Page 1

User's Guide

Introduction

STEP

1

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

Be sure to read and understand this guide before using the machine. We

recommend that you keep this guide nearby for future reference.

www.brother.com

Reference

Page 2

Thank you for purchasing the Brother QL-500.

This guide briefly describes the steps to start using the Brother QL-500.

See the User's Guide for details. The User's Guide can be found in the Manuals folder of

the included CD-ROM.

We strongly recommend that you read this guide carefully before using the Brother

QL-500, and then keep it nearby for future reference.

Page 3

Introduction

Contents

1

STEP1

STEP1

STEP2

STEP2

Introduction •••••••••••••••••••••••••••••••••••••••••••••••••••• 1

Contents ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 1

General Information ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2

Safety precautions••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3

General Precautions •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 5

Getting Started ••••••••••••••••••••••••••••••••••••••••••••••••• 7

Unpacking the Brother QL-500•••••••••••••••••••••••••••••••••••••••••••••• 8

Parts Description••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9

Main Printing Unit•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9

Button descriptions•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9

LED Lamp••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 10

Connecting the power supply ••••••••••••••••••••••••••••••••••••••••••••••• 10

Setting the DK Roll •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 11

Setting the Paper Guide•••••••••••••••••••••••••••••••••••••••••••••••••••••• 12

Maintenance and Troubleshooting •••••••••••••••••••••••••• 13

Maintenance •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 14

Print head maintenance •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 14

Roller maintenance ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 14

Label outlet maintenance •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 15

Replacing the cutter unit ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 16

Troubleshooting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 18

Potential types of problems•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 18

Introduction

STEP

1

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

STEP3

STEP3

Reference••••••••••••••••••••••••••••••••••••••••••••••••••••••• 19

Main specifications •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 20

For Australia Only:••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 21

Reference

Page 4

2

General Information

Compilation and Publication Notice

Under the supervision of Brother Industries Ltd., this guide has been compiled and

published, covering the latest product’s descriptions and specifications.

The contents of this guide and the specifications of this product are subject to

change without notice.

Brother reserves the right to make changes without notice in the specifications and

materials contained herein and shall not be responsible for any damages (including

consequential) caused by reliance on the materials presented, including but not limited to

typographical and other errors relating to the publication.

© 2010 Brother Industries Ltd.

Trademarks

The Brother logo is a registered trademark of Brother Industries, Ltd.

Brother is a registered trademark of Brother Industries, Ltd.

© 2010 Brother Industries, Ltd. All rights reserved.

Microsoft

Corporation, USA.

Macintosh® and Mac OS® are registered trademarks of Apple Inc.

The names of other software or products used in this document are trademarks or

registered trademarks of the respective companies that developed them.

Each company whose software title is mentioned in this guide has a Software Licence

Agreement specific to its proprietary programs.

All other brand and product names mentioned in this Setup & Operation Guide and the

User's Guide are registered trademarks of their respective companies.

®

, Windows Vista® and Windows® are registered trademarks of Microsoft®

Symbols Used in this Guide

The symbols used throughout this guide are as follows:

This symbol shows information or directions that should be followed. If ignored, the

result may be injury, damage, or failed operations.

This symbol shows information or directions that can help you better understand and

use the machine more efficiently.

Page 5

Safety precautions

Read and understand all of these instructions and save them for later reference. Follow

all warnings and instructions marked on the product.

Warning Tells you what to do to avoid the risk of injury.

Caution

The symbols used in this guide are as follows:

Action NOT allowed to do DO NOT disassemble the product.

DO NOT splash the product with or

immerse the product in water.

Mandatory action Unplugging

Alerts to the possibility of electrical

shock

To use the machine safely

Follow these guidelines to avoid fire, electric shock, or other damage.

The Machine

Unplug the power cord immediately and

stop using the machine during an

electrical storm. There may be a remote

risk of electric shock from lightning.

Do not touch any metal parts near the

print head. The print head becomes very

hot during use and remains very hot

immediately after use. Do not touch it

directly with your hands.

Dispose of plastic bags correctly and

keep away from babies and children. Do

not wear or play with plastic bags.

Unplug the power cord immediately and

stop using the

abnormal odour, heat, discolouration,

deformation or anything unusual whilst the

machine

Do not disassemble the machine.

For inspection, adjustment and repair of

the machine contact the retail outlet

where the machine was purchased or

your local authorised service centre.

Tells you about procedures you must follow to prevent damage to the machine.

DO NOT touch a given portion of the

product.

Warning

Do not drop, hit or otherwise bang the

machine.

Do not hold and lift the machine by the

DK Roll cover. The cover could come off

and the machine could fall and become

damaged.

machine

is in use or storage.

if you notice any

Do not allow the

way.

Do not use the machine with foreign

objects in it. If water or any foreign

objects should enter the machine,

unplug the power cord from the electric

outlet and remove the foreign object. If

necessary, contact the retail outlet

where the machine was purchased or

your local authorised service centre.

Do not hold the machine with only one

hand. The machine may slip out of your

hand.

machine

to get wet in any

3

Introduction

STEP

1

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

Reference

Page 6

4

Warning

Follow these guidelines to avoid fire, electric shock, or other damage.

Power Cord

Use only the authorised power source

(220-240V AC) for the machine.

Use only the power cord included with

the machine.

Do not handle the power cord or plug if

your hands are wet.

Do not overload the electrical outlet

sockets with too many appliances or

plug the power cord into a damaged

electrical outlet.

Do not cut, damage, alter or place heavy

objects on the power cord.

Do not use the power cord if it is

damaged.

Ensure the power cord is correctly

inserted into the electrical outlet.

If the machine will not be used for an

extended period, remove the power cord

from the electrical outlet.

Caution

Follow these guidelines to avoid fire, electric shock, or other damage.

The Machine

The electrical outlet should be close to the machine and be easily accessible.

Power Cord

Always hold the power cord when unplugging the power cord from or plugging it into

the electrical outlet. Pulling on the power cord could cause problems.

Cutter Unit

Do not touch the cutter unit.

Do not open the top cover when the cutter is operating.

Installation/Storage

Put the machine on a flat, stable surface

such as a desk.

DK Roll (DK Label, DK Tape)

Be careful not to drop the DK Roll.

DK Rolls use thermal paper and thermal

film. Both the label and print will fade

with sunlight and heat. Do not use DK

Rolls for outdoor use that requires

durability.

Do not put any heavy objects on top of

the machine.

Depending on the area, material, and

environmental conditions, the label may

unpeel or become irremovable, the

colour of the label may change or be

transferred to other objects.

Before applying the label, check the

environmental condition and the

material. Test the label by affixing a

small piece of it to an inconspicuous

area of the intended surface.

Page 7

General Precautions

The Machine

• Never disassemble the machine or allow it to get wet to avoid possible fire or electrical

shock. Do not unplug the power cord from or plug it into the electrical outlet with wet

hands. Doing so could cause an electrical shock or fire.

• Do not touch the cutter. Personal injury could result.

• The machine is a precision machine. Do not drop, hit or otherwise bang the machine.

• Do not lift the machine by the DK Roll compartment cover. The cover could come off and

the machine could fall and become damaged.

• The machine may malfunction if left near a television, radio, etc. Do not use the machine

near any machine that can cause electromagnetic interference.

• Do not expose the machine to direct sunlight or near heaters or other hot appliances, in

any area exposed to extremely high or low temperatures, high humidity or dusty areas.

Doing so could cause the machine to malfunction.

• Do not use paint thinner, benzene, alcohol or any other organic solvents to clean the

machine. Doing so may cause damage to the surface finish. Use a soft, dry cloth to clean

the machine.

• Do not put any heavy objects or objects containing water on top of the machine. If water

or any foreign object enters the machine, contact the retail outlet where the machine was

purchased or your local authorised service centre. If you continue to use the machine

with water or a foreign object in the machine, the machine may be damaged or personal

injury could result.

• Do not insert any objects into or block the label output slot, USB port.

• Do not put any metal parts near the print head. The print head becomes very hot during

use and remains very hot immediately after use. Do not touch it directly with your hands.

• Use only the interface cable (USB cable) included with the machine.

• When not in use for an extended period, remove the DK Roll from the machine.

• Do not attempt to print labels while the DK Roll cover is open.

Power Cord

• Use only the power cord included with the machine.

• If the machine will not be used for an extended period, unplug the power cord from the

electrical outlet.

• Always hold the power cord when unplugging the power cord from or plugging it into

electrical outlet. Do not pull on the power cord. The wire in the electrical cord may

become damaged.

• You should put the machine near an easily accessible, standard electrical socket.

DK Roll (DK Label and DK Tape)

• Use only genuine Brother accessories and supplies (with , marks). Do not use any

unauthorised accessories or supplies.

• If the label is attached to a wet, dirty, or oily surface, it may peel off easily. Before

applying the label, clean the surface to which the label will be applied.

• DK Rolls use thermal paper or film that can fade in colour or peel off surfaces if exposed

to ultraviolet light, wind or rain.

• Do not expose the DK Rolls to direct sunlight, high temperatures, high humidity, or dust.

Store in a cool, dark place. Use the DK Rolls soon after opening the package.

• Scratching the printed surface of the label with your finger nails or metal objects, or

touching the printed surface with hands dampened by water, sweat, or medicated cream,

etc., can cause the colour to change or fade.

• Do not apply labels to any persons, animals, or plants.

5

Introduction

STEP

1

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

Reference

Page 8

6

• As the end of the DK Roll is designed to not adhere to the label spool, the last label may

not be cut properly. If this happens, remove the remaining labels, insert a new DK Roll,

and reprint the last label.

Note: To account for this, the number of DK Labels included on each DK Roll may be

more than indicated on the package.

• If a label is removed after being applied to a surface, some portion of the label may

remain. Remove the remaining portion before attaching a new label.

• Some DK Rolls use permanent adhesive for their labels. These labels cannot be easily

peeled off once attached.

• Prior to using CD/DVD labels, be sure to follow the instructions in your CD/DVD player's

instruction guide regarding applying CD/DVD labels.

• Do not use CD/DVD labels in a slot loading CD/DVD player, for example a CD player in

a car where the CD is slid into a slot in the CD player.

• Do not peel off the CD/DVD label once it is applied to the CD/DVD, a thin surface layer

may come off, resulting in damage to the disk.

• Do not apply CD/DVD labels to CD/DVD disks designed for use with ink jet printers.

Labels peel off these disks easily and using disks with peeled labels can result in loss or

damage of data.

• When applying CD/DVD labels, use the applicator included with the CD/DVD label rolls.

failure to do so could cause damage to the CD/DVD player.

• User's shall take full responsibility for applying CD/DVD labels. Brother accepts no

responsibility for any loss or damage of data caused by the inappropriate use of CD/DVD

labels.

CD-ROM and Software

• Do not scratch or subject the CD-ROM to high or low temperatures.

• Do not put heavy objects on the CD-ROM or apply force to the CD-ROM.

• The software contained on the CD-ROM is meant for use with the machine only. See the

Licence on the CD for details. This software may be installed on multiple computers for

use in an office, etc.

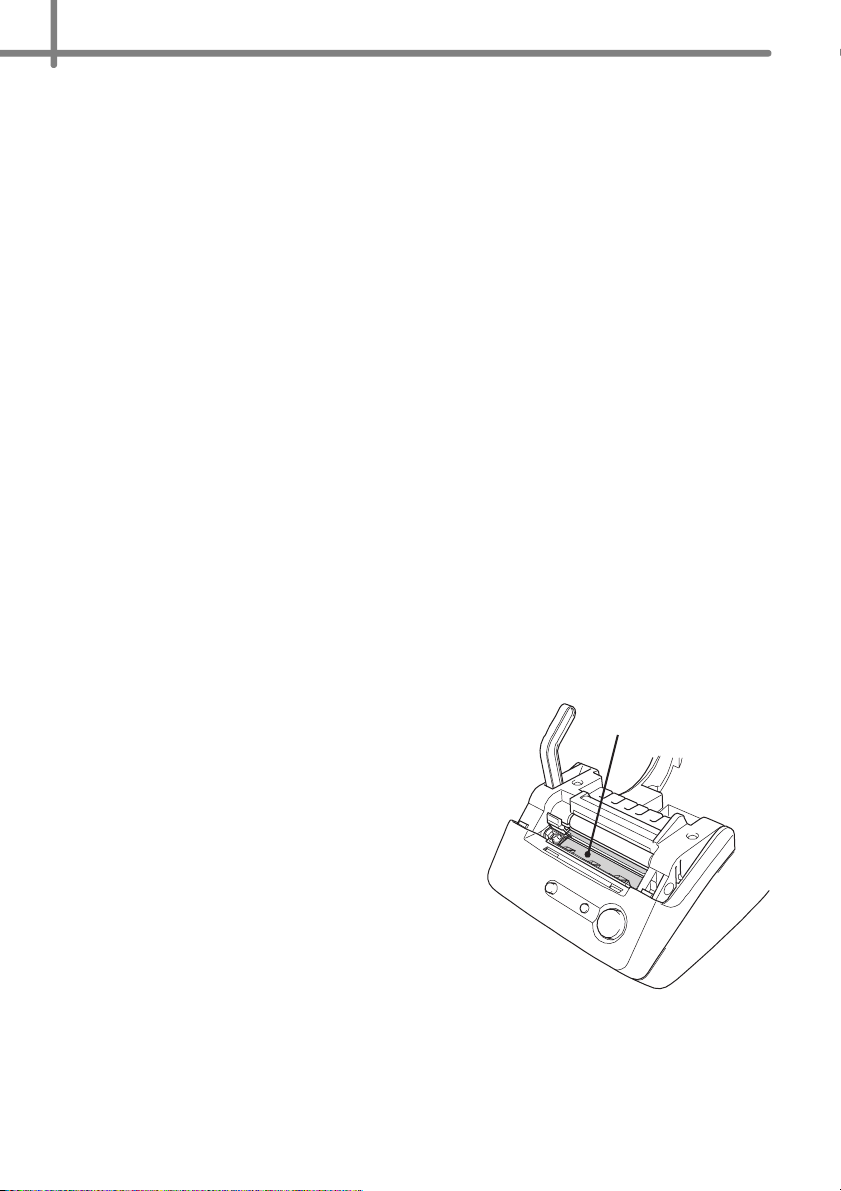

Cutter unit

• The cutter unit contains a very sharp blade. To

prevent injury from a broken cutter blade:

• Make sure the top cover is closed when using

the cutter unit.

• Don't apply too much pressure when fitting or

removing the cutter unit.

• When the cutter unit becomes blunt you

should replace it with a new one.

• If you break the cutter unit, unplug your QL-

500 from the power and remove the cutter

unit carefully with a pair of tweezers.

• If the machine jams due to a build up of adhesive,

you should clean the surface of the paper guide.

Unplug the QL-500 from the power and wipe away

the adhesive build up from the surface of the

paper guide using a cloth or tissue dipped in

isopropyl alcohol. We recommend that you clean the paper guide when replacing the

cutter unit.

• The cutter unit should give you an average number of 5000 cuts or more, depending on

how you use the machine. If your QL-500 does not cut the labels properly or starts to jam

often, the cutter might have reached the end of its life; you should replace the cutter.

Paper guide surface

Page 9

STEP1

STEP1

Getting Started

7

Introduction

STEP

1

Take the printer out of the box and make preparations for the printer before

creating a label. Follow the procedures from "Unpacking the Brother QL-500" on

page 8.

Unpacking the Brother QL-500

Parts Description

Connecting the power supply

Setting the DK Roll

Setting the Paper Guide

ÎPage 8

ÎPage 9

ÎPage 10

ÎPage 11

ÎPage 12

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

Reference

Page 10

STEP1 Getting Started

8

Unpacking the Brother QL-500

Check that the package contains the following before using the Brother QL-500. If any item

is missing or damaged, contact your Brother dealer.

Brother QL-500 User's Guide

USB cable Software Installation Guide

CD-ROM DK Label & Tape Guide

AC Power cord

The illustration is for UK. The shape of the plug

may vary depending on the country/region.

Paper guide

Cleaning Sheet

DK Roll (Starter roll)

The Brother QL-500 includes the following

starter roll :

• One starter roll of DK Die-cut Standard Address

Labels (100 labels)

Page 11

Parts Description

9

Main Printing Unit

Front

DK Roll compartment cover

FEED button

LED lamp

CUT lever

Back

Do not connect the QL-500 to your

personal computer until directed to do so

when installing the printer driver.

Button descriptions

ON/OFF button

AC Power cord

USB port

Introduction

STEP

1

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

Button Condition

ON/OFF button Turns power to the QL-500 on and off.

• When using DK Die-cut Labels, feeds the DK Label Roll to the

beginning of the first label on the roll. If this button is held for more than

one second, the DK Label Roll is fed to the beginning of the next label

FEED button

on the roll.

• When using DK Continuous Tapes, feeds 25.4 mm of the DK Label Roll.

• If there is no DK Label Roll installed, the mode changes to a cleaning

mode and the roller rotates for 8 mm. If this button is held for more than

one second, the roller rotates for 100 mm.

Use CUT lever when cutting a printed label.

CUT Lever

Reference

Page 12

STEP1 Getting Started

10

LED Lamp

Lamp Condition

Not lit

Power is OFF.

Lit

Flashing fast

Flashing slow

Turns off after flashing

fast ten times

Power is ON.

(Normally lit while power is on, the LED flashes during cleaning or if an

error has occurred.)

Indicates one of the following errors.

• Cutter error

• Label sensor error

(DK Roll not installed correctly, end of DK Roll, or label jam)

• DK Roll compartment cover is open during operation

• Incorrect DK Roll installed

• No DK Roll installed

Cooling

(Waiting for temperature of print head to lower)

System error

Turn the QL-500 off and then on again.

If this error re-occurs, contact the retail outlet where the QL-500 was

purchased or your local authorized service center.

Connecting the power supply

Connect the power cord to the Brother QL-500

and then plug the power cord into a electrical

outlet.

• The illustration is for UK. The shape of the plug may

vary depending on the country/region.

• Check that the electrical outlet is 220-240V AC

before plugging the power cord.

• Unplug the power cord from the electrical outlet

after you have finished using the Brother QL-500.

• Do not pull the power cord when unplugging it from

the electrical outlet. The wire in the power cord may

become damaged.

• Do not connect the Brother QL-500 to the computer until directed to do so when

installing the printer driver.

Page 13

Setting the DK Roll

Press the ON/OFF button to turn the

1

QL-500 off. Hold the DK Roll

compartment cover at the sides near

the front of the QL-500 and firmly lift up

to open the cover.

Place the spool into the spool guides in the

2

DK Roll compartment.

• Make sure that the spool arms are inserted

firmly in the spool guides on the left and right.

• Insert the spool with the DK Roll located on the

right hand side of the QL- 500.

11

Introduction

STEP

1

Getting Started

STEP

2

Troubleshooting

Maintenance and

Lift the label lever and then

3

thread the end of the DK Roll into

the slot immediately before the

cutter.

When unable to thread the end of the

DK Roll into the slot, thread it as far

as possible, then lower the label

lever and close the cover. Press the

ON/OFF button to turn the QL-500

on, and then press the FEED button

to set the roll.

STEP

3

Reference

Page 14

STEP1 Getting Started

12

Lower the label lever and then close

4

the DK Roll compartment cover.

Setting the Paper Guide

Your QL-500 comes with a paper guide that

collects strips of printed labels that have not

been cut off from the machine.

Attach the paper guide to the front of the QL-500 as

shown in the figure.

Page 15

STEP2

STEP2

Maintenance and Troubleshooting

13

Introduction

STEP

1

This section of the manual explains how to properly maintain this printer so as to

ensure many years of reliable service.

This section also covers how to troubleshoot potential problems and how to read

and understand error messages.

Maintenance

Print head maintenance

Roller maintenance

Label outlet maintenance

Replacing the cutter unit

ÎPage 14

ÎPage 14

ÎPage 15

ÎPage 16

Troubleshooting

Potential types of problems

ÎPage 18

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

Reference

Page 16

STEP2 Maintenance and Troubleshooting

14

Maintenance

Maintenance of the printer needs only to be done when required. However, some

environments will require that maintenance should be done more frequently (e.g. in dusty

conditions).

Print head maintenance

The DK Roll (thermal recording paper type) used with the printer is designed to clean the

print head automatically. When the DK Roll passes the print head during printing and

label feeding, the print head is cleaned.

Roller maintenance

Clean the roller using the cleaning sheet (available separately).

The printer contains only one cleaning sheet.

When doing maintenance on the roller, be sure to use the cleaning sheet supplied

exclusively for this printer.

If using other cleaning sheets, the surface of the roller may be damaged and may

cause a malfunction.

Turn OFF the printers power.

1

Lift both sides of the lower part of the DK Roll

2

cover on the front side of the printer to open

the cover.

Pull up the roll release lever and remove the

3

DK Roll.

Be sure to remove the DK Roll before cleaning the

roller. The roller cleaning function will not operate

correctly if the DK Roll is not removed.

Page 17

Insert edge (A) of the cleaning sheet into the printing unit and guide

4

it out to just in front of the cutter.

• Do not remove part (A) of the cleaning sheet.

• The printed side of the cleaning sheet should be facing upwards.

After inserting the cleaning sheet into the

5

printing unit, push down the roll release lever

and remove the B part of cleaning sheet.

To purchase a cleaning sheet, contact the retail

outlet where the printer was purchased or your local

authorized service centre.

Close the DK Roll cover and turn ON the printer’s power.

6

15

Introduction

STEP

1

Getting Started

STEP

2

Troubleshooting

Maintenance and

Press the Feed button for more than one

7

second.

The roller rotates for 100 mm.

The adhesive face of the cleaning sheet removes any

stains or dust on the roller.

• If you do not press the Feed button for more than

one second, the roller rotates for only 8 mm.

• Dispose the cleaning sheet after use.

Label outlet maintenance

When glue is attached to the label

outlet (metallic plate part and resin

guide part) and the printer damages

the label, pull out the power plug from

the socket and clean the label outlet

with a cloth dipped into ethanol or

isopropyl alcohol.

It is recommended to clean the label

outlet when replacing the cutter unit.

Feed button

STEP

3

Reference

Label outlet

Page 18

STEP2 Maintenance and Troubleshooting

16

Replacing the cutter unit

Eventually the cutting blade on the cutter unit will become dull (blunt) and need to be

replaced. At the appropriate time, purchase a new replacement cutter unit and install it

according to the following procedure.

Check that the cutter unit is located in the home position.

1

Turn OFF the power to the printer and pull out the power cord from

2

the wall socket.

Open the DK Roll cover and pull the roll

3

release lever to the up position. Remove the

DK Roll.

Lift up the cutter cover.

4

Using a cross-head screwdriver, loosen the

5

screw which holds the cutter blade unit inplace.

The screw securing the cutter unit should not be

completely removed. Simply loosen it to remove

the cutter unit from the printer.

Page 19

Grip the tab and lift out the cutter unit.

6

Take care not to touch the blade of the cutter.

Set the new cutter unit in the correct position.

7

17

Introduction

STEP

1

Once set in the correct position, tighten the

8

screw which holds the cutting blade unit in

place.

Set the DK Roll and close the DK Roll cover.

9

For details, refer to Î"Setting the DK Roll" in page 11.

CAUTION

Do not touch the blade of the cutter unit.

Do not open the top cover when the cutter is operating.

Do not apply excessive pressure to the cutter unit.

Getting Started

STEP

2

Troubleshooting

Maintenance and

STEP

3

Reference

Page 20

STEP2 Maintenance and Troubleshooting

18

Troubleshooting

If problems occur while using this printer, the following may help you to solve the

problems.

Potential types of problems

Problem Solution

• Is the USB cable loose?

Check that the USB cable is connected correctly.

•

The QL-500 does not

print, or a printing error

is received.

•

The power button does

not light up or flash.

•

The printed label

contains streaks or

poor quality characters,

or the label is not fed

correctly.

•

A data transmission

error appears on the

PC.

•

Labels are jammed in

the cutter or are not

ejected correctly after

printing.

•

The layout style is not

updated when the Addin is still activated and a

new label roll is

installed.

•

The P-touch Add-in

icon is not displayed in

Microsoft

®

Word.

• Is the DK Roll installed correctly?

If not, remove the DK Rolls and reinstall.

• Is there enough roll remaining?

Check that there is enough roll remaining.

• Is the DK Roll compartment cover open?

Check that the DK Roll compartment cover is closed.

• Is the power supply cord connected correctly?

Check that the power supply cord is connected and plugged in. If

connected correctly, try connecting it to another electrical socket.

* If the power button still does not light up or flash, contact the retail

outlet where the printer was purchased or your local authorized

service centre.

• Is the print head or roller dirty?

While the print head generally remains clean under normal use, lint or

dirt from the roller may become stuck on the printer head. If this occurs,

clean the roller. Refer to "Roller maintenance" in page 14.

• Is the correct port selected?

Check that the correct port is selected from the “Print to the following

port” list in the Printer Properties dialog box.

• Is the QL-500 in cooling mode (the LED lamp is flashing slowly)?

Wait until the LED lamp stops flashing and then try printing again.

• Does the edge of the cutter unit seem to have lost its sharpness?

• Do cutter errors occur frequently?

Replace the cutter. For details, refer to "Replacing the cutter unit" in

page 16.

• Is there dirt or lint on the roller preventing it from rolling freely?

Use a Cleaning Sheet to clean the roller. For details, refer to "Roller

maintenance" in page 14.

• Was a new label roll installed before activating the P-touch Add-In (The

P-touch function is added to your standard Microsoft toolbar)?

Exit the P-touch Add-In, load the second label roll type, reactivate the

P-touch Add-in, choose "Select Layout", and then verify the layout.

• Is Microsoft

• Is Microsoft

Outlook

Due to program limitations, the Microsoft

with the above settings. Quit Microsoft

Microsoft

®

Word started up from Microsoft® Outlook®?

®

Word chosen for the editor usually used for Microsoft®

®

?

®

Word.

®

Word Add-In does not work

®

Outlook®, and restart

Page 21

STEP3

STEP3

Reference

19

Introduction

STEP

1

Getting Started

STEP

2

Main specifications

For Australia Only:

ÎPage 20

ÎPage 21

Troubleshooting

Maintenance and

STEP

3

Reference

Page 22

STEP3 Reference

20

Main specifications

Product specifications

Items Specifications

Display LED lamp (green)

Printing method Direct thermal printing via thermal head

Printing speed

Printing

Buttons

Interface

Power source 220 - 240 VAC 50/60 Hz (0.9 A)

Dimensions 146 (W) × 196 (D) × 152 (H) mm

Weight Approx. 1.3 kg (Without DK Rolls)

Cutter Manual cutter

Print head 300 dpi/720 dot

Maximum Printing

Width

Minimum printing

length

Max.90 mm/sec, Max.56 labels/min.

(Standard Adress Labels)

59 mm

25 mm

ON/OFF button

FEED button

USB (USB Spec. 1.1 protocol)

Page 23

For Australia Only:

21

Warranty & Repair

For details about warranty on your Brother Product, the details are listed

on the following link:

http://www.brother.com.au/ServiceSupport.aspx

For warranty service (repair) of your Brother product you will need to retain

a copy of your sales docket and contact the Support Centre for location of

the nearest Authorised Warranty Centre (AWC).

Support

For technical support for your Brother Product other than what you can

resolve through the User's Guide, please visit our website for FAQs/

Troubleshooting, Drivers & Software, or contact the Product Support

Centre for any technical or customer care/support enquiry.

Product Support Centre: Australia

Brother International (Aust) Pty Ltd

Phone: 02 8875 6000

Fax: 02 9870 7223

E-mail: productsupport@brother.com.au

Web Site: www.brother.com.au

Solutions Site: http://solutions.brother.com

Introduction

STEP

.

1

Getting Started

STEP

2

Maintenance and

STEP

3

Troubleshooting

Reference

Page 24

Printed in China

LB8719001

Loading...

Loading...