Page 1

1

BÜCHI Vac V-500/V-501/V-502/V-503 Table of Contents

Table of Contents

en, Version I (32 pages) Order No.

V-500 Operating Instructions 96696

1 Scope of Delivery 2

1.1 Büchi Vac V-500 2

1.2 Büchi Vac V-501 3

1.3 Büchi Vac V-502 4

1.4 Büchi Vac V-503 5

2 Safety 6

3 Function 9

3.1 Büchi Vac V-500 9

3.2 Büchi Vac V-501 10

3.3 Büchi Vac V-502 11

3.4 Büchi Vac V-503 12

4 Putting into Operation 14

4.3 Büchi Vac V-500 15

4.4 Büchi Vac V-501 15

4.5 Büchi Vac V-502 16

4.6 Büchi Vac V-503 17

4.7 V-500 with more Vacuum Controllers V-800 18

5 Operation 19

6 Maintenance 22

7 Putting out of Operation 28

8 Spare Parts 29

9 Appendix 31

Please read these operating instructions carefully before using

the BÜCHI Vac V-500/501/502/503

..

..

. Keep these

instructions in the proximity of the device so that you can

consult them immediately whenever necessary.

Chapter 2 contains important safety instructions. Read them

carefully; they are essential for the safe operation of the

device.

Technical changes may be made without prior notice. These

operating instructions may not, either wholly or in part, be reproduced or rewritten by the use of electronic or optical systems,

copied, or distributed without the express written permission of

the firm BÜCHI Labortechnik AG. All rights reserved.

Copyright © BÜCHI Labortechnik AG 1998, 1999, 2000

Page 2

2

1 Scope of Delivery

1 Scope of Delivery BÜCHI Vac V-500/V-501/V-502/V-503

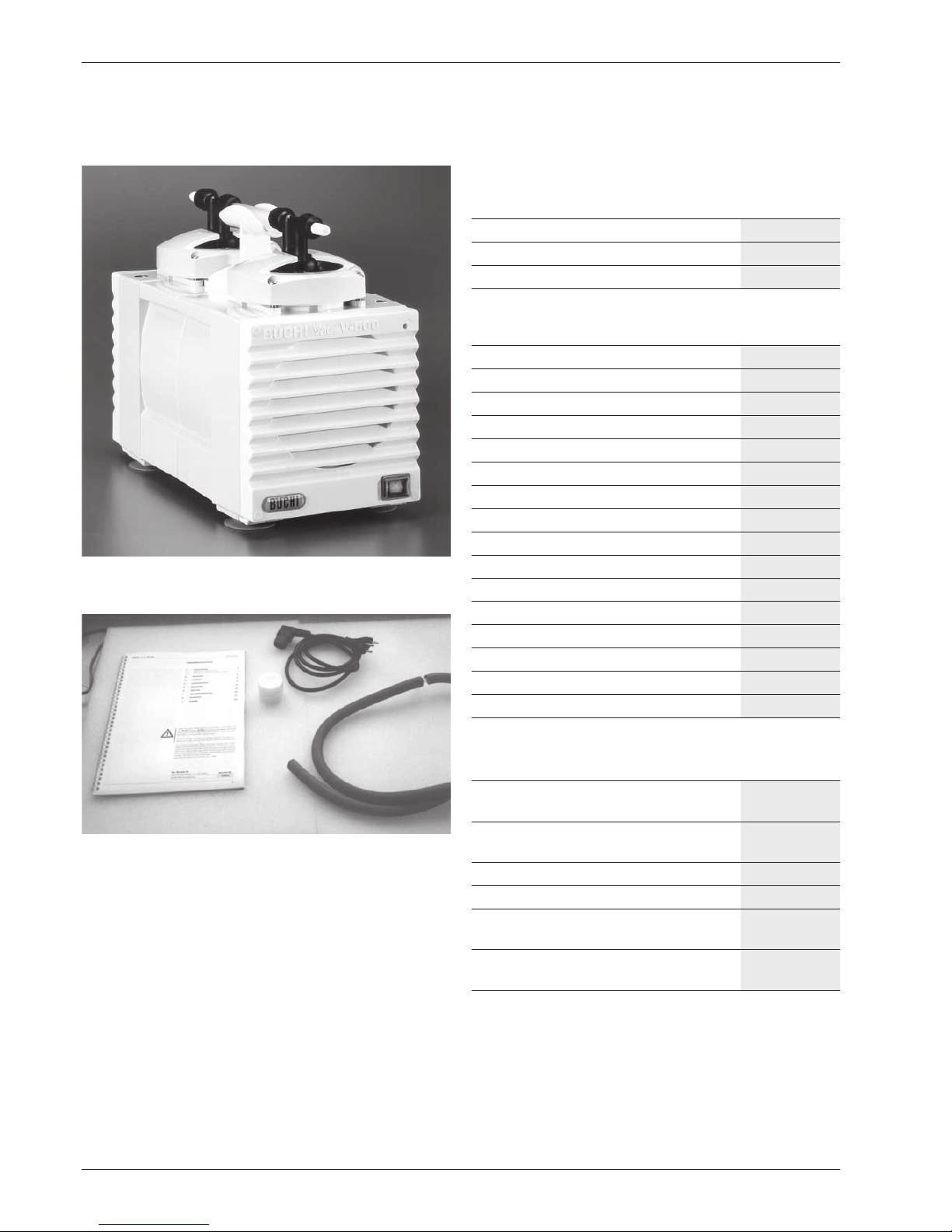

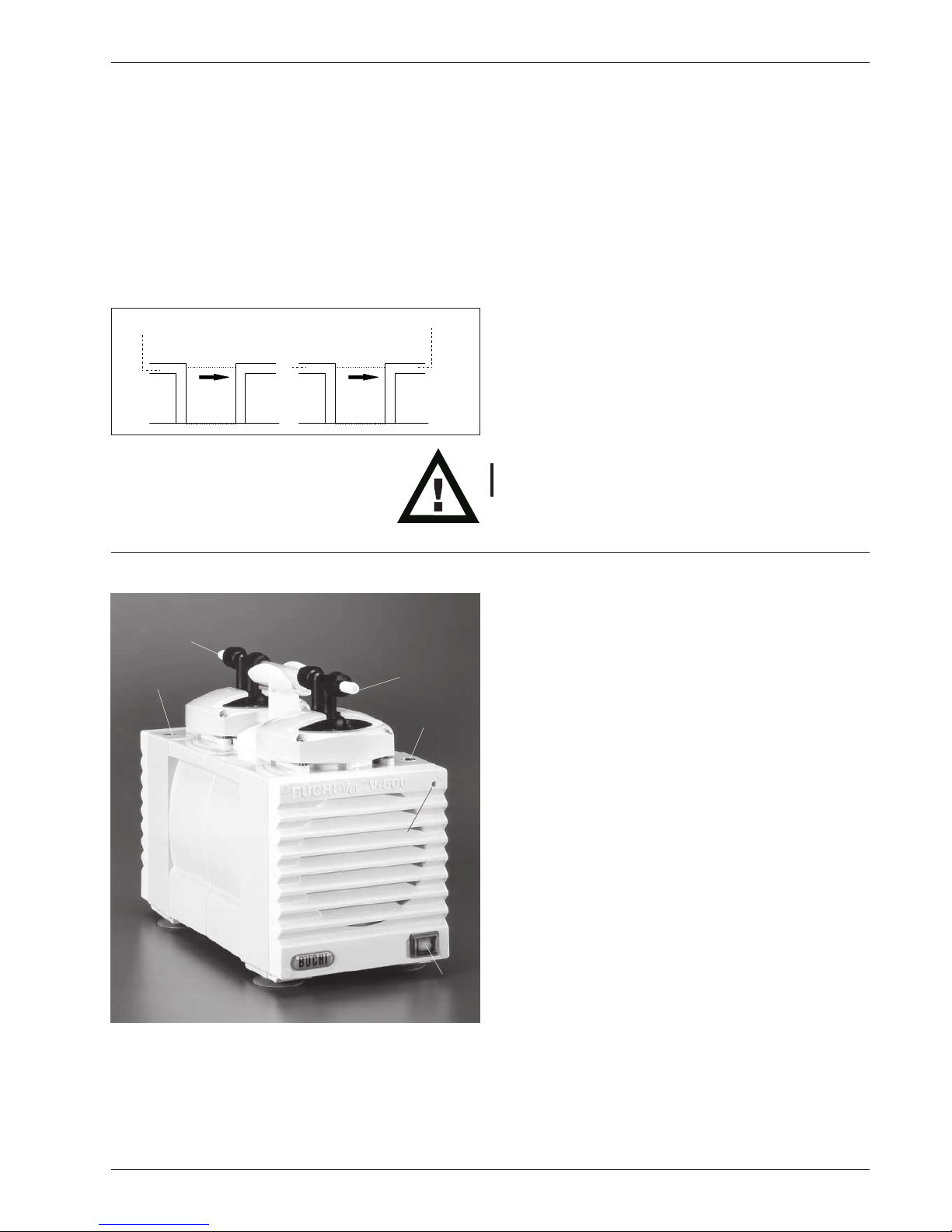

Fig 1: Vac V-500

Fig 2: Enclosed parts Büchi Vac V-500

1.1 Büchi Vac V-500

Description Order No.

Büchi Vac V-500 230 V 50 Hz 37340

Büchi Vac V-500 120 V 50/60 Hz 37339

Büchi Vac V-500 100 V 50/60 Hz 38050

Enclosed parts

1 Sound absorber 37947

2 m Vacuum hose 17622

1 Power cable PNE, 1.5m

Type CH 10010

Type Schuko 10016

Type GB 17835

Type USA 10020

Type AUS 17836

1 Operating instructions:

German 96695

English 96696

French 96697

Italian 96698

Spanish 96699

1 Hose connection GL-14 straight

1 Hose connection GL-14 bent

Table 1: Enclosed parts Büchi Vac V-500

Optional accessories

1 Stand with holder for valve unit, 38021

secondary condenser

1 Secondary condenser complete 38022

with collecting tank

1 Vacuum Controller V-800 230 V 40736

1 Vacuum Controller V-800 120 V 40737

1 Spare parts set consisting of 38120

2 diaphragms, 2 valve heads complete

1 Connecting cable 38010

Vacuum controller to the pump

Table 2: Optinal accessories for Büchi Vac V-500

Page 3

3

BÜCHI Vac V-500/V-501/V-502/V-503 1 Scope of Delivery

Fig 3: Vac V-501 with secondary condenser

Fig 4: Enclosed parts Büchi Vac V-501 with secondary condenser

1.2 Büchi Vac V-501 with secondary condenser

Description Order No.

Büchi Vac V-501 with 38001

secondary condenser 230 V 50 Hz

Büchi Vac V-501 with 38006

secondary condenser 120 V 50/60 Hz

Büchi Vac V-501 with 38051

secondary condenser 100 V 50/60 Hz

Enclosed parts

1 Secondary condenser 37775

1 Collecting tank for 37949

secondary condenser

1 Gasket for secondary condenser 37873

1 Holder for secondary condenser 38086

and collecting tank

1 Stand with holder for 38021

secondary condenser

2 m Vacuum hose 17622

1 Power cable PNE, 1.5 m

(see 1.1 for article number)

1 Operating instructions

(see 1.1 for article number)

1 Hose connection GL-14 straight

1 Hose connection GL-14 bent

1 Spring lock washer 37872

1 Silicone hose 04133

Table 3: Enclosed parts Büchi Vac V-501 with secondary condenser

Optional accessories

1 Vacuum Controller V-800 230 V 40736

1 Vacuum Controller V-800 120 V 40737

1 Valve unit compl. 37968

1 Cooling water valve 31356

1 Control cable for R-134/R-144 31466

to V-500

1 Special cable for KNF controller 38015

1 Special cable for Vacuubrand 38014

1 Thermostatic jacket for 37616

secondary condenser

1 Spare parts set consisting of 2 dia- 38120

phragms, 2 valve heads complete

1 Connecting cable 38010

Vacuum controller to the pump

Table 4: Optional Accessories Büchi Vac V-501 with add. condenser

Page 4

4

1 Scope of Delivery BÜCHI Vac V-500/V-501/V-502/V-503

Fig 5: Vac V-502 with Vacuum Controller

1.3 Büchi Vac V-502 with Vacuum Controller

V-800

Description Order No.

Büchi Vac V-502 with Vacuum 38650

Controller V-800 230 V 50 Hz

Büchi Vac V-502 with Vacuum 38652

Controller V-800 120 V 50/60 Hz

Büchi Vac V-502 with Vacuum 38653

Controller V-800 100 V 50/60 Hz

Enclosed parts

1 Sound absorber 37947

1 Vacuum Controller V-800 230 V 40736

Vacuum Controller V-800 120 V 40737

1 Stand with holder for valve unit, 38021

secondary condenser

1 Valve unit, complete 37968

1 Connecting cable 38010

Vacuum controller to the pump

2 m Vacuum hose 17622

1 Power cable PNE 1.5m

(see 1.1 for article number)

1 Operating instructions:

(see 1.1 for article number)

1 Hose connection GL-14 straight

1 Hose connection GL-14 bent

Table 5: Enclosed parts Vac V-502 with Vacuum Controller

Optional accessories

1 Secondary condenser complete 38022

with collecting tank

1 Cooling water valve 31356

1 Spare parts set consisting of 2 38120

diaphragms, 2 valve heads complete

Table 6: Optional Accessories Vac V-502 mit Vacuum Controller

Page 5

5

BÜCHI Vac V-500/V-501/V-502/V-503 1 Scope of Delivery

Fig 6: Vac V-503 with Vacuum Controller and secondary condenser

Fig 7: Enclosed parts Vac V-503 with Vacuum Controller and

secondary condenser

1.4 Büchi Vac V-503 with secondary condenser

and Vacuum Controller V-800

Description Order No.

Büchi Vac V-503 with Vacuum 38654

Controller V-800 230 V 50 Hz

Büchi Vac V-503 with Vacuum 38656

Controller V-800 120 V 50/60 Hz

Büchi Vac V-503 with Vacuum 38657

Controller V-800 100 V 50/60 Hz

Enclosed parts

1 Vacuum Controller V-800 40736

1 Vacuum Controller V-800 40737

1 Connecting cable 38010

Vacuum controller to the pump

1 Valve unit, complete 37968

1 Secondary condenser 37775

1 Collecting tank for 38949

Secondary condenser

1 Gasket for secondary condenser 37873

1 Holder for secondary condenser 38086

and collecting tank

1 Stand with holder for valve unit, 38021

secondary condenser

2 mVacuum hose 17622

1 Power cable PNE 1.5m

(see 1.1 for article number)

1 Operating instructions

(see 1.1 for article number)

1 Hose connection GL-14 straight

1 Hose connection GL-14 bent

1 Spring lock washer 37872

3m Silicone hose 04133

Table 7: Enclosed parts Büchi Vac V-503 with vacuum controller and

secondary condenser

Optional accessories

1 Thermostatic jacket for 37616

secondary condenser

1 Cooling water valve 24V AC 31356

1 m Vacuum hose 17622

Table 8: Optional Accessories Büchi Vac V-503 with vacuum controller

and secondary condenser

Page 6

6

2 Safety

2 Safety BÜCHI Vac V-500/V-501/V-502/V-503

The device is built with state-of-the-art technology and according

to recognized safety regulations. Nevertheless, using this device

can lead to certain risks and dangers:

• If the device is not used according to these instructions.

• If the device is used by personnel who have not been properly

trained..

2.1 Symbols

Stop

Information about risks which can lead to extensive property

damage or to serious or life-threatening personal injury.

Warning

Information about risks which can lead to damage to one’s

health or to property damage.

Reference

Information which refers to technical requirements. Failure

to heed these requirements can lead to malfunctions, poor

economic performance, and production losses.

Warning

Surface temperature more than 60°C.

2.2 Requirements for the Operator

The device may be used only by laboratory personnel or other

persons who, due to their training or professional experience,

are capable of recognizing possible dangers which might arise

from the use of the device.

Personnel who do not have this training or who are presently

in training must be given careful and exact instruction. These

operating instructions are intended for use as a basis for such

instruction.

2.3 Proper Use

The device was designed and built for laboratory use. Its proper use is the evacuation of laboratory vacuum devices up to

10 mbar. This is done by means of a PTFE diaphragm pump,

with or without regulation through one or more vacuum

controllers.

Uses:

• Evacuation of distillation apparatus, in particular rotation

evaporators.

• Vacuum filtrations

• Vacuum drying cabinets

• Drying ovens

Page 7

7

BÜCHI Vac V-500/V-501/V-502/V-503 2 Safety

2.4 Safety Features

Two fuses (3.15 AT) have been built into the device to protect

it from a short circuit. The pump motor is protected from

overheating by a temperature governor. The pump is 100%

free of oil. The bearings do not require lubrication. All

bearings are completed sealed and self-lubricating.

2.5 Improper Use

Any use of the device other than those given above or any

use of the device which is not in accordance with the

technical data shall be regarded as a misuse. The operator

bears the sole responsibility for any and all damage which

may result from such misuse. The device is not suitable for

pumping liquids or solid particles. The result of such a use

would be the destruction of the pump or a loss in

performance capability.

In particular, the device must not be used in the following ways:

• Use of the device in rooms which require ex-protected

apparatus.

• Processing of samples which can explode or ignite due to

a blow, friction, heat, or sparks (e.g., explosives, etc.).

• Use of the device for digestions (e.g., Kjeldahl)

• Use of the pump to produce over-pressure

• Operation of the device in a surrounding temperature

of > 40° C.

2.6 General Risks

In general, risks can arise from

• Glass parts which are not suitable for use under vacuum

conditions

• Solvents which can react with one another if they mix in

the pump or in the secondary condenser.

• Ignition sources in the immediate vicinity of the pump/

pump system outlet.

• Flammable gases or solvent vapors in the immediate

vicinity of the device.

• Damaged glass equipment

• Bent hoses on the outlet side

Page 8

8

2 Safety BÜCHI Vac V-500/V-501/V-502/V-503

2.7 Safety Measures

Protective clothing such as goggles and laboratory coats

must be worn during operation of the device.

These operating instructions must be available at all times

to operating personnel at the place of operation of the device

and should be regarded as an integral part of the Büchi

Vac V-500-503. Instructions in other languages, which may

be ordered separately, must also be kept with the device.

Modifications

Modifications of the device or of spare parts or of

accessories as well as the use of spare parts or accessories

other than those mentioned in these operating instructions

is allowed only with the prior written permission of BÜCHI

Labortechnik AG.

Responsibility for the operator

The operator is responsible for the instruction of his

personnel. Copies of these operating instructions in various

languages can be ordered for this purpose.

The operator shall inform the manufacturer without delay of

any safety-related events which might occur during operation

of the device.

Regional and local statutes and regulations must be observed.

It is forbidden for anyone other than authorized maintenance

personnel to remove the front or back plate using standard

tools. Damaged glass equipment may not be used under

vacuum conditions.

Touching any parts of the device carrying electrical current

can result in fatal injury!

Page 9

9

BÜCHI Vac V-500/V-501/V-502/V-503 3 Function

Fig. 9a: Vac V-500 front view

3 Function

The Büchi Vac V-500 is a vacuum pump suitable for evacuating

laboratory equipment to a vacuum of <10 mbar. This is done

with a PTFE diaphragm pump. The pump can be used as an

individual device to create a vacuum and can be expanded to

a complete vacuum system by means of the optional

accessories such as secondary condenser and vacuum

controllers (V-501/502/503).

In the following pages, reference will often be made to pump

inlet and pump outlet.

This distinction is important and can be recognized on the

valve heads as follows. Arrows on both valve heads show the

direction of the gas flow.

The pump inlet , is at the beginning of the arrow, the tip of

the arrow is the pump outlet .

Never turn the valve heads so that the arrows point to one

another!

3.1 Function of the Büchi Vac V-500

PTFE diaphragm pump: vacuum pump suitable for evacuating

laboratory devices <10 mbar.

Main switch

Pump outlet GL-14

Pump inlet GL-14

Rod fastening

Stand rod socket, front

Stand rod socket, rear

Fig. 8: Gas flow: valve heads

Pump inlet

Pump outlet

(Direction main switch)

Page 10

10

3 Function BÜCHI Vac V-500/V-501/V-502/V-503

Fig. 10: Vac V 501 with secondary condenser

Fig. 9b: Vac V-500 rear view

Allen wrench

Rod fastening

Connection 24 V ~= Switchbox

Power connection

Installation tool

In case a control cable is connected to the 24V connection

the switchbox switches automatically to external.

The main switch has to be ON (EIN) and can only be

switched ON or OFF via the controller.

3.2 Function of the Büchi Vac V-501

Vacuum system with PTFE diaphragm pump V-500 and

secondary condenser, suitable for evacuating laboratory

equipment to a vacuum of <10 mbar. The secondary

condenser removes any solvent vapors following the pump

(to the physical minimum).

Main switch

Pump outlet

Pump inlet

Secondary condenser

Collecting tank

Supporting ring

Page 11

11

3.3 Function of the Büchi Vac V-502

Vacuum system with PTFE diaphragm pump V-500 and vacuum

controller, suitable for controlled evacuation of laboratory

devices to a vacuum of <10 mbar. This system creates,

regulates, and maintains a vacuum at a constant level by

automatically resuming operation in the event of a vacuum

loss and restoring the vacuum to the set level. To achieve

this, the vacuum pump is turned on and off directly.

The vacuum, selected for the specific solvent, permits almost

100% condensation in the condenser of the distilling device.

This permits a massive reduction of solvent emissions. In

addition, the flow of the cooling water can be controlled during

the distillation process by an optional cooling water valve. 95%

of the cooling water can be saved in this way. The vacuum

controller turns the pump on and off as required by means of

the integrated switchbox.

Main switch

Pump inlet

Sound absorber

Vacuum Controller V-800

Valve unit

Holder

Stand

The sound absorber does not prevent emissions into the

laboratory air. For this reason, the pump must be placed

under a fume hood when the sound absorber is used.

Fig. 11: Vac V-502 with vacuum controller V-800

BÜCHI Vac V-500/V-501/V-502/V-503 3 Function

Page 12

12

Fig. 12: Vac V-503

3 Function BÜCHI Vac V-500/V-501/V-502/V-503

3.4 Function of the Büchi Vac V-503

Vacuum system with PTFE diaphragm pump V-500 and vacuum

controller, suitable for controlled evacuation of laboratory

devices to a vacuum of <10 mbar. This system creates,

regulates, and maintains a vacuum at a constant level by

automatically resuming operation in the event of a vacuum

loss and restoring the vacuum to the set level. To achieve

this, the vacuum pump is turned on and off directly.

The vacuum, selected for the specific solvent, permits almost

100% condensation in the condenser of the distilling device.

This permits a massive reduction of solvent emissions. The

vacuum controller turns the pump on and off as required by

means of the integrated switchbox. The secondary condenser

removes any solvent vapors following the pump. In addition,

the flow of the cooling water can be controlled during the

distillation process by an optional cooling water valve. 95% of

the cooling water can be saved in this way.

Main switch

Pump inlet GL-14

Pump outlet GL-14 – connect to secondary condenser

using vacuum hose (see 3.5)

Secondary condenser

Collecting tank

Vacuum Controller V-800

Valve unit

Holder

Stand

Elastic ring

3.5 Function of the secondary condenser

Cooling water inlet

Cooling water outlet

Intake for exhaust gases from the pump

Outlet for exhaust gases

Assembly:

• Mount gasket in holding ring

• Click holding ring into white holder

• Place the supporting ring on the holding ring and secure

the secondary condenser by pressing down lightly and

turning 60°.

• Mount collecting tank

Fig. 13: Secondary condenser

Page 13

13

BÜCHI Vac V-500/V-501/V-502/V-503 3 Function

3.6 Function of the Vacuum Controllers

See separate operating instructions.

3.7 Function of the valve unit

Hose connection to 1

st

rotation evaporator

Hose connection to 2nd valve unit

Hose connection to vacuum controller

Hose connection to pump inlet (intake end)

Connecting cable to vacuum controller

When the unit is operated with only one rotation evaporator,

the outlet R2 is closed with a cap.

During operation, the valve unit is in a vacuum. Please

examine glass parts for splinters, cracks, stars.

Fig. 14: Valve unit

Page 14

14

4 Putting into operaton BÜCHI Vac V-500/V-501/V-502/V-503

4 Putting into operation

Please check all parts for damage when unpacking. It is

important that any transport damage be discovered when

the parts are unpacked. If necessary, a record of the

condition of the parts should be made immediately (report

to postal service, railway service, or shipping company).

Keep the original packaging for the event of a later transport.

4.1 Placement

The device must be set up on a stable, clean, and level

surface. The surrounding temperature may not exceed 40°

C. Proper air circulation is necessary.

The device must be placed at a minimum of 20 cm from

walls and other objects in order to prevent damage. Containers, chemicals, or other devices may not be placed

behind the pump.

4.2 Connections

4.2.1 Electrical connections

Ensure that the electric current available from the location’s

outlets is the same voltage as that indicated by the label

on the apparatus. The device must always be connected

to a grounded outlet. External couplings and extension cords

must have a protective conductor (3-pin couplings, cables,

or plug and socket connections). There must be no break

in any part of the protective conductor. This will avoid risks

resulting from internal defects.

Connect the pump to the power source with the enclosed

cable.

4.2.2 Other connections

Before putting the device into operation, the screw caps

on the connections must be replaced by GL-14 connections

or sound absorbers.

Please be sure that none of the hoses are bent closed

(bends, the device is resting on the hose).

Replace brittle hoses.

The hoses should be secured with standard hose clamps

or cable binders for safety.

The device must never be put into operation without an

exhaust hose. The exhaust hose must not be pointed

towards hot objects or towards objects which produce

sparks.

The exhaust hose must end in a fume hood so that none of

the vapors from the solvents can be released in the room.

Page 15

15

4.3 Büchi Vac V-500

Sound absorber

Vacuum connection to valve unit

• Screw the sound absorber onto the pump outlet.

• Connect the pump inlet to the rotation evaporator valve

unit using the vacuum hose, as shown in the drawing.

• Connect the power cable.

4.4 Büchi Vac V-501 with secondary condenser

Stand

Holder

Secondary condenser

Collecting tank

Mechanical and electrical connections

• Insert the stand into the desired socket of the pump

and secure it with an allen wrench.

• Secure the white plastic holder to the stand using

an allen wrench.

• Connect the power cable.

Vacuum connections

Connect the pump inlet to the valve unit as shown in the

drawing.

Connect the secondary condenser to the pump outlet.

Secondary condenser

• Secure the secondary condenser and the collecting

tank to the holder. Make sure that the gasket has

been placed between the two glass parts.

• Connect the secondary condenser to the condenser of

the Rotavapor with hoses. The cooling water should flow

first through the secondary condenser, then through the

Rotavapor’s condenser.

• Connect an exhaust hose to the outlet of the secondary

condenser . This hose should run into a fume hood.

Fig. 16: VAC V-501 with secondary condenser

BÜCHI Vac V-500/V-501/V-502/V-503

4 Putting into operaton

Fig. 15: V-500 connection to Rotavapor

Fig. 17: V-501 with secondary condenser connection to Rotavapor

Page 16

16

Fig. 19: Installation Vac V-502 with V-800 with Rotavapor

4 Putting into operation BÜCHI Vac V-500/V-501/V-502/V-503

4.5 Büchi Vac V-502

Stand

Valve unit

Holder

Vacuum Controller V-800

Sound absorber

Mechanical and electrical connections

• Screw sound absorber onto pump outlet

• Insert the stand into the desired socket on the pump

and secure it.

• Secure the white plastic holder to the stand .

• Fasten the vacuum controller V-800 to the stand .

• Insert the valve unit into the holder .

• Attach the cable from the valve unit to the vacuum

controller connection „V“ (Connection A).

• Join the connection Pump of the vacuum controller to the

24 V ~= on the V-500 with the control cable (Connection B).

• Connect the power cable.

Vacuum connections

The following vacuum connections are made using the

vacuum hose:

Pump inlet to the valve unit (via the connection “Pump”).

• Rotation evaporator to the valve unit

(via the connection “R1”).

• Vacuum controller V-800 to the valve unit

(via the connection “V.Contr.”).

• Fit sealing cap on connection R2.

The pump will now be turned on and off by the V-800.

Fig. 18: VAC-502

B

Pump

V. Contr.

R1

R2

A

Page 17

17

4.6 Büchi Vac V-503

Stand

Valve unit

Holder

Vacuum Controller V-800

Secondary condenser

Collecting tank

Mechanical and electrical connections

• Insert the stand into the desired socket on the pump

and secure it.

• Secure the white plastic holder to the stand .

• Fasten the vacuum controller V-800 to the stand .

• Insert the valve unit into the holder .

• Attach the cable from the valve unit to the vacuum

controller connection „V“ (Connection A).

• Join the connection Pump of the vacuum controller to the

24 V ~= on the V-500 with the control cable (Connection B).

• Connect the power cable.

Vacuum connections

The following vacuum connections are made using the vacuum

hose:

•• Pump inlet to the valve unit (via the connection “pump”).

•• Rotation evaporator to the valve unit

(via the connection “R1”).

•• Vacuum controller V-800 to the valve unit

(via the connection “V.Contr.”).

• Fit sealing cap on connection R2.

Secondary condenser

• Secure the secondary condenser and the collecting tank

to the holder as shown in the diagram. Make sure that

the gasket has been placed between the two glass parts.

•• Connect the secondary condenser to the condenser

of the Rotavapor with hoses. The cooling water should

flow first through the secondary condenser, then through

the Rotavapor’s condenser.

•• Connect the pump outlet to the secondary condenser, see

3.5.

•• Connect an exhaust hose to the outlet of the secondary

condenser. This hose should run into a fume hood.

See Section 3.5 for the connections for the secondary

condenser.

Fig. 20: Büchi Vac V-503

BÜCHI Vac V-500/V-501/V-502/V-503 4 Putting into operation

Fig. 21: Installation Vac V-503 with V-800 with Rotavapor

B

Pump

V. Contr.

R1

R2

A

Page 18

18

4 Putting into operation BÜCHI Vac V-500/V-501/V-502/V-503

4.7 Büchi Vac V-500 with multiple Vacuum

Controllers V-800

The vacuum pump and the vacuum system can both be fitted

with 2 or more vacuum controllers at any time.

Hose connections:

R1 to the vacuum connection of the respective rotation

evaporator

Contr. to the respective vacuum controller V-800

Pump first valve unit to the V-500 pump inlet

(intake end)

second “pump” valve unit to R2 on first valve unit

(see A)

fit sealing cap on R2 of the second valve unit

A connection between first valve unit and second valve

unit

B to rotation evaporator 1

C to rotation evaporator 2

Electrical connections:

Valve units connect to Plug „V“ of the respective

vacuum controller

Control cable 1. V-800 join to connection Pump of the first

V-800 and to connection 24 V ~= on

the rear side of the V-500

Control cable 2. V-800 join to connection Pump of the se-

cond V-800 and to the double plug of

the control cable of the first V-800.

Using the same method, additional users can be connected

to each other via valve units.

R1

R2

Pump

Controller

Fig. 22: Connection of multiple vacuum controllers V-800

1. Ventileinheit

B

2. Ventileinheit

C

A

Page 19

19

BÜCHI Vac V-500/V-501/V-502/V-503 5 Operation

Fig. 23: Vac V-501 with secondary condenser

5 Operation

Please be sure that the device has been properly installed

according to the instructions in Chapter 4, Installation.

5.1 Description of the operation features on the

Büchi Vac V-501 with secondary condenser

Main switch

Glass pump heads

Inlet valves

Outlet valves

Pump outlet

Pump inlet (intake end)

Additinal condenser

Collecting tank

5.1.1 Working with the Büchi Vac V-500 with

secondary condenser

Start the pump by using the main switch . If pressure

conditions are too low, the secondary condenser condenses

out the solvent vapors and collects them in the collecting

tank. By twisting this tank clockwise, it can be removed,

emptied, and then returned to operating position.

5.1.2 Adding a vacuum controller to the Büchi

Vac V-500

If you wish to ensure that both the pump and the vacuum

connection to the user are interrupted when the desired

vacuum has been reached, we recommend that you

supplement the vacuum system with a vacuum controller.

Page 20

20

5 Operation BÜCHI Vac V-500/V-501/V-502/V-503

There are several possiblities how the Vacuum System can

be used with a Vacuum Controller.

The most important are:

• 1 Rotavapor with 1 V-800

• 1 Rotavapor with 1 B-168

• 2 Rotavapor with 2 V-800

• 2 Rotavapor with 2 B-168

• 1 Rotavapor with integrated Controller

• 2 Rotavapor with 1 V-800 and 1 B-168

• 1 Rotavapor Vacuum Controller not from Büchi

Connection of vacuum pump to the V-800 controller, valve unit and rotation evaporator

Connection of vacuum pump to the B-168 controller, valve unit and rotation evaporator

Page 21

21

5.2 Description of the integrated switchbox

The integrated switchbox allows particularly quiet and

environmentally-friendly operation. When the desired vacuum

has been reached, the pump is turned off and does not run

again unless the hysteresis set on the V-800 is exceeded.

BÜCHI Vac V-500/V-501/V-502/V-503 5 Operation

Page 22

22

6 Maintenance BÜCHI Vac V-500/V-501/V-502/V-503

6 Maintenance

6.1 Cleaning

Valve head

If the end vacuum of the pump can not be reached the

problem is often caused by stuck valve plates. To clean them

do the following steps:

1) remove all of the connections to the pump and the sound

absorber

2) switch the pump on

3) inject a small amount of about max. 10 ml at one time of

acetone at the inlet side of the pump and wait till the pump

makes the same sound as before injecting the solvent.

The injection should only be done with safety washing bottles

as seen on the picture.

4) Repeat point 3) four to five times

5) Leave the pump running for about 2 minutes and check

then if the end vacuum can be reached.

6) If the end vacuum can not be reached after this cleaning

procedure, repeat it again before going on with Chapter

6.2.

Housing

Before cleaning, please disconnect the apparatus from the

power source.

The housing is made of plastic. Drops of acid must be wiped

away immediately with a damp cloth. Using organic solutions

for cleaning (exception: ethanol) can cause damage and is

not allowed.

Glass parts can be rinsed out with standard cleaning agents

(e.g., mild soap solutions). After they have been cleaned and

dried thoroughly, they must be examined visually for splintered

places or cracks. As the valve unit is in a vacuum during operation, this examination must be carried out conscientiously.

Hoses and gaskets must also be examined visually; if cracks

have developed or if they have become brittle, they must be

replaced with suitable new hoses.

Büchi offers sets of spare parts which make it easier for the

user to obtain spare parts.

The necessary articles can be found in Chapter 8.1, Spare

Parts.

Fig. 24: Cleaning Valve head

Page 23

23

6.2 Removal and Assembly of the Pump Heads,

Valve Heads and Diaphragms

Under conditions of normal usage, the diaphragms and the

valve plates will rarely require replacement.

If the benchmarks of the function checkup (6.1) are not met,

the pump heads, diaphragms, and valve heads should be

cleaned.

If the pump’s performance does not improve, the valve heads

(38025) and possibly the diaphragms must be replaced

(Spare Parts Set 38120).

Attention: Before replacing the diaphragms, please disconnect

the apparatus from the power source.

The parts of the pump head are delicate. Pay close attention

to ensure that the glass head, the valve head, and the diaphragms are not subjected to mechanical damage. Before

assembly, the parts must be examined for nicks, chips, or

deformation.

BÜCHI Vac V-500/V-501/V-502/V-503 6 Maintenance

Page 24

24

6 Maintenance BÜCHI Vac V-500/V-501/V-502/V-503

Removal and cleaning of valve head

1. Release both of the black hose couplings GL-14 between

the pump heads.

2. Using the allen wrench provided, loosen crosswise with a

quarter-turn each and remove the 4 screws on the valve

head top.

3. Carefully remove the valve head top with the valve head

and glass head.

4. Place the entire part on a soft surface. The glass head

can now be removed by applying light pressure to the

valve head.

The valve head, glass head, and diaphragms can now be

cleaned with a suitable cleansing agent (e.g., acetone), or

defective parts can be replaced. The valves of the valve head

can be cleaned by putting the whole valve head into an acetone

bath. If they are still contaminated, use an ultrasonic bath.

Avoid hitting the sides and edges of the glass head. A glass

head which has been dropped may not suffer any apparent

damage, but could break if used again!

Removal of the diaphragms

Only remove the diaphragms if they are broken or can not be

cleaned in a mounted way. They can be released by turning

them counterclockwise.

Replacement of the diaphragms

Before you replace the diaphragm make sure, that the

diaphragm holder fits tight on the lower side of the diaphragm.

There must be no

gap between holder and diaphragm

The diaphragm and the diaphragm holder can then carefully

be screwed on and tightened by hand with the same force as

your have needed to detache it before! Check again if there is

no

gap between diaphragm and holder after replacing the

diaphragm.

Page 25

25

Replacement of the pump head and assembling

1. Before replacing the valve head check if the valves are

not stuck together by holding the head between two fingers.

You should hear a soft clicking while shaking it carefully.

2. Place the valve head into the valve head top. Check if the

rubber sealing is symmetrical placed in the metal part of

the valve head top. Then snap the glass head into the top

so that the knobs on the glass head fit into the spaces on

the valve head. Place the assembled pump head on the

diaphragms.

Pay careful attention to the arrows on the upper part of the

valve heads. They must point in the same direction on both

pump heads.

3. Place the setting gauge side number 1 between the metal

top and thread and screw the first screw (a) in so that

the setting gauge can be removed without force. After

the first screw do the same procedure with the screw

(b) and then with the screw (c) and last but not least

again with the screw (d) (Crosswise).

4. If all screws are on the level 1 change to the side 2 of the

setting gauge. Place this side between metal top and

thread and screw the first screw (a) one quarter-turn in.

After this change the setting gauge to screw (b) and

screw this one also a quarter-turn in. Go on with the

screw (c) and (d) in the same way and repeat this

procedure till you can’t remove the setting gauge without

force. Loosen the screw a little bit to take out the setting

gauge and leave the screw on this position.

Hold the short red part of the allen wrench to tighten the

screws, which will provide for the correct tightness.

You should only use screws with a blue spot on the thread.

The blue spot is a Tufloc coating which prevents the screw

from loosening during operation or transportation of the

pump. If you are using a new screw it could be possible

that you need a slightly higher force to screw this in. This

doesn’t matter and doesn’t influence the result of your work.

BÜCHI Vac V-500/V-501/V-502/V-503 6 Maintenance

Page 26

26

6 Maintenance BÜCHI Vac V-500/V-501/V-502/V-503

5. Now connect the connecting hose, tighten the hose connections, and then assemble the second pump head the

same way as the first one.

6. If the vacuum is not achieved, it may be necessary to

replace or clean the valve head seals. To do this, remove

the valve heads as indicated in 6.2. 1-4.

Carefully take the white sealing rings out of the retainer using

the valve reed and place them in an ultrasonic bath (if possible).

Refit the cleaned individual parts or replacement parts as

shown in the diagram.

6.3 Function control

The function control should be done each year according this

instruction:

• Cleaning (see Chapter 6.1 and 6.2)

• Visual control of the device, connection cable, glass parts

and tube connection.

Deviations:

Suction time of a volume of 3 lt on end vacuum of 20 mbar is

longer than 60 seconds.

Valve head without valves

Insert the valves

Valve head with inserted valves

Page 27

27

BÜCHI Vac V-500/V-501/V-502/V-503 6 Maintenance

6.4 Customer Service

Work on or in the apparatus may be carried out only by authorized service personnel. These are people with sound technical vocational training and knowledge of the risks which result when safety measures are disregarded. BÜCHI customer

service offices have service manuals specific to the various

apparatus; these manuals can be obtained only by authorized

personnel.

The addresses of the official BÜCHI customer service offices

are listed on the last cover page of these operating instructions.

If malfunctions arise or if you have technical questions or problems in operating the apparatus, please turn to these offices.

BÜCHI’s customer service provides the following services:

•• Spare parts service

•• Repair service

•• Maintenance service

•• Technical consulting.

6.5 Working with strong acids / bases on Büchi

VAC V-500 – 513

If strong acids or bases are removed with a Vacuum pump,

protecting clothing such as goggles and laboratory coats must

be worn during operation of the device.

If strong acids or bases are distillated we highly recommend

to rinse the pump after the application to increase the lifetime

of the instrument.

That means 5-10 ml of water should be sucked in trough the

pump inlet and collected directly after the pump outlet. This

process should be repeated as long as the pH of the liquids

coming out of the pump outlet, is between 3-9.

After that the pump is been dried, by sucking air through the

pump for 2-3 min.

Page 28

28

7 Putting out of order BÜCHI Vac V-500/V-501/V-502/V-503

7 Putting out of order

Before the device can be moved, the power cable must be

disconnected and all hoses taken off.

7.1 Storage/Transport

Clean the device thoroughly (see 6.1). Any chemicals

remaining in the device must be removed completely and

the glass parts must be washed. Return the device to the

original packaging for storage and transport.

7.2 Disposal

Chapter 9, Appendix, contains a list of the materials used

in manufacturing the device so that it can be disposed of

in accordance with environmental regulations. This ensures

that the various parts can be separated and recycled properly.

Please observe the valid regional and local statutes in disposing

of the device.

Page 29

29

BÜCHI Vac V-500/V-501/V-502/V-503 8 Spare parts

Only original spare parts and accessories from BÜCHI guarantee that the device will function properly and safely. Spare parts

and accessories from other manufacturers may be used only

with the express permission of BÜCHI AG. General safety

regulations and Chapter 6 must be observed when assembling

or dismantling the device. Before putting the device into

operation, please check that it is fully functional as described in

Chapter 6.2. Production according to this manual is forbidden.

The copyright is owned by the firm Büchi Labortechnik AG.

8.1 Spare parts

1 Spare parts set with 2 valve heads 38120

and 2 diaphragms

1 Glass head set (with 1 glass head) 37966

1 Valve head set (with 2 valve heads) 38025

1 Diaphragm set (with 1 diaphragm) 38020

1 Set of hose connections (2 x bent / 37999

2 x straight / 6 x screw caps)

2 Sealing caps

1 PTFE hose

1 Set of hose connections (4 x bent / 38000

2 x straight / 6 x screw caps)

1 Control cable Vacuum Controller 38010

V-800 to V-500, or B-721 zu 721

1 Secondary condenser 37775

1 Holder for secondary condenser 38086

and collecting tank

1 Collecting tank for secondary condenser 37949

1 Spring lock washer 37872

1 Gasket for secondary condenser 37873

or valve unit

1 Collecting beaker for valve unit 38005

1 Signal cable for KNF vacuum 38015

controller

1 Signal cable for Vacuubrand 38014

vacuum controller

1 Sound absorber 37947

1 Rubber vacuum hose 17622

1 PVC vacuum hose 04113

1 Cooling water hose 04133

1 Stand with holder for valve unit/ 38021

secondary condenser

Table 9a: Spare parts

8 Spare parts

37966

38000

38025

38020

37999

Fig. 25a: Spare parts

Page 30

30

8 Spare parts BÜCHI Vac V-500/V-501/V-502/V-503

1 Valve unit complete 37968

1 Cable set for combination with 31466

Rotavapor R-134/144 or B-168

1 Cooling water valve 31356

1 Thermostatic jacket for 37616

secondary condenser

1 Installation tool 38614

1 Valve set 41977

Table 9b: Spare parts

38614

Fig. 25b: Spare parts

Page 31

31

BÜCHI Vac V-500/V-501/V-502/V-503 9 Appendix

9 Appendix

9.1 Technical data

V-500 V-501 / V-502 / V-503

Measurements (L x B x H) 150 x 294 x 236 mm 230 x 420 x 400 mm

Weight 8 kg 9-11 kg

Electrical supply 230 VAC 50 Hz, +/-10 % 230 VAC 50 Hz, +/-10 %

220 VAC 60 Hz, +/-10 % 220 VAC 60 Hz, +/-10 %

120 VAC 50/60 Hz,+/-10 % 120 VAC 50/60 Hz, +/-10 %

100 VAC 50/60 Hz,+/-10 % 100 VAC 50/60 Hz, +/-10 %

Power consumption 240 W 240 W

Surrounding temperature 5 - 40 °C 5 - 40 °C

Environmental conditions for indoor use only, altitude up to 2000 m.

maximum relativ humidity 80% for temperatures up to 30°C

Final vacuum possible < 10 mbar < 10 mbar

Pumping volume 1.6 m3/h 1.6 m3/h

Relative humidity max. 80% max. 80%

Excess voltage category II II

Degree of contamination 2 2

V-800 see Operating instructions V-800

Connection 24V-Switchbox DC

24V / 30 mA

Table 10: Technical data

Description Material Material code

Pump heads Glas 3.3

Housing Aluminium

Housing cover PBT

Diaphragms PTFE / rubber

Valve plate PEEK

Valve head PEEK

Vacuum hoses PTFE / rubber

Gasket rings valves ETFE

Diaphragms, valve unit Perfluorelastomer

Gasket secondary condenser / valve unit PTFE / PEEK

Table 11: Materials

9.2 Materials used

Page 32

32

9 Appendix BÜCHI Vac V-500/V-501/V-502/V-503

9.3 FCC requirements (for USA and Canada)

English:

This equipment has been tested and found to comply with the limits for a Class A digital device, pusuant to both Part

15 of the FCC Rules and the radio interference regulations of the Canadian Department of Communications. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is like to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Français:

Cet appareil a été testé et s'est avéré conforme aux limites prévues pour les appareils numériques de classe A et à

la partie 15 des règlementation FCC à la règlementation des radio-interférences du Canadian Department of

communications. Ces limites sont destinées à fournir une protection odéquate contre les interférences nétastes

lorsque l'appareil est utilisé dans un environnement commercial.

Cet appareil génère, utilise et peut radier une énergie à fréquence radioélectrique, il est en outre susceprible d'engendrer

des interferences avec les communications radio, s'il n'est pas installé et utilisé conformément aux instructions du

mode d'emploi. L'utilisation de cet appareil dans les zones résidentielles peut causer des interférences nèfastes,

auquel cas l'exploitant sera amené à prendre les dispositions utiles pour polier aux interférences à ses propres frais.

9.4 Declaration of conformity

We Büchi Labortechnik AG

Postfach, CH-9230 Flawil

Switzerland

do hereby declare on our responsibility that the product:

BÜCHI VAC V-500 / V-501 / V-502 / V-503

which is the object of this certification, is in accordance with the following norms:

EN 61010-1:1993 (~ IEC 1010-1, VDE 0411-1)

Safety regulations for electrical measuring, control, regulation, and laboratory devices: general requirements

EN 55011:1991/B (~ VDE 0875/B, VDE 0871/B)

Limits and measuring procedures for interference from industrial, scientific, and medical high-frequency devices

EN 61000-3-2: 1995/1996

Limits for harmonic current emissions

EN 61000-3-3: 1995

Limitation of voltage fluctuations and flicker

In accordance with the regulations of the EU guidelines

73/23/EWG (electrical operating equipment/low-voltage guidelines)

89/336/EWG electromagnetic compatibility)

Flawil, 11.07.2005

BÜCHI Labortechnik AG

Meierseggstrasse 40

9230 Flawil

Schweiz

Tel +41 (0)71 394 63 63 Guido Worch

Fax +41 (0)71 394 65 65 Qualitymanager

buchi@buchi.com

www.buchi.com

Loading...

Loading...