Page 1

Austauschanleitung

Instructions de remplacement

Replacement Instructions

Type 2100

2/2-way Angle Seat Valve

2/2-Wege Schrägsitzventil

Vanne à siège incliné 2/2 voies

Address / Adresse

Germany / Deutschland / Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

www.burkert.com

Manuals and data sheets on the Internet:

www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet:

www.buerkert.de

Instructions de service et fiches techniques sur Internet :

www.buerkert.fr

© Bürker t Werke GmbH, 2013

Replacement Instructions 1309/01_EU-ml_00810231 /

Original DE

www.burkert.com

Page 2

SYMBOLS

→ designates a procedure which you must carry out.

Warning of serious or fatal injuries:

DANGER!

In case of imminent danger.

WARNING!

In case of potential danger.

Warning of minor or moderately severe injuries:

CAUTION!

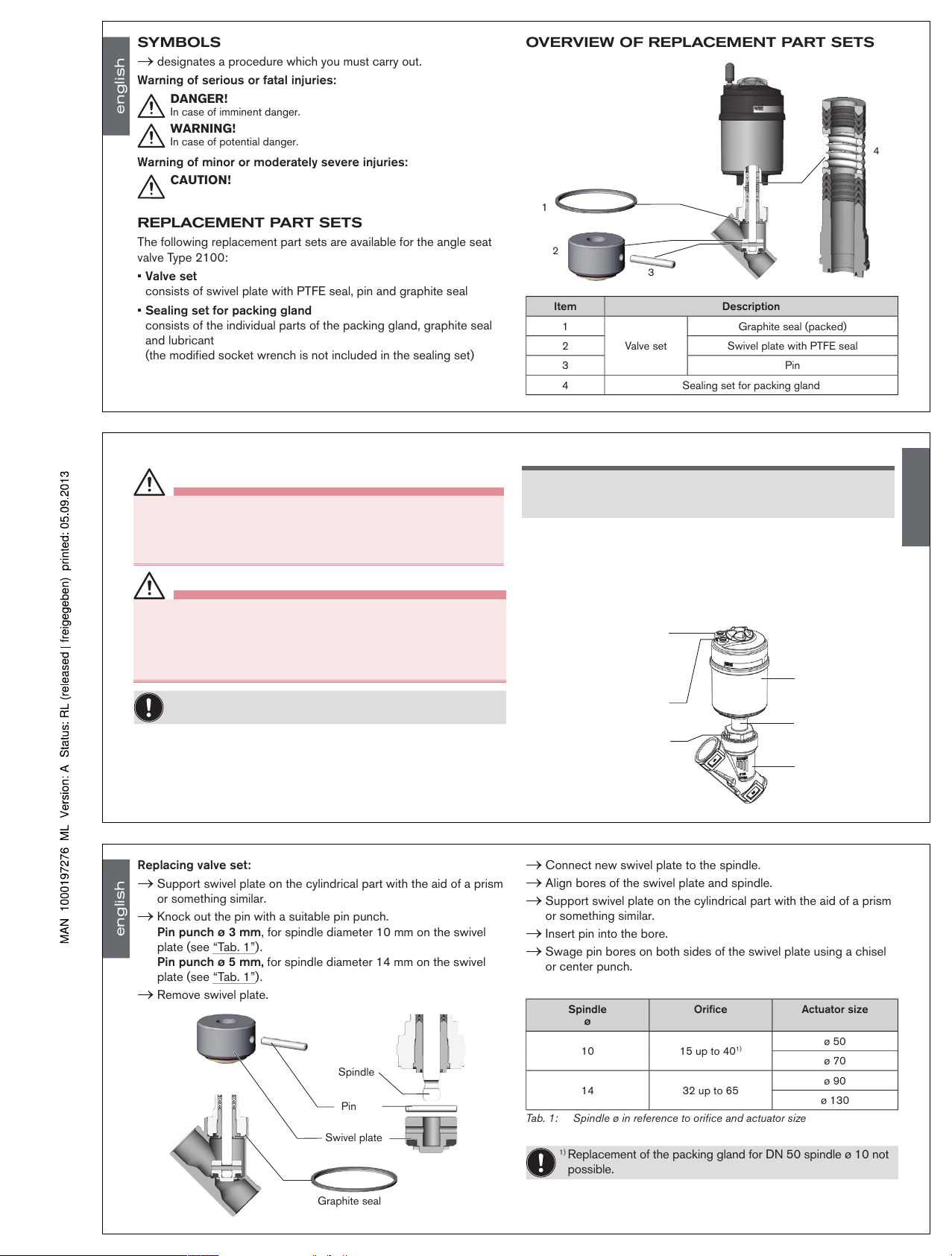

REPLACEMENT PART SETS

The following replacement part sets are available for the angle seat

valve Type 2100:

• Valve set

consists of swivel plate with PTFE seal, pin and graphite seal

• Sealing set for packing gland

consists of the individual parts of the packing gland, graphite seal

and lubricant

(the modified socket wrench is not included in the sealing set)

OVERVIEW OF REPLACEMENT PART SETS

1

2

3

4

Item Description

1

Valve set

Graphite seal (packed)

2 Swivel plate with PTFE seal

3 Pin

4 Sealing set for packing gland

english

NOTE!

Damage to the seat seal or the seat contour!

• When removing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with compressed

air (5 bar): valve opens.

→ Using a suitable open-end wrench, place the wrench flat on the

tube.

→ Unscrew the actuator from the valve body.

Actuator

Nipple

Valve body

Flats for open-end

wrench

Pilot air port

CFA, CFB, CFI

Air discharge connection

CFA, CFB

Pilot air port

CFI

2

1

REPLACING THE VALVE SET

DANGER!

Risk of injury from discharge of medium and pressure!

It is dangerous to remove a device which is under pressure due to

the sudden release of pressure or discharge of medium.

• Before removing a device, switch off the pressure and vent the lines.

WARNING!

Risk of injury if the wrong tools are used!

It is dangerous to use unsuitable tools for installation work as the

device may be damaged.

• To remove the actuator from the valve body, use an open-end wrench,

never a pipe wrench.

Before the valve set can be replaced, the actuator must be

removed from the valve body.

Remove the actuator from the valve body:

→ Clamp the valve body in a holding device

(applies only to valves which have not yet been installed).

english

Replacing valve set:

→ Support swivel plate on the cylindrical part with the aid of a prism

or something similar.

→ Knock out the pin with a suitable pin punch.

Pin punch ø 3 mm, for spindle diameter 10 mm on the swivel

plate (see “Tab. 1”).

Pin punch ø 5 mm, for spindle diameter 14 mm on the swivel

plate (see “Tab. 1”).

→ Remove swivel plate.

Spindle

Pin

Swivel plate

Graphite seal

→ Connect new swivel plate to the spindle.

→ Align bores of the swivel plate and spindle.

→ Support swivel plate on the cylindrical part with the aid of a prism

or something similar.

→ Insert pin into the bore.

→ Swage pin bores on both sides of the swivel plate using a chisel

or center punch.

Spindle

ø

Orifice Actuator size

10 15 up to 40

1)

ø 50

ø 70

14 32 up to 65

ø 90

ø 130

Tab. 1: Spindle ø in reference to orifice and actuator size

1)

Replacement of the packing gland for DN 50 spindle ø 10 not

possible.

english

Type 2100

Page 3

Installing the actuator on the valve body:

→ Check the graphite seal and if required, replace it.

WARNING!

Danger if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen applications there is a risk of an explosion!

• In specific applications, e.g. oxygen or analysis applications, use

appropriately authorised lubricants only.

→ Grease nipple thread before re-installing the actuator (e.g. with

Klüber paste UH1 96-402 from Klüber).

NOTE!

Damage to the seat seal or the seat contour!

• When installing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with compressed

air (5 bar): valve opens.

→ Screw actuator into the valve body.

Observe tightening torque (see “Tab. 2”).

1

2

Pilot air port

CFA, CFB, CFI

Air discharge connection

CFA, CFB

Pilot air port

CFI

Tightening torque

Orifice

(mm)

Tightening torque

[Nm]

15 45 ± 3

20 50 ± 3

25 60 ± 3

32

65 ± 3

40

50

70 ± 3

65

100 ±3

Tab. 2: Tightening torque of valve body / nipples

english

CHANGING THE SEAL SET

WARNING!

Risk of injury if the wrong tools are used!

It is dangerous to use unsuitable tools for installation work as the

device may be damaged.

• To remove the actuator from the valve body, use an open-end

wrench, never a pipe wrench.

DANGER!

Risk of injury from discharge of medium and pressure!

It is dangerous to remove a device which is under pressure due to

the sudden release of pressure or discharge of medium.

• Before removing a device, switch off the pressure and vent the lines.

The seal set for the packing gland contains:

Item Description Item Description

1 1 Support ring 5 1 Spindle guide

2 7 Chevron seals 6 Graphite seal

3 2 Pressure rings 7 Lubricant

4 1 Pressure spring

The packing gland cannot be replaced for the device

combination ø 70 / orifice 50.

Before the packing gland can be replaced, the actuator must

be removed from the valve body and the swivel plate removed.

Remove the actuator from the valve body:

→ Clamp the valve body in a holding device

(applies only to valves which have not yet been installed).

NOTE!

Damage to the seat seal or the seat contour!

• When removing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with compressed

air (5 bar): valve opens.

→ Using a suitable open-end wrench, place the wrench flat on the

tube.

→ Unscrew the actuator from the valve body.

english

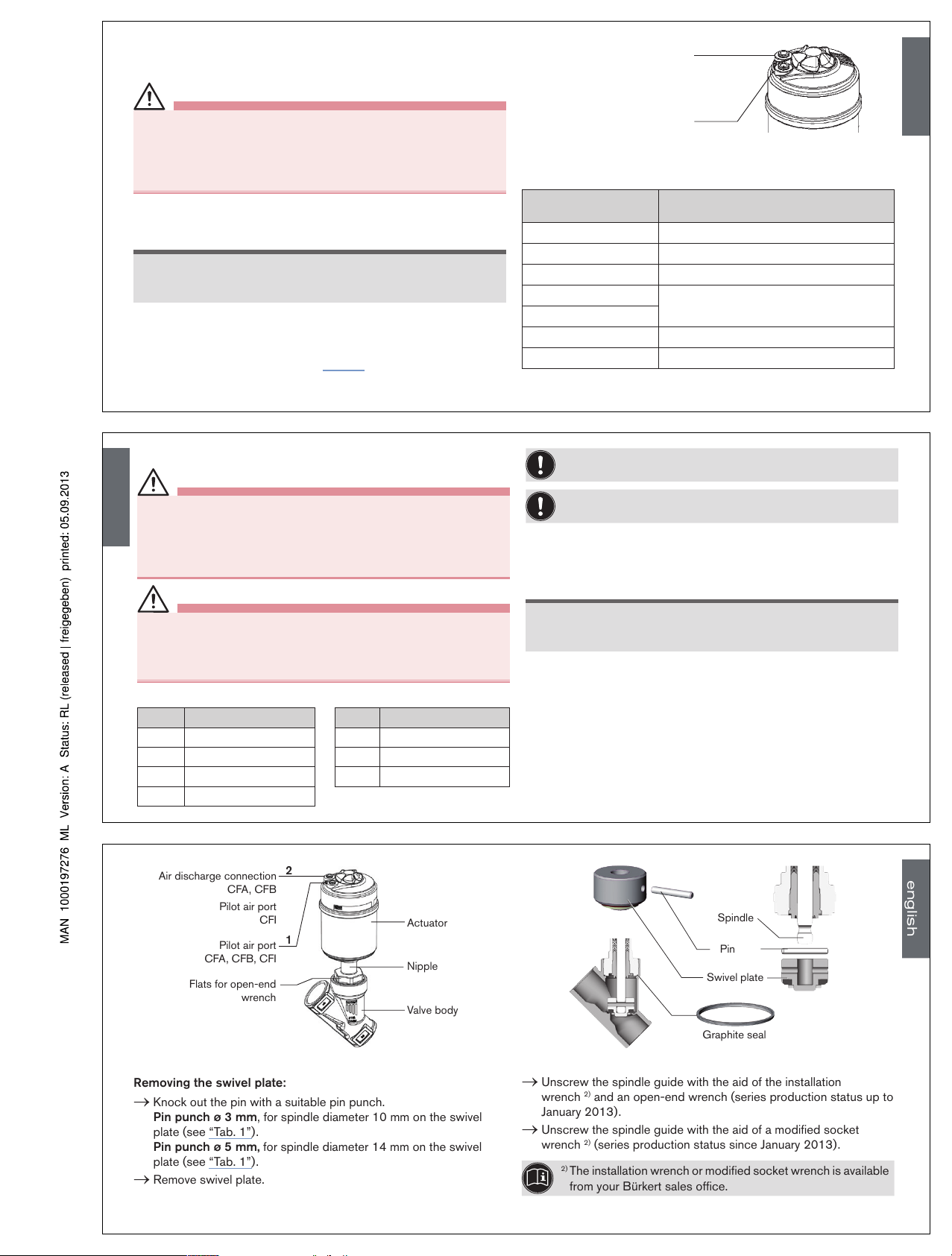

Actuator

Nipple

Valve body

Flats for open-end

wrench

Pilot air port

CFA, CFB, CFI

Air discharge connection

CFA, CFB

Pilot air port

CFI

2

1

Removing the swivel plate:

→ Knock out the pin with a suitable pin punch.

Pin punch ø 3 mm, for spindle diameter 10 mm on the swivel

plate (see “Tab. 1”).

Pin punch ø 5 mm, for spindle diameter 14 mm on the swivel

plate (see “Tab. 1”).

→ Remove swivel plate.

Spindle

Pin

Swivel plate

Graphite seal

→ Unscrew the spindle guide with the aid of the installation

wrench 2) and an open-end wrench (series production status up to

January 2013).

→ Unscrew the spindle guide with the aid of a modified socket

wrench 2) (series production status since January 2013).

2)

The installation wrench or modified socket wrench is available

from your Bürkert sales office.

english

Type 2100

Page 4

Installation wrench

Packing gland

Spindle guide

Spindle

Packing gland tube

Series production

status up to January

2013

Packing gland

Spindle guide

Spindle

Packing gland tube

Series production

status since January

2013

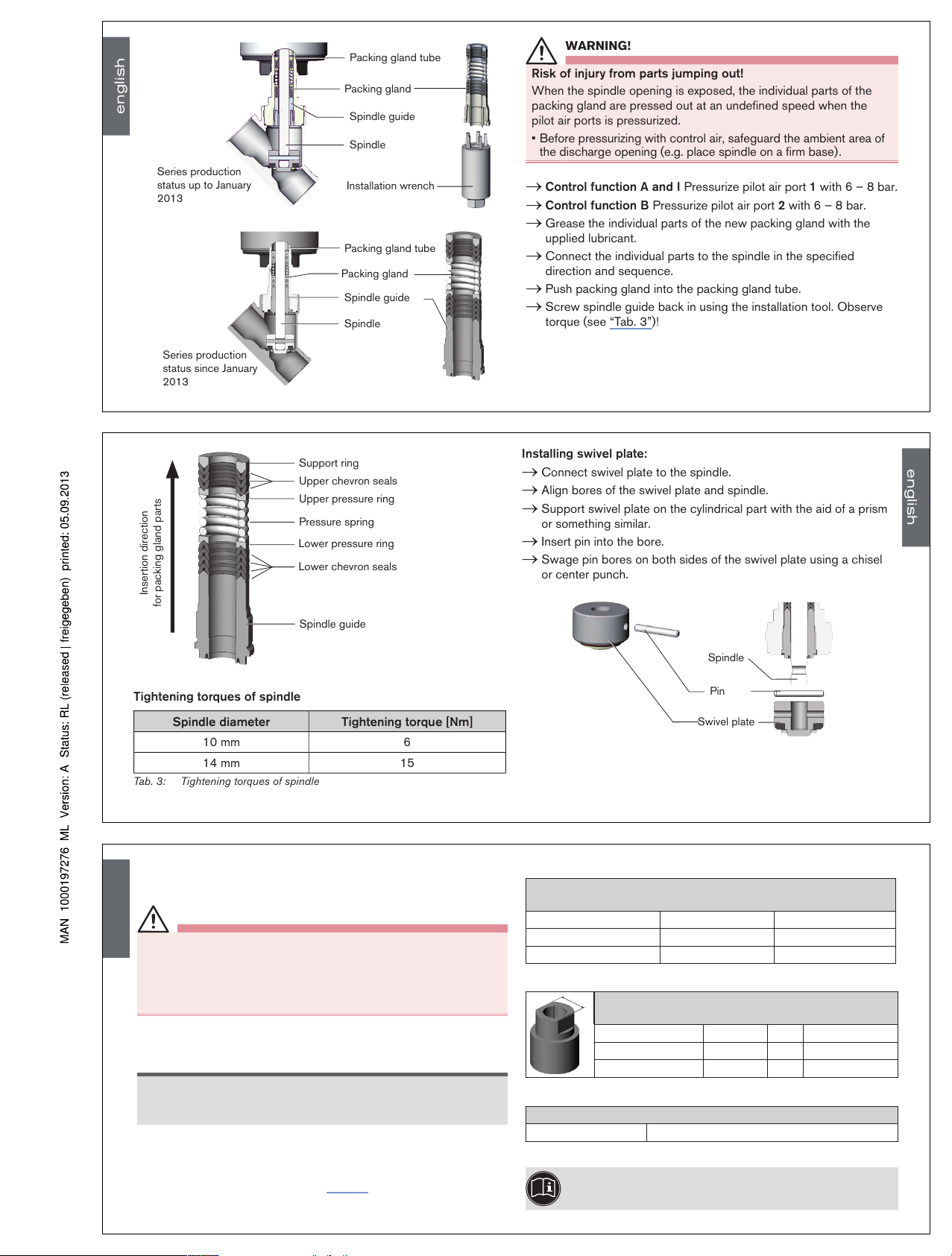

WARNING!

Risk of injury from parts jumping out!

When the spindle opening is exposed, the individual parts of the

packing gland are pressed out at an undefined speed when the

pilot air ports is pressurized.

• Before pressurizing with control air, safeguard the ambient area of

the discharge opening (e.g. place spindle on a firm base).

→ Control function A and I Pressurize pilot air port 1 with 6 – 8 bar.

→ Control function B Pressurize pilot air port 2 with 6 – 8 bar.

→ Grease the individual parts of the new packing gland with the

upplied lubricant.

→ Connect the individual parts to the spindle in the specified

direction and sequence.

→ Push packing gland into the packing gland tube.

→ Screw spindle guide back in using the installation tool. Observe

torque (see “Tab. 3”)!

english

Support ring

Upper chevron seals

Upper pressure ring

Pressure spring

Lower pressure ring

Lower chevron seals

Spindle guide

Insertion direction

for packing gland parts

Tightening torques of spindle

Spindle diameter Tightening torque [Nm]

10 mm 6

14 mm 15

Tab. 3: Tightening torques of spindle

Installing swivel plate:

→ Connect swivel plate to the spindle.

→ Align bores of the swivel plate and spindle.

→ Support swivel plate on the cylindrical part with the aid of a prism

or something similar.

→ Insert pin into the bore.

→ Swage pin bores on both sides of the swivel plate using a chisel

or center punch.

Spindle

Pin

Swivel plate

english

Installing the actuator on the valve body:

→ Check the graphite seal and if required, replace it.

WARNING!

Danger if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen applications there is a risk of an explosion!

• In specific applications, e.g. oxygen or analysis applications, use

appropriately authorised lubricants only.

→ Grease nipple thread before re-installing the actuator (e.g. with

Klüber paste UH1 96-402 from Klüber).

NOTE!

Damage to the seat seal or the seat contour!

• When installing the actuator, ensure that the valve is in open

position.

→ Control function A pressurize the pilot air port 1 with compressed

air (5 bar): valve opens.

→ Screw actuator into the valve body.

Observe tightening torque (see “Tab. 2”).

INSTALLATION TOOLS

Installation wrench for packing gland

(Only for removal of packing glands up to January 2013)

Installation wrench Orifice Order no.

Spindle ∅ 10 mm 15 - 40 665 700

Spindle ∅ 14 mm 32 - 65 665 701

Tab. 4: Installation wrench

SW

Modified socket wrench for packing gland

(Series production status since January 2013)

Socket wrench Orifice SW Order no.

Spindle ∅ 10 mm 15 - 40 19 683 221

Spindle ∅ 14 mm

32 - 65 21 683 223

Tab. 5: Modified socket wrench

Special wrench for rotating the actuator

Order no.

665 702

Tab. 6: Special wrench

If you have any queries, please contact your Bürkert sales

office.

english

Type 2100

Page 5

Austauschanleitung

Instructions de remplacement

Replacement Instructions

Type 2100

2/2-way Angle Seat Valve

2/2-Wege Schrägsitzventil

Vanne à siège incliné 2/2 voies

Address / Adresse

Germany / Deutschland / Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

www.burkert.com

Manuals and data sheets on the Internet:

www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet:

www.buerkert.de

Instructions de service et fiches techniques sur Internet :

www.buerkert.fr

© Bürker t Werke GmbH, 2013

Replacement Instructions 1309/01_EU-ml_00810231 /

Original DE

www.burkert.com

Page 6

DARSTELLUNGSMITTEL

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

Warnung vor schweren oder tödlichen Verletzungen:

GEFAHR!

Bei unmittelbarer Gefahr.

WARNUNG!

Bei möglicher Gefahr.

Warnung vor leichten oder mittelschweren Verletzungen:

VORSICHT!

ERSATZTEILSÄTZE

Als Ersatzteilsätze für das Schrägsitzventil Typ 2100 sind erhältlich:

• Ventilsatz

besteht aus Pendelteller mit PTFE Dichtung, Steckstift und

Graphitdichtung

• Dichtungssatz für Stopfbuchse

besteht aus den Einzelteilen der Stopfbuchse, Graphitdichtung und

Schmierstoff

(der modifizierte Steckschlüssel ist nicht im Dichtungssatz enthalten)

ÜBERSICHT ERSATZTEILSÄTZE

1

2

3

4

Pos. Beschreibung

1

Ventilsatz

Graphitdichtung (verpackt)

2 Pendelteller mit PTFE Dichtung

3 Steckstift

4 Dichtungssatz für Stopfbuchse

deutsch

HINWEIS!

Beschädigung der Sitzdichtung bzw. der Sitzkontur!

• Das Ventil muss sich bei der Demontage des Antriebs in geöffneter

Stellung befinden.

→ Bei Steuerfunktion A (SFA): den Steuerluftanschluss 1 mit Druckluft

(5 bar) beaufschlagen: Ventil öffnet.

→ An der Schlüsselfläche des Nippels mit passendem Gabelschlüssel

ansetzen.

→ Antrieb vom Ventilgehäuse abschrauben.

Antrieb

Nippel

Ventilgehäuse

Schlüsselfläche

für Gabelschlüssel

Steuerluftanschluss

SFA, SFB, SFI

Entlüftungsanschluss

SFA, SFB

Steuerluftanschluss

SFI

2

1

WECHSEL DES VENTILSATZES

GEFAHR!

Verletzungsgefahr durch Mediumsaustritt und Druckentladung!

Der Ausbau eines Geräts das unter Druck steht ist wegen plötzlicher

Druckentladung oder Mediumsaustritt gefährlich.

• Vor dem Ausbau den Druck abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr durch falsches Werkzeug!

Montagearbeiten mit ungeeignetem Werkzeug sind wegen der möglichen Beschädigung des Geräts gefährlich.

• Zur Demontage des Antriebs vom Ventilgehäuse einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden.

Für den Austausch des Ventilsatzes muss zunächst der Antrieb

vom Ventilgehäuse demontiert werden.

Antrieb vom Ventilgehäuse demontieren:

→ Ventilgehäuse in eine Haltevorrichtung einspannen (gilt nur für

noch nicht eingebaute Ventile).

deutsch

Ventilsatz tauschen:

→ Pendelteller am zylindrischen Teil mit Hilfe eines Prismas oder etwas

Ähnlichem abstützen.

→ Steckstift mit einem passenden Splinttreiber herausschlagen.

Splinttreiber ø 3 mm, bei Spindeldurchmesser 10 mm am

Pendelteller (siehe „Tab. 1“).

Splinttreiber ø 5 mm, bei Spindeldurchmesser 14 mm am

Pendelteller (siehe „Tab. 1“).

→ Pendelteller abziehen.

Spindel

Steckstift

Pendelteller

Graphitdichtung

→ Neuen Pendelteller auf die Spindel stecken.

→ Bohrungen von Pendelteller und Spindel zueinander fluchtend

ausrichten.

→ Pendelteller am zylindrischen Teil mit Hilfe eines Prismas oder

etwas Ähnlichem abstützen.

→ Steckstift in die Bohrung einsetzen.

→ Steckstiftbohrungen am Pendelteller beidseitig mit Meißel oder

Körner verstemmen.

Spindel

ø

DN Antriebsgröße

10 15 bis 40

1)

ø 50

ø 70

14 32 bis 65

ø 90

ø 130

Tab. 1: Spindel ø in Bezug zu DN und Antriebsgröße

1)

Austausch der Stopfbuchse für DN 50 Spindel ø 10 nicht

möglich.

deutsch

Typ 2100

Page 7

Antrieb auf Ventilgehäuse montieren:

→ Graphitdichtung prüfen und bei Bedarf erneuern.

WARNUNG!

Gefahr durch falsche Schmierstoffe!

Ungeeigneter Schmierstoff kann das Medium verunreinigen. Bei

Sauerstoffanwendungen besteht dadurch Explosionsgefahr!

• Bei spezifischen Anwendungen wie z. B. Sauerstoff- oder Analyseanwendungen nur entsprechend zugelassene Schmierstoffe

verwenden.

→ Nippelgewinde vor Wiedereinbau des Antriebs einfetten (z. B. mit

Klüberpaste UH1 96-402 der Fa. Klüber).

HINWEIS!

Beschädigung der Sitzdichtung bzw. der Sitzkontur!

• Das Ventil muss sich bei der Montage des Antriebs in geöffneter

Stellung befinden.

→ Bei Steuerfunktion A den Steuerluftanschluss 1 mit Druckluft (5 bar)

beaufschlagen: Ventil öffnet.

→ Antrieb in das Ventilgehäuse einschrauben. Anziehdrehmoment

beachten (siehe „Tab. 2“).

1

2

Steuerluftanschluss

SFA, SFB, SFI

Entlüftungsanschluss

SFA, SFB

Steuerluftanschluss

SFI

Anziehdrehmomente

DN

(mm)

Anziehdrehmomente

[Nm]

15 45 ± 3

20 50 ± 3

25 60 ± 3

32

65 ± 3

40

50

70 ± 3

65

100 ±3

Tab. 2: Anziehdrehmomente Ventilgehäuse / Nippel

deutsch

WECHSEL DES DICHTUNGSSATZES

WARNUNG!

Verletzungsgefahr durch falsches Werkzeug!

Montagearbeiten mit ungeeignetem Werkzeug sind wegen der möglichen Beschädigung des Geräts gefährlich.

• Zur Demontage des Antriebs vom Ventilgehäuse einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden.

GEFAHR!

Verletzungsgefahr durch Mediumsaustritt und Druckentladung!

Der Ausbau eines Geräts das unter Druck steht ist wegen plötzlicher

Druckentladung oder Mediumsaustritt gefährlich.

• Vor dem Ausbau den Druck abschalten und Leitungen entlüften.

Der Dichtungssatz für die Stopfbuchse enthält:

Pos. Beschreibung Pos. Beschreibung

1 1 Stützring 5 1 Spindelführung

2 7 Dachmanschetten 6 Graphitdichtung

3 2 Druckringe 7 Schmierstoff

4 1 Druckfeder

Bei der Gerätekombination ø 70 / DN 50 ist der Austausch der

Stopfbuchse nicht möglich.

Für den Austausch der Stopfbuchse muss zunächst der

Antrieb vom Ventilgehäuse demontiert und der Pendelteller

ausgebaut werden.

Antrieb vom Ventilgehäuse demontieren:

→ Ventilgehäuse in eine Haltevorrichtung einspannen (gilt nur für

noch nicht eingebaute Ventile).

HINWEIS!

Beschädigung der Sitzdichtung bzw. der Sitzkontur!

• Das Ventil muss sich bei der Demontage des Antriebs in geöffneter

Stellung befinden.

→ Bei Steuerfunktion A den Steuerluftanschluss 1 mit Druckluft (5

bar) beaufschlagen: Ventil öffnet.

→ An der Schlüsselfläche des Nippels mit passendem Gabelschlüssel

ansetzen.

→ Antrieb vom Ventilgehäuse abschrauben.

deutsch

Antrieb

Nippel

Ventilgehäuse

Schlüsselfläche

für Gabelschlüssel

Steuerluftanschluss

SFA, SFB, SFI

Entlüftungsanschluss

SFA, SFB

Steuerluftanschluss

SFI

2

1

Pendelteller demontieren:

→ Steckstift mit einem passenden Splinttreiber herausschlagen.

Splinttreiber ø 3 mm, bei Spindeldurchmesser 10 mm am

Pendelteller (siehe „Tab. 1“).

Splinttreiber ø 5 mm, bei Spindeldurchmesser 14 mm am

Pendelteller (siehe „Tab. 1“).

→ Pendelteller abziehen.

Spindel

Steckstift

Pendelteller

Graphitdichtung

→ Spindelführung mit Hilfe des Montageschlüssels

2)

und eines Gabel-

schlüssels herausschrauben (Serienstand bis Januar 2013).

→ Spindelführung mit Hilfe eines modifizierten Steckschlüssels

2)

herausschrauben (Serienstand ab Januar 2013).

2)

Der Montageschlüssel bzw. modifizierter Steckschlüssel

sind über Ihre Bürkert-Vertriebsniederlassung erhältlich.

deutsch

Typ 2100

Page 8

Montageschlüssel

Stopfbuchse

Spindelführung

Spindel

Stopfbuchsenrohr

Serienstand

bis Januar 2013

Stopfbuchse

Spindelführung

Spindel

Stopfbuchsenrohr

Serienstand

ab Januar 2013

WARNUNG!

Verletzungsgefahr durch herausspringende Teile!

Bei freiliegender Spindelöffnung werden beim Beaufschlagen des

Steuerluftanschlusses die Einzelteile der Stopfbuchse mit undefinierter

Geschwindigkeit herausgedrückt.

• Vor dem Beaufschlagen mit Steuerluft den Umgebungsbereich der

Austrittsöffnung absichern (z. B. Spindel auf eine feste Unterlage

aufsetzen).

→ Bei Steuerfunktion A und I den Steuerluftanschluss 1 mit 6 ... 8

bar beaufschlagen.

→ Bei Steuerfunktion B den Steuerluftanschluss 2 mit 6 ... 8 bar

beaufschlagen.

→ Die Einzelteile der neuen Stopfbuchse mit dem mitgelieferten

Schmierstoff einfetten.

→ Die Einzelteile in vorgegebener Richtung und Reihenfolge auf die

Spindel stecken.

→ Stopfbuchsenpackung in das Stopfbuchsenrohr schieben.

→ Spindelführung unter Verwendung des Steckschlüssels wieder

einschrauben. Anziehdrehmoment beachten (siehe „Tab. 3“)!

deutsch

Stützring

obere Dachmanschetten

oberer Druckring

Druckfeder

unterer Druckring

untere Dachmanschetten

Spindelführung

Einschieberichtung

für Stopfbuchsenteile

Anziehdrehmomente Spindelführung

Spindeldurchmesser Anziehdrehmoment [Nm]

10 mm 6

14 mm 15

Tab. 3: Anziehdrehmomente Spindelführung

Pendelteller montieren:

→ Pendelteller auf die Spindel stecken.

→ Bohrungen von Pendelteller und Spindel zueinander fluchtend

ausrichten.

→ Pendelteller am zylindrischen Teil mit Hilfe eines Prismas oder etwas

Ähnlichem abstützen.

→ Steckstift in die Bohrung einsetzen.

→ Steckstiftbohrungen am Pendelteller beidseitig mit Meißel oder

Körner verstemmen.

Spindel

Steckstift

Pendelteller

deutsch

Antrieb auf Ventilgehäuse montieren:

→ Graphitdichtung prüfen und bei Bedarf erneuern.

WARNUNG!

Gefahr durch falsche Schmierstoffe!

Ungeeigneter Schmierstoff kann das Medium verunreinigen. Bei

Sauerstoffanwendungen besteht dadurch Explosionsgefahr!

• Bei spezifischen Anwendungen wie z. B. Sauerstoff- oder Analyseanwendungen nur entsprechend zugelassene Schmierstoffe

verwenden.

→ Nippelgewinde vor Wiedereinbau des Antriebs einfetten (z. B. mit

Klüberpaste UH1 96-402 der Fa. Klüber).

HINWEIS!

Beschädigung der Sitzdichtung bzw. der Sitzkontur!

• Das Ventil muss sich bei der Montage des Antriebs in geöffneter

Stellung befinden.

→ Bei Steuerfunktion A den Steuerluftanschluss 1 mit Druckluft (5 bar)

beaufschlagen: Ventil öffnet.

→ Antrieb in das Ventilgehäuse einschrauben. Anziehdrehmoment

beachten (siehe „Tab. 2“).

MONTAGEWERKZEUGE

Montageschlüssel für Stopfbuchse

(nur zur Demontage von Stopfbuchsen bis Januar 2013)

Montageschlüssel DN Bestellnummer

Spindel ∅ 10 mm 15 - 40 665 700

Spindel ∅ 14 mm 32 - 65 665 701

Tab. 4: Montageschlüssel

SW

Modifizierter Steckschlüssel für Stopfbuchse

(Serienstand ab Januar 2013)

Steckschlüssel DN SW Bestellnummer

Spindel ∅ 10 mm 15 - 40 19 683 221

Spindel ∅ 14 mm

32 - 65 21 683 223

Tab. 5: Modifizierter Steckschlüssel

Spezialschlüssel zum Drehen des Antriebs

Bestellnummer

665 702

Tab. 6: Spezialschlüssel

Wenden Sie sich bei Fragen bitte an Ihre

Bürkert-Vertriebsniederlassung.

deutsch

Typ 2100

Page 9

Austauschanleitung

Instructions de remplacement

Replacement Instructions

Type 2100

2/2-way Angle Seat Valve

2/2-Wege Schrägsitzventil

Vanne à siège incliné 2/2 voies

Address / Adresse

Germany / Deutschland / Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

www.burkert.com

Manuals and data sheets on the Internet:

www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet:

www.buerkert.de

Instructions de service et fiches techniques sur Internet :

www.buerkert.fr

© Bürker t Werke GmbH, 2013

Replacement Instructions 1309/01_EU-ml_00810231 /

Original DE

www.burkert.com

Page 10

SYMBOLES

→ Identifie une opération que vous devez effectuer.

Mise en garde contre les blessures graves ou mortelles :

DANGER !

En cas de danger imminent.

AVERTISSEMENT !

En cas de danger possible.

Mise en garde contre les blessures légères ou moyennement graves :

PRUDENCE !

JEUX DE PIÈCES DE RECHANGE

Les jeux de pièces de rechange suivants sont disponibles pour la

vanne à siège incliné type 2100 :

• Jeu de vannes

comprenant le clapet plat avec joint PTFE, la goupille et le joint

graphite.

• Jeu de joints pour presse-étoupe

comprenant les pièces détachées du pack presse-étoupe, le joint

graphite et le lubrifiant

(la clé à pipe modifiée n’est pas comprise dans le jeu de joints).

VUE D’ENSEMBLE DES JEUX DE PIÈCES DE

RECHANGE

1

2

3

4

Pos. Description

1

Jeu de vannes

Joint graphite (emballé)

2 Clapet plat avec joint PTFE

3 Goupille

4 Jeu de joints pour presse-étoupe

français

REMARQUE !

Endommagement du joint ou du contour de siège.

• Lors de la démontage de l’actionneur, la vanne doit être en position

ouverte.

→ Avec la fonction A il convient d’appliquer de l’air comprimé

(5 bars) au raccord d’air de pilotage: ouverture da la vanne.

→ Positionner à l’aide d’une clé plate appropriée sur l’embout.

→ Dévisser l’actionneur du corps de vanne.

Actionneur

Embout

Corps de vanne

Méplat pour

clé à fourche

Raccord d’air de pilotage

CFA, CFB, CFI

Raccord de purge d’air

CFA, CFB

Raccord d’air de pilotage

CFI

2

1

REMPLACEMENT DU JEU DE VANNES

DANGER !

Risque de blessures dû à la sortie de fluide et à la décharge de

pression !

Le démontage d’un appareil sous pression est dangereux du fait de

la décharge de pression ou de la sortie de fluide soudaine.

• Avant le démontage, coupez la pression et purgez l’air des conduites.

AVERTISSEMENT !

Risque de blessures dû à de mauvais outils !

Les travaux de montage effectués avec des outils non appropriés

sont dangereux du fait de l’endommagement possible de l’appareil.

• Utilisez une clé plate pour démonter l’actionneur du corps de vanne,

en aucun cas une clé à tubes.

Le remplacement du jeu de vannes nécessite le démontage de

l’actionneur du corps de vanne.

Démonter l’actionneur du corps de vanne :

→ Serrer le corps de vanne dans un dispositif de maintien

(uniquement valable pour les vannes pas encore montées).

français

Remplacer le jeu de vannes :

→ Soutenir le clapet plat au niveau de la partie cylindrique à l‘aide

d‘un prisme ou semblable.

→ Sortir la goupille avec un chasse-goupilles adapté.

Chasse-goupilles ø 3 mm, pour diamètre de tige 10 mm sur le

clapet plat (voir « Tab. 1 »).

Chasse-goupilles ø 5 mm, pour diamètre de tige 14 mm sur le

clapet plat (voir « Tab. 1 »).

→ Retirer le clapet plat.

Tige

Goupille

Clapet plat

Joint graphite

→ Mettre un nouveau clapet plat sur la tige.

→ Aligner les alésages du clapet plat et de la tige de façon qu’ils

correspondent.

→ Soutenir le clapet plat au niveau de la partie cylindrique à l’aide

d’un prisme ou semblable.

→ Introduire la goupille dans l’alésage.

→ Assurer le blocage des deux côtés des alésages pour goupille sur

le disque pendulaire avec un burin ou un pointeau.

Tige

ø

Diamètre Taille de

l’actionneur

10 15 - 40

1)

ø 50

ø 70

14 32 - 65

ø 90

ø 130

Tab. 1 : Tige ø par référence à diamètre et taille de l’actionneur

1)

Impossible de remplacer le presse-étoupe de la broche DN 50

de ø 10.

français

Type 2100

Page 11

Monter l’actionneur sur le corps de vanne :

→ Contrôler le joint graphite et si nécessaire, le remplacer.

AVERTISSEMENT !

Danger dû à de mauvais lubrifiants !

Un lubrifiant non approprié peut encrasser le fluide. En cas d’applications

faisant usage d’oxygène il existe alors un risque d’explosion.

• Utilisez uniquement des lubrifiants homologués pour les applications

spécifiques comme par ex. celles faisant usage d’oxygène ou les

applications d’analyse.

→ Avant de remonter l’actionneur, lubrifiez le filet du embout

(par ex. de pâte Klüber UH1 96-402 de la société Klüber).

REMARQUE !

Endommagement du joint ou du contour de siège.

• Lors de la montage de l’actionneur, la vanne doit être en position

ouverte.

→ Avec la fonction A il convient d’appliquer de l’air comprimé (5

bars) au raccord d’air de pilotage: ouverture da la vanne.

→ Visser l’actionneur dans le corps de vanne. Respecter le couple de

serrage (voir « Tab. 2 »).

1

2

Raccord d’air de pilotage

CFA, CFB, CFI

Raccord de purge d’air

CFA, CFB

Raccord d’air de pilotage

CFI

Couples de serrage

Diamètre

(mm)

Couples de serrage

[Nm]

15 45 ± 3

20 50 ± 3

25 60 ± 3

32

65 ± 3

40

50

70 ± 3

65

100 ±3

Tab. 2 : Couples de serrage corps de vanne / embout

français

REMPLACEMENT DU JEU DE JOINTS

AVERTISSEMENT !

Risque de blessures dû à de mauvais outils !

Les travaux de montage effectués avec des outils non appropriés

sont dangereux du fait de l’endommagement possible de l’appareil.

• Utilisez une clé plate pour démonter l’actionneur du corps de vanne,

en aucun cas une clé à tubes.

DANGER !

Risque de blessures dû à la sortie de fluide et à la décharge de

pression !

Le démontage d’un appareil sous pression est dangereux du fait de

la décharge de pression ou de la sortie de fluide soudaine.

• Avant le démontage, coupez la pression et purgez l’air des conduites.

Le jeu de joints du presse-étoupe comprend :

Pos. Description Pos. Description

1 1 anneau de support 5 1 ressort de pression

2 7 manchettes de toit 6 Joint graphite

3 2 bagues de pression 7 Lubrifiant

4 1 guidage de tige

Avec la combinaison d’appareils ø 70 / diamètre 50 , le remplacement du presse-étoupe n’est pas possible.

Le remplacement du presse-étoupe nécessite le démontage

de l’actionneur du corps de vanne et du clapet plat.

Démonter l’actionneur du corps de vanne :

→ Serrer le corps de vanne dans un dispositif de maintien

(uniquement valable pour les vannes pas encore montées).

REMARQUE !

Endommagement du joint ou du contour de siège.

• Lors de la démontage de l’actionneur, la vanne doit être en position ouverte.

→ Avec la fonction A il convient d’appliquer de l’air comprimé (5 bars)

au raccord d’air de pilotage: ouverture da la vanne.

→ Positionner à l’aide d’une clé plate appropriée sur l’embout.

→ Dévisser l’actionneur du corps de vanne.

français

Actionneur

Embout

Corps de vanne

Méplat pour

clé à fourche

Raccord d’air de pilotage

CFA, CFB, CFI

Raccord de purge d’air

CFA, CFB

Raccord d’air de pilotage

CFI

2

1

Démonter le clapet plat :

→ Sortir la goupille avec un chasse-goupilles adapté.

Chasse-goupilles ø 3 mm, pour diamètre de tige 10 mm sur le

clapet plat (voir « Tab. 1 »).

Chasse-goupilles ø 5 mm, pour diamètre de tige 14 mm sur le

clapet plat (voir « Tab. 1 »).

→ Retirer le clapet plat.

Tige

Goupille

Clapet plat

Joint graphite

→ Dévisser le guidage de tige à l’aide d’un outil de montage et d’une

clé plate 2) (etat de série jusqu’en janvier 2013).

→ Dévisser le guidage de tige à l’aide d’une clé à pipe modifiée

2)

(etat de série à partir de janvier 2013).

2)

L’outil de montage ou la clé à pipe modifiée est disponible

auprès de votre filiale de distribution Bürkert.

français

Type 2100

Page 12

Clé de montage

Presse-étoupe

Guidage de tige

Tige

Tube presse-étoupe

Etat de série jusqu’en

janvier 2013

Presse-étoupe

Guidage de tige

Tige

Tube presse-étoupe

Etat de série

à partir de janvier

2013

AVERTISSEMENT !

Risque de blessures dû à l’éjection de pièces.

Lorsque l’ouverture de tige est libre et la pression est appliquée au

raccord d’air de pilotage, les pièces détachées du presse-étoupe

sortent à une vitesse non définie.

• Avant d’appliquer l’air de pilotage, sécurisez l’environnement de

l’ouverture de sortie (par ex. posez la tige sur un support solide).

→ Avec la fonction A et I raccord d‘air de pilotage 1 une pression

de 6 - 8 bars.

→ Avec la fonction B raccord d‘air de pilotage 2 une pression de

6 - 8 bars.

→ Lubrifier les pièces détachées du nouveau presse-étoupe du

lubrifiant fourni.

→ Positionner les pièces détachées dans le sens et l’ordre indiqués

sur la tige.

→ Insérer la garniture presse-étoupe dans le tube presse-étoupe.

→ Revisser le guidage de tige en utilisant l’outil de montage.

Respectez le couple de serrage (voir « Tab. 3 »)!

français

Anneau de support

Manchettes de toit supérieures

Bague de pression supérieure

Ressort de pression

Bague de pression inférieure

Manchettes de toit inférieures

Guidage de tige

Sens d’insertion pour

pièces de presse-étoupe

Couples de serrage de la tige

Diamètre de tige Couple de serrage [Nm]

10 mm 6

14 mm 15

Tab. 3 : Couples de serrage de la tige

Monter le clapet plat :

→ Mettre le clapet plat sur la tige.

→ Aligner les alésages du clapet plat et de la tige de façon qu’ils

correspondent.

→ Soutenir le clapet plat au niveau de la partie cylindrique à l’aide

d’un prisme ou semblable.

→ Introduire la goupille dans l’alésage.

→ Assurer le blocage des deux côtés des alésages pour goupille sur

le clapet plat avec un burin ou un pointeau.

Tige

Goupille

Clapet plat

français

Monter l’actionneur sur le corps de vanne :

→ Contrôler le joint graphite et si nécessaire, le remplacer.

AVERTISSEMENT !

Danger dû à de mauvais lubrifiants !

Un lubrifiant non approprié peut encrasser le fluide. En cas d’applications

faisant usage d’oxygène il existe alors un risque d’explosion.

• Utilisez uniquement des lubrifiants homologués pour les applications

spécifiques comme par ex. celles faisant usage d’oxygène ou les

applications d’analyse.

→ Avant de remonter l’actionneur, lubrifiez le filet du embout

(par ex. de pâte Klüber UH1 96-402 de la société Klüber).

REMARQUE !

Endommagement du joint ou du contour de siège.

• Lors de la montage de l’actionneur, la vanne doit être en position

ouverte.

→ Avec la fonction A il convient d’appliquer de l’air comprimé

(5 bars) au raccord d’air de pilotage: ouverture da la vanne.

→ Visser l’actionneur dans le corps de vanne. Respecter le couple de

serrage (voir « Tab. 2 »).

OUTILS DE MONTAGE

Clé de montage pour presse-étoupe

(Uniquement pour le démontage des presse-étoupe jusqu’en janvier 2013)

Clé de montage Diamètre Numéro de commande

Tige ∅ 10 mm 15 - 40 665 700

Tige ∅ 14 mm 32 - 65 665 701

Tab. 4 : Clé de montage

SW

Clé à pipe modifiée pour presse-étoupe

(Etat de série à partir de janvier 2013)

Clé à pipe

modifiée

Diamètre SW

Numéro de

commande

Tige ∅ 10 mm 15 - 40 19 683 221

Tige ∅ 14 mm 32 - 65 21 683 223

Tab. 5 : Clé à pipe modifiée

Clé spéciale pour la rotation de l’actionneur

Numéro de commande

665 702

Tab. 6 : Clé spéciale

Si vous avez des questions, veuillez contacter votre filiale de

distribution Bürkert.

français

Type 2100

Loading...

Loading...