Page 1

580J

GAS HEAT/ELECTRIC COOLING

PACKAGED ROOFTOP

15 TO 25 NOMINAL TONS

Product Data

(Unit shown with optional economizer.)

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

C09315

the environmentally sound refrigerant

Page 2

TABLE OF CONTENTS

PAGE

PAGE

FEATURES AND BENEFITS 3....................

MODEL NUMBER NOMENCLATURE 4............

F ACTORY OPTIONS AND/OR ACCESSORIES 6.....

AHRI COOLING RATING TABLES 8...............

HEAT RATING TABLE 8.........................

SOUND PERFORMANCE TABLE 9................

PHYSICAL DATA 10.............................

DIMENSIONS 15................................

OPTIONS AND ACCESSORIES WEIGHT

ADDERS 21....................................

580J

APPLICATION/SELECTION DATA 22..............

Your new 15 to 25 Ton Legacy Linet Bryant rooftop unit (RTU) was designed by customers for customers. With a newly

designed cabinet that integrates “no--strip” screw collars, handled access panels, and more we’ve made your unit easy to

install, easy to maintain, easy to use and reliable.

COOLING CAPACITIES 24.......................

STATIC PRESSURE ADDERS 32..................

DAMPER, BAROMETRIC RELIEF & PE PERF 33....

F AN PERFORMANCE 35.........................

ELECTRICAL INFORMATION 40.................

MCA / MOCP 42................................

TYPICAL WIRING DIAGRAMS 46................

SEQUENCE OF OPERATION 48...................

GUIDE SPECIFICATIONS 51......................

Easy to install:

These new Legacy Line units are designed for dedicated factory--supplie d vertical or horizontal air flow duct

configurations. No special field kits are required. Designed to fit on pre--installed curbs by another manufacturer, these

units also fit on past designed Bryant installed curbs with an adapter curb. This new cabinet design also integrates a large

control box that gives you room to work and room to mount Bryant accessory controls.

Easy to maintain:

Easy access handles by Bryant provide quick and easy access to all normally serviced components. Our “no--strip” screw

system has superior holding power and guides screws into position while preventing the screw from stripping the unit’s

metal. Take accurate pressure readings by reading system pressures with panels in place as compressors are strategically

located to eliminate any air bypass.

Easy to use:

The newly designed, master terminal board by Bryant puts all your connections and troubleshooting points in one

convenient place, standard. Most low voltage connections are made to the same board and make it easy to find what you’re

looking for and easy to access it. Bryant rooftops have high and low pressure switches, a filter drier, and 2--in (51mm)

filters standard.

Reliable:

Each unit comes with precision sized and tested scroll compressor that is internally protected from over temperature and

pressures. In addition, each refrigerant circuit is further protected with a high pressure and low pressure switch as well as

containing a liquid line filter drier. Each unit is factory tested prior to shipment to help ensure unit operation once properly

installed.

2

Page 3

FEATURES AND BENEFITS

S Two stage cooling capability with independent circuits and control.

S Round tube/plate fin (RTPF) or NOVATION all aluminum condenser (outdoor) coils. Special coil--coating also available

for coastal and industrial environments

S EER’s up to 10.8.

S IEER’s up to 12.0.

S Gas heating efficiencies up to 81% thermal efficiency.

S Dedicated vertical and horizontal air flow duct configuration models. No field kits required.

S Utility connections through the side or bottom. Bottom connections are also in an enclosed environment to help prevent

water entry.

S Standardized components and layout. Standardized components and controls make service and stocking parts easier.

S Scroll compressors on all units. This makes service, stocking parts, replacement, and trouble--shooting easier.

S Proven Acutrol refrigerant metering system.

S Easy--adjust, belt--drive motor availabl e. Bryant provides a factory solut ion for most points in the fan performance table.

Motor assembly also contains a fan belt break protection system on all models and reliable pillow block bearing system

that allows lubrication thru front of the unit.

S Single--point gas / electrical connection.

S Sloped, composite drai n pan sheds water; and won’t rust.

S Standardized controls and control box layout. Standardized components and controls make stoc king parts and service

easier.

S Clean, easy to use control box.

S Color--coded wiring.

S Large, laminated wiring and power wiring drawings which are affixed to unit make troubleshooting easy.

580J

S Single, central terminal board for test and wiring connections.

S Fast--access, handled, panels for easy access on normally accessed service panels.

S “No--strip” screw system guides screws into the panel and captures them tightly without stri pping the screw, the panel, or

the unit.

S Mechanical cooling (115_Fto30_F/46_Cto--1_C) standard on all models. Low ambient controller all ows operation

down to --20_F/--29_C

S Redundant gas valve for two stage gas heating capacity control with induced--draft flue exhaust design to help ensure no

flue gas can escape into the indoor air stream.

S Exclusive IGC solid stat e gas controller for on board diagnostics with LED error code designation, burner control l ogic

and energy saving indoor fan motor delay.

S 2--in (51mm) disposable filters on all units, with 4--in (102mm) filter track field --installed.

S Refrigerant filter--drier on each circuit.

S High and low pressure switches. Added reliability with high pressure switch and low pressure switch.

S Many factory--installed options ranging from air management economizers, 2 position dampers, manual outdoor air

dampers, plus convenience outlets, disconnect switch and smoke detectors.

S Factory--installed Perfect Humidityt dehumidification system. Available on RTPF condenser coil models only.

S Standard Parts Warranty: 10 year aluminized heat e xchanger, 5 year compressor, 3 year NOVATION condenser coil, 1

year others.

3

Page 4

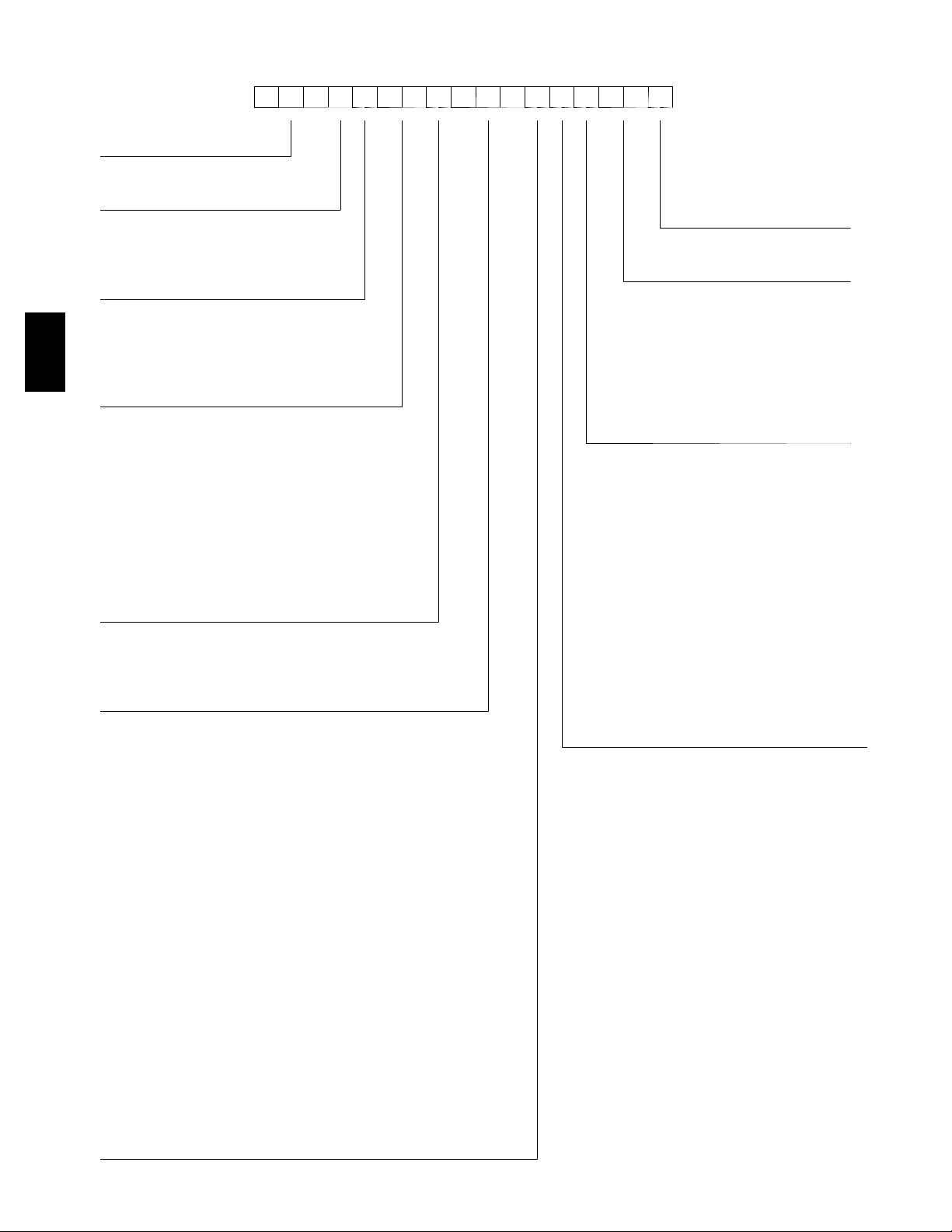

MODEL NUMBER NOMENCLATURE

1234567891011121314151617

5 8 0 J E 1 7 D 3 1 0 G 1 A 0 A A

__________ ______ ________ ______

Unit Type

580 = Gas Heat RTU

Model

J(PuronR Refrigerant) Packaging

Voltage

E = 4 6 0 --- 3 --- 6 0 Factory Installed Options

P = 208/230---3--- 60 0A = None

T = 5 7 5 --- 3 --- 6 0

Cooling Tons A=None

17 = 15 Ton B=Tempeconow/barorelief

580J

20 = 17.5 Ton D=Tempeconow/PE(cent)

24 = 20 Ton H = Enthalpy econo w/ b aro relief

28 = 25 Ton J=Enthalpyeconow/PE(cent)

Refrig. System/Gas Heat Options Q = 2 Position damper

D = 2 --- S t a g e C o m p r e s s o r w / A l u m i n u m g a s h e a t

exchanger Indoor Fan Options

F = 2---Stage Compressor w/Stainless steel gas heat 1 = Standard static option, Vertical

exchanger 2 = Medium static option, Vertical

K = Two Stage C ooling with Aluminum gas heat exchanger 3 = High static option, Vertical

and Perfect Humidity. (only available on RTPF coil B = Medium Static High Eff Motor/Vertical Supply,

models) Return Air Flow

M = Two Stage Cooling with Sainless Steel gas heat C = High Static High Eff Motor/Vertical Supply

exchanger and Perfect Humidity. (only available on Return Air Flow

RTPF coil models)

Heat Level Input 6 = Medium Static option, Horizontal

220 = 220,000 7 = High Static option, Horizontal

310 = 310,000 F = Medium Static High Eff Motor/Horizontal Supply,

400 = 400,000 Return Air Flow

N o v a t i o n C o i l O n l y ( O u t d o o r --- I n d o o r --- H a i l G u a r d ) Return Air Flow

G = Al/Al --- Al/Cu

H = Al/Al --- Cu/Cu

J = A l / A l --- E --- c o a t A l / C u

K = E --- c o a t A l / A l --- A l / C u

L = E --- c o a t A l / A l --- E --- c o a t A l / C u

T = Al/Al --- Al/Cu, Louvered Hail Guards

U = Al/Al --- Cu/Cu, Louvered Hail Guards

V = A l / A l --- E --- c o a t A l/ C u , L o u v e r e d H a i l G u a r d s

W = E --- c o a t A l / A l --- A l / C u , L o u v e r e d H a i l G u a r d s

X = E --- c o a t A l / A l --- E --- c o a t A l / C u , L o u v e r e d H a i l G u a r d s

R o u n d T u b e P l a t e F i n C o i l O p t i o n s ( O u t d o o r --- I n d o o r --- H a i l G u a r d )

A = Al/Cu --- Al/Cu

B = P r e c o a t A l / C u --- A l / C u

C = E --- c o a t A l / C u --- A l / C u

D = E --- c o a t A l / C u --- E --- c o a t A l / C u

E = C u / C u --- A l / C u

F = Cu/Cu --- Cu/Cu

M = A l / C u --- A l / C u --- L o u v e r e d H a i l G u a r d s

N = P r e c o a t A l / C u --- A l / C u --- L o u v e r e d H a i l G u a r d s

P = E --- c o a t A l / C u --- A l / C u --- L o u v e r e d H a i l G u a r d s

Q = E --- c o a t A l / C u --- E --- c o a t A l/ C u --- L o u v e r e d H a i l G u a r d s

R = C u / C u --- A l / C u --- L o u v e r e d H a i l G u a r d s

S = C u / C u --- C u / C u --- L o u v e r e d H a i l G u a r d s

A=Standard

Outdoor Air Options

P = Manual outdoor air damper

5 = Standard Static option, Horizontal

G = High Static High Eff Motor/Horizontal Supply,

4

Page 5

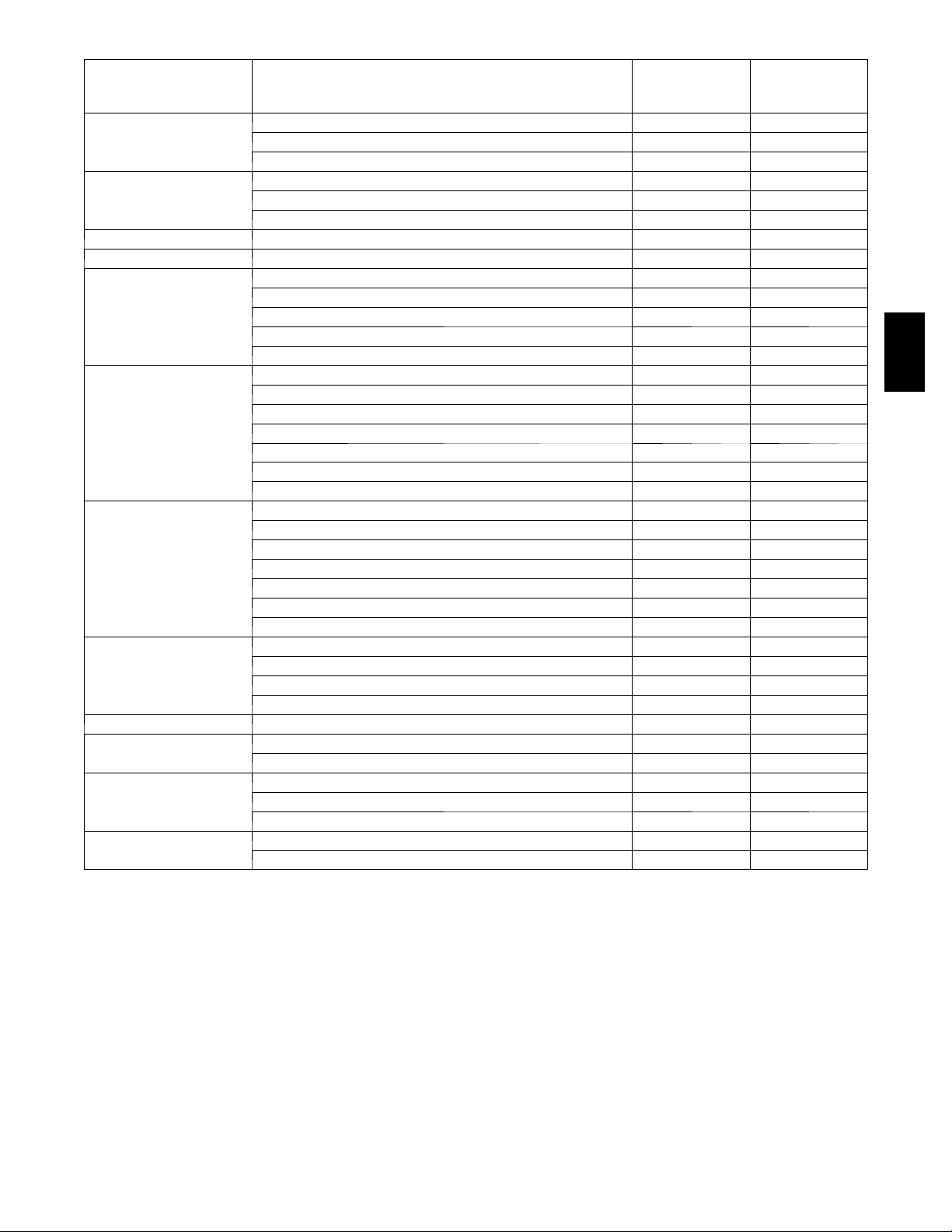

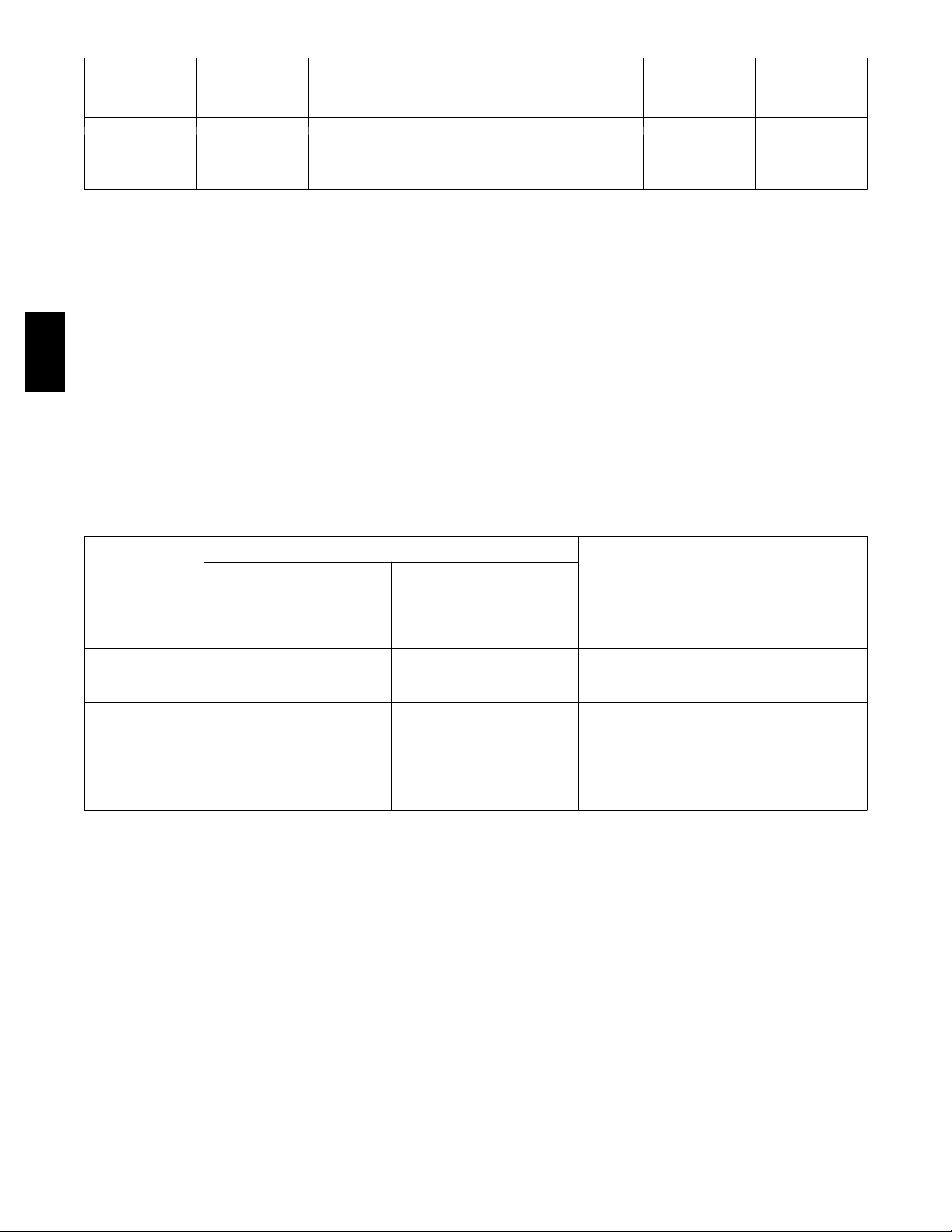

Table 1 – FACTORY--INST ALLED OPTIONS AND FIELD--INSTALLED ACCESSORIES

FACTORY

CATEGORY ITEM

Dedicated Vertical Air Flow Duct Configuration X

Cabinet

Dedicated Horizontal Air Flow Duct Configuration X

Thru--- the---base electrical or gas--- line connections X

Cu/Cu (indoor) coils X

Coil Options

Pre---Coat (outdoor) coils X

E ---coated (outdoor & indoor) coils X

Humidity Control Perfect Humidity™ Dehumidification System X

Condenser Protection Condenser coil hail guard (louvered design) X X

Thermostats, temperature sensors, and subbases X

RTU Open protocol controller X

Controls

Smoke detector (supply and/or return air) X X

Time Guard II compressor delay control circuit X

Phase Monitor X

EconoMi$ert IV (for electro---mechanical controlled RTUs) X X

EconoMi$ert2 (for DDC controlled RTUs) X X

Economizers

& Outdoor Air

Dampers

Motorized 2 position outdoor---air damper X X

Manual outdoor---air damper (25%) X X

Barometric relief

1

Barometric hood (Horizontal economizer) X

Power exhaust–centrifugal blower X X

2

2

2

Economizer Sensors

&

IAQ Devices

Single dry bulb temperature sensors

Differential dry bulb temperature sensors

Single enthalpy sensors

Differential enthalpy sensors

2

2

Wall or duct mounted CO2sensor

Unit mounted CO2sensor

2

4---in Filter Track Assembly X

Propane conversion kit X

Gas Heat

Stainless steel heat exchanger X

High altitude conversion kit X

Flue Discharge Deflector X

Indoor Motor & Drive Multiple motor and drive packages X

Low Ambient

Control

Power

Options

Roof Curbs

Winter start kit

Motormaster head pressure controller

Convenience outlet (powered) X

Convenience outlet (unpowered) X

Non ---fused disconnect

Roof curb 14 ---in (356mm) X

Roof curb 24 ---in (610mm) X

3

3

4

INSTALLED

OPTION

X X

X X

X X

X

X

INSTALLED

ACCESSORY

FIELD

580J

X

X

X

X

X

NOTES:

1. Included with economizer.

2. Sensors used to optimize economizer performance.

3. See application data for assistance.

4. Non -- -fused disconnect switch cannot be used when MOCP electrical rating exceeds 70 amps at 460/575 volt and 150

amps at 208/230 volt. Bryant Packaged RTUBuilder selects this automatically.

5

Page 6

FACTORY OPTIONS AND/OR ACCESSORIES

Economizer (dry--bulb or enthalpy)

Economizers save money. They bring in fresh, outside air

for ventilation; and provide cool, outside air to cool your

building. This is the preferred method of low--ambient

cooling. When coupled to CO

provide even more savings by coupling the ventilation air

to only that amount required.

Economizers are available, installed and tested by the

factory, with either enthalpy or dry--bulb temperature

inputs. There are also models for electromechanical as

well as direct digi tal controllers. Addit ional sensors are

available as accessories to optimize the economizers.

Economizers include gravity controlled, barometric relief

equalizes building pressure and ambient air pressures.

580J

This can be a cast effective solution to prevent building

pressurization. If further control of exha ust air is required,

a dual centrifugal fan power exhaust system is also

available.

sensors, economizers can

2

CO2Sensor

Improves productivity and saves money by working with

the economizer to intake only the correct amount of

outside air for ventilation. As occupants fill your building,

the CO

CO

When the occupants leave, the CO

the sensor appropriately closes the economizer. This

intelligent control of the ventilation air, called Demand

Control Ventilation (DCV) reduces the overall load on the

rooftop, savi ng money.

sensor detects their presence through increasing

2

levels, and opens the economizer a ppropriately.

2

levels decrease, and

2

Smoke Detectors

Non--Fused Disconnect

This OSHA--compliant, factory--installed, safety switch

allows a service technician to locally secure power to the

rooftop.

Power Exhaust with Barometric Relief

Superior internal building pressure control. This

field--installed accessory or factory--installed option may

eliminate the need for costly, external pressure control

fans.

RTU Open Protocol Controller

Connect the rooftop to an existing BAS without needing

complicated translators or adapter modules using the RTU

Open controller. This new controller speaks the 4 most

common building a utomation system languages (Bacnet,

Modbus, N2, and Lonworks). Use this controller when

you have an existing BAS.

Time Guard II Control Circuit

This accessory protects your compressor by preventing

short--cycli ng in the event of some other fail ure, prevents

the compressor from restarting for 30 seconds after

stopping. Not required with RTU Open or authorized

commercial thermostats.

Motorized 2--Position Damper

The new Bryant 2--position, motorized outdoor air damper

admits up to 100% outside air. Using reliable, gear--driven

technology, the 2--position damper opens to allow

ventilation air and closes when the rooftop stops, stopping

unwanted infiltration.

Trust the experts. Smoke detectors make your application

safer and your job easier. Bryant smoke detectors

immediately shut down the rooftop unit when smoke is

detected. They are available, installed by the factory, for

supply air, return air, or both.

Louvered Hail Guards

Sleek, louvered panels protect the condenser coil from

hail damage, foreign objects, and incidental contact.

Convenience Outlet (powered or un--powered)

Reduce service and/or installation costs by including a

convenience outlet in your specification. Bryant will

install this service feature at our factory. Provides a

convenient, 15 amp, 115v GFCI receptacle with “Wet in

Use” cover. The “powered” option allows the installer to

power the outlet from the line side of t he disconnect side

as required by code. The “unpowered” option is to be

powered from a separate 115/120v power source.

Manual OA Damper

Manual outdoor air dampers are an economical way to

bring in ventilation air. The dampers are available in 25%

versions.

Optional P erfect Humidityt Adaptive

Dehumidification System

Bryant’s Perfect Humidity adaptive dehumidification

system is an all--inclusive factory installed option that can

be ordered with any Legacy Line 580J17--28 rooftop unit.

This system expands the envelope of operation of Bryant’s

Legacy Line rooftop products to provide unprecedented

flexibility to meet year round comfort conditions.

The Perfect Humidity adaptive dehumidification system

has the industry’s only dual dehumidification mode

setting. The Perfect Humidity system includes two new

modes of operation.

6

Page 7

FACTORY OPTIONS AND/OR ACCESSORIES (cont.)

The Legac y Line 580J17--28 rooftop coupled with the

Perfect Humidityt system is capable of operating in

normal design cooling mode, subcooling mode, and hot

gas reheat mode. Normal design cooling mode is when the

unit will operate under its normal sequence of operation

by cycling compressors to maintain comfort conditions.

Subcooling mode will operate to satisfy part load type

conditions when the space requires combined sensible and

a higher proportion of latent load control. Hot Gas Reheat

mode will operate when outdoor temperatures diminish

and the need for latent capacity is required for sole

humidity control. Hot Gas Reheat mode will provide

neutral air for maximum dehumidification operation.

Optional Stainless Steel Heat Exchanger

The stainless steel heat exchanger option provides the

tubular heat exchanger be made out of a minimum 20

gauge type 409 stainless steel for applications where the

mixed air to the heat exchanger is expected to drop below

45_F(7_C). Stainless steel may be specified on

applications where the presence of airborne contaminants

require its use (applications such as paper mills) or in area

with very high outdoor humidity that may result in severe

condensation in the heat excha nger during cooling

operation.

Flue Discharge Deflector

Motormaster Head Pressure Controller

The Motormaster motor controller is a low ambient, head

pressure controller kit that is designed to maintain the

unit’s condenser head pressure during periods of low

ambient cooling operation. This devi ce should be used as

an alternative to economizer free cooling not when

economizer usage is either not appropriate or desired. The

Motormaster will either cycle the outdoor--fan motors or

operate them at reduced speed to maintain the unit

operation, depending on the model.

Winter Start Kit

The winter start kit by Bryant extends the low ambient

limit of your rooftop to 25_F(--4_C). The kit bypasses the

low pressure switch, preventi ng nuisance tripping of the

low pressure switch. Other low ambient precautions may

still be prudent.

Propane Heating

Convert your gas heat rooftop from standard natural gas

operation to Propane using this field--installed kit.

High Altitude Heating

High altitudes have less oxygen, which means heat

exchangers need less fuel. The new gas orifices in this

field--installed kit make the necessary adjustment for high

altitude applications. They restore the optimal fuel to air

mixture and maintain healthy combustion at altitudes

above 2000 ft (610m). Kits may not be required in all

areas.

The flue discharge deflector is a useful accessory when

flue gas recirculation is a concern. By venting the flue

discharge upwards, the deflector minimizes the chance for

a neighboring unit to intake the flue exhaust.

Alternate Motors and Drives

Some applications need larger horsepower motors, some

need more airflow, and some need both. Regardless of the

case, your Bryant expert has a factory installe d

combination to meet your application. A wide selection of

motors and pulleys (drives) are available, factory

installed, to handle nearly any application.

Thru--the--Base Connections

Thru--the--base connections, available as a factory option,

are necessary to ensure proper connection and seal when

routing wire and piping through the rooftop’s basepan and

curb. These couplings eliminate roof penetration and

should be considered for gas lines, main power lines, as

well as control power.

Barometric Hood

For Horizontal Economizer applications where relief

damper is installed in duct work. This kit provides the

needed protection.

580J

7

Page 8

Table 2 – AHRI COOLING RATING TABLE 2--STAGE COOLING

UNIT

17 2 15 192.0 18.7 10.8 12.0

20 2 17.5 208.0 19.3 10.8 11.9

24 2 20 242.0 24.7 9.8 10.8

28 2 25 282.0 28.8 9.8 10.4

COOLING

STAGES

NOM.

CAPACITY

(TONS)

NET

COOLING

CAPACITY

(MBH)

TOTAL POWER

(kW)

EER IEER

LEGEND

AHRI --- Air Conditioning, Heating and Refrigeration

Institute Test Standard

ASHRAE --- American Society of Heating, Refrigerating

and Air Conditioning, Inc.

EER --- Energy Efficiency Ratio

IEER --- Integrated Energy Efficiency Ratio

580J

Table 3 – HEATING RATING T ABLE -- NATURAL GAS & PROPANE

MODEL

SIZE

17

20

24

28

HEAT

SIZE

LOW 176 / 142 220 / 178 20 --- 55 81%

MED 248 / 200 310 / 251 30 --- 60 81%

HIGH 320 / 260 400 / 324 35 --- 65 81%

LOW 176 / 142 220 / 178 15 --- 55 81%

MED 248 / 200 310 / 251 25 --- 60 81%

HIGH 320 / 260 400 / 324 30--- 65 81%

LOW 176 / 142 220 / 178 15 --- 55 81%

MED 248 / 200 310 / 251 20 --- 60 81%

HIGH 320 / 260 400 / 324 30--- 65 81%

LOW 176 / 142 220 / 178 10 --- 55 81%

MED 248 / 200 310 / 251 15 --- 60 81%

HIGH 320 / 260 400 / 324 20 --- 65 81%

INPUT / OUTPUT

STAGE 1 (MBH)

NOTES:

Heat ratings are for natural gas heat exchangers operated at or below 2000 ft (610 m). For information on Propane or altitudes above 2000 ft (610 m), see the Application Data section of this book. Accessory Propane/High Altitude kits are also

available.

AL/SS HEAT EXCHANGER

INPUT / OUTPUT

STAGE 2 (MBH)

NOTES:

1. Rated and certified under AHRI Standard 340/360, as

appropriate.

2. Ratings are based on:

Cooling Standard: 80_F(27_C) db, 67_F(19_C) wb

indoor air temp and 95_F(35_C) db outdoor air temp.

IEER Standard: A measure that expresses cooling

part---load EER efficiency for commercial unitary air

conditioning and heat pump equipment on the basis of

weighted operation at various load capacities.

3. All 580J units comply with ASHRAE 90.1 Energy

Standard for minimum EER and IEER requirements.

4. 580J units comply with US Energy Policy Act (2005).

To evaluate code compliance requirements, refer to

state and local codes or visit the following website:

http://bcap -- -energy.org to determine if compliance

with this standard pertains to your state, territory, or

municipality.

TEMP RISE

(DEG F)

THERMAL

EFFICIENCY

(%)

In the USA the input rating for altitudes above 2000 ft (610m) must be derated by 4% for each 1000 ft (305 m) above sea

level. In Canada, the input rating must be derated by 10% for altitudes of 2000 ft (610 m) to 4500 ft (1372 m) above sea level.

8

Page 9

Table 4 – SOUND PERFORMANCE T ABLE

Outdoor Sound (dB)

MODEL

SIZE

LEGEND

dB --- Decibel

COOLING

STAGES

17 2 84.1 84 92.2 83.9 80.4 81.8 78.7 76.5 72.2 65.4

20 2 84.1 84 92.2 83.9 80.4 81.8 78.7 76.5 72.2 65.4

24 2 86.5 87 95.6 87.5 84.2 84.2 81.7 77.9 73.2 66.3

28 2 85.9 86 97.1 88.3 84.4 83.3 80.7 77.4 73.4 67.3

A --- W t g .

AHRI

370

Rating

63 125 250 500 1000 2000 4000 8000

NOTES:

1. Outdoor sound data is measure in accordance with

AHRI standard 270 ---2008.

2. Measurements are expressed in terms of sound power.

Do not compare these values to sound pressure values

because sound pressure depends on specific environmental factors which normally do not match individual

applications. Sound power values are independent of

the environment and therefore more accurate.

3. A ---weighted sound ratings filter out very high and very

low frequencies, to better approximate the response of

“average” human ear. A -- -weighted measurements for

Bryant units are taken in accordance with AHRI standard 270 ---2008.

Table 5 – MINIMUM -- MAXIMUM AIRFLOW RATINGS -- NATURAL GAS & PROPANE

MODEL

SIZE

17

20

24

28

HEAT

SIZE

LOW

MED 3880 7750 3880 7750

HIGH 4620 8570 4620 8570

LOW

MED 3880 9300 3880 9300

HIGH 4620 10000 4620 10000

LOW

MED 3880 11630 3880 11630

HIGH 4620 10000 4620 10000

LOW

MED 3880 15500 3880 15500

HIGH 4620 15000 4620 15000

MINIMUM MAXIMUM MINIMUM MAXIMUM MINIMUM MAXIMUM

COOLING AL HX HEATING S S HX HEATING

2960 8150 2960 8150

4500 7500

2960 10860 2960 10860

5250 9000

2960 10860 2960 10860

6000 10000

2960 16300 2960 16300

7500 12500

580J

9

Page 10

Table 6 – PHYSICAL DATA (COOLING) 15 -- 25 TONS Novation -- All Aluminum Coil Design

580J*17 580J*20 580J*24 580J*28

Refrigeration System

# Circuits / # Comp. / Type 2/2/Scroll 2/2/Scroll 2/2/Scroll 2/2/Scroll

R--- 410a charge A/B (lbs) 9.5/12.0 9.5/12.0 14.4/12.5 12.5/13.0

Metering device Acutrol Acutrol Acutrol Acutrol

High---press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505 630 / 505

Low--- press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117 54 / 117

Compressor Capacity Staging (%) 50 / 100 50 / 100 50 / 100 50 / 100

Evap. Coil

Material Cu / Al Cu / Al Cu / Al Cu / Al

Tube Diameter 3 / 8 --- i n 3/ 8 --- i n 3/ 8 --- i n 3 / 8 --- i n

Rows / FPI 4/15 4/15 4/15 4/15

Tota l fa c e a r e a ( f t 2) 19.56 19.56 22.00 23.11

Condensate drain conn. size 3 / 4 --- i n 3 / 4 --- i n 3 / 4 --- i n 3 / 4 --- i n

Evap. fan and motor

VERTICAL

580J

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 2.2 3.3 4.9 4.9

RPM range 514--- 680 622--- 822 690---863 717---911

Motor frame size 56 56 56 56

Standard Static

Medium Static

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 3.3 4.9 6.5 6.5

RPM range 679--- 863 713--- 879 835 --- 1021 913 --- 1116

Motor frame size 56 56 184T 184T

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 4.9 6.5 8.7 8.7

RPM range 826--- 1009 882--- 1078 941 --- 1176 941 ---1176

Motor frame size 56 184T 213T 213T

High Static

High Eff*

Medium Static

High Eff*

High Static

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15

Motor Qty / Drive type

Max BHP

RPM range

Motor frame size

Fan Qty / Type

Fan Diameter (in)

Motor Qty / Drive type

Max BHP

RPM range

Motor frame size

Fan Qty / Type

Fan Diameter (in)

n/a n/a 1/Belt 1/Belt

n/a n/a 6.5 6.5

n/a n/a 835--- 1021 913 ---1116

n/a n/a 184T 184T

n/a n/a 2/Centrifugal 2/Centrifugal

n/a n/a 15 x 15 15 x 15

n/a 1/Belt 1/Belt 1/Belt

n/a 6.5 8.7 8.7

n/a 882---1078 941---1176 941---1176

n/a 184T 213T 213T

n/a 2/Centrifugal 2/Centrifugal 2/Centrifugal

n/a 15 x 15 15 x 15 15 x 15

* Section 313 of the Energy Independence and Security Act of 2007 (EISA 2007) mandates that the efficiency of general purpose motors we use in our Light

Commercial Rooftops rated at 5.0 HP and larger be increased on or after December 19, 2010. We will offer both high and standard efficient motors u ntil

inventory is depleted and then shift over solely to the high efficient motors only.

10

Page 11

Table 6 – PHYSICAL DATA (con’t) (COOLING) 15 -- 25 TONS Novation -- All Aluminum

Coil Design

580J*17 580J*20 580J*24 580J*28

HORIZONTAL

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 2.2 3.3 4.9 4.9

RPM range 514--- 680 622--- 822 690---863 647---791

Motor frame size 56 56 56 56

Standard Static

Medium Static

High Static

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 3.3 4.9 6.5 6.5

RPM range 614--- 780 713--- 879 835 --- 1021 755--- 923

Motor frame size 56 56 184T 184T

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 4.9 6.5 8.7 8.7

RPM range 746--- 912 882 --- 1078 941 --- 1176 827 ---1010

Motor frame size 56 184T 213T 213T

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11

580J

Motor Qty / Drive type

High Eff*

Medium Static

High Eff*

High Static

Cond. Coil (Circuit A)

Cond. Coil (Circuit B)

Cond. fan / motor

Motor frame size

Fan Diameter (in)

Motor Qty / Drive type

Motor frame size

Fan Diameter (in)

Total face area (ft2) 21.4 21.4 25.1 27.1

Total face area (ft2) 21.4 21.4 17.4 27.1

Qty / Motor drive type 3 / direct 3/direct 4/direct 4/direct

Fan diameter (in) 22 22 22 22

n/a n/a 1/Belt 1/Belt

Max BHP

RPM range

Fan Qty / Type

Max BHP

RPM range

Fan Qty / Type

Coil type Novation Novation Novation Novation

Coil Length (in) 70 70 82 75

Coil Height (in) 44 44 44 52

Coil type Novation Novation Novation Novation

Coil Length (in) 70 70 57 75

Coil Height (in) 44 44 44 52

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100

n/a n/a 6.5 6.5

n/a n/a 835--- 1021 755--- 923

n/a n/a 184T 184T

n/a n/a 2/Centrifugal 2/Centrifugal

n/a n/a 18 x 15/15 x 11 18 x 15/15 x 11

n/a 1/Belt 1/Belt 1/Belt

n/a 6.5 8.7 8.7

n/a 882---1078 941---1176 827---1010

n/a 184T 213T 213T

n/a 2/Centrifugal 2/Centrifugal 2/Centrifugal

n/a 18 x 15/15 x 11 18 x 15/15 x 11 18 x 15/15 x 11

Filters

RAFilter#/size(in) 6/20x25x2 6/20x25x2 6/20x25x2 9/16x25x2

OA inlet screen # / size (in) 4/16x25x1 4/16x25x1 4/16x25x1 4/16x25x1

* Section 313 of the Energy Independence and Security Act of 2007 (EISA 2007) mandates that the efficiency of general purpose motors we use in our Light

Commercial Rooftops rated at 5.0 HP and larger be increased on or after December 19, 2010. We will offer both high and standard efficient motors u ntil

inventory is depleted and then shift over solely to the high efficient motors only.

11

Page 12

Table 7 – PHYSICAL DATA (COOLING) 15 -- 25 TONS RTPF -- Round Tube/Plate Fin Coil Design

580J*17 580J*20 580J*24 580J*28

Refrigeration System

# Circuits / # Comp. / Type 2/2/Scroll 2/2/Scroll 2/2/Scroll 2/2/Scroll

R--- 410a charge A/B (lbs) 16.3/17.5 9.5/12.0 20.6/14.7 19.8/20.4

Perfect Humidity R--- 410a charge A/B (lbs) 25.9/25.7 25.9/25.7 27.9/20.5 27.9/28.9

Metering device Acutrol Acutrol Acutrol Acutrol

High---press. Trip / Reset (psig) 630 / 505 630 / 505 630 / 505 630 / 505

Low--- press. Trip / Reset (psig) 54 / 117 54 / 117 54 / 117 54 / 117

Perfect Humidity Low--- press. Trip / Reset (psig) 27 / 44 27 / 44 27 / 44 27 / 44

Compressor Capacity Staging (%) 50 / 100 50 / 100 50 / 100 50 / 100

Evap. Coil

Material Cu / Al Cu / Al Cu / Al Cu / Al

Tube Diameter 3 / 8 --- i n 3 / 8 --- i n 3 / 8 --- i n 3 / 8 --- i n

Rows / FPI 4/15 4/15 4/15 4/15

Tota l fa c e a r e a ( f t 2) 22.00 22.00 22.00 23.11

Condensate drain conn. size 3 / 4 --- i n 3 / 4 --- i n 3 / 4 --- i n 3 / 4 --- i n

Perfect Humidity Coil

580J

Material Cu / Al Cu / Al Cu / Al Cu / Al

Tube Diameter 3 / 8 --- i n 3 / 8 --- i n 3 / 8 --- i n 3 / 8 --- i n

Rows / FPI 1/17 1/17 1/17 1/17

Tota l fa c e a r e a ( f t 2) 22.00 22.00 22.00 23.11

Evap. fan and motor

VERTICAL

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 2.2 3.3 4.9 4.9

RPM range 514 --- 680 622 --- 822 690 --- 863 717 --- 911

Motor frame size 56 56 56 56

Standard Static

Medium Static

High Static

High Eff*

Medium Static

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 3.3 4.9 6.5 6.5

RPM range 679 --- 863 713 --- 879 835--- 1021 913 --- 1116

Motor frame size 56 56 184T 184T

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 4.9 6.5 8.7 8.7

RPM range 826 --- 1009 882 --- 1078 941 ---1176 941 ---1176

Motor frame size 56 56 213T 213T

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 15 x 15 15 x 15 15 x 15 15 x 15

Motor Qty / Drive type

Max BHP

RPM range

Motor frame size

Fan Qty / Type

Fan Diameter (in)

n/a n/a 1/Belt 1/Belt

n/a n/a 6.5 6.5

n/a n/a 835--- 1021 913 ---1116

n/a n/a 184T 184T

n/a n/a 2/Centrifugal 2/Centrifugal

n/a n/a 15 x 15 15 x 15

Motor Qty / Drive type

Max BHP

RPM range

High Eff*

High Static

Motor frame size

Fan Qty / Type

Fan Diameter (in)

n/a 1/Belt 1/Belt 1/Belt

n/a 6.5 8.7 8.7

n/a 882---1078 941---1176 941---1176

n/a 184T 213T 213T

n/a 2/Centrifugal 2/Centrifugal 2/Centrifugal

n/a 15 x 15 15 x 15 15 x 15

* Section 313 of the Energy Independence and Security Act of 2007 (EISA 2007) mandates that the efficiency of general purpose motors we use in our Light

Commercial Rooftops rated at 5.0 HP and larger be increased on or after December 19, 2010. We will offer both high and standard efficient motors u ntil

inventory is depleted and then shift over solely to the high efficient motors only.

12

Page 13

Table 7 – PHYSICAL DATA (con’t) (COOLING) 15 -- 25 TONS RTPF -- Round Tube/Plate

Fin Coil Design

580J*17 580J*20 580J*24 580J*28

HORIZONTAL

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 2.2 3.3 4.9 4.9

RPM range 514--- 680 622--- 822 690---863 647---791

Motor frame size 56 56 56 56

Standard Static

Medium Static

High Static

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 3.3 4.9 6.5 6.5

RPM range 614--- 780 713--- 879 835 --- 1021 755--- 923

Motor frame size 56 56 184T 184T

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11

Motor Qty / Drive type 1/Belt 1/Belt 1/Belt 1/Belt

Max BHP 4.9 6.5 8.7 8.7

RPM range 746--- 912 882 --- 1078 941 --- 1176 827 ---1010

Motor frame size 56 184T 213T 213T

Fan Qty / Type 2/Centrifugal 2/Centrifugal 2/Centrifugal 2/Centrifugal

Fan Diameter (in) 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11 18 x 15 & 15 X 11

580J

Motor Qty / Drive type

High Eff*

Medium Static

High Eff*

High Static

Cond. Coil (Circuit A)

Cond. Coil (Circuit B)

Cond. fan / motor

Motor frame size

Fan Diameter (in)

Motor Qty / Drive type

Motor frame size

Fan Diameter (in)

Total face area (ft2) 21.4 21.4 25.1 27.1

Total face area (ft2) 21.4 21.4 17.4 27.1

Qty / Motor drive type 3 / direct 3/direct 4/direct 4/direct

Fan diameter (in) 22 22 22 22

n/a n/a 1/Belt 1/Belt

Max BHP

RPM range

Fan Qty / Type

Max BHP

RPM range

Fan Qty / Type

Coil type RTPF RTPF RTPF RTPF

Coil Length (in) 70 70 82 75

Coil Height (in) 44 44 44 52

Coil type RTPF RTPF RTPF RTPF

Coil Length (in) 70 70 57 75

Coil Height (in) 44 44 44 52

Motor HP / RPM 1/4 / 1100 1/4 / 1100 1/4 / 1100 1/4 / 1100

n/a n/a 6.5 6.5

n/a n/a 835--- 1021 755--- 923

n/a n/a 184T 184T

n/a n/a 2/Centrifugal 2/Centrifugal

n/a n/a 18 x 15/15 x 11 18 x 15/15 x 11

n/a 1/Belt 1/Belt 1/Belt

n/a 6.5 8.7 8.7

n/a 882---1078 941---1176 827---1010

n/a 184T 213T 213T

n/a 2/Centrifugal 2/Centrifugal 2/Centrifugal

n/a 18 x 15/15 x 11 18 x 15/15 x 11 18 x 15/15 x 11

Filters

RAFilter#/size(in) 6/20x25x2 6/20x25x2 6/20x25x2 9/16x25x2

OA inlet screen # / size (in) 4/16x25x1 4/16x25x1 4/16x25x1 4/16x25x1

* Section 313 of the Energy Independence and Security Act of 2007 (EISA 2007) mandates that the efficiency of general purpose motors we use in our Light

Commercial Rooftops rated at 5.0 HP and larger be increased on or after December 19, 2010. We will offer both high and standard efficient motors u ntil

inventory is depleted and then shift over solely to the high efficient motors only.

13

Page 14

Table 8 – PHYSICAL DATA (HEA TING) 15 -- 25 TONS

580J*D17 580J*D20 580J*D24 580J*D28

Gas Connection

#ofGasValves 1 1 1 1

Nat. gas supply line press (in. w.g.)/(PSIG) 5 --- 1 3 / 0 . 1 8 --- 0 . 4 7 5 --- 1 3 / 0 . 1 8 --- 0 . 4 7 5 --- 1 3 / 0 . 1 8 --- 0 . 4 7 5 --- 1 3 / 0 . 1 8 --- 0 . 4 7

Propane supply line press (in. w.g.)/(PSIG) 11--- 13 / 0.40 ---0.47 11 ---13 / 0.40---0.47 11 ---13 / 0.40 ---0.47 11---13 / 0.40---0.47

Heat Anticipator Setting (Amps)

1st stage 0.14 0.14 0.14 0.14

2nd stage 0.14 0.14 0.14 0.14

Natural Gas Heat

#ofstages/#ofburners(total) 2/5 2/5 2/5 2/5

Connection size 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T

LOW

Rollout switch opens / closes 195 / 115 195 / 115 195 / 115 195 / 115

Temperatureriserange(F) 25 --- 55 25 --- 55 25 --- 55 25 --- 55

580J

MED

HIGH

Liquid Propane Heat

LOW

MED

HIGH

#ofstages/#ofburners(total) 2/7 2/7 2/7 2/7

Connection size 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T

Rollout switch opens / closes 195 / 115 195 / 115 195 / 115 195 / 115

Temperatureriserange(F) 30--- 60 30--- 60 30 --- 60 30--- 60

#ofstages/#ofburners(total) 2/10 2/10 2/10 2/10

Connection size 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T

Rollout switch opens / closes 195 / 115 195 / 115 195 / 115 195 / 115

Temperatureriserange(F) 35--- 65 35--- 65 35 --- 65 35--- 65

#ofstages/#ofburners(total) 2/5 2/5 2/5 2/5

Connection size 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T

Rollout switch opens / closes 195 / 115 195 / 115 195 / 115 195 / 115

Temperatureriserange(F) 25 --- 55 25 --- 55 25 --- 55 25 --- 55

#ofstages/#ofburners(total) 2/7 2/7 2/7 2/7

Connection size 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T

Rollout switch opens / closes 195 / 115 196 / 115 197 / 115 198 / 115

Temperatureriserange(F) 30--- 60 30--- 60 30 --- 60 30--- 60

#ofstages/#ofburners(total) 2/10 2/10 2/10 2/10

Connection size 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T 3 / 4 --- i n N P T

Rollout switch opens / closes 195 / 115 195 / 115 195 / 115 195 / 115

Temperatureriserange(F) 35--- 65 35--- 65 35 --- 65 35--- 65

14

Page 15

DIMENSIONS

580J

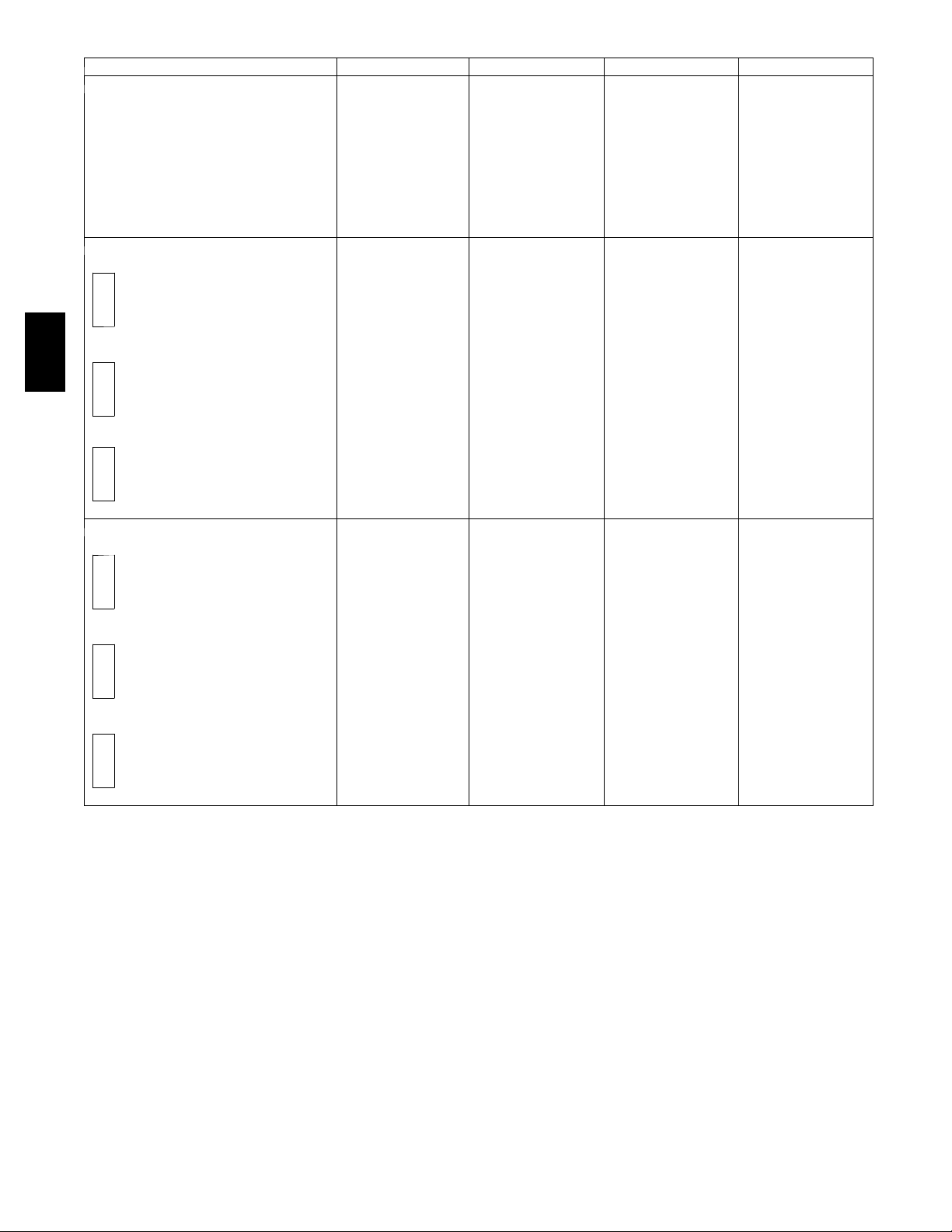

Fig. 1 -- Dimensions 580J*D17--20

15

C101009

Page 16

LOC

DIMENSION

CONDITION

A

36"

Recommended clearance for airflow and service.

B

42"

Recommended clearance for airflow and service.

C

18"

36"

42"

96"

D

42"

580J

DIMENSIONS (cont.)

C101038

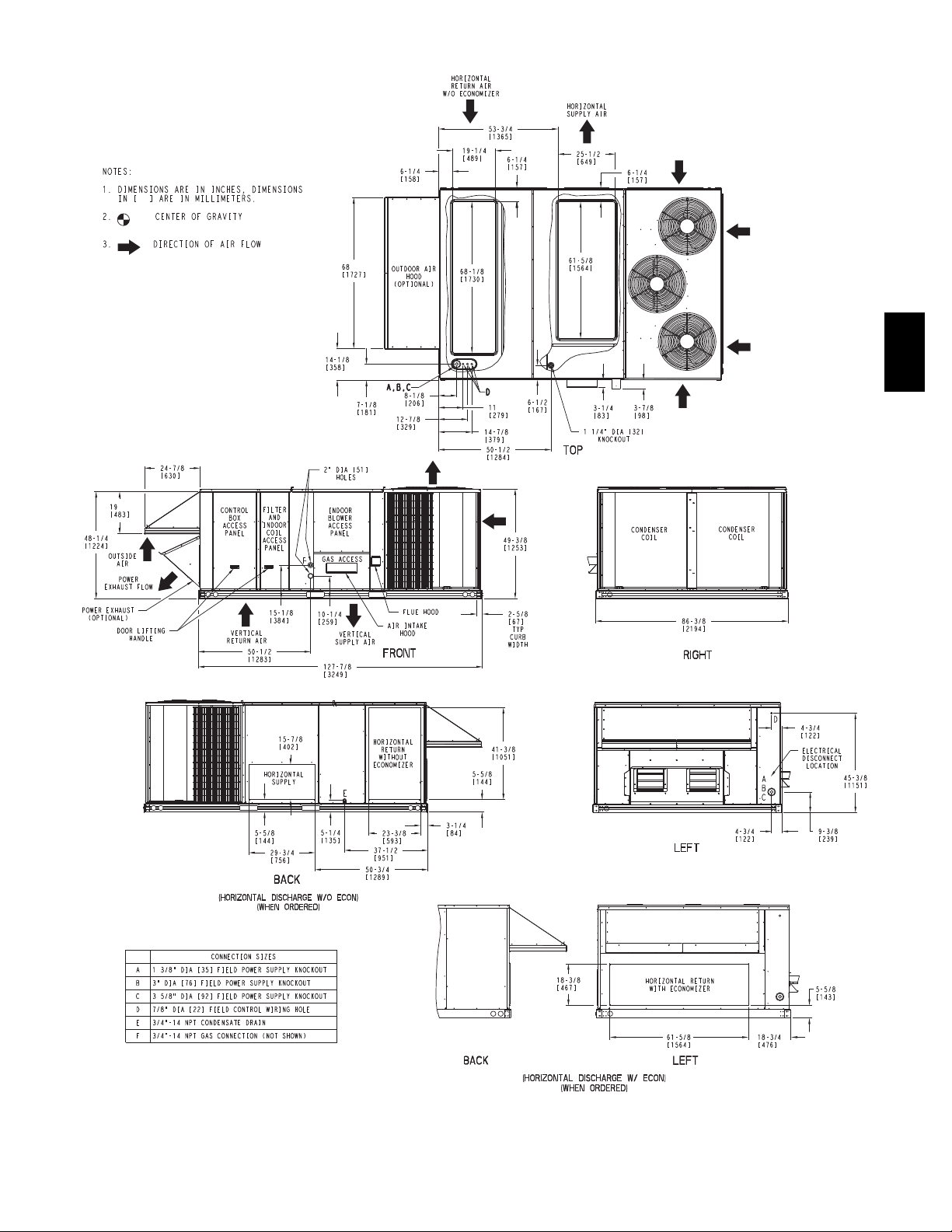

Fig. 2 -- Dimensions 580J*D17--20

1. No CO, 2. No Economizer, 3. No field installed disconnect on economizer hood side (Factory installed disconnect installed).

1. CO installed, 2. Vertical surface behind servicer is electrically non-c onductive (e.g., wood, fiberglas s).

1. CO installed, 2. Vertical surface behind servicer is electrically conductive (e.g., metal, masonry)

1. Economizer and/or Power E xhaust installed. 2. Check for sources of flue products within 10 f eet of economizer fresh air intake.

Recommended clearance for s ervice

C11001

Fig. 3 -- Service Clearance

16

Page 17

DIMENSIONS (cont.)

580J

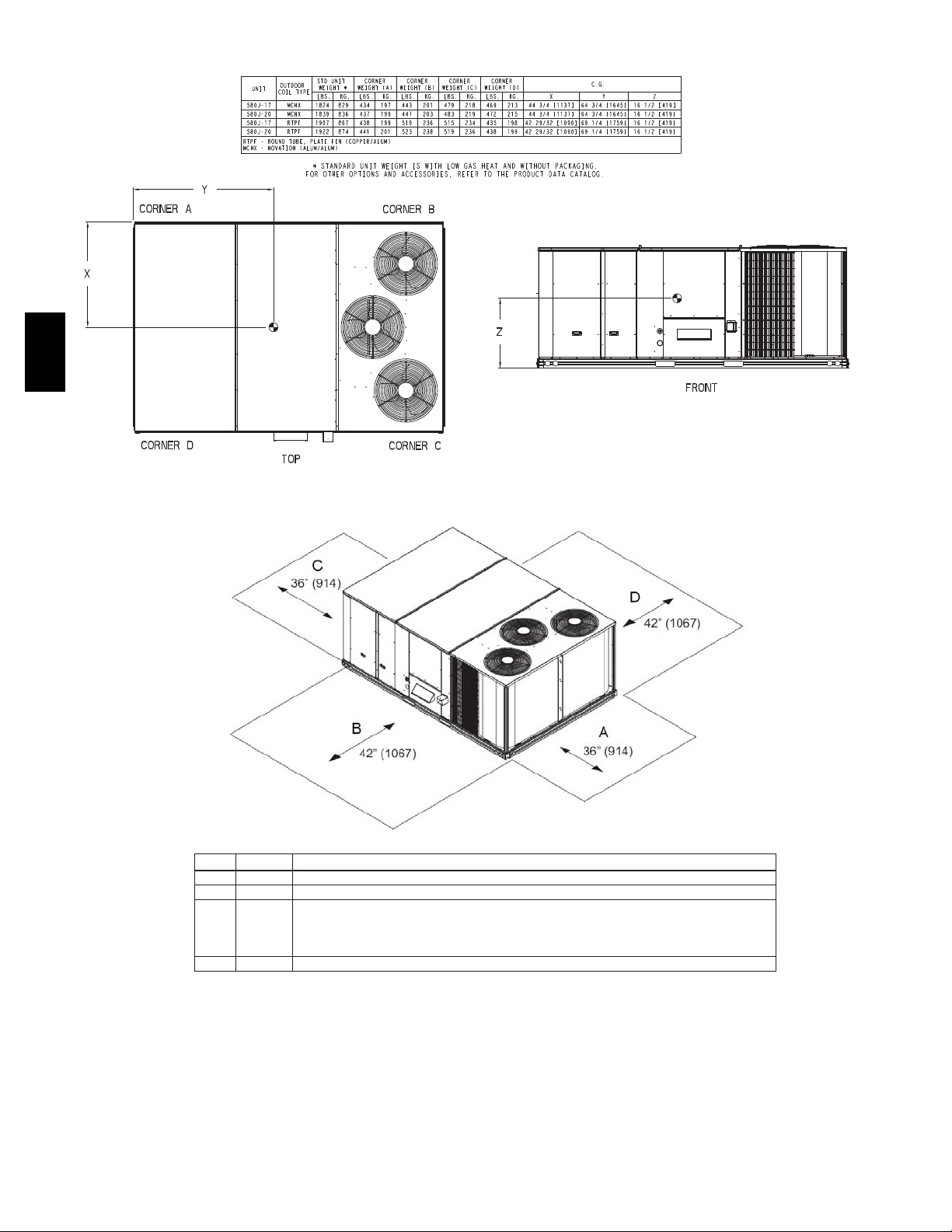

Fig. 4 -- Curb Dimensions 580J*D17 --20

17

C09052

Page 18

580J

DIMENSIONS (cont.)

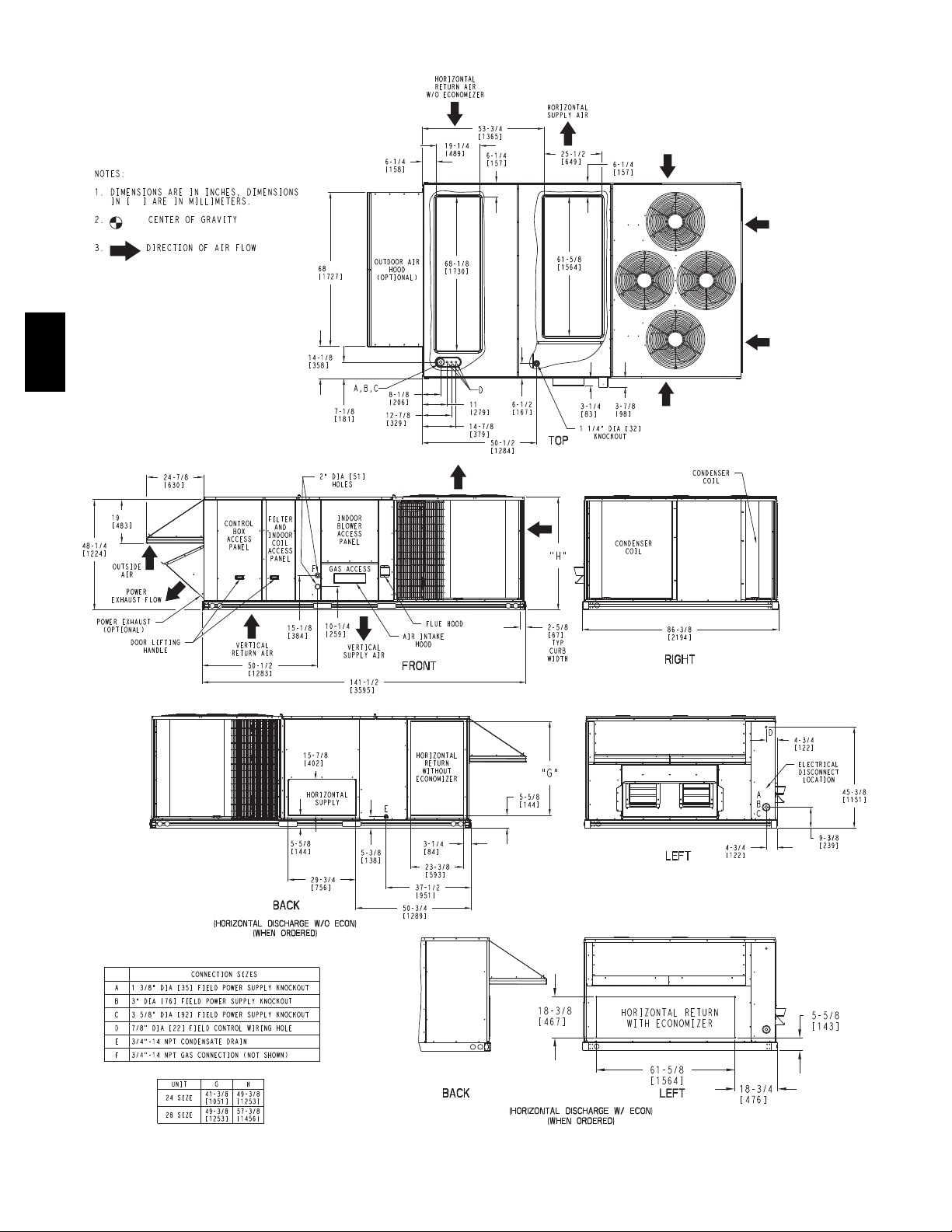

Fig. 5 -- Dimensions 580J*D24--28

18

C101039

Page 19

DIMENSIONS (cont.)

LOC

DIMENSION

CONDITION

A

36"

Recommended clearance for airflow and service.

B

42"

Recommended clearance for airflow and service.

C

18"

36"

42"

96"

D

42"

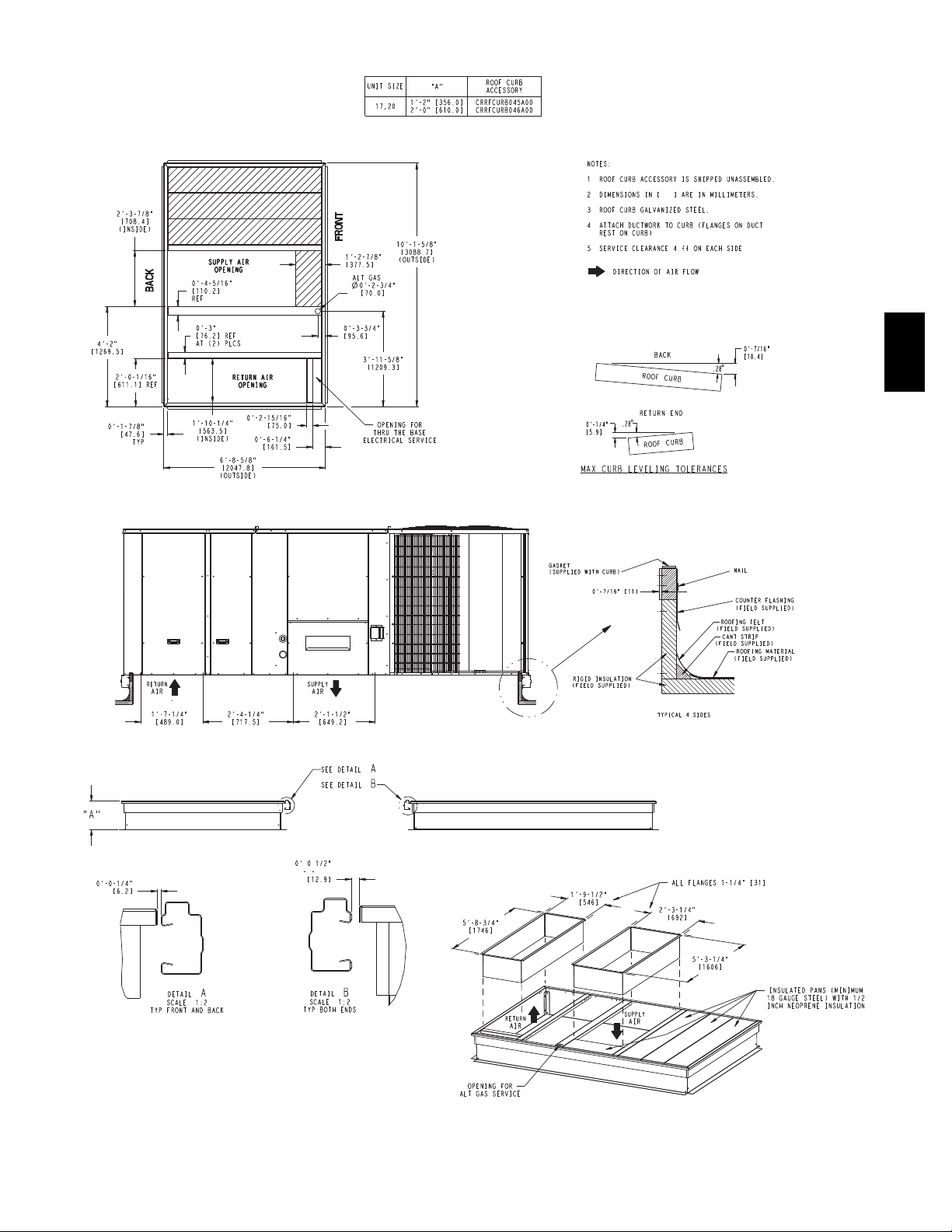

Fig. 6 -- 580JD24--28

580J

C101040B

1. No CO, 2. No Economizer, 3. No field installed disconnect on economizer hood side (Factory installed disconnect installed).

1. CO installed, 2. Vertical surface behind servicer is electrically non-c onductive (e.g., wood, fiberglas s).

1. CO installed, 2. Vertical surface behind servicer is electrically conductive (e.g., metal, masonry)

1. Economizer and/or Power E xhaust installed. 2. Check for sources of flue products within 10 f eet of economizer fresh air intake.

Recommended clearance for s ervice

C11001

Fig. 7 -- Service Clearance

19

Page 20

580J

DIMENSIONS (cont.)

Fig. 8 -- Curb Dimensions

20

C09100

Page 21

OPTIONS AND ACCESSORIES WEIGHT ADDERS

BASE UNIT WITH OPTIONS AND

ACCESSORIES

(Weight Adders)

Perfect Humidity

Base Unit Operating Weight 1907 865 1922 872 2072 940 2197 997

Power Exhaust 125 57 125 57 125 57 125 57

Economizer 170 77 170 77 170 77 195 88

Copper Tube/Fin Evaporator Coil 110 50 110 50 135 61 161 73

Low Gas Heat 85 39 85 39 85 39 85 39

Medium Gas Heat 90 41 90 41 90 41 90 41

High Gas Heat 113 51 113 51 113 51 113 51

Flue Discharge Deflector 7 3 7 3 7 3 7 3

Roof Curb 14 ---in (356mm) 240 109 240 109 240 109 240 109

Roof Curb 24 ---in (610mm) 340 154 340 154 340 154 340 154

Louvered Hail Guard 60 27 60 27 120 54 150 68

CO2sensor 5 2 5 2 5 2 5 2

Return Smoke Detector 5 2 5 2 5 2 5 2

Supply Smoke Detector 5 2 5 2 5 2 5 2

Fan/Filter Status Switch 2 1 2 1 2 1 2 1

Non --- Fused Disconnect 15 7 15 7 15 7 15 7

Powered Convenience Outlet 35 16 35 16 35 16 35 16

Non---Powered Convenience Outlet 5 2 5 2 5 2 5 2

Enthalpy Sensor 2 1 2 1 2 1 2 1

Differential Enthalpy Sensor 3 1 3 1 3 1 3 1

Two Position Motorized Damper 50 23 50 23 50 23 65 29

Manual Damper 35 16 35 16 35 16 40 18

Field Filter Track 4 ---in (102mm) 12 5 12 5 12 5 12 5

MotorMaster Controller 35 16 35 16 35 16 35 16

Standard Static Motor/Drive 0 0 0 0 0 0 0 0

Medium Static Motor/Drive 5 2 6 3 6 3 6 3

High Static Motor/Drive 11 5 12 5 16 7 16 7

Barometric Relief Hood (Horizontal) 25 11 25 11 25 11 25 11

1

For Perfect Humidity add MotorMaster Controller.

1

580J*17 580J*20 580J*24 580J*28

lb kg lb kg lb kg lb kg

83 38 83 38 83 38 92 42

MAX W EIGHT ADDER

580J

21

Page 22

APPLICATION/SELECTION DATA

Min operating ambient temp (cooling):

In mechanical cooling mode, your Bryant rooftop unit can

safely operate down to an outdoor ambient temperature of

30_F(--1_C). It is possible to provide cooling at lower

outdoor ambient temperatures by using less outside air,

economizers, and/or accessory low ambient kits.

Max operating ambient temp (cooling):

The maximum operating ambient temperature for cooling

mode is 115_F(46_C). While cooling operation above

115_F(46_C) may be possible, it could cause either a

reduction in performance, reliability, or a protective action

by the unit’s internal safety devices.

Min mixed air temp (heating):

580J

Using the factory settings, the minimum temperatures for

the mixed air (the combined temperature of the warm

return air and the cold outdoor air) entering the dimpled,

gas heat exchangers are:

Aluminized Stainless Steel

50_F(10_C) continuous

45_F(7_C) intermittent

Operating at lower mixed--air temperatures may be

possible, if a field--supplied, outdoor air thermostat

initiates both heat stages when the temperature is less than

the minimum temperatures listed above. Please contact

your local Bryant representative for assistance.

40_F(4_C) continuous

35_F(2_C) intermittent

Min and max airflow (heating and cooling):

To maint ain safe and reliable operation of your rooftop,

operate within the heating airflow limits during heating

mode and cooling airflow limits during cooling mode.

Operating above the max may cause blow--off, undesired

airflow noise, or airflow related problems with the rooftop

unit. Operating below the min may cause problems with

coil freeze--up and unsafe heating operation. Heating and

cooling limitations differ when evaluating operating CFM,

the minimum value is the HIGHER of the cooling and

heating minimum CFM values published in Table 5 and

the maximum value is the LOWER of the cooling and

heating minimum values published in Table 5.

Heating--to--cooling changeover:

Your unit will automatically change from heating to

cooling mode when using a thermostat with an

auto--change--over feature.

Airflow:

All units are draw--through in cooling mode and

blow--through in heating mode.

Outdoor air application strategies:

Economizers reduce operating expenses and compressor

run time by providing a free source of cooling and a

means of ventilation to match application changing needs.

In fact, they should be considered for most applications.

Also, consider the various economizer control methods

and their benefits, as well as sensors required to

accomplish your application goals. Please contact your

local Bryant representative for assistance.

Motor limits, break horsepower ( BHP) :

Due to internal design of Bryant units, the air path, and

specially designed motors, the f ull horsepower (maximum

continuous BHP) band, as listed in Physical Data Table

Cooling, can be used with the utmost confidence. There is

no need for extra safety factors, as Bryant motors are

designed and rigorously tested to use the entire, listed

BHP range without either nuisance tripping or premature

motor failure.

Propane heating:

Propane has different physical qualities than natural gas.

As a result, Propane requires different fuel to air mixture.

To optimize the fuel/air mixture for Propane, Bryant sells

different burner orifices in an easy to install accessory kit.

To select the correct burner orifices or determine the hea t

capacity for an Propane application, use either the

selection software, or the unit’s service manual.

High altitude heating:

High altitudes have less oxygen, which affects the fuel/air

mixture in heat exchangers. In order to maintain a proper

fuel/air mixture, heat exchangers operating in altitudes

above 2000 ft (610m) require different orifices. To select

the correct burner orifices or determine the heat capacity

for a high altitude application, use either the selection

software, or the unit’s service manual.

High altitudes have less oxygen, which means heat

exchangers need less fuel. The new gas orifices in this

field--installed kit make the necessary adjustment for high

altitude applications. They restore the optimal fuel to air

mixture and maintain healthy combustion on altitudes

above 2000 ft (610m).

NOTE: Typical natural gas heating value ranges from

975 to 1050 Btu/ft

value goes down approximately 1.7% per every thousand

feet elevation. Standard factory orifices can typically be

used up to 2000 ft (610m) elevation without any

operational issues.

NOTE: For installations in Canada, the input rating

should be derated by 10% for altitudes from 2000 ft

(610m) to 4500 ft (1372m) above sea level.

3

at sea level nationally. The heating

22

Page 23

APPLICATION/SELECTION DATA (cont.)

Sizing a rooftop

Bigger isn’t necessarily better. While an air conditioner

needs to have enough capacity to meet the design loads, it

doesn’t need excess capacity. In fact, excess capacity

typically results in very poor part load performance and

humidity control.

Using higher design temperatures than ASHRAE

recommends for your location, adding “safe ty factors” to

the calculated load, are all signs of oversizing air

conditioners. Oversizing the air conditioner leads to poor

humidity control, reduced efficiency, higher utility bills,

larger indoor temperature swings, excessive noise, and

increased wear and tear on the air conditioner.

Rather than oversizing an ai r conditioner, engineers

should “right--size” or even slightly undersize air

conditioners. Correctly sizing an air conditioner controls

humidity better; promotes efficiency; reduces utility bills;

extends equipment life, and maintains even, comfortable

temperatures. Please contact your local Bryant

representative for assistance.

Low ambient applications

The optional Bryant economizer can adequately cool your

space by bringing in fresh, cool outside air. In fact, when

so equipped, accessory low--ambient kit may not be

necessary. In low ambient conditions, unless the outdoor

air is excessively humid or contaminated,

economizer--based “free cooling” is the preferred less

costly and energy conscious method.

In low ambient applications where outside air might not

be desired (such as contaminated or excessively humid

outdoor environments), your Bryant rooftop can operate to

ambient temperatures down to -- 20_F(--29_C) using the

recommended accessory Motormaster low ambient

controller or down to 25_F(--4_C) with the field installed

Winter Start Package.

Application/Selection Option

Selection software by Bryant saves time by performing

many of the steps above. Contact your Bryant sales

representative for assistance.

580J

23

Page 24

Table 9 – COOLING CAPACITIES 2--Stage Cooling 15 TONS

AMBIENT TEMPERATURE

580J*17D

75 80 85 75 80 85 75 80 85 75 80 85

TC 159.6 159.1 163.4 148.7 148.4 155.2 136.1 137.1 146.0 122.4 127.2 136.2

58

SHC 132.6 149.6 163.4 127.0 143.9 155.2 120.7 137.1 146.0 113.9 127.2 136.2

TC 173.9 173.6 173.3 163.1 162.6 162.2 150.5 150.2 149.9 136.8 136.2 136.9

62

SHC 119.4 136.8 153.9 114.1 131.5 148.6 108.2 125.7 142.6 101.9 119.2 135.8

TC 193.4 193.0 192.5 182.5 182.1 181.7 169.9 169.5 169.1 156.0 155.5 155.2

67

SHC 102.3 119.7 137.0 97.3 114.8 132.3 91.7 109.4 126.9 85.7 103.5 121.1

580J

4500 CFM

5250 CFM

6000 CFM

6750 CFM

7500 CFM

EAT (wb)

EAT (wb)

EAT (wb)

EAT (wb)

EAT (wb)

TC 213.7 213.2 212.6 203.5 203.0 202.5 191.0 190.5 189.9 177.1 176.6 176.1

72

SHC 84.0 101.7 119.2 79.7 97.4 115.0 74.6 92.4 109.9 69.1 86.9 104.6

TC --- 227.8 228.5 --- 219.6 219.1 --- 207.9 207.4 --- 194.1 193.5

76

SHC --- 89.9 103.7 --- 82.5 100.2 --- 78.1 95.8 --- 73.0 97.2

TC 168.7 168.5 176.4 157.0 158.2 167.7 143.9 148.2 158.0 129.5 137.5 147.4

58

SHC 161.3 163.9 176.4 138.9 157.2 167.7 132.4 148.2 158.0 125.4 137.5 147.4

TC 184.2 183.8 183.2 172.3 171.8 171.5 159.1 158.5 159.3 144.4 143.8 147.8

62

SHC 129.4 149.6 168.9 123.9 144.0 163.5 117.9 137.9 156.4 111.4 131.3 147.8

TC 204.7 204.0 203.5 193.1 192.6 192.2 179.7 179.2 178.7 164.8 164.3 163.6

67

SHC 109.3 129.5 149.6 104.3 124.7 144.9 98.6 119.1 139.4 92.5 113.1 133.3

TC 224.6 224.1 223.6 214.4 213.7 213.1 202.0 201.4 200.7 187.0 186.4 185.8

72

SHC 87.5 107.9 128.2 83.4 103.9 124.3 78.6 99.2 119.6 72.9 93.6 114.1

TC --- 239.1 239.6 --- 230.6 230.1 --- 218.4 217.7 --- 204.4 203.7

76

SHC --- 92.6 110.2 --- 86.4 107.0 --- 82.0 102.6 --- 77.1 97.8

TC 176.9 178.5 188.9 164.3 168.9 179.6 150.3 158.4 169.1 136.1 146.9 157.7

58

SHC 157.4 178.5 188.9 151.1 168.9 179.6 144.3 158.4 169.1 136.1 146.9 157.7

TC 193.2 192.7 192.2 180.4 179.7 180.7 166.2 165.6 170.1 150.5 150.0 158.1

62

SHC 140.2 162.8 184.2 134.4 156.9 177.8 128.1 150.6 168.9 121.3 143.5 158.1

TC 214.4 213.7 213.0 202.1 201.6 201.0 187.7 187.1 186.4 171.8 171.1 170.4

67

SHC 117.3 140.3 163.0 112.1 135.3 158.2 106.2 129.4 152.2 99.8 123.1 145.9

TC 234.9 234.6 234.2 224.0 223.3 222.5 210.9 210.1 209.3 194.9 194.1 193.4

72

SHC 92.7 115.9 139.1 88.4 111.8 134.8 83.4 106.8 130.0 77.5 101.0 124.3

TC --- 250.7 250.9 --- 240.9 240.1 --- 227.5 226.7 --- 212.7 211.8

76

SHC --- 95.7 118.9 --- 92.1 115.3 --- 87.4 110.8 --- 82.4 105.8

TC 182.5 187.4 198.5 169.3 177.4 188.7 156.0 166.4 177.8 142.9 154.4 165.9

58

SHC 167.5 187.4 198.5 161.2 177.4 188.7 153.0 166.4 177.8 142.9 154.4 165.9

TC 199.3 198.7 199.6 186.0 185.2 188.9 171.2 170.5 208.4 154.7 155.5 166.2

62

SHC 148.6 173.7 196.6 142.8 167.6 188.9 136.4 161.1 208.4 115.2 152.6 166.2

TC 220.4 219.6 218.8 208.2 207.4 206.6 193.2 192.5 191.7 176.8 176.1 175.2

67

SHC 122.6 148.2 173.6 117.6 143.4 168.7 111.6 137.6 162.9 97.2 131.3 156.3

TC 241.2 240.5 240.2 229.8 228.9 228.1 216.3 215.4 214.6 200.2 199.4 198.6

72

SHC 95.1 120.9 146.6 90.8 116.8 142.6 85.8 111.9 137.8 80.0 106.2 118.0

TC --- 257.2 256.7 --- 246.6 245.9 --- 233.0 232.1 --- 217.6 216.7

76

SHC --- 98.4 124.2 --- 94.8 120.7 --- 90.2 116.3 --- 85.1 111.3

TC 187.3 195.3 206.8 174.4 184.9 196.8 161.5 173.5 185.5 148.9 161.1 173.2

58

SHC 177.5 195.3 206.8 169.9 184.9 196.8 161.5 173.5 185.5 148.9 161.1 173.2

TC 204.3 203.5 207.1 190.6 189.9 197.1 175.1 175.4 185.7 158.4 161.2 173.5

62

SHC 156.5 183.9 207.1 150.7 177.9 197.1 144.1 170.2 185.7 137.1 161.2 173.5

TC 225.2 224.4 223.4 213.1 212.2 211.3 197.8 197.0 196.2 180.8 179.9 179.1

67

SHC 127.5 155.8 183.5 122.8 151.2 178.9 116.8 145.5 173.1 110.3 139.0 166.3

TC 246.1 245.5 244.9 234.5 233.6 232.8 220.6 219.7 218.6 204.7 203.7 202.7

72

SHC 97.1 125.6 153.8 92.9 121.6 150.1 87.9 116.8 145.3 82.3 111.2 139.9

TC --- 262.3 261.6 --- 251.3 250.5 --- 237.3 236.3 --- 221.6 220.6

76

SHC --- 100.9 129.2 --- 97.3 125.8 --- 92.8 121.5 --- 87.7 116.6

LEGEND:

--- --- D o n o t o p er a t e

Cfm --- Cubic feet per minute (supply air)

EAT(db) --- Entering air temperature (dry bulb)

EAT(wb) --- Entering air temperature (wet bulb)

SHC --- Sensible heat capacity

TC --- Total capacity

85 95 105 115

EAT (db) EAT (db) EAT (db) EAT (db)

24

Page 25

Table 10 – COOLING CAPACITIES 2--Stage Cooling 15 TONS (con’t)

580J017 (15 TONS) --- UNIT WITH PERFECT HUMIDITY IN SUBCOOLING MODE

AIR ENTERING EVAPORATOR --- CFM/BF

Tem p (F) A ir E n t

Condenser (Edb)

72 67 62 72 67 62 72 67 62

TC 208.5 190.6 172.6 229.2 208.6 188.1 247.8 224.9 202.0

75

SHC 94.0 114.5 135.0 104.5 125.2 145.9 113.0 133.8 154.6

kW 13.42 13.05 12.70 13.60 13.21 12.80 13.82 13.36 13.15

TC 198.3 180.7 163.0 214.9 194.8 174.6 229.8 207.4 185.1

85

SHC 74.1 99.6 125.1 85.2 110.9 136.7 94.1 120.0 145.9

kW 14.79 14.42 14.10 14.97 14.58 14.20 15.19 14.73 14.51

TC 188.2 170.8 153.4 200.6 180.9 161.1 211.9 190.0 168.1

95

SHC 54.4 84.8 115.3 65.9 96.7 127.5 75.1 106.2 137.2

kW 16.23 15.86 15.50 16.41 16.02 15.60 16.63 16.17 15.95

TC 178.1 160.9 143.8 186.4 167.0 147.7 193.9 172.5 151.2

105

SHC 34.6 70.0 105.4 46.5 82.4 118.2 56.1 92.3 128.5

kW 17.47 17.10 16.80 17.65 17.26 16.90 17.87 17.41 17.25

TC 167.9 151.1 134.2 172.1 153.2 134.2 175.9 155.1 134.5

115

SHC 14.8 55.2 95.6 27.2 68.1 109.0 37.1 78.5 119.8

kW 18.87 18.50 18.20 19.05 18.66 18.30 19.27 18.81 18.55

580J017 (15 TONS) --- UNIT WITH PERFECT HUMIDITY IN HOT GAS REH EAT MODE

Tem p (F) A ir E n t

Condenser (Edb)

4,500 6,000 7,500 4,500 6,000 7,500 4,500 6,000 7,500

TC 80.10 85.50 91.30 82.70 90.90 97.10 86.00 95.40 100.50

80

SHC 12.70 22.30 34.20 5.10 12.10 21.20 ---2.10 4.20 10.50

kW 12.44 12.67 12.78 12.55 12.88 13.10 12.65 13.02 13.12

TC 82.30 87.60 93.40 84.70 93.00 99.20 88.10 97.30 102.50

75

SHC 14.30 24.20 36.00 6.70 13.70 23.10 ---0.50 5.80 12.60

kW 12.38 12.62 12.73 12.50 12.83 13.05 12.62 12.98 13.07

TC 84.40 89.60 94.70 87.00 95.10 101.30 90.30 99.50 104.60

70

SHC 16.10 25.70 37.30 8.20 15.80 24.50 1.10 7.50 13.70

kW 12.34 12.58 12.69 12.47 12.78 13.03 12.59 12.93 13.02

TC 88.50 93.90 99.80 91.20 99.40 105.50 94.40 103.70 108.90

60

SHC 19.40 29.20 40.70 11.50 18.60 27.80 4.60 10.50 16.90

kW 12.28 12.52 12.63 12.41 12.73 12.97 12.53 12.84 12.94

TC 92.80 98.10 104.80 95.40 103.60 110.50 98.80 108.00 113.90

50

SHC 22.70 32.20 43.80 14.80 22.10 31.30 7.70 13.90 20.50

kW 12.21 12.45 12.56 12.34 12.68 12.91 12.46 12.75 12.85

TC 97.10 102.50 108.50 99.60 108.00 114.30 103.00 112.40 117.70

40

SHC 26.00 35.40 46.90 17.90 25.30 34.40 10.80 17.10 23.80

kW 12.14 12.38 12.49 12.27 12.60 12.84 12.40 12.70 12.80

LEGEND

Edb --- E n t e r i n g D r y --- B u l b

Ewb --- E n t e r i n g W e t --- B u l b

kW --- Compressor Motor Power Input

Idb --- L e a v i n g D r y --- B u l b

Iwb --- L e a v i n g W e t --- B u l b

SHC --- Sensible Heat Capacity (1000 Btuh) Gross

TC --- Total Capacity (1000 Btuh) Gross

4,500 6,000 7,500

A i r E n t e r i n g E v a p o r a t o r --- --- E w b ( F )

AIR ENTERING EVAPORATOR --- Ewb (F)

75 Dry Bulb 75 Dry Bulb 75 Dry Bulb

62.5 Wet Bulb 64 Wet Bulb 65.3 Wet Bulb

(50% Relative) (56% Relative) (60% Relative)

A i r E n t e r i n g E v a p o r a t o r --- C f m

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

t

ldb=tedb

t

= Wet ---bulb temperature corresponding to enthalpy of air

lwb

leaving evaporator coil (h

h

lwb=hewb

Where: h

sensible capacity (Btuh)

–

–

= Enthalpy of air entering evaporator coil

ewb

1.10 x cfm

)

lwb

total capacity (Btuh)

4.5 x cfm

580J

25

Page 26

Table 11 – COOLING CAPACITIES 2--Stage Cooling 17.5 TONS

AMBIENT TEMPERATURE

580J*20D

75 80 85 75 80 85 75 80 85 75 80 85

TC 180.4 185.6 196.3 167.7 176.1 186.9 154.7 165.3 176.6 142.2 153.6 164.9

58

SHC 166.5 185.6 196.3 160.6 176.1 186.9 152.7 165.3 176.6 142.2 153.6 164.9

TC 196.2 195.5 196.9 183.6 182.9 187.2 169.3 168.7 176.9 153.4 154.1 165.2

62

SHC 146.8 172.1 194.7 141.4 166.6 187.2 135.4 160.5 176.9 128.6 152.5 165.2

TC 216.7 215.9 215.2 204.9 204.1 203.1 190.6 189.7 189.0 174.8 174.0 173.3

67

SHC 120.0 146.1 171.8 115.4 141.5 167.1 109.8 136.1 161.7 103.8 130.2 155.6

580J

5250 CFM

6125 CFM

7000 CFM

7875 CFM

8750 CFM

EAT (wb)

EAT (wb)

EAT (wb)

EAT (wb)

EAT (wb)

TC 237.4 236.8 236.0 226.0 225.1 224.2 212.8 211.9 211.0 197.3 196.4 195.5

72

SHC 92.0 118.3 144.3 87.8 114.3 140.4 83.0 109.6 135.8 77.6 104.2 130.6

TC --- 252.9 253.0 --- 242.5 241.6 --- 229.1 228.2 --- 214.1 213.1

76

SHC --- 95.1 121.4 --- 91.7 118.0 --- 87.3 113.8 --- 82.5 107.1

TC 188.8 198.5 209.3 176.5 188.2 200.2 164.5 176.7 189.0 151.9 164.2 176.7

58

SHC 180.4 198.5 209.3 174.4 188.2 200.2 164.5 176.7 189.0 151.9 164.2 176.7

TC 205.2 204.6 209.6 191.8 191.5 200.4 176.6 177.6 189.2 159.9 164.2 176.9

62

SHC 159.9 188.7 209.6 154.2 183.0 200.4 147.9 174.8 189.2 141.0 164.2 176.9

TC 225.5 224.5 223.5 213.5 212.5 211.7 199.1 198.3 197.4 182.3 181.4 180.9

67

SHC 128.3 158.4 187.8 123.8 154.1 183.5 118.4 148.9 178.1 112.2 142.7 171.6

TC 245.6 245.3 244.6 234.7 233.6 232.6 220.9 219.9 218.8 205.5 204.4 203.4

72

SHC 95.4 125.9 155.7 91.7 122.2 152.4 86.9 117.7 148.1 81.7 112.5 143.1

TC --- 262.0 261.2 --- 250.7 250.1 --- 237.3 236.2 --- 221.6 220.6

76

SHC --- 99.5 129.4 --- 95.9 126.2 --- 91.8 122.4 --- 87.0 117.8

TC 197.4 209.8 221.3 186.1 199.1 211.7 173.8 186.9 200.1 160.3 173.5 186.9

58

SHC 196.8 209.8 221.3 186.1 199.1 211.7 173.8 186.9 200.1 160.3 173.5 186.9

TC 212.7 212.4 221.5 198.4 199.8 212.0 182.3 186.9 200.3 164.7 173.8 187.1

62

SHC 173.4 205.1 221.5 167.4 197.4 212.0 160.8 186.8 200.3 153.4 173.8 187.1

TC 233.7 232.5 231.4 220.8 219.8 218.9 205.6 204.5 204.1 187.8 186.8 188.0

67

SHC 138.0 172.0 205.0 133.4 167.6 200.4 127.8 162.0 194.4 121.3 155.6 185.6

TC 254.3 253.3 252.8 242.7 241.5 240.3 228.0 226.8 225.7 211.8 210.6 209.3

72

SHC 101.3 135.4 169.2 97.3 131.8 165.9 92.3 127.2 161.5 86.9 121.8 156.3

TC --- 270.7 269.9 --- 259.0 258.1 --- 245.0 243.6 --- 228.5 227.1

76

SHC --- 106.1 140.0 --- 102.4 136.5 --- 98.2 132.7 --- 93.2 127.9

TC 205.0 217.2 229.1 193.4 206.9 219.3 180.6 194.3 207.9 166.6 180.5 194.5

58

SHC 205.0 217.2 229.1 193.4 206.9 219.3 180.6 194.3 207.9 166.6 180.5 194.5

TC 216.7 217.4 229.4 202.5 207.1 219.6 185.9 194.5 208.4 168.4 180.7 194.7

62

SHC 183.9 217.4 229.4 178.2 207.1 219.6 171.5 194.5 208.4 141.2 180.7 194.7

TC 237.8 236.7 235.7 224.7 223.5 223.0 209.5 208.3 209.2 191.5 190.3 195.0

67

SHC 144.6 182.4 219.3 140.3 178.2 213.7 134.9 172.7 205.9 113.6 166.2 195.0

TC 258.6 257.5 256.5 246.8 245.7 244.3 231.8 230.5 229.2 215.3 213.9 212.5

72

SHC 103.9 141.8 179.2 100.0 138.3 176.1 95.1 133.9 172.1 89.7 128.6 142.0

TC --- 275.4 274.2 --- 262.7 261.8 --- 248.7 247.6 --- 231.9 230.5

76

SHC --- 109.5 147.0 --- 105.7 143.6 --- 101.5 139.9 --- 96.6 135.4

TC 211.3 223.6 235.9 199.7 213.4 225.7 186.4 200.7 214.3 172.1 186.5 200.9

58

SHC 211.3 223.6 235.9 199.7 213.4 225.7 186.4 200.7 214.3 172.1 186.5 200.9

TC 220.0 223.7 236.3 206.0 213.6 226.1 189.3 200.9 214.5 172.2 186.7 201.2

62

SHC 194.0 223.7 236.3 188.5 213.6 226.1 181.3 200.9 214.5 172.2 186.7 201.2

TC 241.1 240.1 239.7 227.9 226.6 226.9 212.7 211.4 214.9 194.4 193.0 201.4

67

SHC 151.0 192.1 230.2 146.9 188.3 225.2 141.6 182.9 214.8 135.3 176.3 201.4

TC 262.2 261.0 259.7 250.0 248.8 247.7 235.0 233.5 232.1 218.1 216.6 215.2

72

SHC 106.5 148.1 189.0 102.5 144.5 186.0 97.8 140.4 182.1 92.4 135.3 177.1

TC --- 278.9 277.4 --- 266.0 264.8 --- 251.5 250.6 --- 234.7 233.0

76

SHC --- 112.7 153.7 --- 108.9 150.4 --- 104.7 146.7 --- 100.0 142.4

LEGEND:

--- --- D o n o t o p er a t e

Cfm --- Cubic feet per minute (supply air)

EAT(db) --- Entering air temperature (dry bulb)

EAT(wb) --- Entering air temperature (wet bulb)

SHC --- Sensible heat capacity

TC --- Total capacity

85 95 105 115

EAT (db) EAT (db) EAT (db) EAT (db)

26

Page 27

Table 12 – COOLING CAPACITIES 2--Stage Cooling 17.5 TONS (con’t)

580J020 (17.5 TONS) --- UNIT WITH PERFECT HUMIDITY IN SUBCOOLING MODE

AIR ENTERING EVAPORATOR --- CFM/BF

Tem p (F) A ir E n t

Condenser (Edb)

72 67 62 72 67 62 72 67 62

TC 218.7 199.6 180.5 241.4 219.4 197.4 261.7 237.2 212.7

75

SHC 99.9 123.9 147.8 112.7 136.9 161.1 122.9 147.3 171.7

kW 11.81 11.56 11.20 13.81 13.48 13.16 14.82 14.58 14.16

TC 206.6 187.9 169.1 224.9 203.4 181.9 241.3 217.3 193.4

85

SHC 78.9 108.4 137.9 92.2 122.1 152.0 103.0 133.1 163.3

kW 13.18 12.53 12.53 15.18 14.85 14.52 16.21 15.85 15.54

TC 194.7 176.2 157.8 208.4 187.4 166.4 220.8 197.4 174.1

95

SHC 57.8 92.9 128.0 71.7 107.3 142.9 83.0 118.9 154.9

kW 14.56 14.21 13.88 16.56 16.21 15.87 17.56 17.22 16.01

TC 182.7 164.5 146.4 191.9 171.4 150.8 200.3 177.6 154.8

105

SHC 36.8 77.4 118.1 51.3 92.5 133.8 63.0 104.7 146.4

kW 15.93 15.58 15.20 17.94 17.58 17.22 18.95 18.59 18.24

TC 170.6 152.8 135.0 175.4 155.4 135.3 179.8 157.7 135.5

115

SHC 15.7 62.0 108.2 30.8 77.8 124.7 43.0 90.5 128.0

kW 17.31 16.95 16.58 19.32 18.95 18.58 20.32 19.96 19.59

580J020 (17.5 TONS) --- UNIT WITH PERFECT HUMIDITY IN HOT GAS REHEAT MODE

Tem p (F) A ir E n t

Condenser (Edb)

5,250 7,000 8,750 5,250 7,000 8,750 5,250 7,000 8,750

TC 82.20 90.50 92.40 86.70 96.40 97.80 91.60 99.80 101.20

80

SHC 18.20 29.40 41.60 8.60 17.20 27.50 0.50 9.30 13.20

kW 12.64 12.73 12.88 12.78 13.06 13.15 12.96 13.07 13.22

TC 84.40 92.70 94.40 88.80 98.60 99.70 93.70 102.00 103.40

75

SHC 19.70 31.30 43.50 10.10 18.80 29.20 12.10 10.80 15.30

kW 12.60 12.71 12.85 12.75 13.02 13.12 12.93 13.03 13.19

TC 86.70 94.90 96.60 91.00 100.70 102.00 95.90 104.10 105.40

70

SHC 21.30 32.80 44.80 11.60 20.40 30.70 3.80 12.30 16.50

kW 12.56 12.66 12.82 12.70 12.99 13.08 12.89 13.00 13.14

TC 90.90 99.10 100.80 95.20 105.00 106.30 100.20 108.30 109.70

60

SHC 24.80 36.00 48.20 14.90 23.90 35.90 7.20 15.60 19.60

kW 12.49 12.60 12.75 12.64 12.92 13.02 12.83 12.93 13.09

TC 95.00 103.40 105.10 99.50 109.40 110.50 104.40 112.50 113.90

50

SHC 28.10 39.30 51.30 18.20 27.20 37.40 10.30 18.90 23.20

kW 12.43 12.53 12.67 12.57 12.86 12.95 12.76 12.87 13.02

TC 99.20 107.70 109.30 103.70 113.70 114.70 108.60 116.70 118.10

40

SHC 31.40 42.50 54.40 21.30 30.40 40.50 13.40 22.00 26.50

kW 12.35 12.45 12.61 12.50 12.79 12.87 12.68 12.80 12.94

LEGEND

Edb --- E n t e r i n g D r y --- B u l b

Ewb --- E n t e r i n g W e t --- B u l b

kW --- Compressor Motor Power Input

Idb --- L e a v i n g D r y --- B u l b

Iwb --- L e a v i n g W e t --- B u l b

SHC --- Sensible Heat Capacity (1000 Btuh) Gross

TC --- Total Capacity (1000 Btuh) Gross

5,250 7,000 8,750

A i r E n t e r i n g E v a p o r a t o r --- --- E w b ( F )

AIR ENTERING EVAPORATOR --- Ewb (F)

75 Dry Bulb 75 Dry Bulb 75 Dry Bulb

62.5 Wet Bulb 64 Wet Bulb 65.3 Wet Bulb

(50% Relative) (56% Relative) (60% Relative)

A i r E n t e r i n g E v a p o r a t o r --- C f m

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

t

ldb=tedb

t

= Wet ---bulb temperature corresponding to enthalpy of air

lwb

leaving evaporator coil (h

h

lwb=hewb

Where: h

sensible capacity (Btuh)

–

–

= Enthalpy of air entering evaporator coil

ewb

1.10 x cfm

)

lwb

total capacity (Btuh)

4.5 x cfm

580J

27

Page 28

Table 13 – COOLING CAPACITIES 2--Stage Cooling 20 TONS

AMBIENT TEMPERATURE

580J*24D

75 80 85 75 80 85 75 80 85 75 80 85

TC 213.1 217.2 228.7 199.9 207.5 219.4 184.8 195.8 208.4 169.6 182.6 195.6

58

SHC 194.3 217.2 228.7 188.0 207.5 219.4 179.0 195.8 208.4 169.6 182.6 195.6

TC 230.0 229.4 230.4 217.5 217.0 219.7 202.5 201.9 208.8 184.9 184.9 195.9

62

SHC 170.0 199.9 225.9 164.6 194.5 219.7 158.3 187.8 208.8 150.9 178.7 195.9

TC 251.5 251.1 250.6 239.4 238.7 238.1 225.4 224.7 224.0 208.8 208.2 207.4

67

SHC 137.5 168.1 198.4 132.9 163.4 193.7 127.5 158.1 188.2 121.1 151.9 181.9

580J

6000 CFM

7000 CFM

8000 CFM

9000 CFM

10,000 CFM

EAT (wb)

EAT (wb)

EAT (wb)

EAT (wb)

EAT (wb)

TC 274.0 273.8 273.5 262.3 261.7 261.0 248.2 247.4 246.6 232.2 231.3 230.5

72

SHC 104.3 135.1 165.6 100.1 130.9 161.4 95.1 125.9 156.6 89.6 120.5 151.3

TC --- 292.9 292.2 --- 280.5 279.9 --- 266.3 265.6 --- 250.6 249.8

76

SHC --- 108.1 138.6 --- 104.1 134.9 --- 99.6 130.4 --- 94.6 125.5

TC 220.8 229.7 241.7 208.4 219.7 232.2 194.3 208.1 221.0 180.1 194.2 207.9

58

SHC 211.0 229.7 241.7 203.1 219.7 232.2 194.3 208.1 221.0 180.1 194.2 207.9

TC 237.8 237.3 241.9 225.1 224.6 232.3 209.6 210.2 221.3 191.3 196.0 208.2

62

SHC 183.3 217.8 241.9 178.2 212.1 232.3 171.8 203.8 221.3 164.3 196.0 208.2

TC 260.0 259.2 258.5 247.2 246.4 245.7 232.7 231.9 231.7 215.8 215.0 214.3

67

SHC 146.0 181.0 215.7 141.3 176.5 211.2 136.0 171.3 206.3 129.8 165.3 199.4

TC 283.3 282.5 281.8 270.6 269.8 268.9 255.9 255.0 254.1 240.0 238.9 238.0

72

SHC 107.9 143.2 178.1 103.6 139.0 174.1 98.6 134.2 169.5 93.2 129.0 164.4

TC --- 302.3 301.6 --- 289.1 288.4 --- 274.4 273.6 --- 257.9 256.8

76

SHC --- 112.3 147.5 --- 108.3 143.7 --- 103.9 139.4 --- 98.9 134.5

TC 232.1 243.6 256.1 219.8 233.4 246.0 206.9 221.3 234.5 192.1 206.8 221.2

58

SHC 227.5 243.6 256.1 219.8 233.4 246.0 206.9 221.3 234.5 192.1 206.8 221.2

TC 247.8 247.1 256.4 234.7 235.5 246.2 218.7 221.1 234.7 199.5 207.0 221.4

62

SHC 199.5 236.7 256.4 194.3 229.1 246.2 187.8 221.1 234.7 179.9 207.0 221.4

TC 270.2 269.3 268.3 257.0 256.1 255.2 242.1 241.0 240.3 224.5 223.5 223.1

67

SHC 157.6 197.1 235.6 152.7 192.6 231.0 147.3 187.2 225.3 141.0 181.0 215.6

TC 294.1 293.1 292.2 280.7 279.7 278.4 265.9 264.7 263.8 248.9 247.6 246.6

72

SHC 114.8 154.6 193.9 110.3 150.4 190.0 105.4 145.6 185.5 99.7 140.1 180.2

TC --- 313.1 312.3 --- 299.3 298.2 --- 283.8 282.8 --- 266.7 265.4

76

SHC --- 120.2 159.6 --- 116.0 155.9 --- 111.4 151.5 --- 106.2 146.6

TC 238.5 252.5 266.0 226.8 241.6 255.6 213.1 228.2 243.0 197.5 213.0 229.2

58

SHC 238.5 252.5 266.0 226.8 241.6 255.6 213.1 228.2 243.0 197.5 213.0 229.2

TC 253.0 254.1 266.3 238.6 241.6 255.7 221.0 228.4 243.3 201.1 213.2 229.4

62

SHC 211.9 249.1 266.3 206.2 241.6 255.7 199.2 228.4 243.3 164.2 213.2 229.4

TC 276.9 275.8 274.8 263.0 261.8 261.0 246.5 245.2 246.6 228.2 225.9 229.6

67

SHC 165.6 209.9 252.2 160.7 205.1 247.0 154.9 199.3 238.5 132.3 192.7 229.6

TC 302.2 301.0 299.7 287.9 286.6 285.4 272.3 270.9 269.6 254.3 252.9 251.6

72

SHC 118.2 162.8 206.8 113.5 158.4 202.9 108.5 153.4 198.0 102.7 147.8 165.1

TC --- 322.0 320.8 --- 307.7 306.1 --- 291.4 289.9 --- 275.1 272.5

76

SHC --- 124.5 168.7 --- 120.4 164.9 --- 115.6 160.5 --- 110.9 155.3

TC 245.7 259.8 273.9 233.8 248.7 263.2 219.8 235.3 250.5 203.7 219.8 236.5

58

SHC 245.7 259.8 273.9 233.8 248.7 263.2 219.8 235.3 250.5 203.7 219.8 236.5

TC 256.8 260.7 274.2 242.2 249.0 263.3 224.6 235.6 250.6 205.6 220.0 236.8

62

SHC 223.8 258.4 274.2 218.1 249.0 263.3 211.0 235.6 250.6 199.3 220.0 236.8

TC 280.8 279.6 266.3 266.6 265.4 265.8 249.9 248.6 251.0 231.4 229.8 237.3

67

SHC 173.2 221.8 266.3 168.3 217.0 258.7 162.6 211.4 250.7 156.4 204.7 237.3

TC 306.4 305.0 274.8 292.1 290.6 289.3 276.0 274.3 273.0 257.5 256.0 254.6

72

SHC 121.2 170.1 252.2 116.6 165.9 214.8 111.5 161.0 210.0 105.7 155.4 204.5

TC --- 326.2 299.7 --- 311.4 310.0 --- 295.2 293.2 --- 277.0 275.3

76

SHC --- 128.2 206.8 --- 124.0 172.9 --- 119.5 168.9 --- 114.3 163.8

LEGEND:

--- --- D o n o t o p er a t e

Cfm --- Cubic feet per minute (supply air)

EAT(db) --- Entering air temperature (dry bulb)

EAT(wb) --- Entering air temperature (wet bulb)

SHC --- Sensible heat capacity

TC --- Total capacity

85 95 105 115

EA (db) EA (db) EA (db) EA (db)

28

Page 29

Table 14 – COOLING CAPACITIES 2--Stage Cooling 20 TONS (con’t)

580J024 (20 TONS) --- UNIT WITH PERFECT HUMIDITY IN SUBCOOLING MODE

AIR ENTERING EVAPORATOR --- CFM/BF

Tem p (F) A ir E n t

Condenser (Edb)

72 67 62 72 67 62 72 67 62

TC 263.0 240.4 217.7 301.0 274.0 246.9 336.9 305.6 274.4

75

SHC 125.3 151.6 178.0 144.4 171.1 198.0 160.0 186.9 213.9

kW 15.63 15.20 14.65 15.91 15.62 14.98 16.26 15.92 15.21

TC 248.2 226.1 204.0 279.2 252.9 226.6 308.4 278.2 248.0

85

SHC 98.9 131.7 164.5 118.6 152.0 185.3 134.6 168.4 202.2

kW 17.50 17.04 16.50 17.74 17.51 16.75 18.08 17.73 17.03

TC 233.4 211.8 190.2 257.3 231.8 206.4 279.8 250.7 221.5

95

SHC 72.4 111.8 151.1 92.7 132.8 172.9 109.3 149.9 190.6

kW 19.36 18.96 18.35 19.61 19.37 18.67 20.02 19.62 18.97

TC 218.6 197.5 176.5 235.4 210.7 186.1 251.3 223.2 195.1

105

SHC 46.0 91.8 137.7 66.9 113.6 160.4 83.9 131.4 178.9

kW 21.23 20.76 20.18 21.53 21.22 20.52 21.91 21.52 20.77

TC 203.7 183.3 162.8 213.5 189.7 165.8 222.7 195.7 168.7

115

SHC 19.5 71.9 124.2 41.0 94.4 147.9 58.5 112.9 157.2

kW 23.02 22.58 22.02 23.42 23.02 22.38 23.73 23.41 22.57

580J024 (20 T ONS) --- UNIT WITH Perfect Humidity IN HOT GAS REHEAT MODE

Tem p (F) A ir E n t

Condenser (Edb)

6,000 8,000 10,000 6,000 8,000 10,000 6,000 8,000 10,000

TC 91.50 100.80 109.50 95.80 105.70 112.40 102.30 110.80 118.60

80

SHC 12.30 31.20 44.50 0.90 15.10 25.70 ---6.50 3.60 13.90

kW 14.82 15.01 15.24 15.35 15.45 15.52 15.56 15.65 15.73

TC 94.00 103.40 112.00 98.70 108.10 115.10 104.70 113.10 121.10

75

SHC 13.60 32.40 45.70 2.00 16.00 26.60 ---5.60 4.70 15.10

kW 14.90 15.07 15.33 15.43 15.56 15.64 15.69 15.77 15.85

TC 96.50 106.00 114.30 100.90 110.60 117.20 107.20 115.80 123.50

70

SHC 14.50 33.20 45.70 3.30 17.30 28.00 ---4.00 5.90 16.20

kW 14.97 15.17 15.41 15.50 15.66 15.75 15.80 15.87 15.94

TC 101.80 111.30 119.30 106.20 115.60 122.20 112.60 119.40 128.00

60

SHC 16.70 35.50 48.60 5.60 19.40 30.30 ---1.80 8.20 18.50

kW 15.14 15.32 15.58 15.66 15.88 15.97 16.05 16.10 16.19

TC 107.20 116.40 124.30 111.50 120.70 127.30 117.70 125.20 132.90

50

SHC 18.60 37.60 50.70 8.00 22.00 32.70 0.50 10.50 21.00

kW 15.27 15.46 15.76 15.81 16.10 16.23 16.27 16.34 16.41

TC 112.20 121.80 129.20 116.60 125.70 132.00 123.20 130.00 138.00

40

SHC 21.80 39.50 52.90 10.20 24.40 35.20 2.90 13.00 23.40

kW 15.42 15.63 15.93 15.96 16.32 16.44 16.52 16.57 16.65

LEGEND

Edb --- E n t e r i n g D r y --- B u l b

Ewb --- E n t e r i n g W e t --- B u l b

kW --- Compressor Motor Power Input

Idb --- L e a v i n g D r y --- B u l b

Iwb --- L e a v i n g W e t --- B u l b