Page 1

OPERATING AND INSTALLATION MANUAL

Flow transmitter SE56

Basic version

Release number: MASE56_BV_EN_BU_R9_3.91.0XXX.docx

bolt type indicate the software version, visualized at the instrument start up, which the manual refers to.

– The characters of file name in

Page 2

SE56 2SE56

Page 3

INDEX

INTRODUCTION .................................................................................. 4

SAFETY INFORMATIONS ..................................................................... 4

SAFETY CONVENTIONS ........................................................................... 5

TECHNICAL CHARACTERISTICS.......................................................... 6

ENVIRONMENTAL USE CONDITIONS ........................................................ 6

OPERATING TEMPERATURE ..................................................................... 6

Data plate .............................................................................................. 6

ELECTRIC CHARACTERISTICS .................................................................. 6

DIMENSIONS ......................................................................................... 7

ELECTRICAL CONNECTIONS ............................................................... 8

GROUNDING INSTRUCTIONS ................................................................... 8

POWER SUPPLY ...................................................................................... 8

INTERNAL VIEW ..................................................................................... 9

TRANSMITTER TO SENSOR ELECTRICAL CONNECTIONS ............................ 9

DIGITAL INPUT ..................................................................................... 10

INPUT ON/OFF OPERATION .................................................................... 10

OUTPUT WIRINGS ............................................................................. 11

DISPLAY FLAGS AND LED WARNING INTERPRETATION................... 12

TRANSMITTER ACCESS ...................................................................... 13

KEYPAD ................................................................................................ 13

BLIND CONFIGURATION ........................................................................ 13

ACCESSING THE FUNCTIONS AT START-UP (Power On) ............................ 14

FLOW RATE VISUALIZATION ............................................................. 15

ACCESS CODES................................................................................... 16

ACCESS TO THE CONFIGURATION MENU .......................................... 18

EXAMPLE .............................................................................................. 19

FUNCTIONS MENU ............................................................................. 21

FUNCTIONS DESCRIPTION ..................................................................... 24

ALARMS.............................................................................................. 30

CONFORMITY DECLARATION .................................................................. 32

3

Page 4

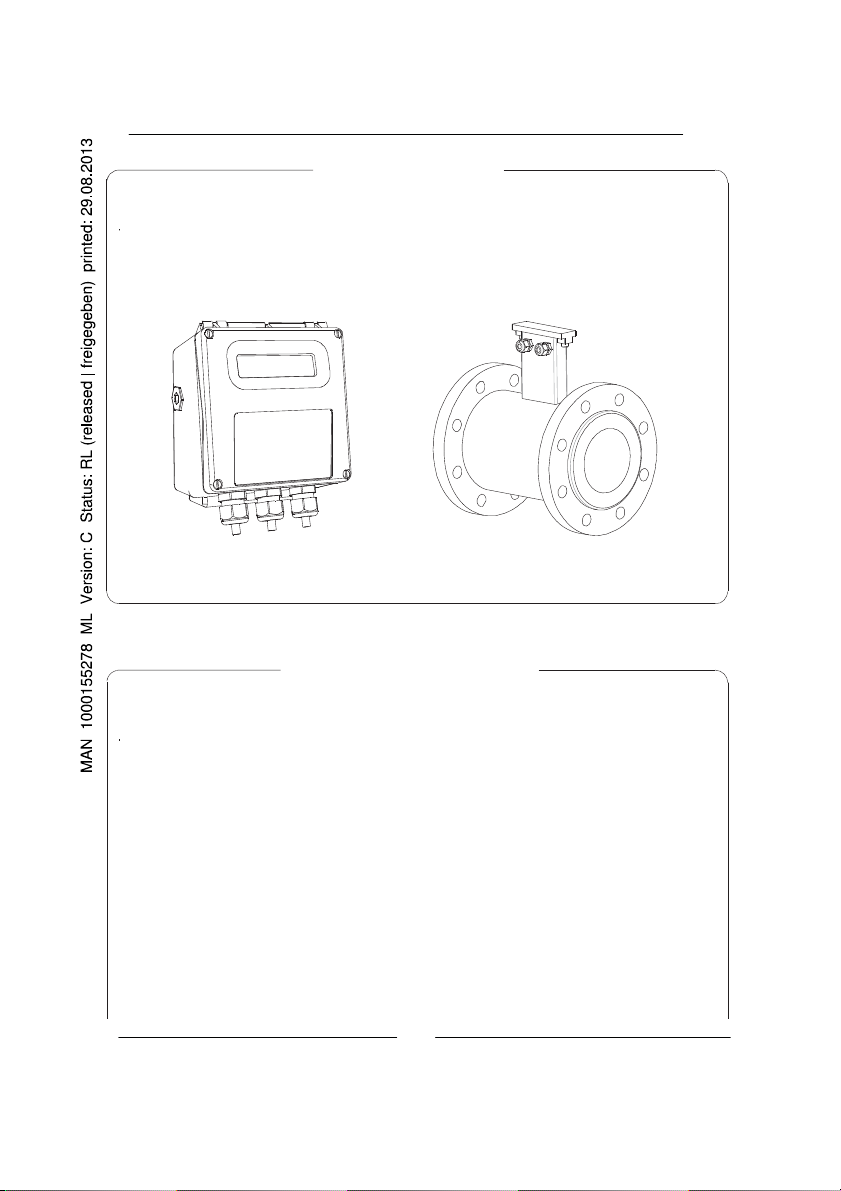

SE56

INTRODUCTION

These operating instructions and description of device functions are provided for the scope

of supply. They could be modified without prior notice. The improper use, possible

tampering of the instrument or parts of it and substitutions of any components not original,

makes the warranty to decay automatically.

The transmitter is to be used only to be coupled directly with a sensor to realize a

measuring device, flow meter, that is to be used for measuring the flow of conductive

liquids in closed pipes with conductivity greater than 5μS/cm.

TRANSMITTER

SENSOR

It is forbidden the reproduction of the present manual and of possible software supplied.

SAFETY INFORMATIONS

Any use other than described here affects the protection provided by the manufacturer and

compromises the safety of people and the entire measuring system and is, therefore, not

permitted.

The manufacturer is not liable for damaged caused by improper or non-designated use.

1) Transport the measuring device to the measuring point in the original packaging. Do

not remove covers or caps until immediately before installation. In case of cartons

package it is possible to place one above the other but no more than three cartons.

In case of wooden package do not place one above the other.

2) Disposal of this product or parts of it must be carried out according to the local

public or private waste collection service.

3) The transmitter must only be installed, connected, commissioned and maintained by

qualified and authorized specialists (e.g. electrical technicians) in full compliance with

the instructions in these Operating Instructions, the applicable norms, legal

regulations and certificates (depending on the application).

4) The specialists must have read and understood these Operating Instructions and

must follow the instructions they contain. If you are unclear on anything in these

Operating Instructions, you must call the service. The Operating Instructions provide

detailed information on the transmitter.

4

Page 5

5) Repairs may only be performed if a genuine spare parts kit is available and this

repair work is expressly permitted.

6) The transmitter should only be installed after have verified technical data provided in

this operating instructions and on the data plate.

7) Specialists must be carefully during installation and use personal protective

equipment as provided by their security plan about risk assessment.

8) Never mount or wire the transmitter while it is connected to the power supply and

avoid any liquid contact with the instrument internal components.

9) Before connecting the power supply check the safety equipment.

10) For the cleaning of the device use only a damp cloth, and for the

maintenance/repairs contact the service center.

Before starting up the equipment please verify the following:

Power supply voltage must correspond to that specified on the data plate

Electric connections must be completed as described

Ground (earth) connections must be completed as specified

Verify periodically (every 3-4 months):

The power supply cables integrity, wiring and other connected electrical parts

The transmitter housing integrity

The suitable tightness of the sealing elements

The front panel integrity (display and keyboard)

The mechanical fixing of the transmitter to the pipe or wall stand.

SAFETY CONVENTIONS

DANGER

Warning indicates an action or procedure which, if not performed correctly,

can result in injury or a safety hazard. Comply strictly with the instructions

and proceed with care.

SE56

WARNING

Caution indicates an action or procedure which, if not performed correctly, can

result in incorrect operation or destruction of the device. Comply strictly with

the instructions.

NOTES

Note indicates an action or procedure which, if not performed correctly, can

have an indirect effect on operation or trigger an unexpected response on the

part of the device.

5

Page 6

TECHNICAL CHARACTERISTICS

x

F

S

z

V

/

z

ELECTRIC CHARACTERISTIC

Transmitter classification: class I, IP65, installation category (overvoltage) II, rated

pollution degree 2.

SE56

Power supply

versions

Power supply

voltage

Power supply

frequency

Max

power

HV 100-240V~ 44-66H

LV

Voltage changes must not exceed ±10% of the nominal one.

Input/output insulated up to 500V.

The output 4-20mA (optional) is electrically connected to the ON/OFF outputs and

18-45

18-45V~ 44-66H

/

6W

the output power supply (24V ).

ENVIRONMENTAL USE CONDITIONS

The transmitter can be installed internally or externally

Altitude: from –200m to 2000m (from -656 to 6560 feet)

Humidity range: 0-85% without condensation

OPERATING TEMPERATURE

Min. * Ma

°C -10 50

°

14 122

Consider the operating temperatures more restrictive between transmitter and sensor

* For discontinuous use, a thermostat heat source installation may be necessary.

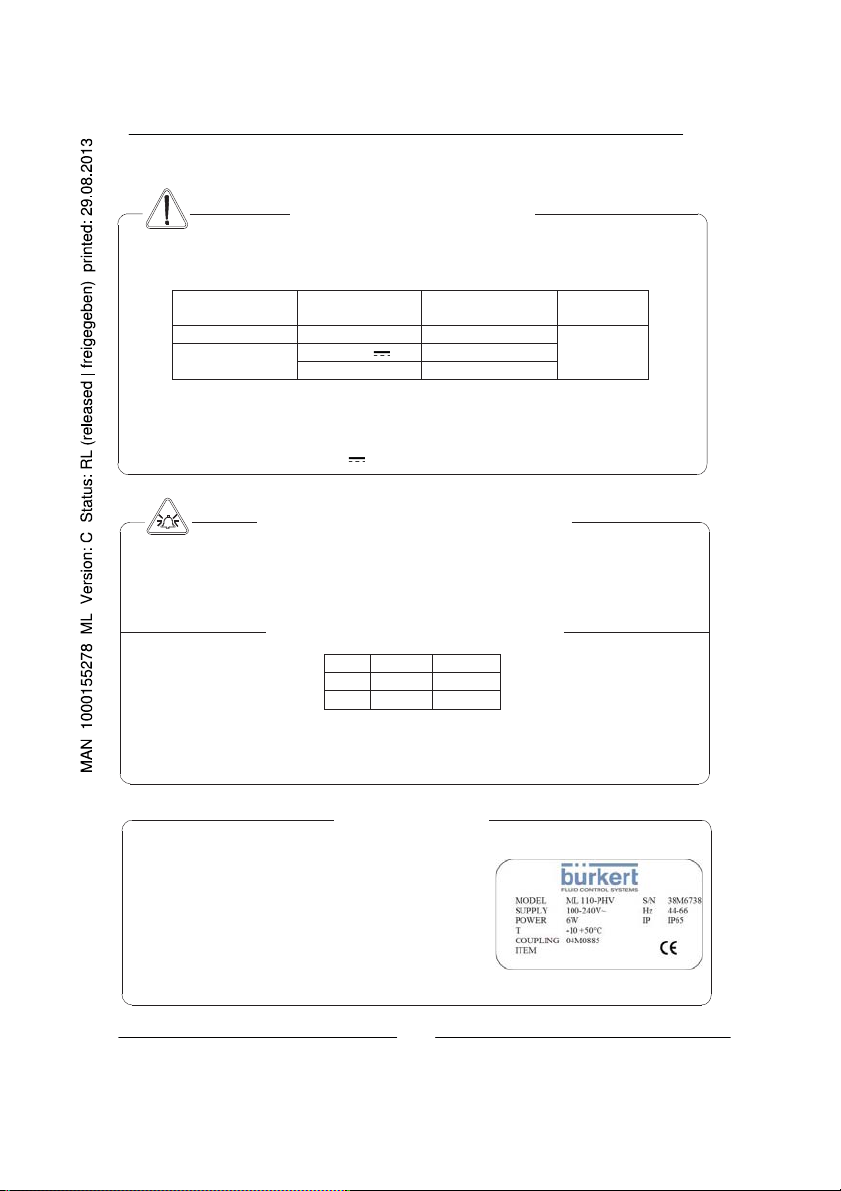

Data plate

On the data plate there is some technical information:

• MODEL: Transmitter Model

• S/N: Serial Number of the transmitter

• SUPPLY: Main power supply

• Hz: Supply frequency (AC)

• POWER: Maximum power consumption

• IP: Protection grade

• T: Operating temperature

• COUPLING: Serial number of sensor coupled

• ITEM: free for user

6

Page 7

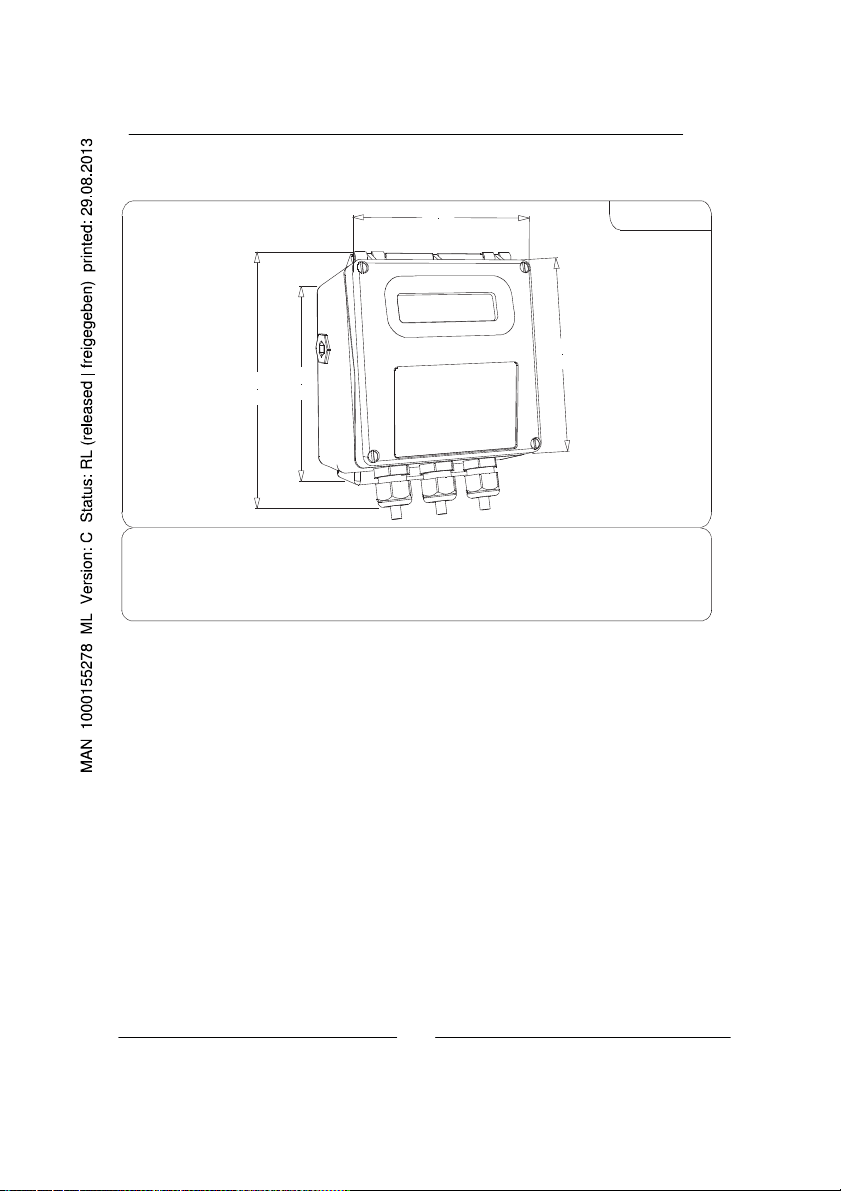

DIMENSIONS

S

SE56

7

2

1

4

2

1

129

168

To guarantee the housing’s IP degree the following torques are required:

cover screws: 0.5Nm

cable glands: 4Nm (in reference conditions)

IF2 cap: 4Nm

TORQUE

Weight: 0.5kg

7

Page 8

ELECTRICAL CONNECTIONS

A

S

SE56

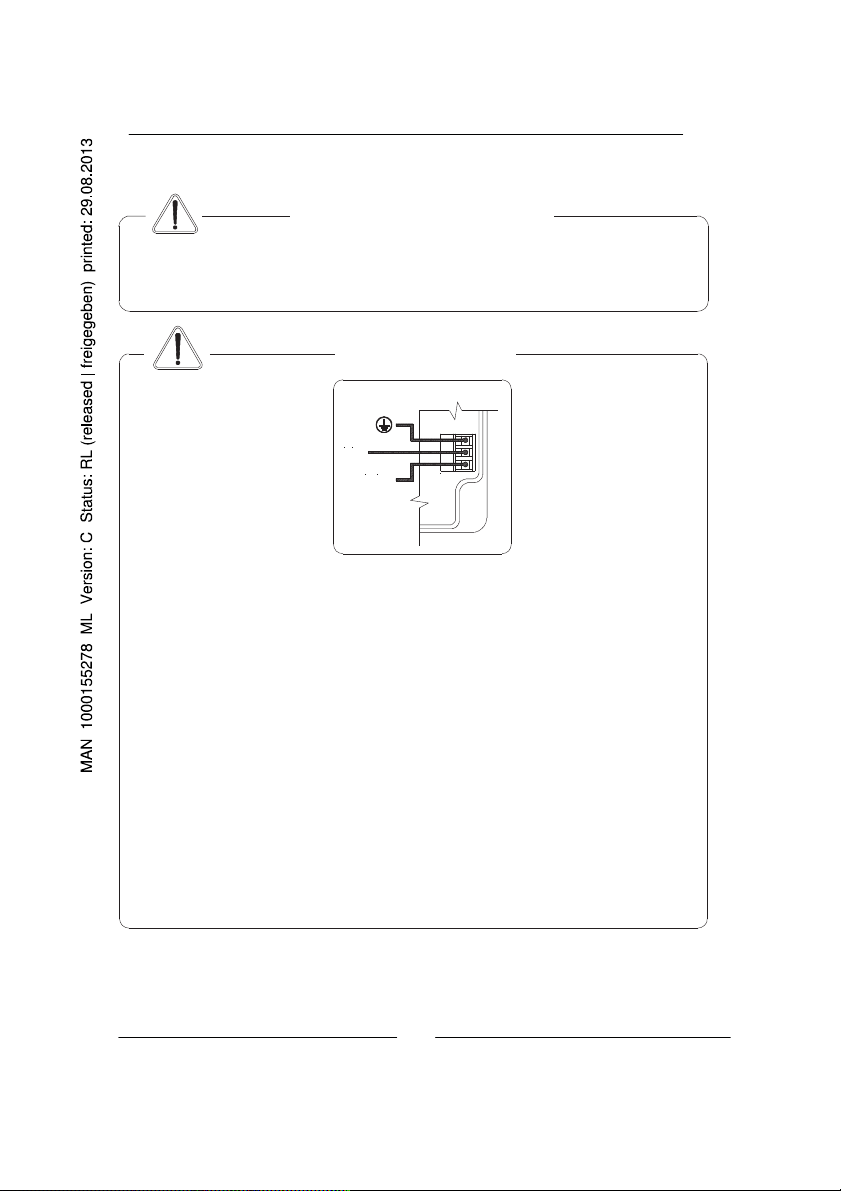

GROUNDING INSTRUCTION

LWAYS ensure that the transmitter and the sensor are grounded (earthed) correctly.

The grounding of the sensor and transmitter ensures that the equipment and liquid are

equipotential.

POWER SUPPLY

L

(-)

N

(+)

Before connecting the power supply, verify that the mains voltage are within the

limits indicated on data plate.

For the connections use only approved conductors, with fire-proof properties, whose

section varies from 0.25mm

2

to 2.50mm2, based on distance/power; as well fix the

power supply wires with a additional fastening system located close to the terminal.

The power supply line must be equipped with an external protection for overload

current (fuse or automatic line breaker).

Provide nearness the transmitter a circuit breaker easily accessible for the operator

and clearly identified; whose symbols must conform to the electrical safety and local

electrical requirements.

Ensure that the component complies with the requirements of the standard for

electrical safety distance.

The sensor, hardwired inputs and outputs are connected to the transmitter through

terminal blocks located inside the transmitter.

To locate the terminal block loosen the 4 screws on the front cover. When the front

cover is lifted, the terminal block is visible. The terminal block is the hardwire

connection of the transmitter to external equipment, including the sensor.

M3

The following pages give informations on the terminal block numbering, and the

respective connecting of the sensor cables, and inputs/outputs.

8

Page 9

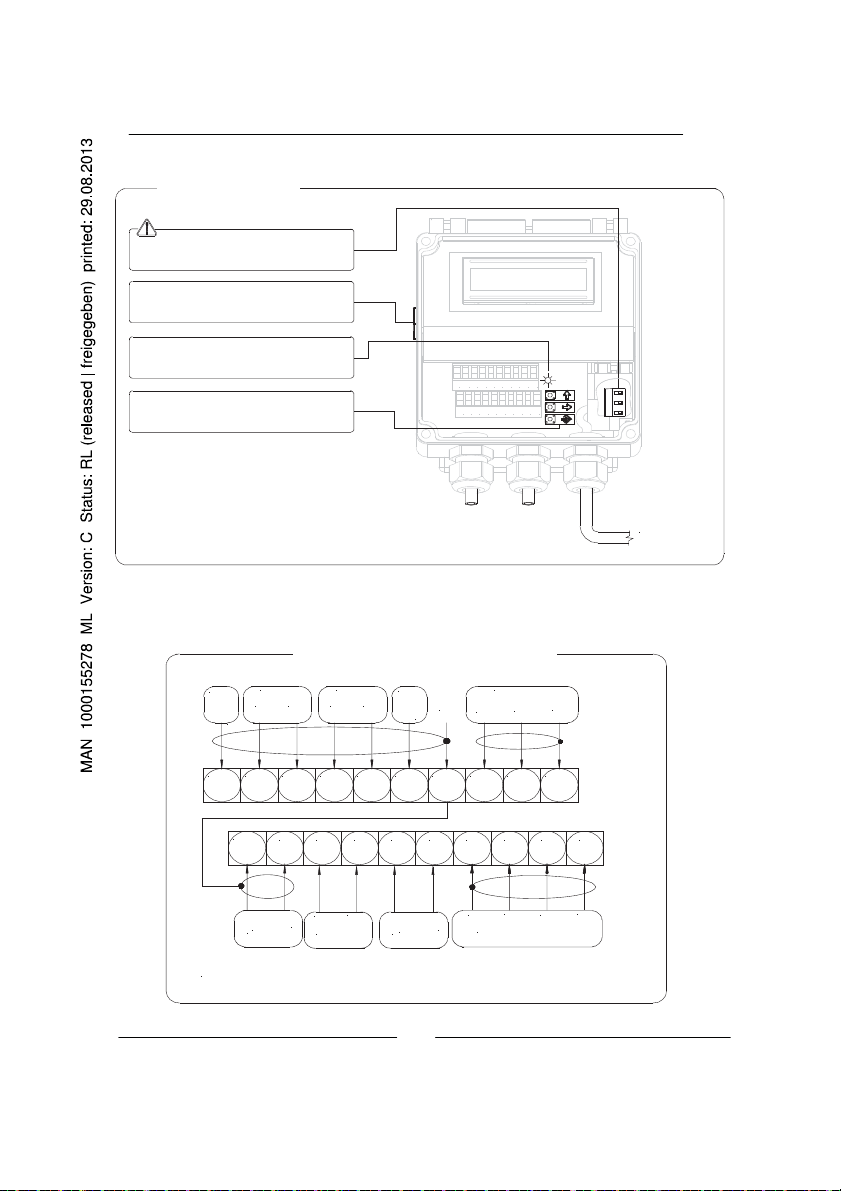

INTERNAL VIEW

Power supply

IF2 socket

Signalling LED: see display flags and led warning

interpretation sectio n

Keyboard

TRANSMITTER TO SENSOR ELECTRICAL CONNECTIONS

SE56

11 1213 14 15 16 17 1819 20

1 2 3 4 5 6 7 8 9 10

Power supply

TERMINAL BLOCK

24V

-

OUT2

E C

OUT1

E

24V

+

C

COILS

SH

B2

SH

B1

11121314151617181920

10

-

+

4-20mA

RS 485* : OPTI ONAL, PROVIDED EXLUSIVELY BY THE MANUFACTURER

RS 485* INPUT

-

BA

+

C

SH

ELECTRODES

9

123456789

E1

E2

Page 10

A

External power supply

(

)

10 K

uto-calibration

AUTOCAL IB. OFF

3-40V

0-1.5V

T

Reset totalizers

BLOCK

3-40V

0-1.5V

T

Block totalizers

3-40V

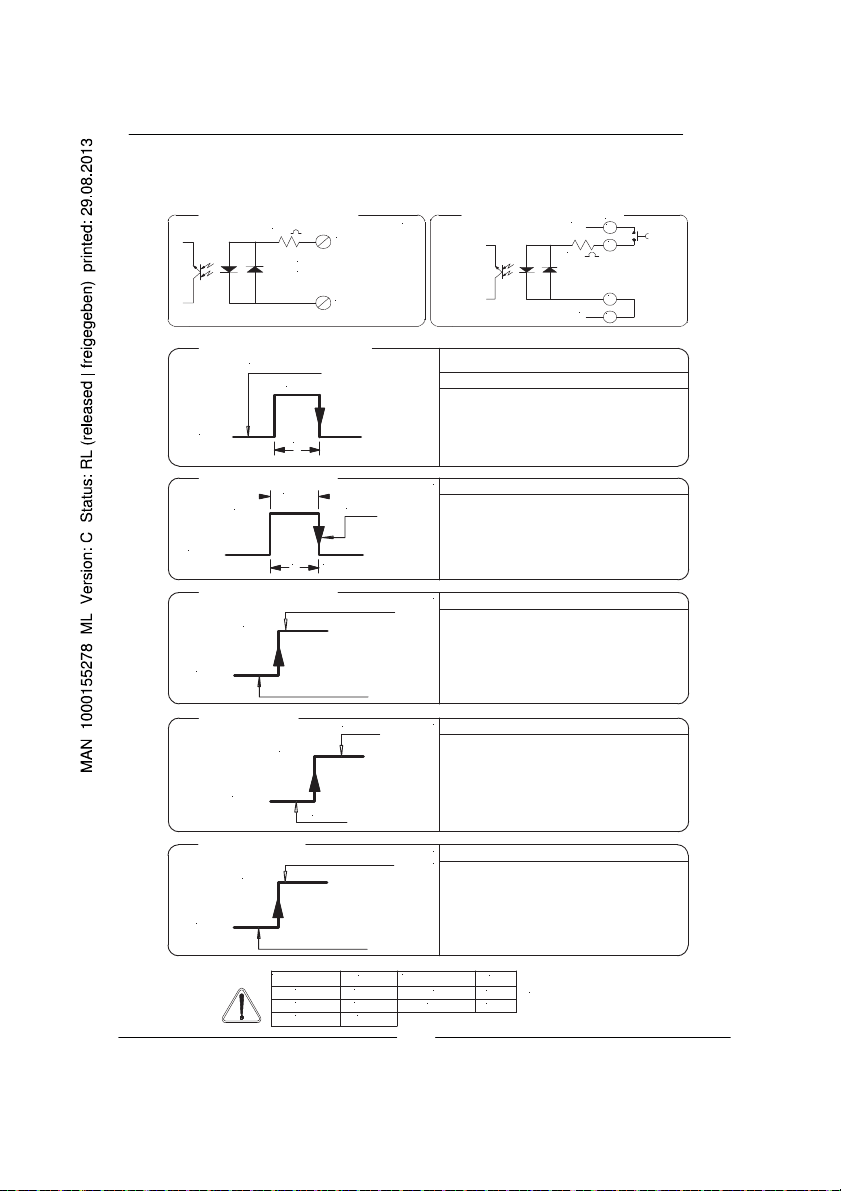

DIGITAL INPUT

INPUT ON/OFF OPERATION

Internal power supply

5 (+)

3/40 Vdc ( ON)

0/1.5 Vdc (OFF)

6 (-)

Tmin<T<1sec. = autoc alibration

T > 1sec. = Auto zero

Necessary conditions for enabling the function

POS. 5.7 ENABLED (Autozero calibration external

command)

Necessary conditions for enabling the function

RESET

Tmin = 100ms

Block totalizers

POS. 5.1 to 5.4 ENABLED (

flow totalizers reset enable).

Necessary conditions for enabling the function

POS. 5.5 ENABLED (totalizers counting lock command)

+24

15

5

10 K

6

0

20

partial positive or reverse

SE56

0-1.5V

Range change

Measure lock

<18V

0-1.5V

18-30V

Totalizers active

3-40V

SCALE 1

Measure blocked

SCALE 2

Necessary conditions for enabling the function

POS. 5.8 ENABLED (range change)

Necessary condition for enabling the function

POS. 5.6 ENABLED

measure lock

Measure

SAMPLE RATE Tmin SAMPLE RATE Tmin

10Hz

20Hz

50Hz

220ms

110m s

45ms

80Hz

150Hz

30ms

15ms

T must be > Tmin

10

Page 11

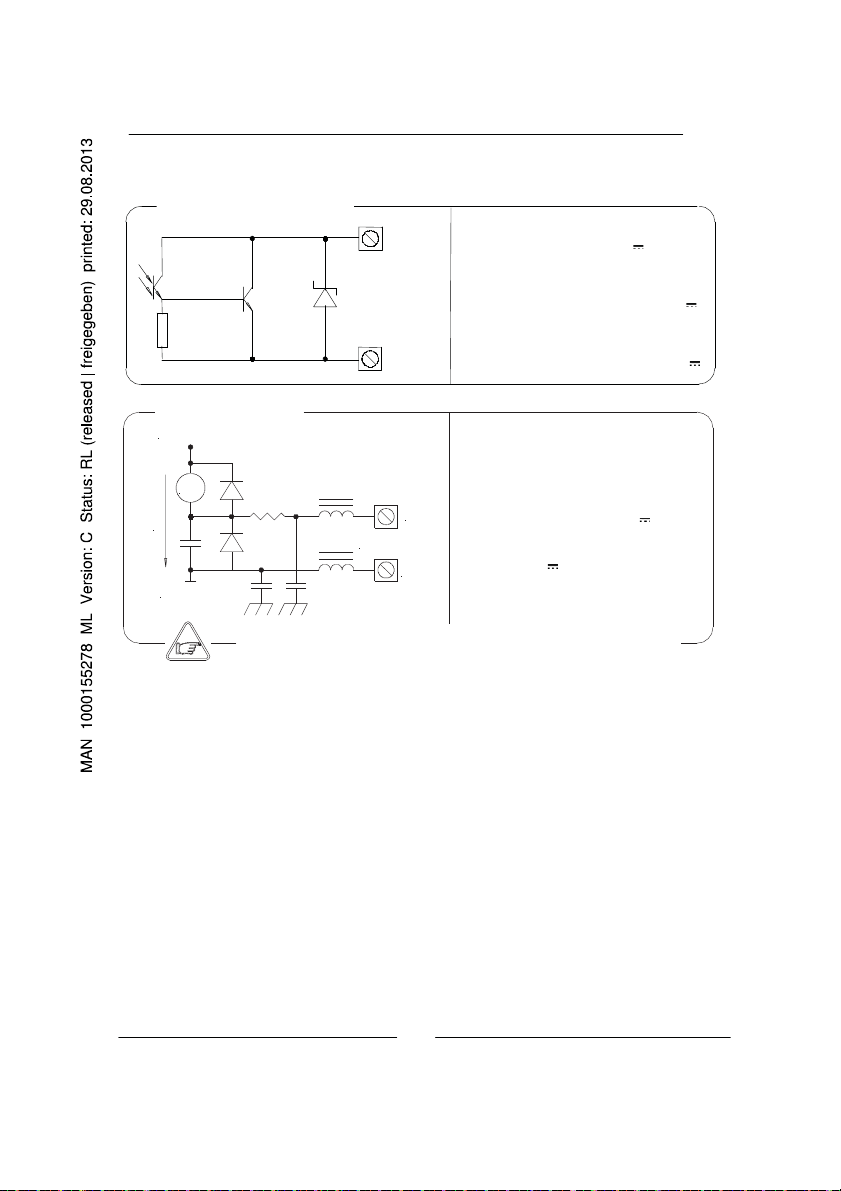

A

OUTPUT WIRINGS

z

SE56

Output on/off 1250H

Opto-insulated o utput with floating collector and

emitter terminals freely connec table

Maximum switching voltage: 40V

Maximum switching current: 100mA

Maximum saturation voltage betw een collector

and emitter @100mA: 1.2V

Maximum switching frequency (load on the

collector or emitter, RL=470Ω, VOUT=24V ):

1250Hz

Maximum reverse current bearable on the input

during and accidental polarity reversion (VEC):

100mA

Insulation from other secondary circuits: 500V

43V

16 (out1)

18 (out2)

17 (out1)

19 (out2)

Output 4-20m

+24V INTERNAL

mA

I

24V COMMON

4-20mA OUT

10 (-)

There is a transmitter load CHECK on the 4–20mA output; to disable this

function set the value "mA v.fault" to 0 (Pos. 4.4)

Opto-insulated output

Maximum load: 1000

9 (+)

Maximum voltage without load: 27V

Refresh frequency is the same of the sample

frequency of the connected sensor

Protected against persistent over voltages to

maximum 30V

NOTE: for the inputs and outputs wirings is recommended the use of shielded cables.

11

Page 12

A

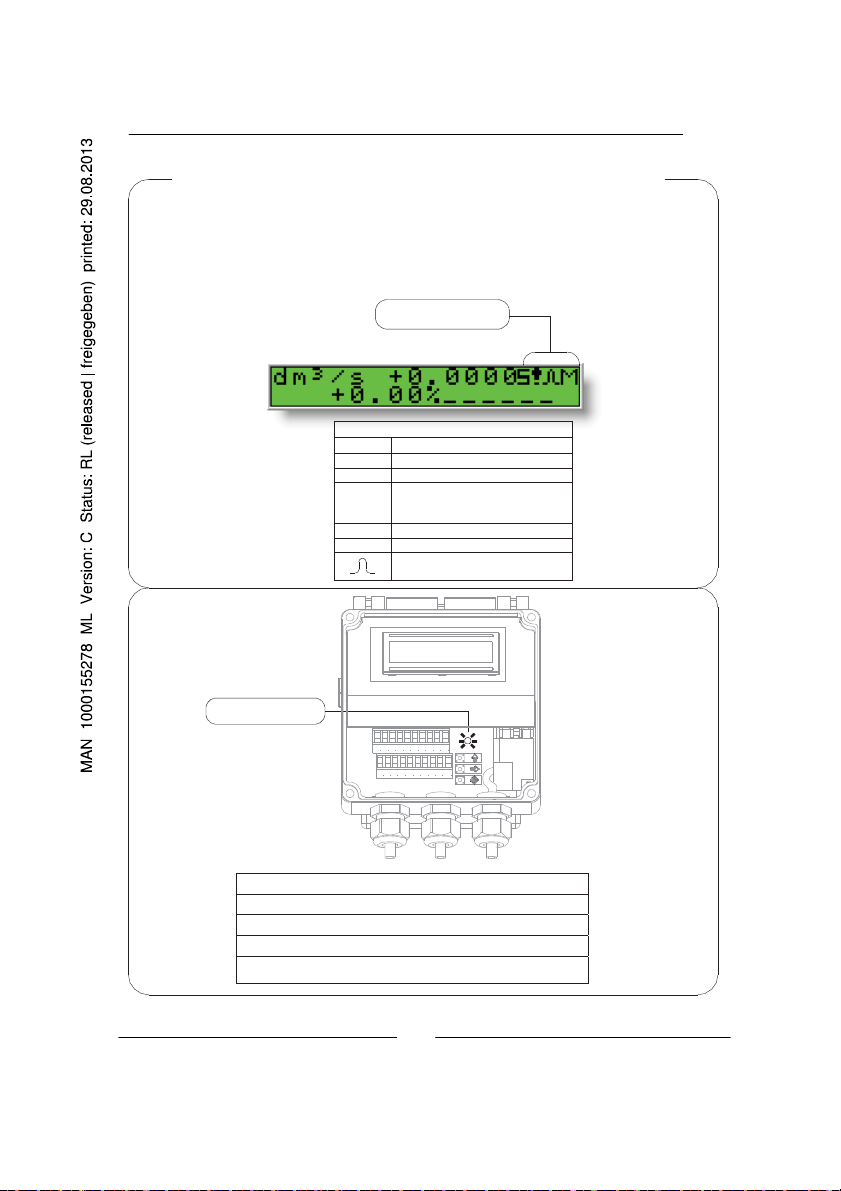

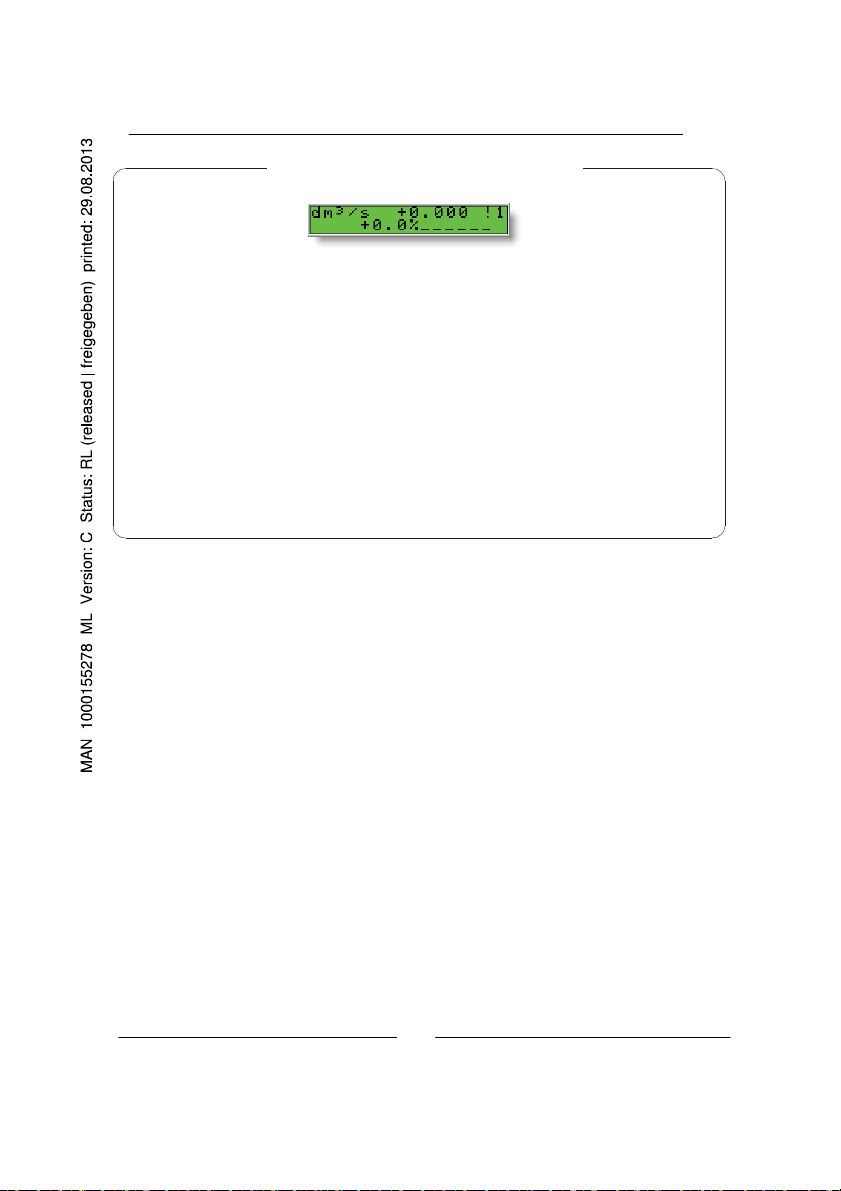

DISPLAY FLAGS AND LED WARNING INTERPRETATION

t ‘Power on’ of the transmitter, the user will see the following display screen. In the

top right hand corner there may be a range of symbols. The symbols can be

interpreted from the table below. Interpretation of the flashing LED can be made

from the LED interpretation table at the bottom of this page.

FLAGS

FLAGS INTERPRETATION

FLAG DESCRIPTION

M Alarm max activated

m Alarm min activated

- Interruption coils circuit

!

- Signal error

- Empty pipe

C Calibration running

S Simulation

Pulse output saturation (reduce

TIME PULSE )

LED

11 1213 14 15 16 17 1819 20

1 2 3 4 5 6 7 8 9 10

SE56

PERMANENT LIGHT: initialization

FLASHING LIGHT (1 sec.): normal function

FLASHING LIGHT (<1 sec.): alarm on

The LED signals the alarm status only if the display shows one of

the suitable visualization screens

12

LED INTERPRETATION

Page 13

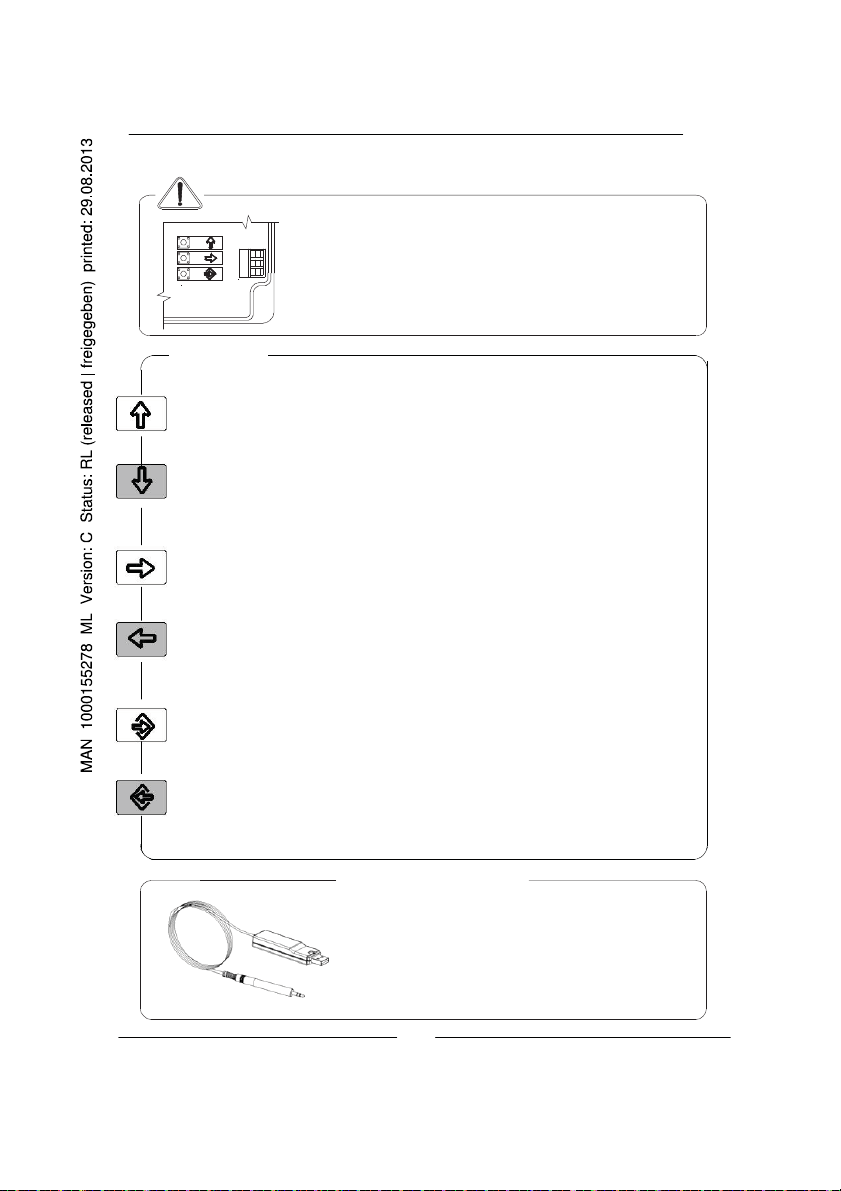

TRANSMITTER ACCESS

The keypad is accessible by loosening the 4 cover screws and

opening the front cover of the transmitter. Three KEYS are set

aside of the M3 power supply terminal block, allowing the user

M3

KEYPAD

KEYPAD

SHORT PRESSING (< 1 SECOND):

Increases the numeric figure or the parameter selected by the cursor

Accesses to the previous subject in the Quick start or Main menus

Batch start/stop (when enabled)

LONG PRESSING (> 1 SECOND):

Decreases the numeric figure or the parameter selected by the cursor

Accesses to the next subject in the Quick start or Main menus

SHORT PRESSING (< 1 SECOND):

Moves the cursor rightwards on the input field

Accesses to the following subject in the Quick start or Main menus

Changes the display of the process data

LONG PRESSING (> 1 SECOND):

Moves the cursor leftwards on the input field

Accesses to the previous subject in the Quick start or Main menus

SHORT PRESSING (< 1 SECOND):

Enters/leaves the selected function

Enables the main menu for the transmitter configuration

Cancels the selected function under progress

LONG PRESSING (> 1 SECOND):

Leaves the current function, in the Quick start or Main menus.

Enables the ‘EXECUTE?’ prompt in the Main menu functions, and total reset

request (when enabled) from the required function

Confirms the selected function

to change display visualizations and select functions. Ensure

that the power supply cover is closed.

SE56

BLIND CONFIGURATION

For the transmitters without keyboard (blind

configuration), the programming is made

through ISOCON (cable and software needed).

Being the housing closure dependent by the

installer, the IP degree may be compromised, so

follow the torques mentioned.

13

Page 14

A

A

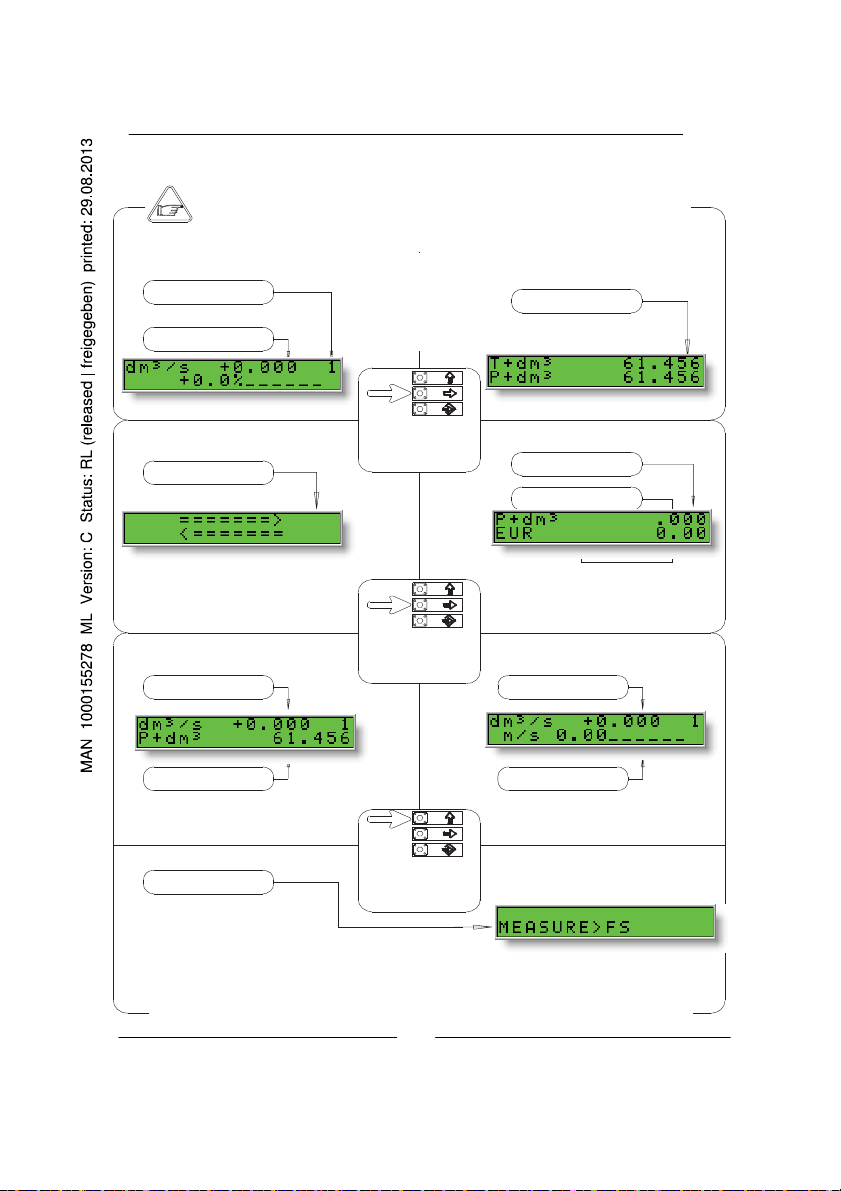

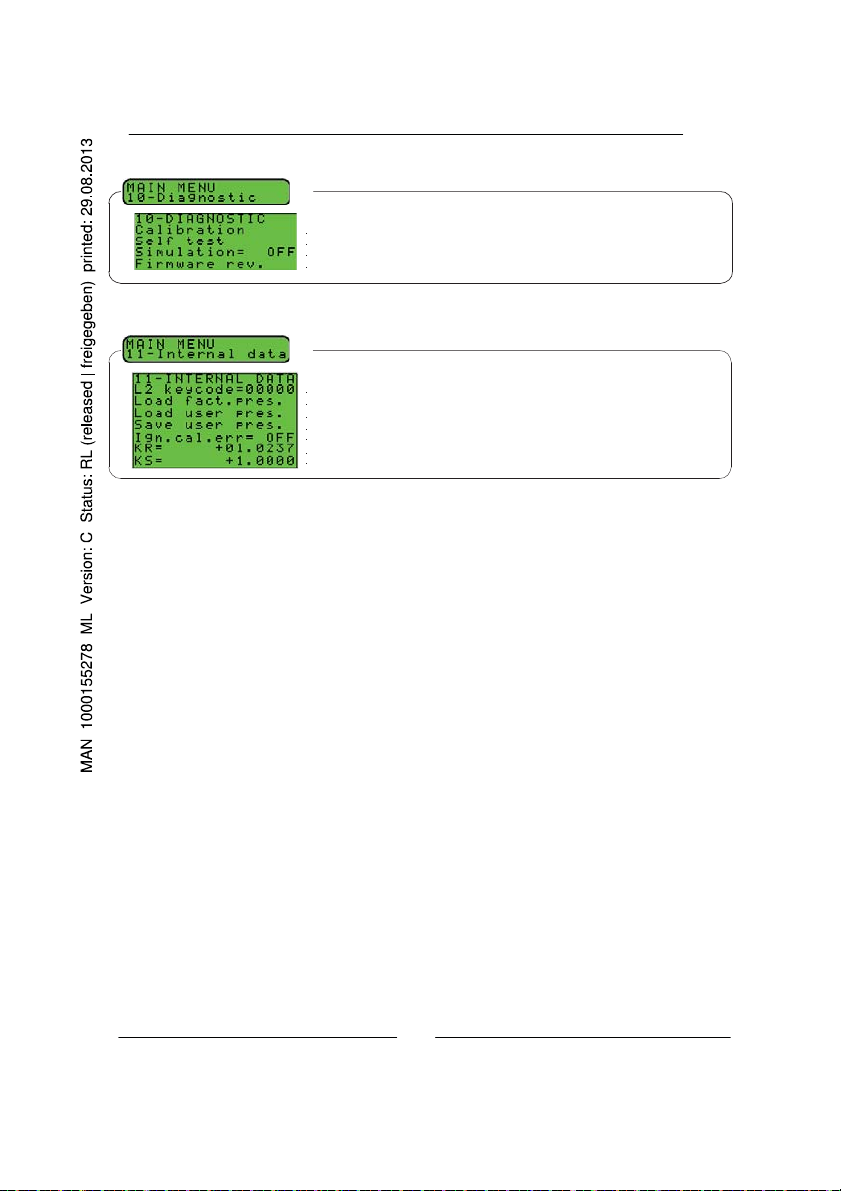

ACCESSING THE FUNCTIONS AT START-UP (Power On)

Example of visualized display pages at start-up

The direct exposure of the transmitter to the solar rays, could damage the liquid crystals display.

Note: The user will see the

screen displayed (left) at

ctive scale

Flow rate visualization

power on of the transmitter.

Use the keys on the keypad as

indicated centrally on this

page to mo ve between the

screens shown (not all

shown).

* Direct/Reverse totalizer

visualization

SE56

Push keypad button

indicated to move

lternate visualization

between pages

Push keypad button

indicated to move

Flow rate visualization Flow rate visualization

* Direct Reverse totalizer Flow speed

Alarm description

* The maximum number shown on the totalizer is 999.999.999 regardless of the number of user selected

decimals (see Pos 2.3). Beyond this value the totalizers are set to zero.

between pages

Push keypad button

indicated to move

between pages

CURRENCY FUNCTION ENABLE

* Direct to talizer

Reverse total izer

Currency value

14

Page 15

SE56

FLOW RATE VISUALIZATION

The ML 110 allows to show a 5 digit character display for flow rate units; this mean the

maximum flow rate value that can be represented on the display is 99999 (no matter the

positioning of the decimal point). The minimum one is 0.0025.

The representable measure unit depends from sensor flow rate and diameter; the

permitted units are those, set the instrument full scale value, allow to be represented with

a numerical field which the maximum value do not exceed 99999.

Example for DN 300:

- Full scale value: 3m/s

- PERMITTED measure unit (example): l/s (216.00); m

- NOT PERMITTED measure unit (example): l/h (777600)..

3

/h (777.60); m3/s (0.2160)

15

Page 16

SE56

ACCESS CODES

Functions in the main menu transmitter are enabled by the access codes. The information

of this manual is related to all the functions available with the L2 level. All higher level

functions are reserved for servicing and not available.

Description of the L2 access code

(menu “11 Internal data” pos. 11.1)

with code L2 = 00000 (only with this code) you can disable the L2 code request

* with L2 customized (freely chosen by the user) you can program all the functions

up to L2 security level, entering this code whenever you enter the Main menu.

* ATTENTION: take careful note of the customized code you have chosen, there is no way

for the user to retrieve or reset it if lost.

Factory preset access codes

The transmitter is delivered with the default L2 (level 2) access code:

11111

16

Page 17

SE56

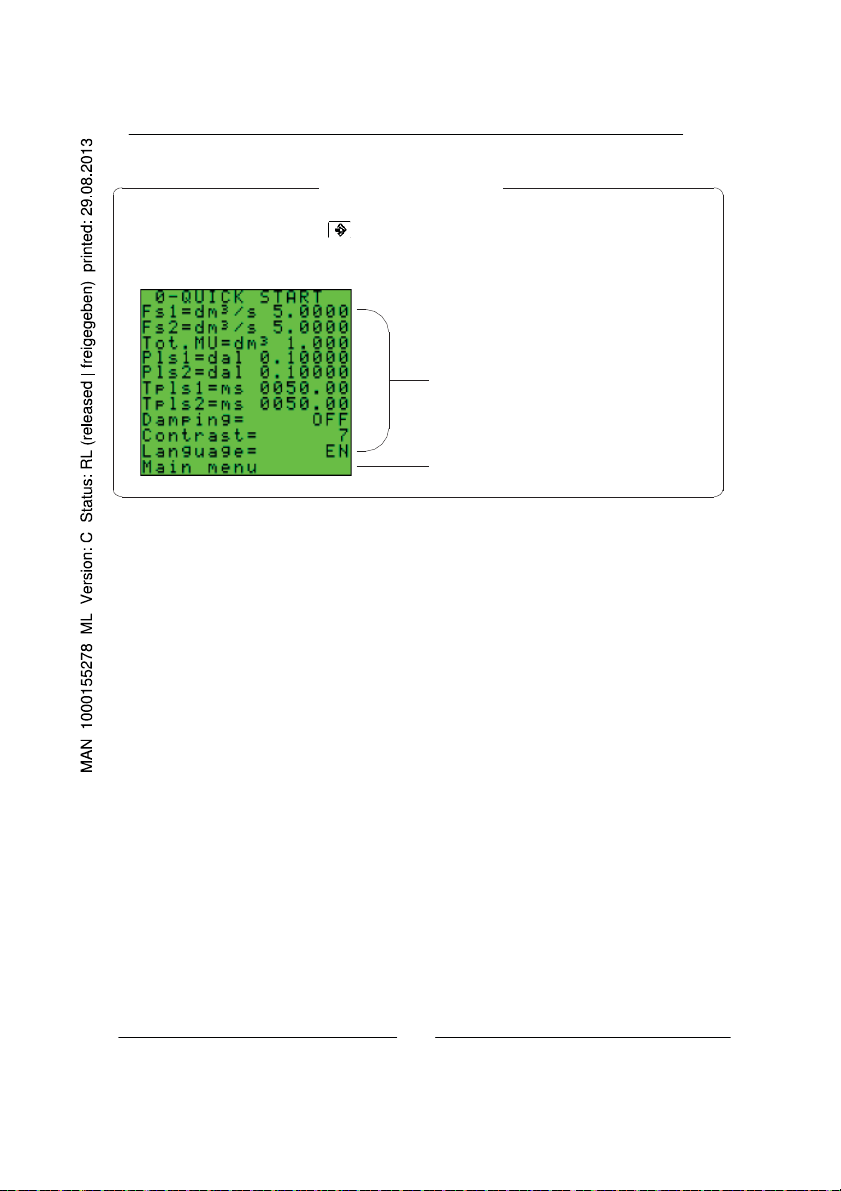

The user has immediate access to the Quick Start menu when the converter is

QUICK START MENU

powered up by pressing the key. If access to the quick start menu does not

occur, then it has been disabled through the function 8.4

See function menu section

Access to all functions

17

Page 18

A

A

CCESS TO THE CONFIGURATION MENU

A

The transmitter configuration menu can be accessed in two different ways:

1) by ISOCON interface

2) by keyboard of transmitter

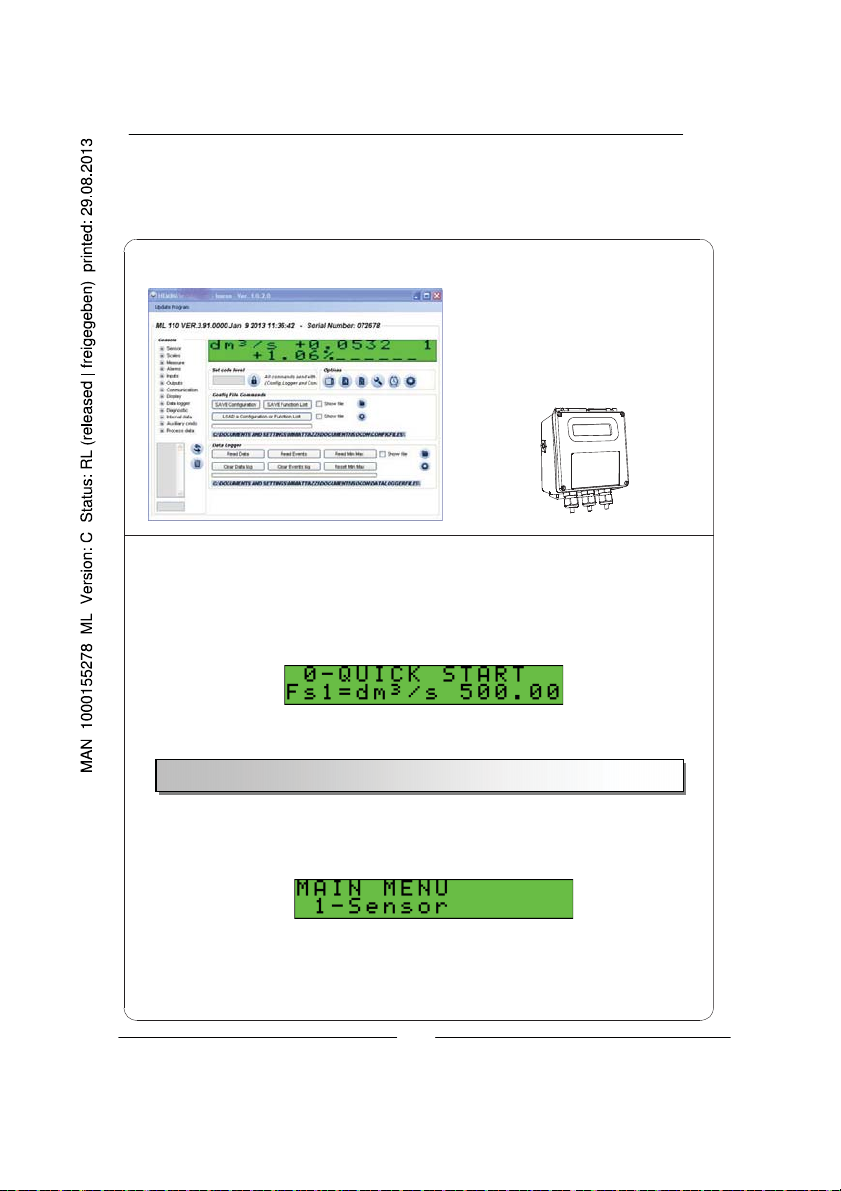

CCESS TO THE CONFIGURATION MENU BY ISOCON INTERFACE

®

Isocon is a Windows

that allows to set all the

transmitter functions and

personalize the menu (IF2X is

required), see suitable manual for

details.

software

CCESS TO THE CONFIGURATION MENU BY THE KEYBOARD

Functions can be accessed by the keyboard in two different ways:

The Quick start menu makes possible to access directly a range of principal

functions for setting the scale reading and display characteristics of the sensor

SE56

Quick start menu can be enabled by function 8.4 (menu display)

Factory pre-setting:

Through the Main menu it is possible to access functions with the access code

level 2. These control the sensor’s monitoring, data processing, input/output as

well further display options.

The following example shows how to change the Full scale by Quick Start menu; the

following example illustrates how to change the function by the Main menu.

QUICK START MENU=ON

18

Page 19

SE56

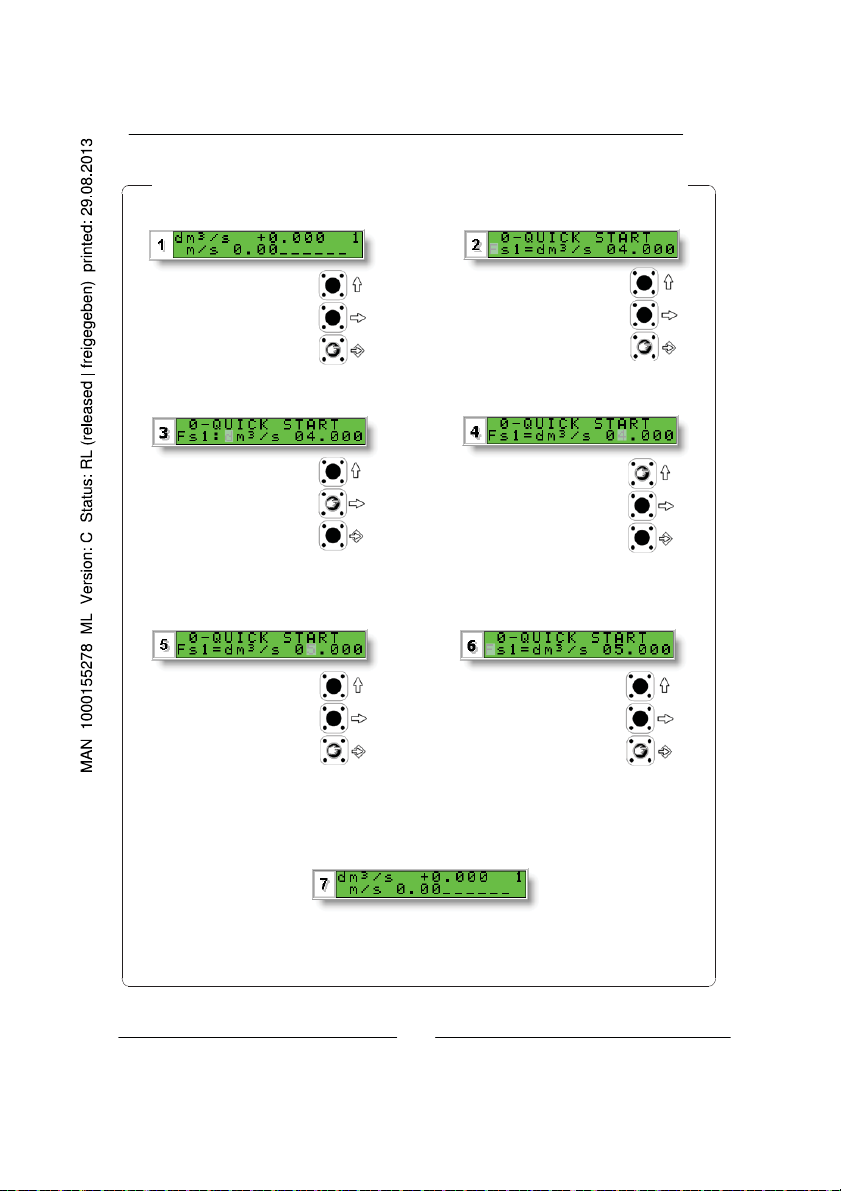

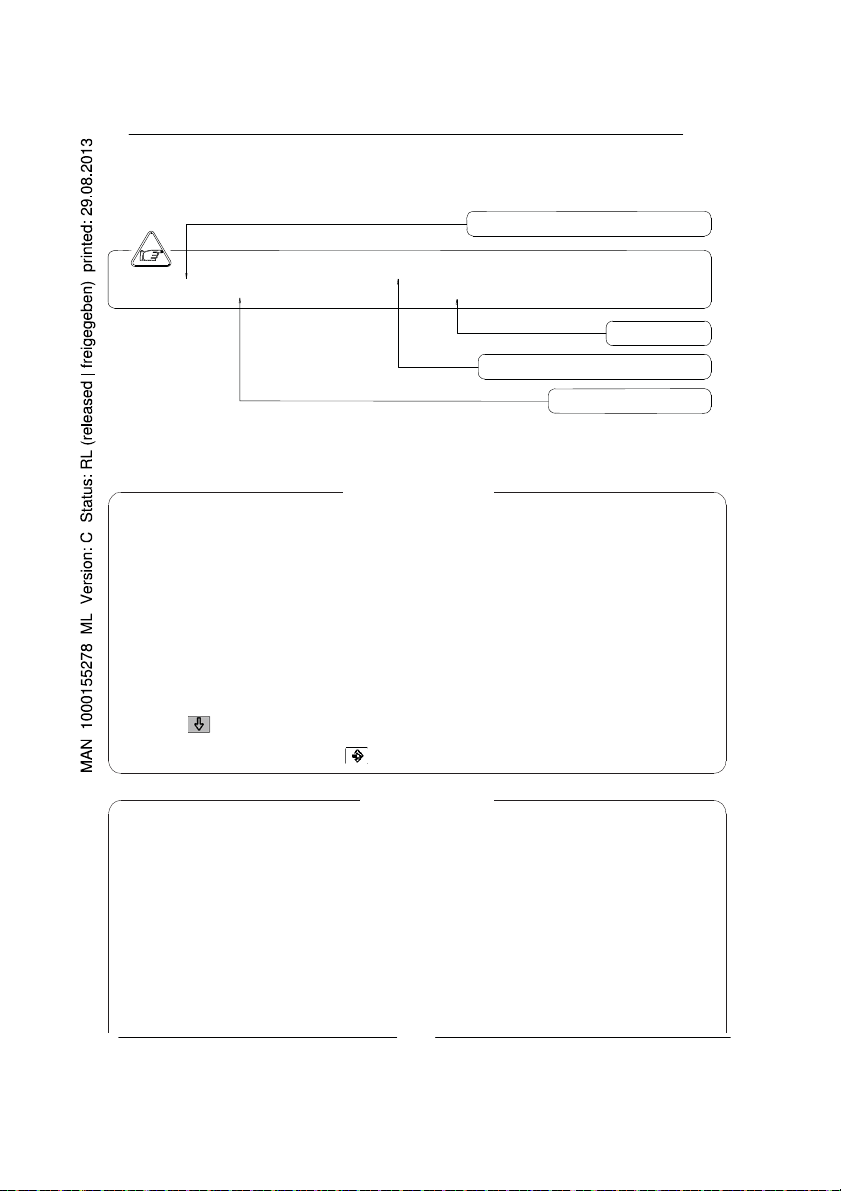

EXAMPLE: “Quick start menu” function modification. Full scale value 1

(Fs1) from 4dm³/s to 5dm³/s.

Enter in the “Q uick start menu”

The keypad button to be pressed at

each step is indicated by the icon

symbol place on one of the three

keys of the ke ypad (her e lower key)

Push the key repeatedly and rapidly

to move the cursor to the value to

modify

Confirm the new value with a

short press of the key (less

than 1 second)

Access the function “Fs1” by

pressing the button indicated for less

than 1 second

To increase the value press

the upper ke y for sho rt

periods of less than 1 second,

to reduce the value press the

upper key for more than 1

second repeatedly

Long push to leave the quick

start menu and r eturn to the

initial visualization page

Initial visualization page

19

Page 20

SE56

page

yp

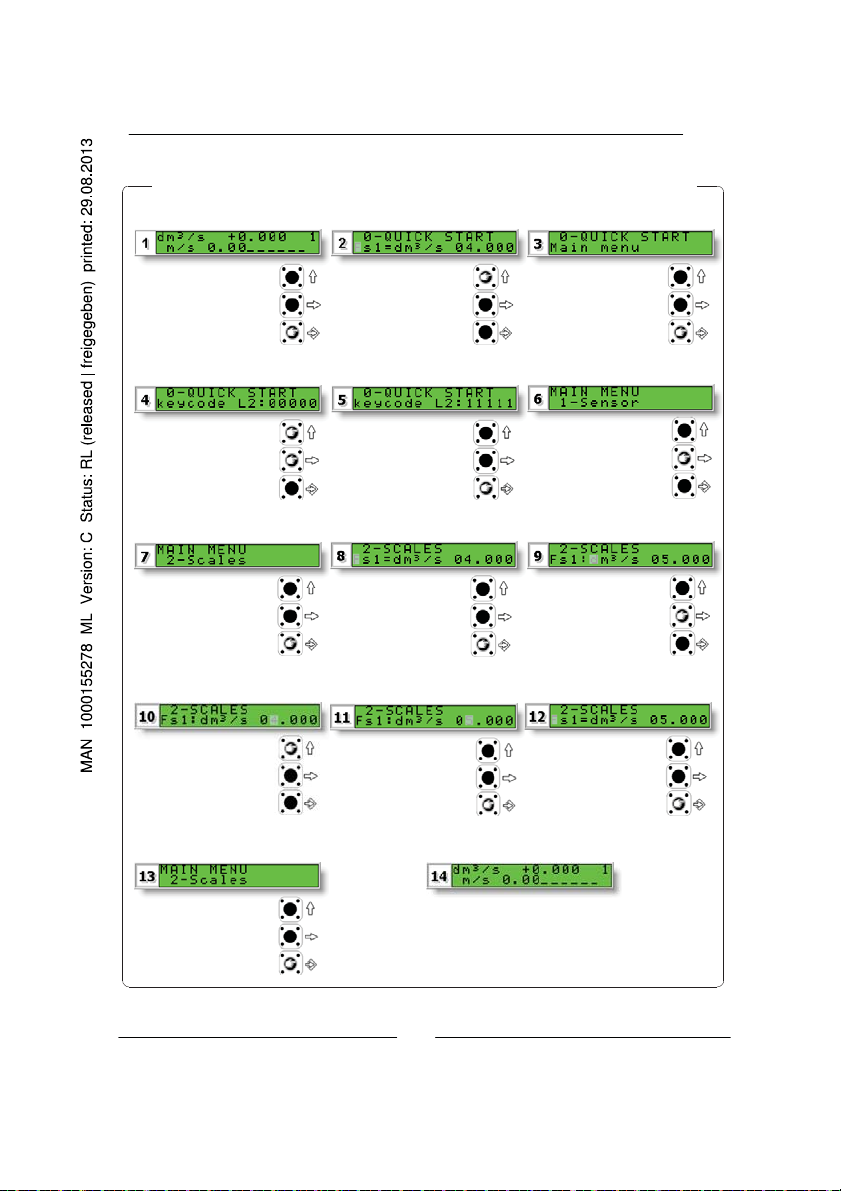

EXAMPLE: “Main menu” function modification. Full scale value 1 (Fs1) from

4dm³/s to 5dm³/s. (Quick start menu enabled)

Press the button indicated

to enter the Main menu

page screen from the Quick

Enter in the “Q uick start menu”

From any of the start-up

(power on) screens

To enter the main menu

input the key code (11111

as default) by increasing

the ‘0’ to ‘1’ and moving to

the next ‘0’ until the key

code is entered

Access the “Scale” menu

with a short key press.

Change the value by pushing

the button rapidly as many

times as required

menu page

To enter the key code press

the lower key

Access the function “Fs1”

with a sho rt key press

Confirm the new value with

a short press of the key

indicated on the keypad

Access to the “Main Menu”

by pressing the key

indicated

To move between main

menu function groups press

the arrow key indicated

Move between the

modifiable options by short

pressing the key indicated

ad

on the ke

Long push to return to

the main menu groups

Initial visualization

Long push to return to

the initialization pages

20

Page 21

SE56

g

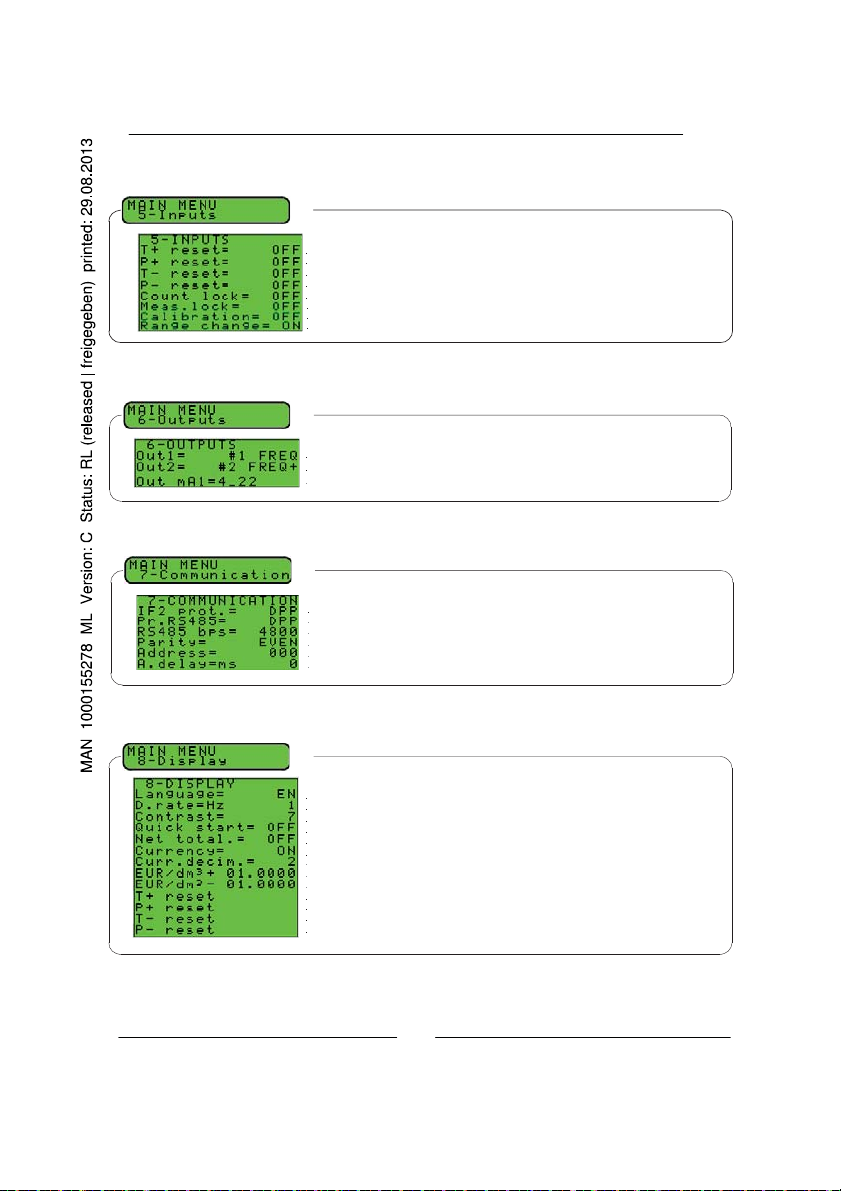

The main menu is selected from the Quick start menu by pressing the key) and entering the factory

FUNCTIONS MENU

code (11111). Functions denoted in grey are displayed only with other active functions, or with optional

modules.

(for functions details with the symbol “*” refer to the next section).

displayed on the transmitter are shown below are reserved for serving purposes only and not

confi

urable.

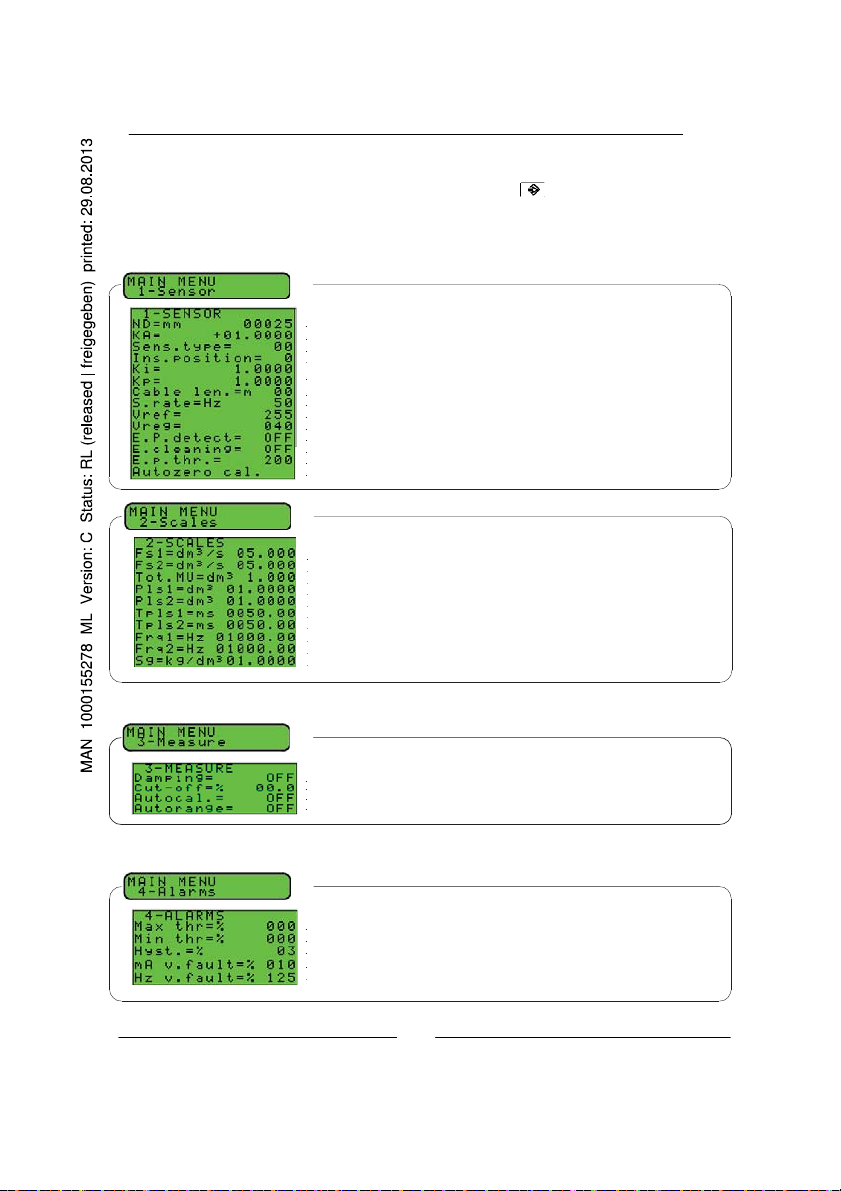

1.1 Nominal Diameter (ND) of sensor, (enter input value 0-3000 mm)

1.2 Sensor calibration data (Enter value as specified on sensor label)

1.3 Type of sensor: Enter the first two characters of the sensor serial number

1.4 Position of insertion sensor: 0=1/8DN, 1=1/2DN, 2=7/8DN

1.5 Factory parameters automatically calculated (ONLY for insertion sensors)

1.6 Length of t he cable con necting the se nsor to the transmitter

1.7 Sample rate

1.8 (only for service purpose)

1.9 (only for service purpose)

1.10 Enables the empty pipe detection feature

1.11*Electrodes cleaning

1.12*Value of empty pipe sensibility detection

1.13* Enable s the automatic procedure of zero calibrat ion

2.1* Full scale value set for range N.1

2.2* Full scale value set for range N.2

2.3* Unit of measure and number of decimal place

2.4* Puls e value o n channe l 1

2.5* Puls e value o n channe l 2

2.6* Duration of the pulse generated on channel 1

2.7* Duration of the pulse generated on channel 2

2.8 Full scale frequency for channel 1 (0.1Hz-1000.0Hz)

2.9 Full scale frequency for channel 2 (0.1Hz-1000.0Hz)

2.10 Volume to mass specific gravity coefficient set in kg/dm³

Not all the functions

3.1* Measure filter

3.2 Low flo w zero threshold: 0-25% of full scale value

3.3 Enable automatic hourly internal calibration cycle. Measurement stopped for 8-15s.

3.4* Automatic change of scale

4.1 Maximum flow rate value alarm setting

4.2 Minimum flow rate value alarm setting

4.3 Hysteresis threshold setting for the minimum and maximum flow rate alarms

4.4* Current output value in case of failure

4.5* Frequency output value in case of failure

21

Page 22

5.1* Total direct (positive) flow totalizers reset enable

5.2* Part ial dire ct (posi tive) flow total izers reset enab le

5.3* Total reverse (negative) flow totalizers reset enable

5.4* Pa rtial revers e (negative) flow total izers reset enable

5.5 Totalise counting lock command (see input on/off operation section)

5.6* Block measures command

5.7* Autozero calibration external command

5.8 Range change external command (see function 3.4)

6.1* Output 1 functions

6.2* Output 2 functions

6.3* Choice of function the range of current output n.1

7.1 Choice of t he communi cation p rotocol for the IF2 devi ce

7.2 Choice of t he communi cation p rotocol for the RS485 port

7.3 Speed of th e RS485 o utput ( possib le choic e: 4800, 9600, 1920 0, 38400 b ps)

7.4 RS485 parity

7.5 Address value of the converter (range 0 - 255)

7.6 Instrument answer delay

SE56

8.1 Choice of the language: EN= English, IT=Italian, FR= French, ES= Spanish, DE=German

8.2 Display update frequency: 1-2-5-10 Hz

8.3 Display contrast

8.4 Quick start menu visualization

8.5 Enable the page of net totalizer

8.6 Visualizes the values of the partial totalizer in the unit of selected currency

8.7 Choice of the numbers of decimals for the visualization currency value: From 0 to 3

8.8* Value of conversion/currency for direct totalizer

8.9* Value of co nversion/currency for reverse t otalizer

8.10* Total direct (positive) fl ow totalizer reset

8.11* Partial direct (positive) flow totalizer reset

8.12* Total reverse (negative) flow totalizer reset

8.13* Partial reverse (negative) flow totalizer reset

22

Page 23

10.1* Calib ration of t he converter

10.2* Autotes t converter

10.3* Flow rate simulation enabling

10.4 Firmware revision/version

11.1 Level 2 access code enter (user choice and setting of access code if required)

11.2 Load factory data pre-set

11.3 Load user data saved

11.4 Save user data

11.5 Ignore the calibration error during the switch on test (enable/disable)

11.6 KR coefficient (only for service purposes)

11.7 KS coefficient (only for service purposes )

SE56

23

Page 24

FUNCTIONS DESCRIPTION

(

y)

(functions description with access code< 3)

SE56

Identification of the function

(POS. 1.1) Nominal diameter of sensor [ND= XXXX]

MENU 1 - SENSOR

Menu visuali zed on the transmitter (from 1 to 11)

The following pages give a description of the most important functions and how they can be changed or

enabled/disabled by the user.

(POS. 1.11) Electrodes cleaning [El. cleaning]

Selectable options: OFF, minimum, average and maximum. It is not recommended the use of this

function (let OFF) when the liquid has a conductivity less than 100μS/cm.

(POS. 1.12) Empty pipe threshold [E.P. thr.=XXX]

This value represents the threshold of measure block to zero in empty pipe condition; the span

function is 0-255. Since the sensibility of empty pipe detection could be changed by the liquid

conductivity, ground connections, type of lining, in case of needed it is possible to adjust manually

the preset threshold. It is recommended to check periodically its proper functioning. Value

increasing means sensibility decreasing.

(POS. 1.13) Autozero calibration [Autozero cal.]

This function activates the zero calibration automatic system. To perform this operation, it is

necessary for the sensor to be full of liquid, and the liquid be perfectly still. Even minimal

movement of the liquid may affect the result, and consequently, the accuracy of the system. Once

you are sure the above conditions have been fulfilled (and the percentage flow rate value is stable)

press the key and automatically activates the zeroing procedure, after which it is necessary to

check that the percentage value showed goes to zero, repeat the operation otherwise. When the

value is stable at zero, then press the key.

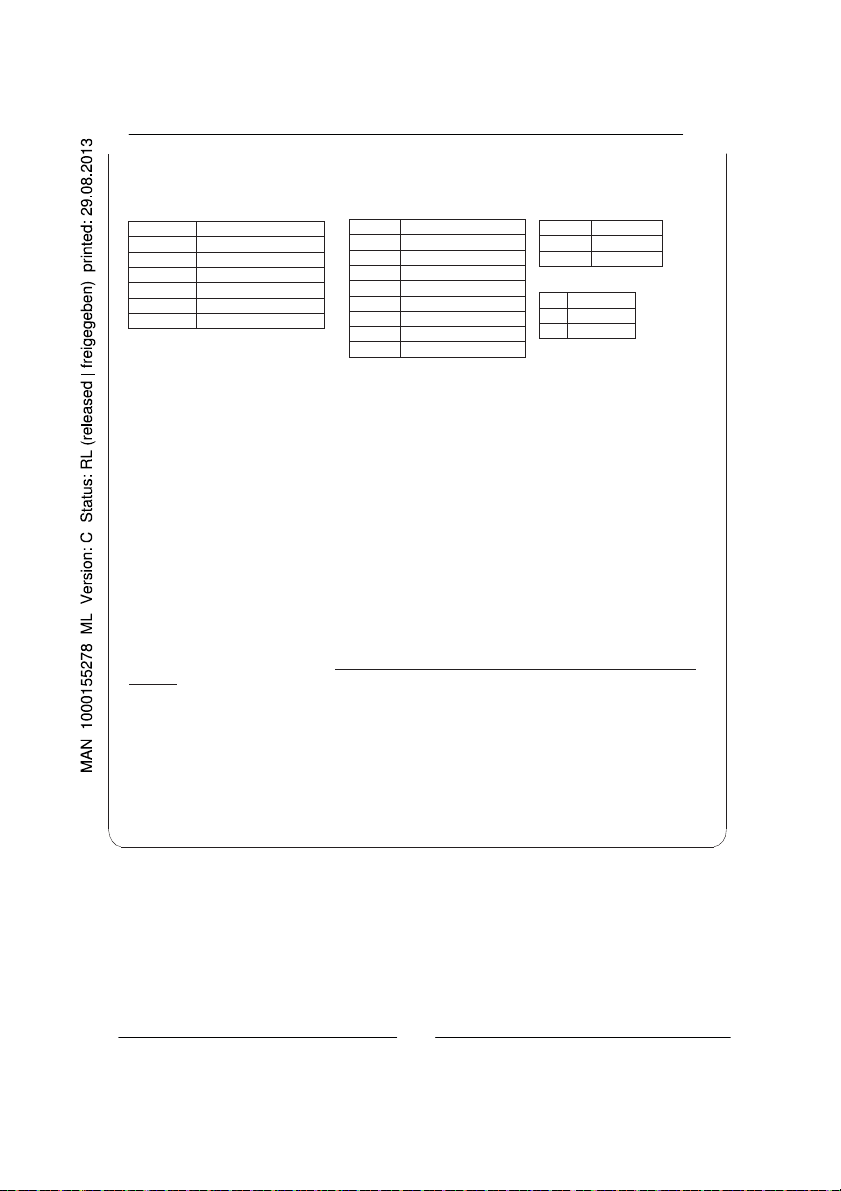

(POS. 2.1-2) Full scale N.1-2 [Fs1-2=dm³/s X.XXXX]

The Full scale range N.1-2 is the corresponding output signal (20mA) to the meters maximum flow

rate (max 10m/s). There are four fields to fill in order to set this parameter, from left to right: 1)

volume measure unit, 2) unit type, 3) time measure unit and 4) numeric value. The selection is

made by positioning the cursor on the field to modify. To change the measure unit type (metric,

British or American, mass or volume) the cursor has to be positioned on the symbol “/” (field N. 2).

When the nominal diameter is set to zero it is possible to modify only the numeric field, since the

measure unit stays at m/sec.

The following tables show the available measure units and the conversion factor by comparison

3

with 1dm

and 1kg. The transmitter accepts any kind of measure units combination satisfying both

the following conditions:

Numeric field value ≤ 9999

1

/25 fs

≤ numeric field value ≤ fs

max

MENU 1 - SENSOR

MENU 2 - SCALES

.

max

not visualized on displa

Transmitter

Synthetic description of the function

24

Page 25

SE56

where fs

speed. The measure units are shown as appear on the display. The British and American units are

diversified by using capital and small characters.

When a mass measure unit is set, the specific gravity function is automatically enabled by the

system. Please, note that the mass measure is heavily affected by the temperature. With certain

liquids this may cause significant measurement errors. The following time measure units can be

selected: s = second, m = minute, h = hour, d = day.

(POS. 2.3) Measure unit and decimal places number [Tot.MU=dm³ X.XXX]

Setting the measure unit and decimals places number displayed for the volumes. To set the

measure unit, position the cursor on the measure unit field. To set the unit type, position the cursor

on the blank space between the measure unit and the numeric value; the decimal places number

can be selected by placing the cursor on numeric field and choosing one of the possible

combinations: 1000-01.00-001.0-00001.

(POS. 2.4-5) Pulse value channel 1-2 and total measure unit [Pls1-2=dm³ X.XXXXX]

Setting of a flow volume by which a corresponding pulse will be emitted on channel 1-2, units must

be identical to ‘Full scale’ and ‘Totalizer’ functions. To set the parameter, complete the three fields,

from left to right: 1) measure unit, 2) unit type and 3) numeric value. The selection is performed by

positioning the cursor in the field to be modified. To change the unit type (metric, British or

American, mass or volume) position the cursor on the blank space between the measure unit and

the numeric value. When the nominal diameter is set to zero it is possible to modify only the

numeric field since the measure unit stays at meters (m) or feet (ft). Only those units described

above are available to be selected. This function is active only if the pulse emission on channel is

enabled.

(POS. 2.6-7) Pulse duration channel 1-2 [Tpls1-2=ms XXXX.XX]

Setting of the pulse duration generated on channel 1-2. This value is expressed in milliseconds and

has to be between 0.4 and 9999.99. When the high frequency output is present, then the minimum

value can be set to a minimum of 0.04 milliseconds. ATTENTION: since the transmitter cannot

detect which device type is connected to the transmitter, the user must verify that the set pulse

duration is compatible with the external device processing such pulses. If, for example, an electromechanical pulse counter is connected, one of two problems may occur; firstly, if the pulse is too

long the coils may burn out, secondly, if the pulse is too short, the counter may not be able to

function, with the possibility of causing damage to the output.

is the maximum full scale value corresponding to the sensor, equal to a 10m/s liquid

max

3

in

cm3Cubic centimeter

ml Milliliter

L Liter

dm3Cubic decimeter

dal Decalitre

hl Hectolitre

m3Cubic meter

Cubic inch

Gal American gallon

GAL British gallon

3

ft

Cubic foot

Bbl Standard barrel

BBL Oil barrel

yd3Cubic yard

kgl KAmerican gallon

KGL KBritish gallon

Oz Ounce

Lb Pound

Ton Short tons

g Gram

kg Kilogram

t Ton

25

Page 26

MENU 3 - MEASURE

(POS. 3.1) Damping [Damping=OFF/SMARTX /(time)]

This section of the manual is extremely important. The correct filter settings ensures a proper

response of the instrument to the measured flow rate. The available dampening filter values range

between no damping (damping=OFF) and maximum damping based of 1000 seconds

(Damping=1000).

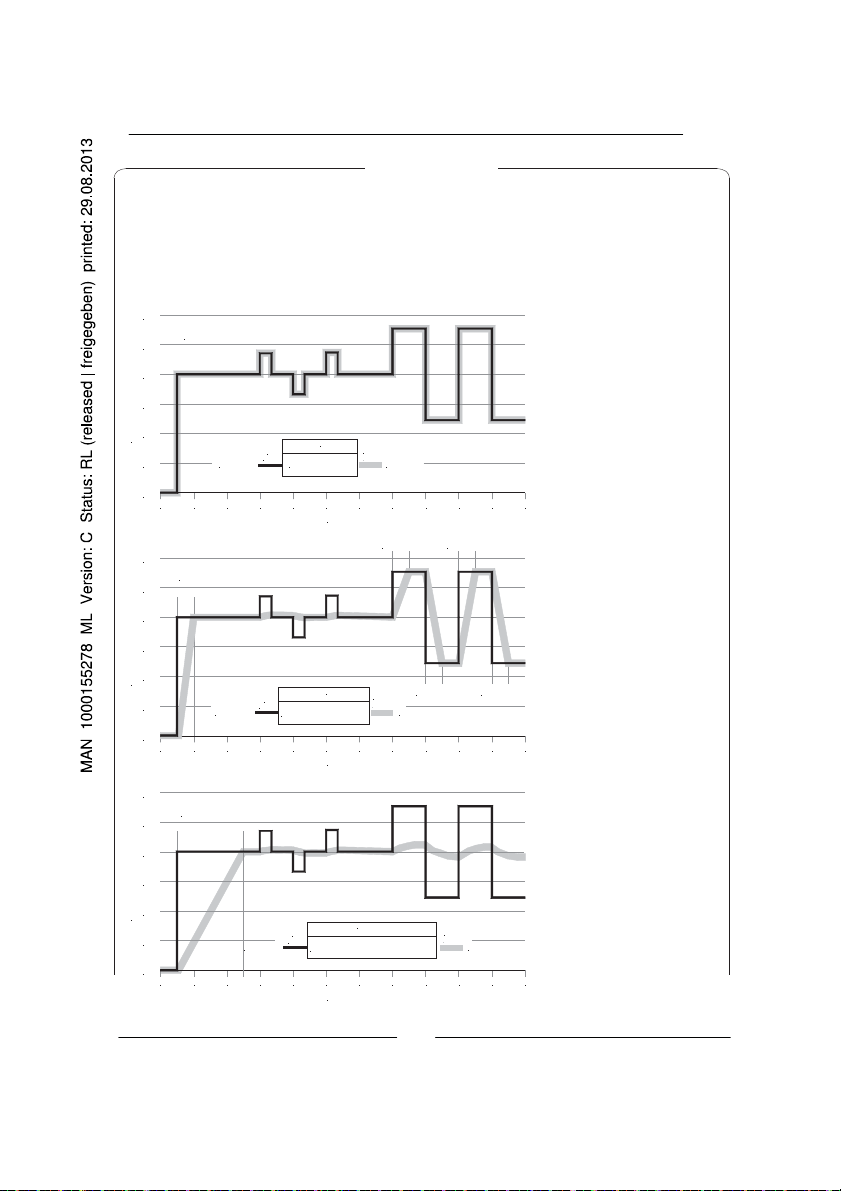

The three diagrams below demonstrate the instrument behavior with different dampening settings

with flow rate changes in the range of 1-100%.

60

Example wi th damping to OFF

50

40

30

20

FLOW RATE (%)

10

0

0 2 4 6 8 10 12 14 16 18 20 22

FLOW RATE MEASURE

60

Example with damping to SMART1

50

IN

>>>>

Damping = OFF

FILTERS

TIME (Sec)

OUT

>>>>

1,0sec.

1,0sec.

40

30

20

FLOW RATE (%)

10

0

FLOW RATE MEASURE

0 2 4 6 8 10 12 14 16 18 20 22

FILTERS

IN

>>>>

Damping = SMART1

TIME (Sec)

OUT

>>>>

1,0sec.

60

Example with damping to 5,0sec.

50

40

30

20

FLOW RATE (%)

10

0

0 2 4 6 8 10 12 14 16 18 20 22

FLOW RATE MEASURE

FILTER S

IN

>>>>

Damping= from 0.2s to 1000s

TIME (Sec)

OUT

>>>>

1,0sec.

Damping function(OFF).

the meter follows the

trend of fast changes in

flow

Damping (Smart 1,2,4):these

settings effect a predefined

filter dampening of the noise

and sudden change in flow

rate on the rise.

Damping mode based on

time (fro

0.2s to 1000s) The measure

is averaged over a number of

samples determined by the

value assigned to the

dampening function. When

the damping parameter is

expressed in seconds, the

filter works damping the

measurement noise and

sudden change of flow rate.

Increasing the parameter of

damping increases the

stability of the

measurement.

SE56

26

Page 27

SE56

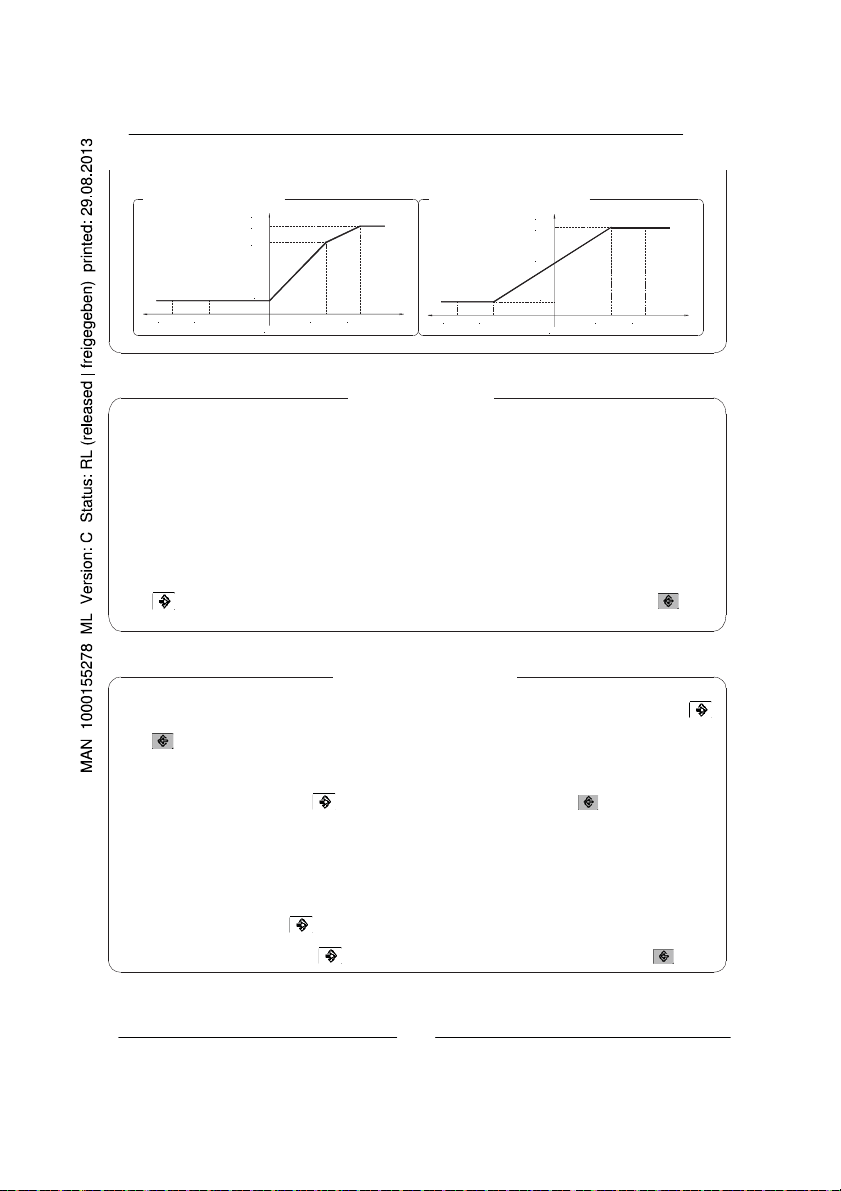

(POS. 3.5) Automatic scale change enable [Autorange=ON/OFF]

Enables/disables the automatic scale change. The meter may have two different working ranges in

order to suit variable process conditions. In order to get the best results out of this function it is

important that range N.2 is greater than N.1. When the flow rate increases and reaches the 100%

of the scale N.1, the meter automatically switches to scale N.2. When the flow rate subsequently

decreases to an equivalent value on scale N.2 (equal to the 90% of full scale N.1), scale N.1 will

assume the active scale. Allowed values for this parameter: ON/OFF.

Note: the autorange does not allow using the manual change of range (pos. 5.8)

(POS. 4.4) Current output value in failure case [mA v.fault =% XXX]

Setting of the value of the 4-20mA current output in one or more of the following cases; empty

pipe, ADC error, and coils interrupted.

The permitted range is from 0% to 120% of the 0-20mA scales, 120% corresponds to 24mA and

does not depend on the selected range (0-20/4-20mA).

The NAMUR NE43 recommendations requires alarms signaling value for a current output lower than

3.6 mA (<18%) or greater than 21mA (>105%). It is preferable to set the value of this function at

10%, so that the current value in cases of a.m. would be 2mA, allowing the following diagnostics:

current < 2mA - 5%: line interrupted, power supply failure or faulty transmitter;

2mA -5% ≤ current ≤ 2mA + 5%: hardware alarm;

4mA ≤ current ≤ 20mA: normal working range;

20mA < current ≤ 22mA: out of range, measure above 100% full scale (f.s.).

(POS. 4.5) Frequency output value in failure case [Hz v.fault=% XXX]

To set the frequency value assigned to the on/off output in one or more of the following cases:

Empty pipe; coils interrupted; ADC error

Allowable range from 0% to 125% of the frequency full scale value.

Although there are no specific rules regulating cases such as these, it would be convenient to use

the failure information as follows:

0% Hz ≤ frequency ≤ 100% f.s.: normal working range;

100% f.s. < frequency ≤ 110% f.s.: overflow, measure above the 100% of the f.s.;

115% f.s. ≤ frequency ≤ 125% f.s.: hardware alarm condition.

(POS. 5.1-2-3-4) Enable reset partial/total totalizers [T+-/P+- reset= ON/OFF]

When one of this function is enabled, the related totalizer may be reset through the on/off input.

(POS. 5.6) “Block measures” command block measures enable [Meas. lock=ON/OFF]

When this function is active (ON), applying a voltage on the on input terminals, the measurement is

stopped, the meter will display zero flow.

(POS. 5.7) Autozero calibration external command enable [Calibration=ON/OFF]

This function enables/disables the automatic zero calibration system. When this function is active,

applying a voltage on the meter’s on/off input terminals performs an autozero calibration cycle.

ATTENTION: if the voltage pulse is less 1 sec., the meter performs an Auto calibration cycle to

compensate possible thermal drifts. If the voltage pulse is more 1 sec, the meter performs an

Autozero measure calibration.

MENU 4 - ALARMS

MENU 5. INPUTS

27

Page 28

SE56

(POS. 6.1) Function choice corresponding to on/off output 1 [Out1=XXXXXX]

Function choice corresponding to digital Output 1. The functions are listed in the table below.

(POS. 6.2) Function choice corresponding to on/off output 2 [Out2=XXXXXX]

Function choice corresponding to digital Output 2. The functions are listed in the table below.

OFF: DISABLED

#1 IMP+: PULSE ON CHANNEL 1 FOR POSITIVE FLOW RATE

#1 IMP-: PULSE ON CHANNEL 1 FOR NEGATIVE FLOW RATE

#1 IMP: PULSE ON CHANNEL 1 FOR POSITIVE AND NEGATIVE FLOW RATE

#2 IMP+: PULSE ON CHANNEL 2 FOR POSITIVE FLOW RATE

#2 IMP-: PULSE ON CHANNEL 2 FOR NEGATIVE FLOW RATE

#2 IMP: PULSE ON CHANNEL 2 FOR POSITIVE AND NEGATIVE FLOW RATE

#1 FREQ+: FREQUENCY CHANNEL 1 FOR P OSITIVE FLOW RATE

#1 FREQ-: FREQUENCY CHANNEL 1 FOR NEGATIVE FLOW RATE

#1 FREQ: FREQUENCY CHANNEL 1 FOR POSITIVE AND NEGATIVE FLOW RATE

#2 FREQ+: FREQUENCY CHANNEL 2 FOR P OSITIVE FLOW RATE

#2 FREQ-: FREQUENCY CHANNEL 2 FOR NEGATIVE FLOW RATE

#2 FREQ: FREQUENCY CHANNEL 2 FOR POSITIVE AND NEGATIVE FLOW RATE

SIGN: FLOW DIRECTION OUTPUT (ENERGIZED = -)

RANGE: RANGE INDICATIO N OUTPUT (ENERGIZED = SCALE 2)

MAX AL.: MAX FLOW RATE OUTPUT(ENERGIZED = AL. OFF)

MIN AL.: MIN F LOW RATE OUTPUT(ENERGIZE D = AL. OFF)

MAX+MIN: MAX AND MIN FLOW RATE ALARM OUTPUT (ENERGIZED = AL. OFF)

P. EMPTY: EMPTY PIPE ALARM OUTPUT (ENERGIZED = FULL PIPE)

OVERFLOW.: OUT OF RANGE ALARM OUTPUT (ENERGIZED = FLOW RATE OK)

HARDW AL.: CUMULATIVE ALARM OUT interrupt coils, empty pipe, measure error (ENERGIZED=NO ALARM)

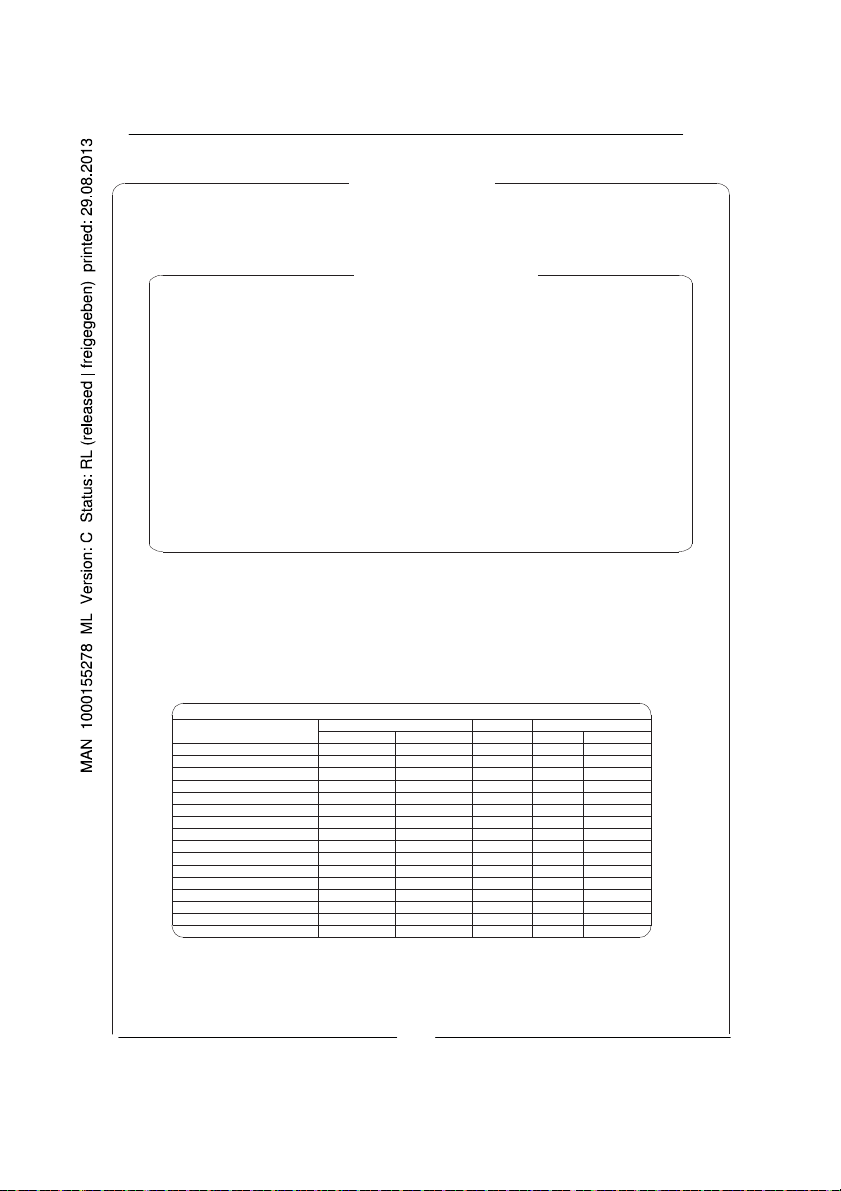

(POS. 6.3) Current output option and range [Out mA=X_XX XXX]

This function sets the current output N.1. This function is optional and will not appear unless the

option has been requested. There are three fields to modify for this function:

• Scale zero: 4 or 0mA

• Full scale: 20 or 22mA

• Field: + = positive, - = negative, blank = both, -0+ = central zero scale

The values corresponding to the scale points are shown in the following chart:

POSSIBLE FIELD

OutmA = 0 - 20 + 0 0 0 20 20

OutmA = 0 - 22 + 0 0 0 20 22

OutmA = 4 - 20 + 4 4 4 20 20

* OutmA = 4 - 22 + 4 4 4 20 22

OutmA = 0 - 20 - 20 20 0 0 0

OutmA = 0 - 22 - 22 20 0 0 0

OutmA = 4 - 20 - 20 20 4 4 4

OutmA = 4 - 22 - 22 20 4 4 4

OutmA = 0 - 20 20 20 0 20 20

OutmA = 0 – 22 22 20 0 20 22

OutmA = 4 - 20 20 20 4 20 20

OutmA = 4 – 22 22 20 4 20 22

OutmA = 0 - 20 –0+ 0 0 10 20 20

OutmA = 0 - 22 –0+ 0 1 11 21 22

** OutmA = 4 - 20 –0+ 4 4 12 20 20

OutmA = 4 - 22 –0+ 4 4.8 12.8 20.8 22

In hardware alarm conditions “HARDW AL.” (interrupted coils, empty pipe, measure error) the

current value is programmed by the function “mA v.fault” (pos. 4.4) and it is expressed as

percentage of a fixed current range, where: 0% = 0mA and 110% = 22mA.

MENU 6 - OUTPUTS

FUNCTIONS FOR OUTPUTS 1 AND 2

CURRENT VALUE S IN mA ASSOCIATE TO THE % FULL S CALE VALUE

REVERSE FLOW VALUE ZERO DIRECT FLOW VALUE

≤ -110% -100% 0% +100% ≥+110%

28

Page 29

SE56

* Example 1: out 4-22 +

-110% F.S. -100% F.S. +100% F.S. +110% F.S.

(POS. 8.8-9) Conversion factor for flow rate totalizers [EUR/dm³+/- =X]

Setting of the conversion/currency value for direct (and reverse) flow totalizers. There are three

setting fields for this parameter, from left to right: 1) monetary symbol, 2) default/personalized

monetary symbol, 3 ) conversion coefficient. To select, set the cursor over the field to be modified.

Setting the monetary symbol can be achieved in two ways:

1. Choosing one of the 7 predetermined monetary symbols (standard ISO 4217-REV81):

EUR=Euro; USD=USA dollar; CAD=Canadian dollar; AUD=Australian dollar; GPB=English

pound; CHF=Swissfranc; JPY=Japanese yen.

2. Entering a three character (numbers or letters) personalized currency. To change the

characters, the cursor must be set on the symbol “/” (second field)

(POS. 8.10-11-12-13) Total/Partial totalizer reset [T/P/-/+ reset]

Activates the reset of total and partial flow totalizer. These functions are activated by pressing the

key during the visualization of the function itself. When "EXECUTE?" is required, press to

proceed. Press any other key to delete the operation.

(POS. 10.1) Meter calibration [Calibration]

Enables the meter calibration function. The activation of this function happens by pressing the key

during the function visualization, at the following question will be visualized: "EXECUTE?", so press

the key to proceed. Press any other key to delete the operation.

(POS. 10.2) Self test function [Self test]

Meter auto test function. This function stops the meter normal functions and performs a complete

test cycle on the measuring input circuits and the excitation generator. To activate this function,

selecting it, by pressing the key , at the prompt: “EXECUTE?” press the key to start the test,

any other key will delete the operation. The test result is shown on the display, the display will

return to one of the visualization pages at the test end. The function is automatically performed

when the device is switched on. For any errors see the next page for corrective actions.

(POS. 10.3) Flow rate simulation [Simulation = ON/OFF]

Flow rate simulation enabling. This function allows for the possible generation of an internal signal

that simulates the flow rate, allowing the outputs and all the connected instruments to be tested.

After enabling it, a ‘S’ appears in the top right of the screen and the flow rate simulation can be:

set: by pushing the key from one of visualization pages, to set the required % flow rate

(Fl.rate=%) and the same key to confirm the value;

finished: by pushing the key from visualization pages and then by pushing the key .

I (mA)

22 mA

20 mA

4 mA

zero

MENU 8 - DISPLAY

MENU 10 - DIAGNOSTIC

** Example 2: out 4-20 –0+

-110% F.S. -100% F.S. +100% F.S. +110% F.S.

I (mA)

20 mA

12 mA

4 mA

zero

29

Page 30

ALARMS

Messages, causes and corrective actions

SE56

MESSAGE CAUSE ACTION TO TA KE

NO ALARMS All works regularly

MAX ALARM The flow rate is higher than the maximum threshold set

MIN ALARM The flow rate is lower than the minimum threshold set

FLOW RATE >FS

PULSE/FREQ >FS

EMPTY PIPE

INPUT NOISY

EXCITATION

FAIL

CURR. LOOP

OPEN

P.SUPPLY FA IL Power supply different from that indicated on the label

The flow rate is higher than the full scale value set on the

instrument

The pulse generation output of the device is saturated and can

not generate the sufficient number of pulses

The measuring pipe is empty or the detection system has not

been properly calibrated

The measure is strongly effec ted by external noise or the

connecting cable from transmitter to the sensor may be broken

The coils or the cable connecting the sensor are interrupted Check the connecting cables to the sensor

The 4-20mA output on board or the optional one are not

correctly closed on a valid load

Check the maximum flow rate threshold set and

the process conditions

Check the minimum flow rate threshold set and

the process conditions

Check the full scale value set on the instrument

and the process conditions

Set a bigger volume unit or, if the c onnected

counting device allows it, reduce the pulse

duration value

Check whether the pipe is empt y, or repeat the

empty pipe calibration procedure

Check the status cables connecting transmitter to

sensor, the devices grounding connections or the

possible presence of noise sources

Verify the load is applied to the output (max 1000

).

To disable the alarm, set the “mA VAL.FAULT”

value (menu alarm) to 0.

Verify that the power supply is as indicated on the

label

//

Anomalies, codes and remedies

CODE ANOMALI E DESCRIPTION ACTION T O TAKE

0001 problem with watch-dog circuit

0002 Wrong work data configuration in eeprom

0004 Wrong safety data configuration in eeprom

0008 Defective eeprom

Defective keyboard (o ne or more keys are pushed

0010

during the test)

0020 Power supply voltage (+3.3) is out of range

0040 Power supply voltage (+13) is too low (<10V)

0080 Power supply voltage (+13) is too high (>14V)

0200 Timeout calibration input (broken input circuit)

0400 Input stage gaining is out of range

0800 Interruption on the coils circuit Check the status cables connecting the transmitter to the sensor

0C00 Cumulative alarm 0800 + 0400 See single code

Check the status cables connecting the transmitter to the sensor, the

grounding connections or the possible presence of strong and

anomalous noise sources

ADDRESS TO SERVICE

30

Page 31

SE56

31

Page 32

CONFORMITY DECLARATION

declares under the own responsibility that the product

Transmitter model

SE 56

Sensors model:

S051 – S054 – S055 – S056

to which this declaration refers, is in compliance with the following

Harmonized European Norms:

EN 61010-1:2010

EN 61326-1:2006

and therefore answering to essential requirement of CE directives:

2006/95/CE (Low voltage directive – LVD)

2004/108/CE (Electromagnetic Compatibility Directive – EMC)

04/03/2011

Page 33

BEDIENUNGS- UND INSTALLATIONSANLEITUNG

Durchfluss-Transmitter

SE56 Basic

Ausgabe Nummer: MASE56_DE_BU_R9_3_91.0XXX.docx

teinamens stehen für die Software-Version, die beim Einschalten des Gerätes angezeigt wird und auf die

sich das Handbuch bezieht.

– Die letzten drei Zeichen des Da-

Page 34

INHALTSVERZEICHNIS

EINLEITUNG ..................................................................................................................................... 3

SICHERHEITSHINWEISE .................................................................................................................. 3

SICHERHEITSZEICHEN ................................................................................................................................. 4

TECHNISCHE DATEN ......................................................................................................................... 5

ELEKTRISCHE DATEN ................................................................................................................................... 5

BETRIEBSBEDINGUNGEN ............................................................................................................................. 5

BETRIEBSTEMPERATUR ............................................................................................................................... 5

TYPENSCHILD.............................................................................................................................................. 5

ABMESSUNGEN ............................................................................................................................................ 6

ELEKTRISCHER ANSCHLUSS ............................................................................................................. 7

ERDUNGSANWEISUNGEN ............................................................................................................................. 7

STROMVERSORGUNG ................................................................................................................................... 7

INNENANSICHT ........................................................................................................................................... 8

ELEKTRISCHE VERBINDUNGEN VOM TRANSMITTER ZUM SENSOR ................................................................. 8

DIGITALEINGANG ............................................................................................................................. 9

BETRIEB BEI EINGANG EIN/AUS ................................................................................................................... 9

VERDRAHTUNG DER AUSGÄNGE ..................................................................................................... 10

STATUSANZEIGEN UND BEDEUTUNG VON LED-WARNUNGEN ........................................................ 11

ZUGANG ZUM TRANSMITTERMENÜ ................................................................................................ 12

TASTENFELD ............................................................................................................................................. 12

Parametrierung mit einem Softwaretool ....................................................................................................... 12

AUFRUFEN DER FUNKTIONEN BEIM EINSCHALTEN ..................................................................................... 13

DURCHFLUSSANZEIGE .................................................................................................................... 14

ZUGANGSCODE .......................................................................................................................... 15

QUICKSTARTMENÜ ......................................................................................................................... 16

AUFRUFEN DER PARAMETRIERMENÜS ........................................................................................... 17

BEISPIEL ................................................................................................................................................... 18

FUNKTIONSMENÜ ........................................................................................................................... 20

FUNKTIONSBESCHREIBUNG ....................................................................................................................... 23

ALARME .......................................................................................................................................... 29

KONFORMITÄTSERKLÄRUNG .......................................................................................................... 31

SE56

2

Page 35

SE56

EINLEITUNG

Diese Bedienungsanleitung und Beschreibung der Gerätefunktionen ist integraler Bestandteil

des Gerätes. Änderungen ohne Vorankündigung sind vorbehalten. Bei unsachgemäßer Verwendung, Veränderungen des Gerätes oder seiner Komponenten oder Einsatz von nicht originalen Ersatzteilen verfällt sofort jeglicher Gewährleistungsanspruch.

Der Transmitter darf nur direkt mit einem Sensor gekoppelt als Durchflussmessgerät verwendet werden, das zur Messung des Durchflusses von Flüssigkeiten mit einer Leitfähigkeit

über 5μS/cm in geschlossenen Rohren verwendet wird.

TRANSMITTER

Die Vervielfältigung dieses Handbuchs und jeglicher mit diesem Transmitter gelieferten

Software ist verboten.

SENSOR

SICHERHEITSHINWEISE

Jeder nicht bestimmungsgemäße Einsatz kann den vom Hersteller gebotenen Schutz beeinträchtigen und die Sicherheit von Personen und dem gesamten Messsystem gefährden und

ist daher nicht zulässig.

Der Hersteller ist nicht haftbar für Schäden durch unsachgemäßen oder nicht bestimmungsgemäßen Gebrauch.

1) Das Messgerät in der Originalverpackung zum Installationsort transportieren. Deckel

und Kappen erst unmittelbar vor der Installation entfernen. Kartonverpackungen

können gestapelt werden, aber nicht mehr als drei Kartons übereinander. Holzverpackungen nicht stapeln.

2) Die Entsorgung dieses Produkts oder seiner Teile muss gemäß den geltenden Bestimmungen erfolgen.

3) Der Transmitter darf nur durch qualifizierte und zugelassene Fachleute (z.B. Elektriker) installiert, angeschlossen, in Betrieb genommen und gewartet werden, wobei alle Anweisungen dieser Bedienungsanleitung, die geltenden Normen, gesetzlichen

Bestimmungen und Angaben in Zertifikaten und Zulassungen (je nach Anwendung)

eingehalten werden müssen.

3

Page 36

4) Die Fachleute müssen diese Bedienungsanleitung gelesen und verstanden haben und

die darin enthaltenen Anweisungen befolgen. Wenn Ihnen irgend etwas in dieser Bedienungsanleitung unklar ist, müssen Sie den Kundendienst anrufen. Die Bedienungsanleitung liefert ausführliche Informationen über den Transmitter.

5) Reparaturen dürfen nur durchgeführt werden, wenn ein Originalersatzteil-Kit verfügbar ist und diese Reparaturarbeiten ausdrücklich genehmigt sind.

6) Der Transmitter darf nur installiert werden, nachdem die technischen Daten in dieser

Bedienungsanleitung und auf dem Typenschild überprüft wurden.

7) Die Fachleute müssen bei der Installation sorgfältig vorgehen und persönliche

Schutzausrüstung verwenden, die je nach Risikobeurteilung gemäß Sicherheitsplan

bereitgestellt wird.

8) Den Transmitter niemals montieren oder anschließen, während er an die Stromversorgung angeschlossen ist, und jeden Kontakt von Flüssigkeit mit den internen Teilen

des Gerätes vermeiden.

9) Vor dem Anschließen der Stromversorgung die Sicherheitsausrüstung überprüfen.

10) Zur Reinigung des Gerätes nur ein feuchtes Tuch verwenden, und für die Wartung/Reparaturen das Kundendienstzentrum kontaktieren.

Überprüfen Sie vor der Inbetriebnahme des Gerätes Folgendes:

Die Versorgungsspannung muss mit der auf dem Typenschild angegebenen Span-

nung übereinstimmen

Die elektrischen Anschlüsse müssen wie beschrieben ausgeführt worden sein

Die Erdungsanschlüsse müssen wie beschrieben ausgeführt worden sein

Überprüfen Sie regelmäßig (alle 3-4 Monate):

Die Unversehrtheit von Netzkabel, Verkabelung und anderen angeschlossenen Teilen

Die Unversehrtheit des Transmitter-Gehäuses

Den festen Sitz der Dichtungselemente

Die Unversehrtheit der Fronttafel (Display und Tastenfeld)

Die Befestigung des Transmitters an der Rohrleitung oder der Wandhalterung.

SE56

GEFAHR

Dieses Zeichen kennzeichnet eine Maßnahme oder ein Verfahren, das bei nicht

ordnungsgemäßer Ausführung zu Verletzungen oder einer Gefahr für die Sicherheit führen kann. Halten Sie die Anweisungen strikt ein und gehen Sie

sorgfältig vor.

WARNUNG

Dieser Vorsichtshinweis kennzeichnet eine Maßnahme oder ein Verfahren, das bei

nicht ordnungsgemäßer Ausführung zu fehlerhaftem Betrieb oder zur Zerstörung des

Gerätes führen kann. Halten Sie die Anweisungen strikt ein.

HINWEIS

Hinweise kennzeichnen Maßnahmen oder Verfahren, die bei nicht ordnungsgemäßer Ausführung eine indirekte Auswirkung auf den Betrieb haben oder

eine unerwartete Reaktion seitens des Gerätes auslösen können.

4

Page 37

TECHNISCHE DATEN

ELEKTRISCHE DATEN

Schutzklasse Transmitter: Schutzklasse I, IP65, Anlagenkategorie (Überspannungs-

schutz) II, bewerteter Verschmutzungsgrad 2.

SE56

Stromversorgungs-

versionen

Versorgungs-

spannung

Stromfrequenz

Max. Leis-

tung

HV 100-240V AC 44-66Hz

LV

Spannungsänderungen dürfen ±10 % der Nennspannung nicht überschreiten.

Die Ein-/Ausgänge sind bis 500 V isoliert.

Der Ausgang 4-20mA (optional) ist elektrisch mit den digitalen Ausgängen und dem

18-45V DC //

18-45V AC 44-66Hz

6W

BETRIEBSBEDINGUNGEN

Der Transmitter kann in Gebäuden und im Freien installiert werden

Höhe: von –200 bis 2000 m (von -656 bis 5602 Fuß)

Luftfeuchtigkeitsbereich: 0-85% nicht kondensierend

BETRIEBSTEMPERATUR

Min. * Max

°C -10 50

°F 14 122

Betrachten Sie die unterschiedlichen Betriebstemperaturen zwischen Transmitter und Sensor. * Bei diskontinuierlicher Verwendung ist möglicherweise eine thermostatisch geregelte Wärmequelle erforderlich.

TYPENSCHILD

Auf dem Typenschild befinden sich verschiedene technische Informationen:

x MODEL: Transmitter-Modell

x S/N: Seriennummer des Transmitters

x SUPPLY: Haupt-Stromversorgung

x Hz: Frequenz der Stromversorgung (AC)

x POWER: Maximaler Leistung

x IP: Schutzklasse

x T: Umgebungstemperatur im Betrieb

x COUPLING: Seriennummer des angeschlossenen Sensors

x ITEM: frei für Benutzer

5

Page 38

ABMESSUNGEN

SE56

4

2

1

Gewicht: 0,5kg

7

2

1

129

168

Um die IP-Schutzklasse des Gehäuses zu garantieren, sind die folgenden Drehmomente

erforderlich:

Deckelschrauben: 0,5Nm

Kabelverschraubungen: 4Nm (unter Referenzbedingungen)

Kappe zur Abdeckung Anschluß-IF2-Stecker: 4Nm

DREHMOMENTE

6

Page 39

ELEKTRISCHER ANSCHLUSS

SE56

ERDUNGSANWEISUNGEN

Damit der Transmitter ordnungsgemäß funktioniert, MÜSSEN Transmitter, Sensor und

Flüssigkeit immer das gleiche Potenzial aufweisen. Erden Sie Sensor und Transmitter

also IMMER.

STROMVERSORGUNG

L

(-)

N

(+)

Stellen Sie vor dem Anschließen der Stromversorgung unbedingt sicher, dass die

Versorgungsspannung in dem auf dem Typenschild angegebenen Bereich liegt.

Für die Verbindungen nur zulässige Leiter mit Brandschutzeigenschaften verwenden,

deren Querschnitt je nach Abstand/Leistung 0,25mm

fixieren Sie außerdem die Stromversorgungskabel mit einem zusätzlichen Befestigungssystem in der Nähe der Anschlussklemmen.

Die Netzleitung muss mit einem externen Überstromschutz (Schmelzsicherung oder

Sicherungsautomat).

Installieren Sie in der Nähe des Transmitters einen Stromkreisunterbrecher, der

leicht für den Benutzer zugänglich ist und deutlich gekennzeichnet ist; seine Symbole müssen den elektrischen Sicherheitsvorschriften und den lokalen elektrischen Anforderungen entsprechen.

Stellen Sie sicher, dass die Komponente die Anforderungen der Norm für elektrische

Sicherheitsabstände einhält.

Der Sensor sowie fest angeschlossene Eingangs- und Ausgangssignale werden über

eine Klemmenleiste innerhalb des Transmitters an den Transmitter angeschlossen.

Die Klemmenleiste ist nach Lösen der 4 Schrauben an der Frontabdeckung zugäng-

lich. Heben Sie die Frontplatte an. Bei angehobener Frontabdeckung ist die Klemmenleiste sichtbar. Die Klemmenleiste dient dem Festanschluss des Transmitters an

externe Geräte, einschließlich des Sensors.

M3

2

bis 2,50mm2 betragen kann;

Auf den folgenden Seiten finden Sie Informationen zur Nummerierung der Klemmenanschlüsse und den jeweiligen Anschluss von Sensorkabeln und Eingängen/Ausgängen.

7

Page 40

SE56

A

A

V

T

INNENANSICH

Stromversorgung

nschluss-Fassung

nzeige-LED: siehe Abschnitt zu Statusanzeigen

und Bedeutung von LED-Warnungen

Tastenfeld

11 12 13 14 15 16 17 18 19 20

1 2 3 4 5 6 7 8 9 10

ELEKTRISCHE VERBINDUNGEN VOM TRANSMITTER ZUM SENSOR

KLEMMENLEISTE M1

24V

OUT2

-

E

OUT1

E

C

24V

+

C

SH

B2

COILS

P

LEN

B1

SH

ersorgungs-

Power supply

spannung

11121314151617181920

10

-

+

4-20mA

RS 485* : OPTIONAL, PROVIDED EXLUSIVELY BY THE MANUFACTURER

RS 485* : OPTIONAL, EXKLUSIV VOM HERSTELLER GEBOTEN

A

RS 485* INPUT

-

B

+

C

SH

ELEKTRODEN

ELECTRODES

8

123456789

E1

E2

Page 41

V

V

A

V

V

V

V

A

V

V

K

V

DIGITALEINGANG

g

A

A

V

V

BETRIEB BEI EINGANG EIN/AUS

Externe Stromversorgun

10 K

5 (+)

3/40 Vdc (ON)

0/1.5 Vdc (OFF)

6 (-)

Interne Stromversorgung

+24

15

5

10 K

6

0

20

SE56

Auto-Kalibrierung

UTOCALIB. OFF

3-40

0-1,5

T

Mengenzähler zurücksetzen

BLOC

3-40

0-1,5

Mengenzähler anhalten

3-40

3-40

0-1,5 V

0-1,5 V

Mengenzähler aktiv

Bereichswechsel

3-40 V

0-1,5 V

Messung sperren

18-30

<18

RESET

Tmin = 100ms

T

Mengenzähler anhalten

Messbereich 2

Messbereich 1

Messung gesperrt

Messung

BTASTRATE

10 Hz

220 ms

20 Hz

110 ms

50 Hz

Tmin

45 ms

Tmin < T < 1 s = Autokalibrierung

T > 1 s = automatischer Nullpunkt

Voraussetzungen für die Aktivierung der Funktion

KTIVIERT (Automatischer Nullabgleich auf ex-

POS. 5.7

ternen Befehl)

oraussetzungen für die Aktivierung der Funktion

POS. 5.1 bis 5.4 AKTIVIERT (Partiellen Mengenzähler für

vorwärts oder rückwärts Durchfluss Rücksetzen)

oraussetzungen für die Aktivierung der Funktion

POS. 5.5 AKTIVIERT (Befehl Mengenzähler Zählen sperren)

oraussetzungen für die Aktivierung der Funktion

POS. 5.8 AKTIVIERT (Bereichswechsel)

Voraussetzungen für die Aktivierung der Funktion

POS. 5.6 AKTIVIERT (Messung blockiert)

BTASTRATE

150 Hz

80 Hz

Tmin

30 ms

T muss > Tmin sein

15 ms

9

Page 42

VERDRAHTUNG DER AUSGÄNGE

V

SE56

Digitalausgang 1250Hz

16 (out1)

18 (out2)

43

17 (out1)

19 (out2)

Optisch isolierter Ausgang mit potentialfreien

Kollektor- und Emitteranschlüssen, die beliebig

verschaltet werden können.

Maximale Schaltspannung: 40 V DC

Maximaler Schaltstrom: 100 mA

Maximale Sättigungsspannung zwischen Kollektor

und Emitter bei 100 mA: 1,2 V

Maximale Schaltfrequenz (Last an Kollektor oder

Emitter, RL = 470 :, VOUT = 24 V DC): 1250 Hz

Maximaler Rückwärtsstrom am Eingang während

versehentlicher Polaritätsumkehr (VEC): 100 mA

Isolation von anderen Sekundärkreisen: 500 V DC

Ausgang 4-20mA

+24V INTERNAL

mA

I

24V COMMON

4-20mA OUT

10 (-)

Am 4–20mA Ausgang befindet sich eine Transmitter-Prüflast; zum Deakti-

vieren dieser Funktion stellen Sie den Wert „mA v.fault“ auf 0 (Pos. 4.4)

Optisch isolierter Ausgang

Maximale Last: 1000 Ohm

9 (+)

Maximale Spannung ohne Last: 27 V DC

Die Aktualisierungsfrequenz ist gleich der Abtast-

frequenz des angeschlossenen Sensors

Geschützt vor persistenten Überspannungen bis

maximal 30 V DC

HINWEIS: Für die Verkabelung von Eingängen und Ausgängen werden abgeschirmte Kabel

empfohlen.

10

Page 43

g

g

gung

STATUSANZEIGEN UND BEDEUTUNG VON LED-WARNUNGEN

Beim Einschalten des Transmitters erscheint die folgende Anzeige auf dem Display. In

der rechten oberen Ecke können mehrere Symbole erscheinen. Die Symbole haben

die in der folgenden Tabelle aufgeführte Bedeutung. Die Bedeutung der blinkenden

LED finden Sie unten auf dieser Seite in der Tabelle „Bedeutung der LED“.

STATUSKÜRZEL

BEDEUTUNG DES KÜRZELS

STATUSKÜRZEL

M Max.-Alarm aktiviert

m Min.-Alarm aktiviert

!

C Kalibrierun

S Simulation

BESCHREIBUNG

- Unterbrechun

- Signalfehler

- Leere Rohrleitung

Sätti

(verkleinern des ZEITIMPULS)

Spulenkreis

läuft

des Impulsausgangs

SE56

LED

11 1213 14 15 16 17 18 19 20

1 2 3 4 5 6 7 8 9 10

BEDEUTUNG DER LED

DAUERLEUCHTEN: Initialisierung

BLINKLICHT (1 s): Normalbetrieb

BLINKLICHT (<1 s): Alarm aktiv

Die LED signalisiert den Alarmstatus nur, wenn das Display eine

passende Anzeigeseite anzeigt

11

Page 44

g

ZUGANG ZUM TRANSMITTERMENÜ

Das Tastenfeld ist nach Lösen der 4 Schrauben der Abdeckung

und Öffnen der Frontabdeckung des Transmitters zugänglich.

Neben der Klemmenleiste der Stromversorgung befinden sich

M3

KEYPAD

TASTENFELD

KURZ DRÜCKEN (< 1 SEKUNDE):

Erhöht den Zahlenwert oder den Parameter, der mit dem Cursor markiert wurde.

Zurück zum vorigen Menüpunkt, sofern Quickstart- oder Hauptmenüs

aufgerufen sind. Dosierung Start/Stopp (sofern aktiviert)

LANG DRÜCKEN (> 1 SEKUNDE):

Vermindert den Zahlenwert oder den Parameter, der mit dem Cursor

KURZ DRÜCKEN (< 1 SEKUNDE):

Verschiebt den Cursor im Eingabefeld nach rechts

Weiter zum nächsten Menüpunkt, sofern Quickstart- oder Hauptmenüs

aufgerufen sind. Ändert die Anzeige von Prozessdaten

LANG DRÜCKEN (> 1 SEKUNDE):

Verschiebt den Cursor im Eingabefeld nach links

Weiter zum vorigen Menüpunkt, sofern Quickstart- oder Hauptmenüs auf-

KURZ DRÜCKEN (< 1 SEKUNDE):

Aufrufen/Verlassen der gewählten Funktion

Aktiviert das Hauptmenü für die Transmitter-Konfiguration

Beendet die ausgewählte, laufende Funktion

LANG DRÜCKEN (> 1 SEKUNDE):

Verlässt die aktuelle Funktion in Quickstart- oder Hauptmenüs.

Aktiviert die Bestätigungsanfrage „EXECUTE?“ in den Hauptmenüfunktionen, und die Rücksetzanforderung für den Mengenzähler (sofern aktiviert)

der an

drei TASTEN, mit denen der Benutzer angezeigte Daten und

Funktionen auswählen kann.

Stellen Sie sicher, dass der Deckel

über den Stromversorgungsklemmen angeschlossen ist.

eforderten Funktion

SE56

-

PARAMETRIERUNG MIT EINEM SOFTWARETOOL

Bei Transmittern ohne Display („blinde Version“) erfolgt die Parametrierung über ISOCON (Kabel und

Software erforderlich). Da das Gehäuse vom Installateur geschlossen wird, kann der IP-Schutzgrad verloren gehen; beachten Sie daher die in dieser Bedienungsanleitung angegebenen Drehmomente.

12

Page 45

A

V

t

A

V

t

AUFRUFEN DER FUNKTIONEN BEIM EINSCHALTEN

T

gig

g

Beispiel der beim Starten angezeigten Seiten

Wird der Transmitter direkter Sonneneinstrahlung ausgesetzt, kann die Flüssigkristallanzeige

(LCD) beschädigt werden.

ktiver Messbereich

Durchflussanzeige

Hinweis: Beim Einschalten des

Transmitters erscheint die links

dargestellte Anzeige. Verwenden

Sie die Tasten des Tastenfelds wie

in der Mitte dieser Seite gezeigt,

um zwischen den gezeigten Anzeigeseiten umzuschalten (nicht alle

sind hier dargestellt).

*Vorwärts/rückwärts

Mengenzähleranzeige

SE56

Zum Umschalten der

Anzeige die gezeigte

Taste des Tastenfelds

Wechselanzeige

drücken

Zum Umschalten der

Anzeige die gezeigte

Taste des Tastenfelds

Durchflussanzeige

orwärts/rückwärts Menge Durchflussgeschwindigkei

*

larmbeschreibung

* Unabhän

zahl des Men

von der eingestellten Anzahl von Nachkommastellen (siehe Pos 2.3) ist die angezeigte Maximal-

enzählers 999999999. Jenseits dieses Werts werden die Mengenzähler auf Null zurückgesetzt.

drücken

Zum Umschalten der

Anzeige die gezeigte

Taste des Tastenfelds

drücken

WÄHRUNGSFUNKTION AKTIVIER

*

orwärtsmenge

Rückwärtsmenge

Kostenwer

Durchflussanzeige

13

Page 46

SE56

DURCHFLUSSANZEIGE

Mit dem SE56 Basic kann eine 5-stellige Digitalanzeige der Durchflusseinheiten angezeigt

werden; dies bedeutet, dass der maximale Durchflusswert, der auf dem Display angezeigt

werden kann, 99999 beträgt (unabhängig von der Kommaposition), und das Minimum

0.0025.

Die darstellbaren Messeinheiten hängen vom Durchfluss und Durchmesser des Sensors ab;

die zulässigen Einheiten sind diejenigen, die beim Messbereichsendwert gewählt wurden.

Zugehörig dazu kann eine Zahl dargestellt werden, deren Maximalwert 99999 nicht übersteigt.

Beispiel für DN 300:

- Messbereichsendwert: 3m/s

3

- ERLAUBTE Messeinheit (Beispiel): l/s (216.00); m

/h (777.60); m3/s (0.2160)

- NICHT ERLAUBTE Messeinheit (Beispiel): l/h (777600).

14

Page 47

SE56

ZUGANGSCODE

Funktionen im „Hauptmenü“ des Transmitters werden durch die Zugangscodes aktiviert.

Die Informationen in diesem Handbuch beziehen sich auf alle Funktionen, die in Zugangsstufe L2 verfügbar sind. Alle Funktionen höherer Zugangsstufen sind dem Service vorbehalten und nicht verfügbar.

Beschreibung des L2-Zugangscodes

(Menü „11 Interne Daten“ Pos. 11.1)

mit Code L2 = 00000 (mit diesem Code) können Sie die Abfrage von Code L2 deak-

tivieren

* mit benutzerdefiniertem L2 (frei gewählt vom Benutzer) können Sie alle Funktion

bis zur Sicherheitsstufe L2 parametrieren, wobei Sie diesen Code immer eingeben müssen, wenn Sie das Hauptmenü aufrufen.

* ACHTUNG: Notieren Sie sich sorgfältig den von Ihnen angepassten Code, denn Sie haben keine Möglichkeit mehr, diesen Code abzufragen, falls Sie ihn einmal vergessen sollten.

Werkseitig voreingestellte Zugangscodes

Der Transmitter wird mit dem Standard-Zugangscode für L2 (Level 2) ausgeliefert.

11111

15

Page 48

SE56

QUICKSTARTMENÜ

Nachdem der Transmitter eingeschaltet wurde hat der Benutzer sofort Zugang zum Quickstartmenü, durch Drücken der Taste . Wenn kein Zugang zum Quickstartmenü erfolgt,

wurde es über Funktion 8.4 deaktiviert

Siehe Abschnitt Funktionsmenü

Zugriff auf alle Funktionen

16

Page 49

)

A

UFRUFEN DER PARAMETRIERMENÜS

Das Konfigurationsmenü des Transmitters kann auf zwei verschiedene Weisen aufgerufen werden:

1) über die ISOCON-Schnittstelle

2

über das Tastenfeld des Transmitters

ZUGANG ZUM KONFIGURATIONSMENÜ ÜBER DIE ISOCON-SCHNITTSTELLE

Isocon ist eine Windows® Software,

mit der alle Transmitter-Funktionen

eingestellt und das Menü angepasst

werden kann (IF2X ist erforderlich),

für Einzelheiten siehe die entsprechende Bedienungsanleitung.

ZUGANG ZUM KONFIGURATIONSMENÜ ÜBER DAS TASTENFELD

Die Funktionen können auf zwei verschiedene Weisen über das Tastenfeld aufgerufen

werden:

Über das Quickstartmenü können eine Reihe wichtiger Funktionen zur Einstel-

lung der Messwertskalierung und der Anzeigeeigenschaften des Sensors direkt

aufgerufen werden

SE56

Das Quickstartmenü kann über Funktion 8.4 (Menüanzeige) aktiviert werden

Werkseitige Voreinstellung:

Über das Hauptmenü können Funktionen aufgerufen werden, für die der Zu-

QUICK START MENU=ON

gangscode2 erforderlich ist. Hiermit können weitere Funktionen wie Sen-

sorüberwachung, Datenverarbeitung, Eingänge/Ausgänge sowie weitere Anzeigeoptionen gesteuert werden.

Das folgende Beispiel zeigt, wie mit dem Quickstartmenü der Messbereichsendwert geändert wird; das anschließende Beispiel illustriert, wie die Funktion über das Hauptmenü

geändert wird.

17

Page 50

SE56

)

BEISPIEL: „Quickstartmenü“ Funktionsänderung. Messbereichsendwert 1 (Fs1) von

4dm³/s auf 5dm³/s.

Rufen Sie das „Quickstartmenü“ auf.

Die bei jedem Schritt zu drückende

Taste wird durch das Symbol vor

einer der drei Tasten des Tastenfelds gekennzeichnet (hier die untere Taste

Drücken Sie die Taste mehrfach und

schnell, um den Cursor auf den zu

ändernden Wert zu positionieren

Bestätigen Sie den neuen Wert

mit einem kurzen Druck

(< 1 s) auf die Taste

Rufen Sie die Funktion „Fs1“ durch

kurzes (< 1 s) Drücken der angegebenen Taste auf

Um den Wert zu erhöhen,

drücken Sie jeweils kurz

(< 1 s) die obere Taste, um

den Wert zu verringern, drücken Sie jeweils lange (> 1 s)

die obere Taste

Durch einen langen Druck

wird das Quickstartmenü

verlassen und wieder die

ursprüngliche Anzeigeseite

aufgerufen

Ursprüngliche Anzeigeseite

18

Page 51

SE56

„

„

Ä

p

BEISPIEL: „Hauptmenü“ Funktionsänderung. Messbereichsendwert 1 (Fs1) von

4dm³/s auf 5dm³/s. (Quickstartmenü aktiviert)

Drücken Sie die angegebene Taste, um von der