Page 1

en / de / fr

Type 2503

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Elektronik Whisper Valve

Boost Close

689998

SYMBOLS

▶ designates an instruction to prevent risks.

Warning of injuries:

DANGER

Immediate danger. Serious or fatal injuries.

Warning of damage:

NOTE

Refers to information in these operating instructions or in

other documentation.

DARSTELLUNGSMITTEL

▶ Markiert eine Anweisung zur Vermeidung einer Gefahr.

Warnung vor Verletzungen:

GEfAhR

Unmittelbare Gefahr! Schwere oder tödlichen Verletzungen.

Warnung vor Sachschäden:

AchTuNG

Verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

SYMBOLS

▶ Identifie une instruction visant à éviter un danger.

Mise en garde contre les blessures :

DANGER

Danger imminent. Les blessures graves ou mortelles.

Met en garde contre des dommages matériels :

REMARQuE

renvoie à des informations dans le présent manuel

d‘utilisation ou dans d‘autres documents.

OPERATING INSTRUCTIONS

The operating instructions contain important information.

▶ Read the operating instructions carefully and follow the safety

instructions in particular, and also observe the operating

conditions.

▶ Operating instructions must be available to each user.

▶ The liability and warranty for Type 2503 are void if the operating

instructions are not followed.

Address / Adresse

Germany / Deutschland / Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10-91 111

Fax + 49 (0) 7940 - 10-91 448

E-mail: info@burkert.com

International

www.burkert.com

Manuals and data sheets on the Internet : www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet: www.buerkert.fr

© Bürker t Werke GmbH & Co. KG, 2017

Operating Instructions 1705/00_EU-ml_00810589/ Original DE

DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

▶ Die Anleitung sorgfältig lesen und besonders die Hinweise zur

Sicherheit beachten.

▶ Die Anleitung aufbewahren und jedem Benutzer zur Verfügung

stellen.

▶ Die Haftung und Gewährleistung für Typ 2503 entfällt, wenn die

Anweisungen der Bedienungsanleitung nicht beachtet werden.

MANUEL D’UTILISATION

Manuel d’utilisation contiennent des informations importantes.

▶ Lire attentivement ce manuel d’utilisation et respecter les

consignes de sécurité.

▶ Le manuel d’utilisation doit être à disposition de chaque

utilisateur.

▶ La responsabilité et la garantie légale concernant le type 2503

sont exclues en cas de non-respect du manuel d’utilisation.

PRODUCT DESCRIPTION

Intended use

2503 Boost Close is designed for use with type 6712 and type 6724

valves.

General description

The ‘Boost Close’ electronic accessories have been developed

specifically for type 6712 and type 6724 solenoid valves. The leaktightness of the valve connection ‘normally closed’ is improved

by the electronics. The return pressure tightness is also increased

significantly for the type 6712 valve.

Polarity of the electronics output voltage is reversed when the

output voltage is ‘low’. This results in the reversal of the actuator

force in the valve. An additional, active closing force is generated.

PRODUKTBESCHREIBUNG

Vorgesehener Einsatzbereich

Der Typ 2503 Boost Close ist für die Verwendung mit den Ventilen

Typ 6712 und Typ 6724 konzipiert.

Allgemeine Beschreibung

Die Zubehörelektronik „Boost Close“ wurde speziell für die

Magnetventile der Baureihen Typ 6712 und Typ 6724 entwickelt.

Durch die Elektronik wird die Dichtheit des Ventilanschlusses

„Normaly Closed“ (stromlos geschlossen) erhöht. Bei Typ 6712 wird

auch die Rückdruckdichtheit deutlich gesteigert.

Bei Steuersignal „low“ wird die Ausgangsspannung der Elektronik

umgepolt. Dadurch kehrt sich auch die Aktorkraft im Ventil um. Es

entsteht eine zusätzliche, aktiv wirkende Schließkraft.

DESCRIPTION DU PRODUIT

Utilisation prévue

Le type 2503 BoostClose est conçu pour être utilisé avec les

vannes types 6712 et 6724.

Description générale

Le module électronique accessoire «Boost Close» a été développé

spécialement pour les électrovannes des séries types 6712 et

6724. Le module électronique permet d’augmenter l’étanchéité du

raccord de vanne «Normally Closed» (fermée sans courant). Sur le

type 6712, l’étanchéité

à la pression de retour est aussi considérablement réduite.

La tension de sortie du module électronique change de pôle avec

le signal de commande «low». Ce qui entraîne également une

inversion de la force d’actionneur dans la vanne. Il s’ensuit une

force de fermeture active supplémentaire.

TYPE LABEL / TYPENSCHILD / PLAQUE SIGNALÉTIQUE

Code-fabricant /

Herstellercode /

Manufacturer

code

ID number /

Identnummer /

Numéro

d‘identification

689998 (A)

16/107

CE marking /

CE-Kennzeichnung /

Marquage CE

Page 2

1 INTENDED USE

2503 Boost Close is designed for use with type 6712 and type

6724 valves.

▶ Use according to the permitted data, operating conditions and

conditions of use specied in the contract documents and operating instructions.

▶ Do not use the device outdoors.

▶ The device may be used only in conjunction with third-party

devices and components recommended and authorised by

Bürkert.

▶ Correct transportation, correct storage and installation and

careful use and maintenance are essential for reliable and

problem-free operation.

▶ Use the device only as intended.

2 BASIC SAFETY INSTRUCTIONSE

These safety instructions do not consider any contingencies or incidents which occur during installation, operation and maintenance.

Risk of injury from high pressure.

▶ Before loosening the lines and valves, turn o the pressure and

vent the lines.

Risk of electric shock.

▶ Before reaching into the system, switch o the power supply and

secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for

electrical equipment.

Risk of burns/Risk of re if used continuously through hot device

surface.

▶ Keep the device away from highly ammable substances and media

and do not touch with bare hands.

General hazardous situations.

▶ Do not make any internal or external changes on the device and do

not subject it to mechanical stress.

▶ Secure the system from unintentional actuation.

▶ Only trained technicians may perform installation and maintenance

work.

▶ The valves must be installed in accordance with the regulations

applicable in the country.

▶ After an interruption, ensure that the process is restarted in a con-

trolled manner.

▶ Observe the general rules of technology.

3 TECHNICAL DATA

3.1 Conformity

Type 2503 conforms with the EU Directives according to the EU

Declaration of Conformity (if applicable).

3.2 Standards

The applied standards, which verify conformity with the EU Directives,

can be found on the EU-Type Examination Certicate and / or the EU

Declaration of Conformity (if applicable).

3.3 General technical data

Type 6712

Valve circuit function A

Seal material

EPDM

(not suitable for FKM and FFKM )

1)

Valve operating voltage 12…24V

Orice 0.8mm

Extended pressure range with

electronics

3)

0...6bar

Permissible return pressure /

dynamic pressure in the valve

Max. 5bar

Type 6724

Valve circuit function A, T

2)

Seal material EPDM, FKM, FFKM

Valve operating voltage 12…24V

Orice 1.2mm

Extended pressure range with

electronics

3)

Vac...7bar

Permissible return pressure /

dynamic pressure in the valve

Max. 5bar

1) with FKM and FFKM the electronics reduces the life time signicantly.

2) 3/2-way valves can be connected. In this case, the leak-tightness of the

normally closed connection (NC) is increased. The leak-tightness of the

normally open connection (NO) remains unchanged.

3) Note! If the electronics operating voltage is switched o, the pressure

values drop to the values without electronics specied in the data sheet.

4 INSTALLATION

NOTE

3/2-way valves can be connected. In this case, the leak-tightness

of ‘the normally closed’ connection (NC) is increased. The

leak-tightness of the ‘normally open’ connection (NO) remains

unchanged.

DANGER

Risk of injury from high pressure

If the operating voltage (+U

B

) is switched o (e.g. at the end of

operation or due to an emergency stop), the ‘active seal eect’

is no longer applicable. The pressure values drop to the default

values of the applied valve (see data sheet).

▶ Pay attention to the maximum permissible return pressure values

and dynamic pressure values stated in the table „3 Technical data“.

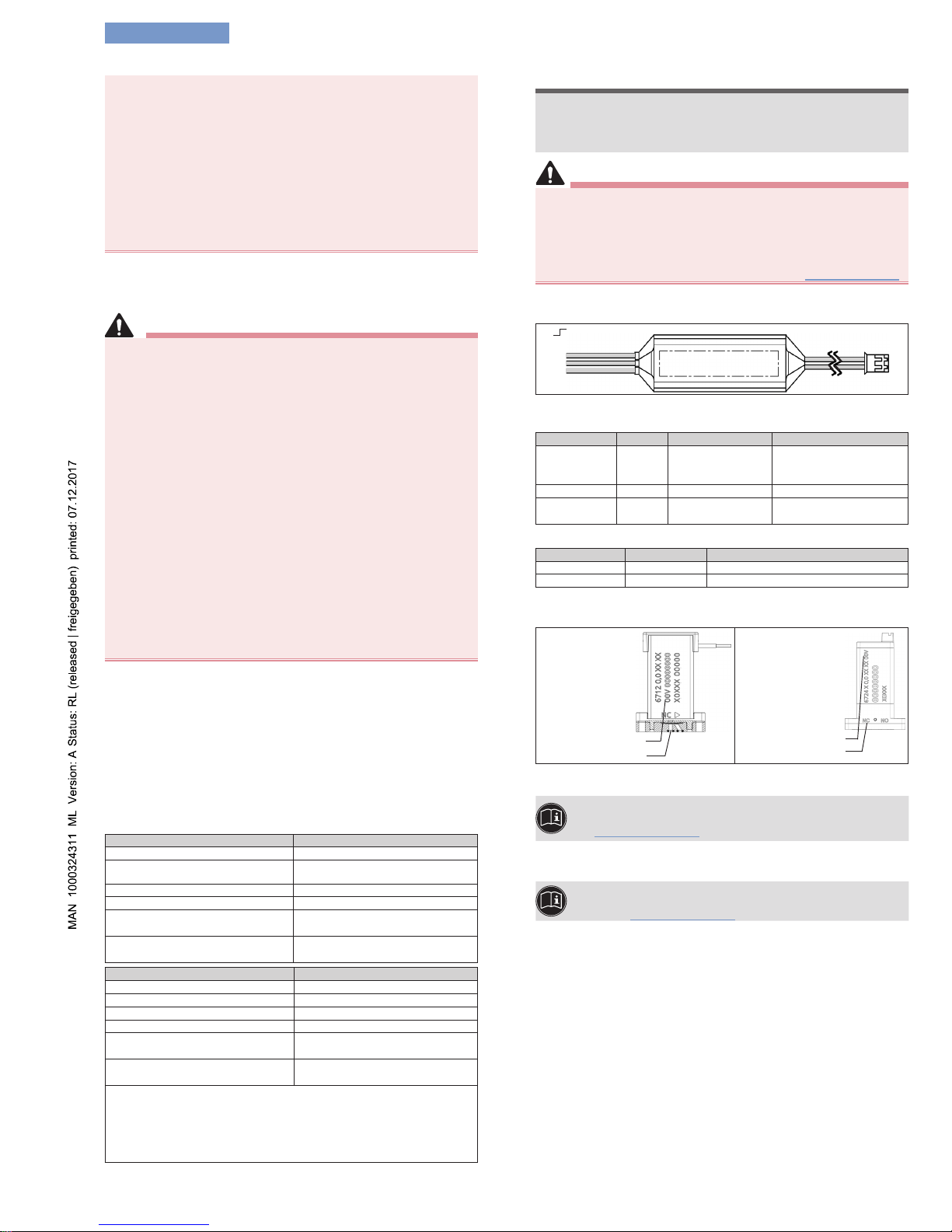

4.1 Connecting the electronics

Identication: see labeling on the electronics.

+ (red)

- (

black)

+ signal IN (gray)

GND (

black)

+U

B

(red)

Fig. 1: Connecting the valve

Input side electronics (3 wires)

Connection Color Description Voltage

+signal IN gray

Control signal

(digital)

‘low signal’ 0…+2V

‘high signal’

+5…+24V

GND black Ground 0 V

+U

B

red

Valve operating

voltage

+12…+24V

(acc. to valve imprint)

Output side electronics (2 wires, valve plug)

Connection Color Description

- black Valve connection -

+ red Valve connection +

4.2 Connecting the valve

Pressure connection at the valve inlet (NC connection):

Druckanschluss

Betriebsspannung

Betriebsspannung

Druckanschluss

Fig. 2: Connecting the valve

Installation instructions for type 6712 and type 6724 valves

can be found in the printed operating instructions or online

at: www.buerkert.com

5 DEINSTALLATION

Deinstallation instructions for type 6712 and type 6724

valves can be found in the printed operating instructions or

online at: www.buerkert.com

6 TRANSPORTATION, STORAGE, DISPOSAL

• Transport and store Type 6724 in shock-resistant packaging to

protect against moisture and dirt.

• Permitted storage temperature: –10 … +65 °C.

• Dispose of the device and packaging according to the applicable

disposal and environmental protection regulations.

Type 2503

english

Page 3

1 BESTIMMUNGSGEMÄSSER GEBRAUCH

Der Typ 2503 Boost Close ist für die Verwendung mit den Ventilen Typ 6712 oder Typ 6724 konzipiert.

▶ Für den Einsatz die in den Vertragsdokumenten und der Bedie-

nungsanleitung spezizierten zulässigen Daten, Betriebs- und

Einsatzbedingungen beachten.

▶ Das Gerät nicht im Außenbereich einsetzen.

▶ Gerät nur in Verbindung mit von Bürkert empfohlenen bzw.

zugelassenen Fremdgeräten und -komponenten einsetzen.

▶ Das Gerät nur in einwandfreiem Zustand betreiben und auf

sachgerechte Lagerung, Transport, Installation und Bedienung

achten.

▶ Das Gerät nur bestimmungsgemäß einsetzen.

2 GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine bei Installation,

Betrieb und Wartung auftretenden, Zufälle und Ereignisse.

WARNuNG!

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶ Vor Arbeiten an Anlage oder Gerät, den Druck abschalten und Lei-

tungen entlüften/entleeren.

Verletzungsgefahr durch Stromschlag.

▶ Vor Arbeiten an Anlage oder Gerät, die Spannung abschalten und

vor Wiedereinschalten sichern.

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für

elektrische Geräte beachten!

Verbrennungsgefahr/Brandgefahr bei längerer Einschaltzeit durch

heiße Geräteoberäche!

▶ Das Gerät von leicht brennbaren Stoen und Medien fernhalten und

nicht mit bloßen Händen berühren.

Allgemeine Gefahrensituationen.

▶ Am Gerät keine inneren oder äußeren Veränderungen vornehmen

und nicht mechanisch belasten.

▶ Produkt oder Anlage vor ungewolltem Einschalten sichern.

▶ Nur geschultes Fachpersonal darf Installations- und Instandhal-

tungsarbeiten ausführen.

▶ Produkt gemäß der im Land gültigen Vorschriften installieren.

▶ Nach Unterbrechung der elektrischen Versorgung einen kontrol-

lierten Wiederanlauf des Prozesses sicherstellen.

▶ Die allgemeinen Regeln der Technik einhalten.

3 TECHNISCHE DATEN

3.1 Konformität

Das Produkt ist konform zu den EU-Richtlinien entsprechend der EUKonformitätserklärung (wenn anwendbar).

3.2 Normen

Die angewandten Normen, mit welchen die Konformität zu den

Richtlinien nachgewiesen wird, sind in der EU-Baumusterprüfbescheinigung und/oder der EU-Konformitätserklärung nachzulesen

(wenn anwendbar).

3.3 Allgemeine Technische Daten

Typ 6712

Ventilwirkungsweise A

Dichtwerksto EPDM

(nicht geeignet für FKM und

FFKM )

1)

Ventilbetriebsspannung 12…24V

Nennweite 0,8mm

Erweiterter Druckbereich mit

Elektronik

3)

0...6bar

Zulässiger Rückdruck / Staudruck im Ventil

max. 5bar

Typ 6724

Ventilwirkungsweise A, T

2)

Dichtwerksto EPDM, FKM, FFKM

Ventilbetriebsspannung 12…24V

Nennweite 1,2mm

Erweiterter Druckbereich mit

Elektronik

3)

Vak...7bar

Zulässiger Rückdruck /Staudruck im Ventil

max. 5bar

1) bei FKM und FFKM führt die Elektronik zu einer deutlichen Reduzierung

der Lebensdauer.

2) Der Anschluss von 3/2-Wege Ventilen ist möglich. In diesem Fall, wird

nur die Dichtheit des Normally-Closed Anschlusses (NC) erhöht. Die

Dichtheit des Normally-Open Anschlusses (NO) bleibt unverändert.

3) Achtung! Wird die Betriebsspannung der Elektronik abgeschaltet,

reduzieren sich die Druckwerte wieder auf die im Datenblatt angegebenen

Werte ohne Elektronik.

4 INSTALLATION

AchTuNG

Der Anschluss von 3/2-Wege Ventilen ist möglich. In diesem

Fall, wird nur die Dichtheit des „Normally-Closed“-Anschlusses

(NC) erhöht. Die Dichtheit des „Normally-Open“-Anschlusses

(NO) bleibt unverändert.

GEfAhR!

Verletzungsgefahr durch hohen Druck

Wird die Betriebsspannung (+U

B

) abgeschaltet (z.B. durch

Betriebsende oder Notaus), entfällt die „aktive Dichtwirkung“.

Die Druckwerte sinken, auf die Standardwerte des verwendeten

Ventils (siehe Datenblatt).

▶ Maximal zulässige Rückdruckwerte und Staudruckwerte laut

Tabelle „3 Technische Daten“beachten.

4.1 Anschluss der Elektronik

Kennzeichnung: siehe Beschriftung auf der Elektronik.

+ (rot)

- (schwarz)

+ Signal IN (grau)

GND (schwarz)

+U

B

(rot)

Bild 1: Anschluss des Ventils

Elektronik Eingangsseite (3 Litzen)

Anschluss Farbe Beschreibung Spannung

+Signal IN grau Steuersignal (digital)

„low-Signal“

0…+2V

„high-Signal“

+5…+24V

GND schwarz Ground 0V

+U

B

rot

Betriebsspannung für

Ventil

+12…+24V

(lt. Ventilaufdruck)

Elektronik Ausgangsseite (2 Litzen, Ventilstecker)

Anschluss Farbe Beschreibung

- schwarz Ventilanschluss + rot Ventilanschluss +

4.2 Anschluss des Ventils

Druckanschluss am Ventileingang (NC- Anschluss):

Druckanschluss

Betriebsspannung

Betriebsspannung

Druckanschluss

Bild 2: Anschluss des Ventils

Installationshinweise zu den Typen 6712 und 6724 nden

Sie in der gedruckten Bedienungsanleitung oder im Internet

unter: www.buerkert.de

5 DEINSTALLATION

Deinstallationshinweise zu den Typen 6712 und 6724

nden Sie in der gedruckten Bedienungsanleitung oder im

Internet unter: www.buerkert.de

6 TRANSPORT, LAGERUNG, ENTSORGUNG

• Typ 2503 vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren und lagern.

• Zulässige Lagertemperatur: –10 … +65 °C.

• Bei der Entsorgung von Gerät und Verpackung die geltenden Ent-

sorgungsvorschriften und Umweltbestimmungen einhalten.

Typ 2503

deutsch

Page 4

1 UTILISATION CONFORME

Le type 2503 Boost Close est conçu pour être utilisé avec les

vannes types 6712 et 6724.

▶ Lors de l’utilisation, il convient de respecter les données et condi-

tions d’utilisation et d’exploitation admissibles spéciées dans les

instructions de service et dans les documents contractuels.

▶ Ne pas utiliser l’appareil à l’extérieur.

▶ L’appareil peut être utilise uniquement en association avec les

appareils et composants étrangers recommandés et homologués par Bürkert.

▶ Les conditions pour l’utilisation sûre et parfaite sont un

transport, un stockage et une installation dans les règles ainsi

qu’une parfaite utilisation et maintenance.

▶ Veillez à ce que l’utilisation de l’appareil soit toujours conforme.

2 CONSIGNES DE SÉCURITÉ FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte des hasards et

des événements pouvant survenir lors du montage, de l‘exploitation

et de l‘entretien.

Risque de blessures dû à la haute pression.

▶ Avant d‘intervenir dans l‘installation ou l‘appareil, couper la pres-

sion et désaérer ou vider les conduites.

Verletzungsgefahr durch Stromschlag.

▶ Avant d‘intervenir dans l‘installation ou l‘appareil, couper la tension

et empêcher toute remise sous tension par inadvertance.

▶ Veuillez respecter les réglementations en vigueur pour les appareils

électriques en matière de prévention des accidents ainsi qu’en

matière de sécurité.

Risque de brûlures et d‘incendie lors d‘une durée de

fonctionnement

prolongée dû à la surface brûlante de l‘appareil.

▶ Tenez les substances et les uides facilement inammables à

l‘écart de l‘appareil et ne touchez pas ce dernier à mains nues.

Situations dangereuses d‘ordre général.

▶ Ne pas entreprendre de modications internes ou externes sur

l‘appareil et ne pas l‘exposer à des sollicitations mécaniques.

▶ Protéger l‘appareil contre toute mise en marche involontaire.

▶ Seul du personnel qualié peut eectuer l‘installation et la

maintenance.

▶ Les vannes doivent être installées conformément à la réglementa-

tion en vigueur dans le pays respectif.

▶ Garantir un redémarrage contrôlé du processus après une

interruption.

▶ Respecter les règles générales de la technique.

3 CARACTÉRISTIQUES TECHNIQUES

3.1 Conformité

Le type 2503 est conforme aux directives UE comme stipulé dans la

déclaration de conformité UE (si applicable).

3.2 Normes

Les normes appliquées justiant la conformité aux directives UE

peuvent être consultées dans l‘attestation d‘examen UE de type et /

ou la déclaration de conformité UE (si applicable).

3.3 Caractéristiques techniques générales

Type 6712

Fonction de la vanne A

Matériau du joint

EPDM (ne convient pas

pour FKM et FFKM )

1)

Tension de service de la vanne 12…24 V

Diamètre nominal 0,8mm

Plage de pression étendue avec

électronique

3)

0...6 bars

Pression de retour / pression dynamique

admise dans la vanne

max. 5 bars

Type 6724

Fonction de la vanne A, T

2)

Matériau du joint EPDM, FKM, FFKM

Tension de service de la vanne 12…24 V

Diamètre nominal 1,2mm

Plage de pression étendue avec

électronique

3)

Vide...7bars

Pression de retour / pression dynamique

admise dans la vanne

max. 5 bars

1) pour FKM et FFKM, l’électronique entraîne une réduction signicative de

la durée de vie.

2) Possibilité de raccorder des vannes à 3/2voies. Dans ce cas, seule

l'étanchéité du raccord Normally-Closed (NC) est augmentée. L’étanchéité

du raccord Normally-Open (NO) reste inchangée.

3) Remarque! Si la tension de service de l’électronique est coupée, les

valeurs de pression retombent aux valeurs sans module électronique indiquées dans la che technique.

4 INSTALLATION

REMARQuE

Possibilité de raccorder des vannes à 3/2voies. Dans ce cas,

seule l‘étanchéité du raccord «Normally-Closed» (NC) est augmentée. L’étanchéité du raccord «Normally-Open» (NO) reste

inchangée.

DANGER

Risque de blessure dû à une pression élevée

Si la tension de service (+U

B

) est coupée (p. ex. à la n du service

ou par un arrêt d’urgence), il n’y a pas de «mode étanche actif».

Les valeurs de pression retombent aux valeurs standard de la

vanne utilisée (voir che technique).

▶ Respecter les valeurs de pression de retour et de pression dyna-

mique maximales admises suivant le tableau „3 Caractéristiques

techniques“ .

4.1 Raccordement de l’électronique

Identication: voir marquage sur le module électronique.

+ (rouge)

- (noir)

+ Signal IN (gris)

GND (noir)

+U

B

(rouge)

Fig. 1 : Raccordement de la vanne

Côté entrée électronique (3torons)

Raccord Couleur Description Tension

+Signal

IN

gris

Signal de

commande

(numérique)

«Signal Low» 0… +2V

«Signal High»

+5…+24V

GND noir Ground 0V

+U

B

rouge

Tension de

service pour la

vanne

+12…+24V

(selon étiquette sur la

vanne)

Côté sortie électronique (2torons, connecteur de vanne)

Raccord Couleur Description

- noir Raccord de vanne + rouge Raccord de vanne +

4.2 Raccordement de la vanne

Raccord de pression à l’entrée de la vanne (raccord NC):

Raccord de pression

Tension de service

Tension de service

Raccord de pression

Fig. 2 : Raccordement de la vanne

Vous trouverez les instructions d’installation des types

6712 et 6724 dans la version imprimée du manuel

d'utilisation ou sur Internet: www.buerkert.fr

5 DÉSINSTALLATION

Vous trouverez les instructions de désinstallation des

types 6712 et 6724 dans la version imprimée du manuel

d‘utilisation ou sur Internet: www.buerkert.fr

6 TRANSPORT, STOCKAGE, ÉLIMINATION

• Transporter et stocker le type 2503 à l‘abri de l‘humidité et des

impuretés et dans un emballage résistant aux chocs.

• Température de stockage autorisée : –10...+65°C.

• Lors de l‘élimination de l‘appareil et de l‘emballage, respecter les

prescriptions en matière d’élimination des déchets et de protection de l’environnement en vigueur.

Type 2503

francais

Loading...

Loading...