Page 1

Type 3005

Electromotive rotary actuator

Elektromotorischer Drehantrieb

Actionneur électrique

Operating Instructions

Bedienungsanleitung

Instructions de Service

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2008 - 2013 Bürkert Werke GmbH

Operating Instructions 1303/03_EU-ML_00805753 / Original DE

Page 3

Type 3005

Electromotive rotary actuator Type 3005

Contents

1. OPERATING INSTRUCTIONS ........................................................................................................................................................5

1.1. Symbols ......................................................................................................................................................................................5

2. CORRECT USE ......................................................................................................................................................................................6

2.1. Restrictions ...............................................................................................................................................................................6

3. GENERAL SAFETY INSTRUCTIONS ..........................................................................................................................................7

4. GENERAL INFORMATION ................................................................................................................................................................8

4.1. Contact address .....................................................................................................................................................................8

4.2. Warranty ......................................................................................................................................................................................8

4.3. Information on the Internet ...............................................................................................................................................8

5. SYSTEM DESCRIPTION ...................................................................................................................................................................9

5.1. Designated Application Area ...........................................................................................................................................9

5.2. General Description ..............................................................................................................................................................9

5.3. Exploded views ....................................................................................................................................................................10

5.4. Options .....................................................................................................................................................................................13

6. TECHNICAL DATA .............................................................................................................................................................................14

6.1. Conformity ..............................................................................................................................................................................14

6.2. Standards ................................................................................................................................................................................14

6.3. Approval ...................................................................................................................................................................................14

6.4. Operating Conditions ........................................................................................................................................................14

6.5. Identification ..........................................................................................................................................................................14

6.6. General Technical Data ....................................................................................................................................................15

7. INSTALLATION ...................................................................................................................................................................................20

7.1. Safety instructions .............................................................................................................................................................20

7.2. Installing the rotary actuator .........................................................................................................................................20

8. INSTALLATION ...................................................................................................................................................................................24

English

3

Page 4

Type 3005

8.1. Safety instructions .............................................................................................................................................................24

8.2. Electrical installation .........................................................................................................................................................24

8.3. Control card ...........................................................................................................................................................................29

9. OPTION: ROTARY ACTUATORS WITH EMERGENCY CURRENT MODEL ...........................................................33

9.1. Description .............................................................................................................................................................................33

9.2. Technical Data ......................................................................................................................................................................33

9.3. Electrical connection of safety block .......................................................................................................................34

9.4. Installation of safety block into the actuator drive ...........................................................................................36

10. START-UP .............................................................................................................................................................................................37

10.1. Safety instructions .............................................................................................................................................................37

10.2. Procedure ................................................................................................................................................................................37

11. OPERATION AND FUNCTION ....................................................................................................................................................38

11.1. Safety instructions .............................................................................................................................................................38

11.2. Manual operation ................................................................................................................................................................38

12. MAINTENANCE, TROUBLESHOOTING .................................................................................................................................39

12.1. Safety instructions .............................................................................................................................................................39

12.2. Maintenance Work ..............................................................................................................................................................39

12.3. Malfunctions ..........................................................................................................................................................................39

13. ACCESSORIES ..................................................................................................................................................................................41

14. PACKAGING AND TRANSPORT ...............................................................................................................................................42

15. STORAGE ..............................................................................................................................................................................................42

16. DISPOSAL ............................................................................................................................................................................................42

4

English

Page 5

Type 3005

Operating Instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user and make these instructions available to every new owner of the device.

WARNING!

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous situations.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

• Failure to observe the warning may result in moderately serious or minor injuries.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the device or the equipment.

Designates additional significant information, tips and recommendations.

Refers to information in these operating instructions or in other documentation.

→ designates a procedure which you must carry out.

English

5

Page 6

Type 3005

Correct Use

2. CORRECT USE

WARNING!

Incorrect use of the electromotive rotary actuator Type 3005 can be dangerous to people, nearby equipment

and the environment.

• The rotary actuator can be used indoors, e.g. to actuate fittings, especially ball valves or shut-off flaps.

• During use observe the permitted data, the operating conditions and conditions of use specified in the contract documents and operating instructions, as described in chapter “5. System Description”.

• The device may be used only in conjunction with third-party devices and components recommended and

authorized by Bürkert (e.g. ATEX-approved components).

• Correct transportation, correct storage and installation and careful use and maintenance are essential for reliable and problem-free operation.

• Use the device only as intended.

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

The electromotive rotary actuator Type 3005 was developed with due consideration given to the accepted

safety rules and is state-of-the-art. However, dangers can still arise.

Operate the device only when it is in perfect condition and in accordance with the operating instructions.

6

English

Page 7

Type 3005

General Safety Instructions

3. GENERAL SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any:

• Contingencies and events which may arise during the installation, operation and maintenance of the devices.

• Local safety regulations; the operator is responsible for observing these regulations, also with reference to the

installation personnel.

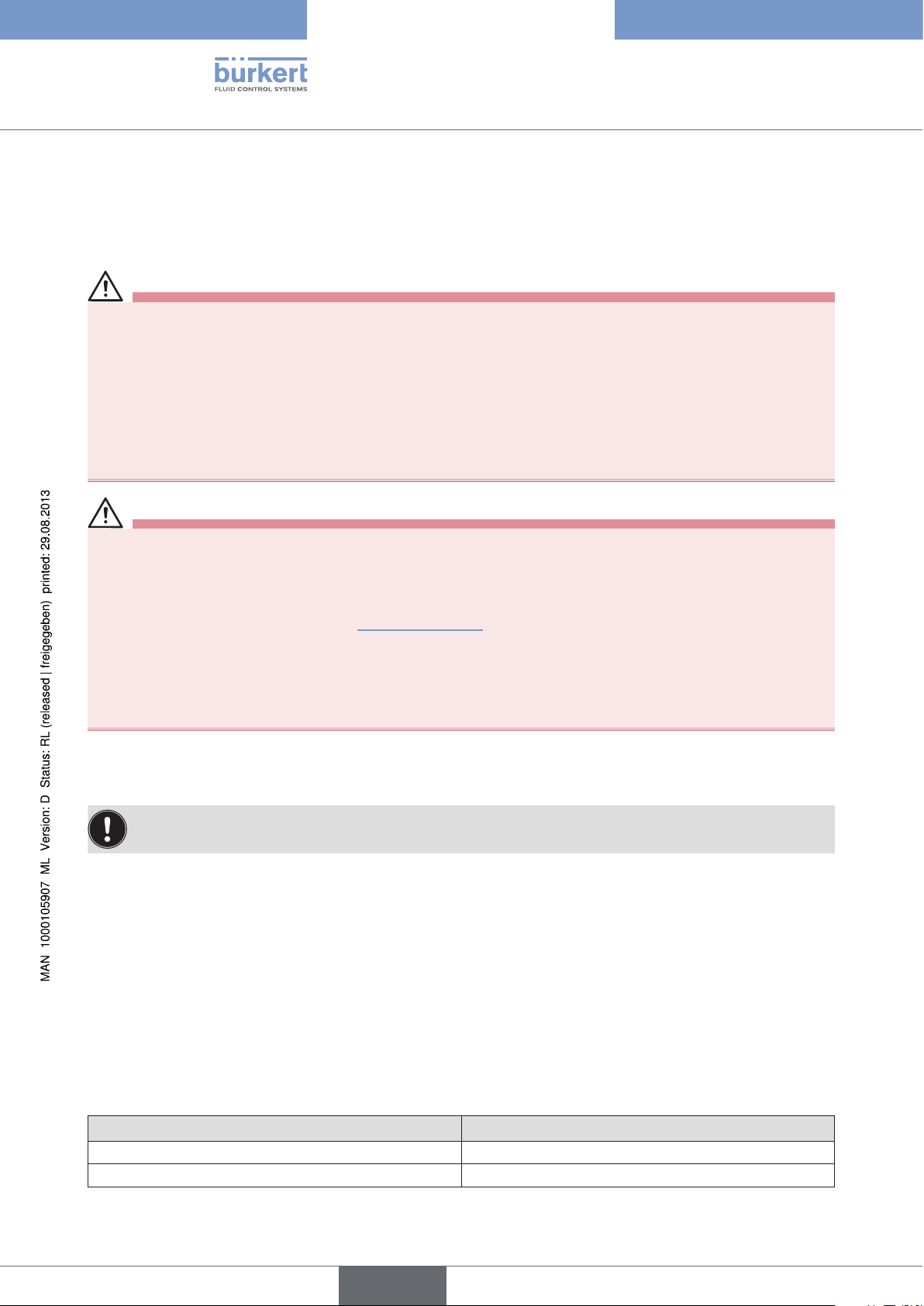

DANGER!

Risk of electric shock!

There is a serious risk of injury when reaching into the device.

• Before reaching into the device, always switch off the power supply and safeguard to prevent re-activation!

• Connect several electromotive rotary actuators always with phase separation via a switch.

• Protect the device with a mains-operated fuse.

• Observe applicable accident prevention and safety regulations for electrical equipment!

Danger of explosion!

For specific device designs there is a risk of explosion if the device is opened in the explosion-protected area.

• Follow the safety instructions on the type label!

Danger of explosion caused by electrostatic charge!

If there is a sudden discharge from electrostatically charged devices or persons, there is a danger of explosion in

the EX area.

• Take appropriate measures to prevent electrostatic charges in the EX area.

• Clean the device surface by wiping it gently with a damp cloth.

General hazardous situations.

To prevent injury, ensure:

• That the system cannot be activated unintentionally.

• Type 3005 must not be used in areas where there is a risk of explosion (in this case please use type 3004).

• Do not put any loads on the body (e.g. by placing objects on it or standing on it).

• Do not make any external modifications to the device bodys. Do not paint the body parts or screws.

• Do not install the actuator with the cover facing down (head first).

• Installation and repair work may be carried out by authorized technicians only and with the appropriate tools.

• After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a

defined or controlled manner.

• The device may be operated only when in perfect condition and in consideration of the operating instructions.

• The general rules of technology apply to application planning and operation of the device.

English

7

Page 8

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Phone: +49 (0)7940 - 10 91 111

Fax: +49 (0)7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Type 3005

General Information

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the internet at:

www.buerkert.com

4.2. Warranty

The warranty is only valid if the electromotive rotary actuator Type 3005 is used as intended in accordance with the

specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Type 3005 can be found on the Internet at:

www.burkert.com

8

English

Page 9

Type 3005

System Description

5. SYSTEM DESCRIPTION

5.1. Designated Application Area

The electromotive rotary actuator Type 3005 (designated below as rotary actuator) was developed to control ball

valves or flap valves with a quarter turn. Optionally the actuator is also available at a rotation angle of 180° and 270°.

5.2. General Description

On account of its modular design the basic device can be expanded with many options.

Options for expanding the basic device can be found in chapter “5.4. Options”.

The rotary actuator is a compact and powerful actuator system which ensures a long service life. The rotary actuator

has been designed for direct or alternating current at varying output and for torques from 25 to 1000 Nm (actuator

with analogue signal 25 - 300 Nm).

The utilized materials guarantee maintenance-free operation and ensure a low thermal load. All standard version rotary

actuators feature manual emergency actuation and two additional limit switches and are tested by the manufacturer.

The limit switches have been set to 0 ... 90° swivel operation.

The electromotive rotary actuator is available as an On/Off or variable speed actuator. It can be combined with the

following components:

• Stainless steel ball valve with two-part body (Type 2651),

• Stainless steel ball valve with three-part body (Type 2654),

• Plastic ball valve (Type 2657),

• Metal flap valve (Type 2671),

• Plastic flap valve (Type 2674).

The actuator direction cannot be reversed in the same operating process. The rotary actuator does not reverse

automatically.

Mechanical operation is also possible via the handwheel on the rotary actuator. In electrical mode the handwheel

is not rotated with the actuator.

English

9

Page 10

Type 3005

System Description

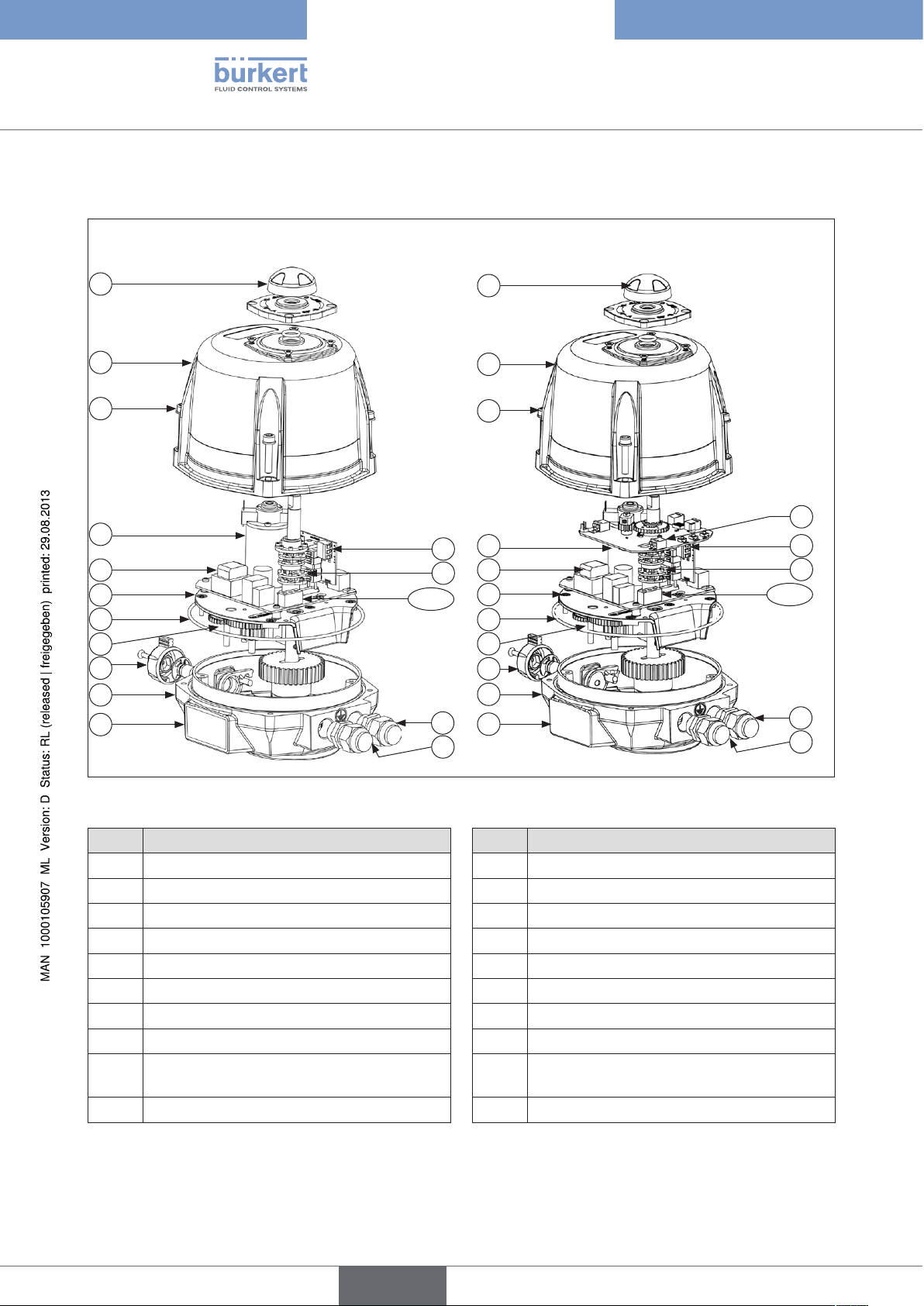

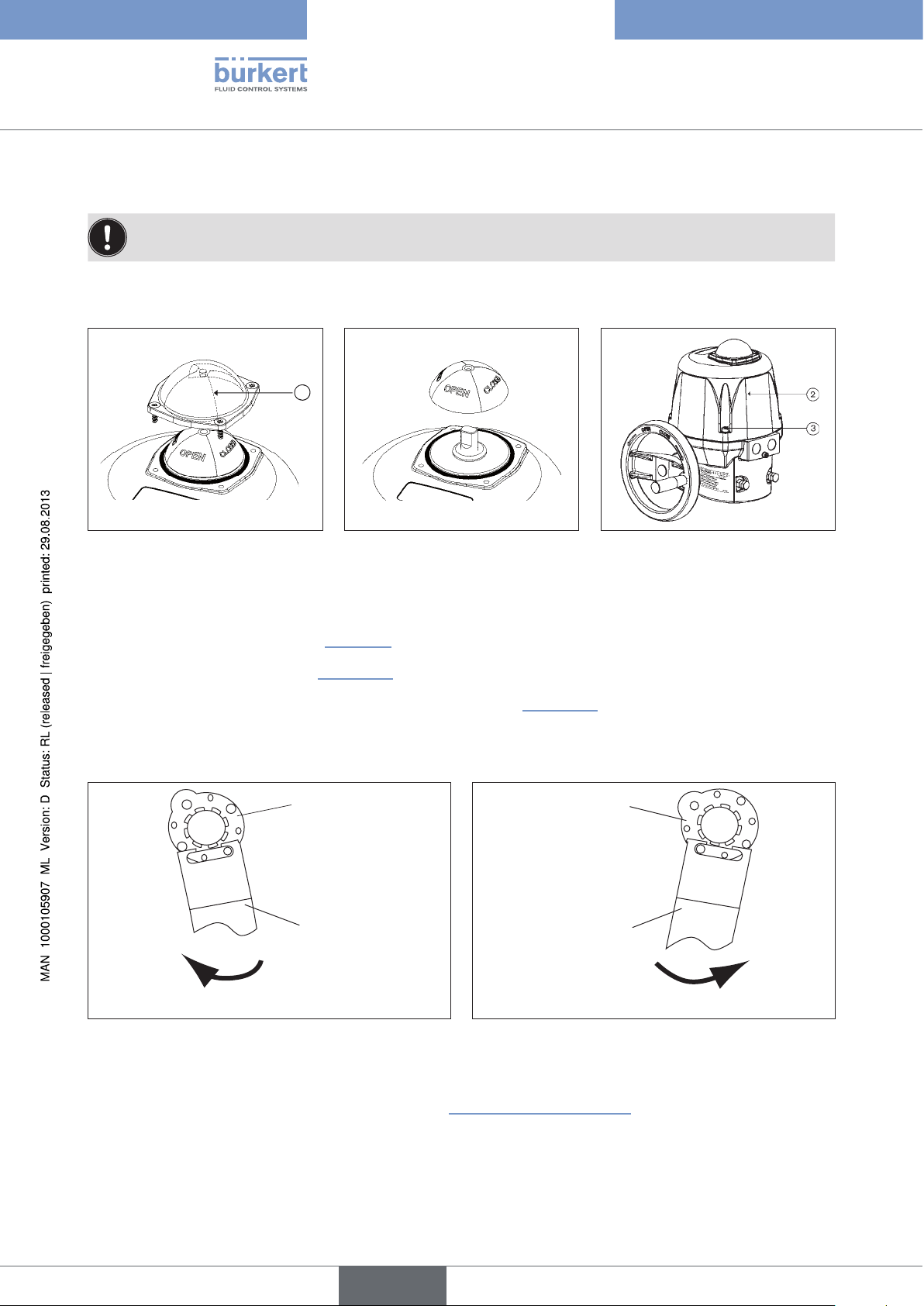

5.3. Exploded views

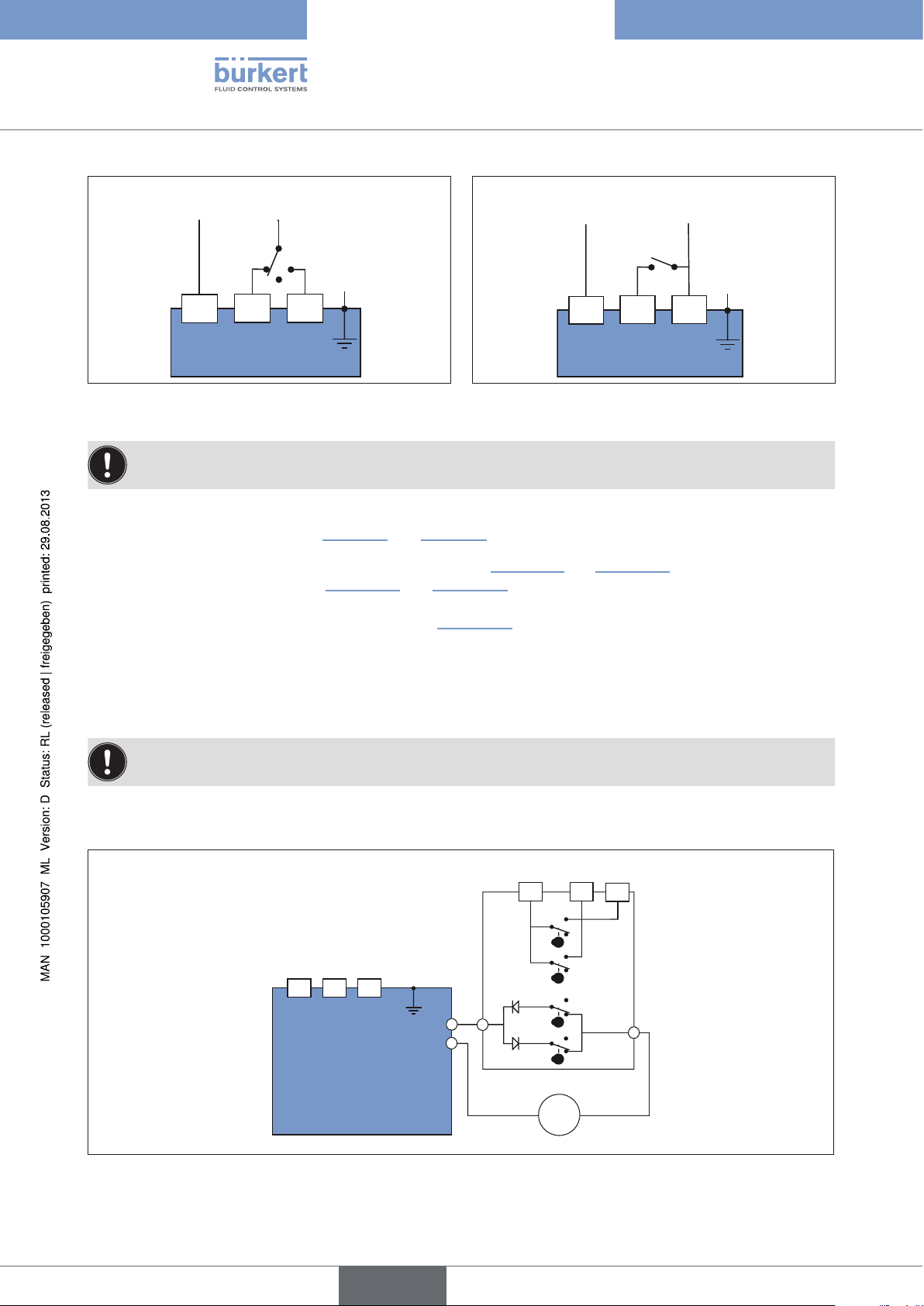

Motor 25 – 75 Nm Motor 25 – 75 Nm with control card

1

2

3

4

5.a

6

7

8

9

10

11

14.a

12

13

15

16

1

2

3

4

5.b

6

7

8

9

10

11

17

12

13

14.b

15

16

10

Figure 1: Exploded view of motor 25 – 75 Nm

No. Designation No. Designation

1 Position indicator 10 Body

2 Hood 11 Place for type label

3 Stainless steel screws 12 Additional limit switch

4 Motor 13 Cams

5.a* Control and power supply card 14.a* Control and power supply

5.b* Power supply card 14.b* Terminal strip for power supply

6 Gear plate 15 Threaded connection ISO M20

7 O-ring 16 Screw for earth

8 Gears 17 Control card (for variable speed actuator

only)

9 Push-button

English

Page 11

Type 3005

System Description

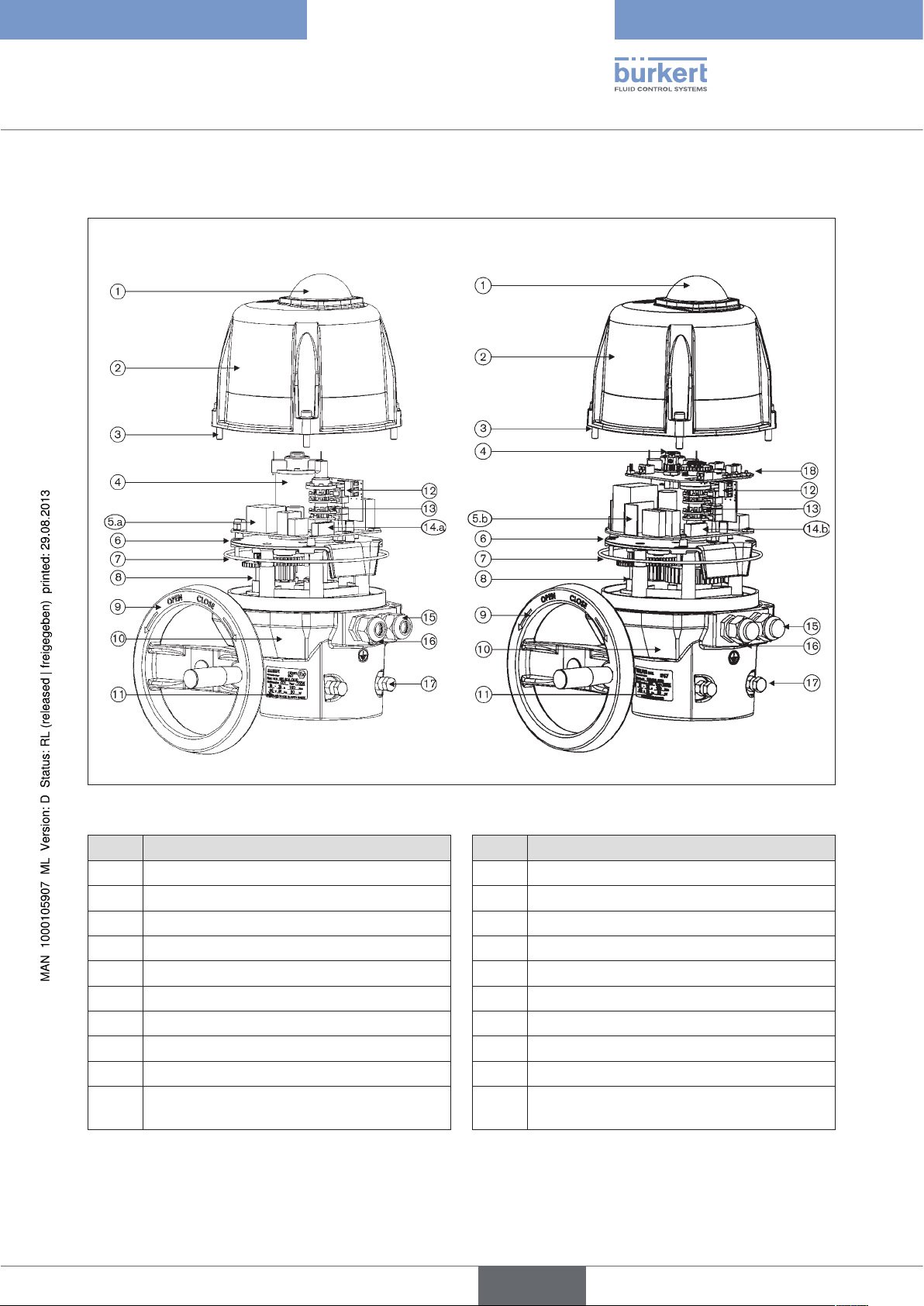

Motor 100 - 300 Nm Motor 100 - 300 Nm with control card

Figure 2: Exploded view of motor 100 – 300 Nm

No. Designation No. Designation

1 Position indicator 10 Body

2 Hood 11 Type label

3 Stainless steel screws 12 Additional limit switch

4 Motor 13 Cams

5.a* Control and power supply card 14.a* Control and power supply

5.b* Power supply card 14.b* Terminal strip for power supply

6 Gear plate 15 Threaded connection ISO M20

7 O-ring 16 Screw for earth

8 Gears 17 Mechanical limit stops

9 Handwheel 18 Control card (for variable speed actuator

only)

11

English

Page 12

Motor 600 - 1000 Nm

Type 3005

System Description

12

Figure 3: Exploded view of motor 600 - 1000 Nm

No. Designation No. Designation

1 Position indicator 9 Handwheel

2 Hood 10 Body

3 Stainless steel screws 11 Place for type label

4 Motor 13 Cams

5 Control and power supply card 15 Threaded connection ISO M20x1.5

6 Gear plate 16 Screw for earth

7 O-ring 17 Mechanical limit stops

8 Gears

English

Page 13

Type 3005

System Description

5.4. Options

• Three-position rotary actuator (180°)

• Rotation angle 180° or 270°

• Rotary actuator with feedback potentiometer

- Potentiometer with resistance values 100 W, 1 KW, 5 KW or 10 KW

- Analogue feedback via signal: 0 – 10 V, 0 – 20 mA, 4 – 20 mA

• Rotary actuator with emergency current model

(see Chapter “9. Option: Rotary actuators with emergency current model”).

• 2 additional limit switches

English

13

Page 14

Type 3005

Technical Data

6. TECHNICAL DATA

6.1. Conformity

The explosion-protected electric rotary actuator Type 3005 conforms to the EC Directives according to the Declaration of Conformity.

6.2. Standards

The applied standards which are used to demonstrate compliance with the EC Directives are listed in the EC

type test certificate and/or the EC Declaration of Conformity.

6.3. Operating Conditions

Ambient temperature: -20 °C ... +70 °C

-10 °C ... + 40 °C Emergency reset

Protection class: IP67 in accordance with EN 60529 with cable bushing ISO 20 or protective

flap

NOTE!

• Avoid heat sources which may result in the permitted temperature range to be exceeded.

6.4. Identification

The rotary actuator is fitted with a type label which uniquely identifies the device and indicates the most important

technical data.

Do not remove the type label from the rotary actuator!

It is essential for identification when installing and servicing the device.

The warranty is void without the type label.

14

English

Page 15

Type 3005

Technical Data

6.4.1. Description of the type label.

Torque

Type designation

Operating voltage

Actuating time for 90°

3005

24V AC/DC ED 50%

150Nm 30 Sek 90° 45W

IP67 OF 076688/ 107

179 725

Identification number

Protection class

Figure 4: Example of type label labelling

6.5. General Technical Data

6.5.1. Mechanical data

Dimensions: See chapter “6.5.2. Dimensions”

Weight: 25 – 75 Nm; 3.1 kg

100 – 300 Nm; 5.6 kg

600 - 1000 Nm; 20 kg

Duty cycle

Output

Actuating angle

S45/07

Body material: Body made of aluminium

Cover made of polyamide (optionally aluminium)

Axles and screws made of stainless steel

Gears made of galvanized steel

Actuating angle: 90° (optional 180°, 270°) ± 5°

Duty cycle: 50% at maximum torque (optionally 80%)

Manual emergency actuation: with open-end wrench on faces of the axle (up to 75 Nm);

by handwheel (from 100 Nm)

Working modes: Open/Closed mode or Three points mode

(see figure “Figure 17” and “Figure 18”)

English

15

Page 16

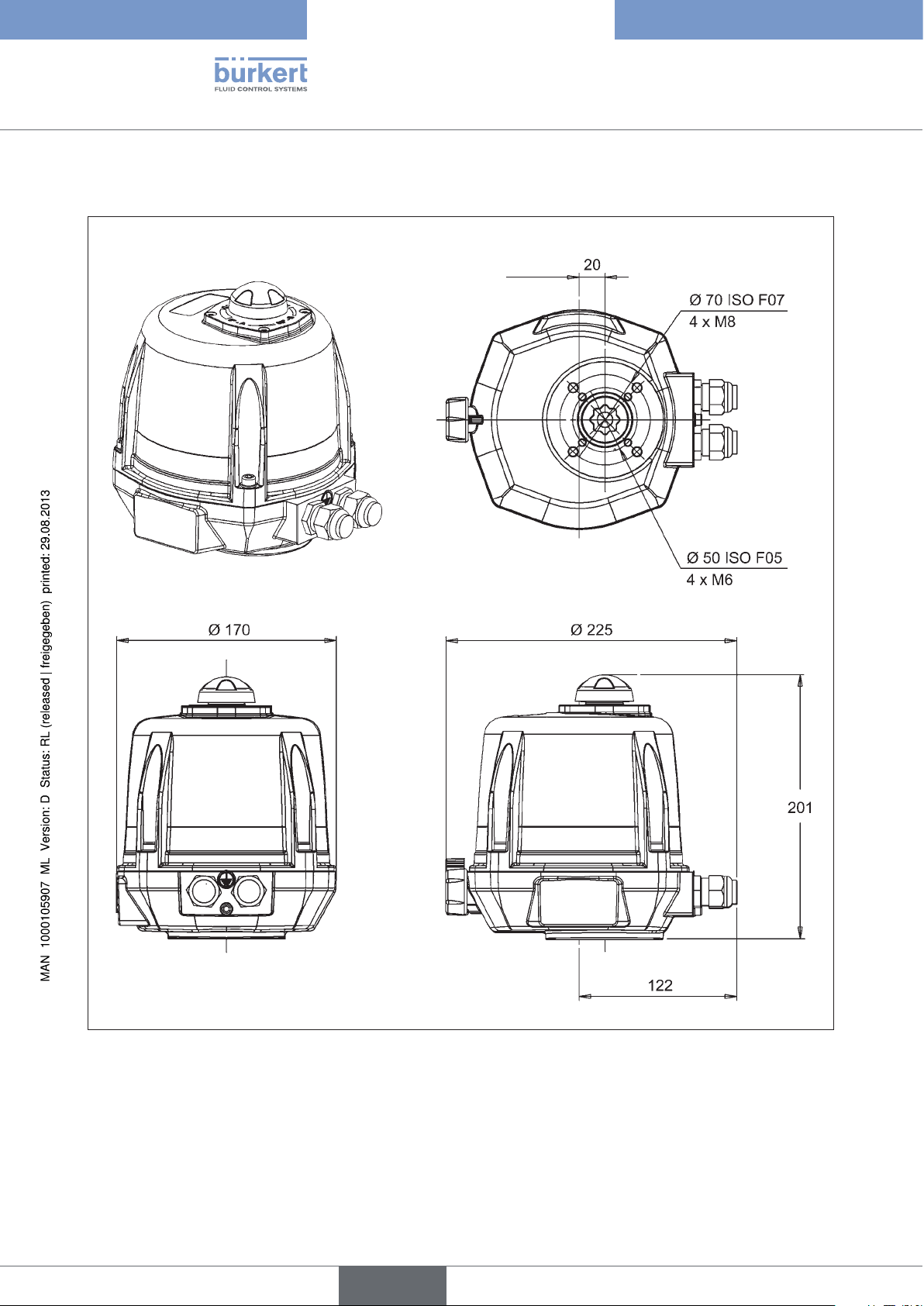

6.5.2. Dimensions

Motor 25 - 75 Nm

Type 3005

Technical Data

16

Figure 5: Dimensions Type 3005 at torque 25 – 75 Nm

English

Page 17

Type 3005

Technical Data

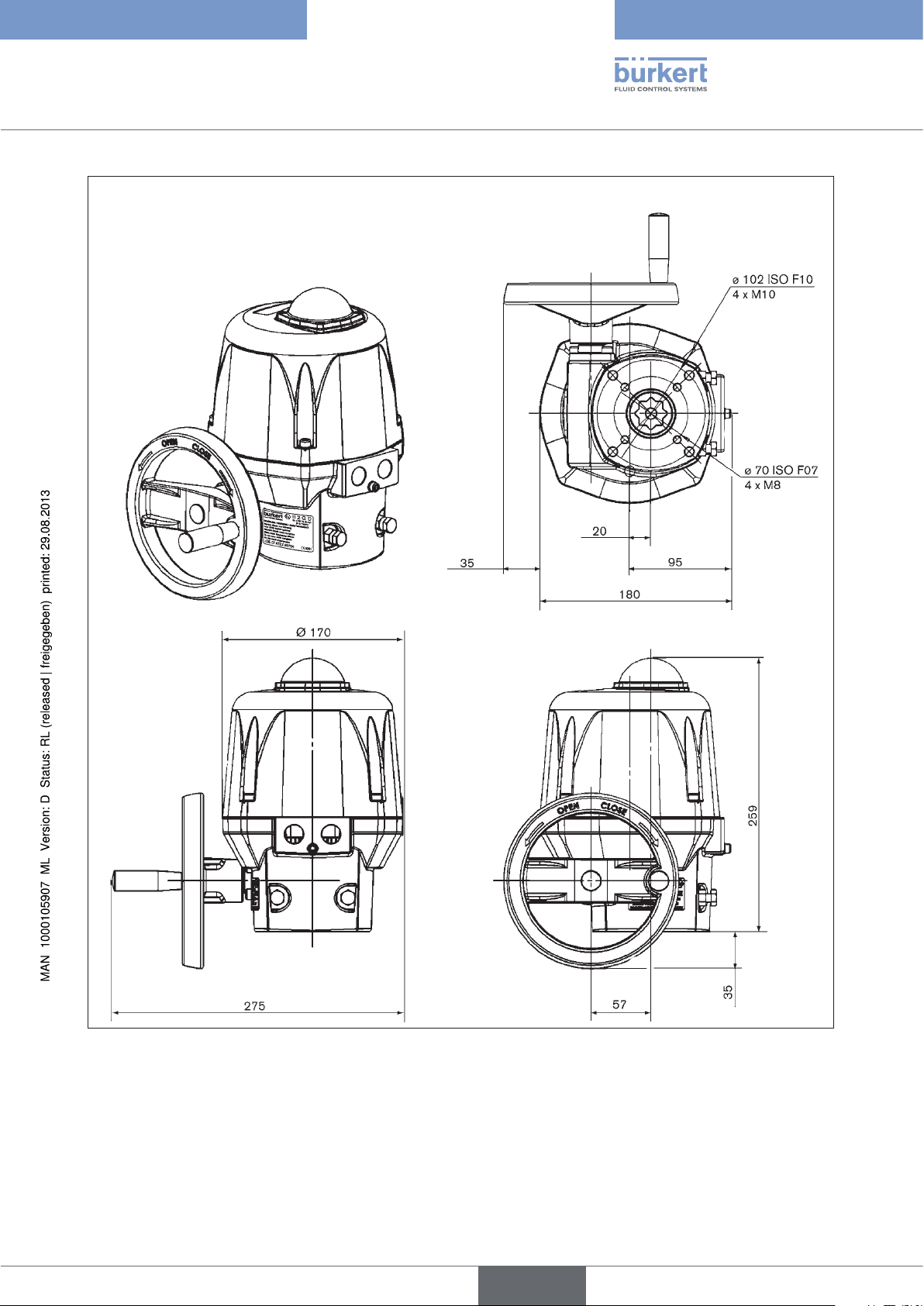

Motor 100 – 300 Nm

Figure 6: Dimensions Type 3005 at torque 100 – 300 Nm

17

English

Page 18

Motor 600 - 1000 Nm

Type 3005

Technical Data

18

Figure 7: Dimensions Type 3005 at torque 600 - 1000 Nm

English

Page 19

Type 3005

Technical Data

6.5.3. Electrical data

Connections: 2 threaded connections ISO 20

Limit switches: 2 limit switches for the motor

2 potential-free limit switches (for position feedback)

Output: max. 250 V AC / 5 A

Electrical data for standard version without analogue signal and position controller version with 4 – 20 mA,

0 – 20 mA or 0 – 10 V analogue input signal

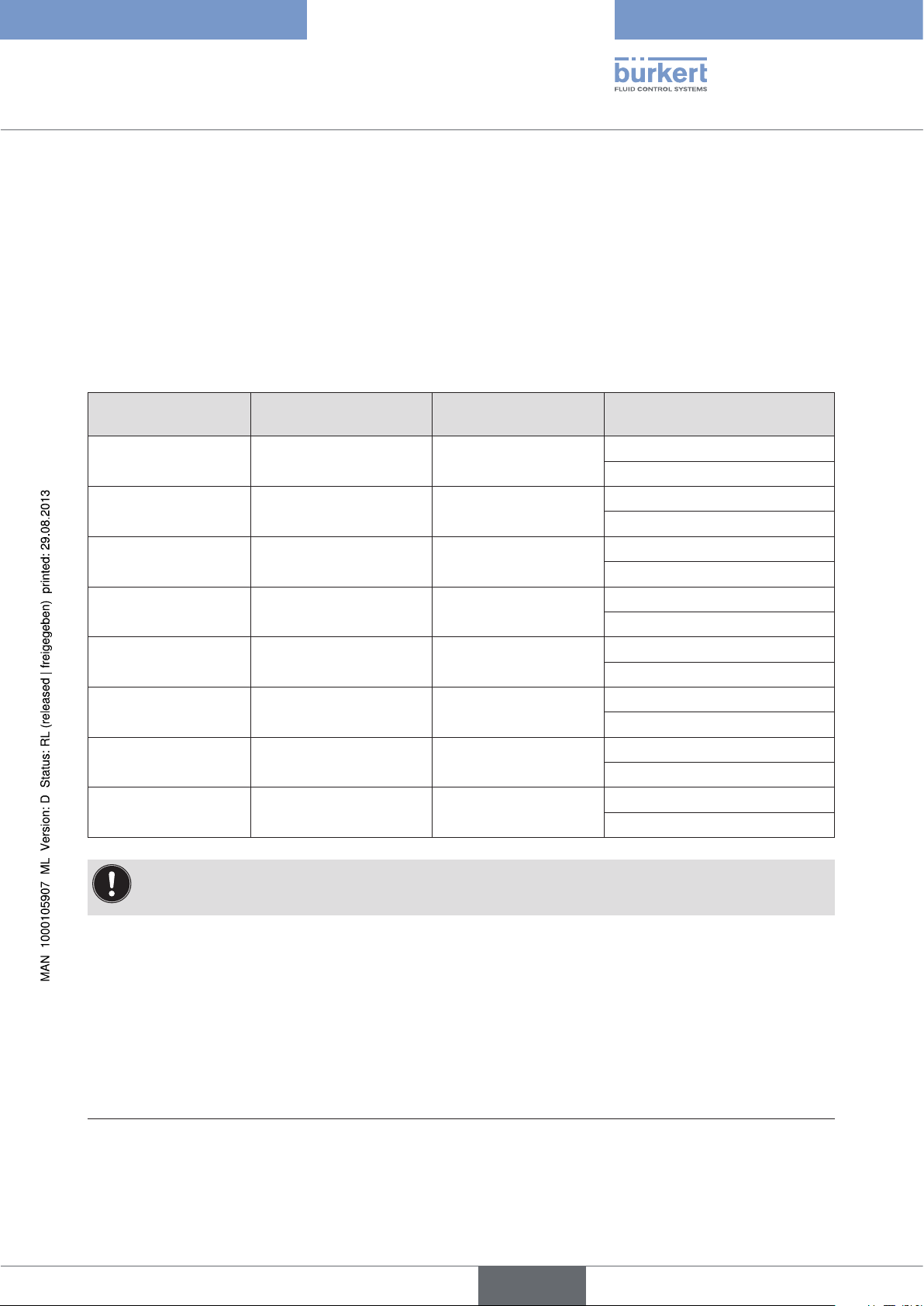

Torque [Nm] 90° actuating time [s] Power input [W]

Voltage / frequency

[V / Hz]

25 7 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

45 15 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

75 20 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

100 15 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

150 30 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

300 60 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

600 38 250 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

1000 38 250 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

)

)

)

)

)

)

)

)

We recommend an actuator designed with 1.5 times the maximum torque of the fitting (with 2 times

the maximum torque for variable speed actuators)

1) The operating voltage must not drop below 11.5 V

19

English

Page 20

Type 3005

Installation

7. INSTALLATION

7.1. Safety instructions

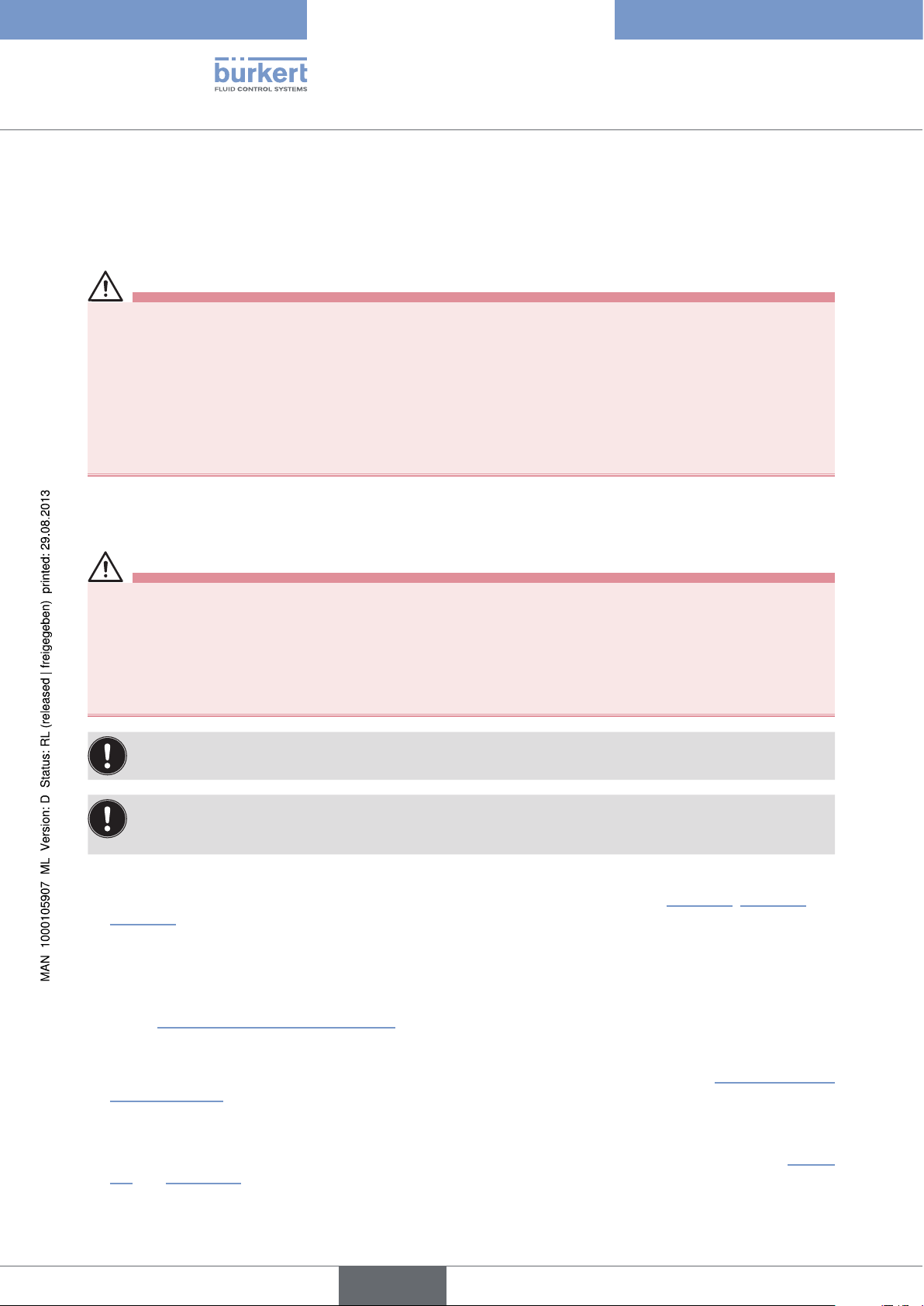

DANGER!

Risk of electric shock!

There is a serious risk of injury when reaching into the device.

• Always disconnect the power and secure it from re-activation before removing the cover, disconnecting the

gears or using the lever.

• Connect several rotary actuators always with phase separation via a switch!

• Protect the rotary actuators with a mains-operated fuse!

• Observe applicable accident prevention and safety regulations for electrical equipment!

WARNING!

Danger - improper installation!

Improper installation may result in injuries as well as damage to the device and the area around it.

• Installation may be carried out by authorised technicians only and with the appropriate tools!

• Observe the specifications in chapter “6. Technical Data”.

Danger due to unintentional activation of the device!

Unintentional activation of the device during installation may result in injuries and damage.

• Take appropriate measures to prevent the device from being accidentally actuated.

7.2. Installing the rotary actuator

The rotary actuator is supplied with the presetting <Closed>.

The rotary actuator can be fitted to a ball valve or flap valve via the following fastening options:

• ISO F05 (4 x M6 with a flange Ø of 50 mm)

• ISO F07 (4 x M8 with a flange Ø of 70 mm)

• ISO F10 (4 x M10 with a flange Ø of 102 mm)

20

• ISO F12 (4 x M12 with a flange Ø of 125 mm)

7.2.1. Shaft end

The sizes of the inner star shape of the shaft end depend on the size of the actuator. Only the standard size of the

inner star shape is enclosed with each actuator (see table).

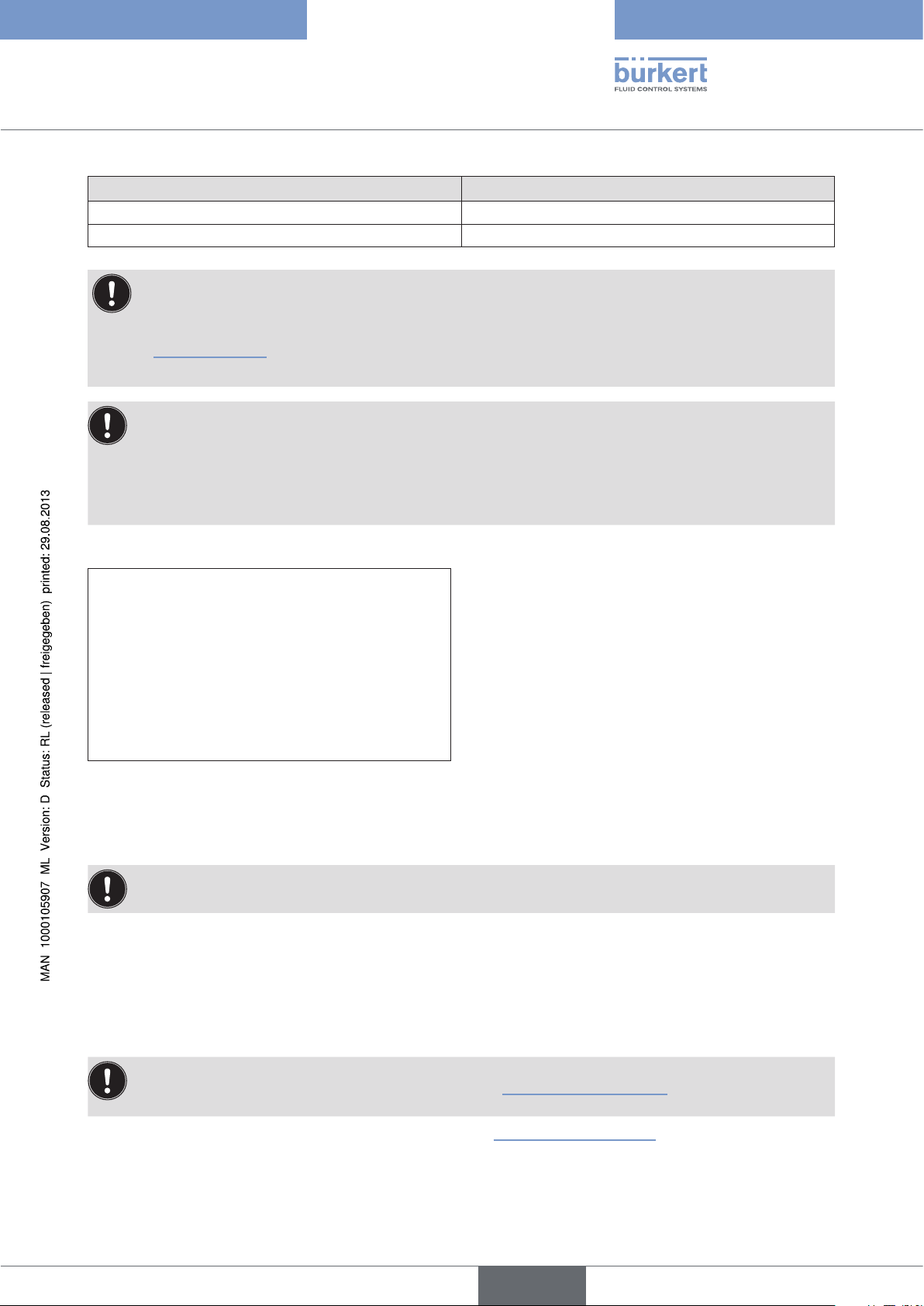

Actuator size [Nm] Standard size of the inner star shape [mm]

25 17 / 11

45 / 75 17 / 14

English

Page 21

Type 3005

Installation

Actuator size [Nm] Standard size of the inner star shape [mm]

100 / 150 / 300 22 / 17

600 / 1000 36

The shaft ends of the ball valves / flap valves can be adjusted to the supplied star shape size with reducing

sleeves which can be purchased separately.

The order numbers and an overview of the available reducing sleeves can be found in the chapter entitled

“13. Accessories”.

Further information is available from your Bürkert sales office.

Important information for continuous function:

Do not attach rotary actuator head first!

Otherwise the medium may run out of the fitting into the actuator.

The required installation height of the rotary actuator above the ball valve / flap valve can be found in the

chapter entitled Dimensions. Specify an additional distance of 100 mm.

Installation procedure:

Figure 8: Standard installation

→ Ensure that the ball valve / the flap valve is in its closed position.

→ Carefully connect the rotary actuator to the shaft of the ball valve / flap valve.

When connecting the rotary actuator, ensure that it is not twisted and that the fastening threads of the rotary

actuator are covered by the fastening bores of the ball valve / flap valve.

→ Screw the fastening screws into the fastening threads of the rotary actuator and tighten them firmly

(max. 3 Nm).

7.2.2. Set mechanical end position limit

(actuators 100 – 1000 Nm)

The mechanical end position limits have been preset at the factory and glued on with Loctite. However, they

can be adjusted by turning the screws M8 Pos. 17 (see “Figure 2” und “Figure 3”). Then the nuts must be

glued on again.

→ Loosen the M8 nuts on the mechanical limit stops 17 (see “Figure 2” und “Figure 3”) and adjust the mechanical

end position limits.

→ Glue nuts on again with Loctite (e. g. Loctite 577).

English

21

Page 22

7.2.3. Adjusting limit switch contacts

The two upper limit switch contacts have been set to 0 – 90° at the factory.

Removing position indicator and hood

1

Type 3005

Installation

Figure 9: Removing glass hood Figure 10: Removing position

indicator

Procedure:

Figure 11: Removing hood

→ Remove glass hood of the position indicator 1 including the sealing ring by loosening the four fastening screws

and remove the glass hood (see “Figure 9”).

→ Remove position indicator (see “Figure 10”).

→ Remove hood 2 by loosening the four fastening screws 3 (see “Figure 11”).

Adjusting cams for limit switch contacts

Cam

Key

Cam

Key

22

Adjustment travel

Figure 12: Adjusting limit switch clockwise Figure 13: Adjusting limit switch anti-clockwise

Procedure:

Adjustment travel

→ Adjust the two upper cams with a suitable key (see “Figure 12” and “Figure 13”).

→ On completion of the adjustment work, re-attach the hood 3, the position indicator, the seal and the glass hood 1.

English

Page 23

Type 3005

Installation

The rotary actuator is supplied ex works with the following settings:

• The limit switch CLOSED (FCF) is actuated by the cam (closed position).

• The limit switch OPEN (FCO) is preset to a rotation angle of 90°.

Feedback

Power supply and control

Figure 14: Internal wiring of actuator

4-6 5

FC2

2 31

T/E

C

C

A

FC1

D

FCF

D

FC0

Motor

=

7

B

English

23

Page 24

Type 3005

Installation

8. INSTALLATION

8.1. Safety instructions

WARNING!

Danger - improper installation!

Improper installation may result in injuries as well as damage to the device and the area around it.

• Fluid and electrical installations may be carried out by authorised technicians only and with the appropriate tools!

Danger due to unintentional activation of the equipment!

Unintentional activation of the equipment during installation work may result in injuries and/or damage.

• Take appropriate measures to prevent the equipment from being unintentionally activated.

8.2. Electrical installation

DANGER!

Risk of electric shock!

There is a serious risk of injury when reaching into the device.

• Before starting work, always switch off the power supply and safeguard to prevent re-activation!

• Observe applicable accident prevention and safety regulations for electrical equipment!

• Attach earthing cable via the earthing screw!

Check on the type label of the rotary actuator whether the indicated voltage corresponds with the mains

voltage.

Cables with a diameter of 7 to 12 mm are permitted for the electrical installation. The utilized cables must

have an upper limit temperature of at least 80 °C.

Use only ATEX-approved cables and cable bushings.

Preparatory work:

→ Remove stainless steel screws 3 for the hood 2 and carefully remove the hood (see “Figure 1”, “Figure 2” and

“Figure 3”).

8.2.1. Earth connection on outside or inside

24

The earthing cable for the power supply and control must be attached with the earthing screw 16 (M5) to the outer

body (see “Figure 1”, “Figure 2” and “Figure 3”).

Procedure:

→ Loosen earthing screw 16 and attach eyelet of the earthing cable to the earthing screw (see “Figure 1”, “Figure

2” and “Figure 3”).

→ Optionally the earthing screw can be connected to Pos. A of the power supply card.

→ To do this, loosen earthing screw and attach eyelet of the earthing cable with the earthing screw (see “Figure

15” and “Figure 16”).

English

Page 25

Type 3005

Installation

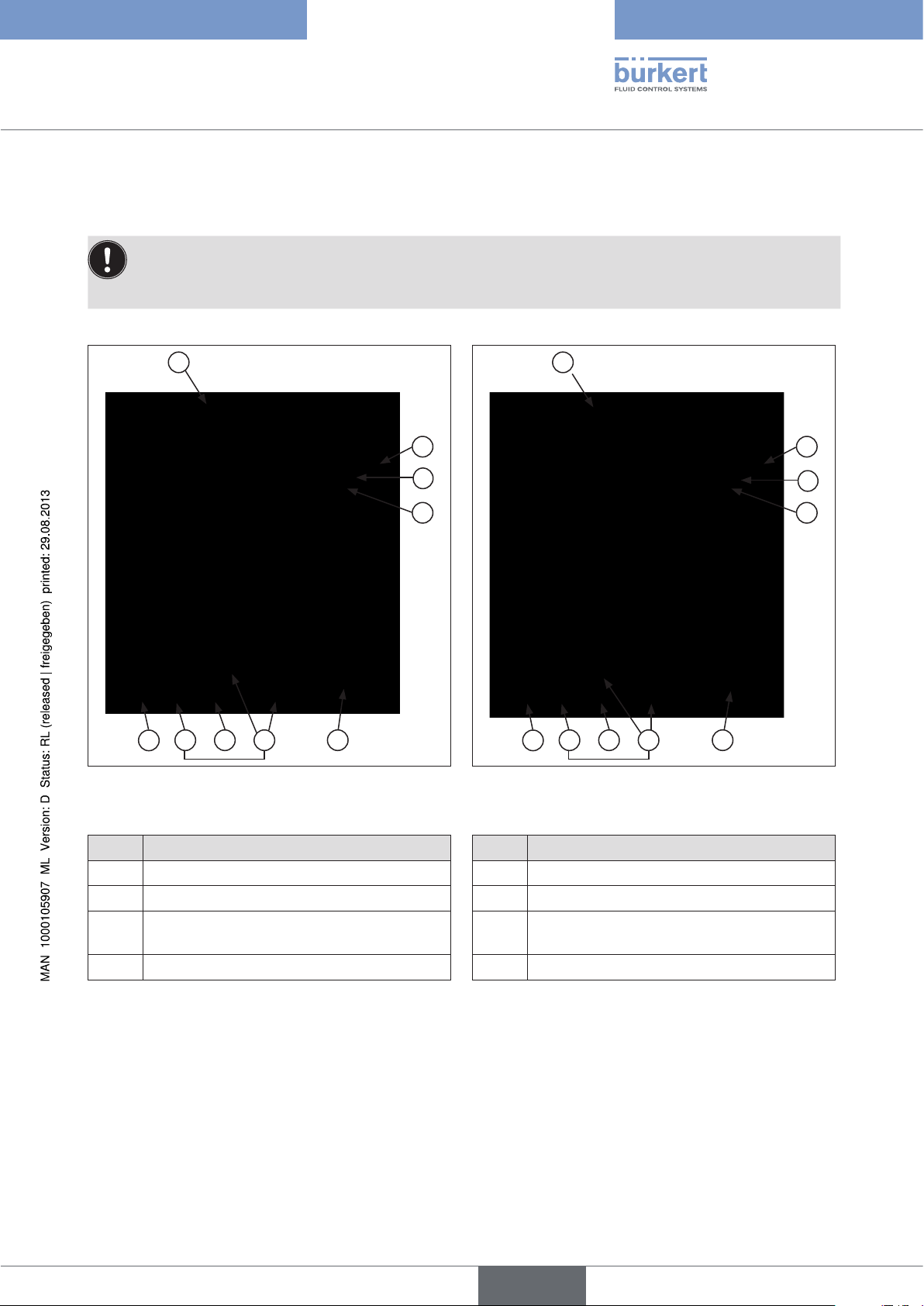

8.2.2. 100-240 V AC (100-350 V DC) or 15-30 V AC (12-48 V DC)

standard version

The power supply voltage of the actuator is 15-30 V AC (12-48 V DC) or 100-240 V AC

(100-350 V DC).

Always observe the specifications on the type label!

H

F

E

D

C B C

A

Figure 15: Power supply circuit board 15-30 V 50/60

Hz (12-48 V DC)

G

H

C B C

A

Figure 16: Power supply circuit board 100-240 V

50/60 Hz (100-350 V DC)

G

F

E

D

No. Designation No. Designation

Screw for earthing

A

Connections for control and power supply

B

Fuse

C

LED 2: Error message

E

LED 3: Power on

F

Connection for error feedback (24 V DC - 3

G

A max)

LED 1: Microprocessor OK

D

Connection 24 V DC

H

The rotary actuator can be connected and operated in two different modes:

1. Three points mode

2. Open / Closed mode

English

25

Page 26

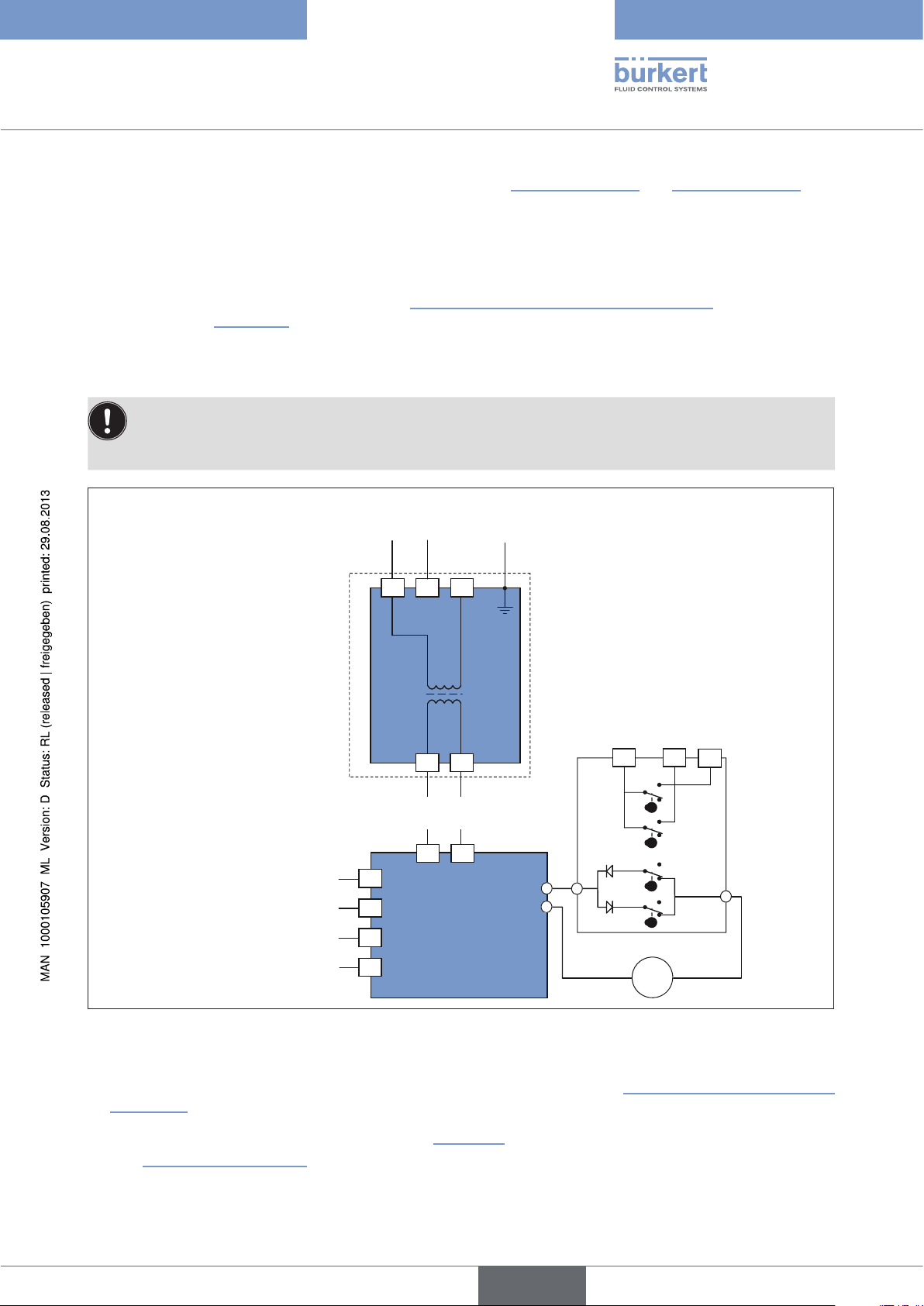

N

Ph

N

Ph

Type 3005

Installation

-

1

Figure 17: Three points mode Figure 18: Open / Closed mode / Emergency current

+

Auf Zu

2 3

T/E

-

1

model

+

Auf

T/E

32

If voltage is applied simultaneously to terminals 2 and 3, terminal 2 is the leading one and the actuator

moves to the OPEN position.

Procedure:

→ Loosen left cable gland 15 (see “Figure 1” and “Figure 2”) and feed through the cable to be connected.

→ Connect cable according to the required control type (see “Figure 17” and “Figure 18”) to the terminal strip Pos.

B of the power supply card (see “Figure 15” and “Figure 16”).

Operating principle for Open / Closed mode (see “Figure 18”) :

• Switch open = actuator closes

• Switch closed = actuator opens

Connecting feedback

The limit switches for the feedback are suitable for a maximum voltage of 250 V AC/DC – 5 A.

The rotary actuator features two additional limit switch contacts which are supplied by the factory in an open position.

These can be used for the feedback of the rotary actuator.

Feedback

4-6 5

FC2

Power supply and control

2 31

T/E

C

C

A

FC1

D

FCF

D

FC0

Motor

=

7

B

26

Figure 19: Internal wiring of actuator

English

Page 27

N-Ph

Type 3005

Installation

The limit switch contacts are actuated via two cams no. 13 (see “Figure 1”, page 10 and “Figure 2”, page 11).

• The white cam is used to record the opening process (FC1).

• The black cam is used to record the closing process (FC2).

Procedure:

→ Connect cable to the terminal strip 12 (see “Figure 1”, page 10 and “Figure 2”, page 11) according to the

schematic (see “Figure 19”).

8.2.3. Version with analog signal input

The power supply voltage of the actuator is 15-30 V AC (12-48 V DC) or 100-240 V AC

(100-350 V DC).

Always observe the specifications on the type label!

Power supply

100-240 V AC

(100-350 V DC)

or

15-30 V AC

(12-48 V DC)

Power supply

24 V DC

+

16

Input

-

15

-

14

Feedback

+

13

0 – 20 mA / 4 – 20 mA / 0 – 10 V

+

2

17 18

N-Ph

T/E

31

Feedback

4-6 5

FC2

+

FC1

1817

C

A

D

C

FCF

D

FC0

Motor

=

7

B

Figure 20: Circuit diagram

Procedure:

→ Loosen left cable gland 15 and feed through the cable to be connected (see “Figure 1”, page 10 and “Figure

2”, page 11).

→ Connect cable according to the circuit diagram (see “Figure 20”) to the terminal strip Pos. 14 of the power supply card

(see “Figure 1” and “Figure 2”).

English

27

Page 28

Type 3005

Installation

Connecting feedback

The limit switches for the feedback are suitable for a maximum voltage of 250 V AC/DC – 5 A.

The rotary actuator features two limit switch contacts which are supplied by the factory in an open position. These

can be used for the feedback of the rotary actuator.

The limit switch contacts are actuated via two cams no. 13 (see “Figure 1” and “Figure 2”).

• The white cam is used to record the opening process (FC1).

• The black cam is used to record the closing process (FC2).

Procedure:

→ Connect cable to the terminal strip 12 (see “Figure 1” and “Figure 2”) according to the schematic (see “Figure

20”).

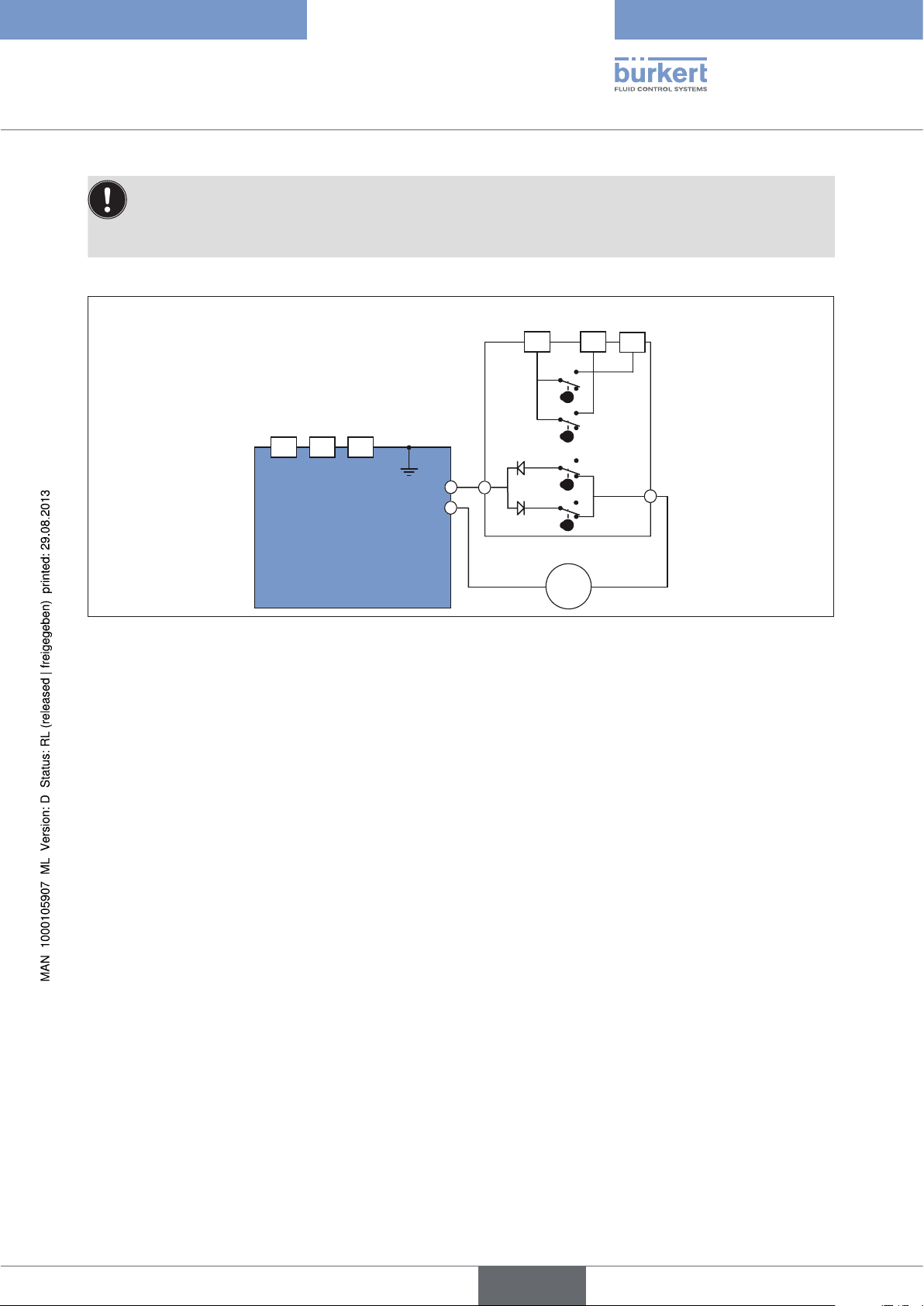

8.2.4. Electric wiring 400 V three-phase current

Power supply

Command

KM1: Open

KM2: Close

Feedback

28

Figure 21: Electric wiring 400 V three-phase current

No. Description No. Description

FCO Open limit switch TLF Torque switch: closing

FCF Close limit switch M Motor

FC1 Auxiliary limit switch 1 F Heating resistor

FC2 Auxiliary limit switch 2 H Motor thermoswitch

TLO Torque switch: opening

English

Page 29

Type 3005

Installation

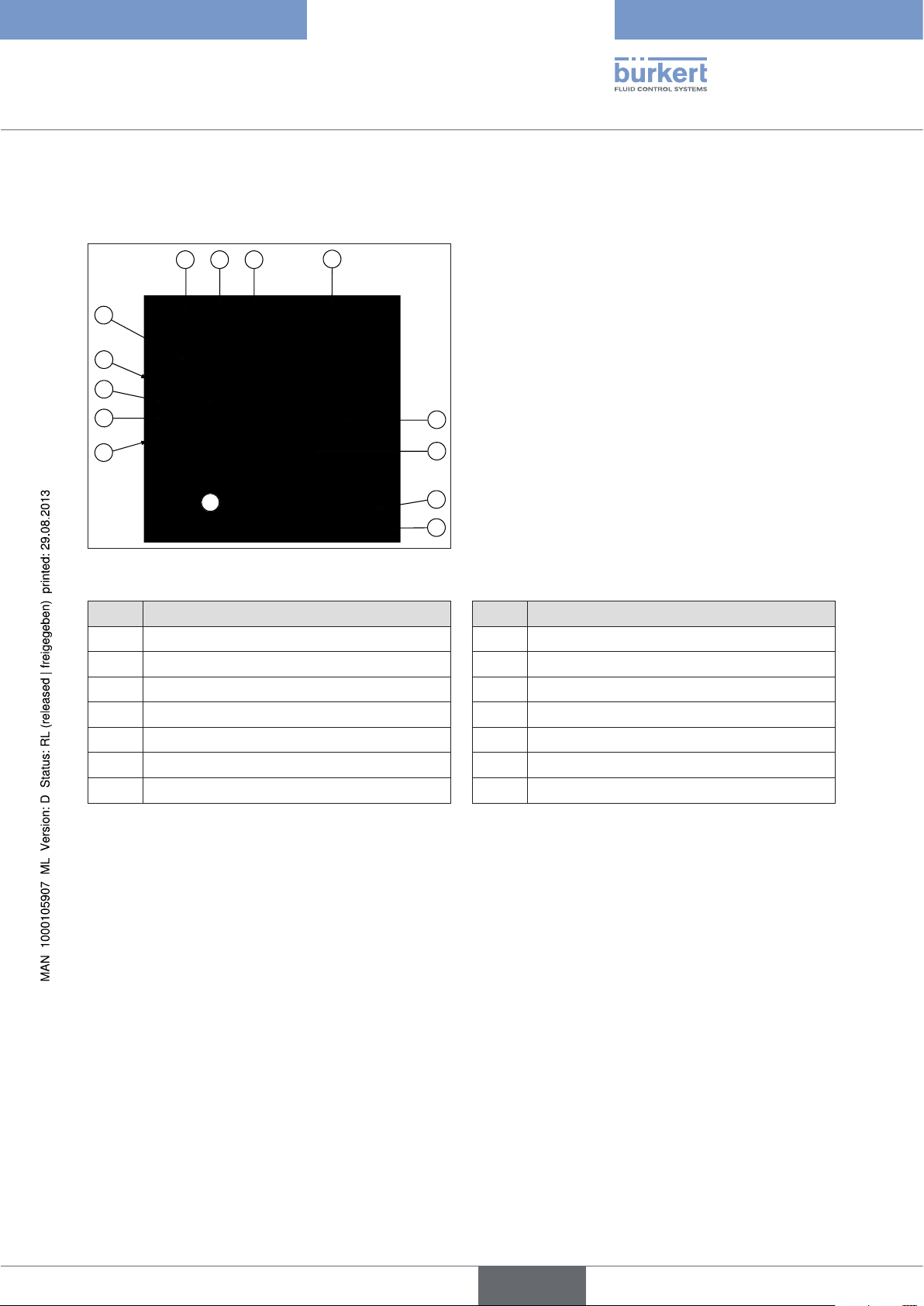

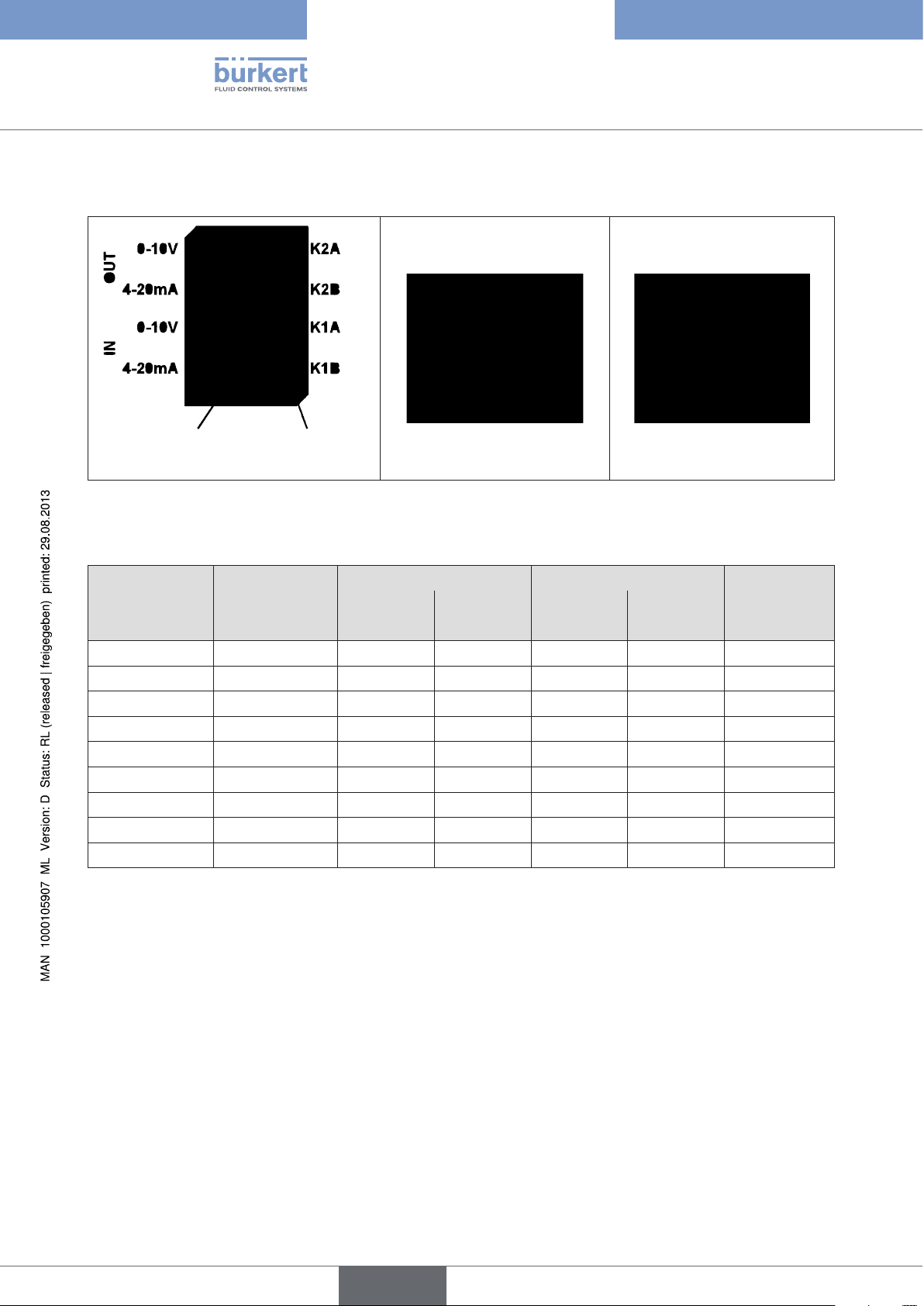

8.3. Control card

For rotary actuator with analogue control

D E C F

I

B

H

G

J

Figure 22: Control card (24 V DC)

A

K

L

M

N

No. Designation No. Designation

24V DC power supply

A

Connection terminals transducer

B

Connection terminals feedback

C

Adjusting button <MEM>

D

Adjusting button <CLOSE>

E

Adjusting button <OPEN>

F

K1 plug-in jumper

G

K2 plug-in jumper

H

K3 plug-in jumper

I

Green and red LEDs

J

Yellow LED: power supply display

K

Potentiometer

L

Connection motor

M

Connection heating resistor

N

English

29

Page 30

8.3.1. The position of the plug-in jumpers

Type 3005

Installation

ON

(turned on)

Figure 23: Plug-in jumper K1 / K2 Figure 24: Plug-in jumper K3

OFF

(turned off)

OFF

Plug-in jumper K1 Plug-in jumper K2

Transducer Feedback

A B A B

0 - 10 V 0 - 10 V

0 - 10 V 0 - 20 mA

0 - 10 V 4 - 20 mA

4 - 20 mA 0 - 10 V

4 - 20 mA 0 - 20 mA

4 - 20 mA 4 - 20 mA

4 - 20 mA* 0 - 10 V

4 - 20 mA* 0 - 20 mA

4 - 20 mA* 4 - 20 mA

ON OFF ON OFF OFF

ON OFF OFF ON OFF

ON OFF OFF ON ON

OFF ON ON OFF OFF

OFF ON OFF ON OFF

OFF ON OFF ON ON

ON OFF ON OFF OFF

ON OFF OFF ON OFF

ON OFF OFF ON ON

Figure 25: Plug-in jumper K3

ON

Plug-in

jumper

K3

30

* Version with emergency reset

English

Page 31

Type 3005

Installation

8.3.2. Parameterization steps

Specify direction of rotation of the shut-off valve

Normal direction of rotation (preset)

→ Press <OPEN> push-button and switch on the card (hold down

push-button).

G

Reverse direction of rotation

R

Specify control signal type

Control signal when voltage 0 – 10 V

R

The GREEN LED lights up.

→ Release <OPEN> push-button and disconnect the card from the power

supply.

→ Press <CLOSE> push-button and switch on the card (hold down

push-button).

The RED LED lights up.

→ Release <CLOSE> push-button and disconnect the card from the

power supply.

→ Press <MEM> push-button and switch on the card (hold down

push-button).

The RED LED lights up 3x.

→ Release <MEM> push-button and disconnect the card from the

power supply.

Control signal when current 0 – 20 mA

→ Press <MEM> and <OPEN> push-buttons and switch on the card

(hold down push-button).

R

The RED LED lights up 3x.

→ Release <MEM> and <OPEN> push-buttons and disconnect the

card from the power supply.

Control signal when current 4 – 20 mA (preset)

→ Press <MEM> and <CLOSE> push-buttons and switch on the card

(hold down push-button).

R

The RED LED lights up 3x.

→ Release <MEM> and <CLOSE> push-buttons and disconnect the

card from the power supply.

31

English

Page 32

Learning mode

R

R

Specify end positions

Type 3005

Installation

→ Press <OPEN> and <CLOSE> push-buttons and switch on the card

(hold down push-button).

The RED and the GREEN LEDs light up.

G

R

→ Release <OPEN> and <CLOSE> push-buttons.

Both LEDs go out.

Learning mode is selected.

→ Press <CLOSE> push-button to move the shut-off valve into the

R

closed position.

The RED LED lights up.

→ Press <MEM> and <CLOSE> push-buttons to save the closed

position.

The RED LED lights up 2x.

G

The GREEN LED lights up.

The GREEN LED lights up 2x.

All positions are now saved.

8.3.3. Normal operation

Display normal operation

G

G

The GREEN LED lights up 3x to indicate that the start process has been

implemented correctly.

In normal operation the GREEN LED lights up when the rotary actuator

opens the shut-off valve.

→ Press <OPEN> push-button to move the shut-off valve into the open

position.

→ Press <MEM> and <OPEN> push-buttons to save the open position.

→ Disconnect the card from the power supply.

→ Switch on card.

R

G

The RED LED lights up when the rotary actuator closes the shut-off valve.

R

If neither of the LEDs is lit, the actuator is not actuated.

The RED and the GREEN LEDs light up if the torque is too high and the

G R

rotary actuator stops.

→ Change direction of rotation of the rotary actuator or switch over the

voltage OPEN/CLOSED to restart the rotary actuator!

32

English

Page 33

Type 3005

Option: Rotary actuators with

emergency current model

9. OPTION: ROTARY ACTUATORS WITH

EMERGENCY CURRENT MODEL

9.1. Description

The emergency current model consists of an integrated safety block for emergency reset.

24 V battery block

Wiring

Screws ST2.2 x 6.5

Electronic printed circuit board

Figure 26: Safety block of the emergency current model; parts designation

9.2. Technical Data

Voltage 24 V DC

Nominal current 0.8 A

Maximum current 2.4 A

Charging time 14 h

English

33

Page 34

Type 3005

Option: Rotary actuators with

emergency current model

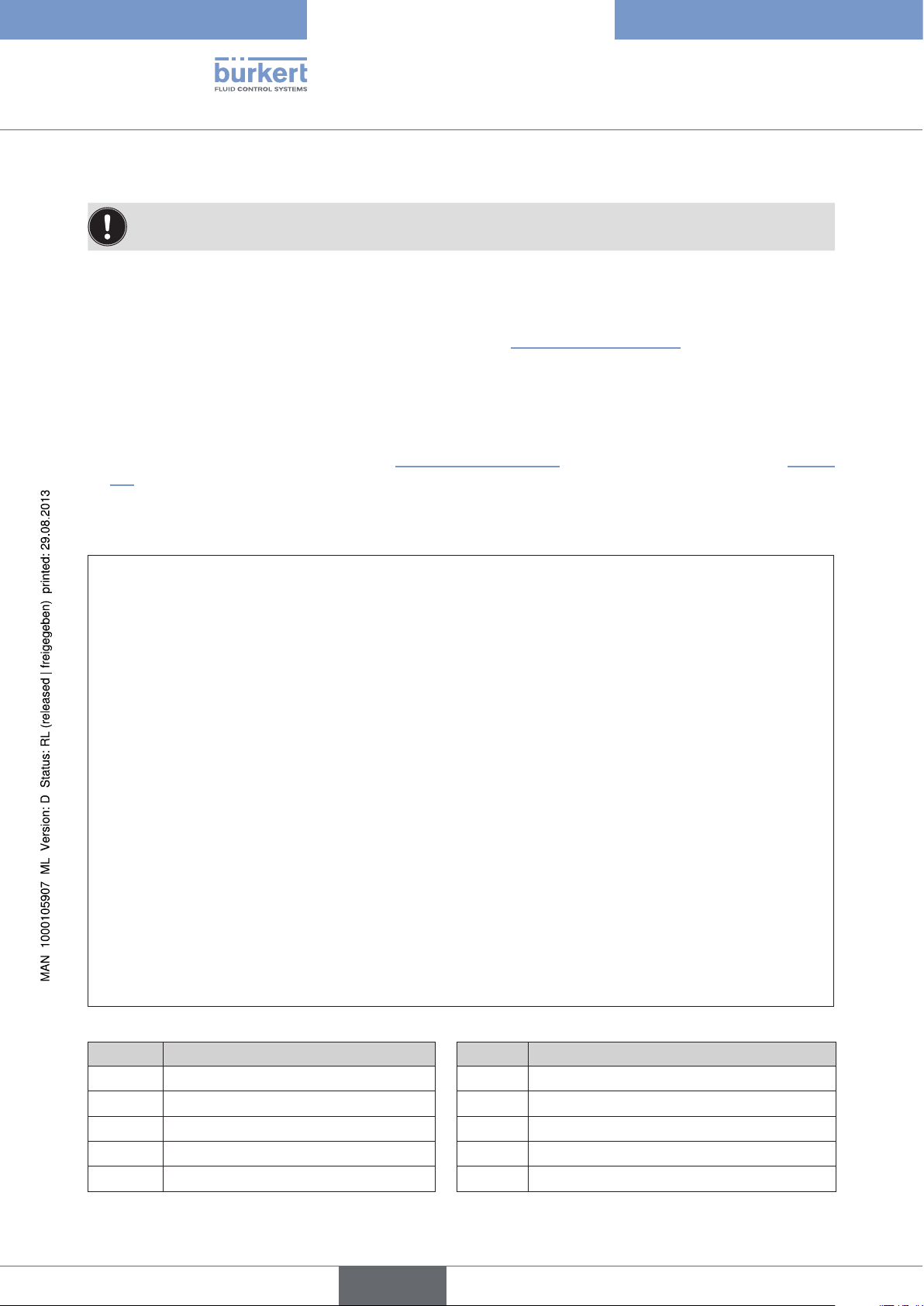

9.3. Electrical connection of safety block

9.3.1. Connection diagram

Battery block

Wire colour

F+

red

Wire colour

E-

black

Load state

feedback

Actuator

wiring

Suggestet customer

wiring

KM1 - Customer

contactor switch

On / Off Mode

F+

E-

65

66

Safety block

Loaded battery: closed

contact

24 V

AC/DC

N

Total security mode

17

18

Control and power supply card

17

100V-240V 50/60 Hz (100V-350V DC)

15V-30V 50/60 Hz (12V-48V DC)

18

B

1 2 3 1 2 3

N

A1

KM1

A2

Open

Ph

B

A

N

A

D1

D2

Open

Ph

Figure 27: Connection diagram of emergency reset

Configuration A or B

A - standard mode: If the actuator is controlled with a programmable controller, the feedback of the charge state

can be connected to it.

34

B - mode - increased safety (if the feedback relay is used, terminals 65 and 66): The actuator does not actuate

the valve unless the safety block is loaded.

English

Page 35

Type 3005

Option: Rotary actuators with

emergency current model

9.3.2. Description of the electronic printed circuit board

LED green

LED red

Connection for feedback signal (charge state)

Battery block connection

Figure 28: Illustration: Electronic printed circuit board

Description of LED status

LED Status Description

Green lit Mains power operation

flashing Battery operation

Red lit Battery is charged

flashing Battery is being charged

24 V DC Connection

English

35

Page 36

Type 3005

Option: Rotary actuators with

emergency current model

9.4. Installation of safety block into the actuator drive

4 fastening screws ST2.2 x 6.5

Figure 29: Illustration: installation of safety block into the actuator drive

→ Fasten the safety block of the emergency current model onto the actuator drive with 4

(see illustration “Figure 29”).

→ Connect the battery in this order:

1. F+ (wire color red)

2. E- (wire color black)

→ Connect the power supply in this order:

1. terminal 18

2. terminal 17

(see “Figure 28: Illustration: Electronic printed circuit board”).

36

English

Page 37

Type 3005

Start-Up

10. START-UP

10.1. Safety instructions

WARNING!

Danger due to improper operation!

Improper operation may result in injuries as well as damage to the device and the area around it.

• Before start-up, ensure that the operating personnel are familiar with and completely understand the contents of

the operating instructions.

• In particular observe the safety instructions and intended use.

• The device/the system may be started by adequately trained personnel only.

10.2. Procedure

→ Ensure that connections and settings are implemented properly according to chapter “7. Installation”.

→ Check whether the rotary actuator and the fitting are in a defined end position, otherwise the fitting may lock.

In this case the actuator switches off automatically.

English

37

Page 38

Type 3005

Operation and function

11. OPERATION AND FUNCTION

11.1. Safety instructions

WARNING!

Risk of electric shock!

There is a serious risk of injury when reaching into the device.

• Switch off the power before operating the rotary actuator manually.

• Observe applicable accident prevention and safety regulations for electrical equipment!

WARNING!

Danger due to improper operation!

Improper operation may result in injuries as well as damage to the device and the area around it.

• The operating personnel must know and have understood the contents of the operating instructions.

• In particular observe the safety instructions and intended use.

• The device/the system may be operated by adequately trained personnel only.

WARNING!

Hazardous situation due to manual intervention!

During manual intervention the process may switch to an undefined state, resulting in hazardous situations.

• Following manual intervention, ensure that the process is restarted in a defined or controlled manner!

11.2. Manual operation

Before operating the rotary actuator manually, ensure that the power supply has been interrupted!

The handwheel can be operated manually without disengaging it. No work steps in particular need to be implemented.

38

English

Page 39

Type 3005

Maintenance, Troubleshooting

12. MAINTENANCE, TROUBLESHOOTING

12.1. Safety instructions

DANGER!

Risk of electric shock!

There is a serious risk of injury when reaching into the device.

• Before starting work, always switch off the power supply and safeguard to prevent re-activation!

• Observe applicable accident prevention and safety regulations for electrical equipment!

WARNING!

Danger due to improper maintenance work!

Improper maintenance may result in injuries as well as damage to the device and the surrounding area.

• Maintenance work may be carried out by authorised technicians only and with the appropriate tools!

Danger due to unintentional activation of the equipment!

Unintentional activation of the equipment during maintenance and repair work may result in injuries and/or

damage.

• Take appropriate measures to prevent the equipment from being unintentionally activated.

12.2. Maintenance Work

The rotary actuator is maintenance-free when operated according to the instructions indicated in this manual.

12.3. Malfunctions

Malfunction Remedial action

The rotary actuator does not function

(initial start-up)

The rotary actuator is jammed in the

OPEN position

→ Check the power supply.

→ Check the connections according to the supplied circuit

diagram.

→ Check the power supply.

→ Check the connections according to the supplied circuit

diagram.

→ Check whether the movement of the electric valve is obstructed.

English

39

Page 40

Malfunction Remedial action

The valve does not fully open or close

The rotary actuator is jammed in the

CLOSED position

Type 3005

Maintenance, Troubleshooting

→ Check the power supply.

→ Check the connections according to the supplied circuit

diagram.

→ Check the limit switches.

→ Check whether an overload has occurred due to excessively

high torque on the valve (our rotary actuators feature electronic

overload protection).

If yes: Interrupt the power supply for approx. 5 minutes.

→ Check the power supply.

→ Check the connections according to the supplied circuit

diagram.

→ Check whether the movement of the electric valve is obstructed.

40

English

Page 41

Type 3005

Accessories

13. ACCESSORIES

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable replacement parts may cause injuries and damage the device and the surrounding area.

• Use only original accessories and original spare parts supplied by Bürkert.

Designation Order no.

Key for adjusting the limit switches 679 946

Reducing sleeve star/square 14/9 mm 665 288

Reducing sleeve star/square 14/11 mm 665 289

Reducing sleeve star/star 22/14 mm 666 684

Reducing sleeve star/square 22/17 mm 684 858

Reducing sleeve square/square 17/14 mm 665 290

Adapter outer square 14/10 mm 668 234

English

41

Page 42

Type 3005

14. PACKAGING AND TRANSPORT

NOTE!

Transport damages!

• Inadequately protected equipment may be damaged during transport.

• During transportation protect the device against wet and dirt in shock-resistant packaging.

• Avoid the action of heat and cold which can lead to temperatures above or below the admissible storage

temperature.

15. STORAGE

NOTE!

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature. -20 °C ...+70 °C.

16. DISPOSAL

→ Dispose of the device and packaging in an environmentally friendly manner.

NOTE!

Damage to the environment caused by device components contaminated with media.

• Observe the relevant disposal and environmental protection regulations.

Note:

Observe national waste disposal regulations.

42

English

Page 43

Typ 3005

Elektromotorischer Drehantrieb Typ 3005

Inhalt

1. DIE BEDIENUNGSANLEITUNG .................................................................................................................................................45

1.1. Darstellungsmittel ..............................................................................................................................................................45

2. BESTIMMUNGSGEMÄSSE VERWENDUNG .......................................................................................................................46

2.1. Beschränkungen .................................................................................................................................................................46

3. GRUNDLEGENDE SICHERHEITSHINWEISE .....................................................................................................................47

4. ALLGEMEINE HINWEISE ..............................................................................................................................................................48

4.1. Kontaktadressen .................................................................................................................................................................48

4.2. Gewährleistung ....................................................................................................................................................................48

4.3. Informationen im Internet ...............................................................................................................................................48

5. SYSTEMBESCHREIBUNG ............................................................................................................................................................49

5.1. Vorgesehener Einsatzbereich ......................................................................................................................................49

5.2. Allgemeine Beschreibung ..............................................................................................................................................49

5.3. Explosionsdarstellung ......................................................................................................................................................50

5.4. Optionen ..................................................................................................................................................................................53

6. TECHNISCHE DATEN .....................................................................................................................................................................54

6.1. Konformität.............................................................................................................................................................................54

6.2. Normen .....................................................................................................................................................................................54

6.3. Zulassungen ..........................................................................................................................................................................54

6.4. Betriebsbedingungen .......................................................................................................................................................54

6.5. Kennzeichnung ....................................................................................................................................................................54

6.6. Allgemeine Technische Daten .....................................................................................................................................55

7. MONTAGE .............................................................................................................................................................................................60

7.1. Sicherheitshinweise ..........................................................................................................................................................60

7.2. Montage des Drehantriebs ............................................................................................................................................60

8. INSTALLATION ...................................................................................................................................................................................64

deutsch

43

Page 44

Typ 3005

8.1. Sicherheitshinweise ..........................................................................................................................................................64

8.2. Elektrische Installation.....................................................................................................................................................64

8.3. Regelkarte ...............................................................................................................................................................................69

9. OPTION: DREHANTRIEBE MIT NOTSTROMVARIANTE ................................................................................................73

9.1. Beschreibung ........................................................................................................................................................................73

9.2. Technische Daten ...............................................................................................................................................................73

9.3. Elektrischer Anschluss des Sicherheitsblocks ..................................................................................................74

9.4. Einbau des Sicherheitsblocks in den Stellantrieb ............................................................................................76

10. INBETRIEBNAHME ..........................................................................................................................................................................77

10.1. Sicherheitshinweise ..........................................................................................................................................................77

10.2. Vorgehensweise ..................................................................................................................................................................77

11. BEDIENUNG UND FUNKTION ...................................................................................................................................................78

11.1. Sicherheitshinweise ..........................................................................................................................................................78

11.2. Manuelle Bedienung .........................................................................................................................................................78

12. WARTUNG, FEHLERBEHEBUNG .............................................................................................................................................79

12.1. Sicherheitshinweise ..........................................................................................................................................................79

12.2. Wartungsarbeiten ................................................................................................................................................................79

12.3. Störungen ...............................................................................................................................................................................79

13. ZUBEHÖR .............................................................................................................................................................................................81

14. VERPACKUNG, TRANSPORT .....................................................................................................................................................82

15. LAGERUNG ..........................................................................................................................................................................................82

16. ENTSORGUNG ...................................................................................................................................................................................82

44

deutsch

Page 45

Typ 3005

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus des Gerätes. Bewahren Sie diese Anleitung so auf,

dass sie für jeden Benutzer gut zugänglich ist und jedem neuen Eigentümer des Gerätes wieder zur Verfügung steht.

WARNUNG!

Die Bedienungsanleitung enthält wichtige Informationen zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt werden.

Bezeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen.

Verweist auf Informationen in dieser Bedienungsanleitung oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den sie ausführen müssen.

deutsch

45

Page 46

Typ 3005

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE VERWENDUNG

WARNUNG!

Bei nicht bestimmungsgemäßem Einsatz des elektrischen Drehantriebs Typ 3005 können Gefahren für

Personen, Anlagen in der Umgebung und die Umwelt entstehen.

• Der Drehantrieb kann z. B. zur Betätigung von Armaturen, insbesondere Kugelhähnen oder Absperrklappen

verwendet werden.

• Für den Einsatz sind die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen

Daten, Betriebs- und Einsatzbedingungen zu beachten die im Kapitel „5. Systembeschreibung“ beschrieben

sind.

• Der elektrische Drehantrieb darf nur in Verbindung mit von Bürkert empfohlenen bzw. zugelassenen Fremdgeräten und Komponenten eingesetzt werden (z. B. ATEX zugelassene Komponenten).

• Voraussetzungen für den sicheren und einwandfreien Betrieb sind sachgemäßer Transport, sachgemäße

Lagerung und Installation, sowie sorgfältige Bedienung und Instandhaltung.

• Das Gerät nur bestimmungsgemäß einsetzen.

2.1. Beschränkungen

Bei der Ausfuhr des Systems/Geräts gegebenenfalls bestehende Beschränkungen beachten.

Der elektrische Drehantrieb Typ 3005 wurde unter Einbeziehung der anerkannten sicherheitstechnischen

Regeln entwickelt und entspricht dem Stand der Technik. Trotzdem können Gefahren entstehen.

Das Gerät nur in einwandfreiem Zustand und unter Beachtung der Bedienungsanleitung betreiben.

46

deutsch

Page 47

Typ 3005

Grundlegende Sicherheitshinweise

3. GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung der Geräte auftreten können.

• Ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch in Bezug auf das Montagepersonal, der

Betreiber verantwortlich ist.

Gefahr durch elektrische Spannung!

Bei Eingriffen in das Gerät besteht akute Verletzungsgefahr.

• Vor Eingriffen in das Gerät in jedem Fall die Spannung abschalten und diese vor Wiedereinschalten sichern!

• Mehrere elektrische Drehantriebe immer mit Phasentrennung über einen Schalter anschließen.

• Das Gerät durch eine netzabhängige Sicherung schützen.

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

Explosionsgefahr!

Bei bestimmten Geräteausführungen besteht bei Öffnung des Gerätes im explosionsgeschützten Bereich

Explosionsgefahr.

• Die Sicherheitshinweise auf dem Typschild beachten!

Explosionsgefahr durch statische Aufladung!

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder Personen besteht im Ex-Bereich

Explosionsgefahr.

• Durch geeignete Maßnahmen sicherstellen, dass es im Ex-Bereich zu keinen elektrostatischen Aufladungen

kommen kann.

• Die Geräteoberfläche durch leichtes Abwischen mit einem feuchten oder antistatischen Tuch reinigen.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Typ 3005 nicht in explosionsgefährdeten Bereichen einsetzen (in diesem Fall Typ 3004 verwenden).

• Das Gehäuse nicht mechanisch belasten (z. B. durch Ablage von Gegenständen oder als Trittstufe).

• Keine äußerlichen Veränderungen an den Gerätegehäusen vornehmen. Gehäuseteile und Schrauben nicht

lackieren.

• Antrieb nicht mit dem Deckel nach unten (kopfüber) einbauen.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt werden.

• Nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung ist ein definierter oder kontrollierter Wiederanlauf des Prozesses zu gewährleisten.

• Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung der Bedienungsanleitung betrieben

werden.

• Für die Einsatzplanung und den Betrieb des Gerätes müssen die allgemeinen Regeln der Technik eingehalten

werden.

deutsch

47

Page 48

Typ 3005

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Kontaktadressen

Deutschland

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. : +49 (0)7940 - 10 91 111

Fax: +49 (0)7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.buerkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des elektischen Drehantriebs Typ

3005 unter Beachtung der spezifizierten Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 3005 finden Sie im Internet unter:

www.buerkert.de

48

deutsch

Page 49

Typ 3005

Systembeschreibung

5. SYSTEMBESCHREIBUNG

5.1. Vorgesehener Einsatzbereich

Der elektromotorische Drehantrieb Typ 3005 (im Folgenden als Drehantrieb bezeichnet) wurde entwickelt, um

Kugelhahn- oder Klappenventile mit Vierteldrehung zu steuern. Optional ist der Antrieb auch mit einem Drehwinkel

von 180° und 270° erhältlich.

5.2. Allgemeine Beschreibung

Das Basisgerät kann durch die modulare Konstruktion mit vielen Optionen erweitert werden.

Optionen zur Erweiterung des Basisgerätes finden Sie im Kapitel „5.4. Optionen“.

Der Drehantrieb ist ein kompaktes und leistungsstarkes Stellantriebssystem, das eine lange Lebensdauer gewährleistet. Der Drehantrieb ist für Gleich- oder Wechselstrom mit unterschiedlicher Leistung konzipiert und für Drehmomente von 25 bis 1000 Nm (Antrieb mit Analogsignal 20 - 300 Nm) ausgelegt.

Die verwendeten Werkstoffe gewährleisten einen wartungsfreien Betrieb und stellen eine niedrige thermische

Belastung sicher. Alle Drehantriebe sind in der Standardausführung mit einer Handnotbetätigung und zwei zusätzlichen Endschaltern ausgestattet und vom Hersteller getestet. Die Endschalter wurden auf 0 ... 90° Schwenkbetrieb

eingestellt.

Der elektromotorische Drehantrieb ist als Auf/Zu- oder Regelantrieb erhältlich. Er ist mit folgenden Komponenten

kombinierbar:

• Edelstahl Kugelhahn mit zweiteiligem Gehäuse (Typ 2651),

• Edelstahl Kugelhahn mit dreiteiligem Gehäuse (Typ 2654),

• Kunststoff Kugelhahn (Typ 2657),

• Metall Klappenventil (Typ 2671),

• Kunststoff Klappenventil (Typ 2674).

Die Antriebsrichtung ist im gleichen Betriebsvorgang nicht umkehrbar. Ein automatischer Rücklauf des Drehantriebs

erfolgt nicht.

Über das Handrad am Drehantrieb ist auch ein mechanischer Betrieb möglich. Im elektrischen Betrieb dreht sich

das Handrad nicht mit.

deutsch

49

Page 50

Typ 3005

Systembeschreibung

5.3. Explosionsdarstellung

Motor 25 - 75 Nm Motor 25 - 75 Nm mit Regelkarte

1

2

3

4

5.a

6

7

8

9

10

11

14.a

12

13

15

16

1

2

3

4

5.b

6

7

8

9

10

11

17

12

13

14.b

15

16

50

Bild 1: Explosionsdarstellung Motor 25 - 75 Nm

Pos. Bezeichnung Pos. Bezeichnung

1 Stellungsanzeige 10 Gehäuse

2 Haube 11 Platz für Typschild

3 Edelstahl-Schrauben 12 Zusätzlicher Endschalter

4 Motor 13 Nocken

5.a* Steuerung und Stromversorgung Karte 14.a* Steuerung und Spannungsversorgung

5.b* Stromversorgungskarte 14.b* Klemmleiste für Spannungsversorgung

6 Getriebeplatte 15 Kabelverschraubung ISO M20

7 O-Ring 16 Schraube für Erde

8 Getriebe 17 Regelkarte (nur bei Regelantrieb)

9 Schaltknopf

deutsch

Page 51

Typ 3005

Systembeschreibung

Motor 100 - 300 Nm Motor 100 - 300 Nm mit Regelkarte

Bild 2: Explosionsdarstellung Motor 100 - 300 Nm

Pos. Bezeichnung Pos. Bezeichnung

1 Stellungsanzeige 10 Gehäuse

2 Haube 11 Typschild

3 Edelstahl-Schrauben 12 Zusätzlicher Endschalter

4 Motor 13 Nocken

5.a* Steuerung und Stromversorgung Karte 14.a* Steuerung und Spannungsversorgung

5.b* Stromversorgungskarte 14.b* Klemmleiste für Spannungsversorgung

6 Getriebeplatte 15 Kabelverschraubung ISO M20

7 O-Ring 16 Schraube für Erde

8 Getriebe 17 Mechanische Endanschläge

9 Handrad 18 Regelkarte (nur bei Regelantrieb)

51

deutsch

Page 52

Motor 600 - 1000 Nm

Typ 3005

Systembeschreibung

52

Bild 3: Explosionsdarstellung Motor 600 - 1000 Nm

Pos. Bezeichnung Pos. Bezeichnung

1 Stellungsanzeige 9 Handrad

2 Haube 10 Gehäuse

3 Edelstahl-Schrauben 11 Platz für Typschild

4 Motor 13 Nocken

5 Steuerung und Stromversorgung Karte 15 Innengewinde M20x1,5

6 Getriebeplatte 16 Schraube für Erde

7 O-Ring 17 Mechanische Endanschläge

8 Getriebe

deutsch

Page 53

Typ 3005

Systembeschreibung

5.4. Optionen

• Dreistellungsdrehantrieb (180°)

• Drehwinkel 180° oder 270°

• Drehantrieb mit Rückmelde-Potentiometer

- Potentiometer mit Widerstandswerten 100 W, 1 KW, 5 KW oder 10 KW

- Analoge Rückmeldung über Signal: 0 ... 10 V, 0 ... 20 mA, 4 ... 20 mA

• Drehantrieb mit Notstromvariante (siehe Kapitel „9. Option: Drehantriebe mit Notstromvariante“)

• 2 zusätzliche Endschalter

deutsch

53

Page 54

Typ 3005

Technische Daten

6. TECHNISCHE DATEN

6.1. Konformität

Der elektromotorische Drehantrieb Typ 3005 ist konform zu den EG-Richtlinien entsprechend der

Konformitätserklärung.

6.2. Normen

Die angewandten Normen, mit denen die Konformität mit den EG-Richtlinien nachgewiesen wird, sind in der EGBaumusterprüfbescheinigung und/oder der EG-Konformitätserklärung nachzulesen.

6.3. Betriebsbedingungen

Umgebungstemperatur: -20 °C ... +70 °C

-10 °C ... +40 °C Notrückstellung

Schutzart: IP67 nach EN 60529 mit Kabelverschraubung ISO 20 oder Schutzkappe

HINWEIS!

• Die Wärmequellen vermeiden, die zur Überschreitung des zulässigen Temperaturbereichs führen können.

6.4. Kennzeichnung

Der Drehantrieb ist mit einem Typschild versehen, das eine eindeutige Identifikation ermöglicht und die wichtigsten

technischen Daten erkennen lässt.

Das Typschild nicht vom Drehantrieb entfernen!

Es ist für die Identifikation bei Installation und Instandhaltung von entscheidender Bedeutung.

Ohne Typschild erlischt die Gewährleistung.

54

deutsch

Page 55

Typ 3005

Technische Daten

6.4.1. Beschreibung des Typschildes

Drehmoment

Typbezeichnung

Betriebsspannung

Stellzeit für 90°

3005

24V AC/DC ED 50%

150Nm 30 Sek 90° 45W

IP67 OF 076688/ 107

179 725

Identnummer

Schutzart

Bild 4: Beschreibung des Typschildes (Beispiel)

6.5. Allgemeine Technische Daten

6.5.1. Mechanische Daten

Abmessungen: Siehe Kapitel „6.5.2. Abmessungen“

Gewicht: 25 -75 Nm; 3,1 kg

100 - 300 Nm; 5,6 kg

600 - 1000 Nm; 20 kg

Einschaltdauer

Leistung

Stellwinkel

S45/07

Gehäusematerial: Gehäuse - Aluminium

Deckel - Polyamid (Aluminium optional)

Achsen und Schrauben - Edelstahl

Getriebe - verzinkter Stahl

Stellwinkel: 90° (optional 180°, 270°) ± 5°

Einschaltdauer: 50 % bei maximalem Drehmoment (optional 80 %)

Handnotbetätigung: mit Gabelschlüssel an Flächen der Achse (bis 75 Nm);

durch Handrad (ab 100 Nm)

Arbeitsmodi: Auf/Zu Modus oder Drei Punkt Modus (siehe „Bild 17“ und „Bild 18“)

deutsch

55

Page 56

6.5.2. Abmessungen

Motor 25 - 75 Nm

Typ 3005

Technische Daten

56

Bild 5: Abmessungen Typ 3005 mit Drehmoment 25 - 75 Nm

deutsch

Page 57

Technische Daten

Motor 100 - 300 Nm

Typ 3005

Bild 6: Abmessungen Typ 3005 mit Drehmoment 100 - 300 Nm

deutsch

57

Page 58

Motor 600 - 1000 Nm

Typ 3005

Technische Daten

58

Bild 7: Abmessungen Typ 3005 mit Drehmoment 600 - 1000 Nm

deutsch

Page 59

Typ 3005

Technische Daten

6.5.3. Elektrische Daten

Anschlüsse: 2 Gewindeanschlüsse ISO 20

Endschalter: 2 Endschalter für den Motor

2 potenzialfreie Endschalter (für Stellungsrückmeldung)

Leistung: max. 250 V AC / 5 A

Elektrische Daten für Standardausführung ohne Analogsignal und Stellungsreglerausführung mit

4 ... 20 mA, 0 ... 20 mA oder 0 ... 10 V Analogsignaleingang

Drehmoment

[Nm]

90° Stellzeit

[s]

Leistungsaufnahme

[W]

Spannung / Frequenz

[V / Hz]

25 7 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

45 15 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

75 20 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

100 15 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

150 30 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

300 60 45 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

600 38 250 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1000 38 250 100-240 / 50/60 (100-350 DC)

15-30 AC (12-48 DC

1)

)

1)

)

1)

)

1)

)

1)

)

1)

)

1)

)

1)

)

Wir empfehlen eine Antriebsauslegung mit dem 1,5-fachen des maximalen Drehmoments der Armatur

(bei Regelantrieben mit dem 2-fachen des maximalen Drehmoments).

1) Die Betriebsspannung darf 11,5 V nicht unterschreiten

59

deutsch

Page 60

Typ 3005

Montage

7. MONTAGE

7.1. Sicherheitshinweise

GEFAHR!

Gefahr durch elektrische Spannung!

Bei Eingriffen in das Gerät besteht akute Verletzungsgefahr.

• Schalten Sie in jedem Fall die Spannung ab und sichern Sie diese vor Wiedereinschalten, bevor Sie den

Deckel entfernen, das Getriebe trennen oder den Hebel benutzen.

• Schließen Sie mehrere Drehantriebe immer mit Phasentrennung über einen Schalter an!

• Schützen Sie die Drehantriebe durch eine netzabhängige Sicherung!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

WARNUNG!

Gefahr durch unsachgemäße Montage!

Unsachgemäße Montage kann zu Verletzungen sowie zu Schäden am Gerät und seiner Umgebung führen.

• Die Montage darf nur durch autorisiertes Fachpersonal und mit geeignetem Werkzeug durchgeführt werden!

• Beachten Sie die Angaben im Kapitel „6. Technische Daten“.

Gefahr durch unbeabsichtigte Betätigung des Geräts!

Ungewolltes Ingangsetzen des Geräts bei der Montage kann zu Verletzungen und Sachschäden führen.

• Durch geeignete Maßnahmen verhindern, dass das Gerät nicht unbeabsichtigt betätigt werden kann.

7.2. Montage des Drehantriebs

Der Drehantrieb wird mit der Voreinstellung <Geschlossen> ausgeliefert.

Die Montage des Drehantriebs auf einen Kugelhahn bzw. Klappenventil erfolgt über folgende Befestigungsvarianten:

• ISO F05 (4 x M6 bei einem Flansch - Ø von 50 mm)

• ISO F07 (4 x M8 bei einem Flansch - Ø von 70 mm)

• ISO F10 (4 x M10 bei einem Flansch - Ø von 102 mm)

60

• ISO F12 (4 x M12 bei einem Flansch - Ø von 125 mm)

7.2.1. Wellenende

Die Größen der Innensternform des Wellenendes ist von der Antriebsgröße abhängig. Jedem Antrieb ist nur die

Standardgröße der Innensternform beigelegt (siehe Tabelle).

Antriebsgröße [Nm] Standardgröße der Innensternform [mm]

25 17 / 11

45 / 75 17 / 14

deutsch

Page 61

Typ 3005

Montage

Antriebsgröße [Nm] Standardgröße der Innensternform [mm]