Page 1

SE 56

E

RRSS223322 SSEERRIIAALL PPOORRTT

RRSS448855 SSEERRIIAALL PPOORRTT

EETTPP aanndd MMOODDBBUUS

S PPRROOTTOOCCOOLL

AAPPPPLLIICCAATTIIOONN NNOOTTE

EDITION APRIL 2008

RS232_485_ETP_MODBUS_BU_REV02.doc

Page 2

INDEX

1. THE HARD WARE CONNECTION WITH THE CONVERTER...................................................................................4

1.1. ML XXX............................................................................................................................... .................................................4

1.2. ML XXX............................................................................................................................... .................................................4

1.3. ML XXX............................................................................................................................... .................................................4

1.4. ML XXX............................................................................................................................... .................................................4

1.5. ML XXX............................................................................................................................... .................................................4

2. AVAILABLE PROTOCOLS ............................................................................................................................................4

3. DPP (DATA PACKET PROTOCOL) .............................................................................................................................5

3.1. INTRODUCTION TO DATA PACKET PROTOCOL............................................................................................................5

3.2. BCP PROTOCOL (BASIC COMMUNICATION PROTOCOL) ............................................................................................5

3.2.1.INTRODUCTION ............................................................................................................................................................5

3.2.2.DATAWORDFORMAT ..................................................................................................................................................5

3.2.3.DATABLOCKFOR MAT ..................................................................................................................................................6

3.2.4.COMMUNICATIONSPEED.............................................................................................................................................6

3.2.5.SERIALPORTSETTINGSFORRS232ANDRS485..........................................................................................................6

3.2.6.COMMANDFORMATS ..................................................................................................................................................7

3.2.7.READINGTHETYPEOFINSTRUMENTANDTHESOFTWAREVERSION .........................................................................7

3.2.8.READINGPROCESSDATAFROMML210 .......................................................................................................................8

3.2.9.READINGPROCESSDATAFROMML211 .....................................................................................................................10

3.2.10.READINGPROCESSDATAFROMML212 ..................................................................................................................12

3.2.11.READINGPROCESSDATAFROMML3F1 ...................................................................................................................13

3.2.12.SETTINGTHESET‐POINTOFTHEML212 ..................................................................................................................15

3.2.13.READINGTHEINTERNALDATA‐LOGGERDATAOFML210/211/212 ....................................................................15

3.2.14.READINGTHEEVENTSONINTERNALDATA‐LOGGERDATAOFML210/211/212 .................................................16

3.2.15.READINGTHEMAX‐MINONINTERNALDATA‐LOGGERDATAOFML210 ................................................................17

3.2.16.LETTURAVALORIMIN‐MAXDELLOGGERINTERNODIML211 ................................................................................17

3.2.17.WRITINGTHEDATEANDTIMEORRESETTHEENABLEDTOTALIZERS .....................................................................18

3.2.18.SEND/RECEVEBATCHPROCESSDATAML210/ML3F1 ..........................................................................................18

3.3. ETP PROTOCOL (ENCAPSULATED TRANSFER PROTOCOL) ...................................................................................... 20

3.3.1.INTRODUCTION ..........................................................................................................................................................20

3.3.2.DATAWORDFORMAT ................................................................................................................................................20

3.3.3.COMMUNICATIONSPEED...........................................................................................................................................20

3.3.4.SERIALPORTSETTINGSFORRS232ANDRS485PORT ..............................................................................................21

3.3.5.GENERALINPUTSYSNTAX ..........................................................................................................................................21

3.3.6.SPECIALCHARACTERS.................................................................................................................................................22

3.3.7.ACCESSCODEFORFUNCTIONWITHPRIVILEGELEVEL ...............................................................................................22

3.3.8.DATABLOCKFOR MAT ................................................................................................................................................23

3.3.9.EXAMPLEOFETPCOMAND ........................................................................................................................................24

3.3.10.EXAMPLEOFRESPONSEFORPRECECDENTETPCOMAND.......................................................................................24

3.3.11.COMUNICATION ................................................................................................................... ....................................25

3.3.12.SUGGESTIONSFORRS485INTERFACEUSE...............................................................................................................26

3.3.13.FLOWCHARTFORSENDINGETPCOMMANDANDRECEPTIONOFTHEANSWER....................................................28

3.3.14.LISTOFSUPPORTEDCOMMANDSGROUPEDSIMILARLYTOTHEINTERNALMENUSYSTEM ..................................30

3.3.15.ETPCOMMANDLISTINALPHABETICALORDER .......................................................................................................64

4. HTP PROTOCOL (HYPER TEXT PROTOCOL) ........................................................................................................67

4.1. INTRODUCTION ............................................................................................................................... ...............................67

4.2. DESCRIPTION AND USE .................................................................................................................................................67

- 2 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 3

4.3. HTP PROTOCOL............................................................................................................................... ................................68

5. MODBUS FIELD BUS.................................................................................................................................................. 71

5.1. INTRODUCTION ............................................................................................................................... ...............................71

5.2. RS485 HARDWARE CONNECTION ............................................................................................................................... .71

5.3. DATA WORD FORMAT ....................................................................................................................................................71

5.4. COMMUNICATION SPEED .............................................................................................................................................. 71

5.5. SERIAL PORT SETTINGS ............................................................................................................................... .................71

5.6. PARAMETER SETTINGS ............................................................................................................................... ...................72

5.7. STANDARD FUNCTIONS............................................................................................................................... ..................72

5.8. CUSTOM FUNCTION .......................................................................................................................................................77

5.9. EXAMPLE OF SOURCE CODE FOR VB .NET 2005 PROJECT........................................................................................80

6. APPENDIX.................................................................................................................................................................. 100

6.1. RS232 SERIAL PORT.....................................................................................................................................................100

6.1.1.CONNECTINGTHECONVERTERVIARS232PORTTOAPRINTER ..............................................................................100

6.1.2.CONNECTINGTHECONVERTERVIARS232PORTTOAPC/MODEM ........................................................................102

6.2. RS485 SERIAL PORT.....................................................................................................................................................103

6.2.1.CONNECTINGTHECONVERTERVIARS485SERIALPORT .........................................................................................103

6.2.2.CONNECTINGTHECONVERTERTOANRS485NETWORK ........................................................................................104

6.2.3.CRITERIAFORDATAEXCHANGE ...............................................................................................................................104

6.2.4.TYPESOFDEVICEFORTHENETWORKCONNECTION ...............................................................................................104

6.2.5.EXTENDINGTHENETWORK ......................................................................................................................................104

- 3 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 4

t

t

t

1. THE HARDWARE CONNECTION WITH THE CONVERTER

1.1. ML XXX

1.2. ML XXX

1.3. ML XXX

1.4. ML XXX

1.5. ML XXX

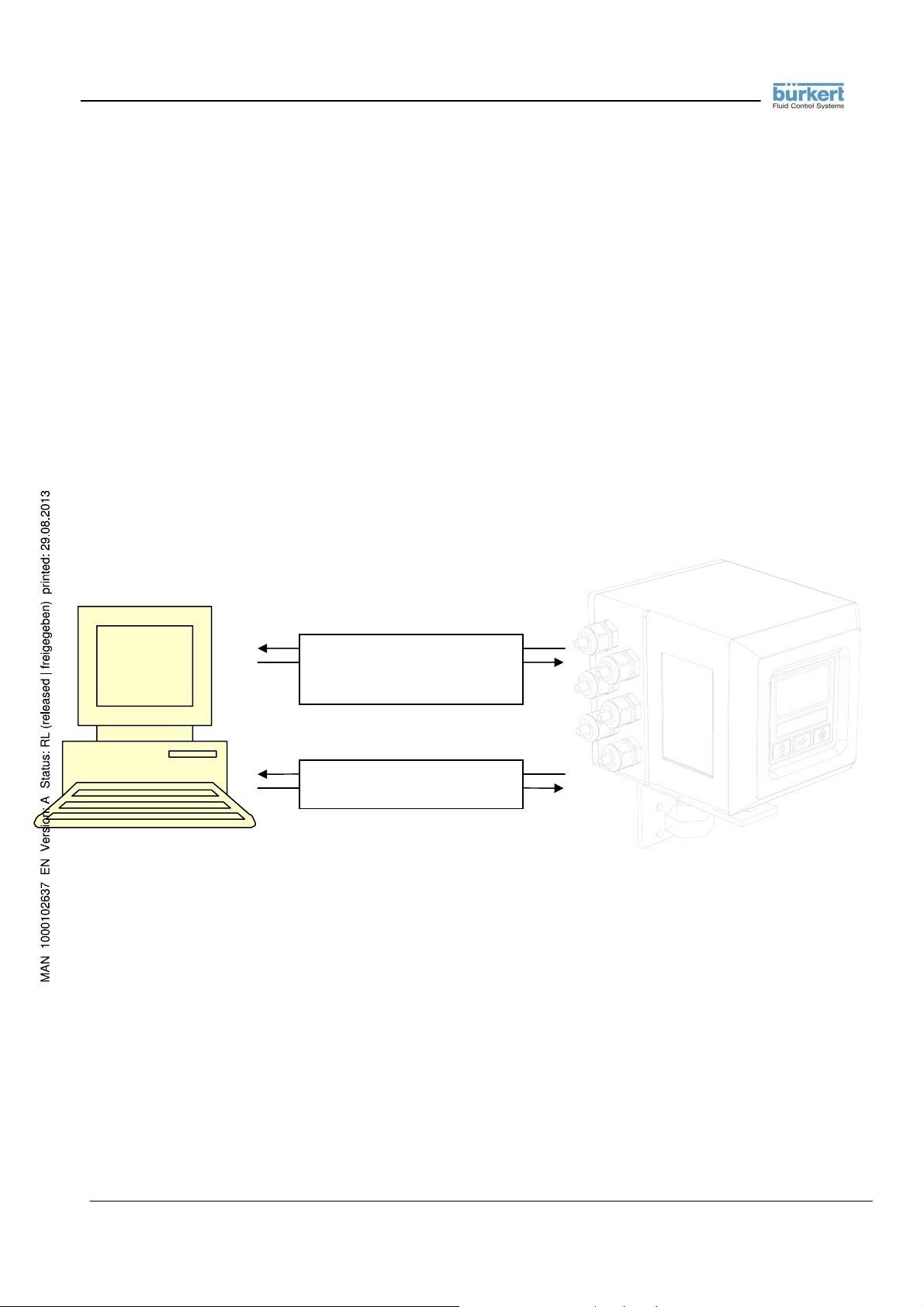

2. AVAILABLE PROTOCOLS

DPP = Data Packet Protocol

Proprietary of Millennium series : it’s a network protocol based on data packets; over this protocol it’s possible to

encapsulate other protocols like BCP (Basic Communication Protocol) or ETP (Encapsulated Transfer Protocol)

HTP = Hyper text protocol

It’s a textual protocol used in point to point connections.

ETP commands can be used over HTP

MODBUS = field bus

It’s a standard field bus that can be used over point to point or over network connections;

MODBUS can encapsulate ETP commands

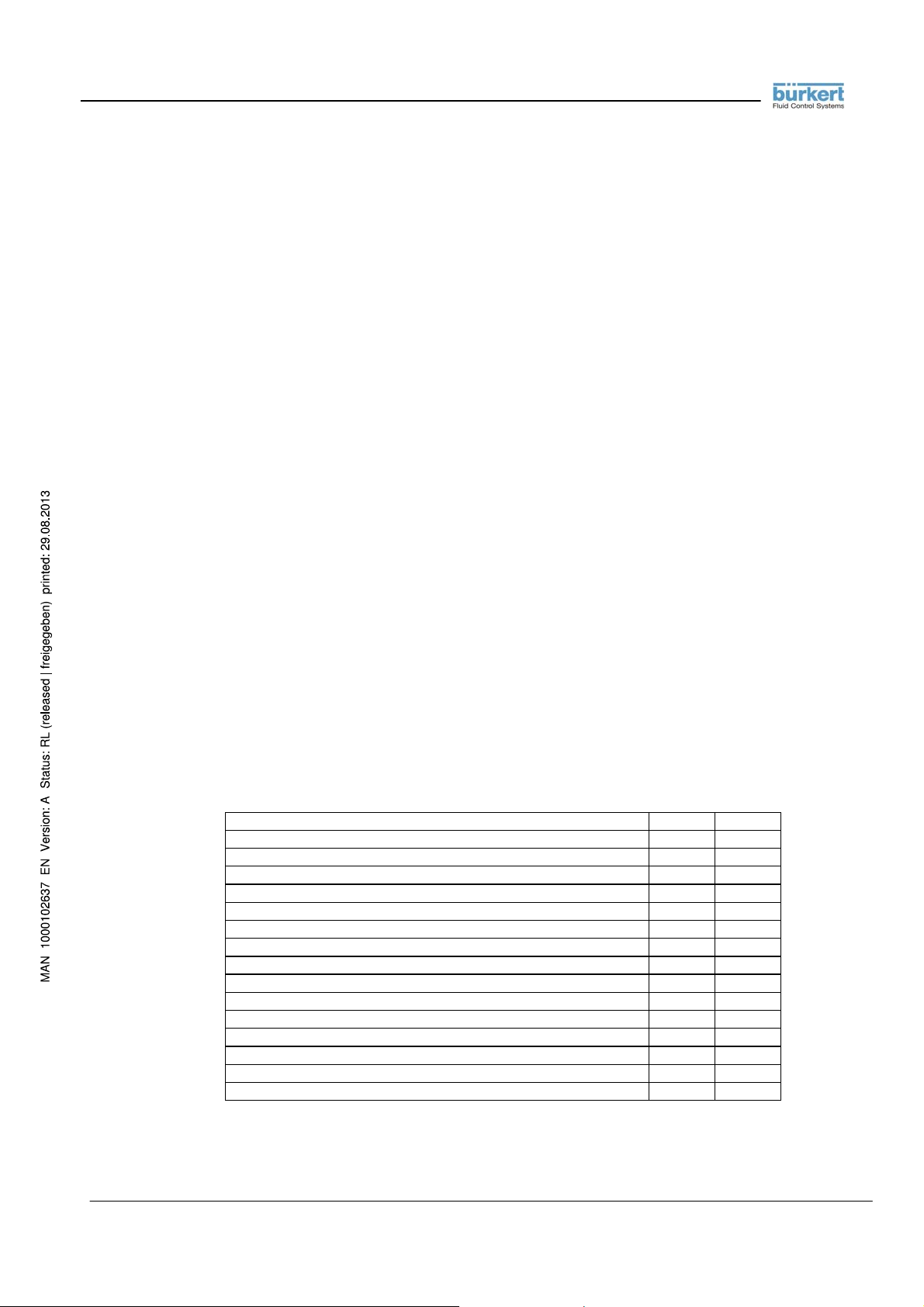

RS 232 port

RS 485 por

DPP protocol

HTP protocol

MODBUS protocol

DPP protocol

MODBUS protocol

RS 232 por

RS 485 por

- 4 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 5

3. DPP (DATA PACKET PR OTOCOL)

3.1. INTRODUCTION TO DATA PACKET PROTOCOL

With Data Packet Protocol it is possible to communicate with the flow meter through protocols with data

packets.

The protocols with data packets available for the flow meter are BCP protocol (Basic Communication

protocol) and the ETP protocol (Encapsulated Transfer protocol)

The flow meter have two serial port, the RS 232 port and the RS 485 port.

When the aux module with the RS 232 port is present in the flow meter, the menu

have the function «RS232 pr.» for the selection of the protocol type.

When the DPP setting is selected in the

possible to send command to RS 232 port of the flow meter with the protocol BCP or with the protocol ETP.

When the flow meter have the option of the MODBUS protocol, the menu

function «RS485 pr.» for the selection of the protocol type.

The possible selections are MODBUS or DPP.

When the DPP setting is selected in the

possible to send command to RS 485 port of the flow meter with the protocol BCP or with the protocol ETP.

If the flow meter don’t have the MODBUS option, the

Communication» and the default protocol type for the RS 485 port is DPP.

For the use of the commands and the structure of the BCP protocol see the relative section.

For the use of the commands and the structure of the ETP protocol see the relative section.

function «RS232 pr.» of the menu «7-Communication», it is

function «RS485 pr.» of the menu «7-Communication», it is

«7-Communication»

«7-Communication» have the

function «RS485 pr.» is not present in the menu «7-

3.2. BCP PROTOCOL (BASIC COMMUNICATION PROTOCOL)

3.2.1. INTRODUCTION

The BCP protocol is a set of formatted commands based on an index.

It is possible to read data from the flow meter as Process data or the Data Logger and it is possible to send command

to the flow meter as the start stop batch for example.

The protocol is available for the RS 232 and for the RS 485 serial port.

3.2.2. DATA WORD FORMAT

The data bytes travelling in serial form on the communication line are enclosed in

10 bits:

1 START BIT

8 DATA BITS = 1 BYTE DI DATI

1 STOP BIT

Each word contains one byte of data plus additional bits which serve to synchronise and make the communication

safer. These extra bits are added automatically in the transmission phase by the transmitter integrated circuit. In the

words

which have a fixed length of

- 5 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 6

reception phase, the reverse operation is executed by the receiver integrated circuit: the eight data bits are extracted

and the others are eliminated. These operations are executed entirely on a hardware level.

The 8 data bits must be serialised staring from bit 0 (the least significant one).

3.2.3. DATA BLOCK FORMAT

Communication takes place through data blocks or packs of variable length which do not exceed 256 bytes overall. A

data block or pack is composed thus::

• ADDRESS TO, Containing the address of the device the block is sent to;

• ADDRESS FROM, Containing the address of the device which sent the block;

• COMMAND, Containing the command code the block refers to;

• LENGTH, Containing the length of the data block in bytes

• DATA BYTES, The block of data of variable length from zero to 250

• CRC CHECKSUM BYTE, Calculated in the following way:

1. CRC initialised to zero

2. CRC rotated to the left by one bit

3. CRC = CRC + block bytes

The process is repeated starting from point 2. for all the block bytes, excluding CRC..

NOTE:

The CRC must be subjected to an operation of

The difference is shown in the following example:

byte value: 10100010

shifting : 1 <= 0100010 <= 0

rotating: 1 1 <= 0100010 <= 1

A block can contain a maximum of 90 data bytes. A block which does not contain data bytes is formed solely by

ADDRESS TO + ADDRESS FROM + COMMAND + LENGTH + CRC CHECKSUM, with LENGTH value equal to

zero.

rotation to the left

and not just a simple

shift

operation.

3.2.4. COMMUNICATION SPEED

The millennium series instruments have 4 communication speeds::

• 4800 bps

• 9600 bps

• 19200 bps

• 38400 bps

3.2.5. SERIAL PORT SETTINGS FOR RS 232 AND RS 485

Serial port settings:

• Data bits: 8

• Parity: none (no parity)

• Stop bits: 1

• Flow control: none (no control lines no xon/xoff characters used)

- 6 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 7

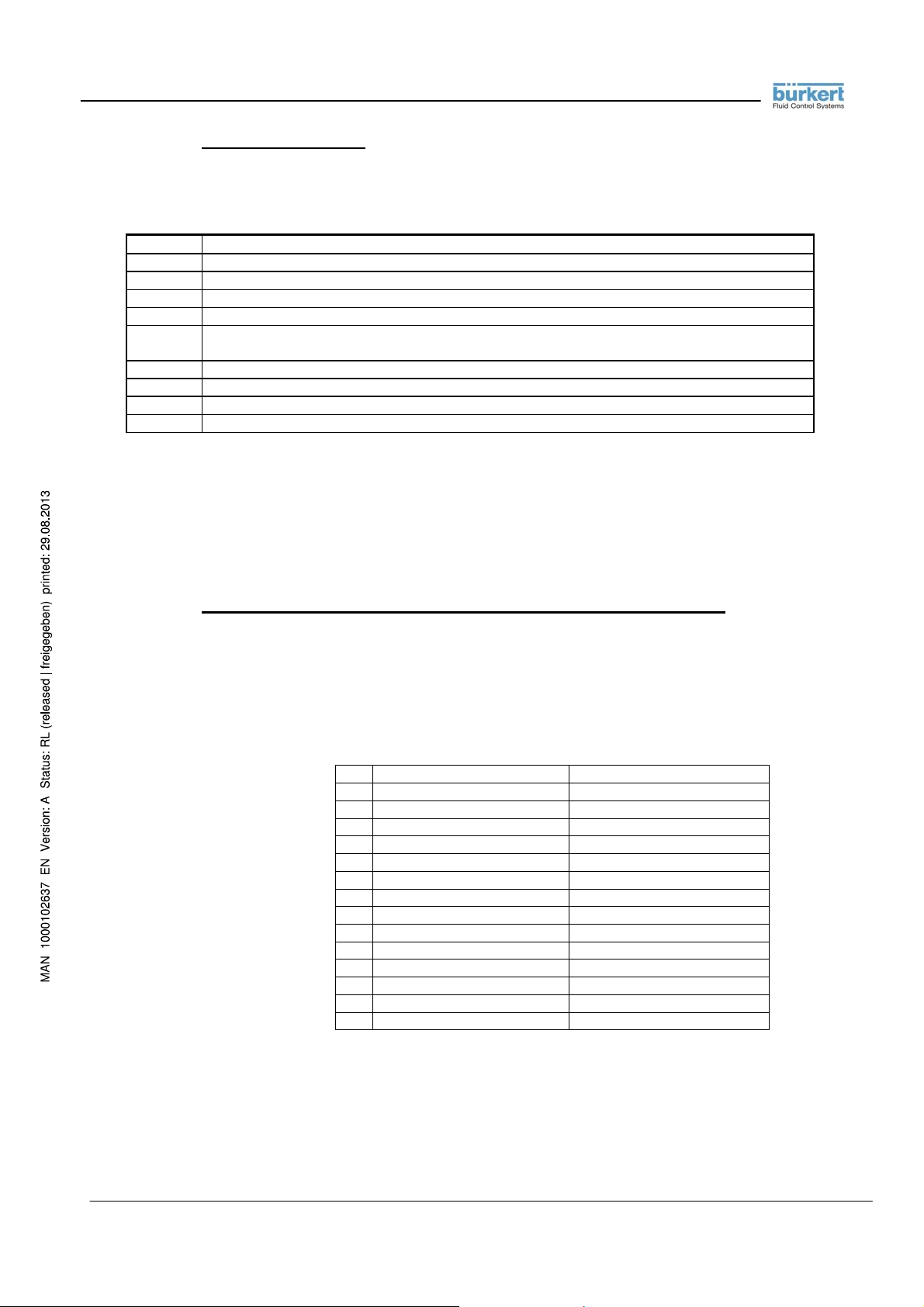

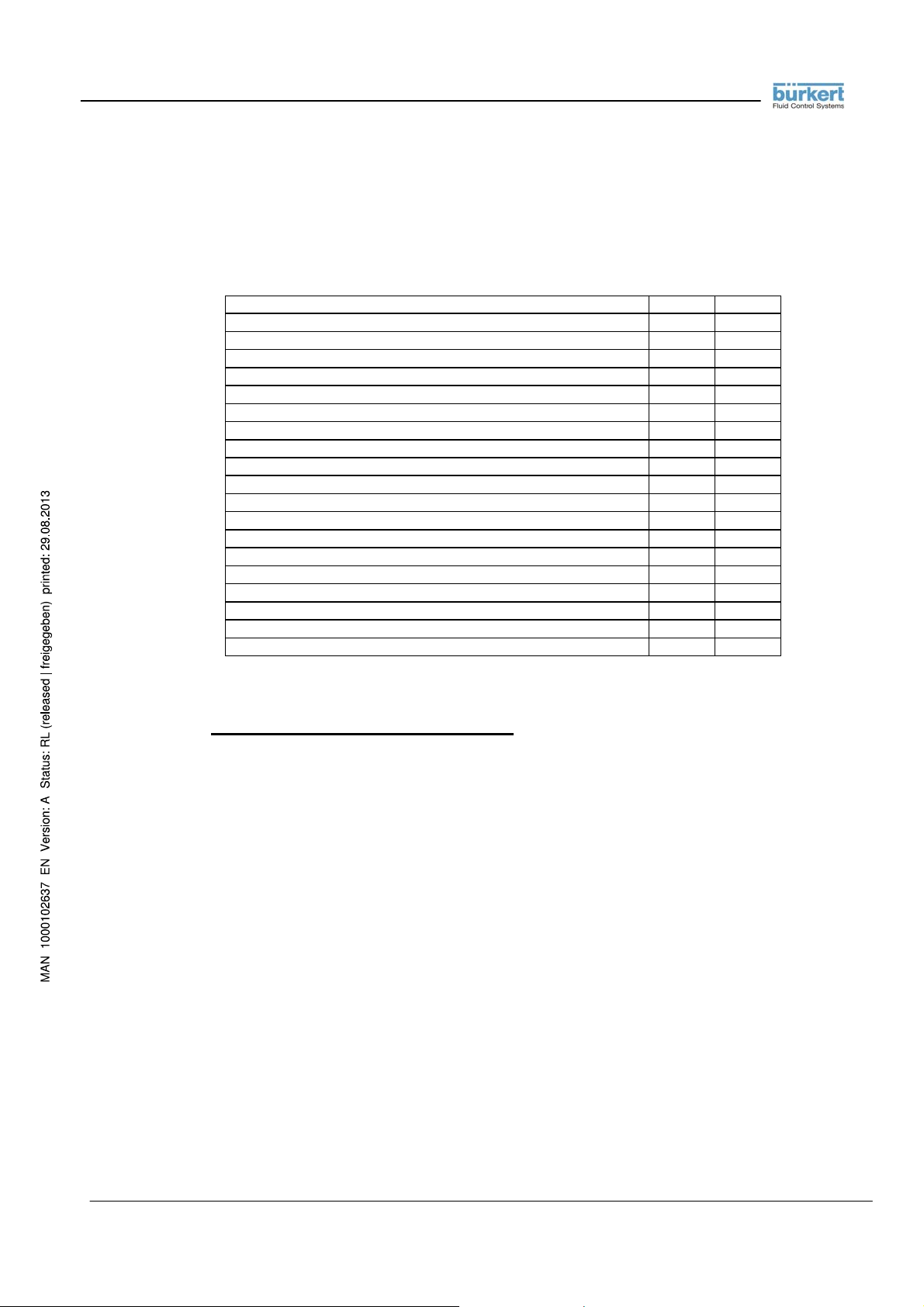

3.2.6. COMMAND FORMATS

A

command

command is the return of one block with the requested data having the same command code + 128 (80H). The

following command codes are available:

codice Action performed by the measuring device after receiving the command.

0 Send the

1 Send the

2 Send the

3 Receive

4,5,6,7,9,

10,13

8

11 Send events data(ML210/211/212)

12 Send

14

NOTE: the commands indicated with the term "RESERVED" are used during factory calibration and diagnosis, are

In this description, the command codes in hexadecimal and (decimal) format and the related data format are shown.

The numeration of the bits is from 0 (LSB) to 15 (MSB). The numeration of the bytes received is from 0 to N, where 0

is the first byte received and N is the last.

is defined as an operating code of 1 byte specifying the type of operation required. The reply to this

type of instrument

process data

data logger’s data

date and time

RESERVED

Send or receive data for batch

min/max

Set set-point

protected by a special password and must not be used by the user under any circumstance.

(ML210/211/212)

(ML212)

and

version

(for all models)

(ML210/211/212)

(ML210/211/212)

(ML210 / ML3-F1)

of the software ( all model )

reset the enabled totalizers

( all model )

3.2.7. READING THE TYPE OF INSTRUMENT AND THE SOFTWARE VERSION

Command code: 0

Command format: ADDRESS TO + ADDRESS FROM + 00H + 00H + CRC CHECKSUM

Reply data format: bytes 0..5: device name («ML 210»)

byte 6: software version (major number)

byte 7: software version (minor number)

bytes 8-9: (16 bits unsigned integer, byte 8=MSB):

hardware / software enabling flags, bit 0 = LSB, bit 15 = MSB:

bits Functions ML210/211/3f1 Functions ML212

0-2 current access level (0..7) current access level (0..7)

3 channel 1 impulses in use impulses for volume in use

4 channel 2 impulses in use duty cycle actuator type in use

5 channel 1 frequency in use frequency for flow rate in use

6 channel 2 frequency in use frequency for actuator in use

7 scale range 2 in use on/off type actuator in use

8 specific weight in use specific weight in use

9 additional output 3 present additional output 3 present

10 additional output 4 present additional output 4 present

11 output 4..20 mA 2 present output 4..20 mA 2 present

12 RS232 present input on/off n.2 present

13 batching functions active analog inputs 1 and 2 present

14 output 4..20 mA 2 present output 4..20 mA 1 present

15 RS485 present RS485 present

- 7 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 8

EXAMPLE:

want to send the command 00H to a measuring device located at address 11H (17 decimal).The device

that interrogates the network has the address FFH (255 decimal). The block to send will be composed thus

address of the measuring device to interrogate (ADDRESS TO)

|

| address of the device that interrogates the network (ADDRESS FROM)

| |

| | command for reading TYPE of INSTRUMENT (COMMAND)

| | |

| | | data block length (LENGTH)

| | | |

| | | | checksum of the entire block (CRC CHECKSUM)

| | | | |

11H FFH 00H 00H 84H

The reply from the measuring device will be the following:

address of the device that interrogated the network and which now must receive the reply (ADDRESS TO)

|

| address of the measuring device which sent the message (ADDRESS FROM)

| |

| | command for reading the TYPE of INSTRUMENT + 80H (128 dec.) (COMMAND)

| | |

| | | length of the data block (=10 bytes) (LENGTH)

| | | |

| | | | type of instrument («ML 200»)

| | | | |

| | | | | versione software (major.minor)

| | | | | |

| | | | | | hardware / software enabling flags

| | | | | | |

| | | | | | | CRC CHECKSUM)

| | | | | | | |

FFH 11H 80H 0AH 4D 4C 20 32 30 30H 01 02H C0 08H 21H

The measuring device has replied that it is an ML200, that its software version is the 1.02, that it has enabled the

RS485 serial port, that the output is 4..20mA and that it is using impulse emission on channel 1 (this last information is

taken from the hardware / software enabling flags).

3.2.8. READING PROCESS DATA FROM ML 210

The process data is contained in a memory block which the user can request whole or in part, depending on the

content of the two command control bytes. Byte 0 (offset) indicates which will be the first data byte of the block to

send, whilst byte 1 specifies the number of successive data bytes we want. In this way we can obtain exactly the data

we want or several pieces of data at the same time.

Command code: 01

Command format: ADDRESS TO

+ ADDRESS FROM

+ 01H

+ 02H

+ byte 0: offset – start of block to transmit

+ byte 1: length of block to transmit

+ CRC CHECKSUM

- 8 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 9

Reply data format when the sending of the entire block is requested (byte 0 = 0 and byte 1 = 46):

bytes 0-3: (32 bit single precision IEEE floating point, MSB first) flow rate in %

bytes 4-7: (32 bit single precision IEEE floating point, MSB first) flow rate scale range in t.u.

bytes 8-11: (32 bit single precision IEEE floating point, MSB first) flow rate in t.u.

bytes 12-16: (5 bytes ASCII) flow rate measurement unit

bytes 17-19: (3 bytes ASCII) measurement unit of the counters

byte 20: (8 bits integer) number of decimals after the point for totalizers display

byte 21: (8 bits integer) number of decimals after the point for flow rate display

bytes 22-25: (32 bit long integer, MSB first) totalizer for TOTAL volume +

bytes 26-29: (32 bit long integer, MSB first) totalizer for PARTIAL volume bytes 30-33: (32 bit long integer, MSB first) totalizer for TOTAL volume - ( or ML210 dosage quantity)

bytes 34-37: (32 bit long integer, MSB first) totalizer for PARTIAL volume - (or ML210 dosed quantity)

bytes 38-41: (32 bit long integer, MSB first) clock expressed in minutes starting from 01-01-1992

bytes 42-43: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the flow rate is lower than the cut-off threshold

bit10=1 if the flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a flow rate simulation is in progress

byte 44: (8 bits integer) measurement samples per second (Hz)

byte 45: (8 bits integer) measurement dynamic variation as a %

To request the transmission of a single parameter, assign the values of byte 0 and byte 1 in the request as follows,

bearing in mind that the data in the memory block has fixed positions:

PARAMETER TO READ Byte 0 Byte 1

Flow rate in % 0 4

Scale range of the flow rate in technical units 4 4

Flow rate in technical units 8 4

Flow rate measurement unit 12 5

Totalizers measurement unit 17 3

Decimal figures for the totalizers 20 1

Decimal figures for flow rate display 21 1

Totalizer for TOTAL volume + 22 4

Totalizer for PARTIAL volume + 26 4

Totalizer for TOTAL volume - (or dosage quantity) 30 4

Totalizer for PARTIAL volume -(or dosed quantity) 34 4

Date and time in minutes 38 4

Process flags 42 2

Measurement samples per second in Hz 44 1

Measurement dynamic variation in % 45 1

NOTES: The values in the “32 bits single precision IEEE floating point” format are floating point numbers which can

be represented during writing by any decimal digits. To keep the same numerical format visible on the

instrument display however, it is necessary to calculate the decimal figures with a rather complex

algorithm which takes account of instrument precision, flow rate measurement unit, etc. For this purpose

- 9 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 10

and to avoid useless calculations, the number of decimals to use to represent the flow rate values is

supplied separately (byte position 21).

The counters are expressed with a 32 bit integer. The «counter decimal figures» parameter, indicates the point position

starting from the right: 0 = no decimal, 1=1 decimal figure, and so on.

The date and time are expressed with a 32 bit integer containing the number of minutes elapsed since 01-01-1992. To

calculate the date starting from this number, see the programming examples at the end of this manual.

3.2.9. READING PROCESS DATA FROM ML 211

This command is similar to the preceding one and differs from it only for the quantity of the data given.

Command code: 01

Command format: ADDRESS TO

+ ADDRESS FROM

+ 01H

+ 02H

+ byte 0: offset – start of block to transmit

+ byte 1: length of block to transmit

+ CRC CHECKSUM

Reply data format when the sending of the entire block is requested (byte 0 = 0 and byte 1 = 78):

bytes 0-3: (32 bit single precision IEEE floating point, MSB first) flow rate in %

bytes 4-7: (32 bit single precision IEEE floating point, MSB first) flow rate scale range in t.u.

bytes 8-11: (32 bit single precision IEEE floating point, MSB first) flow rate in t.u.

bytes 12-16: (5 bytes ASCII) flow rate measurement unit

bytes 17-19: (3 bytes ASCII) measurement unit of the counters

byte 20: (8 bits integer) number of decimals after the point for volume totalizers display

byte 21: (8 bits integer) number of decimals after the point for flow rate display

bytes 22-25: (32 bits long integer, MSB first) totalizer for volume +

bytes 26-29: (32 bits long integer, MSB first) totalizer for volume bytes 30-33: (32 bits long integer, MSB first) totalizer for energy +

bytes 34-37: (32 bits long integer, MSB first) totalizer for energy bytes 38-41: (32 bit long integer, MSB first) clock expressed in minutes starting from 01-01-1992

bytes 42-44: 3 x (8 bits unsigned char) 3 bytes of process flags:

byte 0:

bit 0 =0 (not used)

bit 1 =1 if the flow rate is lower than the cut-off threshold

bit 2 =1 if the flow rate is negative

bit 3 =1 if a new measurement value calculated for the display is available

bit 4 =1 if the counter block signal is active

bit 5 =0 (non used)

bit 6 =1 if a calibration cycle is in progress

bit 7 =1 if a flow rate simulation is in progress

byte 1:

bit 0 =1 if the temperature sensors are disconnected or broken

bit 1 =1 if the maximum alarm for the flow rate is active

bit 2 =1 if the minimum alarm for the flow rate is active

bit 3 =1 if a measure exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

- 10 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 11

byte 2:

bit 0 =1 if the maximum alarm for the thermal power is active

bit 1 =1 if the minimum alarm for the thermal power is active

bit 2 =1 if the maximum alarm for the delta T is active

bit 3 =1 if the minimum alarm for the delta T is active

bit 4 =1 if the maximum alarm for the temperature T1 is active

bit 5 =1 if the minimum alarm for the temperature T1 is active

bit 6 =1 if the maximum alarm for the temperature T2 is active

bit 7 =1 if the minimum alarm for the temperature T2 is active

byte 45: (8 bits integer) number of measure samples per second (hertz)

bytes 46-49: (32 bits single precision IEEE floating point, MSB first) thermal power in %

bytes 50-53: (32 bits single precision IEEE floating point, MSB first) full scale thermal power in t.u.

bytes 54-57: (32 bits single precision IEEE floating point, MSB first) thermal power in t.u.

bytes 58-62: (5 bytes ASCII) measure unit for the thermal power

bytes 63-66: (4 bytes ASCII) measure unit for the thermal energy

byte 67: (8 bits integer) number of decimals after the point for energy totalizers display

byte 68: (8 bits integer) number of decimals after the point for thermal power display

byte 69: (8 bits integer) measure unit for the temperature (C or F degrees)

bytes 70-73: (32 bits single precision IEEE floating point, MSB first) delta T value in t.u.

bytes 74-77: (32 bits single precision IEEE floating point, MSB first) T1 temperature in t.u.

bytes 78-81: (32 bits single precision IEEE floating point, MSB first) T2 temperature in t.u.

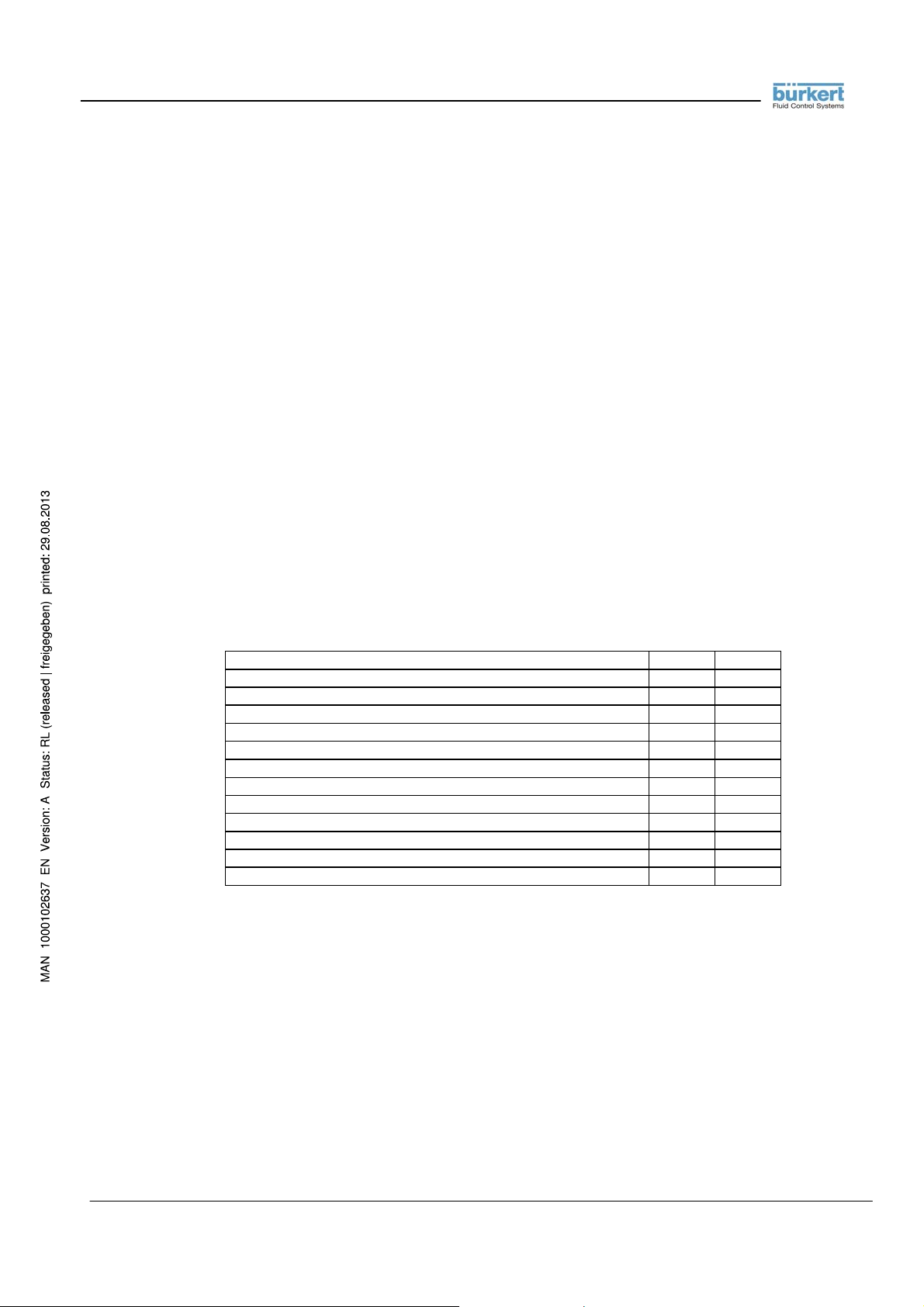

To request the transmission of a single parameter, assign the values of byte 0 and byte 1 in the request as follows,

bearing in mind that the data in the memory block has fixed positions:

PARAMETRO DA LEGGERE Byte 0 Byte 1

Flow rate in % 0 4

Full scale flow rate 4 4

Flow rate in technical units 8 4

Measure unit for the flow rate 12 5

Measure unit for the volume totalizers 17 3

Number of decimal digit after the point for volume totalizers 20 1

Number of decimal digit after the point for the flow rate 21 1

Totalizer for volume + 22 4

Totalizer for volume - 26 4

Totalizer for thermal energy + 30 4

Totalizer for thermal energy - 34 4

Time and date expressed in minutes 38 4

Process flags 42 3

Number of samples per second in Hz 45 1

Thermal power in % 46 4

Full scale thermal power in t.u. 50 4

Thermal power in t.u. 54 4

Measure unit for the thermal power 58 5

Measure unit for the thermal energy 60 3

Number of decimal digit after the point for energy totalizers 63 1

Number of decimal digit after the point for the th. power 64 1

T in technical units 65 1

Delta T in t.u. 66 4

T1 value in t.u. 70 4

T2 value t.u. 74 4

NOTE: For the numeric representations and the number of decimal digits, see the preceding point.

- 11 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 12

3.2.10. READING PROCESS DATA FROM ML212

This command is similar to the preceding one and differs from it only for the quantity of the data given.

Command code: 01

Command format: ADDRESS TO

+ ADDRESS FROM

+ 01H

+ 02H

+ byte 0: offset – start of block to transmit

+ byte 1: length of block to transmit

+ CRC CHECKSUM

Reply data format when the sending of the entire block is requested (byte 0 = 0 and byte 1 = 59):

bytes 0-3: (32 bit single precision IEEE floating point, MSB first) flow rate in %

bytes 4-7: (32 bit single precision IEEE floating point, MSB first) flow rate scale range in t.u.

bytes 8-11: (32 bit single precision IEEE floating point, MSB first) flow rate in t.u.

bytes 12-16: (5 bytes ASCII) flow rate measurement unit

bytes 17-19: (3 bytes ASCII) measurement unit of the counters

byte 20: (8 bits integer) number of decimals after the point for volume totalizers display

byte 21: (8 bits integer) number of decimals after the point for flow rate display

bytes 22-25: (32 bits long integer, MSB first) totalizer for volume +

bytes 26-29: (32 bits long integer, MSB first) totalizer for volume -

bytes 30-33: (32 bits long integer, MSB first) totalizer for actuator closing pulses

bytes 34-37: (32 bits long integer, MSB first) totalizer for actuator opening pulses

bytes 38-41: (32 bit long integer, MSB first) clock expressed in minutes starting from 01-01-1992

bytes 42-43: (16 bit unsigned integer, MSB first) process flags:

bit 0 =1 if the deviation alarm is active

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the measure sample rate is too high for the sensor

bit 9 =1 if the flow rate is lower than the cut-off threshold

bit10=1 if the flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if the actuator positioning alarm is active

bit14=1 if a calibration cycle is in progress

bit15=1 if a flow rate simulation is in progress

byte 44: (8 bits integer) measurement samples per second (Hz)

byte 45: (8 bits integer) measurement dynamic variation as a %

bytes 46-49: (32 bits single precision IEEE floating point, MSB first) set-point value in %

bytes 50-53: (32 bits single precision IEEE floating point, MSB first) regulator output value in %

bytes 54-57: (32 bits single precision IEEE floating point, MSB first) deviation value in %

byte 58: (1 byte ASCII) regulator status flags:

bit 0 =1 if the regulator is in “manual” mode

bit 1 =1 if the regulator output is inverted

bit 2 =1 if the regulator output is in “safety” state

bit 3 =1 if the deviation alarm is active

bit 4 =1 if the actuator alarm is active

- 12 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 13

bit 5 =1 if the measure at the AIN1 input is out of range

bit 6 =1 if the measure at the AIN1 input is out of range

To request the transmission of a single parameter, assign the values of byte 0 and byte 1 in the request as follows,

bearing in mind that the data in the memory block has fixed positions:

PARAMETER TO READ Byte 0 Byte 1

Flow rate in % 0 4

Full scale flow rate 4 4

Flow rate in technical units 8 4

Measure unit for the flow rate 12 5

Measure unit for the volume totalizers 17 3

Number of decimal digit after the point for volume totalizers 20 1

Number of decimal digit after the point for the flow rate 21 1

Totalizer for volume + 22 4

Totalizer for volume - 26 4

Totalizer for actuator closing impulses 30 4

Totalizer for actuator opening impulses 34 4

Date and time in minutes 38 4

Process flags 42 2

Measurement samples per second in Hz 44 1

Measurement dynamic variation in % 45 1

Set-point value in % 46 4

Regulator output value in % 50 4

Deviation value in % 54 4

Regulator status flags 58 1

NOTE: For the numeric representations and the number of decimal digits, see the preceding point.

3.2.11. READING PROCESS D ATA FROM ML 3F1

The process data is contained in a memory block which the user can request whole or in part, depending on the

content of the two command control bytes. Byte 0 (offset) indicates which will be the first data byte of the block to

send, whilst byte 1 specifies the number of successive data bytes we want. In this way we can obtain exactly the data

we want or several pieces of data at the same time..

Command code: 01

Command format: ADDRESS TO

+ ADDRESS FROM

+ 01H

+ 02H

+ byte 0: offset – start of block to transmit

+ byte 1: length of block to transmit

+ CRC CHECKSUM

Reply data format when the sending of the entire block is requested (byte 0 = 0 and byte 1 = 46):

bytes 0-3: (32 bit single precision IEEE floating point, MSB first) flow rate in %

bytes 4-7: (32 bit single precision IEEE floating point, MSB first) flow rate scale range in t.u.

bytes 8-11: (32 bit single precision IEEE floating point, MSB first) flow rate in t.u.

bytes 12-16: (5 bytes ASCII) flow rate measurement unit

bytes 17-19: (3 bytes ASCII) measurement unit of the counters

byte 20: (8 bits integer) number of decimals after the point for totalizers display

byte 21: (8 bits integer) number of decimals after the point for flow rate display

bytes 22-25: (32 bit long integer, MSB first) totalizer 1

bytes 26-29: (32 bit long integer, MSB first) totalizer 2

bytes 30-33: (32 bit long integer, MSB first) everytime to 0

- 13 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 14

bytes 34-37: (32 bit long integer, MSB first) everytime to 0

bytes 38-41: (32 bit long integer, MSB first) everytime to 0

bytes 42-43: (16 bit unsigned integer, MSB first) process flags

bit 0 =1 if the excitation is too fast for the sensor connected

bit 1 =1 if the maximum alarm is active

bit 2 =1 if the minimum alarm is active

bit 3 =1 if the flow rate exceeds the scale range value (overflow)

bit 4 =1 if one or more output impulses are saturated (too many impulses to emit)

bit 5 =1 if the measurement signal is highly disturbed or if the sensor is disconnected

bit 6 =1 if the measurement tube is empty

bit 7 =1 if the circuit powering the coils is not working or the sensor is disconnected

bit 8 =1 if the second measurement scale is active

bit 9 =1 if the flow rate is lower than the cut-off threshold

bit10=1 if the flow rate is negative

bit11=1 if a new measurement value calculated for the display is available

bit12=1 if the counter block signal is active

bit13=1 if dosing is in progress

bit14=1 if a calibration cycle is in progress

bit15=1 if a flow rate simulation is in progress

byte 44: (8 bits integer) measurement samples per second (Hz)

byte 45: (8 bits integer) measurement dynamic variation as a %

To request the transmission of a single parameter, assign the values of byte 0 and byte 1 in the request as follows,

bearing in mind that the data in the memory block has fixed positions:

PARAMETRO DA LEGGERE Byte 0 Byte 1

Flow rate in % 0 4

Scale range of the flow rate in technical units 4 4

Flow rate in technical units 8 4

Flow rate measurement unit 12 5

Totalizers measurement unit 17 3

Decimal figures for the totalizers 20 1

Decimal figures for flow rate display 21 1

Totalizer for T1 22 4

Totalizer for T2 26 4

Process flags 42 2

Measurement samples per second in Hz 44 1

Measurement dynamic variation in % 45 1

NOTES: The values in the “32 bits single precision IEEE floating point” format are floating point numbers which can

be represented during writing by any decimal digits. To keep the same numerical format visible on the

instrument display however, it is necessary to calculate the decimal figures with a rather complex

algorithm which takes account of instrument precision, flow rate measurement unit, etc. For this purpose

and to avoid useless calculations, the number of decimals to use to represent the flow rate values is

supplied separately (byte position 21).

The counters are expressed with a 32 bit integer. The «counter decimal figures» parameter, indicates the

point position starting from the right: 0 = no decimal, 1=1 decimal figure, and so on.

The date and time are expressed with a 32 bit integer containing the number of minutes elapsed since 0101-1992. To calculate the date starting from this number, see the programming examples at the end of

this manual.

- 14 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 15

3.2.12. SETTING THE SET-POINT OF THE ML212

With this command it is possible to send the set-point value in % format to the ML202. If the value is positive, this is

intended as REMOTE set-point value and must be refreshed continuously. The maximum time between two refreshes it

is regulated by the same timer used to signal the deviation alarm condition and thus it is freely changeable. If the

value sent is negative, it is considered as LOCAL set-point value and in this case it is not necessary to refresh it

continuously. In any cases the regulator receives the absolute value of the number sent.

Command code: 14

Command format: ADDRESS TO

+ ADDRESS FROM

+ 0EH

+ 04H

+ 32 bits IEEE floating point containing the set-point value in %

+ CRC CHECKSUM

The same number is returned as answer by the ML212

3.2.13. READING THE INTERNAL DATA-LOGGER DATA OF ML210 / 211 / 212

The data logger can be read one record at a time with this command. If we assign the value AAH to the byte

specifying the address (byte 0), the data logger is cancelled. If we request the address of a record not present in the

memory, the returned data has no sense. For this purpose we recommend starting from the request for record 0 and

to check the number of records present in the memory which is returned by the measuring device.

Command code : 02

Command format: ADDRESS TO

+ ADDRESS FROM

+ 02H

+ 01H

+ byte 0: index of the data logger data to read, AAH to cancel the entire content

+ CRC CHECKSUM

Reply data format in the case where there are registrations present:

byte 0: (8 bits integer) number of record requested

byte 1: (8 bits integer) total number of records present in the memory

bytes 2-5: (32 bits long integer, MSB first) data saving time and date expressed in minutes starting from 01-01-

1992

bytes 6-9: (32 bits long integer, MSB first) data counted +

bytes 10-13: (32 bits long integer, MSB first) data counted bytes 14-17: (32 bits single precision IEEE floating point, MSB first) portata in u.t.

bytes 18-20: (3 bytes ASCII) (3 bytes ASCII) counter measurement unit

byte 21: (8 bits integer) number of decimal figures after the point for counter display

bytes 22-26: (5 bytes ASCII) flow rate t.u.

byte 27: (8 bits integer) number of decimal figures after the point for flow rate

Reply data format in the case where registrations are NOT present or the data logger is disabled

byte 0: (8 bits integer) requested record number

byte 1: (8 bits integer) total number of records present in the memory

Reply data format in the case where the AAH cancellation code is sent:

byte 0: (8 bits integer) AAH code.

NOTE: The time and date of sample collection is expressed in minutes starting from 01/01/1992. For conversion, see

the programming examples at the end of this manual.

- 15 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 16

3.2.14. READING THE EVENTS ON INTERNAL DATA-LOGGER DATA OF ML210 / 211 / 212

The data logger can be read one record at a time with this command. If we assign the value AAH to the byte

specifying the address (byte 0), the data logger is cancelled. If we request the address of a record not present in the

memory, the returned data has no sense. For this purpose we recommend starting from the request for record 0 and

to check the number of records present in the memory which is returned by the measuring device..

Command code : 11

Command format: ADDRESS TO

+ ADDRESS FROM

+ 0BH

+ 01H

+ byte 0: index of the data logger data to read, AAH to cancel the entire content

+ CRC CHECKSUM

Reply data format in the case where there are registrations present:

byte 0: (8 bits integer) number of record requested

byte 1: (8 bits integer) total number of records present in the memory

bytes 2-5: (32 bits long integer, MSB first) data saving time and date expressed in minutes starting

from 01-01-1992

bytes 6-9: (32 bits long integer, MSB first) flags events

bit 00: error sensor RTD / batch alarm

bit 01: alarm max flow

bit 02: alarm min flow

bit 03: alarm overflow

bit 04: alarm overflow pulse

bit 05: input error

bit 06: pipe empty

bit 07: coils interrupt

bit 08: alarm max t. power

bit 09: alarm min t. power

bit 10: alarm max delta T

bit 11: alarm min delta T

bit 12: alarm max T1

bit 13: alarm min T1

bit 14: alarm max T2

bit 15: alarm min T2

bit 16: current loop open

bit 17: power supply error

Code 000300FFH or 0003FFFFH = means converter switch on

Reply data format in the case where registrations are NOT present or the data logger is disabled

byte 0: (8 bits integer) requested record number

byte 1: (8 bits integer) total number of records present in the memory

Reply data format in the case where the AAH cancellation code is sent:

byte 0: (8 bits integer) AAH code.

NOTE: The time and date of sample collection is expressed in minutes starting from 01/01/1992. For conversion, see

the programming examples at the end of this manual.

- 16 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 17

3.2.15. READING THE MAX-MIN ON INTERNAL DATA-LOGGER DATA OF ML210

The data logger can be read one record at a time with this command. If we assign the value AAH to the byte

specifying the address (byte 0), the data logger is cancelled. If we request the address of a record not present in the

memory, the returned data has no sense. For this purpose we recommend starting from the request for record 0 and

to check the number of records present in the memory which is returned by the measuring device..

Command code: 12

Command format: ADDRESS TO

+ ADDRESS FROM

+ 0CH

+ 01H

+ byte 0: index of the data logger data to read, AAH to cancel the entire content

+ CRC CHECKSUM

Reply data format in the case where there are registrations present:

bytes 0-3:(32 bits IEEE floating point, MSB first) MAX FLOW RATE IN T.U.

bytes 4-7:(32 bits IEEE floating point, MSB first) MIN FLOW RATE IN T.U.

3.2.16. LETTURA VALORI MIN-MAX DEL LOGGER INTERNO DI ML211

The data logger can be read one record at a time with this command. If we assign the value AAH to the byte

specifying the address (byte 0), the data logger is cancelled. If we request the address of a record not present in the

memory, the returned data has no sense. For this purpose we recommend starting from the request for record 0 and

to check the number of records present in the memory which is returned by the measuring device..

Command code: 12

Command format: ADDRESS TO

+ ADDRESS FROM

+ 0CH

+ 01H

+ byte 0: index of the data logger data to read, AAH to cancel the entire content

+ CRC CHECKSUM

Reply data format in the case where there are registrations present :

bytes 0-3:(32 bits IEEE floating point, MSB first) MAX FLOW RATE IN T.U.

bytes 4-7:(32 bits IEEE floating point, MSB first) MIN FLOW RATE IN T.U.

bytes 8-11:(32 bits IEEE floating point, MSB first) MAX T. POWER IN T.U.

bytes 12-15:(32 bits IEEE floating point, MSB first) MIN T. POWER IN T.U.

bytes 16-19:(32 bits IEEE floating point, MSB first) deltaT MAX IN T.U.

bytes 20-23:(32 bits IEEE floating point, MSB first) deltaT MIN IN T.U.

bytes 24-27:(32 bits IEEE floating point, MSB first) T1 MAX IN T.U.

bytes 28-31:(32 bits IEEE floating point, MSB first) T1 MIN IN T.U.

bytes 32-35:(32 bits IEEE floating point, MSB first) T1 MAX IN T.U.

bytes 36-39:(32 bits IEEE floating point, MSB first) T1 MIN IN T.U.

- 17 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 18

3.2.17. WRITING THE DATE AND TIME OR RESET THE ENABLED TOTALIZERS

Codice comando: 03

Formato comando: ADDRESS TO

+ ADDRESS FROM

+ 03H

+ 04H

+ 32 bits long integer containing the date and time expressed in minutes starting from 01-01-

1992, or the value FFFFFFFFH to reset the totalizers

the most significant byte must be sent first.

+ CRC CHECKSUM

Reply data format: the same block is returned containing the current clock value in minutes. If the value sent is

outside the limits, (date beyond 31-12-2091), the clock restarts from 01-01-1992. In case

of totalizers reset, the same value FFFFFFFFH is returned.

3.2.18. SEND / RECEVE BATCH PROCESS DATA ML210 /ML 3F1

The batch data can be read or written with the command described below. Th command contains an OPCODE byte

specifying the operation type to be done on the selected batch data. With these commands one of the 16 batch

memories can be written, read or it can be set as active batch process. Once set a selected batch memory, it will be

possible start, stop or reset the batch process. To set a batch memory as active batch process, a write or read

command can be used indifferently, but the bit 6 of the OPCODE must be set to 1

– Command for reading a batch data memory:

Command code: 08

Command format: ADDRESS TO

+ ADDRESS FROM

+ 08H

+ 01H (1 DECIMALE)

+ OPCODE byte, operation code:

bits 0..4 = number of the batch memory to be read (0..15)

bit 5 = must be set to zero

bit 6 = 1 if this batch memory must be set as active batch process, 0 if this batch

memory is to be read only.

bit 7 = must be set to zero

+ CRC CHECKSUM

Format of the returned data: 16 bytes containing the batch data for the selected memory:

bytes 0-7: (8 bytes ASCII) memory batch name (allowed characters: 0..9, a..z, A..Z, space (32 DEC, 20 HEX))

bytes 8-9: (2 bytes 16 bit unsigned integer, MSB first) number of batch processes done for this batch memory.

bytes 10-11: (2 bytes 16 bit unsigned integer, MSB first) value of the safety batch timer expressed in tenths of

seconds.

bytes 12-15: (4 bytes 32 bits unsigned long integer, MSB first) batch quantity value expressed in the same units and

with the same decimal digits of the volume counters.

- 18 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 19

– Comando per scrivere i dati su una memoria di dosaggio:

Command code: 08

Command format: ADDRESS TO

+ ADDRESS FROM

+ 08H

+ 11H (17 DECIMAL)

+ OPCODE byte, operation code:

bits 0..4 = number of the batch memory to be written (0..15)

bit 5 = must be set to one

bit 6 = 1 if this batch memory must be set as active batch process, 0 if this batch

memory is to be written only.

bit 7 = must be set to zero

+ 16 bytes of data to be written on the batch memory:

bytes 0-7: (8 bytes ASCII) batch memory name (allowed characters: 0..9, a..z, A..Z, space

(32 DEC, 20 HEX))

bytes 8-9: (2 bytes 16 bit unsigned integer, MSB first) number of batch processes done for

this batch memory.

bytes 10-11: (2 bytes 16 bit unsigned integer, MSB first) value of the batch safety timer

expressed in tenths of seconds.

bytes 12-15: (4 bytes 32 bits unsigned long integer, MSB first) batch quantity value

expressed in the same units and with the same decimal digits of the volume

counters.

+ CRC CHECKSUM

Format of the returned data: 16 bytes containing the same batch data for the selected memory sent (if there were any

characters or values not allowed, they are corrected to the right values). The data format are the same of the

precedent function.

c) - Command for reading the current batch process state:

Command code: 08

Command format: ADDRESS TO

+ ADDRESS FROM

+ 08H

+ 01H (1 DECIMAL)

+ OPCODE byte = 80H (128 DECIMAL)

+ CRC CHECKSUM

Format of the returned data: 1 byte containing the batch process state:

0 = batch process is correctly terminated (pre-set quantity reached).

1 = batch process is running (the valve is opened and the counters are running).

2 = batch process is suspended (the valve is closed before the pre-set quantity is reached).

d) - Command for starting or suspending the current batch process:

Command code: 08

Command format: ADDRESS TO

+ ADDRESS FROM

+ 08H

+ 01H (1 DECIMAL)

+ OPCODE byte = 81H (129 DECIMAL)

+ CRC CHECKSUM

Format of the returned data: 1 byte containing the batch process state as described above.

- 19 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 20

e) - Command for resetting the current batch process:

Command code: 08

Command format: ADDRESS TO

+ ADDRESS FROM

+ 08H

+ 01H (1 DECIMAL)

+ OPCODE byte = 82H (130 DECIMAL)

+ CRC CHECKSUM

Format of the returned data: 1 byte containing the batch process state as described above. This command resets the

dosing quantity and the safety timer counters.

3.3. ETP PROTOCOL (ENCAPSULATED TRANSFER PROTOCOL)

3.3.1. INTRODUCTION

The ETP is a protocol owner of the converter that has the function of the read and set the parameters of the

converter through formatted strings of characters.

3.3.2. DATA WORD FORMAT

The data bytes travelling in serial form on the communication line are enclosed in

10 bits:

1 START BIT

8 DATA BITS = 1 BYTE DI DATI

1 STOP BIT

Each word contains one byte of data plus additional bits which serve to synchronise and make the communication

safer. These extra bits are added automatically in the transmission phase by the transmitter integrated circuit. In the

reception phase, the reverse operation is executed by the receiver integrated circuit: the eight data bits are extracted

and the others are eliminated. These operations are executed entirely on a hardware level.

The 8 data bits must be serialised staring from bit 0 (the least significant one).

words

which have a fixed length of

3.3.3. COMMUNICATION SPEED

The millennium series instruments have 4 communication speeds::

• 4800 bps

• 9600 bps

• 19200 bps

• 38400 bps

- 20 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 21

3.3.4. SERIAL PORT SETTINGS FOR RS 232 AND RS 485 PORT

Serial port settings:

• Data bits: 8

• Parity: none (no parity)

• Stop bits: 1

• Flow control: none (no control lines no xon/xoff characters used)

3.3.5. GENERAL INPUT SYSNTAX

The information are entered as text line strings, with one or more command-sequences terminated by the <CR>

character. The command-sequences are executed in the same order as they are found in the string. The execution of

the commands contained in the input string does not start until the <CR> character is received. The optional <LF>

character that may follows the <CR> is not considered but it is accepted because usually the Hyper-Terminal or

similar application sends also this extra character when the <CR> is sent.

As a rule, an input string is composed of one or more command-sequences, terminated by the <CR> character and

an optional <LF> character.

The command-sequence is composed by the following elements, exactly in this order:

A five-letter mnemonic command, always present

An operator, always present

An optional value, present only when requested by the operator type

An optional comment-separator, may be present if it is also present the value

A comment, present only if it is also present the comment-separator

An optional command-separator, present only if another command-sequence follows it

With the exception of the comment element, no other extra characters or spaces are allowed in the commandsequence.

Command: The commands are always represented by a five-letters mnemonic code and are case insensitive, so for

example the command MODSV can be written “MODSV”, “Modsv”, “modsv”, “mOdSv” and in any combination of

upper / lower case letters.

Operator: The operators permit to choose one of the three possible functions associated to the command at which

they are attached and they are:

READ, indicated by the ? symbol. It is used to read values.

SET, indicated by the = symbol. It is used to set values.

HELP, indicated by the =? sequence of symbols. It is used to display a set of options or a range of permissible

values related to the command.

Value: The values can be numbers, strings or special formatted fields like the date / time or the IP addresses,

depending on what it is expected by the command.

Numeric values are always checked for validity range and strings are checked for length.

- 21 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 22

IP addresses and date / time fields are checked only for the correct syntax but not for the values, so please be

careful, because in case of misspelled characters or wrong numeric values the result may be different from what it is

expected.

In case of floating-point numbers, the decimal point symbol to be used is the dot (.), not the comma (,).

Comment-separator: This is an optional element and it is indicated by the “:” symbol.

Comment: This element may be present only when the value to input belongs to a list of options, composed by

numbers and descriptions.

Normally the user doesn’t have to supply both, but in case of copying and pasting some values coming from a

previously listed configuration, this ensures the full compatibility between the output and the input formats.

Command-separator: This element is required when more than one command-sequence is submitted in an input

string and it is indicated with the “,” symbol.

For each command-sequence recognized and executed, the converter returns one of the following output types,

depending on it:

a result code, when a function execution was requested

an expression, when a parameter or a process data value was requested

a list of options or a range of values, when an help on a parameter was requested

Each answer is separated from the other by the comma symbol (the same used as command-separator).

The complete output string is terminated by a <CR><LF> sequence.

Unrecognized command-sequences are silently discarded without response and without halting the execution of the

next sequence, if it is present.

Illegal parameter’s values and operations performed in wrong contexts are reported and identified by error codes.

Result-code: The format of the results is the following: code-number:description, without any blank spaces

separating the number from the description.

There are six possible result-codes:

0:OK, the execution was correct

1:CMD ERR, wrong context, execution was not possible due to a configuration limit or wrong working conditions

2:PARAM ERR, the expected parameter was out of the allowed range

3:EXEC ERR, the execution of the command was not successful due to an internal error condition

4:RANGE ADJ, the entered parameter caused an internal automatic adjustment on other ranges

5:ACCESS ERR, the execution of the command was not possible due to an insufficient privilege level

6:BUFFER FULL, the input or the output strings exceed the maximum allowable space.

3.3.6. SPECIAL CHARACTERS

The following characters have special meaning in the protocol and thus they can’t be used for other purposes:

<CR> carriage-return character, value 13 decimal, 0D hexadecimal, terminates the input string and starts the

elaboration

<LF> line-feed character, value 10 decimal, 0A hexadecimal, may follows the <CR> but it is never considered

? question mark character, value 63 decimal, 3F hexadecimal, it is an operator character

= equal sign character, value 61 decimal, 3D hexadecimal, it is another operator character

: colon character, value 58 decimal, 3A hexadecimal, it is the comment-separator character

, comma character, value 44 decimal, 2C hexadecimal, it is the command-separator character

3.3.7. ACCESS CODE FOR FUNCTION WITH PRIVILEGE LEVEL

The access and the changing of some parameters can made only after the inserting of a level code.

This can made sending an access code corresponding to the level L2 as first command before inserting the command.

- 22 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 23

The syntax for inserting the code is: “ACODE=n” with n=access code L2

The lifecycle of the code is limited at the execution of the string command that following the code.

After the acquisition of the command the access level return at default status.

Is necessary to insert the code level every time the command or the list of the command request the insertion of the

code access greater than the default level.

If the level L2 of the converter is set to 0, then is not necessary to insert the code L2.

When the access code is not sufficient for the command, the converter return the following error code:

5:ACCESS ERR

Example of string with command for code level L2=12345 and command for reading model a software version of the

converter:

“ACODE=12345,MODSV?” + chr(13)

3.3.8. DATA BLOCK FORMAT

Communication takes place through data blocks or packs of variable length which do not exceed 256 bytes overall. A

data block or pack is composed thus::

ADDRESS TO, Containing the address of the device the block is sent to;

ADDRESS FROM, Containing the address of the device which sent the block;

BLOCK CODE, Containing the code that it indicates if after this block given there is a successive block;

BLOCK LENGTH, Containing the length of the data block in bytes

BLOCK DATA, The block of data of variable length from zero to 250 bytes

CRC CHECKSUM BYTE, Calculated in the following way:

4. CRC initialised to zero

5. CRC rotated to the left by one bit

6. CRC = CRC + block bytes

The process is repeated starting from point 2. for all the block bytes, excluding CRC..

NOTE:

The CRC must be subjected to an operation of

The difference is shown in the following example:

byte value: 10100010

shifting : 1 <= 0100010 <= 0

rotating: 1 1 <= 0100010 <= 1

NOTE:

The code to insert in BLOCK CODE can have the following values:

91 decimal (5B hex)

Insert 90 decimal when BLOCK DATA length is smaller or equal to 250 characters

If the length of the block data is greater than 250 characters, split the block data in packets of 250

Every packets with BLOCK DATA of 250 characters have BLOCK CODE equal to 91 dec.

The last block of data with numbers of byte smaller or equal to 250 have BLOCK CODE with 90 dec.

90 decimal (5A hex)

characters.

rotation to the left

and not just a simple

shift

operation.

- 23 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 24

3.3.9. EXAMPLE OF ETP COMAND

Reading model and software version of the converter:

mnemonic: MODSV

syntax of the command: “MODSV?”

list of the bytes and corresponding values of the command:

byte 0: address to = chr(0)

byte 1: address from = chr(170)

byte 2: block code = chr(90) (length of the next data block smaller than 250 characters)

byte 3: length = chr(7) (length of the next data block)

byte 4: block data = chr(77) = ‘M’

byte 5: block data = chr(79) = ‘O’

byte 6: block data = chr(68) = ‘D’

byte 7: block data = chr(83) = ‘S’

byte 8: block data = chr(86) = ‘V’

byte 9: block data = chr(63) = ‘?’

byte 10: carriage-return <CR> = chr(13)

byte 11: checksum = chr(239)

List of the bytes to send to the converter in hexadecimal format:

chr(0x00) + chr(0xAA) + chr(0x5A) + chr(0x08) + chr(0x4D) + chr(0x4F) + chr(0x44) + chr(0x53) +

chr(0x56) + chr(0x3F) + chr(0x0D) + chr(0xEF)

3.3.10. EXAMPLE OF RESPONSE FOR PRECECDENT ETP COMAND

Header string response:

byte 0 = chr(170)

byte 1 = chr(0)

byte 2 = chr(218) 218 dec = 0xDA hex (code 218 = length of the next data block smaller than 250 characters)

byte 3 = chr(29) number of characters of the data block = 29 bytes

Body string response:

byte 4 = 77 chr(77) = ‘M’ char 1

byte 5 = 76 chr(76) = ‘L’ char 2

byte 6 = 32 chr(32) = ‘ ’ char 3

byte 7 = 50 chr(50) = ‘2’ char 4

byte 8 = 49 chr(49) = ‘1’ char 5

byte 9 = 48 chr(48) = ‘0’ char 6

byte 10 = 32 chr(32) = ‘ ’ char 7

byte 11 = 86 chr(86) = ‘V’ char 8

byte 12 = 69 chr(69) = ‘E’ char 9

byte 13 = 82 chr(82) = ‘R’ char 10

byte 14 = 46 chr(46) = ‘.’ char 11

byte 15 = 51 chr(51) = ‘3’ char 12

byte 16 = 46 chr(46) = ‘.’ char 13

byte 17 = 54 chr(54) = ‘6’ char 14

byte 18 = 48 chr(48) = ‘0’ char 15

byte 19 = 32 chr(32) = ‘ ’ char 16

byte 20 = 77 chr(77) = ‘M’ char 17

byte 21 = 97 chr(97) = ‘a’ char 18

byte 22 = 121 chr(121) = ‘y’ char 19

- 24 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 25

byte 23 = 32 chr(32) = ‘ ’ char 20

byte 24 = 49 chr(49) = ‘1’ char 21

byte 25 = 53 chr(53) = ‘5’ char 22

byte 26 = 32 chr(32) = ‘ ’ char 23

byte 27 = 50 chr(50) = ‘2’ char 24

byte 28 = 48 chr(48) = ‘0’ char 25

byte 29 = 48 chr(48) = ‘0’ char 26

byte 30 = 55 chr(55) = ‘7’ char 27

byte 31 = 13 chr(13) = char 28

byte 32 = 10 chr(10) = char 29

byte 33 = 247 checksu

3.3.11. COMUNICATION

The above mentioned communication protocol is used to exchange data between one unit defined as the MASTER and

another unit defined as the SLAVE.

The term MASTER is used here to indicate a device capable of initiating data transmission on its own initiative.

The term SLAVE however, is used to indicate a device capable of transmitting data only in reply to a command

received.

Neither of the two types of devices can receive and transmit contemporaneously: these operations take place in two

different time phases.

Two MASTER type units cannot be connected together because both of the devices would begin to transmit

autonomously and would never succeed in synchronizing themselves.

Analogously, two SLAVE type devices could never exchange information because neither of the two is capable of

initiating communication on its own initiative.

The flow of information in both directions therefore takes place alternately using blocks containing a maximum of 95

words each. A word is composed of 10 bits in all: 1 start bit + 8 data bits + 1 stop bit.

These data blocks are received contemporaneously by all the devices connected along the communication line, but

only the device with the address equal to the one contained in the data block will be the real destined.

The words comprising the block must be sent on the serial line in a continuous mode, without dead time between one

word and the next. The maximum dead time permitted between two words must not exceed the duration of one word.

SLAVE type devices always generate a reply to every message sent to them and correctly received. In the case of

reception errors, there is no reply. In the case of command interpretation errors (incorrect format, missing parameters,

etc.) either a block without data or no reply, may be the reply depending on the case.

The that elapses between the sending of the last data word by the MASTER and the sending of the first reply word by

the SLAVE can be schematized as follows:

last word transmitted by the MASTER

|

| reply processing: time variable from 0 to 25 milliseconds at the most

| |

| | time equal to 3 complete words

| | |

| | | first word transmitted by the SLAVE as reply

| | | |

.....xxxxx| t0 | t1 |xxxxxx......

- 25 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 26

Time t0 depends on the type of command sent and the type of converter it is sent to. Time t1 depends on the

communication speed used. A further time t2 - equal to the word length - must be added to these two times. The

integrated circuit receiver needs this time to acquire and extract the data bytes of the first word received.

For the system to work correctly, a MASTER type device must respect the following protocol:

1. block transmission with the code-command;

2. wait for the first reply word for a period of time slightly longer than t0 max. + t1 + t2;

3. reception of the rest of the reply block if arrived or the re-transmission of the block with the code - command.

After a certain number of re-transmissions without reply, an error message may be generated.

The SLAVE reply must always be waited for within a certain time limit (timeout), once this time has elapsed a new

block can be transmitted. If the wait time is too short, a fresh MASTER transmission may take place during the same

time the SLAVE is replying, with the consequent loss of both data blocks.

If the wait time is excessive, the system could become too slow in signalling faults, especially if there are many

instruments connected in the network.

In any case, a timer must be used to indicate the time limit because reply from the SLAVE cannot be trusted with

certainty: in fact, this latter cannot reply in the case of line errors.

If the communication speed is 9600 bps and the format is 10 bits, the length of a word is equal to 1.042 ms. A

reasonable time limit could be calculated thus:

T

= t0 max. + t1 + t2 + 1 ms = 25 + 3 x 1.042 + 1 x 1,042 + 1 = 30.17 ms.

lim

IMPORTANT NOTES: There must be a «silence» interval, equal to at least 3 complete words (30 bits), between each data

block and the successive one in transit on the serial line.Before starting transmission, to the network,

activate the transmitter for a time of no less than 3 words (30 bits) and then begin to send the

output characters. This is to give the devices in the network time to eliminate any false characters

received when the network was not in use status.

3.3.12. SUGGESTIONS FOR RS485 INTERFACE USE

When programs are developed which use this type of interface, it is as well to make a few considerations. Firstly, we

should remember that data transits both in reception and in transmission on the RS485 and that when no transmitter

is enabled, the line is in a condition of relatively high impedance.

Physically the RS485 interface is created by a transmitter with a differential output and by a receiver, also with a

differential input. The output of the first is physically connected to the input of the second, according to the scheme

shown below:

TRANS.

ENABLING

TRANS

INPUT

REC.

OUTPUT

From this scheme we can see how the transmission and reception of different data simultaneously is not possible. Each

function must be activated separately with a specific software command which changes the logical status of an

- 26 - RS232_485_ETP_MODBUS_BU_REV02.doc

+

-

+

-

RS485 LINE

Page 27

interface pin (the transmitter enabling signal). This is the main difference with respect to the RS232 interface normally

present on PCs.

In fact, whilst with the RS232 we do not have to worry about the data traffic because it travels on two separate lines

(RXD and TXD), with the RS485 there is only one line with the traffic suitably managed.

The first operation we must do therefore is to activate the transmitter and then send all the data to the communication

port. Next, we have to wait until the last piece of data has gone from the port to the line and only at this point can we

disables the transmitter.

The management software must also absolutely prevent two different devices on the same line from being activated

for transmission at the same time: this would mean that we would have the outputs of the drivers of the two

transmitters connected in parallel, with a consequent overheating of the components and a loss of information. This

eventuality would not break the devices however as they are thermally protected.

On this matter it is necessary to pay extreme attention to the delay between the transmission of the last data byte (the

checksum) and the effective disabling of the transmitter. This delay must be lower than the time equivalent for

transmitting a 10 bit word, because after this time has elapsed, the device addressed will begin its transmission phase.

For the converter with software version 3.50 or greater, in the menu Communication is present the function A.delay.

This setting value in milliseconds, have the function to insert a delay interval for the response from the converter, so

that the transmitter device have enough time to switch in receiver status.

It is also necessary to note that when the line is not piloted by any transmitter, it is in a condition of relatively high

impedance and this may give rise to the reception of characters without the right meaning and possible disturbance.

On this question, the communication management software must activate the transmitter a few seconds before

transmission starts (typically a time of no less than the length of 3 words at the speed used) so as not to give the line

a defined logical status (MARK) and to permit the receivers connected to eliminate any false characters. In the same

way, during reception, it must take any such characters possibly present during line inactivity and rapidly eliminate

them to prevent saturation of the reception buffers, especially so at high speeds

Furthermore, given that the receiver is anyway connected to the transmitter output, in some types of interface it is

necessary to eliminate any characters possibly present, received during the transmission phase, because they are

copies of what has just been sent. See the next section for some programming examples.

- 27 - RS232_485_ETP_MODBUS_BU_REV02.doc

Page 28

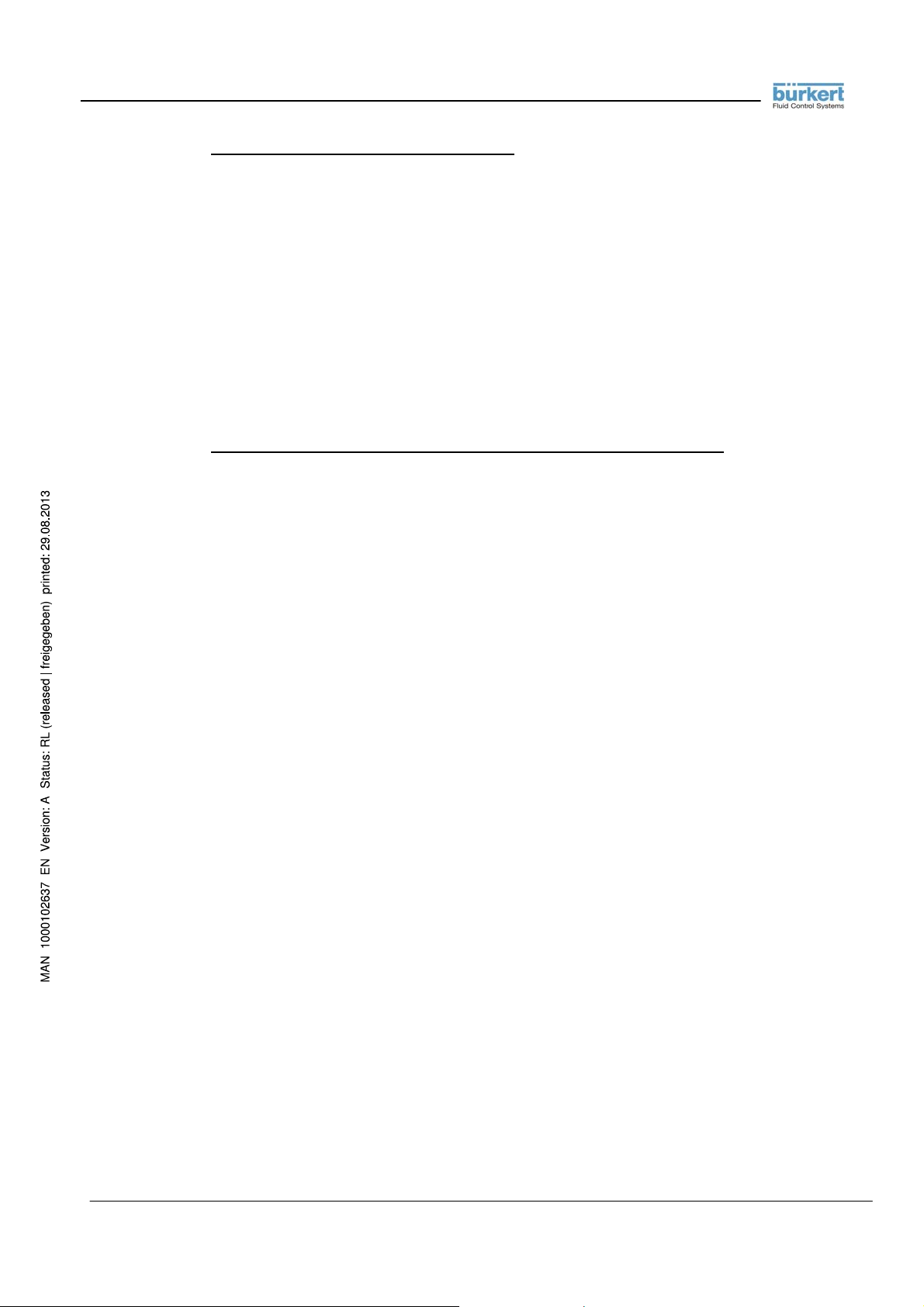

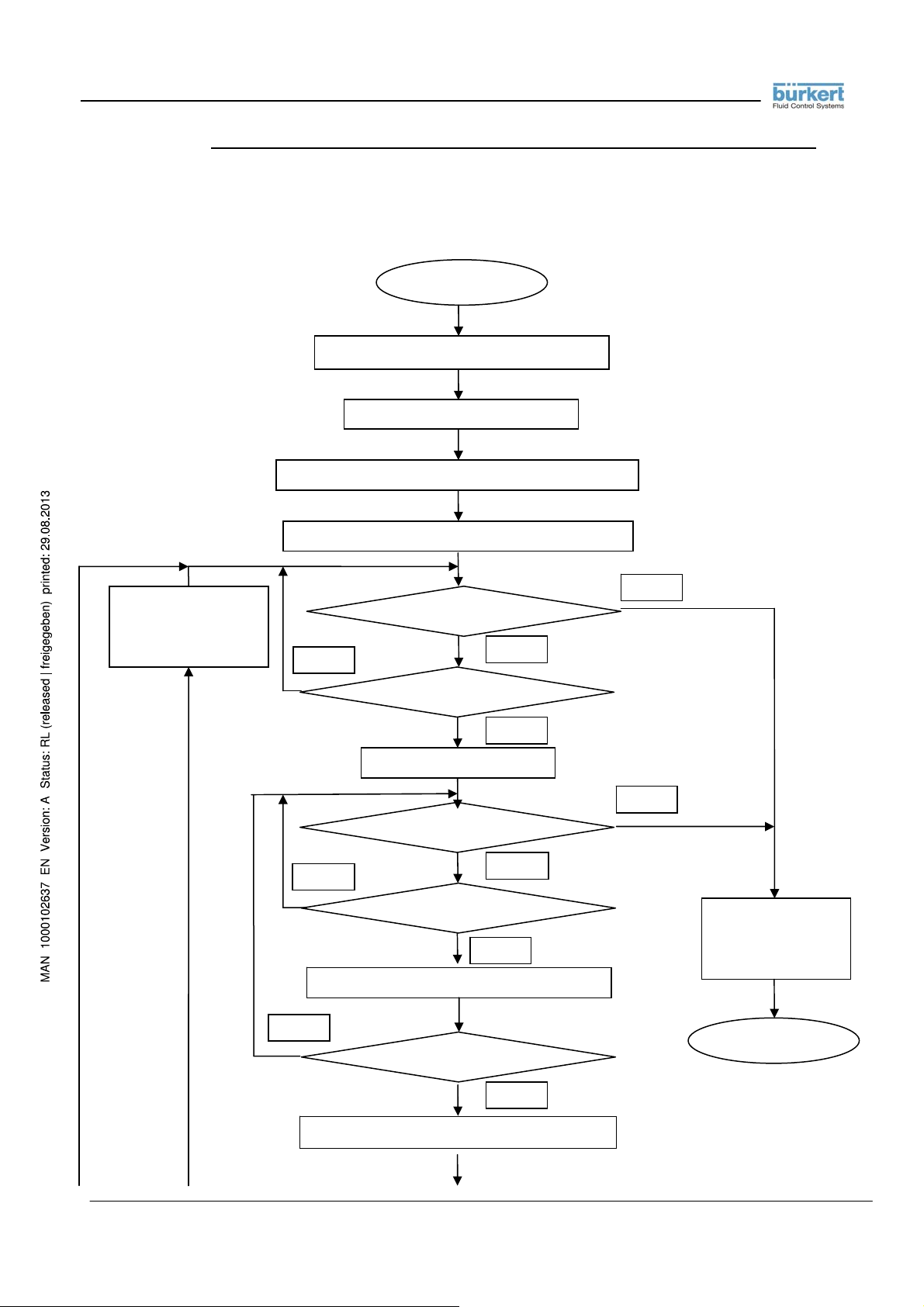

3.3.13. FLOW CHART FOR SENDING ETP COMMAND AND RECEPTION OF THE ANSWER

Flow chart with description of the sending of an ETP command to a converter through the RS 485 port and wait cycle

for the reception of the answer

The MASTER generates ETP command

The MASTER enables the transmitter

The MASTER send ETP command to the addressed SLAVE

The MASTER enable receiver - Start timer T

Packet with addresses

for other device

Packet deleted

T

Reset timer

lim

No

No

No

The MASTER decode the Header answer

START

Timer T

Has it received char ?

Start timer char

Timer char expired ?

Has it received char ?

Reset timer cha r

Has received 4 bytes ?

expired ?

lim

No

Si

No

Si

Si

Si

Si

The Timer has expired

Answer not received

END

- 28 - RS232_485_ETP_MODBUS_BU_REV02.doc

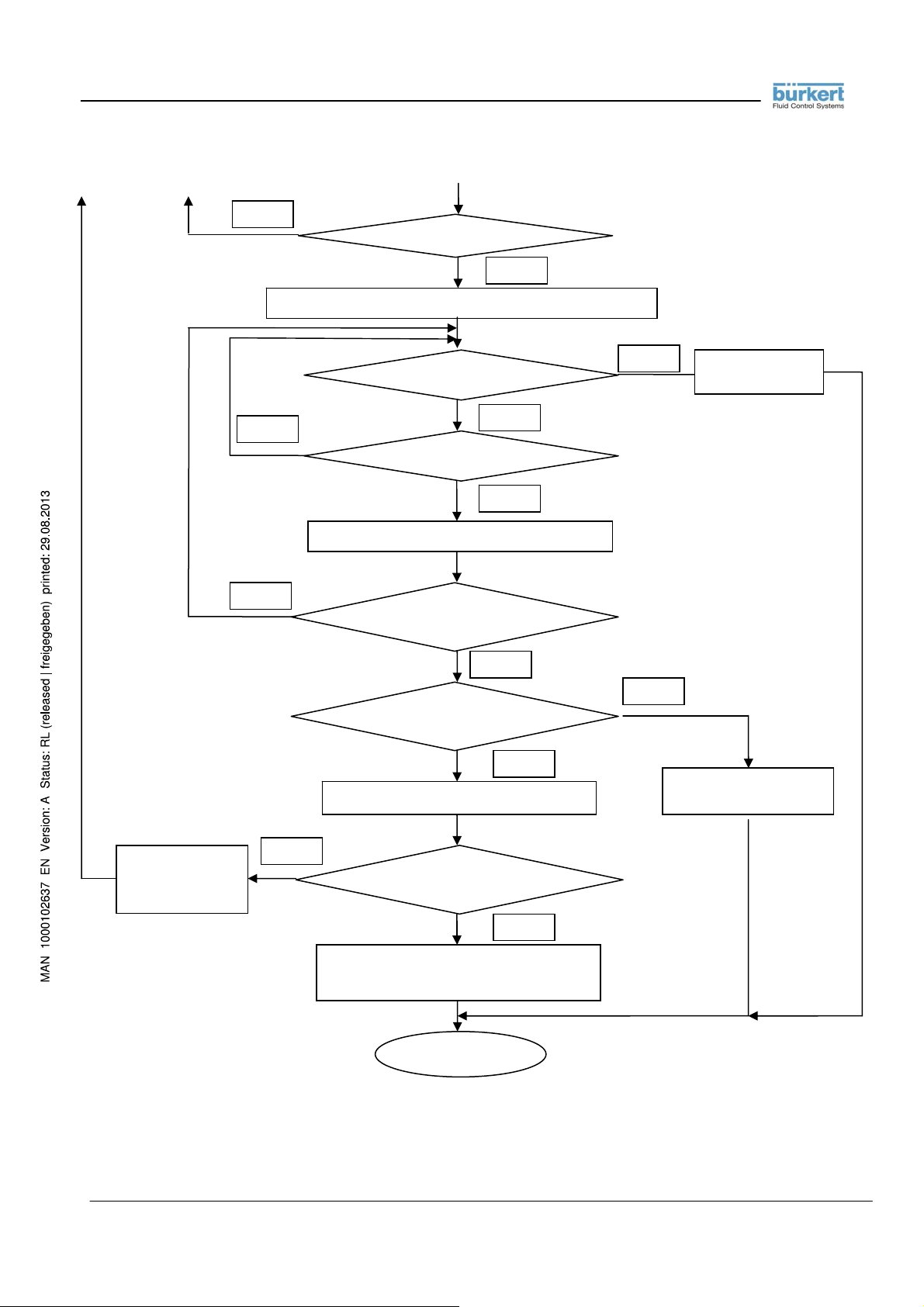

Page 29

Another block to

receive

Note:

The timer char is set to 2.5 time the time necessary for to receive a char: 2.5 * tchar.

Every time there is a char in the receive buffer the timer char is restart.

If the receive buffer doesn’t receive a char in the next 2.5 * tchar, the timer char expire and the reception of data is

terminated.

- 29 - RS232_485_ETP_MODBUS_BU_REV02.doc

No

The address are ok ?

Si

The MASTER read the BLOCK CODE and BLOCK LENGHT

Timer char expired ?

No

Has it received char ?

Reset timer cha r

No

Has the MASTER received

BLOCK LENGHT chars ?

The checksum is ok ?

Decoding of the answer with success

No

Is the Block code = 0xDA ?

Is this the last block

Block code = 0xDA

This is the last block

Reception completed

No

Si

Si

Si

Si

END

Si

No

Packet not

complete

Bad Checksum

Packet corrupted

Page 30

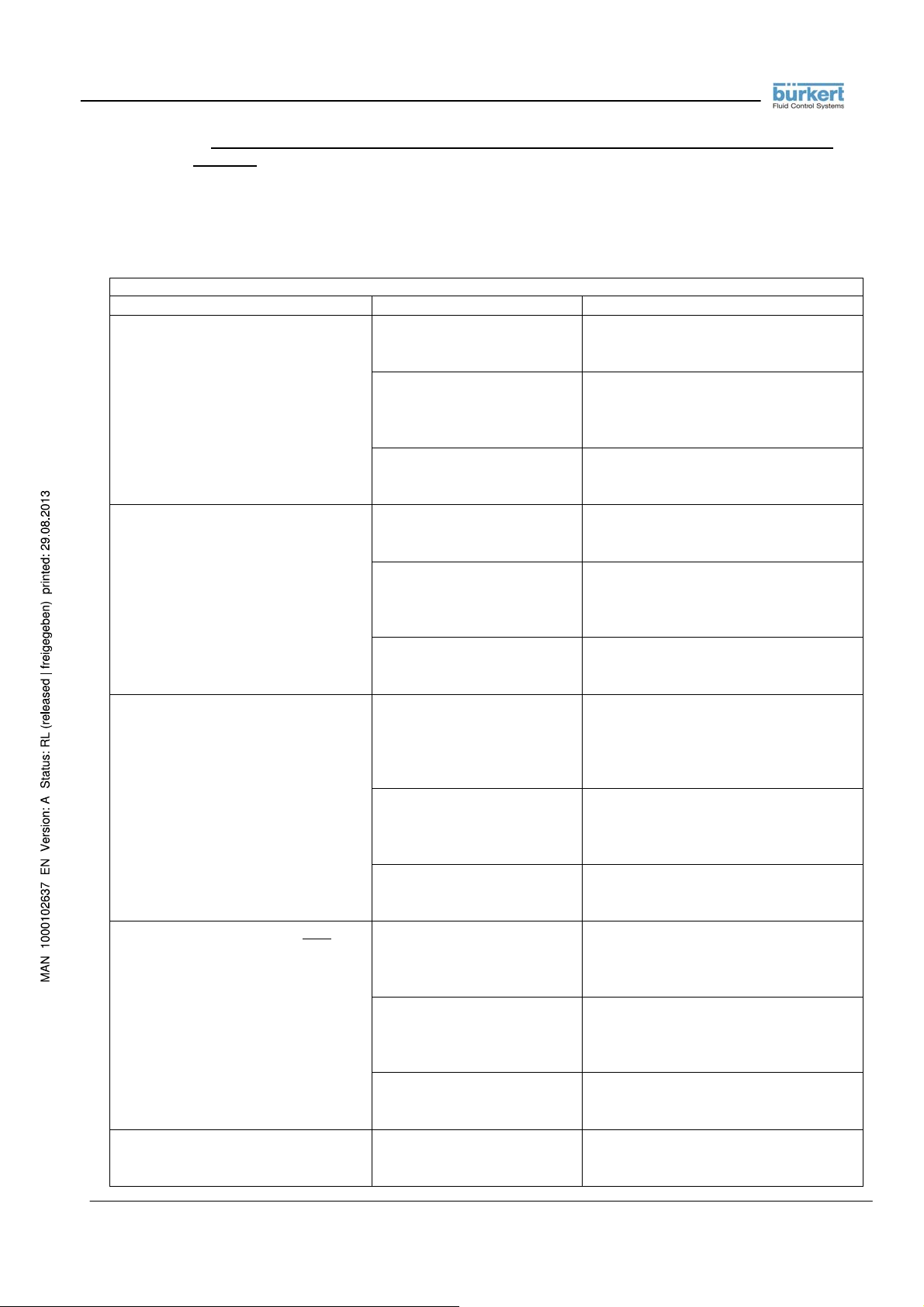

3.3.14. LIST OF SUPPORTED COMMANDS GROUPED SIMILARLY TO THE INTERNAL MENU

SYSTEM

NOTE ( VALID FOR ALL FUNCTIONS ) : returned value 5 = ACCESS ERR ( insufficient access

level )

COMMANDS AND FUNCTIONS EQUIVALENT TO THE “1-SENSOR” MENU

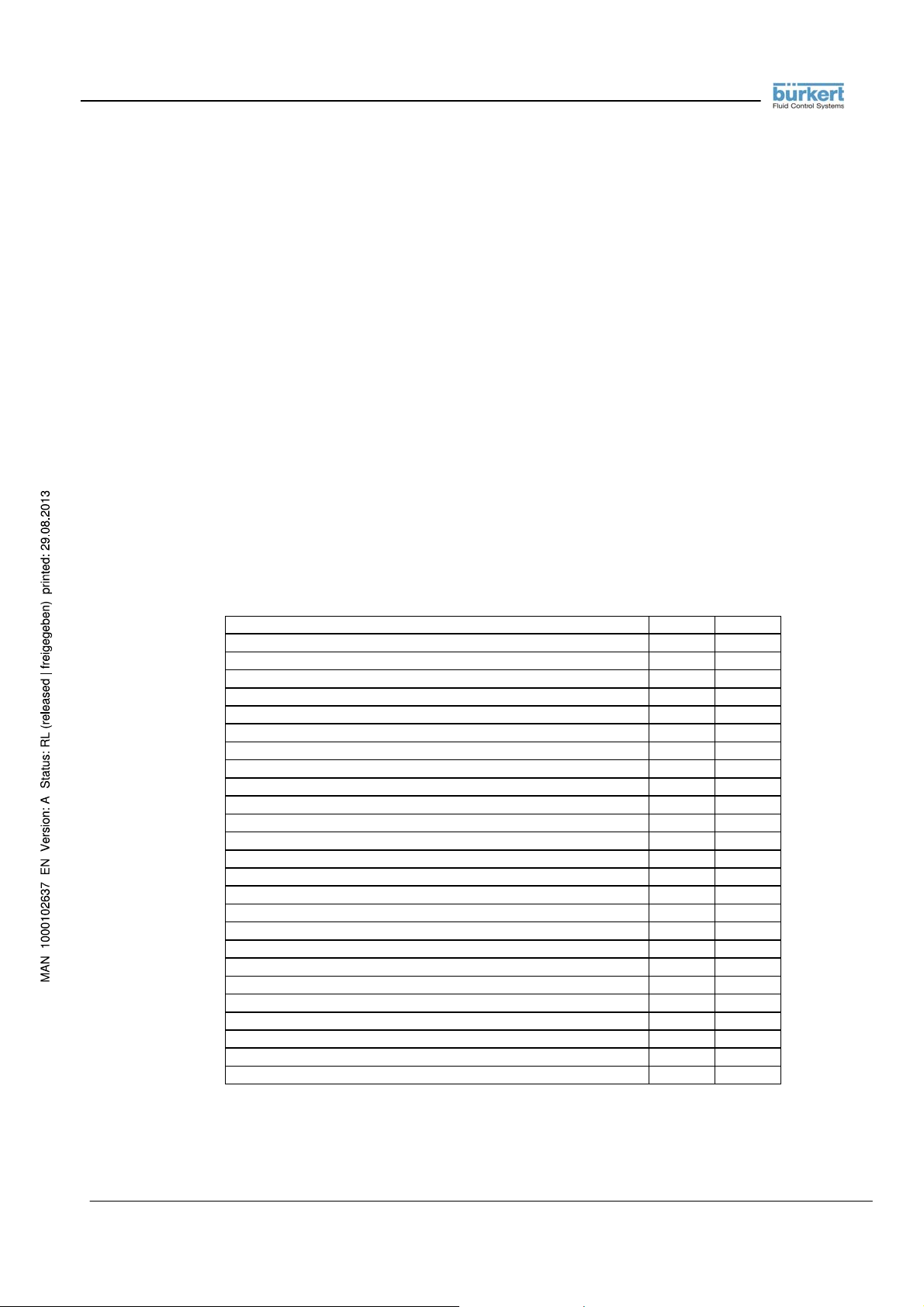

Name and description Modes Returned values or codes

PDIMV (Pipe DIaMeter Value)

Reads or sets the nominal diameter

of the sensor.

CFFKA (CoeFFicient KA) Reads or

sets the value of the gain coefficient