Page 1

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2011 Bürkert Werke GmbH

Operating Instructions 1105/00_EU-ml_00809549 / Original DE

Type 6203 EV

2/2-way solenoid valve

2/2-Wege Magnetventil

Électrovanne 2/2 voies

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

2

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the

device. Keep these instructions in a location which is easily

accessible to every user and make these instructions available

to every new owner of the device.

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

• The operating instructions must be read and understood.

english

3

2. SYMBOLS

In these instructions, the following symbols are used.

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or

serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in a serious or

fatal injury.

CAUTION!

Warns of a possible danger!

• Failure to observe the warning may result in medium or

minor injury.

NOTE!

Warns of damage to property!

Important tips and recommendations.

→ designates a procedure which you must carry out.

english

Page 2

4

3. AUTHORISED USE

Non-authorized use of the solenoid valve Type 6203

EV may be a hazard to people, nearby equipment

and the environment.

• The device is designed to control, shut off and meter

neutral media up to a viscosity of 21 mm

2

/s.

• Provided the device socket is connected and installed

correctly, e.g. Bürkert Type 2508, the device satisfies

protection class IP65 in accordance with DIN EN 60529

/ IEC 60529.

• Use according to the authorized data, operating and

service conditions specified in the contract documents

and operating instructions. These are described in the

chapter on “Technical data”.

• Correct transportation, correct storage and installation

and careful use and maintenance are essential for reliable

and faultless operation.

• Use the device only as intended.

3.1. Restrictions

If exporting the system/device, observe any existing

restrictions.

english

5

3.2. Predictable misuse

• The device may only be used in the explosion-protected

area if an appropriate additional identification is attached

to the type label.

• Do not put any loads on the housing (e.g. by placing objects

on it or standing on it).

• Do not make any external modifications to the device

housings. Do not paint the housing parts or screws.

english

6

4. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the

installation, operation and maintenance of the devices.

• local safety regulations – the operator is responsible for

observing these regulations, also with reference to the

installation personnel.

Danger – high pressure!

• Before loosening the lines and valves, turn off the pressure and vent the lines.

Risk of electric shock!

• Before reaching into the system, switch off the power

supply and secure to prevent reactivation.

• Observe applicable accident prevention and safety

regulations for electrical equipment!

Risk of burns/risk of fire if used for a prolonged switchon time through hot device surface!

• Keep the device away from highly flammable substances

and media and do not touch with bare hands.

english

7

Risk of injury due to malfunction of valves with alternating current (AC).

Sticking core causes coil to overheat, resulting in a

malfunction.

• Monitor process to ensure function is in perfect working order!

Risk of short-circuit/escape of media through leaking

screw joints.

• Ensure seals are seated correctly!

• Carefully screw together coil and device socket or valve

and connection plate!

General Hazardous Situations.

To prevent injuries:

• Ensure that the system cannot be activated unintentionally.

• Installation and maintenance work may only be carried

out by authorized technicians with the appropriate tools.

• After an interruption in the power supply, ensure that the

process is restarted in a defined or controlled manner.

english

Type 6203 EV

Page 3

8

• The device may be installed and operated only when in

a perfect condition and in consideration of the operating

instructions.

• The general rules of technology must be observed for

application planning and operation of the device.

Failure to observe this operating manual and its

operating instructions as well as unauthorized tampering with the device release us from any liability

and also invalidate the warranty covering the device

and accessories!

english

9

5. GENERAL INFORMATION

5.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the

printed operating instructions.

And also on the internet at: www.burkert.com

5.2. Warranty

The warranty is only valid if the device is used as intended in

accordance with the specified application conditions.

5.3. Information on the Internet

The operating instructions and data sheets for Type 6203 EV

can be found on the Internet at: www.burkert.com

english

10

6. TECHNICAL DATA

The following values are indicated on the type label:

• Voltage (Tolerance ±10 %) / Current type

• Coil power consumption

(active power in W - at operating temperature)

• Pressure range

• Housing material

Brass (MS) or stainless steel (VA)

• Seal material

FKM, EPDM, NBR

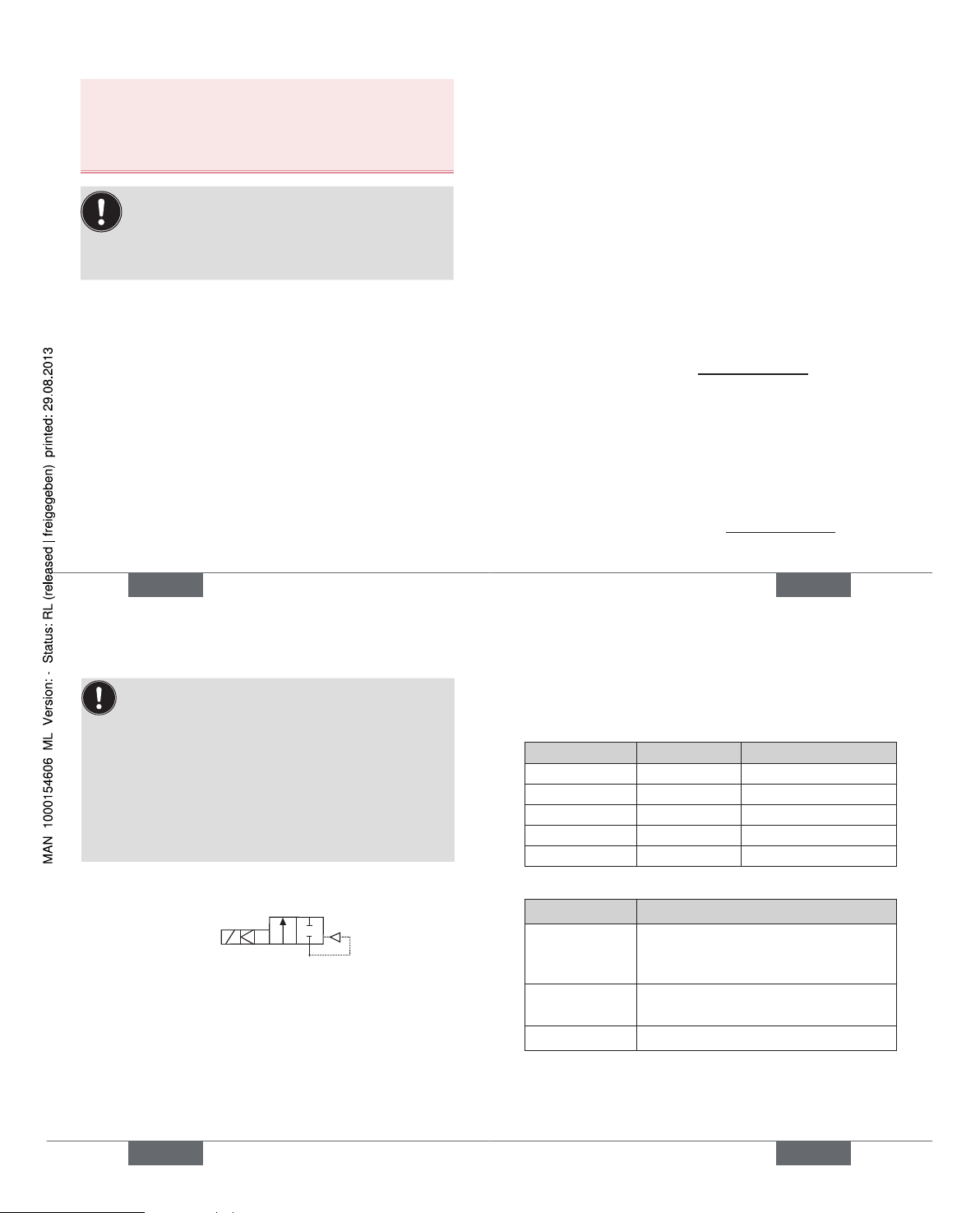

Operating principle 2/2-way valve:

A (NC)

A

P

Protection class: IP65 in accordance with DIN EN

60529 / IEC 60529 with correctly

connected and installed device

socket, e.g. Type 2508

english

11

6.1. Application conditions

Ambient temperature: max. +55 °C

Permitted medium temperature depending on coil and seal

material:

Coil housing Seal material Medium temperature

Polyamide FKM 0 ... +90 °C

Epoxy (NA38) FKM 0 ... +120 °C

Epoxy (NA38) EPDM -30 ... +100 °C

Polyamide EPDM -30 ... +90 °C

Polyamide NBR -10 ... +80 °C

Permitted media depending on seal material:

Seal material Permitted media

1)

FKM Per-solutions, hot oils without addi-

tives, diesel and heating oil without

additives, detergent solution

EPDM Oil and grease-free liquids, cold and

hot water

NBR Cold and warm water

1)

Gaseous media at low differential pressures (e.g. compressed

air and vacuum) can also be actuated in consideration (or due to

restriction) of a lower tightness. We recommend prior clarification

with our sales office regarding the possible application.

english

Type 6203 EV

Page 4

12

Operating duration

Unless otherwise indicated on the type label, the solenoid

system is suitable for continuous operation.

Important information for functional reliability during

continuous operation!

For long switch-on or switch-off times a minimum

actuation of 1-2 switching operations per day is

recommended.

Service life

High switching frequency and high pressures reduce the

service life.

english

13

6.2. Type label

6203 A 10 EPDM MS

Made in Germany

00229009

W14 LU

230V 50Hz 8W

G3/8 P

N0 - 10bar

Type

Operating principle

Orifice

Seal material

Housing material

Identification number

Manufacturer code

Voltage, Frequency, Power

consumption

Connection thread, Nominal pressure

Fig. 1: Location and description of the type label

english

14

7. INSTALLATION

7.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the system , switch off the power

supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

WARNING!

Risk of injury from improper installation!

• Installation may only be carried out by authorized technicians with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

english

15

7.2. Before Installation

Installation position:

Installation can be in any position.

Preferably: Drive at the top.

→ Prior to installation check pipelines for dirt and if

required, clean.

Dirt filter: To ensure that the solenoid valve functions

reliably, a dirt filter (≤ 500 μm) must be installed in front of

the valve inlet.

7.3. Installation

→ Hold the device with a suitable tool (open-end wrench)

on the housing and screw into the pipeline.

NOTE!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

→ Observe direction of flow:

The arrow on the housing indicates the direction of

flow.

english

Type 6203 EV

Page 5

16

7.4. Electrical connection of the

device socket

WARNING!

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the electrical

power supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

If the protective conductor contact between the coil and

housing is missing, there is danger of electrical shock!

• Always connect protective conductor.

• Check electrical continuity between coil and housing.

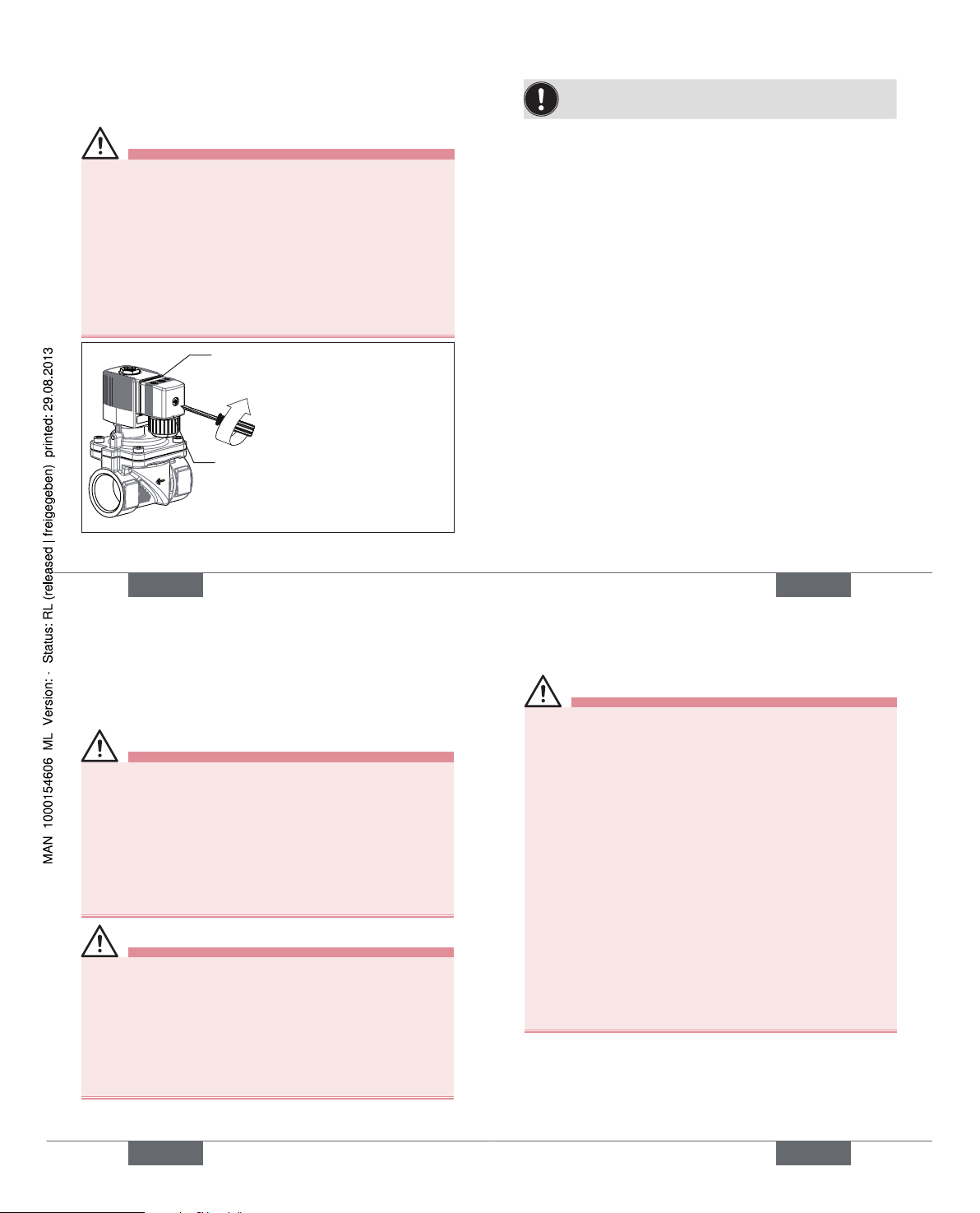

Authorized device socket e.g. Type

2508 in accordance with DIN ISO

175301-803 Form A

Seal

max. 1 Nm

Fig. 2: Electrical connection of the device socket

english

17

Note the voltage and current type as specified on

the type label.

→ Tighten device socket (for permitted types see data

sheet), observing max. torque of 1 Nm.

→ Check that seal is fitted correctly.

→ Connect protective conductor and check electrical con-

tinuity between coil and housing.

english

18

8. MAINTENANCE,

TROUBLESHOOTING

8.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the system , switch off the power

supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

WARNING!

Risk of injury from improper maintenance!

• Maintenance may only be carried out by authorized

technicians with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following maintenance, ensure a controlled restart.

english

19

8.2. Installation of coil

WARNING!

Escaping medium!

When a sticking nut is loosened, medium may escape.

• Do not tighten sticking nut any further.

Electric shock!

If the protective conductor contact between the coil and

housing is missing, there is danger of electrical shock!

• Check protective conductor contact after installing the

coil.

Overheating, risk of fire!

Connection of the coil without pre-assembled valve will

result in overheating and destroy the coil.

• Connect the coil with pre-assembled valve only.

Danger due to electrical shock if coil incorrectly installed!

• During installation ensure that the coil is seated firmly

on the step of the core guide tube so that the protective

conductor connection of the coil has a connection to

the valve housing.

Procedure:

→ Connect coil housing to the core guide pipe.

→ Screw on coil with nut. Observe torque.

→ Check protective conductor.

english

Type 6203 EV

Page 6

20

NOTE!

Device will be damaged if the wrong tools are used!

Always use a wrench to tighten nut. If other tools are used

(e.g. pliers), the device may be damaged.

Observe torque!

(see table below)

Nut

O-ring

Core guide tube

Fig. 3: Coil installation

Torque for fastening nut:

Coil type Coil width Torque [Nm]

AC10 32 mm or 40 mm 5 Nm

english

21

8.3. Malfunctions

If malfunctions occur, check whether:

→ the device has been installed according to the

instructions,

→ the electrical and fluid connections are correct,

→ the device is not damaged,

→ all screws have been tightened,

→ the voltage and pressure have been switched on,

→ the pipelines are clean.

Valve does not switch

Possible cause:

• Short circuit or coil interrupted,

• Core or core area dirty.

• Medium pressure outside the permitted pressure range.

Valve does not close

Possible cause:

• Internal space of the valve is dirty.

• Small control bore in the diaphragm blocked.

english

22

9. SPARE PARTS

CAUTION!

Risk of injury and/or damage by the use of incorrect

parts!

Incorrect accessories and unsuitable spare parts may cause

injuries and damage the device and the surrounding area.

• Use original accessories and original spare parts from

Bürkert only.

9.1. Ordering spare parts

Replacement part sets

When ordering replacement part sets, quote the sets SET 1,

SET 3 or SET 7 and the identification number of the device.

• See replacement part sets 9.2. and 9.3

• The identification number of the device can be found on

the type label. See also chapter “6.2. Type label”.

english

23

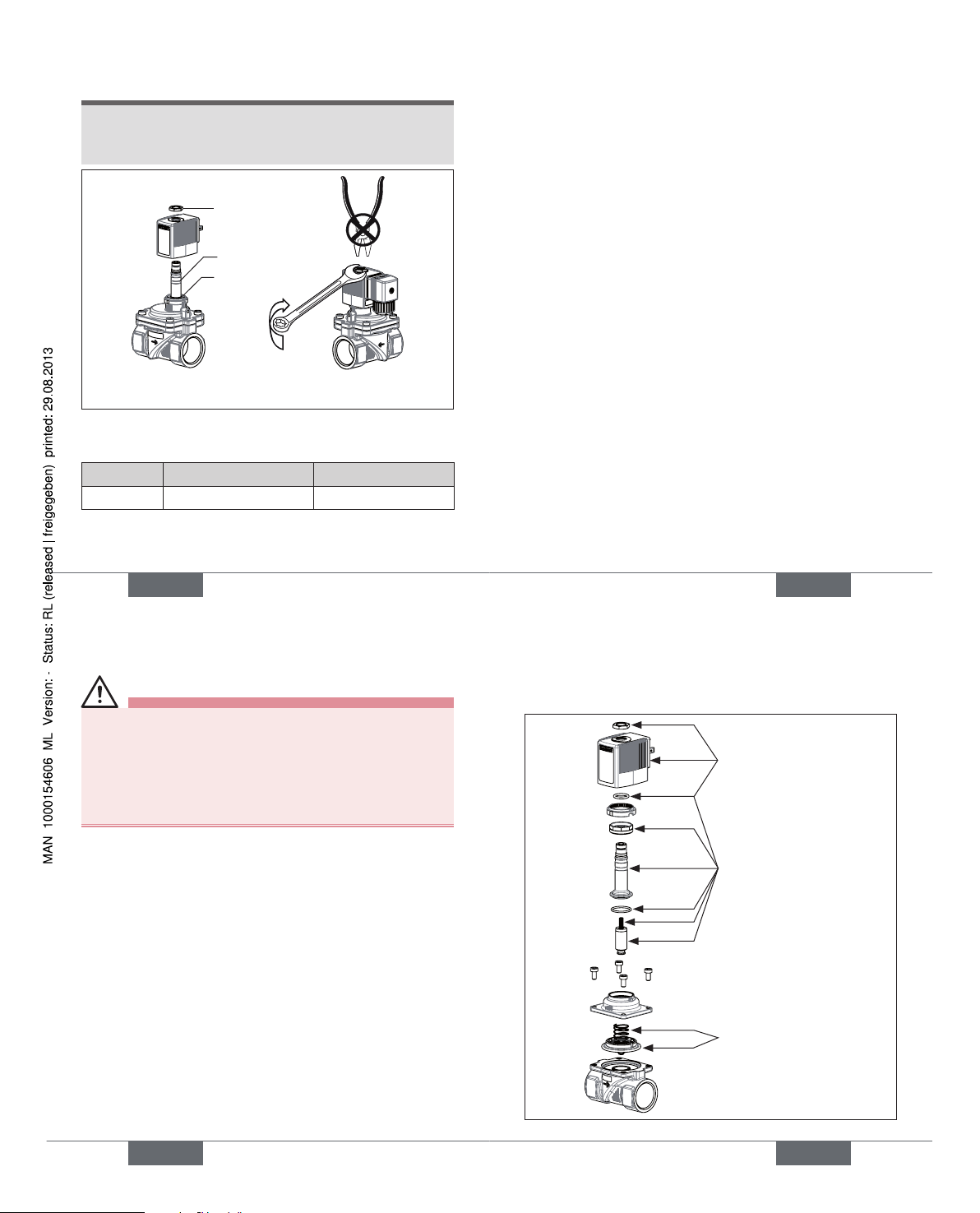

9.2. Overview of replacement part

sets Type 6203 EV, DN 10,

DN 13

Coil set

SET 1

Wearing-parts

set SET 3

Plunger tube set

SET 7

Fig. 4: Replacement part sets Type 6203 EV

english

Type 6203 EV

Page 7

24

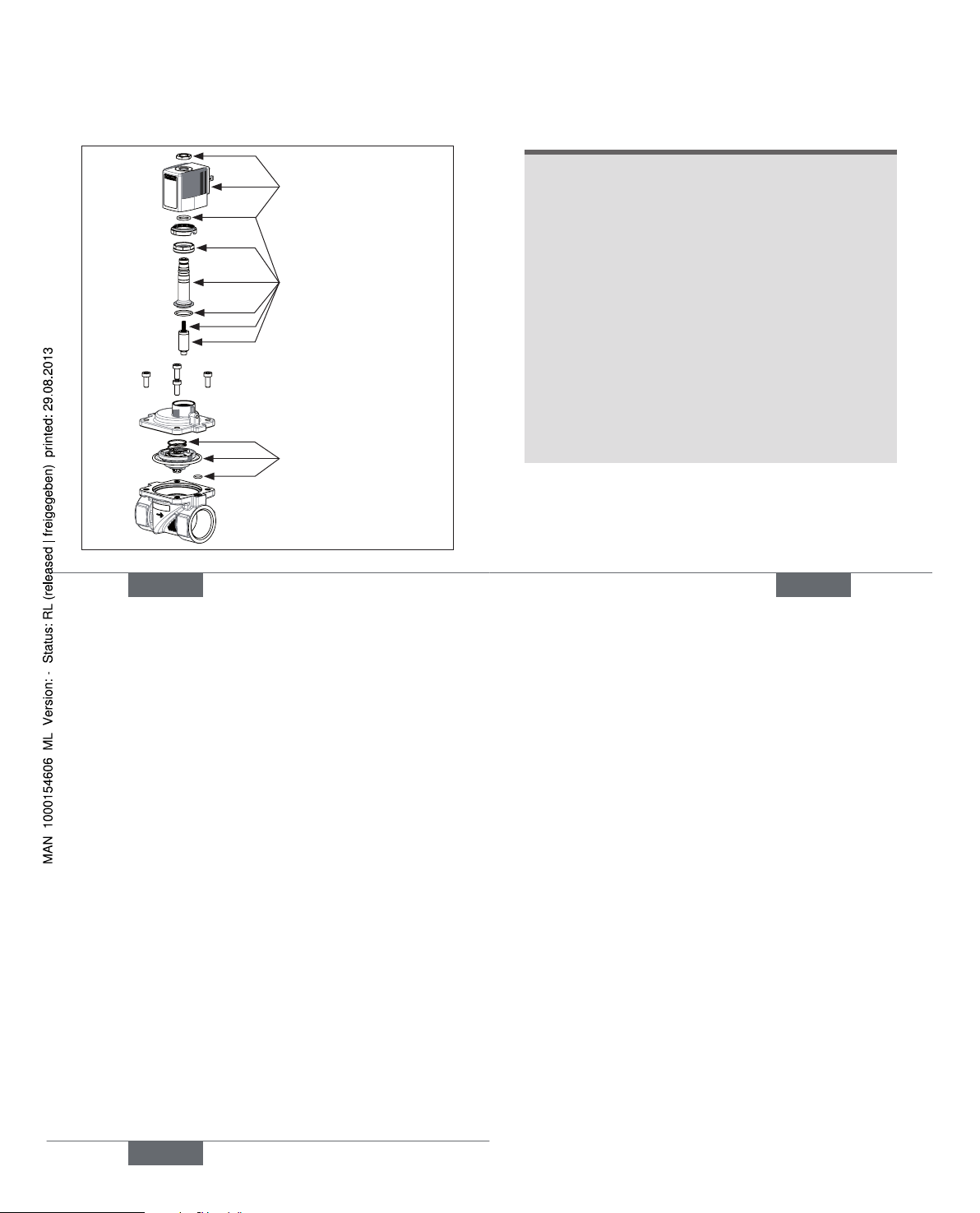

9.3. Overview of replacement part

sets Type 6203 EV, DN 20,

DN 25 and DN 40

Coil set

SET 1

Plunger tube set

SET 7

Wearing-parts

set SET 3

Fig. 5: Replacement part sets Type 6203 EV

english

25

10. PACKAGING, TRANSPORT,

STORAGE, DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged

during transport.

• During transportation protect the device against wet

and dirt in shock-resistant packaging.

• Avoid exceeding or dropping below the allowable

storage temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature. -40 … +80 °C.

Damage to the environment caused by device components contaminated with media.

• Observe applicable regulations on disposal and the

environment.

• Observe national waste disposal regulations.

english

26

english

Type 6203 EV

Page 8

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2011 Bürkert Werke GmbH

Operating Instructions 1105/00_EU-ml_00809549 / Original DE

Typ 6203 EV

2/2-Wege Magnetventil

Bedienungsanleitung

Deutsch

28

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus des Gerätes. Bewahren Sie diese Anleitung so auf,

dass sie für jeden Benutzer gut zugänglich ist und jedem

neuen Eigentümer des Gerätes wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen

Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden

werden.

deutsch

29

2. DARSTELLUNGSMITTEL

In dieser Anleitung werden folgende Darstellungsmittel

verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung können schwere Verletzungen oder

Tod die Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen.

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

deutsch

Page 9

30

3. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Typs

6203 EV können Gefahren für Personen, Anlagen in

der Umgebung und die Umwelt entstehen.

• Das Gerät ist zum Steuern, Absperren und Dosieren von

neutralen Medien bis zu einer Viskosität von 21 mm

2

/s

konzipiert.

• Mit einer sachgemäß angeschlossenen und montierten

Gerätesteckdose, z. B. Bürkert Typ 2508 erfüllt das Gerät

die Schutzart IP65 nach DIN EN 60529 / IEC 60529.

• Für den Einsatz die in den Vertragsdokumenten und

der Bedienungsanleitung spezifizierten zulässigen

Daten, Betriebs- und Einsatzbedingungen beachten.

Diese sind im Kapitel „Technische Daten“ beschrieben.

• Voraussetzungen für den sicheren und einwandfreien

Betrieb sind sachgemäßer Transport, sachgemäße

Lagerung und Installation sowie sorgfältige Bedienung

und Instandhaltung.

• Das Gerät nur bestimmungsgemäß einsetzen.

3.1. Beschränkungen

Bei der Ausfuhr des Systems/Gerätes gegebenenfalls bestehende Beschränkungen beachten.

deutsch

31

3.2. Vorhersehbarer Fehlgebrauch

• Im explosionsgeschützten Bereich darf das Gerät nur

eingesetzt werden, wenn auf dem Typenschild eine entsprechende zusätzliche Kennzeichnung angebracht ist.

• Das Gehäuse nicht mechanisch belasten (z. B. durch

Ablage von Gegenständen oder als Trittstufe).

• Keine äußerlichen Veränderungen an den Gerätegehäusen

vornehmen. Gehäuseteile und Schrauben nicht lackieren.

deutsch

32

4. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb

und Wartung der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren

Einhaltung, auch in Bezug auf das Montagepersonal, der

Betreiber verantwortlich ist.

Gefahr durch hohen Druck!

• Vor dem Lösen von Leitungen oder Ventilen den Druck

abschalten und Leitungen entlasten.

Gefahr durch elektrische Spannung!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung

abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

Verbrennungsgefahr/Brandgefahr bei längerer Einschaltzeit durch heiße Geräteoberfläche!

• Das Gerät von leicht brennbaren Stoffen und Medien

fernhalten und nicht mit bloßen Händen berühren.

deutsch

33

Verletzung durch Funktionsausfall bei Ventilen mit

Wechselspannung (AC).

Festsitzender Kern bewirkt Spulenüberhitzung, die zu

Funktionsausfall führt.

• Arbeitsprozess auf einwandfreie Funktion überwachen.

Kurzschlussgefahr / Austritt von Medium durch

undichte Verschraubungen.

• Auf einwandfreien Sitz der Dichtungen achten.

• Ventil und Anschlussleitungen sorgfältig verschrauben.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden

kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von

autorisiertem Fachpersonal mit geeignetem Werkzeug

ausgeführt werden.

• Nach einer Unterbrechung der elektrischen Versorgung

ist ein definierter oder kontrollierter Wiederanlauf des

Prozesses zu gewährleisten.

deutsch

Typ 6203 EV

Page 10

34

• Das Gerät darf nur in einwandfreiem Zustand und unter

Beachtung der Bedienungsanleitung betrieben werden.

• Für die Einsatzplanung und den Betrieb des Gerätes

müssen die allgemeinen Regeln der Technik eingehalten

werden.

Bei Nichtbeachtung dieser Bedienungsanleitung

und ihrer Hinweise sowie bei unzulässigen Eingriffen

in das Gerät entfällt jegliche Haftung unsererseits,

ebenso erlischt die Gewährleistung auf Geräte und

Zubehörteile!

deutsch

35

5. ALLGEMEINE HINWEISE

5.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

5.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Typs 6203 EV unter Beachtung der

spezifizierten Einsatzbedingungen.

5.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 6203 EV

finden Sie im Internet unter: www.buerkert.de

deutsch

36

6. TECHNISCHE DATEN

Folgende Werte sind auf dem Typenschild

angegeben:

• Spannung (Toleranz ±10 %) / Stromart

• Spulenleistung

(Wirkleistung in W - betriebswarm)

• Druckbereich

• Gehäusewerkstoff

Messing (MS) oder Edelstahl (VA)

• Dichtwerkstoff

FKM, EPDM, NBR

Wirkungsweise 2/2-Wege Ventil:

A (NC)

A

P

Schutzart: IP65 nach DIN EN 60529 / IEC 60529 mit

sachgemäß angeschlossener und montierter

Gerätesteckdose, z. B. Bürkert Typ 2508

deutsch

37

6.1. Einsatzbedingungen

Umgebungstemperatur: max. +55 °C

Zulässige Mediumstemperatur in Abhängigkeit von Spule

und Dichtwerkstoff:

Spulengehäuse Dichtwerkstoff Mediumstemperatur

Polyamid FKM 0 ... +90 °C

Epoxid (NA38) FKM 0 ... +120 °C

Epoxid (NA38) EPDM -30 ... +100 °C

Polyamid EPDM -30 ... +90 °C

Polyamid NBR -10 ... +80 °C

Zulässige Medien in Abhängigkeit vom Dichtwerkstoff:

Dichtwerkstoff Zulässige Medien

1)

FKM Per-Lösungen, heiße Öle ohne

Additive, Diesel und Heizöl ohne

Additive, Waschlauge

EPDM Öl- und fettfreie Flüssigkeiten, Kalt-

und Heißwasser

NBR Kalt- und Warmwasser

1)

Gasförmige Medien bei kleinen Differenzdrücken (z. B. Druckluft

und Vakuum) können unter Berücksichtigung (oder Einschränkung) einer geringeren Dichtheit ebenfalls geschalten

werden. Wir empfehlen eine vorherige Klärung der Einsatzmöglichkeit mit unserer Vertriebsniederlassung.

deutsch

Typ 6203 EV

Page 11

38

Betriebsdauer

Wenn auf dem Typenschild nicht anders angegeben, ist das

Magnetsystem für Dauerbetrieb geeignet.

Wichtiger Hinweis für die Funktionssicherheit bei

Dauerbetrieb!

Bei langen Ein- oder Ausschaltzeiten wird eine

Mindestbetätigung von 1-2 Schaltungen pro Tag

empfohlen.

Lebensdauer

Hohe Schaltfrequenz und hohe Drücke verringern die

Lebensdauer.

deutsch

39

6.2. Typenschild

6203 A 10 EPDM MS

Made in Germany

00229009

W14 LU

230V 50Hz 8W

G3/8 P

N0 - 10bar

Typ

Wirkungsweise

Nennweite

Dichtwerkstoff

Gehäusewerkstoff

Identnummer

Hersteller-Code

Spannung, Frequenz, Leistung

Anschlussgewinde, Nenndruck

Bild 1: Lage und Beschreibung des Typenschildes

deutsch

40

7. MONTAGE

7.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen oder Ventilen den Druck

abschalten und Leitungen entlüften.

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung

abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage!

• Die Montage darf nur autorisiertes Fachpersonal mit

geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der

Anlage und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Montage einen kontrollierten Wiederanlauf

gewährleisten.

deutsch

41

7.2. Vor dem Einbau

Einbaulage:

Die Einbaulage ist beliebig.

Vorzugsweise: Antrieb oben.

→ Rohrleitungen vor dem Einbau auf Verschmutzungen

überprüfen und gegebenenfalls reinigen.

Schmutzfilter: Für die sichere Funktion des Magnetventils

muss vor dem Ventileingang ein Schmutzfilter (≤ 500 µm)

eingebaut werden.

7.3. Einbau

→ Das Gerät mit geeignetem Werkzeug (Gabelschlüssel)

am Gehäuse festhalten und in die Rohrleitung

einschrauben.

HINWEIS!

Vorsicht Bruchgefahr!

• Die Spule darf nicht als Hebelarm benutzt werden.

→ Durchflussrichtung beachten:

Der Pfeil auf dem Gehäuse kennzeichnet die

Durchflussrichtung.

deutsch

Typ 6203 EV

Page 12

42

7.4. Elektrischer Anschluss der

Gerätesteckdose

WARNUNG!

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das Gerät oder Anlage die Spannung

abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

Bei nicht angeschlossenem Schutzleiter besteht die Gefahr

des Stromschlags!

• Schutzleiter immer anschließen.

• Elektrischer Durchgang zwischen Spule und Gehäuse

prüfen.

Zugelassene Gerätesteckdose

z. B. Typ 2508 oder andere nach

DIN ISO 175301-803 Form A

Dichtung

max. 1 Nm

Bild 2: Elektrischer Anschluss der Gerätesteckdose

deutsch

43

Spannung und Stromart laut Typenschild beachten.

→ Gerätesteckdose (zugelassene Typen siehe Datenblatt)

festschrauben, dabei max. Drehmoment 1 Nm beachten.

→ Korrekten Sitz der Dichtung überprüfen.

→ Schutzleiter anschließen und elektrischer Durchgang

zwischen Spule und Gehäuse prüfen.

deutsch

44

8. WARTUNG,

FEHLERBEHEBUNG

8.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen oder Ventilen den Druck

abschalten und Leitungen entlüften.

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung

abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßen

Wartungsarbeiten!

• Die Wartung darf nur autorisiertes Fachpersonal mit

geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten

der Anlage und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Wartung einen kontrollierten Wiederanlauf

gewährleisten.

deutsch

45

8.2. Spulenmontage

WARNUNG!

Mediumsaustritt!

Beim Lösen festsitzender Mutter kann Medium austreten.

• Festsitzende Mutter nicht weiterdrehen.

Stromschlag!

Bei nicht angeschlossenem Schutzleiter besteht die

Gefahr des Stromschlags!

• Schutzleiterkontakt nach der Spulenmontage prüfen.

Überhitzung, Brandgefahr!

Der Anschluss der Spule ohne vormontiertes Ventil führt

zur Überhitzung und zerstört die Spule.

• Spule nur mit vormontiertem Ventil anschließen.

Gefahr durch Stromschlag bei falscher Montage der

Spule!

• Bei der Montage beachten, dass die Spule fest auf der

Stufe vom Kernführungsrohr aufsitzt damit der Schutzleiteranschluss der Spule Verbindung zum Ventilgehäuse hat.

Vorgehensweise:

→ Spulengehäuse auf Kernführungsrohr aufstecken.

→ Spule mittels Mutter verschrauben. Drehmoment

beachten.

→ Schutzleiter prüfen.

deutsch

Typ 6203 EV

Page 13

46

HINWEIS!

Geräteschaden durch falsches Werkzeug!

Mutter immer mit einem Gabelschlüssel festschrauben. Bei

der Verwendung anderer Werkzeuge (z. B. Zange) kann

das Gerät beschädigt werden.

Drehmoment beachten!

(siehe Tabelle unten)

Mutter

O-Ring

Kernführungsrohr

Bild 3: Spulenmontage

Drehmomente für Befestigungsmutter:

Spulentyp Spulenbreite Drehmoment [Nm]

AC10 32 mm bzw. 40 mm 5 Nm

deutsch

47

8.3. Störungen

Überprüfen Sie bei Störungen ob:

→ das Gerät vorschriftsmäßig installiert ist,

→ der elektrische und fluidische Anschluss ordnungsgemäß

ausgeführt ist,

→ das Gerät nicht beschädigt ist,

→ alle Schrauben fest angezogen sind,

→ Spannung und Druck anliegen,

→ die Rohrleitungen schmutzfrei sind.

Ventil schaltet nicht

Mögliche Ursache:

• Kurzschluss oder Spulenunterbrechung.

• Kern oder Kernraum verschmutzt.

• Mediumsdruck außerhalb des zulässigen Druckbereichs.

Ventil schließt nicht

Mögliche Ursache:

• Innenraum des Ventils verschmutzt.

• Kleine Steuerbohrung in der Membrane verstopft.

deutsch

48

9. ERSATZTEILE

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen und Schäden am Gerät und dessen Umgebung

verursachen.

• Nur Originalzubehör sowie Originalersatzteile der Firma

Bürkert verwenden.

9.1. Ersatzteile bestellen

Ersatzteilsätze

Bestellen Sie Ersatzteilsätze unter Angabe der Sätze SET 1,

SET 3 oder SET 7 und der Identnummer des Gerätes.

• Ersatzteilsätze siehe Kapitel 9.2. und 9.3.

• Die Identnummer des Gerätes finden Sie auf dem Typenschild. Siehe auch Kapitel „6.2. Typenschild“.

deutsch

49

9.2. Übersicht Ersatzteilsätze Typ

6203 EV DN 10, DN 13

Spulensatz

SET 1

Verschleißteilsatz

SET 3

Stopfensatz

SET 7

Bild 4: Ersatzteilsätze Typ 6203 EV

deutsch

Typ 6203 EV

Page 14

50

9.3. Übersicht Ersatzteilsätze Typ

6203 EV, DN 20, DN 25 und

DN 40

Spulensatz

SET 1

Stopfensatz

SET 7

Verschleißteilsatz

SET 3

Bild 5: Ersatzteilsätze Typ 6203 EV

deutsch

51

10. VERPACKUNG, TRANSPORT,

LAGERUNG, ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den

Transport beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät

verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur. -40 … +80 °C.

Umweltschäden durch von Medien kontaminierte

Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen einhalten.

deutsch

52

deutsch

Typ 6203 EV

Page 15

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2011 Bürkert Werke GmbH

Operating Instructions 1105/00_EU-ml_00809549 / Original DE

Type 6203 EV

Électrovanne 2/2 voies

Manuel d‘utilisation

Français

54

1. LES INSTRUCTIONS DE

SERVICE

Les instructions de service décrivent le cycle de vie complet

de l‘appareil. Conservez ces instructions de sorte qu‘elles

soient accessibles à tout utilisateur et à disposition de tout

nouveau propriétaire.

Les instructions de service contiennent des informations importantes sur la sécurité !

Le non-respect de ces consignes peut entraîner des

situations dangereuses.

• Les instructions de service doivent être lues et comprises.

français

55

2. SYMBOLES

Les moyens de représentation suivants sont utilisés dans

les présentes instructions de service.

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves

blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement

dangereuse !

• Le non-respect peut entraîner de graves blessures ou la mort.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou

de moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

Conseils et recommandations importants.

→ identifie une opération que vous devez effectuer.

français

Page 16

56

3. UTILISATION CONFORME

L’utilisation non-conforme du type 6203 EV peut

présenter des dangers pour les personnes, les installations avoisinantes et l’environnement.

• L’appareil est conçu pour commander, arrêter et doser

des fluides neutres jusqu’à une viscosité de 21 mm

2

/s.

• Avec prise d’appareil, par ex. le type 2508 de Bürkert,

connectée et montée de manière conforme, l’appareil

est conforme au type de protection IP65 selon DIN EN

60529 / IEC 60529.

• Lors de l’utilisation, il convient de respecter les données

et conditions d’utilisation et d’exploitation admissibles

spécifiées dans les instructions de service et dans les

documents contractuels. Celles-ci sont décrites au

chapitre « Caractéristiques techniques ».

• Les conditions pour l’utilisation sûre et parfaite sont un

transport, un stockage et une installation dans les règles

ainsi qu’une parfaite utilisation et maintenance.

• Veillez à ce que l’utilisation de l’appareil soit toujours

conforme.

3.1. Limitations

Lors de l’exportation du système/de l’appareil, veuillez respecter les limitations éventuelles existantes.

français

57

3.2. Mauvaise utilisation prévisible

• L’appareil ne peut être utilisé dans une zone à atmosphère

explosive que si un marquage additionnel correspondant

se trouve sur la plaque signalétique.

• Ne soumettez pas le corps à des contraintes mécaniques

(par ex. pour déposer des objets ou en l’utilisant comme

marche).

• N’apportez pas de modifications à l’extérieur du corps de

l’appareil. Ne laquez pas les pièces du corps et les vis.

français

58

4. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte

• des hasards et des événements pouvant survenir lors

du montage, de l’exploitation et de la maintenance des

appareils.

• des prescriptions de sécurité locales que l’exploitant est

tenu de faire respecter par le personnel chargé du montage.

Danger dû à la haute pression !

• Avant de desserrer les conduites et les vannes, coupez

la pression et purgez l’air des conduites.

Danger présenté par la tension électrique !

• Avant d’intervenir dans le système, coupez la tension et

empêchez toute remise sous tension par inadvertance.

• Veuillez respecter les réglementations en vigueur pour

les appareils électriques en matière de prévention des

accidents ainsi qu’en matière de sécurité !

Risque de brûlures / d’incendie lors d’une durée de

fonctionnement prolongée dû à la surface brûlante

de l’appareil !

• Tenez les substances et les fluides facilement inflammables à l’écart de l’appareil et ne touchez pas ce dernier

à mains nues.

français

59

Risque de blessure dû à une panne des vannes avec

tension alternative (AC).

Un noyau bloqué provoque la surchauffe de la bobine et

donc une panne.

• Surveiller le bon fonctionnement du processus de travail !

Risque de court-circuit/de sortie du fluide en présence

de vissages non étanches.

• Veiller à l’installation correcte des joints !

• Visser prudemment la bobine et la prise de l’appareil ou

la vanne et la plaque de connexion !

Situations dangereuses d’ordre général.

Pour prévenir les blessures, respectez ce qui suit :

• L’installation ne peut pas être actionnée par inadvertance.

• Les travaux d’installation et de maintenance doivent être

effectués uniquement par des techniciens qualifiés et

habilités disposant de l’outillage approprié.

• Après une interruption de l’alimentation électrique, un

redémarrage défini ou contrôlé du process doit être

garanti.

français

Type 6203 EV

Page 17

60

• L’appareil doit être utilisé uniquement en parfait état et

en respectant les instructions de service.

• Les règles générales de la technique sont d’application

pour planifier l’utilisation et utiliser l’appareil.

Le non-respect de ces instructions de service avec

ses consignes ainsi que les interventions non autorisées sur l’appareil excluent toute responsabilité de

notre part et entraînent la nullité de la garantie légale

concernant les appareils et les accessoires !

français

61

5. INDICATIONS GÉNÉRALES

5.1. Adresse

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages des instructions de service imprimées.

Egalement sur internet sous : www.burkert.com

5.2. Garantie légale

La condition pour bénéficier de la garantie légale est l’utilisation conforme de l’appareil dans le respect des conditions

d’utilisation spécifiées.

5.3. Informations sur Internet

Vous trouverez les instructions de service et les fiches

techniques concernant le type 6203 EV sur Internet sous :

www.buerkert.fr

français

62

6. CARACTÉRISTIQUES

TECHNIQUES

Les valeurs suivantes sont indiquées sur la plaque

signalétique :

• Tension (Tolérance ±10 %) / type de courant

• Puissance de bobine

(puissance active en W - à l’état chaud)

• Plage de pression

• Matériau du corps

laiton (MS) ou acier inoxydable (VA)

• Matériau du joint

FKM, EPDM, NBR

Fonction vanne 2/2 voies :

A (NC)

A

P

Type de protection : IP65 selon DIN EN 60529 / IEC

60529 avec prise de l’appareil autorisée, par le type 2508

français

63

6.1. Conditions d’utilisation

Température ambiante : max. +55 °C

Température admissible du fluide en fonction de la bobine

et du matériau du joint :

Corps de la

bobine

Matériau du

joint

Température du

fluide

Polyamide FKM 0 ... +90 °C

Epoxy (NA38) FKM 0 ... +120 °C

Epoxy (NA38) EPDM -30 ... +100 °C

Polyamide EPDM -30 ... +90 °C

Polyamide NBR -10 ... +80 °C

Fluides utilisables en fonction du matériau du joint :

Matériau du joint Fluides admissibles

1)

FKM Solutions perchloréthylènes, huiles

chaudes sans additifs, diesel et fioul sans

additif, lessive

EPDM Liquides exempts d’huile et de graisse, eau

froide et chaude

NBR Eau froide et chaude

1)

Les fluides gazeux avec faibles différences de pressions (par ex.

air comprimé et vide), peuvent également être utilisés sous conditions (ou restrictions) avec une légère fuite. Nous recommandons

de vérifier au préalable auprès de notre filiale de distribution si

l’utilisation est possible.

français

Type 6203 EV

Page 18

64

Durée de fonctionnement

Si aucune information contraire ne figure sur la plaque

signalétique, le système magnétique est adapté à un fonctionnement continu.

Remarque importante pour la sécurité de fonctionnement lors d’un fonctionnement continu!

En cas de temps d’activation et de coupure de

longue durée, il est recommandé de procéder à

1 - 2 commutations minimum par jour.

Durée de vie

Une fréquence élevée de commutation ainsi que des pressions élevées réduisent la durée de vie.

français

65

6.2. Plaque signalétique

6203 A 10 EPDM MS

Made in Germany

00229009

W14 LU

230V 50Hz 8W

G3/8 P

N0 - 10bar

Type

Fonction

Diamètre nominal

Matériau du joint

Matériau du corps

N° d’identification

Code-fabricant

Tension, Fréquence, Puissance

Raccordement, Pression nominale

Fig. 1 : Emplacement et description de la plaque signalétique

français

66

7. MONTAGE

7.1. Consignes de sécurité

DANGER !

Risque de blessures dû à la présence de haute

pression dans l'installation !

• Avant de desserrer les conduites et les vannes, coupez

la pression et purgez l'air des conduites.

Risque de choc électrique !

• Avant d'intervenir dans le système , coupez la tension et

empêchez toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour

les appareils électriques en matière de prévention des

accidents ainsi qu'en matière de sécurité !

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme !

• Le montage doit être effectué uniquement par un personnel qualifié et habilité disposant de l'outillage approprié !

Risque de blessures dû à la mise en marche involontaire de l'installation et le redémarrage non contrôlé !

• Empêchez tout actionnement involontaire de l'installation.

• Garantissez un redémarrage contrôlé après le montage.

français

67

7.2. Avant le montage

Position de montage :

Position de montage indifférente.

De préférence avec l’entraînement en haut.

→ Préalablement au montage, vérifier si les tuyaux ne pré-

sentent pas de salissures et les nettoyer le cas échéant.

Filtre à impuretés: Pour garantir un fonctionnement fiable

de l’électrovanne, il convient de monter un filtre à impuretés

(≤ 500 μm) avant l’entrée de la vanne.

7.3. Montage

→ Maintenez l’appareil sur le corps à l’aide d’un outil

approprié (clé à fourche) et vissez-le dans la tuyauterie.

REMARQUE !

Attention risque de rupture !

• La bobine ne doit pas être utilisée comme levier.

→ Respectez le sens du débit :

La flèche sur le corps indique le sens du débit.

français

Type 6203 EV

Page 19

68

7.4. Raccordement électrique de la

prise de l’appareil

AVERTISSEMENT !

Risque de choc électrique !

• Avant d'intervenir dans le système, coupez la tension et

empêchez toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour

les appareils électriques en matière de prévention des

accidents ainsi qu'en matière de sécurité !

Il y a risque de choc électrique en l'absence d'un contact

du conducteur de protection !

• Raccordez toujours le conducteur de protection.

• Contrôlez le passage du courant entre la bobine et le boîtier.

Prise de l’appareil homologuée par ex.

Type 2508 ou autre selon

DIN ISO 175301-803 Forme A

Joint

max. 1 Nm

Fig. 2 : Raccordement électrique de la prise de l’appareil

français

69

Respectez la tension et le type de courant selon la

plaque signalétique.

→ Visser la prise d’appareil (types admissibles, voir fiche

technique) en respectant le couple max. de 1 Nm.

→ Vérifier le bon positionnement du joint.

→ Raccorder le conducteur de protection et vérifier le

passage électrique entre la bobine et le corps.

français

70

8. MAINTENANCE, DÉPANNAGE

8.1. Consignes de sécurité

DANGER !

Risque de blessures dû à la présence de haute

pression dans l’installation !

• Avant de desserrer les conduites et les vannes, coupez

la pression et purgez l’air des conduites.

Risque de choc électrique !

• Avant d’intervenir dans l’appareil, coupez la tension et

empêchez toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour

les appareils électriques en matière de prévention des

accidents ainsi qu’en matière de sécurité !

AVERTISSEMENT !

Risque de blessures dû à des travaux de maintenance

non conformes!

• La maintenance doit être effectué uniquement par un personnel qualifié et habilité disposant de l’outillage approprié!

Risque de blessures dû à la mise en marche involontaire de l’installation et le redémarrage non contrôlé!

• Empêchez tout actionnement involontaire de l’installation.

• Garantissez un redémarrage contrôlé après la

maintenance.

français

71

8.2. Montage de la bobine

AVERTISSEMENT !

Fuite de fluide !

Lors desserrage d’un écrou fixe, du fluide peut s’échapper.

• Ne pas continuer de tourner, l’écrou fixe.

Choc électrique !

Il y a risque de choc électrique en l’absence d’un contact du

conducteur de protection.

• Contrôlez le contact du conducteur de protection après

montage de la bobine.

Surchauffe, risque d’incendie !

La raccordement de la bobine sans armature en amont

entraîne la surchauffe et la destruction de la bobine.

• Raccorder la bobine uniquement avec l’armature.

Risque de choc électrique lors d’un mauvais montage de

la bobine !

• Lors du montage, veiller à ce que la bobine soit fermement

posée sur le tube de guidage du noyau afin que le raccord

du conducteur de protection de la bobine soit en contact

avec le boîtier de la vanne.

Procédure:

→ Mettre le corps de la bobine sur le tube de guidage du noyau.

→ Visser la bobine au moyen de l’écrou. Respecter le couple

de serrage.

→ Contrôlez le conducteur de protection.

français

Type 6203 EV

Page 20

72

REMARQUE !

Endommagement de l’appareil dû à un outillage

inadéquat !

Ne serrer les écrous qu’à l’aide d’une clé à fourche. L’utilisation d’autres outils (une pince par ex.) peut endommager

l’appareil.

Couple de serrage!

(voir tableau en bas)

Écrou

Joint torique

Tube de guidage du

noyau

Fig. 3 : Montage de la bobine

Couple de serrage pour l’écrou de fixation :

Type de bobine Largeur de bobine Couple [Nm]

AC10 32 mm ou 40 mm 5 Nm

français

73

8.3. Pannes

En présence de pannes, vérifiez :

→ si l’appareil est installé dans les règles,

→ si le raccord électrique et fluide est correct,

→ si l’appareil n’est pas endommagé,

→ si toutes les vis sont bien serrées,

→ si la tension et la pression sont disponibles,

→ si les tuyauteries sont propres.

La vanne ne s’enclenche pas

Cause possible :

• Court-circuit ou coupure de la bobine.

• Plongeur ou chambre du plongeur encrassé.

• Pression du fluide hors de la plage de pression

autorisée.

La vanne ne se ferme pas

Cause possible :

• Intérieur de la vanne encrassé.

• Petits orifices de pilotage dans la membrane bouchés.

français

74

9. PIÈCES DE RECHANGE

ATTENTION !

Risque de blessures, de dommages matériels dus à

de mauvaises pièces !

De mauvais accessoires ou des pièces de rechange inadaptées peuvent provoquer des blessures et endommager

l'appareil ou son environnement.

• Utiliser uniquement des accessoires et des pièces de

rechange d'origine de la société Bürkert.

9.1. Commander des pièces de

rechange

Jeux de pièces de rechange

Veuillez commander les jeux de pièces de rechange en indiquant les références des jeux SET 1, SET 3 ou SET 7 ainsi

que le numéro d’identification de l’appareil.

• Jeux de pièces de rechange voir 9.2. et 9.3.

• Vous trouverez le numéro d’identification de l’appareil sur

la plaque signalétique. Voir également le chapitre « 6.2.

Plaque signalétique ».

français

75

9.2. Aperçu jeux de pièces de

rechange Type 6203 EV, DN 10

et DN 13

Jeu de bobines

SET 1

Jeu de pièces

d’usure SET 3

Kit de tube de

guidage SET 7

Fig. 4 : Jeu de pièces de rechange Type 6203 EV

français

Type 6203 EV

Page 21

76

9.3. Aperçu jeux de pièces de

rechange Type 6203 EV, DN 20,

DN 25 et DN 40

Jeu de bobines

SET 1

Kit de tube de

guidage SET 7

Jeu de pièces

d’usure SET 3

Fig. 5 : Jeu de pièces de rechange Type 6203 EV

français

77

10. EMBALLAGE, TRANSPORT,

STOCKAGE, ÉLIMINATION

REMARQUE !

Dommages dus au transport !

Les appareils insuffisamment protégés peuvent être

endommagés pendant le transport.

• Transportez l’appareil à l’abri de l’humidité et des

impuretés et dans un emballage résistant aux chocs.

• Évitez le dépassement vers le haut ou le bas de la température de stockage admissible.

Un mauvais stockage peut endommager l’appareil.

• Stockez l’appareil au sec et à l’abri des poussières !

• Température de stockage : -40 … +80 °C.

Dommages à l’environnement causés par des pièces

d’appareil contaminées par des fluides.

• Eliminez l’appareil et l’emballage dans le respect de

l’environnement.

• Respectez les prescriptions en matière d’élimination des

déchets et de protection de l’environnement en vigueur.

français

78

français

Type 6203 EV

Loading...

Loading...