Page 1

BAS-311G

Direct Drive Programmable electronic pattern sewer

with cylinder bed 130mm×100mm

BAS-326G

DirectDriveProgrammableelectronicpatternsewer

withcylinderbed220mm×100mm

BAS-326G-PS

DirectDriveProgrammableelectronicpatternsewer

withPerfectStitchhookandcylinderbed220mm×100mm

●

Sewing data is sewn faithfully and attractively

●

High maximum sewing speed

●

Economical operation with low power consumption

●

Work clamp lift amount can be adjusted easily from the operation panel

●

Easy-to-use programmer PD-3000 (optional product)

Page 2

with Perfect Stitch hook

BAS-326G-PS

Direct Drive Programmable electronic pattern sewer with cylinder bed

220mm×100mm

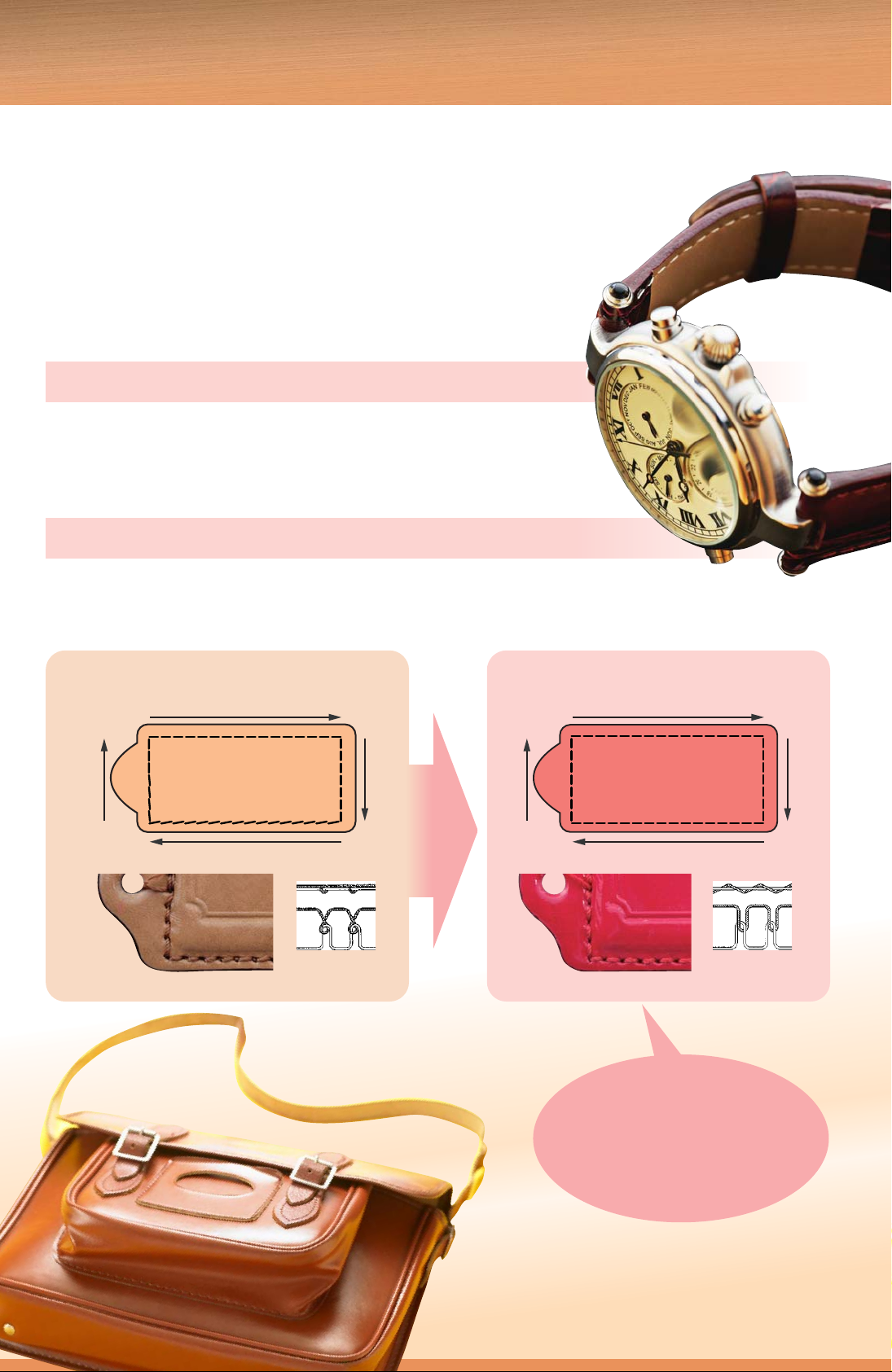

Achieved Perfect stitch area covering more than

90% of the sewing direction while realizing

high quality sewing stitches.

Regardless of material, a superior stable

sewing stitch can be obtained;

Appealing stitches are here to stay.

Realizing amazing high quality stitches

Special hook for perfect stitch has been newly developed and it ensures

excellent thread tightening evenly. Uniform stitches and stable thread

tightening can be obtained as compared with hitch stitch even with the

change of sewing direction and material.

Wide-range perfect stitch area

Complete perfect stitch has been achieved in rectangular pattern stitching as BAS-326G with Perfect

Stitch covers its area at almost all sewing directions. Wide-range perfect stitch area contributes to

improve your product quality and spread your range of sewing products.

〈Usual model〉

Mixture of perfect

and hitch stitches

Perfect Sticth

Perfect Sticth

Hitch Sticth

Perfect Sticth

〈BAS-326G-PS〉

Completeperfectstitch

inalldirections

Perfect Stitch

Realizing beautiful

perfect stitch with special hook

even with leather material

which can usually be

hitch stitch.

Page 3

w

Direct Drive Programmable electronic pattern sewer

BAS-311G

130mm×100mm 220mm×100mm

BAS-326G

with cylinder bed

The world's high-class sewing speed has been achieved and bea

It provides high sewing quality and increases productivity for a

High quality sewn products made with beautiful stitching

High quality stitching exactly the way it is programmed even at high-speed sewing

With adoption of the high-rigid feed mechanism with servo-control, highprecision pattern sewing is available and feed drifting, which is electronic

sewing machinespecific, does not occur even with high speed or weighty

material sewing.

Low thread tension sewing is possible with stable thread tension

The high-rigid feed mechanism with servo-control and the needle bar /

thread take-up mechanism having optimal timing and stroke have realized

stable thread tightening at low tension sewing. It has enlarged the range of

balanced thread tensions.

Presser foot control mechanism always provides uniform thread tightness

When thickness of material has been changed, the height of the stepping

presser foot is changed so that a fixed amount of presser foot moving is

constantly provided. This prevents the stepping presser foot from lifting too

much or being excessively pressed and thus uniform thread tightness can be

obtained.

The height of the stepping presser foot can be set with no tools required, simply

by entering a numeric value from the operation panel or in a program.

Furthermore, you can use user programs to set the stepping presser foot height

to the desired height separately for each sewing program.

Smooth and beautiful stitches can be produced with a minimum resolution of 0.05 mm

Since the data is resolved at 0.05 mm per pulse for the feed, slanted lines and curves are accurately sewn with

beautiful finishes. Also, a simple single point embroidery motif can be sewn, and embroidering on heavy

materials, which is not easy with a general embroidery machine, is also possible.

Productivity is increased with maximum sewing speed of 2,700 sti/min

With the adoption of a Brother's unique direct drive motor, starting and stopping is quick. Machine time has been

reduced by approximately 19% compared to the previous model and thus productivity is increased.

* When sewing at a sewing speed of 2,700sti/min, set the stitch length to 4mm and under.

Economical operation with low power consumption

The direct drive mechanism greatly reduces power transmission losses, and a compact and energy-efficient

motor has also been adopted. These innovations result in energy savings of approximately 50% from previous

models. This is a programmable electronic pattern sewer with the lowest power consumption in the market.

Environmentally friendly

Brother has established its original “Brother Green Label” for the products, in conformity

with ISO 14021 and JIS Q14021.BAS-311G and 326G is certified as an environmentconscious sewing machine according to the “Brother Green Label” standard.

The machine is compliant with the RoHS Directive*. The use of the restricted

substances such as lead, cadmium, hexavalent chromium is absolutely within the

regulation values. Brother has been providing all its products in accordance with the

RoHS Directive for all market areas(excluding machine tools).

* The RoHS Directive(the restriction of the use of certain hazardous substances in electrical and electronic equipment) came into effect in the EU in July 2006.

Industry's top energy saving with

the direct drive system

Use of lead-free solder in all PCB

Significant extension of the hook's lifetime

Page 4

utiful seams can be produced even at high speeds.

ide range of applications while saving energy.

Easy programmer* with large color LCD

Easy programming

• Programs can be easily created in the same procedure as the

programmer of the previous model.

• A shape of pattern data can be checked while it is created.

• Comments can be added to the program. Also, horizontal and

vertical sizes are displayed so that programs of similar figures

can be identified.

Sewing data can be managed with programmer

Sewing data management is easy because sewing data image can

be displayed and sewing data can be copied and moved easily.

*optional product

Large-capacity memory capable of storing bulky data

Large-capacity memory (*512 programs, 500,000 stitches) is embedded

in the sewing machine so that a large quantity of data can be stored.

There is no need to read a program each time it has been changed.

A compact flash (CF) card has been adopted for handling a large amount

of data. Read and write speed is fast, which allows multiple data to be

copied or moved to other sewing machines or computers for data

management.

*The number of patterns and stitches which can be stored depends on the number of stitches

for each program.

PD-3000

Changing sewing pattern is simple

Work clamp can be replaced quickly and accurately

Simply by loosening the two screws, the work clamp

can be replaced quickly. It can also be installed

accurately by using the positioning pins.

Feed plate can be replaced accurately

When replacing the feed plate, stitch data can be easily

and accurately aligned with the feed plate by aligning the

reference holes of the needle plate and the feed plate.

Positioning pins

Work clamp lift amount can be set on operation panel (BAS-311G Motor-driven work clamp spec.)

As the work clamp operation is controlled by a pulse motor, the work

clamp lift amount can be set simply by entering a numeric value at the

operation panel without need of using tools. Furthermore, you can use

the user programs to set desired work clamp lift amount for each

program respectively. No need to adjust the amount at every change

of programs.

Page 5

3 types of work clamp lowering operation

(BAS-311G Motor-driven work clamp spec.)

You can select desired work clamp lowering operation from three patterns by

changing memory switch settings.

Two-step lowering*:

The work clamp is lowered from the highest position to pause at an

intermediate position, then lowered to the lowest position. Quick and

accurate positioning of materials can be made with an optimal work clamp

height. The total cycle time can be reduced.

One-step lowering:

The work clamp is lowered from the highest position to the lowest position

at once. The quick pressing operation is suitable for occasions when

positioning materials with the work clamp is not necessary while it is

positioned with the feed plate beforehand.

Analog lowering:

The work clamp is lowered in

direct proportion to the pedal

depression amount without

steps. You can lower it with

making subtle positioning of

materials.

* The factory setting is two-step lowering.

Simple adjustment

Pulley positioned in convenient location

The pulley is positioned in the

convenient location on the

side of the sewing machine

arm. Needle drop and hook

timing can be checked easily.

Driver phase can be adjusted easily

The driver phase can be adjusted from the side without tilting the

sewing machine. This reduces time taken for the adjustment

and improves productivity when materials are changed.

Options

●Needle cooler*

(SA5559101)

●Thread wiper set*

(Pneumatic type)

(SA5575101)

●Inner clamping device

(100 x 60)(SA7189101)

●

Thread breakage detector

(SA5193101)

●Triple pedal foot switch

(SA6495101)

●Sewing data

programming software

PS-300B

* This device requires the optional

solenoid valve set.

Page 6

Specifications

BAS-311G-0

BAS-326G-0 -

Application Work clamp Application Work clamp Hook

For heavy materials

1

(#20 or similar thread)

For medium materials

2

(#50 or similar thread)

For seat belt

3

(#4 or similar thread)

Motor-driven

S

work clamp

Pneumatic

A

work clamp

BAS-311G-01S BAS-326G-01A

For heavy materials

1

(#20 or similar thread)

For medium materials

2

(#50 or similar thread)

For seat belt

3

(#4 or similar thread)

BAS-326GBAS-311G BAS-326G-PS

Sewing machine

Stitch form

Max. sewing speed

Sewing area (X_Y)

Max.130 x 100 mm

Feed mechanism

Stitch length

Max. number of stitches

Work clamp drive

Work clamp lift amount

2-step work clamp

Pulse motor drive / Pneumatic drive

-0□S: Max. 25 mm

-0□: Max. 30 mm

-0□S: Unit work clamp

-0□A: Separate work clamp

Height of stepping presser foot

Stepping presser foot stroke

Hook

Double-capacity shuttle hook (Standard capacity hook: Option)

Thread wiper

Thread trimmer

Data storage media

Flash memory (Sewing patterns can be added using CF card)

Motor

Weight

Power supply

Machine head: Approx. 88 kg(BAS-311G/326G)・Approx.90kg(BAS-326G-PS),

Operation panel: Approx. 0.6 kg, Control box: 14.2 - 16.2 kg (depending on destination)

Single phase 100V / 220V, 3-phase 200V/220V/380V/400V 400VA

Air pressure/consumption

*Thread counts are for reference. Please consult your local Brother sales office for details.

*1 BAS-326G-PS is for heavy materials only.

*2 When sewing at a sewing speed of 2,700 sti/min, set the stitch length to 4mm and under.

Product specifications are subject to change for improvement without notice.

Please read instruction manual before using the machine for safety operation.

Lock stitch pattern tacking sewing machine

Single needle lock stitch

2,700sti/min

Intermittent feed (pulse motor drive)

0.05 - 12.7mm

20,000 stitches per pattern

22mm

2 - 4.5 mm, 4.5 - 10 mm or 0 (Factory setting:3mm)

Standard equipment

Standard equipment

AC servo motor 550W

0.5Mpa 1.8 l/min

( )

Pneumatic

A

work clamp

2

*

Max. 220 x 100 mm

Pulse motor drive

Max. 30 mm

Separate work clamp

Double-capacity rotary hook

RoHS Compliant

BAS-311G/326G is compliant with the RoHS Directive

(the restriction of the use of certain hazardous

substances in electrical and electronic equipment)

which came into effect in the EU in July 2006.

※01A-PSforheavy

materialsonly

PS

Perfect stitch hook

19.5mm

1

*

CHINA

HONG KONG

1-5, Kitajizoyama, Noda-cho, Kariya-shi, Aichi 448-0803, Japan.

Phone: 81-566-95-0088 Fax: 81-566-25-3721 http://www. brother. com/

Brother Industries, Ltd. Machinery & Solution Company

Kariya and Minato plants acquired ISO 9001 and 14001 certifications.

To preserve the environment, this catalog was printed on ECF paper (Elemental Chlorine-Free) and using SOY INK.

ASIA

EUROPE

AFRICA,MIDDLE EAST

AMERICAS

BROTHER (CHINA) LTD.

http://www.brother-cn.net/

BROTHER INTERNATIONAL (HK) LTD.

http://www.brother.com.hk/

BROTHER INTERNATIONAL SINGAPORE PTE LTD.

http://www.brother.com.sg/

BROTHER INTERNATIONALE INDUSTRIEMASCHINEN G. m. b. H.

http://www.brother-ism.com/

BROTHER INTERNATIONAL CORPORATION

http://www.brother-usa.com/

+86-21-3133-2101

+852-3589-9040

+65-6536-8891

+49-2822-6090

+1-908-704-1700

Printed in Japan 2010.4. I5040882B Vol.4

Loading...

Loading...