Page 1

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous resérve de modification

techniques.

© 2008 - 2011 Bürkert Werke GmbH

Operating Instructions 1107/03_EU-ml_00805824

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Type 2080

BELLOWS VALVE

2/2-way valve with piston actuator and PTFE bellows

2/2-Wege Ventil mit Kolbenantrieb und PTFE-Faltenbalg

Vanne 2/2 voies avec entraînement à piston et soufflet PTFE

english

2

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the

device. Keep these instructions in a location which is easily

accessible to every user and make these instructions available

to every new owner of the device.

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

• The operating instructions must be read and understood.

english

3

2. SYMBOLS

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or

serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in a serious or

fatal injury.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a medium

or minor injury.

NOTE!

Warns of damage to property!

Important tips and recommendations.

→ designates a procedure which you must carry out.

Page 2

english

4

3. INTENDED USE

WARNING!

Incorrect use of the bellows valve Type 2080 can

be dangerous to people, nearby equipment and the

environment.

• The device is designed for the controlled flow of liquid

and gaseous media.

• For use observe the permitted data, operating and application conditions which are described in the contract

documents as well as on the type plate and in the operating instructions in the chapters entitled “Structure and

Function” and “Technical Data”.

• The device may be used only in conjunction with thirdparty devices and components recommended and authorised by Bürkert.

• Correct transport, correct storage and installation and

careful use and maintenance are essential for reliable and

problem-free operation.

• Use the bellows valve Type 2080 only as intended.

english

5

3.1. Possible errors in use

• Do not place any loads on the body (e.g. by placing

objects on it or standing on it).

• Do not make any external modifications to the valve

bodies.

• Do not introduce any aggressive or flammable media into

the pilot air connections of the system.

• Supply the media connections only with those media

which are specified as flow media in the chapter entitled

“Technical Data”.

english

6

4. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any:

• Contingencies and events which may arise during the installation, operation and maintenance of the devices.

• Local safety regulations – the operator is responsible for

observing these regulations, also with reference to the

installation personnel.

DANGER!

Risk of injury from high pressure.

• Before loosening the lines and valves, turn off the pressure and vent the lines!

Risk of burns/fire from continuous operation!

When metering hot media, the device may become very

hot.

• Always wear protective gloves when handling a device

which controls hot media.

• Keep readily flammable materials and media away from

the device.

english

7

General hazardous situations.

To prevent injury, ensure that:

• The system cannot be activated unintentionally.

• Installation and repair work may be carried out by authorized technicians only and with the appropriate tools.

• After an interruption in the power supply or pneumatic

supply, ensure that the process is restarted in a defined

or controlled manner.

• The device may be operated only when in perfect condition and in consideration of the operating instructions.

• The general rules of technology apply to application planning and operation of the device.

Failure to observe this operating manual and its

operating instructions as well as unauthorized tampering with the device release us from any liability

and also invalidate the warranty covering the device

and accessories!

Type 2080

Page 3

english

8

5. GENERAL INFORMATION

5.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel.: +49 (0)7940 - 10 91 111

Fax: +49 (0)7940 - 10 91 448

E-mail: info@de.burkert.com

International

Contact addresses can be found on the final pages of the

printed operating instructions.

And also on the internet at: www.burkert.com

5.2. Warranty

The warranty is only valid if the device valve Type 2080 is

used as intended in accordance with the specified application

conditions.

5.3. Information on the Internet

The operating instructions and data sheets for Type 2080 can

be found on the Internet at: www.burkert.com

english

9

6. STRUCTURE AND FUNCTION

6.1. Modularity

The valve is modular in design and can be supplied with

different media connections (also customized) and actuator

versions according to the application case. It can be used

individually and also in blocks.

6.2. Structure

The valve consists of a pneumatically actuated piston actuator

with return spring, a stainless steel body and PTFE bellows.

The bellows are used to separate media. If the installation

location is appropriate, the valve is self-draining.

The materials used and the inner contours facilitate cleaning

(CIP/SIP).

The pneumatic actuator must be controlled externally via a

pilot valve or a valve island.

english

10

Bolts for attaching the

actuator to the body

Pilot air connections

Threaded ports G 1/8

Connection CF B (NO)

Connection CF A (NC)

Flange Threaded port Welded end

G 3/8

Media connections

Notch for monitoring of

bellow leakage

english

11

7. TECHNICAL DATA

7.1. Operating Conditions

Ambient temperature -10 ... +90 °C

Medium temperature -30 ... +150 °C

(see PT graph)

Media Neutral to aggressive gases

and liquids, technical vacuum

7.2. Restrictions

For Valves with a flow inlet over seat:

WARNING!

Risk of injury from water hammer.

If flow inlet over seat with liquid media, water hammers may

occur. As a consequence, lines or the device may burst

and medium flow out.

• Consider the type of flow inlet and the type of medium

for operation of the device.

• If flow inlet over seat before the use of liquid media,

to avoid water hammers, in case of doubt, clarify the

application conditions (medium, line length and crosssection) with the Bürkert sales office.

Type 2080

Page 4

english

12

7.3. Conformity

The device conforms to the EC directives according to the

EC Declaration of Conformity.

7.4. Standards

The conformity with EC guidelines is guaranteed in accordance with standards:

• EN 13463-1, EN 13463-5

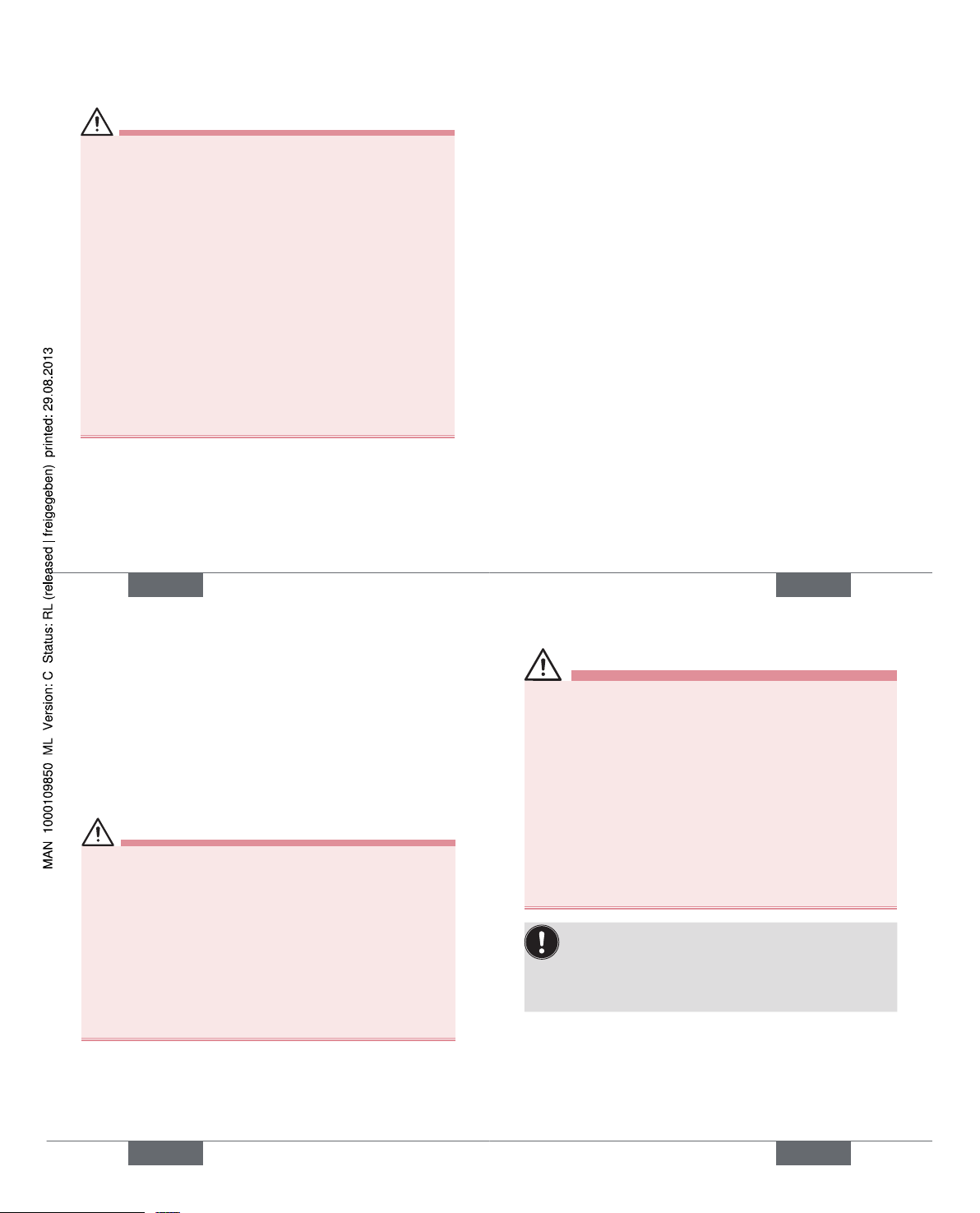

7.5. PT graph

Permitted pressure-temperature compatibility of the PTFE

bellows

(Pressure value [bar]: Measured as overpressure to the

atmospheric pressure)

0

0 20 40 60 80 100 120

140

160 180

1

2

3

4

5

6

7

8

9

Permitted

range

P [bar]

T [°C]

english

13

7.6. Mechanical Data

Dimensions See data sheet

Body material

Fitting Stainless steel 316L (1.4404)

Actuator Stainless steel 304 (1.4301)

Bellows PTFE

Bellows stroke 2.5 mm

Internal surface finish Ra = 0.8 µm

7.7. Fluidic data

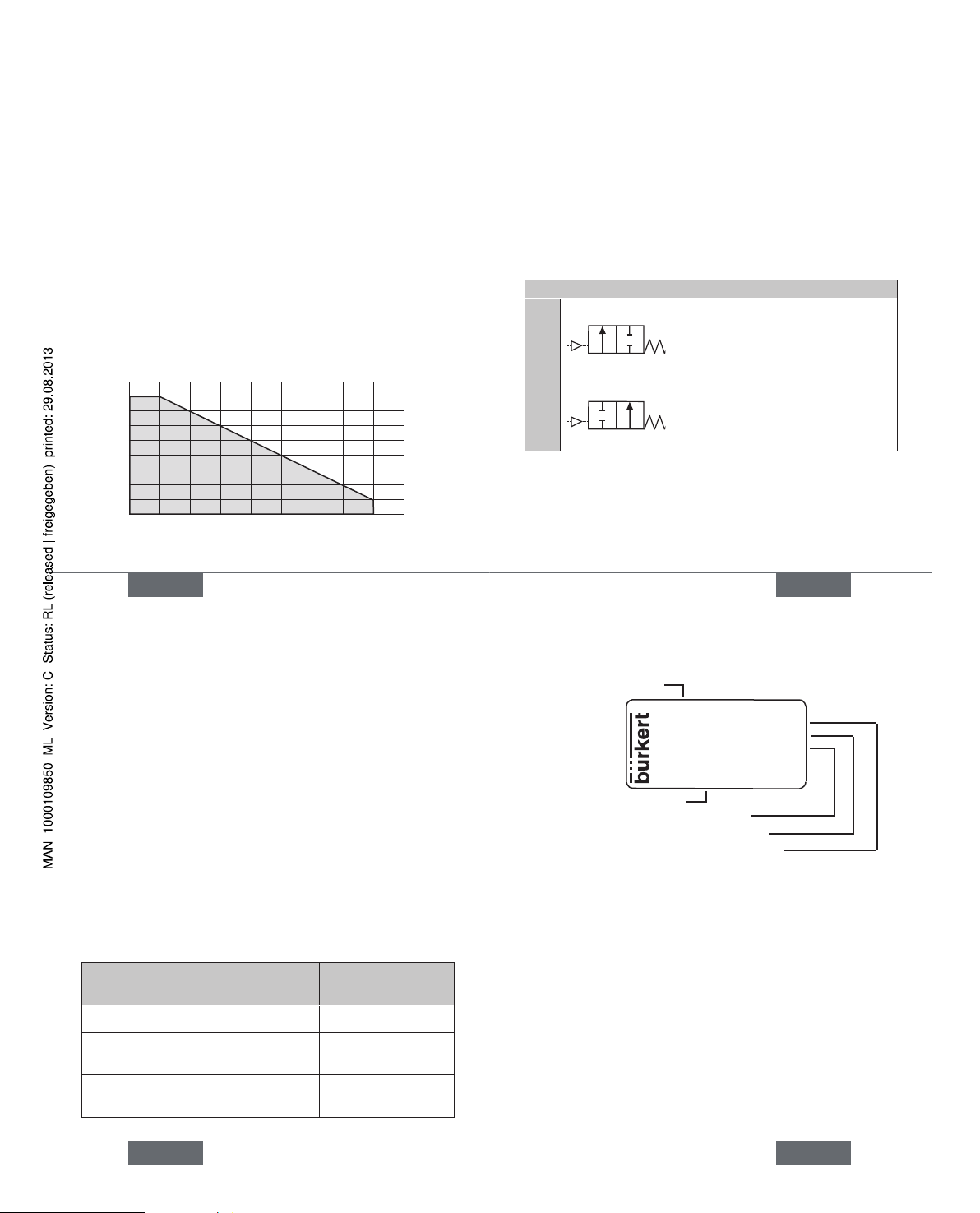

Circuit functions

A

A

P

2/2-way valve, servo-assisted,

closed without pilot air pressure

by spring force, actuation with

pilot valve, valve island or similar.

B

B

P

2/2-way valve, servo-assisted,

opened without pilot air pressure

by spring force, actuation with

pilot valve, valve island or similar.

Fitting

Pressure range of medium Vacuum ... 8 bar

(see PT graph)

Back pressure tightness up to 8 bar

english

14

Orifice DN 4 to DN 10

Line connections

Threaded port G 3/8

Welded ends

13.5 x 1.6 in accordance with ISO 4200

13 x 1.5 in accordance with DIN 1850-2

12.7 x 1.2 in accordance with BS 4825

Flange connection or

customized line connections

Actuator

Pilot air medium Compressed air 4.5 – 10 bar

(dry and filtered)

neutral gases

Pilot air connections Threaded port G 1/8

7.8. Actuator versions

Version

Operating

principle

Actuator Open - Closed CF A and CF B

Actuator Open - Closed

with position indicator

CF A and CF B

3 position actuator (with adjustable

intermediate position)

CF A

english

15

7.9. Label (example)

Made in Germany

00450000

W14UN

CE

Bellows valve

Type 2080 NC DN10

Pmax 8bar

Ppilot 4-10bar

Ident. no.

Nominal pressure

Type, Circuit function, Orifice

Description

Nominal pressure of pilot valve

Type 2080

Page 5

english

16

8. INSTALLATION

8.1. Safety Instructions

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians

only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

8.2. Fluid Installation

DANGER!

Danger – high pressure!

Serious risk of injury when reaching into the equipment.

• Before loosening the lines and valves, turn off the pressure and vent the lines.

Check that the operating conditions correspond

with the performance data of the device.

english

17

Installation position:

Installation can be in any position.

→ Install upright for self-draining (body to bottom and in

the case of threaded port and welded ends install at a

min. gradient of 1° for drainage of media).

Installation

→ Before installation, clean any possible dirt off the pipelines

and flange connections.

→ If necessary, install a dirt trap in front of the valve to protect

it from malfunctions.

Mesh size:

0.1 ... 0.4 mm

WARNING!

Danger - escaping medium!

Leaky connections with seals not properly seated.

• Fit all connections carefully and seal properly.

Seal the threaded port with a suitable sealing

material (PTFE tape is recommended).

english

18

Use the correct size of open-ended wrench to

screw in the pipelines; do not use the valve actuator

as a screwdriver!

The device must not be subject to any lateral

tension forces. The device connections must be in

alignment with the lines!

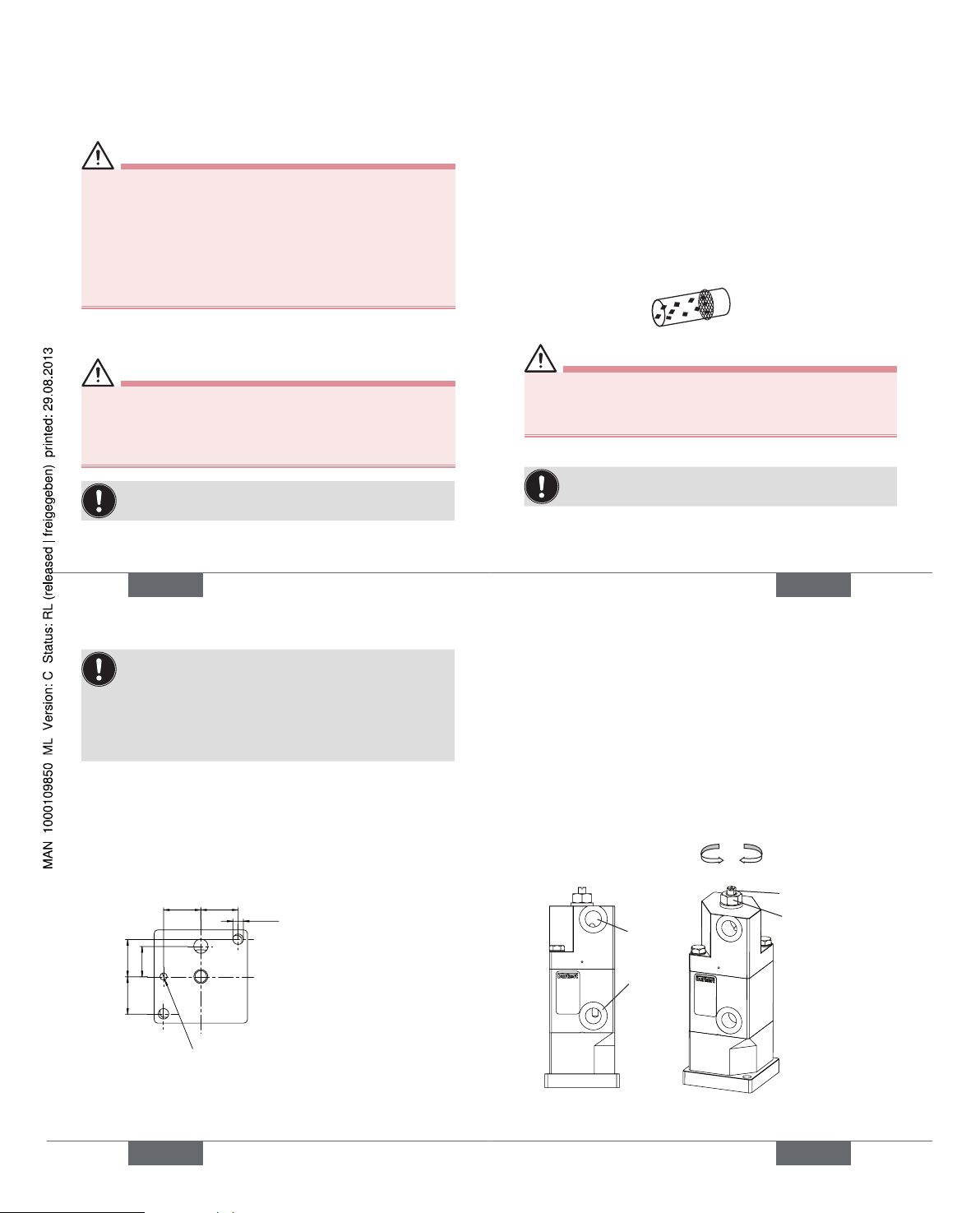

→ Attach the valve according to the connections:

Threaded port by screwing in the pipes,

Welded connection by welding,

Flange by screwing on.

Flange interface on the valve

16 16

Ø 4.5

Ø 3.1; 6 deep;

Option for positioning pin ø 3

(ensure correct location for installation)

16

16

13

english

19

8.3. Option: Valve with 3 position

actuator (with adjustable

intermediate position)

Functions of the valve:

• Closed (without pilot air, by spring force),

• Partial stroke (pilot air simultaneously on X and Y),

• Full stroke (pilot air on X only).

Adjusting spindle

Lock nut

Stroke setting on the spindle

Flange version

Y

X

Flow plus minus

Type 2080

Page 6

english

20

Setting the intermediate position:

→ attach a suitable flow measuring device (measuring

cup, flow meter, etc.),

→ loosen the lock nut,

→ connect pilot air to X and Y,

→ open the medium supply,

→ set the required flow on the adjusting spindle

stroke range = 0 to 2.5 mm (rotating the spindle

clockwise reduces the flow),

→ switch off the pilot air,

→ tighten the lock nut.

english

21

9. MAINTENANCE,

MALFUNCTIONS

9.1. Safety Instructions

DANGER!

Danger – high pressure in the equipment!

There is a serious risk of injury when reaching into the

equipment.

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

WARNING!

Danger due to improper maintenance work!

Improper maintenance may result in injuries as well as

damage to the device and the surrounding area.

• Maintenance work may be carried out by authorised

technicians only and with the appropriate tools!

Danger due to unintentional activation of the equipment!

Unintentional activation of the equipment during maintenance

and repair work may result in injuries and/or damage.

• Take appropriate measures to prevent the equipment

from being unintentionally activated.

english

22

9.2. Maintenance / Cleaning

The bellows situated between the medium compartment and

actuator ensure that the valve switches reliably and protect

the medium from contaminants coming from the actuator

side. These bellows are subject to symptoms of fatigue. If the

bellows are defective, medium will escape out of the leakage

detection opening. To prevent them from being destroyed,

the bellows should be changed prophylactically at regular

intervals (see instructions on changing the bellows). The valve

interior has no gaps and the inner compartment and bellows

have been designed with very smooth contours (surface

roughness max. 0.8 µm). The valve is CIP compatible (CIP =

cleaning in process) and SIP compatible (SIP = sterilization

in process).

9.3. Changing the bellows

Removing the actuator

→ Provide the required spare parts and a size 7 open-

ended wrench,

→ Interrupt the pilot air supply, vent and disconnect the

lines,

→ Interrupt the medium supply and vent the lines,

→ Loosen both fastening screws,

→ Remove the actuator.

english

23

Changing the bellows

→ Unscrew the bellows from the spindle,

→ Clean the inner compartment of the body,

→ Manually screw the new bellows onto the spindle and

tighten them hand-tight.

Attaching the actuator

→ Clean the O-ring 25 x 2 FKM 70 in the body, check

whether it can be re-used and, if required, replace it

with a new O-ring

→ Place the actuator with new bellows on the body;

ensure that the bores in the actuator are correctly

aligned with the thread in the body

→ Attach the actuator to the body with the fastening

screws (tightening torque from 2 to 2.2 Nm).

Restarting the bellows valve

→ Connect the pilot air line,

→ Open the pilot air,

→ Open the medium supply,

→ Conduct a function and leak test,,

→ If the valve functions reliably, it can be restarted.

Type 2080

Page 7

english

24

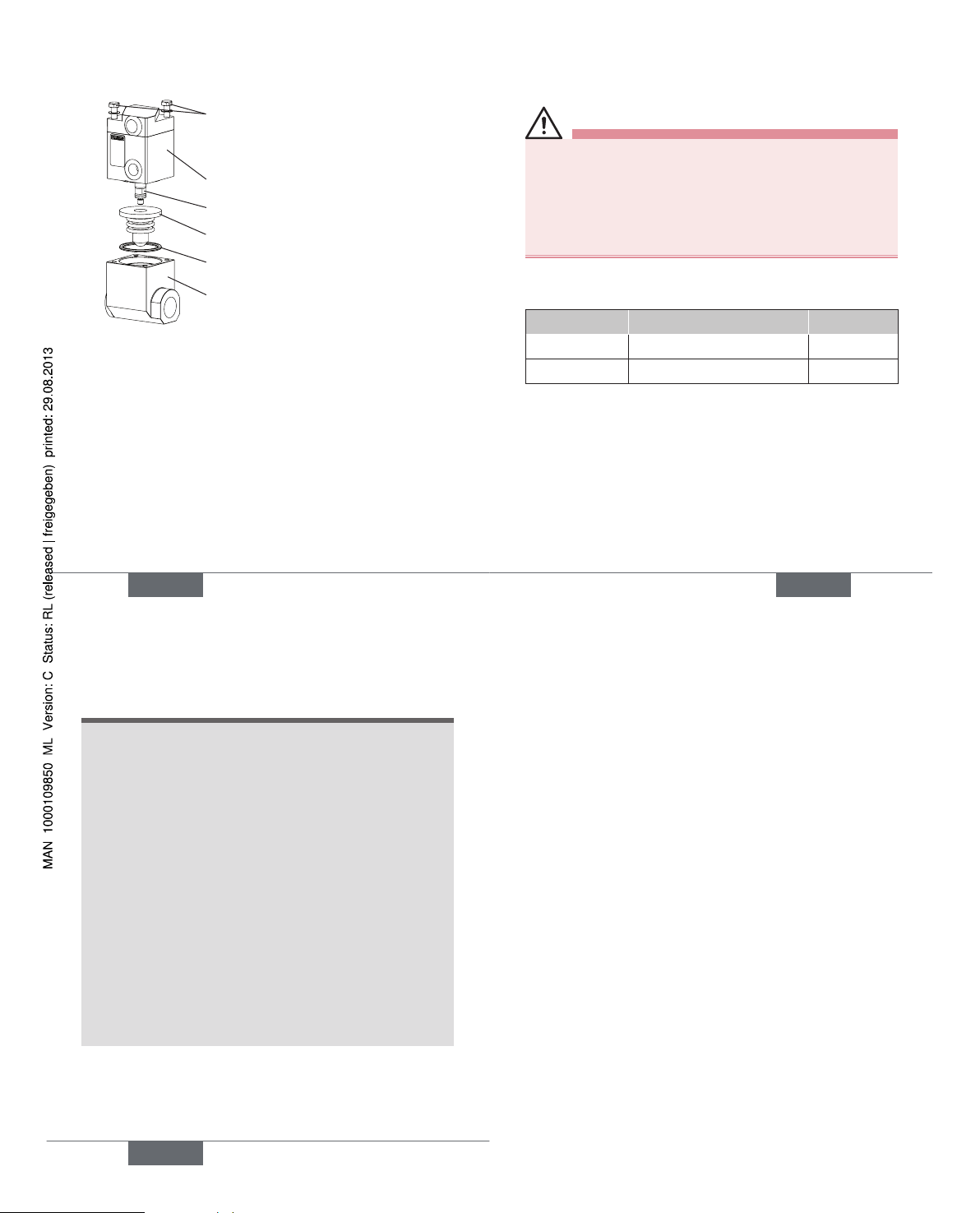

Exploded drawing of changing spare parts, Type 2080

Hexagon screws M4 x 50 in accordance with DIN 933-A4 for attaching

the actuator to the body

Actuator

Spindle

PTFE bellows

O-ring 25 x 2 FKM 70

Body (threaded port version)

9.4. Malfunctions

If malfunctions occur, check:

→ the line connections,

→ the operating pressure,

→ the pilot air supply which actuates the valve,

→ the bellows and, if required, change them (see chapter

9.3).

If the valve still does not switch, please contact your

Bürkert Service.

english

25

10. REPLACEMENT PARTS

CAUTION!

Risk of injury and/or damage by the use of incorrect

parts!

Incorrect accessories and unsuitable spare parts may cause

injuries and damage the device and the surrounding area.

• Use only original accessories and original replacement

parts from Bürkert.

Order table of spare parts

Spare part Description Order no.

Bellows Material PTFE 799 845

O-ring 25 x 2.0 N-FKM 70 914 378

english

26

11. TRANSPORT, STORAGE,

DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged

during transport.

• During transportation protect the device against wet

and dirt in shock-resistant packaging.

• Avoid exceeding or dropping below the allowable

storage temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: -20 ... +65 °C.

Damage to the environment caused by device components contaminated with media.

• Observe applicable regulations on disposal and the

environment.

• Dispose of the device and packaging in an environmentally friendly manner.

Page 8

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous resérve de modification

techniques.

© 2008 - 2011 Bürkert Werke GmbH

Operating Instructions 1107/03_EU-ml_00805824

Bedienungsanleitung

Deutsch

Type 2080

FALTENBALGVENTIL

2/2-Wege Ventil mit Kolbenantrieb und PTFE-Faltenbalg

deutsch

28

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus des Gerätes. Bewahren Sie diese Anleitung so auf,

dass sie für jeden Benutzer gut zugänglich ist und jedem

neuen Eigentümer des Gerätes wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen

Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden

werden.

29

deutsch

2. DARSTELLUNGSMITTEL

In dieser Anleitung werden folgende Darstellungsmittel

verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung können schwere Verletzungen oder

Tod die Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen.

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

Page 9

deutsch

30

3. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Faltenbalgventils Typ 2080 können Gefahren für Personen,

Anlagen in der Umgebung und die Umwelt entstehen.

• Das Gerät ist zur Regelung des Durchflusses von flüssigen und gasförmigen Medien konzipiert.

• Für den Einsatz sind die zulässigen Daten, Betriebs- und

Einsatzbedingungen zu beachten, die in den Vertragsdokumenten, sowie auf dem Typenschild und in der Bedienungsanleitung in den Kapiteln „Aufbau und Funktion“

und „Technische Daten“ beschrieben sind.

• Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw. zugelassenen Fremdgeräten und -komponenten

einsetzen.

• Voraussetzungen für den sicheren und einwandfreien

Betrieb sind sachgemäßer Transport, sachgemäße

Lagerung und Installation sowie sorgfältige Bedienung

und Instandhaltung.

• Das Gerät nur bestimmungsgemäß einsetzen.

31

deutsch

3.1. Vorhersehbarer Fehlgebrauch

• Das Gehäuse nicht mechanisch belasten (z. B. durch

Ablage von Gegenständen oder als Trittstufe).

• Keine äußerlichen Veränderungen an den Ventilgehäusen

vornehmen.

• In die Steueranschlüsse des Systems keine aggressiven

oder brennbaren Medien einspeisen.

• In die Medienanschlüsse nur Medien einspeisen, die im

Kapitel „Technische Daten“ als Durchflussmedien aufgeführt sind.

deutsch

32

4. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb

und Wartung der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren

Einhaltung, auch in Bezug auf das Montagepersonal, der

Betreiber verantwortlich ist.

GEFAHR!

Verletzungsgefahr durch hohen Druck!

• Vor dem Lösen von Leitungen und Ventilen, den Druck

abschalten und Leitungen entlüften!

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb!

Das Gerät kann bei Dosierung heißer Medien sehr heiß

werden.

• Das Gerät steuert heiße Medien und darf nur mit Schutzhandschuhen angefasst werden.

• Leicht brennbare Stoffe und Medien vom Gerät fernhalten.

33

deutsch

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden

kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von

autorisiertem Fachpersonal mit geeignetem Werkzeug

ausgeführt werden.

• Nach einer Unterbrechung der elektrischen Versorgung

ist ein definierter oder kontrollierter Wiederanlauf des

Prozesses zu gewährleisten.

• Das Gerät darf nur in einwandfreiem Zustand und unter

Beachtung der Bedienungsanleitung betrieben werden.

• Für die Einsatzplanung und den Betrieb des Gerätes

müssen die allgemeinen Regeln der Technik eingehalten

werden.

Bei Nichtbeachtung dieser Bedienungsanleitung

und ihrer Hinweise sowie bei unzulässigen Eingriffen

in das Gerät entfällt jegliche Haftung unsererseits,

ebenso erlischt die Gewährleistung auf Geräte und

Zubehörteile!

Typ 2080

Page 10

deutsch

34

5. ALLGEMEINE HINWEISE

5.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. : + 49 (0)7940 - 10 91 111

Fax: + 49 (0)7940 - 10 91 448

E-mail: info@de.burkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

5.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Magnetventils Typ 2080 unter

Beachtung der spezifizierten Einsatzbedingungen.

5.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 2080

finden Sie im Internet unter: www.buerkert.de

35

deutsch

6. AUFBAU UND FUNKTION

6.1. Modularität

Das Ventil ist modular aufgebaut und kann je nach Einsatzfall

mit verschiedenen Medienanschlüssen (auch kundenspezifisch) und Antriebsversionen geliefert werden.

Es ist einzeln und auch auf Blöcken einsetzbar.

6.2. Aufbau

Das Ventil besteht aus einem pneumatisch betätigten Kolbenantrieb mit Rückstellfeder, einem Edelstahlgehäuse und

einem PTFE-Faltenbalg. Der Faltenbalg dient zur Medientrennung. Bei entsprechender Einbaulage arbeitet das Ventil

selbstentleerend.

Die eingesetzten Materialien und die Innenkonturen ermöglichen eine einfache Reinigung (CIP/SIP).

Der pneumatische Antrieb muss extern über ein Pilotventil

oder eine Ventilinsel gesteuert werden.

deutsch

36

Schrauben zur Befestigung

des Antriebs am Gehäuse

Steuerluftanschlüsse

Muffen G 1/8

Anschluss WWB (NO)

Anschluss WWA (NC)

Flansch Muffe G 3/8 Schweißende

Medienanschlüsse

Öffnung zur Leckagekontrolle am Faltenbalg

37

deutsch

7. TECHNISCHE DATEN

7.1. Betriebsbedingungen

Umgebungstemperatur -10 ... +90 °C

Mediumstemperatur -30 ... +150 °C

(siehe PT-Diagramm)

Medien Neutrale bis aggressive Gase

und Flüssigkeiten,

technisches Vakuum

7.2. Einschränkungen

Für Ventile mit Anströmung über Sitz:

WARNUNG!

Verletzungsgefahr durch Schließschlag!

Bei Anströmung über Sitz mit flüssigen Medien kann es

zu Schließschlägen kommen. Als Folge davon können

Leitungen oder Gerät bersten und Medium ausströmen.

• Für den Betrieb des Gerätes die Art der Anströmung und

die Art des Mediums beachten.

• Bei Anströmung über Sitz vor dem Einsatz flüssiger

Medien, zur Vermeidung von Schließschlägen, im Zweifelsfall die Einsatzbedingungen (Medium, Leitungslängeund Querschnitt) mit der Bürkert Vertriebsniederlassung

abklären.

Typ 2080

Page 11

deutsch

38

7.3. Konformität

Das Faltenbalgventil Typ 2080 ist konform zu den EG-Richtlinien entsprechend der EG-Konformitätserklärung.

7.4. Normen

Durch folgende Normen wird die Konformität mit den EGRichtlinien erfüllt:

• EN 13463-1, EN 13463-5

7.5. PT-Diagramm

Zulässige Druck-Temperatur-Verträglichhkeit des PTFEFaltenbalges

(Druckangabe [bar]: Überdruck zum Atmosphärendruck).

0

0 20 40 60 80 100 120

140

160 180

1

2

3

4

5

6

7

8

9

Zulässiger

Bereich

P [bar]

T [°C]

39

deutsch

7.6. Mechanische Daten

Maße siehe Datenblatt

Gehäusematerial

Armatur Edelstahl 316L (1.4404)

Antrieb Edelstahl 304 (1.4301)

Faltenbalg PTFE

Hub Faltenbalg 2,5 mm

Oberflächengüte innen Ra = 0,8 µm

7.7. Fluidische Daten

Wirkungsweisen

A

A

P

2/2 Wege-Ventil, fremdgesteuert,

ohne Steuerdruck durch Federkraft geschlossen, Betätigung mit

Pilotventil, Ventilinsel o.ä.

B

B

P

2/2 Wege-Ventil, fremdgesteuert,

ohne Steuerdruck durch Federkraft geöffnet, Betätigung mit

Pilotventil, Ventilinsel o.ä.

Armatur

Druckbereich Medium Vakuum ... 8 bar

(siehe PT-Diagramm)

Rückdruckdichtheit bis 8 bar

deutsch

40

Nennweite DN 4 bis DN 10

Leitungsanschlüsse Muffenanschluss G 3/8

Schweißenden

13,5 x 1,6 nach ISO 4200

13 x 1,5 nach DIN 11850-2

12,7 x 1,2 nach BS 4825

Flanschanschluss oder

kundenspezifische Leitungsanschlüsse

Antrieb

Steuermedium Druckluft 4,5 ... 10 bar

(getrocknet und gefiltert)

neutrale Gase

Steuerluftanschlüsse Muffenanschluss G 1/8

7.8. Antriebsversionen

Version Wirkungsweise

Antrieb Auf - Zu WWA und WWB

Antrieb Auf - Zu

mit Stellungserfassung

WWA und WWB

3-Positions-Antrieb

(mit einstellbarer Zwischenposition)

WWA

41

deutsch

7.9. Typenschild (Beispiel)

Made in Germany

00450000

W14UN

CE

Faltenbalgventil

Typ 2080 NC DN10

Pmax 8bar

Ppilot 4-10bar

Ident-Nr.

Nenndruck

Typ, Wirkungsweise, Nennweite

Beschreibung

Nenndruck Pilotventil

Typ 2080

Page 12

deutsch

42

8. MONTAGE

8.1. Sicherheitshinweise

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage!

• Die Montage darf nur autorisiertes Fachpersonal mit

geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der

Anlage und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Montage einen kontrollierten Wiederanlauf

gewährleisten.

8.2. Fluidische Installation

GEFAHR!

Gefahr durch hohen Druck!

Akute Verletzungsgefahr bei Eingriffen in die Anlage.

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

Überprüfen Sie die Übereinstimmung der Betriebsbedingungen mit den Leistungsdaten des Gerätes.

43

deutsch

Einbaulage:

Die Einbaulage ist beliebig.

→ Für Selbstentleerung stehend einbauen (Armatur nach

unten und bei Muffenanschluss und Schweißenden

mindestens 1° geneigt für den Medienablauf einbauen).

Montage:

→ Vor der Montage Rohrleitungen und Flanschanschlüsse

von eventuellen Verschmutzungen säubern.

→ Zum Schutz vor Störungen gegebenenfalls einen

Schmutzfänger vor das Ventil einbauen.

Maschenweite:

0,1 ... 0,4 mm

WARNUNG!

Gefahr durch Mediumsaustritt!

Undichte Anschlüsse bei ungenauem Sitz der Dichtungen.

• Alle Anschlüsse sorgfältig und gut dichtend ausführen.

Zum Abdichten der Muffenanschlüsse geeignetes

Dichtmaterial verwenden (empfohlen wird

PTFE-Band).

deutsch

44

Zum Einschrauben der Rohrleitungen Gabelschlüssel

der passenden Schlüsselweite verwenden und den

Ventilantrieb nicht als Einschraubhebel benutzen!

Auf die Anschlüsse des Gerätes dürfen keine seitlichen Verspannungskräfte auftreten. Die Anschlüsse

des Gerätes und die Leitungen müssen fluchten!

→ Ventil entsprechend der Anschlüsse befestigen:

Muffenanschluss durch Einschrauben der Rohre,

Schweißanschluss durch Verschweißen,

Flansch durch Aufschrauben.

Flanschbild am Ventil

16 16

Ø 4,5

Ø 3,1; 6 tief;

Option für Positionierstift Ø 3 (Sicherstellung

der richtigen Lage beim Einbau)

16

16

13

45

deutsch

8.3. Option: Ventil mit 3-PositionsAntrieb (mit einstellbarer

Zwischenposition)

Funktionen des Ventils:

• Geschlossen (ohne Steuerluft, durch Federkraft),

• Teilhub - Position 1 (Steuerluft gleichzeitig an X und Y),

• Vollhub - Position 2 (Steuerluft nur an X).

Stellspindel

Kontermutter

Hubeinstellung an der Stellspindel

Flanschversion

Y

X

Durchfluss plus minus

Typ 2080

Page 13

deutsch

46

Einstellung der Zwischenposition:

→ Geeignete Durchflussmessung anbringen (Mess-

becher, Durchflussmesser o.ä.),

→ Kontermutter lösen,

→ Steuerluft an X und Y anschließen,

→ Medienzufuhr öffnen,

→ An der Stellspindel den gewünschten Durchfluss ein-

stellen

Hubbereich = 0 bis 2,5 mm (beim Drehen der Spindel

im Uhrzeigersinn wird der Durchfluss kleiner),

→ Steuerluft abstellen,

→ Kontermutter festziehen.

47

deutsch

9. WARTUNG, STÖRUNGEN

9.1. Sicherheitshinweise

GEFAHR!

Gefahr durch hohen Druck in der Anlage!

Bei Eingriffen in die Anlage besteht akute Verletzungsgefahr.

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

WARNUNG!

Gefahr durch unsachgemäße Wartungsarbeiten!

Unsachgemäße Wartung kann zu Verletzungen sowie zu

Schäden am Gerät und seiner Umgebung führen.

• Wartungsarbeiten dürfen nur durch autorisiertes Fachpersonal und mit geeignetem Werkzeug durchgeführt

werden!

Gefahr durch unbeabsichtigte Betätigung der Anlage!

Ungewolltes Ingangsetzen der Anlage bei Wartungsund Reparaturarbeiten kann zu Verletzungen und Sachschäden führen.

• Verhindern Sie durch geeignete Maßnahmen, dass die

Anlage unbeabsichtigt betätigt werden kann.

deutsch

48

9.2. Wartung / Reinigung

Der Faltenbalg zwischen Medienraum und Antrieb ermöglicht

ein funktionssicheres Schalten des Ventils und schützt das

Medium vor Verunreinigungen aus der Antriebsseite. Dieser

Faltenbalg unterliegt Ermüdungserscheinungen. Bei defektem

Faltenbalg tritt Medium aus der Öffnung zur Leckagekontrolle.

Zur Vermeidung einer Zerstörung sollte der Faltenbalg in

einem regelmäßigem Zyklus prophylaktisch ausgewechselt

werden (siehe Kapitel 9.3). Das Ventil ist innen spaltfrei und

mit sehr glatten Konturen des Innenraumes sowie des Faltenbalges ausgeführt (Oberflächenrauhtiefe max. 0,8 µm). Das

Ventil ist CIP-fähig (CIP = cleaning in process) und SIP-fähig

(SIP = sterilization in process).

9.3. Wechseln des Faltenbalges

Antrieb demontieren

→ Erforderliche Ersatzteile und einen Gabelschlüssel

SW 7 bereit legen,

→ Steuerluftzufuhr unterbrechen, die Leitungen entlüften

und lösen,

→ Medienzufuhr unterbrechen und die Leitungen entlüften,

→ Beide Befestigungsschrauben lösen,

→ Antrieb abnehmen.

49

deutsch

Faltenbalg wechseln

→ Faltenbalg von der Spindel abschrauben,

→ Innenraum des Gehäuses säubern,

→ Neuen Faltenbalg von Hand auf die Spindel schrauben

und handfest anziehen.

Antrieb montieren

→ O-Ring 25 x 2 FKM 70 im Gehäuse säubern und auf

Wiederverwendung prüfen, falls erforderlich, durch

einen neuen O-Ring ersetzen

→ Antrieb mit neuem Faltenbalg auf das Gehäuse setzen;

achten Sie dabei auf die richtige Ausrichtung der Bohrungen des Antriebs zum Gewinde im Gehäuse

→ Antrieb mit den Befestigungsschrauben am Gehäuse

befestigen

(Anzugsmoment von 2 bis 2,2 Nm).

Wiederinbetriebnahme des Faltenbalgventils

→ Steuerluftleitungen anschließen,

→ Steuerluft öffnen,

→ Medienzufuhr öffnen,

→ Funktions- und Dichtheitstest durchführen,

→ bei Funktionssicherheit kann das Ventil wieder in

Betrieb genommen werden.

Typ 2080

Page 14

deutsch

50

Explosionszeichnung Ersatzteilwechsel Typ 2080

Sechskantschrauben M4 x 50

nach DIN 933-A4 zur Montage des

Antriebs am Gehäuse

Antrieb

Spindel

PTFE-Faltenbalg

O-Ring 25 x 2 FKM 70

Gehäuse (Muffenversion)

9.4. Störungen

Überprüfen Sie bei Störungen:

→ die Leitungsanschlüsse,

→ den Betriebsdruck,

→ die Steuerluftversorgung der Ventilansteuerung,

→ den Faltenbalg und wenn erforderlich wechseln (siehe

Kapitel 9.3).

Falls das Ventil dennoch nicht schaltet, wenden Sie sich

bitte an Ihren Bürkert-Service.

51

deutsch

10. ERSATZTEILE

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können

Verletzungen und Schäden am Gerät und dessen

Umgebung verursachen.

• Verwenden Sie nur Originalzubehör sowie Originalersatzteile der Fa. Bürkert.

Bestelltabelle Ersatzteile

Ersatzteil Beschreibung Bestell-Nr.

Faltenbalg Werkstoff PTFE 799 845

O-Ring 25 x 2,0 N-FKM 70 914 378

deutsch

52

11. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den

Transport beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät

verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur. -20 … +65 °C.

Umweltschäden durch von Medien kontaminierte

Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen einhalten.

Page 15

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous resérve de modification

techniques.

© 2008 - 2011 Bürkert Werke GmbH

Operating Instructions 1107/03_EU-ml_00805824

Manuel d‘utilisation

Français

Type 2080

VANNE A SOUFFLET

Vanne 2/2 voies avec entraînement à piston et soufflet PTFE

français

54

1. LES INSTRUCTIONS DE

SERVICE

Les instructions de service décrivent le cycle de vie complet

de l‘appareil. Conservez ces instructions de sorte qu‘elles

soient accessibles à tout utilisateur et à disposition de tout

nouveau propriétaire.

Les instructions de service contiennent des informations importantes sur la sécurité!

Le non-respect de ces consignes peut entraîner des situations dangereuses.

• Les instructions de service doivent être lues et

comprises.

55

français

2. SYMBOLES

Les moyens de représentation suivants sont utilisés dans

les présentes instructions de service.

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves

blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement

dangereuse !

• Le non-respect peut entraîner de graves blessures ou

la mort.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou

de moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

Conseils et recommandations importants.

→ identifie une opération que vous devez effectuer.

Page 16

français

56

3. UTILISATION CONFORME

AVERTISSEMENT !

L’utilisation non conforme de la vanne à soufflet, type

2080 peut présenter des dangers pour les personnes,

les installations proches et l’environnement.

• L’appareil a été conçu pour la commande du débit de

fluides liquides et gazeux.

• Concernant l’utilisation, il convient d’observer les caractéristiques, conditions d’exploitation et d’utilisation autorisées qui sont décrites dans les documents contractuels,

ainsi que sur la plaque signalétique et dans le mode

d’emploi aux chapitres « Structure et mode de fonction-

nement » et « Caractéristiques techniques ».

• L’appareil peut être utilisé uniquement en association avec

les appareils et composants étrangers recommandés et

homologués par Bürkert.

• Les conditions pour l’utilisation sûre et parfaite sont un

transport, un stockage et une installation dans les règles

ainsi qu’une parfaite utilisation et maintenance.

• Utilisez la vanne à soufflet, type 2080 conformément à

sa destination.

57

français

3.1. Mauvaise utilisation prévisible

• Ne soumettez pas le corps à des contraintes mécaniques

(par ex. pour déposer des objets ou comme marche).

• N’apportez pas de modifications à l’extérieur du corps.

• N'alimentez pas les raccords de commande du système

en fluides agressifs ou inflammables.

• Alimentez les raccords uniquement de fluides repris comme

fluides de débit au chapitre « Caractéristiques techniques ».

français

58

4. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte :

• Des hasards et des événements pouvant survenir lors du

montage, de l‘exploitation et de l‘entretien des appareils.

• Des prescriptions de sécurité locales que l‘exploitant est

tenu de faire respecter par le personnel chargé du montage.

DANGER !

Danger dû à la haute pression !

• Avant de desserrer les conduites et les vannes, coupez

la pression et purgez l’air des conduites !

Risque de brûlures/d'incendie en fonctionnement

continu !

L’appareil peut devenir très chaud suite au dosage de fluides

très chauds.

• Un appareil transportant des fluides très chauds ne peut

être touché qu’avec des gants de protection.

• Tenez les substances et les fluides facilement inflammables

à l'écart de l'appareil.

59

français

Situations dangereuses d’ordre général.

Pour prévenir les blessures, respectez ce qui suit :

• L’installation ne peut pas être actionnée par

inadvertance.

• Les travaux d’installation et de maintenance doivent être

effectués uniquement par des techniciens qualifiés et

habilités disposant de l’outillage approprié.

• Après une interruption de l’alimentation électrique ou

du fluide, un redémarrage défini ou contrôlé du process

doit être garanti.

• L’appareil doit être utilisé uniquement en parfait état et

en respectant les instructions de service.

• Les règles générales de la technique sont à appliquer

pour l’opérationnel et l’utilisation de l’appareil.

Le non-respect de ces instructions de service avec

ses consignes ainsi que les interventions non autorisées sur l’appareil excluent toute responsabilité de

notre part et entraînent la nullité de la garantie légale

concernant les appareils et les accessoires !

Type 2080

Page 17

français

60

5. INDICATIONS GÉNÉRALES

5.1. Adresses

Allemagne

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tél. : +49 (0)7940 - 10 91 111

Fax : +49 (0)7940 - 10 91 448

E-mail : info@de.burkert.com

International

Les adresses se trouvent aux dernières pages des instructions de service imprimées.

Egalement sur internet sous : www.burkert.com

5.2. Garantie légale

La condition pour bénéficier de la garantie légale est l’utilisation conforme de l’appareil type 2080, dans le respect des

conditions d’utilisation spécifiées.

5.3. Informations sur Internet

Vous trouverez les instructions de service et les fiches

techniques concernant le type 2080 sur Internet sous :

www.buerkert.fr

61

français

6. STRUCTURE ET MODE DE

FONCTIONNEMENT

6.1. Modularité

La vanne est de construction modulaire et peut être fournie

selon l’utilisation prévue avec différents raccords de fluides

(également ceux spécifiques du client) et versions d’entraînement. Elle peut être utilisée seule et également sur des

blocs.

6.2. Structure

La vanne est composée d’un entraînement par piston à

commande pneumatique avec ressort de rappel, d’un corps

en acier inoxydable et d’un soufflet en PTFE. Le soufflet sert

à la séparation des fluides. La vanne se vide d’elle-même si

sa position de montage est adaptée.

Les matériaux utilisés et les contours internes permettent un

nettoyage simple (CIP/SIP).

L’entraînement pneumatique doit être commandé de l’extérieur

à l’aide d’une vanne pilote ou d’un îlot de vannes.

français

62

Vis pour la fixation de l’entraînement

sur le corps

Raccords air commande

Manchons G 1/8

Raccord fonction B (NO)

Raccord fonction A (NF)

Bride Manchon G 3/8 Extrémité soudée

Raccords de fluides

Ouverture de contrôle

de fuite sur le soufflet

63

français

7. CARACTÉRISTIQUES

TECHNIQUES

7.1. Conditions d’exploitation

Température ambiante -10 à +90 °C

Température du fluide -30 à +150 °C (voir diagramme PT)

Fluides Gaz neutres à agressifs et liquides,

vide technique

7.2. Limitations

Pour les vannes avec arrivée du flux au-dessus du siège :

AVERTISSEMENT !

Risque de blessures dû à des coups de bélier.

En cas d’arrivée du flux au-dessus du siège avec des produits liquides, des coups de bélier peuvent se produire.

Ceci peut alors faire éclater les conduites ou l’appareil et

provoquer des fuites.

• Respectez le type d’arrivée du flux et le type de fluide

pour l’utilisation de l’appareil.

• En cas d’arrivée du flux au-dessus du siège avant l’utilisation de produits liquides, pour éviter les coups de

bélier, il convient de contacter, en cas de doute, la filiale

de distribution Bürkert pour connaître les conditions

d’utilisation (produit, longueur et section de conduite).

Type 2080

Page 18

français

64

7.3. Conformité

L’appareil est conforme aux directives CE conformément à la

déclaration de conformité CE.

7.4. Normes

La conformité avec les directives CE est satisfaite par les

normes suivantes :

• EN 13463-1, 13463-5

7.5. Diagramme PT

Pression et température admissibles supportées par le

soufflet PTFE

(Indication de la pression [bar]: surpression à la pression

atmosphérique.)

0

0 20 40 60 80 100 120

140

160 180

1

2

3

4

5

6

7

8

9

Plage

admissible

P [bars]

T [°C]

65

français

7.6. Caractéristiques mécaniques

Dimensions voir fiche technique

Matériau du corps

Robinetterie Acier inoxydable 316L (1.4404)

Entraînement Acier inoxydable 304 (1.4301)

Soufflet PTFE

Course du soufflet 2,5 mm

Qualité de surface interne Ra = 0,8 µm

7.7. Données du fluide

Modes de fonctionnement

A

A

P

Vanne 2/2 voies à commande

pilotée, fermée par ressort sans

pression de commande, commande avec vanne pilote, îlot de

vannes ou dispositif semblable

B

B

P

Vanne 2/2 voies pilotée, ouverte

par ressort sans pression de

commande, commande avec

vanne pilote, îlot de vannes ou

dispositif semblable

Robinetterie

Plage de pression fluide Vide … 8 bars

(voir diagramme PT)

français

66

Étanchéité de pression

en retour jusqu’à 8 bars

Diamètre nominal DN 4 à DN 10

Raccords de conduite

Raccord à manchon G 3/8

Extrémités soudées 13,5 x 1,6 selon ISO 4200

13 x 1,5 selon DIN 11850-2

12,7 x 1,2 selon BS 4825

Raccordement bride ou

raccords de conduite spécifiques

au client

Entraînement

Fluide de commande Air comprimé 4,5 à 10 bars

(sec et filtré)

gaz neutre

Raccords d’air de commande Raccord à manchon G 1/8

7.8. Versions d'entraînement

Version Fonctionnement

Entraînement Marche - Arrêt A et B

Entraînement Marche - Arrêt avec

saisie de position

A et B

Entraînement 3 positions

(avec position intermédiaire réglable)

A

67

français

7.9. Plaque signalétique (exemple)

Made in Germany

00450000

W14UN

CE

Vanne à soufflet

Type 2080 NC DN10

Pmax 8bar

Ppilot 4-10bar

N° d’identification

Pression nominale

Type, Mode d’action, Diamètre nominal

Description

Pression nominale vanne pilote

Type 2080

Page 19

français

68

8. MONTAGE

8.1. Consignes de sécurité

AVERTISSEMENT !

Risque de blessures pour montage non conforme !

• Le montage doit être effectué uniquement par un personnel qualifié et habilité disposant de l’outillage approprié !

Risque de blessures dû à la mise en marche involontaire de l’installation et le redémarrage non contrôlé !

• Empêchez tout actionnement involontaire de l’installation.

• Garantissez un redémarrage contrôlé après le montage.

8.2. Installation fluide

DANGER !

Danger dû à la haute pression !

Risque important de blessures en cas d'interventions

dans l'installation.

• Avant de desserrer les conduites et les vannes, coupez

la pression et purgez l’air des conduites.

Vérifiez la concordance des conditions d’exploitation

avec les performances de l’appareil.

69

français

Position de montage:

Position de montage indifférente.

→ Monter verticalement pour la vidange automatique (monter

la robinetterie vers le bas, le raccord à manchon et les

extrémités soudées avec une pente d’au moins 1° pour

l’écoulement du fluide).

Montage

→ Avant le montage, nettoyer la tuyauterie et les raccorde-

ments à bride afin d'enlever les éventuelles saletés.

→ Monter éventuellement un panier en amont de la vanne

pour protéger des dysfonctionnements.

Ouverture de maille:

0,1 à 0,4 mm

AVERTISSEMENT !

Danger dû à la sortie de fluide !

Raccordements non étanches suite au mauvais positionnement des joints.

• Exécutez les raccords avec soin et avec une bonne

étanchéité.

Pour l’étanchéité des raccords à manchon, utilisez

un matériau d’étanchéité approprié (bande PFTE

recommandée).

français

70

Vissez la tuyauterie avec des clés d’ouverture appropriée et n’utilisez pas l’entraînement de vanne comme

levier !

Aucune contrainte latérale ne doit survenir sur les

raccords de l’appareil. Les raccords de l’appareil et

les conduites doivent correspondre !

→ Fixez la vanne conformément aux raccords:

Raccord à manchon par vissage des tuyaux,

Raccord soudé par soudage

Bride par vissage.

Représentation de la bride sur la vanne

16 16

Ø 4,5

Ø 3,1; 6 de profondeur ;

option pour axe de positionnement Ø 3

(garantit la bonne position lors du montage)

16

16

13

71

français

8.3. Option: vanne avec

entraînement 3 positions (avec

position intermédiaire réglable)

Fonctions de la vanne:

• Fermée (sans air de commande, par ressort),

• Course partielle (air de commande en même temps en X

et Y),

• Course complète (air de commande uniquement en X).

Broche d’ajustage

Contre-écrou

Réglage de la course sur la broche

Version à bride

Y

X

Débit plus moins

Type 2080

Page 20

français

72

Réglage de la position intermédiaire:

→ effectuez une nouvelle mesure de débit appropriée

(gobelet gradué, débitmètre, ou semblable),

→ desserrez le contre-écrou,

→ raccordez l’air de commande en X et en Y,

→ ouvrez l’alimentation en fluide,

→ réglez le débit souhaité sur la broche d’ajustage,

→ Course = de 0 à 2,5 mm (le débit diminue en tournant

la broche dans le sens des aiguilles d’une montre),

→ coupez l’air de commande,

→ serrez le contre-écrou à fond.

73

français

9. MAINTENANCE, DÉPANNAGE

9.1. Consignes de sécurité

DANGER !

Danger dû à la présence de haute pression dans

l'installation !

Il y a risque important de blessures lors d’interventions

sur l’installation.

• Avant de desserrer les conduites et les vannes, coupez

la pression et purgez l’air des conduites.

AVERTISSEMENT !

Danger en cas de travaux d’entretien non conformes !

Un entretien non conforme peut entraîner des blessures et

endommager l’appareil et son environnement.

• Ces travaux doivent être effectués uniquement par des

techniciens qualifiés et habilités disposant de l’outillage

approprié !

Danger du fait de l’actionnement involontaire de l’installation !

La mise en marche involontaire de l’installation lors des

travaux d’entretien et de réparation peut entraîner des

blessures et des dommages matériels.

• Evitez l’actionnement involontaire de l’installation par

des mesures appropriées.

français

74

9.2. Entretien / Nettoyage

Le soufflet entre l’espace du fluide et l'entraînement permet

une mise en marche sûre de la vanne et protège le fluide des

impuretés du côté entraînement. Ce soufflet est sujet à des

symptômes de fatigue. Lorsque le soufflet est défectueux, du

fluide sort de l’ouverture de contrôle de fuite. Pour éviter la

destruction, le soufflet devrait être remplacé à titre préventif

et à intervalle régulier (voir instructions pour le remplacement

du soufflet). L'intérieur de la vanne ne présente pas de fente.

Les contours intérieurs sont très lisses ainsi que le soufflet

(rugosité de la surface 0,8 µm maxi). La vanne est compatible

CIP (CIP = cleaning in process) et est compatible SIP (SIP

= sterilization in process).

9.3. Remplacement du soufflet

Démonter l’entraînement

→ préparez les pièces de rechange et une clé plate de 7,

→ coupez l’alimentation en air de commande, purgez l’air

et dévissez la ou les conduites,

→ interrompez l’alimentation en fluide et purgez l’air des

conduites,

→ desserrez les deux vis de fixation,

→ retirez l’entraînement.

75

français

Remplacer le soufflet

→ dévissez le soufflet de la broche,

→ nettoyez l’intérieur du corps,

→ vissez le soufflet neuf à la main sur la broche et serrez-

le à la main.

Monter l’entraînement

→ nettoyez le joint torique 25 x 2 FKM 70 dans le corps,

vérifiez s’il peut être réutilisé et remplacez-le si nécessaire

par un neuf,

→ placez l’entraînement avec le soufflet neuf sur le corps ;

veillez au bon alignement des alésages de l’entraînement

par rapport au filetage dans le corps,

→ fixez l’entraînement au corps avec les vis (couple de 2

à 2,2 Nm).

Remise en service de la vanne à soufflet

→ raccordez la ou les conduites d'air de commande,

→ ouvrez l’alimentation en air de commande,

→ ouvrez l’alimentation en fluide,

→ effectuez un test de fonctionnement et d’étanchéité,

→ lorsque la sécurité de fonctionnement est constatée, la

vanne peut être remise en service.

Type 2080

Page 21

français

76

Vue éclatée du remplacement des pièces de rechange,

type 2080

Vis six pans M4 x 50 selon

DIN 933-A4 pour le montage de

l’entraînement sur le corps

Entraînement

Broche

Soufflet PTFE

Joint torique 25 x 2 FKM 70

Corps (version à manchon)

9.4. Pannes

En présence de pannes, vérifiez:

→ les raccords de câbles,

→ la pression de service,

→ l’alimentation en air de la commande de la vanne,

→ le soufflet, et si nécessaire, remplacez (voir chapitre

9.3),

Si malgré tout la vanne ne fonctionne pas, veuillez contacter

votre service après-vente Bürkert.

77

français

10. PIÈCES DE RECHANGE

ATTENTION !

Risque de blessures, de dommages matériels dus à

de mauvaises pièces !

De mauvais accessoires ou des pièces de rechange inadaptées peuvent provoquer des blessures et endommager

l'appareil ou son environnement.

• Utilisez uniquement des accessoires d'origine de la

société Bürkert.

Tableau de commande des pièces de rechange

Pièce de

rechange

Description Réf. :

Soufflet Matériau PFTE 799 845

Joint torique 25 x 2,0 N-FKM 70 914 378

français

78

11. TRANSPORT, STOCKAGE,

ELIMINATION

REMARQUE !

Dommages dus au transport !

Les appareils insuffisamment protégés peuvent être

endommagés pendant le transport.

• Transportez l'appareil à l'abri de l'humidité et des impuretés et dans un emballage résistant aux chocs.

• Evitez le dépassement vers le haut ou le bas de la température de stockage admissible.

Un mauvais stockage peut endommager l'appareil.

• Stockez l'appareil au sec et à l'abri des poussières !

• Température de stockage: -20 - +65 °C.

Dommages à l’environnement causés par des pièces

d’appareil contaminées par des fluides.

• Respectez les prescriptions en matière d’élimination

des déchets et de protection de l’environnement en

vigueur.

• Eliminez l‘appareil et l‘emballage dans le respect de

l‘environnement.

Loading...

Loading...