Page 1

Page 2

Page 3

CONTENTS

Page

1. General description 4

1.1 Applications 4

1.2 Type key 5

2. Technical data 6

2.1 Mechanical data 6

2.2 Electrical data 6

2.3 Input/output data 6

2.4 Dimensions 7

3. Installation 7

3.1 Safety instructions 7

3.2 Installation environment 7

3.3 Installation of pump 7

3.4 Installation example 8

3.5 Electrical connection 8

3.6 Connection overview 9

4. Functions 10

4.1 Control panel 10

4.2 Start/stop of pump 11

4.3 Priming/venting of pump 11

4.4 Level control 11

4.5 Indicator lights and alarm output 11

4.6 Fieldbus communication 12

4.7 Menu 13

4.8 Operating modes 14

4.9 Manual 14

4.10 Pulse 14

4.11 Analog 14

4.12 Timer 16

4.13 Batch 17

4.14 Anti-cavitation 17

4.15 Capacity limitation 18

4.16 Counters 18

4.17 Resetting 19

4.18 Return 19

4.19 Language 19

4.20 Input setup 20

4.21 Measuring units 21

4.22 Dosing monitoring 22

4.23 Control panel lock 23

5. Start-up 24

6. Calibration 25

6.1 Direct calibration 26

6.2 Indirect calibration 27

6.3 Check calibration 28

7. Maintenance 28

8. Service 28

9. Fault finding chart 29

10. Disposal 29

1. General description

The Buerkert 7800 dosing pump is a self-priming diaphragm pump.

The pump consists of:

•a cabinet incorporating the drive unit and elec-

tronics,

•a dosing head with back plate, diaphragm,

valves, connections and vent valve,

•a contr ol panel incorporating display and buttons .

The control panel can be fitted either to the end or

to the side of the cabinet.

Being equipped with a stepper motor, this dosing

pump is unique in its field. The stepper motor offers

the possibility of varying the capacity by changing

the duration of the dosing stroke.

Furthermore, the motor is controlled in such a way

that the dosing gets as even and constant as possible, irrespective of the capacity range in which the

pump is operating.

This is carried out as follows:

The speed of the suction stroke is kept constant and

the stroke relatively short, irrespective of the capacity . Contrary to conv entional pumps, which generate

the dosing stroke as a short pulse, the duration of

the dosing stroke will be as long as possible. Thus,

an even dosing without peak values is ensured. As

the pump is always dosing at full stroke length, it ensures the same high accuracy and suction capability,

irrespective of the capacity, which is infinitely variable in the ratio of 1:1000.

The pump features an LCD display and a userfriendly control panel which gives access to the

pump functions.

1.1 Applications

The 7800 dosing pump is designed for handling

chemicals within the following ranges of applications,

among others:

• Drinking water treatment.

• Wastewater treatment.

• Swimming pool water treatment.

• Boiler water treatment.

• Cooling water treatment.

• Process water treatment.

• Washing systems.

Before beginning installation procedures,

these installation and operating instructions should be studied carefully. The installation and operation should also be in

accordance with local regulations and accepted codes of good practice.

4

Page 4

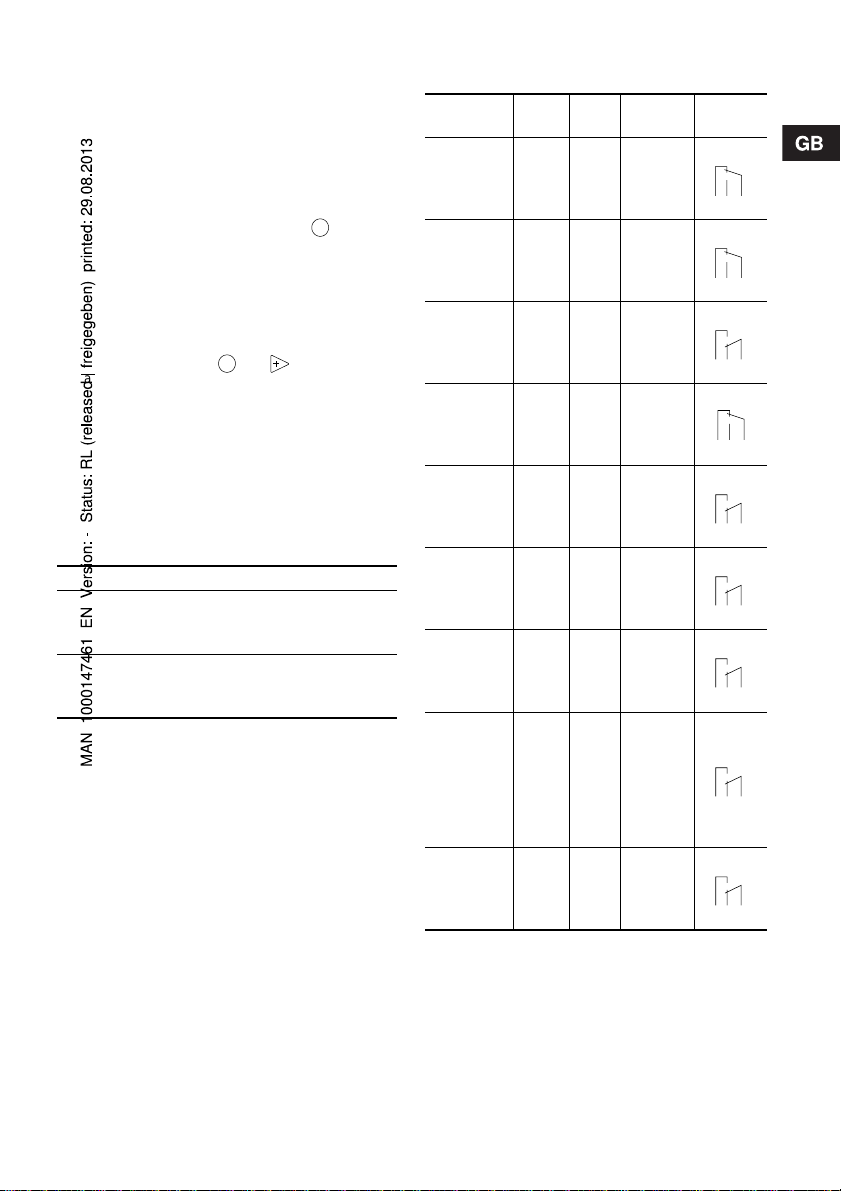

2. Technical data

2.1 Mechanical data

Maximum capacity without anti-cavitation *

Maximum capacity with anti-cavitation *

1

[l/h] 2.5 7.5 12 18.5 48

1

[l/h] 1.8 5.6 9 14.5 37

Maximum pressure [bar] 18 10 6 6.2 2.6

Maximum stroke rate per minute [stroke/min.] 180 180 180 151 151

Maximum suction lift during operation [m] 6

Maximum suction lift when priming with wet valves [m] 1.8 3 3 3 3

Maximum viscosity with spring-loaded valves *

Maximum viscosity without spring-loaded valves *

[mPas]

2

[mPas] 500 500 500 500 100

Diaphragm diameter [mm] 28 38 42.5 55 77

Liquid temperature [°C] 0 to 50

Ambient temperature [°C] 0 to 45

Accuracy of repeatability ±1%

Sound pressure level [dB(A)] <70

*1 Irrespective of counter pressure

2

Maximum suction lift 1 metre

*

2.2 Electrical data

Supply voltage [VAC] 1 x 100-240

Maximum current consumption [A]

Maximum power consumption P

at 100 V 0.30 0.36

at 230 V 0.16 0.26

[W] 18 22

1

Frequency [Hz] 50-60

Enclosure class IP 65

Insulation class B

Supply cable 1.5 m H05RN-F with plug

2.3 Input/output data

The pump offers various input and output possibilities, depending on control variant.

Signal input

Voltage in level sensor input [VDC] 5

Voltage in pulse input [VDC] 5

Minimum pulse-repetition period [ms] 3.3

Impedance in analog 4-20 mA input [Ω] 250

Maximum loop resistance in pulse signal circuit [Ω] 350

Maximum loop resistance in level signal circuit [Ω] 350

Signal output

Maximum load of alarm relay output, at ohmic load [A] 2

Maximum voltage, alarm relay output [V] 250

7800-2 7800-8 7800-12 7800-19 7800-48

2

200 200 200 200 100

7800- 2, 8, 12 7800-19, 48

6

Page 5

2.4 Dimensions

See dimensions at the end of these instructions.

All dimensions are in mm.

3. Installation

3.1 Safety instructions

• The liquid is under pressure and may be hazardous.

• When working with chemicals, local safety rules

and regulations must be observed (e.g. wear protective clothes).

• Before starting work on the dosing pump and system, disconnect the electricity supply to the pump,

ensuring that it cannot be accidentally switched

on. Before reconnecting the electricity supply,

make sure that the dosing hose is positioned in

such a way that any chemical left in the dosing

head is not ejected, thereby exposing persons to

danger.

• If the vent valve in the dosing head is used, it must

be connected to a hose which is led back to the

tank.

• When changing a chemical, make sure that the

materials of the dosing pump and system are resistant to the new chemical. If there is any risk of

chemical reaction between the two types of chemicals, clean the pump and system thoroughly before adding the new chemical.

Proceed as follows:

Place the suction tube in water and press the

button until residual chemical has been removed.

Note: When the buttons and are pressed

simultaneously, the pump can be set to run for a

specific number of seconds at maximum capacity.

The remaining number of seconds will appear in

the display. The maximum value is 300 seconds.

100%

3.2 Installation environment

• Exposure to direct sunlight should be avoided.

This applies especially to pumps with plastic dosing heads, as this material can be damaged by

sunlight.

• If the pump is installed outside, an enclosure or

similar protection is required to protect the pump

against rain and similar weathers.

100%

3.3 Installation of pump

• See also the installation example in section 3.4.

• Note: The dosing head may contain water from

the factory test. If a liquid which must not come

into contact with water is to be dosed, it is recommended to let the pump run with another liquid to

remove the water from the dosing head before installation.

• Note: Tighten the bolts in the dosing head after

2 to 5 operating hours (torque 5 Nm).

• Always install the pump on the supporting foot

with vertical suction and discharge ports.

• Always use suitable tools for the mounting of plastic parts. Never apply unnecessary force.

• Make sure that the dosing pump and system are

designed in such a way that neither system equipment nor buildings are damaged in case of leakage from the pump or rupture of hoses/pipes. The

installation of leakage hoses and collecting tanks

is recommended.

• Make sure that the drain hole in the dosing head

points downwards, see fig. 1.

Note: It is important that the drain pipe/hole is not

inserted direct into the tank contents, as gasses

may penetrate into the pump.

Fig. 1

Drain hole

TM01 8420 5099

7

Page 6

3.4 Installation example

The drawing in fig. 2 shows an installation example.

Fig. 2

The 7800 pump can be installed in many different ways. The sketch below shows a n example with sidefitted control panel. The tank is a Buerkert chemical tank with a Buerkert level control unit.

3.5 Electrical connection

• The electr ical connection of the pump should be

carried out by qual ified perso ns in accordance

with local regulations.

• For electr ical data of the pump, see section 2.2.

• Do not lay signal cables, if any, together with

power cables.

8

TM01 8421 0 204

Page 7

3.6 Connection overview

Fig. 3

Alarm relay (control variant “AR” only)

“NO” black

“NC” blue

“Com” brown

5

4

4

5

1

3

2

Control cable,

see table below

1

3

2

4

1

3

Level cable,

see table below

2

3

1

4

Empty tank

Low level

Control input:

Number / colour 1 / brown 2 / white 3 / blue 4 / black 5 / grey Description

Function

Manual 2 2

Pulse 1 1

Pulse + external on/off 1 1 + 2 2

Analog – + mA signal

Analog + external on/off 2 2 – + mA signal

Timer + external on/off 2 2

Batch 1 1

1 = Contact for pulse signal

2 = Contact for external on/off

Level input:

Number / colour 1 / brown 2 / white 3 / blue 4 / black

Low level Low level

Function

Low level Empty tank Low level + empty tank

Empty tank Empty tank

Dosing monitoring Dosing monitoring

TM01 8422 0603

9

Page 8

4. Functions

4.1 Control panel

Fig. 4

Navigation/

settings,

see section 4.7

Maximum capacity

(priming),

see section 4.3

LCD display,

see section 4.7

ml/h

Navigation/

settings,

see section 4.7

Green

indicator light,

see section 4.5

Red

indicator light,

see section 4.5

Connection

alarm relay/bus.

Control variants

“AR”, “AP” and “AG”,

see sections 4.5 and

4.6

100%

M12 connection

pulse/analog input,

see section 4.4

level control,

see section 4.4

Menu,

see section 4.7

On/off button,

see section 4.7

Mains connectionM12 connection

TM01 8423 0100

10

Page 9

4.2 Start/stop of pump

The pump can be started/stopped in two different

ways:

• Locally on the pump control panel.

• By means of an external on/off switch connected

to the pulse input. See connection overview in

section 3.6.

4.3 Priming/venting of pump

The pump control panel incorporates a button.

Press this button if the maximum pump capacity is

required over a short period, e.g. during start-up.

When the button is released, the pump automatically

returns to the previous operating mode.

During priming/venting, it is recommended to let the

pump run without a counter pressure or to loosen the

vent valve by giving it a 1/8 to 1/4 turn.

Note: When the buttons and are pressed si-

multaneously, the pump can be set to run for a specific number of seconds at maximum capacity. The

remaining number of seconds will appear in the display. The maximum value is 300 seconds.

100%

100%

4.4 Level control

The pump can be fitted with a level control unit for

monitoring of the chemical level in the tank.

The pump can react to two level signals. The pump

will react differently, depending on the influence on

the individual level sensors.

Level sensors Pump reaction

Upper sensor

activated

(closed contact)

Lower sensor

activated

(closed contact)

• Red indicator light is on.

• Pump running.

• Alarm relay activated.*

• Red indicator light is on.

• Pump stopped.

• Alarm relay activated.*

* Control variant “AR” only.

See section 3.6 for connection of the level control

unit and alarm output.

4.5 Indicator lights and alarm output

The green and red indicator lights on the pump are

used for operating and fault indication.

In control variant “AR”, the pump can activate an external alarm signal by means of a built-in alarm relay.

The alarm signal is activated by means of an internal

potential-free contact.

The functions of the indicator lights and the built-in

alarm relay appear from the table below:

Condition

Pump

running

Set to stop

Green

LED

On Off

Flash-

ing

Red

LED

Off

Display

Normal

indication

Normal

indication

Alarm

output

132

NC NO C

132

NC NO C

Pump fault Off On EEPROM

23

1

NC NO C

Supply

failure

Off Off Off

132

NC NO C

Pump running, low

chemical

2

level

Empty

2

tank

Analog

signal

On On

Off On

Off On

< 2 mA

The dosed

quantity is

too small

according

to the signal from the

dosing

monitor

Overheating

1

Control variant AR only.

2

Requires connection to level sensors.

3

Requires activation of the dosing monitoring

function and connection to a dosing monitor.

On On

3

Off On

Normal

indication

Normal

indication

Normal

indication

Normal

indication

MAX.

TEMP.

23

1

NC NO C

23

1

NC NO C

23

1

NC NO C

23

1

NC NO C

23

1

NC NO C

1

11

Page 10

4.6 Fieldbus communication

The pump can be configured for fieldbus applications.

The following bus types are available:

Control variant Bus type

AP Profibus

AG GENIbus

Separate instructions are supplied with each bus

type.

12

Page 11

4.7 Menu

The pump features a user-friendly menu which is activated by pressing the button. During start-up, all

texts will appear in English language. To select language, see section 4.19.

Fig. 5

See section 4.9 See section 4.23

All menu items are described in the following sections. When appears at a menu item, it means

that this item is activated. By selecting “RETURN”

anywhere in the menu structure, you will return to the

operating display without changes.

See section 4.10 See section 4.17

See section 4.11 See section 4.18

See section 4.12 See section 4.19

See section 4.13 See section 4.15

See section 4.14 See section 4.20

See section 6 See section 4.21

See section 4.16

13

Page 12

4.8 Operating modes

Note: The displayed l and ml values are only reliable

if the pump has been calibrated to the actual installation, see section 6.

The pump can run in five different operating modes:

•Manual

•Pulse

•Analog

•Timer (internal batch control)

•Batch (external batch control)

See description in the following sections.

4.9 Manual

The pump is dosing as constantly and evenly as possible, without any external signals.

Set the quantity to be dosed in l/h or ml/h. The pump

automatically changes over between the measuring

units.

Setting range:

DME 2: 2.5 ml/h - 2.5 (1.8*) l/h

DME 8: 7.5 ml/h - 7.5 (5.6*) l/h

DME 12: 12 ml/h - 12 (9*) l/h

DME 19: 18.5 ml/h - 18.5 (14.5*) l/h

DME 48: 48 ml/h - 48 (37*) l/h

* The figures in brackets indicate the maximum ca-

pacity when the anti-cavitation function is activated.

Fig. 6

Set value

4.10 Pulse

The pump is dosing according to an external pulse

signal, i.e. a water meter with pulse output or a controller.

Set the quantity to be dosed per pulse in ml/pulse.

The pump adjusts its capacity according to two factors:

• Frequency of external pulses.

• The set quantity per pulse.

Setting range:

DME 2: 0.000018 ml/pulse - 5 ml/pulse

DME 8: 0.000069 ml/pulse - 15 ml/pulse

DME 12: 0.000111 ml/pulse - 24 ml/pulse

DME 19: 0.000204 ml/pulse - 37 ml/pulse

DME 48: 0.00530 ml/pulse - 96 ml/pulse

Fig. 7

Set quantity in

ml/pulse

Actual capacity

in ml/h or l/h

If the set quantity per pulse multiplied by the pulse

frequency exceeds the pump capacity, the pump will

run at maximum capacity. Excess pulses will be ignored and the “actual capacity” display will flash.

4.11 Analog

The pump is dosing according to an external analog

signal. The dosed quantity is proportional to the input

value in mA.

4-20 (default): 4 mA = 0%.

20-4: 4 mA = 100%.

0-20: 0 mA = 0%.

20-0: 0 mA = 100%.

See fig. 8.

The capacity limitation will influence the capacity.

100% corresponds to the maximum capacity of the

pump or the set maximum capacity, see section

4.15.

Fig. 8

100

80

60

40

20

20 mA = 100%.

20 mA = 0%.

20 mA = 100%.

20 mA = 0%.

[%]

0-20 mA

4-20 mA

0

0 4 8 12 16 20

[mA]

TM02 4498 1102

14

Page 13

Fig. 9

Value

according to

analog signal

If 4-20 mA or 20-4 mA is selected and the signal falls

below 2 mA, the pump will indicate a fault. This situation occurs if the connection is interrupted, for instance if the wire is damaged.

Change the analog mode as illustrated in fig. 10:

Fig. 10

Use the buttons

for navigation

15

Page 14

4.12 Timer

The pump is dosing the set quantity in batches at the

maximum capacity or the set maximum capacity, see

section 4.15.

The time until the first dosing “NX” and the following

sequences “IN” can be set in minutes, hours and

days. The maximum time limit is 9 days, 23 hours

and 59 minutes (9:23:59). The lowest acceptable

value is 1 minute.

if the pump is stopped by means of the on/off button,

empty tank or stop signal, see fig. 11.

During operation, “NX” will always count down from

“IN” to zero. In this way, the remaining time until the

next batch can always be read.

“IN” must be higher than the time required to perform

one batch. If “IN” is lower, the next batch will be ignored.

In case of supply failure, the set quantity to be

dosed, the “IN” time and the remaining “NX” time are

stored. When the supply is reconnected, the pump

will start up with the “NX” time at the time of the supply failure. In this way, the timer cycle will continue,

but it has been delayed by the duration of the supply

failure.

Fig. 11

NX

Setting range:

7800-2: 0.23 ml/batch - 5 l/batch

7800-8: 0.69 ml/batch - 15 l/batch

7800-12: 1.11 ml/batch - 24 l/batch

7800-19: 2.04 ml/batch - 37 l/batch

7800-48: 5.3 ml/batch - 96 l/batch

Only values corresponding to complete dosing

strokes (according to the calibration factor) can be

selected.

Example: If the calibration factor is 23.3 (= 0.233 ml/

stroke), the minimum settable value in timer or batch

mode will be 0.233 ml -> the next will be 0.466 ml ->

the next will be 0.699 ml, etc.

These steps will continue up to a value corresponding to 100 dosing strokes. Above this value, the setting range has standard steps as in other operating

modes.

If the calibration factor is changed after setting of

timer or batch mode, the pump will automatically recalculate a new amount of dosing strokes per batch

and change the display value to the nearest possible

value compared to the first one set.

The internal timer continues even

Quantity per batch

IN

Fig. 12

TM01 8942 0900

Set quantity

per batch

Set IN value

in minutes

Set IN value

in hours

Set IN value

in days

Set NX value

in minutes

Set NX value

in hours

Set NX value

in days

16

Page 15

4.13 Batch

The pump is dosing the set quantity in batches at the

maximum capacity or the set maximum capacity, see

section 4.15.

The quantity is dosed every time the pump receives

an external pulse.

If the pump receives new pulses before the previous

batch is performed, these pulses will be ignored.

Fig. 13

Quantity per batch

Pulse Pulse

The setting range is the same as for Timer, see section 4.12.

Fig. 15

Fig. 14

Set value

per batch

4.14 Anti-cavitation

The pump features an anti-cavitation function. When

this function is selected, the pump extends and

smooths its suction stroke, resulting in softer priming.

The anti-cavitation function is used:

• when pumping liquids of high viscosity,

TM01 8947 0900

• in the case of a long suction tube and

• in the case of a high suction lift.

The maximum pump capacity is reduced when this

function is selected. See section 2.1 Mechanical

data.

Operating display

17

Page 16

4.15 Capacity limitation

This function offers the possibility of reducing the

maximum pump capacity (MAX CAP). It influences

the functions in which the pump is normally operating

at maximum capacity.

Under normal operating conditions, the pump cannot

operate at a capacity which is higher than the one

stated in the display. This does not apply to the maximum capacity button , see section 4.3.

Fig. 16

100%

Fig. 17

Total dosed

quantity

Set maximum

capacity

Operating display

4.16 Counters

The pump can display “non-resettable” counters for:

•“QUANTITY”

Accumulated value of dosed quantity in litres or

US gallons.

•“STROKES”

Accumulated number of dosing strokes.

•“HOURS”

Accumulated number of operating hours.

•“POWER ON”

Accumulated number of times the electricity supply has been switched on.

Total number

of strokes

Total number

of operating

hours

Total number

of starts

18

Operating display

Page 17

4.17 Resetting

When “DEFAULT” is activated, the pump will return

to the factory settings.

Fig. 18

Note: The calibration is also set back to the default

setting. This means that a new calibration is required

when the “DEFAULT” function has been used.

Operating display Operating display

4.18 Return

Fig. 19

The “RETURN” function makes it possible to return

from any level in the menu to the operating display

without changes after the menu functions have been

used.

without changes

4.19 Language

The display text can be displayed in one of the following languages:

• English

•German

•French

•Italian

• Spanish

• Portuguese

•Dutch

• Swedish

• Finnish

• Danish

•Czech

•Slovak

•Polish

• Russian

19

Page 18

Fig. 20

Operating display Operating display

4.20 Input setup

Fig. 21 shows all possible settings.

The level and stop inputs can be changed from NO

(normally open) to NC (normally closed) function. If

changed, the inputs must be short-circuited in normal operation.

Fig. 21

Use the buttons

for navigation

Operating display

without changes

For the analog input, one of the following signal

types can be selected:

• 4-20 mA (default),

• 20-4 mA,

• 0-20 mA,

• 20-0 mA.

See also section 4.11 Analog.

Change the level input to an input for dosing monitor-

ing as illustrated in fig. 21.

20

Page 19

4.21 Measuring units

It is possible to select metric units (litre/millilitre) or

US units (gallons/millilitre).

Metric measuring units:

• In manual and analog modes, set the quantity to

be dosed in litres per hour (l/h) or millilitres per

hour (ml/h).

• In pulse mode, set the quantity to be dosed in

ml/pulse. The actual capacity is indicated in litres

per hour (l/h) or millilitres per hour (ml/h).

• For calibration, set the quantity to be dosed in

ml per 100 strokes.

• In timer and batch modes, set the quantity to be

dosed in litres (l) or millilitres (ml).

• Under the “QUANTITY” menu item in the

“COUNTERS” menu, the dosed quantity is indicated in litres.

Fig. 22

3 x

US measuring units:

• In manual and analog modes, set the quantity to

be dosed in gallons per hour (gph).

• In pulse mode, set the quantity to be dosed in

ml/pulse. The actual capacity is indicated in

gallons per hour (gph).

• For calibration, set the quantity to be dosed in

ml per 100 strokes.

• In timer and batch modes, set the quantity to be

dosed in gallons (gal).

• Under the “QUANTITY” menu item in the

“COUNTERS” menu, the dosed quantity is indicated in US gallons (gal).

Operating display Operating display

21

Page 20

4.22 Dosing monitoring

A dosing monitor is available as an accessory. Separate instructions are supplied with the monitor.

Fig. 23

Dosing stroke measured

Monitor mounted on the suction side of the pump

The dosing monitor is designed to monitor the dosing

of liquids which may cause gas accumulation in the

dosing head, thus stopping the dosing process even

if the pump is still operating.

For every measured dosing stroke, the dosing monitor gives a pulse signal to the level input so that the

pump can compare performed dosing strokes (from

internal stroke sensor) with externally measured

physical strokes (from the dosing monitor). If an external dosing stroke is not measured together with

the internal dosing stroke, this is considered a fault

that may have been provoked by empty tank or gas

in the dosing head.

TM02 2029 3201

22

Page 21

4.23 Control panel lock

It is possible to lock the buttons on the control panel

to prevent malfunction of the pump. The locking

function can be set to “ON” or “OFF”. The default

setting is “OFF”.

A PIN code must be entered to change from “OFF” to

“ON”. When “ON” is selected for the first time,

“_ _ _ _” will appear in the display. If a code has already been entered, it will appear when an attempt

to change to “ON” is made. This code can either be

re-entered or changed.

If no code has been entered, a code must be set in

the same way as the “NX” and “IN” values described

in section 4.12.

If a code has already been entered, active digits are

flashing.

If attempts are made to operate the pump in locked

condition, “LOCKED” will appear in the display for

2 seconds, followed by “_ _ _ _”. A code must be entered. If the entering of a code has not been started

within 10 seconds, the operating display without

changes will appear.

Fig. 24

If a wrong code is entered, “LOCKED” will appear in

the display for 2 seconds, followed by “_ _ _ _”. A

new code must be entered. If the entering of a code

has not been started within 10 seconds, the operating display without changes will appear. This display

will also appear if the entering of the correct code exceeds 2 minutes.

If the locking function has been activated but the

control panel is unlocked, the control panel will be

locked automatically if it is not operated for 2 minutes.

The locking function can also be reactivated by selecting “ON” in the “LOCK” menu. The previously entered code will then appear and must be re-entered

by pressing the button four times. The code can

also be changed.

The control panel can be unlocked either by means

of the selected code or the factory code 2583.

The following buttons and inputs are still active when

the panel is locked:

• Priming ( -button).

100%

• On/off button.

• All external inputs.

Operating display

Activating the locking function and locking the

control panel:

1. Select “LOCK” in the menu.

2. Select “ON” by means of the buttons and

and confirm with .

3. Enter or re-enter a code by means of the buttons

, and .

The locking function has now been activated and the

control panel is locked.

Unlocking the control panel (without deactivating

the locking function):

1. Press once. “LOCKED” appears in the display

for 2 seconds, followed by “_ _ _ _”.

2. Enter the code by means of the buttons ,

and *.

The control panel has now been unlocked and will

automatically be locked again if the control panel is

not operated for 2 minutes.

Operating display

Deactivating the locking function:

1. Unlock the control panel as described above.

2. Select “LOCK” in the menu.

3. Select “OFF” by means of the buttons and

and confirm with .

The locking function has now been deactivated and

the control panel is unlocked.

* The panel can always be unlocked with code 2583.

23

Page 22

5. Start-up

1

2

100%

Step Action

Connect the hoses/pipes:

• Connect the suction and dosing tubes/pipes to the pump.

• Connect a tube to the vent valve, if required, and lead the hose to the

tank.

Switch on the electricity supply:

• The display is on.

• The green indicator light is flashing (the pump has stopped).

• Select language, if required, see section 4.19.

3

Select the operating mode (see section 4.8):

• Manual.

•Pulse.

• Analog.

•Timer.

•Batch.

4

Connect the cables:

• Connect the control/level cables, if any, to the pump, see section 3.6.

5

Start the pump:

• Start the pump by pressing the on/off button.

100%

6

100%

• The green indicator light is permanently on.

Priming/venting:

• Press the button on the pump control panel and let the pump run

without a counter pressure. Loosen the vent valve by giving it a 1/8 to

1/4 turn, if required.

When the buttons and are pressed simultaneously during priming, the pump can be set to run for a specific number of seconds at

maximum capacity.

100%

100%

7

Calibration:

• When the pump has been primed and is running at the right counter

pressure, calibrate the pump, see section 6.

If the pump is not operating satisfactorily, see section 9. Fault finding chart.

24

Page 23

6. Calibration

It is important that the pump is calibrated after installation to ensure that the correct value (ml/h or l/h)

appears in the display.

The calibration can be carried out in three different

ways:

• Direct calibration (recommended).

The dosed quantity of 100 strokes is measured directly. See section 6.1.

• Indirect calibration.

A calibration factor selected from a table is used

for the specific installation. This method can be

used if it is not possible to carry out a direct calibration. Indirect calibration will never be as accurate as direct calibration. See section 6.2.

• Check calibration. See section 6.3.

25

Page 24

6.1 Direct calibration

Before calibration, make sure:

• that the pump is installed with foot valve, injection

valve, etc. in the existing system.

• that the pump is running at the counter pressure it

is supposed to operate at (adjust the counter pressure valve, if required).

• that the pump is operating with the correct suction

lift.

To carry out a direct calibration, proceed as follows:

Action Pump display

1. Prime the dosing head and the suction tubing.

2. Stop the pump. The green LED is flashing.

3. Fill a graduated glass with dosing liquid, Q

7800-2: approx. 40 ml 7800-19: approx. 500 ml

7800-8: approx. 150 ml 7800-48: approx. 1000 ml

.

1

7800-12: approx. 250 ml

4. Read and note the quantity Q

.

1

5. Place the suction tubing in the graduated glass.

Q

1

6. Go to the calibration menu, see section 4.7.

7. Press the button twice.

8. The pump is performing 100 dosing strokes.

9. The factory-calibration value appears in the display.

10.Remove the suction tubing from the graduated

glass and read Q

11.Set the display value to Q

.

2

Q

d

Q

2

= Q1 – Q2.

d

12.Confirm with the button.

13.The pump is now calibrated and returns to the operating display.

26

Set value

to Q

d

Operating display

Page 25

6.2 Indirect calibration

7800-8

7800-12

7800-19

7800-48

A value from the following table is to be added to the

default factory calibration value in the display. To reset the pump to the factory calibration value, activate

the “DEFAULT” function, see section 4.17.

To use the values, the following must be fulfilled:

• The viscosity and density of the liquid to be dosed

must not differ considerably from water at 20°C.

• A Grundfos installation kit or corresponding foot

valve, injection valve and hose diameter must be

used.

• The length of the dosing hose must not exceed

6 metres.

• The suction lift must lie between 0.1 and 1.5 metres.

Pump type

7800-2 1.4 1.1 0.8 0.5 0.2 -0.2 -0.6 -1.2 -1.8 -2.4 -3.0 -3.6

Adding the value:

Fig. 25

Values to be added to the calibration value at various counter pressures [bar]

0-1 1-2 2-3 3-4 4-5 5-6 6-8 8-10 10-12 12-14 14-16 16-18

3.52.72.01.20.4-0.4-1.6-3.1----

2.11.30.4-0.4-1.3-2.1-3.4-----

18.312.26.10-6.1-12.2-21.4-----

24.38.3-8.3---------

Set value

to table value

+ display valu e

Operating display

Operating display

without changes

27

Page 26

6.3 Check calibration

In check calibration, the calibration value is calculated by reading the consumption of chemical in a

specific period and comparing this with the number

of dosing strokes performed in the same period.

This calibration method is very accurate and especially suitable for check calibration after long periods

of operation or if direct calibration is impossible. The

calibration can for instance be carried out when the

chemical tank is replaced or filled.

To carry out a check calibration, proceed as follows:

1. Stop the pump by pressing the button.

2. Read the counter and note the number of dosing

strokes, see section 4.16.

3. Read and note the quantity in the chemical tank.

4. Start the pump by pressing the button and let

it run for at least 1 hour. The longer the pump is

operating, the more accurate the calibration will

be.

5. Stop the pump by pressing the button.

6. Read the counter and note the number of dosing

strokes, see section 4.16.

7. Read and note the quantity in the chemical tank.

8. Calculate the dosed quantity in ml and the

number of dosing strokes performed during the

operating period.

9. Calculate the calibration value as follows:

(dosed quantity in ml/dosing strokes) x 100.

10.Set the calculated value in the calibration menu

like for indirect calibration, see section 6.2.

7. Maintenance

The pump is maintenance-free. However, it is recommended to keep the pump clean.

The dosing pump is produced according to the highest quality standards and has long life. The pump incorporates wear parts such as diaphragm, valve seat

and valve balls.

To ensure long life and to reduce the risk of disturbance of operation, visual checks should be carried

out regularly.

It is possible to order dosing heads, valves and diaphragms in materials which are suitable for the specific liquid to be pumped. See the product numbers

at the end of these instructions.

8. Service

Before returning the pump to Buerkert for service,

the safety declaration at the end of these instructions

must be filled in by authorized personnel and attached to the pump in a visible position.

Note: If a pump has been used for a liquid which is

injurious to health or toxic, the pump will be classified as contaminated.

If Buerkert is requested to service the pump, it must

be ensured that the pump is free from substances

that can be injurious to health or toxic. If the pump

has been used for such substances, the pump must

be cleaned before it is returned.

If proper cleaning is not possible, all relevant information about the chemical must be provided.

If the above is not fulfilled, Buerkert can refuse to

accept the pump for service. Possible costs of returning the pump are paid by the customer.

The safety declaration can be found at the end of these

instructions (only in English).

Note: The replacement of the supply cable must be

carried out by an authorised Buerkert service work-

shop.

28

Page 27

9. Fault finding chart

Fault Cause Remedy

The dosing has

stopped or the output

is too low.

Pump dosing too little

or too much.

Pump dosing irregularly.

Leakage from drain

hole.

Frequent diaphragm

failures.

Valves leaking or blocked. Check and clean valves.

Valves incorrectly installed. Remove and fit valves. Check that the arrow

Suction valve or suction pipe/hose

leaking or blocked.

Suction lift too high. Install the pump in a lower position.

Viscosity too high. Select the anti-cavitation function, see sec-

Pump out of calibration. Calibrate the pump, see section 6.

Pump out of calibration. Calibrate the pump, see section 6.

Valves leaking or blocked. Check and clean the valves.

Diaphragm defective. Install a new diaphragm.

Diaphragm not fastened properly. Install a new diaphragm and ensure that the

Counter-pressure too high (measured at the pump discharge port).

Sediment in dosing head. Clean/flush the dosing head.

on the valve casing is pointing in the liquid

flow direction. Check that all O-rings have

been fitted correctly.

Clean and seal the suction pipe/hose.

Install a priming tank.

tion 4.14.

Install a pipe/hose with larger cross-section.

Fit spring-loaded valves.

diaphragm is fastened properly.

Check the system. Check the injection valve,

if required. Reduce the dosing stroke by fitting

a pulsation dampener.

10. Disposal

Disposal of this product or parts of it must be carried

out according to the following guidelines:

1. Use the local public or private waste collection

service.

2. In case such waste collection service does not

exist or cannot handle the materials used in the

product, please deliver the product or any hazardous materials from it to your nearest Buerkert

company or service workshop.

Subject to alterations.

29

Page 28

15

sectional drawing of the dosing head (7800-19 / -48)

14

13

2

18

4

5

3

6

7

8

10

9

11

12

TM01 9976 3500

30

Page 29

assembly / disassembly of dosing head and valves

31

Page 30

dimensions:

130

110

ml/h

D

160

100%

B

C

98

7800-2 7800-8 7800-12 7800-19 7800-48

A = [mm] 137 192

B = [mm] 239 294

C = [mm] 36 15

D = [mm] 168 188

50

A

TM01 9232 0900

32

Page 31

Page 32

Please copy, fill in and sign this sheet and attach it to the pump returned for service

We hereby declare that this product:

Product type:____________________________

Product number:_________________________

is free from hazardous chemicals, biological and radioactive substances

_________________ _________________

Date and signature Company stamp

60

Loading...

Loading...