Page 1

Type 8045

Electromagnetic flowmeter

Quickstart

English

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2012 - 2013

Operating Instructions 1308/1_EU-ML 00563855 ORIGINAL_FR

1. ABOUT THE QUICKSTART.........................................................................3

2. INTENDED USE ................................................................................................4

3. BASIC SAFETY INFORMATION ...............................................................4

4. GENERAL INFORMATION ...........................................................................6

5. DESCRIPTION OF THE NAME PLATE ..................................................6

6. TECHNICAL DATA ...........................................................................................7

7. INSTALLATION AND WIRING .................................................................11

8. ADJUSTMENT, COMMISSIONING ..........................................................................23

9. MAINTENANCE AND TROUBLESHOOTING ..................................30

10. PACKAGING, TRANSPORT ...................................................................30

11. STORAGE .......................................................................................................30

12. DISPOSAL OF THE PRODUCT ........................................................... 31

Page 3

Type 8045

Warns against material damage.

Failure to observe this warning may result in damage to the device

About the Quickstart

1. ABOUT THE QUICKSTART

The quickstart describes the life cycle of the device. Please keep this

manual in a safe place, accessible to all users and any new owners.

Important safety information.

Respect the safety instructions. Study in particular the chapters

entitled Intended Use and Basic Safety Instructions.

• The quickstart must be read and understood.

The quickstart explains how to install, set, and start-up the device.

A detailed description of the device can be found in the related

operating instructions on the elivered CD.

1.1. Symbols used

danger

Warns against an imminent danger.

• Failure to observe this warning can result in death or in serious

injury.

Warning

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or even

death.

attention

Warns against a possible risk.

• Failure to observe this warning can result in substantial or minor

injuries.

note

•

or system.

Indicates additional information, advice or important

recommendations.

Refers to information contained in this manual or in other

documents.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

The word "device" used within this manual refers to the flowmeter

type 8045.

English

3

Page 4

Type 8045

Intended use

2. INTENDED USE

Use of the device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

• The 8045 flowmeter is intended exclusively to measure flow rate

in liquids.

• This device must be protected against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects of

climatic conditions.

• This device must be used in compliance with the characteristics

and commissioning and use conditions specified in the contractual documents and in the operating instructions.

• Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

• Only use the device as intended.

→ Observe any existing restraints when the device is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during installation,

use and maintenance of the devices.

• the local safety regulations for which the operating company

is responsible including the staff in charge of installation and

maintenance.

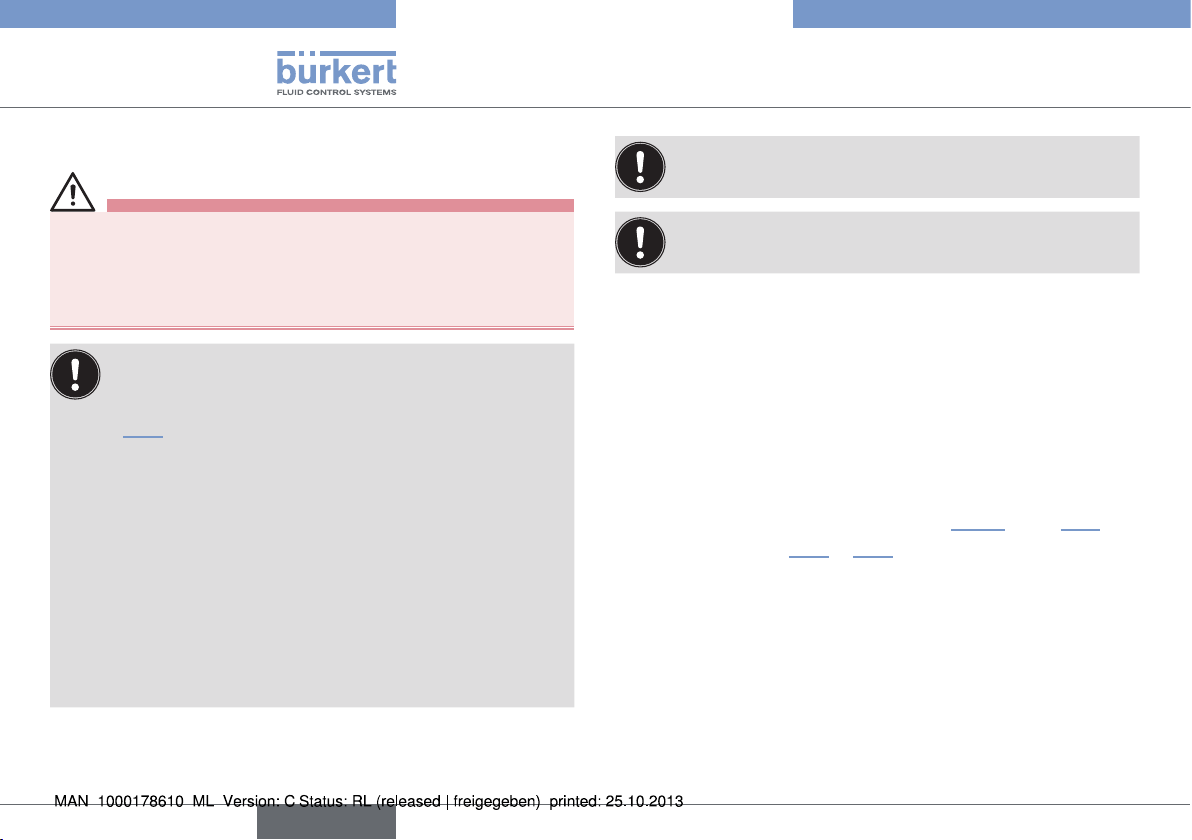

Danger due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Danger due to electrical voltage.

• Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Danger due to high temperatures of the fluid.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Danger due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

4

English

Page 5

Type 8045

Basic safety information

Various dangerous situations

To avoid injury take care:

• not to use the device for the measurement of gas flow rates.

• not to use the device in explosive atmospheres.

• not to use the device in an environment incompatible with the

materials it is made of.

• not to subject the device to mechanical loads (e.g. by placing

objects on top of it or by using it as a step).

• not to make any external or internal modifications to the device.

• to prevent any unintentional power supply switch-on.

• to ensure that installation and maintenance work are

carried out by qualified, authorised personnel in possession of

the appropriate tools.

• to guarantee a defined or controlled restarting of the process,

after a power supply interruption.

• to use the device only if in perfect working order and in compliance with the instructions provided in the operating instructions.

• to observe the general technical rules when installing and using

the device.

note

The device may be damaged by the fluid in contact with.

• Systematically check the chemical compatibility of the component materials of the device and the fluids likely to come into

contact with it (for example: alcohols, strong or concentrated

acids, aldehydes, alkaline compounds, esters, aliphatic compounds, ketones, halogenated aromatics or hydrocarbons,

oxidants and chlorinated agents).

note

Elements / Components sensitive to electrostatic discharges

• This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they are touched by

an electrostatically charged person or object. In the worst case

scenario, these components are instantly destroyed or go out of

order as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 and 5-2 norms.

• Also ensure that you do not touch any of the live electrical

components.

English

5

Page 6

Type 8045

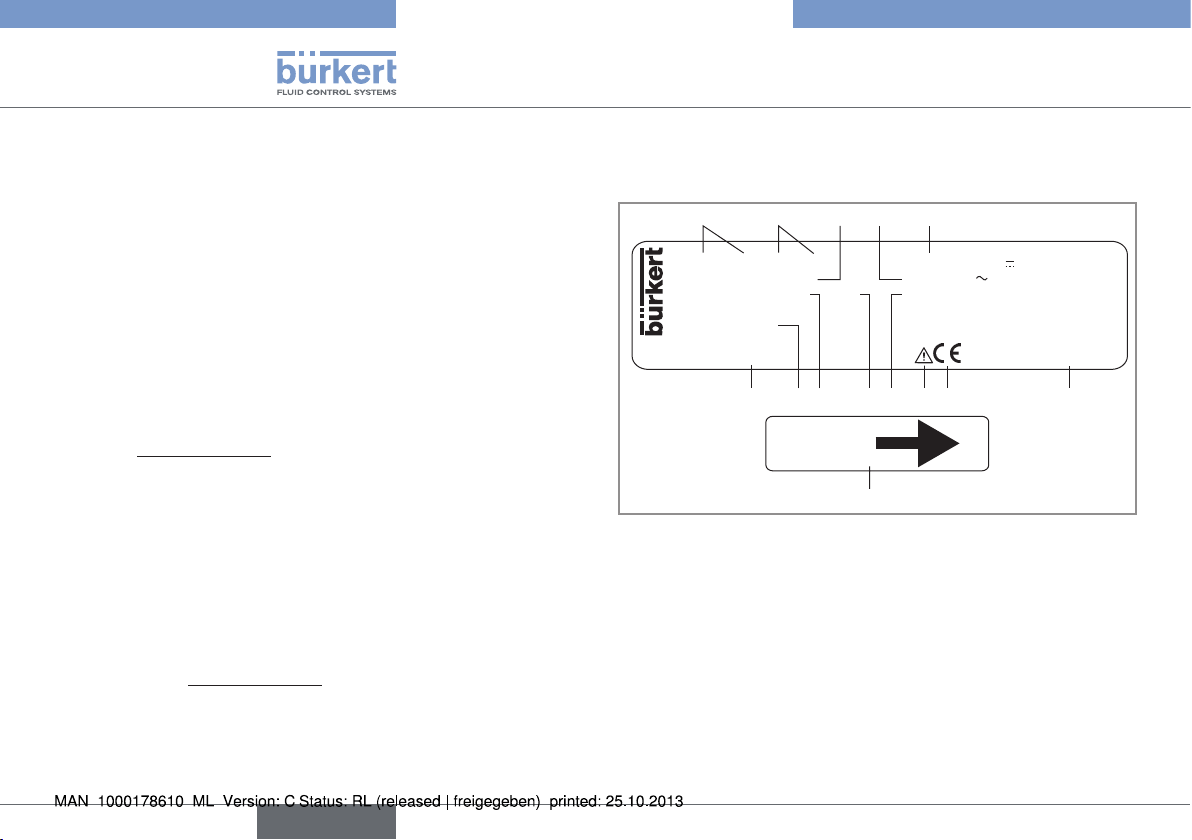

1

2 5

3 4

General information

4. GENERAL INFORMATION

4.1. Manufacturer's address and

international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the

internet at: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of

the 8045 in observance of the operating conditions specified in this

manual.

4.3. Information on the Internet

You can find the user manuals and technical data sheets regarding

the type 8045 at: www.burkert.com

5. DESCRIPTION OF THE NAME

PLATE

FLOW 8045 SST LONG SUPPLY: 18-36V 300 mA

DO1: 5-36V= 100mA DO2/3:250V 3A Max

DI1: 18-36V= 10mA IP65 Fluid: PN16:-15/110°C

S/N 11 162

Made in France

00449673 W43M

13

10

67891112

FLOW

14

6

English

Page 7

Type 8045

Technical data

1. Measured value and type of the device

2. Specification of the flow sensor

3. Specification of the DO1 digital output

4. Specifications of the relay outputs DO2 and DO3

5. Electrical power supply and current consumption

6. Manufacturing code

7. Conformity logo

8. Warning: Before using the device, take into account the tech-

nical specifications described in these operating instructions.

9. Fluid temperature range and fluid nominal pressure

10. Protection class of the device

11. Specification of the DI1 digital input

12. Serial number

13. Order code

14. Shows the flow direction

Fig. 1: Name plate of the 8045 flowmeter

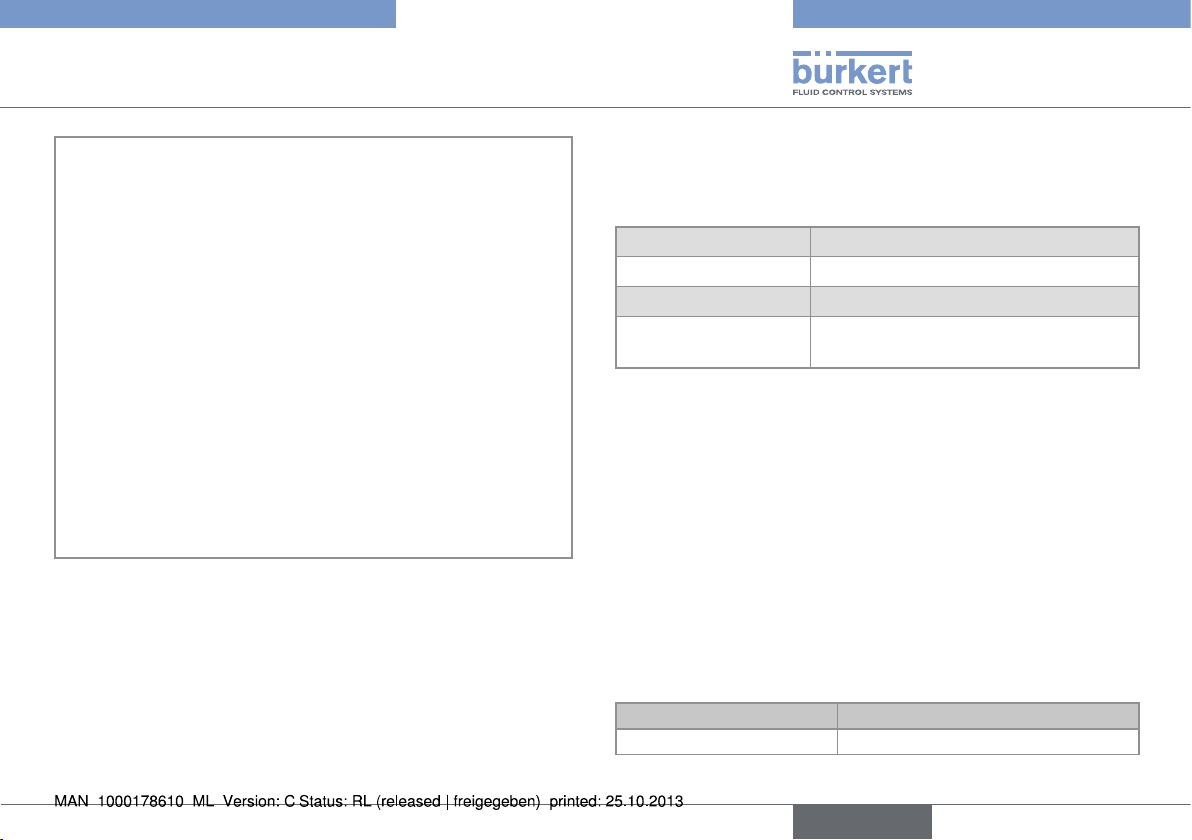

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature -10 to +60 °C

Air humidity < 85%, non condensated

Height above see level max. 2000 m

Protection class acc.

to EN 60529

6.2. Conformity to standards and

directives

The device conforms to the EC directives through the following

standards:

• EMC: EN 61000-6-2, EN 61000-6-3

• LVD: EN 61 010-1

• Vibration: EN 60068-2-6

• Shock: EN 60068-2-27

Pressure: article 3§3 of the Pressure Directive 97/23/CE. Acc. to

the Pressure Directive 97/23/CE: the device can only be used in the

following cases (depending on the max. pressure, the DN of the pipe

and the fluid)

Type of fluid Conditions

Fluid group 1, par. 1.3.a Forbidden

IP65, device wired and cable glands

tightened and cover lid screwed tight.

English

7

Page 8

Type 8045

Technical data

Type of fluid Conditions

Fluid group 2 par. 1.3.a

Fluid group 1 par. 1.3.b PNxDN ≤ 2000

Fluid group 2 par. 1.3.b

DN ≤ 32

or DN > 32 and PNxDN ≤ 1000

DN ≤ 200

or PN ≤ 10

or PNxDN ≤ 5000

6.3. Mechanical data

Part

Housing / seal PC / NBR Black PPA / NBR

Cover with lid /

seal

Front foil Polyester

M20x1,5 cable

glands / seal

Screws Stainless steel

Nut PC PPA

Flow sensor

(exposed to the

fluid)

Material (8045 with

flow sensor in PVDF)

PC / silicone PSU / silicone

PA / neoprene

PVDF Stainless steel 316L

Material (8045

with flow sensor in

stainless steel)

(DIN 1.4404)

Part

Seal FKM 8045 with a G2" nut:

Earth ring of the

flow sensor

Electrodes holder - PEEK

Electrodes Stainless steel 316L (DIN 1.4404) or Alloy

Material (8045 with

flow sensor in PVDF)

Stainless steel 316L

(DIN 1.4404) or Alloy

C22

Material (8045

with flow sensor in

stainless steel)

FKM

-

C22

6.4. General data

Min. fluid conductivity 20 µS/cm

Fluid temperature

• 8045 with flow sensor

in PVDF

• 8045 with flow sensor in

stainless steel

The fluid temperature may be

restricted by the fluid pressure, the

material the flow sensor is made of

and the material the S020 fitting used

is made of.

• 0 to +80 °C

• -15 to +110 °C

8

English

Page 9

Type 8045

A

A

Technical data

Fluid pressure

The fluid pressure may be restricted

by the fluid temperature, the material

the flow sensor is made of, the

material the S020 fitting used is made

of and the DN of the fitting used.

• 8045 with flow sensor

• PN10

in PVDF

• 8045 with flow sensor in

• PN16

stainless steel

P (bar)

10

9

8

7

PVC + PP

6

5

4

3

2

1

0

PVC (PN10)

0 +20 +40 +60 +80

PVDF (PN10) /

PP (PN10)

T (°C)

Metal

A: range of use

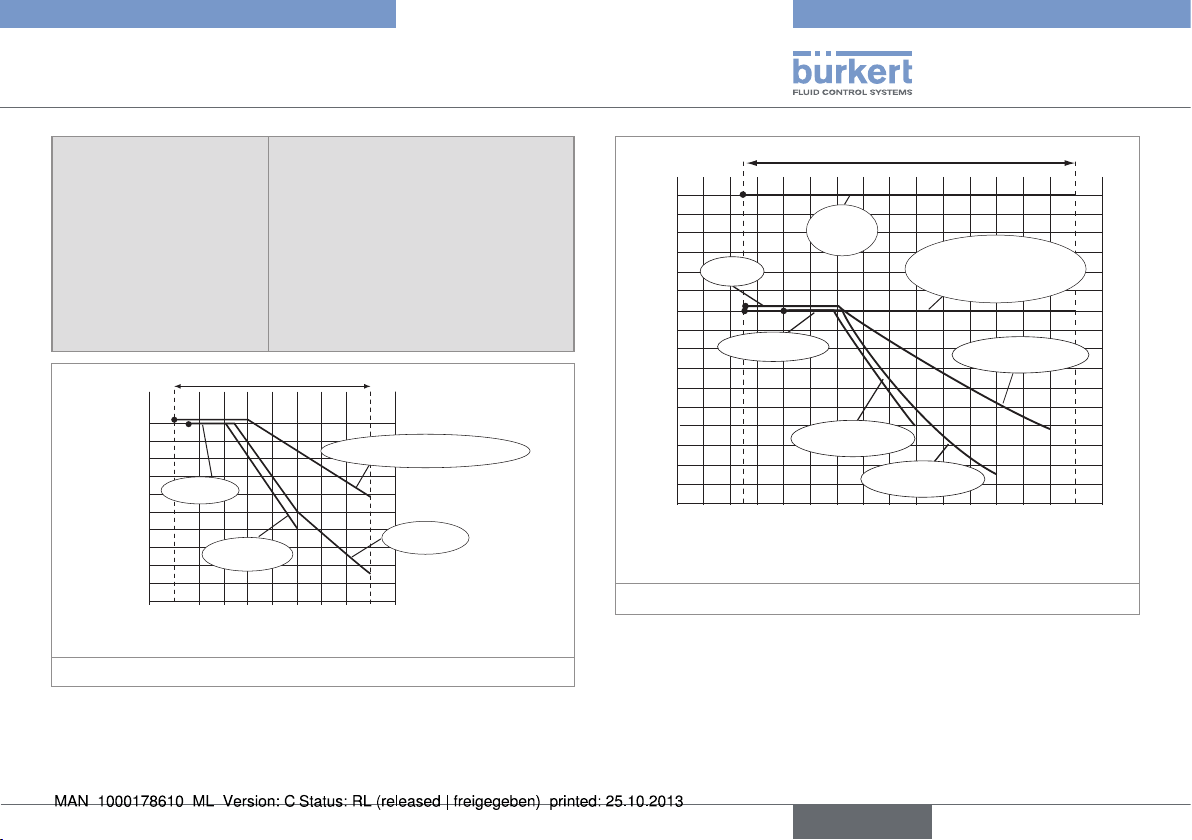

Fig. 2: Fluid pressure /temperature dependency for a 8045 with

PVDF flow sensor and a fitting S020 in metal, PVC, PVDF

or PP

P (bar)

16

15

14

13

12

11

PVDF

Metal

(PN16)

1)

DN100 for measuring

devices with a clamp con-

nection (PN10)

10

9

8

7

PVC + PP

PVDF (PN10)

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100 +120

PVC (PN10)

PP (PN10)

T (°C)

1)

Except DN100 for measuring devices with a clamp connection

A: range of use

Fig. 3: Fluid pressure /temperature dependency for a 8045 with

stainless steel flow sensor and a fitting S020 in metal,

PVC, PVDF or PP

English

9

Page 10

Type 8045

Technical data

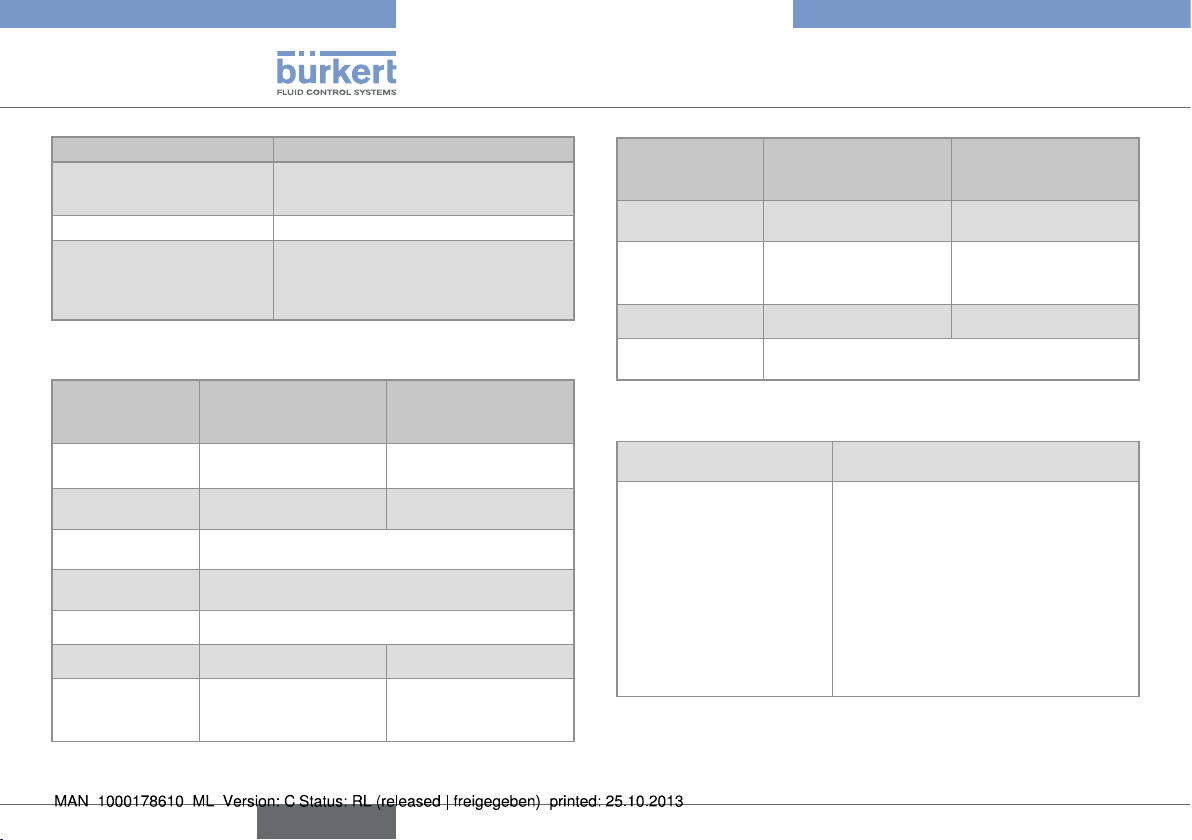

6.5. Electrical data

Power supply • 18-36 V DC, filtered and

regulated

• oscillation rate: ±5 %

Current consumption 300 mA max. (at 18 V DC)

Transistor output DO1

• type

• function

• frequency

• Electrical data

• duty cycle if f > 2 Hz

• min. pulse duration if

f < 2 Hz

• protections

• NPN / PNP (wiring dependent),

open collector

• pulse output (by default), user

configurable

• 0-250 Hz

• 5-36 V DC, 100 mA max.

• 1/2

• 250 ms

• galvanically isolated, and

protected against overvoltages, polarity reversals and

short-circuits

Relay outputs (DO2 and

DO3)

• operating

• electrical data of the load

• max. breaking capacity

• life span

Current output AO1

• specification

• max. loop impedance

Digital input (DI1)

• supply voltage

• input impedance

• min. pulse duration

• protections

• hysteresis (by default), configurable, normally open

• 250 V AC / 3 A or 30 V DC /

3 A (resistive load)

• 750 VA (resistive load)

• min. 100000 cycles

• 4-20 mA, sink or source (wiring

dependent), 22 mA to indicate

a fault

• 1300 W at 36 V DC, 1000 W at

30 V DC, 700 W at 24 V DC,

450 W at 18 V DC

• 18-36 V DC

• 15 kW

• 200 ms

• galvanically isolated, and protected against polarity reversals

and voltage spikes

10

English

Page 11

Type 8045

Installation and wiring

6.6. Electrical connection

Type of connection Through two M20x1,5 cable

glands

Cable specifications

• cable type

• Cross section

• Diameter of each cable:

- if only one cable is used

per cable gland

- if two cables are used per

cable gland

• shielded

• 0,5 to 1,5 mm

- 6...12 mm

- 4 mm, with the supplied

multi-way seal

2

7. INSTALLATION AND WIRING

7.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

Risk of injury due to electrical voltage.

Risk of injury due to high fluid temperatures.

Risk of injury due to the nature of the fluid.

Warning

Risk of injury due to non-conforming installation.

• The electrical and fluid installation can only be carried out by

qualified and skilled staff with the appropriate tools.

• Install appropriate safety systems (correctly rated fuse and/or

circuit-breaker);

• Respect standard NF C 15-100 / IEC 60364.

• Respect the assembly instructions for the fitting used.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

• Take appropriate measures to avoid unintentional activation of

the installation.

• Guarantee a set or controlled restarting of the process subsequent to any intervention on the device.

English

11

Page 12

Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of

the climatic conditions.

7.2. Recommandations for installing

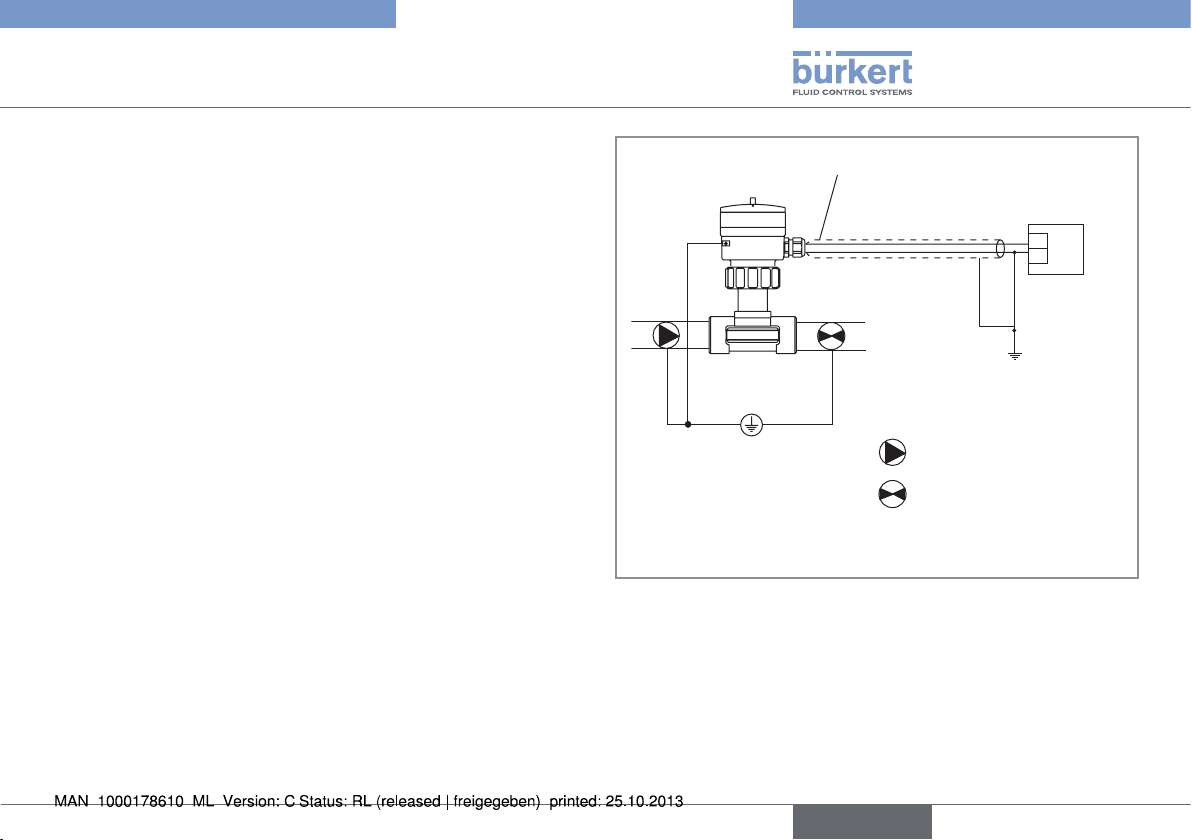

the 8045 on the pipe

→ Choose an S020 fitting appropriate to the velocity of the fluid

inside the pipe.

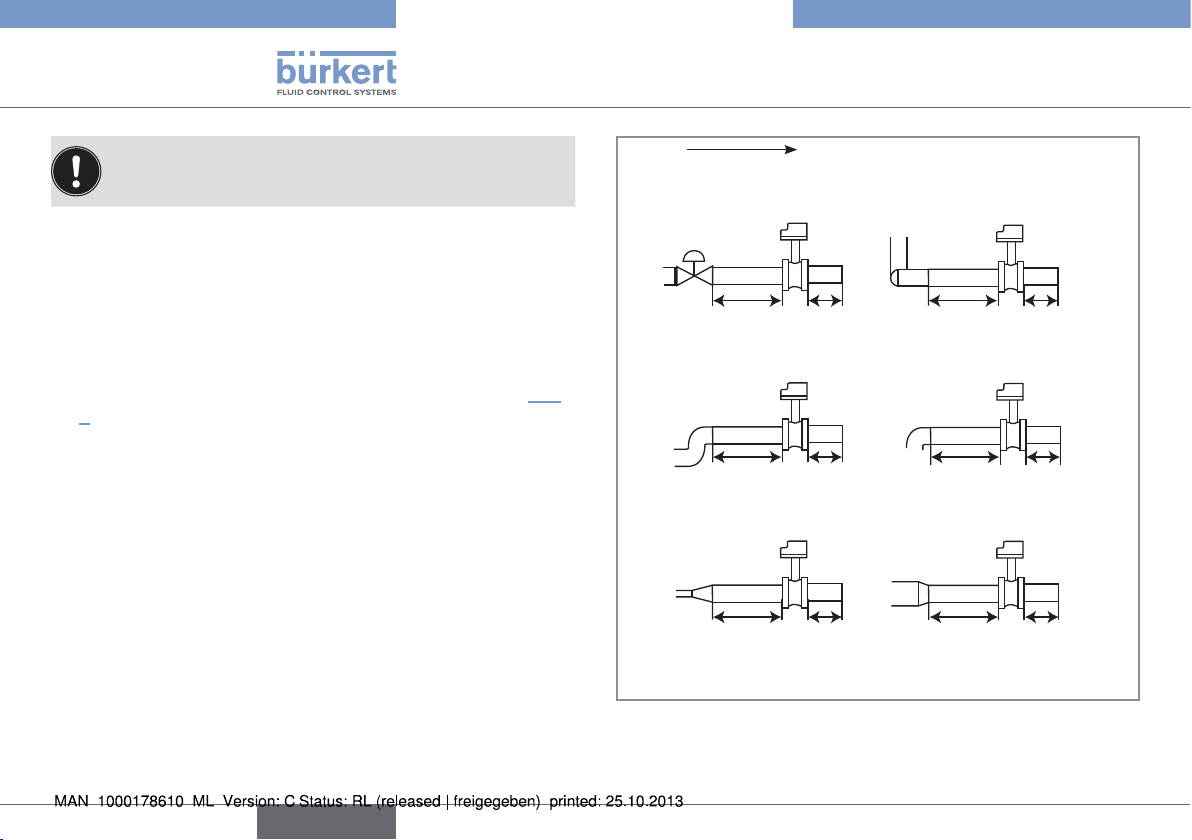

→ Install the device on the pipe in such a way that the upstream

and downstream distances are respected according to the

design of the pipes, refer to standard EN ISO 5167-1 and Fig.

4 :

Type 8045

Installation and wiring

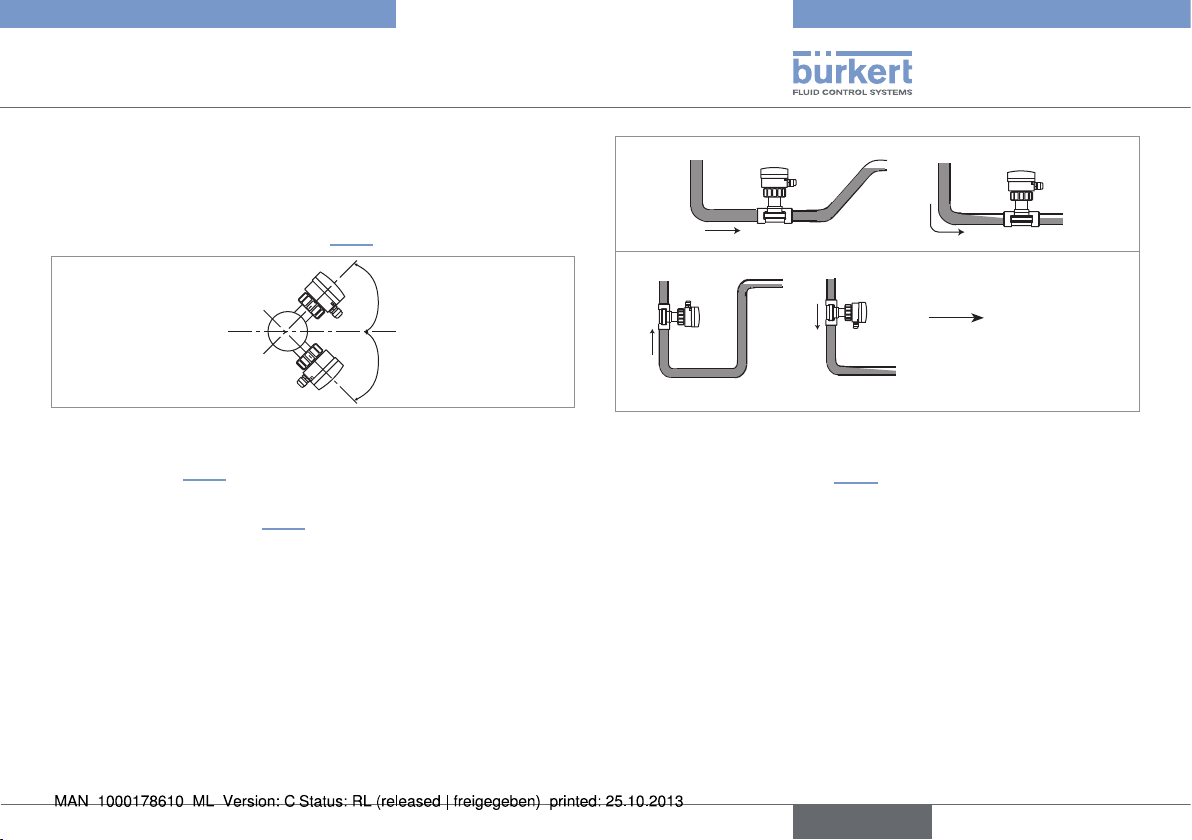

flow direction

50 x DN 5 x DN

With control valve Pipe with 2 elbows at 90° in 3

40 x DN 5 x DN

dimensions

25 x DN 5 x DN 20 x DN 5 x DN

Pipe with 2 elbows at 90° Pipe with 1 elbow at 90° or 1

T-piece

12

18 x DN 5 x DN 15 x DN 5 x DN

With pipe expansion With pipe reduction

Fig. 4: Upstream and downstream distances depending on the

design of the pipes.

English

Page 13

Type 8045

Installation and wiring

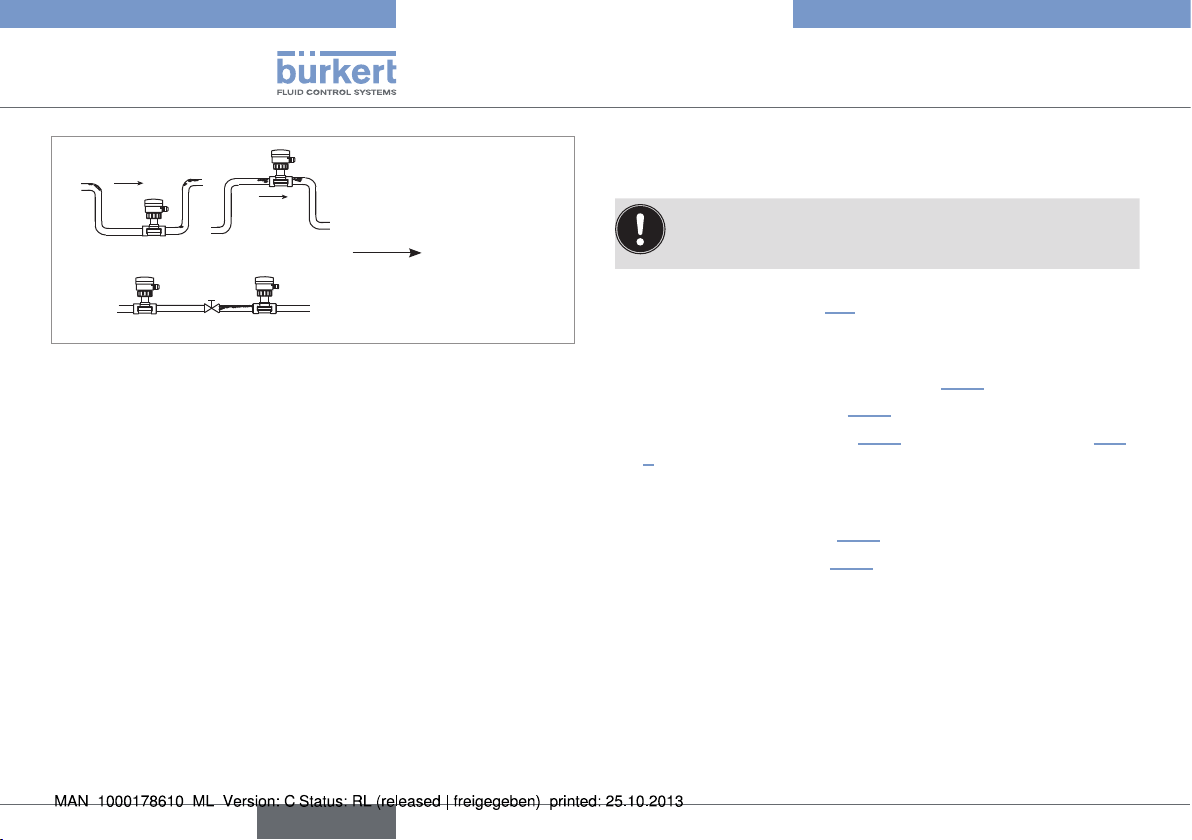

→ Respect the following additional mounting conditions to ensure

that the measuring device operates correctly:

- Preferably install the device at a 45° angle to the horizontal centre of

the pipe to avoid having deposits on the electrodes and false measurements due to air bubbles (see Fig. 5);

45°

45°

Fig. 5: Mounting angle on the pipe

- Ensure that the pipe is always filled in the section around the

device (see Fig. 6).

- When mounting vertically ensure that the flow direction is in an

upward direction (see Fig. 6).

Horizontal mounting

Correct Incorrect

Vertical mounting

flow direction

Correct Incorrect

Fig. 6: Filling of the pipe

- Prevent the formation of air bubbles in the pipe in the section

around the device (see Fig. 7).

- Always mount the device upstream a possible injection point

in the pipe of a high-conductivity fluid (for example: acid, base,

saline,...).

English

13

Page 14

Correct

Correct Incorrect

Fig. 7: Air bubbles within the pipe

Incorrect

flow direction

→ If necessary, use a flow conditioner to improve measurement

precision.

Type 8045

Installation and wiring

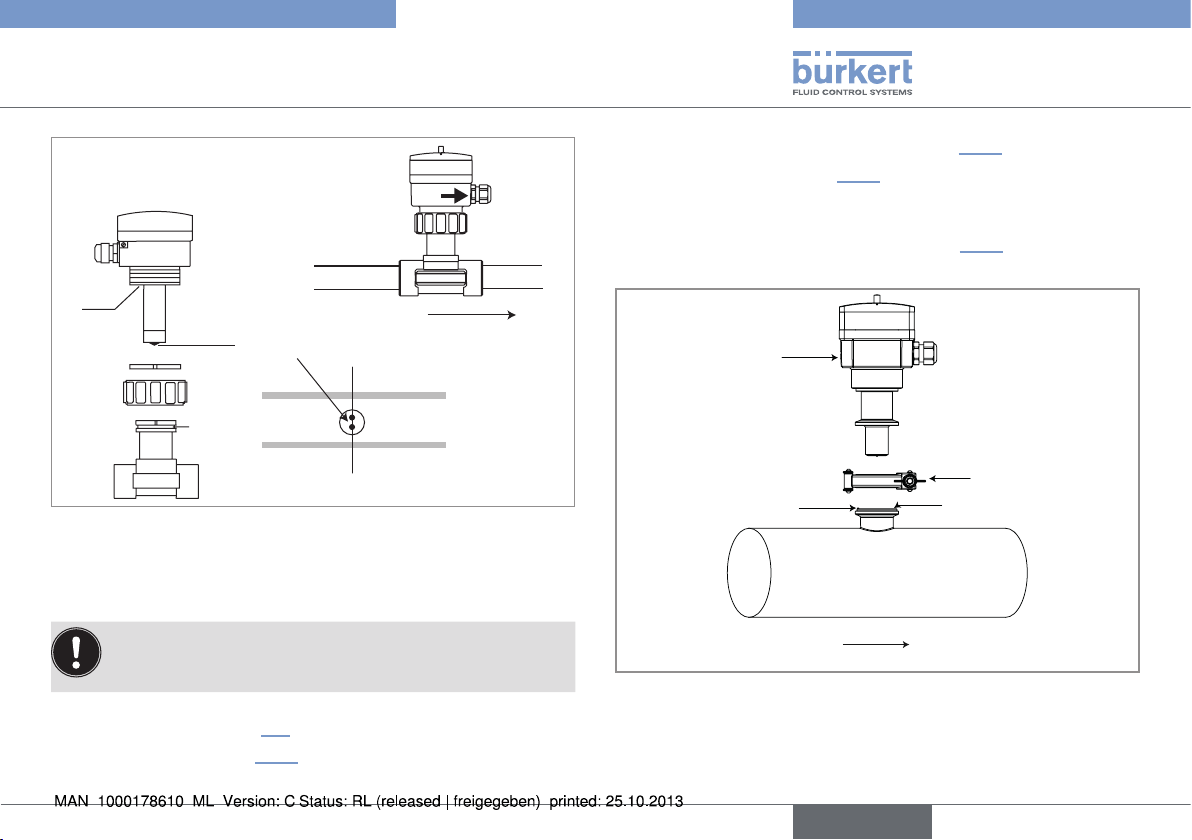

7.3. Installation into the pipe of a

8045 with a G2'' nut

In order to ensure a high accuracy of the measurements and

good stability of the „flow zero“ point, install the device into

the processed medium at least 24 H before calibration.

→ Install the S020 fitting into the pipe taking into account the rec-

ommendations in chap. 7.2.

→ Check that there is a seal on the fitting and that it is not damaged.

Replace the seal if necessary.

→ Check that there is a seal (see mark 6, Fig. 8) on the flow sensor.

→ Insert the nut (see mark 3, Fig. 8) on the fitting.

→ Insert the snap ring (mark 2 Fig. 8) into the groove (mark 5 Fig.

8).

→ Position the arrow on the side of the device in the direction of the

flow: the totalizers will increment.

→ Insert the device (mark 1 Fig. 8) into the fitting.

→ Tighten the nut (mark 3, Fig. 8) by hand on the device.

14

English

Page 15

Type 8045

Installation and wiring

1

FLOW

→ Make sure that the polarizing pin (mark 4 Fig. 9) is on the fitting.

→ Insert the device (mark 1 Fig. 9) into the fitting. Position the

arrow on the side of the device in the direction of the flow: the

totalizers will increment.

→ Tighten by hand the clamp collar (mark 2 Fig. 9).

→ Charge the pipe to make sure the installation is tight.

6

Electrodes

2

3

5

4

flow direction

Fig. 8: Installation into the pipe of a 8045 with a G2'' nut

7.4. Installation into the pipe of a

8045 with a clamp connection

In order to ensure a high accuracy of the measurements and

good stability of the „flow zero“ point, install the device into

the processed medium at least 24 H before calibration.

→ Install the S020 fitting into the pipe taking into account the rec-

ommendations in chap. 7.2.

→ Install the seal (mark 3 Fig. 9) on the S020 fitting.

1

2

4

flow direction

3

Fig. 9: Installation into the pipe of a 8045 with a clamp

connection

English

15

Page 16

Type 8045

Installation and wiring

7.5. Wiring

danger

Risk of injury due to electrical voltage.

• Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

• Use a high quality electrical power supply (filtered and

regulated).

• Make sure the installation is equipotential. See chap.

7.5.1.

• Use shielded cables with a temperature limit of 80 °C

minimum.

• Do not install the cables near high voltage or high frequency cables; If this cannot be avoided, observe a min.

distance of 30 cm.

• Protect the power supply by means of a 300 mA fuse and

a switch.

• Protect the relays by means of a max. 3 A fuse and a

circuit breaker (depending on the process).

• Do not apply both a dangerous voltage and a safety extralow voltage to the relays.

Insert the supplied stopper gasket into the unused cable

gland to ensure the tightness of the device.

If two cables are used in the same cable gland, first insert

the supplied multi-way seal.

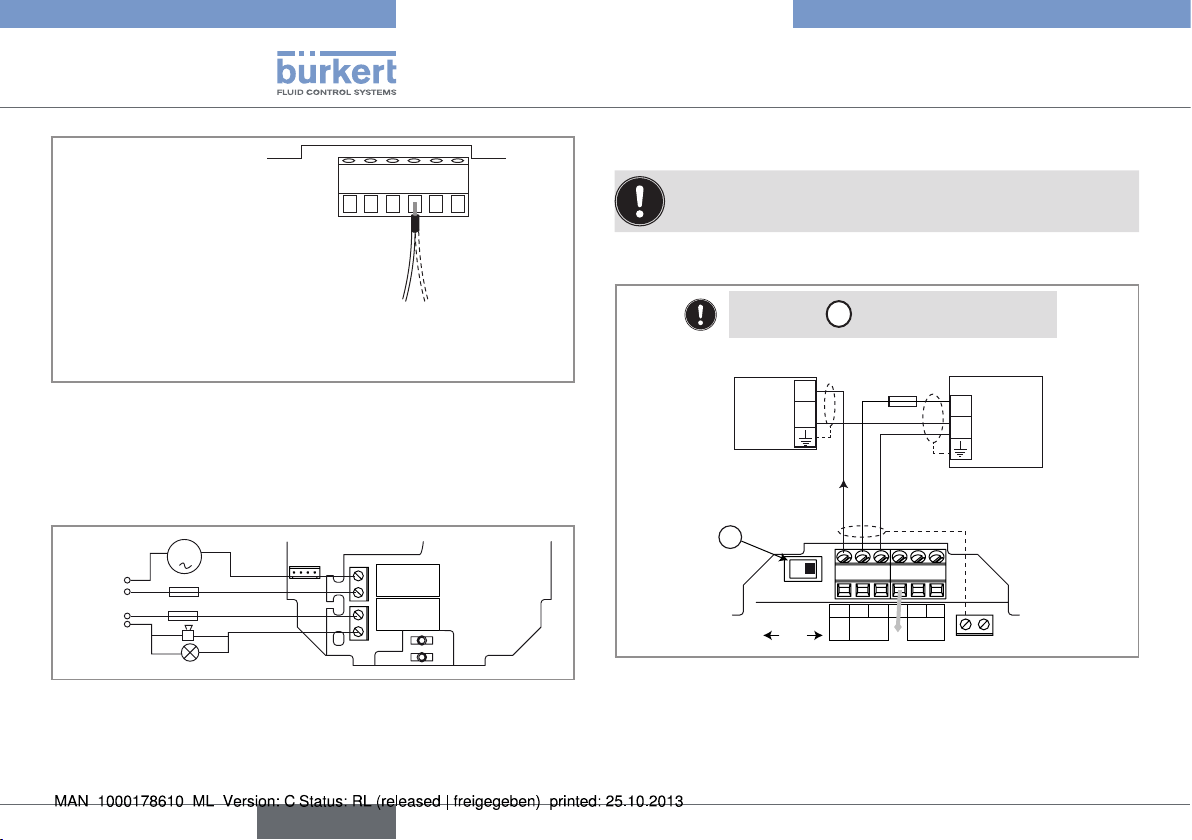

To wire the device:

→ Loosen the screw from the lid.

→ Flip the lid.

→ Loosen the 4 screws from the cover of the housing.

→ Remove the cover.

→ Loosen the nuts of the cable glands.

→ Insert the cable through the nut then through the cable gland.

→ Make sure the earth cable coming from the housing and, on a

version with stainless steel sensor, the cable coming from the

flow sensor, are connected as shown in Fig. 15, chap. 7.5.2.

→ Wire acc. to chap. 7.5.1 to 7.5.3.

7.5.1. Equipotentiality of the installation

To ensure the equipotentiality of the installation (power supply device - fluid):

→ Connect together the various earth spots in the installation to

eliminate the potential differences that may occur between different earthes.

→ Observe faultless earthing of the shield of the power supply

cable, at both ends.

16

English

Page 17

Type 8045

Installation and wiring

→ Connect the negative power supply terminal to the earth to sup-

press the effects of common mode currents. If this connection

cannot be made directly, a 100 nF/50 V capacitor can be fitted

between the negative power supply terminal and the earth.

→ Special attention has to be paid if the device is installed on

plastic pipes because there is no direct earthing possible.

Proper earthing is performed by earthing together the metallic

instruments such as pumps or valves, that are as close as possible to the device. If no such instrument is near the device,

insert metallic earth rings inside the plastic pipes upstream and

downstream the device and connect these parts to the same

earth. The earth rings must be in contact with the fluid.

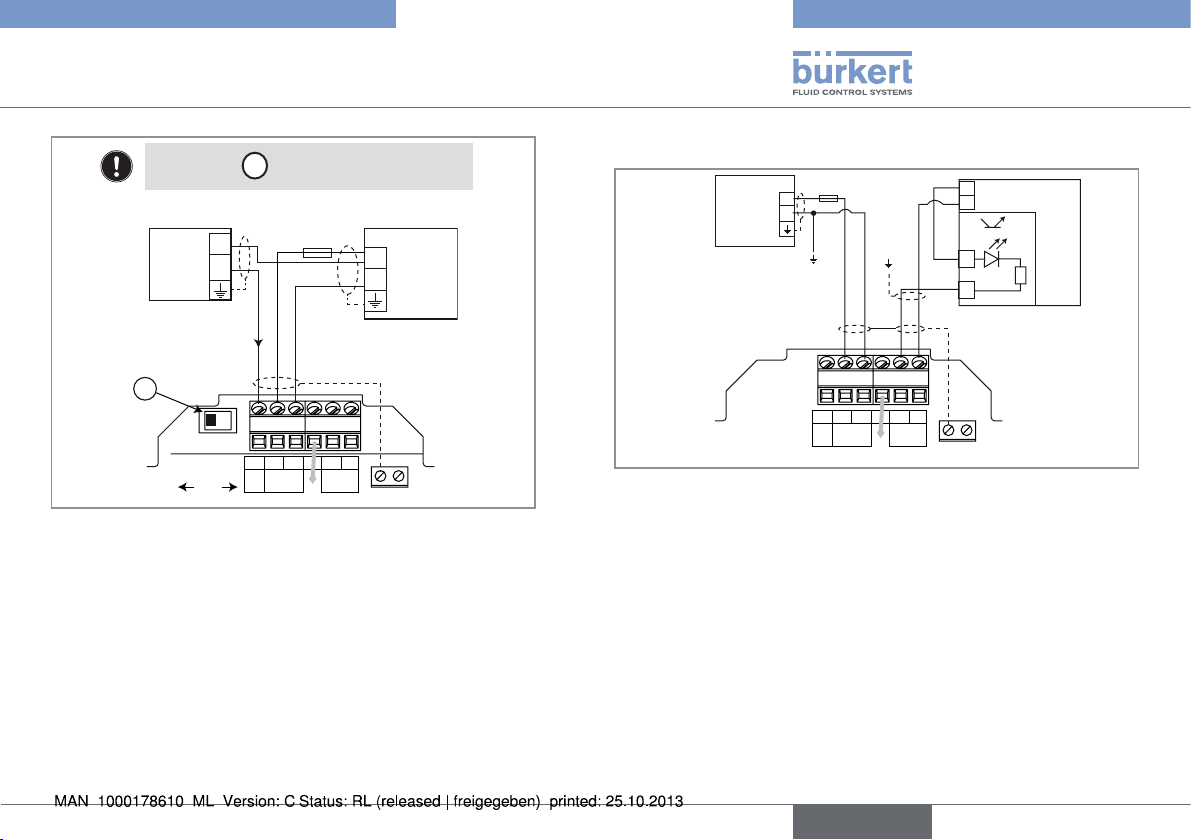

Power cable shield

Power supply

18-36VDC

+

-

1)

Pipes in plastic

Valve, pump,... (or earthing rings,

not provided, inserted into the

pipe)

1)

If a direct earth connection is not possible, fit a 100 nF / 50 V

capacitor between the negative power supply terminal and the earth.

Fig. 10: Equipotentiality skeleton diagram with pipes in plastic

English

17

Page 18

Type 8045

Installation and wiring

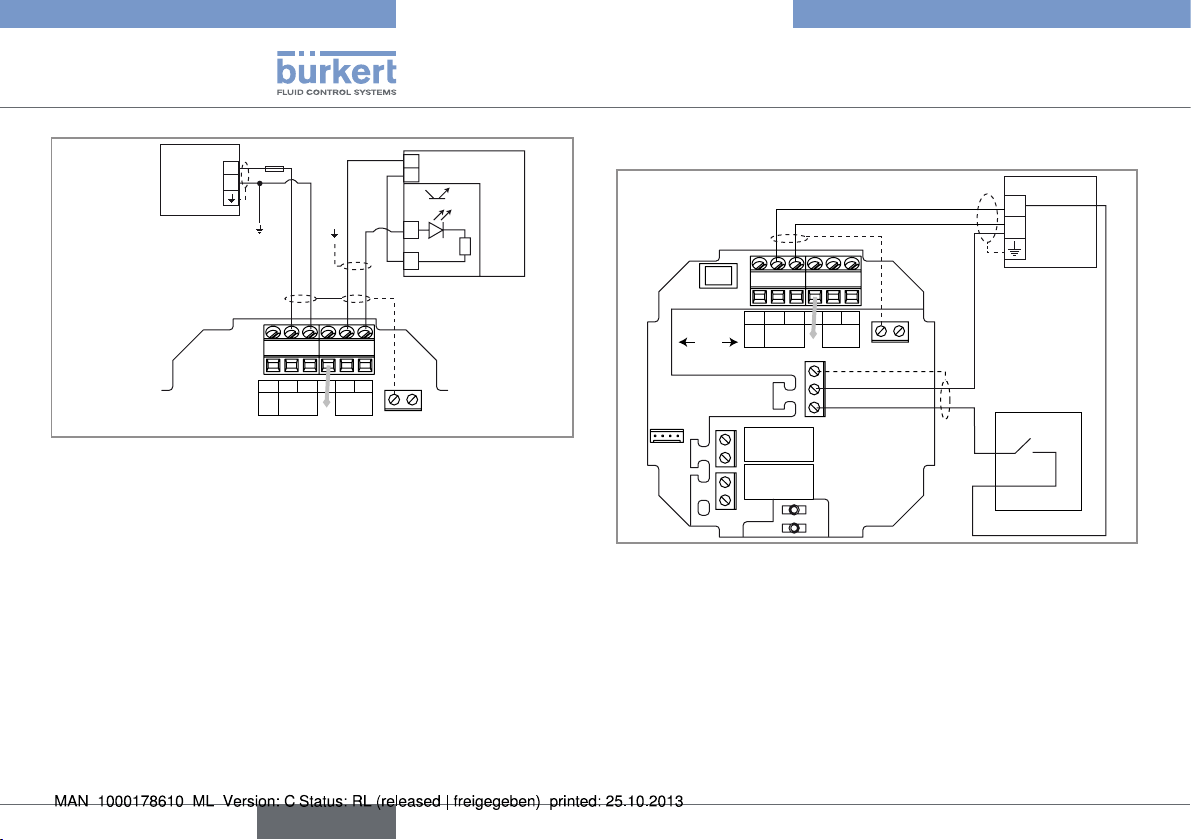

Power cable shield

Power supply

18-36VDC

+

-

1)

Metal pipe

1)

If a direct earth connection is not possible, fit a 100 nF / 50 V

capacitor between the negative power supply terminal and the

earth.

Fig. 11: Equipotentiality skeleton diagram with pipes in metal

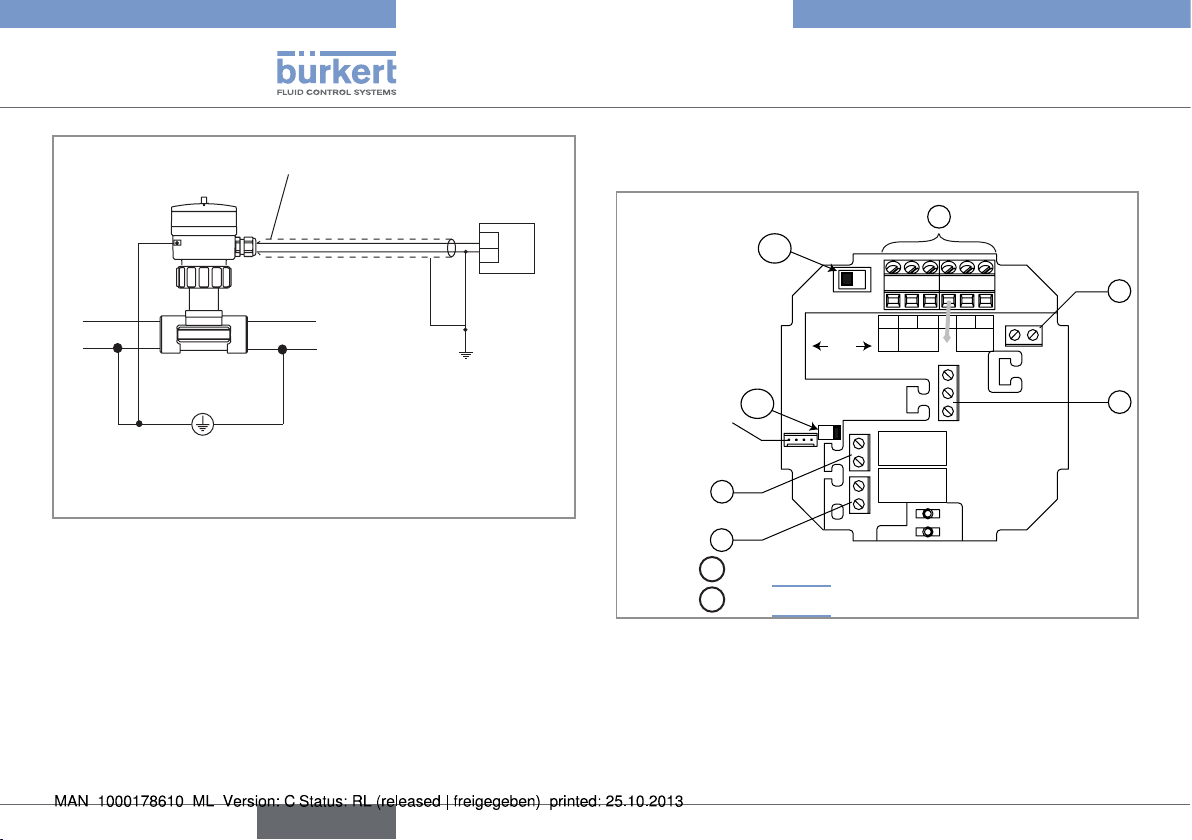

7.5.2. Terminal assignment and use of the

selectors

1

A

2

4 pin ribbon ca-

ble coming from

the flow sensor

Selector

Selector

B

4

5

A

: see Fig. 13

B

: see Fig. 14

CURRENT

OFF ON

DO3

SOURCESINK

DO2

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

PE

-

+

DI1

PULSE

DO1

PE

3

18

English

Page 19

Type 8045

Installation and wiring

Terminal block 1

Iout: 4-20 mA output (AO1)

L+: V+ (positive voltage)

L-: 0V (power supply ground)

PE: functional earth, wired in the factory (see Fig. 15)

P+: positive transistor output (DO1)

P-: negative transistor output (DO1)

Terminal block 2

PE: shieldings of both the power supply cable and the AO1

and DO1 output cables

Terminal block 3

PE: functional earth of the DI1 digital input

-: negative signal of the DI1 input

+: positive signal of the DI1 input

Terminal block 4: wiring the DO2 relay output

Terminal block 5: wiring the DO3 relay output

Fig. 12: Terminal assignment

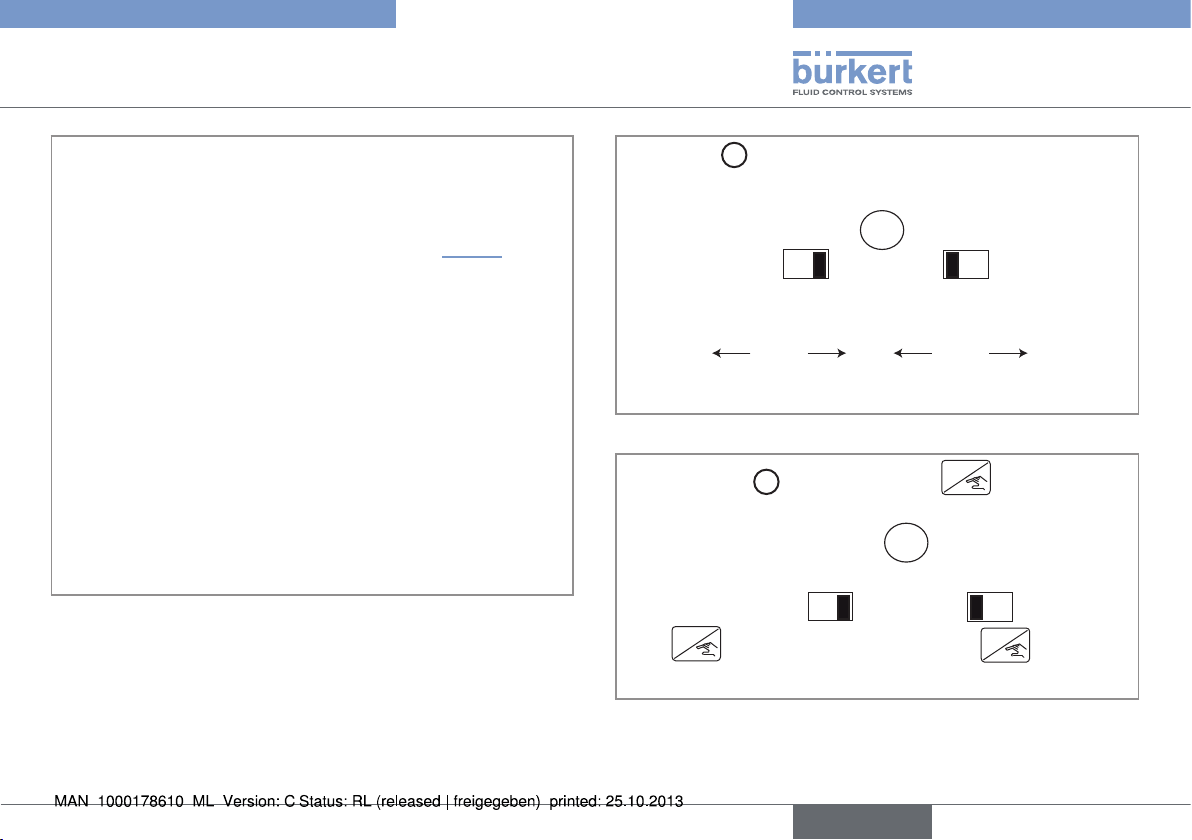

A

Use switch

to configure the wiring of the 4-20 mA cur-

rent output in sinking or sourcing mode.

A

CURRENT

SOURCESINK

Wire the current output

in sourcing mode.

Fig. 13: Sink/source switch

B

Use the switch

unauthorized access to the configuration of the device.

to lock/unlock the

CURRENT

SOURCESINK

Wire the current output in

sinking mode.

ENTER

key to prevent

B

OFF ON

ENTER

The

Fig. 14: Switch to lock/unlock the ENTER key

key is unlocked (de-

fault position).

OFF ON

ENTER

The

locked.

key is

English

19

Page 20

123456

Type 8045

Installation and wiring

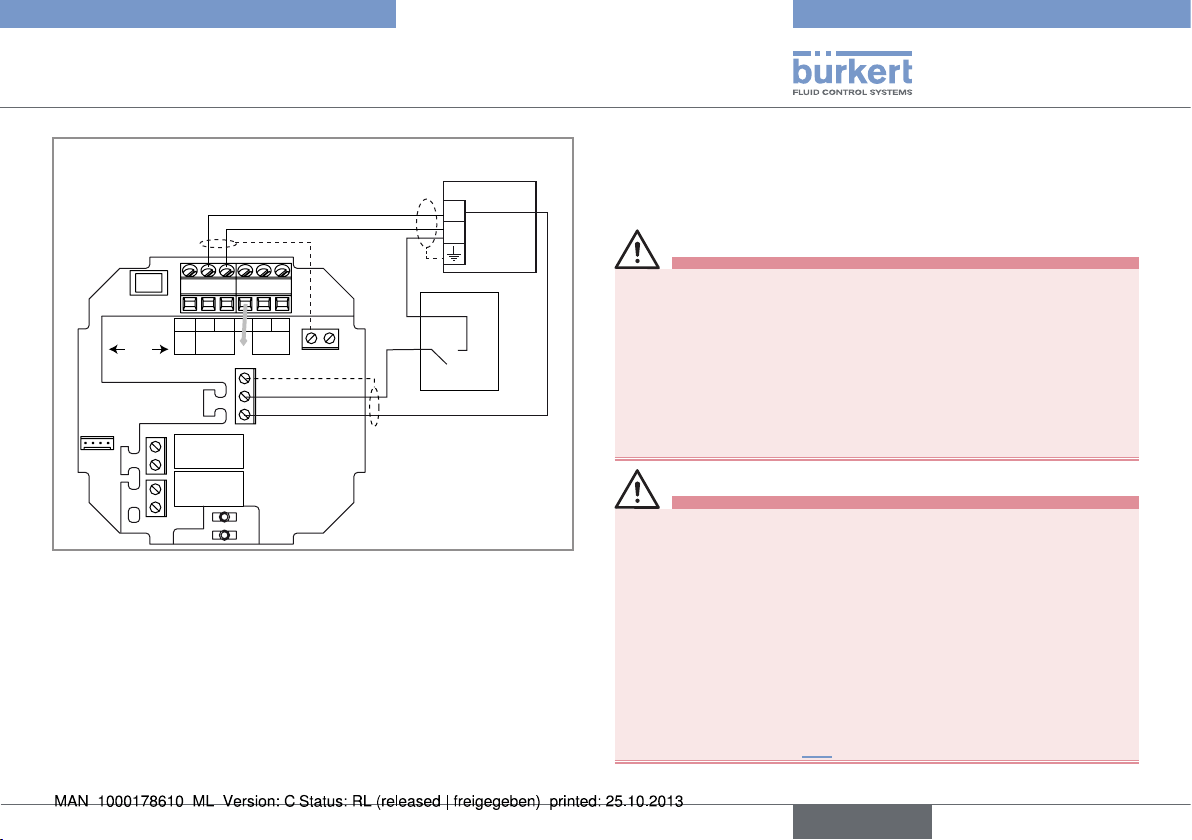

7.5.4. Wiring the AO1 current output

For safety reasons, secure the cables using a non-conducting cable clamp.

The 4-20 mA output can be wired in either sourcing or sinking

mode.

Earth cable coming from the housing.

On a version with stainless steel flow sensor, a second cable

is coming from the sensor.

Fig. 15: Connection of the earth wire coming from the housing

(made in the factory)

7.5.3. Wiring the DO2 and DO3 relay

outputs

m

230 VAC

230 VAC

Fig. 16: Wiring of the DO2 and DO3 relay outputs

20

3 A

3 A

English

DO2

DO3

Position the A switch to the right.

PULSE

DO1

(*)

Power supply

18-36 V DC

+

-

PE

4-20mA input at external

device

A

CURRENT

SOURCESINK

+

300 mA

-

I

L+ L-PEP+P-Iout

Supply

AO1

18...36 Vdc

Fig. 17: Wiring of the 4-20 mA output (AO1) in sourcing mode

*) If a direct earth connection is not possible, fit a 100 nF/50 V

capacitor between the negative power supply terminal and the earth

Page 21

Type 8045

18-36 V DC

Installation and wiring

Position the A switch to the left.

I

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

300 mA

PULSE

DO1

(*)

+

-

Power supply

PE

4-20mA input at external

device

A

CURRENT

SOURCESINK

+

-

Fig. 18: Wiring of the 4-20 mA output (AO1) in sinking mode

*) If a direct earth connection is not possible, fit a 100 nF/50 V

capacitor between the negative power supply terminal and the earth

7.5.5. Wiring the DO1 transistor output

18-36 V DC

Power supply

+

-

(*)

300 mA

L+ L-PEP+P-Iout

Supply

AO1

18...36 Vdc

PULSE

DO1

Fig. 19: NPN wiring of the DO1 transistor output

*) If a direct earth connection is not possible, fit a 100 nF/50 V

capacitor between the negative power supply terminal and the earth

+

5-36 VDC

-

+

-

PE

PLC

English

21

Page 22

Type 8045

Installation and wiring

18-36 V DC

Power supply

300 mA

+

-

(*)

+

5-36 VDC

-

+

-

PLC

L+ L-PEP+P-Iout

Supply

AO1

18...36 Vdc

PULSE

DO1

PE

Fig. 20: PNP wiring of the DO1 transistor output

*) If a direct earth connection is not possible, fit a 100 nF/50 V

capacitor between the negative power supply terminal and the earth

7.5.6. Wiring the DI1 digital input

(*)

CURRENT

SOURCESINK

DO3

DO2

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

DI1

PE

-

+

PULSE

DO1

PE

18-36 V DC

+

-

Power supply

Switch

22

English

Page 23

Type 8045

Adjustment, commissioning

CURRENT

SOURCESINK

DO2

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

PE

-

+

DI1

PULSE

DO1

PE

Power supply

18-36 V DC

+

-

(*)

Switch

8. ADJUSTMENT, COMMISSIONING

8.1. Safety instructions

Warning

Risk of injury due to non-conforming operating.

Non-conforming operating could lead to injuries and damage the

device and its surroundings.

• The operators in charge of operating must have read and understood the contents of these operating instructions.

• In particular, observe the safety recommendations and intended use.

• The device/installation must only be operated by suitably trained

staff.

Warning

DO3

Fig. 21: Possible wirings of the DI1 digital input

*) If a direct earth connection is not possible, fit a 100 nF/50 V

capacitor between the negative power supply terminal and the earth

Danger due to non-conforming commissioning.

Nonconforming commissioning could lead to injuries and damage

the device and its surroundings.

• Before commissioning, make sure that the staff in charge

have read and fully understood the contents of the operating

instructions.

• In particular, observe the safety recommendations and intended use.

• The device / the installation must only be commissioned by suitably trained staff.

• Before commissioning the device, enter the K factor of the fitting used. See chap. 8.6.

English

23

Page 24

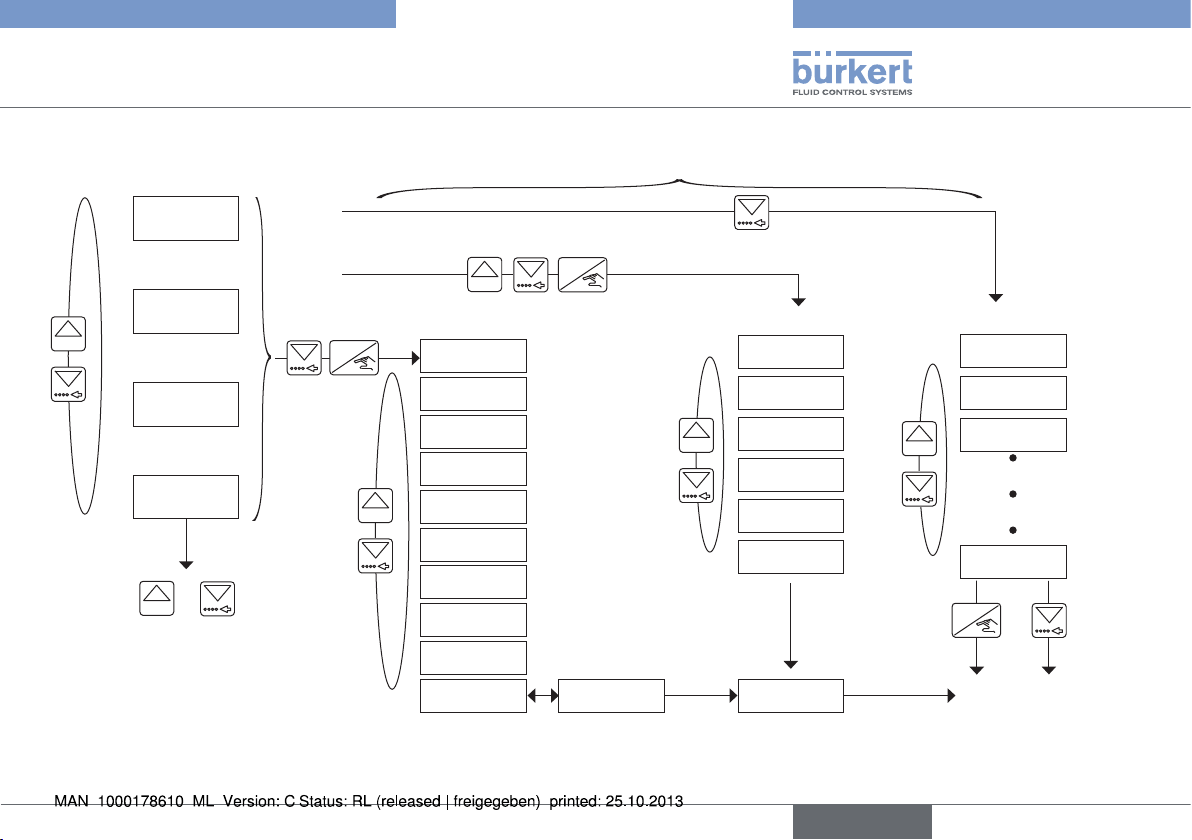

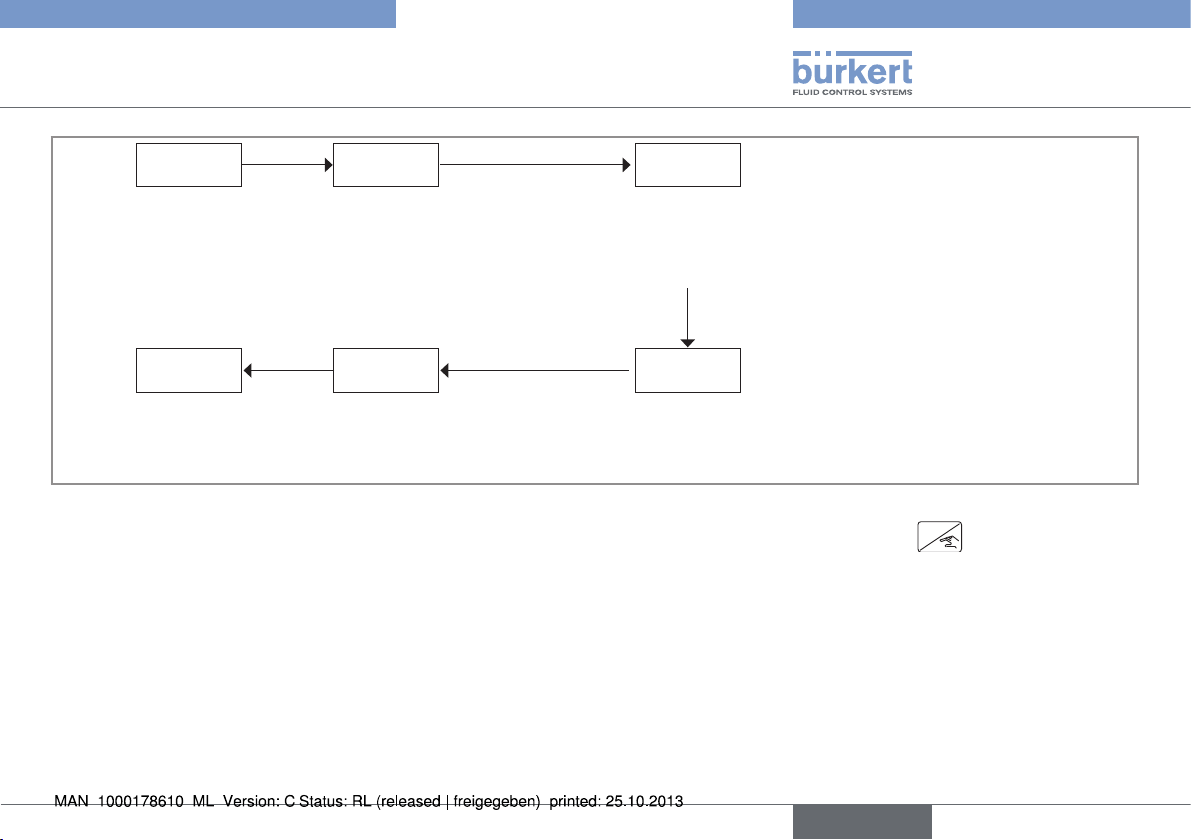

8.2. Operating levels of the device

The device has two operating levels: the Process level and the Configuration level.

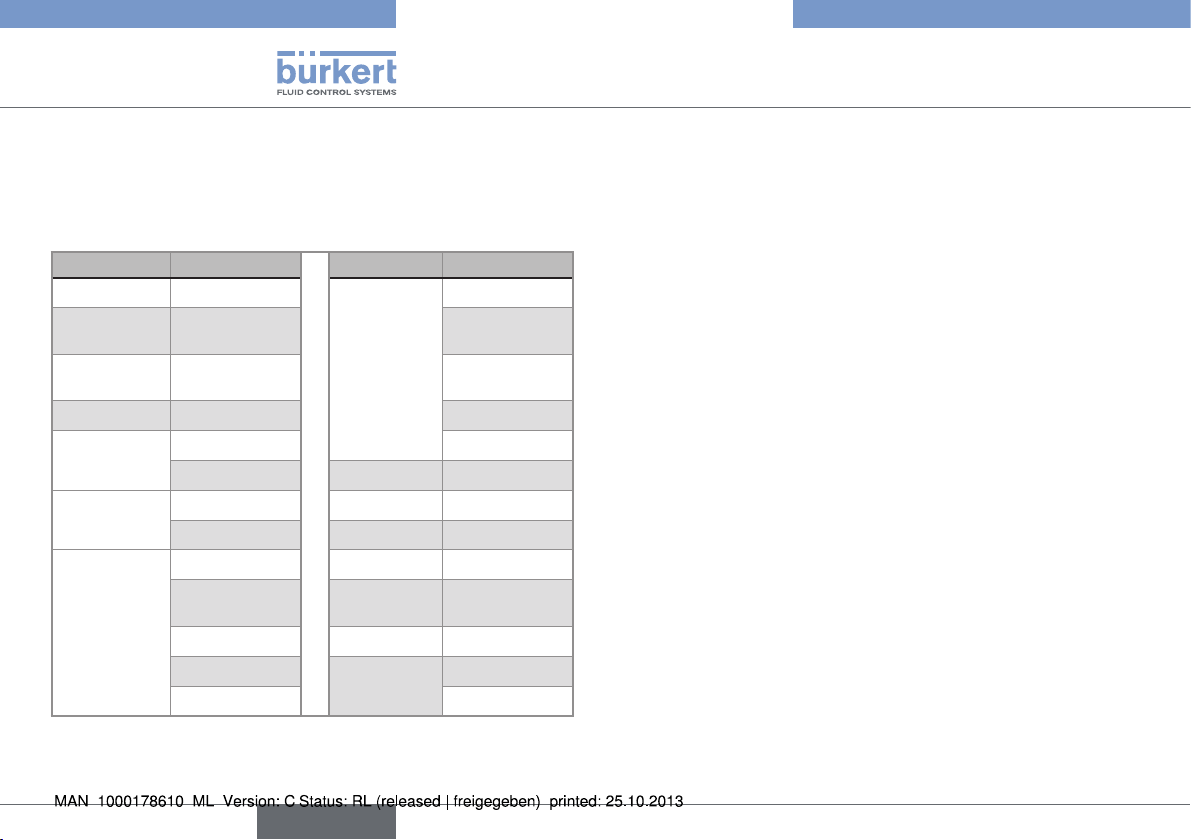

Table 1: Default settings of the device

Function Default value Function Default value

LANGUAGE English OUTPUT

UNIT of the

flow rate

UNIT of the

totalizers

K-FACTOR 1.000 Not inverted

OUTPUT

AO1

OUTPUT

DO1

OUTPUT

DO2

l/min. 3-= 0.000

litre 3+= 0.000

4mA= 0.000

20mA= 0.000 INPUT DI1 disable

pulse FILTER 5, slow

PU= 0.00 litre FREQUENC. 50Hz

Hysteresis CUT-OFF 0.000

2-= 0.000 BACKLIT level 9, acti-

2+= 0.000 K-SENSOR Kw= 1.000

Not inverted FLOW-W. W-= 0.000

time delay = 0

DO3

Hysteresis

time delay = 0

vated for 30s

W+= 0.000

Type 8045

Adjustment, commissioning

24

English

Page 25

Type 8045

Adjustment, commissioning

Process level

12.6 L/s

16.45 mA

0......9

Parameters menu Test Menu

ENTER

LANGUAGE

> 5 s

87654 L

UNit

K-FACtOR

OUtPUt

231 L.

0......9

iNPUt

FiLtER

+

0......9

> 2 s

To reset the daily totalizer (identified by

a dot after the volume units).

tOtAL

FREqUENC.

CUt-OFF

BACKLit

1)

Accessible when the device status LED is orange or red.

2)

If the ENTER key is unlocked.

0......9

> 5 s

Configuration level

ENTER

END

0......9

> 2 s

CAL AO1

CALiB 0

FLOw

K-sENsOR

FLOw-w.

sAVE N/Y

END

Information menu

mEAs. OVF

CAL. FAiL

NEG. FLOw

0......9

END

ENTER

or

2)

Process level

1)

English

25

Page 26

Type 8045

Adjustment, commissioning

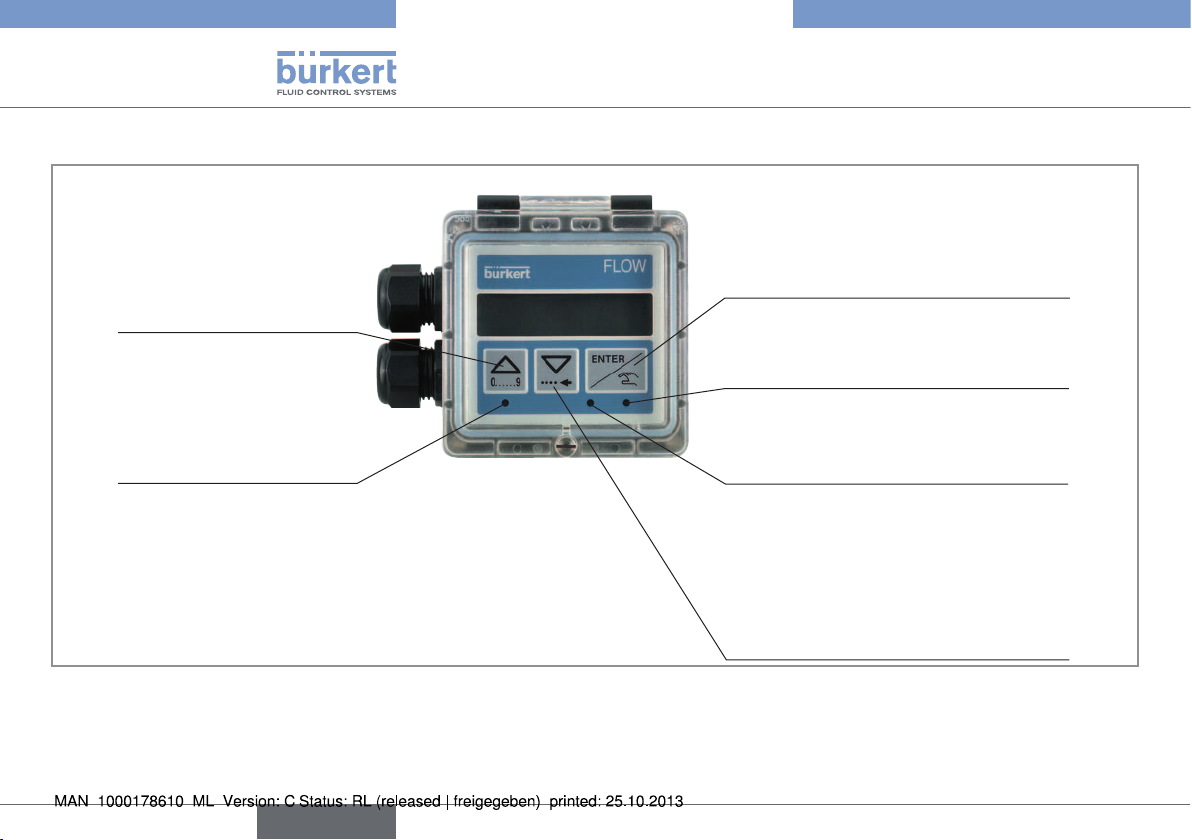

8.3. Description of the navigation keys and the state LEDs

26

• Scrolling up the

parameters

• Incrementing the figure

selected

Device state LED: see following table.

English

• Selecting the displayed parameter

• Confirming the settings

Status LED of relay DO3 (LED ON =

contact closed)

Status LED of relay DO2 (LED ON =

contact closed)

• Reading the messages

• Scrolling through the parameters

• Selecting the figure on the left

Page 27

Type 8045

Adjustment, commissioning

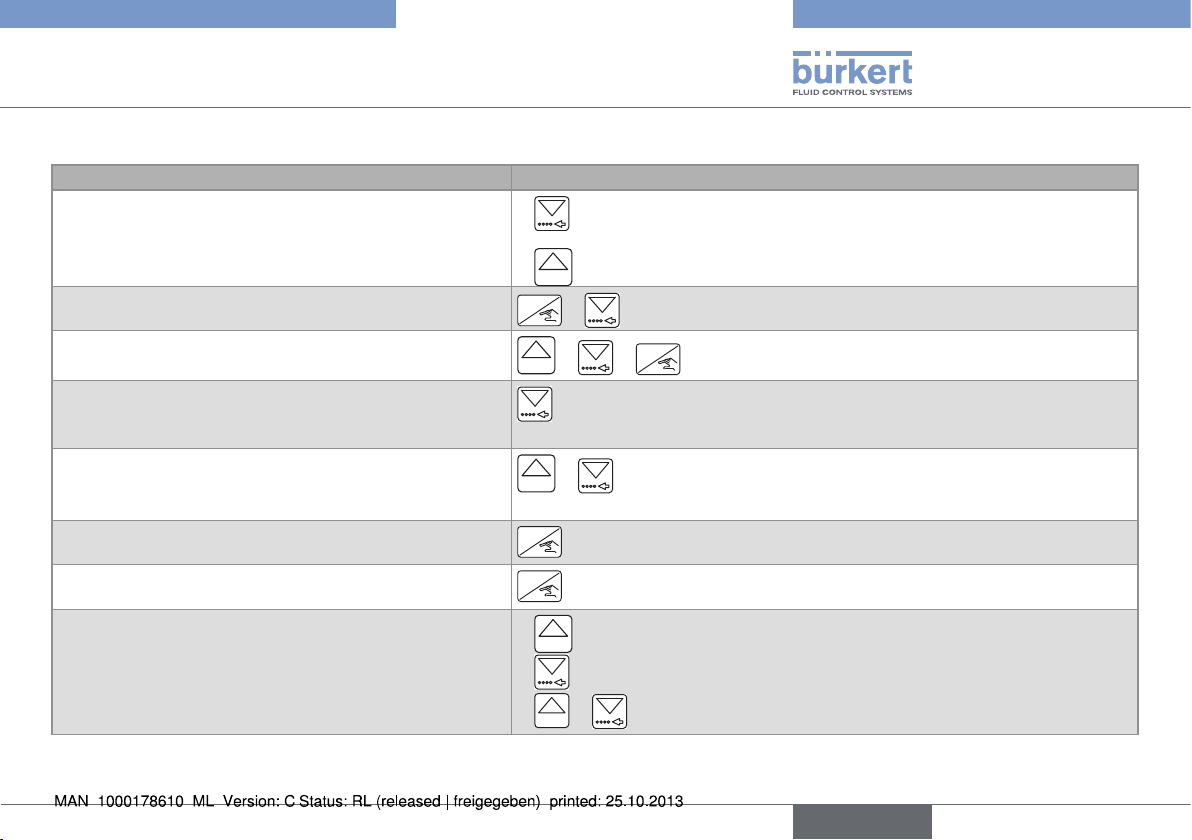

8.4. Using the navigation keys

You want to... Press...

move between parameters within a level or a menu.

access the Parameters menu.

access the Test menu.

access the Information menu.

•

•

ENTER

0......9

0......9

to go to the next parameter.

to go to the previous parameter.

+ simultaneously for 5 s, in the Process level

ENTER

+ +

simultaneously for 5 s, in the Process level

for 2 s, in the Process level, when the device status LED is orange or red.

reset the daily totalizer.

select the displayed parameter.

confirm the displayed value.

modify a numerical value.

0......9

+ simultaneously for 2 s, when the daily totalizer is displayed in the

Process level

ENTER

ENTER

to increase the blinking digit.

•

0......9

to select the digit at the left of the blinking digit.

•

0......9

+ to move the decimal point.

•

English

27

Page 28

Type 8045

Adjustment, commissioning

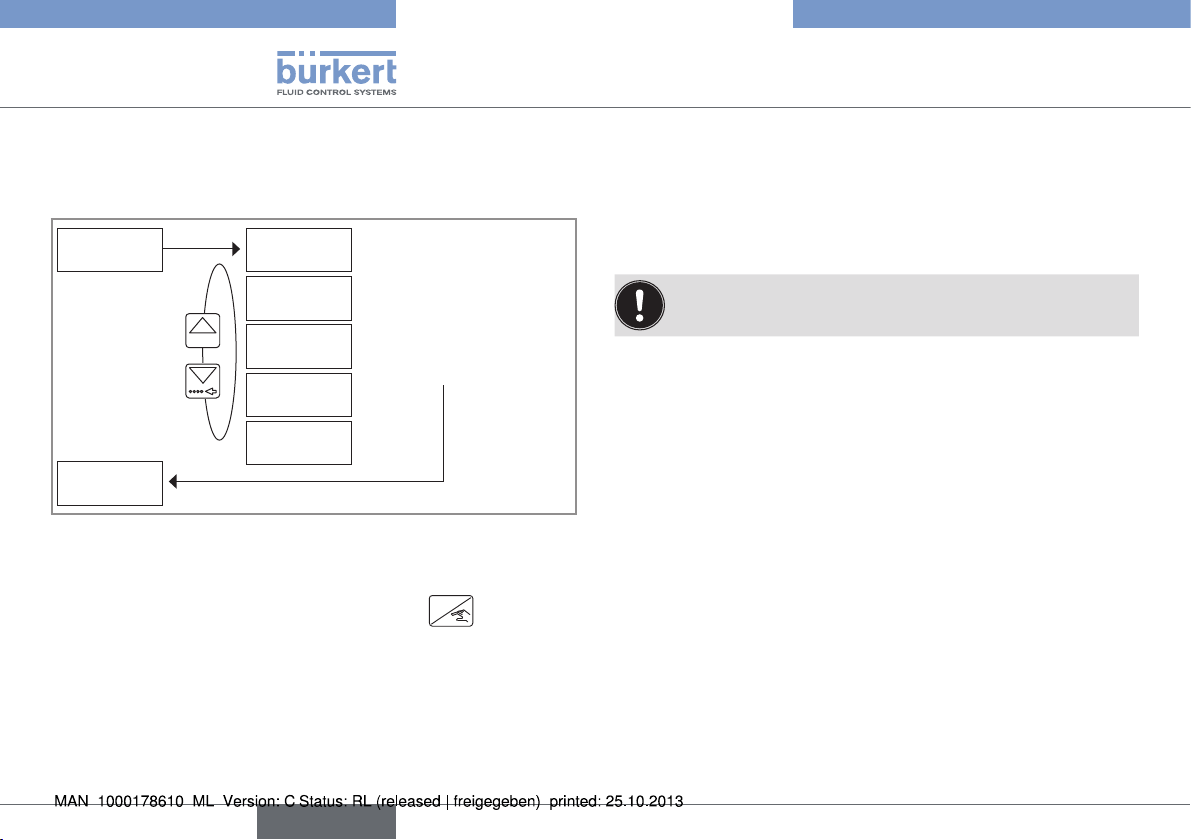

8.5. Choosing the display language

When the device is energized for the first time, the display language

is English.

LANGUAGE ENGLish

0......9

DEUtsCh

FRANçAis

→ Confirm the displayed

language: The selected

language is immediately active.

itALiANO

EsPANOL

UNit

Fig. 22: Diagram of the "LANGUAGE" parameter of the Parameters

menu

→ If you do not want to adjust another parameter, go to the "END"

parameter of the Parameters menu and press

settings or not and go back to the Process level.

ENTER

to save the

8.6. Entering the K factor of the fitting

used:

The device determines the flow rate in the pipe using the fitting K

factor.

The K factor of the fitting used can be entered here.

The device will use the new K factor as soon as "SAVE

YES" is confirmed when leaving the Parameters menu.

28

English

Page 29

Type 8045

Adjustment, commissioning

K-FACtOR K=10.000

The display shows the K factor of the

fitting, may it have been entered or

determined by a teach-in procedure;

this K factor is currently used by the

device

K=2.8500

→ Enter the K factor (value between 0,0001 and

9999,9) of the fitting used.

→ Confirm the displayed value.

→ Edit the parameter.

OUtPUt VALiD N/Y

REtURN

Is only displayed if the K factor has been changed.

→ Confirm the entered K factor or not.

Fig. 23: Entering the K factor of the fitting used

→ If you do not want to adjust another parameter, go to the "END" parameter of the Parameters menu and press

not and go back to the Process level.

ENTER

to save the settings or

English

29

Page 30

Type 8045

Maintenance and troubleshooting

9. MAINTENANCE AND

TROUBLESHOOTING

9.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

Risk of injury due to electrical voltage.

Risk of injury due to high fluid temperatures.

Risk of injury due to the nature of the fluid.

Warning

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Ensure that the restart of the installation is controlled after any

interventions.

→ If a problem occurs, refer to the complete operating instructions

available on the CD delivered with the device.

10. PACKAGING, TRANSPORT

note

Damage due to transport

Transport may damage an insufficiently protected device.

• Transport the device in shock-resistant packaging and away

from humidity and dirt.

• Do not expose the device to temperatures that may exceed the

admissible storage temperature range.

• Protect the electrical interfaces using protective plugs.

11. STORAGE

note

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Storage temperature of the device: -20 to +60 °C.

30

English

Page 31

Type 8045

Disposal of the product

12. DISPOSAL OF THE PRODUCT

→

Dispose of the device and its packaging in an environmentallyfriendly way.

note

Damage to the environment caused by products contaminated by fluids.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

note

Comply with the national and/or local regulations which

concern the area of waste disposal.

English

31

Page 32

Type 8045

32

English

Page 33

Typ 8045

Magnetisch-induktives Durchfluss-Messgerät

Quickstart

Deutsch

Page 34

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2012 - 2013

Operating Instructions 1308/1_EU-ML 00563855 ORIGINAL_FR

1. ÜBER DEN QUICKSTART ...........................................................................3

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ......................................4

3. GRUNDLEGENDE SICHERHEITSHINWEISE ....................................4

4. ALLGEMEINE HINWEISE .............................................................................6

5. BESCHREIBUNG DES TYPENSCHILDS .............................................6

6. TECHNISCHE DATEN ...................................................................................7

7. INSTALLATION UND VERKABELUNG ...............................................12

8. BEDIENUNG UND INBETRIEBNAHME ............................................. 24

9. WARTUNG, FEHLERBEHEBUNG ......................................................... 31

10. VERPACKUNG, TRANSPORT .............................................................. 31

11. LAGERUNG ...................................................................................................31

12. ENTSORGUNG DES GERÄTES .......................................................... 32

Page 35

Type 8045

Warnt vor Sachschäden!

Über den Quickstart

1. ÜBER DEN QUICKSTART

Der Quickstart beschreibt den gesamten Lebenszyklus des Gerätes.

Bewahren Sie diese Anleitung so auf, dass sie für jeden Benutzer

zugänglich ist und jedem neuen Eigentümer des Gerätes wieder zur

Verfügung steht.

Wichtige Informationen zur Sicherheit!

Lesen Sie den Quickstart sorgfältig durch. Beachten Sie vor allem

die Kapitel Grundlegende Sicherheitshinweise und Bestimmungs-

gemäße Verwendung.

• Der Quickstart muss gelesen und verstanden werden.

Der Quickstart erläutert beispielhaft die Montage und Inbetriebnahme des Gerätes.

Die ausführliche Beschreibung des Gerätes finden Sie in der entsprechenden Bedienungsanleitung auf der mitgelieferten CD.

1.1. Darstellungsmittel

GefaHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichteinhaltung sind Tod oder schwere Verletzungen die

Folge.

waRnunG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichteinhaltung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HInweIS!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2. Begriffsdefinition "Gerät"

Der in dieser Anleitung verwendete Begriff "Gerät" steht immer für

das Durchfluss-Messgerät Typ 8045.

deutsch

3

Page 36

Type 8045

Bestimmungsgemässe Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz dieses Gerätes

können Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

• Das Durchfluss-Messgerät 8045 ist ausschließlich für die

Durchflussmessung in Flüssigkeiten bestimmt.

• Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

• Für den Einsatz sind die in den Vertragsdokumenten und der

Bedienungsanleitung spezifizierten zulässigen Daten, Betriebsund Einsatzbedingungen zu beachten.

• Zum sicheren und problemlosen Einsatz des Gerätes müssen

Transport, Lagerung und Installation ordnungsgemäß erfolgen,

außerdem müssen Betrieb und Wartung sorgfältig durchgeführt

werden.

• Achten Sie immer darauf, dieses Gerät auf ordnungsgemäße

Weise zu verwenden.

→ Beachten Sie bei der Ausfuhr des Gerätes gegebenenfalls

bestehende Beschränkungen.

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und

Wartung der Geräte auftreten können.

• Ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Installations- und Wartungspersonal, der Betreiber

verantwortlich ist.

Gefahr durch hohen Druck in der Anlage!

• Vor dem Lösen der Prozessanschlüsse die Anlage druckfrei

schalten und die Flüssigkeitszirkulation stoppen.

Gefahr durch elektrische Spannung!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall alle existierenden am Gerät angeschlossenen Spannungs-Versorgungen ab,

und sichern Sie diese vor unbeabsichtigtem Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

Gefahr durch hohe Flüssigkeitstemperaturen!

• Das Gerät nur mit Schutzhandschuhen anfassen.

• Vor dem Lösen der Prozessanschlüsse die Flüssigkeitszirkulation stoppen und die Rohrleitung leeren.

Gefahr aufgrund der Art der Flüssigkeit!

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung

und der Sicherheit in Kraft sind und die sich auf die Verwendung

gefährlicher Flüssigkeiten beziehen.

4

deutsch

Page 37

Type 8045

Grundlegende Sicherheitshinweise

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten

• Dieses Gerät nicht für die Durchflussmessung von Gas

einsetzen.

• Dieses Gerät nicht in explosionsgefährdeten Bereichen

einsetzen.

• Dieses Gerät nicht in einer Umgebung verwenden, die mit den

Werkstoffen, aus denen es besteht, inkompatibel ist.

• Belasten Sie das Gerät nicht mechanisch (z. B. durch Ablage

von Gegenständen oder als Trittstufe).

• Nehmen Sie keine äußerlichen oder innerlichen Veränderungen

am Gerät vor.

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

• Nach einer Unterbrechung der elektrischen Versorgung ist ein

definierter oder kontrollierter Wiederanlauf des Prozesses zu

gewährleisten.

• Betreiben Sie das Gerät nur in einwandfreiem Zustand und

unter Beachtung der Bedienungsanleitung.

• Bei der Einsatzplanung und dem Betrieb des Gerätes die allgemeinen Regeln der Technik einhalten.

HInweIS!

Das Gerät kann durch das Medium beschädigt werden.

• Kontrollieren Sie systematisch die chemische Verträglichkeit der

Werkstoffe, aus denen das Gerät besteht, und der Flüssigkeiten, die mit diesem in Berührung kommen können (zum Beispiel:

Alkohole, starke oder konzentrierte Säuren, Aldehyde, Basen,

Ester, aliphatische Verbindungen, Ketone, aromatische oder

halogenierte Kohlenwasserstoffe, Oxidations- und chlorhaltige

Mittel).

HInweIS!

Elektrostatisch gefährdete Bauelemente / Baugruppen!

• Das Gerät enthält elektronische Bauelemente, die gegen

elektrostatische Entladung empfindlich reagieren. Berührung

mit elektrostatisch aufgeladenen Personen oder Gegenständen

gefährdet diese Bauelemente. Im schlimmsten Fall werden sie

sofort zerstört oder fallen nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340 -5-1 und 5-2,

um die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

• Achten Sie ebenso darauf, dass Sie elektronische Bauelemente

nicht bei anliegender Versorgungsspannung berühren!

deutsch

5

Page 38

Type 8045

1

2 5

3 4

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Herstelleradresse und

internationale Kontaktadressen

Sie können mit dem Hersteller des Gerätes unter folgender Adresse

Kontakt aufnehmen:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

oder wenden Sie sich an Ihr lokal zuständiges Vertriebsbüro von

Bürkert.

Die internationalen Kontaktadressen finden Sie im Internet unter:

www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des Gerätes unter Beachtung der in der vorliegenden

Bedienungsanleitung spezifizierten Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 8045 finden Sie

im Internet unter: www.buerkert.de

5. BESCHREIBUNG DES

TYPENSCHILDS

FLOW 8045 SST LONG SUPPLY: 18-36V 300 mA

DO1: 5-36V= 100mA DO2/3:250V 3A Max

DI1: 18-36V= 10mA IP65 Fluid: PN16:-15/110°C

S/N 11 162

Made in France

00449673 W43M

13

10

FLOW

14

67891112

6

deutsch

Page 39

Type 8045

Technische Daten

1. Messgröße und Typ des Gerätes

2. Durchfluss-Sensor-Daten

3. DO1-Digitalausgangsdaten

4. DO2- und DO3-Relaisausgangsdaten

5. Betriebsspannung und Stromverbrauch

6. Herstellungscode

7. Konformitäts-Logo

8. Warnung: Bevor das Gerät benutzt wird, die in der

Bedienungsanleitung beschriebenen technischen Daten

berücksichtigen.

9. Flüssigkeits-Druck und -Temperaturbereich

10. Schutzart des Gerätes

11. Daten des DI1-Digitaleingangs

12. Seriennummer

13. Bestellnummer

14. Zeigt die Fließrichtung an

Bild 1: Typenschild des Durchfluss-Messgerätes 8045 (Beispiel)

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

Umgebungstemperatur -10 bis +60 °C

Luftfeuchtigkeit < 85 %, nicht kondensierend

Höhe über

Meeresspiegel

Schutzart nach

EN 60529

6.2. Einhaltung von Normen und

Richtlinien

Durch folgende Normen wird die Konformität mit den EG-Richtlinien

erfüllt:

• EMV: EN 61000-6-2, EN 61000-6-3

• Niederspannungsrichtlinie: EN 61 010-1

• Vibration: EN 60068-2-6

• Schock: EN 60068-2-27

• Druck: Gemäß Artikel 3§3 der 97/23/CE Druckgeräterichtlinie.

Gemäß der 97/23/CE Druckgeräterichtlinie: Das Gerät kann nur

unter folgenden Bedingungen eingesetzt werden (abhängig vom

maximalen Druck, vom DN der Rohrleitung und von der Flüssigkeit)

max. 2000 m

IP65, mit angeschlossenem Gerät und

festgeschraubten Kabelverschraubungen und bis zum Anschlag festgeschraubtem Deckel mit Klappe.

deutsch

7

Page 40

Type 8045

Technische Daten

Art der Flüssigkeit Voraussetzungen

Flüssigkeitsgruppe 1

Kap. 1.3.a

Flüssigkeitsgruppe 2

Kap. 1.3.a

Flüssigkeitsgruppe 1

Kap. 1.3.b

Flüssigkeitsgruppe 2

Kap. 1.3.b

verboten

DN ≤ 32

oder DN > 32 und PNxDN ≤ 1000

PNxDN ≤ 2000

DN ≤ 200

oder PN ≤ 10

oder PNxDN ≤ 5000

6.3. Mechanische Daten

Werkstoff (8045 mit

Teil

Gehäuse /

Dichtung

Deckel mit

Klappe /

Dichtung

Frontfolie Polyester

M20x1,5-Kabelverschraubungen

/ Dichtung

Schrauben Edelstahl

Durchfluss-Sensor

aus PVDF)

PC / NBR PPA, schwarz / NBR

PC / Silikon PSU / Silikon

Werkstoff (8045 mit

Durchfluss-Sensor

aus Edelstahl)

PA / Neopren

Werkstoff (8045 mit

Teil

Überwurfmutter PC PPA

DurchflussSensor (in

Kontakt mit der

Flüssigkeit)

Dichtung FKM 8045 mit G2"-Über-

Erdungsring

des DurchflussSensors

ElektrodenArmatur

Elektroden Edelstahl 316L (DIN 1.4404) oder Alloy C22

Durchfluss-Sensor

aus PVDF)

PVDF Edelstahl 316L (DIN

Edelstahl 316L (DIN

1.4404) oder Alloy

C22

- PEEK

Werkstoff (8045 mit

Durchfluss-Sensor

aus Edelstahl)

1.4404)

wurfmutter: FKM

-

8

deutsch

Page 41

Type 8045

A

Technische Daten

6.4. Allgemeine Daten

Minimale Leitfähigkeit der

Flüssigkeit

Flüssigkeitstemperatur

• 8045 mit DurchflussSensor aus PVDF

• 8045 mit DurchflussSensor aus Edelstahl

Flüssigkeitsdruck

• 8045 mit DurchflussSensor aus PVDF

• 8045 mit DurchflussSensor aus Edelstahl

20 µS/cm

Die Flüssigkeitstemperatur kann durch

den Druck der Flüssigkeit, den Werkstoff des Durchfluss-Sensors und den

Werkstoff des verwendeten Fittings

S020 eingeschränkt sein.

• 0 bis +80 °C

• -15 bis +110 °C

Der Flüssigkeitsdruck kann durch die

Temperatur der Flüssigkeit, den Werkstoff des Durchfluss-Sensors und den

Werkstoff und DN des verwendeten

Fittings S020 eingeschränkt sein.

• PN10

• PN16

P (bar)

10

9

8

7

PVC + PP

6

5

4

3

2

1

0

PVC (PN10)

0 +20 +40 +60 +80

PVDF (PN10) /

Metall

PP (PN10)

T (°C)

A: Verwendungsbereich

Bild 2: Flüssigkeits-Druck-Temperatur-Abhängigkeit eines 8045

mit Durchfluss-Sensor aus PVDF und Fitting S020 aus

Metall, PVC, PVDF oder PP

deutsch

9

Page 42

P (bar)

A

16

15

14

13

12

11

10

PVDF

Metall

(PN16)

1)

DN100

für Messgeräte mit

Clamp-Anschluss

(PN10)

9

8

7

PVC + PP

PVDF (PN10)

6

5

4

3

2

1

0

-20 0 +20 +40 +60 +80 +100 +120

PVC (PN10)

PP (PN10)

T (°C)

1)

Außer DN100 für Messgeräte mit Clamp-Anschluss

A: Verwendungsbereich

Bild 3: Flüssigkeits-Druck-Temperatur-Abhängigkeit eines 8045

mit Durchfluss-Sensor aus Edelstahl und Fitting S020 aus

Metall, PVC, PVDF oder PP

Type 8045

Technische Daten

6.5. Elektrische Daten

Betriebsspannung • 18-36 VDC, gefiltert und

geregelt

• Toleranz: ±5 %

Eigenstromverbrauch 300 mA max. (bei 18 V DC)

Transistor-Ausgang DO1

• Ty p

• Funktion

• Frequenz

• Elektrische Daten

• Taktverhältnis bei f > 2 Hz

• Puls-Mindestdauer bei

f < 2 z

• Schutz

• NPN / PNP (je nach Verkabelung), offener Kollektor

• Pulsausgang (Grundeinstellung), einstellbar

• 0-250 Hz

• 5-36 V DC, max. 100 mA

• 1/2

• 250 ms

• galvanisch getrennt; Schutz

gegen Überspannung, Verpolung und Kurzschluss

10

deutsch

Page 43

Type 8045

Technische Daten

Relais-Ausgänge DO2 und

DO3

• Umschaltbetrieb

• Elektrische Daten der Last

• max. Schaltvermögen

• Lebensdauer

Stromausgang AO1

• Daten

• Schleifenimpedanz max.

Digital-Eingang (DI1)

• Betriebsspannung

• Eingangsimpedanz

• Puls-Mindestdauer

• Schutz

• Hysterese (Grundeinstellung),

einstellbar, stromlos geöffnet

• 250 V AC / 3 A oder 30 V DC /

3 A (ohmsche Last)

• 750 VA (ohmsche Last)

• min. 100000 Zyklen

• 4-20 mA, Senke oder Quelle (je

nach Verkabelung), 22 mA zur

Fehlermeldung

• 1300 W bei 36 V DC, 1000 W

bei 30 V DC, 700 W bei

24 V DC, 450 W bei 18 V DC

• 18-36 V DC

• 15 kW

• 200 ms

• galvanisch getrennt; Schutz

gegen Verpolung und

Spannungsspitzen

6.6. Elektrischer Anschluss

Anschluss-Typ Über zwei

M20x1,5-Kabelverschraubungen

Kabel-Daten

• Kabeltyp

• Querschnitt

• Durchmesser des Kabels:

- bei Verwendung

eines Kabels pro

Kabelverschraubung

- bei Verwendung

zweier Kabel pro

Kabelverschraubung

• abgeschirmt

• 0,5 bis 1,5 mm

- 6...12 mm

- 4 mm, mit mitgelieferter

Mehrweg-Dichtung

2

deutsch

11

Page 44

Type 8045

Installation und Verkabelung

7. INSTALLATION UND

VERKABELUNG

7.1. Sicherheitshinweise

GefaHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

Verletzungsgefahr durch Stromschlag!

Verletzungsgefahr durch hohe Flüssigkeitstemperaturen!

Verletzungsgefahr aufgrund der Art der Flüssigkeit!

waRnunG!

Verletzungsgefahr bei unsachgemäßer Installation!

• Fluidische und elektrische Installationen dürfen nur durch autorisiertes Fachpersonal und mit geeignetem Werkzeug durchgeführt werden!

• Verwenden Sie unbedingt geeignete Sicherheitsvorrichtungen (ordnungsgemäß dimensionierte Sicherungen und/oder Schutzschalter).

• Die Norm NF C 15-100 / IEC 60364 beachten.

• Beachten Sie die Montageanweisungen des verwendeten Fittings.

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach jedem Eingriff an dem Gerät einen kontrollierten Wiederanlauf gewährleisten.

Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

7.2. Empfehlungen für die Montage

des 8045 in die Rohrleitung

→ Das Fitting S020 so auswählen, das der Flüssigkeitsgeschwin-

digkeit in der Rohrleitung geeignet ist.

→ Das Gerät so in die Rohrleitung montieren, dass die Min-

desteinlauf- und -auslaufstrecken je nach Bauart der Rohrleitung

eingehalten werden, siehe Norm EN ISO 5167-1 und Bild 4 :

12

deutsch

Page 45

Type 8045

5 x DN

Installation und Verkabelung

Fließrichtung

→ Die folgenden zusätzlichen Montagebedingungen beachten, um

eine korrekte Funktion des Messgerätes zu gewährleisten:

- Das Gerät mit einem Winkel von 45° zum horizontalen Mittelpunkt

des Rohrs montieren (siehe Bild 5), um eventuelle Ablagerungen

auf den Elektroden sowie verfälschte Messungen durch Luftblasen

zu vermeiden.

50 x DN 5 x DN

Mit Regelventil Rohrleitung mit 2 90°-Krümmern in 3

40 x DN 5 x DN

Dimensionen

25 x DN 5 x DN 20 x DN

Rohrleitung mit 2 90°-Krümmern Rohrleitung mit 1 90°-Krümmer oder

1 T-Stück

18 x DN 5 x DN 15 x DN 5 x DN

Mit Rohraufweitung Mit Rohrreduzierung

Bild 4: Mindestein- und -auslaufstrecken je nach Aufbau der

Rohrleitungen.

45°

45°

Bild 5: Montagewinkel des Gerätes in Bezug zur Rohrleitung

- Darauf achten, dass die Rohrleitung im Bereich des Sensors

immer gefüllt ist (Bild 6).

- Sicherstellen, dass bei der vertikalen Montage die Fließrichtung, wie durch den Pfeil angezeigt, nach oben verläuft

(siehe Bild 6);

deutsch

13

Page 46

Horizontale Montage

Type 8045

Installation und Verkabelung

Richtig Falsch

Vertikale Montage

Fließrichtung

Richtig Falsch

Bild 6: Füllung der Rohrleitung

- Die Bildung von Luftblasen in der Rohrleitung am Gerät vermeiden (Bild 7).

- Das Gerät unbedingt vor Einleitungspunkten von Flüssigkeiten

mit erhöhter Leitfähigkeit (z.B.: Säure, Base, Salzlösung)

anbringen.

Richtig

Richtig Falsch

Falsch

Fließrichtung

Bild 7: Luftblasen in der Rohrleitung

→ Gegebenenfalls einen Strömungsgleichrichter verwenden, um

die Messgenauigkeit zu verbessern.

14

deutsch

Page 47

Type 8045

Installation und Verkabelung

7.3. Installation in die

Rohrleitung eines 8045 mit

G2''-Überwurfmutter

FLOW

Um eine hohe Genauigkeit der Messung und eine gute

Stabilität des Durchfluss-Nullpunkts zu gewährleisten, den

Sensor mindestens 24 Stunden vor der Kalibrierung mit der

Prozess-Flüssigkeit in Kontakt bringen.

→ Das Fitting S020 in die Rohrleitung einbauen und dabei die

Hinweise des Kap. 7.2 beachten.

→ Prüfen, ob die Dichtung auf dem Fitting sitzt und ob sie unversehrt

ist. Die Dichtung erforderlichenfalls ersetzen.

→ Prüfen, ob die Dichtung (Punkt 6 Bild 8) auf dem Durchfluss-

Sensor sitzt.

→ Die Überwurfmutter (Punkt 3 Bild 8) auf das Fitting setzen.

→ Den Sprengring (Punkt 2 Bild 8) in die Rille (Punkt 5 Bild 8)

einsetzen.

→ Das Gerät so positionieren, dass der Pfeil auf der Seite

des Gehäuses in die Fließrichtung zeigt: Die Zähler werden

inkrementiert.

→ Das Gerät (Punkt 1 Bild 8) ins Fitting einsetzen.

→ Die Überwurfmutter (Punkt 3 Bild 8) mit der Hand am Gerät

festschrauben.

1

6

Elektroden

2

3

5

4

Bild 8: Installation in die Rohrleitung eines 8045 mit

G2''-Überwurfmutter

Fließrichtung

7.4. Installation in die Rohrleitung

eines 8045 mit Clamp-Anschluss

Um eine hohe Genauigkeit der Messung und eine gute

Stabilität des Durchfluss-Nullpunkts zu gewährleisten, den

Sensor mindestens 24 Stunden vor der Kalibrierung mit der

Prozess-Flüssigkeit in Kontakt bringen.

→ Das Fitting S020 in die Rohrleitung einbauen und dabei die

Hinweise des Kap. 7.2 beachten.

deutsch

15

Page 48

Type 8045

Installation und Verkabelung

→ Die Dichtung (Punkt 3 Bild 9) auf das Fitting S020 installieren.

→ Anwesenheit des Unverwechselbarkeitsstifts (Punkt 4 Bild 9) auf

dem Fitting prüfen.

→ Das Gerät (Punkt 1 Bild 9) ins Fitting einsetzen. Das Gerät so

positionieren, dass der Pfeil auf der Seite des Gehäuses in die

Fließrichtung zeigt: Die Zähler werden inkrementiert.

→ Clamp-Schelle (Punkt 2 Bild 9) mit der Hand anziehen.

→ Um die Dichtheit zu prüfen, die Rohrleitung unter Druck setzen.

1

2

4

Fließrichtung

Bild 9: Installation in die Rohrleitung eines 8045 mit

Clamp-Anschluss

3

7.5. Verkabelung

GefaHR!

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall alle existierenden am Gerät angeschlossenen Spannungs-Versorgungen ab, und sichern Sie diese vor unbeabsichtigtem

Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

• Verwenden Sie eine hochwertige (gefilterte und geregelte) Stromversorgung.

• Den Potentialausgleich der Installation gewährleisten.

Siehe Kap. 7.5.1.

• Abgeschirmte Kabel mit einer Betriebsgrenztemperatur

höher als 80 °C verwenden.

• Die Verlegung des Kabels in der Nähe von Hochspannungs- oder Hochfrequenzkabeln vermeiden; Wenn eine

benachbarte Verlegung unvermeidlich ist, einen Mindestabstand von 30 cm einhalten.

• Die Stromversorgung mit einer 300 mA-Sicherung und

einem Schutzschalter absichern.

• Das Relais mit einer 3A-Sicherung (max.) und einem

Sicherungsautomat schützen.(für den Prozess geeignet).

• Nicht gleichzeitig eine gefährliche Spannung und eine

Schutzkleinspannung an die Relais anschließen.

16

deutsch

Page 49

Type 8045

Installation und Verkabelung

Den mitgelieferten Stopfen in die nicht verwendete Kabelverschraubung stecken, um die Dichtheit des Gerätes zu

gewährleisten.

Wenn zwei Kabel in einer Kabelverschraubung verwendet

werden, zuerst die Mehrwegdichtung in die Kabelverschraubung einfügen.

Das Gerät folgendermaßen verkabeln:

→ Die Schraube der Klappe aufdrehen.

→ Die Klappe öffnen.

→ Die 4 Schrauben des Gehäusedeckels lösen.

→ Den Deckel absetzen.

→ Die Kabelveschraubungen aufschrauben.

→ Das Kabel durch die Überwurfmutter dann durch die Kabelver-

schraubung führen.

→ Prüfen, ob das Erdungskabel, das vom Gehäuse her kommt, und,

bei einer Ausführung mit Edelstahl-Sensor das Kabel, das vom

Sensor her kommt wie in Bild 15 des Kap. 7.5.2 angeschlossen

sind.

→ Gemäß Kap. 7.5.1 bis 7.5.3 verkabeln.

7.5.1. Potentialausgleich der Installation

gewährleisten

Um die Äquipotentialität der Installation (Versorgungsspannung Gerät - Flüssigkeit) zu gewährleisten,

→ Die verschiedenen Erdungspunkte der Installation aneinander

anschließen, damit die zwischen zwei Erdungspunkten möglicherweise erzeugten Potentialdifferenzen beseitigt werden.

→ Auf vorschriftsmäßige Erdung der Abschirmung des Versor-

gungskabels an beiden Enden achten.

→ Den Minuspol der Stromversorgung an die Erde anschließen, um

die Auswirkungen von Gleichtaktströmen zu unterdrücken. Wenn

die Verbindung nicht direkt vorgenommen werden kann, kann ein

Kondensator mit 100 nF/50 V zwischen Minuspol der Stromversorgung und Erde geschaltet werden.

→ Geben Sie darauf besonders acht, wenn das Gerät auf Kunst-

stoffrohren installiert wird, weil keine direkte Erdung möglich

ist. Zur ordnungsgemäßen Erdung alle die sich in der Nähe des

Geräts befindenden metallischen Apparate, wie Ventile oder

Pumpen, an den selben Erdungspunkt anschließen. Sind keine

solchen Apparate in der Nähe des Gerätes eingebaut, Stromaufund –abwärts des Gerätes Erdungsringe in die Kunststoffrohre

einführen und diese mit derselben Erde verbinden. Die Erdungsringe müssen in Kontakt mit der Flüssigkeit sein.

deutsch

17

Page 50

Type 8045

Installation und Verkabelung

Abschirmung des Versorgungskabels

Versorgungsspannung

18-36VDC

+

-

1)

Rohrleitung aus Kunststoff

Ventil, Pumpe,... (oder Erdungsringe, nicht mitgeliefert, in die

Rohrleitung eingesetzt)

1)

Wenn eine direkte Erdung nicht möglich ist, einen Kondensator

mit 100 nF / 50 V zwischen Minuspol der Stromversorgung und

Erde anschließen.

Bild 10: Prinzipschaltbilder einer Äquipotentialität bei

Rohrleitungen aus Kunststoff

Abschirmung des Versorgungskabels

Versorgungsspannung

18-36VDC

+

-

1)

Rohrleitung aus

Metall

1)

Wenn eine direkte Erdung nicht möglich ist, einen Kondensator

mit 100 nF / 50 V zwischen Minuspol der Stromversorgung und

Erde anschließen.

Bild 11: Prinzipschaltbilder einer Äquipotentialität bei

Rohrleitungen aus Metall

18

deutsch

Page 51

Type 8045

Installation und Verkabelung

7.5.2. Klemmenbelegung und Verwendung

der Auswahl-Schalter

1

A

2

4 poliges Flach-

bandkabel zum

Anschluss des

Durchfluss-

Sensors

Schalter

Schalter

B

4

5

A

: siehe Bild 13

B

: siehe Bild 14

CURRENT

OFF ON

DO3

SOURCESINK

DO2

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

DI1

PE

-

+

PULSE

DO1

PE

3

Klemmleiste 1

Iout: 4-20 mA-Ausgang (AO1)

L+: V+ (positive Stromversorgung)

L-: 0V (Erde der Stromversorgung)

PE: Funktionnelle Erde, im Werk verkabelt (siehe Bild 15)

P+: positiver Transistorausgang (DO1)

P-: negativer Transistorausgang (DO1)

Klemmleiste 2

PE: Abschirmung der Versorgungs- und der AO1- und

DO1-Ausgangs-Kabel

Klemmleiste 3

PE: Funktionnelle Erde des Kabels des DI1 Digitaleingangs

-: negatives Signal des DI1 Digitaleingangs

+: positives Signal des DI1 Digitaleingangs

Klemmleiste 4 : Verkabelung des DO2 Relaisausgangs

Klemmleiste 5 : Verkabelung des DO3 Relaisausgangs

Bild 12: Klemmenbelegung

deutsch

19

Page 52

A

Der Auswahl-Schalter

dient zur Konfiguration des 4-20

mA-Anschlusses als Quelle oder Senke.

A

Type 8045

Installation und Verkabelung

123456

CURRENT

SOURCESINK

Stromausgang als Quelle

anschließen.

Bild 13: Senke/Quelle-Auswahl-Schalters

B

Der Auswahl-Schalter

blocken der

ENTER

-Taste, um die unerlaubte Konfiguration

dient zum Blockieren oder Ent-

CURRENT

SOURCESINK

Stromausgang als Senke

anschließen.

des Gerätes zu vermeiden.

B

OFF ON

ENTER

Taste

Bild 14: Auswahl-Schalter zum Blockieren oder Entblocken der

20

entriegelt (Grund-

einstellung).

ENTER-Taste

OFF ON

ENTER

Taste

verriegelt.

deutsch

Erdungskabel, das vom Gehäuse herkommt.

Bei einer Ausführung mit Durchfluss-Sensor aus Edelstahl

Bild 15: Anschluss des Erdungskabels, das vom Gehäuse her

kommt (im Werk verkabelt)

kommt ein zweites Kabel vom Sensor.

7.5.3. Verkabelung der DO2- und

DO3-Relais-Ausgänge

m

230 VAC

230 VAC

Bild 16: Verkabelung der DO2- und DO3-Relais-Ausgänge

3 A

3 A

DO2

DO3

Page 53

Type 8045

18-36 V DC

Installation und Verkabelung

7.5.4. Verkabelung des

AO1-Stromausgangs

Aus Sicherheitsgründen die Kabel mittels einer nicht leitenden Klemmschelle fixieren.

Der 4-20 mA-Stromausgang kann entweder als Quelle oder als

Senke angeschlossen werden.

Den Schalter A nach Rechts stellen.

18-36 V DC

+

-

(*)

Versorgungsspannung

4-20 mA-Eingang am

externen Gerät

A

+

300 mA

-

I

Den Schalter A nach Linkss stellen.

I

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

300 mA

+

-

(*)

Versorgungsspannung

PULSE

DO1

PE

4-20 mA-Eingang am

externen Gerät

A

CURRENT

SOURCESINK

+

-

Bild 18: Anschluss des 4-20 mA-Stromausgangs (AO1) als Senke

*) Wenn eine direkte Erdung nicht möglich ist, einen Kondensator

mit 100 nF / 50 V zwischen Minuspol der Stromversorgung und

Erde anschließen

CURRENT

SOURCESINK

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

PULSE

DO1

PE

Bild 17: Anschluss des 4-20 mA-Stromausgangs (AO1) als Quelle

*) Wenn eine direkte Erdung nicht möglich ist, einen Kondensator

mit 100 nF / 50 V zwischen Minuspol der Stromversorgung und

Erde anschließen

deutsch

21

Page 54

Type 8045

Installation und Verkabelung

7.5.5. Verkabelung des

DO1-Transistor-Ausgangs

18-36 V DC

Versorgungs-

+

300 mA

-

(*)

spannung

L+ L-PEP+P-Iout

Supply

AO1

18...36 Vdc

PULSE

Bild 19: NPN-Anschluss des DO1-Transistorausgangs

*) Wenn eine direkte Erdung nicht möglich ist, einen Kondensator

mit 100 nF / 50 V zwischen Minuspol der Stromversorgung und

Erde anschließen

DO1

+

5-36 VDC

-

+

-

PE

SPS

18-36 V DC

Versorgungs-

spannung

300 mA

+

-

(*)

+

5-36 VDC

-

+

-

SPS

L+ L-PEP+P-Iout

Supply

AO1

18...36 Vdc

PULSE

DO1

PE

Bild 20: PNP-Anschluss des DO1-Transistorausgangs

*) Wenn eine direkte Erdung nicht möglich ist, einen Kondensator

mit 100 nF / 50 V zwischen Minuspol der Stromversorgung und

Erde anschließen

22

deutsch

Page 55

Type 8045

Installation und Verkabelung

7.5.6. Verkabelung des

DI1-Digitaleingangs

CURRENT

SOURCESINK

DO3

DO2

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

DI1

PE

-

+

PULSE

DO1

PE

18-36 V DC

+

-

(*)

Versorgungsspannung

Schalter

Versorgungsspannung

18-36 V DC

+

-

(*)

CURRENT

SOURCESINK

DO3

DO2

AO1

L+ L-PEP+P-Iout

Supply

18...36 Vdc

PE

-

+

DI1

PULSE

DO1

PE

Schalter

Bild 21: Mögliche Anschlussweise des DI1-Digitaleingangs

*) Wenn eine direkte Erdung nicht möglich ist, einen Kondensator

mit 100 nF / 50 V zwischen Minuspol der Stromversorgung und

Erde anschließen

deutsch

23

Page 56

Type 8045

Bedienung und Inbetriebnahme

8. BEDIENUNG UND

INBETRIEBNAHME

8.1. Sicherheitshinweise

waRnunG!

Verletzungsgefahr bei unsachgemäßer Bedienung!

Nicht sachgemäße Bedienung kann zu Verletzungen, sowie

Schäden am Gerät und seiner Umgebung führen.

• Das Bedienpersonal muss den Inhalt der Bedienungsanleitung

kennen und verstanden haben.

• Besonders zu beachten sind die Sicherheitshinweise und die bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend geschultes

Personal bedient werden.

waRnunG!

Verletzungsgefahr bei unsachgemäßer Inbetriebnahme!

Nicht sachgemäßer Betrieb kann zu Verletzungen sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Besonders zu beachten sind die Sicherheitshinweise und die bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend geschultes

Personal in Betrieb genommen werden.

• Vor der Inbetriebnahme den K-Faktor des verwendeten Fittings

einstellen. Siehe Kap. 8.6.

24

deutsch

Page 57

Type 8045

Bedienung und Inbetriebnahme

8.2. Bedienebenen des Gerätes

Das Gerät verfügt über zwei Bedienebenen: Die Prozess-Ebene und

die Einstellungs-Ebene.

Tab. 1: Grundeinstellung des Gerätes

Funktion

SPRACHE English AUSGANG

EINHEIT des

Durchflusses

EINHEIT der

Zähler

K-FACTOR 1.000 nicht invertiert

AUSGANG

AO1

AUSGANG

DO1

Grundeinstellung

l/min. 3-= 0.000

Liter 3+= 0.000

4mA= 0.000

20mA= 0.000 EINGANG

Puls FILTER 5, langsam

PU= 0.00 Liter FREQUENZ 50Hz

Funktion

DO3

DI1

Grundeinstellung

Hysterese

Verzögerung

= 0

inaktiv

Funktion

AUSGANG

DO2

Grundeinstellung

Hysterese CUT-OFF 0.000

2-= 0.000 BACKLIT Filter 9, Akti-

2+= 0.000 K-SENSOR Kw= 1.000

nicht invertiert DURCHF.-W. W-= 0.000

Verzögerung

= 0

Funktion

Grundeinstellung

vierungsdauer:

30s

W+= 0.000

deutsch

25

Page 58

Type 8045

Bedienung und Inbetriebnahme

Prozess-Ebene

12.6 l/S

> 5 s

0......9

16.45 mA

0......9

Parametriermenü Testmenü

ENTER

SPRACHE

> 5 s

87654 l

EinHEit

K-FACtOR

AuSgAng

231 l.

0......9

EingAng

FiltER

+

0......9

> 2 s

Zurücksetzen des Tageszählers (durch

den Punkt nach der Volumen-Einheit

bestimmt).

1)

Zufriff nur wenn die Geräte-Status-LED orange oder rot ist, möglich.

2)

Wenn die ENTER-Taste entriegelt ist.

tOtAl

FREQuEnZ

Cut-OFF

BACKlit

Einstellungs-Ebene

ENTER

EndE

0......9

> 2 s

CAl AO1

KAliB 0

duRCHFlu.

K-SEnSOR

duRCHF.-W.

EndE

SPEiCH.n/J

Informationsmenü

mEAS. OVF

CAl. FAil

nEg. FlOW

0......9

EndE

ENTER

oder

2)

Prozess-Ebene

1)

26

deutsch

Page 59

Type 8045

Bedienung und Inbetriebnahme

8.3. Beschreibung der Navigations-Tasten und der Status-LEDs

• Funktionen nach oben

durchlaufen

• Ausgewählte Ziffer

erhöhen

Geräte-Status-LED: Siehe

folgende Tabelle.

deutsch

• Angezeigte Funktion auswählen

• Einstellungen bestätigen

Status-LED des DO3-Relais (LED AN =

Kontakt geschlossen)

Status-LED des DO2-Relais (LED AN

= Kontakt geschlossen)

• Meldungen lesen

• Funktionen nach unten durchlaufen

• Auswahl der links stehenden Ziffer

27

Page 60

8.4. Verwendung der Navigations-Tasten

Sie wollen... Drücken Sie...

sich in den Funktionen einer Ebene oder eines Menüs

bewegen.

• nächste Funktion:

Type 8045

Bedienung und Inbetriebnahme

.

das Parametriermenü anzeigen.

das Testmenü anzeigen.

das Informationsmenü anzeigen.

den Tageszähler zurücksetzen.

die angezeigte Funktion auswählen.

den angezeigten Wert bestätigen.

einen numerischen Wert ändern.

28

• vorherige Funktion:

ENTER

0......9

für 2 s in der Prozess-Ebene, wenn die Geräte-Status-LED orange oder rot

ist.

0......9

angezeigt ist

ENTER

ENTER

•

0......9

•

0......9

•

deutsch

.

0......9

+ gleichzeitig für 5 s in der Prozess-Ebene

ENTER

+

gleichzeitig für 5 s in der Prozess-Ebene

+ gleichzeitig für 2 s, wenn der Tageszähler in der Prozess-Ebene

zum Erhöhen der ausgewählten Ziffer.

zur Auswahl der vorherigen Ziffer.

+ zur Verschiebung des Kommas.

Page 61

Type 8045

Bedienung und Inbetriebnahme

8.5. Display-Sprache auswählen

Beim ersten Einschalten ist die Display-Sprache Englisch.

lAnguAgE EngliSH

0......9

dEutSCH

FRAnçAiS

→ Die angezeigte

Sprache bestätigen:

Die ausgewählte

Sprache ist sofort aktiv.

itAliAnO

ESPAnOl

EinHEit

Bild 22: Diagramm der Funktion "SPRACHE" des

Parametriermenüs

→ Wenn kein weiterer Parameter geändert werden soll, gehen Sie

zur Funktion "ENDE" des Parametriermenüs und drücken Sie die

ENTER

Taste

Ebene zurück zu gehen.

, um die Einstellungen zu speichern und zur Prozess-

8.6. K-Faktor des verwendeten

Fittings eingeben

Das Gerät berechnet den Durchfluss der Flüssigkeit in der Rohrleitung mittels des K-Faktors des Fittings.