Page 1

PTB 07 ATEX 2063 X

Magnetspule Typ AC19

Geräte mit II 2G Ex m Zulassung

Device with II 2G Ex m approval

Appareils avec mode de protection II 2G Ex m

Operating Instructions

Bedienungsanleitung

Instructions de Service

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2008 - 2011 Bürkert Werke GmbH

Operating Instructions 1112/01_EU-ML_00806067 / Original DE

Page 3

Table of Contents:

07 ATEX 2063 X

Solenoid coil AC19, device with II 2G Ex m approval

1. OPERATING INSTRUCTIONS ...................................................................4

1.1. Symbols ..............................................................................................4

2. INTENDED USE ................................................................................................5

2.1. Restrictions ........................................................................................ 5

3. GENERAL SAFETY INSTRUCTIONS .....................................................6

4. GENERAL INFORMATION ...........................................................................7

4.1. Contact addresses .......................................................................... 7

4.2. Warranty ............................................................................................. 8

4.3. Approval ............................................................................................. 8

4.4. Information on the Internet ............................................................. 8

5. APPLICATION CONDITIONS ....................................................................8

5.1. Special conditions ...........................................................................8

5.2. Operating Conditions ......................................................................9

5.3. Installation conditions ....................................................................10

5.4. Application in petrol pumps .........................................................10

6. TECHNICAL DATA ........................................................................................ 11

7. INSTALLATION .............................................................................................. 12

7.1. Safety Instructions .........................................................................12

7.2. Installation ........................................................................................13

7.3. Electrical connection .....................................................................14

8. START-UP

8.1. Safety Instructions .........................................................................14

9. MAINTENANCE AND REPAIRS .............................................................15

9.1. Maintenance ....................................................................................15

9.2. Repairs ..............................................................................................15

9.3. Troubleshooting ..............................................................................15

10. TRANSPORT, STORAGE, DISPOSAL .............................................. 15

......................................................................................................... 14

english

3

Page 4

07 ATEX 2063 X

Operating instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

WARNING!

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

understood.

• Carefully read the operating instructions before using the device.

• In particular observe the chapter entitled "Intended use", and

"General safety instructions" as well as the chapter entitled

"Application conditions of the coil AC19".

The operating instructions must be read and

1.1. Symbols

To identify important information, the following symbols are used in

the operating instructions:

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

• Failure to observe the warning may result in moderately serious

or minor injuries.

NOTE!

Warns of damage to property!

designates additional significant information, tips and

recommendations.

refers to information in these operating instructions or in

other documentation.

→ designates a procedure which you must carry out.

4

english

Page 5

07 ATEX 2063 X

Intended Use

2. INTENDED USE

WARNING!

Incorrect use of the coil AC19 can be dangerous to people,

nearby equipment and the environment.

• The solenoid coil AC19 is used to actuate valves which control

gaseous or liquid media. It was designed for use in explosion

group II, category 2D, Ex mbD, IP64, T130°C and in explosion

group II, category 2G and temperature class T4 (see specifications on the

• The coil AC19 is always attached to the core feed pipe of the

valve fitting and secured with a nut. In this way coil and valve

body are connected in such a way that a closed system is formed which may also be used as a category 2 device to control

petrol in petrol pumps. For this application a valve body made of

metal (brass, aluminium or stainless steel) must be used.

When using the device, observe the permitted data, operating

conditions and application conditions which

– are specified in the operating instructions for the solenoid coil

AC19, on the rating plate, in the contract documents

– as well as in the operating instructions for the solenoid valve

actuated with the coil.

The coil may be used only in conjunction with third-party devices

and components recommended and authorised by Bürkert.

Correct transportation, correct storage and installation and careful

use and maintenance are essential for reliable and problem-free

operation.

- approval plate).

• Any other use is considered improper use.Bürkert is not liable

for any resulting damage. The user alone bears the risk.

• Use the device only as intended.

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

2.1.1. Explosion protection approval

The explosion protection approval is only valid if you use the modules

and components authorised by Bürkert, as described in these operating instructions.

The coil AC19 may be used only in combination with the valve types

released by Bürkert, otherwise the explosion protection approval will

be terminated!

If you make unauthorised changes to the system, the modules or components, the explosion protection approval will be terminated.

english

5

Page 6

07 ATEX 2063 X

General Safety Instructions

3. GENERAL SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• local safety regulations, whereby the operator is responsible for their

compliance, by the installation personnel too.

DANGER!

Danger of explosion!

Following installation, solenoid coil and valve body form a closed

system. If used in the EX area, there is a danger of explosion if the

system is opened during operation!

• The system must not be disassembled during operation.

Danger of explosion caused by electrostatic charge!

If there is a sudden discharge from electrostatically charged devices

or persons, there is a danger of explosion in the EX area.

• Take appropriate measures to prevent electrostatic charges in the

EX area.

• Clean the device surface of the solenoid valve by gently wiping

it with a damp cloth

DANGER!

Risk of electric shock!

There is a serious risk of injury when reaching into the equipment.

• Only trained electrical engineers may work on the electrical

system.

• Before starting work, always switch off the power supply and

safeguard to prevent re-activation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

Danger of burns/danger of fire during long-term operation!

The solenoid coil may become very hot during long-term operation.

• Take hold of a device which has been running for a prolonged

period with protective gloves only.

Danger – high pressure!

There is a serious risk of injury when reaching into the system.

• Only skilled and instructed personnel may work on the system

with suitable tools.

• Before disconnecting lines and valves, switch off the pressure

and bleed the lines.

• During installation note the direction of flow.

• Observe applicable accident prevention and safety regulations

for pressurised devices!

• After an interruption in the power supply or fluid supply, ensure

that the process is restarted in a defined or controlled manner!

6

english

Page 7

07 ATEX 2063 X

General Information

WARNING!

General hazards!

• Do not use the valve fitting or the complete device as a lever to

screw the valve into the line system.

• Do not put any loads on the housing (e.g. by placing objects on

it or standing on it).

• Do not make any external modifications to the device housings.

Do not paint the housing parts or screws.

Unintentional activation or unauthorised impairment of the system

may cause general hazardous situations through to physical injury.

• Take appropriate measures to prevent the system from being

accidentally actuated!

• Do not make any unauthorised changes to the system.

Non-observance of the generally acknowledged safety rules may

cause general hazardous situations through to physical injury.

• Observe the generally acknowledged safety rules for resource

planning and operation of the coil AC19 and the associated

solenoid valve.

The coil AC19 was developed with due consideration

given to the accepted safety rules and is state-of-the-art.

However, dangers can still arise.

Operate the coil AC19 and the associated solenoid valve in

perfect working order only and in accordance with the operating

instructions.

4. GENERAL INFORMATION

4.1. Contact addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at:

www.burkert.com

english

7

Page 8

07 ATEX 2063 X

Application conditions

4.2. Warranty

The warranty is only valid if the device is used as intended in accordance

with the specified application conditions.

4.3. Approval

The EC Type Examination Certificate PTB 07 ATEX 2063 X was

issued by the

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig (Germany)

which also audits production (CE0102).

4.4. Information on the Internet

The operating instructions and data sheets for Bürkert products can

be found on the Internet at:

www.burkert.com

5. APPLICATION CONDITIONS

5.1. Special conditions

5.1.1. Short-circuit protection

To protect each solenoid against short-circuit, a fuse (max. 3 x Ib in

accordance with IEC 60127-2-1), corresponding to the rated current,

or a motor protection switch with short-circuit and thermal quick release

(set to rated current) must be connected upstream.

• At very low rated currents of the solenoid the fuse with the lowest

current value is adequate according to the stated IEC standard.

This fuse may be housed in the associated supply unit or must be

connected separately upstream.

• The fuse rated voltage must be the same or higher than the indicated

nominal voltage of the solenoid.

• The interruption rating of the fuse link must be the same or higher than

the maximum short-circuit current to be accepted at the installation

site (usually 1500 A).

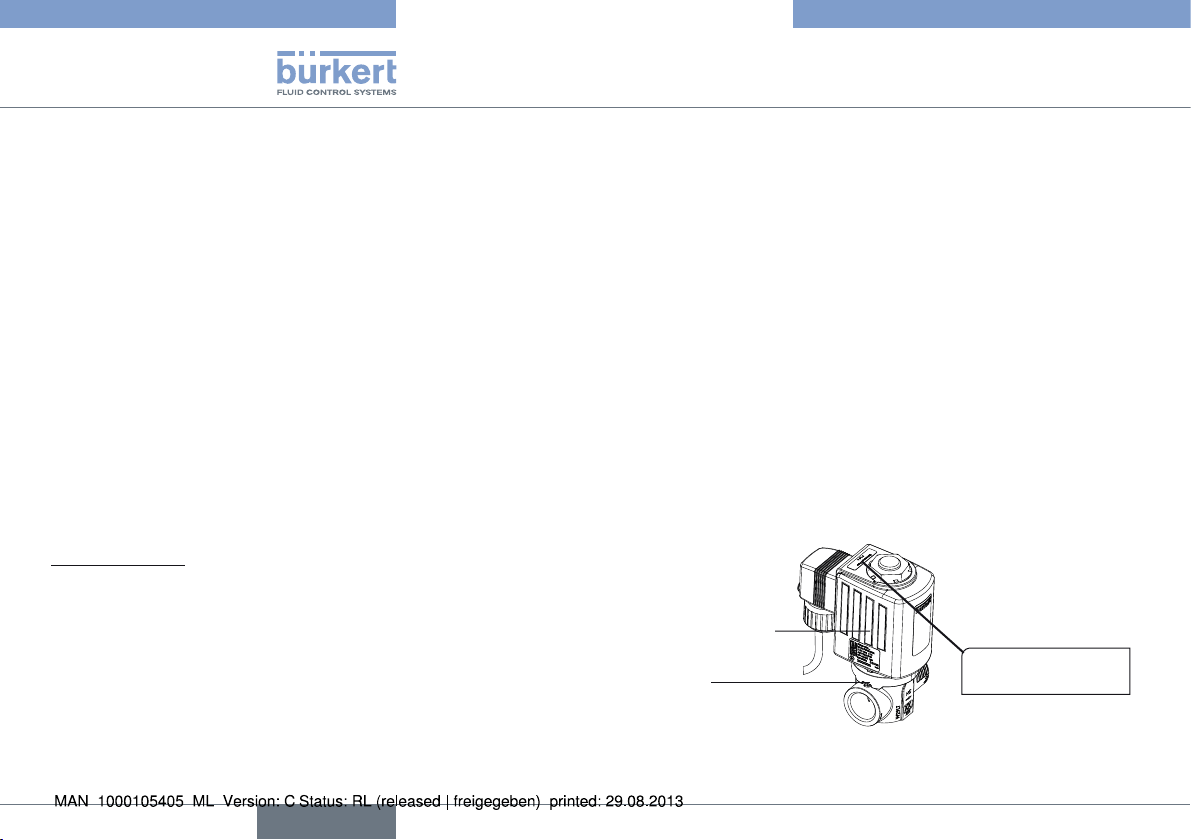

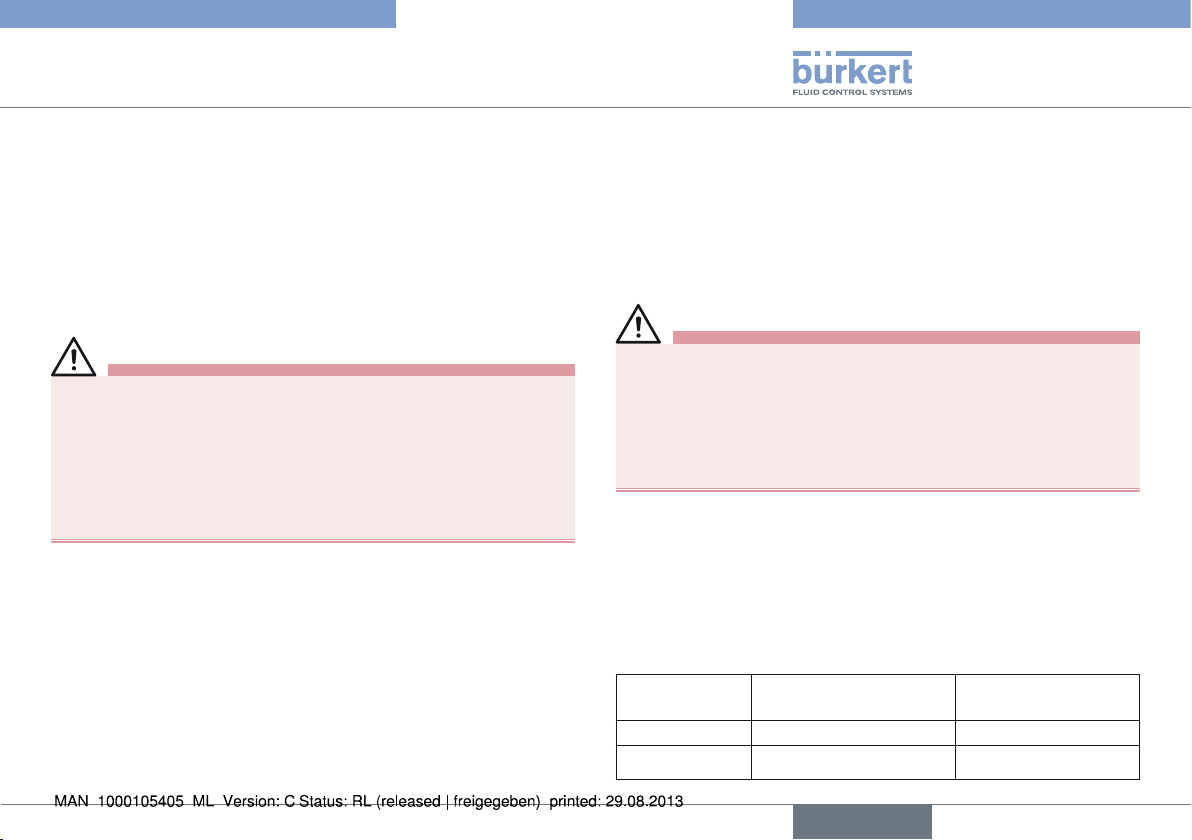

Example 2/2-way

solenoid valve:

Solenoid coil AC19

Valve body

The nominal value of

the fuse is indicated

on the solenoid

Fuse

F . , . . A

Fig. 1 : Example of coil AC19 as part of a closed system.

8

english

Page 9

07 ATEX 2063 X

Application conditions

5.2. Operating Conditions

For operation of the solenoid coils Type AC19-..-.-PF09 and Type

AC19-..-.-PF10 observe the following requirements.

5.2.1. Materials

For the selection of materials for the system observe the applicationspecific, safety requirements.

Valve body:

DANGER!

Danger of explosion!

If the system is used as a category 2 device, only valve bodies

made of metal can ensure the required safety for the control of

petrol in petrol pumps!

• Use only valve bodies made of metal (brass, aluminium or

stainless steel) for the control of petrol in petrol pumps with

category 2 devices.

• For use in petrol pumps

Metal (brass, aluminium, stainless steel)

• Other applications

Metal (brass, aluminium, stainless steel) or plastic (e.g. polyamide

PA 6 GV ...)

Sheathing of the electrical connection cables:

Type AC19-..-.-PF09 PVC

Type AC19-..-.-PF10 PUR

5.2.2. Minimum dimensions

Valve body:

55 mm x 36 mm x 30 mm (L x W x H)

A larger valve body with improved thermal conductivity may be

used at any time.

5.2.3. Application temperature range:

DANGER!

Danger of explosion!

If the max. permitted temperature values for the coil AC19 are

exceeded, there is a danger of explosion.

• Observe the temperature specifications for the coil

• Observe any restrictions by the max. permitted values for the

solenoid valve combined with the coil.

Temperature values of the solenoid coil AC19

Maximum surface temperatur of the coil at 60 °C ambient temperature and nominal voltage: 110 °C (for gas)

130 °C (for dust)

Temperature class (for gas) T4

Max. permitted ambient temperatures

Type Material of the electrical

connection cables

AC19-..-.-PF09 PVC -40 – +55 °C

AC19-..-.-PF10 PUR -40 – +60 °C

Max. permitted

ambient temperature

english

9

Page 10

07 ATEX 2063 X

Application conditions

5.3. Installation conditions

The solenoid coils Type AC19-..-.-PF09 to Type AC19-..-.-PF10 are

suitable for single installation only.

The connection cables must be laid permanently to protect against

damage.

Also observe the specifications in the chapter entitled

"Technical Data".

5.4. Application in petrol pumps

DANGER!

Danger of explosion!

Following installation, solenoid coil and valve body form a closed

system. If used in the EX area, there is a danger of explosion if the

system is opened during operation!

• The system must not be disassembled during operation.

• The valve body may be repaired by the manufacturer only.

Solenoid valves together with the coil AC19 may be used as

category 2 devices only for the control of petrol if there is no air

and no oxygen in the closed system.

• Ensure that the closed system contains no air or oxygen or

cannot be penetrated by air or oxygen.

• When switching off or starting up the system, ensure that neither air nor oxygen has penetrated the system.

If the system is used as a category 2 device, only valve bodies

made of metal can ensure the required safety for the control of

petrol in petrol pumps!

• Use only valve bodies made of metal (brass, aluminium or

stainless steel) for the control of petrol in petrol pumps with

category 2 devices.

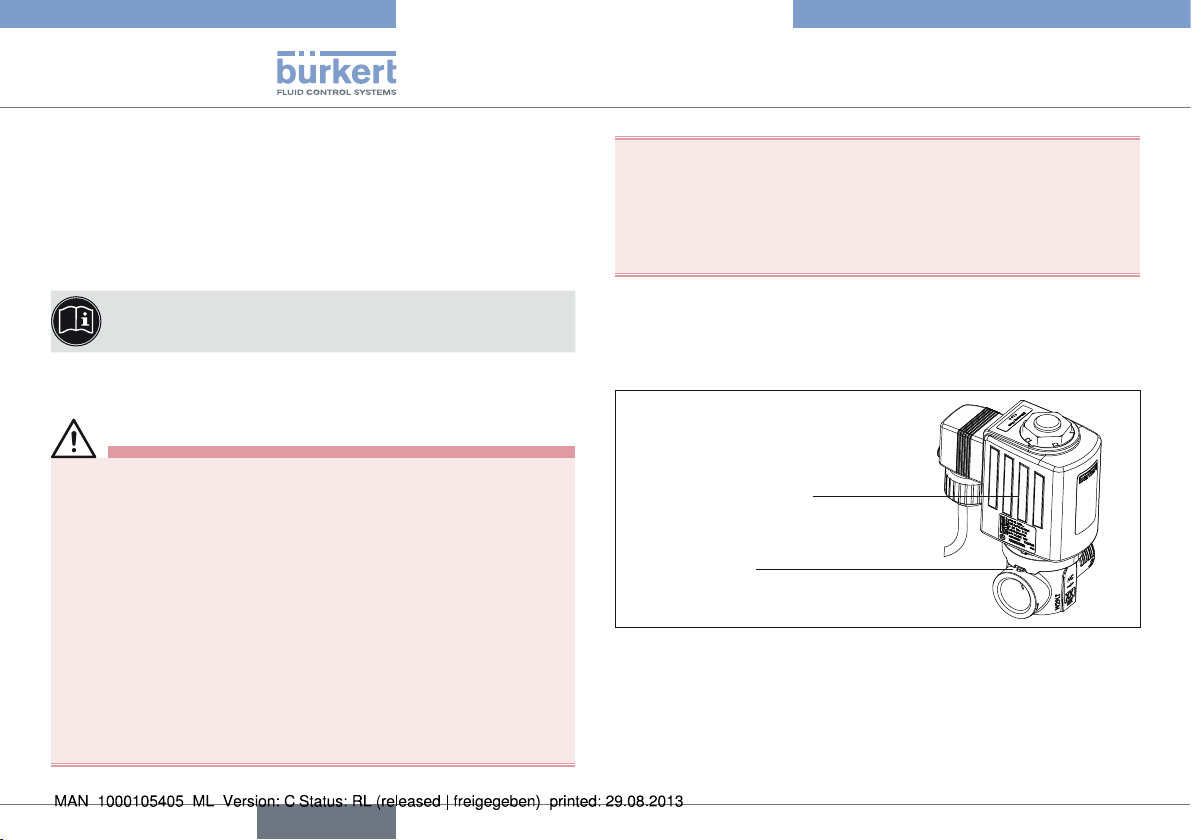

Example: 2/2-way solenoid valve

Solenoid coil AC19

Valve body

Fig. 2 : Example of coil AC19 as part of a closed system.

10

english

Page 11

07 ATEX 2063 X

Technical Data

6. TECHNICAL DATA

DANGER!

Danger of explosion!

If the safety data and values specified on the rating plate are

not observed or maintained, hazardous situations may be the

consequence!

• Observe the degree of protection and temperature class when

using the device.

It is a safety risk to exceed the voltage indicated on the rating

plate, as this may cause the device to overheat!

• Do not connect the device to a higher voltage than indicated on

the rating plate.

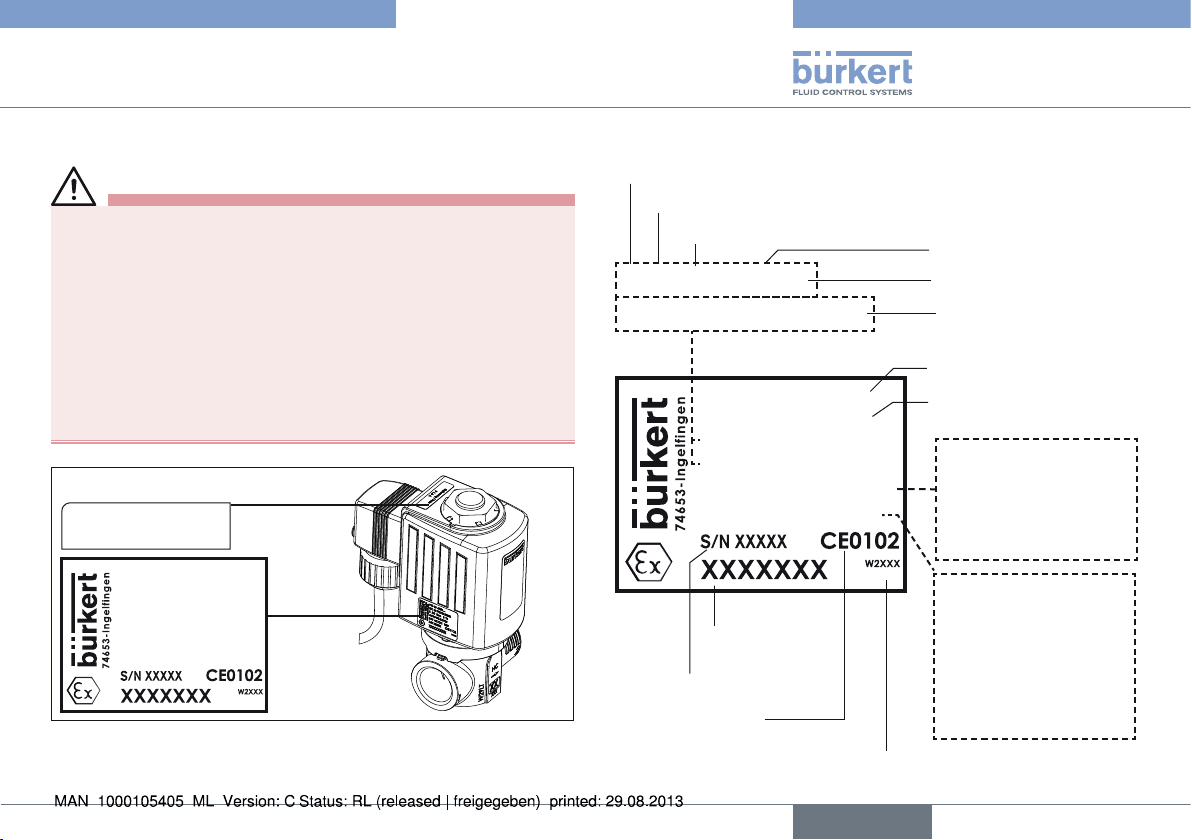

Example

Fuse

F. , . . A

PTB 07 ATEX 2063 X

IEC Ex PTB08.0016X

II 2G Exmb II T4

II 2G Ex mbD21 IP64

Tmed130°C 24V AC/DC

12W AC19-U5-K-PF09

Fig. 3 : Example of rating plate for coil AC19 as part of a closed system.

Wording on the rating plate:

Device group

Device category

Ignition protection type

II 2G Exmb II T4

II 2D Ex mbD21 IP64

PTB 07 ATEX 2063 X

IEC Ex PTB08.0016X

II 2G Exmb II T4

II 2D Ex mbD21 IP64

Tmed130°C 24V AC/DC

12W AC19-U5-K-PF09

Ident. no.

Serial no. of the coil

Monitoring centre

Date of manufacture - factory/month/year

Gas group

Temperature class

Protection class:

PTB approval no.

IEC explosion protection

approval no.

- Maximum surface

temperatur of the coil

(for dust)

- Voltage

- Current type

- Power consumption

- Coil type

- Connection size forfluid component

- Coil size

- Code (specific to

company)

english

11

Page 12

07 ATEX 2063 X

Installation

6.4.1. Electrical Data

Note the electrical data as specified on the rating plate.

7. INSTALLATION

7.1. Safety Instructions

DANGER!

Danger of explosion!

Following installation, solenoid coil and valve body form a closed

system. If used in the EX area, there is a danger of explosion if the

system is opened during operation!

• The system must not be disassembled during operation.

Danger of explosion caused by electrostatic charge!

If there is a sudden discharge from electrostatically charged devices

or persons, there is a danger of explosion in the EX area.

• Take appropriate measures to prevent electrostatic charges in the

EX area.

• Clean the device surface of the solenoid valve by gently wiping

it with a damp cloth

Risk of electric shock!

There is a serious risk of injury when reaching into the equipment.

• Only trained electrical engineers may work on the electrical

system.

• Before starting work, always switch off the power supply and

safeguard to prevent re-activation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

12

english

Page 13

07 ATEX 2063 X

Installation

DANGER!

Risk of short-circuit!

Damaged connection cables may cause a short-circuit.

• The connection cables for the coil must be laid permanently and

protected against damage.

Danger of burns/danger of fire during long-term operation!

The solenoid coil may become very hot during long-term operation.

• Take hold of a device which has been running for a prolonged

period with protective gloves only.

WARNING!

Danger – high pressure!

There is a serious risk of injury when reaching into the system.

• Only skilled and instructed personnel may work on the system

with suitable tools.

• Before disconnecting lines and valves, switch off the pressure

and bleed the lines.

• Observe applicable accident prevention and safety regulations

for pressurised devices!

• After an interruption in the power supply or fluid supply, ensure

that the process is restarted in a defined or controlled manner!

7.2. Installation

The solenoid valve with integrated coil AC19 can be installed in any location. Preferably with top-mounted drive.

Prior to installation:

→ Clean any dirt off the pipelines and flange connections.

Installation:

WARNING!

Risk of injury from leaking connections

Danger of explosion!

There is a danger of explosion in fuel pumps if oxygen or air penetrates the medium through leaking connections.

Risk of injury from escaping medium!

Medium which escapes through leaking connections may result in

injuries (e.g. burns or chemical burns).

• Carefully seal the connection lines.

→ Seal pipeline connections with PTFE tape. The tape must not be

dropped into the pipelines.

→ Screw in pipelines.

Important for function of the device!

Note the direction of flow.

→ Check valve for leakage.

english

13

Page 14

07 ATEX 2063 X

Start-Up

7.3. Electrical connection

DANGER!

Risk of electric shock!

There is a serious risk of injury when reaching into the equipment.

• Only trained electrical engineers may work on the electrical

system.

• Before starting work, always switch off the power supply and

safeguard to prevent re-activation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

→ Connect the power

→ Always connect protective conductor!

The connection cable is encapsulated with the coil AC19

and cannot be removed.

8. START-UP

8.1. Safety Instructions

WARNING!

Danger due to improper operation!

Improper operation may result in injuries as well as damage to the

device and the area around it.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

• In particular observe the safety instructions and intended use.

• The device/the equipment may be started by adequately trained

personnel only.

Before start-up, ensure that

→ the device has been installed according to the instructions,

→ the connection has been made properly,

→ the device is not damaged.

14

english

Page 15

07 ATEX 2063 X

Maintenance and Repairs

9. MAINTENANCE AND REPAIRS

9.1. Maintenance

The coil AC19 is maintenance-free provided the application conditions

described in the instructions are observed

9.2. Repairs

DANGER!

Danger - improper repairs!

Following repairs, the safety and function of the coil AC19 and the

corresponding solenoid valve cannot be guaranteed unless the

repairs were carried out by the manufacturer.

• Have the device repaired by the manufacturer only!

9.3. Troubleshooting

In the event of malfunctions, make sure that

→ the device has been installed according to the instructions,

→ the connection has been made properly,

→ the device is not damaged,

→ the voltage and pressure have been switched on,

→ the pipelines are free.

10. TRANSPORT, STORAGE, DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: -40 … +55 °C.

Damage to the environment caused by device components

contaminated with media.

• Ensure the device and packaging are disposed of in an environmentally sound manner.

• Observe applicable regulations relating to refuse disposal and

the environment.

english

15

Page 16

07 ATEX 2063 X

16

english

Page 17

Inhalt:

PTB 07 ATEX 2063 X

Magnetspule AC19, Gerät mit II 2G Ex m Zulassung

1. BEDIENUNGSANLEITUNG

1.1. Darstellungsmittel ...........................................................................18

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ...................................19

2.1. Beschränkungen ............................................................................19

3. ALLGEMEINE SICHERHEITSHINWEISE...........................................20

4. ALLGEMEINE HINWEISE ..........................................................................21

4.1. Kontaktadressen .............................................................................21

4.2. Gewährleistung. ............................................................................22

4.3. Zulassungen ....................................................................................22

4.4. Informationen im Internet ..............................................................22

5. EINSATZBEDINGUNGEN ........................................................................22

5.1. Besondere Bedingungen .............................................................22

5.2. Betriebsbedingungen ....................................................................23

5.3. Montagebedingungen ...................................................................24

5.4. Einsatz in Tanksäulen.....................................................................24

6. TECHNISCHE DATEN ................................................................................25

......................................................................18

7. MONTAGE .......................................................................................................26

7.1. Sicherheitshinweise .......................................................................26

7.2. Montage ...........................................................................................27

7.3. Elektrischer Anschluss ..................................................................28

8. INBETRIEBNAHME

8.1. Sicherheitshinweise .......................................................................28

9. WARTUNG UND REPARATUR................................................................29

9.1. Wartung ............................................................................................29

9.2. Reparatur..........................................................................................29

9.3. Fehlerbehebung ..............................................................................29

10. TRANSPORT, LAGERUNG, ENTSORGUNG ................................. 29

deutsch

...................................................................................... 28

17

Page 18

PTB 07 ATEX 2063 X

Bedienungsanleitung

1. BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Gerätes

wieder zur Verfügung steht.

WARNUNG!

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

werden.

• Lesen Sie die Bedienungsanleitung vor dem Einsatz des Gerätes

sorgfältig durch.

• Beachten Sie vor allem die Kapitel „Bestimmungsgemäße

Verwendung“, und „Allgemeine Sicherheitshinweise“ sowie das

Kapitel „Einsatzbedingungen der Spule AC19“.

Die Anleitung muss gelesen und verstanden

1.1. Darstellungsmittel

Für die Kennzeichnung wichtiger Informationen werden in der

Anleitung folgende Darstellungsmittel verwendet:

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den sie ausführen müssen.

18

deutsch

Page 19

PTB 07 ATEX 2063 X

Bestimmungsgemässe Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

WARNUNG!

Bei nicht bestimmungsgemäßem Einsatz der Spule AC19

können Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

• Die Magnetspule AC19 dient zum Betätigen von Ventilen welche

gasförmige oder flüssige Medien steuern.

Sie wurde für den Einsatz in in Explosionsgruppe II, Kategorie D,

EX mbD, IP64, T130° und Explosionsgruppe II, Kategorie 2G

und Temperaturklasse T4 konzipiert (siehe Angaben auf dem

- Zulassungsschild).

• Die Spule AC19 wird immer auf das Kernführungsrohr der Ventilarmatur montiert und mittels einer Mutter befestigt. Auf diese

Weise werden Spule und Ventilkörper so verbunden, dass

ein geschlossenes System entsteht, das auch in Tanksäulen

zur Steuerung von Benzin als Kategorie -2- Gerät eingesetzt

werden darf. Für diesen Einsatzzweck muss ein Ventilkörper aus

Metall (Messing, Aluminium oder Edelstahl) verwendet werden.

Für den Einsatz sind die zulässigen Daten, Betriebs- und Einsatzbedingungen zu beachten, die

– in der Bedienungsanleitung für die Magnetspule AC19, auf dem

Typschild, in den Vertragsdokumenten

– sowie in der Bedienungsanleitung für das mit der Spule

betätigte Magnetventil

spezifiziert sind.

Eine andere oder darüber hinausgehende Benutzung gilt als nicht

bestimmungsgemäß.

Für hieraus resultierende Schäden haftet Bürkert nicht.

Das Risiko trägt allein der Anwender.

• Setzen Sie das Gerät nur bestimmungsgemäß ein.

Die Spule darf nur in Verbindung mit von Bürkert empfohlenen

bzw. zugelassenen Fremdgeräten und -komponenten eingesetzt

werden.

Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instandhaltung.

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Gerätes gegebenenfalls

bestehende Beschränkungen.

2.1.1. Ex-Zulassung

Die EX-Zulassung ist nur gültig, wenn Sie die von Bürkert zugelassenen

Module und Komponenten so verwenden, wie es in dieser Bedienungsanleitung beschrieben ist.

Die Spule AC19 dürfen Sie nur in Kombination mit den von Bürkert freigegebenen Ventiltypen einsetzen, andernfalls erlischt die Ex-Zulassung!

Nehmen Sie unzulässige Veränderungen am System, den Modulen

oder Komponenten vor, erlischt die Ex-Zulassung ebenfalls.

deutsch

19

Page 20

PTB 07 ATEX 2063 X

Allgemeine Sicherheitshinweise

3. ALLGEMEINE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

GEFAHR!

Explosionsgefahr!

Magnetspule und Ventilkörper bilden nach der Montage ein

geschlossenes System. Bei Einsatz im EX-Bereich besteht bei

der Öffnung des Systems im Betriebszustand Explosionsgefahr!

• Das System darf nicht während des Betriebs demontiert werden.

Explosionsgefahr durch elektrostatische Aufladung!

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder

Personen besteht im EX-Bereich Explosionsgefahr.

• Stellen Sie durch geeignete Maßnahmen sicher, dass es im EXBereich zu keinen elektrostatischen Aufladungen kommen kann.

• Reinigen Sie die Geräteoberfläche des Magnetventils nur durch

leichtes Abwischen mit einem feuchten Tuch.

GEFAHR!

Gefahr durch elektrische Spannung!

Bei Eingriffen in die Anlage besteht akute Verletzungsgefahr.

• Arbeiten am elektrischen System dürfen nur von ausgebildenten

Elektrofachkräften durchgeführt werden.

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb!

Die Magnetspule kann im Dauerbetrieb sehr heiß werden.

• Fassen Sie ein Gerät das bereits länger in Betrieb ist nur mit

Schutzhandschuhen an.

Gefahr durch hohen Druck!

Bei Eingriffen in das System besteht akute Verletzungsgefahr.

• Arbeiten am System dürfen nur durch fachkundiges und unterwiesenes Personal mit geeignetem Werkzeug durchgeführt

werden.

• Schalten Sie vor dem Lösen von Leitungen und Ventilen den

Druck ab und entlüften Sie die Leitungen.

• Beachten Sie beim Einbau die Durchflussrichtung.

• Halten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für druckbeaufschlagte Geräte ein.

• Gewährleisten Sie nach einer Unterbrechung der elektrischen

oder fluidischen Versorgung einen definierten oder kontrollierten

Wiederanlauf des Prozesses!

20

deutsch

Page 21

PTB 07 ATEX 2063 X

Allgemeine Hinweise

WARNUNG!

Allgemeine Gefährdungen!

• Benutzen Sie, zum Einschrauben des Ventils in das Leitungssystem, die Ventilarmatur bzw. das Komplettgerät nicht als Hebel.

• Belasten Sie das Gerät nicht mechanisch (z. B. als Ablage für

Gegenstände oder als Trittstufe).

• Nehmen Sie keine äußerlichen Veränderungen an den Gerätegehäusen vor. Gehäuseteile und Schrauben nicht lackieren.

• Halten Sie für die Einsatzplanung und den Betrieb der Spule

AC19 und des zugehörigen Magnetventils die allgemein anerkannten sicherheitstechnischen Regeln ein.

Unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung

des Systems können zu allgemeinen Gefahrensituationen bis hin

zur Körperverletzung führen.

• Verhindern Sie durch geeignete Maßnahmen, dass das System

unbeabsichtigt betätigt werden kann!

• Nehmen Sie am System keine unerlaubten Änderungen vor.

Die Spule AC19 wurde unter Einbeziehung der anerkannten

sicherheitstechnischen Regeln entwickelt und entspricht

dem Stand der Technik. Trotzdem können Gefahren

entstehen.

Betreiben Sie die Spule AC19 und das zugehörige Magnetventil nur in einwandfreiem Zustand und unter Beachtung

der Bedienungsanleitung.

4. ALLGEMEINE HINWEISE

4.1. Kontaktadressen

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter:

www.burkert.com

deutsch

21

Page 22

PTB 07 ATEX 2063 X

Einsatzbedingungen

4.2. Gewährleistung.

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch der Spule AC19 unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Zulassungen

Die EG-Baumusterprüfbescheinigung PTB 07 ATEX 2063 X wurde

von der

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig

ausgestellt, die auch die Fertigung auditiert (CE0102).

4.4. Informationen im Internet

Bedienungsanleitungen und Datenblätter der Bürkert Produkte finden

Sie im Internet unter:

www.buerkert.de

Dokumentation Typ

5. EINSATZBEDINGUNGEN

5.1. Besondere Bedingungen

5.1.1. Kurzschlussschutz

Jedem Magneten muss als Kurzschlussschutz eine seinem Bemessungsstrom entsprechende Sicherung (max. 3 x Ib nach IEC 60127-2-1) bzw.

ein Motorschutzschalter mit Kurzschluss- und thermischer Schnellauslösung (Einstellung auf Bemessungsstrom) vorgeschaltet werden.

• Bei sehr kleinen Bemessungsströmen des Magneten ist die Sicherung

mit dem kleinsten Stromwert nach der genannten IEC-Norm ausreichend. Diese Sicherung darf im zugehörigen Versorgungsgerät

untergebracht sein oder muss separat vorgeschaltet werden.

• Die Sicherungs-Bemessungsspannung muss gleich oder größer als

die angegebene Nennspannung des Magneten sein.

• Das Ausschaltvermögen des Sicherungseinsatzes muss gleich

oder größer als der maximal anzunehmende Kurzschlussstrom am

Einbauort (üblicherweise 1500 A) sein.

Beispiel

2/2-WegeMagnetventil:

Magnetspule AC19

Ventilkörper

Der Sicherungsnennwert ist auf

dem Magneten

angegeben

Sicherung / Fuse

F . , . . A

22

Bild 1: Beispiel für Spule AC19 als Teil eines geschlossenen

Systems.

deutsch

Page 23

PTB 07 ATEX 2063 X

Einsatzbedingungen

5.2. Betriebsbedingungen

Für den Betrieb der Magnetspulen Typ AC19-..-.-PF09 und

Typ AC19-..-.-PF10 sind die nachfolgenden Anforderungen zu

beachten.

5.2.1. Werkstoffe

Für die Wahl der Werkstoffe des Systems sind die einsatzspezifischen,

sicherheitstechnischen Anforderungen zu beachten.

Ventilkörper:

GEFAHR!

Explosionsgefahr!

Beim Einsatz des Systems als Kategorie-2-Gerät können

Steuerung von Benzin in Tanksäulen nur Ventilkörper aus Metall

die geforderte Sicherheit gewährleisten!

• Setzen Sie, bei der Steuerung von Benzin in Tanksäulen mit

Kategorie-2-Geräten, nur Ventilkörper aus Metall (Messing,

Aluminium oder Edelstahl) ein.

• Bei Einsatz in Tanksäulen

Metall (Messing, Aluminium, Edelstahl)

• Sonstige Einsatzzwecke

Metall (Messing, Aluminium, Edelstahl) oder Kunststoff

(z.B. Polyamid PA 6 GV ...)

Ummantelung der elektrischen Anschlussleitungen:

Typ AC19-..-.-PF09 PVC

Typ AC19-..-.-PF10 PUR

zur

5.2.2. Mindestabmessungen

Ventilkörper:

55 mm x 36 mm x 30 mm (L x B x H)

Ein größerer Ventilkörper mit besserer Wärmeleitfähigkeit darf

jeder Zeit verwendet werden.

5.2.3. Einsatztemperturbereich:

GEFAHR!

Explosionsgefahr!

Bei Überschreitung der max. zulässigen Temperaturwerte für die

Spule AC19 besteht Explosionsgefahr.

• Halten Sie die Temperaturangaben für die Spule unbedingt ein

• Beachten Sie eventuelle Einschränkungen durch die max. zulässigen Werte für das mit der Spule kombinierte Magnetventil.

Temperaturwerte der Magnetspule AC19

Maximale Oberflächentemperatur der Spule bei 60 °C Umgebungstemperatur und Nennspannung: 110 °C (für Gas)

130 °C (für Staub)

Temperaturklasse (für Gas): T4

Max. zulässige Umgebungstemperaturen

Typ Material der elektrischen

Anschlussleitungen

AC19-..-.-PF09 PVC -40 ... +55 °C

AC19-..-.-PF10 PUR -40 ... +60 °C

Max. zulässige

Umgebungstemperatur

deutsch

23

Page 24

PTB 07 ATEX 2063 X

Einsatzbedingungen

5.3. Montagebedingungen

Die Magnetspulen Typ AC19-..-.-PF09 bis Typ AC19-..-.-PF10 sind

nur zur Einzelmontage geeignet.

Die Anschlussleitungen müssen zum Schutz vor Beschädigungen

fest verlegt werden.

Beachten Sie auch die Angaben des Kapitels „Technische

Daten“.

5.4. Einsatz in Tanksäulen

GEFAHR!

Explosionsgefahr!

Magnetspule und Ventilkörper bilden nach der Montage ein

geschlossenes System. Bei Einsatz im EX-Bereich besteht bei

der Öffnung des Systems im Betriebszustand Explosionsgefahr!

• Das System darf nicht während des Betriebs demontiert werden.

• Reparaturarbeiten am Ventilkörper dürfen nur vom Hersteller

ausgeführt werden.

Magnetventile mit der Spule AC19 dürfen als Kategorie-2-Geräte

nur zur Steuerung von Benzin eingesetzt werden, wenn im

geschlossenen System keine Luft und kein Sauerstoff vorhanden

ist.

• Stellen Sie sicher, dass im geschlossenen System weder Luft

noch Sauerstoff vorhanden sind oder eindringen können.

• Vergewissern Sie sich, beim Abschalten bzw. Anfahren des

Systems, dass weder Luft oder Sauerstoff eingedrungen sind.

Beim Einsatz des Systems als Kategorie-2-Gerät können

Steuerung von Benzin in Tanksäulen nur Ventilkörper aus Metall

die geforderte Sicherheit gewährleisten!

• Setzen Sie, bei der Steuerung von Benzin in Tanksäulen mit

Kategorie-2-Geräten, nur Ventilkörper aus Metall (Messing,

Aluminium oder Edelstahl) ein.

Beispiel:

2/2-Wege-Magnetventil

Magnetspule AC19

Ventilkörper

zur

24

Bild 2: Beispiel für Spule AC19 als Teil eines geschlossenen Systems.

deutsch

Page 25

PTB 07 ATEX 2063 X

Technische Daten

6. TECHNISCHE DATEN

GEFAHR!

Explosionsgefahr!

Werden die auf dem Typschild spezifizierten, sicherheitstechnischen Daten und Werte nicht beachtet oder eingehalten, können

gefährliche Situationen die Folge sein!

• Beachten Sie für den Einsatz des Gerätes die Schutzart und

Temperaturklasse.

Das Überschreiten der auf dem Typschild angegebenen

Spannung ist ein sicherheitstechnisches Risiko, da dies zur Überhitzung des Gerätes führen kann!

• Schließen Sie das Gerät nicht mit einer höheren, als auf dem

Typschild angegebenen, Spannung an.

Beispiel

Sicherung / Fuse

F. , . . A

PTB 07 ATEX 2063 X

IEC Ex PTB08.0016X

II 2G Exmb II T4

II 2G Ex mbD21 IP64

Tmed130°C 24V AC/DC

12W AC19-U5-K-PF09

Bild 3: Beispiel für Typschild der Spule AC19 als Teil eines

geschlossenen Systems

Die Beschriftung des Typschilds:

Gerätegruppe

Gerätekategorie

Zündschutzart

II 2G Exmb II T4

II 2D Ex mbD21 IP64

PTB 07 ATEX 2063 X

IEC Ex PTB08.0016X

II 2G Exmb II T4

II 2D Ex mbD21 IP64

Tmed130°C 24V AC/DC

12W AC19-U5-K-PF09

Ident-Nr.

Serien-Nr. der Spule

Überwachungungsstelle

Herstellerdatum - Werk/Monat/Jahr

Gasgruppe

Temperaturklasse

Schutzart

PTB-Zulassungs-Nr.

IEC Ex-Zulassungs-Nr.

- Max. Oberflächentemperatur der Spule (für

Staub)

- Spannung

- Stromart

- Leistung

- Spulentyp

- Anschlussgröße für

Fluidteil

- Spulengröße

- Code

(firmenspezifisch)

deutsch

25

Page 26

PTB 07 ATEX 2063 X

Montage

6.4.1. Elektrische Daten

Elektrische Daten laut Typschild beachten.

7. MONTAGE

7.1. Sicherheitshinweise

GEFAHR!

Explosionsgefahr!

Magnetspule und Ventilkörper bilden nach der Montage ein

geschlossenes System. Bei Einsatz im EX-Bereich besteht bei

der Öffnung des Systems im Betriebszustand Explosionsgefahr!

• Das System darf nicht während des Betriebs demontiert werden.

Explosionsgefahr durch elektrostatische Aufladung!

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder

Personen besteht im EX-Bereich Explosionsgefahr.

• Stellen Sie durch geeignete Maßnahmen sicher, dass es im EXBereich zu keinen elektrostatischen Aufladungen kommen kann.

• Reinigen Sie die Geräteoberfläche des Magnetventils nur durch

leichtes Abwischen mit einem feuchten Tuch.

Gefahr durch elektrische Spannung!

Bei Eingriffen in die Anlage besteht akute Verletzungsgefahr.

• Arbeiten am elektrischen System dürfen nur von ausgebildenten

Elektrofachkräften durchgeführt werden.

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

26

deutsch

Page 27

PTB 07 ATEX 2063 X

Montage

GEFAHR!

Gefahr durch Kurzschluss!

Durch beschädigte Anschlussleitungen kann es zum Kurzschluss

kommen.

• Die Anschlussleitungen der Spule müssen fest verlegt und vor

Beschädigungen geschützt werden.

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb!

Die Magnetspule kann im Dauerbetrieb sehr heiß werden.

• Fassen Sie ein Gerät das bereits länger in Betrieb ist nur mit

Schutzhandschuhen an.

WARNUNG!

Gefahr durch hohen Druck!

Bei Eingriffen in das System besteht akute Verletzungsgefahr.

• Arbeiten am System dürfen nur durch fachkundiges und unterwiesenes Personal mit geeignetem Werkzeug durchgeführt

werden.

• Schalten Sie vor dem Lösen von Leitungen und Ventilen den

Druck ab und entlüften Sie die Leitungen.

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für druckbeaufschlagte Geräte.

• Gewährleisten Sie nach einer Unterbrechung der elektrischen

oder fluidischen Versorgung einen definierten oder kontrollierten

Wiederanlauf des Prozesses.

7.2. Montage

Die Einbaulage des Magnetventils mit integrierter

Spule AC19 ist beliebig.

Vorzugsweise mit oben liegendem Antrieb.

Vor der Montage:

→ Rohrleitungen und Flanschanschlüsse von eventuellen Verschmut-

zungen säubern.

Montage:

WARNUNG!

Verletzungsgefahr durch undichten Anschlüsse

Explosionsgefahr!

Bei Tankanlagen besteht Explosionsgefahr, wenn durch undichte

Anschlüsse, Sauerstoff oder Luft in das Medium gelangt.

Verletzungsgefahr durch Austritt von Medium!

Durch undichte Anschlüsse austretendes Medium kann zu Verletzungen ( z. B. Verbrennungen oder Verätzungen) führen.

• Dichten Sie die Anschlussleitungen sorgfältig ab.

→ Anschlüsse der Rohrleitungen mit PTFE-Band abdichten. Das

Band darf nicht in die Rohrleitungen gelangen.

→ Rohrleitungen einschrauben.

Wichtig für die Funktion des Gerätes!

Beachten Sie die Durchflussrichtung.

→ Ventil auf Dichtheit prüfen.

deutsch

27

Page 28

PTB 07 ATEX 2063 X

Inbetriebnahme

7.3. Elektrischer Anschluss

GEFAHR!

Gefahr durch elektrische Spannung!

Bei Eingriffen in die Anlage besteht akute Verletzungsgefahr.

• Arbeiten am elektrischen System dürfen nur von ausgebildenten

Elektrofachkräften durchgeführt werden.

• Schalten Sie vor Beginn der Arbeiten in jedem Fall die Spannung ab und sichern Sie diese vor Wiedereinschalten!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

→ Elektrisch anschließen

→ Schutzleiter immer anschließen!

Das Anschlusskabel ist mit der Spule AC19 vergossen und

kann nicht demontiert werden.

8. INBETRIEBNAHME

8.1. Sicherheitshinweise

WARNUNG!

Gefahr durch unsachgemäßen Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen, sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Besonders zu beachten sind die Sicherheitshinweise und die

Bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend geschultes

Personal in Betrieb genommen werden.

Stellen Sie vor Inbetriebnahme sicher, dass

→ das Gerät vorschriftmäßig installiert wurde,

→ der Anschluss ordnungsgemäß ausgeführt wurde,

→ das Gerät nicht beschädigt ist.

28

deutsch

Page 29

PTB 07 ATEX 2063 X

Wartung und Reparatur

9. WARTUNG UND REPARATUR

9.1. Wartung

Die Spule AC19 ist, bei Einhaltung der in der Anleitung beschriebenen

Einsatzbedingungen, wartungsfrei

9.2. Reparatur

GEFAHR!

Gefahr durch unsachgemäße Reparatur

Sicherheit und Funktion der Spule AC19 und des dazugehörigen

Magnetventils sind nach einer Reparatur nur dann gewährleistet,

wenn die Reparaturarbeiten vom Hersteller ausgeführt wurden.

• Lassen Sie das Gerät nur vom Hersteller reparieren!

9.3. Fehlerbehebung

Stellen Sie bei Störungen sicher, dass

→ das Gerät vorschriftmäßig installiert wurde,

→ der Anschluss ordnungsgemäß ausgeführt wurde,

→ das Gerät nicht beschädigt ist,

→ Spannung und Druck anliegen,

→ die Rohrleitungen frei sind.

10. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den Transport

beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur. -40 … +55 °C.

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

deutsch

29

Page 30

PTB 07 ATEX 2063 X

30

deutsch

Page 31

Sommaire:

PTB 07 ATEX 2063 X

Bobine magnétique AC19, appareils avec mode de protection II 2G Ex m

1. INSTRUCTIONS DE SERVICE ............................................................... 32

1.1. Symboles..........................................................................................32

2. UTILISATION CONFORME.......................................................................33

2.1. Limitations ........................................................................................33

3. CONSIGNES DE SÉCURITÉ GÉNÉRALES ..................................... 34

4. INDICATIONS GÉNÉRALES ....................................................................36

4.1. Adresses ..........................................................................................36

4.2. Garantie légale ................................................................................36

4.3. Homologations ................................................................................36

4.4. Informations sur Internet ...............................................................36

5. CONDITIONS D’UTILISATION ..............................................................36

5.1. Conditions particulières ................................................................36

5.2. Conditions d’exploitation ..............................................................37

5.3. Conditions de montage ................................................................38

5.4. Utilisation dans les pompes à essence .....................................38

6. CARACTÉRISTIQUES TECHNIQUES ................................................ 39

français

7. MONTAGE

7.1. Consignes de sécurité ..................................................................40

7.2. Montage ...........................................................................................42

7.3. Raccordement électrique .............................................................42

8. MISE EN SERVICE ....................................................................................... 43

8.1. Consignes de sécurité ..................................................................43

9. MAINTENANCE ET RÉPARATION ........................................................43

9.1. Maintenance ....................................................................................43

9.2. Réparation ........................................................................................43

9.3. Dépannage ......................................................................................43

10. TRANSPORT, STOCKAGE, ÉLIMINATION .....................................44

........................................................................................................ 40

31

Page 32

PTB 07 ATEX 2063 X

Instructions de service

1. INSTRUCTIONS DE SERVICE

Les instructions de service décrivent le cycle de vie complet de l’appareil. Conservez ces instructions de sorte qu’elles soient accessibles

à tout utilisateur et à disposition de tout nouveau propriétaire.

AVERTISSEMENT !

Les instructions de service contiennent des informations

importantes sur la sécurité !

Le non-respect de ces consignes peut entraîner des situations

dangereuses. Les instructions de service doivent être lues et

comprises.

• Lisez attentivement les instructions de service avant d'utiliser

l'appareil.

• Faites particulièrement attention aux chapitres « Utilisation

conforme » et « Consignes de sécurité générales » ainsi que les

« Conditions d'utilisation de la bobine AC 19 ».

1.1. Symboles

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement dangereuse !

• Risque de blessures graves, voire la mort en cas de non-respect.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou de

moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

• L’appareil ou l’installation peut être endommagé(e) en cas de

non-respect.

Désigne des informations supplémentaires importantes, des

conseils et des recommandations d’importance.

Renvoie à des informations dans ces instructions de service

ou dans d’autres documentations.

32

→ identifie une opération que vous devez effectuer.

français

Page 33

PTB 07 ATEX 2063 X

Utilisation conforme

2. UTILISATION CONFORME

AVERTISSEMENT !

L'utilisation non conforme de la bobine AC19 peut présenter

des dangers pour les personnes, les installations proches et

l'environnement.

• La bobine magnétique AC19 sert à actionner les vannes qui

commandent des fluides liquides ou gazeux.Elle a été conçue

pour utilisation dans le groupe d’explosion II, catégorie 2D Ex

mbD, IP64, T130° et le groupe d’explosion II, catégorie 2G et

classe de température T4 (voir indications sur la

d’homologation).

• La bobine AC19 est toujours montée sur la conduite de

guidage principale de la robinetterie de soupape et fixée au

moyen d’un écrou. Ainsi, la bobine et le corps de soupape

sont reliés de manière à former un système fermé pouvant être

utilisé également dans les pompes à essence pour commander

l’essence en tant qu’appareil de catégorie 2. Cette utilisation

requiert un corps de soupape métallique (laiton, aluminium ou

acier inoxydable).

Pour l'utilisation, il convient de respecter les données autorisées,

les conditions d'exploitation et d'utilisation spécifiées

– dans les instructions de service pour la bobine magnétique

AC19, sur la plaque signalétique, dans les documents de

contrat

– ainsi que dans les instructions de service de la vanne magné-

tique actionnée avec la bobine.

- plaque

Toute autre utilisation ou toute utilisation allant au-delà est considérée comme non conforme.

Bürkert décline toute responsabilité pour les dommages qui en

résultent. L’utilisateur est seul à en supporter le risque.

• Veillez à ce que l’utilisation de l’appareil soit toujours conforme.

La bobine peut être utilisée uniquement en association avec les

appareils et composants étrangers recommandés et homologués

par Bürkert.

Les conditions pour l’utilisation sûre et parfaite sont un transport,

un stockage et une installation dans les règles ainsi qu’une utilisation et maintenance parfaites.

2.1. Limitations

Lors de l’exportation du système/de l’appareil, veuillez respecter les

limitations éventuelles existantes.

2.1.1. Homologation Ex

L’homologation Ex n’est valable que si vous utilisez les modules et

composants homologués par Bürkert tel que cela est décrit dans ces

instructions de service.

La bobine AC19 peut être utilisée uniquement avec les types de

soupape autorisés par Bürkert, sinon l’homologation Ex devient

caduque !

L’homologation Ex devient également caduque si vous apportez

des modifications non autorisées au système, aux modules ou aux

composants.

français

33

Page 34

PTB 07 ATEX 2063 X

Consignes de sécurité générales

3. CONSIGNES DE SÉCURITÉ

GÉNÉRALES

Ces consignes de sécurité ne tiennent pas compte

• des hasards et des événements pouvant survenir lors du montage,

de l’exploitation et de l’entretien des appareils.

• des prescriptions de sécurité locales que l’exploitant est tenu de faire

respecter par le personnel chargé du montage.

DANGER !

Risque d'explosion !

Après montage, la bobine magnétique et le corps de soupape

forment un système fermé. Il y a risque d'explosion en cas d'ouverture du système pendant son utilisation dans des zones présentant des risques d'explosion !

• Le système ne doit pas être démonté pendant son utilisation.

Risque d'explosion dû à la charge électrostatique !

Il y a risque d'explosion en cas de décharge soudaine d'appareils ou

de personnes chargés d'électricité statique dans des zones présentant des risques d'explosion.

• Par des mesures appropriées, assurez-vous qu'il ne peut y avoir

de charges électrostatiques dans de telles zones.

• Nettoyez la surface de la vanne magnétique uniquement en

essuyant légèrement avec un chiffon humide .

DANGER !

Danger par tension électrique!

Il y a risque important de blessures lors d’interventions sur

l'installation.

• Les travaux sur le système électrique doivent être effectués

uniquement par des électriciens qualifiés.

• Avant d'effectuer des travaux, coupez toujours la tension et

empêchez toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour les appareils électriques en matière de prévention des accidents ainsi

qu'en matière de sécurité !

Risque de brûlures/d'incendie en fonctionnement continu !

La bobine magnétique peut devenir brûlante en fonctionnement

continu.

• Portez toujours des gants de protection pour toucher un appareil ayant fonctionné pendant longtemps.

Danger dû à la haute pression !

Il y a risque important de blessures lors d’interventions sur le

système.

• Les travaux sur le système doivent être exécutés uniquement par

du personnel qualifié et formé disposant de l’outillage approprié.

• Avant de desserrer les conduites et les soupapes, coupez la

pression et purgez l’air des conduites.

• Lors du montage, respectez le sens du débit.

• Veuillez respecter les réglementations en vigueur pour les appareils sous pression en matière de prévention des accidents ainsi

qu’en matière de sécurité.

34

français

Page 35

PTB 07 ATEX 2063 X

Consignes de sécurité générales

• Après une interruption de l’alimentation électrique ou de

l’alimentation en fluides, garantissez un redémarrage défini ou

contrôlé du processus !

AVERTISSEMENT !

Risques d’ordre général !

• N’utilisez pas la robinetterie de soupape ou l’appareil complet comme levier pour visser la soupape dans le système de

conduites.

• Ne soumettez pas l’appareil à des contraintes mécaniques (par

ex. pour déposer des objets ou en l’utilisant comme marche).

• N’apportez pas de modifications à l’extérieur du boîtier. Ne

laquez pas les pièces du corps ni les vis.

L’actionnement involontaire ou l’intervention non autorisée

peut entraîner des situations dangereuses, voire des blessures

corporelles.

• Evitez l’actionnement involontaire du système par des mesures

appropriées !

• N’apportez pas de modifications non autorisées au système.

Le non-respect des règles reconnues en matière de sécurité peut

entraîner des situations à risques, voire des blessures corporelles.

• Respectez les règles reconnues en matière de sécurité pour

planifier l’utilisation et utiliser la bobine AC19 et la vanne

magnétique correspondante.

La bobine AC19 a été développée dans le respect des

règles reconnues en matière de sécurité et correspond

à l’état actuel de la technique. Néanmoins, des risques

peuvent se présenter.

La bobine AC19 et la vanne magnétique correspondante doivent

être utilisées uniquement en parfait état et en respectant les instructions de service.

français

35

Page 36

PTB 07 ATEX 2063 X

Indications générales

4. INDICATIONS GÉNÉRALES

4.1. Adresses

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages des instructions de

service imprimées. Egalement sur internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie est l’utilisation conforme de

la bobine AC19 dans le respect des conditions d’utilisation spécifiées.

4.3. Homologations

Le certificat d’essai CE PTB 07 ATEX 2063 X a été établi par

le PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100, 38116 Braunschweig

qui effectue également l’audit de production (CE0102).

4.4. Informations sur Internet

Vous trouverez les instructions de service et les fiches techniques

concernant les produits Bürkert sur Internet sous : www.buerkert.fr

5. CONDITIONS D’UTILISATION

5.1. Conditions particulières

5.1.1. Protection contre les courts-circuits

Pour assurer la protection contre les courts-circuits, il convient de

placer en amont de chaque aimant un fusible correspondant à son

courant évalué (maxi 3 x Ib selon CEI 60127-2-1) ou un disjoncteurprotecteur à déclenchement rapide thermique et de court-circuit

(réglage sur le courant évalué).

• Selon la norme CEI citée, le fusible au valeur de courant le plus faible

suffit lorsque les courants évalués de l’aimant sont très faibles. Ce

fusible peut être logé dans l’appareil d’alimentation correspondant

ou placé séparément en amont.

• La tension de mesure du fusible doit être identique ou supérieure à

la tension nominale indiquée de l’aimant.

La puissance de coupure du fusible doit être identique ou supérieure au courant de court-circuit maximal possible sur le lieu de

montage (habituellement 1 500 A).

Exemple :

vanne magnétique

2/2

Bobine magnétique

AC19

Corps de

soupape

Fig. 1 : Exemple pour la bobine AC19 en tant que partie d’un système fermé.

La valeur nominale

du fusible est

indiquée sur l'aimant

Fusible / Fuse

F . , . . A

36

français

Page 37

PTB 07 ATEX 2063 X

Conditions d’utilisation

5.2. Conditions d’exploitation

Les exigences suivantes doivent être respectées pour l’utilisation des

bobines magnétiques des types AC19-..-.-PF09 et AC19-..-.-PF10 .

5.2.1. Matériaux

Les exigences en matière de sécurité spécifiques à l’utilisation doivent

être respectées lors du choix des matériaux du système.

Corps de soupape :

DANGER !

Risque d'explosion !

Seuls les corps de soupape métalliques peuvent garantir la

sécurité exigée en cas d'utilisation du système en tant qu'appareil de catégorie 2 pour la commande d'essence dans les

pompes à essence !

• Pour la commande d'essence dans les pompes à essence

avec des appareils de catégorie 2, veuillez utiliser uniquement

des corps de soupape métalliques (laiton, aluminium ou acier

inoxydable).

• Pour l’utilisation dans les pompes à essence

Métal (laiton, aluminium, acier inoxydable)

• Autres utilisations

Métal (laiton, aluminium, acier inoxydable) ou plastique

(par ex. polyamide PA 6 GV ...)

Enveloppes des câbles de raccordement électriques :

Types AC19-..-.-PF09 PVC

Types AC19-..-.-PF10 PUR

5.2.2. Dimensions minimales

Corps de soupape :

55 mm x 36 mm x 30 mm (L x l x H).

Il est possible d’utiliser à tout moment un corps de soupape plus

grand avec une meilleure conductibilité thermique.

5.2.3. Plage de température d’utilisation :

DANGER !

Risque d'explosion !

Il y a risque d'explosion lorsque la température maximale admissible de la bobine AC19 est dépassée.

• Respectez absolument les températures indiquées pour la bobine.

• Respectez les limitations éventuelles imposées par les valeurs

maximales admissibles de la vanne magnétique combinée à la

bobine.

Températures de la bobine magnétique AC19

Température de surface maximale de la bobine à une température

ambiante de 60 °C et tension nominale : 110 °C (pour gaz)

130 °C (pour poussiére)

Classe de température T4

Températures ambiantes maximales admissibles

Type Matériau des câbles de

raccordement électriques

AC19-..-.-PF09 PVC -40 - +55 °C

AC19-..-.-PF10 PUR -40 - +60 °C

Température ambiante

maximale admissible

français

37

Page 38

PTB 07 ATEX 2063 X

Conditions d’utilisation

5.3. Conditions de montage

Les bobines magnétiques des types AC19-..-.-PF09 à AC19-..-.PF10 conviennent uniquement à un montage individuel.

Les câbles de raccordement doivent être posés à demeure pour les

protéger contre les dommages.

Respectez également les indications du chapitre « Caractéristiques techniques ».

5.4. Utilisation dans les pompes à

essence

DANGER !

Risque d'explosion !

Après montage, la bobine magnétique et le corps de soupape

forment un système fermé. Il y a risque d'explosion en cas d'ouverture du système pendant son utilisation dans des zones présentant des risques d'explosion !

• Le système ne doit pas être démonté pendant son utilisation.

• Les travaux de réparation sur le corps de soupape doivent être

effectués uniquement par le fabricant.

Les vannes magnétiques avec la bobine AC19 ne peuvent être

utilisées en tant qu’appareils de catégorie 2 pour la commande

d’essence que si le système fermé est exempt d’air et d’oxygène.

• Assurez-vous de l’absence d’air et d’oxygène dans le système

fermé et que leur pénétration dans le système est impossible.

• Assurez-vous qu’il n’y pas eu pénétration d’air ou d’oxygène à

l’arrêt et au démarrage du système.

Seuls les corps de soupape métalliques peuvent garantir la

sécurité exigée en cas d’utilisation du système en tant qu’appareil de catégorie 2

pompes à essence !

• Pour la commande d’essence dans les pompes à essence

avec des appareils de catégorie 2, veuillez utiliser uniquement

des corps de soupape métalliques (laiton, aluminium ou acier

inoxydable).

Exemple :

vanne magnétique 2/2

Bobine magnétique AC19

Corps de soupape

pour la commande d’essence dans les

38

Fig. 2 : Exemple pour la plaque signalétique de la bobine AC19 en tant

que partie d’un système fermé.

français

Page 39

PTB 07 ATEX 2063 X

Caractéristiques techniques

6. CARACTÉRISTIQUES TECHNIQUES

DANGER !

Risque d'explosion !

Des situations dangereuses peuvent être créées si les caractéristiques de sécurité et les valeurs spécifiées sur la plaque signalétique ne sont pas respectées !

• Pour l'utilisation de l'appareil, respectez le type de protection et

la classe de température.

Le dépassement de la tension indiquée sur la plaque signalétique

représente un risque en matière de sécurité étant donné que cela

peut entraîner la surchauffe de l'appareil !

• Ne raccordez pas l'appareil à une tension supérieure à celle

indiquée sur la plaque signalétique.

Exemple

Fusible / Fuse

F. , . . A

PTB 07 ATEX 2063 X

IEC Ex PTB08.0016X

II 2G Exmb II T4

II 2G Ex mbD21 IP64

Tmed130°C 24V AC/DC

12W AC19-U5-K-PF09

Fig. 3 : Exemple pour la bobine AC19 en tant que partie d’un système

fermé.

Informations sur la plaque signalétique :

Groupe d’appareils

Catégorie d’appareils

Type de protection à l’allumage

Groupe de gaz

II 2G Exmb II T4

II 2D Ex mbD21 IP64

Classe de température

Type de protection

N° d’homologation PTB

PTB 07 ATEX 2063 X

N° d’homologation Ex CEI

IEC Ex PTB08.0016X

II 2G Exmb II T4

- Température de surface

II 2D Ex mbD21 IP64

Tmed130°C 24V AC/DC

12W AC19-U5-K-PF09

- Tension

- Type de courant

- Puissance

- Type de bobine

- Grandeur de raccor-

N° ID

N° de série de la bobine

- Taille de bobine

- Code (spécifique à

Organisme de surveillance

Date fabricant - Usine/Mois/Année

maximale de la bobine

(pour poussiére)

dement pour partie

fluide

l’entreprise)

français

39

Page 40

PTB 07 ATEX 2063 X

Montage

Caractéristiques électriques

Respectez les caractéristiques électriques selon la plaque

signalétique.

7. MONTAGE

7.1. Consignes de sécurité

DANGER !

Risque d'explosion !

Après montage, la bobine magnétique et le corps de soupape

forment un système fermé. Il y a risque d'explosion en cas d'ouverture du système pendant son utilisation dans des zones présentant des risques d'explosion !

• Le système ne doit pas être démonté pendant son utilisation.

Risque d'explosion dû à la charge électrostatique !

Il y a risque d'explosion en cas de décharge soudaine d'appareils ou

de personnes chargés d'électricité statique dans des zones présentant des risques d'explosion.

• Par des mesures appropriées, assurez-vous qu'il ne peut y avoir

de charges électrostatiques dans de telles zones.

• Nettoyez la surface de la vanne magnétique uniquement en

essuyant légèrement avec un chiffon humide .

40

français

Page 41

PTB 07 ATEX 2063 X

Montage

DANGER !

Danger par tension électrique!

Il y a risque important de blessures lors d’interventions sur

l’installation.

• Les travaux sur le système électrique doivent être effectués

uniquement par des électriciens qualifiés.

• Avant d’effectuer des travaux, coupez toujours la tension et

empêchez toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour les appareils électriques en matière de prévention des accidents ainsi

qu’en matière de sécurité !

Danger dû au court-circuit !

Les câbles de raccordement endommagés peuvent entraîner un

court-circuit.

• Les câbles de raccordement de la bobine doivent être posés à

demeure et protégés pour ne pas être endommagés.

Risque de brûlures/d'incendie en fonctionnement continu !

La bobine magnétique peut devenir brûlante en fonctionnement

continu.

• Portez toujours des gants de protection pour toucher un appareil ayant fonctionné pendant longtemps.

AVERTISSEMENT !

Danger dû à la haute pression !

Il y a risque important de blessures lors d'interventions sur le

système.

• Les travaux sur le système doivent être exécutés uniquement

par du personnel qualifié et formé disposant de l'outillage

approprié.

• Avant de desserrer les conduites et les soupapes, coupez la

pression et purgez l'air des conduites.

• Veuillez respecter les réglementations en vigueur pour les appareils sous pression en matière de prévention des accidents ainsi

qu'en matière de sécurité !

• Après une interruption de l'alimentation électrique ou de

l'alimentation en fluides, garantissez un redémarrage défini ou

contrôlé du processus !

français

41

Page 42

PTB 07 ATEX 2063 X

Montage

7.2. Montage

La position de montage de la vanne magnétique avec

bobine AC19 intégrée est indifférente.De préférence avec

l'entraînement en haut.

Avant le montage :

→ Nettoyez les tuyauteries et les raccordements à brides afin d’enlever

les éventuelles saletés.

Montage :

AVERTISSEMENT !

Risque de blessures dû aux raccords non étanches

Risque d'explosion !

Les stations-service présentent un risque d'explosion si l'oxygène

ou l'air parvient dans le fluide à cause de raccords non étanches.

Risque de blessures dû à la sortie de fluide !

La sortie de fluide de raccords non étanches peut provoquer des

blessures (par ex. des brûlures ou des brûlures par acide).

• Etanchez les conduites de raccordement avec soin.

→ Etanchez les raccords des tuyauteries avec une bande PTFE. La

bande ne doit pas parvenir dans les tuyauteries.

→ Vissez les tuyauteries.

Important pour le fonctionnement de l'appareil !

Respectez le sens du débit.

7.3. Raccordement électrique

DANGER !

Danger par tension électrique!

Il y a risque important de blessures lors d’interventions sur

l'installation.

• Les travaux sur le système électrique doivent être effectués

uniquement par des électriciens qualifiés.

• Avant d'effectuer des travaux, coupez toujours la tension et

empêchez toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour les appareils électriques en matière de prévention des accidents ainsi

qu'en matière de sécurité !

→ Raccordez à l’électricité

→ toujours le conducteur de protection !

Le câble de raccordement est surmoulé avec la bobine

AC19 et ne peut pas être démonté.

→ Contrôlez l’étanchéité de la soupape.

42

français

Page 43

PTB 07 ATEX 2063 X

Mise en service

8. MISE EN SERVICE

8.1. Consignes de sécurité

AVERTISSEMENT !

Danger dû à une utilisation non conforme !

Une utilisation non conforme peut entraîner des blessures et

endommager l'appareil et son environnement.

• Avant la mise en service, il faut s'assurer que le contenu des

instructions de service est connu et parfaitement compris par

les opérateurs.

• Respectez en particulier les consignes de sécurité et l'utilisation

conforme.

• L'appareil/l'installation doit être mis(e) en service uniquement

par un personnel suffisamment formé.

Avant la mise en service, assurez-vous que

→ l’appareil a été installé dans les règles,

→ le raccordement a été correctement effectué,

→ l’appareil n’est pas endommagé.

9. MAINTENANCE ET RÉPARATION

9.1. Maintenance

La bobine AC19 ne nécessite pas d’entretien à condition de respecter

les conditions d’utilisation décrites dans les instructions de service.

9.2. Réparation

DANGER !

Danger dû à une réparation non conforme !

La sécurité et le fonctionnement de la bobine AC19 et de sa

vanne magnétique ne sont pas garantis après réparation que si

celle-ci a été effectuée par le fabricant.

• Faites réparer l'appareil uniquement par le fabricant !

9.3. Dépannage

En présence de pannes, assurez-vous que

→ l’appareil a été installé dans les règles,

→ le raccordement a été correctement effectué,

→ l’appareil n’est pas endommagé,

→ la tension et la pression sont disponibles,