Bryant 580J Series Installation Instructions Manual

580J

SINGLE PACKAGE ROOFTOP, GAS HEATING/ELECTRIC COOLING

VERTICAL AIR FLOW UNIT WITH PURON

15, 17.5, 20, 25, 27.5 TONS -- (SIZES 17, 20, 24, 28, 30)

R

(R--410A) REFRIGERANT

Installation Instructions

NOTE: Read the entire instruction manual before starting

the installation

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 2....................

Rated Indoor Airflow (cfm) 3.....................

INSTALLATION 10..............................

Jobsite Survey 10...............................

Step 1 -- Plan for Unit Location 10.................

Roof Mount 10..............................

Step 2 -- Plan for Sequence of Unit Installation 10.....

Curb--Mount Installation 10....................

Pad--Mount Installation 10.....................

Frame--Mount Installation 10...................

Step 3 -- Inspect Unit 10..........................

Step 4 -- Provide Unit Support 12..................

Roof Curb Mount 12.........................

Alternate Unit Support (In Lieu of Curb Mount) 12..

Step 5 -- Field Fabricate Ductwork 16...............

Step 6 -- Rig and Place Unit 16....................

Positioning on Curb 17.......................

Step 7 -- Install Outside Air Hood — Factory Option 17..

Step 8 -- Install Flue Hood and Combustion Air Hood 18.

Step 9 -- Install Gas Piping 18....................

Gas Supply Line 18..........................

Factory--Option Thru--Base Connections 20.......

Step 10 -- Install External Condensate Trap & Line 21...

Step 11 -- Make Electrical Connections 21...........

Field Power Supply 21........................

Units Without Factory--Installed

Non--Fused Disconnect 22.....................

Units With Factory--Installed

Non--Fused Disconnect 22.....................

All Units 22................................

Convenience Outlets 23.......................

Factory--Option Thru--Base Connections 24......

Units Without Thru--Base Connections 24........

Field Control Wiring 25.......................

Thermostat 25...............................

Unit Without Thru--Base Connection Kit 25.......

Heat Anticipator Settings 25...................

Transformer Connection

for 208--v Power Supply 25.....................

Perfect Humidityt Control Connections 26........

Perfect Humidity -- Space RH Controller 26.......

2--Speed Indoor Fan Motor System with

Variable Frequency Drive (Factory Option) 27......

EconoMi$er X -- Ultra Low Leak Economizer

(Factory Option) 27............................

RTU Open Control System 28...................

Supply Air Temperature (SAT) Sensor 31.........

Outdoor Air Temperature (OAT) Sensor 31.......

EconoMi$er2 32.............................

Field Connections 32..........................

Space Temperature (SPT) Sensors 32............

Indoor Air Quality (CO

Outdoor Air Quality Sensor 33.................

Smoke Detector/Fire Shutdown (FSD) 34.........

Space Humidity Sensor or Humidistat 34.........

Connecting Discrete Inputs 35..................

Communication Wiring -- Protocols 36............

General 36.................................

Local Access 37.............................

RTU Open Troubleshooting 37.................

Outdoor Air Enthalpy Control 38.................

Differential Enthalpy Control 38................

SMOKE DETECTORS 39.........................

Return Air Sensor Tube Installation 39..............

Smoke Detector Test Magnet 39...................

Additional Application Data 39....................

ELECTRICAL DATA FOR UNITS PRODUCED

ON OR AFTER JULY 30, 2012 40..................

ELECTRICAL DATA FOR UNITS PRODUCED

PRIOR TO JULY 30, 2012 45......................

Step 12 -- Adjust Factory--Installed Options 48........

Step 13 -- Install Accessories 48...................

)Sensor 33.............

2

START--UP CHECKLIST 51.......................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock or other conditions which may cause personal

injury or property damage. Consult a qualified installer,

service agency, or your distributor or branch for

information or assistance. The qualified installer or

agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when

installing.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, always turn off main power switch to unit and

install lock(s) and lockout tag(s). Unit may have more

than one power switch.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloths for brazing operations and

have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions attached to

the unit. Consult local building codes and appropriate

national electrical codes (in USA, ANSI/NFPA70,

National Electrical Code (NEC); in Canada, CSA C22.1)

for special requirements.

It is important to recognize safety information. This is the

580J--17--30--V

safety--alert symbol

unit and in instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety--alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or

death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify

unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

!

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect gas piping from unit when leak testing at

pressure greater than 0.5 psig (3450 Pa). Pressures

greater than 0.5 psig (3450 Pa) will cause gas valve

damage resulting in hazardous condition. If gas valve

is subjected to pressure greater than 0.5 psig (3450

Pa), it must be replaced before use. When pressure

testing field--supplied gas piping at pressures of 0.5

psig (3450 Pa) or less, a unit connected to such piping

must be isolated by closing the manual gas valve.

. When you see this symbol on the

WARNING

!

WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

Puronr (R--410A) refrigerant systems operate at

higher pressures than standard R--22 systems. Do not

use R--22 service equipment or components on Puron

refrigerant equipment.

!

WARNING

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could cause personal

injury or death.

Relieve pressure and recover all refrigerant before

system repair or final unit disposal.

Ware safety glasses and gloves when handling

refrigerants. Keep torches and other ignition sources

away from refrigerants and oils.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts and servicing

air conditioning units.

2

Rated Indoor Airflow (cfm)

The table to the right lists the rated indoor airflow used

for the AHRI efficiency rating for the units covered in this

document.

Model Number Full Load Airflow (cfm)

580J*17D/F/K/M 4900

580J*20D/F/K/M 6125

580J*24D/F/K/M 8000

580J*28D/F/K/M 8750

580J*30D/F 9750

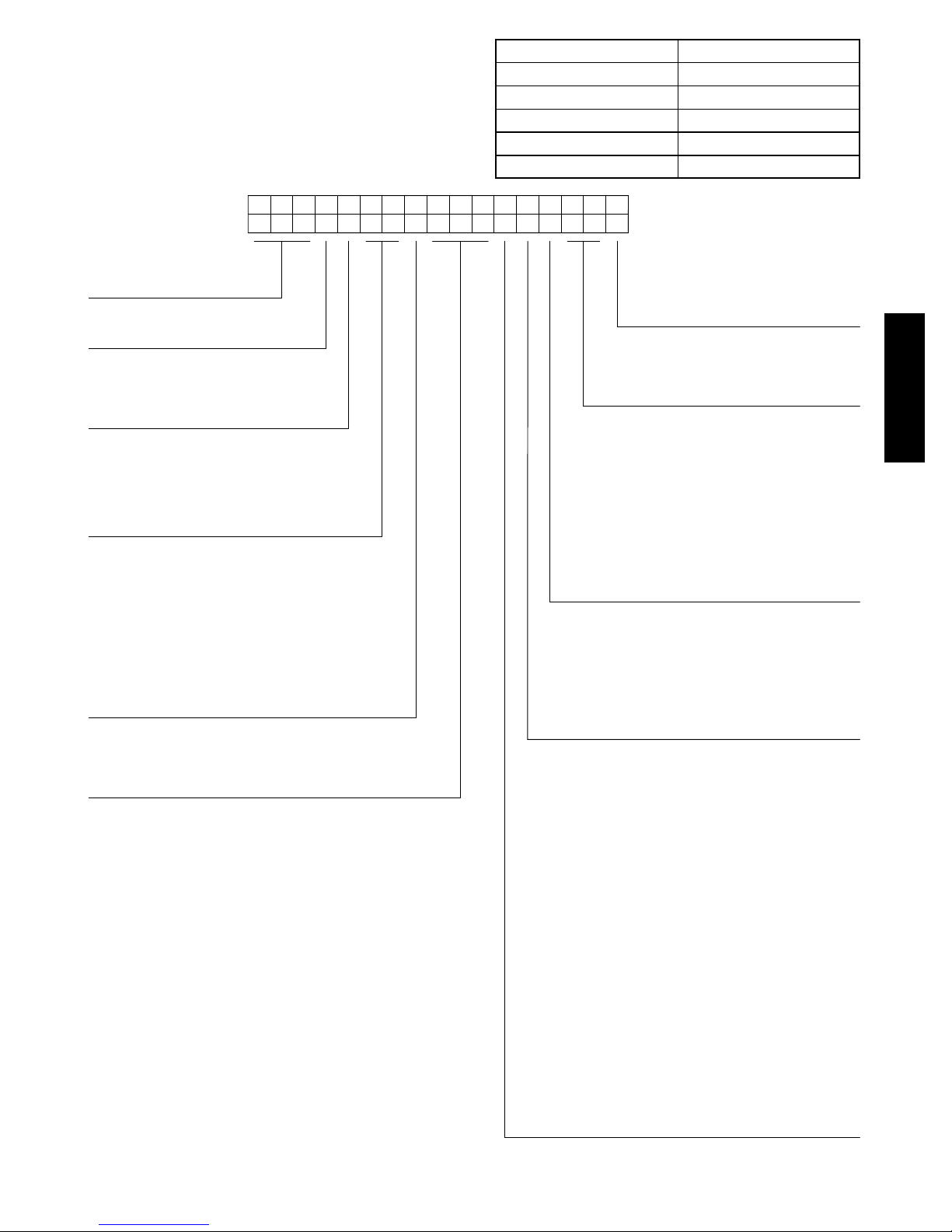

Position:

Example:

Unit Type

580 - Gas Heat RTU

Model

J - Puron

Voltage

E = 460-3-60

P = 208/230-3-60

T = 575-3-60

Cooling Tons (Vertical Air Flow Models Only)

17 = 15 tons

20 = 17.5 tons

24 = 20 tons

28 = 25 tons

30 = 27.5 tons

Refrig. System/Gas Heat Options

D = Two stage compressor with Aluminum gas heat

exchanger

F = Two stage compressor with Stainless Steel gas heat

exchanger

K = Two Stage Cooling with Aluminum gas heat exchanger

and Perfect Humidity™ (only available on 17-28 sizes

with RTPF coil models)

M = Two Stage Cooling with Stainless Steel gas heat

exchanger and Perfect Humidity™ (only available on

17-28 sizes with RTPF coil models)

Heat Level Input

220 = 220,000

310 = 310,000

400 = 400,000

®

(R-410A) Refrigerant

1234567891011 12 13 14 15 16 17

580JE1 7D310G1A0AA

Fig. 1 -- 580J MRT Vertical Airflow Units Model Number Nomenclature (Example)

Packaging & 2-Speed Indoor Fan Motor

A = Standard Packaging

D = Standard Packaging & 2-speed indoor

fan motor

Factory Installed Options

0A = None

NOTE: See the 580J 15 to 27.5 ton Price Pages for

a complete list of factory installed options.

Outdoor Air Options

A = None

B = Temperature Economizer w/ Barometric Relief

D = Temperature Economizer w/ PE (cent)

H =

Enthalpy

J =

P = Manual Outdoor Air Damper

Q = 2 Position Damper

U =

V =

W =

X =

Indoor Fan Options (Vertical Air Flow Models Only)

1 = Standard Static/Vertical Supply, Return Air Flow

2 = Medium Static/Vertical Supply, Return Air Flow

3 = High Static/Vertical Supply, Return Air Flow

B =

Medium Static High Efficiency Motor/Vertical Supply,

Return Air Flow

C = High Static High Efficiency Motor/Vertical Supply,

Return Air Flow

Novation Coil Only (Outdoor - Indoor - Hail Guard)

G = Al/Al - Al/Cu

H = Al/Al - Cu/Cu

J = Al/Al - E-coat Al/Cu

K = E-coat Al/Al - Al/Cu

L = E-coat Al/Al - E-coat Al/Cu

T = Al/Al - Al/Cu — Louvered Hail Guards

U = Al/Al - Cu/Cu — Louvered Hail Guards

V = Al/Al - E-coat Al/Cu — Louvered Hail Guards

W = E-coat Al/Al - Al/Cu — Louvered Hail Guards

X = E-coat Al/Al - E-coat Al/Cu — Louvered Hail Guards

Round Tube Plate Fin (RTPF) Coil Options

(Outdoor - Indoor - Hail Guard)

A = Al/Cu - Al/Cu

B = Precoat Al/Cu - Al/Cu

C = E-coat Al/Cu - Al/Cu

D = E-coat Al/Cu - E-coat Al/Cu

E = Cu/Cu - Al/Cu

F = Cu/Cu - Cu/Cu

M = Al/Cu - Al/Cu — Louvered Hail Guards

N = Precoat Al/Cu - Al/Cu — Louvered Hail Guards

P = E-coat Al/Cu - Al/Cu — Louvered Hail Guards

Q = E-coat Al/Cu - E-coat Al/Cu — Louvered Hail Guards

R = Cu/Cu - Al/Cu — Louvered Hail Guards

S = Cu/Cu - Cu/Cu — Louvered Hail Guards

Economizer w/ Barometric Relief

Enthalpy

Economizer w/ PE (cent)

Temp Ultra Low Leak Economizer w/ Baro Relief

Temp Ultra Low Leak Economizer

Enthalpy Ultra Low Leak Economizer w/ Baro Relief

Enthalpy Ultra Low Leak Economizer

w/ PE (cent)

w/ PE (cent)

580J--17--30--V

C13775

3

580J--17--30--V

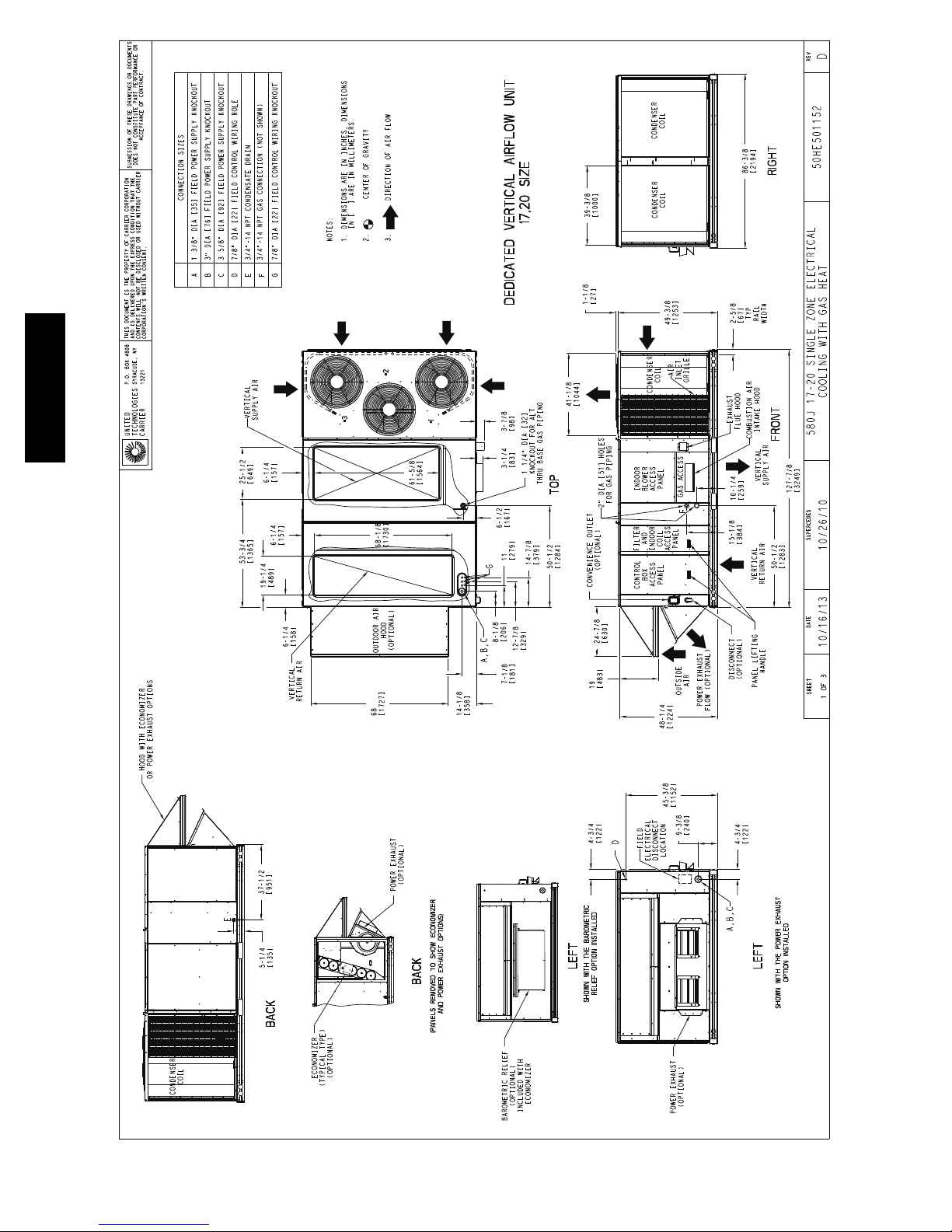

Fig. 2 -- Unit Dimensional Drawing – 17 and 20 Size Unit

C13745

4

580J--17--30--V

Fig. 2 -- Unit Dimensional Drawing – 17 and 20 Size Unit (cont.)

C13747

5

580J--17--30--V

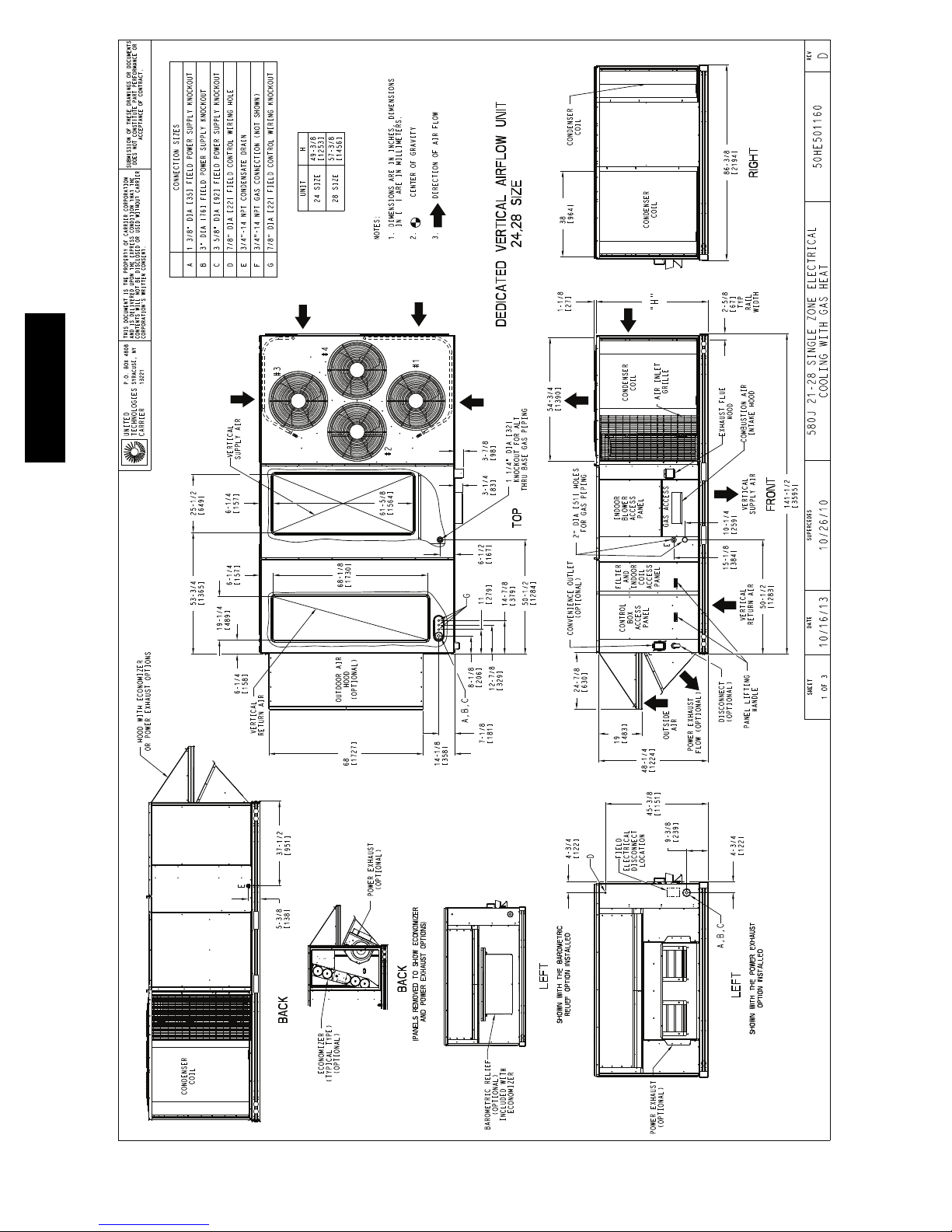

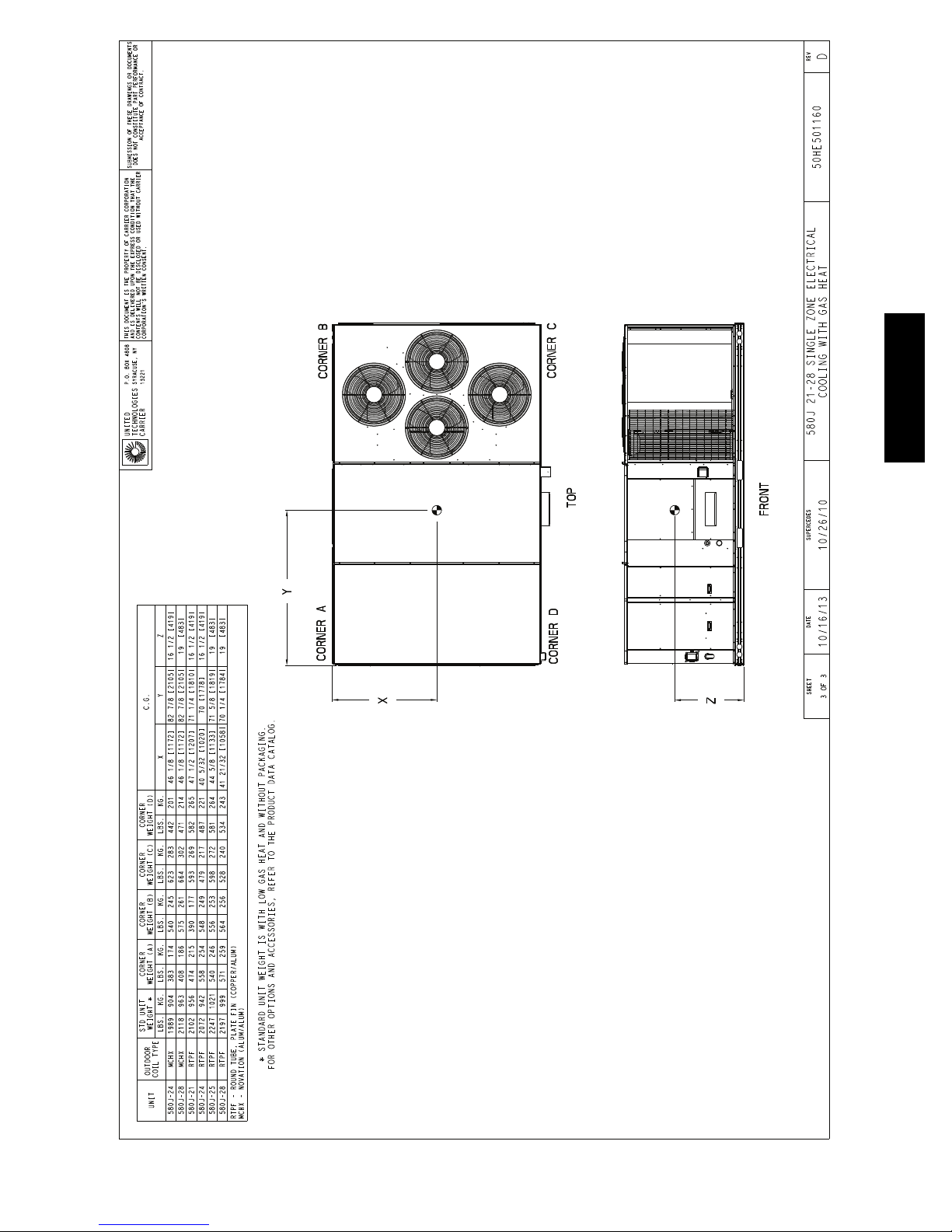

Fig. 3 -- Unit Dimensional Drawing – 24 and 28 Size Units

C13751

6

580J--17--30--V

Fig. 3 -- Unit Dimensional Drawing – 24 and 28 Size Units (cont.)

C13753

7

580J--17--30--V

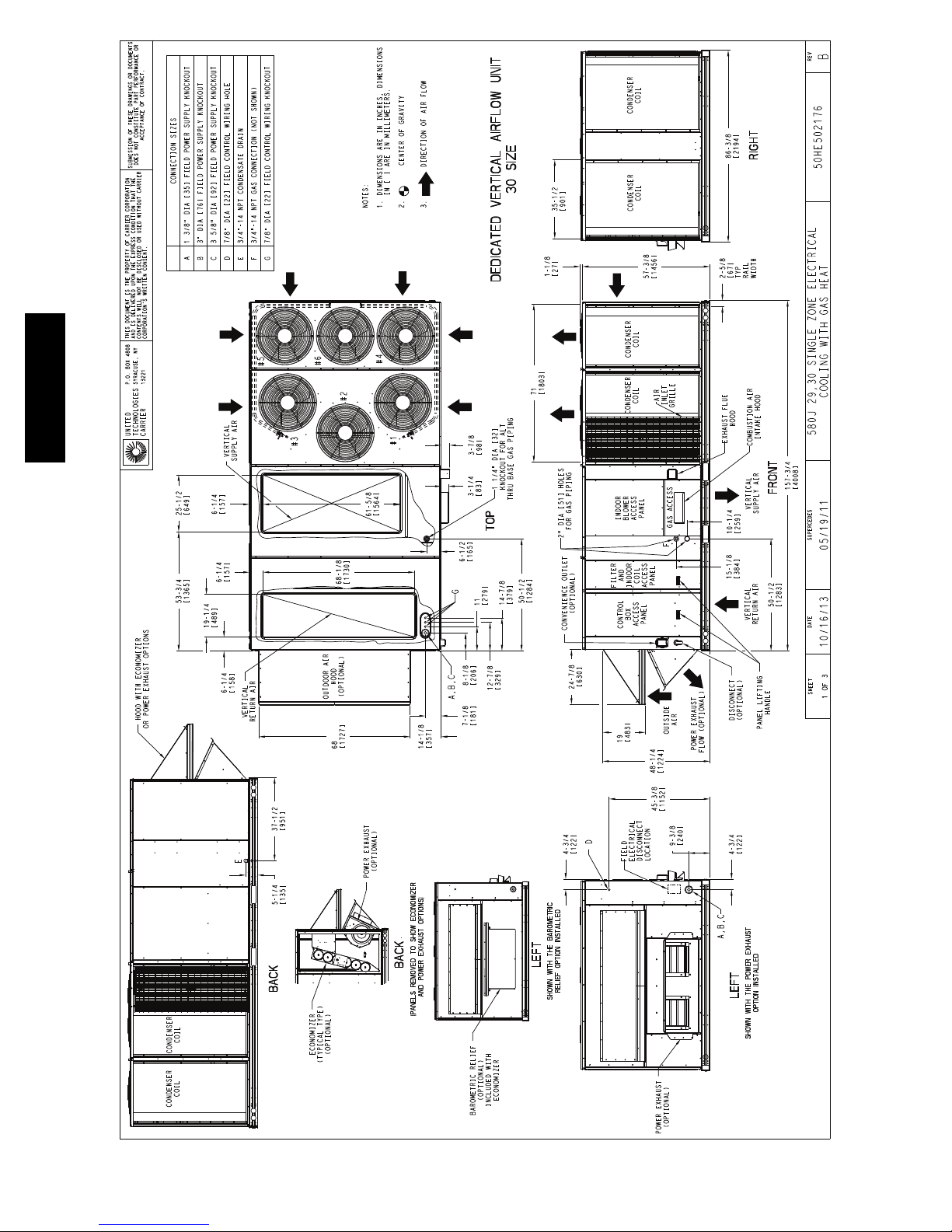

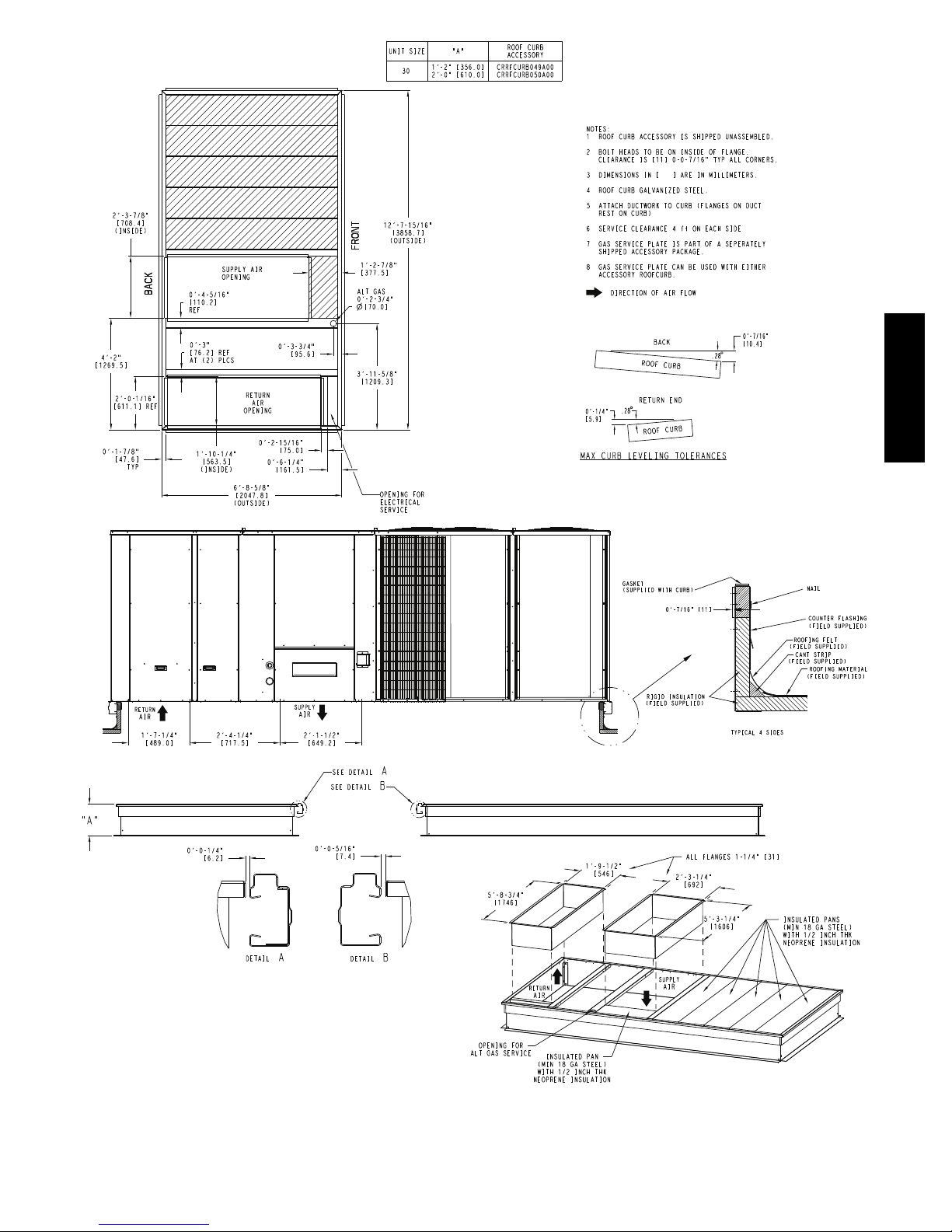

Fig. 4 -- Unit Dimensional Drawing – 30 Size Units

C13757

8

580J--17--30--V

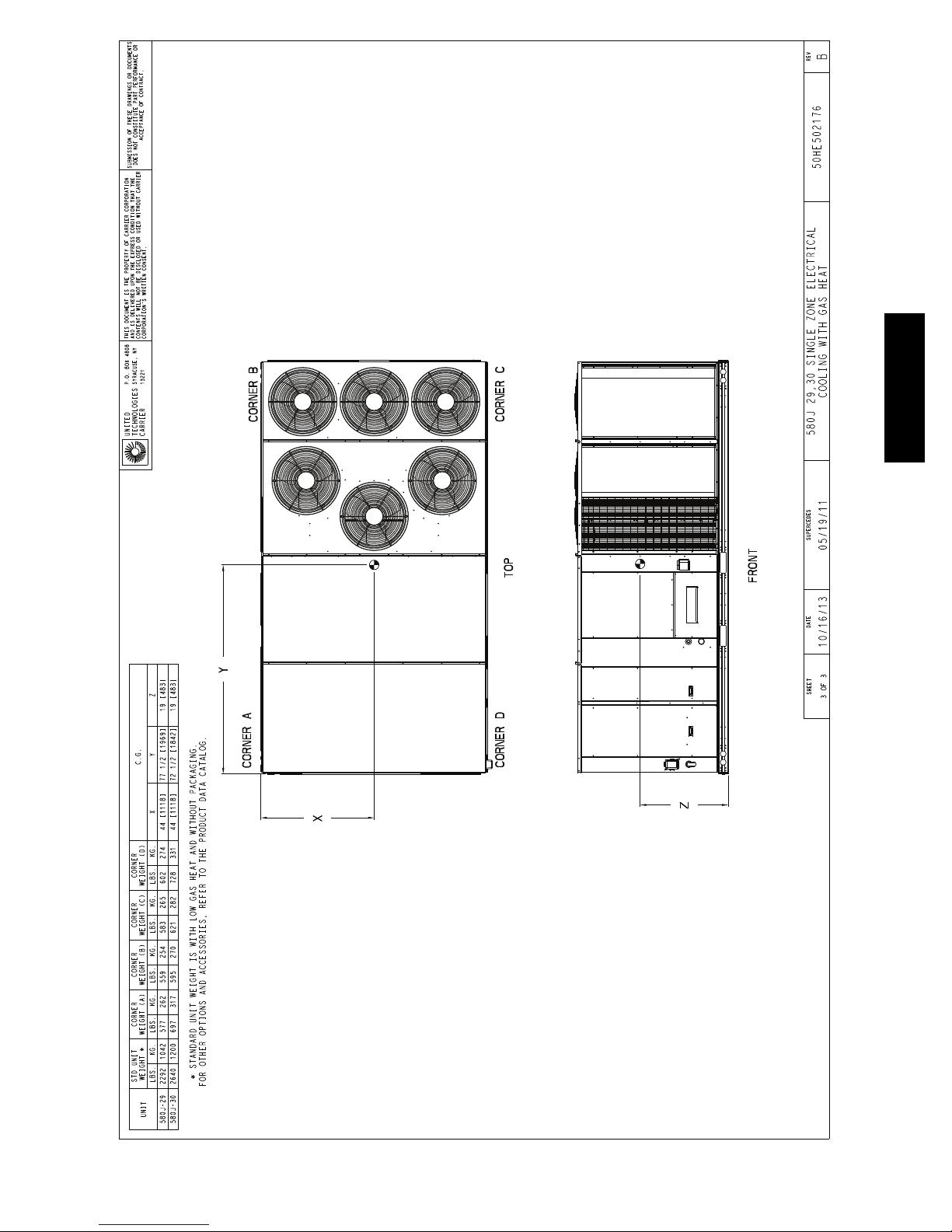

Fig. 4 -- Unit Dimensional Drawing – 30 Size Units (cont.)

C13759

9

INSTALLATION

Jobsite Survey

Complete the following checks before installation.

1. Consult local building codes and the NEC (National

Electrical Code) ANSI/NFPA 70 for special installation requirements.

2. Determine unit location (from project plans) or select

unit location.

3. Check for possible overhead obstructions which may

interfere with unit lifting or rigging.

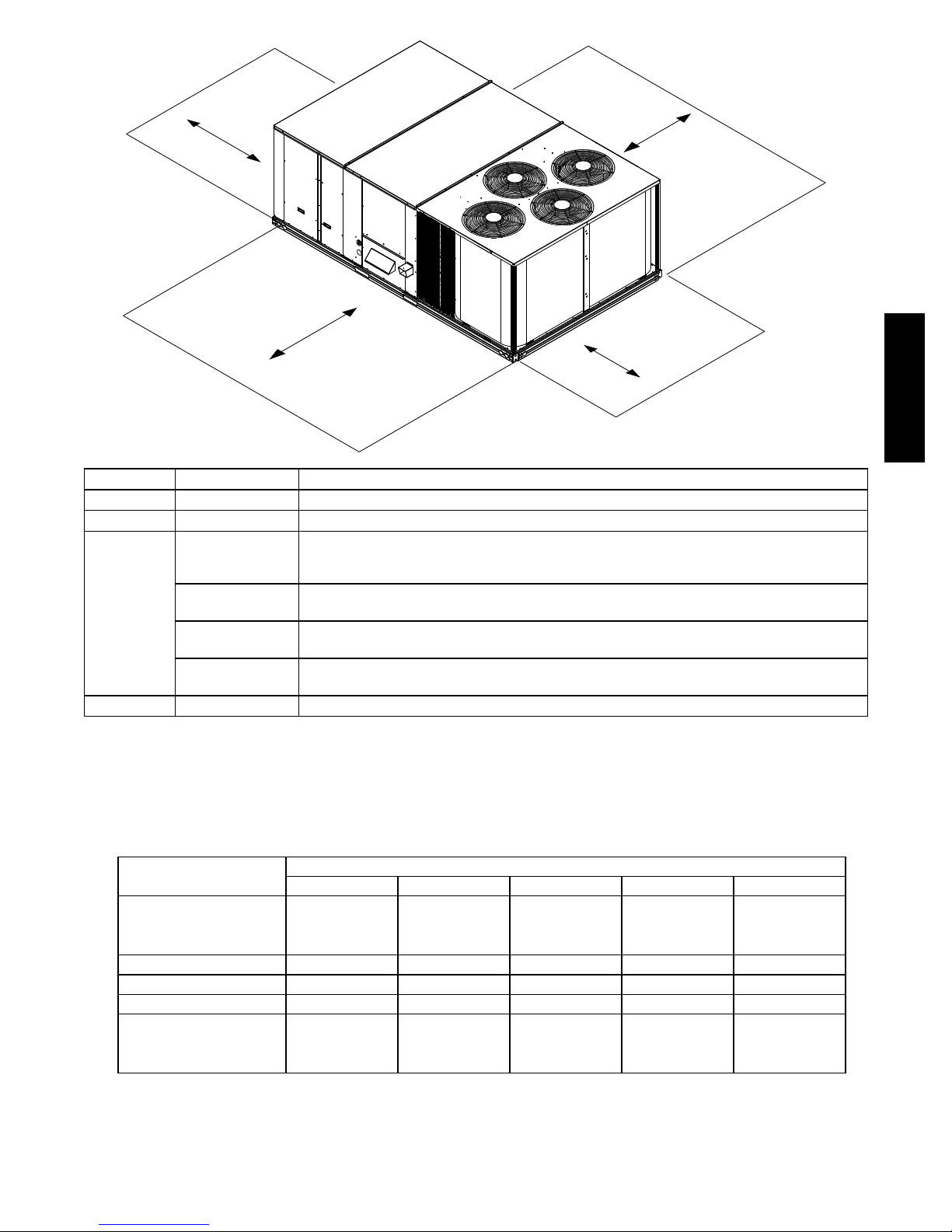

Step 1 — Plan for Unit Location

Select a location for the unit and its support system (curb

or other) that provides for the minimum clearances

required for safety. This includes the clearance to

combustible surfaces, unit performance and service access

below, around and above unit as specified in unit

drawings. See Fig. 5.

NOTE: Consider also the effect of adjacent units.

Be sure that the unit is installed such that snow will not

580J--17--30--V

block the combustion intake or flute outlet.

Unit may be installed directly on wood flooring or on

Class A, B, or C roof--covering material when roof curb is

used.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air. For proper unit operation, adequate combustion and

ventilation air must be provided in accordance with

Section 5.3 (Air for Combustion and Ventilation) of the

National Fuel Gas Code, ANSI Z223.1 (American

National Standards Institute) and NFPA (National Fire

Protection Association) 54 TIA--54--84--1. In Canada,

installation must be in accordance with the CAN1--B149

installation codes for gas burning appliances.

Although unit is weatherproof, avoid locations that permit

water from higher level runoff and overhangs to fall onto

the unit.

Locate mechanical draft system flue assembly at least 4 ft

(1.2 m) from any opening through which combustion

products could enter the building, and at least 4 ft (1.2 m)

from any adjacent building (or per local code). Locate the

flue assembly at least 10 ft (3.05 m) from an adjacent

unit’s fresh air intake hood if within 3 ft (0.91 m) of same

elevation (or per local code). When unit is located

adjacent to public walkways, flue assembly must be at

least 7 ft (2.1 m) above grade.

Select a unit mounting system that provides adequate

height to allow installation of condensate trap per

requirements. Refer to Step 11 — Install External

Condensate Trap and Line – for required trap dimensions.

Roof Mount —

Check building codes for weight distribution

requirements. Unit operating weight is shown in Table 1.

Step 2 — Plan for Sequence of Unit Installation

The support method used for this unit will dictate different

sequences for the steps of unit installation. For example, on

curb--mounted units, some accessories must be installed on

the unit before the unit is placed on the curb. Review the

following for recommended sequences for installation steps.

Curb--mounted installation —

Install curb

Install field--fabricated ductwork inside curb

Install thru--base service connection fittings (affects

curb and unit)

Rig and place unit

Remove top skid

Install outside air hood

Install smoke detector tube

Install combustion air hood

Install flue hood

Install gas piping

Install condensate line trap and piping

Make electrical connections

Install other accessories

Pad--mounted installation —

Prepare pad and unit supports

Rig and place unit

Remove duct covers and top skid

Install smoke detector return air sensor tube

Install field--fabricated ductwork at unit duct openings

Install outside air hood

Install combustion air hood

Install flue hood

Install gas piping

Install condensate line trap and piping

Make electrical connections

Install other accessories

Frame--mounted installation —

Frame--mounted applications generally follow the

sequence for a curb installation. Adapt as required to

suit specific installation plan.

Step 3 — Inspect unit

Inspect unit for transportation damage. File any claim

with transportation agency.

Confirm before installation of unit that voltage, amperage

and circuit protection requirements listed on unit data

plate agree with power supply provided.

On units with hinged panel option, check to be sure all

latches are tight and in closed position.

Locate the carton containing the outside air hood parts; see

Figs. 7 and 13. Do not remove carton until unit has been

rigged and located in final position.

10

C

D

B

LOCATION DIMENSION CONDITION

A 36---in (914 mm) • Recommended clearance for air flow and service

B 42--- in (1067 mm) • Recommended clearance for air flow and service

• No Convenience Outlet

18---in (457 mm)

36---in (914 mm)

C

42---in (1067 mm)

96---in (2438 mm)

D 42 --- in (1067 mm) • Recommended clearance for service.

NOTE: Unit not designed to have overhead obstruction. Contact Application Engineering for guidance on any application planning

overhead obstruction or for vertical clearances.

•NoEconomizer

• No field installed disconnect on economizer hood side (Factory-- -installed disconnect installed).

• Convenience Outlet installed.

• Vertical surface behind servicer is electrically non---conductive (e.g.: wood, fiberglass).

• Convenience Outlet installed.

• Vertical surface behind servicer is electrically conductive (e.g.: metal, masonry).

• Economizer and/or Power Exhaust installed.

• Check for sources of flue products with 10 feet (3 meters) of economizer fresh air intake.

A

Fig. 5 -- Service Clearance Dimensional Drawing

580J--17--30--V

C12384

580J*

Base Unit

Novation™ Coil 1824 (829) 1839 (836) 1989 (904) 2118 (963) N/A

RTPF Coil 1907 (867) 1922 (874) 2072 (942) 2197 (999) 2640 (1200)

Economizer 246 (112) 246 (112) 246 (112) 246 (112) 246 (112)

Powered Outlet 35 (16) 35 (16) 35 (16) 35 (16) 35 (16)

Perfect Humidity™ System 110 (50) 110 (50) 120 (54) 120 (54) N/A

Curb

14--- in/356 mm 240 (109) 240 (109) 255 (116) 255 (116) 255 (116)

24--- in/610 mm 340 (154) 340 (154) 355 (161) 355 (161) 355 (161)

Table 1 – Operating Weights

UNIT LB (KG)

17 20 24 28 30

11

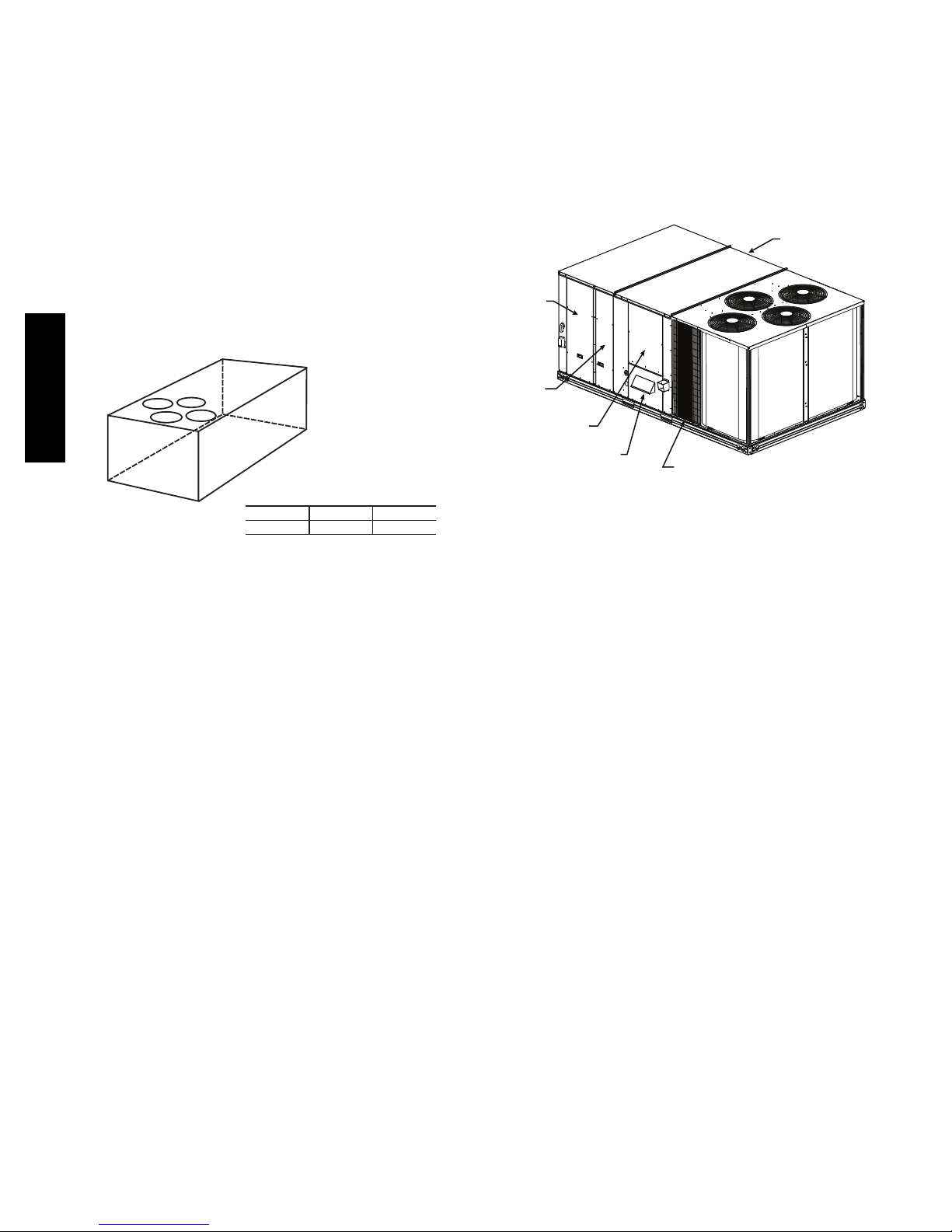

Step 4 — Provide Unit Support

A

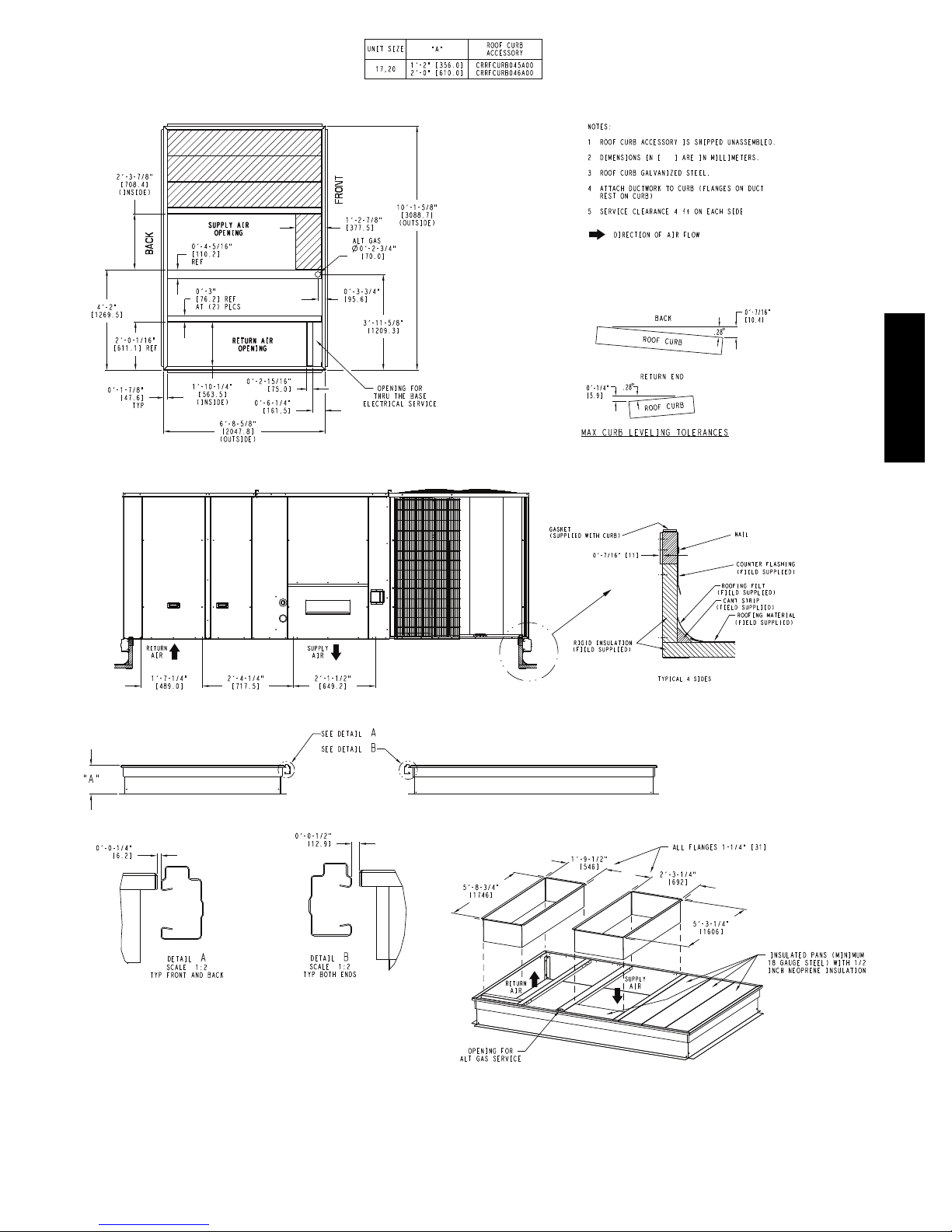

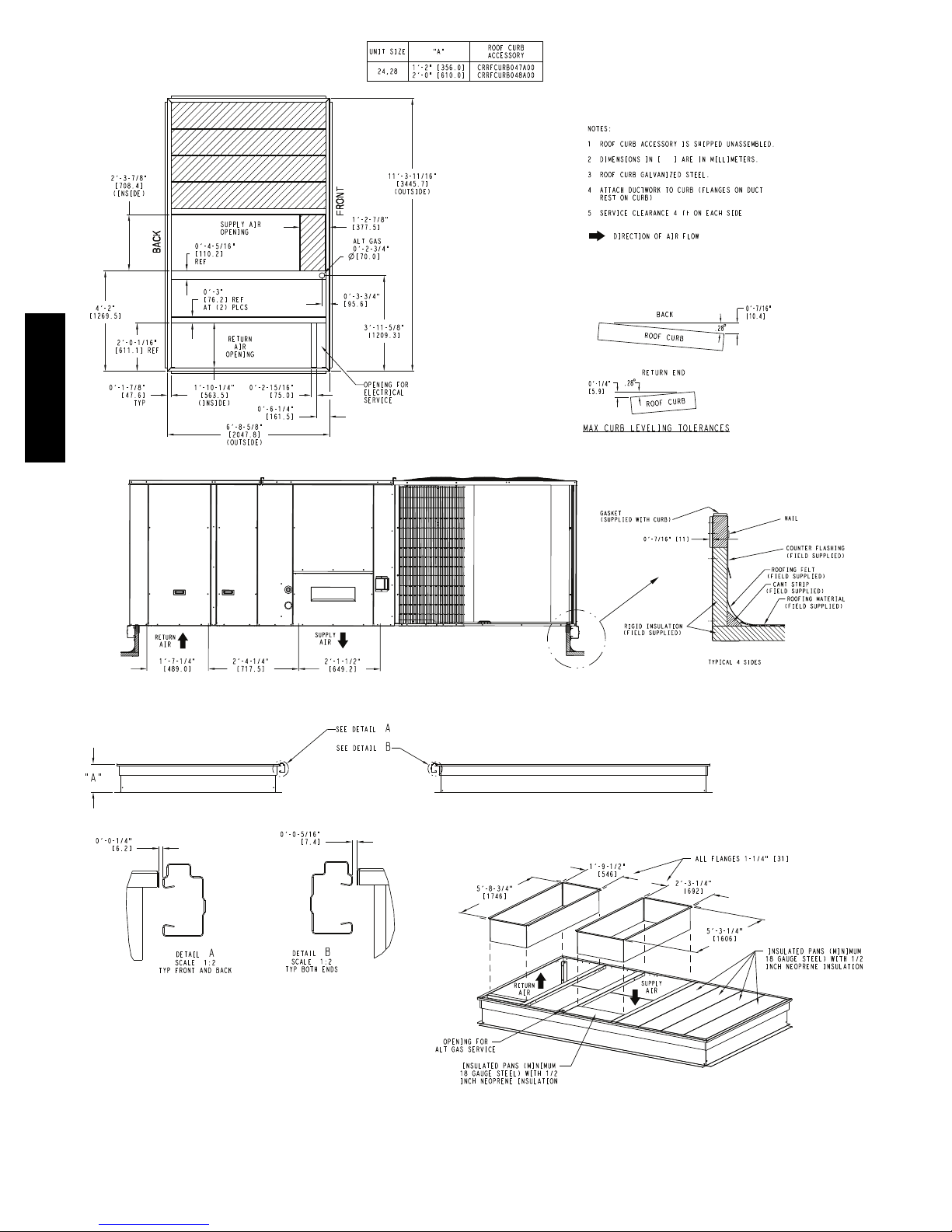

Roof Curb Mount —

Accessory roof curb details and dimensions are shown in

Figs. 8, 9 and 10. Assemble and install accessory roof

curb in accordance with instructions shipped with the

curb.

NOTE: The gasketing of the unit to the roof curb is

critical for a watertight seal. Install gasket supplied with

the roof curb as shown in Figs. 8, 9 and 10. Improperly

applied gasket can also result in air leaks and poor unit

performance.

Curb should be level. This is necessary for unit drain to

function properly. Unit leveling tolerances are show in

Fig. 6. Refer to Accessory Roof Curb Installation

Instructions for additional information as required.

580J--17--30--V

A

B

0.25” (6)

Fig. 6 -- Unit Leveling Tolerances

Install insulation, cant strips, roofing felt, and counter

flashing as shown. Ductwork must be attached to curb and

not to the unit. Thru--the--base power connection must be

installed before the unit is set on the roof curb. If

C

MAXIMUM ALLOWABLE

DIFFERENCE IN. (MM)

A-B

B-C

0.5” (12)

A-C

0.5” (12)

C10628

field--installed thru--the--roof curb gas connections are

desired remove knockout in basepan located in the gas

section, see Fig. 7 for location. Gas connections and

power connections to the unit must be field installed after

the unit is installed on the roof curb.

If electric and control wiring is to be routed through the

basepan remove knockouts in basepan located in control

box area, see Fig. 2, 3 or 4 for basepan knockout

locations. Attach the service connections to the basepan.

Hood Carton Location

(rear access panel)

Control Box

ccess Panel

Filter and

Indoor Coil

Access Panel

Indoor Blower

Access Panel

Gas Heat

Access Panel

Compressor

(each side)

C11154

Fig. 7 -- Typical Access Panel and Compressor Locations

Alternate Unit Support (In Lieu of Curb Mount) —

A non--combustible sleeper rail can be used in the unit

curb support area. If sleeper rails cannot be used, support

the long sides of the unit with a minimum of 4 equally

spaced 4--in. x 4--in. (102 mm x 102 mm) pads on each

side. Locate pads so that they support the rails. Make sure

to avoid the fork openings.

12

580J--17--30--V

Fig. 8 -- Roof Curb Details – 17 and 20 Size Units

C09052

13

580J--17--30--V

Fig. 9 -- Roof Curb Details – 24 and 28 Size Units

C09100

14

580J--17--30--V

C11224

Fig. 10 -- Roof Curb Details – 30 Size Unit

15

Step 5 — Field Fabricate Ductwork

Cabinet return-air static pressure (a negative condition)

shall not exceed 0.5 in. wg (87 Pa) with economizer or

without economizer.

For vertical ducted applications, secure all ducts to roof curb

and building structure. Do not connect ductwork to unit.

Fabricate supply ductwork so that the cross sectional

dimensions are equal to or greater than the unit supply

duct opening dimensions for the first 18 in. (458 mm) of

duct length from the unit basepan.

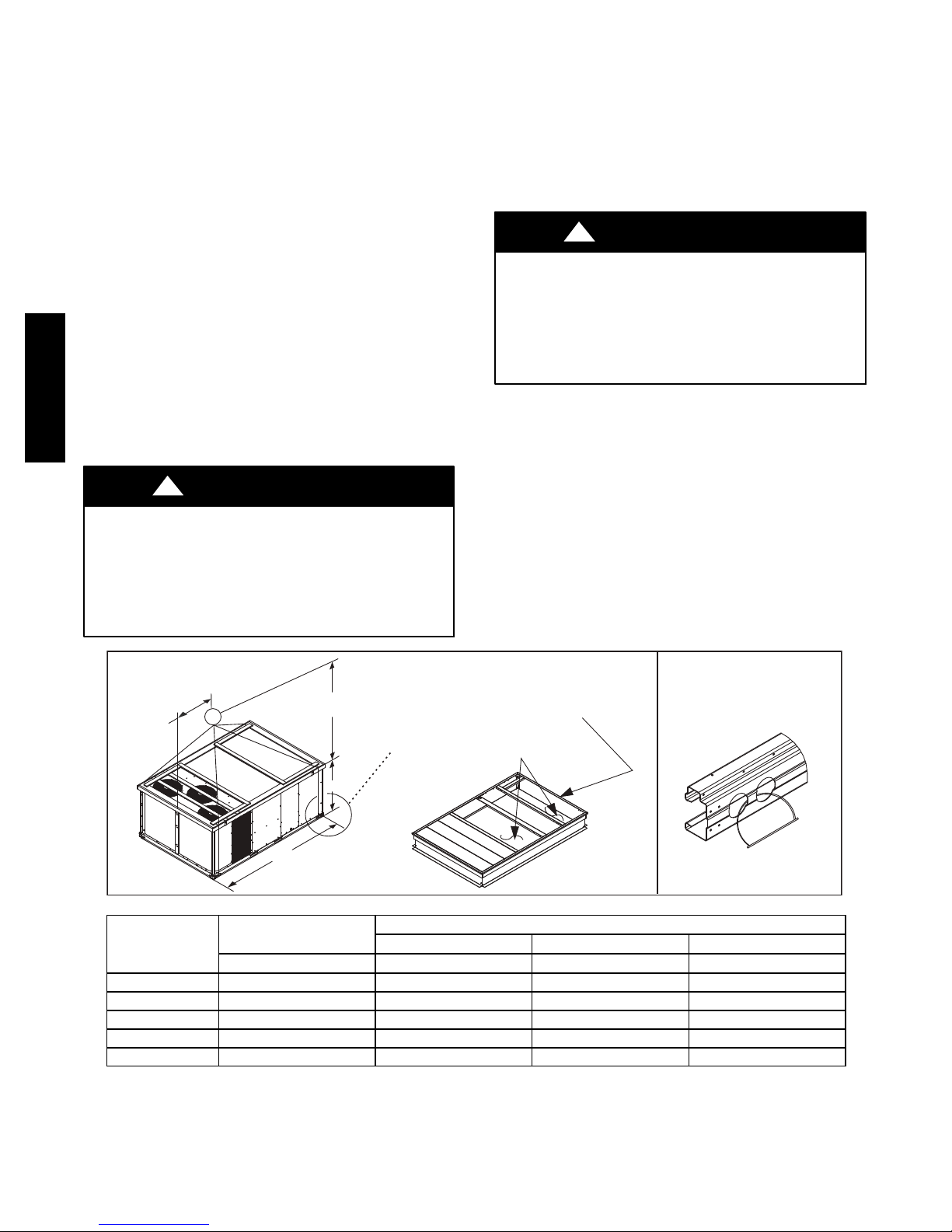

Step 6 — Rig and Place Unit

Keep unit upright and do not drop. Spreader bars are not

required if top crating is left on unit. Rollers may be used

to move unit across a roof. Level by using unit frame as a

reference. See Table 1 (on page 11) and Fig. 11 for

additional information.

Lifting holes are provided in base rails as shown in Fig.

11. Refer to rigging instructions on unit.

!

CAUTION

Insulate and weatherproof all external ductwork, joints,

and roof openings with counter flashing and mastic in

accordance with applicable codes.

Ducts passing through unconditioned spaces must be

insulated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck to comply with

applicable fire codes.

580J--17--30--V

A minimum clearance is not required around ductwork.

!

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in damage

to roofing materials.

Membrane roofs can be cut by sharp sheet metal

edges. Be careful when placing any sheet metal parts

on such roof.

"914-1371"

(36"-54")

"B"

SEE DETAIL A

UNIT DAMAGE HAZARD

Failure to follow this caution may result in

equipment damage.

All panels must be in place when rigging. Unit is not

designed for handling by fork truck when packaging

is removed.

Before setting the unit onto the curb, recheck gasketing on

curb.

PLACE ALL SEAL STRIP

IN PLACE BEFORE PLACING

UNIT ON ROOF CURB.

DUCT END

DETAIL A

"A"

UNIT

580J*17 2355 1068 127.8 3249 58.7 1491 52.3 1328

580J*20 2370 1075 127.8 3249 58.7 1491 52.3 1328

580J*24 2516 1141 141.5 3595 71.5 1816 52.3 1328

580J*28 2652 1203 141.5 3595 71.5 1816 60.3 1532

580J*30 2976 1353 157.8 4007 80.3 2040 60.3 1532

NOTES:

1. Dimensions in ( ) are in inches.

2. Hook rigging shackles through holes in base rail, as shown in detail “A.” Holes in base rails are centered around the unit center of gravity.

Use wooden top to p revent rigging straps from damaging unit.

MAX WEIGHT

LB KG IN MM IN MM IN MM

"C"

C09107

DIMENSIONS

A B C

Fig. 11 -- Rigging Details

16

Loading...

Loading...