Page 1

SERVICE

FOR

BAS-340

MANUNL

PROGRAMMABLE

WITH

CYLINDER BED <PROFILE M>

ELECTRONIC PATTERN SEWER

0 f

I

' /

\ .

Page 2

CONT

ENTS

I MECHANICAL

[]]Needle

[1]

Work

@]

Feed

@]Intermittent

[§]Thread

[§]Tension release

ITJ

Thread

I

DIS

ASSEMBLY I·. .

[]]

Machine

[1]

Machine

@]Presser mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

@]Work

ffiJ

Needle

[§]Upper

[1]

Longitudinal

I]]

Traverse

~

Lower

aiD

Tension release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Til

Thread

DESCRIPTIONS

bar,

thread

clamp

mechanism

clamp

shaft

shaft

lifter

presser

trimmer

wiper

bar

trimmer

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

....

..

covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

head

lifter

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

feed

feed

mechanism (X axis) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

mechanism

I·..

.........

take-up, lowe

mechanism

(X axis) (Y axis) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

mechanism

mechanism

mechani

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

sm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. ...........

...

. . .... . .

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

mechanism (Y ax

.....

.........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . .

..............

...

.........

r s

haft

and

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

....

. . .... . .

....

............

is)

. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

.... .

rotary

....

hook

................

.

..... ·.

.

.................

..

.....

mechanism 1

. . . . . .... 8

.......

. . .

....

...

1

9

10

11

12

19

20

IASSEMBLYJ

[]]Th

[1]

@]Needle

@]Work

[§]Thread tri

[§]Presser mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ITJ

I]]

~Longitudinal

aiD

[Til

....

. . ..............

read

tension

Upper

Feed mechanism (X axis) . .

Lower

Machine

Machine

shaft

bar

mechanism

clamp

mmer

shaft and

head

covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

lift

er mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

rotary

feed (Y axi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

hook

s)

.............

................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

.

....

......

..

...... . . .

. .... . . . . .

..........

...

21

21

31

41

Page 3

;

I STANDARD ADJUSTMENT I·... .

ITJ

Ad

justi

ng

need

11]

Adjusting

11]

Adjusting

[!]Adjusting

liD

Adjusting

[§]Adjusting

[]]Adjusting

[]]Changing

~Adjusting

[1Q]

Needle

[j]

Adjusting

[W

Adjusting

~Adjusting

[M]

Adjusting

[1§1

Adjusting

ffiD

Adjusting

mJ

Adj

usti

[ffi]

Adjusting

need

gap

needle

shuttle

movable

work

work

thread

stop posi

home

tension

tension

backlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

thread

solenoid

ng thread tri

work

le bar

le bar l

between

clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

clamp

clamp

height

ift

receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

race

thread

knife

stroke

wiper

tion

and

position

of

timing

release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

trimmer

lever

mmer driving

height

..........

stroke

needle

guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

work

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

belt

cam

posit i

.... .. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

and

shutt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

feeding

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

position

on

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

lever posit i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

......

le

hook

timing

. . . . . . . . . . . . . . . . . . . . . . . . . . 54

...

...............

point

. . . . . . . . . . . . . . . . . . . . 49

on

. . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . 43

42

44

48

52

53

I ELECTRICAL

ITJ

11]

11]

[!]Explanation

liD

[§]Optional

I TROUBLESHOOTING

ITJ

11]

CHECK

Fuses

Voltage

Control box

Dl P switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric I Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

AND

DIP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

measurement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

of

connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

output

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

I·........

I PROBLEM DETERMINATION

I

SPARE

PARTS

Caution

Using

termina

AND

DEVICE

for

working upon

ls

of lamp

Sv:'ITCH

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

.

.....................

AND

I·

........................

feed plate

and

I·............................

....

...............

SOLUTION

marker light

I·

............................

.... .. ..

blank

. . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . 89

......

..........

..

56

61

.

63

63

74

81

I CONTROL CIRCUIT BLOCK DIAGRAM,

)

................

. ......

. . .

...

. . .

....

90

Page 4

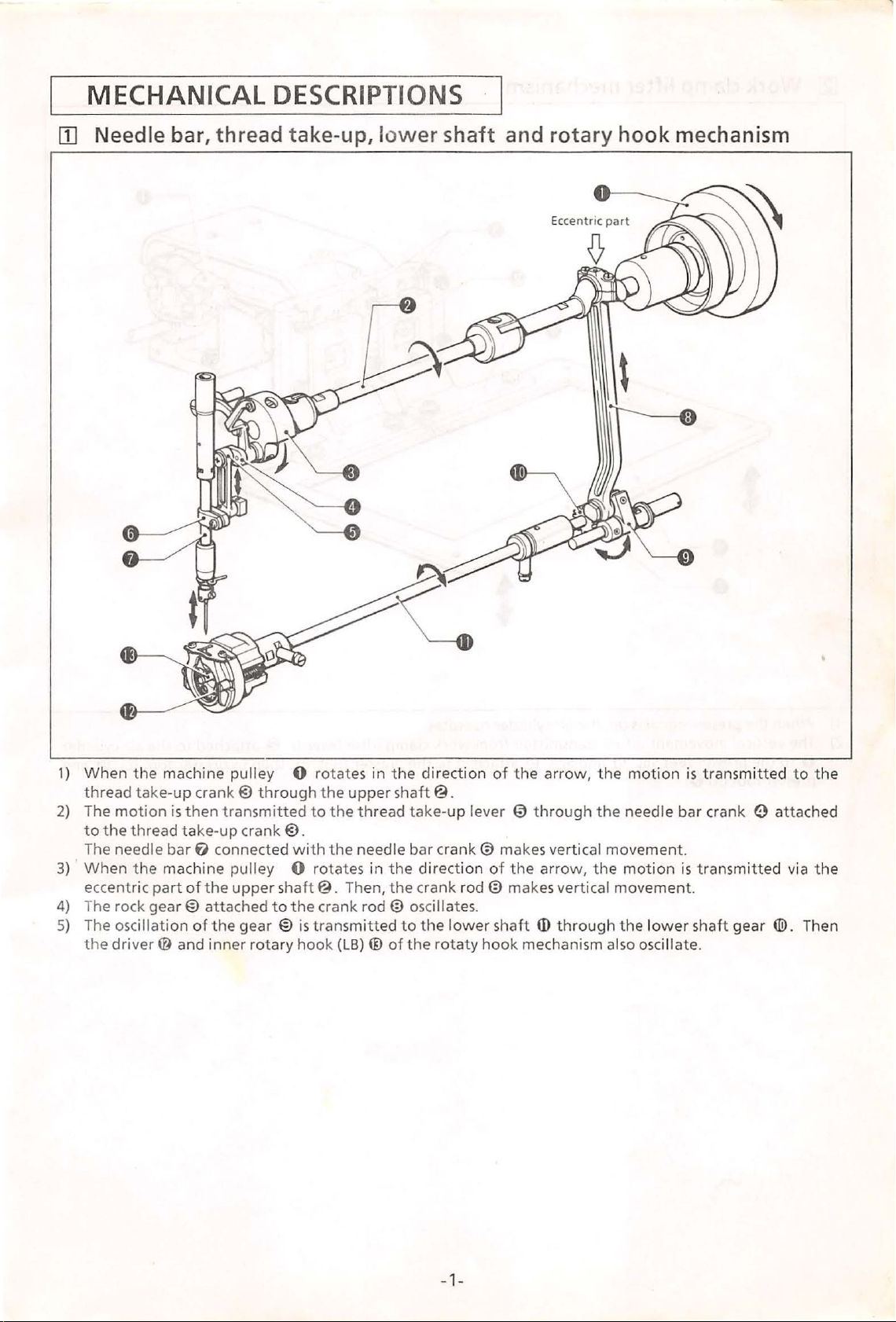

ME

CH

[I]

Needle bar,

ANICAL

thread

DESCRIPTIONS

take-up,

lower

shaft and ro

tary hook

mechanism

1)

When

thread

2)

The

to

The needle

3)

When

eccentric

4) The rock gea

5)

The oscillation

the

the

motion

the

thread

the

driv

take-up

part

er@

machine pulley 0 rotates in

crank@ through

is

then

transmitted

take-up

bar

machine pulley 0 rotates in

of

r@

of

and inner

crank@.

f)

connected

the

upper

attached

the

gear @

to

rotary

the

to

with

the

shaft@.

the

crank

is

transmitted

hook

upper

the

thread

needle bar

Then,

rod@

(LB) ® ofthe

the

direct

shaft@.

take-

the

direction

the

cra

osci

to

the

ion

up

lever

crank@

nk

rod@

llate

s.

lower

rotaty

of

the

arrow,

€)

throu

makes vertical movement.

of

the

arrow,

makes vertical movement.

shaft

ID

hook

mechanism also

the

gh

the

the

through

motion

needle bar crank e attached

motion

the

osc

lower

illate.

is

transmitted

is

tran

smitted via

shaft gear

®.

to

Then

the

the

-1-

Page 5

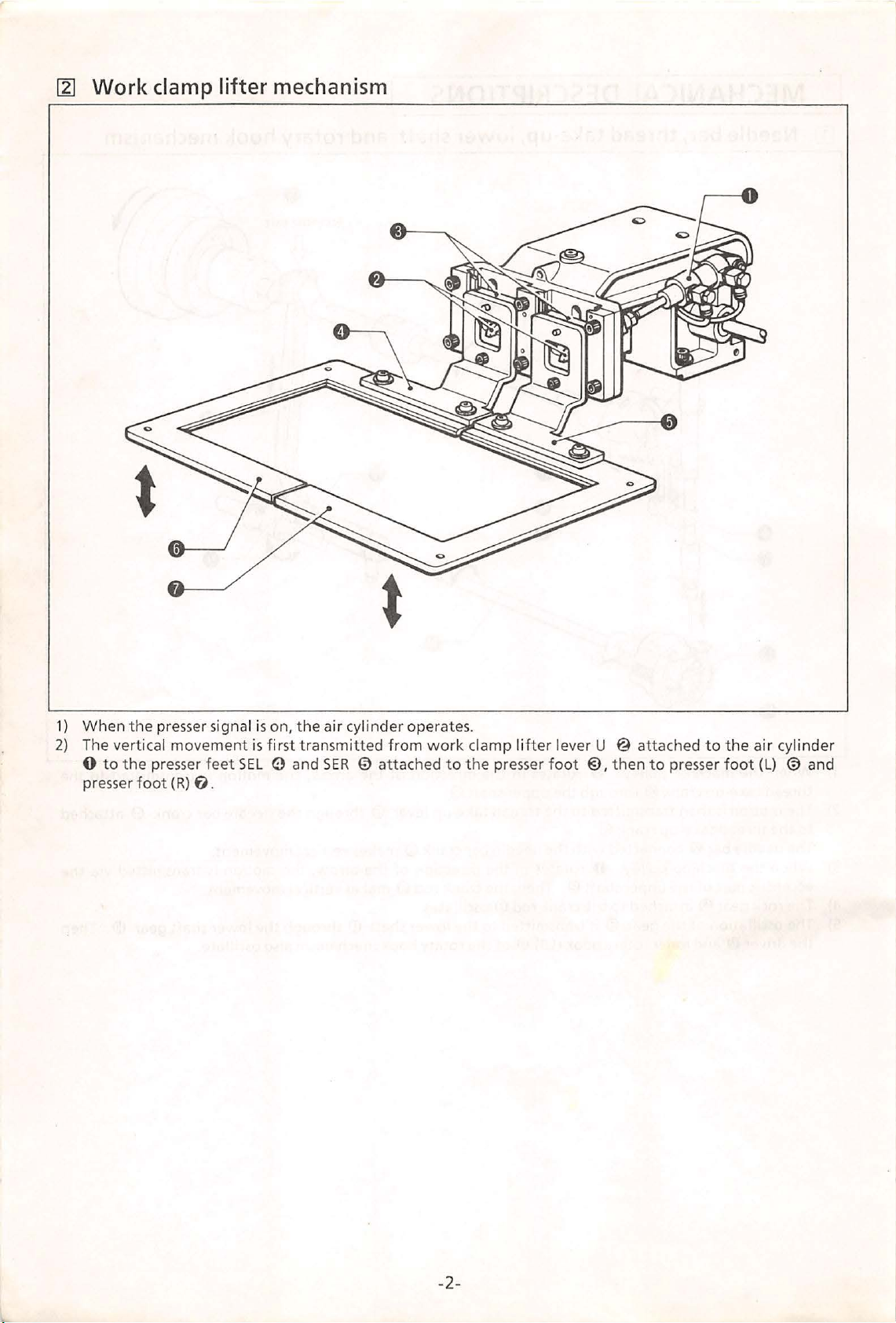

~

Work

clamp

lifter

mechanism

1)

When the

2)

The vertical

0

presser

to

the

foot

pre

sse

r signa l is on,

movement

presser

{R)

f).

the air

is fir

st transmitted

feet SEL 0 and

cylinder operates.

from

SER

0 attached

work

to

clamp

the

presser

lif

ter

lever U @ attached

foot @,then

to

presser

to

the

foot

air

{L)

cyl

inde

@ and

r

-2-

Page 6

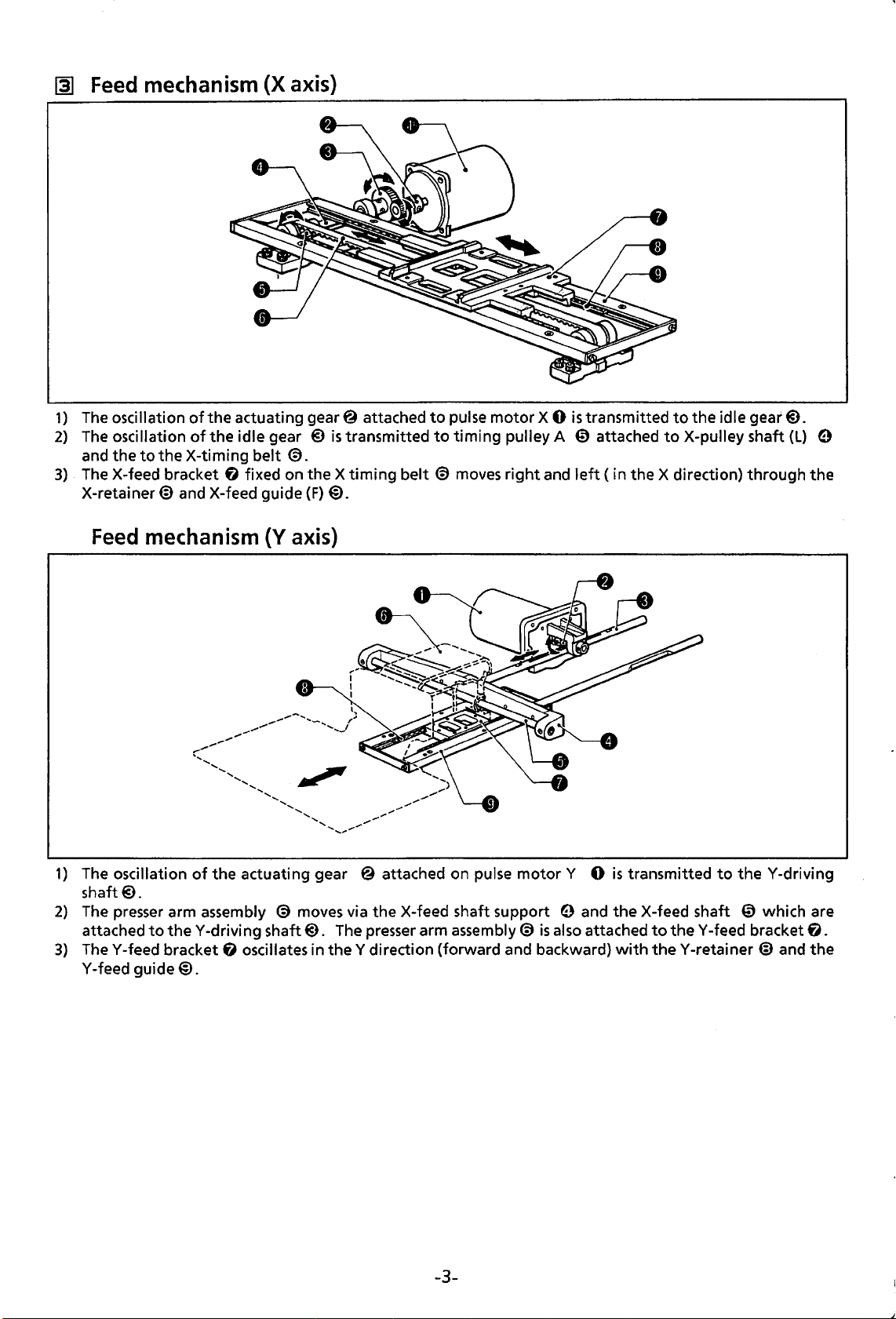

@1

Feed

1)

The

2)

The

and

3)

. The X-feed bracket

X-retainer@ and X-feed guide

mechanism

oscillation

oscillation

the

to

the X-timing

of

the

actuating gear@ attached

of

the

idle gear @

fl

(X

axis)

is

belt

@.

fixed on the X

(F)

@.

transmitted

timing

belt

to

pulse

to

timing

@ moves

motor

pulley A

right

X 0

and

is

transmitted

€)

attached

left

(in

the X direction)

to

the

idle gear@).

to

X-pulley shaft

(L)

through

9

the

Feed

1)

The oscillation

shaft@.

2)

The

attached

3)

TheY-feed bracket

Y -feed

mechanism

presser arm assembly @ moves via the X-feed shaft support 9 and the X-feed shaft

to

guide@.

(Y

axis)

of

the actuating gear @ attached on pulse

theY-driving

shaft@).

f)

oscillates in

The

presser arm assembly@

theY

direction (forward and backward)

motor

is

also attached

Y 0

is

transmitted

to

theY-feed

with

theY-retainer@

to

the

Y-driving

€)

which are

bracket

and

fl.

the

-3-

Page 7

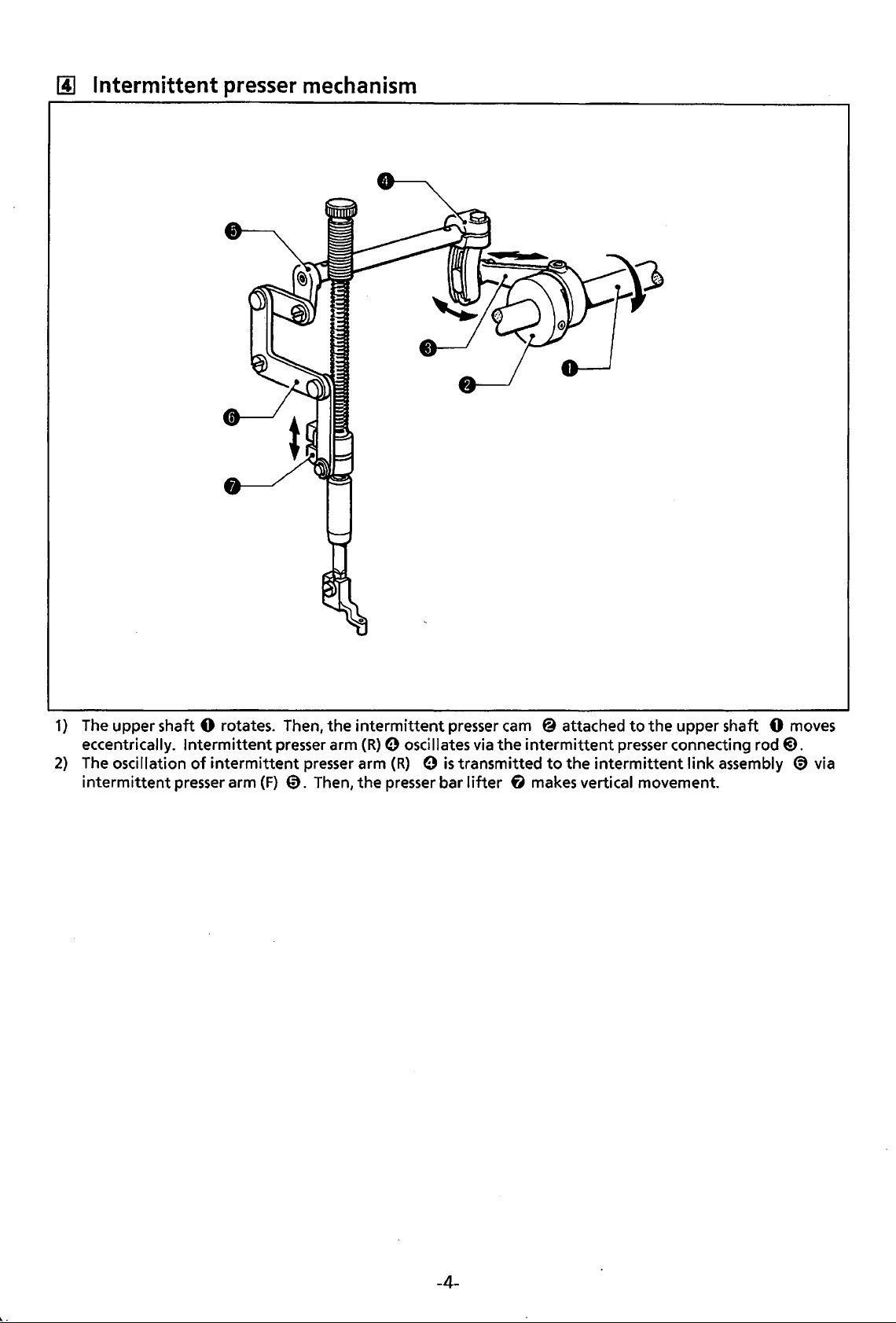

[A]

Intermittent presser mechanism

1)

The upper shaft 0 rotates. Then,

eccentrically.

2)

The

intermittent

oscillation

Intermittent

of

intermittent

presser arm

presser arm

presser arm

(F)

0.

Then,

the

intermittent

(R)

the

presser

0 oscillates via

(R) 0 is

presser bar

transmitted

lifter

cam

@ attached

the

intermittent

to

the

f1 makes vertical movement.

to

the

upper shaft 0 moves

presser connecting

intermittent

rod@.

link

assembly ® via

-4-

Page 8

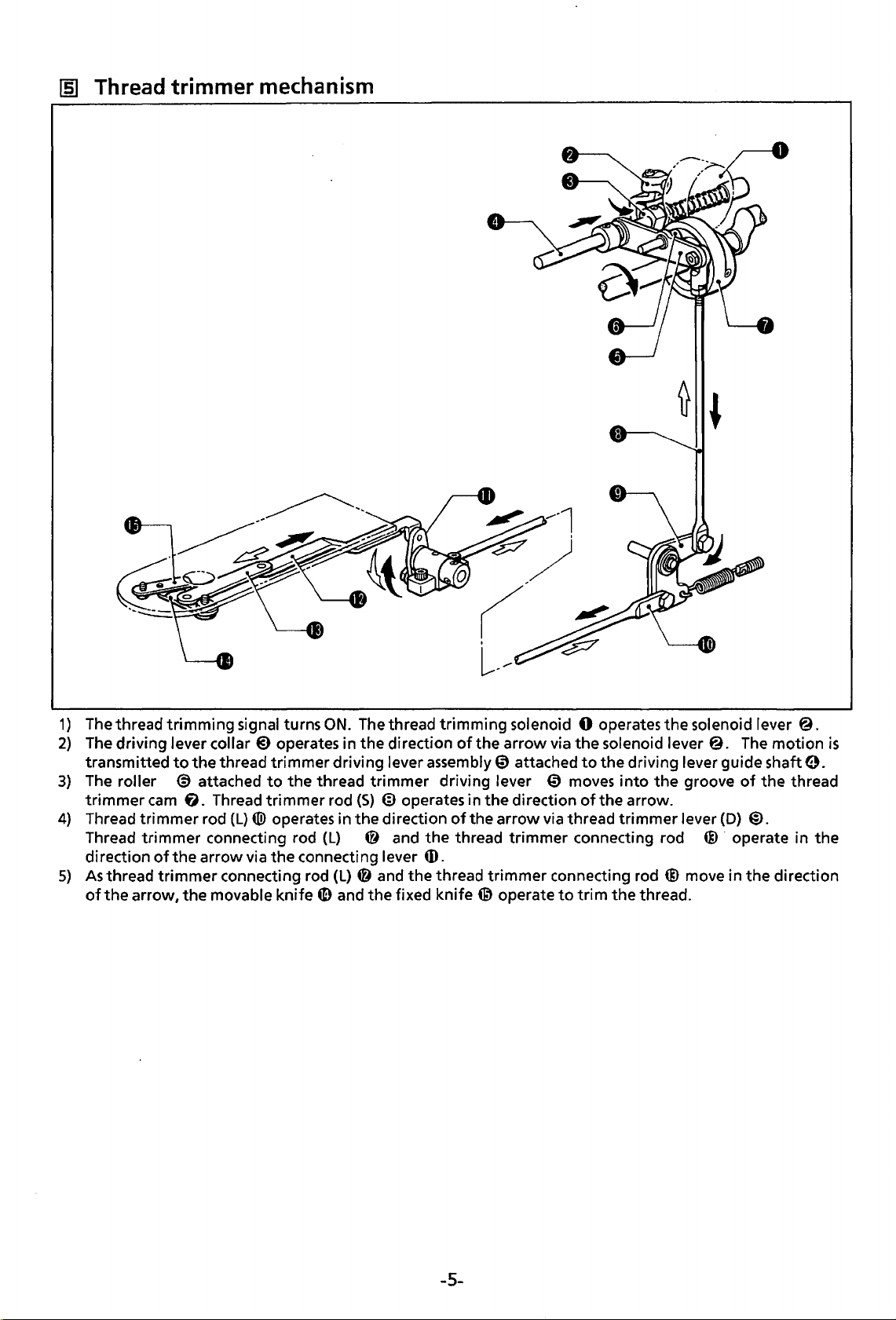

~

Thread trimmer mechanism

1)

The thread trimming signal turns

2)

The driving lever collar

transmitted

3)

The

roller @ attached

trimmer

4)

Thread trimmer rod (L) ® operates in the direction

Thread trimmer connecting rod (L) @ and

direction

5)

As

thread

of

the

to

the thread trimmer driving lever assembly@ attached

cam

fi.

of

the arrow via

trimmer

arrow, the movable knife

@)

operates in the direction

to

Thread trimmer rod

the

connecting rod

ON.

The

the thread trimmer driving lever

(S)

@ operates in

connecting lever

(L)

@ and the thread trimmer connecting rod @ move in the direction

G)

and the fixed

thread trimming solenoid 0 operates the solenoid lever

of

the arrow via the solenoid lever

to

the driving lever guide shaft

€)

moves

the

direction

of

the arrow via thread trimmer lever

the

thread trimmer connecting rod @ · operate in the

into

of

the arrow.

the

@.

groove

(D)

The

motion

of

the thread

@.

4D.

knife~

operate

to

trim

the thread.

@.

is

0.

-5-

Page 9

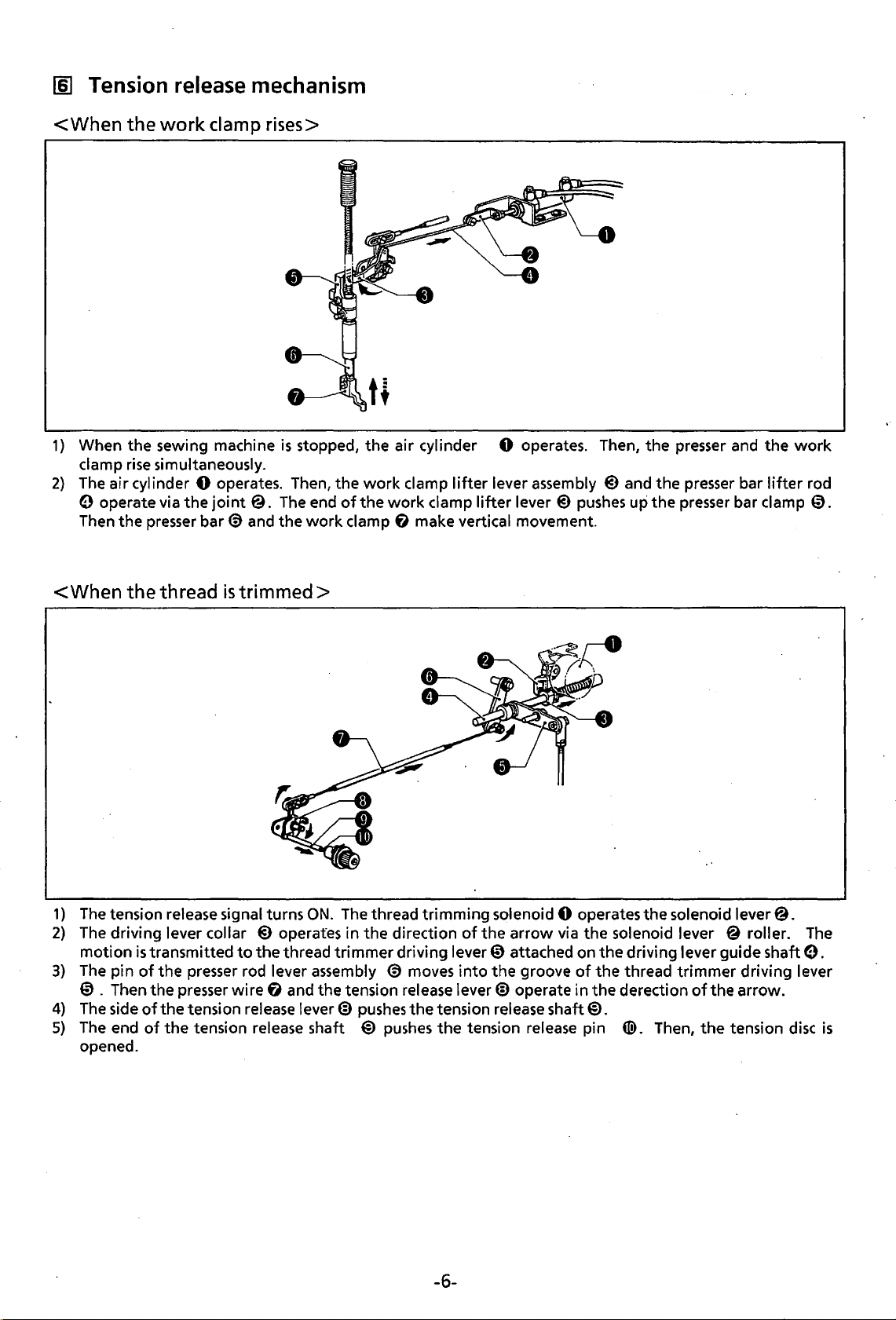

[§]

Tension

release

mechanism

<When

1)

When the sewing machine

clamp

2)

The

0 operate via

Then the

the

work

rise

simultaneously.

air cylinder 0 operates. Then, the

presser

clamp rises>

the

joint

bar

€)

@.

and

is

stopped, the air cylinder 0 operates. Then, the presser and the

work

The

the

end

work

of

the

clamp

clamp

work

f)

lifter

lever assembly

clamp

make vertical movement.

lifter

lever

@)

pushes

@)

and the

up

the

presser

presser

bar

bar clamp

work

lifter

rod

0.

<When

1)

The

2)

The

3)

The pin

the

thread

tension release signal turns

driving lever collar

motion

is

transmitted

of

the

presser

0 . Then the presser wire

4)

The

side

of

the tension release lever@

5)

The

end

of

the tension release shaft @

opened.

is

trimmed>

ON.

@)

operates in the direction

to

the

thread trimmer driving lever 0 attached on the driving lever guide shaft

rod lever assembly

f)

and the tension release lever@ operate in

The

thread trimming solenoid 0 operates the solenoid lever@.

of

the arrow via the solenoid lever @ roller.

€)

pushes

pushes

moves

the

into

the groove

tension release shaft@.

the tension release pin

of

the

the

thread trimmer driving lever

derection

tiD.

Then,

of

the arrow.

the

tension

The

e.

disc

is

-6-

Page 10

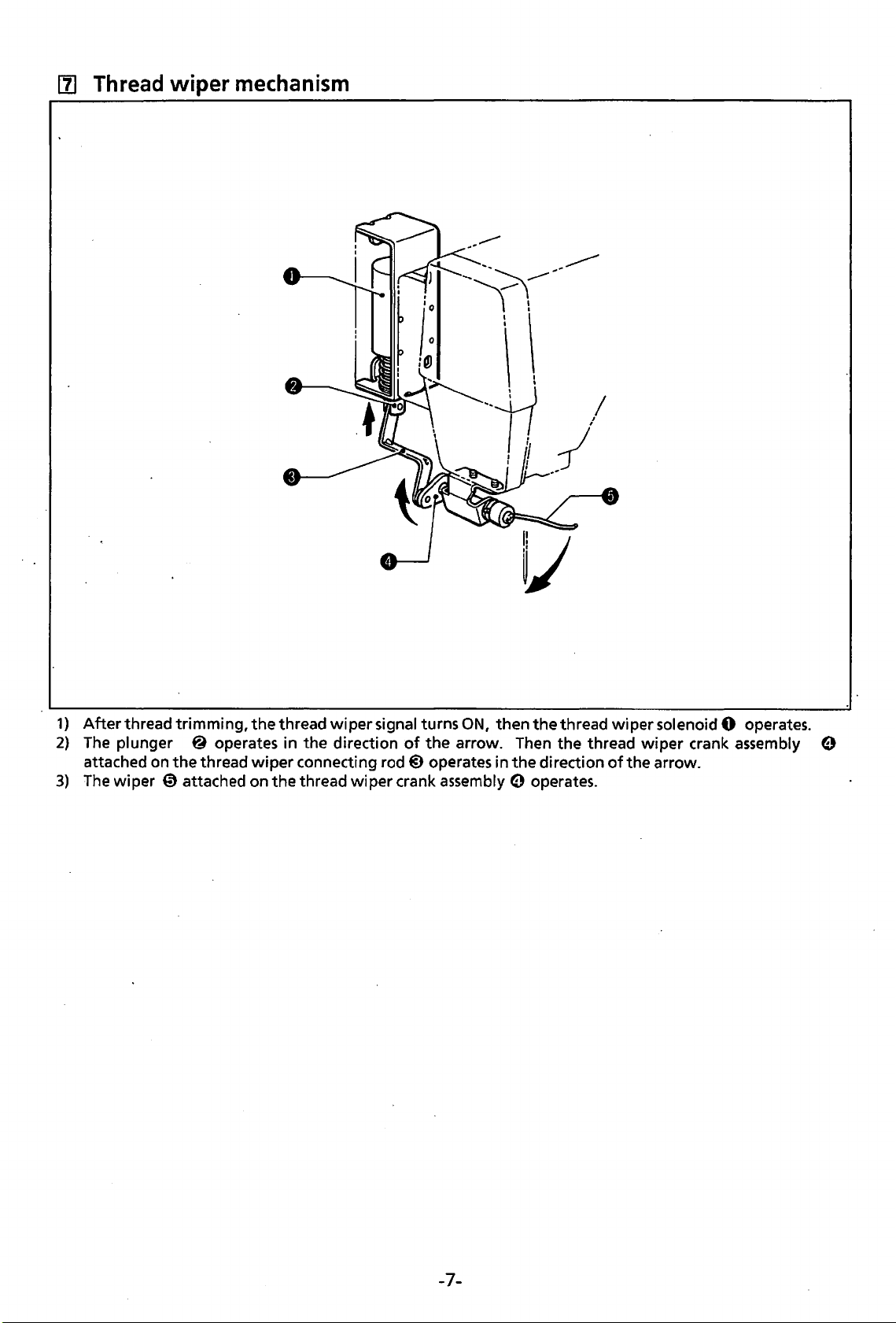

l1J

Thread

wiper

mechanism

1)

After

2)

The

attached on

3)

The

thread trimming,

plunger @ operates in the direction

the

thread

wiper 0 attached on the thread

the

thread

wiper

wiper

signal turns

connecting rod@ operates in

wiper

ON,

then

the

thread wiper solenoid 0 operates.

of

the

arrow. Then the thread

the

direction

crank assembly e operates.

wiper

of

the arrow.

crank assembly e

-7-

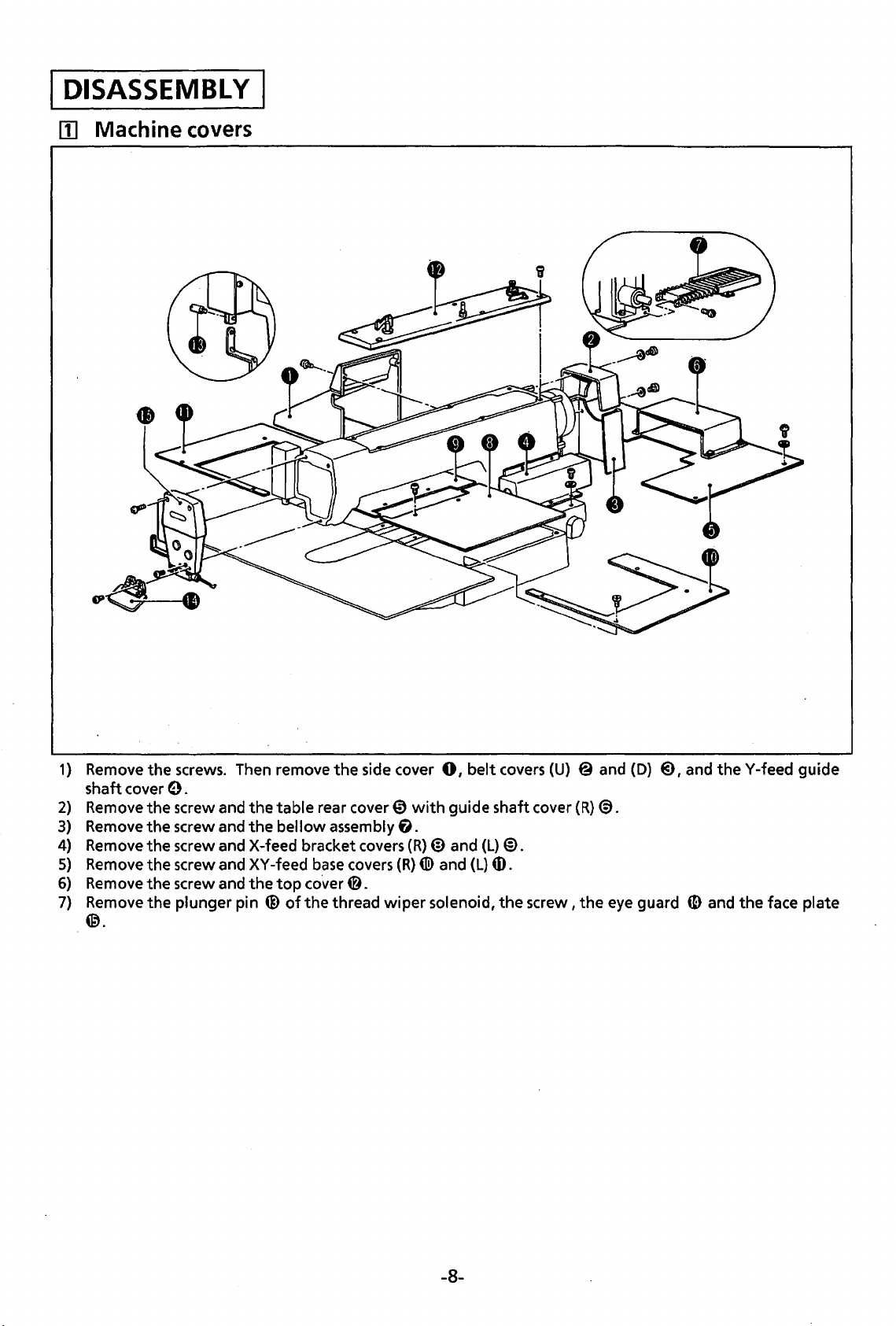

Page 11

DISASSEMBLY

lii

Machine

covers

1)

Remove

shaft cover

2)

Remove

3)

Remove

4)

Remove

5)

Remove

6)

Remove

7)

Remove

@.

the

screws. Then remove

the

0.

the

screw and

the

screw and

the

screw and X-feed bracket covers

the

screw and

the

screw and

the

plunger pin

the

the

XY

the

@of

table

bellow

-feed

top

co.ver

the

rear cover@

assembly

base

thread

side cover

covers

0.

wiper

fl.

(R)

(R)

with

4li>

0,

belt

covers

guide shaft cover (R)@.

@)

and

(L)

and

(L)

ID.

solenoid,

the

(U)

@).

screw,

@ and

the

eye guard

(D)

@),

and

ID

the

Y -feed guide

and

the

face plate

-8-

Page 12

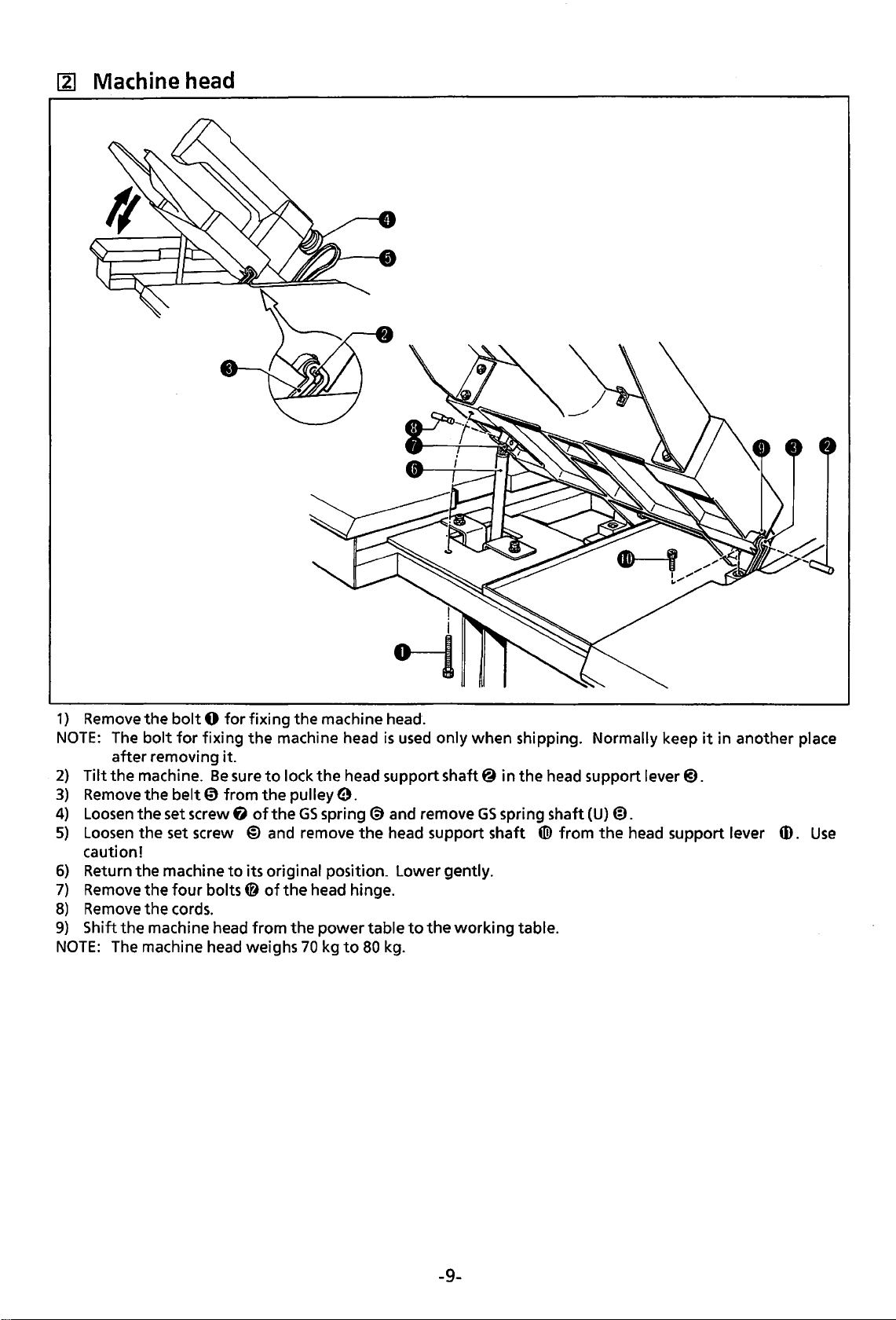

~

Machine head

1}

Remove

NOTE:

2)

Tilt

3}

Remove

4)

Loosen

5)

Loosen

caution!

6}

Return the machine

7)

Remove

8)

Remove

9)

Shift the machine head from the power table

NOTE:

the

bolt 0 for

The

bolt

for

fixing

after removing it.

the

machine.

the belt

the set screw

the set screw

the

the cords.

The

machine head weighs

four

Be

€)

from

bolts@

fixing the machine head.

the

machine head

sure

to

lock

the

the

pulley

9.

f)

of

the

GS

spring

@)

and remove the head support shaft

to

its original position. Lower gently.

of

the

head hinge.

70

kg

is

used

only when shipping. Normally keep

head support shaft@ in the head support lever@).

@)

to

80

and remove

to

the

kg.

GS

spring shaft (U}@.

((i)

working table.

from

the

head support lever (f).

it

in another place

Use

-9-

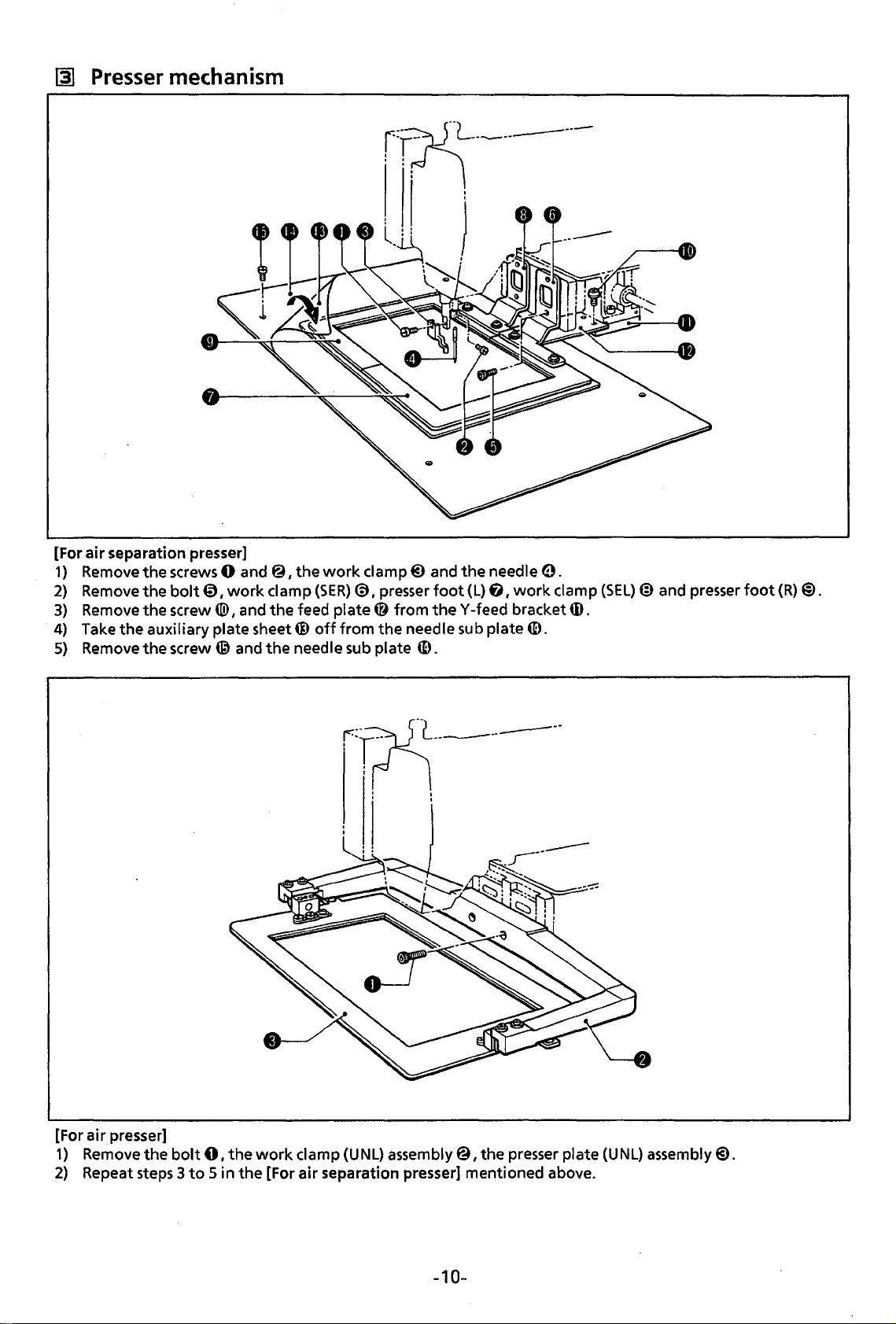

Page 13

~

Presser

mechanism

[For

1)

2)

3)

4)

5)

air

separation presser]

Remove

Remove

Remove

Take

Remove

the

screws 0 and

the

bolt

the

screw«!>

the

auxiliary plate sheet@

the

screw@ and

€)

I

work

I and

@I

the

work

damp

{SER)@)

the

feed

plate@

off

from

the

needle sub plate

damp@

I presser

the

and

from

theY-feed

needle sub plate

4D.

foot

the

{L)

needle

tj

I

work

bracket

6).

0.

clamp

m.

{SEL)@

and presser

foot

{R)@).

[For

air

presser]

1)

Remove

2)

Repeat steps 3

the

bolt

to 5 in

01

the

the

work

[For

damp

{UNL) assembly

air

separation presser] mentioned above.

@I

the

presser plate

-10-

{UNL)

assembly@.

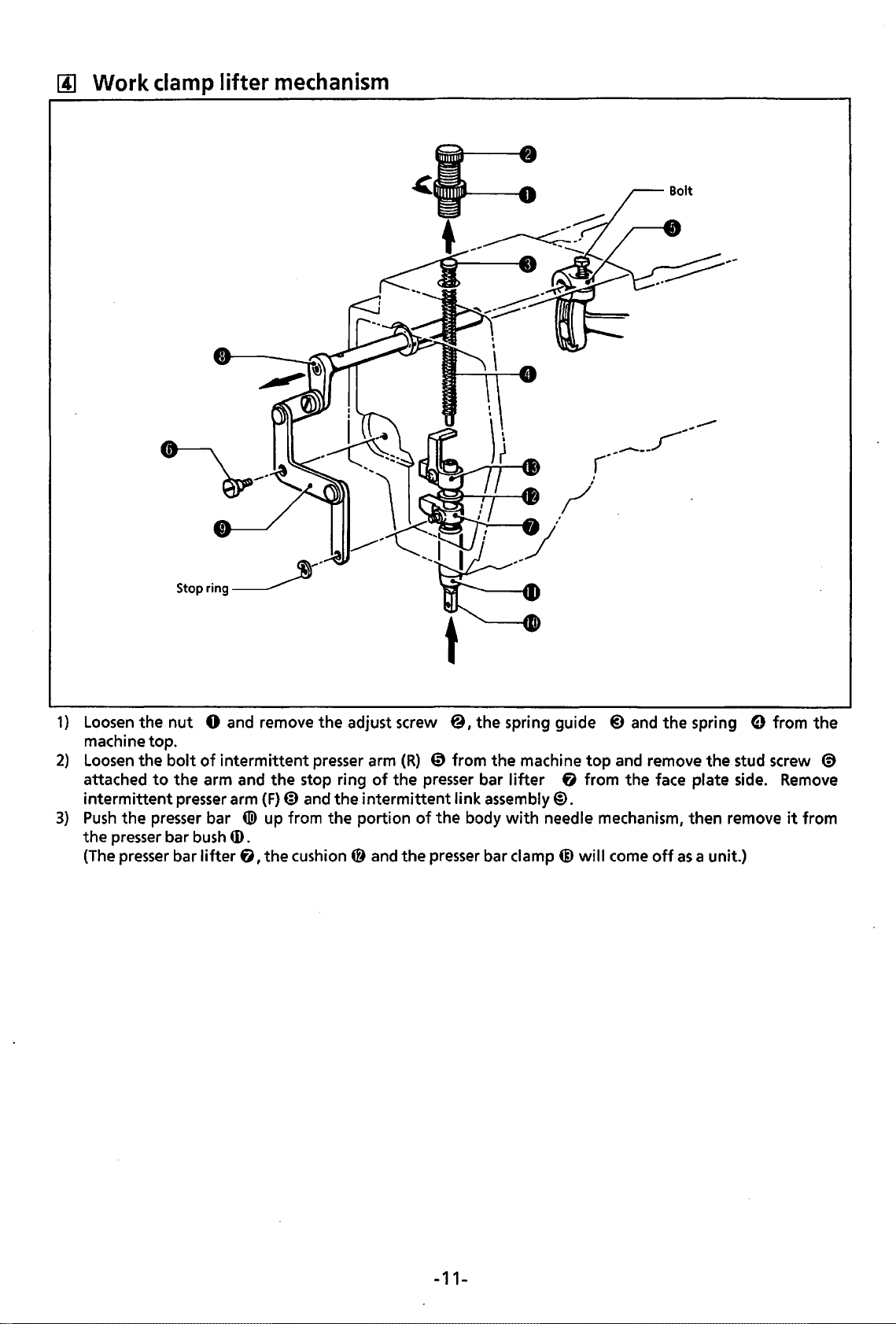

Page 14

[j] Work

clamp

lifter

mechanism

1)

Loosen

machine top.

2)

Loosen

attached

intermittent

3)

Push

the

(The

the

nut

the

bolt

to

the

the

presser bar

presser

bar

presser bar

Stop

ring~

0 and remove

of

intermittent

arm and

presser arm (F)@ and the

tiD

bush

ID.

lifter

f),

....

-

the

adjust screw

presser arm

the

stop ring

up from the portion

the

cushion @

(R)

@ from the machine

of

the presser bar

intermittent

of

the

and

the

presser

@,the

link assembly@.

spring guide

lifter

body

with

bar clamp@

needle mechanism, then remove

@)

and the spring 0 from

top

and remove the stud screw @

f)

from the face plate side.

will

come

off

as

a unit.)

the

Remove

it

from

-11-

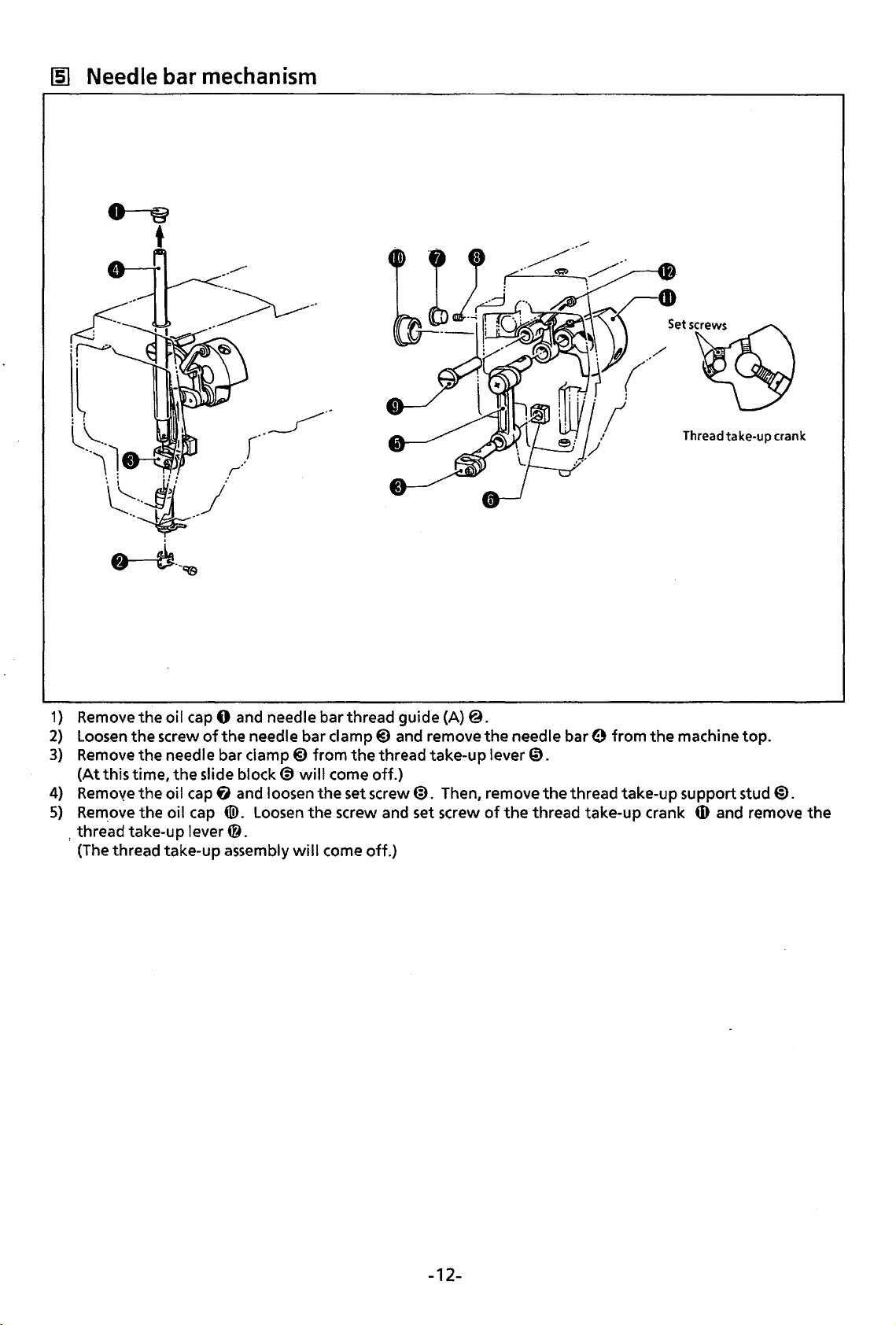

Page 15

~

Needle bar

mechanism

Thread

take-up

crank

1} Remove the oil cap 0 and needle bar thread guide

2}

Loosen

3}

Remove

(At

4}

Remove

5}

Re~ove

, thread take-up lever

(The thread take-up assembly

the

screw

the

this time,

the

the oil cap

of

the needle bar clamp@ and remove

needle bar clamp@

the

slide block@)

oil

cap

6 and loosen

([!).

Loosen

0.

will

from

the

thread take-up lever

will

come off.}

the

set screw@. Then, remove

the

screw and set screw

come off.}

(A}@.

the

of

needle

bare

from

0.

the

thread take-up support stud@).

the

thread take-up crank

the

machine top.

6)

and remove

the

-12-

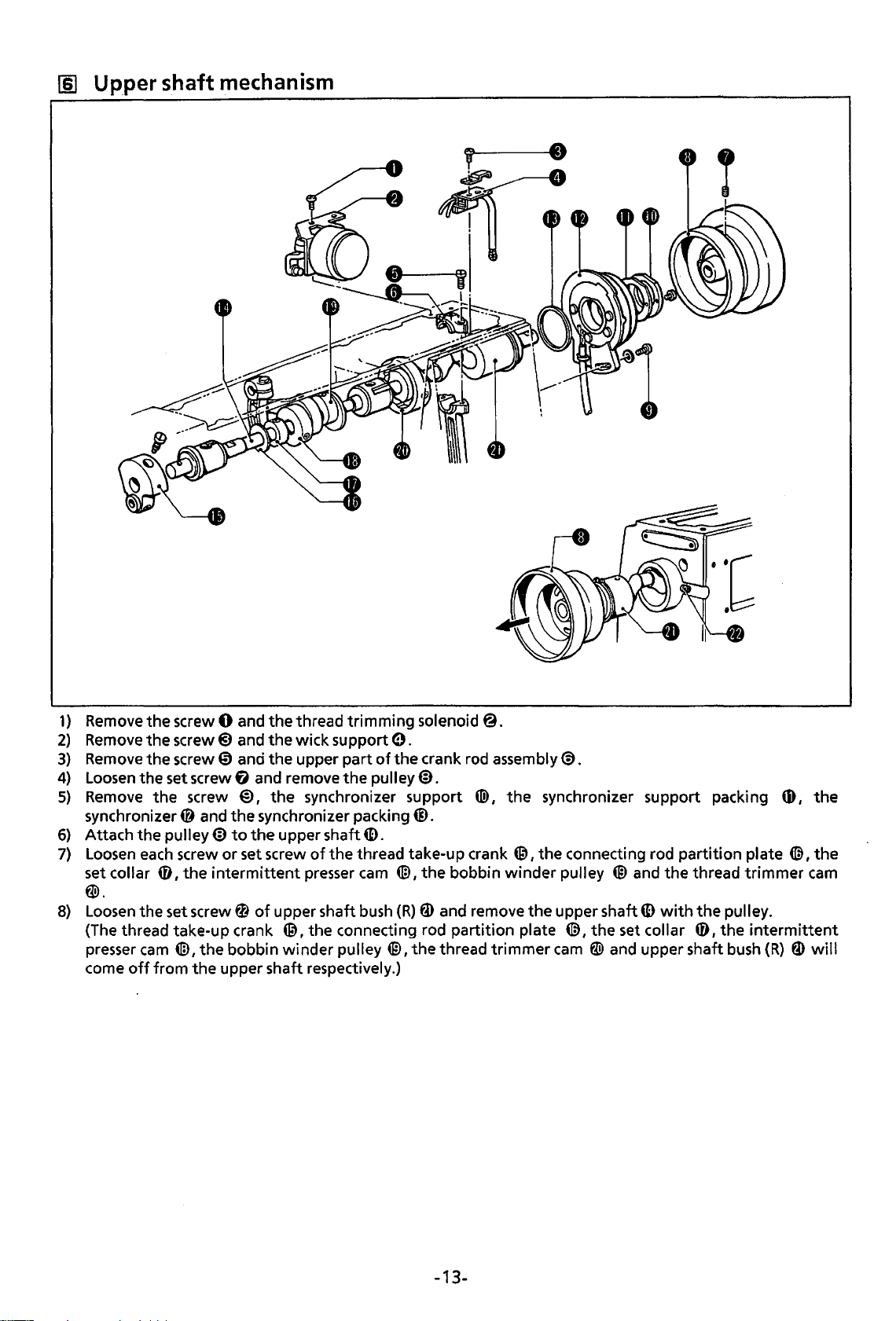

Page 16

III

Up_per

shaft mechanism

1}

Remove

2)

Remove

3)

Remove

4)

Loosen

5)

Remove

synchronizer@ and

6)

Attach the pulley@

7)

Loosen

set collar

the screw 0 and the thread trimming solenoid@.

the

screw@)

the screw 0 and the upper part

the set screw G and remove the pulley@.

the screw

each

screw or set screw

0

the

1

w.

8)

Loosen

(The thread take-up crank

presser

come

the set screw 0

cam

4ID,

the bobbin winder pulley

off

from the upper shaft respectively.)

and the wick support

@)

the

1

the

to

the

intermittent

of

synchronizer support ® 1 the synchronizer support packing

synchronizer packing@.

upper shaft

of

the thread take-up crank

presser

upper shaft

@,the

0.

of

the crank rod assembly@.

ID.

@,the

cam

4ID

I

the

bobbin

bush

(R)

fD

and remove the upper shaft

connecting rod partition plate (@,the

@I

the

thread trimmer

winder

connecting rod partition plate

pulley @

cam

W and upper shaft

and

the thread trimmer

ID

with

the

set

collar 0 I

pulley.

the

intermittent

bush

(R)

tD

the

1

(@ 1 the

cam

fD

will

-13-

Page 17

[1]

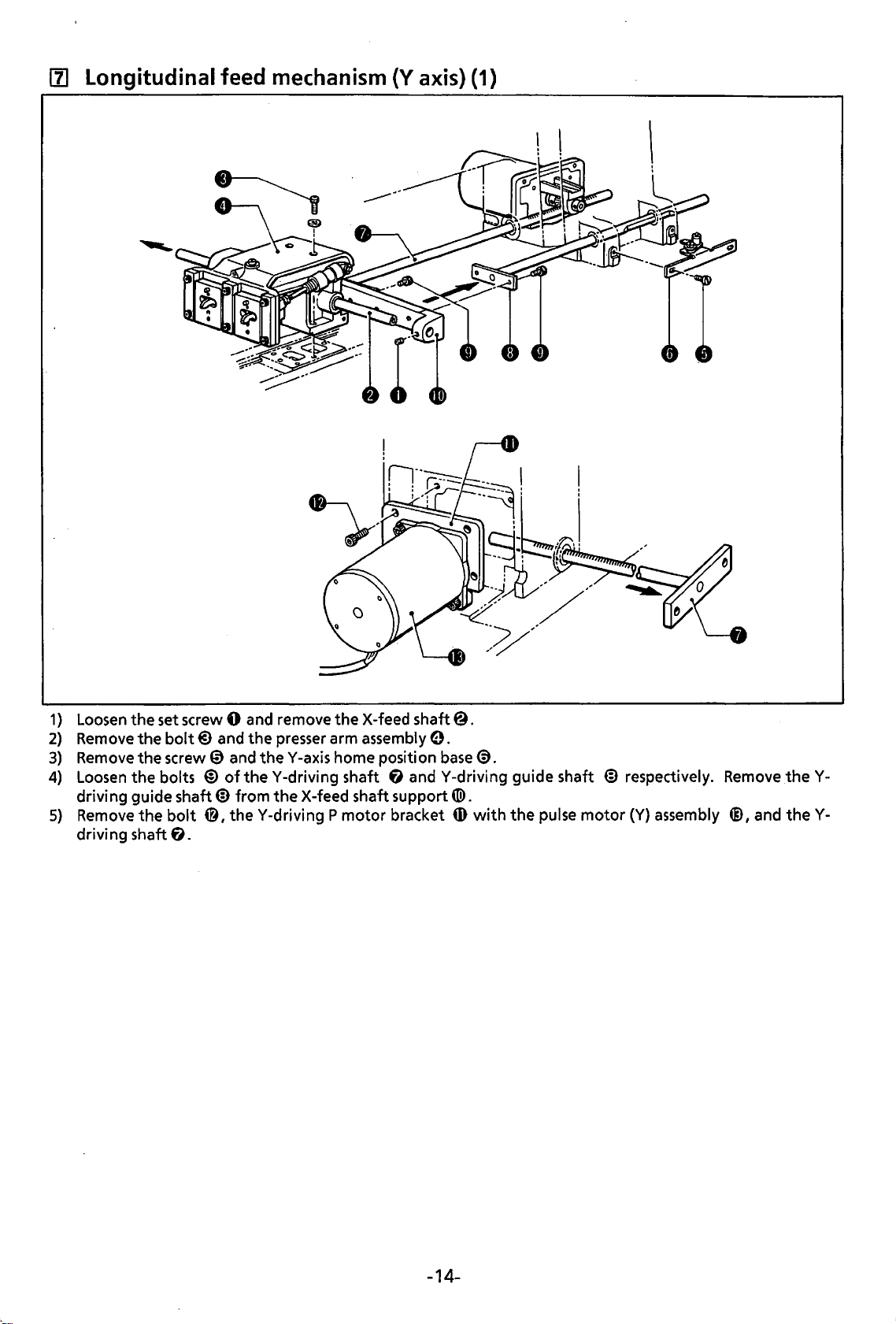

Longitudinal feed mechanism (Y axis) (1)

1}

Loosen

2}

Remove

3}

Remove the screw 0 and

4}

Loosen

drivi ng guide shaft

5}

Remove

driving shaft fJ.

the set screw 0 and remove

the bolt@) and

the bolts

the

bolt

the

X-feed shaft@.

the

presser arm assembly

theY

-axis home position

@)

of

theY-driving

ED

from the X-feed shaft support

0,

theY-driving P motor

shaft

0.

base

@.

f)

andY-driving guide shaft

tiD.

bracket

ID

with

the

pulse

ED

motor

respectively.

(Y}

assembly

Remove

®,and

theYtheY-

-14-

Page 18

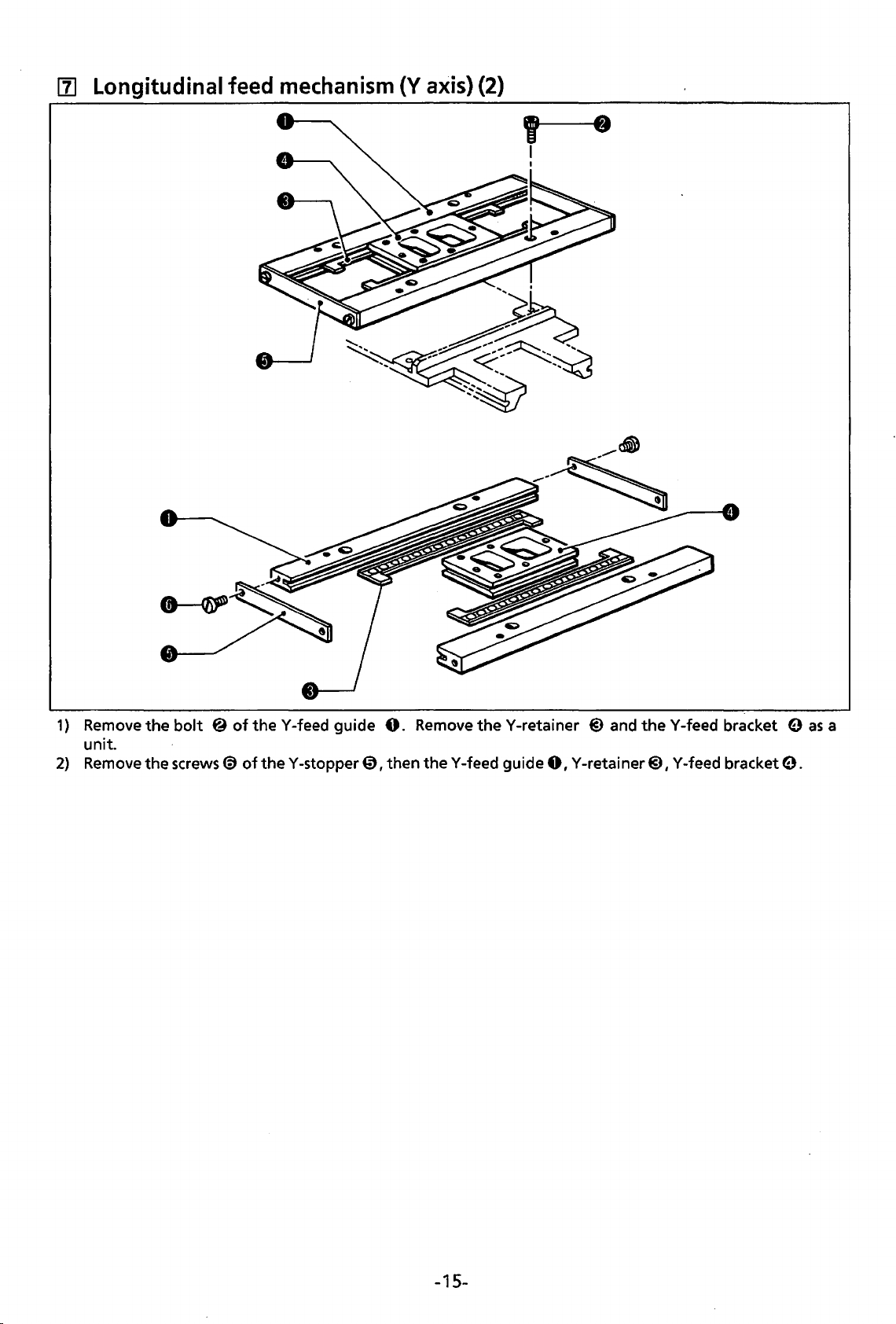

11]

Longitudinal feed

mechanism

{Y

axis)

{2)

' .

I

I

1)

2)

Remove

unit.

Remove

the

bolt @ of

the screws@

theY-feed

of

theY-stopper

guide

0,

0.

Remove

then theY-feed guide

theY-retainer

@)

and

theY-feed

0,

Y-retainer@), Y-feed bracket

bracket 9

9.

as

a

-15-

Page 19

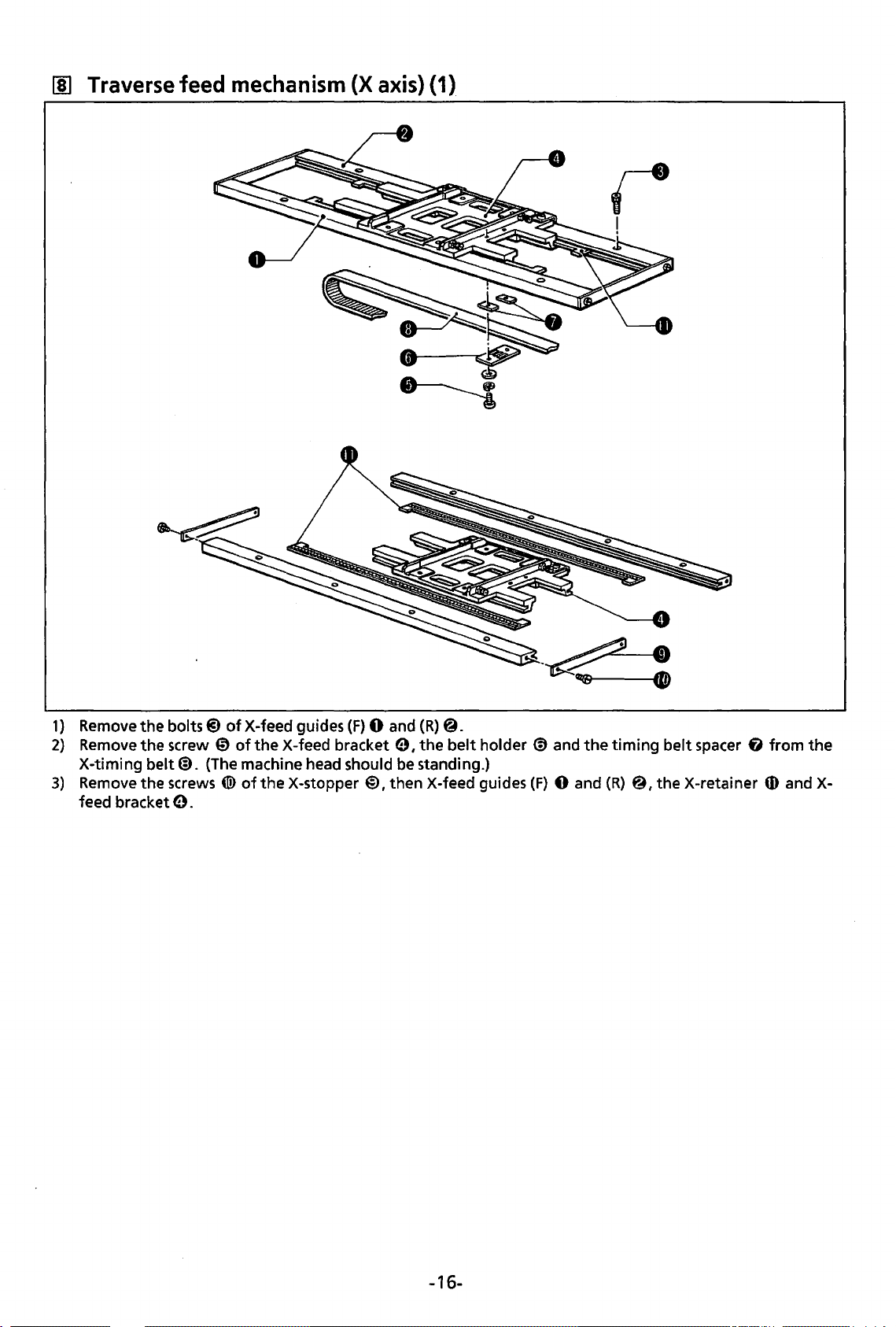

00

Traverse

feed

mechanism

(X

axis)

(1)

r

!

1)

Remove

2}

Remove

X-timing

3}

Remove the screws ®

feed bracket e.

the

bolts@)

the

screw 0

belt@). (The machine head should be standing.}

of

X-feed guides

of

the

X-feed bracket e I

of

the

X-stopper

(F)

0 and

@,then

(R)

@.

the

belt

holder @ and

X-feed guides

(F)

the

0 and

timing

(R}

@

1

belt

the

spacer

X-retainer

fJ

from

ID

and X-

the

-16-

Page 20

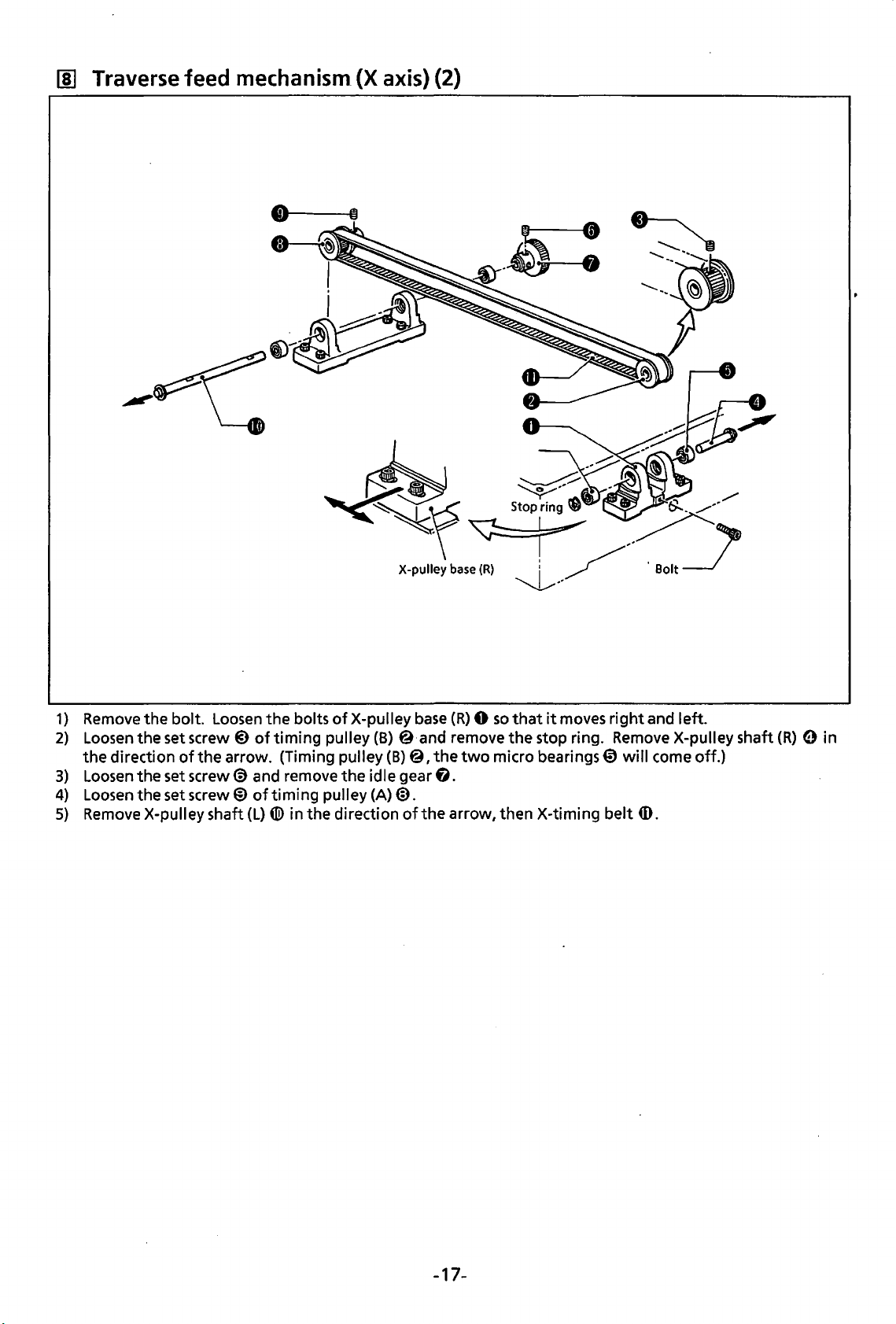

II)

Traverse

feed

mechanism

(X

axis)

(2)

1}

2}

3)

4)

5)

Remove

Loosen

the

direction

Loosen

Loosen

Remove

the bolt.

the setscrew@)

the set

the set

X-pulley shaft

Loosen

of

the arrow. (Timing pulley (B)@, the

screw@)

screw®

X-pulley

the bolts

oftiming

and remove the idle gear

of

timing

(L)

® in the direction

of

X-pulley

pulley(B} @·and remove

pulley (A)@.

of

base

(R)

base

(R} 0 so

two

that

it

the

stop ring. RemoveX-pulleyshaft(R} 0 in

micro bearings 0

6.

the

arrow, then X-timing belt

moves

right

will

and left.

come off.)

ID.

-17-

Page 21

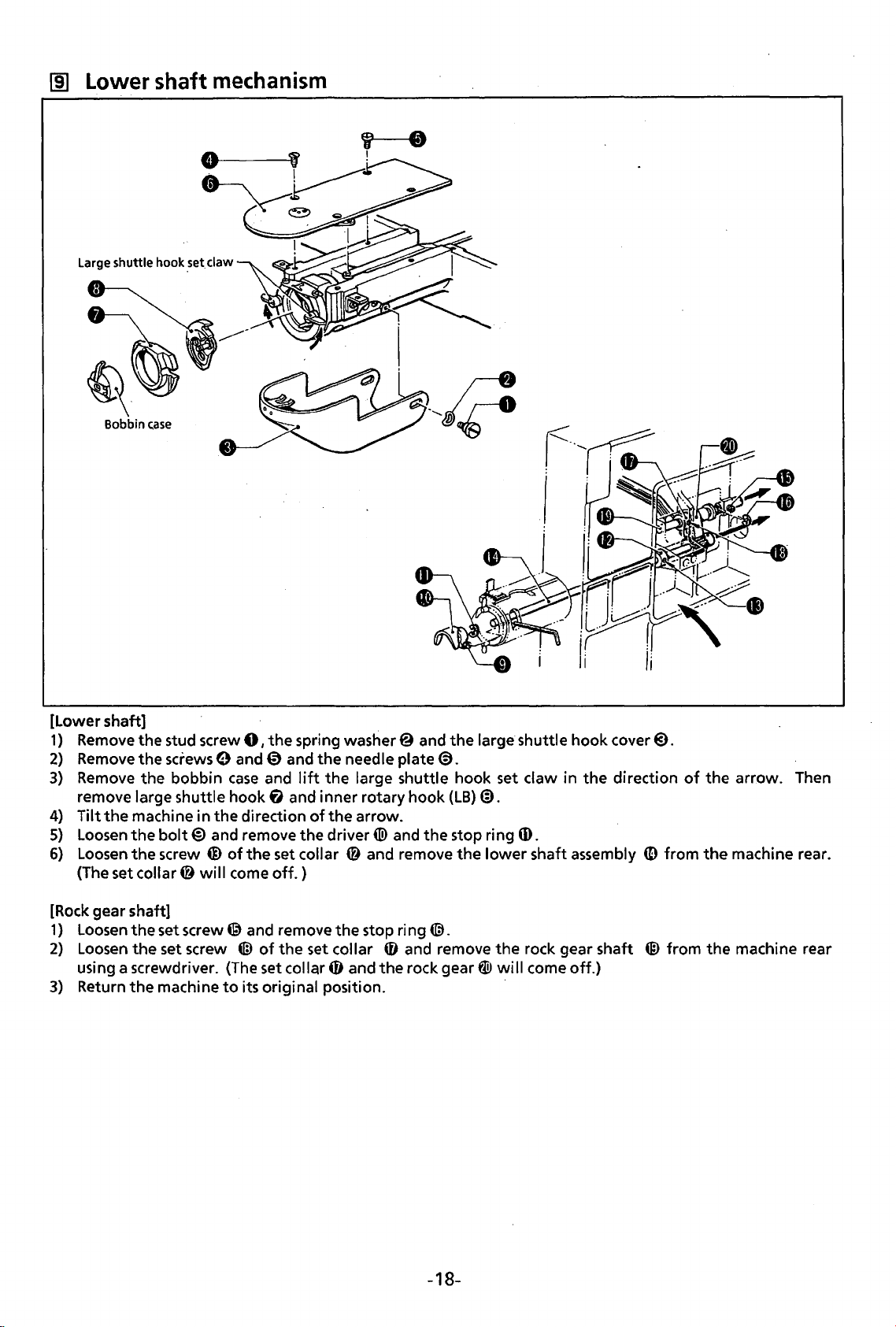

~

Lower shaft

mechanism

Large shuttle hook

.set.

claw

[Lower shaft]

1)

Remove

2)

Remove

3)

Remove

remove

4) Tilt

5)

Loosen

6)

Loosen

(The set

[Rock

1)

Loosen

2)

Loosen

using a screwdriver.

3)

Return

the stud screw

the

the bobbin

large shuttle hook

the

machine in the direction

the

the

collar@

gear shaft]

the set screw @ and remove the stop ring

the

the

screws

bolt@

screw @

set screw

machine

and remove the driver«!> and the stop ring (I).

will

0,

the

spring wastier@ and

the

9 and 0 and the needle plate@.

case

and

lift

the large shuttle hook set claw in the direction

f)

and inner rotary hook (LB)@.

of

the

arrow.

of

the

set collar @ and remove

come

off.)

@.

tiD

of

the

set collar 0 and remove the rock gear shaft ® from the machine rear

(The

set collar 0 and the rock gear W

to

its original position.

large shuttle hook cover@.

the

lower shaft assembly

will

come off.)

(D

of

the arrow. Then

from

the

machine rear.

-18-

Page 22

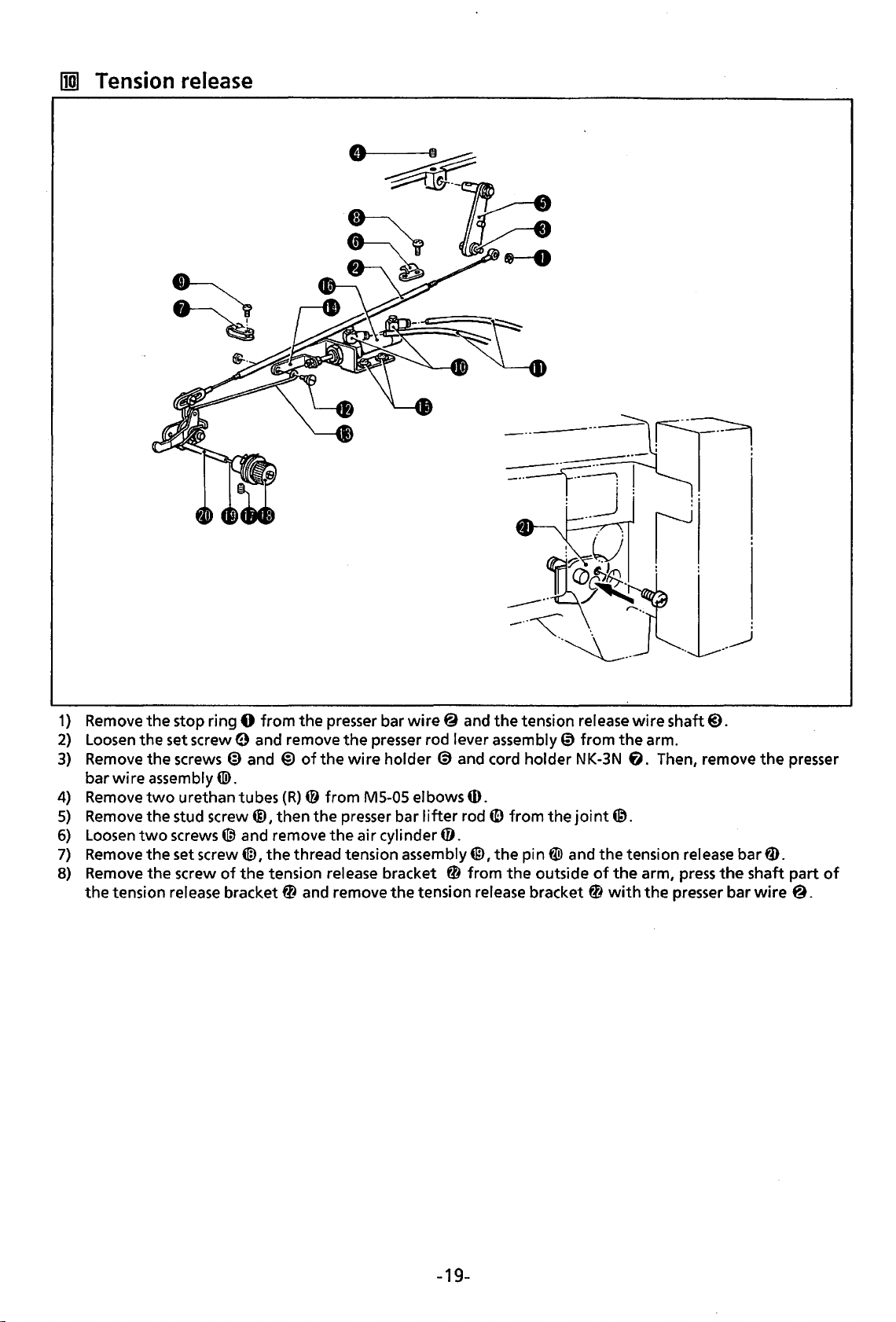

1m!

Tension release

--~r=:r-~

~~~~--:

I J

. .

II

1)

2}

3}

4}

5)

6)

7}

8}

Remove

Loosen

Remove

bar

Remove

Remove

Loosen

Remove

Remove

the

the

stop ring 0

the

set screw e and remove

the

screws @ and @

wire

assembly«!>.

two

urethan tubes (R)@

the

stud screw@,

two

screws@ and remove

the

set screw@,

the

screw

tension release bracket@ and remove

of

from

the

of

the

then

the

the

thread tension assembly@,

the

tension release bracket 0

presser bar

the

wire

from

presser bar

the

air cylinder

wire@

presser rod lever assembly 0

holder ® and cord holder NK-3N

M5-05 elbows ill.

lifter

and

rod

0.

from

the

tension release bracket 0

-·~.

the

tension rei

ID

from

the

the

pin

@>

the

outside

·-~..

ease

wire

from

the

arm.

fi.

joint@.

and

the

tension rei

of

the

arm,

with

the

..

__

_.)

shaft@).

Then, remove

ease

bar

press

the

presser bar

:

the

fD.

shaft

wire@.

presser

part

of

-19-

Page 23

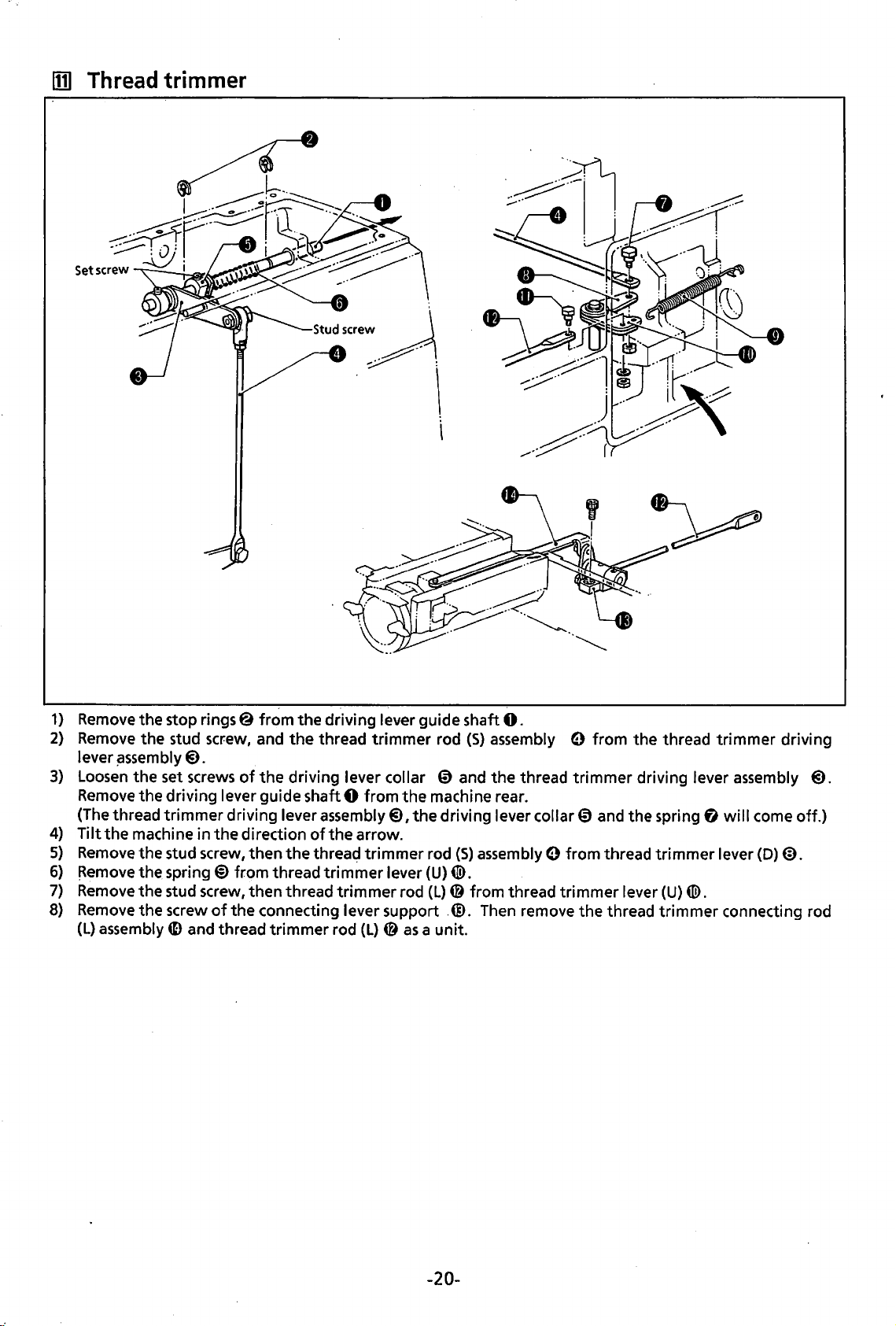

Ill]

Thread trimmer

1}

Remove

2)

Remove

lever

3)

Loosen

Remove

(The thread trimmer driving lever

4)

Tilt

5)

Remove

6)

~emove

7)

Remove

8)

Remove

(L)

the stop rings@ from the driving lever guide shaft

the stud screw, and

~ssembly@).

the set

the driving lever guide shaft 0 from

the

machine in

the stud screw, then

the spring@ from thread

the stud screw, then thread

the screw

assembly

screws

ID

and thread trimmer rod

of

the

direction

of

the connecting lever support

0.

the

thread trimmer rod

the

driving lever collar 0 and the thread trimmer driving lever assembly

the

assembly@),

of

the arrow.

the

threac;j

trimmer

trimmer

trimmer

(L} @ as

the

lever (U)@.

rod (L)@ from thread trimmer lever

(S}

assembly 0 from the thread trimmer driving

machine rear.

driving lever collar 0 and the spring

rod

(S}

assembly 0 from thread

.@.

Then remove the thread

a unit.

fl

trimmer

(U)

tiD.

trimmer

will

lever

connecting rod

@).

come off.}

(D)@).

-20-

Page 24

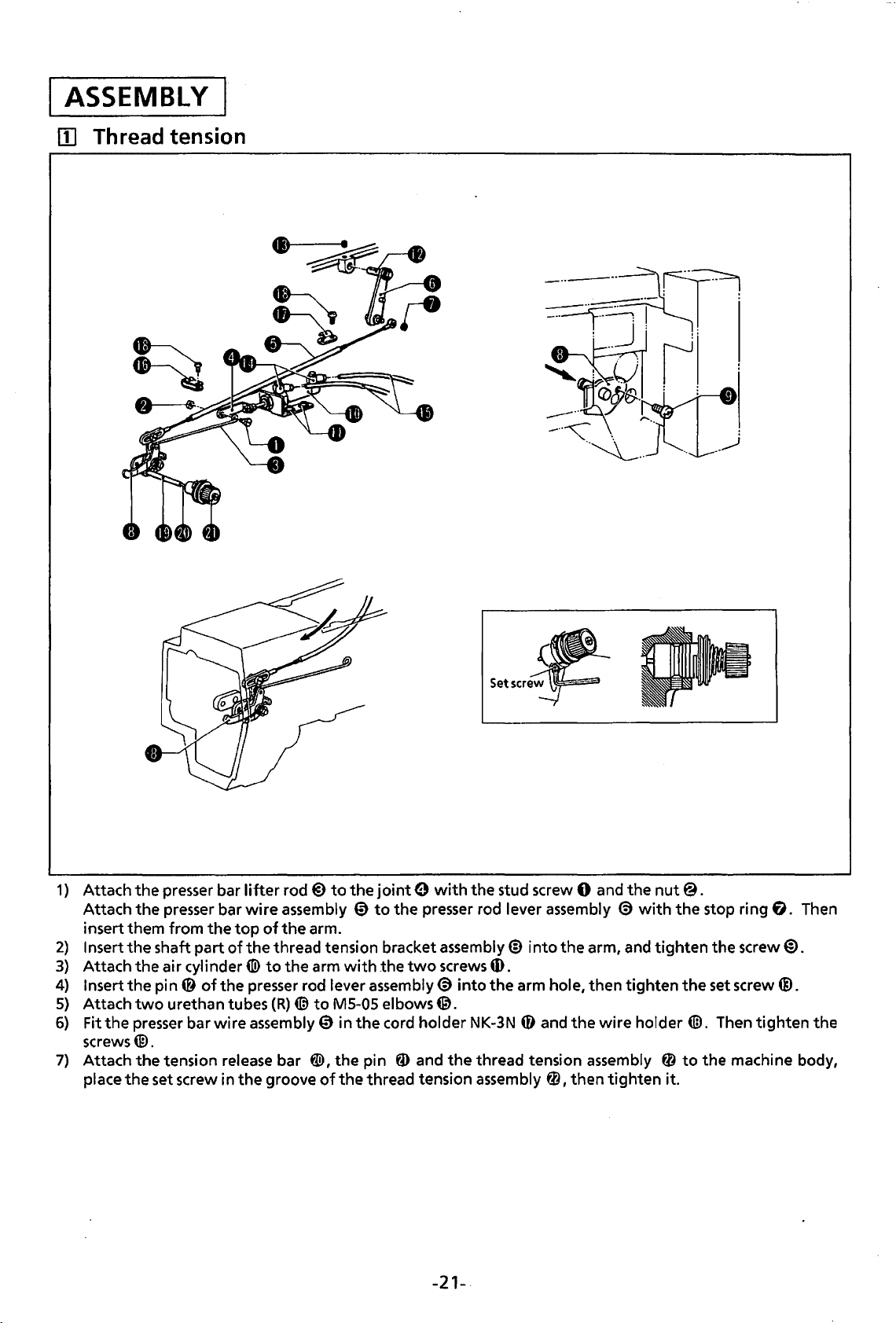

ASSEMBLY

[1]

Thread tension

-··-

~__:_--,!

---~

Setser~

---~--~

.:-----::::::··- ' :

' _j

·-~--

.

1··

.

,.

..

__

_)

l'l~l»>

I

.

1) Attach

Attach

insert

2)

Insert

3)

Attach

4) Insert

5)

Attach

6)

Fit

screws@.

7) Attach

place

the

the

presser bar lifter rod@)

the

presser

them

from

the

shaft

the

air cylinder«!)

the

pin@

two

urethan

presser

the

tension release

the

set

bar

the

top

part

of

of

the

tubes

bar

wire assembly 0 in

screw

in

the

to

the

joint

0 with

wire assembly 0

of

the

arm.

the

thread

to

presser rod lever assembly@) into

(R)

bar

groove

tension bracket assembly@ into

the

arm

([;}to M5-05

@!>,the

of

with

the

the

pin

thread

to

the

the

two

elbows@.

cord holder

ID

and

tension assembly

the

presser rod lever assembly

screws

NK-3N

the

stud screw 0

ID.

the

arm hole,

0 and

thread

tension assembly 0

0,

the

then

-21-.

and

€)

arm, and

then

the

wire holder

tighten

the

nut@.

with

tighten

tighten

it.

the

the

tiD.

to

stop ring

the

screw@).

set

screw®.

Then

tighten

the

machine body,

fl.

Then

the

Page 25

lZJ

Upper shaft mechanism (1)

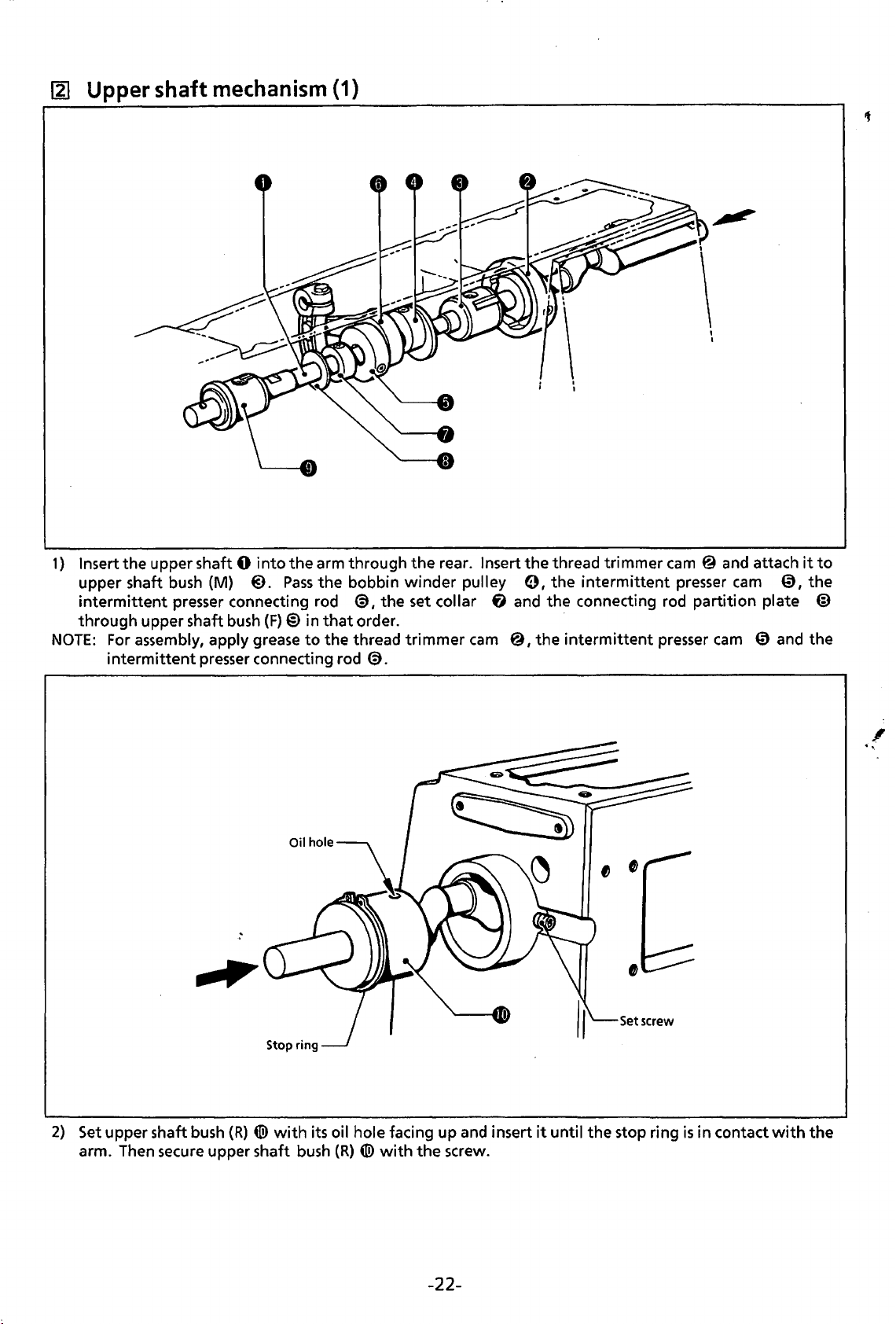

1)

Insert the upper shaft 0

upper shaft

intermittent

through upper shaft

NOTE:

For

intermittent

bush

presser connecting rod

assembly, apply grease

(M)

bush

presser

into

the arm through the rear. Insert the thread trimmer

@).

Pass

the bobbin

(F)@)

in

that

to

the

connecting rod

@,the

order. ·

thread

@.

winder

set collar

trimmer

pulley

fj

cam

0,

the

and the connecting rod partition plate @

@,the

intermittent

intermittent

presser

cam @ and

presser

cam

cam

attach

0,

it

the

to

0 and the

,

...

2)

Set

upper shaft

arm. Then secure upper shaft

bush

(R)

{{!)

with

its oil hole facing up

bush

(R)

{{!)with

the

and

screw.

insert

it

until the stop ring

-22-

is

in contact

with

the

Page 26

~

Upper shaft

mechanism

(2)

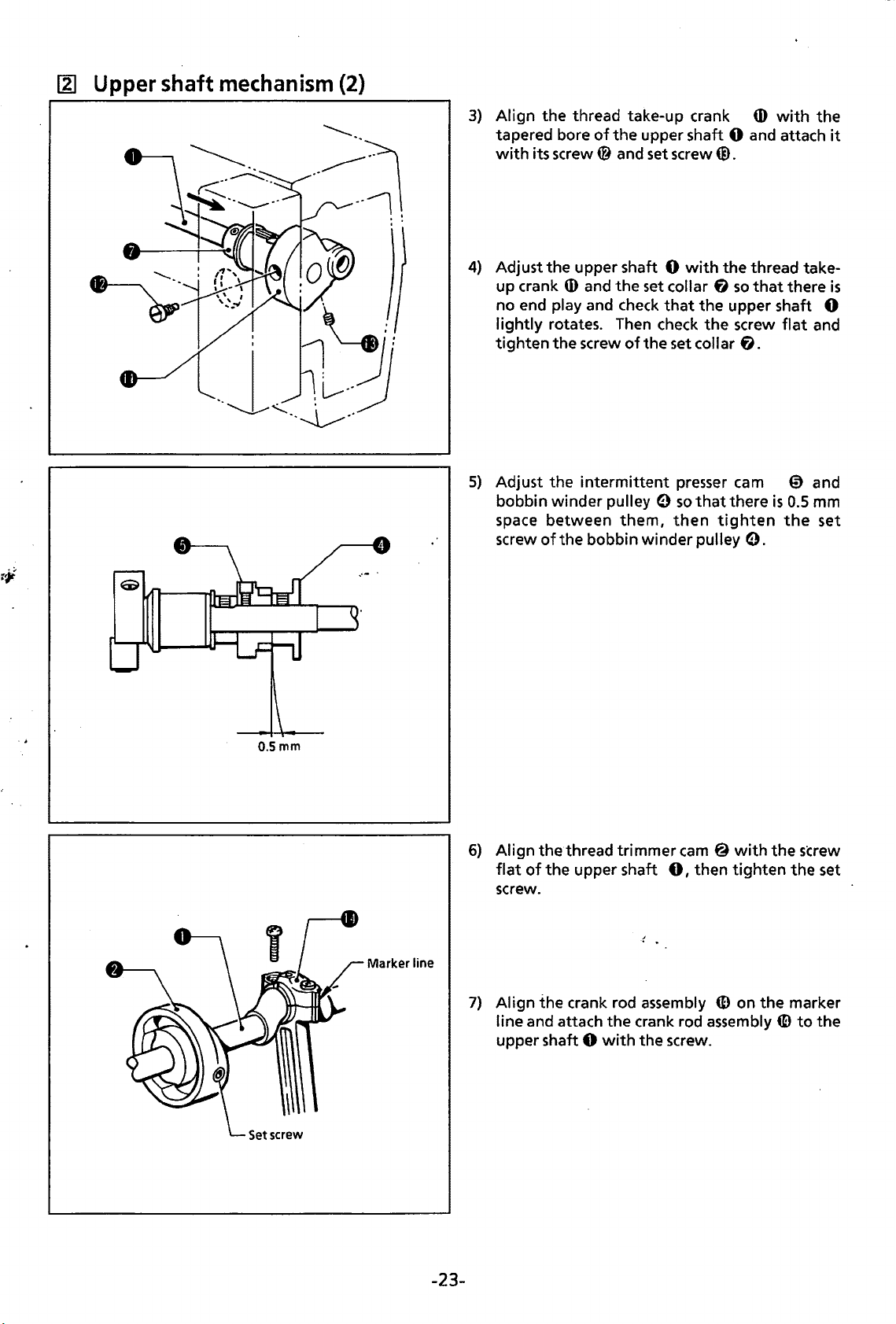

3)

Align

the

thread

tapered

with its screw@ and

4)

Adjust

up crank

no end play

lightly rotates. Then check

tighten

5)

Adjust

bobbin winder pulley 0 so

space

screw

bore

the

upper shaft 0 with

Q)

the

screw

the

intermittent presser cam 0

between

of

the

take-up crank

of

the

and

the

and

check

of

them,

bobbin winder pulley

Q)

with

the

upper shaft 0 and attach it

set

screw@.

the

set collar 6 so

that

the

upper shaft 0

the

screw flat and

the

set

collar

6.

that

there

then

tighten

thread

that

there

is

0.5

the

take-

is

and

mm

set

0.

O.Smm

Marker line

6)

Align

thethread

flat

of

the

screw.

7)

Align

the

crank rod assembly

line

and

attach

upper shaft 0 with

trimmer cam @ with

upper shaft

the

0,

crank rod assembly

the

screw.

then

CD

the

tighten

on

the

CD

screw

the

set

marker

to

the

-23-

Page 27

~

Upper shaft

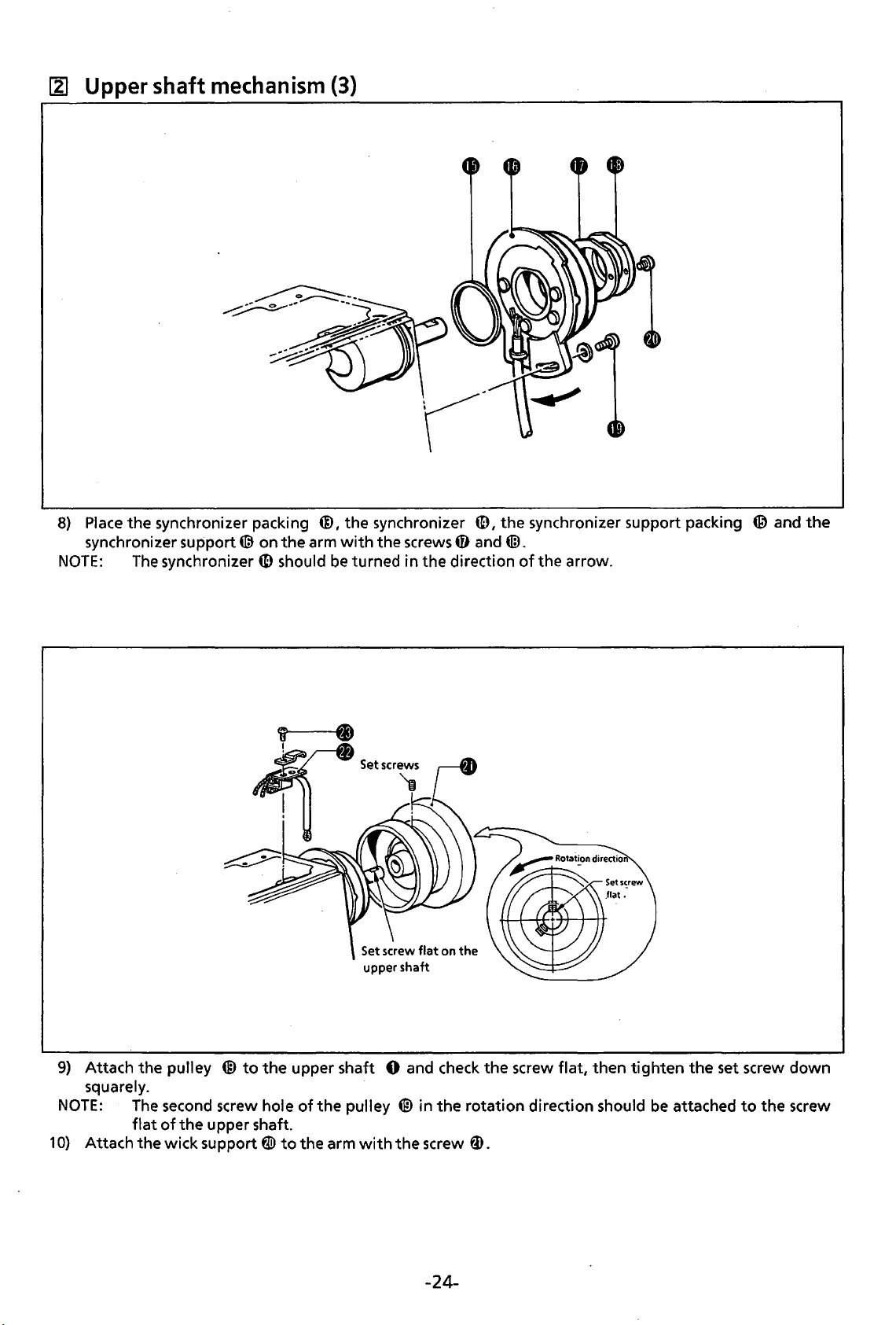

8)

Place

synchronizer

NOTE:

mechanism

the synchronizer packing

support®

The

synchronizer

on

ID

the

should

(3)

@,the

arm

synchronizer

with

the

screws

be

turned in the direction

ID,

the synchronizer support packing @ and the

0 and

@.

of

the arrow.

9)

Attach the pulley @

squarely.

NOTE:

1

0)

The

second

flat

of

Attach the wick support

the upper shaft.

to

the

screw hole

fll)

to

upper shaft 0 and check the screw flat, then tighten the set screw down

of

the

pulley @ in

the arm

with

the

the screw

rotation direction should

tD.

-24-

be

attached

to

the screw

Page 28

@1

Needle

bar

mechanism

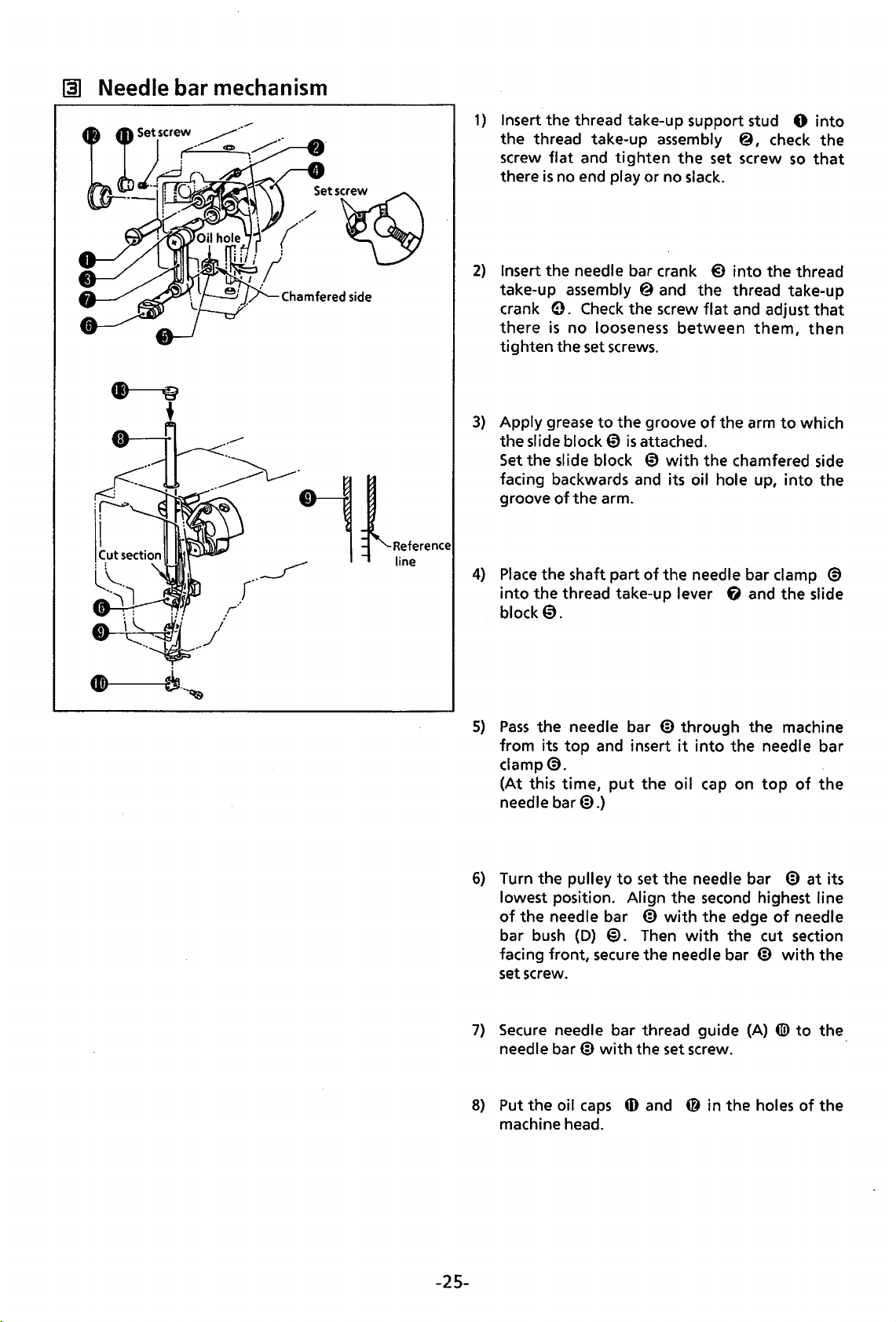

1)

Insert

the

thread

the

thread

screw flat

there

is

2)

Insert

take-up

crank

there

tighten

3)

Apply grease

the

slide block 0

Set

the

facing backwards and its

groove

take-up

and

tighten

no

end

play

the

needle

assembly @

e.

Check

is

no

looseness

the

set

screws.

to

the

slide block 0

of

the

arm.

take-up

bar

the

is

attached.

support

assembly

the

or

no slack.

crank @ into

and

screw flat

between

groove

with

oil hole up, into

stud 0 into

@,

set

screw so

the

thread

and

them,

of

the

arm

the

chamfered side

check

the

thread

take-up

adjust

to

which

the

that

that

then

the

4}

Place

the

shaft

into

the

thread

block

0.

5}

Pass

the

needle

the

the

needle

bush

screw.

top

time,

bar@.}

pulley

(D)

needle

bar@

from its

clamp@.

(At this

needle

6)

Turn

lowest position.

of

bar

facing front, secure

set

7)

Secure

needle

part

of

take-up

bar @

and

insert it into

put

the

to

set

Align

bar

@

@.

Then

the

bar

thread

with

the

the

needle

lever

through

oil

the

needle

the

with

with

needle

set

screw.

guide

bar

f)

and

the

the

cap

on

bar @ at

second highest line

the

edge

the

bar

@ with

(A}

clamp

the

machine

needle

top

of

of

needle

cut

section

(I!)

to

@)

slide

bar

the

its

the

the

8)

Put

the

oil caps

machine head.

-25-

ID

and @ in

the

holes

of

the

Page 29

[A]

Work

clamp

lifter

mechanism

(1)

1)

Insert

the

presser

presser bar clamp 0

2)

Secure

3)

Insert

NOTE:

4) Pass

presser arm

5)

Attach

with

the

the

spring®

Adjust

top,

then

intermittent

the

the

stop ring.

bar@

through

presser

the

(R)@.

intermittent

bar

and

nut

@ so

secure it.

presser arm

into

the

presser

the

presser

clamp 0 with

the

spring guide 6 into

that

there

is

(F) ® through

link assembly

bar

bar@

the

screw.

25

mm distance

@to

bush

0.

in

the

spreader

the

arm with

Pass

that

order.

arm from

between

the

presser bar lifter @),the cushion 0 and

the

top

and attach

the

adjust screw @

shaft bushes (L) and

the

stud screw, and

(R)

to

the

screw@.

top

and

ID,

then

the

presser bar lifter

the

the

machine

insert it into

@)

-26-

Page 30

[!]

Work

clamp lifter mechanism (2)

6)

Turn the pulley

lowest position. Position

arm

(F)(@

flush when

Then tighten the

to

and the

intermittent

set

the needle bar @ at its

intermittent

arm

so

that

their indexes are

rise

is

at its maximum.

bolt

of

presser

arm (R)@.

presser

NOTE:

7)

8)

Check

to

arm

(F) ® has

Attach the

so

that

aligns

Attach the needle@

the

with

work

the

be

top

sure

clamp

edge

top

that

Intermittent

no end play.

(D

to

the presser

of

the

end

of

the screw.

to

the needle bar

work

presser

bar@

clamp (D

@.

+

9)

Turn the pulley

that

the needle @

work

1

0)

Turn the pulley

lowest position.

bar

aligns

the screw

to

turn

the

presser

comes

clamp

(D

hole.

to

set the

Vertically adjust

@

so

that

part A

with

the needle plate top, then tighten

of

the

presser

in the center

presser

of

the

work

bar clamp

bar @

of

bar @

the

presser

clamp (D

0.

at

so

the

its

-27-

Page 31

~

Thread trimmer {1)

1)

Put the thread trimmer driving lever assembly

0 between the thread trimmer

bush

(M)

upper shaft

2)

Attach the thread trimmer rod

to

the

thread trimmer driving lever assembly

Secure

3)

Pass

the

shaft

it

@ and

assembly 0 in

them

with

the driving lever guide shaft 0 through

bush

8 x

15

0

into

the arm from the outside and

through the spring

the

thread

@).

the stud screw and the nut.

®,insert

f),

trimmer

that

order.

the driving lever guide

the driving lever collar

cam

(S)

assembly 0

driving

@ and

0.

pass

lever

4)

Attach the stop rings

shaft

0 and contact the driving lever collar

and the stop ring, then tighten them.

Similarly, attach

lever assembly 0

5)

Put

the

pin part

@)

into

the groove

then

attach

assembly

(li)

the

to

the arm

to

the driving lever guide

the

thread

to

the

stop ring and

of

the solenoid lever assembly

of

the driving lever collar

thread

trimming

with

trimmer

the

two

driving

secure

solenoid

screws.

@)

it.

@,

-28-

Page 32

~

Thread trimmer (2)

.Bolt

t--Setscrew

!

6)

Attach

assembled thread

thread trimmer connecting rod

arm

7)

Attach the thread trimmer connecting rod

to

rod

assembly@

8)

Attach the thread trimmer rod

to

screw(@

Attach thread trimmer rod (L)

trimmer lever

the

the

connecting

trimmer

with

the bolt.

the pin part

(L)

thread trimmer lever

and the

nut

ti9

of

@ and

to

the arm

nut

(U) 0 with

and

the

thread trimmer connecting

attach

i).

washer

lever

support

rod

(L)

the

needle

with

the

screws.

(S)

(D)

@

the stud screw

tD.

(L)

with

ID

@)

ID

and

0

to

the

4D

plate

assembly 0

the stud

to

thread

@,

9)

Hook the spring

thread trimmer lever

10)

Adjust the adjust screw ~ so

the thread trimmer driving lever assembly 0

smoothly

thread trimmer

with

NOTE:

11)

This

large curved

cam

Vertically adjust thread

and

movable knife

plate assembly

lever

goes

the

nut

adjustment should

groove.

(U)

0 and align

(U) 0 with

@to

spring hook

{U)

0.

that

in and

cam

out

the groove

@.

Then

secure them

fD.

be

performed in the

part

of

the

thread

~arge

trimmer

the

V notch ®

with

the index on

@,then

the

nut

secure

(ID.

curved part

levers

thread trimmer

(S)

@)

and

the roller

of

trimmer

(D)

of

the

needle

of

the

@

the

-29-

Page 33

.~~-

"J·:

~;

..

?'

··

·

[§]

Presser mechanism

[For

air

separate presser]

1)

Attach

2)

Put

plateO.

NOTE:

3)

Attach

4)

Attach

assembly®

the

needle sub

the

auxiliary sheet @ on

The sheet should be replaced

the

feed plate 0

work

clamp

with

(SER)

the

bolts.

plate 0 to

the

to

theY-feed

fj

I presser

the

needle sub plate supports

needle sub plate 0

with a new

bracket 0

foot

one every

(L)@ I

with

work

clamp (SEL)@ I presser

top

with

month.

the

screws.

(L)

and (R)@

aligning

with

the

its rear end

foot

(R)

screws.

with

4ID

to

the

the

work

needle sub

clamp

-30-

Page 34

[1]

Feed

1.5 mm

mechanism

(X

axis)

(1)

1)

Place

the

pass

X-pulley shaft

the

screw

NOTE:

2)

NOTE:

Put

Place

the

through

the

X-pulse motor.

Check the screw

·

the

shaft, then secure the idle

Provide a

(A)

X-timing

flat

timing

X-timing belt @ and

the

f)

with

belt@

(R)

9 through

on X-pulley shaft

pulley

micro bearing 8

1.5

(B)@)

flat

on X-pulley shaft

mm gap between

two

set screws.

and

in

timing

the

(R)

e and secure

the

center

timing

@,and

gear®

timing

pulley

attach them

(B)

@ on X-pulley

micro bearing 8

timing

of

X-pulley

pulley (A)

(L)

@ and adjust X-pulley shaft

and

timing

pulley (A)

pulley (A)

€),

pulley (B)@

base

(R)

f)

on X-pulley

to

the

idle gear

f)

and X-pulley

and attach

0 and secure

f)

base

with

(R)

0.

the

with

base

(L)

tiD

by pressing

(L) @ so

the set

base

To

attach

stop ring

the

set screw.

it

with

@.

Pass

that

screws.

(L)

@ and secure

timing

to

the

two

X-pulley shaft

the

there

pulley

the shaft.

set screws.

driving gear m on

is

no end play in

timing

(B)

@,

Check

(L)

@

pulley

·

-31-

Page 35

[11

Feed

mechanism

(X

axis)

(2)

3)

After

Using caution

guides

NOTE:

Wire

applying grease

that

no steel balls (5/32") @ drop

(F)

G)

and

(R)

®.

together

the retainer and

to

the

X-retainer

@I

place steel balls (5/32") @ on

out

the

feed guide. Attaching

of

the

X-retainers

to

the bed

the

X-retainer @ respectively.

@I

assemble them

will

be easier.

to

X-feed

4)

Place

the back side

feed guide (R)@

5)

Put

the

X-feed bracket 0 between X-feed guides

bed

with

the

6)

Attach

7)

Attach the X-stoppers

NOTE:

the

At

this time,

bolt®

bolt

of

X-feed guide

to

the

bed

~.

for

adjustment and

tiD

to

the

the

screwsfD should

with

the

ends

of

(R)

@ on

the

mounting reference planes

bolt~.

(F)

G)

the

nut@

to

the

arm

X-feed guides

be

temporarily tightened.

(F)

and

(R)

as

in figure above.

ID

and (R)@

@ and attach X-feed guide

-32-

with

the screws fD.

in

the

bed and attach X-

(F)

G)

to

the

Page 36

[I]

Feed

mechanism

(X

axis)

(3)

8)

Make the X-retainer 0 touch the

Adjust X-feed guide

no slack

bolt4@.

After

X-feed guide

9)

After

and

adjustment, tighten

the above-mentioned adjustment, tighten the

smoothly moves

(F)

(F)

ID.

right

ID

by pressing the

at

12

the

nut ® to

and

kg or

provide a 1

left

X-stoppers

bolt

@ (within all the area)

less

when

it

is

pushed, and

mm

gap between the end

screws

10)

W.

so

that

the X-feed bracket 0

secure

fD

of

the

right

While putting the X-timing belt @ between

the timing belt

X-feed bracket from the underside

fit

the protrusions

the windows

Then, tighten the

X-feed guide

of

and

left

spacers

of

of

the belt

screws

(F)

ID

bolt

@ and

X-stoppers

fj)

at

the X-timing

holder~.

~.

W.

the bottom

the

of

belt

with

rear

of

the

has

the

of

the

bed,

0 in

Windows

-33-

Page 37

[1]

F~ed

mechanism

(X

axis)

(4)

11} Move the X-feed bracket 0

timing

(which

belt @ and adjust X-pulley

is

the

same

distance when pressing the X-timing

to

the

center and apply a vertical load

base

(R} ~ and

bolt @ so

belt

of

that

the belt deflection

until

it

slightly touches

1000 g

at

the center

is

the

of

the

6.5

mm

to

7 mm

lower shaft}.

X-

-34-

Page 38

00

Lower shaft and rotary hook

{1)

1) Tilt

2)

3)

4) Pass

5)

6)

NOTE:

7)

8) Return

the

Insert

the

collar 0

Put

the

end

play

the

the

set

shaft

assembly

Vertically adjust

collar@).

Adjust

gear@). Then

Place

secure it.

the

Apply grease

the

the

machine.

rock

gear

through

rock

gear

between

lower

shaft

collar

®.Pass

0.

rock

tighten

driver @

machine

shaft

0 into

the

rock

gear

@)

between

rock gear@) and

assembly 0

through

the

lower

shaft

gear

shaft

0 so

the

set

to

the

rock gear@).

on

the

lower

to

its original position.

the

arm from

shaft

0,

and

the

set

collar 0

the

shaft

through

the

shuttle race base assembly

assembly 0 so

that

there

screw.

shaft

assembly 0 and

attach

0.

the

is

the

and

Then

lower

that

no

backlash

-35-

rear. Pass

the

stop ring

the

stop

tighten

shaft

bush from

there

is

between

make

the

washer@,

to

the

ring and vertically adjust so

the

set

screw

the

fi

and place

no end play. Tighten

the

it

touch

shaft

rear

lower

the

the

rock

0.

of

the

set

of

the

the

shaft

stop ring,

gear

collar

arm

stop ring

the

set

gear

@)

and

that

0.

and

insert it into

on

screw

@ and

then

temporarily

the

there

the

of

the

the

set

is

no

lower

set

rock

Page 39

III

Lower shaft and rotary hook (2)

Inner rotary hook

9)

Fit the inner rotary hook in the large shuttle

hook.

0)

Turn the pulley

1

its

lowest position

reference

the

end

of

driver

aligned

tighten

11)

Turn the pulley

point

Loosen

between the needle @ and the inner rotary

hook point

shuttle hook adjust stud @

@>

with

the screw.

with

the set screw

to

raise

the needle bar

until

the

line on the needle bar

needle bar

so

that

the

the center

is

0.01-0.08

bush

(D) (}). Adjust the

the inner rotary hook

center

to

of

needle @ 1 then

align the inner rotary hook

of

the

so

that

mml

to

second highest

«!>

needle

the

then rotate

adjust.

«!>

from

aligns

with

point

@.

clearance

is

the

12)

Turn the pulley

point

with

Loosen

hook adjust stud @

lightly

driver@>.

13)

Removetheneedle0.

14)

Attach the large shuttle hook

race

15)

Insert the bobbin @

then attach them

16)

Attach the large shuttle hook cover 0

arm

washer.

17)

Attach the needle

the set screw and adjust the shuttle

contacts

base.

with

to

align the inner rotary hook

the center

the

to

the

the

stud screw and

0.

of

the needle

so

that

needle receiver

into

the bobbin

inner rotary hook.

0.

the needle 0

of

the

G)

to

the

shuttle

case

@

to

the

the

spring

1

-36-

Page 40

~

Longitudinal feed (Y axis) (1)

1}

Apply grease

Y -feed

2)

Make

the

them

with

3)

Put

theY-feed

feed bracket@. Then attach the X-feed bracket@

4}

Attach

NOTE:

5)

6)

7}

At

Attach the

Make

theY-retainer

attached

or

less.

After

adjustment,

Y -feed bracket

After

above adjustment

with

the

to

theY-retainer

guide@

theY

this time, the screw G

so

back

of

Y-feed guide @ touch mounting reference plane

the

bolt.

bracket

-stoppers@

bolt@

for

that

no steel balls (5/32")@ drop

€)

between

to

the

adjustment and

0 touch

to

the

X-feed bracket

Then, secure

screws G.

@.

the

theY

-feed bracket@

bolt

@ should be secured

is

made, secure theY-stoppers

0 and respectively place

theY-feed

back and

of

theY-stoppers@ should

theY-feed

€)

so

front

the

stoppers@. Adjust

that

theY

guide@

of

theY

nut@

to

-feed bracket

with

the

with

the

steel balls (5/32") @ on

out

of

theY

-retainer

of

attached

to

the X-feed bracket a

-feed

be

the

X-feed bracket

bolt.

the

nut

@)

to

the

guide@

temporarily tightened.

theY-feed

€)

has

no slack and smoothly moves

@)when

at

the

back and

it.

Fit them

0.

the

X-feed bracket a and secure

X-feed bracket a and another

with

the

bolt.

with

the

screws G.

a.

guide@

it

slightly touches

front

by pressing

the

of

theY-feed

the

back

guide @

into

the

bolt@)

at

10

of

the

Y-

kg

-37-

Page 41

~

Longitudinal feed (Y axis) (2)

Pulse

motor

Rack

pa~ctuating

gear

8)

Pass

theY-driving shaft@ through Y-driving shaft

NOTE:

9)

NOTE:

Apply grease

Apply non-sag type liquid gasket (Three

bracket

ID.

Before tightening the bolt, adjust the backlash between the rack part on

the

actuating gear.

Then

to

the rack part

secure

theY

-driving P motor bracket

of

theY

-driving

Bond

bushes

shaft®.

1212)

to

ID

(F)

and

(R).

the mounting plane

with

the bolt.

of

theY-driving P motor

theY-driving

shaft @ and

-38-

Page 42

II]

Longitudinal feed

(Y

axis) (3)

Bush

Deviation X

hole

Q (Align)

Deviation

1

0}

11}

12)

13)

NOTE:

X

Secure

and

Temporarily attach the X-feed shaft support ~ to

with

Temporarily attach the presser arm assembly @

washer. Temporarily

the

secure the

Adjust the X-feed shaft support

the

Attach theY-driving

the Y -home position dog assembly @

pass

theY-driving guide shaft@ through the bush.

the

bolt

and the plain washer.

secure

X-feed shaft @ parallel

presser

X-feed shaft@ are flush or concentric

Check

and the X-feed shaft support

that

arm assembly@ arid theY-feed bracket 0

shaft®

the X-feed shaft @ easily

the X-feed

to

the

ID

and theY-driving feed shaft@

ID

shaft@

bush

hole

inclination

at

hole.

with

of

so

any

passes

{Fig.B,

parallel, concentric}

the screw. Inject grease

theY-driving

to

theY-feed

to

the X-feed shaft support

the

presser

that

the

bush

point

of

the sewing area. (Refer

through the

shaft ® andY-driving guide shaft @

bracket 0

arm assembly @ (Refer

with

the bolt.

hole

to

the X-feed support

bush

hole

of

into

the inside

with

the

bolt

G)

with

the

to

the

presser

of

the presser arm assembly @

arm assembly @ and

to

figure

ID

with

of

and

the

set

screw. Make

figure A). Then,

B.)

the bolt.

the

bush

plain

-39-

Page 43

IJg)

Machine

head

1)

Place

NOTE:

2)

Tilt

then

3)

Set

the

4)

Attach

5)

Return

connector

the

machine head on

Do

not

damage

the

machine.

tighten

the

set

the

GS

spring 0 into

screw.

the

belt

the

machine head

to

its proper position.

electrical cords.

Raise

the

set

screw.

to

the

pulley.

the

power

head

the

machine head and insert

to

its original position. Unlock

table,

support

then

secure

lever @ and pass

the

head hinge 0 with

the

head

GS

spring shaft

the

head

support

(U)

0 into

support

the

shaft

lever

four bolts.

@)

through

the

hole,

@.

the

arm,

then

tighten

Connect each

-40-

Page 44

lll1

Machine

covers

1)

Attach

2)

Attach

3)

Secure

4)

Attach XY-feed

5)

Attach X-feed bracket covers

NOTE:

6)

Secure

4Il>

7)

Attach

8)

Attach

the

side cover

theY-feed

the

table rear cover 0

The back screws on

the

bellow

with

the

screws.

the

top

the

eye

guide shaft cover e

base

assembly

cover®

guard@

0,

belt

covers (D)@ and

with

guide shaft cover

covers

(L)

& and

(R)@)

the

X-feed bracket covers

ID,

the

and

the

face plate

to

the

face plate

(U)@)

with

the

screw.

with

the screw.

(R)

®with

(R)@)

with

the

screws.

and

(L) ® with

presser arm assembly @ and

ID

ID

with

with

the

screws.

(R)@)

and

(L)

their

screws respectively.

screws.

the

screw.

® should

the

not

be attached.

X-feed bracket covers

(R)

@)

and

(L)

-41-

Page 45

STANDARD

ADJUSTMENT

NOTE:

II]

@for needle

When making adjustment, the machine pulley should

Adjusting needle bar height

DP

x 5

be

manually turned.

Turn

the

pulley

lowest position.

the screw@). Vertically adjust the needle bar

that

the

second

needle bar aligns

needle

NOTE:

bush

When using needle

reference

the

needle bar

to

set

the

Remove

lowest reference line

with

the

the bottom end

0.

DP x 5,

I i

ne

®

with

the bottom end

bush

0.

needle bar

cap

@ and loosen

align the highest

®on

of

to

its

so

the

the

of

~

Adjusting needle bar lift stroke

@for

needle

DP

x 5

Turn

the

pulley

lowest position.

the

needle receiver

point

lowest reference line @ on

aligns

bush

NOTE:

aligns

with

0.

When using needle bar

the

second

needle bar aligns

the

needle bar

to

raise

Loosen

@)

with

needle

the bottom end

highest reference line

bush

the needle bar from its

the

screw @ and adjust

so

that

the rotary hook

with

center

of

DP x 5,

the

when

the

needle bar

the needle bar

it

is

when

@on

bottom end

0.

the

the

of

-42-

Page 46

@1

Adjusting gap between needle and shuttle hook point

Turn the pulley

with

the

needle center.

and

turn

provide

the needle and the shuttle hook point.

0.01

to

align the shuttle hook point

Loosen

the shuttle hook adjust stud

mm

-0.08

mm

the

set screw 0

clearance between

@to

III

Adjusting needle receiver

Turn the

with

and adjust

that

needle.

NOTE:

pulley

the needle center.

the needle receiver 0

Excessive

result in skipped stitches.

Insufficient cpntact may

hook

resulting abnormal wear.

to

align the shuttle hook

Loosen

the

shuttle hook adjust stud @

needle-to-driver

tip

to

interrupt

the set screw@

is

contact

contact

cause

the shuttle

,with

the

point

with

the

will

needle,

so

-43-

Page 47

~

Adjusting shuttle race thread guide

r

!

1)

2)

3)

Remove

Remove

and

the needle

Remove

the screw

the auxiliary plate sheet

the

sub

screws

and

the feed plate

plate

@).

and

the needle plate

0.

@,

the screw

0.

Ull

t

4)

Adjust the shuttle

the needle

the shuttle race thread guide ·

pressing

inward,

is

the

secure

race

thread guide 0

centered in the needle groove

shuttle race thread guide 0

it

with

the screw.

0.

so

that

of

Lightly

-44-

Page 48

[i) Adjusting movable knife

Loosen

trimmer

movable knife 0 aligns

needle plate when the machine

the

rod

nut

(L)

@.

Vertically adjust thread

@)

so

that

V notch ®

with

of

the

the index on the

is

stopped.

[Replacing movable knife and fixed knife]

1)

Remove

auxiliary

2)

Remove

plate

connecting rod 6 from the pin part

trimmer

the screw

sheet@).

the

€),

connecting rod

0,

screws

detaching

0 and 0 and the needle

the

feed plate

the

(L)

@.

thread

@and

trimmer

of

thread

the

-45-

Page 49

3)

Replace

Check

knife

provided

*

The

itstype. (T=0.4, T=0.5,

4)

Attach the fixed knife ®

needle hole plate (f).

the movable knife

if

the movable knife @

® cut thread.

to

obtain sharp cutting.

washer thickness are different according

with

If

necessary,

T=0.6mm)

0.5

mm

a new one.

and

the fixed

use

a washer

to

away from the

5)

Place

the thread trimmer connecting rod

of

the pin part

{L) @ and attach the needle

NOTE:

6)

NOTE:

To

check

rod

fl

thread

slightly move

forth prior

0

and

pulled by the thread

rod

fl.

Put the auxiliary sheet

end

with

The

sheet should

one every month.

thread trimmer connecting rod

if

the thread trimmer connecting

is

properly

trimmer

to

tightening the

confirm

the edge

plate®.

fitted

over the pin part

connecting rod

the

needle plate back and

screws 0 and

that

the movable knife @

@)

of

the needle

be

trimmer

with

replaced

connecting

aligning its rear

sub

plate@.

with

(L)

a new

fl

on

of

@,

is

-46-

Page 50

[1]

Changing

The

standard

lift

work

stroke

clamp stroke

of

the

work

damp

is

3 mm. (max. 8 mm)

3mm~

<How

1)

2)

<If

1)

2)

00

to

adjust

Loosen

Loosen

(When the

When

no vertical movement

Remove

Remove

end

of

work

the stud screw@ and open the

the

nut

intermittent

at

the lower position,

the face plate@.

the stud screw

intermittent

Adjusting

clamp

stroke>

intermittent

0 and adjust the position

presser

work

presser

of

the

fl

clamp

connecting rod

it

will

decrease.)

work

clamp

and re-attach the

arm

(R)@).

of

the

intermittent

is

required>

intermittent

cover@.

presser

is

at

the upper position, the

connecting rod

1)

Loosen

the bottom surface

the

the

lowest position.

NOTE:

2)

Turn the pulley by hand.

enters

clamp

needle hole center, remove

loosen

(or

the screw

material

pulley

When

material

high, skipped stitches

into

@.

the screw e and adjust the

presser

connecting rod

@to

@.

so

that

is

turned until the needle bar

the

work

will

slip during sewing. When

the needle hole center

If

the needle does

bar).

0.

lift

stroke

the

screw hole ~ at

Adjust the

of

the

presser

it

is

approx.

clamp

will

Check

not

will

space

foot

0.5

is

too

occur.

if

enters

the

oil cap @,

increase.

between

0 and

mm when

is

low,

the

needle

of

the

into

work

clamp

the

at

its

the

too

work

the

-47-

Page 51

[iJ

Adjusting thread wiper

1)

When the plunger 0

solenoid

and shift the entire solenoid setting plate a

vertically

away from the needle center towards the

of

the machine.

2)

Operate the thread wiper @

with

0 and move

approximately 2 mm clearance

tip.

is

fully retracted, loosen

so

that

the thread wiper @

the needle bar center.

the

thread

of

the

Loosen

wiper

thread

the

so

that

@

with

screw

is

the screw

to

the needle

wiper

15

mm

front

it

aligns

provide

@)

15mrn

Check

that

the

work

in figure

the thread

clamp

A.

wiper @ does

@)

or the needle

not

as

illustrated

strike

-48-

Page 52

1m!

Needle stop position and

work

feeding timing

Top end needle stop position

19mm

Feed plate

in operation

Feed

plate

in operation

not

Adjust the needle upper plate 0

needle

the

NOTE:

Turning the needle upper plate 0 clockwise

will

counterclockwise

tip

comes

needle plate top.

The

timing

feed mechanism is

synchronizer @

operation starts after

out

of

the material and stops before

needle enters the material.

lower

to

between

the

stop

will

a stop

the

adjusted

so

the

position;

raise it.

19

that

so

mm away from

needle and

with

the feeding

needle

has

turning

that

come

the

the

the

the

it

-49-

Page 53

Ill]

Adjusting

1)

Remove the needle

2) Attach

the

home

home position standard plate 0

position.·(1)

0,

work

clamps

(SEL)@

and

with

(SER)@).

the

bolts.

[Adjustment

of

X axis]

X reference

[Programmer]

line

1)

Remove the screw and X-feed bracket cover

2)

Turn on the

3)