Brother PR650C, TN-841A, LT2-B875 MKII, RH-981A, T-8420B Owner's Manual

...

Text for extended option output

This is a complement of the chapter 4 “Extended option output” of the instruction manual for

BAS300E series programmer and helps users take advantage of extended option output showing

programming examples.

This text is composed of two chapters; “Basic” containing the programming examples which

enables operation check using standard sewing machine only, and “Advanced” containing the

programming examples for users who create the check PCB by themselves.

Contents

Basic...................................................................................................................... 3

1. Preparation...........................................................................................................................3

2. Examples of simple option output......................................................................................3

2-1 ON & OFF operation synchronizing with one machine operation............................3

2-2 Modifying programmed data........................................................................................4

2-3 Programming ON and OFF separately.......................................................................4

2-4 Setting option output No. to ON using trigger data during sewing...........................5

2-5 Outputting in succession (sequence output)...............................................................6

2-6 Adding enabling conditions (AND) to sequence output............................................7

3. Copying created option output data ...................................................................................8

4. Deleting extended option output from the machine..........................................................9

Advanced.............................................................................................................10

1. Preparation.........................................................................................................................10

2. Things that can not be done by the extended option output function ............................10

3. Examples of option output (Advanced)............................................................................10

3-1 Automating sewing start.............................................................................................10

3-2 Start control by input check for automatic start........................................................11

3-3 Adding the input check to make 3 input AND ..........................................................11

3-4 Emergency stop during sequence.............................................................................13

4. Programming......................................................................................................................14

4-1 Selecting hardware on output side............................................................................14

4-2 Selecting hardware on input side..............................................................................14

4-3 Creating the I/O layout table.......................................................................................15

4-4 Creating the timing chart and the program setting value table...............................17

4-5 Starting condition added to the first edition ..............................................................17

Appendix..............................................................................................................17

1. Parts for extended option..................................................................................................17

2. Check PCB circuit diagram ..............................................................................................17

3. Block diagram ....................................................................................................................17

2

Basic

1. Preparation

Sewing machine with the pneumatic work clamp (except for BAS-311E solenoid specification)

Control PROM version MN-C or later (products manufactured in or after June 1998 are equipped

with this PROM as a standard part.)

Programmer

Instruction manual for programmer (see the instruction manual for page reference.)

2. Examples of simple option output

Option output can be programmed up to No. 16 (see page 195). No. 15 is the air valve output for the

left work clamp, and No.16 is the air valve output for the right work clamp. If these two outputs are

programmed as option outputs, these do not operate as the work clamps but operate as the option

outputs.

The following example operations are to program No. 15 and 16 and check their operations (if the

right and left work clamps operate as programmed, the operations of No. 15 & 16 are good).

Some of the following examples involve sewing operation with the work clamp raised, be extremely

careful in that case.

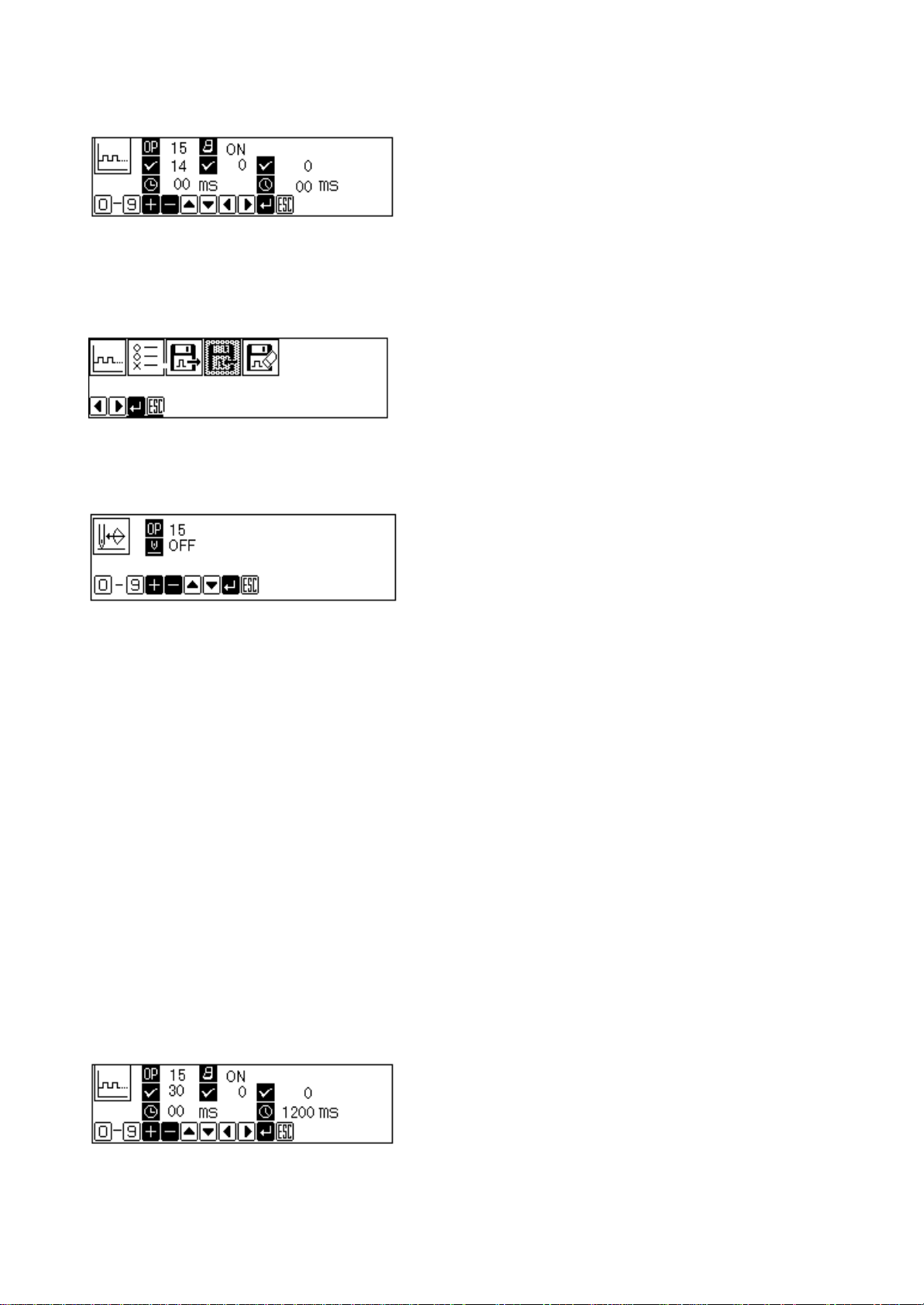

2-1 ON & OFF operation synchronizing with one machine operation

Create program that enables the right and left work clamps automatically to rise and descend

(option output No. 15 is ON and OFF) at sewing start.

•Prepare the programmer, follow “Operating the extended option output” (see page 184) to display

the output setting screen.

‚Referring to the condition number table of machine operation mode (see page 191), set the option

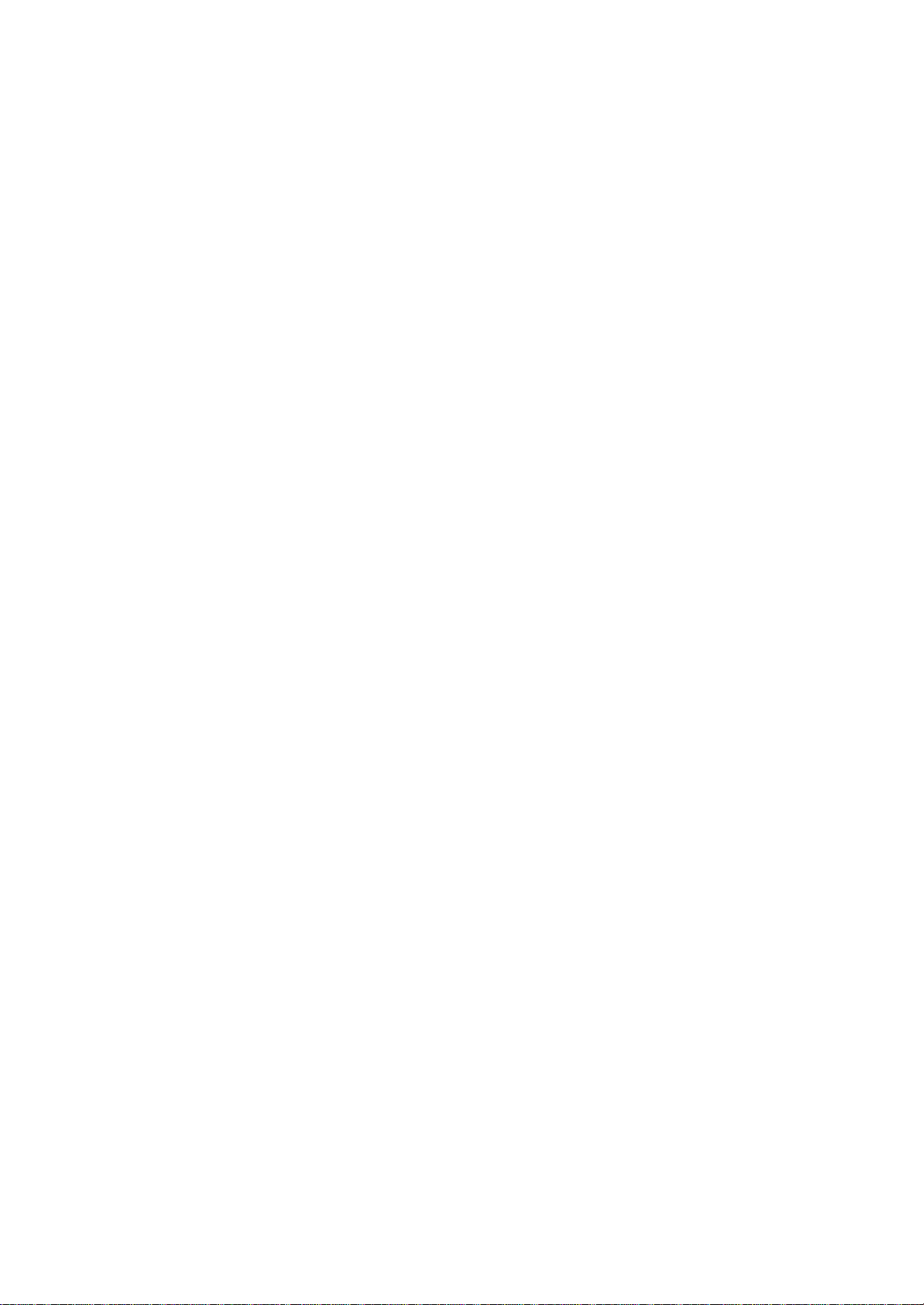

output No. 15 to ON when the condition No. 2 is set, and the timer 2 to 1 second (1000ms). Input on

the setting screen as follows:

Press the RETURN key to save the data after inputting the numerical data.

For input check, move the cursor to OUPTPUT No., set it to No. 16 by pressing the + key once, and

set it back to No. 15 by pressing the − key.

ƒPress the ESC key, and write the data with the FD write icon.

3

„Press the P key to turn off the display of the programmer, and turn the power off and on again.

Since initial setting is done when the power is turned ON, turn the power off and on after writing

extended option output. In this case, the output No. 15 is initial-set to work as an extended option

not as the left work clamp.

…Read short sewing data that consists of around 10 stitches, set the DIP SW A No. 1 (the presser

foot does not rise at sewing finish) to ON, and carry out sewing.

If the left work clamp rises for 1 second and descends every time the feed returns to the sewing start

position, it proves that No. 15 has worked as programmed.

2-2 Modifying programmed data

Modify the data created in the previous procedure 2-1

One FD can store only one option program. (FD file name is “bas900. seq”)

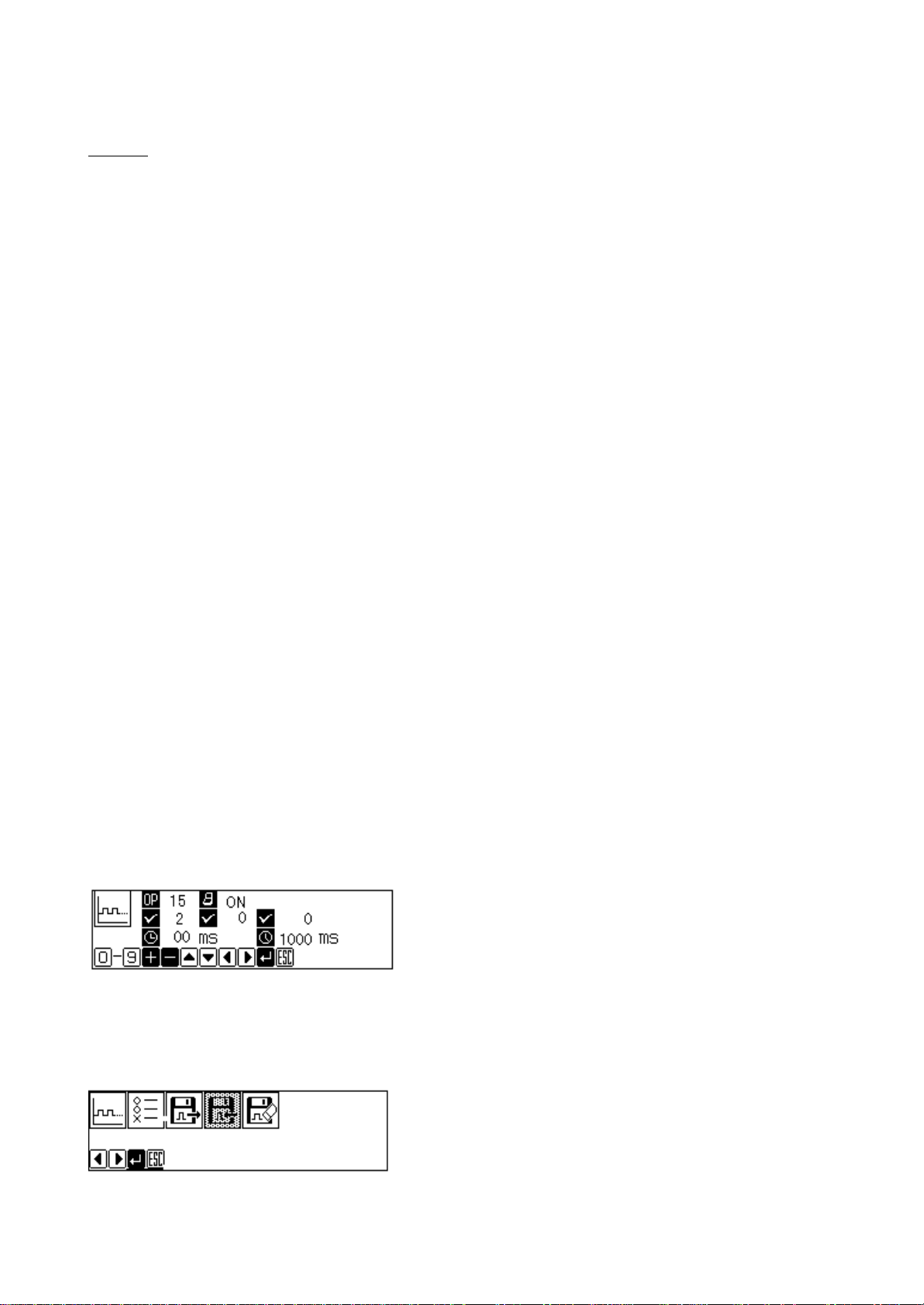

•After checking that the FD written in 2-1 is in the operation panel, display the extended option output

home screen shown in the following.

‚Read the written data with FD read icon.

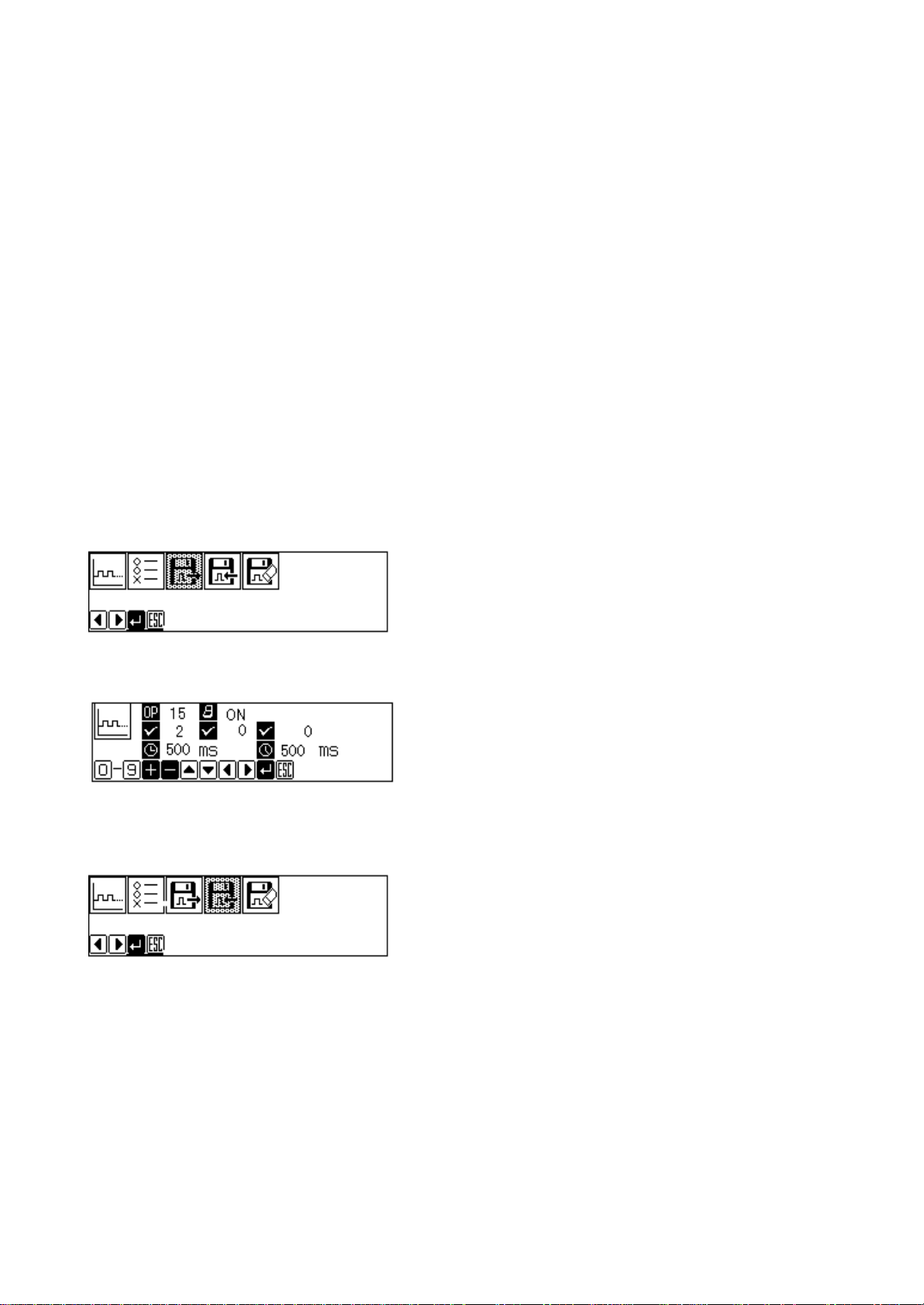

ƒDisplay the output setting screen, set the timer 1 to 0.5sec (500mS) and the timer 2 to 0.5sec

(500mS). Input as follows:

For the timer 2, move the cursor to “1000”, which has already been set, write “0500” over it.

„After overwriting the option program to the FD following the same step of ƒ and„ of 2-1, press the

P key to turn off the display of the programmer, and turn the power off and on again.

…Read the sewing data and carry out sewing. Check that the left work clamp does not rise soon after

the feed returns to the sewing start position (because the timer 1 was set from 0 to 0.5 sec.) and the

time of the work clamp rise has become short (because the timer 2 was set from 1 to 0.5 sec).

2-3 Programming ON and OFF separately

2-1 and 2-2 are examples that No. 15 automatically returns to OFF after it is ON during the set

time of the timer 2.

The following procedure is to create the program which enables the left work clamp automatically

to open at sewing start (option output No. 15: ON) and close at the same time of sewing start

4

(option output No. 15: OFF). This is for checking the case that the output conditions of ON and

OFF are different.

•Prepare the programmer, and display the output setting screen.

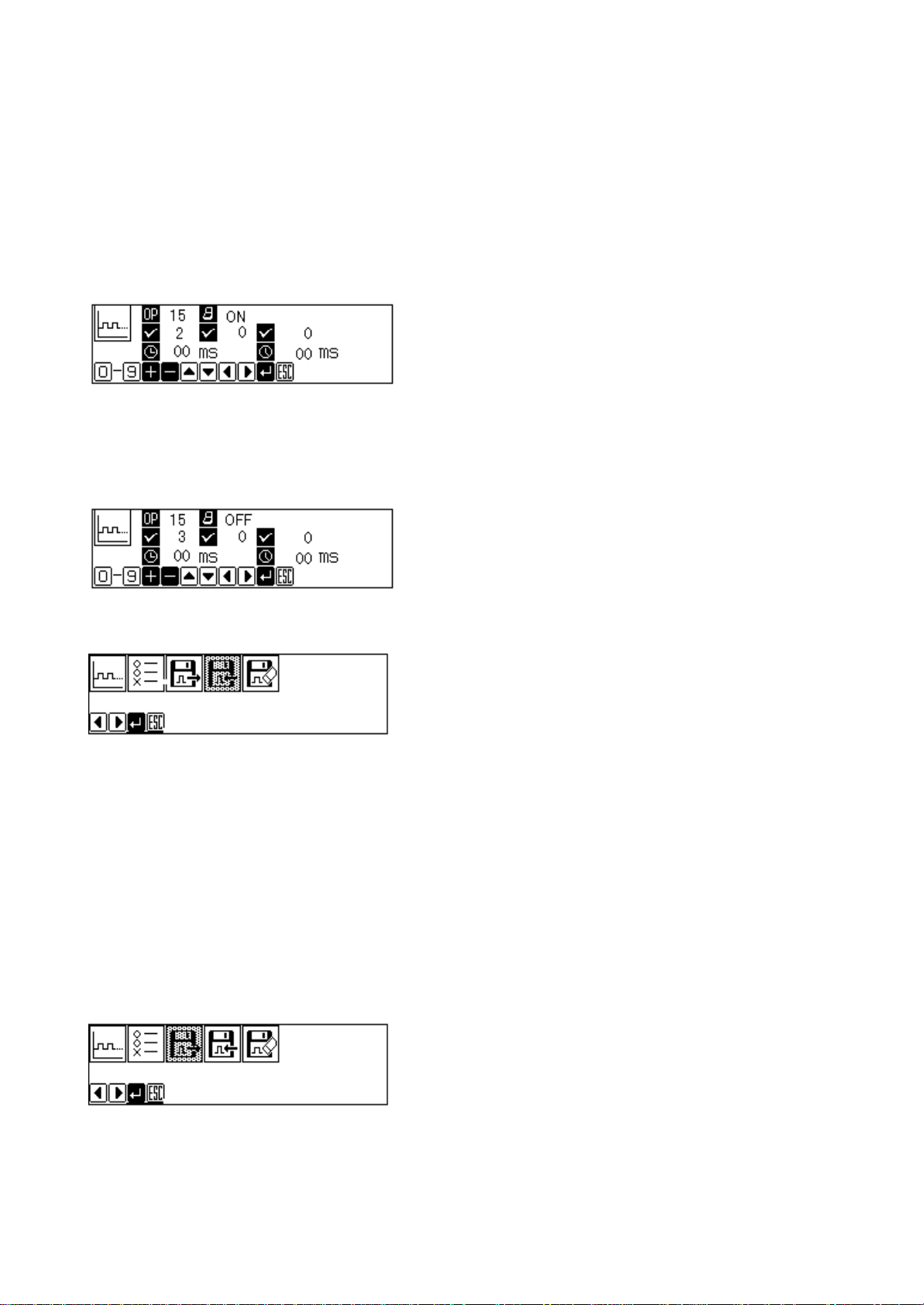

‚Referring to the condition number table of machine operation mode (see page 191), set the option

output No. 15 to ON when the condition No. 2 (after the feed is completed at the sewing start

position) is set, Input on the setting screen as follows:

ƒMove the cursor to “ON”, press the + key. ON, OFF, and F/F are switched every time the + key is

pressed. After setting “OFF”, referring to the condition number table of machine operation mode

(see page 191), set the option output No. 15 to OFF when the condition No. 3 (before sewing start)

is set. Input on the setting screen as follows:

„After overwriting the option program to the FD, press the P key to turn off the display of the

programmer, and turn the power off and on again.

…Read the sewing data and carry out sewing. When the feed returns to the sewing start position,

check that the left work clamp rises, and descends at sewing start.

As shown in the above, when the timer 2 is “00”, the option output number stays ON or OFF after

the condition is met.

2-4 Setting option output No. to ON using trigger data during sewing

No. 15 was set to ON at sewing start position in 2-2. The following procedure is to set No. 15 to

ON during sewing. For OFF setting, keep the setting of 2-3 so that No. 15 stays OFF at sewing

start.

•Read the written data with the FD read icon.

‚Referring to the condition number table of machine operation mode (see page 191), set the No. 15

to ON when the condition No. 14 (trigger data detection) is set. Input on the setting screen by

overwriting as follows:

5

Move the cursor to “ON”, and press the − key to switch to OFF. Check the data that was set in 2-3

remains.

ƒAfter overwriting the option program to the FD, press the P key to turn off the display of the

programmer.

„Press the P key again, read the sewing data and edit it, and input the trigger data at a desired

position (see page 100 of the instruction manual for the programmer). Set the option output No. 15,

and sewing stop: OFF. Input on the setting screen as follows:

…Put the sewing data in memory by a new program No.after inputting the trigger data. Press the P key

to turn off the display of the programmer. Turn the power off and on again.

Carry out sewing. Check that the left work clamp rises at a position of the trigger data and descends

at sewing start.

2-5 Outputting in succession (sequence output)

Create the program for sequence output after the work clamp rises at sewing finish, on the

assumption that the option output is for the stacker (the device that removes and stacks materials

after sewing finish).

Set the option output No. 15 to be ON and OFF first and then No.16 to be ON and OFF

synchronizing with the work clamp rise. The conditions of sewing finish are added in the following

2-6.

•Prepare the programmer, and display the output setting screen.

‚Referring to the condition number table of standard output (see page 192), set the output condition

of No. 15 to ON when the condition No. 30 (after work clamp rise) is set, and the timer 2 to 1.2

seconds (1200ms). Input on the setting screen as follows:

6

Loading...

Loading...