Page 1

&WinB~W

BAS-341E

INSTRUCTION MANUAL

BAS-342E

C:

OJ~BJUI~mA~

c:

OJ~qijlfl~,

INNER CLAMPING DEVICE (FOR PNEUMATIC)

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

cb\

5,

~~~c

l!lt:9

OW~~

t::ue~

<:It:&

<tee!\, lo

o ffJtt Qflmlt:,

~m

lJ

~<tee!\,

'0

Page 2

1. lti

Of'il:tQiUIC:

1.

Before installation ..... .

······

/A

•

:::1::1

~D-JIJffi~?;(.0)1JJt-~mJI:tQ~(ct~"f'rui;(.-1'

t:ll

/A

t:ll

A •

~

A • Turn

~

s~rdJ~:>Z:b'61JJt-~rmr:t-r:<tC:c!t,\o

• Wait at least 5 minutes after turning

from the wall outlet before opening the face plate

high voltages are present can

fF~O)iiJI~tiiJi;(.-1'~7~tJJt>,

~:>Z:fflfi~fflt>c,

• IJ7-{jt*SjliO)IJ7-:::J

lJ

Z:

(lee!\,

off

ing, otherwise the machine will operate

result

• Close the air cock

the needle

\o

the power switch and disconnect the power cord before carrying out troubleshoot-

in injury.

of

the pressure gauge points

S:V::Jb'fFIJ.JlJZ:I:tb'O)mt~c~O~t"o

~?~B.Dt;,

of

the air supply source, and then open the drain cock

A

fBIII

result in severe injury.

/DANGER

iEll21ffaB~r~,J,nQc,

off

the power switch and disconnecting the power cord

of

~7~tJJO,

the control box. Touching areas where

A 5til /CAUTION

tllt:155~•\,\"r:(tcc!\,\o

t-=LI-1'::J:::J

to

~?~t>IJ7-~-:C:,

if

the treadle is pressed

non.

tUi:175~-\,\Z:,

:itl:tb'~9QC:cb'®O~t"

J±:t.JMo.>mtl"~

by

mistake, which could

to

bleed the air until

:tO)fl

raJ

o

I~

1.

11X

t>

f'il:t

1-1 .

r~[!o:>~lmi*J"t:19!ffl

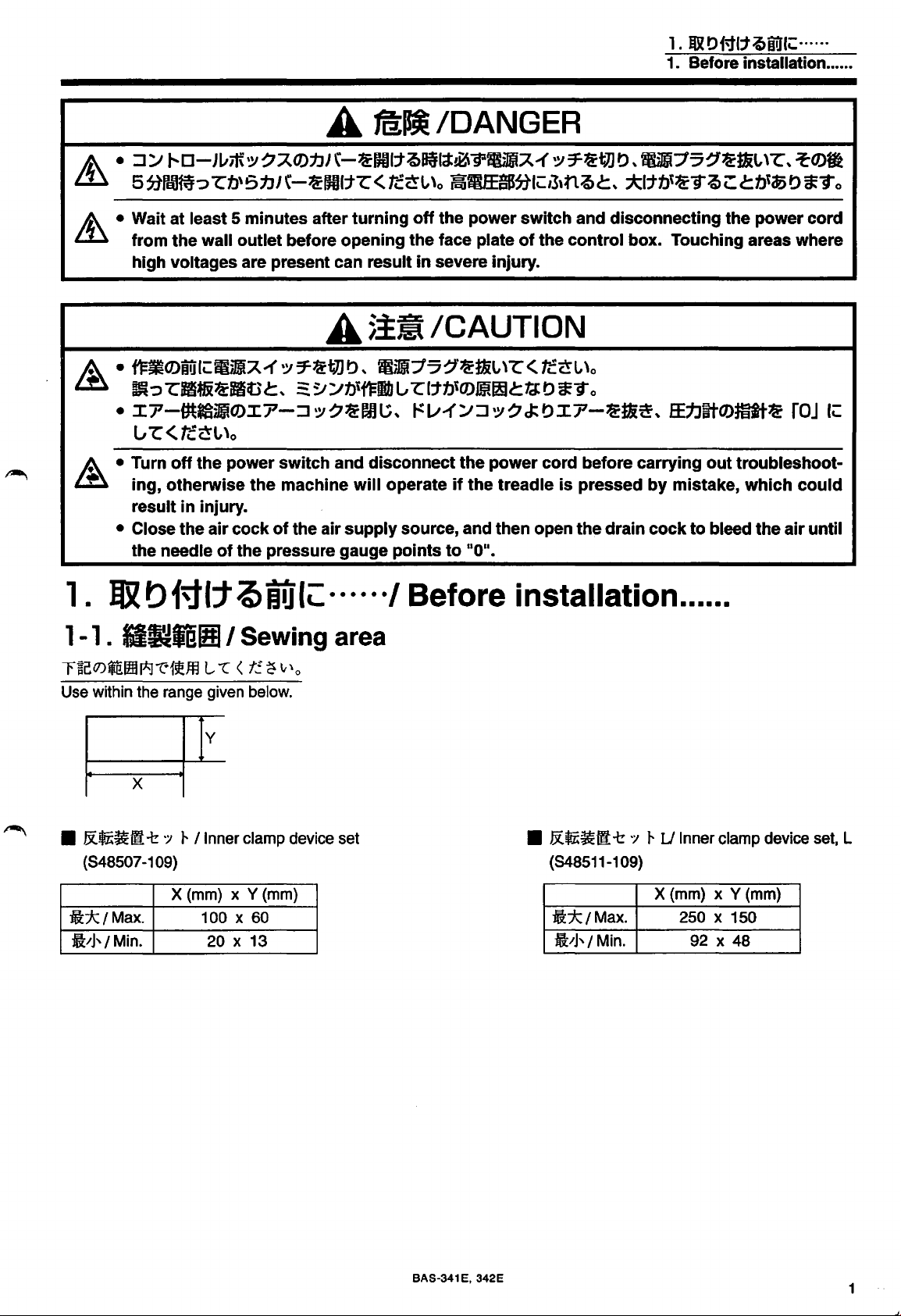

Use within the range given below.

•

ii*/Max.

Jl'J'/ Min.

tl~i'BBI/

X

&~~111!

(848507-109)

7 r I Inner clamp device set

X (mm) x Y (mm)

~

f.ilt:

Sewing area

L

"l

<

t!.

~

v'o

y

100 X 60

20 X 13

······I

Before installation ..... .

•

&~~111!

(848511-109)

ii*tMax.

ft'J'/ Min.

7 r U Inner clamp device set, L

X (mm) x Y (mm)

250 X 150

92 X 48

BAS-341 E, 342E

1

Page 3

1.

lfRt>MI:t~iUI~······

1. Before installation ..... .

1 -2.

MJ;t.fE~

1 -3. m b

9

~ J ~

I

~JiO)fF

b

-O)Ifil b

15

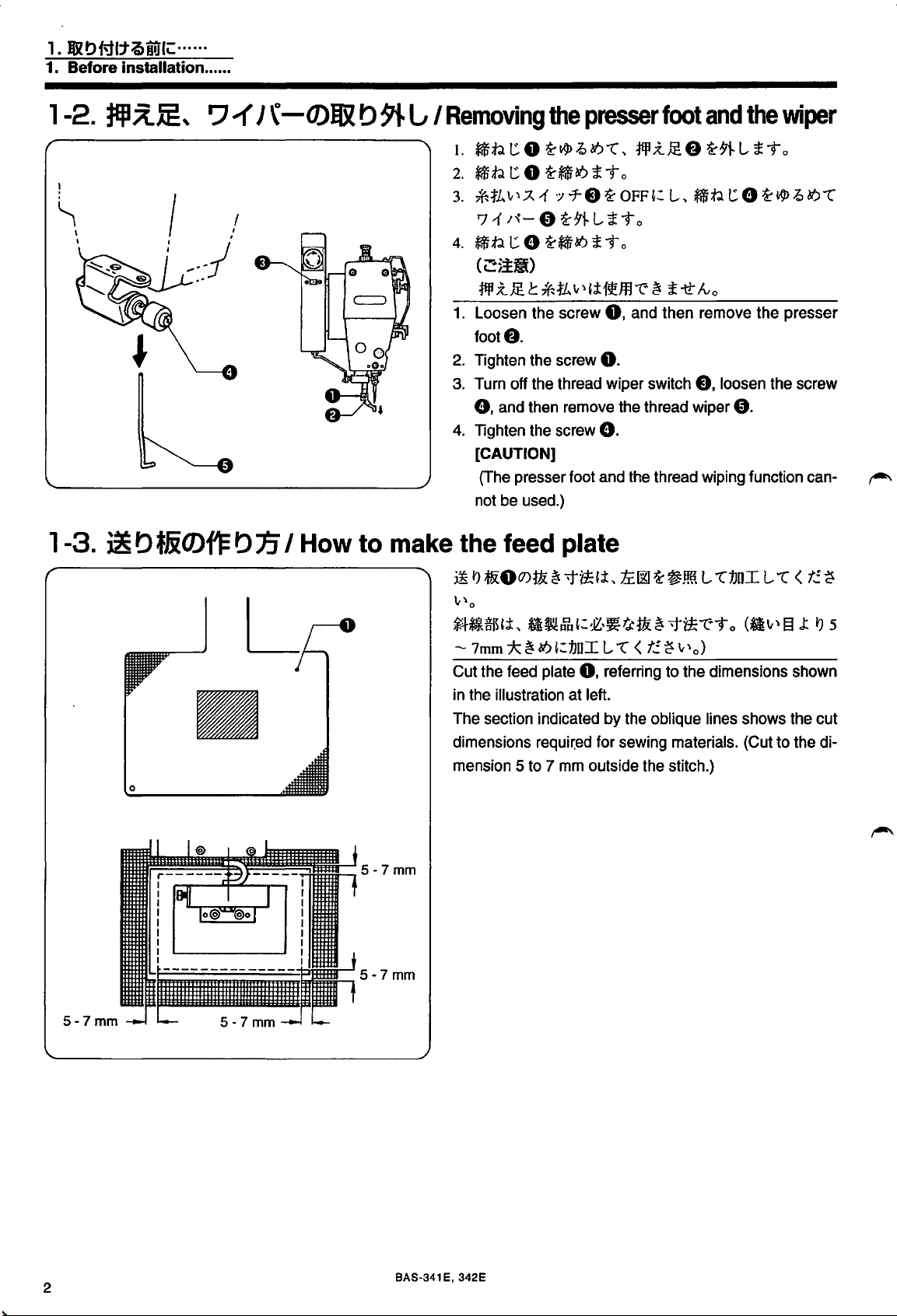

I How to make the feed plate

~

L.,

I

Removing

1.

~t.l

t::

0

2.

~t.l

t::

0

3.

*1L

v-~

.A

'7

1

'"-

4.

~t.l

t::

8

(

c:::~.til)

¥fJ

;t,@ C *1L

1.

Loosen

foot&.

2.

Tighten

3.

Turn

0,

4.

Tighten

[CAUTION]

(The

not

off

and

presser

be

used.)

the screw

the

the

then

the

the

presser

'i-~~9)1.",

'i-~N)

~

-t 0

1 ·:rr 8

e

'i-~N)

screw

thread

screw

'i-91-

L

~

\{\

'j:{5J!ffl

0.

remove

e.

foot

and

'i-

~-to

-t 0

0,

wiper

foot

~.:tJEO

OFF~:

the

'1:

and

switch

thread

the

L,

~

~

-tt"

then

thread

and

the

'i-91-

L

~t.l

t::

8

lvo

remove

8,

loosen

wiper

e.

wiping

function

wiper

~-to

'i-

$

~

N)

1."

the presser

the

screw

can-

r-"·

5-7mm

~

I'J

l&OO)~ ~ >t~'i,

i.!J-it~il!Hi,

- 7mm :k

Cut

the

in

the

The

dimensions

mension 5 to 7 mm

0

5-7mm

*1~&1

~

feed

illustration

section

N)

':1JDI L

plate

at

indicated

requi~ed

tL~

'i-~.lffi

':1l-~~t&:

0,

referring

left.

by

for

outside

1."

<

f!

the

oblique

sewing

the

!i

L

1."1JDI L 1."

-t~-e--t

~

v'o)

to

the

dimensions

lines

materials.

stitch.)

o (*lv'

shows

(Cut

<

13

shown

the

to

the

J:

t!.

~

I')

cut

di-

5

2

BAS-341E, 342E

Page 4

1.

I&t>f'11:t.QiitJ'IC::

1. Before installation

*

~n,&:1'5'Y?hDI

~

~

:foc7

·7

:;_,-

7

~1~ffllJ!l.1

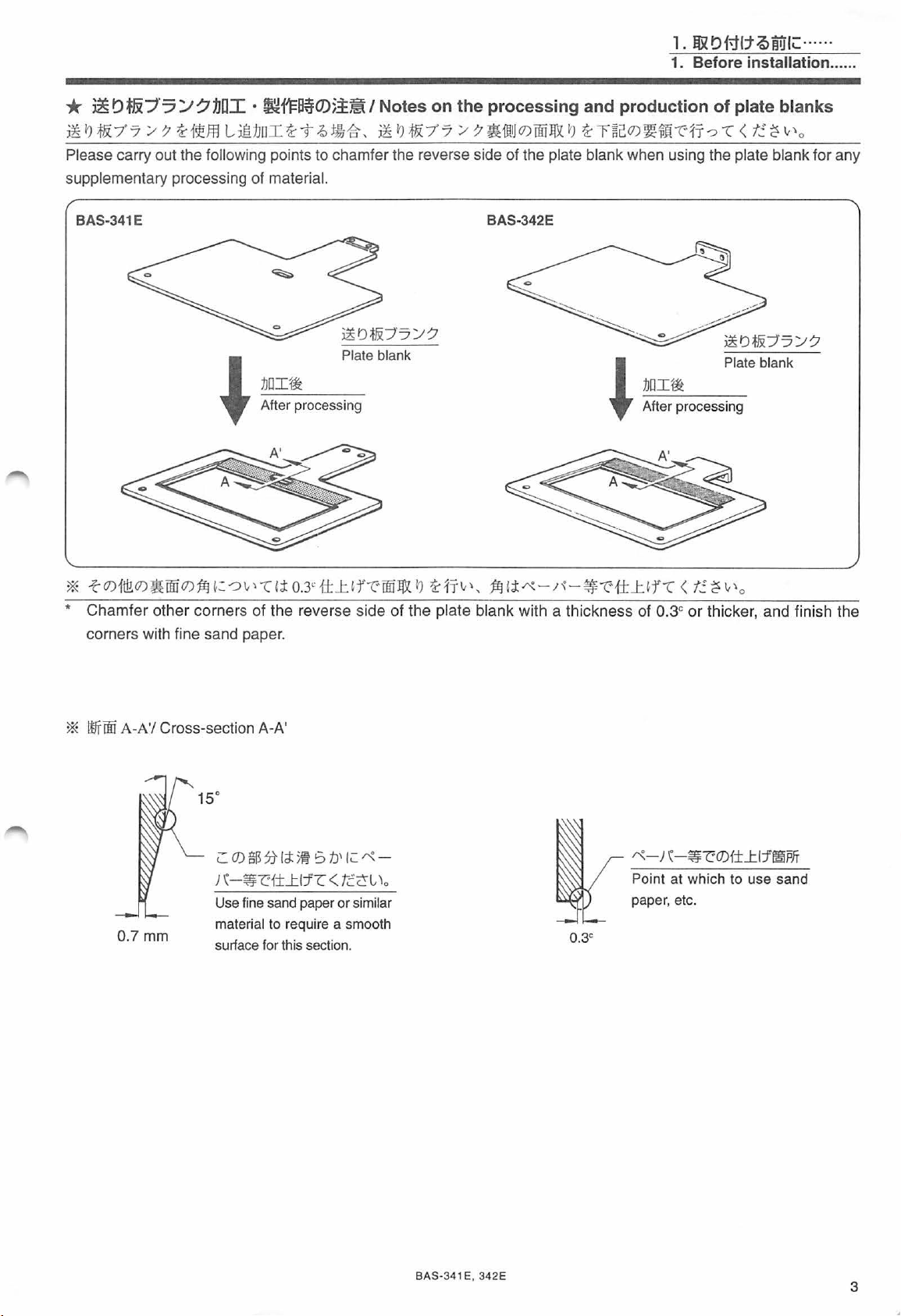

Please carry out the following points to chamfer the reverse side of the plate blank when using the plate blank for any

supplementary processing of

BAS-341E BAS-342E

·

~fl=~0)5.i~l

Jui ~

"t

~

tj)j'fr, ~

material.

Notes

~

if&:7.7 / 7

on

the

processing

?&

1JliJ

and

production

(J)Tiff

~ ~ ~ r~c(J)~~Ji-r:

of

plate blanks

1

:Y?

-c

< t

!.

~

....

..

.... ..

v

'o

Plate blank

1JDI1rt

-

After processing

'

* Chamfer other corners of the reverse side of the

wi

th

corners

*

ltffW

A-A'/

fine sand paper.

Cross-section A-A'

15°

1JDI1rt

-

After processing

'

pl

ate blank with a thickness of 0.3c

Plate blank

or

thicker, and finish the

L.

(])

$ 5}

lei:

5~

s

b'

1;: "'-

; \ -~

c

0.

7mm

f±...tl1-c

Use fine sand paper

material

surface for this section.

to require a smooth

< r

.:

or

similar

c-G

'·

BAS-34

1 E, 342E

"'

-;

\

-~c(J)f±...tlfl!iPJT

Poi nt

at

which

to use sand

paper, etc.

3

Page 5

1.

&OMtt~iUlC:······

1.

Before installation

.•••..

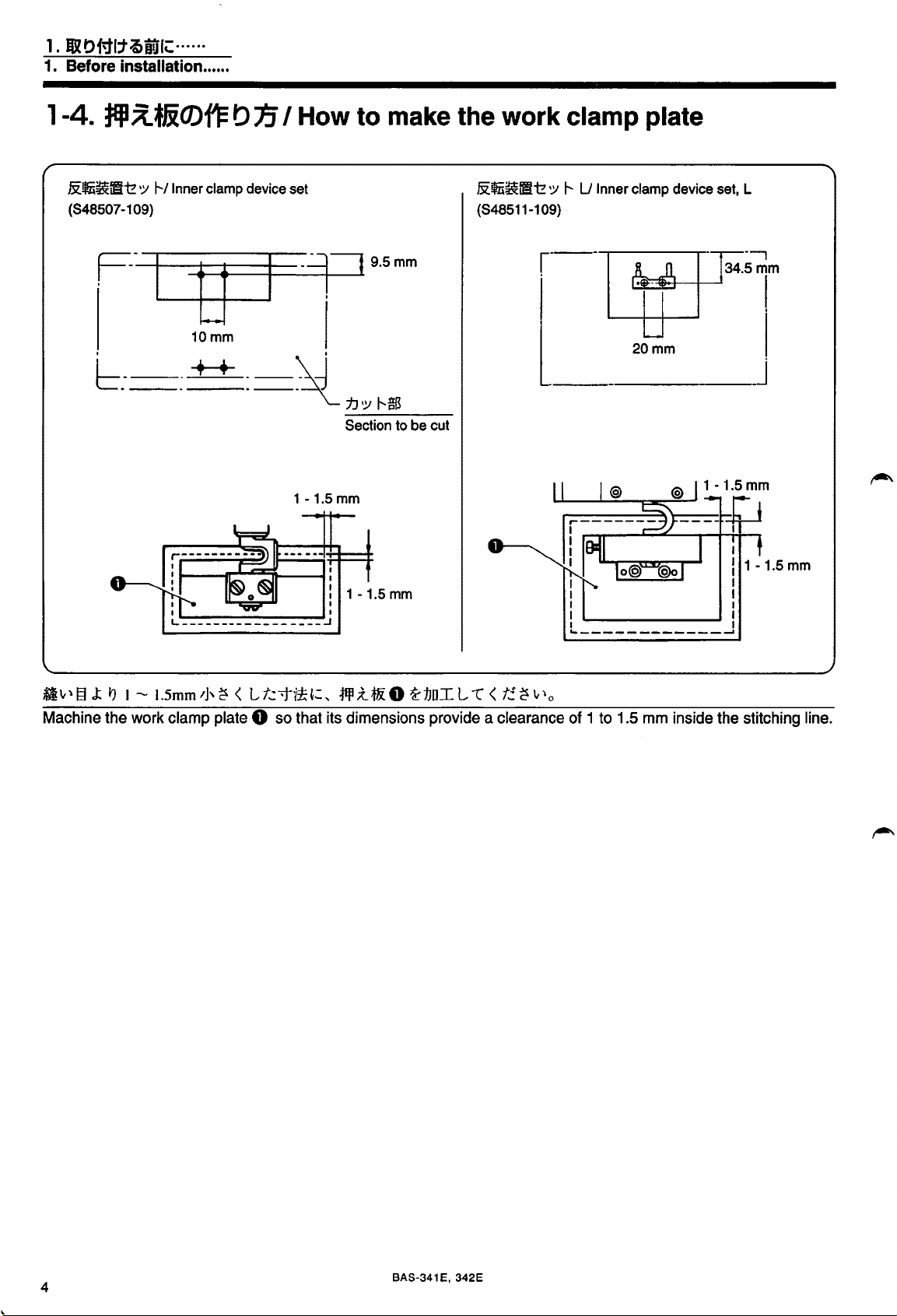

1-4.

tEJI;l~JiO)f'Fb1i

&~~fEliz

(848507-109)

b.---++

I How to make the work clamp plate

'Y !'--/Inner clamp device set

10mm

__

1--fl"':"-~ii----1:

I I

I I

\d

-~

-1.5

mm

1

: 1

1J'Y

!'--$

Section

-1.5

to be cut

mm

&~~~iz

(848511-109)

'Y

~---

1'--

U Inner clamp device set, L

20mm

_______

I

'--------'

--------------~

---,

34.5mm

I

I

,_j

I

I

I

I

I

I

I

I

Machine

the

work

clamp

plate 0

so

that

its

dimensions provide a clearance

of 1 to

1.5

mm

inside

the

stitching

line.

4

BAS-341 E, 342E

Page 6

2.

ijX

t>

f11:t1J

2. INSTALLATION

2.

2-1 .

* Close the air coc k and make sure that the presser assembly moves slightly before carrying out the installation.

•

QXbigl:tJJ

fEJix~UH*

*

:x.

7 -~ ·:;

&!Iii~~

-t

7

·;;

~

1--

/INSTALLATION

I Presser unit

f,M

aty-c,

;jill

X.

J~Jil

I Inner clamp

device

i>"U

<

lWJ

set (S48507

<

~

7(tH:

-1

l

09)

--c

i>'

t?

q:y

-=>

--c < t:.· ~ "'

o

I.

:f1ll

;{_..@

SELO c

2.

*

IJ

;f&:

8

3.

:f1ll;{_

7 7

1. Remove work clamps (SEL) 0 and (SER)

2. Replace the feed plate E) with the feed plate 0 that was made in accordance with "How to make the feed plate".

3.

Attach the work clamp crank

and 0 respectively.

•

&~i~~

-t

:f1ll

;{_..@

~

'./

7 LA

*

IJ

91-l, 1JDI l

*'-!i

SERf)

0

~;jill

~~

t

.:~

X.JE.*-!

l

IJ

IJ

f)

)'

~

l ;t To

fa

0

1:,

~I&

9i-:f1ll

0.

LA

assembly 0 and the external work clamp foot 0 to the work clamp assembly

·:;

1--

U Inner clamp device set, L (S48511-1 09)

IJ

1

•i'

;{_..@

~t

;t

To

0

~

;j1jl

X.

JE.m

0 1: *

IJ

1-t~t

;t To

f)

I.

;jill;{_..@

2. *

3.

:f!flX.

1. Remove work clamps (SEL) 0 and (SER)

2.

Replace the feed plate E) with the feed plate 0 that was made

3.

Attach the presser crank assembly 0 and the outer work clamp 0 to the work clamp assembly

respectively.

SEL0

I?

~ 8 ~

7 7 './ 7 m 0

*

c

:f1ll

;{_..@

I?

91-l,

~

SERf)

1J

:f1ll

X.JE.

DI

~

l

t.:

o 1: ,

I&

I?

9

~

l

*

IJ

~ 0 ~I&

7'

1-:Jill

X.JE.

;t

T o

I?

o

0.

1t

~tiT

o

~

:f1ll

x.JE.

m o 1

BA S·341 E, 342 E

:*

I?

N

in

accordance with "How to make the feed plate".

it

;t

-t

o

f)

and 0

5

Page 7

2.

l8l

t)

Ml:tn

2. INSTALLATION

2-2.

I7-00i~/

Pneumatic system

I.

1J{IJOO

:fJ

1~-0 ~

~mo

1.

Remove the side cover

Manual

for the sewing mschine.)

1&

t)

9} L

£To

(

~

~

:..--

Q)J&:t.&~lljjlf

0.

(Refer to the Instruction

2.

:J

*'

7

;r

8

(1)

®

ms

~

w L r

3.

fltifiJ~Jv7·0

4.

OC~fflilt?inJ~Jv

s.

OC~JfJ1itifiJ~Jv7'*11.0

2.

Push down the

3.

Remove the solenoid valve

4.

Install the solenoid valve

assembly

5. Install the reversal solenoid valve assembly 0 to the leg.

G.

..

e

7'*-0.0

part@

..

0

~

r,

::r..

7 -

.:r

..

:J

~,

7

;r

8

..

1 :.--7

~:

..

1&

"J

1'1-

L

t.:~liBJ~Jv7'0

~JJ!P~:J&

of the connector

0,

0,

e and

IJ

1t't

e and

£

8,

0,

0,

::3-

- 7' ( 6

7"

'"9

o

and pull out the air tubes (6 pes)

the connectors 8 and the integrator

the connectors 8 and the integrator

v-

*)

;r

..

f)

e

e

~51

~1&

..

0

..

t)

:J

~

1t

9} L

*'

7

~

£ i" o

£To

:$'

8

..

1 :.--7

8.

7'"

v-

:$'f)

~1&

"J

1-t~t

f).

f)

to the reversal solenoid valve

£To

6

BAS-341 E, 342E

Page 8

6.

:1

:.--

r

a-

Jv

7. ;

"Jv

7;

\-

:f,

s.

OC$iJfJift*l;'\Jv7tD

L~JJ.

i-to

6.

Open

the control

chine.)

7.

Disconnect

8.

Insert

the

the

pin

terminals

*'

·:;

7 A

V?fi

A ( i 2P) 0

V? ~ :.--

box

cover (circuit

valve

harness

(#11,

(£:§~1>1"1&)

'd:

tR

~

i

-9

7-

~

-t-

board

(12P)

0.

#4)

of

the

'd:

rm

~tiT

o

Jv

( llilt

~

:.--, 4 11t ~ :.--)

installation plate). (Refer

reversal

solenoid

0 (

valve

~

~

:.--

V?~t.&~1Yli=$P.~O

'd:

G)

;'\Jv7·;\-

to

into

connectors

the

;f, A 0

Instruction

#11

and

V?

Manual

#4

2.

Jl)l

o Ml:tn

2. INSTALLATION

:1

*'

7

~

1111t, 4 ilt':£

for the sewing

on

the

valve

harness

ma-

0.

2-3.

~IJ/~R

Cylinder R

12m

1 Piping

~IJ

Y5''L

Cylinder L

1.

Connect

each

air

tube

to

the locations

with

identical

BAS-341 E,

numbers.

342

E

7

Page 9

2.

Ut>i'JI:tJJ

2. INSTALLATION

::J-

1-=i't\J(;?''-

Cord

holder

2.

OC$i~'J

~-h,

3.

iftUlfii

~mo

2.

Bind the air tubes from the reversal cylinder with a

spiral tube and fix it with the cord holder.

3.

Install the side cover

'./¥(J):L7-1-:J..-7~:AJ~17Jv1-:J..-7

~-~*~¥-~t~£~0

7J

;'\-

0

~Ill

l'J

1t~t £ ~

o (

~

~

'./

(J)!Jlt&~IJEJII=

0.

2-4. 7-1

'Y

JA.

~

'Y

70)t}]

b

I§;{

I DIP switch selection

71·:;-j':A.{

L£To

*

.&$i~tl

No.3

(c:!>!il)

71

l (

Turn the selectors

switch

* When the reversal crank device is not used, turn the

@to

selectors

[CAUTION]

Be

switch setting.

-;;1-@(J)No.3,

~19!ffl

t

No.6~

·:;

7":A 1 ·:;

f!.

~

~~aN~~.

No.3

sure to tum off the power before changing the DIP

'-''o

L ~ '-''

"OFF"

-f-(J)~J!(J)~':';t,

No.3,

and

No.6

No.4tNo.6~

t

~

,;t,

71

7

7"

':

L

"'C

(

t!.

~

'-''o

1l·-rit?Jj~-;JJ-?

No.4

and

No.6

on

the DIP switch to 110FF".

"ON"':

:A

1 7

on the DIP

1-(J)

8

BAS-341

E,

342E

Page 10

3

.••

3. ADJUSTMENT

3.

3-

~-/ADJUSTMENT

1 .

~mJ±O)imMI

~

Increase pressure

Adjustment of air pressure

p Increase pressure

1.

~5«.1±

'i,

0.49MPa (5kgf/cm

<JJ~:IJ¥~>

1

:/

7

7·

v-

? 0

IHI

L -cfrv'

~!€*~7ft,±,

iTo

l'

(J)

1'

:/

r'"

2

)

:/

r~

Jv

Jv8

~r"'-~

"t"1i!ffl

8

~51

L -co

LiTo

~

...

tJf-c

'Y

To

t.::.

1

~

)

:/

~(J)~~J±,i,

c

~

~=

..

~;t

7 7

~;tt&:8

:/

7 0

~fJi!fij;T

~-~~~~

~-lmi*J

2 . .&$iffl

~

;t

LiTo

<JJ!€nrt>

.I.

7 - v

.:¥

.:z.

v -

~

0

(J)

1'

:/

r

..

Jv

0

~51

~

~~

t?

@1

L

-r

1T"'

£

To

iffll!€~Tft,±,

To

3. 1

:/

.:;-

~

v 1

:/:1

'J

1. Air pressure should be 0.49 MPa

The air pressure can be adjusted by pulling up and

turning the control knob

After adjustment is complete, push the control knob

8 downward to lock it.

2.

Adjust the air pressure for the reversal cylinder to stay

within such a range that the presser crank

reversely when pressing the sewing material with the

pressure plate

For adjustment, pull up and, turn the control knob 0

on the air regulator

After

adjustment is complete, push the handle 0

downward to lock it.

3.

If water stands

the drain cock

row to drain the water.

1'

:/

r

..

JvO

~r"'-~

v -

~

o

(J)

*'

r

Jv

I*J

~=*~~'f.::.

78~:9c~n(J)jj[tl]~:[HJ

8 on the integrator

L -co

'Y

i

-=>

t.::.

L

-cJJ<~tk~

kg/cm

2

].

[5

0.

0 rotates

e.

0.

in

the bottle of the integrator

8 in the direction indicated by an ar-

0,

~~

I?

7 L i

~=

...t

~-r

-c

7 L i

; , r

£To

turn

..

BAS-341 E, 342E

9

Page 11

3.RII

3. ADJUSTMENT

Adjustment of the work clamp crank horizontal position

•

OC$i~fl-i!

(848507-109)

·:~

r /Inner

clamp

device

set

<MJ;t??

OC$i~

~

, ~

~oab,

When the

Loosen

bolt 0

when

right

•

OC~~tl--1:!

(848511-109)

<

MJ;i??

&$i~

~,

~;t

~oao,~~~O~tliL.A:tLL-c~rtJLiTo

When the

Loosen

that

the

reversal

::1

?1Jti:j@JO)

1

~

.Y(J)77 ~ :/

)

.:t

7 7 ~ 7 8

~Jv

r 0

work

clamp

the

nut 8

so

that

the

work

the

reversal cylinder plunger 0

extreme .

':1

r U Inner

::1?

1J'SflUOJ

1

~

,Y(J)77 ~ :/

)

7 7

~

7 8

work

clamp crank

the

nut 8 and

work

clamp

cylinder

plunger 0 is

l:

~ 0 ~tl-"'-'\-=>

f1i"7.f< ~ ':

~tli

L.A:h.

crank

and

push

clamp

l:

~ 0 ~1:i-"v\-:>

i1r7](.i}Z~:

push

crank 8

i!

>

';fv\tli Lt.: t

~

o .t 1

L -cJ]ft]

is

in

or pull out the adjusting

crank 8

clamp

i!

>

in

the

device

~:,

7-

LiTo

right

can

be

is

moved

set,

';f"\m

~

o

J:

1

~:,

-J-

is

in

the

right

in

or

pull

out

the

screw 0 so

can

be

horizontal

moved

to

the

right

'/ r e

position

horizontal

to the

L

Lt.: t

':1

r 8

position

when

the

extreme.

~

~

10

BAS-341

E,

342E

Page 12

tJiottle(

BAS-300E

_!--==-::_

MENU

series

Q

P~W~A

<

til~>

I.

T A

~A 1 ·;~

:ffll

liT

*

iiC:iFil~

2.

i'T'

.:t

J:J:f ~ Y

w

.:t

[

o

7'.l{/.i;f:n:&~ii"

*

4ifl

.:t

t..:

"?

3.

TA

~

Verification

1.

While pressing

switch

0.

* The indicator shows u n .

2. Tread the presser lifter pedal

Verify that whenever the presser

[

is

trod, the work clamp crank

* Make sure that the work clamp crank

hit the work

3. Press the

7-

0

i-.J1Jl

o

<C

n ) t

;J:

Jv

f)

i-

ff'~l7.

_

u:r~

Y

Jv

f)

7 7 / 7

"(" v \

A1·;~7-0i-

f)

il{

7j:

v \

il'fiffi

1.1

:f1ll

the

test swi

clamp plate 0 and the

te

st

switch again to

l1~n'J{

~

~Jt/l!):A

~

i-t

o

i-t

o

i-ff'~

tr

::·

t

<

IJ

~li-to

'

:f1ll.:t

:+&

0 t ,

\ ill)"(" <

t!.

-ttM~t::hiTo

tch

0.

f).

f)

end

3.

j,\1fl

3. ADJUSTMENT

1

·

;~

7-

0 i-

~=

j1p

.z

7 7 / 7

i-

:f1ll.:t

:+&

0

~=

t::

"\

0

press the

lifter pedal

flips

read/wri

f)

left or right.

f)

does not

0.

the test

mode

.

~

te

Adjustment of the work clamp plate lifting speed

'.;[~fi;'

f)

_t

m~*&:

Loosen the nut 0

so

Jf!(tJ::Q

Sl

ower

BA

the wo

The upper exhaust air t

plate

valve adjusts the descending spe

S·34

1 E, 34

Jv

7·

O)fJI=~;ft

i-

1m

l

"Z"fr'-''

1JliJ

O)~F~*&:

IJ

=Jt

IJ:i'T'

·

~~ii;\Jv7·<D

·

'ilt~1~;\

leno

· Soleno

2E

Sol

id

rk

asce

eno

J

v7'®

valve,

cla

mp

nding

id valve

id val

fJ

'if-0)

-r

·;~

~

0

i-

~

~

&?

,

w.Jm'i

i-t

o

fJ

'if

IJ:

:fffl

i.

il'

_til'~ t ~

.z

i.i'r

n"

~

e:

~

·

..

····

:f1P.Z:f&ffl

......

7J-:f1ll.:t;.f&JfJ

on the exhaust air throttle val

and turn the adjusting scr

plate lifting spe

hrottle valve adju

speed, while the lower exhaust air thro

G)

....

..

ve

® ....

..

ed.

for the work clamp plate

for the external work clamp plate

0)

~

ed.

O)J£

t:: i-,

t::

i-

w.J:tt

ew

f)

sts the work

L.

;~:-t

ve

to

tl

t.

T1ll1J

0)

o

for the

adjust

clamp

ttl

11

e

Page 13

4. NOTE TO SEWING OPERATIONS

4.

4-1.

4-2.

t~•BfO))ti\

I NOTE TO SEWING OPERATIONS

iljJIO)Atl.iJ/ Power switch

itiJH.~

~i~-~~~~~~t-~1'/~~A.tl..i~o

Before turning the power switch on, move the presser arm

into the hatched area.

Y:O

*i~I~J'

YJ]icJ

Sewing

height

:1D~'5~1(:::>L'Z"

,...----~~~

.........

~4.5mm

I Programing

----

Reference

point

area

•

OCfi~i'lt~

I.

~ Lil\t\V?wiHHi,

4.5mm i

1. Reverse stitching is possible within 4.5 mm left and

right from the reference point.

Atl.¢

C

~,

'/ r (848507-109)

~1iJfj~~~

~X~~-~.:L1)

~"\tzfici)V?~~.'i?:

7Y/r(ti]V?*l*'i$

J:

t)

ti:;b~:

o

•

OC$i~~~~

1.

~

La"\

4.7mm,

1. Reverse stitching is possible within

3. 7 mm right from the reference point.

7 r L (848511-109)

V?

w

;fi':

IHHi,

3.2mm i

*I"\

"t:"liJ~~~

!la

N)

V?

o

~if!

,r;?.

J:

4.

7 mm left and

tJ

ti

£:

12

BAS-341 E, 342E

Page 14

4. NOTE TO SEWING OPERATIONS

2.

*l~!fm1.Ji"}¥v'#Ji1r,

1.1{

oc~T

.Q

t ~ ,

ft~it~::i!!jl.ra

t::.

t.:.

L,

:i!!ii.rat.Ji"ft:~~t

~

f~(J)jf:fn1.J{1l,~J...:J.J:.~:-N:

,J,ru!~~=~~

(~$(J)jf*~

2. For thick materials, provide a shunting point at the last

needle

clamp crank 0 from striking the needle after sewing

is

If

positiion, the

be too

sible distance from the last stitch position.

position in the program to prevent the work

completed.

the

shunting point is

needle thread after thread trimming may

long. Set the shunting point at the shortest pos-

*iv'*~b

it

t *

t.:.

t?

~~~ti--t

.t

o

~

<

LiTo

~

tJ:, 35

--

too

40mm

~

f~~:;J11J

~

v'

Mn~

~ ~ ~

far

J:

-?

t!""C

"'ET

from

X.

~:

7 o

t

1.Ji'iiJ

o)

the

v'

7 7 ~ 7 0

~

~

last stitch

7·

7 A

t,

(J)"t."''

(J)

*'m

ft

BAS-341E, 342E

13

Page 15

INSTRUCTION MANUAL

77:;..;·-J:IIflitafl:

BROTHER INDUSTRIES,LTD. NAGOYA JAPAN

~-~B.ijlf

;=

467-8562

Printed in Japan

4!1i!ilMiPJM181200~-

TEll

Ill

~

TEL(052)

824-2392

151-V4l,V42

S93V41-021

1999.04.

H

CD

Loading...

Loading...