Page 1

Operating Instructions

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

Bedienungsanleitung

Instrucions de Service

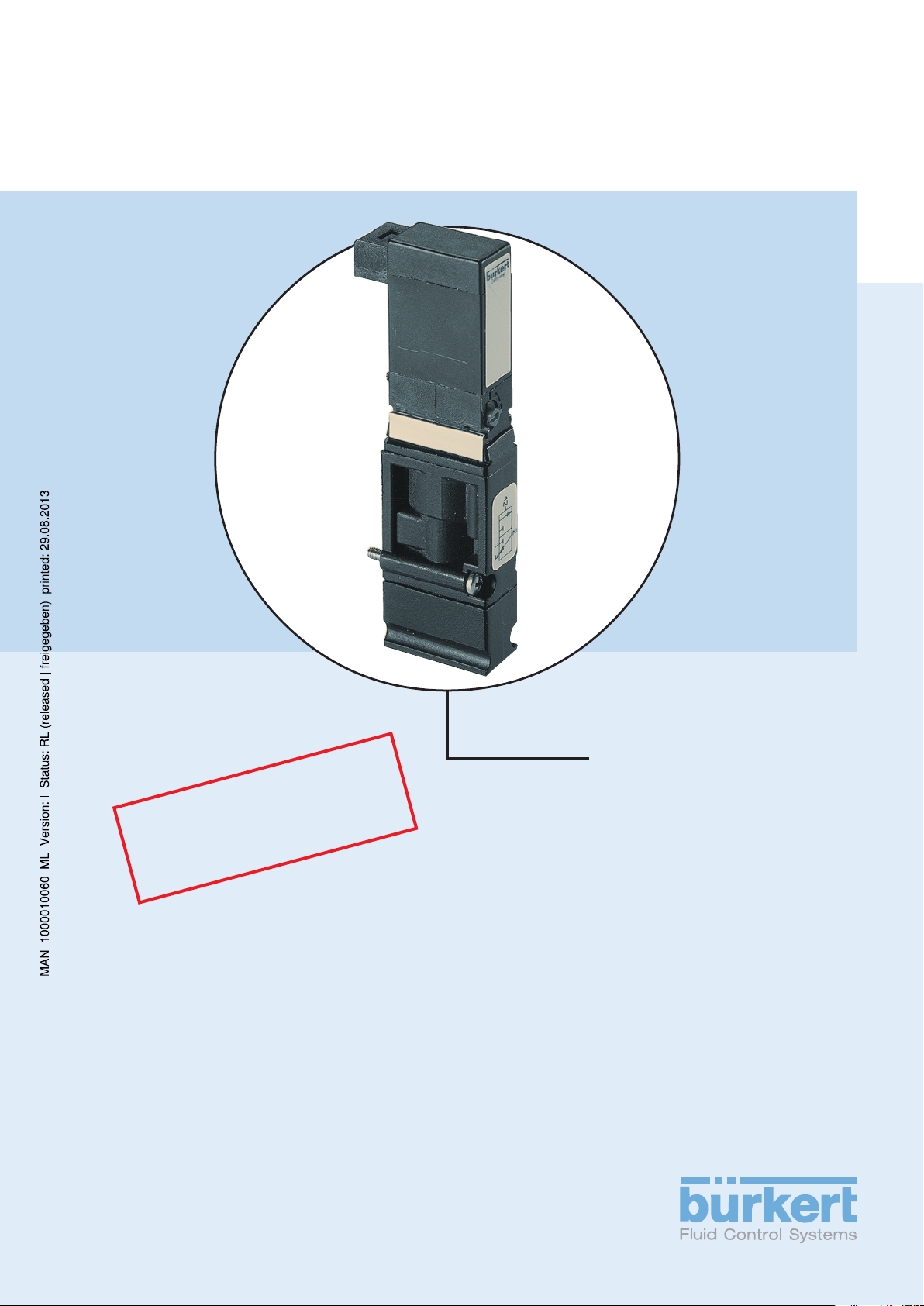

Type 6524 / 6525

3/2- or 5/2-way solenoid valve

for pneumatic systems

3/2- bzw. 5/2-Wege-Magnetventil

für Pneumatik

Electrovanne 3/2 resp. 5/2 voies

pour pneumatique

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2000 Bürkert Werke GmbH & Co. KG

Operating Instructions 0512/06_EU-ML_00804310

Page 3

Contents of the Operating Instructions for

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

3/2- or 5/2-way-solenoid valve

Type 6524 / 6525

GENERAL NOTES........................................................................................................................................................................................................................... 3

Symbols................................................................................................................................................................................................................................................. 4

General safety notes

Safety notes for the valve

Scope of delivery

............................................................................................................................................................................................................ 4

............................................................................................................................................................................................... 5

....................................................................................................................................................................................................................... 6

Warranty conditions

................................................................................................................................................................................................................ 6

TECHNICAL DESCRIPTION........................................................................................................................................................................................... 7

Valve Construction .................................................................................................................................................................................................................. 8

Technical data of the valves Type 6524 / 6525

Inscription example

.............................................................................................................................................................................................................. 10

.................................................................................................................................... 9

INSTALLATION, COMMISSIONING AND MAINTENANCE......................................................................................... 11

Installation ........................................................................................................................................................................................................................................ 12

Measures to be taken before putting into service

Faults

Maintenance

Accessories

........................................................................................................................................................................................................................................................ 16

.................................................................................................................................................................................................................................. 17

.................................................................................................................................................................................................................................. 17

......................................................................................................................... 16

6524/6525 - 1

Page 4

C

ONTENTS

english

2 - 6524/6525

Page 5

GENERAL NOTES

G

ENERAL NOTES

english

Symbols................................................................................................................................................................................................................................................. 4

General Safety notes

Safety notes for the valve

Scope of delivery

Warranty conditions

............................................................................................................................................................................................................ 4

............................................................................................................................................................................................... 5

....................................................................................................................................................................................................................... 6

................................................................................................................................................................................................................ 6

6524/6525 - 3

Page 6

G

ENERAL NOTES

Symbols

In these Operating Instructions, the following symbols are used:

Indicates a working step that you will have to carry out

ATTENTION!

NOTE Indicates important additional information, tips and recommendations.

Indicates information which must be followed. Failure to do this could endanger your

health or the functionality of the device

english

General Safety notes

To ensure that the device will function correctly, and have a long service life, please comply with the

information in these Operating Instructions, as well as with the application conditions and additional data

given in the Type 6524 and Typ 6525 data sheets:

• When planning the application of the device, and during its operation, observe the general technical

rules!

• Installation and maintenance work are only allowed by specialist personnel using suitable tools!

• Observe the relevant accident prevention and safety regulations applicable for electrical equipment

throughout the operation, maintenance and repair of the device!

• Always switch off the voltage supply before working on the system!

• Note that lines and valves must not be unscrewed from systems that are under pressure!

• Take suitable measures to prevent unintentional operation or impermissible impairment!

• After interruption of the electrical or pneumatic supply, make sure the process is restarted in a welldefined, controlled manner!

• If these instructions are ignored, no liability will be accepted from our side, and the guarantee on the

device and on accessories will become invalid!

4 - 6524/6525

Page 7

Safety notes for the valve

• Keep to standard engineering rules in planning the use of and operating the device.

• Take suitable precautions to prevent inadvertent operation or damage by unauthorized action.

• Note that in systems under pressure, piping and valves may not be loosened.

0 bar, psi, kPa

G

ENERAL NOTES

english

Fig.: Fluid connection

• Always switch off the power supply before intervening in the system!

Fig.: Assembly without voltage applied

• To avoid pressure drop on switching, make the volume of the pressure supply as large as

possible!

• The device shall only be operated on direct current .

• Risk of injury!

In continuous operation, the coil can become very hot!

6524/6525 - 5

Page 8

G

ENERAL NOTES

Scope of delivery

Immediately after receipt of the goods, make sure the contents are undamaged and agree with the scope

of delivery stated on the packing slip.

In case of irregularities, contact your local Bürkert branch or our customer service department:

english

Warranty conditions

Bürkert Fluid Control Systems

Service Department

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: (07940) 10-111, Fax: (07940) 10-448

eMail: info@de.buerkert.com

This document contains no warranty statements. In this connection we refer to our general sales and

business conditions.

A prerequisite for validity of the warranty ist unse of the device as intended with observance of the

specified conditions of use.

ATTENTION!

The warranty covers only faultless condition of the 3/2 or 5/2-way-solenoid valve Type

6524 / 6525. No liability will be accepted for consequential damage of any kind that

may arise from failure or malfunctioning of the device.

6 - 6524/6525

Page 9

T

ECHNICAL DESCRIPTION

TECHNICAL DESCRIPTION

english

Valve Construction .................................................................................................................................................................................................................. 8

Technical data of the valves Type 6524 / 6525

Inscription example

.............................................................................................................................................................................................................. 10

.................................................................................................................................. 9

6524/6525 - 7

Page 10

T

ECHNICAL DESCRIPTION

Valve Construction

english

Fig: 3/2-way-solenoid valve for pneumatic systems

Type 6524

• Automation systems are increasingly used in all areas where control duties are to be performed. The

valves form thereby the interface between electronics and pneumatics.

• The valves Type 6524 and 6525 consist of a pilot rocker solenoid valve of Type 6104 and a pneumatic

seat valve. Pilot valve and housing are clipped together. The working principle enables the switching of

high pressures at low power consumption and with short switching times.

• The valves can be connected in series and provided with rear plug connector mainly for valve islands

(types 8640 or 8644) and with front connector lugs mainly on valve blocks for operating pneumatic

drives.

• The pilot valves are provided as standard with a manual actuator.

Fig.: 5/2-way-solenoid valve for pneumatic systems

Type 6525

8 - 6524/6525

Page 11

Technical data of the valves Type 6524 / 6525

• Casing material PA (polyamide)

• Sealing materials FKM , NBR and PUR

• Media compressed air oiled, oil-free,

dry neutral gas

• Media temperature -10 to +50 °C

• Ambient temperature -10 to +55 °C

• Pipe connection Flange

• Pneumatic modules MP11

• Supply connection G 1/4, NPT 1/4

1 (P), 3 (R), 5 (S) plug coupling, Ø 10 mm

T

ECHNICAL DESCRIPTION

• Working connection plug coupling

2 (A), 4 (B) Ø 6 mm, M5, M7

• Flow rate Q

• Operating voltage 24 V DC

• Voltage tolerance ± 10%

• Rated power 1 W

• Nominal mode of operation continuous operation (100 % duty cycle)

• Electrical connection rectangular plug with

on valve 5,08 mm grid

on valve island integral plug socket

on valve block rectangular plug connector

• Protection type IP 40 with rectangular plug connector

• Fitting position any, preferably drive on top

• Manual actuation standard

• Protection class 3 to VDE 0580

• Switching times [ms] measured at valve output at 6 bar and +20 °C

(see Data sheet) opening pressure development 0 to 90%

Nn

Air 300 l/min

closing pressure drop 100 to 10%

english

6524/6525 - 9

Page 12

T

ECHNICAL DESCRIPTION

Inscription of valves

Nominal size

Circuit function

Id. No.

Voltage (±10 %) - Power

Type

english

Pressure range

Fig.: Inscription example

10 - 6524/6525

Page 13

I

NSTALLATION

, C

OMMISSIONING AND MAINTENANCE

INSTALLATION,

COMMISSIONING AND

MAINTENANCE

Installation ........................................................................................................................................................................................................................................ 12

Measures to be taken before putting into service

Faults

Maintenance

Asseccories

...................................................................................................................................................................................................................................................... 16

.................................................................................................................................................................................................................................. 17

.................................................................................................................................................................................................................................. 17

......................................................................................................................... 16

english

6524/6525 - 11

Page 14

I

NSTALLATION

, C

Installation

Circuit function

OMMISSIONING AND MAINTENANCE

C 3/2--way-solenoid valve, servo-controlled

Pressure inlet 1 closed when de-energiesed, outlet 2 vented.

D 3/2-way-solenoid valve, servo-controlled

Pressure inlet 1 is connected to outlet 2 when de-energiesed.

english

H 5/2-way-solenoid valve, servo-controlled

Pressure inlet1 is connected to outlet 2 when de-energised, outlet 4 vented.

Cleaning pipes

Clean pipes before starting assembly to ensure reliable operation of the system.

Fit a dirt collector if necessary to protect against faults.

Assembly position

Can be mounted in any position, preferably with the magnetic system at the top.

Preffered

direction

Fig.: Assembly position

Media

• filtered compressed air (max. particle size 5 µm), preferably non-oiled, dry

• operation is possible with oiled air

• sealing material NBR, FKM and PUR

• permissible temperature medium max. + 50 ° C

NOTE

12 - 6524/6525

ambient max. + 55 ° C

Operate valve at temperatures below O°C only with dry air.

Page 15

I

NSTALLATION

, C

OMMISSIONING AND MAINTENANCE

Connections

Interventions must only be made by technical personnel and with suitable tools.

Always switch off the power supply before working on the system.

Fit a dirt collector if necessary to protect against faults.

Ensure compliance of the operating conditions with the performance data of the unit.

Avoid pressure build-up in the exhaust air ducts by large silencers.

ATTENTION!

Pipes or valves in systems under pressure must not be disconnected!

Electrical connection

Stranded conductor

connection

Fig.: Connection possibilities of type 6104 pilot valves

english

Circular connectorRectangular connector

Servo control valve Type 6104

Read the voltage, electrical power, type of protection and current from the rating plate!

voltage tolerance ±10 %

With 100% duty cycle and maximum ambient temperature the coil heats up

in the single version to approx. + 105 °C

in a block to approx. + 120 °C

NOTE

Ensure a long service life for the pilot valve with 5µ filtering.

ATTENTION!

Note the voltage! Fit a rectifier in series without fail for alternating voltage!

6524/6525 - 13

Page 16

I

NSTALLATION

Manual override

To operate the valve manually, turn the manual override by 90° in the direction of the arrow.

, C

OMMISSIONING AND MAINTENANCE

english

Fig.: Setting the manual mode

Fluid connection

0AUTO

1/P 2/A C

2/A 3/R D

1

1/P 4/A

2/B 3/S

(Symb. show the

zero position)

H

X* Pilot control

exhaust

X*

3/R

2/A

1/P

Fig.: Fluid connection (Valve- Type 6524)

NOTE

Lay out the pressure supply to have as large a volume as possible!

X*

5/R

4/A

1/P

2/B

3/S

Fig.: Fluid connection (Valve- Type 6525)

14 - 6524/6525

Page 17

Mounting the valve

30 Ncm

I

NSTALLATION

, C

OMMISSIONING AND MAINTENANCE

20 Ncm

Fig.: Mounting the valve

english

30 Ncm

20 Ncm

6524/6525 - 15

Page 18

I

NSTALLATION

, C

OMMISSIONING AND MAINTENANCE

Measures to be taken before putting into service

Check all connections, voltages and the operational pressure!

Ensure that the max. operational conditions (see rating plate) will not be exceeded!

Unlock the manual actuator for electrical operation!

Faults

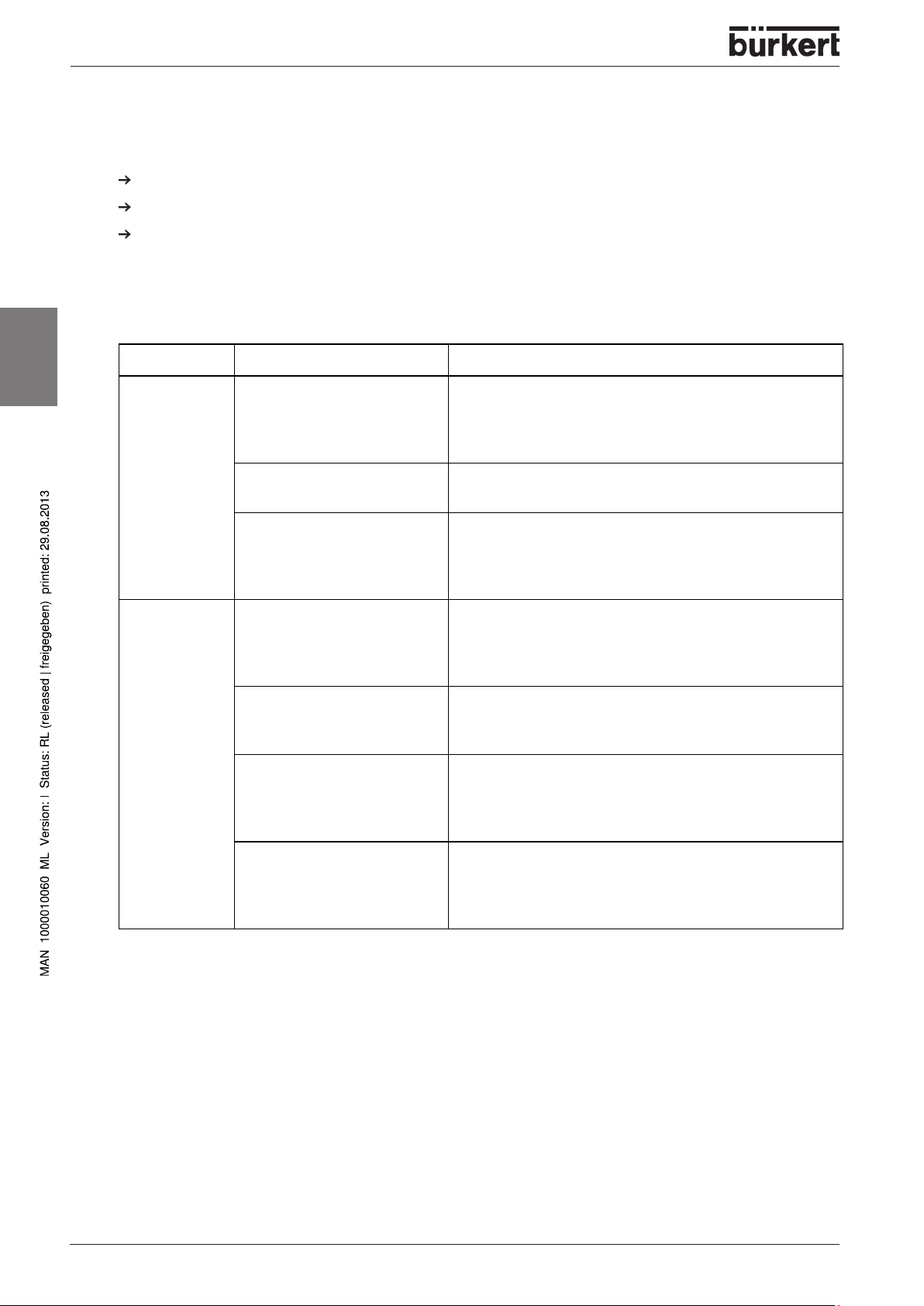

Fault Possible cause Correction

english

Valves does

not switch

Valves switch

with a delay, or

exhaust

through the

venting ports

Operational voltage too low or

not present

Manual override not in neutral

position

Compressed air supply not

available or insufficient

Compressed air supply not

available or insufficient

Valves are not in the starting

position (without current)

during pressure build-up

Insufficient venting of the

exhaust channels due to

silencers that are too small or

are soiled (backpressure)

Check the electrical supply connections.

Ensure that the electrical power supply is the same as

that specified on the rating plate.

Set the manual override to the zero position.

Carry out the dimensioning of the compressed air

connection with volumes as large as possible (including

that of upstream pressure regulators, service units, cutoff valves etc.).

Carry out the dimensioning of the compressed air

connection with volumes as large as possible (including

that of upstream pressure regulators, service units, cutoff valves etc.).

Apply pressure to the valve block before you switch the

valves!

Use silencers or expansion channels with sufficient

dimensions.

Clean soiled silencers.

16 - 6524/6525

Impurities or foreign matter in

the pilot valve or main valve

Blast through the exhaust channels with pulsed

compressed air, to blow out impurities.

Install a new pilot or main valve if these measures bring

no improvement.

Page 19

Maintenance

The valves are maintenance-free if operated according to the directions given in these instructions.

Accessories

• Rectangular plug connector with 3 m cable (133 486 F)

• Rectangular plug connector with 300 mm FEP flexible conductor (644 068 N)

I

NSTALLATION

, C

OMMISSIONING AND MAINTENANCE

english

• Rectangular plug connector with 2 individual contacts (644 067 D)

NOTE

Wearing parts on request!

6524/6525 - 17

Page 20

I

NSTALLATION

english

, C

OMMISSIONING AND MAINTENANCE

18 - 6524/6525

Page 21

I

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

NHALT

Inhaltsverzeichnis

der Betriebsanleitung

3/2- bzw. 5/2-Wege-Magnetventil

Typ 6524 / 6525

ALLGEMEINE HINWEISE.................................................................................................................................................................................................. 21

Darstellungsmittel................................................................................................................................................................................................................... 22

Allgemeine Sicherheitshinweise

Sicherheitshinweise für das Ventil

.......................................................................................................................................................................... 22

..................................................................................................................................................................... 23

deutsch

Lieferumfang

Garantiebestimmungen

.................................................................................................................................................................................................................................. 24

................................................................................................................................................................................................... 24

TECHNISCHE BESCHREIBUNG ......................................................................................................................................................................... 25

Ventilaufbau.............................................................................................................................................................................................................................. 26

Technische Daten der Ventile Typ 6524 / 6525

Beschriftungsbeispiel

........................................................................................................................................................................................................ 28

................................................................................................................................. 27

MONTAGE, INBETRIEBNAHME UND WARTUNG..................................................................................................................... 29

Montage .............................................................................................................................................................................................................................................. 30

Maßnahmen vor Inbetriebnahme

Störungen

Wartung

Zubehör

......................................................................................................................................................................................................................................... 34

............................................................................................................................................................................................................................................... 35

............................................................................................................................................................................................................................................... 35

........................................................................................................................................................................ 34

6524/6525 - 19

Page 22

deutsch

I

NHALT

20 - 6524/6525

Page 23

A

LLGEMEINE HINWEISE

ALLGEMEINE HINWEISE

Darstellungsmittel................................................................................................................................................................................................................... 22

deutsch

Allgemeine Sicherheitshinweise

Sicherheitshinweise für das Ventil

Lieferumfang

Garantiebestimmungen

.................................................................................................................................................................................................................................. 24

................................................................................................................................................................................................... 24

.......................................................................................................................................................................... 22

..................................................................................................................................................................... 23

6524/6525 - 21

Page 24

A

LLGEMEINE HINWEISE

Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder

die Funktionsfähigkeit des Gerätes gefährdet ist.

kennzeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen.

Allgemeine Sicherheitshinweise

deutsch

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen

Daten gemäß den Datenblättern Typ 6524 und Typ 6525, damit das Gerät einwandfrei funktioniert und

lange einsatzfähig bleibt.

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen Regeln der

Technik!

• Installations- und Wartungsarbeiten dürfen nur durch Fachpersonal und mit geeignetem Werkzeug

erfolgen.

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte

während des Betriebes, der Wartung und der Reparatur des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Beachten Sie, dass in Systemen, die unter Druck stehen,Leitungen und Ventile nicht gelöst werden

dürfen.

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung

auszuschließen!

• Gewährleisten Sie nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung einen

definierten und kontrollierten Wiederanlauf des Prozesses!

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung unsererseits, ebenso erlischt die Garantie auf Geräte und Zubehörteile!

22 - 6524/6525

Page 25

Sicherheitshinweise für das Ventil

• Halten Sie sich bei Einsatzplanung und Betrieb des Gerätes an die einschlägigen, allgemein

anerkannten sicherheitstechnischen Regeln.

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigungen auszuschließen.

• Beachten Sie, dass in Systemen, die unter Druck stehen, Leitungen und Ventile nicht

gelöst werden dürfen.

A

LLGEMEINE HINWEISE

0 bar, psi, kPa

Bild: Fluidischer Anschluss

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

Bild: Spannungsfreie Montage

deutsch

• Führen Sie die Druckversorgung möglichst großvolumig aus, um Druckabfall beim Schalten

zu vermeiden!

• Das Gerät darf nur mit Gleichstrom betrieben werden.

• Verletzungsgefahr!

Bei Dauerbetrieb kann die Spule sehr heiss werden!

6524/6525 - 23

Page 26

A

LLGEMEINE HINWEISE

Lieferumfang

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung, dass der Inhalt nicht beschädigt ist und mit

dem auf dem beigelegten Packzettel angegebenen Lieferumfang übereinstimmt.

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an Ihre Bürkert-Niederlassung oder an unseren

Kundenservice:

Garantiebestimmungen

Bürkert Steuer- und Regelungstechnik

Service-Abteilung

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: (07940) 10-111, Fax: (07940) 10-448

eMail: info@de.buerkert.com

deutsch

Diese Druckschrift enthält keine Garantiezusagen. Wir verweisen hierzu auf unsere allgemeinen Verkaufs- und Geschäftsbedingungen.

Voraussetzung für die Garantie ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung

der spezifizierten Einsatzbedingungen.

ACHTUNG!

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit der 3/2 bzw. 5/2-WegeMagnetventile Typ 6524 / 6525. Es wird keine Haftung übernommen für Folgeschäden

jeglicher Art, die durch Ausfall oder Fehlfunktion des Gerätes entstehen könnten.

24 - 6524/6525

Page 27

T

ECHNISCHE BESCHREIBUNG

TECHNISCHE

BESCHREIBUNG

deutsch

Ventilaufbau.................................................................................................................................................................................................................................... 26

Technische Daten der Ventile Typ 6524 / 6525

Beschriftungsbeispiel

........................................................................................................................................................................................................ 28

................................................................................................................................. 27

6524/6525 - 25

Page 28

T

ECHNISCHE BESCHREIBUNG

Ventilaufbau

deutsch

Bild: 3/2-Wege-Magnetventil für Pneumatik Typ 6524 Bild: 5/2-Wege-Magnetventil für Pneumatik Typ 6525

• Automatisierungssysteme finden zunehmend Einsatz in allen Bereichen wo Steuerungs- und

Regelungsaufgaben zu bewältigen sind. Ventile bilden dabei die Schnittstelle zwischen der Elektronik

und Pneumatik.

• Die Ventile vom Typ 6524 / 6525 bestehen aus einem Vorsteuer-Wippenmagnetventil vom Typ 6104

und einem Pneumatiksitzventil. Vorsteuerventil und Gehäuse sind miteinander verklammert. Das

Wirkprinzip erlaubt das Schalten hoher Drücke bei geringer Leistungsaufnahme und mit kurzen

Schaltzeiten.

• Die Ventile sind anreihbar und mit Steckeranschluss hinten vorzugsweise für Ventilinseln (Typen

8640 oder 8644) und mit Steckerfahnen vorn vorzugsweise auf Ventilblöcken zur Ansteuerung pneumatischer Antriebe einsetzbar.

• Die Vorsteuerventile sind serienmäßig mit einer Handbetätigung ausgestattet.

26 - 6524/6525

Page 29

Technische Daten der Ventile Typ 6524 / 6525

• Gehäusewerkstoff PA (Polyamid)

• Dichtwerkstoffe FKM , NBR und PUR

• Medien Druckluft geölt, ölfrei, trocken

neutrale Gase

• Medientemperatur -10 bis +50 °C

• Umgebungstemperatur -10 bis +55 °C

• Leitungsanschluss Flansch

• Pneumatikmodule MP11

• Versorgungsanschluss G 1/4, NPT 1/4

1 (P), 3 (R), 5 (S) Steckkupplung, Ø 10 mm

• Arbeitsanschluss Steckkupplung

2 (A), 4 (B) Ø 6 mm, M5, M7

T

ECHNISCHE BESCHREIBUNG

• Durchfluss Q

• Betriebsspannung 24 V DC

• Spannungstoleranz ± 10%

• Nennleistung 1 W

• Nennbetriebsart Dauerbetrieb (100 % ED)

• Elektrischer Anschluss Rechteckstecker mit

am Ventil Raster 5,08 mm

auf Ventilinsel integrierte Steckerbuchse

auf Ventilblock Rechtecksteckverbinder

• Schutzart IP 40 mit Rechtecksteckverbinder

• Einbaulage beliebig, vorzugsweise Antrieb nach oben

• Handbetätigung serienmäßig

• Schutzklasse 3 nach VDE 0580

• Schaltzeiten [ms] Messung am Ventilausgang bei 6 bar und +20 °C

(siehe Datenblatt) Öffnen Druckaufbau 0 bis 90%

Nn

Luft 300 l/min

Schließen Druckabbau 100 bis 10%

deutsch

6524/6525 - 27

Page 30

T

ECHNISCHE BESCHREIBUNG

Beschriftung der Ventile

Nennweite

Wirkungsweise

Bestell-Nr.

Spannung (±10 %) - Leistung

Druckbereich

deutsch

Ty p

Bild: Beschriftungsbeispiel

28 - 6524/6525

Page 31

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

MONTAGE

INBETRIEBNAHME

UND WARTUNG

deutsch

Montage .............................................................................................................................................................................................................................................. 30

Maßnahmen vor Inbetriebnahme

Störungen

Wartung

Zubehör

......................................................................................................................................................................................................................................... 34

............................................................................................................................................................................................................................................... 35

............................................................................................................................................................................................................................................... 35

........................................................................................................................................................................ 34

6524/6525 - 29

Page 32

M

ONTAGE

Montage

deutsch

, I

NBETRIEBNAHME UND WARTUNG

Wirkungsweise

C 3/2-Wege-Magnetventil, vorgesteuert

In Ruhestellung Druckanschluss 1 gesperrt, Ausgang 2 entlüftet.

D 3/2-Wege-Magnetventil, vorgesteuert

In Ruhestellung Druckanschluss 1 mit Ausgang 2 verbunden.

H 5/2-Wege-Magnetventil, vorgesteuert

In Ruhestellung Druckanschluss 1 mit Ausgang 2 verbunden,

Ausgang 4 entlüftet.

Reinigung der Rohrleitungen

Reinigen Sie vor Beginn der Montage die Rohrleitungen, um den zuverlässigen Betrieb Ihrer Anlage

sicherzustellen.

Schalten Sie gegebenenfalls zum Schutz vor Störungen einen Schmutzfänger vor.

Einbaulage

Die Einbaulage ist beliebig. Montieren Sie die Ventile vorzugsweise mit dem Antrieb nach oben.

Vorzugsrichtung

Bild: Einbaulage

Medien

• gefilterte Druckluft (Partikelgröße max. 5 µm), vorzugsweise ungeölt, trocken

• Betrieb mit geölter Luft ist möglich

• Dichtwerkstoff NBR, FKM und PUR

• zulässige Temperatur Medium max. + 50 ° C

HINWEIS

30 - 6524/6525

Umgebung max. + 55 ° C

Ventil bei Temperaturen unter 0 °C nur mit trockener Luft betreiben.

Page 33

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Anschlüsse

Eingriffe dürfen nur durch Fachpersonal und mit geeignetem Werkzeug erfolgen.

Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab.

Schalten Sie gegebenenfalls zum Schutz vor Störungen einen Schmutzfänger vor.

Achten Sie auf Übereinstimmung der Betriebsbedingungen mit den Leistungsdaten des Gerätes.

Vermeiden Sie Staudrücke in den Abluftkanälen durch großvolumige Schalldämpfer.

ACHTUNG!

In Systemen, die unter Druck stehen, dürfen Leitungen oder Ventile nicht gelöst werden!

Elektrischer Anschluss

Litzenanschluss RundsteckerRechteckstecker

Bild: Anschlussmöglichkeiten der Vorsteuerventile Typ 6104

deutsch

Vorsteuerventil Typ 6104

Entnehmen Sie Spannung, elektrische Leistung, Schutz- und Stromart dem Typenschild!

Spannungstoleranz ±10 %

Bei 100 % Einschaltdauer und maximaler Umgebungstemperatur erwärmt sich die Spule

im Einzelaufbau auf ca. + 105 °C

im Block auf ca. + 120 °C

HINWEIS

Sorgen Sie durch 5µ-Filterung für eine lange Lebensdauer des Vorsteuerventils.

ACHTUNG!

Beachten Sie die Spannung! Schalten Sie bei Wechselspannung unbedingt einen

Gleichrichter vor!

6524/6525 - 31

Page 34

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Handbetätigung

Drehen Sie zur manuellen Betätigung des Ventils die Handbetätigung um 90° in Pfeilrichtung.

deutsch

Bild: Einstellen des Handmodus

Fluidischer Anschluss

0AUTO

1/P 2/A C

2/A 3/R D

1

1/P 4/A

2/B 3/S

(Symb. zeigen

Nullstellung)

H

X* Vorsteuerabluft

X*

3/R

2/A

1/P

Bild: Fluidischer Anschluss (Ventil - Typ 6524)

HINWEIS

Druckversorgung möglichst großvolumig ausführen!

X*

5/R

4/A

1/P

2/B

3/S

Bild: Fluidischer Anschluss (Ventil - Typ 6525)

32 - 6524/6525

Page 35

Montage des Ventils

20 Ncm

30 Ncm

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Bild: Montage des Ventils

20 Ncm

30 Ncm

deutsch

6524/6525 - 33

Page 36

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

Maßnahmen vor der Inbetriebnahme

Überprüfen Sie Anschlüsse, Spannung und Betriebsdruck!

Beachten Sie, dass max. Betriebsdaten (siehe Typenschild) nicht überschritten werden!

Entriegeln Sie bei elektrischem Betrieb die Handbetätigung!

Störungen

Störung mögliche Ursache Behebung

deutsch

Ventile

schalten nicht

Ventile

schalten

verzögert oder

blasen an den

Entlüftungsanschlüssen ab

Keine oder nicht

ausreichende

Betriebsspannung

Handbetätigung nicht in

neutraler Stellung

Druckversorgung nicht

ausreichend oder nicht

vorhanden

Druckversorgung nicht

ausreichend oder nicht

vorhanden

Ventile sind während des

Druckaufbaus nicht in

Grundstellung (stromlos)

keine ausreichende

Entlüftung der Abluftkanäle

durch zu kleine oder

verschmutzte

Geräuschdämpfer

(Rückdrücke);

Überprüfen Sie den elektrischen Anschluss.

Stellen Sie die Betriebsspannung laut Typenschild

sicher.

Bringen Sie die Handbetätigung in Null-Stellung.

Führen Sie die Druckversorgung möglichst großvolumig

aus (auch bei vorgeschalteten Geräten wie

Druckreglern, Wartungseinheiten, Absperrventilen usw.).

Führen Sie die Druckversorgung möglichst großvolumig

aus (auch bei vorgeschalteten Geräten wie

Druckreglern, Wartungseinheiten, Absperrventilen usw.).

Beaufschlagen Sie den Ventilblock mit Druck, bevor Sie

die Ventile schalten!

Verwenden Sie entsprechend groß dimensionierte

Geräuschdämpfer bzw. Expansionsgefäße.

Reinigen Sie verschmutzte Geräuschdämpfer.

34 - 6524/6525

Verunreinigungen bzw.

Fremdkörper im Vorsteueroder Hauptventil.

Beaufschlagen Sie die Abluftkanäle mit impulsartigem

Druck, um die Verunreinigungen auszublasen

Bauen Sie ein neues Vorsteuer- bzw. Hauptventil ein,

wenn diese Maßnahme keinen Erfolg bringt.

Page 37

Wartung

Bei Betrieb entsprechend den in dieser Anleitung gegebenen Anweisungen arbeiten die Ventile wartungsfrei.

Zubehör

M

ONTAGE

• Rechtecksteckverbinder mit 3 mKabel (133 486 F)

, I

NBETRIEBNAHME UND WARTUNG

• Rechtecksteckverbinder mit 300 mm FEP-Litzen (644 068 N)

• Rechtecksteckverbinder mit 2 Einzelkontakten (644 067 D)

HINWEIS

Verschleißteile auf Anfrage!

deutsch

6524/6525 - 35

Page 38

deutsch

M

ONTAGE

, I

NBETRIEBNAHME UND WARTUNG

36 - 6524/6525

Page 39

S

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only

OMMAIRE

Table de matieres

Instructions de service

3/2- resp. 5/2 voies Elektrovanne

Type 6524 / 6525

CONSIGNES GENERALES............................................................................................................................................................................................ 39

Représentation .......................................................................................................................................................................................................................... 40

Consignes générales de sécurité

Consignes de sécurité relatives aux vannes

...................................................................................................................................................................... 40

..................................................................................................................................... 41

Couverture de livraison

Clauses de garantie

.................................................................................................................................................................................................. 42

............................................................................................................................................................................................................ 42

DESCRIPTION TECHNIQUES .................................................................................................................................................................................... 43

Construction de la vanne.............................................................................................................................................................................................. 44

Characteristiques techniques des vannes du type 6524 / 6525

Exemple d’inscription

......................................................................................................................................................................................................... 46

................................................................................ 45

MONTAGE, MISE EN SERVICE ET ENTRETIEN......................................................................................................................... 47

Montage ................................................................................................................................................................................................................................................ 48

Précautions à prendre avant la mise en service

Dérangements

Entretien

Accessoires

............................................................................................................................................................................................................................ 52

............................................................................................................................................................................................................................................. 53

.................................................................................................................................................................................................................................. 53

............................................................................................................................ 52

français

6524/6525 - 37

Page 40

S

OMMAIRE

français

38 - 6524/6525

Page 41

C

ONSIGNES GENERALES

CONSIGNES GENERALES

Représentation .......................................................................................................................................................................................................................... 40

Consignes générales de sécurité

Consignes de sécurité relatives aux vannes

Couverture de livraison

Clauses de garantie

.................................................................................................................................................................................................. 42

............................................................................................................................................................................................................ 42

...................................................................................................................................................................... 40

..................................................................................................................................... 41

français

6524/6525 - 39

Page 42

C

ONSIGNES GENERALES

Représentation

Vous rencontrerez les symboles de précaution suivants dans cette instruction de service:

Ceux-ci définissent une tâche que vous devez effectuer.

ATTENTION!

REMARQUE

Rappelle des consignes dont la non observation est susceptible d’entraîner des

dommages corporels ou de porter atteinte au fonctionnement de l’appareil.

Rappelle les informations supplémentaires importantes, les astuces et

recommandations.

Consignes générales de sécurité

Respectez scrupuleusement les consignes de cette instruction de service, de même que les conditions

d’emploi et les valeurs admissibles conformément à la feuille de données, de façon à ce que l’appareil

fonctionne parfaitement et demeure longtemps opérationnel.

français

• Pour les modalités d’emploi et de fonctionnement de l’appareil, cantonnez-vous aux règles générales de

technologie!

• Les travaux d’installation et de maintenance ne doivent être effectués que par du personnel spécialiste

et en utilisant l’outillage approprié.

• Respectez les prescriptions de sécurité et de prévention en vigueur contre les accidents spécifiques à

l’appareillage électrique au cours de la mise en oeuvre, de l’entretien et des réparations de l’appareil!

• Couper systématiquement la tension de l’installation avant toute intervention!

• Veillez à ne pas desserrer ou démonter les conduites et les vannes de circuits soumis à pressurisation.

• Entourez-vous de toutes les mesures appropriées permettant d’éviter les manipulations involontaires ou

les interventions non autorisées!

• Après toute interruption d’alimentation électrique ou pneumatique, assurez-vous de garantir un

redémarrage de processus défini et contrôlé!

• Le non-respect de telles consignes et des interventions non autorisées sur l’appareil nous exonère de

toute responsabilité et exclut également toute invocation à garantie sur les appareils et les pièces

détachées!

40 - 6524/6525

Page 43

Consignes de sécurité relatives aux vannes

• Pour tout ce qui concerne l’affectation et l’exploitation de l’appareil, conformez-vous aux règles

techniques de sécurité générales et en vigueur qui s’y rapportent.

• Prenez toutes les mesures appropriées destinées à exclure les manipulations involontaires ou

interventions non autorisées.

• Veillez à ne pas desserrer ou démonter les conduites et vannes des circuits soumis à pressurisation.

0 bar, psi, kPa

C

ONSIGNES GENERALES

Fig.: Raccordement fluidique

• Couper systématiquement la tension avant toute intervention sur le système!

Fig.: Montage sans tension

• Ouvrir si possible en grand l’alimentation pressurisation afin d’éviter les chutes de pression!

français

• L’appareil ne doit être alimenté qu’en courant continu.

• Risque de dommages corporels!

Après une période de fonctionnement ininterrompue, la bobine devient très chaude!

6524/6525 - 41

Page 44

C

ONSIGNES GENERALES

Couverture de livraison

Dès réception de la marchandise, assurez-vous immédiatement que le contenu des colis n’a pas été

endommagé en cours de transport et que le contenu de l’envoi correspond bien au bordereau

d’accompagnement. En présence de non conformité, adressez-vous uniquement à notre service clientèle

ou à votre Filiale Bürkert.

Bürkert Technologie de Commande et de Régulation

Clauses de garantie

Division Service

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel.: (07940) 10-111, Fax: (07940) 10-448

eMail: info@de.buerkert.com

Cet imprimé stipule les acceptations de garantie. Nous faisons référence à nos conditions générales de

commercialisation et de vente.

Toute invocation à garantie implique une utilisation de l’appareil conforme aux prescriptions et effectuée

dans le respect des conditions d’emploi spécifiées.

français

ATTENTION!

La garantie s’étend uniquement à la tolérance d’erreur des 3/2 resp. 5/2 voies

electrovannes type 6524 / 6525. Nous déclinons toute responsabilité concernant les

dommages de toute nature induits qui pourraient survenir d’une panne ou d’un

fonctionnement erroné de l’appareil en dehors de cette plage d’utilisation.

42 - 6524/6525

Page 45

D

ESCRIPTION TECHNIQUES

DESCRIPTION TECHNIQUES

Construction de la vanne.............................................................................................................................................................................................. 44

Characteristiques techniques des vannes du type 6524 / 6525

Exemple d’inscription

......................................................................................................................................................................................................... 46

................................................................................ 45

français

6524/6525 - 43

Page 46

D

ESCRIPTION TECHNIQUES

Construction de la vanne

Fig.: Electrovanne 3/2 voies pour application

pneumatique, type 6524

• Les systèmes d’automatisation justifient de plus en plus leur emploi dans tous les domaines où les

français

• Les îlots de vannes de type 6524 et 6525 se composent d’une électrovanne de commande anticipée à

• Les vannes peuvent s’ajouter à la file et, avec raccord par fiche placé derrière, s’utiliser, de préférence,

• Les vannes pilotes sont équipées en série d’une commande manuelle.

Fig.: Electrovanne 5/2 voies pour application

pneumatique, type 6525

fonctions de commande et de régulation doivent être maîtrisées. Au sein de telles applications, les

vannes constituent l’interface de relation entre l’électronique et le pneumatique.

basculement de Type 6104 et d’une vanne de jonction pneumatique. La vanne de commande anticipée

est sertie au corps du bloc. Ce principe de combinaison d’effets permet la commutation sous haute

pression à puissance de consommation réduite et des temps de commutation très courts.

comme îlots de vannes (types 8640 ou 8644) de même qu’avec des languettes enfichables placées

devant, de préférence, sur des blocs de vannes pour commander des entraînements pneumatiques.

44 - 6524/6525

Page 47

D

ESCRIPTION TECHNIQUES

Characteristiques techniques des vannes du type 6524 / 6525

• Matériau boîtier PA (Polyamide)

• Matériaux d’étanchéité FKM , NBR et PUR

• Médiums air pressurisation gras, sec, sèche,

gaz neutres

• Température médium -10 à +50 °C

• Température d’environnement -10 à +55 °C

• Raccord circuit bride

• Modules pneumatiques MP11

• Raccord d'alimentation G 1/4, NPT 1/4

1 (P), 3 (R), 5 (S) couplage par fiche, Ø 10 mm

• Raccord de service couplage par fiche

2 (A), 4 (B) Ø 6 mm, M5, M7

• Düebit Q

• Tension de service 24 V DC

• Tolérance de tension ± 10%

• Puissance nominale 1 W

• Mode d’exploitation nominale continu (100 % ED)

• Raccord électrique fiche carrée avec

• Indice de protection IP 40 avec raccord à fiche carrée

• Position d’intégration au choix, de préférence commande vers le haut

• Commande manuelle de série

• Classe de protection 3 selon VDE 0580

• Temps de commutation [ms] mesure en sortie de vanne à 6 bar et à +20 °C

Nn

sur la vanne grille 5,08 mm

sur îlot de vannes douille à fiche intégrée

sur bloc de vannes connecteur à fiche rectangulaire

(voir fiche technique) ouverture pressurisation de 0 à 90%

air 300 l/min

fermeture dépressurisation de 100 à 10%

français

6524/6525 - 45

Page 48

D

ESCRIPTION TECHNIQUES

Inscription des vannes

Dimension nominale

Fonctionnement

Type

N° id.

Tension (±10 %) - Puissance

Plage de pression

français

Fig.: Exemple d’inscription

46 - 6524/6525

Page 49

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

MONTAGE,

MISE EN SERVICE ET

ENTRETIEN

Montage .............................................................................................................................................................................................................................................. 48

Précautions à prendre avant la mise en service

Dérangements

Entretien

Accessoires

............................................................................................................................................................................................................................ 52

............................................................................................................................................................................................................................................. 53

.................................................................................................................................................................................................................................. 53

............................................................................................................................ 52

français

6524/6525 - 47

Page 50

M

ONTAGE

, M

Montage

Fonctionnement

ISE EN SERVICE ET ENTRETIEN

C Electrovanne 3/2 voies, à vanne pilote

En position de repos, sortie 1 bloqué, sortie 2 à l’air libre.

D Electrovanne 3/2 voies, à vanne pilote

En position de repos, raccord de pression 1 relié à sortie 2.

H Electrovanne 5/2 voies, à vanne pilote

En position de repos, raccord de pression 1 relié à sortie 2,

sortie 4 à l’air libre.

Nettoyage des conduites

Nettoyer les conduites avant de commencer le montage pour assurer un fonctionnement fiable de votre

français

Monter en amont, le cas échéant, un collecteur d’impuretés comme protection anti-pannes.

Position de montage

Position de montage quelconque, de préférence avec système magnétique en haut.

Fig: Position de montage

installation.

Orientation

préférentielle

Médiums

• Air comprimé filtré (grandeur max. des particules 5 µm), de préférence sans huile, sec

• Le fonctionnement avec de l’air huilé est possible

• Matière du joint NBR, FKM und PUR

• Température admissible fluidesmax. + 50 ° C

REMARQUE

48 - 6524/6525

ambiante max. + 55 ° C

Pour des températures inférieures à 0 °C, le fonctionnement est limité à l’air sec.

Page 51

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Raccordements

Des interventions ne doivent être effectuées que par un personnel qualifié équipé de l’outillage

approprié.

Déclencher dans tous les cas la tension avant toute intervention sur le système.

Monter éventuellement un filtre en amont pour prévenir des dérangements.

Veiller à la concordance des conditions d’exploitation avec les caractéristiques de débit de l’appareil.

Eviter les accumulations de pression dans les canaux d’échappement d’air en employant des silencieux

de grand volume.

ATTENTION!

Ne pas démonter des conduites ou des vannes dans des systèmes se trouvant sous

pression!

Raccordement électrique

Raccord par fil torsadé Fiche rondeFiche rectangulaire

Fig.: Possibilités de raccordement des vannes pilotes, type6104

français

Vanne pilote, type 6104

Tension, puissance électrique, type de protection et courant figurent sur la plaque signalétique!

Tolérance de tension ±10 %

En cas de durée d’enclenchement à 100 % et une température ambiante maximale, la bobine s’échauffe

en montage isolé à env. + 105 °C

en bloc à env. + 120 °C

REMARQUE

Assurer une grande longévité de la vanne pilote par un filtrage à 5µ.

ATTENTION!

Veiller à la tension! En tension alternative, monter impérativement un redresseur en

amont!

6524/6525 - 49

Page 52

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Actionnement manuel

Pour l’actionnement manuel de la vanne, tourner l’actionnement manuel de 90° dans le sens de la

flèche.

Fig,: Réglage du mode manuel

Raccordement fluidique

français

0AUTO

1/P 2/A C

2/A 3/R D

1

1/P 4/A

2/B 3/S

(Symb. indiquent

position zéro)

H

X* Gaine d’air

d’echappement de

la commande

pilote

X*

3/R

2/A

1/P

Fig.: Raccordement fluidique (Vanne - Type 6524)

REMARQUE

Exécuter l’alimentation en pression le plus largement possible!

X*

5/R

4/A

1/P

2/B

3/S

Fig.: Raccordement fluidique (Vanne - Type 6525)

50 - 6524/6525

Page 53

Montage de la vanne

20 Ncm

30 Ncm

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

20 Ncm

Fig.: Montage de la vanne

30 Ncm

français

6524/6525 - 51

Page 54

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

Précautions à prendre avant la mise en service

Vérifier les raccordements, la tension et la pression de service!

Veiller à ce que les données de service maximales (voir plaquette signalétique) ne soient pas

dépassées!

En cas de fonctionnement électrique, déverrouiller l’actionnement manuel!

Dérangements

Panne Cause possible Remède

français

Vannes ne

commutent

pas

Vannes

commutent à

retardement ou

crachent aux

raccords de

purge

Tension de service

insuffisante ou absente

Commande manuelle n'est

pas en position neutre

Alimentation en pression

insuffisante ou absente

Alimentation en pression

insuffisante ou absente

Vannes ne sont pas en

position initiale (sans courant)

pendant l'établissement de la

pression

Purge insuffisante des

canaux d'évacuation d'air par

des silencieux trop petits ou

encrassés (contre-pression)

Vérifier le branchements électrique.

Contrôler la tension de service sur la plaque

signalétique.

Mettre la commande manuelle en position zéro.

Assurer généreusement l'alimentation en pression

(également pour les appareils branchés en amont, tels

que régulateurs de pression, unités d'entretien vannes

d'arrêt etc.).

Assurer généreusement l'alimentation en pression

(également pour les appareils branchés en amont, tels

que régulateurs de pression, unités d'entretien vannes

d'arrêt etc.).

Injecter de la pression dans le bloc avant de mettre les

vannes en circuit!

Utiliser des silencieux ou des vases d'expansion

largement dimensionnés.

Nettoyer les silencieux encrassés.

52 - 6524/6525

Impuretés ou corps étrangers

dans la vanne pilote ou la

vanne principale

Injecter de la pression par impulsions dans les canaux

d'évacuation d'air pour éjecter les impuretés.

Monter une nouvelle vanne pilote ou vanne principale, si

ces mesures sont sans effet.

Page 55

Entretien

Si les instructions figurant dans cette notice sont bien suivies en cours de service, les vannes

fonctionneront sans entretien.

Accessoires

• Connecteur à fiche rectangulaire avec 3 m de cable(133 486 F)

• Connecteur à fiche rectangulaire avec 300 mm de cordon FEP (644 068 N)

M

ONTAGE

, M

ISE EN SERVICE ET ENTRETIEN

• Connecteur à fiche rectangulaire avec 2 contacts séparés (644 067 D)

REMARQUE

Pièces de rechange sur demande!

français

6524/6525 - 53

Page 56

Bürkert Company Locations

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Page 57

Loading...

Loading...