Page 1

Type 2101

2/2-way Globe valve

2/2-Wege Geradsitzventil

Vanne à siège droit 2/2 voies

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2008 - 2013 Bürkert Werke GmbH

Operating Instructions 1309/05_EU-ML_00806076 / Original DE

Page 3

Type 2101

Globe valve Type 2101

1 OPERATING INSTRUCTIONS ................................................................4

1.1 Symbols .......................................................................................4

1.2 Definition of term / abbreviation .............................................4

2 AUTHORIZED USE ......................................................................................5

2.1 Restrictions .................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................5

4 GENERAL INFORMATION ........................................................................7

4.1 Contact address ........................................................................7

4.2 Warranty ......................................................................................7

4.3 Information on the Internet ......................................................7

5 PRODUCT DESCRIPTION ........................................................................7

5.1 General description ..................................................................7

5.2 Versions .......................................................................................7

5.3 Properties .................................................................................... 8

5.4 Designated application area ................................................... 8

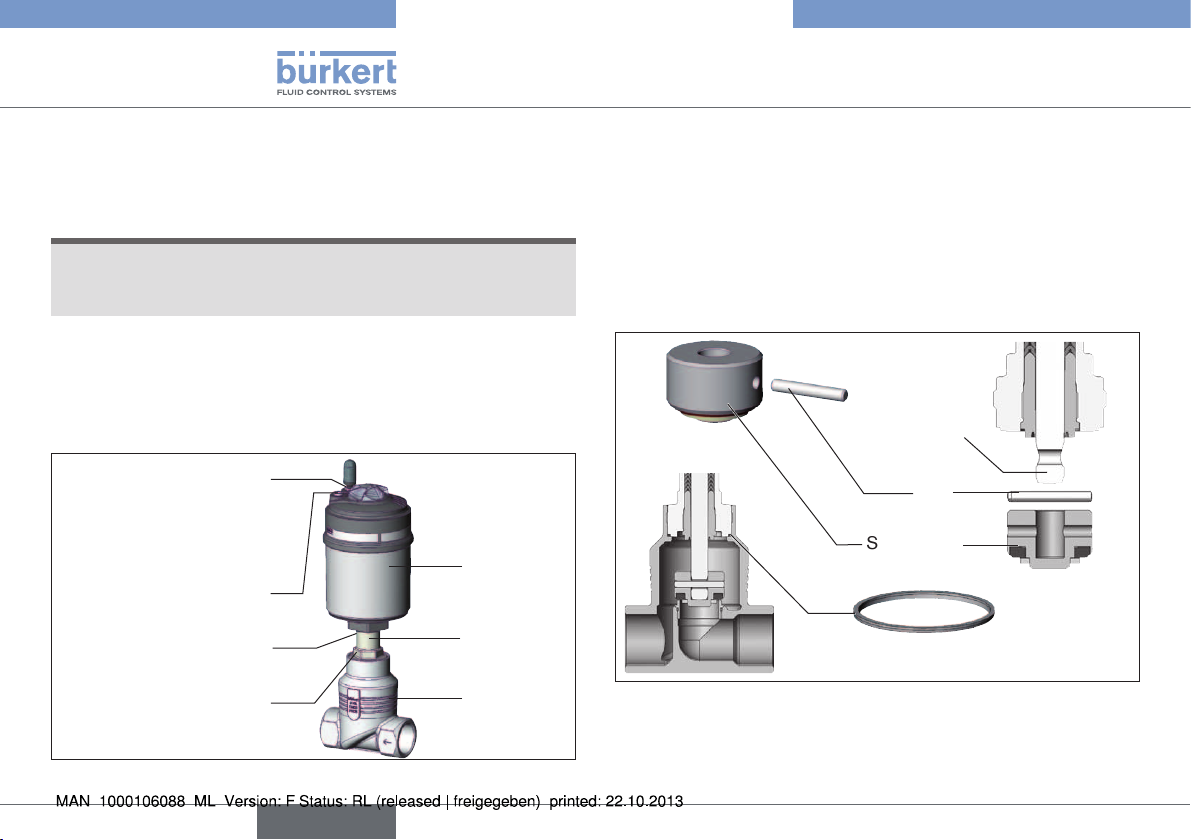

6 STRUCTURE AND FUNCTION...............................................................9

6.1 Structure ...................................................................................... 9

6.2 Function .....................................................................................10

7 TECHNICAL DATA .....................................................................................12

7.1 Conformity .................................................................................12

7.2 Standards ..................................................................................12

7.3 Type label ..................................................................................12

7.4 Operating conditions ..............................................................13

7.5 General technical data ...........................................................17

8 INSTALLATION ............................................................................................ 18

8.1 Safety instructions ...................................................................18

8.2 Before installation ....................................................................18

8.3 Installation .................................................................................19

8.4 Pneumatic connection ............................................................22

8.5 Removal .....................................................................................23

9 ELECTRICAL CONTROL UNIT ............................................................ 24

10 MAINTENANCE, CLEANING ................................................................24

10.1 Safety instructions ...................................................................24

10.2 Maintenance work ...................................................................25

10.3 Replacing the wearing parts .................................................26

11 MALFUNCTIONS ........................................................................................33

12 REPLACEMENT PARTS .......................................................................... 34

12.1 Replacement part sets ...........................................................34

12.2 Installation tools .......................................................................36

13 PACKAGING, TRANSPORT, STORAGE ..........................................36

english

3

Page 4

Type 2101

Operating instructions

1 OPERATING INSTRUCTIONS

The operating instructions describes the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user, and make these instructions available to every new owner

of the device.

WARNING!

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

▶ The operating instructions must be read and understood.

1.1 Symbols

DANGER!

Warns of an immediate danger!

▶ Failure to observe the warning may result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

▶ Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

▶ Failure to observe this warning may result in a moderate or

minor injury.

NOTE!

Warns of damage to property!

▶ Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

→ Designates a procedure which you must carry out.

1.2 Definition of term / abbreviation

The term “device” used in these instructions always stands for the

globe valve Type 2101.

The abbreviation “Ex” used in these instructions always stands for

“explosion-protected”.

4

english

Page 5

Type 2101

Authorized use

2 AUTHORIZED USE

Non-authorized use of the globe valve Type 2101 may be a

hazard to people, nearby equipment and the environment.

▶ The device is designed for the controlled flow of liquid and

gaseous media.

▶ The admissible data, the operating conditions and conditions of

use specified in the contract documents, operating instructions

and on the type label are to be observed during use. These are

described in the chapter entitled “5 Product description”.

▶ The device may be used only in conjunction with third-party

devices and components recommended and authorized by

Bürkert.

▶ Correct transportation, correct storage and installation and

careful use and maintenance are essential for reliable and faultless operation.

▶ Use the device only as intended.

2.1 Restrictions

If exporting the system/device, observe any existing restrictions.

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• local safety regulations, whereby the operator is responsible for their

compliance, by the installation personnel too.

DANGER!

Danger – high pressure!

▶ Before dismounting the lines and valves, turn off the pressure

and vent the lines.

Risk of electric shock!

▶ Before reaching into the device, switch off the power supply

and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury when opening the actuator!

The actuator contains a tensioned spring. If the actuator is

opened, there is a risk of injury from the spring jumping out!

▶ The actuator must not be opened.

Risk of injury from moving parts in the device!

▶ Do not reach into openings.

english

5

Page 6

Type 2101

Basic safety instructions

CAUTION!

Risk of burns!

The surface of the device may become hot during long-term

operation.

▶ Do not touch the device with bare hands.

General hazardous situations.

To prevent injury, ensure:

▶ That the system cannot be activated unintentionally.

▶ Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The device may be operated only when in perfect condition and

in consideration of the operating instructions.

▶ The general rules of technology apply to application planning and

operation of the device.

▶ In the potentially explosion-risk area the globe valve Type 2101 may

be used only according to the specification on the separate Ex type

label. For use observe the additional information enclosed with the

device together with safety instructions for the explosion-risk area.

▶ Devices without a separate Ex type label may not be used in a

potentially explosive area.

To prevent damage to property of the device, ensure:

• Supply the media connections only with those media which are

specified as flow media in the chapter entitled “7 Technical data”.

• Do not put any loads on the valve (e.g. by placing objects on it

or standing on it).

• Do not make any external modifications to the valves. Do not paint

the body parts or screws.

The globe valve Type 2101 was developed with due consideration given to the accepted safety rules and is state-of-the-art.

Nevertheless, dangerous situations may occur.

6

english

Page 7

Type 2101

General information

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. : 07940 - 10 91 111

Fax: 07940 - 10 91 448

E-mail: info@de.burkert.com

International

Contact addresses are found on the final pages of the printed operating manual.

You can also find information on the Internet under:

www.burkert.com

4.2 Warranty

The warranty is only valid if the device is used as authorized in accordance with the specified application conditions.

4.3 Information on the Internet

The operating instructions and data sheets for Type 2101 can be found

on the Internet at: www.burkert.com

5 PRODUCT DESCRIPTION

5.1 General description

The 2/2-way globe valve Type 2101 is suitable for liquid and gaseous

media.

It uses neutral gases or air (control media) to control the flow of water,

alcohol, oil, fuel, hydraulic fluid, saline solution, lye, organic solvent and

steam (flow media).

A special feature of globe valves are screwed-in seats which can be

used to reduce the orifice of the control valve in particular.

According to the general understanding of Bürkert, DN

designates the orifice of the seat, not the orifice of the line

connection.

5.2 Versions

There are 2 versions of the globe valve type 2101:

• Standard version – without separate Ex type label.

The standard version must not be used in the potentially explosive

area.

• Ex version – with separate Ex type label.

The Ex version may be used in the potentially explosive area. In

doing so, observe the specifications on the separate Ex type label

and the additional information enclosed with the device together

with safety instructions for the Ex area.

english

7

Page 8

Type 2101

Product description

5.3 Properties

• High tightness by self-adjusting packing glands

(spindle sealing element).

• High seat tightness by swivel plate.

• Actuator can be rotated steplessly through 360 °.

• Maintenance-free under normal conditions.

5.3.1 Options

• Control unit

Different versions of the control units are available depending on

the requirement.

• Stroke limitation

Limit of the maximum open position /flow rate by means of

adjusting screw.

• Feedback indicator

The device features mechanical limit switches or inductive proximity switches.

5.3.2 Device versions

The globe valve is available for the following actuator sizes:

ø 50 mm, ø 70 mm, ø 90 mm, ø 130 mm.

5.3.3 Restrictions

WARNING!

Risk of injury from water hammer.

A water hammer could crack the lines and device.

Due to the risk of water hammer, valves with a flow direction

above seat must not be used for liquid media.

▶ Consider the type of flow direction and the type of medium for

operation of the device.

5.4 Designated application area

Observe the maximum pressure range according to the

type label!

• Neutral gases and liquids up to 16 bar.

• Steam up to 11 bar absolute / 185 °C.

• Aggressive media.

5.4.1 Application areas

e.g. Plant construction

Food processing

Chemical engineering

Sterilizer construction

8

english

Page 9

Type 2101

Structure and function

6 STRUCTURE AND FUNCTION

6.1 Structure

The globe valve consists of a pneumatically actuated piston actuator

and a 2/2-way valve body.

The actuator is manufactured from polyphenylene sulphide (PPS).

The tried and tested, self-adjusting packing gland ensures high

tightness. The flow-enhancing valve body made of stainless steel

enables high flow values.

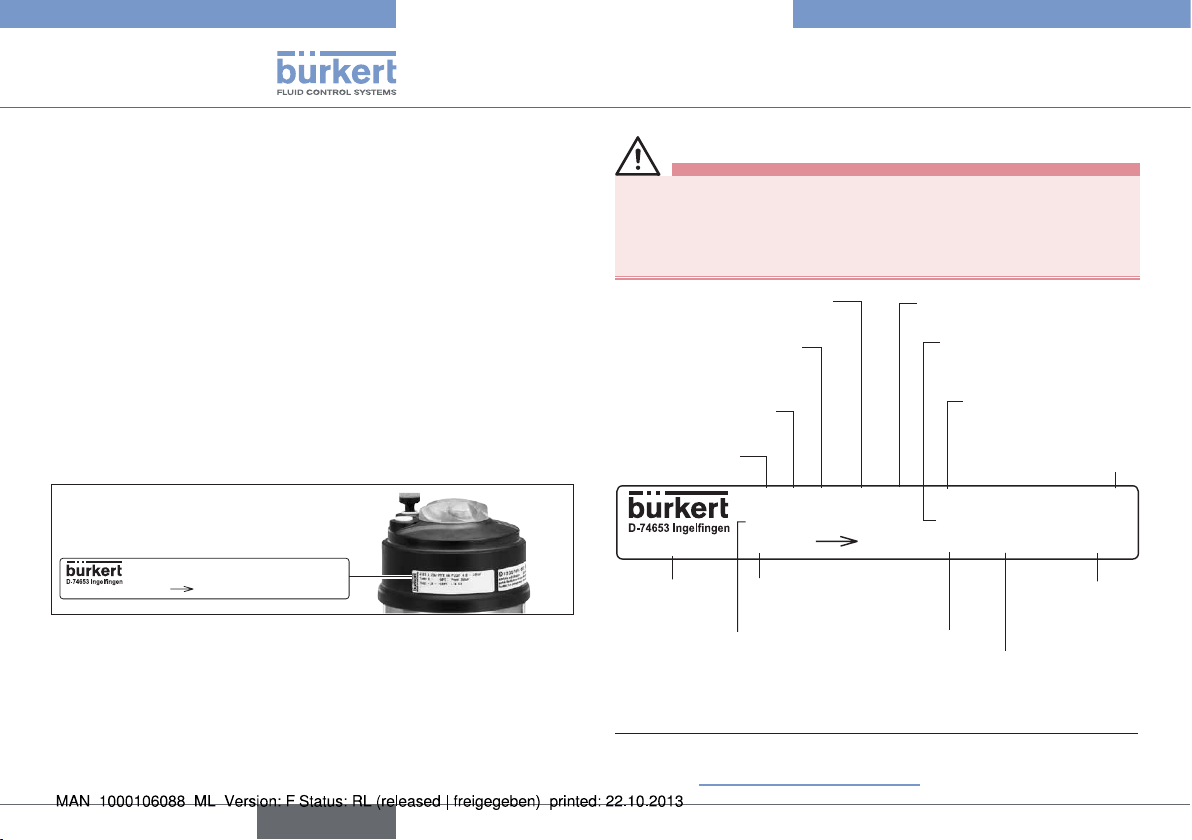

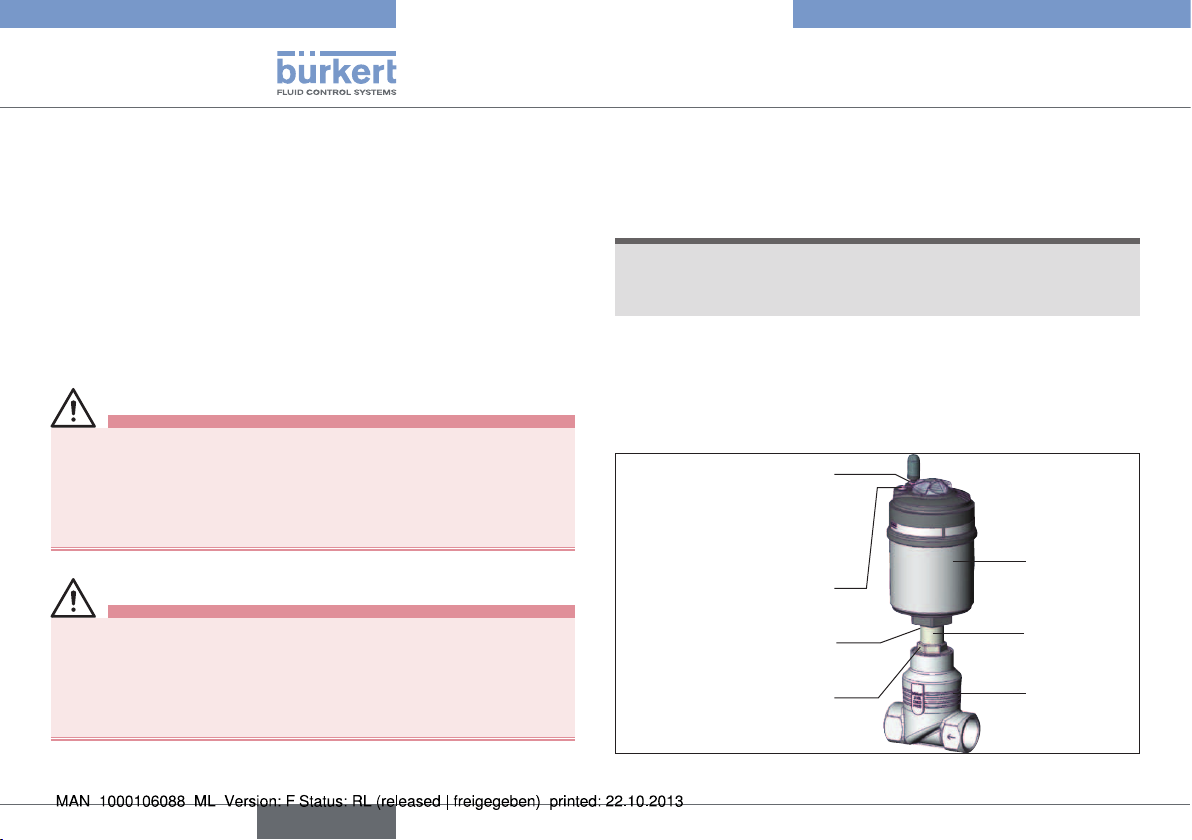

Transparent cap with position indicator

Actuator cover

Actuator body

Globe valve body

Flow direction arrow or

numbers for indicating the

direction of flow

Fig. 1: Globe valve Type 2101, structure and description (1)

The description of the control function (CF) can be found in

chapter entitled “6.2.1 Control functions (CF)”.

Air discharge connection for CFA, CFB

Pilot air port for CFI

Pilot air port for CFA, CFB, CFI

Release bore

Interface actuator/body

with flats

Port connection

Fig. 2: Globe valve Type 2101, Structure and Description (2)

2

1

english

9

Page 10

2(A)

2(B)

2(A)

Type 2101

Structure and function

6.2 Function

Depending on the version, the seat of the valve is closed with or

against the medium flow.

Spring force (CFA) or pneumatic pilot pressure (CFB and CFI) generates the closing force on the swivel plate. The force is transferred

via a spindle which is connected to the actuator piston.

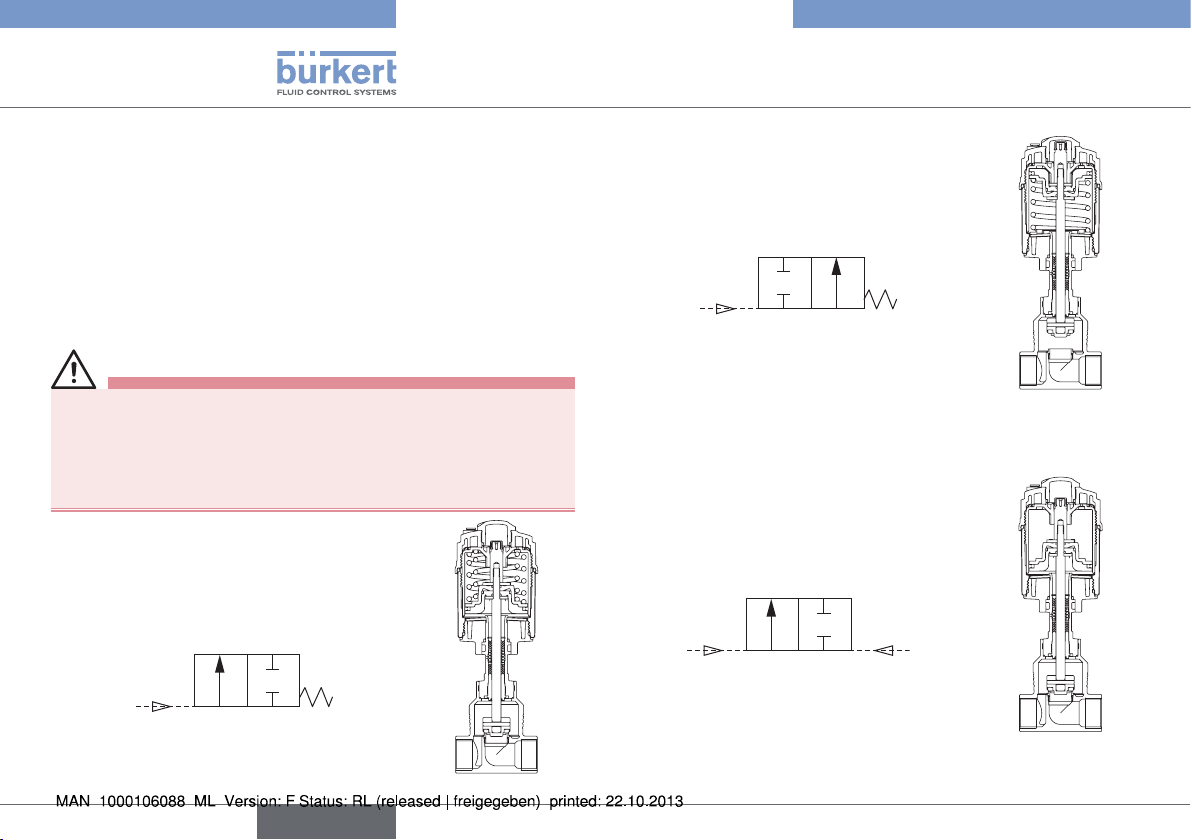

6.2.1 Control functions (CF)

WARNING!

For control function I – Danger if pilot pressure fails!

For control function I control and resetting occur pneumatically. If

the pressure fails, no defined position is reached.

▶ To ensure a controlled restart, first pressurise the device with

pilot pressure, then switch on the medium.

Control function A (CFA)

Normally closed by spring action

1(P)

Control function B (CFB)

Normally open by spring action

1(P)

Control function I (CFI)

Actuating function via reciprocal pressurisation.

1(P)

10

english

Page 11

english

Type 2101

Structure and function

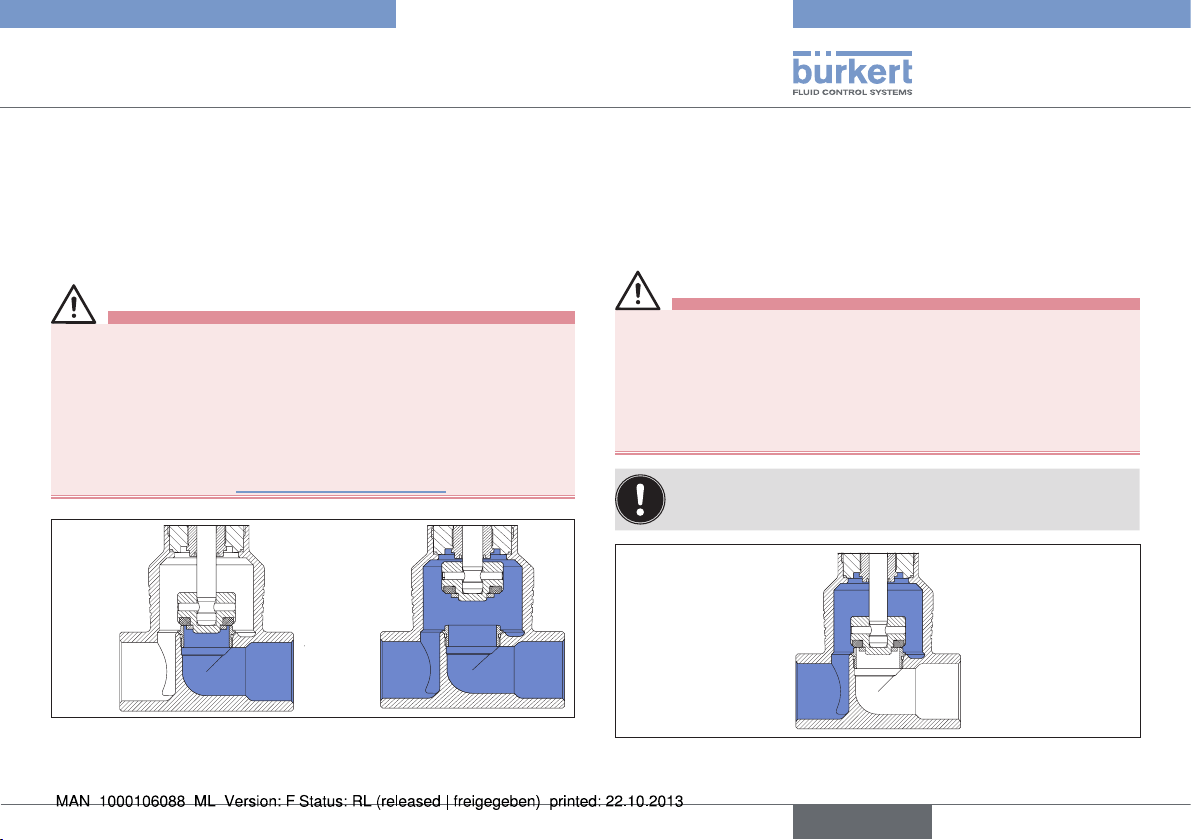

6.2.2 Flow direction below seat

Depending on the version, the valve is closed against the medium

flow with spring force (control function A, CFA) or with pilot

pressure (control function B or I, CFB or CFI).

As the medium pressure is under the swivel plate, this pressure

contributes to the opening of the valve.

WARNING!

Medium may be discharged if minimum pilot pressure is too

low or medium pressure too high!

If the minimum pilot pressure is too low for CFB and CFI or the

permitted medium pressure is exceeded, leaks may occur.

▶ Observe minimum pilot pressure

▶ Do not exceed medium pressure.

▶ See chapter entitled “7.4.1 Temperature ranges”.

CFA CFB /

CFI

6.2.3 Flow direction above seat

The valve is closed by spring force (control function A, CFA) with

the medium flow. As the medium pressure is over the swivel plate, it

supports the closing process of the valve and also contributes to the

sealing of the valve seat. The valve is opened by the pilot pressure.

WARNING!

Risk of injury from water hammer.

A water hammer could crack the lines and device.

Due to the risk of water hammer, valves with a flow direction

above seat must not be used for liquid media.

▶ Consider the type of flow direction and the type of medium for

operation of the device.

To ensure complete opening, the minimum pilot pressure

must be used!

Fig. 3: Flow direction below seat

(Rest open/closed, closing against medium)

Fig. 4: Flow direction above seat (rest closed, closing with

medium)

11

Page 12

Type 2101

Technical data

7 TECHNICAL DATA

7.1 Conformity

Type 2101 conforms with the EC Directives according to the EC

Declaration of Conformity.

7.2 Standards

The applied standards, which verify conformity with the EC Directives, can be found on the EC-Type Examination Certificate and / or

the EC Declaration of Conformity.

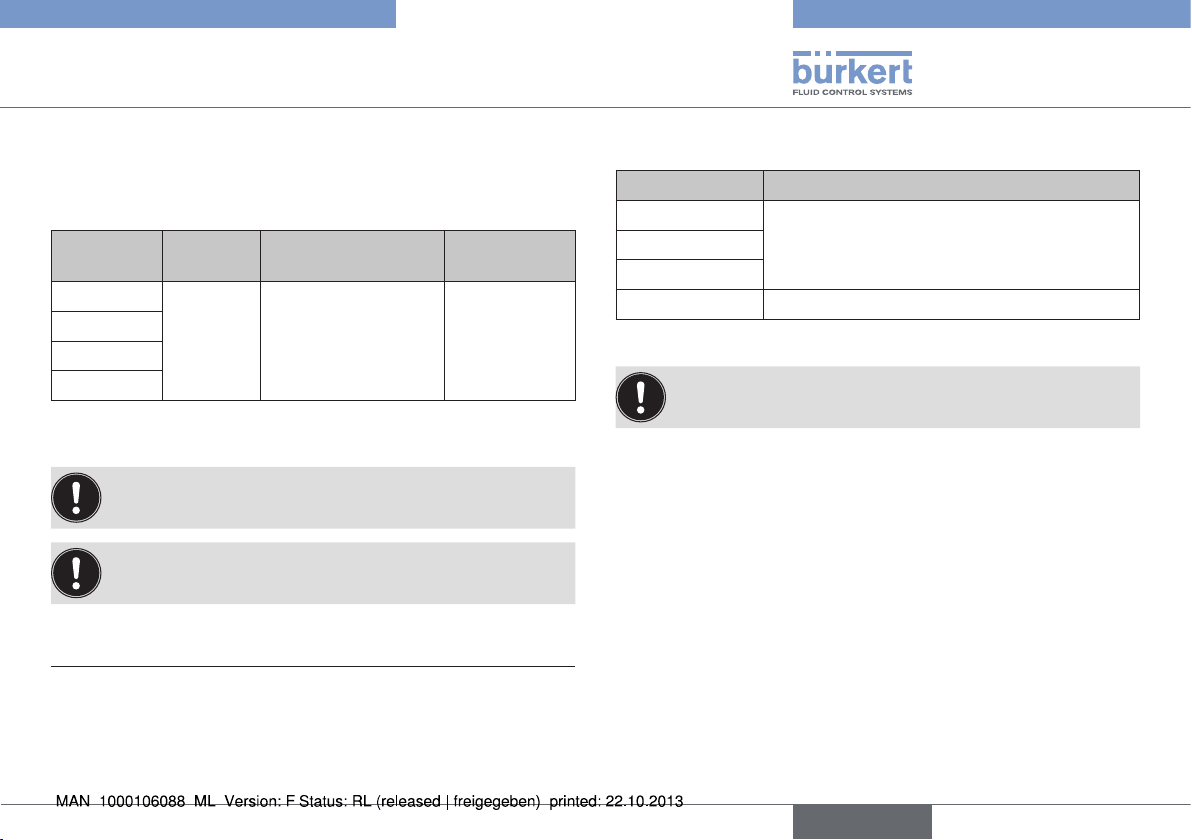

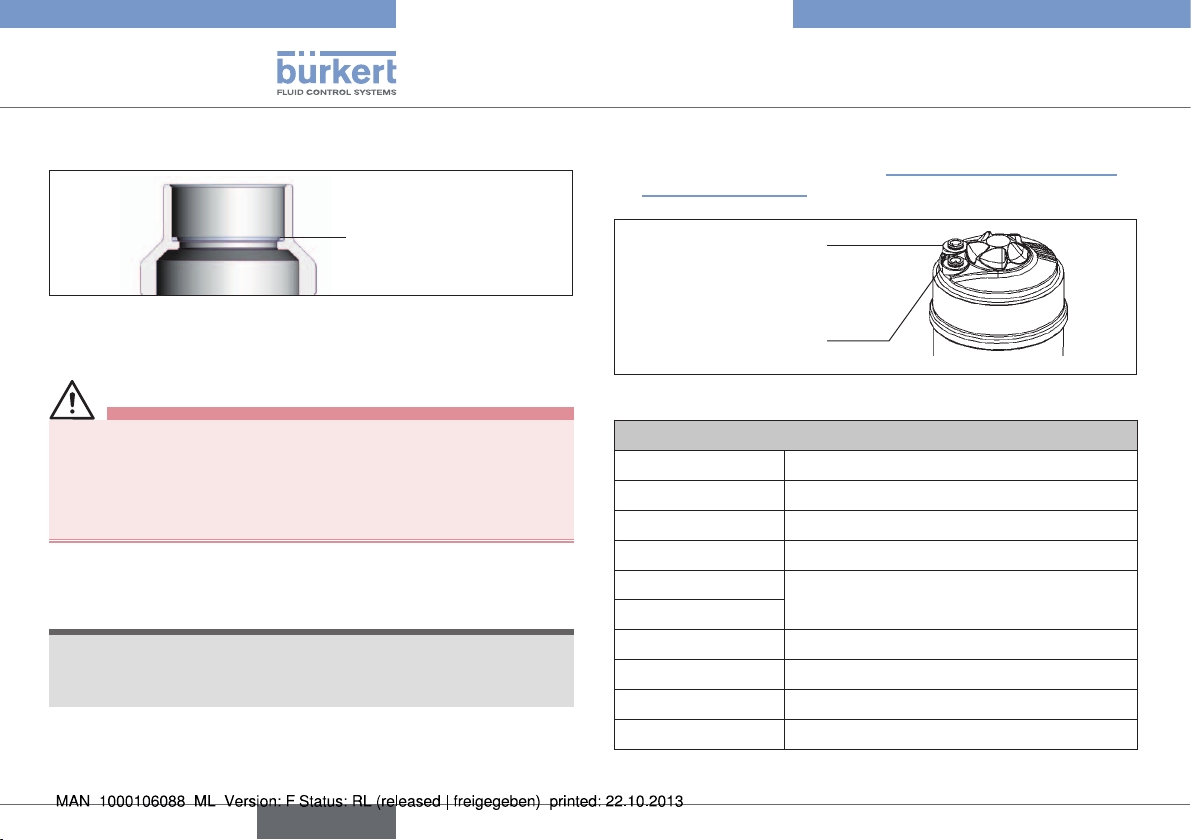

7.3 Type label

Example:

CE

W3ZLT

00189700

2101 A 25M PTFE VA

Tmed -10°C - +180°C

Flow 1 2 DIN

Pilot 4,8-10bar

Pmed 16,0bar

DN25 Kv13,0

Fig. 5: Example of type label

WARNING!

Risk of injury from high pressure!

Important device-specific technical specifications are indicated on

the type label.

▶ Observe permitted pressure range on the type label of the device.

Sealing material

Orifice of the body /

actuator size

Control function

(CF)

Type

00189700

ID number of

the device

Permitted medium

temperature

1)

2101 A 25M PTFE VA

Tmed -10°C - +180°C

Flow 1 2 DIN

Flow direction

Main dimensions

port connection

Body material

Permitted

medium pressure

Pilot 4,8-10bar

Pmed 16,0bar

DN25 Kv13,0

1)

Permitted

pilot pressure

CE identification

W3ZLT

Date of

manufacture

(encoded)

Flow capacity in

standard production

conditions

CE

12

1) For a description of the versions see the following chapter

entitled “7.5 General technical data”.

english

Page 13

Type 2101

Technical data

7.4 Operating conditions

7.4.1 Temperature ranges

Actuator

size

ø 50 mm

ø 70 mm

ø 90 mm

ø 130 mm

Tab. 1: Temperature Ranges

3) Pilot air ports with push-in connector

4) Pilot air ports with threaded bushing

Actuator

material

Medium

(for PTFE seal)

PPS -10 – +185 °C

2) If a pilot valve is used, the max. ambient temperature is

+55 °C.

The globe valve is suitable for steam sterilization.

Environment

0 – +60 °C

0 – +100 °C

7.4.2 Pressure ranges

Actuator size Maximum pilot pressure

ø 50 mm

2)

10 barø 70 mm

ø 90 mm

ø 130 mm 7 bar

3)

4)

Tab. 2: Pressure Ranges

5) For the device version ø 70 / Orifice 50 / MC 13 the

maximum permitted pilot pressure is limited to 7 bar.

5)

english

13

Page 14

Type 2101

Technical data

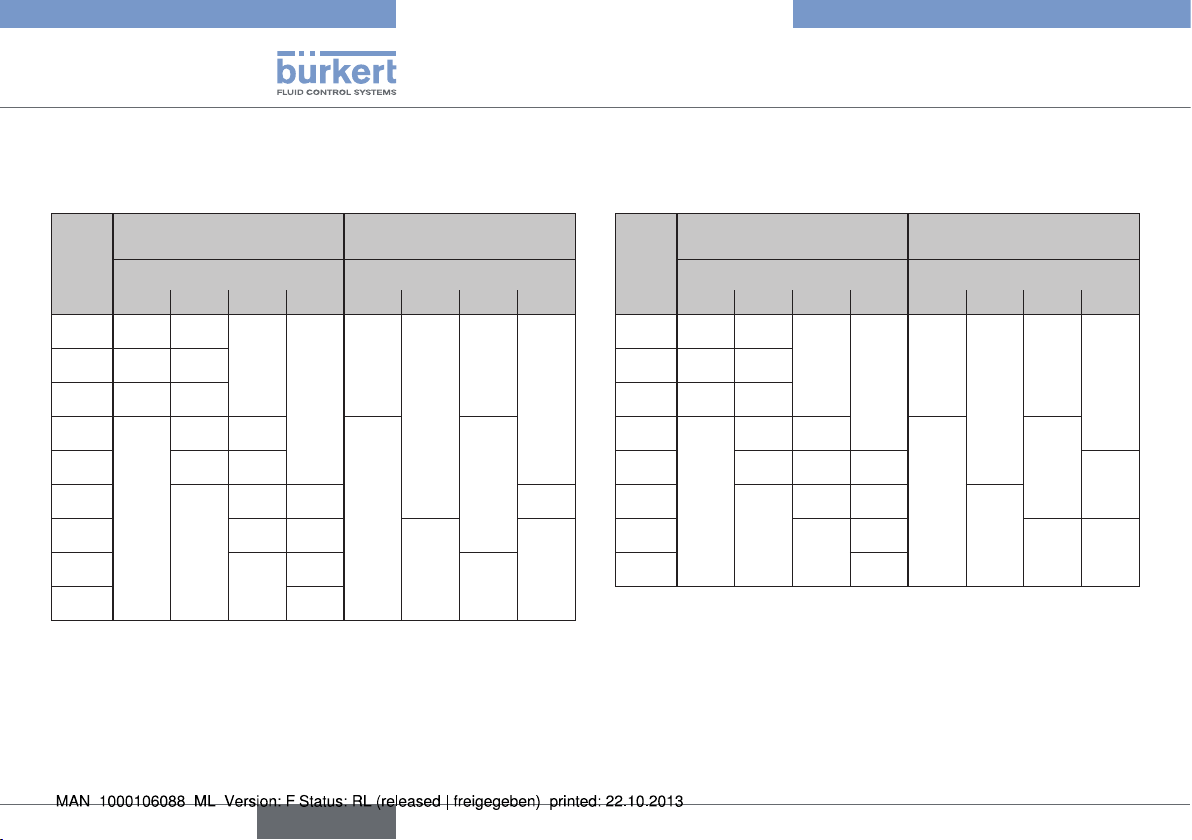

Medium and pilot pressure for control function A, flow direction

below the seat (standard)

Maximum medium pressure

Orifice

DN

50 70 90 130 50 70 90 130

10/15 25 25

20 16 20

25 9 16

32

40 6 16

50

-

65 5.0 16

100 6

Tab. 3: Medium and pilot pressure for CFA, standard

[bar]

Actuator size ø [mm] Actuator size ø [mm]

-

8.5 16

10 16 5

10

-

Minimum pilot pressure

5.2

-

-

[bar]

-

-

4.8

5

- 5.680

-

Medium and pilot pressure for control function A, flow direction

below the seat reduced pressure spring force (EC04)

Maximum medium pressure

Orifice

DN

50 70 90 130 50 70 90 130

10/15 14 16

20 6 12

25 3 6

32

50

80 5

Tab. 4: Medium and pilot pressure for CFA, reduced pressure

-

spring force (EC04)

[bar]

Actuator size ø [mm] Actuator size ø [mm]

-

-

3.5 9

3.5 10

-

7.5

-

Minimum pilot pressure

[bar]

3.2

2.5

-

-

2.540 2 6 16

-65

- 3.2

-

2.5

14

english

Page 15

Type 2101

Technical data

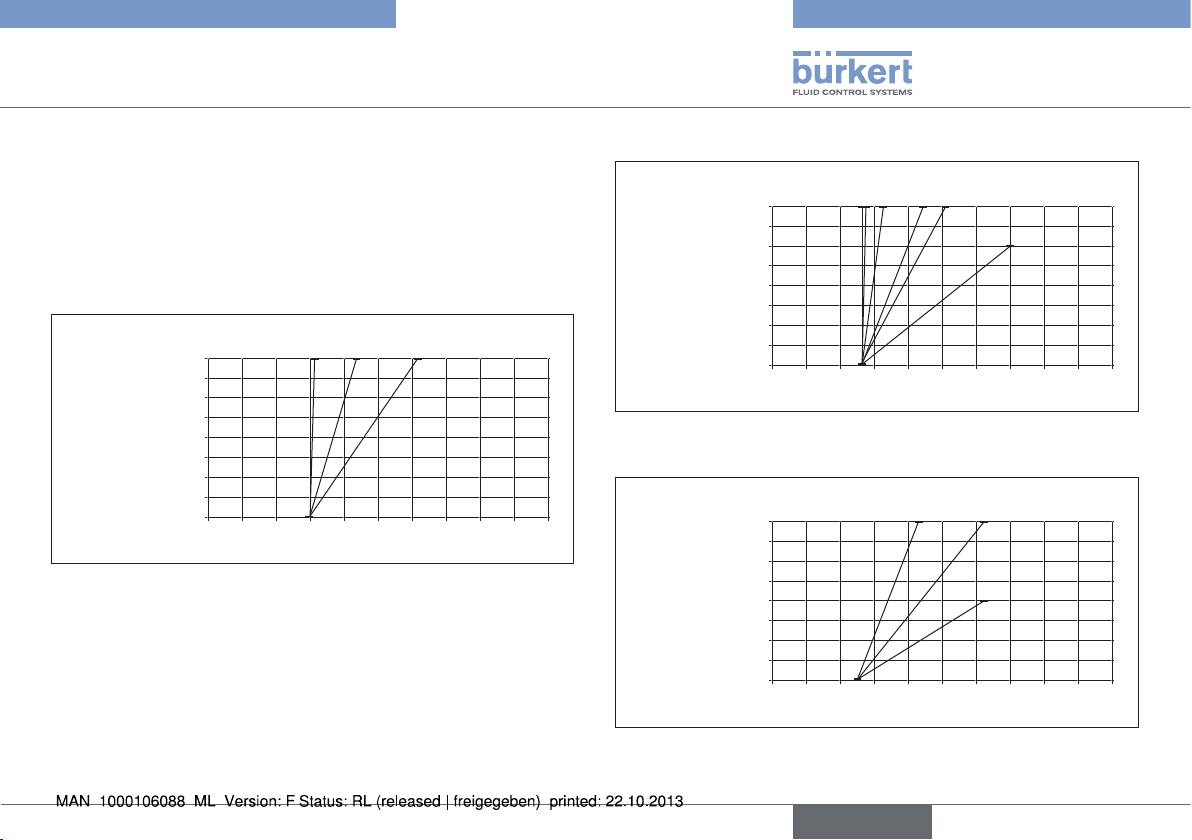

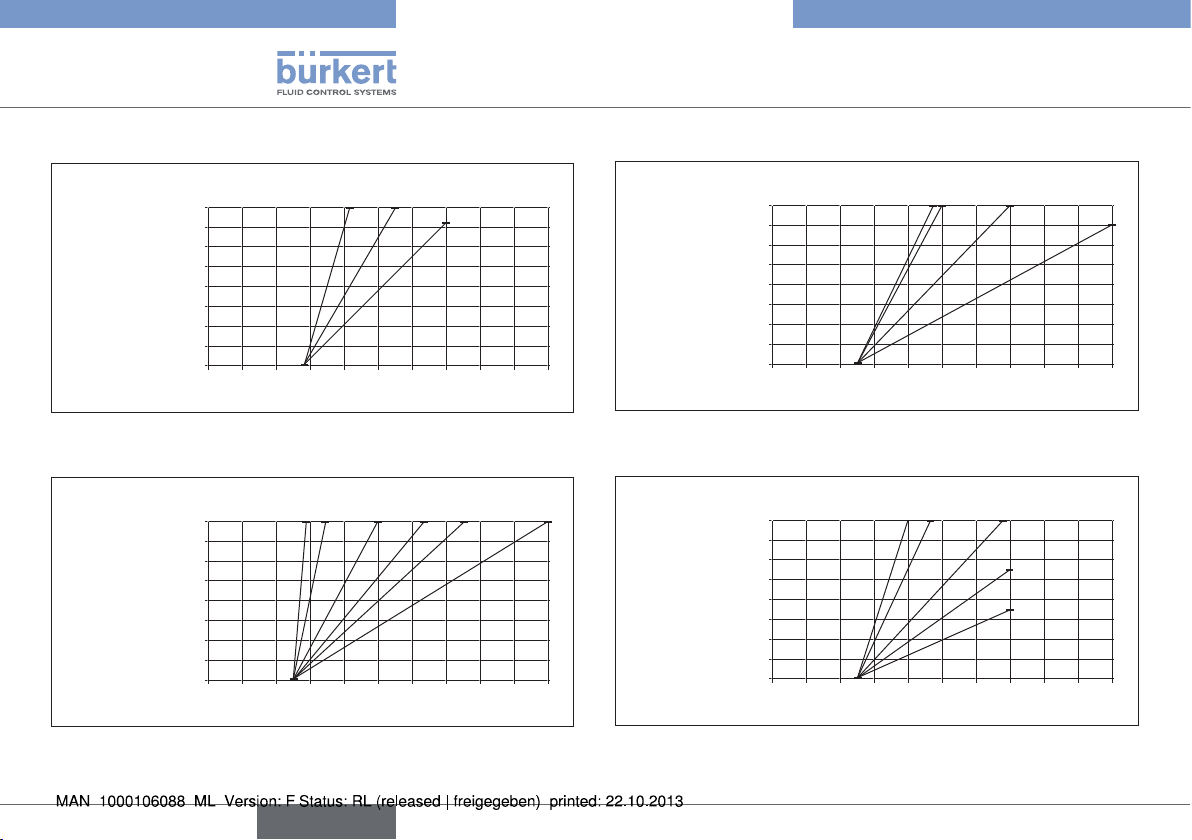

Required minimum pilot pressure depending on medium

pressure

The following graphs illustrate the required minimum pilot pressure

depending on the medium pressure for control functions A, B and I.

Control function A, flow direction above seat

ø 50

CFA above seat

16

14

12

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9 10

Medium pressure [bar]

DN15

DN20

DN25

Pilot pressure [bar]

Fig. 6: Pressure graph, actuator ø 50 mm, control function A, flow

direction above seat

ø 70

CFA above seat

16

14

12

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9 10

Medium pressure [bar]

DN15

DN20

DN25

DN32

DN40

Pilot pressure [bar]

DN50

Fig. 7: Pressure graph, actuator ø 70 mm, control function A, flow

direction above seat

ø 90

CFA above seat

16

14

12

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9 10

Medium pressure [bar]

DN40

DN50

DN65

Pilot pressure [bar]

Fig. 8: Pressure graph, actuator ø 90 mm, control function A, flow

direction above seat

english

15

Page 16

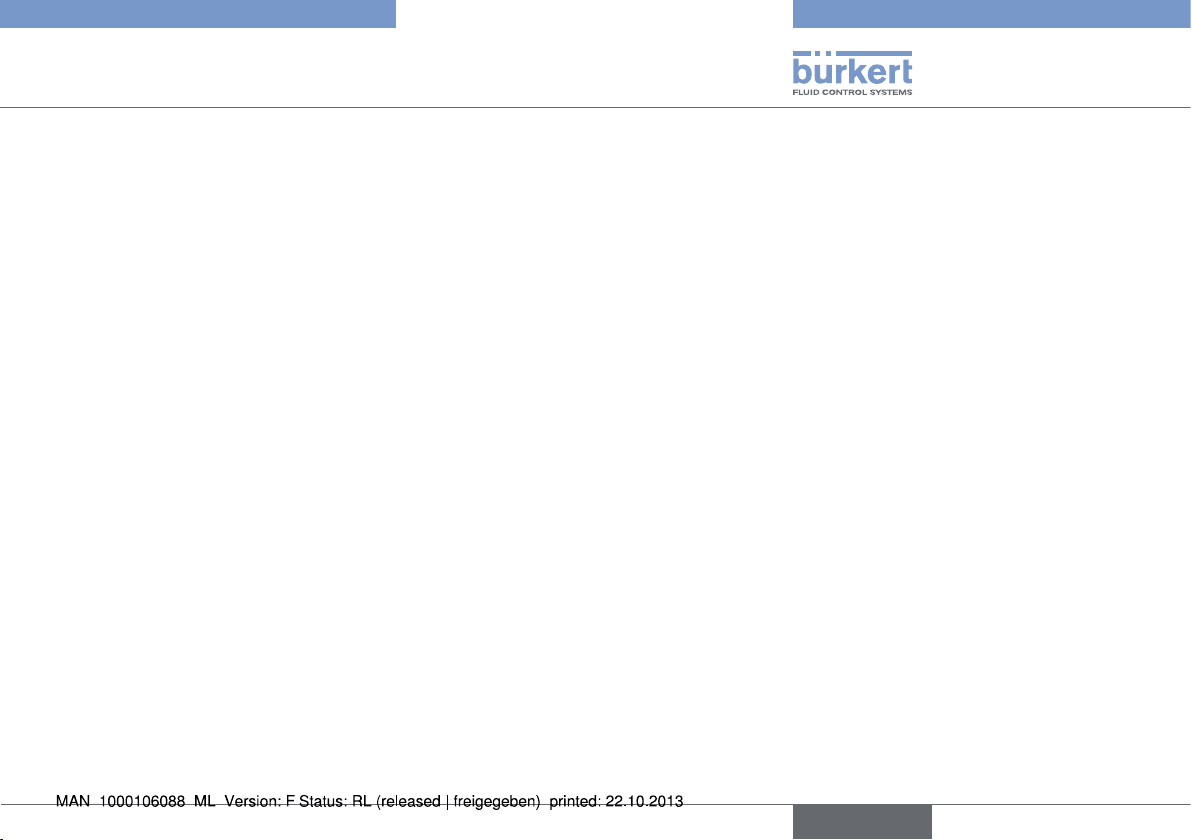

Control functions B and I, flow direction below seat

ø 50 CFB/CFI

below seat

16

14

12

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9 10

Medium pressure [bar]

DN15

DN20

DN25

Pilot pressure [bar]

Fig. 9: Pressure graph, actuator ø 50 mm, control functions B and I,

flow direction below seat

Type 2101

Technical data

ø 90 CFB/CFI

below seat

DN32

16

14

12

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9 10

Medium pressure [bar]

Pilot pressure [bar]

DN40

DN50

DN65

Fig. 11: Pressure graph, actuator ø 90 mm, control functions B and I,

flow direction below seat

ø 70 CFB/CFI

below seat

DN25

DN32

DN15

16

14

12

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9 10

Medium pressure [bar]

DN20

DN40

DN50

Pilot pressure [bar]

Fig. 10: Pressure graph, actuator ø 70 mm, control functions B and I,

flow direction below seat

16

english

ø 130 CFB/CFI

below seat

DN40

16

14

12

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9 10

Medium pressure [bar]

DN50

DN65

DN80

DN100

Pilot pressure [bar]

Fig. 12: Pressure graph, actuator ø 130 mm, control functions B and

I, flow direction below seat

Page 17

Type 2101

Technical data

7.5 General technical data

Control functions (CF)

Control function A Normally closed by spring action

Control function B Normally open by spring action

Control function I Actuating function via reciprocal

pressurization

Actuator sizes ø 50 mm

ø 70 mm

ø 90 mm

ø 130 mm

Materials

Body 316L

Actuator PPS and stainless steel

Sealing elements FKM and EPDM

Spindle sealing PTFE V rings with spring compensation

(with silicone grease)

Seat seal PTFE (NBR, EPDM, FKM on request)

Swivel plate

Spindle 1.4401 / 1.4404

Spindle guide

DN10-65 PEEK

DN80-100 1.4401 / 1.4404

Connections

Pilot air port Plug-in connector 6/4 mm or 1/4”

others on request

Medium connection Socket: G ½ – G 4 (NPT, RC on request)

Weld end connection: in accordance with

ISO 4200, DIN 11850 R2

other connections on request

Media

Control medium Neutral gases, air

Flow media Water, alcohol, fuel, hydraulic liquids,

saline solutions, lye, organic solvents

Installation position as required, preferably with actuator in

upright position.

Protection class IP67 in accordance with IEC 529 /

EN 60529

english

17

Page 18

Type 2101

Installation

8 INSTALLATION

8.1 Safety instructions

DANGER!

Risk of injury from high pressure!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

WARNING!

Risk of injury from improper installation!

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

For control function I – Danger if pilot pressure fails!

For control function I control and resetting occur pneumatically. If

the pressure fails, no defined position is reached.

▶ To ensure a controlled restart, first pressurize the device with

pilot pressure, then switch on the medium.

Risk of injury from moving parts in the device!

▶ Do not reach into openings.

8.2 Before installation

• The globe valve can be installed in any installation position, preferably with the actuator face up.

• Before connecting the valve, ensure the lines are flush.

• Observe direction of flow (see type label).

8.2.1 Preparatory work

→ Clean pipelines (sealing material, swarf, etc.).

Devices with welded body

Remove the actuator from the valve body:

→ Clamp the valve body in a holding device.

NOTE!

Damage to the seat seal or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→ Using a suitable open-end wrench, place the wrench flat on the

tube.

→ Unscrew the actuator from the valve body.

18

english

Page 19

Type 2101

Installation

Air discharge connection

CFA, CFB

Pilot air port

Pilot air port

CFA, CFB, CFI

Release bore

Flats for open-end

wrench

Fig. 13: Installation

Other device versions

2

CFI

1

→ Do not remove actuator unless this is a customer-specific

requirement.

→ Procedure see “Devices with welded body”.

Actuator

Nipple

Valve body

8.3 Installation

WARNING!

Risk of injury from improper assembly!

Assembly with unsuitable tools or non-observance of the tightening torque is dangerous as the device may be damaged.

▶ For installation use an open-end wrench, never a pipe wrench.

▶ Observe the tightening torque (see “Tab. 5: Tightening torques

of valve body / nipples”).

Dirt trap for devices with authorization in accordance with DIN

EN 161

In accordance with DIN EN 161 “Automatic shut-off valves for gas

burners and gas appliances” a dirt trap must be connected upstream

of the valve and prevent the insertion of a 1 mm plug gauge.

→ If the authorisation also applies to stainless steel bodies, the

same type of dirt trap must be attached in front of the globe

valve.

8.3.1 Installation of the valve body

Welded bodies

→ Weld valve body in pipeline system.

Other body versions

→ Connect body to pipeline.

english

19

Page 20

Type 2101

Installation

8.3.2 Install actuator (welded body)

Graphite seal

Fig. 14: Graphite seal

→ Check the graphite seal and if required, replace it.

WARNING!

Danger if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen

applications there is a risk of an explosion!

▶ In specific applications, e.g. oxygen or analysis applications,

use appropriately authorised lubricants only.

→ Grease nipple thread before re-installing the actuator (e.g. with

Klüber paste UH1 96-402 from Klüber).

NOTE!

Damage to the seat seal or the seat contour!

▶ When installing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→ Screw actuator into the valve body.

Observe tightening torque (see “Tab. 5: Tightening torques of

valve body / nipples”).

Air discharge connection

CFA, CFB

Pilot air port

Pilot air port

CFA, CFB, CFI

Fig. 15: Connections

Tightening torques of valve body / nipples

DN Tightening torque [Nm]

13/15 45 ±3

20 50 ±3

25 60 ±3

32

40

50 70 ±3

65 100 ± 3

80 120 ± 5

100 150 ± 5

Tab. 5: Tightening torques of valve body / nipples

2

CFI

1

65 ±3

20

english

Page 21

Type 2101

Installation

8.3.3 Rotating the actuator

The position of the connections can be aligned steplessly by rotating

the actuator through 360°.

NOTE!

Damage to the seat seal or the seat contour!

▶ When rotating the actuator, ensure that the valve is in open

position.

Procedure:

→ Clamp the valve body in a holding device

(applies only to valves which have not yet been installed).

→ Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→ Counter on the flats of the nipple with a suitable open-end

wrench.

→ Actuator with hexagon:

Place suitable open-end wrench on the hexagon of the actuator.

→ Actuator without hexagon:

Fit special wrench6) exactly to the underside of the actuator.

6) The special key (identification number 665 702) is available from

your Bürkert sales office.

WARNING!

Risk of injury from discharge of medium and pressure!

If the direction of rotation is wrong, the body interface may

become detached.

▶ Rotate the actuator module in the specified direction only (see

“Fig. 16”)!

→ Actuator with hexagon:

Rotate counter-clockwise (as seen from below) to bring the

actuator module into the required position.

→ Actuator without hexagon:

Rotate clockwise (as seen from below) to bring the actuator

module into the required position.

Open-end wrench

Special key

with hexagon

Fig. 16: Rotating with special key / open-end wrench

without hexagon

english

21

Page 22

Type 2101

Installation

8.4 Pneumatic connection

DANGER!

Danger – high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

WARNING!

Risk of injury from unsuitable connection hoses!

Hoses which cannot withstand the pressure and temperature

range may result in hazardous situations.

▶ Use only hoses which are authorised for the indicated pressure

and temperature range.

▶ Observe the data sheet specifications from the hose

manufacturers.

For control function I – Danger if pilot pressure fails!

For control function I control and resetting occur pneumatically. If

the pressure fails, no defined position is reached.

▶ To ensure a controlled restart, first pressurize the device with

pilot pressure, then switch on the medium.

8.4.1 Connection of the control medium

If the position of the pilot air ports for installation of the

hoses is unfavorable, these can be aligned steplessly by

rotating the actuator through 360°.

The procedure is described in the chapter entitled “8.3.3

Rotating the actuator”.

Air discharge connection

CFA, CFB

Pilot air port CFI

Pilot air port

CFA, CFB, CFI

Fig. 17: Pneumatic connection

Control functions A and B:

2

1

→ Connect the control medium to the pilot air port 1 of the actuator

(see “Fig. 17”).

Silencer

For the versions with a plug-in connection the silencer for reducing

the exhaust air noise is supplied loose.

→ Plug the silencer into the free air discharge connection 2

(see “Fig. 17”).

If used in an aggressive environment, we recommend

conveying all free pneumatic connections into a neutral

atmosphere with the aid of a pneumatic hose.

22

english

Page 23

Type 2101

Installation

Control function I:

→ Connect the control medium to the pilot air port 1 and 2 of the

actuator (see “Fig. 18: Pneumatic connection”)

Pressure on connection 1 opens the valve.

Pressure on connection 2 closes the valve.

Air discharge connection

CFA, CFB

Pilot air port CFI

Pilot air port

CFA, CFB, CFI

Fig. 18: Pneumatic connection

Control air hose:

6/4 mm or 1/4” control air hoses can be used.

Optionally a pilot air port is possible via a G 1/8 thread.

2

1

8.5 Removal

DANGER!

Risk of injury from discharge of medium and pressure!

It is dangerous to remove a device which is under pressure due to

the sudden release of pressure or discharge of medium.

▶ Before removing a device, switch off the pressure and vent the

lines.

Procedure:

→ Loosen the pneumatic connection.

→ Remove the device.

english

23

Page 24

Type 2101

Electrical control unit

9 ELECTRICAL CONTROL UNIT

The valve Type 2101 can be combined with following control units:

• Type 8690 Pneumatic Control Unit

• Type 8691 Control head (actuator size ∅ 70 - ∅ 130)

• Type 8695 Control head (actuator size ∅ 50)

• Type 8645 Automation system FreeLINE

• Type 6012 Pilot valve

• Type 6014 P Pilot valve

The electrical connection of the pilot valve or the control

unit is described in the respective operating instructions for

the pilot valve/control unit.

10 MAINTENANCE, CLEANING

10.1 Safety instructions

DANGER!

Danger – high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the system, switch off the power supply

and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper maintenance!

▶ Maintenance may be performed by authorised technicians only!

▶ To screw on or unscrew valve body or actuator, use an open-end

wrench, never a pipe wrench, and observe tightening torques.

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

24

english

Page 25

Type 2101

Maintenance, Cleaning

WARNING!

For control function I – Danger if pilot pressure fails!

For control function I control and resetting occur pneumatically.

If the pressure fails, no defined position is reached.

▶ To ensure a controlled restart, first pressurize the device with

pilot pressure, then switch on the medium.

Risk of injury from moving parts in the device!

▶ Do not reach into openings.

10.2 Maintenance work

Actuator:

The actuator of the globe valve is maintenance-free provided it is

used according to these operating instructions.

Wearing parts of the globe valve:

Parts which are subject to natural wear:

• Seals

• Swivel plate

→ If leaks occur, replace the particular wearing part with an appro-

priate spare part.

(For spare-part sets and installation tools see chapter entitled

“12 Replacement parts”).

Visual inspection:

Perform regular visual inspections according to the application

conditions:

→ Check media connections for leaks.

→ Check release bore on the tube for leaks.

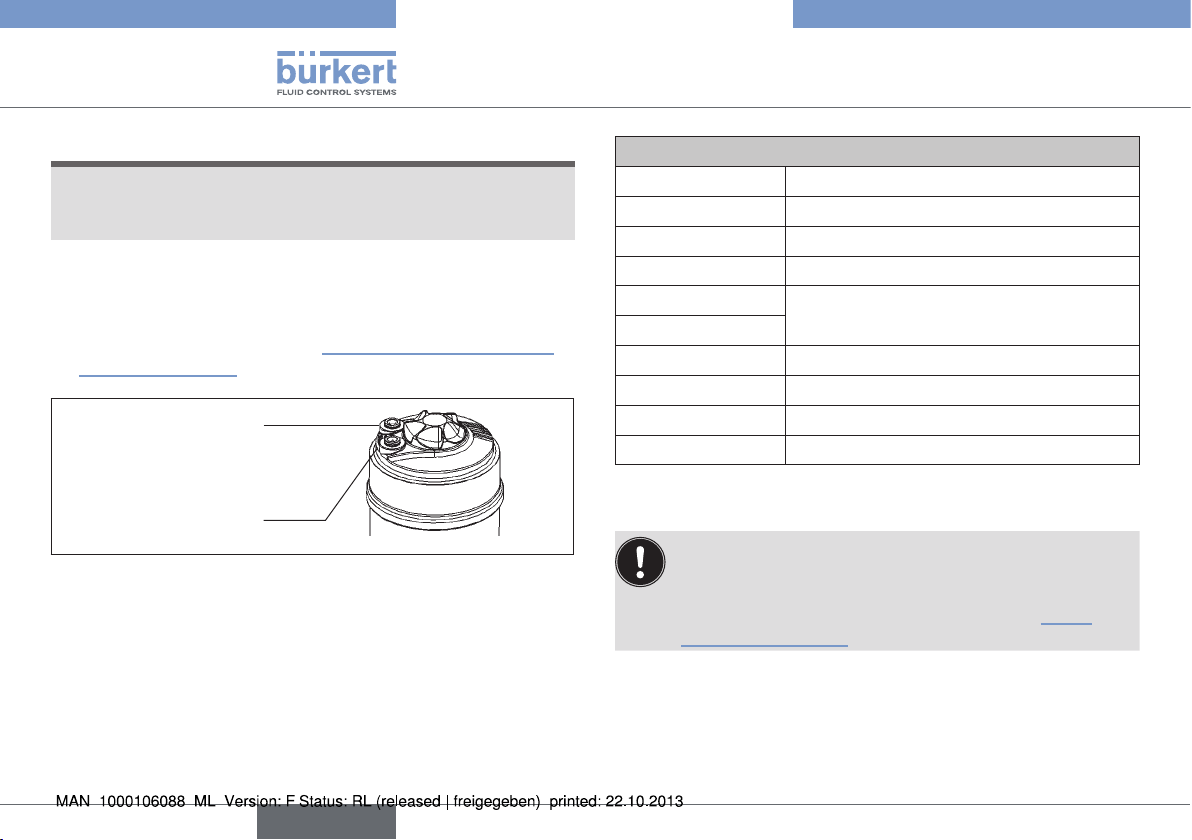

Release bore

Fig. 19: Release bore

10.2.1 Cleaning

Commercially available cleaning agents can be used to clean the

outside.

NOTE!

Avoid causing damage with cleaning agents.

▶ Before cleaning, check that the cleaning agents are compatible

with the body materials and seals.

The replacing of the wearing parts is described in chapter

“10.3 Replacing the wearing parts”.

english

25

Page 26

Type 2101

Maintenance, Cleaning

10.3 Replacing the wearing parts

10.3.1 Replacing the valve set

The valve set consists of

• Swivel plate

• Pin

• Graphite seal

Before the valve set can be replaced, the actuator must be removed

from the valve body.

DANGER!

Risk of injury from discharge of medium and pressure!

It is dangerous to remove a device which is under pressure due to

the sudden release of pressure or discharge of medium.

▶ Before removing a device, switch off the pressure and vent the

lines.

WARNING!

Risk of injury if the wrong tools are used!

It is dangerous to use unsuitable tools for installation work as the

device may be damaged.

▶ To remove the actuator from the valve body, use an open-end

wrench, never a pipe wrench.

Remove the actuator from the valve body:

→ Clamp the valve body in a holding device

(applies only to valves which have not yet been installed).

NOTE!

Damage to the seat seal or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→ Using a suitable open-end wrench, place the wrench flat on the

tube.

→ Unscrew the actuator from the valve body.

CFI

2

1

Actuator

Nipple

Valve body

Air discharge connection

CFA, CFB

Pilot air port

Pilot air port

CFA, CFB, CFI

Release bore

Flats for open-end

wrench

26

Fig. 20: Designation parts

english

Page 27

Type 2101

Maintenance, Cleaning

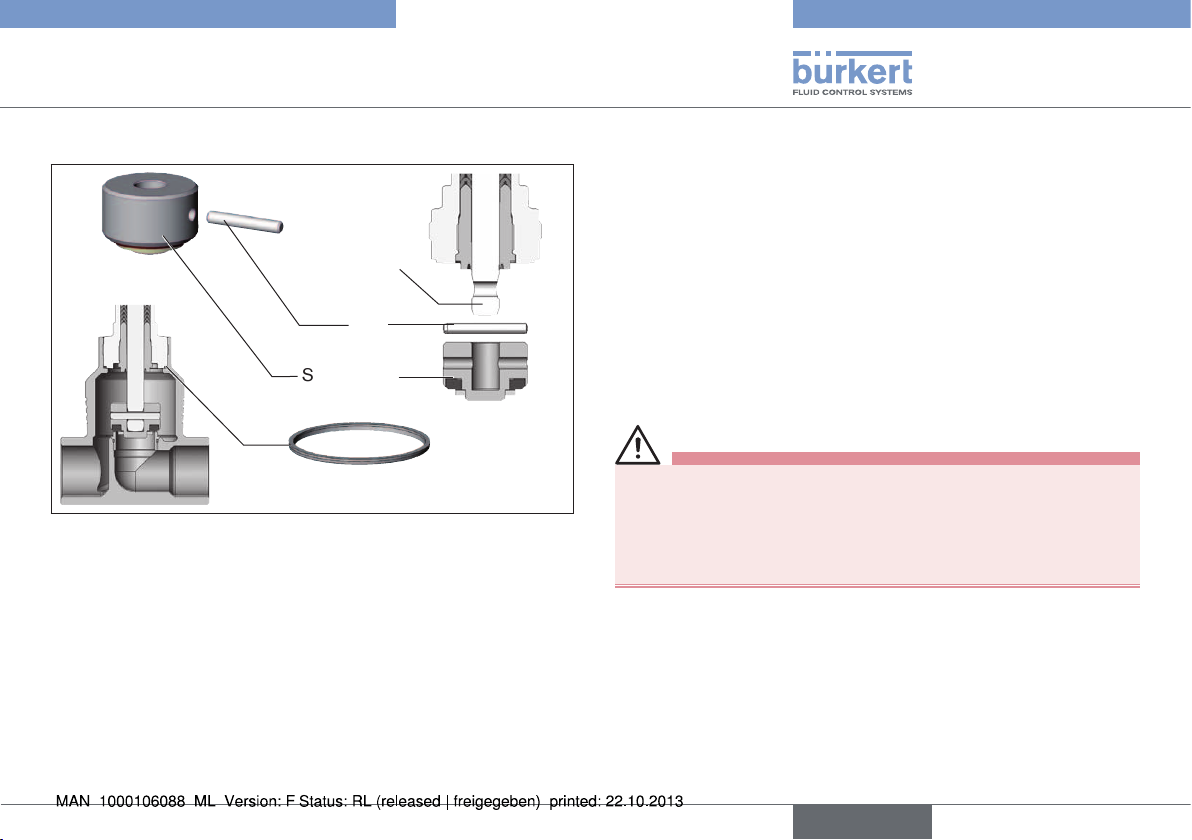

Replacing valve set

Spindle

Pin

Swivel plate

Graphite seal

Fig. 21: Valve set

Procedure:

→ Support swivel plate on the cylindrical part with the aid of a

prism or something similar.

→ Knock out pin with a suitable pin punch.

Pin punch ø 3 mm, for spindle diameter 10 mm on the swivel

plate.

Pin punch ø 5 mm, for spindle diameter 14 mm on the swivel

plate.

→ Remove swivel plate.

→ Connect new swivel plate to the spindle.

→ Align bores of the swivel plate and spindle.

→ Support swivel plate on the cylindrical part with the aid of a

prism or something similar.

→ Insert pin into the bore.

→ Swage pin bores on both sides of the swivel plate using a chisel

or center punch.

Installing the actuator on the valve body

→ Check the graphite seal and if required, replace it.

WARNING!

Danger if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen

applications there is a risk of an explosion!

▶ In specific applications, e.g. oxygen or analysis applications, use

appropriately authorised lubricants only.

→ Grease nipple thread before re-installing the actuator (e.g. with

Klüber paste UH1 96-402 from Klüber).

english

27

Page 28

Type 2101

Maintenance, Cleaning

NOTE!

Damage to the seat seal or the seat contour!

▶ When installing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→ Screw actuator into the valve body.

Observe tightening torque (see “Tab. 6: Tightening torques of

valve body / nipples”).

Air discharge connection

CFA, CFB

Pilot air port

Pilot air port

CFA, CFB, CFI

Fig. 22: Connections

2

CFI

1

Tightening torques of valve body / nipples

Orifice Tightening torque [Nm]

13/15 45 ±3

20 50 ±3

25 60 ±3

32

40

50 70 ±3

65 100 ±3

80 120 ±5

100 150 ±5

Tab. 6: Tightening torques of valve body / nipples

If the position of the pilot air ports for installation of the

hoses is unfavorable, these can be aligned steplessly by

rotating the actuator through 360°.

The procedure is described in the chapter entitled “8.3.3

Rotating the actuator”.

65 ±3

28

english

Page 29

Type 2101

Maintenance, Cleaning

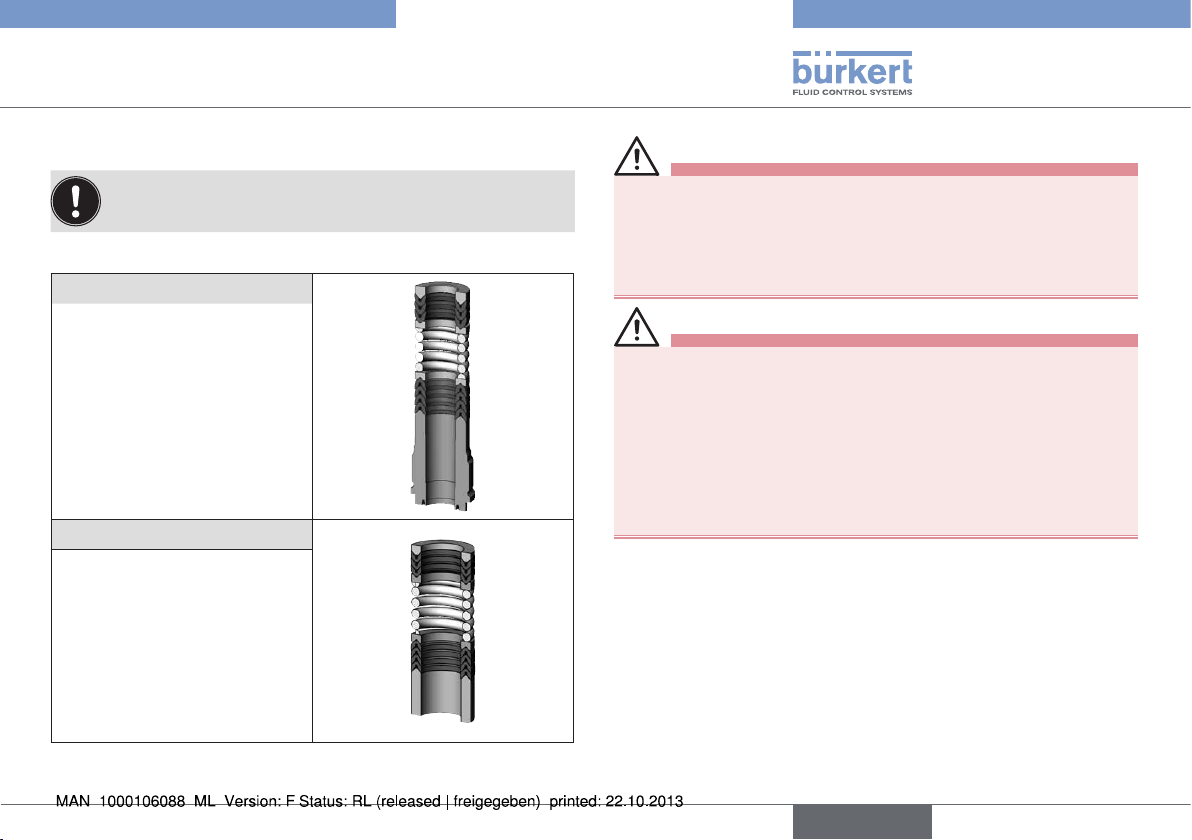

10.3.2 Replacing the packing gland

The packing gland cannot be replaced for the device

combination ø 70 / orifice 50.

The seal set for the packing gland contains

SP10 / SP14

• 1 support ring

• 7 chevron seals

• 2 pressure rings

• 1 pressure spring

• 1 spindle guide

• 1 graphite seal

• Lubricant

SP22

• 1 support ring

• 7 chevron seals

• 2 pressure rings

• 1 pressure spring

• 1 spacer

• 1 graphite seal

• Lubricant

Fig. 23: Seal set for packing gland

DANGER!

Risk of injury from discharge of medium and pressure!

It is dangerous to remove a device which is under pressure due to

the sudden release of pressure or discharge of medium.

▶ Before removing a device, switch off the pressure and vent the

lines.

WARNING!

Risk of injury if the wrong tools are used!

It is dangerous to use unsuitable tools for installation work as the

device may be damaged.

▶ To remove the actuator from the valve body, use an open-end

wrench, never a pipe wrench.

▶ To replace the packing gland, use a special installation wrench,

modified socket wrench or a socket wrench.

▶ Observe tightening torques.

Before the packing gland can be replaced, the actuator must be

removed from the valve body and the swivel plate removed.

english

29

Page 30

Type 2101

Maintenance, Cleaning

Remove the actuator from the valve body:

→ Clamp the valve body in a holding device

(applies only to valves which have not yet been installed).

NOTE!

Damage to the seat seal or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→ Using a suitable open-end wrench, place the wrench flat on the

tube.

→ Unscrew the actuator from the valve body.

CFI

2

1

Actuator

Nipple

Valve body

Air discharge connection

CFA, CFB

Pilot air port

Pilot air port

CFA, CFB, CFI

Release bore

Flats for open-end

wrench

Removing the swivel plate

→ Knock out the pin with a suitable pin punch.

Pin punch ø 3 mm, for spindle diameter 10 mm on the swivel

plate.

Pin punch ø 5 mm, for spindle diameter 14 mm on the swivel

plate.

→ Remove swivel plate.

Spindle

Pin

Swivel plate

Graphite seal

Fig. 25: Valve set

Fig. 24: Designation parts

30

english

Page 31

Maintenance, Cleaning

Replacing packing gland

Type 2101

Packing gland tube

Packing gland tube

Packing gland

Spindle guide

Spindle

Series production status

up to January 2013

Fig. 26: Replacing packing gland (series production status up to

January 2013)

Series production status since January 2013

SP10 / SP14

Fig. 27: Replacing packing gland SP10 / SP14 (series production

status since January 2013)

Installation wrench

Packing gland tube

Packing gland

Spindle guide

Spindle

Packing gland

Spacer

Spindle

VA spindle guide

SP22

Fig. 28: Replacing packing gland SP22

Series production status up to January 2013:

→ Unscrew the spindle guide with the aid of the installation

wrench7) and an open-end wrench.

Series production status since January 2013 SP10 / SP14:

→ Unscrew the spindle guide with the aid of a modified socket

wrench7).

SP22:

→ Unscrew the VA spindle guide with the aid of an open-end wrench.

7) The installation wrench or modified socket wrench is available

from your Bürkert sales office.

english

31

Page 32

Type 2101

Maintenance, Cleaning

WARNING!

Risk of injury from parts jumping out!

When the spindle opening is exposed, the individual parts of the

packing gland are pressed out at an undefined speed when the

pilot air ports is pressurized.

▶ Before pressurizing with control air, safeguard the ambient area

of the discharge opening (e.g. place spindle on a firm base).

→ Control function A and I Pressurize pilot air port 1 with 6 – 8

bar (see “Fig. 24: Designation parts”).

→ Control function B Pressurize pilot air port 2 with 6 – 8 bar (see

“Fig. 24: Designation parts”).

→ Grease the individual parts of the new packing gland with the

upplied lubricant.

→ Connect the individual parts to the spindle in the specified

direction and sequence (as illustrated in “Fig. 29: Seal set for

packing gland”).

→ Push packing gland into the packing gland tube.

→ Screw spindle guide / VA spindle guide back in using the socket

wrench / open-end wrench. Observe torque (see “Tab. 7: Tightening torques of spindle”).

Support ring

Upper chevron seals

Upper pressure ring

Pressure spring

Lower pressure ring

Lower chevron seals

Insertion direction

for packing gland parts

SP10 / SP14

Fig. 29: Seal set for packing gland

Tightening torques of spindle

Spindle diameter Tightening torque [Nm]

10 mm 6

14 mm 15

22 mm 60

Tab. 7: Tightening torques of spindle

Spacer

Spindle guide

VA spindle guide

8)

SP22

32

8) Is not included in the seal set

english

Page 33

Type 2101

Maintenance, Cleaning

Installing swivel plate

→ Connect swivel plate to the spindle.

→ Align bores of the swivel plate and spindle.

→ Support swivel plate on the cylindrical part with the aid of a

prism or something similar.

→ Insert pin into the bore.

→ Swage pin bores on both sides of the swivel plate using a chisel

or center punch.

Spindle

Pin

Swivel plate

Fig. 30: Swivel plate

Installing the actuator on the valve body

For description see chapter entitled “Installing the actuator on the

valve body”, page 27.

11 MALFUNCTIONS

Malfunction Remedial action

Actuator does

not switch

Pilot air port interchanged

CFA: → Connecting pilot air port 1

CFB:

CFI:

Pilot pressure too low

→ Connecting pilot air port 1

→ Pilot air port 1: Open

Pilot air port 2: Close

→ Observe pressure specifications on the

type label

Medium pressure too high

→ Observe pressure specifications on the

type label

Flow direction reversed

→ Observe direction arrow on the body

9)

english

33

Page 34

Type 2101

Replacement parts

Malfunction Remedial action

Valve is not

sealed

Dirt between seal and valve seat

→ Installing dirt trap

Seat seal worn

→ Installing new swivel plate

Flow direction reversed

→ Observe direction arrow on the body

Medium pressure too high

→ Observe pressure specifications on the

type label

Pilot pressure too low

→ Observe pressure specifications on the

type label

Valve is leaking on

the release bore

Tab. 8: Malfunctions

9) See “8.4 Pneumatic connection”.

Packing gland worn

→ Renew packing gland or replace actuator

12 REPLACEMENT PARTS

WARNING!

Risk of injury when opening the actuator!

The actuator contains a tensioned spring. If the actuator is

opened, there is a risk of injury from the spring jumping out!

▶ The actuator must not be opened.

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable replacement parts may

cause injuries and damage the device and the surrounding area.

▶ Use only original accessories and original replacement parts

from Bürkert.

12.1 Replacement part sets

The following replacement part sets are available for the globe valve

Type 2101:

• Valve set

consists of swivel plate with seal, pin and graphite seal.

• Sealing set for packing gland

consists of the individual parts of the packing gland, graphite seal

and lubricant

(the (modified) socket wrench is not included in the sealing set).

34

english

Page 35

Type 2101

Replacement parts

Valve set with PTFE seal

Orifice Order no.

15 011 134

20 011 171

25 160 737

32 011 208

40 011 209

50 216 431

65 241 777

80 155 492

100 155 493

Tab. 9: Valve set with PTFE seal

Sealing set for packing gland

Spindle ∅ Orifice

10 15 – 40

14 32 – 65

22 80 – 100 ∅ 130 252 545

Tab. 10: Sealing set for packing gland

Actuator

size

∅ 50

∅ 70

∅ 90

∅ 130

Order no.

216 433

216 435

VA spindle guide for packing gland

Spindle ∅ Orifice

22 80 – 100 ∅ 130 252 543

Tab. 11: VA spindle guide for packing gland

1 Graphite seal

2 Swivel plate

3 Pin

4 Sealing set for

packing gland

SP10 / SP14

5 Sealing set for

packing gland SP22

6 VA spindle guide

SP22

1

2

Fig. 31: Replacement parts

Sealing set

3

Actuator

size

Order no.

4

5

6

english

35

Page 36

Type 2101

Packaging, Transport, Storage

12.2 Installation tools

Installation wrench for packing gland

(Only for removal of packing glands up to January 2013)

Installation wrench Orifice Order no.

Spindle ∅ 10 mm 15 – 40 665 700

Spindle ∅ 14 mm 32 – 65 665 701

Tab. 12: Installation wrench

Modified socket wrench for packing gland

(Series production status since January 2013)

AF

Socket wrench Orifice AF Order no.

Spindle ∅

10 mm

Spindle ∅

14 mm

Tab. 13: Modified socket wrench

Special wrench for rotating the actuator

Order no.

Tab. 14: Special wrench

If you have any queries, please contact your Bürkert sales

office.

15 – 40 19 683 221

32 – 65 21 683 223

665 702

13 PACKAGING, TRANSPORT,

STORAGE

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the permitted storage

temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature -20 – +65 °C.

Damage to the environment caused by device components

contaminated with media.

▶ Dispose of the device and packaging in an environmentally

friendly manner.

▶ Observe applicable regulations on disposal and the environment.

Note:

Observe national waste disposal regulations.

36

english

Page 37

Typ 2101

Geradsitzventil Typ 2101

1 DIE BEDIENUNGSANLEITUNG .........................................................38

1.1 Darstellungsmittel ....................................................................38

1.2 Begriffsdefinition / Abkürzung ..............................................38

2 BESTIMMUNGSGEMÄSSE VERWENDUNG................................39

2.1 Beschränkungen ......................................................................39

3 GRUNDLEGENDE SICHERHEITSHINWEISE .............................. 39

4 ALLGEMEINE HINWEISE ....................................................................... 41

4.1 Kontaktadresse ........................................................................41

4.2 Gewährleistung ........................................................................41

4.3 Informationen im Internet .......................................................41

5 PRODUKTBESCHREIBUNG ................................................................ 41

5.1 Allgemeine Beschreibung .....................................................41

5.2 Ausführungen ...........................................................................41

5.3 Eigenschaften...........................................................................42

5.4 Vorgesehener Einsatzbereich ...............................................42

6 AUFBAU UND FUNKTION .................................................................... 43

6.1 Aufbau ........................................................................................43

6.2 Funktion .....................................................................................44

7 TECHNISCHE DATEN ............................................................................. 46

7.1 Konformität ................................................................................46

7.2 Normen ......................................................................................46

7.3 Typschild ....................................................................................46

7.4 Betriebsbedingungen .............................................................47

7.5 Allgemeine Technische Daten ..............................................51

8 MONTAGE .....................................................................................................52

8.1 Sicherheitshinweise ................................................................52

8.2 Vor dem Einbau........................................................................52

8.3 Einbau ........................................................................................53

8.4 Pneumatischer Anschluss .....................................................56

8.5 Demontage ...............................................................................57

9 ELEKTRISCHE ANSTEUERUNG ........................................................58

10 WARTUNG, REINIGUNG ........................................................................ 58

10.1 Sicherheitshinweise ................................................................58

10.2 Wartungsarbeiten ....................................................................59

10.3 Austausch Verschleißteile .....................................................60

11 STÖRUNGEN ............................................................................................... 67

12 ERSATZTEILE .............................................................................................. 68

12.1 Ersatzteilsätze...........................................................................68

12.2 Montagewerkzeuge .................................................................70

13 TRANSPORT, LAGERUNG, VERPACKUNG ..................................70

deutsch

37

Page 38

Typ 2101

Die Bedienungsanleitung

1 DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Geräts. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Geräts

wieder zur Verfügung steht.

WARNUNG!

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

▶ Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1 Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

▶ Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

▶ Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

▶ Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

▶ Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2 Begriffsdefinition / Abkürzung

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht immer für

das Geradsitzventil Typ 2101.

Die in dieser Anleitung verwendete Abkürzung „Ex“ steht immer für

„explosionsgeschützt“.

38

deutsch

Page 39

Typ 2101

Bestimmungsgemäße Verwendung

2 BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Geradsitzventils

Typ 2101 können Gefahren für Personen, Anlagen in der

Umgebung und die Umwelt entstehen.

▶ Das Gerät ist für die Steuerung des Durchflusses von flüssigen

und gasförmigen Medien konzipiert.

▶ Für den Einsatz sind die in den Vertragsdokumenten, der Bedie-

nungsanleitung und auf dem Typschild spezifizierten zulässigen

Daten, Betriebs- und Einsatzbedingungen zu beachten. Die

vorgesehenen Einsatzfälle sind im Kapitel „5 Produktbeschreibung“ aufgeführt.

▶ Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw.

zugelassenen Fremdgeräten und -komponenten einsetzen.

▶ Voraussetzungen für den sicheren und einwandfreien Betrieb

sind sachgemäßer Transport, sachgemäße Lagerung und Installation sowie sorgfältige Bedienung und Instandhaltung.

▶ Setzen Sie das Gerät nur bestimmungsgemäß ein.

2.1 Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls

bestehende Beschränkungen.

3 GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

GEFAHR!

Gefahr durch hohen Druck!

▶ Vor dem Lösen von Leitungen und Ventilen den Druck abschal-

ten und Leitungen entlüften.

Gefahr durch elektrische Spannung!

▶ Vor Eingriffen in das Gerät die Spannung abschalten und vor

Wiedereinschalten sichern!

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr beim Öffnen des Antriebs!

Der Antrieb enthält eine gespannte Feder. Beim Öffnen des Antriebs

kann es durch die herausspringende Feder zu Verletzungen kommen!

▶ Der Antrieb darf nicht geöffnet werden.

Verletzungsgefahr durch sich bewegende Teile im Gerät!

▶ Nicht in Öffnungen fassen.

deutsch

39

Page 40

Typ 2101

Grundlegende Sicherheitshinweise

VORSICHT!

Verbrennungsgefahr!

Bei Dauerbetrieb kann die Geräteoberfläche heiß werden.

▶ Das Gerät nicht mit bloßen Händen berühren.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

▶ Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

▶ Installations- und Instandhaltungsarbeiten dürfen nur von auto-

risiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

▶ Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung ist ein definierter oder kontrollierter Wiederanlauf des

Prozesses zu gewährleisten.

▶ Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung

der Bedienungsanleitung betrieben werden.

▶ Für die Einsatzplanung und den Betrieb des Geräts müssen die

allgemeinen Regeln der Technik eingehalten werden.

▶ Im explosionsgefährdeten Bereich darf das Geradsitzventil Typ

2101 nur entsprechend der Spezifikation auf dem separaten ExTypschild eingesetzt werden. Für den Einsatz muss die dem Gerät

beiliegende Zusatzinformation mit Sicherheitshinweisen für den

Ex-Bereich beachtet werden.

▶ Geräte ohne separates Ex-Typschild dürfen nicht im explosions-

gefährdeten Bereich eingesetzt werden.

Zum Schutz vor Sachschäden am Gerät ist zu beachten:

• In die Medienanschlüsse nur Medien einspeisen, die im Kapitel „7

Technische Daten“ aufgeführt sind.

• Ventil nicht mechanisch belasten (z. B. durch Ablage von Gegenständen oder als Trittstufe).

• Keine äußerlichen Veränderungen an den Ventilen vornehmen.

Gehäuseteile und Schrauben nicht lackieren.

Das Geradsitzventil Typ 2101 wurde unter Einbeziehung der

anerkannten sicherheitstechnischen Regeln entwickelt und

entspricht dem Stand der Technik. Trotzdem können Gefahren

entstehen.

40

deutsch

Page 41

Typ 2101

Allgemeine Hinweise

4 ALLGEMEINE HINWEISE

4.1 Kontaktadresse

Deutschland

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2 Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Geräts unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3 Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 2101 finden Sie im

Internet unter: www.buerkert.de

5 PRODUKTBESCHREIBUNG

5.1 Allgemeine Beschreibung

Das 2/2-Wege-Geradsitzventil Typ 2101 ist geeignet für flüssige

und gasförmige Medien. Es steuert mittels neutraler Gase oder Luft

(Steuermedien) den Durchfluss von Wasser, Alkohol, Öl, Treibstoff,

Hydraulikflüssigkeit, Salzlösung, Lauge, organischem Lösungsmittel

und Dampf (Durchflussmedien).

Ein besonderes Merkmal der Geradsitzventile sind eingeschraubte

Sitze, die insbesondere beim Regelventil (Typ 2301) zur Reduzierung

der Nennweite eingesetzt werden können.

Definition DN

DN bezeichnet die Nennweite des Sitzes, nicht die Nennweite des Leitungsanschlusses.

5.2 Ausführungen

Das Geradsitzventil Typ 2101 gibt es in 2 Ausführungen:

• Standardausführung – ohne separates Ex-Typschild.

Die Standardausführung darf nicht im explosionsgefährdeten

Bereich eingesetzt werden.

• Ex-Ausführung – mit separatem Ex-Typschild.

Die Ex-Ausführung darf im explosionsgefährdeten Bereich

eingesetzt werden. Dabei müssen die Spezifikationen auf dem

separaten Ex-Typschild und die dem Gerät beiliegende Zusatzinformation mit Sicherheitshinweisen für den Ex-Bereich beachtet

werden.

deutsch

41

Page 42

Typ 2101

Produktbeschreibung

5.3 Eigenschaften

• Hohe Dichtheit durch selbstnachstellende Stopfbuchsen

(Spindeldichtelement).

• Hohe Sitzdichtheit durch Pendelteller.

• Antrieb um 360° stufenlos drehbar.

• Unter normalen Bedingungen wartungsfrei.

5.3.1 Optionen

• Ansteuerung

Je nach Anforderung stehen Ansteuerungen verschiedener Ausführungen zu Verfügung.

• Hubbegrenzung

Begrenzung der maximalen Offenstellung / Durchflussmenge

mittels Einstellschraube.

• Rückmelder

Das Gerät gibt es mit mechanischen Endschaltern oder induktiven

Näherungsschaltern.

5.3.2 Gerätevarianten

Das Geradsitzventil ist für folgende Antriebsgrößen lieferbar:

ø 50 mm, ø 70 mm, ø 90 mm, ø 130 mm.

5.3.3 Einschränkungen

WARNUNG!

Verletzungsgefahr durch Schließschlag!

Ein Schließschlag könnte zum Bersten von Leitungen und Gerät

führen.

Wegen Schließschlaggefahr dürfen Ventile mit Anströmung

über Sitz nicht für flüssige Medien eingesetzt werden.

▶ Für den Betrieb des Geräts die Art der Anströmung und die Art

des Mediums beachten.

5.4 Vorgesehener Einsatzbereich

Den maximalen Druckbereich laut Typschild beachten!

• Neutrale Gase und Flüssigkeiten bis 16 bar.

• Dampf bis 11 bar absolut / 185 °C.

• Aggressive Medien.

5.4.1 Anwendungsgebiete

z. B. Anlagenbau

Lebensmittelverarbeitung

Chemische Verfahrenstechnik

Sterilisatorenbau

42

deutsch

Page 43

Typ 2101

Aufbau und Funktion

6 AUFBAU UND FUNKTION

6.1 Aufbau

Das Geradsitzventil besteht aus einem pneumatisch betätigten Kolbenantrieb und einem 2/2-Wege-Ventilgehäuse.

Der Antrieb ist aus Polyphenylensulfid (PPS) gefertigt. Die bewährte,

selbstnachstellende Stopfbuchse gewährleistet hohe Dichtheit. Das

strömungsgünstige Ventilgehäuse aus Edelstahl ermöglicht hohe

Durchflusswerte.

Klarsichthaube mit Stellungsanzeige

Antriebsdeckel

Antriebsgehäuse

Geradsitzgehäuse

Durchflussrichtungspfeil oder

Ziffern zur Kennzeichnung der

Durchflussrichtung

Bild 1: Geradsitzventil Typ 2101, Aufbau und Beschreibung (1)

Die Beschreibung der Steuerfunktionen (SF) finden Sie in

Kapitel „6.2.1 Steuerfunktionen (SF)“

Entlüftungsanschluss für SFA, SFB

Steuerluftanschluss für SFI

Steuerluftanschluss für SFA, SFB, SFI

Entlastungsbohrung

Schnittstelle Antrieb / Gehäuse

mit Schlüsselfläche

Leitungsanschluss

Bild 2: Geradsitzventil Typ 2101, Aufbau und Beschreibung (2)

2

1

deutsch

43

Page 44

2(A)

2(B)

2(A)

Typ 2101

Aufbau und Funktion

6.2 Funktion

Je nach Ausführung wird der Sitz des Ventils mit oder gegen den

Mediumstrom geschlossen.

Federkraft (SFA) oder pneumatischer Steuerdruck (SFB und SFI)

erzeugen die Schließkraft auf den Pendelteller. Über eine Spindel,

die mit dem Antriebskolben verbunden ist, wird die Kraft übertragen.

6.2.1 Steuerfunktionen (SF)

WARNUNG!

Bei Steuerfunktion I – Gefahr bei Steuerdruckausfall!

Bei Steuerfunktion I erfolgt die Ansteuerung und Rückstellung

pneumatisch. Bei Druckausfall wird keine definierte Position erreicht.

▶ Für einen kontrollierten Wiederanlauf, das Gerät zunächst mit

Steuerdruck beaufschlagen, danach erst das Medium aufschalten.

Steuerfunktion A (SFA)

In Ruhestellung durch Federkraft geschlossen

1(P)

Steuerfunktion B (SFB)

In Ruhestellung durch Federkraft geöffnet

1(P)

Steuerfunktion I (SFI)

Stellfunktion über wechselseitige

Druckbeaufschlagung.

1(P)

44

deutsch

Page 45

Typ 2101

deutsch

Aufbau und Funktion

6.2.2 Anströmung unter Sitz

Je nach Ausführung wird das Ventil mit Federkraft (Steuerfunktion A,

SFA) oder mit Steuerdruck (Steuerfunktion B bzw. I, SFB bzw. SFI)

gegen den Mediumstrom geschlossen.

Da unter dem Pendelteller der Mediumsdruck ansteht, trägt dieser

zur Öffnung des Ventils bei.

WARNUNG!

Sitzundichtheit bei zu geringem Mindeststeuerdruck oder zu

hohem Mediumsdruck!

Ein zu geringer Mindeststeuerdruck bei SFB und SFI oder das

Überschreiten des zulässigen Mediumsdrucks kann zu Undichtigkeit am Sitz führen.

▶ Mindeststeuerdruck einhalten

▶ Mediumsdruck nicht überschreiten

▶ Siehe Kapitel „7.4.2 Druckbereiche“.

SFA SFB /

SFI

6.2.3 Anströmung über Sitz

Das Ventil wird durch Federkraft (Steuerfunktion A, SFA) mit dem

Mediumstrom geschlossen. Da der Mediumsdruck über dem Pendelteller ansteht, unterstützt er den Schließvorgang des Ventils und

trägt zusätzlich zum Abdichten des Ventilsitzes bei.

Das Öffnen des Ventils erfolgt durch den Steuerdruck.

WARNUNG!

Verletzungsgefahr durch Schließschlag.

Ein Schließschlag könnte zum Bersten von Leitungen und Gerät

führen. Wegen Schließschlaggefahr dürfen Ventile mit Anströmung

Über Sitz nicht für flüssige Medien eingesetzt werden.

▶ Für den Betrieb des Geräts die Art der Anströmung und die Art

des Mediums beachten.

Um ein vollständiges Öffnen zu gewährleisten, muss der

Mindeststeuerdruck eingesetzt werden!

Bild 3: Anströmung unter Sitz

(Ruhe auf/zu, gegen Medium schließend)

Bild 4: Anströmung über Sitz (Ruhe zu, mit Medium schließend)

45

Page 46

Typ 2101

Technische Daten

7 TECHNISCHE DATEN

7.1 Konformität

Das Geradsitzventil Typ 2101 ist konform zu den EG-Richtlinien entsprechend der EG-Konformitätserklärung.

7.2 Normen

Die angewandten Normen, mit denen die Konformität mit den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformitätserklärung nachzulesen.

7.3 Typschild

Beispiel:

CE

W3ZLT

00189700

2101 A 25M PTFE VA

Tmed -10°C - +180°C

Flow 1 2 DIN

Pilot 4,8-10bar

Pmed 16,0bar

DN25 Kv13,0

Bild 5: Typschild Beispiel

WARNUNG!

Verletzungsgefahr durch hohen Druck

Wichtige gerätespezifische technische Angaben sind auf dem

Typschild angegeben.

▶ Zulässiger Druckbereich auf dem Typschild des Geräts beachten.

Beispiel:

Dichtungswerkstoff

Nennweite Gehäuse /

Antriebsgröße

Steuerfunktion (SF)

Typ

2101 A 25M PTFE VA

Tmed -10°C - +180°C

00189700

Identnummer

Flow 1 2 DIN

Durchflussrichtung

des Geräts

Zulässige

Mediumstemperatur

1)

Gehäusewerkstoff

Hauptmaße

Leitungsanschluss

Zulässiger

Mediumsdruck

Zulässiger

Steuerdruck

CE-Kennzeichnung

Pilot 4,8-10bar

Pmed 16,0bar

DN25 Kv13,0

Durchflusskapazität in

Serienbedingungen

1)

CE

W3ZLT

Herstellerdatum

(verschlüsselt)

46

1) Variantenbeschreibung siehe „7.5 Allgemeine Technische Daten“

deutsch

Page 47

Typ 2101

Technische Daten

7.4 Betriebsbedingungen

7.4.1 Temperaturbereiche

Antriebsgröße

ø 50 mm

ø 70 mm

ø 90 mm

ø 130 mm

Tab. 1: Temperaturbereiche

3) Steuerluftanschlüsse als Schlauchsteckverbinder

4) Steuerluftanschlüsse als Gewindebuchse.

Antriebswerkstoff

Medium

(bei PTFE-Dichtung)

PPS -10 ... +185 °C

2) Bei Verwendung eines Vorsteuerventils beträgt die

max. Umgebungstemperatur +55 °C.

Das Geradsitzventil ist für die Dampfsterilisation geeignet.

Umgebung

0 ... +60 °C

0 ... +100 °C

7.4.2 Druckbereiche

Antriebsgröße Maximaler Steuerdruck

ø 50 mm

2)

10 barø 70 mm

ø 90 mm

3)

4)

ø 130 mm 7 bar

Tab. 2: Druckbereiche

5) Für die Gerätevariante ø 70 / DN 50 / MC 13

ist der max. zulässige Steuerdruck auf 7 bar begrenzt.

5)

deutsch

47

Page 48

Typ 2101

Technische Daten

Mediums- und Steuerdruck bei Steuerfunktion A,

Anströmung unter Sitz (Standard)

Nenn-

weite

DN

10/15 25 25

100 6

Tab. 3: Mediums- und Steuerdruck SFA, Standard

Maximaler Mediumsdruck

[bar]

Antriebsgröße ø [mm] Antriebsgröße ø [mm]

50 70 90 130 50 70 90 130

20 16 20

25 9 16

32

40 6 16

50

65 5,0 16

8,5 16

-

-

-

10 16 5

10

-

Minimaler Steuerdruck

[bar]

5,2

4,8

-

- 5,680

Mediums- und Steuerdruck bei Steuerfunktion A,

Anströmung unter Sitz, reduzierte Druckfederkraft (EC04)

Nenn-

weite

DN

10/15 14 16

-

-

5

-

Tab. 4: Mediums- und Steuerdruck SFA, reduzierte

Maximaler Mediumsdruck

[bar]

Antriebsgröße ø [mm] Antriebsgröße ø [mm]

50 70 90 130 50 70 90 130

-

-

-

3,5 10

7,5

-

20 6 12

25 3 6

32

50

80 5

Druckfederkraft (EC04)

3,5 9

-

Minimaler Steuerdruck

[bar]

3,2

2,5

-

-

2,540 2 6 16

-65

- 3,2

-

2,5

48

deutsch

Page 49

Typ 2101

Technische Daten

Erforderlicher Mindeststeuerdruck in Abhängigkeit vom

Mediumsdruck

In den nachfolgenden Diagrammen ist für die Steuerfunktionen A,

B und I der erforderliche Mindeststeuerdruck in Abhängigkeit vom

Mediumsdruck dargestellt.

Steuerfunktion A, Anströmung über Sitz

ø 50

SFA über Sitz

16

14

12

10

8

6

4

2

0

Mediumsdruck [bar]

0 1 2 3 4 5 6 7 8 9 10

DN15

DN20

DN25

Steuerdruck [bar]

Bild 6: Druckdiagramm, Antrieb ø 50 mm, Steuerfunktion A,

Anströmung über Sitz.

ø 70

SFA über Sitz

16

14

12

10

8

6

4

2

0

Mediumsdruck [bar]

0 1 2 3 4 5 6 7 8 9 10

DN15

DN20

DN25

DN32

DN40

DN50

Steuerdruck [bar]

Bild 7: Druckdiagramm, Antrieb ø 70 mm, Steuerfunktion A,

Anströmung über Sitz

ø 90

SFA über Sitz

16

14

12

10

8

6

4

2

0

Mediumsdruck [bar]

0 1 2 3 4 5 6 7 8 9 10

DN40

DN50

DN65

Steuerdruck [bar]

Bild 8: Druckdiagramm, Antrieb ø 90 mm, Steuerfunktion A,

Anströmung über Sitz

deutsch

49

Page 50

Steuerfunktion B und I, Anströmung unter Sitz

ø 50 SFB/SFI

unter Sitz

16

14

12

10

8

6

4

2

0

Mediumsdruck [bar]

0 1 2 3 4 5 6 7 8 9 10

DN15

DN20

DN25

Steuerdruck [bar]

Bild 9: Druckdiagramm, Antrieb ø 50 mm, Steuerfunktionen B und I,

Anströmung unter Sitz

Typ 2101

Technische Daten

ø 90 SFB/SFI

unter Sitz

DN32

16

14

12

10

8

6

4

2

0

Mediumsdruck [bar]

0 1 2 3 4 5 6 7 8 9 10

DN40

DN50

DN65

Steuerdruck [bar]

Bild 11: Druckdiagramm, Antrieb ø 90 mm, Steuerfunktionen B und I,

Anströmung unter Sitz

ø 70 SFB/SFI

unter Sitz

DN25

DN15

16

14

12

10

8

6

4

2

0

Mediumsdruck [bar]

0 1 2 3 4 5 6 7 8 9 10

DN20

DN32

DN40

DN50

Steuerdruck [bar]

Bild 10: Druckdiagramm, Antrieb ø 70 mm, Steuerfunktionen B und I,

Anströmung unter Sitz

50

deutsch

ø 130 SFB/SFI

unter Sitz

DN40

16

14

12

10

8

6

4

2