Page 1

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2009 - 2013 Bürkert Werke GmbH

Operating Instructions1306/07_EU-ml_00805879 / Original DE

Type 6650

Solenoid valve

2/2 and 3/2-way flipper solenoid valve

2/2- und 3/2-Wege Flipper-Magnetventil

Electrovanne Flipper 2/2 ou 3/2

Operating Instructions

Bedienungsanleitung

Manuel d’utilisation

2

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the

device. Keep these instructions in a location which is easily

accessible to every user and make these instructions available

to every new owner of the device.

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous situations.

• The operating instructions must be read and

understood.

1.1. Definition of Term “Device”

The term “device” used in these instructions always stands

for the flipper solenoid valve type 6650.

english

3

2. SYMBOLS

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or

serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in a serious or

fatal injury.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderately severe or minor injury.

NOTE!

Warns of damage to property!

Important tips and recommendations for safe and

problem-free operation of the device.

→ designates a procedure which you must carry out.

english

3

Type 6650

Page 2

4

3. INTENDED USE

Incorrect use of the flipper solenoid valves type 6650

can be dangerous to people, nearby equipment and

the environment.

• The device is a media-separated solenoid valve and

has been designed for use in conjunction with gases

and fluids (see Bürkert Chemical Resistance Chart:

www.burkert.com).

• Do not use the device outdoors without appropriate

protective measures.

• Use according to the permitted data, operating conditions and conditions of use specified in the contract

documents and operating instructions.

• The device is not intended for operation without suitable power reduction electronics and must be operated only within the framework of the intended duty

cycle.

• Transport, store, install, operate and maintain the

device correctly as described in the operating

instructions.

• Use the device only as intended.

3.1. Restrictions

If exporting the system/device, observe any existing

restrictions.

english

5

4. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the

installation, operation and maintenance of the devices.

• local safety regulations; the operator is responsible for

observing these regulations, also with reference to the

installation personnel.

Danger – high pressure!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Risk of burns/risk of fire if used continuously through

hot device surface!

• Keep the device away from highly flammable substances and media and do not touch with bare hands.

• Do not exceed the max. permitted duty cycle (see chapter “6.1. Operating Conditions”)

• Do not obstruct the heat dissipation that is required for

the operation.

General hazardous situations.

• The flipper solenoid valve type 6650 is not to be used

in areas where there is a risk of explosion.

english

5

6

• The connection clamps between coil and fluid housing

must not be removed under any circumstances.

• Do not make any internal or external changes to the

device.

• Do not put any loads on the housing (e.g. by placing

objects on it or standing on it).

• Installation and repair work may be carried out by

authorised technicians only.

• Ensure that the system cannot be activated

unintentionally.

• After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a

defined or controlled manner.

• The device may be operated only when in perfect

condition and in consideration of the operating

instructions.

• The general rules of technology apply to application

planning and operation of the device.

english

7

NOTE!

Electrostatic sensitive components / modules!

The power reduction electronics, which is available as an

accessory, contains electronic components which react

sensitively to electrostatic discharge (ESD). Contact with

electrostatically charged persons or objects is hazardous

to these components. In the worst case scenario, they

will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN

61340-5-1 and 5-2 to minimize or avoid the possibility

of damage caused by a sudden electrostatic discharge!

• Do not touch live electronic components!

english

7

Type 6650

Page 3

8

5. GENERAL INFORMATION

5.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Centre

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of

these operating instructions.

And also on the internet at: www.burkert.com

5.2. Warranty

The warranty is only valid if the device is used as authorized

in accordance with the specified application conditions.

5.3. Information on the Internet

The operating instructions and data sheets for Type 6650

can be found on the Internet at:

www.burkert.com

english

9

6. TECHNICAL DATA

6.1. Operating Conditions

WARNING!

Risk of injury

Malfunction if used outside!

• The valve must not be used outside without appropriate protective measures.

• Avoid heat sources which may cause the permitted

temperature range to be exceeded.

Permitted temperatures

Ambient temperature:

+10 - +50 °C

Medium temperature: +15 - +50 °C

Media: aggressive and neutral gaseous and liquid

media according to resistance

(see Bürkert Chemical Resistance Chart)

Max. duty cycle: 50 s for block structure

60 s for single mounting

Longer duty cycle permitted with power

reduction electronics only

(see chapter “6.5. Electrical data”)

Degree of protection: IP65 to EN 60529

Protection class: 3 acc. to VDE 0580

english

9

10

6.2. Mechanical data

(without electrical connector plug)

Add-on dimension 4.5 mm

Weight: 12.5 g

Dimensions: 4.5 x 38.5 x 41.2 mm

Housing material: PEEK

Sealing material: FFKM

english

11

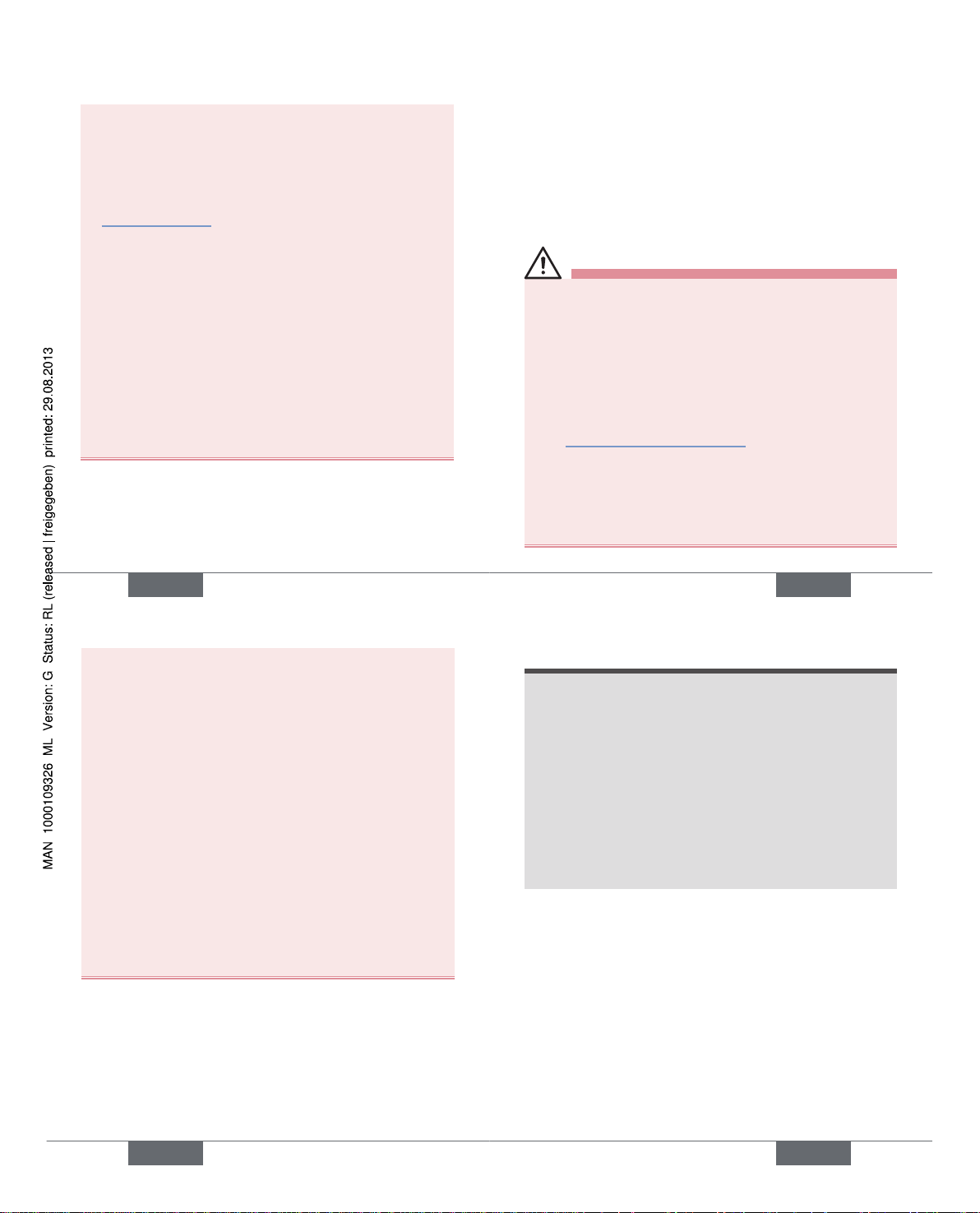

6.3. Fluidic data

*

)

DN = Orifice

**

)

Observe direction of flow.

Output pressure must

not be higher than input

pressure.

***

)

In vacuum mode observe

permitted differential

pressure.

Made in Germany

2/2-way NC

Circuit function A

DN*)NC IN ΔP max.

***

)

NC

IN

0.4

vak -

7 bar

vak -

7 bar

7 bar

0.8

- **

)

vak -

3 bar

3 bar

3/2-way universal

Circuit function T

DN NC COM NO ΔP max.

***

)

COM

NC

NO

0.8

vak -

1 bar

vak -

1 bar

vak -

1 bar

1 bar

3/2-way distributor

Circuit function F

DN NC COM NO ΔP max.

***

)

COM

NC

NO

0.8

- **

)

vak -

3 bar

- **

)

3 bar

english

11

Type 6650

Page 4

12

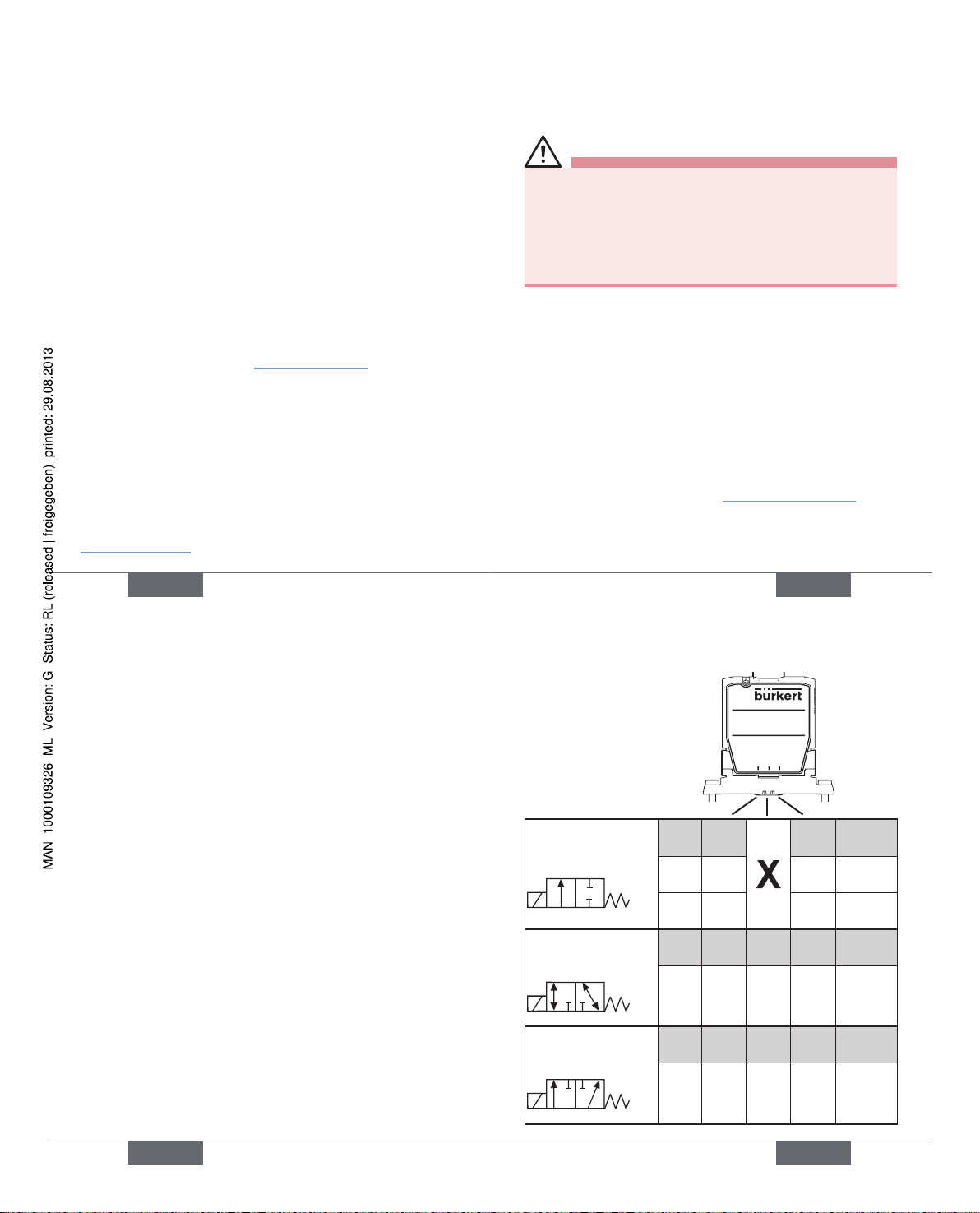

6.4. Label / Identification of

connections

Example:

Made in Germany

6650 T 0,8 CC PK

24V-PWM vac-1bar

00189292

Circuit

function

Type

Voltage

Identification

number

Pressure range

Orifice [DN]

Sealing material

(CC=FFKM

FF = FKM)

Housing material

(PK=PEEK)

Identification

of the fluid

connections

6.5. Electrical data

Connections: Type-specific plug-in connector,

see data sheet

Electrical power supply: 12 V, 24 V

Voltage tolerance: ± 10 %

Power input: Start/activation impulse: 5.7 W

Holding power: 0.7 W

The indicated values (power consumption) describe

the heat output. When designing the power supply, pay

attention to appropriate reserves.

english

13

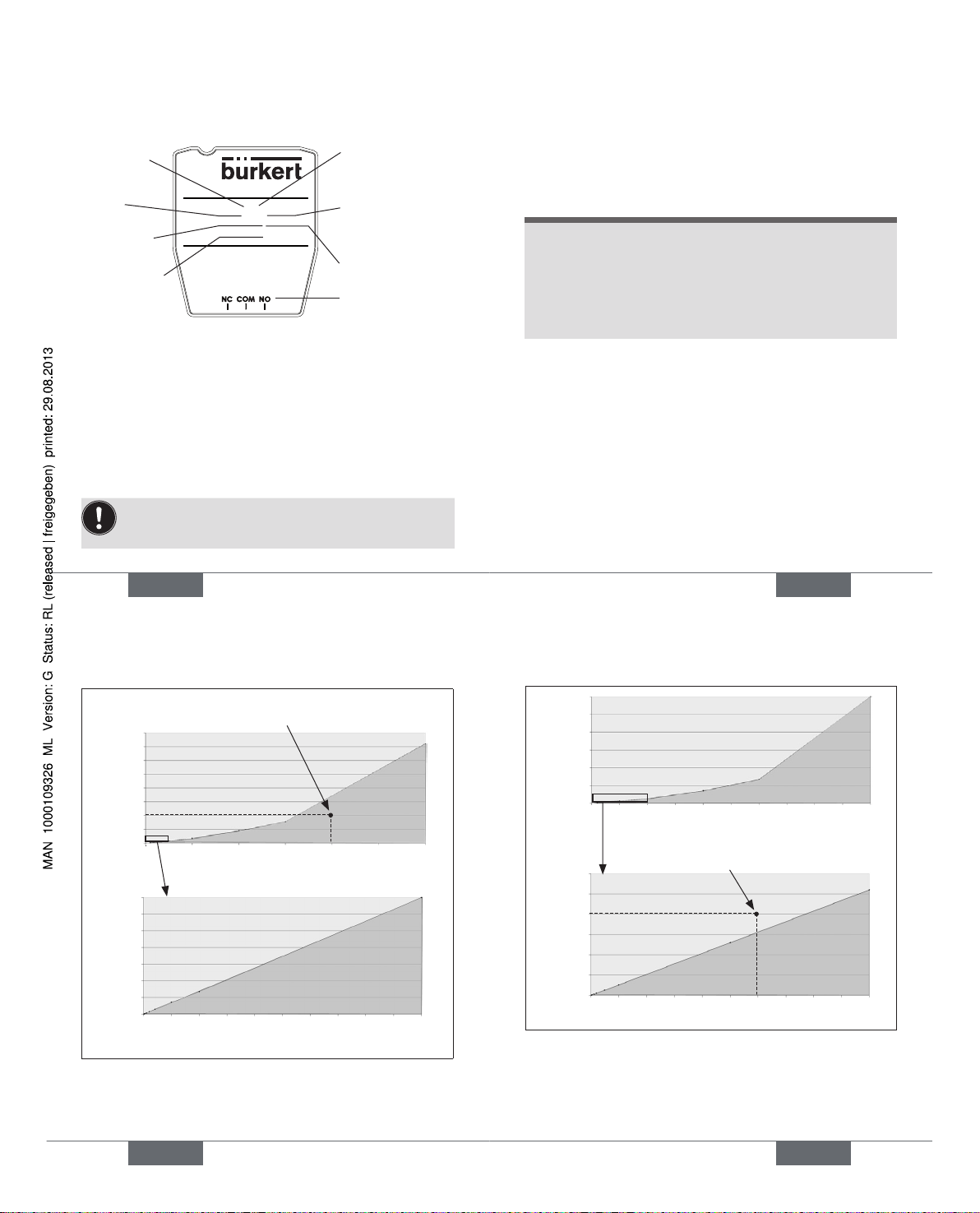

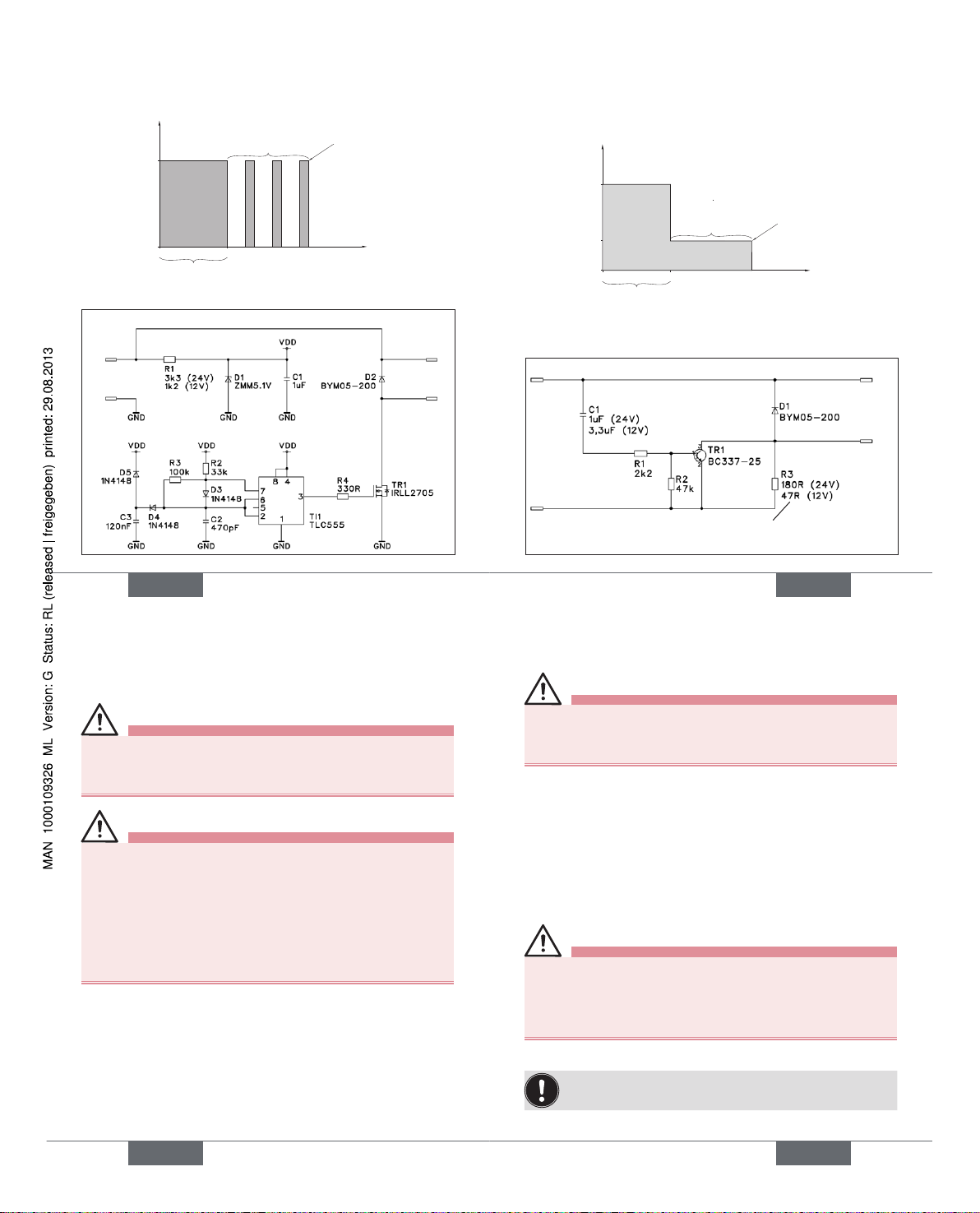

6.5.1. Continuos operation with power

reduction electronics

For the continuous operation of valve type 6650, a power

reduction electronics is required. It is recommended to use

the electronics, which is available as an accessory (see

data sheet).

NOTE!

Malfunction due to overheating!

• If required, use suitable power reduction electronics.

• For a switch-on time >50 s (for single mounting >60 s)

always use a power reduction electronics!

• The electronics 670178, available as an accessory,

are suitable for a nominal voltage of 24 V only.

The following graphs provide a guideline for estimating

whether a power reduction electronics is required. If the

gap between the individual units is <10 mm, use the graph

for the block structure. A power reduction electronics is not

required if the intersection point of switch-on and switchoff time is in the upper area of the corresponding graph.

english

13

14

Single device

(Pulse / interval ratio at ambient temperature of 22 °C)

0

50

100

150

200

250

300

350

400

0 10 20 30 40 50 60

switch-on time [s]

switch-off time [s]

Example: 40 s on - 100 s off

→ power reduction electronics required

0

1

2

3

4

5

6

7

switch-off time [s]

0 1 2 3 4 50,5 1,5 2,5 3,5 4,5

switch-on time [s]

If the intersection point is on or below the plotted line or if

the duty cycle is longer than 60 seconds, power reduction

electronics are essential.

english

15

Block structure

(Pulse / interval ratio at ambient temperature of 22 °C)

0

200

400

600

800

1000

1200

switch-off time [s]

0 10 20 30 40 505 15 25 35 45

switch-on time [s]

0

10

20

30

40

50

60

switch-off time [s]

0 2 4 6 8 101 3 5 7 9

switch-on time [s]

Example: 6 s on - 40 s off

→ power reduction electronics not required

If the intersection point is on or below the plotted line or if

the duty cycle is longer than 50 seconds, power reduction

electronics are essential.

In case the Bürkert electronics is not used, but another

power reduction electronics is implemented, the following

parameters should be applied:

english

15

Type 6650

Page 5

16

• in case of a PWM voltage drop:

Duty cycle 33 %, f=20kHz

PWM-signal

20 kHz

switch-off point

switch-on pulse

5 ms

0

100 %

U

t

For OEM electronics (PWM) recommended circuit diagram:

valve

supply voltage

Circuit diagram for 24 V design

english

17

• for resistance reduction:

Switch-on pulse 100 % nominal voltage for 5 ms, then

holding voltage 35 % nominal voltage

switch-off point

Switch-on pulse

5 ms

0

100 %

U

35 %

holding voltage

t

For OEM electronics (resistance reduction) recommended

circuit diagram:

Caution : Drop approx. 1.6 W

Alternatively series or parallel connection of several resistors

Connection

coil

Circuit diagram for 24 V design

english

17

18

7. INSTALLATION

7.1. Safety instructions

DANGER!

Danger – high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorised technicians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

english

19

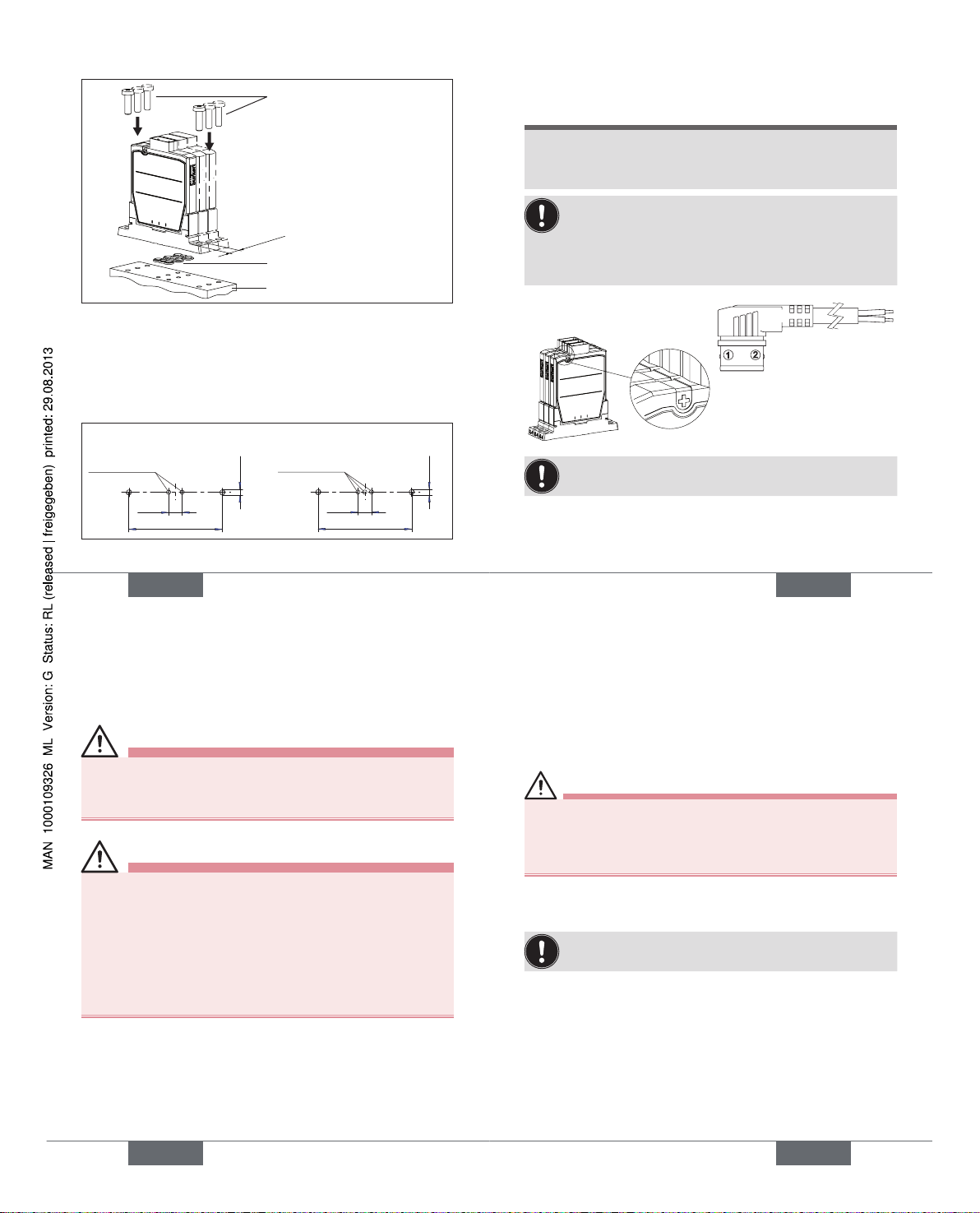

7.2. Fluid Installation

DANGER!

Danger – high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Installation position: any, actuator preferably upwards.

Procedure:

→ Before installation, clean any possible dirt off the pipe-

lines and flange connections.

→ Install a dirt trap to prevent malfunctions (Mesh size:

5 µm).

WARNING!

Danger through spillage of medium!

Leaking connections if seal seated incorrectly.

• Ensure that the supplied sealing gasket is seated

correctly!

The add-on dimension must not fall short of 4.5 mm!

english

19

Type 6650

Page 6

20

Sealing gasket

Manifold

4.5 mm

Flange screws

Recommended

torque:

0.24 Nm ± 0.04 Nm

→ Insert the sealing gasket into the valve.

→ Correctly allocate the fluid connection configuration 1,

2 and 3 to the valve and the manifold.

→ Screw valve onto the manifold.

Dimensional drawing for manifold:

4.8

33

M2

min. 6 deep

max. ∅ 1.4

2-way normally closed:

4.8

33

M2

min. 6 deep

max. ∅ 1.4

3-way universal function:

→ Check valve for leakage.

english

21

7.3. Electrical Installation

NOTE!

Without proper power reduction electronics, the valve

type 6650 is not suitable for continuous operation!

Please refer to the chapter titled "Electrical data".

In the block structure all valves must be poled identically. The mark (+) on the valve and the numerals

1 and 2 on the plug-in connector are used as orientation. Example: On all units the plug-in connector

with numeral 2 points to the mark (+).

plug-in connector

1 = brown

2 = white

If the power reduction electronics are used, observe

the following polarity: brown + / white -

A type-specific plug-in connector with or without integrated

power reduction electronics is available as an accessory

(see data sheet).

english

21

22

8. MAINTENANCE,

TROUBLESHOOTING

8.1. Safety instructions

DANGER!

Danger – high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

WARNING!

Risk of injury from improper maintenance!

• Maintenance may be carried out by authorised technicians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following maintenance, ensure a controlled restart.

english

23

8.2. Maintenance Work

The valve is maintenance-free under normal operating

conditions.

If the exterior is very dirty, it is recommended to clean it

with suitable cleaning agents. If required, determine the

suitability of the cleaning agent by conducting a test.

WARNING!

Discharge of medium and malfunction if the connection clamps are removed!

• The connection clamps between coil and fluid housing

must not be removed.

8.3. Malfunctions

If operating with power reduction electronics,

ensure that the power supply flank is quick enough.

If malfunctions occur, check

→ the line connections

→ the operating pressure

→ the power supply and valve control

If the valve still does not switch, please contact your

Bürkert Service.

english

23

Type 6650

Page 7

24

9. TRANSPORT, STORAGE,

DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged

during transport.

• During transportation protect the device against wet

and dirt in shock-resistant packaging.

• Avoid exceeding or dropping below the permitted

storage temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: -10 - 65 °C.

Damage to the environment caused by device components contaminated with media.

• Observe applicable regulations on disposal and the

environment.

• Observe national waste disposal regulations.

english

Type 6650

Page 8

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2009 - 2013 Bürkert Werke GmbH

Operating Instructions1306/07_EU-ml_00805879 / Original DE

Typ 6650

Magnetventil

2/2- und 3/2-Wege Flipper-Magnetventil

Bedienungsanleitung

Deutsch

26

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus des Geräts. Bewahren Sie diese Anleitung so auf, dass

sie für jeden Benutzer gut zugänglich ist und jedem neuen

Eigentümer des Geräts wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen

Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden

werden.

1.1. Begriffsdefinition Gerät

Der in dieser Anleitung verwendete Begriff „Gerät“ steht

immer für das Flipper-Magnetventil Typ 6650.

deutsch

27

2. DARSTELLUNGSMITTEL

In dieser Anleitung werden folgende Darstellungsmittel

verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen

die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung können schwere Verletzungen oder

Tod die Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen für die Sicherheit

und einwandfreie Funktion des Geräts.

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

deutsch

Typ 6650

Page 9

28

3. BESTIMMUNGSGEMÄSSER

GEBRAUCH

Bei nicht bestimmungsgemäßem Einsatz der

Flipper-Magnetventile Typ 6650 können Gefahren für

Personen, Anlagen in der Umgebung und die Umwelt

entstehen.

• Das Gerät ist ein mediengetrenntes Magnetventil und

zum Einsatz bei Gasen und Flüssigkeiten konzipiert

(siehe Bürkert Beständigkeitstabelle: www.buerkert.de).

• Das Gerät nicht ohne passende Schutzvorkehrungen

im Außenbereich einsetzen.

• Für den Einsatz die in den Vertragsdokumenten und

der Bedienungsanleitung spezifizierten zulässigen

Daten, Betriebs- und Einsatzbedingungen beachten.

• Das Gerät ist nicht für den Betrieb ohne geeignete

Leistungsabsenkung bestimmt, bzw. nur im Rahmen

der bestimmungsgemäßen Einschaltdauer zu

betreiben.

• Das Gerät wie in der Bedienungsanleitung beschrieben

sachgemäß transportieren, lagern, installieren, bedienen

und instandhalten.

• Das Gerät nur bestimmungsgemäß einsetzen.

3.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls bestehende Beschränkungen.

deutsch

29

4. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb

und Wartung der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren

Einhaltung, auch in Bezug auf das Montagepersonal, der

Betreiber verantwortlich ist.

Gefahr durch hohen Druck!

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb

durch heiße Geräteoberfläche!

• Das Gerät von leicht brennbaren Stoffen und Medien

fernhalten und nicht mit bloßen Händen berühren.

• Die max. zulässige Einschaltdauer nicht überschreiten

(siehe Kapitel „6.1. Betriebsbedingungen“).

• Die für den Betrieb notwendige Wärmeabfuhr nicht

behindern.

Allgemeine Gefahrensituationen

• Den Typ 6650 nicht in explosionsgefährdeten Bereichen

einsetzen.

deutsch

30

• Die Verbindungsklammern zwischen Spule und Fluidgehäuse dürfen unter keinen Umständen entfernt werden.

• Am Gerät keine inneren oder äußeren Veränderungen

vornehmen.

• Das Gehäuse nicht mechanisch belasten (z. B. durch

Ablage von Gegenständen oder als Trittstufe).

• Nur geschultes Fachpersonal darf Installations- und

Instandhaltungsarbeiten ausführen.

• Darauf achten, dass die Anlage nicht unbeabsichtigt

betätigt werden kann.

• Nach einer Unterbrechung der elektrischen oder

pneumatischen Versorgung für einen definierten oder

kontrollierten Wiederanlauf des Prozesses sorgen.

• Das Gerät nur in einwandfreiem Zustand und unter

Beachtung der Bedienungsanleitung betreiben.

• Für die Einsatzplanung und den Betrieb des Geräts

die allgemeinen Regeln der Technik einhalten.

deutsch

31

HINWEIS!

Elektrostatisch gefährdete Bauelemente /

Baugruppen!

Das Gerät enthält elektronische Bauelemente, die gegen

elektrostatische Entladung (ESD) empfindlich reagieren.

Berührung mit elektrostatisch aufgeladenen Personen

oder Gegenständen gefährdet diese Bauelemente. Im

schlimmsten Fall werden sie sofort zerstört oder fallen

nach der Inbetriebnahme aus.

• Die Anforderungen nach EN 61340-5-1 und 5-2

beachten, um die Möglichkeit eines Schadens durch

schlagartige elektrostatische Entladung zu minimieren

bzw. zu vermeiden!

• Elektronische Bauelemente nicht bei anliegender Versorgungsspannung berühren!

deutsch

Typ 6650

Page 10

32

5. ALLGEMEINE HINWEISE

5.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13–17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten

dieser Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

5.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Typs 6650 unter Beachtung der

spezifizierten Einsatzbedingungen.

5.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 6650

finden Sie im Internet unter: www.buerkert.de

deutsch

33

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

WARNUNG!

Verletzungsgefahr

Funktionsausfall bei Einsatz im Außenbereich!

• Das Ventil darf nicht ohne passende Schutzvorkehrungen im Außenbereich eingesetzt werden.

• Wärmequellen vermeiden, die zur Überschreitung des

zulässigen Temperaturbereichs führen können.

Zulässige Temperaturen

Umgebungstemperatur: +10 ... +50 °C

Mediumstemperatur: +15 ... +50 °C

Medien: aggressive, neutrale gasförmige und flüssige

Medien entsprechend Beständigkeit (siehe

Bürkert Beständigkeitstabelle)

Max. Einschaltdauer: 50 s bei Blockaufbau

60 s bei Einzelmontage

Längere Einschaltdauer nur mit

Leistungsabsenkung zulässig (siehe

Kapitel „6.5. Elektrische Daten“)

Schutzart: IP65 nach EN 60529

Schutzklasse: 3 nach VDE 0580

deutsch

34

6.2. Mechanische Daten

(ohne elektrischen Stecker)

Anreihmaß: 4,5 mm

Gewicht: 12,5 g

Maße: 4,5 x 38,5 x 41,2 mm

Gehäusematerial: PEEK

Dichtungsmaterial: FFKM

deutsch

35

6.3. Fluidische Daten

*

)

DN = Nennweite

**

)

Durchflussrichtung

beachten. Ausgangsdruck

darf nicht höher sein als

Eingangsdruck.

***

)

Bei Vakuumbetrieb

zulässigen Differenzdruck

beachten.

Made in Germany

2/2-Wege NC

Wirkungsweise A

DN*)NC IN ΔP max.

***

)

NC

IN

0,4

vak -

7 bar

vak -

7 bar

7 bar

0,8

- **

)

vak -

3 bar

3 bar

3/2-Wege Universal

Wirkungsweise T

DN NC COM NO ΔP max.

***

)

COM

NC

NO

0,8

vak -

1 bar

vak -

1 bar

vak -

1 bar

1 bar

3/2-Wege Verteiler

Wirkungsweise F

DN NC COM NO ΔP max.

***

)

COM

NC

NO

0,8

- **

)

vak -

3 bar

- **

)

3 bar

deutsch

Typ 6650

Page 11

36

6.4. Typschild /

Anschlusskennzeichung

Beispiel:

Made in Germany

6650 T 0,8 CC PK

24V-PWM vac-1bar

00189292

Wirkungsweise

Typ

Spannung

Identnummer

Druckbereich

Nennweite [DN]

Dichtungsmaterial

(CC=FFKM

FF = FKM)

Gehäusematerial

(PK=PEEK)

Kennzeichnung

der fluidischen

Anschlüsse

6.5. Elektrische Daten

Anschlüsse: typspezifischer Steckverbinder,

siehe Datenblatt

Spannungsversorgung: 12 V, 24 V

Spannungstoleranz: ± 10 %

Leistungsaufnahme: Anzugs-/Einschaltimpuls: 5,7 W

Halteleistung: 0,7 W

Die angegebenen Werte (Leistungsaufnahme)

beschreiben die Warmleistung. Bei der Auslegung der

Stromversorgung auf entsprechende Reserven achten.

deutsch

37

6.5.1. Kontinuierlicher Betrieb mit

Leistungsabsenkung

Für den kontinuierlichen Betrieb des Ventils Typ 6650 ist

eine Leistungsabsenkung erforderlich. Es wird empfohlen,

die als Zubehör erhältliche Elektronik zu verwenden (siehe

Datenblatt).

HINWEIS!

Funktionsausfall durch Überhitzung!

• Wenn erforderlich, geeignete Leistungsabsenkung

verwenden.

• Für eine Einschaltzeit >50 s (bei Einzelmontage

>60 s) ist immer eine Leistungsabsenkung zu

verwenden!

• Die als Zubehör lieferbare Elektronik 670178 ist nur

für Nennspannung 24 V geeignet.

Nachfolgende Diagramme bieten eine Richtlinie, um die

Notwendigkeit einer Leistungsabsenkung abschätzen zu

können. Bei einem Abstand der Einzelgeräte <10 mm ist

das Diagramm für den Blockaufbau zugrunde zu legen.

Keine Leistungsabsenkung ist notwendig, wenn der

Schnittpunkt von Ein- und Ausschaltzeit im oberen Bereich

des entsprechenden Diagramms liegt.

deutsch

38

Einzelgerät

(Impuls-/Pausenverhältnis bei 22 °C Umgebungstemperatur)

0

50

100

150

200

250

300

350

400

0 10 20 30 40 50 60

Einschaltzeit [s]

Ausschaltzeit [s]

Beispiel: 40 s ein - 100 s aus

→ Leistungsabsenkungselektronik erforderlich

0

1

2

3

4

5

6

7

Ausschaltzeit [s]

0 1 2 3 4 50,5 1,5 2,5 3,5 4,5

Einschaltzeit [s]

Liegt der Schnittpunkt auf oder unterhalb der eingezeichneten

Linie oder ist die Einschaltzeit länger als 60 Sekunden ist eine

Leistungsabsenkung zwingend erforderlich.

deutsch

39

Blockaufbau

(Impuls-/Pausenverhältnis bei 22 °C Umgebungstemperatur)

0

200

400

600

800

1000

1200

Ausschaltzeit [s]

0 10 20 30 40 505 15 25 35 45

Einschaltzeit [s]

0

10

20

30

40

50

60

Ausschaltzeit [s]

0 2 4 6 8 101 3 5 7 9

Einschaltzeit [s]

Beispiel: 6 s ein - 40 s aus

→ keine Leistungsabsenkungselektronik erforderlich

Liegt der Schnittpunkt auf oder unterhalb der eingezeichneten

Linie oder ist die Einschaltzeit länger als 50 Sekunden ist eine

Leistungsabsenkung zwingend erforderlich.

Wird die Bürkert Elektronik nicht verwendet, aber dennoch

eine Leistungsabsenkung eingesetzt, sind folgende Parameter zu verwenden:

deutsch

Typ 6650

Page 12

40

• bei PWM Spannungsabsenkung:

Tastgrad 33 %, f = 20 kHz

PWM-Signal

20 kHz

Abschaltpunkt

Einschaltimpuls

5 ms

0

100 %

U

t

Für OEM-Elektroniken (PWM) empfohlener Schaltplan:

Ventil

Versorgungs-

spannung

Schaltplan für 24 V Auslegung

deutsch

41

• bei Widerstandsabsenkung:

Einschaltimpuls 100 % Nennspannung für 5 ms, danach

Haltespannung 35 % Nennspannung

Abschaltpunkt

Einschaltimpuls

5 ms

0

100 %

U

35 %

Haltespannung

t

Für OEM-Elektroniken (Widerstandsabsenkung) empfohlener Schaltplan:

Achtung: Leistungsaufnahme ca. 1,6 W

Alternativ Reihen- oder Parallelschaltung mehrerer Widerstände

Anschluss

Spule

Schaltplan für 24 V Auslegung

deutsch

42

7. INSTALLATION

7.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Installation!

• Die Installation darf nur autorisiertes Fachpersonal mit

geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten

der Anlage und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Installation einen kontrollierten Wiederanlauf

gewährleisten.

deutsch

43

7.2. Fluidische Installation

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

Einbaulage: beliebig, vorzugsweise Antrieb nach oben.

Vorgehensweise:

→ Vor der Montage Rohrleitungen und Flanschanschlüsse

von eventuellen Verschmutzungen säubern.

→ Zum Schutz vor Störungen einen Schmutzfänger ein-

bauen (Maschenweite: 5 µm).

WARNUNG!

Gefahr durch Mediumsaustritt!

Undichte Anschlüsse bei unkorrekt sitzender Dichtung.

• Achten Sie auf den richtigen Sitz der mitgelieferten

Dichtmatte!

Das Anreihmaß von 4,5 mm darf nicht unterschritten

werden!

deutsch

Typ 6650

Page 13

44

Dichtmatte

Anschlussplatte

4,5 mm

Flanschschrauben

Empfohlenes

Anziehdrehmoment:

0,24 Nm ± 0,04 Nm

→ Dichtmatte in das Ventil einlegen.

→ Fluidische Anschlussbelegung 1, 2 und 3 an Ventil und

Anschlussplatte richtig zuordnen.

→ Ventil auf Anschlussplatte schrauben.

Maßzeichnung für Anschlussplatte:

4,8

33

M2

min. 6 tief

max. ∅ 1,4

2-Wege-Ausführung:

4,8

33

M2

min. 6 tief

max. ∅ 1,4

3-Wege-Ausführung:

→ Ventil auf Dichtheit prüfen.

deutsch

45

7.3. Elektrische Installation

HINWEIS!

Das Ventil Typ 6650 ist ohne eine bestimmungsgemäße Leistungsabsenkung nicht für den Dauerbetrieb geeignet! Siehe Kapitel „Elektrische Daten“.

Im Blockaufbau müssen alle Ventile gleich gepolt

sein. Als Orientierung dient die Markierung (+) am

Ventil und die Ziffern 1 und 2 auf dem Steckverbinder. Beispiel: Bei allen Geräten zeigt der Steckverbinder mit der Ziffer 2 zur Markierung (+).

Steckverbinder

1 = braun

2 = weiß

Bei Verwendung der Leistungabsenkungselektronik

ist folgende Polarität zu beachten: braun+ / weiß –

Ein typspezifischer Steckverbinder ist als Zubehör (siehe

Datenblatt) sowohl mit als auch ohne integrierte Leistungsabsenkungselektronik erhältlich.

deutsch

46

8. WARTUNG,

FEHLERBEHEBUNG

8.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr bei unsachgemäßen

Wartungsarbeiten!

• Die Wartung darf nur autorisiertes Fachpersonal mit

geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten

der Anlage und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Wartung einen kontrollierten Wiederanlauf

gewährleisten.

deutsch

47

8.2. Wartungsarbeiten

Das Ventil arbeitet unter Normalbedingungen wartungsfrei.

Bei starker äußerer Verschmutzung wird eine Reinigung mit

geeigneten Reinigungsmitteln empfohlen. Die Eignung des

Reinigungsmittels sollte gegebenenfalls per Test ermittelt

werden.

WARNUNG!

Mediumsaustritt und Fehlfunktion bei Entfernen der

Verbindungsklammern!

• Die Verbindungsklammern zwischen Spule und Fluidgehäuse dürfen nicht entfernt werden.

8.3. Störungen

Bei Betrieb mit Leistungsabsenkungselektronik

darauf achten, dass die Flanke der Versorgungsspannung genügend schnell ist.

Überprüfen Sie bei Störungen

→ die Leitungsanschlüsse,

→ den Betriebsdruck,

→ die Spannungsversorgung und Ventilansteuerung.

Falls das Ventil dennoch nicht schaltet, wenden Sie sich

bitte an Ihren Bürkert-Service.

deutsch

Typ 6650

Page 14

48

9. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den

Transport beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät

verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur –10 … +65 °C.

Umweltschäden durch von Medien kontaminierte

Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen einhalten.

deutsch

Typ 6650

Page 15

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2009 - 2013 Bürkert Werke GmbH

Operating Instructions1306/07_EU-ml_00805879 / Original DE

Type 6650

Electrovanne

Electrovanne Flipper 2/2 voies ou 3/2 voies

Manuel d’utilisation

Français

50

1. LE MANUEL D’UTILISATION

Le manuel d’utilisation décrivent le cycle de vie complet de

l’appareil. Conservez ces instructions de sorte qu’elles soient

accessibles à tout utilisateur et à disposition de tout nouveau

propriétaire.

Le manuel d’utilisation contiennent des informations

importantes sur la sécurité !

Le non-respect de ces consignes peut entraîner des

situations dangereuses.

• Les instructions de service doivent être lues et

comprises.

1.1. Définition du terme « appareil »

Le terme « appareil » utilisé dans ces instructions désigne

toujours le electrovanne flipper type 6650

français

51

2. SYMBOLES

Les symboles suivants sont utilisés dans les présentes

instructions de service.

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves

blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement

dangereuse !

• Le non-respect peut entraîner de graves blessures ou

la mort.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou

de moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

Conseils et recommandations importants pour la

sécurité et le parfait fonctionnement de l’appareil.

→ identifie une opération que vous devez effectuer.

français

Type 6650

Page 16

52

3. UTILISATION CONFORME

L’utilisation non conforme des vannes magnétiques

Flipper de type 6650 peut présenter des dangers

pour les personnes, les installations proches et

l’environnement.

• L'appareil est une électrovanne avec séparation des

fluides destinées aux gaz et aux liquides (voir « Résistances chimique « Bürkert : www,burkert.fr).

• N'utilisez pas l'appareil à l'extérieur sans mesures de

protection adaptées.

• Lors de l'utilisation, il convient de respecter les

données et conditions d'utilisation et d'exploitation

admissibles spécifiées dans le manuel d’utilisation et

dans les documents contractuels.

• L'appareil n'est pas destiné au fonctionnement sans

une baisse de puissance adaptée, ou doit uniquement

être exploité dans le cadre de la durée d'enclenchement conforme.

• Transporter, stocker, installer, manœuvrer et entretenir

l‘appareil de manière appropriée comme décrit dans le

mode d‘emploi.

• Veillez à ce que l’utilisation de l’appareil soit toujours

conforme.

3.1. Limitations

Lors de l’exportation du système/de l’appareil, veuillez respecter les limitations éventuelles existantes.

français

53

4. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte

• des hasards et des événements pouvant survenir lors

du montage, de l'exploitation et de la maintenance des

appareils.

• des prescriptions de sécurité locales que l’exploitant

est tenu de faire respecter par le personnel chargé du

montage.

Danger dû à la haute pression !

• Avant de desserrer les conduites et les vannes, coupez la pression et purgez l’air des conduites.

Risque de brûlures/d'incendie en fonctionnement

continu dû à des surfaces d'appareils brûlantes !

• Tenez les substances et les fluides facilement inflammables à l'écart de l'appareil et ne touchez pas ce

dernier à mains nues.

• Ne pas dépasser la durée d‘enclenchement max. admissible (voir chapitre « 6.1. Conditions d’exploitation »)

• Ne pas gêner l’évacuation de la chaleur nécessaire au

fonctionnement.

français

54

Situations dangereuses d'ordre général.

• La électrovanne Flipper type 6650 ne doit pas être utilisée dans des zones présentant des risques d’explosion.

• Les brides de raccordement entre la bobine et le boîtier

fluidique ne doivent en aucun cas être retirées.

• Ne pas apporter de modifications intérieures ou extérieures à l‘appareil.

• Ne soumettez pas le corps à des contraintes mécaniques

(par ex. pour déposer des objets ou en l’utilisant comme

marche).

• Les travaux d'installation et de maintenance doivent

être effectués uniquement par des techniciens qualifiés et habilités disposant de l’outillage approprié.

• Veiller à ce que l‘installation ne puisse pas être actionnée de manière intempestive.

• Après une interruption de l'alimentation électrique ou

pneumatique, un redémarrage défini ou contrôlé du

processus doit être garanti.

• L'appareil doit être utilisé uniquement en parfait état et

en respectant le manuel d’utilisation.

• Les règles générales de la technique sont d'application pour planifier l’utilisation et utiliser l’appareil.

français

55

REMARQUE !

Eléments/sous-groupes sujets aux risques

électrostatiques !

L'électronique de baisse de puissance disponible sous

forme d'accessoire contient des éléments électroniques

sensibles aux décharges électrostatiques (ESD). Ces

éléments sont affectés par le contact avec des personnes ou des objets ayant une charge électrostatique.

Au pire, ils sont immédiatement détruits ou tombent en

panne après mise en service.

• Respecter les exigences selon EN 61340-5-1 et 5-2

afin de minimiser ou éviter le risque d‘un dommage par

une décharge électrostatique brusque !

• Ne pas toucher les composants électroniques lorsque

la tension d‘alimentation est présente !

français

Type 6650

Page 17

56

5. INDICATIONS GÉNÉRALES

5.1. Adresse

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tél. : + 49 (0) 7940 - 10 91 111

Fax : + 49 (0) 7940 - 10 91 448

E-mail : info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages de ces instructions de service.

Egalement sur internet sous : www.burkert.com

5.2. Garantie légale

La condition pour bénéficier de la garantie légale est

l‘utilisation conforme de l‘appareil dans le respect des conditions d‘utilisation spécifiées.

5.3. Informations sur Internet

Vous trouverez le manuel d’utilisation et les fiches techniques concernant le type 6650 sur Internet sous :

www.burkert.fr

français

57

6. CARACTÉRISTIQUES

TECHNIQUES

6.1. Conditions d'exploitation

AVERTISSEMENT !

Risque de blessures

Panne lors de l'utilisation à l'extérieur !

• La vanne ne doit pas être utilisée à l'extérieur sans les

mesures de protection adaptées.

• Eviter les sources de chaleur pouvant entraîner le

dépassement de la plage de température admissible.

Températures admissibles

Température ambiante : +10 - +50 °C

Température du fluide : +15 - +50 °C

Fluides : Fluides liquides et gazeux, agressifs et neutres,

conformément à la résistance (voir « Résistances chimique « Bürkert)

Durée

d‘enclenchement max. : 50 s pour une structure en bloc

60 s pour un montage individuel

Une durée d‘enclenchement plus

longue est uniquement admissible

moyennant une baisse de puissance (voir chapitre « 6.5 »)

français

58

Degré de protection : IP65 selon EN 60529

Classe de protection : 3 selon VDE 0580

6.2. Caractéristiques mécaniques

(sans connecteur électrique)

Cote de jonction 4,5 mm

Poids : 12,5 g

Dimensions : 4,5 x 38,5 x 41,2 mm

Matériau du boîtier : PEEK

Matériau du joint : FFKM

français

59

6.3. Données fluidiques

*

)

DN = Diamètre nominal

**

)

Respecter le sens d‘écoulement. La pression de sortie

ne peut pas être plus élevée

que la pression d‘entrée.

***

)

En cas de fonctionnement

sous vide, tenir compte de

la différence de pression

Made in Germany

2/2 voies NC

Fonction A

DN*)NC IN ΔP max.

***

)

NC

IN

0,4

vak -

7 bar

vak -

7 bar

7 bar

0,8

- **

)

vak -

3 bar

3 bar

3/2 voies universel

Fonction T

DN NC COM NO ΔP max.

***

)

COM

NC

NO

0,8

vak -

1 bar

vak -

1 bar

vak -

1 bar

1 bar

3/2 voies distributeur

Fonction F

DN NC COM NO ΔP max.

***

)

COM

NC

NO

0,8

- **

)

vak -

3 bar

- **

)

3 bar

français

Type 6650

Page 18

60

6.4. Plaque signalétique/

Identification des raccordements

Exemple :

Made in Germany

6650 T 0,8 CC PK

24V-PWM vac-1bar

00189292

Fonction

Type

Tension

Numéro

d‘identification

Plage de pression

Diamètre

nominal [DN]

Matériau d‘étanchéité

(CC=FFKM

FF = FKM)

Matériau du boîtier

(PK=PEEK)

Identification des

raccordements

fluidiques

6.5. Caractéristiques électriques

Raccordements : Connecteur enfichable spéci-

fique, voir fiche technique

Alimentation en tension : 12 V , 24 V

Tolérance de tension : ± 10 %

Puissance absorbée : Impulsion d'actionnement/

d'enclenchement : 5,7 W

Puissance de maintien : 0,7 W

Les valeurs indiquées (puissance absorbée) se

rapportent à la puissance calorifique.

Lors du dimensionnement de l’alimentation électrique,

il convient de prévoir des réserves.

français

61

6.5.1. Fonctionnement continu avec

baisse de puissance

Une baisse de puissance est nécessaire pour le fonctionnement continu de la vanne type 6650. Il est recommandé

d'utiliser l'électronique et disponible comme accessoire

(voir fiche technique).

REMARQUE !

Panne due à la surchauffe !

• Si nécessaire, utiliser la baisse de puissance appropriée.

• Pour une durée d’enclenchement >50 s (avec montage individuel >60 s) il convient de toujours utiliser

une baisse de puissance !

• L‘électronique 670178 disponible comme accessoire

convient uniquement pour la tension nominale de 24 V.

Les diagrammes suivants indiquent comment évaluer la

nécessité d’une baisse de puissance. Avec un écartement

<10 mm entre les différents appareils, se baser sur le

diagramme de la structure en bloc. Aucune baisse de puissance n’est nécessaire si l’intersection de la durée d’enclenchement et d’arrêt se situe dans la plage supérieure du

diagramme.

français

62

Appareil individuel (Rapport impulsions / pauses à une

température ambiante de 22 °C)

0

50

100

150

200

250

300

350

400

0 10 20 30 40 50 60

durée d’enclenchement [s]

durée d’arrêt [s]

Exemple : 40 s marche - 100 s arrêt,

→ électronique de baisse de puissance nécessaire

0

1

2

3

4

5

6

7

durée d’arrêt [s]

0 1 2 3 4 50,5 1,5 2,5 3,5 4,5

durée d’enclenchement [s]

Si l’intersection se situe au-dessus ou en dessous de la

ligne tracée ou si la durée de fonctionnement dépasse les

60 secondes, une baisse de puissance est absolument

nécessaire.

français

63

Structure en bloc (Rapport impulsions / pauses à une

température ambiante de 22 °C).

0

200

400

600

800

1000

1200

durée d’arrêt [s]

0 10 20 30 40

50

5 15 25 35 45

durée d’enclenchement [s]

0

10

20

30

40

50

60

durée d’arrêt [s]

0 2 4 6 8 101 3 5 7 9

durée d’enclenchement [s]

Exemple : 6 s marche - 40 s arrêt → aucune électronique de baisse de puissance nécessaire

Si l’intersection se situe au-dessus ou en dessous de la ligne

tracée ou si la durée de fonctionnement dépasse les 50

secondes, une baisse de puissance est absolument nécessaire.

Si l'électronique Bürkert n'est pas utilisée, mais qu'une baisse

de puissance est tout de même employée, utiliser les paramètres suivants :

français

Type 6650

Page 19

64

• lors de la baisse de puissance PWM :

Degré de modulation 33 %, f = 20 kHz

PWM-Signal

20 kHz

consigne d’arrêt

impulsion d’enclenchement

5 ms

0

100 %

U

Schéma des connexions recommandé pour les électroniques OEM (PWM):

vanne

alimentation

en tension

Schéma de câblage pour la version 24 V

français

65

• avec une baisse de résistance : impulsion d’enclenchement

100 % de la tension nominale pendant 5 ms, ensuite tension

de maintien 35 % de la tension nominale

consigne d’arrêt

impulsion d’enclenchement

5 ms

0

100 %

U

35 %

tension de

maintien

t

Schéma des connexions recommandé pour les électroniques

OEM (baisse de résistance)

Attention : Chute env. 1,6 W

Alternative : branchement en ligne ou en parallèle

de plusieurs résistances

Raccordement

bobine

Schéma de câblage pour la version 24 V

français

66

7. INSTALLATION

7.1. Consignes de sécurité

DANGER !

Risque de blessures dû à la présence de haute

pression dans l'installation !

• Avant de desserrer les conduites et les vannes, coupez la pression et purgez l’air des conduites.

AVERTISSEMENT !

Risque de blessures dû à un montage non

conforme !

• Le montage doit être effectué uniquement par un

personnel qualifié et habilité disposant de l’outillage

approprié !

Risque de blessures dû à la mise en marche involontaire de l'installation et le redémarrage non contrôlé !

• Empêchez tout actionnement involontaire de

l'installation.

• Garantissez un redémarrage contrôlé après le montage.

français

67

7.2. Installation fluide

DANGER !

Risque de blessures dû à la présence de haute

pression dans l'installation !

• Avant de desserrer les conduites et les vannes, coupez la pression et purgez l’air des conduites.

Position de montage : au choix, de préférence entraî-

nement vers le haut.

Procédure à suivre :

→ Avant le montage, nettoyer la tuyauterie et les raccor-

dements à bride afin d'enlever les éventuelles saletés.

→ Installez un panier comme protection contre les dys-

fonctionnements (mailles : 5 µm).

AVERTISSEMENT !

Danger en cas de sortie du fluide !

Raccordements non étanches suite au mauvais positionnement des joints.

• Veillez au bon positionnement du joint d'isolation fourni !

La cote de jonction min. de 4,5 mm doit être

respectée !

français

Type 6650

Page 20

68

Joint d‘isolation

Embase

4,5 mm

Vis à bride

Couple de serrage

recommandé :

0,24 Nm ± 0,04 Nm

→ Placez le joint dans la vanne.

→ Affectez correctement les raccordements fluide 1, 2 et

3 à la vanne et à la embase.

→ Vissez la vanne sur la embase.

Plan coté pour la plaque de raccordement :

4,8

33

M2

prof. min. 6

max. ∅ 1,4

Modèle 2 voies :

4,8

33

M2

prof. min. 6

max. ∅ 1,4

Modèle 3 voies :

→ Contrôlez l’étanchéité de la vanne.

français

69

7.3. Installation électrique

REMARQUE !

La vanne type 6650 n'est pas prévue pour le fonctionnement permanent sans une baisse de puissance conforme ! Voir chapitre « Caractéristiques

électriques ».

Toutes les soupapes doivent avoir la même polarité

dans la structure en bloc. Le marquage (+) sur la

vanne et les chiffres 1 et 2 sur le connecteur enfichable servent de repère. Exemple : Sur tous les

appareils, le connecteur enfichable avec le chiffre 2

est dirigé vers le marquage (+).

connecteur enfichable

1 = marron

2 = blanc

En cas d’utilisation de l’électronique de baisse de

puissance, la polarité suivante doit être respectée :

marron +

blanc -

français

70

Un connecteur enfichable spécifique au type est disponible

comme accessoire (voir fiche technique), avec ou sans

électronique de baisse de puissance intégrée.

français

71

8. MAINTENANCE, DÉPANNAGE

8.1. Consignes de sécurité

DANGER !

Risque de blessures dû à la présence de haute

pression dans l'installation !

• Avant de desserrer les conduites et les vannes, coupez la pression et purgez l’air des conduites.

AVERTISSEMENT !

Risque de blessures dû à des travaux de maintenance non conformes !

• L'entretien doit être effectué uniquement par un

personnel qualifié et habilité disposant de l'outillage

approprié !

Risque de blessures dû à la mise en marche involontaire de l'installation et le redémarrage non contrôlé !

• Empêchez tout actionnement involontaire de

l'installation.

• Garantissez un redémarrage contrôlé après la

maintenance.

français

Type 6650

Page 21

72

8.2. Travaux de maintenance

Dans des conditions normales, la vanne ne nécessite

aucun entretien.

En cas de fort encrassement extérieur, le nettoyage avec

des produits de nettoyage appropriés est recommandé. Le

cas échéant, effectuez un test afin de vérifier si le produit

de nettoyage est adapté.

AVERTISSEMENT !

Sortie de fluide et dysfonctionnement en cas de suppression des crampons !

• Les crampons entre la bobine et le boîtier fluidique ne

doivent pas être enlevés.

8.3. Pannes

En cas de fonctionnement avec l‘électronique de

baisse de puissance, veiller à ce que le flanc de la

tension d‘alimentation soit suffisamment rapide.

En présence de pannes, vérifiez

→ les raccords de câbles

→ la pression de service

→ l'alimentation en tension et la commande de la vanne

Si malgré tout la vanne ne fonctionne pas, veuillez

contacter votre service après-vente Bürkert.

français

73

9. TRANSPORT, STOCKAGE,

ELIMINATION

REMARQUE !

Dommages dus au transport !

Les appareils insuffisamment protégés peuvent être

endommagés pendant le transport.

• Transportez l'appareil à l'abri de l'humidité et des impuretés et dans un emballage résistant aux chocs.

• Évitez le dépassement vers le haut ou le bas de la température de stockage admissible.

Un mauvais stockage peut endommager l'appareil.

• Stockez l'appareil au sec et à l'abri des poussières !

• Température de stockage : -10 - 65 °C.

Dommages à l’environnement causés par des pièces

d’appareil contaminées par des fluides.

• Respectez les prescriptions en matière d’élimination

des déchets et de protection de l’environnement en

vigueur.

• Respectez les prescriptions nationales en matière

d’élimination des déchets.

français

Type 6650

Loading...

Loading...