Page 1

Type

A

2861, 2863, 2865,

2871, 2873, 2875

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Proportional Valves with Control

Electronics

Proportionalventile mit Ansteuerelektronik

Électrovannes proportionnelles avec

électronique de commande

en / de / fr

I. OPERATING PRINCIPLES

WIRKUNGSWEISEN / MODES D’ACTION

A

P

2/2-way valve, normally closed.

2/2-Wege Ventil, stromlos geschlossen.

Vanne 2/2 voies,normalement fermée.

II. TYPE-PLATE / TYPENSCHILD

PLAQUE SIGNALÉTIQUE

Observe the voltage, current type, and pressure specified

on the type label.

Die auf dem Typenschild angegebene Daten für Spannung,

Stromart und Druck beachten.

Observer les données indiquées sur la la plaque signalétique

pour la tension, le type de courant et la pression.

Address / Adresse

Germany / Deutschland / Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

www.burkert.com

Manuals and data sheets on the Internet : www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet: www.buerkert.fr

© 2011 - 2012 Bürkert Werke GmbH

Operating Instructions 1203/01_EU-ml _00809633 / Original DE

SYMBOLS

→

designates a procedure which you must carry out.

Warning of serious or fatal injuries:

DANGER!

In case of imminent danger.

WARNING!

In case of potential danger.

Warning of minor or moderately severe injuries:

CAUTION!

DARSTELLUNGSMITTEL

→

markiert einen Arbeitsschritt den Sie ausführen müssen.

Warnung vor schweren oder tödlichen Verletzungen:

GEFAHR!

Bei unmittelbarer Gefahr.

WARNUNG!

Bei möglicher Gefahr.

Warnung vor leichten oder mittelschweren Verletzungen:

VORSICHT!

Description / Beschreibung:

Wirkungsweise / Modes d’action

Operating principle

Pressure range / Druckbereich

Plage de pression

Connecting thread

Anschlussgewinde

Filetage de raccordement

Voltage, Spannung,

Tension (±10 %)

Identification number

Identnummer

No. d‘identification

Type

Typ

2873 A2,0 FKMMS

G1/4 PNVAK - 8bar

24V DC 9W

001084

MADE IN GERMANY

Orifice / Nennweite

Diamètre nominal

Seal material

Dichtungsmaterial

Matériau d‘étanchéit

Housing material

Gehäusematerial

Matériau du corps

Power

consumption

W11LA

Leistung

Puissance

III. ELECTRICAL CONTROL/ ELEKTRISCHE

ANSTEUERUNG / COMMANDE ÉLECTRIQUE

For all designs (wires and plugs)

Für alle Ausführungen (Litzen, Stecker)

Pour toutes les versions (torons et connecteurs)

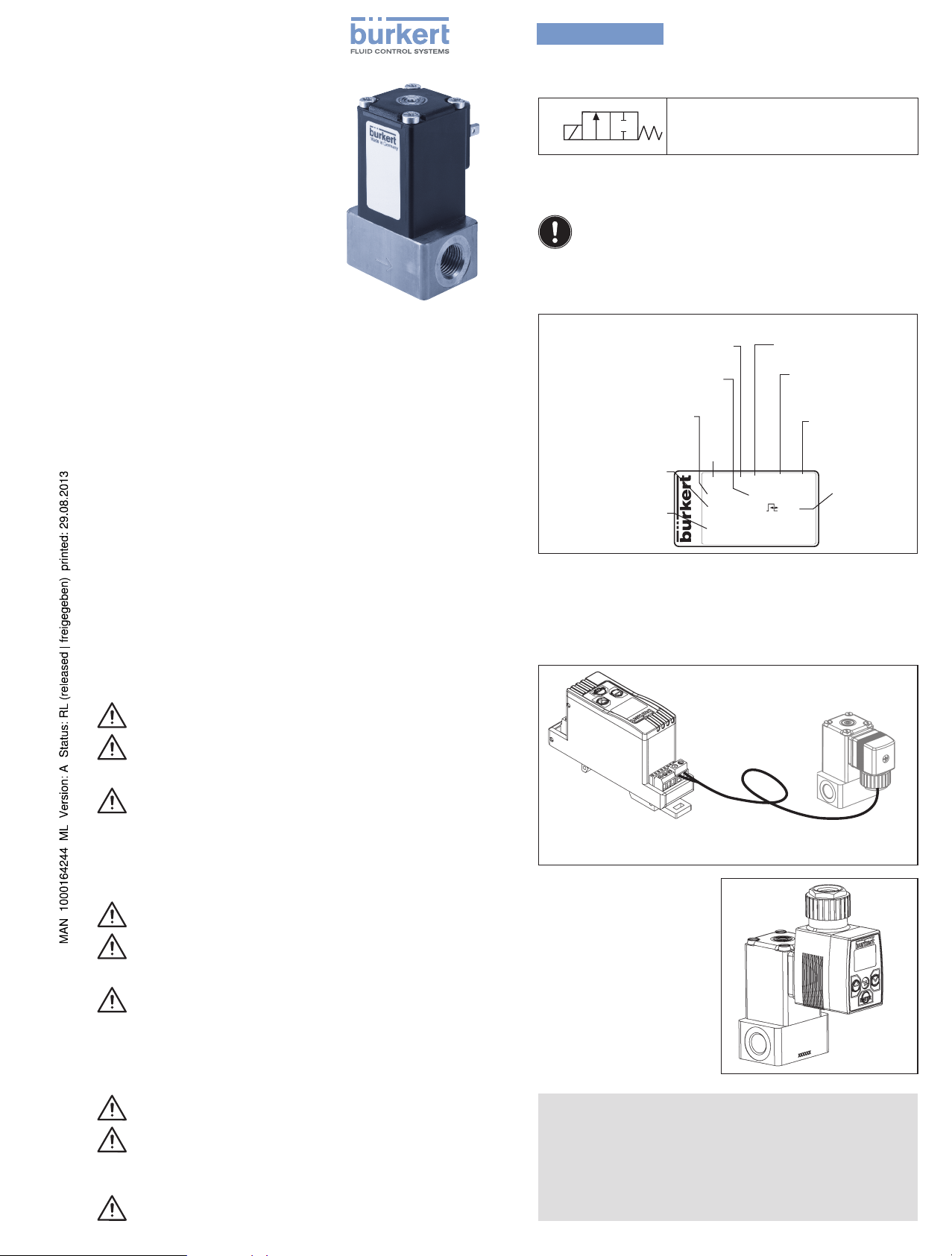

Type / Typ 8605

Top-hat rail

variant

Hutschienenvariante

Variante sur profilé chapeau

For plug designs with coil

size 32 mm and 49 mm

Für Steckerausführungen

mit Spulengröße 32 mm und

49 mm

Pour versions avec

connecteurs et tailles de

bobine de 32 et 49 mm

Example with device socket type 2508

Beispiel mit Gerätesteckdose Typ 2508

Example avec connecteur type 2508

Cable lenght / Leitungslänge /

Longueur de ligne: max. 50 m

Type / Typ

8605

SYMBOLES

→

identifie une opération que vous devez effectuer.

Mise en garde contre les blessures graves ou mortelles :

DANGER!

En cas de danger imminent

AVERTISSEMENT!

En cas de danger possible.

Mise en garde contre les blessures légères ou moyennement

graves :

ATTENTION!

attachable

aufsteckbar

enfichable

NOTE /HINWEIS / REMARQUE!

Functional impairment at incorrect PWM frequency!

• For PWM frequency see instructions for the control electronics.

Funktionsbeeinträchtigung bei falscher PWM-Frequenz!

• PWM-Frequenz siehe Anleitung der Ansteuerelektronik.

Dysfonctionnement dû à une mauvaise fréquence PWM !

• Fréquence PWM, voir instructions de service de l’électronique

de commande.

Page 2

English

Type 2861 ... 2875

1. OPERATING INSTRUCTIONS

The operating instructions contain important information.

• Read the instructions carefully and follow the safety instructions

in particular, and also observe the operating conditions.

• Keep the instructions in a location where they are available to

every user.

• The liability and warranty for the proportional valve are void if the

operating instructions are not followed.

2. INTENDED USE

The direct-acting proportional valve can be used as an actuating

element for the process control.

• Do not use in potentially explosive areas.

• Do not use outside.

• Operate only when in perfect condition and pay attention to correct

storage, transportation, installation and operation.

• Do not make any internal or external changes.

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any contingencies and events which may arise during installation, operation

and maintenance.

WARNING!

Danger – high pressure!

• Before loosening lines or valves, turn off the pressure and vent

the lines.

Risk of burns/risk of fire if used continuously through hot

device surface!

• Keep the proportional valve away from highly flammable substances and media and do not touch with bare hands.

• Do not obstruct the heat release required for operation.

To prevent injury, ensure the following:

• Secure equipment/device from unintentional actuation.

• Only trained technicians may perform installation and maintenance work.

• After an interruption in the power supply, ensure that the process is restarted in a controlled manner.

• Observe the general regulations of technology.

5. INSTALLATION

WARNING!

Risk of injury from high pressure in the equipment.

• Before loosening lines or valves, turn off the pressure and vent

the lines.

Installation position: any position, preferably with actuator above.

→ Clean pipelines and flange connections.

→ Install dirt filter in the direction of flow in front of the valve

(mesh size 0.02 – 0.4 mm; according to orifice).

WARNING!

Danger from medium!

• Make sure that the supplied seal fits properly.

→ Insert seal into valve.

NOTE!

• The proportional valve must not be removed and the central

adjusting screw must not be adjusted.

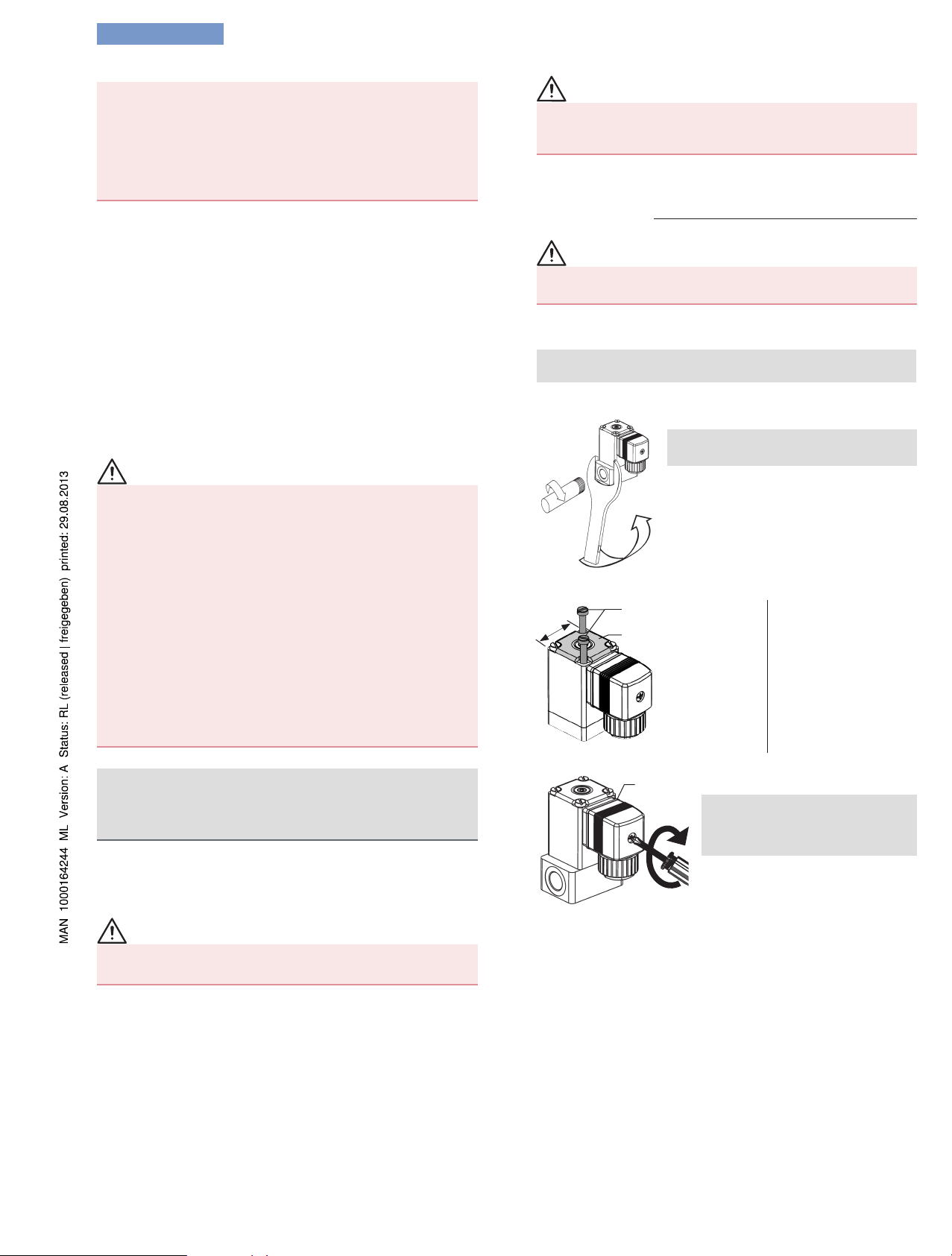

Screwing in pipeline:

NOTE!

• Use suitable tool (open-end wrench)

and do not use coil as a lever arm.

→ Hold the proportional valve on the fluid

housing using an open-end wrench.

→ Screw in pipeline.

→ Check installation for leaks.

Attaching the mounting plate:

Tightening torque

according to coil size:

20 mm = max. 1.0 Nm

32 mm = max. 1.2 Nm

49 mm = max. 1.5 Nm

mm*

Fastening screws (2)

Mounting plate

* Coil size

Electrostatic sensitive components/modules!

Observe the requirements in accordance with EN 61340-5-1 and

5-2 to minimize/avoid the possibility of damage caused by a sudden

electrostatic discharge!

4. TECHNICAL DATA

4.1. Operating conditions

CAUTION!

Malfunction in unauthorized temperature range.

• Avoid exceeding or dropping below the temperature range.

Ambient temperature: 0 ... +55 °C

Medium temperature: -10 ... +90 °C

Media: neutral gases, technical vacuum

Protection class: IP65 in accordance with DIN EN 60529

4.2. Mechanical and pneumatic data

Materials, pressure range, line connectors: see rating plate

4.3. Electrical Data

Operating voltage, power input: see rating plate.

Nominal operating mode: Long-term operation ED 100 % in

accordance with DIN EN 60034-1

Electrical connection: (depending on type and design) wires, plug

tabs in accordance with DIN EN 175301-803 shape A, shape B

Connecting device socket:

Seal

NOTE!

• Note the voltage and current

type as specified on the rating

plate. Ensure that the seal is fitted

correctly.

→ Insert seal.

max.

0.9 Nm

→ Attach device socket and secure

with screw.

Tightening torque max. 0.9 Nm.

→ Connect protective conductor.

6. MAINTENANCE

Under normal operating conditions, the valve is maintenance-free.

7. MALFUNCTIONS

If malfunctions occur, check

• the line connectors,

• whether the operating pressure is within the permitted range,

• the power supply and valve control.

8. TRANSPORTATION, STORAGE, DISPOSAL

• Transport and store the proportional valve in shock-resistant

packaging to protect against moisture and dirt.

• Permitted storage temperature: -20 … +70 °C.

• Dispose of the device and packaging according to the applicable disposal and environmental protection regulations.

Page 3

deutsch

Typ 2861 ... 2875

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

• Die Anleitung sorgfältig lesen und besonders die Hinweise zur

Sicherheit, sowie die Betriebsbedingungen beachten.

• Die Anleitung so aufbewahren, dass sie jedem Benutzer zur

Verfügung steht.

• Die Haftung und Gewährleistung für das Proportionalventil

entfällt, wenn die Anweisungen der Bedienungsanleitung nicht

beachtet werden.

2. BESTIMMUNGSGEMÄSSER GEBRAUCH

Das direktwirkende Proportionalventil kann als Stellglied zur Prozessregelung eingesetzt werden.

• Nicht in explosionsgefährdeten Bereichen einsetzen.

• Nicht im Außenbereich einsetzen.

• Nur in einwandfreiem Zustand betreiben und auf sachgerechte

Lagerung, Transport, Installation und Bedienung achten.

• Keine inneren oder äußeren Veränderungen vornehmen.

3. GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine Zufälligkeiten und

Ereignisse, die bei Montage, Betrieb und Wartung auftreten können.

WARNUNG!

Gefahr durch hohen Druck!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entleeren.

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb durch

heiße Geräteoberfläche!

• Das Proportionalventil von leicht brennbaren Stoffen und

Medien fernhalten und nicht mit bloßen Händen berühren.

• Die für den Betrieb notwendige Wärmeabfuhr nicht behindern.

Zum Schutz vor Verletzungen beachten:

• Anlage/Gerät vor unbeabsichtigter Betätigung sichern.

• Nur geschultes Fachpersonal darf Installations- und Instandhaltungsarbeiten ausführen.

• Nach Unterbrechung der elektrischen Versorgung für einen

kontrollierten Wiederanlauf des Prozesses sorgen.

• Die allgemeinen Regeln der Technik einhalten.

5. INSTALLATION

WARNUNG!

Verletzungsgefahr durch hohen Druck in der Anlage.

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entleeren.

Einbaulage: beliebig, vorzugsweise Antrieb oben.

→ Rohrleitungen und Flanschanschlüsse säubern.

→ Schmutzfilter in Strömungsrichtung vor dem Ventil einbauen

(Maschenweite 0,02 ... 0,4 mm; je nach Nennweite).

WARNUNG!

Gefahr durch Medium!

• Auf den richtigen Sitz der mitgelieferten Dichtungen achten.

→ Dichtung in Ventil einlegen.

HINWEIS!

• Das Proportionalventil darf nicht demontiert und die zentrale

Justierschraube nicht verstellt werden.

Rohrleitung einschrauben:

HINWEIS!

• Geeignetes Werkzeug (Gabelschlüssel)

verwenden und Spule nicht als Hebelarm benutzen.

→ Das Proportionalventil mit einem Gabel-

schlüssel am Fluidgehäuse festhalten.

→ Rohrleitung einschrauben.

→ Installation auf Dichtheit prüfen.

Befestigen der Montageplatte:

Anzugsdrehmoment

bei Spulengröße:

20 mm = max. 1,0 Nm

32 mm = max. 1,2 Nm

49 mm = max. 1,5 Nm

mm*

Befestigungsschrauben (2)

Montageplatte

* Spulengröße

Elektrostatisch gefährdete Bauelemente / Baugruppen!

Beachten Sie die Anforderungen nach EN 61340-5-1 und 5-2, um

die Möglichkeit eines Schadens durch schlagartige elektrostatische

Entladung zu minimieren bzw. zu vermeiden!

4. TECHNISCHE DATEN

4.1. Betriebsbedingungen

VORSICHT!

Funktionsausfall bei unzulässigem Temperaturbereich.

• Über- oder Unterschreitung des Temperaturbereichs

vermeiden.

Umgebungstemperatur: 0 ... +55 °C

Mediumstemperatur: -10 ... +90 °C

Medien: neutrale Gase, technisches Vakuum

Schutzart: IP65 nach DIN EN 60529

4.2. Mechanische und pneumatische Daten

Werkstoffe, Druckbereich, Leitungsanschlüsse: siehe Typschild

4.3. Elektrische Daten

Betriebsspannung, Leistungsaufnahme: siehe Typschild.

Nennbetriebsart: Dauerbetrieb ED 100 % nach DIN EN 60034-1

Elektrischer Anschluss: (abhängig von Typ und Ausführung) Litzen,

Steckerfahnen nach DIN EN 175301-803 Form A, Form B

Gerätesteckdose anschließen:

Dichtung

HINWEIS!

• Spannung und Stromart laut

Typschild beachten. Auf einwandfreien Sitz der Dichtung achten.

→ Dichtung einlegen.

→ Gerätesteckdose aufstecken und

mit Schraube befestigen.

max.

0,9 Nm

6. WARTUNG

Das Ventil arbeitet unter Normalbedingungen wartungsfrei.

7. STÖRUNGEN

Überprüfen Sie bei Störungen

• die Leitungsanschlüsse,

• ob sich der Betriebsdruck im zulässigen Bereich befindet,

• die Spannungsversorgung und Ventilansteuerung.

8. TRANSPORT, LAGERUNG, ENTSORGUNG

• Das Proportionalventil vor Nässe und Schmutz geschützt in

einer stoßfesten Verpackung transportieren und lagern.

• Zulässige Lagertemperatur: -20 … +70 °C.

• Bei der Entsorgung von Gerät und Verpackung die geltenden

Entsorgungsvorschriften und Umweltbestimmungen einhalten.

Anzugsdrehmoment max. 0,9 Nm.

→ Schutzleiter anschließen.

Page 4

français

Type 2861 ... 2875

1. INSTRUCTIONS DE SERVICE

Les instructions de service contiennent des informations

importantes.

• Lire attentivement les instructions et tenir particulièrement compte

des consignes de sécurité ainsi que des conditions d'exploitation.

• Conserver les instructions afin qu'elles soient accessibles à tous

les utilisateurs.

• La responsabilité et la garantie légale concernant la vanne proportionnelle sont exclues en cas de non-respect des instructions

de service.

2. UTILISATION CONFORME

La vanne proportionnelle à action directe peut être utilisée comme

élément de réglage pour la régulation du process.

• Ne pas utiliser dans des zones présentant des risques d’explosion.

• Ne pas utiliser à l’extérieur.

• Utiliser uniquement en parfait état et veiller au stockage, au

transport, à l'installation et à l'utilisation conformes.

• Ne pas effectuer de modifications internes ou externes.

3. CONSIGNES DE SÉCURITÉ FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte des hasards et

des événements pouvant survenir lors du montage, de l'exploitation

et de l'entretien.

AVERTISSEMENT !

Danger dû à la haute pression !

• Avant de desserrer les conduites et les vannes, couper la pression et purger l'air des conduites.

Risque de brûlures/d'incendie en fonctionnement continu dû

à des surfaces d'appareils brûlantes !

• Tenir les substances et les fluides facilement inflammables à

l'écart de la vanne et ne pas toucher celle-ci à mains nues.

• Ne pas gêner l'évacuation de la chaleur nécessaire au

fonctionnement.

Pour prévenir les blessures, veuillez tenir compte de ce qui suit :

• Empêcher tout actionnement involontaire de l'installation/de

l'appareil.

• Seul du personnel qualifié peut effectuer l'installation et la

maintenance.

• Garantir un redémarrage contrôlé du process après la coupure

de l'alimentation électrique.

• Respecter les règles générales de la technique.

Eléments/sous-groupes sujets aux risques électrostatiques !

Respecter les exigences selon EN 61340-5-1 et 5-2 pour minimiser ou éviter la possibilité d'un dommage causé par une soudaine

décharge électrostatique !

4. CARACTÉRISTIQUES TECHNIQUES

4.1. Conditions d'exploitation

ATTENTION !

Panne en cas de plage de température non autorisée.

• Eviter d'être au-dessus ou en dessous de la plage de température.

Température ambiante : 0 ... +55 °C

Température du fluide : -10 ... +90 °C

Fluides : gaz neutres, vide technique

Type de protection : IP65 selon DIN EN 60529

4.2. Caractéristiques mécaniques et pneumatiques

Matériaux, plage de pression, raccords de conduite : voir plaque

signalétique

4.3. Caractéristiques électriques

Tension de service, puissance absorbée : voir plaque signalétique.

Mode opératoire nominal : fonctionnement continu ED 100 %

selon DIN EN 60034-1

Raccordement électrique : (en fonction du type et de la version)

torons, barettes de raccordement selon DIN EN 175301-803,

forme A, forme B

5. INSTALLATION

AVERTISSEMENT !

Risque de blessures dû à la présence de haute pression

dans l'installation.

• Avant de desserrer les conduites et les vannes, couper la pression et purger l'air des conduites.

Position de montage : au choix, de préférence actionneur vers le

haut.

→ Nettoyer les tuyauteries et les raccordements à bride.

→ Monter le filtre à impuretés dans le sens de l'écoulement en amont

de la vanne (mailles de 0,02 à 0,4 mm ; selon diamètre nominal).

AVERTISSEMENT !

Danger dû au fluide !

• Veiller au bon positionnement des joints fournis.

→ Placer le joint dans la vanne.

REMARQUE !

• Le démontage de la vanne proportionnelle ainsi que le réglage

de la vis d'ajustage centrale sont interdits.

Visser la tuyauterie :

REMARQUE !

• Utiliser des outils appropriés (clé plate)

et ne pas utiliser la bobine comme levier.

→ Maintenir la vanne proportionnelle avec

une clé plate sur le boîtier de fluide.

→ Visser la tuyauterie.

→ Contrôler l'étanchéité de l'installation.

Fixation de la plaque de montage :

Vis de fixation (2)

mm*

Raccorder la prise de l'appareil :

Plaque de montage

* Taille de bobine

Joint

REMARQUE !

Respectez la tension et le type de courant

selon la plaque signalétique. Veiller à

l'installation correcte du joint.

Couple de serrage

avec taille de bobine :

20 mm = max. 1,0 Nm

32 mm = max. 1,2 Nm

49 mm = max. 1,5 Nm

→ Placer le joint.

→ Mettre la prise de l’appareil en place

max.

0,9 Nm

et la fixer avec une vis.

Couple de serrage max. 0,9 Nm.

→ Raccorder le conducteur de protection.

6. ENTRETIEN

Dans des conditions normales, la vanne ne nécessite aucun entretien.

7. PANNES

En présence de pannes, vérifier

• les raccords de conduite,

• la présence d'une pression de service située dans la plage autorisée,

• l'alimentation en tension et la commande de la vanne.

8. TRANSPORT, STOCKAGE, ÉLIMINATION

• Transporter et stocker la vanne proportionnelle à l'abri de l'humidité

et des impuretés et dans un emballage résistant aux chocs.

• Température de stockage autorisée : -20 à +70 °C.

• Lors de l'élimination de l'appareil et de l'emballage, respecter

les prescriptions en matière d’élimination des déchets et de

protection de l’environnement en vigueur.

Loading...

Loading...