Page 1

installation, start-up and

service instructions

SINGLE PACKAGE ROOFTOP

ELECTRIC COOLING/GAS HEATING UNITS

Cancels: II 580G,H-240-1 II 580G,H-240-2

580G,H

Sizes 240-360

11/1/97

CONTENTS

Page

SAFETY CONSIDERATIONS ...................... 1

INSTALLATION ................................ 2-20

I. Provide Unit Support ...................... 2

II. Rig and Place Unit ........................ 2

III. Field Fabricate Ductwork ................... 7

IV. Unit Duct Connections ..................... 7

V. Flue Hood ................................ 8

VI. Trap Condensate Drain ..................... 8

VII. Gas Piping ............................... 8

VIII. Electrical Connections ..................... 9

IX. Outdoor-Air Inlet Assembly ................ 14

X. Power Exhaust/Barometric Relief

Damper Hood ........................... 18

XI. Accessories ............................ 19

PRE-START-UP ................................20,21

START-UP ....................................21-28

I. Cooling Section Start-Up and

Adjustments ............................ 21

II. Heating Section Start-Up and

Adjustments ............................ 22

III. Field Test Operation ...................... 24

IV. Indoor Airflow and Airflow

Adjustments ............................ 24

V. Gas Valve Adjustment .................... 25

VI. Main Burners ........................... 28

VII. Power Exhaust Operation .................. 28

VIII. Head Pressure Control ................... 28

IX. Low Ambient Kit ......................... 28

CARE AND MAINTENANCE ..................... 28

SERVICE .....................................29-32

I. Cleaning ............................... 29

II. Lubrication ............................. 29

III. Evaporator Fan Service and

Replacement ............................ 31

IV. Evaporator-Fan Motor Replacement ........ 31

V. Power Failure ........................... 31

VI. Refrigerant Charge ....................... 31

VII. Filter Drier .............................. 32

VIII. Thermostatic Expansion Valve (TXV) ........ 32

IX. Protective Devices ....................... 32

X. Relief Devices ........................... 32

XI. Control Circuits ......................... 32

XII. Compressor Lockout Logic ............... 32

XIII. Replacement Parts ....................... 32

TROUBLESHOOTING ...........................33-41

I. Diagnostic LEDs ......................... 33

II. Error Code Summary ..................... 34

III. Input/Output Channel Designations ......... 34

START-UP CHECKLIST ....................CL-1, CL-2

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters.Allother

operations should be performed by trained service personnel.

When working on air-conditioning equipment, observe precautions in the literature, tags and labels attached to the unit,

and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire

extinguishers available for all brazing operations.

WARNING:

nance operations on unit, turn off main power switch

to unit. Electrical shock could cause personal injury.

WARNING:

1. Improper installation, adjustment, alteration, service, or maintenance can cause property damage, personal injury, or loss of life. Refer to the User’s

Information Manual provided with this unit for more

details.

2. Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

What to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch, or use any phone in

your building.

3. IMMEDIATELY call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

4. If you cannot reach your gas supplier, call the fire

department.

WARNING:

pressure testing at pressure greater than 0.5 psig. Pressures greater than 0.5 psig will cause gas valve damage resulting in hazardous condition. If gas valve is

subjected to pressure greater than 0.5 psig, it must be

replaced before use. When pressure testing fieldsupplied gas piping at pressures of 0.5 psig or less, a

unit connected to such piping must be isolated by closing the manual gas valve(s).

Before performing service or mainte-

Disconnect gas piping from unit when

Page 2

INSTALLATION

I. PROVIDE UNIT SUPPORT

CAUTION:

All panels must be in place when rig-

ging. Unit is not designed for handling by fork truck.

A. Roof Curb

Assemble and install accessory roof curb in accordance with

instructions shipped with the curb. Accessory roof curb and

information required to field fabricate a roof curb or horizontal adapter are shown in Fig. 1. Install insulation, cant strips,

roofing, and counter flashing as shown. Ductwork can be

secured to roof curb before unit is set in place.

IMPORTANT: The gasketing of the unit to the roof curb is

critical for a leak-proof seal. Install gasket supplied with the

roof curb as shown in Fig. 1. Improperly applied gasket can

result in air leaks and poor unit performance.

Curb should be level. This is necessary to permit unit drain

to function properly. Unit leveling tolerance is shown in

Fig 1. Refer to Accessory Roof Curb Installation Instructions

for additional information as required. When accessory roof

curb is used, unit may be installed on class A, B, or C roof

covering material.

NOTES:

1. Unless otherwise specified, all dimensions are to outside of part.

2. Roof curb accessory is shipped disassembled.

3. All roof curb parts are to be 16 ga galvanized steel.

4. Dimensions are in inches.

NOTE: On retrofit jobs, ductwork may be attached to old unit

instead of roof curb. Be careful not to damage ductwork when

removing old unit.

B. Alternate Unit Support

When the preferred curb or adapter cannot be used, support

unit with sleepers using unit curb or adapter support area. If

sleepers cannot be used, support long sides of unit (refer to

Fig. 2 and 3) with 3 equally spaced 4-in. x 4-in. pads on each

side. Unit may sag if supported by corners only.

II. RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

transportation agency. Keep unit upright, and do not drop.

Use spreader bars over unit to prevent sling or cable damage. Rollers may be used to move unit across a roof. Level by

using unit frame as a reference; leveling tolerance is shown

in. Fig. 1. See Fig. 4 for additional information. Unit weight

is shown in Table 1.

Four lifting lugs are provided on the unit base rails as shown

in Fig. 4. Refer to rigging instructions on unit.

(Copy continued on page 7.)

NOTE: To prevent standing water in the drain pan of the

indoor section and the heat exchangers, UNIT CAN ONLY BE

PITCHED AS SHOWN.

UNIT LEVELING TOLERANCES

Deg. in. Deg. in.

*From edge of unit to horizontal.

DIMENSIONS*

(Degrees and Inches)

AB

1.0 2.9 .50 .75

Fig. 1 — Roof Curb (Sizes 240-360)

—2—

Page 3

NOTES:

1. Weights include economizer (STD).

2. Center of gravity.

3. Do not locate adjacent units with flue discharge

facing economizer inlet. Min. clearances to be:

Adjacent Units: 158-09

Top of Units: No Overhang

Condenser Coil: 48-09

Economizer Side: 68-09

Heat Side: 48-09

FilterAccess Side: 108-09 (For Removalof Evaporator Coil)

4. For smaller service andoperational clearances, contact Carrier Application Engineering department.

5. Bottom ducts designed to be attached to accessory roof curb. If unit is mounted on dunnage, it is

recommended the ducts be supported by braces

as done on accessory roof curb.

UNIT SIZE

580G

OPERATING

WEIGHT

lb ft-in. ft-in. 1 2 3 4

240 350 4176 6- 0

240 525 4256 6- 1

300 350 4262 5- 9

300 525 4342 5-10

324 350 4262 5- 9

324 525 4342 5-10

360 350 4262 5- 9

360 525 4342 5-10

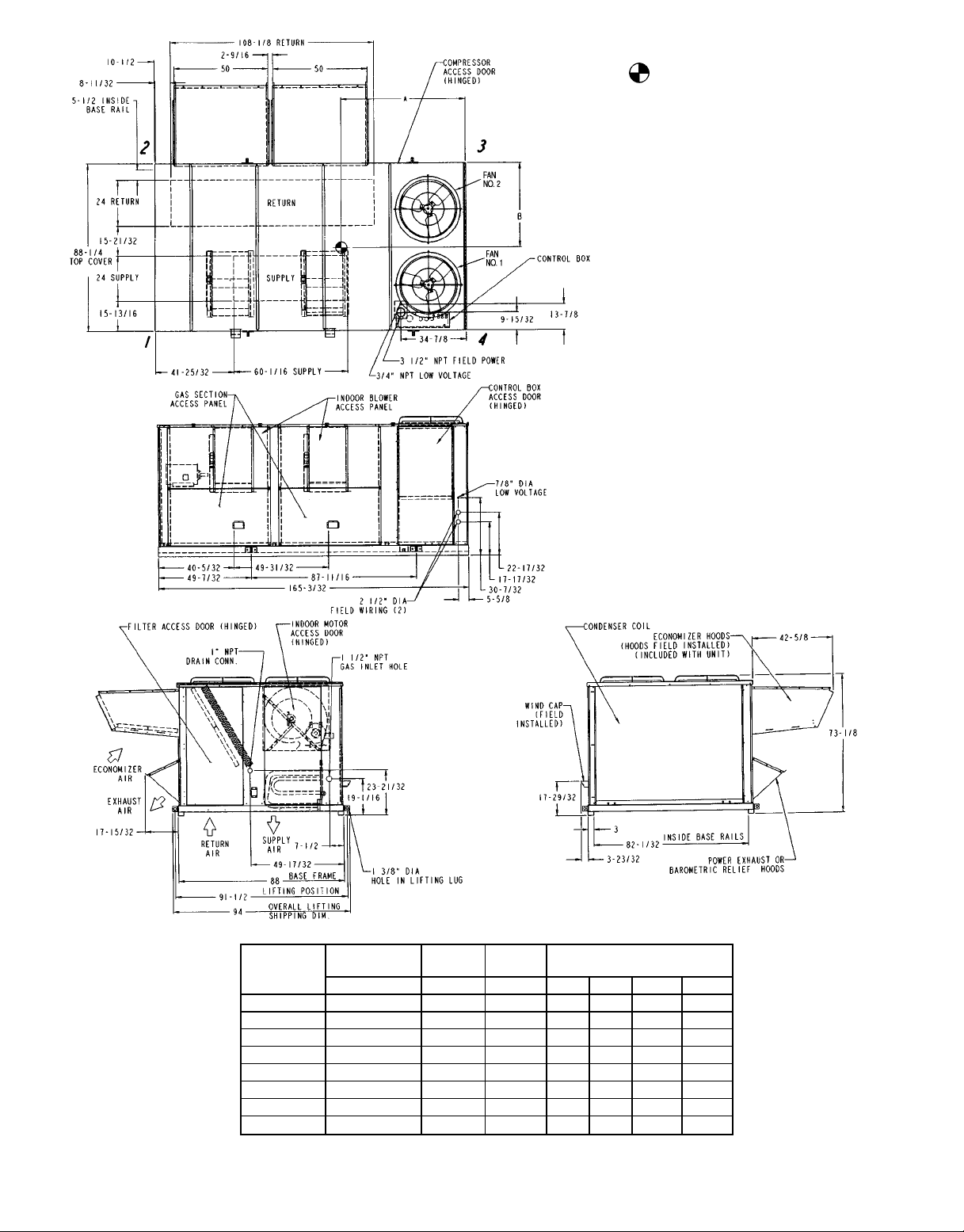

Fig. 2 — Base Unit Dimensions, 580G240-360

AB

3

⁄83-63⁄

5

⁄163-611⁄

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄

8

16

16

16

16

CORNER WEIGHT

(lb)

879 954 1220 1124

917 973 1218 1148

929 916 1240 1257

929 916 1240 1257

929 916 1240 1257

—3—

Page 4

NOTES:

1. Weights include economizer (STD).

2. Center of gravity.

3. Do not locate adjacent units with flue discharge facing

economizer inlet. Min. clearances to be:

Adjacent Units: 158-09

Top of Units: No Overhang

Condenser Coil: 48-09

Economizer Side: 68-09

Heat Side: 48-09

Filter Access Side: 108-09 (For Removal of Evaporator Coil)

4. For smaller service and operational clearances, contact Application Engineering department.

5. Dimensions are in inches.

6. For side supply/return applications a single return and

supply ductwork connection is recommended for covering both return and both supply openings.

UNIT SIZE

580H

OPERATING

WEIGHT

lb ft-in. ft-in. 1 2 3 4

240 350 4176 6- 0

240 525 4256 6- 1

300 350 4262 5- 9

300 525 4342 5-10

324 525 4262 5- 9

324 525 4342 5-10

360 350 4262 5- 9

360 525 4342 5-10

Fig. 3 — Base Unit Dimensions, 580H240-360

AB

3

⁄83-63⁄

5

⁄163-611⁄

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄

5

⁄83-8 899 899 1232 1232

1

⁄83-85⁄

8

16

16

16

16

CORNER WEIGHT

(lb)

879 954 1220 1124

917 973 1218 1148

929 916 1240 1257

929 916 1240 1257

929 916 1240 1257

—4—

Page 5

CAUTION: NOTICE TO RIGGERS: ALL PANELS

MUST BE IN PLACE WHEN RIGGING.

NOTE: Rig with four cables and spread with two 92 in.

(2337 mm) spreader bars. Maintain a distance of 74 in.

(1880 mm) from top of unit to eyehook.

NOTE:

Add 32 lb (14.5 kg) for domestic crating.

Add 312 lb (142 kg) for export crating.

Add 220 lb (100 kg) for copper condenser coil.

Add 250 lb (113 kg) for power exhaust.

UNIT

580G,H

240 350 4176 1894

240 525 4256 1930 73.3 1862 42.7 1085

300 350

360 350

300 525

360 525

WEIGHT A B C

lb kg in. mm in. mm in. mm

72.4 1839 42.4 1072

4262 1933 69.6 1768 44.0 1118324 350

4342 1969 70.1 1781 44.3 1125324 525

87.68 2227

Fig. 4 — Rigging Label

—5—

Page 6

Table 1 — Specifications

UNIT 580G,H 240 300 324 360

NOMINAL CAPACITY (tons) 20 25 27 30

OPERATING WEIGHT (lb)

Unit

Al/Al* (Lo Heat/Hi Heat) 4176/4256 4262/4342 4262/4342 4262/4342

Al/Cu* (Lo Heat/Hi Heat) 4396/4476 4482/4562 4482/4562 4482/4562

Roof Curb (14-in. curb) 365 365 365 365

COMPRESSOR

Type Ckt 1 06D328 06D328 06D537 06D537

Ckt 2 06D818 06D328 06D328 06D537

Number of Refrigerant Circuits 22 2 2

Oil (oz) (Ckt 1, Ckt 2) 115, 88 115 ea. 115 ea. 115 ea.

REFRIGERANT TYPE R-22

Operating Charge (lb-oz)

Circuit 1† 25-0 25-0 25-0 25-0

Circuit 2 31-0 25-0 25-0 25-0

CONDENSER COIL Cross-Hatched

Quantity 11 1 1

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 33.3 33.3 33.3 33.3

CONDENSER FAN Propeller Type

Nominal Cfm 13,420 13,420 13,420 13,420

Quantity...Diameter (in.) 2...30 2...30 2...30 2...30

Motor Hp (1075 Rpm) 11 1 1

EVAPORATOR COIL Cross-Hatched

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 31.7 31.7 31.7 31.7

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...20x15 2...20x15 2...20x15 2...20x15

Type Drive Belt Belt Belt Belt

Nominal Cfm 8,000 10,000 11,000 12,000

Motor Hp 5 10** 15 7.5 10** 15 10 15** 20 10 15** 20

Motor Frame Size

Standard S184T S215T D254T S213T S215T D254T S215T D254T S256T S215T D254T S256T

High Efficiency S184T S215T S254T S213T S215T S254T S215T S254T S256T S215T S254T S256T

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable Rpm 1200 1200 1200 1200

Motor Pulley Pitch Diameter 4.8 4.4 5.7 5.4 6.1 5.5 4.4 4.9 5.9 4.4 5.7 5.9

Nominal Motor Shaft Diameter (in.) 1

Fan Pulley Pitch Diameter (in.) 12.4 8.6 9.1 12.4 11.1 8.7 9.4 8.1 8.7 9.0 9.1 8.7

Nominal Fan Shaft Diameter (in.) 115⁄

Belt, Quantity...Type

Belt, Length (in.)

Pulley Center Line Distance (in.) 16.0-18.7 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9 15.6-18.4 15.0-17.9

Factory Speed Setting (rpm) 717 924 1096 773 962 1106 848 1059 1187 884 1096 1187

FURNACE SECTION

Rollout Switch Cutout Temp (F)†† 225 225 225 225

Burner Orifice Diameter

(in. ...drill size)

Natural Gas Std .111...34 .111...34 .111...34 .111...34

Liquid Propane Alt .089...43 .089...43 .089...43 .089...43

Thermostat Heat Anticipator

Setting (amps)

Stage 1 0.1 0.1 0.1 0.1

Stage 2 0.1 0.1 0.1 0.1

Gas Input (Btuh) Stage 1 Low 262,500 262,500 262,500 262,500

Efficiency (Steady State) (%) 82 82 82 82

Temperature Rise Range 15-45/35-65 15-45/35-65 15-45/35-65 15-45/35-65

Manifold Pressure (in. wg)

Natural Gas Std 3.5 3.5 3.5 3.5

Liquid Propane Alt 3.5 3.5 3.5 3.5

Gas Valve Quantity 22 2 2

Field Gas Connection Size

(in.-FPT)

HIGH-PRESSURE SWITCH (psig)

Cutout 426 426 426 426

Reset (Auto.) 320 320 320 320

LOW-PRESSURE SWITCH (psig)

Cutout 77 7 7

Reset (Auto.) 22 22 22 22

RETURN-AIR FILTERS

Quantity...Size (in.) 10...20x24x2 10...20x24x2 10...20x24x2 10...20x24x2

OUTDOOR-AIR FILTERS 8...16×25

Quantity...Size (in.) 4...20×25

POWER EXHAUST Direct Drive, 3-Speed, Single Phase Motor (Factory Wired for High Speed), Forward-Curved Fan

Motor, Quantity...Hp 4...1

Fan, Diameter...Width (in.) 11...10

High 394,000 394,000 394,000 394,000

Stage 2 Low 350,000 350,000 350,000 350,000

High 525,000 525,000 525,000 525,000

1

⁄

8

13⁄

8

15⁄

1...BX59622...BX51542...5VX530531...BX59621...5VX590592...5VX530532...BX52552...5VX500502...5VX530532...BX51542...5VX530532...5VX530

16

1.5 1.5 1.5 1.5

LEGEND

Al — Aluminum

Cu — Copper

*Evaporator coil fin material/condenser coil fin material.

†Circuit 1 uses the lower portion of condenser coil; Circuit 2 uses the upper portion. All

units have intertwined evaporator coils.

3

⁄89 Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

3

⁄89 Copper Tubes, Aluminum Plate Fins, Intertwined Circuits

8

13⁄

8

13⁄

8

15⁄

8

13⁄

8

15⁄

8

15⁄

8

115⁄

16

**Motor and drive shown will deliver approximately 2.5 in. net external static. For more

fan motor data, see Table 2.

††Rollout switch is manual reset.

115⁄

16

13⁄

8

15⁄

8

15⁄

8

115⁄

16

53

—6—

Page 7

Table 2 — Evaporator Fan Motor Data

UNIT

MOTOR

SIZE

580G,H

240

300

324

360

NOTE: Motor shaft speed is 1750 rpm. The fan shaft diameter is 1

MOTOR

SHAFT

HP

10 1.38 924 2BK50 4.4 None-1.375 2B5V86 8.6 B-1.9375 (2) BX51 54 5.21

15 1.62 1096 2B5V56 5.7 B-1.625 2B5V90 9.1 B-1.9375 (2) 5VX530 53 6.00

7.5 1.38 773 BK60H 5.4 H-1.375 1B5V124 12.4 B-1.9375 BX59 62 6.48

10 1.38 962 1B5V60 6.1 H-1.375 1B5V110 11.1 B-1.9375 5VX590 59 7.37

15 1.62 1106 2B5V54 5.5 B-1.625 2B5V86 8.7 B-1.9375 (2) 5VX530 53 6.12

10 1.38 848 2BK50 4.4 None-1.375 2B5V94 9.4 B-1.9375 (2) BX52 55 5.27

15 1.62 1059 2B5V48 4.9 B-1.625 2B5V80 8.1 B-1.9375 (2) 5VX500 50 6.63

20 1.62 1187 2B5V58 5.9 B-1.625 2B5V86 8.7 B-1.9375 (2) 5VX530 53 7.31

10 1.38 884 2BK50 4.4 H-1.375 2B5V90 9.0 B-1.9375 (2) BX51 54 5.24

15 1.62 1096 2B5V56 5.7 B-1.625 2B5V90 9.1 B-1.9375 (2) 5VX530 53 6.00

20 1.62 1187 2B5V58 5.9 B-1.625 2B5V86 8.7 B-1.9375 (2) 5VX530 53 7.31

DIA.

(in.)

5 1.12 717 BK55 4.8 None-1.125 1B5V124 12.4 B-1.9375 BX59 62 5.10

FAN

SHAFT

SPEED

(rpm)

MOTOR

SHEAVE

MOTOR

SHEAVE

PITCH

DIAMETER

(in.)

DIAMETER

11

⁄16inches.

BUSHING

(in.)

A. Positioning

Provide clearance around and above unit for airflow, safety,

and service access (Fig. 2 and 3).

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air.

For proper unit operation, adequate combustion and ventilation air must be provided in accordance with Section 5.3 (Air

for Combustion and Ventilation) of the National Fuel Gas Code,

ANSI Z223.1 (American National Standards Institute).

Although unit isweatherproof,guardagainst water from higher

level runoff and overhangs.

B. Roof Mount

Check building codes for weight distribution requirements.

FAN

SHEAVE

FAN

SHEAVE

PITCH

DIAMETER

(in.)

BUSHING

DIAMETER

(in.)

BELT

(QUANTITY)

OUTSIDE

BELT

LENGTH

BELT

TENSION

(lb at

.24 in.)

B. 580H Units

Remove shipping covers from supply and return air openings.Attachfield-suppliedductworkto unit. Use a single duct

over both return openings and a single duct over both supply openings. See Fig. 3 for duct opening dimensions. Secure

all ducts to the building structure. See Fig. 6. Use flexible

duct connectors between unit and ducts as required.

Install accessory barometric relief or power exhaust in

the field-fabricated return ductwork. Refer to Power

Exhaust/Barometric Relief Damper Hood section for more

information.

III. FIELD FABRICATE DUCTWORK

Secure all ducts to building structure. Use flexible duct connectors betweenunitandducts as required. Insulate and weatherproof all external ductwork, joints, and roof openings with

counter flashing andmasticinaccordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

To attach ductwork to roof curb, insert ductwork approximately 10 to 11 in. up into the curb. Connect ductwork to

14-gage roof curb material using sheet metal screws driven

from inside the duct.

WARNING:

For vertical supply and return units, tools

or parts could drop into ductwork and cause an injury.

Install 90 degree elbow turns in the supply and return

ductwork between the unit and the conditioned space.

If a 90 degree elbow cannot be installed, then grilles of

sufficient strength and density should be installed to

prevent objects from falling into the conditioned space.

IV. UNIT DUCT CONNECTIONS

A. 580G Units

Unit is shipped for through-the-bottom duct connections. Ductwork openings are shown in Fig. 2. Attach all ductwork to

roof curb. Air distribution is shown in Fig. 5. Refer to

installation instructions shipped with accessory roof curb for

more information.

Fig. 5 — Air Distribution — Thru-the-Bottom

Fig. 6 — Air Distribution — Thru-the-Side

—7—

Page 8

V. FLUE HOOD

Flue hood is shipped inside gas section of unit. To install, secure flue hood to access panel. See Fig. 7.

NOTE: When properly installed, flue hood will line up with

combustion fan housing. See Fig. 8.

Fig. 7 — Flue Hood Location

Fig. 9 — Condensate Drain Connections

(Typical Roof Curb or

Slab Mount Shown)

Condensate pans are sloped sothatwaterwillcompletelydrain

from the condensate pan to comply with indoor air quality

guidelines.

VII. GAS PIPING

Unit is equipped for use with natural gas. Installation must

conform with local building codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1.

1

Install manual gas shutoff valve with a

⁄8-in. NPT pressure

tap for test gage connection at unit. Field gas piping must

include sediment trap and union. See Fig. 10.

WARNING:

Do not pressure test gas supply while

connected to unit. Always disconnect union before

servicing.

Fig. 8 — Combustion Fan Housing Location

VI. TRAP CONDENSATE DRAIN

See Fig. 2, 3, and 9 for drain location. Condensate drain is

open to the atmosphere and must be trapped. Install a trapped

drain at the drain location. One 1-in. NPT coupling is provided inside unit evaporator section for condensate drain connection. A trap at least 4-in. deep must be used. Trap must

be installed to prevent freeze-up.

Natural gas pressure at unit gas connection must not be less

than 5 in. wg or greater than 13.5 in. wg.

Size gas-supply piping for 0.5-in. wg maximum pressure drop.

Do not use supply pipe smaller than unit gas connection.

Fig. 10 — Field Gas Piping

—8—

Page 9

VIII. ELECTRICAL CONNECTIONS

A. Controls Options

The standard constant volume (CV) units, as shipped, are

operable as stand-alone units, using a standard (mechanical

or electronic) 2-stage heat, 2-stage cool thermostat.

Withastandard thermostat (programmable is optional), heating and cooling operation is set by space temperature. The

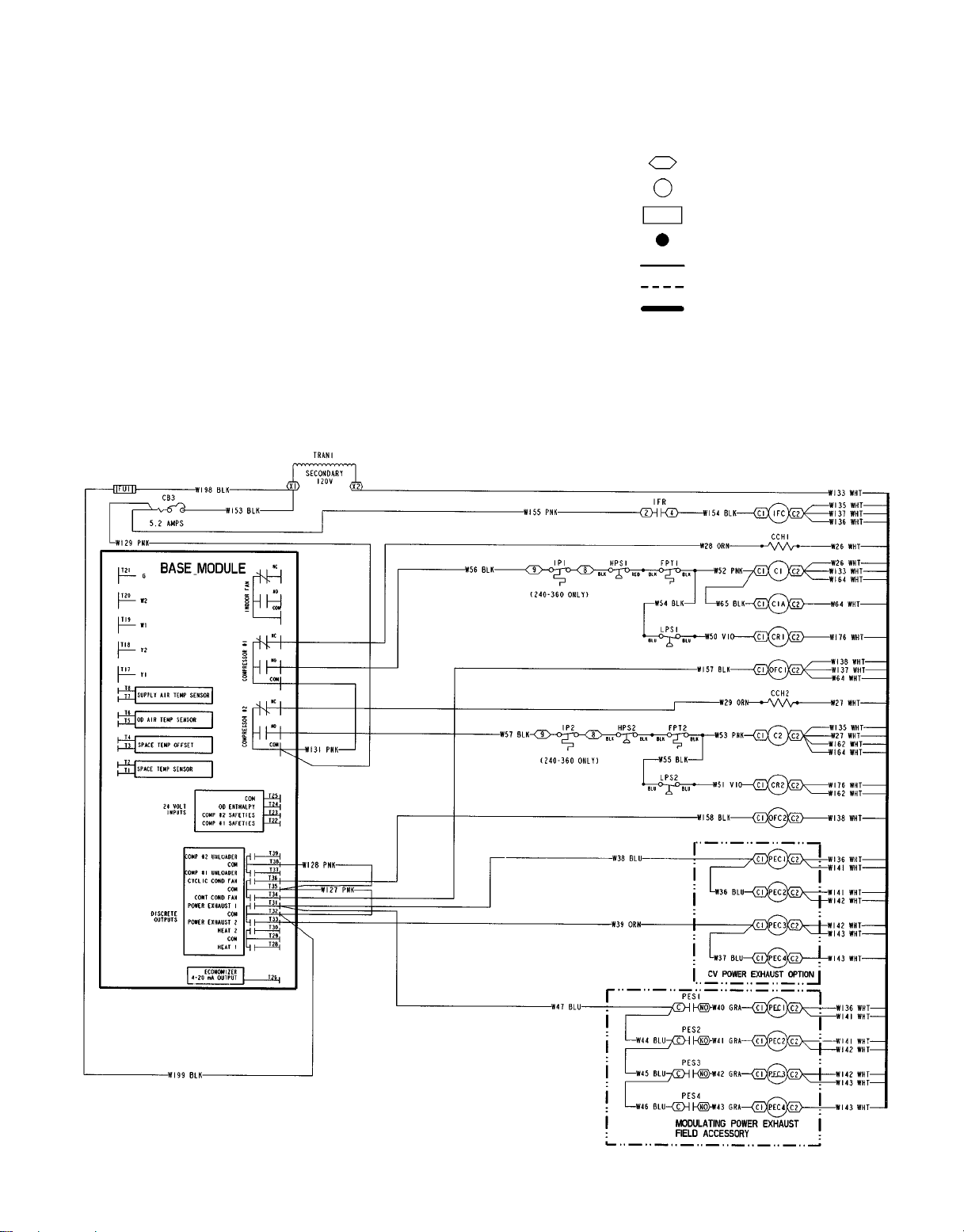

standard DDC (direct digital controls) are installed in the control box. The DDC control board diagram is shown in Fig. 11.

Features with Thermostat Control of Unit

• two-stage heating

• two-stage cooling

• control of unit using Y1, Y2, W1, W2, and G thermostat

inputs

• control of the indoor fan

• outdoor-air temperature/supply-air temperature

monitoring

• control of modulating economizer damper to provide free

cooling when outdoor conditions are suitable, using supplyair temperature as a control point

• control of the economizer damper and indoor fan to obtain

unoccupied free cooling

• provide power exhaust output to an external power

exhaust controller

• support a field test for field checkout

• control of 2 stages of CV power exhaust

• compressor time delay for power up and minimum off and

on times

An electronic expansion board may be field-installed to provide the following features:

• control of modulating economizer damper to maintain

indoor air quality (IAQ) when outdoor conditions are

suitable

NOTE: The IAQ sensor must be set for current output (4 to

20 mA). This requires removing the sensor cover and removing a jumper on the sensor. See Fig. 12.

• provide discrete inputs for fan status, filter status, fieldapplied status, and demand limit

• provide an output for the external alarm light indicator

• provide power exhaust fire outputs for directcontrolofpower

exhaust stages during fire or smoke control modes

• control of smoke control modes including evacuation, smoke

purge, pressurization, and fire shutdown (non-modulating

or modulating power exhaust required)

B. Power Wiring

Units are factory wiredforthevoltageshownon the unit nameplate. The main terminal block is suitable for use with aluminum or copper wires.

When installing units, provide a disconnect per NEC

(National Electrical Code) of adequate size (MOCP [maximum overcurrent protection]ofunitis on the informative plate).

All field wiring must comply with NEC and all local codes.

Size wire based on MCA (minimum circuit amps) on the unit

informative plate. See Fig. 13 for power wiring connections

to the unit power terminal block and equipment ground.

The main power terminal block is suitable for use with aluminum or copper wire. See Fig. 13. Units have circuit breakers for compressors, fan motors, and control circuit. If required

by local codes, provide an additional disconnect, per NEC and

local codes requirements, of adequate size (Table 3). Whenever external electrical sources are used, unit must be electrically grounded in accordance with local codes, or in absence

of local codes, with NEC, ANSI C1-latest year.

All field wiring must comply with NEC and local code

requirements.

C. Field Power Supply

Unit is factory wired for voltage shown on nameplate. See

Table 3 for electrical data.

Field wiring can be brought into the unit from bottom (through

basepan and roof curb) or through side of unit (corner post

next to control box).

1

⁄2-in. NPT knockout for field power wiring and a3⁄4-in.

A3

NPT knockout for 24-v control wiring are provided in base-

1

pan. In the side post, there are two 2

⁄2-in. knockouts for the

field power wiring. See Fig. 2 and 3. If control wiring is to be

7

brought in through the side of unit, a

⁄8-in. diameter hole is

provided in the condenser side post next to the control box.

If disconnect box is mounted to corner post, be careful not to

drill any screws into the condenser coil.

Routing Through Bottom of Unit

If wiring is brought in through bottom of unit, use fieldsupplied watertight conduit to run power wiring from base-

1

pan out through bottom 3

⁄2-in. hole to the disconnect box and

back into unit to the main control box.

1

Use strain relief going into control box through 2

⁄2-in. diameter hole provided. After wires are in unit control box, connect to power terminal block (see Power Wiring section

on this page).

Low-voltage wiring must be run in watertight conduit from

the basepan to control box and through 1-in. diameter hole

provided in bottom of unit control box. Field-supplied strain

relief must be used going into the box. After wiring is in control box, make connections to proper terminals on terminal

blocks (see Field Control Wiring section on page 11).

Install conduit connector in unit basepan or side panel openings provided. Route power and ground lines through connector to connections in unit control box as shown on unit

wiring diagram and Fig. 13.

Routing Through Side of Unit

Route power wiring in field-supplied watertight conduit into

1

unit through 2

⁄2-in. hole. Strain relief (field supplied) must

be used in hole.

Use field-supplied strain relief going into control box through

1

⁄2-in. diameter hole provided. After wires are in unit con-

2

trol box, connect to power terminal block (see Power Wiring

section on this page).

Bring low-voltage control wiring through factory-drilled

7

⁄8-in. diameter hole in condenser side post. Use strain relief

going into

7

⁄8-in. diameter hole in bottom of unit control box.

After wiring is in control box, make connection to proper terminals on terminal blocks (see Field Control Wiring section

on page 11).

WARNING:

The unit must be electrically grounded

in accordance with local codes and NEC ANSI/NFPA70

(National Fire Protection Association).

—9—

Page 10

—10—

Fig. 11 — Control Board Diagram

LEGEND

COM — Common R—Relay

D—Diode SIO — Serial Input/Output

LED — Light-Emitting Diode SW — Switch

N.C. — Normally Closed T—Terminal

N.O. — Normally Open

*Where X is the unit control software version number (1 or 2).

Page 11

JUMPER CONNECTION

FOR VOLTAGE OUTPUT

JUMPER CONNECTION

FOR CURRENT OUTPUT

Fig. 12 — Indoor Air Quality Sensor Configuration

3. Cap orange wire.

4. Splice red wire and black unit power wire. Cap wires.

IMPORTANT: Becertain unused wires are capped. Failure to

do so may damage the transformers.

D. Field Control Wiring

Install an approved accessory thermostat. Control box diagram is shown in Fig. 14.

Thermostat Wiring

Install an approved accessory thermostat assembly (per cur-

rent price pages) according to the installation instructions included with the accessory, or these instructions. Locate thermostat assembly on a solid wall in the conditioned space to

sense average temperature.

Route thermostat cable or equivalent single leads of

no. 18AWG (American Wire Gage) colored wire from subbase

terminals to low-voltage connections as shown on unit label

wiring diagram and in Fig. 15.

NOTE: For wire runs up to 50 ft, use no. 18 AWG insulated

wire (35 C minimum). For 50 to 75 ft, use no. 16 AWG

insulated wire (35 C minimum). For over 75 ft, use no. 14

AWG insulated wire (35 C minimum). All wire larger than

no. 18 AWG cannot be directly connected to the thermostat

and will require a junction box and splice at the thermostat.

Set heat anticipators settings to .1 for all voltages. Settings

may be changed slightly to provide a greater degree of comfort for a particular installation.

LEGEND

EQUIP — Equipment NEC — National Electrical Code

GND — Ground TB — Terminal Block

NOTE: TB1 Maximum wire size is 500 MCM.

Fig. 13 — Field Power Wiring Connections

Operating voltage to compressor must be within voltage range

indicated on unit nameplate. On 3-phase units, voltages between phases must be balanced within 2% and the current

must be balanced within 10%.

Use the formula in Table 3 to determine the percentage of

voltage imbalance.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

Unit failure as a result of operation on improper line voltage

or excessive phase imbalance constitutes abuse and may cause

damage to electrical components.

On 208/230-v units, transformer no. 1 is wired for 230-v. If

208/230-v unit is to be run with 208-v power supply ,the transformer must be rewired as follows:

1. Remove cap from red (208-v) wire.

2. Remove cap from spliced orange (230-v) wire. Disconnect orange wire from black unit power wire.

LEGEND

C—Compressor/Contactor

CB — Circuit Breaker

DIP — Dual In-Line Package

FU — Fuse

HR — Heater Relay

IF — Indoor Fan

OF — Outdoor Fan

PEC — Power Exhaust Controller

TB — Terminal Block

TRAN — Transformer

Fig. 14 — Control Box Diagram

—11—

Page 12

Table 3— Electrical Data — 580G,H240-360

UNIT

SIZE

580G,H

240

300

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Fuse or HACR circuit breaker.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where aphaseimbalance in supply voltage is

greater than 2%.

voltage imbalance.

% Voltage Imbalance

= 100 x

NOMINAL

VOLTAGE

(3 Ph 60 Hz)

208/230 187 254 39.1 228 25.6 160 2 1 5.3

460 414 508 19.9 114 11.5 80 2 1 2.7

575 518 632 16.0 91 9.6 64 2 1 2.4

208/230 187 254 39.1 228 39.1 228 2 1 5.3

460 414 508 19.9 114 19.9 114 2 1 2.7

575 518 632 16.0 91 16.0 91 2 1 2.4

max voltage deviation from average voltage

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty Hp

LEGEND

or

Use the following formula to determine the percent

average voltage

COMPRESSOR

No. 1 No. 2

OFM IFM

FLA

Hp FLA FLA LRA FLA MCA MOCP*

(ea)

5

10

15

5 7.6

10 14.0

15 21.0

5 6.1

10 11.0

15 17.0

7.5

10

15

7.5 11.0

10 14.0

15 21.0

7.5 9.0

10 11.0

15 17.0

EXAMPLE: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 − 452=5v

(BC) 464 − 457=7v

(AC) 457 − 455=2v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

POWER

EXHAUST

16.7/

— — 0.96 101.8/100.3 125/125

15.2

23.6 41.6 0.96 125.4/123.9 150/150

30.8/

— — 0.96 115.9/113.1 150/150

28.0

23.6 41.6 0.96 139.5/136.7 175/175

46.2/

— — 0.96 131.3/127.1 150/150

42.0

23.6 41.6 0.96 154.9/150.7 175/175

— — 0.50 49.4 60

12.6 23.6 0.50 62.0 80

— — 0.50 55.8 70

12.6 23.6 0.50 68.4 80

— — 0.50 62.8 80

12.6 23.6 0.50 75.4 90

— — 0.50 40.5 50

12.6 23.6 0.50 53.1 60

— — 0.50 45.4 60

12.6 23.6 0.50 58.0 70

— — 0.50 51.4 60

12.6 23.6 0.50 64.0 80

24.2/

— — 0.96 122.8/120.6 150/150

22.0

23.6 41.6 0.96 146.4/144.2 175/175

30.8/

— — 0.96 129.4/126.6 150/150

28.0

23.6 41.6 0.96 153.0/150.2 175/175

46.2/

— — 0.96 144.8/140.6 175/175

42.0

23.6 41.6 0.96 168.4/164.0 200/200

— — 0.50 61.2 80

12.6 23.6 0.50 73.8 90

— — 0.50 64.2 80

12.6 23.6 0.50 76.8 90

— — 0.50 71.2 90

12.6 23.6 0.50 83.8 100

— — 0.50 49.8 60

12.6 23.6 0.50 62.4 70

— — 0.50 51.8 60

12.6 23.6 0.50 64.4 80

— — 0.50 57.8 70

12.6 23.6 0.50 70.4 80

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

COMBUSTION

FAN MOTOR

= 1.53%

452 + 464 + 455

1371

=

3

= 457

7

457

POWER SUPPLY

3

—12—

Page 13

Table 3— Electrical Data — 580G,H240-360 (cont)

UNIT

SIZE

580G,H

324

360

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Fuse or HACR circuit breaker.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where aphaseimbalance in supply voltage is

greater than 2%.

voltage imbalance.

% Voltage Imbalance

= 100 x

NOMINAL

VOLTAGE

(3 Ph 60 Hz)

208/230 187 254 57.1 266 39.1 228 2 1 5.3

460 414 508 25.6 120 19.9 114 2 1 2.7

575 518 632 20.5 96 16.0 91 2 1 2.4

208/230 187 254 57.1 266 57.1 266 2 1 5.3

460 414 508 25.6 120 25.6 120 2 1 2.7

575 518 632 20.5 96 20.5 96 2 1 2.4

max voltage deviation from average voltage

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty Hp

LEGEND

or

Use the following formula to determine the percent

average voltage

COMPRESSOR

No. 1 No. 2

OFM IFM

FLA

Hp FLA FLA LRA FLA MCA MOCP*

(ea)

10

15

20

10 14.0

15 21.0

20 27.0

10 11.0

15 17.0

20 22.0

10

15

20

10 14.0

15 21.0

20 27.0

10 11.0

15 17.0

20 22.0

EXAMPLE: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

(AB) 457 − 452=5v

(BC) 464 − 457=7v

(AC) 457 − 455=2v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

POWER

EXHAUST

30.8/

— — 0.96 151.9/149.1 200/200

28.0

23.6 41.6 0.96 175.5/172.7 225/225

46.2/

— — 0.96 167.3/163.1 200/200

42.0

23.6 41.6 0.96 190.9/186.7 225/225

59.4/

— — 0.96 180.5/175.1 225/225

54.0

23.6 41.6 0.96 204.1/198.7 250/250

— — 0.50 71.3 90

12.6 23.6 0.50 83.9 100

— — 0.50 78.3 100

12.6 23.6 0.50 90.9 110

— — 0.50 84.3 100

12.6 23.6 0.50 96.9 110

— — 0.50 57.4 70

12.6 23.6 0.50 70.0 90

— — 0.50 63.4 80

12.6 23.6 0.50 76.0 90

— — 0.50 68.4 80

12.6 23.6 0.50 81.0 100

30.8/

— — 0.96 169.9/167.1 225/200

28.0

23.6 41.6 0.96 193.5/190.7 250/225

46.2/

— — 0.96 185.3/181.1 225/225

42.0

23.6 41.6 0.96 208.9/204.7 250/250

59.4/

— — 0.96 198.5/193.1 250/250

54.0

23.6 41.6 0.96 222.1/216.7 275/250

— — 0.50 77.0 100

12.6 23.6 0.50 89.6 110

— — 0.50 84.0 100

12.6 23.6 0.50 96.6 110

— — 0.50 90.0 110

12.6 23.6 0.50 102.6 125

— — 0.50 61.9 80

12.6 23.6 0.50 74.5 90

— — 0.50 67.9 80

12.6 23.6 0.50 80.5 100

— — 0.50 72.9 90

12.6 23.6 0.50 85.5 100

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

COMBUSTION

FAN MOTOR

= 1.53%

452 + 464 + 455

1371

=

3

= 457

7

457

POWER SUPPLY

3

—13—

Page 14

TOP

FLANGE

Fig. 15 — Field Control Thermostat Wiring

IX. OUTDOOR-AIR INLET ASSEMBLY

A. Economizer

NOTE: If accessory power exhaust or barometric relief pack-

ages are being added to the unit, install power exhaust or

barometric relief before installing economizer hoods.

BLACK

SEAL

STRIP

HOOD SIDE

Fig. 16 — Adding Seal Strip to Top of Hood Sides

Economizer Hood Assembly

The economizer hood is shipped in a package secured to the

outside of the unit and must be field assembled. There are

2 hoods on every unit. The 580H units are side supply and

side return. The return duct limits access to economizer

filters from below. Filter tracks (mounting angle without tabs)

must be installed correctly to allow access to economizer

filters from each side.

NOTE: Before assembly of the economizer hood, check along

the outer edges of the economizer assembly for any seal strip

protruding past the flanges. Trim the excess seal strip so that

it is flush with the economizer assembly flanges.

Perform the following procedure to assemble the economizer

hood:

a. Apply black seal strip (provided in package) to out-

1.

side top edge of hood sides. Wrap seal strip over to

cover top flange (4 hood sides). Make certain seal strip

1

covers screw holes.Allowstrip to overhang

⁄8in. past

end opposite mounting flange. See Fig. 16.

b. Assemble hood sides, top, and cross member with gas-

keted screws provided. See Fig. 17.

c. Attach 10 green speed clips (provided) to hood top.

d. Apply black seal strip to mountingflanges(coverholes)

of hood sides. See Fig. 18.

NOTE: Each hood assembly has a slotted side that should be

adjacent to the other hood when mounted to the unit.

e. Apply black seal strip to hood top mounting flange.

Seal strip of hood top mounting flange must press

against seal strip of hood side mounting flanges. See

Fig. 19.

f. Add gray foam strip (provided) to cross members at

bottom tray. See Fig. 20.

NOTE: Left side economizer hood has mounting angle withouttabs and

filter track assembled end on opposite side.

Fig. 17 — Economizer Hood Assembly

(Right-Side Economizer Hood Shown)

Exhaust Mounting Details

g. Place gray foam strip on inside of slotted hood side

between filter and cross member opposite mounting

end. See Fig. 21.

h. Attach gray foam strip to blockoff baffle on outer face

area of flange. See Fig. 22.

2. Remove the screws on each end and along top of damper

assembly of unit. Remove top 2 screws on each side of

filter panel under damper assembly. Set hood assembly

in place and attach to unit using these screws.

3. Attach accessory enthalpy bracket on hood side furthest from control box end. Locate bracket on inside

upper righthandcornerusing hood mounting holes. Mount

outdoor-air thermistor to enthalpy bracket (if purchased).Attachandwireenthalpy assembly. Place quick

connects on enthalpy wires.

—14—

Page 15

P

HOOD SIDE

(SLOTTED)

MOUNTING

FLANGE

HOOD SIDE

Fig. 18 — Adding Seal Strip to Mounting Flange

of Hood Sides

HOOD SIDE

HOOD TO

HOOD

TOP

Fig. 21 — Adding Foam Strip to Hood Side

BLOCKOFF BAFFLE

Fig. 19 — Add Seal Strip to Hood Top Mounting Flange

GRAY FOAM STRIP

CROSS MEMBER

GRAY FOAM STRIP

Fig. 22 — Adding Foam Strip To

Blockoff Baffle

Fig. 20 — Adding Foam Strip to Cross Member

—15—

Page 16

4. Remove screws along bottom of damper assembly. Locate and mount blockoff baffle using these screws.

5. Assemble 2 filter tracks side-by-side with the assembled ends together.

a. Attach mounting angle (without tabs) to the as-

6.

sembled end of the filter track. See Fig. 23.

b. Attach 6 green clips (provided) to mounting angles.

Engagement section of clip faces inside of rack.

c. Attach remaining mounting angle (with tabs) to other

end of the filter track with no. 10 screws provided.

See Fig. 24.

a. Place filter track assembly in bottom of hood by plac-

7.

ing tabbed end into slotted side (with tab on bottom)

and attaching opposite end to hood with speed clips

and gasketed screws provided. Tabscan be hand bent

after inserted into the side.

NOTE: The filter track assembly end with screws should face

away from the other hood when mounted on the unit.

NOTE: Tabs from both filter tracks will be in the same space.

After one filter track has been inserted into board, bend the

tabs so they will not interfere with installation of the second

hood.

b. Attach black seal strip to filter cover.Sealstripshould

be applied to flange (coveringholes)andcenteroflarge

flange. See Fig. 25.

8. Slide two 20 x 25-in. filters into cross members of hood

assembly. Attach filter cover over filters with screws and

speed clips provided.

Minimum Damper Position Setting

Setting of the outdoor air damper position is performed in

conjunction with a shortened version of the field run test. This

is performed by first opening DIP switch no. 4 then no. 6.

The outdoor-air damper closes. The control allows 90 seconds

for the damper to close in case it is in the full open position.

Next, the indoor-fan contactor will energize. The outdoor air

damper will remain at 0% for 30 seconds. It will then move

to the 10% position for another 30 seconds. This will be

repeated at every 10% increment for 30 seconds until the

damper reaches 100% open. Close DIP switch no. 4 during

the 30 seconds immediately after the desired outdoor air minimum damper position. The 30-second time period is to allow

time where DIP switch no. 4 can be closed. The default value

of the minimum outdoor air damper position is 20%. If the

desired minimum position is 30%, allow the damper position to go to 10% for 30 seconds, then 20% for 30 seconds,

and when it reaches 30% close DIP switch no. 4 during the

30-second period following the 30% position.

The minimum outdoor air damper position is now set. Close

DIP switch no. 6.

B. Economizer Settings

Accessory Enthalpy Control (Fig. 26)

The control (HH57AC077) is mounted in the economizer hood.

See Fig. 17. The enthalpy setting adjustment is on the enthalpy control. For maximum benefit of outdoor air, set enthalpy sensor control to A. See Fig. 27 and 28.

Enthalpy Control Installation

The outdoor air enthalpycontrolisinstalledonthe inside panel

of the outdoorairhood.The enthalpy control should be mounted

when the outdoor air hoods are assembled. To install the control, perform the following procedure:

1. Turn off all power. Ensure disconnect is locked out.

2. Remove the economizer inlet filters from the bottom of

the right hand economizer hood. See Fig. 29.

MOUNTING ANGLE

(WITHOUT TABS)

FILTER TRACK

ASSEMBLY

Fig. 23 — Mounting Angle (Without Tabs)

Attached to Filter Track Assembly

MOUNTING ANGLE

(WITH TABS)

Fig. 24 — Mounting Angle (With Tabs)

Attached to Filter Track Assembly

BLACK SEAL STRIP

(CENTERED)

FILTER COVER

Fig. 25 — Attaching Seal Strip to Filter Cover

—16—

Page 17

HH57AC077

ENTHALPY CONTROL

NOTE: Switches shown in high enthalpy state. Terminals 2 and 3 close on enthalpy decrease.

Fig. 27 — Wire Connections for Solid-State

Enthalpy Control (HH57AC077)

C7400A1004

+

HH57AC078

ENTHALPY SENSOR (USED WITH

ENTHALPY CONTROLFOR DIFFERENTIAL ENTHALPY OPERATION)

Fig. 26 — Enthalpy Control and Sensor

3. Mount the outdoor air enthalpy sensor inside the right

economizer hood on the right side panel of the hood,

adjacent to the outdoor-air thermistor.

4. Locate the red, violet, and brown wires near the out-

door air thermistor. Remove the splice from the red and

violet wires. Remove the cap from the brown wire.

1

5. Install a

⁄4-in. push on terminal (field-supplied) on the

violet and brown wires.

1

6. Connect a

⁄4-in. push on terminal (field-provided) to one

end of a 18-gage, 6-in. jumper wire (field-provided). Con-

1

nect the other end to the red wire and attach a

⁄4-in.

push on connector (field-provided).

7. Connect the red wire with the jumper to terminal TR1.

Connect the jumper to terminal 2. Connect the brown

wire to terminal TR. Connect the violet wire to terminal 3. All connections are on the enthalpy control.

8. Replace the economizer filters.

9. Return power to unit.

Accessory Differential Enthalpy Control (Fig. 26)

The control (HH57AC077), in conjunction with the accessory

enthalpy sensor (HH57AC078), controls economizer operation according to the differential enthalpy. The control is

mounted in the economizer hood. The sensor is mounted in

the return duct (580G) or the return air plenum (580H).

Differential Enthalpy Sensor Installation

To install the control, perform the following procedure:

1. Turn off all power. Ensure disconnect is locked out.

2. Remove the economizer inlet filters from the bottom of

the right hand economizer hood.

3. Remove the factory-installed, 620-ohm jumper between terminals SR and + on the enthalpy control

located inside the outdoor air hood.

4. Connect the violet wire from the enthalpy sensor kit to

the + terminal on the enthalpy control. Connect the blue

wire from the enthalpy sensor kit to the SR terminal

on the terminal control.

CONTROL

CURVE

RH — Relative Humidity

CONTROL POINT

(APPROX. DEG.)

A 73 (23)

B 70 (21)

C 67 (19)

D 63 (17)

AT 50% RH

Fig. 28 — Psychrometric Chart for Enthalpy Control

5. Turntheenthalpycontrolsetpointpotentiometerclockwise past the ‘‘D’’setting on the enthalpy control to configure the control to operate on differential enthalpy.

6. Remove the return-air enthalpy sensor from the accessory package. Using the screws provided, mount the

sensor inside the return duct near the unit. Do not

locate the control too far from the unit, or the wires

will not reach from the sensor to the control. On 580H

units, the enthalpy sensor can be installed in the

return air section of the unit, under the return air

dampers.

7. Route the wires from the enthalpy sensor to the

return air enthalpy control through the holes on the

inside of the hinged filter access panel. The holes are

blocked by plug buttons which should be removed.

—17—

Page 18

8. Use field-supplied wire ties to attach the violet wire to

the + terminal and the blue wire to the SR terminal.

9. Replace economizer filters.

10. Return power to unit.

Disable Economizer

For applications where the economizer will not be used

(areas of high humidity), the economizer should be disabled.

To disable the economizer, perform the following:

1. Turn off power. Lock out disconnect.

2. Locate the OAT(outdoorairthermistor)intherighthand

outdoor air damper area.

3. Locate the splice connecting the violet wire coming from

T24 on the base module board to the red wire coming

from T29 on the base module board. Remove the wire

nut and break the red to violet wire splice.

4. Cap off both wires. When the connection is broken, the

base module is fooled into thinking that the enthalpy is

not acceptable and economizer operation is disabled.

NOTE: Economizer operation can also be disabled by disconnecting the OAT. This is not recommended due to the fact

that Unoccupied Free Cooling, IAQ Purge, and Low Ambient

Fan Cycle Control are also disabled. An OAT failure alarm

will also be issued.

X. POWER EXHAUST/BAROMETRIC RELIEF DAMPER HOOD

All electrical connections have been made and adjusted at the

factory. The power exhaust blowers and barometric reliefdampers are shipped assembled and tilted back into the unit for

shipping. Brackets and extra screws are shipped in shrink

wrap around the dampers. If ordered, each unit will have

4 power exhaust blowers and motors or 4 barometric relief

dampers.

1. Remove 9 screws holding each damper assembly in place.

See Fig. 30. Each damper assembly is secured with

3 screws on each side and 3 screws along the bottom.

Save screws.

2. Pivot each damper assembly outward until edges of

damper assembly rest against inside wall of unit.

CAUTION:

Be careful when tilting blower assembly.

Hoods and blowers are heavy and can cause injury if

dropped.

3. Secure each damper assembly to unit with6screwsacross

top (3 screws provided) and bottom (3 screws from

Step 1) of damper.

4. With screws saved from Step 1, install brackets on each

side of damper assembly.

5. Remove tape from damper blades.

NOTE: Partitionsshown indicate both sidesupply (580H)

and vertical supply (580G) units.

Fig. 29 — Economizer Details

—18—

Page 19

NOTES:

1. Unless otherwise specified, all dimensions are to outside of part.

2. Dimensions are in inches.

Fig. 30 — Barometric Relief Damper and Power Exhaust Mounting Details

XI. ACCESSORIES

After all the factory-installed options have been adjusted, install all field-installed accessories. Refer to the accessory installation instructions included with each accessory.

A. MotormasterT III Control Installation

Install Field-Fabricated Wind Baffles

Wind baffles must be field-fabricated for all units to ensure

proper cooling cycle operation at low-ambient temperatures.

See Fig. 31 for baffle details. Use 20-gage, galvanized sheet

metal, or similar corrosion-resistant metalforbaff les.Use fieldsupplied screws to attach baffles to unit. Screws should be

1

⁄4-in. diameter and5⁄8-in. long. Holes for wind baffles are pre-

punched in the unit sheet metal.

CAUTION:

To avoid damage to the refrigerant coils

and electrical components, use recommended screw sizes

only.

The wind baffles attach to flanges formed on the outer sheet

metal of the unit where the condenser coil tube sheets

attach.

Install Motormaster III Controls

Only one Motormaster III control is required per unit.

Motor — The circuit no. 1 (lead compressor) outdoor-fan

motor (OFM) will need to be changed out in the field to

accommodate the Motormaster III accessory. The replacement motor part no. is HD52AK652.

The no. 1 compressor is located at the left side of the unit

looking from the compressor end.

Sensor — Install the sensor for thermistor input control in

the location shown in Fig. 32. Connect sensor leads to the

violet and grey control signal leads on the Motormaster III

control.

Signal Selection Switch — Remove the cover of the Motormaster III control. Set the switch to accept the thermistor

sensor input signal. Set the frequency to match the unit power

supply (60 Hz).

1

BOTH SIDES

18

77.7

0.312 DIA

HOLES

61

17.167

BETWEEN

HOLES

(TYPICAL)

4.62

NOTE: All dimensions are in inches. Material: 20 gage galvanized steel

or other non-corrosive material.

CROSS-BREAK

78.7

0.5

Fig. 31 — Motormaster III Baffle Details

Motormaster III Control — The recommended mounting

location is in the indoor fan section, mounted on the panel

that separates the indoor and outdoor sections.

Electrical Connections

WARNING:To avoid possibility of electrical shock and

personal injury, turn off all power to unit before making electrical connections.

When replacing the OFM, reconnect the black, yellow, and

blue wires from the outdoor fan contactor to the black, yellow, and blue wires of the Motormaster III control. Run new

wires from the red, orange, and brown wires to the leads of

the new OFM. Connect the green wire from the control to

ground.

NOTE: On all 575-v units, 2 transformers (part no.

HT01AH851) must be used for each Motormaster III control

to lower the supply voltage to the control to 460-v. Transformers can be mounted anywhere outside the control box.

—19—

Page 20

Fig. 32 — Low Ambient Kit Sensor Location

PRE-START-UP

WARNING:

ings could result in serious personal injury:

1. Follow recognized safety practices and wear protective goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric

power to unit unless compressor terminal cover is

in place and secured.

3. Do not remove compressor terminal cover until all

electrical sources have been disconnected.

4. Remove and reclaim refrigerant from system before touching or disturbing anything inside terminal box if refrigerant leak is suspected around

compressor terminals.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System contains oil and refrigerant under pressure.

To remove a component, wear protective goggles

and proceed as follows:

a. Shut off electrical power to unit.

b. Remove and reclaim refrigerant from system.

c. Cut component-connecting tubing with tubing

d. Carefully unsweat remaining tubing stubs when

Proceed as follows to inspect and prepare the unit for initial

start-up:

1. Remove all access panels.

2. Read and follow instructions on all WARNING, CAUTION, andINFORMA TIONlabels attached to, or shipped

with, unit.

Failure to observe the following warn-

cutter and remove component from unit.

necessary. Oil can ignite when exposed to torch

flame.

3. Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections

and on unit base. Detecting oil generally indicates

a refrigerant leak. Leak-test all refrigerant tubing

connections usingelectronicleakdetector,halidetorch,

or liquid-soap solution.

c. Inspect all field- and factory-wiring connections. Be

sure that connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and

handling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

a. Make sure that condenser-fan blades are correctly

positioned in fan orifices. Blades should clear fan

motor and fan orifice ring.

b. Make sure that return-air filters and outdoor-air

inlet screens are in place.

c. Make sure that the condensate trap is filled with

water to ensure proper drainage.

d. Make sure that all toolsandmiscellaneouslooseparts

have been removed.

5. Loosen the compressor holddown bolts until sideways

movement of the washer under each holddown bolt can

be obtained. Do not loosen completely as bolts are selflocking and will maintain adjustment. Open compressor valves.

6. Make sure refrigerant service port caps are tight. Each

refrigerant system has one suction port located in the

top of the compressor motor casing. All units also have

one service port on the liquid line valve and one on the

compressor discharge valve.

7. Crankcase heaters are energized as long as there is

power to the unit, except when the compressors are

operating.

IMPORTANT: Unit power must be on for 24 hours prior to

start-up. Otherwise, damage to compressor may result.

8. Ensure that the suction, discharge, and liquid line service valves are open. Damage to the compressor could

result if they are left closed.

9. Check Direct Digital Controls DIP (dual-in-line package) switch configuration. The Direct Digital Control

(DDC) board must be configured for each application. The DDC board is configured through the DIP

switches located on the board. There are 8 DIP switches

which configure 8 differentapplicationsoftheDDC.See

Table 4. DIP switch 1 is on the left of the block. DIP

switch 8 is on the right of the block. To open a DIP

switch, push the switch up with suitable tool (smallblade screwdriver).To close a DIPswitch,push the switch

down. Factory settings are shown in Table 5.

The DIP switch configurations for the unit control software are as follows:

• DIP switch 1 should be set to closed (CV operation)

• DIP switch 2 should be set to closed (thermostat)

• DIP switch 3 is used to enable expansion board

operation

• DIP switch 4 is used to field test the unit

• DIP switch 5 is used to specify the type of power

exhaust

—20—

Page 21

Table 4 — DIP Switch Configuration

SETTING 1 2 3 4 5 6 7 8

Time GuardT

Override ON

IN CONJUNCTION

WITH FIELD TEST —

Set Minimum

Damper Position

Time Guard

Override OFF

Gas Heat

Electric Heat

Heat Pump

Operation

Air Conditioner

Operation

OPEN ——

CLOSED CV

LEGEND

CV — Constant Volume

Thermostat

Used

Expansion

Board

Operation

Base Control

Board Only

Field

Test

ON

Field

Test

OFF

Modulated

Power

Exhaust

CV

Power

Exhaust

NOTES:

1. TheOPEN side of the DIPswitch is marked ‘‘OPEN.’’When the rocker

switch is on the ‘‘OPEN’’ side of the switch, the switch is open.

2. When the unit is being field-tested (DIP switch 4 to OPEN), the function of DIPswitch 6 changes andit is used to settheminimum damper

position.

Table 5 — DIP Switch Factory Settings

UNIT 12345678

580G,H Closed Closed Closed Closed Closed Closed Open Closed

• DIP switch 6 configures the Time Guard override and,

when used with the field test function, sets the minimum damper position

• DIP switch 7 configures the unit for gas heat or electric heat

• DIP switch 8 configures the unit for heat pump or

air conditioner operation

10. Adjust economizer. Check that outdoor-air damper is

closed and return-air damper is open.

IMPORTANT: Unit power must be on for 24 hours prior to

start-up. Otherwise, damage to compressor may result.

11. The optional non-modulating power exhaust is a two-

stage design where the operation of the exhaust fans

is linked to economizer position. When the supply fan

is running and the economizer is 25% open, the base

module closes contacts, activating 2 exhaust fans. When

the economizer position reaches75%open,thebase module activates the other 2 exhaust fans. The fans will

turn off when the economizer closes below the same

points.

START-UP

I. COOLING SECTION START-UP AND ADJUSTMENTS

CAUTION:

Complete the required procedures given

in the Pre-Start-Up section on page 20 before starting

the unit.

Do not jumper any safety devices when operating the

unit.

Do not operate the compressor when the outdoor temperature is below 40 F (unless accessory low ambient

kit is installed).

Do not rapid-cycle the compressor. Allow 5 minutes

between ‘‘on’’ cycles to prevent compressor damage.

A. Checking Cooling Control Operation

Start and check the unit for proper cooling control operation

as follows:

Place SYSTEM switch in COOL position and FAN switch in

AUTO. position. Set cooling control below room temperature.

Observe that compressor, condenser fan motor, and evaporator blower motors start. Observe that cooling cycle shuts down

when control setting is satisfied.

B. Cooling Sequence of Operation

On power up, the control module will activate the initialization software. The initialization software reads DIP switch

no. 1 to determine it is in the closed position. Next, DIP switch

no. 2 is read to determine it is closed for thermostat operation. The initialization sequence clears all alarms and alerts;

re-maps the input/output database for operation; sets maximum heat stages to 2; and sets maximum cool stages to 3.

Power up takes a random 1 to 63 seconds plus 5 minutes.

The TSTAT function performs a thermostat based control by

monitoring Y1, Y2, W1, W2 and G inputs. These functions

control stages: cool1, cool2, heat1, heat2 and the indoor fan,

respectively.

The control module will operate economizer and run diagnostics to monitor alarms at all times.

If the thermostat energizes the G input, the control module

will turn on the indoor fan and open the economizer dampers

to minimum position. If thermostats are used to deenergize

the G input, the control module will turn off the indoor fan

and close the economizer dampers.

When cooling, G must be energized before cooling can operate. The control module determines if outdoor conditions are

suitable for economizer cooling. For the economizer to function for outside air cooling: the enthalpy must be below the

enthalpy set point; the outdoor-air temperature must be equal

to or less than 65 F; the SAT (supply-air temperature) thermistor must not be in alarm; and the outdoor air reading is

available. When these conditions are satisfied,thecontrolmodule will use economizer as the first stage of cooling.

When Y1 input is energized, the economizer will be modulated to maintain SAT at the set point temperature. The

default is 55 F. When SAT is above the set point, the economizer will be 100% open. When SAT is below the set point,

the economizer will modulate between minimum and 100%

open position. When Y2 is energized, the control module will

turn on compressor 1 and continue to modulate the economizer as described above. If the Y2 remains energized and

the SAT reading remains above the set point for 15 minutes,

—21—

Page 22

compressor 2 will turn on. If Y2 is deenergized at any time,

only the last stage of compression that was energized will be

turned off. If outdoor conditions are not suitable for economizer cooling, the economizer will go to minimum position

and cycle compressors 1 and 2 based on demand from Y1 and

Y2 respectively. The compressors will be locked out when the

SAT temperature is too low (less than 40 F for compressor 1

and less than 45 F for compressor 2.) After a compressor is

locked out, it can restart after normal time-guard period.

The compressor time delay function maintains a minimum

off time of 5 minutes, a minimum on time of 10 seconds, and

a minimum delay before starting the second compressor of

10 seconds.

When heating, the heat stages respond to the demand

from W1 and W2 of the thermostat input. Heating and cooling will be mutually locked-out on demand on a first call

basis. The heating and the cooling functions cannot operate

simultaneously.

C. Cooling Capacity Control

The cooling capacity staging is shown in Table 6.

Table 6 — Cooling Capacity Staging Table,

Units with 2 Compressors

STAGES 0

Compressor 1 Off Off On On

Compressor 2 Off Off Off On

NOTE: On units which require additional unloading, add suction pres-

sure unloaders to compressor no. 1 only.

1

ECONOMIZER

23

II. HEATING SECTION START-UP AND ADJUSTMENTS

CAUTION:

Complete the required procedures given

in the Pre-Start-Up section on page 20 before starting

unit. Do not jumper any safety devices when operating

the unit.

Verify gas pressures before turning on heat as follows:

a. Turn off manual gas stop.

b. Connect pressure gage to supply gas tap (See Fig. 10

on page 8).

c. Connect pressure gage to manifold pressure tap on

gas valve.

d. Supply gas pressure mustnotexceed13.5 in. wg. Check

pressure.

e. Turnonmanual gas stop and set thermostat to HEAT

position. After the unit has run for several minutes,

verify that incoming pressure is 5.0 in. wg or greater,

and that the manifold pressure is 3.5 in. wg. If manifold pressure must be adjusted, refer to Gas Valve

Adjustment section on page 25.

A. Checking Heating Control Operation

Start and check the unit for proper heating control operation

as follows:

1. Turn on manual gas stop.

2. Set thermostat setting to HEAT position.

3. The evaporator fan and first-stage heat will start immediately. If unit is equipped with 2 heaters, secondstage heat will energize upon a call for additional heat.

Check for heating effect at supply diffusers.

4. The evaporator fan and heaters will cycle off with no

delay after thermostat temperature is satisfied.

B. Gas Heating

The gas heat units incorporate two separate systems to provide gas heat. Each system incorporates its own induced draft

motor,Integrated Gas Control (IGC) board, 2-stage gas valve,

manifold, etc. The systems are operated in parallel, for

example, when there is a call for first stage heat, both

induced draft motors operate, both gas valves are energized

and both IGC boards initiate spark.

All of the gas heating control is performed through the IGC

boards. The base module board serves only to initiate and

terminate heating operation.

The base module board is powered by 24 vac. When the thermostat or room sensor calls for heating, power is sent from

the base module board to W on each of the IGC boards. A

light-emitting diode (LED) on the IGC board will be on during normal operation. Acheck is made to ensure that the rollout switches and limit switches are closed and the induced

draft motors are not running. The induced-draft motors are

then energized and when speed is proven with the hall effect

sensor on the motor,theignitionactivationperiodbegins.The

burners will ignite within 5 seconds.

When ignition occurs the IGC board will continue to monitor

the condition of the rollout and limit switches, the hall effect

sensor as well as the flame sensor. If the unit is controlled

through a room thermostat set for fan auto., 45 seconds after

ignition occurs, the indoor-fan motor will be energized and

the outdoor-air dampers will open to their minimum position. If for some reason the overtemperature limit opens prior

to the start of the indoor fan blower, on the next attempt, the

45-second delay will be shortened to 5 seconds less than the

time from initiation of heat to when the limit tripped. Gas

will not be interrupted to the burners and heating will continue. Once modified, the fan on delay will not change back

to 45 seconds unless power is reset to the control.

When additional heatisrequired,W2closes and initiates power

to the second stage of the main gas valves. When the thermostat is satisfied, W1 and W2 open and the gas valves close

interrupting the flow of gas to the main burners. If the call

for W1 lasted less than 1 minute, the heating cycle will not

terminate until 1 minute after W1 became active. If the unit

is controlled through a room thermostat set for fan auto., the

indoor-fan motor will continue to operate for an additional

45 seconds then stop and the outdoor-air dampers will close.

If the over-temperature limit opens after the indoor motor is

stopped within 10 minutes of W1 becoming inactive, on the

next cycle the time will be extended by 15 seconds. The maximum delay is 3 minutes. Once modified, the fan off delay will

not change back to 45 seconds unless power is reset to the

control.

C. Power Exhaust Operation

The optional power exhaust packages are factory- or fieldinstalled with vertical units and optionally installed in the

return air ductwork for horizontal applications. The standard and the modulating power exhaust (used with nonmodulatng to modulating conversion package) are the two

packages offered. The modulating power exhaust package is

equipped with a field-adjustable static pressure controller to

stage up to 4 power exhaust stages which will maintain a

building static pressure. The blue controller located in the

control box below the control board can be adjusted, by

removing the covers and adjusting the set point dial to

the desired building pressure. The blue controller monitors

the 4 individual sequencers which activate the 4 individual

power exhaust motors. The standard power exhaust package

—22—

Page 23

controls up to 2 stages of power exhaust to maintain building

pressure. The power exhaust package can be configured to

deliver positive or negative building pressure. These power

exhaust stages are staged according to a percentage of the

economizer dampers position. Default values are 25% for

Stage 1 and 75% for Stage 2.

D. Smoke Control Modes

The 580G,H units with an optional expansion board perform

fire and smoke control modes. The expansion board provides

4 modes which can be used to control smoke within the conditioned area. The modes of operation are fire shutdown, pressurization, evacuation, and smoke purge. See Table 7.

E. Smoke Detector

A smoke detector can be used to initiate fire shutdown. This

can be accomplished by a set of normally closed pilot relay

contacts which will interrupt power from the 24-v transformer, secondary ‘‘B’’ terminal to the control circuit breaker

(CB4). See Fig. 33. The wire that connects these two points is

white and labeled ‘‘W78.’’

NOTE: On standard gas models, the indoor fan will continue

to run 45 seconds after the call for heat has been terminated.

If fire shutdown is initiated the fan will stop immediately.

No 45-second delay will occur.

The smoke detector may be mounted in the return air duct

or the supply duct.

F. Indoor Air Quality Control

The accessory expansion board and accessory IAQ sensor are

required for IAQ control. The IAQ sensors operate with a

4 to 20 mA signal. The 4 to 20 mA signal is connected to

T11 (+) and T12 (−) on the expansion board for the IAQ sensor, and T13 (+) and T14 (−) on the expansion board for the

OAQ (Outdoor Air Quality) sensor. The sensor is fieldmounted and wired to the expansion board installed in the

unit main control box. The IAQ sensor must be powered by a

field-supplied 24-v power supply (ungrounded). Do not use the

unit 24-v power supply to power the sensor.

Once installed, the sensor must be enabled. The sensor is configured with default values which may be changed through

network access software. To work properly, the IAQ sensor

high and low reference points for the sensor that is used

must match the configured values. The expansion board

reacts toa4to20mAsignal from the IAQ sensor. The low

reference (4 mA output) must be configured to the minimum

IAQ sensor reading. The high reference (20 mA output) must

be configured to the maximum IAQ sensor reading.

The IAQ sensor can be configured to either low or high priority. The priority value can be changed by the user. The

default is low.

Low Priority

When the priority is set to low, the initial control is to the

IAQ set point, but the outside air damper position will change

to its minimum position when the spacetemperatureisgreater

than the occupied cooling set point plus 2° F or when the space

temperature is less than the occupied heating set point

minus 2° F. The damper will also change to minimum position when the outdoor air quality is greater than the outdoor

air quality set point (ppm).

High Priority

When the priority is set to high, the IAQ set point controls

the outside air damper exclusively,with no regard to comfort

conditioning.

G. Time GuardT Circuit

The Time Guard function (built into the rooftop control board)

maintains a minimum off time of 5 minutes, a minimum on

time of 10 seconds, and a 10-second delay between compressor starts.

H. Crankcase Heater

Unit main power supply must remain on to provide crankcase heater operation. The crankcase heater in each compressor keeps oil free of refrigerant while compressor is off.

Table 7 — Smoke Control Modes

DEVICE PRESSURIZATION SMOKE PURGE EVACUATION FIRE SHUTDOWN

Economizer 100% 100% 100% 0%

Indoor Fan ON ON OFF OFF

Power Exhaust (all outputs) OFF ON ON OFF

Heat Stages OFF OFF OFF OFF

Fig. 33 — Field-Supplied Smoke Detector Wiring

—23—

Page 24

I. Head Pressure Control

Each unit has a fan cycling, outdoor thermostat to shut off

the outdoor-fan motor(s) at 55 F. The head pressure control

permits unit to operate with correct condensing temperatures down to 35 F outdoor-air temperature.

J. MotormasterT III Control

The Motormaster III Solid-State Head Pressure Control is a

field-installed accessory fan speed control device actuated by

a temperature sensor. It is specifically designed for use on

Bryant equipment and controls the condenser-fan motor speed

in response to the saturated condensing temperature. For outdoor temperatures down to −20 F, it maintains condensing

temperature at 100 F. Refer to the accessory Motormaster