Page 1

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Type 3232, 3233, 3233 K, 3234, 3235, 3239

Manually operated diaphragm valves, Diameter DN8 - DN100

Handbetätigte Membranventile, Nennweiten DN8 - DN100

Vannes à membrane, commandé manuelle, Piston section nominale DN8 - DN100

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürker t Werke GmbH & Co. KG, 20 - 2017

Operating Instructions 1706/0_EU-EN_008 / Original DE

Page 3

3

Contents

1 OPERATING INSTRUCTIONS ................................................................4

1.1 Definition of the term “device” ................................................4

1.2 Symbols ....................................................................................... 4

2 AUTHORIZED USE ......................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................5

4 GENERAL INFORMATION ........................................................................6

4.1 Contact addresses ...................................................................6

4.2 Warranty ...................................................................................... 6

4.3 Information on the Internet ......................................................6

5 SYSTEM DESCRIPTION ............................................................................7

5.1 General description ..................................................................7

5.2 Intended application area ........................................................ 7

6 TECHNICAL DATA ........................................................................................7

6.1 Conformity ................................................................................... 7

6.2 Standards .................................................................................... 7

6.3 Operating conditions ................................................................ 7

6.4 Description of the type label ................................................... 9

6.5 Labeling of the forged body ..................................................10

6.6 Labeling of the tube valve body (VP) ..................................10

6.7 General technical data ...........................................................11

6.8 Flow values ...............................................................................11

7 STRUCTURE AND FUNCTION............................................................14

7.1 Structure ....................................................................................14

7.2 Type description ......................................................................14

7.3 Function .....................................................................................15

8 INSTALLATION ............................................................................................ 15

8.1 Before installation ....................................................................15

8.2 Installation .................................................................................18

9 MAINTENANCE, CLEANING ................................................................20

9.1 Maintenance work ...................................................................20

10 REPAIRS.........................................................................................................21

10.1 Replacing the diaphragm ......................................................21

11 SPARE PARTS, ACCESSORIES ........................................................23

11.1 Order table ................................................................................24

11.2 Handwheel locking device option .......................................26

12 TRANSPORT, STORAGE, DISPOSAL ..............................................26

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 4

4

Operating instructions

1 OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

Important safety information.

Failure to observe these instructions may result in hazardous

situations.

▶ The operating instructions must be read and understood.

1.1 Definition of the term “device”

In these instructions, the term “device” always refers to the Type

3232, 3233, 3233 K, 3234, 3235 and 3239.

1.2 Symbols

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning may result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a medium or minor

injury.

NOTE!

Warns of damage to property.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

▶ designates instructions for risk prevention.

→ designates a procedure which you must carry out.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 5

5

Authorized use

2 AUTHORIZED USE

Non-authorized use of the devices may be dangerous to people,

nearby equipment and the environment.

▶ The diaphragm valves of Types 3232, 3233, 3233 K, 3234, 3235

and 3239 are designed for the control of contaminated, ultra-pure

or sterile media, as well as for abrasive or aggressive media (also

with higher viscosity).

▶ In the potentially explosion-risk area the device may be used only

according to the specification on the separate Ex type label. For

use observe the additional information enclosed with the device

together with safety instructions for the explosion-risk area.

▶ Devices without a separate Ex type label may not be used in a

potentially explosive area.

▶ During use observe the authorized data, the operating conditions

and conditions of use specified in the contract documents and

operating instructions.

▶ The device may be used only in conjunction with third-party devices

and components recommended and authorized by Bürkert.

▶ Correct transportation, correct storage and installation and care-

ful use and maintenance are essential for reliable and faultless

operation.

▶ Use the device only as intended.

3 BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any

• Contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing

these regulations, also with reference to the installation personnel.

Danger – high pressure.

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of electric shock.

▶ Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

Danger of bursting from overpressure.

▶ Observe the specifications on the type label for maximum control

and medium pressure.

▶ Observe permitted medium temperature.

Risk of burns or risk of fire if used continuously through hot

device surface.

▶ Keep the device away from highly flammable substances and media

and do not touch with bare hands.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 6

6

General information

General hazardous situations.

To prevent injury, ensure that:

▶ The system cannot be activated unintentionally.

▶ When closing the valve, tighten it hand-tight only. Overtightening

may prematurely damage the diaphragm.

▶ Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The device may be operated only when in perfect condition and

in consideration of the operating instructions.

▶ The general rules of technology apply to application planning

and operation of the device.

To prevent damage to property of the device, ensure:

▶ The devices may be used only for media which do not attack

the body and seal materials (see type label). Information on the

resistance of materials to the media is available on the Internet at:

www.burkert.com

▶ Do not put any loads on the body.

▶ Do not make any external modifications to the device body. Do

not paint the body parts or screws.

4 GENERAL INFORMATION

4.1 Contact addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@burkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2 Warranty

The warranty is only valid if the device is used as intended in accordance

with the specified application conditions.

4.3 Information on the Internet

The operating instructions and data sheets for Types 3232, 3233,

3233 K, 3234, 3235, 3239 can be found on the Internet at:

www.burkert.com

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 7

7

System description

5 SYSTEM DESCRIPTION

5.1 General description

Type 3232, 3233, 3233 K, 3234, 3235 and 3239 is a manually controlled diaphragm valve with diaphragm seal. The valve is self-draining

in appropriate installation position.

5.2 Intended application area

The diaphragm valve of Type 3232 is designed for the control of contaminated and aggressive media. The valves of Type 3233, 3233 K,

3234, 3235 and 3239 can be used even for ultra-pure or sterile media

with a higher viscosity.

The valves may only control media which do not attack the body and

seal materials (see type label). Information on the resistance of materials

to the media is available from your Bürkert sales office.

6 TECHNICAL DATA

6.1 Conformity

Type 3232, 3233, 3233 K, 3234, 3235, 3239 conforms with the EU

Directives according to the EU Declaration of Conformity.

6.2 Standards

The applied standards, which verify conformity with the EU Directives,

can be found on the EU-Type Examination Certificate and / or the EU

Declaration of Conformity.

6.3 Operating conditions

WARNING!

Danger of bursting from overpressure.

If the device ruptures, the medium may cause injuries, chemical

burns or scalds.

▶ Do not exceed the maximum medium pressure. Observe specifi-

cations on the type label!

▶ Observe permitted ambient and media temperature.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 8

8

Technical data

6.3.1 Allowable temperatures

Ambient temperature for actuators:

Material Temperature

PPS Up to 130 °C (briefly up to 150 °C)

Stainless steel Up to 130 °C (briefly up to 150 °C)

Gray cast iron Up to 130 °C (briefly up to 150 °C)

Tab. 1: Ambient temperature for actuators

Medium temperature for body:

Body material Temperature

Stainless steel -10...+140 °C

PVC (see PT-Graph) -10...+60 °C

PVDF (see PT-Graph) -10...+120 °C

PP (see PT-Graph) -10...+80 °C

Tab. 2: Medium temperature for body

Medium temperature for diaphragms:

Material Temperature Remarks

EPDM (AB) -10...+130 °C Steam sterilisation up to +140 °C / 60 min

EPDM (AD) -5...+143 °C Steam sterilisation up to +150 °C / 60 min

FKM (FF) 0...+130 °C No steam / dry heat up to +150 °C /

60 min

PTFE (EA) -10...+130 °C Steam sterilisation up to +140 °C / 60 min

Material Temperature Remarks

Advanced

PTFE (EU)

-5...+143 °C Steam sterilisation up to +150 °C / 60 min

Advanced

PTFE (ET)

-10...+90 °C -

Gylon (ER) -5...+130 °C Steam sterilisation up to +140 °C / 60 min

Tab. 3: Medium temperature for diaphragms

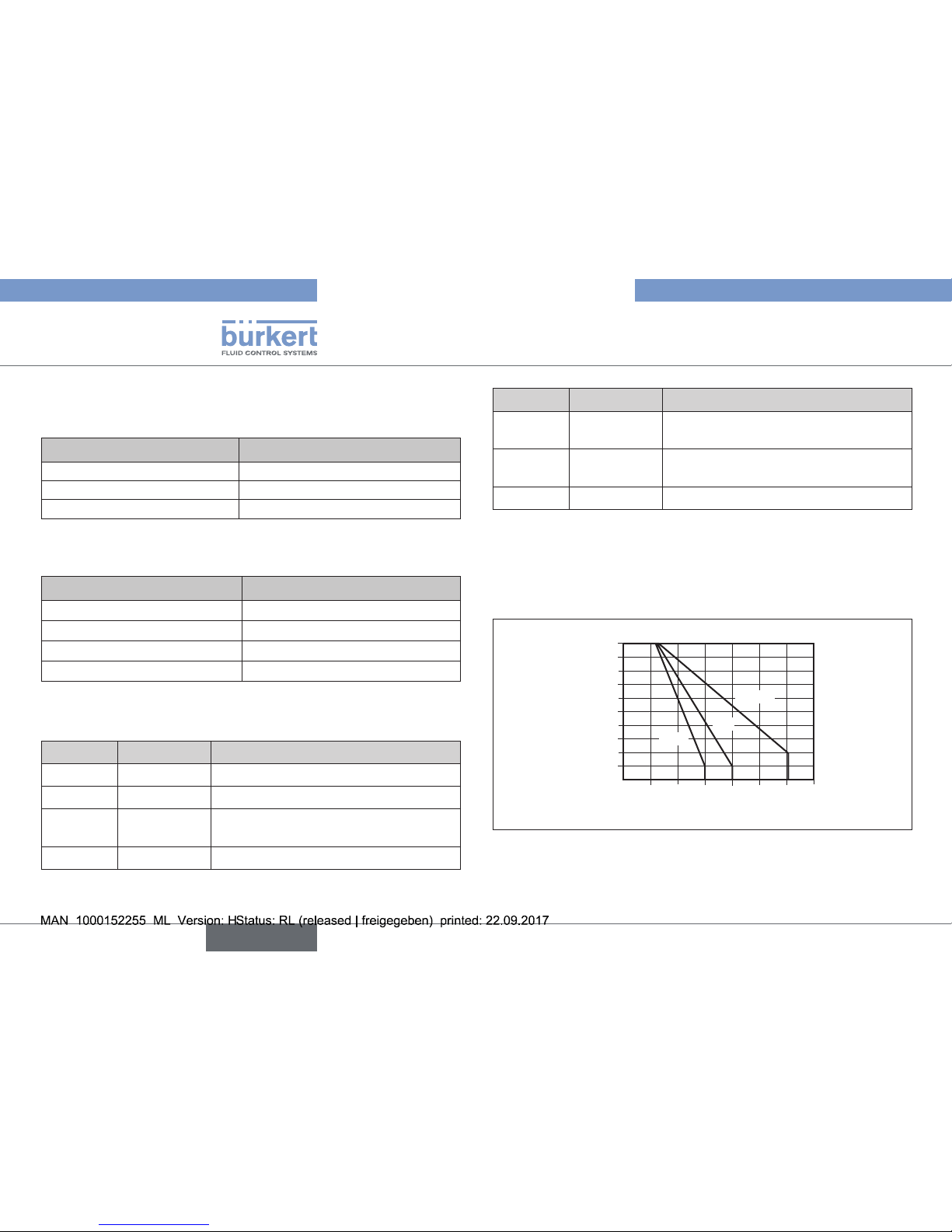

6.3.2 Maximum permitted medium pressure

Permitted medium pressure depending on the medium temperature:

DN 15 - 65

10

8

6

4

2

20 40 60

80

100 120

140

PVC

PVDF

PP

Temperature [°C]

Medium pressure [bar]

Fig. 1: Graph of medium pressure / Medium temperature

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 9

9

Technical data

Maximum permitted medium pressure

The values apply to body made of:

• plastic,

• stainless steel: block material, forged, casted and tube valve body.

Orifice

(Diaphragm

size)

DN

[mm]

Max. switchable medium pressure [bar]

Handwheel and bonnet

PPS

Handwheel PPS / Bonnet

stainless steel

EPDM/FKM PTFE/

advanced

PTFE/

laminated

advanced

PTFE

EPDM/FKM PTFE/

advanced

PTFE/

laminated

advanced

PTFE

8 10 10 10 10

15 10 10 10 10

20 10 10 10 10

25 10 10 10 10

32 10 10 10 10

40 10 10 10 10

50 7 7 10 10

Tab. 4: Maximum permitted medium pressure

Maximum permitted medium pressure

Orifice

(Diaphragm

size)

DN

[mm]

Max. switchable medium pressure [bar]

Handwheel and bonnet stainless steel

EPDM/FKM PTFE/advanced PTFE/

laminated advanced

PTFE

65 10 10

80 10 10

100 6 6

Tab. 5: Maximum permitted medium pressure

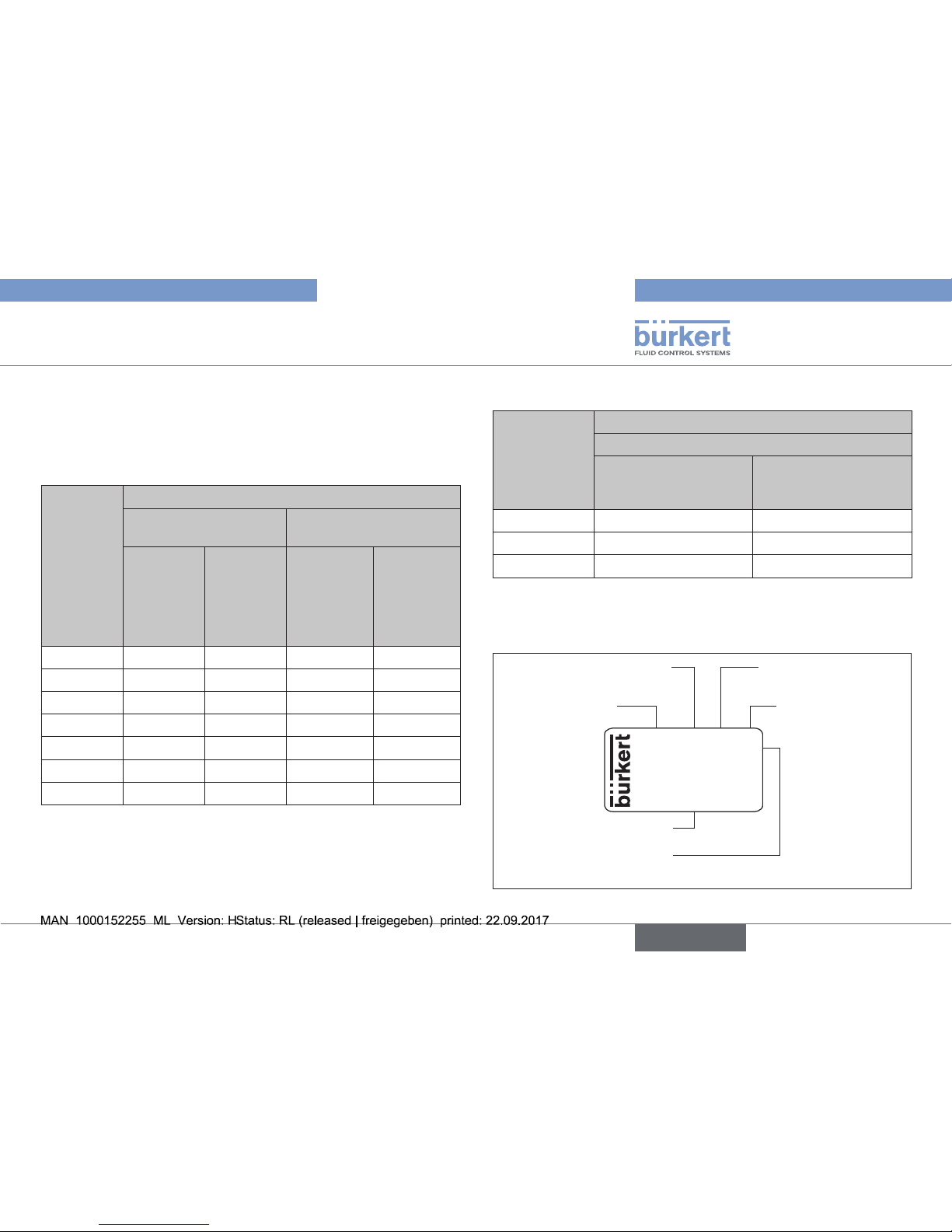

6.4 Description of the type label

3233 25,0 EPDM VS

Made in Germany

00442376

W36LP

TG44 Pmed

10bar

Type

Orifice

(Diaphragm size)

Body material

Identification number

Seal material

Port connection,

Max. medium pressure

Fig. 2: Description of the type label (example)

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 10

10

Technical data

6.5 Labeling of the forged body

XXXXXXXXXX

XX F

1.4435/316L(VS)

PN16/CWP150

XXXXXXXX/XXX

XXXXXX

XXXX

Batch number/

manufacturing code

Company logo

Material

Nominal pressure

Production/order

number (F-part)

Serial number

Self-drain angle

Customized text

(optional)

Connection orifice

and tube sizes

Fig. 3: Labeling of the forged body

6.6 Labeling of the tube valve body

(VP)

1.4435

316L(VP)

XXXXXXXX

XXXXXXXXXX

PN16 / CWP150

XXXXXXXX / XXX

XXXX / XXXXXX

Material HeatCompany logo

Nominal pressure

Connection orifice

and pipe dimensions

Self-drain angle /

Customer-specific text

(optional)

Production number

order number / Serial

number

Fig. 4: Labeling of the tube valve body (VP)

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 11

11

Technical data

6.7 General technical data

Materials

Body Tube valve body (VA, VP),

Precision casting (VG), Forged steel (VS), PP,

PVC, PVDF

Actuator Handwheel and bonnet PPS

Handwheel PPS and bonnet stainless steel

Handwheel and bonnet stainless steel

DN65 to DN100

Diaphragm EPDM, PTFE, FKM

Connections

Medium connection Welded connection according to DIN EN

1127 (ISO 4200), DIN 11850 series 2,

DIN 11866 (ASME-BPE 2005)

other connections on request

Media

Flow media Type 3232; contaminated, aggressive,

ultrapure, sterile media and media with higher

viscosity

Installation position

In any position, floor drain valve type 3235;

actuator face down

6.8 Flow values

6.8.1 Flow values for forged bodies

Kvs values [m3/h] for forged bodies

Diaphragm

size

Orifice

connection (DN)

Actuator

size

Seal

material

DIN ISO ASME BS SMS

8 6 C/40 EPDM 1.1

PTFE 1.1

8 / 1/4"

C/40 EPDM 1.7 1.5 0.7 0.5

PTFE 1.9 2.0 0.7 0.5

10 / 3/8"

C/40 EPDM 1.5 1.5 1.6 1.4

PTFE 1.9 2.0 1.8 1.6

15 / 1/2"

C/40 EPDM 1.5

PTFE 1.9

15

10 / 3/8"

E/63 EPDM 3.5 5.5

PTFE 3.4 5.2

15 / 1/2"

E/63 EPDM 6.5 6.5 3.1 3.7

PTFE 6.0 6.0 3.1 3.6

20 / 3/4"

E/63 EPDM 6.5

PTFE 6.0

20

20 / 3/4"

F/80 EPDM 12.4 12.5 8.4 8.9

PTFE 12.0 12.0 8.5 8.8

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 12

12

Technical data

25

25 / 1"

F/80 EPDM 20.0 18.0 15.5 16.0

PTFE 17.0 16.0 14.5 14.8

40 32 H/125 EPDM 34.0

PTFE 34.0

40 / 1

1/2"

H/125 EPDM 40.0 41.0 37.0 38.0

PTFE 40.0 40.0 37.5 38.0

50

50 / 2"

H/125 EPDM 66.0 66.0 66.0 66.0

PTFE 66.0 67.0 66.0 66.0

2 1/2"

H/125 EPDM 66.0

PTFE 66.0

Tab. 6: Kvs values for forged bodies

6.8.2 Flow values for cast bodies and

plastic bodies

Kvs value [m3/h] for cast bodies VG and plastic bodies PD. PP. PV

Diaphragm

size

Orifice

connection

(DN)

Seal

material

Cast body

VG (all

standards)

Plastic body

(all materials)*

8 8 EPDM 0.95 -

PTFE 1.5 -

15 15 EPDM 5.6 3

PTFE 5.3 3

20 20 EPDM 10.7 7

PTFE 10.5 6.7

25 25 EPDM 14.6 11.4

PTFE 13.6 10

32 32 EPDM - 17.5

PTFE - 17.1

40 40 EPDM 35.0 24.5

PTFE 35.0 24.0

50 50 EPDM 47.0 41.5

PTFE 48.0 41.5

Tab. 7: Kvs values for cast bodies and plastic bodies

* Plastic bodies: measured with bodies ASV

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 13

13

Technical data

6.8.3 Flow values for tube valve body

Kvs values [m3/h] for tube valve body VP (IHU2) TVB3G

Diaphragm

size

Orifice

connection

(DN)

Actuator

size

Seal

material

DIN ISO ASME

8

8 / 1/4"

C/40 EPDM 1.9

PTFE 2.4

10 / 3/8"

C/40 EPDM 1.9

PTFE 2.4

15 / 1/2"

C/40 EPDM

PTFE 2.2

15

15 / 1/2"

E/63 EPDM 7.2 7

PTFE 6.7 6.6

20 / 3/4"

E/63 EPDM 6.9

PTFE 5.5 6.5

20

20 / 3/4"

F/80 EPDM 13.5

PTFE 12.1

25 / 1"

F/80 EPDM 14.9

PTFE 13.7 12.7

25

25 / 1"

E/63 EPDM 17.3

PTFE 14.1

32 E/63 EPDM 18.6

PTFE 14.2

25 / 1"

F/80 EPDM 19.1

PTFE 15.6

32 F/80 EPDM 20.0

PTFE 15.8

32 32 G/100 EPDM 36.0

PTFE 36.0

40 / 1 1/2"

G/100 EPDM 35.0

PTFE 34.5 32.0

40

40 / 1 1/2"

H/125 EPDM 48.0

PTFE 47.0

50 / 2"

H/125 EPDM 46.0

PTFE 43.5 45.0

50

50 / 2"

H/125 EPDM 70.0

PTFE 70.0

Tab. 8: Kvs values for tube valve body VP

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 14

14

Structure and Function

7 STRUCTURE AND FUNCTION

7.1 Structure

The manually actuated diaphragm valve consists of a manual actuator

and a 2/2-way valve body.

7.2 Type description

The types differ in the body.

7.2.1 Type 3232, 3233 and 3233 K

Handwheel with position

indicator (see chapter “7.3.1”)

Attachment

Diaphragm body

Port connection

Fig. 5: Example of the 2/2-way valve type 3232, 3233

and 3233 K

7.2.2 Types 3234, 3235 and 3239

Type Body Structure

T-Valve

Type 3234

T-Valve body

Tank bottom

valve

Type 3235

Tank bottom

valve with

welding flange

Y-Valve

Type 3239

Y-Valve body

Tab. 9: Structure. Types 3234, 3235 and 3239

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 15

15

Installation

7.3 Function

The manual actuation of the handwheel transfers the force via a spindle

and opens and closes the valve.

7.3.1 Position indicator

Actuator size DN4, DN6, DN8 and DN10

When the valve is opened, a yellow mark is visible between the bonnet

and the handwheel.

Actuator size DN15 to DN50

From DN15 a yellow cylinder provides information on the valve

position:

• Yellow cylinder completely retracted in the handwheel:

Valve closed (CLOSED position)

• Yellow cylinder projects all the way out of the handwheel:

Valve opened (OPEN position)

Actuator size DN65, DN80 and DN100

From DN65 an spindle extension indicates the valve position:

• Spindle extension completely retracted in the handwheel:

Valve closed (CLOSED position)

• Spindle extension projects all the way out of the handwheel:

Valve opened (OPEN position)

8 INSTALLATION

DANGER!

Risk of injury from high pressure in the equipment.

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock.

▶ Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

Risk of injury from unintentional activation of the system and

an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

8.1 Before installation

• Before connecting the valve, ensure the pipelines are flush.

• The flow direction is optional.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 16

16

Installation

8.1.1 Installation position general

Installation for self-drainage of the body

It is the responsibility of the installer and operator to ensure

self-drainage.

Installation for leakage detection

One of the bores in the diaphragm socket for monitoring

leakage must be at the lowest point.

8.1.2 Installation position 2/2-way valve

• The manually actuated diaphragm valve can be installed in any

position.

To ensure self-drainage:

→ Install body inclined by angle α = 10° to 40° to the horizontal

(see “Fig. 6”). Forged and cast body feature a mark which must

face upwards (12 o’clock position, see “Fig. 7”).

→ Observe an inclination angle of 1° – 5°.

→ One of the bores in the diaphragm socket for monitoring leakage

must be at the lowest point.

α

Angle α: 10° to 40°

Inclination to the line axis 1° – 5°

Fig. 6: Installation position for self-drainage of the body

Mark for self-drainage

angle

Fig. 7: Mark for the correct installation position

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 17

17

Installation

8.1.3 Installation position T-valve Type 3234

For the installation of the T-valves into circular pipelines, we recommend

the following installation positions:

When media is supplied: When media is removed:

Fig. 8: Installation position type 3234

8.1.4 Installation position Y-valve Type 3239

For the installation of the Y-valves into systems, we recommend the

following installation positions:

When media is supplied: When media is removed:

Fig. 9: Installation position type 3239

8.1.5 Installation of the tank bottom valve

Type 3235

For further information on containers and welding instructions,

please refer to the standard ASME VIII Division I.

It is recommended to weld the valve prior to the container

installation. However, it is possible to weld the valves to readyassembled containers.

Prior to welding, please check to ensure that:

• The tank bottom valve does not collide with other equipment compo-

nents and assembly/disassembly of the actuator is always possible.

• A minimal distance between two welding joints three times the

thickness of the container wall is adhered to.

It is recommended to weld the valve in the center of the drain

to ensure optimum draining of the container.

The diameter of the hole in the container and the flange must be equal.

The valve has two welding edges to make welding and positioning

of the valve easier. The length of the welding edges is approximately

3 mm. In case the thickness of the container wall exceeds 3 mm, the

valve must be positioned as shown in “Fig. 10”.

→ Prior to welding the valve, grind the outlet wall.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 18

18

Installation

Grinding point

on tank

Fig. 10: Grinding point on tank

Prior to commencing the welding process, check the charge

number indicated on the supplied manufacturer‘s certificate

3.1.

→ Position the flange into the hole so that the flange surface is

tangent to the drain surface.

→ Tack 4 welding points and check the position of the valve.

→ Weld the valve evenly to the inside and outside of the container,

with gas being supplied and using welding material compatible

with the valve‘s stainless steel 316 L (DIN 1.4435).

→ Allow the welds to cool down before burnishing and cleaning

them according to the applicable specifications.

These instructions assist in the installation of the tank bottom valves and

allow the prevention of deformation and softening within the containers.

Please observe the applicable laws and regulations of the

respective country with regard to the qualification of welders

and the execution of welding work.

8.1.6 Preparatory work

→ Clean pipelines (sealing material, swarf, etc.).

→ Support and align pipelines.

Devices with welded or glued body:

Before welding or gluing the body, the actuator and the

diaphragm must be removed.

8.2 Installation

WARNING!

Risk of injury from improper installation!

Non-observance of the tightening torque is dangerous as the

device may be damaged.

▶ Observe tightening torque during installation (see “8.2.2 Tight-

ening torques for diaphragms”).

8.2.1 Devices with welded or glued body

NOTE!

To prevent damage.

Before welding or gluing the body, the actuator and the diaphragm

must be removed.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 19

19

Installation

→ Cross-loosen fastening screws and remove actuator with dia-

phragm from the body.

→ Weld or glue body in the pipeline.

→ After welding or gluing in the body, smooth the body surface (if

required) by grinding.

→ Clean the body carefully.

→ Place actuator on the body.

→ Lightly cross-tighten the fastening screws until the diaphragm is

between the body and actuator.

Do not tighten screws yet.

→ Activate the diaphragm valve twice to position the diaphragm

correctly.

→ Tighten the fastening screws up to the permitted tightening

torque (see tables in chapter “8.2.2 Tightening torques for

diaphragms”).

8.2.2 Tightening torques for diaphragms

Orifice

(Diaphragm size)

DN [mm]

Actuator PPS or stainless steel

Diaphragm

EPDM / FKM

Diaphragm

PTFE/advanced

PTFE/laminated

advanced PTFE

8 2 2,5

15 3,5 4

20 4 4,5

25 5 6

32 6 8

40 8 10

50 12 15

Tab. 10: Tightening torques for diaphragms. Actuator PPS or

stainless steel

Orifice

(Diaphragm size)

DN [mm]

Actuator stainless steel

Diaphragm

EPDM / FKM

Diaphragm

PTFE/advanced

PTFE/laminated

advanced PTFE

65 20 30

80 30 40

100 40 50

Tab. 11: Tightening torques for diaphragms. Actuator stainless steel

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 20

20

Maintenance, Cleaning

9 MAINTENANCE, CLEANING

DANGER!

Risk of injury due to electrical shock.

▶ Before reaching into the system , switch off the power supply

and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper maintenance.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

Risk of injury from unintentional activation of the system and

an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

9.1 Maintenance work

The following maintenance work is required for the diaphragm valve:

→ After the first steam sterilization or when required

retighten body screws crosswise.

9.1.1 Wearing parts of the diaphragm valve

Parts which are subject to natural wear:

• Seals

• Diaphragm

→ If leaks occur, replace the particular wearing parts with an appro-

priate spare part (see chapter “11”).

A bulging PTFE diaphragm may reduce the flow-rate.

9.1.2 Service life of the diaphragm

The service life of the diaphragm depends on the following factors:

• Diaphragm material,

• Medium,

• Medium pressure,

• Medium temperature.

9.1.3 Actuator

The actuator of the diaphragm valve is maintenance-free provided it

is used according to these operating instructions.

9.1.4 Cleaning

Commercially available cleaning agents can be used to clean the

outside.

NOTE!

Avoid causing damage with cleaning agents.

▶ Before cleaning, check that the cleaning agents are compatible

with the body materials and seals.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 21

21

Repairs

10 REPAIRS

DANGER!

Risk of injury from high pressure in the equipment.

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock.

▶ Before reaching into the system , switch off the power supply

and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper maintenance.

▶ Repairs may be carried out by authorized technicians only and

with the appropriate tools.

▶ Observe the tightening torques.

▶ On completion of the work check valve for leaks and function.

Risk of injury from unintentional activation of the system and

an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

10.1 Replacing the diaphragm

DANGER!

Risk of injury from discharge of medium (acid, alkali, hot media).

It is dangerous to remove the device under pressure due to the

sudden release of pressure or discharge of medium.

▶ Before removing a device, switch off the pressure and vent the lines.

▶ Completely drain the lines.

Fastening types

Orifice

(Diaphragm size)

DN [mm]

Fastening types for diaphragm

PTFE EPDM / FKM

8 Diaphragm buttoned Diaphragm buttoned

15

Diaphragm with

bayonet catch

Diaphragm with

bayonet catch

20

25

Diaphragm with

bayonet catch

Diaphragm screwed in

40

50

65

80

Diaphragm with

bayonet catch

Diaphragm screwed in

100

Tab. 12: Fastening types for diaphragm

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 22

22

Repairs

Diaphragm

4 fastening

screws

Manual

actuator

4 fastening

screws

Body

Mark tab for

direction of flow

Fig. 11: Replacing the diaphragm

→ Clamp valve body in a holding device (applies only to valves not

yet installed).

→ Cross-loosen fastening screws and remove actuator with dia-

phragm from the body.

→ Detach or unscrew old diaphragm. If bonnet is with a bayonet

catch, loosen the diaphragm by turning it 90°. For orifice DN25DN50 observe chapter “10.1.1”.

→ Turn handwheel all the way clockwise (CLOSED position).

→ Install new diaphragm in the actuator (see “Tab. 12”).

→ Turn handwheel all the way counter-clockwise (OPEN position).

→ Align diaphragm.

Note marker for direction of flow!

→ Place actuator back on the body.

→ Lightly cross-tighten the fastening screws until the diaphragm is

between the body and actuator.

Do not tighten screws yet.

→ Activate the diaphragm valve once to position the diaphragm

correctly.

→ Tighten the fastening screws with the valve in the open position up

to the permitted tightening torque (see tables in chapter “10.1.2

Tightening torques for diaphragms”).

→ Check the tightening torque of the screws again.

10.1.1 Switch between PTFE and EPDM

diaphragms

Orifice DN8:

→ Detach PTFE diaphragm and attach new EPDM diaphragm.

Orifice DN15 and DN20:

→ Loosen PTFE diaphragm bayonet and attach new EPDM diaphragm.

Orifice DN25 up to DN50:

→ Loosen PTFE diaphragm bayonet.

→ Place the insert in the pressure piece.

→ Insert and screw in EPDM diaphragm.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 23

23

Spare parts, Accessories

10.1.2 Tightening torques for diaphragms

Orifice

(Diaphragm size)

DN [mm]

Actuator PPS or stainless steel

Diaphragm

EPDM / FKM

Diaphragm

PTFE/advanced

PTFE/laminated

advanced PTFE

8 2 2,5

15 3.5 4

20 4 4.5

25 5 6

32 6 8

40 8 10

50 12 15

Tab. 13: Tightening torques for diaphragms, actuator PPS or

stainless steel

Orifice

(Diaphragm size)

DN [mm]

Actuator stainless steel

Diaphragm

EPDM / FKM

Diaphragm

PTFE/advanced

PTFE/laminated

advanced PTFE

65 20 30

80 30 40

100 40 50

Tab. 14: Tightening torques for diaphragms, actuator stainless steel

11 SPARE PARTS, ACCESSORIES

CAUTION!

Risk of injury and/or damage by the use of incorrect parts.

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the device and the surrounding area.

▶ Use only original accessories and original spare parts from

Bürkert.

The following spare parts are available for the manually actuated

diaphragm valves type 3232, 3233, 3233 K, 3234, 3235 and 3239:

• Manual actuator complete,

• Diaphragm.

Manual actuator

Diaphragm

Fig. 12: Spare parts

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 24

24

Spare parts, Accessories

11.1 Order table

11.1.1 Order tables for manual actuators

(types 3232, 3233 and 3233 K)

Orifice

(Diaphragm

size)

[mm]

Handwheel and

bonnet PPS

Handwheel PPS, bonnet

stainless steel

Diaphragm

EPDM, FKM

Diaphragm

PTFE/

advanced

PTFE/

laminated

advanced

PTFE

Diaphragm

EPDM, FKM

Diaphragm

PTFE/

advanced

PTFE/

laminated

advanced

PTFE

8 194 809 194 809 271 974 271 974

15 432 978

1)

432 978 432 980

1)

432 980

20 432 985

1)

432 985 432 987

1)

432 987

25 432 991 432 992 432 993 432 994

32 432 998 432 999 433 000 433 001

40 433 005 433 006 433 007 433 008

50 433 012 433 013 433 014 433 015

Tab. 15: Order table for manual actuator

1)

Use diaphragm with bayonet connection (BC) (see “Tab. 17”).

Manual actuators for orifice DN65, DN80 and DN100 on

request.

Orifice

(Diaphragm

size)

[mm]

Handwheel and bonnet

stainless steel

Handwheel and bonnet

stainless steel (for T or

tank bottom valve)

Diaphragm

EPDM, FKM

Diaphragm

PTFE/

advanced

PTFE/

laminated

advanced

PTFE

Diaphragm

EPDM, FKM

Diaphragm

PTFE/

advanced

PTFE/

laminated

advanced

PTFE

8 271 975 271 975 271 977 271 977

15 432 981

1)

432 981 441 270

1)

441 270

20 432 988

1)

432 988 449 128

1)

449 128

25 427 755 432 995 441 267 441 271

32 427 756 433 002 - -

40 427 757 433 009 441 268 441 276

50 427 758 433 016 441 269 441 277

Tab. 16: Order table for manual actuators

1)

Use diaphragm with bayonet connection (BC) (see “Tab. 17”).

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 25

25

Spare parts, Accessories

11.1.2 Order table for diaphragms

Orifice

(Diaphragm

size)

DN [mm]

Order numbers for diaphragms

EPDM

(AB*)

EPDM

(AD*)

FKM

(FF*)

PTFE

(EA*)

Advanced PTFE

(EU*)

Laminated advanced

PTFE (ET*)

8 677 663 E02** 688 421 E03** 677 684 F01** 677 674 L04** 679 540 L05** 677 694 L02**

15 BC** 693 162 E02** 693 163 E03** 693 164 F01**

- - -

15 677 664 E02** 688 422 E03** 677 685 F01** 677 675 E02-PTFE** 679 541 E02-PTFE+Hole** 677 695 L02**

20 BC** 693 165 E02** 693 166 E03** 693 167 F01** - - -

20 677 665 E02** 688 423 E03** 677 686 F01** 677 676 E02-PTFE** 679 542 E02-PTFE+Hole** 677 696 L02**

25 677 667 E01** 688 424 E03** 677 687 F01** 677 677 E02-PTFE** 679 543 E02-PTFE+Hole** 677 697 L01**

32 677 668 E01** 688 425 E03** 677 688 F01** 677 678 E02-PTFE** 679 544 E02-PTFE+Hole**

-

40 677 669 E01** 688 426 E03** 677 689 F01** 677 679 E02-PTFE** 679 545 E02-PTFE+Hole** 677 698 L01**

50 677 670 E01** 688 427 E03** 677 690 F01** 677 680 E02-PTFE** 679 546 E02-PTFE+Hole** 677 699 L01**

65 677 671 E01** 688 428 E03** 677 691 F01** 677 681 E02-PTFE** 679 743 E02-PTFE+Hole**

-

80 677 672 E01** 688 429 E03** 677 692 F01** 677 682 E02-PTFE** 679 744 E02-PTFE+Hole**

-

100 677 673 E01** 688 430 E03** 677 693 F01** 677 683 E02-PTFE** 679 745 E02-PTFE+Hole**

-

Tab. 17: Order table for diaphragms

* SAP-Code

** Identification on the diaphragm

Further information on spare parts can be found on the data sheets for the piston-controlled diaphragm valves type 3232, 3233, 3233 K,

3234 and 3235. The data sheets can be found on the Internet at: www.burkert.com.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 26

26

Transport, Storage, Disposal

11.2 Handwheel locking device option

The handwheel locking device option (from actuator size DN15 to

DN50) prevents unintentional or unauthorized operation of the valve.

Handwheel can be locked in 12 detent positions per revolution (30°

each).

Lock

Pin

→ Using a key, press the pin

into the lock and turn all the

way to the left.

→ Remove key.

Valve is locked.

Fig. 13: Handwheel with lock

12 TRANSPORT, STORAGE,

DISPOSAL

NOTE!

Transport damages.

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location.

• Storage temperature: -40…+55 °C.

Damage to the environment caused by device components

contaminated with media.

• Dispose of the device and packaging in an environmentally friendly

manner.

• Observe applicable regulations on disposal and the environment.

Note:

Observe national waste disposal regulations.

english

Type 3232, 3233, 3233 K, 3234,

3235, 3239

Page 27

Page 28

www.burkert.com

Loading...

Loading...