.....

_

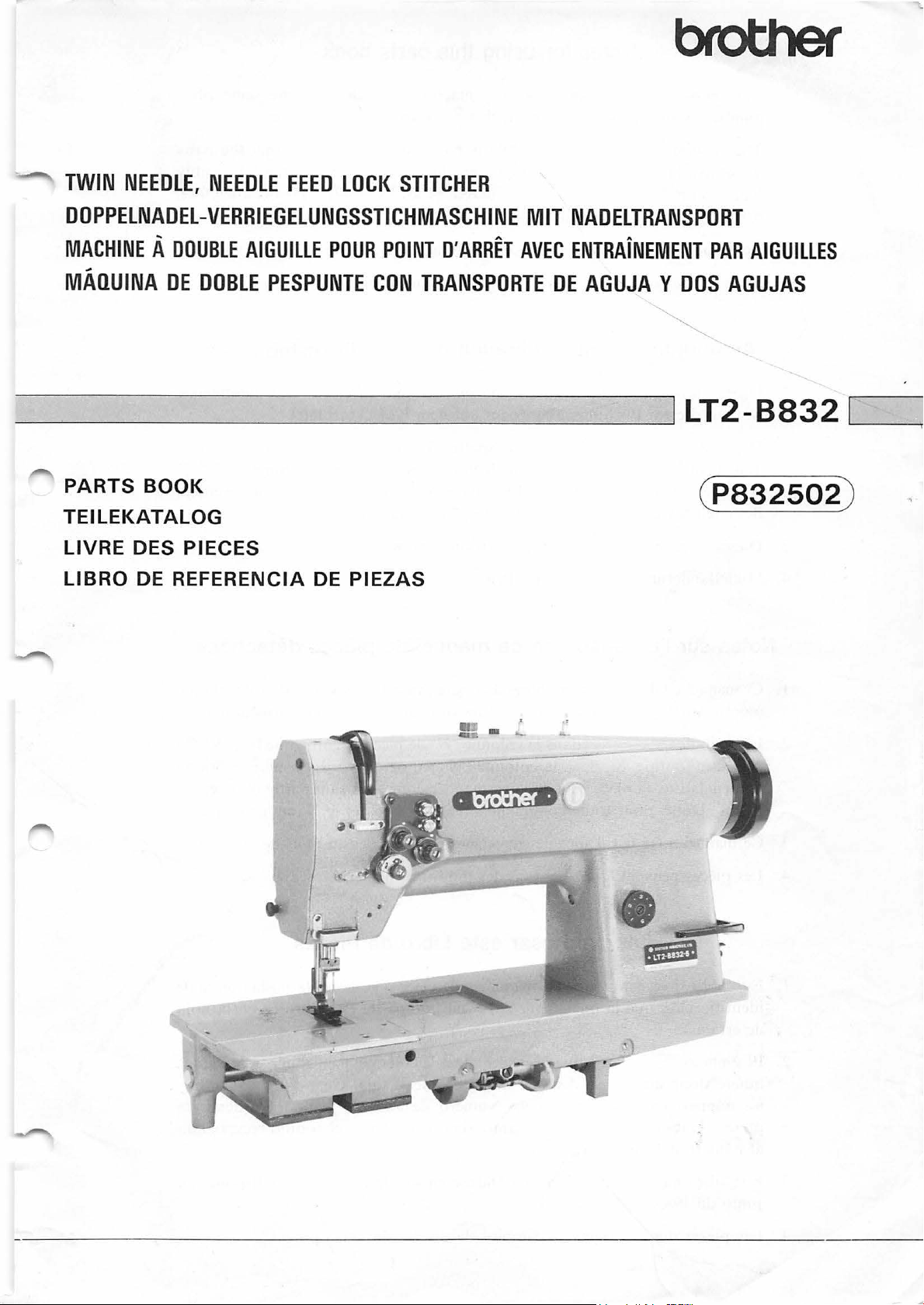

TWIN

DOPPELNADEL-VERRIEGELUNGSSTICHMASCHINE

MACHINE A DOUBLE

MAQUINA

___

PARTS

TEILEKATALOG

LIVRE

LIBRO

NEEDLE,

NEEDLE

FEED

AIGUILLE

DE

DOBLE

_

______

BOOK

DES

DE REFERENCIA DE

PIECES

PESPUNTE

LOCK

POUR

POINT

CON

PIEZAS

STITCHER

D'ARRET

TRANSPORTE

_

___

MIT

AVEC

DE

NADELTRANSPORT

ENTRAiNEMENT

AGUJA Y DOS

___J

PAR

AIGUILLES

AGUJAS

LT2-

(

8832

P832502

)

L--1

_______,.

--

'

--

Notes for using this parts book

I. This book

number as shown on the cover

2.

The

symbol

is

not available for supply.

No."

column, the parts can be ordered as an assembly. Please, therefore,

is

applicable to sewing machines which have the same plate

of

I~

this book

I in the "Parts

If,

however, there

(or

correction sheet).

No.~'

column indicates that the parts

is

a number in the ffAssembly

order by using the Assembly No.

3.

This

book

was prepared based on information available in June, I 983.

4.

Parts are subject to changes in design w.ithout prior notice.

Anmerkungen zum Gebrauch dieses Stilcklistebuches

I.

Dieses

wie

2.

Dieses Zeichen I

Teil nicht lieferbar ist. Wenn jedoch in der Spalte

Nummer steht, kann dieser Teil als ein Gerateteilsatz bestellt werden.

Bestellen Sie daher bitte mit dieser Geratesatznummer.

Buch

bezieht sich

auf

diesem Buchumschlag ( oder

~I

auf

die Nahmaschinen mit derselben Kennungsnummer

auf

dem Korrekturblatt).

in der Spalte "Teilnummer" bedeutet, daB dieser

"Geratesatznummer" eine

~I

3.

Dieses Buch basiert

4.

Modellanderungen sind vorbehalten.

Notes sur l'utilisation

I. Ce manuel

montre

2.

Le symbole

peut

nomenclature, Ia

pieces. Done,

3.

Ce manuel a ete fait d'apres

4.

Les pieces peuvent Stre sujettes a des modifications sans preavis.

~

est

destine aux machines a coudre ayant

sur

Ia couverture de ce manuel (ou sur Ia feuille de corrections).

I~

Stre fournie. Si, dans la colonne "No

auf

den lnformationen vom J uni,

de

ce

manuel de pieces detachees

le

m@me

1983.

numero de plaque

I dans Ia colonne "No de piece" signifie que la piece ne

jeu

de pees",

piece peut Stre commandee comme faisant partie

pour

toute commande, veuillez specifier le

les

renseignements valables au mois de Juin,

il

No

y a un numero de

d'un

jeu de

de jeu de pieces.

1983.

~·

'\

Notas para usar este Libro de Piezas

I.

Este libro sirve para todas las maquinas de coser que llevan

identificaci6n que

Ia

que se puede ver en Ia

tapa

de este libro ( o en Ia hoja

de erratas).

Ia

misma placa de

2.

El

simbolo I

quiere decir que no se dispone de dicha

nfimero en

un

pieza con todo el juego.

~

I,

que

Ia

columna del

Por

se

encuentra en

"Numero

Ia

columna del "Nfimero de Pieza",

pieza:

sola.

de Juego", se podra ordenar Ia

lo tanto, sera mejor hacer

al nfimero del juego respectivo.

3.

Este libro ha sido compilado basandose en los datos de que se disponia en

junio

4.

Las piezas quedan sujetas a cambios de disefio sin aviso previo.

de

1983.

Cuando,

el

pedido recurriendo

empero, hay

~

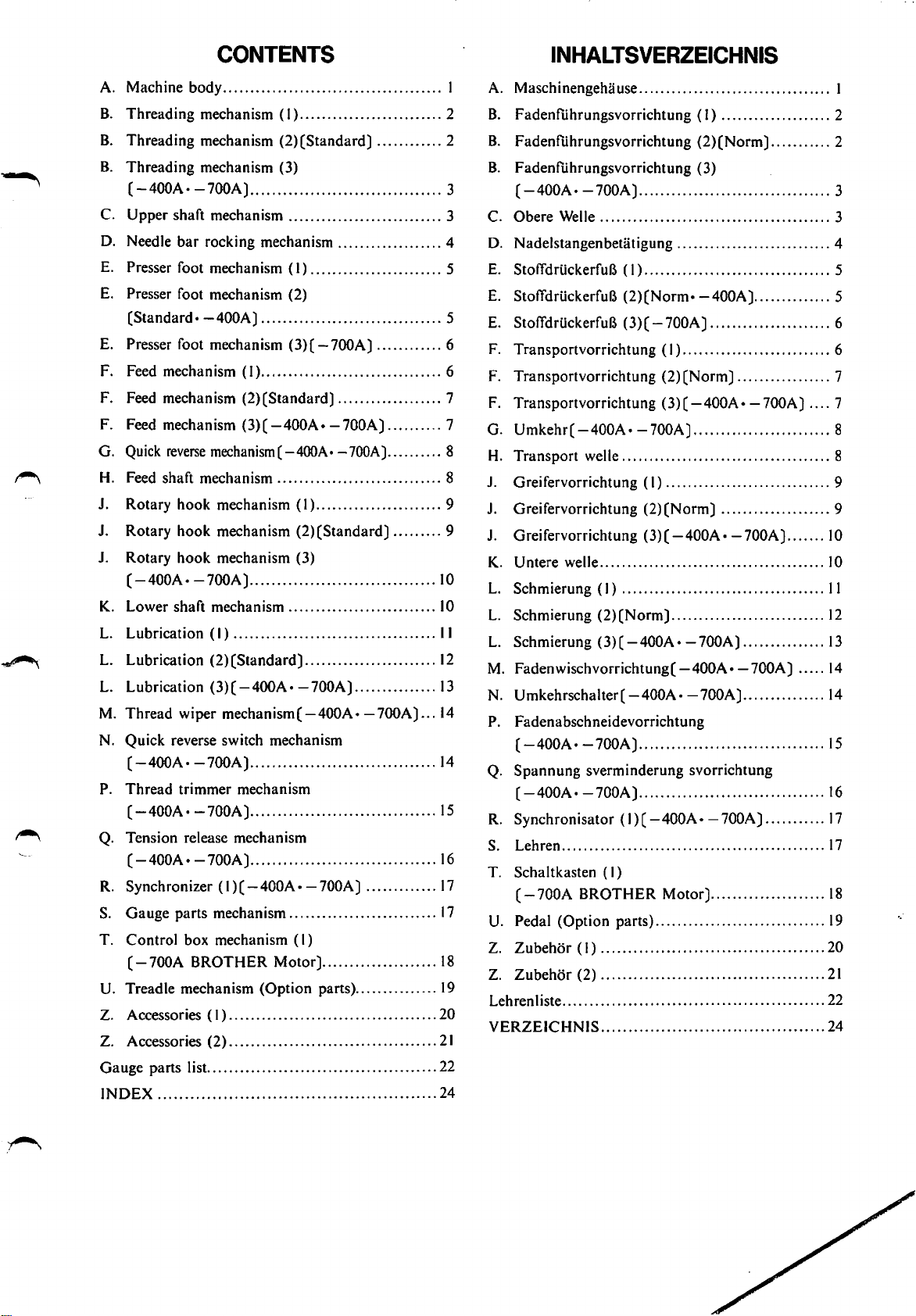

CONTENTS

INHALTSVERZEICHNIS

A. Machine body

B.

Threading mechanism

B.

Threading mechanism

B.

Threading mechanism (3)

(

-400A·

C.

Upper shaft mechanism

D.

Needle

Presser foot mechanism

E.

E.

Presser foot mechanism (2)

(Standard·

E. Presser foot mechanism

F. Feed mechanism

F. Feed mechanism (2)(Standard)

F. Feed mechanism

Quick

G.

H.

J.

J. Rotary hook mechanism (2) (Standard)

J. Rotary hook mechanism (3)

K.

L. Lubrication

L. Lubrication

L. Lubrication

M.

N. Quick reverse switch mechanism

P.

Q. Tension release mechanism

R. Synchronizer

S.

T. Control box mechanism

U. Treadle mechanism (Option parts)

Z. Accessories ( I )

Z. Accessories (2)

Gauge parts list.

INDEX

reverse

Feed shaft mechanism

Rotary hook mechanism ( 1)

(

-400A·

Lower shaft mechanism

Thread wiper mechanism(

(

-400A·

Thread trimmer mechanism

(

-400A·

( - 400A • - 700A)

Gauge parts mechanism

(

-700A

...................................................

........................................

(I)

..........................

(2)(Standard)

-700A)

bar

-700A)

-700A)

-700A)

BROTHER

...................................

............................

rocking mechanism

(I)

........................

-400A)

mechanism(

(I)

(2)(Standard)

(3)(

.........................................

.................................

(3)(

-700A)

(I)

.................................

(3)(

-400A·

-400A·

..............................

.......................

..................................

...........................

.....................................

........................

-400A·

..................................

..................................

..................................

(I)(

-400A·

......................................

......................................

-700A)

-400A·

-700A)

...........................

(I)

Motor)

............

...................

............

...................

-700A)

-700A)

...............

-700A)

.............

.....................

...............

..........

..........

.........

...

1

2

2

3

3

4

5

5

6

6

7

7

8

8

9

9

10

I 0

II

12

13

14

14

15

I 6

17

17

18

19

20

2 I

22

24

A.

Maschinengehause

B.

Fadenftihrungsvorrichtung

B.

Fadenflihrungsvorrichtung

B.

Fadenftihrungsvorrichtung (3)

(

-400A·

C.

Obere Welle

D.

Nadelstangenbetatigung

E.

StoffdrUckerfuB

E.

StoffdrUckerfuB

E.

StoffdrUckerfuB

F.

Transportvorrichtung

F.

Transportvorrichtung (2)

F.

Transportvorrichtung

Umkehr(

G.

H.

Transport welle

J. Greifervorrichtung

J.

Greifervorrichtung

J.

Greifervorrichtung

K.

Untere welle

L. Schmierung

L. Schmierung

L. Schmierung

M.

Fadenwischvorrichtung(

N. Umkehrschalter(

P.

Fadenabschneidevorrichtung

(

-400A·

Q. Spannung sverminderung svorrichtung

(

-400A·

R.

Synchron isator

S.

Lehren

T. Schaltkasten ( I )

(

-700A

U.

Pedal (Option parts)

Z.

Zubehor ( 1)

Z.

Zubehor

Lehrenliste

VERZEICHNIS

-700A)

-400A·

-700A)

-700A)

................................................

BROTHER

(2)

................................................

...................................

(I)

....................

(2)(Norm)

...................................

..........................................

............................

(I)

..................................

(2)(Norm·

(3)(

-700A)

......................................

(I)

(2)(Norm)

(3)(

.........................................

(I)

.....................................

(2)(Norm)

(3)(

-400A·

-400A·

..................................

..................................

(I)(-

.........................................

.........................................

.........................................

-400A)

-700A)

(I)

...........................

(Norm)

(3)(

-400A·

.........................

..............................

-400A·

............................

-700A)

-400A·

-700A)

400A • - 700A)

Motor)

...............................

..............

......................

.................

-700A)

....................

-700A)

...............

-700A)

...............

.....................

...........

.......

.....

...........

....

I

2

2

3

3

4

5

5

6

6

7

7

8

8

9

9

10

10

II

12

13

14

14

15

16

17

17

18

19

20

21

22

24

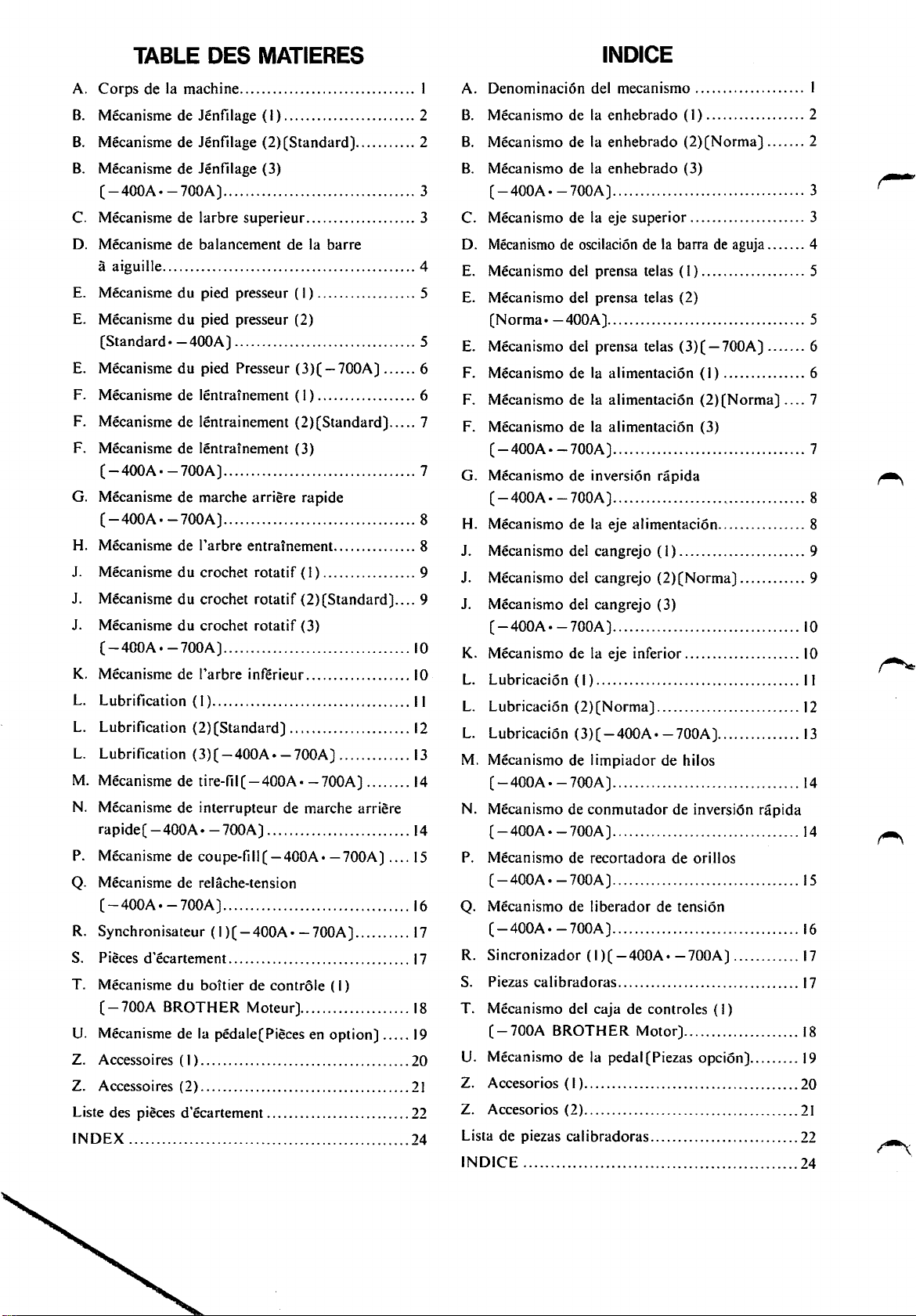

TABLE

A.

Corps

de

B.

Mecanisme

B.

Mecanisme

B.

Mecanisme

-400A·

(

C. Mecanisme

D. Mecanisme

a aiguille

E. Mecanisme

E. Mecanisme

(Standard· -400A)

E. Mecanisme

F.

Mecanisme de lentrainement

F. Mecanisme

F. Mecanisme

(

-400A·

G. Mecanisme

-400A·

(

H. Mecanisme

J. Mecanisme

J. Mecanisme

J. Mecanisme

(

-400A·

K. Mecanisme

L. Lubrification

L. Lubrification

L. Lubrification

M.

Mecanisme

N. Mecanisme

rapide(

P. Mecanisme

Q. Mecanisme de relache-tension

(R. Synchronisateur

S. Pieces d'ecartement

T. Mecanisme

(-

U. Mecanisme de

Z. Accessoires

Z. Accessoires (2)

Liste des pieces d'ecartement

INDEX

-400A·

400A • - 700A)

700A

...................................................

DES

Ia

machine

de

Jenfilage

de

Jenfilage

de

Jenfilage (3)

-700A)

de

larbre superieur

de

balancement

..............................................

du

pied presseur

du

pied presseur (2)

du

pied Presseur

de

lentrainement

de

lentrainement (3)

-700A)

de

marche arriere

-700A)

de

l'arbre

du

crochet

du

crochet

du

crochet

-700A)

de

l'arbre

(I)

(2)(Standard)

(3)(

de

tire-fit(

de

interrupteur

-700A)

de

coupe-fill (

(I)(-

du

boitier

BROTHER

Ia

(I)

......................................

......................................

MATIERES

................................

(I)

........................

(2)(Standard).

...................................

de

.................................

...................................

...................................

entrainement.

rotatif

rotatif

rotatif

..................................

inferieur

....................................

-400A ·-700A)

-400A·

de

..........................

-400A • -700A)

..................................

400A ·-700A)

.................................

de

controle

Moteur)

pedale(Pieces en

..........................

..........

....................

Ia

barre

(I)

..................

(3)(

-700A)

(I)

..................

(2)(Standard)

rapide

..............

(I)

.................

(2)(Standard)

(3)

...................

......................

.............

-700A)

marche arriere

....................

........

..........

(I)

option)

......

.....

....

....

.....

10

I 0

II

12

13

14

14

15

16

17

17

18

19

20

21

22

24

IN

A.

I

2

2

3

3

4

5

5

6

6

7

7

8

8

9

9

Denominaci6n

B.

Mecanismo

B.

Mecanismo

B.

Mecanismo de

(

-400A·

C.

Mecanismo de

D. Mecanismo

E. Mecanismo del prensa telas

E. Mecanismo del prensa telas (2)

(Norma·

E. Mecanismo del prensa telas

F. Mecanismo de Ia alimentaci6n

F. Mecanismo

F. Mecanismo

-400A·

(

G. Mecanismo

(

-400A·

H. Mecanismo

J. Mecanismo del

J. Mecanismo del cangrejo

J. Mecanismo del cangrejo (3)

-400A·

(

K. Mecanismo de

L. Lubricacion

L. Lubricacion

L. Lubricacion

M. Mecanismo

(

-400A·

N. Mecanismo de

(

-400A·

P. Mecanismo de recortadora

(

-400A·

Q. Mecanismo de

(

-400A·

R.

Sincronizador

S. Piezas

T. Mecanismo del

U.

Z.

Z. Accesorios (2)

Lista

INDICE

calibradoras

(-

700A

Mecanismo

Accesorios

de

piezas

..................................................

del mecanismo

de

Ia

de

Ia

Ia

-700A)

Ia

de

oscilaci6n

-400A)

de

Ia alimentaci6n

de

Ia alimentaci6n (3)

-700A)

de

inversion

-700A)

de

Ia

cangrejo

-700A)

Ia

(I)

.....................................

(2)(Norma)

(3)(

-400A·

de

limpiador

-700A)

conmutador

-700A)

-700A)

liberador

-700A)

(I)(

caja

BROTHER

de

Ia

(I)

.......................................

.......................................

calibradoras

DICE

....................

enhebrado

enhebrado

enhebrado

...................................

eje

superior

....................................

...................................

.................... , ..............

eje alimentacion

..................................

eje inferior

..................................

..................................

..................................

..................................

-400A·

.................................

de

Motor).

pedal (Piezas

(I)

..................

(2)(Norma)

(3)

.....................

de

Ia

barra de aguja

(I)

...................

(3)(

-700A)

(I)

...............

(2)(Norma)

rapida

................

(I)

.......................

(2)(Norma)

.....................

..........................

-700A).

de

hilos

de

de

de

tension

-700A)

controles

....................

...........................

............

..............

inversion

orillos

............

(I)

opcion).

.......

.......

.......

rapida

........

....

I

2

2

3

3

4

5

5

6

6

7

7

8

8

9

9

10

10

II

12

13

14

14

15

16

17

17

18

19

20

21

22

24

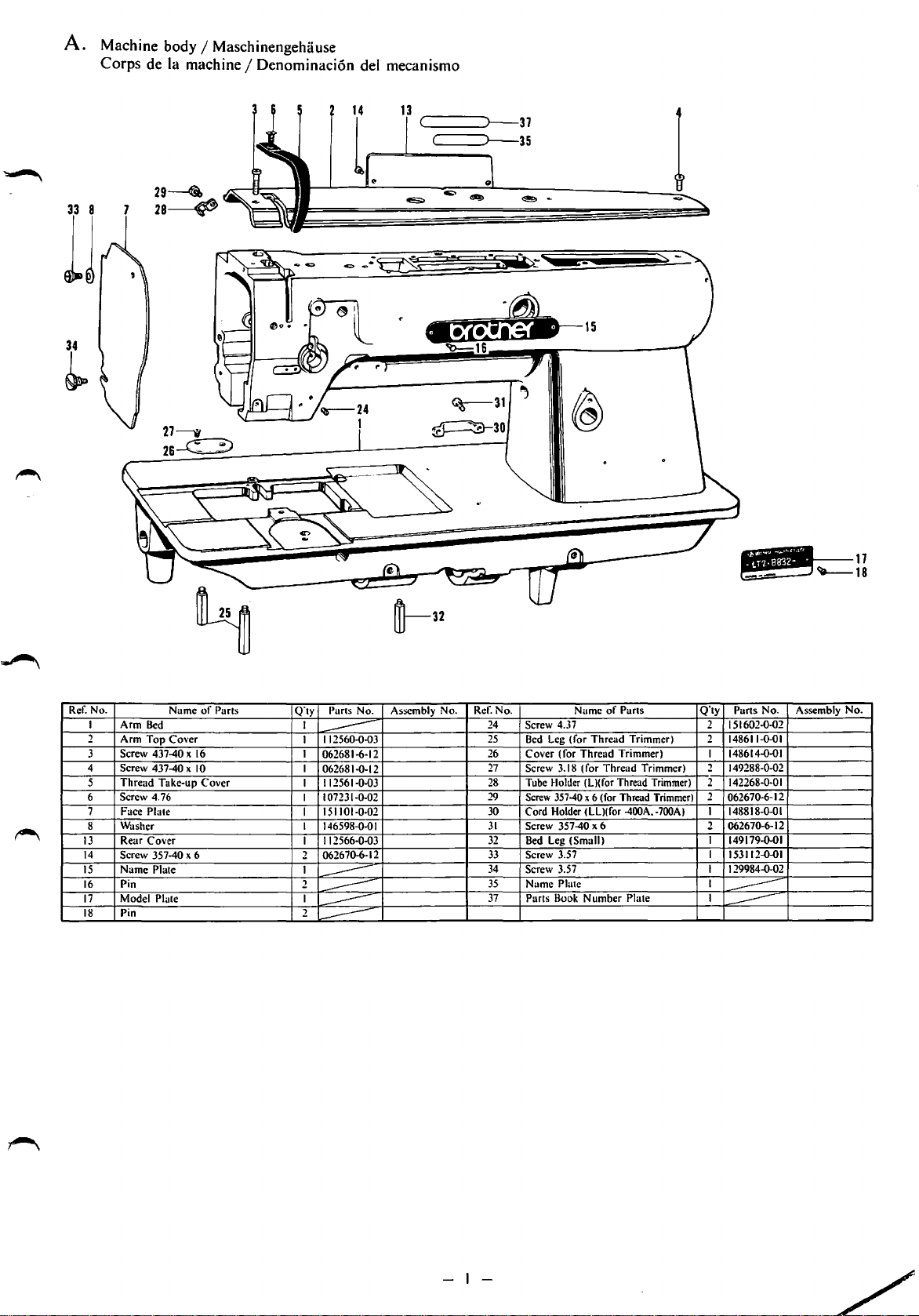

A. Machine body I Maschinengehause

Corps

de

Ia

machine I Denominaci6n del mecanismo

ll

7

29------4

28~

21----"'ll

~

26~

1

'%--31

~30

Ref. No.

I

2

3

4

5

6

7

8

13

14

15

16

17

18

Bed

Top

Take-up

Pl<tle

Cover

Plale

Name

Cover

Arm

Arm

Screw 437-40 x

Screw 437-40 x

Thread

Screw 4.76

F<tce

Washer

Rear

Screw 357-40 x 6

Name

Pin

Model Plale

Pin

of

16

10

Cover

Paris

Q'ly

Paris

I

112560-0-03

I

----

I

062681·6·12

I

062681-0-12

112561-0-03

I

I I 07231-0-02

I 151101·0·02

I 146598-0.01

112566-0.03

I

0626 70-6-12

2

I

2

----

I

----

2

----

----

No.

Assembly No. Ref. No.

N<tme

of

Screw 4.37 2 151602-0-02

24

Bed Leg (for

25

26

Cover

27

28

29

30

31

32

33

34

35

37

(for

Screw 3.18

Tube Holder (L)(for Thread Trimmer) 2 142268·0·0 I

Screw

357-40

Cord Holder (LL)(for -400A. -700A) I 148818-0-0 I

Screw 357-40 x 6 2

Bed Leg

(Small)

Screw 3.57 I

Screw 3.57

Name

Plate

Paris

Book

Paris

Thread

Thread

(for

Trimmer)

Trimmer)

Thread

Trimmer) 2

x 6 (for Thread Trimmer)

Number

Plale

Q'ly

Paris

No.

2 148611-0-01

148614.0.0 I

I

149288-0.02

2

062670·6·12

062670-6-12

I 149179-0-01

153112.0.01

I 129984.0.02

I

~

I

-----

Assembly

No.

-I-

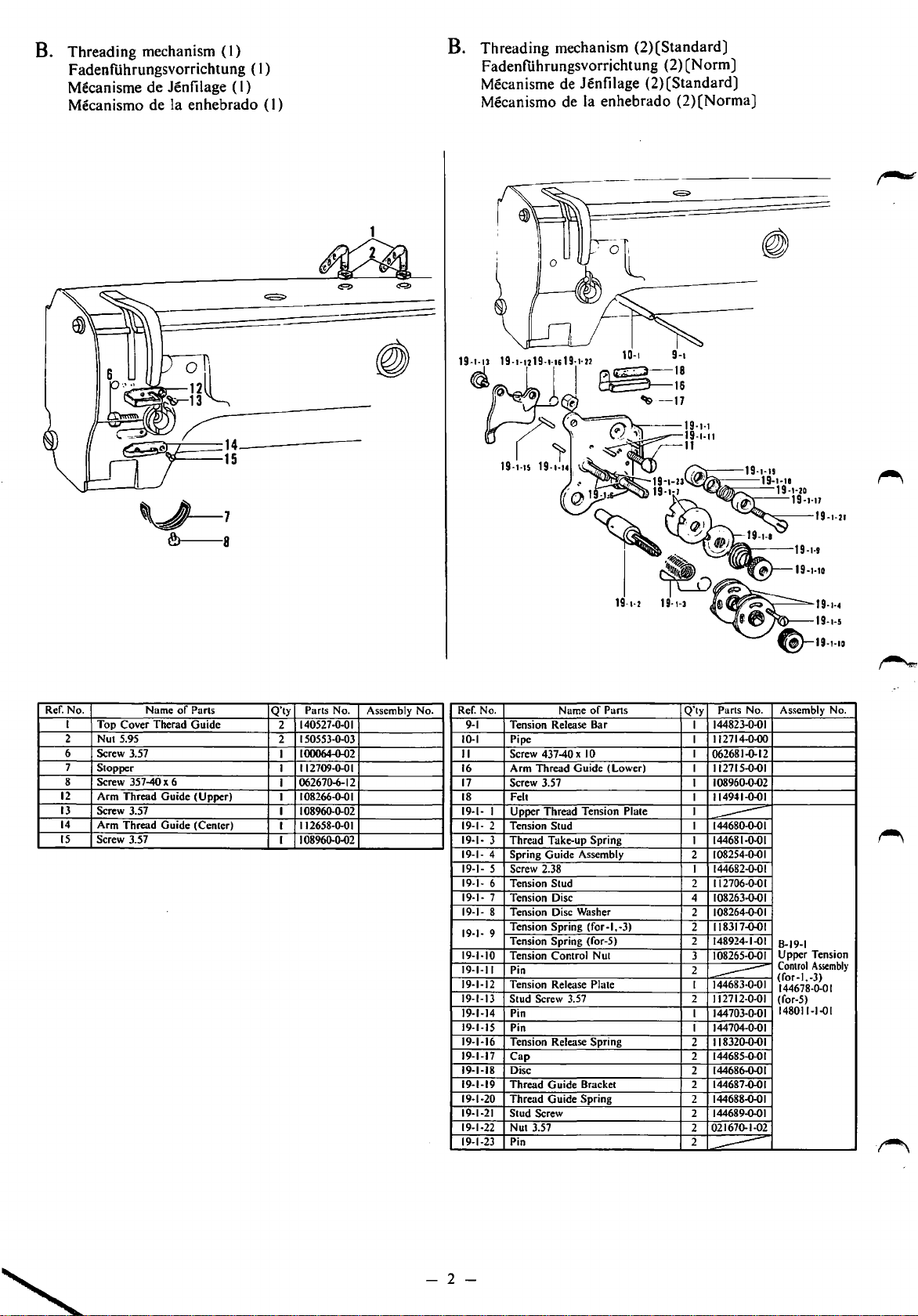

B.

Threading mechanism

Fadenflihrungsvorrichtung

Mecanisme de Jenfilage

Mecanismo de

Ia

enhebrado

(I)

(I)

(I)

(I)

B.

Threading mechanism

Fadenflihrungsvorrichtung (2)

Mecanisme de Jenfilage

Mecanismo de

Ia

enhebrado

(2)(Standard)

(Norm)

(2)(Standard)

(2)(Norma)

v-7

Ref.

No. Name

I Top Cover Therad Guide

2

6

7 Stopper

8

12

13

14

15

5.95

Nut

Screw

3.57

Screw 357-40 x 6

Arm Thread Guide (Upper)

Screw

3.57

Arm Thread Guide (Center)

Screw 3.57

~8

of

Parts Q'ty

140527-0-01

2

2

150553-0-03

I 00064-0-02

I

112709-0-01

I

0626

I

108266-0-01

I

I 08960-0-02

I

112658-0-01

I

I

I 08960-0-02

Parts No.

70-6-12

Assembly No.

Ref.

No.

9-1

10-1

II Screw 437-40 x

16

17

18

19·1· I

19-119-119-119-119-119-119-1-

19-119-1-10

19-t-11

19-1-12

19-1-13

19-1-14

19-1-15

19-1-16

19-1-17

19-1-18

19-1-19

19-1-20

19-t-21

19-1-22

19-1-23

Tension Release Bar

Pipe

Arm Thread Guide (Lower)

Screw

Felt

Upper Thread Tension Plate I

2

Tension

3

Thread Take-up Spring

4

Spring Guide Assembly

5

Screw

6

Tension

7

Tension Disc 4 I 08263-0-0 I

8

Tension Disc Washer

Tension Spring (for-1,-3)

9

Tension Spring (for-5)

Tension Control Nut

Pin

Tension Release Plate

Stud Screw

Pin

Pin

Tension Release Spring

Cap

Disc

Thread Guide Bracket 2

Thread Guide Spring

Stud Screw 2

Nut

Pin

Name

3.57

Stud

2.38

Stud

3.57

3.57

10

of

Parts

Q'ty Parts

144823-0-01

I

I

12714-0-00

I

I

062681-0-12

112715-0-01

I

I

08960-0-02

I

114941-0-01

I

144680-0-0

I

-----

144681-0-0

I

I 08254-0-0 I

2

144682-0-01

I

112706-0-01

2

I

08264-0-0 I

2

118317-0-01

2

2

148924-1-01

I 08265-0-0 I

3

2

144683-0-01

I

-----

112712-0-01

2

144703-0-01

I

I

144

704-0-0 I

118320-0-01

2

144685-0-01

2

144686-0-01

2

144687-0-01

144688-0-0

2

144689-0-0

021670-1-02

2

2

No.

I

I

I

I

Assembly No.

B-19-1

Upper Tension

Control

Assembly

(for-t,-3)

144678-0-01

(for-5)

148011-1-01

-

2-

-----

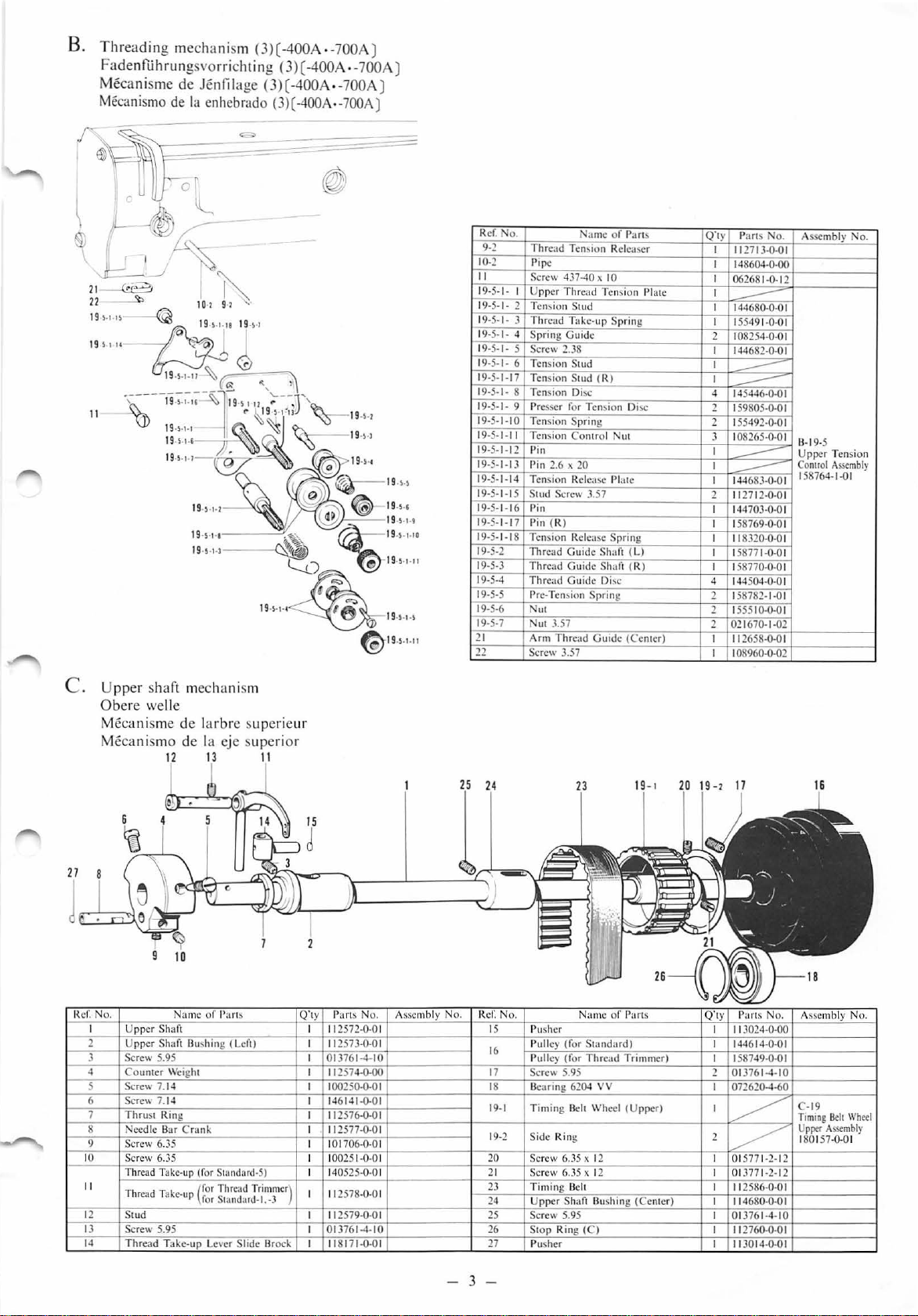

B.

Threading mec

Fadenfuhrungsvorrichting

Mecani

Mecanisme de

l

I

11

sme

de

Ia

hani

sm

(3)(-400A ·-700A)

(3)(

Jenfil

-400A ·

age

(3}(-400A·-700A)

-700A)

enhebrado (3}(-400A ·-700A)

19

19

-H

+ 1

Ref:..!'l_

o.

9-~

10.2

II

19·5·

1· I

19·5·1 · 2

19·5·1·

1

9·5·1·

1

9·5

·1 · 5

19-5

-1·

19-5-1-17

19-5-119-5-1- 9

19·5·1-10

19·5· 1·

11

19·5-1·12

19-5-1-13

19-5-1-14

19-5-1-15

19-5-1-16

19-5

-1-17

19-5-1-18

19-5-2

19-5-3

19-5·4

19-5-5

19·5

·6

19-5-7

21

22

Thread

P

ipe

Screw

Upper

Tension

3

Thr

ead

4

Spring

Screw 2.38

6

Tension

Ten

sion

8

Tension Di>c

Prcs>

er

Tension

Ten

>ion

Pin

Pin

2.6

Te ns

ion Relea

Sltld

Screw

Pin

Pin

(R)

Ten>ion Relca

Thread

Thread

Thread

Tcn>io n Spring

Prc-

I

Nul

1

Nul

3.57

Arm

Thread Gui

Screw

Na

me

of

Ten

, ion

Releaser

437-40

>.

10

Thr

ead

Ten;i

Sltld

Take-up

Spring

Guide

SIUd

Slud

( R)

for Tensio n Disc

Sprin

g

Comrol NUl

X 20

se Pl

ale

3.57

>e

Sprin

Guide

Sha

Guide

Guide

3.57

fl

Shafl (R)

Di'

e

de (Cemer

Part

s

on Pla1e

g I

( L)

)

o·•

y

Pans No

I 112713-0.01

I 148604·0·

I

062681..0

I

=::::::::::

I

680·0·0

144

I 1

55491·0·0

2

I

08254·0·0

I

144682·0.01

I

I

~

--

4

145446·0·01

2

159805·0·0

2 1

55492·0·0

3 I 08

265·0·0

I

=::::::::::

I

I

144683·0·01

--

2

11271

I 144703·

I

I 158771-0.01

I 158770-0·0 I

4

2 1

2 1

2

I 112658-0.01

I

2·0

1

58769·0·0

118320·0.0

14450-l-0-01

587

82-1·01

555

10·0·01

021670-1·02

1

08960

·12

·01

0·0

·0.02

.

00

I

1

I

I

I

I

I

I

1

ss

embly No.

A

13-19-5

Upper Tension

Conuol A

sse

8764-1..()1

mbl

15

y

C.

Ref. No.

I

2

4

5

6

8

9

10

II

12

13

14

Upper

Obere

Mecani

sha

welle

sme

Mecanisme

Upper

Shafl

Upper Shafl

Screw

5.95

Coumer

Screw

7.14

Screw 7.14

Thrusl Ring

Needle

Bar

Screw

6.35

Screw

6.35

Thread Take-up (for

Tl d T k

uea

a e-up for

Slud

Screw

5.

95

Thread

Take-up Lever

ft

mechanism

de larb

de

Ia eje superi or

12

13

I

Name

of

Part>

Bus

hin

g ( Lefl)

Weigh!

Crank

Slandard·Sl

cor Thread Trimmer)

Slandard·l.·)

rc s

Slide

uperieur

11

Brock

Q' ly

Pans No.

112572-().01

112573·0·01

013761-4-

10

II

2 57 4.().()0

I 00250-0..0 I

146141-0.01

112576..()..()1

112577..()..()1

I 0 170

6-0·0

100251-0-01

140525-0·01

112

578·0·0

112579-0..() 1

013761-4-10

11

817

1-0..() 1

Asse

mbly

No.

Rei: N

o.

15

Pusher

Pulley (for

16

Pu

17

Screw

18

Dearing

19-1

Timing

19·2

I

1

20

21

23

24

25

26

27

Side

Screw

Screw

Timing

Upper

Screw

SlOp

Pusher

Name

of P

art

s

Swndard)

lley

(for

Thread Trimmer)

5.95

620-l

VV

Dell

Whe

el ( U

ppe

r)

Ring

6.35 x 12

6.35 x 12

Bell 1125

Shafl

Dus

hing

(Cenler)

5.95

Ring

(C)

11

1446 14·0·01

158749·0·01

2

013761-1

114680·0·0

013761·4-

112760..0·01

113014-0.01

3024·0·00

·10

86·0·0

10

Assembly No.

C-19

T1m

ing

U

pJl<f

1801 57-0-01

I

I

lleh Wheel

Assembly

3

-

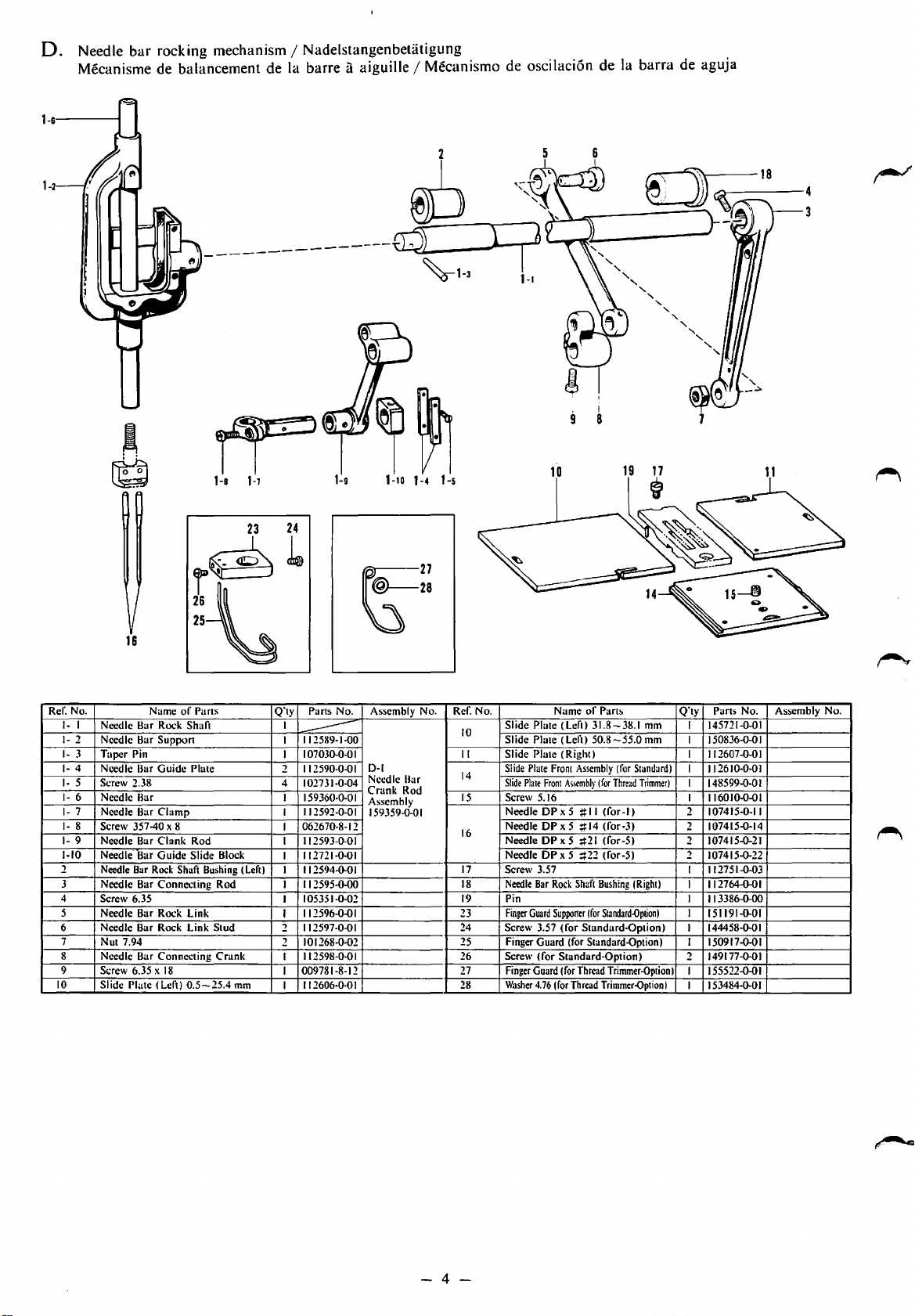

D. Needle

Mecanisme

bar

rocking

de

balancement

mechanism I Nadelstangenbetatigung

de

Ia

barre

a aiguille I

Mecanismo

de

oscilaci6n

9

de

I

8

Ia

barra

de

.

aguja

4

3

~

~

®~

r

26~

25

16

Ref.

No.

1-

I

Needle Bar Rock Shaft I

1-

2

Needle

Taper

-

3

4

Needle Bar Guide

5 Screw

6 Needle Bar

7

Needle

8 Screw 357-40 x 8

9

Needle Bar Clank Rod

10

Needle· Bar Guide Slide Block

2

Needle

3

Needle Bar Connecting Rod

4

Screw 6.35

5 Needle Bar Rock Link

6 Needle Bar Rock Link Stud

1

Nut 7.94

8 Needle Bar Connecting Crank

9 Screw 6.35 x

10

Slide Plate (Left)

Name

Bar Support

Pin

2.38

Bar Clamp

Bar

Rock

Shaft

18

of

Parts

Plate

Bushing

0.5-25.4

~

1-a

1-1

24

23

Q'ty

Parts No. Assembly No.

I

12589-1-00

I

----

I 07030-0-0 I

I

2

112590-0-01

I

027

4

I

159360-0-01

112592-0-01

I

0626

I

I

112593-0-01

112721-0-01

I

(left)

mm

12594-0-0

I

I

I 112595-0-00

I 05351-0-02

I

112596-0-01

I

2

112597-0-01

I 01268-0-02

2

112598-0-01

I

009781-8-12

I

112606-0-0 I

I

~~

1-9

1-10

~21

D-1

Needle

31-0-04

Crank Rod

Assembly

159359-0-01

70-8-12

I

Bar

1-4

28

1-5

Ref.

No. Name

10

II

14

15

16

17

18

19

23

24

25

26

21

28

10

of

Slide Plate (Left) 31.8-38.1

Slide Plate (Left)

Slide Plate

Slide

Plate

Pin

Finger

Finger

Finger

Plare

Bar

Guard

Guard

4.76

From

Fronr

3.57

Rock

3.57

Guard

Slide

Screw 5.16

Needle DP x 5

Needle DP x 5

Needle DP x 5 #21 (for-5)

Needle DP x 5

Screw

Needle

Screw

Screw (for Standard-Option)

Washer

Parts

50.8-55.0mm

(Right)

Assembly

A>seml>ly

Supponer

(for Standard-Option)

(for

(for

(for

(for

(for

Thread

#II

(for-I) 2

#14

(for-3)

#22

(for-5) 2 I 07415-0-22

Shafl

Bushing

(for

SL'Indard.Option)

Srandard-Option) I

Thread

Trimmer-Option)

Thread

Trimmer-Option)

mm

Standard)

Trimmer)

(Right)

Q'ty

I

I

I

I

I

I

2

2

I

I

I

I

I

2

I

I

Parts No.

145721-0-01

150836-0-0 I

112607-0-01

12610-0-0

I

148599-0-0

116010-0-01

107415-0-11

107415-0-14

107415-0-21

112751-0-03

112764-0-01

113386-0-00

151191-0-01

144458-0-01

150917-0-01

149177-0-01

155522-0-01

153484-0-01

11

Assembly No.

I

I

-

4-

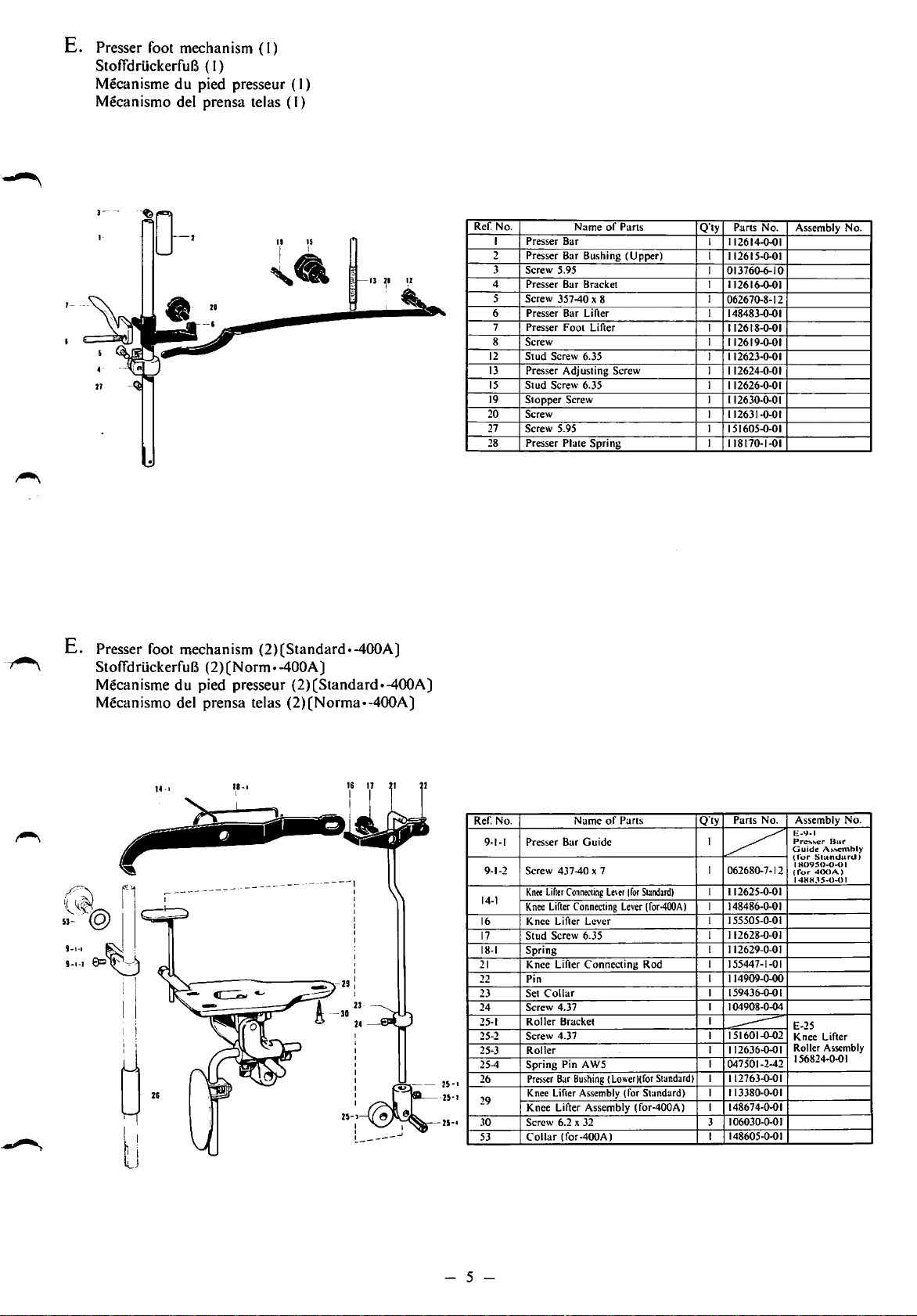

E.

Presser foot mechanism

StoffdrUckerfuB

Mecanisme

(I)

du

pied presseur ( I)

Mecanismo del prensa telas

1--

(I)

(I)

i

01

Ref.

No.

I

Presser Bar

2

Presser

Screw

3

Presser

j'

4

5

Screw 357-40 x 8

Presser

6

Presser

7

Screw

8

12

Stud Screw 6.35 I 12623-0-0 I

13

Presser

15

Stud Screw

19

Stopper

Screw

20

27

Screw

28

Presser Plate Spring

Name

of

Parts Q'ty

Bar

Bushing (Upper)

5.95

Bar Bracket

Bar

Lifter

Foot Lifter

Adjusting Screw

6.35 I 12626-0-0 I

Screw

5.95

Parts No.

112614-0-01

112615-0-01

013760-6-10

112616-0-01

0626

70-8-12

148483-0-0 I

112618-0-01

112619-0-01

12624-0-0

I

112630-0-0

112631-0-01

151605-0-01

118170-1-01

Assembly No.

I

I

E.

Presser foot mechanism

StoffdrUckerfuB

Mecanisme

(2)(Norm·-400A)

du

pied presseur

Mecanismo del prensa telas

t4-1

9-1-1

9-1-1

-----------29

(2)(Standard·-400A)

(2)(Standard·-400A)

(2)(Norma·-400A)

--------1

I

I

I

I

I

I

I

I

I

I

I

:

23

--30

24

25-l

1 25-t

l------'

25

·25-1

Q'ty

Ref.

No.

9-1-1

Presser Bar Guide

9-1-2

Screw 437-40 x 7

Knee

14-1

Knee

Knee Lifter Lever

16

Stud Screw 6.35

17

Spring

18-1

21

22

23

24

25-1

-·

Knee Lifler Connecting Rod

Pin

Set

Screw

Roller Bracket

25-2

Screw

25-3

Roller

Spring Pin

25-4

Presser

26

Knee

29

Knee Lifter Assembly (for-400A)

Screw

30

Collar (for-400A) I

53

Lifter

Lifter

Collar

4.37

4.37

Bar

Lifter

6.2

Name

of

Connec1ing

Le\er

Connecting

AW5

Bushing

(lower)(

Assembly

x

32

Parts

(for

Lever

(for

Slandard)

(for-400A)

for

Standard)

Standard)

Parts No. Assembly No.

I

~

062680-7-12

112625-0-01

148486-0-0 I

155505-0-01

112628-0-0 I

I 12629-0-0 I

155447-1-01

114909-0-00

159436-0-01

I 04908-0-04

151601-0-02

------

112636-0-0

047501-2-42

112763-0-01

113380-0-01

148674-0-01

I 06030-0-0 I

3

148605-0-01

E-9-1

Pr.,,..c:r

Guide A ...

(lor

I

K09SO-O-OI

(for

14KK.'S-O-OI

E-25

Knee Lifter

Roller

I

156824-0-0 I

Uur

....:mbly

Standard

400A)

Assembly

•

-

5-

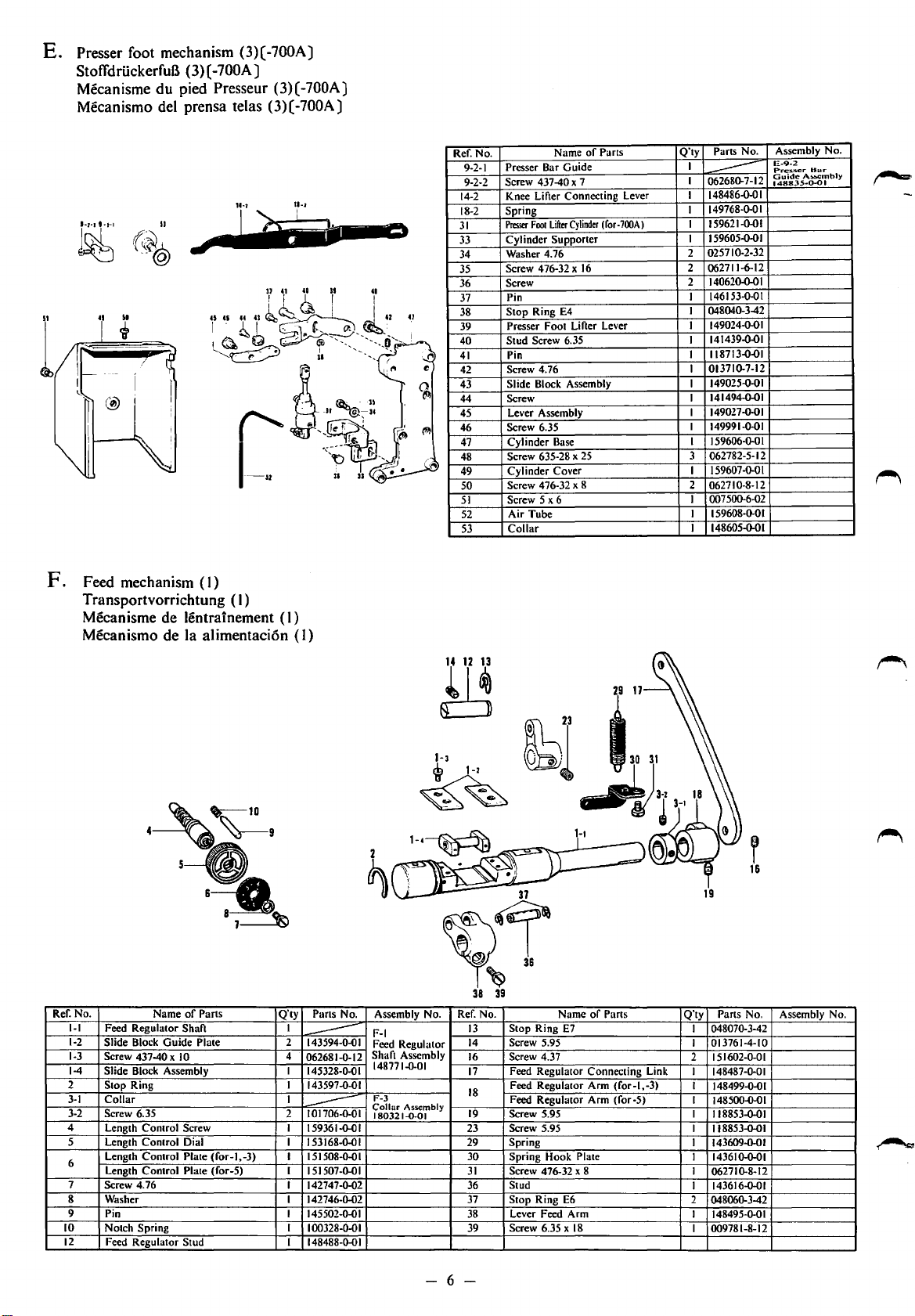

E. Presser foot mechanism (3)(-700A)

StoffdrlickerfuB

Mecanisme du pied Presseur (3)(-700A)

Mecanismo del prensa telas (3)(-700A)

(3)(

-700A)

l

F. Feed mechanism

Transportvorrichtung

Mecanisme de lentrainement

Mecanismo de

(I)

(I)

Ia

alimentaci6n

(I)

(I)

Ref. No.

9-2-1

9-2-2

14-2

18-2

31

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

Name

of

Presser Bar

Screw 437-40 x 7

Knee Lifter Connecting Lever

Spring

Presser

Fool

Lifter

Cylinder

Supporter

Washer 4.76

Screw

476-32 x

Screw

Pin

Stop

Ring

Foot

Presser

Stud

Screw 6.35

Pin

Screw

4.76

Block Assembly

Slide

Screw

Lever Assembly

6.35

Screw

Cylinder

635-28 x

Screw

Cylinder

Screw

476-32 x 8

5 x 6

Screw

Air

Tube

Collar

Guide

Cylinder

16

E4

Lifter Lever

Base

25

Cover

Parts

(for-700A)

Q'ty

I

I

I

I

I

I

2

2

2

I

I

I

I

I

I

I

I

I

I

I

3

I

2

I

I

I

062680-7-12

148486-0-01

149768-0-01

159621-0-01

159605-0-0 I

025710-2-32

062711-6-12

140620-0-01

146153-0-01

048040-3-42

013710-7-12

062782-5-12

06271 0-8-12

007500-6-02

Parts No.

----

149024-0-01

141439-0-01

118713-0-01

149025-0-01

141494-0-01

149027-0-01

149991-0-0 I

159606-0-01

159607-0-01

159608-0-0 I

148605-0-0 I

Assembly

E-9-2

Presser

Guide

Assembly

148835-o-ol

No.

Hur

Ref. No. Name

1-1

Feed Regulator Shaft

1-2

Slide Block

1-3

Screw 437-40 x 10

1-4

Slide Block Assembly I

2

Stop

3-1

3-2

4

Ring

Collar

Screw 6.35

Length

5 Length

Length

6

Length

7 Screw 4.76

8

Washer I

9

Pin I

10

Notch

12

Spring

Feed Regulator Stud I 148488-0-0 I

of

Parts

Guide

Plate

Control

Screw I

Control

Dial I 153168-0-01

Control

Plate (for-1,-3)

Control

Plate (for-5) I

Q'ty

Parts No.

I

2

143594-0-01

----

4

062681-0-12

145328-0-01

I 143597-0-01

I

2

101706-0-01

----

159361-0-01

I 151508-0-0 I

151507-0-01

I

142747-0-02

142746-0-02

145502-0-01

I

I

00328-0-0 I

Assembly No. Ref. No.

F-1

Feed Regulator

Shaft Assembly

148771-0-01

F-3

Collar

Assembly

180321-0-01

13

14

16

17

18

19

23

29

30

31

36

37

38

39

Stop

Screw

Screw

Feed Regulator

Feed

Feed Regulator

Screw

Screw

Spring

Spring

Screw

Stud

Stop

Lever Feed

Screw

Name

Ring

E7

5.95

4.37

Regulator

5.95

5.95

Hook

476-32 x 8

Ring

E6

Arm

6.35 x

-6-

of

Connecting

Arm

Arm

Plate

18

Parts

(for-1,-3)

(for-5)

Link

f

16

Q'ty

Parts No. Assembly No.

048070-3-42

I

013761-4-10

I

2

151602-0-0 I

I

148487-0-01

I

148499-0-01

I

148500-0-01

I

118853-0-01

118853-0-01

I

143609-0-0 I

I

I 143610-0-01

I

062710-8-12

I 143616-0-01

2

048060-3-42

I 148495-0-01

I 009781-8-12

Loading...

Loading...