Page 1

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODEL: FAX3550/3650/8000P/8200P

MFC4450/4550/4550plus

MFC6550MC/7550MC/7650MC

MFC9000/9500

Page 2

© Copyright Brother 1998

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

Page 3

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation, and maintenance of the Brother facsimile equipment. It includes information required for

field troubleshooting and repair—disassembly, reassembly, and adjustment—so that service

personnel will be able to understand equipment function, to rapidly repair the equipment and

order any necessary spare parts.

To perform appropriate maintenance so that the facsimile equipment is always in best condition

for the customer, the service personnel must adequately understand and apply this manual.

This manual is made up of six chapters and appendices.

CHAPTER I. GENERAL DESCRIPTION

CHAPTER II. INSTALLATION

CHAPTER III. THEORY OF OPERATION

CHAPTER IV. DISASSEMBL Y/REASSEMBLY AND LUBRICATION

CHAPTER V. MAINTENANCE MODE

CHAPTER VI. ERROR INDICATION AND TROUBLESHOOTING

APPENDICES Circuit Diagrams

This manual describes the model and its versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

Page 4

SAFETY INFORMATION

Laser Safety (110 - 120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health

and Safety Act of 1968. This means that the printer does not produce hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective housings and

external covers, the laser beam cannot escape from the machine during any phase of user operation.

CDRH Regulations (110 - 120V Model only)

The Center for Device and Radiological Health (CDRH) of the US Food and Drug Administration

implemented regulations for laser products on August 2, 1976. These regulations apply to laser

products manufactured from August 1, 1976. Compliance is mandatory for products marketed in the

United States. The label shown below indicates compliance with the CDRH regulations and must be

attached to laser products marketed in the United States.

The label for Japanese products

MANUFACTURED: AUGUST 1998 K

BROTHER INDUSTRIES, LTD.

15-1 Naeshiro-cho Mizuho-ku Nagoya 467-8561, Japan.

This product complies with FDA radiation

performance standards, 21 CFR Subchapter J.

Page 5

CHAPTER I.

GENERAL DESCRIPTION

Page 6

CONTENTS

1. EQUIPMENT OUTLINE................................................................................. I-1

1.1External Appearance and Weight........................................................... I-1

1.2Components............................................................................................I-1

2. SPECIFICATIONS..........................................................................................I-2

Page 7

1. EQUIPMENT OUTLINE

1.1 External Appearance and Weight

The figure below shows the equipment appearance and approximate dimensions.

251 (H)

Weight: Machine proper Approx. 8.5 kg (excluding the drum unit and toner cartridge)

In package Approx. 13.5 kg (FAX3550/3650/8000P/8200P)

1.2 Components

The equipment consists of the following major components:

Multi-purpose

sheet feeder

Drum unit with toner

cartridge loaded

Laser unit

383 (W)

(excluding the handset)

Approx. 14 kg (MFC4450/4550/4550plus/6550MC/7550MC/

452 (D)

(Unit: mm)

7650MC/9000/9500)

Top cover

Control panel ASSY

Heat-fixing unit

Inner cover

Handset

Gear drive unit

Low-voltage power

supply ASSY

Bottom plate

Main cover

Scanner frame ASSY

NCU PCB ASSY

Main PCB

Relay PCB

High-voltage power

supply ASSY

I – 1

Page 8

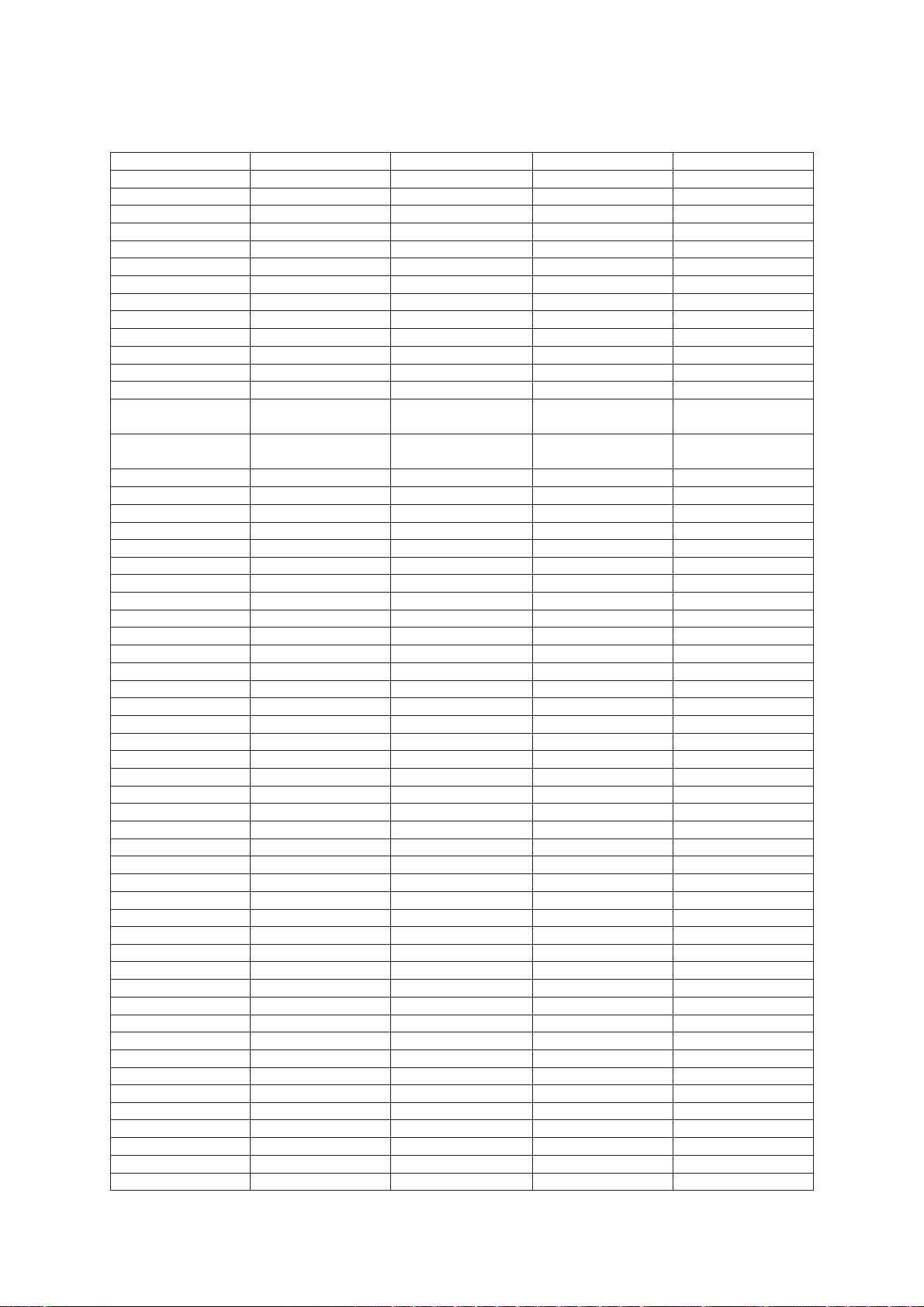

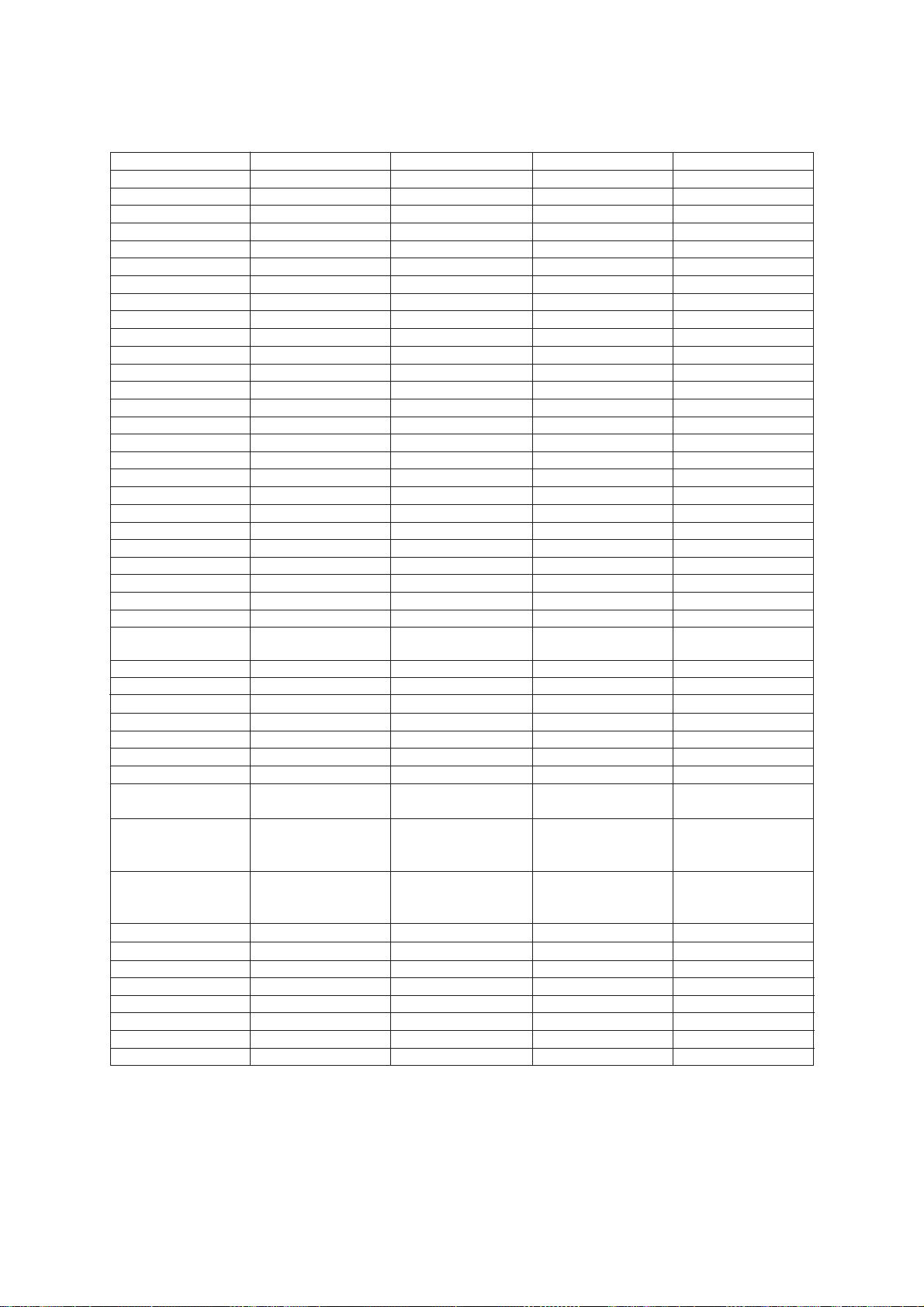

2. SPECIFICATIONS

MODEL FAX3550 MFC4550 MFC6550MC MFC7550MC

COLOR 1267 1138 1138 1138

PRINTER Option

Engine — HL-720 HL-730 HL-730

PPM — 6 6 6

dpi — 600 x 600 600 x 600 600 x 600

Paper Capacity 200 200 200 200

Standards — Windows GDI (600x600) Windows GDI (600x600) Windows GDI (600x600)

Emulation — No PCL4 (300x300) PCL4 (300x300)

Memory (Typical) — 512 KB 512 KB 1 MB

Memory (Min.) — 300 KB 400 KB 1 MB

Fonts Resident — No 24-bit map (PCL4 Comp) 24-bit map (PCL4 Comp)

Fonts Disk Based — No Yes Yes

Paper Handling LTR, LGL, A4 LTR, LGL, EXE, A4, B5, A5 LTR, LGL, EXE, A4, B5, A5 LTR, LGL, EXE, A4, B5, A5

Multi-purpose Sheet Custom Size (2.85x5-8x14) Custom Size (2.85x5-8x14) Custom Size (2.85x5-8x14) Custom Size (2.85x5-8x14)

Feeder

Printer Driver — Windows 3.1, 95 Driver with Windows 3.1, 95 Driver with Windows 3.1, 95 Driver with

Toner Life (5%/page) 2200 pages 2200 pages 2200 pages 2200 pages

Utility Software — — RPC RPC

SCANNER Option

Color/Mono — Mono Mono Mono

Gray Scale — 64 256 256

dpi — 400 x 400 600 x 600 600 x 600

Twain — Yes Yes Yes

ADF Capacity (pages) (30) 30 30 30

Formats — TIFF/BMP (by M/L) TIFF/BMP (by M/L) TIFF/BMP (by M/L)

OCR — Option Yes Yes

Envelope (BL/C5/COM 10/Mona) Envelope (BL/C5/COM 10/Mona) Envelope (BL/C5/COM 10/Mona) Envelope (BL/C5/COM 10/Mona)

Auto Installer Program Auto Installer Program Auto Installer Program

(1/2)

COPY

dpi 200 x 400 200 x 400 600 class 600 class

No. of Copies 1-99 1-99 1-99 1-99

Sorting No No Yes Yes

Reduction/Enlargement 50-200% 50-200% 50-200% 50-200%

FAX

Modem ROCKWELL V12 ROCKWELL V12 ROCKWELL V24 ROCKWELL V24

Modem Speed 14400 bps (FAX only) 14400 bps (FAX only) 14400 bps (FAX only) 14400 bps (FAX only)

CCITT Group G3 G3 G3 G3

Coding Method MH/MR/MMR MH/MR/MMR MH/MR/MMR MH/MR/MMR

Transmission Speed 6 sec. 6 sec. 6 sec. 6 sec.

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

LCD Size 16 x 1 16 x 2 16 x 2 16 x 2

Super Fine Yes (Send only) Yes (Send only) Yes (Send only) Yes

Gray Scale 64 64 64 64

Smoothing Yes Yes Yes Yes

Handset Yes Yes Yes Yes

One-touch Dial 20 x 2 12 x 2 12 x 2 12 x 2

Speed Dial 100 36 36 100

Telephone Index Yes Yes Yes Yes

Contrast Super L/Auto/Super D Super L/Auto/Super D Super L/Auto/Super D Super L/Auto/Super D

Multi-resolution Transmission

FAX/TEL Switch Yes Yes Yes Yes

Distinctive Ringing Yes Yes Yes Yes

Caller ID Yes Yes Yes Yes

Next FAX-reservation Yes Yes Yes Yes

Help Yes Yes Yes Yes

TAD Interface Yes Yes Yes Yes

Yes Yes Yes Yes

I – 2

Page 9

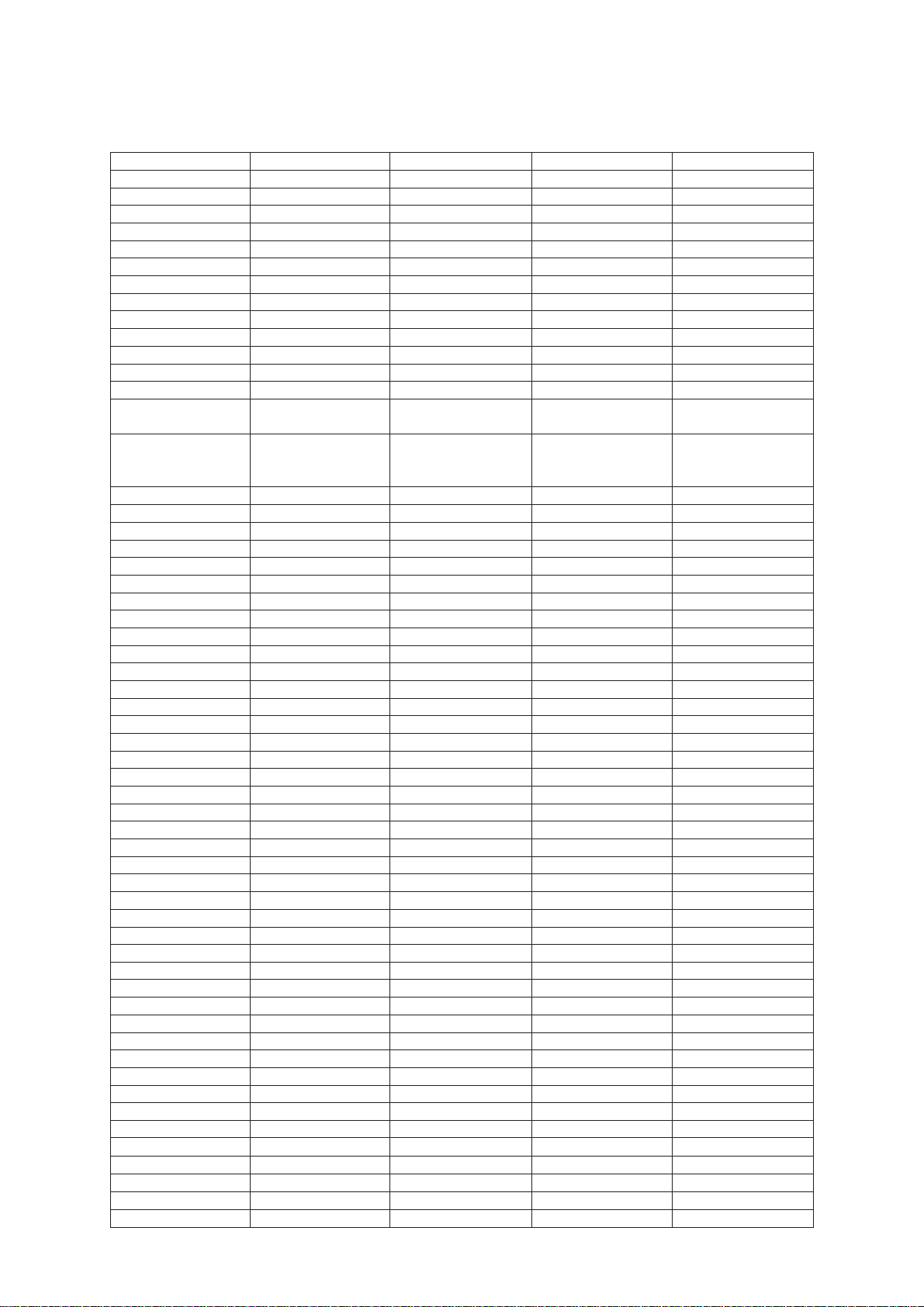

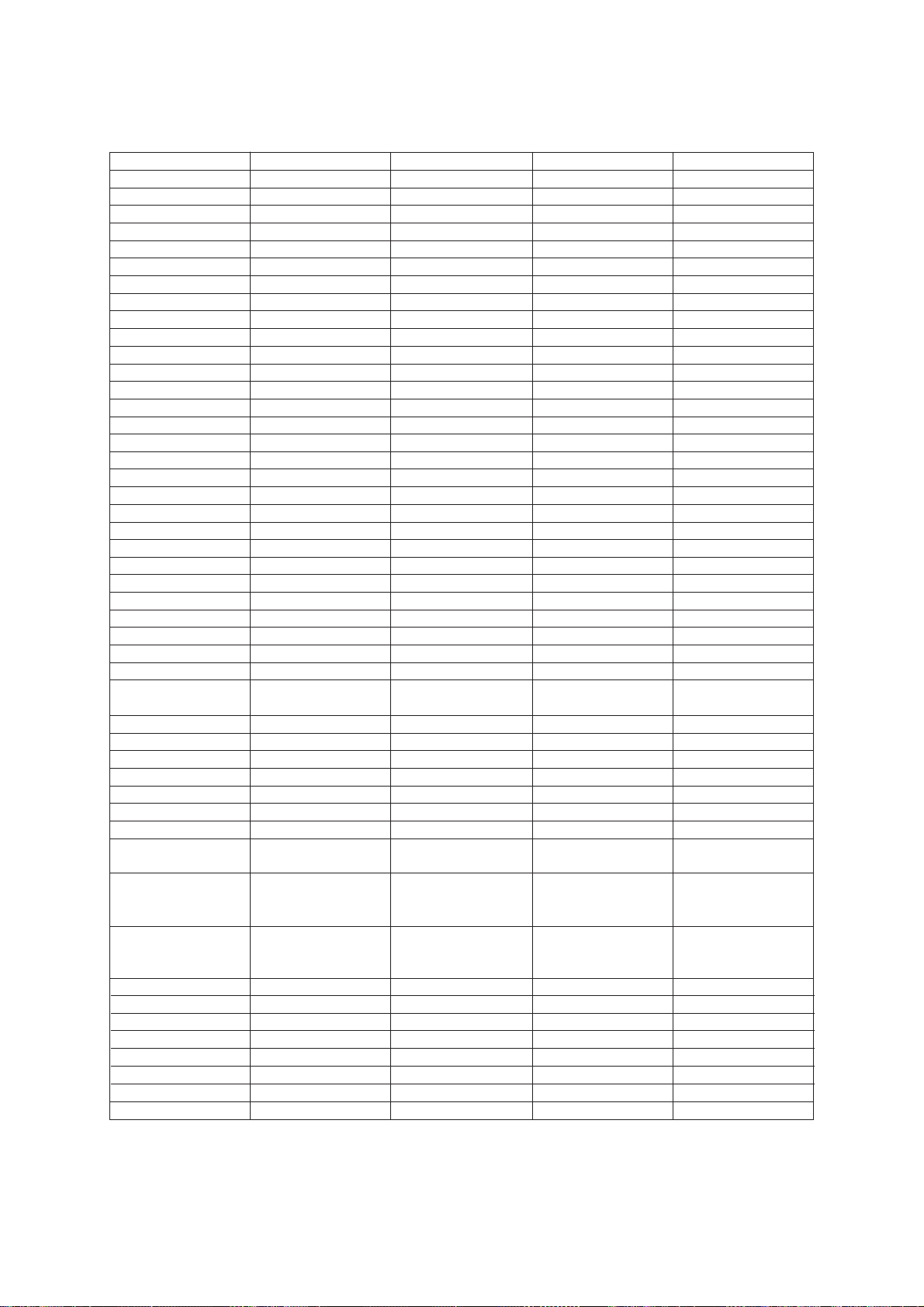

MODEL FAX3650 MFC4450 MFC4550plus MFC7650MC

COLOR 1267 1138 1138 1138

PRINTER Option

Engine — HL-720 HL-720 HL-730

PPM — 6 6 6

dpi 200 x 200 600 x 600 600 x 600 600 x 600

Paper Capacity 200 200 200 200

Standards Windows GDI (200x200) Windows GDI (600x600) Windows GDI (600x600) Windows GDI (600x600)

Emulation — No PCL4 (300x300) PCL4 (300x300)

Memory (Typical) — 512 KB 512 KB 1 MB

Memory (Min.) — 300 KB 400 KB 600 KB

Fonts Resident — No 24-bit map (PCL4 Comp) 24-bit map (PCL4 Comp)

Fonts Disk Based — No Yes Yes

Paper Handling LTR, LGL, A4 LTR, LGL, A4, B5, A5 LTR, LGL, A4, B5, A5 LTR, LGL, A4, B5, A5

Multi-purpose Sheet — Custom Size (2.85x5-8x14) Custom Size (2.85x5-8x14) Custom Size (2.85x5-8x14)

Feeder

Printer Driver — Windows 3.1, 95 Driver with Windows 3.1, 95 Driver with Windows 3.1, 95 Driver with

Toner Life (5%/page) 2200 pages 2200 pages 2200 pages 2200 pages

Utility Software — — RPC RPC

SCANNER Option

Color/Mono — Mono Mono Mono

Gray Scale — 64 64 256

dpi — 400 x 400 400 x 400 600 x 600

Twain — Yes Yes Yes

ADF Capacity (pages) — 30 30 30

Formats (Import) —

Formats (Export) — TIFF/BMP/UNI TIFF/BMP/MAX TIFF/BMP/MAX

OCR — Option Yes Yes

Envelope (BL/C5/COM 10/Mona) Envelope (BL/C5/COM 10/Mona) Envelope (BL/C5/COM 10/Mona)

Auto Installer Program Auto Installer Program Auto Installer Program

TIFF/BMP/PCX/DCX/BTF/BTX/UNI TIFF/BMP/PCX/DCX/BTF/BTX/MAX TIFF/BMP/PCX/DCX/BTF/BTX/MAX

(1/2)

COPY

dpi 200 x 400 200 x 400 200 x 400 600 class

No. of Copies 1-99 1-99 1-99 1-99

Sorting Yes No No Yes

Reduction/Enlargement 50-200% 50-200% 50-200% 50-200%

FAX

Modem ROCKWELL V12 Toshiba ROCKWELL V12 ROCKWELL V24

Modem Speed 14400 bps (FAX only) 9600 bps (FAX only) 14400 bps (FAX only) 14400 bps (FAX only)

CCITT Group G3 G3 G3 G3

Coding Method MH/MR/MMR MH/MR/MMR MH/MR/MMR MH/MR/MMR

Transmission Speed 6 sec. 9 sec. 6 sec. 6 sec.

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

LCD Size 16 x 1 16 x 2 16 x 2 16 x 2

Super Fine Yes Yes Yes Yes

Gray Scale 64 64 64 64

Smoothing Yes Yes Yes Yes

Handset Yes No Yes Yes

One-touch Dial 20 x 2 12 x 2 12 x 2 12 x 2

Speed Dial 100 36 36 100

Telephone Index Yes Yes Yes Yes

Contrast Super L/Auto/Super D Super L/Auto/Super D Super L/Auto/Super D Super L/Auto/Super D

Multi-resolution Transmission

FAX/TEL Switch Yes Yes (with External) Yes Yes

Distinctive Ringing Yes Yes (with External) Yes Yes

Caller ID Yes No Yes Yes

Next FAX-reservation Yes Yes Yes Yes

Help Yes Yes Yes Yes

TAD Interface Yes Yes Yes Yes

Yes Yes Yes Yes

I – 3

Page 10

MODEL FAX8000P MFC9000 MFC9500 FAX8200P

COLOR 1138 1138 1138 1138

PRINTER Option Option

Engine — HL-730 HL-730 —

PPM — 6 6 —

dpi —

Paper Capacity 200 200 200 200

Standards — Windows GDI Windows GDI —

Emulation — PCL4 PCL4 —

Memory (Typical) — 512 KB 512 KB —

Memory (Min.) — 400 KB 400 KB —

Fonts Resident — 24-bit map (PCL4 Comp) 24-bit map (PCL4 Comp) —

Fonts Disk Based — Yes Yes —

Paper Handling A4, B5, A5 A4, B5, A5 A4, B5, A5 A4

Multi-purpose Tray

Printer Driver — Windows 3.1, 95 Driver with Windows 3.1, 95 Driver with

Toner Life (5%/page) 2200 pages 2200 pages 2200 pages 2200 pages

Utility Software —

SCANNER Option Option

Color/Mono — Mono Mono —

Gray Scale — 256 256 —

dpi — 600 x 600 600 x 600 —

Twain — Yes Yes —

ADF Capacity (pages) 30 30 30 —

Formats — TIFF/BMP TIFF/BMP —

OCR — Option Yes —

Custom Size (73x127-126x350 mm) Custom Size (73x127-216x350 mm) Custom Size (73x127-216x350 mm)

Envelope (DL/C5/COM 10/Mona) Envelope (DL/C5/COM 10/Mona) Envelope (DL/C5/COM 10/Mona)

600 x 600 (GDI) / 300 x 300 (PCL4) 600 x 600 (GDI) / 300 x 300 (PCL4)

Auto Installer Program Auto Installer Program

Mac Driver (Option) Mac Driver (Option)

Remote Priter Console (RPC) Remote Printer Console (RPC)

—

—

—

—

(1/2)

COPY

dpi 200 x 400 300 x 400 300 x 400 200 x 400

No. of Copies 1-99 1-99 1-99 1-99

Sorting

Reduction/Enlargement 50-200% 50-200% 50-200% 50-200%

FAX

Modem ROCKWELL V12 ROCKWELL V12 ROCKWELL V24 ROCKWELL V12

Modem Speed 14400 bps (FAX only) 14400 bps (FAX only) 14400 bps (FAX only) 14400 bps (FAX only)

CCITT Group G3 G3 G3 G3

Coding Method MH/MR/MMR MH/MR/MMR MH/MR/MMR MH/MR/MMR

Transmission Speed 6 sec. 6 sec. 6 sec. 6 sec.

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

LCD Size 16 x 1 16 x 2 (STN) 16 x 2 (STN) 16 x 1

Super Fine (Send) Yes Yes Yes Yes

Super Fine (Receive)

Gray Scale 64 64 64 64

Smoothing Yes Yes Yes Yes

Handset No No No No

One-touch Dial 20 x 2 12 x 2 12 x 2 20 x 2

Speed Dial 100 100 100 100

Telephone Index Yes Yes Yes Yes

Contrast Light/Auto/Dark Light/Auto/Dark Light/Auto/Dark Light/Auto/Dark

Multi-resolution Transmission

FAX/TEL Switch Yes Yes Yes Yes

Distinctive Ringing Yes Yes Yes —

Caller ID

Next FAX-reservation Yes Yes Yes Yes

Help Yes Yes Yes Yes

TAD Interface Yes Yes Yes Yes

Available with optional memory

Available with optional memory Available with optional memory Available with optional memory

Yes Yes Yes Yes

Yes (U.K., Sweden, Holland and France) Yes (U.K., Sweden, Holland and France) Yes (U.K., Sweden, Holland and France) Yes (U.K., Sweden, Holland and France)

Yes Yes Yes

Yes

I – 4

Page 11

MODEL FAX3550 MFC4550 MFC6550MC MFC7550MC

FAX

Coverpage Yes, Super Yes, Super Yes, Super Yes, Super

Polling Type Std/Del/Seq Std/Del/Seq Std/Del/Seq Std/Del/Seq

Receive password Yes Yes Yes Yes

Delayed Transmission Yes, 3 timings Yes, 3 timings Yes, 3 timings Yes, 3 timings

Call Reservation Yes Yes Yes Yes

Callback Message Yes Yes Yes Yes

Page Memory (TX)* 300 KB (30 pgs: MMR) 200 KB (20 pgs: MMR) 300 KB (30 pgs: MMR) 700 KB (70 pgs: MMR)

Out-of-paper Reception* 400 KB (40 pgs: MMR) 400 KB (40 pgs: MMR) 600 KB (60 pgs: MMR) 1.5 MB (150 pgs: MMR)

Super Quick Scan Yes Yes Yes Yes

Auto Reduction Yes Yes Yes Yes

ECM Yes Yes Yes Yes

Broadcasting Y e s Yes Yes Yes

Multi Transmission Yes Yes Y es Yes

MESSAGE CENTER

TAD Feature No No Yes (Hardware & PC) Yes (Hardware & PC)

ICM Recording Time No No Hardware: 15 min. Hardware: 30 min.

Paging No No Yes (Hardware & PC) Yes (Hardware & PC)

Toll Saver No No Yes (Hardware & PC) Yes (Hardware & PC)

OGM No No Yes (Hardware & PC) Yes (Hardware & PC)

Mail Box No No Yes (PC only) Yes (PC only)

Fax-on-demand No No Yes (PC only) Yes (PC only)

Voice-on-demand No No Yes (PC only) Yes (PC only)

FAX Forwarding Yes Yes Yes Yes

FAX Retrieval Yes Yes Yes Yes

(2/2)

MACHINE MEMORY 0.75 MB 0.75 MB 1 MB 2 MB

OPTIONAL MEMORY 1 or 2 MB 1 or 2 MB 1 or 2 MB 1 or 2 MB

(FAX & PRINTER FLEX)

PC FAX (Send/Receive) Option Yes (by M/L) Yes (by M/L) Yes (by M/L)

Standard — Class 1, 2 Class 1, 2 Class 1, 2

DATA MODEM No No No No

INTERFACE

Printer Interface —

PC Interface

Extended I/O Interface — —

Simultaneous

Sends FAX and Prints — Yes Yes Yes

Receives FAX and Prints

Receives FAX and Scans

Prints and Scans — Yes Yes Yes

Receives FAX and Copies

Prints and Copies — Yes Yes Yes

RS-232C

(8-pin modular connector)

MULTI-FUNCTION LINK

— Yes Yes Yes

— Yes Yes Yes

— Yes Yes Yes

Centronics parallel (w/o cable) Centronics parallel (w/o cable) Centronics parallel (w/o cable)

MULTI-FUNCTION LINK PRO MULTI-FUNCTION LINK PRO MULTI-FUNCTION LINK PRO

———

RS-232C and RS-422 RS-232C and RS-422

(supported by an optional serial (supported by an optional serial

interface board RS-100M) interface board RS-100M)

* CCITT#1 Chart in the Standard Mode, MMR

I – 5

Page 12

MODEL FAX3650 MFC4450 MFC4550plus MFC7650MC

FAX

Coverpage Yes, Super Yes, Super Yes, Super Yes, Super

Polling Type Std/Del/Seq Std/Del/Seq Std/Del/Seq Std/Del/Seq

Delayed Transmission Yes, 13 timings Yes, 3 timings Yes, 3 timings Yes, 13 timings

Call Reservation Yes Yes (with External) Yes Yes

Callback Message Yes Yes Yes Yes

Page Memory (TX)* 1 MB (100 pgs: MMR) 300 KB (30 pgs: MMR) 300 KB (30 pgs: MMR) 800 KB (80 pgs: MMR)

Out-of-paper Reception* 1.1 MB (110 pgs: MMR) 600 KB (60 pgs: MMR) 600 KB (60 pgs: MMR) 1.0 MB (100 pgs: MMR)

Super Quick Scan Yes Yes Yes Yes

ECM Yes Yes Yes Yes

Broadcasting Yes Yes Yes Yes

Multi Transmission No Yes Yes No

MESSAGE CENTER

ICM Recording Time No No No Hardware: 30 min.

Paging Yes (Hardware & PC) Yes (Hardware & PC) Yes (Hardware & PC) Yes (Hardware & PC)

Toll Saver No No No Yes (Hardware & PC)

OGM No No No Yes (Hardware & PC)

Mail Box No No Yes (PC only) Yes (PC only)

Fax-on-demand No No No Yes (PC only)

Voice-on-demand No No No Yes (PC only)

FAX Forwarding Yes Yes Yes Yes

FAX Retrieval Yes Yes Yes Yes

(2/2)

MACHINE MEMORY 2 MB 1 MB 1 MB 2 MB

OPTIONAL MEMORY 1 or 2 MB No 1 or 2 MB 1 or 2 MB

(FAX & PRINTER FLEX)

PC FAX (Send/Receive) Option Yes (by M/L) Yes (by M/L) Yes (by M/L)

Standard — SMSI SMSI SMSI

DATA MODEM No No No No

INTERFACE

Printer Interface —

PC Interface

Extended I/O Interface — — —

Simultaneous

Sends FAX and Prints — Yes Yes Yes

Receives FAX and Prints

Receives FAX and Scans

Prints and Scans — Yes Yes Yes

Receives FAX and Copies

Prints and Copies — Yes Yes Yes

RS-232C

(8-pin modular connector)

MULTI-FUNCTION LINK

— Yes Yes Yes

— Yes Yes Yes

— Yes Yes Yes

Centronics parallel (w/o cable) Centronics parallel (w/o cable) Centronics parallel (w/o cable)

MULTI-FUNCTION LINK PRO MULTI-FUNCTION LINK PRO MULTI-FUNCTION LINK PRO

———

RS-232C and RS-422

(supported by an optional serial

interface board RS-100M)

* CCITT#1 Chart in the Standard Mode, MMR

I – 6

Page 13

MODEL FAX8000P MFC9000 MFC9500 FAX8200P

FAX

Coverpage Yes, Super Yes, Super Yes, Super Yes, Super

Polling Type Std/Del/Seq/Sec Std/Del/Seq/Sec Std/Del/Seq/Sec Std/Del/Seq/Sec

Receive password Yes/Plus Yes/Plus Yes/Plus Yes/Plus

Delayed Transmission Yes, 3 timings Yes, 3 timings Yes, 3 timings Yes, 3 timings

Call Reservation Yes Yes Yes Yes

Callback Message Yes Yes Yes Yes

Page Memory (TX)* 300 KB (30 pgs: MMR) 300 KB (30 pgs: MMR) 300 KB (30 pgs: MMR) 1 MB (100 pgs: MMR)

Out-of-paper Reception* 400 KB (40 pgs: MMR) 600 KB (40 pgs: MMR) 600 KB (60 pgs: MMR) 1.1 MB (110 pgs: MMR)

Super Quick Scan Yes Yes Yes Yes

Auto Reduction Yes Yes Yes Yes

ECM Yes Yes Yes Yes

Broadcasting Up to 140 destinations Up to 124 destinations Up to 124 destinations Up to 190 destinations

Multi Transmission Yes Yes Y es Yes

MESSAGE CENTER

TAD Feature No No Yes (Hardware & PC) No

ICM Recording Time No No Hardware: 15 min. No

Paging No No Yes (Hardware & PC) No

Toll Saver No No Yes (Hardware & PC) No

OGM UK/SWISS/AUS/GER UK/SWISS Yes (Hardware & PC) UK/SWISS/GER

Mail Box No No Yes (PC only) No

Fax-on-demand No No Yes (PC only) No

Voice-on-demand No No Yes (PC only) No

FAX Forwarding Yes Yes Yes Yes

FAX Retrieval Yes Yes Yes Yes

(2/2)

MACHINE MEMORY 0.75 MB 1 MB 1 MB 2 MB

OPTIONAL MEMORY 1 or 2 MB 1 or 2 MB 1 or 2 MB 1 or 2 MB

(FAX & PRINTER FLEX)

PC FAX (Send/Receive) Option Yes Yes Option

Standard — Class 2 Class 2 —

DATA MODEM No No No No

INTERFACE

Printer Interface —

PC Interface

CONNECT 5000 INTERFACE CONNECT 5000 INTERFACE

Extended I/O Interface —

Simultaneous

Sends FAX and Prints — Yes Yes —

Receives FAX and Prints

Receives FAX and Scans

Prints and Scans — Yes Yes —

Receives FAX and Copies

Prints and Copies — Yes Yes —

RS-232C

(8-pin modular connector) (8-pin modular connector)

—YesYes—

—YesYes—

—YesYes—

Centronics parallel (w/o cable) Centronics parallel (w/o cable) —

MULTI-FUNCTION LINK PRO MULTI-FUNCTION LINK PRO

——

RS-232C and RS-422 RS-232C and RS-422

(supported by an optional serial (supported by an optional serial

interface board RS-100M) interface board RS-100M)

RS-232C

—

* CCITT#1 Chart in the Standard Mode, MMR

I – 7

Page 14

CHAPTER II.

INSTALLATION

Page 15

CONTENTS

1. INSTALLING THE UPDATE DATA TO THE FACSIMILE EQUIPMENT...............II-1

Page 16

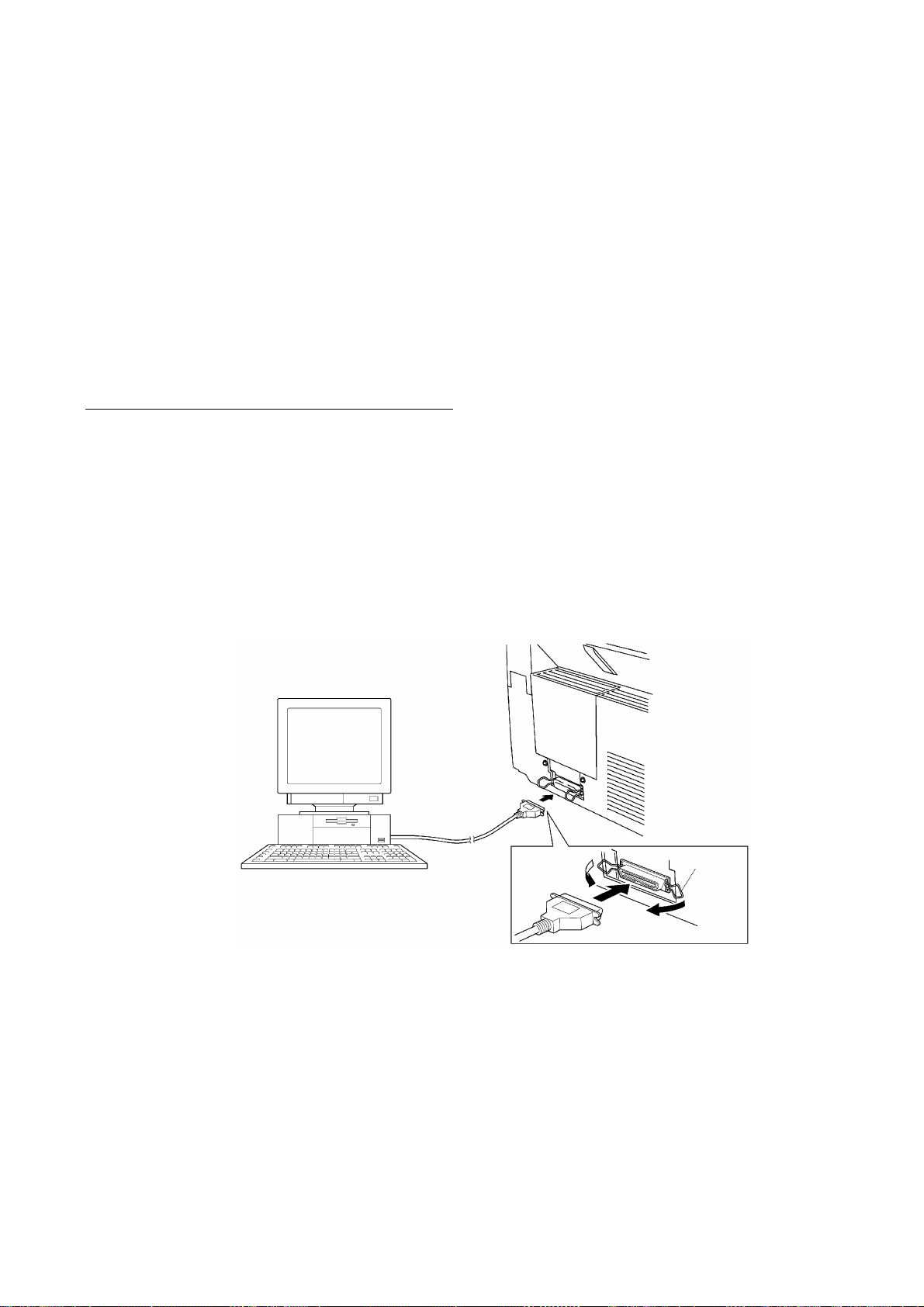

1. INSTALLING THE UPDATE DATA TO THE

FACSIMILE EQUIPMENT

If the program version is updated or the main PCB is replaced, install the update program onto the

flash ROM of the main PCB.

The program installation requires a host computer satisfying the following requirements:

- CPU Pentium 75 or higher

- RAM 8MB or greater (16MB recommended for Windows 95)

- OS Windows 3.1/3.11 or Windows 95

Connecting the equipment to your computer

(1) Make sure that the equipment's power cord is unplugged from a wall socket.

(2) Make sure that your computer is powered off.

(3) Connect the interface cable to the parallel interface port on the back of the equipment and

secure it with the lock wires.

(4) Connect the other end of the interface cable to the printer port of your computer and secure

it with the two screws.

(5) Power on your computer.

(6) Plug the equipment's power cord into a wall socket.

Host computer

Interface cable

Lock

wires

II - 1

Page 17

Installing the update data onto the flash ROM of the facsimile equipment

(1) Load the floppy disk which stores the update data and transfer utility into the floppy disk

drive of your computer.

(Or, copy the update data and transfer utility onto the same directory of the hard disk.)

(2) Click the Start button, point to Programs, and then click MS-DOS Prompt to open an MS-

DOS window.

(3) Type the drive letter where the update data and transfer utility are located. If it is a floppy

disk drive, type A:\ from the command line and press the ENTER key.

(4) Check that your computer is connected with the facsimile equipment correctly.

(5) To start the transfer utility transmitting the update data to the flash ROM of the facsimile

equipment, type the following:

A:\ICEN filename /b

Then press the ENTER key.

The equipment beeps and shows the "CONNECTING" on the LCD for one second.

Then, the equipment shows the "DOWNLOADING" on the LCD and starts receiving data

downloaded from the host computer.

During downloading, the equipment beeps intermittently.

Upon completion of the downloading, the equipment beeps continuously.

II - 2

Page 18

CHAPTER III.

THEORY OF OPERATION

Page 19

CONTENTS

1. OVERVIEW.....................................................................................................III-1

2. MECHANISMS................................................................................................III-2

2.1Scanner Mechanism.............................................................................. III-3

2.1.1Document feeding and ejecting mechanism................................... III-3

2.1.2Document scanning mechanism..................................................... III-3

2.2Laser Printing Mechanism...................................................................... III-4

2.2.1Paper pulling-in, registration, feeding, and ejecting mechanism..... III-4

2.2.2Print process mechanism................................................................ III-6

(1) Charging process.................................................................... III-7

(2) Exposing process.................................................................... III-7

(3) Developing process................................................................. III-8

(4) Transferring process................................................................ III-8

(5) Erasing process....................................................................... III-8

2.2.3Heat-fixing mechanism................................................................... III-9

2.3Sensors and Actuators........................................................................... III-10

3. CONTROL ELECTRONICS........................................................................... III-12

3.1Configuration...........................................................................................III-12

3.2Main PCB................................................................................................III-13

3.3Relay PCB..............................................................................................III-23

3.4NCU PCB................................................................................................III-24

3.5Control Panel PCB................................................................................. III-27

3.6Power Supply PCBs............................................................................... III-28

[ 1 ]Low-voltage power supply PCB.................................................. III-28

[ 2 ]High-voltage power supply PCB................................................. III-29

Page 20

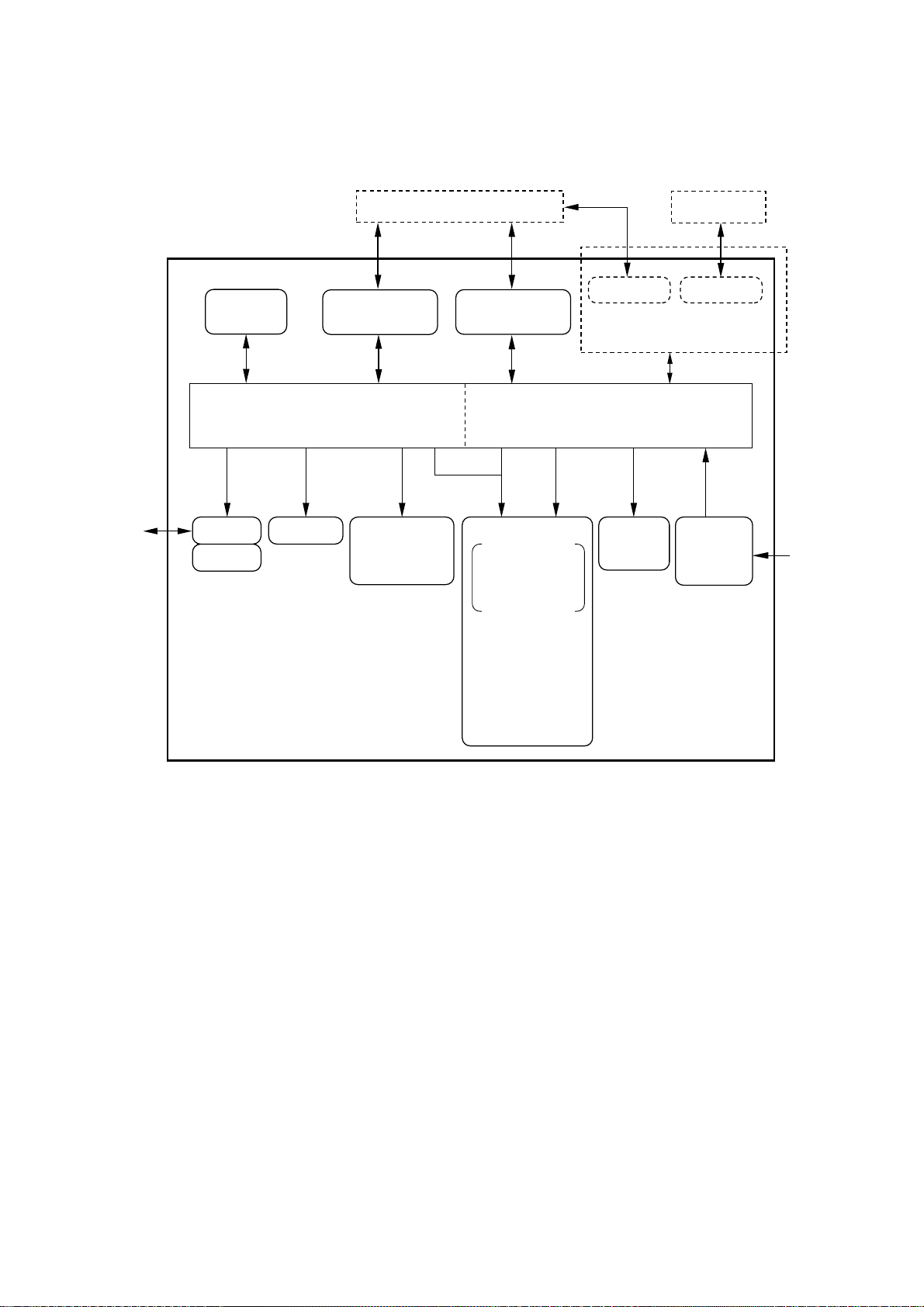

1. OVERVIEW

Line

Control

panel

NCU

Handset

PC/AT

RS-232C RS-422

RS-232C

(Modular connector)

[FAX3550/3650/

8000P/8200P]

Centronics

parallel interface

[MFC4450/

4550/4550plus/

6550MC/7550MC/7650MC/

9000/9500]

Optional serial interface

(Extended I/O connector)

[MFC6550MC/7550MC/

7650MC/9000/9500]

Fax Control Section Laser Printing Control Section

Printer

data

Laser printing unit

Charging, exposing,

developing,

transferring, erasing,

and heat-fixing

processes

- Electrical charger

- Laser unit

(including the polygon

motor)

- Laser-sensitive drum

- Developer roller

- Transfer roller

- Eraser lamp

- Heater roller

- Main motor

Paper

feeding

mechanism

Low- and

high-voltage

power

supplies

Speaker

Scanner unit

- LED array

- CCD unit

- Scanner motor

Fax data

MAC

AC

III – 1

Page 21

2. MECHANISMS

The equipment is classified into the following mechanisms:

■ SCANNER MECHANISM – Document feeding and ejecting mechanism

■ LASER PRINTING MECHANISM – Paper pulling-in, registration, feeding, and

■ SENSORS AND ACTUA TORS

Paper pulling-in and

registration mechanism

– Document scanning mechanism

ejecting mechanisms

– Print process mechanism (consisting of

charging, exposing, developing, transferring,

and erasing processes)

– Heat-fixing mechanism

Document feeding

and ejecting mechanism

Document scanning

mechanism

Paper ejecting mechanism

Heat-fixing mechanism

Print process mechanism

LASER PRINTING

MECHANISM

SCANNER

MECHANISM

With paper feeding

mechanism

III – 2

Page 22

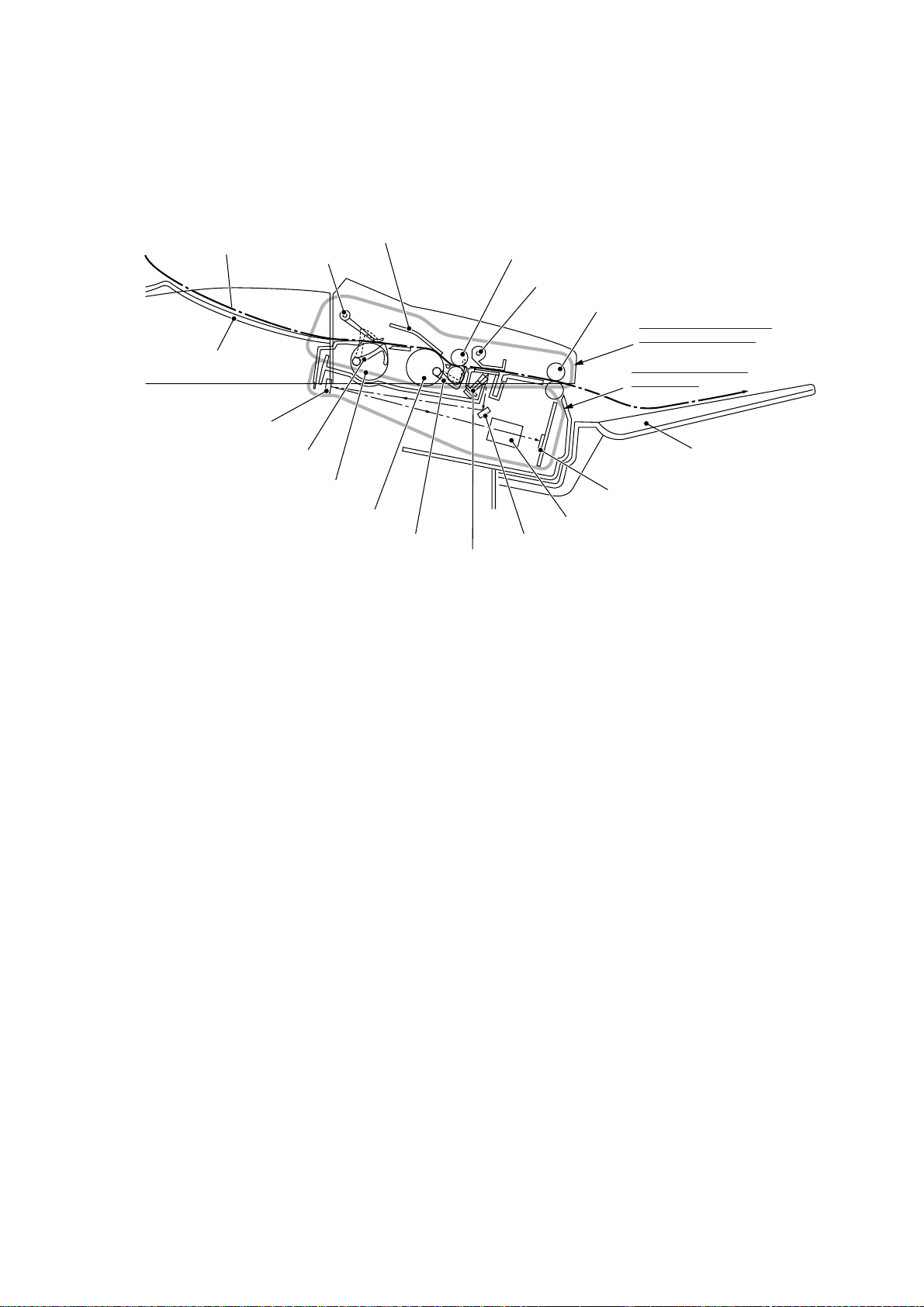

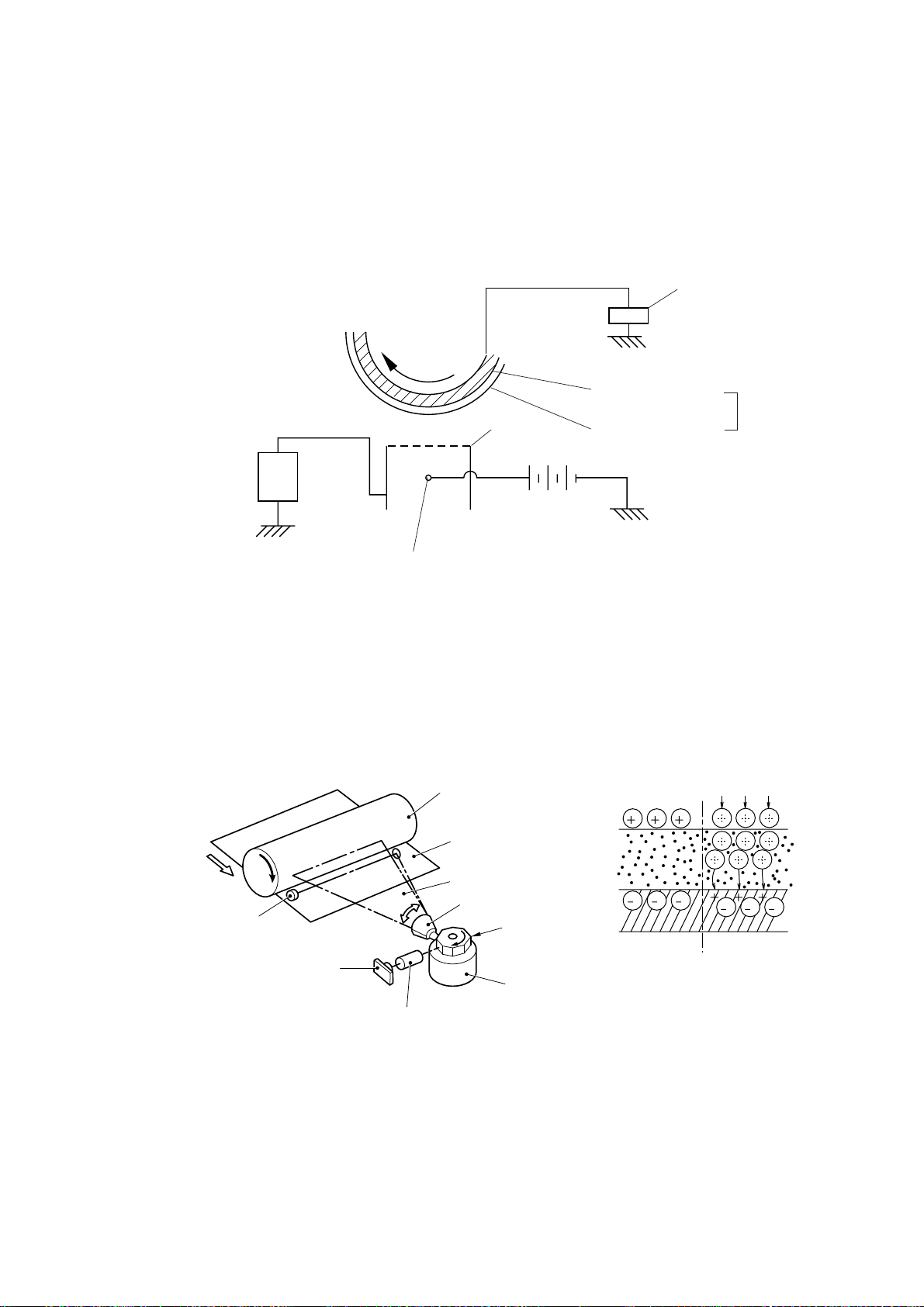

2.1 Scanner Mechanism

Document

Document stacker

2nd mirror

Document front sensor actuator

Document take-in roller ASSY

Separation roller ASSY

Document rear sensor actuator

Nip-related

parts

ADF parts

LED array

2.1.1 Document feeding and ejecting mechanism

Document feed roller ASSY

Document pressure bar

Document ejection roller ASSY

Document feeding and

ejecting mechanism

Document scanning

mechanism

CCD unit

Lens

1st mirror

Document tray

(Front)

This mechanism consists of the document stacker, automatic document feeder (ADF), document feed roller ASSY, and document sensors. (For details about the sensors, refer to Section 2.3.)

If the operator sets documents on the document stacker and starts the scanning operation,

the scanner motor rotates so that the ADF (which consists of the document take-in roller

ASSY, separation roller ASSY, ADF parts and nip-related parts) feeds those documents into

the equipment, starting from the bottom sheet to the top, page by page. Each document

advances with the document feed roller ASSY to the scanner, and then it is fed out of the

equipment with the document ejection roller ASSY.

2.1.2 Document scanning mechanism

The scanner uses a charge coupled device (CCD) image sensor.

As illustrated above, the LED array illuminates a document and the reflected light of the

scanned image data is transmitted via the mirrors into the lens which reduces the scanned

data so as to form the image on the CCD.

III – 3

Page 23

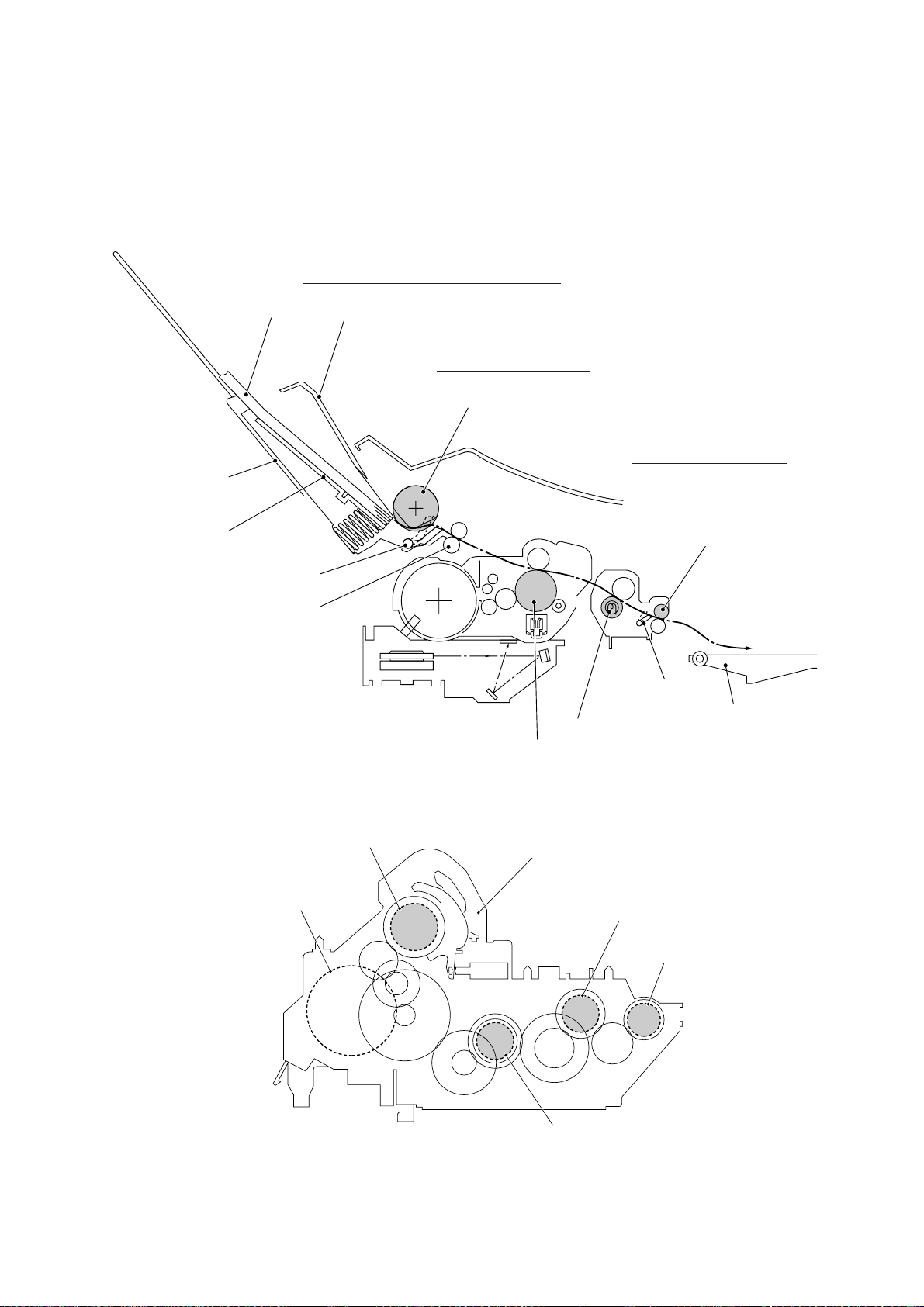

2.2 Laser Printing Mechanism

2.2.1 Paper pulling-in, registration, feeding, and ejecting mechanism

Paper pulling-in and registration mechanism

Paper

Multi-purpose

sheet feeder

Hopper

Registration sensor actuator

Registration roller

Sheet feeder cover

Paper feeding mechanism

Pull-in roller

Paper ejecting mechanism

Paper ejection roller

Paper ejection

sensor actuator

Paper tray

Heater roller

Laser-sensitive drum

Pull-in roller drive gear

Main motor

Gear drive unit

Heater roller drive gear

Paper ejection

roller drive gear

Drum drive gear

III – 4

Page 24

Paper pulling-in and registration mechanism

Solenoid lever

Paper feed solenoid

Gear drive unit

Heater roller drive gear

Paper ejection

roller drive gear

Clutch release lever

Solenoid spring

Clutch spring

Pull-in roller drive gear

Intermediate gear

Clutch gear

Gear 20/90

Drum drive gear

Planetary

gear

system

(Front)

Main motor

The paper pulling-in and registration mechanism consists of the pull-in roller gear (incorporated in the multi-purpose sheet feeder), planetary gear system, paper feed solenoid, solenoid lever, clutch release lever, and registration sensor. (For the details about the sensor,

refer to Section 2.3.)

If the main motor rotates clockwise, the rotation is transmitted to the intermediate gear of the

planetary gear system. As the intermediate gear rotates, the pull-in roller drive gear also rotates since the clutch gear is locked by the solenoid lever and the clutch release lever. Accordingly, the pull-in roller in the multi-purpose sheet feeder rotates to pull in paper into the

equipment, a sheet at a time.

If the paper feed solenoid is retracted and the clutch release lever is operated according to

the cam profile of the pull-in roller gear so as to release the clutch gear, the clutch gear rotates and the pull-in roller drive gear does not rotate. In this way, the clutch gear switches

the transmission of the motor rotation on and off to the pull-in roller drive gear.

The solenoid on/off timing and the clutch release lever timing allow this mechanism to pull in

a sheet and register it against the registration roller.

Paper feeding and ejecting mechanism

If the main motor rotates clockwise, the rotation is transmitted via the gear train to the drum

drive gear, heater roller drive gear, and paper ejection roller drive gear.

After the paper passes through the heat-fixing process, it will be ejected onto the paper tray.

If the leading edge of the paper pushes up the actuator of the paper ejection sensor, the

photo sensor becomes opened, signaling the start of paper ejection. If the trailing edge has

passed through the sensor actuator, the sensor becomes closed, signaling the completion of

paper ejection. Then, the main motor stops rotation.

III – 5

Page 25

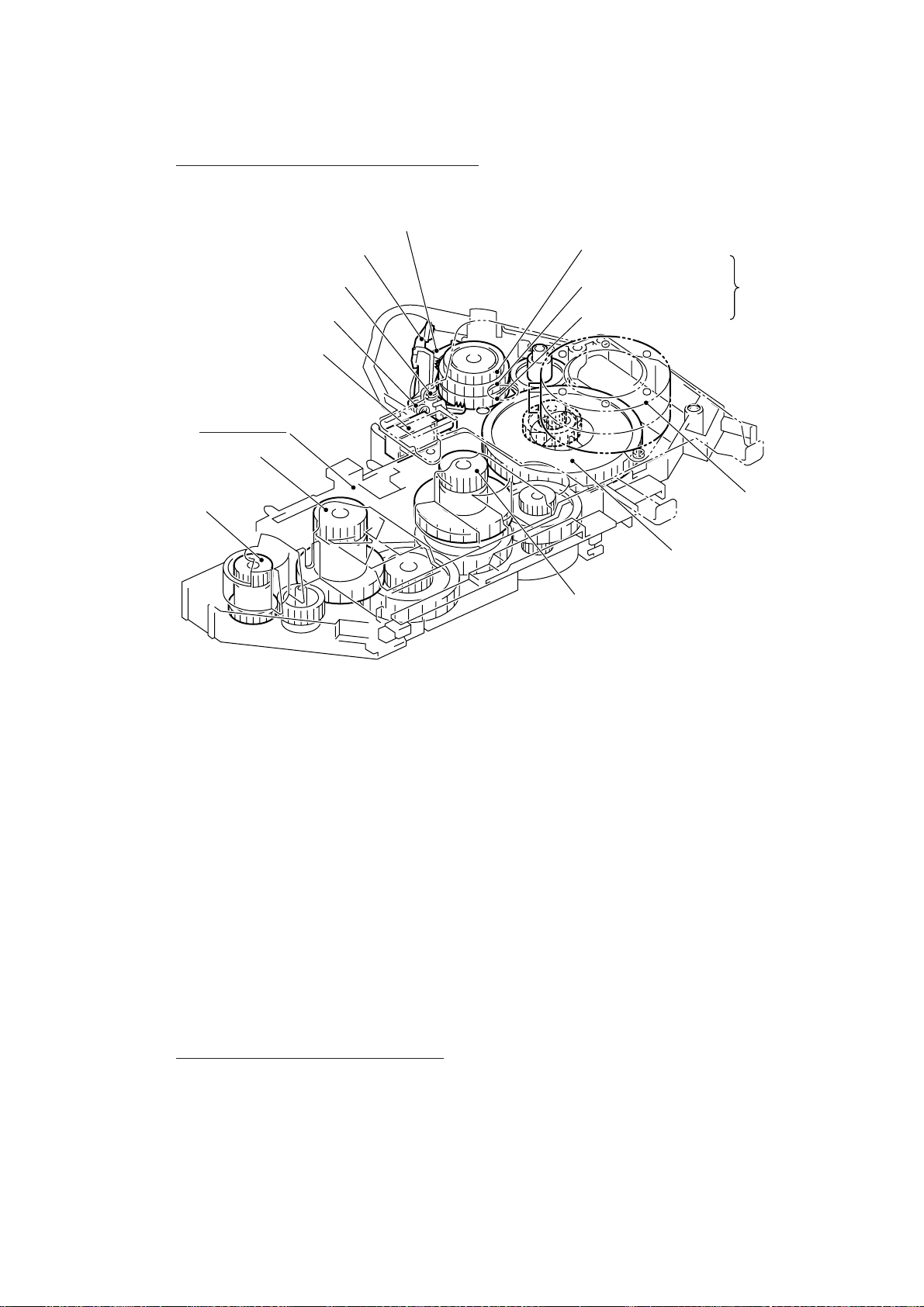

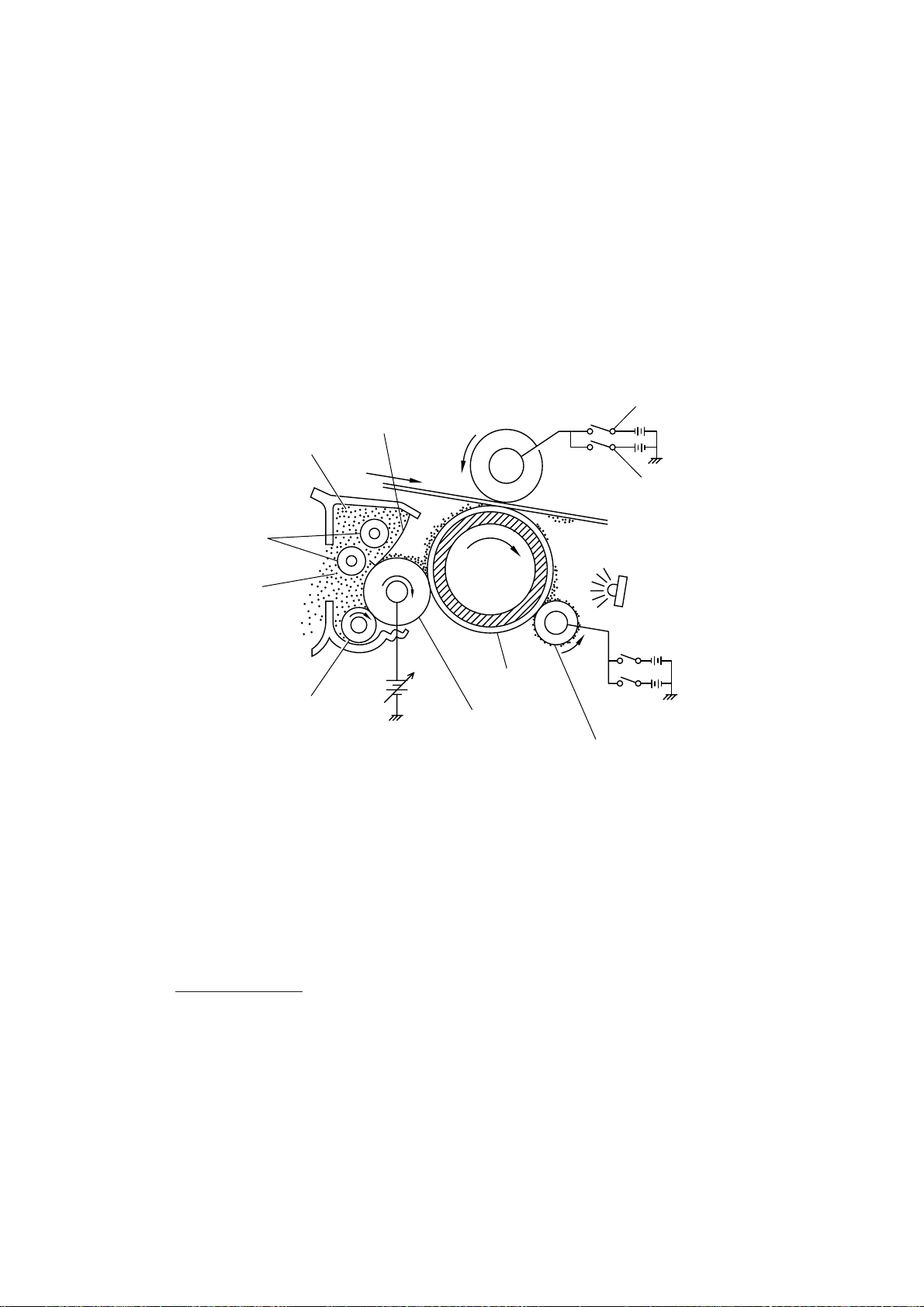

2.2.2 Print process mechanism

Toner augers

Toner cartridge

Toner sensor

Polygon mirror

Polygon motor

Laser unit

Paper

Developer

roller

Toner supply

roller

Transfer roller

Drum unit

Laser-sensitive drum

Cleaner roller

Charger (Corona wire)

Mirror

Mirror

Cover glass

The print process unit works with laser beam, electrical charges, and toner. The graph below shows the transition of electrical charge on the surface of the laser-sensitive drum

through the five processes: charging, exposing, developing, transferring, and erasing processes.

A single cycle of laser-sensitive

drum operation

1 Charges the drum surface positively .

1

+1000

+700

+400

+300

Electrical charge on the drum surface (V)

(a)

(b)

2

3

4

2 Exposes the drum surface to a laser beam to

form a latent image and develops the latent

image with toner.

(a) Unexposed area (Non-image area)

(b) Exposed area (Image area)

3 Transfers the toner-formed image from the

drum to paper.

4 Erases the residual potential.

Time

III – 6

Page 26

(1) Charging process

The high-voltage power supply applies DC bias to the corona wire to generate ion on the

grid. The ion uniformly charges the surface of the laser-sensitive drum to approx. 1000V

which is kept by the varister grounding the grid to the frame.

Varister

+

+

+

Approx. 1000V

Approx. 280V

-

-

-

-

-

+

+

-

-

-

---

+

+

+

+

+

+

+

Corona wire

+

+

+

+

+

+

+

+

+

Grid

High-voltage

power source

Aluminum drum

Laser-sensitive layer

Positive charging

source

Drum

(2) Exposing process

When the laser-sensitive drum holds a positive electrical charge, the laser beam issued from

the laser unit scans the drum according to the print image to expose the drum surface for

neutralizing the spots where black should be, forming an electrostatic latent image.

Laser detector

Laser diode

Laser-sensitive drum

Paper

Laser beam

f θ lens

Lens

Laser beam

Polygon mirror

Polygon motor

III – 7

Page 27

(3) Developing process

The developing process develops an electrostatic latent image formed on the drum in the

exposing process, into a toner image.

The developer roller attracts the toner particles fed from the toner cartridge by the toner supply roller, and then conveys them to the contact section with the laser-sensitive drum.

On the contact section between the developer roller and drum, the positive toner particles

stick to the neutralized spots on the drum according to the principles of attraction and repulsion, transforming a latent image into a toner image.

The toner augers (which agitate toner particles in the chamber) and the blade allow toner

particles to be fed onto the developer roller at an even thickness.

Switch “a” (ON for the

transfer process)

Switch “b” (ON for repulsing

toner from the transfer roller)

Toner augers

Chamber

Blade

Transfer roller

Toner

Toner supply roller

DC bias

Laser-sensitive

drum

Developer

roller

Eraser lamp

Cleaner roller

(4) Transferring process

When a paper passes between the drum and the transfer roller, the switch “a” (see the

above illustration) is turned on to negatively charge the transfer roller. The toner is positive,

so the toner image formed on the drum will be transferred onto the paper according to the

same principle as for the developing process.

If the toner image fails to stick to the paper due to paper jam or other errors, it will stick to the

transfer roller. To repulse this toner, the switch “b” (see the above illustration) is turned on to

positively charge the transfer roller. The toner returns from the transfer roller to the drum.

Cleaning the drum

In the transferring process, not all the toner particles on the drum are transferred onto the

paper but some toner particles remain on the drum. The cleaner roller cleans the drum surface and collects the residual toner. When printing starts or during non-printing, the toner

collected on the cleaner roller will be discharged onto the drum and returned to the chamber

through the developer roller for recycling in the subsequent developing process.

(5) Erasing process

The eraser lamp emits light to expose the drum surface, which erases the residual electrical

charge.

III – 8

Page 28

2.2.3 Heat-fixing mechanism

Pressure roller

Heater roller

(including the FU lamp)

Heat-fixing unit

(Paper ejection roller)

Paper

(Paper ejection sensor actuator)

As the paper passes between the heater roller and the pressure roller in the fixing unit, the

heater roller fuses the toner on the paper.

III – 9

Page 29

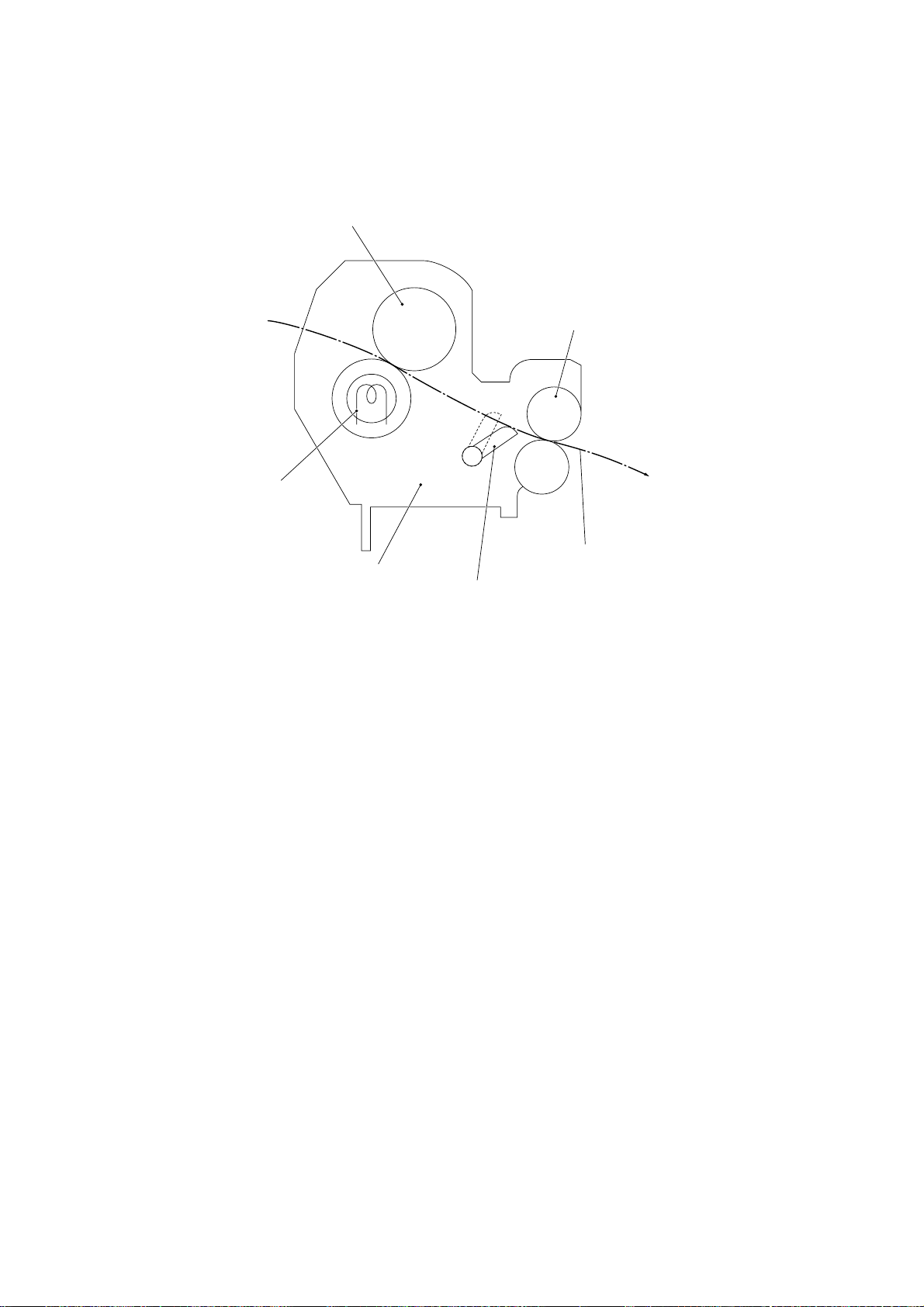

2.3 Sensors and Actuators

This equipment has ten sensors: two microswitches, six photosensors and two thermisters

as described below.

Sensor name Type Located on

Hook switch sensor Microswitch Hook switch PCB

Cover sensor Microswitch Relay PCB

Registration sensor Photosensor (PC1) Relay PCB

Sheet feeder cover sensor Photosensor (PC2) Relay PCB

Paper ejection sensor Photosensor (PC1) High-voltage power supply PCB

Document front sensor Photosensor (PC1) Document sensor PCB

Document rear sensor Photosensor (PC2) Document sensor PCB

Toner sensor Photosensor (PH1) Toner sensor PCB (on the laser unit)

Toner thermister P1 Toner sensor PCB (on the laser unit)

Heater thermister __ Fixing unit

• Hook switch sensor which detects whether the handset is placed on the handset mount.

• Cover sensor which detects whether the top cover is closed.

• Registration sensor which detects the leading and trailing edges of paper, which allows

the controller to determine the registration timing and check paper jam.

• Sheet feeder cover sensor which detects whether the sheet feeder cover is closed.

• Paper ejection sensor which detects whether the recording paper goes out of the equipment.

• Document front sensor which detects the presence of documents.

• Document rear sensor which detects the leading and trailing edges of pages to tell the

control circuitry when the leading edge of a new page has reached the starting position

and when the scan for that page is over.

• Toner sensor which detects whether there is toner or a toner cartridge is loaded.

• Toner thermister which detects the temperature of the toner cartridge.

• Heater thermister which detects the temperature of the heater roller of the fixing unit.

These photosensors are a photointerrupter consisting of a light-emitting diode and a lightsensitive transistor. Each of them has an actuator separately arranged as shown on the next

page.

III – 10

Page 30

Registration sensor actuator

Registration sensor (Photosensor)

(Main PCB)

Toner thermister

(On back of PCB)

Toner sensor

(Low-voltage power

supply PCB)

Hook switch sensor

(Microswitch)

Hook switch sensor

actuator

(Eraser lamp board)

Document front sensor actuator

Document front sensor (Photosensor)

(Document sensor PCB)

(Relay PCB)

(Toner

sensor

PCB)

(Fixing unit)

Sheet feeder cover sensor actuator

Sheet feeder cover sensor

(Photosensor)

Cover sensor actuator

Cover sensor (Microswitch)

(High-voltage power

supply PCB)

Paper ejection sensor

actuator

Paper ejection sensor

(Photosensor)

Heater thermister

Document rear sensor actuator

Document rear sensor

(Photosensor)

Location of Sensors and Actuators

III – 11

Page 31

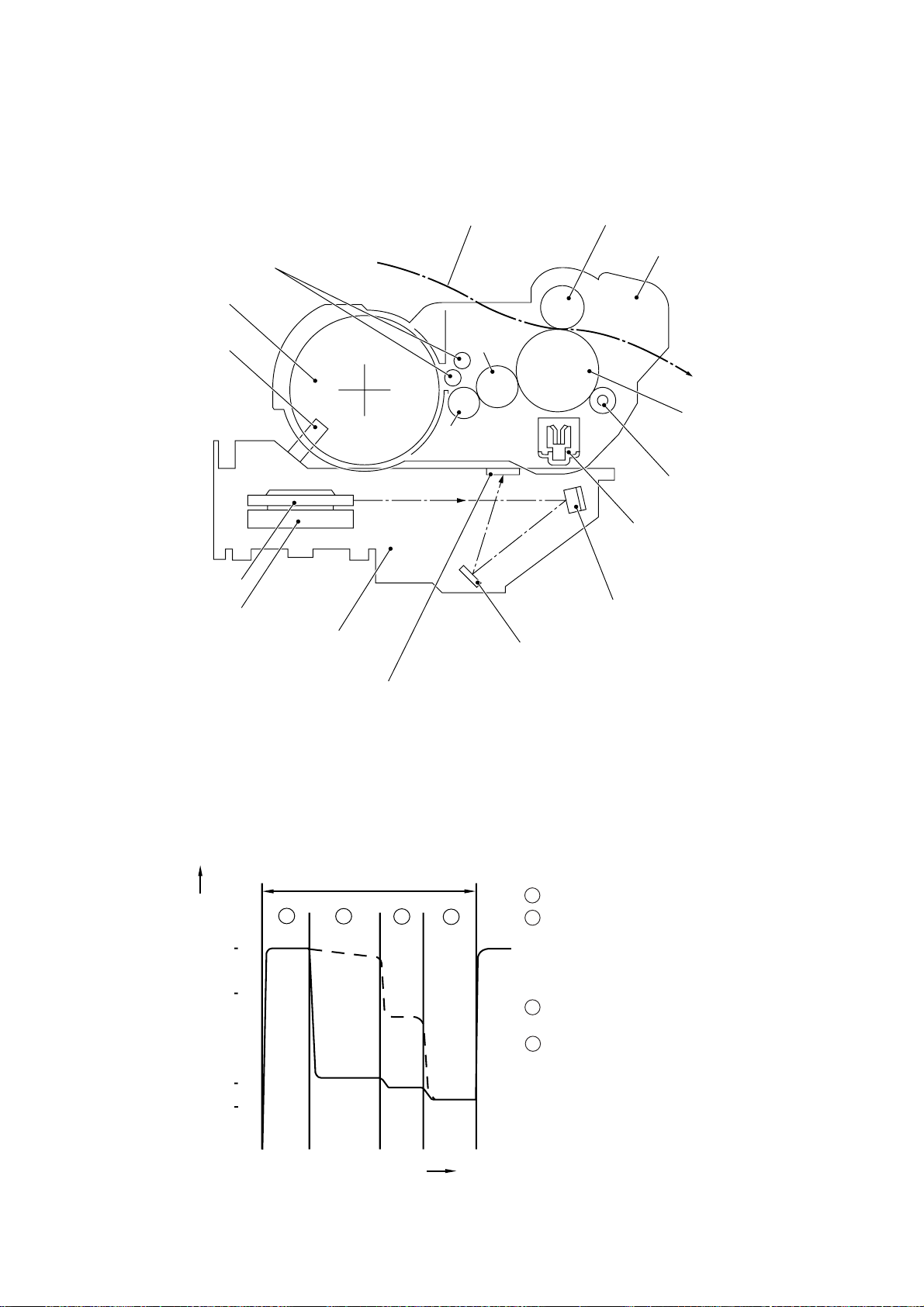

3. CONTROL ELECTRONICS

3.1 Configuration

The configuration of the facsimile equipment is shown below.

Centronics parallel

interface (MFC4450/

4550/4550plus/

6550MC/7550MC/

7650MC/9000/9500)

Modular

connector for

PC interface

(FAX3550/3650/

8000P/8200P)

Extended RAM

connector

P15

P1

8-pin

Main PCB

P2

40-pin

36-pin

ASIC

MODEM

Control

panel

PCB

5-pin

P5

P13

26-pin

P18

P9

P8

P7

Relay

PCB

2-pin

4-pin

2-pin

5-pin

1

*

5-pin

P3

5-pin

P2

P4

12-pin

4-pin

P1

Low-voltage

power supply

PCB

Laser unit

Laser diode

Polygon motor

Toner sensor PCB *

3

High-voltage

*

power supply PCB

Fan 2

Main motor

Solenoid

2

3-pin

Eraser lamp board

4-pin

Heater thermister

Heater (FU lamp)

LASER PRINTING

UNIT

Fan 1

Fixing

Unit

AC line

Extended I/O

connector

(MFC6550MC/

7550MC/7650MC/

P3

30-pin

P4

11-pin

9000/9500)

P10

P16

P6

P11

*1On the relay PCB are these sensors:

• Cover sensor

• Sheet feeder cover sensor

• Registration sensor

*2On the toner sensor PCB are these sensors:

• Toner sensor

• Toner thermister

3

*

On the high-voltage power supply PCB is the paper

ejection sensor.

6-pin

2-pin

(Note)

2-pin

Document

sensor PCB

Speaker

NCU PCB

Hook switch

PCB

4

*

SCANNER

UNIT

LED array

CCD unit

Scanner

motor

Line

External TEL

Handset

5

*

4

On the document sensor PCB are these sensors:

*

(Note)

12-pin: U.S.A. versions

18-pin: European and Asian

versions

• Document front sensor

• Document rear sensor

5

*

On the hook switch PCB is the hook switch sensor.

Configuration

III – 12

Page 32

3.2 Main PCB

The main PCB, which is the nucleus controlling the entire operation of the equipment, consists of a FAX engine (ASIC), memories, MODEM, motor drive circuits, sensor detection circuitry, and analog circuits for scanning, printing, and power transmission shifting.

Main PCB

(MFC4450/

4550/4550plus/

6550MC/7550MC/

7650MC/9000/9500)

Modular

connector for PC interface

(RS-232C)

(FAX3550/3650/8000P/8200P)

ROMs

DRAM(s)

Extended RAM

connector

Centronics

parallel interface

E2PROM(s)

ASIC

Main motor

driver

Image

processor

Scanner

motor driver

Control panel

Relay PCB

Fan 2

Main motor

Solenoid

Low-voltage

power supply

PCB

Document

sensor PCB

Scanner

motor

Extended I/O

connector for

optional serial

interface board

(RS-232C and

RS-422)

(MFC6550MC/7550MC/

7650MC/9000/9500)

Amplifiers

MODEM

E2PROM: Electrically Erasable Programmable Read-only Memory

DRAM: Dynamic Random Access Memory

Analog switch

operational

amplifiers

Block Diagram of Main PCB

III – 13

Speaker

NCU PCB

Hook switch

PCB

Page 33

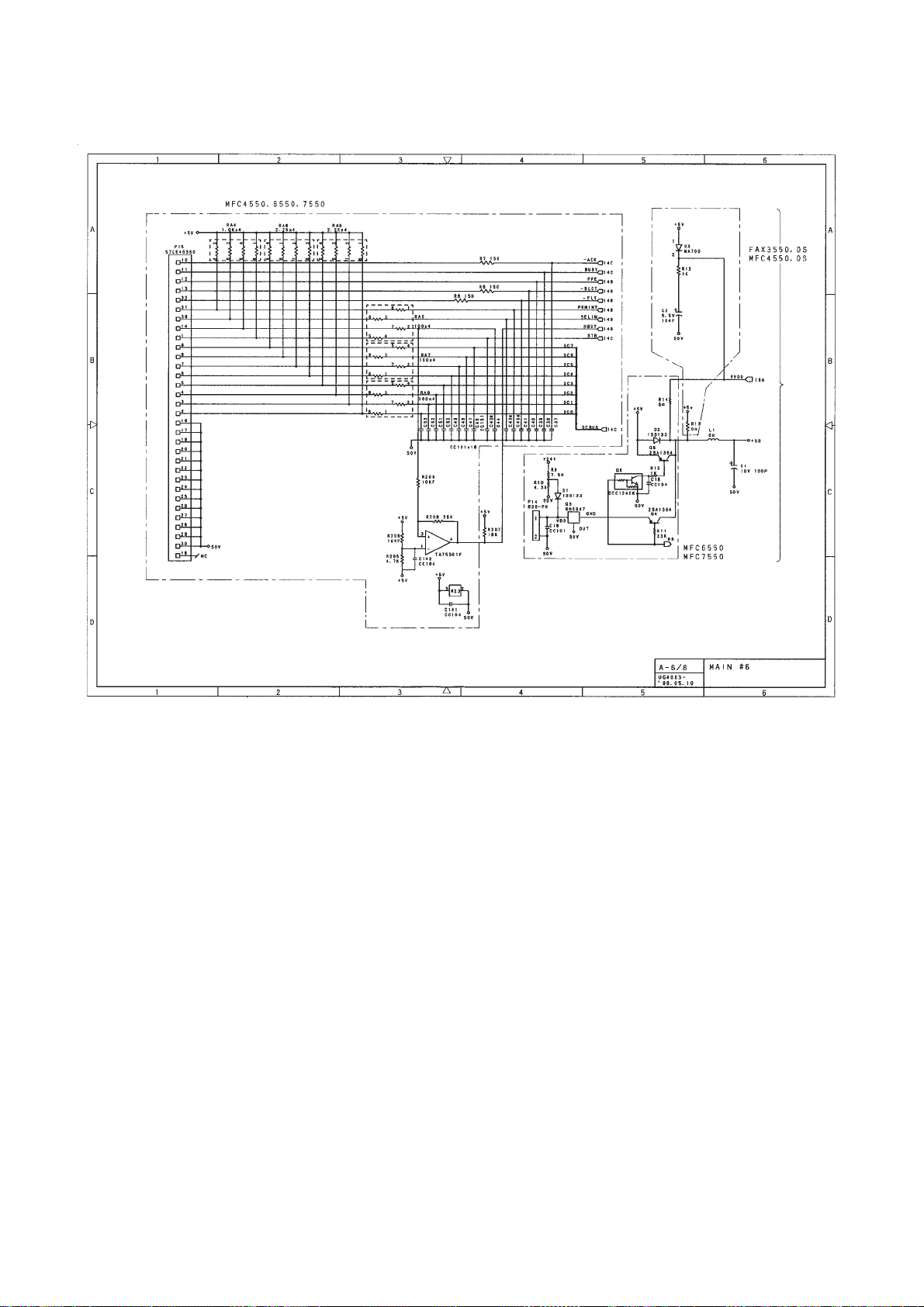

1

2

Main PCB Circuit Diagram 1/7

1 FAX engine (ASIC) which manages the I/Os, memories, drivers and image proces-

sor as well as controlling the laser printing unit.

2 8-pin modular connector for the PC interface (RS-232C), provided on the FAX3550/

3650/8000P/8200P.

III – 14

Page 34

1

#12

3

#11

2

4

#2 #3

Main PCB Circuit Diagram 2/7

#15

5

#10

1 FAX3550/3650/8000P/8200P/MFC4450/4550/6550MC/7550MC/9000/9500:

ROM (8-megabit, 512K x 16 bits) which stores programs.

MFC4550plus/7650MC: Flash ROM (8-megabit) which stores programs.

2 ROM (8-megabit, 512K x 16 bits)

FAX3550/3650/8000P/8200P/MFC4450/4550/4550plus:

This ROM is used only on the qualification machines for demonstration.

MFC6550MC/7550MC/7650MC/9000/9500:

This ROM stores the PCL4 (Driver programs for high-quality print).

3 DRAMs

FAX3550/8000P/MFC4550/6550MC/7550MC/9000/9500:

DRAM No.

Model

FAX3550/MFC4550 –– 4M x 8 bits 4M x 8 bits ––

FAX8000P/MFC6550MC/ –– 4M x 8 bits 4M x 8 bits ––

9000/9500

MFC7550MC –– –– –– 16M x 16 bits

#10 #11 #12 #15

FAX3650/8200P/MFC4450/4550plus/7650MC:

DRAM No.

Model

FAX3650/8200P –– 16M x 16 bits

MFC4450 4M x 16 bits 4M x 16 bits

MFC4550plus 4M x 16 bits 4M x 16 bits

MFC7650MC –– 16M x 16 bits –– : Not installed

#10 #15

6

–– : Not installed

III – 15

Page 35

4 E2PROMs which store user settings.

FAX3550/8000P/MFC4550/6550MC/7550MC/9000/9500:

E2PROM No.

Model

FAX3550 16K x 1 bit 16K x 1 bit

MFC4550 –– 16K x 1 bit

MFC6550MC –– 16K x 1 bit

FAX8000P/MFC6550MC/ 16K x 1 bit 16K x 1 bit

9000/9500

#2 #3

–– : Not installed

FAX3650/8200P/MFC4450/4550plus/7650MC:

E2PROM No.

Model

FAX3650/8200P 16K x 1 bit 16K x 1 bit

MFC4450 –– 16K x 1 bit

MFC4550plus –– 16K x 1 bit

MFC7650MC –– 32K x 1 bit

#2 #3

–– : Not installed

5 Extended RAM port which allows you to add a memory up to two megabytes.

6 Extended I/O connector for an optional serial interface board RS-100M which supports

the RS-232C and RS-422. (Only for the MFC6550MC/7550MC/7650MC/9000/9500)

III – 16

Page 36

1

2

1-1

1-2

1-3

1-4

1-5

3

Main PCB Circuit Diagram 3/7

1 Connector for the document sensor PCB

1-1: Current sink transistor for driving the LED array

1-2: Synchronous clocks for the CCD unit

1-3: Image signal from the CCD unit

1-4: Signal from the document front sensor

1-5: Signal from the document rear sensor

2 Connector for the control panel

3 Image signal processor

FAX3550/3650/8000P/8200P/MFC4450/4550/4550plus: 200 dpi

MFC6550MC/7550MC/7650MC/9000/9500: 300 dpi

III – 17

Page 37

1-1

2

1-2

1 Operational amplifiers for modem-to-line interface

2 Modem

3 Short pin

1

Main PCB Circuit Diagram 4/7

1-1: RIN, signal from line to modem

1-2: TXO, signal from modem to line

Mounted on the Turkish versions only.

3

III – 18

Page 38

1

3

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

5

2

6

4

7

8

Main PCB Circuit Diagram 5/7

1 Connector for the relay PCB

1-1: Laser drive signals

1-2: High-voltage power supply control signals

1-3: Eraser lamp ON/OFF signal

1-4: Fan 1 control signal

1-5: Signal input from the paper ejection sensor

1-6: Signal input from the registration sensor

1-7: Signal input from the sheet feeder cover sensor

1-8: Signal input from the cover sensor

1-9: Signal input from the toner sensor

1-10: Signal input from the heater thermister

1-11: Signal input from the toner thermister

2 Heater control circuit which prevents the heater from overheating due to ASIC or soft-

ware malfunction. (The ASIC controls the HTON signal with the hysteresis characteristics for stabilized heater control.)

3 Connector for the low-voltage power supply

4 Main motor driver which controls recording paper feeding and drum rotation.

5 Fan 2 driver circuit

6 Paper pull-in solenoid circuit

7 Scanner motor driver and its control circuitry

8 Signal input from the hook switch

III – 19

Page 39

1

2-1

2

2-2

Main PCB Circuit Diagram 6/7

1 Centronics parallel interface circuitry (for the MFC4450/4550/4550plus/6550MC/

7550MC/7650MC/9000/9500)

Connector P15 is compatible with the standard Centronics parallel interface.

2 Backup circuit for the calendar clock of the control panel

2-1: For FAX3550/3650/8000P/8200P/MFC4450/4550/4550plus/9000

2-2: For MFC6550MC/7550MC/7650MC/9500 (This circuit backs up also the im-

age and voice data.)

III – 20

Page 40

1

2-2

2-1

3

3-1

2

2-3

Main PCB Circuit Diagram 7/7

1 Connector for the NCU PCB

CMLL: NCU relay ON/OFF signal

PLS: Dial pulse output

TLOF: Off-hook signal which is active Low for the external telephone.

CI: Call signal which is active Low.

TXD: Line output signal from the MODEM

TLSL: Handset microphone signal

RL1: Line input signal to the MODEM

RL2: Line monitor signal

ADLC: Line current detection input

DASEND: Output level matching signal

DAST: Side tone level matching signal (Only in the European versions.)

DPS: External telephone switching signal

EAT: Earth function signal

POL: Polarity inversion detection signal

2-7

2-4

2-6

4-2

4-1

2-5

3-2

4

III – 21

Page 41

2 Switching devices that are controlled by the ASIC

2-1: Device TEL. If 0, the equipment works as a telephone; if 1, it sends a fac-

simile message.

2-2: Device HSPLY. If 0, the equipment works as a telephone; if 1, it plays back

a TAD recorded message.

2-3: Device TADH. If 0, the equipment works regularly; if 1, it allows you to

record a message through the microphone.

2-4: Device CMLH. If 0, the equipment is placed in monitor mode; if 1, it is nor-

mally connected to the line.

2-5: Device RNG. If 0, the speaker rings; if 1, it transfers control to the device

MSL.

2-6: Device MSL. If 0, the speaker works for converting line signals to sound; if

1, it works for playing back a TAD recorded message.

2-7: Device MUTE that mutes the receiver tone.

3 Speaker amplifiers

3-1: For FAX3550/3650/8000P/8200P/MFC4450/4550/4550plus/9000

3-2: For MFC6550MC/7550MC/7650MC/9500

4 Speaker volume control circuitry

4-1: VOL1 that controls the speaker volume to two levels: High and Low.

4-2: VOL2 that augments VOL1 to handle four levels: High, Medium-high, Me-

dium-low, and Low. (MFC6550MC/7550MC/7650MC/9500 only)

III – 22

Page 42

3.3 Relay PCB

1

4

2

3

8

7

5

6

9

Relay PCB Circuit Diagram

1 Connector for the main PCB

2 Registration sensor (PC1) circuit

3 Sheet feeder cover sensor (PC2) circuit

4 Cover switch (SW1)

5 Connector for the high-voltage power supply PCB

6 Connector for the toner sensor PCB

7 Connector for the laser diode of the laser unit

8 Switching circuit which feeds 24V power to the polygon motor during the printing pro-

cess.

9 Connector for the polygon motor

III – 23

Page 43

3.4 NCU PCB

The NCU PCB switches the communications line to telephone or built-in MODEM, under the

control of the main PCB.

2

1

3

4

5

6

2

2

9

7

A

8

:

NCU PCB Circuit Diagram (U.S.A. versions)

1 Surge absorber

2 Noise filters

3 Line relay (CML relay)

4 Line transformer

5 Circuit related to the line transformer

6 High-impedance transformer circuit

7 Calling signal detector

8 Loop current detector

9 Dial pulse generator

: Telephone circuit

A Reference voltage generation circuit for the operational amplifier in ⑤.

III – 24

Page 44

1

2

2

8

3

4

5

2

2

2

2

2

B

3

6

C

9

7

A

:

NCU PCB Circuit Diagram (European versions)

1 Surge absorber

2 Noise filters

3 Line relay (CML relay)

4 Line transformer

5 Circuit related to the line transformer

6 High-impedance transformer circuit

7 Calling signal detector

8 Loop current detector

9 Dial pulse generator & loop current detector

: Telephone circuit

A Reference voltage generation circuit for the operational amplifier in ⑤.

B Pulse shaper

C Line current detection input circuit

III – 25

Page 45

• The primary function of the NCU (which is shared by facsimile and telephone units) is to

switch a line to the facsimile unit or to the telephone, which is carried out by the line relay.

• Since the direct connection of a facsimile equipment to the line is not allowed for protect-

ing the line, it is essential to insert a line transformer between the line and the facsimile

equipment to insulate them from each other in the direct current band.

The above two components, line relay and line transformer, are the minimum requirements

for the NCU of the facsimile equipment.

• If an external telephone is connected to the facsimile equipment, the NCU should have a

loop current detector to identify the hook state by detecting the loop current.

• If the facsimile equipment has an automatic answering facility (TAD), the NCU should be

equipped with a calling signal detector which detects a calling signal and tells it to the

CPU in the FAX engine (ASIC).

• The circuit related to a line transformer allows the line transformer to be invariant by se-

lecting the constants of the parts in this circuit so as to conform to the communications

regulations or codes of each country.

In addition to the above basic components of the NCU, the following components are also

required depending upon additional functions of the facsimile equipment:

• The dial pulse generator generates dial pulses within the facsimile equipment.

• The surge absorber is a protection circuit which absorbs lightning surges.

• The noise filter eliminates noise including radiation noise in order to prevent them from

flowing out onto the communications line.

• The high-impedance transformer circuit detects the remote activation, and F/T switching

sent from the line in ON-HOOK state without any interference to the line.

• The telephone circuit includes an amplifier that amplifies output signals of the handset mi-

crophone. It also includes a transistor that amplifies receive signals from the communications lines to sound the handset receiver.

III – 26

Page 46

3.5 Control Panel PCB

The control panel PCB and the main PCB communicate with each other by serially transmitting commands and data.

The control panel unit consists of a gate array, an LCD, and LEDs, which are controlled by

the gate array according to commands issued from the FAX engine on the main PCB.

The calendar clock is backed up by the backup circuit on the main PCB.

The panel FPC is a flexible keyboard PCB which integrates the key matrix having rubber

keytops.

FAX

Engine

+5B

+5V

Backup

Circuit

Main PCB

SDIN

SDOUT

PCLK

Control Panel PCB and its Related Circuit

Control Panel PCB

Serial

Communications

Ports

+5V

Reset

Circuit

POWER

RESET

Gate Array

I/O Ports

LCD

Panel FPC

(Key Matrix)

LED

S

III – 27

Page 47

3.6 Power Supply PCBs

[ 1 ] Low-voltage power supply PCB

The low-voltage power supply uses the switching regulation system to generate DC power

(+5V and +24V) from a commercial AC power supply for the driver circuits. The +5V source

is fed to the logic, control panel, sensors, CCD unit, etc.; the 24V source is fed to the motors,

solenoid, fans, LED array, and the high-voltage power supply PCB.

The low-voltage power supply also feeds AC power to the heater of the fixing unit.

(Heater)

Fuse

Line

Filter

Lightning

Surge

Absorber

Rectifier

Thermal

Fuse

Heater

Circuit

FU lamp

Feedback

Switching

Circuit

24V

Detector

5V

Regulation

Circuit

Low-voltage Power Supply Circuit

III – 28

(Driver circuits)

24V

5V

Page 48

[ 2 ] High-voltage power supply PCB

This power supply generates high-voltage power sources from the 24V source fed from the

low-voltage power supply for charging, developing, and transferring in the laser printing process.

Fuse Type Resistor

R1

11

24VI

Control 1

(TIDN TAIDEN)

Control 2

(GENZ GENZOU)

Control 3A

(TENH TESHAH)

0.22

1/6w

6

7

10

Current

Regulator

(250µA)

B1 Q1

Voltage

Regulator

(600 ± 10V)

(275 ± 7V)

VR33 VR31 VR34

Current

Regulator

(-3.0µA)

OUT1

OUT2

OUT3

Developer

Roller

Transfer Roller

Laser-sensitive

Drum

Cleaner Roller

Grid

Corona Wire

Control 3B

(TENL TESHAL)

GND

VCLN

B51 Q51

Voltage

9

12

8

Regulator

(1.8kV)

Q56

B52

Voltage

Regulator

(1.0kV)

VR201

Voltage

Regulator

(275V)

VR101

Voltage

Regulator

(700V)

VR32

VR53

910

Z201

GRID

DRMBIAS

VCLN

High-voltage Power Supply Circuit

III – 29

Page 49

CHAPTER IV.

DISASSEMBLY/REASSEMBLY

AND LUBRICATION

Page 50

CONTENTS

1. DISASSEMBLY/REASSEMBLY.................................................................... IV-1

■Safety Precautions.................................................................................... IV-1

■Preparation................................................................................................IV-3

■How to Access the Object Component...................................................... IV-3

■Disassembly Order Flow........................................................................... IV-4

1.1 Top Cover...............................................................................................IV-5

1.2 Handset Mount and Hook Switch PCB (for handset-equipped versions)

Side Cover (for non-handset versions)............................................................ IV-5

1.3 Multi-purpose Sheet Feeder.................................................................. IV-6

1.4 Control Panel ASSY.............................................................................. IV-6

1.5 Panel Rear Cover and Control Panel.................................................... IV-7

1.6 Document Feed Roller ASSY and Ejection Roller ASSY...................... IV-8

1.7 Inner Cover............................................................................................IV-8

1.8 Scanner Frame ASSY........................................................................... IV-10

1.9 Insulation Cover.................................................................................... IV-12

1.10Fixing Unit, FU Lamp, and Paper Ejection Sensor Actuator.................. IV-13

1.11Laser Unit...............................................................................................IV-15

1.12Bottom Plate..........................................................................................IV-16

1.13Low-voltage Power Supply PCB........................................................... IV-17

1.14High-voltage Power Supply PCB and Fan 1......................................... IV-18

1.15Main PCB...............................................................................................IV-19

1.16Relay PCB.............................................................................................IV-21

1.17Shield Bracket and NCU PCB ASSY.................................................... IV-22

1.18Gear Drive Unit......................................................................................IV-23

1.19Duct Cover, Fan 2, and Speaker........................................................... IV-25

1.20Sheet Feeder Cover Sensor Actuator, Registration Sensor Actuator,

and Cover Sensor Actuator................................................................... IV-26

1.21Microphone (MFC9500 only)........................................................................... IV-27

1.22Cleaning of High-voltage Contacts and Grounding Contacts................ IV-28

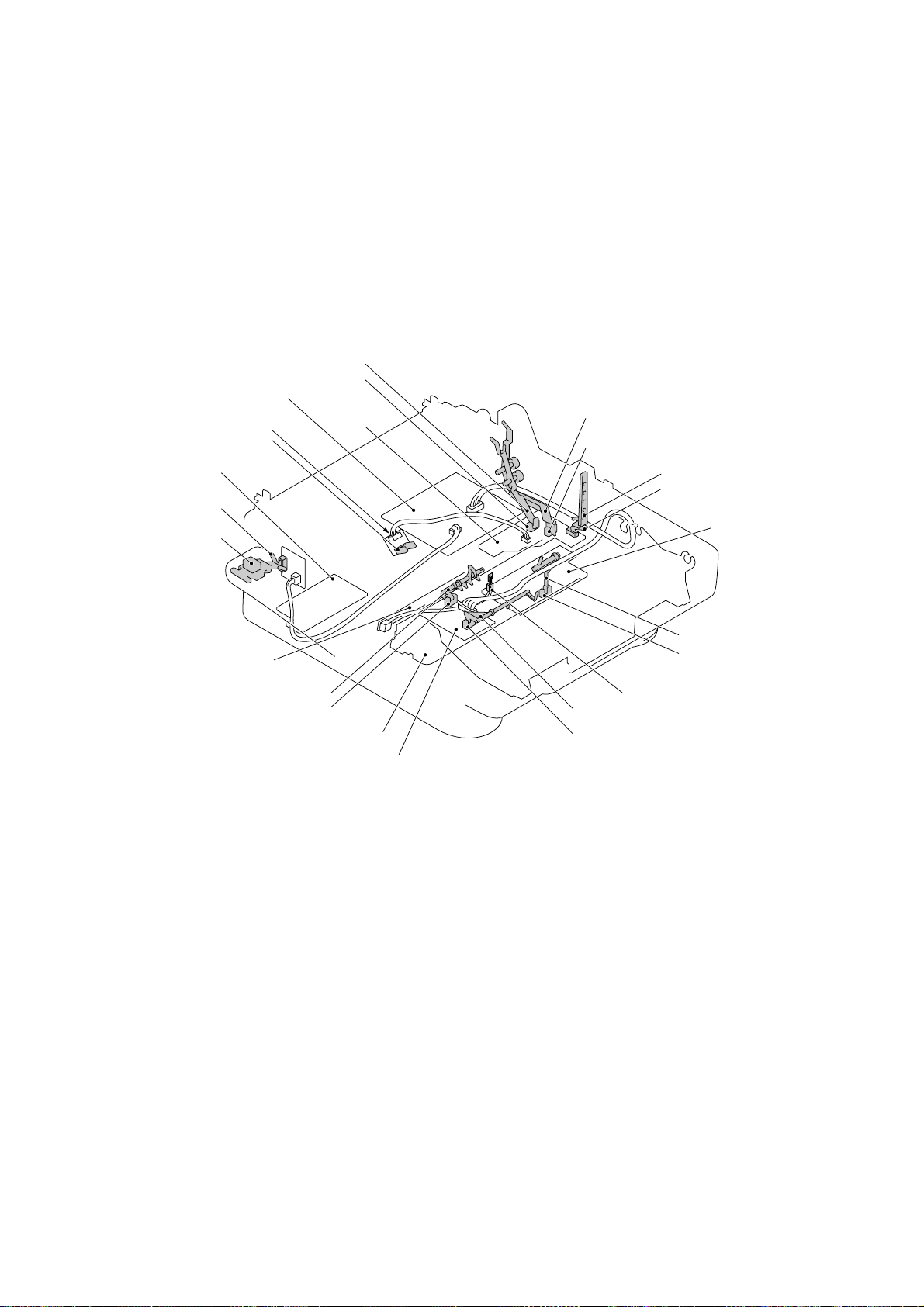

1.23Harness Routing................................................................................... IV-29

2. LUBRICATION................................................................................................IV-30

Page 51

1. DISASSEMBLY/REASSEMBLY

■ Safety Precautions

To prevent the creation of secondary problems by mishandling, observe the following precautions during maintenance work.

(1) Always unplug the power cord before replacing parts or units. When having access to

the power supply, be sure to unplug the power cord from the power outlet.

(2) When servicing the optical system of the laser printing unit, be careful not to place

screwdrivers or other reflective objects in the path of the laser beam. Be sure to take

off any personal accessories such as watches and rings before working on the printer.

A reflected beam, though invisible, can permanently damage your eyes.

(3) If the equipment has been printing, allow the fixing unit sufficient time to cool down. It is

HOT!

(4) Be careful not to lose screws, washers, or other parts removed for parts replacement.

(5) Do not remove gears from the document LF roller ASSY or ejection roller ASSY if at all

possible. Once removed, they will become unusable and new gears will have to be put

back in.

(6) When using soldering irons and other heat-generating tools, take care not to damage

the resin parts such as wires, PCBs, and covers.

(7) Before handling the PCBs, touch a metal portion of the equipment to discharge static

electricity; otherwise, the electronic parts may be damaged due to the electricity

charged in your body.

(8) When transporting PCBs, be sure to wrap them in conductive sheets such as aluminum

foil.

WARNING

For the MFC6550MC/7550MC/7650MC/9000/9500 which has a nickel-hydrogen battery

on the main PCB, be sure to remove that battery before transporting the PCB (in alu-

minium foil). Failure to do so may result in a short circuit, overcurrent flow, or fire.

(9) Be sure to reinsert self-tapping screws correctly, if removed.

(10) Tighten screws to the torque values listed on the next page.

(11) When connecting or disconnecting cable connectors, hold the connector bodies not the

cables. If the connector has a lock, always slide the connector lock to unlock it.

(12) Before reassembly, apply the specified lubricant to the specified points. (Refer to Sec-

tion 2 in this chapter.)

(13) After repairs, check not only the repaired portion but also that the connectors and other

related portions function properly before operation checks.

IV – 1

Page 52

Tightening Torque List

Location Screw type Q'ty Tightening torque (kgf•cm)

Handset mount Taptite, cup B M3x10 2 5 ±1

Hook switch PCB Taptite, cup B M3x6 1 5 ±1

Panel rear cover Taptite, cup B M3x8 2 3 ±1

Inner cover Taptite, cup B 4x12 2 8 ±1

Taptite, cup B 3x10 3 8 ±1

Scanner motor Screw, pan (washer) 3x8DB 1 7 ±2

Fixing unit Taptite, bind B 4x12 1 10 ±1

Taptite, bind B 3x10 2 8 ±1

Laser unit Taptite, bind B 4x12 3 8 ±1

Toner sensor PCB Taptite, cup B 3x8 1 6 ±1

Bottom plate Taptite, cup B 4x12 5 8 ±1

(On the main shield bracket) Taptite, cup S 3x6 2 5 ±1

(On the gear drive unit) Taptite, cup S 3x6 2 8 ±1

Grounding wire Screw, pan (washer) 4x8DB 1 7 ±2

Low-voltage power supply PCB Taptite, bind 4x12 1 10 ±1

High-voltage power supply PCB Taptite, bind 4x12 1 10 ±1

Interface plate Taptite, bind 3x6 3 5 ±1

Relay PCB Taptite, bind B 4x12 1 10 ±1

Shield bracket Taptite, cup B 3x10 3 5 ±1

NCU PCB ASSY Taptite, cup B 3x10 1 5 ±1

Drive unit Taptite, cup B 4x20 3 12 ±1

Taptite, bind B 4x12 1 10 ±1

IV – 2

Page 53

■ Preparation

Prior to proceeding to the disassembly procedure,

(1) Unplug

- the modular jack of the telephone line,

- the modular jack of the curled cord (and remove the handset), and

- the modular jack of an external telephone set if mounted. (Not shown below.)

(2) Remove

- the wire extension,

- the document tray,

- the paper tray, and

- the drum unit (with the toner cartridge loaded).

Handset and curled cord

Drum unit (with toner cartridge loaded)

Wire extension

Document tray

■ How to Access the Object Component

• On the next page is a disassembly order flow which helps you access the object component. To remove the relay PCB, for example, first find it on the flow and learn its number

(F in this case). You should remove parts numbered 1, 3, B, and E so as to access

the relay PCB.

• Unless otherwise specified, the disassembled parts or components should be reassembled in the reverse order of removal.

Telephone line cord

Paper tray

IV – 3

Page 54

■ Disassembly Order Flow

Control panel ASSY

4

bar

Panel rear cover

- Document pressure

- ADF parts

- Nip-related parts

5

Document ejection

6

Control panel

- Control panel PCB

- FPC key

Document feed

6

roller ASSY

Inner cover

7

roller ASSY

Document sensor actuators

Document sensor PCB

Scanner frame ASSY

8

Mirrors

Ejection leaf

Cover sensor

actuator

20

20

Separation roller ASSY

Document take-in roller

ASSY

Scanner motor

Pressure roller

spring

• Sheet feeder

ASSY

cover sensor

actuator

sensor actuator

• Registration

Insulation cover

FU lamp

Fixing unit

9

10

Microphone

(MFC9500 only)

21

Paper ejection sensor actuator

10

Multi-purpose

sheet feeder

3

Bottom plate

12

Main PCB

15

High-voltage

power supply PCB

14

Low-voltage

power supply

PCB

13

Relay PCB

16

Fan 1

14

Shield bracket

17

- Duct cover

- Fan 2

- Speaker

19

Main motor

Gear drive unit

18

NCU PCB ASSY

17

Gears

Solenoids

Top cover

1

Handset mount*

Side cover**

Hook switch PCB*

2

2

Laser unit

11

IV – 4

*For handset-equipped versions

**For non-handset versions

Page 55

1.1 Top Cover

(1) Open the top cover.

(2) Push the arm of the top cover outwards with your thumb to unhook it from the main

cover.

(3) Turn the top cover upright and slide it to the rear.

Top cover

Top cover

turned upright

Arm

Main cover

1.2 Handset Mount and Hook Switch PCB (for handset-equipped versions)

Side Cover (for non-handset versions)

(1) Remove the two screws from the handset mount* or the side cover.**

(2) Twist the handset mount* or the side cover** so that it tilts over to the left and its upper

end works out of the bosses provided on the main cover.

(3) To remove the hook switch PCB*, disconnect the hook switch harness* and remove the

screw.

(Non-handset versions)

Side cover**

Hook switch sensor*

Bosses

(Handset-equipped

versions)

Hook

switch*

Handset

mount*

*For handset-equipped versions

**For non-handset versions

Hook switch PCB*

Hook switch harness*

Main cover

IV – 5

Page 56

1.3 Multi-purpose Sheet Feeder

(1) Pull either one of the right and left tabs provided on the main cover outwards and

slightly lift up the multi-purpose sheet feeder, then release the other end of the sheet

feeder also.

(2) Take up the sheet feeder.

Tab on the

main cover

Multi-purpose sheet feeder

Tab on the

main cover

Boss

■ Reassembling Notes

• To install the sheet feeder, align the right and left end of the front edge with the bosses of

the main cover and then push down the rear.

1.4 Control Panel ASSY

(1) Slightly open the control panel ASSY as shown below.

(2) Push the right and left arms of the control panel ASSY outwards with your thumbs to

unhook them from the bosses provided on the main cover, then slide the control panel

ASSY to the rear.

(3) Disconnect the main-panel harness from the control panel PCB.

Arm of the control panel ASSY

Control panel PCB

Control panel ASSY

Arm

Main-panel harness

IV – 6

Page 57

1.5 Panel Rear Cover and Control Panel

(1) Place the control panel ASSY upside down.

(2) Remove the document pressure bar, ADF parts, and nip-related parts from the panel

rear cover.

(3) Remove the two screws from the panel rear cover.

(4) While lifting up the front edge of the panel rear cover, unhook it from the 15 pawls "X"

provided on the control panel.

(5) Unhook the control panel PCB from the three pawls "Y" on the control panel and take it

out together with the FPC key.

Document pressure bar

Spring plate A

Separation rubber

ADF

parts

Spring plate B

Nip-related parts

Panel rear cover

15 "X" pawls

FPC key

Control panel PCB

Control panel

(placed upside down)

3 "Y" pawls

■ Reassembling Notes

• When installing the spring plate B and separation rubber, align their cutouts with the boss

on the panel rear cover.

IV – 7

Page 58

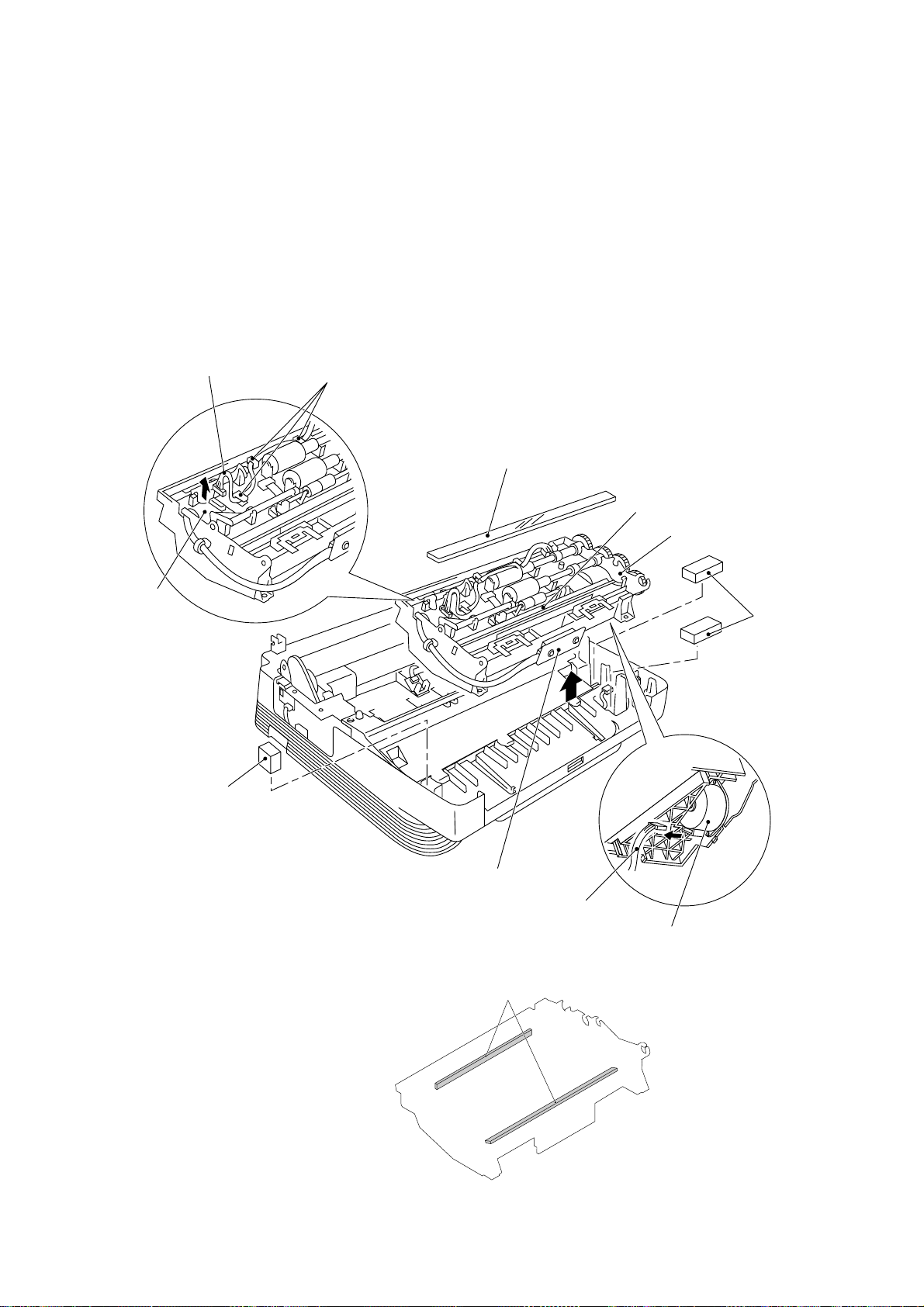

1.6 Document Feed Roller ASSY and Ejection Roller ASSY

(1) Push arm rib "A" to the rear, then shift the document feed roller ASSY to the right and

upwards.

(2) Push arm rib "B" to the rear, then shift the document ejection roller ASSY to the right

and upwards.

Document feed roller ASSY

"A"

Document ejection roller ASSY

1.7 Inner Cover

(1) Remove the five screws.

(2) Unlatch the pawl "a" by hand.

(3) While lifting up the inner cover, unlatch the four pawls "b" and "c."

NOTE: Take care not to scratch or drop the cover glass on the scanner frame ASSY.

Control panel lock

(Leaf spring)

"B"

Viewed from

the left side

"c"

"c"

Inner cover

"b"

"a"

Sponge

"b"

Pinch rollers

IV – 8

Page 59

■ Reassembling Notes

• Before putting the inner cover on the main cover, make sure that:

- The control panel locks (leaf springs) are set in the inner cover as shown on the previous page.

- The pinch rollers are set with their fringes facing outwards as shown on the previous

page.

- The main-panel harness connector comes out from the cutout provided in the inner

cover as shown below.

Main-panel harness

Inner cover

- After installing the inner cover, be sure to put the sponge back into place.

IV – 9

Page 60

1.8 Scanner Frame ASSY

(1) You can remove the following parts from the top of the scanner frame ASSY without

taking out the ASSY from the main cover:

• Cover glass. Turn the cover glass up towards you.

• Ejection leaf springs. Remove them while slightly pulling up the front edges.

• Document take-in roller ASSY. Unhook the latch of the gear, take it off, and lift up the

ASSY.

• Separation roller ASSY. First unhook the latch of the adjacent gear and take it off,

and then remove the separation roller ASSY in the same way as for the document

take-in roller ASSY.

• Pressure roller ASSY. While pressing down the leaf springs, remove the ASSY.

• Bar lens and LED array.

• Document front sensor actuator.

• Document rear sensor actuator. While pressing down the leaf spring and pulling the

boss "X" provided on the scanner frame ASSY to the front, slightly move the actuator

to the left and lift it up.

• Document sensor PCB. Disconnect the CCD harness and LED array harness from

the document sensor PCB. Take the main-sensor harness out of the three clamps

(see the illustration on the next page) and then disconnect it from the PCB.

Document take-in

roller ASSY

Document rear

sensor actuator

Document front

sensor actuator

Separation roller ASSY

Pressure roller ASSY

Cover glass

Document

sensor PCB

Boss "X"

PC1

P1

P2

PC2

P3

PC1: Document front sensor

PC2: Document rear sensor

Leaf springs

Bar lens and LED array

CCD unit

(Do not remove)

Ejection leaf

springs

(Front)

CCD harness

Main-sensor harness connector

CCD harness connector

IV – 10

Page 61

(2) Before taking out the scanner frame ASSY, make sure that the cover glass is removed

and the main-sensor harness is disconnected.

(3) Slightly lift up the scanner frame ASSY and disconnect the scanner motor harness from

the motor, then take out the ASSY.

NOTE: Take care not to scratch the mirrors (see the illustration below), CCD unit, or

bar lens.

NOTE: NEVER remove or replace the CCD unit. Its mounting position has been ad-

justed in the factory.

Document

sensor PCB

Main-sensor harness

Clamps

Cover glass

(Remove before taking out the scanner

frame ASSY .)

Bar lens and LED array

Scanner frame ASSY

Sponges

Sponge

CCD unit

(Do not remove)

Scanner motor harness

Scanner motor

Mirrors

(Front)

IV – 11

Page 62

■ Reassembling Notes

• Check that the mirrors and cover glass are not stained. Wipe them with a soft cloth if

necessary.

• If you have disassembled the gear train on the right side of the scanner frame ASSY, reassemble it referring to the illustration below.

Separation roller gear

Document take-in

roller gear

(Front)

• After installing the scanner frame ASSY, be sure to put the sponges back into place as

shown on the previous page.

1.9 Insulation Cover

(1) Lift up the insulation cover.

(Rear)

Scanner frame

ASSY

Scanner motor gear

(Right side view)

Insulation cover

IV – 12

Main cover

Page 63

1.10 Fixing Unit, FU Lamp, and Paper Ejection Sensor Actuator

(1) Remove the screw "a."

(2) Lift up the fixing unit and then disconnect the heater harness (blue and brown wires).

Disconnect the heater thermister harness from the eraser lamp board.

Fixing unit

Eraser lamp

board

Blue heater

harness

Brown heater

harness

"a"

Paper ejection

sensor actuator

Heater thermister harness

"b"

"b"

Paper ejection

sensor actuator

(3) Remove the paper ejection sensor actuator from the main cover.

(4) To take out the FU lamp from the fixing unit, remove the two screws "b" from the fixing

unit.

(5) Unhook the two latches outwards with the tip of a small flat screwdriver and open the

upper cover. (See the next page.)

(6) Fully open the upper cover and remove it.

IV – 13

Page 64

(7) Remove the screw "d" and loosen the screw "c."

(8) Take the lock plate of the FU lamp with your fingers and pull out the FU lamp from the

heater roller to the left.

CAUTION: Never toutch the FU lamp. If you touch it, clean it throughly with alcohol.

"b"

"b"

Upper cover

"c" (Loosen this.)

Latch

FU lamp

"d"

Lower cover

Setting the FU lamp

Heater roller

Folded lock

plate

Lock plate

Latch

Insert the right

edge of the wire

into the folded