MULTI-FUNCTION CENTER

SERVICE MANUAL

MODEL: MFC9600/MFC9850/MFC9870

DCP1200/MFC9750

© Copyright Brother 2000

All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation,

and maintenance of the Brother machine. It includes information required for field troubleshooting

and repair--disassembly, reassembly, and lubrication--so that service personnel will be able to

understand machine function, to rapidly repair the machine and order any necessary spare parts.

To perform appropriate maintenance so that the machine is always in best condition for the

customer, the service personnel must adequately understand and apply this manual.

This manual is made up of six chapters and appendices.

CHAPTER I. GENERAL DESCRIPTION

CHAPTER II. INSTALLATION

CHAPTER III. THEORY OF OPERATION

CHAPTER IV. DISASSEMBLY/REASSEMBLY AND LUBRICATION

CHAPTER V. MAINTENANCE MODE

CHAPTER VI. ERROR INDICATION AND TROUBLESHOOTING

Appendix 1. EEPROM Customizing Codes

Appendix 2. Circuit Diagrams

This manual describes the models and their versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

SAFETY INFORMATION

Laser Safety (110-120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health

and Safety Act of 1968. This means that the printer does not produce hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective housings and

external covers, the laser beam cannot escape from the machine during any phase of user

operation.

CDRH Regulations (110-120V Model only)

The Center for Device and Radiological Health (CDRH) of the US Food and Drug Administration

implemented regulations for laser products on August 2, 1976. These regulations apply to laser

products manufactured from August 1, 1976. Compliance is mandatory for products marketed in

the United States. The label shown below indicates compliance with the CDRH regulations and

must be attached to laser products marketed in the United States.

The label for Chinese products

MANUFACTURED: JULY 1999 C

BROTHER CORP. (ASIA) LTD.

BROTHER BUJI NAN LING FACTORY

Gold Garden Industry, Nan Ling Village, Buji,

Rong Gang, Shenzhen, China.

This product complies with FDA radiation

performance standards, 21 CFR Subchapter J.

CHAPTER I.

GENERAL DESCRIPTION

CHAPTER I. GENERAL DESCRIPTION

CONTENTS

1. MACHINE OUTLINE.............................................................................................I-1

1.1External Appearance and Weight.................................................................I-1

1.2Components.................................................................................................I-1

2. SPECIFICATIONS................................................................................................I-2

1. MACHINE OUTLINE

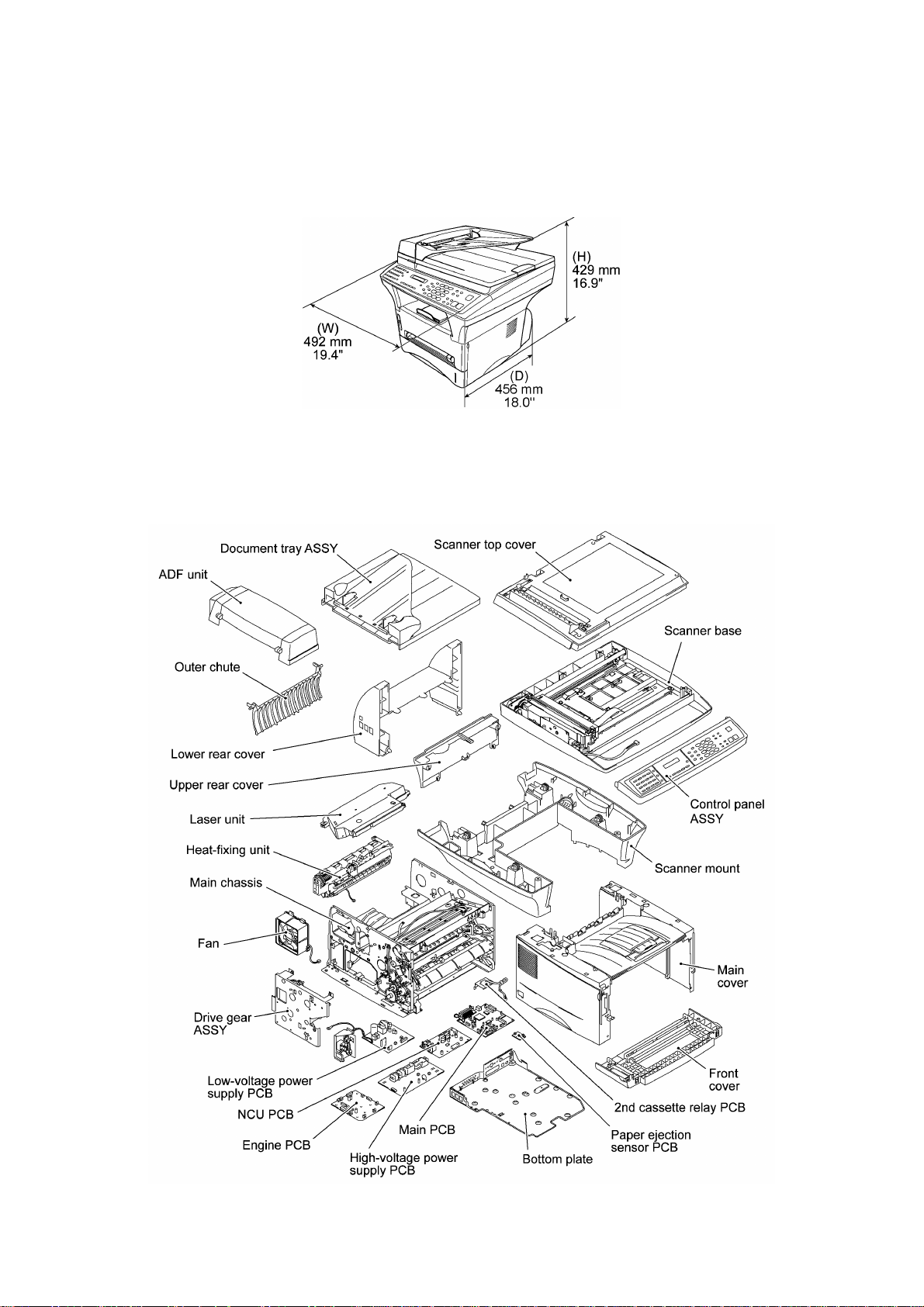

1.1 External Appearance and Weight

The figure below shows the machine appearance and approximate dimensions.

Weight: Machine proper 15.2 kg

Machine (incl. drum unit & toner cartridge) 17.0 kg

In package 21.2 kg

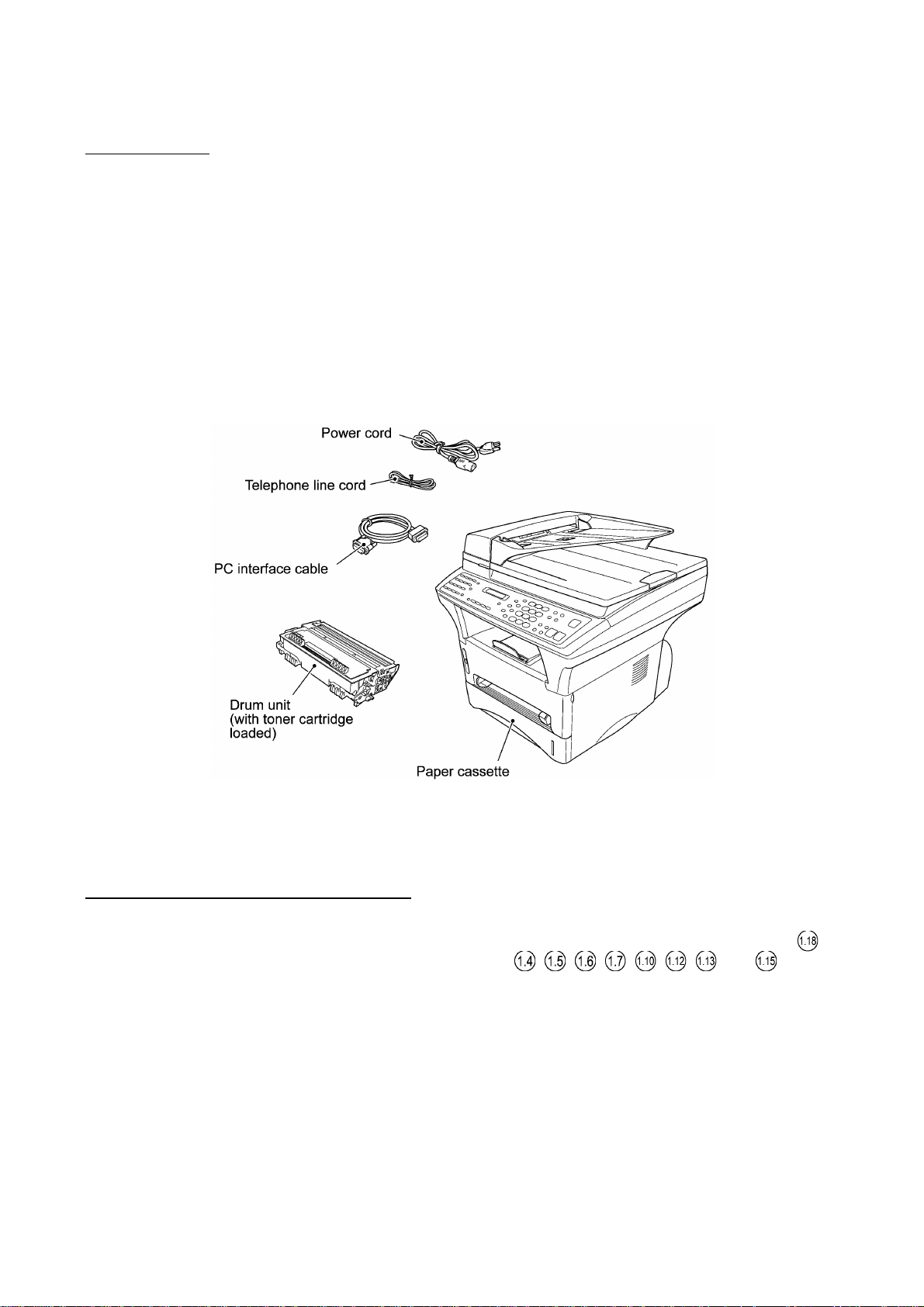

1.2 Components

The machine consists of the following major components:

I - 1

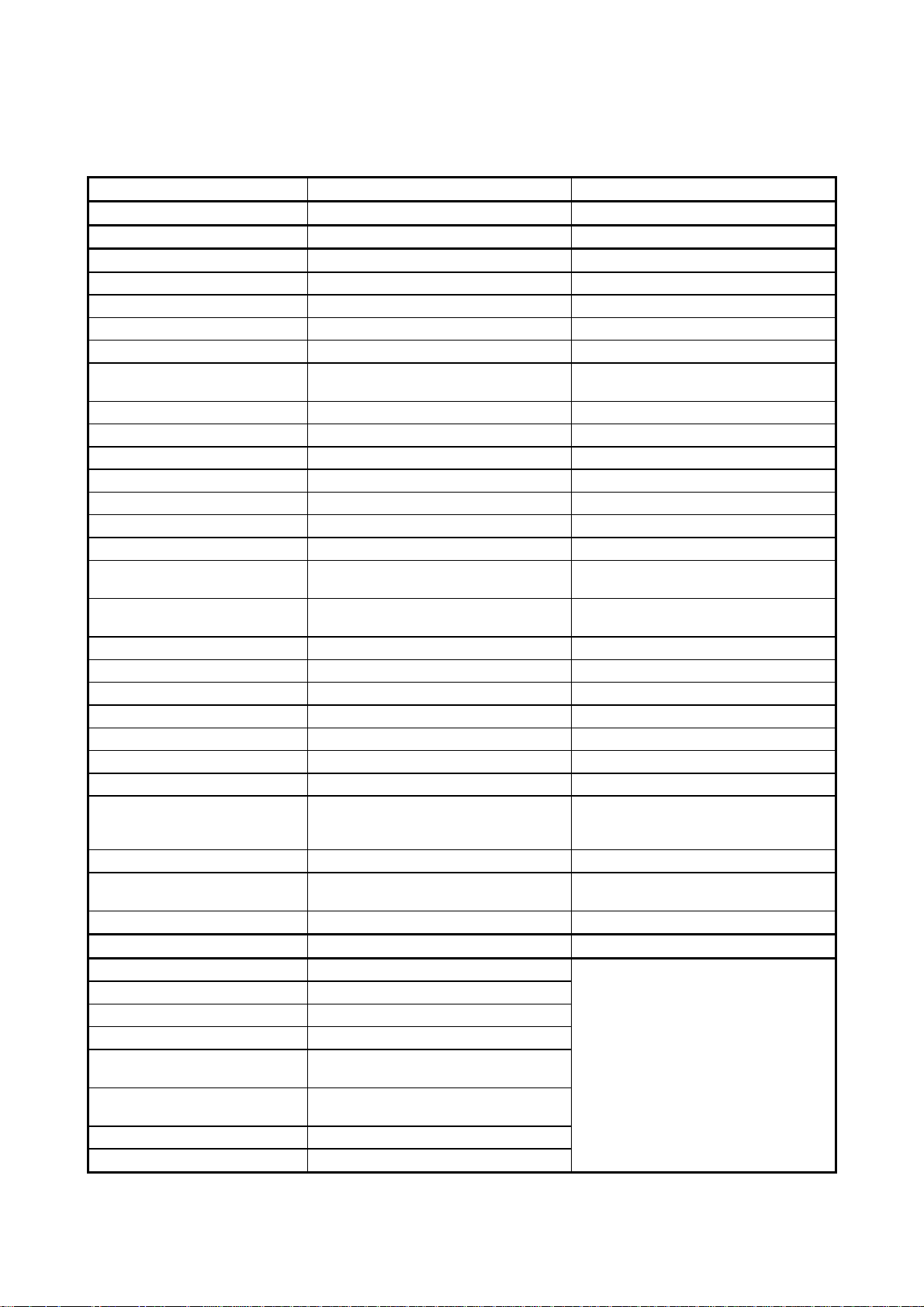

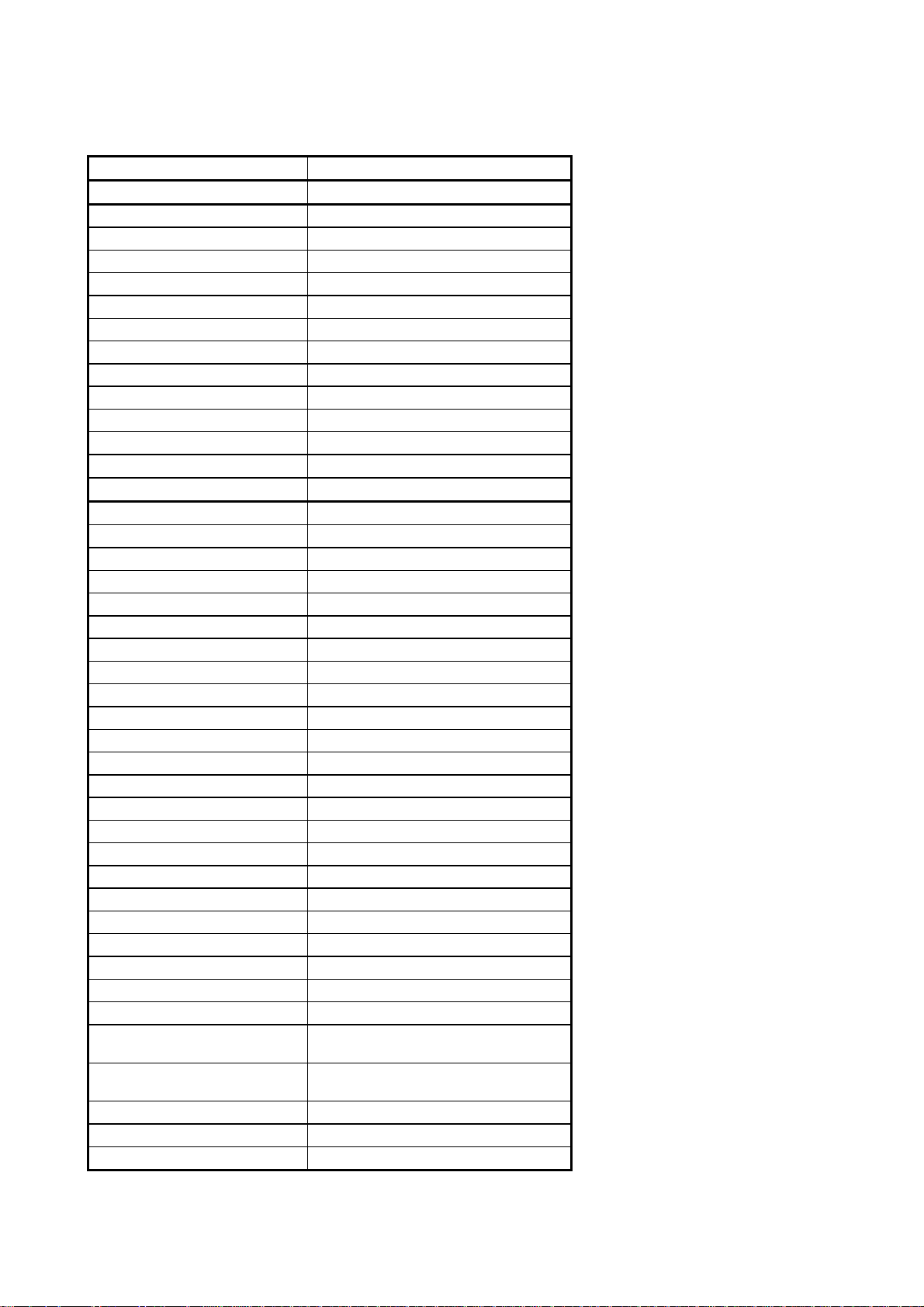

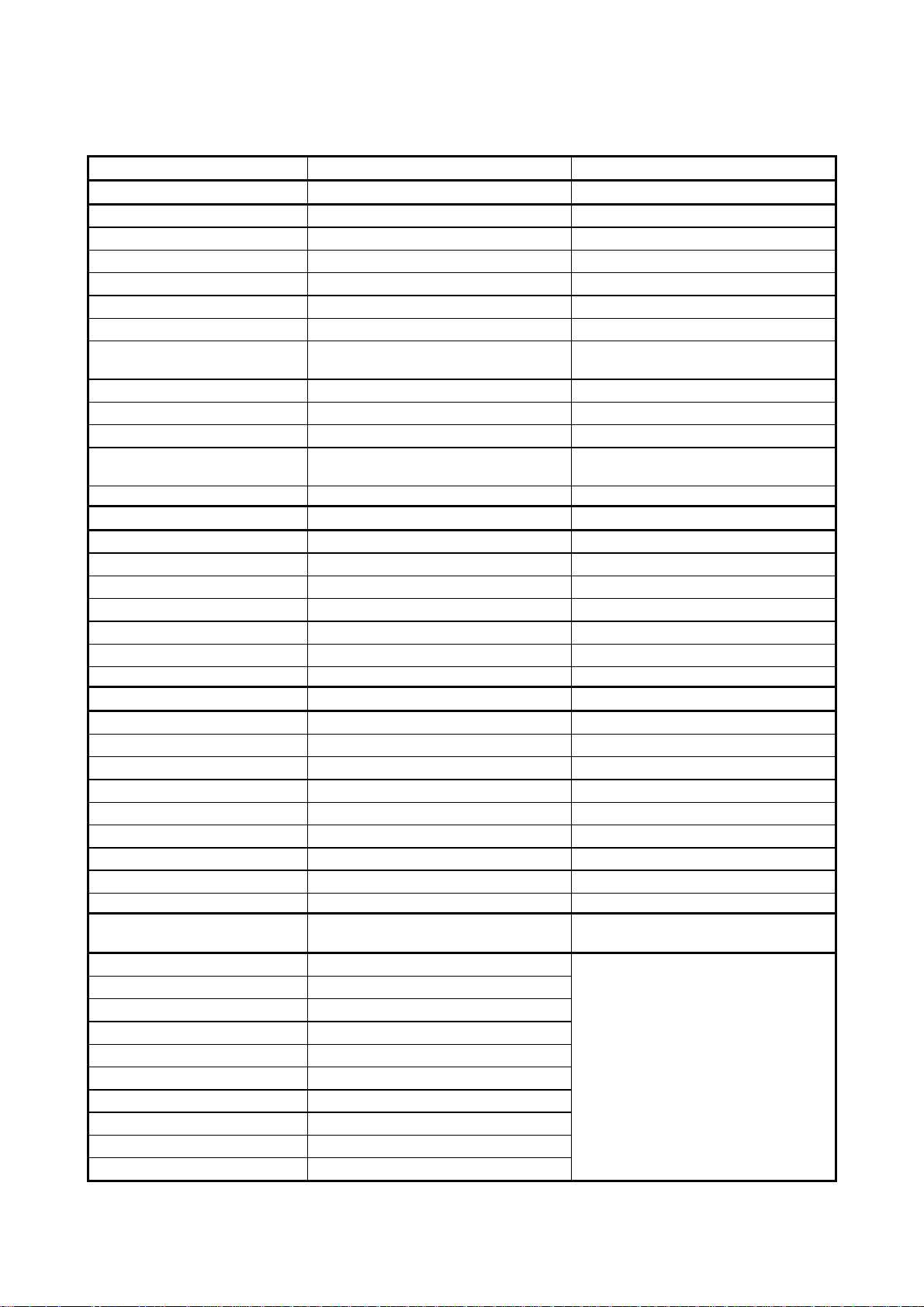

2. SPECIFICATIONS

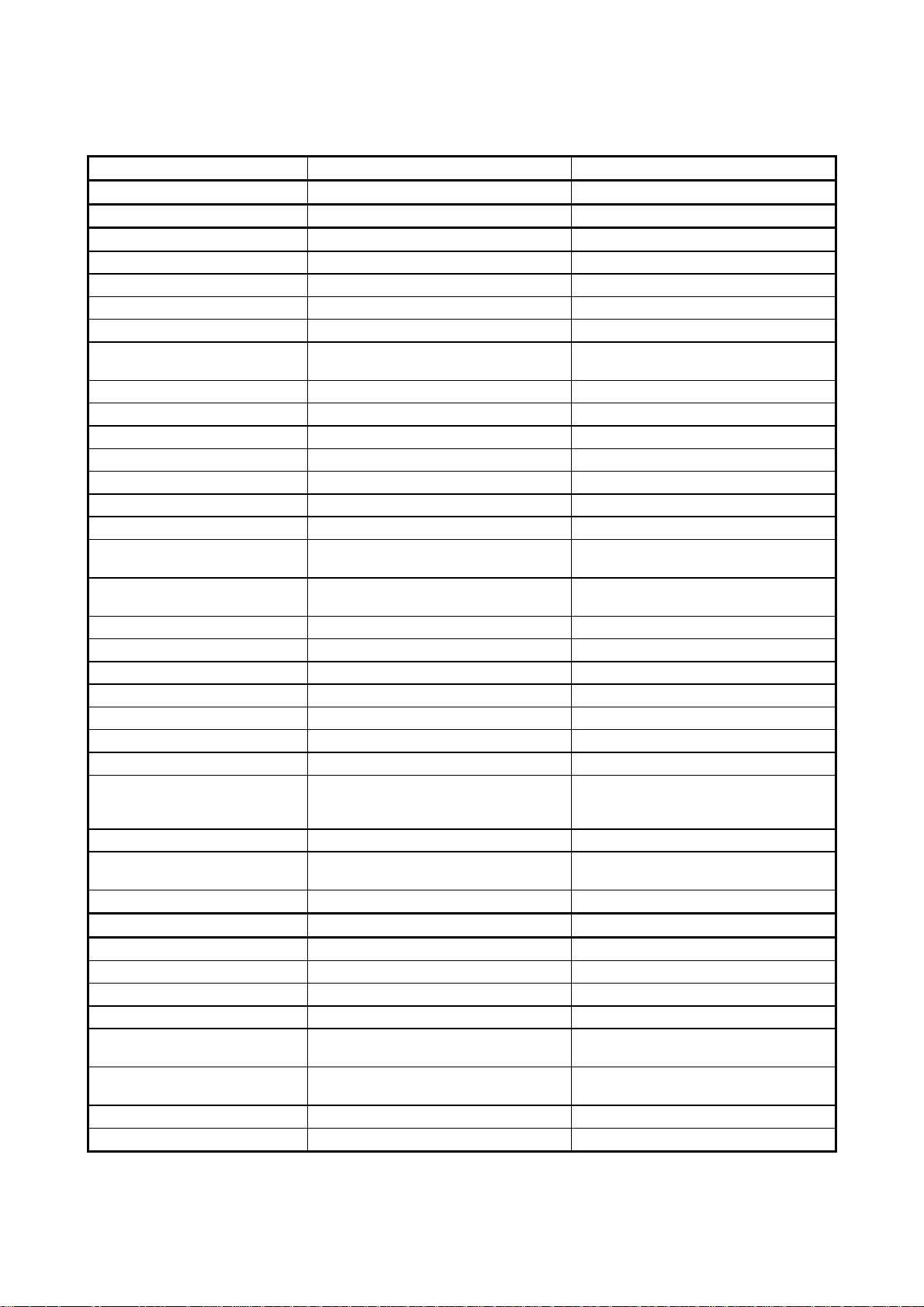

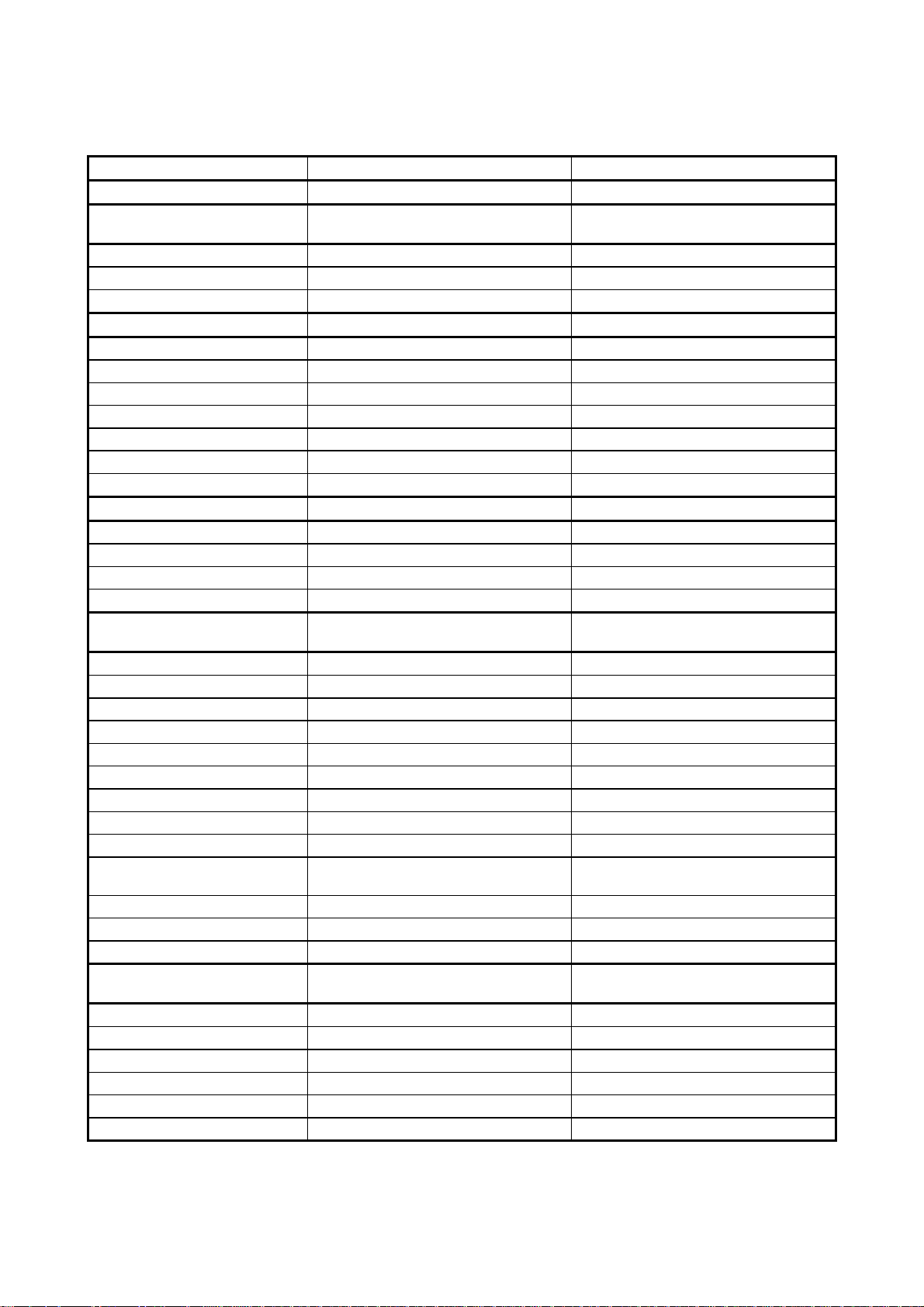

Machine Type Multi-Function Center w/ Fax Multi-Function Center w/o Fax

Model MFC9600 DCP1200

GENERAL

Print Engine Laser (ZL) Laser (ZL)

Modem Speed (bps) 14,400 (Fax)

Transmission Speed (sec.) 5

ITU-T Group G3

Coding System MH/MR/MMR/JBIG

Input/Output Width FB: 8.5" x 11"

ADF: 5.8" to 8.5"/2.75" to 8.5"

ADF (pages) Up to 50 Up to 50

LCD 16 chars x 2 lines 16 chars x 2 lines

On-Screen Programming Yes Yes

Backup Clock Yes (1 hour) Yes (1 hour)

Memory Capacity 8 MB 8 MB

Backup Memory No No

Optional Memory Yes (8 & 16 MB) Yes (8 & 16 MB)

Dimensions w/ Carton (WxDxH) 23.5 x 22.3 x 22.8 inches

598 x 567 x 580 mm

Dimensions w/o Carton (WxDxH) 19.4x18x16.9 inches

492x456x429 mm

Weight w/o Carton 17 kg 17 kg

Weight w/ Carton 21.2 kg 21.2 kg

Color Gray 1495 Gray 1495

Standby Mode Yes Yes

PC-Fax Protocol Compliance Class 2

Simultaneous Operation Yes (Print/Fax, Print/Copy, Print/Scan) Yes (Print/Copy, Print/Scan)

Energy Star Compliance Yes Yes

Operating Environment

Temperature

Humidity

Power Source 120 VAC, 50/60 Hz 120 VAC, 50/60 Hz

Power Consumption

(Sleep/Standby/Peak)

On/Off Switch No Yes

TELEPHONE No

Automatic Redial Yes

Handset No

One-Touch Dial 32 (16x2)

Speed Dial 100

Max. Number of Digits for One-

Touch & Speed Dial

Registerable Number Of

Characters

Telephone Index Yes (Normal)

Speaker Phone No (Only On-HOOK/Monitor Available)

Less than 14W/60W/850W Less than 14W/60W/850W

5°C to 35°C

60% ±25%

20 digits

15 chars

ADF: 5.8" to 8.5"/2.75" to 8.5"

FB: 8.5" x 11"

23.5 x 22.3 x 22.8 inches

598 x 567 x 580 mm

19.4x18x16.9 inches

492x456x429 mm

5°C to 35°C

60% ±25%

(1/6)

I - 2

(1/6)

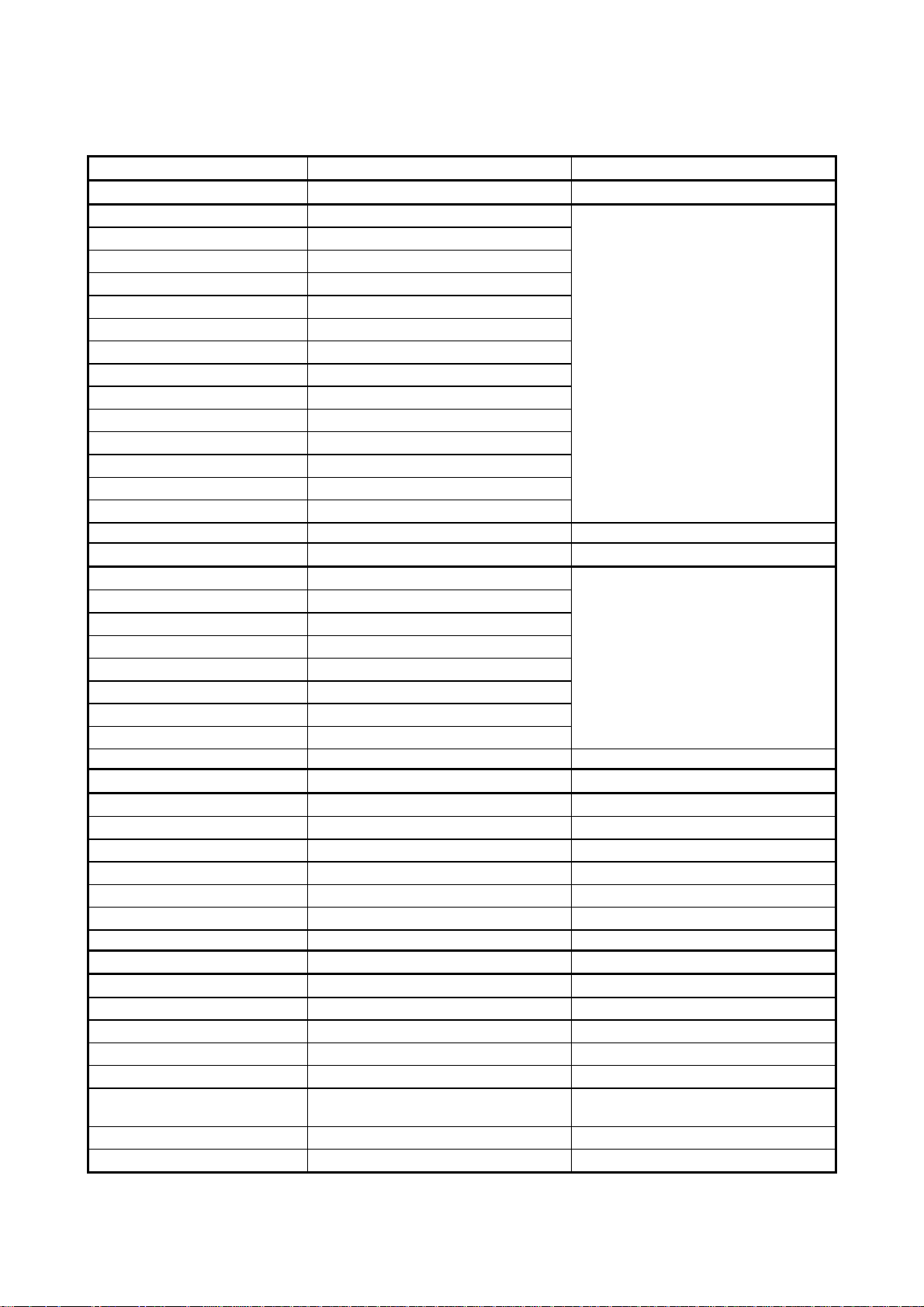

Machine Type Multi-Function Center w/ Fax Multi-Function Center w/ Fax

Model MFC9870 MFC9850

GENERAL

Print Engine Laser (ZL) Laser (ZL)

Modem Speed (bps) 14,400 (Fax) 14,400 (Fax)

Transmission Speed (sec.) 5 5

ITU-T Group G3 G3

Coding System MH/MR/MMR/JBIG MH/MR/MMR/JBIG

Input/Output Width FB: 8.5" x 11"

ADF: 5.8" to 8.5"/2.75" to 8.5"

ADF (pages) Up to 50 Up to 50

LCD 16 chars x 2 lines 16 chars x 2 lines

On-Screen Programming Yes Yes

Backup Clock Yes (9 hours) Yes (9 hours)

Memory Capacity 4 MB (RAM) + 4 MB (flash ROM) 4 MB (RAM) + 2 MB (flash ROM)

Backup Memory 2 MB (flash ROM) 2 MB (flash ROM)

Optional Memory Yes (RAM: 8 & 16 MB, ROM: 4 & 2 MB) Yes (RAM: 8 & 16 MB)

Dimensions w/ Carton (WxDxH) 23.5 x 22.3 x 22.8 inches

598 x 567 x 580 mm

Dimensions w/o Carton (WxDxH) 19.4x18x16.9 inches

492x456x429 mm

Weight w/o Carton 17 kg 17 kg

Weight w/ Carton 21.2 kg 21.2 kg

Color Gray 1495 Gray 1495

Standby Mode Yes Yes

PC-Fax Protocol Compliance Class 2

Simultaneous Operation Yes (Print/Fax, Print/Copy, Print/Scan) Yes (Print/Fax, Print/Copy, Print/Scan)

Energy Star Compliance Yes Yes

Operating Environment

Temperature

Humidity

Power Source 220 VAC, 50/60 Hz 220 VAC, 50/60 Hz

Power Consumption

(Sleep/Standby/Peak)

On/Off Switch No No

TELEPHONE

Automatic Redial Yes Yes

Handset No No

One-Touch Dial 32 (16x2) 32 (16x2)

Speed Dial 100 100

Max. Number of Digits for One-

Touch & Speed Dial

Registerable Number Of

Characters

Telephone Index Yes (Normal) Yes (Normal)

Speaker Phone No No

Less than 14W/60W/800W Less than 14W/60W/800W

5°C to 35°C

60% ±25%

20 digits 20 digits

15 chars 15 chars

ADF: 5.8" to 8.5"/2.75" to 8.5"

FB: 8.5" x 11"

23.5 x 22.3 x 22.8 inches

598 x 567 x 580 mm

19.4x18x16.9 inches

492x456x429 mm

5°C to 35°C

60% ±25%

I - 3

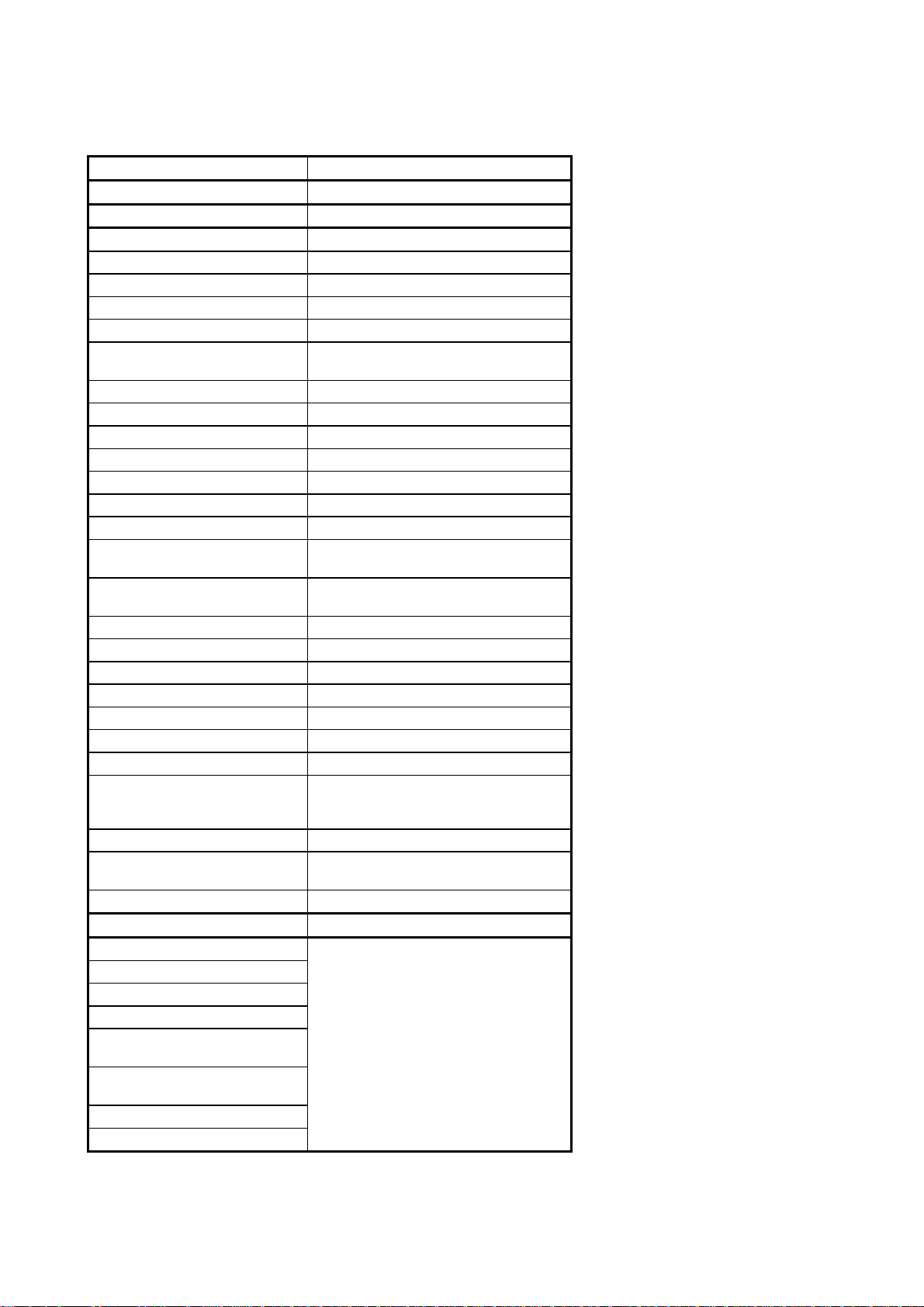

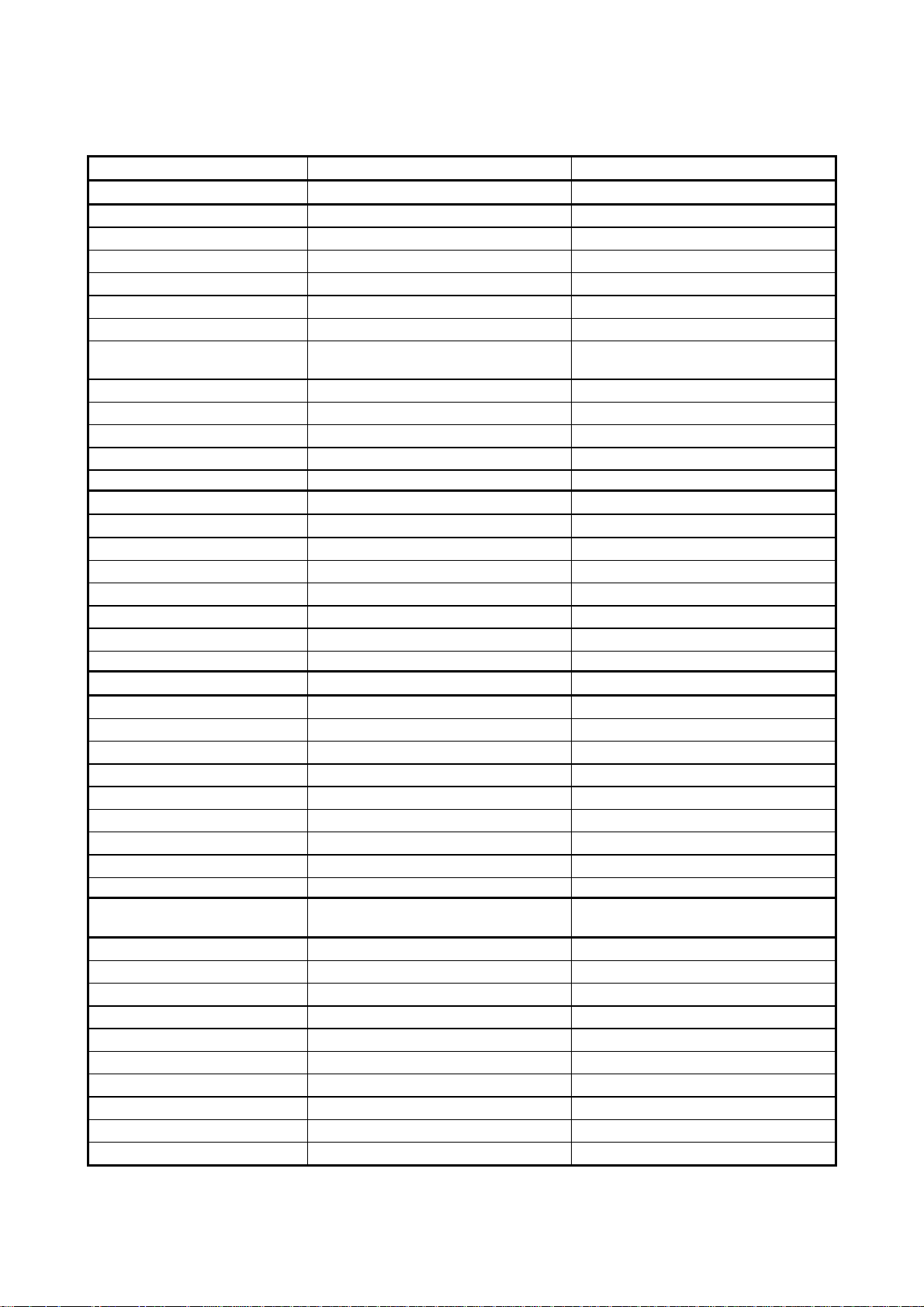

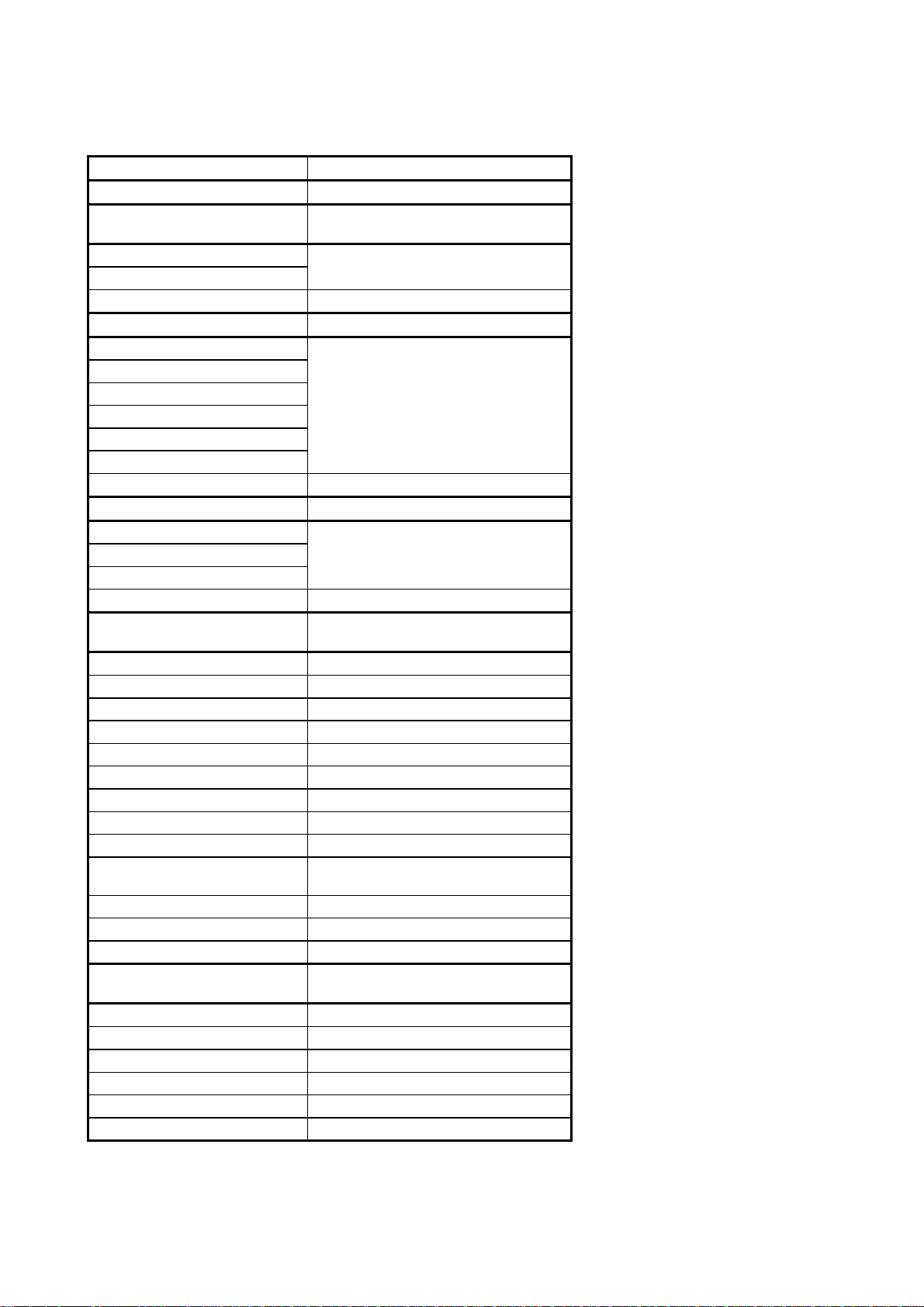

Machine Type Multi-Function Center w/o Fax

Model MFC9750

GENERAL

Print Engine Laser (ZL)

Modem Speed (bps)

Transmission Speed (sec.)

ITU-T Group

Coding System

Input/Output Width FB: 8.5" x 11"

ADF: 5.8" to 8.5"/2.75" to 8.5"

ADF (pages) Up to 50

LCD 16 chars x 2 lines

On-Screen Programming Yes

Backup Clock No

Memory Capacity 4 MB (RAM)

Backup Memory No

Optional Memory Yes (RAM: 8 & 16 MB)

Dimensions w/ Carton (WxDxH) 23.5 x 22.3 x 22.8 inches

598 x 567 x 580 mm

Dimensions w/o Carton (WxDxH) 19.4x18x16.9 inches

492x456x429 mm

Weight w/o Carton 17 kg

Weight w/ Carton 21.2 kg

Color Gray 1495

Standby Mode Yes

PC-Fax Protocol Compliance

Simultaneous Operation Yes (Print/Copy, Print/Scan)

Energy Star Compliance Yes

Operating Environment

Temperature

Humidity

Power Source 220 VAC, 50/60 Hz

Power Consumption

(Sleep/Standby/Peak)

Less than 14W/60W/800W

5°C to 35°C

60% ±25%

(1/6)

TELEPHONE No

Automatic Redial

Handset

One-Touch Dial

Speed Dial

Max. Number of Digits for One-

Touch & Speed Dial

Registerable Number Of

Characters

Telephone Index

Speaker Phone

I - 4

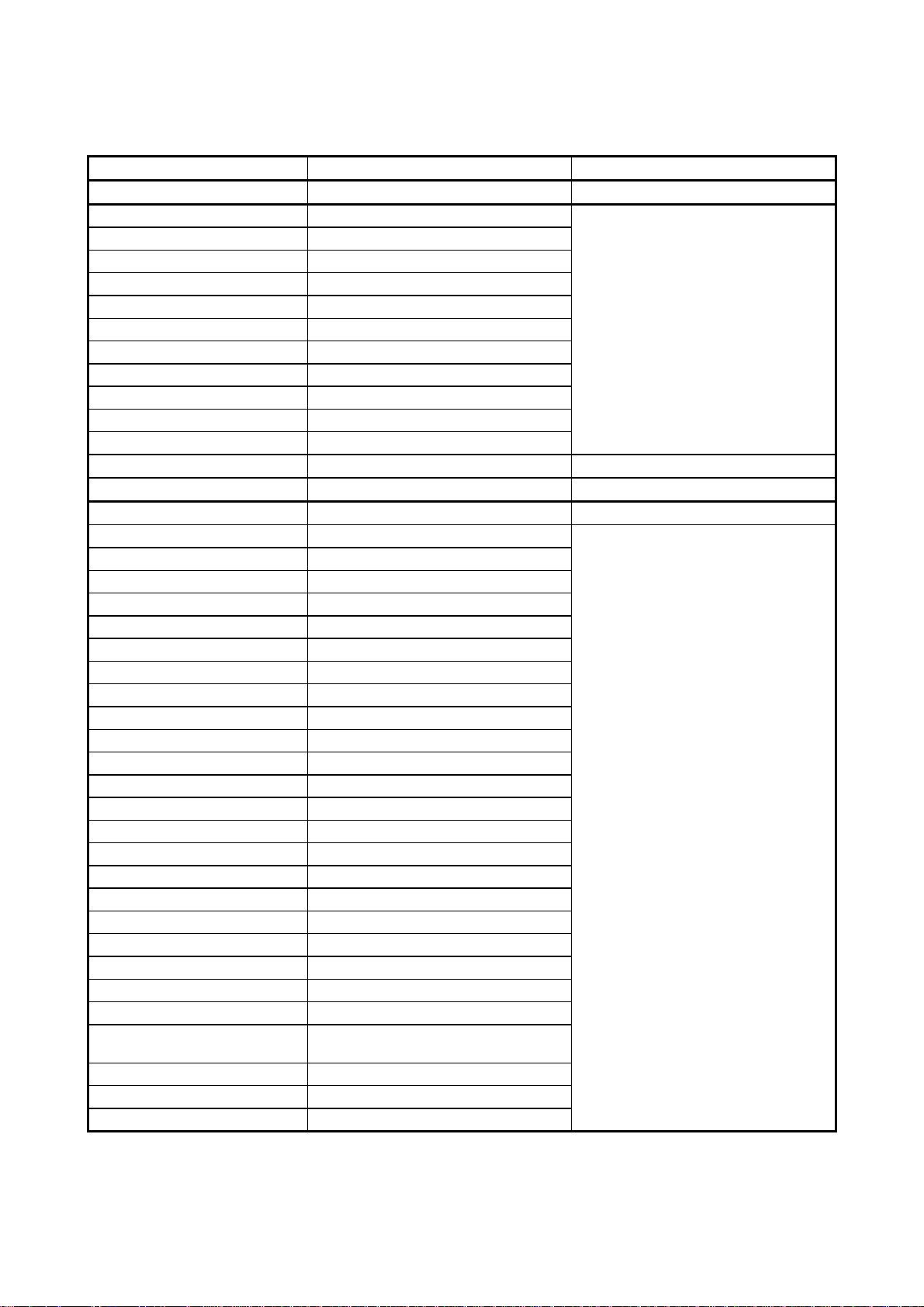

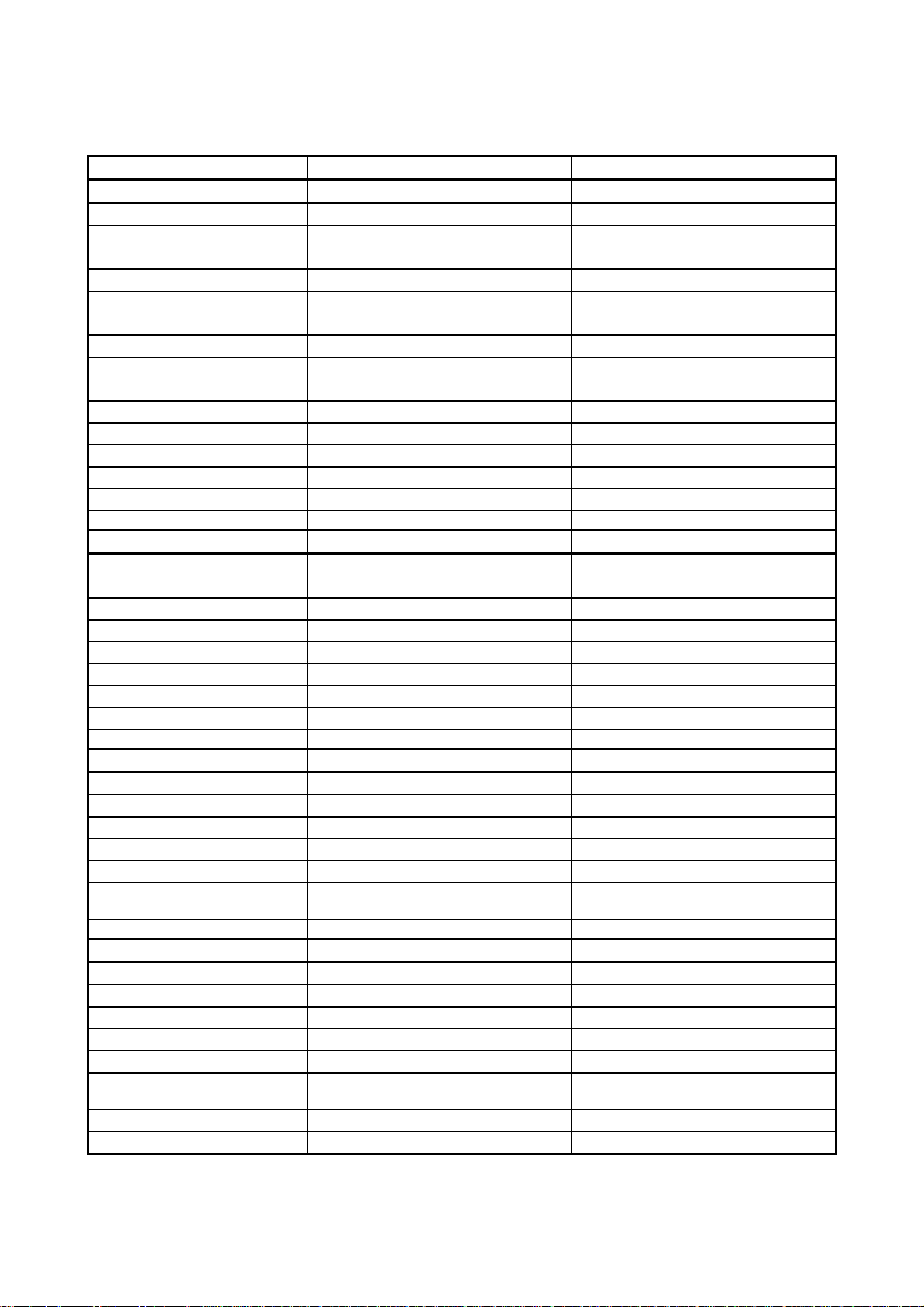

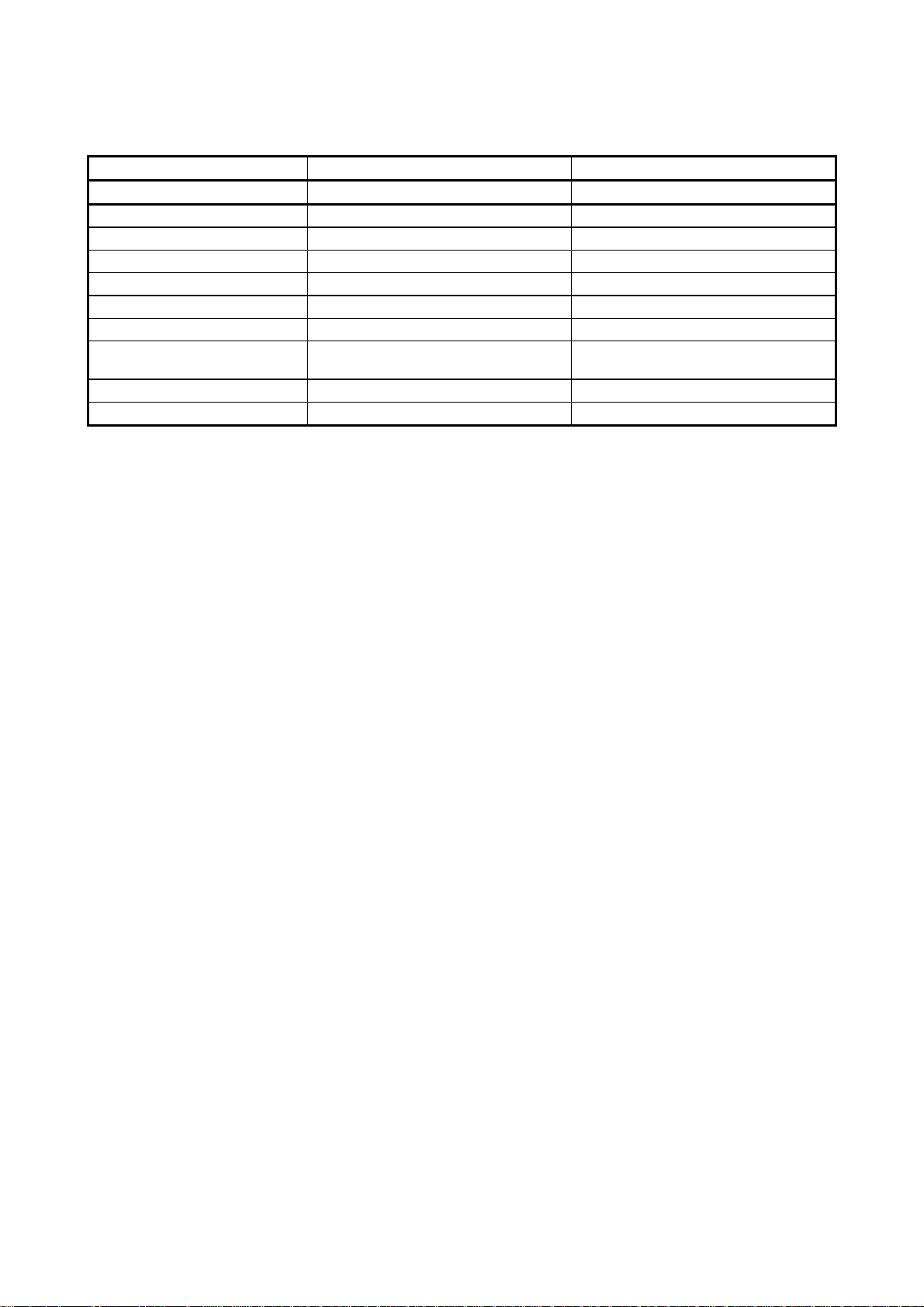

Machine Type Multi-Function Center w/ Fax Multi-Function Center w/o Fax

Model MFC9600 DCP1200

Chain Dialing Yes

Caller ID Yes

Call Waiting Caller ID No

Distinctive Ringing Yes

Hold/Mute Key No

Power Failure Dialing No

Speaker Volume Yes (3 steps + OFF)

Ringer Volume Yes (3 steps + OFF)

Handset Volume No

PBX Feature No

Transfer Method Flash

FAX No

Internet FAX Yes (Network/PC) LAN, NetCentric Yes (Network/PC), NetCentric

Data Modem No

Easy Receive/Fax Detect Yes

Fax/Tel Switch No

Super Fine Yes (TX & RX)

300 dpi Transmission No

Gray Scale 64

Contrast Yes (Auto/S.Light/S.Dark)

Smoothing Yes

Call Reservation Over Auto TX No

Password Check No

Enhanced Remote Activation Yes

Multi-Resolution Transmission Yes

Multi-Transmission No

Next-Fax Reservation Yes (Dual Access)

Delayed Timer Yes (50 timers/50 jobs)

Polling Yes (Std/Seq)

Quick-Scan Key (Memory TX w/o key)

Scan Speed (A4:Standard) Approx. 2 sec./page (A4:standard)

Memory Transmission 700 pages

Broadcasting Yes (182 locations)

Batch Transmission Yes

Auto Reduction Yes

Out-of-Paper Reception

(Brother #1 Chart)

Dual Access Yes

ECM (Error Correction Mode) Yes

ITU SUB Addressing No

Up to 310 pages

(2/6)

I - 5

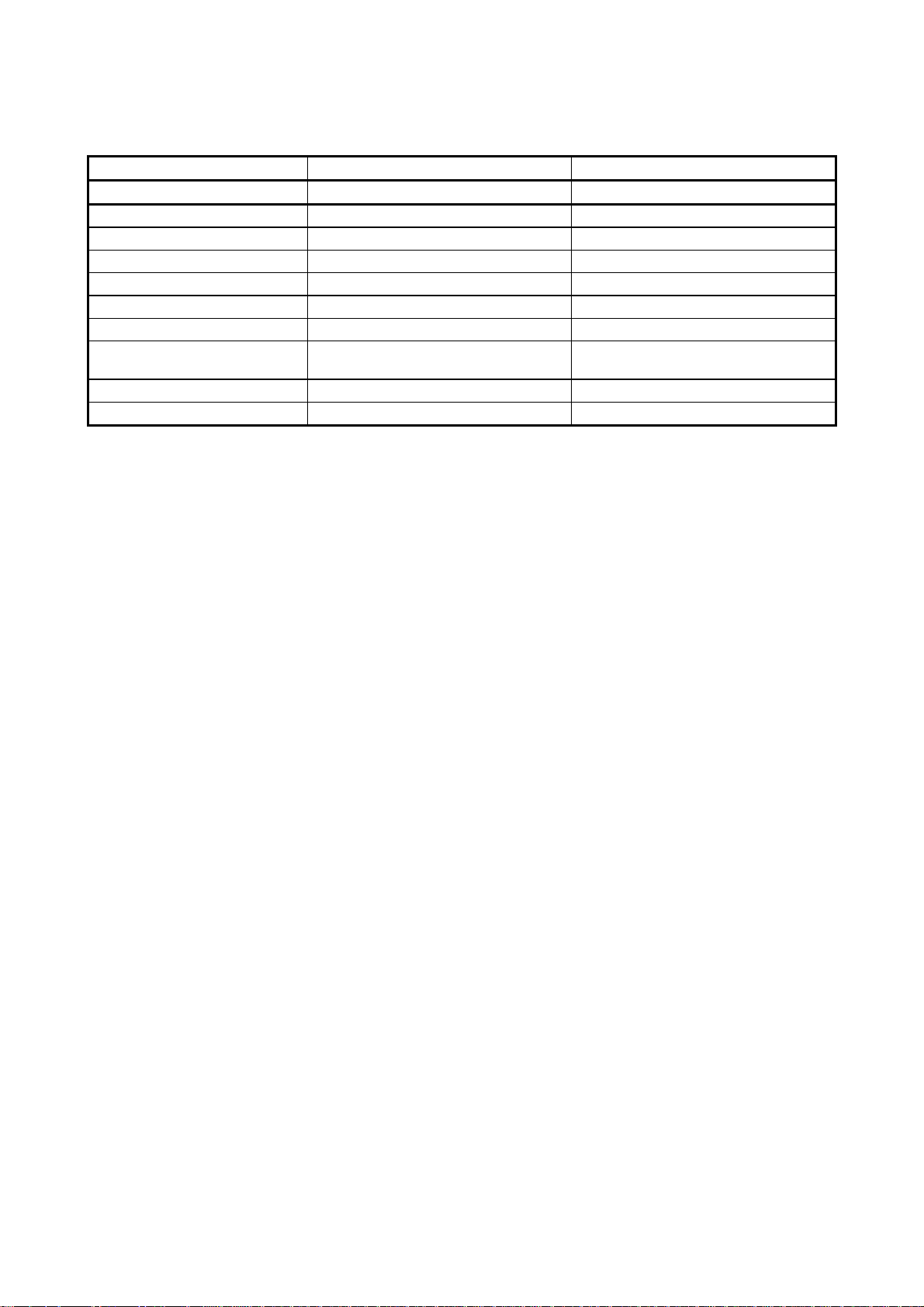

Machine Type Multi-Function Center w/ Fax Multi-Function Center w/ Fax

Model MFC9870 MFC9850

Chain Dialing Yes Yes

Caller ID No No

Call Waiting Caller ID No No

Distinctive Ringing Yes (U.K. DEN) Yes (U.K. DEN)

Hold/Mute Key No No

Power Failure Dialing No No

Speaker Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Ringer Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Handset Volume No No

PBX Feature Yes Yes

Transfer Method Flash Flash

FAX

Internet FAX Yes (Network), available w/ option No

Data Modem No No

Easy Receive/Fax Detect Yes Yes

Fax/Tel Switch No No

Super Fine Yes (TX & RX) Yes (TX & RX)

300 dpi Transmission No No

Gray Scale 64 64

Contrast Yes (Auto/S.Light/S.Dark) Yes (Auto/S.Light/S.Dark)

Smoothing Yes Yes

Call Reservation Over Auto TX No No

Password Check No No

Enhanced Remote Activation Yes Yes

Multi-Resolution Transmission Yes Yes

Multi-Transmission No No

Next-Fax Reservation Yes (Dual Access) Yes (Dual Access)

Delayed Timer Yes (50 timers/50 jobs) Yes (50 timers/50 jobs)

Polling Yes (Std/Seq/Sec/Del) Yes (Std/Seq/Sec/Del)

Quick-Scan Key (Memory TX w/o key) (Memory TX w/o key)

Scan Speed (A4:Standard) Approx. 2 sec./page (A4:standard) Approx. 2 sec./page (A4:standard)

Memory Transmission 250 pages 250 pages

Broadcasting Yes (182 locations) Yes (182 locations)

Batch Transmission Yes Yes

Auto Reduction Yes Yes

Out-of-Paper Reception

(ITU-T Chart)

Dual Access Yes Yes

ECM (Error Correction Mode) Yes Yes

ITU SUB Addressing Yes (Wordcraft S/W) No

Up to 150 pages Up to 150 pages

(2/6)

I - 6

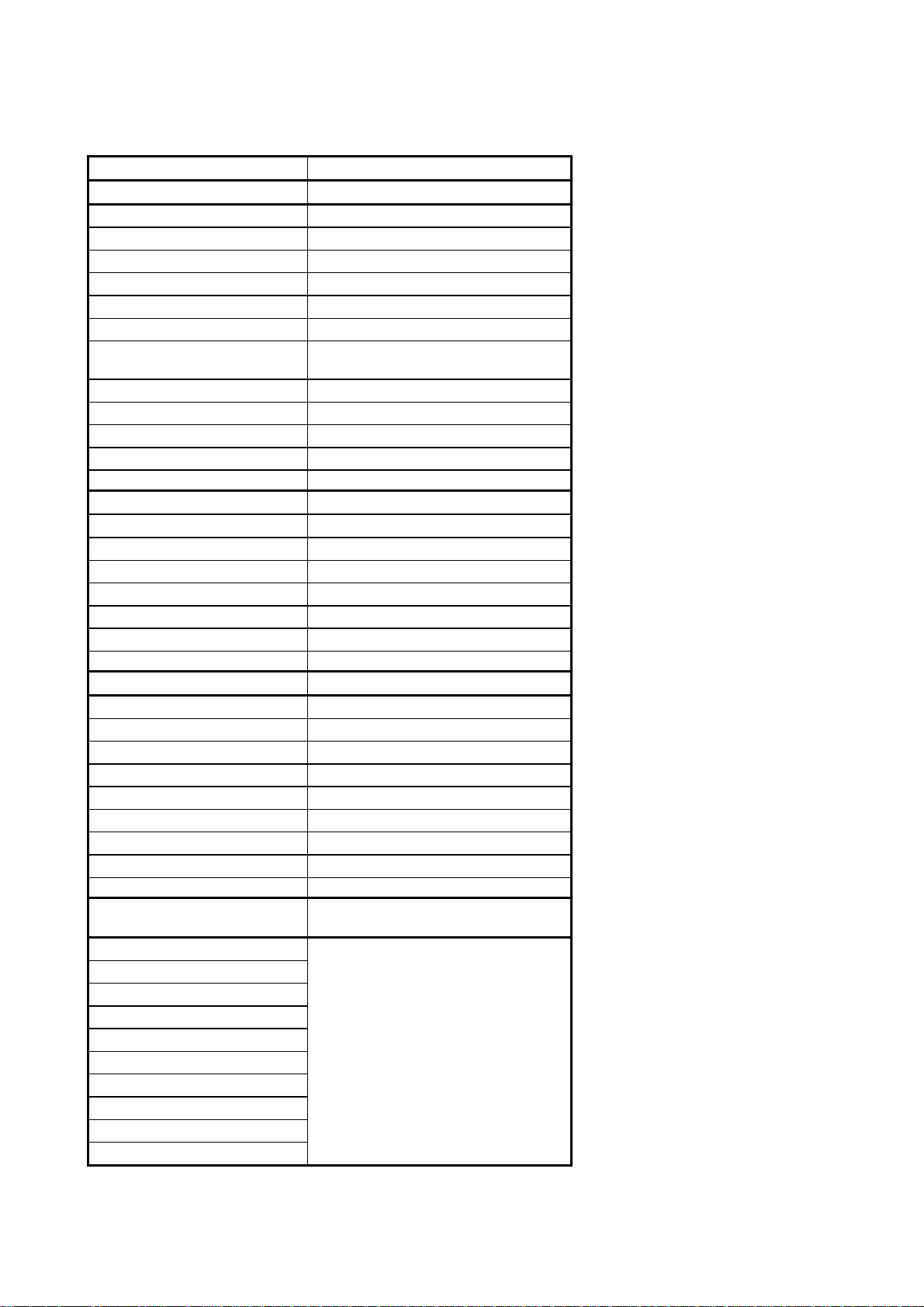

Machine Type Multi- Function Center w/o Fax

Model MFC9750

Chain Dialing

Caller ID

Call Waiting Caller ID

Distinctive Ringing

Hold/Mute Key

Power Failure Dialing

Speaker Volume

Ringer Volume

Handset Volume

PBX Feature

Transfer Method

FAX No

Internet FAX

Data Modem

Easy Receive/Fax Detect

Fax/Tel Switch

Super Fine

300 dpi Transmission

Gray Scale

Contrast

Smoothing

Call Reservation Over Auto TX

Password Check

Enhanced Remote Activation

Multi-Resolution Transmission

Multi-Transmission

Next-Fax Reservation

Delayed Timer

Polling

Quick-Scan Key

Scan Speed (A4:Standard)

Memory Transmission

Broadcasting

Batch Transmission

Auto Reduction

Out-of-Paper Reception

(Brother #1 Chart)

Out-of-Paper Reception

(ITU-T Chart)

Dual Access

ECM (Error Correction Mode)

ITU SUB Addressing

(2/6)

I - 7

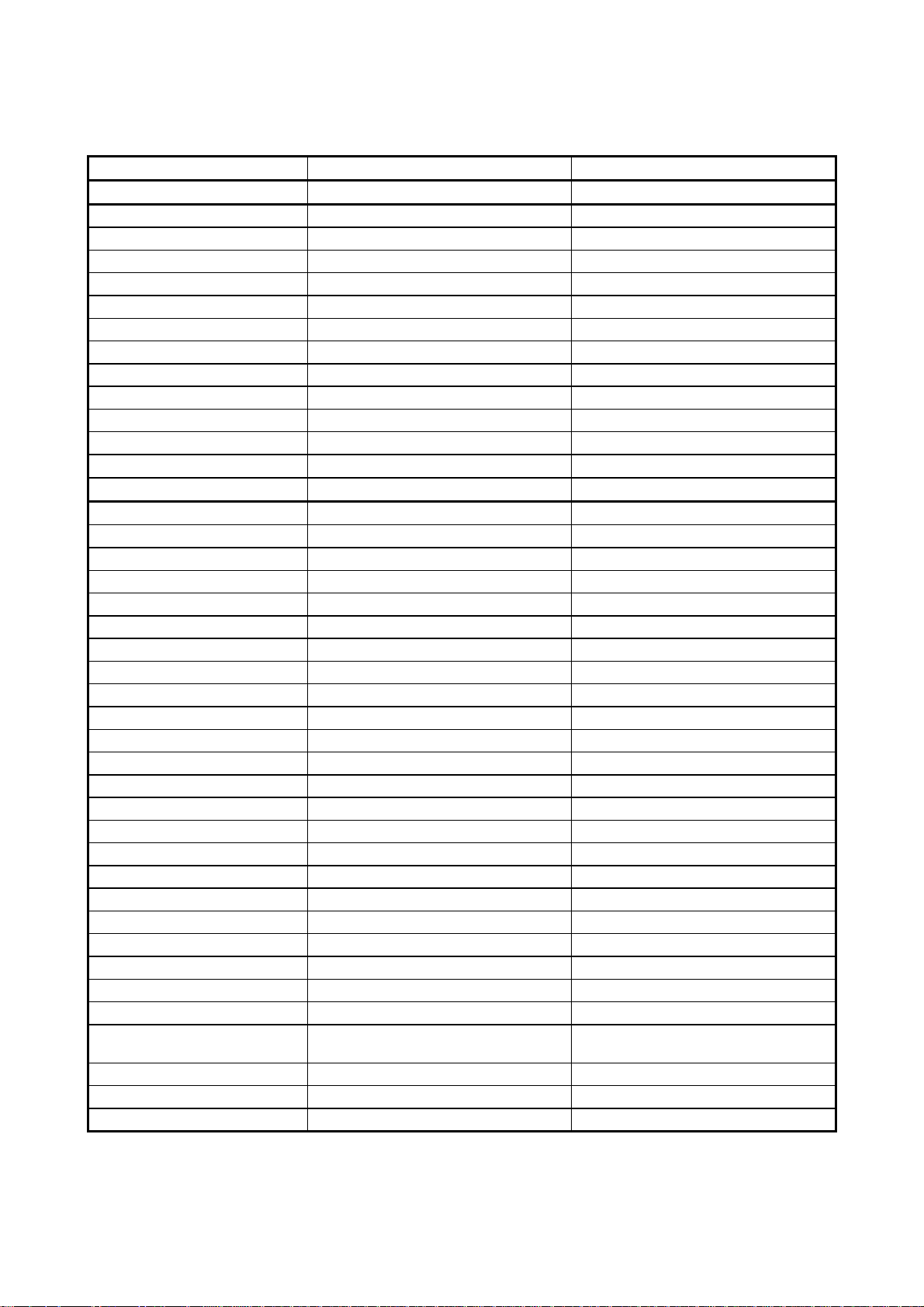

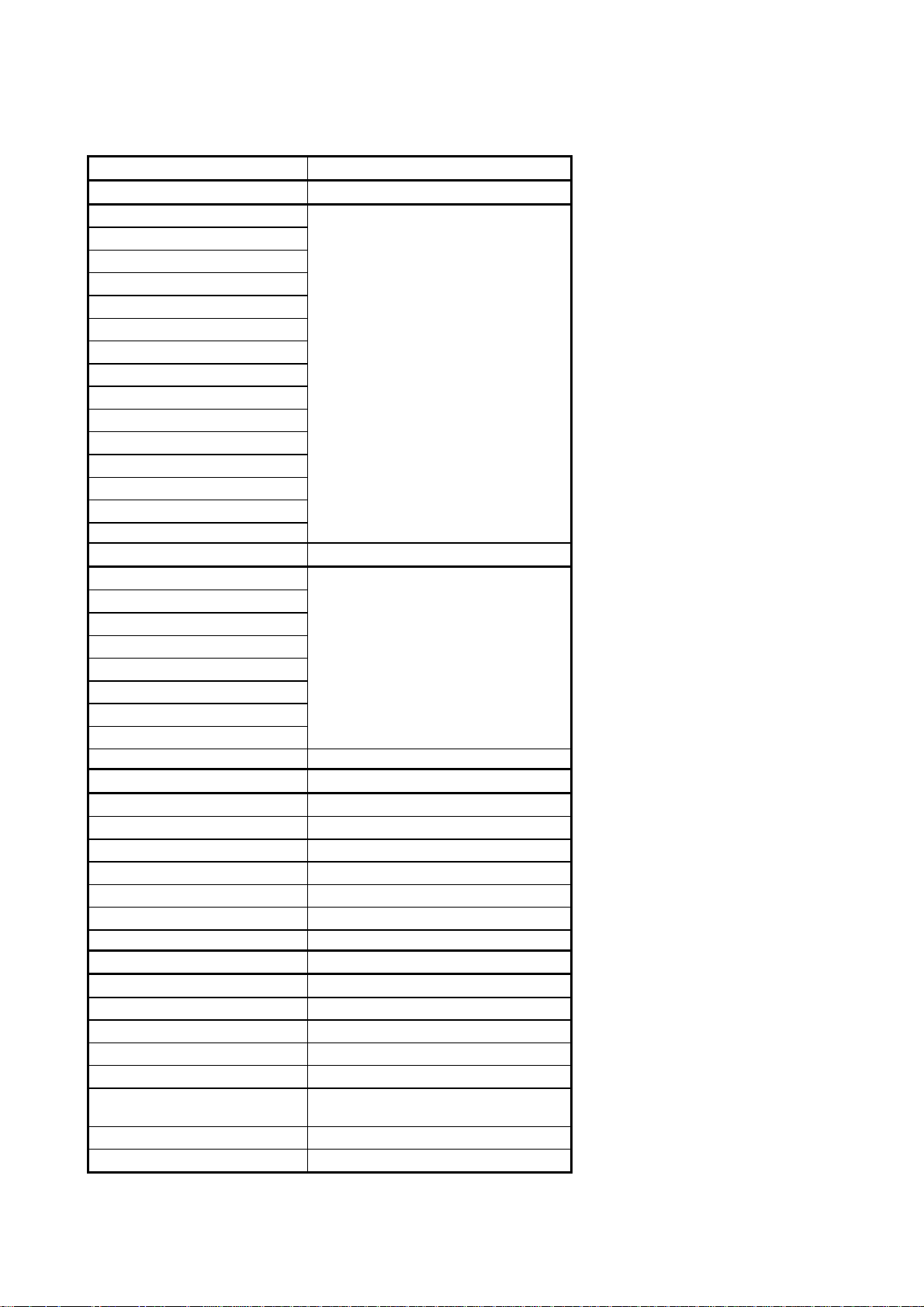

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/o Fax

Model MFC9600 DCP1200

Group Dial Yes (6)

Error Re-Transmission No

Station ID 1 (20 digits/20 chars)

Off-Hook Alarm No

Remote Maintenance Yes

Call Reservation Over Manual TX No

RX Mode Indication LCD

Resolution Indication LED

Memory Security No

Color FAX No

Manual Broadcasting Yes

LCD Language English

OPEN LCR No

E-MAIL FAX Via Net work/PC

LIST/REPORT No

Activity Report/Journal Report Yes (up to 50)

Transmission Verification Report Yes

Coverpage Yes (Super)

Help List Yes

Callback Message No

Caller ID List Yes

ALL Dial List Yes

Tel Index List Yes

(3/6)

INTERFACE

External TAD Interface Yes No

Missing Link/PC Interface No No

Host Interface (Serial) No No

Host Interface (IEEE1284) Yes Yes

Host Interface (USB) Yes Yes

LAN Interface Yes (10-Base T: LAN Board) Yes

PRINTER

Color/Mono Mono Mono

Engine Type Laser (ZL) Laser (ZL)

Resolution (dpi) 600 x 600 600 x 600

Speed (ppm) 12 12

Paper Capacity (sheets) 250 250

Additional Paper Capacity

(sheets)

Output Paper Capacity (sheets) 150 150

Standard Print Language Windows GDI (600 x 600) Windows GDI (600 x 600)

250 (User Option) 250 (User Option)

I - 8

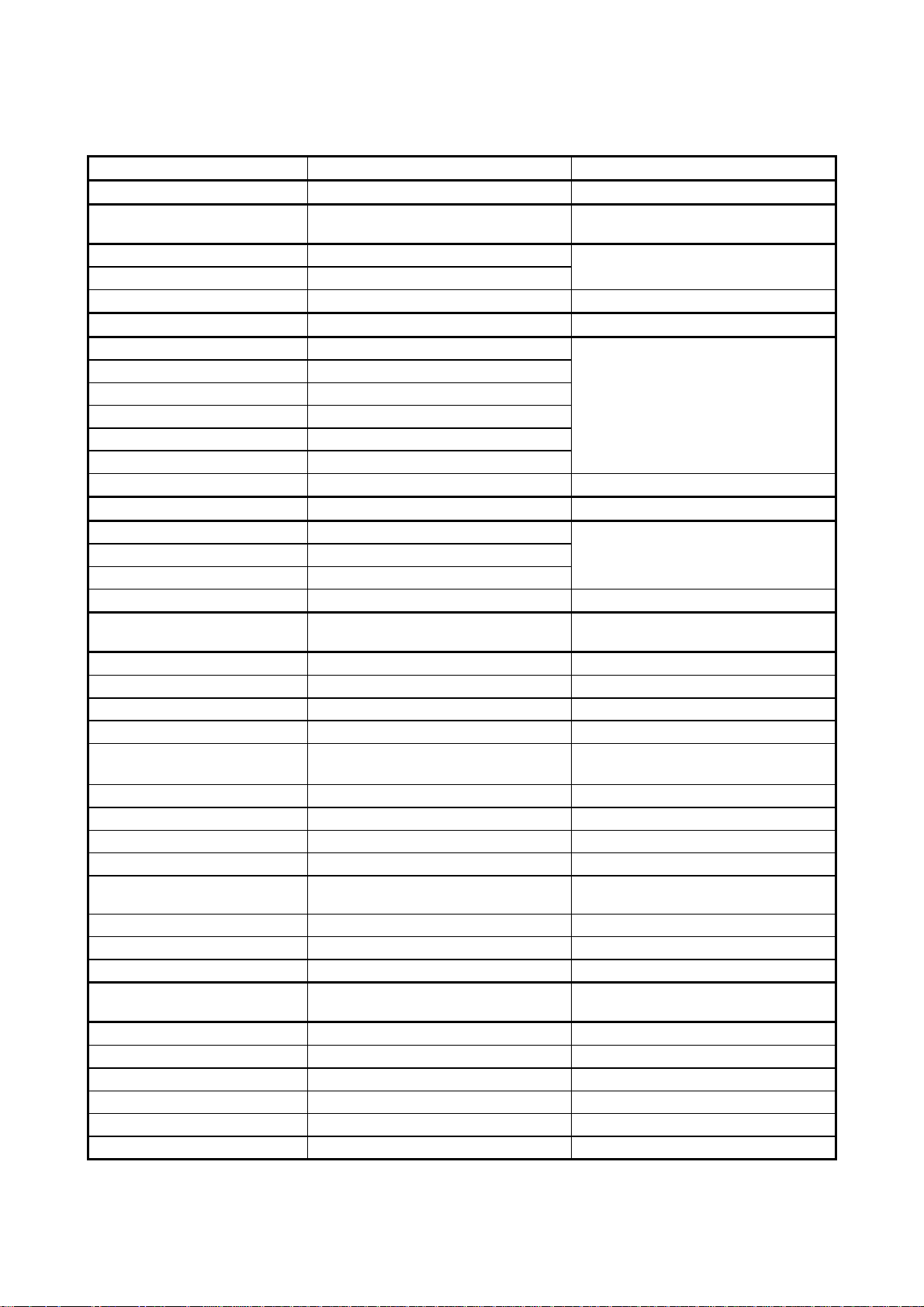

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/ Fax

Model MFC9870 MFC9850

Group Dial Yes (6) Yes (6)

Error Re-Transmission No No

Station ID 1 (20 digits/20 chars) 1 (20 digits/20 chars)

Off-Hook Alarm Yes Yes

Remote Maintenance Yes Yes

Call Reservation Over Manual TX No No

RX Mode Indication LCD LCD

Resolution Indication LED LED

Memory Security Yes Yes

Color FAX No No

Manual Broadcasting Yes Yes

LCD Language English English

OPEN LCR No No

E-MAIL FAX Yes (Via Network) No

LIST/REPORT

Activity Report/Journal Report Yes (up to 50) Yes (up to 50)

Transmission Verification Report Yes Yes

Coverpage Yes (Super) Yes (Super)

Help List Yes Yes

Callback Message No No

Caller ID List No No

ALL Dial List Yes Yes

Tel Index List Yes Yes

(3/6)

INTERFACE

External TAD Interface Yes Yes

Missing Link/PC Interface No No

Host Interface (Serial) No No

Host Interface (IEEE1284) Yes Yes

Host Interface (USB) Yes Yes

LAN Interface Yes (10-Base T: LAN Board),

PRINTER Yes Yes

Color/Mono Mono Mono

Engine Type Laser (ZL) Laser (ZL)

Resolution (dpi) 600 x 600 600 x 600

Speed (ppm) 12 12

Paper Capacity (sheets) 250 250

Additional Paper Capacity

(sheets)

Output Paper Capacity (sheets) 150 150

Standard Print Language Windows GDI (600 x 600) Windows GDI (600 x 600)

available w/ option

250 (User option) 250 (User option)

No

I - 9

Machine Type Multi- Function Center w/o Fax

Model MFC9750

Group Dial

Error Re-Transmission

Station ID

Off-Hook Alarm

Remote Maintenance

Call Reservation Over Manual TX

RX Mode Indication

Resolution Indication

Memory Security

Color FAX

Manual Broadcasting

LCD Language

OPEN LCR

E-MAIL FAX

LIST/REPORT No

Activity Report/Journal Report

Transmission Verification Report

Coverpage

Help List

Callback Message

Caller ID List

ALL Dial List

Tel Index List

(3/6)

INTERFACE

External TAD Interface No

Missing Link/PC Interface No

Host Interface (Serial) No

Host Interface (IEEE1284) Yes

Host Interface (USB) Yes

LAN Interface No

PRINTER Yes

Color/Mono Mono

Engine Type Laser (ZL)

Resolution (dpi) 600 x 600

Speed (ppm) 12

Paper Capacity (sheets) 250

Additional Paper Capacity

(sheets)

Output Paper Capacity (sheets) 150

Standard Print Language Windows GDI (600 x 600)

250 (User option)

I - 10

(4/6)

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/o Fax

Model MFC9600 DCP1200

Emulation PCL4 PCL4

Resident Fonts 24 bitmap (PCL4 Comp.) 24 bitmap (PCL4 Comp.)

Fonts Disk Based Yes (35 TrueType) Yes (35 TrueType)

Paper Handling Size LTR, LGL, A4, B5, A5, A6, EXE LTR, LGL, A4, B5, A5, A6, EXE

Manual Feed Slot Custom Size (2.75" x 5" to 8.5" x 14") Custom Size (2.75" x 5" to 8.5" x 14")

Other Paper Type OHP, Envelopes, Labels, Organizer OHP, Envelopes, Labels, Organizer

Sheet Weight (Paper Cassette)

(Manual Slot)

Printer Driver Win3.1x, 95/98, and NT4.0 Driver Win3.1x, 95/98, and NT4.0 Driver

Utility Software Yes (Remote Printer Console for PCL4) Yes (Remote Printer Console for PCL4)

Bundled Cable Yes (Parallel) Yes (Parallel)

Network Optional LAN Board (Brother)

COPY

Color/Mono Mono Mono

Speed (ppm) Up to 12 Up to 12

Multi Copy (Stack) Up to 99 Up to 99

Multi Copy (Sort) Yes Yes

Reduction/Enlargement (%) 25 to 400% in 1% increments 25 to 400% in 1% increments

Resolution (dpi) 300 x 600 300 x 600

64-105 g/m2 (17 to 28 lb)

64-157 g/m2 (17 to 43 lb)

Printer/Internet FAX

64-105 g/m2 (17 to 28 lb)

64-157 g/m2 (17 to 43 lb)

Optional LAN Board (Brother) Printer only

SCANNER

Color/Mono Color/Mono Color/Mono

Resolution (dpi) 1,200 x 1,200 (Int.)/300 x 600 (Opt.) 1,200 x 1,200 (Int.)/300 x 600 (Opt.)

Speed (sec) 2 2

Gray Scale 256 256

TWAIN Compliant Yes Yes

PCI Scanner (Parallel/Serial) Parallel Parallel

E-MAIL Scan Key Yes Yes

Scan Key Yes Yes

MESSAGE CENTER/MESSAGE

MANAGER

ICM Recording Time N/A

Page Memory N/A

OGM N/A

TAD Type N/A

Memo/Recording Conversation N/A

Fax Forwarding Yes

Fax Retrieval Yes

Paging Yes

Remote Access Yes

Toll Saver N/A

No

I - 11

(4/6)

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/ Fax

Model MFC9870 MFC9850

Emulation PCL4 No

Resident Fonts 24 bitmap (PCL4 Comp.) No

Fonts Disk Based Yes (35 TrueType) Yes (35 TrueType)

Paper Handling Size LTR, A4, B5, A5, B6, A6, EXE LTR, A4, B5, A5, B6, A6, EXE

Manual Feed Slot Custom Size (2.75" x 5" to 8.5" x 14") Custom Size (2.75" x 5" to 8.5" x 14")

Other Paper Type OHP, Envelopes, Labels, Organizer OHP, Envelopes, Labels, Organizer

Sheet Weight (Paper Cassette)

(Manual Slot)

Printer Driver Win3.1x, 95/98, and NT4.0 Driver Win3.1x, 95/98, and NT4.0 Driver

Utility Software Yes (Remote Printer Console for PCL4) No

Bundled Cable Yes (Parallel) Yes (Parallel)

Network Option (Brother) No

COPY

Color/Mono Mono Mono

Speed (ppm) Up to 12 Up to 12

Multi Copy (Stack) Up to 99 Up to 99

Multi Copy (Sort) Yes Yes

Reduction/Enlargement (%) 25 to 400% in 1% increments 25 to 400% in 1% increments

Resolution (dpi) 300 x 600 300 x 600

64-105 g/m2 (17 to 28 lb)

64-157 g/m2 (17 to 43 lb)

64-105 g/m2 (17 to 28 lb)

64-157 g/m2 (17 to 43 lb)

SCANNER Yes No

Color/Mono Color/Mono N/A

Resolution (dpi) 1,200 x 1,200 (Int.)/300 x 600 (Opt.) N/A

Speed (sec) 2 N/A

Gray Scale 256 N/A

TWAIN Compliant Yes N/A

PCI Scanner (Parallel/Serial) Parallel N/A

E-MAIL Scan Key No N/A

Scan Key No N/A

MESSAGE CENTER/MESSAGE

MANAGER

ICM Recording Time N/A N/A

Page Memory N/A N/A

OGM N/A N/A

TAD Type N/A N/A

Memo/Recording Conversation N/A N/A

Fax Forwarding Yes Yes

Fax Retrieval Yes Yes

Paging No No

Remote Access Yes Yes

Toll Saver N/A N/A

I - 12

(4/6)

Machine Type Multi- Function Center w/o Fax

Model MFC9750

Emulation PCL4

Resident Fonts 24 bitmap (PCL4 Comp.)

Fonts Disk Based Yes (35 TrueType)

Paper Handling Size LTR, A4, B5, A5, B6, A6, EXE

Manual Feed Slot Custom Size (2.75" x 5" to 8.5" x 14")

Other Paper Type OHP, Envelopes, Labels, Organizer

Sheet Weight (Paper Cassette)

(Manual Slot)

Printer Driver Win3.1x, 95/98, and NT4.0 Driver

Utility Software Yes (Remote Printer Console for PCL4)

Bundled Cable No

Network

COPY

Color/Mono Mono

Speed (ppm) Up to 12

Multi Copy (Stack) Up to 99

Multi Copy (Sort) Yes

Reduction/Enlargement (%) 25 to 400% in 1% increments

Resolution (dpi) 300 x 600

64-105 g/m2 (17 to 28 lb)

64-157 g/m2 (17 to 43 lb)

SCANNER Yes (Option)

Color/Mono Color/Mono

Resolution (dpi) 1,200 x 1,200 (Int.)/300 x 600 (Opt.)

Speed (sec) 2

Gray Scale 256

TWAIN Compliant Yes

PCI Scanner (Parallel/Serial) Parallel

E-MAIL Scan Key No

Scan Key No

MESSAGE CENTER/MESSAGE

MANAGER

ICM Recording Time

Page Memory

OGM

TAD Type

Memo/Recording Conversation

Fax Forwarding

Fax Retrieval

Paging

Remote Access

Toll Saver

No

I - 13

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/o Fax

Model MFC9600 DCP1200

MESSAGE CENTER

Pro/MESSAGE MANAGER Pro

Fax/Voice Mail Box N/A

Fax/Voice on Demand N/A

MESSAGE CENTER (PC MC) No

Fax Forwarding N/A

Paging N/A

ICM Recording Time N/A

OGM MC;MC Pro;Paging N/A

Fax/Voice Mail Box N/A

Fax/Voice on Demand N/A

VIDEO CAPTURE No

Video Capture Yes (Color)

Video Print Yes (Mono)

Video Format NTSC

No

(5/6)

BUNDLED SOFTWARE

(For Windows)

Printer Driver Brother Brother

TWAIN Brother Brother

Veiwer Scan Soft Scan Soft

PC Fax SMSI No

Others Auto E-mail printing

Netcentric (PC internet Fax)

Formats (Import) TIFF/BMP/PCX/DCX/BTF/BTX/MAX/PDF TIFF/BMP/PCX/DCX/BTF/BTX/MAX/PDF

Formats (Export) TIFF/BMP/MAX/PDF TIFF/BMP/MAX/PDF

OCR Yes (Xerox TextBridge) Yes (Xerox TextBridge)

Pop Up Menu Yes (ScanSoft) Yes (ScanSoft)

PCI Remote Setup

(Remote Diagnostics)

Remote Setup for Time Yes No

Remote Setup for Tel No. Yes No

BUNDLED SOFTWARE

(For iMAC)

Printer Driver Brother Brother

TWAIN Yes Yes

Veiwer No No

PC Fax No No

Others No No

Yes Yes

Auto E-mail printing

I - 14

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/ Fax

Model MFC9870 MFC9850

MESSAGE CENTER

Pro/MESSAGE MANAGER Pro

Fax/Voice Mail Box N/A N/A

Fax/Voice on Demand N/A N/A

MESSAGE CENTER (PC MC) No No

Fax Forwarding N/A N/A

Paging N/A N/A

ICM Recording Time N/A N/A

OGM MC;MC Pro;Paging N/A N/A

Fax/Voice Mail Box N/A N/A

Fax/Voice on Demand N/A N/A

VIDEO CAPTURE

Video Capture No No

Video Print No No

Video Format No No

No No

(5/6)

BUNDLED SOFTWARE

(For Windows)

Printer Driver Brother Brother

TWAIN Brother No

Veiwer Wordcraft No

PC Fax Wordcraft No

Others

Formats (Import) TIFF/BMP/PCX/DCX/BTF/BTX/MAX/PDF No

Formats (Export) TIFF/BMP/MAX/PDF No

OCR Yes (Wordcraft) No

Pop Up Menu Yes No

PCI Remote Setup

(Remote Diagnostics)

Remote Setup for Time Yes No

Remote Setup for Tel No. Yes No

BUNDLED SOFTWARE

(For iMAC)

Printer Driver N/A N/A

TWAIN N/A N/A

Veiwer N/A N/A

PC Fax N/A N/A

Others N/A N/A

Yes No

I - 15

Machine Type Multi- Function Center w/o Fax

Model MFC9750

MESSAGE CENTER

Pro/MESSAGE MANAGER Pro

Fax/Voice Mail Box

Fax/Voice on Demand

MESSAGE CENTER (PC MC) No

Fax Forwarding

Paging

ICM Recording Time

OGM MC;MC Pro;Paging

Fax/Voice Mail Box

Fax/Voice on Demand

VIDEO CAPTURE No

Video Capture

Video Print

Video Format

No

(5/6)

BUNDLED SOFTWARE

(For Windows)

Printer Driver Brother

TWAIN No

Veiwer No

PC Fax No

Others

Formats (Import) TIFF/BMP/PCX/DCX/BTF/BTX/MAX/PDF

Formats (Export) TIFF/BMP/MAX/PDF

OCR Yes (Wordcraft) (Option)

Pop Up Menu No

PCI Remote Setup

(Remote Diagnostics)

Remote Setup for Time No

Remote Setup for Tel No. No

BUNDLED SOFTWARE

(For iMAC)

Printer Driver N/A

TWAIN N/A

Veiwer N/A

PC Fax N/A

Others N/A

No

I - 16

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/o Fax

Model MFC9600 DCP1200

Formats (Import) Depends on viewer Depends on viewer

Formats (Export) Depends on viewer Depends on viewer

OCR No No

Pop Up Menu No No

PCI Remote Setup No No

Remote Setup for Date/Time No No

Remote Setup for Tel No.

Registration

No No

(6/6)

I - 17

Machine Type Multi- Function Center w/ Fax Multi- Function Center w/o Fax

Model MFC9870 MFC9850

Formats (Import) N/A N/A

Formats (Export) N/A N/A

OCR N/A N/A

Pop Up Menu N/A N/A

PCI Remote Setup N/A N/A

Remote Setup for Date/Time N/A N/A

Remote Setup for Tel No.

Registration

N/A N/A

(6/6)

I - 18

Machine Type Multi- Function Center w/ Fax

Model MFC9750

Formats (Import) N/A

Formats (Export) N/A

OCR N/A

Pop Up Menu N/A

PCI Remote Setup N/A

Remote Setup for Date/Time N/A

Remote Setup for Tel No.

Registration

N/A

(6/6)

I - 19

CHAPTER II.

INSTALLATION

CHAPTER II. INSTALLATION

CONTENTS

1. INSTALLING THE UPDATE DATA TO THE MACHINE.......................................II-1

1. INSTALLING THE UPDATE DATA TO THE

MACHINE

If the program version is updated or the main PCB is replaced, install the update program onto the

flash ROM of the main PCB.

The program installation requires a PC/AT-compatible computer (which is capable of running MSDOS or its compatible OS).

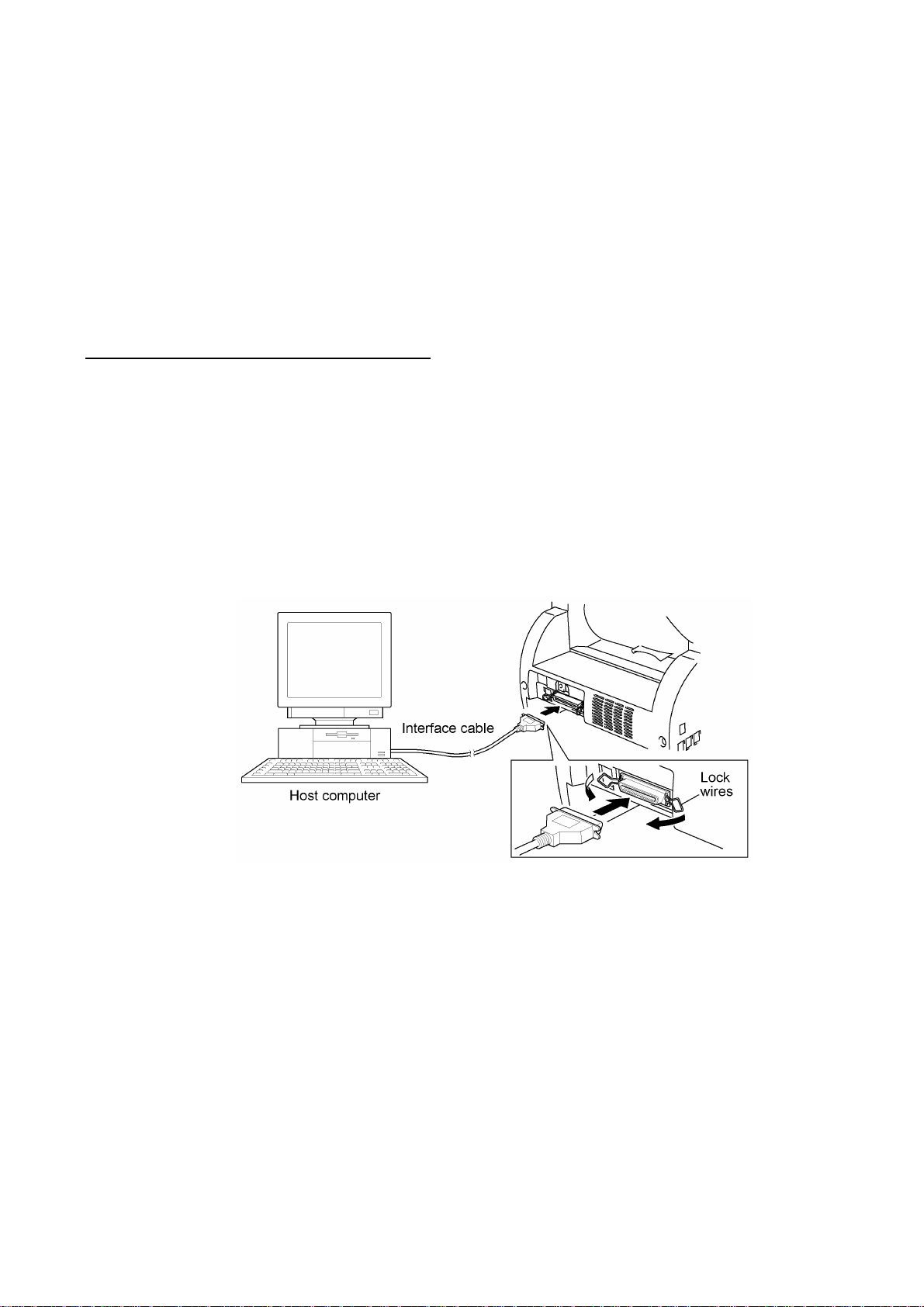

Connecting the machine to your computer

(1) Make sure that the machine's power cord is unplugged from a wall socket.

(2) Make sure that your computer is powered off.

(3) Connect the interface cable to the parallel interface port on the back of the machine and

secure it with the lock wires.

(4) Connect the other end of the interface cable to the printer port of your computer and secure

it with the two screws.

(5) Power on your computer.

(6) Plug the machine's power cord into a wall socket.

II - 1

Installing the update data onto the flash ROM of the machine

(1) Copy the update data and transfer utility onto the desired directory of the hard disk.

e.g., C:\UPDATE

(2) Click the Start button, point to Programs, and then click MS-DOS Prompt to open an MS-

DOS window.

(3) Type the drive letter where the update data and transfer utility are located. In the above

example, type C:\ from the command line and press the ENTER key.

Then type CD UPDATE and press the ENTER key.

(4) Check that your computer is connected with the machine correctly.

(5) To start the transfer utility transmitting the update data to the flash ROM of the machine,

type the following:

ICEN filename /b

Then press the ENTER key.

During downloading, the machine beeps intermittently.

Upon completion of the downloading, the machine beeps continuously.

NOTE: If the machine cannot return to the standby state after completion of downloading,

turn the power off and on.

II - 2

CHAPTER III.

THEORY OF OPERATION

CHAPTER III. THEORY OF OPERATION

CONTENTS

1. OVERVIEW...........................................................................................................III-1

2. MECHANISMS......................................................................................................III-2

2.1 Scanner Mechanism....................................................................................III-3

2.2 Laser Printing Mechanism...........................................................................III-5

2.2.1 Paper pick-up and registration mechanism............................................III-5

2.2.2 Print process mechanism......................................................................III-6

2.2.3 Heat-fixing mechanism..........................................................................III-8

2.2.4 Paper ejecting mechanism.....................................................................III-9

2.3 Sensors and Actuators.................................................................................III-10

3. CONTROL ELECTRONICS..................................................................................III-12

1. OVERVIEW

III - 1

* Provided on models supporting facsimile function.

2. MECHANISMS

The machine is classified into the following mechanisms:

n SCANNER MECHANISM - ADF mechanism

n LASER PRINTING MECHANISM - Paper pick-up and registration mechanism

n SENSORS AND ACTUATORS

- Document scanning mechanism

- Print process mechanism (consisting of charging,

exposing, developing, and transferring processes)

with paper feeding mechanism

- Heat-fixing mechanism with paper feeding

mechanism

- Paper ejecting mechanism

III - 2

2.1 Scanner Mechanism

This mechanism consists of the following:

- document tray ASSY which consists of a document chute and document tray,

- automatic document feeder (ADF) unit which consists of a document feed roller ASSY,

document ejection roller ASSY, ADF motor, and document front and rear sensors, and

- scanner unit which consists of a scanner top cover, CCD unit, CCD drive mechanism, CCD HP

sensor, and scanner base.

For details about the sensors, refer to Section 2.3.

III - 3

This scanner mechanism supports a dual scanning system.

(1) If you set documents with their faces up on the document chute and start the scanning

operation, the ADF motor rotates so that the document feed roller ASSY feeds those

documents into the ADF unit, starting from the top sheet to the bottom, page by page. Each

document curves downwards and turns to the right so as to advance above the CCD unit, and

then it is fed out to the document tray with the document ejection roller ASSY.

This way, documents move above the CCD unit being kept in a stationary position.

(2) If you open the scanner unit, put a sheet of document (or put a bound book opened) on the

glass of the scanner top cover, close the scanner unit, and start the scanning operation, then

the CCD drive mechanism will be driven. That is, the CCD motor rotates and its rotation will

be transmitted via the gear train to the CCD drive belt.

The CCD unit, which is supported and guided by the CCD rail, is secured to the CCD drive

belt. Clockwise and counterclockwise rotations of the CCD motor move the CCD unit to the

right and left, respectively.

In this scanning system, the CCD unit moves horizontally beneath a document being kept in

stationary position.

The CCD unit contains a charge coupled device (CCD) image sensor. The cold-cathode

fluorescent lamp illuminates a document and the reflected light of the scanned image data is

transmitted via the mirrors into the lens which reduces the scanned data so as to form the image

on the CCD.

III - 4

2.2 Laser Printing Mechanism

2.2.1 Paper pick-up and registration mechanism

III - 5

At the 1st stage, the controller drives the main motor without energizing the solenoid so that the

paper feed roller simply idles.

At the 2nd stage, the controller energizes the solenoid so that the paper feed roller no longer

rotates and the paper pick-up roller starts rotating to pick up paper into the machine, a sheet at a

time. After the leading edge of the pulled-in paper passes through the manual insertion sensor

actuator, the paper is further fed for the specified time length. Accordingly, the leading edge will

reach the paper feed roller where the paper skew will be eliminated.

At the 3rd stage, the controller deenergizes the solenoid to rotate the paper feed roller for feeding

paper to the transfer block in the drum unit.

When the leading and trailing edges of the paper pass through the registration sensor actuator, the

sensor signals them to the controller. According to those signals, the controller may determine the

first print position on the paper.

2.2.2 Print process mechanism

III - 6

The print process unit works with laser beam, electrical charges, and toner. The graph below

shows the transition of electrical charge on the surface of the laser-sensitive drum through the four

processes: charging, exposing, developing, and transferring processes.

III - 7

2.2.3 Heat-fixing mechanism

As the paper passes between the heater roller and the pressure roller in the heat-fixing unit, the

heater roller fuses the toner on the paper.

The controller monitors the internal resistance of the heater thermistor to keep the surface

temperature of the heater roller constant by turning the halogen heater lamp on and off.

III - 8

2.2.4 Paper ejecting mechanism

After the paper passes through the heat-fixing process, it will be ejected from the heat-fixing unit

by the paper ejection roller.

If the leading edge of the paper pushes up the actuator of the paper ejection sensor, the sensor

signals the start of paper ejection. If the trailing edge has passed through the sensor actuator, the

sensor signals the completion of paper ejection.

The paper will be turned over along the outer chute and ejected onto the main cover by the exit

roller.

III - 9

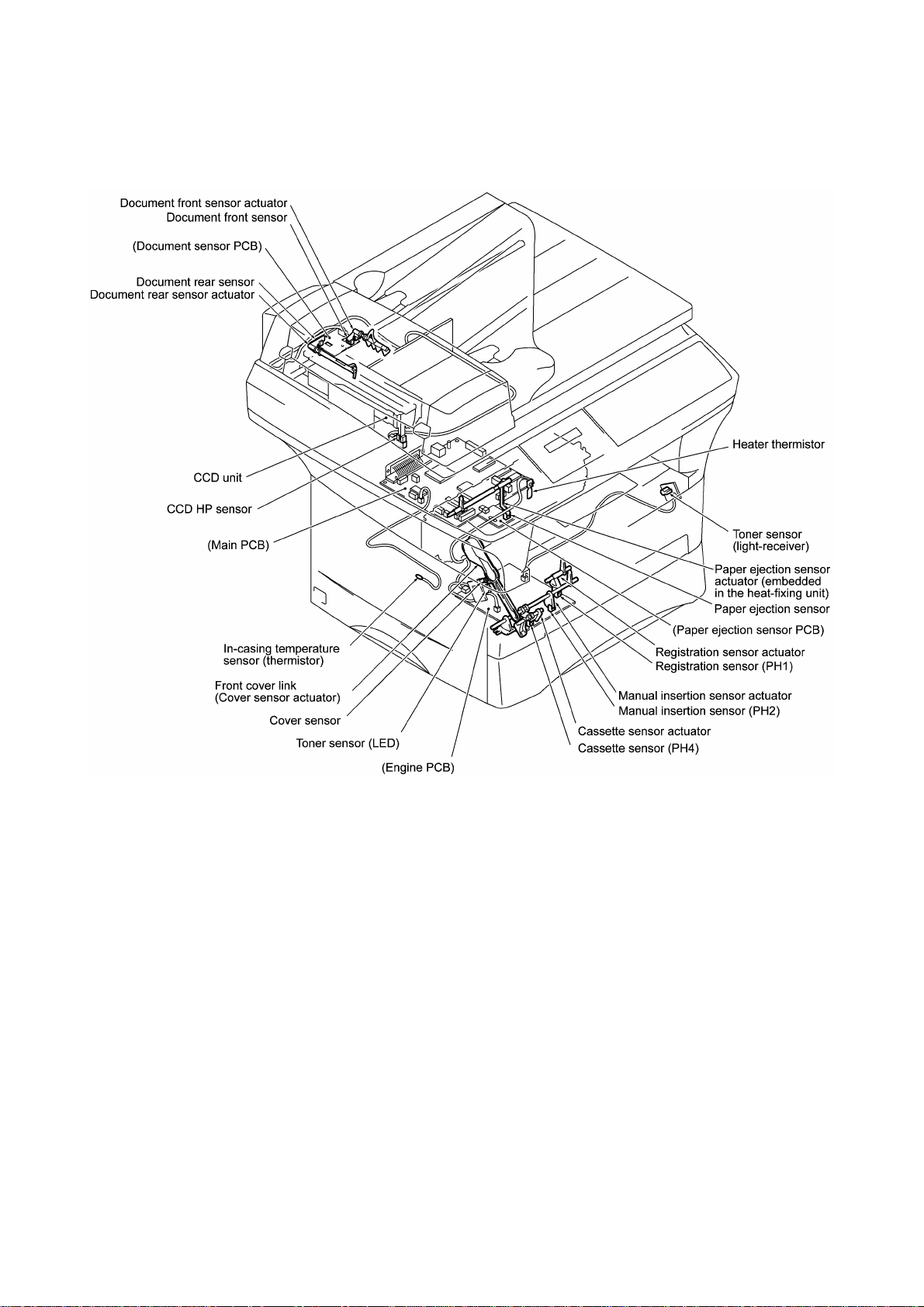

2.3 Sensors and Actuators

This machine has ten sensors: eight photosensors and two thermistors as described below.

Sensor name Type Located on

Document front sensor Photosensor Document sensor PCB

Document rear sensor Photosensor Document sensor PCB

Manual insertion sensor Photosensor Engine PCB

Registration sensor Photosensor Engine PCB

Cassette sensor Photosensor Engine PCB

Paper ejection sensor Photosensor Paper ejection sensor PCB

Toner sensor Photosensor Toner sensor (LED) PCB and toner

Cover sensor Photosensor Toner sensor (LED) PCB

Heater thermistor Thermistor Heat-fixing unit

In-casing temperature sensor Thermistor Left-hand plate of the main chassis

• Document front sensor which detects the presence of documents.

• Document rear sensor which detects the leading and trailing edges of pages to tell the control

circuitry when the leading edge of a new page has reached the starting position and when the

scan for that page is over.

• Manual insertion sensor which detects whether paper is inserted manually through the paper

slot or whether paper fed through the paper cassette has jammed.

• Registration sensor which detects the leading and trailing edges of recording paper, which

allows the controller to determine the registration timing and check paper jam.

• Cassette sensor which detects whether the paper cassette is loaded.

• Paper ejection sensor which detects whether the recording paper goes out of the machine.

• Toner sensor which detects whether there is toner or a toner cartridge is loaded.

• Cover sensor which detects whether the front cover is closed.

• Heater thermistor which allows the controller to monitor the temperature of the heater roller of

the fixing unit.

• In-casing temperature sensor which allows the controller to monitor the temperature inside the

machine.

sensor (light-receiver) PCB

The above photosensors are a photointerrupter consisting of a light-emitting

diode and a light-sensitive transistor. Each

of them has an actuator separately arranged

as shown on the next page.

III - 10

Location of Sensors and Actuators

III - 11

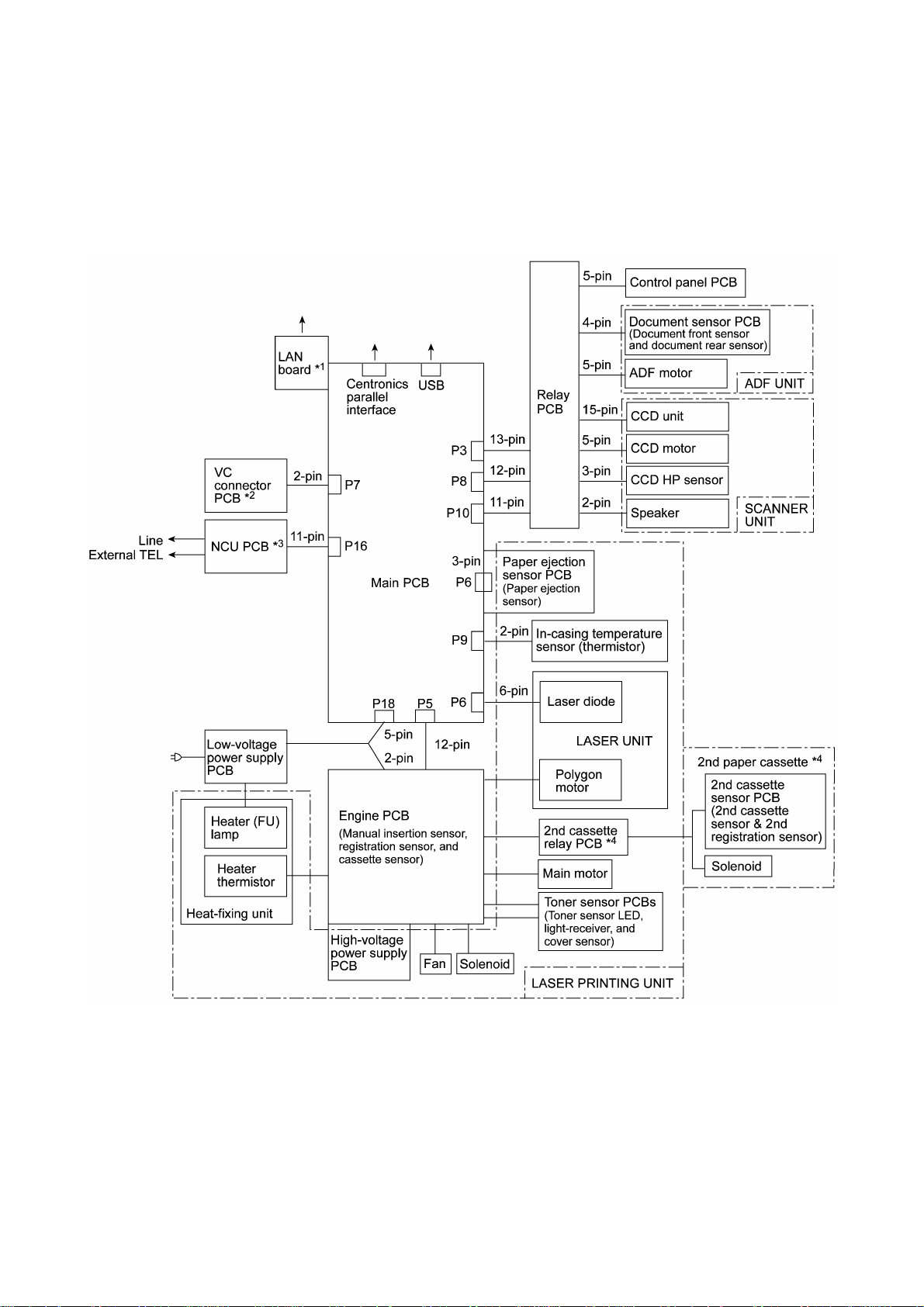

3. CONTROL ELECTRONICS

The hardware configuration of the machine is shown below.

*1Provided on models supporting LAN interface.

*2Provided on models supporting video capture.

*3Provided on models supporting facsimile function.

*4Provided on models available with a 2nd paper cassette (as an option).

Configuration of Machine

III - 12

CHAPTER IV.

DISASSEMBLY/REASSEMBLY AND

LUBRICATION

CHAPTER IV. DISASSEMBLY/REASSEMBLY AND

LUBRICATION

CONTENTS

1. DISASSEMBLY/REASSEMBLY...........................................................................IV-1

n Safety Precautions..............................................................................................IV-1

n Preparation.........................................................................................................IV-2

n How to Access the Object Component................................................................IV-2

n Disassembly Order Flow.....................................................................................IV-3

1.1 Lower Rear Cover..........................................................................................IV-4

1.2 Access Plates R and F...................................................................................IV-4

1.3 Paper Cassette...............................................................................................IV-5

1.4 Document Tray ASSY....................................................................................IV-6

1.5 Upper Rear Cover..........................................................................................IV-8

1.6 ADF Unit........................................................................................................IV-9

[ Disassembling the ADF Unit ].......................................................................IV-11

1.7 Scanner Unit and Control Panel ASSY...........................................................IV-16

[ Disassembling the Scanner Unit ].................................................................IV-19

[ Disassembling the Control Panel ASSY ]......................................................IV-24

1.8 Relay PCB.....................................................................................................IV-25

1.9 Speaker..........................................................................................................IV-26

1.10 Scanner Mount...............................................................................................IV-27

1.11 Paper Sub Tray and Tray Holder....................................................................IV-30

1.12 VC Cover, VC Bracket, and VC Connector PCB (for models supporting

video capture)................................................................................................IV-31

1.13 Front Cover

Front Sub Cover (for models not supporting video capture)............................IV-32

1.14 Outer Chute and Paper Pinch Rollers.............................................................IV-33

1.15 Main Cover.....................................................................................................IV-34

1.16 Switch Cover (for models not equipped with a power switch)..........................IV-35

1.17 Laser Unit.......................................................................................................IV-36

1.18 Heat-fixing Unit and FU Lamp........................................................................IV-37

1.19 Fan.................................................................................................................IV-41

1.20 Drive Gear ASSY and Main Motor ASSY........................................................IV-43

1.21 NCU Shield and NCU PCB*............................................................................IV-45

1.22 Bottom Plate, Main PCB, and Bottom Insulation Film.....................................IV-47

1.23 Low-voltage Power Supply PCB and Power Inlet............................................IV-51

i

1.24 Inner Insulation Film, High-voltage Power Supply PCB, Engine PCB,

and 2nd Cassette Relay PCB*........................................................................IV-53

1.25 Toner Sensor (light-receiver) PCB and Toner Sensor (LED) PCB...................IV-55

1.26 Gears and Paper Pick-up Roller.....................................................................IV-56

1.27 Paper Feed Roller ASSY................................................................................IV-57

1.28 Clutch Levers, Cassette Guide L, and Solenoid..............................................IV-58

1.29 Cleaning of High-voltage Contacts and Grounding Contacts...........................IV-59

2. LUBRICATION.....................................................................................................IV-61

[ 1 ] ADF unit.................................................................................................IV-61

[ 2 ] Scanner mount.......................................................................................IV-62

[ 3 ] Drive gear ASSY....................................................................................IV-63

[ 4 ] Paper cassette........................................................................................IV-64

ii

1. DISASSEMBLY/REASSEMBLY

nn Safety Precautions

To prevent the creation of secondary problems by mishandling, observe the following precautions

during maintenance work.

(1) Unplug the power cord from the power outlet before accessing parts or units inside the

machine. When having access to the power supply, be sure to unplug the power cord from

the power outlet.

(2) When servicing the optical system of the laser printing unit, be careful not to place

screwdrivers or other reflective objects in the path of the laser beam. Be sure to take off any

personal accessories such as wrist watches and rings before working on the printer. A

reflected beam, though invisible, can permanently damage your eyes.

(3) If the machine has been printing, allow the heat-fixing unit (inside this unit is a red-colored

heater roller) sufficient time to cool down before starting maintenance jobs. It is HOT!

(4) Be careful not to lose screws, washers, or other parts removed for parts replacement.

(5) Do not remove gears from the document feed roller ASSY or document ejection roller ASSY if

at all possible. Once removed, they will become unusable and new gears will have to be put

back in.

(6) When using soldering irons and other heat-generating tools, take care not to damage the resin

parts such as wires, PCBs, and covers.

(7) Before handling the PCBs, touch a metal portion of the machine to discharge static electricity;

otherwise, the electronic parts may be damaged due to the electricity charged in your body.

(8) When transporting PCBs, be sure to wrap them in conductive sheets such as aluminum foil.

(9) Be sure to reinsert self-tapping screws correctly, if removed. Unless otherwise specified,

tighten screws to the following torque values:

Taptite, bind B and cup B M3: 0.7 N•m

M4: 0.8 N•m

Taptite, cup S M3: 0.8 N•m

Other screws M3: 0.7 N•m

M4: 0.8 N•m

(10) When connecting or disconnecting cable connectors, hold the connector bodies not the

cables. If the connector has a lock, always slide the connector lock to unlock it.

(11) Before reassembly, apply the specified lubricant to the specified points. (Refer to Section 2 in

this chapter.)

(12) After repairs, check not only the repaired portion but also that the connectors and other

related portions function properly before operation checks.

IV - 1

nn Preparation

Prior to proceeding to the disassembly procedure,

(1) Unplug

- the power cord,

- the modular jack of the telephone line,

- the PC interface cable, and

- the modular jack of an external telephone set if connected. (Not shown below.)

(2) Remove

- the paper cassette and

- the drum unit (with toner cartridge loaded).

nn How to Access the Object Component

• On the next page is a disassembly order flow which helps you access the object components.

To remove the heat-fixing unit, for example, first find it on the flow and learn its number ( in

this case). You need to remove parts numbered , , , , , , , and so as to

access the heat-fixing unit.

• Unless otherwise specified, the disassembled parts or components should be reassembled in

the reverse order of removal.

IV - 2

nn Disassembly Order Flow

IV - 3

1.1 Lower Rear Cover

(1) Remove the three screws (two "a" and one "b") from the lower rear cover. Screw "b" is

provided on those models available with a 2nd paper cassette (as an option).

(2) Lightly pressing sections "X," pull out the lower rear cover.

"a" and "b": Screw, pan (washer) M4x10DB

1.2 Access Plates R and F

(1) Remove screw "c" that secures access plates R and F together to the main chassis.

(2) Remove screws "d" and "e" from access plate R.

(3) Take out access plates R and F together.

(4) Remove screw "f" to separate those access plates.

"c" to "f": Taptite, cup S M3x6

(Tightening torque: 0.5 N•m)

nn Reassembling Notes

• When reinstalling access plate F, fit the two tabs provided on the front end underneath the

center edge of the main chassis.

IV - 4

1.3 Paper Cassette

(1) Pull the pressure plate release lever to the front to release the pressure plate.

(2) Fully slide the side guide (R or L) inwards (in the direction of arrow •) and remove the screw.

Then release the latches (arrow ‚) and pull up the side guide (arrow ƒ).

(3) Release the pressure plate from the bosses (arrow „) and remove it (arrow …).

(4) Fully slide the paper rear guide to the front and lift it up (arrow †).

IV - 5

1.4 Document Tray ASSY

(1) Fully open the document tray ASSY.

(2) Lift up the document tray ASSY straight and pull the hinges up and out of the scanner unit.

(3) Remove the three screws from each of the hinges.

IV - 6

(4) Remove screw "a," then lightly tap the left end of the document chute to release the three

hooks from the document tray.

(5) Remove the sponge.

(6) Remove screw "b" to take off the support plate.

IV - 7

1.5 Upper Rear Cover

(1) Remove the two screws from the upper rear cover.

(2) Release section "a" from the latch provided on the scanner mount and pull the top of the

upper rear cover to the rear and upwards.

nn Reassembling Notes

• When installing the upper rear cover, first hook sections "b" onto the supports of the scanner

mount and push the upper rear cover into place.

IV - 8

1.6 ADF Unit

(1) Remove screw "a" from the harness support.

(2) Remove screw "b" to release the grounding wires.

(3) Disconnect the following from the relay PCB:

• CCD flat cable (P4)

• ADF motor harness (4-pin, P3)

• Document sensor harness (4-pin, P8)

IV - 9

"a": Taptite, cup B M3x8

"b": Taptite, cup S M3x6

(4) Turn the ADF unit in the direction of arrow •, remove the plastic retaining ring, and release

the arm (arrow ‚) from the boss provided on the scanner top cover. Turn the ADF unit back

into place.

(5) Open the ADF cover (arrow ƒ) and remove two screws "c."

(6) Lift up the ADF unit while pulling out the ADF motor harness, document sensor harness, and

grounding wire. The ADF supports also come off.

(7) Take off the harness support by removing screw "d."

IV - 10

"c" and "d": Taptite, cup B M3x8

[ Disassembling the ADF Unit ]

1) Open the ADF cover. Pull the ADF side cover outwards and release the ADF cover from the

bosses provided on the ADF side covers.

2) At each of the ADF side covers F and R, remove the screw, pull the unscrewed corner

outwards to release it from the document ejection chute, and unhook the latch.

3) Remove the document ejection chute (which has been secured with the screws removed in

step 2) above).

IV - 11

4) At the front end of the document feed roller shaft, remove the pawled bushing by pulling its

pawls outwards. At the rear end, pull the bushing outwards and lift up the document feed

roller ASSY.

5) At the front end of the upper LF roller (gray) shaft, remove the pawled bushing by pulling its

pawls outwards. At the rear end, pull the bushing outwards and lift up the upper LF roller

ASSY.

6) Remove the two screws and take off the ADF motor.

If you do not need to remove the ADF parts, skip to step 10).

7) Peel off the ADF film.

NOTE: Once removed, the ADF film will become unusable and a new part will have to be put

back in.

8) Remove the screw and take off the spring plate A, separation rubber, rubber holder, and

compression spring.

9) Push the hooks provided on the upper ADF chute and remove the pressure rollers and their

springs.

IV - 12

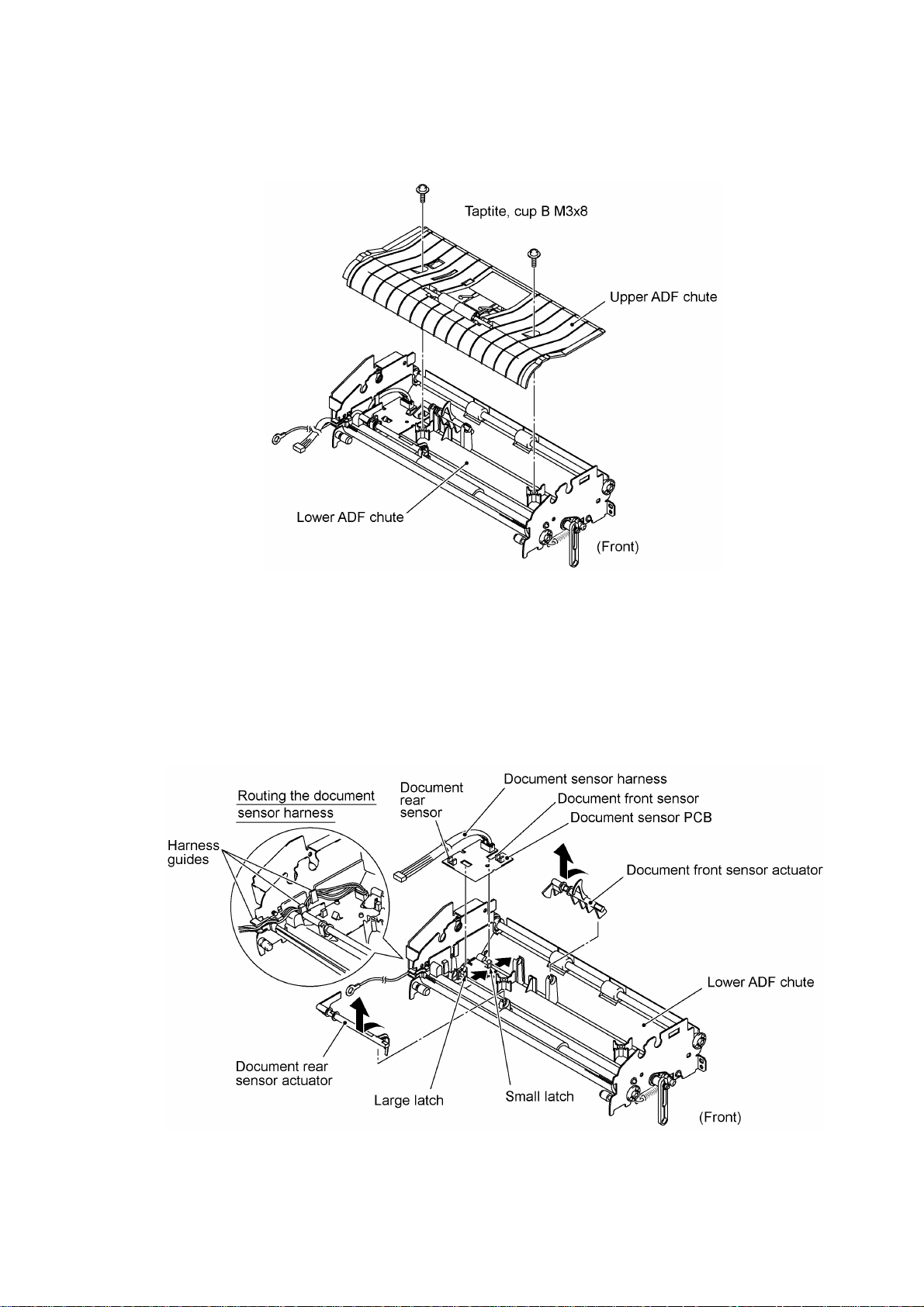

10) Remove the two screws and lift up the upper ADF chute.

11) Turn the document front sensor actuator as shown below and lift it up.

12) Turn the document rear sensor actuator as shown below and lift it up.

13) Disconnect the document sensor harness from the document sensor PCB and take out its

harness from the harness guides.

14) Unhook the two latches (large and small latches in this order) from the document sensor PCB

and lift it up.

IV - 13

15) At the front end of the document ejection roller shaft, remove the pawled bushing by pulling its

pawls outwards. At the rear end, pull the bushing outwards and lift up the document ejection

roller ASSY.

16) Remove the three screws and take off the motor bracket.

17) At the front end of the lower LF roller (black) shaft, remove the pawled bushing by pulling its

pawls outwards. At the rear end, pull the bushing outwards and remove the lower LF roller

ASSY.

18) Turn the lower ADF chute upside down.

19) Pull the arm outwards and take it off.

20) At the rear side of the lower ADF chute, remove the gear 19/36 by pulling its pawl outwards.

21) Remove the gear 64 by pulling its pawl outwards.

22) Unhook the two springs.

23) Pull out the white roller bushing F by pulling its pawls outwards.

24) Remove the white roller together with the white roller bushing R and gear 27.

IV - 14

nn Reassembling Notes

• Take care not to mistake the upper LF roller ASSY (gray) for the lower LF roller ASSY (black).

• When setting the document sensor PCB back into place, do not push it down straight, but first

fit the PCB in the large latch and then fit it in the small latch (see the illustration given on page

IV-13).

• Be sure to route the document sensor harness through the three harness guides so that it will

not interfere with the document rear sensor actuator. (See the illustration given on page IV-13.)

• Reinstall the ADF motor with its connector side facing up. (See the illustration given on page

IV-12.)

• Reinstall the ADF side covers so that the tabs of the ADF side plates become fitted inside the

ribs provided on the ADF side covers. (See the illustration given on page IV-11.)

• When reinstalling the ADF side cover R, be sure to route the document sensor harness, ADF

motor harness, and grounding wire between the boss and the ADF side cover R. (See the

illustration given on page IV-11.)

• When reinstalling the ADF unit, first set the ADF support onto rear pin "x" of the ADF unit, set

the ADF unit back into place, set the other ADF support onto front pin "y," then secure those

ADF supports with two screws "c." (See the illustration given on page IV-10.)

• When connecting the ADF motor harness, document sensor harness, and grounding wires to

the relay PCB, route them as shown below.

IV - 15

1.7 Scanner Unit and Control Panel ASSY

(1) Disconnect the following from the relay PCB:

- CCD motor harness

- Panel harness

- Scanner HP sensor harness

IV - 16

(2) Slide the scanner unit (with the control panel ASSY) to the rear by approx. 5 mm and then lift

it up. (For the disassembly procedure of the scanner unit, refer to page IV-19.)

IV - 17

(3) Remove the three screws from the underside of the scanner base.

(4) Insert the tip of a flat screwdriver into each of the four holes provided in the scanner base and

unhook the four latches while lifting up the control panel ASSY.

(5) Disconnect the panel harness from the control panel PCB. (For the disassembly procedure of

the control panel ASSY, refer to page IV-24.)

nn Reassembling Notes

• When reinstalling the scanner unit, fit the holes and cutouts provided in the scanner unit over

screws "A" and pawls of the scanner mount, respectively, and then slide the scanner unit to the

front. (Refer to page IV-17.)

• When connecting the CCD motor harness, panel harness, and scanner HP sensor harness to

the relay PCB, route them as shown below.

IV - 18

• When connecting the CCD motor harness, panel harness, and scanner HP sensor harness to

the relay PCB, route them as shown below.

[ Disassembling the Scanner Unit ]

The disassembling job of the scanner unit should be done in a clean room to prevent dust or dirt

from getting into the scanner unit.

1) Remove the four screws from the scanner top cover.

2) Separate the scanner top cover from the scanner base.

IV - 19

3) Turn the gear 17/97 to move the CCD unit to the right to make the following job easier.

4) Remove screw "a" and take out the CCD rail clamp. (See the illustration given on the next

page.)

5) Remove two screws "b" from the CCD idle pulley holder, then remove the CCD drive belt

from the idle pulley.

6) Lift up the CCD rail together with the CCD unit and CCD drive belt, and then disconnect the

CCD flat cable.

NOTE: When handling the CCD unit, do not touch the CCD PCB or glasses but hold the

hatched sections as shown below.

7) Pull out the CCD rail from the CCD unit.

8) Remove the CCD lock.

IV - 20

"a": Taptite, cup B M3x8

"b": Taptite, pan B M3x10

9) Pull up the CCD motor harness and disconnect it from the CCD motor.

10) Remove three screws "c" from the motor bracket.

11) Lift up the motor bracket.

12) Remove two screws "d" from the CCD motor. The scanner grounding wire also comes off.

13) Disconnect the CCD HP sensor harness from the sensor.

14) Remove the CCD HP sensor.

IV - 21

15) Remove the four screws and take off the flat cable clamp. Remove sponge 3 attached with

adhesive tape.

16) Remove the CCD flat cable (which is attached with adhesive tape).

17) Remove the four screws and take off the guide plate.

18) Remove tape and sponges 1, then take out the panel harness and CCD HP sensor harness.

NOTE: Once removed, the sponges 1 will become unusable and new ones will have to be put

back in.

IV - 22

nn Reassembling Notes

• Route the panel harness and CCD HP sensor harness through the three notches, then tape

them as illustrated on the previous page.

• When replacing the CCD flat cable with a new one, be sure to arrange the new cable as

illustrated below, then route it along the positioning rib as shown on the previous page.

• Set the CCD motor back into place with its connector side facing up as shown on page IV-21.

When securing the motor with screws "d," be sure to secure the scanner grounding wire also as

shown on page IV-21.

• Route the CCD motor harness and scanner grounding wire as illustrated below.

• Set the CCD lock in the release (forward) position. If the CCD lock is placed in the lock

position, the CCD home positioning will fail in the next powering-up sequence. If this happens,

turn the CCD lock to the release position.

IV - 23

[ Disassembling the Control Panel ASSY ]

1) Turn the control panel ASSY upside down.

2) Remove two screws "a."

3) Slightly lift up the control panel PCB, then unlock the FPC key connector and disconnect the

FPC key. Next, unlock the LCD cable connector and disconnect the LCD flat cable.

4) Remove six screws "b."

5) Remove the key support plate and FPC key.

"a": Taptite, cup B M2.6x8

"b": Taptite, cup B M3x6

6) As shown below, slightly pull the clamp outwards and take out the LCD while pulling the LCD

flat cable gently.

NOTE: Do not take out the LCD except when the LCD is defective and requires replacement.

nn Reassembling Notes

• Before reinstalling the LCD to the control panel, wipe fingerprints or dust off the LCD surface

and control panel window with a soft cloth.

• A new LCD is covered with a protection sheet. Before installing it, remove the protection sheet.

IV - 24

1.8 Relay PCB

(1) Disconnect the following harnesses from the relay PCB:

- Speaker harness

- Main-relay (panel) harness

- Main-relay (CCD) harness

- Main-relay (motors) harness

(2) Remove the two screws.

(3) Take out the relay PCB.

nn Reassembling Notes

• When setting the relay PCB back into place, be careful with the installation direction. The

printed letters should not be upside down.

IV - 25

1.9 Speaker

(1) Press the pawl in the direction of arrow À and slide the speaker spring in the direction of

(2) Lift up the speaker.

arrow Á.

IV - 26

1.10 Scanner Mount

(1) Remove two screws "a."

(2) Open the front cover and remove two screws "b."

(3) Pull the tabs of the scanner mount to the front and upwards (in the direction of arrows À) to

release them from the bosses provided on the main cover.

(4) Lift up the scanner mount in the direction of arrow Á.

"a": Stepped screw

(Tightening torque: 0.78 N•m)

"b": Taptite, cup S M3x10

(Tightening torque: 0.78 N•m)

IV - 27

(5) Turn the scanner mount upside down.

(6) Peel off anti-static brushes.

NOTE: Once removed, they will become unusable and new parts will have to be put back in.

(7) As shown below, warp the gear-equipped end of the exit roller and remove it.

IV - 28

nn Reassembling Notes

• When setting the scanner mount back into place:

- at the right-hand side, raise the main-relay (panel) harness coming through the main cover up

and through cutout "x" provided in the scanner mount.

- at the left-hand side, pull up the main-relay (motors) harness and chassis grounding wire and

raise them up and through square cutout "y" provided in the scanner mount. Also pull up the

main-relay (CCD) harness and raise it up and through round cutout "z."

IV - 29

1.11 Paper Sub Tray and Tray Holder

(1) Pull out the paper sub tray.

(2) While pushing down the center of the paper sub tray to warp it (in the direction of arrow À),

pull it out of the tray holder (arrow Á).

(3) Insert the tip of a small flat screwdriver into the tray holder (in the direction of arrow À) and

pull up the tray holder (arrow Á).

IV - 30

1.12 VC Cover, VC Bracket, and VC Connector PCB (for models supporting video capture)

(1) Remove two screws ("a" and "b"), then take off the VC cover.

(2) Remove screw "c," take out the VC bracket together with the VC connector PCB, and

disconnect the VC harness.

(3) Remove two screws "d," then take off the VC connector PCB.

nn Reassembling Notes

• The routing of the VC harness is shown on page IV-34.

"a": Taptite, cup S M3x10

"b": Taptite, bind S M3x8

"c" and "d": Taptite, cup S M3x6

IV - 31

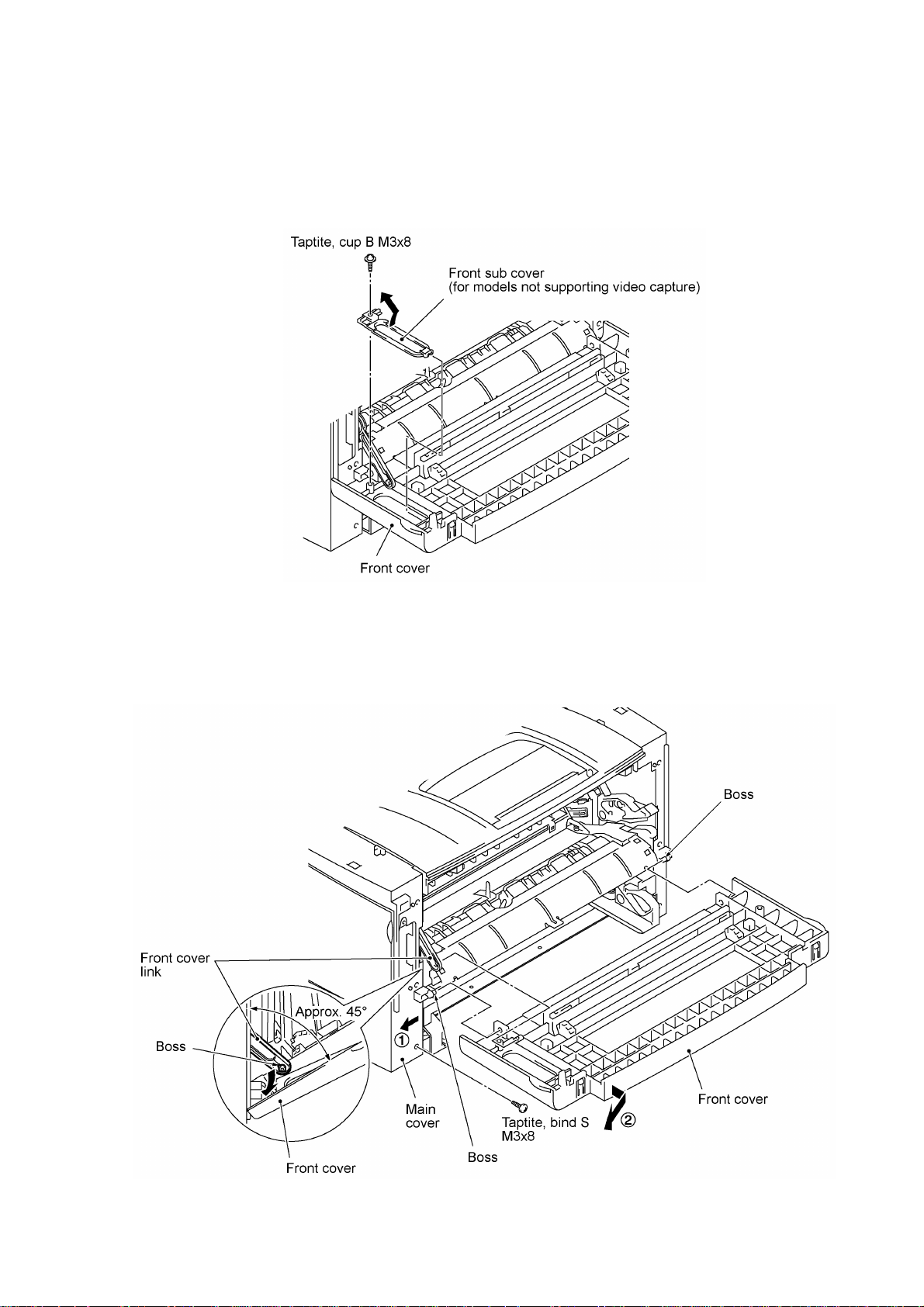

1.13 Front Cover

Front Sub Cover (for models not supporting video capture)

(1) For models not supporting video capture:

Remove the screw and take off the front sub cover from the front cover.

(2) Remove the screw from the left bottom of the front side of the main cover.

(3) Hold the front cover at an angle of 45° and pull the front cover link to the left to release it from

the front cover.

(4) Pull the bottom left front corner of the main cover to the left (in the direction of arrow •) and

release the front cover from the boss provided on the main cover (arrow ‚).

IV - 32

1.14 Outer Chute and Paper Pinch Rollers

(1) Pull up the outer chute and open it (in the direction of arrow •).

(2) Remove the chute springs from the hooks provided on the main cover (arrow ‚), then lift up

the outer chute (arrow ƒ).

(3) Remove the paper pinch rollers, their supports, and their springs.

IV - 33

1.15 Main Cover

(1) Remove two screws "a" from the front side of the main cover.

(2) Remove two screws "b" from the rear side of the main cover, and then pull corner edges "X"

outwards to dislocate the main cover from the main chassis. Make sure that the cutout

provided in the main cover is dislocated from the power inlet.

(3) Unhook the two latches with the tip of a flat screwdriver, then lift up the main cover.

nn Reassembling Notes

• When reinstalling the main cover, route the main-relay (panel) harness, main-relay (CCD)

harness, and main-relay (motors) harness through the respective cutouts provided in the main

cover, as illustrated above.

"a" and "b": Taptite, bind S M3x8

IV - 34

1.16 Switch Cover (for models not equipped with a power switch)

(1) Push the locks of the switch cover as shown below and remove it.

IV - 35

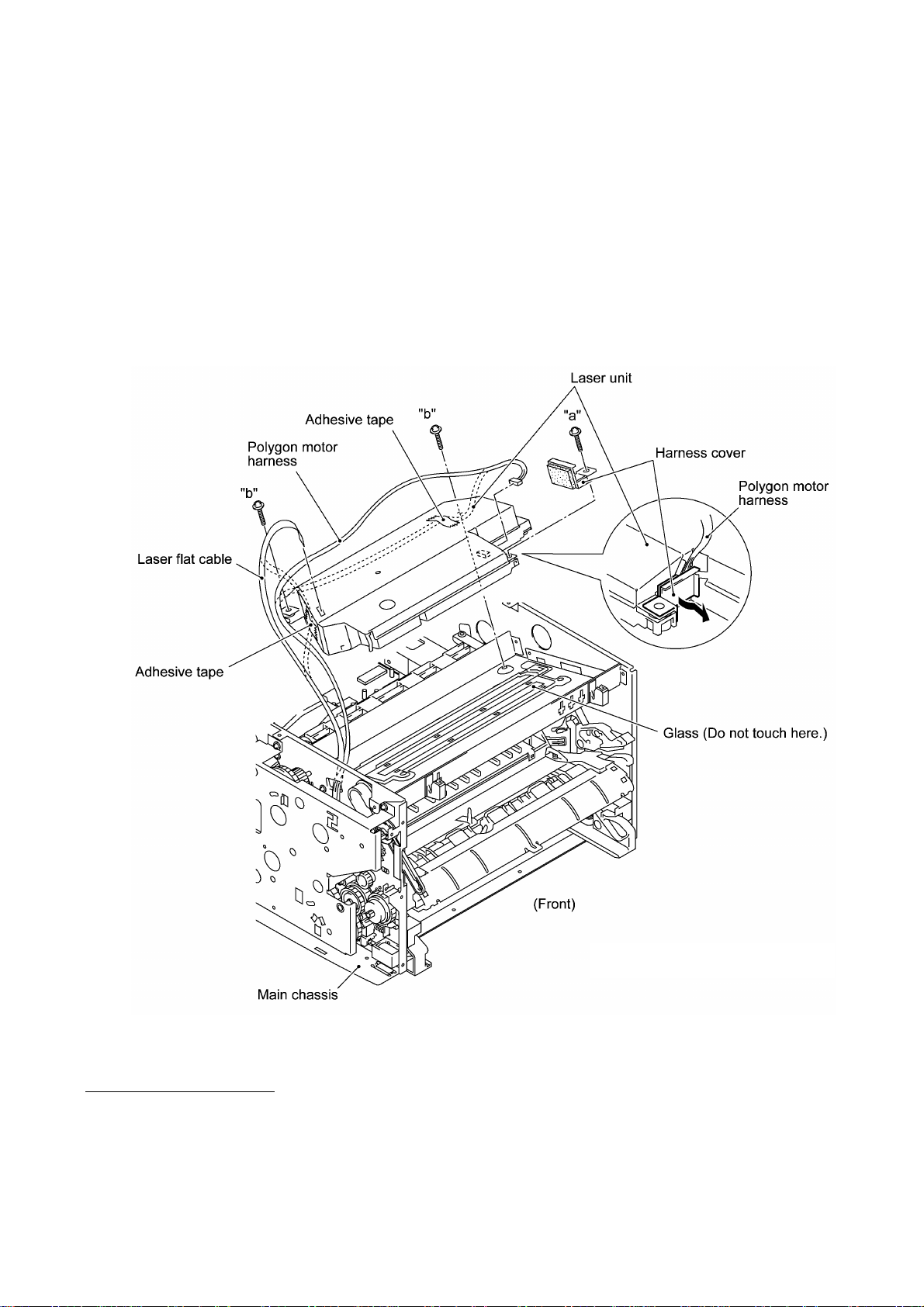

1.17 Laser Unit

(1) Remove screw "a" and take off the harness cover.

(2) Remove two screws "b."

(3) Disconnect the polygon motor harness and laser flat cable from the laser unit.

(4) Lift up the laser unit.

NOTE: When handling the laser unit, take care not to touch the inside of the unit, glass, or

mirror.

NOTE: On the small PCB in the laser unit is a 2-pin connector which is for the adjustment in

the factory. Do not disturb it.

nn Reassembling Notes

• Before putting the laser unit back into place, check for any toner particles, paper dust or dirt,

and clean them out.

• After routing the polygon motor harness and laser flat cable, tape them onto the laser unit as

shown above.

"a" and "b": Taptite, cup S M3x16

IV - 36

1.18 Heat-fixing Unit and FU Lamp

(1) Remove the screw from the harness duct. The chassis grounding wire also comes off.

(2) Peel off tape and take off the main-relay (motors) harness, main-relay (CCD) harness, and VC

harness* from the harness duct.

(3) Unhook the harness duct from the main chassis in the directions of arrows • and ‚.

*Provided on models supporting video capture

IV - 37

(4) Remove three screws (two "a" and one "b").

(5) Disconnect the long heater wire (of the heater harness) from the upper center of the heat-

fixing unit.

(6) Disconnect the short heater wire (of the heater harness) from the left end of the heat-fixing

unit.

(7) Lift up the heat-fixing unit and disconnect the heater thermistor harness from the engine PCB.

IV - 38

"a": Stepped screw

"b": Taptite, cup S M3x8

(8) To take out the FU lamp from the heat-fixing unit, remove two screws "c."

(9) Unhook the two latches outwards (in the direction of arrows •) with the tip of a flat

screwdriver and open the upper cover (arrow ‚). The upper and lower covers will become

separated from each other.

(10) Loosen screw "d" (arrow ƒ).

(11) Remove screw "e," slightly lift up the heater roller gear (arrow „), hold the lock plate L of the

FU lamp between your fingers, and pull out the FU lamp from the heater roller (arrow …).

CAUTION: Do not touch the FU lamp. If you have touched it, clean it thoroughly with

alcohol.

nn Reassembling Notes

• When setting the FU lamp into the heat-fixing unit, be sure to insert the right end of the wire

into the lock plate R as illustrated above.

"c": Taptite, cup B M3x20

"d": Pan cup M3x6

"e": Taptite, pan M3x10DB

IV - 39

• When securing the lock plate R with screw "d," be sure to use the plastic jig as shown below to

avoid damaging the edge of the FU lamp with a screwdriver.

Lock plate R

FU lamp

"d"

Plastic jig

• A new heat-fixing unit will be provided with the heater thermistor harness being taped to the

unit. Before installing the unit, remove the tape.

• When setting the heat-fixing unit back into place, make sure that the heater wires are routed

through the latch of the fan duct (see the illustration given on page IV-41) and then route the

long heater wire as shown below.

• If you remove and reinstall the heat-fixing unit because of any failure, make the machine enter

the maintenance mode (see Note) after completion of reassembly and then make it exit from

the mode (by pressing the 9 key twice). Otherwise, the heat-fixing unit may not become

energized because of the following reason:

If the failure of the heat-fixing unit is caused by an opening of the thermistor circuit (that senses

the temperature of the heat-fixing unit), the system misinterprets the hot heater as being cold.

As a result, the temperature of the heat-fixing unit may become excessively high. To prevent

the system from heating the hot heater further at the next powering-on, it is designed so that

the heater will not be energized. To cancel this setting, you need to carry out the above

maintenance-mode procedure.

(Note) Entry into the maintenance mode

Machines w/ fax: Press the Function/Menu, *, 2, 8, 6, and 4 keys.

Machines w/o fax: Press the Menu, 0, 2, 8, 6, and 4 keys.

IV - 40

1.19 Fan

(1) Disconnect the fan harness from the engine PCB.

(2) Remove two screws, take out the heater wires from the latch of the fan duct, and take off the

fan duct together with the fan.

IV - 41

(3) As shown below, pull the fan duct outwards and take out the fan.

nn Reassembling Notes

• Put the fan back into place so that the rating label faces outwards and upside down.

• Route the heater wires through the latch of the fan duct as shown on the previous page.

IV - 42

1.20 Drive Gear ASSY and Main Motor ASSY

(1) Remove five screws from the drive gear ASSY.

(2) Tilt the drive gear ASSY towards you while taking care not to drop the develop joint and

spring, and then disconnect the main motor harness.

(3) Remove the front cover link and idle gear 56 from the main chassis.

IV - 43

*Provided on models supporting video capture

(4) Remove four screws and take off the main motor ASSY from the drive gear ASSY.

nn Reassembling Notes

• If you have removed the gear 39/98 from the drive gear ASSY, hook the spring and tape it as

shown below.

IV - 44

1.21 NCU Shield and NCU PCB*

(1) Remove three screws from the NCU shield, then take off the NCU shield.

(*Provided on models supporting facsimile function.)

(2) USA version: Disconnect the main-NCU harness from the main PCB.

European version: Disconnect the main-NCU harness and main-NCU harness 2 from the main

PCB. See the illustration given on the next page.

(3) Remove the screw from the NCU PCB and take out the PCB.

IV - 45

nn Reassembling Notes

[USA version]

• Route the main-NCU harness above the main-relay (motors) harness as illustrated below.

[European version]

• As illustrated below, route the main-NCU harness and main-NCU harness 2 between the NCU

PCB and the power supply bracket to prevent them from interfering with the primary circuitry on

the NCU PCB. Then install the NCU shield.

IV - 46

1.22 Bottom Plate, Main PCB, and Bottom Insulation Film

(1) Disconnect the following harnesses and flat cable from the main PCB:

• Main-relay (panel) harness (13-pin, P3)

• Main-LV-engine harness (5-pin, P18)

• Laser flat cable (P6)

• Engine-main harness (12-pin, P5)

• VC harness*1 (2-pin, P7)

• Main-relay (CCD) harness (12-pin, P8)

• In-casing temperature sensor harness (2-pin, P9)

• Main-relay (motors) harness (11-pin, P10)

*1 Provided on models supporting video capture

*2 Provided on the European version

IV - 47

(2) Turn the main chassis upside down.

(3) Remove 14 screws (nine "a" and five "b").

(4) Slightly lift up the bottom plate and pull it to the rear until you can remove screw "c."

(5) Remove screw "c" to release the grounding wire.

(6) For models available with a 2nd paper cassette: Removes screw "d" that secures the 2nd

cassette relay PCB bracket to the bottom plate.

(7) Pull the bottom plate to the rear and out of the main chassis.

"a" and "d": Taptite, cup S M3x6

"b" Taptite, bind B M4x12

"c": Screw, pan (washer) M3.5x6

IV - 48

(8) Remove screw "d" and disconnect the paper ejection sensor PCB from the main PCB.

(9) Remove five screws (three "e" and two "f"), then take off the main PCB from the bottom plate.

(10) Remove the bottom insulation film.

nn Reassembling Notes

• When putting the bottom plate back into place, make sure that the grounding wire is looped and

routed through the support film (as illustrated on page IV-51) and then secure the grounding

wire to the bottom plate with screw "c" (shown on the previous page).

• After you replace the main PCB, be sure to follow the flowchart given on the next page.

"d" and "e": Taptite, cup S M3x6

"f": Machine screw, pan M3x6

IV - 49

Setting up the main PCB after replacement

IV - 50

1.23 Low-voltage Power Supply PCB and Power Inlet

(1) Remove two screws "g" and take off the rear underbar.

(2) Remove screw "h."

(3) Slightly lift up the low-voltage power supply PCB and disconnect the heater harness and

main-LV-engine harness. The low-voltage power supply PCB is connected to the power inlet

with soldered lead wires.

(4) Remove screw "i."

(5) While holding up the low-voltage power supply PCB, take out the power inlet from the main

chassis to the inside in the direction of the arrow shown below.

(6) To separate the power inlet from the low-voltage power supply PCB, unsolder the two lead

wires from the PCB.

IV - 51

"g" and "i": Taptite, cup S M3x6

"h": Taptite, cup S M3x6

(Tightening torque: 0.5 N•m)

nn Reassembling Notes

• When connecting the power inlet to the low-voltage power supply PCB, insert the brown and

blue lead wires into eyelets L and N in the PCB, respectively, and then solder those wires on

the solder side of the PCB.

• After setting the power inlet back into place, fold the grounding wire into two and route the fold

through cutout "Y" provided in the support film as shown on the previous page.

• When reinstalling the low-voltage power supply PCB, route the main-LV-engine harness

through cutout "X" provided in the support film as shown on the previous page.

IV - 52

1.24 Inner Insulation Film, High-voltage Power Supply PCB, Engine PCB, and 2nd Cassette Relay

PCB*

(*Provided on models available with a 2nd paper cassette)

(1) Remove screw "a" and take off the inner insulation film.

(2) Remove three screws (two "b" and one "c") from the high-voltage power supply PCB and

engine PCB.

(3) Slightly lift up the high-voltage power supply PCB and disconnect it from the engine PCB.

(4) Pull the spring up and out.

(5) Slightly hold up the engine PCB and disconnect the following harnesses:

• Toner sensor (light-receiver) harness (3-pin, P1)

• Main-LV-engine harness (2-pin, P15)

• 2nd cassette relay harness* (8-pin, P8)

• Heater thermistor harness (2-pin, P6), if the heat-fixing unit has not been removed

• Fan harness (2-pin, P7), if the fan has not been removed

• Toner sensor (LED) harness (4-pin, P10)

• Main motor harness (6-pin, P9)

• Polygon motor harness (5-pin, P12)

• Solenoid harness (2-pin, P13)

"a," "b," and "c": Taptite, bind B M4x12

IV - 53

(6) For models available with a 2nd paper cassette: Pull the 2nd cassette relay PCB bracket to

take out its harness. Remove the screw and take off the 2nd cassette relay PCB from its

bracket.

nn Reassembling Notes

• Before reinstalling the high-voltage power supply PCB, push in the spring with a flat

screwdriver until it snaps into place as shown below.

• Before reinstalling the high-voltage power supply PCB, check the high-voltage contacts for any

toner particles, paper dust or dirt, and clean them out.

IV - 54

Loading...

Loading...