Page 1

installation, start-up,

583B

and operating instructions

3-PHASE SINGLE PACKAGE

GAS HEATING/AIR CONDITIONERS

WITH PURON® (R-410A) REFRIGERANT

Low NOx Models Available

NOTE: Read the entire instruction manual before starting the

installation.

Index Page

SAFETY CONSIDERATIONS .....................................................1

RULES FOR SAFE INSTALLATION AND OPERATION....1-2

RECEIVING AND INSTALLATION ..........................................2

CHECK EQUIPMENT ..................................................................2

PROVIDE UNIT SUPPORT .........................................................2

Roof Curb..................................................................................2

Slab Mount................................................................................2

Ground Mount...........................................................................2

FIELD FABRICATE DUCTWORK..........................................2-3

PROVIDE CLEARANCES ........................................................4-7

RIG AND PLACE UNIT ...........................................................7-8

CONNECT CONDENSATE DRAIN ...........................................8

INSTALL FLUE HOOD ...............................................................8

INSTALL GAS PIPING............................................................... 9

INSTALL DUCT CONNECTIONS ..................................... 10-11

INSTALL ELECTRICAL CONNECTIONS.........................12-14

High-Voltage Connections......................................................12

Special Procedures for 208-V Operation ...............................12

Control Voltage Connections .................................................13

Standard Connection...............................................................13

Heat Anticipator Setting....................................................13-14

Transformer Protection ...........................................................14

PRE-START-UP ......................................................................... 14

START-UP ............................................................................ 14-23

MAINTENANCE....................................................................23-27

REFRIGERANT SYSTEM..........................................................27

QUICK REFERENCE GUIDE....................................................28

TROUBLESHOOTING......................................................... 29-31

START-UP CHECKLIST............................................................32

NOTE TO INSTALLER — Before the installation, READ

THESE INSTRUCTIONS CAREFULLY AND COMPLETELY.

Also, make sure the User’s Manual and Replacement Guide are

left with the unit after installation. the furnace is NOT to be used

for temporary heating of buildings or structures under construction.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified personnel should install, repair, or service

air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of

cleaning coils and filters. All other operations should be performed

by trained service personnel. When working on air-conditioning

equipment, observe precautions in the literature, tags and labels

attached to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for unbrazing operations. Have fire extinguisher

available for all brazing operations.

Sizes

030-060

Cancels: New II 583B-30-1

2-06

Fig. 1—Unit 583B

RULES FOR SAFE INSTALLATION AND OPERATION

WARNING: Improper installation, adjustment, alter-

ation, service, maintenance, or use can cause carbon

monoxide poisoning, fire, or an explosion which can

result in serious injury or unit damage. Consult a qualified installer, service agency, or gas supplier for information or assistance. The qualified installer or agency

must use only factory-authorized kits or accessories when

modifying this product.

Understand the signal words —DANGER, WARNING, and

CAUTION. DANGER identifies the most serious hazards which

will result in severe serious injury or death. WARNING indicates

a condition that could result in serious injury or death. CAUTION

is used to identify unsafe practices which would result in minor or

moderate injury or product and property damage.

The power supply (volts, phase, and hertz) must correspond to that

specified on unit rating plate.

The electrical supply provided by the utility must be sufficient to

handle load imposed by this unit.

This installation must conform with local building codes and with

NEC (National Electrical Code) and NFPA 70, NFPA 54/ANSI

Z223.1 latest revision, and NFGC (National Fuel Gas Code). Refer

to provincial and local plumbing or waste water codes and other

applicable local codes.

Approved for outdoor installation on wood flooring or on class A,

B or C roof covering materials.

C99087

—1—

Page 2

WARNING: Before performing service or maintenance

operations on unit, turn off gas supply then unit main

power switch. Electrical shock or explosion could cause

serious injury or death.

CAUTION: Puron (R-410A) systems operate at higher

pressures than standard R-22 systems. Do not use R-22

service equipment or components on Puron (R-410A)

equipment. Ensure service equipment is rated for Puron

(R-410A).

A

B

Fig. 2—Unit Leveling Tolerances

C

MAXIMUM ALLOWABLE

DIFFERENCE (in.)

A-B B-C A-C

1/4 1/4 1/4

C99065

A. General

The 583B units (see Fig. 1) are fully self-contained, combination

Category I gas heating/electric cooling units designed for outdoor

installation. See Fig. 6 and 7 for unit dimensions. All unit sizes

have discharge openings for both horizontal and downflow configurations, and are factory shipped with all downflow duct

openings covered . Units may be installed either on a rooftop,

cement slab, or directly on the ground (if permitted by local

codes). See Figs. 4 and 5 for roof curb dimensions.

Models with an N in the thirteenth position of the model number

are dedicated Low NO

units designed for California installation.

x

These models meet the California maximum oxides of nitrogen

) emissions requirements of 40 nanograms/joule or less as

(NO

x

shipped from the factory and must be installed in California Air

Quality Management Districts where a Low NO

rule exists.

x

RECEIVING AND INSTALLATION

I. CHECK EQUIPMENT

IDENTIFY UNIT — The unit model number and serial number

are stamped on unit identification plate. Check this information

against shipping papers and job data.

INSPECT SHIPMENT — Inspect for shipping damage while unit

is still on shipping pallet. If unit appears to be damaged or is torn

loose from its anchorage, have it examined by transportation

inspectors before removal. Forward claim papers directly to

transportation company. Manufacturer is not responsible for any

damage incurred in transit.

Check all items against shipping list. Immediately notify the

nearest Bryant Air Conditioning office if any item is missing.

To prevent loss or damage, leave all parts in original packages

until installation.

II. PROVIDE UNIT SUPPORT

ROOF CURB — Install accessory roof curb in accordance with

instructions shipped with curb. See Figs. 4 and 5 and Table 1 for

roof curb dimensions. Install insulation, cant strips, roofing, and

flashing. Ductwork must be attached to curb.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a watertight seal. Install gasketing material supplied

with the roof curb. Improperly applied gasketing can also result in

air leaks and poor unit performance.

Curb should be level to within 1 /4 inch. This is necessary for unit

drain to function properly. Refer to accessory roof curb installation

instructions for additional information as required (see Fig. 2).

2"

(50.8mm)

OPTIONAL

RETURN

AIR

OPENING

EVAP.

COIL

COND.

COIL

OPTIONAL

SUPPLY

AIR

OPENING

C99014

Fig. 3—Slab Mounting Details

SLAB MOUNT — Place the unit on a solid, level concrete pad

that is a minimum of 4 in. thick with 2 in. above grade. The slab

should be flush on the compressor end of the unit (to allow

condensate drain installation) and should extend 2 in. on the three

remaining sides of the unit. See Fig. 3. Do not secure the unit to the

slab except when required by local codes.

GROUND MOUNT — The unit may be installed either on a slab

or placed directly on the ground if local codes permit. Place the

unit on level ground prepared with gravel for condensate discharge.

III. FIELD FABRICATE DUCTWORK

Secure all ducts to roof curb and building structure on vertical

discharge units. Do not connect ductwork to unit. For horizontal

applications, unit is provided with flanges on the horizontal

openings. All ductwork should be secured to the flanges. Insulate

and weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applicable

codes.

Ducts passing through an unconditioned space must be insulated

and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be

ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork. Cabinet

return-air static shall not exceed -.25 in. wg.

—2—

Page 3

6

C

46 3/16

44 5/16

B

17 3/8

TYP.

D

1 TYP.

3

SUPPORT B

B

SUPPORT A (2)

SIDE

(2)

A

7/8

13/16

2

END VIEW

END

(2)

DECK PAN (INSULATED)

Fig. 4—Roof Curb Dimensions

A99320

Top View

SIDE PANEL

0.75"

SUPPORT RIB(S)

SEAL STRIP

(FACTORY SUPPLIED)

3.0"

BASE PAN

BOTTOM SUPPLY

4.0"

COUNTER FLASHING

(FIELD SUPPLIED)

ROOFING FELT

(FIELD SUPPLIED)

CANT STRIP

(FIELD SUPPLIED)

NAILER

ROOFING MATERIAL

(FIELD SUPPLIED)

Fig. 5—Roof Curb Dimensions

Side View

—3—

INSULATION

(FIELD SUPPLIED)

A99340

Page 4

TABLE 1—ROOF CURB DIMENSIONS

UNIT SIZE ODS ORDER NUMBER

ROOF

CURB

Notes:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied as required to unit being installed.

3. Dimensions in ( ) are in millimeters.

4. Roof curb is made of 16 gauge steel.

5. Table lists only the dimensions per part number that have changed.

6. Attach ductwork to curb (flanges of duct rest on curb).

7. Insulated panels: 1-in. thick fiberglass 1 lb. density.

8. Dimensions are in inches.

583B030-036

583B042-060

CPRFCURB006A00 8 (203) 11 27/32 (301) 30 5/8 (778) 28 3/4 (730)

CPRFCURB007A00 14 (356) 11 27/32 (301) 30 5/8 (778) 28 3/4 (730)

CPRFCURB008A00 8 (203) 15 27/32 (402) 42 1/8 (1070) 40 1/4 (1022)

CPRFCURB009A00 14 (356) 15 27/32 (402) 42 1/8 (1070) 40 1/4 (1022)

A

IN. (MM)

B

IN. (MM)

C

IN. (MM)

D

IN. (MM)

IV. PROVIDE CLEARANCES

The required minimum operating and service clearances are shown

in Fig. 6 and 7. Adequate combustion, ventilation, and condenser

air must be provided, in accordance with section 5.3, Air for

Combustion and Ventilation, of the National Fuel Gas Code ANSI

(American National Standards Institute) Z223.1 (in Canada, sections 7.2, 7.3 or 7.4 or Can/CGA (Canadian Gas Association)

B149 Installation Codes), or applicable provisions of local building code.

CAUTION: Do not restrict condenser airflow. An air

restriction at either the outdoor-air inlet or the fan

discharge can be detrimental to compressor life.

The condenser pulls air through the condenser coil and discharges

it through the top cover. Be sure that the fan discharge does not

recirculate to the condenser coil. Do not locate the unit in either a

corner or under an overhead obstruction. The minimum clearance

under a partial overhang (such as a normal house overhang) is

48-in. above the unit top. The maximum horizontal extension of a

partial overhang must not exceed 48 inches.

Do not place the unit where water, ice, or snow from an overhang

or roof will damage or flood the unit. Do not install the unit on

carpeting, tile, or other combustible materials. The unit may be

installed on wood flooring or on Class A, B, or C roof covering

materials.

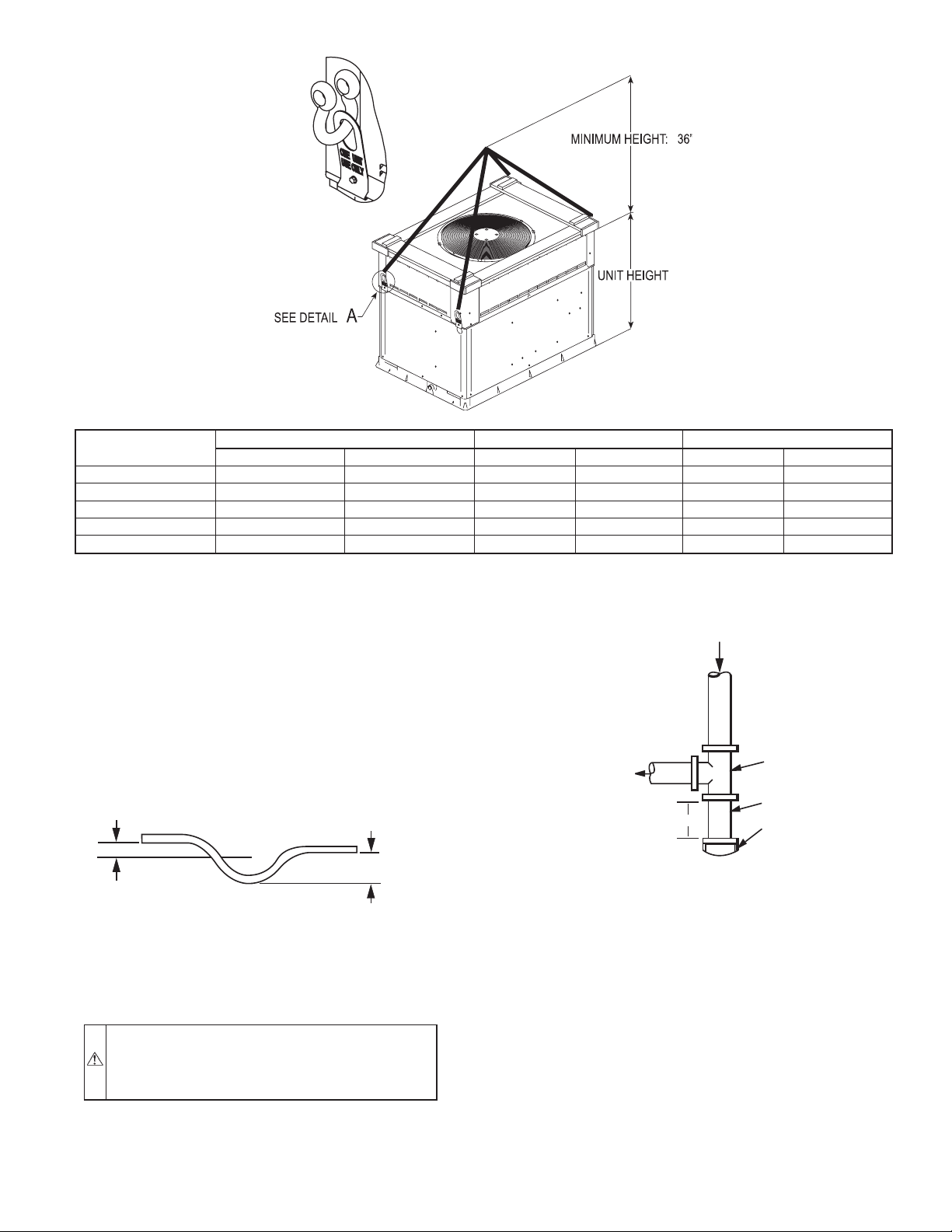

V. RIG AND PLACE UNIT

Rigging and handling of this equipment can be hazardous for many

reasons due to the installation location (roofs, elevated structures,

etc.).

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers and labels attached to the equipment,

and any other safety precautions that might apply.

Training for operations of the lifting equipment should include, but

NOT be limited to the following:

1. Application of the lifter to the load and adjustment of the

lifts, if any, that adapts it to various sizes or kinds of loads.

2. Instruction in any special operation or precaution.

3. Condition of the load itself, required for operation of the

lifting kit, such as balance, temperature, etc.

Follow all applicable safety codes. Wear safety shoes and work

gloves.

WARNING:

Never exceed 200 lbs. per bracket lifting force.

Accessory lifting kit is only to be used with Small

Packaged units which have a composite base pan with

molded hand holds.

Never stand beneath rigged units or lift over people.

Lifting point should be directly over the center of gravity

for the unit.

A dropped unit could cause serious injury or death.

INSPECTION — Prior to initial use, and at monthly intervals, all

rigging brackets and straps should be visually inspected for any

damage, evidence of wear, structural deformation, or cracks.

Particular attention should be paid to excessive wear at hoist

hooking points and load support areas. Brackets or straps showing

any kind of wear in these areas must not be used and should be

discarded.

INSTALLATION:

1. Position the lifting bracket assembly around the base of the

unit. Leave the top shipping skid on the unit to act as a

spreader bar. Be sure the strap does not twist.

2. Place each of the four (4) metal lifting brackets into the

handholds in the composite pan.

3. Tighten the ratchet strap until tight. Lifting brackets should

be secure in the handholds.

4. Attach the clevis or hook of sufficient strength to hole in the

lifting bracket as shown in Fig. 8.

5. Attach safety straps directly to the field supplied rigging

straps or clevis clip. Do not attach the safety straps to the

lifting brackets.

6. Use the top of the unit as a spreader bar to prevent the

rigging straps from damaging the unit. If the wood top is not

available, use a spreader bar of sufficient length to not

damage the unit.

VI. CONNECT CONDENSATE DRAIN

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

The 583B units dispose of condensate water through a 3/4 in. NPT

fitting which exits through the compressor access panel. See Fig.

6 and 7 for location.

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in groundlevel installations. Install a field-supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least 1 in. lower than the drain pan

condensate connection to prevent the pan from overflowing. See

Fig. 9. Prime the trap with water. When using a gravel apron, make

sure it slopes away from the unit.

—4—

Page 5

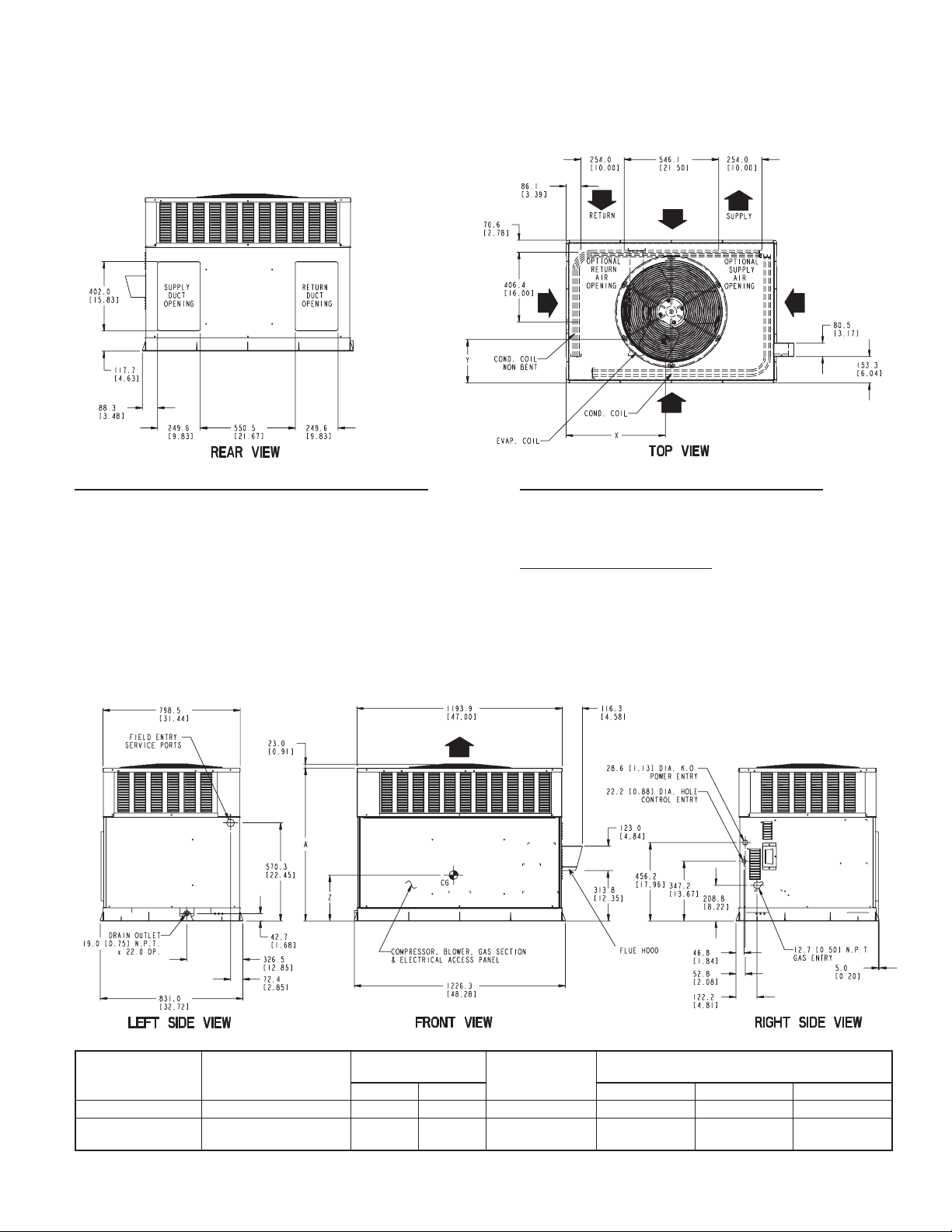

REQ’D CLEARANCES FOR OPERATION AND SERVICING. in. (mm)

Evaporator coil access side ..................36(914)

Power entry side (except for NEC requirements) .........36(914)

Unittop ..........................48(1219)

Side opposite ducts .....................36(914)

Duct panel ........................12

Flue Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36 (914.4)

*Minimum distances: If unit is placed less than 12 in. (304.8 mm) from wall

system, then the system performance may be compromised.

LEGEND

CG - Center of Gravity

COND - Condenser

EVAP - Evaporator

NEC - National Electrical Code

REQ'D - Required

Note: Dimensions are in in. (mm)

(304.8)*

REQ’D CLEARANCES TO COMBUSTIBLE MAT’L. in. (mm)

Topofunit.........................14(355.6)

Duct side of unit .......................2(50.8)

Side opposite ducts .....................14(355.6)

Bottomofunit.......................0.50(12.7)

NEC REQ’D CLEARANCES. in. (mm)

Between units, power entry side ..............42(1066.8)

Unit and ungrounded surfaces, power entry side .........36(914)

Unit and block or concrete walls and other grounded

surfaces, control box side .................42(1066.8)

C99017

CENTER OF GRAVITY

IN. (MM)

UNIT

ELECTRICAL

CHARACTERISTICS

UNIT WEIGHT

lb. kg. X Y Z

UNIT HEIGHT

IN. (MM)

"A"

583B030040/060 208/230-3-60 313.0 142.0 39.02 (991.1) 22.0 (558.8) 15.3 (387.4) 17.6 (447.0)

583B036060/090

208/230-3-60,

460-3-60

321.0 145.6 35.02 (889.5) 22.0 (558.8) 15.3 (387.4) 16.5 (419.1)

Fig. 6—583B030, 036 Unit Dimensions

—5—

Page 6

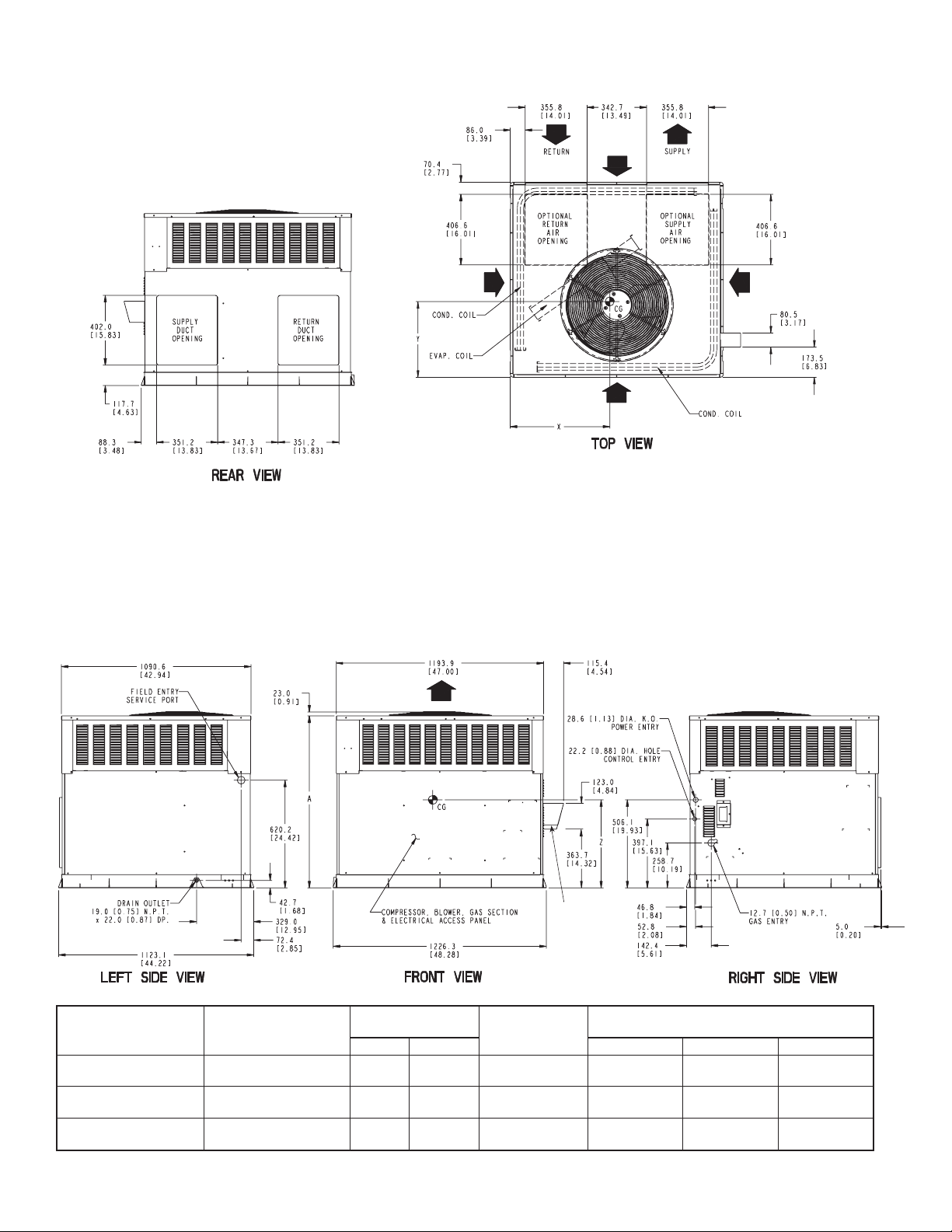

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

EVAP. COIL ACCESS SIDE..............................................................36.00 [914.0]

POWER ENTRY SIDE......................................................................36.00 [914.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP.........................................................................................36.00 [914.0]

SIDE OPPOSITE DUCTS ................................................................36.00 [914.0]

DUCT PANEL ...................................................................................12.00 [304.8] *

FLUE HEAT PANEL

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 12.00 [304.8] FROM

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE.

.................................................................36.00 [914.4]

in. [mm]

REQUIRED CLEARANCE TO COMBUSTIBLE MATL.

TOP OF UNIT...................................................................................14.00 [355.6]

DUCT SIDE OF UNIT.........................................................................2.00 [50.8]

SIDE OPPOSITE DUCTS ................................................................14.00 [355.6]

BOTTOM OF UNIT.............................................................................0.50 [12.7]

NEC. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE ....................................42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE ...36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE.........................42.00 [1066.8]

FLUE HOOD

in. [mm]

in. [mm.]

UNIT

583B042060/090

583B048090/115/130

583B060090/115/130

ELECTRICAL

CHARACTERISTICS

208/230-3-60

460-3-60

208/230-3-60

460-3-60

208/230-3-60,

460-3-60

UNIT WEIGHT

lb. kg. X Y Z

UNIT HEIGHT

IN. (MM)

"A"

CENTER OF GRAVITY

IN. (MM)

382 173.3 38.98 (990.2) 23.0 (584.2) 16.3 (412.8) 16.6 (421.6)

421 191.0 38.98 (990.2) 21.5 (546.1) 16.6 (422.1) 18.0 (457.2)

468 212.3 42.98 (1091.7) 23.5 (596.9) 16.3 (412.8) 17.6 (447.0)

Fig. 7—583B042-060 Unit Dimensions

—6—

C99074

Page 7

DETAIL A

UNIT 583B

SIZE

030 335 152 22.0 558.5 15.3 388.6

036 343 156 22.0 558.5 15.3 388.6

042 404 183 23.0 584.2 16.3 414.0

048 443 201 21.5 546.1 16.3 414.0

060 490 222 23.5 596.9 16.3 414.3

MAXIMUM WEIGHT A B

lb kg in. mm in. mm

Fig. 8—Suggested Rigging

A05179

If the installation requires draining the condensate water away

from the unit, install a 2-in. trap at the condensate connection to

ensure proper drainage. See Fig. 9. Make sure that the outlet of the

trap is at least 1 in. lower than the drain pan condensate connection

to prevent the pan from overflowing. Prime the trap with water.

Connect a drain tube using a minimum of 3/4 -in. PVC or 3/4 -in.

copper pipe (all field-supplied) at the outlet end of the 2-in. trap.

Do not undersize the tube. Pitch the drain tube downward at a

slope of at least one in. for every 10 ft of horizontal run. Be sure

to check the drain tube for leaks.

1” (25mm) MIN.

TRAP

OUTLET

2” (50mm) MIN.

C99013

Fig. 9—Condensate Trap

VII. INSTALL FLUE HOOD

The flue hood assembly is shipped screwed to the coil panel in the

indoor blower compartment. Remove the service access panel to

locate the assembly.

CAUTION: The venting system is designed to ensure

proper venting. The flue hood assembly must be installed

as indicated in this section of the unit installation instructions.

NOTE: Dedicated low NOxmodels MUST be installed in Cali-

fornia Air Quality Management Districts where a Low NO

rule

x

exists.

IN

OUT

3˝ MIN

TEE

NIPPLE

CAP

C99020

Fig. 10—Sediment Trap

These models meet the California maximum oxides of nitrogen

(NO

) emissions requirements of 40 nanograms/joule or less as

x

shipped from the factory.

NOTE: Low NO

requirements apply only to natural gas instal-

x

lations.

Install the flue hood as follows:

1. This installation must conform with local building codes

and with the National Fuel Gas Code (NFGC), ANSI

Z223.1 (in Canada, CAN/CGA B149.1, and B149.2) or

NFPA (National Fire Protection Association) latest revision. Refer to Provincial and local plumbing or waste water

codes and other applicable local codes.

2. Remove flue hood from shipping location (inside the

blower compartment). Place vent cap assembly over flue

panel. Orient screw holes in vent cap with holes in the flue

panel.

—7—

Page 8

3. Secure flue hood to flue panel by inserting a single screw on

the right side and the left side of the hood.

VIII. INSTALL GAS PIPING

The gas supply pipe enters the unit through the access hole

provided. The gas connection to the unit is made to the 1/2-in. FPT

gas inlet on the manual shutoff or gas valve.

Install a gas supply line that runs to the heating section. Refer to

Table 4 and the NFGC for gas pipe sizing. Do not use cast-iron

pipe. It is recommended that a black iron pipe is used. check the

local utility for recommendations concerning existing lines. Size

gas supply piping for 0.5 in. wg maximum pressure drop. Never

use pipe smaller than the 1/2-in. FPT gas inlet on the unit gas

valve.

For natural gas applications, the gas pressure at unit gas connection

must not be less than 4.0 in. wg or greater than 13 in. wg while the

unit is operating. For propane applications, the gas pressure must

not be less than 7.0 in. wg or greater than 13 in. wg at the unit

connection.

A 1/8-in. NPT plugged tapping accessible for test gauge connection must be installed immediately upstream of the gas supply

connection to the gas valve.

When installing the gas supply line, observe local codes pertaining

to gas pipe installations. Refer to the NFGC ANSI Z223.1, NFPA

54 latest edition (in Canada, CAN/CGA B149.1, B149.2 latest

edition). In the absence of local building codes, adhere to the

following pertinent recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe 1/4 in.

in every 15 ft. to prevent traps. Grade all horizontal runs

downward to risers. Use risers to connect to heating section

and to meter.

2. Protect all segments of piping system against physical and

thermal damage. Support all piping with appropriate straps,

hangers, etc. Use a minimum of one hanger every 6 ft. For

pipe sizes larger than 1/2 in., follow recommendations of

national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied

petroleum gases as specified by local and/or national codes.

Never use Teflon tape.

4. Install sediment trap in riser leading to heating section per

Fig. 10. This drip leg functions as a trap for dirt and

condensate.

5. Install an accessible, external, manual main shutoff valve in

gas supply pipe within 6 ft. of heating section.

6. Install ground-joint union close to heating section between

unit manual shutoff and external manual main shutoff

valve.

7. Pressure-test all gas piping in accordance with local and

national plumbing and gas codes before connection of

piping to unit.

NOTE: The supply piping must be disconnected from the gas

valve during the testing of the piping systems when test pressure is

in excess of 0.5 psig (13.8 WC). If the test pressure is equal to or

less than 0.5 psig, the unit heating section must be isolated from

the gas piping system by closing the external main manual shutoff

valve and slightly opening the ground-joint union.

CAUTION: Unstable operation may occur when the gas

valve and manifold assembly are forced out of position

while connecting improperly routed rigid gas piping to

the gas valve. Use a backup wrench when making

connection to avoid strain on, or distortion of, the gas

control piping.

CAUTION: If a flexible conductor is required or allowed by the authority having jurisdiction, black iron

pipe shall be installed at the gas valve and shall extend a

minimum of 2 in. outside the unit casing.

WARNING: Never use a match or other open flame

when checking for gas leaks. Never purge gas line into

combustion chamber. Failure to follow this warning

could result in an explosion causing serious injury or

death

8. Check for gas leaks at the field-installed and factoryinstalled gas lines after all piping connections have been

completed. Use soap and water solution (or method specified by local codes and/or regulations).

IX. INSTALL DUCT CONNECTIONS

The unit has duct flanges on the supply- and return-air openings on

the side and bottom of the unit. For downshot applications the

ductwork can be connected to the roof curb. See Fig. 6 and 7 for

connection sizes and locations.

CONFIGURING UNITS FOR DOWNFLOW (VERTICAL) DISCHARGE

WARNING: Before performing service or maintenance

operations on the system, turn off main power to unit.

Electrical shock could cause serious injury or death.

1. Open all electrical disconnects before starting any service

work.

2. Remove return duct cover located on duct panel by breaking

connecting tabs with screwdriver and a hammer (Fig. 11).

3. To remove supply duct cover, break front and right side

connecting tabs with a screwdriver and a hammer. Push

louver down to break rear and left side tabs (Fig. 12).

4. If unit ductwork is to be attached to vertical opening flanges

on the unit basepan (jackstand applications only), do so at

this time. Collect ALL screws that were removed. Do not

leave screws on rooftop as permanent damage to the roof

may occur.

5. It is recommended that the basepan insulation around the

perimeter of the vertical return-air opening be secured to the

basepan with aluminum tape. Applicable local codes may

require aluminum tape to prevent exposed fiberglass.

6. Cover both horizontal duct openings with the duct covers

from the accessory duct cover kit. Ensure opening is air-and

watertight.

7. After completing unit conversion, perform all safety checks

and power up unit.

NOTE: The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

nonresidence-type air conditioning and ventilating systems, NFPA

90A or residence-type, NFPA 90B; and/or local codes and

residence-type, NFPA 90B; and/or local codes and ordinances.

—8—

Page 9

TABLE 2—PHYSICAL DATA — UNIT 583B — 030040-042090

UNIT SIZE 583B 030040 030060 036060 036090 042060 042090

NOMINAL CAPACITY (ton) 21/2 21/2 3 3 31/2 31/2

OPERATING WEIGHT (lb) 313 313 321 321 382 382

COMPRESSORS

Quantity

REFRIGERANT (R-410A) Qty (lb) 5.5 5.5 6.9 6.9 9.0 9.0

REFRIGERANT METERING DEVICE

Orifice ID (in.)Check-Flo-Rater® Piston

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal CFM

Diameter (in.)

Motor Hp (RPM)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (CFM)

Size (in.)

Motor Hp

FURNACE SECTION*

Burner Orifice No.

(Qty...Drill Size) Natural

Burner Orifice No.

(Qty...Drill Size) Propane

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

LOSS-OF-CHARGE/LOW-PRESSURE

SWITCH (Liquid Line) (psig)

Cutout

Reset (Auto.)

RETURN-AIR FILTERS (in.)Throwaway 20 x 24x1 20 x 24x1 20 x 24x1 20 x 24x1 24 x 30x1 24 x 30x1

.057 .057 .065 .065 .070 .070

1/17

12.7

2350

22

1/8 (825)

3/15

3.7

800

10x10

1/4

2...44

2...50

1/17

12.7

2350

22

1/8 (825)

3/15

3.7

1000

10x10

1/4

2...38

2...46

1/8 (825)

10x10

2/17

9.1

2350

22

3/15

3.7

1200

1/2

2...38

2...46

Scroll

1

610 ± 15

420 ± 25

20 ± 5

45 ± 10

2/17

9.1

2350

22

1/8 (825)

3/15

3.7

1200

10x10

1/2

3...38

3...46

2/17

12.3

2350

22

1/8 (825)

3/15

4.7

1400

11x10

3/4

2...38

2...46

2/17

12.3

2350

22

1/8 (825)

3/15

4.7

1400

11x10

3/4

3...38

3...46

A. Adhere to the following criteria when selecting,

sizing, and installing the duct system:

1. Units are shipped for side shot installation.

2. Select and size ductwork, supply-air registers, and return-air

grilles according to American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) recommendations.

3. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

screwed or bolted to duct flanges. Use suitable gaskets to

ensure weather tight and airtight seal.

4. All units must have field-supplied filters or accessory filter

rack installed in the return-air side of the unit. Recommended sizes for filters are shown in Tables 2 and 3.

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid abrupt

duct size increases or decreases or performance may be

affected.

6. Adequately insulate and weatherproof all ductwork located

outdoors. Insulate ducts passing through unconditioned

space, and use vapor barrier in accordance with latest issue

of Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) and Air Conditioning Contractors

of America (ACCA) minimum installation standards for

heating and air conditioning systems. Secure all ducts to

building structure.

7. Flash, weatherproof, and vibration-isolate all openings in

building structure in accordance with local codes and good

building practices.

X. INSTALL ELECTRICAL CONNECTIONS

WARNING: The unit cabinet must have an uninter-

rupted, unbroken electrical ground to minimize the possibility of serious injury if an electrical fault should occur.

This ground may consist of an electrical wire connected

to the unit ground lug in the control compartment, or

conduit approved for electrical ground when installed in

accordance with NEC (National Electrical Code) ANSI/

NFPA 70 (latest edition) (in Canada, Canadian Electrical

Code CSA (Canadian Standards Association) C22.1) and

local electrical codes. Do not use gas piping as an

electrical ground. Failure to adhere to this warning could

result in serious injury or death.

—9—

Page 10

TABLE 3—PHYSICAL DATA — UNIT 583B — 048090-060130

UNIT SIZE 583B 048090 048115 048130 060090 060115 060130

NOMINAL CAPACITY (ton) 444555

OPERATING WEIGHT (lb) 421 421 421 468 468 468

COMPRESSORS

Quantity

REFRIGERANT (R-410A) Qty (lb) 9.5 9.5 9.5 10.0 10.0 10.0

REFRIGERANT METERING DEVICE

Orifice ID (in.)Check-Flo-Rater® Piston

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor Hp

FURNACE SECTION*

Burner Orifice No.

(Qty...Drill Size) Natural

Burner Orifice No.

(Qty...Drill Size) Propane

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

LOSS-OF-CHARGE/LOW-PRESSURE

SWITCH (Liquid Line) (psig)

Cutout

Reset (Auto.)

RETURN-AIR FILTERS (in.)Throwaway 24x30 24x30 24x30 24x30 24x30 24x30

.073 .073 .073 .086 .086 .086

2/17

12.3

3300

22

1/4 (1100)

4/15

4.7

1600

11x10

3/4

3...38

3...46

2/17

12.3

3300

22

1/4 (1100)

4/15

4.7

1600

11x10

3/4

3...33

3...42

1/4 (1100)

11x10

2/17

12.3

3300

22

4/15

4.7

1600

3/4

3...31

3...41

Scroll

1

610 ± 15

420 ± 25

20 ± 5

45 ± 10

2/17

16.4

3300

22

1/4 (1100)

4/15

4.7

1750

11x10

1.0

3...38

3...46

2/17

16.4

3300

22

1/4 (1100)

4/15

4.7

1750

11x10

1.0

3...33

3...42

2/17

16.4

3300

22

1/4 (1100)

4/15

4.7

1750

11x10

1.0

3...31

3...41

TABLE 4—MAXIMUM GAS FLOW CAPACITY*

NOMINAL IRON PIPE SIZE (IN.) INTERNAL DIAMETER (IN.)

1/2 .622 175120 97 827366615753504440— —

3/4 .824 360 250 200 170 151 138 125 118 110 103 93 84 77 72

1 1.049 680 465 375 320 285 260 240 220 205 195 175 160 145 135

1-1/4 1.380 1400 950 770 600 580 530 490 460 430 400 360 325 300 280

1-1/2 1.610 2100 1460 1180 990 900 810 750 690 650 620 550 500 460 430

*Capacity of pipe in cu. ft. of gas per hr. for gas pressure of 0.5 psig or less. Pressure drop of 0.5-in. wg (based on a 0.60 specific gravity gas). Refer to Table C-4, National

Fire Protection Association NFPA 54

†This length includes an ordinary number of fittings.

10 20 30 40 50 60 70 80 90 100 125 150 175 200

LENGTH OF PIPE, FT†

—10—

Page 11

SUPPLY

DUCT

OPENING

RETURN

DUCT

OPENING

Fig. 11—Supply and Return Duct Opening

C99089

The field-supplied disconnect switch box may be mounted on the

unit over the high-voltage inlet hole when the standard power and

low-voltage entry points are used. See Fig. 6 and 7 for acceptable

location.

See unit wiring label and Fig. 14 for reference when making high

voltage connections. Proceed as follows to complete the highvoltage connections to the unit.

1. Run the high-voltage (L1, L2, L3) and ground leads into the

control box.

2. Connect ground lead to chassis ground connection.

3. Locate the black and yellow wires connected to the lines

side of the contactor.

4. Connect field L1 to black wire on connection 11 of the

compressor contactor.

5. Connect field wire L2 to yellow wire on connection 13 of

the compressor contactor.

6. Connect field wire L3 to Blue wire from compressor.

B. Special Procedures For 208-V Operation

WARNING: Make sure that the gas supply then the

power supply to the unit is switched OFF before making

any wiring changes. Electrical shock or explosion could

cause serious injury or death.

DUCT COVERS REMOVED

C99012

Fig. 12—Vertical Duct Cover Removed

CAUTION: Failure to follow these precautions could

result in damage to the unit being installed:

1. Make all electrical connections in accordance with

NEC ANSI/NFPA 70 (latest edition) and local electrical codes governing such wiring. In Canada, all electrical connections must be in accordance with CSA

standard C22.1 Canadian Electrical Code Part 1 and

applicable local codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4. Do not damage internal components when drilling

through any panel to mount electrical hardware, conduit, etc.

5. On 3-phase units, ensure phases are balanced within

2%. Consult local power company for correction of

improper voltage and/or phase imbalance (refer to

Table 5).

A. HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a fieldsupplied, water-proof, disconnect switch mounted at, or within

sight from the unit. Refer to the unit rating plate for maximum

fuse/ circuit breaker size and minimum circuit amps (ampacity) for

wire sizing. See Table 5 for electrical data.

With disconnect switch open, move yellow wire from transformer

(3/16 in.) terminal marked 230 to terminal marked 200. This retaps

transformer to primary voltage of 208 vac.

C. CONTROL VOLTAGE CONNECTIONS

NOTE: Do not use any type of power-stealing thermostat. Unit

control problems may result.

Use no. 18 American Wire Gage (AWG) color-coded, insulated

(35° C minimum) wires to make the control voltage connections

between the thermostat and the unit. If the thermostat is located

more than 100 ft from the unit (as measured along the control

voltage wires), use no. 16 AWG color-coded, insulated (35° C

minimum) wires.

STANDARD CONNECTION — Remove knockout hole located

in the flue panel adjacent to the control access panel. See Fig. 6

and 7. Remove the rubber grommet from the installer’s packet

(included with unit) and install grommet in the knockout opening.

Provide a drip loop before running wire through panel.

Run the low-voltage leads from the thermostat, through the inlet

hole, and into unit low-voltage splice box.

Locate five 18-gauge wires leaving control box. These low-voltage

connection leads can be identified by the colors red, green, yellow,

brown, and white. (See Fig. 14.) Ensure the leads are long enough

to be routed into the low-voltage splice box (located below right

side of control box). Stripped yellow wire is located in connection

box. Route leads through hole in bottom of control box and make

low-voltage connections as shown in Fig. 14. Secure all cut wires,

so that they do not interfere with operation of unit.

HEAT ANTICIPATOR SETTING — The room thermostat heat

anticipator must be properly adjusted to ensure proper heating

performance. Set the heat anticipator, using an ammeter between

the W and R terminals to determine the exact required setting.

NOTE: For thermostat selection purposes, use 0.18 amp for the

approximate required setting.

Failure to make a proper heat anticipator adjustment will result in

improper operation, discomfort to the occupants of the conditioned

space, and inefficient energy utilization; however, the required

setting may be changed slightly to provide a greater degree of

comfort for a particular installation.

—11—

Page 12

TABLE 5—ELECTRICAL DATA — 583B

UNIT

SIZE 583B

V-PH-HZ

VOLTAGE

RANGE

Min Max RLA LRA FLA FLA MCA MOCP*

030 208/230-3-60 187 253 9.6 63.0 0.8 2.1 14.9 20

036

042

048

060

208/230-3-60 187 253 12.2 77.0 0.8 3.6 19.7 30

460-3-60 414 506 5.1 35.0 0.8 1.9 9.1 15

208/230-3-60 187 253 13.5 77.0 1.6 4.1 22.6 35

460-3-60 414 506 6.3 39.0 0.9 2.0 10.8 15

208/230-3-60 187 253 14.7 91.0 1.6 4.1 24.1 35

460-3-60 414 506 6.5 46.0 0.9 2.0 11.0 15

208/230-3-60 187 253 18.1 137.0 1.6 6.2 30.4 45

460-3-60 414 506 9.0 62.0 0.9 3.2 15.4 20

COMPRESSOR OUTDOOR FAN MOTOR INDOOR FAN MOTOR POWER SUPPLY

LEGEND

FLA — Full Load Amps

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

RLA — Rated Load Amps

CKT BKR

—

Circuit Breaker

®

NOTES:

1. In compliance with NEC (National Electrical Code) requirements

for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the

unit shall be Power Supply fuse. Canadian units may be

fuse or circuit breaker.

2. Minimum wire size is based on 60 C copper wire. If other than

60 C wire is used, or if length exceeds wire length in table,

determine size from NEC.

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the percentage of voltage imbalance.

Use the following formula to determine

% Voltage imbalance

= 100 x

max voltage deviation from average voltage

average voltage

Fig. 13—Electrical Data Legend

EXAMPLE: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

452 + 464 + 455

3

1371

=

3

= 457

Determine maximum deviation from average voltage.

(AB) 457

(BC) 464

(AC) 457

452=5v

457=7v

455=2v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

% Voltage Imbalance = 100 x

7

457

= 1.53%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

C99024

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

FIELD-SUPPLIED

FUSED DISCONNECT

WHT(W1)

YEL(Y)

GRN(G)

RED(R)

BRN(C)

CONTROL BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

GND

SPLICE BOX

Fig. 14—High- and Control-Voltage Connections

—12—

W

Y

G

R

C

POWER

SUPPLY

THERMOSTAT

(TYPICAL)

C99018

Page 13

TRANSFORMER PROTECTION — The transformer is of the

energy-limiting type. It is set to withstand a 30-second overload or

shorted secondary condition.

PRE-START-UP

WARNING: Failure to observe the following warnings

could result in serious injury or death:

1. Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric

power to unit unless compressor terminal cover is in

place and secured.

3. Do not remove compressor terminal cover until all

electrical sources are disconnected.

4. Relieve and recover all refrigerant from both high- and

low-pressure sides of system before touching or disturbing anything inside terminal box if refrigerant leak

is suspected around compressor terminals.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure. To remove

a component, wear protective goggles and proceed as

follows:

a. Shut off gas supply and then electrical power to unit.

b. Relieve and reclaim all refrigerant from system

using both high- and low-pressure ports.

c. Cut component connecting tubing with tubing cutter

and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

Proceed as follows to inspect and prepare the unit for initial

startup:

1. Remove access panel.

2. Read and follow instructions on all DANGER, WARNING,

CAUTION, and INFORMATION labels attached to, or

shipped with, unit.

3. Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections and

on unit base. Detecting oil generally indicates a refrigerant leak. Leak test all refrigerant tubing connections

using electronic leak detector, halide torch, or liquidsoap solution. If a refrigerant leak is detected, see Check

for Refrigerant Leaks section of this manual.

c. Inspect all field- and factory-wiring connections. Be sure

that connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and han-

dling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

WARNING: Do not purge gas supply into the combustion chamber. Do not use a match or other open flame to

check for gas leaks. Failure to follow this warning could

result in an explosion causing serious injury or death.

a. Before lighting the unit for the first time, perform the

following with the gas valve in the "OFF" position: If the

gas supply pipe was not purged before connecting the

unit, it will be full of air. It is recommended that the

ground joint union be loosened, and the supply line be

allowed to purge until the odor of gas is detected. Never

purge gas lines into a combustion chamber. Immediately

upon detection of gas odor, re-tighten the union. Allow 5

minutes to elapse, then light unit.

b. Make sure that condenser-fan blade is correctly posi-

tioned in fan orifice. Leading edge of condenser-fan

blade should be 1/2 in. maximum from fan orifice (see

Fig. 15).

c. Ensure fan hub is 1/8 in. max from motor housing.

d. Make sure that air filter(s) is in place.

e. Make sure that condensate drain trap is filled with water

to ensure proper drainage.

f. Make sure that all tools and miscellaneous loose parts

have been removed.

MOTOR

1/8" MAX BETWEEN

MOTOR AND FAN HUB

MOTOR SHAFT

FAN GRILLE

1/2˝

C99009

Fig. 15—Fan Blade Clearance

START-UP

Use the Start-Up Checklist supplied at the end of this book, and

proceed as follows:

A. CHECK FOR REFRIGERANT LEAKS

Proceed as follows to locate and repair refrigerant leaks and charge

the unit:

1. Locate leak and make sure that refrigerant system pressure

has been relieved and refrigerant recovered from both highand low-pressure ports.

2. Repair leak following accepted practices.

NOTE: Replace filter drier whenever the system has been opened

for repair.

3. Check system for leaks using an approved method.

4. Evacuate refrigerant system and reclaim refrigerant if no

additional leaks are found.

5. Charge unit with R-410a refrigerant, using a volumetriccharging cylinder or accurate scale. Refer to unit rating

plate for required charge.

B. Start Up Heating Section and Make Adjustments

IMPORTANT: Complete the required procedures given in the

Pre-Start-Up section above before starting the unit.

Do not jumper any safety devices when operating the unit.

Make sure that burner orifices are properly aligned. Unstable

operation may occur when the burner orifices in the manifold are

misaligned.

NOTE: Make sure that gas supply has been purged, and that all

gas piping has been checked for leaks.

CHECK HEATING CONTROL — Start and check the unit for

proper heating control operation as follows. (see furnace lighting

instructions located inside burner or blower access panel.):

1. Place room thermostat SYSTEM switch in the HEAT

position and the FAN switch in the AUTO position.

2. Set the heating temperature control of the thermostat above

room temperature.

—13—

Page 14

TABLE 6—HEATING INPUTS

HEATING

INPUT

(BTUH)*

40,000 2 4.0 13.0 7.0 13.0 3.5 3.5

60,000 2 4.0 13.0 7.0 13.0 3.5 3.5

90,000 3 4.0 13.0 7.0 13.0 3.5 3.5

115,000 3 4.0 13.0 7.0 13.0 3.5 3.5

130,000 3 4.0 13.0 7.0 13.0 3.5 3.5

*When a unit is converted to propane, different size orifices must be used. See separate natural-to-propane conversion kit instructions.

†Based on altitudes from sea level to 2000 ft. above sea level. For altitudes above 2000 ft., reduce input rating 4% for each 1000 ft. above sea level. In Canada, from 2000

ft. above sea level to 4500 ft. above sea level, derate the unit 10%.

NUMBER

OF

ORIFICES

Min Max Min Max Natural Propane†

3. The induced-draft motor will start.

4. After a call for heating, the main burner should light within

5 seconds. If the burners do not light, there is a 22-second

delay before another 5-second try. If the burners still do not

light, this sequence is repeated. If the burners do not light

within 15 minutes from the initial call for heat, there is a

lockout. To reset the control, break the 24-v power to W.

5. The evaporator fan will turn on 45 seconds after the flame

has been established. The evaporator fan will turn off 45

seconds after the thermostat has been satisfied.

CHECK GAS INPUT—Check gas input and manifold pressure

after unit start-up (see Table 6.) If adjustment is required, proceed

as follows:

The rated gas inputs shown in Table 6 are for altitudes from sea

level to 2000 ft. above sea level. These inputs are based on natural

gas with a heating value of 1050 Btu/ft

3

at 0.65 specific gravity, or

propane gas with a heating value of 2500 Btu/ft

GAS SUPPLY PRESSURE

Natural Propane†

(IN. WG)

6. Multiply result of Step 5 by Btu heating value of gas to

EXAMPLE: Assume that the size of test dial is 1 cu. ft., one

revolution takes 32 seconds, and the heating value of the gas is

1050 Btu/ft

Proceed as follows:

1. 32 seconds to complete one revolution.

2. 3600 ÷ 32 = 112.5

3. 112.5x1=112.5 ft

4. 112.5 x 1050 = 118,125 Btuh input.

If the desired gas input is 115,000 Btuh, only a minor change in the

manifold pressure is required.

3

at 1.5 specific

obtain total measured input in Btuh. Compare this value

with heating input shown in Table 6. (Consult the local gas

supplier if the heating value of gas is not known.)

3

.

MANIFOLD PRESSURE

(IN. WG)

3

of gas flow/hr.

gravity. For elevations above 2000 ft., reduce input 4% for each

1000 ft. above sea level. When the gas supply being used has a

different heating value, or specific gravity, refer to national and

local codes, or contact your distributor to determine the required

orifice size.

CAUTION: These units are designed to consume the

rated gas inputs using the fixed orifices at specified

manifold pressures as shown in Table 6. DO NOT

REDRILL THE ORIFICES UNDER ANY CIRCUMSTANCES.

ADJUST GAS INPUT—The gas input to the unit is determined by

measuring the gas flow at the meter or by measuring the manifold

pressure. Measuring the gas flow at the meter is recommended for

natural gas units. The manifold pressure must be measured to

determine the input of propane gas units.

MEASURE GAS FLOW (Natural Gas Units)—Minor adjustment

to the gas flow can be made by changing the manifold pressure.

The manifold pressure must be maintained between 3.4 and 3.6 in.

wg. If larger adjustments are required, change main burner orifices

following the recommendations of national local codes.

NOTE: All other appliances that use the same meter must be

turned off when gas flow is measured at the meter.

Proceed as follows:

1. Turn off gas supply to unit.

2. Remove pipe plug on manifold (see Fig. 16) then connect

manometer at this point. turn on gas to unit.

3. Record number of seconds for gas meter test dial to make

one revolution.

4. Divide number of seconds in Step 3 into 3600 (number of

seconds on one hour).

5. Multiply result of Step 4 by the number of cu. ft. shown for

one revolution of test dial to obtain cu. ft. of gas flow per

hour.

MANIFOLD PIPE PLUG

C99019

Fig. 16—Burner Assembly

Observe manifold pressure and proceed as follows to adjust gas

input:

1. Remove cover screw over regulator adjustment screw on

gas valve.

2. Turn regulator adjustment screw clockwise to increase gas

input, or turn regulator adjustment screw counterclockwise

to decrease input. Manifold pressure must be between 3.4

and 3.6 in. wg.

WARNING: Unsafe operation of the unit may result if

manifold pressure is outside this range. Serious injury or

unit damage may result.

3. Replace cover screw cap on gas valve.

4. Turn off gas supply to unit. Remove manometer from

pressure tap and replace pipe plug on gas valve. Turn on gas

to unit and check for leaks.

—14—

Page 15

TABLE 7—AIR DELIVERY (CFM) AT INDICATED TEMPERATURE RISE AND RATED HEATING INPUT

HEATING

INPUT

(BTUH)

INPUT

40,000 1500 1200 1000 857 750 667 600 ————

60,000 2250 1800 1500 1286 1125 1000 900 818 750 692 —

90,000 — 2700 2250 1929 1688 1500 1350 1227 1125 1038 964

115,000 — — — 2464 2156 1917 1725 1568 1438 1327 —

130,000 ————24382167 1950 1773 1625 1500 1393

NOTE: Dashed areas do not fall within the approved temperature rise range of the unit.

20 25 30 35 40 45 50 55 60 65 70

TEMPERATURE RISE °F

MEASURE MANIFOLD PRESSURE (Propane Units)—The

main burner orifices on a propane unit are sized for the unit rated

input when the manifold pressure reading matches the level

specified in Table 6.

WARNING: If converting to propane gas, remove the

burner assembly and inspect the heat exchanger tubes. If

there are V-shaped NOx baffles installed in the firing

tubes, THEY MUST BE REMOVED.

Discard the baffles after removal.

Refer to Maintenance section for information on burner

removal.

Proceed as follows to adjust gas input on a propane gas unit:

1. Turn off gas to unit.

2. Remove pipe plug on manifold (see Fig. 16) then connect

manometer at this point.

3. Turn on gas to unit.

4. Remove cover screw over regulator adjustment screw on

gas valve.

5. Adjust regulator adjustment screw to the correct manifold

pressure, as specified in Table 6. Turn adjusting screw

clockwise to increase manifold pressure, or turn adjusting

screw counterclockwise to decrease manifold pressure.

6. Replace cover screw.

7. Turn off gas to unit. Remove manometer from pressure tap.

Replace pipe plug on gas valve, then turn on gas to unit.

check for leaks.

CHECK BURNER FLAME—With burner access panel removed,

observe the unit heating operation. Watch the burner flames to see

if they are light blue and soft in appearance, and that the flames are

approximately the same for each burner. Propane will have blue

flame with yellow tips. (See Fig. 17). Refer to Maintenance section

for information on burner removal.

BURNER FLAME

BURNER

MANIFOLD

C99021

Fig. 17—Monoport Burners

AIRFLOW AND TEMPERATURE RISE—The heating section

for each size unit is designed and approved for heating operation

within the temperature rise range stamped on the unit rating plate.

Table 7 shows the approved temperature rise range for each

heating input, and the air delivery cfm at various temperature rises.

The heating operation airflow must produce a temperature rise that

falls within the approved range.

Refer to Indoor Airflow and Airflow Adjustments section on the

following pages to adjust heating airflow when required.

HEATING SEQUENCE OF OPERATION—See Fig. 18-19 and

unit wiring label.

On a call for heating, terminal "W" of the thermostat is energized,

starting the induced-draft motor. When the hall-effect sensor on

the induced-draft motor senses that it has reached the required

speed, the burner sequence begins. This function is performed by

the integrated gas control (IGC). The evaporator fan motor is

energized 45 seconds after flame is established. When the thermostat is satisfied and "W" is de-energized, the burners stop firing and

the evaporator fan motor shuts off after a 45-second time-off delay.

An LED (light-emitting diode) indicator is provided on the control

board to monitor operation. The control board is located by

removing the burner access panel. During normal operation, the

LED is continuously on. See Table 8 for error codes.

TABLE 8—LED INDICATIONS

ERROR CODE LED INDICATION

Normal Operation On

Hardware Failure Off

Fan On/Off Delay Modified 1 Flash

Limit Switch Fault 2 Flashes

Flame Sense Fault 3 Flashes

Four Consecutive Limit Switch Faults 4 Flashes

Ignition Lockout Fault 5 Flashes

Induced-Draft Motor Fault 6 Flashes

Rollout Switch Fault 7 Flashes

Internal Control Fault 8 Flashes

Internal Software Fault 9 Flashes

NOTES:

1.There is a 3-second pause between error code displays.

2. If more than one error code exists, all applicable error codes will be

displayed in numerical sequence.

3. This chart is on the wiring diagram located inside the burner access

panel.

LIMIT SWITCHES—Normally closed limit switch (LS) completes the control circuit through the thermostat R circuit. Should

the leaving-air temperature rise above the maximum allowable

temperature, the limit switch opens and the R control circuit

"breaks". Any interruption in the R control circuit instantly closes

the gas valve and stops gas flow to the burners and pilot. The

blower motor continues to run until LS resets.

When the air temperature at the limit switch drops to the

low-temperature setting of the limit switch, the switch closes and

completes the R control circuit. The electric spark ignition system

cycles and the unit returns to normal heating operation. When this

fault occurs, the IGC LED will display FAULT CODE 2.

—15—

Page 16

AUXILIARY LIMIT SWITCH (ROLLOUT)—The function of

the switch is to close the main gas valve in the event of flame

rollout. The switch is located above the main burners. When the

temperature at the auxiliary switch reaches the maximum allowable temperature, the R control circuit trips, closing the gas valve

and stopping gas flow to the burners. The indoor (evaporator) fan

motor (IFM) and induced draft motor continue to run until switch

is reset. The IGC LED will display FAULT CODE 7.

C. Start-Up Cooling Section and Make Adjustments

CAUTION: Complete the required procedures given in

the Pre-Start-Up section on previous pages before starting

the unit.

Do not jumper any safety devices when operating the

unit.

Do not operate the compressor when the outdoor temperature is below 40° F (unless accessory low-ambient kit

is installed).

Do not rapid-cycle the compressor. Allow 5 minutes

between "on" cycles to prevent compressor damage.

CHECKING COOLING CONTROL OPERATION—Start and

check the unit for proper cooling control operation as follows:

1. Place room thermostat SYSTEM switch in OFF position.

Observe that blower motor starts when FAN switch is

placed in ON position and shuts down when FAN switch is

placed in AUTO position.

2. Place SYSTEM switch in COOL position and FAN switch

in AUTO position. Set cooling control below room temperature. Observe that compressor, condenser fan, and

evaporator blower motors start. Observe that cooling cycle

shuts down when control setting is satisfied. The evaporator

fan will continue to run for 30 seconds.

3. When using an auto-changeover room thermostat, place

both SYSTEM and FAN switches in AUTO positions.

Observe that unit operates in Heating mode when temperature control is set to "call for heating" (above room

temperature) and operates in Cooling mode when temperature control is set to "call for cooling" (below room

temperature).

IMPORTANT: Three-phase, scroll compressor units are

direction-oriented. These units must be checked to ensure proper

compressor 3-phase power lead orientation. If not corrected within

5 minutes, the internal protector will shut off the compressor. The

3-phase power leads to the unit must be reversed to correct

rotation. When turning backwards, scroll compressors emit elevated noise levels, and the difference between compressor suction

and discharge pressures may be dramatically lower than normal.

CHECKING AND ADJUSTING REFRIGERANT

CHARGE—The refrigerant system is fully charged with R-410A

(Puron) refrigerant, and is tested and factory sealed.

NOTE: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R-410A

charge. The charging label and the tables shown refer to system

temperatures and pressures.

A refrigerant charging chart label is attached to the outside of the

compressor access door. The chart includes the required suction

line temperature at given suction line pressures and outdoor

ambients..

An accurate superheat, thermocouple- or thermistor-type thermometer, and a gauge manifold are required when using the

superheat charging method for evaluating the unit charge. Do not

use mercury or small dial-type thermometers because they are not

adequate for this type of measurement.

IMPORTANT: When evaluating the refrigerant charge, an indicated adjustment to the specified factory charge must always be

very minimal. If a substantial adjustment is indicated, an abnormal

condition exists somewhere in the cooling system, such as insufficient airflow across either coil or both coils.

REFRIGERANT CHARGE—The amount of refrigerant charge is

listed on the unit nameplate. Refer to Bryant Refrigeration Service

Techniques Manual, Refrigerants section.

Unit panels must be in place when unit is operating during

charging procedures.

NO CHARGE: Use standard evacuating techniques. After evacuating system, weigh in the specified amount of refrigerant (refer to

system data plate).

LOW CHARGE COOLING: Measure outdoor ambient using

Cooling Charging Charts (Figs. 20-24). Vary refrigerant until the

conditions of the chart are met. Note that charging charts are

different from type normally used. Charts are based on charging

the units to correct superheat for the various operating conditions.

Accurate pressure gauge and temperature sensing devices are

required. Connect the pressure gauge to the service port on the

suction line. Mount the temperature sensing device on the suction

line and insulate it so that the outdoor ambient does not effect the

reading. Indoor air CFM must be within the normal operating

range of the unit.

TO USE COOLING CHARGING CHARTS: Take the outdoor

ambient temperature and read the suction pressure gauge. Refer to

the chart to determine what the suction temperature should be.

NOTE: If the problem causing the inaccurate readings is a

refrigerant leak, refer to Check for Refrigerant Leaks section in

this document.

D. Indoor Airflow and Airflow Adjustments

CAUTION: For cooling operation, the recommended

airflow is 350 to 450 cfm for each 12,000 Btuh of rated

cooling capacity. For heating operation, the airflow must

produce a temperature rise that falls within the range

stamped on the unit rating plate.

Table 7 shows the temperature rise at various air-flow rates. Table

9 shows both heating and cooling airflows at various external static

pressures. Refer to these tables to determine the airflow for the

system being installed.

NOTE: Be sure that all supply- and return-air grilles are open,

free from obstructions, and adjusted properly.

WARNING: Shut off gas supply then disconnect elec-

trical power to the unit before changing blower speed.

Electrical shock or explosion could cause serious injury

or death.

Airflow can be changed by changing the lead connections of the

blower motor.

All 583B units are factory wired for low speed and may need to be

wired for medium or high speed in the field.

For 208/230-v — The motor leads are color-coded as follows:

3-SPEED 2-SPEED

black = high speed black = high speed

blue = medium speed ---

red = low speed red = low speed

To change the speed of the blower motor (BM), remove the fan

motor speed leg lead from the blower relay (BR). This wire is

attached to terminal BM for single-phase and 3-phase units. To

change the speed, remove and replace with lead for desired blower

motor speed. Insulate the removed lead to avoid contact with

chassis parts.

—16—

Page 17

C99077

Fig. 18—208/230-3-60 Wiring Diagram

—17—

Page 18

C99078

Fig. 19—460-3-60 Wiring Diagram

—18—

Page 19

For 460-v GE Motors — The motor leads are color coded as

follows:

3-SPEED 2-SPEED

black = high speed black = high speed

violet = jumper blue = jumper

orange = medium speed ---

red = low speed red = low speed

To change the speed of the blower motor (BM), remove fan motor

speed lead from the blower relay (BR) and replace with the lead

for the desired blower motor speed. The motor speed lead is

attached to terminal BM. For low and medium speeds black must

be connected to the jumper wire. Insulate removed lead end to

avoid contact with chassis parts. To select high speed on 460-v GE

motors, separate the black female quick connect (QC) from the

jumper lead male quick connect (QC) and connect the black lead

to the BR. Insulate the jumper to avoid contact with any chassis

parts.

COOLING SEQUENCE OF OPERATION — With the room

thermostat SYSTEM switch in the COOL position and the FAN

switch in the AUTO. position, the cooling sequence of operation is

as follows:

When the room temperature rises to a point that is slightly above

the cooling control setting of the thermostat, the thermostat

completes the circuit between thermostat terminal R to terminals Y

and G. These completed circuits through the thermostat connect

contactor coil (C) (through unit wire Y) and blower relay coil (BR)

(through unit wire G) across the 24-v secondary of transformer

(TRAN).

The normally open contacts of energized contactor (C) close and

complete the circuit through compressor motor (COMP) to condenser (outdoor) fan motor (OFM). Both motors start instantly.

The set of normally open contacts of energized relay BR close and

complete the circuit through evaporator blower (indoor) fan motor

(IFM).

NOTE: Once the compressor has started and then has stopped, it

should not be started again until 5 minutes have elapsed.

The cooling cycle remains ‘‘on’’ until the room temperature drops

to a point that is slightly below the cooling control setting of the

room thermostat. At this point, the thermostat ‘‘breaks’’ the circuit

between thermostat terminal R to terminals Y and G. These open

circuits de-energize contactor coil C and relay coil BR. The

condenser and compressor motors stop. After a 30-second delay,

the blower motor stops. The unit is in a ‘‘standby’’ condition,

waiting for the next ‘‘call for cooling’’ from the room thermostat.

MAINTENANCE

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic maintenance

must be performed on this equipment. This combination

heating/cooling unit should be inspected at least once each year by

a qualified service person. To troubleshoot heating or cooling of

units, refer to tables at the back of the book.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

WARNING: The ability to properly perform maintenance on this equipment requires certain expertise, mechanical skills, tools, and equipment. If you do not

possess these, do not attempt to perform any maintenance

on this equipment other than those procedures recommended in the User’s Manual. FAILURE TO HEED

THIS WARNING COULD RESULT IN SERIOUS INJURY AND POSSIBLE DAMAGE TO THIS EQUIPMENT.

WARNING: Failure to follow these warnings could

result in serious injury or death:

1. Turn off gas supply, then turn off electrical power to

the unit before performing any maintenance or service

on the unit.

2. Use extreme caution when removing panels and parts.

As with any mechanical equipment, serious injury can

result from sharp edges, etc.

3. Never place anything combustible either on, or in

contact with, the unit.

4. Should overheating occur, or the gas supply fail to shut

off, shut off the external main manual gas valve to the

unit, then shut off the electrical supply.

CAUTION: Errors made when reconnecting wires may

cause improper and dangerous operation. Label all wires

prior to disconnection when servicing.

The minimum maintenance requirements for this equipment are as

follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel for cleanliness and check

lubrication each heating and cooling season. Clean when

necessary. For first heating season, inspect blower wheel

bimonthly to determine proper cleaning frequency.

4. Check electrical connections for tightness and controls for

proper operation each heating and cooling season. Service

when necessary.

5. Check and inspect heating section before each heating

season. Clean and adjust when necessary.

6. Check flue hood and remove any obstructions if necessary.

A. Air Filter

IMPORTANT: Never operate the unit without a suitable air filter

in the return-air duct system. Always replace the filter with the

same dimensional size and type as originally installed. See Tables

2 and 3 for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway-type) or clean (cleanable-type) at least twice during

each heating and cooling season or whenever the filter(s) becomes

clogged with dust and lint.

B. Evaporator Blower and Motor

NOTE: All motors are pre-lubricated. Do not attempt to lubricate

these motors.

For longer life, operating economy, and continuing efficiency,

clean accumulated dirt and grease from the blower wheel and

motor annually.

WARNING: Turn off the gas supply, then disconnect

and tag electrical power to the unit before cleaning the

blower motor and wheel. Failure to adhere to this warning

could cause serious injury or death.

To clean the blower motor and wheel:

1. Remove and disassemble blower assembly as follows:

a. Remove unit access panel.

b. Disconnect motor lead from blower relay (BR). Discon-

nect yellow lead from terminal L2 of the contactor.

—19—

Page 20

(030) 60 Hz CHARGING CHART

1241 180

170

1172

160

1103

150

1034

140

965

130

896

SUCTION LINE PRESSURE (PSIG)

120

827

SUCTION LINE PRESSURE (KILOPASCALS)

110

758

690 100

20.0

-7 272116104-1

FOR USE WITH UNITS USING R410A REFRIGERANT

SUCTION LINE TEMPERATURE (DEG. F)

SUCTION LINE TEMPERATURE (DEG. C)

80.070.060.050.040.030.0

Fig. 20—Cooling Charging Chart, 583B030 Units

OUTDOOR

TEMP

F C

125 52

115 46

105 41

95 35

85 29

75 24

65 18

55 13

45 7

C99080

(036) 60 Hz CHARGING CHART

1241 180

1172

170

1103

160

1034

150

965

140

896

130

SUCTION LINE PRESSURE (PSIG)

827

120

SUCTION LINE PRESSURE (KILOPASCALS)

758

110

690 100

20.0

-7 272116104-1

FOR USE WITH UNITS USING R410A REFRIGERANT

SUCTION LINE TEMPERATURE (DEG. F)

SUCTION LINE TEMPERATURE (DEG. C)

Fig. 21—Cooling Charging Chart, 583B036 Units

(048) 60 Hz CHARGING CHART

1241 180

170

1172

160

1103

150

1034

140

965

130

896

SUCTION LINE PRESSURE (PSIG)

120

827

SUCTION LINE PRESSURE (KILOPASCALS)

110

758

690 100

20.0

-7 272116104-1

FOR USE WITH UNITS USING R410A REFRIGERANT

SUCTION LINE TEMPERATURE (DEG. F)

SUCTION LINE TEMPERATURE (DEG. C)

80.070.060.050.040.030.0

80.070.060.050.040.030.0

OUTDOOR

TEMP

F C

125 52

115 46

105 41

95 35

85 29

75 24

65 18

55 13

45 7

OUTDOOR

TEMP

F C

125 52

115 46

105 41

95 35

85 29

75 24

65 18

55 13

45 7

C99081

(042) 60 Hz CHARGING CHART

1241 180

170

1172

160

1103

150

1034

140

965

130

896

SUCTION LINE PRESSURE (PSIG)

120

827

FOR USE WITH UNITS USING R410A REFRIGERANT

SUCTION LINE PRESSURE (KILOPASCALS)

110

758

690 100

20.0

-7 272116104-1

SUCTION LINE TEMPERATURE (DEG. F)

SUCTION LINE TEMPERATURE (DEG. C)

Fig. 22—Cooling Charging Chart, 583B042 Units

(060) 60 Hz CHARGING CHART

1241 180

170

1172

160

1103

150

1034

140