Page 1

Type 8006 / 8702

MFM, Mass Flow Meter IP65

Type 8626 / 8712

MFC, Mass Flow Controller IP65

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2013-2015

Operating Instructions 1505/03_EU-ML 00563581

Page 3

Type 8006, 8702 / 8626, 8712

1. ABOUT THIS MANUAL .................................................................................4

1.1. Symbols used ..........................................................................................4

1.2. Definition of the word "device" .......................................................4

2. INTENDED USE ................................................................................................5

3. BASIC SAFETY INSTRUCTIONS .............................................................5

4. GENERAL INFORMATION ...........................................................................7

4.1. Manufacturer's address and international contacts ............ 7

4.2. Warranty conditions ..............................................................................7

4.3. Information on the Internet ...............................................................7

5. DESCRIPTION OF THE SYSTEM ............................................................7

5.1. General description ..............................................................................7

5.2. Operation of an MFM or MFC sensor ..........................................8

5.3. Detailed operation of an MFC .........................................................8

6. TECHNICAL DATA ........................................................................................11

6.1. Markings on the device.................................................................... 11

6.2. Conditions of use ................................................................................ 12

6.3. Compliance to standards and directives ................................ 13

6.4. Mechanical data ................................................................................... 13

6.5. Fluidic data .............................................................................................13

6.6. Electrical data, devices with an 8 pin M16 female fixed

connector ..........................................................................................................16

6.7. Electrical data, devices with a 9 pin Sub-D male fixed

connector, with RS485 interface .......................................................... 17

7. INSTALLATION AND COMMISSIONING ...........................................18

7.1. Safety instructions .............................................................................. 18

7.2. Prior to installation .............................................................................18

7.3. Description of the MFM / MFC ....................................................19

7.4. Sequence of the steps to be performed ................................ 20

7.5. Setting the parameters .................................................................... 20

7.6. Mechanical installation ..................................................................... 23

7.7. Fluid installation ................................................................................... 23

7.8. Electrical installation .........................................................................25

8. OPERATION AND FUNCTION ................................................................26

8.1. Safety instructions .............................................................................. 26

8.2. Operation .................................................................................................26

8.3. MFC operating modes ...................................................................... 32

9. MAINTENANCE, TROUBLESHOOTING ............................................ 36

9.1. Safety instructions .............................................................................. 36

9.2. Maintenance ........................................................................................... 36

9.3. Troubleshooting ................................................................................... 38

10. ACCESSORIES / SPARE PARTS ......................................................41

10.1. Accessories ......................................................................................... 41

10.2. Spare part .............................................................................................44

11. SHUTDOWN .................................................................................................. 44

11.1. Safety instructions ........................................................................... 44

11.2. Dismounting of the MFM / MFC ............................................... 45

12. PACKAGING, STORAGE, TRANSPORT ..........................................45

12.1. Packaging, Transport ...................................................................... 45

12.2. Storage ................................................................................................... 45

13. RETURNING THE DEVICE ..................................................................... 46

14. DISPOSAL OF THE PRODUCT ........................................................... 46

English

3

Page 4

Type 8006, 8702 / 8626, 8712

About this manual

1. ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please keep

this manual in a safe place, accessible to all users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations.

• This manual must be read and understood.

1.1. Symbols used

danger

Warns against an imminent danger.

• Failure to observe this warning can result in death or in

serious injury.

Warning

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury

or even death.

attention

Warns against a possible risk.

• Failure to observe this warning can result in substantial

or minor injuries.

note

Warns against material damage.

• Failure to observe this warning may result in damage to the

device or system.

Indicates additional information, advice or important

recommendations.

Refers to information contained in this manual or in

other documents.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

The word "device" used within this manual refers to a Mass Flow

Meter (MFM) type 8006 or 8702, or a Mass Flow Controller (MFC)

type 8626 or 8712.

English

4

Page 5

Type 8626, 8712

Intended use

2. INTENDED USE

Nonconforming use of the MFM / MFC types 8006,

8702 / 8626, 8712 may pose a danger to people, nearby

equipment and the environment.

• Mass flow meter types 8006, 8702 are designed exclusively for

measuring the mass flow rate of clean, dry gases.

• Mass flow controller types 8626, 8712 are designed for

controlling the mass flow rate of clean, dry gases.

• Only use the fluids stated on the name plate and the calibration

protocol.

• Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of the

climatic conditions.

• This device must be used in compliance with the specifications

and commissioning and use conditions specified in the

contractual documents and in the user manual.

• Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

• Only use the device as intended.

• Observe any existing restrictions when the device is exported.

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not take into account:

• any contingencies or occurrences that may arise during

installation, use and maintenance of the devices.

• the local safety regulations, which the operating company is

responsible for ensuring the staff in charge of installation and

maintenance adhere to.

Danger from the heated surfaces when used for prolonged

periods.

• The device must be kept away from any highly flammable

materials or fluids.

• Wear protective gloves to handle the device.

Danger due to high pressure in the installation.

• Shut off the gas flow, relief the pressure and drain the pipe

before loosening the process connections.

Danger due to electrical voltage.

• Shut down and isolate the electrical power supply before

carrying out work on the system.

• Observe all applicable accident protection and safety

regulations for electrical equipment.

English

5

Page 6

Type 8006, 8702

English

Basic safety instructions

Danger from the outflow of operating fluid

Respect the prevailing regulations on accident prevention and

safety relating to the operating fluids used.

Various dangerous situations

To avoid injury take care:

• to prevent unintentionally switching on the power supply.

• to ensure that installation and maintenance work is carried out

by qualified, authorized personnel in possession of the

appropriate tools,

• to keep the device away from any highly flammable materials or

fluids and avoid any contact with bare hands,

• to guarantee a defined or controlled restarting of the process,

after an interruption to the power supply or medium supply,

• to use the device only if in perfect working order and in compliance

with the instructions provided in the instruction manual,

• to observe best industry practice for the installation and use of

these devices,

• not to use MFM / MFC types 8006, 8702 / 8626, 8712 for

controlling and/or measuring the flow rate of fluids which contain

particles (particle size > 25 µm),

• not to operate the device without the stainless steel mesh filter

disc installed at the factory,

• not to operate the device in a mounting position which deviates

from the calibration conditions,

• not to operate the device with higher pressures than the

specified tightness pressure (MFC) respectively calibration

pressure (MFM),

• not to subject the device to mechanical loads (e.g. by placing

objects on top of it or by using it as a step).

• not to make any external modifications to the device. Do not

paint or varnish any part of the device. Do not feed any other

fluids into the system other than the designated operating

fluid indicated on the device name plate. Exception: agent for

cleaning and decontaminating the device (see also section

„9.2.1“). In doing so, observe the compatibility of the materials

used for the device. You will find a chemical compatibility chart

on our website, under:

www.burkert.com

Resistance Chart

If in doubt, contact the manufacturer.

note

Elements / Components sensitive to electrostatic discharges

• This device contains electronic components sensitive to

electrostatic discharges. They may be damaged if they are

touched by an electrostatically charged person or object. During

electrostatic discharge, they will become defective immediately

or will fail when energized.

• To minimize or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the standard

EN 61340-5-1.

• Also ensure that you do not touch any of the live electrical

components.

Documentation

Brochures

Chemical

6

Page 7

Type 8626, 8712

General information

4. GENERAL INFORMATION

4.1. Manufacturer's address and international contacts

To contact the device manufacturer, use the following address:

Bürkert SAS

Rue du Giessen

F-67220 TRIEMBACH-AU VAL

The addresses of the international subsidiaries are available on the

web page at: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of

the MFM / MFC in observance of the operating conditions specified

in this manual.

4.3. Information on the Internet

You can find the user manuals and technical data sheets regarding the

MFM / MFC at: www.burkert.com

5. DESCRIPTION OF THE SYSTEM

5.1. General description

• Mass flow meter MFM types 8006, 8702 are devices designed for

measuring the mass flow rate of clean, dry gases.

• Mass flow controller MFC types 8626, 8712 are devices designed

for controlling the mass flow rate of clean, dry gases.

Type of device Type of sensor

MFM 8006 Inline

8702 MEMS

MFC 8626 Inline

8712 MEMS

5.1.1. General operation of the Mass Flow

Meter (MFM)

The MFM integrates a sensor for measuring the flow rate. The measured

value for the mass flow rate is transmitted to a remote device via an

analogue or a digital output (fieldbus).

English

7

Page 8

Type 8006, 8702

Description of the system

5.1.2. General operation of the Mass Flow

Controller (MFC)

The MFC comprises:

• a sensor for measuring the mass flow rate,

• a control electronics,

• a control valve with low-friction and high sensitivity.

5.2. Operation of an MFM or MFC sensor

• The integrated flow rate sensors use the thermal measurement

principle (anemometric and calorimetric) to measure the mass

flow rate. The main components are a heating resistor and a

temperature probe. The gas which passes through the device

modifies the temperature difference measured between

both resistors.

• The thermal measurement principle allows the MFC to control the

required mass flow rate completely independently of the pressure

and temperature fluctuations in the application concerned.

To obtain an output signal for the effective, dynamic

or uniform value, the damping of the output signal can

be changed with the "Mass Flow Communicator" software

(see section „10.1.4“).

On the MFMs and MFCs types 8712 and 8702, the

integrated sensor technology requires filters to be fitted

upstream of the product when highly soiled fluids are present.

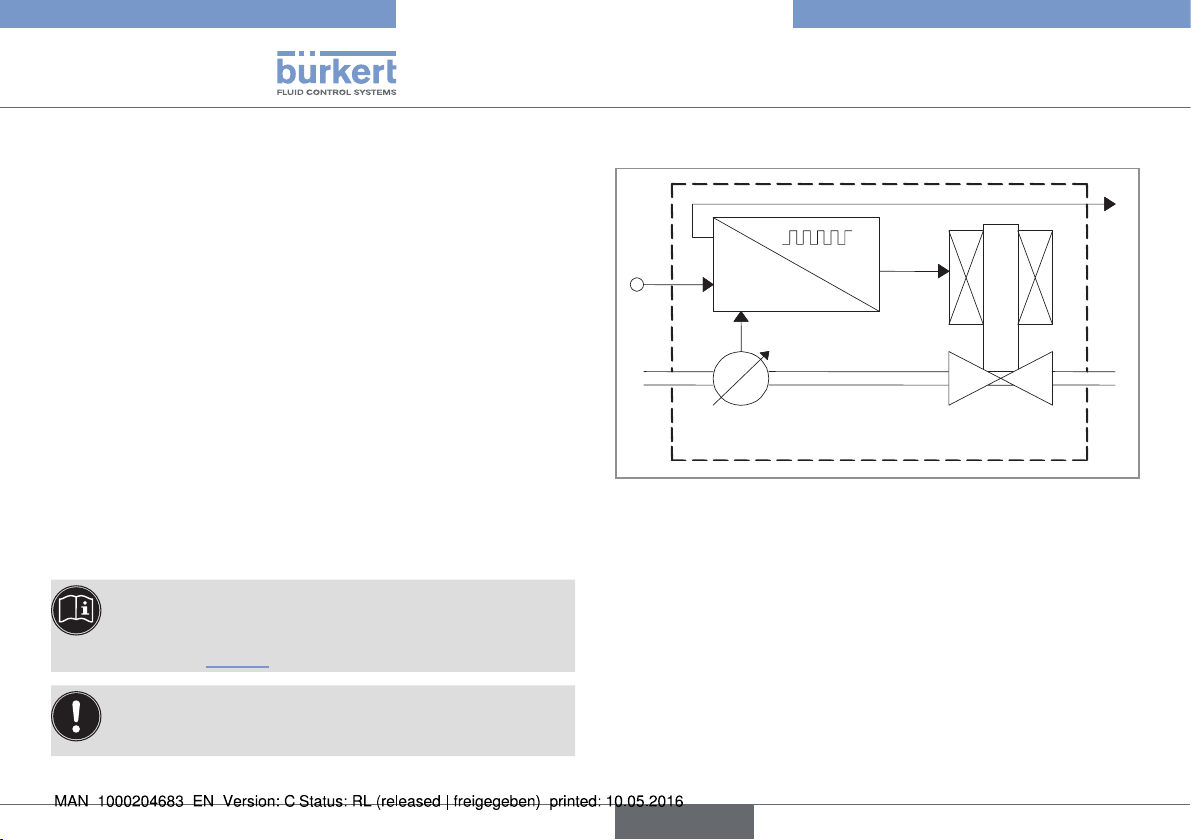

5.3. Detailed operation of an MFC

x

out

w

= w-x

x

d

Gas

inlet

Fig. 1: Operating principle for the Mass Flow Controller

The control electronics compare the mass flow rate (x) measured

by the integrated flow sensor with the mass flow rate setpoint value

(w) supplied to the MFC. The control electronics then calculate the

actuating variable (y) to be supplied to the solenoid valve to control

its opening. The flow rate is either maintained at a constant value,

or modified to a predefined profile.

The control operates independently of fluctuations in pressure or

increases in the flow resistance which may be caused by soiling of the

filter. The rapidly responding solenoid valve and the sensor dynamics

define the overall response time.

The measured value for the mass flow rate is also transmitted (xout) to

a remote device via an analogue output or a digital output (fieldbus).

x

Sensor

Control

electronics

y

Gas

outlet

Actuating element

(solenoid valve)

8

English

Page 9

Type 8626, 8712

Description of the system

5.3.1. Control electronics

The control electronics:

• process the mass flow rate setpoint values and measured values,

• control the solenoid valve.

Setpoint value

The setpoint value (w) is transmitted either by an analogue input signal

or digitally via the serial or the fieldbus interface. If the setpoint value

is supplied by analogue transmission, the following assignments are

applied:

Signal

range

4...20 mA 4 mA, w = 0 % 20 mA, w = 100 %

0...20 mA 0 mA, w = 0 % 20 mA, w = 100 %

0...5 V 0 V, w = 0 % 5 V, w = 100 %

0...10 V 0 V, w = 0 % 10 V, w = 100 %

For the control of a system where quick flow rate changes are not

permitted, a ramp function can be activated. The settings for a raising

and a falling setpoint value can be set separately.

More detailed information on the ramp function and on all

other functions can be found in the software documentation

for the MFM / MFC.

Control settings

The initial control settings are set at the factory.

Setpoint associated

with the range min.

Setpoint associated

with the range max.

• Amplification factors:

After start-up, the controller operates with amplification factors

dependent on the loop properties. When the autotune function runs,

these are determined automatically. This function enables the control

settings to be optimized for the system's actual conditions.

• Control dynamics setting:

The device has a setting which can change the control dynamics

with the aid of the "Mass Flow Communicator" software

(see section „10.1.4“). Its extreme effects are:

1. a very quick adjustment in which overshoots are possible.

This enables the controller to respond immediately to very low

control deviations; which causes the control to be very turbulent,

2. a slower adjustment to the required flow rate. If the system is less

dynamic, the behaviour of the controller may be damped so that

minor fluctuations in the measured value or setpoint value are only

adjusted slowly.

Zero point shut-off

A zero point shut-off is integrated to ensure the sealing function of the

valve. This is activated if the following conditions occur at the same time:

Setpoint value < 2 % of

nominal flow rate Q

(with control range 1:50)

If the zero point shut-off is active, the PWM signal is set to

0 % so that the valve is completely closed.

nom

Measured value < 2 % of

and

nominal flow rate Q

(with control range 1:50)

nom

English

9

Page 10

5.3.2. MFC solenoid control valve

The solenoid valve used for an MFC is a direct-acting, normally closed

solenoid control valve.

The orifice size of the solenoid valve is determined by the required

nominal flow rate Q

the process and the density of the operating fluid.

If the device is operated within the specified pressure range,

the solenoid valve also takes over the sealing function

together with the control function. Limitation: in the case

of special hard seal materials, the sealing function cannot

be ensured. In this case an additional shut-off valve may

be required.

, the pressure and temperature conditions in

nom

Type 8006, 8702

Description of the system

10

English

Page 11

Type 8626, 8712

8006 35.0 Nm3/h

Calibration data 00182381

Technical data

6. TECHNICAL DATA

attention

Risk of injury from pressure and outflow of fluid.

Important device-specific technical data is indicated on the name plate and the calibration plate (see section „6.1“).

• Observe the permitted fluid according to the name plate (depending on seal material).

• Observe the permitted pressure range on the calibration plate of the device.

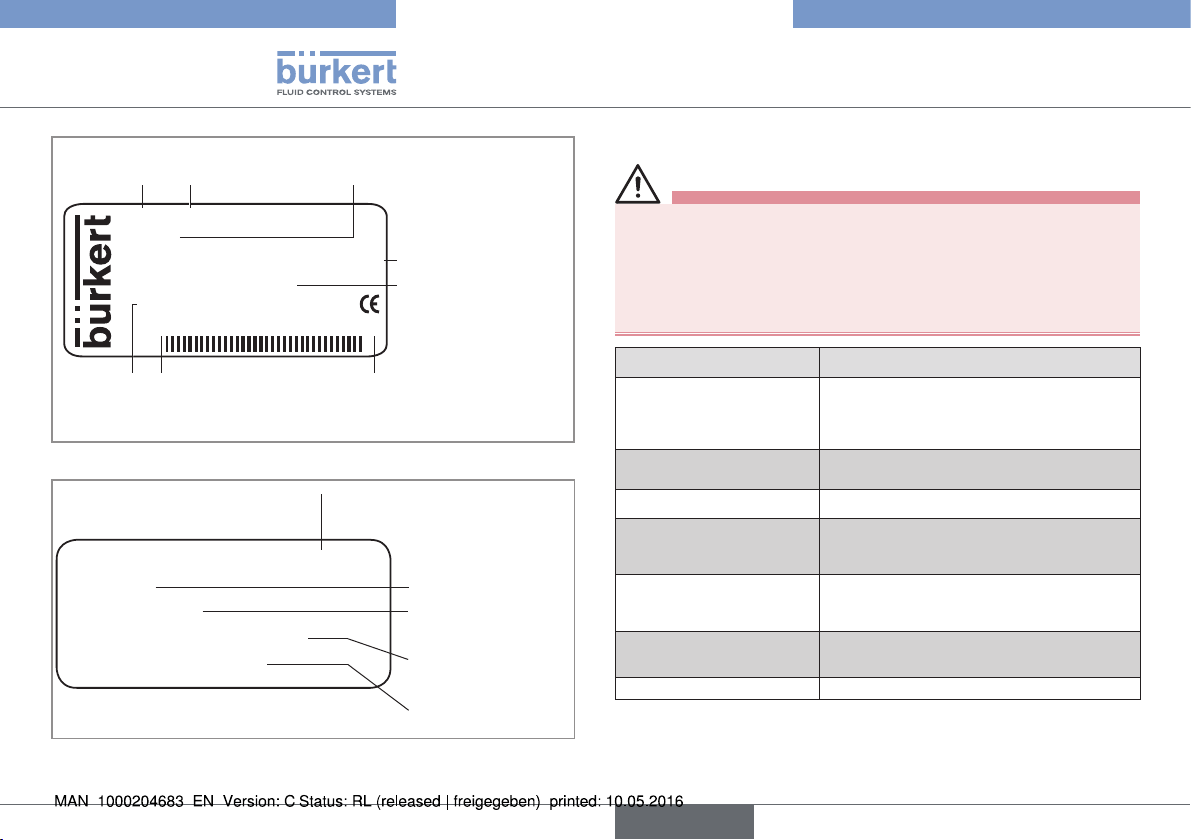

6.1. Markings on the device

Fig. 2: Name plate, calibration plate

Examples:

English

Calibration plate

Medium 1

P1 : 0,800 barg

Mounting: horizontal upright

QC passed: 25.11.2011

Name plate

CH4

24V DC 13W DP

S/N 1004

00182381

Made in France

W49MM

FKM

11

Page 12

Type 8006, 8702

Technical data

Type of the

device

Nominal flow rate

(Q

) and unit

nom

8006 35.0 Nm3/h

CH4

24V DC 13W DP

Operating medium

FKM

S/N 1004

00182381

Made in France

Serial

number

Fig. 3: Details of a name plate (example)

the device

Order code of the device

Calibration data 00202378

Medium

P1:

Mounting: Horizontal mounting

QC

1

0.700 barg

passed: 25.11.2011

W49MM

Construction codeOrder code of

Material of the seal

Supply voltage

Maximum power

consumption

Electrical interface

Calibration fluid

Calibration

pressure

Mounting

position

Calibration date

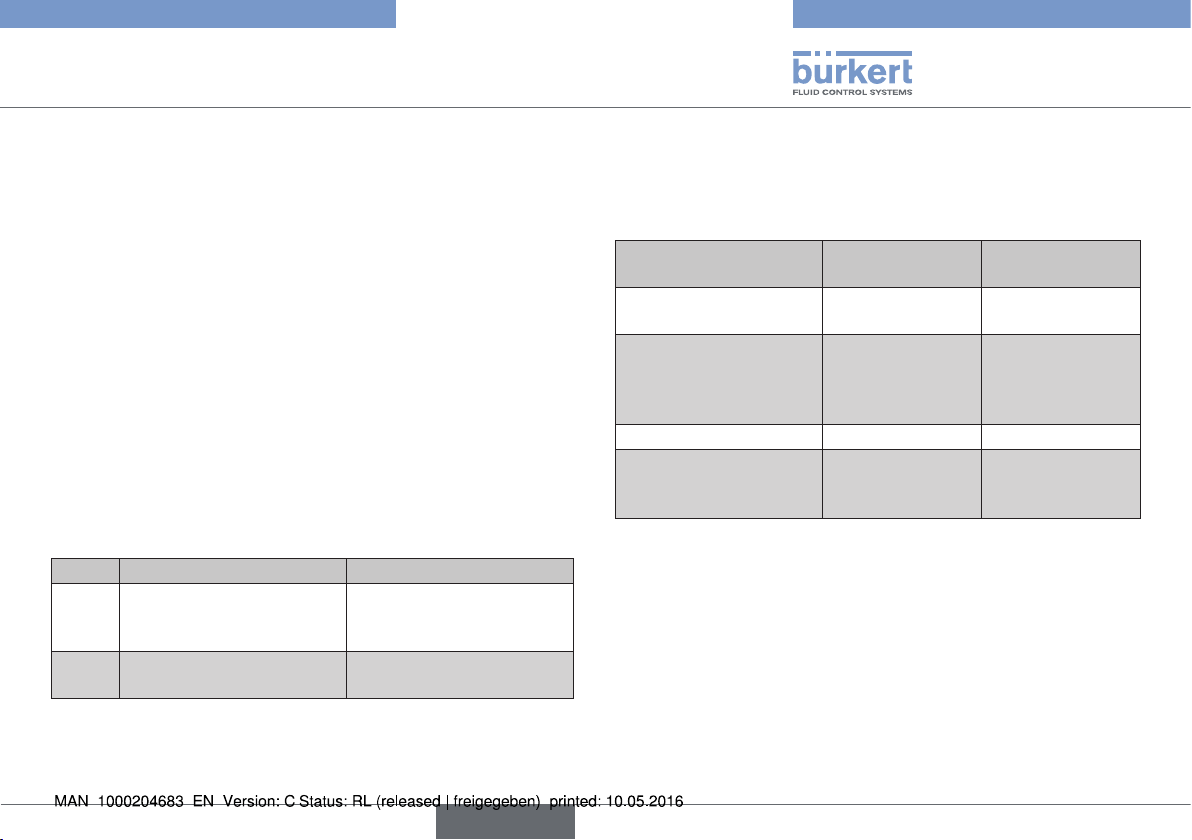

6.2. Conditions of use

Warning

Risk of injury from malfunction due to effects of the weather!

The MFM / MFC is not designed for unrestricted use outdoors.

• Protect the device from direct sunlight.

• Observe the ambient temperature range of the device.

• Protect the device from humidity.

Setting Value

Ambient temperature Types 8702 / 8712: -10 °C to +50 °C

Types 8006 / 8626: -10 °C to +45 °C

For UL devices: 0 °C to 40 °C

Medium temperature for oxygen: -10 °C to +60 °C

Air humidity < 95%, without condensation

Relative humidity for UL

devices

Protection class

according to EN 60529

Absolute height above

sea level for UL devices

Operating environment Indoors, with pollution degree 2

for other fluids: -10 °C to +70 °C

80% up to a temperature of 31°C,

with a linear decrease to a relative

humidity of 50% at 40°C

Only if devices are cabled and the

connectors are plugged in and

tightened: IP65

2000 m max.

Fig. 4: Details of a calibration plate (example)

12

English

Page 13

Type 8626, 8712

Technical data

6.3. Compliance to standards and directives

MFM/MFC conformity with the EC directives comes through the

following standards:

• EMC: EN 61000-6-2, EN 61000-6-3.

The MFMs/MFCs compliant with ATEX Directive 94/9/EEC adhere to

the standards below:

• EN 60079-15

• EN 61241-1.

The MFM / MFC UL devices conform to the following standards:

• UL 61010-1

• CAN/CSA-C22.2 no. 61010-1.

6.4. Mechanical data

The device may be mounted in a horizontal or vertical position: see the

calibration plate and/or the calibration protocol.

Type Base block material Material of the housing

8006,

8626

8702,

8712

Sealing material: FKM or EPDM (see name plate)

Other parts of the solenoid control valve in contact with the medium:

1.4310, 1.4113 and 1.4305

1.4305 stainless steel,

1.4404 stainless steel or

anodized aluminium

Stainless steel 1.4404 Polycarbonate (PC)

Painted pressure cast

aluminium

6.5. Fluidic data

6.5.1. Overview of measurement

specifications

Type 8006, 8626 8702, 8712

Full scale range ref. to

2 (lN/min)

N

Measuring accuracy

(after heating time)

Span/control range

Settling time (MFC) or

response time (MFM)

(ms)

*) 1:20 in case of vertical mounting, with downward flow.

**) Higher span (e.g. 1:100) possible on request.

Repeatability: ± 0.1% of the full scale.

16 … 1500 0.01 … 80

± 1.5 % of the

measured value

± 0.3 % of the full

scale

1 : 50 *) 1 : 50 **)

< 500 < 150

± 0.8 % of the

measured value

± 0.3 % of the full

scale

English

13

Page 14

Type 8006, 8702

∆p [mbar]

00

Technical data

6.5.2. Operating fluids

• Operating fluids: clean, dry gas.

• Operating fluid for UL devices: neutral, uncontaminated gas.

Other hazardous gases are possible on request; the devices

do not release any hazardous gases under normal operating

conditions. However, to use an MFC with natural gas, only

the solenoid valve Bürkert type 2875 can be used : in this

case, the order key must include the letter "-D" (for example

8626-0100L-CH4-E-A-GM82-ALFF-D-08,0).

• Calibration fluid: operating fluid or air.

• Max. operating pressure: 10 bar (depending on valve nominal

diameter).

To obtain the required measuring accuracy or control quality,

but also to respect the safety requirements, the gas or

gaseous mixture must conform to the following safety criteria,

compliant with ISO standard 8573-1 (Compressed air -

Part 1: Contaminants and purity classes):

• Maximum particle size and density: class 2:

Maximum particle size: 1 µm

Maximum particle density: 1 mg/m³

• Maximum dew point under pressure: class 4: 3 °C

• Maximum oil concentration: class 1: 0.01 mg/m³

1)

1)

1)

6.5.3. Pressure loss specifications

200

180

160

140

120

100

80

60

40

20

0

0100

200

300

1/4''

400

500

600

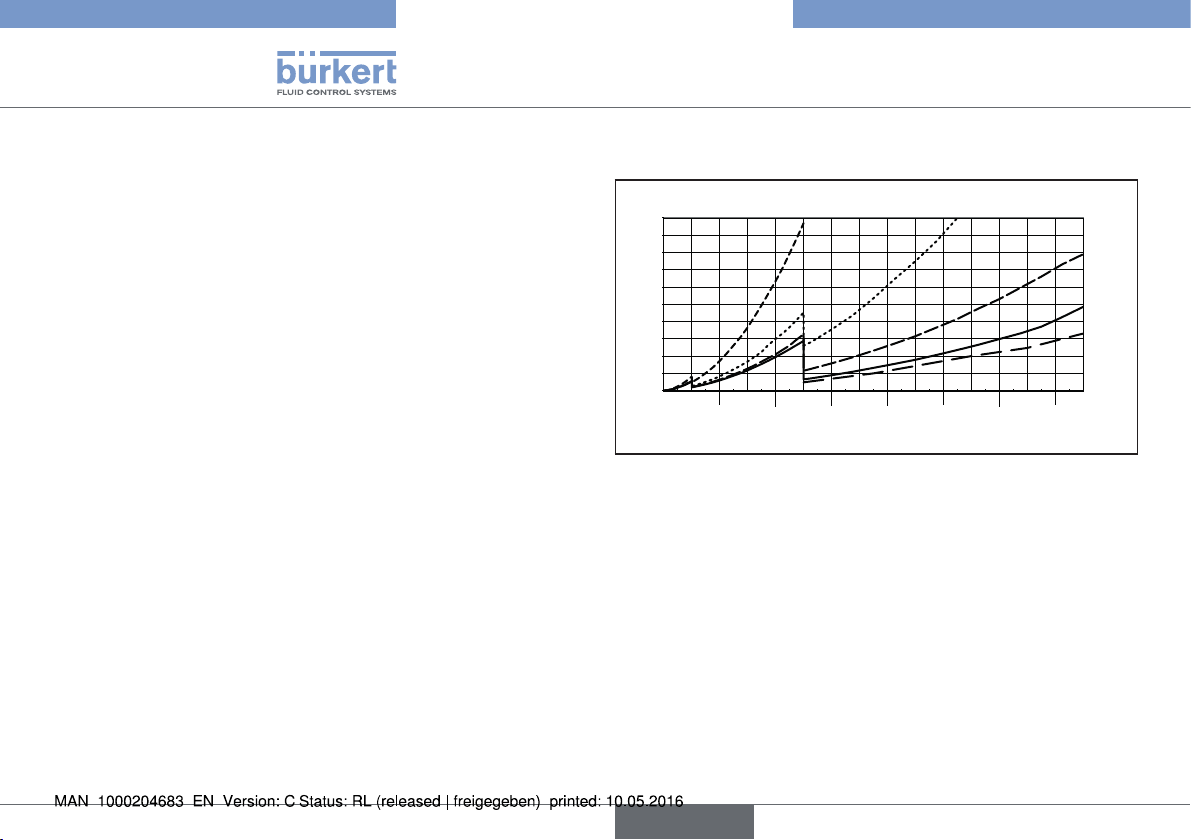

Fig. 5: Pressure loss diagram (ref. air, with 250 µm inlet filter),

type 8006

The characteristic diagram shows the air pressure loss in the device

for 3 different bases (up to 100 Nl/min, from 100 to 500 Nl/min,

from 500 to 1500 Nl/min) and 4 different connections (1/4'', 1/2'',

3/4'', 3/8'' and 1'').

For determining the pressure loss with another gas first calculate the

equivalent air flow rate of the other gas.

700

800

3/8''

900

1000

1100

1200

1/2''

3/4''

1300

1''

1400

Q [lN/min]

15

1)

For more information refer to ISO 8573-1

14

English

Page 15

Type 8626, 8712

80

∆p [mbar]

Technical data

130

120

110

100

90

80

70

60

50

40

30

20

10

0

0510 15 20 25 30 35 40 45 50 55 60 65 70 75

flanges

1/4''

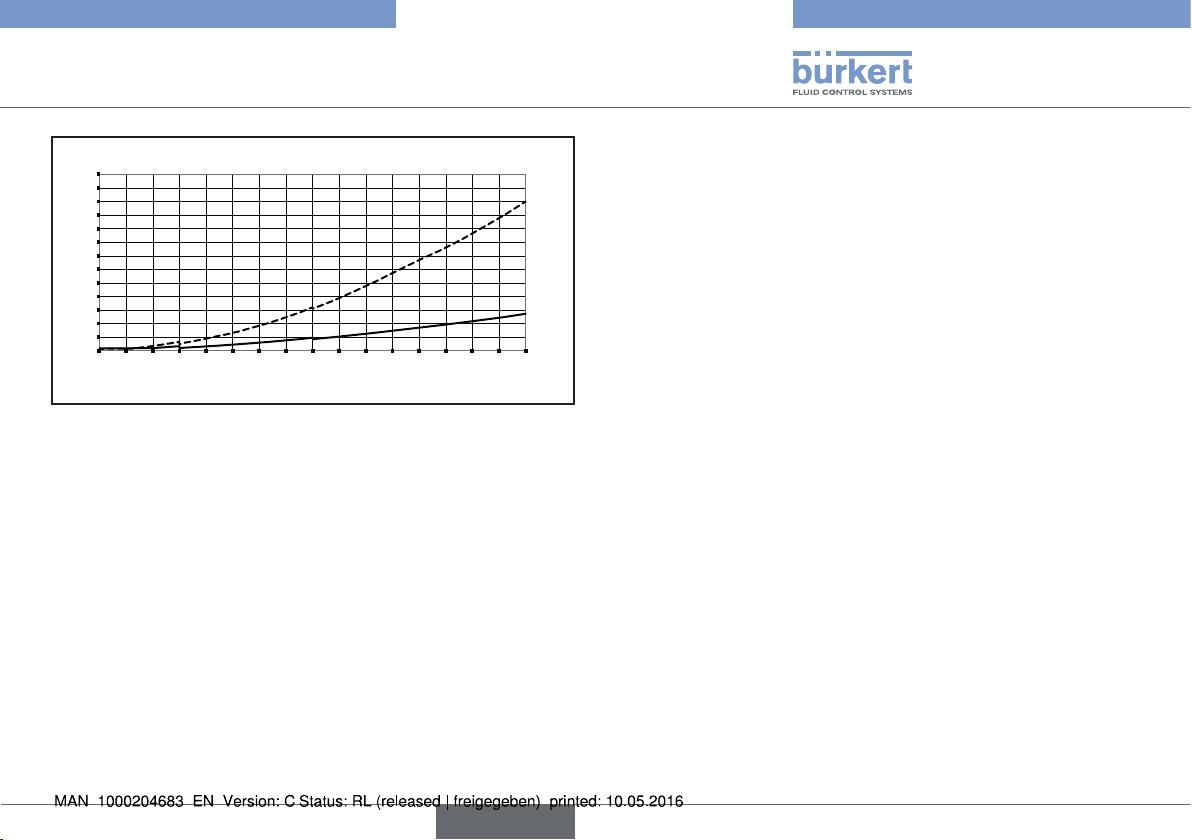

Fig. 6: Pressure loss diagram (ref. air, with 250 µm inlet filter),

type 8702

The characteristic diagram shows the air pressure loss in the

device for versions with flange connections and versions with 1/4''

connections.

For determining the pressure loss with another gas first calculate

the equivalent air flow rate of the other gas and respect the fluidics

needed with the other gas.

Q [lN/min]

English

15

Page 16

Type 8006, 8702

Technical data

6.6. Electrical data, devices with an 8 pin M16 female fixed connector

Operating voltage 24 V DC ± 10%; residual ripple < 2% (5% for UL devices)

Power supply (not provided) for UL devices Power supply limited to class 2

Power required (max. in Watt) depending on the type of the

device

MFC only:

Analogue input (configurable)

Binary inputs (configurable) 3 binary inputs

Analogue output (configurable) • 0/4 - 20 mA

On certain versions: Fieldbus communication

(alternative to "analogue input + outputs")

Relay outputs (configurable) 2 relay outputs

LEDs (configurable) 4 LEDs

Electrical connections 8 pin M16 female fixed connector, and 15-pin Sub-HD

Additional connections for version with fieldbus 5 pin M12 male or female fixed connector, or 9 pin Sub-D female fixed

8006 8702 8626 8712

12.5 5 36.5 14

• 0/4 - 20 mA

Max. input impedance: 300 Ω, resolution: 5 µA

• 0 - 5/10 V

Min. input impedance: 20 kΩ, resolution: 2.5 mV

Low active

Connect to DGND for activation

Max. load: 600 Ω, resolution: 20 µA

• 0 - 5/10 V

Max. current: 10 mA, resolution: 10 mV

PROFIBUS DP V1, DeviceNet or CANopen

Potential-free changer 60 V, 1 A, 60 VA

Status display for Power, Communication, Limit, Error

connector

16

English

Page 17

Type 8626, 8712

Technical data

6.7. Electrical data, devices with a 9 pin Sub-D male fixed connector, with RS485 interface

Operating voltage 24 V DC ± 10%; residual ripple < 2% (5% for UL devices)

Power supply (not provided) for UL devices Power supply limited to class 2

Power required (max. in Watt) depending on the type of the

device

Binary inputs (configurable) 1 binary input

Communication interface RS485, full-duplex or half-duplex

Relay outputs (configurable) 1 relay output

LEDs (configurable) 4 LEDs

Electrical connections 9 pin Sub-D male fixed connector

8006 8626

12.5 36.5

Low active

Connect to DGND for activation

RS422, supports the MODBUS RTU protocole

Potential-free make contact 25 V, 1 A, 25 VA

Status display for Power, Communication, Limit, Error

English

17

Page 18

Type 8006, 8702

Installation and commissioning

7. INSTALLATION AND COMMISSIONING

7.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Shut off the gas flow, relief the pressure and drain the pipe

before loosening the process connections.

Danger due to electrical voltage.

• Shut down and isolate the electrical power supply before

carrying out work on the system.

• Observe all applicable accident protection and safety

regulations for electrical equipment.

Risk of injury from the outflow of operating fluid

• Respect the prevailing regulations on accident prevention and

safety relating to the operating fluids used.

Warning

Danger due to nonconforming installation or commissioning

• Installation and commissioning can only be carried out by

qualified and skilled staff with the appropriate tools.

Risk of injury due to the installation being accidentally

energized or an uncontrolled restart.

• Take appropriate measures to avoid the installation being

accidentally energized.

• Ensure the installation is subject to a controlled restart after any

intervention on the device.

7.2. Prior to installation

→ Before installing the MFM / MFC, remove dirt from the pipes and

fluid system components.

→ Connect a suitable filter (≤ 25 µm mesh size) upstream to ensure

that the operating fluid is kept clean.

note

• Use a power supply unit with adequate power.

• Observe the maximum permitted residual ripple of the

operating voltage.

18

English

Page 19

Type 8626, 8712

Installation and commissioning

7.3. Description of the MFM / MFC

5 pin M12 male or female fixed connector,

or 9 pin Sub-D female fixed connector, fieldbus

LEDs

15 pin Sub HD female fixed

connector, setpoint input /

Measured flow rate input /

Binary inputs / RS232

Screw for earth

connection

8 pin M16 female fixed

connector,

24 V power supply /

Relay outputs

Fig. 7: Description of the devices with an 8 pin M16 female fixed

connector

Connection to the

pipe

9 pin Sub-D male fixed

connector,

fieldbus /

24 V power supply /

Binary input /

Relay output /

RS485

Screw for earth connection

Connection to the pipe

Fig. 8: Description of the devices with a 9 pin Sub-D male fixed

connector, with RS485 interface

LEDs

English

19

Page 20

7.4. Sequence of the steps to be performed

1. Mechanical installation

2. Fluid installation

3. Electrical installation

4. Set the device parameters

5. Pressurize the lines with operating fluid

6. Flush the lines with operating fluid at the calibration pressure and

deaerate completely

7.5. Setting the parameters

7.5.1. Setting the bus address

To ensure trouble-free adjustment, reset the device by

switching off the power supply to the device.

The bus address of the device can be set either via the Bürkert

"Mass Flow Communicator" software tool in the "Views" window →

PROFIBUS / DeviceNet / CANopen or directly via the master bus.

The address must be reinitialized after a change on the slave and on

the master. Depending on the bus, it may be necessary to send a

corresponding telegram.

Type 8006, 8702

Installation and commissioning

20

English

Page 21

Type 8626, 8712

15

14

13

12

11

10

Installation and commissioning

7.5.2. Pin assignment, devices with an 8 pin M16 female fixed connector

8 pin M16 female fixed connector Pin Assignment

1 24 V - Supply +

2 Relay 1 - centre contact

3 Relay 2 - centre contact

4 Relay 1 - break contact

5 Relay 1 - make contact

6 24 V - GND supply

7 Relay 2 - make contact

8 Relay 2 - break contact

1)

Setpoint value input + Not used

1

1)

Setpoint value input GND Not used

2

2)

Measured value output +

3

4 Binary input 2

5 12 V - output (for internal use only)

6 RS232 T x D (direct connection to PC)

7 Binary input 1

8 DGND (for binary inputs)

9 Internal use only (do not assign!)

10 12 V - output (for internal use only)

11 12 V - output (for internal use only)

12 Binary input 3

2)

Measured value output GND

13

14 RS232 R x D (direct connection to PC)

15 DGND (for RS232 interface)

8

7

3

5

2

6

1

4

15 pin Sub-HD female fixed connector Pin Assignment of types 8626, 8712 Assignment of types 8006, 8002

5

4

9

3

8

2

7

1

6

1)

On the fieldbus version of MFC types 8626 / 8712, these pins are not assigned.

2)

On the fieldbus version of MFC types 8626 / 8712 and MFM types 8702 / 8706, these pins are not assigned.

English

21

Page 22

Type 8006, 8702

9

8

7

6

5

4

3

2

1

Installation and commissioning

Pin assignment for fieldbus versions

PROFIBUS DP M12 female fixed connector, B

Pin Assignment

encoded (DP V1 max. 12 MBaud)

5

4

1

1 VDD

2 R x D / T x D - N (line A)

3 DGND

1)

4 R x D / T x D - N (line B)

5 Not used

3

2

1)

Only use this voltage to energize the PROFIBUS termination resistor.

DeviceNet or CANopen M12 male fixed connector Pin Assignment

5

3

2

1 Shield

2 N. C. / 24V, depending on the version

3 DGND

2)

4 CAN_H

5 CAN_L

2)

4

1

If the power supply is connected to the DeviceNet or CANopen M12 male fixed

connector, do not connect a power supply to the M16 female fixed connector.

9 pin Sub-D female fixed connector Pin Profibus assignment DeviceNet assignment

1 Shield (FE), functional earth Shield (FE), functional earth

2 N.C. (not connected) CAN-L data line

3 RxD/TxD-P line B GND

4 RTS control signal for repeater N. C.

5 GND data transmission potential N. C.

6 VDD supply voltage + (P5V) N. C.

7 N. C. CAN-H data line

8 RxD/TxD-N line A N. C.

9 N. C. N. C.

22

English

Page 23

Type 8626, 8712

6

7

8

9

1

2

3

4

5

Installation and commissioning

7.5.3. Pin assignment, devices with a 9 pin

Sub-D male fixed connector, with

RS485 interface

9 pin Sub-D male

fixed connector,

with RS485

1) For half-duplex operation, connect with jumpers, pin 6 to pin 9 ,

and pin 7 to pin 8.

Pin Assignment

1 Binary input

2 GND

3 24 V - Supply voltage +

4 Relay - Make contact

5 Relay - Break contact

1)

TX+ (RS485 - Y)

6

1)

TX- (RS485 - Z)

7

1)

RX- (RS485 - B)

8

1)

RX+ (RS485 - A)

9

7.6. Mechanical installation

Observe the mounting position shown on the calibration plate or the

calibration protocol.

English

7.7. Fluid installation

danger

Risk of injury due to high pressure in the installation.

• Shut off the gas flow, relief the pressure and drain the pipe

before loosening the process connections.

Select the fluid connections suitable for the maximum flow rate and

with the optimum pressure loss. There is no minimum upstream

piping length to be observed.

On request, the device may be supplied with the fluid connections fitted.

Warning

Danger from leaks

If flow rates are low and pressures high, ensure that the system

is sealed to prevent incorrect metering or the operating fluid

from leaking.

• To ensure that the seal is secure, observe the operations

described below.

Install the fittings without subjecting them to any stresses. To seal

the system properly, use fittings with olives.

Use a line with a suitable diameter and a smooth surface.

→ Cut the line squarely [1] and deburr [2].

23

Page 24

1

2

→ In order, fit the nut [A] and the olive onto the line.

Type 8006, 8702

Installation and commissioning

C

B

C

Olive

A

B

→ Insert the line and manually tighten the nut [A].

→ Fit the washer [C] and screw the fitting [B] to the device.

A

24

English

Page 25

Type 8626, 8712

Installation and commissioning

→ Finish tightening the nut with a suitable wrench to ensure the

mounting is sealed.

7.8. Electrical installation

danger

Risk of injury due to electrical shock

• Shut down and isolate the power supply before carrying out any

work on the system.

• Observe all applicable accident protection and safety

regulations for electrical equipment.

Warning

Risk of fire and ignition due to electrostatic discharge

If the device is electrostatically charged, highly flammable fluid

vapours may ignite if electrostatic discharge occurs.

• To avoid electrostatic charges, connect the device to the

functional earth (FE) using the shortest possible cable with the

largest possible cross section.

Danger from electromagnetic fields

If the FE connection is not connected, electromagnetic

compatibility is not assured.

• Connect the device to the functional earth (FE) via the shortest

possible cable (largest possible cross section).

note

Important information to ensure trouble-free operation

of the device

The GND or earth connections of the MFM / MFC must always be

connected individually.

If all the GND connections are connected together and only a

single common connection is set up with a view to activation,

the analogue signals risk being subjected to fluctuations

and interference.

English

→ Connect the functional earth (FE) to the screw indicated,

for example using an earth terminal. The connection cable must

25

Page 26

Type 8006, 8702

Operation and function

be as short as possible and its cross section must be as large

as possible.

8. OPERATION AND FUNCTION

8.1. Safety instructions

Warning

Risk of injury due to nonconforming operation.

Nonconforming operation could lead to injuries and damage the

device and its surroundings.

• Operating personnel must familiarize themselves with the

contents of the operating instructions.

• Observe the safety instructions and use the devices as

indicated in this manual.

• Only adequately trained personnel may operate the device.

8.2. Operation

8.2.1. Operation, devices with an M16

female fixed connector

The devices with an M16 female fixed connector are operated by means

of analogue standard signals and/or fieldbus communication as well

as binary inputs. Four LEDs and two relay output signals indicate the

operating state.

There is a serial interface (RS232) which can be used to connect to a

computer, using the "Mass Flow Communicator" software.

26

English

Page 27

Type 8626, 8712

Operation and function

Fieldbus

Binary inputs

Relay outputs

LEDs

• Selecting the standard signals / Assigning the

binary input ports

The standard signal type as well as the assignment of the

binary input ports can be specified on order placement or

configured via the "Mass Flow Communicator" PC software

(see also section „10.1.4“).

• LED assignment / Binary output ports assignment

The "Communication" and "Limit(y)" LED assignment, and the

binary output ports assignment can be configured via the

software (see also section „10.1.4“).

There is a serial interface (RS485) which can be used to connect to a

computer, using the "Mass Flow Communicator" software.

Fieldbus /

Binary input /

Relay output

LEDs

• Assigning the binary input port

The assignment of the binary input port can be specified

on order placement or configured via the "Mass Flow

Communicator" PC software (see also section „10.1.4“).

• LED assignment / Binary output port assignment

The "Communication" and "Limit(y)" LED assignment, and

the binary output port assignment can be configured via the

software (see also section „10.1.4“).

8.2.2. Operation, devices with a Sub-D

male fixed connector

The devices with a 9 pin Sub-D male fixed connector are operated by

means of fieldbus communication as well as a binary input. 4 LEDs

and 1 relay output signal indicate the operating state.

English

27

Page 28

Type 8006, 8702

Operation and function

8.2.3. LED default assignment

Indicator light status Possible cause

Power LED (green)

on

Power LED (green)

flashes

Communication LED

(yellow) on

The device is energized.

The Autotune function

is in progress.

The device is communicating via the

fieldbus or the serial interface (RS232 /

RS485 / USB).

Indicator light status Possible cause

Limit (y) LED (blue) on

Limit (y) LED (blue)

flashes

Error LED (red) on

Error LED (red) flashes

MFM: indicates that the measured value

has almost reached the nominal flow rate.

MFC: indicates that the actuating variable

of the proportional valve has almost

reached 100%. In practice this usually

means that the pressure on the controller

is not adequate to reach the required flow

rate.

The device is in an operating state other

than the control mode or Autotune function.

Minor fault, for example the Autotune

function has failed.

Major fault, sensor damaged, internal

power supply voltage incorrect or operating

pressure too high.

28

English

Page 29

Type 8626, 8712

Operation and function

8.2.4. Inputs

Analogue input/output

The analogue input (MFC only) allows the setpoint value, i.e. the

required flow rate value in the line, to be received.

The analogue output enables the measured flow rate value to be

supplied to the device to which it is connected.

Activation binary

input 1

Bus connection (fieldbus version only)

The setpoint value received and the measured value are sent digitally

via the fieldbus. It is possible to choose between PROFIBUS DP,

DeviceNet and CANopen (see also the additional operating instructions

for fieldbus devices).

Binary input ports

If the binary inputs are activated, different operations can be run on the

MFC and the latter can be switched to a specific operating mode. This

is achieved by connecting the binary input to DGND for at least 0.5 s.

Activation

binary input 1

Fig. 9: Activation of the binary inputs, devices with an 8 pin M16

female fixed connector

Activation

binary input 2

English

Fig. 10: Activation of the binary input, devices with a 9 pin Sub-D

male fixed connector, with RS485

Input Default assignment

Binary input 1 Autotune actuation

Binary input 2 • Not used on devices with an 8 pin M16

Binary input 3

Table 11: Default assignment of binary input signals.

female fixed connector.

• Not available on devices with a 9 pin Sub-D

male fixed connector.

29

Page 30

Type 8006, 8702

Operation and function

Function Description

Actuate Autotune

Start of Autotune function for optimization of

the control settings to the conditions available

in the system (see section „8.3“).

Switch to

specification 2

The calibration curve saved under Gas 2 as

well as all settings entered there are used.

Totalizer Reset The integrated totalizer (quantity integrator)

is reset.

Start setpoint value

profile

Control mode

Start of the saved setpoint value profile

(see section „8.3“).

Enables the solenoid valve to be opened at a

given value (see section „8.3“).

Correct safety

value*

The safety value stored in the device is used

as a flow rate setpoint value.

In this case, the flow rate setpoint value

received by the analogue input or fieldbus

is ignored.

Close the valve

completely*

Valve completely closed.

In this case, the flow rate setpoint value

is ignored.

Open the valve

completely*

Valve completely opened.

In this case, the flow rate setpoint value

is ignored.

Table 12: Possible binary input functions.

* The operating principle of the binary input (active / inactive) can

be selected for these functions

8.2.5. Relay output signals

Depending on the version, MFMs / MFCs are equipped with 1 or 2

relay outputs to indicate the operating state, limit values outside the

maximum / minimum or a fault.

Output Assignment

Relay output 1 y2 Limit

Relay output 2

1)

Only available on a device with an 8 pin M16 female fixed

connector

Table 13: Relay output default assignment

Function Description

Not used No function is assigned to the relay output

Power ON The device is energized.

Autotune activated The Autotune function is in progress.

Gas 1 or 2 active Calibration curve 1 or 2 is used.

User-defined

calibration active

Binary input

1 or 2 active

Activate relay

output by fieldbus

Correct safety

value active

1)

Fault (in case of a major fault, such as

defective sensor or defective internal voltage)

The device operates at the calibration

adjusted by customer.

Binary input 1 or 2 has been activated.

The status of the relay outputs is specified via

the fieldbus or the serial interface.

The safety value is used as the setpoint value.

30

English

Page 31

Type 8626, 8712

Operation and function

Function Description

Setpoint value

profile active

Control mode

active

Close valve

completely active

Open valve

completely active

Defective power

requirement

Defective internal

power supply

Defective power

supply to the

sensor

Defective data

storage

Sensor fault The device is able to detect a defective

The setpoint value profile stored in the device

is used as the setpoint value.

The control mode is active, i.e. the solenoid

valve is opened at a given value.

The close valve completely function is

activated.

The open valve completely function is

activated.

The power requirement of the device is

monitored. If this value is outside defined

limits, this function is actuated. An excessively

high or low power requirement may indicate a

defective device.

The operating voltage of the device is

monitored. If the defined limits exceed the

maximum or drop below the minimum, this

function is actuated.

The power supply voltage to the sensor is

monitored. If the defined limits exceed the

maximum or drop below the minimum, this

function is actuated.

If data storage is in the non-volatile memory of

the device, a fault has occurred.

sensor via a self-test.

If this is the case, this function is activated.

Function Description

MFI fault The fieldbus module (MFI) is defective or

incorrectly equipped. Fieldbus communication

is not possible.

x Limit The measured value has exceeded or dropped

below a limit value which can be configured.

w Limit The setpoint value has exceeded or dropped

below a limit value which can be configured.

y2 Limit The actuating variable has exceeded or

dropped below a limit value which can be

configured.

Totalizer Limit The totalizer has exceeded or dropped below

a limit value which can be configured.

Table 14: Relay output signals possible functions

English

31

Page 32

8.3. MFC operating modes

The MFC can adopt different operating modes:

Type 8006, 8702

Operation and function

Operating mode Status of the LEDs

(default setting)

Standard control mode

(see section „8.3.1“)

Autotune function

(see section „8.3.2“)

Safety function

(see section „8.3.3“)

Power LED (green) on - • Autotune function

Power LED (green)

flashes

Limit LED (blue) flashes As long as the input is active -

Binary input activation mode This operating mode may be interrupted

or ended by

• Safety function

• Setpoint value profile

• Control mode

Input active for at least 0.5 s (permanent

input activation leads to a function restart)

• Safety function

• Device reset

32

English

Page 33

Type 8626, 8712

Operation and function

Operating mode Status of the LEDs

(default setting)

Setpoint value profile

(see section „8.3.4“)

Control mode

(see section „8.3.5“)

Table 15: Overview of the operating modes.

Limit LED (blue) flashes Input active for at least 0.5 s (permanent

Limit LED (blue) flashes As long as the input is active • Autotune function

Binary input activation mode This operating mode may be interrupted

or ended by

• Autotune function

input activation leads to a function restart)

• Safety function

• Device reset

• Safety function

• Device reset

8.3.1. Standard control mode

In this operating mode, the flow rate is controlled to the specified setpoint value with a high dynamic.

The MFC is in this operating mode once energized, after a brief initialization phase. The green power indicator is on.

The setpoint value is specified via the analogue input or the fieldbus, depending on the device version.

The controller settings are set in such a way that setpoint value changes or actuating variables are corrected as quickly as possible without

appreciable overshoot occurring.

The measured flow rate value is available on the analogue output or the fieldbus, depending on the device version.

English

33

Page 34

Type 8006, 8702

Operation and function

For the MFC:

If the blue Limit (y) LED is on, this means that the control

signal of the solenoid control valve is approaching the

100% limit (see section „9.3“).

The cause may be:

• either an insufficient pressure difference over the MFC,

for example an insufficient inlet pressure,

• or a dirty inlet filter

This means that the set point cannot be achieved and a

difference between the set point and the measured value

(w-x) exists.

For the MFM:

If the blue Limit (y) LED is on, the measured mass flow is

approaching the nominal flow rate or has even exceeded it

(see section „9.3“).

If a high exceeding of the nominal flow rate occurs, a

difference between the measured and the real flow rates

may appear.

To permit an external reaction to this gap, a binary output

is activated.

8.3.2. Autotune function

The Autotune function is run through during the final

inspection in the factory, at the operating pressure and with

the calibration fluid indicated in the calibration protocol.

Therefore, the re-actuation of this function is not essential.

However, the Autotune function should be activated if:

• the pressure conditions in the system have changed

significantly,

• the calibration fluid does not correspond to the

operating fluid.

In this operating mode, the device calculates and optimizes the control

settings to the conditions present in the system.

The solenoid control valve is activated according to a predefined profile

resulting in flow rate changes. Thereby several control settings are

adjusted to the conditions on-site. These settings are stored in the

non-volatile memory of the device at the end of a successful Autotune.

This function of the MFC is obtained by activating a binary input

(configured on this function) for at least 0.5 s. The Power LED (green)

flashes to signal that the function is in progress.

34

English

Page 35

Type 8626, 8712

Operation and function

Warning

Various flow rate changes occur when the Autotune is active.

• Do not switch off the power supply to the MFC.

• Keep the supply pressure constant.

→ Before activating the Autotune function, bring the medium

pressure to a pressure close to the calibration pressure.

While the Autotune function is running, the MFC is not in control mode.

When the Autotune function ends, the MFC returns to the operating

mode it was in prior to activation.

8.3.3. Safety function

In this operating mode, the device behaves as in control mode, except

that the setpoint value is ignored and replaced by a predefined safety

setpoint value. The default safety setpoint value is 0%. This can be

modified with the "Mass Flow Communicator" software.

This function of the MFC is obtained by activating a binary input or via

the fieldbus, depending on the configuration of the device. The Limit

LED (blue) flashes to signal that the function is in progress.

8.3.4. Setpoint value profile

In this operating mode, the device behaves as in standard control

mode, except that the external setpoint value is ignored and replaced

by a predefined chronology of up to 30 flow rate values (configurable

with the "Mass Flow Communicator" software).

This function of the MFC is obtained by activating a binary input

(configured on this function) for at least 0.5 s. The Limit LED (blue)

flashes to signal that the function is in progress.

If the setpoint value profile has been activated by binary input and the

input has been reset, once the setpoint value profile has been executed,

the device returns to the operating mode it was prior to activation.

8.3.5. Control mode

In this operating mode, the setpoint value enables a duty cycle to be

directly supplied to the proportional valve, for example setpoint value

10% → duty cycle of the valve = 10%.

This function of the MFC is obtained by activating a binary input or via

the fieldbus, depending on the configuration of the device (configurable

with the "Mass Flow Communicator" software). The Limit LED (blue)

flashes to signal that the function is in progress.

English

35

Page 36

Type 8006, 8702

Maintenance, Troubleshooting

9. MAINTENANCE,

TROUBLESHOOTING

9.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Shut off the gas flow, relief the pressure and drain the pipe

before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power supply before

carrying out work on the system.

• Observe all applicable accident protection and safety

regulations for electrical equipment.

Warning

Risk of injury due to nonconforming maintenance.

• This work may only be carried out by qualified, authorized

technicians trained for working in environments where there is a

risk of explosion and using the appropriate tools.

• Ensure that the installation is subject to a controlled restart after

the power supply is switched off.

9.2. Maintenance

The need to check and possibly to recalibrate the device depends on

the application and no rule can be given.

We recommend to check the device every 2 years, with reference to

an external standard.

Anyway it is common practice that a user checks their measurement

equipment once a year and, if necessary, adjusts or recalibrates

them.

attention

Risk of injury from operating faults and device failure if the

device is opened.

Inside the device are elements to condition the flow and measure

the flow rate. Work may only be carried out inside the device,

for example for cleaning, as described in section „9.2.1“.

Any other work carried out inside the device causes a change to

the sensor signal, requiring recalibration at the factory.

• Do not open the device.

• Cleaning other than that described in section „9.2.1“ and

calibration may only be performed by the manufacturer.

36

English

Page 37

Type 8626, 8712

1

Maintenance, Troubleshooting

9.2.1. Maintenance if used with highly

soiled fluids

If highly soiled fluids are used:

→ Regularly check that the stainless steel mesh filter disc [5] is not

soiled.

→ Clean or replace it if necessary.

7

6

5

4

3

2

1 - Screws

2 - Inlet flange plate

3 - O-ring

4 - O-ring

5 - Stainless steel mesh filter

6 - Orifice tube

7 - O-ring

Fig. 16: Maintenance, Cleaning

Procedure:

→ To gain access to the stainless steel mesh filter disc, detach the

input flange plate [2] (see „Fig. 16“).

→ Take out the stainless steel mesh filter disc.

→ Clean the stainless steel mesh filter disc [5] using distilled water

(not tap water), acetone, isopropanol or compressed air.

→ Dry the parts after cleaning.

→ Re-engage parts in the correct sequence and position (see

„Fig. 16“). The fine mesh of the filter disc [5] must face the input

flange plate [2].

9.2.2. Cleaning and recalibration at the

factory

If the sensor is excessively soiled or damaged by the operating gas,

the device may deviate significantly in terms of the mass flow rate

measurement. Cleaning or replacement followed by recalibration at

the factory will then be required.

note

• Recalibration must be carried out at the factory as it requires

the use of very precise references and a specific digital

communication system.

English

37

Page 38

Type 8006, 8702

Maintenance, Troubleshooting

9.3. Troubleshooting

Problem Possible cause Recommended action

The Power LED is off No power supply. Check the electrical connections.

The Power LED flashes

The Autotune function is in progress. See section „8.3“.

The Power LED goes off

periodically

The Limit (y) LED comes

on

38

The Power supply cuts out periodically; the device

implements a reset.

The voltage drop in the connection cable is too high. Increase the cable cross section.

MFC: the solenoid valve adjustment has almost reached

100%. The setpoint value has not been obtained.

MFM: the measured flow rate has almost reached or

exceeded the nominal flow rate.

Use a power supply with adequate power.

Reduce the cable length.

Increase the operating pressure (observe the maximum

permitted supply pressure).

Check the cable resistance and reduce if required.

Check the system dimensions.

Check the filters installed in the line and clean

if required.

Reduce the flow rate.

English

Page 39

Type 8626, 8712

Maintenance, Troubleshooting

Problem Possible cause Recommended action

The limit (y) LED is

flashing

The device is in an operating state other than standard

control mode or the Autotune function.

See section „8.3“.

The Error LED is on

The Error LED flashes

No flow rate available The setpoint value is below the limit for the zero point

Minor fault; for example the Autotune function has failed. Repeat the Autotune

The residual ripple of the supply voltage is too high. Use a power supply with a smooth output voltage at

A major fault has occurred, for example: defective

sensor or internal voltage fault.

The sensor was operated above the permitted maximum

operating pressure.

shut-off.

The device is in an operating state other than standard

control mode.

The lines have been sized too large or may not yet have

been completely deaerated.

English

function or reset the device to acknowledge the fault.

the required power.

Return the device to the manufacturer to have the fault

repaired.

Reduce the operating pressure.

Return the device to the manufacturer to have the fault

repaired.

Increase the setpoint value to > 2% of the nominal flow

rate.

Check the operating state; see also section „8.3“.

Deaerate the lines.

Change the line diameter.

39

Page 40

Type 8006, 8702

Maintenance, Troubleshooting

Problem Possible cause Recommended action

The measured value

fluctuates

Setpoint value at 0%, but

the fluid is circulating

Setpoint value = 0%,

valve is closed, no flow

rate in the line;

but the measured flow

rate is not zero

Setpoint value is

not reached

The earth connection (FE) is not correct. Connect the FE to the earthing point (cable as short as

possible, wire at least 2.5 mm²).

The controller must continuously correct fluctuations in

an unstable pressure supply, e.g. by pumping.

The residual ripple of the supply voltage is too high. Use a power supply with a smooth output voltage at

The operating pressure is above the operating pressure

maintained by the proportional valve.

The mounting position of the device is incorrect. Install the MFC in the mounting position shown in the

A fluid other than that designated by the calibration is

used.

The filter is blocked. Clean or replace the filter.

The primary pressure is too low. Increase primary pressure to calibration pressure.

The back pressure is too high. Check components for soiling downstream of the

Connect a suitable pressure controller upstream.

Install a buffer tank to absorb pressure fluctuations.

the required power.

Reduce the operating pressure.

Return the device to the manufacturer to have the fault

repaired.

calibration protocol or the calibration plate and run an

Autotune function to adjust to the operating conditions.

→ Use the designated calibration fluid.

→ or send the device back to the manufacturer to have

it calibrated with the new fluid.

device and if required clean.

40

English

Page 41

Type 8626, 8712

Accessories / Spare parts

10. ACCESSORIES / SPARE PARTS

attention

Risk of injury and/or damage caused by the use of

unsuitable parts.

Incorrect accessories and unsuitable replacement parts may

cause injuries and damage the device and the surrounding area.

• Use only original accessories from Bürkert.

10.1. Accessories

The Bürkert accessories indicated below are recommended to ensure

problem-free operation, maintenance and repair of the device.

10.1.1. Electrical accessories, devices with

an 8 pin M16 female fixed connector

Types Item Order code

8006,

8702,

8626,

8712

8 pin M16 male connector (to

be soldered)

8 pin M16 male connector, with

5 m cable, with stripped end

8 pin M16 male connector, with

10 m cable, with stripped end

15 pin Sub-HD male connector

with 5 m cable, with stripped

end

15 pin Sub-HD male connector

with 10 m cable, with stripped

end

RS232 adapter for PC

connection with an extension

cable (order code 917039)

9 pin Sub-D extension cable,

RS232, 2 m

RS422 adapter 666 370

USB adapter 670 696

USB cable, 2 m 772 299

Software "Mass Flow

Communicator"

918 299

787 733

787 734

787 735

787 736

654 757

917 039

Can be

downloaded at

www.burkert.com

English

41

Page 42

Type 8006, 8702

Accessories / Spare parts

Types Item Order code

Profibus

version

DeviceNet /

CANopen

version

* The two previous M12 connectors cannot be used side by side on the

Y-junction. At least one of the two M12 connectors must be a commercial

connector with a smaller diameter.

Straight M12 male connector

(code B)

Straight M12 female connector

(code B)

PROFIBUS* Y-piece 902 098

PROFIBUS T-piece 918 531

PROFIBUS termination resistor,

male connector, code B

GSD file

Straight M12 male connector

(code A)

Straight M12 female connector

(code A)

DVN/CAN* Y-piece 772 420

DVN/CAN terminal resistor

Male connector (code A)

Female connector (code A)

EDS file for DeviceNet

918 198

918 447

902 553

Can be

downloaded at

www.burkert.com

917 115

917 116

772 424

772 425

Can be

downloaded at

www.burkert.com

10.1.2. Electrical accessories, devices with

a 9 pin Sub-D male fixed connector

with RS485

Accessory Order code

9 pin Sub-D female connector (to be soldered) 917 623

USB adapter 670 693

USB cable, 2 m 772 299

10.1.3. Fluid accessories

The MFM / MFC are equipped with a connection plate which uses a

DIN ISO 228/1 thread process connection.

A threaded fitting available as an accessory is used to connect the

device to a line:

• the connection to the device side has a DIN ISO 228/1 thread,

• the connection to the line side is available in a range of

dimensions.

A sealing ring must be ordered for each screw fitting!

42

English

Page 43

Type 8626, 8712

Accessories / Spare parts

Connection to the device,

with DIN ISO 228/1 thread

G 1/4 6 mm 901 538 901 575

G 1/4 8 mm 901 540 901 575

G 1/4 1/4 " 901 551 901 579

G 1/4 3/8 " 901 553 901 579

G 3/8 8 mm 901 542 901 576

G 3/8 10 mm 901 544 901 576

G 3/8 1/4" 901 555 901 580

G 3/8 3/8" 901 556 901 580

G 1/2 10 mm 901 546 901 577

G 1/2 12 mm 901 548 901 577

G 1/2 1/2" 901 557 901 581

G 1/2 3/4" 901 558 901 581

G 3/4 12 mm 901 549 901 578

G 3/4 3/4" 901 559 901 582

Other accessories for the fluid connection of an

MFM / MFC can be found under Type 1013 in the

Bürkert accessories catalogue.

Diameter of

the line

Order code

of the olive

connection

Order code

of the seal

10.1.4. Mass Flow Communicator

(Software)

The "Mass Flow Communicator" software is made for the communication

with the Mass Flow Controllers and Liquid Flow Controllers supplied

by Bürkert.

The software runs on the Windows platform and

communicates with the MFM / MFC via a serial interface

(RS232 / RS485 / USB).

This software enables:

• information specific to the device to be read,

• the assignment of binary inputs and outputs to be changed,

• the assignment of LEDs to be changed,

• various functions to be activated,

• certain dynamic properties to be modified,

• a user specific calibration to be performed,

• the firmware to be updated,

• the bus address to be set,

• ...

English

43

Page 44

Type 8006, 8702

Shutdown

10.1.5. Additional documentation

Designation Order code

Supplement to the operating instructions for

fieldbus devices

Contamination Declaration 806 075

"Configuration via PROFIBUS with GDS file"

addendum

804 553

805 923

10.2. Spare part

Designation Order code

Stainless steel mesh filter, mesh size 250 µm,

for 8626 / 8006 (standard fluid base)

Stainless steel mesh filter, mesh size 250 µm,

for 8626 / 8006 (high fluid flow rate base)

Stainless steel mesh filter, mesh size 250 µm,

for 8702

Stainless steel mesh filter, mesh size 25 µm,

for 8712

646 808

651 694

654 733

676 329

11. SHUTDOWN

11.1. Safety instructions

danger

Danger due to high pressure in the installation.

• Shut off the gas flow, relief the pressure and drain the pipe

before loosening the process connections.

Danger from the outflow of operating fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the operating fluids used.

Danger due to electrical voltage.

• Shut down and isolate the electrical power supply before

carrying out work on the system.

• Observe all applicable accident protection and safety

regulations for electrical equipment.

Warning

Risk of injury from nonconforming dismounting.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

44

English

Page 45

Type 8626, 8712

Packaging, Storage, Transport

11.2. Dismounting of the MFM / MFC

Procedure:

B

A

C

→ Relieve the operating medium pressure in the system.

→ Control the solenoid valve to open.

→ Clean the device using a neutral fluid (nitrogen, for example).

→ Relieve the rinsing medium pressure in the system.

→ Switch off the power supply [A].

→ Disconnect the electrical connections [B].

→ Disconnect the fluid connections [C].

→ Remove the MFM / MFC.

12. PACKAGING, STORAGE, TRANSPORT

12.1. Packaging, Transport

note

Damage due to transport

Inadequately protected equipment may be damaged during transport.

• Remove all cables, connections, separate filters and installation material.

• Clean and air contaminated devices.

• Protect fluid connections from damage and leaks by fitting

protective caps and seal.

• Pack the device in two suitable bags, sealed with protective film.

• During transportation protect the device against humidity and

dirt in shock-resistant packaging.

• Do not expose the device to temperatures outside the storage

temperature range.

12.2. Storage

note

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Storage temperature: -10 °C to +70 °C.

English

45

Page 46

Type 8006, 8702

English

Returning the device

13. RETURNING THE DEVICE

No work or tests will be carried out on the device until

there is a valid contamination declaration.

The Contamination Declaration can be downloaded from our

homepage or requested from your local after-sales service.

www.buerkert.fr

Commissioning

To return a device already in use, a returns number

is required.

If you would like to return a device already in use to Bürkert, proceed

as follows:

Service

Contamination Declaration

Servicing/Maintenance/

→ Complete the Contamination Declaration.

→ Send the declaration to the address indicated on the form:

Bürkert will fax or e-mail you a service number for confirmation.

→ Pack the device in consideration of the information in section

„12.1“.

→ Return the device to Bürkert with the contamination declaration,

and mention the service number given before.

Address:

Bürkert Fluid Control Systems

Corporate Quality / Complaint Management

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 599

Fax + 49 (0) 7940 - 10 91 490

E-mail: service.international@burkert.com

14. DISPOSAL OF THE PRODUCT

→

Sort out used products according to their type.

→ Dispose of the device and its packaging in an environmentally-

friendly way.

note

Damage to the environment caused by products

contaminated by fluids.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

Comply with the national and/or local regulations which

concern the area of waste disposal.

46

Page 47

Page 48

www.burkert.com

Loading...

Loading...