Page 1

SERVICE

FOR

MANUAL

BAS

-4

11

BAS -415

SINGLE HEAD ELECT RONIC EMBROIDERY

MACHINE

I

· ·.~

-

Page 2

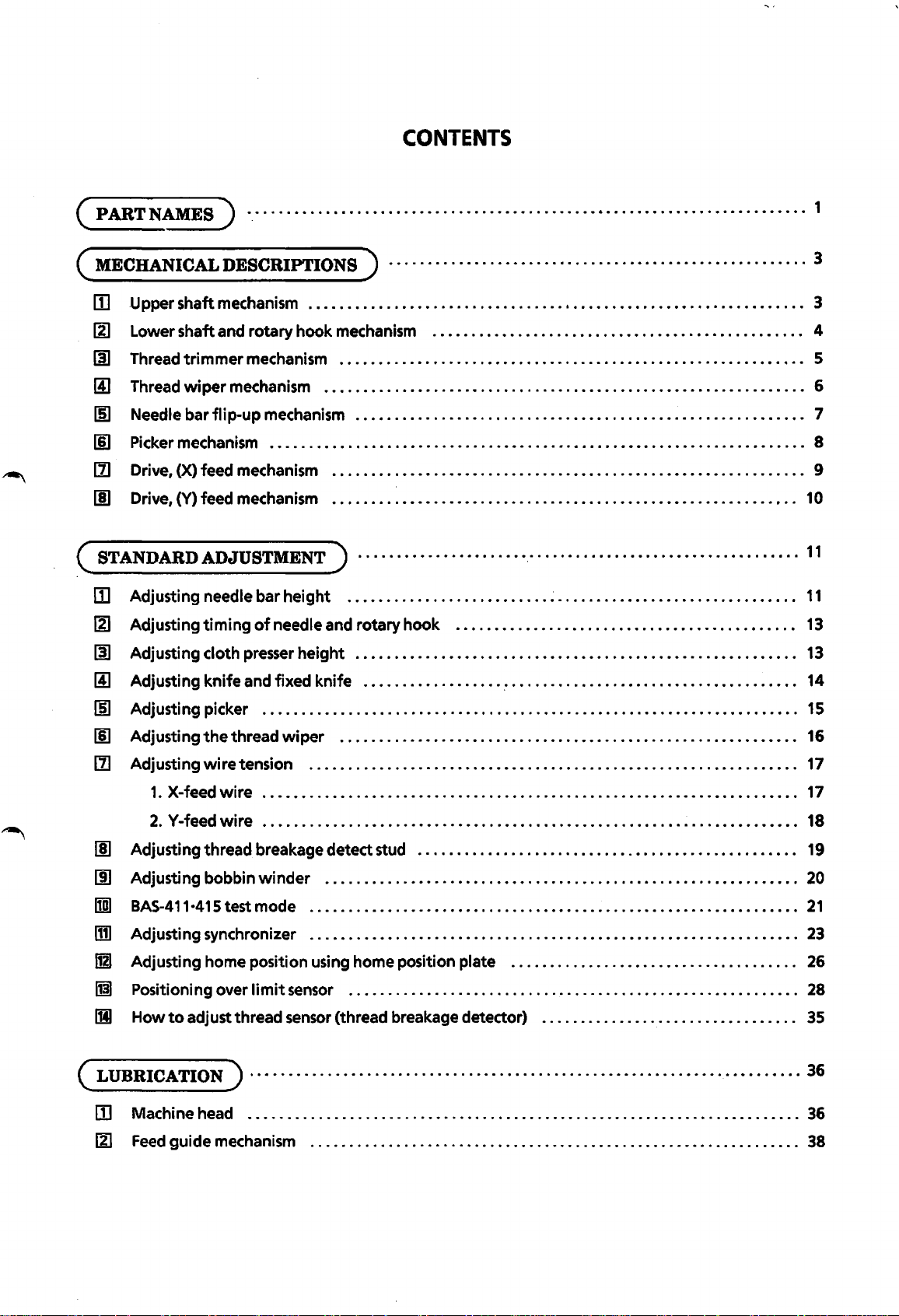

(

PART

NAMES )

CONTENTS

·.

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1

( MECHANICAL

[I] .upper

00

Lower

00

Thread

[j]

Thread

[§] Needle

[§] Picker mechanism • . . . . . . . . . . . . . . . . . . . . . . . . . . . • . • • . . . . . . . • . . . . . . . • . • . . • • . • . . . . . . • . . . . . . 8

[1]

Drive, (X)

[I]

Drive, (Y)

( STANDARD ADJUSTMENT ) · · · · · · · · · · · · · · · · · · · · ·

[I]

Adjusting

~

Adjusting

00

Adjusting

[j]

Adjusting

[§]

Adjusting

DESCRIPTIONS ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

shaft

mechanism . . . . . • . . . . . . . . . . . . . . . . . • • . . . . . . . . • . . . . . . . . . . • . . • • . . • . . . . . . . . . . . . 3

shaft

and

rotary

trimmer

wiper

bar

feed

feed

mechanism . • . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . • • • • • • . • 5

mechanism . • . . • . . . . . . . . . . . . . . • . • . . . . . . . . . . . . . . . . . . . • • • • • . • • . • . . . . . . . • . . . 6

flip-up

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • • • . . . . • . . . • . . . . . . . . . . . . . . . • . 9

mechanism . . . . . . . . . . . . . . . . . . . . • . • . . . . . . . . . . . . . . . . • . • . . • . . . . . . . . . . . . • • . 10

needle

timing

cloth

presser

knife

and

picker . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . • • • • . . 15

hook

mechanism . . . . . . • • • • • . . . . . . . . . . . . . . . • . . . • • . . • • . . . . . . . • . . . . 4

mechanism . . • • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . • • • . • • . 7

·.

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

bar

height

of

needle and

height

fixed

...•..............••......

rotary

hook

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . • . . . . . . . . . . . . . . . . • . 13

knife

. • . . . . . . . . . . . . . • • . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . 14

. . • . . . • • . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . • • • • . • 13

~

. . . . . . . . . • • . . . . . . . . • . . • • • • • • • • •

11

11

[§]

Adjusting

[1]

Adjusting

00

Adjusting

00

Adjusting

lim

BAS-411·415

In]

Adjusting

1m

Adjusting

lj}

Positioning

IB1

How

1. X-feed

2. Y -feed

the

thread

wire

wire

wire

thread

bobbin

test

synchronizer . . . . . . . • . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . 23

home

over

to

adjust

thread

wiper

tension

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . • . . . . . . • . . . . . . . . . . . . . • . • • • • • . 17

. . . . . . . . . . . . . . • . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . • . . . . 18

breakage

winder

mode

position

limit

sensor

sensor (thread breakage detector) . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . • . . . . . . . . . • . . . . . . . • • 16

.....•.................•........................••...•.•...••••

detect

...................•.........................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • • • • • • . . . . • . . . . . . . . .

using

stud

..........................•.•.....•.•............

home

position

...................................•..••..•...............

plate

. . . . . . . . . . . . . . . . • . . . • . . . . . . . . . • . . . . . . 26

17

19

20

21

28

( LUBRICATION ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 36

[I]

~

Machine

Feed

head . . . . . . . . . . . . . . . . . . . . . . . . • . . . • . . . . . . . . . . . . . . . . . . . . . . • • • • • . . • . . . . . . . . . . . . 36

guide

mechanism

.......................................•........•..............

38

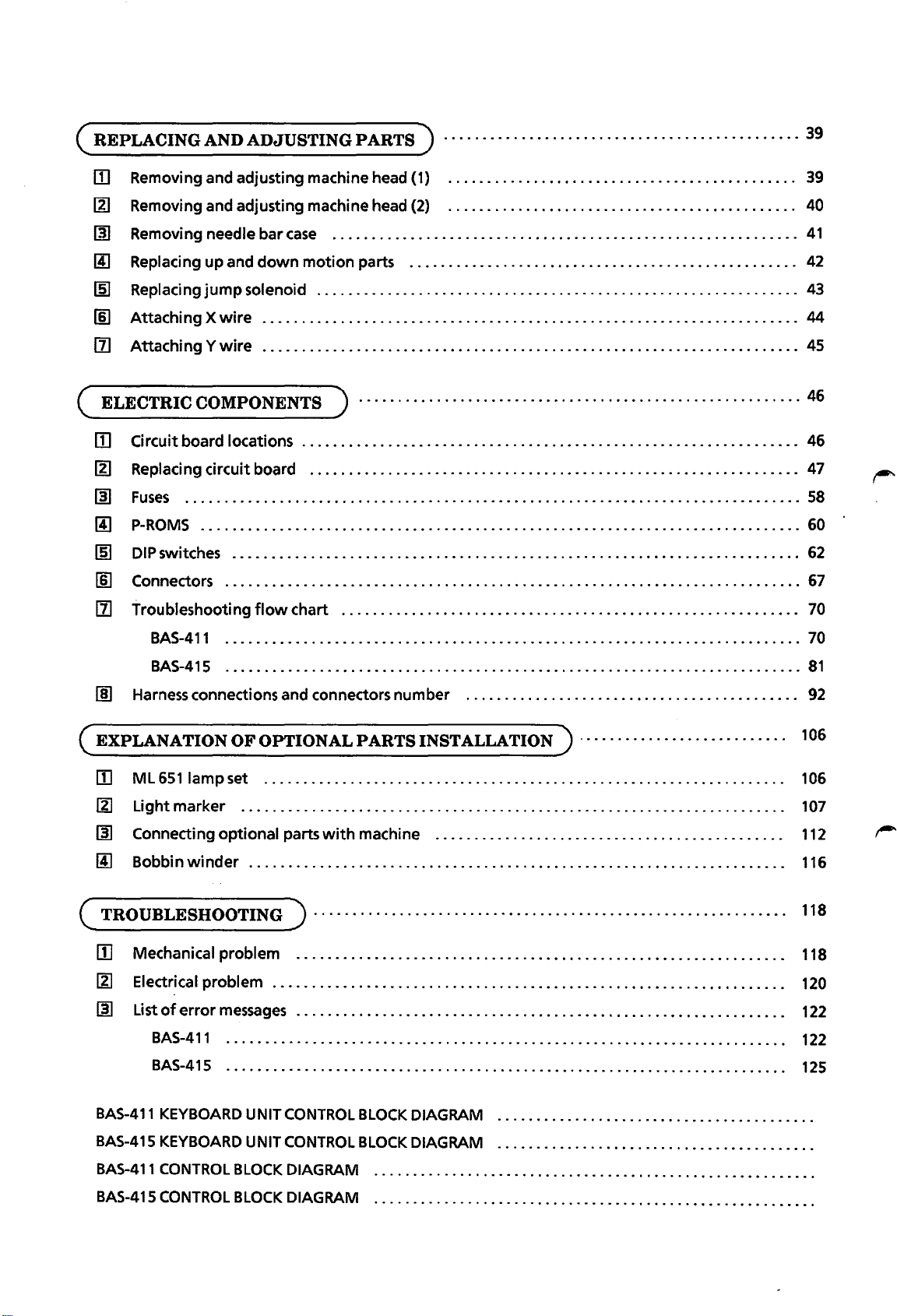

Page 3

(

REPLACINGANDADJUSTINGPARTS)

[I]

Removing and

~

Removing and

lm

Removing needle

1!1

Replacing

~

Replacing

[§]

Attaching X wire

[1]

Attaching Y wire

(

ELECTRIC

[!)

Circuit

~

Replacing

00

Fuses

(!]

P-ROMS

~

DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

[§]

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

board

...............................................................................

up

and

jump

adjusting

adjusting

bar

down

solenoid

machine head (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

machine head (2) .

case

............................................................

motion

.....................................................................

.....................................................................

parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

..............................................................

COMPONENTS ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 46

locations

circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

board

...•............................................................

...............................................................

· · · ·

..

··

. . . . .

· · · · · · · · · · · · ·

.. . ..

..

. . . . . . .

··

· · · ·

..

··

· · · · · · · ·

. . . . .

.. ..

··

..

.. .. ..

· · · · · · ·

. . . . 40

··

39

41

43

44

45

46

47

58

[1]

troubleshooting

BAS-411

BAS-415

00

Harness connections and connectors

(

EXPLANATIONOFOPTIONALPARTSINSTALLATION)

[]]

ML

6511amp set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

~

Light

marker

00

Connecting

1!1

Bobbin

(

TROUBLESHOOTING)·····························································

winder

[!) Mechanical

~ Electrical

00

List

BAS-411 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

of

problem

error

flowchart

..........................................................................

..........................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

optional

problem

messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

...........................................................

number

with

machine . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

...........................................

..

..

. . . . . . . . . . . . .

70

70

81

92

· · · · · · · · · · · · · · · · · · · · · · · · · · · 106

.. ..

. . . .

..

. .

..

. . . . .

..

. 112

118

BAS-415 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

BAS-411 KEYBOARD

BAS-415 KEYBOARD UNIT CONTROL

BAS-411 CONTROL

BAS-41

5 CONTROL

UN

IT CONTROL

BLOCK

BLOCK

DIAGRAM

DIAGRAM

BLOCK

BLOCK

DIAGRAM

DIAGRAM

.........................................................

.........................................................

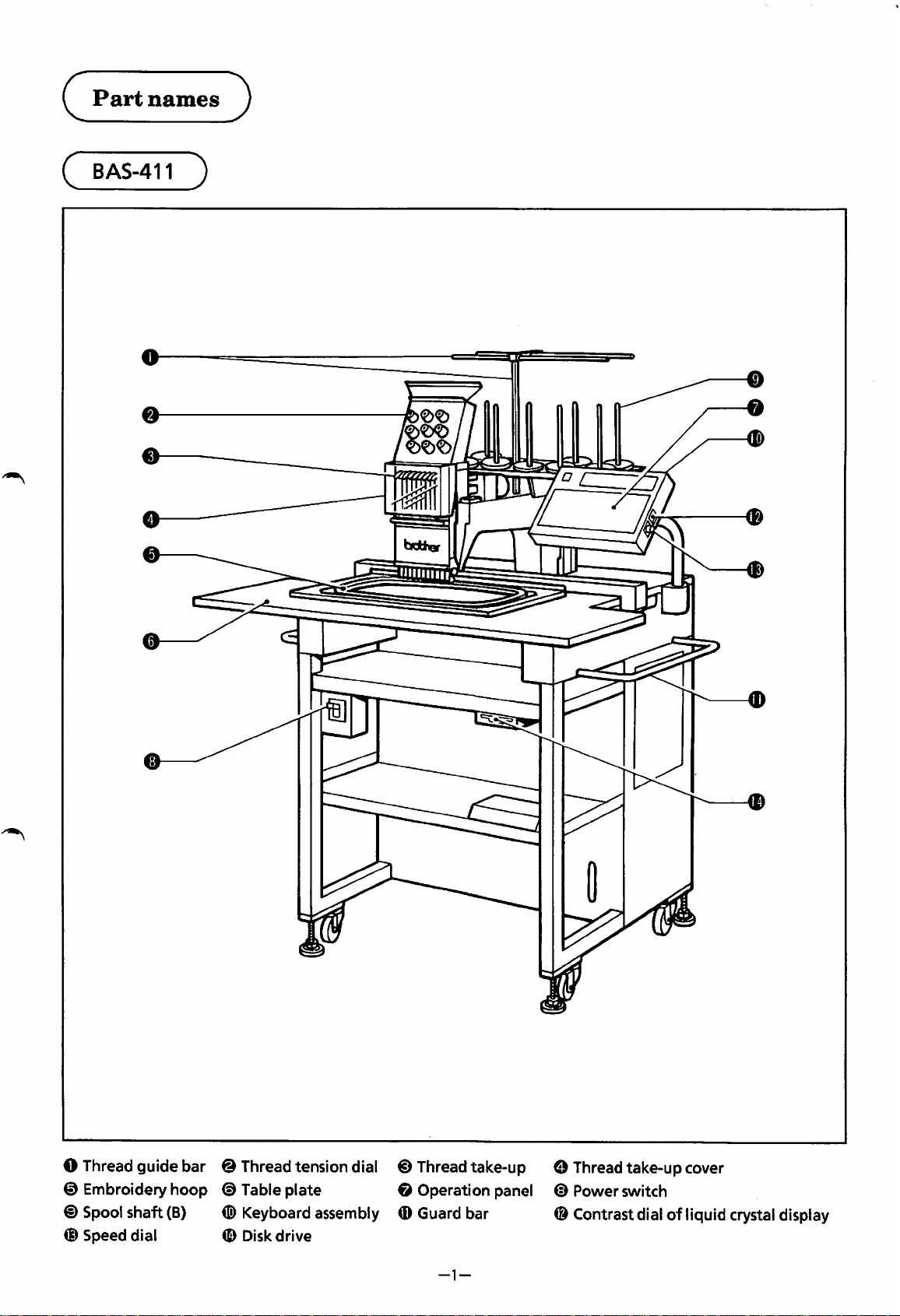

Page 4

(

Part

(

BAS-411

names

)

)

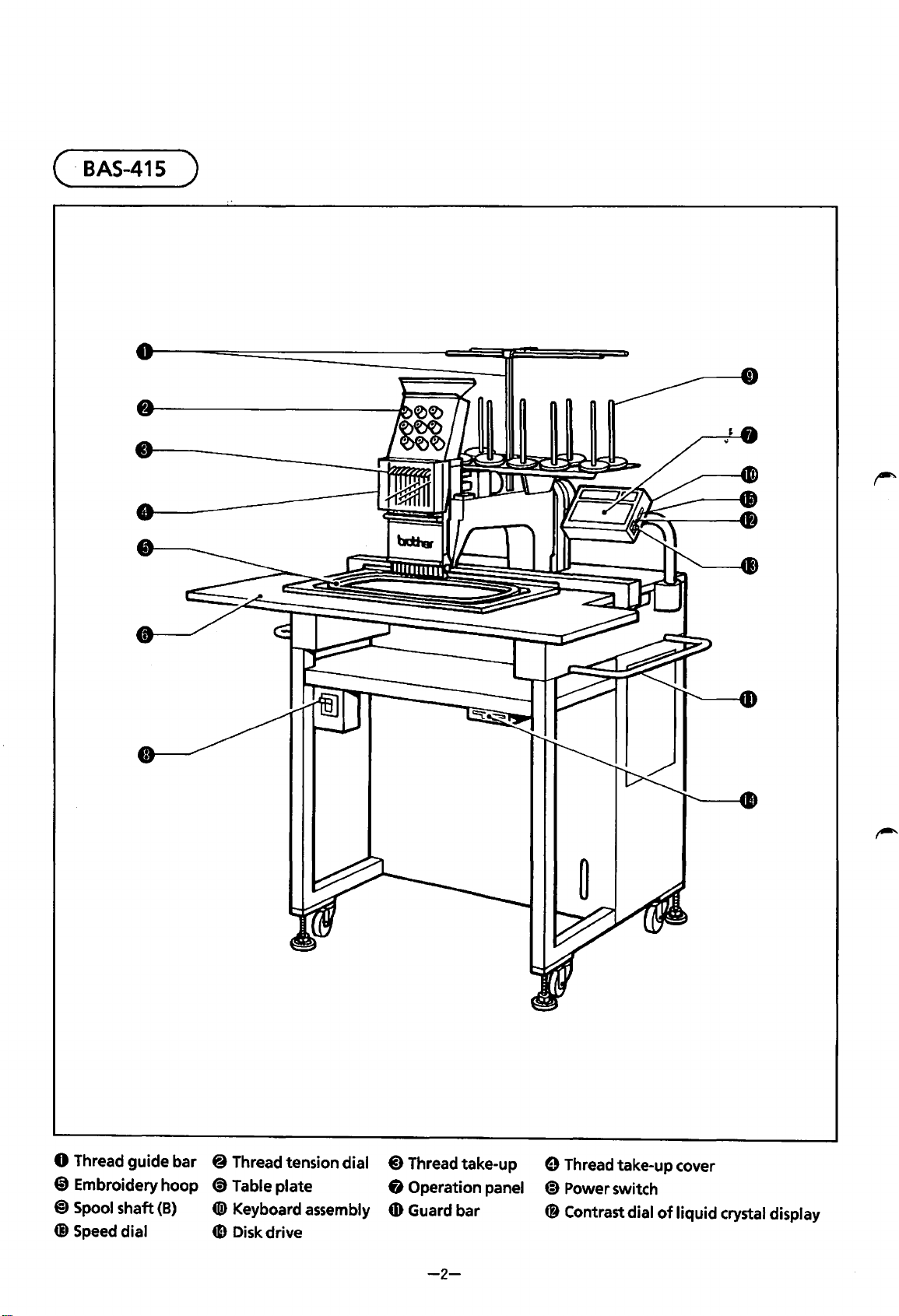

0 Thread

0 Embroidery

@)Spool

@ Speed dial

guide

shaft

bar

hoop

(B)

@ Thread tension dial

<9

Table plate 6 Operation panel

(!) Keyboard assembly

4D

Disk drive

@)

Thread take-up

CD

Guard bar

-1-

0 Thread take-up cover

@)

48

Power switch

Contrast dial

of

liquid

crystal display

Page 5

( ·

BAS-415

)

0 Thread

@ Embroidery

@)

Spool

Q) Speed dial

guide

shaft

bar 8 Thread tension dial

hoop

(B)

(!) Table

tD)

4D

plate

Keyboard assembly

Disk drive

@)

Thread take-up

8 Operation panel

4D

Guard bar

8 Thread take-up cover

~

C8

-2-

Power switch

Contrast dial

of

liquid

crystal display

Page 6

(MECHANICAL

DESCRIPTIONS )

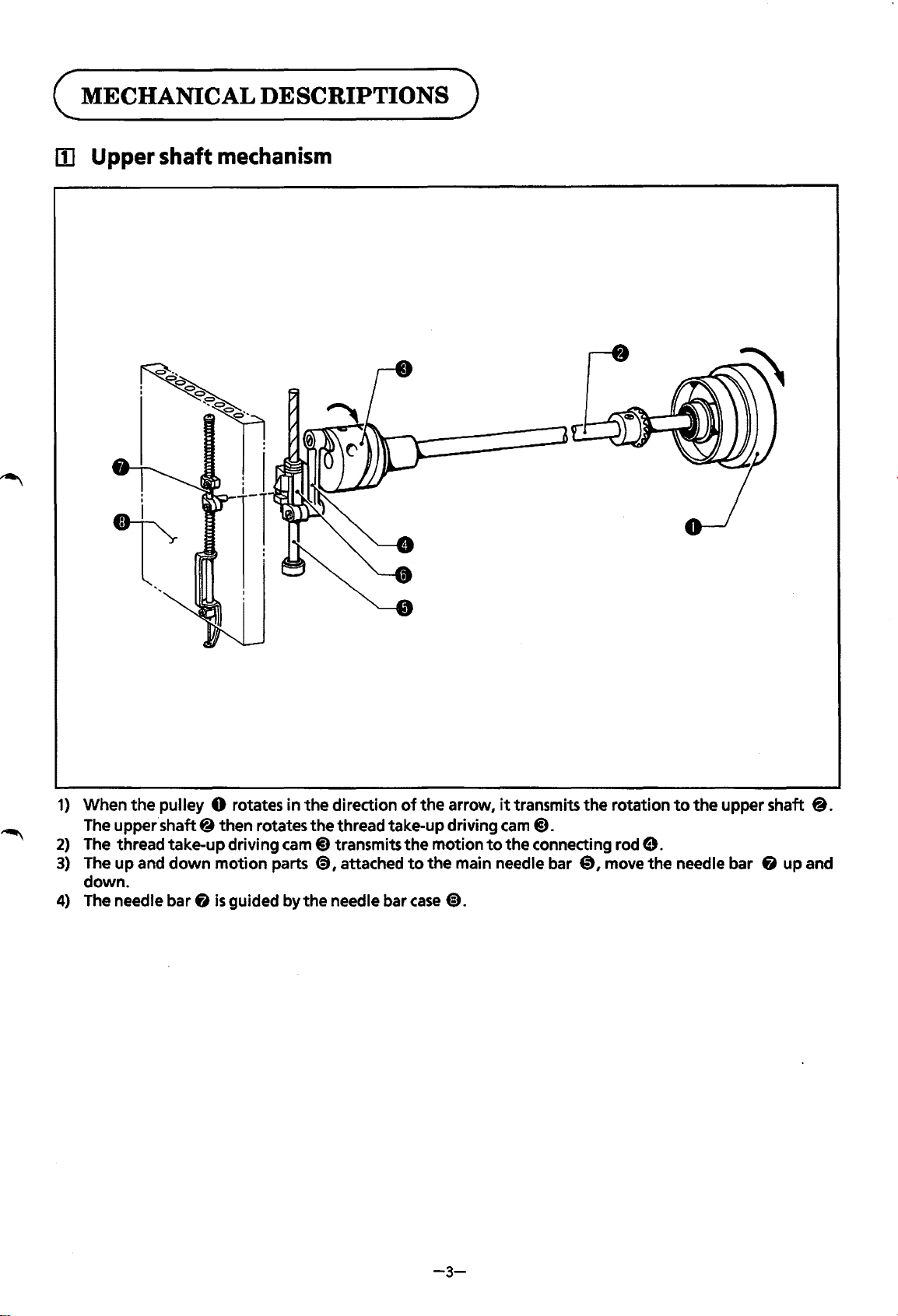

lii Upper shaft

mechanism

1)

When

the

pulley 0 rotates

The upper.shaft 8 then rotates

2)

The thread take-up driving

3)

The

up

and

down

motion

down.

4)

The needle bar 8

is

guided by

in

cam@)

parts

the

direction

the

thread take-up driving

transmits

<9,

attached

the

needle bar

of

the

to

case

the

arrow,

motion

the

@).

it

cam

to

the

main needle bar

transmits

@).

connecting rod

the

0,

rotation

9.

move

the

to

the

upper shaft

needle bar 8 up and

8.

-3-

Page 7

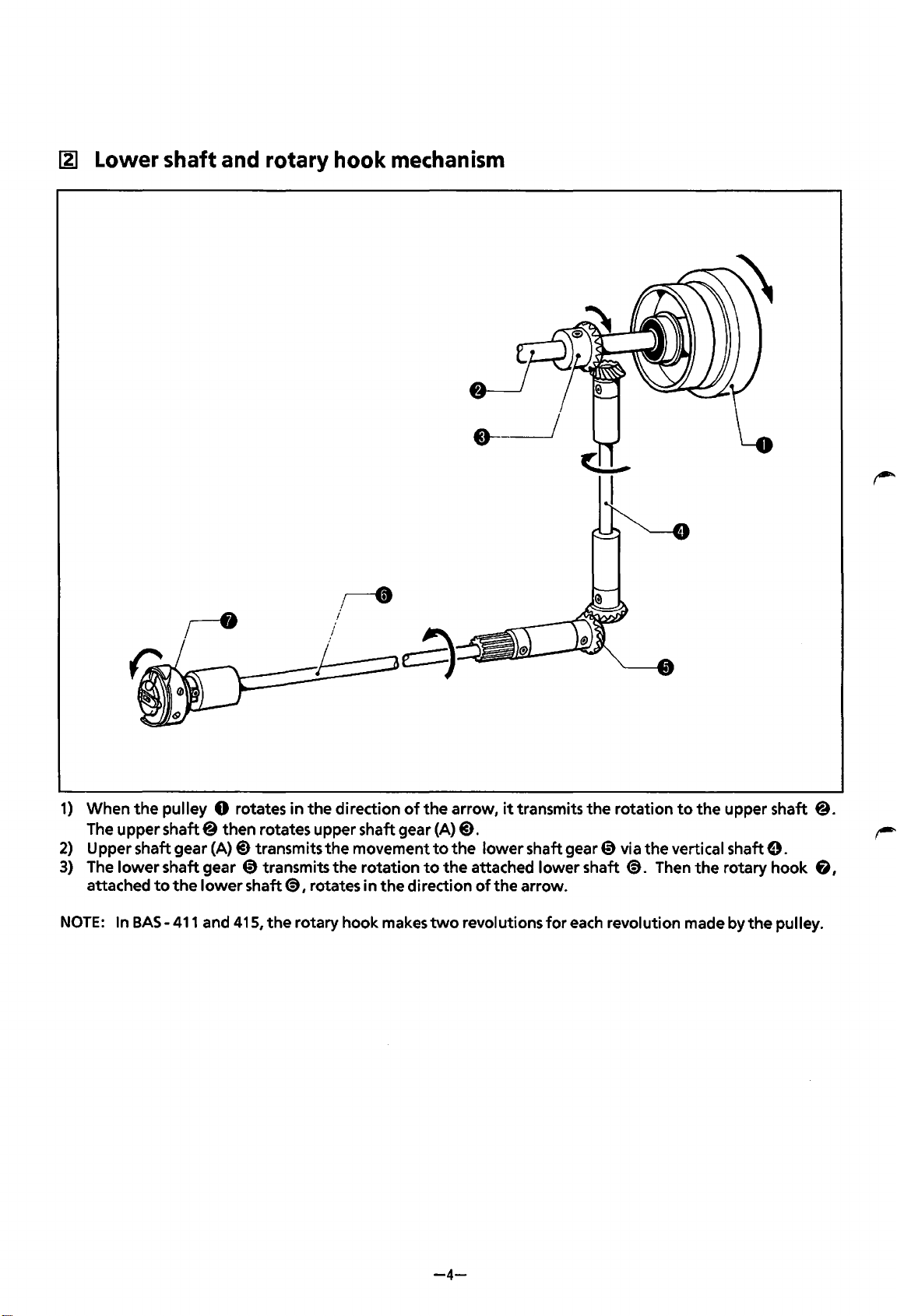

~

Lower shaft and rotary hook mechanism

1)

When

the

The upper

2)

Upper shaft gear

3)

The

lower

attached

NOTE:

In BAS-

pulley 0 rotates

shaft@

shaft gear 0 transmits

to

the

411

then rotates upper shaft gear (A)@).

(A)@)

lower

and 415,

in

transmits

shaft@), rotates in

the

rotary hook makes

the

direction

the

the

of

the

movement

rotation

the

direction

to

to

the

two

arrow,

the

it

transmits

lower

shaft gear 0 via the vertical shaft

attached lower shaft

of

the arrow.

revolutions

the

rotation

@).

for

each revolution made by

to

Then

the

upper shaft @.

the

rotary hook

the

e.

6,

pulley.

-4-

Page 8

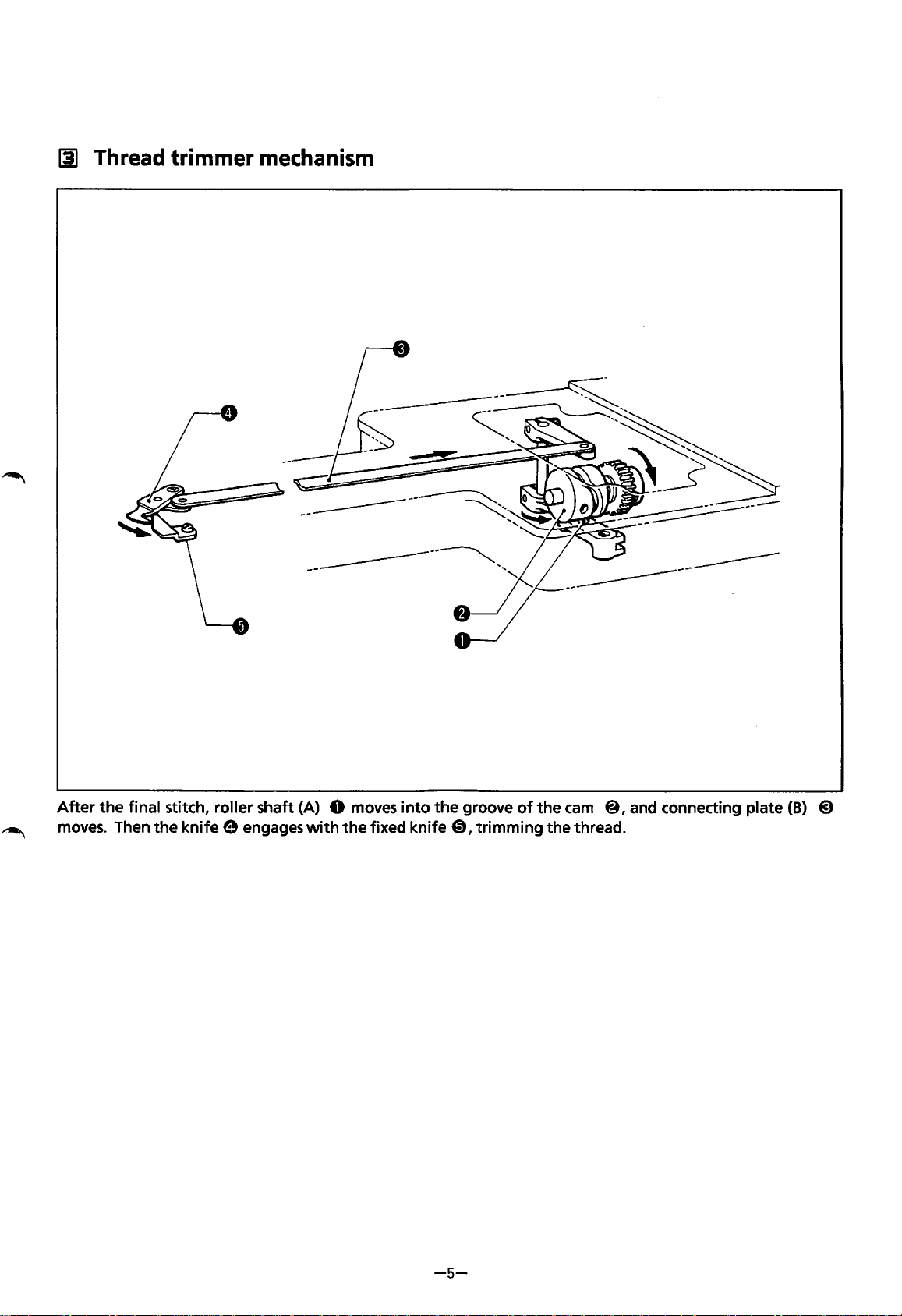

~

Thread trimmer

mechanism

-------------------

~

After

moves.

the

final stitch, roller shaft (A) 0

Then the knife 0 engages

moves

with

the fixed knife

into

the

groove

0,

of

trimming the thread.

the

cam

@,and connecting plate

(B)

@)

-5-

Page 9

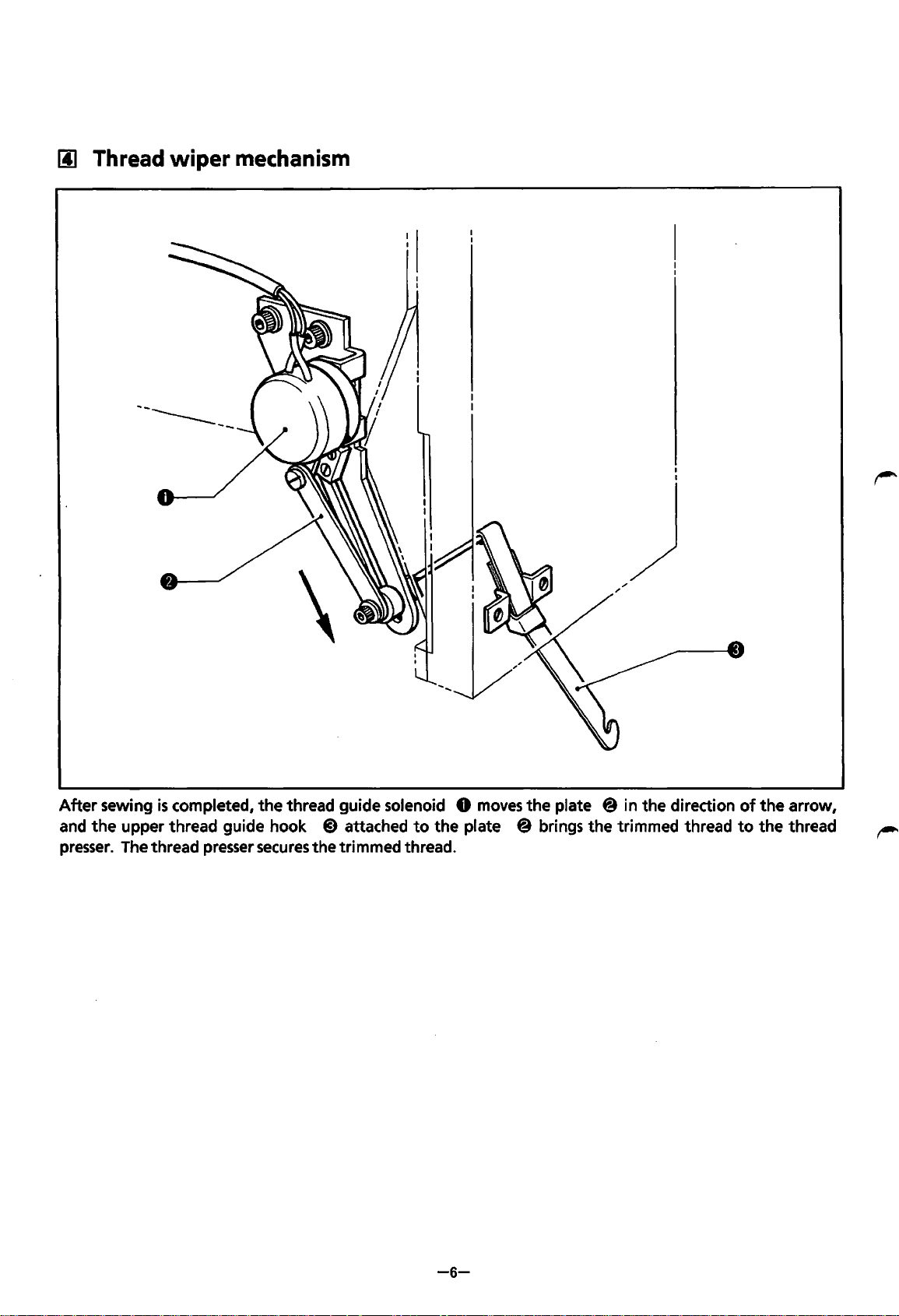

II]

Thread

wiper

mechanism

~--------

After

sewing

and

the

presser.

is

completed,

upper thread guide hook

The thread presser

the

thread guide solenoid 0

secures

@)

attached

the trimmed thread.

to

the plate @ brings the trimmed thread

moves

the

plate

@in

the direction

of

to

the

the

arrow,

thread

-6-

Page 10

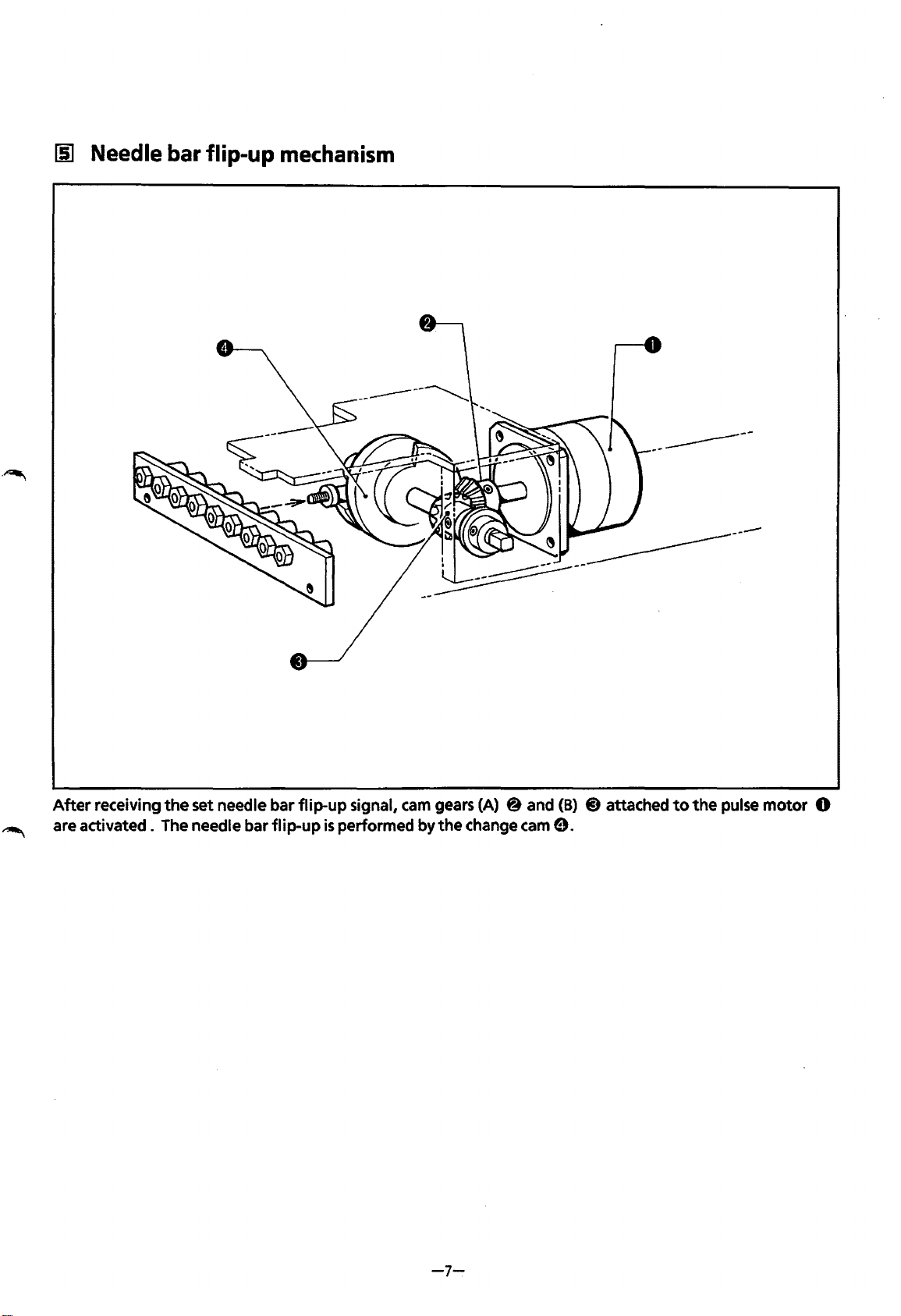

[§]

Needle

bar

flip-up

mechanism

~~------

After

are

activated.

receiving

the

set needle bar

The needle bar

flip-up

flip-up

signal,

is

performed

cam

gears (A) 8 and

by

the

change cam

(B)

9.

@)

attached

to

the

pulse

motor

0

-7-

Page 11

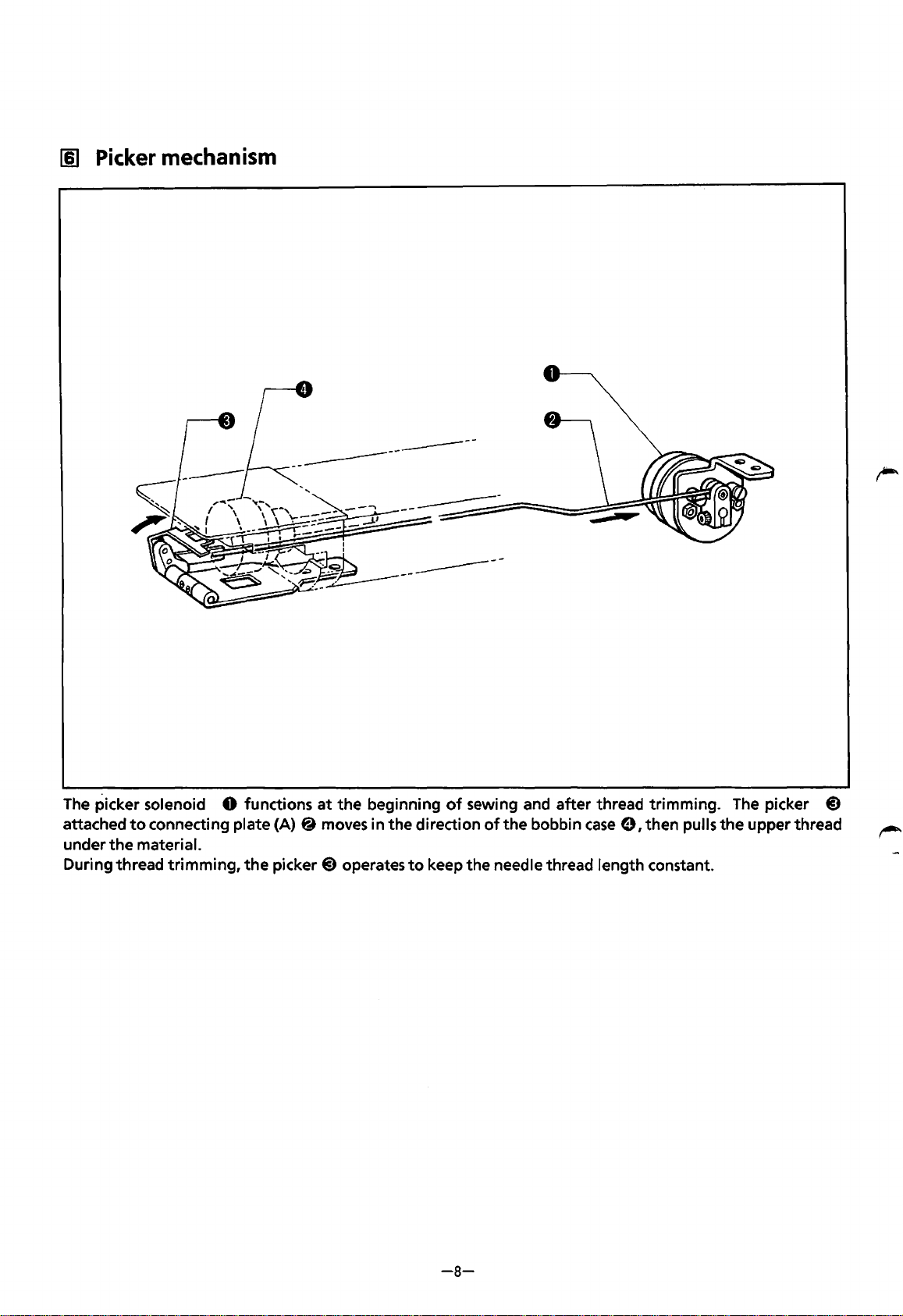

[§]

Picker

mechanism

------------

The

picker solenoid 0 functions

attached

under

During thread trimming,

to

connecting plate

the

material.

at

the

(A)@

the

picker@) operates

moves in the direction

beginning

to

keep the needle thread length constant.

of

sewing and after thread trimming.

of

the bobbin

case

e, then pulls the upper thread

The

picker

@)

-8-

Page 12

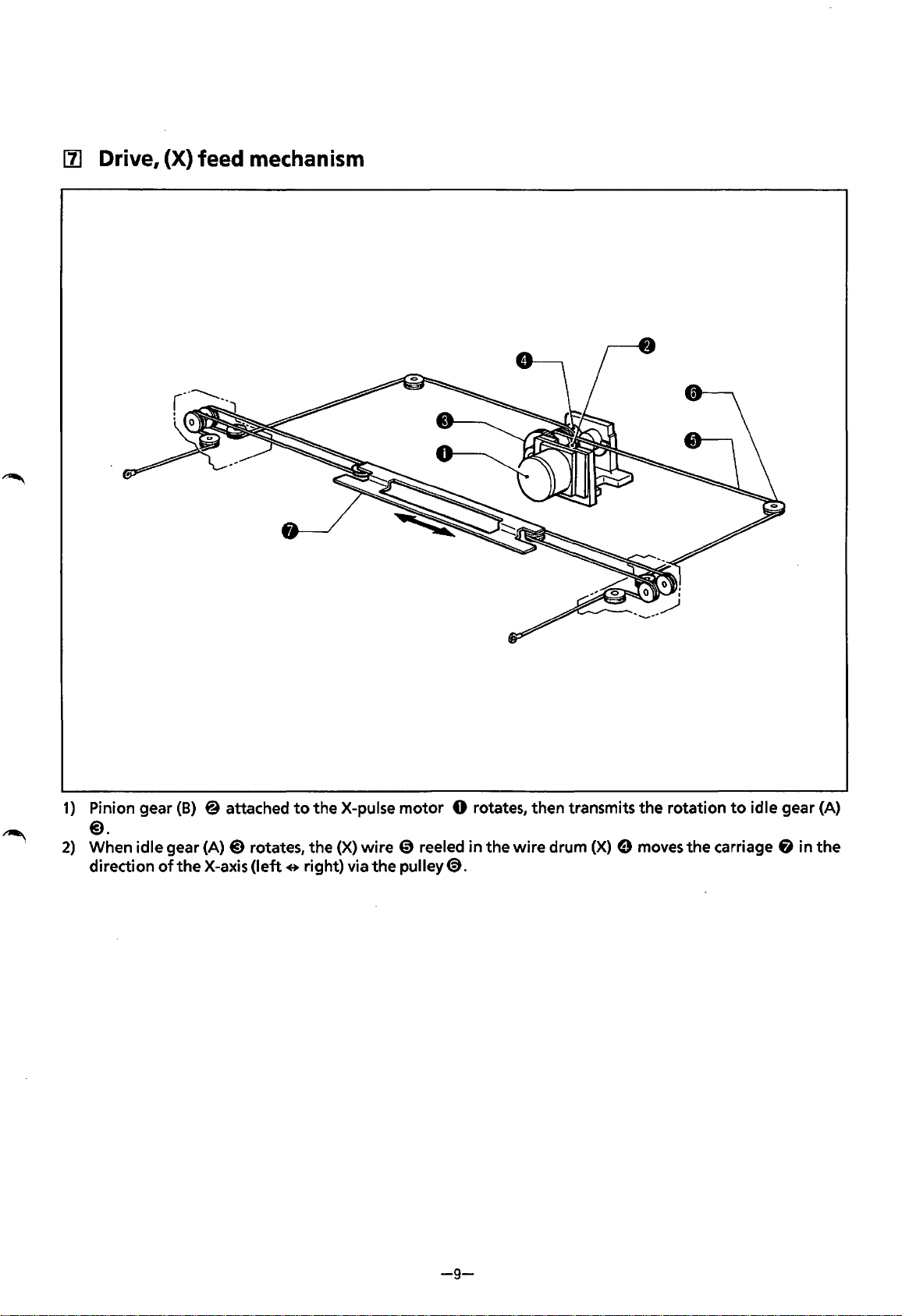

[1]

Drive, (X) feed mechanism

1)

Pinion gear

@).

2)

When idle gear (A)@) rotates, the (X) wire

direction

of

(B)

@ attached

the

X-axis

(left

e right) via

to

the X-pulse motor 0 rotates, then transmits the rotation

the

CD

reeled in the wire drum

pulley

<9.

(X)

e moves

to

the

carriage & in

idle gear (A)

the

-9-

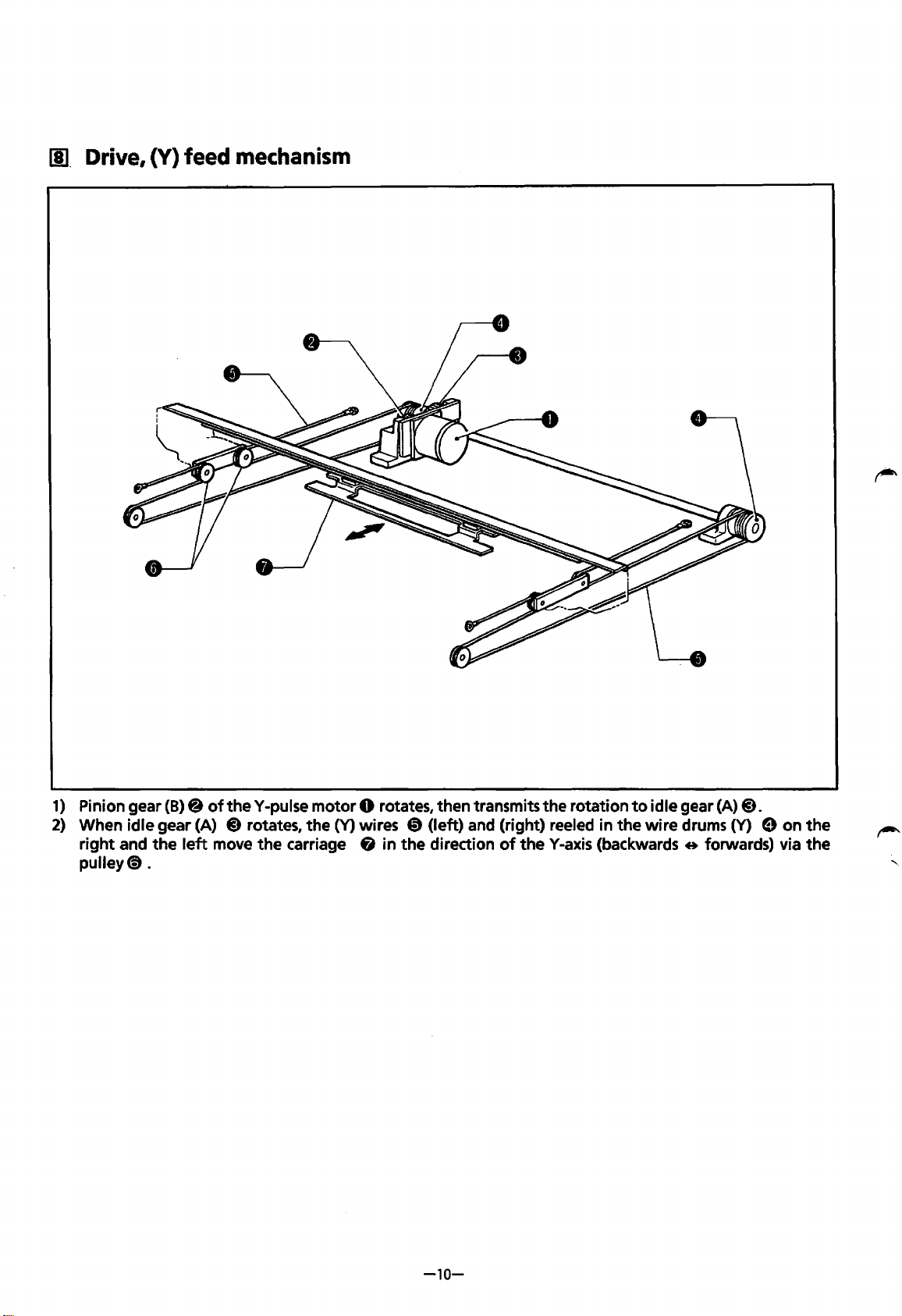

Page 13

[II.

Drive, (Y) feed

mechanism

1)

Pinion gear (B)@

2) When idle gear (A) @)rotates, the

right

and the

pulley8.

of

theY-pulse motor 0 rotates, then transmits the rotation

left

move the carriage

(Y)

wires @)(left) and (right) reeled in

fi

in the direction

of

theY-axis (backwards e forwards) via the

to

idle gear

the

wire drums

(A)@).

(Y)

8 on

the

-10-

Page 14

c

STANDARD

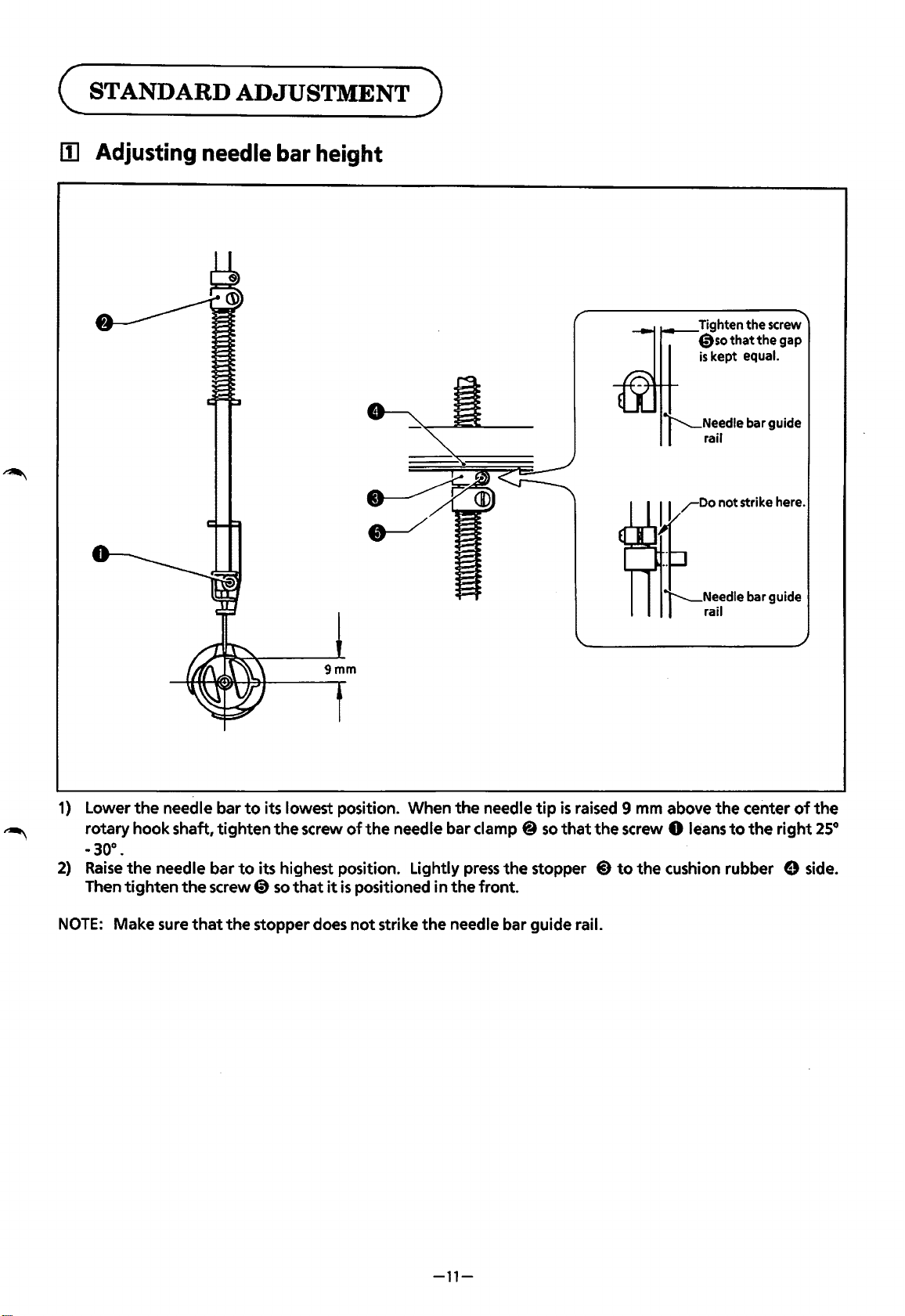

lii

Adjusting

ADJUSTMENT

needle

bar

height

)

Tighten the screw

0so

that

the

is

kept equal.

gap

~

1)

Lower

rotary hook shaft,

the

-30°.

2)

Raise

the

Then

tighten

NOTE:

Make sure

needle bar

tighten

needle bar

the

screw 0

that

the

to

its lowest position. When

the

screw

of

the

needle bar clamp @

to

its highest position. Lightly

so

that

it

is

positioned in

stopper does

not

strike

the

needle

press

the

stopper

the

front.

the

needle bar guide rail.

tip

is

raised 9 mm above

so

that

the

screw 0 leans

@)

to

the

center

to

the

the

cushion rubber 9 side.

of

right

the

25°

-11-

Page 15

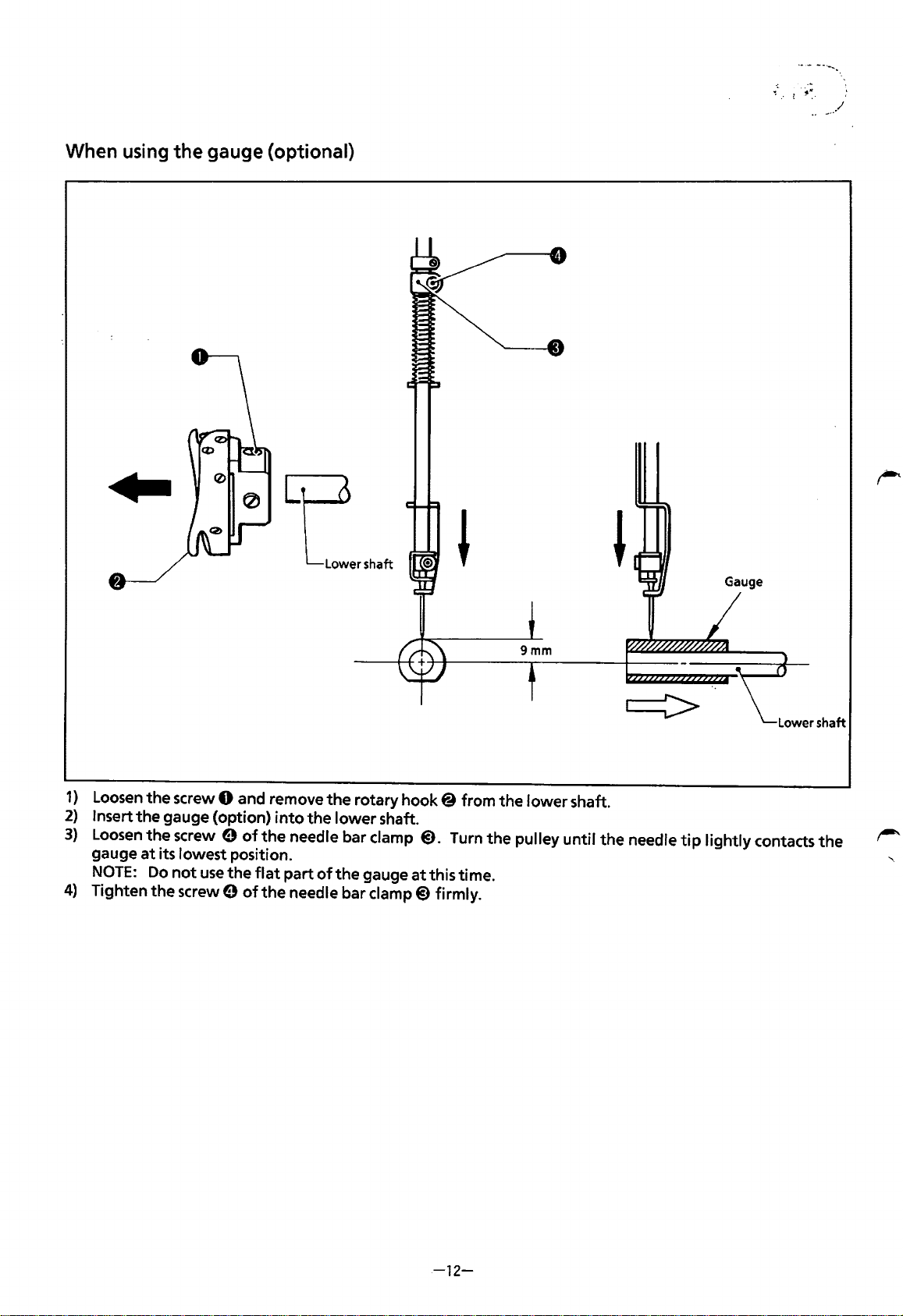

When using

the

gauge (optional)

Gauge

1)

Loosen

2)

Insert the gauge (option)

3)

Loosen

gauge

NOTE:

4)

Tighten

the screw 0 and remove

the

screw e

at

its lowest position.

Do

not

use

the

screw 9

of

the

of

the

into

the lower shaft.

the

needle bar clamp

flat

part

of

the

the

needle bar

rotary

gauge

clamp@)

hook@

@).

Turn

at

this time.

firmly.

from the lower shaft.

the

pulley until the needle

tip

lightly contacts

the

-12-

Page 16

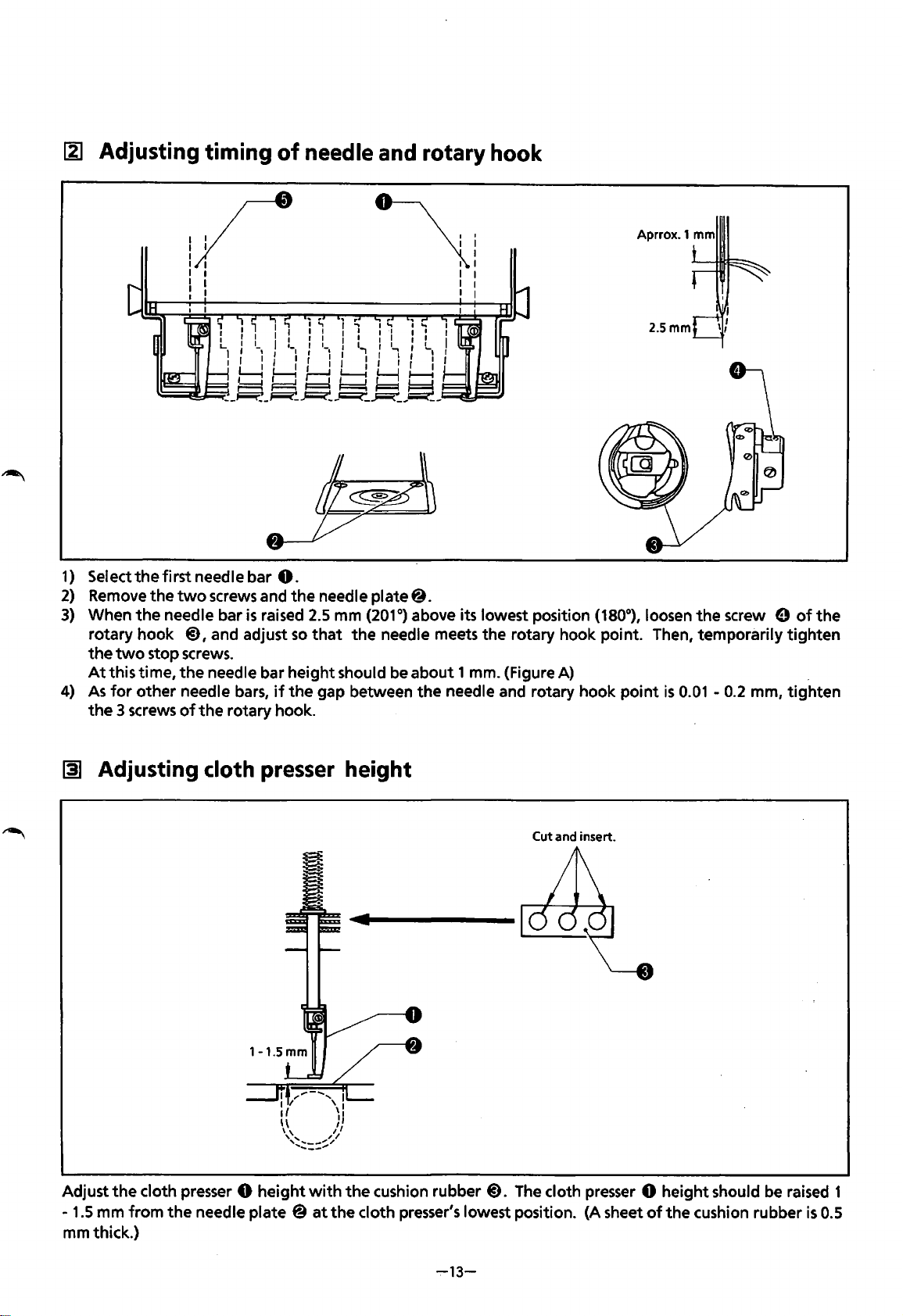

~ Adjusting timing

of

needle and rotary hook

I I

1/

I

I

I

I I

I I

: I

1)

Selectthefirstneedlebar

2)

Remove

3)

When

rotary hook

the

At

4)

As

the

the

two

the

needle bar

@),

two

stop screws.

this time,

for

3 screws

the

other needle bars,

of

the

I

I

\

I I

I I

I I

I

I

Aprrox.1 mm

2.5mm

0.

screws and

and adjust

needle bar height should be about 1 mm. {Figure A) .

rotary hook.

is

raised

the

needle plate@.

2.5

mm

so

that

if

the

gap between

(201°)

the

needle meets

above its lowest position (180°), loosen

the

rotary hook point. Then, temporarily

the

needle and rotary hook

point

is

0.01 -0.2

the

screw 0

mm,

of

tighten

tighten

the

~

Adjusting cloth presser height

Adjust

mmthick.)

1.5

the

cloth presser 0

mm

from

the

needle plate @

height

with

at

the

Cut and insert.

the

cushion rubber

cloth presser's lowest position. {A sheet

@).

The cloth presser 0 height should be raised 1

of

the

cushion rubber

is

0.5

~13-

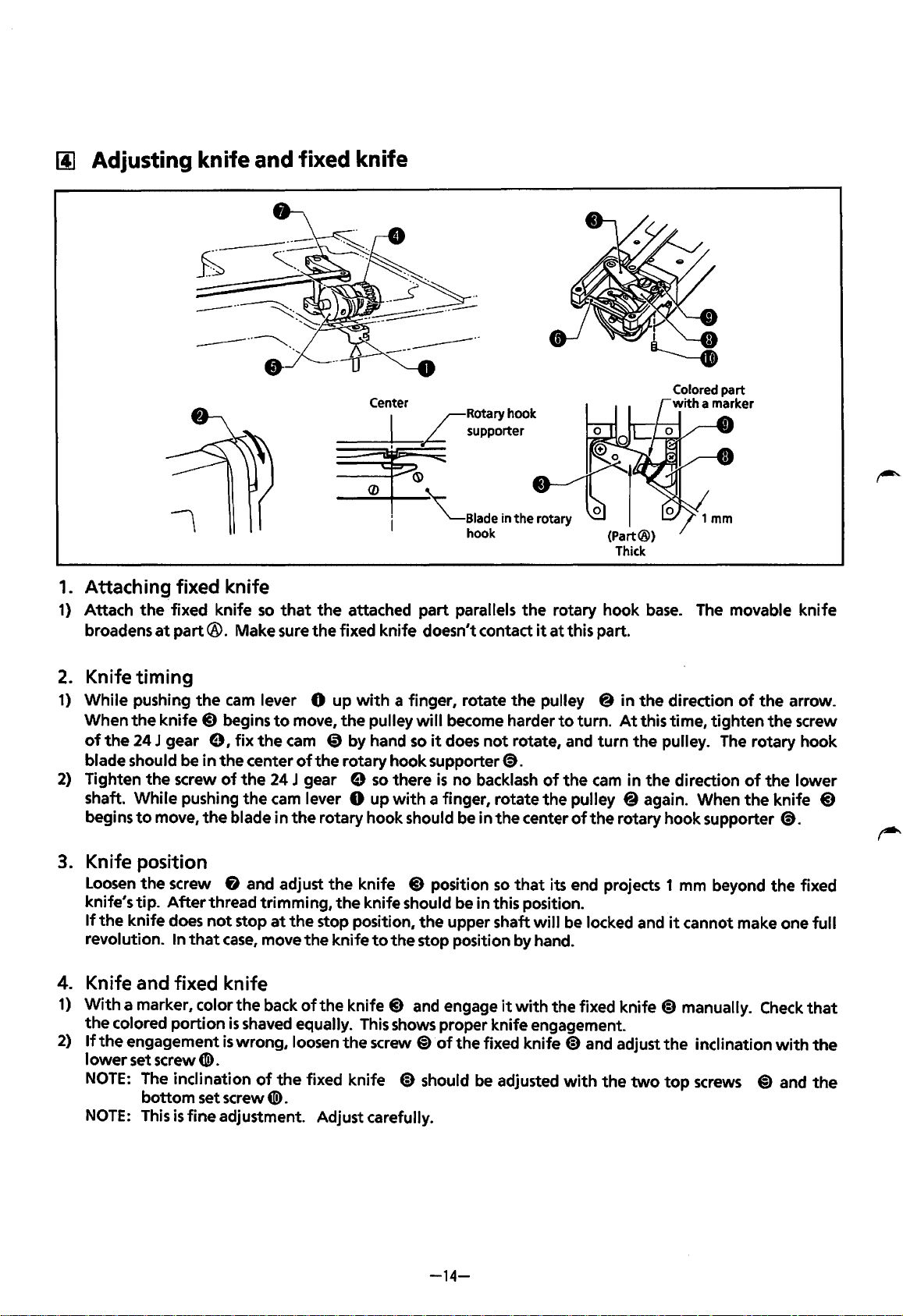

Page 17

(j] Adjusting knife

1.

Attaching fixed knife

1)

Attach

broadens

the

fixed knife

at

part®.

Make sure

and

fixed knife

so

that

the

the

attached part parallels

fixed knife doesn't contact

the

rotary hook

it

at

this part.

base.

~-

The movable knife

2.

Knife timing

1)

While pushing

When

the

of

the

24 J gear e I

blade should be in

2)

Tighten

shaft. While pushing

begins

3.

Knife position

Loosen

knife's tip.

If

the

revolution. In

4.

Knife and fixed knife

1)

With

the

2)

If

the

lower

NOTE:

NOTE:

the

to

the

knife does

a marker, color

colored portion

engagement

set screw

The inclination

bottom set screw

This

the

knife

@)

screw

move,

screw & and adjust

After

that

CD).

is

fine adjustment. Adjust carefully.

cam

lever 0 up

begins

the

of

the

thread trimming,

not

case,

is

to

move,

fix

the

cam

center

the

the

blade in

stop

the

is

shaved equally.

wrong, loosen

of

24 J gear e

cam

lever 0 up

the

at

the

move

the

back

of

of

the

fixed knife @)should

CD).

with

a finger, rotate

the

pulley

CD

by hand

the rotary hook supporter@).

rotary hook should be in

the

knife

the

knife should be in this position.

stop position,

knife

the

knife

This

the

will

become harder

so

it

does

so

there

is

no backlash

with

a finger, rotate

@)

position

the

upper shaft

to

the

stop position by hand.

@)

and engage

shows proper knife engagement.

screw

@)

of

the

the

not

rotate, and

the

so

that

it

fixed knife

be

adjusted

pulley @ in

to

turn.

of

the

cam

the

pulley @again. When

center

with

of

the

its end projects 1 mm beyond

will

be locked and

the fixed knife

@)

and adjust

with

the

direction

At

this time, tighten

turn

the

pulley.

in

the

direction

rotary hook supporter

it

cannot make one

@)

manually.

the

the

two

top

of

the

The

rotary hook

of

the

Check

inclination

screws

@)

the

the

knife

@).

the

with

and

arrow.

screw

lower

@)

fixed

full

that

the

the

-14-

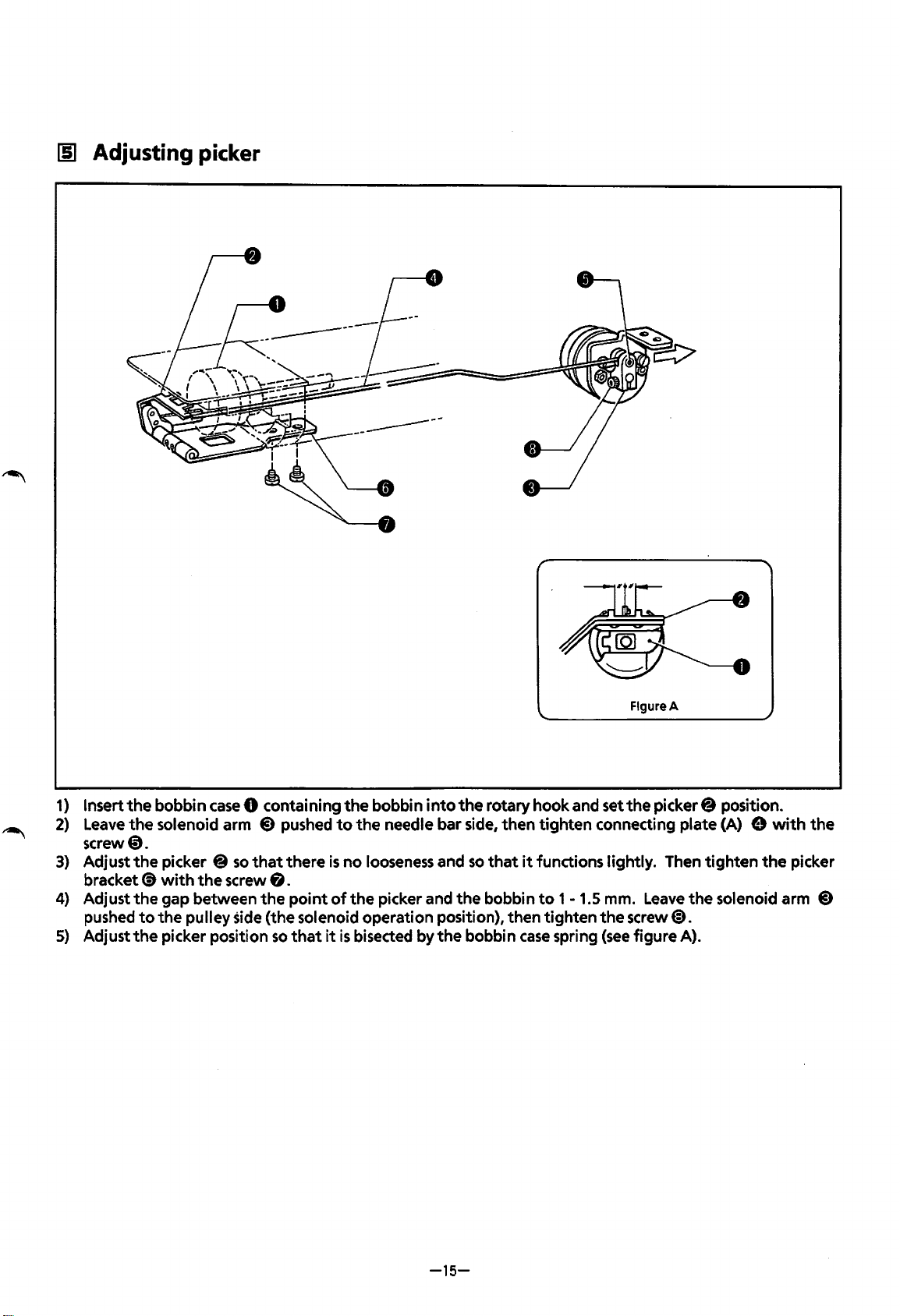

Page 18

1§1

Adjusting

picker

1)

Insert

2)

Leave

screw0.

3)

Adjust

bracket(!)

4)

Adjust

pushed

5)

Adjust

the

bobbin

the

solenoid arm

the

picker @

with

the

gap between

to

the

pulley side (the solenoid operation position), then tighten

the

picker position

case

the

so

screw

0 containing

@)

pushed

that

there

is

8.

the

point

of

so

that

it

the

bobbin

to

the

needle bar side, then

no

looseness and

the

picker and

is

bisected by

into

the

the

rotary hook and set

tighten

so

that

it

functions lightly. Then

the

bobbin

bobbin

to 1 -1.5

case

spring

Figure A

the

picker@ position.

connecting plate (A) e

tighten

mm.

Leave

the

solenoid arm

the

screw@).

(see

figure A).

with

the

the

picker

@)

-15-

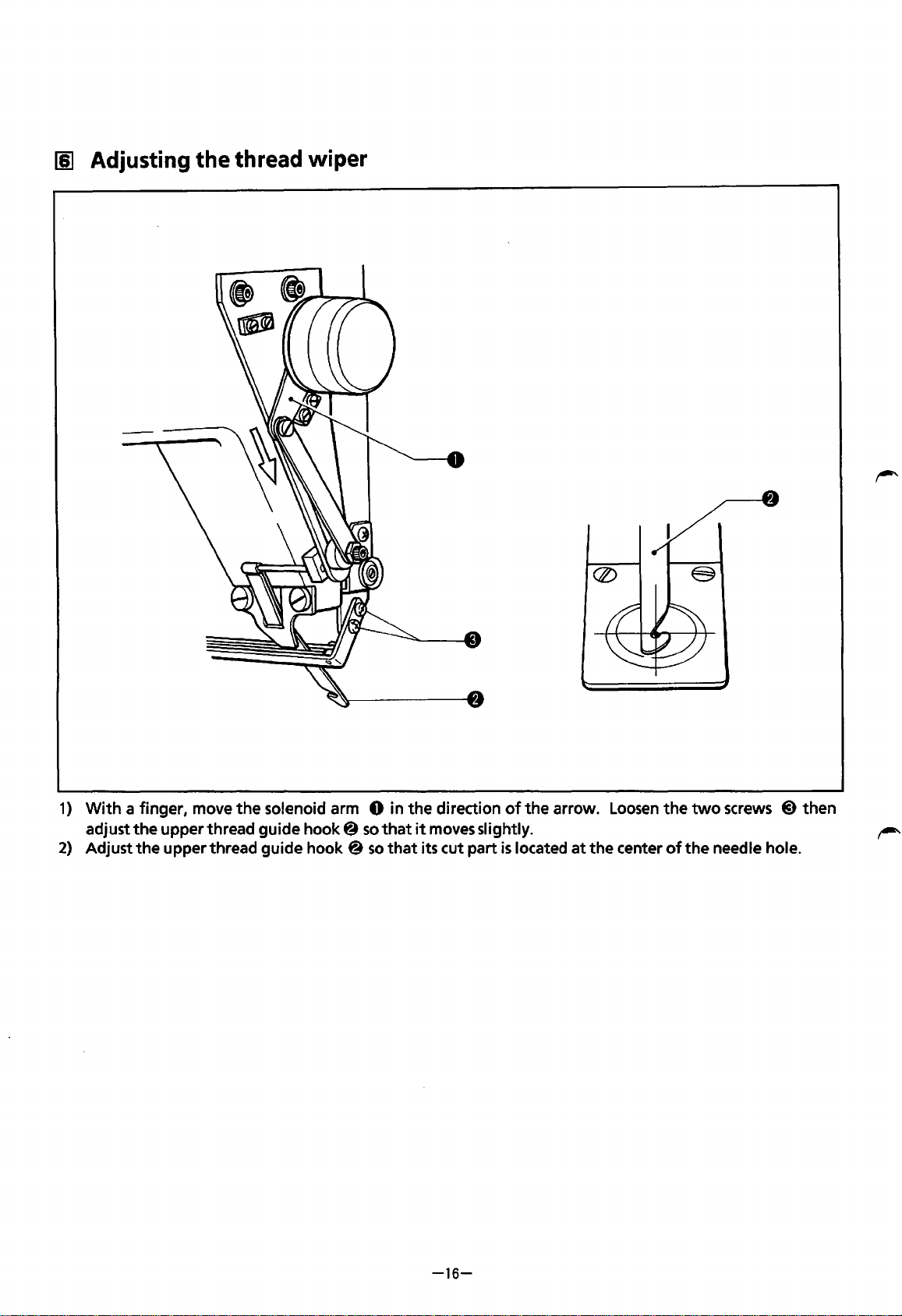

Page 19

[§]

Adjusting

the

thread wiper

1)

2)

With

a finger, move

adjust

the

Adjust

the

the

solenoid arm 0 in

upper thread guide

upper thread guide hook @

hook@

so

so

the

that

that

direction

it

moves slightly.

its cut part

of

the

is

located

arrow.

at

the

Loosen

center

the

of

two

screws @ then

the

needle hole.

-16-

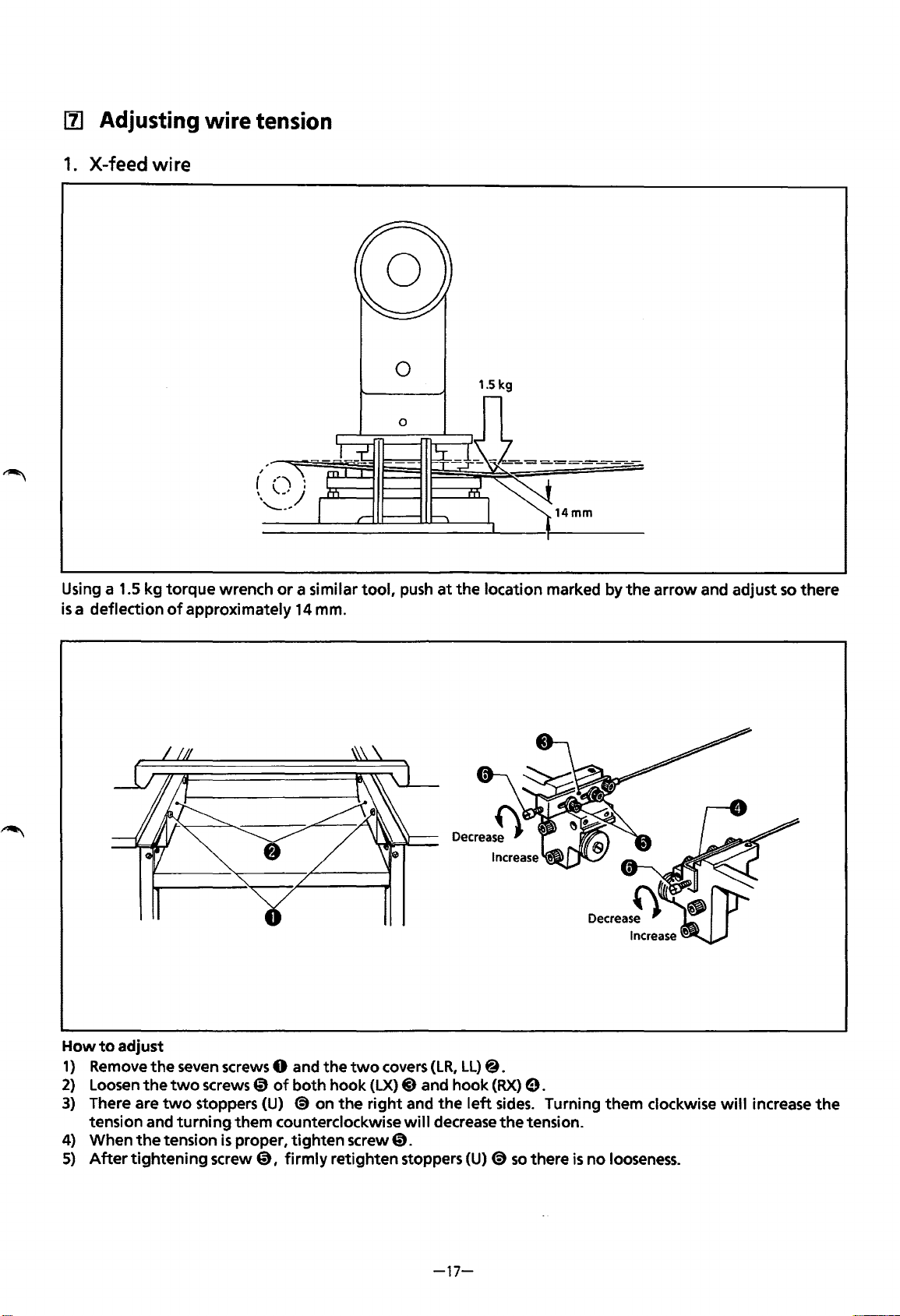

Page 20

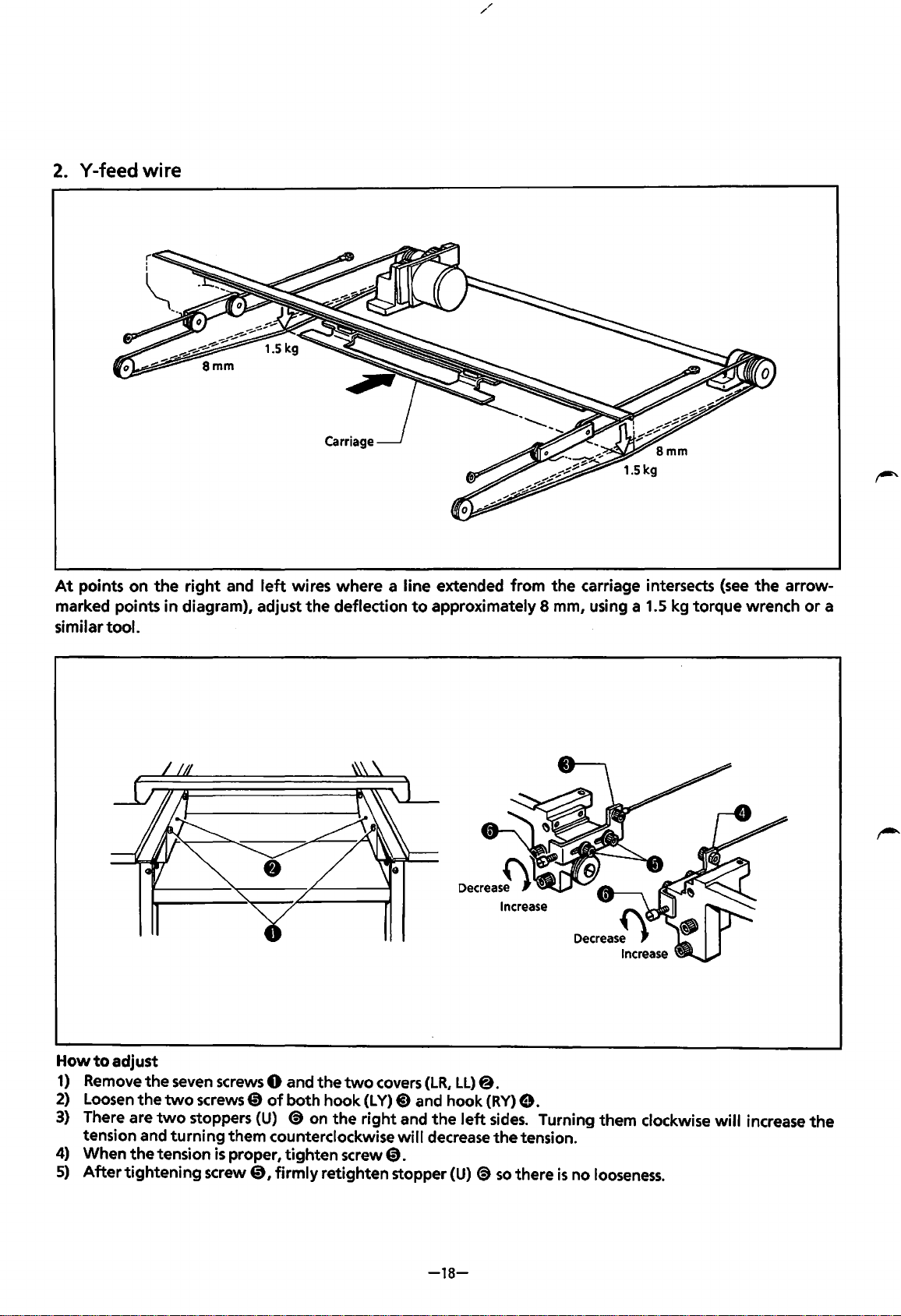

111

Adjusting

1.

X-feed wire

wire

tension

Using a 1.5 kg

is

a deflection

torque

of

wrench

approximately

or

a similar

14

mm.

tool,

0

push

at

1.5 kg

the

location marked by

the

arrow

and adjust

so

there

How

to

adjust

1)

Remove

2)

Loosen

3)

There are

tension and

4) When

5)

After

the

seven screws 0 and

the

two

two

stoppers (U)

turning

the

tension

tightening

the

screws 0

is

screw

of

both

(S)

on

them counterclockwise

proper,

0,

tighten

firmly

two

covers

hook

(LX)

the

right

screw

retighten stoppers

@)

and hook

and

will

0.

(LR,

the

decrease

-17-

LL)@.

(RX)

left

(U)

(S)

0.

sides.

the

so

Turning them clockwise

tension.

there

is

no

looseness.

will

increase

the

Page 21

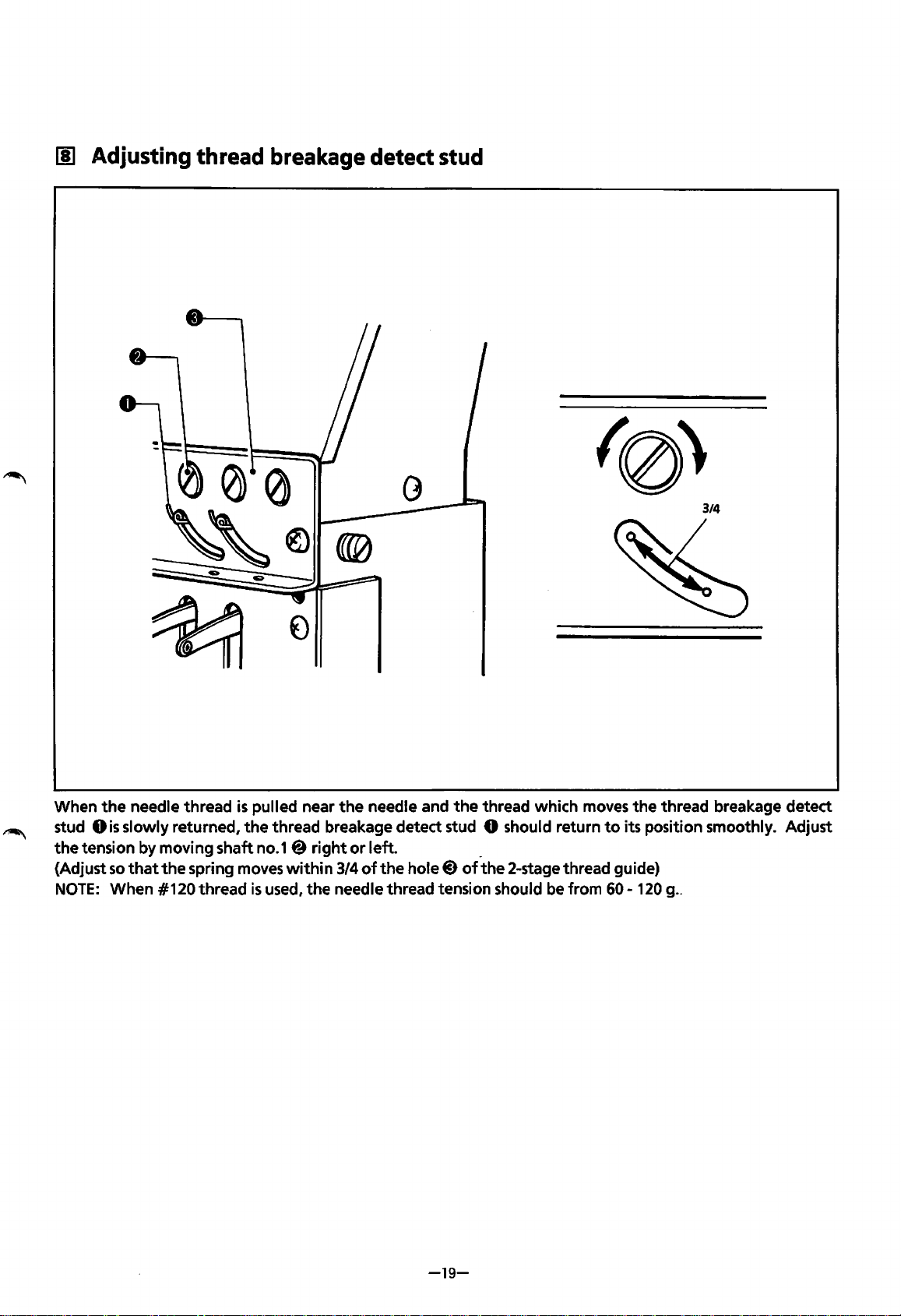

2.

Y-feed wire

At

points

marked points

similar

on

tool.

the

right

and

in

diagram), adjust

left

wires where a line extended from

the

deflection

to

approximately 8

the

carriage intersects

mm,

using a 1.5 kg torque wrench

(see

the

arrow-

or

a

How

to

adjust

1)

Remove

2)

Loosen

3)

There are

tension and

4)

When

5)

After

the

seven

the

two

two

stoppers

turning

the

tension

tightening

screws 0 and

screws

CD

of

(U)

them counterclockwise

is

proper,

screw@,

the

both hook

(S)

on

tighten

firmly

retighten stopper

two

covers

(L

Y)

the

right

screw@.

(LR,

@)

and hook

and

the

will

decrease

-18-

LL)

left

(U)

@.

(RY)

(S)

8.

sides.

the

tension.

so

there

Turning them clockwise

is

no

looseness.

will

increase

the

Page 22

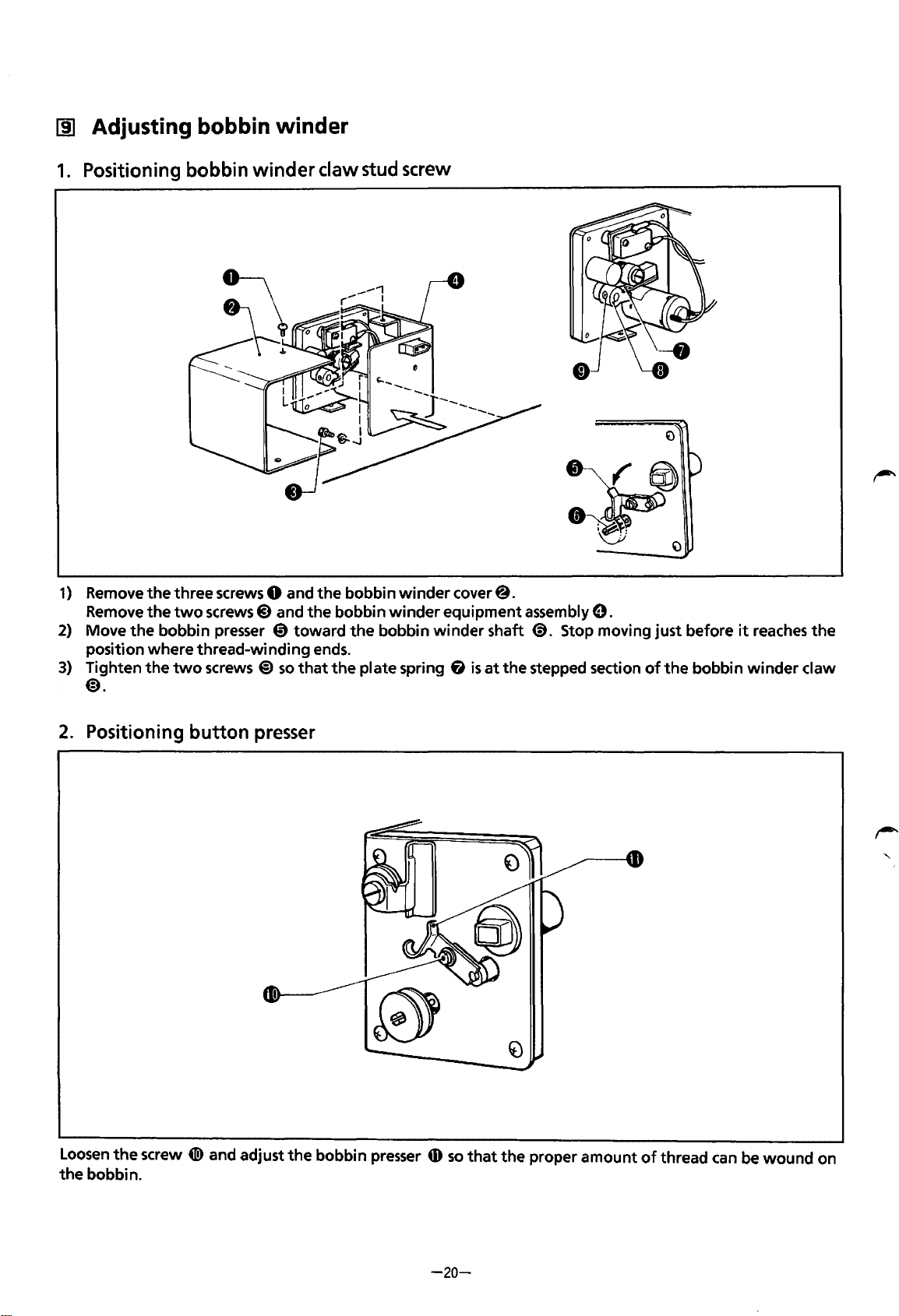

[!] Adjusting thread breakage detect

stud

3/4

When

stud

the

{Adjust

the

needle thread

Ois

slowly returned,

tension by moving shaft no.1@

so

that

the

spring moves

NOTE:

When #120 thread

is

the

pulled near

thread breakage detect stud 0 should return

within

is

used,

the

needle and

right

or

left. _

3/4

of

the

the

needle thread tension should be from

hole@)

the

thread which moves

of

the

2-stage thread guide)

the

thread breakage detect

to

its position smoothly. Adjust

60-

120 g ..

-19-

Page 23

[j] Adjusting bobbin winder

1.

Positioning bobbin

winder

claw stud screw

1)

Remove

Remove

2)

Move

position where thread-winding ends.

3)

Tighten

the

three screws 0 and

the

two

screws 8 and

the

bobbin presser @)toward

the

two

screws

@)

so

@).

2.

Positioning

button

presser

the

the

that

bobbin

bobbin

the

bobbin

the

plate spring

winder

winder

cover@.

equipment assembly

winder

fi

shaft

<9.

is

at

the stepped section

9.

Stop moving just before

of

the

bobbin

it

reaches

winder

the

claw

Loosen

the

the

bobbin.

screw

41!)

and adjust

the

bobbin presser

tD

-20-

so

that

the

proper

amount

of

thread

can

be

wound

on

Page 24

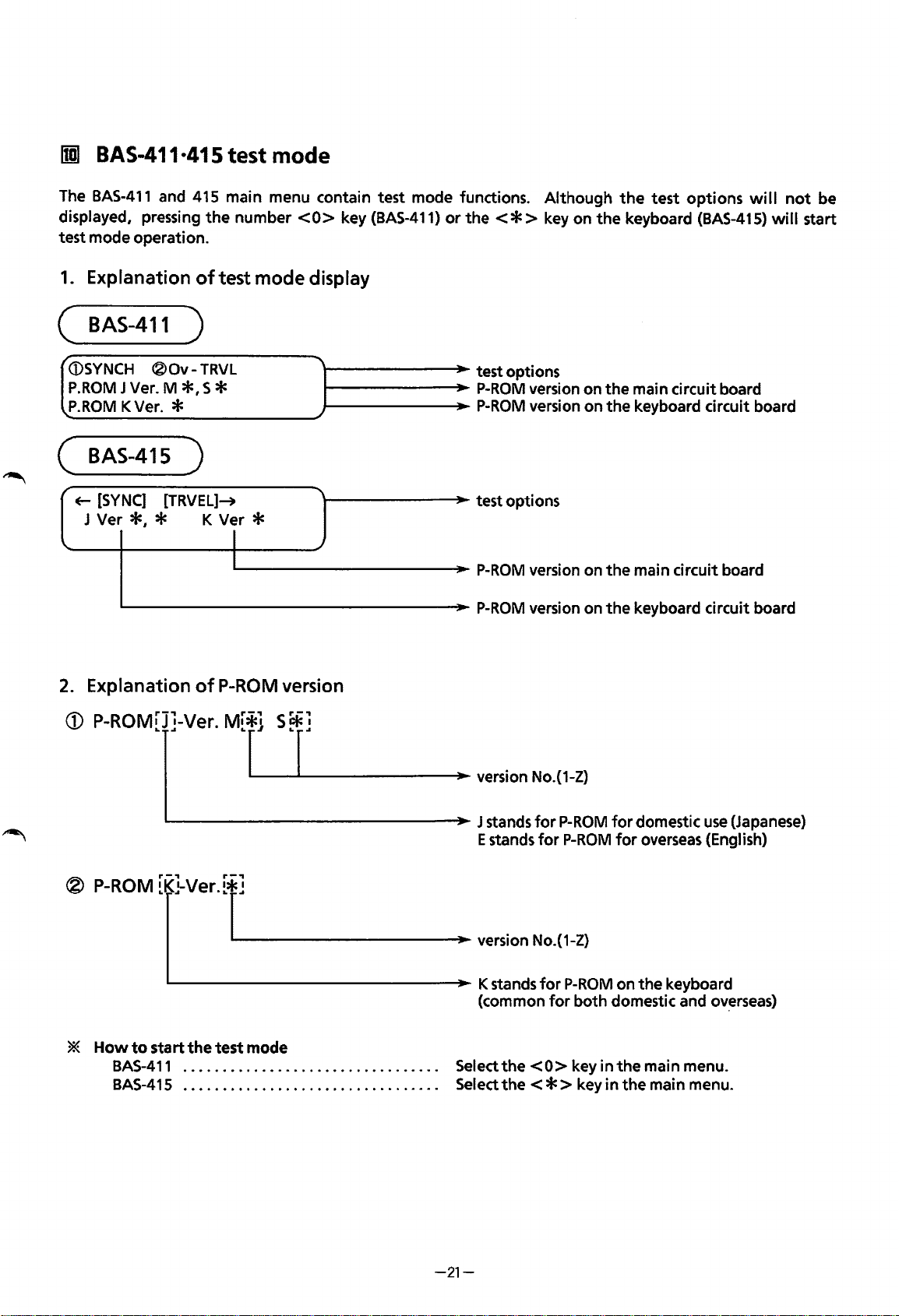

rml

BAS-411·415 test mode

The

BAS-411

displayed, pressing

test mode operation.

1.

Explanation

(

BAS-411

/

(i)SYNCH

P.ROM

P.ROM

and 415 main menu contain test mode functions. Although

the

number

of

test mode display

)

®Ov-

J Ver. M

K Ver. *

TRVL

*•

S *

( BAS-415 )

<0>

key

(BAS-411)

l--------J~~oo-

1------~_..~

1--------J~~oo-

or

the<*>

test options

P-ROM

P-ROM

the

test

options

key on

version on

version on the keyboard circuit board

the

keyboard

the

main circuit board

(BAS-415)

will

not

will

be

start

~

[SYNC]

J Ver

*,

'------------------J~~oo-

2.

Explanation

CD

P-ROM[]J]-Ver.

®

P-ROM

[TRVEL]~

* K Ver *

I

IL...------------J~~oo-

of

P-ROM

version

M[*r.j_S~.....__r]

- - •: version No.(1-Z)

[K[}Ver.[r.__]

_______

- : version

\--------"'JIIoo-

___

test options

P-ROM

P-ROM

....,.

- J stands

E stands

_....,..

version on

version on

for

P-ROM

for

P-ROM

No.(1-Z)

the

main circuit board

the

keyboard circuit board

for

domestic

for

overseas (English)

use

(Japanese)

'---------------~-

*

Howtostartthetestmode

BAS-411

BAS-41

.................................

5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Select

K stands

(common

Selectthe<O>keyinthemainmenu.

-21-

for

for

the

< * > key in

P-ROM

on the keyboard

both domestic and

the

main menu.

ov~rseas)

Page 25

3.

Explanation

1)

of

test menu

( ____

The

2)

(

____ ® ___

The

Pressing

After

adjustment,

~

___ s __ v __ N

menu

for

adjusting

r

___

r

menu

for

adjusting

alphanumeric

press

__

c ___ H

the

needle

__ a __ v ___ e __

the

position

keys < 1 >

the

<END>

_____

position

l

____

_,)

of

or

< 2 > will set

key

)

detecting

the

overtravel sensor.

the

to

return

to

synchronizer

machine

the

main

on

the

machine

into

one

of

the

test

modes.

menu. (BAS-411·415)

upper

shaft.

-22-

Page 26

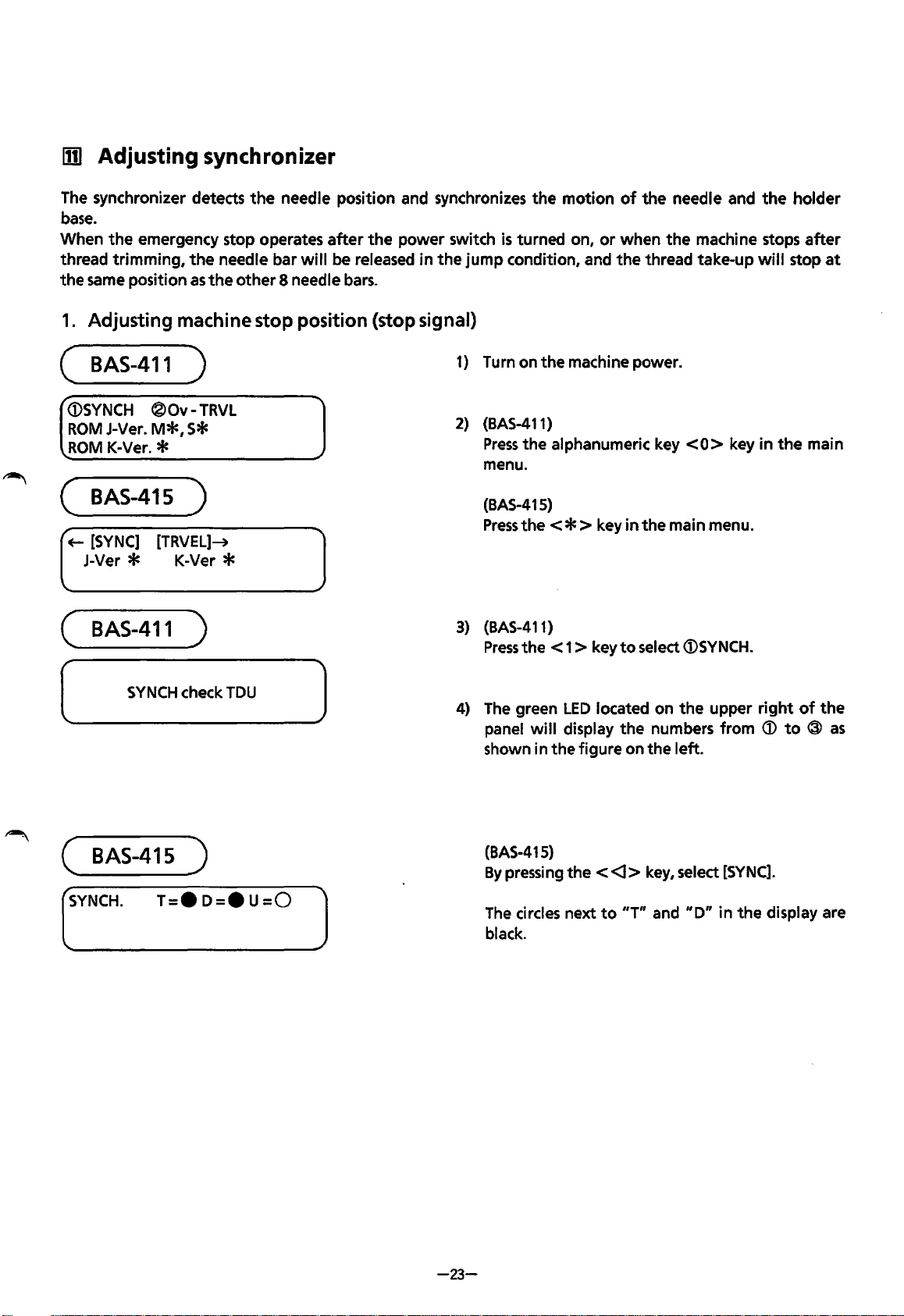

IDJ

Adjusting synchronizer

The

synchronizer detects

base.

When

thread trimming,

the

1.

the

emergency stop operates

the

same position

as

Adjusting machine stop position (stop signal)

the

needle bar

the

other

needle position and synchronizes

after

the

power switch

will

be released in

8 needle bars.

the

is

turned on,

jump

condition, and

the

motion

or

of

the

needle and

when

the

the

thread take-up

the

machine stops

will

stop

holder

after

at

(

BAS-411

<DSYNCH

ROM

ROM

(

BAS-415

+-

[SYNC]

J-Ver * K-Ver *

(

BAS-411

(

®Ov-

J-Ver.

M*,

K-Ver. *

SYNCH

S*

[TRVEL]-+

check

)

TRVL

)

)

TDU

)

1) Turn on

2)

(BAS-411)

Press

the

menu.

(BAS-415)

Press

the<*>

3)

(BAS-411)

Press

the

4)

The

green

panel

shown in

the

machine power.

alphanumeric key

key

in

< 1 > key

LED

will

display

the

to

located on

the

figure on

<0>

key

the main menu.

select

<DSYNCH.

the

upper

numbers from

the

left.

in

the

right

<D

to ® as

main

of

the

(

BAS-415

(_SY_N_C_H·

__

)

T_=_·_D_=_•_U_=_O

__

(BAS-415)

By

pressing

The

]

-23-

circles next

black.

the < <l>

to

"T"

key, select

and

"D"

[SYNC].

in

the

display are

Page 27

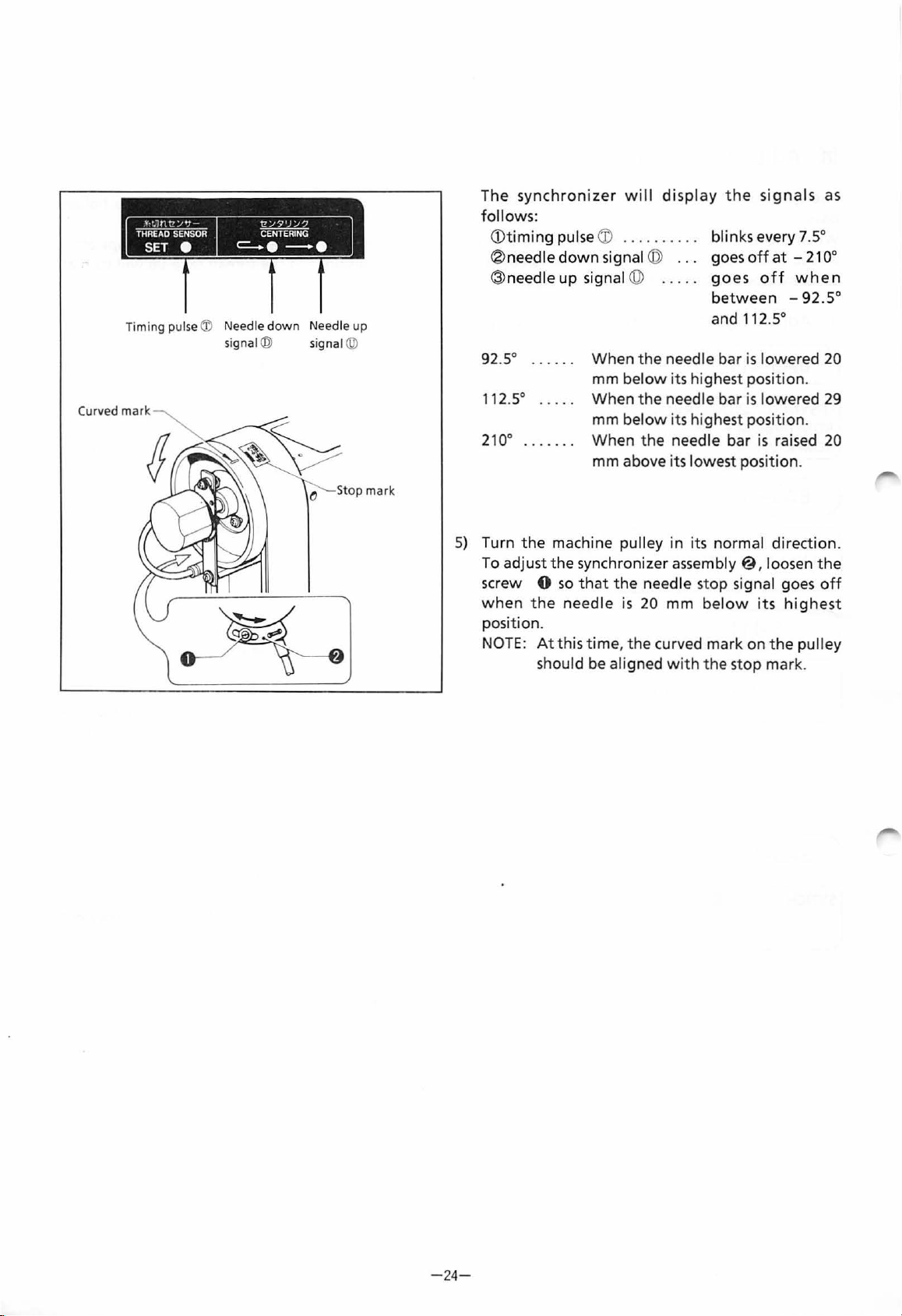

Timing pulse ® Needle do

Curved mark

si

gnal@

wn Nee

si

gnal @

dl e up

Stop

mar

The

synchronizer will

display

the

signals

as

follows:

bl

in

<D

timing

® needle

@needle

pulse

CD .........

down

signal ©

up

signal @

..

.

goes

.

goes

between

ks every 7.5°

off

at -21

off

when

-92.5

oo

°

and 112.5°

92

.5° . . . . . . When t he needle bar

mm

112S

210

° . . . . . . .

below

When the

mm b

When

its highest position.

needle bar is lowered

elow

its highest

the needle bar

is

lowered 20

positio

is

n.

raised

29

20

mm above its lowest position.

k

5)

Turn

the

machine pulley in i

To adjust

sc

rew 0 so that

when

pos

NOTE:

the ne ed

ition

At

the

.

this time, the curved mark on

should

synchronizer

the

needle s

le

is

20 mm bel

be aligned wi

ts

normal direct

assembly@

top signal goes

ow its

th th

e st

op

ion

, loosen the

off

highe

st

the

pulley

mark.

.

-24

-

Page 28

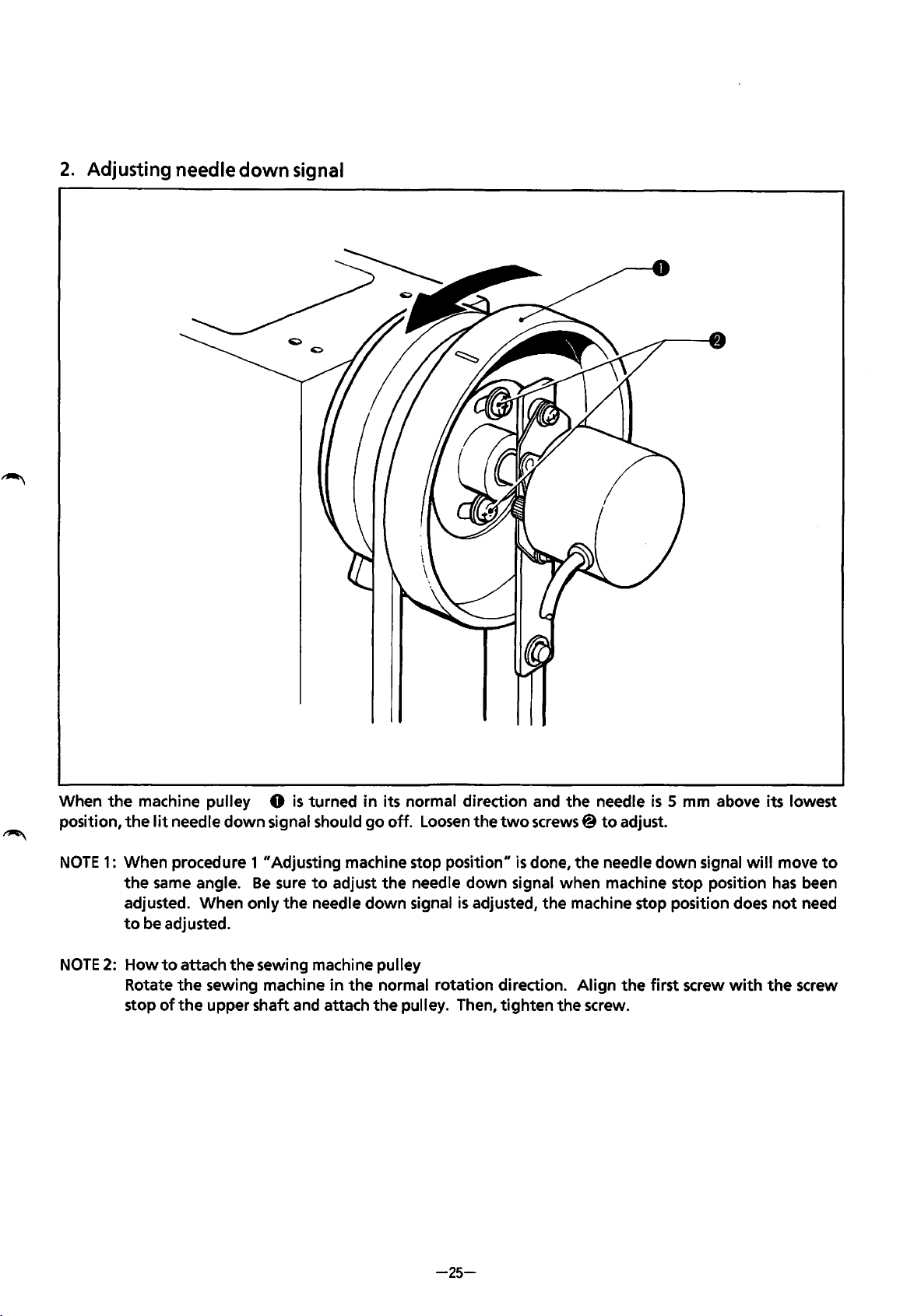

2.

Adjusting needle down signal

When

position,

NOTE

NOTE

the

1:

2: How

machine pulley 0

the

lit

needle

When procedure 1 "Adjusting machine stop position"

the

same

adjusted. When only

to

be adjusted.

to

Rotate

stop

the

of

down

angle.

attach

the

the

sewing machine

upper shaft and attach

is

turned

signal should

Be

sure

to

the

needle

sewing machine pulley

adjust

in

the

in

its normal direction and

go

off.

the

down

normal rotation direction. Align

the

pulley. Then,

Loosen

needle down signal when machine stop position

signal

the

two

is

adjusted,

tighten

screws@

is

done,

the

the

needle

to

the

needle

machine stop position does

the

screw.

is

adjust.

down

the

first screw

5 mm above its lowest

signal

with

will

move

has

not

the

to

been

need

screw

-25-

Page 29

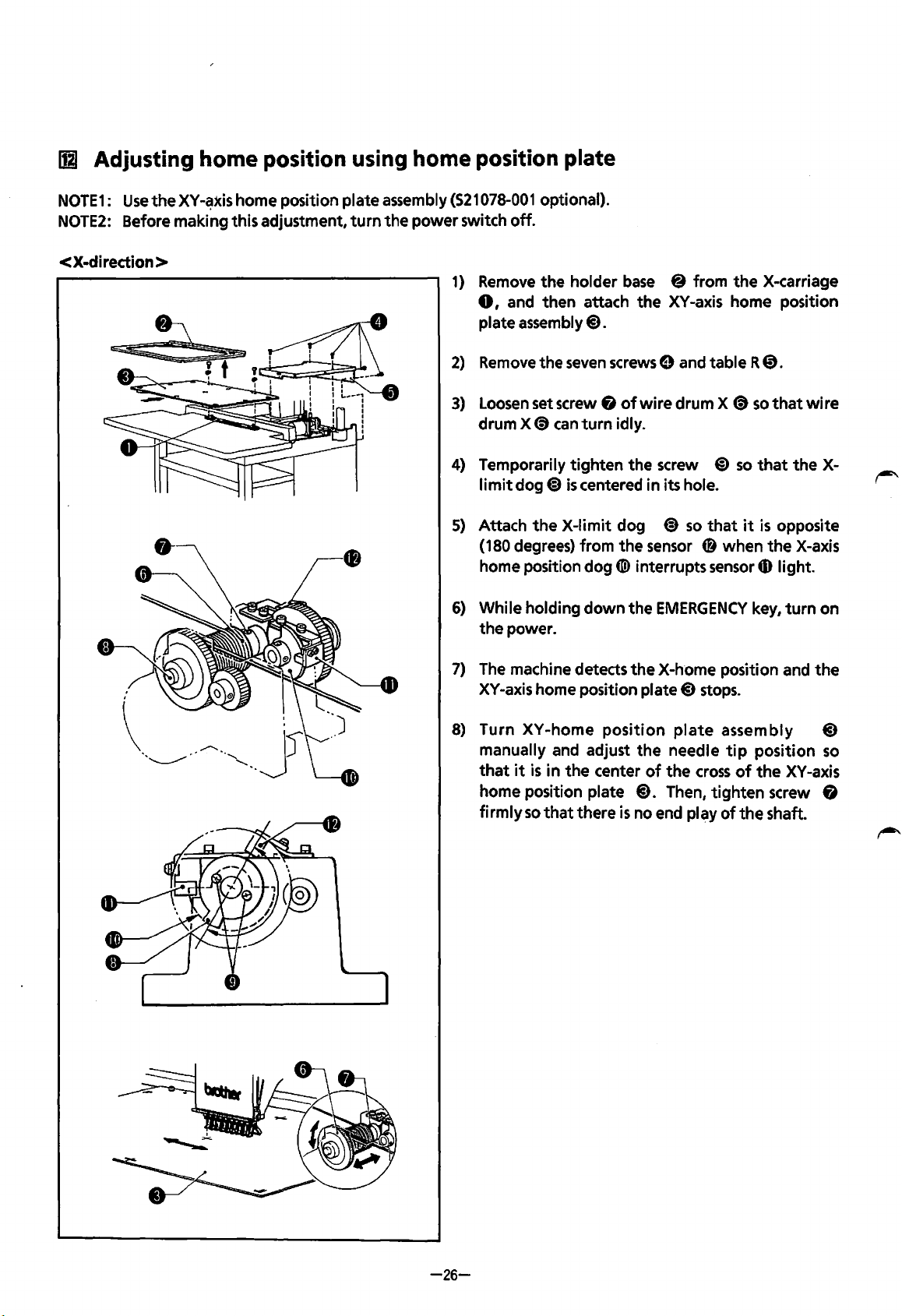

Ill

Adjusting

home

position using home position plate

NOTE1:

NOTE2:

Use

the

Before making this adjustment,

< X-direction >

XY-~xis

home position plate assembly

turn

the power switch

(521078-001

1)

Remove

0,

plate

2)

Remove

3)

Loosen

drum X

4)

Temporarily tighten the screw

limit

5)

Attach

(180 degrees) from

home position

6)

While holding down the

the power.

optional).

off.

the holder

and then attach the

assembly@).

the

seven

set screw &

<9

can

dog~

is

the

X-limit dog

base

screws

of

turn

idly.

centered in its hole.

the

dog([!) interrupts

8 from

XY

-axis home position

0 and table R

wire drum X

@)

~

so

that

sensor

CD

sensor

EMERGENCY

the

<9

so

so

it

when

key,

X-carriage

0.

that

wire

that

the

is

opposite

the

X-axis

4D

light.

turn

X-

on

7)

The

machine detects

XY-axis home position plate@)

8)

Turn XY-home

manually and adjust

that

it

is

in

the

home position plate

firmly

so

that

there

the

position

center

is

X-home position and

stops.

plate

the

needle

of

the

@).

Then, tighten screw &

no end play

assembly

tip

cross

of

position

of

the

the

XV

shaft.

the

@)

so

-axis

-26-

Page 30

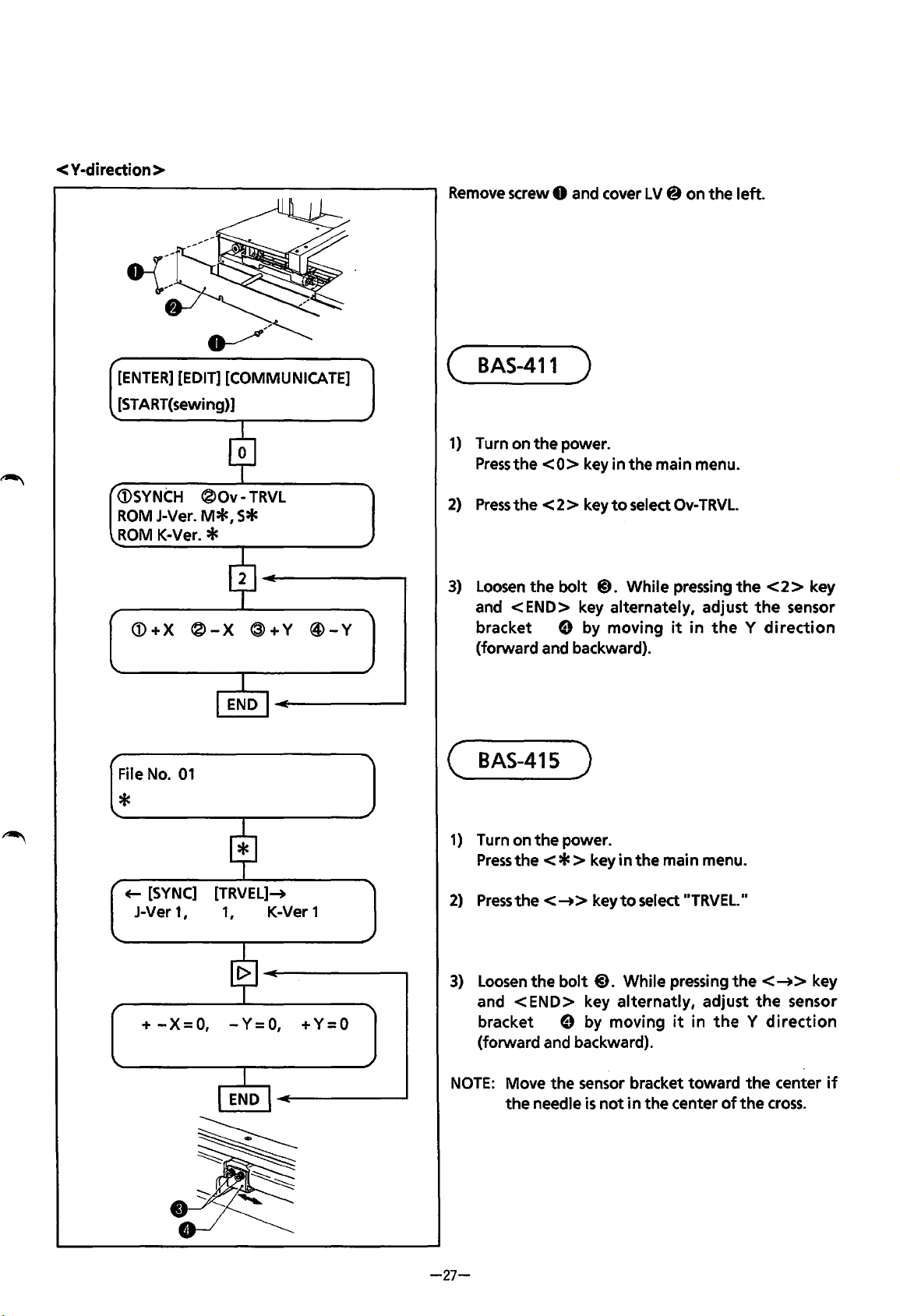

< Y·diredion >

[ENTER]

[START(sewing)]

[EDIT]

[COMMUNICATE]

Remove

(

1)

screw 0 and cover LV@ on the left.

BAS-411

Turn on the power.

Press

the

<0>

)

key in the main menu.

<DSYNCH

ROM

J-Ver.

ROM

K-Ver. *

<D+X

File

No.

01

*

~

[SYNC]

J-Ver 1 I 1

®Ov-

M*,

®-X

[TRVEL]-+

S*

1

TRVL

®+Y

K-Ver 1

@-Y

2)

Press

the

< 2 > key

3)

Loosen

and

bracket

(forward and backward).

(

BAS-415

1)

Turn on

Press

2)

Press

the

bolt

<END>

e by moving

the

power.

the<*>

the<-+>

key alternately, adjust

)

to

select

@).

While pressing

key

in

the main menu.

key

to

select

Ov-

TRVL.

the

it

in

the y direction

..

TRVEL.

..

<2>

the

key

sensor

3)

+

-X=

0,

- Y =

0,

+ Y = 0

Loosen

and

bracket

(forward and backward).

NOTE:

-27-

the bolt@). While pressing

<END>

e by moving

Move the sensor bracket toward

the

needle

the<-+>

key alternatly, adjust

it

j n

the y direction

is

not

in

the center

of

the

the

the

sensor

center

cross.

key

if

Page 31

!nl

Positioning over

limit

sensor

<Over

(

<X-direction

limit

BAS-411

[ENTER]

[ST

sensor

location>

)

>

[EDIT] [COMMUNICATE]

ART(sewi ng)]

1)

Press

the

numeric key

<0>

in

the

main menu.

CD

SYNCH ®Ov-

P-

ROM

J-Ver.

P-ROM

1---C_OD_E

CD

+X

CD

+X

SPEED

K-Ver. *

®

®

N_o

TRV

M*,

S*

-X

@

-X

@

.

~'21

'21

l!;_][g

L

+Y

+Y

ffilljl

L!JQJ

@

@

-Y

-Y

rpm.

2)

Press

the

3)

Press

the

move 227

displayed on

under

4) Loosen

so

that

figure

227 .5

pressed.

<2

> key to select ® Ov -

< 1 > key. The

.3

mm

to

the

the

panel and

the

number CD.

two

screws

the

thread sensor

on

the

display

mm

when

left

of

the

between

<E-->

hoop

and

. The

the

X-limit

indicator

and

TRVL.

the

holder

figure

cursor appears

dog

lights

227.0

<~>

base

"227

.3"

and adjust

with

mm and

keys

is

the

are

5)

Pressthe <END

-

28-

> key.

Page 32

I

<D+X

(j)

+X

®-X

¢

®-X

$$

®+Y

®+Y

@-Y

@-Y

~

6)

Press

the

move 227.3

displayed on

under the number

·

7)

Loosen

so

that

the

on

when

<2>

key.

The

mm

the

to

the

right.

panel and

hoop and

the

The

figure 11227.3

the

cursor appears

holder

0.

two

screws

the

centering indicator lights

display between 227.0 mm - 227.5 mm

jog

keys<~>

of

the

and

X-limit

<~>are

dog and adjust

pressed.

with

figure

base

..

is

CODE

SPEED

(j)

+X

'

<.DSYNCH

P-ROM

P-ROM

[ENTER]

[ST

J-Ver. MO,

K-Ver. 4

ART(sewi

No.

I

®-X

I

®Ov-TRVL

I

[EDIT]

ng)]

[2][2]~[31~

rpm.~

8)

Press

END

I

®+Y

END

SO

END

[COMMUNICATE]

®-Y

I

I

~

9)

the

11

CAUTION

and the holder

Press

the

menu.

<END>

MOVING!

base

<END>

Screws

key

twice.

II

is

displayed and

move

to

key again

the

to

The message

the

center.

return

to

the

hoop

main

-29-

Page 33

<Y·diredion>

[ENTER]

[START(sewi

<DSYNCH

ROM

ROM

t--~-~ED_E~_No_.

J-Ver. MO,

K-Ver.4

<D+X

<D+X

[EDIT]

(COMMUNICATE]

ng)]

®Ov-

®-X

®-X

TRVL

SO

®+Y

~+Y

----~[]~

@-Y

@-Y

8][5]

rpm.

1)

Press

the

numeric key

2)

Press

the < 2 > key

3)

Press

the

<3>

move 143.5 mm toward

"143.5"

appears under

4)

Loosen

position

with

-

144.0 mm when < f >

(143.5

is

displayed on

two

so

that

the

figure on the display between 143.0 mm

mm

desireble)

<0>

in

the

main menu.

to

select

®Ov-

key.

The

hoop and

the

the

the

number®.

bolts.

Adjust

the thread sensor indicator lights

TRVL.

the

holder

operator. The figure

panel and

sensor

or

<

J,

>

the

cursor

bracket

is

pressed.

base

A

<D+X

®-X

®+Y

@-Y

5)

Press

the

<END>

key.

-30-

Page 34

<D+X

®-X

I

®+Y

®-Y

6)

Press

the

<4>

key.

The

hoop and

move

figure

cursor appears under the number@.

143.5

11

143.5"

mm

away

from

is

displayed on the panel and

the

holder

the

operator. The

base

the

r

t--c_oo_E

SPEED

N_o.

<D+X

--~OJ~

I

END

®-X

I

END

8][5]

I

®+Y

I

_

rpm.~

®-Y

""'

7)

Adjust sensor

centering indicator lights

display between 143.0 mm • 144.0 mm

< f >

desireble)

8)

Press

main menu.

or

the

bracket B position

<

.L

>

is

pressed. (143.5 mm

<END>

key three times

with

the

so

that

figure on

to

return

the

the

when

most

to

the

(j)SYNCH

P-ROM

ROM

[ENTER]

[START(sewi

\..

J-Ver * MO,

K-Ver. *

[EDIT]

®Ov • TRVL

SO

*

I

END

I

[COMMUNICATE]

ng)]

-31-

Page 35

( BAS-415 )

<Y-diredion>

File No.

01

*

+--

[SYNC]

J-Ver

+

-X=O, -Y=O,

+

-X=O,

length

+

-X=O,

length

[TRVEL]-+

1, 1,

-Y=O,

-Y=O,

K-Ver 1

+Y=O

+Y=O

= 143.5 mm

+Y=•

= 143.5 mm

1)

Press

the

< * > key in

2)

Press

the<

I>> keytoselectTRAVEL.

3)

Press

the

<V

> key. The hoop and

base

move 143.5 mm

figure 11143.5

4)

Press

the

adjust

circle

of

between 143.0 mm and 143.7 mm.

11

is

<V

> key again. Loosen

the

sensor bracket A position

the

..

+ Y

the

toward

displayed on

=0"

turns black

main menu.

the

operator and

the

display.

two

when

the

holder

bolts and

so

that

length is

the

the

5)

After

adjustment,

+

-X=O,

+

-X=O, -Y=O,

length

-Y=O,

= 143.5 mm

+Y=•

+Y=O

-32-

6)

Press

the

<6

base

move 143.5 mm away

the

figure 11143.5"

7)

Press

the

<6

adjust

circle

between 143.3 mm and 143.7 mm.

the

sensor bracket B position

of

the

press

the<

END> key.

> key.

The

from

is

displayed on

hoop and

> key again. Loosen

11

-Y=O

..

turns black

the

the

operator and

the

display.

two

bolts and

so

when

holder

that

the

length

is

Page 36

+

-X=O,

+

-X=O,

length

-Y=e,

= 143.9mm

I

I

END

I

-Y=e,

I

+Y=O

+Y=O

8)

After

returns

pressing

main menu.

adjustment, pressing the

the

machine

it

three times returns

to

its home position and

<END>

the

machine

key twice

to

the

"

CAUTION

"

+-

[SYNC]

J-Ver

r

File

No.

*

"

<X-diredion

MOVING

1,

01

>

I

I

END

I

I

[TRVEL]-+

1,

K-Ver 1

I

I

END

I

I

""'I

.I

File

No.

01

*

+-

[SYNC]

J-Ver

-X=O,

+

+

-X=O,

length =227.3mm

1,

[TRVEL]-+

1,

-Y=O,

-Y=O,

K-Ver 1

+Y=O

+Y=O

1)

2)

3)

Press

the

< * > key in the main menu.

Press

the<

Press

the < <l > key.

base

move

11

227.3

11

is

Screws

I>> keytoselectTRAVEL.

The

hoop and

227.3

mm

to

the

left

displayed on the display.

and

the

the

holder

figure

-33-

Page 37

+

-x=e,

length =227.3mm

+

-x=e,

+

-X=O,

length

+

-X=•,

length

-Y=O,

-Y=O,

-Y=O,

=227.3mm

-Y=O,

=227.3

+Y=O

+Y=O

+Y=O

+Y=O

mm

4)

Press

the <

<l

> key again.

the X-limit dog and adjust

II+

-X=

Oil

turns black when length

227.0

mm

and

227.5

5)

After adjustment,

Press

6)

7)

the <

base

move

11

227.3

Press

the<[>>

the X-limit dog

II+

-X=0

227.0

mm

I>

>

227.3

11

is

displayed on the display.

and

11

turns black when length

and

227.5

mm.

press

the

key.

The

mm

to

the right and the figure

key again.

adjust

mm.

Loosen

so

that

<END>

hoop

Loosen

so

that

two

screws

the circle

is

between

key.

and

the holder

two

screws

the circle

is

between

of

of

of

the

~

of

the

+

-X=•,

CAUTION

+-[SYNC]

J-Ver

1,

File

No.

01

*

-Y=O,

MOVING

[TRVEL]-+

1,

I

I

END

I

+Y=O

K-Ver 1

I

8)

After adjustment,

returns the machine

pressing

main menu.

.)

it

three times returns the machine

pressing

to

the

<END>

its home position and

key twice

to

the

-34-

Page 38

rHI

How

If

the

thread sensor does

to adjust thread sensor (thread breakage detector)

not

function

:

1)

Make sure

on.

2)

Remove

that

bar position.

the

that

the

adjustment

swit

ch

the

thread sensor

@ indicator lights

base

indicator

~

and make sure

at

each needle

0 is

I

I

0 X

Stud

0 X

3)

If

the

indicator

most needle bar positions, adjust the switch @

position.

4)

If

the

indicator

specific

detect stud

NOTE

needle bar, adjust its

: Do

of

the

switch @ does

of

the

switch @ does

0

by

gently

not

overbend. The stud 0 may break.

bending it

not

thread

with

not

a plier.

light

at

light

at

a

breakage

-

35-

Page 39

c

LUBRICATION)

II1

Machine

head

Lubrication

Everyday before using

NOTE:

1)

Lubricate these six places:

is

necessary

<DBe

sure

to

use

®Overlubrication may

for

keeping

the

machine, add

Brother-specified sewing machine oil

cause

the

machine in good condition.

1-2

oil

to

drop(s)

drip

on

to

of

oil

the

at

each location in

for

lubrication.

material.

the

figure marked by an arrow.

2)

Add a

drop

of

oil

at

the

reel

of

the

NOTE:

3)

Do

not

lubricate aside from

Lubricate

needle bar. (18 places should be lubricated

two

places

on

the

each

rotary hook.

rotary hook.

needle

on

in

the

all.)

-36-

Page 40

4) Move

apply one

When

the

needle bar

or

the

machine

two

case

drop(s)

is

used

all

the

way

to

the

right

or

the

left

side. From

of

grease

every day, lubricate daily before using. ·

to

the

base

needle bar and

the

base

the

side

of

needle bar felt.

the

machine head,

-37-

Page 41

~

Feed

guide

mechanism

linear

guide rail: X· axis

Linear guide

rail: Y· axis

NOTE

NOTE

NOTE

NOTE

1: For

2:

3:

4: Before

lubrication,

Be

sure

After

applying

use

Brother-specified grease

to

lubricate every 6 months.

grease

applying

to

the

grease, remove covers

X·Y

guide

tank

rail, move

to

make

-38-

30.

the

the

work

X carriage

easier.

right

and

left

2-3 times.

Page 42

c

REPLACING

lii

Removing

AND

and

adjusting

ADJUSTING

machine

head

PARTS

(1)

)

1)

Remove

2)

Remove

3)

Remove

4) Loosen

to

the

X-carriage cover

the

belt & from

the

wires

from

the

four

nuts @)securing

the

machine head, remove

0,

table (R)@,

the

pulley (i).

the

curcuit board,

the

the

table

the

synchronizer, and

sewing machine

machine head.

(L)@),

-39-

base

and

@.

belt

covers (A) e and (B)@ in

the

With

ground.

the

sewing machine

that

base

@ attached

order.

Page 43

~

Removing

and

adjusting

machine

head

(2)

1)

2)

3)

Use

the

four

nuts@

Be

sure

to

have

The

distance from table

Use

the

two

rear

After

adjustment, tighten

and@)

an

approximately 2 mm

nuts@)

on the

(C)~

to

to

adjust.

the

four

base 0 to

space

the

end

of

the

nuts@ and@).

adjust.

between

cyrindrical

nut

9 and

bed®,

nut

0 when adjusting.

and distance® should

be

the

same.

-40-

Page 44

[II

Removing needle bar

case

Before replacing parts related

1)

2)

3)

Loosen

Remove

Adjust

the

four

the

four

the

needle bar

screws@

screws e

case

to

the

needle bar mechanism, be sure

of

the

thread presser base

of

the

needle bar

@)so

that

it

moves

case@)

right

0.

and

and

the

left

to

case.

slightly

remove

when

the

needle bar

attached

with

case.

four

screws.

-41-

Page 45

[j] Replacing up and

down

motion parts

1)

Loosen

2)

Move

or

3)

Loosen

Remove

above.

4)

Remove

5)

When assembling, reverse

NOTE1:

NOTE2:

NOTE3:

the

four

screws@ on

the

thread take-up shaft

2 thread take-up lever(s) 0 and thread take-up stopper(s)

the

screw & on

theE

ring @)attached

the

up

and

down

When attaching

which

When attaching

there

that

wi

II

is a 0.5

Make sure

it

is

in

be

that

the

the

right

and

the

@)

and

the

thread take-up supporter shaft 0

the

bottom

motion parts

the

the

attached

the

mm

space

the

thread take-up stopper

thread take-up support

of

the

right

to

the

main needle bar

([i)

from

above procedure.

main needle

to

the

thread take-up lever(s) 0 and

between

bar@,

main needle bar@).

@)

and

left

sides

side

of

the

the

connecting rod

secure

tD

or@)

CD

@.

(Fig.A)

of

the

<9.

arm.

@,then

the

and

does

bottom

of

the

thread take-up

30-

pull

out

the

4D.

bearing

the

@.

not

@by

pressing

thread take-up stopper

contact

the

thread take-up lever 0 and

base

40 mm, and remove 1

main needle bar

it

with

theE

<9,

fix

0.

@from

ring

them

@)

so

-42-

Page 46

[§]

Replacing

jump

solenoid

0.2mm

..

1,

..

I

7.2mm

1)

Loosen

2)

Remove

3) Remove

4) When assembling, reverse

NOTE1:

NOTE2:

the

set screw@

the

two

set screws e from

the

nut~

The end

distance between them

Adjustment references:

When

mm.

When

mm.

To

base@).

the

the

avoid mispositioning

of

of

the

of

the

solenoid

solenoid rod

solenoid rod

front

cover

(L)

0 and move cover

the

solenoid

solenoid @. Then, remove

the

above procedure.

@should

to

approximately 0.2 mm by moving

is

pushed,

is

returned,

of

the

solenoid,

cover@)

not

contact

the

distance between

the

distance between the end

do

the

not

(L) 0 to

and

the

solenoid

the

up and

remove

the

bottom left.

cover.

while

turning

down

nut~.

the

end

the

solenoid bracket

it.

motion parts

of

the

rod and

of

the

rod and

4.0mm

fi.

@)

the

the

or

Adjust

nut

nut

the

bracket

is

is

the

7.2

4.0

-43-

Page 47

(§]

Attaching X

wire

Carriage

1)

Position the carriage in the back, toward the

2)

Attach the wire end (the end closer

3)

Feed

the wire around pulley

from the

wind

4)

After

Then, put the

Fit the wire completely

5)

Feed

6)

Wind the wire

7)

Wind the wire over pulley (I) from above, then around pulley

Attach the wire

NOTE:

left

side,

and

over pulley

it

around pulley@ from the right.

winding the wire around pulley@, feed

ball on the wire into the hole

into

the groove, then wind the wire eight times around the wire drum.

the wire around the back

onto

pulley~

to

hook

(LX) @ with

Be

careful

durability.

not

to

scratch the wire.

to

the ball)

@)

from the

@).

of

pulley

from below, then around pulley

bolt

left

of

the machine, making

to

hook

left

side,

then under pulley

Then,

feed the wire around pulley & from the left, and finally

some

of

wire drum

tiD

I then around pulley m from the left.

4D.

The

wire

(RX) 0 with

slack

into the wire.

(X)@).

is

coated

bolt@.

@from

@from

with

resin

sure

0.

Then

the left.

the left.

and a

it

does

feed

scratch

not

move.

it

behind pulley @

may

decrease

r-"'

its

-44-

Page 48

[Z]

Attaching Y wire

Ywire(L)

1)

Push

2)

Use

the

3)

Put

the

Wind

Ywire(R)

1)

Pull

the

2)

Use

the

3)

Put

the

Wind

the

carriage 0

bolt 0 to

wire

onto

the

wire

carriage 0 forward and secure it.

bolt@)

wire

on

the

wire

to

the

back and secure it.

attach

pulleys 0 and(!). Then,

four

to

attach (Y)

to

four

times,

pulley

times,

(Y)

put

4).

put

wire

L@ end (the end furthest from the ball)

it

around

wireR

Then,

it

around pulleys@ and

put

the

wire

pulley~,

ID

end (the end closest

put

the

wire

then attach

ball

into

CD,

ball

the

into

the hole

it

to

stand

to

the

ball)

hole

of

wire

then, attach

to

of

(RL)@)

to

stand

drum (Y)

it

to

hook

wire

drum

with

(RR)

hook

(RY) @ with

(L

Y)@.

the

0.

@.

(Y)

6.

bolt(!).

the

bolt

@.

-45-

Page 49

c

ELECTRIC

IIJ

Circuit board locations

(

BAS-411

COMPONENTS

)

)

0 Main circuit board

@ PMD circuit board

@

Sew

ing machine

0 Synchronizer circuit board

0 Keyboard circuit board

motor

circuit board

( BAS-415 )

-

46-

Page 50

~

Replacing

circuit

boards

Main circuit board

Be

sure

to

turn

off

1)

Disconnect

2)

Press

Replace

3)

Place

support clamps

4)

Connect

Be

sure

15

the

six

circuit board support clamps inward and remove

the

main circuit board.

new

main circuit board on the supports. Secure the circuit board by pushing

the

connectors

not

to

Suppo:---n

the

power

connectors.

until

treat

and open

it

snaps

into

position.

while

supporting

the

circuit board forcefully.

the

cover before replacement.

the

circuit board from

the

main circuit board from

the

back side.

P13

down

the

supports.

near each

of

the

NOTE1:

NOTE2:

NOTE3:

NOTE4:

NOTES:

NOTE6:

When replacing connectors,

connectors.

Note

that

the

flat

cable

P13

direction.

Treat

the

circuit boards carefully.

Also,

do

not

touch

IC

pins.

Do

not

bend circuit boards. The circuit pattern

large size

Check

When

while

of

the

that

new

turning

holding

circuit board.

main circuit board

the

power

down

on

the

emergency stop switch. This clears

treat

them

c~refully.

is

directional {refer

for

MOS-IC

has a CPU

the

first

in

time

Do

to

the arrow).

the

circuit boards

or

IC

may

{HD64180) and

after

replacing

not

pull on

be

two

the

-47-

the

wires when detaching

It

can

not

be inserted in

is

easily damaged by static electricity.

broken by external force due

EP-ROMs{27512).

the

main circuit board, be sure

internal memory.

the

opposite

to

to

the

the

do

it

Page 51

PMD

pulse

motor

circuit board

1)

Disconnect the

2)

Push

the

inside and remove the pulse

Replace the pulse

3)

Place

supports. Secure

down

will

new

near each

snap

four

five circuit board supports towards

motor

pulse

of

into

position, securing the circuit board.

connectors.

motor

circuit board.

circuit board.

motor

the

the

circuit

circuit

supports. The support tips

board

board by pushing

on

the

the

Machine

motor

circuit board

1) Disconnect

2)

Push

the

four

inside and remove

board.

Replace

3)

Place

supports. Secure

down

will

the

new machine

near each

snap

into

the

three connectors.

circuit board supports towards

the

machine

machine

position, securing the circuit board.

of

motor

motor

the

the

circuit board.

circuit

circuit

supports. The support tips

motor

board on

board by pushing

the

circuit

the

-48-

Page 52

Synchronizer circuit board

1)

Disconnect

2)

Remove

3)

Remove the

Memory expansion circuit board (option)

the

connector

the

three screws@ and

four

screws 0 and the synchronizer circuit board

0.

the

circuit board attachment

base@).

0.

1)

Remove

board@.

NOTE:

four

screws 0 and then remove the memory expansion circuit board

When

circuit board

will

turning

be cleared.

on

@,

power

be

sure

of

BAS-411·415

to

do

it

while

holding down

for

the

first

time

after replacing

the

EMERGENCY

-49-

@from

the

switch. The inside memory

the

main circuit

memory expansion

Page 53

(

BAS-411

Keyboard circuit board {1)

)

1)

Manually loosen

2)

Loosen

At

3)

Disconnect

this

the

time,

the

two

screws@. Pull

do

not

pull strongly on

the

EMERGENCY

two

screws@

in

the

the

upper

the

EMERGENCY

switch 0 connector

keyboard cable 0 and remove it.

part

of

the

panel 0

stop switch@ cable.

C9

from

-50-

toward

the

keyboard circuit board

yourself and detach

fi.

it.

Page 54

Keyboard circuit board (2}

Pull

the

hatched part

the

flat

cable shown in

the

lock and pull

4) Disconnect

5)

Disconnect

6)

Loosen

the

panel

the

the

connector 0

the

flat

four

base

~.

cables@)

screws(!) on

from

and 0

the

the

keyboard circuit

from

the

right

and

left

board@.

keyboard circuit board @.

sides

of

the

supporter

-51-

0.

of

the

flat

Remove

the

black connector attached

the

figure on

cable

the

toward

key sheet

the

left.

yourself.

Release

fi

from

to

Page 55

Keyboard circuit board (3)

the

7) Loosen

8)

Remove

9)

When

screw@

the

four

assembling, reverse

so

screws@ and

that

the

knob 0

the

the

above procedure. For assembling, note

can

be removed easily. Then, remove

keyboard circuit board

0.

the

the

followin

knob

0.

g points.

NOTE

1:

NOTE2:

Attach

Align

Insert

the

Pull

If

and insert

the

the

the

hatched

the

flat

cable

flat

contrast

white

point

connectors

part

ofthe

cables 0

is

loose,

into

the

slots correctly.

knob 0 as

of

of

connector

and@

the

follows:

the

knob 0 with

White

point

the

flat

cab

to

lightly

cables may have been improperl y inserted

~Jjt

SPEED

les

0 and @

lock

to

che

the

position line. Tighten

.

while

it

in pl

ace.

ck

if

they

are locked properly.

ffv

the

screw@.

Position line

the

black connector lock

into

the

slots.

is

released. Insert

Release

the

lock

~

0

__.__..-

~~

~ " -

"

-----v

\ 0

-52

-

Page 56

Keyboard

unit

When rep I acing

1)

Manually loosen

2)

Remove

stand

Atthis

3)

When assembling, reverse

LCD

module

the

whole

the

the

four

screws 0 on

0.

time, be careful

assembmly

keyboard

two

screws@ in

not

to

the

\ _

unit,

follow

the

the

back side

drop

the

above procedure.

the

board cable 0 and remove it.

of

keyboard unit@).

_.

procedures below.

the

keyboard unit@). Then remove

it

from

the

keyboard

1)

2)

3)

4)

5)

6)

Loosen

Remove

Remove

Remove

Remove

Remove

two

screws@

two

screws@)

the

flat

four

screws@)

the

LCD

four

screws~

of

and

cables@)

and

module

and

the

keyboard cable 0 and remove

the

411

panel

0.

and

(S)

from

the

keyboard circuit board

the

support@).

assembly«!>

the

connector

LCD

module assembly

4D

-53-

from

«!>.

the

cable from the keyboard unit.

fj.

the

keyboard circuit board

fj.

Page 57

(

BAS-415

)

Keyboard circuit board (1)

1)

Manually

2) Loosen

At

this

3) Disconnect

loosen

the

time,

the

four

screws@). Pull

do

not

the

EMERGENCY

two

pull

screws@

strongly

in

the

the

upper

on

the

switch@) connector

keyboard cable 0 and remove

part

of

the

EMERGENCY

<9

panel 0

stop switch@) cable.

from

toward

the

keyboard circuit

-54-

it.

yourself and detach

board&.

it.

Page 58

Keyboard circuit board (2)

Pull

the

hatched part

the

flat

cable shown in

the

lock and pull

4) Disconnect

5)

Disconnect

6)

Lift

the

the

connector@)

the

flat

cable@)

from

from

the

keyboard circuit board

the

keyboard circuit board

key sheet support (!) and remove

it

from

the

panel

6.

6.

base

m.

-55-

the

ofthe

black connector attached

the

figure on

flat

cable

toward

the

left.

yourself.

to

Release

Page 59

Keyboard circuit board (3)

7)

Loosen

8)

Remove

9)

When assembling, reverse

the

the

screw@

four

screws@)

so

that

the

knob 0 can

and

the

keyboard circuit board

the

above procedure.

be

removed easily. Then, remove

0.

For

assembling, note

the

following

the

knob

points.

0.

NOTE1:

NOTE2:

Attach

Align

Insert

of

Pull

If

and insert

the

the

the

connector

the

flat

cable

the

flat

contrast knob 0

white

point

of

flat

cable 0 connector

to

.lock

cable 0

is

into

lightly

loose,

the

the slots correctly.

as

follows:

the knob 0

it

in place.

to

check

cables may have been improperly inserted

with

while

if

the

position line. Tighten

the

black connector lock

it

is

locked properly.

is

the

screw@.

released. Insert

into

the

slots.

the

hatched

Release

the

part

lock

-56-

Page 60

Keyboard

unit

When

1)

Manually

2)

Remove

stand

At

3)

When

LCD

module

1)

Remove

2)

Remove

replacing

the

loosen

the

four

whole

the

0.

this

time,

be careful

assembling, reverse

assembmly

the