Page 1

Basic Operation Manual

BAS-342G PS

DIRECT DRIVE

PROGRAMMABLE ELECTRONIC PATTERN SEWER

<PERFECT STITCH>

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

This basic operation manual describes basic

operations including sewing machine operations.

For cleaning, standard adjustments and more details,

please refer to the instruction manual contained in

the Document CD.

Page 2

Thank you very much for buying a BROTHER sewing machine. Before using your new machine,

please read the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of

moving parts such as the needle and thread take-up lever, and consequently there is always a

danger of injury that can be caused by these parts. Follow the instructions from training personnel

and instructors regarding safe and correct operation before operating the machine so that you will

know how to use it correctly.

BAS-342G PS

Page 3

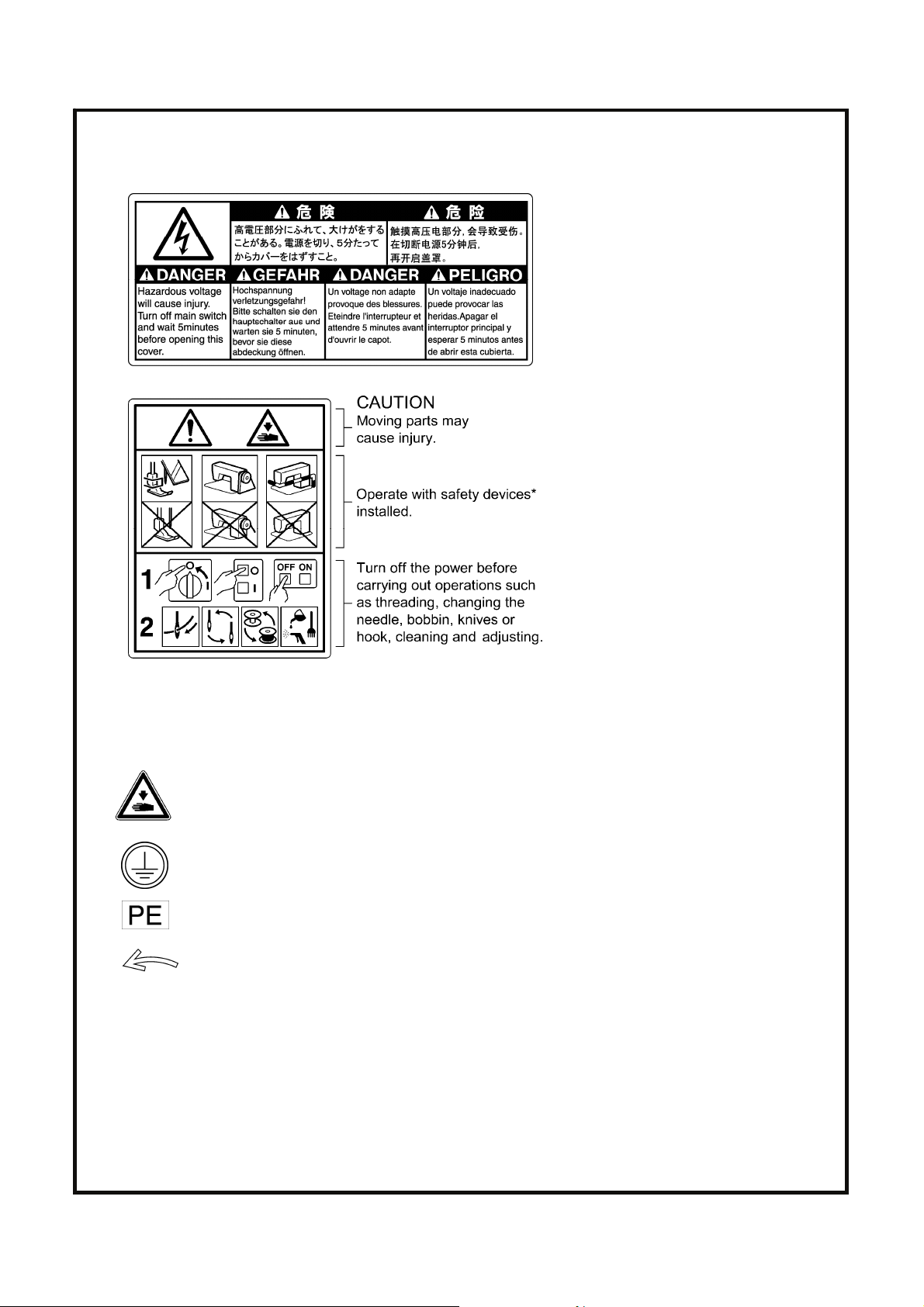

SAFETY INSTRUCTIONS

[1] Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

IMPORTANT

Symbols

・・・・・・

・・・・・・

・・・・・・

The instructions which follow this term indicate situations where failure to follow the

instructions will result in death or serious injury.

The instructions which follow this term indicate situations where failure to follow the

instructions may result in minor or moderate injury.

The instructions which follow this term indicate situations where failure to follow the

instructions may result in physical damage to equipment and surroundings or result in

problems with equipment operation.

This symbol ( ) indicates something that you should be careful of. The picture inside the triangle

indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

This symbol ( ) indicates something that you must not do.

This symbol ( ) indicates something that you must do. The picture inside the circle indicates the

nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

BAS-342G PS

i

Page 4

[2] Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the cover of the control box. Touching areas where high voltages are present can result in severe

injury.

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from

sources of strong electrical noise such as electrical

line noise or static electric noise.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage should

be within ±10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than the

requirements for the sewing machine's power

consumption.

Insufficient power supply capacity may cause

problems with correct operation.

The pneumatic delivery capability should be greater

than the requirements for the sewing machine's total

air consumption.

Insufficient pneumatic delivery capability may cause

problems with correct operation.

Installation

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs approximately 160 kg.

Use equipment such as a crane or hoist when

installing the machine head and adjusting the height

of the table.

If you try to lift the machine head yourself, it may

cause injuries such as back injury.

Do not connect the power cord until installation is

complete. If the foot switch is depressed by mistake,

the sewing machine might start operating and injury

could result.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

In addition, do not subject the machine head to extra

force while it is tilted back. If this is not observed, the

machine head may become unbalanced and fall

down, and serious injury or damage to the sewing

machine may result.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems with

correct operation may also occur.

The ambient temperature should be within the range

of 5°C to 35°C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation should

occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation.

All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too firmly

with staples, otherwise there is the danger that fire or

electric shocks could occur.

Install the safety covers to the machine head and

motor.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Use a table with a height of 84 cm or less. If the table

is too high, the machine head may become

unbalanced and fall down, and serious injury or

damage to the sewing machine may result.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin. If the oil

and grease get into your eyes or onto your skin,

inflammation can result.

Furthermore, do not drink or eat the lubricating oil or

grease. They may cause diarrhea or vomiting.

Keep the oil out of the reach of children.

ii

BAS-342G PS

Page 5

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary training

in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may enter

your eyes and injury may result.

Turn off the power switch at the following times. If the

foot switch is depressed by mistake, the sewing

machine might start operating and injury could result.

• When threading the needle

• When replacing the bobbin and needle

• When not using the machine and when leaving the

machine unattended

Cleaning

Turn off the power switch before carrying out

cleaning. If the foot switch is depressed by mistake,

the sewing machine might start operating and injury

could result.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the

machine.

If an error occurs in machine operation, or if abnormal

noises or smells are noticed, immediately turn off the

power switch. Then contact your nearest Brother

dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin. If the oil

and grease get into your eyes or onto your skin,

inflammation can result.

Furthermore, do not drink or eat the lubricating oil or

grease. They may cause diarrhea or vomiting.

Keep the oil out of the reach of children.

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Turn off the power switch and disconnect the power

cord before carrying out the following operations. If

the foot switch is depressed by mistake, the sewing

machine might start operating and injury could result.

• Inspection, adjustment and maintenance

• Replacing consumable parts such as the rotary hook

Disconnect the air hoses from the air supply and wait

for the needle on the pressure gauge to drop to “0”

before carrying out inspection, adjustment and repair

of any parts which use the pneumatic equipment.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

In addition, do not subject the machine head to extra

force while it is tilted back. If this is not observed, the

machine head may become unbalanced and fall

down, and serious injury or damage to the sewing

machine may result.

If the power switch and air need to be left on when

carrying out some adjustment, be extremely careful to

observe all safety precautions.

When replacing parts and installing optional

accessories, be sure to use only genuine Brother

parts.

Brother will not be held responsible for any accidents

or problems resulting from the use of non-genuine

parts.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly before

using the machine.

To prevent accidents and problems, do not modify

the machine yourself.

Brother will not be held responsible for any accidents

or problems resulting from modifications made to the

machine.

IMPORTANT

Do not allow any liquids to get onto this sewing machine, otherwise smoke or fire may occur.

If any liquid gets inside the sewing machine (machine head or control box), immediately turn off the power and

disconnect the power plug from the electrical outlet, and then contact the place of purchase or a qualified technician.

BAS-342G PS

iii

Page 6

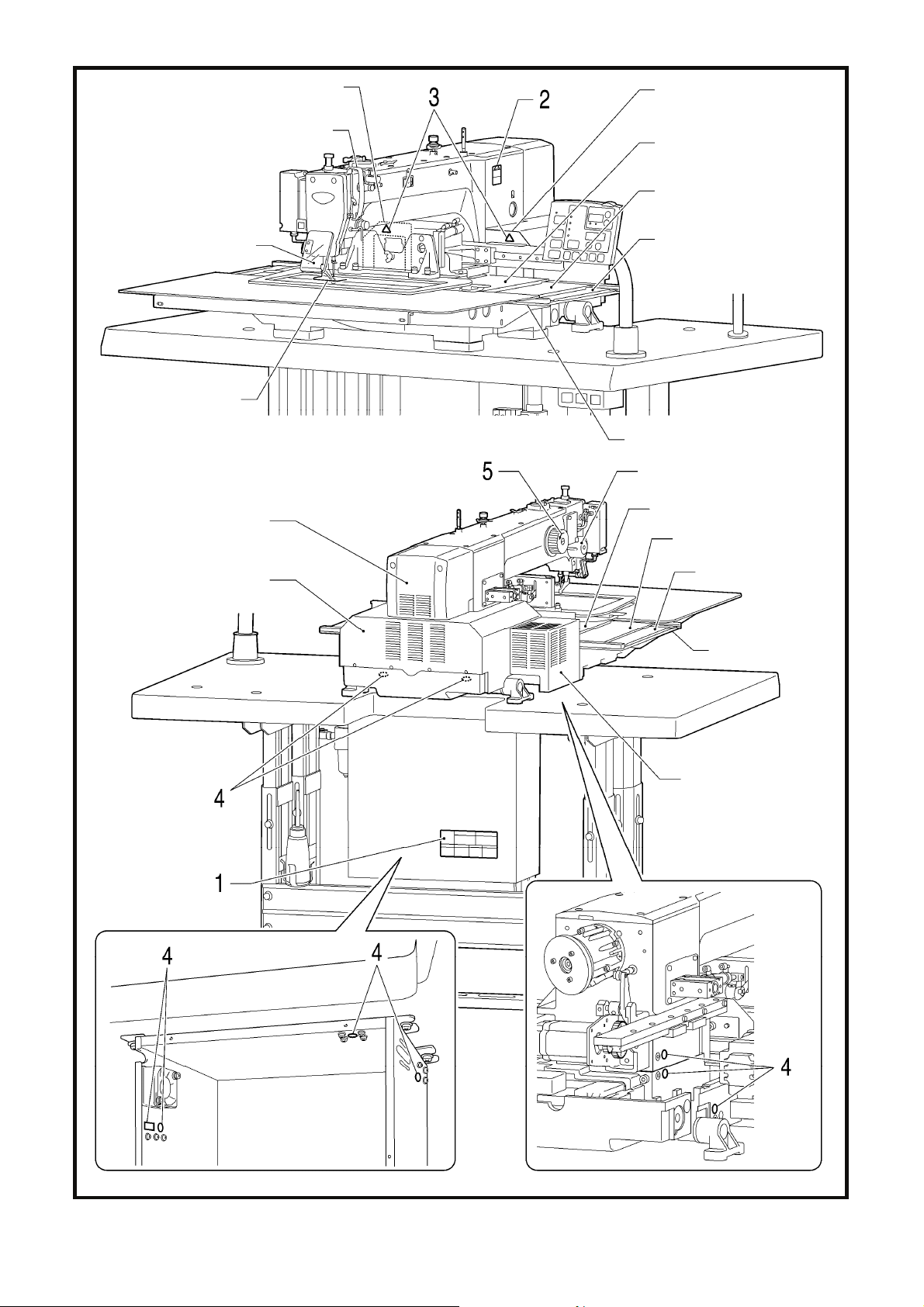

[3] Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are

difficult to read, please contact your nearest Brother dealer.

1

2

*Safety devices

Devices such as eye guard, finger guard, thread take-up cover, motor cover, X motor cover,

tension release solenoid cover, inside cover, outside cover, middle cover, fixed cover and rear cover

3

Be careful to avoid getting hands caught in sliding parts.

4

5

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving

a serious electric shock, and problems with correct operation may also occur.

Direction of operation

iv

BAS-342G PS

Page 7

r

r

r

Rear cove

Rear cover

Thread take-up cover

Inside cover R

Middle cover

Eye guard

Finger guard

Motor cover

Rear cove

Outside cover

Fixed cover

Tension release solenoid cover

Inside cover L

Middle cove

Outside cover

Fixed cover

X motor cover

2740B

BAS-342G PS

v

Page 8

CONTENTS

1. NAMES OF MAJOR PARTS ................ 1

2. USEFUL FUNCTIONS

FOR OPTIMUM SEWING ..................... 2

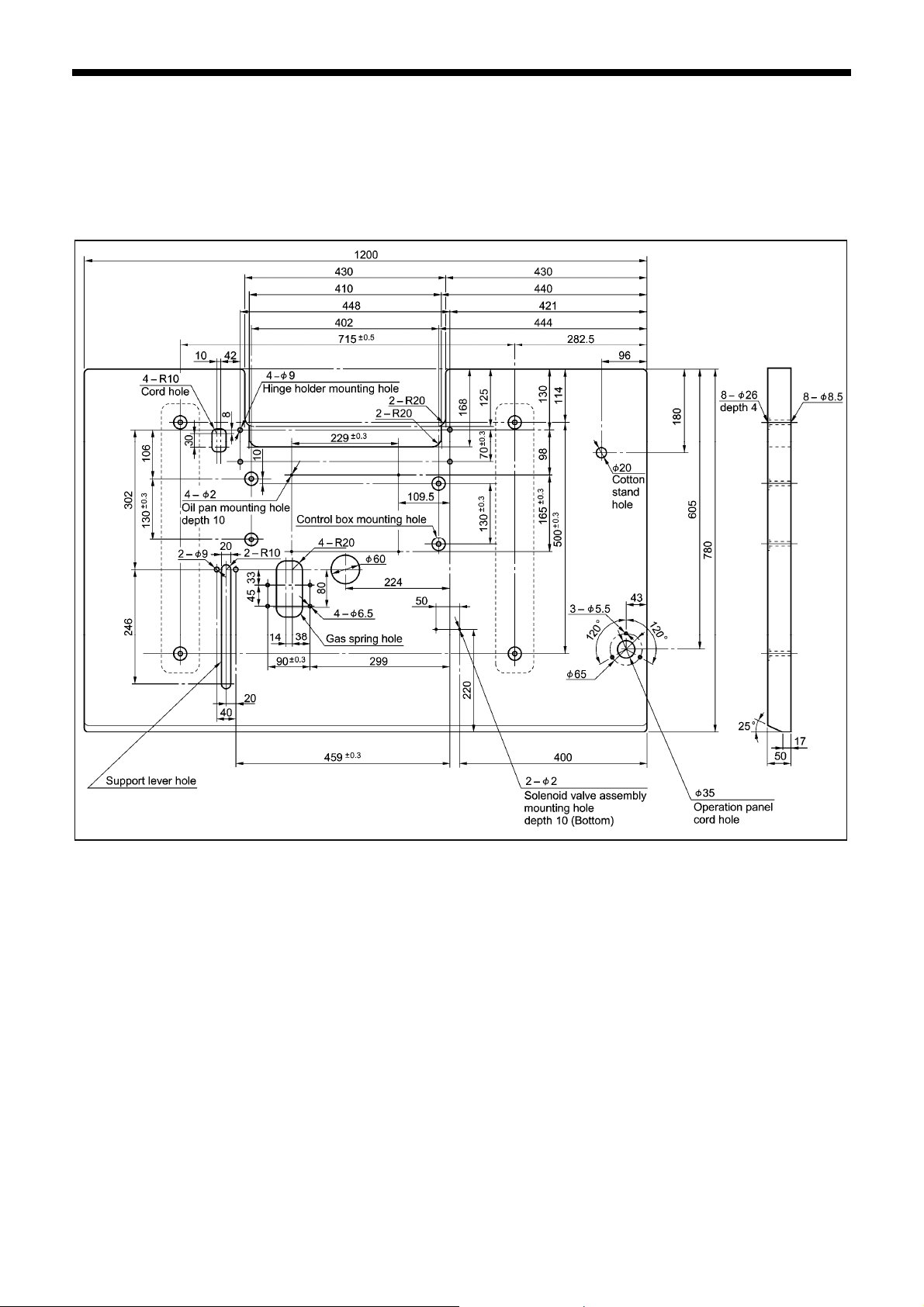

3. TABLE PROCESSING DIAGRAM ....... 3

4. INSTALLATION.................................... 4

4-1. Removing the machine head fixing bolts [1]..... 4

4-2. Installing the control box [2].............................. 5

4-3. Installing the oil pan and support lever base.... 6

4-4. Installing the machine head.............................. 6

4-5. Tilting back and returning the machine head ... 7

4-6. Installing the gas spring.................................... 8

4-7. Installing the operation panel [3]....................... 9

4-8. Installing the solenoid valve assembly .............10

4-9. Connecting the air tubes [4].............................. 10

4-10. Installing the air hose [5]................................. 10

4-11. Adjusting the air pressure [6].......................... 11

4-12. Adjusting the speed controller [7] ................... 11

4-13. Connecting the cords [8]................................. 12

4-14. Connecting the ground wire [9] ...................... 14

4-15. Securing the cords and air tubes [10]............. 15

4-16. Installing the eye guard [11] ...........................16

4-17. Installing the cotton stand [12]........................ 16

4-18. Lubrication [13] ............................................... 17

4-19. Connecting the power cord [14] ..................... 18

4-20. Checking the safety switch [15] ...................... 18

6. USING THE OPERATION PANEL

(BASIC OPERATIONS) .......................26

6-1. Name and function of each operation

panel item..........................................................26

6-2. Loading sewing data .........................................28

6-3. Setting the program number .............................28

6-4. Setting the X-scale and Y-scale........................29

6-5. Setting the sewing speed..................................29

6-6. Checking the sewing pattern.............................30

6-7. Setting the height of the intermittent presser foot...31

6-8. Notes on handling CF cards (sold separately) ...32

7. SEWING ...............................................33

7-1. Sewing ..............................................................33

7-2. Using the STOP switch .....................................34

7-3. Using the thread wiper switch...........................34

Document CD ...........................................36

5. PREPARATION BEFORE SEWING.....19

5-1. Installing the needle.......................................... 19

5-2. Operating the 2-pedal foot switch..................... 19

5-3. Threading the upper thread .............................. 20

5-4. Winding the lower thread..................................22

5-5. Installing the bobbin case................................. 23

5-6. Thread tension.................................................. 24

5-6-1. Lower thread tension.............................. 24

5-6-2. Upper thread tension.............................. 24

5-7. Home position detection ................................... 25

BAS-342G PS

Page 9

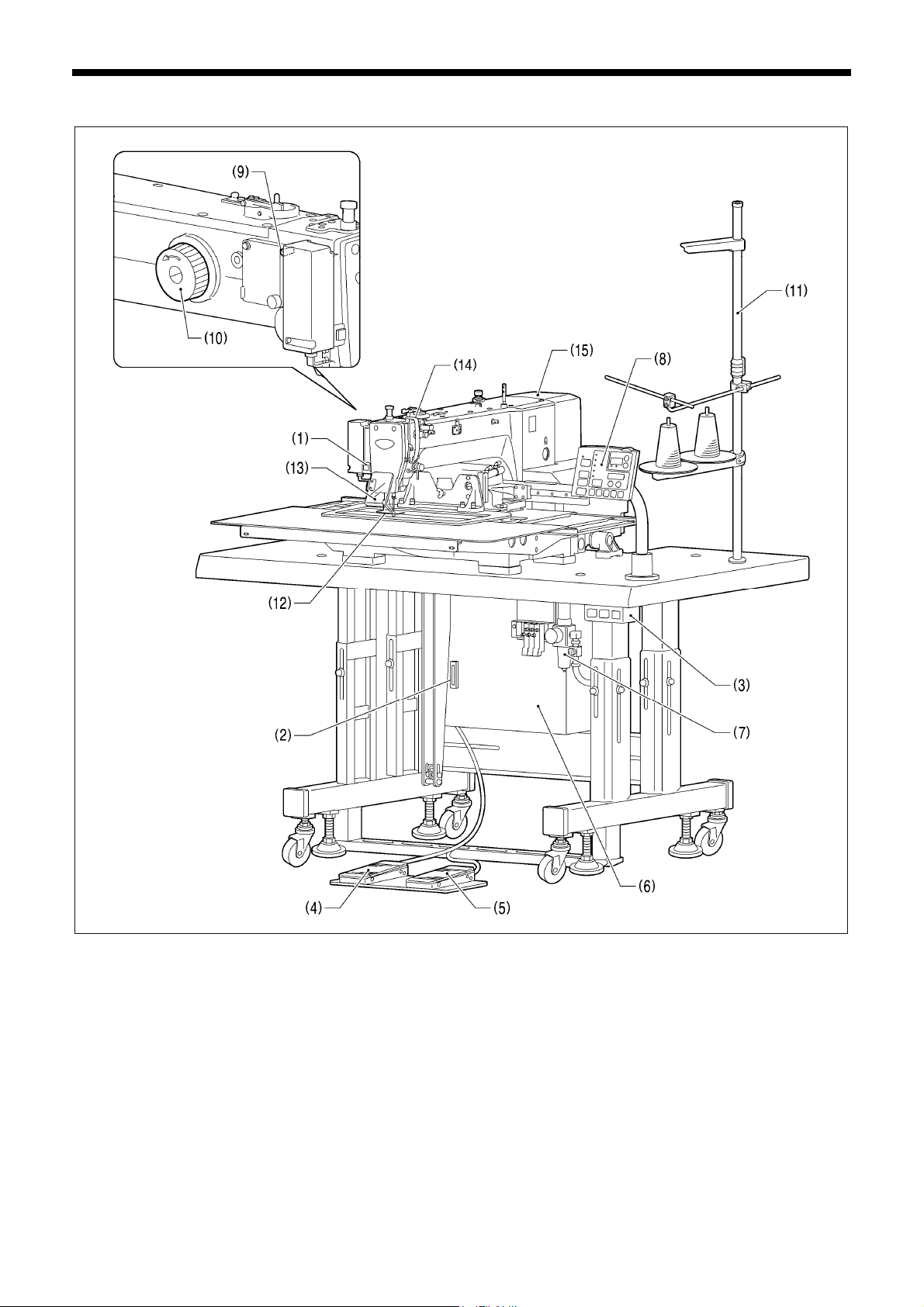

1. NAMES OF MAJOR PARTS

(1) STOP switch

(2) CF slot (12) Finger guard

(3) Power switch (13) Eye guard

(4) Work clamp switch (14) Thread take-up cover

(5) Start switch (15) Motor cover

(6) Control box

(7) Solenoid valve

(8) Operation panel

(9) Thread wiper switch

(10) Pulley

(11) Cotton stand

TM

CF

is a trademark of SanDisk Corporation.

Safety devices:

1. NAMES OF MAJOR PARTS

2741B

BAS-342G PS

1

Page 10

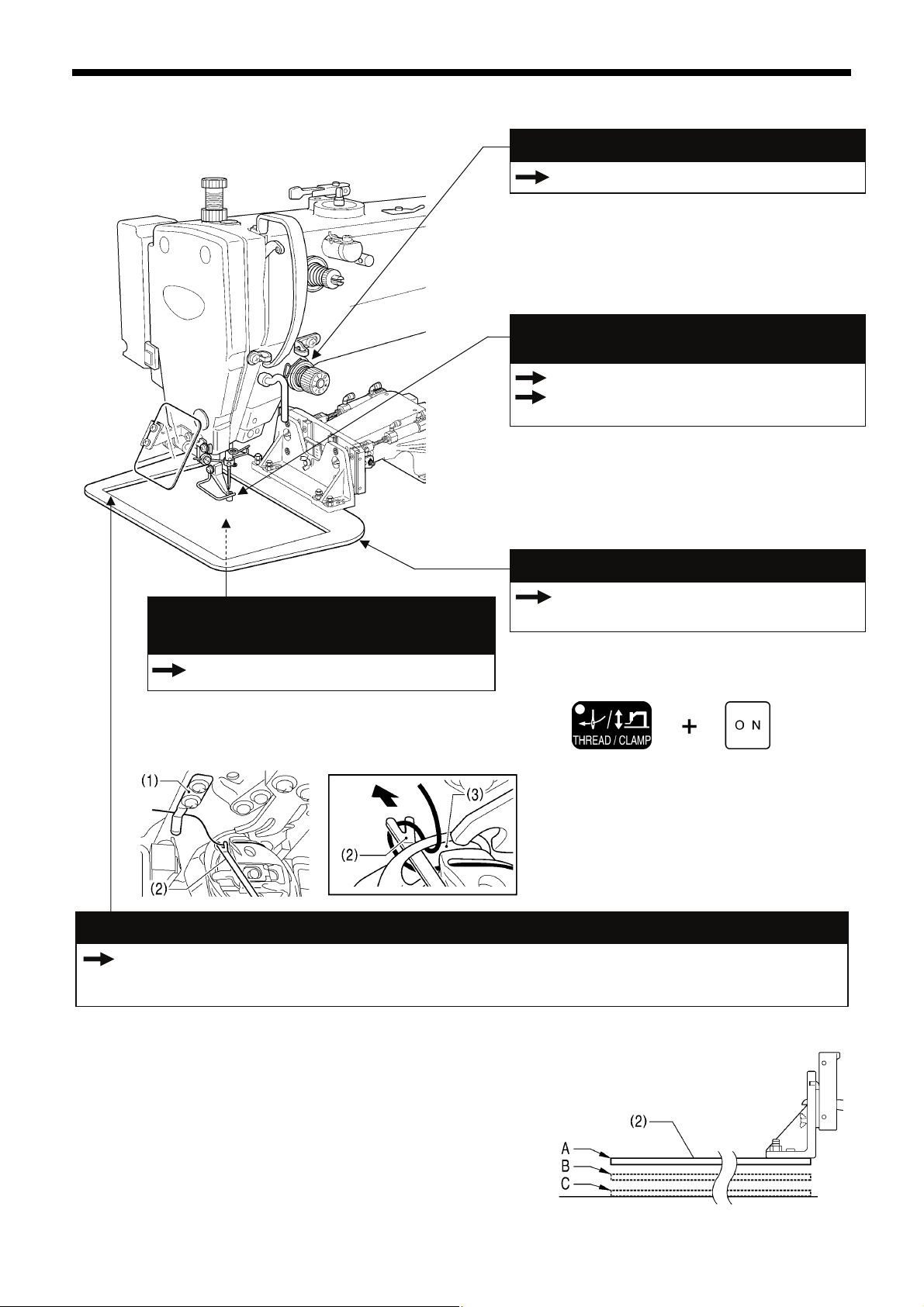

2. USEFUL FUNCTIONS FOR OPTIMUM SEWING

2. USEFUL FUNCTIONS FOR OPTIMUM SEWING

Easy threading in threading mode

Page 21

When using threading mode for threading, the tension

discs will open so that the thread can be threaded

more easily.

Furthermore, threading mode is safe because the

sewing machine will not start even when the foot

switch is depressed.

Intermittent presser foot height can be set easily

using the panel

Page 31

INSTRUCTION MANUAL CD

7-7. Using user programs

The height of the intermittent presser foot can be set

simply by entering a numeric value at the panel,

without the need for tools.

Furthermore, you can use user programs to set the

intermittent presser foot height to the desired height

separately for each sewing program.

Easy and accurate feed plate replacement

INSTRUCTION MANUAL CD

The lower thread can be easily threaded

using the threading bar

Page 23

If you clamp the lower thread in the thread hold

spring (1) and then push it gently using the threading

bar (2), you can make the lower thread pass easily

through the window (3) of the inner rotary hook.

Two types of work clamp dropping operation

INSTRUCTION MANUAL CD 5-8. Setting 2-step operation for the work clamp

7-2. Setting memory switches

7-3. List of memory switch settings

11-10-1. Installing the feed plate

The feed plate installation position can be obtained

accurately by using the panel, which makes feed

plate replacement much easier.

Feed plate installation mode

2919B

2920B

You can select one of two different types of dropping operation for

the work clamp (2) by changing memory switch settings.

<Work clamp dropping in one step>

When the work clamp switch is depressed, the work clamp (2)

drops in one movement from its highest position A to its lowest

position C.

<Work clamp dropping in two steps>

1. When the work clamp switch is depressed to the 1st step, the

work clamp (2) drops from its highest position A to the

intermediate position B.

2. When the work clamp switch is then depressed to the 2nd

step, the work clamp (2) drops to its lowest position C.

2

BAS-342G PS

4057M

Page 11

3. TABLE PROCESSING DIAGRAM

M

3. TABLE PROCESSING DIAGRAM

• The thickness of the table should be at least 50 mm, and it should be strong enough to bear the weight and vibration of the

sewing machine.

• If using casters, use ones which can bear the total weight of sewing machine and table.

• Check that the control box is at least 10 mm away from the leg. If the control box and the leg are too close together, it may result

in incorrect sewing machine operation.

4053

BAS-342G PS

3

Page 12

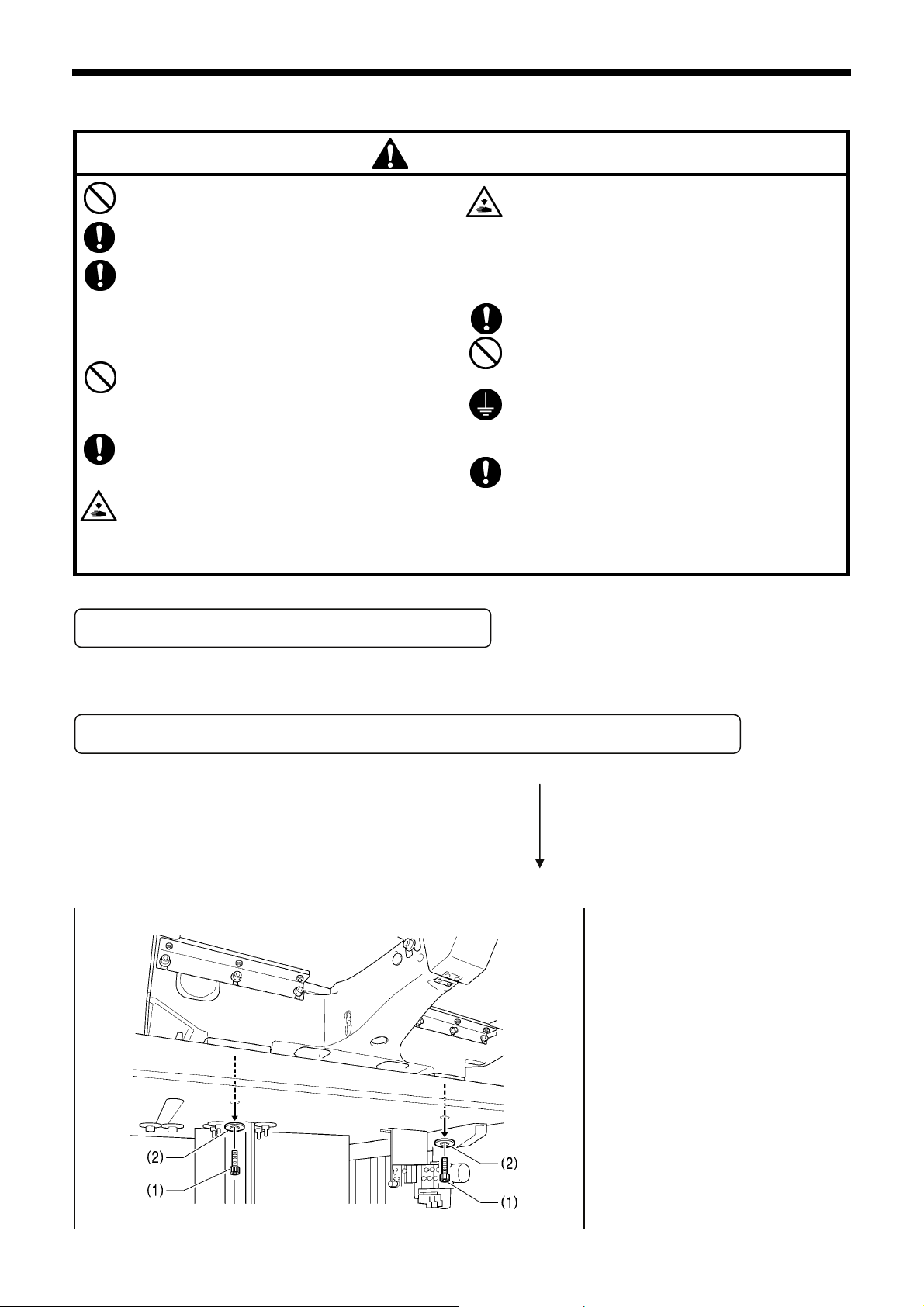

4. INSTALLATION

4. INSTALLATION

CAUTION

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician for

any electrical work that may need to be done.

The sewing machine head weighs approximately 160

kg.

Use equipment such as a crane or hoist when installing

the machine head and adjusting the height of the table.

If you try to lift the machine head yourself, it may cause

injuries such as back injury.

Do not connect the power cord until installation is

complete.

If the foot switch is depressed by mistake, the sewing

machine might start operating and injury could result.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Use a table with a height of 84 cm or less. If the table is

too high, the machine head may become unbalanced

and fall down, and serious injury or damage to the

sewing machine may result.

When placing the sewing machine on the table

Hold the machine head with both hands when tilting it

back or returning it to its original position.

In addition, do not subject the machine head to extra

force while it is tilted back. If this is not observed, the

machine head may become unbalanced and fall down,

and serious injury or damage to the sewing machine

may result.

All cords should be secured at least 25 mm away from

any moving parts. Furthermore, do not excessively bend

the cords or secure them too firmly staples, otherwise

there is the danger that fire or electric shocks could

occur.

Be sure to connect the ground. If the ground connection

is not secure, you run a high risk of receiving a serious

electric shock, and problems with correct operation may

also occur.

Install the safety covers to the machine head and motor.

Carry out the procedure starting from "4-2. Installing the control box" on the next page.

If the sewing machine was already installed to the table when it was delivered

Carry out the procedures indicated by [1] to [15] in the titles in the order of the numbers.

4-1. Removing the machine head fixing bolts [1]

If the sewing machine was already

installed to the table when it was

delivered, remove the two machine head

fixing bolts (1) and the two plain washers

(2).

2742B

4

BAS-342G PS

Page 13

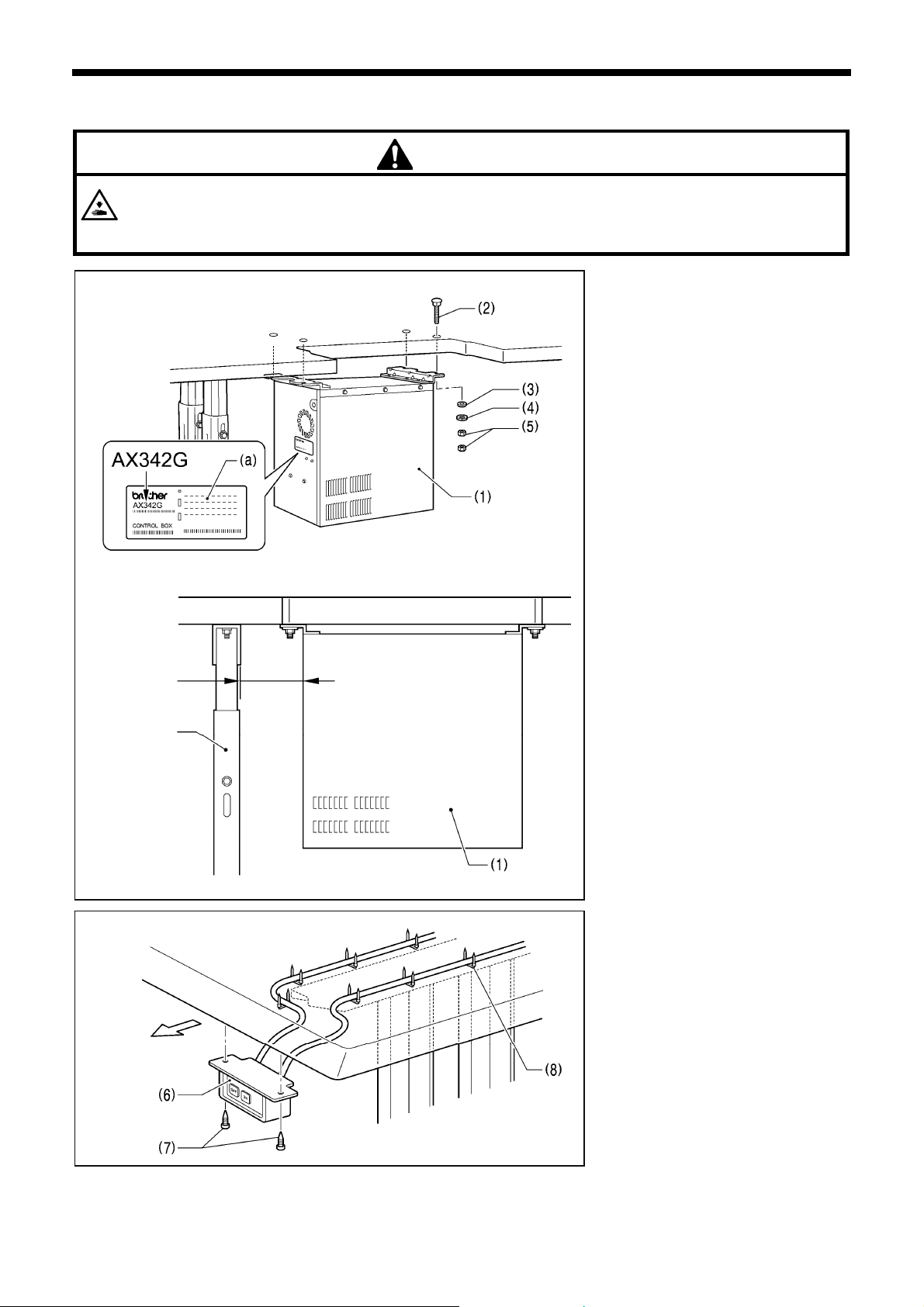

M

4-2. Installing the control box [2]

CAUTION

The control box is heavy, so installation should be carried out by two or more people.

In addition, take steps to make sure that the control box does not fall down.

If this is not done, injury to feet or damage to the control box may result.

4. INSTALLATION

3961

10mm or more

Operator

Leg

3962M

3963M

Before installing the control box (1), check

that the model plate (a) on the control box

(1) is “AX342G” to indicate that it is an

RX-control box for BAS-342G sewing

machines.

* If the sewing machine is installed to the

table, tilt back the machine head.

(Refer to "4-5. Tilting back and returning

the machine head".)

(1) Control box

(2) Bolts [4 pcs.]

(3) Plain washers [4 pcs.]

(4) Spring washers [4 pcs.]

(5) Nuts [8 pcs.]

NOTE:

Check that the control box (1) is at

least 10 mm away from the leg. If the

control box (1) and the leg are too

close together, it may result in

incorrect sewing machine operation.

(6) Power switch

(7) Wood screws [2 pcs.]

(8) Staples [7 pcs.]

NOTE:

Take care when tapping in the staples

(8) to make sure that they do not

pierce the power cord.

BAS-342G PS

5

Page 14

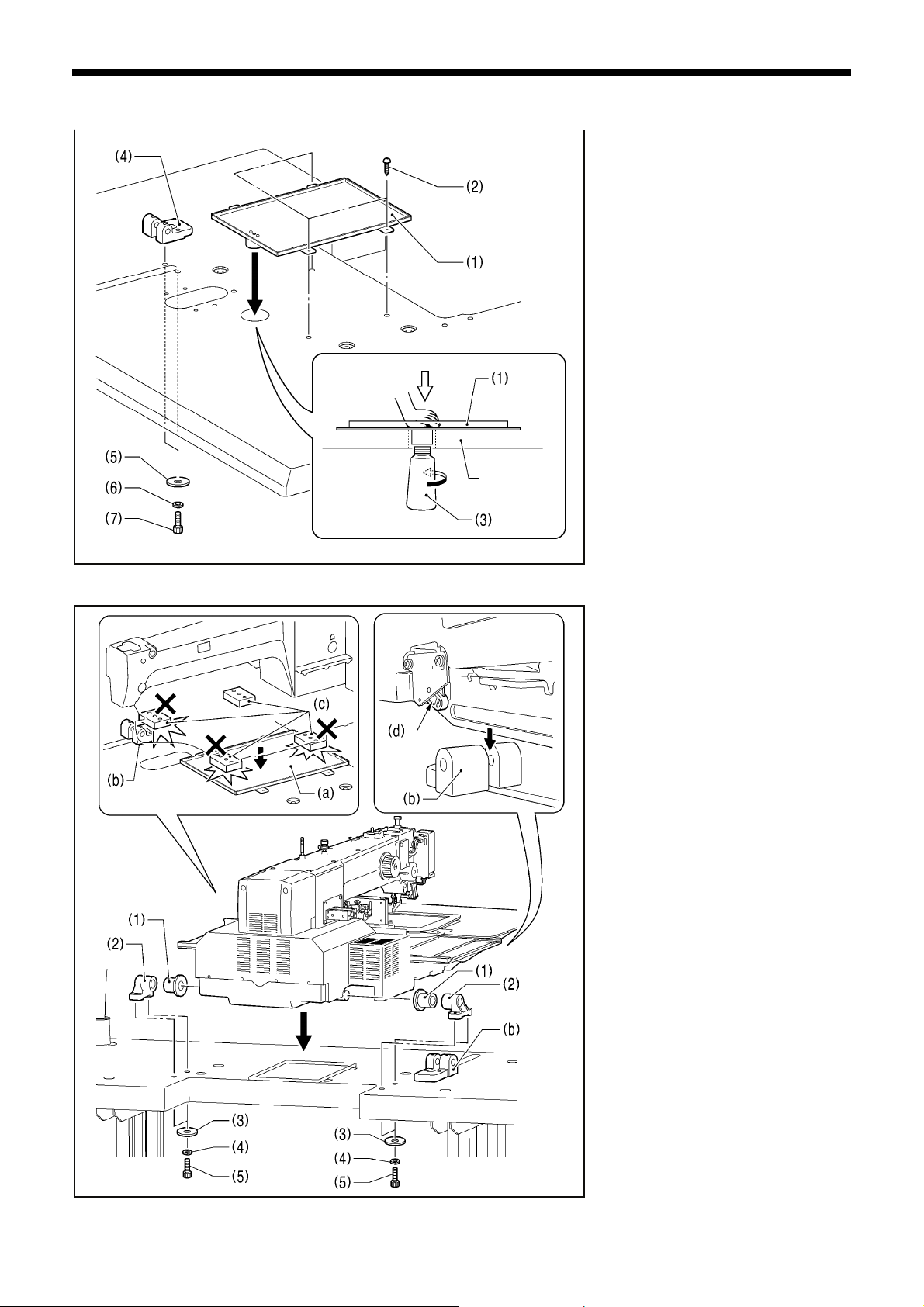

4. INSTALLATION

B

4-3. Installing the oil pan and support lever base

Table

3964M

(1) Oil pan

(2) Wood screws [4 pcs.]

(3) Oiler

(4) Support lever base

(5) Plain washers [2 pcs.]

(6) Spring washers [2 pcs.]

(7) Bolts [2 pcs.]

4-4. Installing the machine head

2743

1. Place the machine head onto the

table.

NOTE:

• Use a crane or hoist to install the

sewing machine.

• Be careful of the following when

lowering the machine head onto the

table.

! Do not let any cords get clamped

between the machine head and

the table.

! Do not place the machine head

cushion (c) on top of the oil pan

(a) or the support lever base (b).

! Do not let the side (d) of the

safety switch lever touch the

support lever base (b).

(1) Rubber bushes (2 pcs.)

(2) Hinge holders (2 pcs.)

(3) Plain washers [4 pcs.]

(4) Spring washers [4 pcs.]

(5) Bolts [4 pcs.]

(Continued on next page)

6

BAS-342G PS

Page 15

4. INSTALLATION

M

2. After placing the machine head onto the table, remove the

bolt (6) and the spacer (7).

The bolt (6) and the spacer (7) are necessary for

*

securing the support lever (8) when the machine head is

removed from the table, so keep them in a safe place.

3. Pass the support lever shaft (9) through the hole in the

support lever base (10) and through the groove (f) in the

support lever (8), and push it in until it is flush with the

surface of the support lever base (10).

If it is difficult to pass the support lever shaft (9) through

*

the groove (f) in the support lever (8), move the end of

the support lever (8) up and down while passing the

support lever shaft (9) through.

Flush

3966

4-5. Tilting back and returning the machine head

CAUTION

Hold the machine head with both hands when tilting it back or returning it to its original position.

In addition, do not subject the machine head to extra force while it is tilted back. If this is not observed, the machine head

may become unbalanced and fall down, and serious injury or damage to the sewing machine may result.

Always be sure to engage the stopper of the support lever (1) when tilting back the machine head.

If the stopper is not engaged, the machine head may return to its original position and your hands may get caught and

injury may result.

When disengaging the stopper, hold it by the knob (a).

If you hold at the place indicated by (b), your hand will get caught between the support lever (1) and the table when the

machine head is returned to its original position and injury will result.

Disengaging

the stopper

Engaging

the stopper

The machine head can be tilted

back and returned to one of three

heights.

3967M

BAS-342G PS

7

Page 16

4. INSTALLATION

4-6. Installing the gas spring

2744B

1. Tilt back the machine head, and then secure the support lever (1) at stopper position (a).

Refer to "4-5. Tilting back and returning the machine head".)

(

NOTE: Use equipment such as a crane or hoist to tilt back the machine head.

2. Tighten the two set screws (2) to secure the support lever shaft (3).

Crane or hoist

Engaging

the stopper

Disengaging

the stopper

Be sure to install so that

the side with “UP” on it is

facing upward.

Note that the L and R

shapes are different.

2915B

3. Install the gas spring (8).

(4) Gas spring holders [L and R]

(5) Spacer

(6) Bolt

(7) Nut

(8) Gas spring

(9) Shaft collars [2 pcs.]

(10) Gas spring shaft D

(11) Plain washers [2 pcs.]

(12) Retaining rings E [2 pcs.]

(13) Bolts [4 pcs.]

(14) Plain washers [4 pcs.]

(15) Spring washers [4 pcs.]

(16) Nuts [4 pcs.]

(17) Gas spring shaft U

(18) Set screw

After installing the gas spring (8), gently

*

return the machine head to its original

position.

(

returning the machine head".)

Refer to "4-5. Tilting back and

8

BAS-342G PS

Page 17

M

4-7. Installing the operation panel [3]

3970

< If the sewing machine was already installed to the table when it was delivered >

3971M

4. INSTALLATION

(1) Cushion A

(2) Operation panel base

(3) Plain washers (medium) [3 pcs.]

(4) Bolts [3 pcs.]

(5) Cushions B [3 pcs.]

(6) Plain washers (large) [3 pcs.]

(7) Nuts [6 pcs.]

* Tighten until the thickness of

cushion B (5) is about 1 mm.

(8) Rubber seat

(9) Operation panel stand

(10) Operation panel

* Pass the cords of the operation

panel (10) through the operation

panel stand (9) and under the

table.

(11) Bolts [3 pcs.]

(12) Bolt

(1) Operation panel

(2) Bolts [3 pcs.]

* Pass the cords of the operation

panel (1) through the operation

panel stand (3) and under the

table.

BAS-342G PS

9

Page 18

4. INSTALLATION

B

4-8. Installing the solenoid valve assembly

4-9. Connecting the air tubes [4]

Plugs 4

Branch unions Y

Connect as shown in

the illustration while

checking the marks.

2745B

Install underneath the work table. (Refer

to "3. Table processing diagram" for the

installation positions.)

(1) Solenoid valve assembly

(2) Washers [2 pcs.]

(3) Wood screws [2 pcs.]

NOTE:

Make sure that the solenoid valve

assembly does not touch the control

box or the leg of the table.

2746B

4-10. Installing the air hose [5]

1. Close the cock (1).

Close

Open

2747

10

BAS-342G PS

2. Turn the nut (3) at the end of the air hose (2) and connect it

to the valve (4).

3. Open the cock at the compressor.

* Check that no air is leaking from the connection of the

valve (4) and air hose (2).

4. Open the cock (1).

(The meter pointer will turn clockwise.)

NOTE:

Turn the cock (1) gently to open it.

5. Adjust the air pressure. (Refer to the next page.)

Page 19

B

B

4-11. Adjusting the air pressure [6]

2748

4-12. Adjusting the speed controller [7]

Upper knob

Lower knob

Val ve 3

Val ve 2

4. INSTALLATION

Lift up the handle (2) of the regulator (1) and then turn it to

adjust the air pressure to 0.5 MPa.

After adjustment is complete, push the handle (2) downward to

lock it.

< Adjusting the lifting and lowering speeds for the work

clamp >

You can adjust the lifting and lowering speeds for the work

clamp using the knobs on valves 1 and 2.

• When the upper knob is tightened, the lifting speed becomes

slower. When it is loosened, the lifting speed becomes faster.

• When the lower knob is tightened, the lowering speed

becomes slower. When it is loosened, the lowering speed

becomes faster.

Reference adjustments

Val ve 1

Val ve 2

Upper knob Fully tighten

Lower knob

Upper knob

Lower knob Fully tighten

Fully tighten and then loosen by

8 turns

Fully tighten and then loosen by

5 turns

Val ve 1

2749

You can operate the work clamp when the power is turned off

by pressing the manual buttons (1).

< Adjusting the speed of the thread trimming air cylinder >

Valve 3 is used for adjusting the speed of the thread trimming

air cylinder. To use, fully tighten both the upper and lower knobs,

and then loosen them both by 6 turns.

* If the knobs are not at the tightening settings mentioned

above, upper thread trimming may not work correctly.

BAS-342G PS

11

Page 20

4. INSTALLATION

M

4-13. Connecting the cords [8]

<Main P.C. board>

3977

1. Remove the cover of the control box.

2. Loosen the two screws (1), and then

open the cord presser plate (2) in the

direction of the arrow.

3. Pass the bundle of cords from the

machine head through the hole in the

table, and then pass it through the

hole in the control box together with

the following cords.

• Tow-pedal foot switch (3)

• Operation panel (Do not pass the

ground wires through the hole.)

• Solenoid valve assembly

4. Securely connect the connectors as

indicated in the table below.

NOTE:

• Check that the connector is facing the

correct way, and then insert it firmly

until it locks into place.

• Secure the cables with cable ties and

cord clamps, while being careful not to

pull on the connector.

* Be sure to make the ground connection.

(Refer to "4-14. Connecting the ground

wire".)

X pulse motor encoder 5-pin white P20 (X-ENC) (3)

Y pulse motor encoder 5-pin blue P4 (Y-ENC) (3)

Intermittent presser foot pulse motor encoder 5-pin black P5 (P-ENC) (3)

Foot switch 10-pin P6 (FOOT) (3)

Operation panel 8-pin P1 (PANEL) (3)

Safety switch 3-pin P9 (HEAD-SW) (4)

Home position sensor assembly 12-pin P8 (SENSOR1) (4)

STOP switch 6-pin P13 (HEAD) (4)

Valve harness 12-pin P12 (AIR1) (4)

Programmer relay harness 8-pin P7 (PRG) (3)

Fan 6-pin P10 (SENSOR2) (4)

Solenoid selection harness 4-pin P3 (CUTTER)

2916B

12

Thread trimming cylinder sensor harness 16-pin P23 (EX-IN1) (4)

Connector

BAS-342G PS

Connection location on

main P.C. board

Lock the cord

clamp securely.

Cord clamp

-

(Continued on next page)

Page 21

<Power supply motor P.C. board>

<PMD P.C. board>

Machine head memory 7-pin P3 (HEAD-M) (4)

Upper shaft motor 3-pin P4 (UVW) (5)

Synchronizer 14-pin P5 (SYNC) (5), (6)

Work clamp pulse motor 4-pin black P3 (PPM) (5), (6)

Thread trimmer solenoid 6-pin P6 (SOL1) (5), (6)

Tension release solenoid 4-pin P7 (SOL2) (5), (6)

Y pulse motor 4-pin blue P8 (YPM) (5), (6)

X pulse motor 4-pin white P10 (XPM) (5), (6)

2568B

Connector

Connector

4. INSTALLATION

<Removing>

<Securing>

NOTE:

Route the X, Y and work clamp pulse motor

harnesses so that they do not touch the

PMD P.C.

* Be sure to make the ground connection.

(Refer to "4-14. Connecting the ground

wire".)

Connection location on

power supply motor P.C.

board

Connection location on

PMD P.C. board

Cord clamp/cable tie

Cable tie

Press

the tab.

BAS-342G PS

13

Page 22

4. INSTALLATION

B

4-14. Connecting the ground wire [9]

CAUTION

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious electric

shock, and problems with correct operation may also occur.

(1) Ground wire from upper shaft motor harness

(2) Ground wire from the machine head

(3) Ground wire from operation panel

(4) Ground wires from two-pedal foot switch harnesses (2 wires)

NOTE: Make sure that the ground connections are secure in order to ensure safety.

2750

14

BAS-342G PS

Page 23

4-15. Securing the cords and air tubes [10]

<Seen from underneath table>

Leg

Control box

Table

Operation panel

Solenoid valve

assembly

2751B

3982M

4. INSTALLATION

Secure the three air tubes (a), the

solenoid valve assembly cord (b) and the

operation panel cord (c) together

underneath the table with the three cord

holders (1).

(1) Cord holders [3 pcs.]

(2) Wood screws [3 pcs.]

Checking the cords>

<

1. Gently tilt back the machine head.

(

Refer to "4-5. Tilting back and

returning the machine head".

2. Check that none of the cords are

being pulled.

3. Return the machine head to its

original position.

4. Close the cord presser plate (3) in the

direction of the arrow, and secure it by

tightening the two screws (4).

NOTE:

Close the cord presser plate (3)

securely so that no foreign objects,

insects or small animals can get

inside the control box.

5. Secure the cover of the control box by

tightening the eight screws (5).

Check that the cords are not clamped

by the cover at this time.

)

BAS-342G PS

15

Page 24

4. INSTALLATION

M

4-16. Installing the eye guard [11]

Attach all safety devices before using the sewing machine.

If the machine is used without these devices attached, injury may result.

CAUTION

(1) Screw (loosen)

(2) Eye guard (tilt forward)

(3) Eye guard assembly

(4) Plain washers [2 pcs.]

(5) Screws [2 pcs.]

After installing the eye guard assembly

(3), return the eye guard (2) to its original

angle, and then tighten the screw (1) to

secure it in place.

2367B

4-17. Installing the cotton stand [12]

3983

(1) Cotton stand

NOTE:

Fit the washer (2), and then securely

tighten the nut (3) so that the cotton

stand does not move.

16

BAS-342G PS

Page 25

4-18. Lubrication [13]

Do not connect the power cord until lubrication is complete.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do not get into

your eyes or onto your skin. If the oil and grease get into your eyes or onto your skin, inflammation can result.

Furthermore, do not drink or eat the lubricating oil or grease. They may cause diarrhea or vomiting.

Keep the oil out of the reach of children.

CAUTION

• The sewing machine should always be lubricated and the oil

supply replenished before it is used for the first time, and

also after long periods of non-use.

• Use only the lubricating oil <JX Nippon Oil & Energy

Corporation Sewing Lube 10N; VG10> specified by Brother.

* If this type of lubricating oil is difficult to obtain, the recommended

oil to use is <Exxon Mobil Essotex SM10; VG10>.

1. Fill the arm oil tank and the bed oil tank with oil.

NOTE:

Be sure to add more oil when the oil level drops down

to about one-third full in the oil gauge window (1). If the

oil drops below the one-third full level in the oil gauge

window (1), there is the danger that the sewing

machine may seize during operation.

2. Remove the bobbin case and add 2-3 drops of oil to the

rotary hook race (2).

4. INSTALLATION

2752B

2753B

3986M

3. If using the needle cooler (3), fill it with silicon oil (100

BAS-342G PS

2

/s).

mm

(Refer to "5-3. Threading the upper thread" for details on

using the needle cooler (3).)

17

Page 26

4. INSTALLATION

4-19. Connecting the power cord [14]

CAUTION

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious electric

shock, and problems with correct operation may also occur.

<Single-phase

specifications>

1. Attach an appropriate plug to the power cord (1). (The

green and yellow wire is the ground wire.)

2. Insert the plug into a properly-grounded AC power supply.

* The inside of the control box uses single-phase power.

NOTE:

• If the ground connection is not secure, electric shocks,

operating errors or damage to electronic components

such as P.C. boards may occur.

• Do not use an extension cord. If this is not observed, it

may cause problems with correct operation.

<Three-phase

specifications>

Green and yellow wire

(ground wire)

Green and yellow wire

(ground wire)

3988M

4-20. Checking the safety switch [15]

1. If the machine head is tilted back, gently return it to its

original position.

the machine head".

2. Turn on the power switch.

3. Check that no error numbers are displayed on the operation

panel.

(Refer to "4-5. Tilting back and returning

)

<

If error [E050], [E051] or [E055] is displayed >

If the safety switch (1) is not turned on, error [E050], [E051] or

[E055] will occur.

Check the installation position of the safety switch (1).

1. Turn off the power switch.

2. Loosen the two screws (2).

3. Push down the right side of the safety switch (1) so that the

safety switch (1) turns on, and then tighten the two screws

(2).

4. Turn on the power and check that no error numbers are

displayed.

18

3989M

BAS-342G PS

Page 27

5. PREPARATION BEFORE SEWING

5-1. Installing the needle

CAUTION

Turn off the power switch before installing the needle.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

1. Loosen the set screw (1).

2. Insert the needle (2) as far as it will go with the

hollow (3) facing to the front, and then securely

tighten the set screw (1). [Figure A]

<If hitch stitches appear in one direction during

square sewing>

1. Loosen the set screw (1).

2. Insert the needle (2) as far as it will go so with

the hollow (3) facing to the front and so that it’s

angle matches the angle of reference line (4),

and then securely tighten the set screw (1).

[Figure B]

* If the installation angle of the needle has been

changed, be sure to readjust the needle

clearance. (Refer to “11-6. Adjusting the needle

2754B

Front Front

clearance” in the instruction manual CD.)

5. PREPARATION BEFORE SEWING

5-2. Operating the 2-pedal foot switch

3991M

Work clamp switch

Start switch

2755B

When the work clamp switch (left side) is depressed, the

intermittent presser foot (1) and the work clamp (2) are

lowered, and when the start switch (right side) is then

depressed, the sewing machine starts operating.

*

The work clamp (2) lowering method can be changed

using memory switch No. 002. (Refer to "7-3. List of

memory switch settings" in the instruction manual CD.)

BAS-342G PS

19

Page 28

5. PREPARATION BEFORE SEWING

5-3. Threading the upper thread

Thread the upper thread correctly as shown in the illustration below.

* When using threading mode for threading, the tension discs (1) will open so that the thread can be threaded more easily.

(Refer to following page.)

[If using cotton thread or spun thread]

[If using synthetic thread]

Thread the upper thread

Needle cooler

2756B

• Turn the machine pulley (2) and raise the thread take-up (3) to its highest position before threading the upper thread.

(This will make threading easier and it will prevent the thread from coming out at the sewing start.)

• When threading the thread through the needle, allow a distance of approximately 45 mm between the needle hole and the

end of the thread.

If the trailing length of the thread is too long, it may cause the thread to become tangled.

2572B

2757B

20

BAS-342G PS

Page 29

5. PREPARATION BEFORE SEWING

<Threading mode>

Threading mode is safe because the sewing machine will not start even when the foot switch is depressed.

1

2

All indicators switch off

THREAD/CLAMP indicator illuminates

MENU indicator switches off

Threading the thread.

3

• When 5 minutes have passed, the buzzer will sound and the tension discs will close.

* When memory switch No. 564 is set to "2", the buzzer will sound after one minute has elapsed, and the tension

discs will close.

Ending threading mode

4

THREAD/CLAMP indicator switches off

Turn on the power switch.

Press the THREAD/CLAMP key.

• The work clamp and the intermittent presser foot will be

lowered.

• The tension discs will open.

Press the THREAD/CLAMP key.

• The work clamp and the intermittent presser foot will

return to the position they were at before threading mode

began.

4421Q

4427Q

BAS-342G PS

21

Page 30

5. PREPARATION BEFORE SEWING

5-4. Winding the lower thread

CAUTION

Do not touch any of the moving parts or press any objects against the machine while winding the lower thread.

Injury or damage to the sewing machine may result.

2759B

2760B

2775B

More thread

Less thread

For case A

For case B

2758B

1. Place the bobbin onto the bobbin winder shaft (1).

2. Thread the thread as shown in the illustration, wind the

thread around the bobbin several times, and then press

the bobbin presser arm (2).

3. Turn on the power switch.

4. Depress the work clamp switch (3) to lower the work

clamp, and then depress the start switch (4). (Home

position detection will be carried out.)

5. Check that the needle is not touching the work clamp.

6. Depress the work clamp switch (3) to lower the work

clamp.

7. While pressing the TENSION/WIND key (5), depress the

start switch (4).

8. Release the TENSION/WIND key (5) after the machine

starts operating, and keep depressing the start switch (4)

until the lower thread stops being wound onto the bobbin.

(If you release the start switch (4) while this operation is

in progress, hold down the TENSION/WIND key (5) and

then depress the start switch (4) to restart winding of the

thread.)

9. Once winding of the set amount of lower thread (80 - 90%

of the bobbin capacity) is completed, the bobbin presser

arm (2) will return automatically.

10. Remove the bobbin, hook the thread onto the knife (6),

and then pull the bobbin in the direction of the arrow to

3997M

cut the thread.

3999M

Adjusting the bobbin winding amount

Loosen the screw (7) and move the bobbin presser (8) to

adjust.

If the thread winds onto the bobbin unevenly

Loosen the set screw (9) and move the bobbin winder

tension assembly (10) up and down to adjust.

* For case A, move the bobbin winder tension assembly

(10) down, and for case B, move it upward.

22

BAS-342G PS

Page 31

5. PREPARATION BEFORE SEWING

5-5. Installing the bobbin case

CAUTION

Turn off the power switch before installing the bobbin case.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

2761B

1873B

1. Pull the hook cover (1) downward to open it.

2. While holding the bobbin so that the thread winds to the right, insert the bobbin into the bobbin case.

3. Pass the thread through the thread slot (2), pass it underneath the spring (3), and then pass it through the thread guide (4),

leaving a trailing-out length of about 35 mm.

4. Hold the latch on the bobbin case and insert the bobbin case into the rotary hook.

5. Clamp the lower thread in the thread hold spring (5).

6. Use the threading bar (6) to pass the thread through the window of the inner rotary hook. (The thread will be released from

the thread hold spring (5).)

1897B

1874B

BAS-342G PS

23

Page 32

5. PREPARATION BEFORE SEWING

5-6. Thread tension

[Thread tension reference]

Upper thread #20 or similar

Lower thread #20 or similar

Upper thread tension (N)

Lower thread tension (N)

Pre-tension (N)

Needle DP x 17 #19

Normal sewing speed 2,000 sti/min

1.0 − 1.6

0.4 − 0.6

0.3 − 0.6

5-6-1. Lower thread tension

Weaker

Stronger

5-6-2. Upper thread tension

Weaker

Weaker

Stronger

Stronger

1875B

2573B

Adjust the lower thread tension by turning the adjusting

screw (1).

1. Turn the tension nut (1) (main tension) to adjust the

tension as appropriate for the material being sewn.

2. Use the tension nut (2) (sub tension) to adjust the upper

thread trailing length to about 45 mm.

24

BAS-342G PS

Page 33

5-7. Home position detection

Aligned

2574B

2918B

4421Q

5. PREPARATION BEFORE SEWING

Before starting home position detection, check that the

needle bar is at the needle up stop position.

Turn the pulley (1) until the ridge at the bottom of the thread

take-up (2) is aligned with the { mark on the arm.

1. Turn on the power switch.

The POWER indicator (3) will illuminate, and the model

name [342] will appear in the PROGRAM No. display (4)

and [A-PS] will appear in the menu display (5).

After this, the program number will flash in the

PROGRAM No. display (4).

2. Depress the work clamp switch (6) to lower the work

clamp, and then depress the start switch (7). (After home

position detection is carried out, the work clamp will move

to the sewing start position and then it will rise.)

2762B

4007M

* For programs with a large number of stitches, the

buzzer will sound after the home position is detected,

and then the work clamp will move to the sewing start

position.

NOTE:

If error "E110" is displayed when the start switch (7) is

depressed, turn the pulley (1) in the direction of

operation to clear the error display.

4008M

BAS-342G PS

25

Page 34

6. USING THE OPERATION PANEL (BASIC OPERATIONS)

6. USING THE OPERATION PANEL

(BASIC OPERATIONS)

6-1. Name and function of each operation panel item

4435Q

(1) Power indicator

Illuminates when the power is turned on.

(2) CAUTION indicator

Illuminates when an error occurs.

(3) RESET key

Used to reset errors.

(4) TEST key

Used to start test mode.

(5) TEST indicator

Illuminates when the TEST key (4) has been pressed.

(6) THREAD/CLAMP key

Used to start threading mode or work clamp height setting mode.

(7) THREAD/CLAMP indicator

Illuminates when the THREAD/CLAMP key (6) has been pressed.

(8) TENSION/WIND key

Used to wind the lower thread.

(9) TENSION/WIND indicator

Used when the digital tension set (option) is installed.

26

BAS-342G PS

Page 35

6. USING THE OPERATION PANEL (BASIC OPERATIONS)

(10) X-SCALE indicator

Illuminates when the SELECT key (15) is pressed to shown the X-scale setting.

(11) Y-SCALE indicator

Illuminates when the SELECT key (15) is pressed to shown the Y-scale setting.

(12) SPEED indicator

Illuminates when the SELECT key (15) is pressed to shown the sewing speed setting.

(13) COUNTER indicator

Illuminates when the SELECT key (15) is pressed to shown the lower thread or production counter setting.

(14) SPLIT No. indicator

Illuminates when the SELECT key (15) is pressed to show the split setting when split data (for specifying a pause while

the program is running) exists.

(15) SELECT key

Used to select a menu (X-scale, Y-scale, sewing speed and counter).

(16) Menu display

Displays information such as menu setting values, memory switch settings and error codes.

(17) Setting keys

Used to change the value which is displayed in the menu display (16).

In addition, it is used to move the needle position forward and back when sewing has been paused.

(18) PROGRAM No. display

Displays information such as program numbers.

(19) Setting keys

Used to change the value which is displayed in the PROGRAM No. display (18).

(20) CF media indicator

Illuminates when a CF card (external media) is inserted while the power is turned on.

(21) FD media indicator

Illuminates when the FDD set (option) is connected.

(22) Function keys [F1, F2, F3, F4]

Used to select user programs and to set and select cycle programs.

(23) R/W key

Used to read data from and write data to external media.

CFTM is a trademark of SanDisk Corporation.

BAS-342G PS

27

Page 36

6. USING THE OPERATION PANEL (BASIC OPERATIONS)

6-2. Loading sewing data

Refer to "6-8. Notes on handling CF cards (sold separately)" for details on using CF cards.

1

2

CF media indicator illuminates

3

Loading

Loading complete

4

The PROGRAM No. display will change from " P" to the selected program number.

Turn off the power switch, remove the CF card, and then close the cover of the CF slot.

With the power turned off, insert the CF card into the CF

slot.

NOTE:

• Make sure the CF card is facing the correct way

when inserting it.

• Always be sure to keep the cover closed except

when inserting and removing the CF card. If this is

not done, dust may get inside and cause problems

with operation.

Turn on the power switch.

Press the or key to select the program number

(100 − 999).

* The "---" display is used to check the feed home

position.

Press the R/W key.

• The buzzer will sound and the selected sewing data

will be loaded from the CF card and copied into the

sewing machine's internal memory.

4453Q

4421Q

4457Q

4498Q

6-3. Setting the program number

4012M

28

1. Press the or key (1) to select the program number

that is loaded into the internal memory.

• The program number will flash in the PROGRAM No.

display (2).

• "---" will appear at the time of shipment from the

factory. (For checking feed home position)

2. Depress the work clamp switch (3) to lower the work

clamp, and then depress the start switch (4).

• The work clamp will move to the sewing start position,

and then the program number will be applied.

• The program number will stop flashing and illuminate

steadily.

NOTE:

After completing the setting, be sure to refer to "6-6.

Checking the sewing pattern" to check that the needle

drop position is correct.

BAS-342G PS

Page 37

6-4. Setting the X-scale and Y-scale

4013M

6-5. Setting the sewing speed

6. USING THE OPERATION PANEL (BASIC OPERATIONS)

The scales are set to 100 (%) at the time of shipment from

the factory.

1. Press the SELECT key (1) so that the X-SCALE

indicator (2) (for X-scale setting) or the Y-SCALE

indicator (3) (for Y-scale setting) is illuminated.

• The setting value (%) will appear in the menu display

(4).

* When memory switch no. 402 is set to "ON", the

settings will be displayed in units of mm.

2. Press the

• The program number will flash in the PROGRAM No.

display (6).

3. Depress the work clamp switch (7) to lower the work

clamp, and then depress the start switch (8).

• The work clamp will move to the sewing start position,

and then the scales will be applied.

• The program number will stop flashing and illuminate

steadily.

NOTE:

After completing the setting, be sure to refer to "6-6.

Checking the sewing pattern" to check that the needle

drop position is correct.

The sewing speed is set to 2000 (sti/min) at the time of

shipment from the factory.

1. Press the SELECT key (1) until the SPEED indicator (2)

illuminates.

• The setting value (sti/min) will appear in the menu

display (3).

2. Press the

(Sewing speed setting: 400 − 2700)

or key (5) to set the scale (0 − 400).

or key (4) to set the sewing speed.

4956Q

BAS-342G PS

29

Page 38

6. USING THE OPERATION PANEL (BASIC OPERATIONS)

6-6. Checking the sewing pattern

Use test feed mode to check the needle movement with only the work clamp operating.

Check that the needle hole in the needle plate does not come out from the frame of the work clamp.

1

TEST indicator illuminates

2

COUNTER indicator illuminates

Starting continuous test feed mode

3

TEST indicator illuminates

TEST indicator switches off

If test feeding continues until the

4

final stitch, the work clamp will move

to the sewing start position and then

stop.

TEST indicator switches off

Press the TEST key.

Select the program number to be checked, and then set the X-scale and

the Y-scale.

• The program number will flash.

Depress the work clamp switch (1) to lower the work clamp, and then

depress the start switch (2).

• The work clamp will move to the sewing start position, and then the

program number will stop flashing and illuminate steadily.

• The number of stitches will appear in the menu display.

Depress the work clamp switch (1) to lower the work clamp, and then

depress and release the start switch (2).

• The work clamp will start moving continuously one stitch at a time.

[Fast-forward test mode]

If the work clamp switch (1) is depressed while the work clamp is moving,

the feeding speed can be increased while the work clamp switch (1) is

depressed.

When the

forward by one stitch, and when the

pressed, the work clamp will move backward by one

stitch. (It will move quicker if you keep the key pressed

down.)

key is pressed, the work clamp will move

4957Q 4014M

4014M

4443Q

key is

If you would like sewing to start while test feeding is in

progress, press the TEST key to switch off the TEST

indicator.

When the start switch (2) is depressed, sewing will

start.

4014M

Press the TEST key.

30

BAS-342G PS

Page 39

6. USING THE OPERATION PANEL (BASIC OPERATIONS)

6-7. Setting the height of the intermittent presser foot

You can use the operation panel to change the setting value for the intermittent presser foot height.

1

2

All indicators switch off

THREAD/CLAMP indicator illuminates

MENU indicator switches off

<Changing modes>

Ending setting mode

3

THREAD/CLAMP indicator switches off

Intermittent presser foot operation

During standby

When lowered

While sewing

Press the THREAD/CLAMP key.

The sewing machine will switch to threading mode.

• " 1" will appear in the PROGRAM No. display and the

intermittent presser foot (1) will drop.

Press the key.

The sewing machine will switch to intermittent presser foot height

setting mode.

• " 4" will appear in the PROGRAM No. display and the

intermittent presser foot (1) will rise to the setting value that

appears in the menu display.

(Intermittent presser foot height setting: 0.0 − 10.0)

Press the or key to set the intermittent presser foot

height.

• The intermittent presser foot (1) will be raised or lowered to the

height of the new value that has been set.

NOTE:

After making the setting, be sure to turn the pulley once by

hand and check that the intermittent presser foot (1) does not

touch the needle bar.

" 1" Threading mode

↑ ↓

" 4" Intermittent presser foot height setting mode

Press the THREAD/CLAMP key.

• The setting values will be memorized.

• The intermittent presser foot (1) will return to the status that it

was at before the sewing machine was switched to setting

mode.

1 Intermittent presser foot lift amount

2 Intermittent presser foot height

The settings can be made by the above

operations.

However, if the intermittent presser foot

height is set to a smaller setting than the

intermittent presser foot stroke, the

intermittent presser foot will not drop in

order to prevent it from coming into contact

with the needle plate.

3 Intermittent stroke

When making the adjustment, refer to

"11-13. Changing the intermittent stroke" in

the instruction manual CD.

4445Q

2158B

5225Q

4016M

2763B

BAS-342G PS

31

Page 40

6. USING THE OPERATION PANEL (BASIC OPERATIONS)

6-8. Notes on handling CF cards (sold separately)

• Use a CF card with a memory capacity of 32, 64, 128, 256, 512 MB, 1GB or 2GB.

(CF cards with a capacity of more than 2GB are not supported.)

• Do not disassemble or modify the CF card.

• Do not bend, drop or scratch CF cards or place heavy objects on top of them.

• Avoid contact with liquids such as water, oil, solvents or drinks.

• Use and store CF cards in locations that are free from strong static electricity and electrical interference.

• Do not use or store CF cards in places where they may be subject to vibrations or shocks, direct sunlight, high

temperature or humidity or strong magnetic fields from equipment such as speakers, or places which are dusty from thread

scraps, etc.

• Do not subject CF cards to shocks or impacts or remove them from the sewing machine while data is being loaded or

written.

• The data on the CF cards may become lost or corrupted due to some malfunction or accident. It is recommended that you

make a backup of important data.

• CF cards should only be removed after the power for the sewing machine has been turned off.

• CF cards are already formatted when they are purchased, and so you should not reformat them.

• The recommended CF cards are commercially-available ones from SanDisk or HAGIWARA SYS-COM. CF cards from

other manufacturers can be used, but different formatting methods may mean that loading from or writing to such cards

may not be possible.

For more information, refer to the documentation provided with the CF card.

* This product is compatible with CF cards that have been formatted using the FAT16 method. Cards that have been

formatted using the FAT32 method cannot be used.

* CFTM is a trademark of SanDisk Corporation.

* Company names and product names appearing in this manual are trademarks or registered trademarks of the

respective owners. However, no TM or other similar symbols appear in the main text of this manual.

32

BAS-342G PS

Page 41

7. SEWING

CAUTION

Turn off the power switch at the following times.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

• When threading the needle

• When replacing the bobbin and needle

• When not using the machine and when leaving the machine unattended

Do not touch any of the moving parts or press any objects against the machine while sewing, as this may result in

personal injury or damage to the machine.

7-1. Sewing

4978Q

4020M

2764B

Use a work clamp and a feed plate which will hold the article securely so that it does not slip.

If using the standard work clamp and feed plate and the article being sewn is slipping, take measures to stop the work

clamp and feed plate from being slippery.

1. Turn on the power switch.

2. Press the

number that you would like to use.

* Refer to "6-2. Loading sewing data" for details on

reading sewing data from a CF card.

3. Depress the work clamp switch (2) to lower the work

clamp (3), and then depress the start switch (4).

• The work clamp will move to the sewing start

position.

• Home position detection will be carried out

immediately after the power switch is turned on.

4. Place the article to be sewn underneath the work clamp

(3).

5. Depress the work clamp switch (2).

• The work clamp (3) will drop.

6. Depress the start switch (4).

• The sewing machine will start sewing.

7. When sewing is complete, the thread will be trimmed

and the work clamp (3) will rise.

or key (1) to select the sewing program

7. SEWING

BAS-342G PS

33

Page 42

7. SEWING

7-2. Using the STOP switch

If you press the STOP switch (1) while sewing or test feeding is in progress, the CAUTION indicator (2) will illuminate and

the sewing machine will stop immediately.

2264B

4982Q

<Clearing>

1. Press the RESET key (3).

• The thread will be trimmed, and then the CAUTION

indicator (2) will switch off and the buzzer will stop

sounding.

2. If you do not wish to continue sewing, press the RESET

key (3) once more.

• The program number will flash. Carry out preparation

for the next sewing.

<Continuing sewing from a stopping point>

If you have pressed the STOP switch (1) at times such as if the thread breaks while sewing or the lower thread runs out, you

can resume sewing from the point where the thread ran out.

1

Press the RESET key.

• The thread will be trimmed, and then the CAUTION indicator will switch

off and the buzzer will stop sounding.

2

3

Press the key to return the work clamp to the position where sewing is

to be continued.

• When the

stitch, and when the

forward by one stitch. (It will move quicker if you keep the key pressed

down.)

Depress the start switch (4).

key is pressed, the work clamp will move backward by one

key is pressed, the work clamp will move

4443Q

• The sewing machine will start operating and sewing will start.

4022M

7-3. Using the thread wiper switch

The thread wiper switch (1) can be used to turn the thread

wiper (2) on and off.

34

4023M

BAS-342G PS

Page 43

MEMO

BAS-342G PS

35

Page 44

Document CD

For cleaning, standard adjustments and more details, please refer to the instruction

manual contained in the Document CD.

3168M

Contents of the Document CD

The following documents are contained in PDF format.

・ Basic Operation Manual

・ Instruction Manual

・ Parts Book

Recommended system configuration for using the Document CD

OS: Windows® XP Service Pack 2, Windows Vista®, Windows® 7

Browser version: Microsoft® Internet Explorer 6 Service Pack 1 or higher

Screen resolution: 1024 x 768 pixeles or more

Plug in (required to access): Adobe Reader 8.0 or higher

Adobe, the Adobe logo, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the

United States and/ or other countries.

Windows® and Microsoft® Internet Explorer are either registered trademarks of Microsoft Corporation in the United States

and/ or other countries.

© 2010 Brother Industries, Ltd. All Rights Reserved.

This is the original instructions.

BAS-342G PS

SB2117-001 E

2010.11. B (1)

Loading...

Loading...