Page 1

BRDR250TECH

Technical Instructions Machine Compatibility OEM Info Tools 1

rother DCP-1000

C

ORPORATE

LOS ANGELES, USA

US 1 800 394.9900

Int’l +1 818 837.8100

FAX 1 800 394.9910

I

nt’l +1 818 838.7047

ATLANTA, USA

US 1 877 676.4223

Int’l +1 770 516.9488

FAX 1 877 337.7976

I

nt’l +1 770 516.7794

DALLAS, USA

US 1 877 499.4989

Int’l +1 972 840.4989

FAX 1 877 774.1750

Int’l +1 972 840.1750

MIAMI, USA

US 1 800 595.429

Int’l +1 305 594.3396

FAX 1 800 522.8640

Int’l +1 305 594.3309

NEW YORK, USA

US 1 800 431.7884

Int’l +1 631 345.0121

FAX 1 800 431.8812

Int’l +1 631345.0690

SANFORD,USA

US 1 800 786.9049

Int’l +1 919 775.4584

FAX 1 800 786.9049

Int’l +1 919 775.4584

TORONTO, CAN

CAN 1 877 848.0818

Int’l +1 905 712.9501

FAX 1 877 772.6773

l +1 905 712.9502

’

t

In

BUENOS AIRES, ARG

G 0810 444.2656

AR

Int’l +011 4583.5900

AX +011 4584.3100

F

MELBOURNE, AUS

US 1 800 003. 100

A

Int’l +62 03 9561.8102

FAX 1 800 004.302

Int’l +62 03 9561-7751

SYDNEY, AUS

US 1 800 003.100

A

Int’l +62 02 9648.2630

FAX 1800 004.302

’l +62 02 9548.2635

t

In

MONTEVIDEO,URY

URY 02 902.7206

Int’l +5982 900.8358

FAX +5982 908.3816

JOHANNESBURG, S.A.

S.A. +27 11 974.6155

FAX +27 11 974.3593

B

Brother Fax 8070 P

rother IntelliFAX-2800

B

Brother IntelliFAX-2900

Brother IntelliFAX-3800

Brother MFC-4800

Brother MFC-6800

Brother MFC-9030

Brother MFC-9070

Brother MFC-9160

rother MFC-9180

B

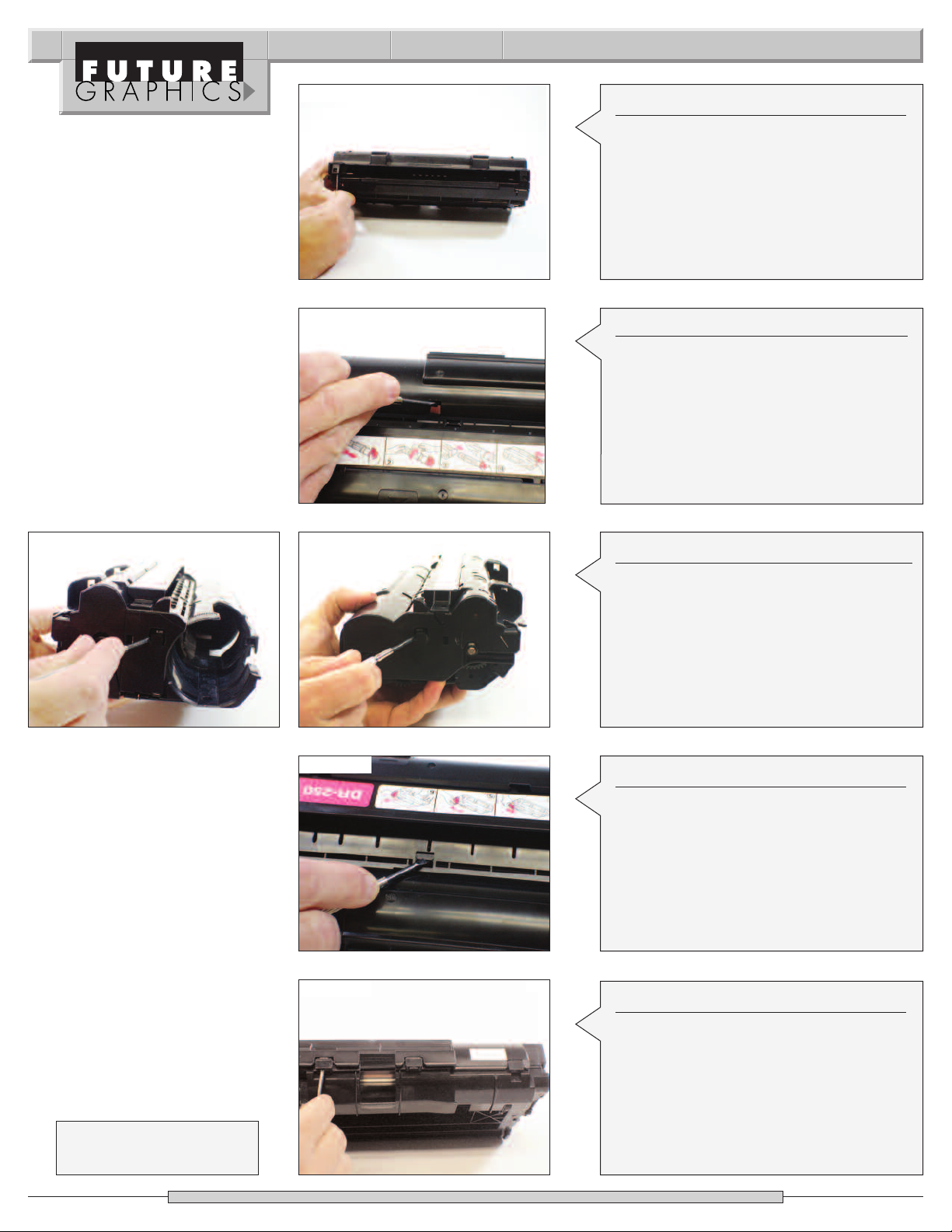

Photo 1

Photo 2

hoto 3

P

Part Number: DR-250

Yield @ 20,000 pgs

Pages/Min.: 6

Resolution: 600x600 dpi

ep 1

St

Remove the two Philip screws from the

top of the drum unit.

(See Photo 1)

Step 2

Locate the two locking tabs on the top of

the cartridge. (See Photo 2) Using a small

flat blade screw driver, squeeze the legs

of the two inserts together. These inserts

prevent the lock tabs on the top of the

cartridge from being released.

(See Photo 3) Remove the inserts.

NNOOTTEE:

the removal process, be careful not to

lose the inserts as they will need to be

reinstalled.

:

These inserts can go flying during

Phillips Screwdriver

mall flat blade Screwdriver

S

SSuupppplliieess RReeqquuiirreedd:

:

Cotton Swab

99% Alcohol

Replacement Drum

E-mail: info@futuregraphicsllc.com Website: www.futuregraphicsllc.com

Page 2

2 Brother DR-250 Technical Instructions

Photo 4

Photo 5

Photo 6 Photo 7

Step 3

Step 3: Using a small flat blade screwdriver, release the two locking clips on the

back of the cartridge. (See Photo 4)

Step 4

Next to the locking tabs located on the

top of the cartridge there are two slots

were you can see the metal toner filling

cover. Using a screwdriver push the cover

down (towards the drum) till the guide

tab is exposed.

(See Photo 5)

Step 5

Release the locking tabs on both sides of

the cartridge.

o 8

hot

P

Photo 9

(See Photo 6 & 7)

Step 6

Using a flat blade screwdriver release

o locking tabs from the top of the

w

the t

cartridge.

(See Photo 8)

Step 7

Step 7: Release the three locking tabs

om the fr

fr

(See Photo 9)

ont of the cartridge.

Need trustworthy, detailed Technical

Instructions for another engine?

Visit: www.futuregraphicsllc.com

Page 3

Brother DR-250 Technical Instruction 3

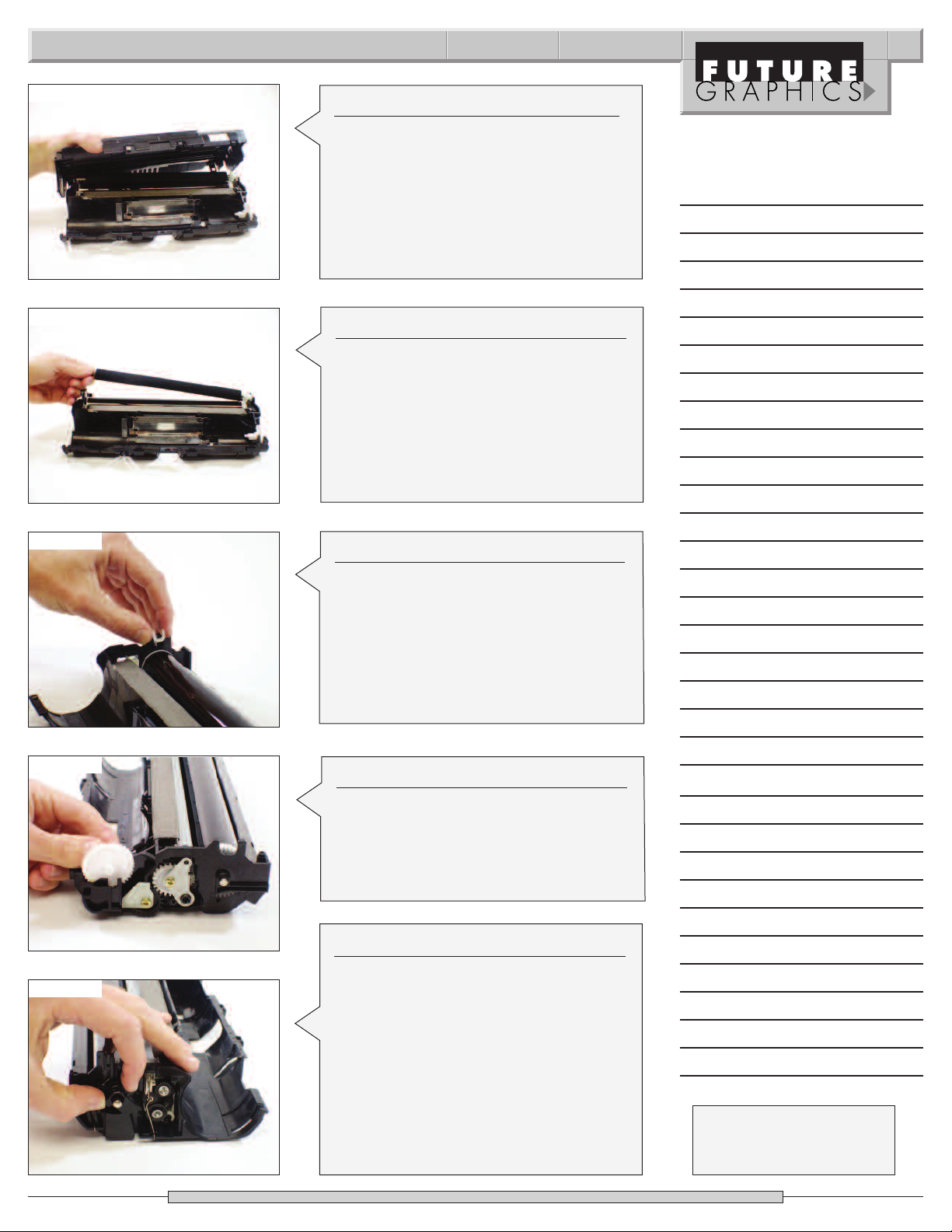

Photo 10

Step 8

Lift the top cover of the cartridge to

separate the two sections.

See Photo 10)

(

Notes

Photo 11

Photo 12

o 13

hot

P

Step 9

Lift the transfer roller away from the

drum.

(See Photo 11) Clean the transfer

roller using dry compressed air.

Step 10

Remove the white transfer roller saddle

from the non-gear side of the cartridge.

(See Photo 12)

Step 11

Remove the toner agitator drive gear

from the side of the cartridge.

Photo 14

(See Photo 13)

Step 12

Rotate the drum locking hub counter-

ckwise and remove the hub from the

clo

um axle

dr

(See Photo 14)

.

N

eed help with a particular remanu-

facturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

Page 4

4 Brother DR-250 Technical Instructions

Notes

Photo 15

Photo 16

Photo 17

Step 13

lide the drum axle out from the drum.

S

(See Photo 15)

Step 14

Lift out the drum from the cartridge.

Remove the gray drive gear from the end

of the drum. (See Photo 16)

NNOOTTEE:

:

The drive gear will need to be used

with the new drum. It is important not to

lose the gear.

Step 15

Remove the Philips screw holding the

metal gear housing end plate on the side

of the cartridge.

o 18

hot

P

Photo 19

(See Photo 17)

Step 16

elease the two locking tabs that hold

R

the gear housing end pla

e in place

t

.

(See Photo 18)

.

e

emo

R

e the gear housing end pla

v

t

Step 17

Remove the large white gear and the

developer roller drive gear from the end

.

idge

tr

of the c

(See Photo 19)

ar

Need trustworthy, detailed Technical

Instructions for another engine?

Visit: www.futuregraphicsllc.com

Page 5

Brother DR-250 Technical Instruction 5

Photo 20

Photo 21

Photo 22

Step 18

Remove the metal developer roller bearing from the gear side of the cartridge.

See Photo 20)

(

Step 19

Move the developer roller contact bar to

the side.

(See Photo 21 & 22)

Notes

o 23

hot

P

Photo 24

ep 20

St

Move the drive gear end of the developer

roller out and slide the roller away from

the contact end.

(See Photo 23)

Step 21

Remove the gear and the metal developer

earing from the contact side of the

oller b

r

.

oller

r

(See Photo 24)

N

eed help with a particular remanu-

facturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

Page 6

6 Brother DR-250 Technical Instructions

Notes

Photo 25

Photo 26

Photo 27

S

tep 22

Carefully remove the developer roller.

(See Photo 25)

Clean the cartridge using dry compressed

air or a vacuum.

Step 23

Remove the bearing and spring from the

end of the developer roller.

Clean the roller using a dry lint free cloth.

NNOOTTEE:

:

Visually inspect the developer

rollers. These rollers usually have a lot of

wear and maybe unusable for a second

cycle.

(See Photo 26)

Step 24

Clean the doctor blade using a cotton

swab and Acetone.

Photo 28

o 29

hot

P

(See Photo 27)

Step 25

Place the spring and bearing onto the

developer roller. Install the developer

roller back into the cartridge.

(See Photo 28)

ep 26

St

Install the developer roller bearing that’s

has the smaller ID and the small gear

onto the roller axle on the contact side.

(See Photo 29)

E-mail: info@futuregraphicsllc.com Website: www.futuregraphicsllc.com

Page 7

Brother DR-250 Technical Instruction 7

Photo 30

Photo 31

Photo 32

S

tep 27

Pull the drive gear end of the developer

roller out of the cartridge again. Install the

ontact end gear onto the developer

c

roller axle. Place the contact bar back onto

the developer roller.

(See Photo 30)

Step 28

Install the developer roller bearing, drive

gear and the large white gear onto the

end of the cartridge. Place the metal gear

housing end plate onto the cartridge and

install the screw that holds the end plate

in place.

(See Photo 31)

ep 29

St

Clean the corona wire using a cotton

swab and alcohol.

Notes

Photo 33

hoto 34

P

(See Photo 32)

ep 30

St

lace the drive gear ont

P

t

install the dr

(See Phot

um in

o 33)

o the drum and

o the c

ar

tr

idge

.

Step 31

Slide the drum axle through the drum

starting on the contact side. Install the

drum axle locking hub onto the drum

. Rotate the hub clock-wise to lock the

axle

hub in position.

(See Photo 34)

N

eed help with a particular remanu-

facturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

Page 8

8 Brother DR-250 Technical Instructions

Photo 35

Photo 36

Photo 37

Step 32

Install the white transfer roller saddle

onto the contact side of the cartridge.

lace the transfer roller into position,

P

atop of the drum.

(See Photo 35)

Step 33

Place the toner agitator gear onto the

cartridge.

(See Photo 36)

Step 34

Place the top of the section of the

cartridge onto the bottom. Press down

till the top of the cartridge snaps into

place.Install the two screws that hold the

lid in place.

(See Photo 37)

RREESSEETTTTIINNGG TTHHEE DDRRUUMM CCOOUUNNTTEER

R

Step 1

Install the jagged end of the clear

reset sheet into the cartridge

between the drum and transfer

roller.

(See Photo 1)

Photo 1

Step 2

Rotate the drum so the reset sheet

is fed into the cartridge and the end

of the sheet is flush with the end of

the cartridge with the jagged end

of the sheet sticking out the top of

the cartridge.

(See Photo 2)

Photo 38

Photo 39

ep 35

St

Install the two inserts into the two locking taps on top of the cartridge.

(See Photo 38)

NNOOTTEE:

:

The two legs on the inserts will

face up away from the locking tabs.

ep 36

St

Slide the toner fill cover plate up so the

top of the plate covers the guide tads

on the t

op section of the cartridge.

(See Photo 39)

ep 37

St

Insert toner cartridge and test.

NNOOTTEE:

:

Once the sheet is f

ed

through the printer, the machine

will reset the drum counter.

Photo 2

Need help with a particular remanufacturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

Page 9

Brother DR-250 Technical Instruction 9

Remanufacturing the Brother DR-250

his new family of multifunction

T

machines was released to replace the

now discontinued Brother HL 720. Like

the HL720, these of machines use separate drum and toner units. Similar looking in appearance to the DR200, the new

DR-250 uses different drum gears and

employs molding differences in the cartridge prevents the cartridges from

being interchangeable.

However, the same problems that

haunt the DR-200 also plague the DR-250.

treaking caused by worn developer

S

rollers is a common problem with these

drum units. Careful visual inspection of

the developer roller is important to producing a quality product.

As with most new releases, an

improvement to the engines performance was accomplished by increasing

the printers speed to 10 pages per

minute while maintaining the same 600

x 600dpi print resolution.

DR-250

None of FG's products are genuine OEM replacement parts and no affiliation or sponsorship is to be implied between FG and any OEM.

Future Graphics (FG) is a distributor of compatible replacement parts and products for imagining equipment.

Loading...

Loading...