EN

'/<

Quick Reference Guide

Be sure to rst read the “Important Safety Instructions” in the Product Safety Guide.

This Quick Reference Guide contains basic instructions and information for your Brother machine.

Store this Quick Reference Guide in a safe place, where it can be easily accessed for future reference.

Refer to the Operation Manual for detailed instructions.

The Operation Manual as well as other instructions can be downloaded

from the Brother Solutions Center (http://s.brother/cmoae/).

IMPORTANT

STEP 3

Install the Holder

21

3

4

5

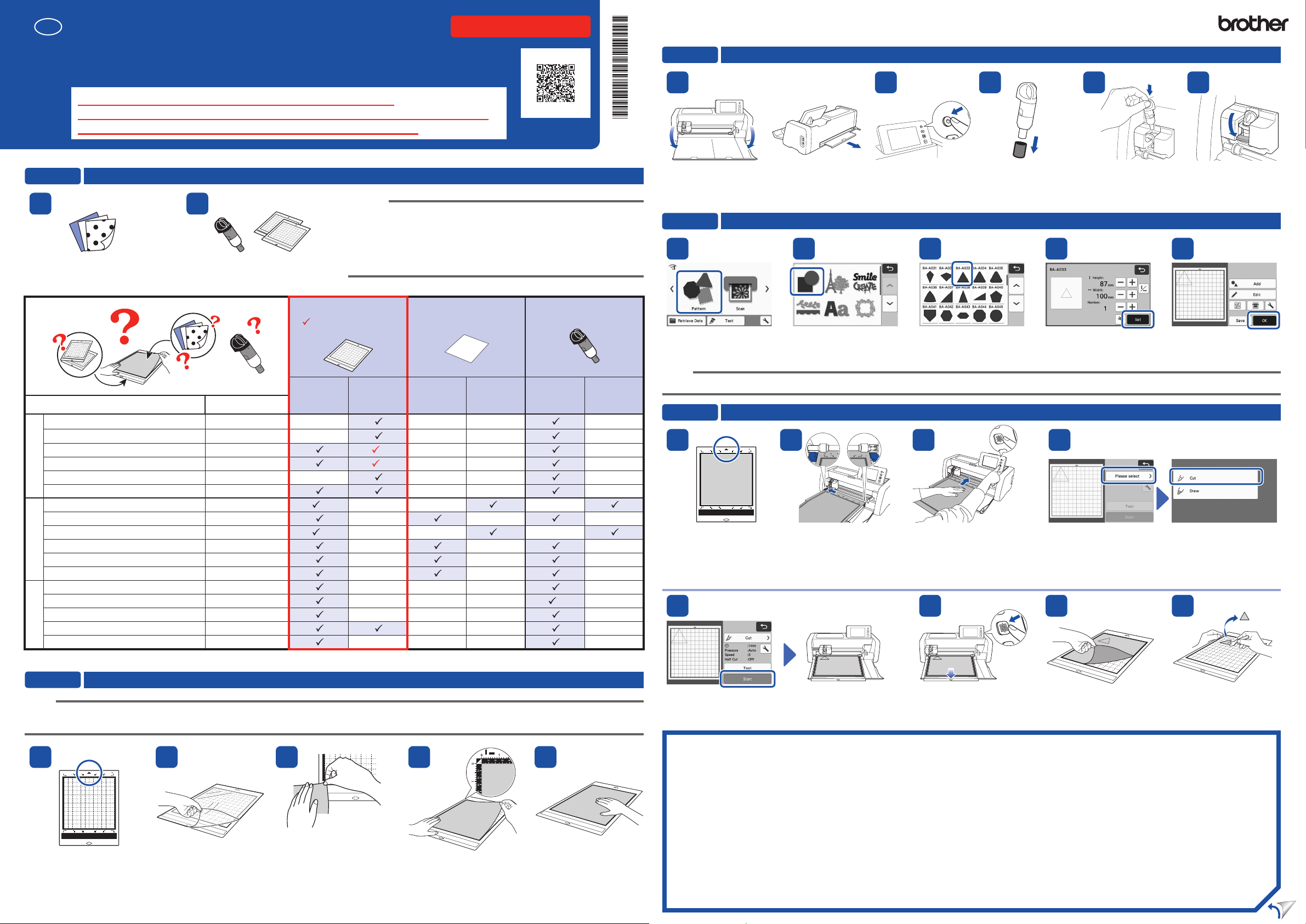

STEP 1

1 2

Prepare the material to be cut. Referring to the following table,

Printer paper 80 g/m² (0.1 mm)

Scrapbook paper (thin) 120 g/m² (0.15 mm)

Scrapbook paper (medium-thick)

Cardstock 280 g/m² (0.35 mm)

Paper

Vellum, tracing paper 0.07 mm

Poster board 400 g/m² (0.5 mm)

Thin cotton fabric (for quilt piece) 0.25 mm

Thin cotton fabric (except for quilt piece) 0.25 mm

Flannel (for quilt piece) 0.5 mm

Flannel (except for quilt piece) 0.5 mm

Fabric

Felt 3 mm

Denim 14 oz 0.75 mm

Plastic sheet (PP) 0.2 mm

Vinyl 0.2 mm

Magnet 0.3 mm

Others

Sticker or seal 0.2 mm

Foam sheet 3 mm

STEP 2

Mat and Blade Selection

select a mat and blade appropriate

for the material.

Material Thichkness

200 g/m² (0.25 mm)

*1: Fabric Mat (CADXMATF12) can be used instead of the Standard Tack Adhesive Mat and the High Tack Adhesive Fabric Support Sheet.

*2: Vinyl Auto Blade Holder included in Vinyl Auto Blade Kit (CADXVBKIT1) and Disney Vinyl Auto Blade Kit (CADXVBDSNKIT1) is also recommended.

Attach the Material to the Mat

Memo

● An auto blade holder is included with this machine. Using the auto blade

holder, the thickness of the material is detected, and the blade extension

automatically adjusts based on the material’s thickness.

● Use the mat designed specically for ScanNCut DX.

● Depending on your machine model, some accessories may not be

included. Additional purchase may be required.

Mat (for ScanNCut DX)

* When cutting paper with

a smooth surface

Standard Tack

Adhesive Mat

Low Tack

Adhesive Mat

X

*

*

*1

*1

Sheet for fabric cutting Auto blade holder

Iron-on Fabric

Appliqué Contact

Sheet

(White Backing)

High Tack

Adhesive Fabric

Support Sheet

*1

*1

Auto Blade

(Black)

*2

Thin Fabric Auto

Blade (Beige)

Note

● Craft paper or fabric covered with decorative layer (that can easily separate) such as lamé or foil is not recommended for use. If such media is used or tested

it is recommended to clean the scanner glass inside the machine after every use.

cord to the machine,

and then open the

front tray cover.

STEP 4

Select the Pattern

1

Select “Pattern”.

Pull out the rear tray.

2

Select your choice of

pattern category.

Turn on the machine.Connect the power

3

Select your choice of

pattern.

Remove the

protective cap.

4

Check the pattern size and

number of pattern(s), and

then touch the “Set” key.

Hold the blade holder

and then install it in the

carriage with the Brother

Logo facing you.

Check the pattern(s)

placement, and then

touch the “OK” key.

Press down the

holder lock lever.

5

Note

● We recommend performing “Test/Trial Cut” before cutting your project. Please refer to “Test/Trial Cut (For Desired Cutting Results)” on the next page.

STEP 5

Load the mat (arrow

facing up).

Load the Mat and Start Cutting

For smooth feeding, align the

top of the mat with the guides

on the right and left sides

of the feed slot and insert it

under the feed rollers.

Lightly place your hand on

the center of the mat and

gently push it forward while

pressing the “Feed” button

on the operation panel.

3

421

Touch “Please select” key then select “Cut” in the

preview screen.

5 76 8

Touch the “Start” key to

start cutting.

When cutting is nished,

touch the “OK” key on

the screen.

Press the “Feed” button

in the operation panel to

release the mat.

Peel off the material. Use the spatula to peel off

the cutout pattern.

*After using a mat, cover it with the protective sheet.

1

Make sure that the arrow

is facing the machine

feeder (top side up).

2

Peel off the protective

sheet.

*Keep the protective sheet for

storage use.

3

Before attaching your choice

of material onto the mat, check

if the strength of the adhesive

is suitable by test attaching the

material onto the edge of the

adhesive side of the mat.

4

If the adhesive is ok,

attach the material onto

the mat’s adhesive.

5

Apply some pressure to

rmly attach the material

onto the mat.

Fabric Cutting Basics

Refer to the “Mat and Blade Selection” table, and

use an iron-on fabric appliqué contact sheet, a

high tack adhesive fabric support sheet or fabric

mat to cut fabric. Refer to the instructions included

with the iron-on fabric appliqué contact sheet, high

tack adhesive fabric support sheet or fabric mat

for details. If these accessories are not included

with your machine, purchase the optional iron-on

fabric appliqué contact sheet (CASTBL1), high tack

adhesive fabric support sheet (CASTBL2) or fabric

mat (CADXMATF12). Some optional accessories

may not be available in other countries.

Iron-On Fabric Appliqué Contact Sheet

● Reinforces the fabric so that various patterns can be cut out.

● Original texture may change because it remains attached to the back of the fabric.

Use the standard mat. Do not place fabric with an iron-on fabric appliqué contact sheet

*

attached to the back directly onto a mat with a high tack adhesive fabric support sheet

attached.

High Tack Adhesive Fabric Support Sheet

● By attaching this adhesive sheet to the standard mat, the adhesive strength of the mat will

increase.

● Cut results may vary depending on the shape of the selected pattern.

Fabric Mat

● With this mat, High Tack Adhesive Fabric Support Sheet is not required.

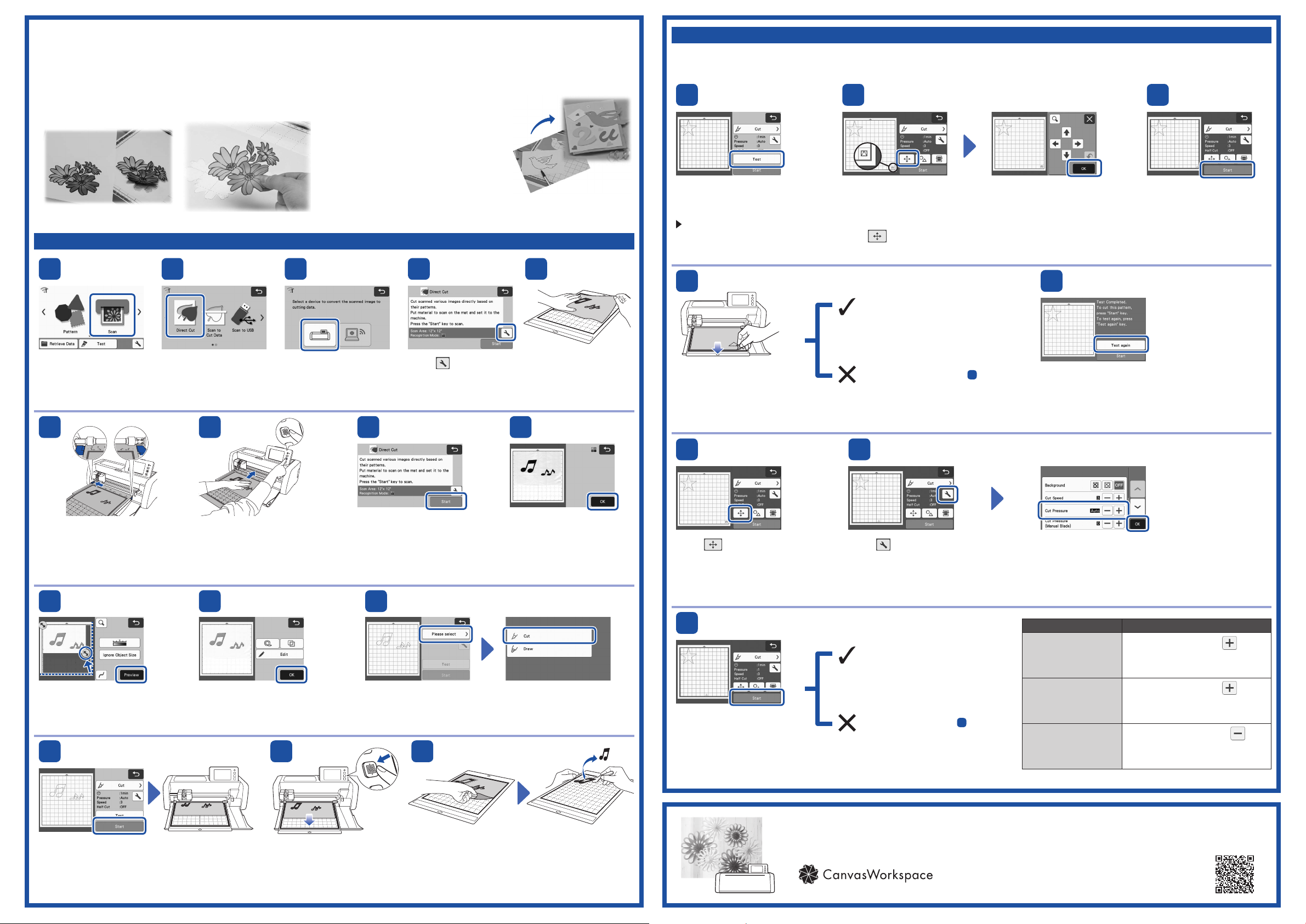

Scanning Functions

Scan an illustration, photo or your own drawing to create personalized cut designs. The design can then be cut out or saved as data.

Direct Cut

An original illustration can be scanned and its outline can be cut out.

Scan to Cutting Data

An original illustration can be scanned,

converted to cutting lines for cutting/

drawing with this machine, then saved

as data.

Refer to the Operation Manual for

*

detailed instructions.

Test/Trial Cut (For Desired Cutting Results)

Before working on your actual project, using your choice of material we recommend that you test cut or test the pen/ink (for draw function) to make sure

that you’ll get the desired results. If you achieved your desired results, continue with your project using the same materials you tested.

1

2

3

Direct Cut (Scan and Cut Material’s Pattern(s))

1

Select “Scan”.

2 3

Select “Direct Cut”. Select the destination for

the cutting data.

6

After selecting “Cut” in the

preview screen, touch the “Test”

key.

The test pattern will appear at

the bottom right.

4

5

4

Touch

the scan settings.

key to specify

87

Attach the original

(stamped paper, printed

paper/sticker, etc.) to the

mat.

9

without feeding out the mat,

peel off the cutout and check

the “Test/Trial Cut” results.

6

Make sure that the test pattern

does not overlap the pattern

for your project. To change

the test pattern location,

touch .

If the result of the “Test/Trial Cut” is

good (clean and no-fray) continue

cutting your project by touching the

“Start” key on the screen.

If you are not satised with the “Test/

Trial Cut” result, follow the pressure

settings procedure from

perform “Test/Trial Cut(s)” until you

have the best result.

7

After making the desired

changes, touch the “OK” key.

5

5

, and

Touch the “Test again” key.When “Test/Trial Cut” is done,

Touch the “Start” key to start

test/trial cutting.

top of the mat with the guides

on the right and left sides of the

feed slot and insert it under the

feed rollers.

10

After selecting the area to be

cut out, touch the “Preview”

key and then “OK” key.

13

Touch the “Start” key to

start cutting.

When cutting is nished,

touch the “OK” key.

Lightly place your hand on the

center of the mat and gently

push it forward while pressing

the “Feed” button on the

operation panel.

Touch the “OK” key.

14

Press the “Feed” button

in the operation panel to

release the mat.

Touch the “Start” key to start

scanning.

Touch the “OK” key.For smooth feeding, align the

1211

Touch “Please select” key then select “Cut” in the preview

screen.

15

Peel off the material.

Use the spatula to peel

off the cutout pattern.

Touch

pattern in a different location.

to move the test

8

Touch the “Start” key to start

test/trial cutting.

Touch to adjust the cutting

pressure.

If the result of the “Test/Trial

Cut” is good (clean and no-fray)

continue cutting your project by

touching the “Start” key on the

screen.

If the material could not be cut

cleanly, return to step

perform “Test/Trial Cut” again.

Getting More Out of ScanNCut

The following website provides methods for getting more out of your ScanNCut using CanvasWorkspace

application, procedures for customizing pattern data, and much more.

5

and

Referring to the “Test/Trial Cut”

Result table below, adjust the

cutting pressure according to

the cutting results, and then

touch the “OK” key.

“Test/Trial Cut” Result Adjustment Operation

Part of the material is

not cut.

The entire pattern is

not cut.

There are cutting lines

completely through

the mat.

Pressure too light: Touch

settings screen once to increase the

pressure.

Pressure too light: Touch in the

settings screen once to increase the

pressure.

Pressure too strong: Touch

settings screen once to decrease the

pressure.

http://CanvasWorkspace.Brother.com

in the

in the

Loading...

Loading...