Page 1

Type 8025/8035

Flowmeter-Totalizer, battery-powered

Durchflussmessgerät-Mengenzähler mit Batterien

Débitmètre-totalisateur à piles

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2013 Bürkert SAS

Operating Instructions 1307/1_EU-ML 00564407 Original_FR

Page 3

Type 8025/8035 battery powered

1. ABOUT THIS MANUAL .................................................................................3

1.1. Symbols used....................................................................................3

1.2. Definition of the word "device" ......................................................3

2. INTENDED USE ................................................................................................4

3. BASIC SAFETY INFORMATION ...............................................................4

4. GENERAL INFORMATION ...........................................................................6

4.1. Manufacturer's address and international contacts .................6

4.2. Warranty conditions .........................................................................6

4.3. Information on the Internet ............................................................. 6

5. DESCRIPTION ...................................................................................................6

5.1. Area of application ........................................................................... 6

5.2. General description ......................................................................... 6

5.3. Description of the name plates ..................................................... 6

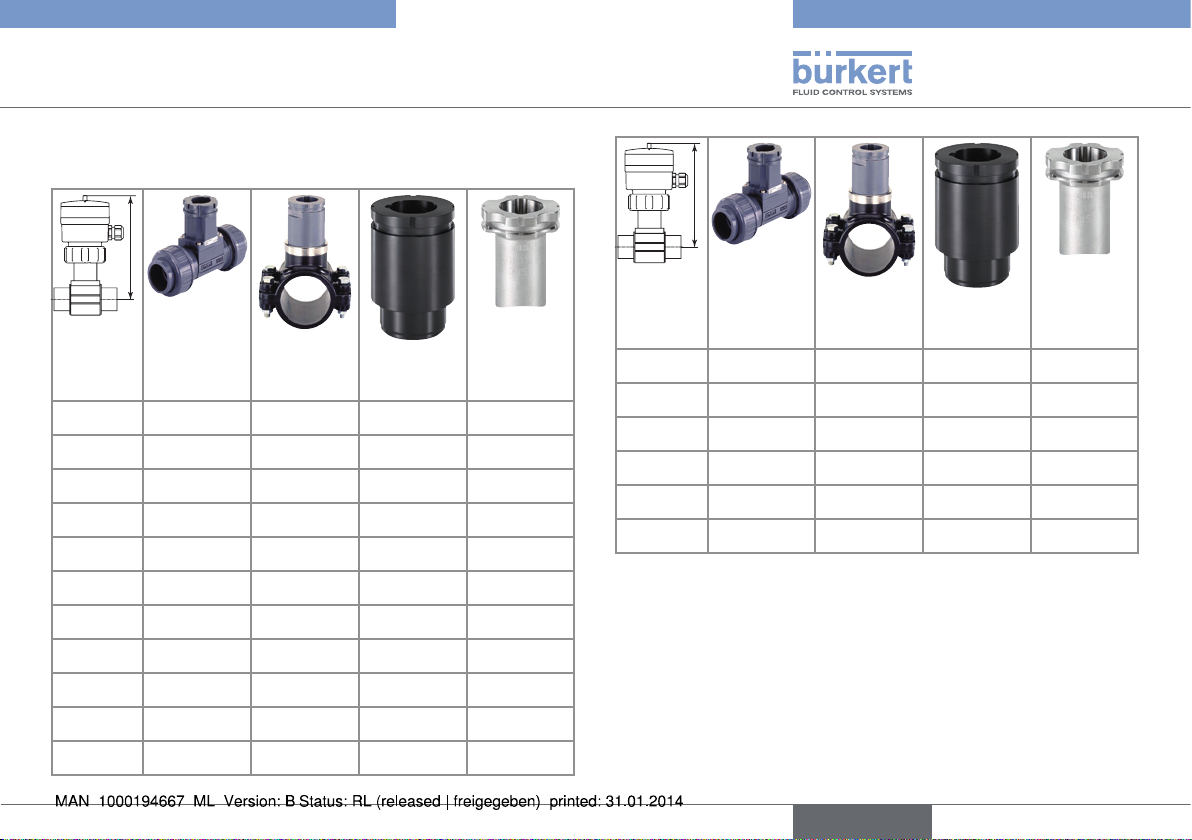

5.4. Available versions .............................................................................7

6. TECHNICAL DATA ...........................................................................................7

6.1. Conditions of use ............................................................................. 7

6.2. Conformity to standards and directives ...................................... 7

6.3. General technical data ....................................................................8

6.3.1. Mechanical data ....................................................................8

6.3.2. General data .........................................................................10

7. INSTALLATION ............................................................................................... 11

7.1. Safety instructions .........................................................................11

7.2. Installation onto the pipe ..............................................................12

7.2.1. Installation of the fitting onto the pipe ............................12

7.2.2. Installation of 8025 on the S020 fitting .........................14

7.2.3. Installation of the SE35 electronic module on

the S030 fitting-sensor ......................................................14

7.3. Description of the electronic board connections....................14

8. OPERATING AND COMMISSIONING.................................................15

8.1. Safety instructions .........................................................................15

8.2. Switch on the device and lock/unlock the ENTER key ........15

8.3. Operating levels of the device ....................................................16

8.4. Description of the navigation keys .............................................17

8.5. Details of the Process level .........................................................18

8.6. Details of the Configuration level ...............................................18

8.6.1. Choosing the display language .......................................19

8.6.2. Choosing the flow rate units, the number of

decimals and the units of the totalizers ..........................19

8.6.3. Entering or determining the K factor of the

fitting used ...........................................................................21

8.6.4. Configuring the filter ...........................................................23

8.6.5. Resetting both totalizers ....................................................23

9. MAINTENANCE AND TROUBLESHOOTING ..................................23

9.1. Safety instructions .........................................................................23

9.2. Cleaning the device .......................................................................24

9.3. Cleaning the flow sensor of the 8025 .......................................24

9.4. Replacing the batteries .................................................................24

English

1

Page 4

9.5. If you encounter problems ............................................................25

10. SPARE PARTS AND ACCESSORIES ...............................................25

10.1. SE35 electronic module .............................................................25

10.2. 8025 flowmeter-totalizer ............................................................26

11. PACKAGING, TRANSPORT ...................................................................26

12. STORAGE ....................................................................................................... 26

13. DISPOSAL OF THE PRODUCT ........................................................... 27

Type 8025/8035 battery powered

2

English

Page 5

Type 8025/8035 battery powered

About this manual

1. ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please

keep this manual in a safe place, accessible to all users and any new

owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations.

• This manual must be read and understood.

1.1. Symbols used

danger

Warns against an imminent danger.

• Failure to observe this warning can result in death or in serious

injury.

Warning

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or

even death.

attention

Warns against a possible risk.

• Failure to observe this warning can result in substantial or minor

injuries.

note

Warns against material damage.

• Failure to observe this warning may result in damage to the

device or system.

Indicates additional information, advice or important

recommendations.

Refers to information contained in this manual or in other

documents.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

The word "device" used within this manual refers to the battery

powered flowmeter-totalizer type 8025 or 8035.

English

3

Page 6

Type 8025/8035 battery powered

Intended use

2. INTENDED USE

Use of the device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

• The flowmeter-totalizer 8025 or 8035 is intended to measure

the flow rate and totalize the volume of liquid.

• This device must be protected against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects

of climatic conditions.

• This device must be used in compliance with the characteristics

and commissioning and use conditions specified in the contractual documents and in the user manual.

• Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

• Only use the device as intended.

→ Observe any existing restraints when the device is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during installation,

use and maintenance of the devices.

• the local safety regulations for which the operating company

is responsible including the staff in charge of installation and

maintenance.

Danger due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Danger due to electrical voltage.

• Put the power switch to OFF before carrying out work on the

device.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for

electrical equipment.

Danger due to high temperatures of the fluid.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Danger due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and safety

relating to the use of aggressive fluids.

4

English

Page 7

Type 8025/8035 battery powered

Basic safety information

Various dangerous situations

To avoid injury take care:

• not to use the device for the measurement of gas flow rates.

• not to use the device in explosive atmospheres.

• not to use the device in an environment incompatible with the

materials it is made of.

• not to use fluid that is incompatible with the materials the device

is made of.

• not to subject the device to mechanical loads (e.g. by placing

objects on top of it or by using it as a step).

• not to make any external or internal modifications to the device.

• to prevent any unintentional power supply switch-on.

• to ensure that installation and maintenance work are

carried out by qualified, authorised personnel in possession of

the appropriate tools.

• to use the device only if in perfect working order and in compliance with the instructions provided in the operating instructions.

• to observe the general technical rules when installing and using

the device.

note

The device may be damaged by the fluid in contact with.

• Systematically check the chemical compatibility of the component materials of the device and the fluids likely to come into

contact with it (for example: alcohols, strong or concentrated

acids, aldehydes, alkaline compounds, esters, aliphatic compounds, ketones, halogenated aromatics or hydrocarbons,

oxidants and chlorinated agents).

note

Elements / Components sensitive to electrostatic discharges

• This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they are touched by

an electrostatically charged person or object. In the worst case

scenario, these components are instantly destroyed or go out of

order as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 and 5-2 norms.

• Also ensure that you do not touch any of the live electrical

components.

English

5

Page 8

1

2

Type 8025/8035 battery powered

General information

4. GENERAL INFORMATION

4.1. Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the

internet at: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use

of the 8025 or the 8035 in observance of the operating conditions

specified in this manual.

4.3. Information on the Internet

You can find the user manuals and technical data sheets regarding

the type 8035 or 8025 at: www.burkert.com

5. DESCRIPTION

5.1. Area of application

The battery powered flowmeter-totalizer 8025 or 8035 is intended

to measure the flow rate and totalize the volume of liquid.

5.2. General description

The device type 8025 is made up of a flow sensor with paddle

wheel and an electronic module with display.

The device type 8035 is made up of an SE35 electronic module

and of an S030 fitting-sensor incorporating the paddle wheel which

measure the flow.

The device is fed with 2 batteries.

5.3. Description of the name plates

1. Type of the device

TOTAL :8025- SUPPLY: BATT9V

COIL SHORT - OUT: /

S/N 1439

Made in France

00418403 W43MA

Fig. 1: Name plate of the

8025

2. Power supply

3. Type of output: without

4. Manufacturing code

5. Conformity logo

457836

6. Specification of the flow sensor

7. Serial number

8. Order code

6

English

Page 9

1 2

Type 8025/8035 battery powered

Technical data

1. Type of the device

TOTAL :SE35/8035 COIL 9V

IP65

S/N 1439

Made in France

00423921 W43MA

2. Specification of the flow sensor

3. Power supply

4. Manufacturing code

5. Conformity logo

457836

6. Protection rating

Fig. 2: Name plate of the

8035

7. Serial number

8. Order code

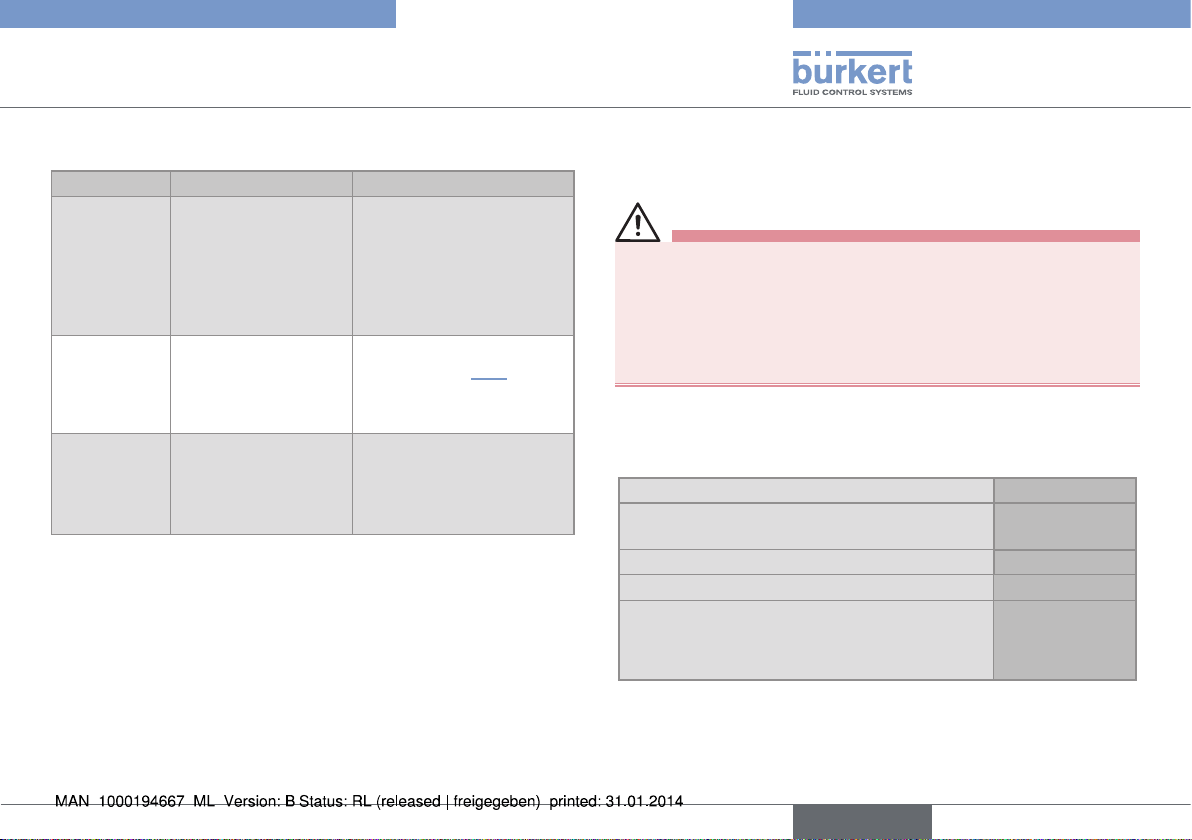

5.4. Available versions

• The flowmeter-totalizer type 8035 is made up of an SE35 elec-

tronic module with order code 423921 and of an S030 fittingsensor which has to be ordered separately.

• The flowmeter-totalizer type 8025 exists in 2 versions:

Type of flow sensor Seal material Order code

short, with coil FKM

long, with coil FKM

418403

418405

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature 0 to +60 °C

Air humidity < 80%, without condensation

Height above see

level

Protection rating IP65, cover lid screwed tight and screwed

6.2. Conformity to standards and directives

The device conforms to the EC directives through the following

standards:

• EMC: EN 61000-6-2, EN 61000-6-3

• LVD: EN 61 010-1

• Vibration: EN 60068-2-6

• Shock: EN 60068-2-27

• Pressure: article 3§3 of the Pressure Directive 97/23/CE. Acc. to

the Pressure Directive 97/23/CE: the device can only be used in

the following cases (depending on the max. pressure, the DN of

the pipe and the fluid)

max. 2000 m

plugs.

English

7

Page 10

203

Type 8025/8035 battery powered

Technical data

Type of fluid Conditions

8025 8035

Fluid group 1 §

1.3.a

Fluid group 2 §

1.3.a

Fluid group 1 §

1.3.b

Fluid group 2 §

1.3.b

1)

For the type 8035 : S030 fitting-sensor, DN6 to DN65, in PP,

only DN25 DN ≤ 25

DN ≤ 32

or DN > 32 and

PNxDN ≤1000

DN ≤ 32

or DN > 32 and

PNxDN ≤ 1000

DN ≤ 25

or DN > 25 and

PNxDN ≤ 2000

PNxDN≤ 2000

DN ≤ 400 DN ≤ 200

PVC, PVDF, brass or stainless steel.

6.3. General technical data

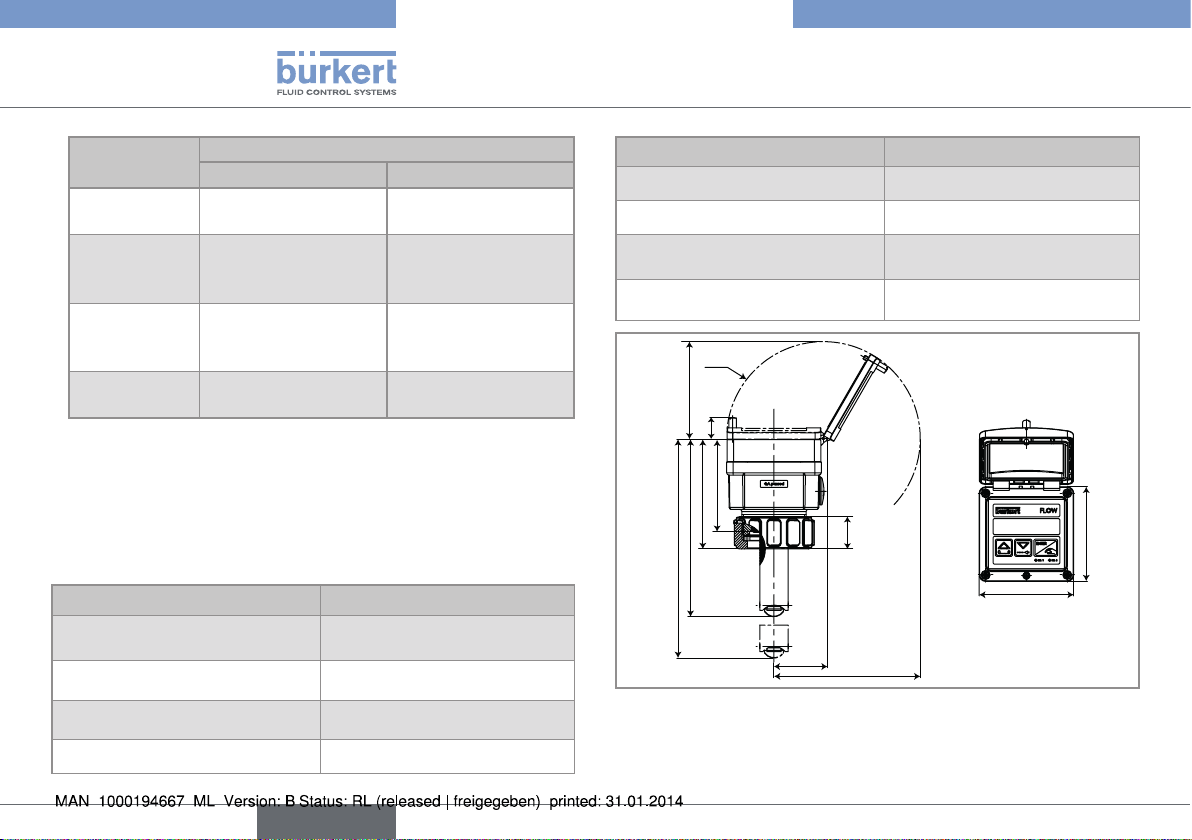

6.3.1. Mechanical data

Part Material

Housing / seal PC / NBR

Cover with lid / seal PC / silicone

Front foil Polyester

1)

Screws Stainless steel

Nut PC

Part Material

Flow sensor (exposed to the

PVDF / FKM

fluid) / seal (only with 8025)

Axis and bearings of the paddle

ceramic

wheel

R=90

91

21

85.5

102

164.5

49.5

30

88

136

88

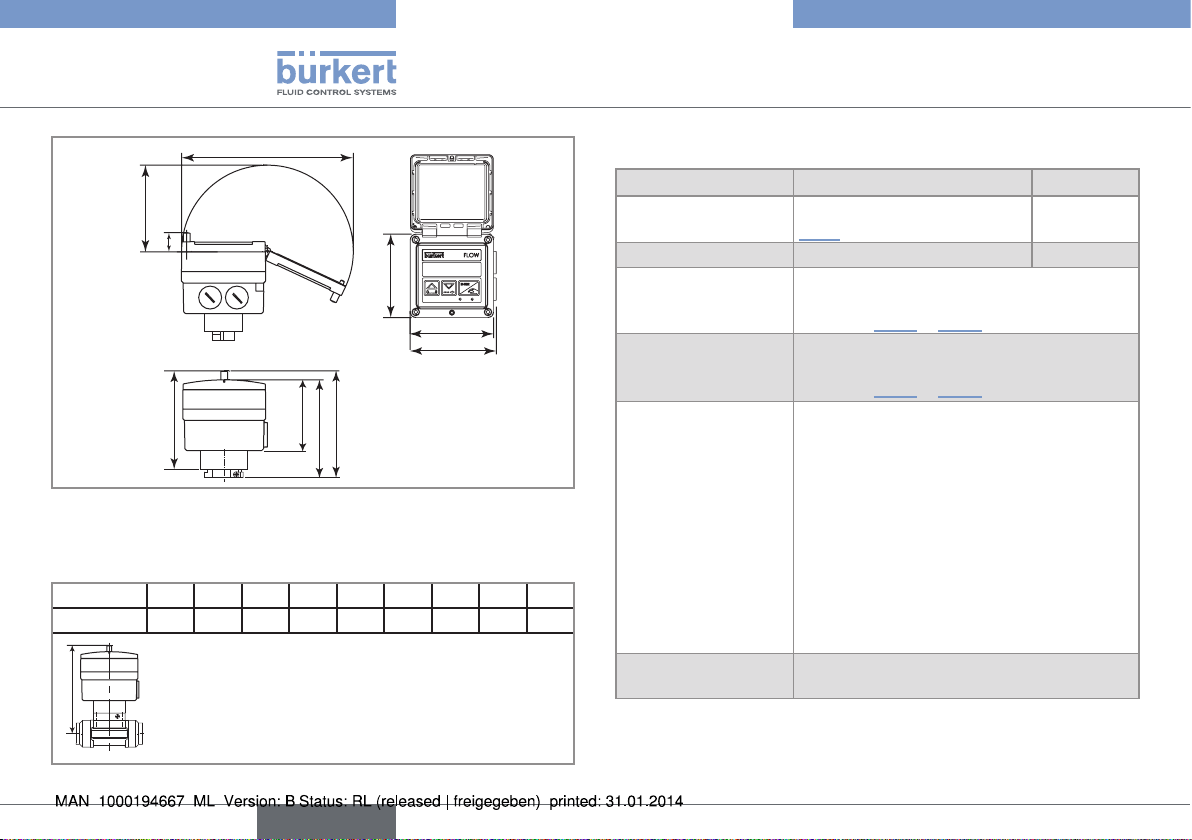

Fig. 3: Dimensions in mm of the 8025

M20x1.5 screw plugs / seal PA / neoprene

8

English

Page 11

Type 8025/8035 battery powered

Technical data

Table 1: Height H in mm of flowmeter-totalizer 8025 associated to

an S020 fitting

H

H

T-fitting

Saddle

Spigot, in

plastic

Welding tab

with radius,

in stainless

steel

DN20 185

DN25 185

DN32 188

DN40 192 188

DN50 198 223 193

DN65 198 221 206 199

DN80 226 212 204

DN100 231 219 214

DN110 227

DN125 234 254 225

DN150 244 261 236

T-fitting

Saddle

Spigot, in

plastic

Welding tab

with radius,

in stainless

steel

DN180 268

DN200 280 282 257

DN250 300 317

DN300 312 336

DN350 325 348

DN400 340

English

9

Page 12

Type 8025/8035 battery powered

Technical data

180

91

21

88

88

95

105

75

104

114

Fig. 4: Dimensions in mm of the SE35 electronic module

Table 2: Height H in mm of SE35 electronic module associated to

an S030 fitting-sensor

DN (mm) 06 08 15 20 25 32 40 50 65

H (mm) 134 134 139 137 137 140 144 151 151

1)

H

The height H does not

depend on the type of connection or on the material.

6.3.2. General data

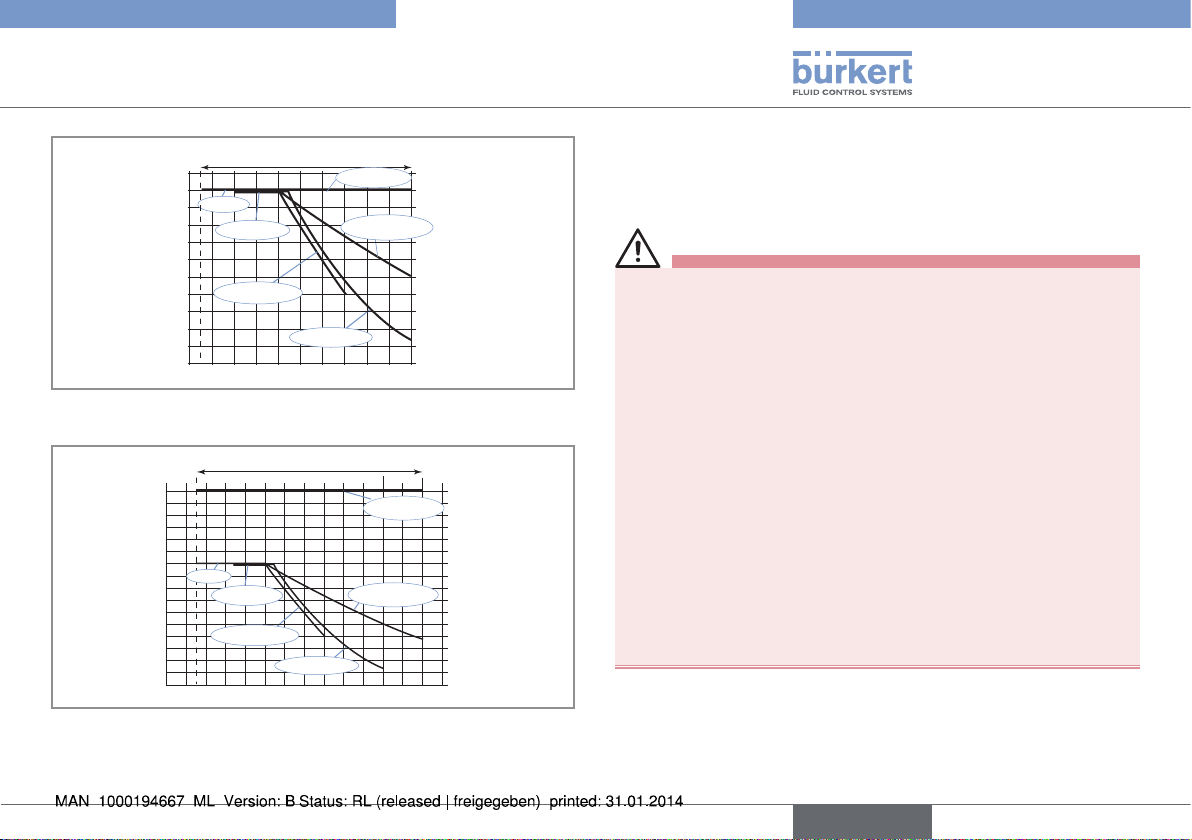

Type 8025 8035

Pipe diameter

Type of fitting S020 S030

Fluid temperature

Fluid pressure

Flow rate measurement

• Measurement range

• Measurement error

with a teach-in

procedure (teach-in

function)

• Measurement error

with K factor of fitting

used

• Linearity

• Repeatability

Power supply 2 batteries of 9 V (6LR61)

1)

Determined in the following reference conditions: fluid = water,

water and ambient temperatures = 20 °C, upstream and downstream distances respected, appropriate pipe dimensions.

DN20 (except for DN specified

p.13) to DN400

DN6 to

DN65

The fluid temperature may be restricted by the

fluid pressure and by the material of the fitting

used. See Fig. 5 et Fig. 6

The fluid pressure may be restricted by the fluid

temperature and by the material of the fitting

used. See Fig. 5 et Fig. 6

• 0,2 to 10 m/s

• ±0,5 % of the full scale

• ± (0,5% of the full scale + 2,5 % of the

measured value) 1)

• ±0,5 % of the full scale 1)

• ±0,4 % of the measured value

Minimum autonomy: 1 year at 20° C

10

English

Page 13

11

Type 8025/8035 battery powered

Installation

PVDF

PVC + PP

PVC (PN10)

application range

Metal

PVDF (PN10)

PP (PN10)

+80

P fluid (bar)

10

9

8

7

6

5

4

3

2

1

0

-15 0 +20 +40+60

Fig. 5: Type 8025, temperature-pressure dependency curves,

depending on the S020 fitting material

application range

PVC + PP

PVC (PN10)

A

Metal

PVDF (PN10)

PP (PN10)

P fluid (bar)

16

15

14

13

12

11

10

9

PVDF

8

7

6

5

4

3

2

1

0

-10 +10 +30 +50+70 +90 +110

-30

Fig. 6: Type 8035, temperature-pressure dependency curves,

depending on the S030 sensor-fitting material

T fluid (°C)

T fluid (°C)

7. INSTALLATION

7.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Put the power switch to OFF before carrying out work on the

device.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

English

11

Page 14

Warning

Risk of injury due to non-conforming installation.

• The fluid installation can only be carried out by qualified and

skilled staff with the appropriate tools.

• Respect the assembly instructions for the fitting used.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

• Take appropriate measures to avoid unintentional activation of

the installation.

• Ensure that the restart of the installation is controlled after any

interventions.

Protect this device against electromagnetic interference, ultraviolet rays and, when installed outdoors, the

effects of the climatic conditions.

7.2. Installation onto the pipe

danger

Type 8025/8035 battery powered

Installation

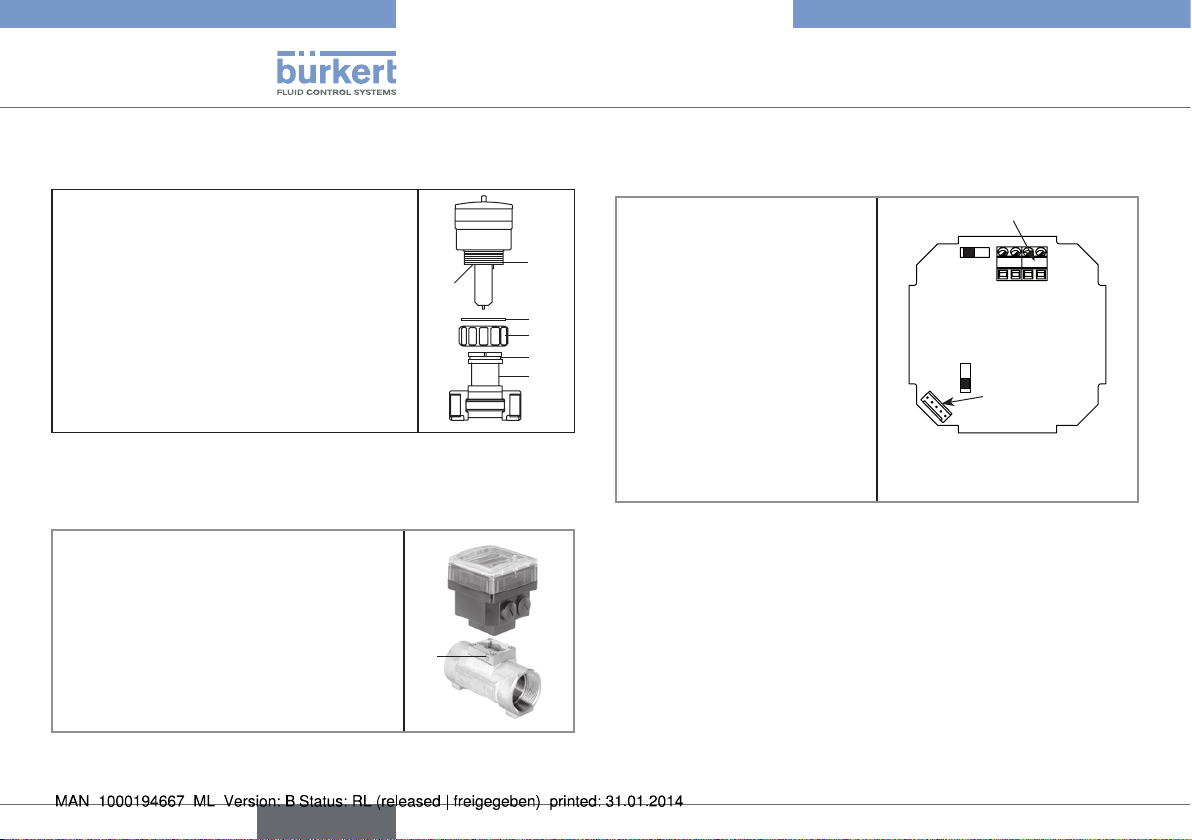

The 8025 flowmeter-totalizer has to be inserted into an S020 fitting

mounted on a pipe.

The SE35 electronic module has to be inserted into an S030 fittingsensor mounted on a pipe.

7.2.1. Installation of the fitting onto the pipe

→ Choose an S020 or S030 fitting appropriate to the velocity of

the fluid inside the pipe: refer to the graphs at right.

→ Install the fitting on the pipe as described in the operating

instructions of the fitting used.

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

12

English

Page 15

gpm

Type 8025/8035 battery powered

Installation

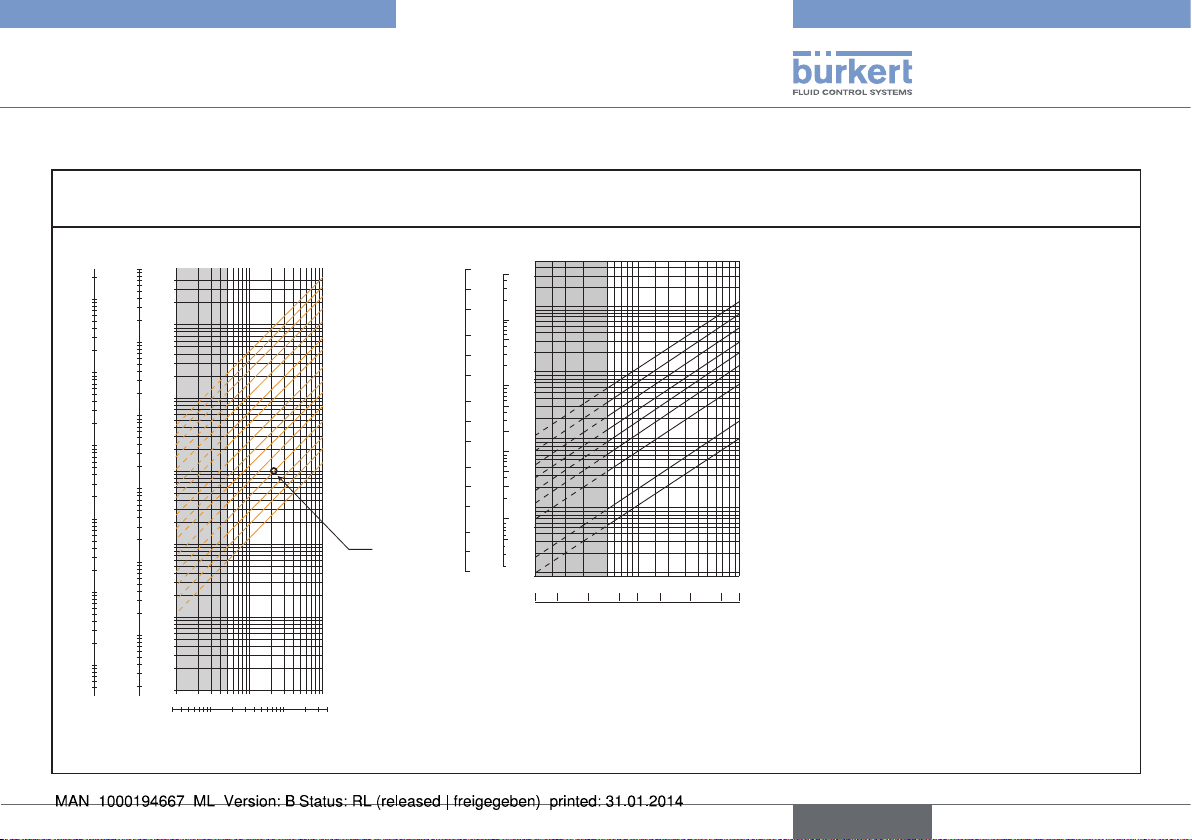

Table 3: Diagram flow/ fluid velocity/ DN of S020 fitting (on left) and S030 fitting-sensor (on right)

Example: for a nominal flow = 10 m3/h and an optimal flow velocity between 2 and 3 m/s.

→ use a DN40 fitting (or DN50 for the asterisked fittings).

US gpm

20000

10000

5000

2000

1000

500

200

100

50

20

10

5

2

1

0.5

0.2

0.1

0.05

Flow rate

l/min

100000

50000

30000

20000

10000

5000

3000

2000

1000

500

200

100

50

20

10

5

2

1

0.5

0.2

3

/h

m

5000

2000

1000

500

200

100

50

20

10

5

2

1

0.5

0.2

0.1

0.05

0.02

0.01

0.10.3 0.51 35 10

0.30.5 13510

Fluid velocity

DN 400

DN 350

DN 300

DN 250

DN 200

DN 150

DN 125

DN 100

DN 80

DN 65

DN 50 (DN65)*

DN 40 (DN50)*

DN 32 (DN40)*

DN 25 (DN32)*

DN 20 (DN25)*

Example

m/s

30

fps

Flow rate

m3/h

l/min

2000

1000

500

200

100

50

20

10

1)

0.5

0.2

0.1

0.05

500

5000

200

2000

100

1000

50

500

20

200

10

100

5

50

2

20

5

2

1

1

10

0.5

5

3

0.2

2

0.1

1

0.05

0.5

0.02

0.3

0.2

0.01

0.1 0.2 0.3 0.5 1235 10

0.3 0.5 1235 10 20 30

Fluid velocity

* For the fittings:

• with external thread connections acc. to SMS 1145,

• with welding end connections acc. to SMS 3008, BS 4825 / ASME BPE or DIN 11850 Rg 2,

• Clamp acc. to SMS 3017 / ISO 2852, BS 4825 / ASME BPE or DIN 32676.

1)

The device cannot be installed on the DN20 fittings listed above

DN 65

(DN65)*

DN 50

DN 40

(DN50)*

DN 32

(DN40)*

DN 25

(DN32)*

DN 20

(DN25)*

DN 15

(DN15 / DN20)*

DN 08

DN 06

m/s

fps

English

13

Page 16

Type 8025/8035 battery powered

Installation

7.2.2. Installation of 8025 on the S020 fitting

→ Insert nut 3 on the fitting 5.

→ Insert the snap ring 2 into the groove 4.

→ Check that seal 6 is correctly inserted on the

flow sensor.

→ Slowly insert the device 1 into the fitting.

If the mounting is correctly done the device cannot

turn around anymore.

6

1

2

→ Hand lock the assembly with the nut 3.

Fig. 7: Installation of 8025 on the S020 fitting

7.2.3. Installation of the SE35 electronic module on the S030 fitting-sensor

→ Insert the electronic module 2 in the

S030 fitting-sensor.

→ Secure with a 30° clockwise rotation.

→ Tighten the lateral screw 3 to lock

the electronic module with the

fitting-sensor.

3

7.3. Description of the electronic board connections

Terminal block:

+ : positive supply (red wire)

- : negative supply (black wire)

3

4

5

2

1

Connector : branchement du

capteur de débit

Terminal block

OFF ON

Connector

Fig. 9: Electronic board

connections

Fig. 8: Installation of the SE35 electronic module on the S030

fitting-sensor

14

English

Page 17

Type 8025/8035 battery powered

Operating and commissioning

8. OPERATING AND COMMISSIONING

8.1. Safety instructions

Warning

Risk of injury due to non-conforming operating.

Non-conforming operating could lead to injuries and damage the

device and its surroundings.

• The operators in charge of operating must have read and understood the contents of this manual.

• In particular, observe the safety recommendations and intended

use.

• The device/installation must only be operated by suitably trained

staff.

Warning

Danger due to non-conforming commissioning.

Non-conforming commissioning could lead to injuries and damage

the device and its surroundings.

• Before commissioning, make sure that the staff in charge have

read and fully understood the contents of the manual.

• In particular, observe the safety recommendations and intended

use.

• The device / the installation must only be commissioned by

suitably trained staff.

8.2. Switch on the device and lock/ unlock the ENTER key

→ Unfasten the screw and flip

the lid.

→ Unfasten the 4 screws and

take off the cover of the

housing.

Switch on the device:

→ Put the switch 1 to ON

ENTER key unlocked

Fig. 11: Lock and unlock the ENTER key

Switch 1

OFF ON

Switch 2: see

Fig. 11

Fig. 10: Electronic board

ENTER key locked

English

15

Page 18

ENTER

Type 8025/8035 battery powered

Operating and commissioning

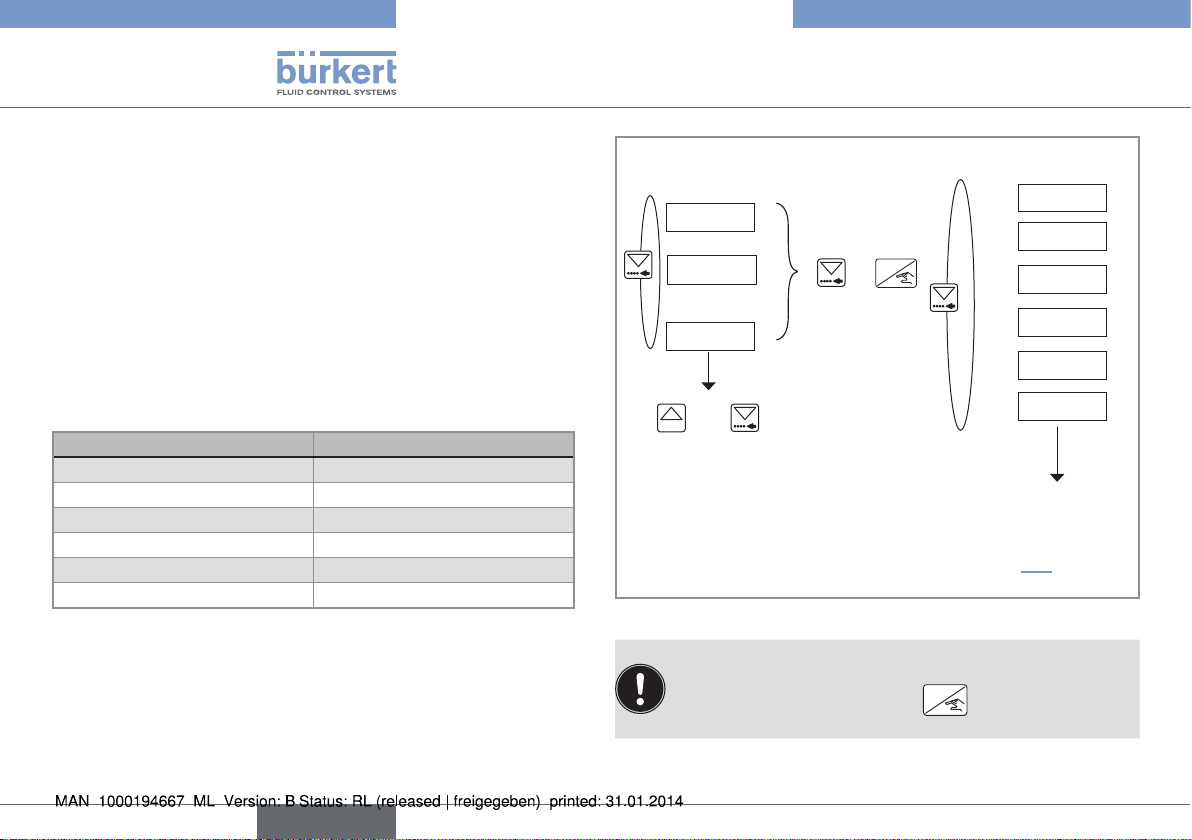

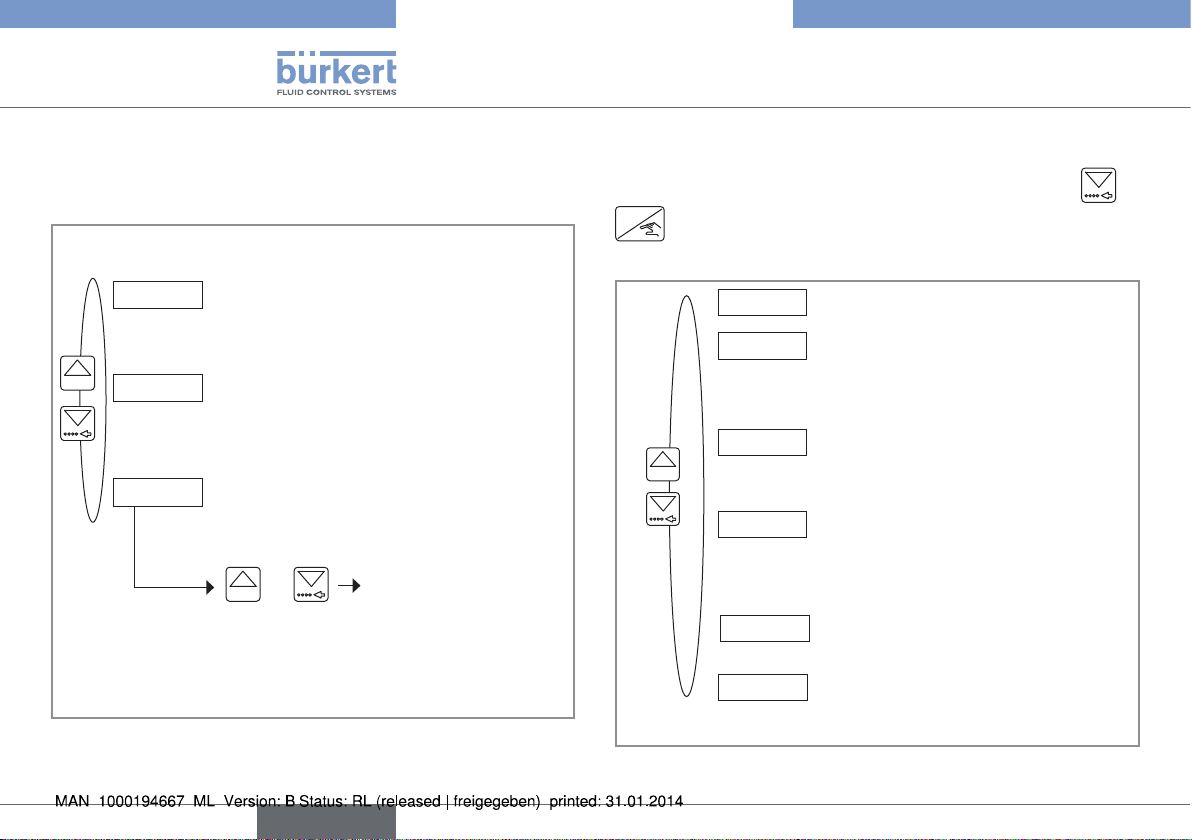

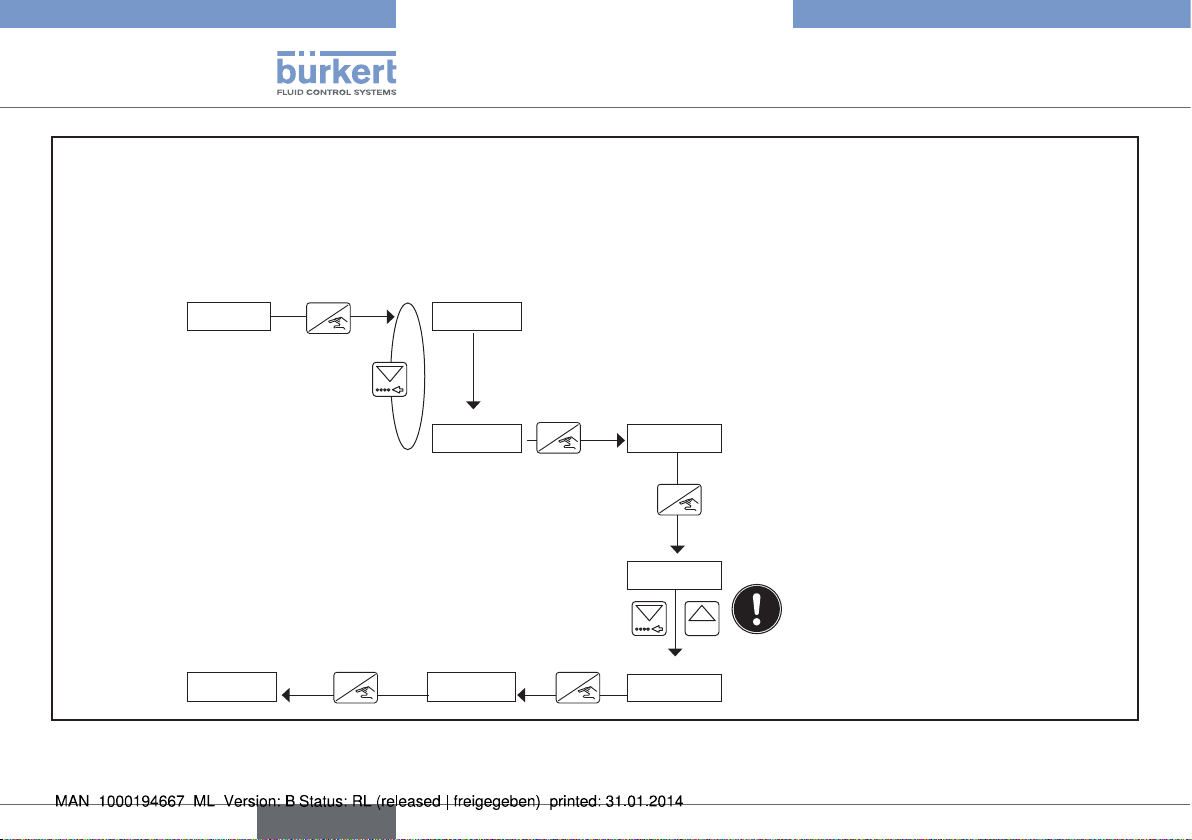

8.3. Operating levels of the device

The device has two operating levels: the Process level and the Configuration level.

The Process level makes it possible:

• to read the flow rate measured by the device and the value of the

totalizers, the main and the daily one.

• to reset the daily totalizer.

• to access the Configuration level.

The Configuration level makes it possible to set the device

parameters.

Table 4: Default settings of the device

Function Default value

LANGUAGE English

UNIT of the flow rate l/s

UNIT of the totalizers litre

Number of decimals 2

K FACTOR 46,60

FILTER Filter 2

Process level

Configuration level

12.6 l/s

87654 l

+

> 5 s

2)

231 l.

+

0......9

> 2 s

To reset the daily

totalizer (identified by

a dot after the volume

units).

2)

Possible if the ENTER key is unlocked (see chap. 8.2)

Fig. 12: Diagram of the levels of the device

Once the settings of a parameter is done if you do not want

to adjust another parameter, go to the "END" parameter of

the Configuation level and press

ENTER

to save the settings

and go back to the Process level.

lANGUAGE

UNit

K-FACtOR

FiltER

tOtAl

END

Process level

16

English

Page 19

Type 8025/8035 battery powered

Operating and commissioning

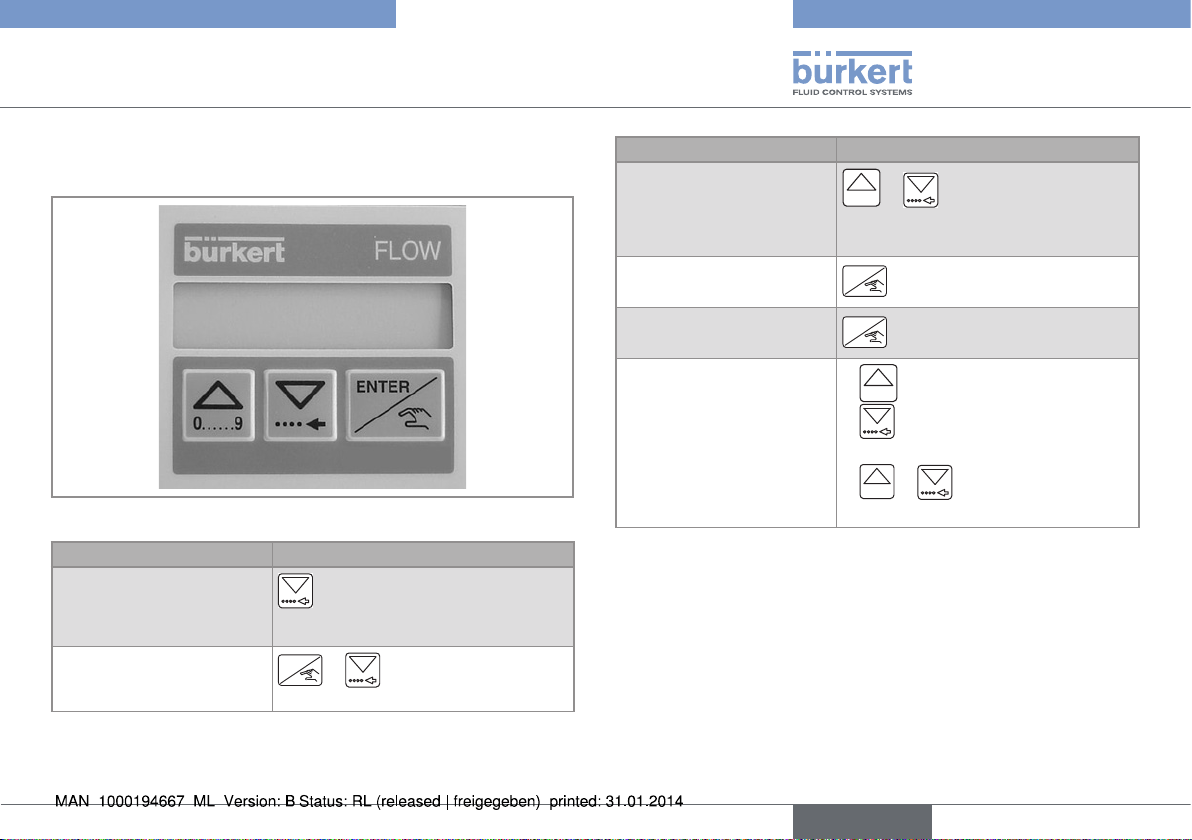

8.4. Description of the navigation

keys

Fig. 13: Foil of the device

You want to... Press...

Move in the parameters of

a level.

Access the Configuration

level.

To go to the next parameter.

ENTER

+ simultaneously for 5 s,

in the Process level

You want to... Press...

Reset the daily totalizer.

0......9

+ simultaneously for 2 s,

when the daily totalizer is displayed in

the Process level

Select the displayed

ENTER

parameter.

Confirm the displayed

ENTER

value.

Modify a numerical value.

•

0......9

•

the blinking digit.

0......9

•

point.

to increase the blinking digit.

to select the digit at the left of

+ to move the decimal

English

17

Page 20

Type 8025/8035 battery powered

Operating and commissioning

8.5. Details of the Process level

This level is active by default when the device is energized.

Value of the measured flow rate, displayed

in the unit chosen in the "UNIT" parameter of

the Configuration level.

Value of the main totalizer, total volume of

fluid counted by the device since the last

reset.

Value of the daily totalizer (identified by a

dot after the volume units), volume of fluid

counted by the device since the last reset.

0......9

+

> 2 s

Resetting the daily

totalizer.

0......9

12.6 l/s

87654 l

231 l.

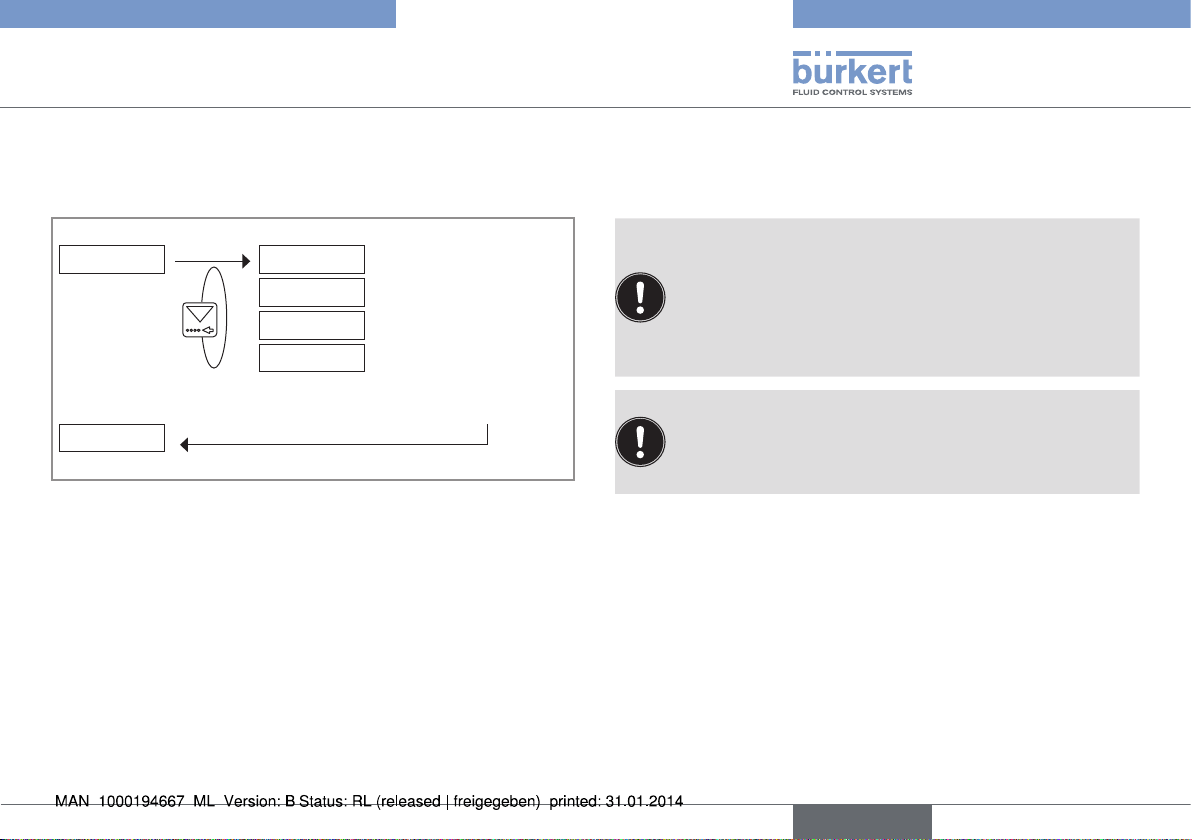

8.6. Details of the Configuration level

To access the Configuration level, simultaneously press keys

ENTER

for at least 5 s.

This level comprises the following configurable parameters:

lANGUAGE

UNit

K-FACtOR

0......9

FiltER

tOtAl

Choosing the display language

Choosing the flow rate unit, the

number of decimals and the unit

the totalizers are displayed in.

Entering the K factor of the fitting

used or have it defined through a

teach-in procedure.

Choosing the degree of attenuation

of the measured flow rate variations, with effect on the displayed

flow rate.

Resetting both totalizers.

Going back to the Process level

END

and saving the settings.

Fig. 14: Details of the Process level

18

English

Fig. 15: Diagram of the Configuration level

Page 21

Type 8025/8035 battery powered

Operating and commissioning

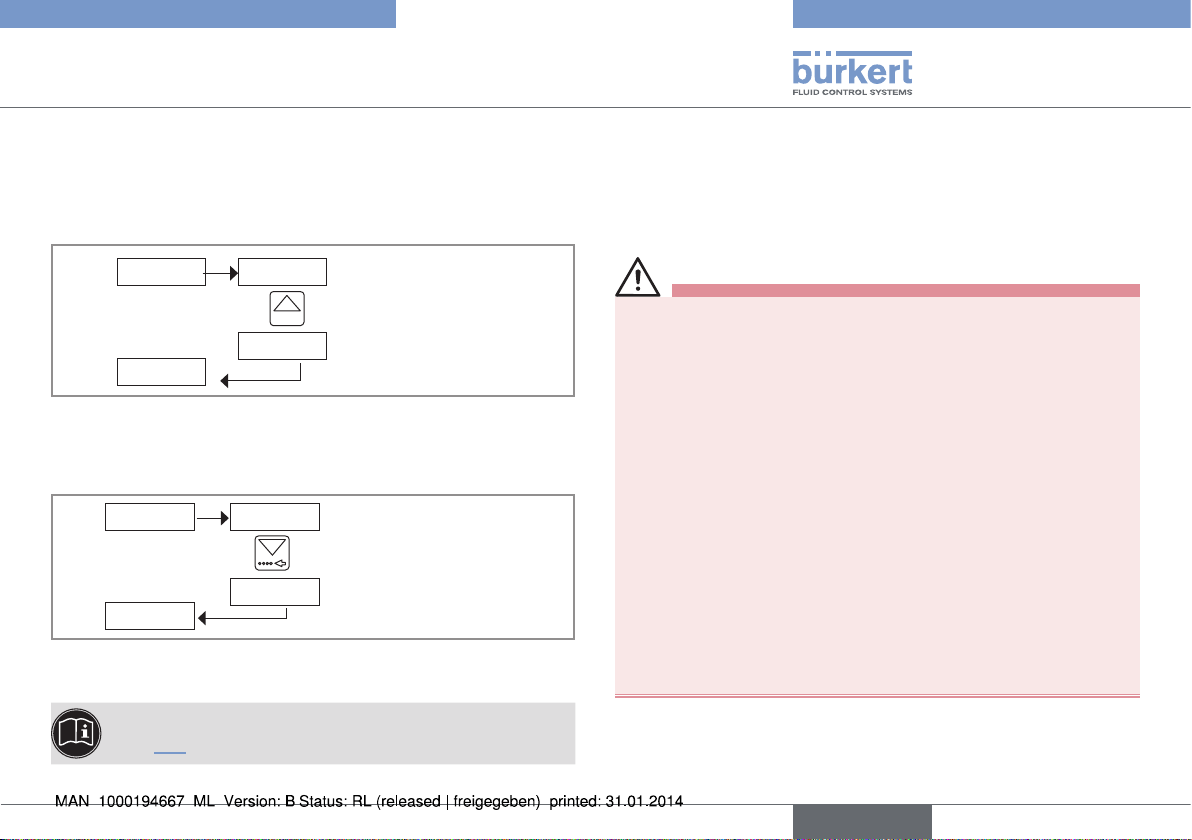

8.6.1. Choosing the display language

When the device is energized for the first time, the display language

is English.

lANGUAGE ENGlish

DEUtsCh

FRANçAis

itAliANO

→ Confirm the dis-

played language:

The selected language is immediately

active.

UNit

Fig. 16: Diagram of the "LANGUAGE" parameter of the

Configuration level

8.6.2. Choosing the flow rate units, the number of decimals and the units of the totalizers

The max. flow rate that can be displayed depends on the

number of decimals chosen:

• 9999 if the number of decimals = 0,

• 999,9 if the number of decimals = 1,

• 99,99 if the number of decimals = 2,

• 9,999 if the number of decimals = 3.

The maximal volume that can be displayed by the totalizers

depends on the unit of the chosen volume:

• 9 999 999 if the chosen volume unit is "litre",

3

• 999 999 if the chosen volume unit is "m

The "UNIT" parameter makes it possible to choose:

• the flow rate units.

• a fixed number of decimals (choose 0, 1, 2 or 3) to display the

flow rate in the Process level.

• the volume units of the totalizers if the unit previously chosen is in

litres or in m

3

.

", or "gallon".

English

19

Page 22

Type 8025/8035 battery powered

Operating and commissioning

UNit

FlOw RAtE

lit/sEC

lit/miN

lit/h

m3/miN

m3/h

Us GAl/s

Us GAl/m

Us GAl/h

imp GA/s

imp GA/m

GA/h

tOtAl

K-FACtOR

Fig. 17: Diagram of the "UNIT" parameter of the Configuration level

→ Choose the flow rate unit.

→ Confirm

DEC pt 0

DEC pt 1

DEC pt 2

DEC pt 3

If the chosen unit is in litres or m3.

litRE

→ Choose the totalizer unit.

→ Confirm

m3

→ Choose the number

of decimal positions.

→ Confirm

If the chosen unit

is in gallons.

20

English

Page 23

Type 8025/8035 battery powered

Operating and commissioning

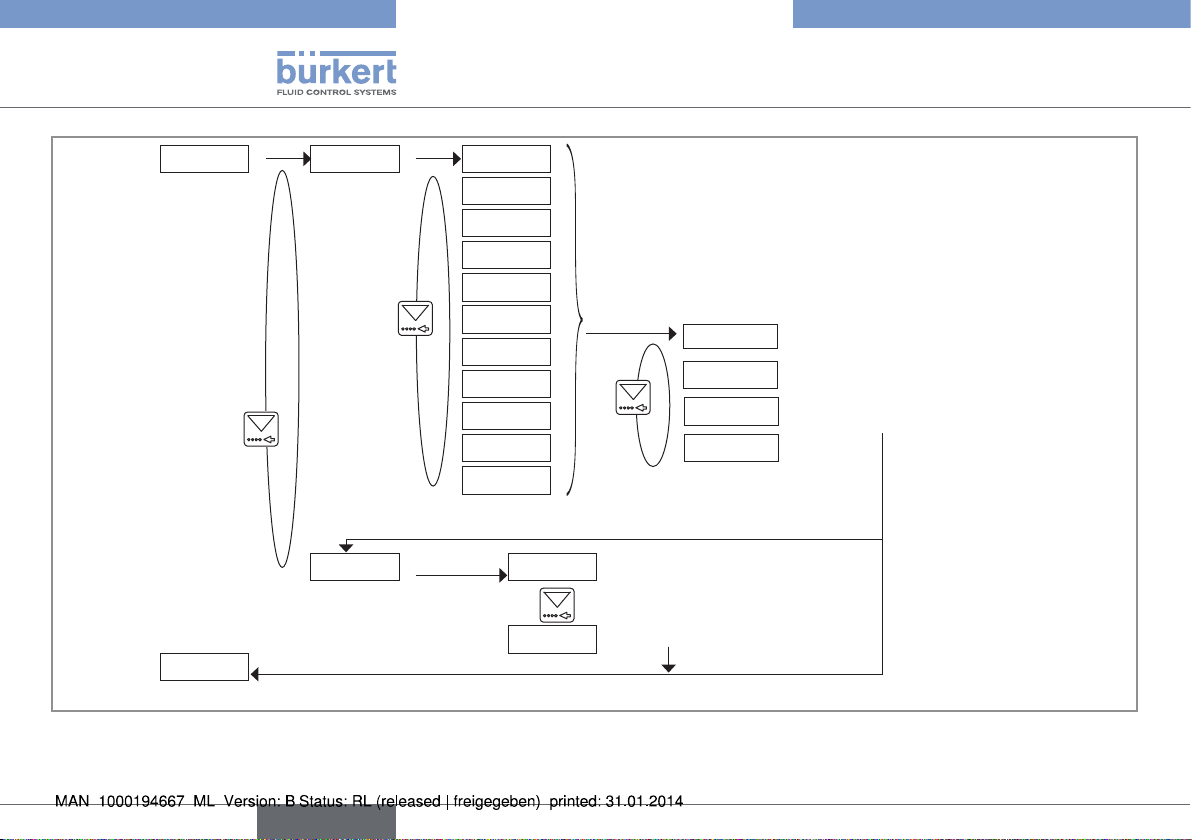

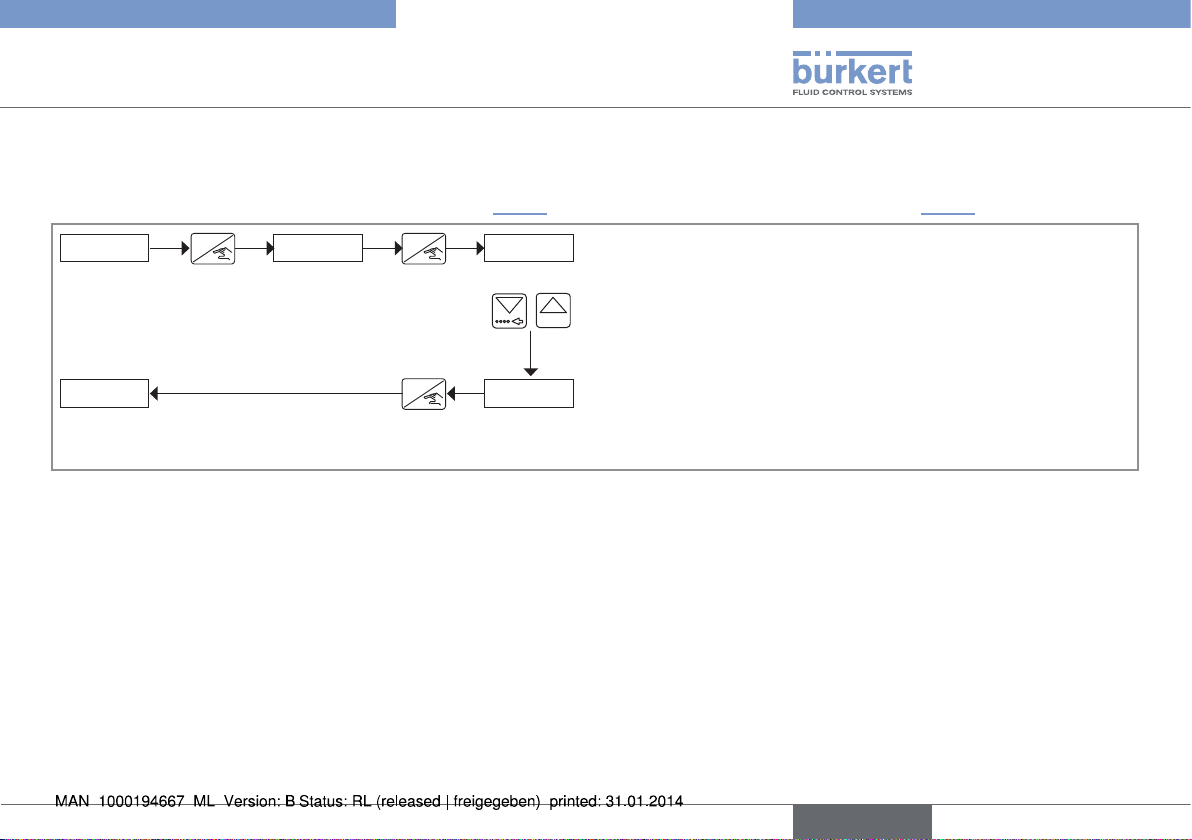

8.6.3. Entering or determining the K factor of the fitting used

The device determines the flow rate in the pipe using the fitting K factor.

The K factor of the fitting used can either be entered (see Fig. 18) or determined using a teach-in procedure (See Fig. 19).

K-FACtOR

ENTER

tEACh NO K=000.0

ENTER

The display shows the last K factor of the fitting, may it have been

entered or determined by a teach-in procedure.

→ Edit the parameter.

0......9

ENTER

Fig. 18: Entering the K factor of the fitting used

→ Enter the K factor (value between 0,0001 and 9999,9) of the

K=48.30FiltER

fitting used.

→ Confirm the displayed value.

English

21

Page 24

The teach-in procedure is done depending on a known volume.

→ Prepare a tank with a known volume.

→ Stop the fluid circulation.

→ confirm "TEACH Y.": "FILL END." is displayed.

Type 8025/8035 battery powered

Operating and commissioning

K-FACtOR tEACh NO

ENTER

tEACh Y Fill END

The device calculates

the K factor of the

fitting and displays it.

ENTER

Fig. 19: Teach-in procedure depending on a volume

22

English

K=48.30FiltER

ENTER

ENTER

ENTER

0000.0 l

0......9

0100.0 l

→ Charge the pipe to fill the tank.

→ When the tank is full, confirm "FILL END":

Do not enter a volume value of 0,0

because the calculated K-factor would

be of 0,0 and the device would not be

operating.

→ Enter the volume (value > 0,0 and ≤ 9999,9)

of fluid that passed in the circuit.Confirm.

Page 25

Type 8025/8035 battery powered

Maintenance and troubleshooting

8.6.4. Configuring the filter

This parameter makes it possible to dampen the fluctuations ot the

display.

Ten filters are available.

FiltER FiltER 0

→ Choose the filter.

0......9

FiltER 9

tOtAl

Fig. 20: Diagram of the "FILTER" parameter of the Configuration level

8.6.5. Resetting both totalizers

tOtAl REs NO

→ Confirm

→ Choose to reset the

two totalizers or not.

REs YEs

END

Fig. 21: Diagram of the "TOTAL" parameter of the Configuration

level

The daily totalizer can be reset from the Process level (see

chap. 8.5).

→ Confirm

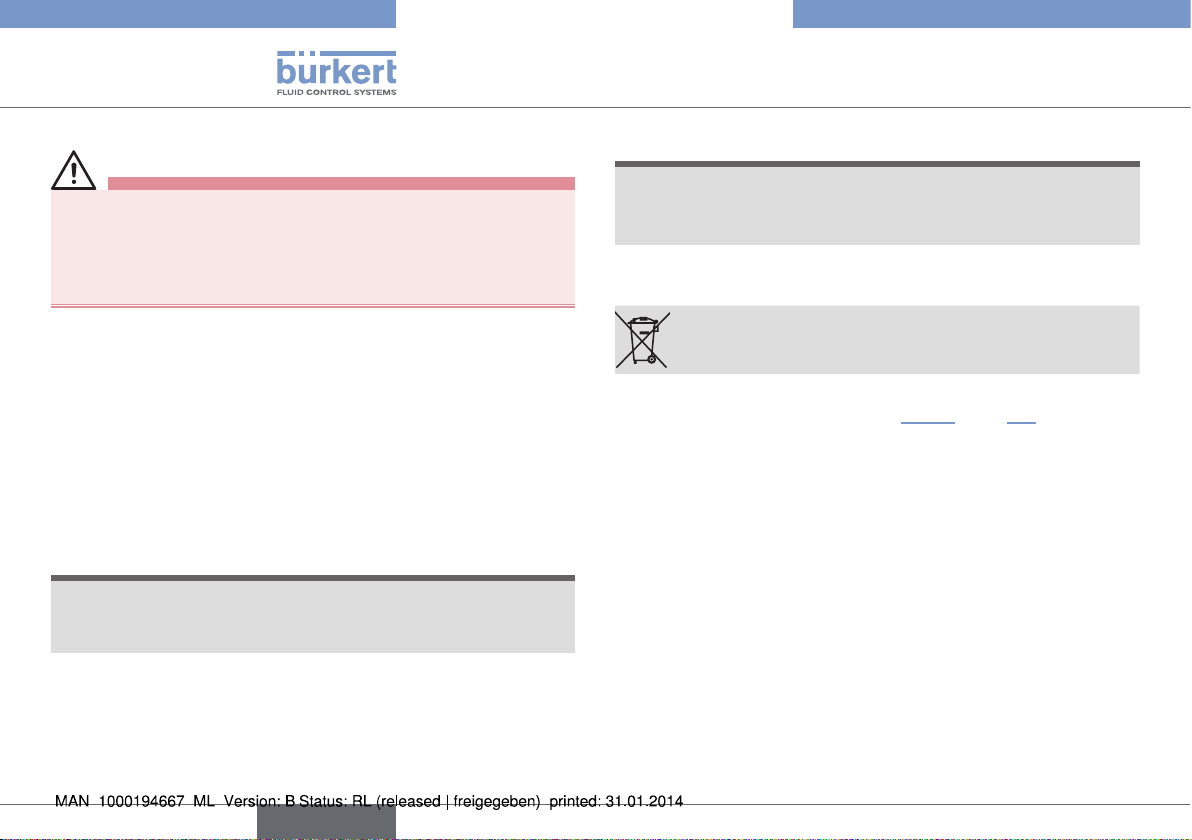

9. MAINTENANCE AND TROUBLESHOOTING

9.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Put the power switch to OFF before carrying out work on the

device.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

English

23

Page 26

Type 8025/8035 battery powered

Maintenance and troubleshooting

Warning

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Ensure that the restart of the installation is controlled after any

interventions.

9.2. Cleaning the device

The device can be cleaned with a cloth dampened with water or a

detergent compatible with the materials the device is made of.

Please feel free to contact your Bürkert supplier for any additional

information.

9.3. Cleaning the flow sensor of the 8025

note

• Use a cleaning product that is compatible with the materials the

flow sensor is made of.

• Do not use any abrasive acting materials.

note

After cleaning of the flow sensor:

• Rinse the flow sensor.

• Check the seal and replace it if necessary.

9.4. Replacing the batteries

Dispose of the used batteries in compliance with the prevailing legislation.

→ Open the housing as indicated in Fig. 10 chap. 8.2.

→ Disconnect the flow sensor to make easier the access to the

batteries.

→ Take off the batteries connectors.

→ Replace the batteries one after the other to keep the data regis-

tered in the device.

→ Plug the connectors onto the batteries.

→ Reconnect the flow sensor.

→ Close the cover.

→ Tighten the screws.

→ Close the lid.

→ Tighten the screw.

24

English

Page 27

Type 8025/8035 battery powered

Spare parts and accessories

9.5. If you encounter problems

Display Possible cause Recommended action

"ERROR" The user parameters

are lost.

→ Parameterise the

device again.

→ If the message appears

repeatedly send the

device back to your

supplier.

"LOW BATT" The battery power

is too low to ensure

the operating of the

device.

Value of the

flow rate or of

the totalizer

fashes

The battery power

is getting low but

the device is still

operating.

→ Replace the batteries

(see chap. 9.4).

→ Plan to replace the

batteries

10. SPARE PARTS AND ACCESSORIES

attention

Risk of injury and/or damage caused by the use of unsuitable

parts.

Incorrect accessories and unsuitable replacement parts may

cause injuries and damage the device and the surrounding area.

• Use only original accessories and original replacement parts

from Bürkert.

10.1. SE35 electronic module

Spare part Order code

Cover in PC, with lid, incl. window, screws,

sticked foil and electronic board

Set with 8 FLOW foils 553191

Housing incl. coil as a measuring element 425247

Set including:

• 2 M20x1.5 screw plugs

• 2 flat seals

425433

444705

English

25

Page 28

Type 8025/8035 battery powered

Packaging, Transport

10.2. 8025 flowmeter-totalizer

Spare part Order code

Cover in PC, with lid, incl. window, screws,

sticked foil and electronic board

Set with 8 FLOW foils 553191

Set including:

• 2 M20x1.5 screw plugs

• 2 flat seals

Set including:

• 1 green FKM seal

• 1 black EPDM seal

Housing incl. snap ring and nut 552398

Snap ring 619205

Nut 619204

Flow sensor with coil (short sensor) for

DN ≤100 + replacement instructions

Flow sensor with coil (long sensor) for

DN ≥100 + replacement instructions

425433

444705

552111

633366

634757

11. PACKAGING, TRANSPORT

note

Damage due to transport

Transport may damage an insufficiently protected device.

• Transport the device in shock-resistant packaging and away

from humidity and dirt.

• Do not expose the device to temperatures that may exceed the

admissible storage temperature range.

12. STORAGE

note

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Storage temperature of the device: 0 to +60 °C.

26

English

Page 29

Type 8025/8035 battery powered

Packaging, Transport

13. DISPOSAL OF THE PRODUCT

Dispose of the device and its packaging in an environmentally-

→

friendly way.

note

Damage to the environment caused by products contaminated by fluids.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

note

Comply with the national and/or local regulations which

concern the area of waste disposal.

English

27

Page 30

Type 8025/8035 battery powered

28

English

Page 31

Typ 8025 / 8035 mit Batterien

1. DIE BEDIENUNGSANLEITUNG ...............................................................3

1.1. Darstellungsmittel ............................................................................. 3

1.2. Begriffsdefinition "Gerät" ................................................................ 3

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ......................................4

3. GRUNDLEGENDE SICHERHEITSHINWEISE ....................................4

4. ALLGEMEINE HINWEISE .............................................................................6

4.1. Herstelleradresse und internationale Kontaktadressen ........... 6

4.2. Gewährleistung.................................................................................6

4.3. Informationen im Internet ................................................................ 6

5. BESCHREIBUNG .............................................................................................6

5.1. Vorgesehener Einsatzbereich ........................................................ 6

5.2. Allgemeine Beschreibung .............................................................. 6

5.3. Beschreibung der Typenschilder ..................................................6

5.4. Verfügbare Ausführungen ..............................................................7

6. TECHNISCHE DATEN ...................................................................................7

6.1. Betriebsbedingungen ......................................................................7

6.2. Einhaltung von Normen und Richtlinien ...................................... 7

6.3. Allgemeine Technische Daten ....................................................... 8

6.3.1. Mechanische Daten ..............................................................8

6.3.2. Allgemeine Daten ................................................................10

7. INSTALLATION ............................................................................................... 11

7.1. Sicherheitshinweise .......................................................................11

7.2. Fluidischer Anschluss ...................................................................12

7.2.1. Installation des Fittings in die Rohrleitung .....................12

7.2.2. Installation des 8025 in ein Fitting S020 ......................14

7.2.3. Installation des Elektronikmoduls SE35 in ein

Sensor-Fitting S030 ...........................................................14

7.3. Beschreibung der Anschlüsse auf der Elektronikplatine ......14

8. BEDIENUNG UND INBETRIEBNAHME ............................................. 15

8.1. Sicherheitshinweise .......................................................................15

8.2. Einschalten des Gerätes und Blockieren / Entblocken

der ENTER-Taste ....................................................................................15

8.3. Bedienebenen des Gerätes .........................................................16

8.4. Beschreibung der Navigations-Tasten ......................................17

8.5. Details der Prozess-Ebene ..........................................................18

8.6. Details der Einstellungs-Ebene ...................................................18

8.6.1. Display-Sprache auswählen .............................................19

8.6.2. Durchflusseinheit, Dezimalstellen und Mengen-

zähler-Einheit auswählen ...................................................19

8.6.3. K-Faktor des Fittings eingeben oder bestimmen ........21

8.6.4. Filter einstellen ....................................................................23

8.6.5. Beide Mengenzähler zurückstellen ..................................23

9. WARTUNG, FEHLERBEHEBUNG ......................................................... 23

9.1. Sicherheitshinweise .......................................................................23

9.2. Reinigung des Gerätes .................................................................24

9.3. Reinigung des Durchfluss-Sensors des 8025 ........................24

9.4. Batterien wechseln ........................................................................24

deutsch

1

Page 32

9.5. Problemlösung ................................................................................25

10. ERSATZTEILE UND ZUBEHÖR...........................................................25

10.1. Elektronikmodul SE35 ................................................................25

10.2. Durchflussmessgerät-Mengenzähler 8025 ...........................26

11. VERPACKUNG, TRANSPORT ..............................................................26

12. LAGERUNG ................................................................................................... 26

13. ENTSORGUNG DES GERÄTES ..........................................................27

Typ 8025 / 8035 mit Batterien

2

deutsch

Page 33

Typ 8025 / 8035 mit Batterien

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für

jeden Benutzer zugänglich ist und jedem neuen Eigentümer des

Gerätes wieder zur Verfügung steht.

Diese Bedienungsanleitung enthält wichtige Informationen

zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Diese Bedienungsanleitung muss gelesen und verstanden

werden.

1.1. Darstellungsmittel

Gefahr!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichteinhaltung sind Tod oder schwere Verletzungen die

Folge.

WarnunG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichteinhaltung drohen schwere Verletzungen oder Tod.

VOrSIChT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

hInWeIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2. Begriffsdefinition "Gerät"

Der in dieser Anleitung verwendete Begriff "Gerät" steht immer für

das Durchflussmessgerät / der Mengenzähler mit Batterien Typ

8025 oder 8035.

deutsch

3

Page 34

Typ 8025 / 8035 mit Batterien

Bestimmungsgemässe Verwendung

2. BESTIMMUNGSGEMÄSSE VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz dieses Gerätes

können Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

• Das Durchfluss-Messgerät / Der Mengenzähler mit Batterien

Typ 8025 oder 8035 dient zur Messung des Durchflusses einer

Flüssigkeit und zählt das Volumen der Flüssigkeit zusammen.

• Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

• Für den Einsatz sind die in den Vertragsdokumenten und der

Bedienungsanleitung spezifizierten zulässigen Daten, Betriebsund Einsatzbedingungen zu beachten.

• Zum sicheren und problemlosen Einsatz des Gerätes müssen

Transport, Lagerung und Installation ordnungsgemäß erfolgen,

außerdem müssen Betrieb und Wartung sorgfältig durchgeführt

werden.

• Achten Sie immer darauf, dieses Gerät auf ordnungsgemäße

Weise zu verwenden.

→ Beachten Sie bei der Ausfuhr des Gerätes gegebenenfalls

bestehende Beschränkungen.

3. GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und

Wartung der Geräte auftreten können.

• Ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf das Installations- und Wartungspersonal, der

Betreiber verantwortlich ist.

Gefahr durch hohen Druck in der Anlage!

• Vor dem Lösen der Prozessanschlüsse die Anlage druckfrei

schalten und die Flüssigkeitszirkulation stoppen.

Gefahr durch elektrische Spannung!

• Das Gerät vor Beginn der Arbeiten auschalten (Schalter auf

OFF setzen).

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab, und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

Gefahr durch hohe Flüssigkeitstemperaturen!

• Das Gerät nur mit Schutzhandschuhen anfassen.

• Vor dem Lösen der Prozessanschlüsse die Flüssigkeitszirkulation stoppen und die Rohrleitung leeren.

4

deutsch

Page 35

Typ 8025 / 8035 mit Batterien

Grundlegende Sicherheitshinweise

Gefahr aufgrund der Art der Flüssigkeit!

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung und der Sicherheit in Kraft sind und die sich auf die

Verwendung gefährlicher Flüssigkeiten beziehen.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten

• Dieses Gerät nicht für die Durchflussmessung von Gas einsetzen.

• Dieses Gerät nicht in explosionsgefährdeten Bereichen einsetzen.

• Dieses Gerät nicht in einer Umgebung verwenden, die mit den

Materialien, aus denen es besteht, inkompatibel ist.

• Keine Flüssigkeit verwenden, die sich nicht mit den Werkstoffen

verträgt, aus denen das Gerät besteht.

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Belasten Sie das Gerät nicht mechanisch (z. B. durch Ablage

von Gegenständen oder als Trittstufe).

• Nehmen Sie keine äußerlichen oder innerlichen Veränderungen

am Gerät vor.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt werden.

• Betreiben Sie das Gerät nur in einwandfreiem Zustand und

unter Beachtung der Bedienungsanleitung.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten

• Bei der Einsatzplanung und dem Betrieb des Gerätes die allgemeinen Regeln der Technik einhalten.

hInWeIS!

Das Gerät kann durch das Medium beschädigt werden.

• Kontrollieren Sie systematisch die chemische Verträglichkeit der

Werkstoffe, aus denen das Gerät besteht, und der Flüssigkeiten,

die mit diesem in Berührung kommen können (zum Beispiel: Alkohole, starke oder konzentrierte Säuren, Aldehyde, Basen, Ester,

aliphatische Verbindungen, Ketone, aromatische oder halogenierte Kohlenwasserstoffe, Oxidations- und chlorhaltige Mittel).

hInWeIS!

Elektrostatisch gefährdete Bauelemente / Baugruppen!

• Das Gerät enthält elektronische Bauelemente, die gegen elektrostatische Entladung (ESD) empfindlich reagieren. Berührung

mit elektrostatisch aufgeladenen Personen oder Gegenständen

gefährdet diese Bauelemente. Im schlimmsten Fall werden sie

sofort zerstört oder fallen nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340 -5-1 und 5-2,

um die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

• Achten Sie ebenso darauf, dass Sie elektronische Bauelemente

nicht bei anliegender Versorgungsspannung berühren!

deutsch

5

Page 36

1

2

Typ 8025 / 8035 mit Batterien

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Herstelleradresse und internationale Kontaktadressen

Sie können mit dem Hersteller des Gerätes unter folgender Adresse

Kontakt aufnehmen:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

oder wenden Sie sich an Ihr lokal zuständiges Vertriebsbüro von

Bürkert.

Die internationalen Kontaktadressen finden Sie im Internet unter:

www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des Gerätes unter Beachtung der im vorliegenden

Handbuch spezifizierten Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zu den Typen 8025 oder

8035 finden Sie im Internet unter: www.buerkert.de

5. BESCHREIBUNG

5.1. Vorgesehener Einsatzbereich

Das Durchfluss-Messgerät / Der Mengenzähler mit Batterien Typ

8025 oder 8035 dient zur Messung des Durchflusses einer Flüssigkeit und zählt das Volumen der Flüssigkeit zusammen.

5.2. Allgemeine Beschreibung

Das Gerät Typ 8025 besteht aus einem Elektronikmodul mit Display

und einem Durchfluss-Sensor mit Flügelrad.

Das Gerät Typ 8035 besteht aus einem Elektronikmodul SE35 und

einem Sensor-Fitting S030 mit Flügelrad.

Das Gerät wird mit zwei Batterien versorgt.

5.3. Beschreibung der Typenschilder

1. Typ des Gerätes

TOTAL :8025- SUPPLY: BATT9V

COIL SHORT - OUT: /

S/N 1439

Made in France

00418403 W43MA

Bild 1: Typenschild des

8025

2. Betriebsspannung

3. Ausgang: Keiner

4. Herstellungscode

5. Konformitäts-Logo

457836

6. Durchfluss-Sensor-Daten

7. Seriennummer

8. Bestellnummer

6

deutsch

Page 37

1 2

Typ 8025 / 8035 mit Batterien

Technische Daten

1. Typ des Gerätes

TOTAL :SE35/8035 COIL 9V

IP65

S/N 1439

Made in France

00423921 W43MA

2. Durchfluss-Sensor-Daten

3. Betriebsspannung

4. Herstellungscode

5. Konformitäts-Logo

457836

6. Schutzart

Bild 2: Typenschild des

8035

7. Seriennummer

8. Bestellnummer

5.4. Verfügbare Ausführungen

• Der Durchflussmessgerät-Mengenzähler 8035 besteht aus einem

Elektronikmodul SE35 mit Bestell-Nummer 423921 und einem

Sensor-Fitting S030, der separat bestellt wird.

• Der Durchflussmessgerät-Mengenzähler 8025 ist in zwei Ver-

sionen verfügbar:

Typ des

Durchfluss-Sensors

kurz, mit Spule FKM

lang, mit Spule FKM

Werkstoff der

Dichtung

Bestellnummer

418403

418405

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

Temperaturbereich 0 bis +60 °C

Luftfeuchtigkeit < 80 %, nicht kondensierend

Höhe über

Meeresspiegel

Schutzart IP65, Klappe des Deckels bis zum

6.2. Einhaltung von Normen und Richtlinien

Durch folgende Normen wird die Konformität mit den EG-Richtlinien

erfüllt:

• EMV: EN 61000-6-2, EN 61000-6-3

• Niederspannungsrichtlinie: EN 61 010-1

• Vibration: EN 60068-2-6

• Schock: EN 60068-2-27

• Druck: Gemäß Artikel 3§3 der 97/23/CE Druckgeräterichtlinie.

Gemäß der 97/23/CE Druckgeräterichtlinie: Das Gerät kann nur

unter folgenden Bedingungen eingesetzt werden (abhängig vom

maximalen Druck, vom DN der Rohrleitung und von der Flüssigkeit)

max. 2000 m

Anschlag und beide Schraubstopfen

festgeschraubt.

deutsch

7

Page 38

203

Typ 8025 / 8035 mit Batterien

Technische Daten

Art der

Flüssigkeit

Voraussetzungen

8025 8035

1)

Flüssigkeitsgruppe 1

nur DN25 DN ≤ 25

Kap. 1.3.a

Flüssigkeits-

gruppe 2

Kap. 1.3.a

Flüssigkeitsgruppe 1

Kap. 1.3.b

DN ≤ 32

oder DN > 32 und

PNxDN ≤ 1000

DN ≤ 25

oder DN > 25 und

PNxDN ≤ 2000

DN ≤ 32

oder DN > 32 und

PNxDN ≤ 1000

PNxDN ≤ 2000

Flüssigkeitsgruppe 2

DN ≤ 400 DN ≤ 200

Kap. 1.3.b

1)

Für Typ 8035: Sensor-Fitting S030, DN6 bis DN65, aus PP, PVC,

PVDF, Messing oder Edelstahl.

6.3. Allgemeine Technische Daten

6.3.1. Mechanische Daten

Teil Werkstoff

Gehäuse / Dichtung PC / NBR

Deckel mit Klappe / Dichtung PC / Silikon

Frontfolie Polyester

Teil Werkstoff

M20x1,5 Schraubstopfen /

PA / Neopren

Dichtung

Schrauben Edelstahl

Überwurfmutter PC

Durchfluss-Sensor (in Kontakt mit

PVDF / FKM

der Flüssigkeit) / Dichtung (nur

8025)

Axe und Lager des Flügelrads Keramik

R=90

91

21

85.5

102

164.5

49.5

30

136

Bild 3: Abmessungen des 8025 [mm]

88

88

8

deutsch

Page 39

Typ 8025 / 8035 mit Batterien

Technische Daten

Tab. 1: Abmessung H in mm des Durchflussmessgeräts-

Mengenzählers 8025 verbunden mit einem Fitting S020

H

H

T-Ftting

AnschlussSchellen

Schweißstutzen, aus

Kunststoff

Schweißstutzen mit

Radius aus

Edelstahl

DN20 185

DN25 185

DN32 188

DN40 192 188

DN50 198 223 193

DN65 198 221 206 199

DN80 226 212 204

DN100 231 219 214

DN110 227

DN125 234 254 225

T-Ftting

AnschlussSchellen

Schweißstutzen, aus

Kunststoff

Schweißstutzen mit

Radius aus

Edelstahl

DN150 244 261 236

DN180 268

DN200 280 282 257

DN250 300 317

DN300 312 336

DN350 325 348

DN400 340

deutsch

9

Page 40

Typ 8025 / 8035 mit Batterien

Technische Daten

180

91

21

88

88

95

105

75

104

114

Bild 4: Abmessungen [mm] des Elektronikmoduls SE35

Tab. 2: Abmessung H in mm des Elektronikmoduls SE35

verbunden mit einem Sensor-Fitting S030

DN (mm) 06 08 15 20 25 32 40 50 65

H [mm] 134 134 139 137 137 140 144 151 151

1)

H

Die Höhe H ist unabhängig

von den Anschlüssen sowie

dem Werkstoff des Fittings

6.3.2. Allgemeine Daten

Typ 8025 8035

Durchmesser der

Leitungen

DN20 (außer diejenigen auf Seite

13 angegeben) bis DN400

Typ des Fittings S020 S030

Flüssigkeitstemperatur

Die Flüssigkeitstemperatur kann durch

den Druck der Flüssigkeit und den Werkstoff des verwendeten Fittings eingeschränkt sein: Siehe Bild 5 und

Flüssigkeitsdruck

Der Flüssigkeitsdruck kann durch die

Temperatur der Flüssigkeit und den

Werkstoff des verwendeten Fittings eingeschränkt sein: Siehe Bild 5

Durchflussmessung

• Messbereich

• Messfehler, mit Teach-

• 0,2 bis 10 m/s

• ±0,5 % des Messbereichsendes

In-Kalibrierverfahren

• Messfehler mit K-Faktor

des verwendeten Fittings

• Linearität

• Wiederholbarkeit

• ± (0,5% des Messbereichsendes +

2,5 % des Messwertes)

• ±0,5 % vom Messbereichsende

• ±0,4 % vom Messwert

Versorgungsspannung Zwei 9 V-Batterien (6LR61)

Mindest-Autonomie: 1 Jahr bei 20° C

1)

Unter folgenden Referenzbedingungen bestimmt: Flüssigkeit

= Wasser, Temperatur des Wassers und der Umgebung =

20 °C, Mindestein- und -auslaufstrecken eingehalten, passende

Rohrdurchmesser.

DN6 bis

DN65

1)

1)

10

deutsch

Page 41

11

Typ 8025 / 8035 mit Batterien

Installation

P Flüssigkeit (bar)

10

9

8

7

6

5

4

3

2

1

0

Verwendungsbereich

Metall

PVDF

PVC + PP

PVC (PN10)

-15 0 +20 +40+60

PVDF (PN10)

PP (PN10)

+80

T Flüssigkeit (°C)

Bild 5: Druck-Temperatur-Abhängigkeitskurven der Flüssigkeit für

den 8025, je nach Werkstoff des Fittings S020

Verwendungsbereich

A

Metall

PVDF

PVC + PP

PVC (PN10)

PP (PN10)

-10 +10 +30 +50+70 +90 +110

PVDF (PN10)

P Flüssigkeit (bar)

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

-30

T Flüssigkeit (°C)

7. INSTALLATION

7.1. Sicherheitshinweise

Gefahr!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen der Prozessanschlüsse die Anlage druckfrei

schalten, die Flüssigkeitszirkulation stoppen und die Rohrleitung

leer laufen lassen.

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab, und sichern Sie diese vor Wiedereinschalten!

• Das Gerät vor Beginn der Arbeiten auschalten (Schalter auf

OFF setzen).

• Beachten Sie geltende Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

Verletzungsgefahr durch hohe Flüssigkeitstemperaturen!

• Das Gerät nur mit Schutzhandschuhen anfassen.

• Vor dem Lösen

keitszirkulation stoppen und die Rohrleitung leeren.

Verletzungsgefahr aufgrund der Art der Flüssigkeit!

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung

und der Sicherheit in Kraft sind und die sich auf die Verwendung

gefährlicher Flüssigkeiten beziehen.

der Prozessanschlüsse die Flüssig-

Bild 6: Druck-Temperatur-Abhängigkeitskurven der Flüssigkeit für

den 8035, je nach Werkstoff des Sensor-Fittings S030

deutsch

11

Page 42

WarnunG!

Verletzungsgefahr bei unsachgemäßer Installation!

• Fluidische Installation darf nur durch autorisiertes Fachpersonal

und mit geeignetem Werkzeug durchgeführt werden!

• Beachten Sie die Montageanweisungen des verwendeten Fittings.

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach jedem Eingriff an der Anlage einen kontrollierten Wiederanlauf gewährleisten.

Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung vor

Witterungseinflüssen.

7.2. Fluidischer Anschluss

Gefahr!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen der Prozessanschlüsse die Anlage druckfrei

schalten, die Flüssigkeitszirkulation stoppen und die Rohrleitung

leer laufen lassen.

Verletzungsgefahr aufgrund der Art der Flüssigkeit!

• Beachten Sie die Regeln, die auf dem Gebiet der Unfallverhütung

und der Sicherheit in Kraft sind und die sich auf die Verwendung

gefährlicher Flüssigkeiten beziehen.

Typ 8025 / 8035 mit Batterien

Installation

Der Durchflussmessgerät-Mengenzähler 8025 wird in ein auf der

Rohrleitung montiertes Fitting S020 eingesteckt.

Das Elektronikmodul SE35 wird in ein auf der Rohrleitung montiertes

Sensor-Fitting S030 eingesteckt.

7.2.1. Installation des Fittings in die Rohrleitung

→ Das Fitting S020 oder Sensor-Fitting S030 so auswählen, das

der Flüssigkeitsgeschwindigkeit in der Rohrleitung geeignet ist.

Siehe folgende Diagramme.

→ Das Fitting oder Sensor-Fitting gemäß der Bedienungsanleitung

des verwendeten Fittings in die Rohrleitung einbauen.

12

deutsch

Page 43

gpm

Typ 8025 / 8035 mit Batterien

Installation

Tab. 3: Diagramme Durchfluss/ Flüssigkeitsgeschwindigkeit/ DN der Fittings S020 (links) und der Sensor-Fittings S030 (rechts)

Beispiel: Bei einem Nenndurchfluss = 10 m3/h und eine optimale Fließgeschwindigkeit zwischen 2 und 3 m/s,

→ einen DN40 (oder DN50 für (*) genannte Fittings) Fitting verwenden.

US gpm

20000

10000

5000

2000

1000

500

200

100

50

20

10

5

2

1

0.5

0.2

0.1

0.05

Durchfluss

l/min

100000

50000

30000

20000

10000

5000

3000

2000

1000

500

200

100

50

20

10

5

2

1

0.5

0.2

3

/h

m

5000

2000

1000

500

200

100

50

20

10

5

2

1

0.5

0.2

0.1

0.05

0.02

0.01

0.10.3 0.51 35 10

0.30.5 13510

Fließgeschwindigkeit

DN 400

DN 350

DN 300

DN 250

DN 200

DN 150

DN 125

DN 100

DN 80

DN 65

DN 50 (DN65)*

DN 40 (DN50)*

DN 32 (DN40)*

DN 25 (DN32)*

DN 20 (DN25)*

Beispiel

m/s

30

fps

Durchfluss

m3/h

l/min

2000

1000

500

200

100

50

20

10

0.5

0.2

0.1

0.05

500

5000

200

2000

100

1000

50

500

20

200

10

100

5

50

2

20

5

2

1

1

10

0.5

5

3

0.2

2

0.1

1

0.05

0.5

0.02

0.3

0.2

0.01

0.1 0.2 0.3 0.5 1235 10

0.3 0.5 1235 10 20 30

Fließgeschwindigkeit

DN 65

(DN65)*

DN 50

DN 40

(DN50)*

DN 32

DN 25

(DN32)*

DN 20

(DN25)*

DN 15

(DN15 / DN20)*

DN 08

DN 06

m/s

fps

(DN40)*

* Für die Fittings

• mit Außengewinde-Anschlüssen nach SMS 1145,

• mit Schweißstutzen-Anschlüssen nach SMS 3008, BS 4825 / ASME BPE oder DIN 11850 Reihe2,

• Clamp nach SMS 3017 / ISO 2852, BS 4825 / ASME BPE oder DIN 32676

1)

Das Gerät nicht in die vorgenannten DN20 Fittings einbauen.

deutsch

13

Page 44

2

1

3

4

5

6

1

2

3

Typ 8025 / 8035 mit Batterien

Installation

7.2.2. Installation des 8025 in ein Fitting S020

→ Überwurfmutter 3 auf Fitting 5 setzen.

→ Sprengring 2 in Rille 4 befestigen.

→ Prüfen, dass Dichtung 6 richtig auf dem

Durchfluss-Sensor sitzt.

→ Gerät 1 vorsichtig ins Fitting einsetzen.

Bei korrektem Einbau darf sich das Gerät nicht

drehen lassen.

→ Einheit mit Überwurfmutter 3 verriegeln, diese

nur mit der Hand festziehen.

Bild 7: Installation des 8025 in ein Fitting S020

7.2.3. Installation des Elektronikmoduls SE35 in ein Sensor-Fitting S030

→ Elektronikmodul 2 in Sensor-Fitting

S030 einsetzen.

→ Mit einer 30°-Drehung im Uhrzei-

gersinn befestigen.

→ Seitenschraube 3 festziehen, um das

Elektronikmodul an das Sensor-Fitting

befestigen.

Bild 8: Installation des Elektronikmoduls SE35 in ein Sensor-Fitting

14

S030

deutsch

7.3. Beschreibung der Anschlüsse auf der Elektronikplatine

Klemmleiste:

+: positive Stromversorgung

(rote Ader)

-: negative Stromversorgung

(schwarze Ader)

Stecker: Anschluss des

Durchfluss-Sensors

OFF ON

Klemmleiste

Stecker

Bild 9: Anschlüsse auf der

Elektronikplatine

Page 45

Typ 8025 / 8035 mit Batterien

Bedienung und Inbetriebnahme

8. BEDIENUNG UND INBETRIEBNAHME

8.1. Sicherheitshinweise

WarnunG!

Verletzungsgefahr bei unsachgemäßer Bedienung!

Nicht sachgemäße Bedienung kann zu Verletzungen, sowie

Schäden am Gerät und seiner Umgebung führen.

• Das Bedienpersonal muss den Inhalt der Bedienungsanleitung

kennen und verstanden haben.

• Besonders zu beachten sind die Sicherheitshinweise und die

bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend geschultes

Personal bedient werden.

WarnunG!

Verletzungsgefahr bei unsachgemäßer Inbetriebnahme!

Nicht sachgemäßer Betrieb kann zu Verletzungen sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Besonders zu beachten sind die Sicherheitshinweise und die

bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend geschultes

Personal in Betrieb genommen werden.

8.2. Einschalten des Gerätes und Blockieren / Entblocken der ENTER-Taste

→ Schraube lösen und Klappe

öffnen

→ Die 4 Schrauben lösen

dann Gehäuse-Deckel

abnehmen.

Das Gerät unter Spannung

setzen

Schalter 1

OFF ON

Schalter 2: Siehe

Bild 11

→ Schalter 1 auf ON setzen.

Bild 10: Elektronikplatine

ENTER-Taste entblockt

Bild 11: Blockieren / Entblocken der ENTER-Taste

ENTER-Taste

blockiert

deutsch

15

Page 46

ENTER

Typ 8025 / 8035 mit Batterien

Bedienung und Inbetriebnahme

8.3. Bedienebenen des Gerätes

Das Gerät verfügt über zwei Bedienebenen: Die Prozess-Ebene und

die Einstellungs-Ebene.

Die Prozess-Ebene ermöglicht es,

• den durch das Gerät gemessene Durchfluss und die Werte der

Tages- und Haupt-Mengenzähler abzulesen.

• den Tages-Mengenzähler zurück zu setzen.

• auf die Einstellungs-Ebene zu wechseln.

Die Einstellungs-Ebene ermöglicht die Einstellung der Parameter

des Gerätes.

Tab. 4: Grundeinstellungen des Gerätes

Funktion Grundeinstellung

SPRACHE English

EINHEIT des Durchflusses l/s

EINHEIT der Mengenzähler Liter

Dezimalstellen 2

K-FAKTOR 46,60

FILTER Filter 2

Prozess-Ebene

Einstellungs-Ebene

12.6 l/s

87654 l

+

> 5 s

2)

231 l.

+

0......9

> 2 s

Zurücksetzen des Tageszählers (durch den Punkt

nach der Volumen-Einheit

Prozess-Ebene

erkennbar).

2)

Wenn die ENTER-Taste entblockt ist (siehe Kap. 8.2)

Bild 12: Diagramm der Bedienebenen des Gerätes

Wenn ein Parameter eingestellt wurde und kein weiterer

Parameter geändert werden soll, zur Funktion "ENDE" des

Parametriermenüs gehen und die Taste

ENTER

um die Einstellungen zu speichern und zur Prozess-Ebene

zurück zu gehen.

sPRACHE

EinHEit

K-FAKtOR

FiltER

tOtAl

EndE

drücken,

16

deutsch

Page 47

Typ 8025 / 8035 mit Batterien

Bedienung und Inbetriebnahme

8.4. Beschreibung der

Navigations-Tasten

Bild 13: Folie des Gerätes

Sie wollen... Drücken Sie...

sich in den Funktionen

einer Ebene bewegen.

auf die Einstellungs-Ebene

wechseln.

nächste Funktion:

ENTER

+ gleichzeitig für 5 s in

der Prozess-Ebene.

Sie wollen... Drücken Sie...

den Tageszähler

zurücksetzen.

0......9

+ gleichzeitig für 2 s,

wenn der Tages-Mengenzähler in der

Prozess-Ebene angezeigt wird.

die angezeigte Funktion

ENTER

auswählen.

den angezeigten Wert

ENTER

bestätigen.

einen numerischen Wert

zum Erhöhen der ausgewählten

•

ändern.

0......9

Ziffer.

zur Auswahl der vorherigen

•

Ziffer.

0......9

+ zur Verschiebung des

•

Kommas.

.

deutsch

17

Page 48

Typ 8025 / 8035 mit Batterien

Bedienung und Inbetriebnahme

8.5. Details der Prozess-Ebene

Beim Einschalten des Gerätes ist diese Ebene aktiv.

Durchfluss-Messwert, in der in der Funktion

"EINHEIT" des Parametriermenüs ausgewählten Einheit.

Haupt-Mengenzähler-Wert, durch das Gerät

gezähltes Flüssigkeits-Volumen seit der

letzten Zurückstellung des Mengenzählers.

Tages-Mengenzähler-Wert (durch den Punkt

nach der Volumeneinheit erkennbar), Flüssigkeits-Volumen seit der letzten Zurückstellung des Mengenzählers.

0......9

+

> 2 s

Zurücksetzen des

Tages-Mengenzählers.

0......9

12.6 l/s

87654 l

231 l.

8.6. Details der Einstellungs-Ebene

ENTER

Für den Zugriff auf die Einstellungs-Ebene die Tasten

mehr als 5 s gleichzeitig drücken.

Diese Ebene erlaubt es, folgende Geräte-Parameter einzustellen:

sPRACHE

EinHEit

K-FAKtOR

0......9

FiltER

tOtAl

EndE

Display-Sprache auswählen.

Durchfluss-Einheit, Dezimalstellen

und Einheit zur Anzeige der Mengenzähler auswählen.

K-Faktor des verwendeten Fittings

eingeben oder mittels einer TeachIn-Kalibrierung ermitteln.

Filter des gemessenen Durchflusses auswählen, mit Effekt auf

den angezeigten Durchfluss.

Beide Mengenzähler zurücksetzen.

Zur Prozess-Ebene zurückgehen

und die Einstellungen speichern.

Bild 14: Details der Prozess-Ebene

18

Bild 15: Details der Einstellungs-Ebene

deutsch

Page 49

Typ 8025 / 8035 mit Batterien

Bedienung und Inbetriebnahme

8.6.1. Display-Sprache auswählen

Beim ersten Einschalten ist die Display-Sprache Englisch.

lAnGuAGE EnGlisH

dEutsCH

FRAnçAis

itAliAnO

→ Die angezeigte

Sprache bestätigen:

Die ausgewählte

Sprache ist sofort

aktiv.

EinHEit

Bild 16: Diagramm des Parameters "SPRACHE" der

Einstellungs-Ebene

8.6.2. Durchflusseinheit, Dezimalstellen und Mengenzähler-Einheit auswählen

Der maximale anzeigbare Durchflusswert hängt von den

ausgewählten Dezimalstellen ab:

• 9999 bei Dezimalstellen = 0,

• 999,9 bei Dezimalstellen = 1,

• 99,99 bei Dezimalstellen = 2,

• 9,999 bei Dezimalstellen = 3.

Der maximale Volumenwert, der durch die Mengenzähler

angezeigt werden kann, hängt von der ausgewählten Volumeneinheit ab:

• 9 999 999 bei Volumeneinheit "Liter",

3

• 999 999 bei Volumeneinheit "m

Die Funktion "EINHEIT" ermöglicht es Folgendes auszuwählen:

• Die Durchflusseinheit.

• Einen Festpunkt (Auswahl 0, 1, 2 oder 3) zur Anzeige des Durch-

flusswertes in der Prozess-Ebene.

• Die Volumeneinheit der Mengenzähler, wenn die oben ausge-

wählte Durchflusseinheit Liter oder m

" oder "gallon".

3

ist.

deutsch

19

Page 50

Typ 8025 / 8035 mit Batterien

Bedienung und Inbetriebnahme

EinHEit

duRCHFlu.

tOtAl

K-FACtOR

Bild 17: Diagramm des Parameters "EINHEIT" der

Einstellungs-Ebene

lit/sEC

lit/min

lit/H

m3/min

m3/H

us GAl/s

us GAl/m

us GAl/H

imP GA/s

imP GA/m

imP GA/H

Wenn die ausgewählte Einheit in Liter oder m3 ist.

→ Durchflusseinheit

auswählen

→ Bestätigen.

litER

→ Mengenzählereinheit

KOmmA 0

KOmmA 1

KOmmA 2

KOmmA 3

auswählen.

→ Dezimalstellen

auswählen.

→ Bestätigen.

→ Bestätigen.

m3

Wenn die ausgewählte Einheit in

Gallonen ist.

20

deutsch

Page 51

Typ 8025 / 8035 mit Batterien