Page 1

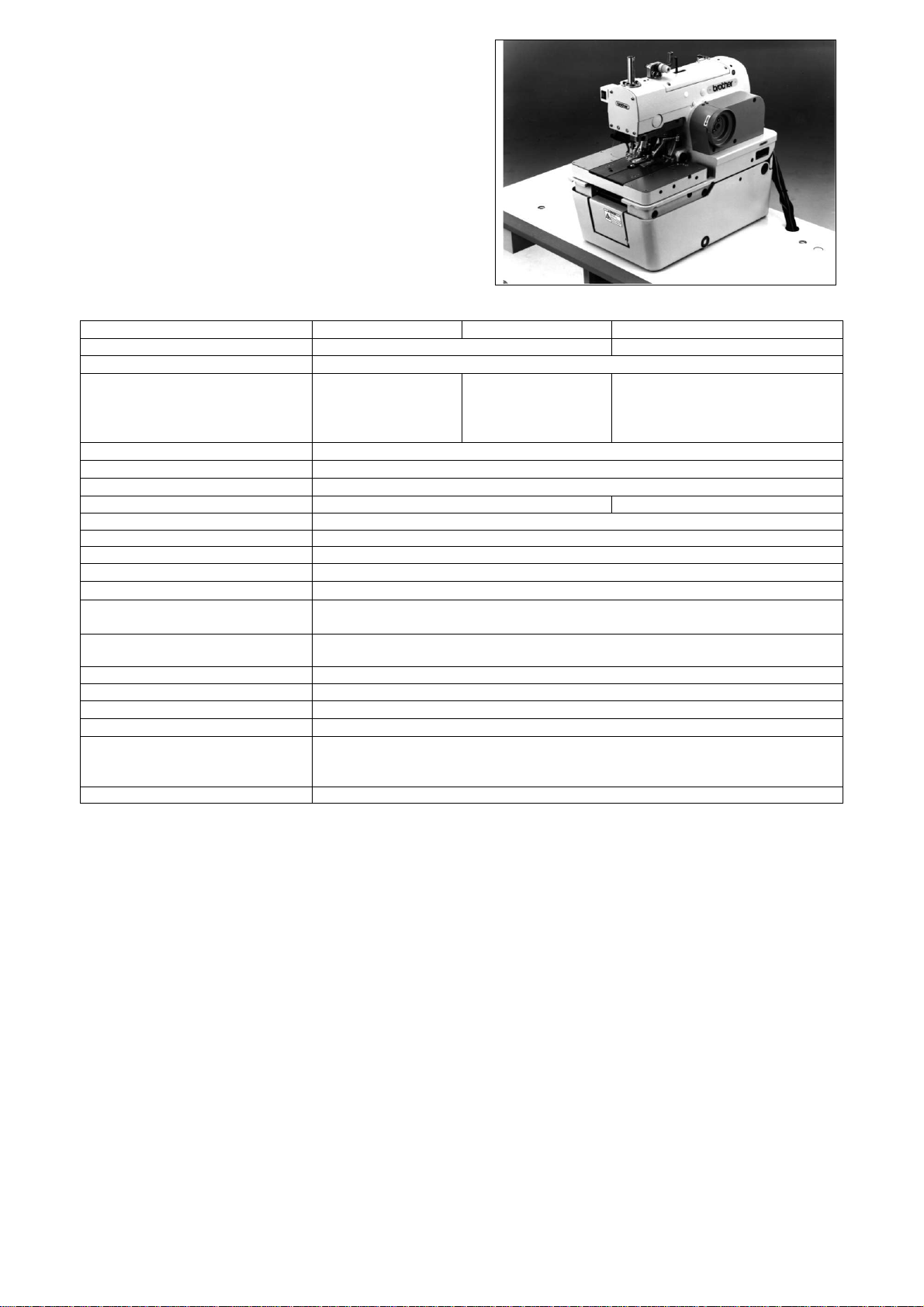

RH−9800

Electronic Eyelet Button Holer

Specifications

Specifications

Main use Men’s clothes and ladies’ clothes Jeans and work clothes

Sewing speed

Buttonhole length

Stitch length

Stitch width

Tacking length

Cloth presser height 12 mm 16 mm

Stitch shape changing Selected by a program

Cut timing selection Selected by a switch

Starting method Dual switch (cloth presser switch and start switch) or single switch

Feed method

Needle

Safety equipment

Air pressure

Air consumption 43.2 l / min (8 cycle / min)

Noise level 81 dB at max. speed of 2,000 rpm, measured according to ISO 10821

Dimensions

Work table legs

Power supply

Weight 175 kg

Built−in emergency stop function and automatic stopping device which stops the machine

−00 −01 −02

1,000−2,000 rpm (100−rpm steps)

10 − 50mm 10 − 38 mm

0.5 − 2.0 mm (0.1 mm steps)

1.5 − 3.2 mm

0 mm, 3 − 43 mm (1 mm steps)

Intermittent feed by three pulse motors (X, Y, θ)

DO × 558 #80 − #120 (Schumetz)

when the safety circuit is activated.

Main regulator: 0.49 Mpa

Knife pressure regulator: 0.3 Mpa

1,200 mm (W) × 590 mm (D) × 1,120 mm (H)

T−shaped height−adjustable type

Single−phase 110, 200, 220, 230, 240 V

Three phase 220, 380, 415 V

Max. electric power consumption: 1kVA

L1: 14 − 18 mm L5: 28 − 32 mm

L2: 18 − 22 mm L6: 32 − 36 mm

L3: 22 − 26 mm L7: 36 − 40 mm

L4: 26 − 30 mm

2002.10

RH-9800 1/17

Page 2

Device for each sub-class

RH−−−−9800−−−−

Upper

thread

trimmer

00

01

Standard bar tacking

02 {

/ eyelet buttonhole

03 {

with taper bar

04 {{

05

12

Straight bar tacking

15

Eyelet button hole

52

with taper bar

55

(with fly indexer)

Lower thread

trimmer

Long Short

{

{{

{

{

{

{

{

−−

{*1 Option Option

−

−−

{*1 { Option

−

{*1 Option

−

{*1

−

{*1 Option

−

{*1

−

Upper

thread

nipper*2

Option*2

Option*2

−

{

−

{

{

{{

Fly indexer Upper

−

−

−−−− −

−−−− −

−−−− −

−−−− −

{

gimp guide

Option*2 Option Option Option *3

Option*2 Option Option Option *3

−−− −

−−− −

−−− −

−−− −

Circular

stitching

buttonhole

set

Round bar

tacking set

*1 If using the lower thread trimmer (short type), please specify the buttonhole length when ordering.

There is 10 mm of difference in the knife installation positions between L1 − L4 and L5 − L7.

*2 The upper thread nipper cannot be used in conjunction with the upper gimp guide.

*3 The special lapel cutting device can be used only when the feed bracket is set to the front position.

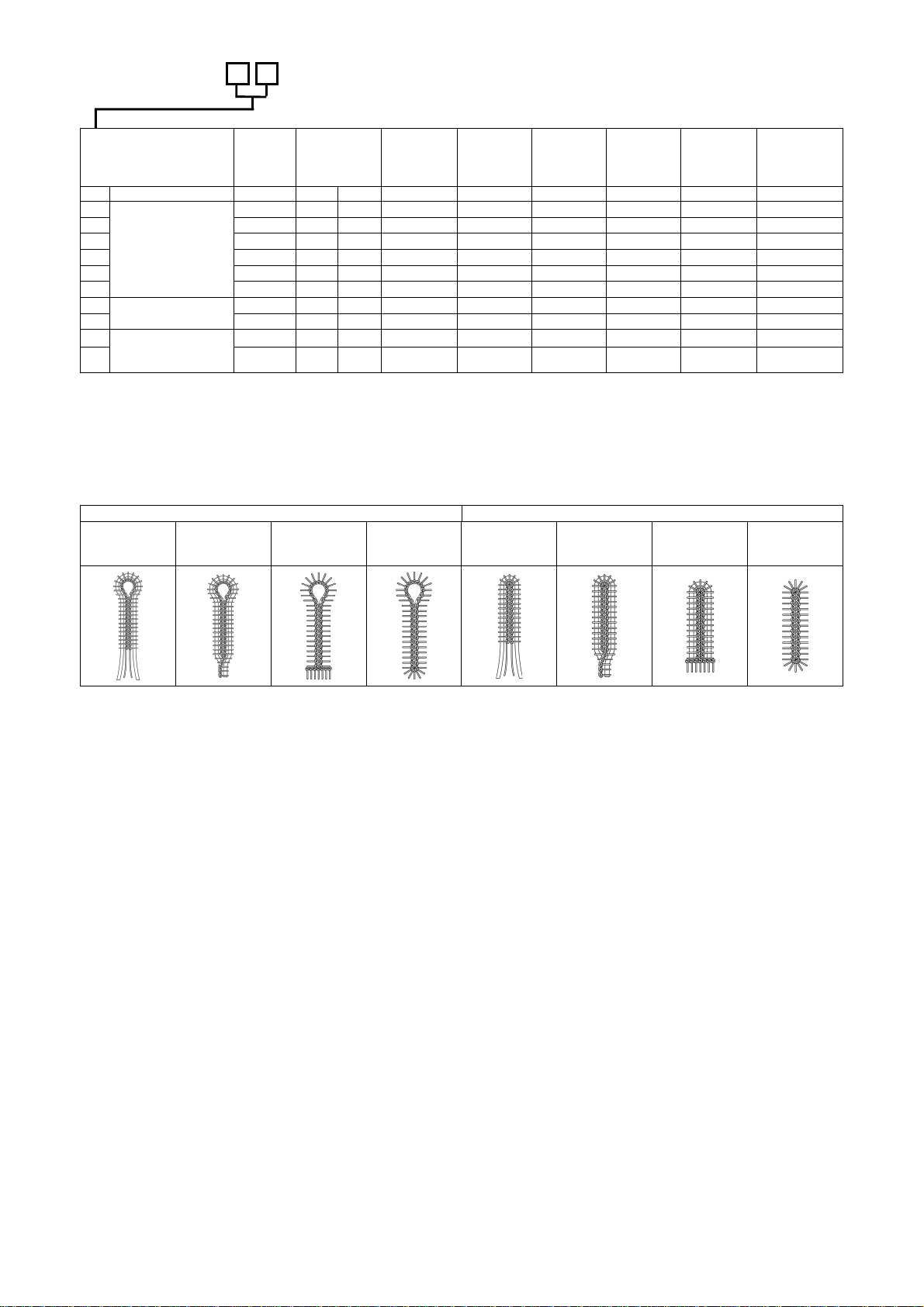

Sewing shape

Eyelet

buttonhole

Eyelet buttonhole Straight buttonhole

Eyelet

Buttonhole

with taper

With straight

bar tack

With round

bar tack

Straight

buttonhole

Straight

buttonhole with

taper

With straight

bar tack

Special lapel

cutting device

With round bar

tack

RH-9800 2/17

2002.10

Page 3

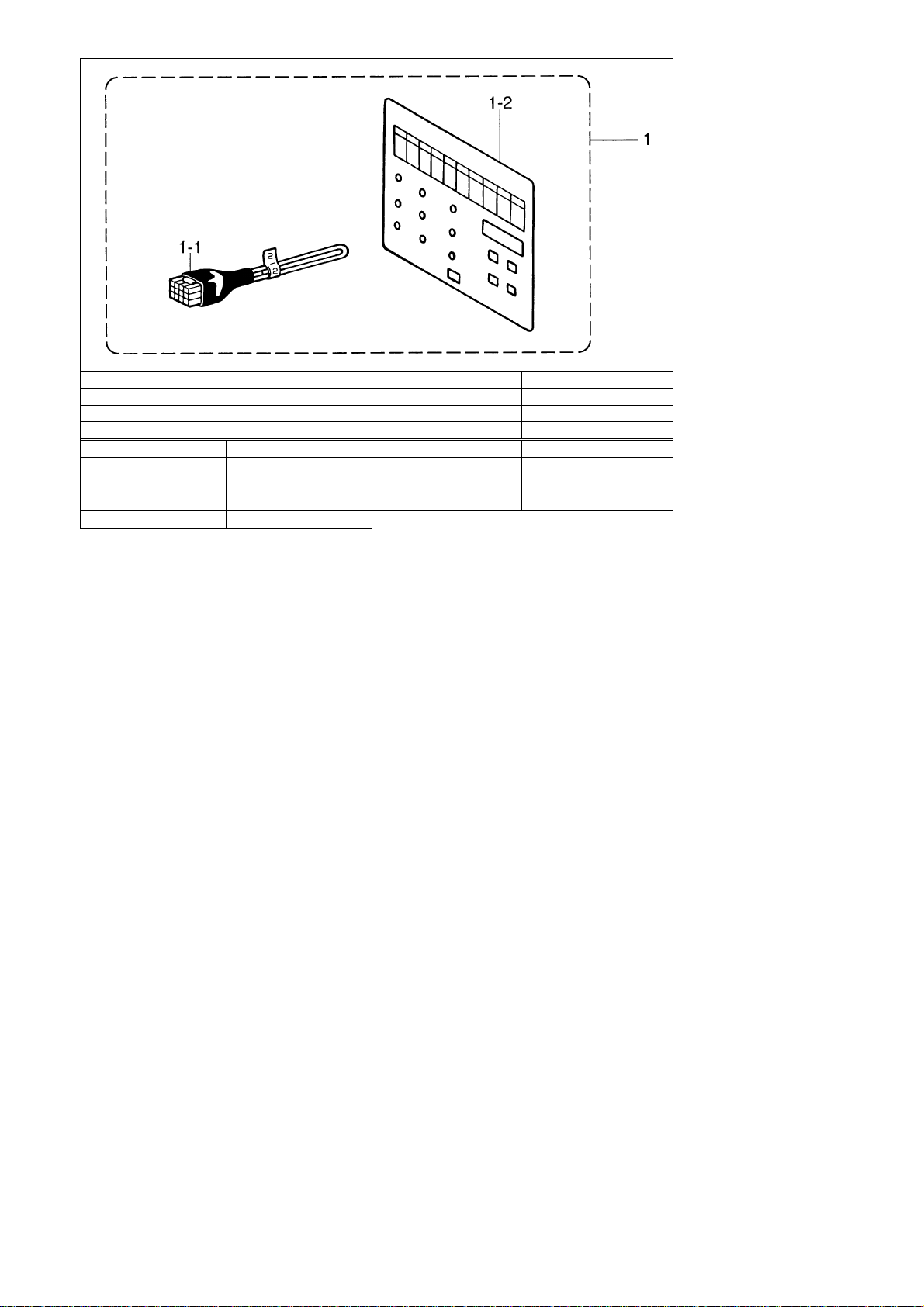

Round bar tacker set

Ref. No. Part name

1 Round bar tacker set S45195-000

1-1 Harness S44954-000

1-2 Panel sheet S44953-000

Pressers Buttonhole length Pressers Buttonhole length

L1

L2

L3

L4

16 − 19 mm

20 − 23 mm

24 − 27 mm

28 − 31 mm

L5

L6

L7

Part code

30 − 33 mm

34 − 37 mm

38 − 41 mm

*When a short thread trimmer is attached, each presser is designated as L1−L4 according to the stitch length. Use

the appropriate presser as per the table above.

2002.10

RH-9800 3/17

Page 4

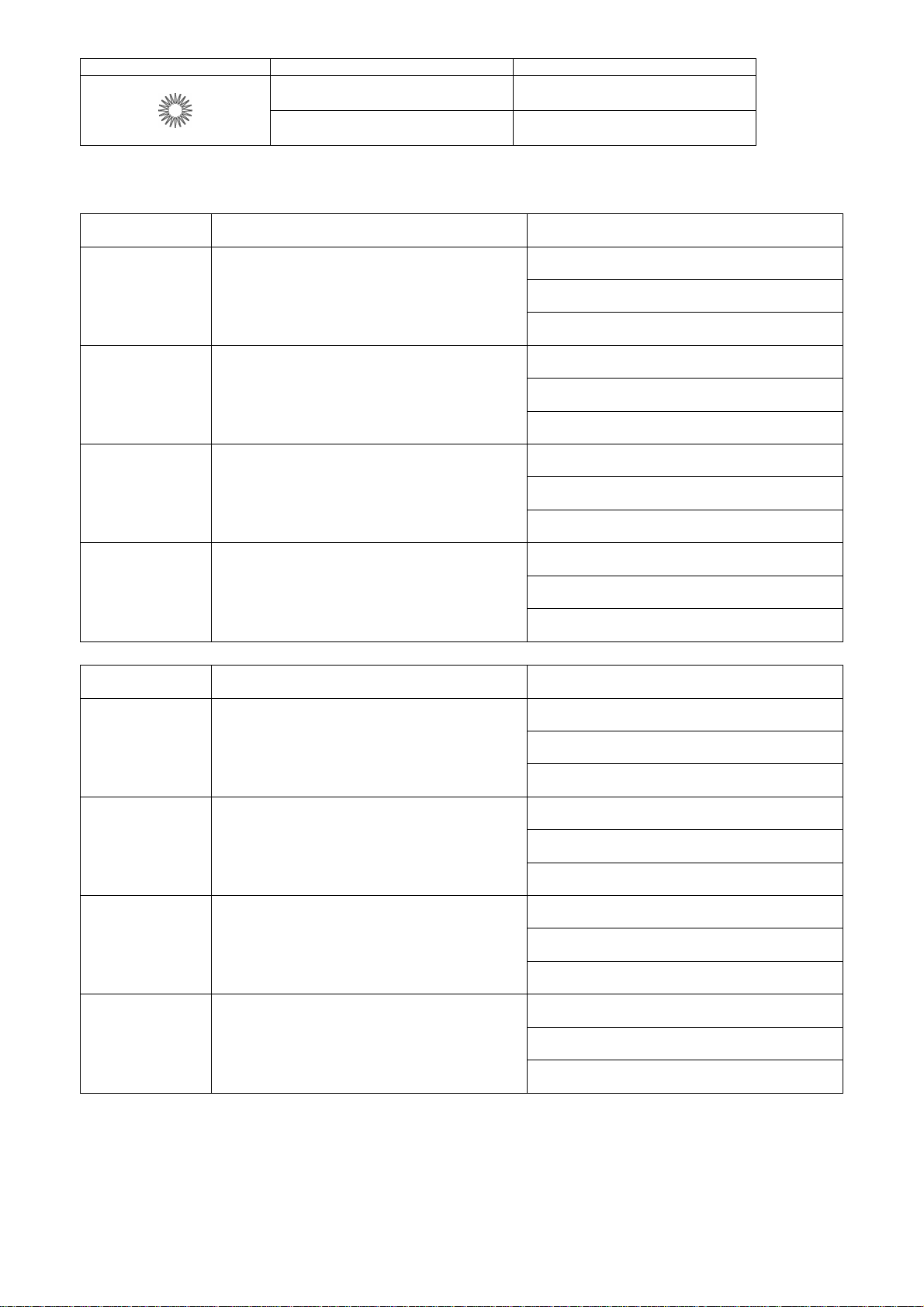

Circular stitching set

Sewing shape Outer diameter of circular stitching Presser harness

−10 mm −

Presser harness D13

Exchange parts set

– 00 用用用用 / For – 00

Stitching diameter

(mm)

2

3

4

5

For – 01

Stitching diameter

(mm)

2

3

4

5

−12 mm

Parts set

Exchange parts set D2 (-00)

S42174-001

Exchange parts set D3 (-00)

S41998-001

Exchange parts set D4 (-00)

S42175-001

Exchange parts set D5 (-00)

S41999-001

Parts set

Exchange parts set D2 (-01)

S42176-001

Exchange parts set D3 (-01)

S42000-001

Exchange parts set D4 (-01)

S42177-001

Exchange parts set D5 (-01)

S42001-001

S41506−000

Contents

Cloth presser set D11 (-00)

S43934-001

Knife (D2)

S41346-001

Hammer (D3)

S41344-001

Cloth presser set D11 (-00)

S43934-001

Knife (D3)

S41347-001

Hammer (D3)

S41344-001

Cloth presser set D13 (-00)

S43935-001

Knife (D4)

S41348-001

Hammer (D5)

S41345-001

Cloth presser set D13 (-00)

S43935-001

Knife (D5)

S41349-001

Hammer (D5)

S41345-001

Contents

Cloth presser set D11 (-01)

S43936-001

Knife (D2)

S41346-001

Hammer (D3)

S41344-001

Cloth presser set D11 (-01)

S43936-001

Knife (D3)

S41347-001

Hammer (D3)

S41344-001

Cloth presser set D13 (-01)

S43937-001

Knife (D4)

S41348-001

Hammer (D5)

S41345-001

Cloth presser set D13 (-01)

S43937-001

Knife (D5)

S41349-001

Hammer (D5)

S41345-001

RH-9800 4/17

2002.10

Page 5

Option parts

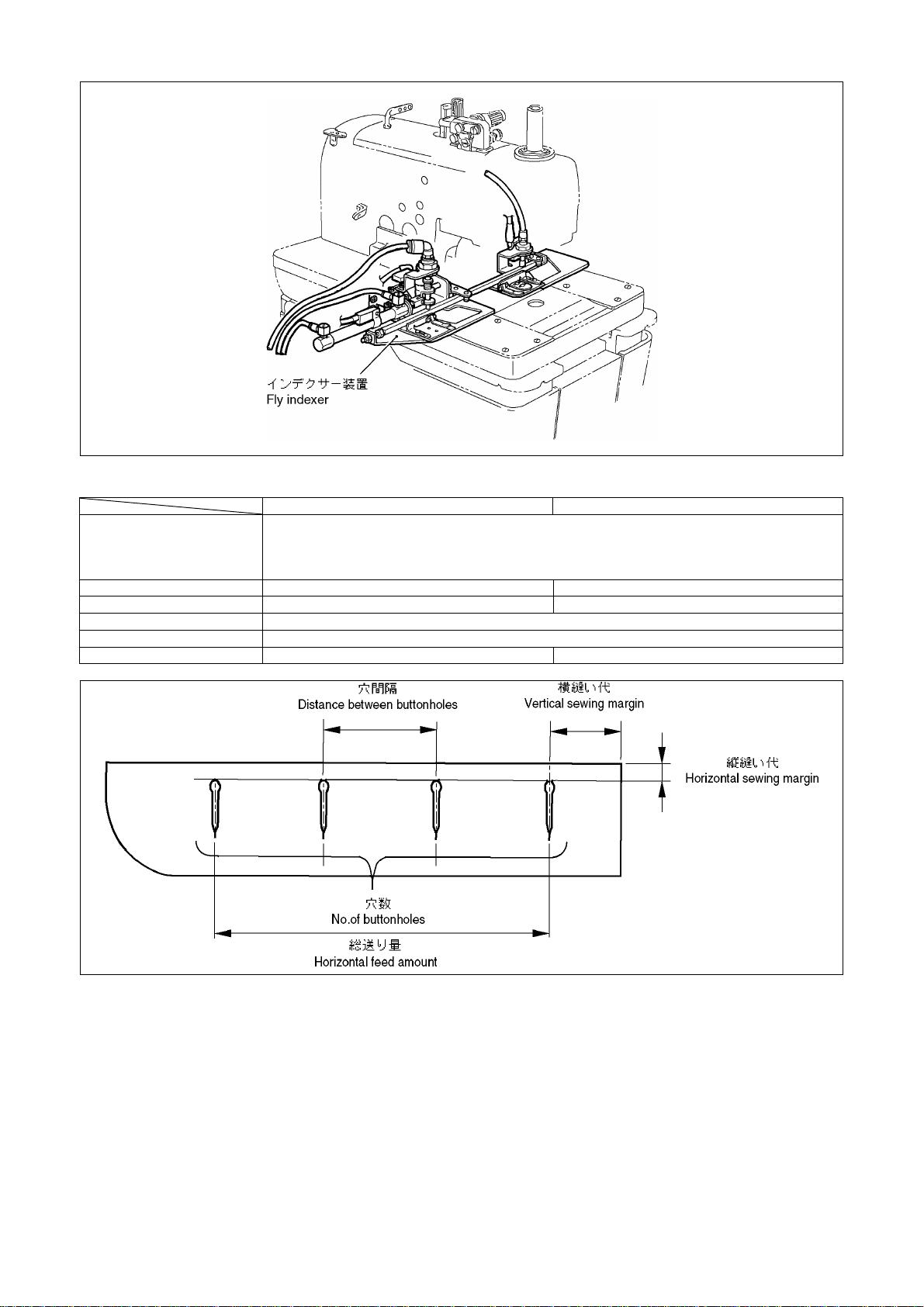

Fly indexer

Specifications

L1 (Buttonhole length : 14 - 18 mm), L5 (Buttonhole length : 28 - 32 mm)

Applicable specifications

Distance between button holes

No. of buttonholes

Horizontal sewing margin

Vertical sewing margin

Max. horizontal feed amount

L2 (Buttonhole length : 18 - 22 mm), L6 (Buttonhole length : 32 - 36 mm)

L3 (Buttonhole length : 22 - 26 mm), L7 (Buttonhole length : 36 - 40 mm)

L4 (Buttonhole length : 26 - 30 mm)

Standard size

38.1 mm, 50.8 mm, 44.45 mm

1 - 4 holes

(L1 - L4) 9 - 21 mm, (L5 - L7) 9 - 11 mm

152.4 mm

30 - 40 mm

38.1 mm, 50.8 mm, 44.45 mm, 57.15 mm

Large size

1 - 6 holes

285.75 mm

2002.10

RH-9800 5/17

Page 6

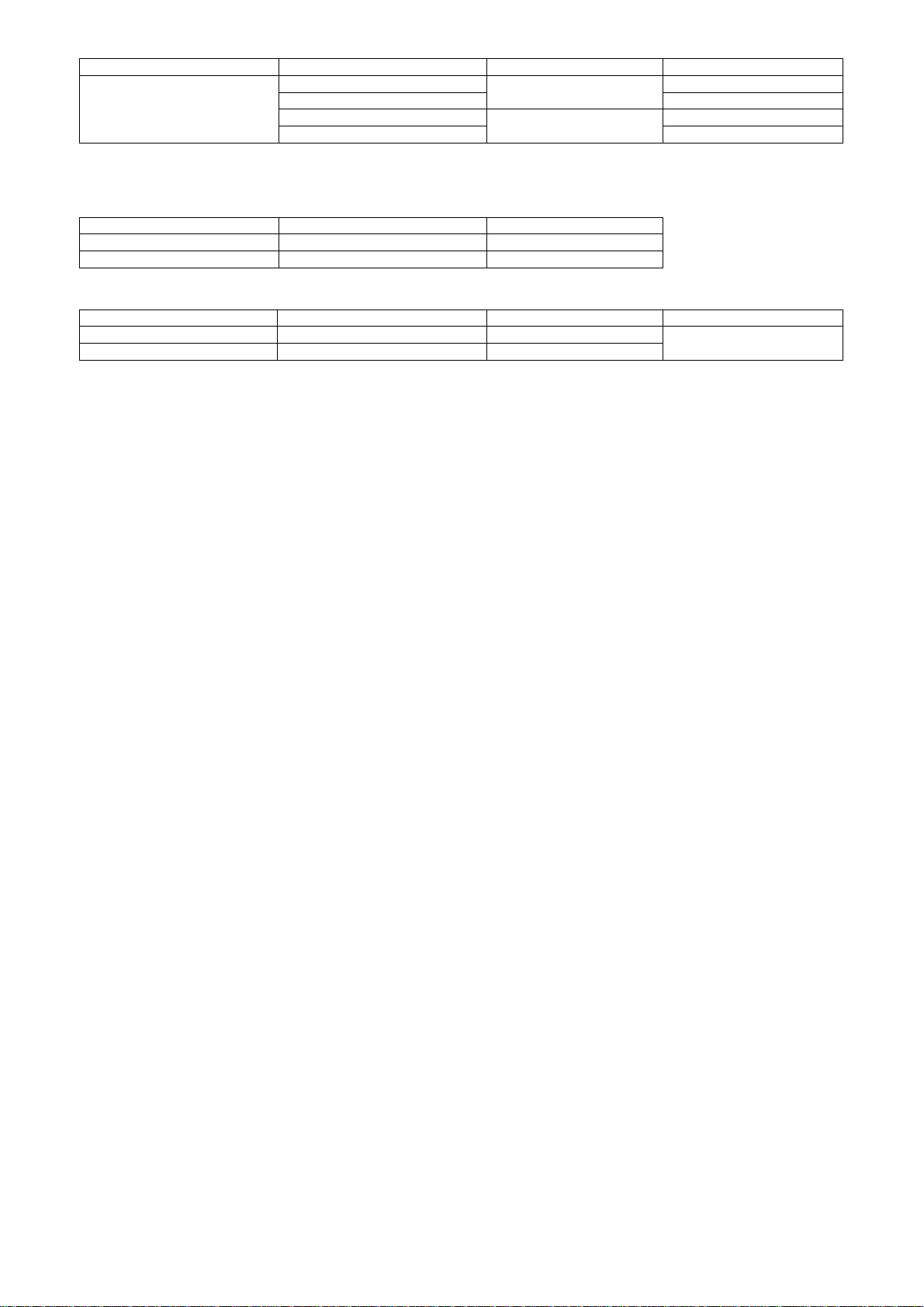

Parts for the standard-sized fly indexer (Conventional parts)

Part name

Fly indexer assy

*If the standard-sized fly indexer is used for sewing with a non-standard distance between buttonholes and a non-standard number of

buttonholes (up to 9), you need to make additional holes in the cloth feed bar (F) assy (optional part). For this processing, refer to the

instruction manual supplied with this optional part.

Part code

S42168-101

S42169-101

S42110-101

S42170-101

Applicable specifications

For L1, L2, L5

For L3, L4, L6, L7

Remarks

Without upper thread nipper

With upper thread nipper

Without upper thread nipper

With upper thread nipper

Part name

Cloth feed bar (F) assy (L1, L2)

Cloth feed bar (F) assy (L3, L4)

Part code

S45193-101

S45194-101

Applicable specifications

L1, L2, L5

L3, L4, L6, L7

Parts for the large-sized fly indexer

Part name

Fly indexer (LS) assy S48329-101 L1, L2, L5

Fly indexer (LL) assy S48334-101 L3, L4, L6, L7

Part code

Applicable specifications

*There are only four types of the distances between buttonholes for large−sized fly indexer.

Remarks

Without upper thread nipper

RH-9800 6/17

2002.10

Page 7

Option parts

Upper thread nipper

Thread nipper device set

Part name Part code Q’ty

S43406−301

1

2002.10

RH-9800 7/17

Page 8

Option parts

Gimp device

Parts set

Upper gimp guide set

S42656-001

Contents

Upper gimp guide set

S44503-001

Cotton stand assy, 4DTHF

S29854-109

RH-9800 8/17

2002.10

Page 9

Option parts

Hand start switch

Ref. No. Part name Part code Q’ty

1 Hand start switch assy

1−1

1−2

1−3

1−4

1−5

1−6

1−7

1−8

1−9

1−10

1−11 Screw, bind M3 × 6 060300−616

1−12

1−13 Screw, bind M4 × 8 060400−816

Switch set plate

Switch lever spring

Hand switch

Switch cover

Switch lever (L)

Switch lever (R)

Stud screw, M4

Stud screw, M4

Nut, 2M4

Screw, M2.38

Band PLTIM

S39909−001

S39913−001

S39914−001

S39915−000

S39910−001

S39911−001

S39912−001

S34922−101

S34966−001

012400−202

146124−001

S04557−000

1

1

1

1

1

1

1

1

2

3

2

2

1

2

2002.10

RH-9800 9/17

Page 10

Special lapel cutting device

*When sewing straight buttonholes, needle rotates 6 mm in front of the tip of the eyelet buttonhole knife, so that the

seam length for straight buttonholes will be as shown in the table.

*The standard hammers are 5 mm and 7 mm.

*The special lapel cutting device can be used only when the feed bracket is set to the front position.

Specifications Eyelet buttonhole Straight buttonhole

RH-9800-00 10 – 50 mm 10 – 44 mm

RH-9800-01 10 – 38 mm 10 – 32 mm

RH-981A-00 5 – 50 mm 5 – 44 mm

RH-981A-01 5 – 38 mm 5 – 32 mm

RH-9800 10/17

2002.10

Page 11

Ref. No. Part name Part code Q’ty

15 Special lapel cutting device S53906-101 1

15-1 Selector assy, hammer S53907-001 1

15-1-1 Support plate, cylinder S53908-001 1

15-1-2 Setting plate, cylinder S53909-001 1

15-1-3 Bolt, socket SM3.57x8 154965-001 2

15-1-4 Washer, plain 105161-004 2

15-1-5 Screw, pan M3x6 062300-605 2

15-1-6 Setting lever, hammer S53910-001 1

15-1-7 Bolt, socket SM3.57x8 154965-001 1

15-1-8 Partition plate, sensor S53914-001 1

15-1-9 Set screw, SM3.57-40x4.5 144458-001 1

15-1-10 Sensor, hammer home position S53915-000 1

15-1-11 Sensor, hammer position S53916-000 1

15-1-12 Sensor bracket, MS-GL8 S53917-000 2

15-1-13 Screw, pan M3x8 062300-805 2

15-1-15 Rotary cylinder assy S53918-001 1

15-1-1 Rotary cylinder plate assy S54026-001 1

15-1-15-1-1 Setting plate, sensor S53913-001 1

15-1-15-1-2 Bolt, socket M3x16 018301-636 2

15-1-15-2 Throttle tube joint S19900-000 1

15-1-16 Tube elbow, w/valve S16603-000 1

15-1-17 Air tube, 4x2.5-60 S53920-000 1

15-1-18 Air tube, 4x2.5-61 S53921-000 1

15-2 Band, PLT1M S04557-000 1

15-2- Sensor plate assy, B-hole S53923-001 1

15-2-1 Setting plate, cloth sensor S53924-001 1

15-2-2 Y-driving shaft holder S31568-000 1

15-2-3 Bolt, socket M5x16 018501-622 1

15-2-4 Bolt, socket SM4.37x8 018680-822 2

15-2-5 Washer 100645-003 2

15-2-6 Photo sensor S53925-000 1

15-2-7 Screw, pan (S/P washer) M3x8 0A4300-805 2

15-2-8 Harness, B-hole sensor S53926-000 1

15-2-9 Band, PLT1M S04557-000 1

15-3 Setting shaft, sensor S53922-001 1

15-4 Valve assy S53927-000 1

15-4-1 Valve, VZ3120-F S53928-001 1

15-4-1-1 Valve, VZ3120 S13578-000 1

15-4-1-2 Bracket S53929-000 1

15-4-2 Half union S04905-000 1

15-4-3 Elbow union, 4M5 S11426-000 2

15-5 Wood screw, round M3.5x16 032361-602 2

15-6 Valve harness S53930-000 1

15-7 Hammer plate, 7 S53911-001 1

15-8 Bolt, socket M3x5 018300-536 2

15-9 Bolt, socket M4x8 018400-832 2

15-10 Cord holder, 6N 146202-000 1

15-11 Screw, pan M4x16 062401-616 1

15-12 Washer, plain M6 025060-236 1

15-13 Band, PLT1M S04557-000 3

15-14 Half union, ;KQH04-01S S04910-000 1

15-15 Air tube, 4x2.5-62 S53939-000 1

15-16 Cover, H ;N-rotation S53937-001 1

15-17 Cord holder, 10N 552907-000 1

16 Hammer plate, 5 S53912-001 1

2002.10

RH-9800 11/17

Page 12

Option parts

Cloth guide

Part name Part code Q’ty

Cloth guide, J S37870-000 1

Movable knife cover

Ref. No. Part name Part code Q’ty

<L1, L2, L5, L6>

1 Movable knife cover, L1-2 S37698-000 1

<L3, L4, L7>

2 Movable knife cover, L3-4 S37699-000 1

For changing to –02 from –01

Replace with the parts shown in the table below.

L1: 14 - 18 mm L2: 18 - 22 mm L3: 22 - 26 mm L4: 26 - 30 mm

S38572-001 S38573-001 S38574-001 S38575-001

Exchange parts set, L1 Exchange parts set, L2 Exchange parts set, L3 Exchange parts set, L4

S38584-001

Exchange parts set, -2

L2: 28 - 32 mm L3: 32 - 36 mm L4: 36 - 40 mm

S41467-00 S41468-001 S41469-001

Exchange parts set, L5 Exchange parts set, L6 Exchange parts set, L7

S38584-001

Exchange parts set, -2

RH-9800 12/17

2002.10

Page 13

Replacement parts list for specification changes

The sewing machine can be changed to any one of L1 to L7 for –02 and –52 specifications by replacing the specified

parts with the appropriate parts given below.

-02 specifications

Plate R assemblySpecifications

Plate L assembly

S38576-301 S37702-001 (S12)L1

S38577-201 S37704-001 (S16)

S38578-301 S37704-001 (S16)L2

S38579-201 S37706-001 (S20)

S38580-301 S37706-001 (S20)L3

S38581-201 S37708-001 (S24)

S38582-301 S37708-001 (S24)L4

S38583-201 S42053-001 (S28)

S41470-101 S37197-001 (26)L5

S41471-101 S37199-001 (30)

S41472-101 S37199-001 (30)L6

S41473-101 S37201-001 (34)

S41474-101 S37201-001 (34)L7

S41475-101 S35093-001 (38)

Hammer Specification harness

S37869-100

S37871-000

S37872-100

S37873-000

S41476-000

S41477-000

S41478-000

(buttonhole length)

(14 - 18mm)

(18 - 22mm)

(22 - 26mm)

(26 - 30mm)

(28 - 32mm)

(32 - 36mm)

(36 - 40mm)

Replacement parts set

S38572-001

S38573-001

S38574-001

S38575-001

S41467-001

S41468-001

S41469-001

Note: There is 10 mm of difference in the knife cutting position between L1 – L4 and L5 – L7 specifications.

-52 specifications

Specifications

(buttonhole length)

L1

(14 - 18mm)

L2

(18 - 22mm)

L3

(22 - 26mm)

L4

(26 - 30mm)

L5

(28 - 32mm)

L6

(32 - 36mm)

L7

(36 - 40mm)

Note: There is 10 mm of difference in the knife cutting position between L1 – L4 and L5 – L7 specifications.

Plate R assembly

Plate L assembly

S38576-301 S37702-001(S12)

S38577-201

S38578-301 S37704-001(S16)

S38579-201

S38580-301 S37706-001(S20)

S38581-201

S38582-301 S37708-001(S24)

S38583-201

S41470-101 S37197-001(26)

S41471-101

S41472-101 S37199-001(30)

S41473-101

S41474-101 S37201-001(34)

S41475-101

Hammer Cloth feed plate R

S37704-001(S16)

S37706-001(S20)

S37708-001(S24)

S42053-001(S28)

S37199-001(30)

S37201-001(34)

S35093-001(38)

S43809-001

S43809-001

S42139-101

S42139-101

S43809-001

S42139-101

S42139-101

2002.10

RH-9800 13/17

Page 14

Gauge parts list

(For -00, -01, -02) Work clamp

L

R

S35455−001 S39929−001 S35197−001 S39931−001

S35454−001 S39930−001 S35198−001 S39932−001

<10 − 18 mm> <18 − 22 mm> <22 − 26 mm> <26 − 30 mm>

−00

&

−01

L

R

−02

S35453−001 S35200−101 S37679−001 S37677−101

S35452−001 S35199−101 S37680−001 S37678−101

<26 − 38 mm>

S37755−001 S37689−001 S37691−001 S37759−001

S37754−001 S37690−001 S37692−001 S37758−001

L1 <14 − 18 mm> L2 <18 − 22 mm> L3 <22 − 26 mm> L4 <26 − 30 mm>

S41848-001 S41486-101 S41488-001 S43408-001 S43410-001

S41483-001 S41485-101 S41487-001 S43409-001 S43411-001

L5 <28 − 32 mm>

L6 <32 − 36 mm> L7 <36 − 40 mm>

<38 mm> <50 mm> <50 mm>

L3W <22 − 26 mm> L4W <26 − 30 mm>

For circular stitching work clamp

R & L

−00

&

−01

S41336−001 S41337−001

D11 < − 10 mm>

D13 < − 12 mm>

<For waist belt presser>

RH-9800 14/17

2002.10

Page 15

Gauge parts list

Needle plate

L

R

−00

&

−01

S35308−101 (L) S35307−101 (SL) S37683−101 (L−50) S37681−101 (SL−50)

S35309−101 (R) S35306−101 (SR) S37684−101 (R−50) S37682−101 (SR−50)

<38 mm>

<38 mm> <50 mm> <50 mm>

L

R

−02

S37643−101 (L1L) S37645−101 (L2L) S37647−101 (L3L) S37649−101 (L4L)

S37644−101 (L1R) S37646−101 (L2R) S37648−101 (L3R) S37650−101 (L4R)

L1 <14 − 18 mm> L2 <18 − 22 mm> L3 <22 − 26 mm> L4 <26 − 30mm>

S40823-001 (L5L) S41480-001 (L6L) S41482-001 (L7L)

S40822-001 (L5R) S41479-001 (L6R) S41481-001(L7R)

L5 <28 − 32 mm>

L6 <32 − 36 mm> L7 <36 − 40 mm>

For circular stitching needle plate

L S41339-001 S41341-001

R S41338-001 S41340-000

D11 < − 10 mm>

D13 < − 12 mm>

−00

&

−01

RH-9800 15/17

2002.10

Page 16

Gauge parts list

Knife

S35439−101 S35437−101 S35480−101 S35482−101 S35408−101 (S)

<38 mm> <38 mm> <38 mm> <38 mm> <38 mm>

S35438−101 S35436−101 S35481−101 S35483−101 S35409−101 (S)

<50 mm> <50 mm> <50 mm> <50 mm> <50 mm>

For circular stitching knife

S41346-001 S41347-001 S41348-001 S41349-001

<D2> <D3> <D4> <D5>

Hammer

Size (mm) 10 12 14 16

−00

&

−01

−02

Part code

Size (mm) 18 20 22 24

Part code

Size (mm) 26 28 30 32

Part code

Size (mm) 34 36 38 50

Part code

Size (mm) S10 S12 S14 S16

Part code

Size (mm) S18 S20 S22 S24

Part code

Size (mm) S26 S28

Part code

S37211−001 S37210−001 S37209−001 S37208−001

S37194−001 S35092−001 S37195−001 S37196−001

S37197−001 S37198−001 S37199−001 S37200−001

S37201−001 S37202−001 S35093−001 S35479−001

S37701−001 S37702−001 S37703−001 S37704−001

S37705−001 S37706−001 S37707−001 S37708−001

S37709−001

For circular stitching hammer

−00 & −01

Size (mm)

Part code

φ5 (D2, D3) φ7 (D4, D5)

S41344−001 S41345−001

Harness

SpecificationL1L2L3L4

-02

Part code S37869-100 S37871-000 S37872-100 S37873-000

Specification L5 L6 L7

Part code S41476-000 S41477-000 S41478-000

S42053-001

RH-9800 16/17

2002.10

Page 17

Gauge parts list

Double chain stitch looper mechanism

Eye Looper

Use

Looper, R

Spreader, L

Spreader, R

Standard

For heavy

For single chain stitch

S35411-001

S35471-001

S49078-001

S35410-001

Throat plate

Throat plate

Use

For -00 and -01 A = 1.8 mm B = 4.6 mm

For -00 and -01 (For small hole) A = 1.8 mm B = 4.6 mm

For -02 A = 1.8 mm B = 4.6 mm

For straight bar tack A = --------- B = 4.6 mm

S47033-001

S47034-001

S37752-001

S39923-101

S35413-101

S35472-101

S49079-001

S35412-101

2002.10

RH-9800 17/17

Loading...

Loading...