Page 1

OPERATION MANUAL

Model

XL2010

brother

Page 2

CAUTKM

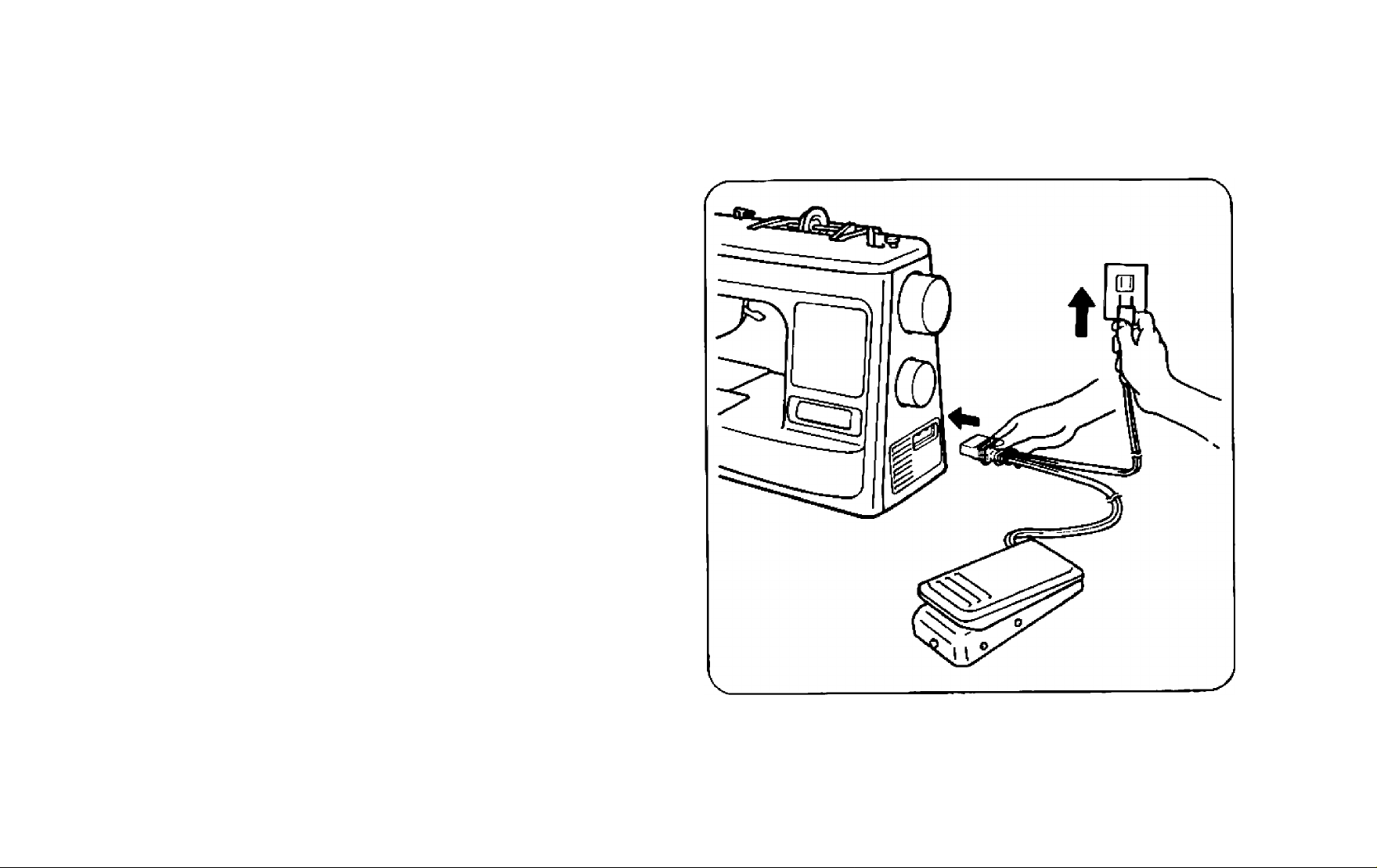

When leaving the sewing machine unattended, the power suppty

plug must be removed from the outlet. When servicing the sewing

machine, removing covers or changing the bulb, the machine or

electrical set must be disconnected from the power supply by

removing the plug from the outlet.

Page 3

CONTENTS

Page

KNOWING YOUR SEWING MACHINE

Principal parts .......................................................... 1

Accessories ............................................................

VARIOUS CONTROLS ................................................. 3

Pattern selector......................................................... 3

Stitch length dial ...................................................... 5

Reverse sewing button

Foot controller........................................................... 5

Sew-light

Free-arm model ...................................................... 6

Twin needle.............................................................. 6

THREADING THE MACHINE......................................... 7

Winding the bobbin.................................................... 7

Lower threading

Upper threading

To draw up lower thread

Tension controls

RELATIVE CHART OF SEWING FABRICS,

NEEDLE AND THREAD.............................................. 12

STRAIGHT AND ZIGZAG STITCHING

Straight stitch

Zigzag stitch

...

...

........................................................

........................................................

......................................................

..........................................................

...

.....................................................

....

.......................................

.....

................................... 10

....................................................

.........................

........................

1

2

5

5

8

9

11

13

13

15

BUILT-IN STITCHES

Blind hem stitch ...................................................... 16

Overedging stitch

Elastic stitch............................................................ 18

BUTTONHOLE AND BUTTON SEWING

Buttonhole

Button sewing ........................................................ 21

USING ATTACHMENTS AND

APPLICATIONS

Zipper insertion ....................................................... 22

Darning.................................................................. 23

Applique

Monogramming and Embroidering

MAINTENANCE.......................................................... 25

Changing the needle

Changing the bulb.................................................. 26

Cleaning................................................................. 27

Oiling ................................................................... 28

Performance check list

Repacking the machine

INDEX........................................................................ 32

................................................................

..................................................

................................................

.....................

............................................................

.........................................................

............................

............................................

..........................................

...

....................................... 31

16

17

19

19

22

23

24

25

29

Page 4

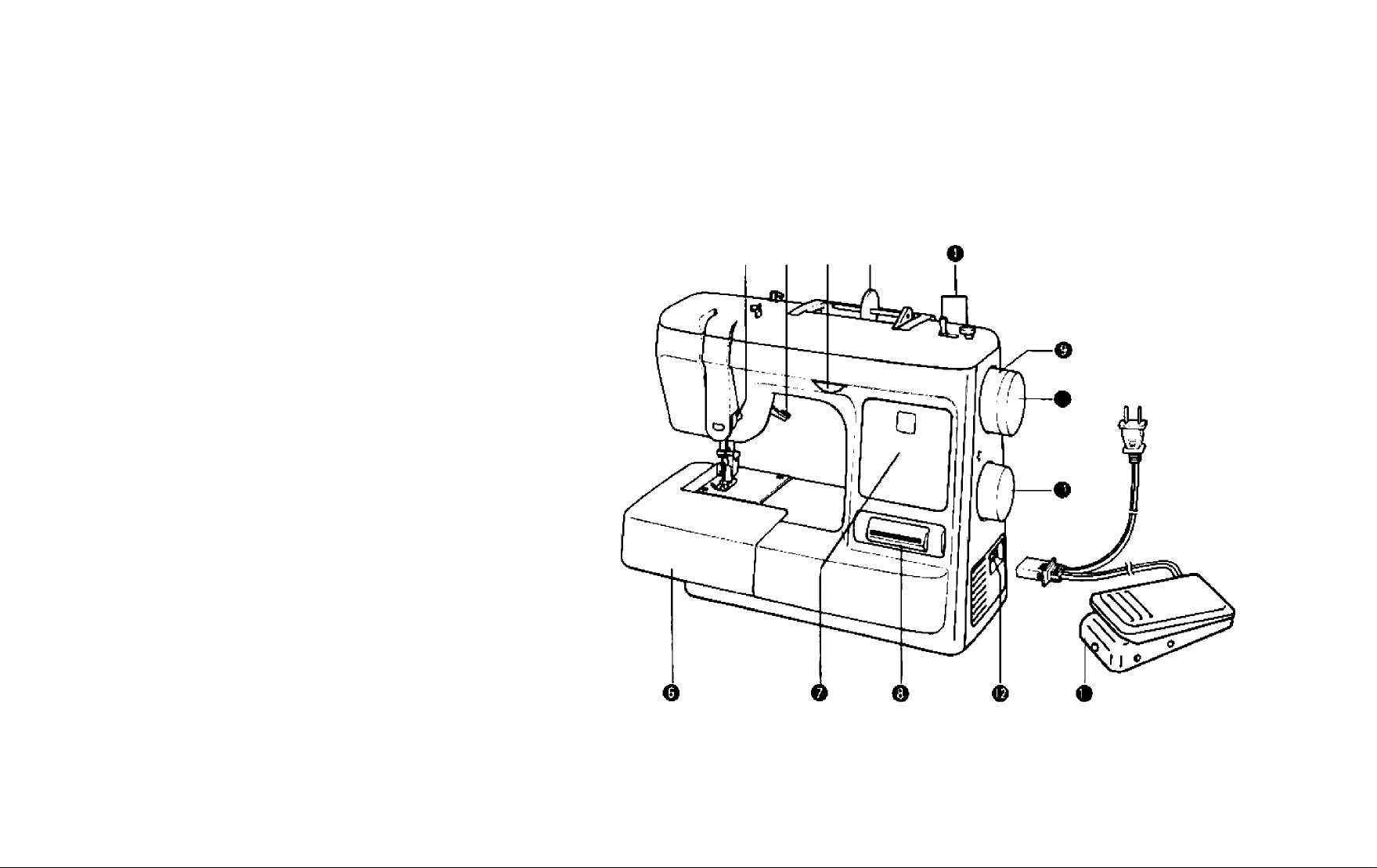

KNOWING YOUR SEWING MACHINE

Principal parts

O BOB8IN WINDER DEVICE

Winds the lower thread onto the bobbin.

O SPOOL HOLDER

0 STITCH LENGTH DIAL

Controls the feed of stitches.

O PRESSER FOOT LEVER

0 UPPER TENSION CONTROL DIAL

Controls the upper tension.

O EXTENSION TABLE & ACCESSORIES COMPARTMENT

O PATTERN INDICATION PANEL

O REVERSE SEWING BUTTON

Push for reverse stitching.

O BALANCE WHEEL

Turn toward you to iower and raise the needle.

0

CLUTCH RELEASE KNOB

0

PATTERN SELECTOR

Turn in any direction to select the desired stitch.

0 FOOT CONTROLLER RECEPTACLE

Insert the foot controller plug for operation.

0

FOOT CONTROLLER

0 o e o

Page 5

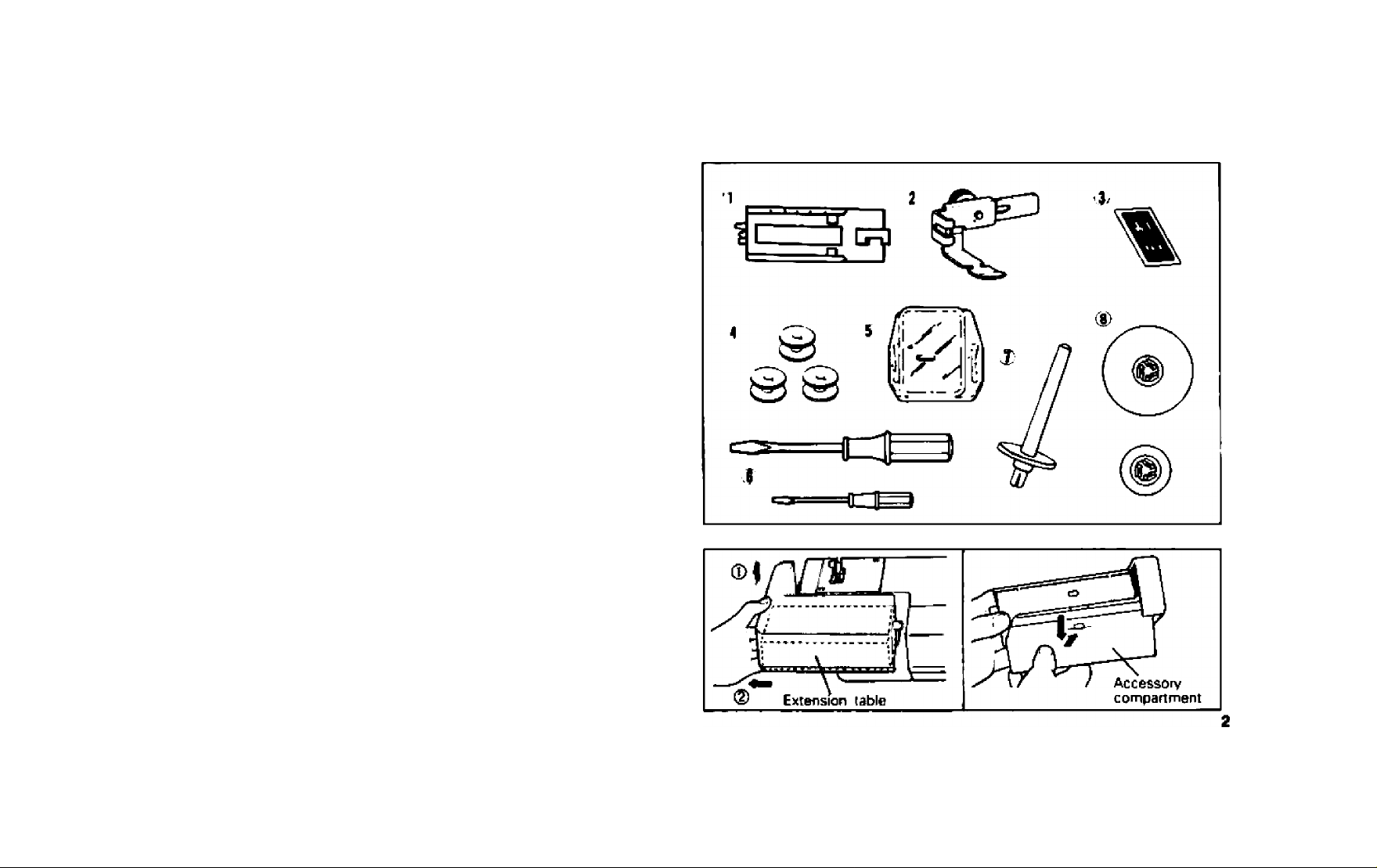

Accessories

(D Buttonhole & Button Sewing

X Zipper Foot

X' Needle Pack

(Regular Single Needle No. 14 ..

(Twin Needle

X Bobbin

X Darning Plate

T Screw Driver (Large & Small)

7 Extra Spool Pin

B Spool Holder (Large Si Small)

The above accessories are stored in the accessory compart

ment under the extension table. These accessories have been

designed tor easy and perfect sewing. For more details, see

each page listed.

........................

*.......

1 pc. (Page 19-21)

1 pc. (Page 22)

...................

......................

2 pcs. (Page 25,2B)

2 pcs. (page 7, 9)

3 pcs.)

1 pc.)

3 pcs. (Page 7)

1 pc. (Page 23)

1 pc. (Page 6)

1 set

Accessory compartment

Lift the extension table up and slide it out.

Then draw the accessory compartment down pushing its

underside.

Page 6

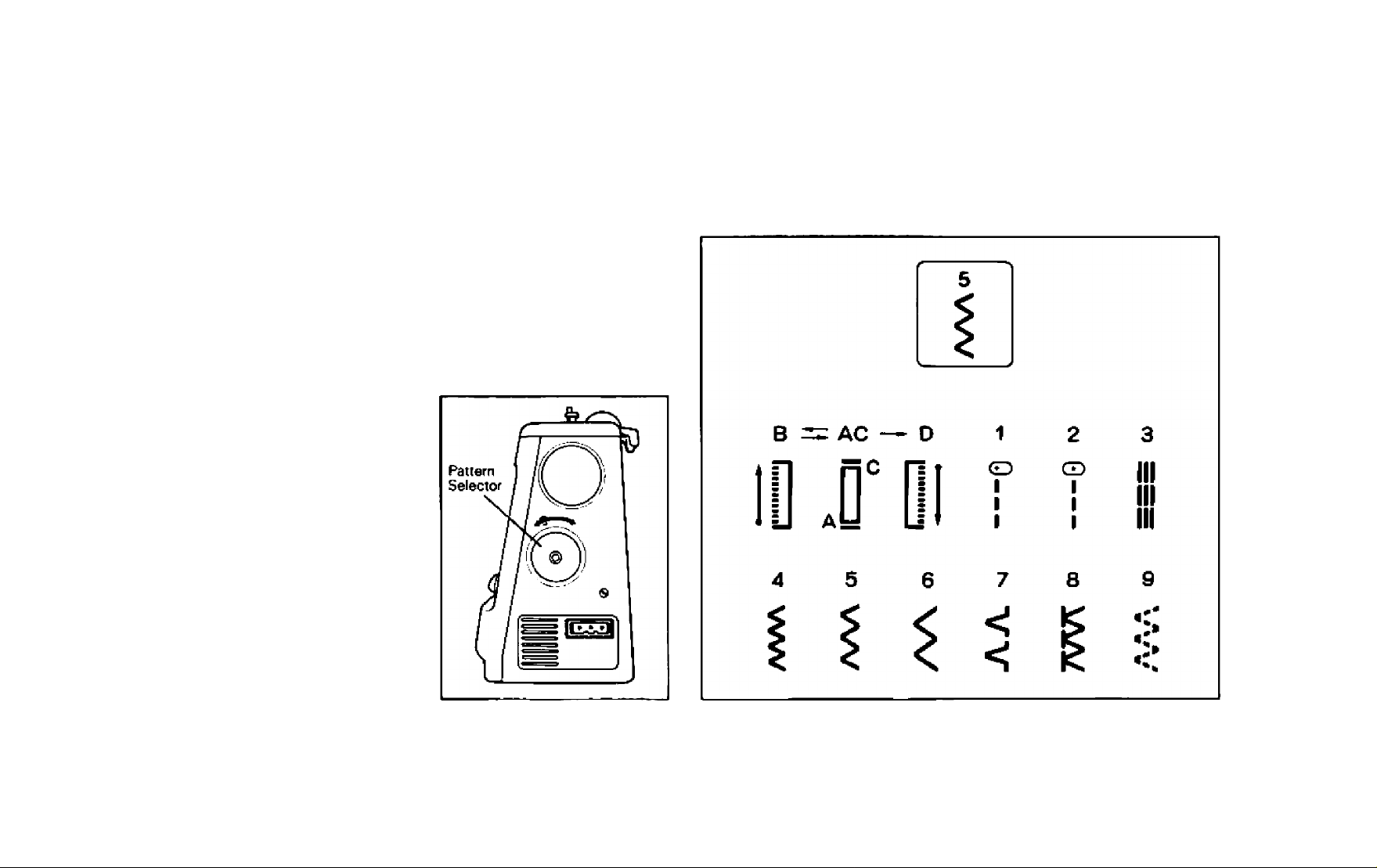

VARIOUS CONTROLS

Pattern selector

To select a stitch, simply turn the pattern selector located on

the end of the machine. All stitches are preset in width,

therefore, the stitch length is the only adjustment.

The following table represents the preset width of each stitch

and the recommended range of stitch length.

Page 7

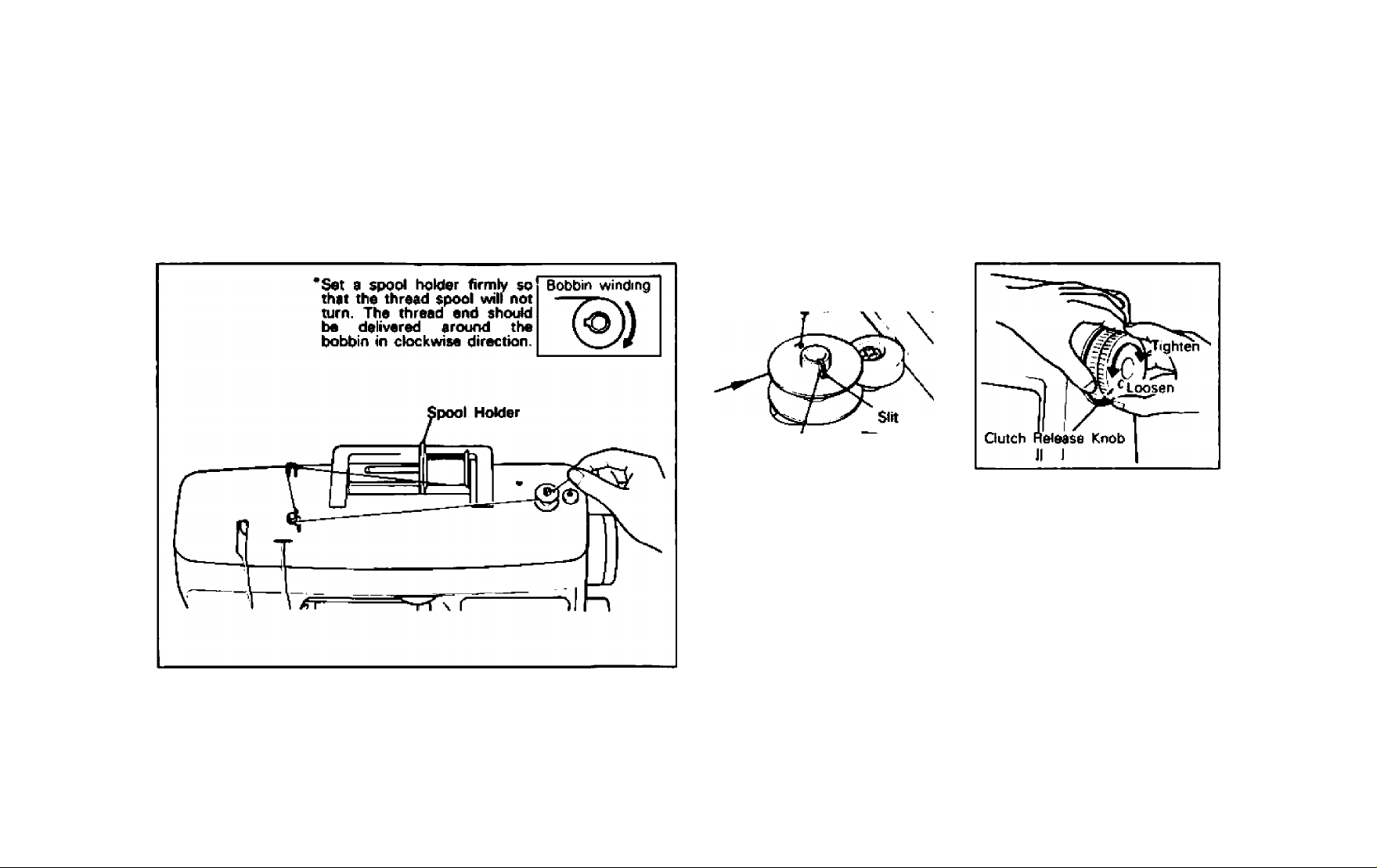

RECOMMENDED LENGTH

PATTERN STITCH NAME

A-B-C-D

1

2

3

4

5

6

7 Blind Hem Stitch 3

8

Automatic Buttonhole 4.8 F-3 19

Straight Stitch

(Left needle position)

Straight Stitch

(Center needle position)

Stretch Straight Stitch

Zigzag Stitch 1,6 F-4 15

Zigzag Stitch

Zigzag Stitch 4.8 F-4 15

Elastic Overlock

PRESET WIDTH

(MM)

0 F-4

0 F-4

0

3.6

4,8 4 17

RECOMMENDED

LENGTH (MM)

4 13

F-4

1-2 16

PAGE

13

13

15

9

Elastic Stitch

4.8 1-2 18

Page 8

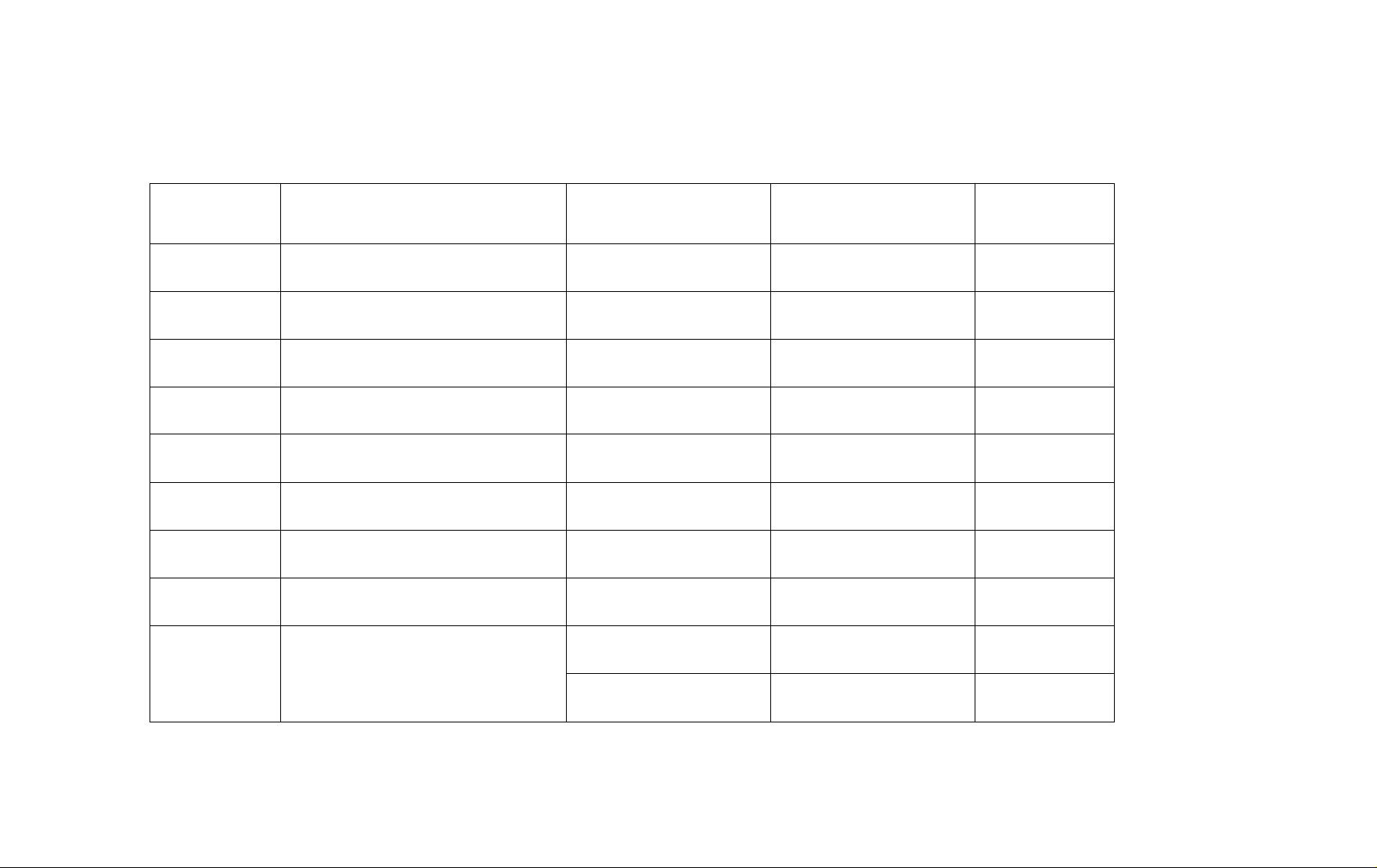

Stitch length dial

Reverse sewing

button

Foot controller

Sew-light

Depending on the stitch select

ed, you may need to adjust the

stitch length.

The numbers marked on the dial

represent the stitch length.

THE HIGHER THE NUMRER, THE

LONGER THE STiTCH.

The ‘‘O” means the material does

not feed.

The area is used for making a

SATIN stitch (closed stitch) for

buttonhole and decorative

stitches.

To sew in reverse, push the

button as far as it goes. Hold the

button in this position until you

wish to sew forward. When the

button is released, it will spring

back in original position and the

machine will sew forward. Re

verse sewing is used for backtacking and reinforcement of

seams.

When the foot controller is de

pressed lightly, the machine will

run at a low speed.

When the pressure on the foot

controller is increased, the ma

chine will pick up the speed.

When the foot controller is re

leased, the machine will stop.

Care should be taken that noth

ing is placed on the foot control

ler when the machine is not in

use.

To turn the sew-light on or off,

push the sew-light switch.

Page 9

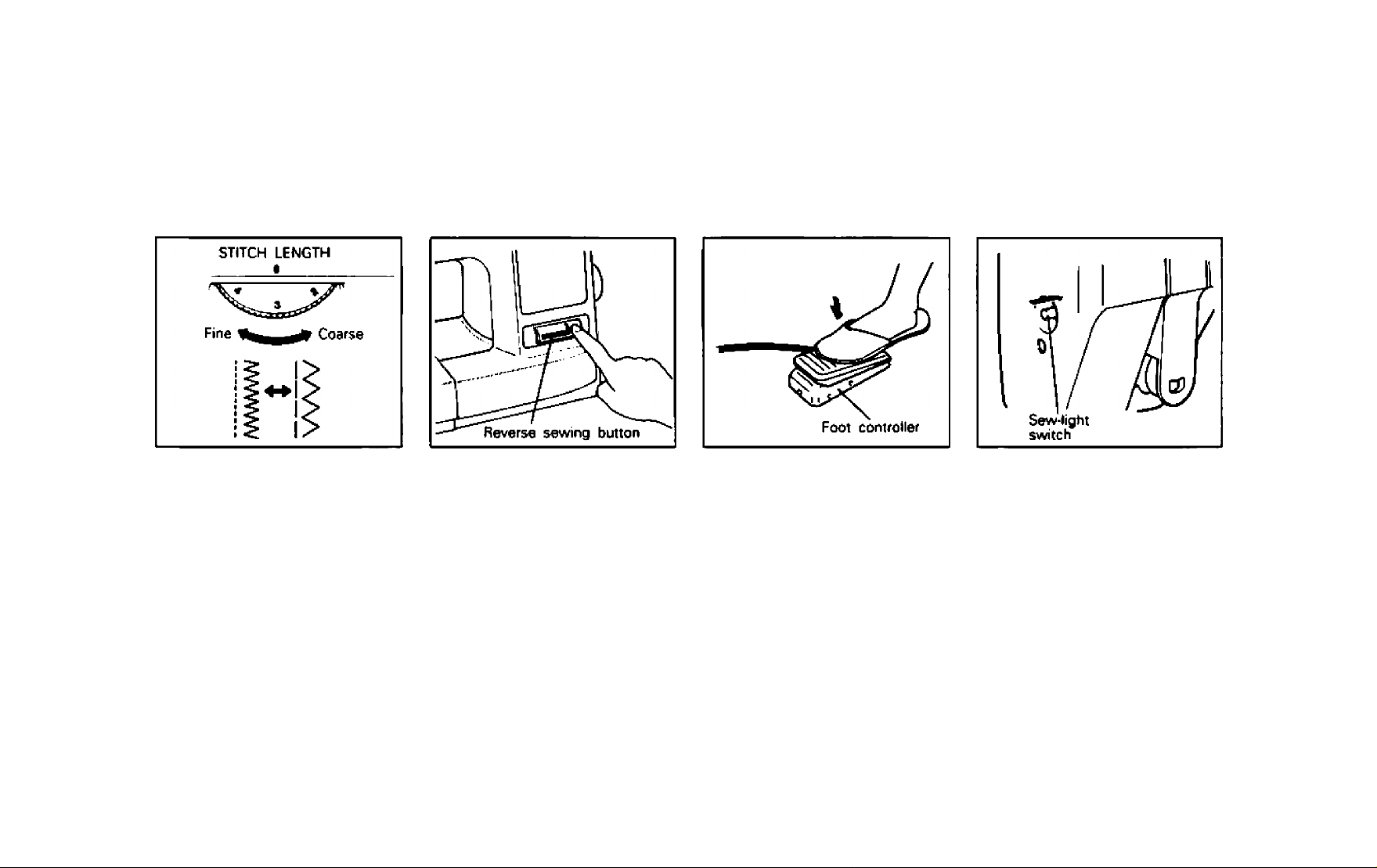

Free-arm model

Twin needle

For sewing tubular and hard-toreach garment areas, free-arm

sewing is convenient, To change

your machine to a free-arm mod

el, simply lift the extension table

then slide it out.

Vour sewing machine is designed for twin needle sewing with

Straight Stitch (Center) and Stretch Straight Stitch.

INSERTING TWIN NEEDLE

Insert the twin needle in the same manner as single needle.

THREADING TWIN NEEDLE

Set the extra spool pin into a hole on the top of the machine. Follow

the instructions for single needle threading (See page 9), but thread

each needle separately.

6

Page 10

THREADING THE MACHINE

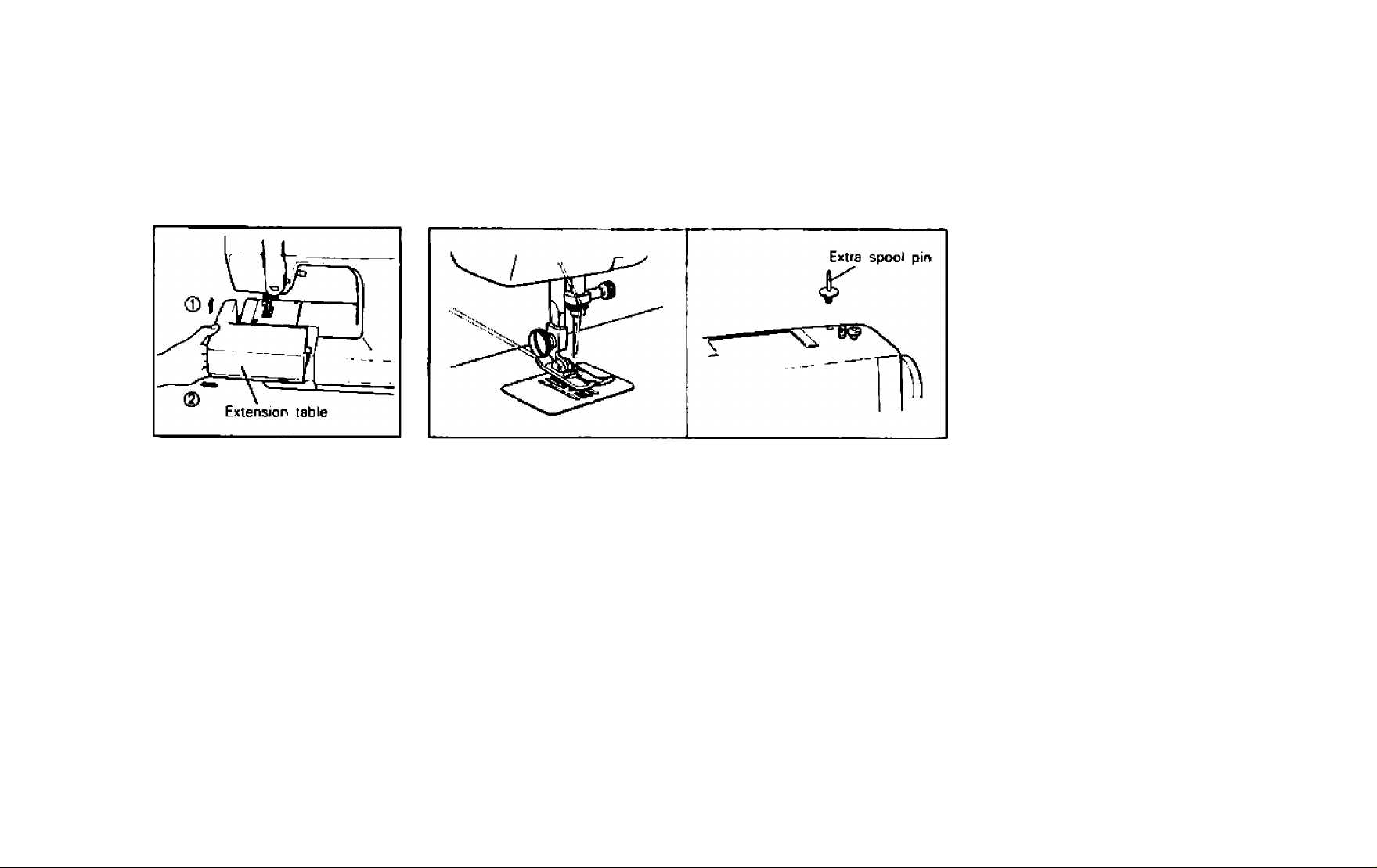

Winding the bobbin

1 ¥WVltSdWUScK^ 1

Spring

1, Dalhrar thread through tho thraad-guidas as illustrated.

2. Holding tho thread and, push

tha bobbin windar shaft to

the right.

*Tha slit on tha bobbin should

match with the spring on the

shaft.

3. Loosen tha Clutch Ralaasa

Knob by turning toward you.

Page 11

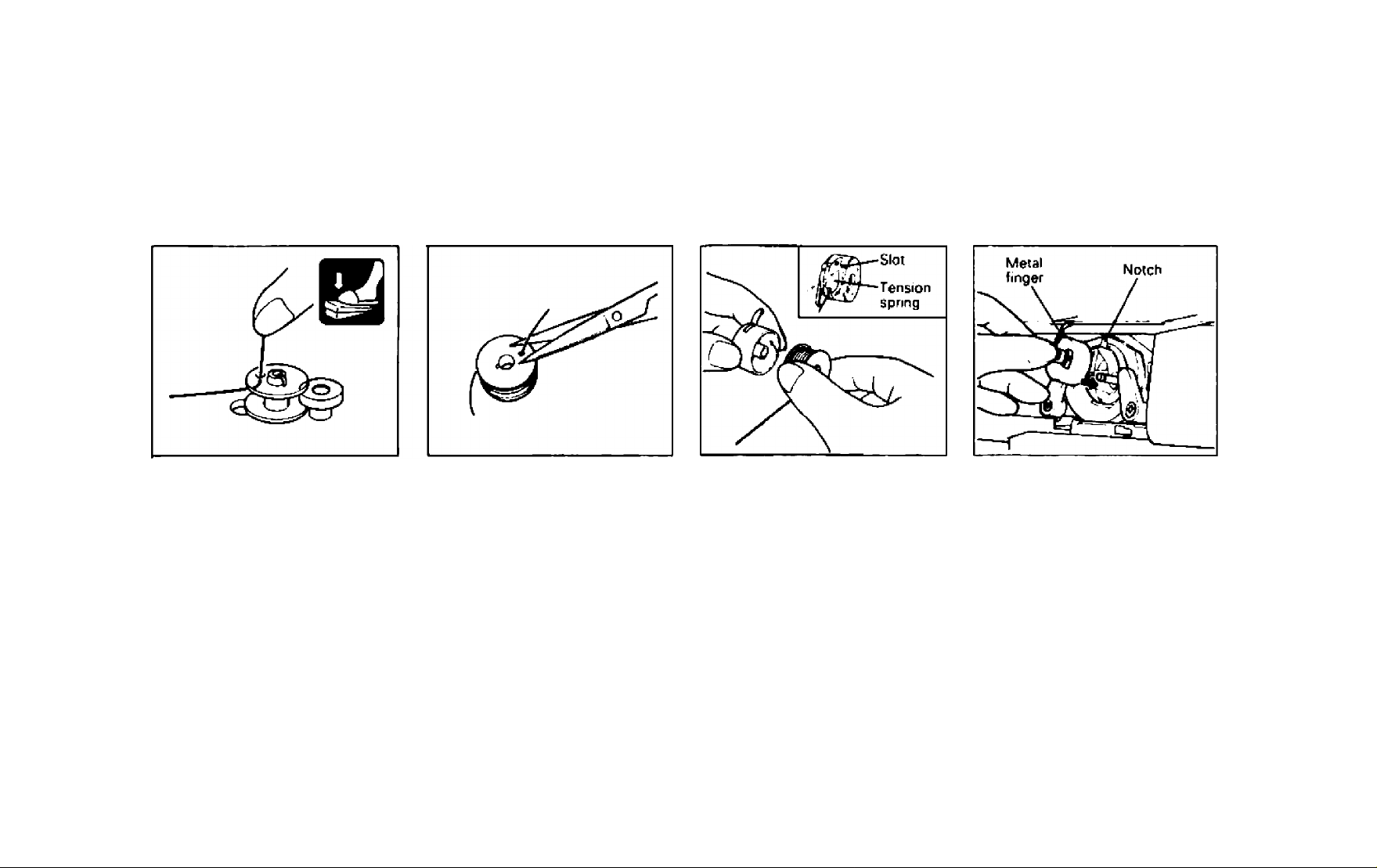

Winding the bobbin (CONTINUED)

Lower threading

Holding the thread end, de

press the foot controller to

wind the thread.

The machine stops automati

cally when the bobbin is full.

S. Push the shaft to the left.

Remove the full bobbin from

the shaft, and trim the excess

thread.

Tighten the clutch release

knob securely.

Unwind about 4 inches (10

cm( from the bobbin, and

insert the bobbin into the

bobbin case. Pull the trailing

thread into the slot, down

and to the left until it enters

the delivery eye under the

tension spring.

Holding the bobbin case

latch, insert the bobbin into

the shuttle race. Make sure to

fit the metal finger into the

notch at the top of race.

8

Page 12

Upper threading

1. Raiw th« pr«s««r foot l«v«r.

2. Raiso the needle to its high’est position by turning the

balance wheel toward you.

{Large} (Small)

PiBca a thread ^wol on

horizontal spool pin.

Choose an appropriate spoof

holder according to type and

diameter of spool being used.

(The diameter of spool holder

should be larger than that of

the spool itself)

Press the spool holder firmly

to the spool.

9

7. Make sure to guide the

thread through thread-take-

up lever from right to left.

6. Deliver the upper thread as Illustrated.

Page 13

To draw up lower thread

1. Rai«s the needle and the

presser foot to the highest

position. With left hand, hold

the end of upper thread and

with right hand, turn baiance

wheel toward you until the

needle moves down and up

again to its highest position.

2. The upper thread has caught 3. Pull about 4 inches (10 cm) of

the lower thread in a loop.

Pull the upper thread toward

you and the lower thread will

come up from the bobbin in a

large loop.

thread under the toe of the

presser foot toward the back

of the machine.

10

Page 14

Tension controls

11

■ Upper tension is

loo tight.

Locks appear on the

fabric surface.

■ Upper tendon Is

too loose.

Locks appear on the

reverse side of the

fabric.

o

O

f(

Upper Tension DisI

Decrease tension

Lower number

Bobbin

Correct tension is important be

cause too much or too little ten

sion will weaken your seems or

cause puckers on your fabric.

Page 15

RELATIVE CHART OF SEWING FABRICS, NEEDLE AND THREAD

SEWING MATERIALS

VERY THIN

LIGHTWEIGHT

MEDIUM

HEAVY

Fine tricot. Fine lace.

Thin linen. Silk, Tulle,

Chiffon

Organdy, Jersey, Voile,

T afteta, Synthetics,

Silk,

6a^e

Cotton, Gingham, Poplin,

Percale, Pique, Satin,

Velvet, Lightweight wool.

Fine corduroy. Suitings

Denim, Gabardine,

Tweed, Corduroy

NEEDLE

SIZES

9

11

14

16

NOTE;

1. Select the correct needle end thread size from the above chart.

2. Use the same size thread for the upper and lower threads.

THREAD SIZES

Cotton; 80

Synthetic

Fine Mercerized Cotton

Cotton: 60'80

Silk: “A"

Synthetic

Mercerized 50

Cotton: 50-60

Silk; “A"

Synthetic

^^гceгized 50-60

Cotton: 40-50

Mercerized Heavy Duty

12

Page 16

STRAIGHT AND ZIGZAG STITCHING

13

Straight stitch

1 (Left needle position)

2 (Center needle position)

3 (Stretch Straight Stitch)

How to Start Sowing

1. Raise the needle to its highest

position and lift the presser

foot.

Pattorn

Stitch Length

1-4

2. Pull up the lower thread by

turning the balance wheel

toward you and pull both up'

per and lower thread to the

back of presser foot.

3. Place fabric under the presser

foot and position needle 5/8

inch (10 mm) beyond fabric

edge.

4. Lower the presser foot.

5. To back tack, push the Re

verse Sewing Button as far as

it goes. Reserve sewing is

used for locking end of seam

and where reinforcement is

needed.

6. Release the Reverse Sewing

Bunon and start sewing in

forward direction.

How to Change Sewing Direc>

lion

1. Stop the machine at the turn

ing point while the needle is in

the fabric.

2. Raise the presser foot and

turn the fabric to its new di

rection while the needle acts

as the axis.

3. Lower the presser foot and

start sewing in new direction.

Page 17

How to Finish Your Sowing

Projsct

Reverse stitching is used to lock

the threads at the end of the

seam or wherever reinforcement

is needed.

1, This is done by stitching to

the end of the seam. Then

stop.

2. Push the Reverse Sewing But

ton and stitch backward for

3/8 inch (10 mm) from end of

the seam fabric.

How to Remove from Machine

1. Stop the machine.

2. Raise the needle to its highest

position and make sure that

the thread take-up lever is

also in the highest position.

3. Lift the presser foot and pull

out the fabric gently to the left

side.

4. Cut both threads by the

thread cutter equipped with

the machine.

5. To prepare the machine for

the next seam, pull 4 inches

(10 cm) of thread between the

toe of the presser foot toward

the back of the machine.

Top Stitching atKf Stretch Mate

rials

No. 1 (Left needle position) is

used for Top stitching and sew

ing light weight fabrics.

No. 3 (Stretch Straight Stitch) is

for stretchable fabrics.

14

Page 18

Zigzag stitch

Pattern

4 (Stitch Width at 1.6

15

Stitch Length

5 (Stitch Width at 3.6 mm|

6 (Stitch Width at 4.8 mm)

SIMPLE ZIGZAG STITCHING

Select the Pattern number de

pending on the width you need

and select the stitch length.

It is recommended to sew the

straight stitch at the beginning

and end of zigzag stitches,

F-4

SATIN STITCH

When stitch length is set at “F”

position, it produces the "SATIN

STITCH" used for making button

holes or decorative stitches.

Page 19

BUILT-IN STITCHES

Blind hem stitch p^twn

Stitch Length

1 7 (Blind Hem Stitch) 1-2

1. Thread used should be the

same color as the fabric used.

2. Fold the fabric to the size of

hem desired and then fold

back as shown in Figure A.

Leave 1/4 inch overlap at

edge.

3. Sew on the fold as in Figure B.

4. When the fabric is unfolded

you will have a blind stitch

hem as in Figure C.

Fig. B

16

Page 20

Overedging stitch

Pattern

Stitch Langth

8 (Elastic Overiock Stitch) 4

Position the fabric under the

presser foot so the right (zigzag)

side of the stitch pattern forms

along the cut edge of the fabric.

The left hand (straight stitch pat*

tern) forms the seam stitching

tine of approximately 1M inch

seam allowance, tf the seam al

lowance is wider than the stitch

pattern, trim away any excess

fabric after stitching.

17

Page 21

Elastic stitch

Pattern

I

9 (Elastic StKch)

Stitch Langth

1-2

/ ^

;l:

1

MENDING

1. Set the stitch Length Dial be

tween F-1-

2. Place reinforcement fabric un

der tear.

3. Following the line of tear, sew

using the elastic to join both

sides of the tear.

SEWING ELASTIC

1. Place the elastic on the fabric.

2. As stretch elastic

both in front and in back of

the presser foot as shown in

illustration.

H.. Ir

JOINING STITCH

1. The elastic stitch is used to

join fabric together.

2. Place fabric edge to edge un

der the presser foot.

3. Sew together using elastic

stitch. Care should be taken to

keep the two fabric edges

close together.

18

Page 22

BUTTONHOLE AND BUTTON SEWING

Buttonhole

Pattern

В AC D F-3 Buttonhole foot

Stitch Length Foot

Automatic buttonhote making is a simple process that provides

reliable results.

MAKING BUTTONHOLE

1. Use buttonhole foot with sliding portion.

2. Using tailor chalk, mark the position of buttonhole on the fabric.

3. Attach the buttonhole foot and push its sliding portion backward

until it stops.

4. Place the fabric under the presser foot so that front end of bar tack

can be sewn first.

19

NOTE; It is a good idea to practice making a buttonhole on a scrap of

fabric before attempting the actual garment.

Page 23

PROCEDURE OF MAKING BUTTONHOLE

Stop

Step A

(Front

end of

bar

tack)

StepB

(Left

side

row)

StepC

(Back

end of

bar

tack)

StepD

(Right

side

row)

Sowing

Pattorn

How to sow

1. Set the pattern at A.

2. Lower presser foot and sew 5

to 6 stitches.

3. Stop machine and raise needle

from the material.

I 1. Turn the pattern selector and

I set at B.

I 2. Sew predetermined length,

j 3. Stop machine and raise the

needle.

1. Turn the selector and set at C

(same position as A).

2. Sew 5 to 6 stitches.

3. Stop machine and raise the

needle.

1. Set at 0.

2. Sew the right side row until the

needle reaches position D.

HOW TO SECURE STITCHING

AND CUT MATERIAL FOR BUT

TONHOLE.

1. To secure stitching, turn the

material 90 degrees counter

clockwise and sew 5-6

straight stitches.

2. Remove the material from the

machine. Cut opening in but

tonhole with seam ripper tool.

Care should be taken not to

cut through any stitching.

3. It is recommended that pins

are placed across both ends

of buttonhole as a protection

against cutting bar tack stitch

ing.

20

Page 24

Button sewing

Pattern

4 or 5 or 6

Stitch Length

Any position

Foot

Button Sewing

Foot

1, Measure the distance between the holes and select the Pattern.

Others

Darning plate

21

Button sewing foot

Distance of

holes

1.6 mm

{0.06 inch)

3.6 mm

(0.14 inch)

4.8 mm

(0.19 inch)

2. By removing the sliding portion of buttonhole foot, you will have a

button sewing foot.

3. Place the Darning Plate on the needle plate.

4. Place a button between the foot and fabric, and make sure that

needle enters both holes without hitting the button.

5. At slow speed, sew approximately 10 stitches.

6. Remove the button from the machine. Cut upper and lower

threads and tie both threads at back side.

k—

Pattern

4

5

6

________________^

Page 25

USING ATTACHMENTS AND APPUCATIONS

Zipper insertion ;

______

Stitch Length

2-3

Zipper foot is used to sew vari

ous types of zippers and can

easily be positioned to right or

left side of needle. When zipper

is sewn at right side of the nee

dle, place the zipper foot by

loosening thumb screw and slid

ing zipper foot to the left.

When the zipper is sewn at left

side of needle, place the zipper

foot by loosening thumb screw

and sliding zipper foot to the

right.

Foot

____

Zipper Foot

1. Lower needle into side notch

located on the presser foot

(right or left).

2. Tighten the thumb screw to

lock presser foot into position.

3. To sew opposite side of zip

per loosen thumb screw and

place the zipper foot (right or

left.)

22

Page 26

23

Darning

! Pattern Dial

r 2 ^

1. Set the darning plate on the

needle plate as illustrated.

2. Place portion to be darned

under the presser foot to

gether with fabric underlav for

reinforcement.

3. Lower the presser foot.

Stitch Length

fikny position

Others

Darning Plate

4. Sew alternately drawing the

work gentty away from you

and pulling it toward you.

5. Repeat this motion until the

portion to be darned is filled

with parallel lines of stitching.

Applique

Pattern Stitch Lanoth

4 or 5 or 6

F-2

1. Baste the cut design to the

fabric.

2. Sew carefully around the

edge of the cutout design.

3. Cut away surplus fabric out

side of stitching.

4. Remove basting.

NOTE: Make reinforcement

straight stitches at be

ginning and the end of

the stitches.

Page 27

Monogramming and Embroidering

Pattern

Stitch Length

4 or 5 or 6 At any position

PREPARATION FOR MONO

GRAMMING AND EMBROIDER

ING

1, Place the darning plate on the

needle plate.

2. Set your sewing machine as

per the above instructions.

Foot Others

Remove Darning plate

3. Draw lettering (for monogramming) or design (for em

broidering) on the right side

of the fabric,

4. Stretch work between em

broidery hoops as firmly as

possible.

5. Place the work under the nee

dle and lower the presser bar.

6. Pull the lower thread up

through the work at starting

position by turning balance

wheel and make a few hold

ing stitches.

6. Hold the hoop with thumb

and forefingers of both hands

while pressir^g the fabric with

middle and third fingers and

supporting the outside of

hoop with smaller finger.

1. Sew, moving hoop slowly

along the lettering at the same

speed.

2. Secure with a few straight

stitches.

(NOTE: These instructions also

apply to embroidering.)

1. Stitch the outline of the de

sign by moving the embroi

dery hoop accordingly,

2, Fill in design stitch from the

outline of the design to the

inside and from inside to edge

of the outline alternately until

design is completely filled in.

Keep stitching close together.

NOTE: A long stitch is made by

moving the embroidery

hoop rapidly and a short

stitch is made by mov

ing it slowly.

24

Page 28

MAINTENANCE

Changing the needle

25

• Remove the power supply plug from the outlet.

1. Remove the needle

Lower the presser foot

loosen the screw,

and

Inserting the needle

With the flat side facing back,

insert the needle as far as it

will go against the needle

stopper. Tighten the screw.

• How to check the needle.

for smooth sewing.

as shown

right.

in illustration at

Page 29

Changing the bulb

• Remove the power supply plug from the outlet.

1. Loosen the screw.

machine.

4. Attach the face plate and fas*

ten the screw.

26

Page 30

Cleaning

Remove the power supply plug from the outlet.

27

Lint and dust easily accumulate. Always keep clean.

Retaining ring

Latch lever

yww

HOW TO REMOVE THE SHUTTLE HOOK

1. Raise the needle to its highest position.

2. Open the shuttle cover.

3. Take out the bobbin case.

4. Push latch levers outside and remove the retaining ring.

5. Remove the hook by grasping center post of the hook.

NOTE: When needle is lowered, shuttle hook cannot be

removed.

Hook

sa.co

Race body

Driver

Retaining ring

t

CLEANING SHUTTLE RACE

1. Remove accumulated lint and thread

from the retaining ring, hook, driver and

race body with brush.

2. A cloth dampened with machine oil

should be used to wipe shuttle race

clean.

3. Clean shuttle hook in same manner as

above.

4. Reassemble and push the latch levers

inside.

CLEANING FEED DOG

1. Take out the needle plate.

2. Clean the upper part of feed

dog and shuttle race body

with a brush.

Page 31

Oiling

Remove the power supply plug from the outlet.

OIL ONCE A WEEK IF THE MACHINE IS USED MORE THAN ONE

HOUR PER DAY.

IF THE MACHINE IS USED MORE OFTEN OIL EVERY DAY.

• OIL 2 TO 3 DROPS TO THE POINTS MARKED

• After oiling, run the machine fast without thread.

• Be sure to wipe off any excess oil.

Page 32

Performance check list

Whenever sewing difficulty is encountered, review the section of the instruction book that explains the operation you are performing to make

sure you are using the machine correctly. If the problem still exists, the following check list may help you correct it.

If you still have difficulties, contact your nearest service center.

29

UPPER

THREAD

BREAKS

LOWER

THREAD

BREAKS

SKIPPED

STITCHES

LOOP IN

SEAM

Upper threading

is not correct.

T”

'^PagaS

-^Page 10

Needle is not

correctly

inserted.

►Pageto

Thread tension

is not correct.

—►PageTi

No

upper thread is

tangled.

Bobbin is not

threaded pro>

perly in the

shuttle hook.

No

Inferior needle

is used.

No

No

Upper thread

tension is too

tight.

' ►Pages ^- ►PageIT

No

Lower thread

tension is

too tight.

►Pages

No

^Page 25

^ ►Page 11

The combina

tion of needle/

thread/ fabric is

wrong.

TT

w^Page12 -►Page 27

Spool of thread

^ is not correctly

set.

•Page?

No

No

Lint is clinging

under the

needle plate.

No

Needle is bent or

not sharp.

No

Threading is not

correct.

’age 25

•Page 9

The combine'

No

tion of needle/

thread/ fabric ie

wrong.

No

No

I—fc-Pagel 2

U

(A

I

O

u

Page 33

-►Page 27 -Page 28

LU

u

lU

U

>

s

§

No

30

Page 34

Repacking the machine

Keep the carton and packing materials for future uee when it is necessary to reship the sewing machine. Improper

packing or improper packing material could result in damage during shipping, Instructions for repacking the

machine are illustrated below.

31

Page 35

INDEX

Page

Accessories

Applique ....

Blind hem stitch

Buttonhole

Button sewing ..

Changing the bulb ...

Changing the needle

Cleaning

Darning

Draw up lower thread

Elastic stitch..................................................................................... IB

Foot controller .

Free-arm model

Lower threading

Monogramming and embroidering

Oiling

Overedging stitch

..........

....................

.......................

.................................

.................................................

................................

.... 2

.... 23

16

19

21

26

25

27

23

10

24

28

17

Page

Pattern selector

Performance check List.................................................................. 29

Principal parts................................................................................... 1

Relative chart of sewing fabrics, needle and thread.............................. 12

Repacking the machine.................................................................... 31

Reverse sewing button ...................................................................... 5

Sewing-light....................................................................................... 5

Stitch length dial................................................................................. 5

Straight stitch .................................................................................. 13

Tension controls

Twin needle ...................................................................................... 6

5

6

8

Upper threading ............................................................................... 9

Winding the bobbin .......................................................................... 7

Zigzag stitch..................................................................................... 15

Zipper insertion................................................................................ 22

.................................................................................

..............................................................................

3

11

32

Loading...

Loading...