Page 1

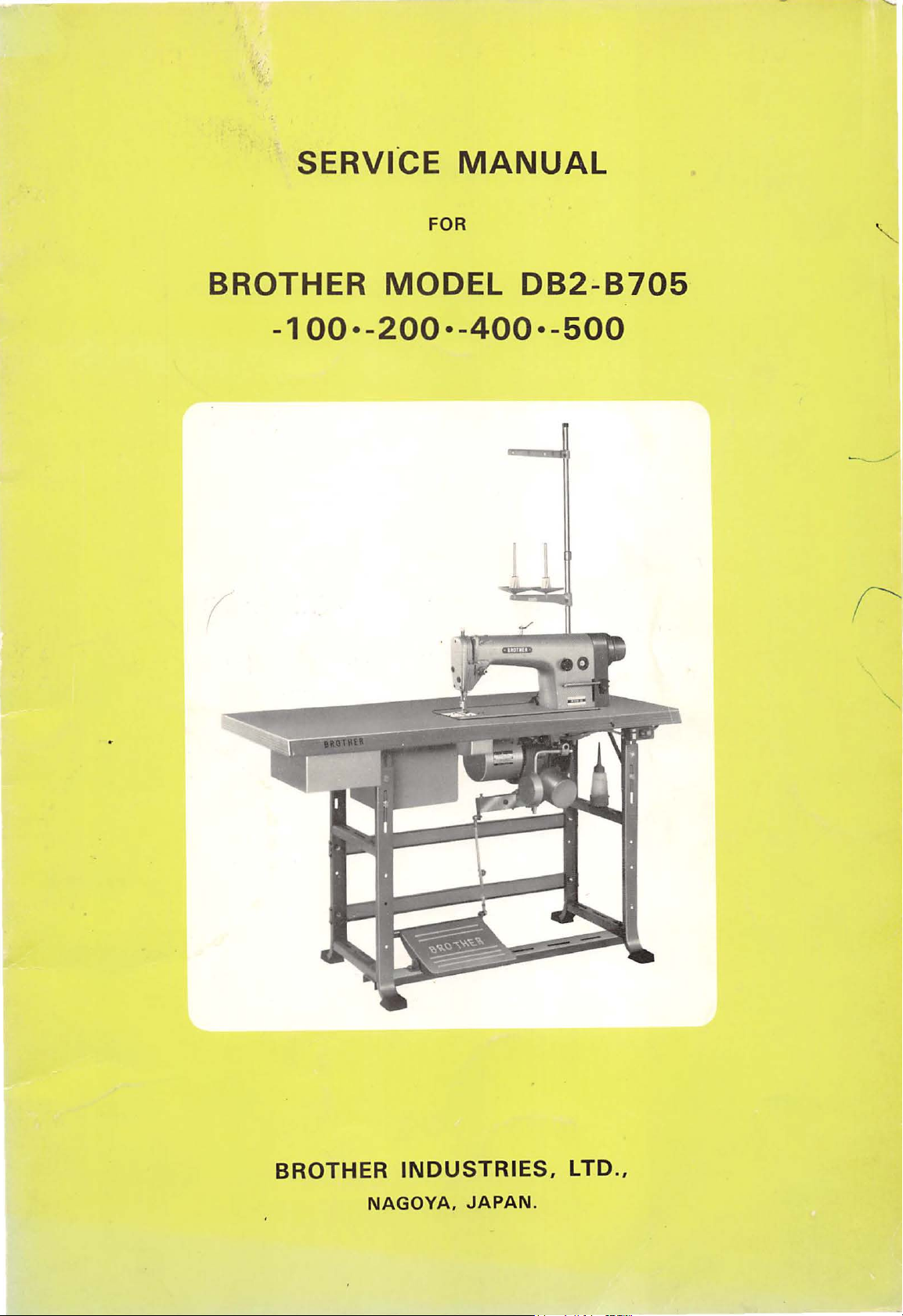

SERVfCE

MANUAL

BROTHER

-1

00·-200·-400·-500

(

FOR

MODEL

DB2-B705

\

r

----

BROTHER

INDUSTRIES,

NAGOYA,

JAPAN

.

LTD.,

Page 2

PREFACE

Thi

s service manual is

tr

imm

er seri

es,

Norma

l troubl

es occur

made

BROTHER

in your

for the

Model 082-8705-100 Series .

sew

purpo

se

of getting

ing room will be solved wi

acquai

nted with our newly designed

th

the knowledge

of instruction manual

thread

encl osed

this

knowled

Incide

however, if you u

We sincerely hop e th

pamphlet.

with th

se

rvi

ce

ge on this machine by this servi

ntall

e machine, however,

manual ma

y,

this

covers

se

y be helpful for you r

the description on

with ot

at

you wi

her bran's, pi

ll

overco

in order

ce

manual

our

ease

me the

to

get

much m

bette

r ma intenance. We duly h

as well

newly developed

refer to one

tro

ubles which

ore perfect

as instruction

BROTHER

published by

may ari

BROTHER INDUSTR

knowledge

manuals

Needle Positioning Motor,

tho

se

manufa

se

in

ope

and

your

on

this machine,

that

you

parts catalog

cture

r.

factory wi

IES,

get full

ues.

th

this

LTD

.

Page 3

CONTENTS

1.

Features.......................................................................................................................... 1

2.

Specifications................................................................................................................... 2

3.

N arne of major components.............................................................................................. 3

4.

Thread trimming mechanism............................................................................................. 3

5.

Construction chart of Brother

6.

Electric circuits................................................................................................................ 9

7.

Setting

8.

Test running ...................................................................................................................

9.

Sewing tensions................................................................................................................

10.

Adjusting

up

the machine . .. .. .. . .. . . . . . . . . . . .. .

on

sewing machine . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . .

N.

P.

Motor . .. .

..

. . . . . .

..

. .. .. .. . . . .. . .. . .. .. .. . .. .. .. .. . ... . . . .. .. . .

..

.. . . . . . . . . . . .. . . . . . . . . . . . .. . .. .. . .. . . . . . . . . .. . . . .

..

. . . . . . . . . . . . . . . .. .. . . . . . . . . . . . . .

..

. ..

..

..

. . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . .. . . . . . . . . . .. . . . . . . .

..

..

. . . 8

13

17

18

20

(1) Adjusting thread trimming mechanism ..........................................................................

(2)

Adjusting tension releaser . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . .

(3)

Adjusting thread wiper ................................................................................................

(4)

Adjusting qichback device ............................................................................................

(5)

Adjusting presser lifter ................................................................................................

(6)

Adjusting synchronizer .................................................................................................

11.

Adjusting motor ...............................................................................................................

12.

Maintenance of motor . . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .. .. . . . . . . . . . . .. . . . . . . . . .. . . . . . . .. . . . . . . . . .

13.

Trouble shooting . . . . . . . . . . . . . . . .. . . . . . . . . . .

(1)

In relation with the sewing machine bead.....................................................................

(2)

In relation with control box and

..

. . .

..

. .. . . . . .. . . . . . . . . . . . . . . . .

N.

P.

Motor

.. ..

..

. . . . .. . . . . . . . . . . . . . . . .

..

..

.. . ..

..

.. .. .. . . ..

..

.. . .. .. .. .

..

. . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . . . . . . . . . . .. .. . . . . . . .

..

.. .. .. . .. .. .. .. ....

20

24

25

25

26

27

28

31

35

35

..

.. .

37

Page 4

1. Features

(Head)

1..

It ensures high graded sewing conditions and perfect durability

stitches per minute.

2.

It is equipped with built-in bobbin winder with compact design and high performance.

3.

Belt cover

4.

Plunger pump is adopted

at

slow speed operation. This pump can be easily disassembled by the mechaics.

(Thread trimming mechanism)

5.

Simple thread trimming mechanism is adopted

and maintenance and it also features very safe construction.

6.

Stable thread trimming jobs can be obtained because of the thread trimming mechanism driven

by lower shaft.

7.

Rotary knife around rotary hook is adopted to do faster trimming jobs and thread tails are

shortened considerably

8.

All

accessories including feed dogs, presser feet and needle plates can be used with this machine

in

other words, such parts are common with other lock stitch sewing machines.

9.

Built in thread wiper ensures much productivity.

is

at

maximum high speed of

equipped with as standard accessories, thus it ensures operators' safety.

on

this machine, thus it ensures perfect oil return to oil reservoir even

on

in

co~parison

with

this machine, so that it

the

conventional machine.

is

quite easy adjustment

(-200)

4,500

10.

11.

(N.P.

12.

13.

14.

15.

The

solenoid reverse mechanism operates with a soft touch and permits even the beginner to sew

backward easily. (Type

The

pneumatic thread cutter sewing machine has a presser lifter which can be controlled with a

single pedal operation and thus prevents operator fatigue. (Type

Motor)

This motor is newly designed with clutch mechanism

215

r.p.m., thus it ensures faster actions of thread trimming and stopping jobs.

400

specifications)

500

specifications)

on

slow speed motor with the speed of

Even the beginner can use this machine with single treadle pedal for inching, sewing, needle

and down position and thread trimming.

Synchronizer

is

designed with "Lead Switch" and all control circuits are not used with relays, thus

its reliability and durability are very high.

Printed Circuit Boards (P.C.B.)

are

very easy to change and all components are designed to do so,

which ensures easy maintenance.

up

- 1 -

Page 5

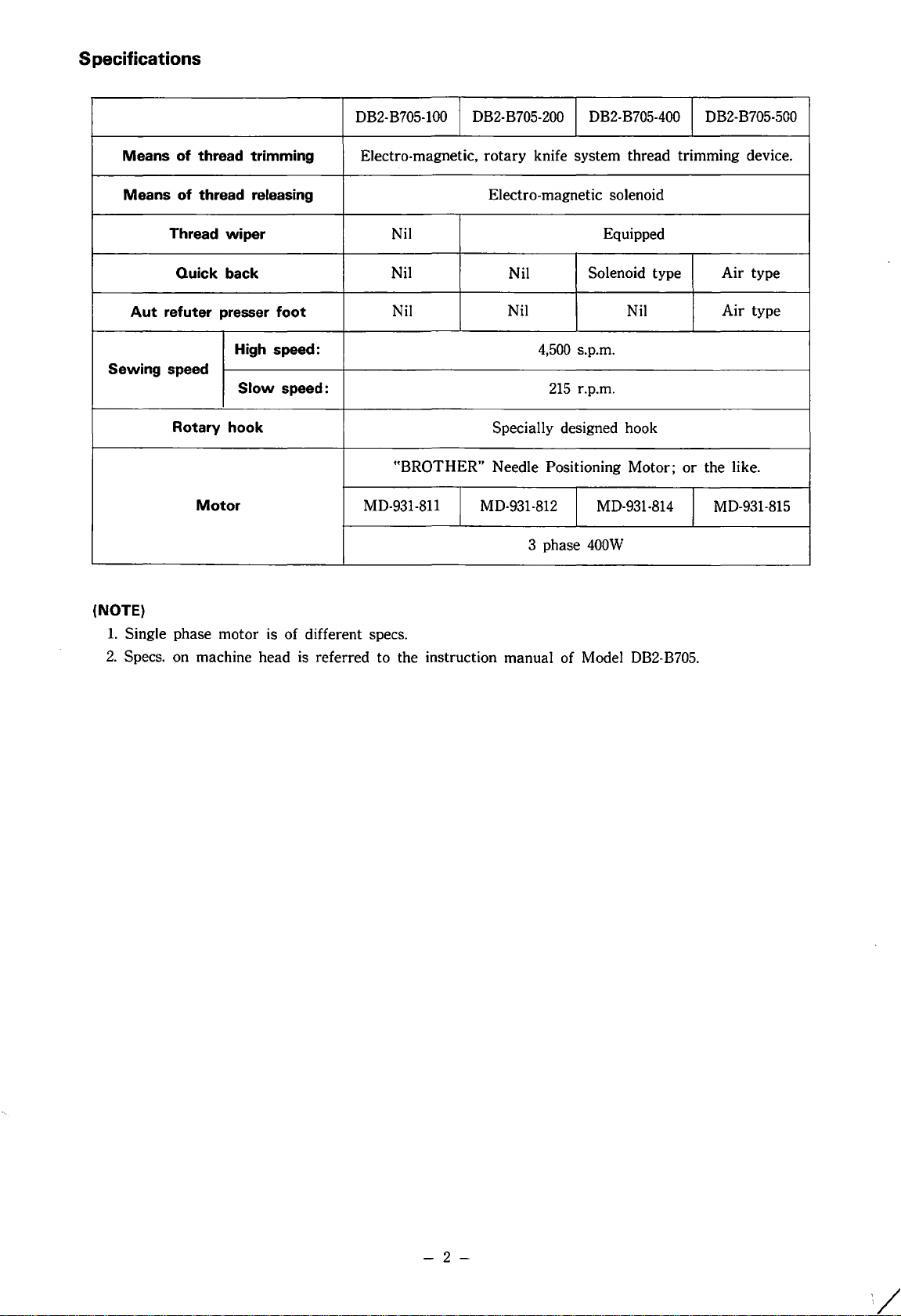

S pacifications

DB2-B705-100 DB2-B705-200 DB2-B705-400

Means of thread trimming

Means of thread releasing Electro-magnetic solenoid

Thread wiper Nil

Quick back

Aut

refuter presser foot

High speed:

Sewing speed

Slow

speed:

Rotary hook

Motor

Electro-magnetic,

Nil

Nil

"BROTHER"

MD-931-811

rotary

MD-931·812

knife

system

Equipped

215

Solenoid

r.p.m.

MD-931-814

400W

Nil

Nil

4,500 s.p.m.

Specially designed hook

Needle Positioning

3 phase

thread

type

Nil

Motor;

DB2-B705-500

trimming

Air

Air

or

the

MD-931-815

device.

type

type

like.

(NOTE)

1.

Single

2.

Specs. on

phase

machine

motor

is

of

different specs.

head

is

referred

to

the

instruction

manual

of Model DB2-B705.

-

2-

Page 6

3.

Name

This machine is componed of the following

components.

(1)

(2)

(3)

4.

Thread

of

major

Head

a.

Head

b.

Thread trimming mechanism

c. Treadle pedal

d.

Tension releaser

e. Synchronizer

f.

Thread wiper (Optional parts for

Control box

Needle Positioning Motor

trimming

components

mechanism

-200)

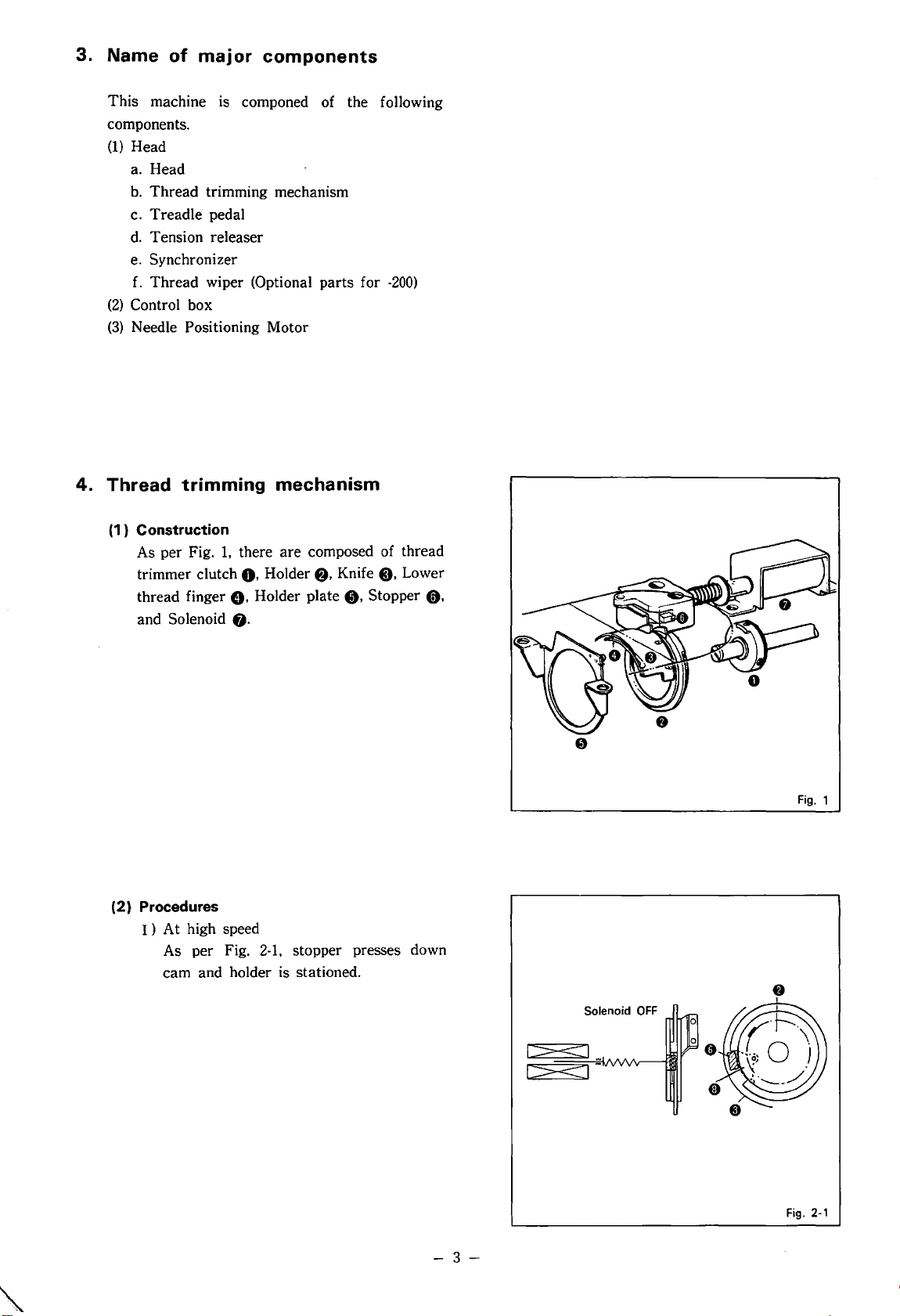

(1) Construction

As per Fig.

trimmer clutch

thread finger

and Solenoid

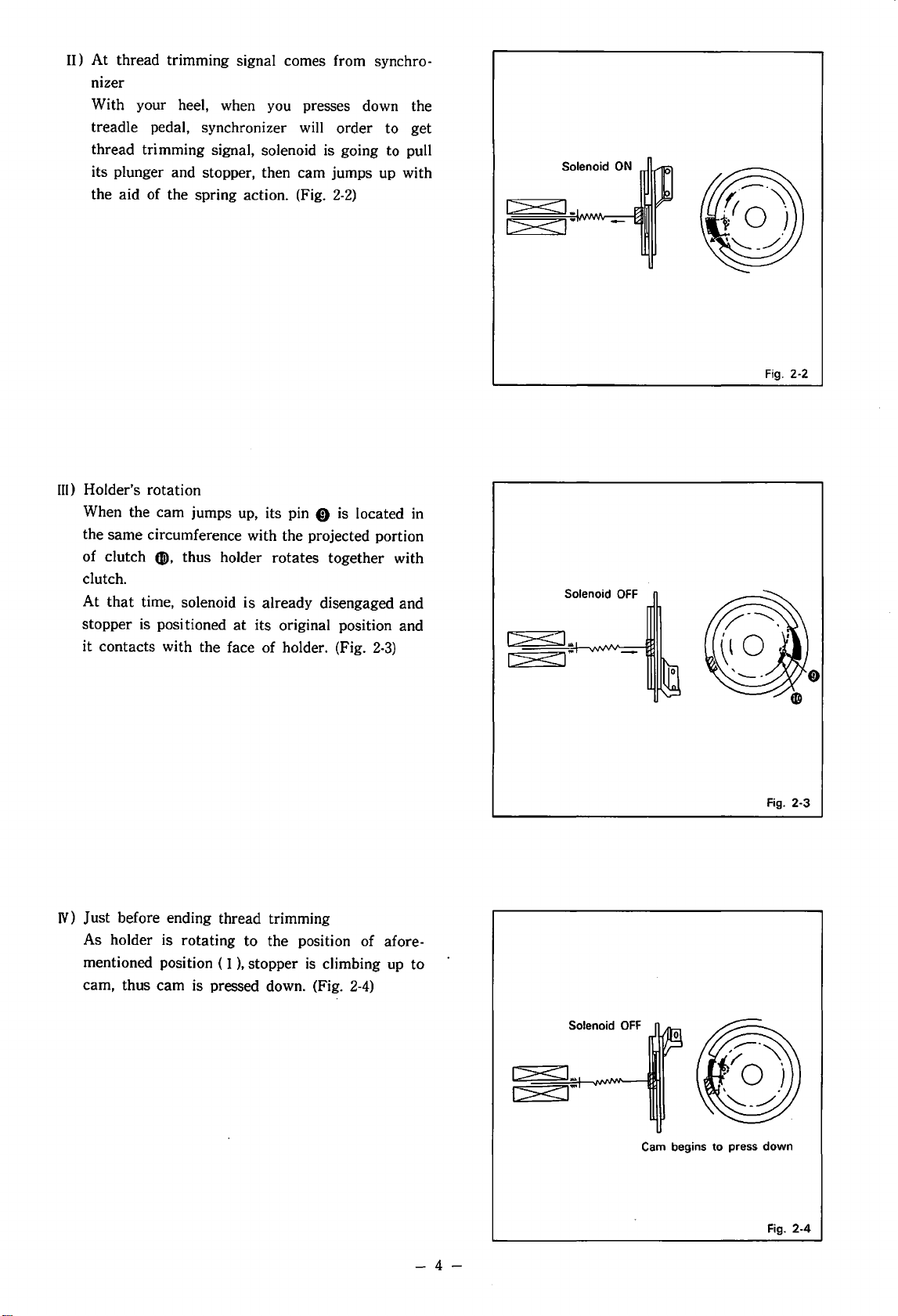

(2) Procedures

I)

At high speed

As per Fig.

cam and holder is stationed.

1,

there are composed of thread

0.

Holder

G.

Holder plate

fj.

2·1,

fj,

Knife

0.

e.

Stopper C),

stopper presses down

Lower

Fig.

1

1~1-

-

3-

Fig.

2·1

Page 7

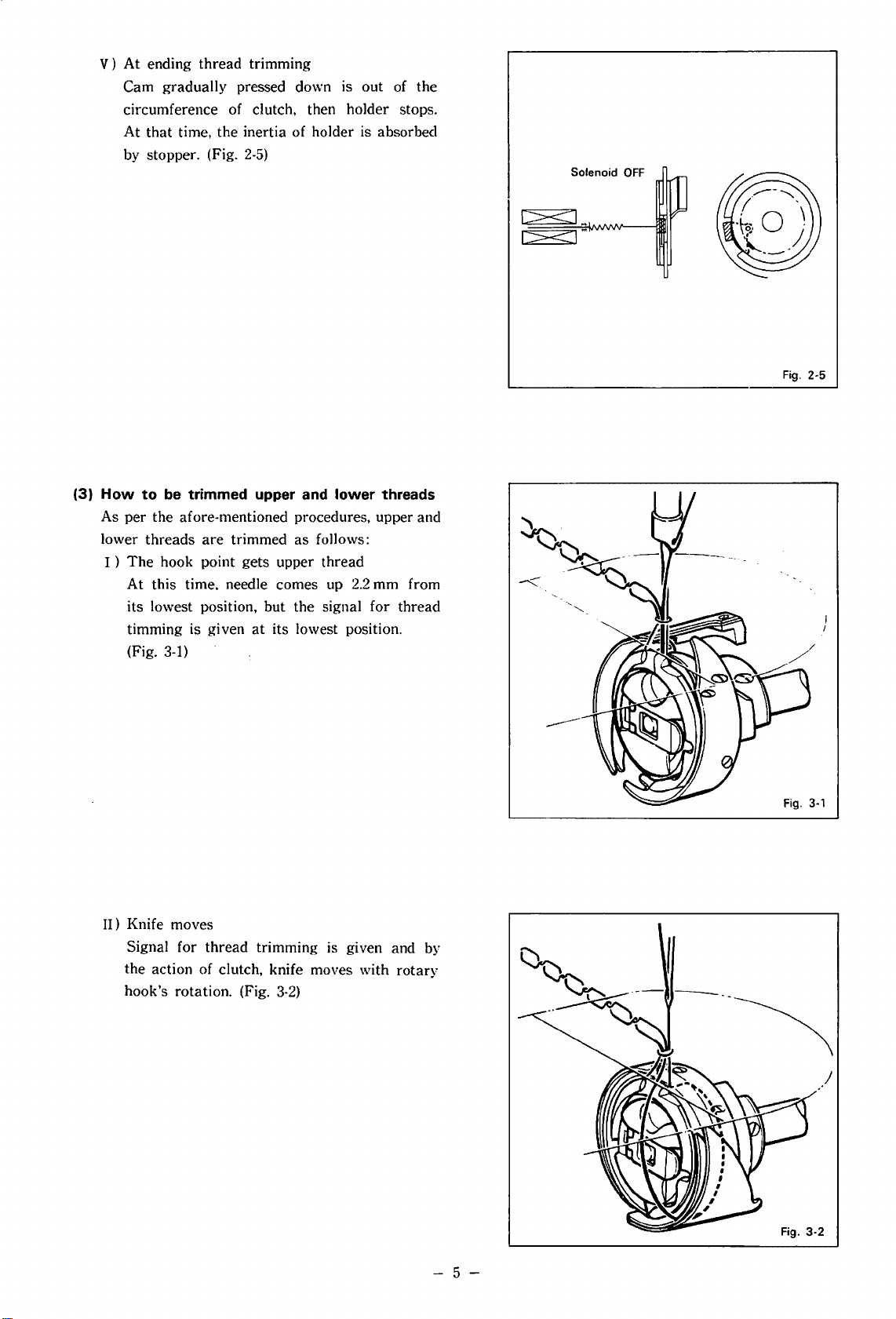

II)

At

thread trimming signal comes from synchronizer

With your heel, when you presses down the

treadle pedal, synchronizer will order to get

thread trimming signal, solenoid is going to pull

its plunger and stopper, then cam jumps up with

the aid of the spring action. (Fig.

III)

Holder's rotation

When the cam jumps up, its pin

the same circumference with the projected portion

(li),

of clutch

clutch.

At

that

stopper is positioned

it contacts with the face of holder. (Fig.

thus holder rotates together with

time, solenoid is already disengaged and

at

its original position and

2-2)

0 is located in

2-3)

I>"<:

I><

I_.

I.

Solenoid

I:>< I ..

OFF

Fig.

2-2

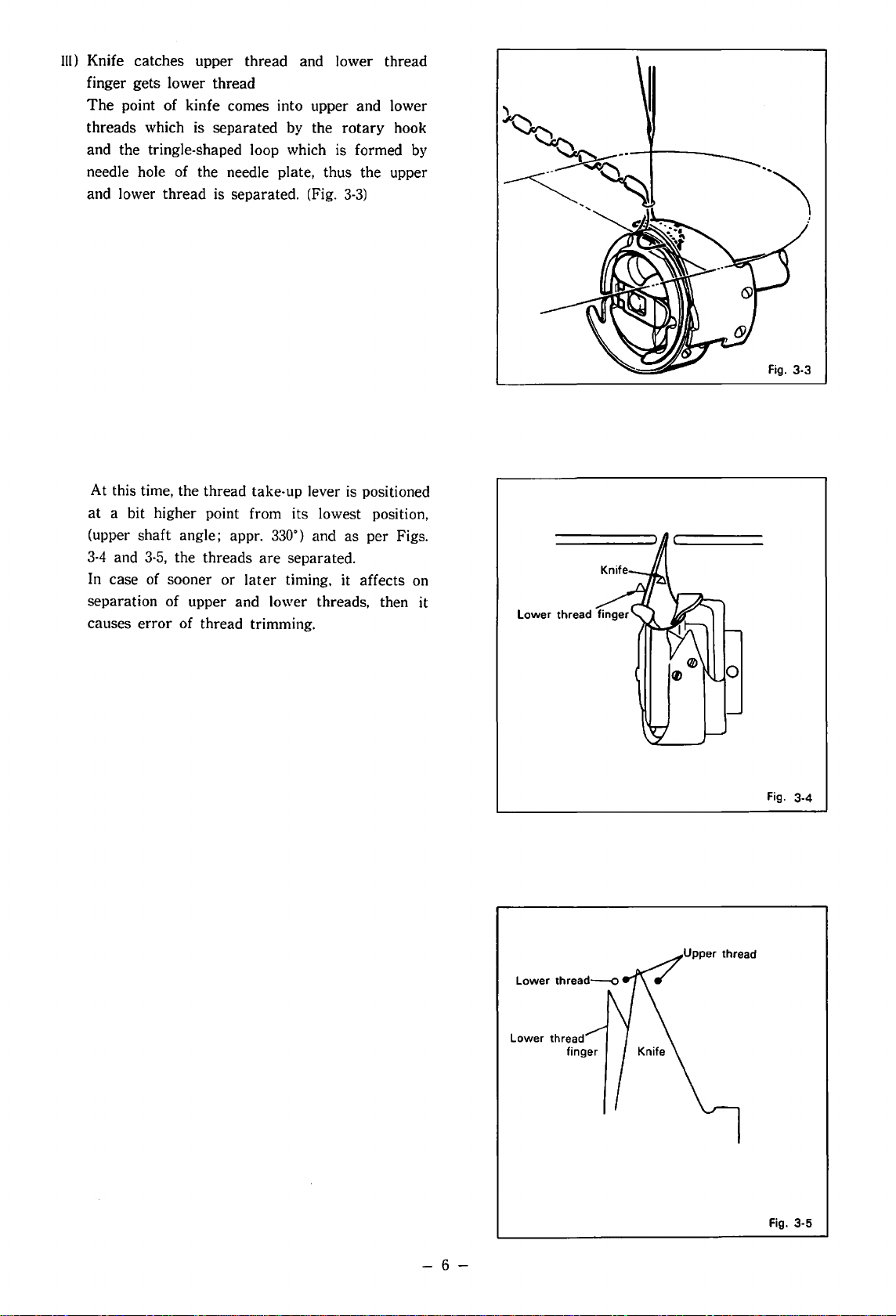

N) Just before ending thread trimming

As holder is rotating to the position of afore-

),

mentioned position ( I

cam, thus cam is pressed down. (Fig.

stopper

is

climbing up to

2-4)

Solenoid

c><L

r><J"'

OFF

0

Cam begins to press down

Fig.

2-3

Fig. 2-4

-4-

Page 8

V)

At

ending thread trimming

Cam gradually pressed down is

circumference of clutch, then holder stops.

At

that

time, the inertia of holder is absorbed

by stopper. (Fig.

2-5)

out

of the

Solenoid

OFF

(3)

How

to

be trimmed upper and

As per the afore-mentioned procedures, upper and

lower threads

I )

The

At this time. needle comes up

its lowest position, but the signal for thread

timming is given

(Fig.

are

trimmed as follows:

hook point gets upper thread

at

its lowest position.

3-1)

lower

2.2

mm from

threads

1><1

..

1><:1"'

Fig.

2-5

II) Knife moves

Signal for thread trimming is given and by

the action of clutch, knife moves with

hook's rotation. (Fig.

3-2)

rotary

- 5 -

Page 9

III)

Knife catches upper thread and lower thread

finger gets lower thread

The

point of kinfe comes into upper and lower

threads which is separated by the

and the tringle-shaped loop which is formed by

needle hole of the needle plate, thus the upper

and lower thread is separated. (Fig.

At this time, the thread take-up lever is positioned

at

a bit higher point from its lowest position,

(upper shaft angle; appr.

3-4

and

3-5,

the threads are separated.

In case of sooner or

separation of upper and lower threads, then it

causes error of thread trimming.

330·) and

later

timing, it affects on

rotary

3-3)

as

hook

per Figs.

..

")

Fig.

Fig.

3-4

3-5

-

6-

Page 10

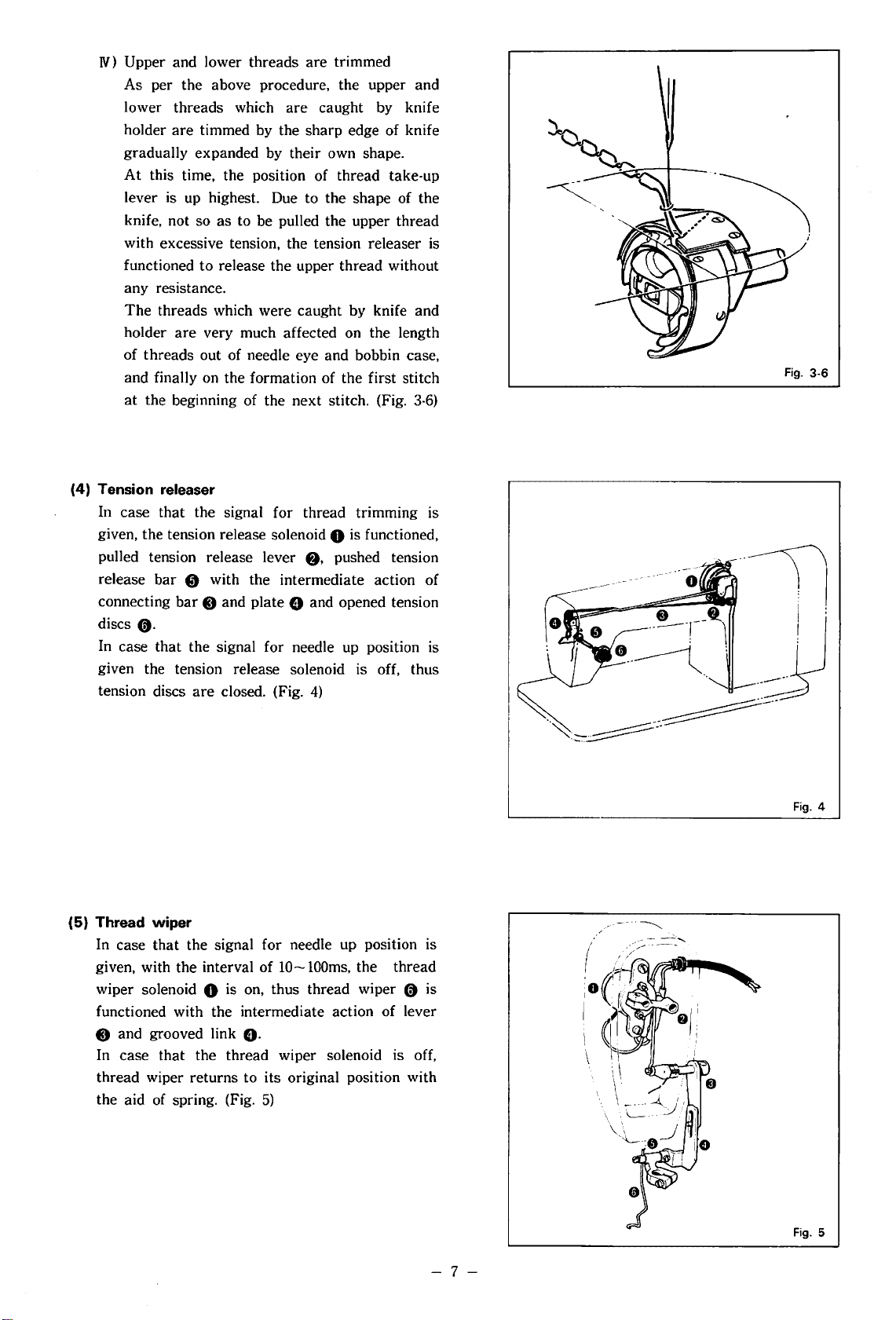

N) Upper and lower threads are trimmed

As per the above procedure, the upper and

lower threads which are caught by knife

holder are timmed by the sharp edge of knife

gradually expanded by their own shape.

At

this time, the position of thread take-up

lever is up highest. Due to the shape of the

knife, not so as to be pulled the upper thread

with excessive tension, the tension releaser

functioned to release the upper thread without

any resistance.

The

threads which were caught by knife and

holder are very much affected on the length

of threads out of needle eye and bobbin case,

and finally on the formation of the first stitch

at

the beginning of the next stitch. (Fig.

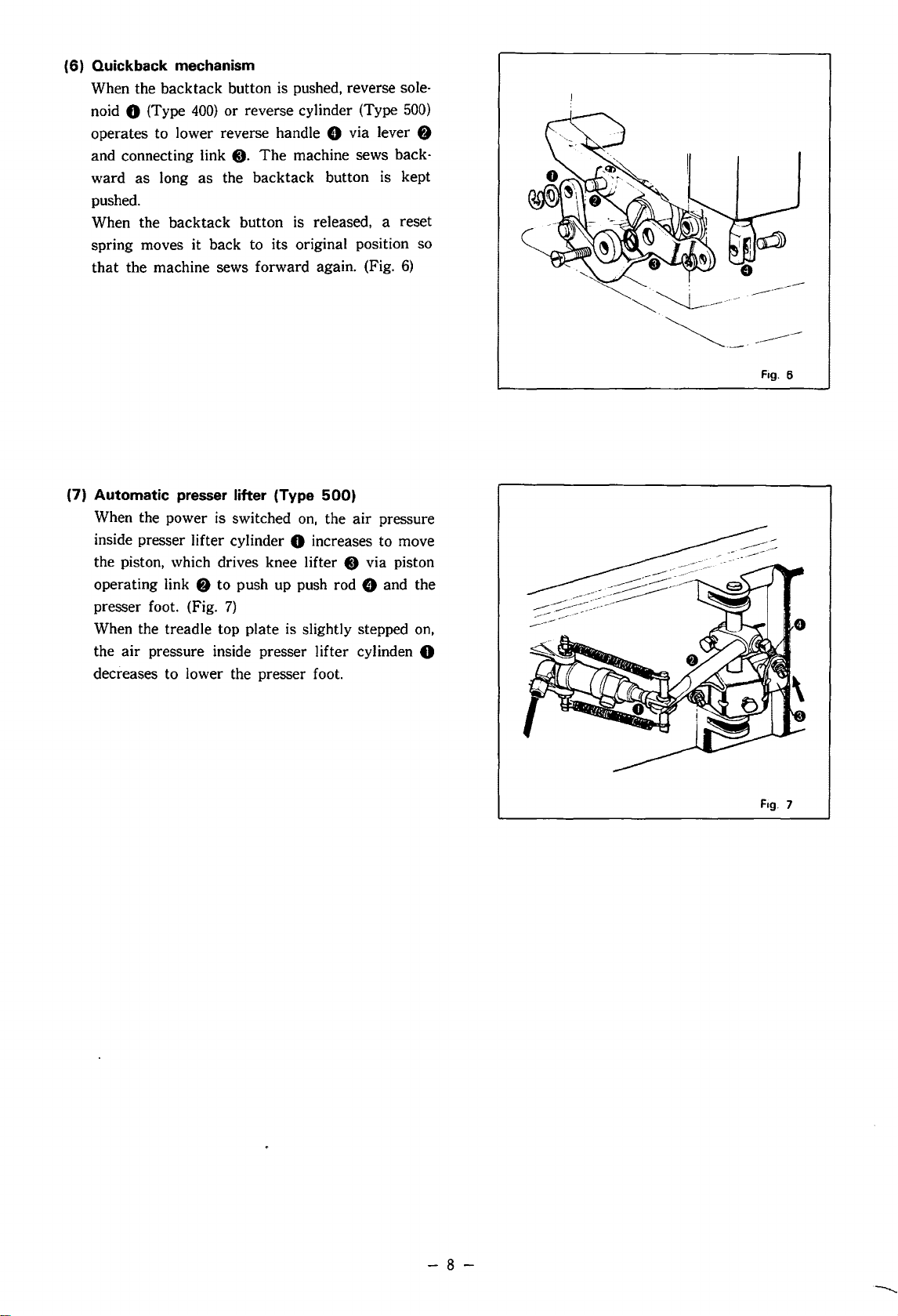

(4) Tension releaser

In case that the signal for thread trimming is

given, the tension release solenoid

pulled tension release lever

release bar

connecting

discs

(t.

In

case that the signal for needle

8 with the intermediate action of

bar

0 and plate 8 and opened tension

0 is functioned,

f),

pushed tension

up

position

given the tension release solenoid is off, thus

are

tension discs

closed. (Fig.

4)

3-6)

is

is

Fig.

3-6

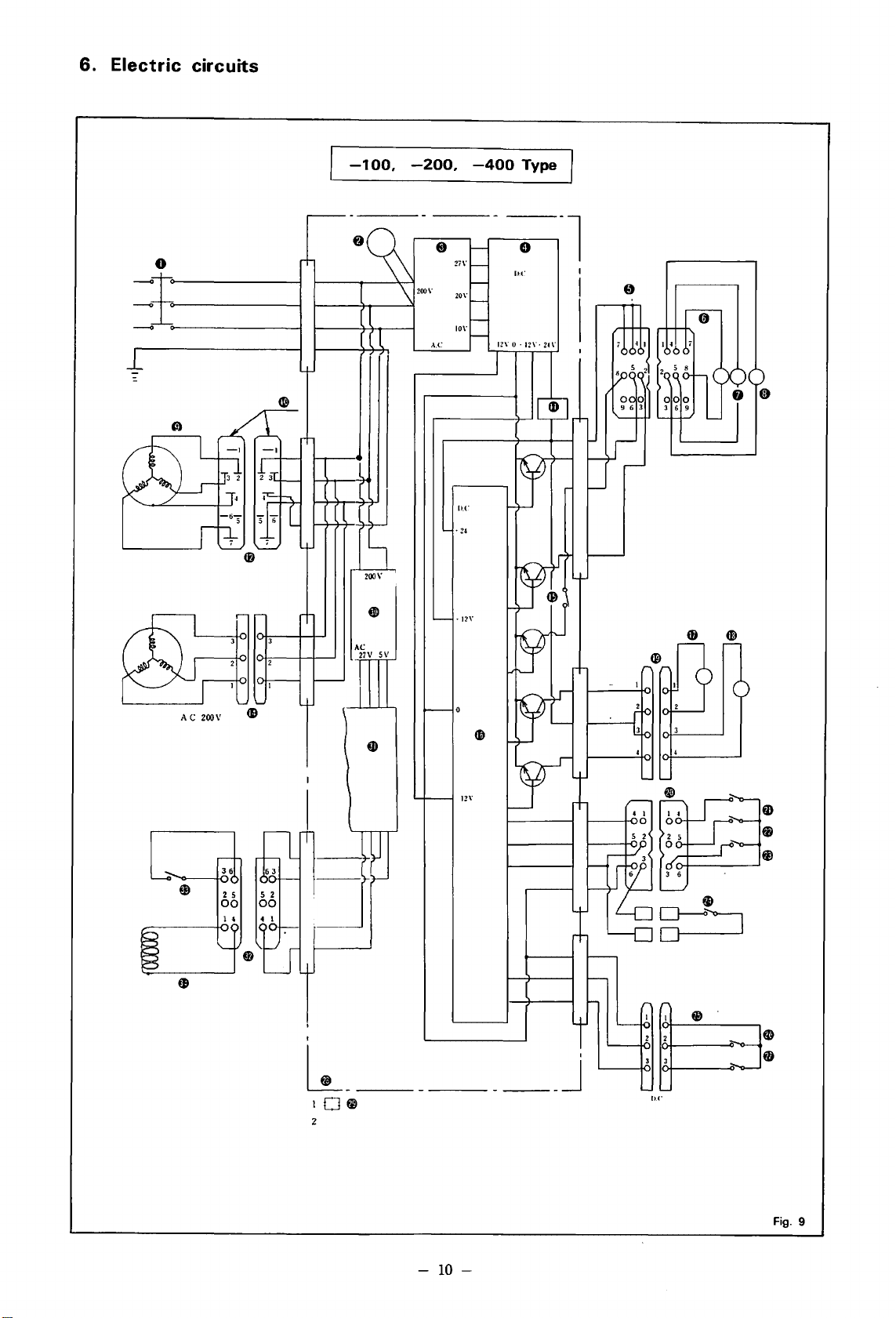

(5) Thread wiper

In case that the signal for needle

given, with the interval of

wiper solenoid

0 is

10-lOOms, the thread

on,

thus thread wiper 0 is

up

position is

functioned with the intermediate action of lever

0 and grooved link

O·

In case that the thread wiper solenoid is off,

thread wiper returns to its original position with

the aid of spring. (Fig.

5)

I>;=~=='

~--......._

Fig.

Fig.

4

5

-

7-

Page 11

(6) Quickback mechanism

When the backtack button is pushed, reverse sole-

noid

0 (Type

operates to lower reverse handle 8 via lever

and connecting link C).

as

ward

pushed.

When the backtack button is released, a reset

spring moves it back to its original position so

that

the machine sews forward again. (Fig.

long

400)

or reverse cylinder (Type

The

machine sews back-

as

the backtack button is kept

500)

f)

6)

.

---------------

Fcg.

6

(7) Automatic presser lifter (Type

When the power is switched

inside presser lifter cylinder

the piston, which drives knee lifter

f)

operating link

presser foot. (Fig.

When the treadle top plate is slightly stepped on,

the air pressure inside presser I ifter cylinden

decreases to lower the presser foot.

to push up push rod 8 and the

7)

500)

on,

the

air

0 increases to move

8 via piston

pressure

0

Fcg.

7

-

8-

--........

Page 12

5.

Construction

chart

of

Brother

N. P.

Motor

0 Synchronizer

f)

Needle up position

8 Needle

0 Thread trimming

0

0 Main

Slow

down

speed

motor

position

motor

-9-

f)

Clutch lever

0 Brake

0 Clutch

tii)

Switch

CD

Treadle pedal

for

thread trimming

Fig. 8

Page 13

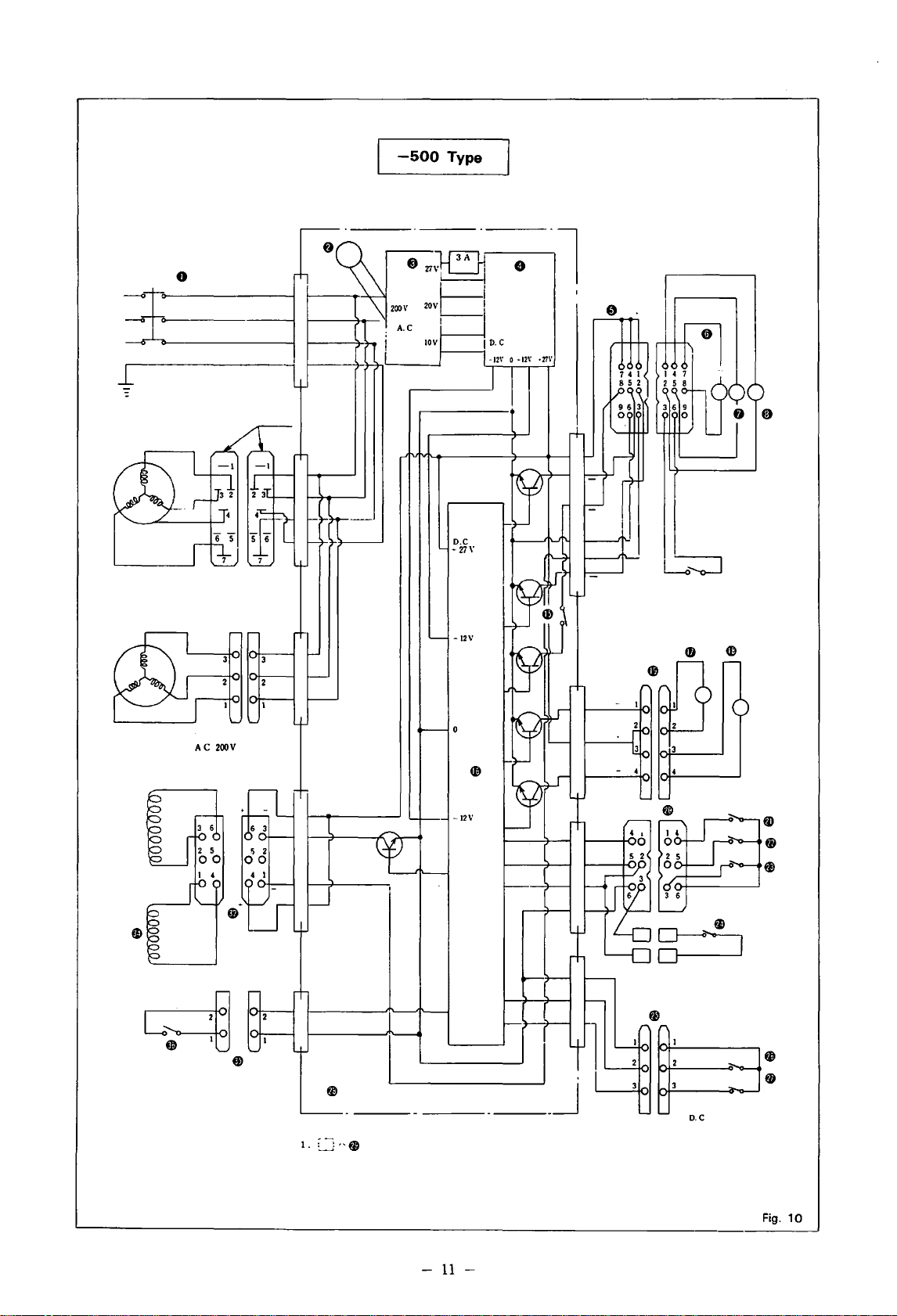

6.

Electric

circuits

0

=±

-

-

-100,

-200,

,\,C

ll.C

• 12\"

-400

12\' 0 •

Type

8

ll.C

12\'.

-l

0

24\'

AC

27V

SV

~--

____

12\'

I

j

11.1"

-

10-

Fig.

9

Page 14

I

-500

Type

I

-

11

-

~

~-

D.C

Page 15

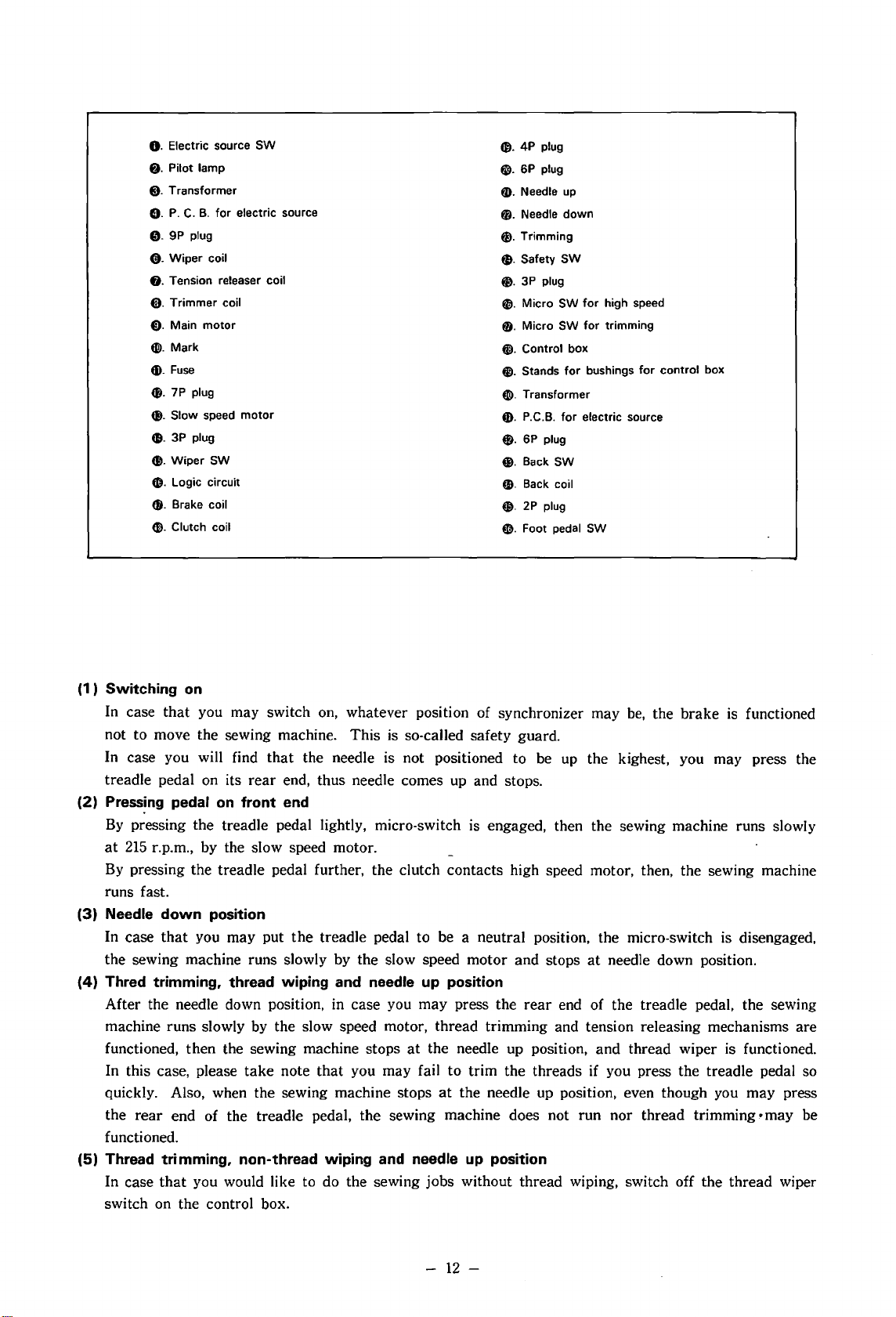

0.

Electric source SW

f).

Pilot lamp

@).

Transformer

8.

P.

C.

B.

for

e.

9P plug

0.

Wiper

coil

8.

Tension releaser coil

0.

Trimmer

C).

Main

tli).

Mark

G).

Fuse

(8. 7P plug

tl). Slow speed

coil

motor

tl. 3P plug

Cl.

Wiper

SW

(D. Logic circuit

$.

Brake coil

C]!).

Clutch coil

electric source

motor

fl). 4P plug

•·

6P plug

fD.

Needle

up

t».

Needle

down

fj.

Trimming

fJ.

Safety

SW

fl). 3P plug

fi.

Micro SW

tj.

Micro SW for trimming

fi.

Control box

@).

Stands

.:I!).

Transformer

i).

P.C.B.

e.

6P plug

1).

Back SW

@).

Back coil

6).

2P plug

~.

Foot pedal

for

for

bushings

for

electric source

SW

high speed

for

control box

(1

) Switching

In case that you may switch

on

on,

whatever position of synchronizer may

be,

the brake is functioned

not to move the sewing machine. This is so-called safety guard.

In case you will find that the needle is not positioned to be

treadle pedal

(2)

Pressing

By

pressing the treadle pedal lightly, micro-switch

at

215

By

pressing the treadle pedal further, the clutch contacts high speed motor, then, the sewing machine

r.p.m., by the slow speed motor.

pedal

on

on

its

rear

front end

end, thus needle comes

up

and stops.

is

engaged, then the sewing machine runs slowly

up

the kighest, you may press the

runs fast.

(3) Needle

In case

the sewing machine runs slowly by the slow speed motor and stops

(4)

Thred trimming, thread wiping and needle up position

After the needle down position, in case you may press the

down

that

you may put

position

the

treadle pedal to be a neutral position, the micro-switch is disengaged,

at

needle down position.

rear

end of the treadle pedal, the sewing

machine runs slowly by the slow speed motor, thread trimming and tension releasing mechanisms are

functioned, then the sewing machine stops

take

note

that

In this case, please

you may fail to trim the threads if you press the treadle pedal so

quickly. Also, when the sewing machine stops

rear

the

end of the treadle pedal, the sewing machine does not run nor thread trimming • may be

at

the needle up position, and thread wiper is functioned.

at

the needle up position, even though you may press

functioned.

(5) Thread trimming, non-thread wiping and needle

In case

that

you would like to do the sewing jobs without thread wiping, switch off the thread wiper

up

position

switch on the control box.

-

12-

Page 16

7.

Setting

up

the

machine

Setting

refer

the i

(NOTE)

Do

(1)

Motor

r--·

the h

ead

. oil reservoi r.

nstruction manual for l\l

not

hold

the

synchronizer in case you hold

pulley and

50

liz High speed 4,550 4.300

60

I Iz High

V-belt

Slow

speed

spee

Slow speed 215

thread

odel 082-8705.

115

L

-

f-

95mm

d 4.

stand

mm

--

215 200

550

I

on

table

is

M

otor

105mm

exactly

the

sewing machine head.

pulley

100

111111

same

as i\lode l DB2-8705's. Th

95mm

--

4.050 T 3.850

---

190

90

mm

4.300 4.100 3.850 3.550

200 190

85mm

180

-t--

80 mm

-

180

90 mm

3.650

70

1

75m

m

1

65

erefore,

85mm

~

I

I

3,450

-

1

60

(2)

V-belt : 42 inches for 60 l iz

Motor

Ir

(I) Rem

(2) f

(3)

(4) In

(NOTE)

pulley change

you wish

asten sec

Get the prop

instruction manual

If

sition

the

tate

and pu

The pulley

is

recommended

K pulley, although

pulleys are

to

cha n

ove pull

the

case

motor.

bracket

ey

cover

urely the nut

er

tension of V-bell. (See the

tension is

is

not

accurate.

you

may

loosen

fj

ll

rod 0 is right angle.

to

be used

a~plicable.

ge

the motor pulley, p

0 and

of

Model D82-8705).

too

loose, the

change

three

so

that

to

use

the

change

~

-

the

position of

bolts 0 and

clutch

with

this

with

BROTHER

commonly

stop

lever

motor

lease

the pull

po-

ro-

0

sold

take

ey

.J3 inches

note

f)

.

for

50

I-1

z

the followings (Fig. 11)

0

0

Fig.

11

-

13

-

Page 17

(3)

Connection

of

wires

I ) Put the plugs out of sewing machine head

and synchronizer into the table top hole

The wire out of synchronizer should be fixed

f)

on

with wire supporter

the belt cover.

Connect the plugs 8 comes from control

8.

(Figs.

12,

box

II)

To

earth wire

prevent the static electricity, connect the

13)

C) out of table hinge to the

bracket of motor.

III)

Pass the plugs through the hole in the table

and connect them to the plug sockets leading

from control box

0 and treadle 8). (Fig.

box

(A)

plug for Types

(B)

plug for Types

(C)

plug for Type

(D)

plug for Type

(E) plug for Type

(F) plug for Types

C), safety device

13,

Fig.

100,

200,

400,

500

100,

200,

400,

500

400

500

500

100,

200,

400,

500

ct.

14)

O·

valve

Fig.

12

Fig.

Fig.

13

14

·-

14-

Page 18

Ill)

To

connect the

disconnect

over

them

Insert

the

the nul \\'ith your fingers,

nut

once

cannot

(Fig.

be removed when pulled by hand.

18)

air

nut 8 and

the tube end

tube

end in

or

twice with a

tube to the connector, first

sleeve 0

as

shown in the figure.

to

the socket, tighten

spanner

and

and

then

so the

then fit

turn

the

tube

\

3 - 5

mm

-

Fog. 18

(5) Air pressure (Type

(1) Keep

(2)

air

pressure

It can be regulated with the valve box reducing \·alve.

loosen hexagonal

clockwise.

the knob counterclockwise,

tack

button

pressure,

again.

nal nul

If

water coll

compressor

push up

and

After

to

drain

If

If

the

or

then increase the air pressure

its

fix the

ects

to

lower the air pressure

cock 0

500)

at

5kg

em~

± 0.5kg cm

the

air

pressure is too low,

nut 0 and

air

pressure is too high,

the

treadle

regulation. tighten the hexago-

knob

. (Fig.

inside bottle @.

and

turn

operate

to lower the

19)

discharge the water.

2

knob

turn

the back-

air

stop

the

and

then

•

f)

Fog. 19

-

16

-

Page 19

8.

Test

running

Remove the needle from needle bar.

It is vitally important for you to

If

you will find out any troubles, look into the trouble shooting

(1) Switch on and make sure whether pilot lamp is put on, then switch off. At

make

sure each procedure and

take

in

this service manual and

motor should be examined.

(NOTE)

1 .

If

you

will

find

out

that

the

sewing machine

should be changed.

2. This BROTHER Needle Postioning

changing

tor.

nector

3. Green coloured

4.

Do

(2)

Make sure whether slow speed motor runs smoothly pressing the treadle pedal lightly.

(3)

Make sure whether the sewing machine stops

at

the neutral after pressing the pedal

(4)

Make sure whether the sewing machine stops

pedal is pressed

(5)

After making sure all the above procedures, put the needle and

If

you

matching

not

switch

the

position

change

red markings.

wire

on

while

at

the rear.

of

the

position

is earth

you

the

plug located

wire

Motor

of

the

plug,

which

are pressing

at

the front.

rotation

is

not

in

the

motor

motor

should be grounded.

the

treadle pedal. Pedal should be neutral position.

at

the needle down position, when the pedal is positioned

at

the needle up position

is reverise,

featured

body

does

not

start

the following step.

that

either

to

get

reverse

similar

run.

to

BROTHER

Connect

after

knife's rotation, when the

sewing.

take

proper step.

time, the direction of

two

of

three

wires

rotation

the

plug

by

merely

Clutch

with

Mo-

con-

(Treadle Pedal)

Its operation and function is as per Fig.

(NOTE)

1 .

Switch

motor

val,

2.

Do

3.

Switch

sewing machine as

for

4.

Do

switching

5.

Do

plugs

on

and

running

you

may

not

set

the

off

without

adjustment

not

disconnect

on.

not

pull

the

or

terminals.

after

recognition

with a few

take

the

wires

on

fail

well

and repair.

the

wire

to

second

steps.

moving

to

as

plugs

disconnect

check

the

13.

of

the

inter-

parts.

the

motor

while

the

0

•

0.

Lower presser foot.

f).

Low-speed sewing

@).

High-speed sewing

G).

Neutral (Machine stops

down;

presser

foot

0.

Thread cut and removed; machine

stops

with

needle up.

is

raised).

with

needle

Fig.

20

-

17-

Page 20

9.

Sewing

(1

) Pre-tension

tensions

When the threads are trimmed, the upper

tension assembly is released, then the pre-

on

tension is the only tension

If

thread.

tension

you may get the stronger the

on

it, the shorter the upper thread

the upper

out of the needle eye after thread trimming

To

is done, and vice versa.

the thread-off, skip stitching

adjust the tension,

at

the beginning

and thread tail on the top of material can

be eliminated.

The

standard length of thread after trimming

is about

(2)

Upper tension

Upper tension is almost same

B705,

30-35

however,

mm.

(Fig.

21-1)

as

take

note the followings be-

Model

cause of the thread trimming mechanism.

On

I )

the synthetic threads, if you will

loosen the tension, you may encounter

the thread breakage

22-2)

(Fig.

at

the beginning.

DB2-

Fig.

21-1

II)

Make sure the upper thread is given out

of thread stand without much resistance.

(After thread trimming, there causes

at

thread-off

the beginning because of

short upper thread out of the needle eye.)

III)

In case of skip stitches, the upper thread

cannot be trimmed although the lower

thread can

N)

In order to avoid the skip stitch and

upper thread-off

be

trimmed.

at

the beginning, select

the following parts with much attention.

23)

(Fig.

a)

Needle plate;

The

b)

Presser foot;

The

smaller the hole

smaller on the

©.

the better.

points®

the better. But, the thicker thread

#50, use the standard presser

over

foot.

c)

Rotary hook ;

Special hook.

"BROTHER" hook for Model

100

Series.

d)

Feed dog;

Standard feed dogs can be used.

But, the thicker feed dog cannot be

recommended because the knife may

hit the feed dog in case of too thick

feed dog.

& @,

B705-

18

Fig.

22-2

Fig.

23

-

Page 21

(3) Lower tension

In order to prevent the bobbin from idle run, this

machine is adopted with bobbin case with spring.

Bobbin is recommended to be alminium one.

24)

(Fig.

The

recommended winding on bobbin is less than

80%.

The

lower thread must be pulled out of eye of

bobbin case.

The

standard tension of bobbin spring is

How

to

adjust bobbin tension

a. Loosen lower tension adjusting screw 0 and

get

the

tension of adjusting spring to be "0".

b.

Adjust the lower thread tension to turn the

adjusting screw

bobbin case. (Fig.

(NOTE)

*

If

you feel the unevenness to pull the thread

out of bobbin case, correct the shape

tension spring.

*Incorrect

following troubles.

a. In case of excessive tension; lower thread

will

jam

run.

b.

In case of weak tension; not properly

trimmed with the knife.

Recommended lower thread tension;

To

obtain the above range of

in total, adjust the lower tension adjusting

screw

bobbin spring.

after

8 putting

25)

tension of the bobbin case causes

in the bobbin case due to idle

completion of adjustment of

the

bobbin into the

10

to

5-10

gr.

of

10-25gr.

25

grams

-

Fig.

Fig.

24

25

-

19-

Page 22

1

0.

Adjustment

( 1 ) Adjusting thread trimming mechanism

on

sewing

I ) Changing knife

Firstly, remove dust cover

stopper guide. After completion, make

sure to fix it for safety sake.

Then, remove needle plate, and

needle's lowest position, push stopper

with your finger as per Fig.

Turn

the pulley and get the position so

as

to loosen flat head screws for knife.

(Fig.

27)

machine

0 from

at

26.

the

f)

Fig.

26

Change knife 8 by loosening flat head

screws

C). At

only although

0 are removed. (Fig.

finger

Spacer

thickness

Needle plate

washer thickness

that

time, change the knife

spacert)

and lower thread

28)

Standard

Thick material

Standard

Thick material

0.5mm

0.7mm

0.2mm

0.5mm

Fig.

Fig.

27

28

-

20

-

Page 23

To

set the knife correctly, let the point of knife

meet with needle, turn the pulley reversely and

make

sure the point of

the centre

Also

lower

rotary

cotton

After completion, turn the pulley

get the knife positioned

II)

Adjusting knife holder

In

case

the holder

remove holder

Adjust the position of holder

holder moves smoothly without n}uch clearance.

After completion, fasten the screw securely.

(Fig.

axis

of the needle

make

sure

the clearances between knife and

thread

30)

finger, and lower thread finger and

hook must be averaged about

thread'

that

pass without any resistance.

you may remove knife holder

about

half rotation, and

bracket

knif~

as

at

its beginning.

0.

then holder.

may

contact

per Fig.

toward

at

this position,

bracket

that

you and

so

with

29.

of # 8

8.

turn

that

_--l:il--------

----

------

I

lr

Neeedle

N

11\

1

Knife

)

Fig.

29

III) Adjusting

Loosen the slit so

be 4mm. (Fig.

stopper

31)

that

the

stroke

of stopper

may

Fig.

Fig.

30

31

-

21

-

Page 24

When fixing stopper guide, firstly fix solenoid

temporarily, and fix it onto the bed. Then, bring

the needle down to its lowest position and push

the stopper with your finger to its fullest extent,

and turn the pulley slowly toward you, and

sure

that

the holder begins to move, stopper drops

into the recess portion of holder, pawl

ratchet

on holder

bracket

drops into the first

make

0 of

second tooth of knife holder, and stops. (Fig.

If

knife holder drops prior to the correct position,

fasten stopper guide

tioned far from lower shaft. (Fig.

em>

so that it may be posi-

33)

or

32)

IV)

Adjusting solenoid for thread trimming

Fix

solenoid so

Fix stopper guide so

that

its

stroke

that

the left surface of stop-

may be 3.5mm.

per may be in contact with ® surface of holder

bracket.

Then,

your finger, and you

the

in

stroke

case

that

you may push the stopper by

get

of solenoid is kept

0.5mm

as

per Fig34,

as

correct, 3.5mm.

Fig.

Fig.

33

34

-

22

-

Page 25

If. on the con

sc

re\\'s

the

and

if

that

the stopper is

\\·hen

you

so

len

oid

V)

i\cljusting clutc

It is dete

get c

orr

If

you

remove the needle pl

adjust

clutch

p

ull

ey

i

nto

the h

that the centre

\\'hen

nex l to

trary. thi

for

solenoid

small.

tO\\'c

to

push i l \\·it h yo

nw\'in,g

h

rmi

ned by the pos

ect

timing of

ing

hole

Hcl yo

ole

and

of needle meets

A h

s stroke

righ

t.

In

returned

it left

or rig

thr

ead t

s as per fig.

u.

put the hexagona I spann er

get the

ole

meets

is too big. loosen

Q)

and mo\·e

this

case.

\\·ith its spr ing

ur

fi

ngcr. you fi

ht. (Fig.

iti

on

of clut

rimmin

ate

. you m

:25. Turn

position

\\'ith hook

hole

a. (

it

makin

35)

g.

ay

of clu tch so

Fi

to

g sure

action

:-;

ch ®

find ou t

ing the

point.

g.

36)

left.

the

to

Fig.

35

In case

and

D.

in

to

B.

get

the correct

Then.

of

adj ustment. loosen

and

lastly

sere\\'

and turn

fasten three scrc\\'S

ing

the pulley

timing

of needle and

at

first

~.

putting

siO\dy

securely. (Fig.

the spanner

to\\·ard

hook poin

scrc\\'s c

~·ou.

37)

Fig.

36

t.

Fig.

37

-

23

-

Page 26

(NOTE)

1.

In

the

ting

the

jected

in

up,

pin,

tion

hit

on

2.

In

knife

missing

case

of

knife

trims

excessively

angle

between

portion

this

result, prior

projected

clutch

of

the

the

knife.

this

adjustment.

case

of

will

of

setting

threads

~

portion

will

lower

So

setting

function

thread

prior

prior

to

pin

4D

of

clutch

to

function

shaft

that,

(Figs.

after

later, thus

trimming

to

correct

in

advance.

correct

of

the

pin

of

clutch

after

and

please

38 & 39)

correct

cam

is

's

needle

.

timing

timing,

and

so

small,

climbing

passes

one

be

careful

timing,

it

causes

Set-

pro-

rota

will

,

-

Fig.

38

(2)

Adjusting

tension

1 ) Adjusting ten sion re

Fix

tension rel

that

time,

sion rel

at

\\'hen

ease

the lo

west

fixing tension rel

of tension rel

the end

of

II) Adjusting t

\\

'hen soleno

so that

ther

tension discs. also when

tione

d.

make sure that the space do

exi

st

bel ween two tension di

releaser

leas

e solenoid

ease sol

seeing

Je,·

from

er

f)

eno

rear

so

id

0 on the

cover.

that

it is position

when you turn it clockwise.

ease Je,·e

ease lev

solenoid

ens

id

e exi

er

sho

uld

be

shaft.

8.

(Fig.

ion

releaser

is functioned . set the

sts

lmm

space

sole

noid is

scs

.

bet\\·een

arm.

fasten ten -

r.

side

face

in

I ine ,,.i th

40)

collar

not

func -

es

at

ed

0

two

not

Fig.

Fig.

39

40

-

24-

Page 27

(3) Adjusting thread wiper

1)

Fix thread wiper solenoid 0 with face plate.

that

At

tioned equally against horizontal shaft. (Fig.

time. fasten solenoid link 8 to be func-

41)

Fig.

41

(4) Quickback device assembly

I ) Fit connecting link 0 over reverse handle

8.

shaft

the order shown in the figure.

II) Connect the lever to plunger

Ill)

N) Backward stitches can be adjusted to a shorter

V)

and assemble lever 8 with the arm in

plunger into the reverse solenoid which is

mounted on the base, and then install the base

on the arm. (Type

Install the cylinder support, to which the reverse cylinder has been attached, on the arm.

Assemble the lever and reverse cylinder

together. (Type

length than forward stitches with the reverse

stopper.

When stopper knob

wise,

backward

If

backward stitches must be adjusted so short

as

to require loosening the stopper knob

almost out of contact with screw

nut

f)

and tighten the screw from under the

bed. (Fig.

43)

400)

500)

0 is turned counterclock-

stitches will become shorter.

(Fig.

and

adjustment

in

e.

42)

Insert the

0.

8

loosen

Fig.

42

-

25

-

Fig.

43

Page 28

(5) Automatic presser lifter assembly and adjust-

ment (Type

I ) Connect presser lifter cylinder

operating link

II) Position knee lifter 0 with push rod 0

lowest position, and tighten knee lifter

500)

0 with piston link coupling

f)

and piston

in

cou-

pling e with the piston inserted all the way

into the cylinder.

III)

Adjust knee lifter stopper

presser foot

N) A delay device

will rise 8

is

provided so that the presser

mm.

fj

so that the

(Fig.

44)

foot will rise after the threads have been cut.

VR-3

Delay time increases when

is

turned clockwise. (See

box

V )

If

the presser foot rises before the thread

the control

11.3.)

wiper returns to its original position, the

needle may interfere with thread wiping.

The

valve box has an adjuster for regulating presser rising speed. When its knob is turned clock-

wise, the speed decreases. (Fig.

VI)

The

tension of treadle top plate 0 can be

45)

adjusted by regulating the tension of pull

CD>

spring

spring hook

by moving

0.

If

is too great, the machine will

in

or

out treadle pull

the treadle top plate tension

start

running

before the presser foot lowers fully.

If

the tension is too small, the presser foot

will not rise.

VII)

Adjust the position of microswitch

CD

so

that

it will be OFF before the top plate contact

the treadle.

tB

Top plate adjusting screw

adjusting the travel of the top plate.

is used for

If

it is

too small, the presser foot may not rise

cause the microswitch may not be closed

when the top plate is released. (Fig.

46)

0.

the

be-

li

L.)

Fig.

Fig.

44

45

-

26

-

Fig.

46

Page 29

(6) Adjusting synchronizer

Follow (Fig.47)to disassemble and assemble.

Fig.

47

Fix synchronizer with its supporter

1) Adjusting position of thread trimming signal

of

Adjust the position

that

lead switch

the needle

bar's

thread trimming signal so

f)

is in line

lowest position.

\·vith

The

as

per Fig.

magnet 0

adjustment

is made by moving the position of lead switch.

49)

(Fig.

48.

at

Fig.

48

-

27

-

Fig.

49

Page 30

2)

Adjusting position of needle down signal

vVhen

the sewing machine stops

position

neutral position, adjust to move the position of

needle down lead switch

so

set screw and the surface of needle plate may be

16-22mm.

obtained by turning it clockwise and the lower,

counter clockwise.

after

high speed sewing and treadle pedal's

0 by loosening its screw

that

the distance from the lower part of needle

(Fig.·

50)

The

3)

Adjusting position of needle up signal

\Vhen the sewing machine stops

needle

sed down

the position of needle up lead switch

up

position

by

your heel. adjust to move

(Fig.

49)

by loosening it screw so

the distance from point of needle and top

surface of needle plate may be

(Fig_

51)

at

its needle down

higher position will be

after

treadle pedal pres-

7 -lOmm.

at

its

8

that

--·

-------

16-22mm

_

.....

--·

Fig.

50

7

-10mr•

11.

Adjusting

(1)

Adjusting clutch play

After long usage of the motor causing

of clutch lining, thus the play becomes too

large, adjust it as per following procedures.

(Fig.

1)

Loosen nut

2)

Pull clutch lever downward and adjust the

play to be 0.8-1.2mm fastening clutch adjusting screw

screw

3)

After adjustment is over, lift clutch lever

upward, fasten screw

O. then fasten screw

4)

Make

the lever

5)

It is not necessary to adjust micro-switch

on this adjustment.

motor

52)

0.

can

screw 8 and

8.

get

lmm

The

play to

0.

clutch adjusting

rotate

f),

lock with nut

0.

sure the play is existing by moving

up

and down.

it

wear

360°.

-

Fig. 52

28

Page 31

(2)

Adju

I)

In

case t

you

r fee l

by

pressing

Loos

Fa

sten bolt 0 .

it.

the lighter.

Aft

er

bolt

Adjusting treadle pedal

Y

ou

can get

be

matched

so on.

an

gle

and

making sure clutch l

the most

with you on its weight.

In

this

case.

do adjustment on

positio n of treadle pecl<

ever

straightecl. (Fig. 53)

sting weight

hat

on

en nut 0 and

adjustm

f)

. (

Fig

at

slow

you

may gel inching

the

tread

it

lightly

as

adjust b

the

hea\

ent

is

over. fas

. 54-1)

speed sew

le pe

per

·ier

suit

able

and

by

dal

or

follO\\·ing

olt

f)

.

the

weight: and l

ten

nul 0 not

condition to

play

ll after

pull

rod

to

ing (inching)

merely pu

may

not

procedu

to mo\·e

and

the

be

lling

gel

res.

oosen

Fig.

53

it

2)

Adjusting

L

oosen nut 8 and

Fasten

it.

bolt 0 . th e h

the lighter. (Fi

weig

ht

at

g. 54-2)

thre

adjust

eav

ad

ier

trimmin

bolt

0 .

the

weight: and l

Fig. 54-1

g

oosen

Fig. 54-2

-

29-

Page 32

3)

Adjusting play

Loosen nut

Fasten bolt

the larger. (Fig.

The

bolt 0 can get

at

thread trimming

0 and adjust bolt

0.

the smaller the play; and loosen it,

0.

54-3)

1.8mm

play to rotate

the end of the lever.

At this adjustment, adjust the position of

switch

(3) Adjusting control box

as

well. (Refer Page

1)

Adjusting needle down position

33)

In case of irregular stoppage

at

needle down

position, or sewing machine runs

ously

at

slow speed without stoppage, ad·

just the timer

a. Remove

b.

Turn

VR-1

in

the control box. (Fig.

rear

lid of control box.

0 clockwise on Printed Circuit

Board.

Switch on, and press lightly the treadle

c.

pedal and set it as neutral.

that

At

ously

d.

At the above condition, turn

time, sewing machine runs continu-

at

slow speed.

VR-1

clockwise very clowly, and you will find

out the position where sewing machine

at

stops

VR-1

Switch off and put

e.

the needle down position, then turn

about

300.

counter-clockwise.

rear

lid onto control

box.

2)

Adjusting thread wiper

rear

a. Remove

b.

Turn

VR-2

lid of control box.

f)

clockwise and after needle

up position and time to begin to operate

the thread wiper becomes longer.

Also turn

VR-3 8 clockwise and after

thread wiping job and time to return the

wiper becomes longer.

Accordingly, to adjust the timing of two

regulators, you can get the most suitable

timing of thread wiper.

In case you may not need to wipe off the

thread, switch off switch

(NOTE)

To adjust regulators

VR-3,

careful not

those regulators.

with

screw driver, please be

to

touch anything except

8.

VR-1,

continu·

counter-

VR-2

360°

micro·

55)

and

at

Fig.

Fig. 55

54-3

-

30

-

Page 33

12.

Maintenance

( 1 ) Change of micro-switches

1)

Micro switch for inching

a.

Loosen screw 0 and remove micro switch

8 out of clutch lever.

b.

Pull out terminals 8 and relace switch.

Loosen nut

and adjust

c. Switch on, and

8 pressing by your finger, then sewing

bolt

machine runs slowly.

d.

Detatch your finger, turn bolt

and fix it by nut

2) Micro switch for thread trimming

a. Loosen screw

tioned-above. (Same micro switch is used

both for inching and thread trimming).

b.

Loosen nut 8 and bolt

c. Switch on, press the treadle pedal light

and get it

Press down the treadle pedal by your heel

after

@)

slowly pressing it

Fig.

42,

120°,

d. Detatch the treadle pedal and turn bolt

about

(Fig.

0,

in

at

needle down position, then fasten bolt

and sewing machine moves about

and gets needle

120°

and fasten. it with nut

57)

of

motor

unscrew bolt

the following manner.

as

per Fig.

0.

(Fig.

8.

41,

fasten slowly

56)

0 and replace it

@).

neutral position.

by

your finger

up

position.

fix switch

180°

further

as

men-

as

per

8.

@)

Fig.

56

Fig. 57

(2) Changing linings

In

case you replace the parts,

please clean up every points.

1)

Changing

slow speed motor.

a. Remove screw

••

b.

Remove bolt 8 and replace

brake

selation

c.

To

fix it, put the end of

spring

of

brake

end of spring into the hole

of spring fixture

45°

as per Fig.

bolt@).

brake

disc for

0 and cover

disc 8 together with

8.

0 into the hole 8

disc and another

8 and turn

58,

and fasten

-

31

-

Fig.

58

Page 34

2)

Changing clutch plate for slow speed motor

a. Detatch the plug out of slow speed motor

0 as per Fig.

wire

b.

Loosen screw

c. Loosen flat head screw 8 and replace clutch plate

f)

and remove slow speed motor

59.

8.

Fig.

59

••

d.

In

this case, replace friction disc 0 and selation

8.

as

well, by loosening screw fi). (Fig.

To

assemble it, take steps

ble,

at

that time, it

clearance.

e. Install clutch plate

f. Insert one end of spring

retainer

0 and the other end into the hole in disc

is

0 with screw

as

reverse to disassem-

unnecessary to adjust the

CD>

into the hole in spring

60)

8.

0 on the other side, and then attach them to the

motor shaft.

g.

The

hole in disc 0 is about

elliptical end of the motor shaft (Fig.

0 about

disc

(Fig.

60-2)

h.

Insert the spline shaft, and tighten washer m with

fi).

screw

i. Install motor 8 with screws

j.

Insert auxiliary motor cord plug 0 into the plug

socket. (Fig.

*No

clearance adjustment

60"

counterclockwise and fix it.

60)

60"

a way from the

f).

is

necessary.

60-1),

so turn

'

'

_>

..................

~--

----

------

......

--

__

~

-~~-

~

Fig.

60

(NOTE)

1.

Spring

spring

former.

2.

When replacing the spline shaft, replace also

the disc.

tD

so

is

wound opposite

the

latter eannot be

to

the brake

used

for the

-

32

-

Fig. 60-1

Fig.

60-2

Page 35

(4) Changing lead switch

a. Remove cover and pull out the terminal

b.

Remove screw 8 and replace lead switch

c.

To

put the terminal 0 must be done with red

wire to be sewing machine pulley. (Fig.

(NOTE)

Do not knock or drop LEAD

to

give extra-ordinary shocks.

0.

C).

64)

SWITCH

. Fig.

64

-

34

-

Page 36

13.

Trouble

shooting

(A) In relation with the sewing machine

(1)

Fail

to

trim the threads.

a. Both threads

CAUSE:

are

caught by knife

Knife is not sharp enough.

( I ) Flaw on the knife.

ADJUSTMENT:

CAUSE:

ADJUSTMENT:

CAUSE:

Replace

(II)

Knife is worn out.

Replace

(III)

Incorrect setting the knife, especially check the space between knife and lower

thread finger.

ADJUSTMENT:

b.

Upper thread

Remove lints

Is

trimmed but comes out of needle eye

or

trimmed.

CAUSE:

Incorrect setting of the knife.

the needle.

ADJUSTMENT:

(I)

Fasten securely two flat head screws for knife. (See

CAUSE: Incorrect position of the lower thread finger.

ADJUSTMENT:

Make

sure the clearances between knife and lower thread finger is 3mm.

(See Page

23-

29)

c. Upper thread is not trimmed.

head

dusts and/or replace.

The

point of knife should be

at

the beginning

or

lower thread is not

in

the centre axis of

Page

20-21)

CAUSE: Out of timing the knife.

ADJUSTMENT:

d.

Needle

breaks

CAUSE:

ADJUSTMENT:

Correct it. (See Page

at

the beginning.

of timing the thread trimming signal.

Out

19

V)

) .

At the needle's lowest position, get the synchronizer magnet

switch for thread trimming.

(See

Page

27-28

(6))

e. Knife does not move.

CAUSE: Solenoid does not function.

ADJUSTMENT:

f.

Thread

trimming signal functions properly, but knife does not move.

CAUSE: Out of adjustment

ADJUSTMENT:

( I ) Make sure

(II)

Check the circiut (See Page

(III)

Adjusting of knife stopper (See

that

you press the treadle pedal by your heel.

41

(13))

Page

21-23,

on

thread trimmer knife stopper.

Fig.

Adjust knife stopper to get 3.5mm clearance by pushing it by your finger.

(See Page

22

N)

g. Knife does not trim the threads sharply and abnormal noise comes from

CAUSE: Knife does not move

( I ) Incorrect setting of knife stopper.

ADJUSTMENT:

Readjust two fastening screws for stopper guide

holder detanches so quickly.

CAUSE:

ADJUSTMENT:

(II)

Heavy movement of holder.

Adjust the fixture of holder

360°.

(See

bracket

Page

21

so

as

contact between clutch and

III)

that

holder moves without much re-

sistance.

CAUSE:

ADJUSTMENT:

(III)

Too

early timing of needle up position.

Delay the timing a little. (See Page

27-28

(6))

31,

rotary

32, 33,

in

line with lead

34,

35)

hook.

-

35-

Page 37

h.

When removing the materials, you feel resistance.

CAUSE:

ADJUSTMENT:

i . Lower thread is not trimmed.

CAUSE: Incorrect

ADJUSTMENT:

Upper thread is not trimmed.

j .

CAUSE: Skip stitch on the final stitch.

ADJUSTMENT: ( 1)

CAUSE: Improper setting the hook position bracket.

ADJUSTMENT:

(2) Thread-off at the beginning.

a. CAUSE:

ADJUSTMENT:

b.

CAUSE:

ADJUSTMENT:

c.CAUSE:

ADJUSTMENT:

d.CAUSE: Incorrect combination on thread and needle size.

ADJUSTMENT:

e.

CAUSE: Position of the knife and the flaw on it.

ADJUSTMENT:

f.

CAUSE: Timing of the knife.

ADJUSTMENT:

Upper thread for the

It prevents smooth movement of the knife, therefore, get stronger tension on the

pre-tension. Especially, in

recommended to be about 30mm.

rotary

Use special

Set the needle correctly.

(II)

Get the smaller

(III)

Adjust the needle down position. (See

Adjust the position of

you put the machine head on the head rest.

Thread

Check the circuit. (See

Too

small opening on tension discs.

Check the position of tension release lever. collar and upper tension regulator,

and get the correct positions.

Too

high the position

Get weak tension, also check the thread passes

the upper thread.

In

case of thinner thread against needle size, it causes such a trouble, then,

check the size.

Needle

#7-9

#

11-14

#

16-18

In case

eye.

In

the upper thread out of the needle eye.

Advanced timing of the knife causes too short thread out of the needle eye, thus

check the timing of clutch.

rotary

release solenoid does not function.

of

existing flaw on the knife, it causes the sf1orter thread

case of improper position of the knife causes thread trimming even on

next

stitch is so long.

case

of thick thread, the thread out of needle eye is

hook is used.

hook, for BROTHER 8705-100 Series.

stroke

Thread

#

#80-50

#40-20

of thread take-up spring.

rotary

Page

at

100-120

hook position

41

(13))

the needle up position.

(See

Page

Page

Check it, adjust

23

V)

28

Fig.

bracket

in

order to

50)

to be the downmost when

get

smooth supply of

out

of

the

needle

or

replace it.

(3)

Skip stitch

a ·CAUSE:

ADJUSTMENT:

b. CAUSE: Improper usage of needle, plate and presser foot.

ADJUSTMENT:

at

the

beginning.

Too

short

thread

Get the proper length of thread. (See Page

Use correct ones. (See

out of the needle eye.

Page

18)

-

36

-

18)

Page 38

c. CAUSE:

ADJUSTMENT:

d.

CAUSE:

ADJUSTMENT:

e.CAUSE: Knife is not

ADJUSTMENT:

(4)

A bad thread wiper

a.

Thread

CAUSE: Operating time too long.

ADJUSTMENT:

CAUSE: Presser foot is automatically raised too soon.

ADJUSTMENT:

b.

Thread

CAUSE: Uper thread too long.

ADJUSTMENT:

CAUSE: Cloth and presser foot have too

ADJUSTMENT:

CAUSE: Operating time too short.

ADJUSTMENT:

CAUSE:

ADJUSTMENT:

wiper hits needle and will not return.

wiper cannot remove upper thread from work.

Lower thread does not come up.

lnproper usage of bobbin and bobbin case.

When the thread trimming is done, bobbin runs idly

length of the lower

Get the proper spring action of the bobbin case to be

Also use alminium flat sided bobbin.

Shape of

In

to catch the lower thread.

case the upper thread loop fails to catch the lower thread.

Excessive oil supply to the

thus

Get the little oil flow to the rotary hook.

In

too excessively by the knife movement, thus it causes idle running

case.

Adjust operating time.

Adjust presser foot operating time.

Adjust pre-tension

Replace presser foot with one having.

Adjust operating time.

Thread

Adjust operating time.

rotary

case of improper shape of the

same

trouble

sharp

case of dull knife. when thread trimming is done. the lower thread is pulled

wiper operates too soon, wiping thread before tension disc closes fully.

thread is shortened.

hook and oil to the hook.

The

lower thread is wound into the hook in which

as

above

enough.

rotary

hook causes the lower thread stick to the hook,

\Vill

cause.

great

(See Page

rotary

resistance.

hook, especially on the point of groove

19)

in

the bobbin case, thus the

5-10

grams.

in

the bobbin

NOTICE ON CHECKING MOTOR AND CONTROL BOX

1.

Make

sure to switch off when you plug in and off.

2.

On

Blue plug, the voltage on this circuit is very low, then it is not so dangerous even though you may be

short circuit.

3.

To

check the resistance on Blue plug, please use the tester with X

avoid troubles on various switches.

4.

Check the voltage ONLY on White plug out of control box.

5.

To

check the resistances on White plug and others, please use the tester with X 1 Ohm Range.

6.

To

check the circuit with the tester, running the sewing machine, it

a slight movement.

7.

Switch off when you may remove the

8.

To

replace Fuse,

make

sure to use 3A's.

rear

lid of the control box.

-

37

-

1000

Ohm Range

is

alright for the circuit if tester shows

or

more,

in

order to

Page 39

1 )

Motor

a. CAUSE: No electricity puts

ADJUSTMENT:

b.

CAUSE: Out of function on switch

ADJUSTMENT:

c.

CAUSE: Out of order on pilot lamp.

ADJUSTMENT:

2)

High speed motor does not run.

does not run. Pilot lamp

Check the electricity by the tester.

Check the circuits by the tester.

Replace.

on

the control box

in.

and/or

is

off.

wires.

a. CAUSE: Incorrect adjustment on the clutch spacing.

ADJUSTMENT:

( I ) Press the threadle pedal on the front without electricity and turn the sewing

machine pulley by hand. Running smoothly is right.

(II) Make sure the play on the treadle pedal to be 7mm

b.

CAUSE: Incorrect or imcomplete plug-in on high speed motor.

ADJUSTMENT:

c.

CAUSE: High speed motor runs as single phase.

ADJUSTMENT:

d.

CAUSE: Mal-winding on motor.

ADJUSTMENT:

( I ) Plug should be inserted with red marking on the connector.

(II)

Plug should be inserted to its fullest extent.

Plug off out of the receptacle on the motor body, and switching on, check the

3,

2 and

7,

3 and

voltage between 2 and

If

the tester shows the voltage you

7.

are

now using there, it is alright.

Replace motor itself.

or

more.

(3)

Reverse rotation of high speed motor.

a. CAUSE: Electricity is not proper.

ADJUSTMENT:

(NOTE)

The reverse rotation cannot

clutch motor features.

(4) Sewing machine runs

Change two wires out of three.

be

obtained with this BROTHER N. P.

at

slow speed continuously.

a. CAUSE: · Out of adjustment on micro-switch for high speed sewing

ADJUSTMENT:

( I ) Plug off the wire for micro-switch for high speed sewing, then switch on.

If

it stops, the micro-switch is out of order.

(II) Remove the micro-switch for high speed sewing out of clutch lever cover.

Check the circuit between terminals.

In

case of the circuit being short, adjust the micro-switch.

In

case of the circuit being right, replace micro-switch.

CAUSE:

b.

ADJUSTMENT:

Mal-function of

If

it does not stop

P.

C.

at

B.

step

(I),

the P.

C.

B.

must be replaced.

Motor

or

out of order.

as·

BROTHER

- 38 -

Page 40

(5) Sewing machine does not run

at

slow speed.

a. CAUSE: Setting of

ADJUSTMENT:

b.

CAUSE:

ADJUSTMENT:

c.

CAUSE: Micro-switch for high speed sewing is out of order

ADJUSTMENT:

CAUSE: Mal-function on slow speed motor.

d.

ADJUSTMENT:

If

the sewing machine pulley moves smoothly by your hand, it is alright.

Fuse

Switch on, then if the sewing machine pulley does not move, it is alright.

In

case

( I )

(II)

(III)

Plug off 3P plug, being short on the junction box terminal I-3 on the control box,

and switch on. In case

switch is out of

case

In

( I ) Remove micro-switch for high speed sewing, plug

Push the pull rod and if the sewing machine runs

is not correct.

(II) In case

nals for micro-switch, and if the sewing machine runs

is

out of order.

(III)

In

case of not running

Mal-function on

Check the resistance between I and

off

3P plug.

brake

lining is out of order

or

P.

C.

B.

is

out

of

order.

that

the pulley moves, mal-function on control circuits.

Fuse·· .... Remove and check it.

P.

C.

B.

P.

C.

B.

of running

In case

Use 3A Fuse

for electricity } Plug off

for electronic control swttchmg on, check the voltage to be

order

at

that

the sewing machine does not run, being short between the termi-

that

the sewing machine does not run in step

P.

C.

If

the tester shows between 0 to oo, it is alright.

as

replacement.

that

the sewing machine runs

or

adjustment.

slow speed;

at

slow speed;

B.

or

Fuse.

or

gears

either between the terminal No. I and

3 and 4 on the control box junction terminal.

This

must be alright.

2,

1 and

are

out of order.

4P

plug for clutch and brake,

or

adjustment.

at

slow speed, the micro-

in

3P

plug and switch on.

at

slow speed, the adjustment

at

slow speed, micro-switch

(I),

wire is wrong.

3,

and 2 and 3 on the motor being

27V

2,

or

e.

CAUSE: Wrong wire on slow speed motor.

ADJUSTMENT:

f

· CAUSE: Coils

ADJUSTMENT:

(6) Reverse rotation of slow speed motor.

a. CAUSE: Wrong wiring.

ADJUSTMENT:

Being off 3P plug, switch on, and check the voltage between the terminals 1 and

2,

I and

3,

and 2 and 3 on the control box.

If

the tester shows the voltage you

are

damaged.

Being off 4P plug, check the resistance between 1 and

If

the teste): shows between 0 and oo, it is alright.

Correct it.

are

now using, it is alright.

2,

and 3 and 4 on the motor.

-

39

-

Page 41

(7) Sewing machine does not stop.

a. CAUSE: Reed switch for needle down position

ADJUSTMENT:

b.

CAUSE:

ADJUSTMENT:

Being off

on and let the treadle pedal

If

the sewing machine stops, reed switch

adjustment.

Timer

( I ) Being off

6P

is out

plug for synchronizer, short on 5 and 6 on the control box, switch

at

If

the, sewing machine does not stop,

of

adjustment.

6P

plug, switch on, and let the treadle pedal

then check the circuit between 5 and 6 on the pin out of synchronizer.

If

it can get ON

or

OFF, the timer

(II) Remove synchronizer cover and check the circuit for needle down position.

If

it can get only OFF, reed switch is out of order.

If

it

can

get

ON

or

OFF, the wire is wrong.

(Ill)

If

it does not stop even though the timer

order.

(8) Sewing machine does

not

run constantly

at

high speed.

a. CAUSE: Screws for adjusting clutch play

ADJUSTMENT:

Readjust.

is

out of order

the neutral position.

is

out of order,

P.

is

out of adjustment.

is

well adjusted,

are

loosened.

or

wires

or

the timer is out of

C. B.

is mal-functioned.

at

the

are

damaged.

neutral position,

6P

plug is out of

(9) Sewing machine stops

a. CAUSE:

ADJUSTMENT:

b.

CAUSE: Out of adjustment on the timer.

ADJUSTMENT:

at

random

Weak

tension of V-belt.

at

its needle down position.

Tighten it.

In

this case, stop position is

at

needle down position

Check the timer and correct it.

c. CAUSE: Out of order on reed switch for needle down position.

ADJUSTMENT:

(1

0)

Sewing machine stops

a. CAUSE:

ADJUSTMENT:

Sewing machine stops in any position. Replace reed switch.

at

needle up position.

P.

C.

B.

for electronic control is out of order.

Being off 3P plug, switch on and short the circuit between 1 and 2 on the control box and

detach

it. In case of getting the needle up position,

after

making sure

that

the sewing machine runs

is out of order, and replace it.

b.

CAUSE:

ADJUSTMENT:

Micro-switch for thread trimming is out of adjustment

In case of getting the needle down position remove the micro-switch out

cover, plug

in

3P plug switch on, and let the treadle pedal to be

position.

Needle up position ......... Micro-switch is out

Needle down

p~sition

..... Micro-switch is out of adjustment.

of

order.

or

too much irregular .......

at

P.

C.

B.

for electronic control

or

order.

at

slow speed,

of

lever

the neutral

( 11 ) Incorrect position

at

needle

down

position.

a. CAUSE: Incorrect position of reed switch.

ADJUSTMENT:

Adjust the synchronizer.

40

l

Page 42

(12)

Sewing machine does not run

at

slow speed.

a. CAUSE: Micro- switch for thread trimming is out of order.

ADJUSTMENT:

Being off plug for micro-switch, set the position

on, and be short the circuit between 1 and 3 on the control box.

If

it runs, micro-switch for thread trimming

If

it does not run,

b.

CAUSE: Micro-switch for thread trimming is out of adjustment.

ADJUSTMENT:

( I ) Remove micro-switch for thread trimming out of lever cover, plug

on, set the needle

If

it runs, micro-switch for thread trimming is out of adjustment.

If

it does not run, micro-switch for thread trimming is out of order.

(II) At the step ( 1

If

it runs, micro-switch is out of order.

If

it does not run, wire is wrong·.

(13)

Thread trimming

and

releasing does not function.

P.

C.

B.

for electronic control is out of order.

at

its down position, and push the pull rod upward.

),

be short the circuit of terminal of micro-switch.

at

needle down position, switch

is

out of order

or

adjustment.

in,

switch

a. CAUSE:

ADJUSTMENT:

b. CAUSE:

ADJUSTMENT:

Too

short timing to press the treadle pedal down.

Press it down until needle goes

P.

C.

B.

for electronic control

(I

) Being off 9P plug, switch on, and

down position, and let the treadle pedal down by your heel.

At

that

time, check the voltage between 1 and 3 on the control box while needle

moving up from its down position.

If

the tester shows a slight movement,

trimming is out of order.

Check the voltage between 4 and

(II)