Page 1

RH-981A

ELECTRONIC EYELET BUTTON HOLER

ENGLISH

Page 2

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please read the safety

instructions below and the explanations given in the instruction manual.

With industrial sewing m achines, it is norm al to carr y out work while posit ioned direct ly in front of m oving parts suc h as

the needle and thread tak e-up lever, and consequently there is a lways a danger of injury that can be caused by these

parts. Follow the instructions from training personnel and instructors regarding safe and correct operation before

operating the machine so that you will know how to use it correctly.

SAFETY INSTRUCTIONS

1.

Safety indications and their meanings

This instruction m anual and the indications and s ymbols that are used on the mac hine itself are provided in order to

ensure safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

Symbols

DANGER

CAUTION

........................................This symbol ( ) indicates something that you should be careful of. The

........................................This symbol (

........................................This symbol ( ) indicates something that you must do. The picture

(For example, the symbol at left means “you must make the ground

The instructions which follo w this term indic ate situations where f ailure to f ollow the

instructions will almost certainly result in death or severe injury .

The instructions which follo w this term indic ate situations where f ailure to f ollow the

instructions could cause injury when using the machine or physical damage to

equipment and surroundings.

picture inside the triangl e indic ates t he na ture of the caution that m ust be

taken.

(For example, the symbol at left means “beware of injury”.)

) indicates something that you must not do.

inside the circle indicates the nature of the thing that must be done.

connection”.)

i

RH-981A

Page 3

2.

p

g

g

p

p

p

g

g

p

y

p

y

g

y

p

p

g

y

g

p

g

y

y

g

p

g

g

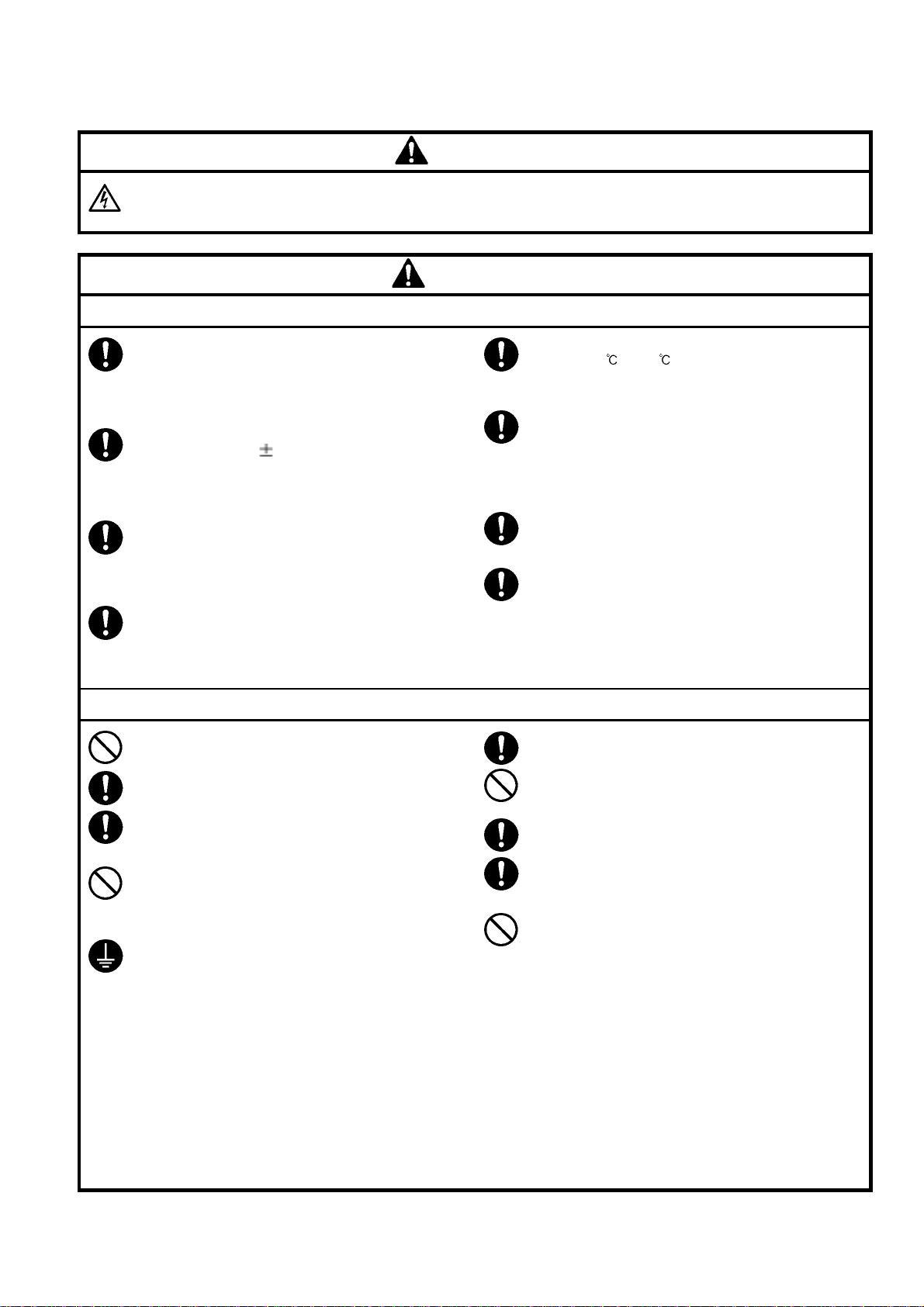

Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before o

severe injury.

ening the face plate of the control box. Touching areas where high voltages are present can result in

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is f ree

from sources of stron

high-frequency welders.

Sources of stron

problems with correct operation.

Any fluctuations in the power supply voltage

should be within

the machine.

Voltage fluctuations which are greater than this

may cause problems with correct operation.

The

ower supply capacity should be greater than

the requirements for the sewing machine’s

electrical consumption.

Insufficient

problems with correct operation.

The

reater than the requirements for the sewin

machine's total air consumption.

Insufficient

cause problems with correct operation.

ower supply capacity may cause

neumatic delivery capability should be

neumatic delivery capability ma

electrical noise such as

electrical noise may cause

10% of the rated voltage for

Installation

Machine installation s hould only be carried out b

a qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be d one.

The sewin

The installation should be carried out by two or

more people.

Do not connect the

complete, otherwise the machine m ay operate if

the start swit ch is pressed by mistake, which could

result in injury.

Be sure to connect the

connection is not secure, you run a high risk of

receiving a serious electric shock, and problem s

with correct operation may also occur.

machine weighs more than 87 kg.

ower cord until installation is

round. If the ground

The ambient temperature should be within the

range of 5 to 35 during use.

eratures which are lower or higher than this

Tem

may cause problems with correct operation.

The relative humidit

45% to 85% durin

should occur in any devices.

Excessively dry or humid environm ents and dew

formation ma

operation.

Avoid exposure to direct sunlight during use.

osure to direct sunlight may cause problems

Ex

with correct operation.

In the event of an electrical storm, turn off the

ower and disconnect the power cord from the

wall outlet.

Li

htning may cause problems with correct

operation.

All cords should be secured at least 25 mm awa

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too

firml

with staples, otherwise there is the danger

that fire or electric shocks could occur.

Install the belt covers to the machine head and

motor.

If usin

casters should be secured in such a way so that

they cannot move.

Be sure to wear

when handlin

that they do not get into your eyes or onto your

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the

under any circumstances, as they can cause

vomiting and diarrhoea.

Keep the oil out of the reach of children.

a work table which has casters, the

should be within the range of

use, and no dew formation

cause problems with correct

rotective goggles and gloves

the lubricating oil and grease, so

rease

RH-981A

ii

Page 4

CAUTION

g

y

p

y

y op

p

g

y

y

g

y

y

y

p

y

p

p

p

g

y

y

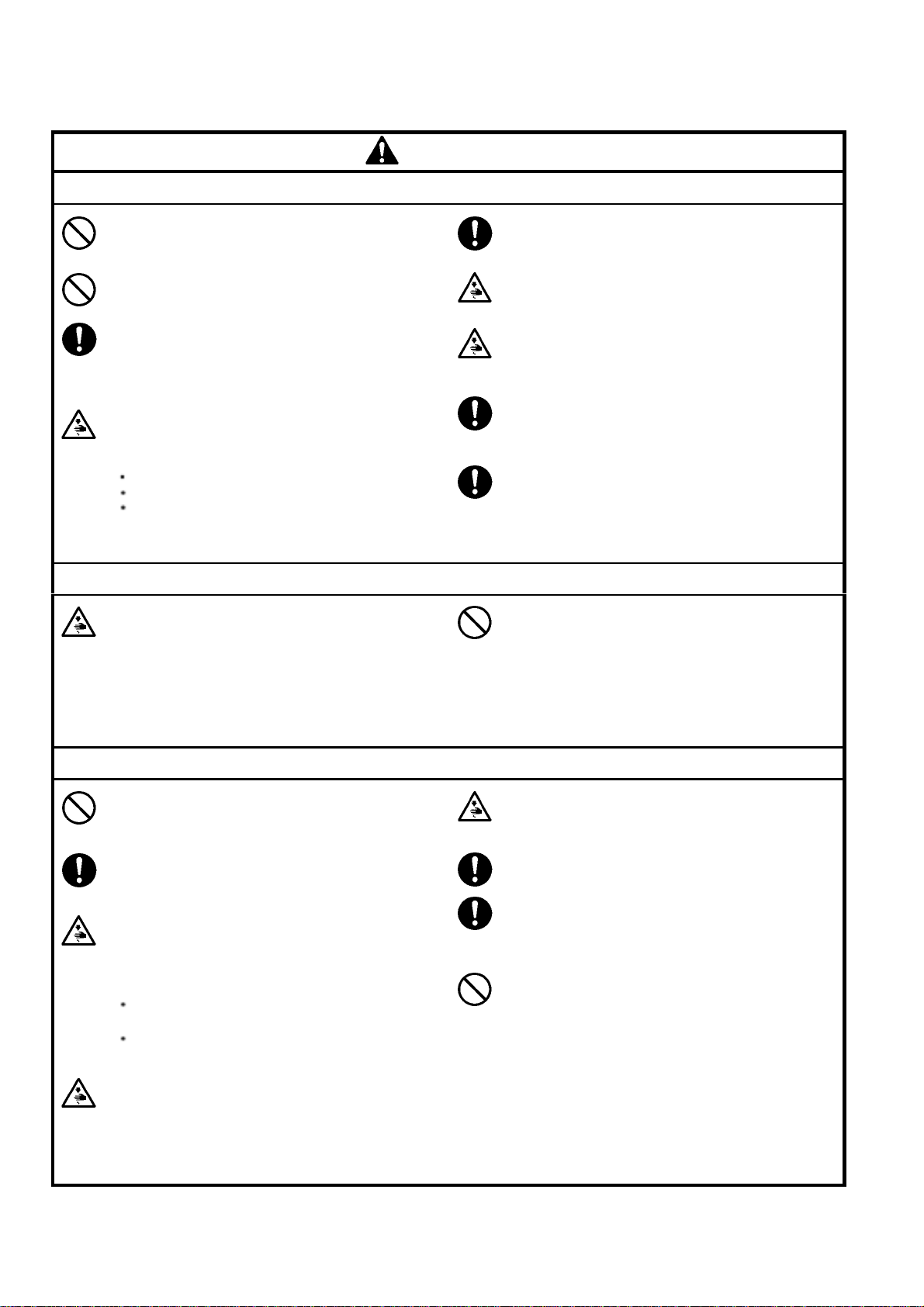

Sewing

This sewing machine should only be used by

operators who have received the necessary

training in safe use beforehand.

The sewin

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the d anger that if

a needle breaks,

enter your eyes and injury may result.

Turn off the power switch at the foll owing times,

otherwise the machine ma

switch is

injury.

When threading the needle

When replacing the needle

When not using the machine and when leavin

the machine unattended

machine should not be us ed for an

arts of the broken needle ma

erate if the start

ressed by mistake, which could result in

Cleaning

Turn off the power switch before carrying out

cleaning, otherwise the machine may operate if

the start swit ch is

result in injury.

ressed by mistake, which could

If using a work table which has casters, the

casters should be secured in such a wa

they cannot move.

Attach all safet

machine. If the machine is used without these

devices attached, injury may result.

Do not touch an

objects against the machine while se wing, as this

result in personal injury or damage to the

ma

machine.

If an error occurs in machine o

noises or smells ar e not ice d, im medi atel

ower switch. Then contact your nearest Brother

dealer or a qualified technician.

If the machine develo

nearest Brother dealer or a qualified technician.

Be sure to wear protective goggles and gloves

when handlin

that the

skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease

under an

vomiting and diarrhoea.

Keep the oil out of the reach of children.

do not get into your eyes or onto your

devices before using the sewin

of the moving parts or press an

eration, or if abno rmal

s a problem, contact your

the lubricating oil and grease, so

circumstances, as they can cause

so that

turn off the

Maintenance and inspection

Maintenance and inspection of the sewing

machine should only be carried out b y a qualified

technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspecti on of the

electrical system.

Turn off the power switch and disconnect the

power cord from the wall outlet at the following

times, otherwise the m achine may operate if the

start switch is pressed by mistake, which could

result in injury.

When carrying out inspection, adj ustment and

maintenance

When replacing consum able par ts such as the

loopers and knife

Disconnect the air hoses from the air supply and

wait for the needle on the pres sure gauge to dr op

to “0” before carrying out inspection, adjustment

and repair of any parts which use the pneumatic

equipment.

If the power switch and air need to be left on when

carrying out some adjustment, be extremely

careful to observe all safety precautions.

Use only the proper replacement parts as

specified by Brother.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly

before using the machine.

Any problems in machine operation which result

from unauthorized modifications to the machine

will not be covered by the warranty.

iii

RH-981A

Page 5

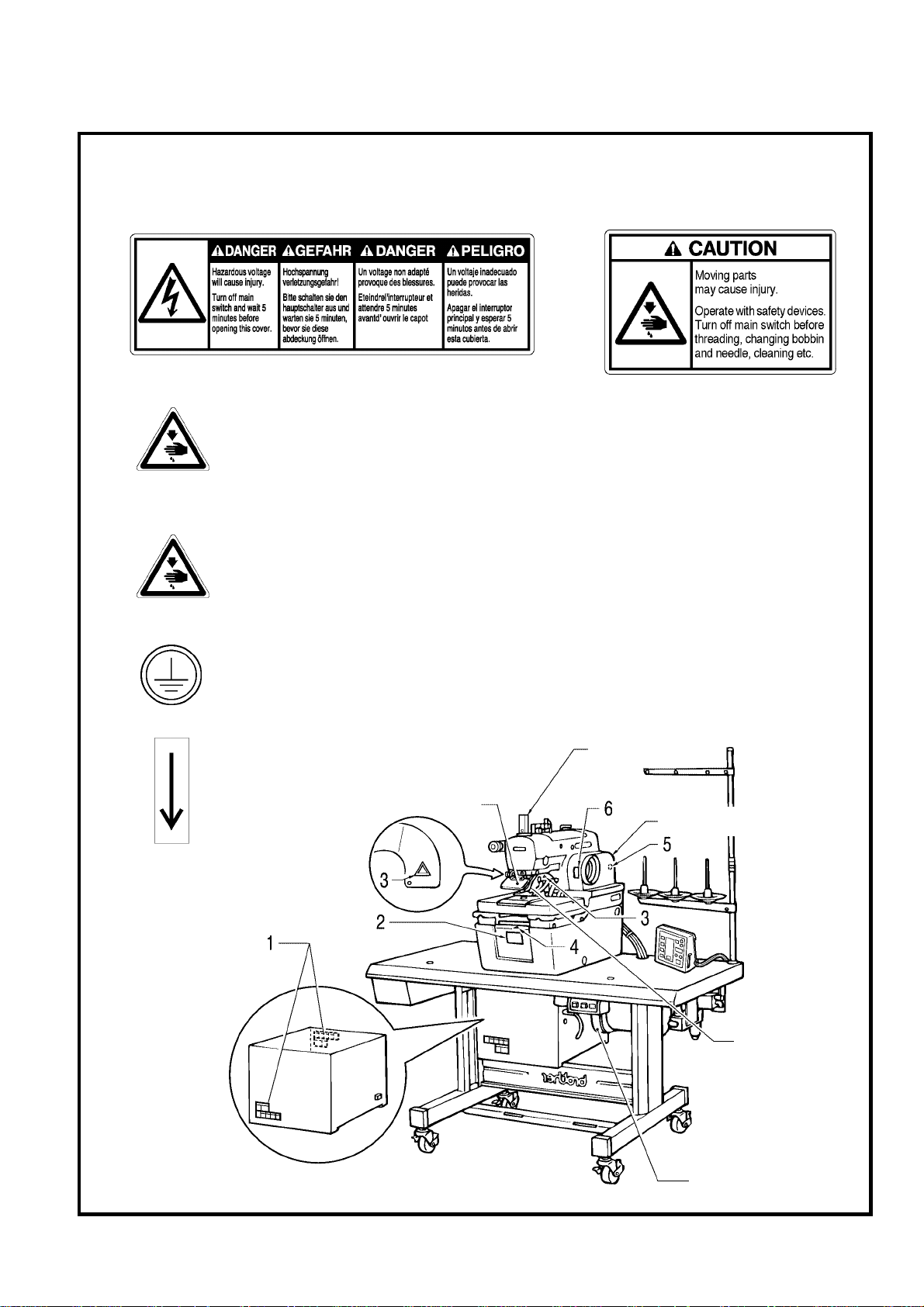

3. W a rnin g lab e ls

5

f

The following warning labels appear on the sewing machine.

Please follow the in str uc tions on the labe ls at a ll t imes when using the machine. If the labels hav e bee n removed

or are difficult to read, please contact your nearest Brother dealer.

1

3

4

Do not touch the knif e or press any objects

against the machine while sewing, as this

may result in personal injury or damage to

the machine.

Be careful not to clamp your fingers when

closing the front cover.

Be sure to connect the ground. If the ground connection is not secure, you run a high risk o

receiving a serious electric shock, and problems with correct operation may also occur .

2

Safety devi ces

Eye guard

Finger guard

Needle bar guard

Belt cover, etc.

3122Q

6

Direction of operation

Eye guard

Needle bar guard

Belt cover

(Rear)

Finger guard

Belt cover

RH-981A

iv

Page 6

CONTENTS

1. NAMES OF EACH P A RT

2. SPECIFICATIONS

2-1. Specifications ...................................................... 2

2-2. Sewing shape ..................................................... 3

2-3. Optional parts ...................................................... 3

2-4. PD-9810, Programmer ....................................... 3

2-5. Replacement parts list for

specification changes ......................................... 4

3. INST ALLATION

3-1. Table processing diagram ................................ 5

3-2. Installing the motor ............................................ 6

3-3. Installing the motor pulley ................................. 7

3-4. Installing the control box ................................... 7

3-5. Installing the machine head .............................. 8

3-6. Installing the oil container ............................... 10

3-7. Installing the operation panel .......................... 10

3-8. Tightening the V-belt ....................................... 11

3-9. Installing the spool stand ................................ 12

3-10.Installing the hand switch ................................ 12

3-11.Installing the air unit and the valve unit .......... 12

3-12.Connecting the wiring...................................... 13

3-12-1. Connections inside the control box......... 14

3-12-2. Connecting the motor cables................... 15

3-12-3. Connecting the air tubes.......................... 15

3-12-4. Securing the cables.................................. 16

3-13.Connecting the air tubes ..................................17

3-13-1. Adjusting the air pressure........................ 17

3-14.Connecting the power cord ............................. 18

3-15.Installing the programmer

(sold separately)............................................... 19

3-16.Installing the foot switch (option)..................... 19

3-17.Installing the indexer (option) .......................... 20

3-17-1. Installing the indexer main unit................ 20

3-17-2. Installing the upper thread presser ......... 21

3-17-3. Replacing the plate presser and

presser plate ............................................ 21

3-17-4. Installing the valve unit ................................ 21

3-17-5. Connecting the connectors.......................... 22

3-17-6. Connecting the air tubes ............................. 23

3-17-7. Securing the air tubes and cables............... 23

3-17-8. Installing the hand switch............................. 24

4. LUBRICATION

4-1. Adding oil ......................................................... 25

4-2. Lubrication ....................................................... 25

.............................................. 2

.................................................... 5

...................................................... 25

................................ 1

5. CORRECT USE

5-1. Data initialization............................................... 27

5-2. Changing the lower thread and

gimp trimming .................................................. 27

5-3. Installing the needle ......................................... 28

5-4. Threading the upper thread ............................. 28

5-5. Threading the lower thread.............................. 29

5-6. Threading the gimp ......................................... 30

5-7. Setting the material .......................................... 31

5-8. Setting the installation position

for cloth feed plate (L) (-52 specifications)...... 33

5-9. Replacing the PROMs ..................................... 34

6. OPERATION

6-1. Name and function of

each operation panel item................................ 35

6-2. Starting up......................................................... 36

6-3. Program setting method .................................. 37

6-3-1. Parameter table ( Taper bar )..................... 37

6-3-2. Parameter table ( Straight bar tacking )......40

6-4. Cy cle program.................................................. 43

6-5. Production counter ........................................... 44

6-6. Using the program memos.............................. 44

7. SEWING

7-1. Automatic sewing............................................. 45

7-2. Using the EMERGENCY STOP switch ......... 46

7-3. Adjusting the thread tension ............................ 47

7-4. Needle and knife position................................. 48

7-5. Setting the feed bracket to

7-6. Switching between single-pedal

7-7. Using test feed mode....................................... 50

7-8. Using manual mode......................................... 51

7-9. Changing the mode during an operation ........ 52

7-10.Moving the cloth feed bar

8.

CLEANING AND MAINTENANCE

8-1. Cleaning ........................................................... 53

8-2. Draining the oil ................................................. 54

8-3. Checking the air filter........................................ 54

................................................................ 45

the front position............................................... 49

and dual-pedal operation ................................. 49

(-52 specifications) ........................................... 52

9. STANDARD ADJUSTMENTS

9-1. Adjusting the height of the

spreader and looper......................................... 55

9-2. Adjusting the needle and looper timing........... 56

9-3. Adjusting the loop stroke.................................. 57

9-4. Adjusting the height of the needle bar............. 58

................................................. 27

......................................................... 35

............

....................... 55

53

RH-981A

Page 7

9-5. Adjusting the clearance between the

looper and needle ............................................ 58

9-6. Adjusting the needle guard.............................. 59

9-7.

Adjusting the spreader mounting positions

9-8. Adjusting the spreader timing.......................... 60

9-9. Adjusting the needle racking width

(stitch width)...................................................... 60

9-10.Changing the knife cutting length

(Replacing the hammer).................................. 61

9-11.Adjusting the contact between the knife

and the hammer .............................................. 62

9-12.Replacing the knife .......................................... 63

9-13.

Adjusting the cutting pressure ........................ 63

Adjusting the position of the work

9-14.

clamp plate ........................................................64

9-15.

Adjusting the cloth opening amount ............... 65

Adjusting the trimming

9-16.

of the upper thread .......................................... 66

9-17.Adjusting the trimming

of the lower thread and gimp .......................... 66

9-18.Adjusting the gimp length after trimming

(-02, -52 specifications) ................................... 67

9-19.Lower thread presser

(-02

specifications) .................................... 67

, -52

........ 59

9-20.Auxiliary clamp arm

(-02, -52 specifications).................................... 68

9-21.Adjusting the cloth feeding speed

(-52 specifications) ........................................... 68

9-22.Adjusting the cloth feed bar home position

(-5 2 s pe ci fi cat io ns )............................................. 69

9-23.Adjusting the indexer hole spacing

(-52 specifications) ........................................... 70

9-24.Adjusting the position of limit switch L

(-52 specifications) .......................................... 71

9-25.Adjusting the position of limit switch R

(-52 specifications) .......................................... 71

10. CHANGING FUNCTIONS USING

THE MEMORY SWITCHES

10-1.Memory switch table ........................................ 73

........................ 72

11. CHA NGING FUNCTIONS USING

THE DIP SWITCHES

11-1. Panel DIP switches....................................... 74

11-2. Circuit board DIP switches............................ 75

.................................... 74

12. LIST OF ERROR CODES

13. TROUBLESHOOTING

................................... 80

............................ 77

RH-981A

Page 8

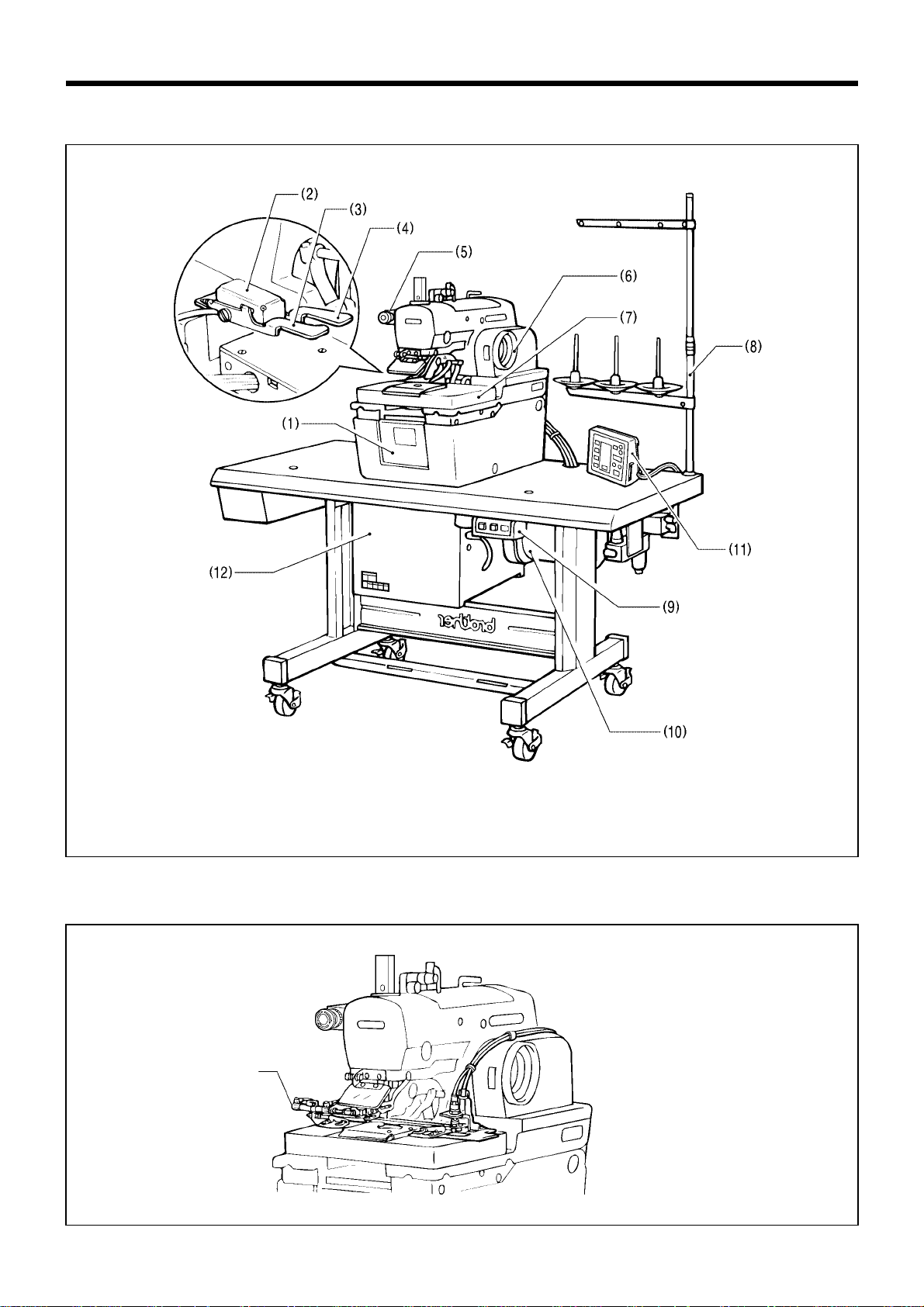

1. NAMES OF EACH PART

1. NAMES OF EACH PART

3123Q

(1) Front cover (2) Hand switch (3) Cloth presser switch (4) Start switch

(5) EMERGENCY STOP switch (6) Upper shaft pulley (7) Feed bracket (8) Spool stand

(9) Power switch (10) Motor (11) Operation panel (12) Control box

Fly indexer (-52 specifications)

Fly indexer

2380Q

1

RH-981A

Page 9

2. SPECIFICATIONS

2-1. Specifications

2. SPECIFICATIONS

Upper thread trimmer

-00 -- -

-01 --

-02 - -

-52 -

* -02 and -52 specifications are further divided into L1 - L7

specifications in accordance with the stitch lengt h. Please be sur e

to specify the stitch length when ordering.

Specification RH-981A-00 RH-981A-01 RH-981A-02, RH-981A-52

Application Men’s clothes and ladies’ clothes Jeans and work clothes

Sewing speed 1,000 - 2,200rpm (100-rpm steps)

Stitch length 5 - 50 mm 5 - 38 mm

Stitch pitch 0.5 - 2.0 mm

Stitch width 1.5 - 3.2 mm

Tacking length 0 - 20 mm

Work clamp height 12 mm 16 mm

Starting method Dual switch (cloth presser switch and start switch) or single switch

Feed method

Needle DO X 558 Nm 80 - Nm 120 (Schmetz 558)

Safety equipment

Motor Inverter-type induction motor

Air pressure

Air consumption 43.2 l/ min. (8 cycles/min.)

Noise level 85dB at max. speed of 2,200r pm, measured according to ISO 10821

Dimensions 1,200 mm (W) X 590 mm(D) X 1,120 mm (H)

Work table legs T-shape height-adjustable type

Power supply

Weight 163.5 kg

Built-in emergency stop function and automatic stopping device which stops the machine

Intermittent feed by three pulse motors (X, Y, θ)

when the safety circuit is activated

Main regulator: 0.5MPa

Knife pressure regulator: 0.3MPa

Single-phase 220 V

3-phase 220 V, 380 V, 400 V

Maximum electric power consumption: 1kvA

Lower thread trimmer

Long type Short type

L1 14 - 18 mm L5 28 - 32 mm

L2 18 - 22 mm L6 32 - 36 mm

L3 22 - 26 mm L7 36 - 40 mm

L4 26 - 30 mm

Fly indexer specifications (-52 specifications)

Standard Large size

Max. hole spacing

Max. overall feed amount

No. of holes 3 - 4*

Horizontal sewing margin 9 - 21 mm (9 - 11 mm*2)

Vertical sewing margin 30 - 40 mm

*1 The cloth feed bar F assembly (sold separately) can be

processed and used so that 1 to 9 buttonholes can be sewn.

50.8 mm

(2 inch)

152.4 mm

(2 inch X 3)

1

57.15 mm

(2 1/4 inch)

285.75 mm

(2 1/4 inch X 5)

3 - 6*

1

Hole spacing

No. of holes

Overall feed amount

Vertical sewing

margin

Fly indexer

Horizontal

sewing

margin

0792Q

*2 L5 - L7 specifications

RH-981A

2

Page 10

2. SPECIFICATIONS

Q

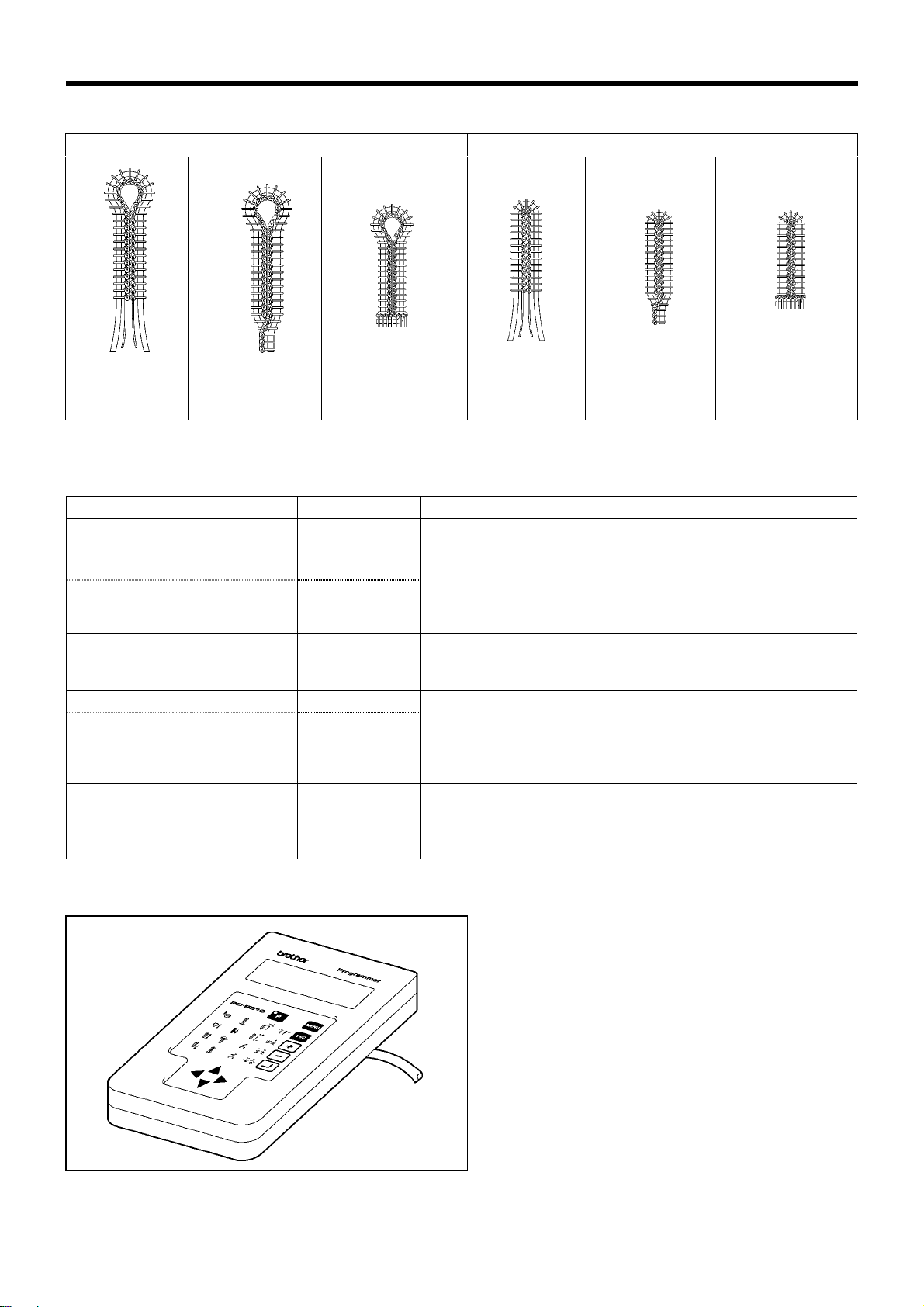

2-2. Sewing shape

Eyelet buttonhole Straight buttonhole

Without bar

tacking

With taper With straight bar

tacking (*)

* The DIP switch settings must be changed. (Refer to page 74.)

2-3. Optional parts

Parts name Parts code

Two-pedal foot switch S42838-101

Waist belt presser

Cloth presser (L3W) set

Cloth presser (L4W) set

Upper thread nipper

S43701-001

S43704-001

S43406-301

Fly indexer

Fly indexer assembly for L1, L2

and L5 specification s

Fly indexer assembly for L3, L4,

L6 and L7 specification s

Special lapel cutting dev i ce

S44279-101

S44281-101

S53906-201

This allows the work clamp to raised and lowered and the

sewing machine to be started by pedal operation.

When sewing eyelet buttonholes into wa ist belts with which

have differences in thickness, this presser provides secure

clamping for the differ ent thickness. It prevents an y slippage

of the material during sewing.

This device prevents the thread from pulling out at the sewing

start, thus contributing to a m ore accurate and higher-qual ity

seam finish.

This is an indexer which is specially for use when sewing flys.

It allows from one to nine buttonholes to be set, and

automatically feeds the mater ial. Using this de vic e makes the

sewing of buttonholes for flys much quicker.

Eyelet buttonhole and straight buttonhole can be sewn

automatically without replacing hammer and knife. It is

effective for men’s jacket cycle sewing (eyelet buttonholeflower hole).

Without bar

tacking

With taper With straight bar

tacking (*)

2-4. PD-9810, Programmer

3

You can use the icon keys to retrieve p arameter s at a

single touch, and to displa y them as ic ons on the LED

screen so that the settings can be changed easil y. It

allows you to easily transfer data between different

sewing machines.

2381

RH-981A

Page 11

2. SPECIFICATIONS

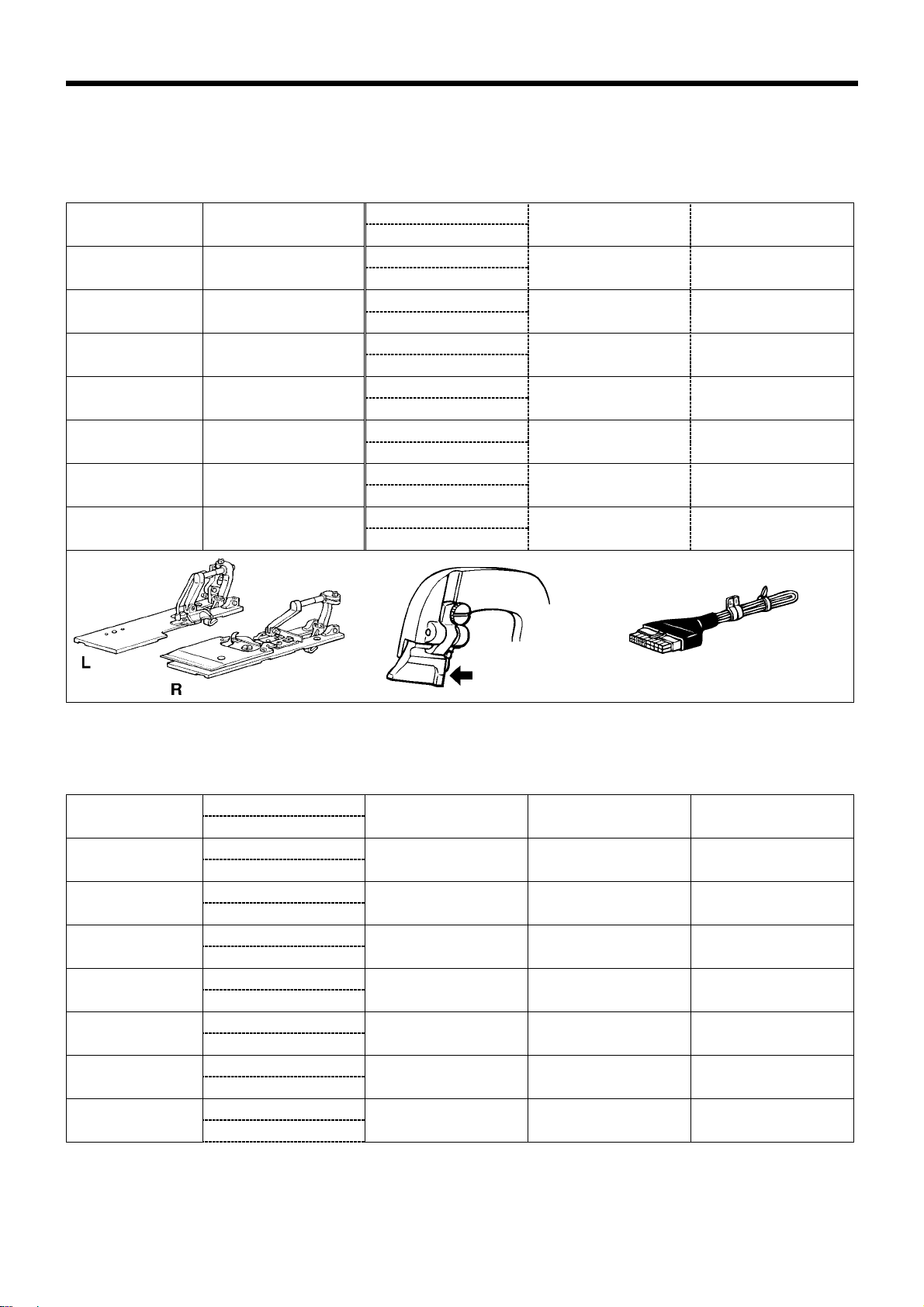

2-5. Replacement parts list for specification changes

The sewing machine can be cha nged to an y one of L1 - L7 f or - 02 and -52 specif icatio ns by rep lacing the s pecif ied

parts with the appropriate parts given below.

-02 specifications

(buttonhole length)

(14 - 18 mm)

(18 - 22 mm)

(22 - 26 mm)

(26 - 30 mm)

(28 - 32 mm)

(32 - 36 mm)

(36 - 40 mm)

Replacement parts set

S44238-001

S44239-001

S44240-001

S44271-001

S44272-001

S44273-001

S44274-001

Plate R assemblySpecifications

Plate L assembly

S38576-301 S37702-001 (S12)L1

S38577-201 S37704-001 (S16)

S38578-301 S37704-001 (S16)L2

S38579-201 S37706-001 (S20)

S38580-301 S37706-001 (S20)L3

S38581-201 S37708-001 (S24)

S38582-301 S37708-001 (S24)L4

S38583-201 S42053-001 (S28)

S41470-101 S37197-001 (26)L5

S41471-101 S37199-001 (30)

S41472-101 S37199-001 (30)L6

S41473-101 S37201-001 (34)

S41474-101 S37201-001 (34)L7

S41475-101 S35093-001 (38)

Hammer Specification harnes s

S43337-000

S43338-000

S43339-000

S43340-000

S43341-000

S43342-000

S43343-000

0797Q

0799Q

Note: There is 10 mm of difference in the knife cutting position between L1 - L4 and L5 - L7 specifications. (Refer to

page 63.)

-52 specifications

Plate R assemblySpecifications

(buttonhole length)

Plate L assembly

S38576-301 S37702-001 (S12)L1

(14 - 18 mm)

S38577-201 S37704-001 (S16)

S38578-301 S37704-001 (S16)L2

(18 - 22 mm)

S38579-201 S37706-001 (S20)

S38580-301 S37706-001 (S20)L3

(22 - 26 mm)

S38581-201 S37708-001 (S24)

S38582-301 S37708-001 (S24)L4

(26 - 30 mm)

S38583-201 S42053-001 (S28)

S41470-101 S37197-001 (26)L5

(28 - 32 mm)

S41471-101 S37199-001 (30)

S41472-101 S37199-001 (30)L6

(32 - 36 mm)

L7

(36 - 40 mm)

S41473-101 S37201-001 (34)

S41474-101 S37201-001 (34)

S41475-101 S35093-001 (38)

Note: There is 10 mm of differenc e in the knif e cutting pos ition betwe en L1 - L4 and L5 - L7 spec ific ations. (R efer

to page 63.)

Hammer Specification harness Cloth feed plate R

S43360-000 S43809-001

S43361-000 S43809-001

S43362-000 S42139-101

S43363-000 S42139-101

S43364-000 S43809-001

S43365-000 S42139-101

S43366-000 S42139-101

RH-981A

4

Page 12

3. INSTALLATION

3. INSTALLATION

CAUTION

Machine installation should only be carried o ut

by a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may need to

be done.

The sewing machine weighs mor e than 87 kg.

The installation should b e carried out by two or

more people.

Do not connect the power cord until installat ion

is complete, otherwise the machine may

operate if the start switch is pressed by mistake,

which could result in injury.

All cords should be secured at least 25 mm

away from any moving parts.

Furthermore, do not excessivel y bend the cor ds

or secure them too firmly staples, otherwise

there is the danger that fire or electric shocks

could occur.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

Install the belt covers to the machine head and

motor.

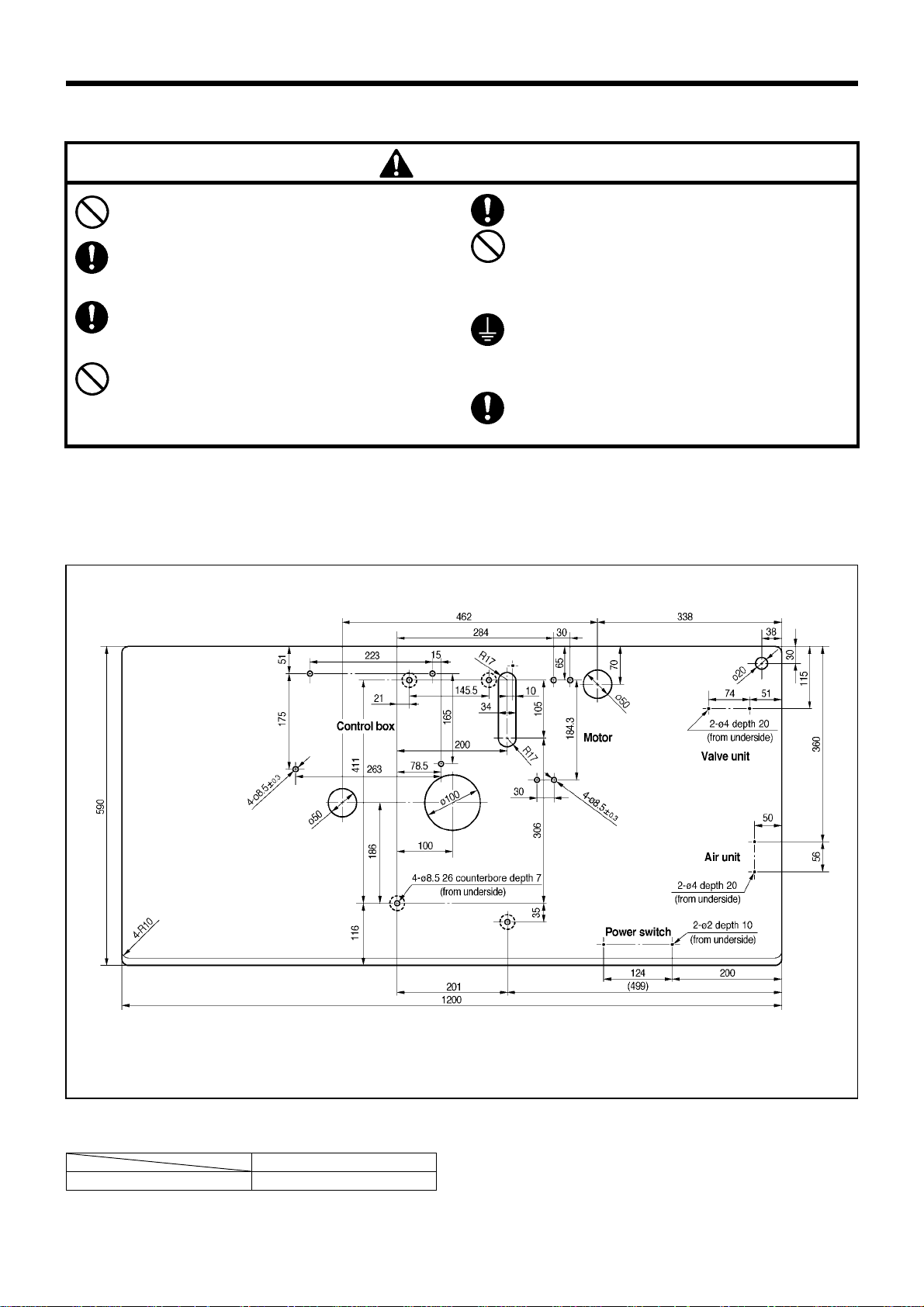

3-1. Table processing diagram

The top of the table should be 50 mm in thickness and should be strong enough to hold the weight and withstand the

vibration of the sewing machine. Drill holes in the table as shown in the diagram below.

* There is the special table indicated below.

Model code

Table/legs assembly 127-981-04902

5

0800Q

RH-981A

Page 13

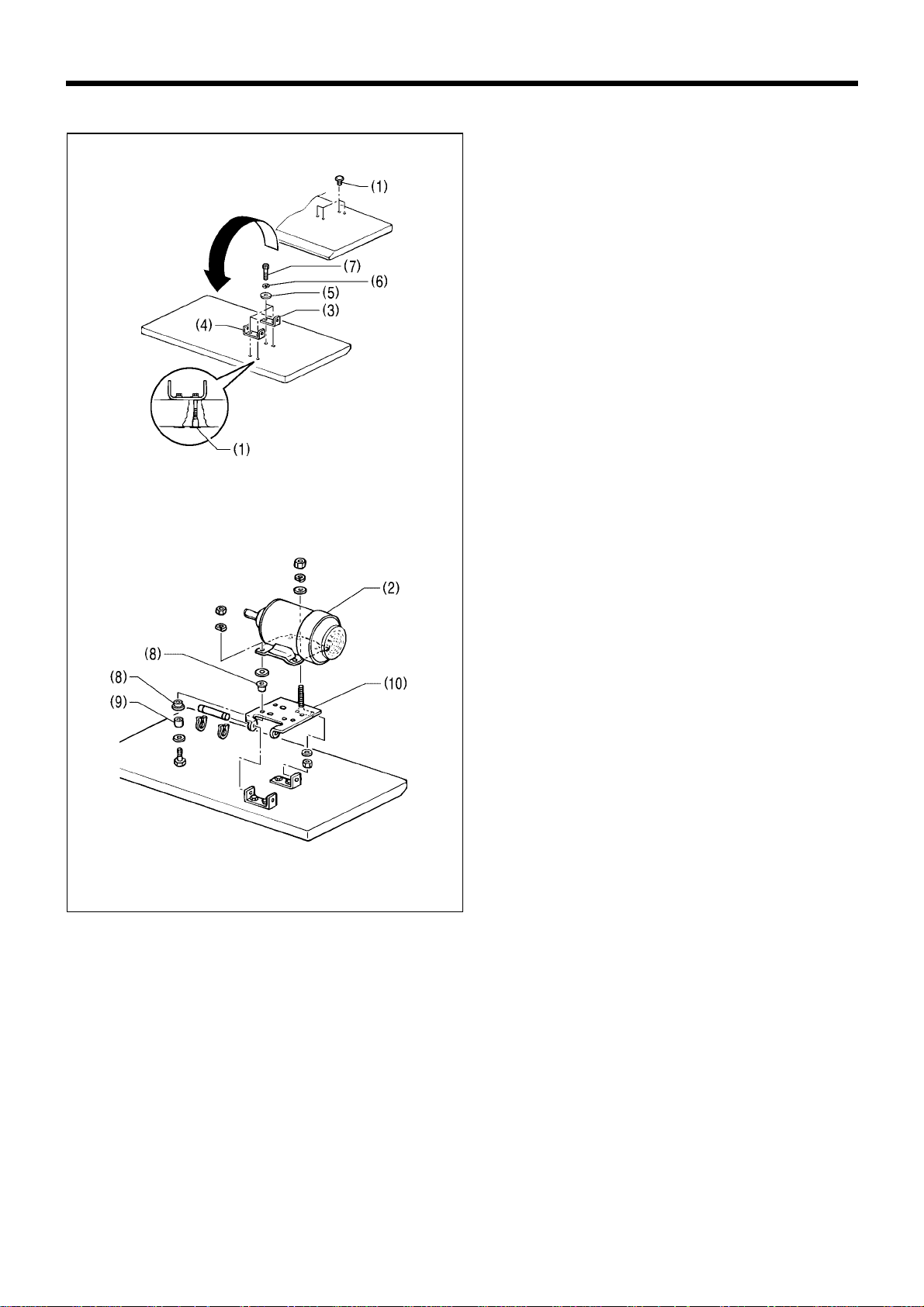

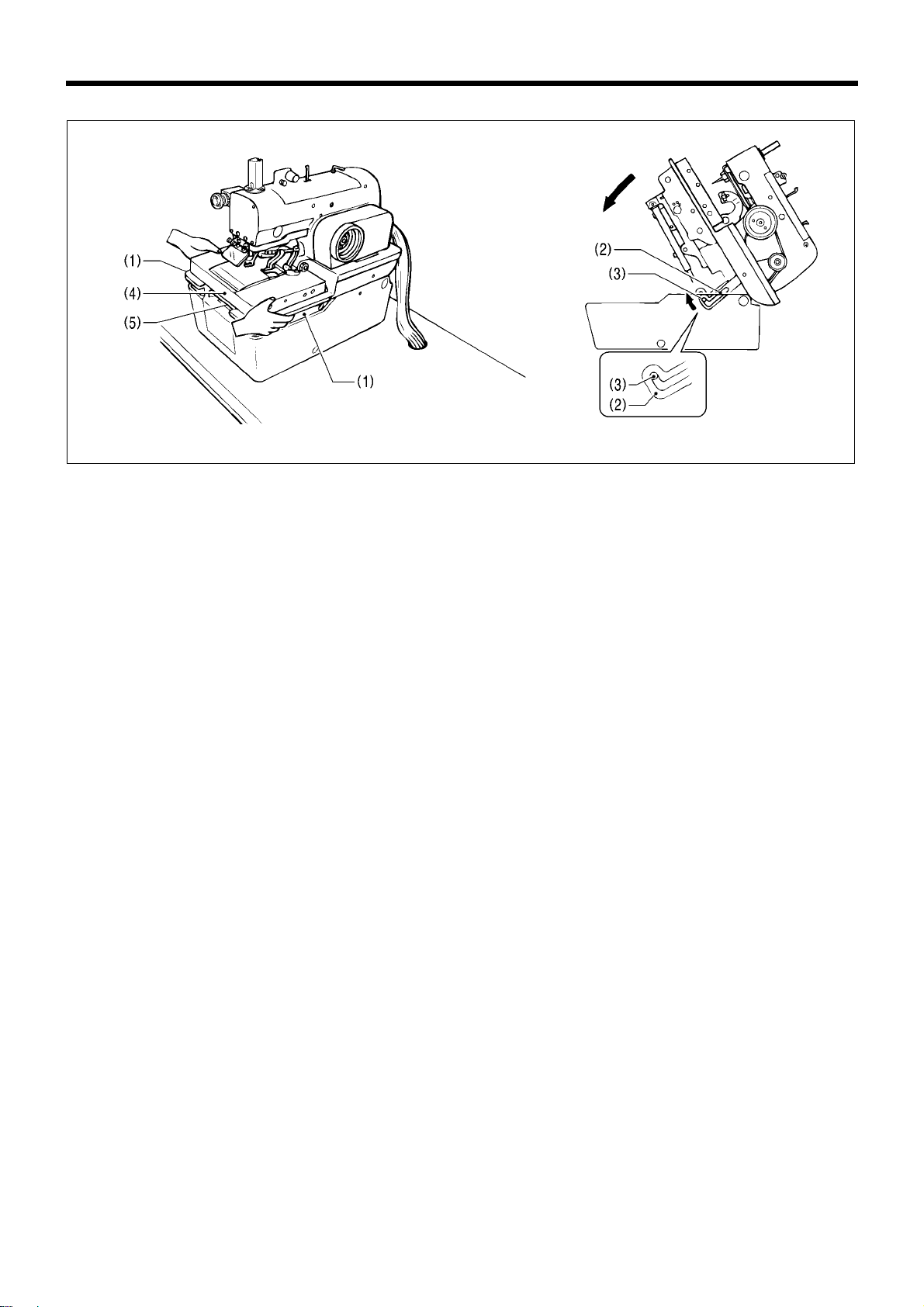

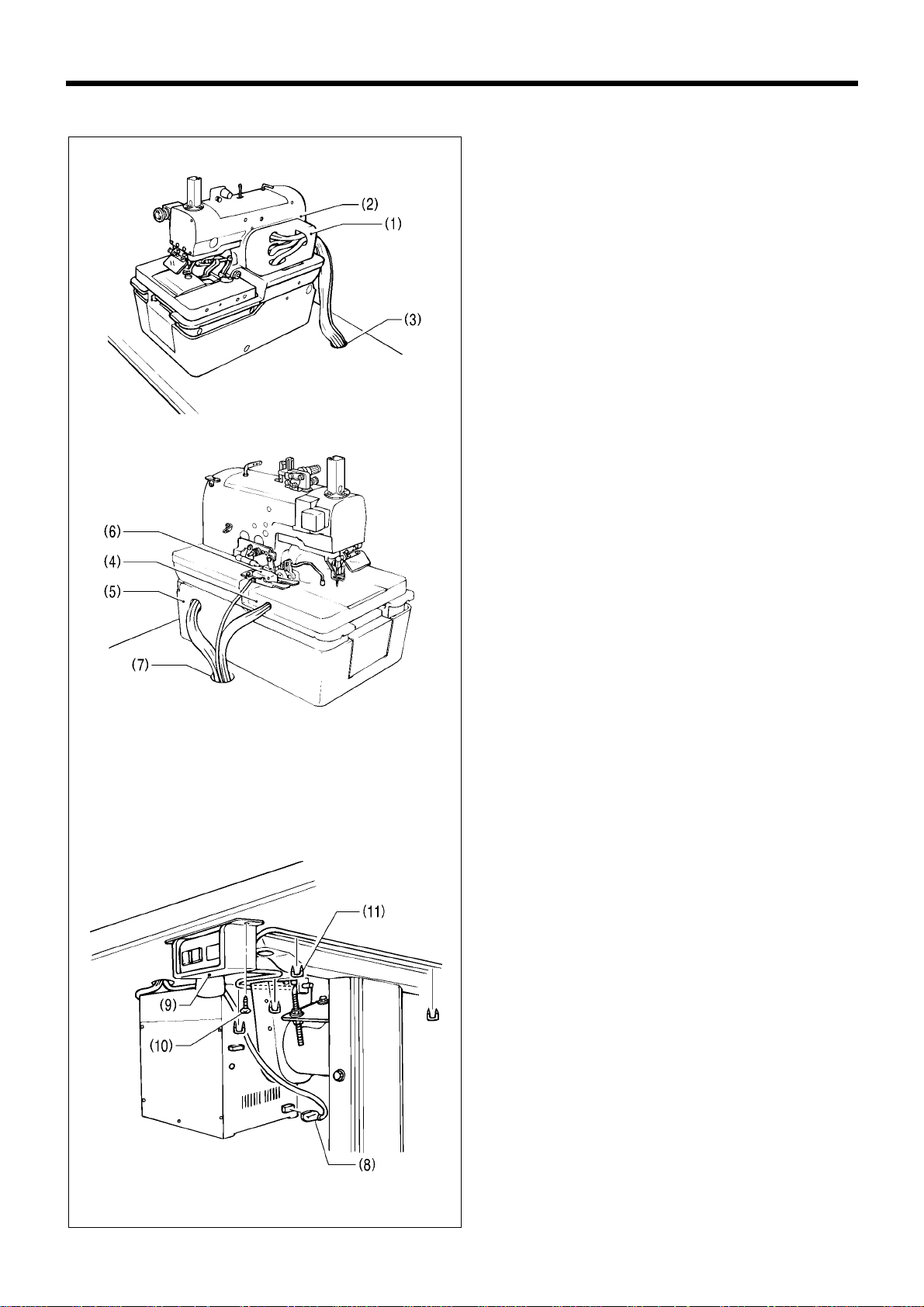

3-2. Installing the motor

3. INSTALLATION

3124Q

1. Insert the four nuts (1) into the work table.

2. Turn the work table upside down to make it easier to

install the motor (2).

3. Align the holder plate (3) and the motor plate (4)

with the nuts (1), and t hen install them with the four

washers (5), the four spring washers (6) and the

four bolts (7).

4. Place the eight accessory cushions (7) and the four

accessory cushion collars (8) onto the motor base

plate (9), and then install the motor as shown in the

illustration.

3125Q

Note: The vibration of the motor may cause the bolts

to come loose. Make sure that the bolts are

securely tightened.

RH-981A

6

Page 14

3. INSTALLATION

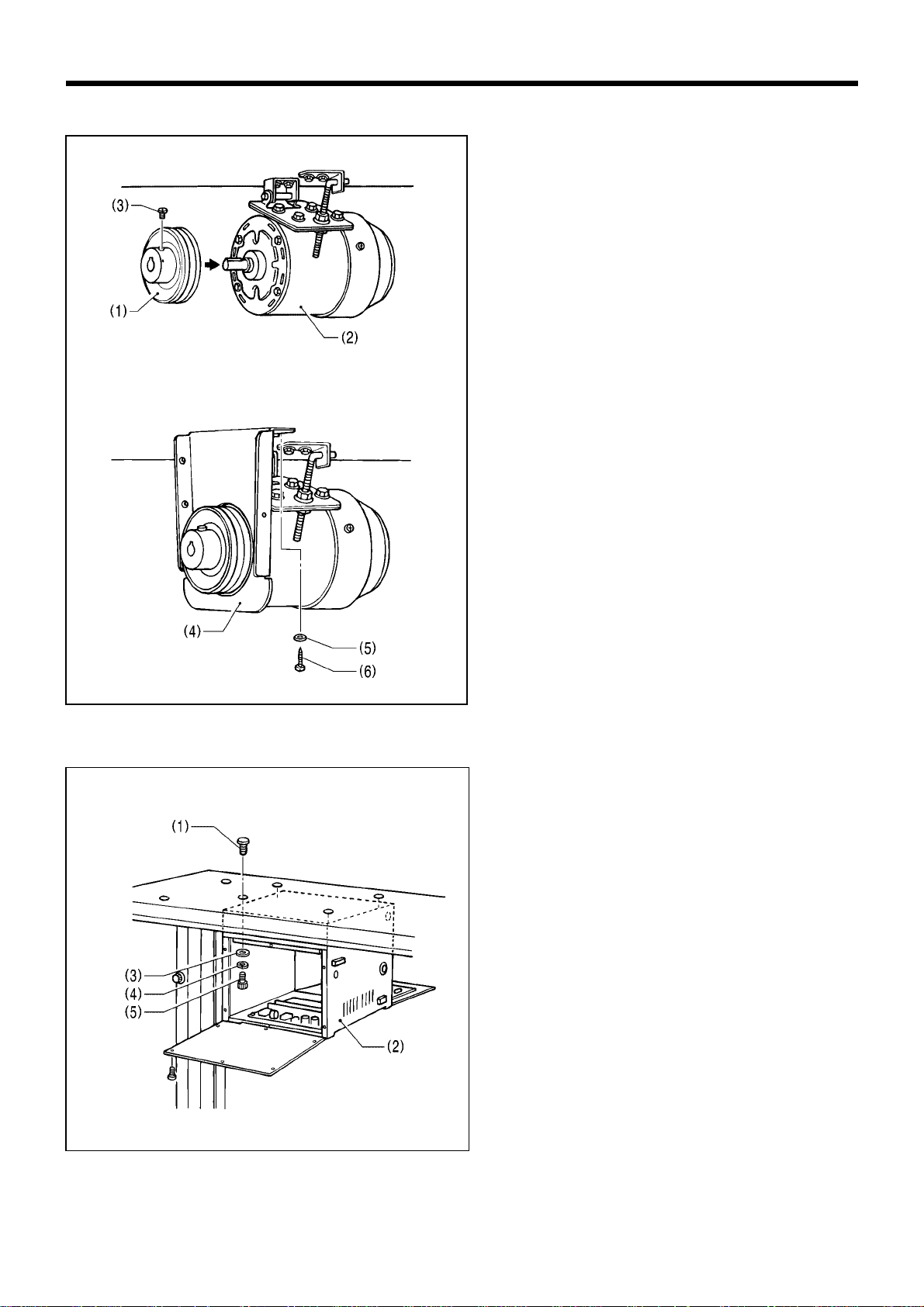

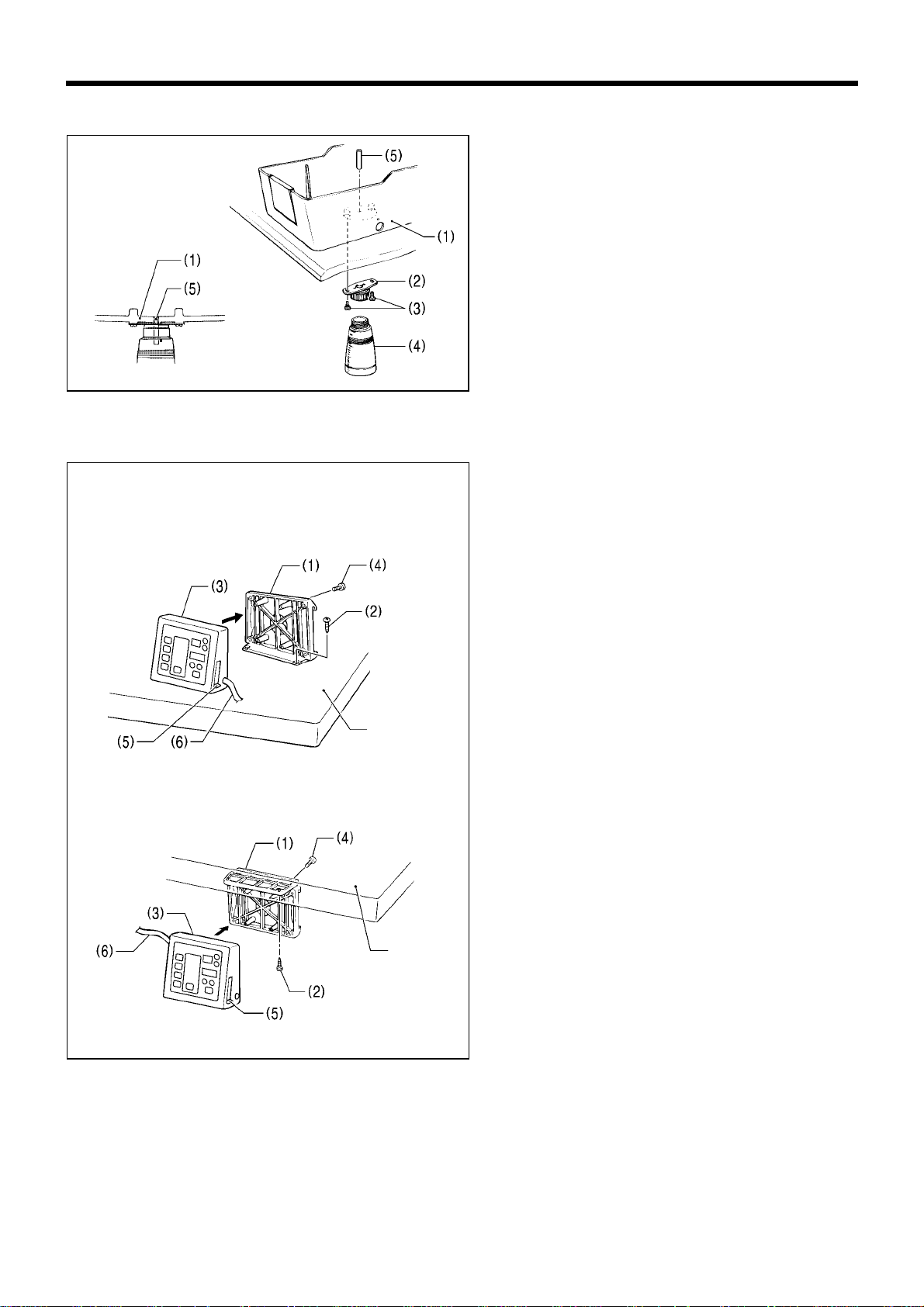

3-3. Installing the motor pulley

3126Q

1. Place the motor pulley (1) onto the shaft of the

motor (2) so that the key grooves are alig ned, and

then tighten the set screws (3) so that the center of

the V groove in the motor pulley (1) is aligned as

closely as possible with the center of the belt hole in

the power table.

2. Install the m otor rear cover support (4) with the two

flat washers (5) and the two screws (6).

Note: Check that the motor rear cover support (4)

does not touch the motor pulley (1) or the

edge of the motor.

3-4. Installing the control box

3127Q

1. Insert the four nuts (1) into the work table.

2. Open the front and rear covers of the control box

(2).

3. Align the control box (2) with the nuts (1), and then

install it with the four flat washers (3), spring

washers (4) and bolts (5).

Note: Be careful not to drop any small parts such

as washers onto the circuit board when

installing the bolts.

3128Q

7

RH-981A

Page 15

3-5. Installing the machine head

3. INSTALLATION

2980Q

2981Q

1. Insert the accessory bed base cushions A (1) into the bed base, and then plac e the machine head on top of the

work table.

Note: When placing the machine head on top of the work table, have two or more people there to hold the

handles and rear of the head as indicated in the illustration.

2. Open the front cover (2), and then use the bolt (3), washer (4), rubber s heet (5), bed stand cushion A (1) , large

washer (6) and nut (7) to attach the front right corner of the bed base to the work table.

3. Attach the bed base to the work table in two places inside the base in the same way as in step 2. above.

4. Remove the bolt (8) and the washer.

Note: The bolt (8) and washer should be kept, as they will be needed again if the machine head is moved.

5. Raise the machine head, and then attach the front left corner of the bed base to the work table in the same way as

in the steps above.

Note: Make sure that steps 2. to 4. above have been completed before raising the machine head.

6. Install the bed base cover (9) to the rear of the bed (10) with the four screws (11).

Note: Be careful not to injure yourself on the spring hinge.

RH-981A

2982Q

8

Page 16

3. INSTALLATION

Raising the machine head

When machine

head is lowered

2983Q

2984Q

1. While holding the handles of the machine head (1) with both hands, gently raise the machine head.

Note: Be sure to turn the power supply off before raising the machine head.

2. If you wish to keep the machine head in the raised position, i nsert the head support lever (2) securely into the

hinge lever support shaft (3).

Note: Always check that the head support lever (2) and the hinge lever support shaft (3) are meshed.

Lowering the machine head

Pull the machine head down toward you gently, remove the head support lever (2) from the hinge lever support shaft

(3), and then gently lower the machine head.

Note: Do not hold the mac hine head by the feed bracket (4) or X feed shaft A (5) when it is bein g raised and

lowered.

When machine head is raised

9

RH-981A

Page 17

3-6. Installing the oil container

2985Q

3-7. Installing the operation panel

Top of work table

Table

2986Q

2987Q

3. INSTALLATION

1. Install the oil draining cap suppor t (2) to th e base of

the bed base (1) with the two screws (3).

2. Sc rew the oil container (4) into the oil draining cap

support (2).

3. Push the oil draining spring pin (5) into the bed base

(1) until the pin is flush with the surface of the base.

4. Lower the machine head. (Refer to "Lowering the

machine head" on previous page.)

The operation panel ca n be installed to either the top

or bottom of the work table.

1. Install the rear frame (1) to the work table (top or

bottom) with the four wood screws (2).

2. Install the front frame assembly (3) to the rear

frame (1) with the four screws (4).

* The vertical orientation of the front frame

assembly (3) is the same whether it is installed to

the top or the bottom of the work table.

* Pull the harnesses such as the ground harness

out of the way so that t he operation panel side

cover (5) can be opened and closed.

3. Insert the connector cord (6) into the control box

through the hole at the side of the box.

Bottom of work table

Table

2988Q

RH-981A

10

Page 18

3. INSTALLATION

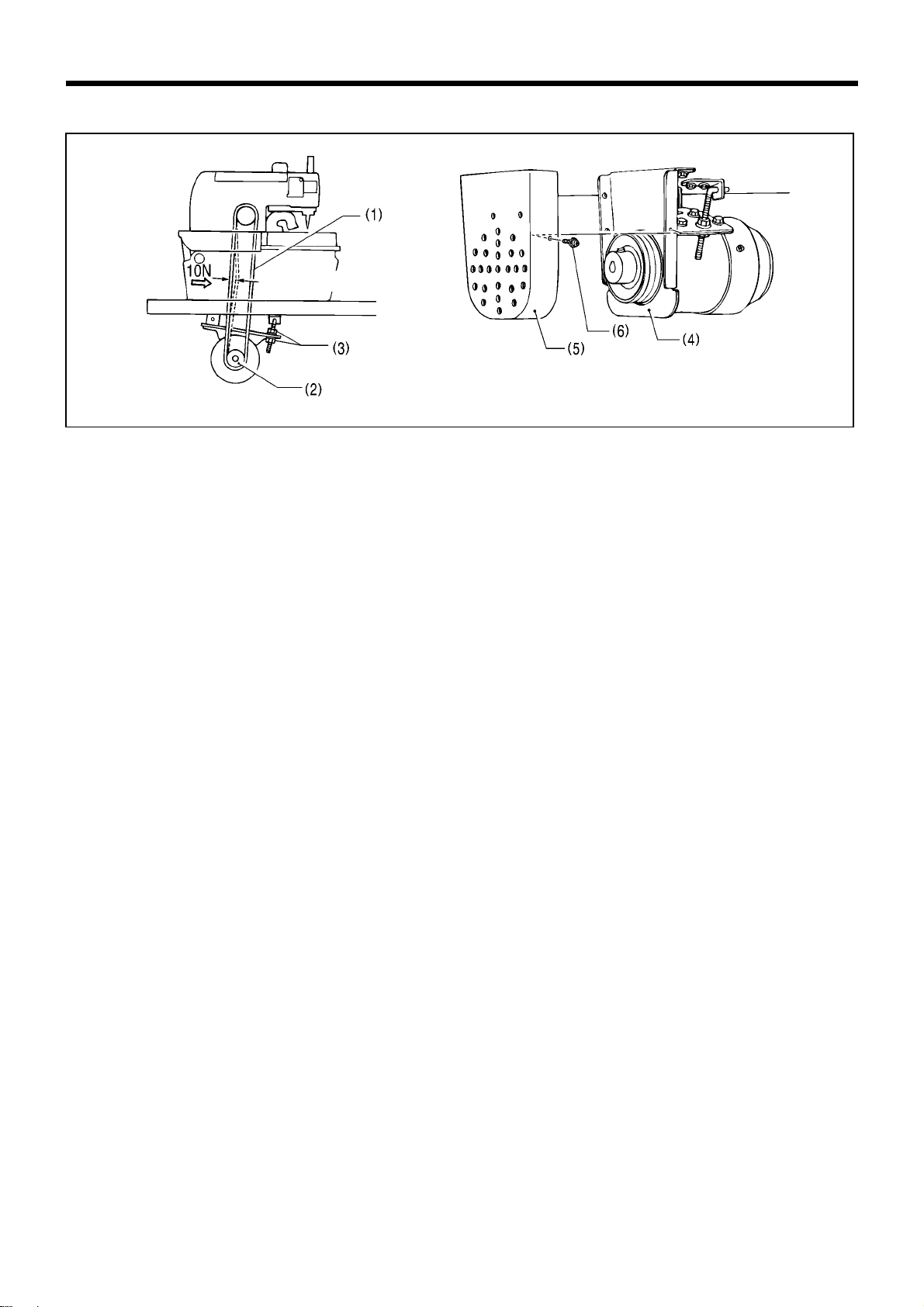

3-8. Tightening the V-belt

Approx.10 mm

2990Q

2991Q

1. Open the rear cover.

2. Pass the V-belt (1) through the base of the bed base and through the hole in the work table.

3. Place the V-belt (1) onto the motor pulley (2).

4. Check that there is approximately 10 mm of deflection in the V-belt (1) when it is pushed in the middle with a load

of 10 N.

If the tightness needs adjusting, loosen the t wo nuts (3) and move the m otor up or down. After adjusting, t ighten

the nuts (3).

Note: Check that the motor rear cover support (4) does not touch the motor pulley (1) or the edge of the motor.

5. Install the motor cover (5) with the three screws (6).

Note: After a long period of use, the V-belt will become run in and will loosen around the motor pulley. When

this happens, turn off the power and adjust by the procedure given in step 4. above.

11

RH-981A

Page 19

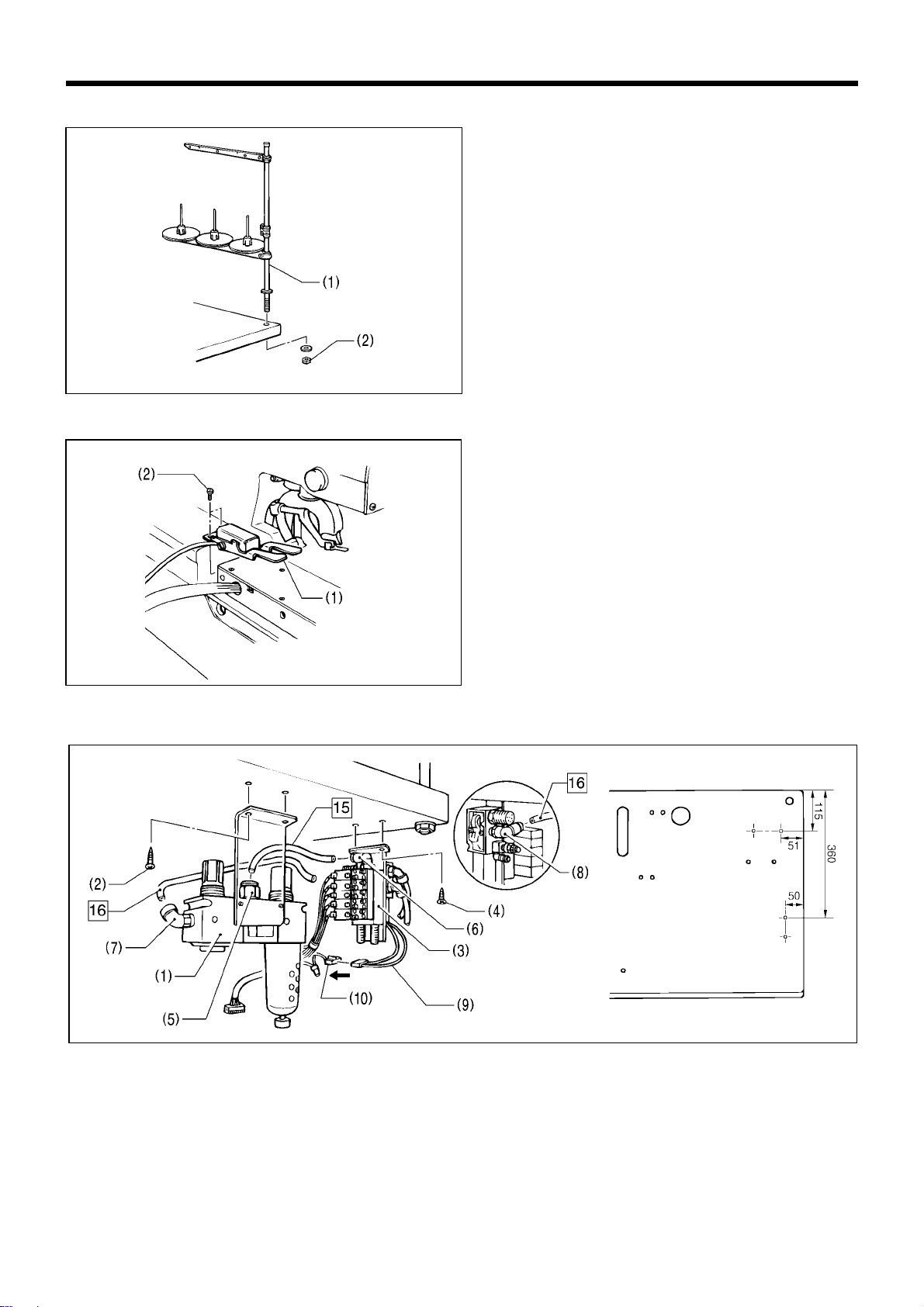

3-9. Installing the spool stand

3-10. Installing the hand switch

3. INSTALLATION

1. To assemble the spool stand (1), follow the

instructions in the m anual that c ame with the spool

stand (1).

2. Secure the spoo l stand (1) to the rear right corner

of the work table with the washer and nut (2).

2989Q

Install the hand switch (1) with the two screws (2).

3129Q

3-11. Installing the air unit and the valve unit

2387Q

Valve unit

Air unit

2992Q

1. Install the air unit (1) to the underside of the work table with the two screws (2).

2. Install the valve unit (3) with the two screws (4).

3. Connect air tube No. 15 to the intermediate joint (5) of the air un it (1) and to the j o int (6) of the va lv e un it ( 3), and

connect air tube No. 16 to joints (7) and (8).

Installation position

Connecting the valve cables

Insert the cable (9) which is coming out of the valve unit to the 2-pin connector (10) of the valve cable assembly.

RH-981A

12

Page 20

3. INSTALLATION

3-12. Connecting the wiring

2994Q

1. Pass the cable and air tube which are coming out of

the belt cover (1) and the machine head ( 2) thro ugh

the cable hole (3) in the work table.

2. Pass the cables and air tube which are com ing out

of the feed bracket (4) and the lef t side of the bed

base (5) and the cable for the hand switch (6)

through the cable hole (7) in the work table.

Note: Leave enough looseness in the cables so

that they will not be pulled when the

machine head is tilted back.

Adjust the looseness after all connections to

the control box are complete.

3130Q

3. Connect the hand switch connector (8) to the control

box connector.

4. Install th e power switch (9) to the underside of the

work table with the two screws (10).

5. Secure the cables using staples (11) (in four

locations).

13

3131Q

RH-981A

Page 21

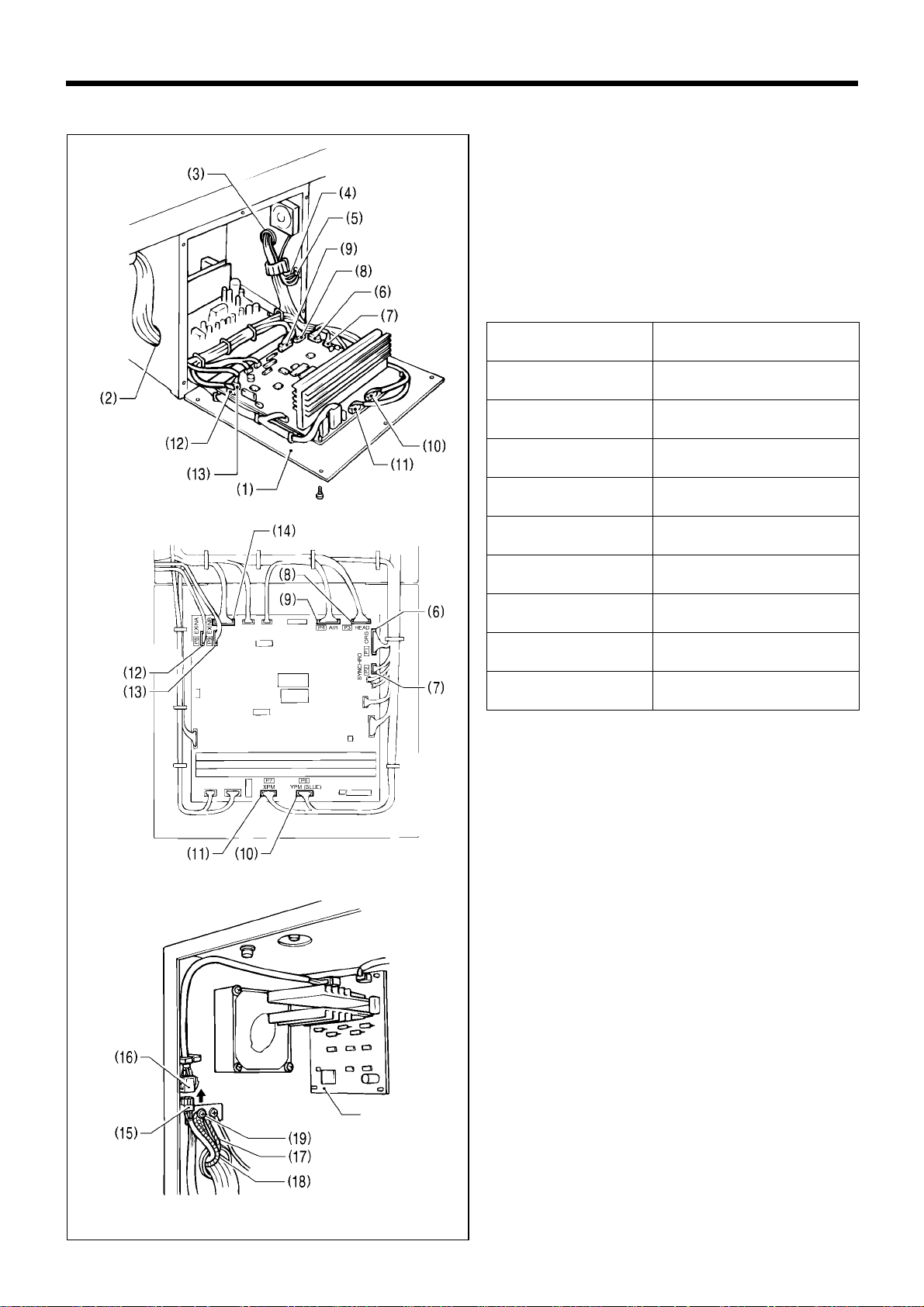

3-12-1. Connections inside the control box

3. INSTALLATION

2997Q

1. Open the rear cover (1) of the control box.

2. Pass the cables through the holes (2) and (3) in th e

side of the control box.

3. Loosen the screw (5), and then connect the three

ground cables (4) that are coming f rom the m ac hine

head.

4. Securely insert each of the connectors (6) - (14) as

indicated below.

Machine head

connectors

Connector (6)

(12-pin with [1] mark)

Connector (7)

(5-pin with [2] mark)

Connector (8)

(9-pin with [3] mark)

Connector (9)

(12-pin with [4] mark)

Connector (10)

(5-pin with [6] mark)

Connector (11)

(5-pin with [7] mark)

Connector (12)

(16-pin with [8] mark)

Connector (13)

(18-pin with [9] mark)

Connector (14)

(10-pin)

(Connection indications)

* This is indicated on the P.C. board.

P1 (ORG)

P2 (SYNCHRO)

P3 (HEAD)

P4 (AIR)

P6 (YPM) (BLUE)

P7 (XPM)

P8 (EXINA)

P9 (EXINB)

P18 (PANEL)

2998Q

PMD circuit

Board

2999Q

RH-981A

5. Insert the connector (15) (6-pin with [1][R] mark) to

the connector (16).

6. Loosen the middle screw (19) and then install the

ground cable (17) and the thr ee ground cables (18)

from the operation panel.

7. Secure the cables with the c abl e clamp as shown in

the illustration.

Note: W hen secur ing the cables, do not l et any of

the cables touch the components on the

circuit board or the heat s ink. Furthermore,

adjust the lengths of the cables from outside

the control box so that there is no looseness

in the cables inside the control box.

14

Page 22

3. INSTALLATION

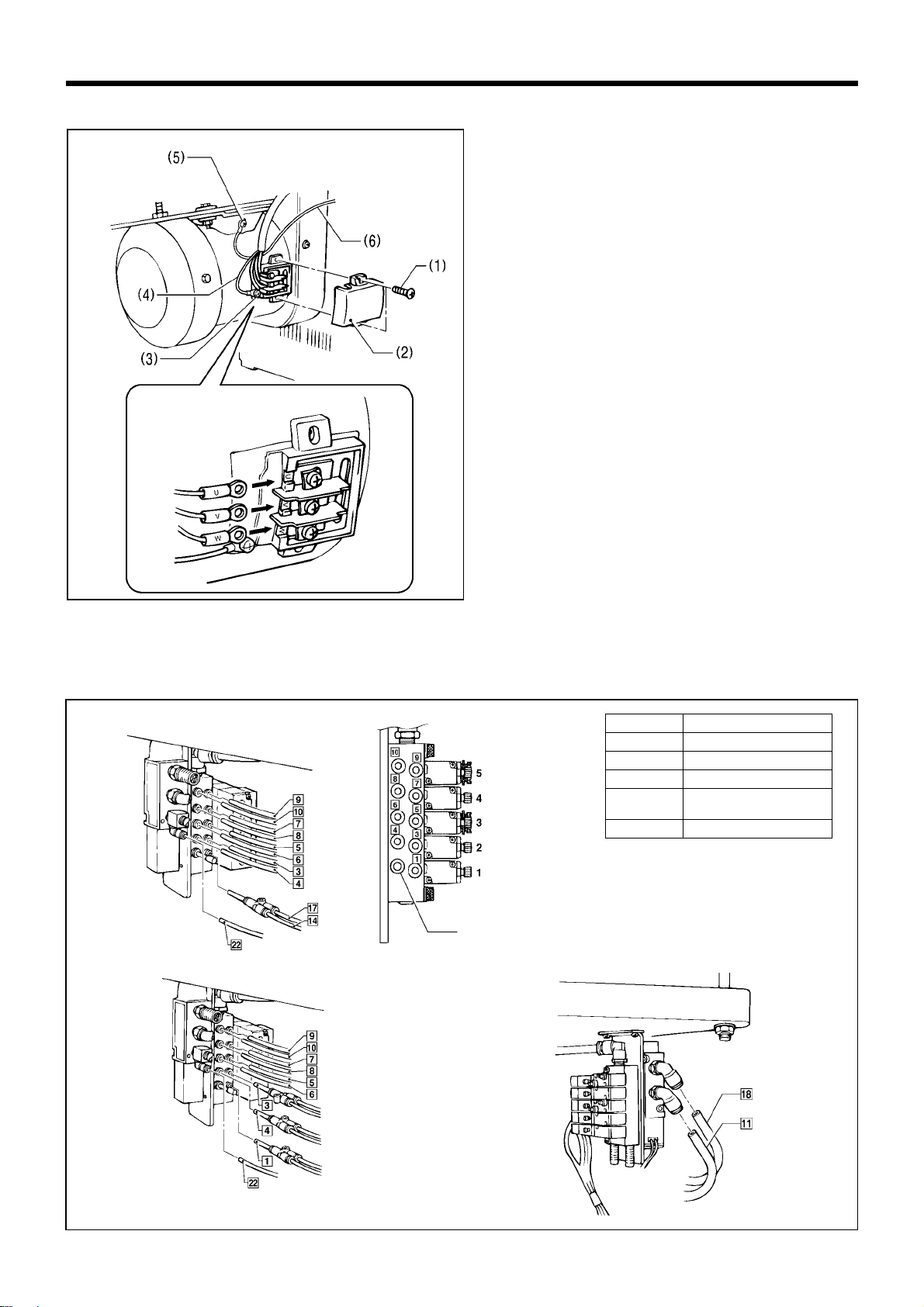

3-12-2. Connecting the motor cables

1. Remove the screws (1), and then open the terminal

block cover (2) of the motor.

2. Loosen the screw (3) and connect the ground cable

(4) for the motor.

3. Loosen the screw (5) and connect the ground cable

(6) from the control box.

4. Connect the cables so that the cable m arks (U, V,

W) match the symbols on the screw terminals.

5. Close the cover (2).

Note: Be careful not to clamp the cables when

closing the cover.

3000Q

3-12-3. Connecting the air tubes

Connect the air tubes to the joints of the solenoid valve assembly, using the illustration below as a reference.

Numbers are marked on each of the air hoses which come out of the sewing machine.

Plug 4

0827Q

Label No.

5

4

3

2

1

*1 If the lower thread trimmer is not

installed, solenoid valve [3] is not

used.

*2 The auxiliary clamp arm can only be

used for machines with -02

specification.

Solenoid valve

Upper thread trimming

Upper thread tightening

Lower thread trimming *1

Cloth spreading

(Auxiliary clamp arm *2)

Wor k clamp

< -00, -01 >

0826Q

< -02 >

0828Q

15

0829Q

RH-981A

Page 23

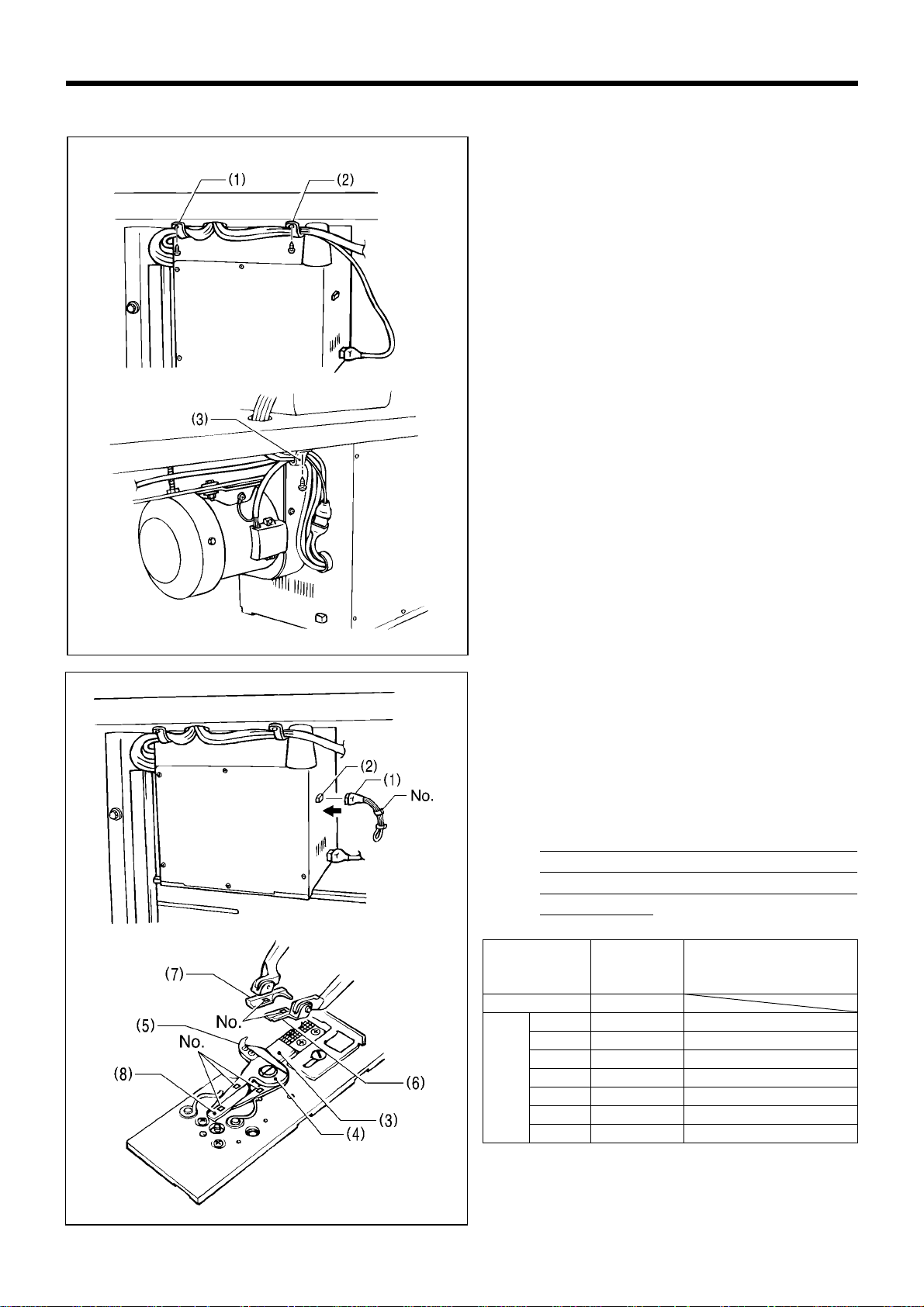

3-12-4. Securing the cables

3. INSTALLATION

3132Q

Note: Leav e enough loos eness in t he cables s o that

they will not be pulled when the machine head

is tilted back.

1. Pass the cable through the cable holder (1), and

then secure the cable holder (1) to the und erside of

the work table with the screw.

2. Pass the air tube and the hand switch cable through

the cable holder (2), and then secure the cable

holder (2) to the underside of the work table with the

screw.

3. Place the machine head cable together with the

valve cable assembly and motor cable, pas s them

all through the cable holder (3), and th en sec ur e the

cable holder (3) to the underside of the work table

with the screw.

3002Q

3003Q

Insert the specific ation harnes s (1) into the control box

connector (2).

Note: Check that the label number on the

specification harness (1) matches the movable

knife (R) (3), movable knife (L) (4), thread

handler (5), work clamp (R) (6), work clamp (L)

(7) and movable knife driving cam (8) numbers

before inserting the spec ification harness (1).

(If a connector with an incorrect label n umber

is connected, it may cause problem s such as

damage to the sewing machine or thread

trimming errors.)

Right/left work clamp No.

Right/left mo v abl e knife No.

Thread handler No.

Specification

Label No.

of harness

-00, -01 0

L1 1 1

L2 2 2

L3 3 3

-02

L4 4 4

L5 5 5

L6 6 6

L7 7 7

* There is 10 mm of difference in the knife installat ion

positions between L1 - L4 and L5 - L7.

3004Q

RH-981A

16

Page 24

3. INSTALLATION

3-13. Installing the air tubes

Connect the air tube from the compressor to the air unit underneath the work table.

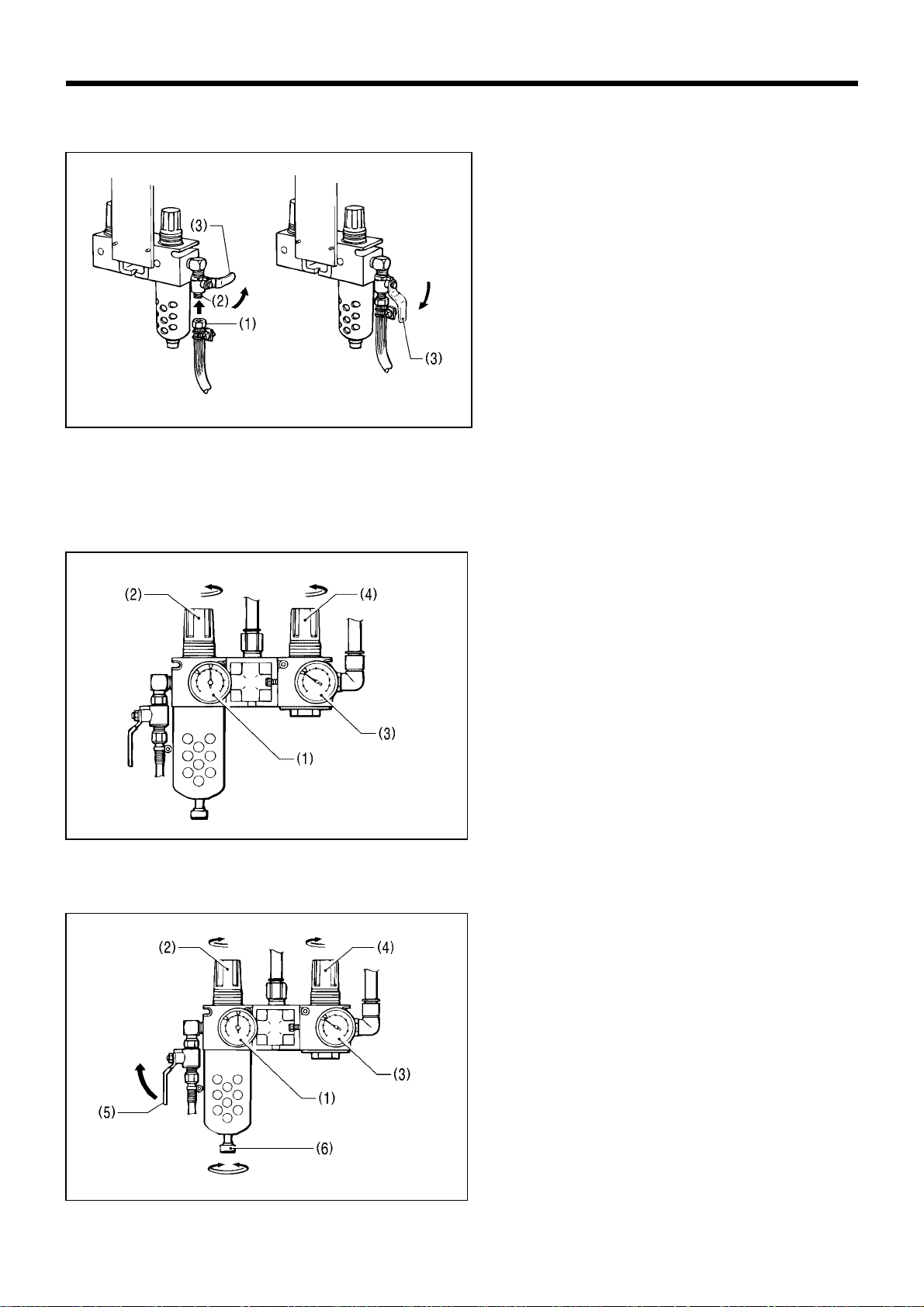

1. T urn the nut (1) at the end of the air tube, and the n

connect the tube to the valve (2).

2. Open the air cock (3) on the compressor.

Check that there is no air leaking from the valve

connection.

Open

Closed

3005Q

3-13-1. Adjusting the air pressure

Set the air pressure for the k nife pres sur e adj ustment regulator (3) to the lowest pressur e at which the knife can still

cut the material. Set the standard air pressure for the main regulator (1) to 0.5 MPa.

3. Open the cock (3) by turning it in the direction of the

arrow.

The meter needle will move clockwise.

4. Adjust the air pressure.

To increase the air pressure

(0.5MPa)

To decrease the air pressure

To close

To loosen

To tighten

(0.5Mpa)

(0.3MPa)

(0.3Mpa)

3006Q

3007Q

1. Gently lif t the k nob (2 ) of the m ain r egulator (1) and

turn it in the direction of the arrow in the illustration.

The pressure will increase when the knob (2) is

turned clockwise.

2. Gently lift the knob (4) of the knife pressure

adjustment regulator (3) and turn it in the dir ection

of the arrow in the illustration.

The pressure will increase when the knob (4) is

turned clockwise.

* The pressure for the knife pressure adjustment

regulator (3) is adjusted to 0.3 MPa. Be careful not

to increase this pressure needlessly, otherwise

poor cutting performanc e or damage to the knife

may result.

1. Close the cock (5). (The needle will remain at the

high pressure position.)

2. Turn the knob screw (6) in the d irec tion of the ar row

in the illustration to loosen it. Make sure that you

turn it in the correct direction.

The air will escape from the reservoir and the needle

will drop.

3. Tighten the knob screw (6).

4. To reduce the air pressure, gently lift knob (2) or

knob (4) and turn it counterclockwise.

5. Open the cock (5). Air will enter the reservoir and

the needle will move

17

RH-981A

Page 25

3-14. Connecting the power cord

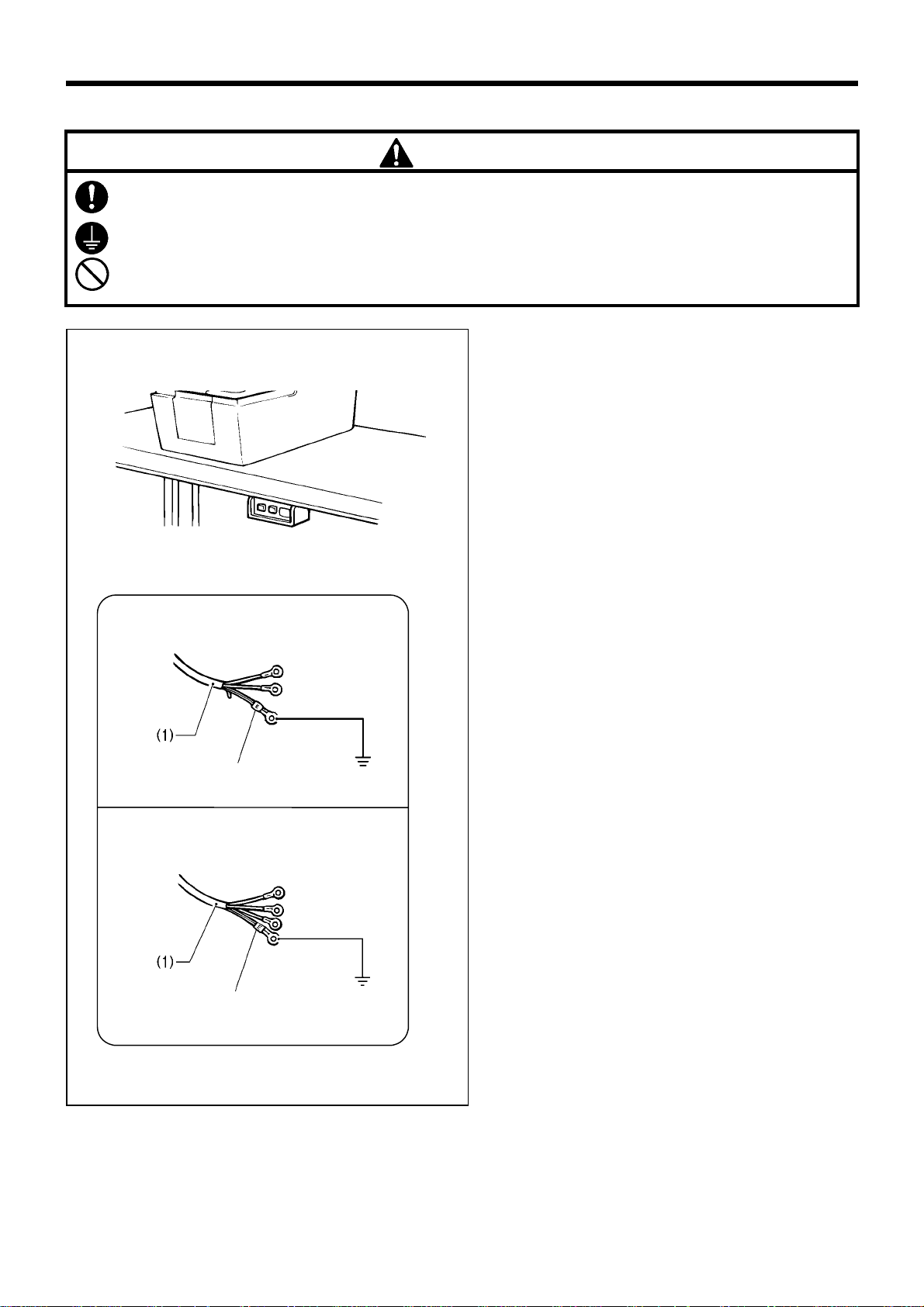

Contact your Brother dealer or a qualified electrician for any electrical work that may need to be done.

Be sure to connect the ground. If the gr ound connection is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct operation may also occur.

Do not connect the power cord until installation is complete, otherwise the machine may operate if the start

switch is pressed by mistake, which could result in injury.

CAUTION

3. INSTALLATION

Single phase

Green and yellow wire

(ground wire)

3133Q

0838Q

1. Attach an appropriate plug to the power cord (1).

(The green and yellow wire is the ground wire.)

2. Insert the plug into properly-grounded AC power

supply.

Note: Do not use extension cords, otherwise

machine operation problems may result.

Three phase

Green and yellow wire

(ground wire)

3134Q

RH-981A

18

Page 26

3. INSTALLATION

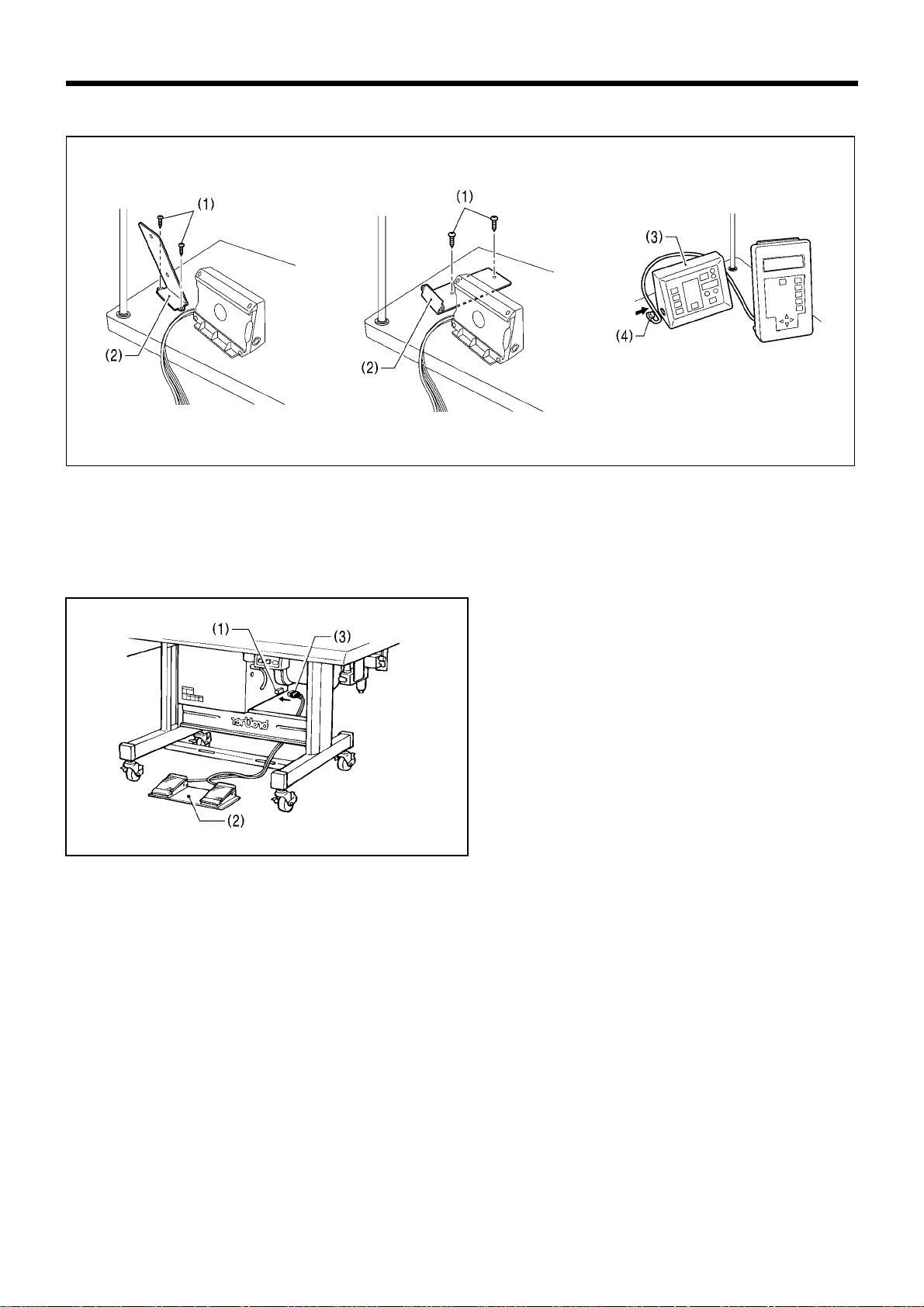

3-15. Installing the programmer (sold separately)

[Vertical]

3010Q 3011Q

[Flat]

1. Install the programmer support (2) to the work table with the two screws (1).

2. Insert the programmer connector (4) securely into the left side of the operation panel (3).

3-16. Installing the foot switch (option)

3012Q

3135Q

Insert the connector (3) of the foot switch (2) into the

control box connector (1).

19

RH-981A

Page 27

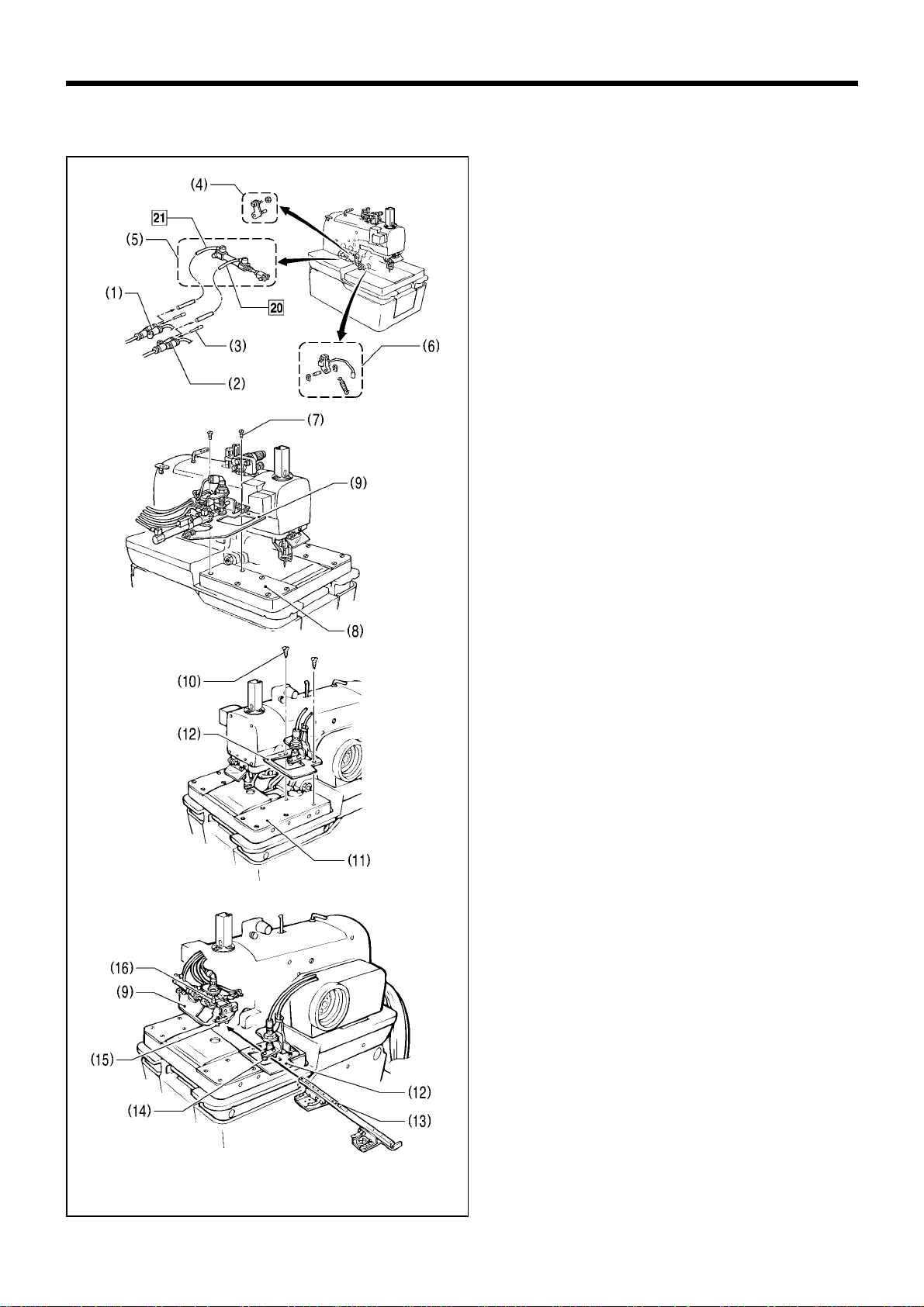

3-17. Installing the indexer (option)

3-17-1. Installing the indexer main unit

3015Q

3. INSTALLATION

1. After disconnecting air tubes [20] and [21], insert the

two plugs (3) into joints (1) and (2). In addition,

remove parts (4), (5) and (6) indicated in the

illustration.

2. Remove the screws (7) from feed bracket cover (L)

(8), and then install feed base (L) (9).

3016Q

3017Q

3. Remove the screws (10) from feed bracket cover

(R) (11), and then install feed base (R) (12).

4. Pas s the cloth feed bar (13) bet ween the rollers of

feed bar guide (R) (14) and feed bar guide (L) (15),

and place it on top of feed base (L) (9) and feed

base (R) (12).

* Push down the chuck pin (16) and c heck that it

goes smoothly into all of the holes in the cloth

feed bar (13).

If it does not go in smoothly, re-adjust the

installation positions of feed base (L) (9) and feed

base (R) (12).

3018Q

RH-981A

20

Page 28

3. INSTALLATION

3-17-2. Installing the upper thread presser

3019Q

1. Loosen the screw (1), and then remove the thr ead

guide (2).

2. Ins tall the upp er thread pres s er s uppor t (3) with the

screw (1).

* Adjust the height of the upper thread presser

support (3) so that it presses against the u pper

thread presser plate (5) when the upper thread

take-up lever (4) is lowered.

3020Q

3-17-3. Replacing the plate presser and presser plate

Remove the plate presser (1) and presser plate (U) (2),

and replace them with plate presser (I) (3) and presser

plate (I) (4).

3-17-4. Installing the valve unit

3022Q

3021Q

Installation position

2400Q

1. Install the valve unit (1) with the screw (2).

2. Remove the stopper plug (with the P mark) (4) from the valve unit (3), and then install the joint (5).

3. Connect the 6mm-diameter air tube (7) to joints (5) and (6).

21

RH-981A

Page 29

3-17-5. Connecting the connectors

3023Q

3. INSTALLATION

1. Insert the 3-pin connectors [8], [9] and [10] of the

valve harness into th e solenoid valves of the valve

unit (1) so that the label numbers match.

2. Insert the 15-pin connector (2) into the conn ector of

the indexer cord (3).

3. Open the rear cover (4) of the control box.

4. Insert the connector (5) of the indexer cord (3) in the

position shown in the illustration.

5. Secure the cord with the cord clamp.

3024Q

6. Insert the two pins of limit switch (R) ( 6) and the tw o

pins of limit s witch (L) (7) into the 15-pi n connector

terminals with matching numbers.

7. Connect the three pins of the cylinder sensor (8) into

the 15-pin connector so that the cable colors m atch

the connector numbers as given in the table below.

* If the cable colors are red, white a nd black, refer

to the colors in brackets.

Note: First disconnect the connector before

inserting the pins, and then after inserting the

pins, re-connect the connector.

Limit switch

(R) (6)

Limit switch

(L) (7)

Cylinder

sensor (8)

Switch pin

No.

7White7

12 Black 12

10 White 10

15 Black 15

Cable color

15-pin

Connector

Brown (Red) 4

Black (White) 9

Blue (Black) 14

8. Secure the cable with the cable clamp (9).

3025Q

RH-981A

22

Page 30

3. INSTALLATION

3-17-6. Connecting the air tubes

0855Q

Connect air tubes [50], [51], [52] and [53] to the places

with the corresponding numbers on the valve unit.

Label No. Solenoid valve type

[50], [51] For cloth feed drive cylinder

[52] For chucking cylinder

[53] For holding cylinder

3-17-7. Securing the air tubes and cables

0856Q

3026Q

1. Remove the screw (length 8 mm) (1).

2. Secure the air tube (2) and cable (3) with the cord holder (4), screw (length 16 mm) (5) and washer (6).

* Leave enough slack in the air tube (2) and c able (3) at th is tim e to allo w for the movem ent of the f eed brack et

(7).

23

RH-981A

Page 31

3. INSTALLATION

3003Q

3004Q

Insert the indexer specification harness (1) into the

control box connector (2).

* If another specification harness has been inserted

into this connector, firs t disconnec t this harness and

then insert the indexer specification harness (1).

Note: Check that the label number on the indexer

specification harness (1) matches the movable

knife (R) (3), movable knife (L) (4), thread

handler (5), work clamp (R) (6), work clamp (L)

(7) and movable knife driving cam (8) numbers

before inserting the spec ification harness (1).

(If a connector with an incorrect label n umber

is connected, it may cause problem s such as

damage to the sewing machine or thread

trimming errors.)

Right/left work clamp No.

Right/left mov abl e knife No.

Thread handler No.

Specification

Label No.

of harness

L1 1 1

L2 2 2

L3 3 3

-52

L4 4 4

L5 5 5

L6 6 6

L7 7 7

* Ther e is 10 mm of difference in the knif e installation

positions between L1 - L4 and L5 - L7.

* If using both an upper thre ad clam ping de vice and a

fly indexer, L5 to L7 cannot be used.

3-17-8. Installing the hand switch

1. Install the hand switch support plate (1) with the two

screws (2) in the position shown in the illustration.

2. Install the hand switch (3) to the hand switch

support plate (1) with the two screws (4).

3027Q

RH-981A

24

Page 32

4. LUBRICATION

4. LUBRICATION

CAUTION

Turn off the power switch before starting lubricating, otherwise the machine may operate if the start switch

is pressed by mistake, which could result in injury.

Be sure to wear protective goggles and gl oves when handling the l ubricating oil and gr ease, so that they

do not get into your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the greas e under any circum stances, as they can c ause vom iting

and diarrhoea.

Keep the oil out of the reach of children.

Use only specified Brother oil (Nisseki Mitsubishi Sewing Lube 10 N; VG 10) for the machine oil.

4-1. Adding oil

Check the oil level by looking at the sight glass. If the oil level is low, replenish the oil supply.

Filling the arm oil tank Filling the bed base oil tank

3028Q

Pour approximately 10 cc of machine oil into the arm

oil tank (1) (until it is about four-fifths full).

1. Raise the machine head.

2. Pour approximately 20 cc of machine oil into the

bed base oil tank (2) (until it is about four-fifths full).

3. Lower the machine head.

3029Q

4-2. Lubrication

Oil these parts once a day.

Oil the moving parts of the needle bar , looper and spreader m echanism s and also the cam gr oove, roller, the f elt at

the base of the wick and the wick before using the se wing machine for the first time, and also after long periods of

non-use.

When oiling, some oil will get onto the thread. Carry out a test s ewing to ensure that your material does not get

stained with oil.

Oiling the needle bar and cam

Add 2-3 drops of oil in the places indicated by the

arrows.

25

0861Q

RH-981A

Page 33

Oiling the looper, spreader and looper base

<Removing the work clamp plates>

4. LUBRICATION

3031Q

3030Q

3032Q

1. Turn the upper shaft pulley (1) toward you until the m ark on the pulley (A) is aligned with the n otch in the pu lley

cover (2).

2. Move the feed bracket (3) toward you.

3. Turn the left and right plate pressers (4) in the directions indicated by the arrows.

4. Lift up the clamp lever (6) and the notched section (7) of the right work clamp plate (5), remove the right work

clamp plate (5) from the pin (8), and then pull the right work clamp plate (5) toward you to remove it.

Note: If the lower thread tr immer has been installed, move presser plate U (9) to a position where it can be

removed without its touching the needle.

Raise presser plate U (9), pass the needle through the hole, and then remove presser plate U (9) from the

pin (8).

5. Remove the left work clamp plate (10) in the same way as the right work clamp plate (5) was removed.

3035Q

0865Q 3033Q

3034Q

6. Open the front cover.

7. T urn the looper base and add a few drops of oil to the spreader driving cam (11), and to the supp orts for the

looper link (12) and spreader link (13).

8. Add a few drops of oil to the shafts of the right spreader (14), left spreader (15) and LS-holder bracket (16).

9. Fill the felt tank (17) on the looper base with oil also.

10. Add 5 - 6 drops of oil to the felt (18) which is attached to the sliding surfaces of the looper base and the bed.

11. Close the front cover.

12. Install the work clamp plates by carrying out the steps 5., 4. and 3. in that order.

RH-981A

26

Page 34

5. CORRECT USE

5. CORRECT USE

5-1. Data initialization

When using the sewing machine for the first time, initialize the data by following the procedure below.

1. While pressing the RESET key (1), turn on the

power switch.

* While the data is being initialized, all LEDs will

illuminate and the buzzer will sound a series of

short beeps.

* All parameters, memory switches, cycle

programs and the production counter will be

initialized.

2. When the data writing is complete, the buzzer will

stop and the machine will go to the normal startingup condition.

Note: The data is retained for approximately one

month after the power supply is turned off. If

more than one month passes s ince the power

supply was last turned on, "E-59" may be

3036Q

displayed the next tim e the power is turned on.

If this happens, you will need to re-initial ize the

data.

5-2. Changing the lower thread and gimp trimming

The sewing machine is set to lower thread and gimp trimming when it is shipped from the factory. (DIP switch C (3)

No. 6 is set to ON.)

For setting the lower thread and gimp thread trimming to OFF, carry out the following procedure.

Note: For -00 specification, be sure to set the lower thread and gimp thread trimming to OFF.

1. Turn off the power.

Trimming

No trimming

3037Q

2. Remove the six screws (1).

3. Open the rear plate (2) of the control box.

4. Set DIP switch C (3) No. 6 on the circuit board to

OFF.

5. Close the rear plate (2) and tighten the six screws

(1).

27

RH-981A

Page 35

5-3. Installing the needle

Turn off the power switch before installing the needle, otherwise the machine may operate if the start

switch is pressed by mistake, which could result in injury.

CAUTION

5. CORRECT USE

5-4. Threading the upper thread

Turn off the power switch before threading the thread, otherwise the machine may operate if the start

switch is pressed by mistake, which could result in injury.

3039Q

3040Q3038Q

CAUTION

Use only Schmetz DO x 558 Nm80 - Nm120 needles.

1. Raise the finger guard (1).

2. Loosen the screw (2), and then rem ove the needle

(3).

3. Insert the new needle (3) as far as it will go so that

the groove is facing toward you.

4. Securely tighten the screw (2).

5. Remove the work clamp plates. (Refer to page 26.)

Note: After removing the work clamp plates, check

6. Lower the finger guard (1).

that the index mark (4) on the mac hine head is

aligned with the index mark (5) on the looper

base before inserting the needle (3) (when the

looper base is turned fully to the right).

Thread the upper thread as shown in the illustration below.

*Use the accessory needle threader (1).

0875Q

0876Q

<-52 specifications>

(1)

0874Q

2403Q 0878Q

RH-981A

28

Page 36

5. CORRECT USE

5-5. Threading the lower thread

Remove the work clamp plates ( refer to page 26), and then thread the lo wer thread as shown in the illustration

below.

For upper thread trimming specifications (-00)

0880Q

0879Q

For upper and lower thread trimming specifications (-01, -02 and -52)

0881Q

0883Q

0882Q

29

0881Q

RH-981A

Page 37

5. CORRECT USE

5-6. Threading the gimp

Remove the work clamp plates (refer to page 26), and then thread the gimp as shown in the illustration below.

Once threading is complete, replace the work clamp plates.

<-00,-01>

0884Q

0885Q

<-02,-52>

Pass the gimp through the hole of

the thread tension stud (1).

3041Q

Refer to “9-18. Adjusting the gimp length after trimming” (Page 67).

RH-981A

30

Page 38

5. CORRECT USE

5-7. Setting the material

<-00, -01, -02 specifications>

10 - 30 mm

3042Q

3043Q

1. Insert the material so that it touches the right and left cloth guides (1).

2. The sewing margin can be adjusted to within 10 - 30 mm.

3. Loosen the screws (2) at left and right and move the cloth guides (1) back and forth to adjust the sewing margin.

<-52 specifications>

0892Q

9 - 21 mm for

L1 - L4

9 - 11 mm for

L5 - L7

3044Q

30 - 40 mm

1. Place the material (fly) on top of the feed bracket ( 1), and then f eed the material (fly) in unti l it reac hes h ori zontal

cloth set guide (L) (2) and horizontal cloth set guide (R) (3).

* Check that the right edge of the material (fly) is straight against the left edge of the vertical cloth set guide (4) at

this time.

2. The vertical sewing margin can be adjusted between 9 - 21 mm for L1 - L4 and 9 - 11 mm for L5 - L7.

Loosen the four screws (5), and th en move horizontal cloth set guide (L) ( 2) and hor izon tal c l oth set gu ide ( R) (3)

forward or back to adjust.

3. The horizontal sewing margin can be adjusted between 30 - 40 mm.

Loosen the two screws (6), and move the vertical cloth set guide (4) to the left or right to adjust.

31

RH-981A

Page 39

Cloth setting position

5. CORRECT USE

Left setting position

0893Q

Right setting position

0894Q

The sewing start position can be set to either the left setting position or the horizontal setting position. (Refer to page

73.)

When set to the left setting position

This is the normal setting position for the cloth.

* After the last buttonhole is sewn, the cloth feed bar returns to the left setting position.

Horizontal setting position

The cloth is set to both the left setting position and right setting position.

* The next piece of cloth is set at the position that the last buttonhole was sewn.

RH-981A

32

Page 40

5. CORRECT USE

Q

Q

. Setting the installation position for cloth feed pla te (L) (-52 specificat ions)

5-8

The installation position for cloth feed plate (L) can be set to one of four positions depending on the spacing between

buttonholes and the number of buttonholes to be sewn. When the s pacing between buttonho les and the num ber of

buttonholes sewn have been changed, the installation position for cloth feed plate (L) should also be changed. Refer

to the illustration and table below at this time.

Standard Large size

3045

Install the cloth feed plate (L) (1) to the cloth feed bar (3) with the screws (2).

Installation position

<Standard specification>

Hole spacing

No. of holes

3 (D) (D) (C)

4(C)(B)(A)

<Large size specification>

Hole spacing

No. of holes

3 (L) (K) (L) (L)

4 (L) (K) (J) (I)

5 (J) (I) (H) (F)

6(G)(F)(E)

0897Q

38.1 mm 44.45 mm 50.8 mm

38.1 mm 44.45 mm 50.8 mm 57.15 mm

(A) 207- 217 mm (E) 346.5 - 356.5 mm

(B) 192.5 - 202.5 mm (F) 321.5 - 331.5 mm

(C) 167.5 - 177.5 mm (G) 279.5 - 289.5 mm

(D) 142.5 - 152.5 mm (H) 270.5 - 280.5 mm

3046

(I) 234.5 - 244.5 mm

(J) 209.5 - 219.5 mm

(K) 195 - 205 mm

(L) 184.5 - 194.5 mm

33

RH-981A

Page 41

5. CORRECT USE

5-9. Replacing the PROMs

Refer to the following when r eplacing the PROMs (for ex ample, when upgradin g the version num ber). At this time,

be particularly careful not to make a mistake with the direction of the PROM.

<Control circuit board>

The PROM which is marked “MN” is the main PROM.

This PROM is mounted in position (1).

The PROM which is marked “MT” is the machine

motor PROM.

3047Q

This PROM is mounted in position (2).

<Panel circuit board>

3048Q

The PROM which is marked “PL” is the panel PROM.

This PROM is mounted in position (3).

* The figure inside the box indicates

the version number.

2430Q

RH-981A

34

Page 42

6. OPERATION

6. OPERATION

6-1. Name and function of each operation panel item

(1) Power indicator

Illuminates when the power is turned on.

(2) Warning indicator

Illuminates when an error occurs.

(3) RESET key

Press to reset errors, and to clear the production counter.

(4) BEFORE indicator

Illuminates when cutting before sewing has been set.

(5) BEFORE key

Press to set cutting before sewing.

(6) OFF indicator

Illuminates when no cutting has been set.

(7) OFF key

Press to set no cutting.

(8) AFTER indicator

Illuminates when cutting after sewing has been set.

(9) AFTER key

Press to set cutting after sewing.

(10) Automatic m ode indic ator

Illuminates during automatic mode.

(11) Test feed mode indicator

Illuminates during test feed mode.

(12) Manual mode indicator

Illuminates during manual mode.

3049Q

35

RH-981A

Page 43

(13) Program mode indicator

Illuminates during program mode.

(14) Cycle program mode indicator

Illuminates during cycle program mode.

(15) SELECT k ey

Press to change the mode.

• When an independent program (1 - 9) is selected, the mode changes in the following order.

Automatic mode → Test feed mode → Manual mode → Program mode → Automatic mode

• When a cycle program (A - D) is selected, the mode changes in the following order.

Automatic mode → Test feed mode → Manual mode → Cycle program mode → Automatic mode

(16) Program number display

Displays the program number and the parameter number.

(17) Program No. UP key ( key)

Press to increase the value in the program number display.

(18) Program No. DOWN key ( key)

Press to decrease the value in the program number display.

(19) Detail displ ay

• In automatic mode, this display shows the production counter or the stitch length.

However, if a cycle program is selected, the cycle program step number and setting details are

displayed.

• In test feed mode and manual mode, the number of stitches remaining is displayed.

• In program mode, the parameter details are shown.

• In cycle program mode, the cycle program details are shown.

(20) Detail UP key ( key)

Press to increase the value in the detail display.

(21) Detail DOWN key ( key)

Press to decrease the value in the detail display.

(22) ENTER k ey

Press to accept the values appearing in the program number display and detail display.

6. OPERATION

6-2. Starting up

3136Q

3137Q

1. Press the power switch (23) to turn on the power.

* The power indicator (1) will illuminate, and "--"

and "----" will appear in the program number

display (16) and detail display (19) respectively.

Note: If "E-10" appears in the detail display, turn

the upper shaft pulley by hand to set the

upper shaft to the needle up stop position.

2. Press the start switch (24).

* The feed bracket will move to the cloth setting

position.

* The panel displays will return to the same

displays as when sewing last finished.

RH-981A

36

Page 44

6. OPERATION

6-3. Program setting method

3051Q

1. Press the SELECT key (1) to change the mode to

automatic, manual or test feed mode.

2. Press the and keys to select the program

number (1 - 9) for the independent progr am to be

changed.

Note: Program mode is not available if a cycle program

has been selected.

3. Press the SELECT key (1). The program mode

indicator (2) will illuminate.

* The parameter number "00" will appear in the

program number displa y ( 3), and the parameter

details will appear in the detail display (4).

4. Press the and keys to select the number of

the parameter to be changed.

5. Press the and keys to change the parameter

setting. (Refer to "Parameter table".)

* The flashing display indicates that the value has

not yet been accepted.

6. Press the ENTER key (5) to accept the changed

setting. (The display will then illuminate steadily.)

7. Repeat steps 4 to 6 to change other parameter

settings.

8. Press the SELECT key (1) to change the mode to

automatic mode.

* The program settings will be memorized.

6-3-1. Parameter table ( Taper bar )

The allowable setting range for s ome parameters may vary from the range specified, depending on the s ettings of

other parameters.

No. Setting items Setting range Unit Default

00 Sewing speed 1,000 - 2,200 rpm 100 1,800

01 Eyelet pattern 1 - 6 1 2

02 Button hole length (*1) -00: 5 - 50 mm

-01: 5 - 38 mm

-02 (L1): 14 - 18 mm

(L2): 18 - 22 mm

(L3): 22 - 26 mm

(L4): 26 - 30 mm

(L5): 28 - 32 mm

(L6): 32 - 36 mm

(L7): 36 - 40 mm

03 Tacking length 0 - 20 mm 1 6

1 -00: 25 mm

-01: 25 mm

-02 (L1): 16 mm

(L2): 20 mm

(L3): 24 mm

(L4): 28 mm

(L5): 30 mm

(L6): 34 mm

(L7): 38 mm

*1 The Button hole length setting value and the default value vary depending on the machine sub-class.

37

RH-981A

Page 45

6. OPERATION

No. Setting items Setting range Unit Default

04 Offset 0.5 - 2.0 mm 0.1 1.5

05 Stitch pitch 0.5 - 2.0 mm 0.1 1.0

06 Number of eyelet stitches 4 - 20 stitches 1 9

07 Cutting space -0.3 - 0.5 mm 0.1 0

08 Knife X position compensation -0.5 - 0.5 mm 0.1 0

09 Knife Y position compensation -0.7 - 0.7 mm 0.1 0

10 Start tying stitches 0 - 2 1 0

11 End tying stitches 0 - 2 1 0

12 X alignment -1 - 6 1 0

RH-981A

38

Page 46

6. OPERATION

No. Setting items Setting range Unit Default

13 Y alignment -1 - 6 1 0

14

15

θ1 alignment

θ2 alignment

-3 - 3 1 0

-3 - 3 1 0

16 Eyelet machine speed (*2) -600 - 0 rpm 100 0

17 Eyelet radius OFF, 1 - 5 1 OFF

18 Taper tact radius OFF, 1 - 5 1 OFF

19 Taper tact angle -5 - 5 1 0

20 Slow start stitches 0 - 3 stitches 1 0

21 Slow start speed (*3) 400 - 1,500 rpm 100 1,000

22 Stitch width correction -1.0 - 1.0 mm 0.1 0

29 Program copy OFF, 1 - 9

1OFF

(Specify copy source)

*2 The standard eyelet machine speed is the value that has been set by parameter 00 (sewing speed).

*3 If the sewing speed is set to a speed that is slower than the slow s tart speed, the slow start speed used for

sewing will be the same as the normal sewing speed.

39

RH-981A

Page 47

6. OPERATION

6-3-2. Parameter table ( Straight bar tacking )

The allowable setting range f or some param eters may vary from the range specified, de pending on the sett ings of

other parameters.

No. Setting items Setting range Unit Default

00 Sewing speed 1,000 - 2,200 rpm 100 1,800

01 Eyelet pattern 1 - 6 1 2

02 Button hole length (*1) L1: 14 - 18 mm

L2: 18 - 22 mm

L3: 22 - 26 mm

L4: 26 - 30 mm

L5: 28 - 32 mm

L6: 32 - 36 mm

L7: 36 - 40 mm

03 Tacking length

04 Tacking stitches 5 - 18 stitches 1 7

05 Stitch pitch 0.5 - 2.0 mm 0.1 1.0

2.0 - 6.0 mm

( Up to 3.0 mm on one side )

1 L1: 16 mm

L2: 20 mm

L3: 24 mm

L4: 28 mm

L5: 30 mm

L6: 34 mm

L7: 38 mm

0.1 4.0

06 Number of eyelet stitches 4 - 20 stitches 1 9

07 Cutting space -0.3 - 0.5 mm 0.1 0

*1 The Button hole length setting value and the default value vary depending on the machine sub-class.

RH-981A

40

Page 48

6. OPERATION

No. Setting items Setting range Unit Default

08 Knife X position compensation -0.5 - 0.5 mm 0.1 0

09 Knife Y position compensation -0.7 - 0.7 mm 0.1 0

10 Start tying stitches 0 - 2 stitches 1 0

11 End tying stitches 0 - 2 stitches 1 0

12 X alignment -1 - 6 1 0

13 Y alignment -1 - 6 1 0

14

15

θ1 alignment

θ2 alignment

-3 - 3 1 0

-3 - 3 1 0

16 Eyelet machine speed (*2) -600 - 0 rpm 100 0

*2 The standard eyelet machine speed is the value that has been set by parameter 00 (sewing speed).

41

RH-981A

Page 49

6. OPERATION

No. Setting items Setting range Unit Default

17 Eyelet radius OFF, 1 - 5 1 OFF

18 Width correction value -1.0 - 0 mm 0.1 0

19 Tacking overlap amount 0 - 2.0 mm 0.1 1.0

20 Slow start stitches 0 - 3 stitches 1 0

21 Slow start speed (*3) 400 - 1,500 rpm 100 1,000

22 Stitch width correction -1.0 - 1.0 mm 0.1 0

23 Tacking X alignment -1.0 - 1.0 mm 0.1 0

24 Tacking angle compensation -3 - 1 1 0

29 Program copy OFF, 1 - 9

1OFF

(Specify copy source)

*3 If the sewing speed is set to a speed that is slower than the slow start speed, the slow start speed used for sewing

will be the same as the normal sewing speed.

RH-981A

42

Page 50

6. OPERATION

6-4. Cycle program

Cycle programs can consist of up to a maximum of four independent programs (A to D).

A single cycle program can contain up to a maximum of eight steps.

The following shows an exam ple of storing a cycle program into c ycle program A that consists of four steps of

program 1 with knife operation on, and one step of program 3 with knife operation off.

Step 1 Step 2 Step 3 Step 4 Step 5

Program No.11113

Knife operation ON ON ON ON OFF

3052Q

2410Q

1. Press the SELECT k ey (1) to change the m ode to

automatic, manual or test feed mode.

2. Press the and keys to select cycle program

"A".

Note: Cycle program mode is not available if an

independent program has been selected.

3. Press the SELECT key (1). The cycle program

mode indicator (2) will illuminate.

* The cycle program number "A" and the step

number "1" will appear in the progr am number

display (3), and the cycle program details will

appear in the detail display (4).

4. Press the and keys to change the setting for

step 1 to "1.", and then press the ENTER key (5) to

accept the "1." setting.

* "." signifies that knife operation is on.

* "-" signifies a clear status. If "-" is set, the setting

details for all subsequent steps will be cleared.

5. Press the and keys to change the step

number to "2", and then repeat step 4 above.

6. Press the and keys to change the step

number to "3", and then repeat step 4 above.

7. Press the and keys to change the step

number to "4", and then repeat step 4 above.

8. Press the and keys to change the step

number to "5".

9. Press the and keys to change the setting for

step "5" to "3.".

10. Press the OFF key (6) so that the "." disappears,

and then press the ENTER key (5) to accept the

"3" setting.

11. Press the SELECT key (1). Cycle program m ode

will end and the mode will change to automatic

mode.

43

2411Q

RH-981A

Page 51

6-5. Production counter

6. OPERATION

3053Q

1. Press the SELECT key (1) to change the mode to automatic mode.

2. Press the key and key simultaneously.

* "PC" will flash in the program number displa y (2), and the production c ounter value will appe ar in the detail

display (3).

3. Press the keys to change the production counter setting.

* The production counter setting will flash while the setting is being changed.

* If you would like to set the production counter to "0", press the RESET key (4).

4. Press the ENT ER ke y (5). The production count er va lue wil l be accepted and the mode wil l return to a utom atic

mode.

* If you press the SELECT key (1) while the production counter value is still f lashing, the mode will return to

automatic mode without the production counter value being changed.

6-6. Using the program memos

Insert the program memos (1) into the rear of the

operation box (2) for safekeeping.

Program memo contents

1. Easy reference guide

2. Error code table

3. Parameter table

4. Program notes

Use a lead pencil to make any additions to the

parameter table and for writing anything into the

program notes. If you do so, additions can be removed

using an eraser and the space can be re-used. The

program notes are useful for recording what patterns

have been entered into which programs.

3054Q

RH-981A

44

Page 52

7. SEWING

7. SEWING

CAUTION

Turn off the power switc h at the follo wing times, otherwise the machine m ay operate if the start switch is

pressed by mistake, which could result in injury.

• When threading the needle

• When replacing the needle

• When not using the machine and when leaving the machine unattended.

Do not touch any of the moving parts or pr ess any obj ects against the machine while sewing, as th is m ay

result in personal injury or damage to the machine.

7-1. Automatic sewing

When carrying out automatic sewing for the first time, be sure to carry out a test sewing first.