Page 1

Type 2060, 2061, 2063, 2064, 2065

Max. stroke limitation / Min., max. stroke limitation

Electrical position indicator / Inductive proximity switch

Max. Hubbegrenzung / Min., max. Hubbegrenzung

Elektrischer Stellungsrückmelder / Induktiver Näherungsschalter

Limitation de course max. / Limitation de course min. max.

Indicateur de position électrique / Détecteur de proximité inductif

Accessories

Zubehör

Accessoires

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert Werke GmbH & Co. KG, 2017

Operating Instructions 1708/00_EU-ML_00810584 / Original DE

Page 3

Type 2060, 2061, 2063, 2064, 2065

Contents

1 ABOUT THESE INSTRUCTIONS .......................................... 4

1.1 Auxiliary materials ....................................................... 4

1.2 Symbols ....................................................................... 4

2 AUTHORIZED USE ............................................................... 5

3 BASIC SAFETY INSTRUCTIONS .......................................... 5

4 GENERAL INFORMATION .................................................... 6

4.1 Contact addresses ...................................................... 6

4.2 Warranty ...................................................................... 6

4.3 Information on the Internet .......................................... 6

5 OVERVIEW OF OPTIONS ..................................................... 7

5.1 Max stroke limit ........................................................... 7

5.2 Min and max stroke limit ............................................. 7

5.3 Threaded nipple for inductive proximity switch

M12 x 1 ........................................................................ 8

5.4 Mounting bracket for two inductive proximity

switches M12 x 1 ........................................................ 8

5.5 Electrical position indicator Type 8697

(with adaptation) .......................................................... 9

6 OPTION: MAX STROKE LIMIT ............................................. 9

6.1 Before installation ...................................................... 10

6.2 Installation of the max stroke limit ............................. 10

7 OPTION: MIN AND MAX STROKE LIMIT ........................... 11

7.1 Before installation ...................................................... 11

7.2 Installation of the min and max stroke limit,

actuator size D and M ............................................... 12

7.3 Installation of the min and max stroke limit,

actuator size N and P ................................................ 13

8 OPTION: THREADED NIPPLE ............................................ 14

8.1 Tasks before installation ............................................ 15

8.2 Installing the threaded nipple .................................... 15

9 OPTION: MOUNTING BRACKET ........................................ 16

9.1 Tasks before Installation ............................................ 17

9.2 Installing the mounting bracket,

actuator size D and M ............................................... 17

9.3 Installing the mounting bracket,

actuator size N and P ................................................ 19

10 OPTION: POSITION FEEDBACK TYPE 8697 ..................... 21

10.1 Tasks before installation ............................................ 22

10.2 Installing the position feedback,

actuator size D and M ............................................... 22

10.3 Installing the position feedback,

actuator size N and P ................................................ 24

10.4 Electrical installation .................................................. 26

11 ORDER NUMBERS ............................................................. 26

English

3

Page 4

Type 2060, 2061, 2063, 2064, 2065

About these instructions

1 ABOUT THESE INSTRUCTIONS

These installation instructions describe the procedure for installation and start-up of the accessory options of types 2060, 2061,

2063, 2064 and 2065. Keep these instructions ready to hand at the

operation site.

Important safety information.

▶ Carefully read these instructions.

▶ Observe the safety instructions and intended use.

▶ Persons, who work on the device, must read and understand

these instructions.

A detailed description of the Types 2060, 2061, 2063,

2064 and 2065 can be found in the operating instructions

at: www.burkert.com

1.1 Auxiliary materials

The following auxiliary materials are recommended in these

instructions for assembly:

Type of auxiliary

materials

Sealer and antiseize agents

Liquid adhesive LOCTITE 274 Henkel Loctite

Tab. 1: Auxiliary materials

Designation Manufacturer

Multi-Silikonfett

OKS 1110

OKS Schmierstoe GmbH

www.oks-germany.com

Deutschland GmbH

www.loctite.de

1.2 Symbols

DANGER!

Warns of an immediate danger!

▶ Failure to observe the warning will result in fatal or serious

injuries.

WARNING!

Warns of a potentially dangerous situation!

▶ Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a potential danger!

▶ Failure to observe the warning may result in a moderate or

minor injury.

NOTE!

Warns of damage!

Important information, tips and recommendations.

Refers to information in these operating instructions or in

other documentation.

Designates an instruction which you must follow to

prevent a hazard.

Designates a procedure which you must carry out.

4

English

Page 5

Type 2060, 2061, 2063, 2064, 2065

Authorized use

2 AUTHORIZED USE

The actuators and their accessory parts must only be used

for the specic applications provided for and described in the

relevant operating instructions, and only in combination with

third-party devices and components that are recommended

and/or authorized by Bürkert. Any other or more extensive

usage is considered contrary to authorized use.

Follow the directions and conditions of use of these installation

instructions as well as the authorized data specied in the

operating instructions and on the rating plates of the components that are used.

Correct transportation, proper storage and installation, and

careful operation and maintenance are essential for ensuring

problem-free and reliable operation of the devices.

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not consider any contingencies or

incidents which occur during assembly, operation and maintenance.

The operator is responsible for observing the location-specic safety

regulations, also with reference to the personnel.

Risk of injury from high pressure and discharge of medium.

▶ Before working on the system or device, switch o the pres-

sure and vent or drain lines.

Risk of injury from electric shock.

▶ Before working on the device or system, switch o the

power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regula-

tions for electrical equipment.

Risk of injury from ejected parts.

The actuators contain tensioned springs. If the actuator housing is

opened, there is a risk of injury from the spring jumping out.

▶ Do not open actuator housing.

English

5

Page 6

Type 2060, 2061, 2063, 2064, 2065

General information

General hazardous situations.

To prevent injury, ensure the following:

▶ Operate the device only in perfect state and in consideration

of the operating instructions.

▶ Do not transport, install or remove heavy devices without

the aid of a second person and using suitable auxiliary

equipment.

▶ Secure device or system to prevent unintentional activation.

▶ Only trained technicians may perform installation and main-

tenance work.

▶ Install the device according to the regulations applicable in

the country.

▶ After an interruption in the power supply, ensure that the

process is restarted in a controlled manner.

▶ Observe the general rules of technology.

4 GENERAL INFORMATION

4.1 Contact addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelngen

Tel. + 49 (0) 7940 - 10-91 111

Fax + 49 (0) 7940 - 10-91 448

E-mail: info@burkert.com

International

Contact addresses can be found on the nal pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2 Warranty

The warranty is only valid if the device is used as intended in accor-

dance with the specied application conditions.

4.3 Information on the Internet

The operating instructions and data sheets for Bürkert products

can be found on the Internet at: www.burkert.com

6

English

Page 7

Type 2060, 2061, 2063, 2064, 2065

Overview of options

5 OVERVIEW OF OPTIONS

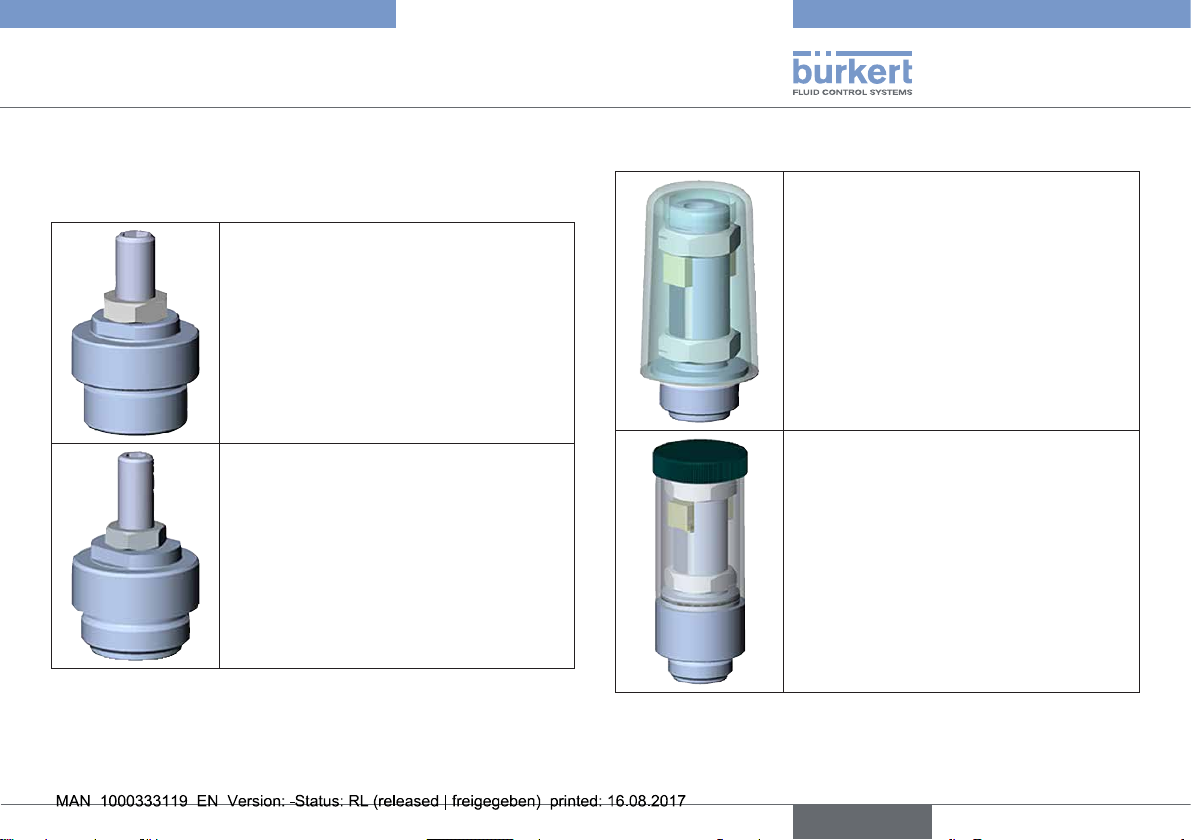

5.1 Max stroke limit

Actuator size D (50 mm), M (70 mm)

Special feature:

• to limit the upper end position

• for control function A only

Actuator size N (90 mm), P (130 mm)

Special feature:

• to limit the upper end position

• for control function A only

Tab. 2: Max stroke limit

5.2 Min and max stroke limit

Actuator size D (50 mm), M (70 mm)

Special feature:

• to limit the upper and lower end

position

• with optical position indicator

• for incoming ow under seat only

Actuator size N (90 mm), P (130 mm)

Special feature:

• to limit the upper and lower end

position

• with optical position indicator

• for incoming ow under seat only

• pilot pressure reduction for actuator

size P (130) with control function I

Tab. 3: Min and max stroke limit

English

7

Page 8

Type 2060, 2061, 2063, 2064, 2065

Overview of options

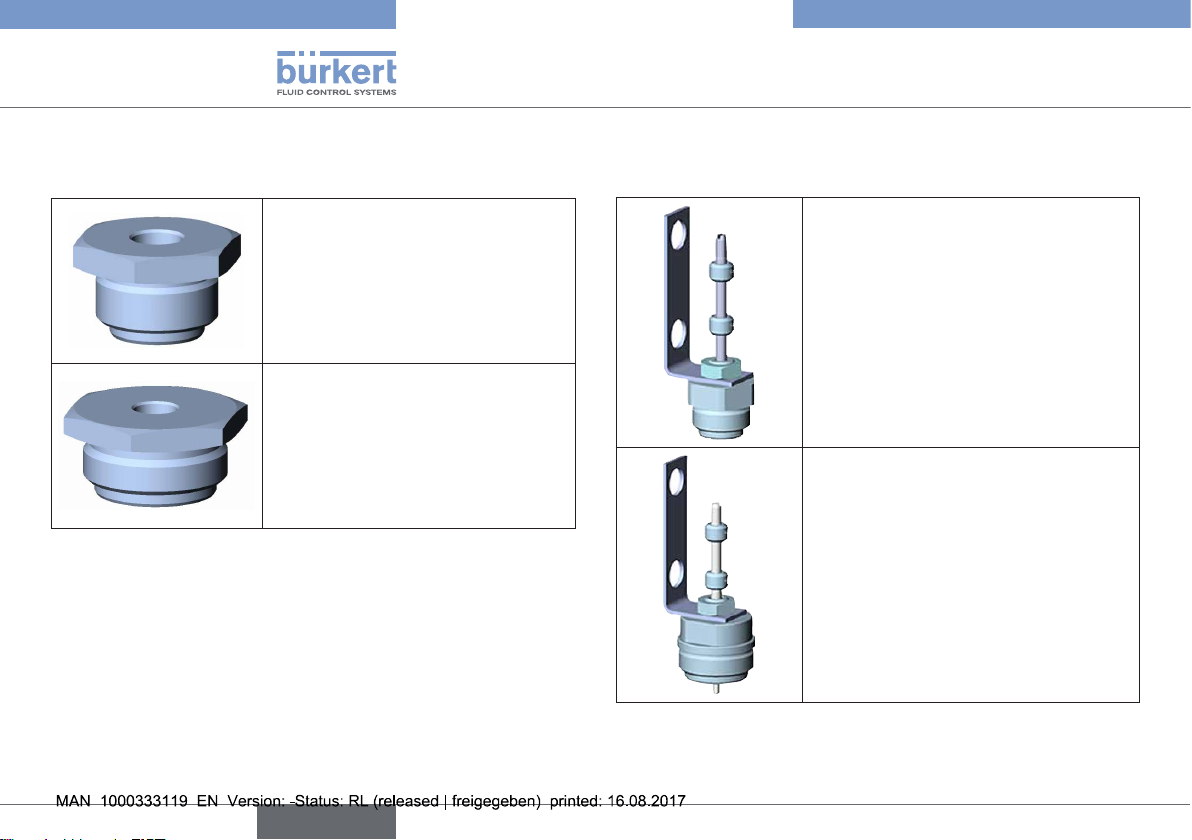

5.3 Threaded nipple for inductive proximity switch M12 x 1

Actuator size D (50 mm), M (70 mm)

Special feature:

• for control function A only

• for upper end position feedback

Actuator size N (90 mm), P (130mm)

Special feature:

• for control function A only

• for upper end position feedback

Tab. 4: Threaded nipple for inductive proximity switch M12 x 1

5.4 Mounting bracket for two inductive proximity switches M12 x 1

Actuator size D (50 mm), M (70 mm)

Special feature:

• upper and lower end position

feedback

Actuator size N (90 mm), P (130 mm)

Special feature:

• upper and lower end position

feedback

Tab. 5: Mounting bracket for two inductive proximity

switches M12 x 1

8

English

Page 9

Type 2060, 2061, 2063, 2064, 2065

Option: max stroke limit

5.5 Electrical position indicator Type 8697 (with adaptation)

Actuator size D (50 mm),

M (70 mm)

Special feature:

+

+

Tab. 6: Electrical position indicator Type 8697 (with adaptation)

• upper and lower end

position feedback

• with optical position

indicator

Actuator size N (90 mm),

P (130 mm)

Special feature:

• upper and lower end

position feedback

• with optical position

indicator

6 OPTION: MAX STROKE LIMIT

WARNING!

Risk of injury from forcibly ejected parts.

If this option is used with incoming medium ow over seat,

there is a danger that parts of the device could be forcibly

ejected by strong opening impacts.

▶ Use the option with incoming ow under seat only.

Use the max stroke limit option only with:

• Control function A.

A

C

B

E

D

A

Transparent cap

B

Position indicator

C

Actuator cover

D

Spindle extension

E

O-ring

Fig. 1: Description of the parts, actuator size D, M, N and P

Pilot air port 2

Pilot air port 1

English

9

Page 10

Type 2060, 2061, 2063, 2064, 2065

Option: max stroke limit

6.1 Before installation

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the system or device, switch o the pres-

sure and vent or drain lines.

→ Interrupt the ow of medium.

→ Switch o the pilot air.

→ Empty the valve body.

A

→ Unscrew the transparent cap

DANGER!

Risk of injury from high pressure.

Without the transparent cap, the actuator blows freely upward

when the pilot pressure is applied to the wrong connection.

▶ Apply the pilot pressure for control functions A and I only on

pilot air port 1.

→ To remove the optical position indicator

to the upper end position:

Apply the pilot pressure to connection 1.

→ Unscrew the optical position indicator

extension.

from the actuator cover C.

B

move the actuator

B

from the spindle

6.2 Installation of the max stroke limit

1

2

3

C

Fig. 2: Installation of the max stroke limit

→ Screw the threaded nipple

Observe tightening torques: Actuator D and M: 20 Nm.

→ Turn the threaded spindle

→ Secure the threaded spindle

→ Check the valve for function and leaks.

Actuator cover

C

Required parts:

1

Threaded spindle

Nut

2

Threaded nipple

3

3

into the actuator cover C.

Actuator N and P: 25 Nm.

1

to adjust the upper end position.

1

with nut 2.

10

English

Page 11

Type 2060, 2061, 2063, 2064, 2065

Option: Min and max stroke limit

7 OPTION: MIN AND MAX STROKE

LIMIT

WARNING!

Risk of injury from forcibly ejected parts.

If this option is used with incoming medium ow over seat,

there is a danger that parts of the device could be forcibly

ejected by strong opening impacts.

▶ Use the option with incoming ow under seat only.

Use the max stroke limit option only with:

• Incoming ow under seat.

A

C

B

E

D

A

Transparent cap

B

Position indicator

C

Actuator cover

D

Spindle extension

E

O-ring

Fig. 3: Description of the parts, actuator size D, M, N and P

Pilot air port 2

Pilot air port 1

7.1 Before installation

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the system or device, switch o the pres-

sure and vent or drain lines.

→ Interrupt the ow of medium.

→ Switch o the pilot air.

→ Empty the valve body.

A

→ Unscrew the transparent cap

DANGER!

Risk of injury from high pressure.

Without the transparent cap, the actuator blows freely upward

when the pilot pressure is applied to the wrong connection.

▶ Apply the pilot pressure for control functions A and I only on

pilot air port 1.

→ Control function A and I:

To remove the optical position indicator

to the upper end position:

Apply the pilot pressure to pilot air port 1 (one pressure pulse

is sucient for control function I).

→ Unscrew the position indicator

→ For actuator size N and P:

Check the position of the O-ring

reposition it on the base.

from the actuator cover C.

B

move the actuator

B

from the spindle extension D.

E

and if necessary

English

11

Page 12

Type 2060, 2061, 2063, 2064, 2065

Option: Min and max stroke limit

7.2 Installation of the min and max stroke limit, actuator size D and M

Actuator cover

8

4b

4a

7

Fig. 4: Installation of the min and max stroke limit, actuator D

and M

3

→ Fit O-ring

→ Lubricate pipe

in the recess in the pipe 2.

2

and spindle 1 with e.g. multi-silicone

grease OKS 1110.

C

6

D

5

1

2

3

D

C

Spindle extension

(actuator)

Required parts:

Spindle (stroke limit)

1

Pipe

2

O-ring 10 x 2

3

4a

4b

5

Bar

Cylinder head screw M6 x 16

6

Flat seal

7

Hood

8

2 groove M20 x 1.5

1

→ To secure the spindle

, apply a little Loctite 274 in the

threaded hole of the spindle.

→ Screw the spindle

actuator

D

(hexagon socket wrench size 4).

→ Mount at seal

→ Screw nut

4a

→ Lubricate pipe

1

onto the spindle extension of the

7

on pipe 2.

onto the pipe 2 and all the way to the bottom.

2

in the running area of the O-ring 3 with

e.g. multi-silicone grease OKS 1110.

→ Carefully pull the pipe

you do not damage the O-ring

2

over the spindle 1, ensuring that

3

.

→ Control function B:

Place the bar

the actuator cover

5

on the spindle 1 and screw the pipe 2 into

C

(2-edge, wrench size 17).

Observe tightening torque of 20 Nm.

→ Control function A and I:

Screw pipe

2

into actuator cover C (2-edge with wrench

size 17). Observe tightening torque of 20 Nm. Place the

5

bar

on the spindle 1.

→ To secure the cheese-head screw

6

apply a little Loctite 274

to the thread of the cheese-head screw.

→ Screw the cheese-head screw

→ Screw the upper nut

4b

onto the pipe 2.

→ Limit the stroke appropriately with the upper nut

→ Screw on the hood

8

nger-tight.

6

into the spindle 1.

4b

.

→ Check the valve for function and leaks.

12

English

Page 13

Type 2060, 2061, 2063, 2064, 2065

Option: Min and max stroke limit

Note the hardening time of the Loctite before placing the

valve in operation.

7.3 Installation of the min and max stroke limit, actuator size N and P

WARNING!

Risk of injury from forcibly ejected parts.

If this option is used

- with incoming medium ow over seat or

- for actuator size P (130) control function I and a pilot

pressure > 5 bar

there is a danger that parts of the device could be forcibly

ejected by strong opening impacts.

▶ Use the option with incoming ow under seat only.

▶ For actuator size P (130) with control function I, reduce the

pilot pressure to max. 5 bar.

Actuator cover

10

6b

9

6a

1

C

7

D

8

4

Required parts:

2

1

3

2

5

D

3

C

4

5

6a

7

8

9

10

Spindle extension

(actuator)

Pipe

O-ring 15 x 2

O-ring 40 x 2

Spindle (stroke limit)

Spindle coupling

2 nut M30 x 1.5

6b

Cheese-head screw M8 x 25

Bar

Protective pipe (acrylic glass)

Cover

Fig. 5: Installation of the min und max stroke limit, actuator

size N and P

→ To secure the spindle coupling

5

, apply a little Loctite 274 in

the threaded hole.

→ Screw spindle coupling

actuator

→ Screw nut

D

(wrench size 13).

6a

onto the pipe 1 and all the way to the bottom.

5

onto the spindle extension of the

English

13

Page 14

Type 2060, 2061, 2063, 2064, 2065

Option: Threaded nipple

→ Fit O-ring

→ Lubricate spindle

3

in pipe 1.

4

in the running area of the O-ring 2 with

e.g. multi-silicone grease OKS 1110.

→ Lubricate O-ring

2

in the pipe 1 with e.g. multi-silicone

grease OKS 1110.

→ Carefully pull the pipe

you do not damage the O-ring

1

over the spindle 4, ensuring that

2

.

→ Control function B:

Place the bar

screw pipe

8

on the spindle of the stroke limitation 4 and

1

into the actuator cover C.

Observe tightening torque of 25 Nm.

→ Control functions A and I:

Screw pipe

size 24), tightening torque 25 Nm. Place the bar

spindle of the stroke limitation

→ To secure the cheese-head screw

1

into the actuator cover C (2-edge, wrench

4

.

7

apply a little Loctite 274

8

to the thread of the cheese-head screw.

→ Screw the cheese-head screw

→ Screw the upper nut

6b

onto the pipe.

→ Limit the stroke appropriately with the nuts

→ Place protective pipe

→ Screw on the cover

9

10

nger-tight.

7

into the spindle 4.

on pipe 1.

6a 6b

.

→ Check the valve for function and leaks.

Note the hardening time of the Loctite before placing the

valve in operation.

on the

8 OPTION: THREADED NIPPLE

FOR INDUCTIVE PROXIMITY

SWITCH M12 x 1

Use this option only for:

• Control function A.

The option makes it possible to adapt an inductive proximity switch

M12 x 1 (e.g. Turck or Balluf) for ush installation on the actuator.

This option records the upper end position of the actuator. The

target is the spindle extension. The proximity switch is not included

in the scope of supply.

A

C

B

E

D

A

Transparent cap

B

Position indicator

C

Actuator cover

D

Spindle extension

E

O-ring

Fig. 6: Representation of the parts, actuator size D, M, N and P

Pilot air port 2

Pilot air port 1

14

English

Page 15

Type 2060, 2061, 2063, 2064, 2065

Option: Threaded nipple

8.1 Tasks before installation

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the system or device, switch o the pres-

sure and vent or drain lines.

→ Interrupt the supply of medium ow.

→ Switch o the pilot air.

→ Empty the valve body.

A

→ Unscrew transparent cap

DANGER!

Risk of injury from high pressure.

Without the transparent cap, the actuator blows freely upward

when the pilot pressure is applied to the wrong connection.

▶ Apply pilot pressure for control function A to connection 1 only.

→ To remove the position indicator

upper end position:

Apply pilot pressure to connection 1.

→ Unscrew position indicator from

o the actuator cover C.

B

, move the actuator to the

B

spindle extension D.

8.2 Installing the threaded nipple

1

Actuator cover

C

C

Required parts:

1

Threaded nipple

Fig. 7: Installing the threaded nipple for inductive proximity

switch

1

→ Screw threaded nipple

tightening torque of 15 Nm.

NOTE!

If the proximity switch is screwed in too deeply, it may be

damaged by the switching movement of the valve.

▶ Align the screw-in depth of the proximity switch with the upper

end position of the actuator (note the switching distance of the

proximity switch).

→ To install the proximity switch, move the actuator to the upper

end position:

Apply pilot pressure to connection 1.

into the actuator cover C. Observe

English

15

Page 16

Type 2060, 2061, 2063, 2064, 2065

Option: Mounting bracket

→ Screw the proximity switch into the threaded nipple

→ Secure the screw-in depth of the proximity switch with a lock

nut (included in the scope of supply of the proximity switch).

→ Check the valve for function and leaks.

1

.

9 OPTION: MOUNTING BRACKET

FOR TWO INDUCTIVE

PROXIMITY SWITCHES M12 x 1

The option makes it possible to adapt two inductive proximity

switches M12 x 1 (for example Turck or Balluf ) for ush installation

on the actuator. The upper and lower end positions of the actuator

are recorded. The target is the switch cam. Lower proximity switches

are not included in the scope of supply.

A

C

B

E

D

A

Transparent cap

B

Position indicator

C

Actuator cover

D

Spindle extension

E

O-ring

Fig. 8: Representation of the parts, actuator size D, M, N and P

Pilot air port 2

Pilot air port 1

16

English

Page 17

Type 2060, 2061, 2063, 2064, 2065

Option: Mounting bracket

9.1 Tasks before Installation

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the system or device, switch o the pres-

sure and vent or drain lines.

→ Interrupt the supply of medium ow.

→ Switch o the pilot air.

→ Empty the valve body.

A

→ Unscrew transparent cap

DANGER!

Risk of injury from high pressure!

Without the transparent cap, the actuator blows freely upward

when the pilot pressure is applied to the wrong connection.

▶ Apply the pilot pressure for control functions A and I only on

connection 1.

→ Control functions A and I:

To remove the position indicator

upper end position:

Apply pilot pressure to connection 1 (one pressure pulse is

sucient for control function I).

→ Unscrew position indicator from

→ Check the position of the O-ring

base if required.

o the actuator cover C.

B

, move the actuator to the

B

spindle extension D.

E

and reposition it on the

9.2 Installing the mounting bracket, actuator size D and M

2

1

6

1

Fig. 9: Installing mounting bracket for 2 proximity switches,

actuator size D and M

7

7

4

3

5

C

D

Actuator cover

C

D

Spindle extension

(actuator)

Required parts:

Switch cams

1

Switch spindle

2

Hexagon nut

3

O-ring 5 x 1.5

4

5

Threaded nipple

Mounting bracket

6

Setscrews M3 x 3

7

English

17

Page 18

Type 2060, 2061, 2063, 2064, 2065

Option: Mounting bracket

9.2.1 Installing the mounting bracket

→ Apply a little Loctite 274 in the threaded hole M6 of the

switch spindle

→ Fit O-ring

→ Lubricate switch spindle

silicone grease OKS 1110.

→ Guide threaded nipple

screw into the actuator cover

of 15 Nm.

→ Screw switch spindle

D

using a screwdriver, max. tightening torque: 1Nm.

This is facilitated by moving the actuator into the upper end

position.

Control functions A and I:

Apply pilot pressure to connection 1

(one pressure pulse is sucient for control function I).

→ Fasten the mounting bracket

→ Pull the two switch cams

5

nipple

screw in the setscrews

2

.

4

in the undercut in the threaded nipple 5.

2

and O-ring 4 with e.g. multi-

5

over the switch spindle 2 and

C

. Observe tightening torque

2

onto end of spindle extension thread

6

with nut 3 on the threaded

.

1

onto the switch spindle 2 and

7

(do not tighten).

9.2.2 Installing the proximity switch

The proximity switch is not included in the scope of

supply.

→ Fasten the proximity switch (normally included in the scope

of supply of the proximity switch) into the designated holes in

the mounting bracket using two nuts each

→ Adjust the screw-in depth of the proximity switches to match

the switching distance to the switch cams.

If required, loosen the mounting bracket 6 on the nut 3

and turn it around the actuator axis.

6

.

9.2.3 Positioning of the switch cams

→ Align the position of the lower switch cam 1 to the lower

proximity switch while the actuator is in the lower end

position. Fix switch cam

setscrew

Tightening torque: 0.4...0.6 Nm.

→ Align the position of the upper switch cam

proximity switch while the actuator is in the upper end

position. Fix switch cam

setscrew

Tightening torque: 0.4...0.6 Nm.

→ Check the valve for function and leaks.

Note the hardening time of the Loctite before placing the

valve in operation.

7

.

7

.

1

to the switch spindle 2 using

1

with the upper

1

to the switch spindle 2 using

18

English

Page 19

Type 2060, 2061, 2063, 2064, 2065

Option: Mounting bracket

1

1

7

1

7

2

3

6

Fig. 10: Positioning of the switch cams

For control function A the lower end position is the rest position.

The upper end position is reached by applying a pilot pressure to

connection 1.

For control function B the lower end position is reached by

applying a pilot pressure to connection 1. The upper end position

is the rest position.

For control function I the lower end position is reached by a

pressure pulse on connection 2 and the upper end position is

reached by a pressure pulse on connection 1.

Switch cam (2x)

2

Switch spindle

3

Nut

6

Mounting bracket

7

Setscrew

9.3 Installing the mounting bracket, actuator size N and P

1

6

1

Fig. 11: Installing mounting bracket for 2 proximity switches,

actuator size N and P

2

7

7

3

4

5

C

D

Actuator cover

C

D

Spindle extension

(actuator)

Required parts:

Switch cams

1

Switch spindle

2

Hexagon nut

3

Lip seal 5 x 10 x 4

4

5

Threaded nipple

Mounting bracket

6

Setscrews M3

7

English

19

Page 20

Type 2060, 2061, 2063, 2064, 2065

Option: Mounting bracket

9.3.1 Installing the mounting bracket

→ Apply a little Loctite 274 in the upper threaded hole (M3) of

the spindle extension

actuator into the upper end position.

Control functions A and I:

Apply pilot pressure to connection 1

(one pressure pulse is sucient for control function I).

→ Fit the lip seal

→ Lubricate switch spindle

silicone grease OKS 1110.

→ Screw threaded nipple

Tightening torque: 25 Nm.

→ Screw the switch spindle

spindle extension

torque 1 Nm.

→ Fasten the mounting bracket

nipple.

→ Pull the two switch cams

screw in the setscrews

D

. This is facilitated by moving the

4

in the undercut of the threaded nipple 5.

2

and lip seal 4 with e.g. multi-

5

into the actuator cover C.

2

D

using a screwdriver. Tightening

into the threaded hole of the

6

with nut 3 on the threaded

1

onto the switch spindle 2 and

7

(do not tighten).

9.3.2 Installing the proximity switch

The proximity switch is not included in the scope of

supply.

→ Fasten the proximity switch (normally included in the scope

of supply of the proximity switch) into the designated holes in

the mounting bracket using two nuts each

→ Adjust the screw-in depth of the proximity switches to match

the switching distance to the switch cams.

If required, loosen the mounting bracket 6 on the nut 3

and turn it around the actuator axis.

6

.

9.3.3 Positioning of the switch cams

→ Align the position of the lower switch cam 1 to the lower

proximity switch while the actuator is in the lower end

position. Fix switch cam

setscrew

Tightening torque: 0.4...0.6 Nm.

→ Align the position of the upper switch cam

proximity switch while the actuator is in the upper end

position. Fix switch cam

setscrew

Tightening torque: 0.4...0.6 Nm.

→ Check the valve for function and leaks.

Note the hardening time of the Loctite before placing the

valve in operation.

7

.

7

.

1

to the switch spindle 2 using

1

with the upper

1

to the switch spindle 2 using

20

English

Page 21

Type 2060, 2061, 2063, 2064, 2065

Option: Position feedback Type 8697

1

1

7

1

7

Switch cam (2x)

2

Switch spindle

3

Nut

6

Mounting bracket

7

Setscrew

2

3

6

Fig. 12: Positioning of the switch cams

For control function A the lower end position is the rest position.

The upper end position is reached by applying a pilot pressure to

connection 1.

For control function B the lower end position is reached by

applying a pilot pressure to connection 1. The upper end position

is the rest position.

For control function I the lower end position is reached by a

pressure pulse on connection 2 and the upper end position is

reached by a pressure pulse on connection 1.

10 OPTION: POSITION FEEDBACK

TYPE 8697

A

C

B

E

D

A

Transparent cap

B

Position indicator

C

Actuator cover

D

Spindle extension

E

O-ring

Fig. 13: Representation of the parts, actuator size D, M, N and P

Pilot air port 2

Pilot air port 1

English

21

Page 22

Type 2060, 2061, 2063, 2064, 2065

Option: Position feedback Type 8697

10.1 Tasks before installation

→ Interrupt the supply of medium ow.

→ Switch o the pilot air.

→ Empty the valve body.

→ Unscrew transparent cap

DANGER!

Risk of injury from high pressure!

Without the transparent cap, the actuator blows freely upward

when the pilot pressure is applied to the wrong connection.

▶ Apply the pilot pressure for control functions A and I only on

connection 1.

→ Control functions A and I:

To remove the position indicator

upper end position:

Apply pilot pressure to connection 1

(one pressure pulse is sucient for control function I).

→ Unscrew position indicator from

A

o the actuator cover C.

B

, move the actuator to the

B

spindle extension D.

10.2 Installing the position feedback, actuator size D and M

Actuator cover

C

2

D

Max.

gap

4

5

8

Fig. 14: Installing electrical position feedback Type 8697,

actuator size D and M

3

7

1

6

E

D

C

Spindle extension

(actuator)

O-ring

E

Required parts:

Guide element

1

Switch spindle

2

Switch cam

3

Guide bushing

4

5

Lip seal

O-ring(s)

6

Spacer sleeve

7

Gasket

8

22

English

Page 23

Type 2060, 2061, 2063, 2064, 2065

Option: Position feedback Type 8697

10.2.1 Installing the switch spindle

NOTE!

Lip seal will be damaged if incorrectly installed.

The lip seal is pre-mounted in the guide element and must be

"locked into position" in the undercut.

▶ When installing the switch spindle, do not damage the lip

seal.

2

→ Push switch spindle

→ To secure the switch spindle, apply a little threadlocker

(Loctite 290) in the threaded hole of the switch spindle.

→ Check that the O-ring

→ Screw guide element

tightening torque 8 Nm.

→ Screw switch spindle

this, there is a slot on the upper side. Maximum tightening

torque 1 Nm.

→ Push spacer sleeve

guide element

1

through the guide element 1.

6

is in the correct position.

1

to the actuator cover C. Maximum

2

onto the spindle extension D. To do

7

onto the switch spindle 2 up to the

.

10.2.2 Positioning the switch cam on the

switch spindle

→ Push lower switch cam 3 up to the spacer sleeve 7.

→ Push upper switch cam

the spindle.

Ensure that the gap between the two switch cams is

maximum (see “Fig. 14”).

→ Push electrical feedback onto the actuator.

→ Push electrical feedback all the way down to the actuator and

turn it into the required position.

NOTE!

If the torque is too high when screwing in the fastening screw,

the degree of protection IP65 / IP67 cannot be guaranteed!

▶ The fastening screw may be tightened to a maximum torque

of 0.5 Nm only.

→ Attach the electrical feedback to the actuator using the two

side fastening screws. In doing so, tighten the fastening

screws hand-tight only. Maximum tightening torque 0.5 Nm.

3

until it is 3mm from the start of

English

23

Page 24

Type 2060, 2061, 2063, 2064, 2065

Option: Position feedback Type 8697

10.3 Installing the position feedback, actuator size N and P

Fastening screws

Fig. 15: Tightening fastening screws

Actuator cover

C

2

3

D

4

5

8

Fig. 16: Installing electrical position feedback Type 8697,

actuator size N and P

7

1

6

E

D

C

Spindle extension

(actuator)

O-ring

E

Required parts:

Guide element

1

Switch spindle

2

Switch cam

3

Guide bushing

4

5

Lip seal

O-ring(s)

6

Spacer sleeve

7

Gasket

8

24

English

Page 25

Type 2060, 2061, 2063, 2064, 2065

Option: Position feedback Type 8697

10.3.1 Installing the switch spindle

NOTE!

Lip seal will be damaged if incorrectly installed.

The lip seal is pre-mounted in the guide element and must be

"locked into position" in the undercut.

▶ When installing the switch spindle, do not damage the lip

seal.

2

→ Push switch spindle

→ To secure the switch spindle

(Loctite 290) in the threaded hole of the switch spindle.

→ Check that the O-ring

→ Screw guide element

tightening torque 8 Nm.

→ Screw switch spindle

this, there is a slot on the upper side. Maximum tightening

torque 1 Nm.

→ Push spacer sleeve

guide element

1

through the guide element 1.

2

, apply a little threadlocker

6

is in the correct position.

1

to the actuator cover C. Maximum

2

onto the spindle extension D. To do

7

onto the switch spindle 2 up to the

.

10.3.2 Positioning the switch cam on the

switch spindle

→ Push lower switch cam 3 up to the spacer sleeve 7.

→ Push upper switch cam

the spindle.

Ensure that the gap between the two switch cams is

maximum (see “Fig. 16”).

→ Push electrical feedback onto the actuator.

→ Push electrical feedback all the way down to the actuator and

turn it into the required position.

NOTE!

If the torque is too high when screwing in the fastening screw,

the degree of protection IP65 / IP67 cannot be guaranteed!

▶ The fastening screw may be tightened to a maximum torque

of 0.5 Nm only.

→ Attach the electrical feedback to the actuator using the two

side fastening screws. In doing so, tighten the fastening

screws hand-tight only. Maximum tightening torque 0.5 Nm.

3

until it is 3mm from the start of

English

25

Page 26

Type 2060, 2061, 2063, 2064, 2065

Order numbers

11 ORDER NUMBERS

Fastening screws

Fig. 17: Tightening fastening screws

10.4 Electrical installation

Electrical installation is described in the operating instructions for Type 8697. Operating instructions can be found

on the Internet at: www.burkert.com

Accessories Actuator size Order number

Maximum stroke

limitation

Minimum and

maximum stroke

limitation

Threaded nipple for

inductive proximity

switch

Mounting bracket for

two inductive proximity switches

Electrical position

feedback Type 8697

(adaption set for FA05)

D (50 mm) 699 550

M (70 mm)

N (90 mm) 699 994

P (130 mm)

D (50 mm) 699 986

M (70 mm)

N (90 mm) 699 998

P (130 mm)

D (50 mm) 698 536

M (70 mm)

N (90 mm) 698 537

P (130 mm)

D (50 mm) 699 990

M (70 mm)

N (90 mm) 699 992

P (130 mm)

D (50 mm) 699 551

M (70 mm)

N (90 mm) 580 000

P (130 mm)

26

English

Page 27

Page 28

www.burkert.com

Loading...

Loading...