Brother DDL-8700 Instruction Manual

ENGLISH

DDL-8700

INSTRUCTION MANUAL

i

CONTENTS

1. SPECIFICATIONS .......................................................................................................1

2. INSTALLATION ..........................................................................................................1

3. INSTALLING THE BELT COVER AND THE BOBBIN WINDER ...............................2

4. ADJUSTING THE HEIGHT OF THE KNEE LIFTER ..................................................2

5. INSTALLING THE THREAD STAND ..........................................................................3

6. LUBRICATION ............................................................................................................3

7. ADJUSTING THE AMOUNT OF OIL (OIL SPLASHES) IN THE HOOK ....................4

8. ATTACHING THE NEEDLE ........................................................................................5

9. SETTING THE BOBBIN INTO THE BOBBIN CASE ..................................................5

10. ADJUSTING THE STITCH LENGTH ..........................................................................5

11. PRESSER FOOT PRESSURE ....................................................................................6

12. HAND LIFTER .............................................................................................................6

13. ADJUSTING THE HEIGHT OF THE PRESSER BAR ................................................6

14. THREADING THE MACHINE HEAD ..........................................................................7

15. THREAD TENSION .....................................................................................................8

16. THREAD TAKE-UP SPRING ......................................................................................8

17. ADJUSTING THE THREAD TAKE-UP STROKE .......................................................8

18. NEEDLE-TO-HOOK RELATIONSHIP ........................................................................9

19. HEIGHT OF THE FEED DOG .....................................................................................9

20. TILT OF THE FEED DOG .........................................................................................10

21. ADJUSTING THE FEED TIMING ..............................................................................10

22. ADJUSTING THE FEED TIMING (DDL-8700L) .......................................................11

23. MOTOR PULLEYS AND BELTS ..............................................................................12

i

1. SPECIFICATIONS

Application

Sewing speed

Stitch length

Needle

Presser foot lift (by knee lifter)

Lubricating oil

Noise

Application

Sewing speed

Stitch length

Needle

Presser foot lift (by knee lifter)

Lubricating oil

Noise

DDL-8700

General fabrics, light-weight

and medium-weight materials

Max. 5,500 sti/min

Max. 5 mm

DB x 1 #9 to #18 (134 #65 to #110)

10 mm (Standard) 13 mm (Max.)

- Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 83.5 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.2 -ISO 11204

GR2 at 5,000 sti/min.

- Sound power level (LWA) ;

A-weighted value of 88.0 dB; (Includes KWA = 2.5 dB); according to ISO 10821- C.6.2 -ISO 3744

GR2 at 5,000 sti/min.

3,000 sti/min

- Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 83.5 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.2 -ISO 11204

GR2 at 5,000 sti/min.

- Sound power level (LWA) ;

A-weighted value of 88.0 dB; (Includes KWA = 2.5 dB); according to ISO 10821- C.6.2 -ISO 3744

GR2 at 5,000 sti/min.

Ge nera l fabri s, light -wei ght

materials

DA x 1 #9 to #11 (134 #65 to #75)

Max. 4,000 sti/min (for feed pitch of 5 mm or less)

Max. 3,200 sti/min (for feed pitch of 5 mm or more)

DB x 1 #20 to #23 (DP x 5 #16 to #18)

DDL-8700A

Max. 4,000 sti/min

Max. 4 mm

9 mm (Max.)

JUKI New Defrix Oil No. 1

DDL-8700L

For heavy-weight materials

Max. 7 mm

13 mm (Max.)

JUKI New Defrix Oil No. 1

DB x 1 #20 to #23 (134 #125 to #160)

10 mm (Standard) 13 mm (Max.)

DDL-8700H

Medium-weight materials,

heavy-weight materials

Max. 4,000 sti/min

Max. 5 mm

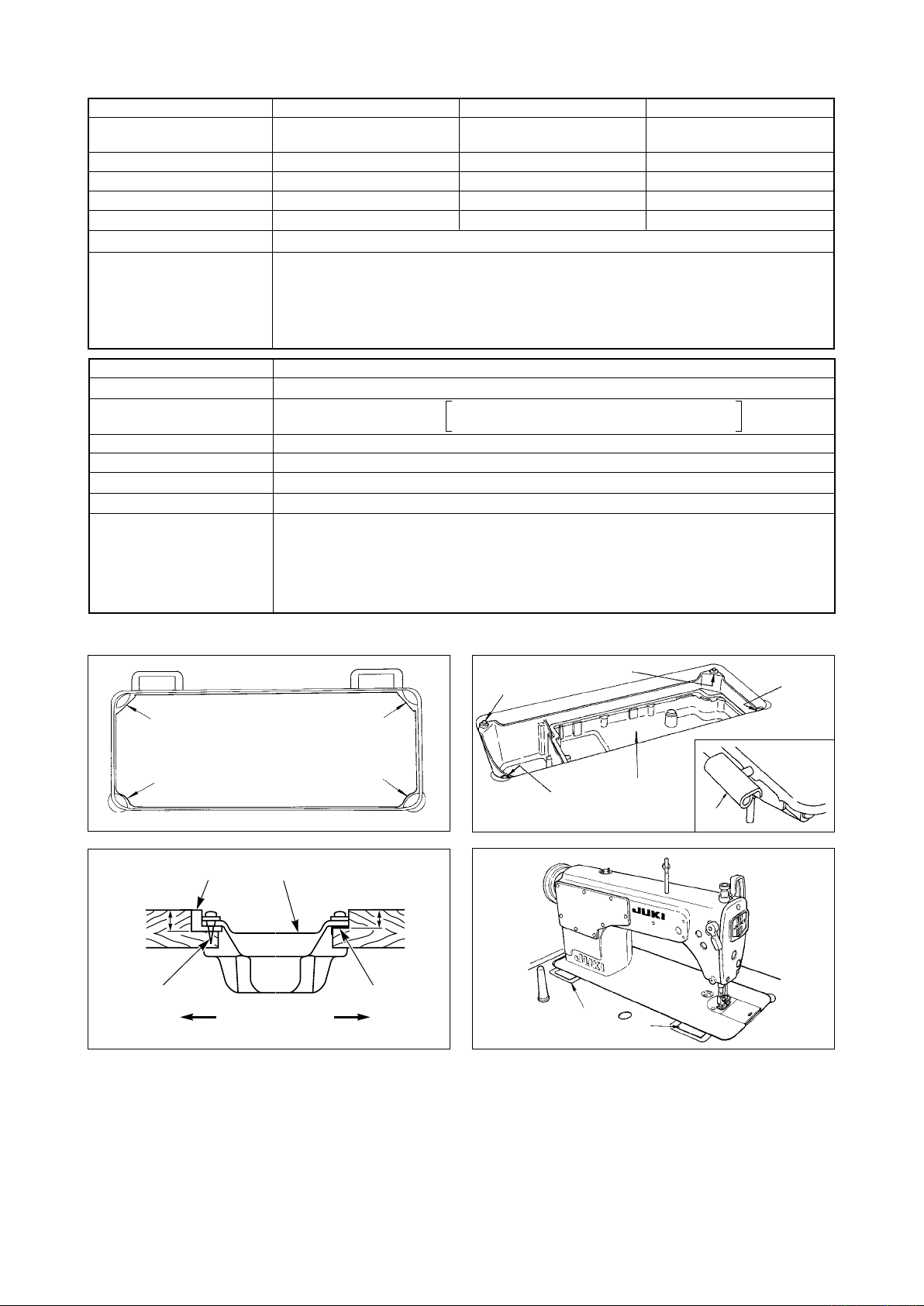

2. INSTALLATION

3

3

3

1

1

4

22.5 mm

2

A

B

(1) Installing the under cover

1) The under cover should rest on the four corners of the machine table groove.

2) Two rubber seats

portion of the table by hitting the nail 2 , and the other two rubber cushion seats 3 on the hinge side

are xed by using a rubber-based adhesive. Then, oil pan 4 is placed.

B

3) Fit hinge

into the opening in the machine bed, and t the machine head to table rubber hinge 2 be-

1

fore placing the machine head on cushions 3 on the four corners.

for supporting the head portion on the operator side A are xed on the extended

1

3

1

18.5 mm

3

3

4

1

2

1

3

– 1 –

– 2 –

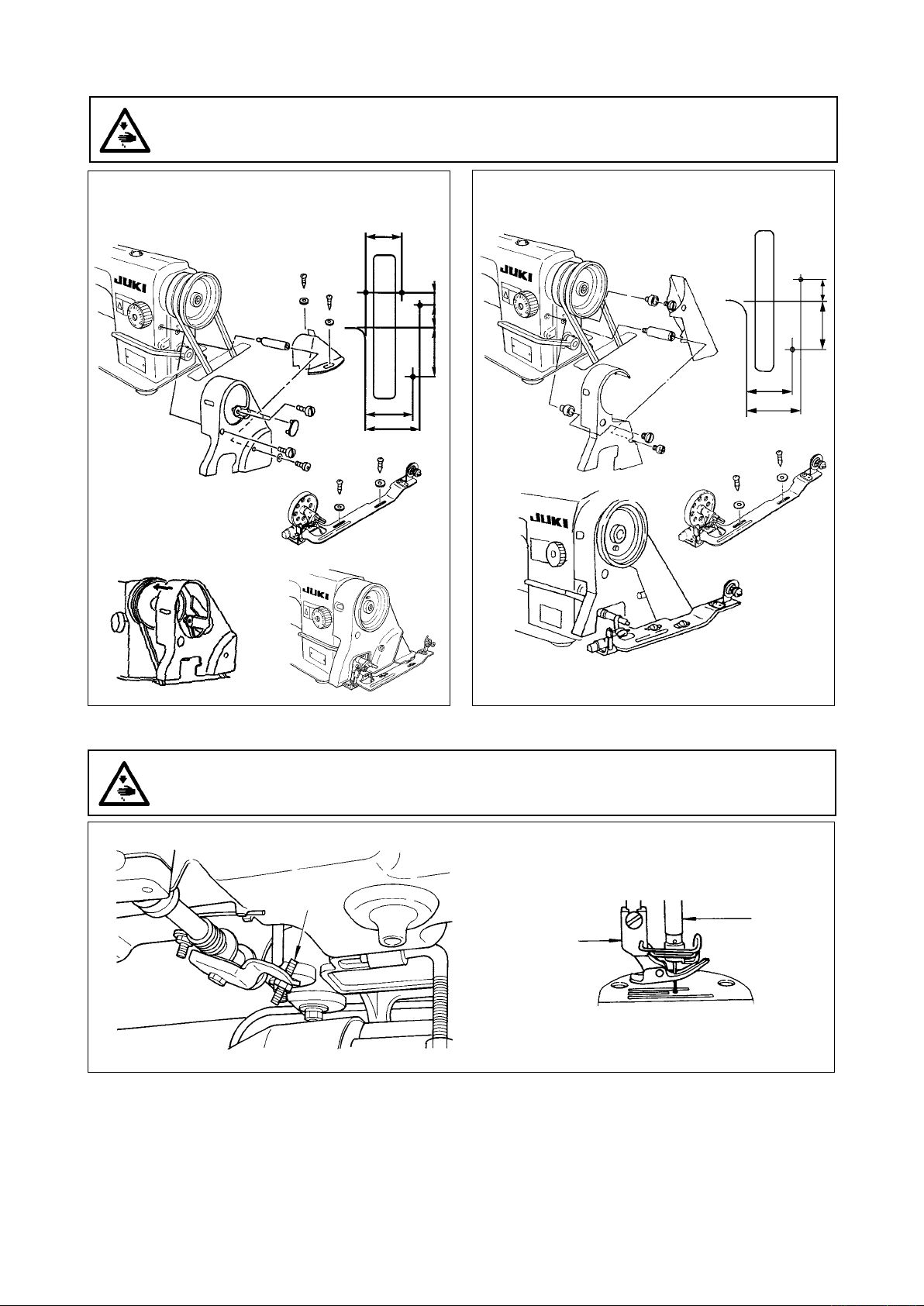

3. INSTALLING THE BELT COVER AND THE BOBBIN WINDER

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

47

63.5

75.5

(mm)

(DDL-8700L)

33

62

(mm)

33

62

63.5

75.5

4. ADJUSTING THE HEIGHT OF THE KNEE LIFTER

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

2

3

1) The standard height of the presser foot lifted using the knee lifter is 10 mm.

2) You can adjust the presser foot lift up to 13 mm using knee lifter adjust screw 1. (Max. 9 mm for A type)

3) When you have adjusted the presser foot lift to over 10 mm, be sure that the bottom end of needle bar

in its lowest position does not hit presser foot 3.

2

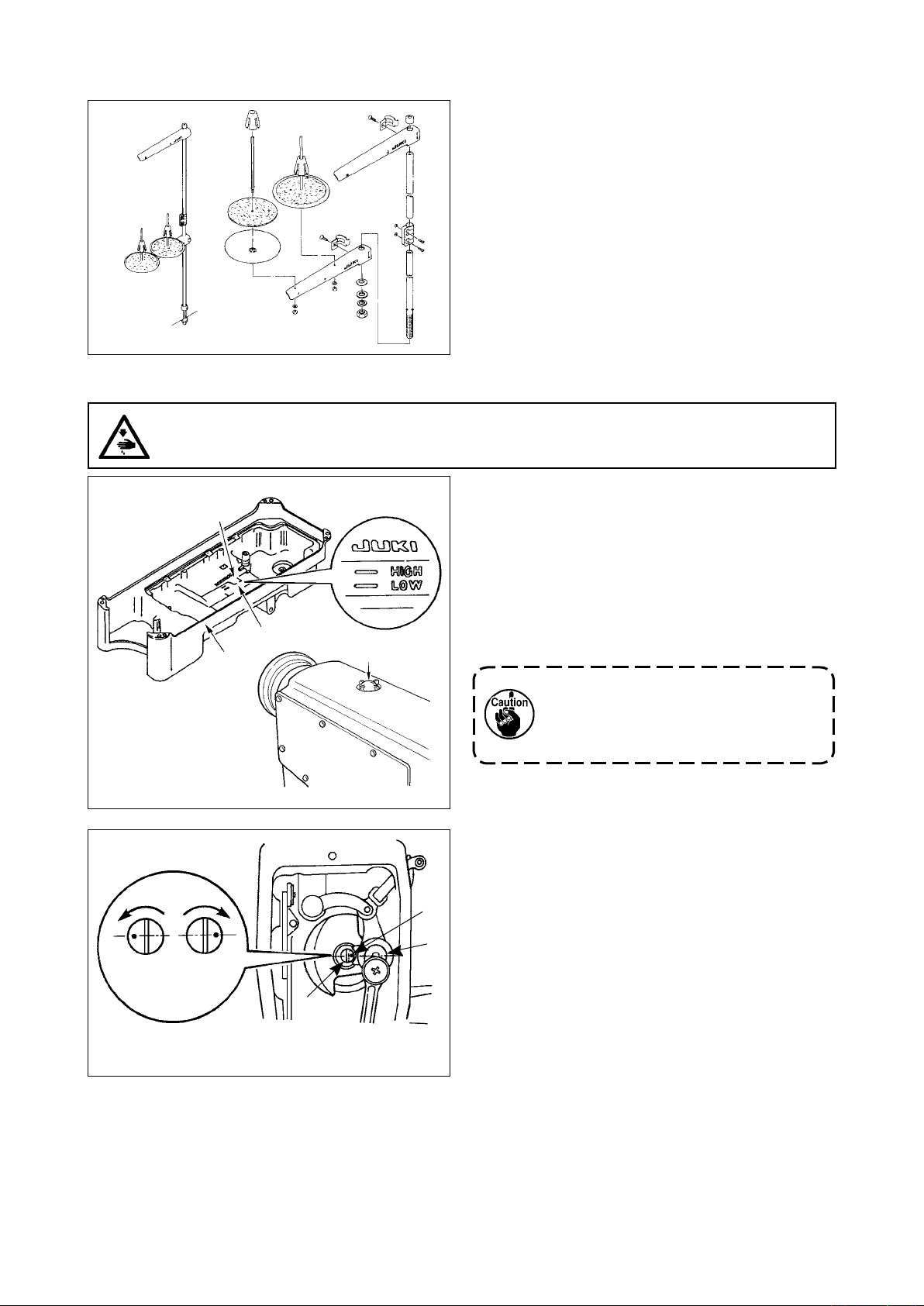

5.

INSTALLING THE THREAD STAND

6. LUBRICATION

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

A

B

1

2

(1) Information on lubrication

1) Fill oil pan 1 with JUKI New Defrix Oil No. 1 up

to HIGH mark A.

2) When the oil level lowers below LOW mark B,

rell the oil pan with the specied oil.

3) When you operate the machine after lubrication,

you will see splashing oil through oil sight window

if the lubrication is adequate.

2

4) Note that the amount of the splashing oil is unre-

lated to the amount of the lubricating oil.

When you rst operate your machine after setup or after an extended period of

disuse, run your machine at 3,000 sti/min.

for about 10 minutes for the purpose of

break-in.

C

maximum

B

1

minimum

1

A

(2)

Adjusting the amount of oil supplied

to the face plate parts

1) Adjust the amount of oil supplied to the thread

take-up and needle bar crank 2 by turning adjust

pin 1.

2) The minimum amount of oil is reached when

2

– 3 –

marker dot A is brought close to needle bar

crank 2 by turning the adjust pin in direction B.

3) The maximum amount of oil is reached when

marker dot A is brought to the position just opposite from the needle bar crank by turning the

adjust pin in direction C.

Loading...

Loading...