Operation Manual

Cutting Machine

Product Code: 893-Z05/Z09

Be sure to read this document before using the machine.

Terms of Use

IMPORTANT-PLEASE READ CAREFULLY:

This Terms of Use (“Agreement”) is a legal agreement between Brother Industries, Ltd. (“Company”) and you

that governs your use of any Software, installed on or made available by Company for use with sewing or craft

products (“Company Product”). The term of “Software” means any and all contents data, design data, data

format, firmware of Company Product, and PC application or mobile device application.

By using the Software and Company Product, you shall be deemed to have agreed to be bound by the terms of

this Agreement. If you do not agree to the terms of this Agreement, Company is unwilling to license the Software

and you are not allowed to use the Software. Amendments and supplements to this Agreement may be attached

to the Software.

An individual who accepts this Agreement on behalf of an entity represents to Company that he or she has the

legal right to enter into a binding legal agreement for that entity.

Terms and Conditions

1 Grant of License.

1.1 Subject to this Agreement, Company hereby grants you a personal, non-exclusive, nontransferable and revocable license to use the Software only within the Company Product.

1.2 Your right to use of the Software is licensed and not sold, and solely for your use subject to this

Agreement. Company or its suppliers retains all right, title, and interest relating to Software,

including without limitation all intellectual property rights relating thereto.

2 Restrictions

2.1 Except as expressly set out in this Agreement or as required by any local law, you shall undertake:

2.1.1 not to disassemble, de-compile, reverse engineer, translate or otherwise attempt to learn

the source code of the Software(including the data or contents created by using the

Company Product or contents editing application software; hereinafter the same shall

apply in this Clause 2.);

2.1.2 not to create derivative works based on the whole or any part of the Software;

2.1.3 not to distribute, provide or make available the Software in any form, in whole or in part

to any person without prior written consent from Company;

2.1.4 not to copy the Software, except where such copying is incidental to normal use of the

Software with Company Product or where it is necessary for the purpose of back-up or

operational security;

2.1.5 not to transfer, rent, lease, sub-license, loan, translate, merge, adapt, vary, alter or modify,

the whole or any part of the Software nor permit the Software or any part of it to be

combined with, or become incorporated in, any other programs;

2.1.6 to include Company’s copyright notice and this Agreement on all entire and partial copies

of the Software; and

2.1.7 not to use the Software for any purpose (including, but not limited to, use with

unauthorized sewing/craft products or software) other than as provided under Clause 1 of

this Agreement.

3No warranty

TO THE EXTENT PERMISSIBLE BY APPLICABLE LAW, THIS SOFTWARE IS PROVIDED TO YOU

"AS IS" WITHOUT WARRANTIES OR CONDITIONS OF ANY KIND, WHETHER ORAL OR

WRITTEN, EXPRESS OR IMPLIED. COMPANY SPECIFICALLY DISCLAIMS ANY IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY QUALITY, NONINFRINGEMENT AND/OR FITNESS FOR A PARTICULAR PURPOSE.

4 Limitation of liability

4.1 COMPANY SHALL NOT BE LIABLE TO YOU, ITS END-USERS OR ANY OTHER ENTITY FOR

ANY LOSS OF PROFITS OR INCOME OR SAVINGS, LOSS OF DATA, INTERRUPTION OF USE,

OR CONSEQUENTIAL, INCIDENTAL, SPECIAL, PUNITIVE OR INDIRECT DAMAGES

INCURRED BY SUCH PARTY (WHETHER IN AN ACTION IN CONTRACT OR TORT), EVEN IF

COMPANY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, ARISING OUT

OF OR RELATING TO THE SOFTWARE, SUPPORT SERVICE OR THIS AGREEMENT. THESE

i

LIMITATIONS SHALL APPLY TO THE MAXIMUM EXTENT ALLOWED BY APPLICABLE LAW

NOTWITHSTANDING ANY FAILURE OF ESSENTIAL PURPOSE OF ANY LIMITED REMEDY.

4.2 NOTWITHSTANDING THE CLAUSE 3 OR 4.1 HEREOF, THIS AGREEMENT DOES NOT

PURPORT TO EXCLUDE OR RESTRICT COMPANY'S LIABILITY FOR DEATH OR PERSONAL

INJURY RESULTING FROM NEGLIGENCE OR LIMIT THE STATUTORY RIGHTS OF A

CONSUMER.

5Termination

5.1 Company shall have the right to terminate this Agreement at any time by providing a written

notice to you if you commit a material breach of any terms of this Agreement and fail to

immediately rectify such breach upon Company’s request.

5.2 Upon termination for any reason all rights granted to you under this Agreement shall cease, you

shall cease all activities authorized by this Agreement and you shall immediately delete or

remove the Software from all computer equipment in your possession and delete or destroy all

copies of the Software or its derivative works in your possession. In addition to the above, you

shall delete contents or design data created by you from the Company Product in your

possession.

6 Miscellaneous terms

6.1 You shall not export or re-export the Software or any copy or adaptation thereof in violation of

any applicable laws or regulations.

6.2 You shall not assign all or any part of this Agreement to any third party or any interest therein,

without prior written consent of Company. A change of control or reorganization of you

pursuant to a merger, sale of assets or stock shall be deemed to be an assignment under this

Agreement.

6.3 You agree that a breach of this Agreement will cause irreparable injury to Company for which

monetary damages would not be an adequate remedy and Company shall be entitled to seek

equitable relief in addition to any remedies it may have hereunder or at law without a bond,

other security, or proof of damages.

6.4 If any provisions of this Agreement shall be declared or determined as void or unenforceable by a

court of competent jurisdiction, such provisions shall be severable and independent from the

other provisions of this Agreement and the validity of the other provisions and of the entire

Agreement shall not be affected thereby.

6.5 This Agreement, together with all exhibits or other attachments referenced herein, constitutes the

entire agreement between the parties on the subject matter hereof, and supersedes all proposals,

oral and written, between the parties on this subject.

6.6 If Company fails to insist that you perform any of your obligations under this Agreement, or if

Company does not enforce any rights against you, or if Company delay in doing so, that will not

mean that Company have waived any rights against you and will not mean that you do not have

to comply with those obligations. If Company does waive a default by you, Company will only

do so in writing, and that will not mean that Company will automatically waive any later default

by you.

6.7 The laws of the state or country where you live (or, if a business, where your principal place of

business is located) govern all claims and disputes concerning the Software or this Agreement.

ii

INTRODUCTION

Thank you for purchasing this machine.

Before using this machine or attempting any maintenance, carefully read the “IMPORTANT SAFETY

INSTRUCTIONS” on the Product Safety Guide, and then read the Operation Manual for the correct operation of

the various functions. In addition, after you have finished reading this manual, store it where it can quickly be

accessed for future reference. Failure to follow these instructions may result in an increased risk of personal

injury or damage to property, including through fire, electrical shock, burns or suffocation.

IMPORTANT NOTICE

This machine is intended for household use.

●

● This machine is approved for use in the country of purchase only.

● Due to product quality improvements, the specifications or appearance of this machine may change without notice.

● The screens in this manual are for illustration purposes only and may differ from the actual screens.

● The contents of this document are subject to change without notice.

● The contents of this document may not be duplicated or reproduced, partially or in full, without permission.

● We assume no responsibility for damages arising from earthquakes, fire, other disasters, actions of third parties, the user’s

intentional or negligent operation, misuse or operation under other special conditions.

● For additional product information, visit our web site at www.brother.com

IMPORTANT SAFETY INSTRUCTIONS

Symbols Used in This Document

The following symbols are used in this document.

WARNING

CAUTION

Failure to observe instructions with this marking may result in fatal or

critical injuries.

Failure to observe instructions with this marking may result in serious

injuries.

1

CONTENTS

Terms of Use .................................................. i

INTRODUCTION .......................................... 1

IMPORTANT NOTICE ................................... 1

IMPORTANT SAFETY INSTRUCTIONS ......... 1

Symbols Used in This Document........................... 1

FEATURES...................................................... 4

Patterns (“Pattern” mode) ...................................... 4

Scanning (“Scan” mode)........................................ 4

Transferring Data using the Wireless Network

Connection Function.............................................. 5

1 GETTING STARTED............6

PARTS AND FUNCTIONS ............................. 6

Unit Descriptions - Front........................................ 6

Unit Descriptions - Rear......................................... 7

Unit Descriptions - Operation Panel ...................... 7

Included Accessories ............................................. 7

BEFORE USE .................................................. 8

Removing the Packing Materials............................ 8

Turning On/Off the Machine................................... 8

Preparing for Feeding the Mat ............................... 9

Operation of LCD Panel ......................................... 9

MACHINE SETTINGS .................................. 10

Settings Screen.................................................... 10

Auto Shutdown..................................................... 12

2 BASIC OPERATIONS........13

FIRST STEPS................................................. 13

Selecting the Mat Appropriate for the Material.... 13

Reference Table of Mat and Material Combinations

............................................................................. 14

Attaching the material to the mat......................... 16

Blade and Material Combination.......................... 23

Installing and Uninstalling the Holder................... 24

Test Cut (Trial Cut) ............................................... 25

PATTERN CUTTING .................................... 29

Tutorial 1 - Cutting Patterns................................. 29

Tutorial 2 - Cutting Advanced Patterns................ 32

PATTERN SELECTION ................................. 38

Selecting a Single Pattern.................................... 38

Selecting Multiple Patterns .................................. 38

3

ADVANCED OPERATIONS

CUTTING AND EDITING FUNCTIONS ...... 40

Pattern Editing Functions..................................... 40

Pattern Editing Functions - Multiple Patterns ...... 41

Mat Layout Screen............................................... 41

Layout Editing Functions...................................... 42

Object Editing Screen .......................................... 43

Undoing an Operation.......................................... 44

Grouping/Ungrouping Patterns............................ 44

Welding (Merging the Outlines of Multiple Patterns)

............................................................................. 46

Aligning Patterns.................................................. 47

...40

Auto Layout Functions......................................... 49

Scanning a Background Image ............................ 50

Character Input Functions.................................... 51

MEMORY FUNCTIONS ............................... 53

Saving .................................................................. 53

Retrieve Data........................................................ 54

Retrieve from CanvasWorkspace (Via a Wireless

Network Connection) ........................................... 55

Retrieve from CanvasWorkspace (Using a USB

Cable) (compatible only with Windows) ............... 56

Importing Designs................................................ 57

Retrieving Embroidery Data for Cutting

(Compatible Models Only) ...........................58

Preparing .phc or .pes Files ................................. 58

Retrieving the Pattern to the Cutting Machine ..... 58

Creating Appliqué Data ........................................ 59

Creating Embroidering Line Data ......................... 59

DRAWING FUNCTIONS ............................. 62

Drawing ................................................................ 62

Cutting Around Drawings..................................... 63

Using Drawing Functions to Fill Patterns/Make

Outlines Thicker ................................................... 67

4

SCANNING FUNCTIONS

... 69

SCANNING FOR CUTTING (Direct Cut).....69

Tutorial 3 - Scanning and Cutting........................ 69

Advanced Cutting Functions for “Direct Cut” ...... 73

CREATING CUTTING DATA (Scan to Cut

Data)............................................................ 75

Tutorial 4 - Creating Cutting Data........................ 75

Adjusting Image Detection Levels........................ 81

SCANNING IMAGES (Scan to USB).............83

Notes on Scanning............................................... 83

Tutorial 5 - Scanning to USB ............................... 83

Selecting the Area to be Saved............................ 85

Transferring an Image to CanvasWorkspace....... 85

5 APPENDIX ....................... 87

CONSUMABLES...........................................87

Replacement Criteria............................................ 87

Replacing the Blade............................................. 87

CARE AND MAINTENANCE ........................89

Cleaning ............................................................... 89

Cleaning the Scanner Glass................................. 91

Adjusting the Screen............................................ 92

Adjusting the Scanning/Cutting Position ............. 92

Adjusting the Position of the Feed Roller............. 94

TROUBLESHOOTING ................................. 95

ERROR MESSAGES....................................... 99

UPDATING THE SOFTWARE..................... 102

Automatic Update Function ............................... 102

Update Procedure Using USB Flash Drive ........ 103

Update Procedure Using the Application

(CanvasWorkspace) ........................................... 103

OPTIONAL ACCESSORIES .........................105

2

PRODUCT SPECIFICATIONS .................... 105

INDEX ....................................................... 106

3

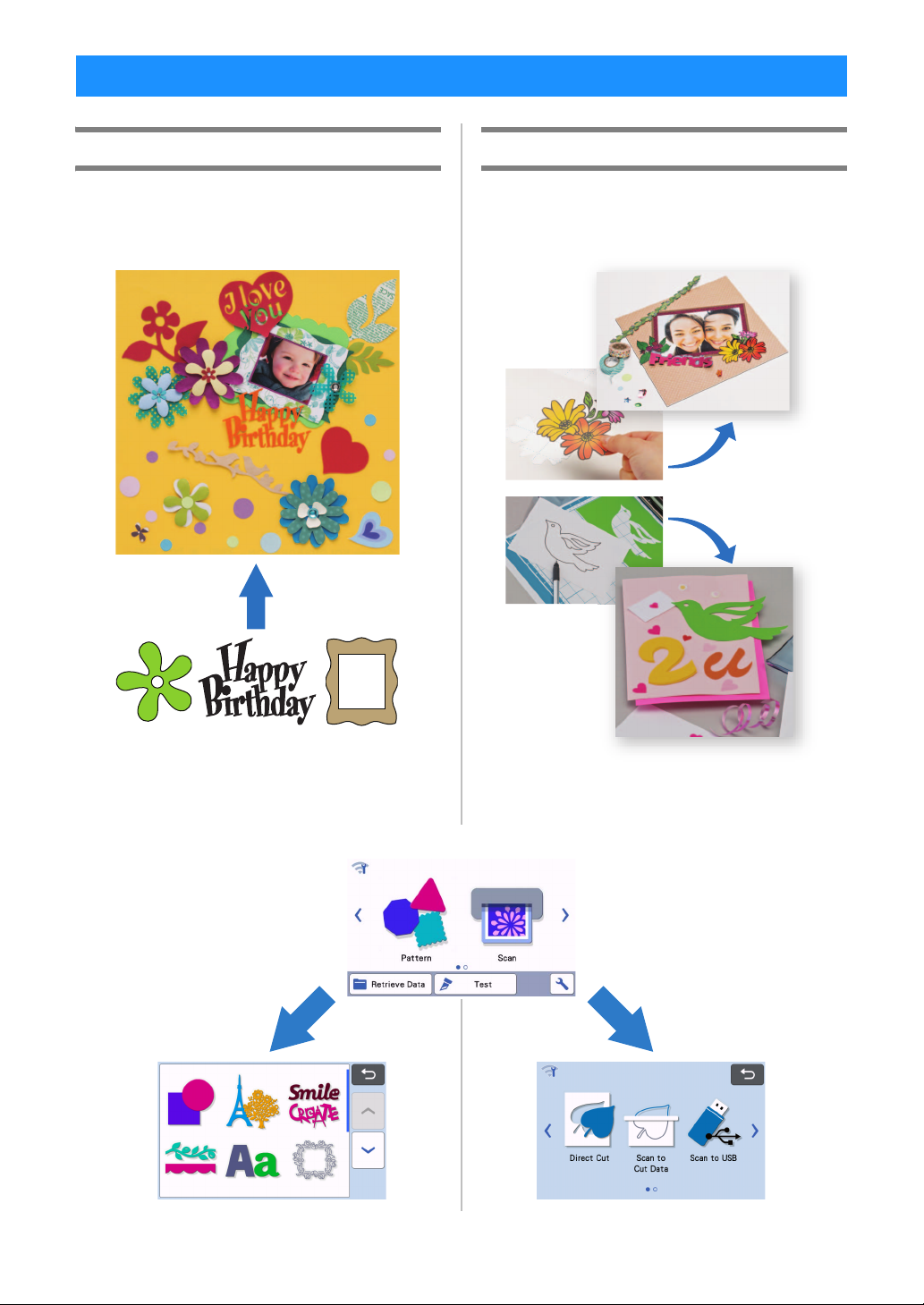

FEATURES

Patterns (“Pattern” mode)

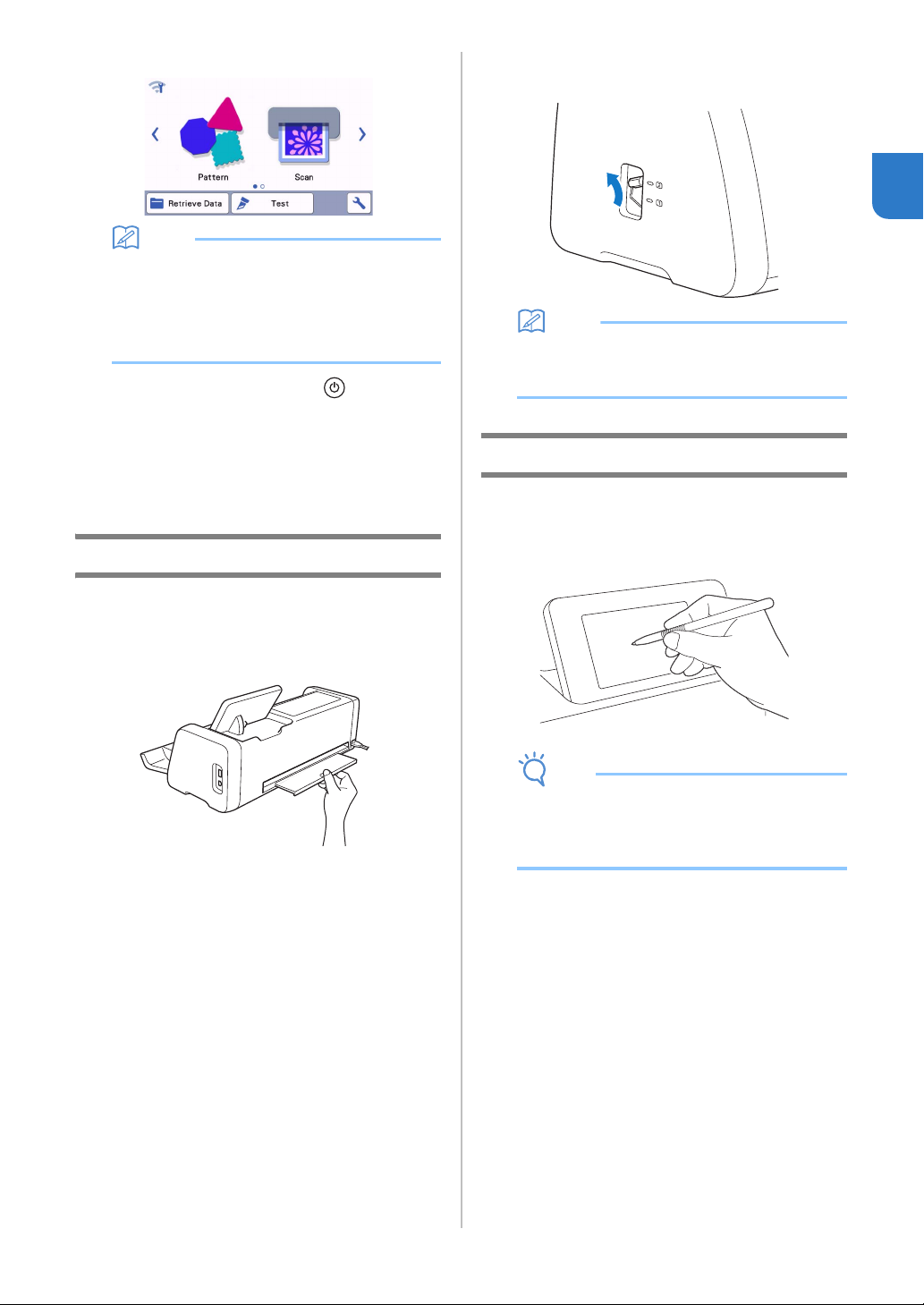

Select a pattern and edit it to create your own design.

By simply loading craft paper or fabric, you can

quickly create precision paper and fabric cutouts.

Scanning (“Scan” mode)

Scan an illustration, photo or your own drawing to

create personalized cut designs. The design can then

be cut out or saved as data.

The editing functions of ScanNCut DX will allow you to

easily edit the built-in patterns to create your own

design.

Select a pattern.

“Tutorial 1 - Cutting Patterns”

on page 29

“Tutorial 2 - Cutting

Advanced Patterns” on

page 32

4

Home screen

Without your PC or mobile device, you can scan your

choice of pattern, use/edit the scanned design, and

save the pattern for later use.

Scan an image.

“Tutorial 3 - Scanning and

Cutting” on page 69

“Tutorial 4 - Creating Cutting

Data” on page 75

“Tutorial 5 - Scanning to

USB” on page 83

Transferring Data using the Wireless Network Connection Function

This machine is equipped with a wireless network connection function. With this function, patterns edited in the

dedicated application CanvasWorkspace can be transferred to the machine via a wireless network connection.

Refer to the following to use the wireless network connection function.

1. Connecting to a wireless network:

Touch in the home screen to specify the wireless network connection settings. For the connection

procedure, refer to “Wireless Network Setup Guide”.

2. Login to CanvasWorkspace Internet version.

In order to use CanvasWorkspace, a CanvasWorkspace (formerly ScanNCutCanvas) login ID is necessary. If

you do not have a free account, go to <http://CanvasWorkspace.Brother.com> to create a new account.

3. Register machine under CanvasWorkspace.

In order to save or retrieve patterns, your machine must first be registered with CanvasWorkspace. For

details, refer to “Wireless Network Setup Guide”.

4. Retrieving/saving patterns:

Patterns can be downloaded or uploaded, without using a USB flash drive. For details, see “Saving” on

page 53 and “Retrieve Data” on page 54.

CanvasWorkspace (PC Version) is a PC based application that allows you to create and edit cutting or drawing

pattern data to download to your cutting machine. The PC version allows you to edit the pattern data without

an Internet connection.

You can download this application from the following URL:

http://s.brother/cuoad/

The CanvasWorkspace Internet version provides you access to a variety of projects with step by step

instructions.

5

Chapter 1 GETTING STARTED

h

i

a

b

c

e

d

e

f

g

k

j

l

f

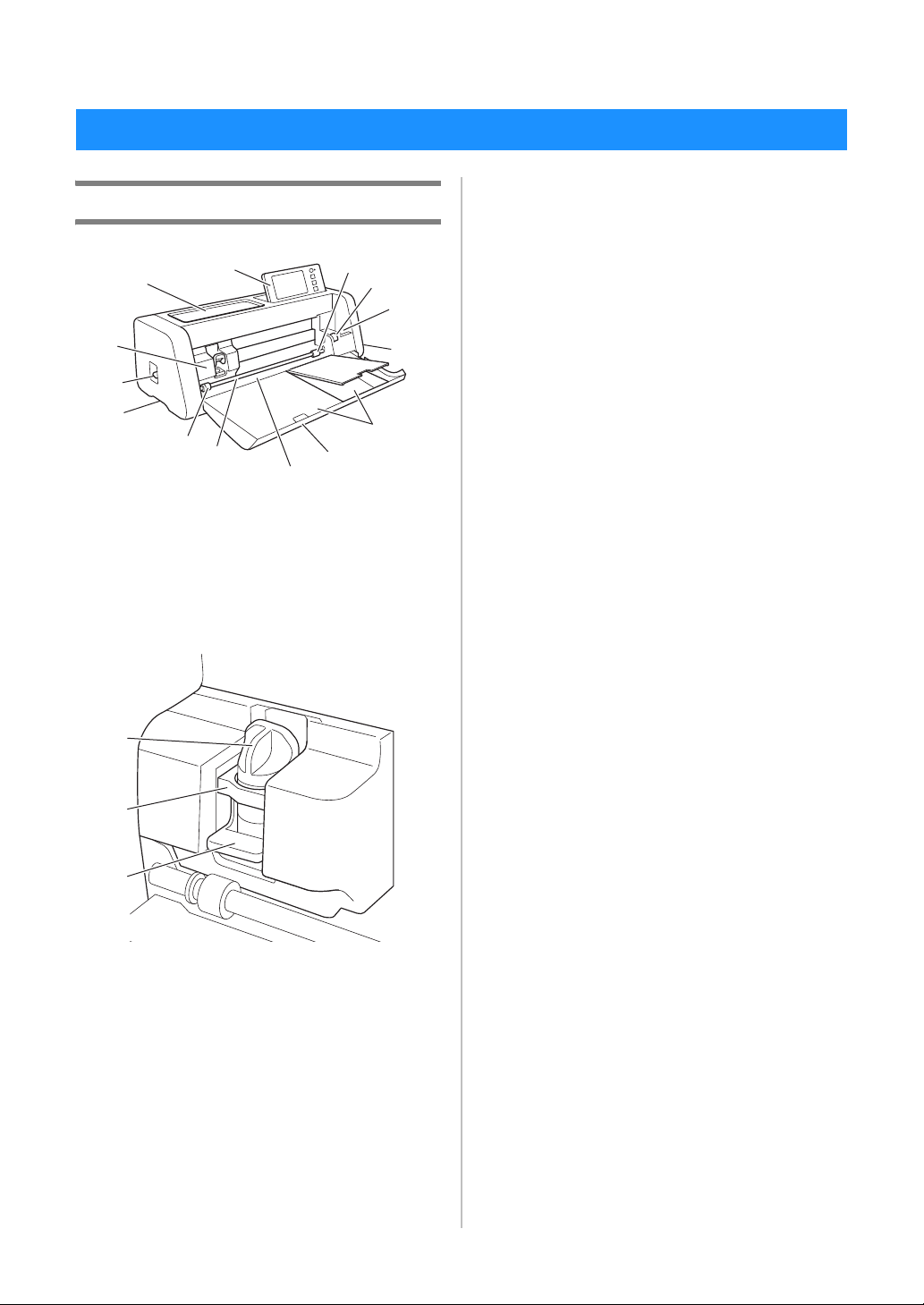

PARTS AND FUNCTIONS

Unit Descriptions - Front

a Operation Panel

Allows you to control the unit and specify settings with

the LCD panel and operating buttons. The angle of the

operation panel can be adjusted.

b Tool Tray

Stores accessories for easy access during use.

c Carriage

Moves the installed holder for cutting or drawing.

d Scanner Lever

Adjusted according to the operation being performed.

For details, see “Preparing for Feeding the Mat” on

page 9.

e Grips

Grasped when moving the machine.

f Feed Rollers

Should be adjusted on the right side when the

optional roll feeder is used. For details, see “Adjusting

the Position of the Feed Roller” on page 94.

g Shaft

Drives a feed roller on each end to feed the mat.

h Feeder Release Lever

Locks or releases the shaft when the optional roll

feeder is used. For normal operations, set to the

locked position. For details, see “Adjusting the

Position of the Feed Roller” on page 94.

i Tool Holder

Holds accessories upright for easy access during use.

j Storage

Stores accessories.

k Front Tray Cover

Protects the feed rollers, carriage and holder. Open

the cover while the machine is operating.

l Feed Slot

Feeds in the mat when it is loaded.

a

b

c

1 Holder

Installs in the carriage to cut or draw on craft paper

or fabric. Use the holder designed specifically for

cutting or drawing.

2 Holder Guide

The guide secures the holder.

3 Holder Lock Lever

Releases the holder when the lever is raised. Locks

the holder when the lever is lowered.

6

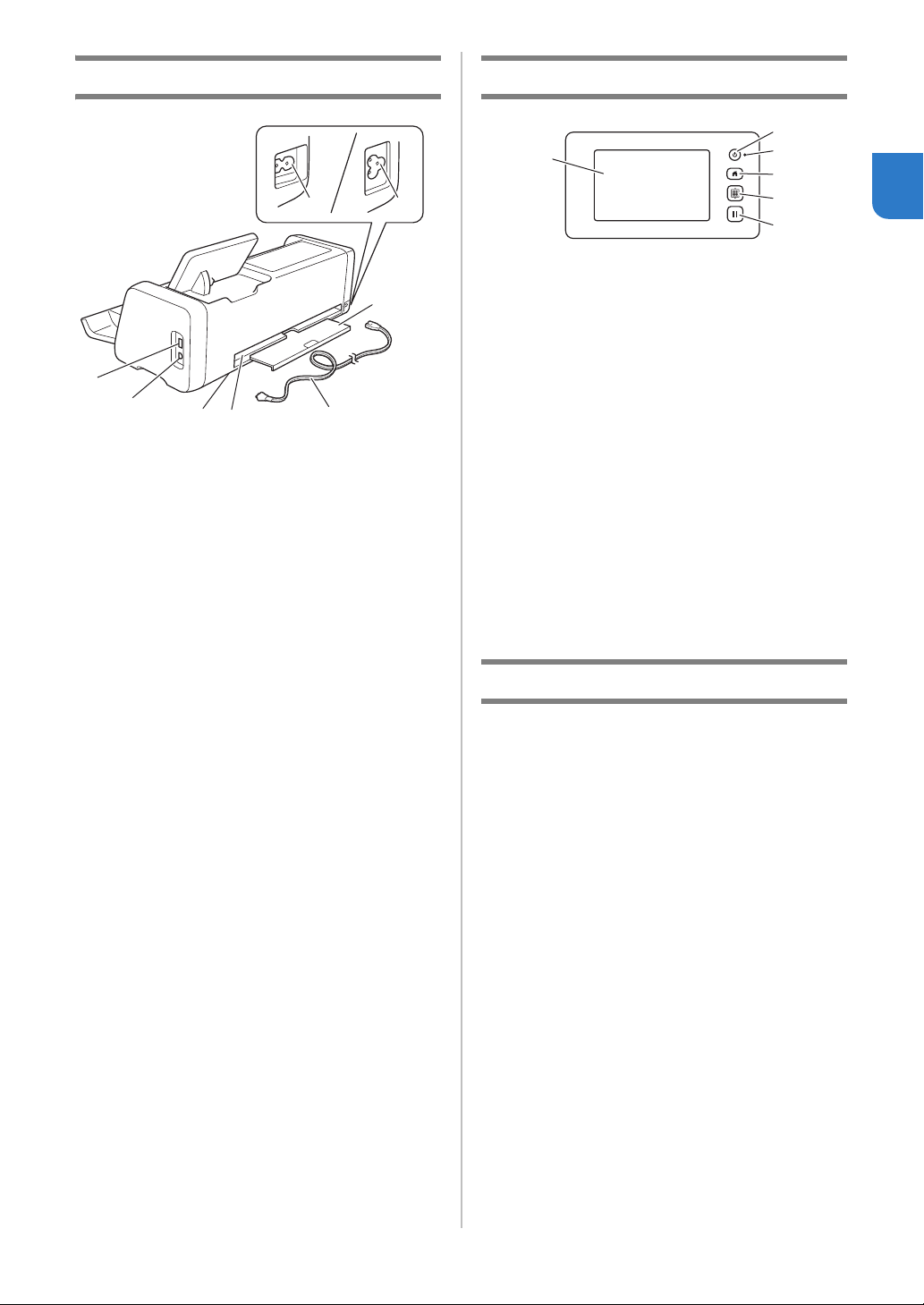

Unit Descriptions - Rear

a

c

g

d

f f

e

b

a USB Port (for a USB flash drive)

Allows a USB flash drive to be connected for saving

and recalling data.

b USB Port (for a computer)

Allows a USB cable to be connected for saving and

recalling data. For Computers and Operating

Systems, see “Connecting Your Machine to the

Computer” on page 56.

c Scanner Glass (inside of machine)

Can be maintained after the rear tray has been

removed. For details, see “Cleaning the Scanner

Glass” on page 91.

d Slot

Allows a mat to be fed back and forth during an

operation. Do not place any objects near the slot that

would prevent the mat from being fed out.

e Rear Tray

Supports the mat when it is fed out of the slot during

operation. Be sure to pull out this tray before using the

machine.

f AC Power Jack

g AC Power Cord

Unit Descriptions - Operation Panel

b

a

a LCD Panel

Displays operation screens, preview images of

patterns and error messages.

b Power Button

Turns the machine on/off.

c Power Indicator

Lights up when the machine is turned on, and flashes

when the machine enters the sleep mode (powersaving mode) or the machine’s software is being

updated.

d Home Button

Displays the home screen (starting screen for

operating this machine).

e Feed Button

Feeds the loaded mat in to or out from the feed slot.

Be sure to press this button to feed the mat when

loading or unloading it.

f Pause/Stop Button

Stops or pauses operation being performed by the

machine.

c

d

e

f

Included Accessories

For details on the included accessories, refer to the

“Included Accessories” insertion.

1

7

Note

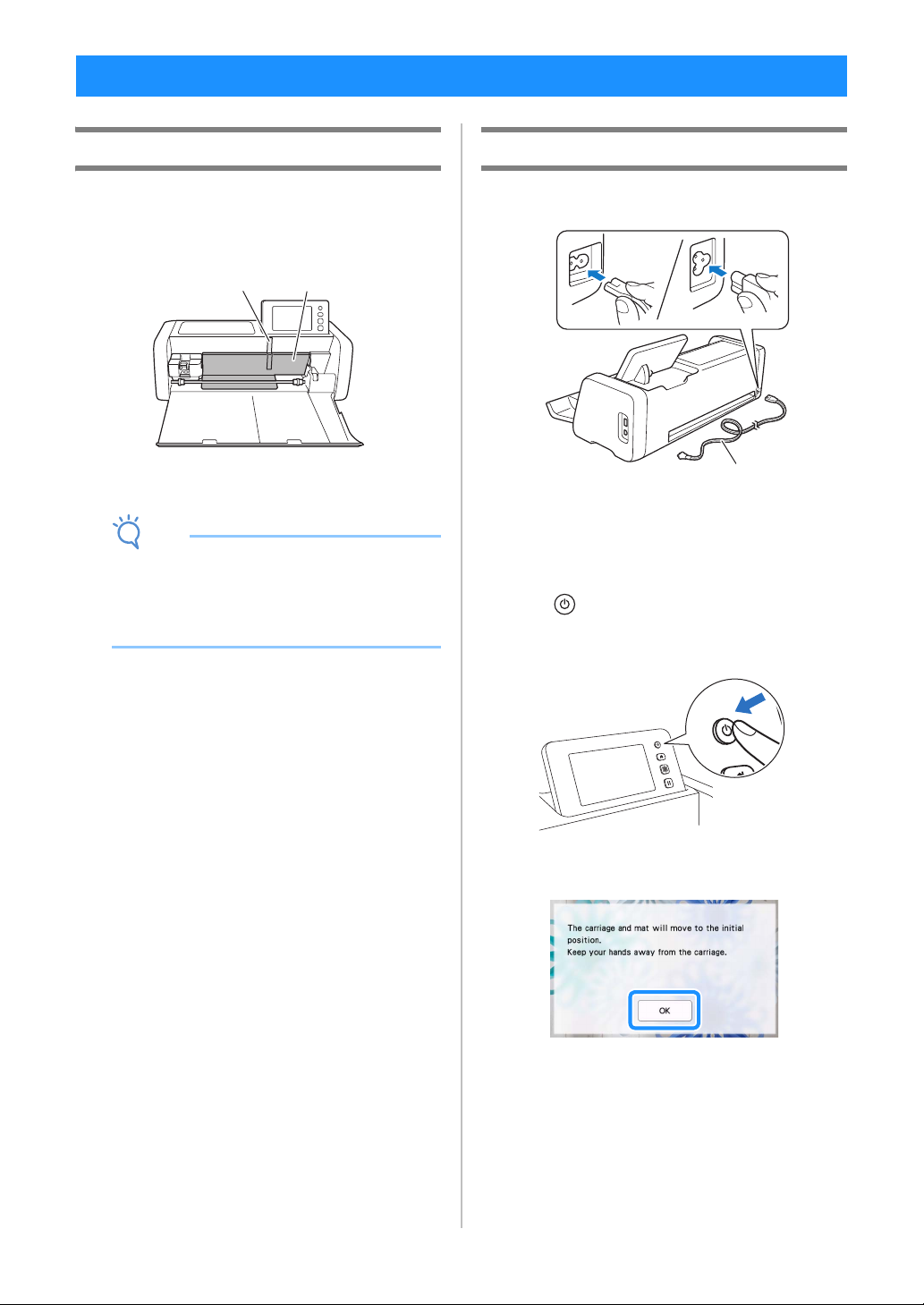

BEFORE USE

a

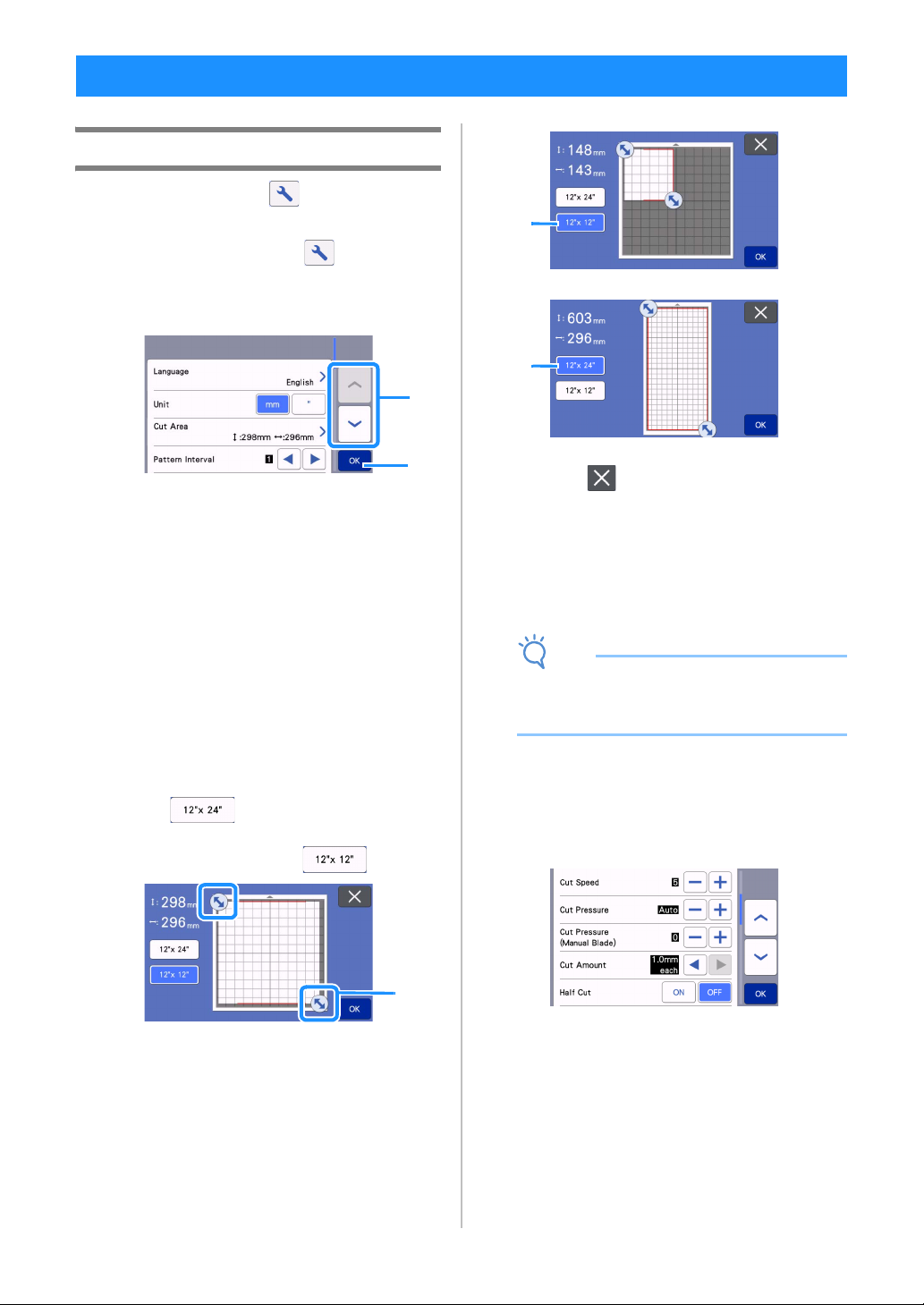

Removing the Packing Materials

Before turning on the machine, open the front tray

cover, and then remove all shipping tapes (in front

and back of the machine) and the cardboard shockabsorbing material.

a

a Shipping tape

b Cardboard shock-absorbing material

• If the packing materials were removed after the

machine was turned on, turn the machine off,

then on again. Continuing to use the machine

without restarting it may result in incorrect

operation.

b

Turning On/Off the Machine

a Connect the power cord to the machine.

a Power cord

b Plug the power cord into an electrical outlet.

c Press in the operation panel.

When the opening screen appears, touch anywhere on

the display.

8

When the following message appears, touch the

“OK” key.

The home screen appears.

Memo

Memo

Note

• LCD panels commonly have bright spots

(permanently lit dots) and dark spots (unlit

dots). It may cause some unexpected luminous

spots to appear and tiny picture elements to be

missed in the screen. Please note that this is

not a sign of malfunction.

d To turn off the machine, press in the

operation panel.

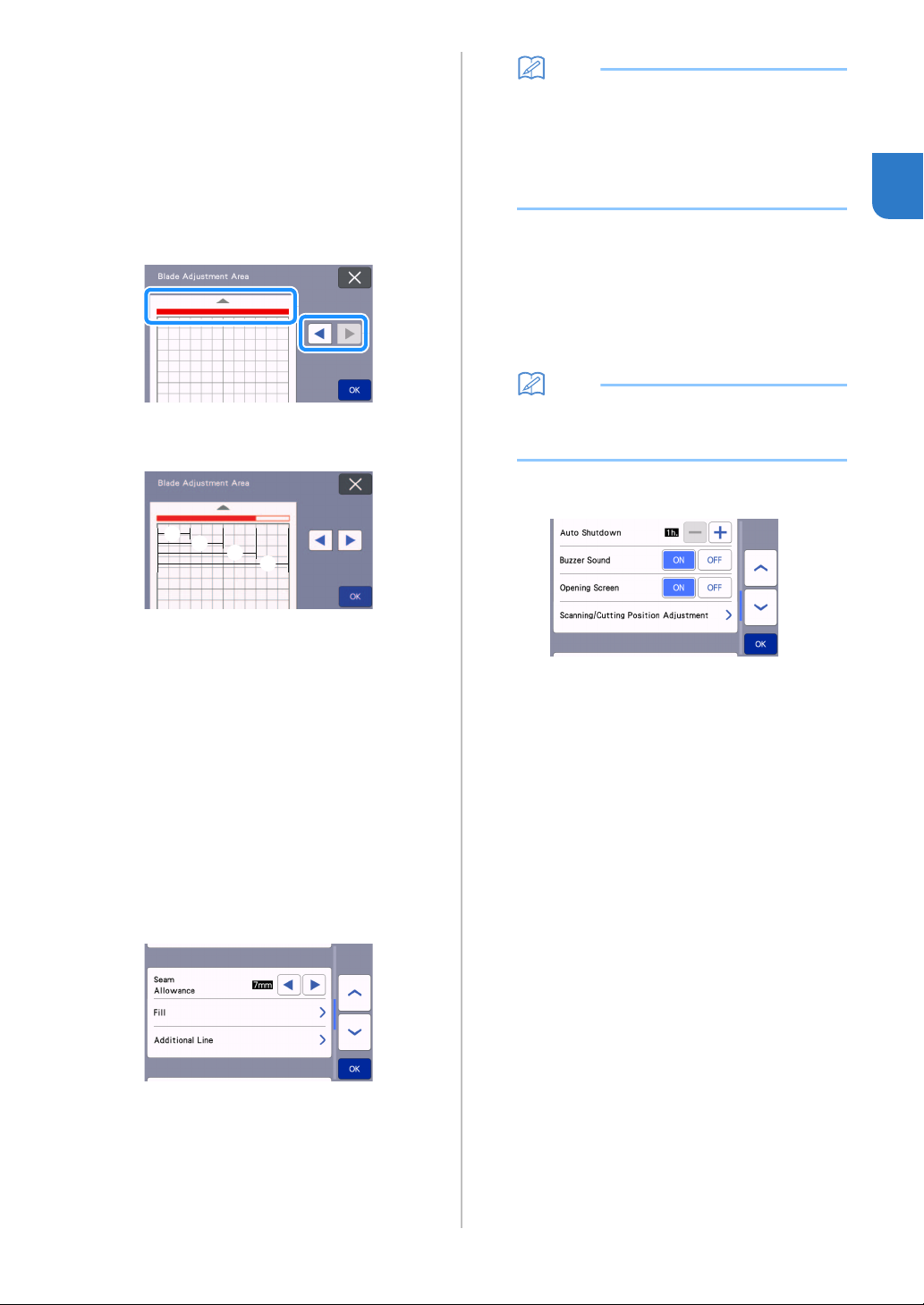

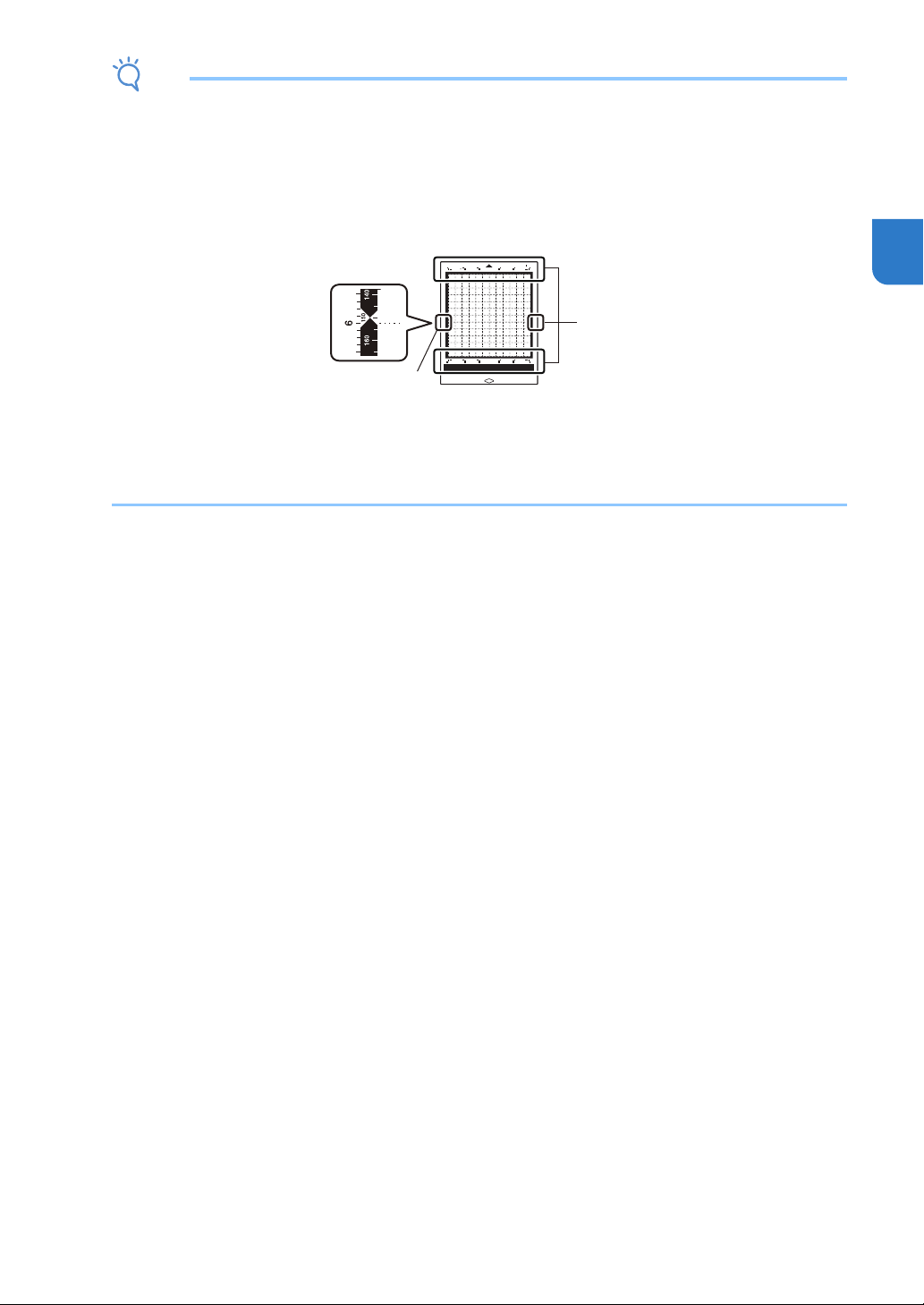

b Raise the scanner lever (on the left side of the

machine) to “2”.

1

• Before scanning thin material, set the lever to

“1”. Leaving the lever raised may result in

blurred scans.

e Unplug the power cord from the electrical

outlet.

f Disconnect the power cord from the machine.

Preparing for Feeding the Mat

a Pull out the rear tray.

Before using the machine, be sure to pull out the rear

tray.

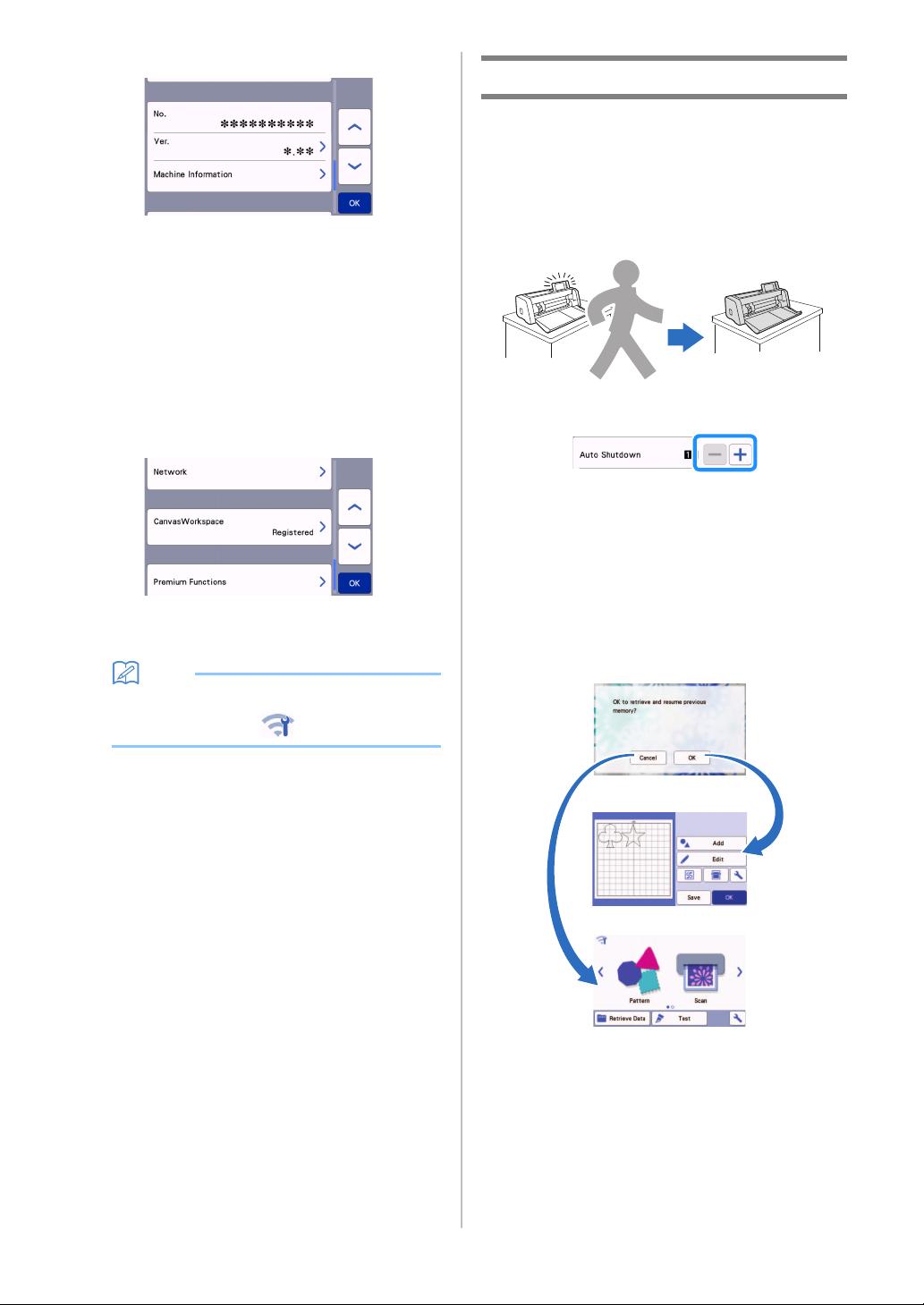

Operation of LCD Panel

After the machine is turned on, the operation screens

appear in the touch panel. To perform operations in

the screens, use the included touch pen (stylus).

• Never use a hard or pointed object, such as a

mechanical pencil or screwdriver, to make a

selection on the screens. Otherwise, damage to

the machine may result.

9

Note

MACHINE SETTINGS

b

a

a

b

b

Settings Screen

From the LCD panel, touch to select and adjust

the settings for each function.

This section contains descriptions of the machine

settings which will appear when is selected on

the home screen.

■ Group 1

a Touch to display the previous or next item.

* Swiping the touch pen (stylus) over the screen

will also display a different screen.

b Touch to finish specifying settings.

Language

Select the display language. Touch this button, select

the desired display language, and then touch the

“OK” key.

Unit

Select either millimeters or inches as the displayed

measurement units.

Cut Area

Specify the area for cutting/drawing according to the

size of material to be used. Touch this button, and

then touch and drag the area resizing keys to specify

the area. When using a 12" × 24" (305 mm × 610 mm)

mat, touch to select a larger mat size, and

then specify the area size. When using a 12" × 12"

(305 mm × 305 mm) mat, touch .

b Mat size key

• Touch the “OK” key to apply the settings.

Touch to return to the previous screen

without applying the settings.

Pattern Interval

Specify the spacing between patterns as well as white

space around the edges of cutting area when patterns

on the mat layout screen are automatically arranged.

The larger the number setting, the further spacing

between patterns.

• Set the pattern interval to “3” or higher when

lightweight fabric is attached to the mat with a

high tack adhesive fabric support sheet.

Background

Adjust the contrast of a background image scanned

with the background scanning function. For details,

see “Scanning a Background Image” on page 50.

■ Group 2

a Area resizing key (Using the touch pen (stylus),

touch the key, and then drag it around the

screen to specify the area.)

10

Cut Speed

Adjust the cutting speed.

Cut Pressure

Adjust the cutting pressure.

Cut Pressure (Manual Blade)

Specify the cutting pressure when the optional

manual blade is used.

Cut Amount

Specify the cutting depth. Adjust the blade cut

amount when a pattern with a sharp corner is cut from

soft, thick material.

Half Cut

Memo

Memo

1

2

3

4

Select whether or not to make half-cuts. For details,

see “Half Cut (Kiss Cut) Settings” on page 28.

Cut Pressure (Half Cut)

Specify the cutting pressure for half-cuts.

Blade Adjustment Area

Select from 1/4, 1/2, 3/4 or whole cutting area to be

used for blade adjustment. Before cutting out a

pattern, this machine performs an automatic blade

adjustment, which adjusts the direction of the blade

outside of the adhesive area of the mat.

• When multiple patterns are cut at the same

time, the setting specified in this screen is

applied to all patterns.

• If cutting line data saved with a different seam

allowance is imported and used, the setting

specified in this screen will have priority over

the saved setting.

Fill

Select the design that will be used to fill patterns. For

details, see “Using Drawing Functions to Fill Patterns/

Make Outlines Thicker” on page 67.

Additional Line

With [Number of Additional Line], specify the number

of lines to be added. With [Additional Line Spacing],

specify the spacing of the lines to be added.

1

• With each press of the left or right arrow key,

the size of the blade adjustment area changes

by 1/4.

a 1/4

b 2/4

c 3/4

d Entire area

Draw Speed

Adjust the drawing speed.

Draw Pressure

Adjust the drawing pressure. Adjustments to the

drawing pressure will affect the finished product. Use

the same material that the pattern will be drawn on to

make the adjustments in advance. If the pressure is

too high, the pen tip may be damaged. Adjust the

pressure appropriately.

■ Group 3

• For details for Fill and Additional Line setting,

refer to “Using Drawing Functions to Fill

Patterns/Make Outlines Thicker” on page 67.

■ Group 4

Auto Shutdown

Specify the length of time for the auto shutdown

function. The setting can be specified in 1-hour

increments. For details, see “Auto Shutdown” on

page 12.

Buzzer Sound

Select whether or not an operation sound is

produced, for example, when a key is touched.

Opening Screen

Select whether the opening slide show is displayed

after the machine is turned on. If the slide show is

displayed, touch the screen to display the home

screen.

Scanning/Cutting Position Adjustment

The scanning/cutting position can be adjusted. To

adjust the position, touch this button to display the

settings screen. For details, see “Adjusting the

Scanning/Cutting Position” on page 92.

Seam Allowance

Specify the seam allowance. This is applied when

drawing on fabric, then cutting it, for example, when

making quilt pieces. For details, see “Cutting Around

Drawings” on page 63.

11

■ Group 5

Memo

No.

Displays the number for this machine.

Ver.

Displays the version information for this software.

Touch this button to update the machine’s software.

For details, see “UPDATING THE SOFTWARE” on

page 102.

Machine Information

Touch this button, this page displays machine

information.

■ Group 6

Network

Touch this button to set up a wireless network. For

details, refer to “Wireless Network Setup Guide”.

Auto Shutdown

If the machine is not used for a specified length of

time, it will automatically turn off. The length of time

until the machine turns off can be specified in the

settings screen.

If the machine is automatically turned off after you

reach the mat layout screen, the stored information

can be recalled when the machine is turned on

again. Following the instructions in the message

screen that appear when the machine is turned on

again, touch the “OK” key to display the mat layout

screen or touch the “Cancel” key to return to the

home screen.

• The wireless network connection can also be

set up by touching in the home screen.

■ Group 7

CanvasWorkspace

Touch this button to specify settings for registering

the machine with CanvasWorkspace. These settings

are necessary in order to transfer patterns via a

wireless network connection. For details, refer to

“Wireless Network Setup Guide”.

■ Group 8

Premium Functions

Activate optional accessories and specify settings for

their functions.

a

b

c

a Message screen

b Mat layout screen

c Home screen

If the machine is automatically turned off before you

reach the mat layout screen, the home screen will be

displayed when the machine is turned on again.

12

Chapter 2

BASIC OPERATIONS

FIRST STEPS

The following procedures describe basic operations, from preparing the material to performing trial cutting.

1. Selecting the Mat Appropriate for the Material....................................P.13

2. Attaching the material to the mat..........................................................P.16

3. Selecting the Blade Appropriate for the Material ................................P.23

4. Installing the Holder in the Machine......................................................P.24

5. Trial Cutting (Test Cut)............................................................................P.25

Selecting the Mat Appropriate for the Material

Refer to the following table and the “Reference Table of Mat and Material Combinations” on page 14 for the

appropriate mat and sheet for fabric cutting according to the material to be used for cutting or drawing.

Depending on the machine model, some accessories listed in the chart may not be included. In that case, they

must be purchased separately.

Sheet for fabric cutting

Mat

Use one of the following sheets

when cutting fabric.

2

Standard tack

adhesive mat

Low tack

adhesive mat

Our standard tack adhesive mat has a

high adhesive strength for use with

cutting.

* Use the low tack adhesive mat with

copy paper and smooth paper.

Since the standard tack adhesive

mat has a high adhesive strength,

materials may remain stuck to the

mat, causing the mat to become

unusable.

Low adhesive mat; suitable for copy

paper and smooth paper.

Iron-on fabric

appliqué

contact sheet

(white backing)

(See page 17)

High tack

adhesive fabric

support sheet

(See page 20)

• Reinforces the fabric so that various

patterns can be cut out.

• Original texture may change

because it remains attached to the

back of fabric.

* For use with the standard tack

adhesive mat.

* Do not place fabric backed with

iron-on contact sheet directly onto a

mat with high tack fabric support

sheet.

• For best results when cutting fabric,

attach the high tack adhesive fabric

support sheet to the standard tack

adhesive mat in order to increase

the strength of the adhesive.

• Depending on the shape, the pattern

may not be cleanly cut.

13

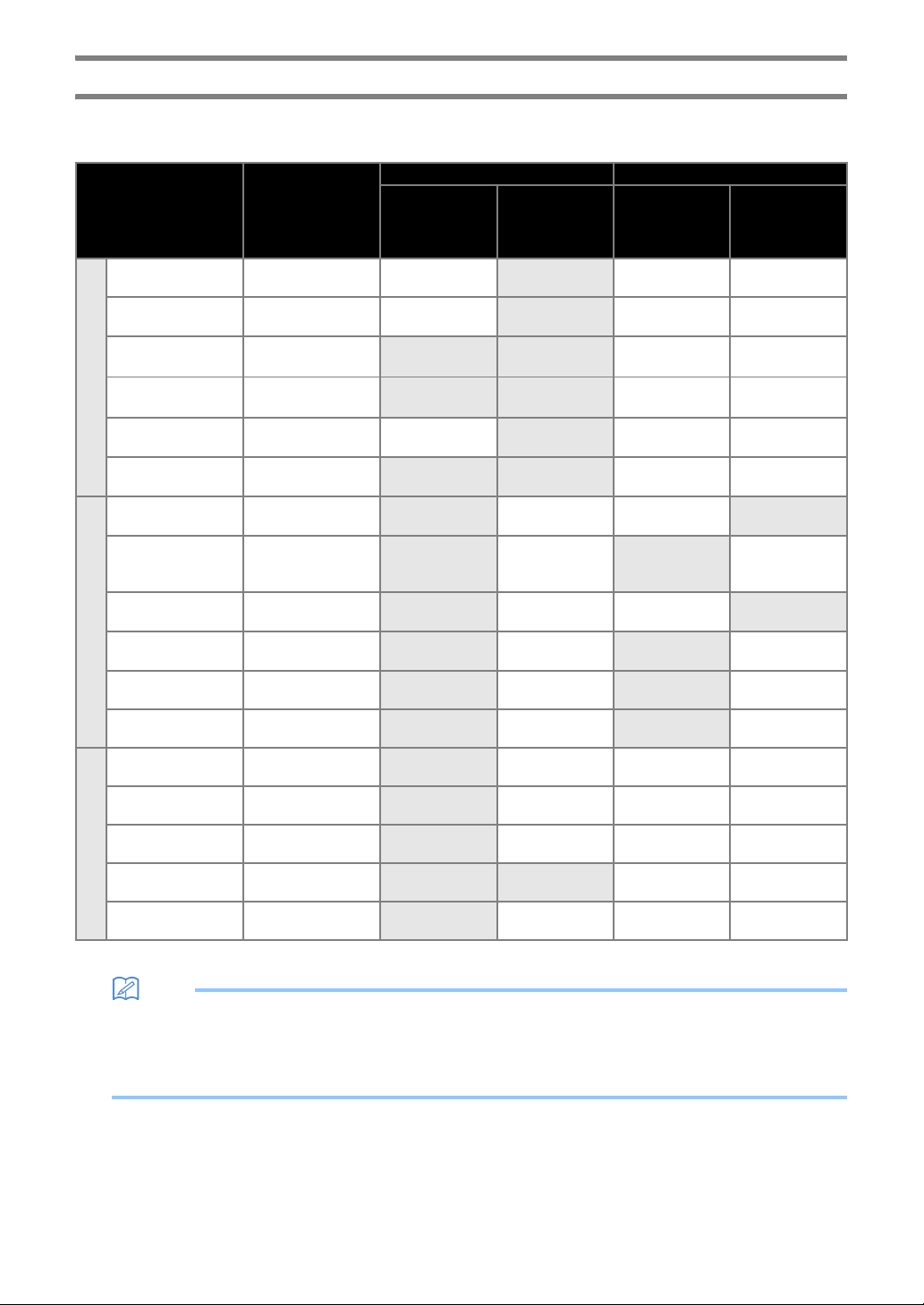

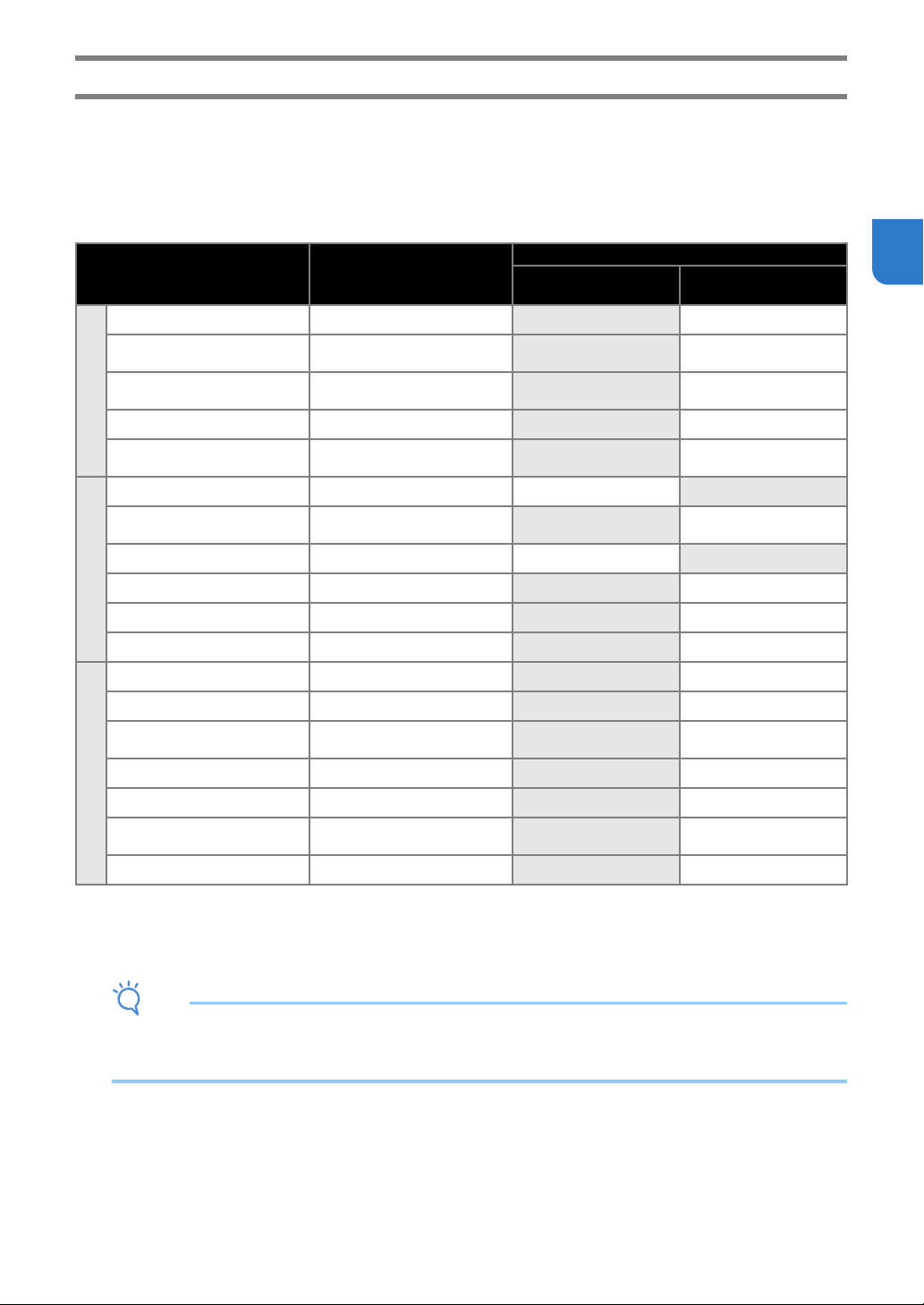

Reference Table of Mat and Material Combinations

Memo

Use a mat appropriate for the material, as referred to in this table. Before using materials from your project, test

attaching the material to check the adhesion to the mat.

Material

Printer paper 80 g/m² (0.1 mm)

Scrapbook paper

(thin)

Scrapbook paper

(medium-thick)

Paper

Cardstock

Vellum, tracing

paper

Poster board

Thin cotton fabric

(for quilt piece)

Thin cotton fabric

(except for quilt

piece)

Flannel (for quilt

piece)

Fabric

Flannel (except for

quilt piece)

Felt 3 mm

Thickness

120 g/m²

(0.15 mm)

200 g/m²

(0.25 mm)

280 g/m²

(0.35 mm)

0.07 mm

400 g/m²

(0.5 mm)

0.25 mm

0.25 mm

0.5 mm

0.5 mm

Mat (for ScanNCut DX)

Standard Tack

Adhesive Mat

Low Tack

Adhesive Mat

Sheet for fabric cutting

Iron-on Fabric

Appliqué Contact

Sheet (White

Backing)

*

*

High Tack

Adhesive Fabric

Support Sheet

Denim 14 oz 0.75 mm

Plastic sheet (PP) 0.2 mm

Vinyl 0.2 mm

Others

Magnet 0.3 mm

Sticker or seal 0.2 mm

Foam sheet 3 mm

* When cutting paper with a smooth surface

• When using a 12" × 12" (305 mm × 305 mm) mat, the maximum work area for cutting/drawing is 296 mm × 298

mm (11.65" × 11.73").

• When using an optional 12" × 24" (305 mm × 610 mm) mat, the maximum work area for cutting/drawing is 296

mm × 603 mm (11.65" × 23.74").

• Some fabrics with uneven surfaces can be cut if turned upside down.

14

Note

• Avoid using craft paper or fabric covered with decorative layer (that can easily separate), such as lamé or foil.

a

a

The separate layer may stick to the machine’s scanning device or feed rollers during operation, resulting in

damage to the machine. It may also damage the cutting blade. When using such material, be sure to clean the

scanner glass inside the machine after every use (page 91).

• Tape material that can easily peel off, such as foam sheets, to secure it in place.

• Be careful since tape with an extremely high adhesive strength may damage the mat.

• Do not affix masking tape, etc., over the scanning marks. Otherwise, the mat may not be correctly recognized or

images may not be correctly scanned.

a Scanning marks

• Do not affix tape on both long edges of the cutting mat as it may attach to the feed rollers during operation.

• Do not attach any material or tape that will go beyond the adhesive area of the mat as the auto blade holder

may not recognize the material thickness and may not accurately cut the material.

2

15

Attaching the material to the mat

Note

Note

Note

a

After preparing the mat and sheet (when cutting

fabric) appropriate for the material, attach the

material to the mat. For the mat and sheet

appropriate for the material, see “Reference Table of

Mat and Material Combinations” on page 14.

• Do not discard the protective sheet peeled off

the mat; save it for later use.

• In order to maintain the adhesive strength,

attach the protective sheet to the adhesive side

of the mat after use.

• When the mat is not being used, clean the

adhesive side and affix the protective sheet

before storing it. For details, see “Cleaning the

Mat” on page 89.

b Test attaching the material.

Before attaching the material to the mat, use a corner

of the adhesive side of the mat to test attaching it.

If any of the following problems occur when test

attaching, the adhesive strength of the mat is too high

for the material. Use different material.

• When the material is peeled off, color from the

material remains on the mat.

• When the material is peeled off, it tears or is

deformed.

Material

“Paper” on page 16

“Fabric (Other Than for Quilt Piecing)” on page 17

“Fabric (for Quilt Piecing)” on page 20

■ Paper

a Mat suitable for the material

Attaching the Material (Paper)

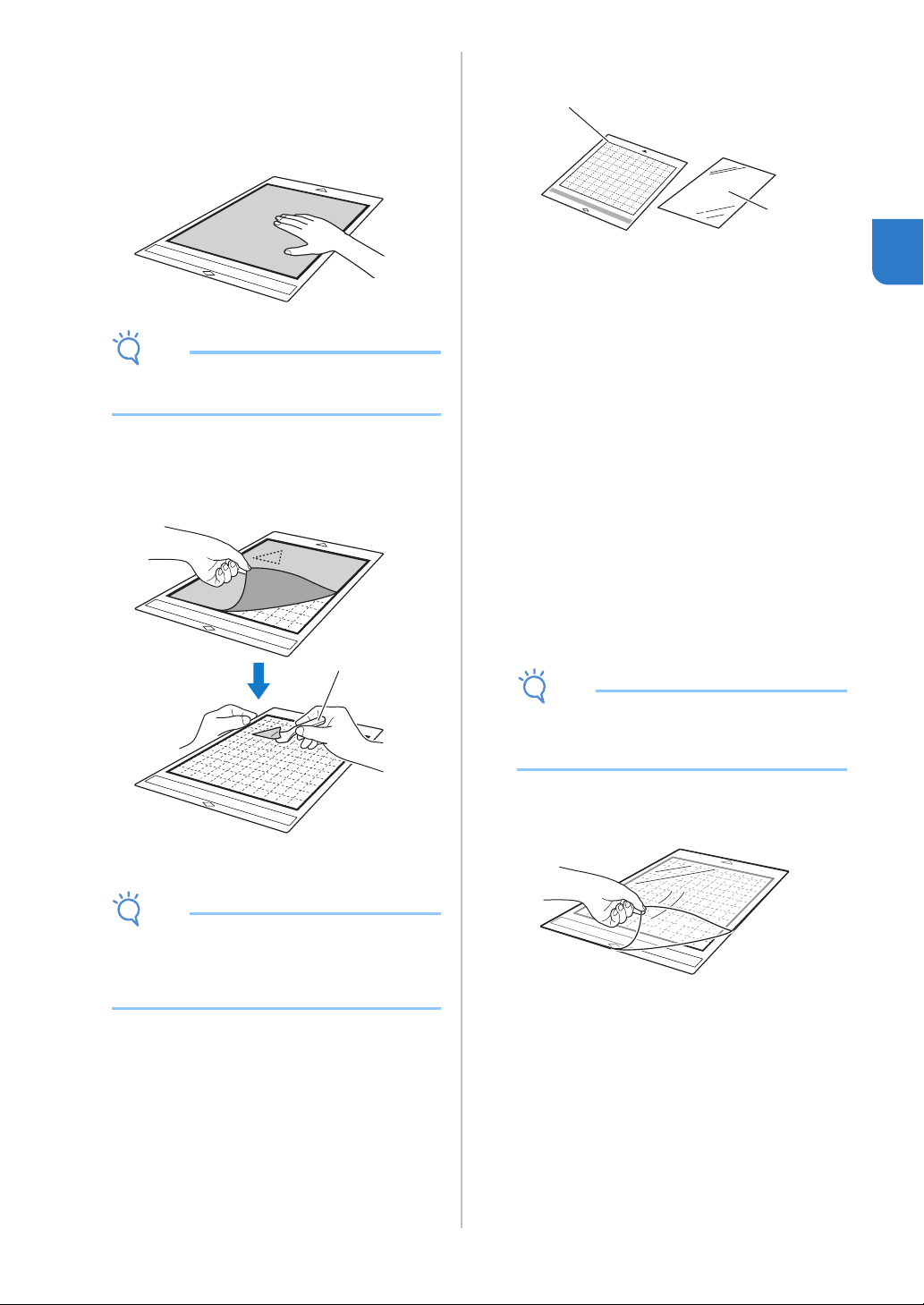

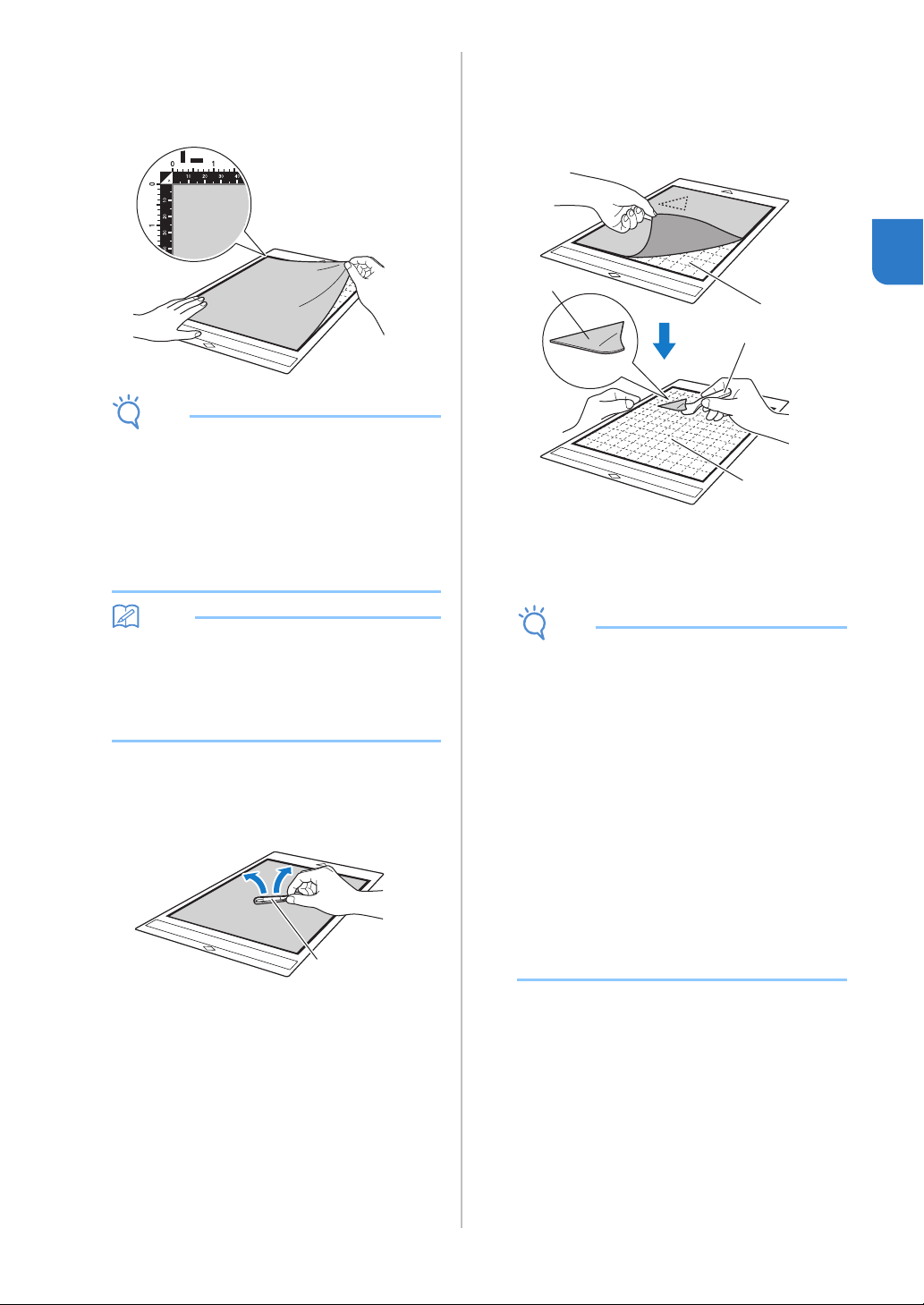

a Peel off the protective sheet from the adhesive

side of the mat.

• Use the low tack adhesive mat with copy paper

and smooth paper. Since the standard tack

adhesive mat has a high adhesive strength,

materials may remain stuck to the mat, causing

the mat to become unusable

c Attach the material to the mat’s adhesive side.

• Place the material within the attaching area

(grid area) on the adhesive side. If the material

extends from the attaching area, it may be

caught on the feed rollers when the mat is fed,

damaging the machine.

• Insert the mat into the machine in the direction

of the arrow. Pay attention to the mat’s

orientation to avoid inserting the mat in the

wrong direction.

16

d Firmly attach all of the material to the mat so

Note

Note

Note

a

that there are no wrinkles and no part can curl

off.

• Otherwise, curls in the material may become

caught when the mat is inserted.

■ Fabric (Other Than for Quilt Piecing)

a

b

• If the mat is dirty, clean it. For details, see

“Cleaning the Mat” on page 89.

Peeling Off the Material (Paper)

After cutting the material, use a spatula to slowly

peel off the paper.

a Standard tack adhesive mat

b Iron-on fabric appliqué contact sheet (white

backing)

Attaching Fabric Material (Excluding

Quilt Piecing)

Iron the specially designed contact sheet to the

back of fabrics (excluding quilt piecing) and then

attach them to the standard tack adhesive mat.

The double-faced adhesive type of the iron-on

fabric appliqué contact sheet reinforces the fabric

and enables any pattern to be cut easily,

including appliqués. The sheet cannot be

removed once it has been attached to the back of

fabrics.

For Quilt Piecing, use the high tack adhesive

fabric support sheet and avoid using the iron-on

fabric appliqué contact sheet. For details on using

fabric for quilt piecing, see “Fabric (for Quilt

Piecing)” on page 20.

• The contact sheet may not adhere to a fabric

surface that is so rough that the two surfaces

cannot be heat-set to adhere to each other.

2

a Spatula

• When peeling off the material, insert the spatula

as level as possible into the space between the

material and mat. Strongly rubbing the adhesive

side of the mat may damage it.

a Peel off the protective sheet from the adhesive

side of the standard tack adhesive mat.

17

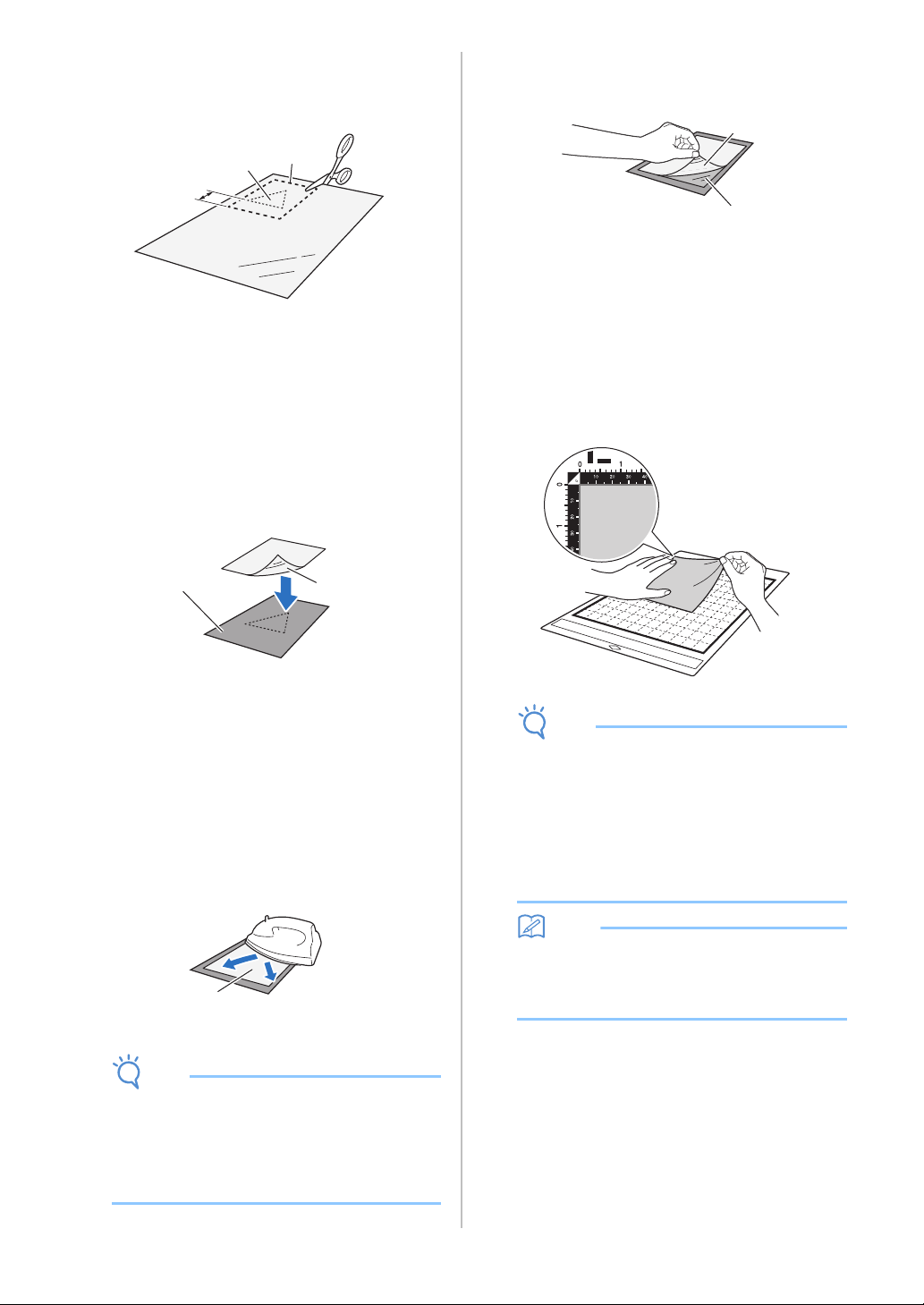

b Cut the iron-on fabric appliqué contact sheet to

Note

Note

Memo

a

c

b

a

b

a

a size 2 cm (3/4") or more larger than the

outline of the pattern to be cut.

a Pattern to be cut

b Cutting line of sheet

c Margin of 2 cm (3/4") or more

c With the glossy side of the contact sheet facing

down, place it on the wrong side of the fabric.

Be sure to first iron the fabric to remove any wrinkles.

Before placing the contact sheet on the fabric, make

sure that the fabric has been allowed to cool after

ironing.

e Peel off the backing from the contact sheet.

Before peeling off the backing, allow all parts to cool.

b

a

a Contact sheet

b Backing

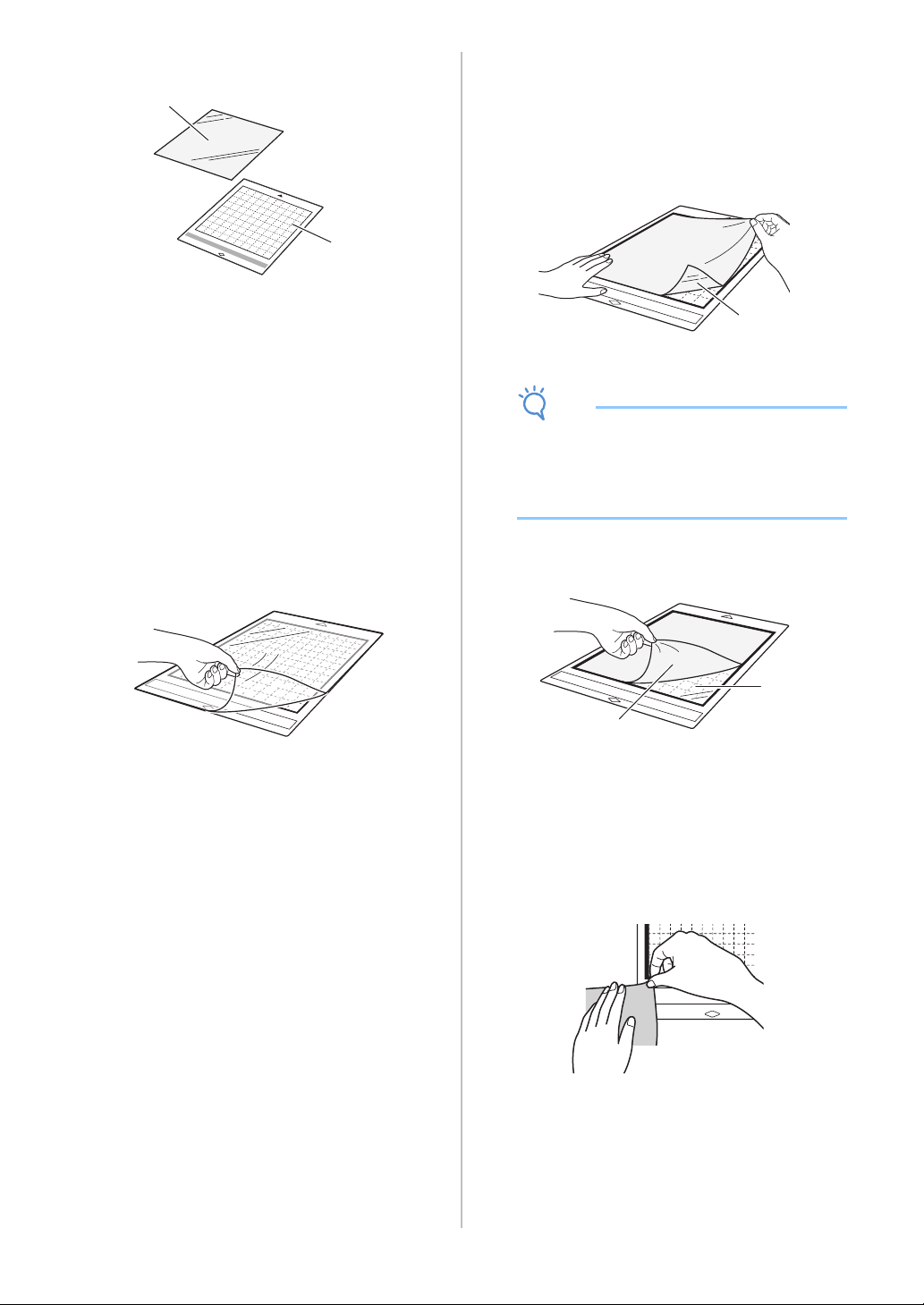

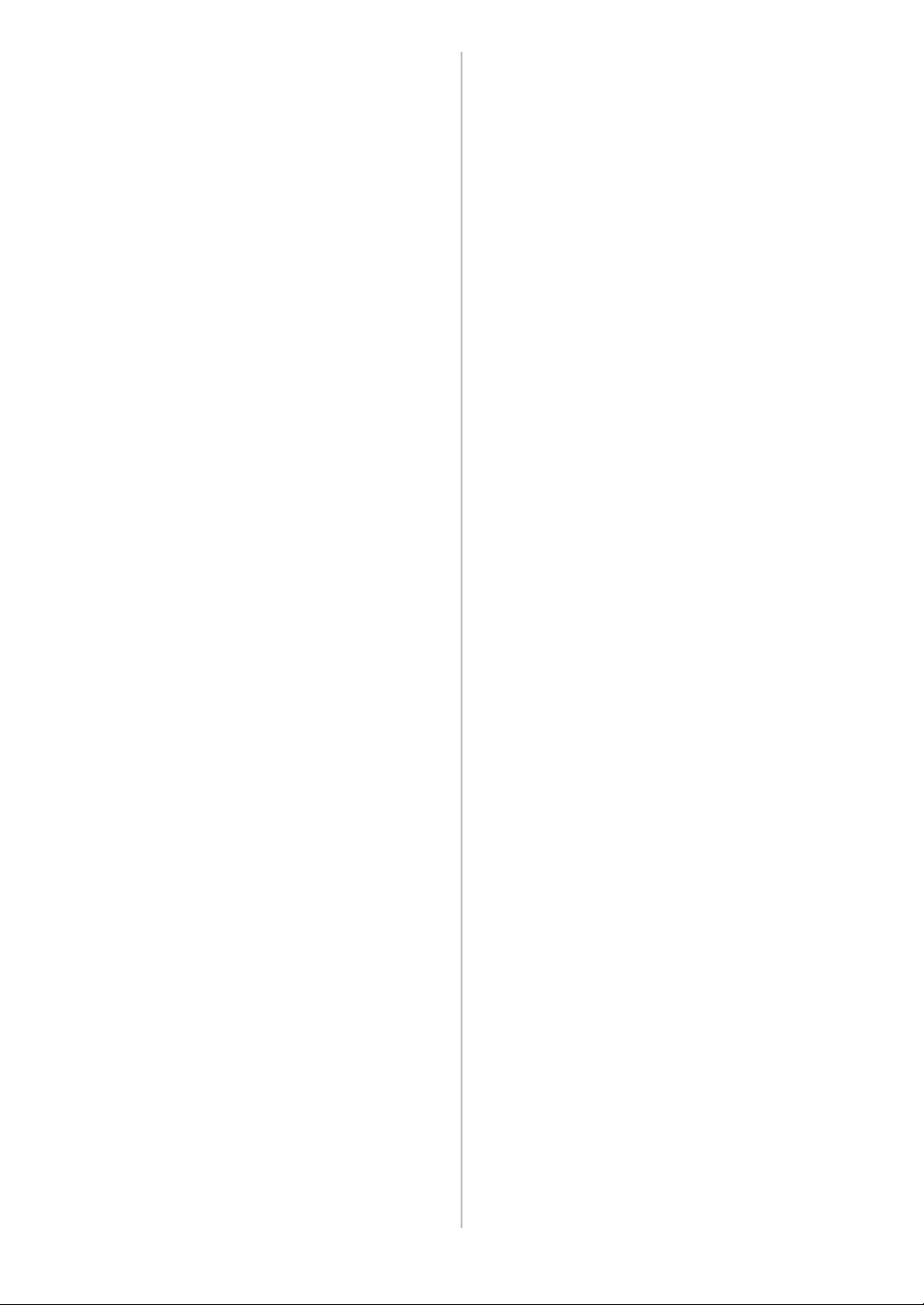

f With the side of the fabric that the contact

sheet is attached to facing down, attach the

material to the mat from its edges.

Slowly attach the entire surface of the material from its

edges while pressing out any air with a ruler, etc., so

that no air is trapped between the mat and the

material.

a Glossy side of contact sheet

b Wrong side of fabric

d Evenly iron the entire contact sheet to affix it to

the wrong side of the fabric.

With the iron on a medium temperature setting (140

°C to 160 °C (284 °F to 320 °F)), press each part of the

sheet for about 20 seconds (the length of time differs

depending on the material).

Be sure to apply pressure on the top of the backing

and push out any air between the sheet and fabric.

a Backing

• Before attaching the contact sheet to the fabric,

use a piece of the sheet to test attach it. If any

problems occur when test attaching, use

different material.

• Leaving the iron in the same place for too long

may scorch or melt the material.

• Place the material within the attaching area

(grid area) on the adhesive side. If the material

extends from the attaching area, it may be

damaged by the feed rollers when the mat is

fed.

• Insert the mat into the machine in the direction

of the arrow. Pay attention to the mat’s

orientation to avoid inserting the mat in the

wrong direction.

• Be sure that the vertical grain of the attached

fabric runs straight up and down. The built-in

patterns are automatically arranged suitable for

fabric with vertical grain.

g Firmly attach all of the material to the mat so

that there are no wrinkles and no part can curl

off.

• Otherwise, curls in the material may become

caught when the mat is inserted.

18

Peeling Off the Material (Excluding Quilt

Note

Note

a

b

c

a

b

Piecing)

After cutting the material, use a spatula to peel off

the fabric together with the attached contact

sheet.

a Pattern that was cut out

b Contact sheet

c Spatula

• Do not wash fabrics attached together with a

double-sided adhesive contact sheet.

• When attaching fabrics with the double-sided

adhesive, iron carefully, being sure that the

material and adhesive surfaces are properly

heat-set.

• When attaching fabrics of different weights with

the double-sided adhesive, first iron the lighterweight fabric to affix the contact sheet.

• When attaching fabric with an iron-on sheet

attached or paper to the mat, cleanly peel off

the support sheet from the mat, or attach the

material to a different standard tack adhesive

mat without a support sheet attached.

Notice on Use of Iron-on Fabric

Appliqué Contact Sheet

• Store the contact sheet at room temperature

and in a location not exposed to high

temperatures, high humidity or direct sunlight.

2

• Do not place anything heated on the fabric

attached with a contact sheet. Adhesive will

permeate any other pieces of fabric around.

• When peeling off the material, insert the spatula

as level as possible into the space between the

material and mat. Strongly rubbing the adhesive

side of the mat may damage it.

Attaching Fabrics With the Double-

Sided Adhesive

Place a cutout on a base fabric and apply pressure

on the top of the cutout using an iron. (The

contact sheet may not adhere well to some

fabrics.) Hand or machine stitch to ensure that the

cutout stays in place.

a Base fabric

b Cutout with a contact sheet

19

■ Fabric (for Quilt Piecing)

Note

b

a

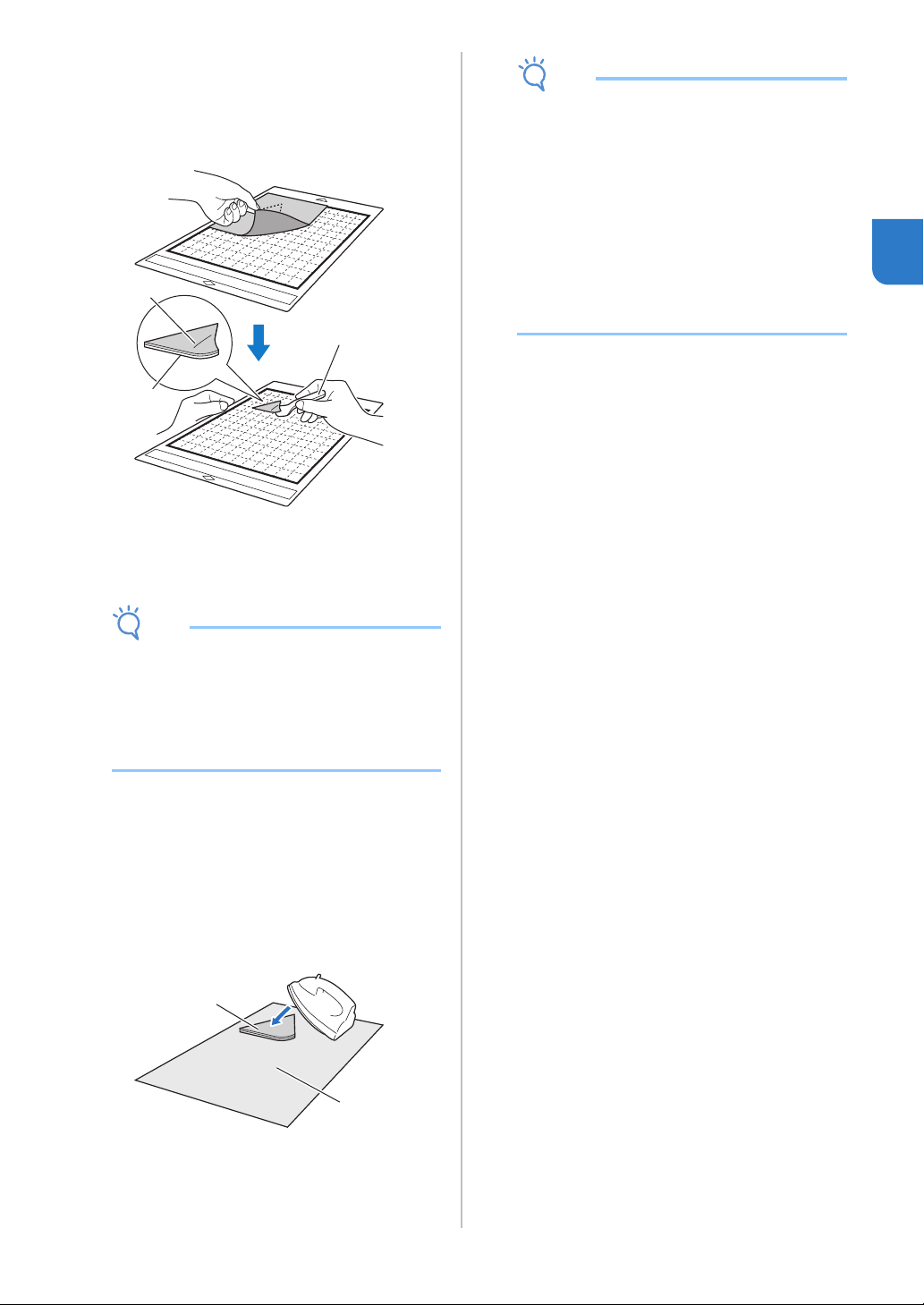

b With the glossy side of the high tack adhesive

fabric support sheet facing down, attach it to

the mat’s adhesive side.

Slowly attach the entire surface of the support sheet

from its edges while pressing out any air with a ruler,

etc., so that no air is trapped between the mat and the

sheet.

a Standard tack adhesive mat

b High tack adhesive fabric support sheet

Attaching the Material (for Quilt Piecing)

Use the high tack adhesive fabric support sheet to

attach fabrics for quilt piecing to the standard tack

adhesive mat. These sheets should only be used

with patterns that have a seam allowance. The

high tack adhesive fabric support sheet can be

repeatedly used until their adhesive strength has

decreased. (Once the support sheet has been

peeled off the mat, it can no longer be used.)

a Peel off the protective sheet from the adhesive

side of the standard tack adhesive mat.

a

a Glossy side of support sheet

• Place the support sheet within the attaching

area (grid area) on the adhesive side of the mat.

If the sheet extends from the attaching area, it

may be damaged by the feed rollers when the

mat is fed.

c Peel off the backing from the top of the support

sheet.

b

a

a Backing

b Adhesive

d Test attaching the material.

Before attaching the material to the mat, use a corner

of the adhesive side of the mat to test attach it. If any

problems occur when test attaching, the adhesive

strength of the mat is too high for the material. Use

different material.

20

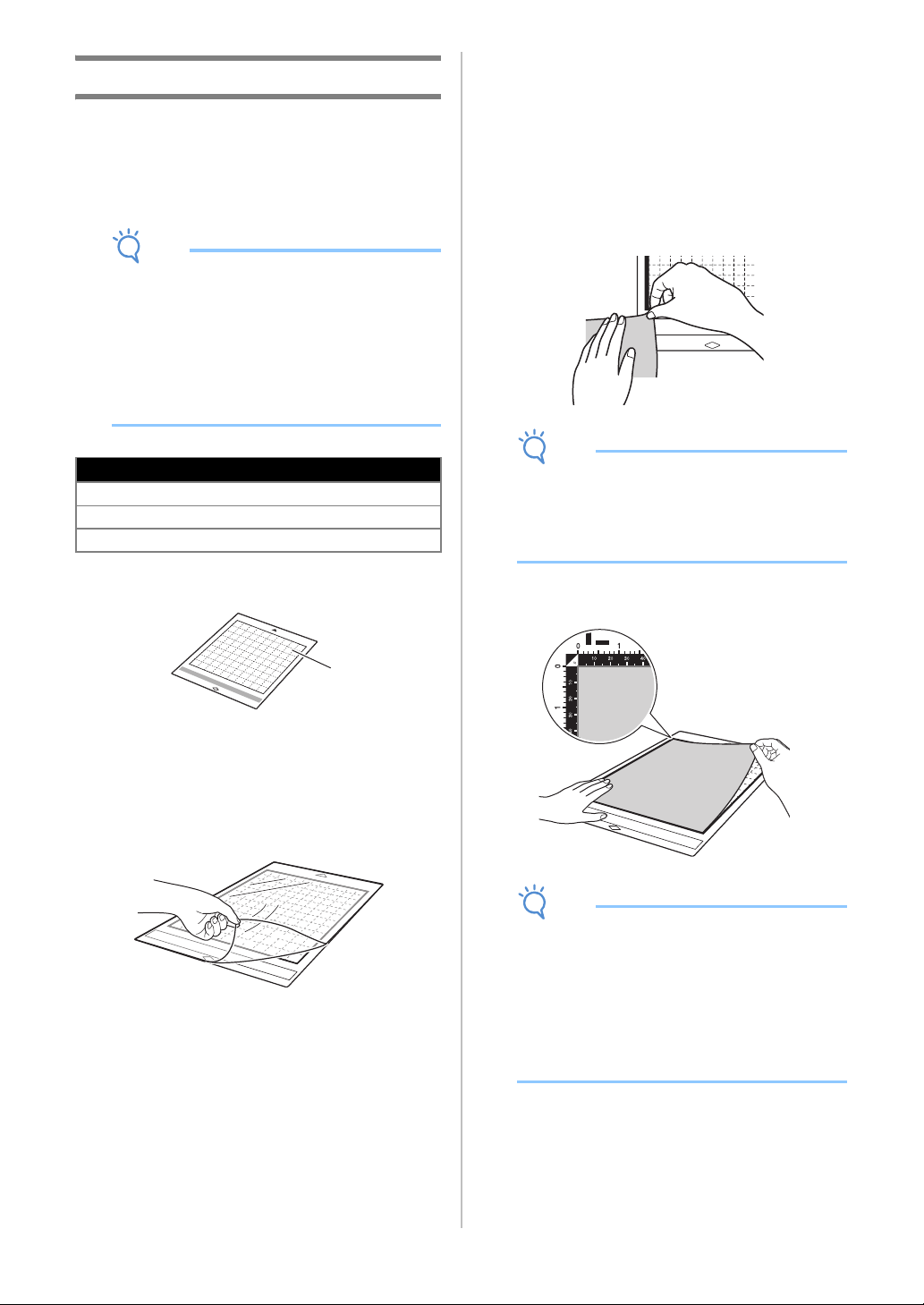

e From its edges, attach the material to the

Note

Memo

Note

a

adhesive side of the mat so that there are no

wrinkles in the material.

Be sure to first iron the fabric to remove any wrinkles.

• Place the material within the attaching area

(grid area) on the adhesive side. If the material

extends from the attaching area, it may be

damaged by the feed rollers when the mat is

fed.

• Insert the mat into the machine in the direction

of the arrow. Pay attention to the mat’s

orientation to avoid inserting the mat in the

wrong direction.

Peeling Off the Material (Fabric for Quilt

Piecing)

After cutting the material, use a spatula to slowly

peel off just the fabric. Try not to peel off the

support sheet.

2

a

b

c

b

a Fabric cut out

b Support sheet remaining on mat

c Spatula

• Be sure that the vertical grain of the attached

fabric runs straight up and down. The built-in

patterns are automatically arranged suitable for

fabric with vertical grain.

• When drawing a seam allowance, attach the

fabric to the mat with its wrong side facing up.

f Firmly move the spatula handle across the

surface of the fabric to remove any wrinkles

and firmly attach the fabric to the mat.

a Spatula

• The support sheet may be unintentionally

peeled off while you are removing the fabric

from the mat under the following conditions:

- The adhesive between the mat and support

sheet is becoming weak after repeated uses.

- The support sheet tends to be strongly

attached to a certain types of fabrics.

• In this case, use the included spatula to hold

the support sheet on the mat and remove the

fabric using your hand.

• After cutting, carefully remove any fibers

remaining on the support sheet.

• Do not leave material attached to a mat with a

support sheet attached for a long period of

time; otherwise, the adhesive will permeate the

material.

• When peeling off the material, insert the spatula

as level as possible into the space between the

material and mat. Strongly rubbing the adhesive

side of the mat may damage it.

21

Notice on Use of High Tack Adhesive

Fabric Support Sheet

• When the sheet’s adhesive strength decreases

or fabric becomes twisted while being cut,

replace the sheet with a new one.

• When peeling the sheet off the mat or replacing

the sheet, use the spatula to carefully remove

the old sheet.

• Store the mat in between uses with the

protective sheet affixed to the support sheet.

• If a mat with a support sheet attached is not to

be used for a certain length of time, peel the

support sheet off the mat and affix the

protective sheet on the adhesive side of the mat

before storing it.

• Do not reuse a support sheet that has been

attached to the mat.

• Store the support sheet at room temperature

and in a location not exposed to high

temperatures, high humidity or direct sunlight.

• Do not bend the support sheet to store it.

• We recommend attaching it to a new cutting

mat.

22

Blade and Material Combination

Note

The appropriate blade differs depending on the material type and thickness. Before cutting the material, be sure

to perform test cut (trial cut). For details on trial cutting, see “Test Cut (Trial Cut)” on page 25.

Use the following table to select the appropriate cutting blade according to the material that will be cut.

Material compability may vary. Always perform a test/trial cut to confirm a successful cut.

If you need additional help, the Brother Solutions Center offers the latest FAQs and troubleshooting tips.

Visit us at “ http://s.brother/cpoac/ ”.

Auto blade holder

Material

Printer paper 80 g/m² (0.1 mm)

Scrapbook paper

Paper

Thin cotton fabric (for quilt piece) 0.25 mm

Thin cotton fabric (except for quilt

Fabric

Flannel (except for quilt piece) 0.5 mm

Adhesive Craft Vinyl (backing sheet

Others

Sticker Sheet (backing sheet :

• Use a high tack adhesive fabric support sheet or a iron-on fabric appliqué contact sheet when you cut a piece of

fabric out. For details, see “Reference Table of Mat and Material Combinations” on page 14.

• Depending on the model, the thin fabric auto blade may not be included. In that case, it can be purchased as an

optional accessory.

Cardstock

Vellum, tracing paper 0.07 mm

Poster board

piece)

Flannel (for quilt piece) 0.5 mm

Felt 3 mm

Denim 14 oz 0.75 mm

Plastic sheet (PP) 0.2 mm

Vinyl 0.2 mm

: 0.1 mm)

Magnet 0.3 mm

Sticker or seal 0.2 mm

0.15 mm)

Foam sheet 3 mm

Thickness

200 g/m²

(0.25 mm)

280 g/m²

(0.35 mm)

400 g/m²

(0.5 mm)

0.25 mm

0.07 mm

0.15 mm

Auto Blade (Black)

Thin Fabric Auto Blade

(Beige)

2

• An auto blade holder is included with this machine. With this blade holder, the thickness of the material is

detected, and the blade extension is automatically adjusted.

• Thick or hard material will automatically be cut multiple times.

23

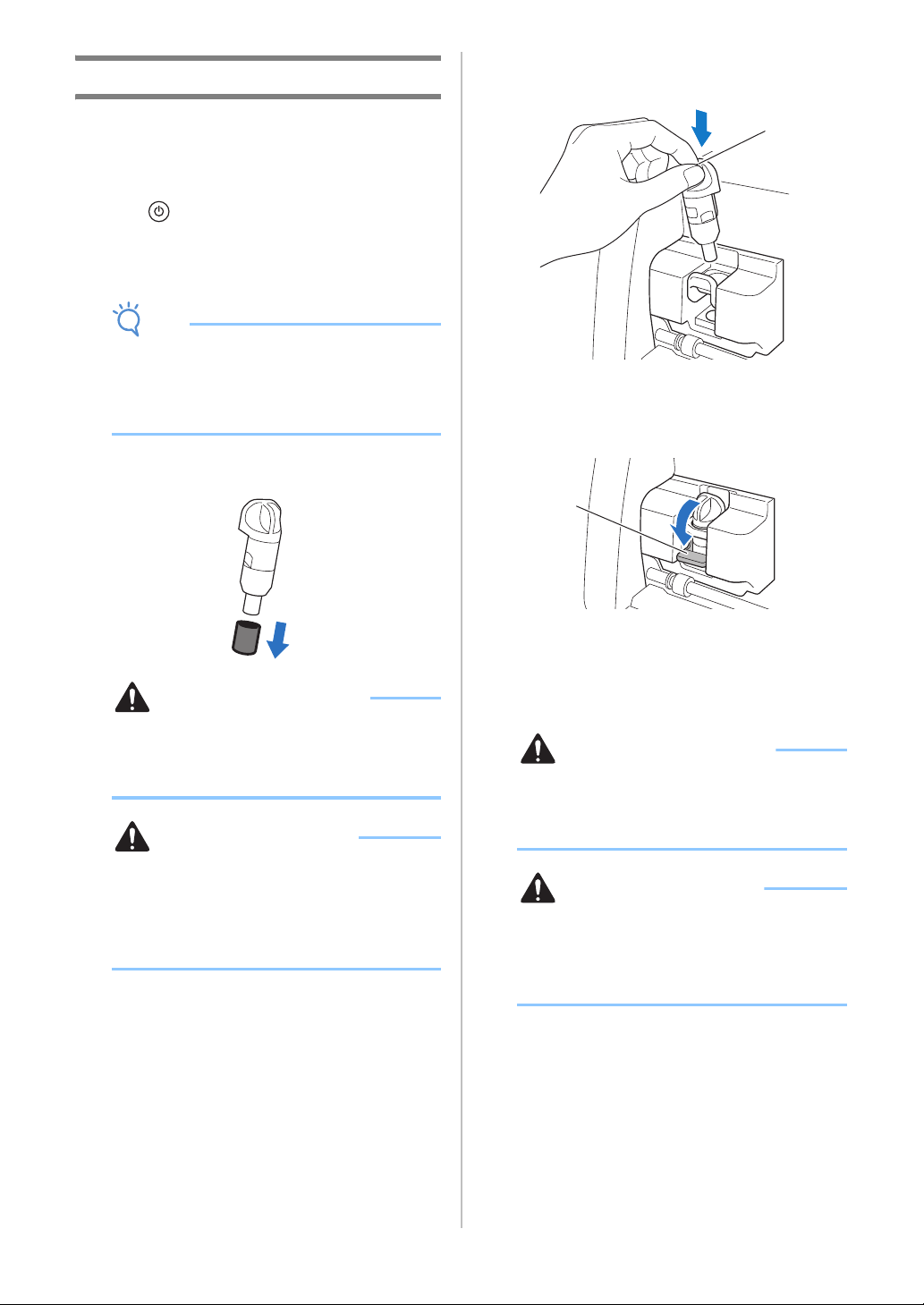

Installing and Uninstalling the Holder

Note

WARNING

CAUTION

WARNING

CAUTION

aa

a

Select the holder appropriate for the material, and

then install it into the machine. For details on the

holder appropriate for the material, see “Blade and

Material Combination” on page 23.

a Press in the operation panel to turn on the

machine.

For details, see “Turning On/Off the Machine” on

page 8.

• Be sure to turn on the machine before installing

the holder.

• If the holder is installed while the machine is off,

the blade may break and material may not be

cut cleanly.

b Remove the protective cap.

c Grasp the holder grip, and then insert the

holder into the carriage.

a Grip

d Push down on the holder lock lever.

Firmly push down until the holder is locked in place.

• This is not a toy and is not intended to be used

by children. In order to prevent choking

hazards, do not allow infants/children to put the

protective caps in their mouths.

• Please remove protective cap from blade

holder before placing it into the machine

carriage.

• Do not press the tip of the holder with your

hand or fingers because the tip of the blade will

extend and may result in injuries.

a Holder lock lever

e Reverse the installation procedure to uninstall

the holder.

• This is not a toy and is not intended to be used

by children. In order to prevent choking

hazards, do not allow infants/children to put the

protective caps in their mouths.

• After removing the blade holder from the

machine, be sure to attach the protective cap.

• Do not press the tip of the holder with your

hand or fingers because the tip of the blade will

extend and may result in injuries.

24

Test Cut (Trial Cut)

Memo

a b c

a

cb d

Perform test/trial cut or draw on the type of material

to be used in your project, to check that the desired

result can be achieved.

This section describes the procedure for performing

test cut.

b Check that the pattern to be cut out is arranged

within a cutting area specified according to the

size of the material.

■ Turning On the Machine

Press in the operation panel to turn on the machine.

• For details, see “Turning On/Off the Machine” on

page 8.

■ Setting the Holder

Install the cutting blade holder into the carriage of the

machine.

• For details, see “Installing and Uninstalling the

Holder” on page 24.

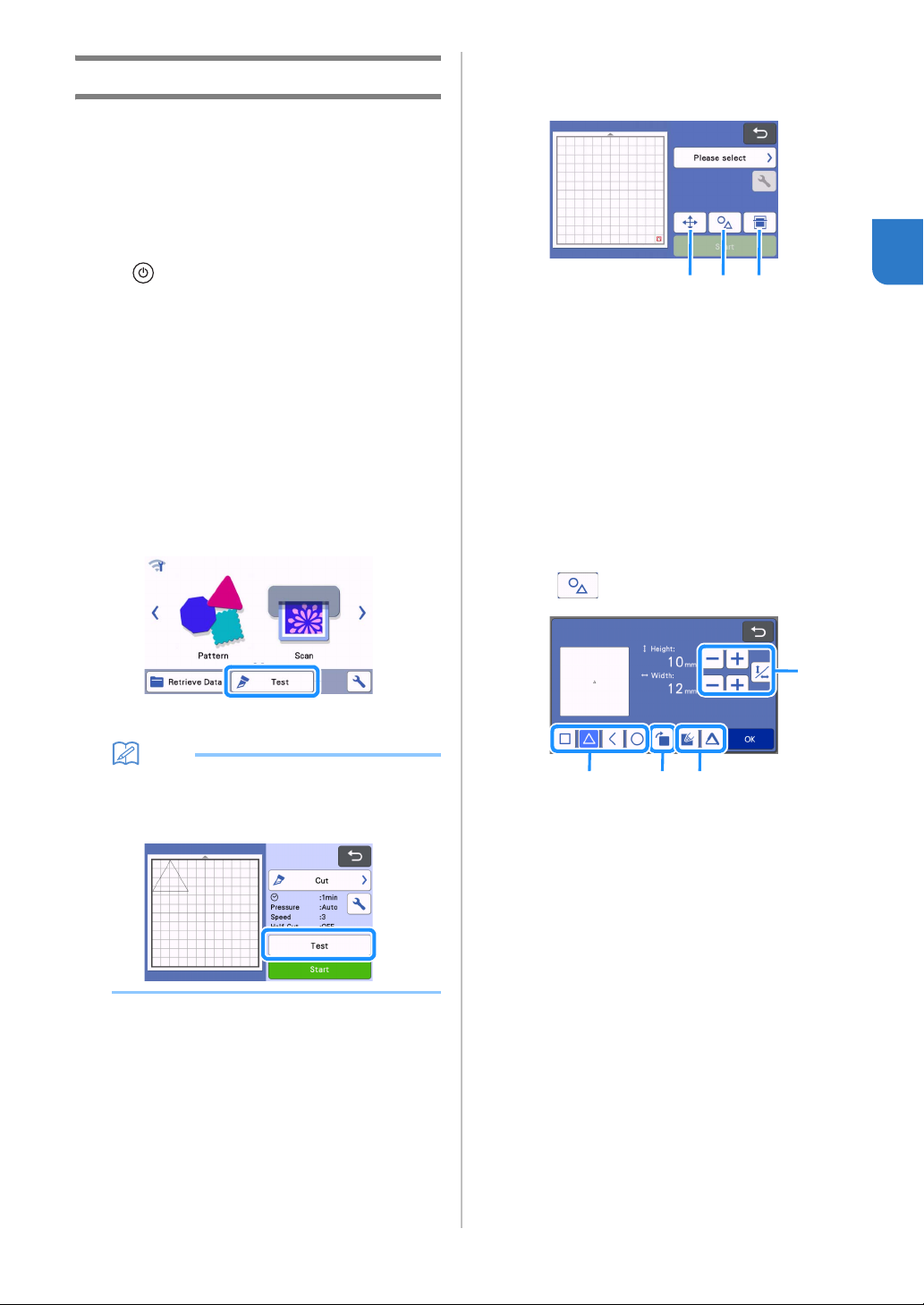

■ Selecting the Test Pattern

Cut out the test pattern.

a Touch the "Test" key in the home screen.

The pattern is automatically arranged in the test

screen.

a Pattern Arrangement Key

Touch to make adjustments in the mat editing

screen when changing the arrangement of the

pattern. If changes are applied to the pattern

arrangement, the pattern will be automatically

arranged in the same location the next time

test/trial cut is performed.

b Size/Shape Adjustment Key

Touch to adjust the pattern shape and size.

For details on making changes, see step

c Background Scanning Key

Scan a background image. For details, see

“Scanning a Background Image” on page 50.

c To change the shape and size of the pattern,

c.

touch .

2

• Test/trial cut can also be performed after

selecting an operation in the preview screen,

displayed after a pattern is selected. For details,

see “Tutorial 1 - Cutting Patterns” on page 29.

a Size Adjustment Keys

Change the size of the pattern. For details, see

“Pattern Editing Functions” on page 40.

b Test Pattern Selecting Keys

Select the test pattern.

c Test Pattern Rotating Key

Rotate the test pattern. Touch the key that

shown in the screen for the desired angle to

rotate the pattern. For details, see “Object

Editing Screen” on page 43.

d Test Pattern Fill/Additional Line Setting Keys

Select whether or not to fill or add lines to the

test pattern. These functions are not available

when you select the "Cut" or "Emboss"

operation mode.

Touch the “OK” key to return to the test screen.

25

■ Loading the Mat

Note

Note

a

b

a

b

■ Cutting

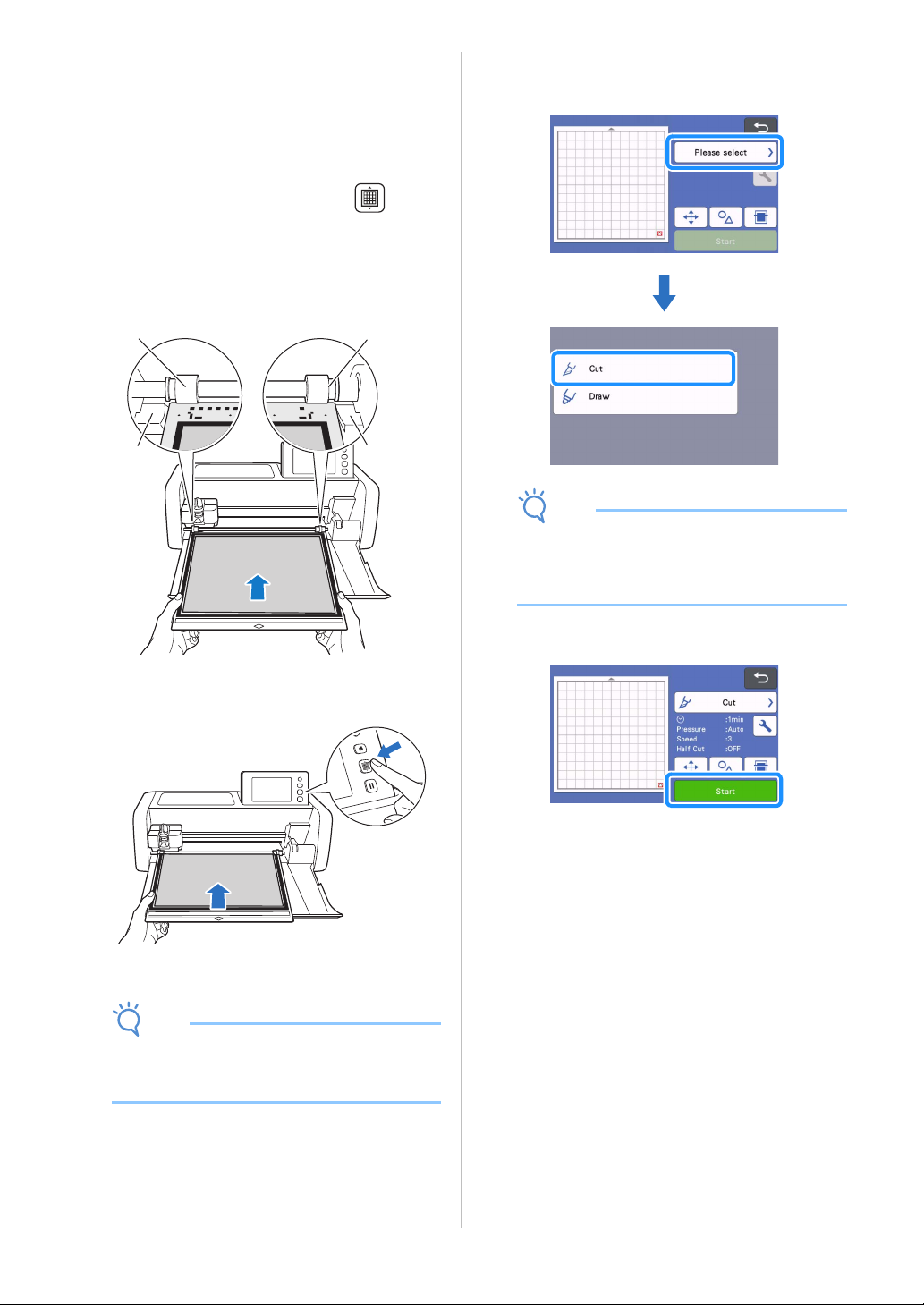

a Attach the material that will be cut to the mat.

• For details on attaching material to the mat, see

“Attaching the material to the mat” on page 16.

b While holding the mat level and lightly

inserting it into the feed slot, press in the

operation panel.

Insert the tip of the mat so that it aligns with the guides

on the left and right sides of the feed slot and is tucked

under the feed rollers. Insert the end of the mat marked

with an arrow into the machine.

a Select “Cut” in the test screen.

• To make half cuts (kiss cuts), turn on half cut

(kiss cut) in the settings screen. For details on

specifying the settings, see “Half Cut (Kiss Cut)

Settings” on page 28.

a Guides

b Feed rollers

The mat is fed in to complete the preparations for

cutting.

• Do not forcefully pull the mat while it is being

fed in. Otherwise, damage, for example, to the

feed rollers, may result.

b Touch the "Start" key to start cutting.

When cutting is finished, the message “Finished

cutting.” appears on the display. Touch the “OK”

key to return to the test screen.

26

■ Unloading the Mat

Note

Note

a

a Press in the operation panel to feed out

the mat.

• Do not forcefully pull the mat while it is being

fed out. Otherwise, damage, for example, to the

feed rollers, may result.

■ Checking the Test/Trial Cut Results

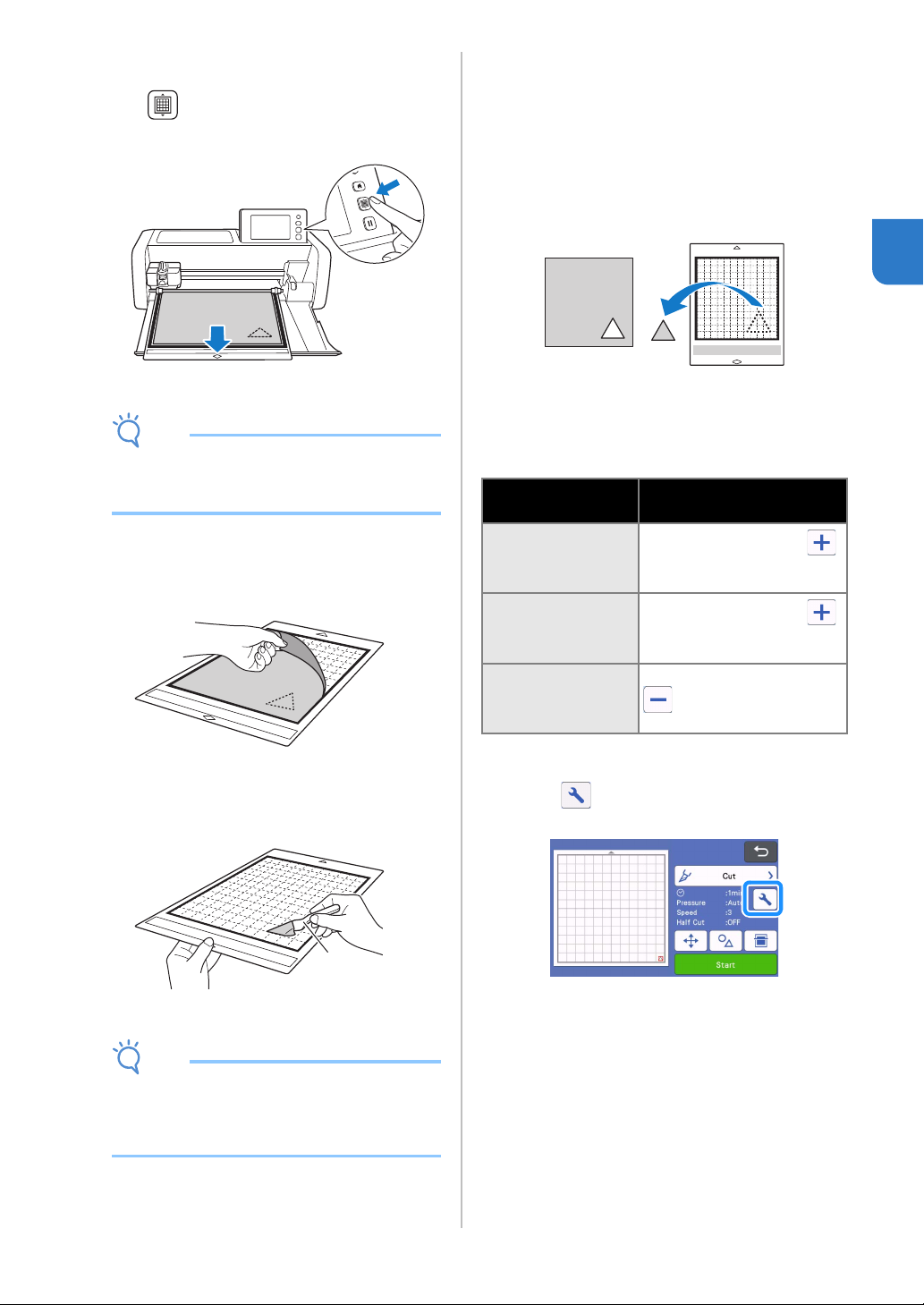

Adjust the cutting pressure according to the test/trial cut

results.

Repeatedly perform test/trial cut and adjust the cutting

pressure until the material is cut cleanly.

With an Appropriate Cutting Pressure

When the material is peeled off, a faint trace of

the cut remains on the mat surface.

■ Changing the Auto Cutting Pressure

If the material could not be cut cleanly, refer to the

following table, and adjust the setting for the cutting

pressure.

Test/Trial Cut

results

Tips for adjustment

2

b Peel off the material from an area that is easily

removable, such as a corner, and then slowly

peel while maintaining an even pressure.

c Holding the mat with your hand, use the

included spatula to carefully peel off the cutout patterns.

a Spatula

Part of the pattern is

not cut.

The entire pattern is

not cut.

There are deep cuts

completely through

the mat.

Pressure too light: Touch

in the settings screen once to

increase the pressure.

Pressure too light: Touch

in the settings screen once to

increase the pressure.

Pressure too strong: Touch

in the settings screen

once to decrease the pressure.

Changing the Cut Pressure Setting

a Touch in the test screen to display the

settings screen.

• When peeling off the material, insert the spatula

as level as possible into the space between the

material and mat. Strongly rubbing the adhesive

side of the mat may damage it.

27

b Touch or to adjust the cutting

Note

pressure, and then touch the "OK" key.

c Check that the settings have changed in the test

screen, and then perform test/trial cut again.

• Be careful not to increase the pressure too

much. Otherwise, the blade may break. If the

pressure is too strong, the material may not be

cut cleanly. In addition, the mat will deteriorate

more quickly.

■ Half Cut (Kiss Cut) Settings

To make half cuts (kiss cuts), turn on half cut (kiss cut) in

the settings screen before beginning to cut.

a Touch in the preview screen to display the

settings screen.

b Turn on “Half Cut”, and then touch the “OK”

key.

• The pressure for half cut (kiss cut) can adjusted

with “Cut Pressure (Half Cut)”. Adjust the cutting

pressure until half cut (kiss cut) result is as desired.

28

Memo

PATTERN CUTTING

b

a

b

a

The following procedures use built-in patterns to

describe the entire series of operations, from

selecting a pattern and editing it to cutting.

Tutorial 1 - Cutting Patterns

In this tutorial, we will cut two built-in patterns.

■ Turning On the Machine

Press to turn on the machine.

• For details, see “Turning On/Off the Machine” on

page 8.

b Select the category for the pattern to be cut out

in the pattern category selection screen.

For this example, select .

2

a Touch to return to the previous screen.

b Pattern categories

• The pattern categories and built-in patterns that

appear in the operation screens differ

depending on the machine model. For details

on the built-in patterns, refer to the “Pattern

List”. The “Pattern List” can be downloaded

from the Brother Solutions Center (http://

s.brother/cmoae/).

c Select the first pattern to be used in the pattern

selection screen.

■ Setting the Holder

Install the cutting blade holder into the carriage of the

machine.

• For details, see “Installing and Uninstalling the

Holder” on page 24.

■ Selecting and Editing the First

Pattern

a Select “Pattern” in the home screen.

a Touch to scroll up.

b Touch to scroll down.

d Edit the size and number of the pattern using

the pattern editing screen.

After editing is finished, touch the “Set” key.

• For details on the editing functions, see “Pattern

Editing Functions” on page 40.

• To select a different pattern, touch , cancel

the selection, and then select a pattern again.

29

■ Selecting and Editing the Second

Note

a

Pattern

a Touch the “Add” key in the mat layout screen.

b Select the location of the pattern to be added.

• For this example, touch the “Pattern” key to add a

built-in pattern. For details on recalling pattern

data, see step

c Select the category for the pattern to be cut

out.

c in “Retrieve Data” on page 54.

e Edit the pattern.

After editing is finished, touch the “Set” key.

• For details on the editing functions, see “Pattern

Editing Functions” on page 40.

• To select a different pattern, touch , cancel

the selection, and then select a pattern again.

f Check the pattern arrangement.

The two patterns that will be cut out appear in the mat

layout screen. After checking the arrangement, touch

the “OK” key.

• From this screen, an individual pattern can be

edited, moved or deleted. For details on the

functions that can be used in the mat layout

screen, see “Layout Editing Functions” on

page 42.

• By using the auto layout function, the

arrangement of the patterns can easily be

adjusted. For details, see “Auto Layout

Functions” on page 49.

• Select the “Cut Area” setting appropriate for the

mat being used. (See page 10.)

a Touch to return to the previous screen.

d Select the second pattern to be used.

30

The preview screen appears.

• Depending on the pattern type and material to

be cut, the patterns may not be cleanly cut if

their spacing is too small. In that case,

rearrange the patterns to separate them.

Memo

■ Cutting

Note

• To move a pattern within the cutting/drawing

area, touch the pattern on the screen and drag

it to the desired position.

• To delete a pattern from the arrangement,

select the pattern in the mat editing screen, and

then use the function for deleting.

Touch the "Edit" key in the mat layout screen.

Touch the pattern to be deleted in the screen.

To delete multiple patterns, use the function for

selecting multiple patterns. For details, see

“Selecting Multiple Patterns” on page 38.

a Select “Cut” in the preview screen.

2

• Before continuing operation, make sure that

patterns that will be cut out are arranged in the

cutting area corresponding to the size of the

material to be used.

• To make half cuts (kiss cuts), turn on half cut

(kiss cut) in the settings screen before

beginning to cut. For details, see “Half Cut (Kiss

Cut) Settings” on page 28.

Touch in the mat editing screen to delete

the selected pattern(s).

■ Loading the Mat

While holding the mat level and lightly inserting it into

the feed slot, press in the operation panel.

• For details, see “Loading the Mat” on page 26.

b Touch the "Start" key to start cutting.

When cutting is finished, the preview screen

appears again.

31

Note

• Touch the “Test” key in the preview screen to

Memo

b

a

perform test/trial cut. When test/trial cut is

finished, the following screen appears.

■ Selecting and Editing the First

Pattern Piece

a Select “Pattern” in the home screen.

- Touch the “Start” key to start cutting the

pattern.

- Touch the “Test again” key to return to the

test screen. Change the settings, and then

perform test/trial cut again.

■ Unloading the Mat

Feed out the mat, and then use the included spatula to

peel off the patterns.

For details, see “Unloading the Mat” on page 27.

Tutorial 2 - Cutting Advanced Patterns

b Select the category in the pattern category

selection screen.

a Touch to return to the previous screen.

b Pattern categories

• The pattern categories and built-in patterns that

appear in the operation screens differ

depending on the machine model. For details

on the built-in patterns, refer to the “Pattern

List”. The “Pattern List” can be downloaded

from the Brother Solutions Center (http://

s.brother/cmoae/).

c Select the sub-category in the pattern sub-

category selection screen.

In this tutorial, we will cut a built-in pattern in the

category.

32

d Select the pattern to be cut out in the pattern

Memo

b

a

b

a

selection screen.

• The pattern pieces displayed in the pattern

piece list screen are automatically arranged so

that the grain is vertical when fabric is used as

the material for cutting. Therefore, the angle at

which the pattern appears in the pattern piece

list may differ from the actual angle of the

pattern piece to be cut out.

a Touch to scroll up.

b Touch to scroll down.

e Edit the size of the entire pattern using the

pattern sizing screen.

After editing is finished, touch the “OK” key.

• For details on the pattern sizing screen, see

“Pattern Sizing” on page 41.

f Select the piece to be edited first in the pattern

piece list screen, and then touch the “OK” key.

From the pattern piece list that appears in the screen,

touch a pattern piece to edit it individually.

2

a Appearance in pattern piece list

b Actual arrangement of the pattern piece to be

cut out

• Change the angle of pattern piece using the

rotating function according to your project. For

details, see “Editing the Pattern Piece” on

page 41.

• A key showing all pattern pieces appears at the

end of the pattern piece list. Press this key to

select all pattern pieces and arrange them on

the mat. This key is useful when cutting the

pattern outline and cutting multiple pattern

pieces within the same mat, see “Editing and

Cutting the Second Pattern Piece” on page 35.

g Edit the pattern piece using the pattern piece

editing screen.

After editing is finished, touch the “Set” key.

• For details on the editing functions, see “Editing the

Pattern Piece” on page 41.

33

hCheck the pattern piece arrangement using the

Note

mat layout screen.

The pattern piece to be cut out appears in the screen.

After checking the arrangement, touch the “OK” key.

• From this screen, an individual pattern piece can

be edited, moved, deleted or saved. For details on

the editing functions in the mat layout screen, see

“Mat Layout Screen” on page 41.

• Select the “Cut Area” setting appropriate for the

mat being used. (See page 10.)

The preview screen appears.

■ Loading the Mat

Attach the material that the first pattern piece will be cut

out of to the mat, and then feed in the mat from the feed

slot.

When cutting a pattern consisting of multiple pieces in

different colors, edit the pattern piece for each color,

and then change the material to cut out each piece.

• For details on preparing the material and loading

the mat, see “Loading the Mat” on page 26.

• Before continuing operation, make sure that

patterns that will be cut out are arranged in the

cutting area corresponding to the size of the

material to be used.

• To make half cuts (kiss cuts), turn on half cut

(kiss cut) in the settings screen before

beginning to cut. For details, see “Half Cut (Kiss

Cut) Settings” on page 28.

b Touch the "Start" key to start cutting.

After the first pattern piece has been cut out, the

following message appears. In order to cut out

the second pattern piece, touch the “Select the

next part” key.

Touching the “Select the next part” key erases all

editing information for the first pattern piece and

displays the pattern piece list screen again.

■ Unloading the Mat

■ Cutting the First Pattern

a Select “Cut” in the preview screen.

a Press in the operation panel to feed out

the mat.

In order to replace the material with one of a different

color, the material used for the first pattern piece must

be fed out.

b Peel from the mat the pattern piece that was

cut out.

For details on peeling the material from the mat, see

“Unloading the Mat” on page 27.

34

■ Editing and Cutting the Second

Memo

a

a

Pattern Piece

■ Editing and Cutting the all Pattern

Pieces

a Select and edit the second pattern piece, and

then touch the “OK” key.

For details on editing the pattern, follow steps f-h

(page 33) in “Selecting and Editing the First Pattern

Piece”.

a Touch to return to the pattern category

selection screen for selecting another pattern.

b Follow the procedures described in “Loading

the Mat” (page 26) and “Cutting” (page 26) to

load the material to be used for the second

pattern piece and cut it out.

When cutting is finished, a message appears.

c After all pattern pieces have been cut out,

touch the “Finish” key.

Cutting the pattern outline

a Select and edit the all pattern pieces, and then

touch the “OK” key.

2

b Edit the pattern piece using the pattern piece

editing screen.

• For details on the editing functions, see “Editing the

Pattern Piece” on page 41.

c Touch to ungroup the pattern pieces.

After editing is finished, touch the “Set” key.

The preview screen appears again.

■ Unloading the Mat

Peel from the mat the pattern piece that was cut out.

For details on peeling the material from the mat, see

“Unloading the Mat” on page 27.

a Grouping/Ungrouping Key

• Grouping/Ungrouping patterns can also be

adjusted in the object editing screen. For

details, see “Grouping/Ungrouping Patterns” on

page 44.

d Check the pattern piece arrangement using the

mat layout screen and then touch the “Edit”

key.

35

e Touch the “Object Edit” key.

a

f Touch to weld the pattern.

• For details on the welding, see “Welding (Merging

the Outlines of Multiple Patterns)” on page 46.

Touch the “OK” key in the editing screen to

return to the mat layout screen.

g Touch the “OK” key.

Cutting all the pattern piece within the

same mat

a Select and edit the all pattern pieces, and then

touch the “OK” key.

b Edit the pattern piece using the pattern piece

editing screen.

• For details on the editing functions, see “Editing the

Pattern Piece” on page 41.

c Touch to ungroup the pattern pieces.

After editing is finished, touch the “Set” key.

hFollow the procedures described in “Loading

the Mat” (page 26) and “Cutting” (page 26) to

load the material to be cut.

When cutting is finished, a message appears.

i After all pattern pieces have been cut out,

touch the “Finish” key.

a Grouping/Ungrouping Key

d Check the pattern piece arrangement using the

mat layout screen and then touch to

arrange all the pattern pieces layout

automatically.

• For details on the auto layout function, see “Auto

Layout Functions” on page 49.

Touch the “OK” key in the editing screen to

return to the mat layout screen.

36

e Touch the “OK” key.

f Follow the procedures described in “Loading

the Mat” (page 26) and “Cutting” (page 26) to

load the material to be cut.

When cutting is finished, a message appears.

g After all pattern pieces have been cut out,

touch the “Finish” key.

2

37

Memo

PATTERN SELECTION

a

a

The following four pattern selection functions are

available in the mat editing screen depending on

your preference:

● Selecting a Single Pattern

● Selecting Desired Patterns

● Selecting All Patterns

● Specifying the Selection Area

Touch the "Edit" key in the mat layout screen to

use the pattern selection functions.

Selecting a Single Pattern

Select an individual pattern to be edited by either

touching it in the editing screen or using and

.

The selected pattern is surrounded with a red box.

b Individually touch all the patterns you want to

select in the screen, and then touch the “OK”

key.

a Selected patterns

• Touching a selected (surrounded with a red

box) pattern again clears its multiple selection.

• Touching any blank space in the screen clears

all the pattern selections.

■ Selecting All Patterns

a Touch in the mat editing screen for

making multiple pattern selection.

b Touch to select all the patterns on the

screen.

c Check the selection, and then touch the “OK”

Selecting Multiple Patterns

key.

All the selected patterns are surrounded with a

red box.

■ Selecting Desired Patterns

a Touch in the mat editing screen for

making multiple pattern selection.

38

■ Specifying the Selection Area

Memo

Note

a

b

a Touch in the mat editing screen for

making multiple pattern selection.

b Touch for specifying an area to select the

patterns.

• Make sure that is not selected before

specifying the area to select.

c Touch and drag the area resizing keys to specify

the area, and then touch the “OK” key.

2

a Keys for specifying the area

b Patterns to be selected

• Make sure to specify to include more than two

patterns in the area.

• This method of selecting patterns within a

specified area is useful for welding or unifying

patterns and deleting unwanted images when

scanning (page 46, page 80).

39

Chapter 3 ADVANCED OPERATIONS

Note

a

b

c