Page 1

BUTTON

FEEDER

--

INSTRUCTION

--

-----

MANUAL

-----~

CB3-B917

/BA-1 0 ....__

_

Page 2

{

Main

Part Names ) ....

...........

CONTENTS

....................................................

..............

.............

.....

................................ .

( Installation ) .

OJ

Work

table

[2)

Starter ...

~

Vibration

~

Control

[Q]

Sewing

[Q]

Button

CZl

Cord

~

Cover .......................................

~

Shooter

[Q]

Starter

feeder ....

connections

connecting

..

. . . . . .

..

prep

arat

.......................................................

bowl .....................

box ....

machine

............................

head ..............................................................................

....... ....... ...........

........................................................... .......................................................................... 4

.......... .....................................................

rod

. . . .. .. . . . .

.. . ...

. . .. .

..

. . . . . . . . . .

...

. ...

... . ..

. . . . .. . .

..

. .

.. . ..

. .

...

. .

..

. . ... . . . .

..

. . . . . . .

..

. .

.. ... . .

...

. .

... . ... . .. . ...

ion ...................................................................................................................

......

.....

..... ..

and

...........................................

......

..........

......

...................................

...

..........

................................................................................................

............................................... .........

.........

........

..........................................................................................

....

................. ......................... ........................................ 6

operating

lever ...........

..........

....

............

....................... .........................

....

...... .....

...

....

....

..... ....... ....

..........................................

................................ 2

.......................

...... ....... .....

............. 6

. . ... . .

..

. . 2

......... 2

...

......... 3

..

......... 3

....

....

..

...... 6

3

4

( Correct Operation) .

OJ

Vibration

[2)

Operation

~

Sewing ....

~

Adjustment

[Q]

Tilting

[Q]

Need le installation

ball ...........................

panel

switches .... ........ ...............

.....

....

.....

....

for

excess

the head ............................................. ............................

................................................

( Button Replacement)

OJ

Adjustment

[2)

Adjustment

~

Nee

dle location

for

buttons of

when

button thickness changes

adjustment

..

. . . . .

..

. .

..

. . .

..

. . . . .

....

.....

.........

................... ................

buttons

.....

in

the

..

. . .

..

. . ........

different

..

. .

..

. . .

..

. . ...

....

..

. . . . . . . .

..

. .

..

...

.. .....

..

. . .

..

..

. . .

..

. .

..

. ..

...

. .. .

..

. .

..

. .. . . . .

.. . .. . ...

. . . ... .

....

.................................................................................................... 7

.......... .......... ...... .......... ................................ ......................... 8

....

..............................................................................

butt

on

..

.. ... . . . . . . . . . . . ..

exte rnal di

shooter ...

ameter

..................................

......

...........................................

................................

..........

............................... .......................................... 9

...

. .

..

. . .

...

. . . .

..

. .

..

. . .

..

. . . . .

..

. .

..

. . .

..

. .

..

.....

.......................................................................... 10

......................................................

...... ............

............................... 9

...

. .

...

. . . . ..

..

..

. ..

....

... . ...

...

..

..

. . 1 o

..

11

12

7

8

8

( Adjustment Guide)

....

............

...

............

....

.........

...............

...

...... ...............

......

..........

..........

.....

........... .

..

15

Page 3

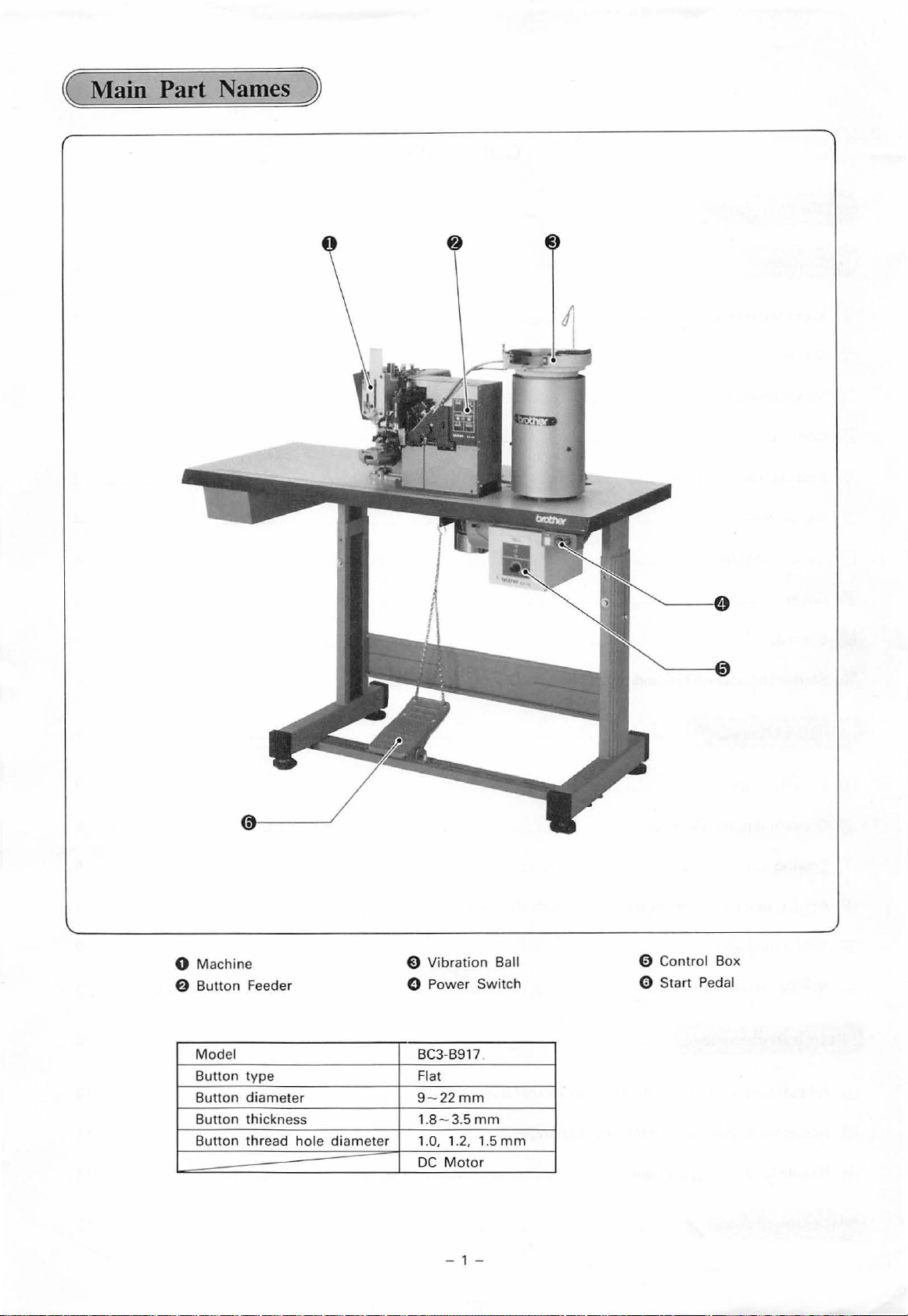

( Main Part Names )

0

Machine

6

Button

Model

Button

Button di

Button thickness

Button

Feeder

type

ameter

thr

ead

hole

diameter

Vibration

0

Power

BC3-B917

Flat

22

9-

1.8 - 3.5

1.0, 1.2, 1.5

DC

Motor

- 1 -

Ball

Switch

mm

mm

mm

E)

0

Contro

l Box

0 Start Pedal

Page 4

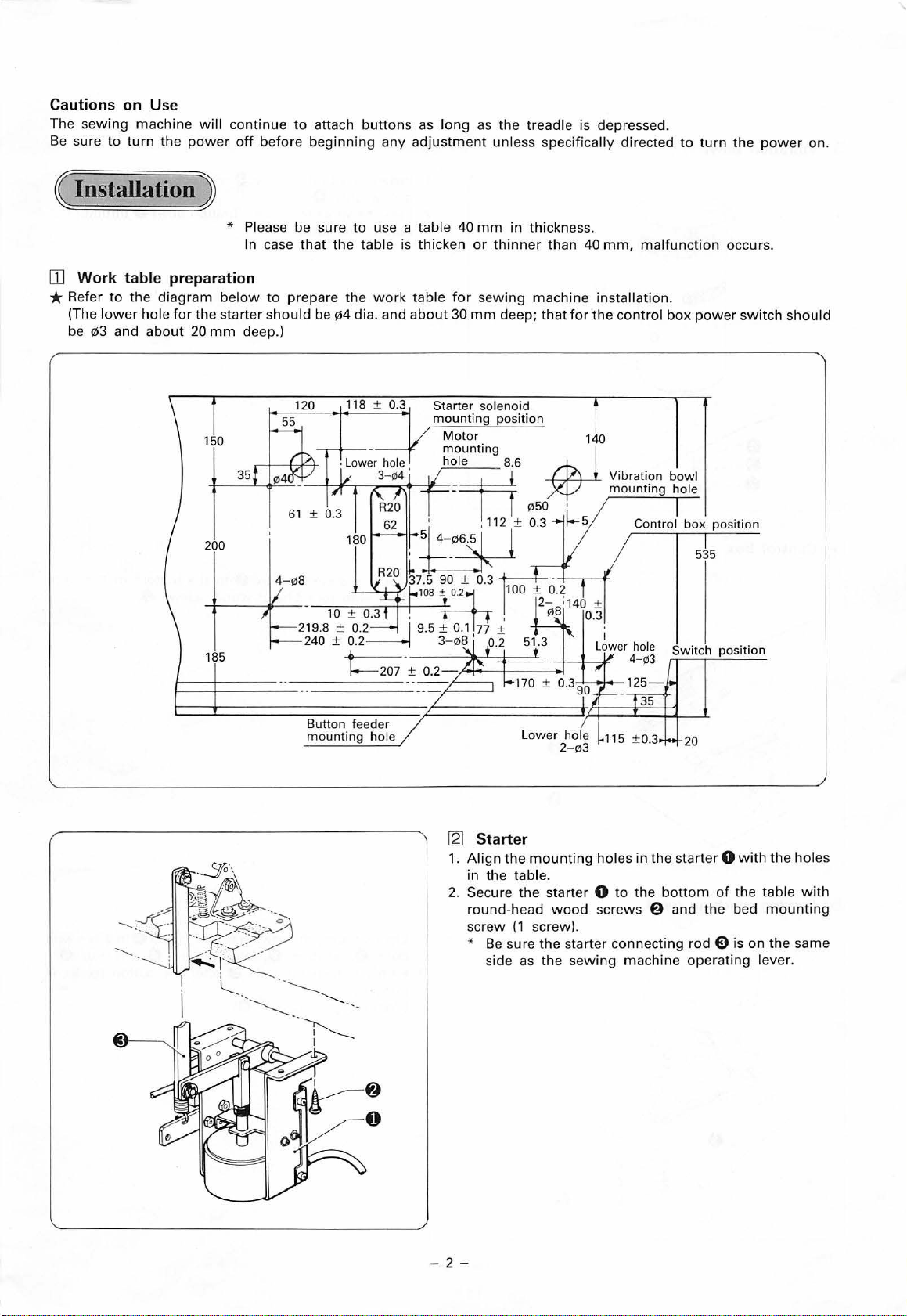

Cautions on Use

The

sewing

Be sure

to

machine

turn

the

power

( Installation )

OJ

Work table preparation

* Re

fer

to

the

diagram

low

er

and

hole for

about

20

(The

be

!1l3

will continu e

off befo

* Plea

In case

below

to

the

starter

should

mm

deep

150

35

to

attach

re

beginning any

se

be sure

that

prepare

be

.)

61 ± 0.3

buttons

to

use a table 40

the

table is thicken

the

work

!1l4

dia

. and

118

± 0.3

as

long

adjustment

or

table

for sewing

about

30

mm

as

the

treadle is depressed.

unless specifically directed

mm

in

thickn

ess.

thinner

deep; that

than 40

machine installation

for

mm,

the

control

to

turn

malfunction

.

box

power swit

the

power

occurs.

ch

on.

should

200

185

4- 08

Button feeder

mounting

hole

[2] Starter

1.

Align

the

in the table.

2.

Secure

round-head

screw

the

(1

* Be sure

s

ide

as

mounting

starter 0 to the

screw).

the start

the

holes

wood

screws @ and the bed

er

connecting

sewing

535

20

in

the starter 0 with

bottom

rod

machine opera

position

of

the

0 is on

ting

the

holes

table

with

mounting

the same

lever.

-2-

Page 5

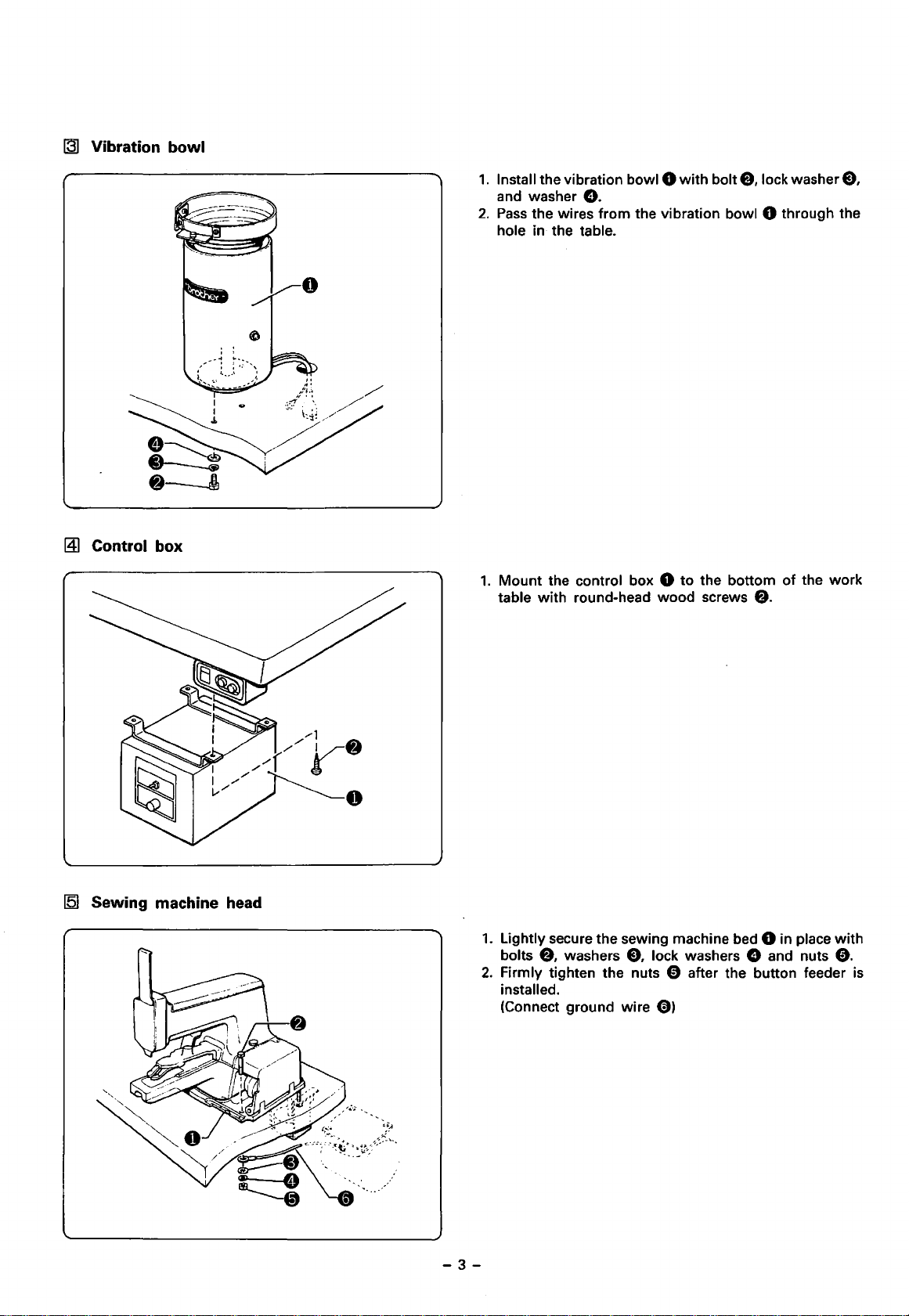

[31

Vibration

~

Control box

bowl

1.

Install the vibration

and washer

2.

Pass

the wires from the vibration bowl 0 through the

hole in the table.

1.

Mount

table

the control box 0

with

round-head

e.

bowiO

wood

with

bolt

to

the bottom

screws

e,

lock washer E),

of

the

e.

work

[5]

Sewing machine head

1.

Lightly secure the sewing machine bed 0 in place

bolts

e.

washers

2.

Firmly tighten the nuts 0 after the button feeder

installed.

(Connect ground wire

-3-

e.

lock washers e and nuts

0)

with

0.

is

Page 6

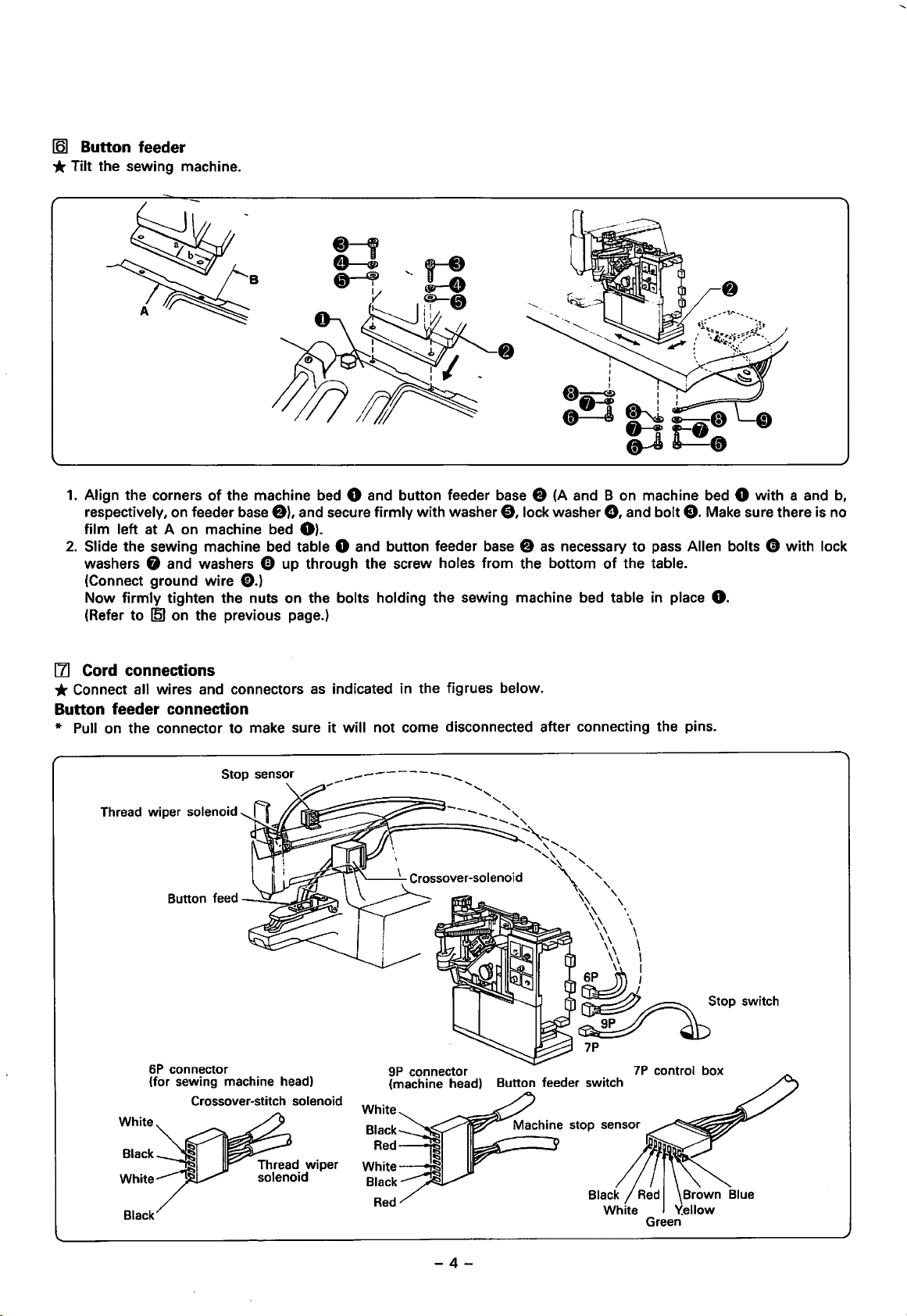

161

Button feeder

*Tilt

the sewing machine.

1.

Align the corners

respectively, on feeder base

film left at A on machine bed

2.

Slide the sewing machine bed table 8 and button feeder base 8

washers 0 and washers 0 up through the screw holes from the bottom

(Connect ground wire E).)

Now firrrily tighten the nuts on the bolts holding the sewing machine bed table in place

(Refer to

151

of

the machine bed 8 and button feeder base 8 (A and B on machine bed 8 with a and

f)),

and secure firmly with washer

8).

on the previous page.)

0,

lock washer

as

0,

necessary

of

and bolt

the table.

8.

Make sure there is no

to

pass Allen bolts 0 with lock

8.

b,

[1] Cord connections

* Connect all wires and connectors

Button feeder connection

* Pull on the connector to make sure

Thread wiper solenoid

Button feed

6P

connector

(for sewing machine head)

Crossover-stitch

solenoid

as

indicated in the figrues below.

it

will not come disconnected after connecting the pins.

9P

connector

(machine head) Button feeder switch

White

7P

Black~

Red,

White

Black.---·~

~

Red

control box

-4-

Page 7

Control box connection

* Connect

the

ground

wire

from

the vibration bowl

to

the motor.

9P

connector

2P

connector

3P

connector (female)

Black

White

Power switch connection

White

Black

Green

Power switch connector

(control box)

Control box

Green--"'"""''

Black--~IL.

White--""""''

....

Red----ftO\'

White

Brown

Red

~;;;;;;

-5-

Page 8

IB1

Cover

~

Shooter

* Attach the button feeder cover 8

f)

with

screw

e,

lock washer

*

Be

sure

to

pass the wires through the hole in the cover

when attaching the button feeder cover

1.

Raise the shooter lock pin 8 on the vibration bowl

and secure the shooter e

through the notch in the shooter.

2.

Secure the shooter 8

feeder

0.

with

to

the button feeder

e,

and washer

by

inserting the pin e

thumb

screw 8 on button

8.

0.

8,

H]J

Starter connecting rod and operating lever

1.

Tilt the sewing machine.

2.

Mount

3.

Mount

4.

Pass

with washer

·* After this installation refer

the spring peg 8 on the bottom

the operating lever spring 8 on the peg.

the starter connecting rod pin 8 through the starter connecting rod 0 and operating lever

0 and snap ring

to

8.

page

of

the sewing machine bed table.

22

and readjust the starter solenoid.

* As shown in the figure above, the hole in the starter connecting rod 8 are not located in the center

Mount

the rod

with

the

wider

hole-to-edge gap towards the operating lever spring

-6-

f).

0,

and secure the pin

of

the

rod.

Page 9

( Correct Operation )

ill

Vibration ball

(1)

Switch

Switch

(2)

Turn

(3)

The amount

increase

decrease

ON

ON

the

adjustment

when

when the

the

pow

er

switc

the switch 0

knob

of

vibration

the

knob

knob is

for

is

turned

h.

@.

of

turned

the con

the

vibration ba

to

the r

to

tro

the

l box.

ight,

and

left.

ll w ill

will

Adjustment of

btother

the

vibration ball

BA-1

0

*The vibrating

If the

buttons

(1) Loosen

plate B 0 and the

(

2)

Loosen

plate C 9 and the v

Make sure any st

(3) L

oosen and

pla

te

(4) L

oose

oose

(5) L

is

approximately 0.7

(6) Loosen scr

mm

2

When

(7)

at the e

* The

bowl

are

not

and

adjust

and

adjust

adjust

A 0

and

n a

nd

adjust

n a

nd adju

ew

0 . and

so that

buttons jam

vibrating

ntran

the button

ce.

arranges the face

fed

properly, adjust

set

screw@

vibrat

set

screw 0 so

ibrating

anding

set

screw 0 so that

the vi

brating

bolt 0 so that the

st

screw

mm.

adjust

at

the

bow

l s

hould

so

ing

bow

bow

buttons

bowl.

~

so

that the

the

s will be fed sm

entra nce

be a

of the

that

two

l.

that

one

l.

are

turned

one

button

gap

gap

between

to

the shooter,

djust

ed each

buttons

as

in

the same

follows

buttons

button can pass

button

between

oothly

.

can pass

dow

n, and

can pass thr

faces are ali

the

the button

to the

loosen

time

-

7-

direction,

through

through the

that

the

buttons flow

ough

gned

when

bottom

thumb

the

of

the hei

and button width

shoo

ter.

scr

ew

button

s are changed .

and

the

gap

gap between

the

gap

the

sorting

ght

'f)

and turn

feeds the

bet

ween

smoothly.

between

pla

control

contro

l plate

so

plate 0

that

buttons

the

bottom

the

bottom of

the bot

te

0 is

G)

the

to

of alignment

tom

of

slid

and

the

to

appro

buttons

the

shooter.

alignment

ali

gnment

in and out.

button

xima

tely

do

not

jam

top

Page 10

[21

Operation panel

[3)

Sewing

switches

'---------'L----1

...;r-+-ii--·

1.

Button feeder switch

*

Be

sure

to

set the switch 0

2.

Trouble indicator

(1)

When buttons are being fed

the trouble indicator

(2)

When the trouble indicator

are not supplied

If the emergency stop indicator on the operation panel

is blinking, press EMERGENCY

indicator off.

3.

Manual switch

* Operates as the button-feeding switch.

6).

to

the button clamp.

* Only operable when the

"head"

4.

Crossover-stitch switch 8

*

Can

crossover stitch

* When

twice

*

If

once.

and the stop lamp is

be used

"crossover" is selected, sewing is started only

for

selection

for

4-hole buttons.

"no

crossover" is selected, sewing is started

for

one button.

to

to

f)

will

be

f)

is flashing, buttons

STOP

mode

not

of

crossover stitch

ON.

the button clamp,

OFF.

·to turn the

switch is set

flashing.

or

to

no

~

Adjustment

for

excess

buttons

in

the

button

*Turn

shooter

(1)

(2)

(3)

the power switch on.

clamp, the button

will

If

a button is in the button

be sewn on

wlien

the start pedal

0 is pressed.

Buttons

held depressed. Release the pedal

To feed a button

bowl and button feeder switch on.

Turn the button carrier 0 by hand in the direction

the arrow, and remove any button(s)

to remove any excess buttons

point

Press the manual switch to feed a button

clamp. Press the pedal

will

continue

to

be attached

if

the pedal 0 is

0.

to

the button clamp, turn the vibrating

from

the button

carrier pin

With the button carrier 0 in this position, pull lever

A. ·

e.

from

to

begin sewing.

the shooter at

to

the button

of

6)

-8-

Page 11

151

Tilting the head

* Before making this adjustment, be sure to switch

161

Needle installation

OFF

the power switch and stop the

(1)

Remove bed base cover R 8 and remove the V-belt f.).

For installation and removal

easily removed

more

machine side is being manually turned.

(2) Remove the arm bed holding belt 0 and

machine

downward.

while

motor

of

the V-belt f.), it can be

the pulley e at the

pulley.

tilt

the

(1) With the long groove

front, insert the

set screw

Use TO x 1

needle all the way in and secure

e.

of

the needle 8 facing

to

the

with

-9-

Page 12

( Button Replacement )

III Adjustment for buttons

1.

Bed

slide adju

stment

0 '

(1)

Adjust

the

width of

smooth

The bed sl

Adjust so that the clearance

(2) There are

installed.

To

Adjust

(3)

scr

attach

the

ew

0 and ad

ly.

ide

two diff

butto

button gui

tab

ns

the s

le

eren t

from

ju

st

of

different external diameter

lide

table

assembly

between

button

15 to

22

de

sha

ft

button

assembly

f)

can be adjusted

upper

mm

in

and the plate

stopper s

f)

the

buttons 0 and the edge

covers 0 . The

diam

eter, loosen scr

cam

haft 0 so

by

using the slide table

for

butt

on di

cove

r for standard button sizes

ew

0 a

so

that

the

button

that

button

screw

ame

ters

of

the slide table

nd

replace

s are se

stopper

E)

so

that

of

9 to

22

assembly

cover 0 (non

nt along one

sha

ft 0 intervenes

the

buttons

mm.

of 9 to

standard accessories).

by

one

0 pass a

f)

is 0.5 - 1.0

17

mm

. Loosen

between

is initially

the thum

buttons.

long

mm.

b

2.

Button

(1) Loosen step

(2)

(3)

(4

) Firm ly

clamp

adj ustment

Lightly

Close the

tighten step scr

tighten

screw

button

step

0 and insert a

ew

0 . and

clamp

screw

f)

opening 0.5 to 1.0

0 .

button

remove

into the

the

button.

mm

button

using

clamp

the plate

0.5 mm- 1.0

f)

.

E)

.

mm

- 1

0-

Page 13

3.

Shooter replacement

(1)

Lift the shooter lock pin

(2)

Remove

Adjust

the table below.

thumb

for

button diameter and thickness as shown in

screw

0,

and remove the shooter

8,

and replace the shooter

e.

e.

121

Adjustment

Thickness

when

button

thickness changes

Shooter

Mart

A

~-

B

c

D

E

F

G

H

J

K

L

M

N

p

(1)

Check to be sure that buttons 0 are being

sent

(2)

Adjust the bed slide height so the buttons 0 slide

smoothly.

Install accessory spacers

thickness.

(3)

Check

grasped

~b

a

15mm

17mm

25mm

13mm

13mm

15mm

15mm

17mm

18mm

20mm

20mm

21

mm

22mm

25mm

to

the shooter

to

be sure that buttons are being securely

by

the button clamp.

b

2.7mm

3.5mm

4.0mm

2.5mm

3.0mm

3.2mm

3.8mm

4.0mm

4.5mm

3.5mm

4.0mm

4.5mm

5.7mm

4.7mm

e.

* The standard gap is

Button

~

Diameter

9-12mm

11-14mm

12-16mm

16-22

mm

9-12rnm

11-14mm

11-14mm

12-16mm

12-17mm

14-18mm

14-18mm

15-19

mm

15-19

mm

16-22

mm

Replace the shooter.

as

required

for

buttons 1.8 to 2.2

Thickness

1.9-2.3mm

2.5-3.1

2.8-3.6mm

1.8-2.1

2.1-2.6mm

2.2-2.8mm

2.7-3.4mm

2.8-3.6mm

3.2-4.1

2.5-3.1

2.8-3.6mm

3.2-4.1

4.0-5.3mm

3.3-4.3mm

smoothly

by

the button

mm

Thickness

mm

mm

mm

mm

mm

thick.

0

* When using the button catch plate 4

--,a

r-

®.-0b

-

~

A

B

c

D

E

F

G

H

J

a: hole gap

3.3mm

3.8mm

2.6mm

2.8mm

3.0mm

3.2mm

3.4mm

3.6mm

3.8mm

0b:

1.2mm

1.2mm

1.0mm

1.2mm

1.2mm

1.2mm

1.2mm

1.2mm

1.2mm

hole

I

I

Spacers

B~tton

thrckness

mm

in height, attach the washer (No. 506029-001

h

!

II

I

h: height

3 c

3 D

4

4

4

4

4

4

4

~

A

B

E

F

G

H

J

K

L

-

11

-

thickness

1.8--

2.2

2.2-

2.6

2.6-

3.0

3.0-

3.4

@_0b

a: hole gap

2.7mm

3.1

mm

2.4mm

2.2mm

2.4mm

2.6mm

2.8mm

3.0mm

3.2mm

3.4mm

3.6mm

mm

mm

mm

mm

as

----

----

----

No

0

0b:

1.2mm

1.2mm

1.2mm

1.0mm

1.0mm

1.2mm

1.2mm

1.2mm

1.2mm

1.5mm

1.5mm

0.4mm

0

-------

---

---

).

A

hole

Accessory

0.8

mm

1.2

mm

----

---- ----

0

----

0

----

----

l h

h: height

3

3

3

4

4

4

4

4

4

4

4

Page 14

~

Needle location adjustment

* The a

1. Horizontal feed

Button hole gap

(1) Insert a

(2) Disengage the

(3)

(4) T

djustment

Make s

If

the needle a

w

ill

urn the

If the

ure the needle is

ent

hor

0 .

Af

ter adju s

* If the p

is required whenever the

posi

tion

button

er

izonta l feed

into

clut

nd

the

center

pulley

to ali

ting

the

ull

ey is turned

not

the

ch, a

nd

butt

on h

of

butt

gn the needle with

position

button

bent.

button

ole cannot

clamp 0 so

clamp

turn

the pull

on

hole A.

is

not

properly ad

by

hand, be sure

but

ton carri

er

is replaced

0 .

ey

to align the needle

be aligned, l

the needle enters the center

oosen

bolt

6 , and s

button hole

justed, loosen horizont

to

turn

B.

the pull

ey

(button

with button

hift the

al

of

button

thro

ugh the

hole

gap

hole

A.

button

feed adjustment nut 0 and

holes A

clamp

and

end

of the stitch.

is chagned).

0 so

th

B, firmly ti

at the needle

adj

ust scale

ghten

bolt

6 .

2.

Vertical feed

*

Whe

n sew

*

When sewing

horizontal feed

(1) After adjusting the

(

2) Adju

(3) L

oosen

(4) T

urn

" Check that the ne edle enters the center of b

position

ing

buttons

buttons

st vertical feed

bolt

the

pulley

Adj

ust the horizontal feed for

Adjust

the

lever

6 ,

vertica

with

two

hol

es,

set the vertical feed

with

four

he~les,

set the vertical feed

scal

e.

Butt

on

hole

gap

hor

izontal feed positio

adjustment

and shift

to

the butt

check that the needle enters the cen ter of

l feed f

lever 0 to the vertical feed scale

on clamp 0 so

or

button holes

button

n, co

holes

ntinue

turn

that

the

utt

on holes A, B, C, and

A

~

B a

A

~

C.

- 12 -

adjustmen

adjustment lever

ing the

t l

pulley

ever 0 to

to

0.

needle will

nd

C •

enter

button holes C and D.

D.

0 to the

ali

gn

the need le

the

cent

D.

@.

er

but

of

button

ton hole

with butt

holes A and

gap

on

on

hole

the

C.

C.

Page 15

3.

If button hole arrangements differ

<-->

4.

Adjustment

of

the button receiver

fOCJ\

\f25J)

4 mm

Q

Washer

506029-001

®

(1) Loosen the screw 0 and exchange the button carrier

plate

G).

CAOSSOVER

snTO£S

@@@

48,

Four holes

ON

switch

or

position.

ON

right.

Two

holes

(1)

Check whether

(2)

While pressing and holding the manual switch

(3)

While continuing

* Assist the button clamp

(4)

Adjust so that the needle tip and the button receiving pin ~ coincide.

Loosen

bolt ~ and adjust the entire button feeder left

or

not

the feeder switch

to

hold the manual switch

by

lifting up.

G)

is at the

48,

move the arm 0

the

power

for

button movement until

switch.

it

grasps a button.

-

13-

Page 16

5.

Button

* Please use

clamp

and

button

following

carrier

3 types

adjustment

of

button

clamp

depending

on

the

slape

of

button.

A

B

c

Button application

U Button

0 Button face is a curved shape.

hollow

is larger and flat.

D

D

0

Button

clamp

Part No.

505356-000

Part No.

506569-000

Part No. [Standard)

506570-000

()

Button

!Installation)

(1) Remove the

(2)

Remove and change the

(3)

Move

the

button

(4)

Move

the

button

(5) Remove the gauge 0

"

(6)

Attach the

Repeat

(4)

button

hollow

button

and check again.

is a conical shape.

clamp

carrier

carrier plate e so

clamp

O.

button

shutter

from

fit

carrier plate

0 in the direction

that

the shaft 0 is in the gauge

the

for

button

the

carrier plate

button

e.

(Tighten the screw E)

of

the arrow, and set the gauge 0 in the

0.

e.

and

tighten

type.

the

temporarily.)

screw

E).

button

carrier plate

e.

-

14-

Page 17

Adjustment guide

Refer to this guide when different buttons are used

utt

When b

diameter

changes

on

(D) thickness (t) t

8J

o

Wh

en

changes

button

===}

When

hole

changes

button

gap (B)

Page

Vibrating

~

Butt

on Slide Base

B

utton

Catch Plate

~

ju

st

Ad

bottom

Ad

just bu

ust bed

Adj

Adj

ust the st

Replace

cove

r

butt

on top/

selecto r

tto

n gui

Ad

slide w

the

de

just butt

Replace

opper

butto

n t

adjust

on

th

e shooter coil

idth

op

-------------

Adjust height control

plate

ment dial

Adjust ri

and

button

ons

positi

butto

ght/left

carrier

n

needle

pin

2

2

2

2

6

5

5

5

6

8

8

Machine Head

5

7

- 15 -

Loading...

Loading...