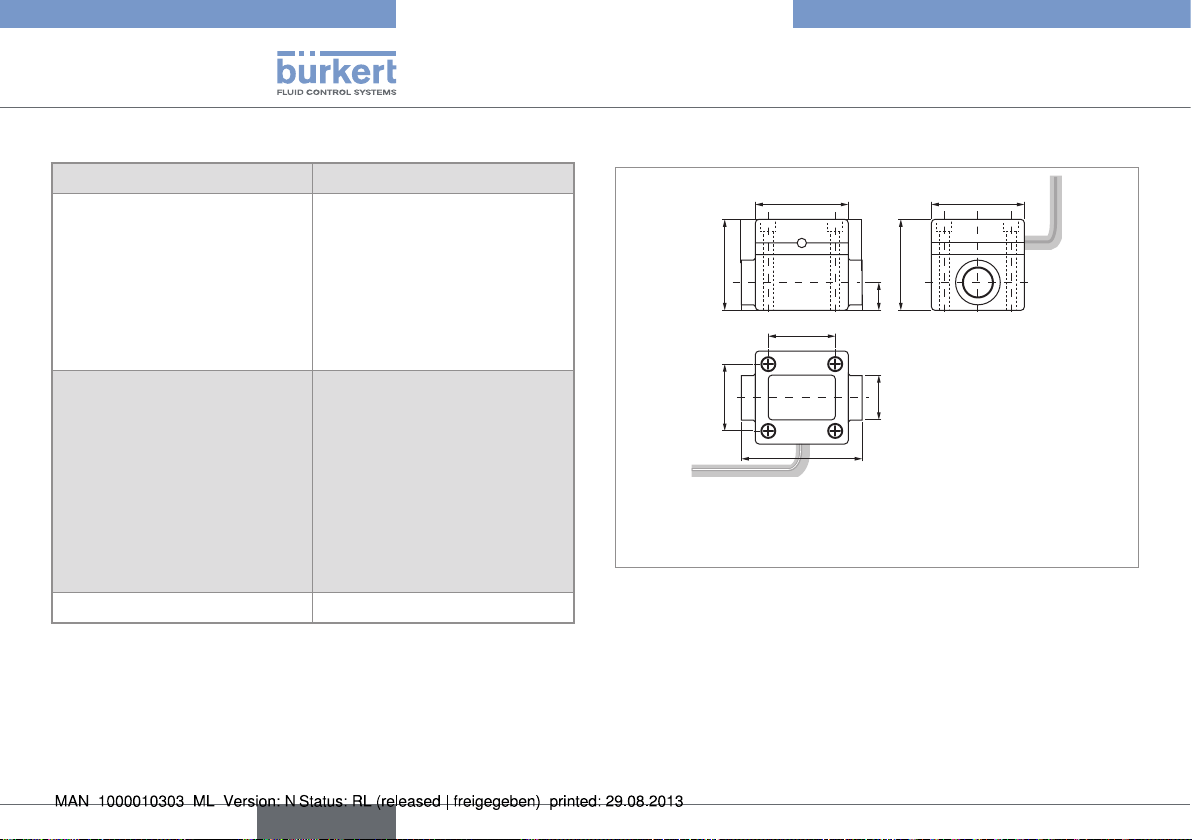

6.3. Dimensions

51/51/60*

48

A24

36,5

36,5

60/50/64*

cable 1000 mm

* Aluminium / Stainless steel / PPS housing

A: 17...18 mm depending on the housing material

Fig. 3: Dimensions of the device

51/51/60*

48

12

English

Page 13

Type 8071

Installation and Wiring

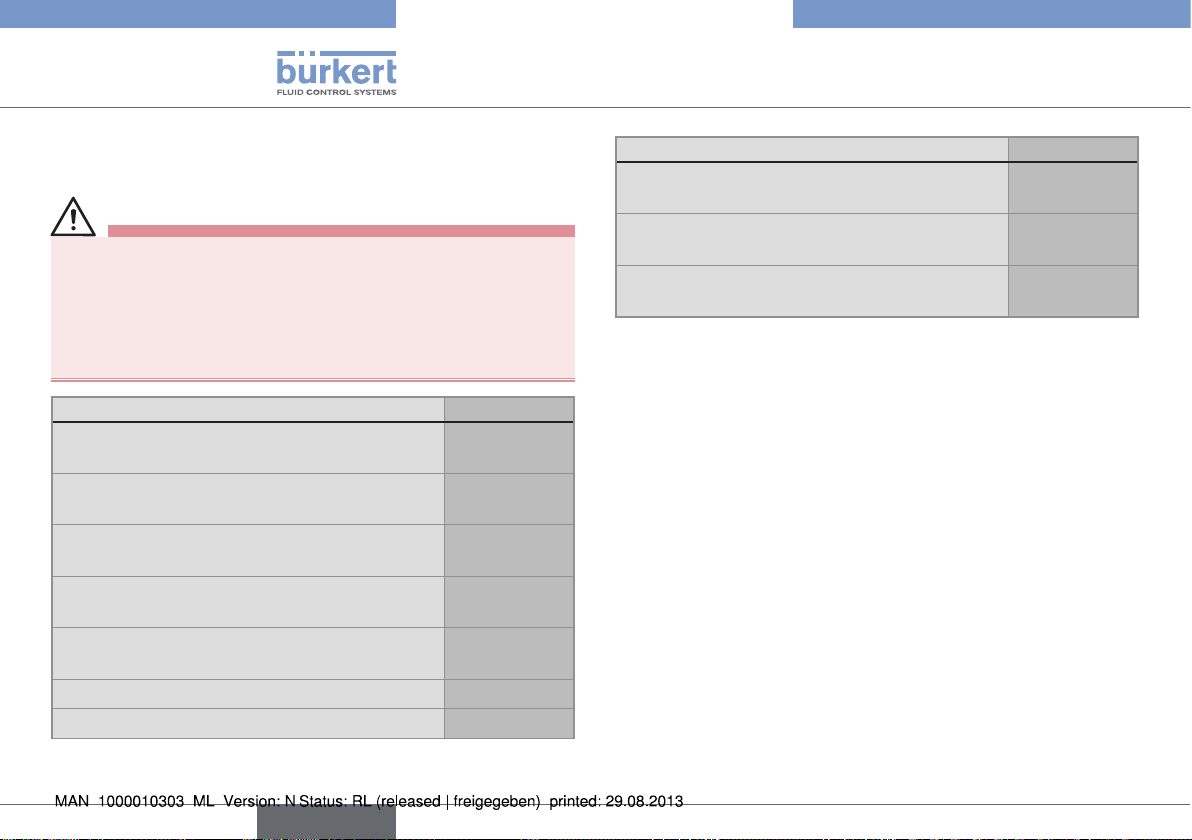

6.4. K factors (in pulse/l)

Flow rate range K factor (in pulse/l)

0,5- 50 l/h 1552

2- 100 l/h 1000

15- 500 l/h 400

If the device is combined with an instrument which does not

automatically convert the K factors, make the conversion

using one of the following formulae:

K factor in pulse/gallon US = K factor in pulse/l x 3,785 to

obtain flow rate in gallon US / time unit

K factor in pulse/gallon UK = K factor in pulse/l x 4,546 to

obtain flow rate in gallon UK / time unit.

7. INSTALLATION AND WIRING

7.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power source before

carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

• Keep all easily flammable material and fluid away from the

device.

English

13

Page 14

Type 8071

Installation and Wiring

Warning

Risk of injury due to non-conforming installation.

• The electrical and fluid installation can only be carried out by

qualified and skilled staff with the appropriate tools.

• Install the appropriate security devices (correctly dimensioned

fuse and/or circuit breaker).

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

• Take appropriate measures to avoid unintentional activation of

the installation.

• Guarantee a set or controlled restarting of the process subsequent to the installation of the device.

7.2. Installation instructions

note

Risk of damaging the device if it is subjected to mechanical

stress.

• Use flexible hoses.

note

The oval rotors may be damaged if particles with diameter > 75 µm go into the fitting.

• Install a strainer of 75 µm upstream and as close as possible to

the device.

→ Install a by-pass line on your installation to service the device

and the strainer without stopping the process (see Fig. 4).

filter

valve

8071

direction of flow

Fig. 4: Installation of a by-pass line

→ Install the device onto the pipe so that the shafts of the rotors

are in a horizontal plane.

Seal the external threads of the fitting with a product compatible with the materials from which the device housing

and the pipe are made.

→ Screw the device onto the pipe.

14

English

Page 15

Type 8071

Installation and Wiring

7.3. Wiring

danger

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power source before

carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

• Use a high quality electrical power supply (filtered and

regulated).

• Make sure the installation is equipotential.

Red wire

Black wire

White wire

Yellow wire

Green wire

Table 1: Connection wire assignment

Power supply (+)

Power supply (-)

NPN transistor output

Reed switch

Reed switch

7.3.1. Wiring the NPN transistor output and

the Reed switch output

L+ (4,5 - 24 V DC)

(red wire)

L- (black wire)

NPN transistor out-

put (white wire)

R=1,8 kW pull-up at 24 VDC

Fig. 5: Wiring of NPN transistor output and the Reed switch

output

IN

+-

IN = pulse input on remote transmitter

Remote transmitter

Fig. 6: Example for the connection of the NPN transistor output to

a remote transmitter

R

V DC

NPN

X

yellow wire

green wire

L+

L-

V DC

X

8071

English

15

Page 16

Type 8071

Commisioning

8. COMMISIONING

8.1. Safety instructions

Warning

Risk of injury due to nonconforming commissioning.

Non conforming commissioning may lead to injuries and damage

the device and its surroundings.

• Before commissioning, make sure that the staff in charge have

read and fully understood the contents of the manual.

• In particular, observe the safety recommendations and intended

use.

• The device / the installation must only be commissioned by

suitably trained staff.

Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of

the climatic conditions.

The pipe must be full of liquid whitout air bubbles.

→ Drain air from the pipe by gradually filling the pipe with fluid.

→ Make sure the installation is tight.

9. MAINTENANCE AND TROUBLESHOOTING

9.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power source before

carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

• Keep all easily flammable material and fluid away from the

device.

16

English

Page 17

Type 8071

Maintenance and troubleshooting

Warning

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Guarantee a set or controlled restarting of the process, after a

power supply interruption.

9.2. Maintenance of the strainer

→ After the circulation of 200 liters of fluid, examine the strainer for

particles. If necessary clean the strainer with a product compatible with the materials from which it is made.

→ Regularly examine the strainer for good condition, in particular

when the flow rate decreases. If necessary clean the strainer

with a product compatible with the materials from which it is

made.

9.3. Maintenance of the device

→ Regularly examine the seal and the oval rotors for good

condition. Follow the instructions on chap. 9.4 et 9.5.

Clean the device with a cloth slightly dampened with water or a

cleaning liquid compatible with the materials the device is made of.

Your Bürkert supplier is at your disposal for any further information.

9.4. Dismantle the device

grooves

1

2

3

4

5

Fig. 7: Exploded view of the device

→ Unscrew the 4 screws (mark 5 Fig. 7) and remove the cover

including the electronic module (mark 4 Fig. 7).

→ Remove the seal (mark 3 Fig. 7).

→ Examine the seal for good condition. If not, replace it by a new

one (see chap. "10. Spare parts and accessories").

→ Remove the rotors (mark 2 Fig. 7).

→ Examine the rotors for good condition. If necessary, clean or

replace them (see chap. 10).

English

17

Page 18

9.5. Assemble the device

Type 8071

Maintenance and troubleshooting

Put the magnetized rotor on the same side as the groove

(see Fig. 8 and table below).

→ Put the rotors inside the housing, at 90° (see Fig. 8).

groove

Magnetized oval rotor

Neutral oval rotor (without magnet)

Fig. 8: Position of the oval rotors

Flow rate range Magnetized oval rotor

0.5-50 l/h hole of the magnet seat is visible (set towards

the cover)

• 0.5-50 l/h

• 2-100 l/h

• 15-500 l/h

hole of the magnet seat is not visible (set

towards the bottom of the housing)

→ Set the radius of curvature present on the periphery of the oval

rotors towards the bottom of the rotor housing (see Fig. 9).

A A

right angle

round-off

A-A

Fig. 9: Cross-section of an oval rotor

→ Make sure that the magnet is in place by using a detector.

→ Make sure that the rotors freely turn by turning them slowly with

the finger.

→ Put the seal (mark 3 Fig. 7) in its groove.

→ Put the cover (mark 4 Fig. 7) on the housing, aligning the groove

on the cover with the one of the housing.

→ Tighten the 4 screws (mark 5 Fig. 7), carefully to avoid damages

to the housing, and in an alternating pattern at the following

torque:

- 1 Nm for a PPS housing

- 2 Nm for an aluminium housing

- 9 Nm for a stainless steel housing

18

English

Page 19

Type 8071

Maintenance and troubleshooting

9.6. If a problem occurs

Problem Cause Solution

Fluid does not

flow through the

device any more

Obturated device

Obturated strainer (if present)

Rotors damaged

→ Remove and clean the oval rotors (see chap. "9.4. Dismantle the device" and

"9.5. Assemble the device").

→ Add a strainer of 75 µm upstream of the device.

→ Clean the strainer.

→ Replace the rotors (see chap. "10. Spare parts and accessories", "9.4. Dis-

mantle the device" and "9.5. Assemble the device").

Reduced flow

rate through the

device

Incoherent

measurement

No frequency

output

Strainer (if present) partially obturated

Fluid too viscous Use rotors for fluids with a viscosity > 1000 mPa.s.

Flow rate range not adapted

Air within the pipe

Friction due to an incorrect assembly

of the device

Incorrect wiring of the outputs

Rotors incorrectly mounted

Magnet damaged

Hall sensor or Reed switch defective

→ Clean the strainer.

→ Verify specifications, adjust the device or the flow rate (see chap. "6.2.2.

General data").

→ Slowly drain air from the pipe.

→ Verify the assembly of the rotors in the fitting (see chap. "9.4. Dismantle the

device" and chap. "9.5. Assemble the device").

→ Make sure that the device has been wired correctly (see chap. "7.3. Wiring").

→ Dismantle the device and modify the position of the rotors (see "9.4. Dismantle

the device" and "9.5. Assemble the device").

→ Replace the rotors (see chap. "10. Spare parts and accessories", "9.4. Dis-

mantle the device" and "9.5. Assemble the device").

→ Replace the cover with electronic module (see chap. "10. Spare parts and

accessories", 9.4 and 9.5).

English

19

Page 20

Type 8071

Spare parts and accessories

10. SPARE PARTS AND

ACCESSORIES

caution

Risk of injury and damage caused by the use of unsuitable

parts.

Incorrect accessories and unsuitable spare parts may cause

injuries and damage the device and the surrounding area.

• Use only original accessories and original spare parts from

Bürkert.

Spare part Order code

Set of 2 oval rotors in stainless steel, flow rate

range of 0.5-50 l/h

Set of 2 oval rotors in stainless steel, flow rate

range of 2-100 l/h

Set of 2 oval rotors in stainless steel, flow rate

range of 15-500 l/h

Set of 2 oval rotors in PPS, flow rate range of

2-100 l/h

Set of 2 oval rotors in PPS, flow rate range of

15-500 l/h

FKM seal 550923

FFKM seal 550959

560180

550919

550920

550921

550922

Spare part Order code

Cover in stainless steel with electronic module

including Hall effect sensor and Reed switch

Cover in PPS with electronic module including

Hall effect sensor and Reed switch

Cover in aluminium with electronic module

including Hall effect sensor and Reed switch

553653

553654

on request

20

English

Page 21

Type 8071

Packaging, Transport

11. PACKAGING, TRANSPORT

note

Damage due to transport

Transport may damage an insufficiently protected device.

• Transport the device in shock-resistant packaging and away

from humidity and dirt.

• Do not expose the device to temperatures that may exceed the

admissible storage temperature range.

• Protect the electrical interfaces using protective plugs.

12. STORAGE

note

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Storage temperature: -10...+60 °C.

13. DISPOSAL OF THE DEVICE

→

Dispose of the device and its packaging in an environmentallyfriendly way.

note

Damage to the environment caused by products contaminated by fluids.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

note

Comply with the national and/or local regulations which

concern the area of waste disposal.

English

21

Page 22

Type 8071

22

English

Page 23

Type 8071

English

23

Page 24

Type 8071

24

English

Page 25

Typ 8071

Typ 8071

1. DIE BEDIENUNGSANLEITUNG ..............................................................4

1.1. Darstellungsmittel .............................................................................4

1.2. Begriffsdefinition "Gerät" ............................................................... 4

2. BESTIMMUNGSGEMÄSSE VERWENDUNG .....................................5

3. GRUNDLEGENDE SICHERHEITSHINWEISE ................................... 5

4. ALLGEMEINE HINWEISE ............................................................................ 7

4.1. Kontaktadressen ................................................................................ 7

4.2. Gewährleistung ................................................................................... 7

4.3. Informationen im Internet .............................................................. 7

5. BESCHREIBUNG ............................................................................................ 7

5.1. Vorgesehener Einsatzbereich ..................................................... 7

5.2. Allgemeine Beschreibung ............................................................. 7

5.3. Beschreibung des Typenschilds ................................................ 8

5.4. Verfügbare Versionen ...................................................................... 9

6. TECHNISCHE DATEN ............................................................................... 11

6.1. Betriebsbedingungen ................................................................... 11

6.2. Allgemeine technische Daten .................................................. 11

6.3. Abmessungen ................................................................................... 12

6.4. K-Faktoren (in Pulse/Liter) ........................................................ 13

7. INSTALLATION UND VERKABELUNG .............................................. 13

7.1. Sicherheitshinweise ...................................................................... 13

7.2. Empfehlungen für die Installation .......................................... 14

7.3. Verkabelung ....................................................................................... 15

8. INBETRIEBNAHME ..................................................................................... 16

8.1. Sicherheitshinweise ...................................................................... 16

9. WARTUNG, PROBLEMLÖSUNG .......................................................... 16

9.1. Sicherheitshinweise ...................................................................... 16

9.2. Wartung des Filters ........................................................................ 17

9.3. Wartung des Gerätes .................................................................... 17

9.4. Ausbau des Gerätes ...................................................................... 17

9.5. Wiederaufbau des Gerätes ........................................................ 18

9.6. Problemlösung ................................................................................. 19

10. ERSATZTEILE, ZUBEHÖR .................................................................... 20

11. VERPACKUNG, TRANSPORT .............................................................21

12. LAGERUNG .................................................................................................. 21

13. ENTSORGUNG DES GERÄTES ......................................................... 21

deutsch

Page 26

Typ 8071

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer zugänglich ist und jedem neuen Eigentümer des Gerätes

wieder zur Verfügung steht.

Diese Bedienungsanleitung enthält wichtige Informationen

zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Diese Bedienungsanleitung muss gelesen und verstanden

werden.

1.1. Darstellungsmittel

Gefahr!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichteinhaltung sind Tod oder schwere Verletzungen die

Folge.

WarnunG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichteinhaltung drohen schwere Verletzungen oder Tod.

VOrSIChT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

hInWeIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2. Begriffsdefinition "Gerät"

Der in dieser Anleitung verwendete Begriff "Gerät" steht immer für

das Durchfluss-Messgerät Typ 8071.

4

deutsch

Page 27

Typ 8071

Bestimmungsgemässe Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Gerätes können

Gefahren für Personen, Anlagen in der Umgebung und die

Umwelt entstehen.

• Das Gerät ist zur Durchflussmessung von Flüssigkeiten, insbesondere viskosen Flüssigkeiten bestimmt.

• Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

• Für den Einsatz sind die in den Vertragsdokumenten und der

Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs-

und Einsatzbedingungen zu beachten.

• Zum sicheren und problemlosen Einsatz des Gerätes müssen

Transport, Lagerung und Installation ordnungsgemäß erfolgen,

außerdem müssen Betrieb und Wartung sorgfältig durchgeführt

werden.

• Achten Sie immer darauf, dieses Gerät auf ordnungsgemäße

Weise zu verwenden.

→ Beachten Sie bei der Ausfuhr des Gerätes gegebenenfalls bes-

tehende Beschränkungen.

3. GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• Ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf das Installations- und Wartungspersonal, der

Betreiber verantwortlich ist.

Gefahr durch hohen Druck in der Anlage!

Gefahr durch elektrische Spannung!

Gefahr durch hohe Flüssigkeitstemperaturen!

Gefahr aufgrund der Art der Flüssigkeit!

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Die Anlage nicht unbeabsichtigt betätigen.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

deutsch

5

Page 28

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Nach einer Unterbrechung der elektrischen Versorgung ist ein

definierter oder kontrollierter Wiederanlauf des Prozesses zu

gewährleisten.

• Betreiben Sie das Gerät nur in einwandfreiem Zustand und

unter Beachtung der Bedienungsanleitung.

• Bei der Einsatzplanung und dem Betrieb des Fittings die allgemeinen Regeln der Technik einhalten.

• Das Gerät nicht in einer explosionsfähigen Atmosphäre verwenden.

• Das Gerät nicht in einer Umgebung verwenden, die mit den Materialien, aus denen es besteht, inkompatibel ist.

• Keine Flüssigkeit verwenden, die sich nicht mit den Werkstoffen

verträgt, aus denen das Gerät besteht.

• Das Gerät nicht für die Durchflussmessung von Gas einsetzen.

• Belasten Sie das Gerät nicht mechanisch (z. B. durch Ablage von

Gegenständen oder als Trittstufe).

• Nehmen Sie keine äußerlichen Veränderungen an den Gehäusen

vor. Lackieren Sie keinen Teil des Gerätes.

Typ 8071

Grundlegende Sicherheitshinweise

hInWeIS!

Das Gerät kann durch das Medium beschädigt werden.

• Kontrollieren Sie systematisch die chemische Verträglichkeit der

Werkstoffe, aus denen das Gerät besteht, und der Flüssigkeiten, die mit diesem in Berührung kommen können (zum Beispiel:

Alkohole, starke oder konzentrierte Säuren, Aldehyde, Basen,

Ester, aliphatische Verbindungen, Ketone, aromatische oder

halogenierte Kohlenwasserstoffe, Oxidations- und chlorhaltige

Mittel).

hInWeIS!

Elektrostatisch gefährdete Bauelemente / Baugruppen!

Das Gerät enthält elektronische Bauelemente, die gegen elektrostatische Entladung (ESD) empfindlich reagieren. Berührung mit

elektrostatisch aufgeladenen Personen oder Gegenständen

gefährdet diese Bauelemente. Im schlimmsten Fall werden sie

sofort zerstört oder fallen nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340 -5-1 und 5-2,

um die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

• Achten Sie ebenso darauf, dass Sie elektronische Bauelemente

nicht bei anliegender Versorgungsspannung berühren!

6

deutsch

Page 29

Typ 8071

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Kontaktadressen

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

oder wenden Sie sich an Ihren lokal zuständigen Vertriebsmitarbeiter

von Bürkert.

Die internationalen Kontaktadressen finden Sie im Internet unter:

www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des Gerätes unter Beachtung der im vorliegenden Handbuch spezifizierten Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 8071 finden Sie im

Internet unter: www.buerkert.de

5. BESCHREIBUNG

5.1. Vorgesehener Einsatzbereich

Das Gerät ermöglicht aufgrund seiner Ovalräder die Durchflussmessung viskoser Flüssigkeiten. Es muss in Verbindung mit einem

abgesetzten Gerät (z.B. Transmitter 8025 Universal oder Dosiergerät

8025 Batch) zur Erfassung/Konvertierung der durch die Rotation der

Ovalräder erzeugten Impulsfrequenz verwendet werden.

5.2. Allgemeine Beschreibung

5.2.1. Aufbau

Das Gerät besteht aus einem Fitting mit integrierten Ovalrädern und

einem Deckel mit Elektronikmodul, das ein Halleffekt-Sensor und ein

Reed-Schalter enthält.

Die Ovalräder des Fittings enthalten Magnete.

Alle Ausführungen des Sensors weisen einen NPN Transistorausgang

und einen Reed-Schalter auf.

Der elektrische Anschluss erfolgt über einen 1m-langen 5-adrigen

Kabel.

5.2.2. Messprinzip

Die durch die Rohrleitung fließende Flüssigkeit bewirkt das Drehen

der Ovalräder, die Magnete enthalten (siehe Bild 1). Die Bewegung

der Magnete erzeugt eine Magnetfeldänderung. Der Sensor misst die

Magnetfeldänderung und konvertiert dieses Signal in eine Frequenz.

Diese Frequenz ist dann an dem NPN-Transistorausgang und dem

deutsch

7

Page 30

Reed-Schalter-Ausgang verfügbar.

Bild 1: Funktionsweise/Bewegung der Ovalräder

Das abgesetzte Instrument konvertiert die Frequenz mit dem geeigneten K-Faktor in einen Durchflusswert.

5.3. Beschreibung des Typenschilds

Type 8071 Flow Sensor

1

Model

2

Flow Range

3

Max Pressure

4

Max Temp

Serial No

5

Bild 2: Typenschild des Gerätes

1. Bestell-Nummer des Gerätes

2. Messbereich des Durchflusses

3. Max. Druck

4. Höchsttemperatur

5. Seriennummer

433864N

2-100LPH

1000kPa/55Bar

120°C

D34128

Typ 8071

Beschreibung

8

deutsch

Page 31

Typ 8071

Beschreibung

5.4. Verfügbare Versionen

Durchfluss-Messbereich Werkstoffe

ProzessAnschluss

Viskosität

> 1 mPa.s und

< 1000 mPa.s

Viskosität

< 1 mPa.s

Gehäuse Räder / Achse Dichtung

G 1/8'' 0.5-50 l/h 5-50 l/h Aluminium Edelstahl FKM 5 bar

Edelstahl Edelstahl FFKM 55 bar

NPT 1/8'' 0.5-50 l/h 5-50 l/h Aluminium Edelstahl FKM 5 bar

Edelstahl Edelstahl FFKM 55 bar

Durchfluss-Messbereich Werkstoffe

ProzessAnschluss

Viskosität

> 5 mPa.s und

< 1000 mPa.s

Viskosität

< 5 mPa.s

Gehäuse Räder / Achse Dichtung

G 1/4'' 2-100 l/h 12.5-100 l/h PPS PPS / Hastalloy C FFKM 5 bar

Edelstahl Edelstahl FFKM 55 bar

15-500 l/h 40-500 l/h PPS PPS / Hastalloy C FFKM 5 bar

Edelstahl Edelstahl FFKM 55 bar

NPT 1/4'' 2-100 l/h 12.5-100 l/h PPS PPS / Hastalloy C FFKM 5 bar

Edelstahl Edelstahl FFKM 55 bar

15-500 l/h 40-500 l/h PPS PPS / Hastalloy C FFKM 5 bar

Edelstahl Edelstahl FFKM 55 bar

max.

Druck

max.

Druck

Bestellnummer

1)

Bestellnummer

1)

552818

552820

552819

552821

432288

433864

430856

437518

448654

448656

448655

448657

deutsch

9

Page 32

Typ 8071

Beschreibung

ProzessAnschluss

Durchfluss-Messbereich Werkstoffe

Viskosität > 1000 mPa.s Gehäuse Räder / Achse Dichtung

max.

Druck

G 1/4'' 15-500 l/h Edelstahl Edelstahl FFKM 55 bar

NPT 1/4'' 15-500 l/h Edelstahl Edelstahl FFKM 55 bar

1)

Hochdruckversion auf Anfrage erhältlich

2)

Weitere Hochviskosität-Versionen auf Anfrage erhältlich

1)

BestellNummer

552426

553652

2)

10

deutsch

Page 33

Typ 8071

Technische Daten

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

Umgebungs-Temperatur

• Gehäuse aus Aluminium

oder PPS

• Gehäuse aus Edelstahl

Luftfeuchtigkeit < 85%, nicht kondensierend

Schutzart IP54 (NEMA 13)

6.2. Allgemeine technische Daten

6.2.1. Mechanische Daten

Teil Werkstoff

Gehäuse • Aluminium

Räder • PPS

Achse • Hastalloy C

Dichtung FKM oder FFKM

• max. 80 °C

• max. 120 °C

• PPS

• Edelstahl 316F (1.4401)

• Edelstahl 316F (1.4401)

• Edelstahl 316F (1.4401)

6.2.2. Allgemeine Daten

Prozess-Anschluss Innengewinde, G 1/8", G 1/4",

NPT 1/8’’oder NPT 1/4’’

Max. Flüssigkeitsdruck

• Gehäuse aus PPS oder

Aluminium

• Gehäuse aus Edelstahl

Viskosität

Messbereich des Durchflusses

Genauigkeit ≤ ± 1 % des Messwertes

Wiederholbarkeit ≤ ± 0,03 % des Messwertes

Max. Partikel-Größe 75 µm

• 5 bar

• 55 bar (550 bar auf Anfrage)

je nach Ausführung (siehe

Kap. 5.4)

je nach Ausführung (siehe

Kap. 5.4)

deutsch

11

Page 34

Typ 8071

Technische Daten

6.2.3. Elektrische Daten

Betriebsspannung 4,5 - 24 V DC

Transistor-Ausgang

• Ausgangs-Typ

• Max. Intensität des

Hallsensors

• Empfohlene Last

Reed-Schalter-Ausgang

• Ty p

• Schaltspannung

• Schaltstrom

• Max. Arbeitsstrom

• Anzahl Zyklen (typisch))

Elektrischer Anschluss 5-adriges Kabel, 1m lang

• Frequenz über Open Kollektor, NPN, max. 25 mA, 4,5

bis 24 V DC

• 25 mA

• 1,8 Kohm Pull up bei 24 VDC

• Frequenz

• 30 VDC

• 0,5 A

• 0,5 A

6

• 500 x 10

Zyklen (bei

10 VDC und 10 mA)

6.3. Abmessungen

51/51/60*

48

A24

36,5

36,5

60/50/64*

1000 mm-Kabel

* Gehäuse aus Aluminium / Edelstahl / PPS

A: 17...18 mm je nach Werkstoff des Gehäuses

Bild 3: Abmessungen des Gerätes

51/51/60*

48

12

deutsch

Page 35

Typ 8071

Installation und Verkabelung

6.4. K-Faktoren (in Pulse/Liter)

Durchfluss-Messbereich K-Faktor (in Pulse/Liter)

0,5- 50 l/h 1552

2- 100 l/h 1000

15- 500 l/h 400

Wenn das Gerät mit einem Instrument verbunden ist,

das die K-Faktoren nicht automatisch umrechnet, die

Umrechnung mit einer der folgenden Formeln vornehmen:

K-Faktor in Pulse/US-Gallone = K-Faktor in Pulse/Liter x

3,785 zur Umrechnung des Durchflusses in US-Gallonen/

Zeiteinheit

K-Faktor in Pulse/UK-Gallone = K-Faktor in Pulse/Liter x

4,546 zur Umrechnung des Durchflusses in UK-Gallonen/

Zeiteinheit

7. INSTALLATION UND

VERKABELUNG

7.1. Sicherheitshinweise

Gefahr!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen der Prozessanschlüsse die Anlage druckfrei

schalten und die Flüssigkeitszirkulation stoppen.

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab, und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

Verletzungsgefahr aufgrund der Art der Flüssigkeit!

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung

und der Sicherheit in Kraft sind und die sich auf die Verwendung

gefährlicher Produkte beziehen.

Verletzungsgefahr durch hohe Flüssigkeitstemperaturen!

• Das Gerät nur mit Schutzhandschuhen anfassen.

• Vor dem Lösen der Prozessanschlüsse die Flüssigkeitszirkulation stoppen und die Rohrleitung leeren.

• Leicht brennbare Materialien und Medien vom Gerät fernhalten.

deutsch

13

Page 36

Typ 8071

Installation und Verkabelung

WarnunG!

Verletzungsgefahr bei unsachgemäßer Installation!

• Fluidische und elektrische Installationen dürfen nur durch autorisiertes Fachpersonal und mit geeignetem Werkzeug durchgeführt werden!

• Verwenden Sie unbedingt geeignete Sicherheitsvorrichtungen (ordnungsgemäß dimensionierte Sicherungen und/oder

Sicherungsautomat).

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Instalaltion einen kontrollierten Wiederanlauf

gewährleisten.

7.2. Empfehlungen für die Installation

hInWeIS!

Gefahr der Beschädigung des Gerätes, wenn dieser mechanisch belastet wird.

• Schläuche verwenden.

hInWeIS!

Gefahr der Beschädigung der Ovalräder, wenn Partikel mit

einem Durchmesser > 75 µm in den Sensor gelangen.

• Einen 75-µm-Filter so dicht wie möglich vor dem Gerät

installieren.

→ Um die Wartung des Gerätes und des Filters durchführen zu

können, ohne den Prozess zu unterbrechen, einen Bypass in

Ihrer Anlage vorsehen (siehe Bild 4).

Filter

Ventil

8071

Flüssigkeits-Richtung

Bild 4: Installation des Bypass

→ Das Gerät so in der Rohrleitung installieren, dass die Achsen der

Räder in einer Horizontalebene liegen.

Die Außengewinde mit einem Produkt abdichten, das

sich mit den Werkstoffen des Fittings und der Rohrleitung

verträgt.

→ Das Gerät an die Rohrleitung schrauben.

14

deutsch

Page 37

Typ 8071

Installation und Verkabelung

7.3. Verkabelung

Gefahr!

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab, und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

• Eine hochwertige (gefilterte und geregelte) Stromversorgung verwenden.

• Den Potentialausgleich der Installation gewährleisten.

Rote Ader

Schwarze Ader

Weiße Ader

Gelbe Ader

Grüne Ader

Tab. 1: Belegung des Anschluss-Kabels

Stromversorgung (+)

Stromversorgung (-)

NPN-Transistorausgang

Reed-Schalter

Reed-Schalter

7.3.1. Anschluss des NPNTransistorausgangs und des

Reed-Schalterausgangs

L+ (4,5 - 24 V DC)

(rote Ader)

L- (schwarze Ader)

NPN-Transistoraus-

gang (weiße Ader)

1,8 WKohm Pull up bei 24 V DC

Bild 5: Anschluss des NPN-Transistorausgangs und des

Reed-Schalterausgangs

IN

+-

IN = Pulseingang des angeschlossenen Transmitters

angeschlossener

Transmitter

R

V DC

NPN

X

gelbe Ader

grüne

Ader

L+

L-

V DC

X

8071

Bild 6: Beispiel für den Anschluss des NPN-Transistorausgangs

an ein abgesetzter Transmitter

deutsch

15

Page 38

Typ 8071

Inbetriebnahme

8. INBETRIEBNAHME

8.1. Sicherheitshinweise

WarnunG!

Verletzungsgefahr bei unsachgemäßer Inbetriebnahme!

Nicht sachgemäße Inbetriebnahme kann zu Verletzungen sowie

Schäden am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Besonders zu beachten sind die Sicherheitshinweise und die

bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend geschultes

Personal in Betrieb genommen werden.

Schützen Sie das Gerät vor elektromagnetischen

Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

Die Rohrleitung muss gefüllt und luftblasenfrei sein.

→ Die Luft aus der Rohrleitung entfernen, indem das Rohr nach

und nach mit Flüssigkeit gefüllt wird.

→ Die Dichtheit der Anlage kontrollieren.

9. WARTUNG, PROBLEMLÖSUNG

9.1. Sicherheitshinweise

Gefahr!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen der Prozessanschlüsse die Anlage druckfrei

schalten und die Flüssigkeitszirkulation stoppen.

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab, und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

Verletzungsgefahr aufgrund der Art der Flüssigkeit!

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung

und der Sicherheit in Kraft sind und die sich auf die Verwendung

gefährlicher Produkte beziehen.

Verletzungsgefahr durch hohe Flüssigkeitstemperaturen!

• Das Gerät nur mit Schutzhandschuhen anfassen.

• Vor dem Lösen der Prozessanschlüsse die Flüssigkeitszirkulation stoppen und die Rohrleitung leeren.

• Leicht brennbare Materialien und Medien vom Gerät fernhalten.

16

deutsch

Page 39

Typ 8071

Wartung, Problemlösung

WarnunG!

Gefahr durch unsachgemäße Wartungsarbeiten!

• Wartungsarbeiten dürfen nur durch autorisiertes Fachpersonal

und mit geeignetem Werkzeug durchgeführt werden!

• Nach einer Unterbrechung der elektrischen Versorgung ist ein

definierter oder kontrollierter Wiederanlauf des Prozesses zu

gewährleisten.

9.2. Wartung des Filters

→ Nach Durchlauf der ersten 200 Liter Flüssigkeit kontrollieren, ob

der Filter Späne oder Ablagerungen enthält. Ihn erforderlichenfalls mit einem Produkt reinigen, das sich mit den Materialien

verträgt, aus denen er besteht.

→ Den Filterzustand regelmäßig überprüfen, insbesondere wenn

der Durchfluss der Flüssigkeit geringer wird. Ihn erforderlichenfalls mit einem Produkt reinigen, das sich mit den Materialien

verträgt, aus denen er besteht.

9.3. Wartung des Gerätes

→ Regelmäßig den Zustand der Dichtung und der Ovalräder

des Gerätes überprüfen. Vorgehen wie unter Kap. 9.4 und 9.5

beschrieben.

Das Gerät nur mit einem Tuch oder Lappen reinigen, der leicht mit

Wasser oder mit einem Mittel befeuchtet ist, das sich mit den Werkstoffen des Gerätes verträgt.

Wenn Sie ergänzende Informationen wünschen, steht Ihnen Ihr Lieferant Bürkert voll und ganz zur Verfügung.

9.4. Ausbau des Gerätes

Rillen

1

2

3

4

5

Bild 7: Explosionszeichnung des Gerätes

→ Die 4 Schrauben (Marke 5 Bild 7) lösen und den Deckel mit

Elektronikmodul (Marke 4 Bild 7) abnehmen.

→ Die Dichtung (Marke 3 Bild 7) entfernen.

→ Den Zustand der Dichtung überprüfen. Wenn sie beschädigt ist,

ersetzen (siehe Kap. "10. Ersatzteile, Zubehör").

→ Die Räder herausnehmen (Marke 2 Bild 7).

→ Den ordnungsgemäßen Zustand der Räder kontrollieren. Sie

reinigen bzw. ersetzen, falls erforderlich (siehe Kap. 10).

deutsch

17

Page 40

9.5. Wiederaufbau des Gerätes

Typ 8071

Wartung, Problemlösung

Das mit dem Magnet versehene Rad muss wieder auf der

Seite mit der Rille eingesetzt werden (siehe Bild 8 und die

folgende Tabelle).

→ Die um 90° gegeneinander versetzten Räder wieder in das

Gehäuse einsetzen (siehe Bild 8).

Rille

Ovalrad mit Magnet

neutrales Ovalrad (ohne Magnet)

Bild 8: Positionierung der Ovalräde

DurchflussMessbereich

0.5-50 l/h Die Öffnung der Magnetaufnahme ist sichtbar

• 0.5-50 l/h

• 2-100 l/h

• 15-500 l/h

Ovalrad mit Magnet

(zeigt zum Deckel)

Die Öffnung der Magnetaufnahme ist nicht

sichtbar (zeigt zum Gehäuseboden)

→ Krümmungsradius am Umfang der Ovalräder gegen Gehäuse-

boden orientieren (siehe Bild 9).

A A

rechter Winkel

Abrundung

A-A

Bild 9: Schnittzeichnung eines Ovalrads

→ Das Vorhandensein des Magneten mit einem Detektor

überprüfen.

→ Überprüfen, ob die Räder sich frei drehen, indem sie vorsichtig

mit dem Finger gedreht werden.

→ Die Dichtung (Marke 3 Bild 7) wieder einsetzen.

→ Den Deckel (Marke 4 Bild 7) wieder aufsetzen, dabei die Rille

des Deckels auf diejenige des Gehäuses ausrichten.

→ Die 4 Schrauben (Marke 5 Bild 7) vorsichtig, um das Gehäuse

nicht zu beschädigen, mit folgendem Anzugsdrehmoment über

Kreuz festziehen:

- 1 Nm bei einem Gehäuse aus PPS

- 2 Nm bei einem Gehäuse aus Aluminium

- 9 Nm bei einem Gehäuse aus Edelstahl

18

deutsch

Page 41

Typ 8071

Wartung, Problemlösung

9.6. Problemlösung

Problem Ursache Lösung

Die Flüssigkeit

läuft nicht mehr

durch das Gerät

ab

Gerät verstopft

Filter verstopft (falls vorhanden)

Räder beschädigt

→ Die Räder demontieren und reinigen (siehe Kap. "9.4. Ausbau des Gerätes"

und "9.5. Wiederaufbau des Gerätes").

→ 75-µm-Filter vor dem Gerät einbauen.

→ Den Filter reinigen.

→ Die Räder auswechseln (siehe Kap. "10. Ersatzteile, Zubehör", "9.4. Ausbau

des Gerätes" und "9.5. Wiederaufbau des Gerätes").

Durchfluss

durch das Gerät

verringert

Widersprüchliche

Messwerte

Kein Signal am

Frequenzausgang

Filter (falls vorhanden) teilweise

verstopft

Flüssigkeit zu viskos Räder für Viskositäten höher als 1000 mPa.s verwenden.

Ungeeignetes

Durchfluss-Messbereich

Luft in der Rohrleitung

Reibung aufgrund fehlerhafter Wiedermontage des Gerätes

Falsche Verkabelung der Ausgänge

Räder falsch herum montiert

Magnet defekt

Hallsensor oder Reed-Schalter defekt

→ Den Filter reinigen.

→ Technische Daten überprüfen, Gerät oder Durchfluss anpassen (siehe

Kap. "6.2.2. Allgemeine Daten").

→ Langsam die Luft aus der Rohrleitung ablassen.

→ Die Montage der Räder im Gerät überprüfen (siehe Kap. "9.4. Ausbau des

Gerätes" und Kap. "9.5. Wiederaufbau des Gerätes").

→ Die Verkabelung überprüfen (siehe Kap. "7.3. Verkabelung").

→ Das Gerät demontieren und die Position der Räder ändern (siehe "9.4.

Ausbau des Gerätes" und "9.5. Wiederaufbau des Gerätes").

→ Die Räder auswechseln (siehe Kap. "10. Ersatzteile, Zubehör", "9.4. Ausbau

des Gerätes" und "9.5. Wiederaufbau des Gerätes").

→ Den Deckel mit Elektronikmodul ersetzen (siehe Kap. "10. Ersatzteile,

Zubehör", 9.4 und 9.5).

deutsch

19

Page 42

Typ 8071

Ersatzteile, Zubehör

10. ERSATZTEILE, ZUBEHÖR

VOrSIChT!

Verletzungsgefahr, Sachschäden durch ungeeignete Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen und Schäden am Gerät und dessen Umgebung

verursachen.

• Verwenden Sie nur Originalzubehör sowie Originalersatzteile

der Fa. Bürkert.

Ersatzteil Bestellnummer

Satz mit 2 Ovalrädern aus Edelstahl,

Durchfluss-Messbereich 0.5-50 l/h

Satz mit 2 Ovalrädern aus Edelstahl,

Durchfluss-Messbereich 2-100 l/h

Satz mit 2 Ovalrädern aus Edelstahl,

Durchfluss-Messbereich 15-500 l/h

Satz mit 2 Ovalrädern aus PPS, DurchflussMessbereich 2-100 l/h

Satz mit 2 Ovalrädern aus PPS, DurchflussMessbereich 15-500 l/h

Dichtung aus FKM 550923

Dichtung aus FFKM 550959

Deckel aus Edelstahl mit Elektronikmodul mit

Hallsensor und Reed-Schalter

560180

550919

550920

550921

550922

553653

Ersatzteil Bestellnummer

Deckel aus PPS mit Elektronikmodul mit

Hallsensor und Reed-Schalter

Deckel aus Aluminium mit Elektronikmodul mit

Hallsensor und Reed-Schalter

553654

auf Anfrage

20

deutsch

Page 43

Typ 8071

Verpackung, Transport

11. VERPACKUNG, TRANSPORT

hInWeIS!

Transportschäden!

Ein unzureichend geschütztes Gerät kann durch den Transport

beschädigt werden.

• Transportieren Sie das Gerät vor Nässe und Schmutz geschützt

in einer stoßfesten Verpackung.

• Das Gerät keinen Temperaturen außerhalb des zulässigen Temperaturbereichs für die Lagerung aussetzen.

• Verschließen Sie die elektrischen Schnittstellen mit Schutzkappen vor Beschädigungen.

12. LAGERUNG

hInWeIS!

Falsche Lagerung kann Schäden am Gerät verursachen!

• Lagern Sie das Gerät trocken und staubfrei!

• Lagerungstemperatur: -10...+60 °C.

13. ENTSORGUNG DES GERÄTES

→

Entsorgen Sie das Gerät und die Verpackung umweltgerecht.

hInWeIS!

Umweltschäden durch Teile, die durch Flüssigkeiten kontaminiert wurden!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten!

Hinweis!

Beachten Sie die nationalen Abfallbeseitigungsvorschriften.

deutsch

21

Page 44

Typ 8071

22

deutsch

Page 45

Typ 8071

deutsch

23

Page 46

Typ 8071

24

deutsch

Page 47

Type 8071

Type 8071

1. À PROPOS DE CE MANUEL ..................................................................... 4

1.1. Symboles utilisés ...............................................................................4

1.2. Définition du terme "appareil" .....................................................4

2. UTILISATION CONFORME.........................................................................5

3. CONSIGNES DE SÉCURITÉ DE BASE ...............................................5

4. INFORMATIONS GÉNÉRALES .................................................................7

4.1. Adresse et contacts internationaux ......................................... 7

4.2. Conditions de garantie .................................................................... 7

4.3. Informations sur internet ............................................................... 7

5. DESCRIPTION .................................................................................................. 7

5.1. Secteur d'application .......................................................................7

5.2. Description générale ........................................................................ 7

5.3. Description de l'étiquette d'identification ..............................8

5.4. Versions disponibles ........................................................................ 9

6. CARACTÉRISTIQUES TECHNIQUES ............................................... 11

6.1. Conditions d'utilisation ................................................................. 11

6.2. Caractéristiques techniques générales .............................. 11

6.3. Dimensions ........................................................................................ 12

6.4. Facteurs K (en imp./l) ................................................................... 13

7. INSTALLATION ET CÂBLAGE ÉLECTRIQUE ................................. 13

7.1. Consignes de sécurité ................................................................. 13

7.2. Recommandations d'installation ............................................. 14

7.3. Câblage électrique ......................................................................... 15

8. MISE EN SERVICE ...................................................................................... 16

8.1. Consignes de sécurité ................................................................. 16

9. MAINTENANCE ET DEPANNAGE ....................................................... 16

9.1. Consignes de sécurité ................................................................. 16

9.2. Entretien du filtre ............................................................................ 17

9.3. Entretien de l'appareil ................................................................... 17

9.4. Démonter l'appareil ........................................................................ 17

9.5. Remonter l'appareil ........................................................................ 18

9.6. En cas de problème ...................................................................... 19

10. PIÈCES DE RECHANGE ET ACCESSOIRES .............................. 20

11. EMBALLAGE ET TRANSPORT ...........................................................21

12. STOCKAGE .................................................................................................. 21

13. ÉLIMINATION DE L’APPAREIL ............................................................ 21

français

Page 48

Type 8071

À propos de ce manuel

1. À PROPOS DE CE MANUEL

Ce manuel décrit le cycle de vie complet de l'appareil. Conservez-le

de sorte qu'il soit accessible à tout utilisateur et à disposition de tout

nouveau propriétaire.

Ce manuel contient des informations importantes relatives à

la sécurité.

Le non-respect de ces consignes peut entraîner des situations

dangereuses.

• Ce manuel doit être lu et compris.

1.1. Symboles utilisés

danger

Met en garde contre un danger imminent.

• Son non-respect peut entraîner la mort ou de graves blessures.

avertissement

Met en garde contre une situation éventuellement

dangereuse.

• Son non-respect peut entraîner de graves blessures, voire la

mort.

attention

Met en garde contre un risque éventuel.

• Son non-respect peut entraîner des blessures légères ou de

gravité moyenne.

remarque

Met en garde contre des dommages matériels.

• Son non-respect peut entraîner des dommages sur l'appareil ou

l'installation.

désigne des informations supplémentaires, des conseils ou

des recommandations importants.

renvoie à des informations contenues dans ce manuel ou

dans d'autres documents.

→ indique une opération à effectuer.

1.2. Définition du terme "appareil"

Dans ce manuel d‘utilisation, le terme "appareil" désigne toujours le

débitmètre 8071.

4

français

Page 49

Type 8071

Utilisation conforme

2. UTILISATION CONFORME

L'utilisation non conforme de l'appareil peut présenter des

dangers pour les personnes, les installations proches et

l‘environnement.

• L'appareil est destiné à la mesure du débit de liquides, particulièrement de liquides visqueux.

• Protéger cet appareil contre les perturbations électromagnétiques, les rayons ultraviolets et, lorsqu'il est installé à l'extérieur,

des effets des conditions climatiques.

• Utiliser cet appareil conformément aux caractéristiques et

conditions de mise en service et d'utilisation indiquées dans les

documents contractuels et dans le manuel utilisateur.

• L'utilisation en toute sécurité et sans problème de l'appareil

repose sur un transport, un stockage et une installation corrects

ainsi que sur une utilisation et une maintenance effectuées avec

soin.

• Veiller à toujours utiliser cet appareil de façon conforme.

→ Respecter les restrictions éventuelles lorsque l'appareil est

exporté.

3. CONSIGNES DE SÉCURITÉ DE BASE

Ces consignes de sécurité ne tiennent pas compte :

• des imprévus pouvant survenir lors de l'assemblage, de l'utilisation

et de l'entretien des appareils.

• des prescriptions de sécurité locales que l'exploitant est tenu de

faire respecter par le personnel chargé de l'assemblage et de

l'entretien.

Danger dû à la pression élevée dans l'installation.

Danger dû à la tension électrique.

Danger dû à des températures élevées du fluide.

Danger dû à la nature du fluide.

Situations dangereuses diverses

Pour éviter toute blessure, veiller à :

• empêcher toute mise sous tension involontaire de l'installation.

• ce que les travaux d'installation et de maintenance soient

effectués par du personnel qualifié et habilité, disposant des

outils appropriés.

français

5

Page 50

Situations dangereuses diverses

Pour éviter toute blessure, veiller à :

• garantir un redémarrage défini et contrôlé du process, après

une coupure de l'alimentation électrique.

• n'utiliser l'appareil qu'en parfait état et en tenant compte des

indications du manuel utilisateur.

• respecter les règles générales de la technique lors de l'implantation et de l'utilisation de l'appareil.

• ne pas utiliser l'appareil dans une atmosphère explosible.

• ne pas utiliser l'appareil dans un environnement incompatible avec

les matériaux qui le composent.

• ne pas utiliser de fluide incompatible avec les matériaux composant

l'appareil.

• ne pas utiliser l'appareil pour la mesure de débit de gaz.

• ne pas soumettre l'appareil à des contraintes mécaniques (par ex.

en y déposant des objets ou en l'utilisant comme marchepied).

• n'apporter aucune modification extérieure au corps. Ne peindre ni

laquer aucune partie de l'appareil.

Type 8071

Consignes de sécurité de base

remarque

L'appareil peut être endommagé par le fluide en contact.

• Vérifier systématiquement la compatibilité chimique des matériaux composant l'appareil et les produits susceptibles d’entrer

en contact avec celui-ci (par exemple : alcools, acides forts ou

concentrés, aldéhydes, bases, esters, composés aliphatiques,

cétones, aromatiques ou hydrocarbures halogénés, oxydants et

agents chlorés).

remarque

Éléments / Composants sensibles aux décharges électrostatiques

Cet appareil contient des composants électroniques sensibles

aux décharges électrostatiques. Ils peuvent être endommagés

lorsqu'ils sont touchés par une personne ou un objet chargé électrostatiquement. Dans le pire des cas, ils sont détruits instanta-

nément ou tombent en panne sitôt effectuée la mise en route.

• Pour réduire au minimum voire éviter tout dommage dû à une

décharge électrostatique, prenez toutes les précautions décrites

dans les normes EN 61340-5-1 et 5-2.

• Veiller également à ne pas toucher les composants électriques

sous tension.

6

français

Page 51

Type 8071

Informations générales

4. INFORMATIONS GÉNÉRALES

4.1. Contact

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

Vous pouvez également contacter votre revendeur Bürkert.

Les adresses des filiales internationales sont disponibles sous :

www.burkert.com

4.2. Conditions de garantie

La condition pour bénéficier de la garantie légale est l’utilisation

conforme de l'appareil dans le respect des conditions d’utilisation

spécifiées dans le présent manuel utilisateur.

4.3. Informations sur internet

Retrouvez sur internet les manuels utilisateur et les fiches techniques

relatifs au type 8071 sous : www.burkert.fr/

5. DESCRIPTION

5.1. Secteur d'application

L'appareil permet de mesurer, grâce à ses roues ovales, le débit de

liquides visqueux. Il doit être associé à un instrument déporté (par

exemple, transmetteur 8025 Universal ou contrôleur de dosage 8025

Batch) d'acquisition/conversion de la fréquence des impulsions liées

à la rotation des roues ovales.

5.2. Description générale

5.2.1. Construction

L'appareil est composé d'un raccord à roues ovales et d'un couvercle

avec module électronique incluant un capteur à effet Hall et un interrupteur Reed.

Les roues ovales du raccord contiennent des aimants.

Toutes les versions de l'appareil présentent une sortie transistor NPN

et une sortie interrupteur Reed.

Le raccordement électrique s'effectue à l'aide d'un câble à 5 fils d'un

mètre de long.

5.2.2. Principe de fonctionnement

Le fluide circulant dans la canalisation fait tourner les roues ovales qui

contiennent des aimants (voir Fig. 1). Le déplacement des aimants

provoque une variation du champ magnétique. Le capteur mesure la

variation du champ magnétique et convertit ce signal en fréquence.

Cette fréquence est alors disponible sur la sortie transsitor NPN et la

français

7

Page 52

sortie interrupteur Reed.

Fig. 1 : Fonctionnement/Déplacement des roues ovales

L'instrument déporté d'acquisition/conversion convertit la fréquence

en débit en utilisant le facteur K approprié.

5.3. Description de l'étiquette d'identification

Type 8071 Flow Sensor

1

Model

2

Flow Range

3

Max Pressure

4

Max Temp

Serial No

5

Fig. 2 : Étiquette d'identification du débitmètre 8071

1. Référence de commande de l'appareil

2. Plage de mesure du débit

3. Pression max.

4. Température max.

5. Numéro de série

433864N

2-100LPH

1000kPa/55Bar

120°C

D34128

Type 8071

Description

8

français

Page 53

Type 8071

Description

5.4. Versions disponibles

Plage de débit Matériaux

Raccordement

au process

viscosité

> 1 mPa.s et

< 1000 mPa.s

viscosité

< 1 mPa.s

boîtier roues / axe joint

G 1/8'' 0.5-50 l/h 5-50 l/h aluminium acier inoxydable FKM 5 bar

acier inoxydable acier inoxydable FFKM 55 bar

NPT 1/8'' 0.5-50 l/h 5-50 l/h aluminium acier inoxydable FKM 5 bar

acier inoxydable acier inoxydable FFKM 55 bar

Plage de débit Matériaux

Raccordement

au process

viscosité

> 5 mPa.s et

< 1000 mPa.s

viscosité

< 5 mPa.s

boîtier roues / axe joint

G 1/4'' 2-100 l/h 12.5-100 l/h PPS PPS / Hastalloy C FFKM 5 bar

acier inoxydable acier inoxydable FFKM 55 bar

15-500 l/h 40-500 l/h PPS PPS / Hastalloy C FFKM 5 bar

acier inoxydable acier inoxydable FFKM 55 bar

NPT 1/4'' 2-100 l/h 12.5-100 l/h PPS PPS / Hastalloy C FFKM 5 bar

acier inoxydable acier inoxydable FFKM 55 bar

15-500 l/h 40-500 l/h PPS PPS / Hastalloy C FFKM 5 bar

acier inoxydable acier inoxydable FFKM 55 bar

Pression

max.

Pression

max.

Référence de

1)

commande

Référence de

1)

commande

552818

552820

552819

552821

432288

433864

430856

437518

448654

448656

448655

448657

français

9

Page 54

Type 8071

Description

Raccordement

au process

Plage de débit Matériaux

viscosité > 1000 mPa.s boîtier roues / axe joint

Pression

max.

G 1/4'' 15-500 l/h acier inoxydable acier inoxydable FFKM 55 bar

NPT 1/4'' 15-500 l/h acier inoxydable acier inoxydable FFKM 55 bar

1)

Versions haute pression disponibles sur demande

2)

Autres versions pour haute viscosité disponibles sur demande

Référence de

1)

commande

2)

552426

553652

10

français

Page 55

Type 8071

Caractéristiques techniques

6. CARACTÉRISTIQUES

TECHNIQUES

6.1. Conditions d'utilisation

Température ambiante

• boîtier en aluminium ou

en PPS

• boîtier en acier inoxydable

Humidité de l'air < 85%, non condensée

Indice de protection IP54 (NEMA 13)

6.2. Caractéristiques techniques générales

6.2.1. Caractéristiques mécaniques

Élément Matériau

Boîtier • Aluminium

Roues • PPS

• max. 80 °C

• max. 120°C

• PPS

• Acier inoxydable 316F (1.4401)

• Acier inoxydable 316F (1.4401)

Élément Matériau

Axe • Hastalloy C

• Acier inoxydable 316F (1.4401)

Joint FKM ou FFKM

6.2.2. Caractéristiques générales

Raccordement au process Taraudage G 1/8" ou G 1/4",

NPT 1/8’’ou NPT 1/4’’

Pression du fluide max.

• Boîtier PPS ou aluminium

• Boîtier acier inoxydable

Viscosité

Plage de mesure du débit

Précision ≤ ± 1 % de la valeur mesurée

Répétabilité ≤ ± 0,03 % de la valeur mesurée

Taille max. des particules 75 µm

• 5 bar

• 55 bar (550 bar sur demande)

fonction de la version (voir

chap. 5.4)

fonction de la version (voir

chap. 5.4)

français

11

Page 56

Type 8071

Caractéristiques techniques

6.2.3. Caractéristiques électriques

Tension d'alimentation 4,5 - 24 V DC

Sortie transistor :

• Type de sortie

• Intensité max. du capteur Hall

• Charge préconisée

Sortie interrupteur Reed :

• Type

• Tension max. commutable

• Courant max. commutable

• Courant de travail max.

• Nombre de cycles (typique)

Raccordement électrique Câble 5 fils, longueur 1m

• Fréquence sur collecteur

ouvert, NPN, max. 25 mA, 4,5

à 24 V DC

• 25 mA

• 1,8 Kohm Pull up à 24 VDC

• Fréquence

• 30 VDC

• 0,5 A

• 0,5 A

6

• 500 x 10

cycles (à 10 VDC

et 10 mA)

6.3. Dimensions

51/51/60*

48

36,5

36,5

60/50/64*

câble 1000 mm

* boîtier en aluminium / acier inoxydable / PPS

A : 17...18 mm selon le matériau du boîtier

Fig. 3 : Dimensions de l'appareil

48

A24

51/51/60*

12

français