Page 1

Stamp Creator PRO

SERVICE MANUAL

MODEL: SC-2000 Version A

Page 2

Stamp Creator PRO

SERVICE MANUAL

MODEL: SC-2000

Page 3

Copyright Brother 1999

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing from

the publisher.

Specifications are subject to change without notice.

Page 4

Stamp Creator PRO SC-2000

Mechanical Part

CONTENTS

CHAPTER I SPECIFICATIONS...................................................................................I-1

1. MECHANICAL SPECIFICATIONS................................................................................................I-1

1.1 Overview.........................................................................................................................I-1

1.2 Input Specifications.........................................................................................................I-2

1.3 Display Specifications......................................................................................................I-2

1.4 Printing Specifications.....................................................................................................I-2

1.5 Engraving Stamp Specifications.......................................................................................I-3

1.6 Xenon Unit Specifications................................................................................................I-3

1.7 Ribbon Cassette Specifications........................................................................................I-3

1.8 Magazine Tray Specifications..........................................................................................I-3

1.9 Stamp Specifications.......................................................................................................I-4

1.10 Draft Sheet Specifications................................................................................................I-6

1.11 ID Label Specifications....................................................................................................I-6

CHAPTER II THEORY OF MECHANISM OPERATION.............................................II-1

1. PRINTING MECHANISM.............................................................................................................II-1

1.1 Construction of Thermal Head........................................................................................II-1

1.2 Theory of Printing...........................................................................................................II-1

1.3 Configuration of Character and Graphics........................................................................II-1

2. ENGRAVING STAMP MECHANISM............................................................................................II-2

2.1 Theory of Engraving Stamp............................................................................................II-2

2.2 Positioning the Holder.....................................................................................................II-3

3. FEEDING MECHANISM..............................................................................................................II-4

3.1 Feeding Draft Sheet.......................................................................................................II-4

3.2 Feeding Draft Sheet and ID Label...................................................................................II-5

1

Page 5

CHAPTER III DISASSEMBLY AND REASSEMBLY.................................................III-1

1. DISASSEMBLING PROCEDURES.............................................................................................III-2

1.1 Disassembly of the I/F Cable and the AC Cord..............................................................III-2

1.2 Disassembly of the Magazine Tray Assy and the Xenon Unit.........................................III-3

1.3 Disassembly of the Ribbon Cassette Assy.....................................................................III-4

1.4 Disassembly of the Main PCB Assy...............................................................................III-5

1.5 Disassembly of the Capacitor Case...............................................................................III-7

1.6 Disassembly of the Body Cover.....................................................................................III-9

1.7 Disassembly of the Main Chassis and the Bottom Cover.............................................III-12

1.8 Disassembly of the Power Supply PCB Assy...............................................................III-15

1.9 Disassembly of the Thermal Head Unit........................................................................III-16

1.10 Disassembly of the Sensor Assys................................................................................III-17

1.11 Disassembly of the Micro Switches..............................................................................III-18

1.12 Disassembly of the Platen Unit Assy............................................................................III-19

1.13 Disassembly of the Presser Unit Assy.........................................................................III-21

1.14 Disassembly of the Head Holder Assy.........................................................................III-26

1.15 Disassembly of the Gears and Pulleys.........................................................................III-28

1.16 Disassembly of the Motor Holder Assy and the Motors................................................III-29

1.17 Disassembly of the Rollers..........................................................................................III-30

1.18 Disassembly of the Label Guide Assy..........................................................................III-31

1.19 Disassembly of the Film Path Assy..............................................................................III-33

1.20 Disassembly of the Drawer Connector.........................................................................III-35

2. REASSEMBLING PROCEDURES............................................................................................III-36

2.1 Reassembly of the Drawer Connector..........................................................................III-36

2.2 Reassembly of the Film Path Assy..............................................................................III-37

2.3 Reassembly of the Label Guide Assy...........................................................................III-42

2.4 Reassembly of the Rollers...........................................................................................III-45

2.5 Reassembly of the Motor Holder Assy and the Motors.................................................III-48

2.6 Reassembly of the Gears and Pulleys.........................................................................III-49

2.7 Reassembly of the Head Holder Assy..........................................................................III-51

2.8 Reassembly of the Presser Unit Assy..........................................................................III-54

2.9 Reassembly of the Platen Unit Assy............................................................................III-61

2.10 Reassembly of the Micro Switches..............................................................................III-63

2.11 Reassembly of the Sensor Assys................................................................................III-64

2.12 Reassembly of the Thermal Head Unit.........................................................................III-65

2.13 Reassembly of the Power Supply PCB Assy................................................................III-66

2.14 Reassembly of the Bottom Cover and the Main Chassis..............................................III-67

2.15 Reassembly of the Body Cover....................................................................................III-69

2.16 Reassembly of the Capacitor Case..............................................................................III-72

2.17 Reassembly of the Main PCB Assy..............................................................................III-74

2

Page 6

2.18 Reassembly of the Ribbon Cassette Assy....................................................................III-77

2.19 Reassembly of the Xenon Unit.....................................................................................III-78

2.20 Reassembly of the Magazine Tray Assy......................................................................III-79

2.21 Reassembly of the AC Cord and the I/F Cable.............................................................III-79

2.22 Lubrication during Reassembly....................................................................................III-80

CHAPTER IV TROUBLESHOOTING........................................................................IV-1

1. GENERALS................................................................................................................................IV-1

2. PRECAUTIONS ON REPAIRING................................................................................................IV-1

3. ACTIONS TO BE TAKEN AFTER REPAIRS...............................................................................IV-1

3

Page 7

CHAPTER I SPECIFICATIONS

1. MECHANICAL SPECIFICATIONS

1.1 Overview

(1) External view See Fig. 1.1.

(2) Dimensions 470 mm (W) × 238.3 mm (D) × 180.8 mm (H)

(without the magazine tray assy)

(3) Weight Approx. 8 kg

(4) Total weight Approx. 11 kg

(machine and package)

238.3 mm

180.8 mm

470 mm

Fig. 1.1 External Dimensions

I - 1

Page 8

1.2 Input Specifications

(1) Type of keys Tactile switch

(2) Number of keys 2

(3) Key layout See Fig. 1.2

1.3 Display Specifications

(1) Display method Character type LCD

Fig. 1.2 Control Panel

(2) Number of characters 15 columns × 1 line

(3) Dots CG construction 5 dots × 7 dots + the cursor

(4) Dot size 0.58 mm wide by 0.524 mm high

(5) Dot pitch 0.65 mm wide by 0.594 mm high

1.4 Printing Specifications

(1) Printing type Thermal fusion and printing method by

(2) Printing speed 99.2 dots/sec. (4.2 mm/sec.)

(3) Thermal head construction Thin film thermal head 960 dots × 1 dot

thermal head

Vertical pitch 0.0425 mm (1/600 inch)

Dimensions of a heating element

0.035 mm wide by

0.060 mm high

I - 2

Page 9

1.5 Engraving Stamp Specifications

(1) Engraving stamp method Light engraving stamp method

(2) Operation load 98 N (10 kgf) or lower

(3) Light source Xenon lamp (xenon unit)

1.6 Xenon Unit Specifications

(1) Light source Xenon lamp

(2) Light emission times 2000 times or more

(3) Construction Xenon tube, reflector, acrylic plate, and glass

(4) Packaged standard xenon unit Yes (1 piece)

1.7 Ribbon Cassette Specifications

(1) Ink color Black

plate

(2) Printing times 150 or more printing surfaces

(3) Packaged standard ink Yes (1 piece)

ribbon cassette

1.8 Magazine Tray Specifications

(1) Capacity 50 draft sheets

(2) Separation method Separation method by claws

(3) Packaged standard Yes (1 piece)

magazine tray

(1 printing surface includes both an ID label

and a draft sheet.)

I - 3

Page 10

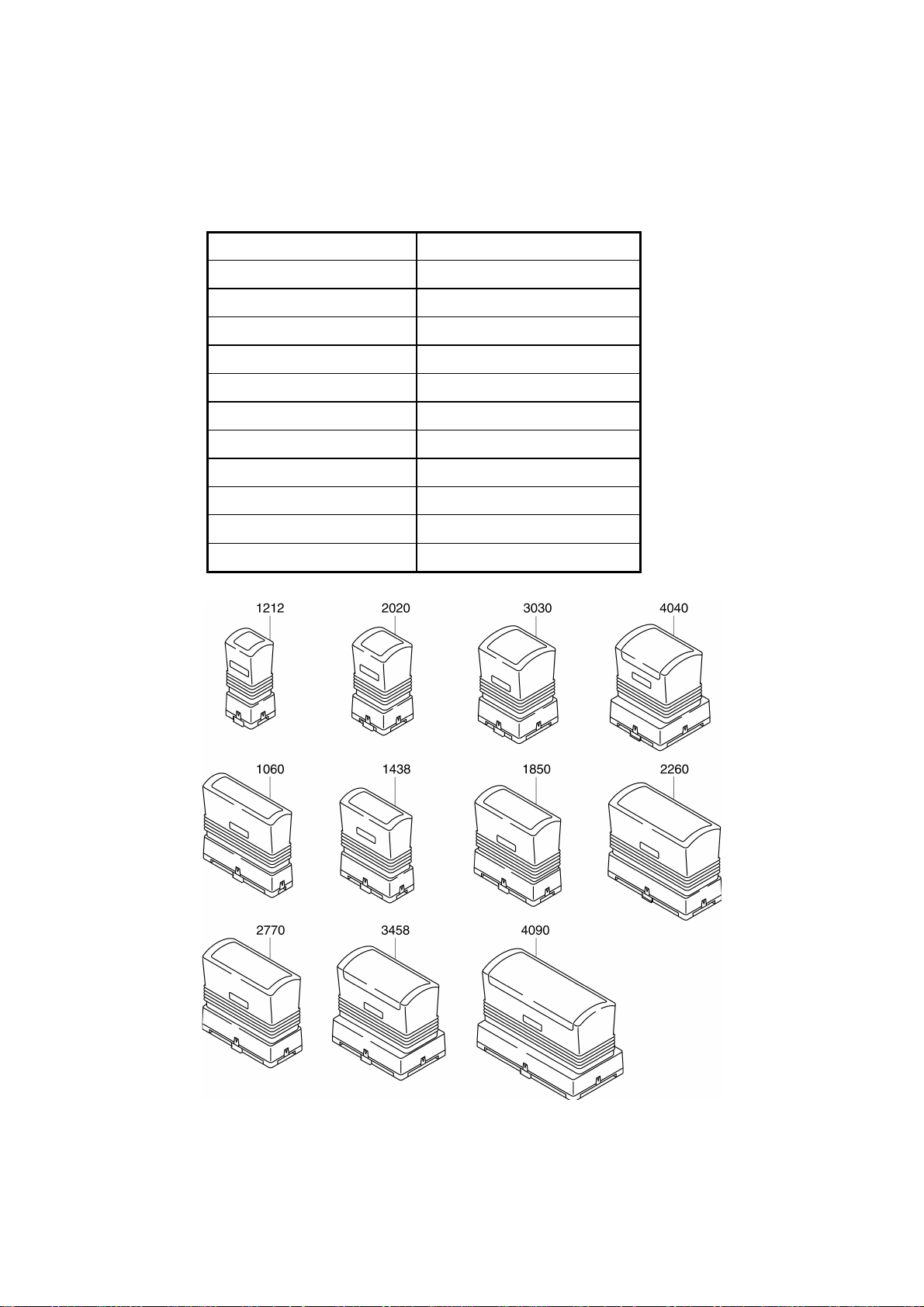

1.9 Stamp Specifications

(1) Types and sizes of stamp

Size Dimensions (mm)

1212

2020

3030

4040

1060

1438

1850

2260

2770

3458

4090

28 × 31

36 × 39

47 × 50

57 × 60

26 × 79

30 × 57

34 × 69

38 × 79

43 × 90

51 × 78

57 × 110

Fig. 1.3 Stamp Types

I - 4

Page 11

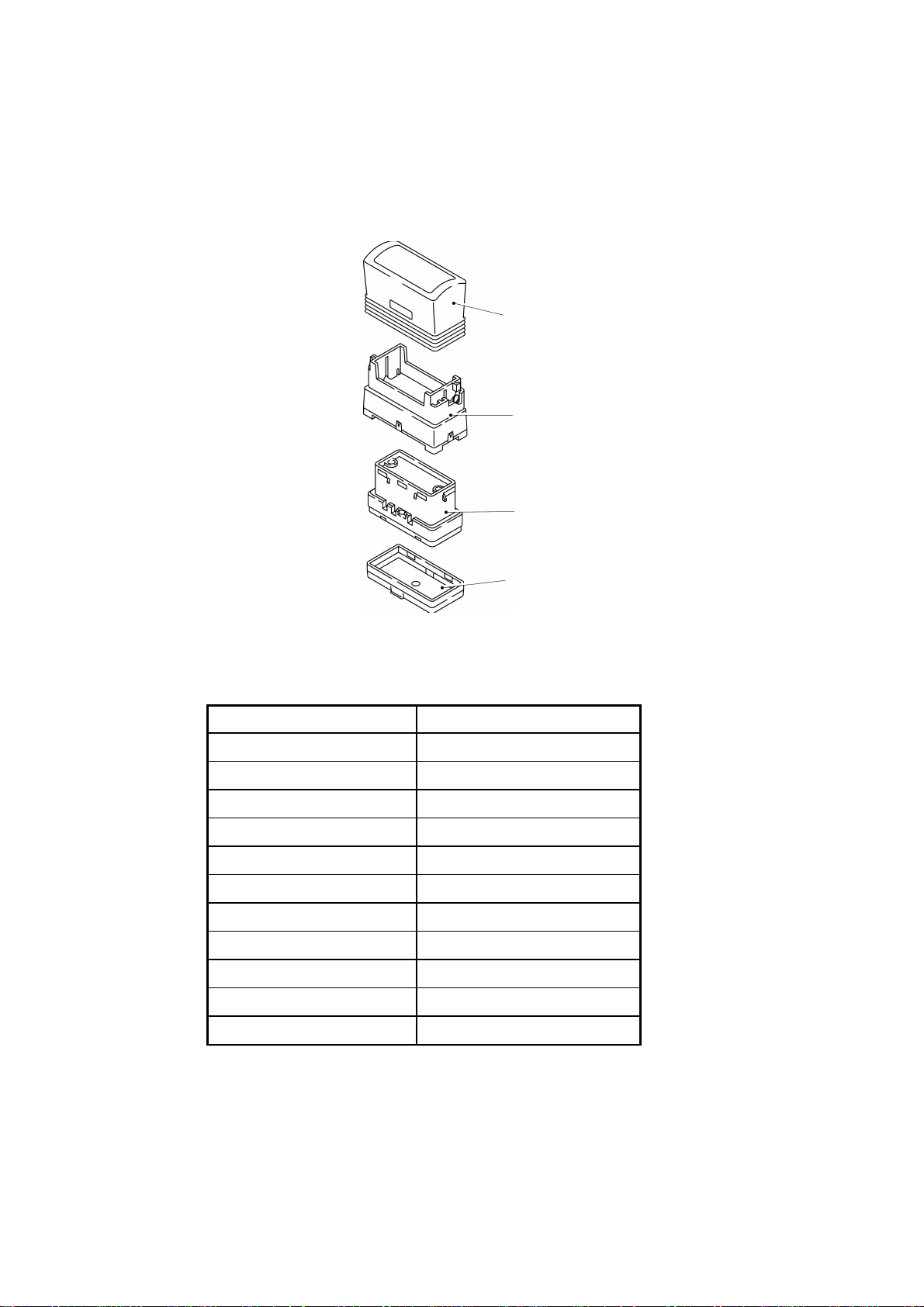

(2) Configuration Grip, skirt, holder, and cap

(The holder consists of printing material,

an absorption sheet, an ink pack, and an

inside plate.)

Grip

Skirt

Holder

Cap

Fig. 1.4 Stamp Configuration

(3) Effective printing area

Size Dimensions (mm)

1212

2020

3030

4040

1060

1438

1850

2260

2770

3458

4090

9.9 × 9.8

18.0 × 18.0

27.2 × 27.1

37.4 × 37.3

7.8 × 57.9

11.9 × 36.2

16.0 × 47.8

19.0 × 56.9

23.8 × 67.1

31.3 × 54.9

37.4 × 86.7

(4) Ink color (for each size) Black, red, and blue

(5) Packaged standard stamp Yes (1438 and 1850: 2 pieces,

2770: 1 piece)

I - 5

Page 12

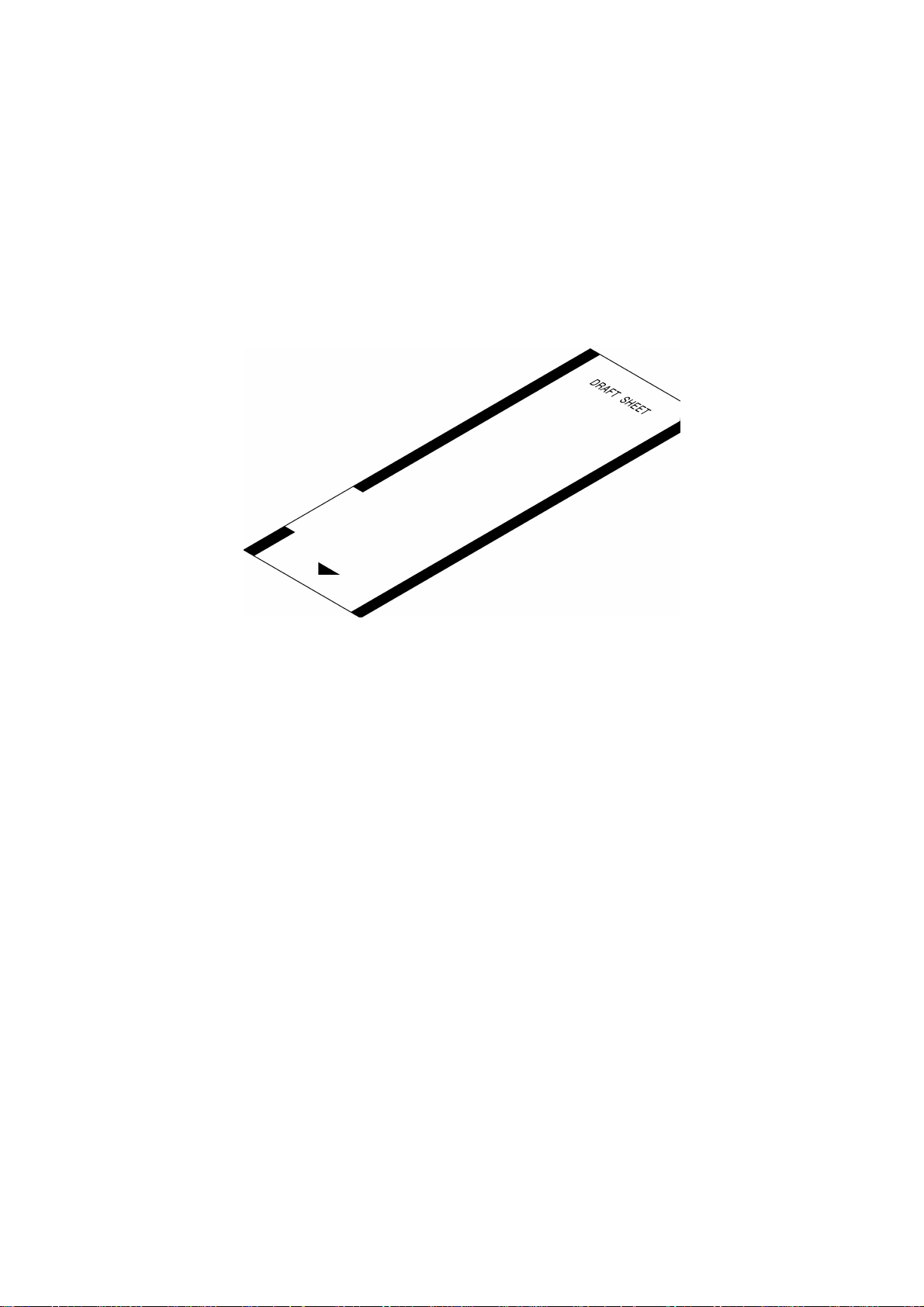

1.10 Draft Sheet Specifications

(1) Dimensions 58 mm × 172 mm × 0.1 mm

(2) Material PET film

(3) Packaged standard draft sheet Yes (150 sheets)

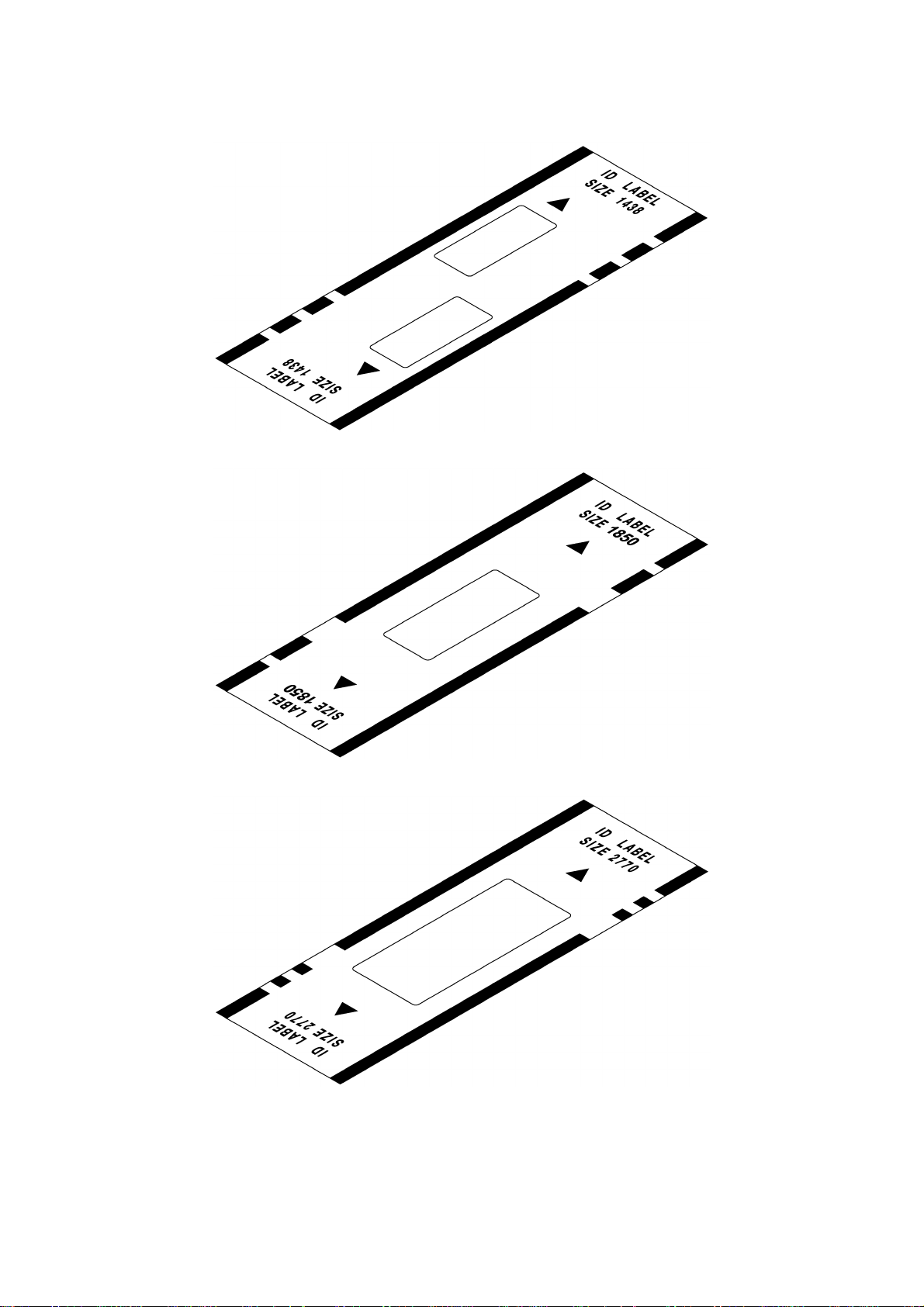

1.11 ID Label Specifications

(1) Dimensions 58 mm × 170 mm × 0.15 mm

(2) Material White PET film

(3) Type A total of 11 types (1212, 2020, 3030, 4040,

(4) Packaged standard ID label Yes (1438 and 1850: 2 labels,

Fig. 1.5 Draft Sheet

(with adhesive and a separator on the back)

1060, 1438, 1850, 2260, 2770, 3458, and

4090)

2770: 1 label)

I - 6

Page 13

Fig. 1.6 ID Label 1438

Fig. 1.7 ID Label 1850

Fig. 1.8 ID Label 2770

I - 7

Page 14

CHAPTER IITHEORY OF MECHANISM OPERATION

1. PRINTING MECHANISM

1.1 Construction of Thermal Head

The thermal head contains 960 heating elements vertically arranged. The size of

one heating element is 0.035 mm wide by 0.060 mm high, as shown in Fig. 2.1.

0.0425 mm

40.7925 mm

0.035 mm

0.060 mm

Fig. 2.1 Heating Elements of the Thermal Head

1.2 Theory of Printing

During printing operation, the thermal head crimps the ink ribbon and a draft sheet

(or an ID label) on the cylindrical rubber platen. In this state, the CPU selects the

required heating elements out of the 960 heating elements to energize them. When

the energized heating elements are heated, the ink in the ink ribbon is fused, and

the ink is transferred to an adhered draft sheet (or an ID label) to print dots. The ink

ribbon and the draft sheet (or the ID label) are fed to the next printing position

simultaneously at the same speed to start the next printing cycle. By repeating the

printing cycles in this manner, a character and graphics is printed on the surface of

a draft sheet (or an ID label).

1.3 Configuration of Character and Graphics

The driving motor continuously feeds a draft sheet (or an ID label) and the ink

ribbon by 0.0423 mm in 9 ms, during which the CPU heats the thermal head once to

print a character and graphics.

II - 1

Page 15

2. ENGRAVING STAMP MECHANISM

2.1 Theory of Engraving Stamp

The draft sheet printed with a character and graphics is fed onto the transparent

plate on the light emitting part of the xenon unit. Position the holder on the draft

sheet with the printing material (made of porous resin) facing down, and apply a

load on the holder by closing the engraving stamp cover to cause the xenon lamp to

emit light. As for the draft sheet's area printed with no character or graphics, the

light is directly irradiated on the printing surface. The light heats the carbon

contained in the printing material to thermally fuse the printing material, and the

pressure closes up the holes in the printing material. This manufactures the printing

surface with holes left only on the area with a character and graphics. After

engraving stamp, setting the grip on the holder fills the inside of the holder with the

ink from the ink pack to enable imprinting.

Draft sheet

Stamp holder

Xenon lamp

Fig. 2.2 Stamp Holder Mounting

II - 2

Page 16

2.2 Positioning the Holder

The holder is positioned at the engraving stamp position by the two interlocked

shutters that open and close back and forth and the triangular projections in the

centers of the shutters. At this time, the six micro switches send ON/OFF signals

according to the shapes of the hollows in the holder, which depend on the size of

the holder, to detect the size of the holder, as shown in Fig. 2.3.

Shutter rear

Shutter front

Holder

Triangular hollow in the

holder

Triangular projection of the shutter

Note: The above shows holder 1850.

Holder

Micro switch

(for stamp size detection)

Fig. 2.3

Holder

II - 3

Page 17

3. FEED MECHANISM

3.1 Feeding Draft Sheet

The draft sheets, set in the magazine tray assy, are fed one by one from the side

contacting the paper feed roller, and then separated by the separating claws, as

shown in Fig. 2.4.

Magazine tray assy

Draft sheet

Paper feed roller

Separating claws

Fig. 2.4

II - 4

Page 18

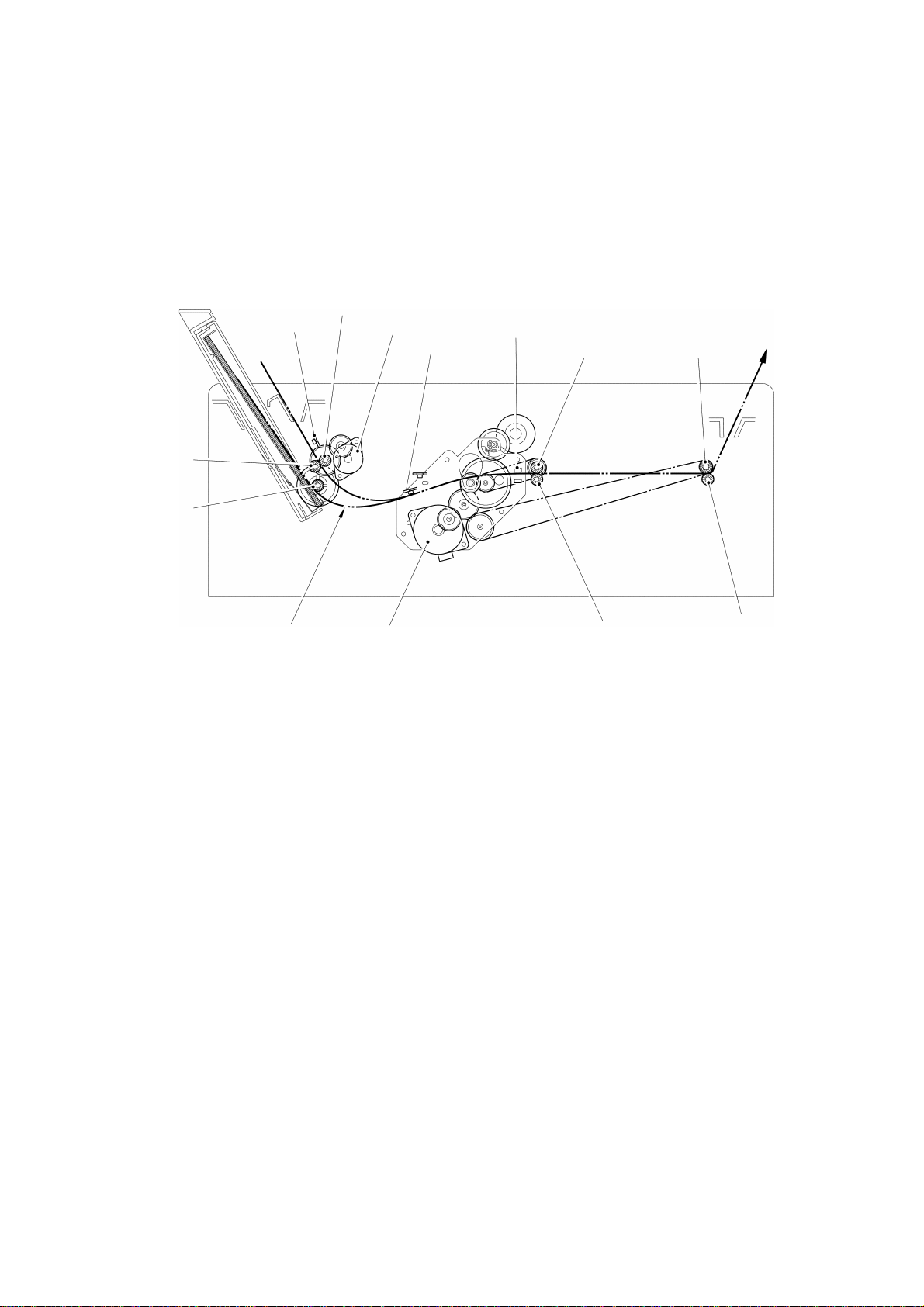

3.2 Feeding Draft Sheet and ID Label

The driving motor rotates each roller via a gear train and the timing belt (MXL belt)

to feed a draft sheet and an ID label, as shown in Fig. 2.5. The feeding position of

the draft sheet is detected by the transparent sensors to control the printing start

position and the engraving stamp position.

Paper feed roller

Reflective sensor

Nip roller

Paper feed

roller

Paper feed motor

Reflective sensor

Transparent sensor

Paper eject rollerDriving roller

Draft sheet

Main motor

Nip roller

Eject roller shaft

(Xenon unit assy)

Fig. 2.5 Feeding Path

II - 5

Page 19

CHAPTER III DISASSEMBLY AND REASSEMBLY

Precautions on Safety

(1) Disassemble and reassemble the machine on a grounded antistatic sheet.

Touching electronic components such as an LSI with an electrified hand will

break them, as they are easily affected by static electricity.

(2) Wrap the machine in an electrically conductive aluminum sheet before carrying

it.

(3) When using heating tools such as soldering iron, take care not to thermally

break resin components such as a wire, a PCB, and a cover.

(4) Take care not to lose small components, such as a screw and a washer, which

have been removed to replace other components.

(5) Never remove main capacitor charge PCB from the capacitor case since

the PCB may be charged with high voltage.

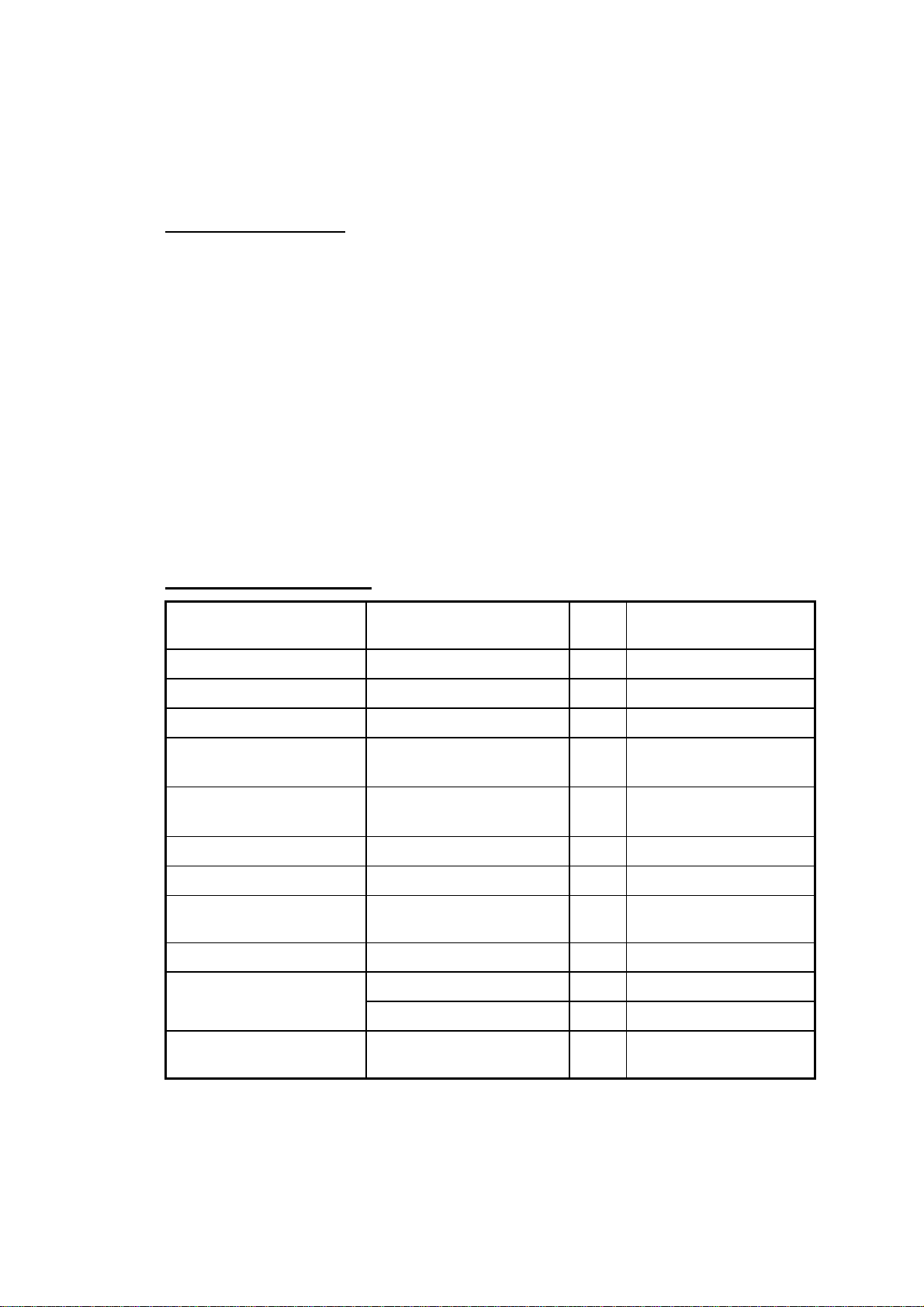

List of Tightening Torque

Position Screw Qty. Tightening torque

N·cm (kgf·cm)

Paper feed motor

Main motor

Motor holder sub assy

Presser unit assy Screw, pan

Presser unit assy

(front: shutter cover)

Thermal head unit

Main chassis

Control panel PCB

holder

Body cover (rear)

Body cover (top)

Main capacitor unit

assy

Screw, bind M2.6 × 5

Screw, bind M3 × 5

Screw, bind M3 × 5

(S/P washer) M3 × 6DB

Screw, pan

(S/P washer) M3 × 6DB

Screw, bind M3 × 5

Taptite, bind B M3 × 12

Taptite, bind B M3 × 12

Screw, bind B M3 × 12

Screw, bind M3 × 5

Screw, bind M3 × 8

Screw, bind B M3 × 12

2

2

3

12

2

2

6

2

3

1

2

4

49 ± 9.8 (5 ± 1)

58.8 ± 9.8 (6 ± 1)

58.8 ± 9.8 (6 ± 1)

117.6 ± 9.8 (12 ± 1)

117.6 ± 9.8 (12 ± 1)

58.8 ± 9.8 (6 ± 1)

78.4 ± 9.8 (8 ± 1)

78.4 ± 9.8 (8 ± 1)

78.4 ± 9.8 (8 ± 1)

58.8 ± 9.8 (6 ± 1)

58.8 ± 9.8 (6 ± 1)

78.4 ± 9.8 (8 ± 1)

III - 1

Page 20

1. DISASSEMBLY PROCEDURES

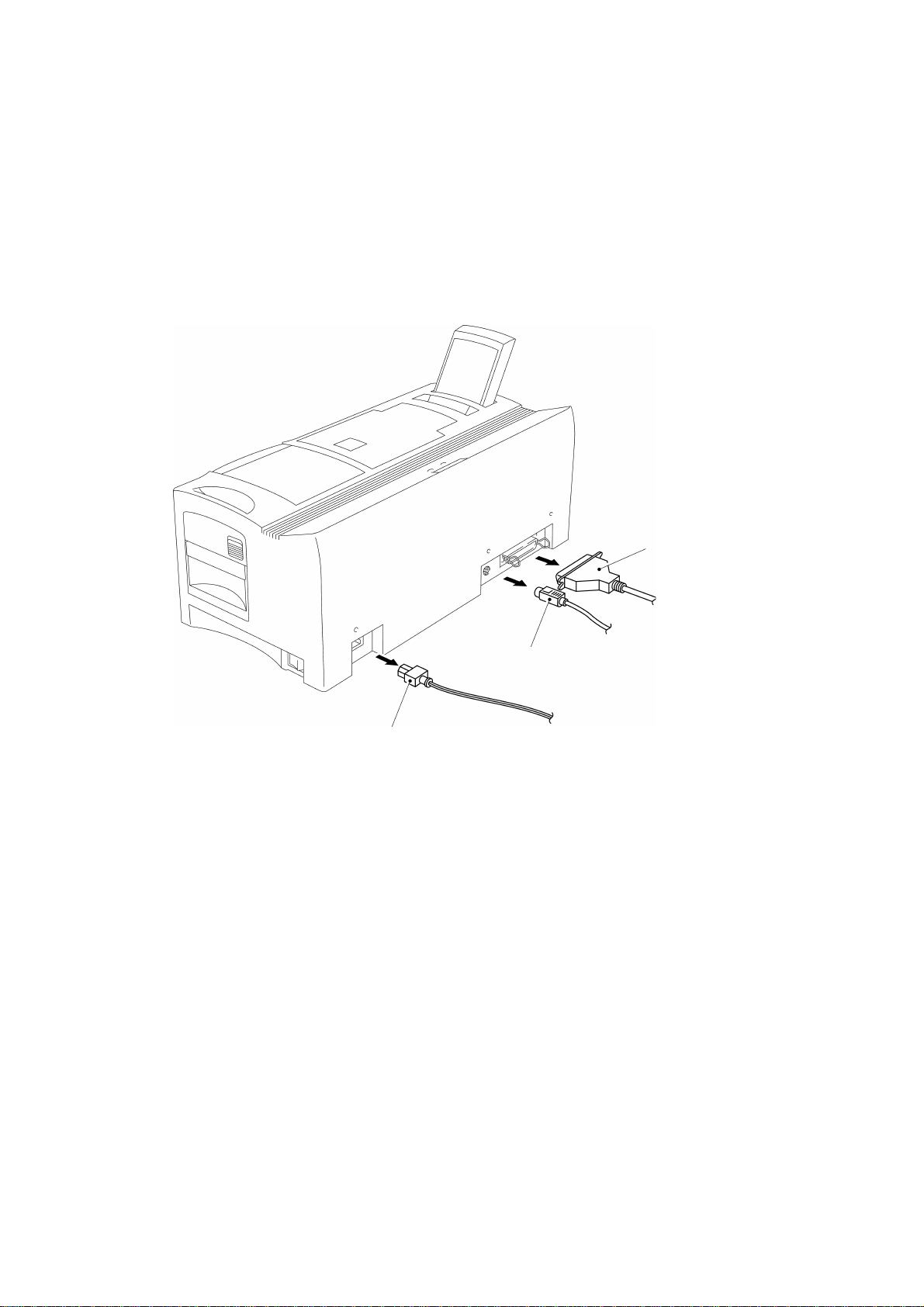

1.1 Disassembly of the I/F Cable and the AC Cord

Remove the I/F cable and the AC cord in the back of the machine, as shown in Fig.

3.1.

Parallel I/F cable

Serial I/F cable

AC cord

Fig. 3.1

III - 2

Page 21

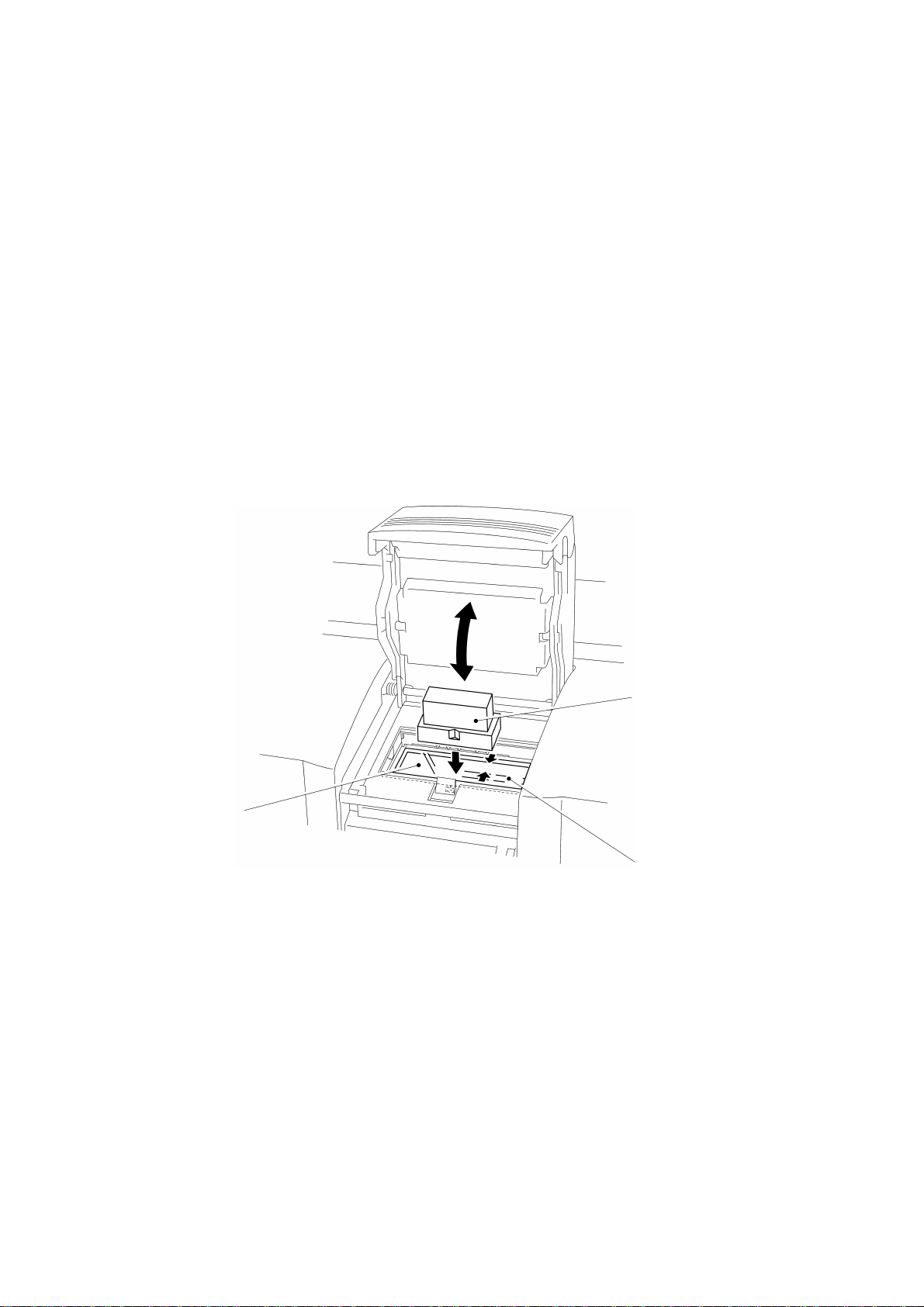

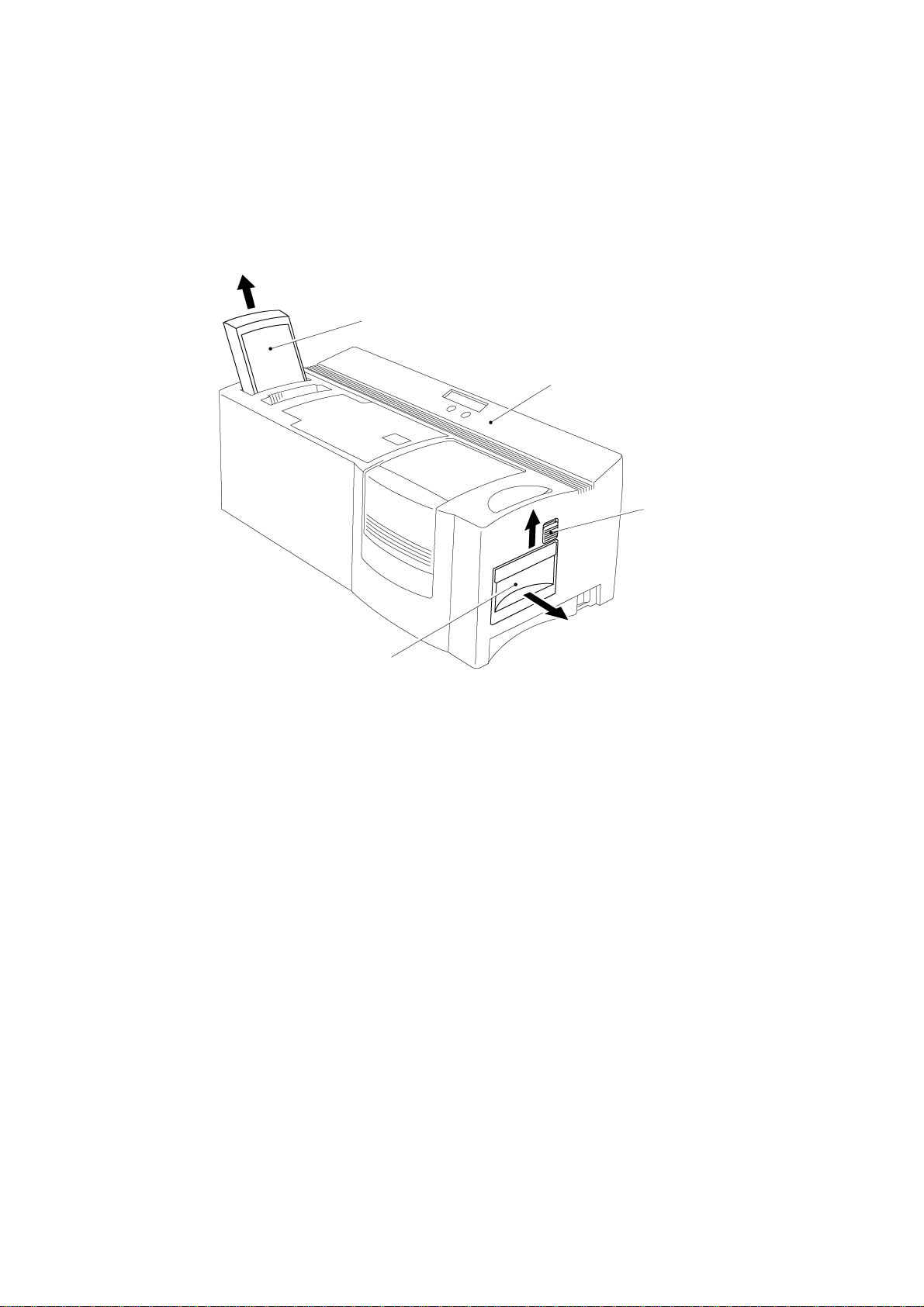

1.2 Disassembly of the Magazine Tray Assy and the Xenon Unit

Remove the magazine tray assy by lifting it diagonally.

While sliding the slide lever on the side of the machine upwards, pull out the xenon

unit, as shown in Fig. 3.2.

Magazine tray assy

Body cover

Slide lever

Xenon unit

Fig. 3.2

III - 3

Page 22

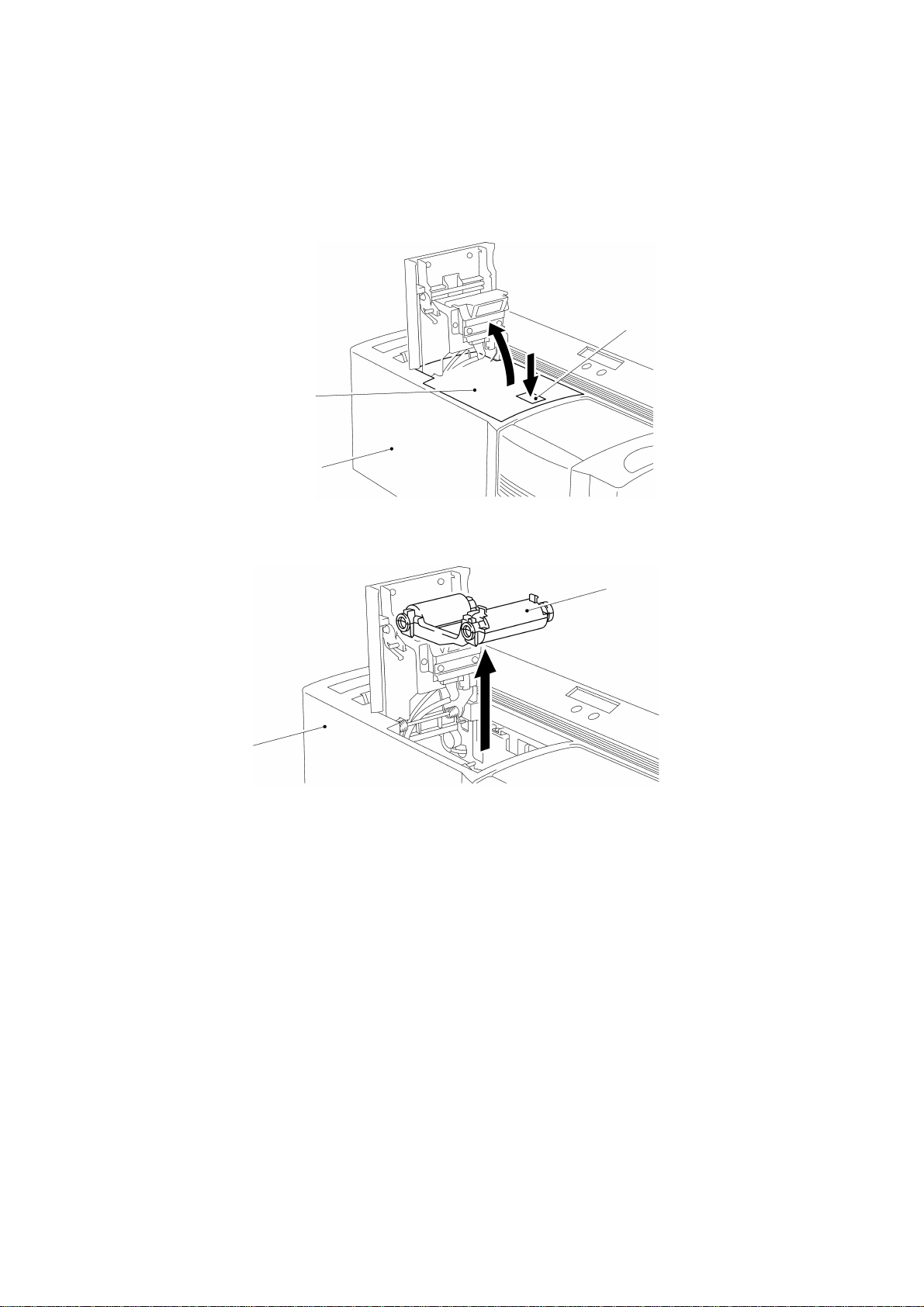

1.3 Disassembly of the Ribbon Cassette Assy

Press the open button on top of the machine to open the cassette cover, and

remove the ribbon cassette assy, as shown in Figs. 3.3 and 3.4.

Cassette cover

Body cover

Fig. 3.3

Open button

Ribbon cassette assy

Body cover

Fig. 3.4

III - 4

Page 23

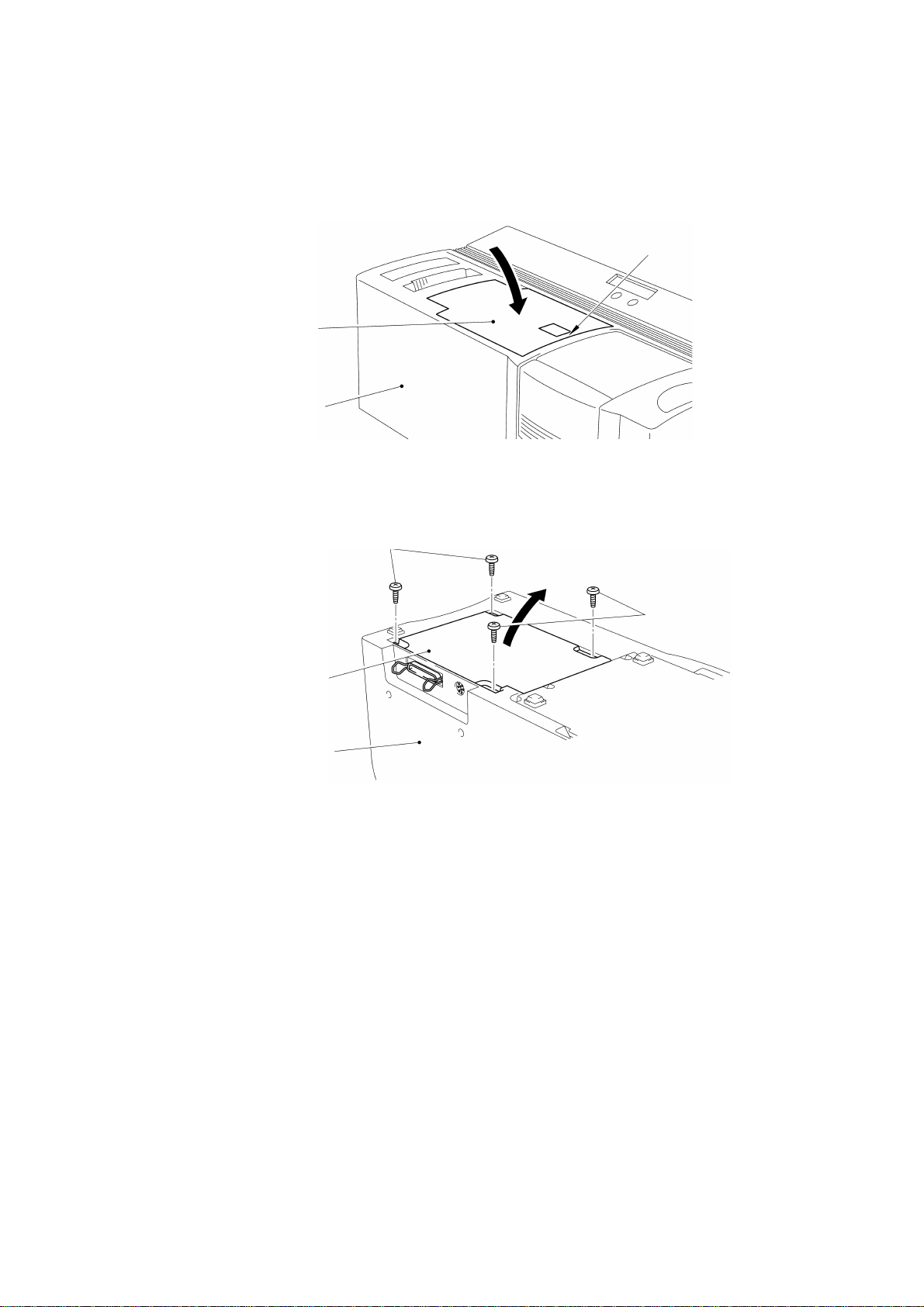

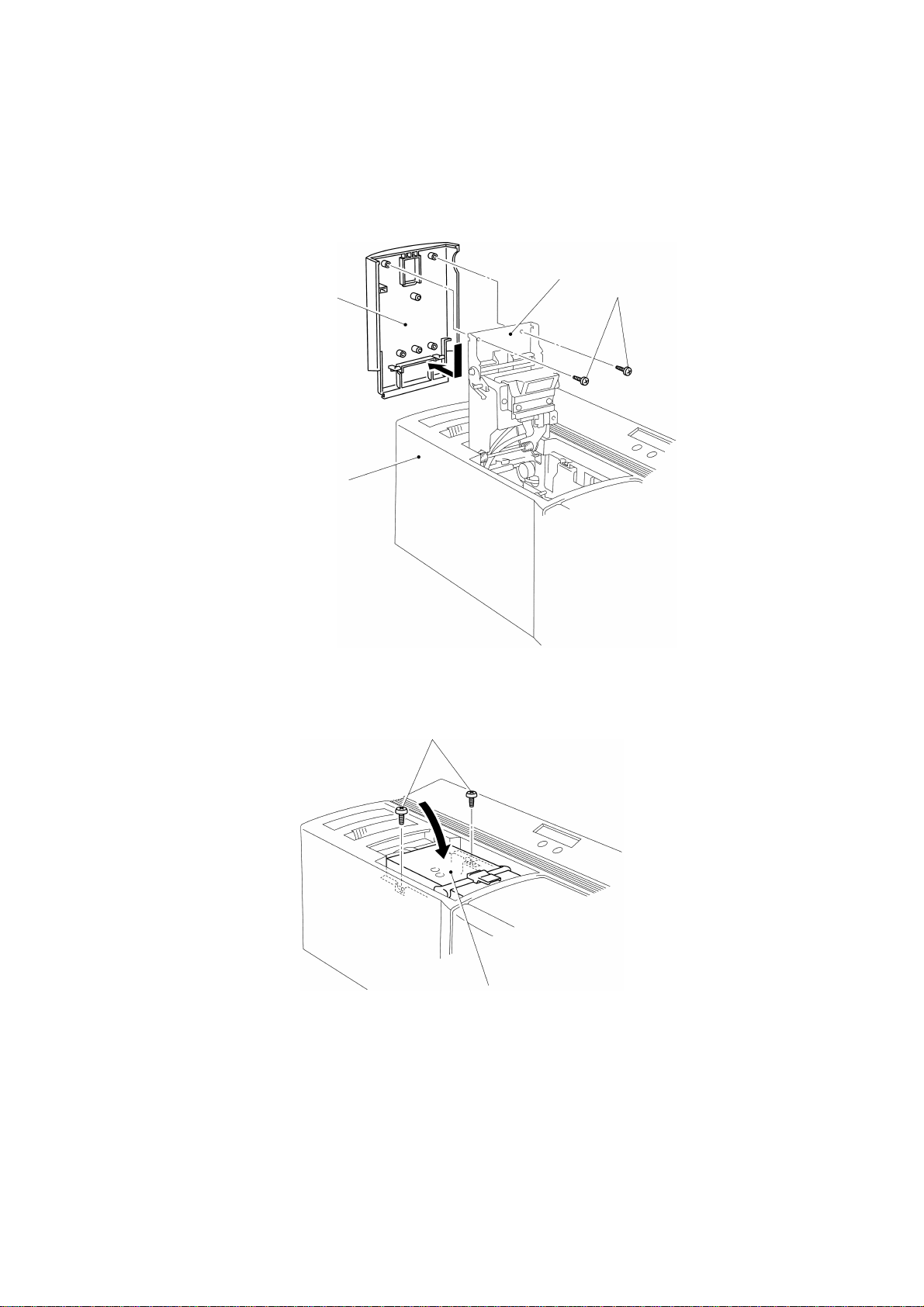

1.4 Disassembly of the Main PCB Assy

Press part A of the cassette cover to close it, as shown in Fig. 3.5.

Cassette cover

Body cover

Fig. 3.5

Turn the machine over and remove the four screws to remove the main PCB assy,

as shown in Fig. 3.6.

Screws

A

Screws

Main PCB bottom plate

Body cover

Fig. 3.6

III - 5

Page 24

Pull out the connectors from the main PCB assy.

Remove the screw to remove the ground wire from the main chassis, as shown in

Fig. 3.7.

Note: Put on a static control wrist band before handling PCBs.

Screw

Ground wireMain chassis

Fig. 3.7

Main PCB assy

Main PCB

bottom plate

Remove the five screws to remove the main PCB assy from the main PCB bottom

plate, as shown in Fig. 3.8.

Screws

Screws

Main PCB

Main PCB assy

Fig. 3.8

bottom plate

III - 6

Page 25

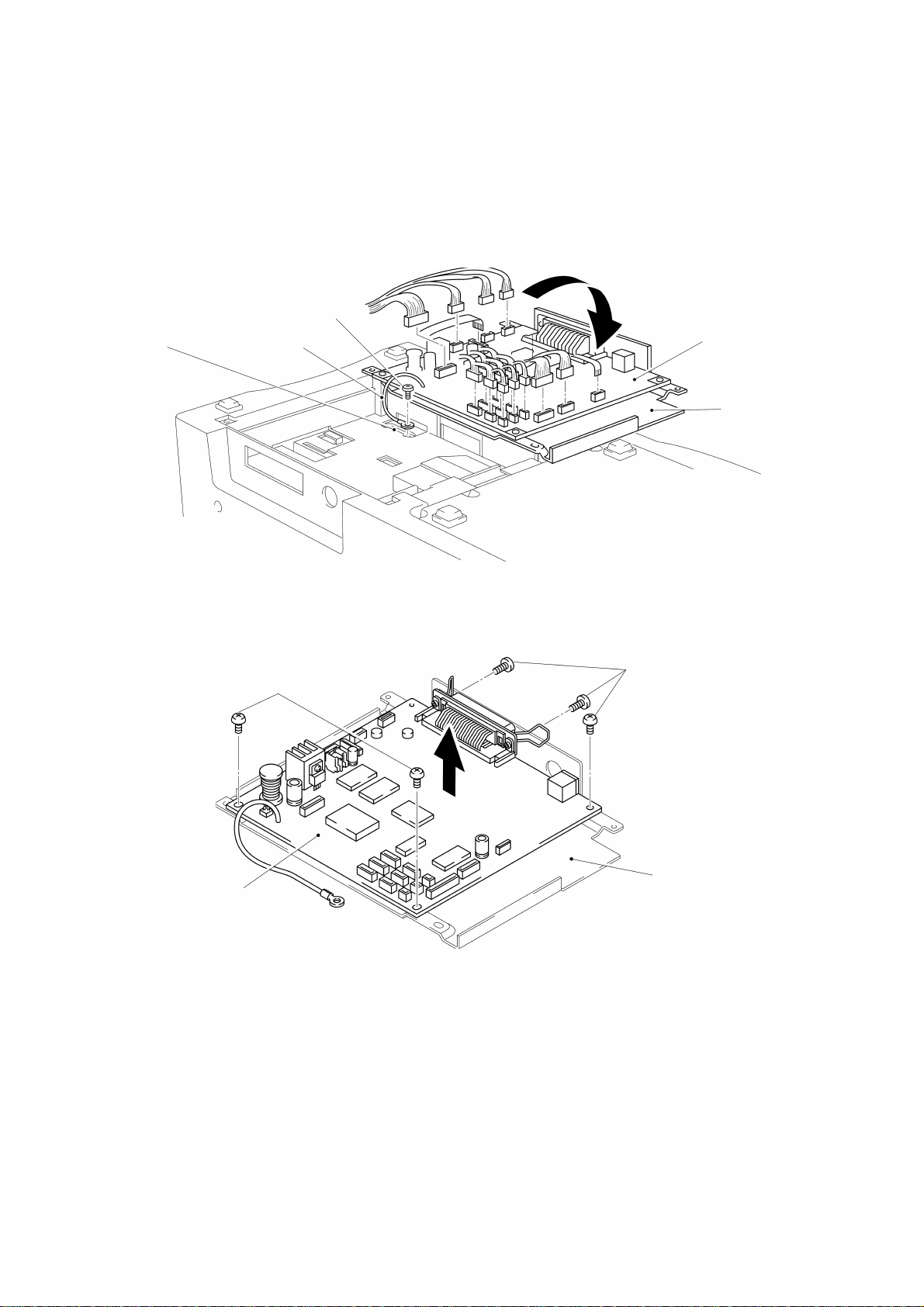

1.5 Disassembly of the Capacitor Case

Remove the shield plate and pull out the connector of the power supply harness

from the power supply PCB assy, as shown in Fig. 3.9.

Body cover

Shield plate

Power supply PCB assy

Power supply harness

Fig. 3.9

III - 7

Page 26

Remove the four screws to remove the capacitor case from the bottom cover.

Remove the capacitor harness from the connector of the capacitor case, and

remove the screw to remove the ground wire, as shown in Fig. 3.10.

Screws

Capacitor case

Screws

Capacitor harness

Ground wire

Body cover

Bottom cover

Fig. 3.10

III - 8

Page 27

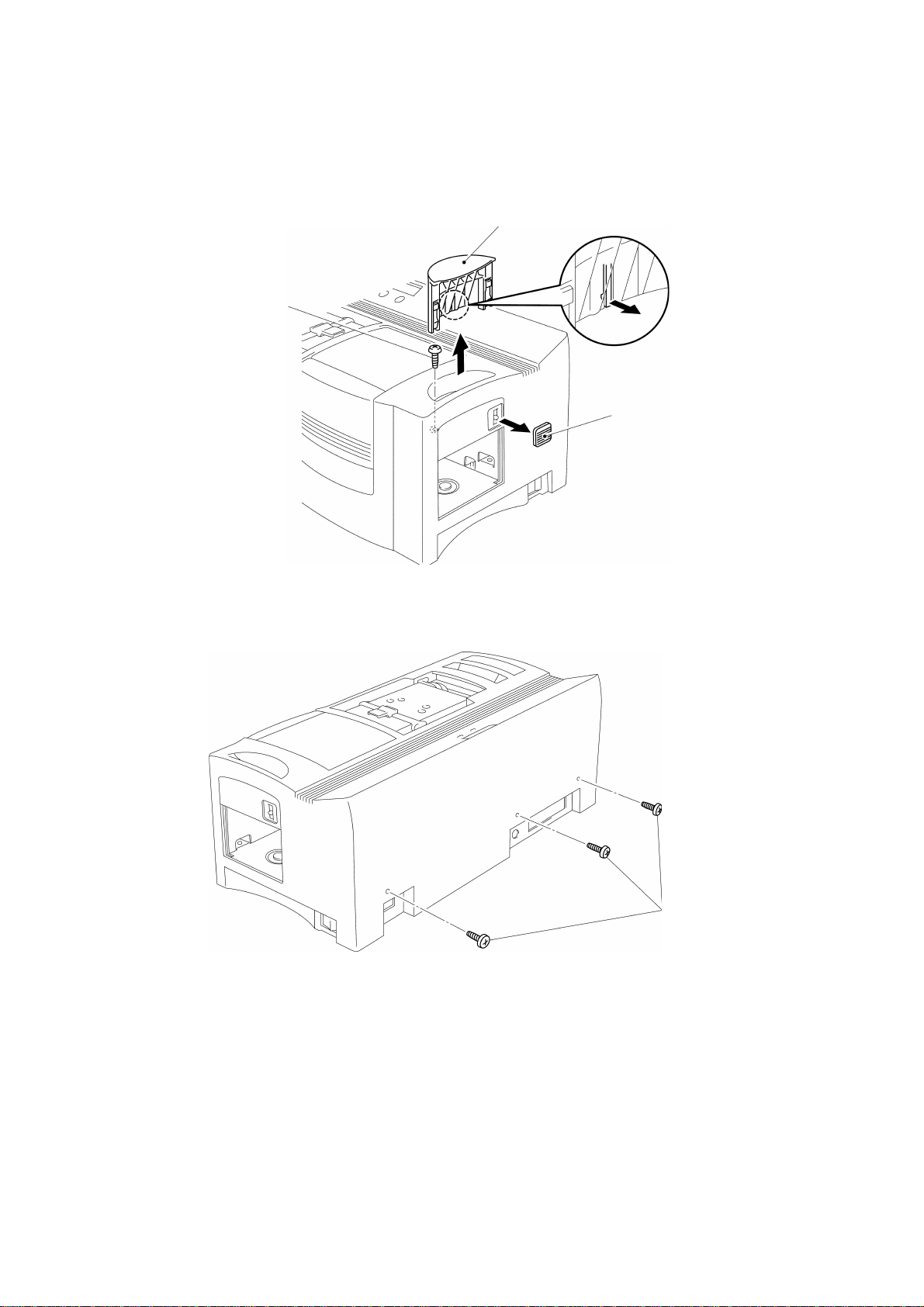

1.6 Disassembly of the Body Cover

Turn the machine over with the right side up, open the cassette cover, and remove

the two screws to remove the cassette cover, as shown in Fig. 3.11.

Cassette cover

Body cover

Head holder assy

Screws

Fig. 3.11

Close the head holder assy and remove the two screws, as shown in Fig. 3.12.

Screws

Head holder assy

Fig. 3.12

III - 9

Page 28

Remove the eject cover and the screw.

Remove the slide lever, as shown in Fig. 3.13.

Eject cover

Screw

Fig. 3.13

Slide lever

Remove the three screws in the back of the cover, and remove the body cover by

lifting it, as shown in Figs. 3.14 and 3.15.

Screws

Fig. 3.14

III - 10

Page 29

Body cover

Bottom cover

Fig. 3.15

Remove the two screws to remove the control panel PCB holder from the body

cover. Remove the screw from the control panel PCB holder to remove the control

panel PCB assy, as shown in Fig. 3.16.

Screw

Control panel

PCB assy

Control panel PCB holder

Screws

Body cover

Fig. 3.16

III - 11

Page 30

1.7 Disassembly of the Main Chassis and the Bottom Cover

Press the open button to open the head holder assy, as shown in Fig. 3.17.

Head holder assy

Open button

Fig. 3.17

Remove the six screws to remove the main chassis from the bottom cover, and

remove the two cores, as shown in Fig. 3.18.

Screws

Screws

Screws

Main chassis

Bottom cover

Fig. 3.18

III - 12

Page 31

Remove the two screws to remove the ground wire from the PS PCB shield plate

and the main chassis, as shown in Fig. 3.19.

Screw

Main chassis

Ground wire

Screw

PS PCB shield plate

Fig. 3.19

Remove the size detection PCB harness from the bottom cover, as shown in Fig.

3.20.

Main chassis

Size detection PCB harness

Fig. 3.20

Bottom cover

III - 13

Page 32

Remove the harness coming out of the main chassis from the bottom cover, as

shown in Fig. 3.21.

Main chassis

Bottom cover

Fig. 3.21

III - 14

Page 33

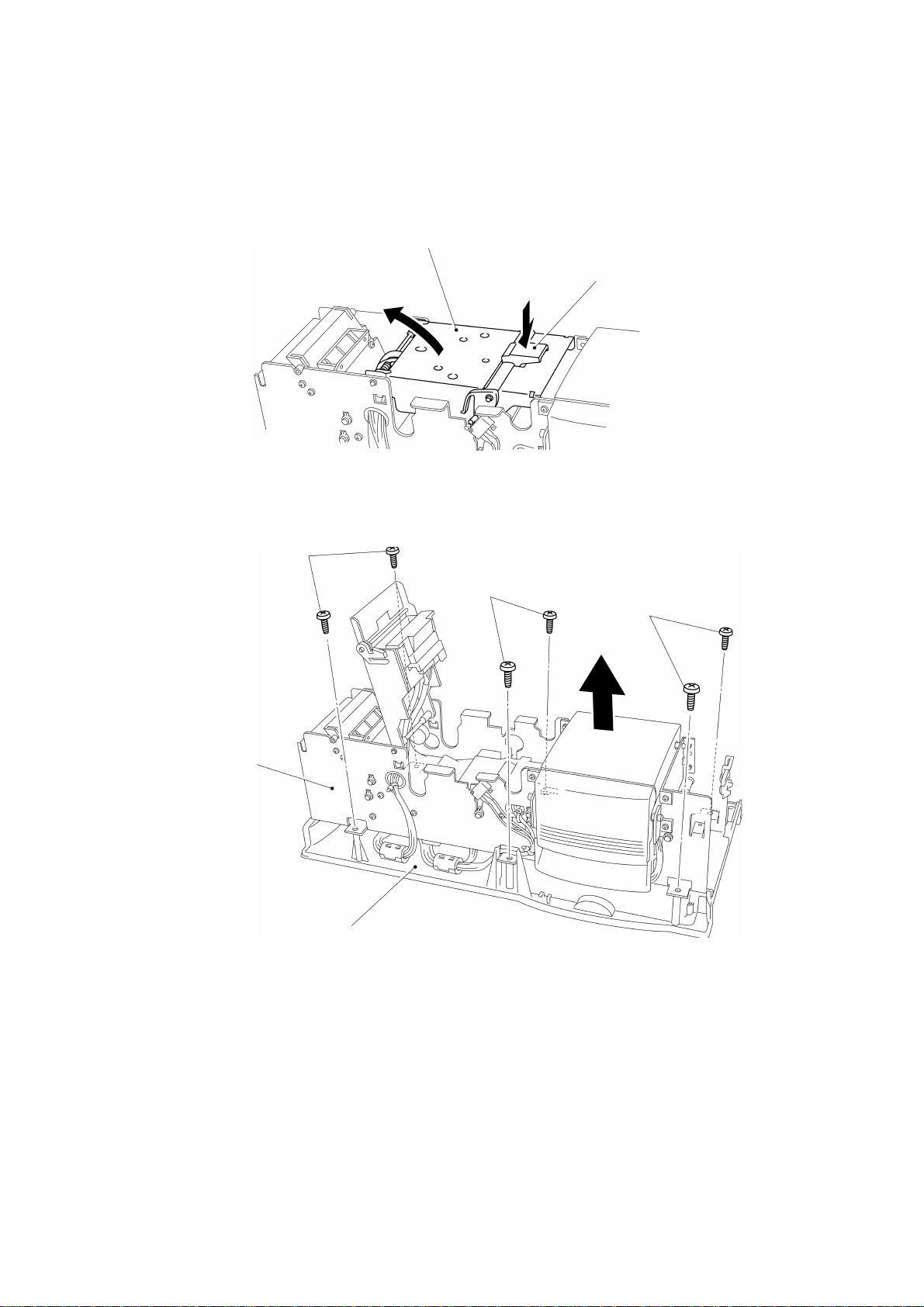

1.8 Disassembly of the Power Supply PCB Assy

Turn the bottom cover over, and remove the two screws securing the power supply

PCB assy on the bottom cover to remove the power supply PCB assy. Then,

remove the PS PCB shield plate, as shown in Fig. 3.22.

Note: Put on a static control wrist band before handling PCBs.

Power supply PCB assy

PS PCB shield plate

Screws

Bottom cover

Fig. 3.22

III - 15

Page 34

1.9 Disassembly of the Thermal Head Unit

Cut two fastening bands L100 that secure the harness on the main chassis, as

shown in Fig. 3.23.

Free bush 50

Fastening

band L100

Hole

Main chassis

Fastening

band L100

Fig. 3.23

Press the open button to open the head holder assy.

Pull parts A of the head protection cover in the direction of the arrow to remove it

from the head guide shaft.

Remove the two screws to remove the thermal head unit from the head holder, as

shown in Fig. 3.24.

Free bush 15

Harness

Note: Take care not to touch the thermal head heat generating points.

A

Head guide shaft

Head protection cover

Head holder

Thermal head unit

Screws

Fig. 3.24

III - 16

Page 35

1.10 Disassembly of the Sensor Assys

Remove the screw to remove reflective sensor assy A from the head holder.

Remove the screws to remove reflective sensor assys B and C from the sensor

brackets.

Remove the screw to remove transparent sensor assy A from the film path.

Remove the screw to remove transparent sensor assy B from the presser unit assy,

as shown in Fig. 3.25.

Head holder assy

Screw

Screw

Reflective sensor assy C

Reflective sensor assy A

Reflective sensor assy B

Screw

Fig. 3.25

Screw

Transparent

sensor assy A

Transparent

sensor assy B

Screw

III - 17

Page 36

1.11 Disassembly of the Micro Switches

Remove the screw to remove micro switch assy A for cassette cover open/close

detection from the main chassis, as shown in Fig. 3.26.

Micro switch assy A

Screw

Fig. 3.26

Remove the screw to remove micro switch assy B for xenon reset from the main

chassis.

Main chassis

Slide and pull out the xenon lock claw in the directions of arrows, as shown in Fig.

3.27.

Main chassis

Xenon lock claw

Micro switch assy B

Fig. 3.27

Screw

III - 18

Page 37

1.12 Disassembly of the Platen Unit Assy

After removing the two screws, lift the platen unit assy in the directions of the

arrows, as shown in Fig. 3.28.

Main chassis

Platen unit assy

Fig. 3.28

Screws

Slide the platen unit assy in the direction of arrow 1, pass gear A through the hole in

the main chassis, turn the projection of the bearing down, tilt the platen unit assy in

the direction of arrow 2, and pull it out in the direction of arrow 3, as shown in Fig.

3.29.

A

Platen unit assy

Main chassis

Bearing

3

2

1

Fig. 3.29

III - 19

Page 38

Subsequently, separate the film guide from the platen unit, as shown in Fig. 3.30.

Film guide

Platen unit

Fig. 3.30

III - 20

Page 39

1.13 Disassembly of the Presser Unit Assy

Open the presser unit cover in the direction of the arrow.

Remove the 12 screws securing the presser unit assy on the main chassis to

remove the presser unit assy, as shown in Fig. 3.31.

Screws

Screws

Presser unit cover

Screws

Screws

Fig. 3.31

III - 21

Page 40

Remove the four retaining rings to remove the presser plate hinge shaft from the

presser frame sub assy, as shown in Fig. 3.32.

Retaining ring

Presser plate

Presser plate hinge shaft

Retaining ring

Retaining rings

Presser frame sub assy

Fig. 3.32

While bending two claws A of the presser plate cover and the presser plate in the

directions of the arrows, remove the presser plate cover, as shown in Fig. 3.33.

Presser plate cover

Presser plate

A

A

Fig. 3.33

III - 22

Page 41

Remove the two retaining rings to remove the presser plate positioning shaft from

the presser plate.

While bending the four claws in the directions of the arrows, remove the presser

lever cover, as shown in Fig. 3.34.

Presser lever cover

Presser lever

Retaining ring

Positioning presser plate

Presser plate

Retaining ring

Presser plate positioning shaft

Fig. 3.34

III - 23

Page 42

Remove the two presser bearings, and then pull the presser plate lever shaft and

presser plate lock shaft out from the presser lever, as shown in Fig. 3.35.

Presser lever

Presser bearing

Presser plate lever shaft

Presser bearing

Presser plate lock shaft

Presser plate lock spring

Presser plate lock

Fig. 3.35

III - 24

Page 43

Remove the two retaining rings and the two bearings to remove the presser frame

shaft.

While bending the four claws and the two tongues, remove the shutter cover from

the presser frame sub assy.

Remove the two shutter springs from the shutter front and the shutter rear.

Remove the shutter front, shutter rear, and the two pinions 14 from the presser

frame sub assy.

Remove the three screws to remove the shield plate rear and the size detection

PCB assy from the shutter rear, as shown in Fig. 3.36.

Shutter cover

Tongue

Shutter

front

Shutter springs

Shutter rear

Shutter front

Retaining

ring

Bearing

Presser frame shaft

Pinions 14

Shutter rear

Size detection PCB assy

Shield plate rear

Screws

Presser frame sub assy

Bearing

Retaining ring

Fig. 3.36

III - 25

Page 44

1.14 Disassembly of the Head Holder Assy

Remove hooks A of the two head holder springs from the grooves of the main

chassis.

Remove the two retaining rings and pull out the rotation shaft in the direction of the

arrow, as shown in Fig. 3.37.

Head holder guide

Retaining ring

Main chassis

Head guide spring

Retaining ring

Rotation shaft

Head holder springs

A

Fig. 3.37

III - 26

Page 45

Remove the two retaining rings and pull out the lever shaft in the direction of the

arrow, and remove the lever hook.

Remove the two retaining rings and pull out the head guide shaft in the direction of

the arrow, as shown in Fig. 3.38.

Lever hook

Lever shaft

Head guide shaft

Head holder

Lever hook

return spring

Head holder guide

Compression springs

Protection cover spring

Fig. 3.38

III - 27

Page 46

1.15 Disassembly of the Gears and Pulleys

Remove the gears and pulleys in the numerical order shown in Fig. 3.39.

Gear 25

Pulley 18

Gear 50A

Ã

Pulley 25

Â

Gear 19/84

Á

Gear 20/50

Gear 21/47

Gear 20/50

À

Gear 44

Gear 21/47

Ä

Gear 68

Å

Ç

Æ

Fig. 3.39

III - 28

Page 47

1.16 Disassembly of the Motor Holder Assy and the Motors

Remove the three screws securing the motor holder sub assy on the main chassis

to remove the motor holder sub assy.

Remove the two screws to remove the main motor from the motor holder sub assy.

Remove the two screws to remove the paper feed motor from the main chassis, as

shown in Fig. 3.40.

Paper feed motor

Screws

Screws

Main motor

Motor holder sub assy

Fig. 3.40

Screws

Main chassis

III - 29

Page 48

1.17 Disassembly of the Rollers

Remove the two retaining rings and bearings to remove the driving roller.

Remove the retaining ring, paper eject roller spring, and two bearings to remove the

paper eject roller.

Remove the two retaining rings and bearings to remove the paper feed roller.

Remove the clutch spring, the washer, and the retaining ring from the paper feed

roller.

Remove the two retaining rings to remove the nip roller, as shown in Fig. 3.41.

Bearing

Retaining

ring

Retaining ring

Bearing

Retaining ring

Retaining ring

Bearing

Bearing

Driving

roller

Clutch spring

Washer

Retaining ring

Nip roller

Retaining ring

Paper feed roller

Bearing

Retaining

ring

Retaining ring

Paper eject roller

Bearing

Paper eject roller spring

Fig. 3.41

III - 30

Page 49

1.18 Disassembly of the Label Guide Assy

Remove the five screws securing the label guide assy on the main chassis, and

remove the label guide assy by pressing projections A and B of the label guide to

release them from the holes, as shown in Fig. 3.42.

Screws

Screw

A

Label guide assy

B

Screws

Main chassis

Fig. 3.42

III - 31

Page 50

Remove label nip springs R and L.

Remove the two screws to remove the sensor bracket from the label guide.

Remove the two retaining rings to remove the ribbon cassette shaft from the label

guide, as shown in Fig. 3.43.

Label guide

Label nip spring L

Retaining ring

Label nip spring R

Ribbon cassette shaft

Fig. 3.43

Sensor bracket

Screws

III - 32

Page 51

1.19 Disassembly of the Film Path Assy

Remove the two retaining rings and bearings to remove the paper feed roller.

Remove the clutch spring, the washer, and the retaining ring from the paper feed

roller.

Remove the seven screws securing the film path assy on the main chassis, press

two projections A of the film path to release them from the holes, and remove the

film path assy.

Remove torsion springs R and L.

Remove the two retaining rings to remove the nip roller, as shown in Fig. 3.44.

Paper feed roller

Film path assy

Main chassis

Bearing

Retaining ring

Screws

A

Retaining ring

Fig. 3.44

Bearing

A

Retaining ring

Screws

Retaining ring

Torsion springs

R and L

Nip roller

III - 33

Page 52

Remove the retaining rings, pull out the two outer plate shafts, and remove the

outer plate, the lock plate, and the two return springs.

Remove the two screws to remove the sensor bracket.

Remove the two magazine springs, and the magazine lift sub assy while pressing

parts A and B of the film path to release them, as shown in Fig. 3.45.

Screw

Screw

Magazine lift

sub assy

B

Sensor bracket

A

Magazine springs

Film path

Lock plate

Outer plate shafts

Outer plate

Retaining ring

Retaining ring

Return spring

Return spring

Fig. 3.45

III - 34

Page 53

1.20 Disassembly of the Drawer Connector

Remove the two screws to remove the drawer connector from the main chassis, as

shown in Fig. 3.46.

Screws

Main chassis

Drawer connector

Fig. 3.46

Remove free bush 50, and free bushes 15 and 70, as shown in Fig. 3.47.

Main chassis

Free bush 50

Free bush 15

Free bush 70

Fig. 3.47

III - 35

Page 54

2. REASSEMBLY PROCEDURES

2.1 Reassembly of the Drawer Connector

Set free bush 50, and free bushes 15 and 70 on the holes in the main chassis, as

shown in Fig. 3.48.

Main chassis

Free bush 50

Free bush 15

Free bush 70

Fig. 3.48

Pass the drawer connector assy harness through hole A in the main chassis. Insert

the drawer connector into hole B, and secure it with the two screws, as shown in

Fig. 3.49.

Note: Insert the drawer connector so that its projection will be inserted into groove

D of the main chassis.

Drawer connector assy

Projection

Main chassis

Hole B

Groove D

Hole A

Fig. 3.49

III - 36

Page 55

2.2 Reassembly of the Film Path Assy

While bending two parts A of the film path in the directions of the arrows, insert

them into the holes in the magazine lift sub assy, as shown in Fig. 3.50.

Magazine lift sub assy

Fig. 3.50

Set the two magazine springs on two hooks B of the film path assy, and then two

hooks C of the magazine lift sub assy, as shown in Fig. 3.51.

Parts A

Film path

Magazine lift sub assy

Hooks C

Film path assy

Magazine springs

Hooks B

Fig. 3.51

III - 37

Page 56

After setting the sensor bracket on two parts D of the film path assy, set the film

path assy so that the two locating pins on the film path assy will be inserted into

holes E in the sensor bracket, and secure the film path assy with the two screws, as

shown in Fig. 3.52.

Screws

Sensor bracket

Locating pin

Sensor bracket

Film path

Holes E

Locating pin

Film path

Part D

Fig. 3.52

III - 38

Page 57

Pass one outer plate shaft through the hole in the film path in the direction of the

arrow, through the holes in the outer plate, the return spring, and the hole on the

opposite side of the film path, before setting the retaining ring on the outer plate

shaft.

Note 1: The hook of the return spring must be between the ribs of the film path, as

shown in Fig. 3.53.

Ribs

Outer plate shaft

Outer plate

Film path

Retaining ring

Hook

Return spring

Outer plate

Film path

Fig. 3.53

III - 39

Page 58

In the same manner, pass the other outer plate shaft through the hole in the film

path in the direction of the arrow, through the holes in the lock plate, the return

spring, and the hole on the opposite side of the film path, before setting the

retaining ring on the outer plate shaft.

Note 2: The hook of the return spring must be outside the rib of the film path, as

shown in Fig. 3.54.

Film path

Outer plate

shaft

Return spring

Lock plate

Rib

Film path

Return spring

Lock plate

Fig. 3.54

III - 40

Page 59

Set torsion spring R on the projection of the main chassis so that hook A of torsion

spring R will be inserted into the hole in the main chassis.

In the same manner, set torsion spring L on the opposite side.

Pass each end of the nip roller through the hole from the inside of the main chassis,

and set the retaining rings on both ends of the nip roller from the outside of the

main chassis.

Set the film path in the main chassis, and secure it with the seven screws.

Note 3: Insert the hooks of the torsion springs into the grooves of the nip roller.

Note 4: Make sure that part D of the outer plate is inserted into hole E in the main

chassis, as shown in Fig. 3.55.

Paper feed roller

Film path

Main

chassis

Retaining

ring

Bearing

Screws

Retaining ring

Bearing

E

Torsion springs

Retaining ring

Screws

Retaining ring

D

A

Nip roller

Film path

Outer

plate

Fig. 3.55

III - 41

Main

chassis

Page 60

2.3 Reassembly of the Label Guide Assy

Set the retaining ring, the washer, and the clutch spring on the paper feed roller

shaft.

Note 1: Before setting the clutch spring, apply grease on the shaft.

Pass end A of the paper feed roller through the hole in the main chassis from the

inside, and then pass end B through the hole on the opposite side of the main

chassis.

Set the bearings and the retaining rings on both ends of the paper feed roller from

the outside of the main chassis. (Insert the hook of the clutch spring into the groove

of the bearing, as shown in Fig. 3.56.)

Paper feed roller

Retaining ring

Washer

Clutch spring

A

B

Main chassis

Groove

Bearing

Retaining ring

Clutch spring

Hook

Bearing

Paper feed roller

Fig. 3.56

Bearing

Retaining ring

III - 42

Page 61

Set the sensor bracket on the two locating pins on the label guide, and secure the

sensor bracket on the label guide with the two screws.

Set label nip spring L on the pin on the label guide, and set the two hooks of the

label nip spring L in hook A and then hook B of the label guide.

Set the ribbon cassette shaft on the label guide, and set the two retaining rings on

the ribbon cassette shaft.

In the same manner, set label nip spring R, as shown in Fig. 3.57.

Label guide

Locating pin

Locating pin

B

A

Label nip spring L

Ribbon cassette roller

Label nip

spring R

Sensor bracket

Screws

Fig. 3.57

III - 43

Page 62

While bending two parts D of the label guide assy to the inside, set the label guide

assy in the main chassis.

Secure the label guide assy in the main chassis with the five screws.

Note 2: Make sure that two parts D of the label guide is properly inserted into the

holes in the main chassis, as shown in Fig. 3.58.

Screws

Label guide

Screw

D

D

Screws

Fig. 3.58

Main chassis

III - 44

Page 63

2.4 Reassembly of the Rollers

While pressing ends A of the label nip springs in the directions of the arrows, pass

each end of the nip roller through the hole from the inside of the main chassis.

Slide the label nip springs so that their ends A will contact parts B of the nip roller.

Note 1: Check that ends A of the label nip springs make contact with parts B of the

nip roller, then apply grease to parts B of the nip roller.

Set the retaining rings on both ends of the nip roller from the outside of the main

chassis. Then, set the paper guide on the sensor bracket, as shown in Fig. 3.59.

Nip roller

Sensor bracket

Label guide assy

Label nip spring

Retaining ring

Paper guide

Retaining ring

Label guide

Label nip spring

End A

Label nip spring

Part B

Nip roller

Main chassis

Fig. 3.59

III - 45

Page 64

Set the retaining ring, the washer, and the clutch spring on the paper feed roller.

Note 2: Before setting the clutch spring, apply grease to the portion on the paper

feed roller where the clutch spring is to make contact with.

Insert end A of the paper feed roller into the hole in the main chassis from the

inside, and end B of the paper feed roller into the hole on the opposite side of the

main chassis, while pressing the nip roller.

Set the bearings and the retaining rings on both ends of the paper feed roller from

the outside of the main chassis, as shown in Fig. 3.60.

(Insert the hook of the clutch spring into the groove of the bearing.)

A

Paper feed roller

Retaining ring

Washer

Clutch spring

Bearing

Retaining ring

Fig. 3.60

B

Bearing

Nip roller

Retaining ring

III - 46

Page 65

Insert end A of the driving roller into the hole in the main chassis from the inside,

and then insert end B of the driving roller into the hole on the opposite side of the

main chassis.

Set the bearings and the retaining rings on both ends of the driving roller from the

outside of the main chassis.

Insert both ends of the paper eject roller through the holes of the main chassis.

Set the bearings on both ends of the paper eject roller.

Set the retaining ring on the left end of the roller, and the paper eject roller spring

on the other end of the roller, as shown in Fig. 3.61.

Note 3: Fit the end of the paper eject roller spring in the groove of the bearing.

Note 4: Before setting the paper eject roller spring, apply grease to the portion on

the paper eject roller where the spring is to make contact with.

A

Driving roller

Bearing

Retaining ring

B

Bearing

Bearing

Retaining ring

Retaining

ring

Paper eject roller

B

A

Bearing

Main chassis

Paper eject roller spring

Bearing

Paper eject roller spring

Fig. 3.61

III - 47

Page 66

2.5 Reassembly of the Motor Holder Assy and the Motors

Set the main motor in the hole in the motor holder sub assy so that the end of the

harness will be at a lower position, and secure the main motor on the motor holder

sub assy with the two screws.

Set the motor holder sub assy on locating embosses A on the main chassis, and

secure the motor holder sub assy on the main chassis with the three screws.

Set the paper feed motor in the hole in the main chassis so that the end of the

harness will be at a lower position, and secure the paper feed motor on the main

chassis with the two screws.

Pass the paper feed motor harness to the outside of the main chassis through hole

B from the inside of the main chassis, as shown in Fig. 3.62.

A

Motor holder sub assy

Paper feed motor

Screws

Screws

Main

chassis

Screws

Main motor

B

Fig. 3.62

III - 48

Page 67

2.6 Reassembly of the Gears and Pulleys

(1) Set gear 21/47 on shaft A.

(2) After inserting shaft B through the clutch spring A, set gear 20/50.

(3) After inserting shaft C through the clutch spring A, set gear 68 and the

retaining ring.

(4) Set gear 21/47 and the retaining ring on shaft D.

(5) Set the clutch spring C on gear 25, and set gear 25 and then gear 50A on shaft

E.

Insert the hook of the clutch spring C into the groove of gear 50A, and set the

retaining ring.

(6) Set pulley 25 and gear 19/84 on shafts F and G respectively, and set the timing

belt (MXL belt B69) on pulley 25 and gear 19/84.

Set the flanges and the retaining rings on shafts F and G.

(7) Set pulley 18 on shaft H.

Set the timing belt (MXL belt 221) on shaft H and gear 44, and set gear 44 and

the retaining ring on shaft I.

Set the flange and the retaining ring on shaft H.

Note: Check that the end of the paper eject roller spring is fitted in the groove of the

bearing.

(8) Set gear 20/50, the flange, and then retaining ring on shaft J, as shown in Fig.

3.63

III - 49

Page 68

Bearing

Shaft H

Shaft E

Shaft G

Paper eject

roller spring

Pulley 18

Pulley 25

MXL belt 221

Gear 19/84

Gear 20/50

Gear 25

Clutch spring C

Gear 50A

Gear 44 Gear 21/47 Gear 68

MXL belt B69

Shaft F

Fig. 3.63

Shaft I

Shaft J

Gear 20/50

Shaft D

Shaft A

Shaft B

Shaft C

Gear 21/47

Clutch spring A

III - 50

Page 69

2.7 Reassembly of the Head Holder Assy

Place two compression springs on two burrs of the head holder as shown in

Fig.3.64. Hook two catches A of the head holder on the head holder guide, then fit

two burrs of the head holder guide over the compression springs.

Lower the head holder guide. Insert the head guide shaft through the head holder

guide, head holder, and protection cover spring, then mount the retaining rings on

both ends of the shaft.

Move the protection cover spring toward the end of the shaft, then fit arm B of the

protection cover spring in portion B of the head holder.

Assemble the head protection cover so that portions D fit over the head guide shaft,

then fit arm C of the protection cover spring in the hook of the head protection

cover.

Hooks A of the head

holder mate with these parts.

Head holder guide

Head guide shaft

Compression springs

Hooks A

Burrs

Head holder

B

Arm B

Protection cover spring

Arm C

Hook

D

Head protection cover

Fig. 3.64

III - 51

Page 70

Set the lever hook on the head holder guide, insert the lever shaft into the hole in

the head holder guide, pass the lever shaft through the lever hook return spring,

and insert the lever shaft into the hole on the opposite side of the head holder guide

in the direction of the arrow. Then, set the retaining rings on both ends of the lever

shaft, as shown in Fig. 3.65

Lever hook

Lever shaft

Stopper

Head holder guide

Head holder guide

Lever hook return spring

Lever hook

Head holder guide

Fig. 3.65

III - 52

Page 71

Pass the rotation shaft through the hole in the main chassis from the outside in the

direction of the arrow.

Pass the rotation shaft through the head guide spring, the head holder assy, head

holder springs R and L, and the hole on the opposite side of the main chassis, and

set the two retaining rings on the rotation shaft.

Set the hooks of head holder springs R and L on the projections of the main

chassis, as shown in Fig. 3.66.

Head holder assy

Head guide spring

Head holder spring R

Retaining ring

Head holder spring L

Retaining ring

Rotation shaft

Main chassis

Fig. 3.66

III - 53

Page 72

2.8 Reassembly of the Presser Unit Assy

Set the size detection PCB assy and the shield plate rear on the shutter rear, and

secure them with the three screws.

Set two pinions 14 on the two shafts in the presser frame sub assy.

Set the shutter rear and then the shutter front, as shown in Fig. 3.67.

Shutter front

Shutter rear

Size detection

PCB assy

Shield plate rear

Presser frame sub

assy

Pinions 14

Fig. 3.67

III - 54

Page 73

Adjust the ends of the ribs of the shutter rear to the centers of the pinion shafts.

Set the shutter front so that there will be no clearance between the ends of the ribs

of the shutter front and those of the shutter rear, as shown in Fig. 3.68.

Shutter rear

Shutter front

Fig. 3.68

III - 55

Page 74

Set the two shutter springs on the two hooks of the shutter front and the shutter

rear.

Insert the four claws of the shutter cover into the holes in the presser frame sub

assy.

Pass the presser frame shaft through the presser frame sub assy, and set the

retaining rings and the bearings on both ends of the presser frame shaft.

Note 1: Make sure that the two pinion shafts of the presser frame sub assy are

inserted into two holes A in the shutter cover, as shown in Fig. 3.69.

Shutter cover

Hole A

Shutter springs

Presser frame

sub assy

Retaining ring

Bearing

Presser frame shaft

Bearing

Retaining ring

Fig. 3.69

III - 56

Page 75

Pass the positioning shaft through the presser plate and the positioning presser

plate, and set the retaining rings on both ends of the positioning shaft.

Pass the presser plate lock shaft through the hole in the presser lever from the

outside in the direction of the arrow.

Pass it through the presser plate lock, the presser plate lock spring, and through the

hole on the opposite side of the presser lever.

Insert hook A of the presser plate lock spring into the hole C in the presser lever.

Pass the presser plate lever shaft through the presser plate and the presser lever.

Set the presser bearings on both ends of the presser plate lever shaft.

Set the presser lever cover on the presser lever.

Note 2: Make sure that two hooks B of the presser lever cover and the two locating

pins are properly set, as shown in Fig. 3.70.

Presser lever

cover

B

Presser bearing

Presser lever

Presser plate

lock spring

Presser plate lock

Positioning presser plate

Presser plate

C

A

Fig. 3.70

Presser plate lever shaft

Presser bearing

Presser plate lock shaft

Positioning shaft

III - 57

Page 76

Pass the hinge shaft through the hole in the presser frame sub assy from the

outside in the direction of the arrow.

Pass it through the presser plate hinge spring, the presser plate, and the hole on

the opposite side of the presser frame sub assy, and set the four retaining rings, as

shown in Fig. 3.71.

Presser plate hinge spring

Hook

Hinge shaft

Shutter cover

Presser frame sub assy

Fig. 3.71

III - 58

Page 77

On assembling the presser unit assy with the main chassis, adjust the position using

the presser jig assy and adjustment jig according to the following steps.

Note 3: Use caution when handling and taking custody of the jigs.

(1) Place the main chassis on the presser jig assy (part of the presser base assy)

at the specified position, as shown in Fig. 3.72A.

Note 4: Check that there is not any gap (A) between the main chassis and presser

jig assy.

Locating pin

Locating pins

Main chassis

Locating pin

Presser jig assy

(part of the presser

base assy)

Locating pins

Locating pins

A

Fig. 3.72A

(2) Place the presser sub unit assy on the main chassis, as shown in Fig. 3.72B.

Head holder assy

Presser sub unit assy

Main chassis

Fig. 3.72B

III - 59A

Page 78

(3) Open the presser plate, then place the adjustment jig in the presser sub unit

assy, as shown in Fig. 3.72C.

Adjustment jig

Presser plate

Presser frame sub assy

Main chassis

Fig. 3.72C

(4) Close the presser plate.

Note 5: Check that the presser plate is locked (B), as shown in Fig. 3.72D.

Presser frame shaft

Presser sub unit assy

Presser plate lock

Fig. 3.72D

B

Main chassis

(5) Align the presser frame sub assy with the main chassis at four portions (C),

with no gap being allowed between them, as shown in Fig. 3.72C.

III - 59B

Page 79

(6) Place the presser jig assy on the presser frame sub assy, as shown in Fig.

3.73A.

Note 6: Before securing the presser jig assy, check the following items.

Presser side plate

Presser hook base

Presser jig assy

(part of the presser base assy)

D

Catch clip assy

Presser hook

Presser side plate

D

Presser frame sub assy

Main chassis

Fig. 3.73A

* Check that the presser frame sub assy is aligned with the main chassis at four

portions (C), with no gap being allowed between them, as shown in Fig. 3.72C.

* Check that the harnesses including the FPC are not caught between the presser

jig assy and presser frame sub assy.

* Check that the presser frame sub assy and main chassis fit in four dented portions

(D) on the presser side plates R/L of the presser jig assy, as shown in Fig. 3.73A

and Fig. 3.73B.

F

(It is impossible to check

the item by taking a look.)

Presser hook base

D

Presser hookPresser hook

Main chassis

Presser frame sub assy

Presser side plate

D

Fig. 3.73B

III - 59C

Page 80

* Check that the frame of the presser frame sub assy supports the side plates R/L

base assy)

of the presser jig assy from inside (E).

Also check that the protrusion (F) of the presser jig assy presses the frame of the

presser frame sub assy downward by checking that D and E are properly set, as

shown in Fig. 3.73A to Fig. 3.73C.

Side plate L

(Presser jig assy)

Side plate R

(Presser jig assy)

EE

Frame

(Presser frame sub assy)

Frame

(Presser frame sub assy)

Fig. 3.73C

* Check that the protrusion of the presser frame sub assy fit in the hole of the main

chassis at two portions (G), as shown in Fig. 3.73D.

Presser jig assy

Presser frame sub assy

Presser sub

unit assy

G (It is possible to check

the item by taking a look.)

Main chassis

Presser jig assy

(part of the presser

G (It is impossible to check

the item by taking a look.)

Fig. 3.73D

(7) Secure the presser jig assy using two catch clip assys, as shown in Fig. 3.73A.

Note 7: Lock the presser jig assy at its front and rear in this order.

III - 60A

Page 81

(8) Tighten ten screws in the order specified in Fig. 3.74A to 3.74B.

base assy)

Note 8: Tighten those screws twice.

Pressser jig assy

Main chassis

Screws

Presser sub unit assy

Fig. 3.74A

Screws

Main chassis

Presser jig assy

(part of the presser

Presser jig assy

(9) Remove the presser jig assy.

Screw

Screws

Screws

Fig. 3.74B

III - 60B

Page 82

(10) Open the presser plate, then tighten two screws, as shown in Fig. 3.74C.

Note 9: Tighten those screws twice.

Presser plate

Adjustment jig

Main chassis

Screws

Fig. 3.74C

(11) Remove the presser jig assy (part of the presser base assy) and adjustment jig.

(12) Attach the presser plate cover to the presser plate, as shown in Fig. 3.74D.

Note 10: Check that two hooks and locating pins of the presser plate cover fit in

the holes of the presser plate.

Hooks

Presser plate cover

Locating pins

Presser plate

Main chassis

Fig. 3.74D

III - 60C

Page 83

2.9 Reassembly of the Platen Unit Assy

Set the platen unit on the film guide, as shown in Fig. 3.75.

Fig. 3.75

Insert part A of the platen unit assy into the hole in the main chassis from the inside.

Then, insert part B of the platen unit assy into the hole on the opposite side of the

main chassis, and insert the platen unit assy into the two grooves of the main

chassis, with the projection of the bearing turned upwards, as shown in Fig. 3.76.

Film guide

Platen unit

Set part C of the platen unit assy between the two ribs of the film path.

B

Platen unit assy

Main chassis

Bearing

Fig. 3.76

C

A

III - 61

Page 84

Secure the platen unit assy with the two screws, as shown in Fig. 3.77.

Screws

Main chassis

Platen unit assy

Fig. 3.77

III - 62

Page 85

2.10 Reassembly of the Micro Switches

Set hole A in the micro switch assy A for cassette cover open/close detection on the

emboss on the main chassis.

Screw the switch on the main chassis where hole B in the switch and the hole in the

main chassis overlap, as shown in Fig. 3.78.

Hole A

Hole B

Screw

Micro switch assy A

(for cassette cover open/close detection)

Fig. 3.78

Insert part A of the xenon lock claw into hole B in the main chassis.

Emboss

While bending the resin spring, insert the two hooks of the xenon lock claw into two

holes C in the main chassis.

Set hole D in the micro switch assy B for xenon reset on the emboss on the main

chassis.

Screw the switch on the main chassis where hole E in the switch and the hole in the

main chassis overlap. Then, secure the harness of the switch for xenon reset with

the fastening band, as shown in Fig. 3.79.

Hole B

Hole C

A

Xenon lock claw

Main chassis

Emboss

Hole E

Hole D

Screw

Micro switch assy B

(for xenon reset)

Fig. 3.79

III - 63

Page 86

2.11 Reassembly of the Sensor Assys

Secure reflective sensor assy A on the head holder with the screw.

Pass the reflective sensor assy A harness between the rotation shaft and the head

holder guide, and pass it through hole E in the main chassis and to the outside.

Secure reflective sensor assys B and C on the sensor brackets with the screws.

Pass the harnesses of reflective sensor assys B and C through hole E in the main

chassis and to the outside.

Secure transparent sensor assy A on the film path with the screw.

Pass the transparent sensor assy A harness through hole F in the main chassis and

to the outside.

Insert transparent sensor assy B in the direction of the arrow, and secure it on the

presser unit assy with the screw.

Pass fastening band L100 through holes E and F, and secure the harness coming

out of hole E and F in the main chassis, as shown in Fig. 3.80.

Rotation

Head holder assy

shaft

Head holder

Screw

Label guide assy

Hole E

Main chassis

Fastening

band L100

Hole

Free bush 50

Reflective sensor

assy C

Transparent

sensor assy A

Reflective sensor assy A

Reflective sensor assy B

Screw

Screw

Fastening band

L100

Transparent

sensor assy A

Screw

Transparent

sensor assy B

Hole F

Screw

Free bush 15

Fig. 3.80

III - 64

Page 87

2.12 Reassembly of the Thermal Head Unit

Fig. 3.81 shows the thermal head unit.

Caution: Take care not to touch the thermal head heat generating points.

Heat generating points

Thermal head unit

Fig. 3.81

Set the thermal head unit on the two embosses on the head holder, and secure it

with the two screws.

Pass the thermal head unit harness between the rotation shaft and the head holder

guide, and pass it through the hole in the main chassis and to the outside, as shown

in Fig. 3.82.

Thermal head unit

Screws

Fig. 3.82

Secure the thermal head unit harness on the main chassis with fastening band

L100, that is also used to secure the sensor assy, as shown in Fig. 3.80.

III - 65

Page 88

2.13 Reassembly of the Power Supply PCB Assy

Insert two parts A of the PS PCB shield plate into two holes B in the bottom cover.

After setting the power supply PCB assy on the two hooks C of the bottom cover,

set the power supply PCB assy on the locating boss on the bottom cover, and

secure the power supply PCB assy on the bottom cover with the two screws, as

shown in Fig. 3.83.

Note: Put on a static control wrist band before handling PCBs.

Power supply

PCB assy

Screw

A

PS PCB shield plate

Screw

Bottom cover

C

Locating boss

C

B

Fig. 3.83

III - 66

Page 89

2.14 Reassembly of the Bottom Cover and the Main Chassis

B

Insert the end of the size detection PCB harness into the hole in the bottom cover,

and set it into hooks A, B, C, and D, as shown in Fig. 3.84.

Size detection PCB harness

A

D

C

B

Fig. 3.84

Set the thermistor to the bottom cover and secure it in place using tape. Then, pass

the connector through hole A.

Pass the paper feed motor harness through hole C in the bottom cover.

Pass the drawer connector harness through hole B in the bottom cover.

Bundle all other harnesses coming out of the main chassis, and pass them through

hole A in the bottom cover.

Secure the harness of the transparent sensor assy B and the switch for the xenon

cassette with the harness of the transparent sensor assy A and the switch for

opening/closing the cover using fastening band L100, as shown in Fig. 3.85.

Paper feed motor harness

Main chassis

C

Fastening band L100

Harness of switch for

xenon reset

Thermistor harness

Bottom cover

A

Rib A

Harness of transmission

sensor assy B

Drawer connector

harness

Fig. 3.85

Note: Arrange the harnesses at the left of rib A.

III - 67

Page 90

Set the main chassis assy on the two locating bosses on the bottom cover, and

secure it on the bottom cover with the six screws. Then, set the two cores, as

shown in Fig. 3.86.

Screws

Screws

Main chassis

Locating boss

Bottom cover

Screws

Locating boss

Fig. 3.86

Set the ground wire on the main chassis and the PS PCB shield plate with the two

screws, as shown in Fig. 3.87.

Screw

PS PCB

shield plate

Bottom cover

Main chassis

Ground wire

Screw

Fig. 3.87

III - 68

Page 91

2.15 Reassembly of the Body Cover

Set the control panel PCB assy on the control panel PCB holder, and secure it with

the screw.

Set the control panel PCB assy on the back of the body cover, and secure it on the

body cover with the two screws.

Attach the control panel PCB harness on the body cover with a tape at two

positions, as shown in Fig. 3.88.

Screw

Core

Control panel

PCB assy

Control panel

PCB holder

Body cover

Screws

Two positions where the

harness is attached with a tape.

Core

Body cover

Control panel PCB harness

Fig. 3.88

III - 69

Page 92

After passing the control panel PCB harness through the hole in the bottom cover,

set the body cover on the bottom cover, and secure it with the six screws.

Set the eject cover and the slide lever on the body cover, as shown in Fig. 3.89.

Control panel PCB

harness

Bottom cover

Body cover

Screws

Eject cover

Screws

Slide lever

Fig. 3.89

III - 70

Page 93

Set the cassette cover on the head holder guide by setting the two hooks of the

cassette cover on the head holder guide, and secure it with the two screws, as

shown in Fig. 3.90.

Note: Make sure that the two locating bosses and hooks are properly set.

Cassette cover

Head holder guide

Locating bosses

Hook

Head holder guide

Screws

Body cover

Fig. 3.90

III - 71

Page 94

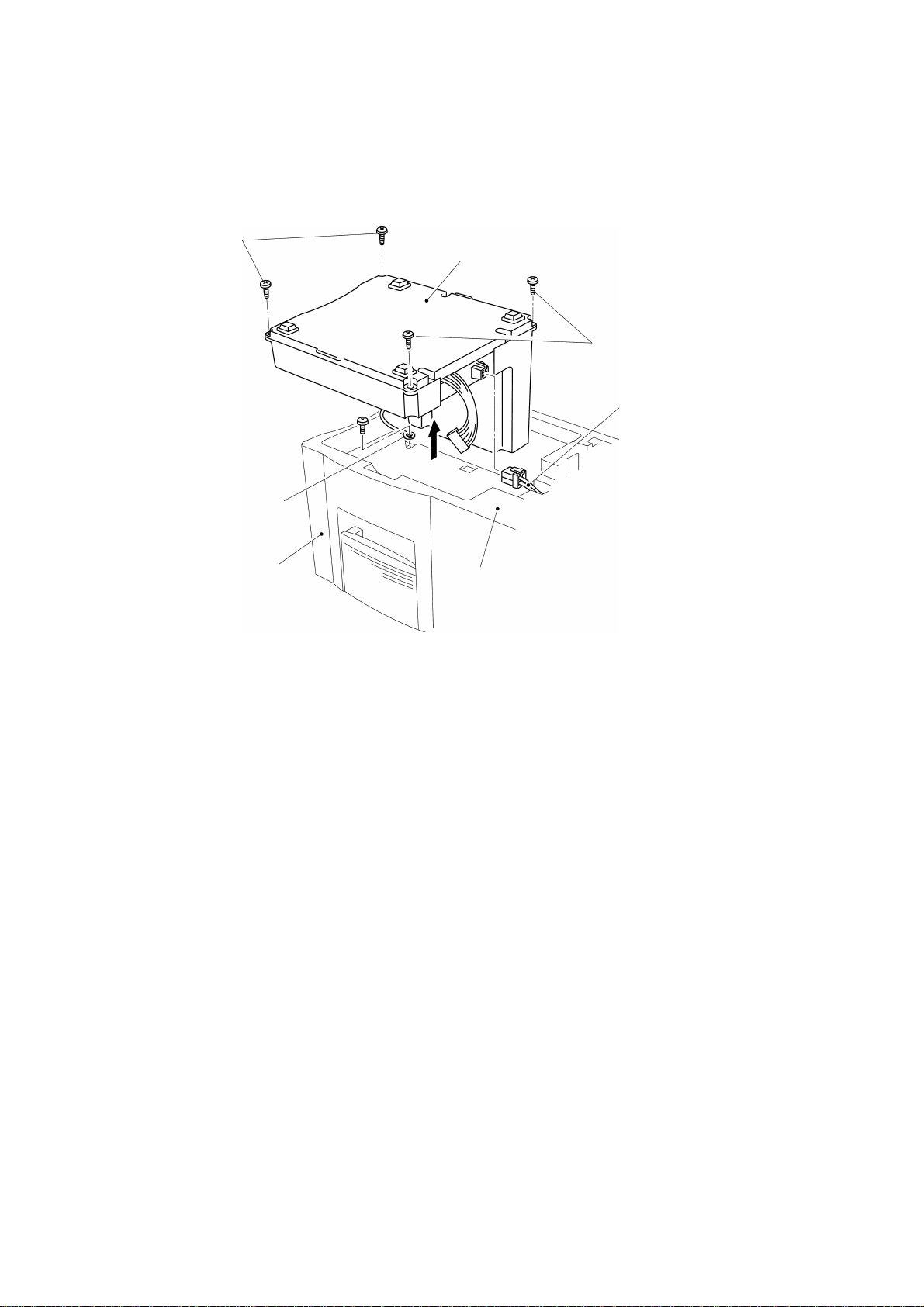

2.16 Reassembly of the Capacitor Case

Set the ground wire of the capacitor case on the main chassis with the screw, pass

connector A of the capacitor case through the hole in the bottom cover, and

connect it to the connector of the power supply PCB assy.

Connect connector D coming out of the bottom cover to connector B of the

capacitor case.

Set the capacitor case on the bottom cover, and secure it with the four screws, as

shown in Fig. 3.91.

Screws

Capacitor case

Capacitor case rank number

Ground wire

Main chassis

Screws

Connector B

Connector A

Connector C

Connector D

Bottom cover

Fig. 3.91

III - 72

Page 95

When exchanging the capacitor case and main PCB assy, perform the

following steps after completing reassembly.

Capacitor Case Rank Setting Procedure

(1) Turn the power switch ON while holding the MODE key.

(2) Press the MODE key for 10 seconds until the LCD unit displays "<<Ver **.**>>".

[[.[[: Program version No.

(3) Press the SET key, and the LCD unit displays “N = [[[[[”.

[[[[[: Total number of printing times (light emission times of xenon lamp)

(4) Press the SET key, and the LCD unit displays “C-BOX RANK = [”

Current setting

(5) Check the rank printed on the capacitor box.

The capacitor case rank is printed at the bottom of the case.

Example) 8E29 11000 D

Rank (A to J)

Capacitance

Mf g. No.

(6) Set the capacitor case rank according to the printed rank by pressing the

MODE key.

The rank display changes in the following sequence as the MODE key is

pressed.

(7) Press the SET key.

This completes the setting of the capacitor case rank and the machine is reset.

III - 73

Page 96

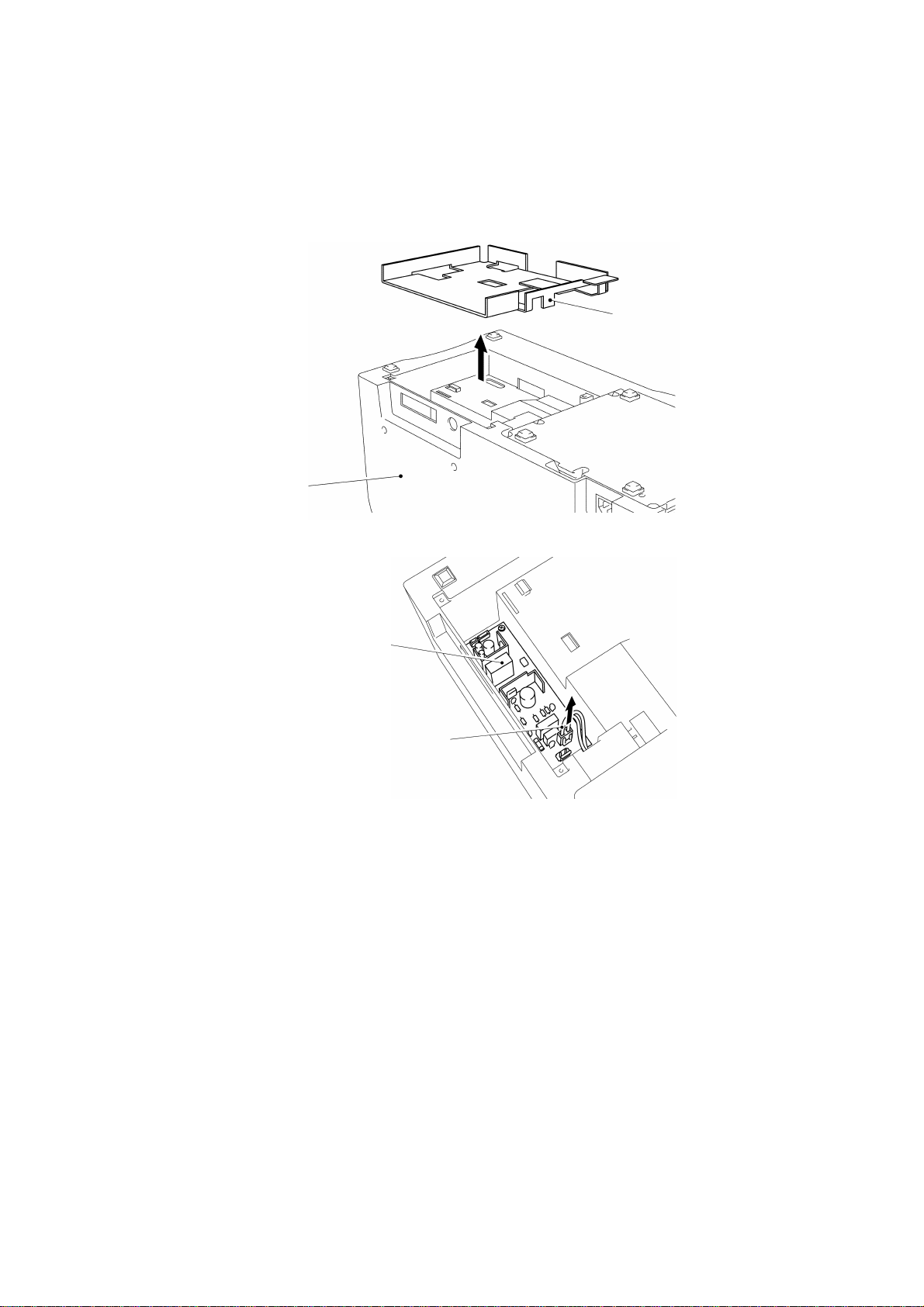

2.17 Reassembly of the Main PCB Assy

Pass the harness through the hole of the shield plate, and set the shield plate on

the bottom cover, as shown in Fig. 3.92.

Shield plate

Power supply

PCB harness

Control panel

PCB harness

Bottom cover

Paper feed motor

harness

Size detection

PCB harness

Fig. 3.92

Secure the main PCB assy on the main PCB bottom plate with the five screws, as

shown in Fig. 3.93.

Note: Put on a static control wrist band before handling PCBs.

Main PCB assy

Main PCB

bottom plate

Fig. 3.93

III - 74

Page 97

Connect the harness to each connector on the main PCB assy, as shown in Fig.

3.94.

Power supply PCB

Shield plate

Xenon unit detection/

release sensor

Control panel PCB

Power supply PCB

Thermal head

Room temperature

detection

Ribbon detection

Paper feed motor

Manual feed detection

Automatic feed

position detection

Trigger detection

Stamp size detection sensor

Main motor

Main capacitor charge PCB

Not in use

Cover open/close detection

Xenon unit release detection

Printing position detection

Fig. 3.94

Set the ground wire of the main PCB assy on the main chassis with the screw.

Secure harnesses A and B in hook C of the bottom cover, as shown in Fig.3.95.

Harness B

Screw

Ground wire

Harness A

Main PCB

Main PCB bottom plate

Hook C

Fig. 3.95

III - 75

Page 98

Secure the main PCB bottom plate on the bottom cover with the four screws, as

shown in Fig. 3.96.

Screws

Screws

Main PCB

bottom plate

Bottom cover

Fig. 3.96

III - 76

Page 99

2.18 Reassembly of the Ribbon Cassette Assy

Turn the machine over with the right side up, and press the open button on the

cassette cover to open the cassette cover.

Set the ribbon cassette assy, and close the cassette cover, as shown in Fig. 3.97.

Cassette cover

Body cover

Ribbon cassette assy

Fig. 3.97

III - 77

Page 100

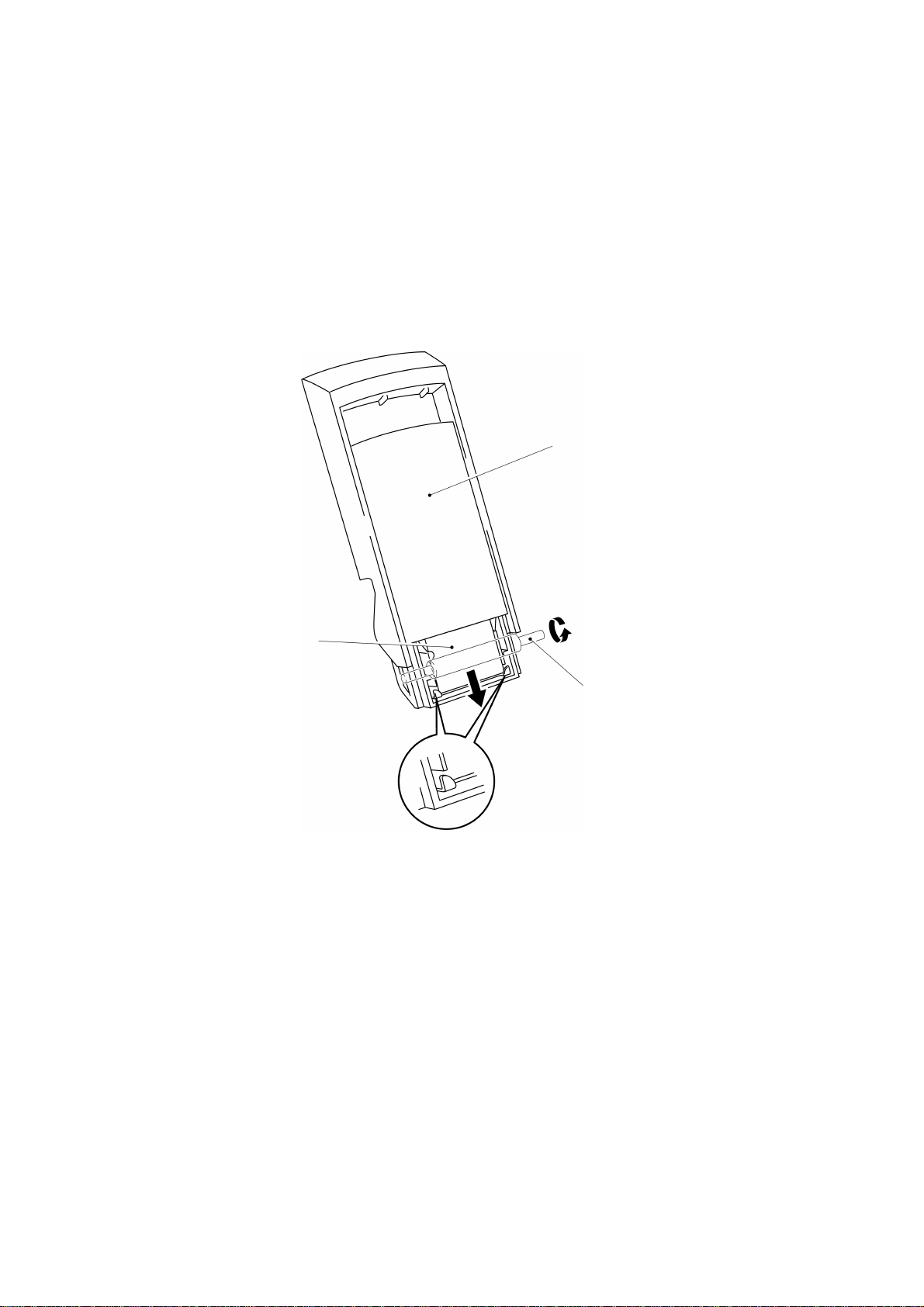

2.19 Reassembly of the Xenon Unit Assy

Insert the xenon unit assy into the machine at its right side, as shown in Fig. 3.98.

Note: Insert the xenon unit assy all the way until it is locked.

Fig. 3.98

Body cover

Xenon unit assy

III - 78

Loading...

Loading...