Page 1

SERVICE

MANUAL

FOR

BAS-361

PROGRAMMABLE ELECTRONIC

PATTERN SEWER

Profile

L

Page 2

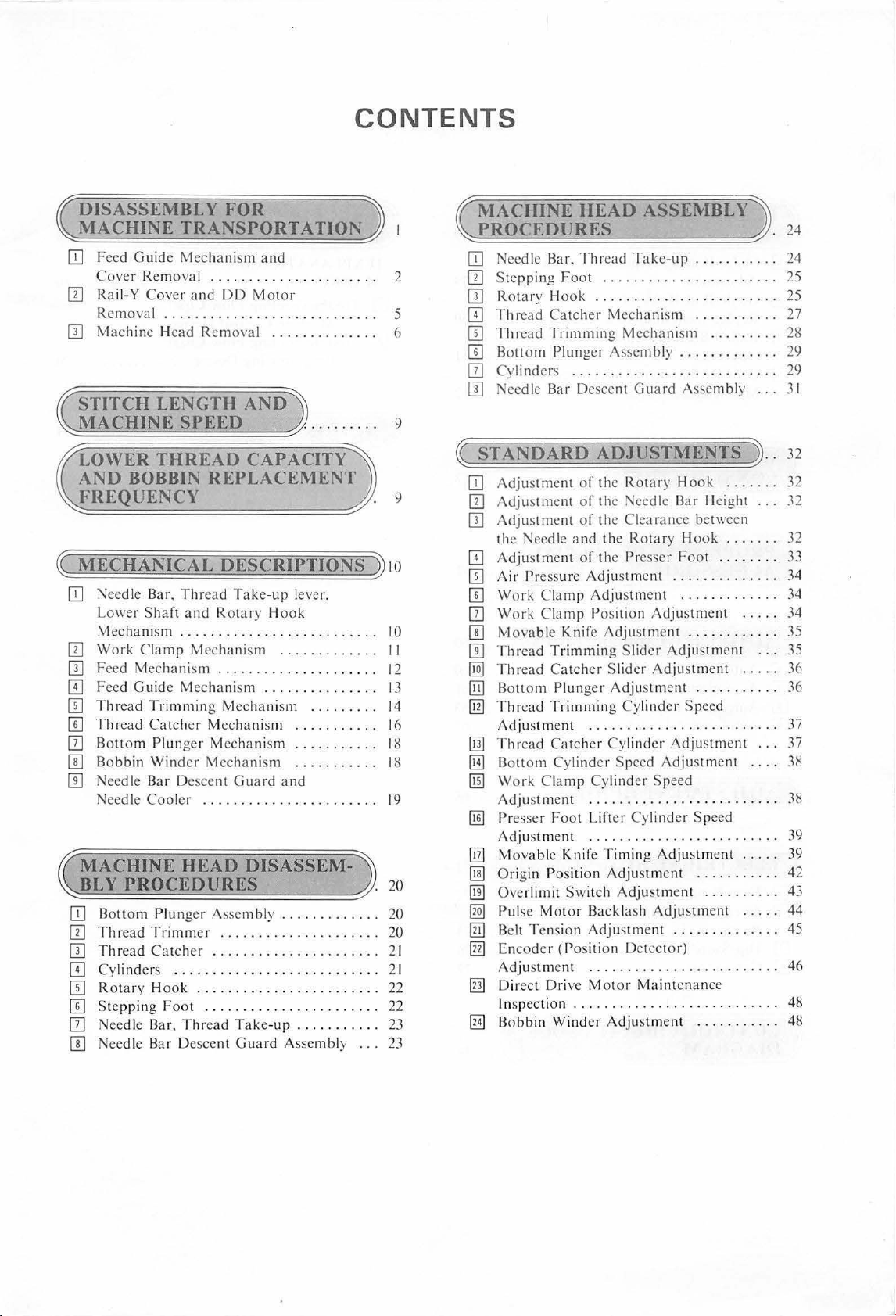

CONTENTS

DISASSEMBLY

MACHINE

OJ

Feed Guide Mechani sm and

Cover Removal . . . . . . . . . . . . . . . . . . . . . . 2

[I]

Rail-Y Cover

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

[]] Machine Head Removal . . . . . . . . . . . . . . 6

STITCH

LENGTH

MACHINE

LOWER

AND

THREAD

BOBBIN

FOR

TRANSPORTATION

and

DO

Motor

AND

SPEED

CAPACITY

REPLACEMENT

FREQUENCY

~

MECHANICAL

OJ

Needle Bar. Thread Take-up lever,

Lower Shaft

Mechanism

[I]

Work

Clamp

Feed Mechani sm . . . . . . . . . . . . . . . . . . . . . 12

[]]

Feed Guide Mechanism

m

[[]

Thread Trimming Mechanism

Thread Catcher Mechanism

lil

Bottom Plunger Mechanism .

m

[]]

Bobbin Winder Mechani sm

ecdle Bar Descent

!Il

Needle Cooler

MACHINE

BLY

PROCEDURES

OJ

Bottom Plung

[I]

Thread

[]]

Thr

IT]

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . .

[[]

Rotary

[I]

Stepping Foo t

[I]

Needle Bar. Thread

[I]

Needle Bar Descent Guard Assembly .

ead

Trimmer

Catcher

Hook .

DESCRIPTIONS

and Rotar

.......

Mechani sm . . . . . . . . . . . . . II

...................

HEAD

er

......

.......................

y Hook

..

................

.........

...........

...........

Guard

and

DISASSEM-

Assembly

.......

..................

Take-up

.............

..

............

..

...............

...........

.

.......

..........

.....

. . . .

.

. . 14

...

..

9

9

~

10

. 10

13

16

IS

IS

19

20

20

20

21

21

22

22

23

23

MACHINE

[

PROCEDURES

OJ

Needle Bar.

[I]

Stepp ing

OJ

Rotary Hook

IT]

Thread Catcher Mechanism

[}]

Thread Trimming Mechanism .

[I]

Bottom Plunger Assembly . .

[I]

Cylinders

[I]

Needle Bar Descent Guard Assembly

~

STANDARD

OJ

Adjustment

[I]

Adjustment

[]] Adjustment

the Needle

IT]

Adjustment

[[] Air Pressure Adjustment

[I]

Work Clamp Adju stment .

[I]

Work Clamp Position Adjustment

[]]

Mo

vable Knife Adjustment

!Il

Thread Trimming Slider Adjustment

[I£]

Thread Catcher S

(DJ

Bottom Plun

@]

Thr

ead Trimming Cylinder Speed

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . .

[ill Thread Catcher Cylinder Adjustment

[ill Bottom Cylinder Speed Adjustment . . . .

[ill Work Clamp Cylind er Speed

Adju stment

[ill Presser Foot Lift

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . .

[ill Movable Knife Timing Adjus tment

[ill Origin Position Adjustment . . . . . . . . . . . 42

[ill Ovcrlimit Switch Adjustment

~

Pulse

[ill Belt Tension Adjustment

0]

Encoder (Position Detector)

Adjustment . .

[Til

Direct Drive

Inspection

[E)

Bobbin Win

Foot

...

and

Motor

......

HEAD

Thr

...............

........................

ASSEMBLY

ead

Take

-up

......................

.........

.

....

...........

........

...........

ADJUSTMENTS

of

the

Rotar

y Hook

of

the

1'\ccd

lc

Bar Height ...

of

the Clearance between

the Ro

tar

y Hook

of

the Presser

lid

ger

Adju stment

........

er

Backlash Adjustment . . .

.......................

Motor

..

der

Adjustment

Foot

..............

er Adjustment

.................

Cylinder Speed

............

Maintenance

........

.......

......

........

............

............

...........

..........

.

..........

...........

J

_ .

. .

.. ..

l ·

.....

...

.....

...

..... 39

. 25

.

..

..

~

24

25

27

2S

29

29

31

32

32

.12

32

33

34

34

.14

35

35

36

.16

37

37

.IX

3X

39

43

44

45

46

4S

4S

Page 3

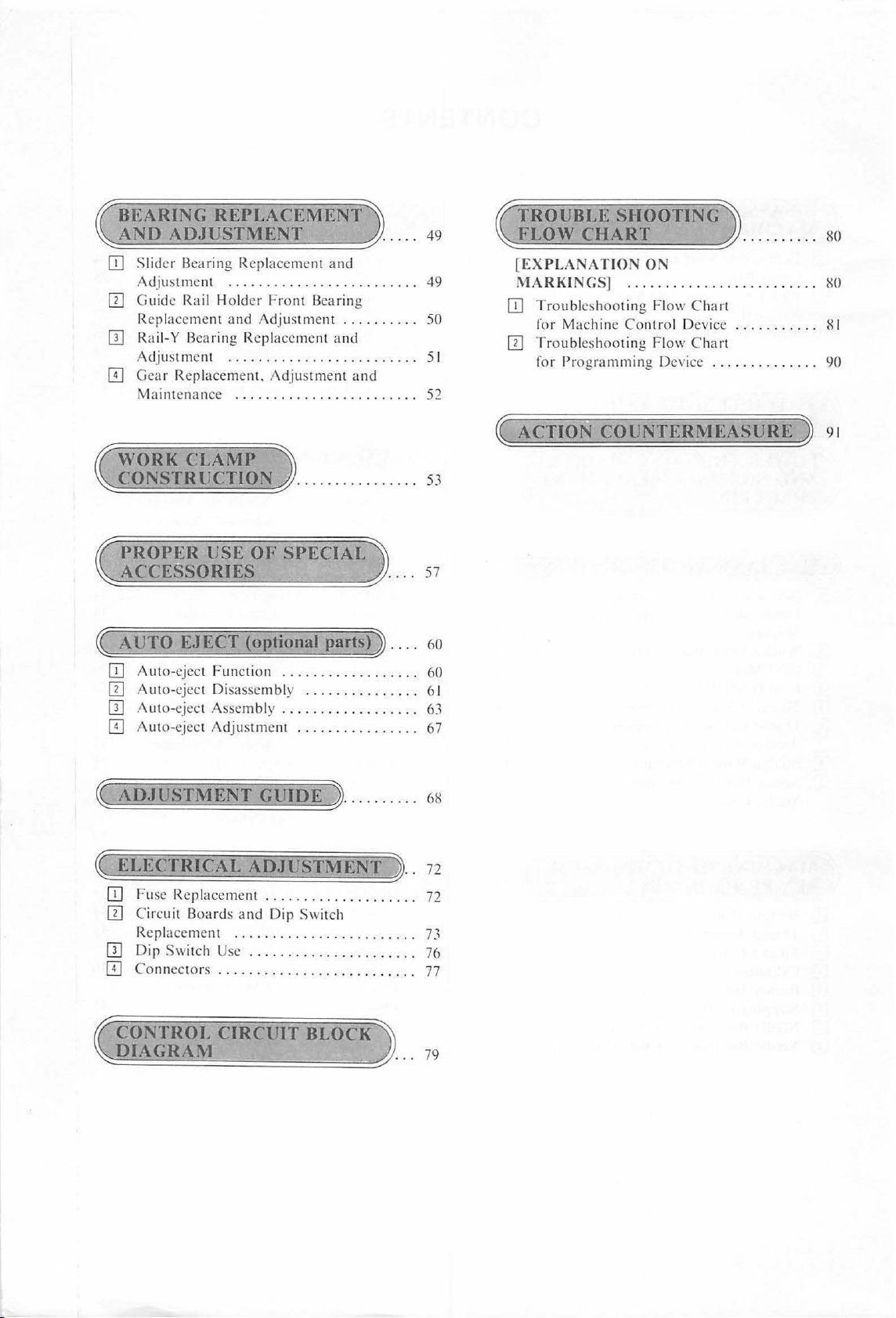

BEARING REPLACEMENT

AND ADJUSTMENT

[JJ

Slider Bearing Replacement

Adjustment

[I]

Guide Rail Hold

Replacement and Adju stment

[]] Raii-Y Bearing Replacement

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . .

1IJ

Gear Replacement. Adjustment

Mai ntenan

.........................

er

Front

ce

......................

and

Bearing

..........

and

and

49

49

50

51

. . 52

TROUBLE SHOOTING

FLOW

lEXPLANATION ON

MARKINGS]

[JJ

[I]

CHART

.........................

Troubleshooting Flow

for Machine

Troub

for Pr

ogramm

Control

leshooting Flow Chart

ing De vice

Device ........... !l

Chart

........

....

......

......

80

80

l

90

WORK

CONSTRUCTION

CLAMP

................

PROPER USE OF SPECIAL

ACCESSORIES

~

AUTO

[JJ

[I]

[]] /\tHo-eject Assembly

1IJ

~

ADJUSTMENT

~

ELE[TRICAL ADJUSTMENT

E.J

ECT

(optional parts)) . . . .

Auto-eject

Auto-eject Disassembly

Auto-eject Adjustment

Fun

ction

..................

..................

@IDE

...............

...

..........

~

-

.........

53

60

60

61

63

...

67

68

~

-.

72

~ACTION

COUNTERMEASURE~

91

[JJ

Fu

se

Replacement . . . . . . . . . . . . . . . . . . . .

[I]

Circuit Boards

Re

pl

acemen t . . . . . . . . . . . . . . . . . . . . . . . .

[]] Dip Swit

!Il

Con

nectors . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL CIRCUIT

ch

and

Dip Switch

Usc

......................

BLOCK

DIAGRAM .

..

72

73

76

77

79

Page 4

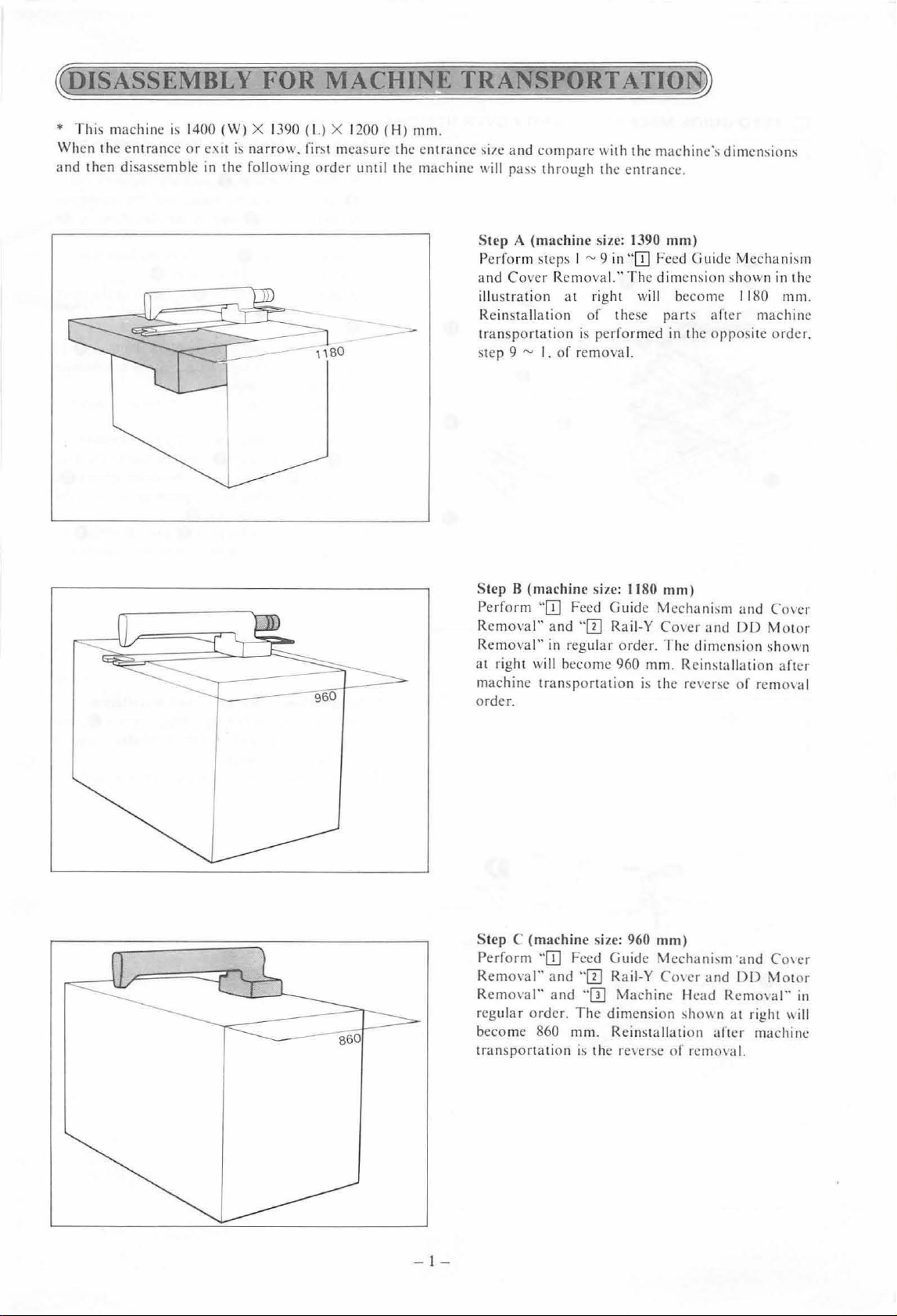

~DISASSEMBLY

FOR

MACHIN~

TRANSPORTATIO~

* This machine

Wh

en the entrance or e:w is narrow. fir

and then

di

i

~

14

sas~em

bl c

00 (W) X

in the following order until the machine

1390

(L) X

1200 (H) mm.

l!t

mca~ure

the entrance

- - transportatio n

~itc.:

a

nd

compa re

11

ill

pas~

through the entrance.

St

ep A (machine

Perfo

rm

steps I

and Cover

illustration at right

R

ei

nstallation

step 9

Removal." The dimension shown

"'

I.

of

11ith

size: 1390

"'9

in''ITJ Feed

of

these

is

performed

rem ova

the

machine·~

mm)

Guid

will

become 1180

parb

in the

I.

dimcnsiom

~.:

Mechanism

in the

mm

after machine

opposite orde

.

r.

Step 8 (machine

Perform

Removal"

Removal"

at righ t will become 960 mm . Rein!.taii<Hion aft

machine transportation

o

rder

St

Perform "

Remol'al"

Remo1al" and "

regular order.

become 860 mm. Rcinl!

t

ra

"ITJ

.

ep C (machine

ITJ

nsportation

size:

1180

mm)

Feed Guid e

and "!II Raii-Y Cover and

in

regular order.

size: 960

Feed Guide Mechani,m and Co1cr

and

"!II Raii-Y C01er and

ITJ

The

dimension

i~

the rc1er

Mcchani~m

The

i

~

the re1ersc

mm)

Machine Head Rcm01al"

l!l1011

tallation aft..:r machine

sc

of

rcmo1al.

and Cover

DD

dim ension shown

of

DD

n at right 11i

Mot or

rem01a l

Motor

er

in

ll

- I -

Page 5

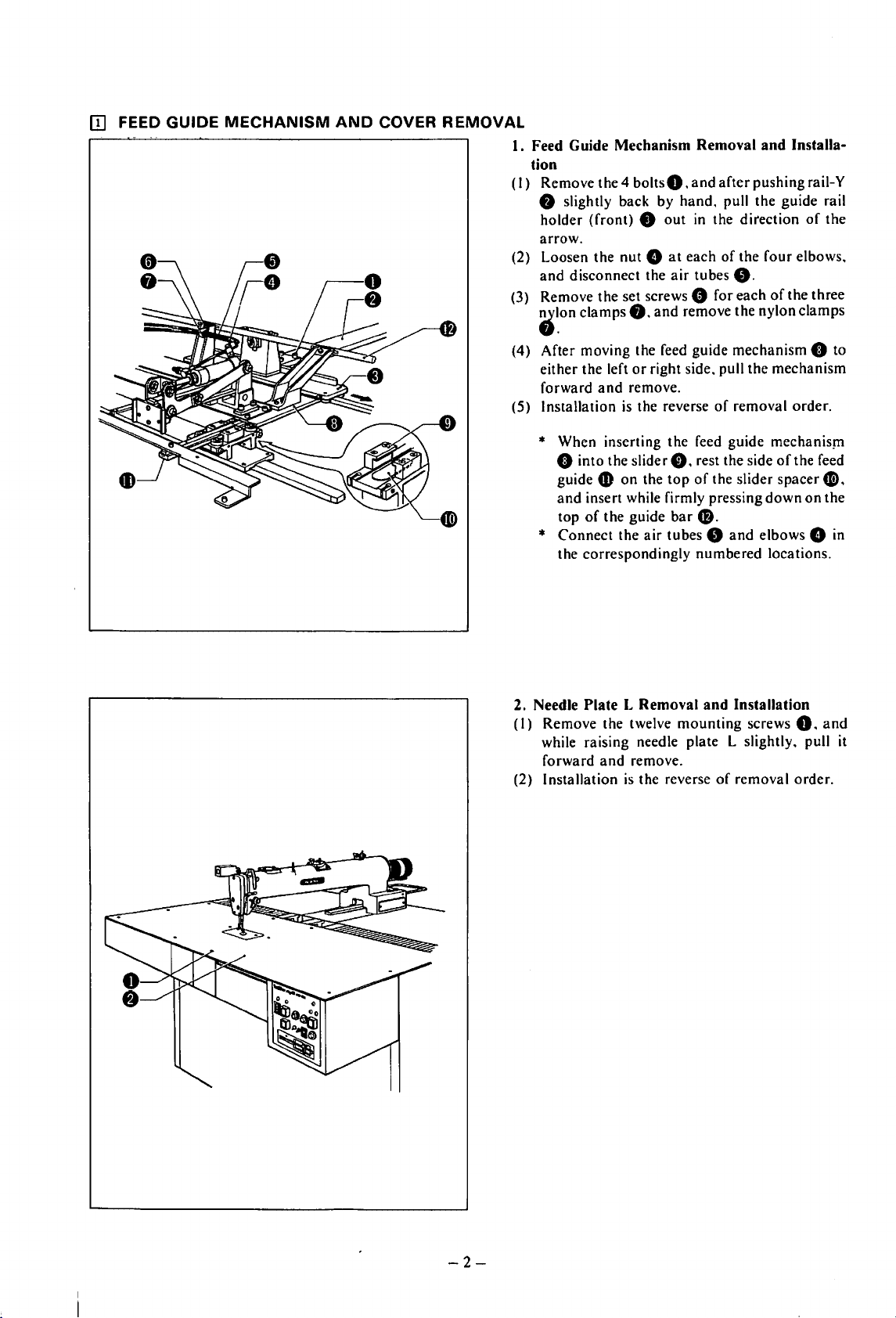

OJ

FEED GUIDE

MECHANISM

AND

COVER

REMOVAL

I.

(I)

(2) Loosen the nut 8

(3) Remove the set screws 0 for each

Feed Guide

tion

Remove the 4

f)

slightly back by

holder

arrow.

and

-~on

(front) 8 out

disconnect the

clamps

Mechanism

boltsO,

hand.

at

air

8.

and

remove the nylon clamps

Removal

and

in

the direction

each

tubes

and

after

pushing rail-Y

pull the guide rail

of

the four elbows,

8.

Installa-

of

the three

of

the

(4) After moving the feed guide mechanism

or

either the left

forward

(5) Installation

and

right side, pull the mechanism

remove.

is

the reverse

of

removal order.

* When inserting the feed guide mechanism

0 into the slider

guide

CD

on

and

insert while firmly pressing

top

of

the guide

*

Connect

the correspondingly

2. Needle

(I)

Remove the twelve

while raising needle plate L slightly, pull it

forward

(2) Installation

the

Plate L Removal

and

is

f),

the

top

bar

air

tubes 8

mounting

remove.

the reverse

rest the side

of

the slider spacer

down

48.

and

elbows 8 in

numbered

and

of

locations.

Installation

screws

removal order.

of

the feed

0.

0 to

4B,

on

the

and

-2-

Page 6

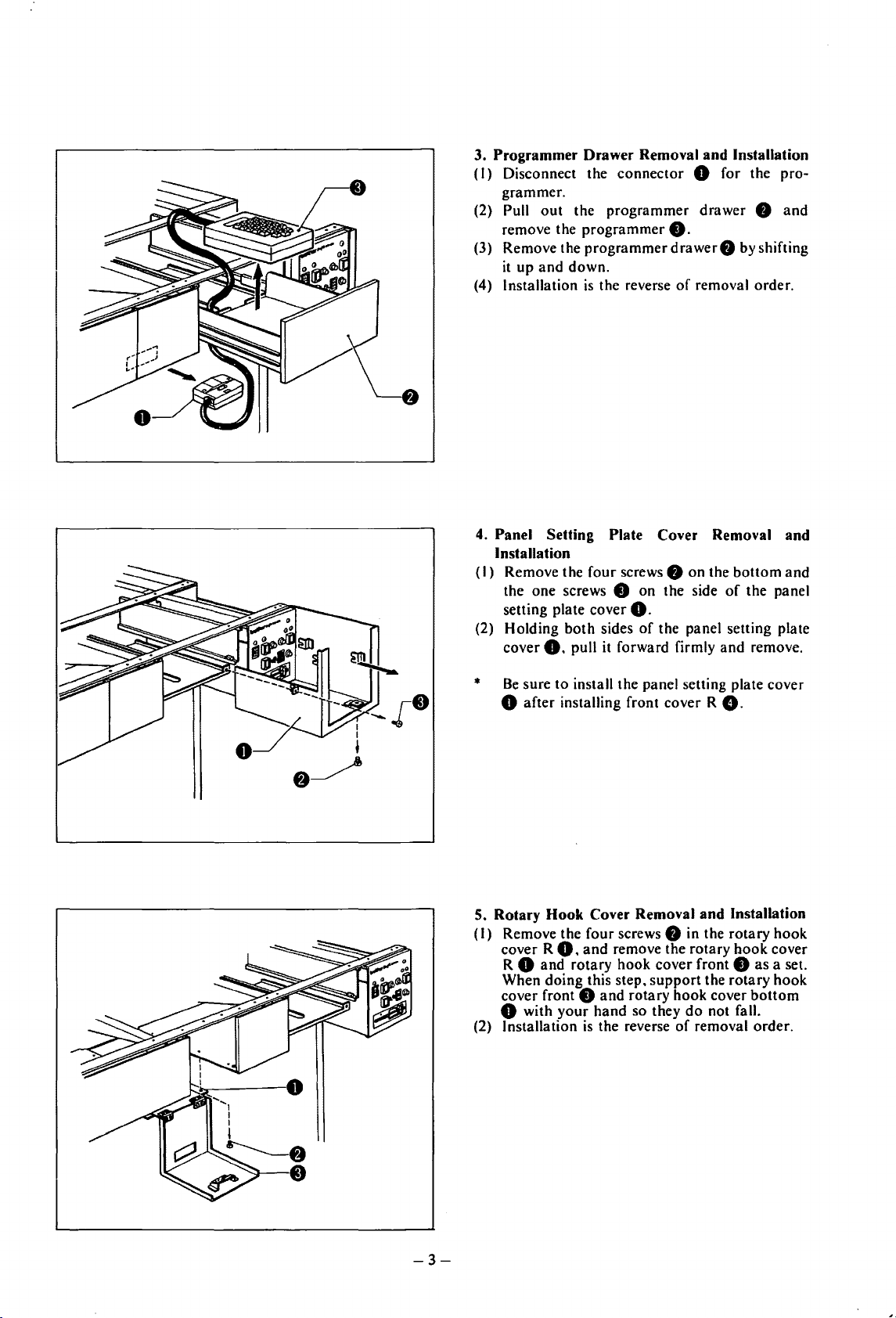

3. Programmer Drawer Removal and Installation

(I)

Disconnect the connector 8 for the pro-

grammer.

(2) Pull

(3) Remove the programmer

(4) Installation

4. Panel Setting Plate Cover Removal and

(I)

(2) Holding both sides

out

the programmer drawer 8 and

remove the programmer

it

up

and

down.

is

the reverse

Installation

Remove the four screws 8 on the bottom and

the one screws

setting plate cover

cover

8.

8 on the side

pull it forward firmly and remove.

8.

drawer8

of

by shifting

removal order.

of

8.

of

the panel setting plate

the panel

Be

sure

to

*

8 after installing front cover R

5. Rotary Hook Cover Removal and Installation

(I)

Remove the four screws 8 in the rotary hook

cover R

8 and rotary hook cover front 8

R

When doing this step,

cover front

8 with your hand so they

(2) Installation

install the panel setting plate cover

8.

8,

and

remove the rotary hook cover

as

bottom

not fall.

8

and

is

the reverse

support

rotary hook cover

the rotary hook

do

of

removal order.

a set.

-3-

Page 7

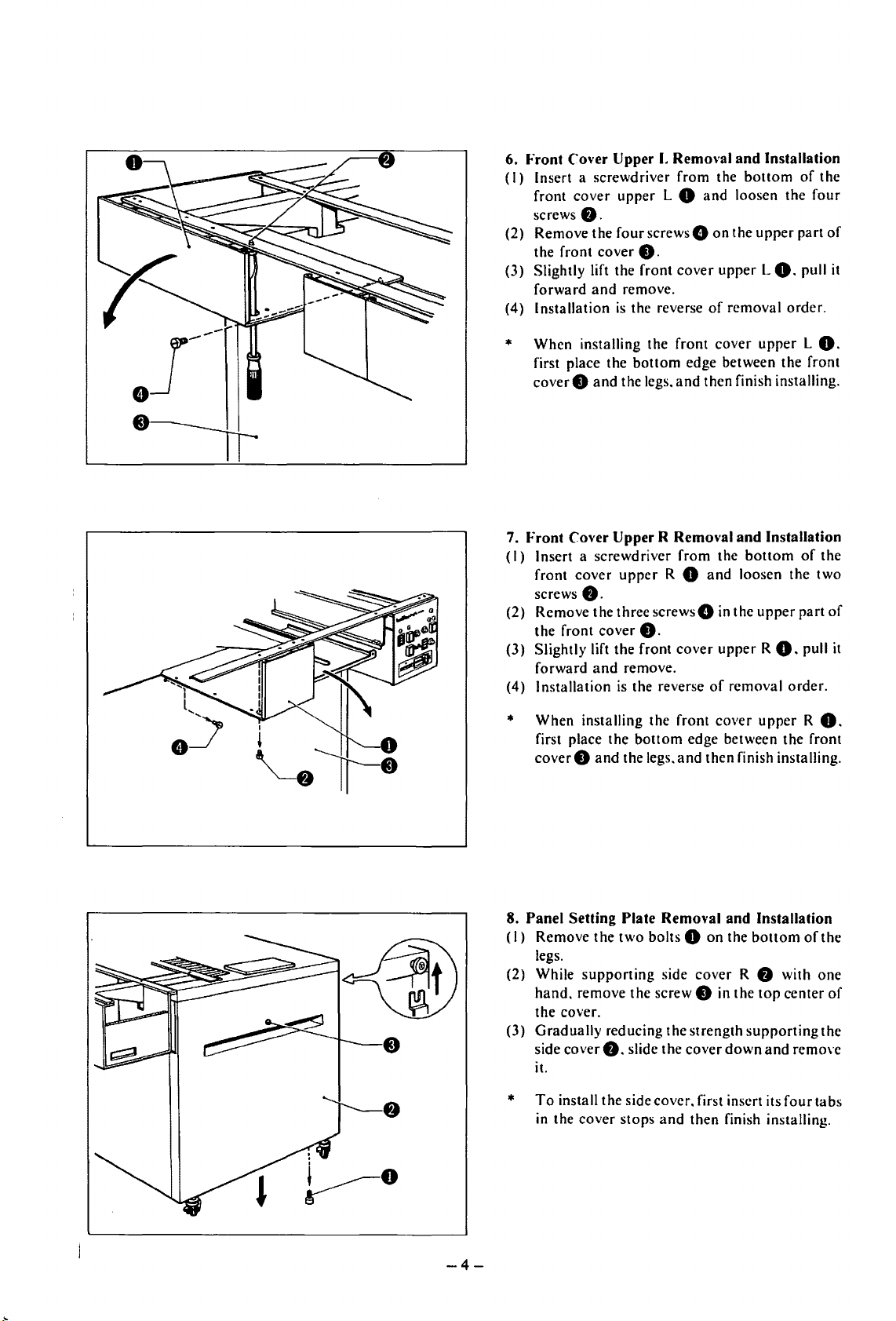

6. Front ('over Upper

(I)

Insert a screwdriver

front

cover

upper

screws

8.

(2)

Remove

the

(3) Slightly lift the

forward

Installation

(4)

*

When

first place the

cover 0 and

front

installing

the

fourscrews8

cover

and

remove.

is

the reverse

bottom

the legs.

0.

front

I.

Removal

from

L 0

cover

the

front

edge between

and

and

Installation

the

bottom

and

loosen the

on

the

upper

of

removal

cover

then finish installing.

upper

L

0.

upper

the

of

four

part

pull it

order.

L

front

the

of

0.

7. Front Cover Upper R Remm·al

(I)

Insert a

front

screws

(2)

Remove

the

(3)

Slightly

forward

Installation

(4)

When

*

first place

coverO

screwdriver

cover

upper

8.

the

three

front

cover

lift the front

and

is the reverse

installing the

the

and

R 0

screws8

0.

remove.

bottom

the legs.

from

cover

front

edge between

and

and

Installation

the

bottom

and

loosen the

in the

upper

of

removal

cover

then finish installing.

upper

R

0.

upper

the

of

two

part

pull it

order.

R O.

front

the

8. Panel Setting Plate Removal and Installation

(I)

Remove

legs.

(2) While

hand.

the

(3)

Gradually

side

it.

the

supporting

remove

cover.

cover

8.

two

bolts 0

the

screw 0 in the

reducing

slide the

side

the

on

cover

strength

cover

the

bottom

R 8 with

top

supporting

down

and

of

one

center

remO\·e

the

the

of

of

To

*

install

in the

-4-

the

cover

side

stops

cover.

and

first insert its

then

finish installing.

four

tabs

Page 8

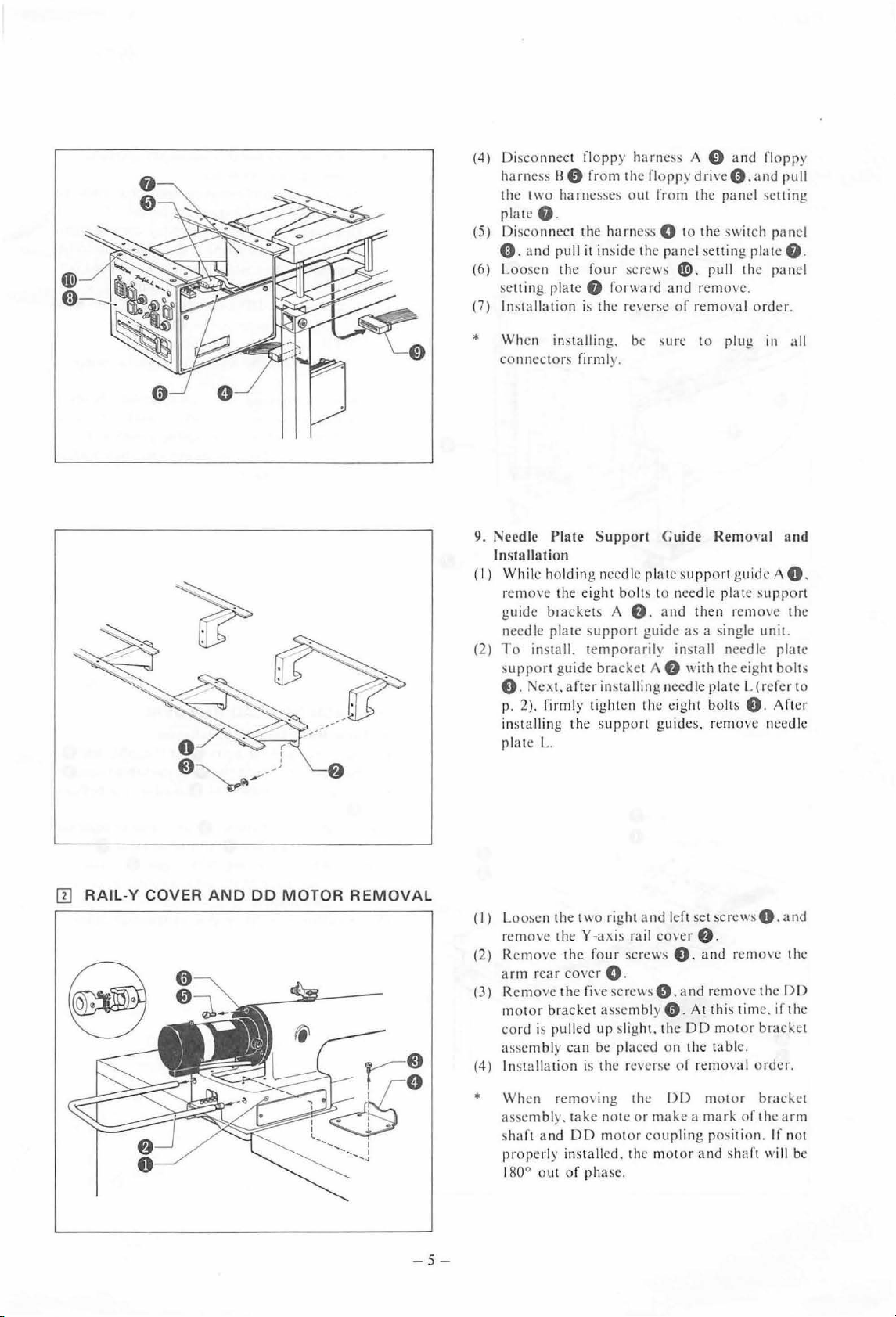

(4) Disconnect floppy

harne

!>~

B 0 from the floppy

the two

plate

(5)

Di!>eon

0.

{6)

Loosen the four screw:-

setting plate

(7)

l

mtallation

harnessc~

f)

.

nect the barne

and

pull it inside the panel setting plate

f)

forward and remove.

is

the reverse

harne!>s

out from the panel

A 0

and flop

dri,

·e 0 . and pull

s:-

0 to the switch panel

~.

pull the panel

of

removal order.

py

~etting

f)

.

When installing.

*

connectors firml

9. Needle Pl

Installation

(I) While holding need

remove th e eight bolts to needle plate support

guide brackets A

needle plate

To

(2)

~upport

e. I ex

p. 2). firmly tighten the eight bolts

in

stalling the

ate

pl

ate

install. temporarily install needle plate

guide bracket A e with the eight

t.

after installing needle plate

L.

be

~urc

to plug in all

y.

Support Guide Remo\'al and

le

plate support guidc A 0 .

e.

and

then remo

suppor

t guide

support

as

a single unit.

guides. remove needle

ve

bolt~

L(refer

e.

Af

the

to

ter

ITJ

RAlL-Y COVER AND DO MOTOR REMOVAL

(I) Loo!>e

(2) Remove the four screws e. and rcmO\C the

{3)

(4) Installation

*

n the two right a nd left set

remove

arm

Remo

motor

cord

as~embly

When

assembly. take note

shaft

prope

180° out

theY

rear cover 0 .

ve

the five

bracket assembly

is

pulled up slight. t

can

rcmo'

and

rl

y installed. the mot

of

-5-

-axis rail cover e.

serew!>

O . and

0.

he

be placed on the tabl

is

the

rC\Cr~e

ing the

DD motor

phase.

()()

or

make a mark

coupling posi ti on. If not

sen:wsO.and

remo\e

At this time. if the

DD

of

removal order.

motor

or

and shaft will

the

motor bracket

e.

brad.et

of

the arm

DO

be

Page 9

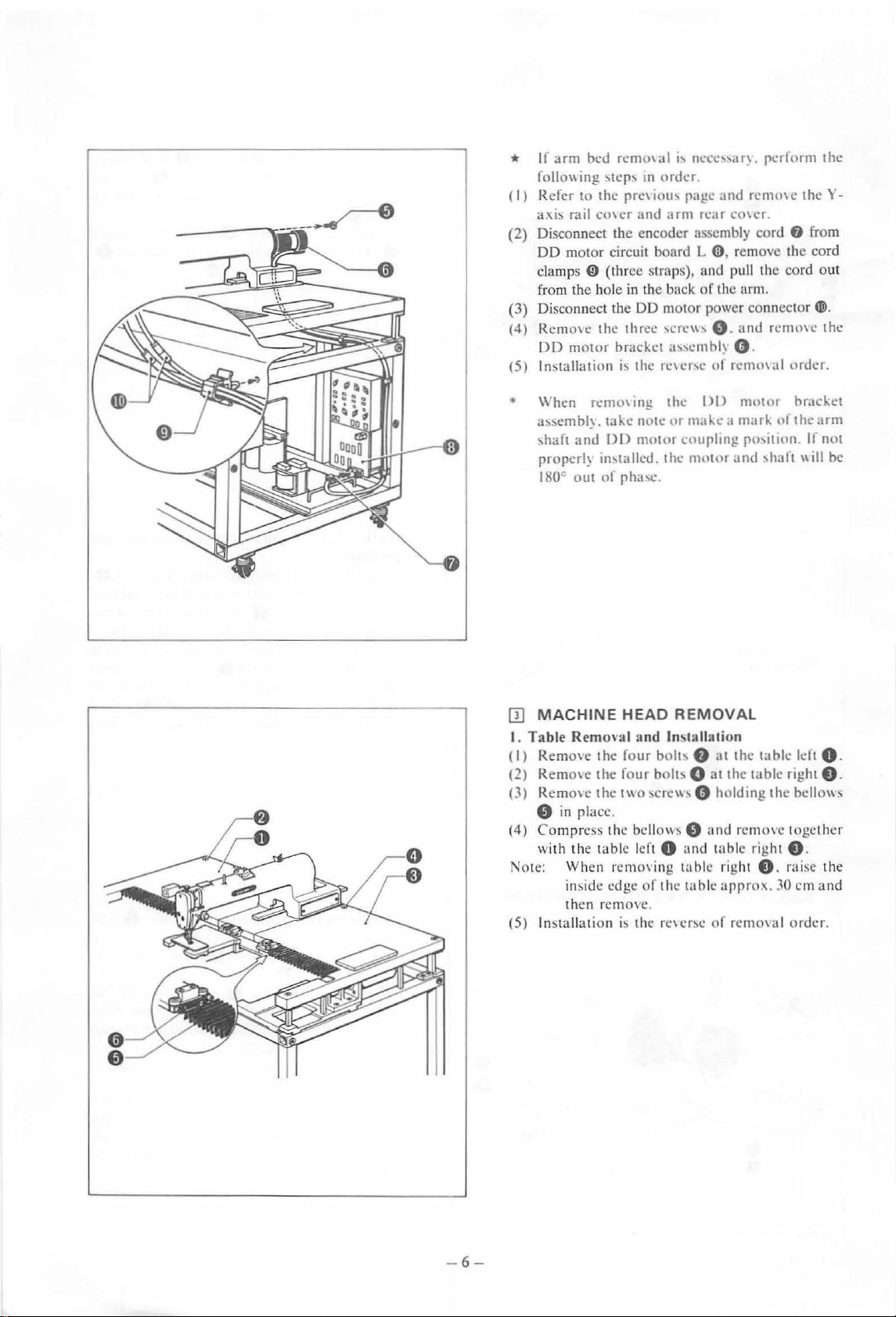

II

arm

bed

*

foliO\\

(I)

Refer

a:-.is rail

Disconnect

(2)

DO motor

clamps

from the hole in the back

Disco

(3)

(4)

R

emo\e

DO

motor

ln::.tallati

(5)

remm

ing

\tep~

to

the

pre\iou'

co\cr

the encoder

circuit

0

(three strap

nnect th e DO m

the three

bracket

on

i'

a I "

neee,,a

Ill

order

.

page

and

arm

rear

assembly

board

L 0 , remove the cord

s), and pull the cord

of

oto

r power

'ere"'

0 .

a"embh

the

re\er'c

ot

r~.

and

rernme

co\er.

cord

the arm.

connector(@.

and

()

.

rcmmal

pert

orm

0 from

remme

order.

1 he

theY-

out

the

\\'hen

•

a!>~embl~.

-,haft

proper!~

J8Q

IIJ

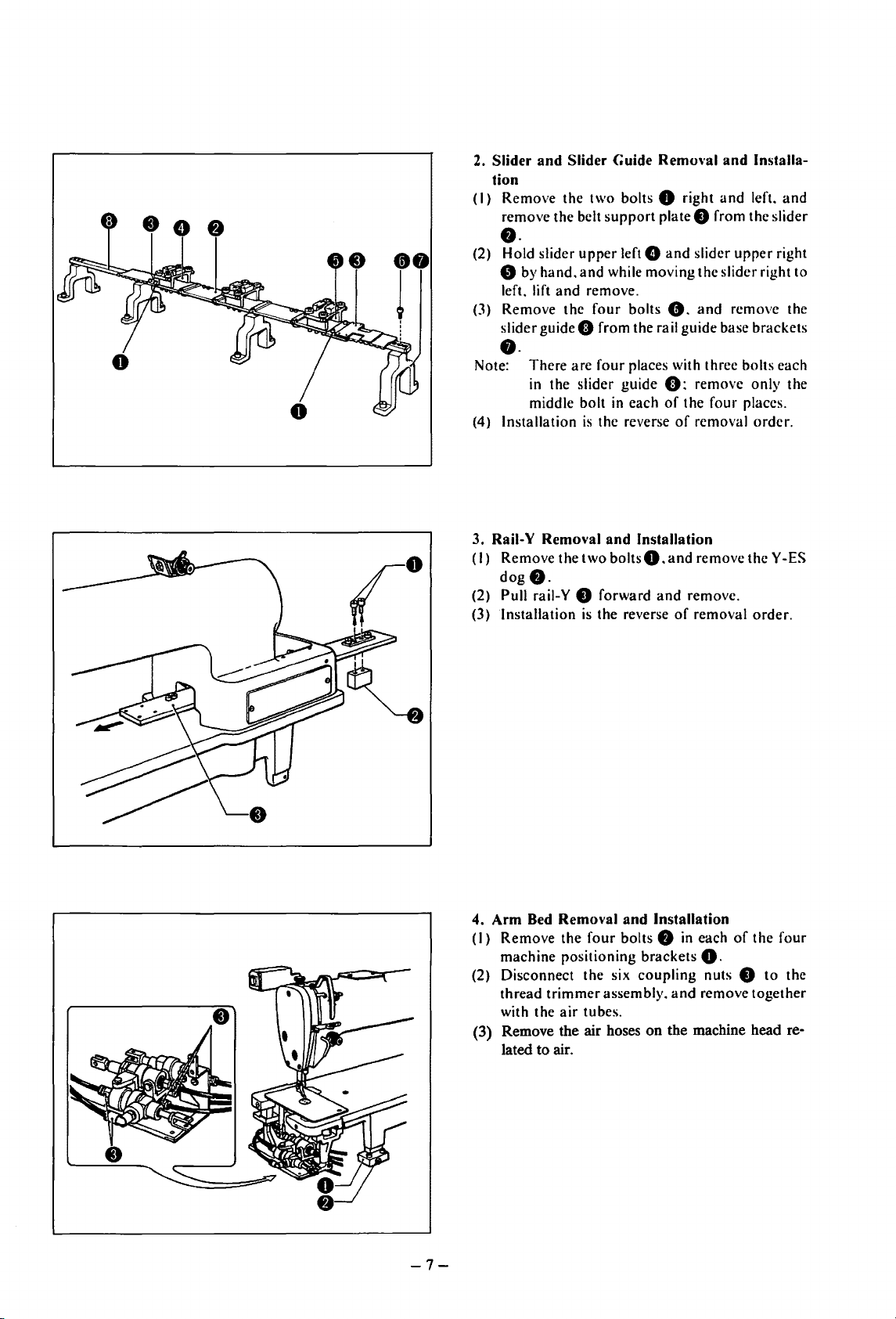

MACHINE

I. Table

(

I)

Remo\c

(2)

Remo\e

(3) RemO\ e

0

Co

(4)

with the t

1

0te:

(5) I

rcmO\ tng

and

C

OUt

Remo,·al and ln!>

in

place.

mp

ress the bellows 0

Wh

en rern

in

side

then

nstallation

take

note

DD

motor

in\talled.

of

pha\C .

HEAD

the

four

the

four

the

t\\0

able

left 0

o\

edge

of the table

remove.

is

the r

the

I)

I)

motor

ur

m.tke a mark

coupling

the

nwtor

po,tlton. If

and

REMOVAL

tallation

bolt' 8 at

bolt-. 0

sere\\\ e holding

and

ing

table

c,crsc

the

at

the

table

and

remove together

table right 0 .

right 0 . ra ise

approx

of

rcmoHtl

uf

'halt

table

the

.

.10

brJckct

the

arm

not

"'II

be

left 0 .

right 0 .

bellO\\!>

th

e

em

and

order.

-6-

Page 10

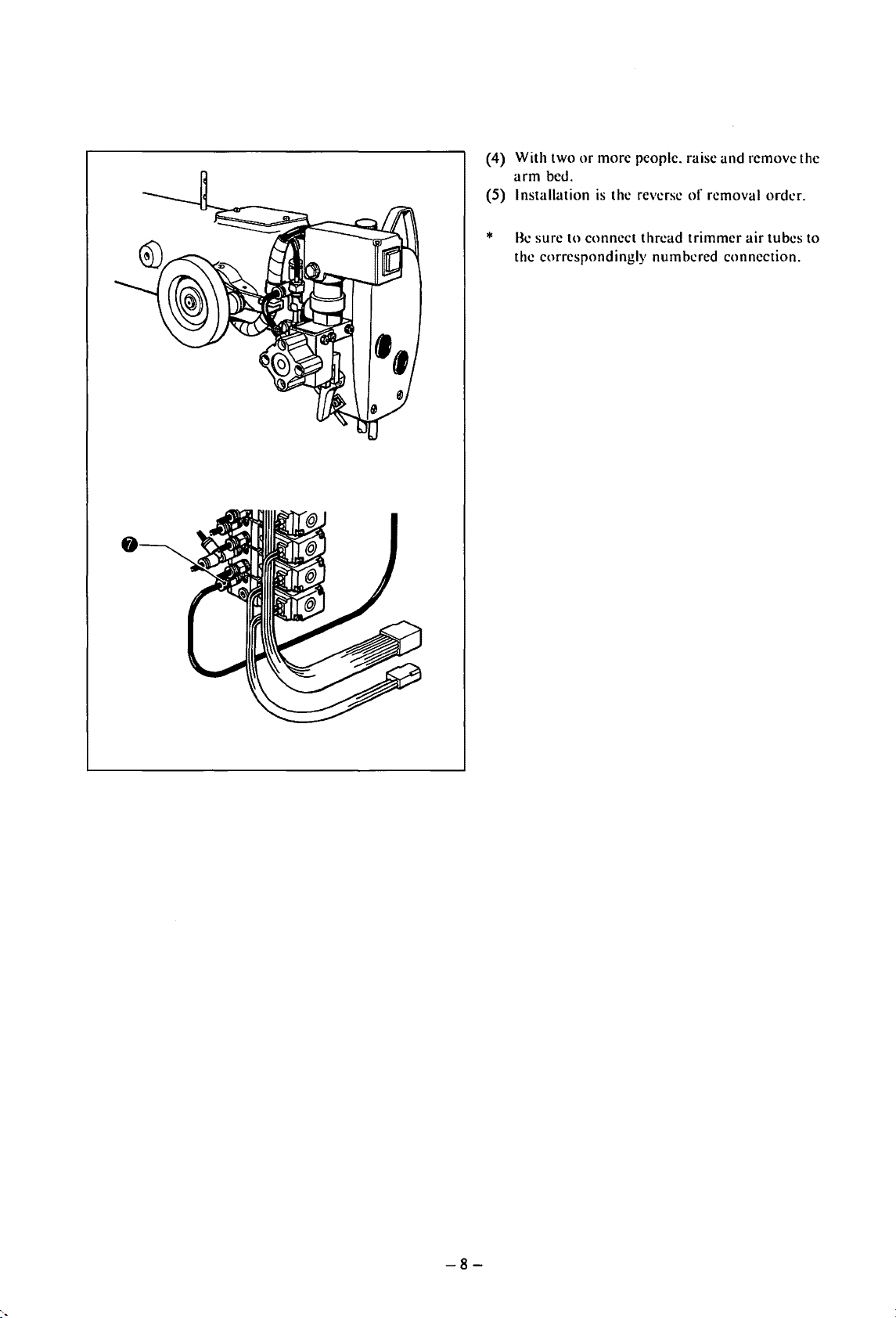

2.

Slider

and

Slider

tion

(I ) Remove the

remove the belt

••

(2) Hold slider

e by

hand.

left. lift

(3)

Remove the

slider

••

Note:

(4)

Installation

and

guideO

There

arc

in the slider guide

middle bolt

Guide

Remm·al

two

bolts 0 right

support

upper

and

while moving the slider right to

remove.

four

from the rail guide base brackets

four

plate e from the slider

left G

and

bolts

8.

places with three bolts each

0:

in

each

of

is

the reverse

of

and

Installa-

and

left.

slider

upper

and

remove the

remove only the

the four places.

removal

order.

and

right

3. Raii-Y

(I)

(2) Pull rail-Y 8 forward

(3)

4.

Arm

(I)

(2) Disconnect the six

(3) Remove the air hoses

Removal

Remove the

dog

f).

Installation

Bed

Remove

machine positioning brackets

trimmer

thread

with the

lated

to

air.

and

two

is

the reverse

Removal

the

four

assembly.

air

tubes.

Installation

boltsO.and

and

bolts

coupling

remove

and

remove.

of

removal

Installation

f)

in

each

theY

of

0.

nuts 8

and

remove together

on

the machine head re-

-ES

order.

the four

to

the

-7-

Page 11

(4) With two

arm

(5) Installation

*

Be

the correspondingly numbered connection.

or

more people. raise

bed.

is

the reverse

sure to connect thread trimmer

and

of

removal order.

remove the

air

tubes to

-8-

Page 12

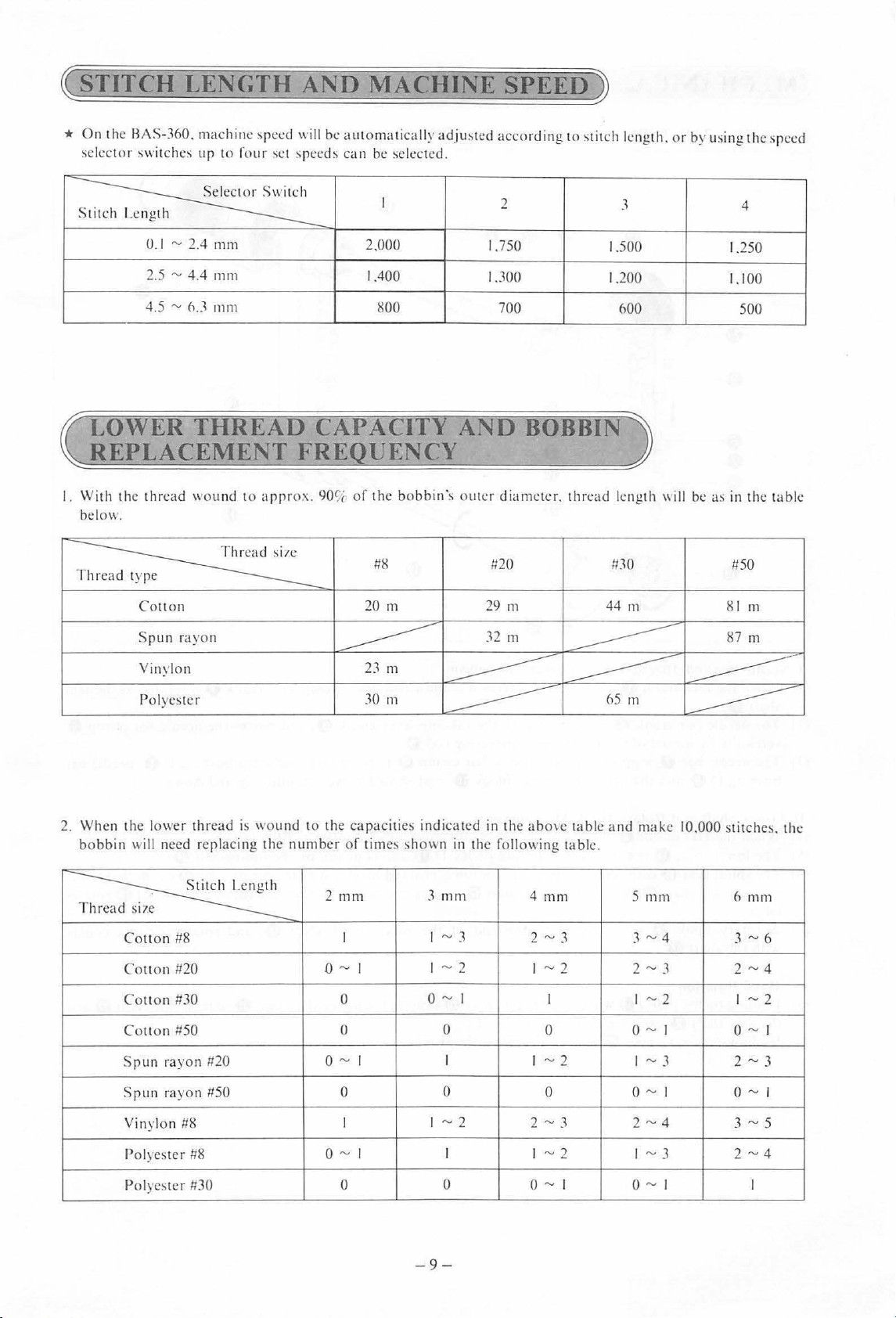

~STITCH

*

On

the HAS-360. machine

selector switches

LENGTH

sreed will be automatically

ur

10

four set

AND

~reeds

can

MACHINE

adju~ted

be

selected.

SPEED~

according to stitch length. or by using the

sreed

s

~

0.1 ~ 2.4

2.5 ~ 4.4

4.5

LOWER

mrn

mm

~I'

d

mm

THREAD

REPLACEMENT

I.

With t

he

thread wou nd

be

low.

~

.

Col! on

Srun

rayon

to

appr

2.000

1.400

800

CAPACIT

FRE

ox.

90

UENCY

~[

of

the

#8

20

I

bobbin\

m

2

1.750

1.300

700

AND

outer diameter. thread length will

BOBBIN

#20

29

111

32

m

3

1.500

1.200

600

11

30

44 m

4

1.250

1.

100

500

be

as in the table

#50

81

m

87

m

Yinylon

Polyester

2.

When the lower thread

bobbin

~

will need

e

Col!on #8

Couon

Couon

Couon

Sru

Srun rayo n #50 0

Yinylon

#20

#30 0

#50 0 0 0

n rayon #20

#8

rer

lacing the

23m

-----------

30

111

is

wound to the caracities ind icated

number

of

tim

e~

shown in the following table.

2 mm

I

o

~

I

o

~

I I I

I

3 mrn

t~3

t~2

o

~

0

~2

I

~

---------

~

65

---------

in

the

abo

\C

table and make 10.000

4 mm 5

2 ~ 3

~2

I

I I

~2

0

2

"'

3

m

111111

3~4

2

~

3

1

~2

o~

t

~3

o~t

2"-' 4

----------

=----------

s

titchc

~.

the

6

111111

3~6

2~4

t

~2

t

o~t

2 ~ 3

o~t

3

"'

5

Polyest

er

#8

Polyester #30

0"'1

0 0

I 1 "-'2 1 "-'3

"-'

1

0

- 9 -

0"-'

2 ~ 4

1

I

Page 13

~MECHANICAL

OJ

NEEDLE

BAR.

THREAD

DE§CRIPTIONS

TAKE-UP

LEVER. LOWER

))

SHAFT.

AND

ROTARY

HOOK

MECHANISM

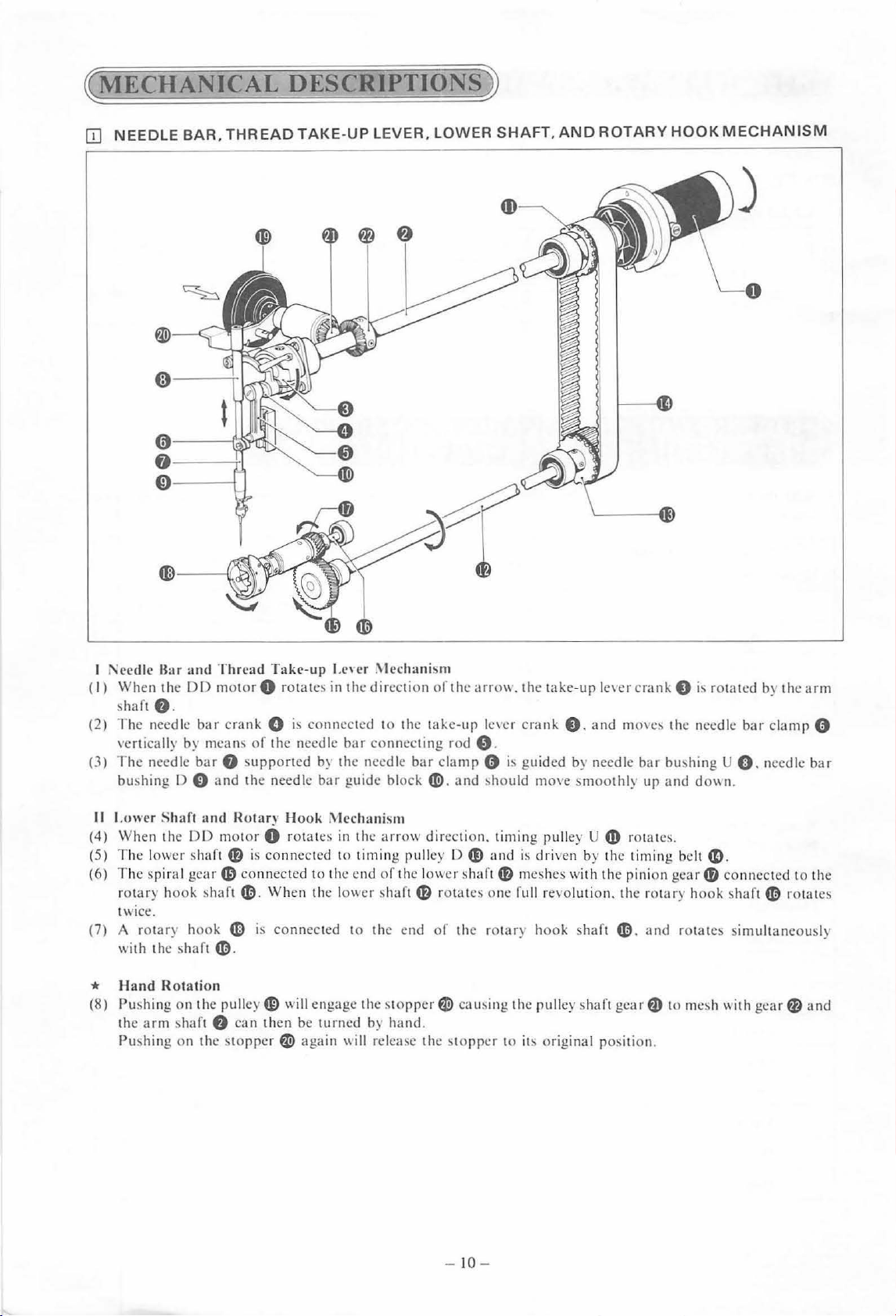

I Needle

(I ) When the

(2)

(3)

II

(4)

(5)

(6)

{7)

*

(8)

Bar

and

Thread Take-up

DO

motor

shaft e.

The nee

vertically by mea ns

The needle

bw.hing [) 0 and the needle

Lower

When the

The lower shaft

The sp iral gear

rotary hook

twice.

A rot

with

Hand

Pushing

the a rm

Pushing

dle.:

bar

bar

Shaft

DD

ary

hook

the shaft

Rotation

on

the pulley

~ha

ft

on the

cr

ank 0

f)

sup

and

Hotary

motor

4B

(0

connected to the end

shaft~-

4D

~

-

8

can

stoppe

I.e'

cr .\lechanism

0 rotates in t

is

of

the needle

ported by the needle

Hook

0 rotates

is co nnected to timin

When the lower shaft

is connected to the end of the rotar) hook shaft

G)

will engage the

then be turned by hand.

r~

again

he

direction

connected to the take

bar

connecting rod e.

bar

guide

~lcchanism

in

the

arrow

of

stopper~

"ill

release the

of

bar

clamp 0

block~-

direction . timing pulley U

g pul

ley

the lower shaft

4B

rotates one full revolution . the

the

arro\\.

-up

and

D (I) and

causing the pulley shaft

stopper

the take-up len:r

le\er

crank

0.

is

guided by needle

~hould

move

smoothly

is

driven by the timing be

4B

meshes with the pinion gea r

to

it!.

original position.

and

4D

4D.

gear

crank

0

i~

rotated by the

mo\e~

the need

bar

bushing U 0 . needle

up and dO\\n.

rotates.

lt

a.

4D

rotar

y hook

and

rotates simultaneously

f)

to me!>h \\ith

arm

le

bar

clamp 0

bar

.

connected to the

s

haft~

ro tates

gearfl)

and

-10-

Page 14

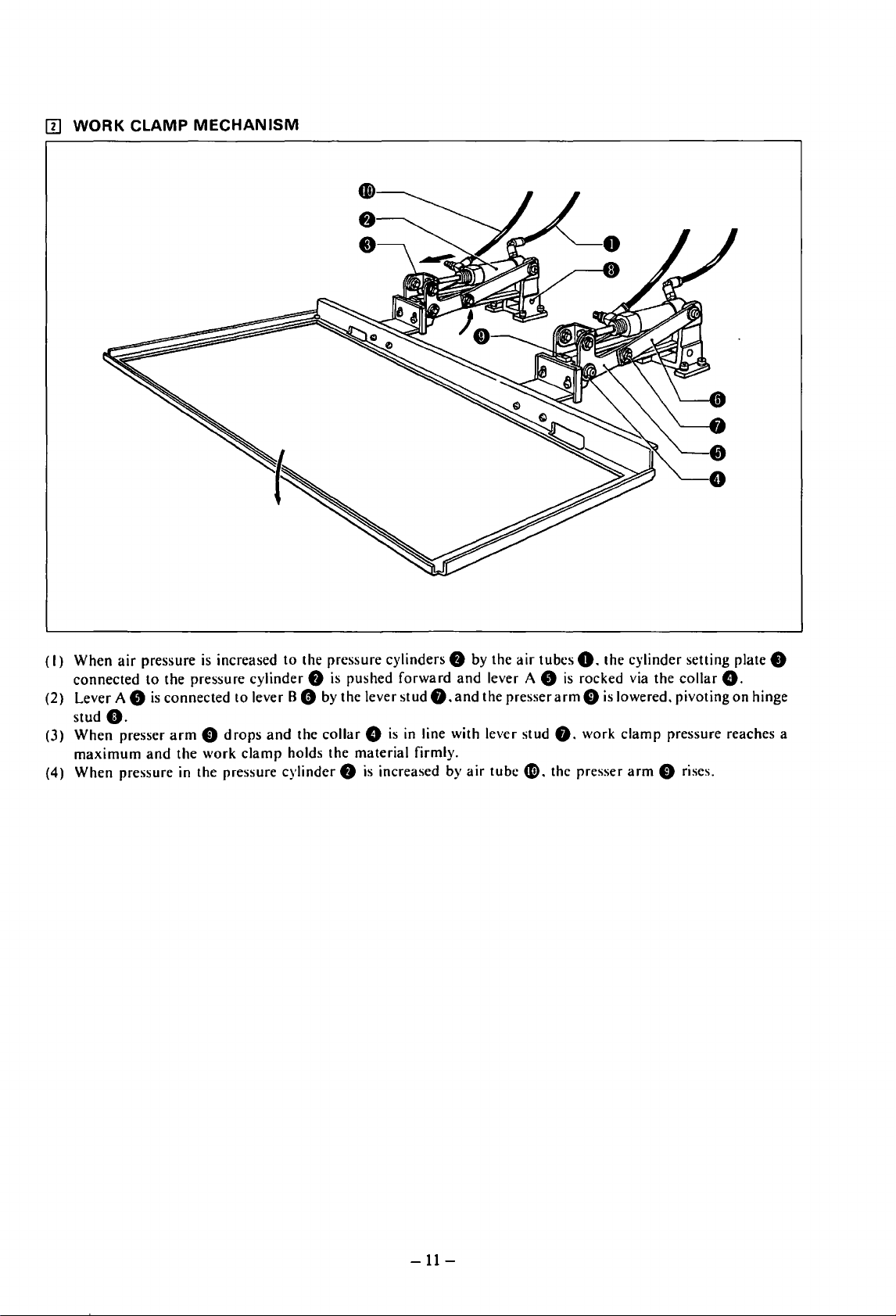

[I]

WORK CLAMP

MECHANISM

(I)

When

air

pressure

connected

(2) Lever A 8

stud

(3)

When

maximum

(4) When pressure in the pressure cylinder 8

to

is

e.

presser

and

is

increased

the pressure cylinder 8

connected

arm 0 drops

the

to

work

to

the pressure cylinders 8 by the

lever B 8 by the lever

and

the

clamp

holds the material firmly.

is

collar G is

pushed

is

increased by

forward

stud

in

and

lever A 8

f).

and

the presser

line with lever stud

air

tube

air

tubes

0.

is

rocked via the

arm 0 is

f).

work

O. the presser

the

cylinder setting plate 8

collar

G.

lowered. pivoting

clamp

pressure reaches a

arm

0 rises.

on

hinge

-11-

Page 15

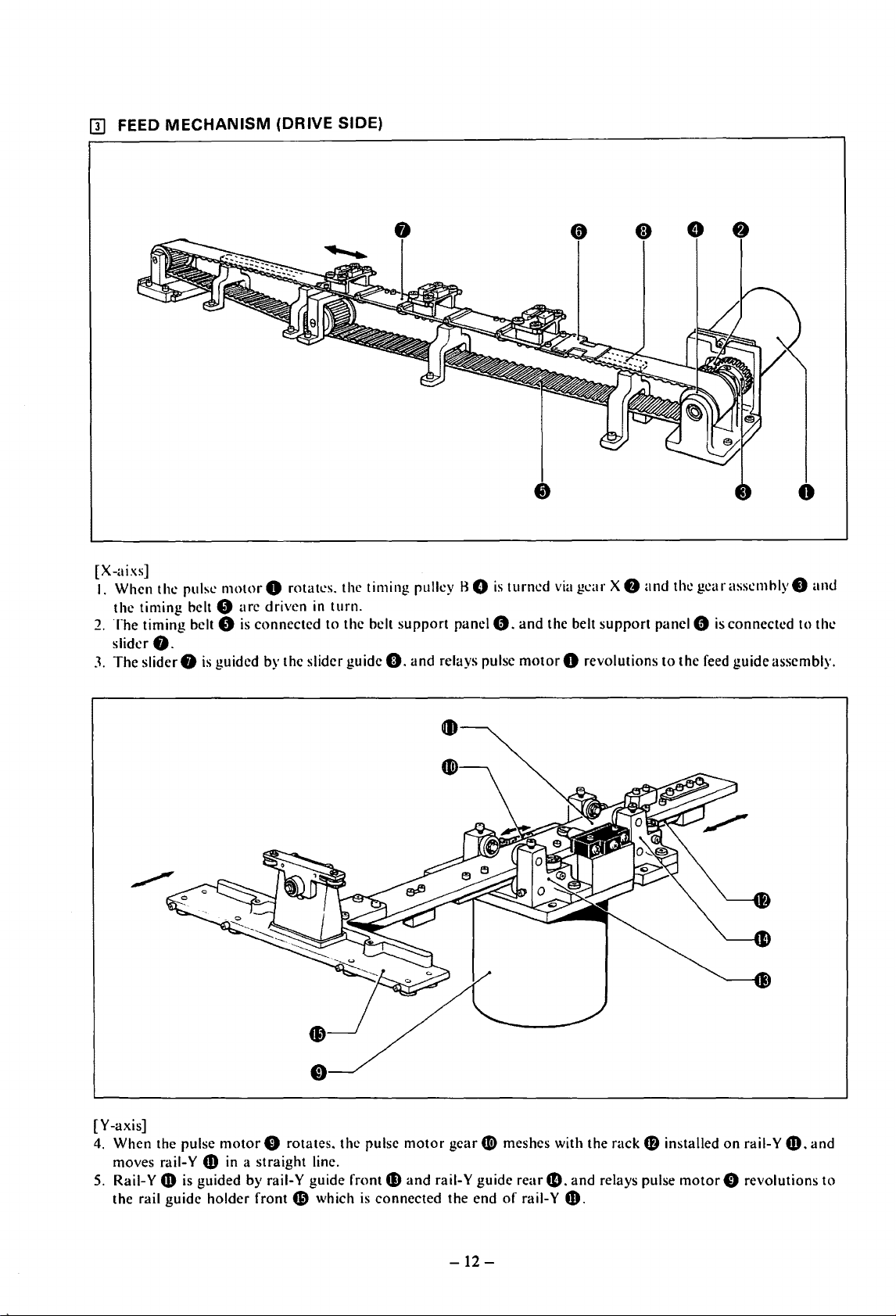

IIJ

FEED

[X-aixs]

1.

When the pulse

the timing belt e

2.

The

slider

3.

The

MECHANISM

timing belt 8

8.

slider 8

(DRIVE SIDE)

motor

0 rotat..:s. the timing pulley H 0

arc

driven

is

connected to the belt

is

guided by the slider guide G.

in

turn.

support

and

is

panel

0.

relays pulse

turned

and

motor

via

g..:ar X 8

the belt

support

0 revolutions

and

the

gear

assemhly 8

panel 0

to

is

connected to the

the feed guide assembly.

and

[Y-axis]

motor

4. When the pulse

moves rail-Y $ in a straight line.

5.

Rail-Y

the rail guide holder front 6' which

4D

is guided by raii-Y guide front

0 rotates. the pulse

motor

gear

4»

and

rail-Y guide

is

connected the end

G)

meshes with the rack 8 installed

readD.

of

rail- Y

$.

-12-

and

relays pulse

motor

on

rail- Y

f)

revolutions

$.and

to

Page 16

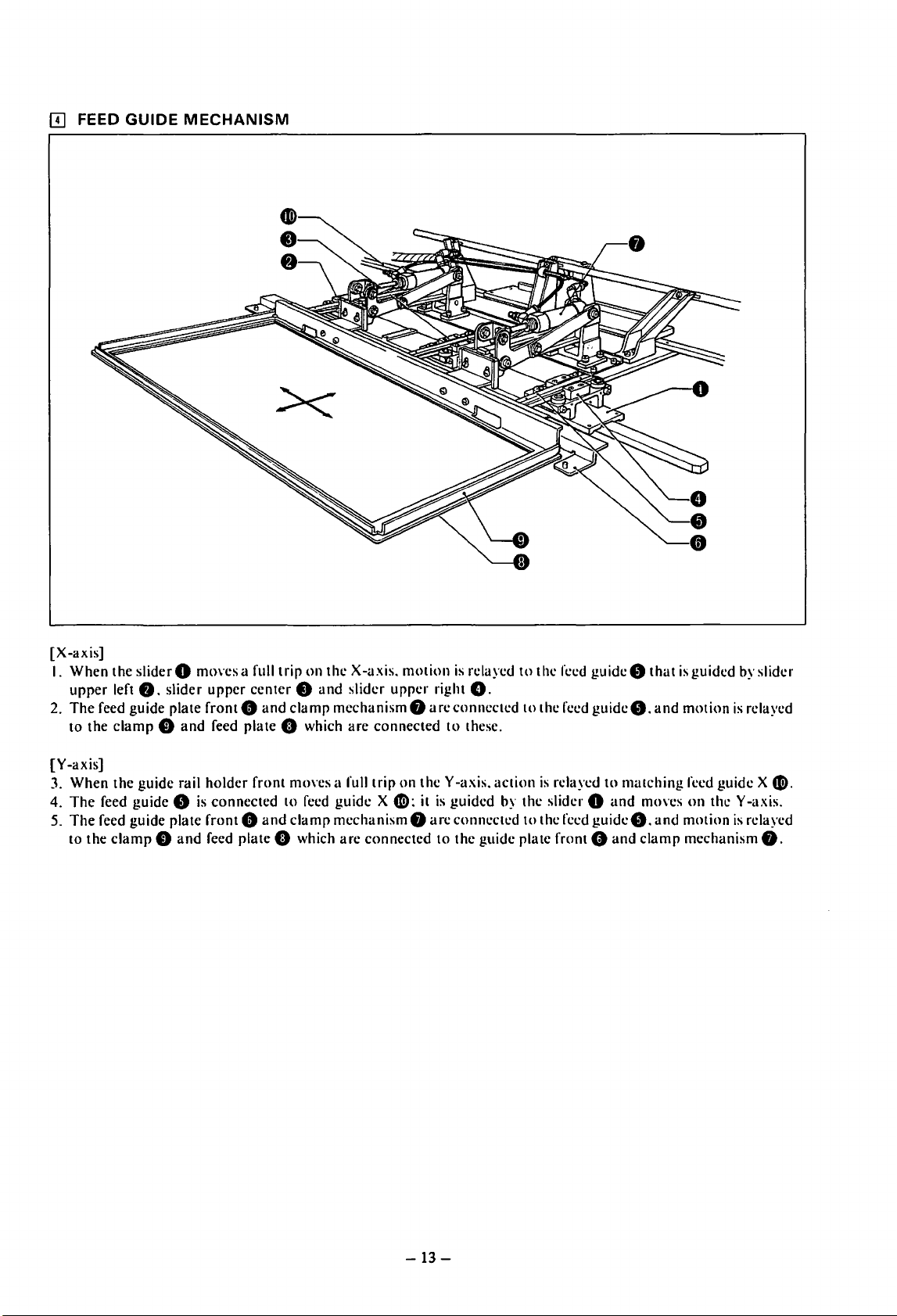

[I]

FEED

GUIDE

MECHANISM

[X-axis]

I. When the

upper

2.

The

to the

[Y-axis]

3. When the guide rail holder front

4.

The

The

5.

to the

sliderO

left

8.

feed guide plate front 0

clamp

feed guide 0

feed guide plate front 0

clamp

slider

f)

f)

and

and

moves a full

upper

feed plate 0 which

is

connected

feed plate 0 which

center 0 and

and

and

trip

on

the X-a.xis.

slider

clamp

mechanism

arc

mm·es a full trip

to

feed guide X

clamp

mechanism

arc

connected

motion

upper

f)

arcconneetcd

connected

on

theY

41>:

it

f)

arc

is

relayed

right

0.

to

these.

-a

.xis.

is

guided by the slider 0

connected

to

the guide plate front 0

to

to

action

to

the feed

the feed

is

relayed

the feed

guideO

guide8.and

guideO.

to

matching

and

and

that

mo,·es

clamp

is

guided by slider

motion

feed guide X

on

the Y -axis.

and

motion

mechanism

is

relayed

is

relayed

41).

0.

-13-

Page 17

IT]

THREAD

TRIMMING

MECHANISM

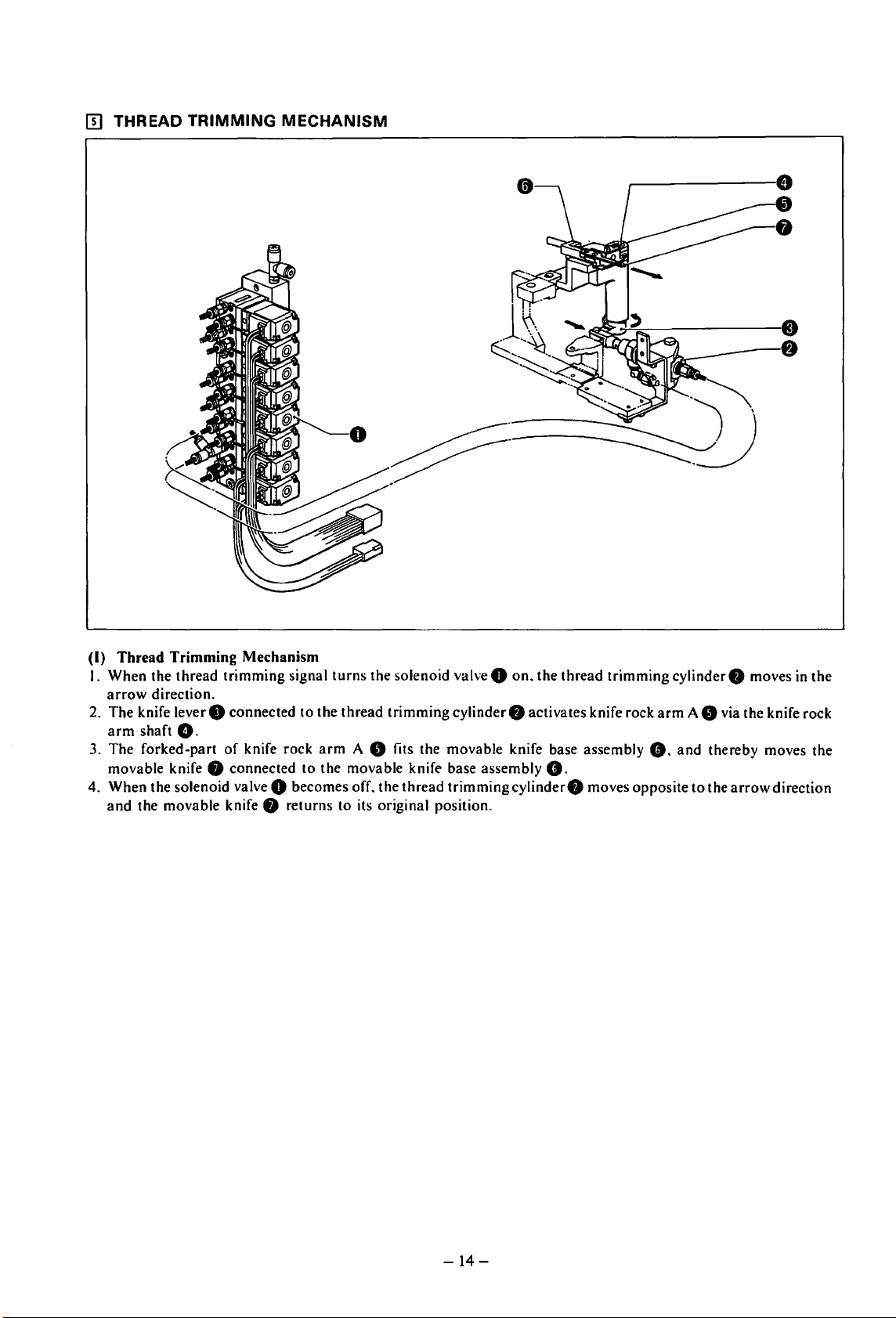

(I)

Thread

I.

When

arrow

The

2.

arm

3.

The

movable knife

4. When the solenoid valve 0 becomes off. the

and

Trimming

the thread

direction.

knife lever 8 connected

shaft

G.

forked-part

the movable knife 8 returns

Mechanism

trimming

of

knife rock

8 connected

signal

to

the

arm

to

the movable knife base assembly

turns

the solenoid valve 0

thread

trimming

A 8 fits the movable knife base assembly

to

its original position.

thread

on.

the

thread

trimming

cylinder 8 activates knife rock

8.

trimming

cylinder8

moves opposite

cylinder 8 moves in

arm

A 8 via the knife rock

8.

and

thereby moves the

to

the

arrow

the

direction

-14-

Page 18

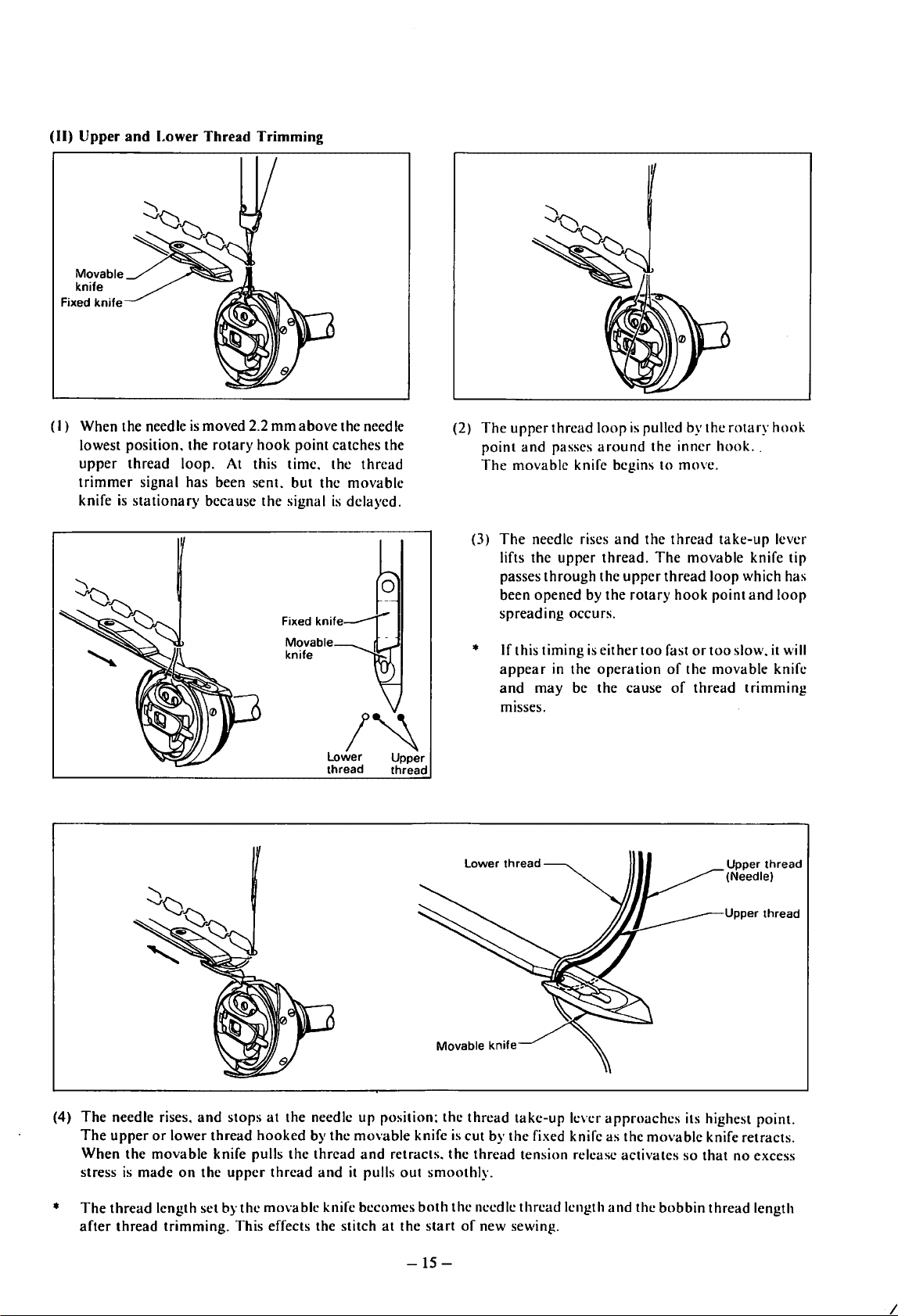

(II)

Upper

and

(I)

When the needle

lowest position. the

upper

trimmer

knife

thread

is

stationary

Lower

signal has been sent.

Thread

is

moved 2.2

loop. At this time. the

because

rotary

Trimming

mm

hook

the

above

point

but

signal

the needle

catches the

thread

the

movable

is

delayed.

(2)

The

point

The

The

(3)

been opened by

spreading

upper

thread

loop

and

passes

around

movable knife begins

needle rises

lifts the

passes

upper

through

and

thread.

the

the

occurs.

is

pulled by the

the

inner

to

the

thread

The

upper

thread

rotary

hook

move.

movable

loop

point

rotary

hook

..

take-up

knife tip

which has

and

hook

lever

loop

Movable

knife

•

Lower

Movable

If this timing

appear

and

m1sses.

thread

knife

in

may be the cause

is

the

operation

either

too

fast

of

of

or

the

thread

too

slow. it will

movable knife

trimming

(4)

The

*

needle rises.

The

upper

When

stress

The

thread

after

the

is

made

thread

and

stops

at

the needle up position; the

or

lower thread

movable

on

the

length set by the movable knife becomes

trimming.

hooked

knife pulls

upper

This effects the stitch

the

thread

by

thread

and

the

it pulls

movable

and

retracts.

at

knife

out

smoothly.

both

the

start

thread

is

cut by

the

thread

the

needle

of

new sewing.

take-up

the

fixed knife as the

tension release activates

thread

length

-15-

lever

approaches

movable

and

the

bobbin

its highest

knife retracts.

so

that

no

thread length

point.

excess

I

Page 19

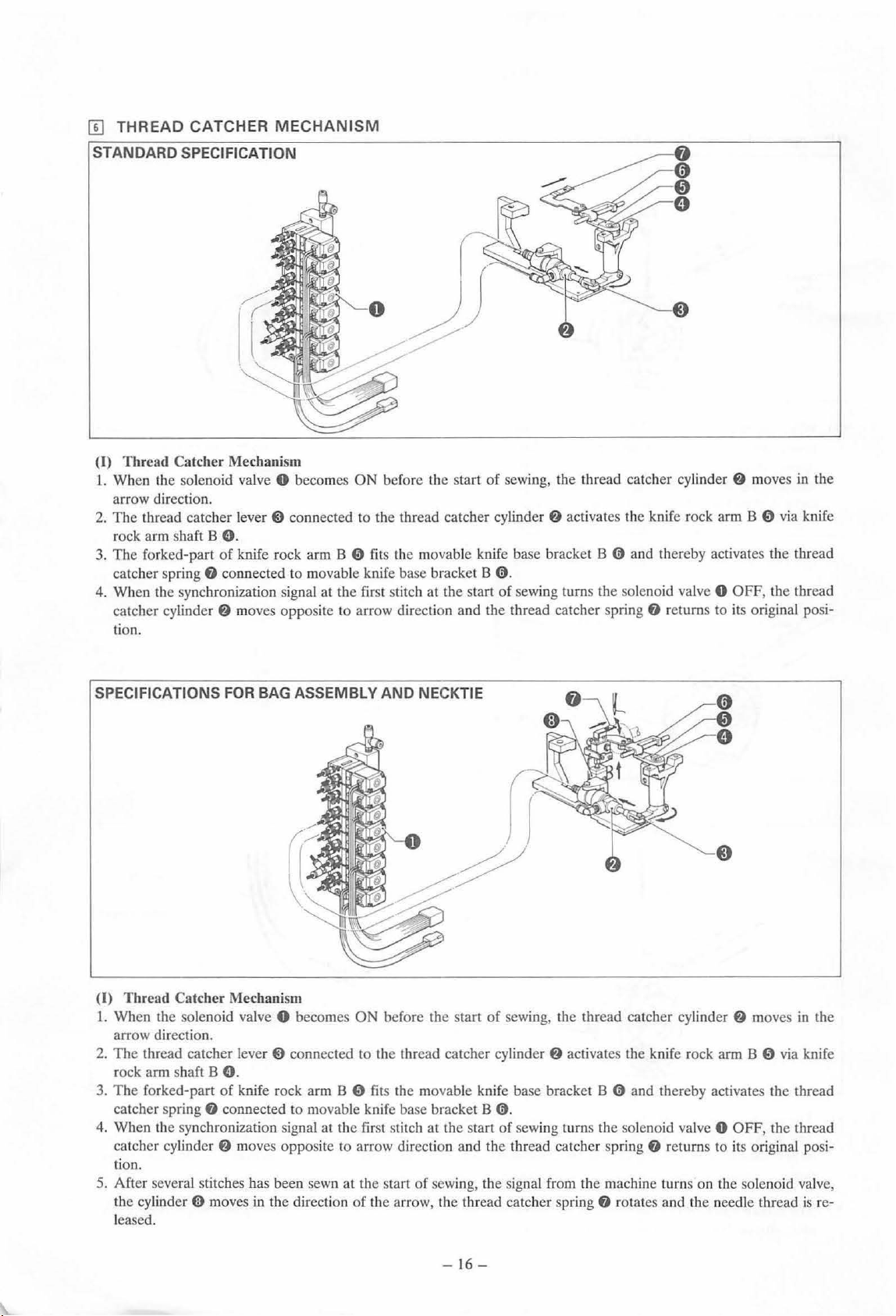

[II

THREAD

CATCHER

MECHANISM

STANDARD SPECIFICATION

(I)

Thread Catcher Mechanism

L.

When the solenoid valve 0 becomes

ON

before the start

arrow direction.

2.

The

thread catcher

rock arm shaft B

3.

The forked-part

catcher spring

4.

When the synchronization signal at the first stitch at the start

catcher cylinder

lever@

connected to the thread catcher cylind

0.

of

knife rock arm B 0

8

co

nnected to movable knife base bracket B 0 .

f)

moves opposite

fits th

e movable knife base brack

to

arrow direction and the thread catcher spring

tion.

of

sewing,

of

the thread catcher cylinder

er

f}

activates the knife rock arm B 0 via knife

et

B 0 and th ereby activates the thread

sewing turns the solenoid valve 0

f)

f}

moves

in the

OFF

, the thread

returns to its original posi-

SPECIFICATIONS

(I)

Thread Catc

1.

When the solenoid valve 0 becomes

FOR

her

Mechanism

BAG ASSEMBLY AND NECKTIE

ON

before the start

of

sewin

g,

the thread catcher cylinder

arrow direction.

The

2.

thread catcher lever ~ connected to the thread catcher cylinder

rock arm shaft B

3.

The

forked-part of knife rock arm B 0 fits the mo vab le knife base bracket B 0 and thereby activates the thread

catcher spring

0.

8 connected to movable knife base bracket B

0.

f)

activates the knife rock arm B 0 via knife

4. When the synchronization signal at the first stitch at the start of sewing turns the solenoid valv

catcher

cylinder

f}

moves

oppo

site to arrow direction and the thread catcher spring

f)

returns to its original posi-

tion.

d1

e start

of

5. After several stitches has been sewn at

cy

linder

(j)

mo

the

ves in the direction

of

the arro

sewing, the signal from the machine turns on the solenoid valve,

w,

the thread catcher spring

f)

rotates and the needle thread is re-

leased.

f)

moves

in

the

e 0 OFF, the thread

-16-

Page 20

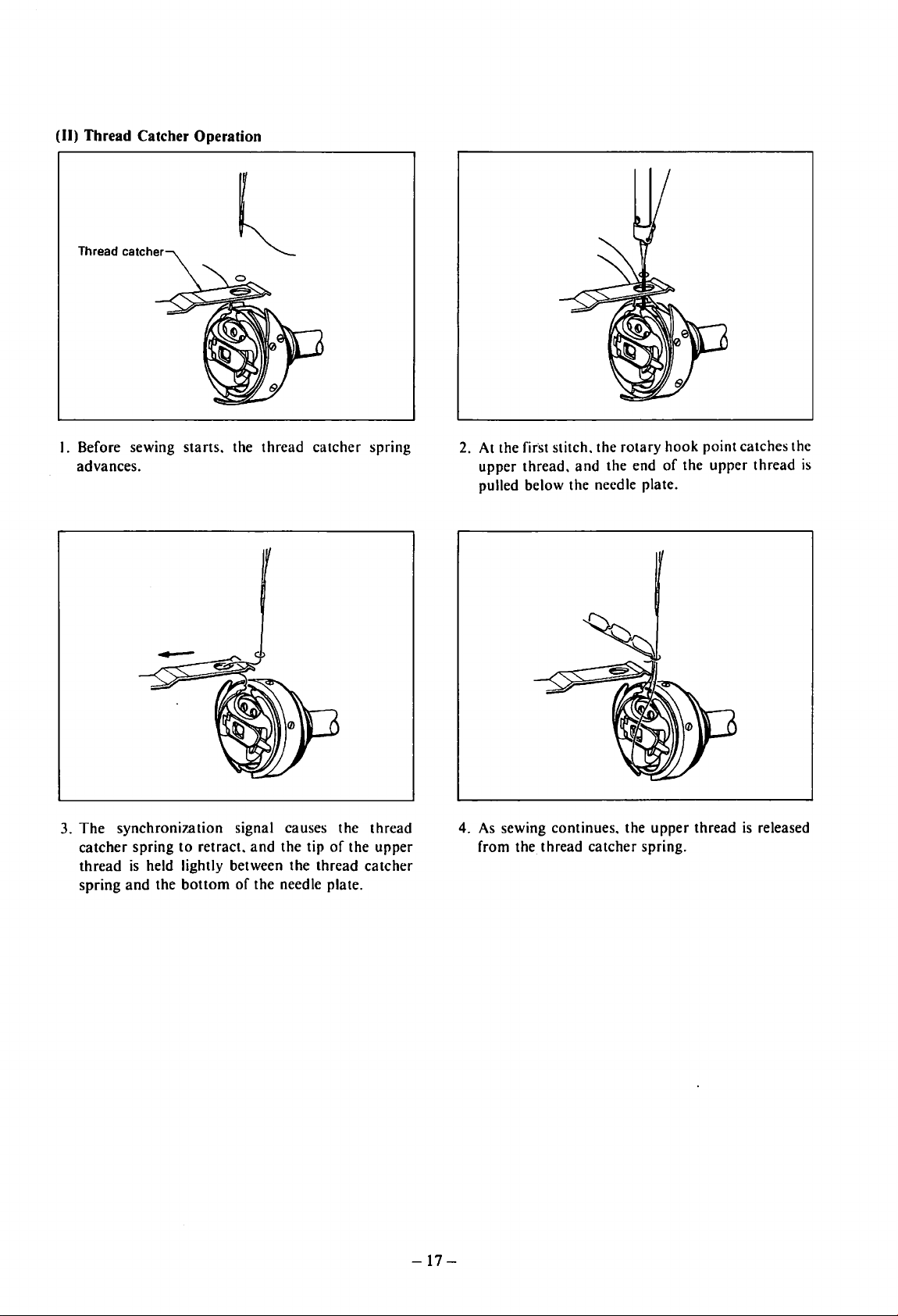

(II) Thread Catcher Operation

Thread catcher

I. Before sewing starts. the thread catcher spring

advances.

2.

At the first stitch. the rotary hook point catches the

upper thread.

pulled below the needle plate.

and

the end

of

the upper thread

is

The

3.

catcher

thread

spring

synchronization signal causes the thread

spring

to

retract.

is

held lightly between the thread catcher

and

the

bottom

and

the tip

of

the needle plate.

of

the upper

-17-

4.

As

sewing continues. the upper thread

from the thread catcher spring.

is

released

Page 21

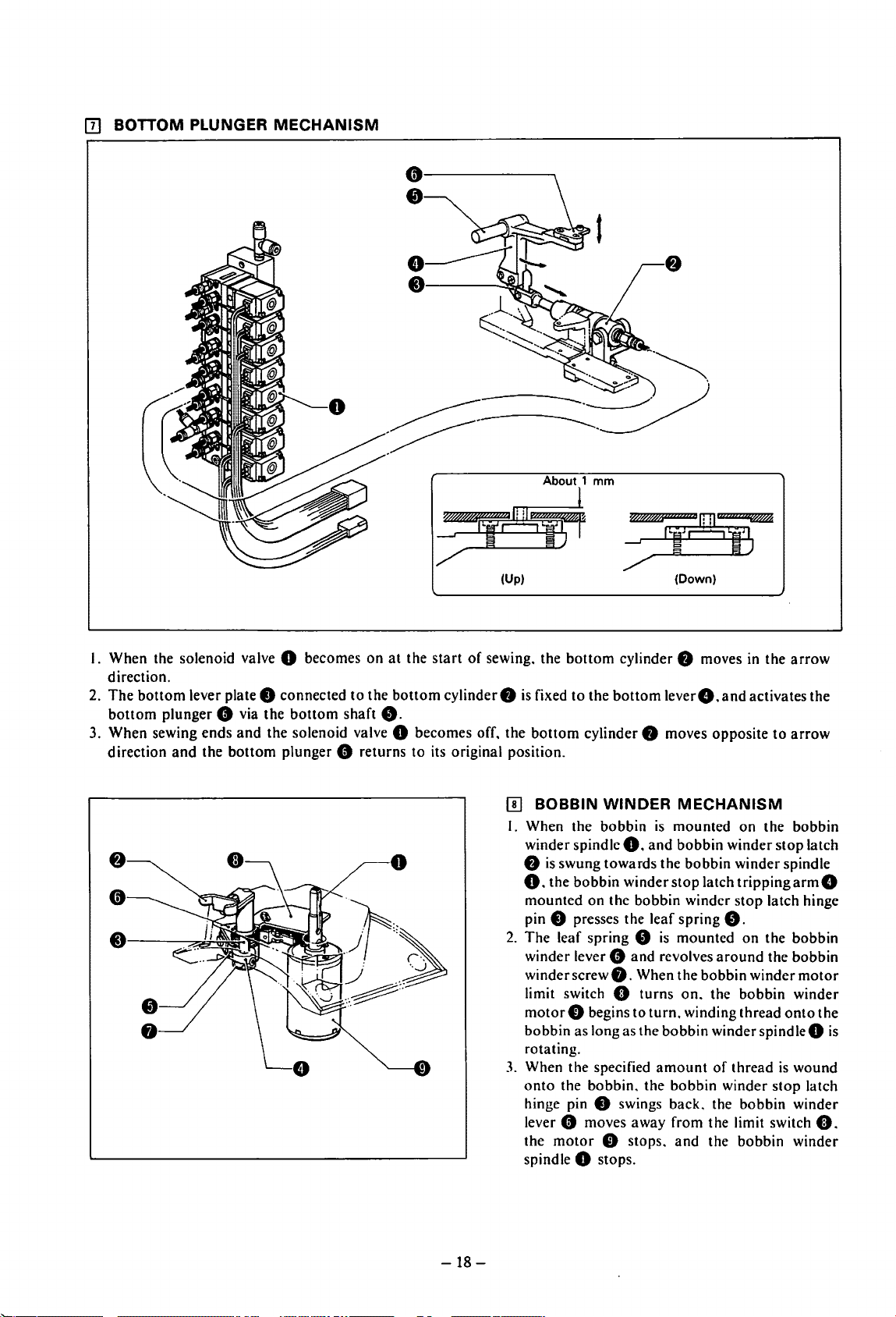

[!]

BOTTOM PLUNGER

MECHANISM

;?f8if'

(Up) (Down)

I. When the solenoid valve 0 becomes

direction.

2.

The

bottom

bottom

3. When sewing ends

direction

lever plate 8 connected

plunger 8 via the

and

the solenoid valve 0 becomes off. the

and

the

bottom

plunger 8 returns to its original position.

bottom

shaft

to

on

the

at

bottom

8.

the

start

of

cylinder8

sewing. the

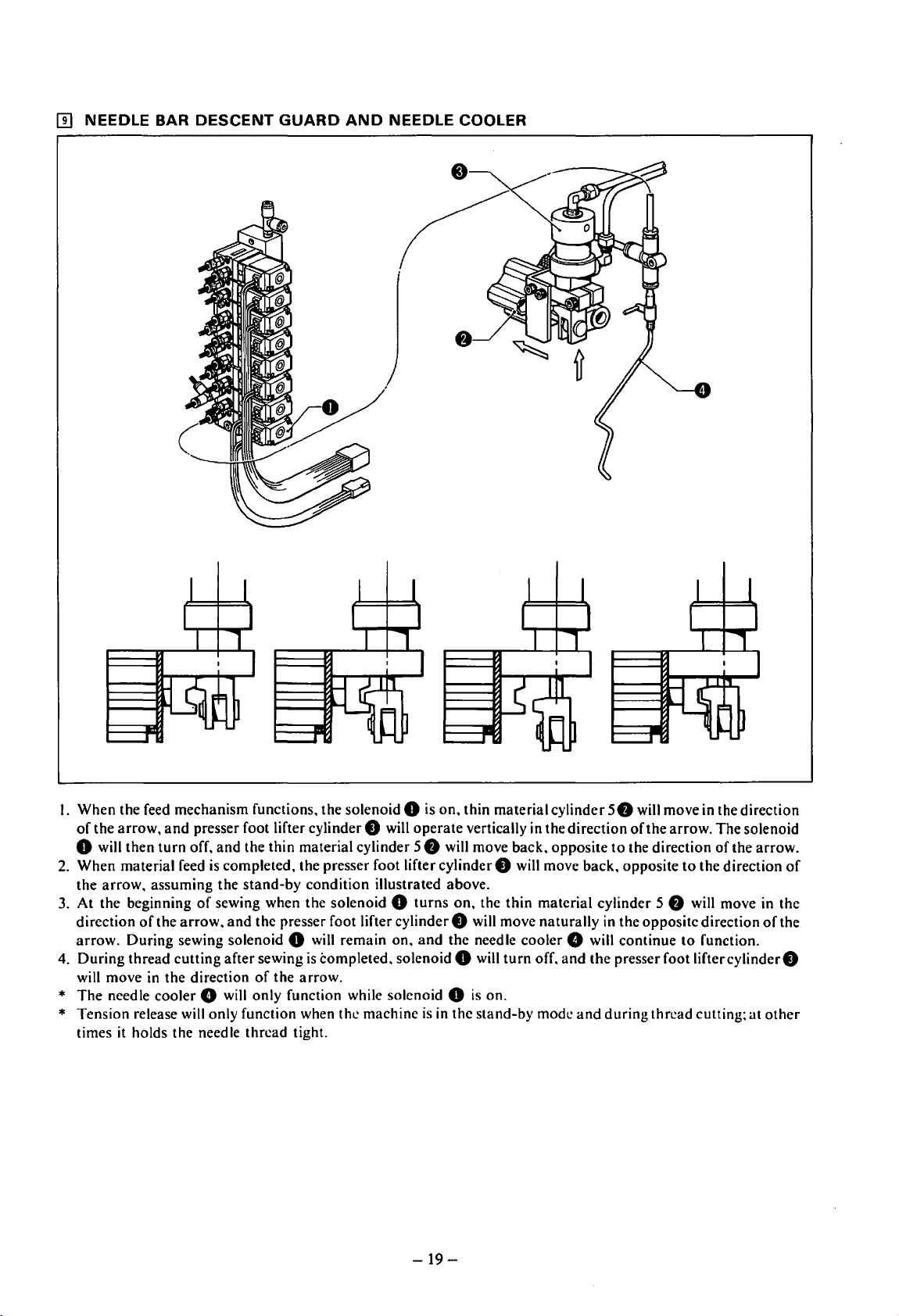

[I)

I. When the bobbin

bottom

is fixed to the

bottom

BOBBIN

winder spindle

8

is

swung towards the bobbin winder spindle

cylinder 8 moves in the

bottom

cylinder 8 moves opposite

WINDER

0.

and

leverG.and

is

O. the bobbin winder

mounted on the bobbin winder

pin

8 presses the leaf spring

2.

The leaf spring 8

winder lever

winder screw

limit switch 0 turns

motor

bobbin as long as the bobbin winder

rotating.

3.

When the specified

onto

the bobbin. the bobbin winder

hinge pin

lever

8 moves away from the limit switch

the

motor

spindle

8

8.

0 begins to

0 swings back. the bobbin winder

0 stops.

0 stops.

is

and

revolves

When the bobbin winder

turn.

amount

activates the

MECHANISM

mounted

bobbin

stop

on

winder

latch

trippingarmG

stop

8.

mounted

on.

winding thread

and

on

around

the bobbin winder

of

thread

the bobbin winder

arrow

to

arrow

the bobbin

stop

latch

latch hinge

the bobbin

the bobbin

motor

onto

the

spindleO

is

wound

stop

latch

0.

is

-18-

Page 22

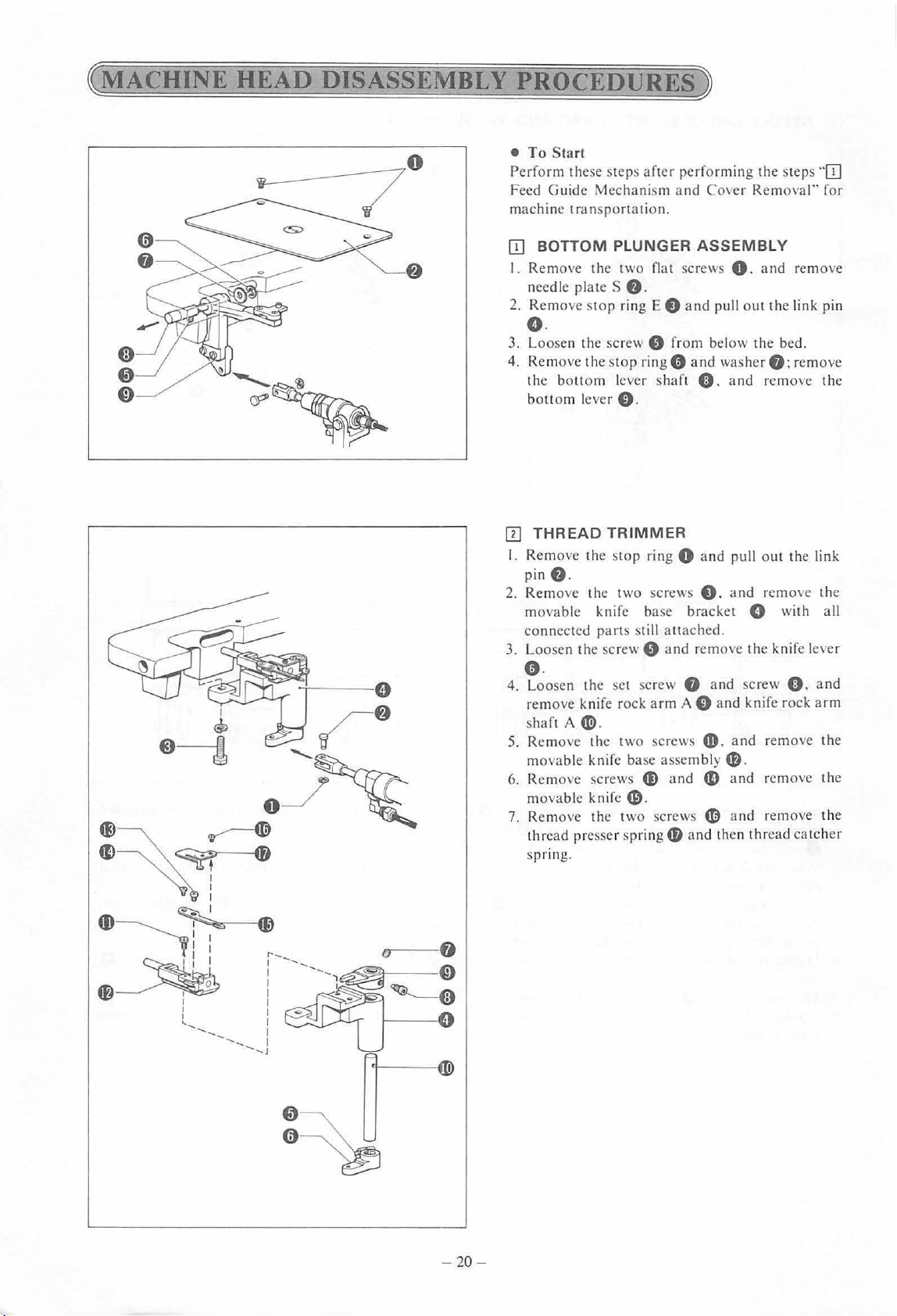

IT]

NEEDLE BAR

DESCENT

GUARD

AND

NEEDLE COOLER

I. When the feed mechanism functions. the solenoid 0 is on. thin material cylinder

of

the

arrow,

0 will

2.

When material feed

the

arrow.

3. At the beginning

direction

arrow.

4.

During

will move

*

The

needle cooler 8 will only function while solenoid 0

* Tension release will only function when the machine

times

it

and

presser foot lifter cylinder 0 will

then

turn

off.

and

the thin material cylinder

is

completed. the presser foot lifter cylinder 0 will move back. opposite

assuming

of

the

During sewing solenoid 0 will remain on.

thread cutting after sewing

in

the direction

holds the needle thread tight.

the

stand-by

of

sewing when the solenoid 0

arrow.

and

the presser foot lifter cylinder 0 will move naturally

of

condition illustrated above.

is

completed. solenoid 0 will

the

arrow.

operate

58

turns

and

vertically

will move back. opposite

on,

the thin material cylinder

the

needle cooler 8 will continue

is

is

in

the stand-by mode

on.

turn

in

off. and

the direction

the

and

-19-

58

will move in the direction

of

the

arrow.

The

to

the direction

58

in

the

opposite direction

presser foot

during

thread cutting;

of

to

the direction

will move in the

to

function.

liftercylinderO

solenoid

the arrow.

of

of

the

at

other

Page 23

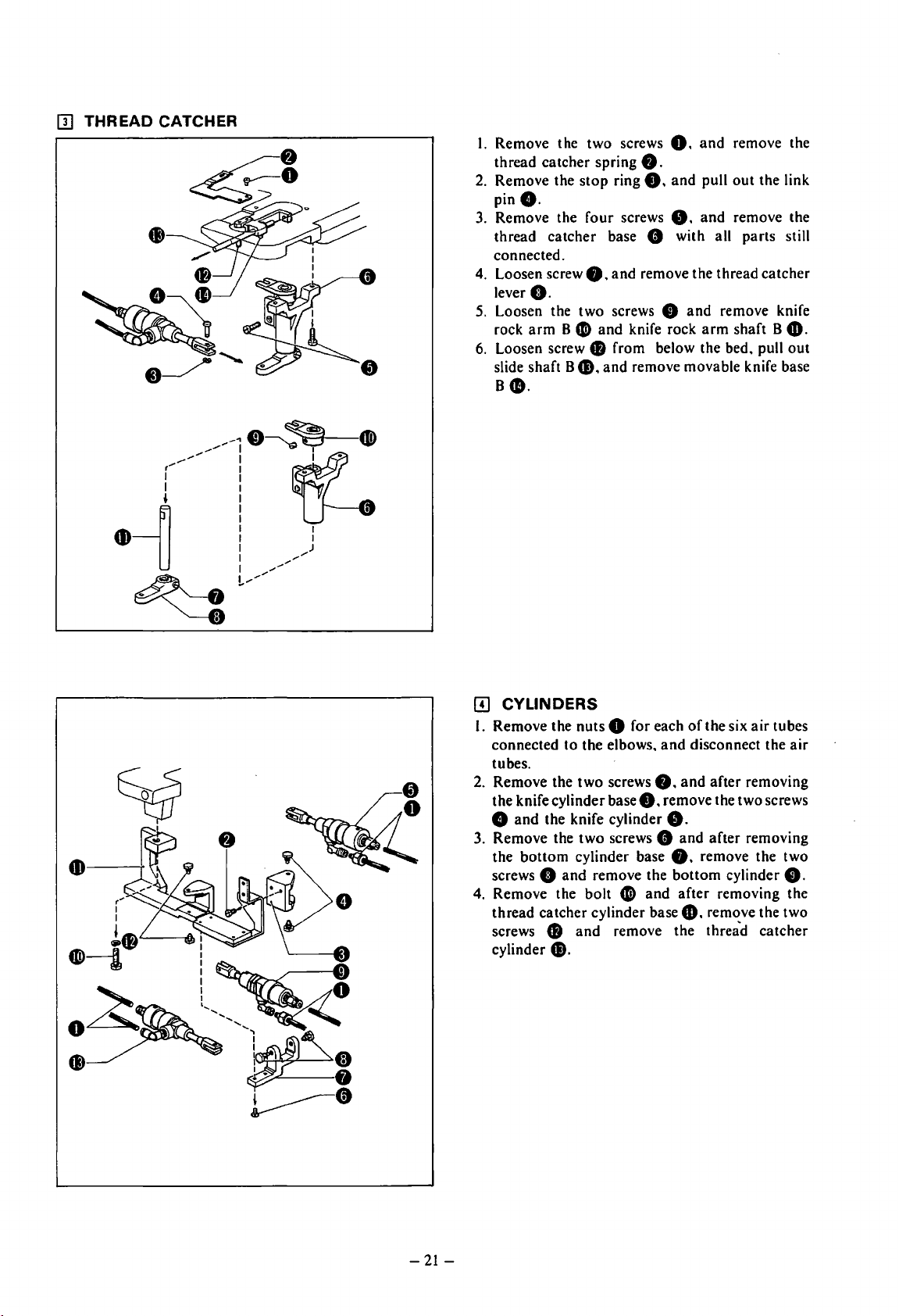

~MACHINE

(;)

HEAD

0

0

DISASSEMBLY

PROCEDURES)

•

To

S

tar

t

Perform these steps aft

Feed Guide Mechanism a

machine tran sportation.

OJ

BOTTOM PLUNGER

I. Remove the two flat screws

needle

2.

Remo

plates

ve

sto

p ring E 8

e.

er

performing the steps

nd

ASSEMBLY

and

e.

3. Loo

se

n the screw 8 from

0

4. Remove the stop ring

the bottom lever shaft

bott om lever

IT]

THREAD

I.

Remove the st

e.

pin

2. Remo

3. Loosen

ve

movable

connected parts still attached.

C).

TRIMMER

op

the t

wo

knife

th

e screw 8 and remove the knife lever

and

0.

ring 0 and pull out the link

screws

base bracket G with all

8.

o.

4.

Loosen the set

remove knife rock

sha

ft

A~-

5.

Remo

ve

the two screws

movable knife base assem bly

6. Remove screws

movable knife

7. Remove the two screws

thread presser spring

s

pnn

g.

sc

rew 8 and screw

arm

A 0

4D.

fD

and

4D

G).

4D

4D

and then thr

"OJ

Cover Removal" for

0.

and

remove

pull out the link pin

be

low the bed.

washer

an

8;

remove

and remove the

and remove the

0.

and

d knife rock

and

remo

ve

arm

the

f».

and remove the

an

d remove the

ead catch

er

-20

-

Page 24

[l]

THREAD CATCHER

I. Remove the two screws O.

thread catcher spring

2.

Remove the

pinG.

3.

Remove the four screws

thread

connected.

4.

Loosen screw

G.

lever

5.

Loosen the two screws 0

rock

arm

6.

Loosen screw 8 from below the bed. pull

slide shaft 8

8

•.

stop

catcher

0.

8 0

48.

8.

ring

8.

base 8 with all parts still

and

remove the thread catcher

and

knife rock

and

remove movable knife base

and

8.

and

and

pull

out

and

remove knife

arm

remove the

the link

remove the

shaft 8

4D.

out

11]

CYLINDERS

I. Remove the nuts 0 for each

connected to the elbows.

tubes.

2.

Remove the

the knife cylinder base

8

and

3. Remove the

the

bottom

screws

4. Remove the bolt 0

thread catcher cylinder base

screws

cylinder

two

screws

the knife cylinder

two

screws 8

cylinder base

0

and

remove the

8

and

remove the threa'd

48.

and

8.

8.

remove the two screws

8.

and

of

the six

air

tubes

disconnect the

and

after removing

and

after removing

0.

remove the two

bottom

after removing the

cylinder

49.

remove the two

0.

catcher

air

-21-

Page 25

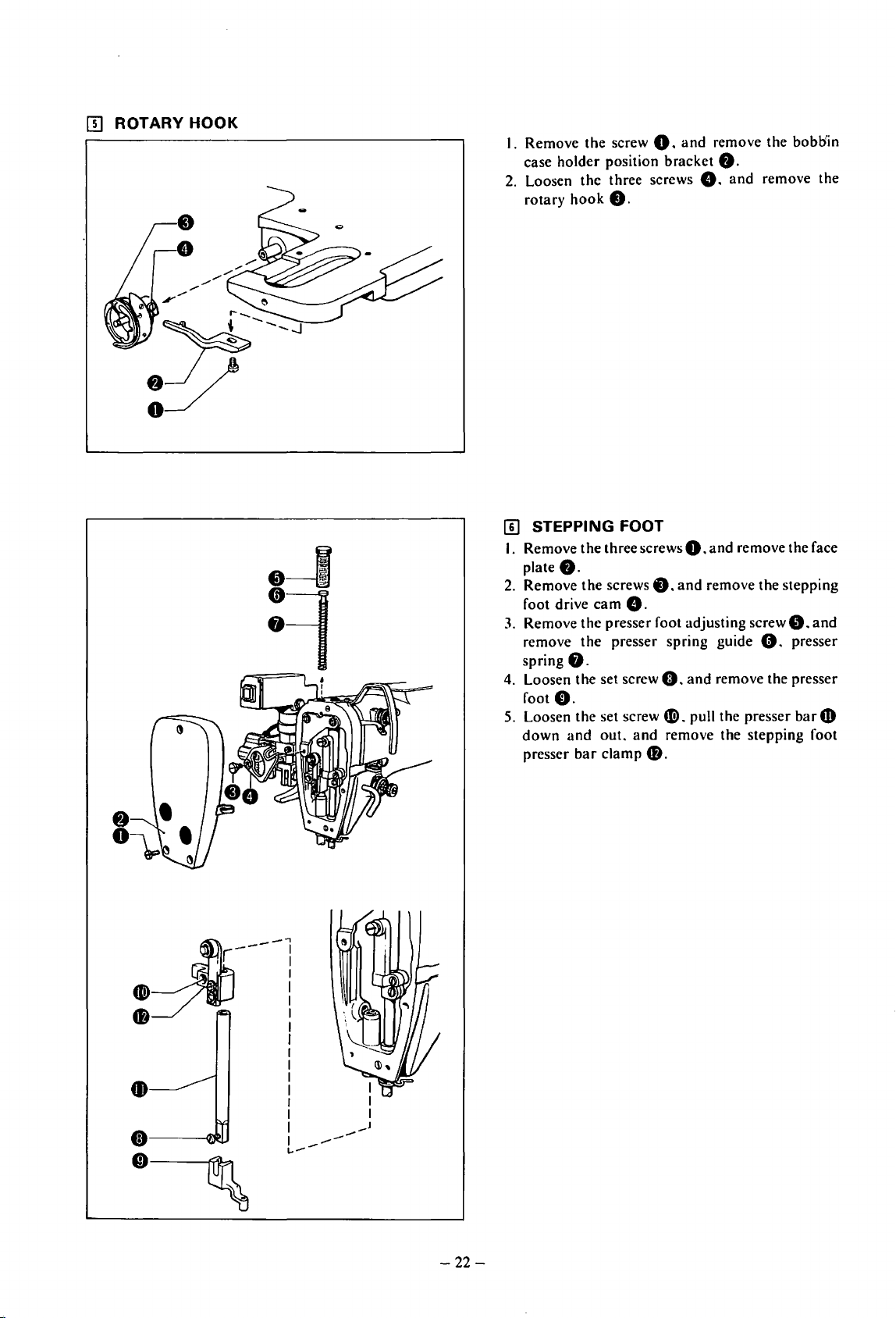

rn

ROTARY

HOOK

I. Remove the screw

case holder position bracket

2.

Loosen the three screws

rotary

!I]

I.

Remove the three screws

plate

2.

Remove the screws O.

foot drive

3.

Remove the presser foot adjusting

remove the presser spring guide G. presser

spring

4.

Loosen the set screw

foot

5.

Loosen the set screw

down

presser

hook

STEPPING FOOT

8.

cam

8.

O.

and

out.

bar

clamp

0.

0.

and

remove the bobliin

8.

8.

and

0.

and remove the face

and

remove the stepping

8.

screwO.

0.

and

remove the presser

41!).

pull the presser

and

remove the stepping foot

f).

remove the

and

badD

-~----~

48

:

I

I

I

I

I

I

I

I

1

...

-~

----

----

--

-22-

Page 26

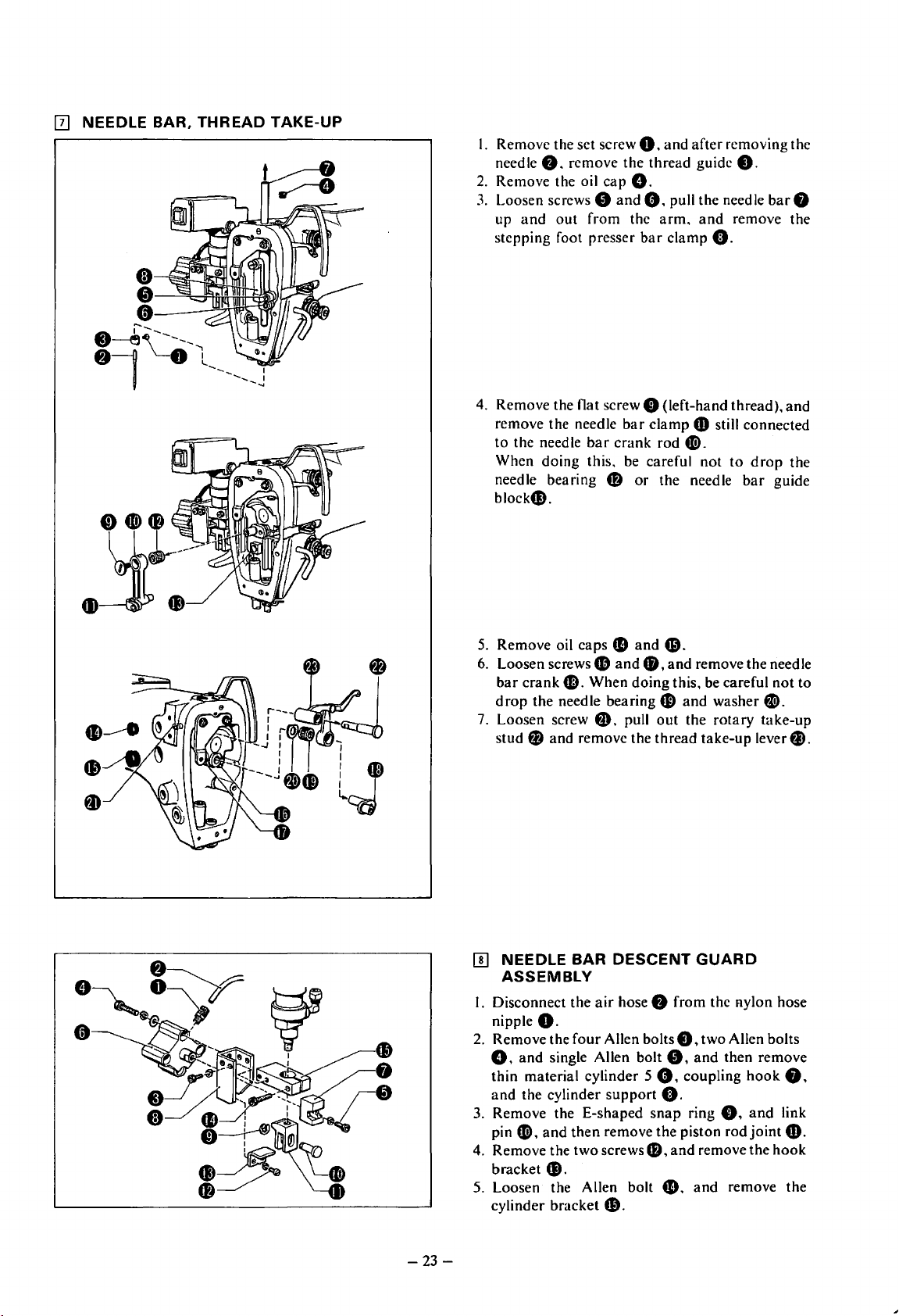

12]

NEEDLE BAR, THREAD TAKE-UP

I.

Remove the set screw

needle

8.

remove the thread guide

2.

Remove the oil

3.

Loosen screws 0

up

and

out

from the

stepping foot presser

4.

Remove the flat screw 0 (left-hand thread), and

remove the needle

to the needle

When doing this. be careful not

needle bearing

block$.

bar

0.

capO.

and

0.

bar

bar

clamp

crank rod

4D

or

and

after removing the

pull the needle

arm.

and

remove the

clamp

O.

G)

still connected

Gi).

to

the needle

8.

drop

bar

bar

the

guide

8

5.

Remove oil caps

6.

Loosen screws

bar

crank

f,D.

drop

the needle bearing

7.

Loosen screw @). pull

stud

0 and remove the thread take-up lever

[!]

NEEDLE BAR

ASSEMBLY

I.

Disconnect the

nipple

O.

2.

Remove the

0.

and

single Allen bolt

thin material cylinder

and

the cylinder support

3.

Remove the E-shaped

pin

Gi),

and

4.

Remove the two screws fl),

bracket

5.

Loosen the Allen bolt

cylinder bracket

41).

fD

fl

and

When doing this, be careful

DESCENT

air

hose 8 from the nylon hose

four

Allen bolts

then

remove the piston rod

$.

and

8,

5

snap

6}.

and

remove the needle

G)

and

washer

out

the rotary take-up

GUARD

8.

two Allen bolts

0.

and

then remove

e.

coupling

0.

ring

0.

and

remove the

fl.

and

remove the

not

fJ).

f).

hook

••

and

link

joint@).

hook

to

-23-

Page 27

~MACHINE

HEAD

ASSEMBLY

PROCEDURES)

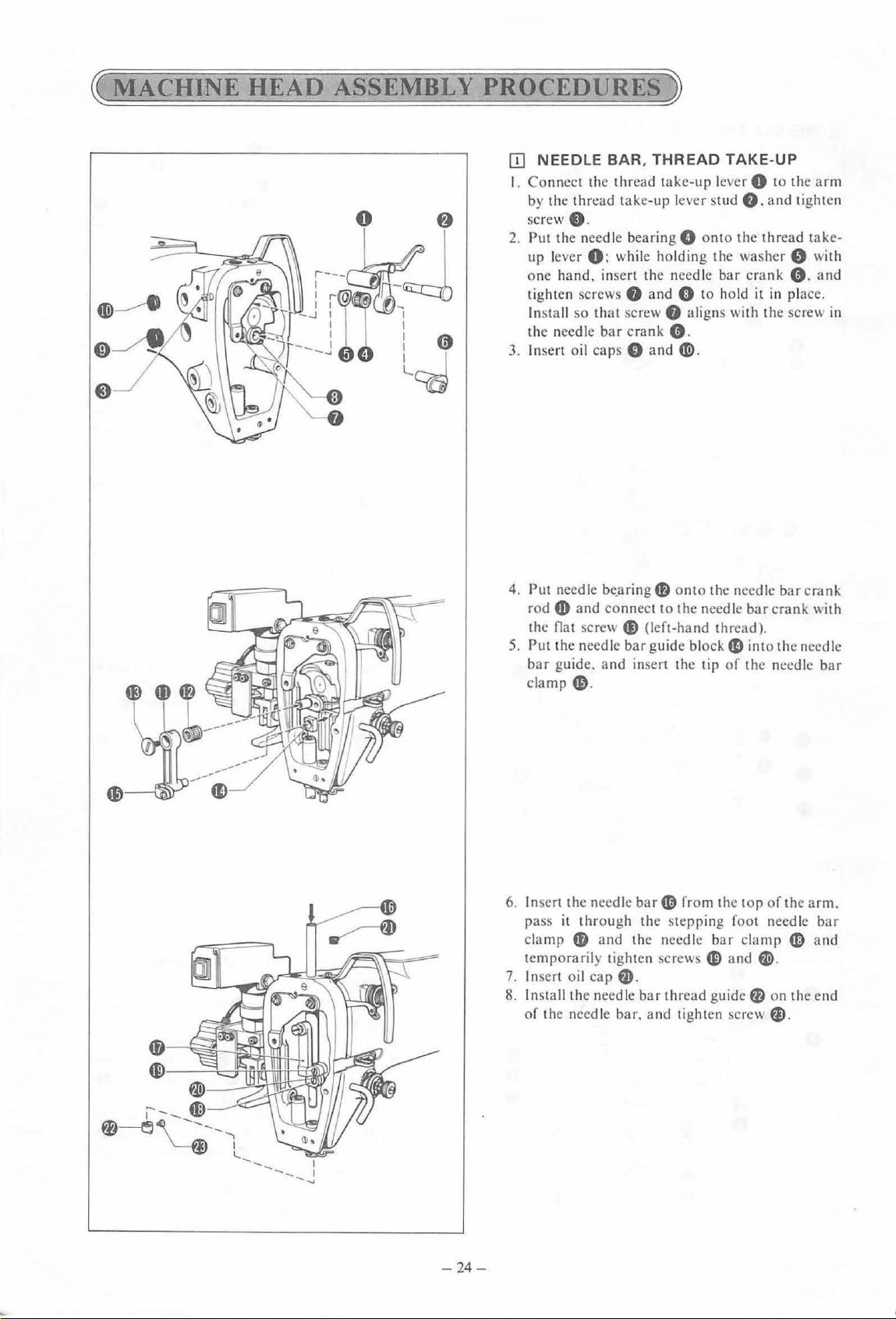

[!]

NEEDLE BAR,

I. Connect the thread take-up lever 0 to the

by

the thread take-up lever stud

sc

rew e.

2. Put the need le bearing 0

up lever

one

tighten screw s

In

the needle

3. Insert o

0:

hand.

in

stall so that screw

bar

il

caps 0 and

THREAD

wh

il

e holding the washer 0

sert the needle bar crank e.

f)

and

0 to ho

f)

crank e.

~

TAKE-UP

f).

onto

the thread take-

ld

aligns with the screw

-

and

tighten

wi

it in place.

arm

th

an

in

d

4. Put need le be_

rod

4D

the nat scre\\

5.

Put t

he

bar

guide.

clamp

6. Insert

7. Insert o

8. Install the needle

the needle

pass

it

cl

amr

temporarily tighten screws

of

the needle ba

aringf)

and connect to the needle

~(l

needle bar gu

and

insert the tip

6)

.

bar~

through the stepping foot needle

4D

a

nd

the needle

il

cap

fJ)

.

bar

r.

and tight

onto t

he

needle ba r crank

bar

crank with

eft-hand

id

thread guide 0 on the end

thread).

e block e into the needle

of

the needle

from the t

bar

fP)

and

en scr

or

of

clamp

~

ew

fl).

the

«)

-

bar

arm.

bar

and

- 24 -

Page 28

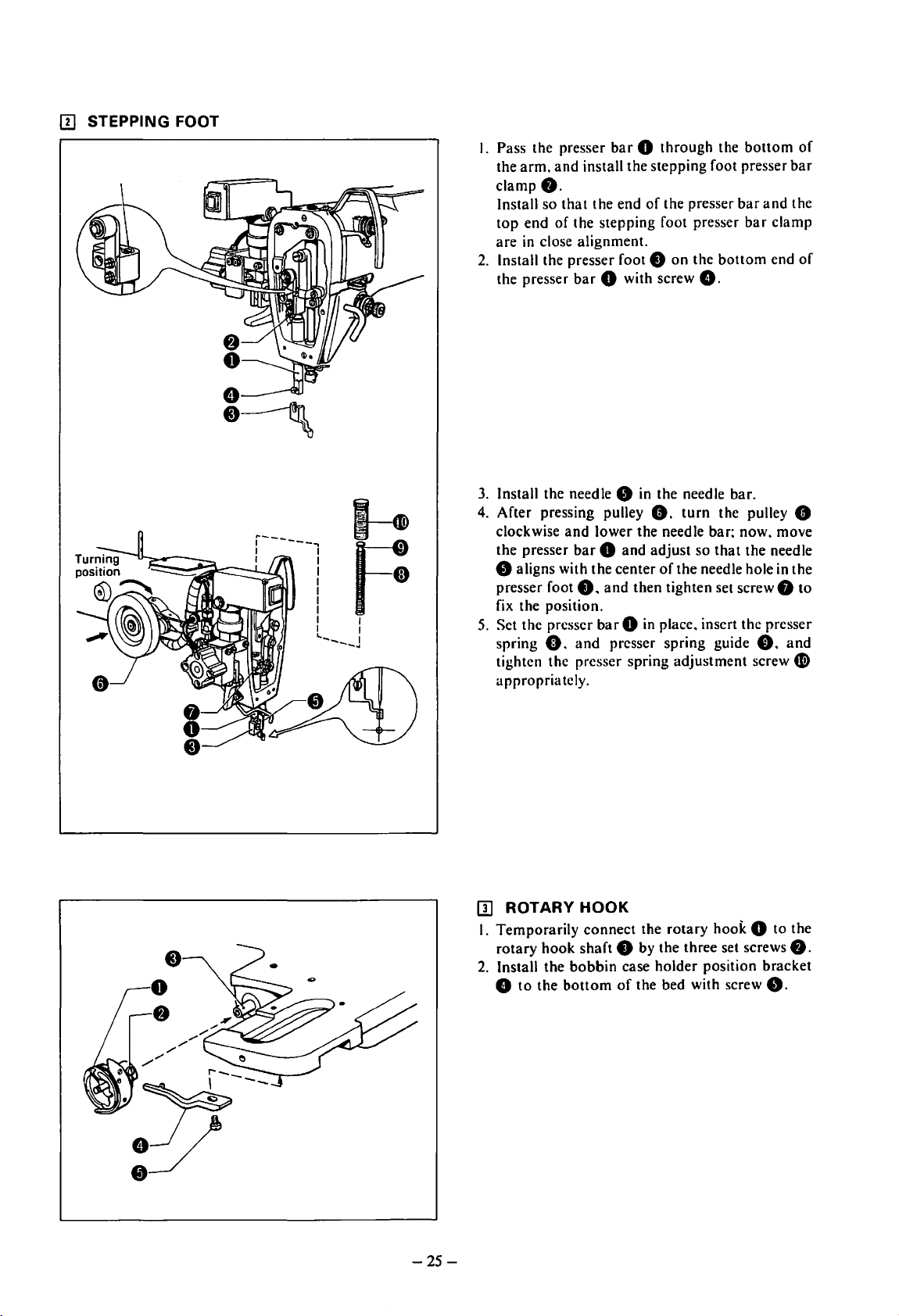

[!]

STEPPING FOOT

I.

Pass the presser

the

arm,

and

clamp

8.

Install so

top

are

2.

Install the presser foot 8 on the

the presser

3.

Install the needle 8 in the needle bar.

4.

After pressing pulley

clockwise

the presser

that

end

of

in

close alignment.

8 aligns with the center

presser foot

fix the position.

5.

Set the presser

spring

tighten the presser spring adjustment screw

appropriately.

o.

bar 0 through

install the stepping foot presser

the end

the stepping foot presser

bar

of

the presser

0 with screw

8.

and

lower the needle bar; now, move

bar 0 and

8.

barO

and

adjust

of

and

then tighten set screw

in

place, insert the presser

presser spring guide

8.

turn

so

that

the

needle hole

the

bar

bottom

the pulley 8

bottom

bar

the needle

and

clamp

end

e.

in

f)

of

bar

the

of

the

to

and

Ci)

[I]

ROTARY HOOK

I. Temporarily

rotary

hook

2.

Install the

8

to

the

bottom

r---

:?7

--

-25-

connect

shaft

bobbin

the

rotary

8 by the three set screws

case

holder

of

the bed with screw

hook 0 to

the

8.

position bracket

8.

Page 29

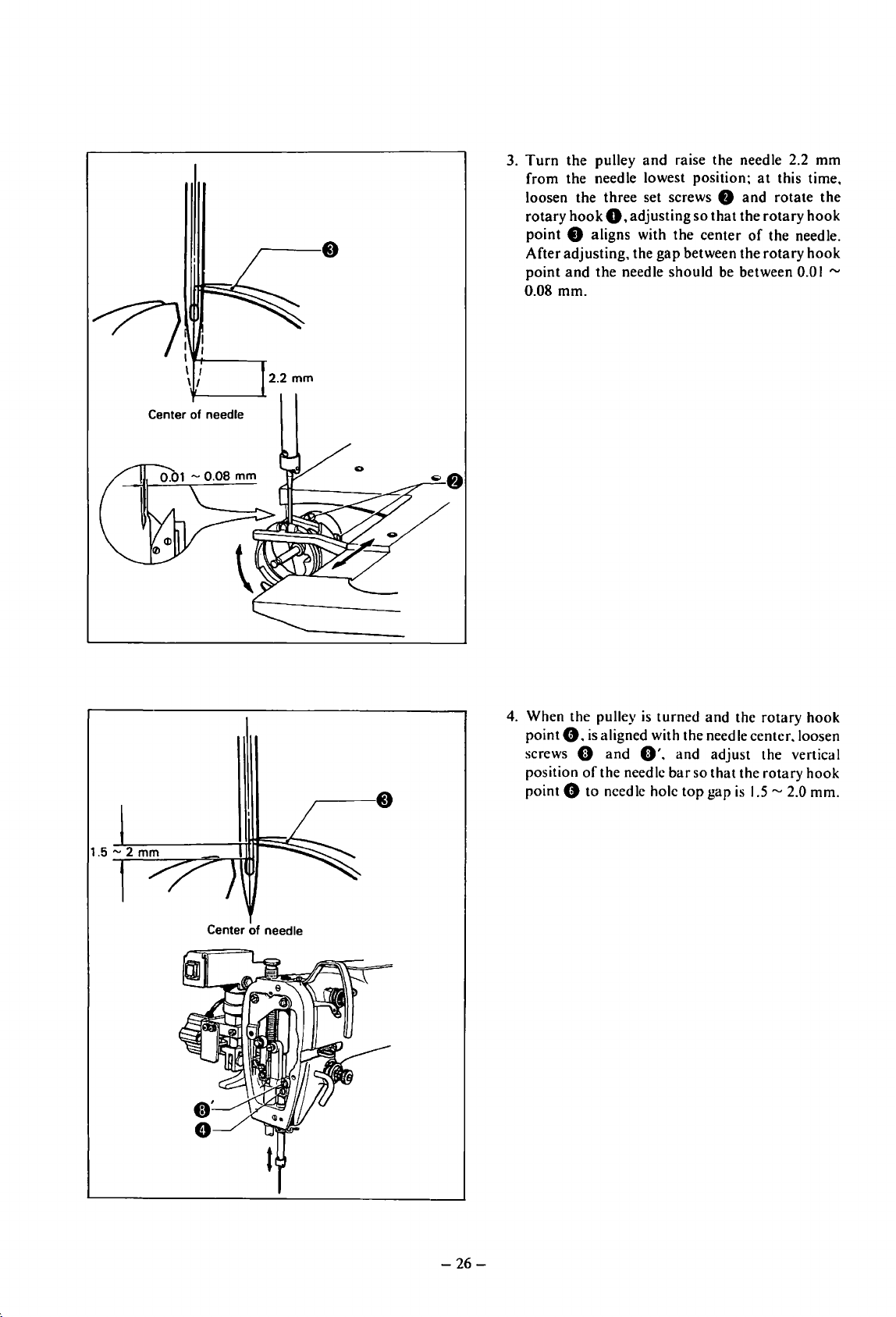

3.

Turn

the pulley

from the needle lowest position;

loosen the three set screws

rotary

hook

point 8 aligns with the center

After adjusting, the

point

and

0.08 mm.

and

raise the needle 2.2 mm

0.

adjusting

the needle should

so

gap

between the rotary

8

and

that

the

of

be

between 0.0 I

at

this time,

rotate the

rotary

hook

the needle.

hook

"'

~:

Center

f+-l

\/

of

-----.-

needle

2.2

mm

4.

When the pulley

point

e.

is

aligned with the needle center. loosen

screws

position

point 0 to needle hole

0

and

of

the needle

is

turned and the rotary hook

0'.

and adjust the vertical

bar

so

that

the rotary

top

gap

is

1.5"'

2.0 mm.

hook

Center

of

needle

-26-

Page 30

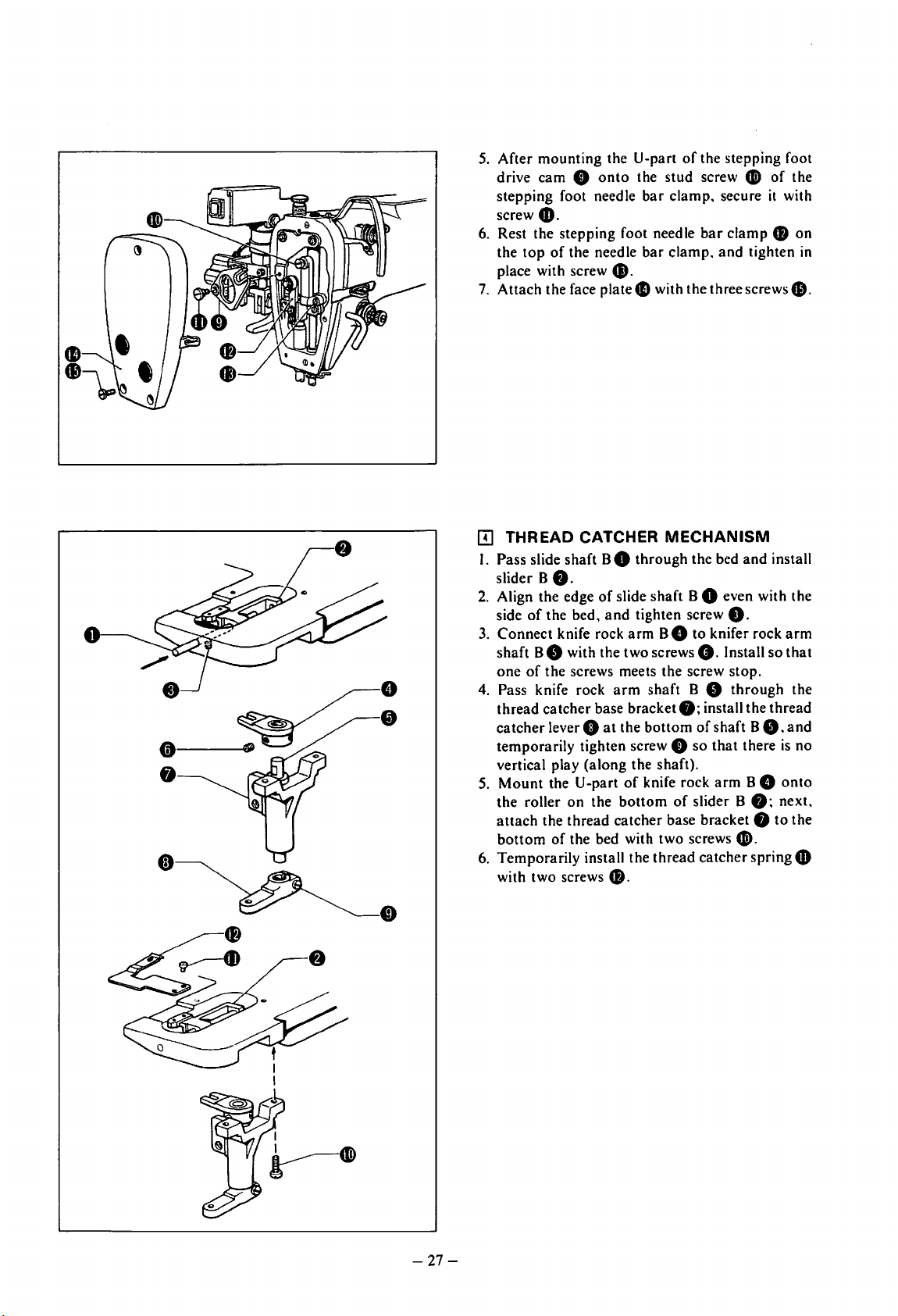

0

5.

After mounting the U-part

drive cam

stepping foot needle

screw

6. Rest the stepping foot needle

the

top

place with screw

7.

Attach the face plate4D with the three

[!]

THREAD CATCHER

I. Pass slide shaft B 0 through the bed

slider B

2.

Align the edge

side

3.

Connect knife rock

shaft B 8 with the two screws

one

of

4.

Pass knife rock

thread catcher base bracket

catcher

temporarily tighten screw 0

vertical play (along the shaft).

5.

Mount

the roller

attach

bottom

6. Temporarily install the thread catcher spring

with two screws

0

onto

4D.

of

the needle

41.

f).

of

slide shaft B 0 even with the

of

the bed,

the screws meets the screw stop.

lever 0

the U-part

the thread catcher base bracket 8 to the

of

and

tighten screw

arm

arm

at

the

of

on

the

bottom

the bed with two screws G).

48.

of

the stepping foot

the stud screw

bar

clamp. secure

bar

clamp

bar

clamp.

and

MECHANISM

8.

B 8 to knifer rock

0.

Install

shaft B 8

f);

install the thread

bottom

knife rock

of

so

of

slider B

shaft B

that

arm

G)

of

it

48

tighten

screws&.

and

install

so

through

0.

there

B 8

f);

next,

the

with

on

in

arm

that

the

and

is

no

onto

4D

-27-

Page 31

[[]

THREAD

0

TRIMMING

«o

I I

l....

---

-........

--.J

r----

I

I I

I

I •

I

I

I

I

MECHANISM

e\

~

--~~r

I. Install the slider assembly 0

trimming

2.

Install knife rock

arm

set screw 8

alignment

Pass knife rock

3.

thread

thread

A

8.

there

Mount

4.

the roller

temporarily

bracket

base bracket 8 with two screws

arm

A 0

shaft

A 8 with set screws 8

is

aligned with the position

hole when tightening

arm

shaft

trimming

trimming

and

temporarily

is

no vertical play (along the shaft).

the U-part

at

the

bottom

install

base

bracket

lever 8

on

tighten screw 0 so

of

knife rock

of

the

the

thread

8 with the two bolts

onto

the

thread

onto

knife rock

and

8.

Be

the

screws.

A 8

through

f):

install the

the

bottom

arm

slider assembly

trimming

of

A 0

0.

8.

sure

the

shaft

that

onto

0:

base

5.

Install the movable knife

CD

and

screw

tighten screw

so

that

the movable knife

or

thread

the pulley

arrow,

8

the

movable

after

screw

left.

knifeCii)

right

6.

Set the

the movable

two screws

horizontally.

7.

Turn

8. While pressing with

movable

the

bracket

of

center:

and

48.

4B

in the middle

catcher

knife41!)

C.

so

and

and

move

both

and

movable

knife

adjusting. tighten the

4B.

41!)

with flat head screw

At this time.

41!>

spring

and

temporarily tighten

that

the spring does not slide

lower the needle bar.

your

finger

sliding

it

the

thread

knife

41!)

aligns with the needle

temporarily

of

the screw hole

can be adjusted

G)

directly below

on

the

in

the direction

trimming

Cli)

so

that

two

top

of

the tip

bolts 0

the

the

of

base

-28-

Page 32

I!]

BOTTOM PLUNGER ASSEMBLY

0

•

f)

•

•

_bv3-rm

I.

Pass the

and

2.

Put the washer 8 on the

and

3. Align the end

the side

[1]

CYLINDERS

(I)

Thread Catcher Cylinder

I.

Connect

thread catcher cylinder base

cylinder mounting screws

2.

Temporarily install the

base

both

3.

Connect

and

and

connecting, check

cylinder moves smoothly,

tighten bolt

4.

Connect

tubes to the elbows.

5.

Move the thread catcher cylinder by

when the thread catcher spring

retracted, loosen screw

catcher lever

spring

0.5 mm.

6. Move the thread catcher cylinder by

fully advance the thread catcher spring

turn

adjust

left

oval hole.

bottom

install the

attach

of

the thread catcher cylinder 8

lever shaft 8

bottom

the

stop

of

the

the bed

lever

bottom

ring

8.

bottom

and

tighten screw

through

8.

lever shaft

lever shaft 8 with

8 with the two

8.

thread

8 with bolt 8

the bed

the thread catcher lever 0 with link pin

secure the link pin with

and

the

thread

8

the correspondingly numbered

0

4D

and

movable knife

the pulley, loosen the two screws

the needle so

and

right sides

and

thread catcher base

catcher cylinder rod

that

and

the two screws

G)

so

that

that

of

the needle when it is in the

catcher

the two screws 8 to

stop

ring G). After

the thread

and

then firmly

and

move the thread

the

gap

between the

f)

is

between 0.3

the spaces are even

8.

8.

8.

hand

4D

hand,

CD;

the bed,

8.

to

the

cylinder

joint

8

8.

catcher

air

and

is

fully

"'

and

next,

41.

and

on

Thread catcher

spring retract

Thread catcher

spring advance

-29-

Page 33

0.3-0.5

mm

-

(2) Thread Trimming Cylinder

I. Install the

thread

cylinder

2.

Temporarily

base

the two set screws

3.

Connect

8

and

0

and

these.

moves

screws

4.

Connect

tubes to the elbows.

5. While lightly pressing the

knife

trimming

and

adjusting

base

movable knife

thread

trimming

mounting

0

on

the cylinder

the thread

the

thread

attach

confirm

smoothly.

8.

the correspondingly numbered

CD

with

cylinder by

move the thread

the

4B

to

trimming

cylinder base 0 with the two

screws

install the thread

e.

connecting

8.

trimming

trimming

stop

that

the

and

your

gap

between the slider4D

within 0.3

is

moved

leverO

ring

f).

thread

then tighten the two set

finger. move

hand;

trimming

"'

both

cylinder 8

trimming

cylinder rod

After connecting

trimming

top

of

loosen set screw

0.5

mm

forward

on

cylinder

plate 8 with

with link pin

cylinder

the movable

the

thread

lever

and

when

and

the

joint

air

G)

0.

slider

the

back.

---0

(3) Bottom Cylinder

I. Install the

cylinder base 0 with the two cylinder

screws

2.

Temporarily

onto

2 set screws

3.

Connect

bottom

stop

that

then tighten the two set screws

4. Connect the correspondingly numbered

tubes to the elbows.

bottom

cylinder 8

e.

install the

the

thread

catcher

8.

the

bottom

lever plate 0 with link pin 0

ri.ng

f).

After connecting these.

the

bottom

bottom

cylinder base 8 with the

cylinder rod

cylinder moves

on

the

bottom

mounting

cylinder base 0

joint 8 and

and

attach

confirm

smoothly.

8.

the

and

air

-30-

Page 34

5.

Install needle plate S ~ with two flat head

screws

6.

the

the

needle plate; next, raise the

fully,

plunger~

then firmly tighten the two set screws 8 in this

position.

49.

Moving the

bottom

bottom

and

bottom

plunger~

plunger~

adjust

is I mm

cylinder by

and

with the

so

that

above

the needle plate,

hand.

align the

top

surface

bottom

the

top

first lower

top

plunger~

end

end

of

of

of

the

the

and

(Up)

About 1 mm

(Down)

* If the up

is

gap

Likewise, if the

decrease the gap.

[!]

I.

Mount

foot lifter cylinder

bolt

2.

Mount

lifter cylinder

secure it with the E-shaped

3.

Mount

support

material cylinder 5 ~ with two Allen bolts

4.

Mount

G)

screw

5.

Mount

bracket

connect the

6.

Finally. push the

screwdriverto

does not. loosen screw

49.

and

and

down

stroke

less

than I mm,

between the

NEEDLE BAR

ASSEMBLY

the cylinder bracket 0

loosen nut G),

stopper

stroke

DESCENT

f),

and

8.

the piston rod

the

hook

joint 8 on

f),

insert the link pin

bracket 0

0 with the two screws

the

coupling

on

the thin material cylinder 5

in

the nylon hose nipple

the cylinder

0 with

air

adjust

the

then retighten the screw

hook~

support 0 on

four

Allen bolts

hose

4D

coupling

confirm

0

hook

so

of

the

bottom

and

increase the

CD

and

rod

is

greater

secure with the Allen

than I mm,

GUARD

on

the presser

the presser foot

snap

ring O.

on

the cylinder

0.

and

with the Allen bolt

~.and

e.

the cylinder

49.

to

the

nipple

hook

41

that

it moves freely. If it

and

Allen bolts

that

it does move freely.

and

bolts.

plunger

joint

8.

the

and

CD.

with a

CD

&.

and

thin

CD.

then

then

and

-31-

Page 35

~

STANDARD

ITJ

ADJUSTMENT

ADJUSTMENTS

OF

THE

ROTARY

0

~

HOOK

~

Center of

:

?-r---l ----.

I I

11

the

nee

* T urn the pulley and rai

the rotary hook

aligned with the

[I]

ADJUSTMENT

e to make an adjustment in such a

ce

nter of the needl

OF

2.2

mm

dle

se

the needle b

THE

NEEDLE BAR HEI

0

ar

2.2 mm from the lowest

wa

e.

GHT

y that

p o~itio n.

th

Then.l

e hoo k point 0 of

oosc n the set screws

the rotar

y hook becomes

f)

a

nd

turn

Center of the needle

Turn the pull

8 . a

nd

face p

ey

la

0 to needle hole top g

OJ

ADJUSTMENT

and align the rotary hook point with the needle center. Remove the

te e . loosen screws 0 a

ap

is 1

.5

OF

THE

CLEARANCE

nd

"' 2.0 m

o.

and vertically adjust the needle

m.

BETWEEN THE

NEEDLE

*

Turn

rotary hoo k w

loos

en

moving the rotary hook 8 so that

cl

eara

nd the hoo k point of the rotary hook.

a

bar

AND

the pulley a

it

the scr

ew

nce ofO.

OI "'0.08 mm betw

so that the ro tary hook point

THE

ROTARY

nd

align the hook point of th e

h the center

s 0

and

make an adjustment

0

thr

ee sc rews

HOOK

of

the needle. T hen.

there

een the needle

by

i a

- 32 -

Page 36

[I]

ADJUSTMENT

+

OF THE PRESSER FOOT

* Lower the presser foot

and

make

following

To

lower the presser foot:

adjustments

procedure.

to

the lowest position,

according

© Before sewing

Turn

the test

and

then press the step back switch

presser foot.

© When emergency

sewing

First release the emergency

step back switch.

down

to lower the presser foot

©

During

First release the test/intermediate sewing switch.

and

then press the

presser foot

mechanism will again function when the

tcst/intcrmcd iatc sewing switch is pressed again.

(I)

Turn

need

lc

presser foot

adjustment

cap

0.

adjustment

After

the presser

screw

Note:

being used,

misaligned

On

the

sufficiently, it

occur.

(2) Loosen the set screw

the position

presser foot

surface

and

intermediate sewing switch

to

lower the

stop

switch is pressed

stop

switch. press the

and

set the presser foot

position. Now press the read/write switch

to

the lowest position.

test feed

read/

write switch

to

the lowest position.

the pulley.

enters the center

loosen the set screw

making the necessary

and

check

of

the needle hole

f).

If not. loosen the presser

screw 0 sufficiently. remove

by moving the presser foot.

adjustment.

adjustment

screw 0

to

confirm

0.

to

and

and

lower the

The

that

make

0.

that

when

the

stepping presser foot is

the

sewing material can become

if

the

presser foot

other

hand,

can

cause stitch-skipping

0.

at

which the lower surface

f)

lightly

of

the sewing material.

is

if

it is

and

contacts

lowered

not

then

tighten it at

lowered

the

to

the

on.

during

to

the

feed

the

of

the

the

an

tighten

the set

not

too

far.

to

of

the

upper

Ill If the stepping presser foot

If the stepping presser foot

can be removed in the following procedure.

(I)

Remove the face plate.

Turn

(2)

(J)

the pulley.

highest position.

Remove the

stepping presser

-33-

stud

is

not

is

not to be used.

and

raise the needle bar

screwO.

cam

and

f).

to

be

used.

it

to

the

then remove the

Page 37

[!]

WORK

CLAMP

ADJUSTMENT

[[]

AIR PRESSURE

• Use an air pressure at 5 kgf/cm

Pull

up

the cap

adjust the pressure. After adjustment, push the

cap down

• When water has gathered in the bottle

the air cock 8 and push the drain cock 0

remove the water.

to

lock it.

ADJUSTMENT

at

the

top

of

2

•

the air unit 0 and

8,

close

to

To

adjust the work

clamp

to

the

top

nut

0 and slide nut

opening increases. Adjust the nut left

* Increasing the work

opening

increases work

clamp

install a

of

the needle plate should be within 45

f)

in

or

clamp

clamp

standard

out

and

opening makes

pressure.

work

clamp.

adjust

as needed. When adjusting. if

or

right

as

needed.

it

harder

The distance from the

~55

to hold material securely. Decreasing the work clamp

-34-

mm when the work

nut

[2]

WORK CLAMP POSITION

bottom

clamp

f)

of

the back

is

raised: if

is

turned right. the work clamp

ADJUSTMENT

The

work clamp should be positioned so

work

clamp

adjust. loosen the four Allen screws 0

the clamp guide

necessary. When using a unit work

to adjust the

right

and

pressure evenly over the material.

f)

in

the

arrow

clamp

guide angle the same on

left.

of

it

is

not.

direction

clamp.

the work

loosen

as

to

apply

and

move

be sure

both

To

as

Page 38

III MOVABLE KNIFE

ADJUSTMENT

0

* Adjust after releasing the

I.

Remove the screws 0

••

2.

Turn

the pulley

3.

While pressing

8 with your finger

8 in the

and

tip aligns with the needle center.

arrow

screw 8 to adjust

and

and

lower the ·needle.

on

the

top

and

sliding the movable knife

direction. loosen set screw 8

so

that

air

pressure.

remove needle

of

the movable knife

the movable knife

plateS

Movable knife

* When

[!]

thread

illustration. Note

THREAD

~-

If

this part is not shaprened

smoothly, that causes the

upper thread to snap.

trimming leaves the tip

that

the movable knife

TRIMMING

SLIDER

-

0.3-0.5

mm

::e>

of

the. thread rough

cannot

ADJUSTMENT

be sharpened: replace

Fixed knife

or

ragged. sharpen the fixed knife as shown in the

it

with a new movable knife.

0

•

* Adjust

While pressing lightly

loosen set screw

between 0.3

after

"'

0.5 mm.

releasing the

on

the

8

and

move knife rock

air

pressure.

top

of

the movable knife 0

arm

and

moving the slider 8 by hand in the

A

8.

adjusting the gap between the

* Install the lower thread catcher spring 8 directly below the movable knife

-35-

slider&

0.

arrow

and

the slider base 8

direction,

to

Page 39

1!2]

THREAD CATCHER SLIDER

6)

ADJUSTMENT

0.3-0.5

I

_==iiJ?> l

0

I

Thread catcher spring retract Thread

* Adjust

(I)

(2) Move slider B

[ill BOTTOM PLUNGER

after

releasing the

Move slider B 0 by

rock

arm

B

8.

adjusting

catcher

spring 8 is

0 by

needle is lowered

that

the spaces

into

on

hand

within 0.3

hand

the oval hole, loosen set screw G

the left

ADJUSTMENT

mm

air

pressure.

and

fully retract the

both

front

"'

and

with the

and

right sides

catcher

and

0.5 mm.

Needle

spring advance

thread

back so that the

thread

of

the needle

catcher

catcher

spring

8:

gap

between the movable knife 8

spring 8 fully

and

move the

are

equal.

loosen set screw G

advanced.

thread

turn

catcher

spring

and

move knife

and

thread

the pulley: when the

8.

adjusting so

* Adjust

(I)

(2) Move the rod

* Adjustment

(3) With the

after

releasing the

Move the rod

bottom

stopper 8 and

8

plunger

and

lever

is

bottom

move the

8.

~A-

'

(Bottom

(Bottom up)

air

pressure.

joint

0 by hand

e.

adjusting

joint

0 by

rod

joint 0 so

easier if the cylinder has been disconnected.

lever G raised manually.

bottom

and

so

that

hand.

and

that

plunger.

lower the

the

top

lift the

the

top

adjusting

of

bottom

of

turn

so

down)

bottom

the

bottom

the

bottom