Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

Type 6520 NAMUR

Valve with 24 V connection

Ventil mit 24 V-Anschluß

Vanne avec raccordement 24 V

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2002 Bürkert Werke GmbH & Co. KG

Operating Instructions 0512/09_EU-ML_00800608

Page 3

Type 6520 NAMUR Valve with 24 V connection

CONTENTS

1 GENERAL NOTES .......................................................................................................................................... 2

1.1 Symbols ......................................................................................................................................... 2

1.2 General Safety instructions ..................................................................................................2

2 GENERAL DESCRIPTION ......................................................................................................................... 3

2.1 Type 6520 NAMUR Valve with 24 V connection .........................................................3

3 GENERAL TECHNICAL DATA ................................................................................................................ 4

3.1 Type 6520 NAMUR with 24 V connection ..................................................................... 4

3.2 Valve construction................................................................................................................... 4

3.3 Operation .................................................................................................................................... 5

3.4 Medium......................................................................................................................................... 5

4 INSTALLATION AND COMMISSIONING OF THE VALVE .................................................... 6

4.1 Mounting the valve / pneumatic position indicator ..................................................... 7

4.2 Measures to be taken before commissioning ................................................................ 7

4.3 Electrical connection of the Type 6520 NAMUR valve with the 24 V

connection .................................................................................................................................. 8

5 FAULTS .................................................................................................................................................................. 9

6520 - 1

Page 4

1 GENERAL NOTES

1.1 Symbols

In these Operating Instructions, the following symbols are used:

Indicates a working step that you have to carry on.

ATTENTION!

english

NOTE

Indicates information which must be followed. Failure to do

this could endanger your health or the functionality of the

device..

Indicates important additional information, tips and

recommendations.

1.2 General Safety instructions

To ensure that the device functions correctly, and will have a long service life,

please comply with the information in these Operating Instructions, as well as

the application conditions and permissible data given in the Type 6520 data

sheet:

• When planning the application of the device, and during its operation,

observe the general technical rules!

• Observe the relevant accident prevention and safety regulations applicable

for electrical equipment throughout the operation, maintenance and repair

of the device! Always switch off the voltage supply before working on the

system!

• Note that line connections and valves must not be loosened while the

system is under pressure

• Take suitable measures to prevent impairment due to improper use.

• If these instructions are ignored, no liability will be accepted from our side,

and the guarantee on the device and on accessories will become invalid!

2 - 6520

Page 5

2 GENERAL DESCRIPTION

Type 6520 NAMUR valve for the control of process valves with electrical

connections, available with either a 24 V connection.

2.1 Type 6520 NAMUR Valve with 24 V connection

• Pilot-driven pneumatic valve with a piezo valve as the pilot control

• Very low switching and standby current

english

6520 - 3

Page 6

3 GENERAL TECHNICAL DATA

3.1 Type 6520 NAMUR with 24 V connection

Operating voltage: 24 V DC ±10%

Pressure range: 2,5 to 7 bar

Flange: NAMUR flange

Standby current: < 150 µA at 24 V

english

Power dissipation: < 10 mW

Permissible temperature range

Ambient: - 20 to +55 ° C

Medium: - 20 to +50 ° C

Protection class: IP 65

The valve can be supplied in explosion protection class

to EN 50020, II 2G EEx ia IIC T6

3.2 Valve construction

• Drives: - Piezo drive,

• Valve housing with membrane and seat seals (5/2)

• Service ports 2 (B) / 4 (A) with change-over plate to MAMUR flange layout,

plus feed and drain connections 1, 3 and 5 with G 1/4 internal thread

• Can be installed in any position, preferably with connection at top

NOTE

4 - 6520

Under normal conditions, the devices work maintenance-free.

Page 7

3.3 Operation

5/2 way valve:

In standby position, pressure port 1 connected to outlet 2.

Outlet 4 vented

3/2 way valve with return of exhaust:

In standby position, pressure port 1 blocked, outlet 2 vented

into output 4

The integrated exhaust air feedback prevents the penetration of ambient air into

the spring recess of the drive.

english

NOTE

Application in either 5/2 or 3/2 way type.

To convert from the 5/2 to the 3/2 way model, or vice versa,

turn the change-over plate through 180°. When using as a 3/2

way valve, close off outlet 3 with the supplied G1/4 locking

screw. This ensures that the integrated feedback of outgoing

air functions correctly.

3.4 Medium

• Filtered compressed air, oiled or unoiled (max. particle size 5 µm)

• Sealing material: PB = Polyurethane and NBR

• Permissible temperature range: - 20 to +50 ° C

• Operating pressure range: 2,5 to 7 bar

ATTENTION!

The valve is driven using instrument air, and serves as a 3/2 or 5/2-way valve

for the switching of non-inflammable media. The valve must only be operated in

the mounted condition, unless it is ensured that explosive atmospheres can

only rarely penetrate the interior of the valve, and only for short periods.

Note the permissible pressure range given on the rating

plate. Pressure difference between port 1 and 3/5 > 2,5 bar.

6520 - 5

Page 8

4 INSTALLATION AND COMMISSIONING OF THE VALVE

Work on the device should only be carried out by specialist staff using the

correct tools!

Before carrying out work on the system, always switch off the voltage

supply!

Implement the pressure supply with as large a volume as possible (even for

pilot devices such as pressure regulators, service units etc.);

english

Operating pressure ≥ 2,5 bar;

Minimum flow rate 270 l/min at P connection of valve

Before mounting the valve, clean out the pipelines!

Note, that contamination impairs the function of the PIEZO pilot valve!

Where necessary, fit a dirt trap upstream to protect from faults.

Ensure that the operating conditions agree with the performance data of

the unit!

Avoid back pressure in the exhaust channels by means of a large-volume

silencer!

1)1)

1)

1)1)

ATTENTION!

1)

6 - 6520

Line connections and valves must not be loosened while

the system is under pressure !

There are no replacement parts for the unit! In case of fault,

please return the unit to the manufacturer.

In the case of version with reduced flow rate

(ID no. 141 721 Z; ID no. 141 72 S), the flow rate is reduced to 150 l/min.

Page 9

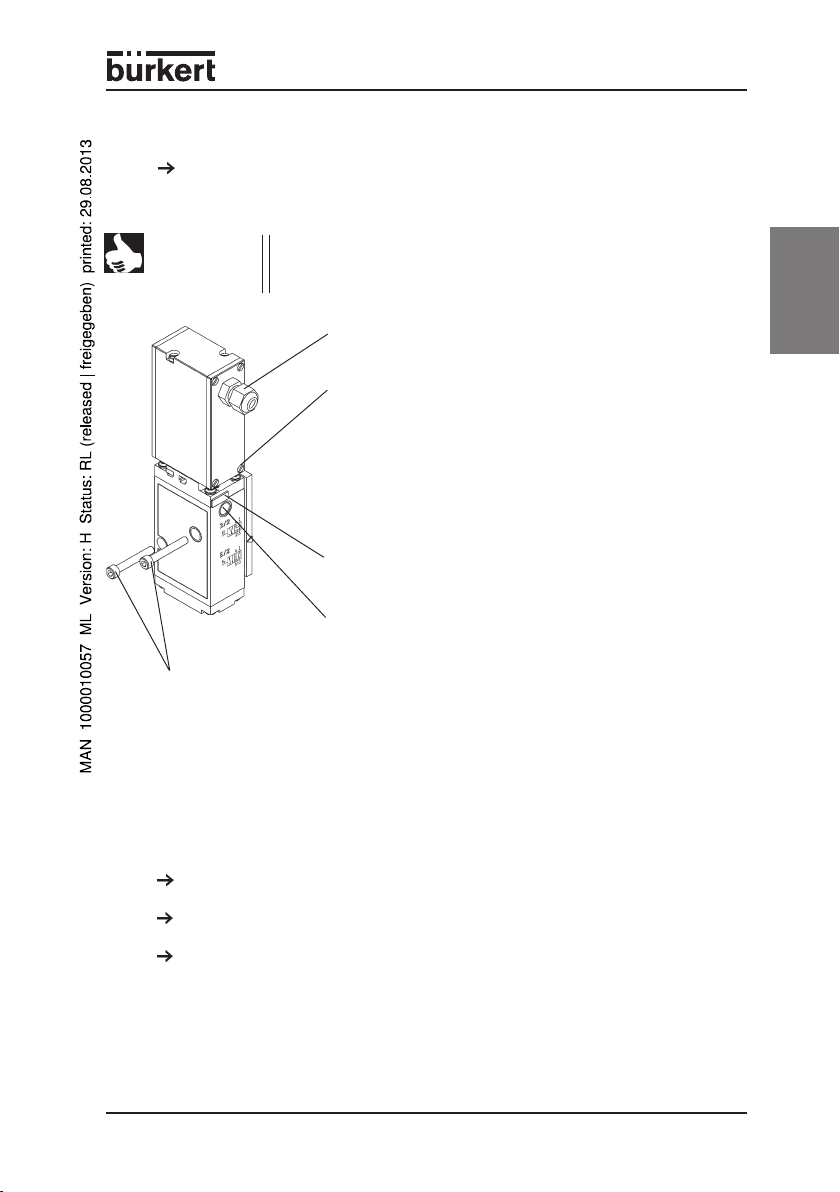

4.1 Mounting the valve / pneumatic position indicator

Mount the valve directly onto the NAMUR connection flange of the

pneumatic drive using the 2 supplied M5 x 35 screws.

NOTE

M3 x 35 screws

Fig. 3: Mounting the valve / Pneumatic position indicator

The supplied coded pin ensures that the device can only be

mounted in the foreseen position. (guarantees the pre-defined

direction of operation of the drive).

24 V connection

Indicator pin to show the pneumatic position

In an unswitched valve, the red indicator pin can be

pressed in. If the valve is switched, the indicator pin

travels out, and remains in this position. Every time a

functional check is carried out, this pin must be pressed

in again.

Identification label (removable for marking / inscription)

Port 14

• Not used in standard model

• Used as an control air boost connection and as a

connection for pneumatic controls

english

4.2 Measures to be taken before commissioning

Check all connections, voltages and the operational pressure!

Ensure that the max. operating data (see rating plate) id not exceeded!

Check the correct connection of ports 1 and 3 or 5 respectively in

accordance with the regulations. On no account must these be reversed!

6520 - 7

Page 10

4.3 Electrical connection of the Type 6520 NAMUR valve with the 24

V connection

Connection:

Terminal 1124 V

english

Terminal 13 0 V / Ground

8 - 6520

Page 11

5 FAULTS

Valve does not

switch:

Valves switches

delayed or

blows out from

the bleed ports:

Possible causeFault

Insufficient or no

operating voltage;

Pressure supply insufficient or not present.

Pressure supply insufficient or not present;

Remedy

Check the electrical

connetctions

Ensure the operating voltage is

as given on the rating plate

Implement the pressure supply

with as large a volume as possible (even for pilot devices

such as pressure regulators,

service units, shut-off valves,

etc.);

minimum operating pressure

≥≥

≥ 2,5 bar,

≥≥

minimum flow rate 270 l/min

at P connection of valve

1)

Implement the pressure supply

with as large a volume as possible (even for pilot devices

such as pressure regulators,

service units, shut -off valves,

etc.);

minimum operating pressure

≥≥

≥ 2,5 bar,

≥≥

minimum flow rate 270 l/min

at P connection of valve

1)

english

Insufficient venting of

the exhaust channels

due to a silencer that is

Use silencers or expansion

vessels with correspondingly-

large dimensions.

soiled or is too small

(back pressure);

Soiling or foreign bodies

in the pilot or main valve.

Clean soiled silencers.

Pressure load the exhaust

channels with pressure pulse to

blow away the dirt; Install a

new pilot or main valve if this

measure is unsuccessful.

1)

In the case of version with reduced flow rate

(ID no. 141 721 Z; ID no. 141 72 S), the flow rate is reduced to 150 l/min.

6520 - 9

Page 12

NOTES

english

10 - 6520

Page 13

Ventil Typ 6520 NAMUR mit 24 V-Anschluss

INHALT:

1 ALLGEMEINE HINWEISE........................................................................................................................ 12

1.1 Darstellungsmittel ................................................................................................................... 12

1.2 Allgemeine Sicherheitshinweise ..................................................................................... 12

2 ALLGEMEINE BESCHREIBUNG ....................................................................................................... 13

2.1 Ventil Typ 6520 NAMUR mit 24 V-Anschluss ............................................................. 13

3 ALLGEMEINE TECHNISCHE DATEN ............................................................................................. 14

3.1 Typ 6520 NAMUR mit 24 V-Anschluss ........................................................................ 14

3.2 Ventilaufbau............................................................................................................................ 14

3.3 Wirkungsweisen .................................................................................................................... 15

3.4 Medium ..................................................................................................................................... 15

4 MONTAGE UND INBETRIEBNAHME DES VENTILS ...........................................................16

4.1 Befestigung des Ventils / pneumatische Stellungsanzeige ................................ 17

4.2 Maßnahmen vor der Inbetriebnahme ............................................................................ 17

4.3 Elektr. Anschluss des Ventils Typ 6520 mit 24 V-Anschaltung .......................... 18

5 STÖRUNGEN ..................................................................................................................................................19

deutsch

6520 - 11

Page 14

1 ALLGEMEINE HINWEISE

1.1 Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre

Gesundheit oder die Funktionsfähigkeit des Gerätes

gefährdet ist.

kennzeichnet wichtige Zusatzinformationen,

Tipps und Empfehlungen.

deutsch

1.2 Allgemeine Sicherheitshinweise

Beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten gemäß Datenblatt Typ 6520, damit das

Gerät einwandfrei funktioniert und lange einsatzfähig bleibt:

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an

die allgemeinen Regeln der Technik!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte während des Betriebs, der Wartung

und der Reparatur des Gerätes; schalten Sie vor Eingriffen in das System

in jedem Fall die Spannung ab!

• Beachten Sie, daß in Systemen, die unter Druck stehen, Leitungen und

Ventile nicht gelöst werden dürfen!

• Treffen Sie geeignete Maßnahmen, um unzulässige Beeinträchtigung

auszuschließen!

• Bei Nichtbeachtung dieser Hinweise entfällt jegliche Haftung unsererseits,

ebenso erlischt die Garantie auf Geräte u. Zubehörteile!

12 - 6520

Page 15

2 ALLGEMEINE BESCHREIBUNG

Ventil Typ 6520 NAMUR zur Ansteuerung von Prozeßventilen mit elektrischem

Anschluss, wahlweise mit 24 V-Anschluss

2.1 Ventil Typ 6520 NAMUR mit 24 V-Anschluss

• hilfsgesteuertes Pneumatikventil mit Piezoventil als Vorsteuerung

• sehr geringe Schalt- und Ruheströme

deutsch

6520 - 13

Page 16

3 ALLGEMEINE TECHNISCHE DATEN

3.1 Typ 6520 NAMUR mit 24 V-Anschluss

Betriebsspannung: 24 V DC ±10%

Druckbereich: 2,5 bis 7 bar

Flansch: NAMUR Flansch

Ruhestrom: < 150 µA bei 24 V

Verlustleistung: < 10 mW

Zulässiger Temperaturbereich:

Umgebung: - 20 bis +55 ° C

Medium: - 20 bis +50 ° C

Schutzart: IP 65

deutsch

Das Ventil ist in Explosionsschutzart nach

EN 50020, II 2G EEx ia IIC T6 lieferbar.

3.2 Ventilaufbau

• Antriebe: - Piezoantrieb,

• Ventilgehäuse mit Membran und Sitzdichtungen (5/2)

• Arbeitsanschlüsse 2 (B) / 4 (A) mit Wechselplatte nach Namur Flanschbild

sowie Ver- und Entsorgungsanschlüsse 1, 3 und 5 mit G 1/4 - Innengewinde

• beliebige Einbaulage, vorzugsweise mit Anschaltung oben

HINWEIS

14 - 6520

Die Geräte arbeiten unter normalen Bedingungen wartungsfrei.

Page 17

3.3 Wirkungsweisen

5/2-Wege-Ventil:

in Ruhestellung Druckanschluss 1 mit Ausgang 2 verbunden,

Ausgang 4 entlüftet.

3/2-Wege-Ventil mit Abluftrückführung:

in Ruhestellung Druckanschluss 1 gesperrt,

Ausgang 2 in Ausgang 4 entlüftet.

Die integrierte Abluftrückführung verhindert das Eindringen von Umgebungsluft

in den Federraum des Antriebs.

HINWEIS

Anwendung wahlweise in 5/2- oder 3/2-Wege-Ausführung.

ZumUmbau von der 5/2- in die 3/2-Wege-Ausführung bzw.

umgekehrt, drehen Sie die Wechselplatte um 180°. Verschließen Sie bei Verwendung als 3/2-Wegeventil den Anschluss 3

mit den mitgelieferten Verschlussstopfen G1/4. Dadurch ist

gewährleistet, daß die integrierte Abluftrückführung funktioniert.

3.4 Medium

• Gefilterte Druckluft, geölt oder ungeölt (Partikelgröße max 5 µm)

• Dichtwerkstoffe: PB = Polyurethan und NBR

• Zulässiger Temperaturbereich: - 20 bis +50 ° C

• Betriebsdruckbereich: 2,5 bis 7 bar

ACHTUNG!

Das Ventil wird mit Instrumentenluft gesteuert und dient als 3/2- bzw. 5/2Wegeventil zum Schalten nicht brennbarer Medien. Das Ventil darf nur im

eingebauten Zustand betrieben werden, es sei denn, es wird sichergestellt,

daß explosionsfähige Atmosphäre nur selten und kurzzeitig in den Ventilinnenraum gelangen kann.

Beachten Sie den zulässigen Druckbereich, der auf dem

Typenschild angegeben ist.

Druckdifferenz zwischen Anschluss 1 und 3/5 > 2,5 bar.

deutsch

6520 - 15

Page 18

4 MONTAGE UND INBETRIEBNAHME DES VENTILS

Eingriffe dürfen nur durch Fachpersonal und mit geeignetem Werkzeug

erfolgen!

Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

Führen Sie die Druckversorgung auch bei vorgeschalteten Geräten wie

Druckreglern, Wartungseinheiten usw. möglichst großvolumig aus;

Betriebsdruck ≥ 2,5 bar;

Mindestdurchflußmenge 270 l/min am P-Anschluss des Ventils1);

Säubern Sie vor Montage des Ventils die Rohrleitungen!

Verschmutzungen beeinträchtigen die Funktion des PIEZO-Vorsteuerventils!

deutsch

ACHTUNG!ACHTUNG!

ACHTUNG!

ACHTUNG!ACHTUNG!

1)

Schalten Sie gegebenenfalls zum Schutz vor Störungen einen Schmutzfänger vor.

Achten Sie auf Übereinstimmung der Betriebsbedingungen mit den

Leistungsdaten des Gerätes!

Vermeiden Sie Staudrücke in den Abluftkanälen durch großvolumige

Schalldämpfer!

In Systemen, die unter Druck stehen, dürfen Leitungen oder

Ventile nicht gelöst werden!

Für das Gerät gibt es keine Ersatzteile! Senden Sie das

Gerät bei einem Defekt bitte zurück an den Hersteller.

Bei Ausführungen mit reduziertem Durchfluß

(Id.-Nr. 141 721 Z; Id.-Nr. 141 722 S)

reduziert sich die Mindestdurchflußmenge auf 150 l/min.

16 - 6520

Page 19

4.1 Befestigung des Ventils / pneumatische Stellungsanzeige

Befestigen Sie das Ventil mit den zwei mitgelieferten M5x35 Schrauben

direkt an der NAMUR-Anschlussfläche des pneumatischen Antriebs.

HINWEIS

M5x35 Schrauben

Bild 3: Befestigung des Ventils / Pneumatische Stellungsanzeige

Der mitgelieferte Kodierstift stellt sicher, daß das Gerät nur in

der vorgesehenen Lage montiert werden kann (Sicherstellung

der festgelegten Wirkrichtung des Antriebs).

24 V-Anschaltung

Anzeigestift zur Anzeige der pneumatischen

Stellung.

Bei ungeschaltetem Ventil läßt sich der rote Anzeigestift eindrücken. Wird das Ventil geschaltet,

fährt der Anzeigestift aus und bleibt in dieser

Stellung. Bei jeder Funktionsüberprüfung muß der

Anzeigestift erneut eingedrückt werden.

Kennzeichnungsschild

(abnehmbar für Markierungen/Beschriftungen)

Anschluss 14

• in Standardausführung nicht belegt

• dient als Steuerhilfsluftanschluss und als

Anschluss für pneumatische Ansteuerungen

deutsch

4.2 Maßnahmen vor der Inbetriebnahme

Überprüfen Sie Anschlüsse, Spannung und Betriebsdruck!

Beachten Sie, daß max. Betriebsdaten (siehe Typenschild) nicht überschrittenwerden!

Überprüfen Sie die vorschriftsmäßige Belegung der Anschlüsse 1 und 3

bzw. 5, diese dürfen auf keinen Fall vertauscht werden!

6520 - 17

Page 20

4.3 Elektr. Anschluss des Ventils Typ 6520 NAMUR mit

24 V-Anschluss

Anschluss:Anschluss:

Anschluss:

Anschluss:Anschluss:

Klemme 11 24 V

Klemme 13 0 V / Ground

deutsch

18 - 6520

Page 21

6 STÖRUNGEN

Störung

Ventile schalten

nicht:

Ventile schalten

verzögert oder

blasen an den

Entlüftungsanschlüssen ab:

mögliche Ursache

keine oder nicht

ausreichende Betriebsspannung;

Druckversorgung nicht

ausreichend oder nicht

vorhanden.

Druckversorgung nicht

ausreichend oder nicht

vorhanden;

keine ausreichende

Entlüftung der Abluftkanäle durch zu kleine

oder verschmutzte

Geräuschdämpfer

(Rückdrücke);

Behebung

Überprüfen Sie den elektrischen Anschluss.

Stellen Sie die Betriebsspannung laut Typenschild sicher.

Führen Sie die Druckversorgung möglichst großvolumig aus (auch bei vorgeschalteten

Geräten wie Druckreglern,

Wartungseinheiten, Absperrventilen usw.).

Mindestbetriebsdruck

≥≥

≥ 2,5 bar;

≥≥

Mindestdurchflußmenge

270 l/min am P-Anschluss

des Ventils

1)

Führen Sie die Druckversorgung möglichst großvolumig

aus (auch bei vorgeschalteten

Geräten wie Druckreglern,

Wartungseinheiten, Absperrventilen usw.).

Mindestbetriebsdruck

≥ ≥

≥ 2,5 bar;

≥ ≥

Mindestdurchflußmenge

270 l/min am P-Anschluss

des Ventils

1)

Verwenden Sie entsprechend

groß dimensionierte Geräuschdämpfer bzw. Expansionsgefäße.

Reinigen Sie verschmutzte

Geräuschdämpfer.

deutsch

Verunreinigungen bzw.

Fremdkörper im Vorsteuer- oder Hauptventil.

Beaufschlagen Sie die

Abluftkanäle mit impulsartigem

Druck, um die Verunreinigungen auszublasen; bauen Sie

ein neues Vorsteuer- bzw.

Hauptventil ein, wenn diese

Maßnahme keinen Erfolg bringt.

1)

Bei Ausführungen mit reduziertem Durchfluß (Id.-Nr. 141 721 Z;

Id.-Nr. 141 722 S) reduziert sich die Mindestdurchflußmenge auf 150 l/min.

6520 - 19

Page 22

NOTIZEN

deutsch

20 - 6520

Page 23

Vanne type 6520 NAMUR avec raccordement 24 V

TABLE DES MATIÈRES:

1 REMARQUES GENERALES................................................................................................................... 22

1.1 Modes de représentation ................................................................................................... 22

1.2 Indications generales de sécurite .................................................................................. 22

2 DESCRIPTION GENERALE.................................................................................................................... 23

2.1 Vanne type 6520 NAMUR avec raccordement 24 V ............................................. 23

3 CARACTERISTIQUES TECHNIQUES GENERALES .............................................................24

3.1 Type 6520 NAMUR avec raccordement 24 V ........................................................... 24

3.2 Construction de la vanne .................................................................................................. 24

3.3 Mode de fonctionnement .................................................................................................. 25

3.4 Fluide ......................................................................................................................................... 25

4 MONTAGE ET MISE EN SERVICE DE LA VANNE................................................................. 26

4.1 Fixation de la vanne / affichage pneumatique de position .................................. 27

4.2 Précautions à prendre avant la mise en service ...................................................... 27

4.3 Raccordement électrique de la vanne type 6520 NAMUR

avec raccordement 24 V ................................................................................................... 28

français

5 DÉRANGEMENTS ........................................................................................................................................ 29

6520 - 21

Page 24

1 REMARQUES GENERALES

1.1 Modes de représentation

On utilise dans ces instructions de service les modes de représentation

suivants:

marque une phase de travail que vous devez exécuter.

ATTENTION!

REMARQUE

caractérise des indications dont l’observation peut mettre

en danger votre santé ou la fonctionnalité de l’appareil.

caractérise des indications supplémentaires, des conseils et

des recommandations.

1.2 Indications generales de sécurite

Observez les indications de ces instructions de service ainsi que les

conditions d’utilisation et les caractéristiques admissibles selon la fiche

technique du type 6520, afin que l’appareil fonctionne parfaitement et reste

français

longtemps en état de fonctionnement:

• respectez lors du projet d’utilisation et de l’exploitation de l’appareil les

règles générales reconnues de la technique;

• observez les dispositions en vigueur sur la prévention des accidents et la

sécurité pour les appareils électriques, pendant l’exploitation, l’entretien et

la réparation de l’appareil; déclenchez la tension électrique dans tous les

cas avant toute intervention dans le système;

• remarquez que les conduites et les vannes qui se trouvent sous pression

ne doivent pas être démontées;

• prenez les mesures appropriées afin d’exclure tout préjudice inadmissible;

• en cas d’inobservation de cette indication, toute responsabilité de notre

part sera exclue, de même la garantie sur l’appareil et les accessoires sera

supprimée.

22 - 6520

Page 25

2 DESCRIPTION GENERALE

Vanne type 6520 NAMUR pour le pilotage de vannes de processus avec

raccordement 24 V.

2.1 Vanne type 6520 NAMUR avec raccordement 24 V

• Vanne pneumatique à commande assistée avec pilote piézo-électrique

• Courants de commutation et de repos très réduits

français

6520 - 23

Page 26

3 CARACTERISTIQUES TECHNIQUES GENERALES

3.1 Type 6520 NAMUR avec raccordement 24 V

Tension de service: 24 V DC ±10%

Plage de pression: 2 á 7 bars

Bride: bride NAMUR

Courant de repos: < 150 µA sous 24 V

Pertes: < 10 mW

Plage de température admissible:

ambiante: - 25 á 55 ° Celsius

fluide: - 25 á 50 ° Celsius

Mode de protection: IP 65

La vanne est aussi livrable en version antidéflagrante selon

EN 50020, II 2G EEx ia IIC T6.

3.2 Construction de la vanne

français

• Actionnement: - piézo-électrique,

• Corps de vanne avec membrane et joints de siège (5/2)

• Raccords de travail 2 (B) / 4 (A) avec plaque interchangeable selon bride

NAMUR

ainsi que raccords d’alimentation et d’évacuation 1, 3 et 5 avec taraudage

G 1/4

• Position de montage quelconque, de préférence avec connexion en haut

REMARQUE

24 - 6520

Les appareils fonctionnent sans demander d’entretien dans

les condition normales.

Page 27

3.3 Mode de fonctionnement

Vanne à 5/2 voies:

en position de repos, raccord de pression 1 relié à la

sortie 2, sortie 4 à l’air libre

Vanne à 3/2 voies:

en position de repos, raccord de pression 1 bloqué,

sortie 2 à l’air libre

Le retour intégré de l’air sortant empêche l’air ambiant de pénétrer dans

l’espace ressort du mécanisme d’actionnement.

REMARQUE

Application au choix en exécution à 5/2 voies ou 3/2 voies:

Pour la transformation de l’exécution à 5/2 voies en 3/2 voies

ou inversement, tourner la plaque interchangeable de 180°.

Fermer en cas d’utilisation comme vanne à 3/2 voies le

raccord 3 avec le bouchon G 1/4 joint. On assure ainsi le

fonctionnement du retour intégré de l’air expulsé.

3.4 Fluide

• Air comprimé filtré, huilé ou non (grandeur max. des particules 5 µm)

• Matière du joint: BP = NBR et polyéthylène

• Plage de température admissible: - 20 á 50 ° Celsius

• Domaine de pression de service: 2,5 á 7 bar

ATTENTION!

La soupape est commandée par l'air des instruments et sert de soupape à 3/2

ou 5/2 voies pour commuter les fluides non combustibles. La supape ne doit

être exploitée que lorsqu'elle est montée, à moins que l'on s'assure que

l'atmosphère déflagrante ne peut parvenir que rarement et brièvement à

l'intérieur de la soupape.

Observez le domaine de pression admissible indiqué sur la

plaquette signalétique!

Différence de pression entre raccords 1 et 3/5 > 2 bars

français

6520 - 25

Page 28

4 MONTAGE ET MISE EN SERVICE DE LA VANNE

Des interventions ne doivent être effectuées que par un personnel qualifié

équipé de l’outillage approprié!

Déclencher dans tous les cas la tension avant toute intervention sur le

système!

Nettoyer les conduites avant le montage de la vanne!

Réaliser l'alimentation de la pression à un volume aussi grand que

possible, même avec les appareils placés en amont, tels que pressostats,

unités d'entretien etc.

Pression de service ≥ 2,5 bar

Débit minimal 270 l/min au raccord P de la vanne

Monter éventuellement un filtre en amont pour prévenir des dérangements!

Veiller à la concordance des conditions d’exploitation avec les

caractéristiques de débit de l’appareil!

Eviter les accumulations de pression en employant des silencieux de grand

volume dans les canaux d’échappement d’air!

1)

français

ATTENTION!

1)

26 - 6520

Ne pas démonter des conduites ou des vannes dans des

systèmes se trouvant sous pression!

Il n'y a pas de pièces de rechange pour l'appareil!

Renvoyez l'appareil, s'il est défectueux, au fabricant.

Dans les versions à débit réduit (N° id. 141 721 Z; N° id. 141 722 S) le

débit se réduit à 150 l/min.

Page 29

4.1 Fixation de la vanne / affichage pneumatique de position

Fixer le bloc de vannes avec les 2 vis M5x35 jointes directement contre la

surface de raccordement NAMUR de l’entraînement pneumatique.

REMARQUE

Vis M5x35

Figure 3: Fixation de la vanne / affichage pneumatique de position

La tige de codage jointe assure que l’appareil ne puisse être

monté que dans la position prévue (pour assurer le sens

d’action prévu de l’entraînement.

Connexion 24 V

Tige de codage pour l’affichage de la position

pneumatique.

Si la vanne n’est pas connectée, on peut

enfoncer la tige de codage rouge. Si la vanne

est connectée, la tige de codage sort et reste

dans cette position. A chaque contrôle de

fonctionnement, la tige de codage doit de

nouveau être enfoncée.

Plaquette signalétique (amovible pour

marquages/inscriptions)

Raccord 14

• pas occupé en exécution standard

• sert de raccord auxiliaire de commande et de

raccord pour les pilotages pneumatiques

français

4.2 Précautions à prendre avant la mise en service

Vérifier les raccordements, la tension et la pression de service!

Veiller à ce que les données de service maximales (voir plaquette

signalétique) ne soient pas dépassées!

Vérifier le raccordement conforme aux prescriptions des raccords 1 et 3,

resp. 5, qui ne doivent en aucun cas être permutés!

6520 - 27

Page 30

4.3 Raccordement électrique de la vanne type 6520 NAMUR

avec raccordement 24 V

Raccordement:

Borne 11 24 V

Borne 13 0 V / masse

français

28 - 6520

Page 31

5 DÉRANGEMENTS

Dérangement

Les vannes ne

commutent pas:

Les vannes dommutent à

retardement ou

sifflent aux

raccors

d'échappement

d'air:

Tension de service

absente ou insuffisante;

Pression d'alimentation

absente ou insuffisante.

Pression d'alimentation

absent ou insuffisante;

RemèdeCause possible

Vérifier le raccordement

électrique.

Assurer la tension de service

selon la plaquette

signaleétique.

Exécuter l'alimentation en

pression avec le plus grand

volume (aussi avec les

appareils en amont tels que

régulateurs de pression, unités

de donditionnement, vannes

d'arrêt, etc.).

Pression de service

minimale

≥≥

≥ 2,5 bar

≥≥

Débit minimal 270 l/min au

raccord P de la vanne

Exécuter l'alimentaion pression

avec le plus grand volume

possible (aussi avec les

appareils en amont tels que

régulateurs de pression, unités

de conditionnement, vannes

d'arrêt, etc.).

Pression de service

minimale

≥≥

≥ 2,5 bar

≥≥

Débit minimal 270 l/min au

raccord P de la vanne

1)

français

1)

Aération des canaux

d'échappement d'air

insuffisantes à cause

de silencieux trop petits

Utiliser des silencieux resp.

des vases d'expansion dimensionnés assez grands.

Nettoyer les silencieux sales.

ou sales (contrepressions);

Saletés ou corps

étrangers dans la

vanne de pilotage

ou principale.

Appliquer des impulsions de

pression sur les canaux

d'échappement d'air pour

expulser les saletés ou monter

une nouvelle vanne de

pilotage ou principale si cette

mesure n'a pas de succès.

1)

Dans les versions à débit réduit (N° id. 141 721 Z; N° id. 141 722 S) le débit

se réduit à 150 l/min.

6520 - 29

Page 32

Bürkert Company Locations

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Page 33

The smart choice

of Fluid Control Systems

www.buerkert.com

Loading...

Loading...