Page 1

INSTRUCTION MANUAL

BAS-300G

BAS-311G

BAS-326G

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

DIRECT DRIVE

PROGRAMMABLE ELECTRONIC PATTERN SEWER

Page 2

Thank you very much for buying a BROTHER sewing machine. Before using your new machine,

please read the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of

moving parts such as the needle and thread take-up lever, and consequently there is always a

danger of injury that can be caused by these parts. Follow the instructions from training personnel

and instructors regarding safe and correct operation before operating the machine so that you will

know how to use it correctly.

BAS-300G, BAS-311G, BAS-326G

Page 3

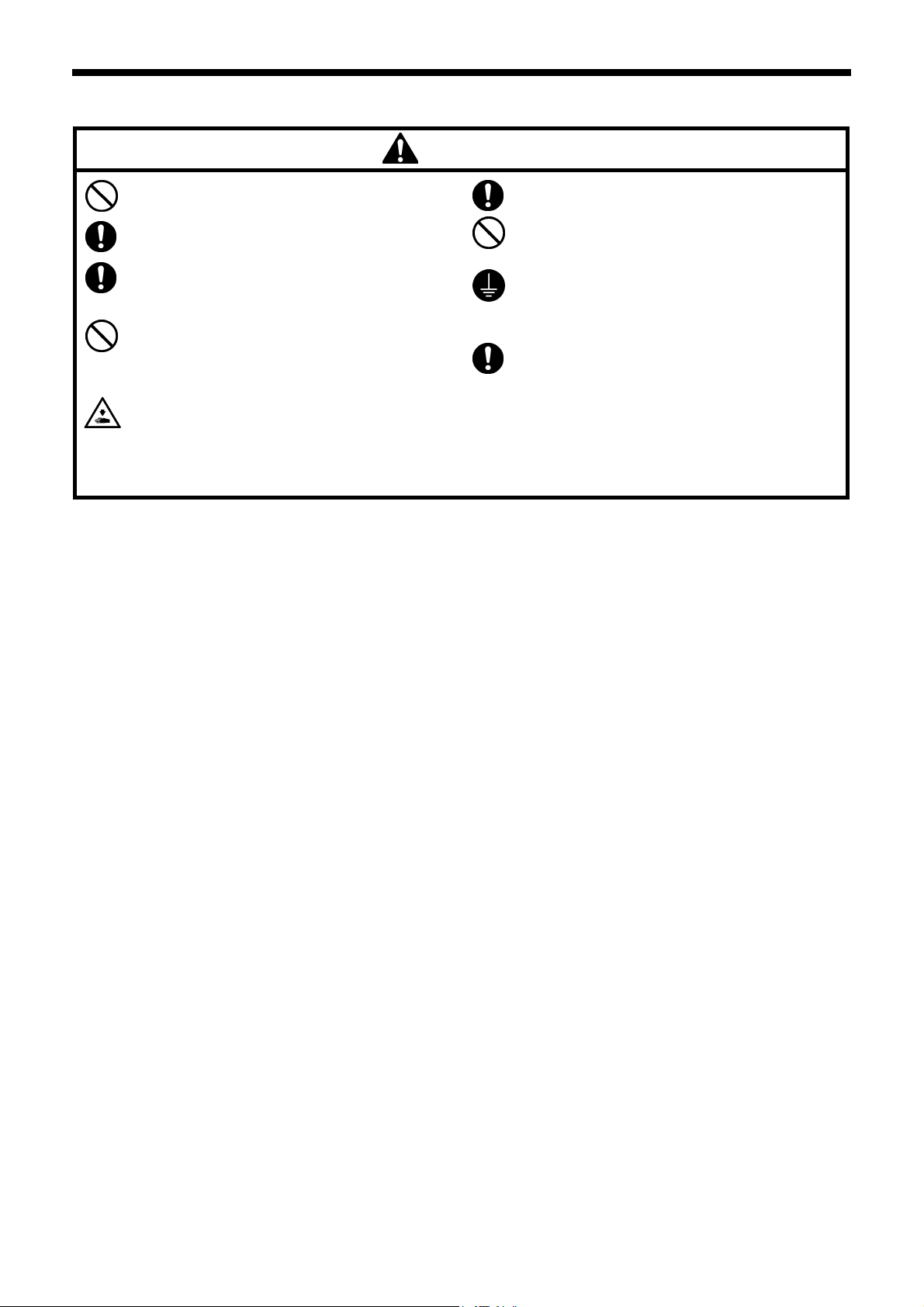

SAFETY INSTRUCTIONS

[1] Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

DANGER

The instructions which follow this term indicate situations where failure to follow the

instructions will result in death or serious injury.

WARNING

CAUTION

Symbols

・・・・・・

・・・・・・

・・・・・・

The instructions which follow this term indicate situations where failure to follow the

instructions could result in death or serious injury.

The instructions which follow this term indicate situations where failure to follow the

instructions may result in minor or moderate injury.

This symbol ( ) indicates something that you should be careful of. The picture inside the triangle

indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

This symbol ( ) indicates something that you must not do.

This symbol ( ) indicates something that you must do. The picture inside the circle indicates the

nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

BAS-300G, BAS-311G, BAS-326G

i

Page 4

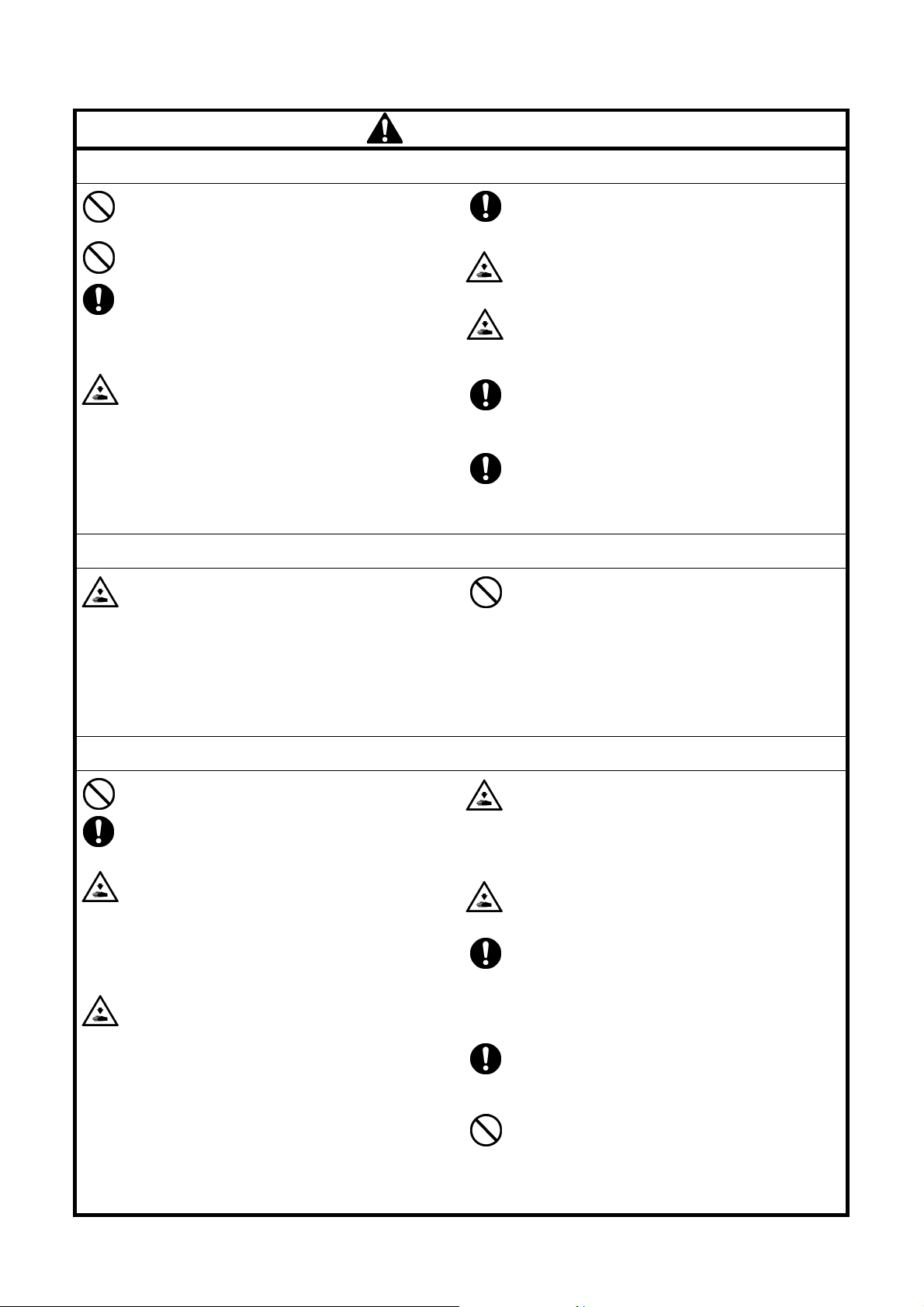

[2] Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the cover of the control box. Touching areas where high voltages are present can result in severe

injury.

Do not allow any liquids to get onto this sewing machine, otherwise fire, electric shocks or operating problems may

occur.

If any liquid gets inside the sewing machine (machine head or control box), immediately turn off the power and

disconnect the power plug from the electrical outlet, and then contact the place of purchase or a qualified

technician.

DANGER

WARNING

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from

sources of strong electrical noise such as electrical

line noise or static electric noise.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage should

be within ±10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than the

requirements for the sewing machine's power

consumption.

Insufficient power supply capacity may cause

problems with correct operation.

Installation

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs approximately 88 kg.

The installation should be carried out by two or more

people.

Do not connect the power cord until installation is

complete. If the foot switch is depressed by mistake,

the sewing machine might start operating and injury

could result.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

Furthermore, do not apply excessive force when

tilting back the machine head. The sewing machine

may become unbalanced and fall down, and serious

injury or damage to the sewing machine may result.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems with

correct operation may also occur.

The pneumatic delivery capability should be greater

than the requirements for the sewing machine's total

air consumption.

Insufficient pneumatic delivery capability may cause

problems with correct operation.

The ambient temperature should be within the range

of 5°C to 35°C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation should

occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation.

All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too firmly

with staples, otherwise there is the danger that fire or

electric shocks could occur.

Install the safety covers to the machine head and

motor.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin. If the oil

and grease get into your eyes or onto your skin,

inflammation can result.

Furthermore, do not drink or eat the lubricating oil or

grease. They may cause diarrhea or vomiting.

Keep the oil out of the reach of children.

ii

BAS-300G, BAS-311G, BAS-326G

Page 5

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary training

in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may enter

your eyes and injury may result.

Turn off the power switch at the following times. If the

foot switch is depressed by mistake, the sewing

machine might start operating and injury could result.

• When threading the needle

• When replacing the bobbin and needle

• When not using the machine and when leaving the

machine unattended

Cleaning

Turn off the power switch before carrying out

cleaning. If the foot switch is depressed by mistake,

the sewing machine might start operating and injury

could result.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the

machine.

If an error occurs in machine operation, or if abnormal

noises or smells are noticed, immediately turn off the

power switch. Then contact your nearest Brother

dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they

do not get into your eyes or onto your skin. If the oil

and grease get into your eyes or onto your skin,

inflammation can result.

Furthermore, do not drink or eat the lubricating oil or

grease. They may cause diarrhea or vomiting.

Keep the oil out of the reach of children.

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Turn off the power switch and disconnect the power

cord before carrying out the following operations. If

the foot switch is depressed by mistake, the sewing

machine might start operating and injury could result.

• Inspection, adjustment and maintenance

• Replacing consumable parts such as the rotary

hook

Disconnect the air hoses from the air supply and wait

for the needle on the pressure gauge to drop to “0”

before carrying out inspection, adjustment and repair

of any parts which use the pneumatic equipment.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

Furthermore, do not apply excessive force when

tilting back the machine head. The sewing machine

may become unbalanced and fall down, and serious

injury or damage to the sewing machine may result.

If the power switch needs to be left on when carrying

out some adjustment, be extremely careful to observe

all safety precautions.

When replacing parts and installing optional

accessories, be sure to use only genuine Brother

parts.

Brother will not be held responsible for any accidents

or problems resulting from the use of non-genuine

parts.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly before

using the machine.

To prevent accidents and problems, do not modify

the machine yourself.

Brother will not be held responsible for any accidents

or problems resulting from modifications made to the

machine.

BAS-300G, BAS-311G, BAS-326G

iii

Page 6

r

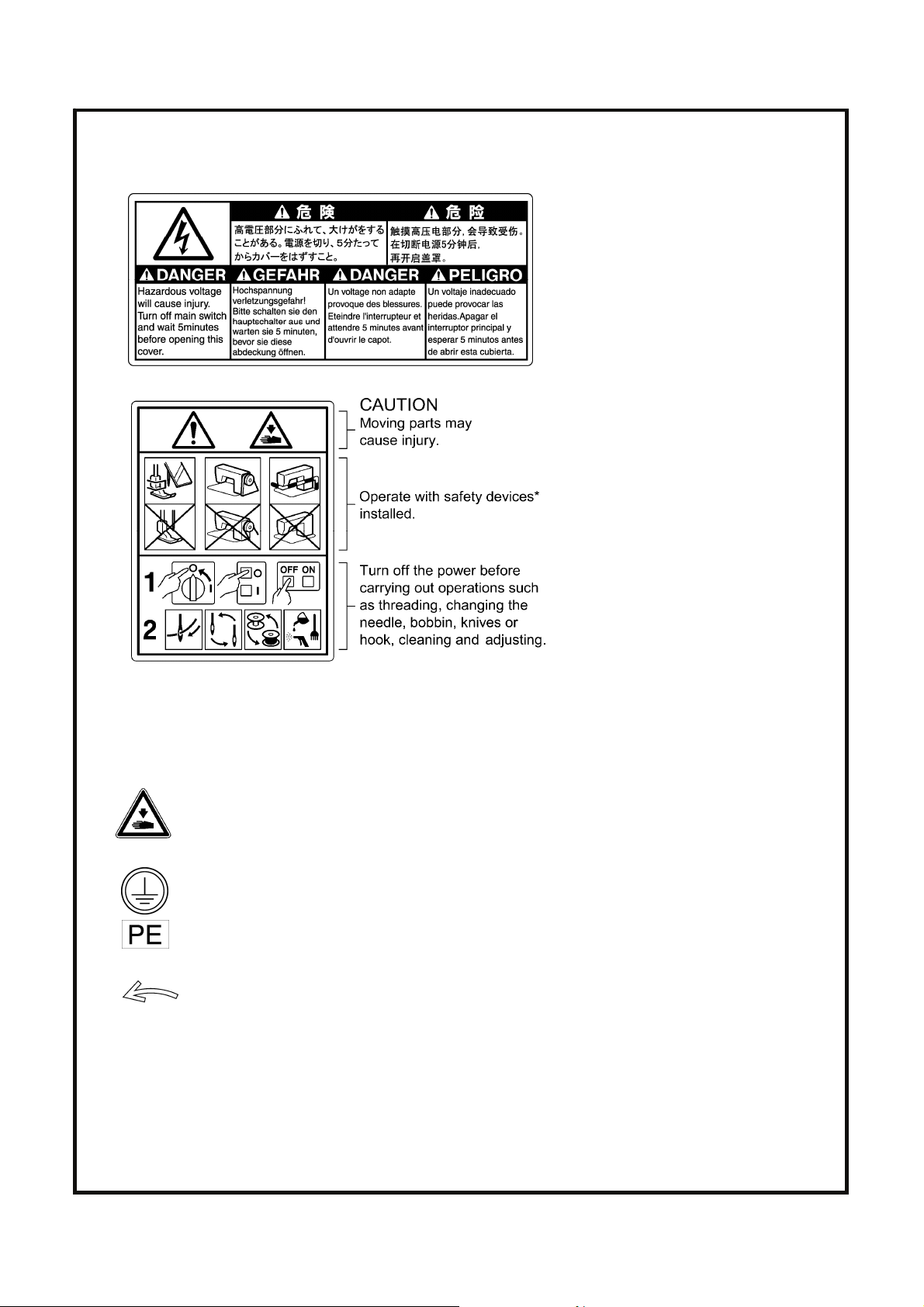

[3] Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are

difficult to read, please contact your nearest Brother dealer.

1

2

*Safety devices

Devices such as eye guard, finger guard, thread take-up

cover, motor cover, tension release solenoid cover, inne

cover, outer cover, fixed cover and gas spring support cover

.

3

4

5

Be careful not to get your hand caught when tilting back the machine head and returning it to its

original position.

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving

a serious electric shock, and problems with correct operation may also occur.

Direction of operation

iv

BAS-300G, BAS-311G, BAS-326G

Page 7

Motor cover

Eye guard

Tension release solenoid cover

Inner cover L

Outer cover

Fixed cover L

Motor cover L

Thread take-up cover

Inner cover R

Outer cover

Fixed cover R

2960B

Motor cover R

Finger guard

Gas spring support cover

2961B

BAS-300G, BAS-311G, BAS-326G

v

Page 8

CONTENTS

1. NAMES OF MAJOR PARTS ................ 1

2. SPECIFICATIONS ................................ 2

3. INSTALLATION.................................... 3

3-1. Table processing diagram ................................ 4

3-2. Installing the control box................................... 5

3-3. Installing the oil pan.......................................... 5

3-4. Installing the machine head.............................. 6

3-5. Tilting the sewing machine head ...................... 9

3-6. Installing the operation panel............................ 10

3-7. Installing the treadle unit

(motor-driven work clamp specifications) ......... 11

3-8. Installing the two-pedal foot switch

(pneumatic work clamp specifications) ............... 11

3-9. Connecting the cords........................................ 12

3-10. Connecting the ground wire............................ 14

3-11. Connecting the power cord............................. 15

3-12. Installing the cotton stand...............................15

3-13. Installing the pneumatic unit

(pneumatic work clamp specifications) ............. 16

3-14. Installing the eye guard .................................. 17

3-15. Installing the motor cover ............................... 17

3-16. Lubrication ...................................................... 18

3-17. Installing the machine head fixing bolt ........... 19

4. PREPARATION BEFORE SEWING.....20

4-1. Installing the needle.......................................... 20

4-2. Threading the upper thread .............................. 20

4-3. Winding the lower thread..................................22

4-4. Installing the bobbin case................................. 23

4-5. Thread tension.................................................. 24

4-5-1. Lower thread tension.............................. 24

4-5-2. Upper thread tension.............................. 24

4-6. Home position detection ................................... 25

5. USING THE OPERATION PANEL

(BASIC OPERATIONS) .......................26

5-1. Name and function of each operation

panel item..........................................................26

5-2. Loading sewing data .........................................28

5-3. Setting the program number .............................28

5-4. Setting the X-scale and Y-scale........................29

5-5. Setting the sewing speed..................................29

5-6. Checking the sewing pattern.............................30

5-7. Setting the work clamp lift amount ....................31

6. USING THE OPERATION PANEL

(ADVANCED OPERATIONS) ..............

6-1. List of advanced functions ................................33

6-2. Setting memory switches ..................................34

6-3. List of memory switch settings ..........................35

6-4. Using the lower thread counter .........................36

6-5. Using the production counter ............................37

6-6. Setting the split number ....................................38

6-7. Using user programs.........................................39

6-8. Using cycle programs .......................................42

6-9. Direct selection (combination table)..................44

6-10. X and Y parallel movement of sewing pattern ...45

6-11. Clearing memory data (reinitialization) ...........46

33

7. USING CF CARDS ...............................47

7-1. Notes on handling CF cards (sold separately) ...47

7-2. Structure of a CF card folder.............................47

7-3. Data read/write mode........................................48

7-3-1. Reading all sewing data from the

CF card at once ......................................49

7-3-2. Writing all sewing data to the CF card at

once ........................................................50

BAS-300G, BAS-311G, BAS-326G

Page 9

8. SEWING................................................51

8-1. Sewing .............................................................. 51

8-2. Using the STOP switch..................................... 52

8-3. Using the thread wiper switch........................... 52

9. CLEANING ...........................................53

9-1. Cleaning the rotary hook ..................................53

9-2. Cleaning the control box air inlet ports ............. 54

9-3. Draining the oil.................................................. 54

9-4. Cleaning the eye guard .................................... 54

9-5. Checking the needle.........................................54

9-6. Lubrication ........................................................ 54

10. STANDARD ADJUSTMENTS ............55

10-1. Checking the machine head switch................ 55

10-2. Thread take-up spring .................................... 56

10-3. Arm thread guide R ........................................ 56

10-4. Adjusting the needle bar height...................... 57

10-5. Adjusting the needle bar lift amount ............... 57

10-6. Adjusting the needle contact pressure

of the driver...................................................... 57

10-7. Adjusting the needle clearance ...................... 58

10-8. Adjusting the shuttle race thread guide .......... 58

10-9. Rotary hook lubrication amount...................... 58

10-10. Adjusting the position of the movable knife.... 59

10-11. Replacing the movable and fixed knives ...... 61

10-11-1. Installing the feed plate .................. 62

10-12. Adjusting the thread wiper............................ 63

10-13. Presser foot installation position................... 63

10-14. Changing the intermittent stroke .................. 64

10-15. Adjusting the work clamp lift amount............66

10-16. Adjusting the air pressure

(pneumatic work clamp specifications)............66

11. TABLE OF ERROR CODES...............67

12. TROUBLESHOOTING........................ 71

13. 7-SEGMENT DISPLAY....................... 74

BAS-300G, BAS-311G, BAS-326G

Page 10

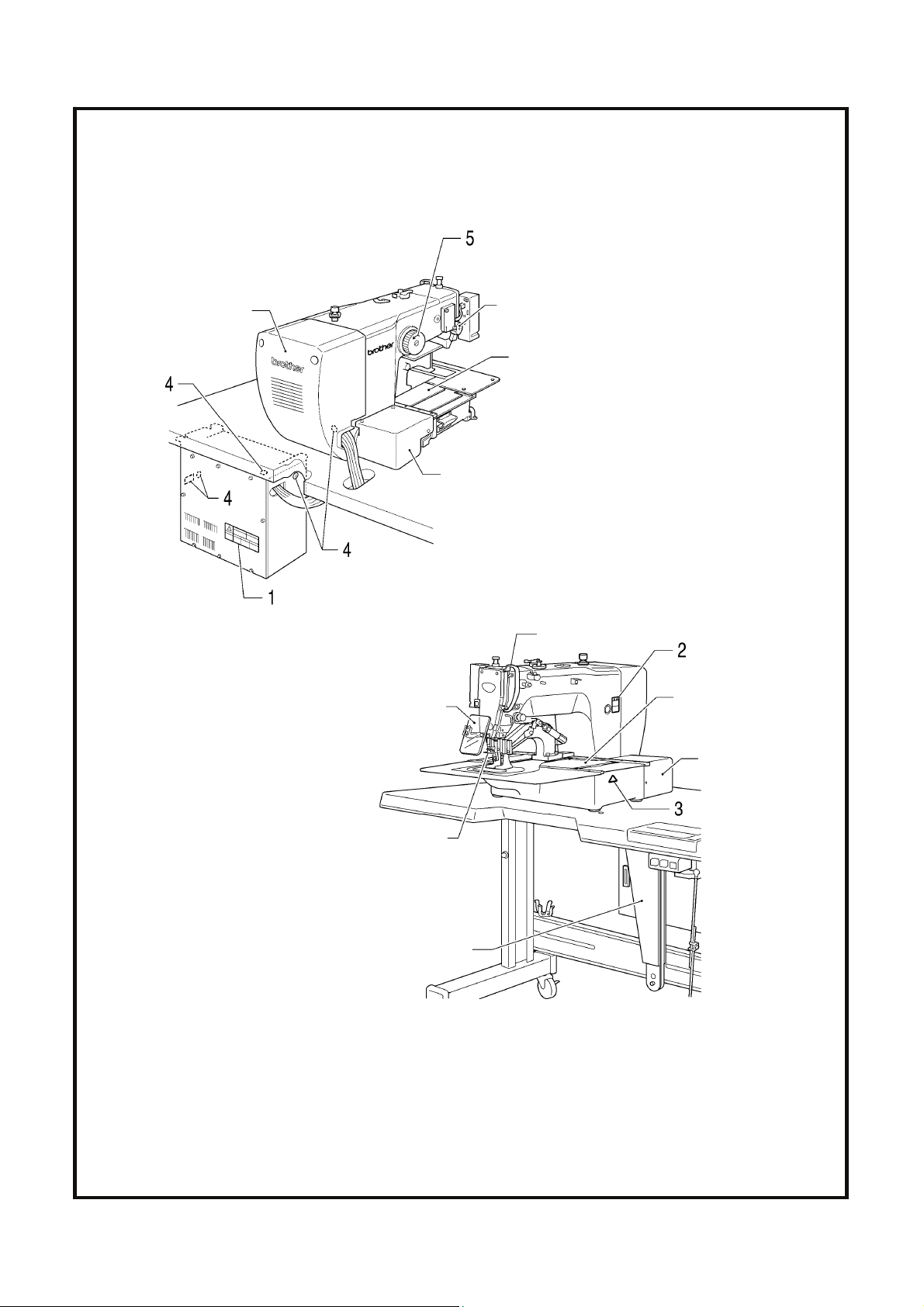

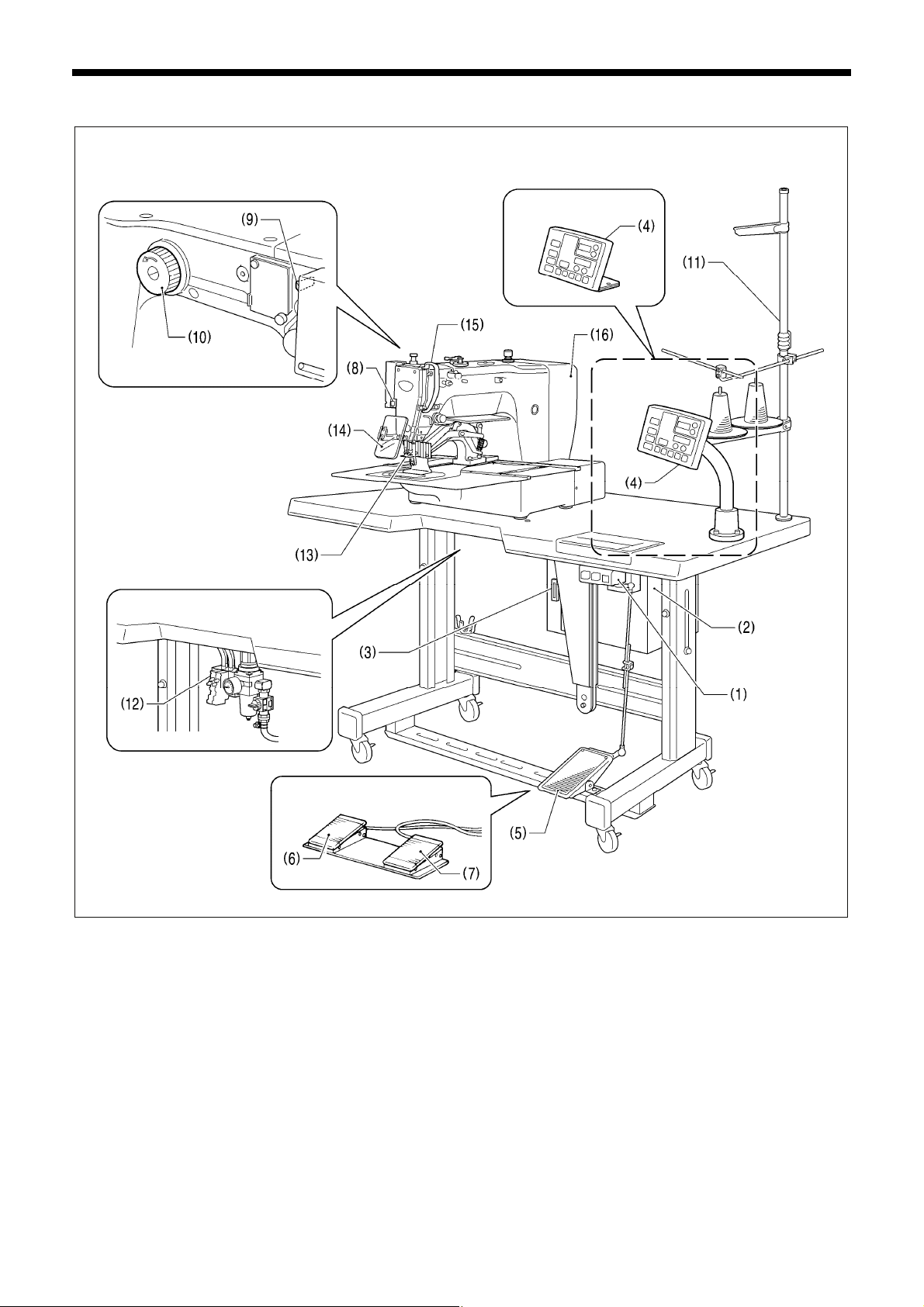

1. NAMES OF MAJOR PARTS

1. NAMES OF MAJOR PARTS

(1) Power switch

(2) Control box (13) Finger guard

(3) CF slot (14) Eye guard

(4) Operation panel (15) Thread take-up cover

(5) Foot switch (motor-driven work clamp specifications) (16) Motor cover

(6) Work clamp switch (pneumatic work clamp specifications)

(7) Start switch (pneumatic work clamp specifications)

(8) STOP switch

(9) Thread wiper switch

(10) Pulley

(11) Cotton stand

(12) Solenoid valve (pneumatic work clamp specifications)

TM

is a trademark of SanDisk Corporation.

CF

Two-pedal foot switch

<BAS-300G>

<BAS-311G>

<BAS-326G>

Safety devices:

2962B

1

BAS-300G, BAS-311G, BAS-326G

Page 11

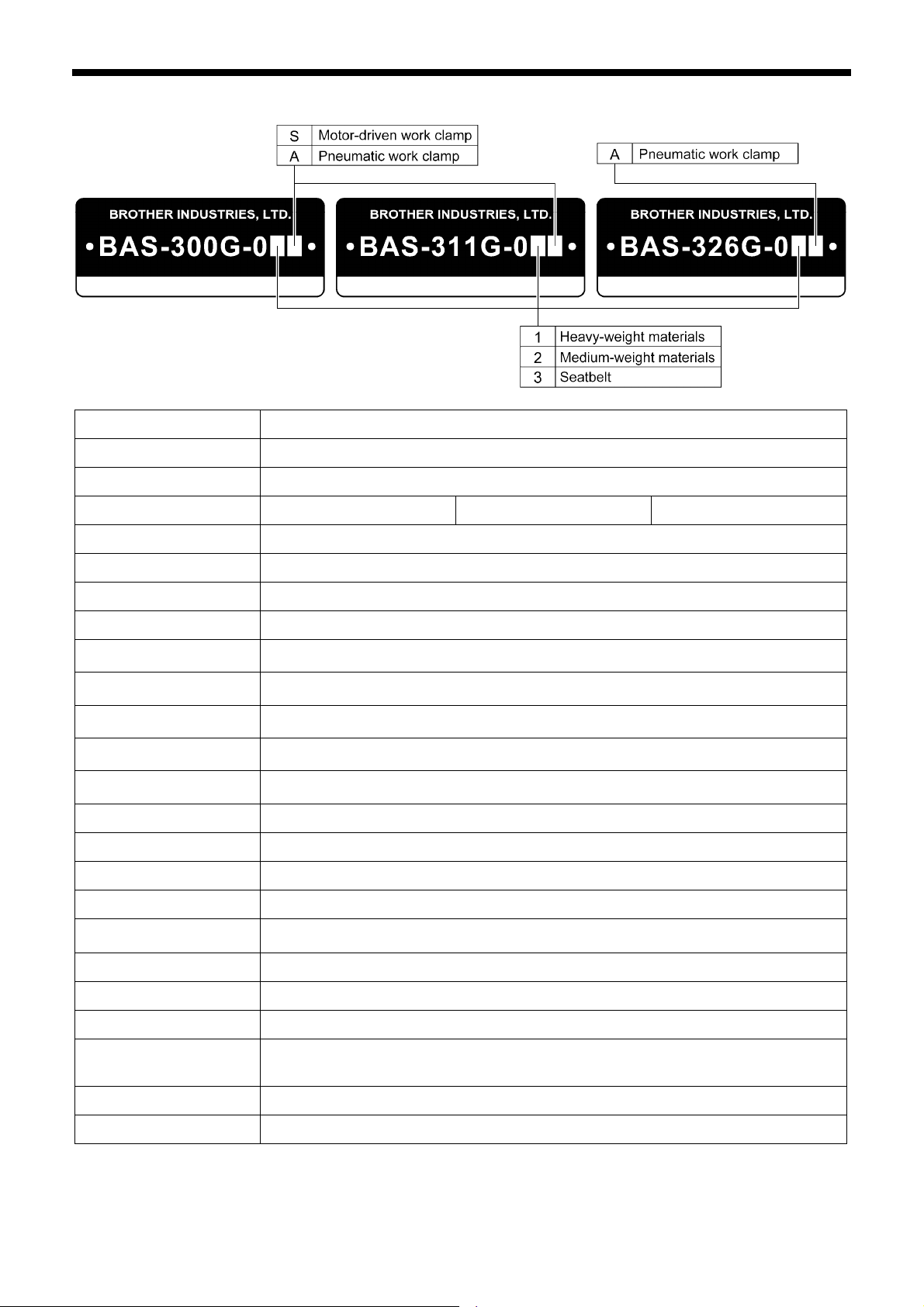

2. SPECIFICATIONS

2. SPECIFICATIONS

Sewing machine Lock stitch pattern tacking sewing machine (with large shuttle hook)

Stitch formation Single needle lock stitch

Max. sewing speed 2,700 sti/min

Max. sewing area (XxY) BAS-300G: 130 x 60 mm BAS-311G: 130 x 100 mm BAS-326G: 220 x 100 mm

2997B

Feed mechanism Intermittent feed, pulse motor drive

Stitch length

No. of stitches 500,000-stitch internal memory (*1)

Maximum no. of stitches 20,000 stitches (per program)

No. of sewing data items

that can be stored

Work clamp lift method

Work clamp height

2-step work clamp

Intermittent presser foot lift

amount

Intermittent stroke

Hook Double-capacity shuttle hook (standard shuttle hook sold separately)

Wiper device Standard equipment

Thread trimmer Standard equipment

Data storage method

User programs 50

Motor-driven work clamp specifications: Pulse motor drive method

Pneumatic work clamp specifications: Pneumatic method

Motor-driven work clamp specifications: Integrated-type work clamp

Pneumatic work clamp specifications: Separate-type work clamp

Internal memory (Flash memory), CF card (32 MB − 2 GB)

Internal memory: 512 (*1), CF card: 900

Motor-driven work clamp specifications: Max. 25 mm

Pneumatic work clamp specifications: Max. 30 mm

2 − 4.5 mm, 4.5 − 10 mm or 0 (Default setting 3 mm)

3.5 floppy disk 2HD/1.44MB, 2DD (*2)

0.05 − 12.7 mm

22 mm

Cycle programs 9

Motor 550 W AC servo motor

Weights

Power supply Single-phase 110 V/120 V/220 V/240 V, Three-phase 220 V/400 V 400 VA

Air pressure 0.5 MPa 1.8 l/min.

(*1) The number of data items and stitches that can be stored will vary depending on the number of stitches in each

program.

(*2) Supply of parts relating to 3.5-inch floppy disks has already been discontinued. (However the mechanism will still

function.)

Machine head approx. 88 kg, operation panel approx. 0.6 kg

Control box 14.2 − 16.2 kg (Differs depending on destination)

BAS-300G, BAS-311G, BAS-326G

2

Page 12

3. INSTALLATION

3. INSTALLATION

CAUTION

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine head weighs approximately

88kg. The installation should be carried out by two or

more people.

Do not connect the power cord until installation is

complete.

If the foot switch is depressed by mistake, the sewing

machine might start operating and injury could result.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

Furthermore, do not apply excessive force when tilting

back the machine head. The sewing machine may

become unbalanced and fall down, and serious injury

or damage to the sewing machine may result.

All cords should be secured at least 25 mm away from

any moving parts. Furthermore, do not excessively

bend the cords or secure them too firmly staples,

otherwise there is the danger that fire or electric

shocks could occur.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems with

correct operation may also occur.

Install the safety covers to the machine head and

motor.

3

BAS-300G, BAS-311G, BAS-326G

Page 13

3. INSTALLATION

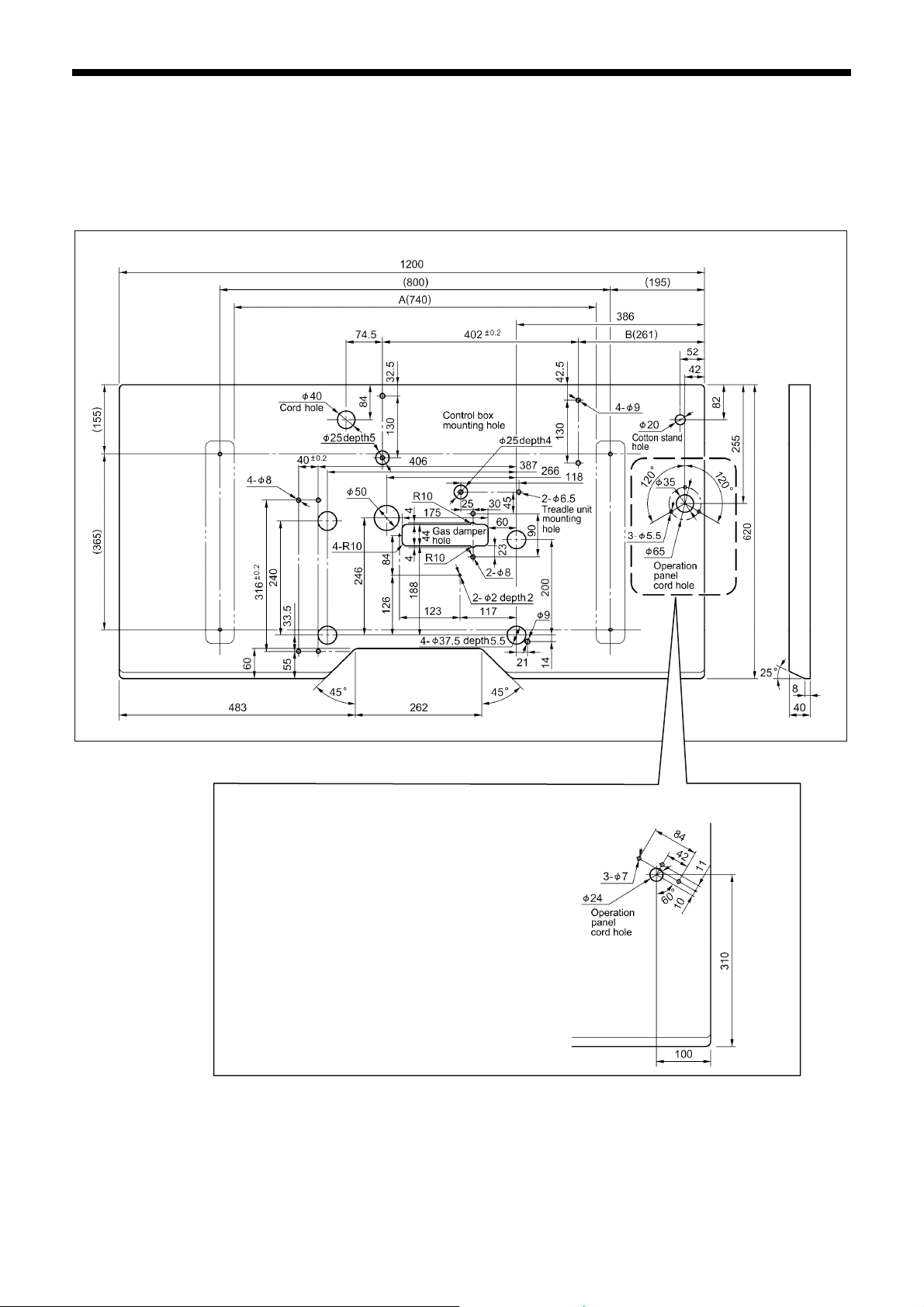

3-1. Table processing diagram

• The thickness of the table should be at least 40 mm, and it should be strong enough to bear the weight and vibration of the

sewing machine.

• If the distance A between the insides of the legs is less than 740 mm, move the control box installation position to the left (B =

261mm).

• Check that the control box is at least 10 mm away from the leg. If the control box and the leg are too close together, it may result

in incorrect sewing machine operation.

<For BAS-311G and 326G>

<For BAS-300G>

Only the holes for installing the operation panel and

the hole for the cord differ from the above diagram.

Refer to the diagram above for all other dimensions.

* The operation panel can be moved to any

preferred position as long as it is in a position

where the cord reaches the PCB inside the

control box.

(Reference position)

3003B

3000B

BAS-300G, BAS-311G, BAS-326G

4

Page 14

3. INSTALLATION

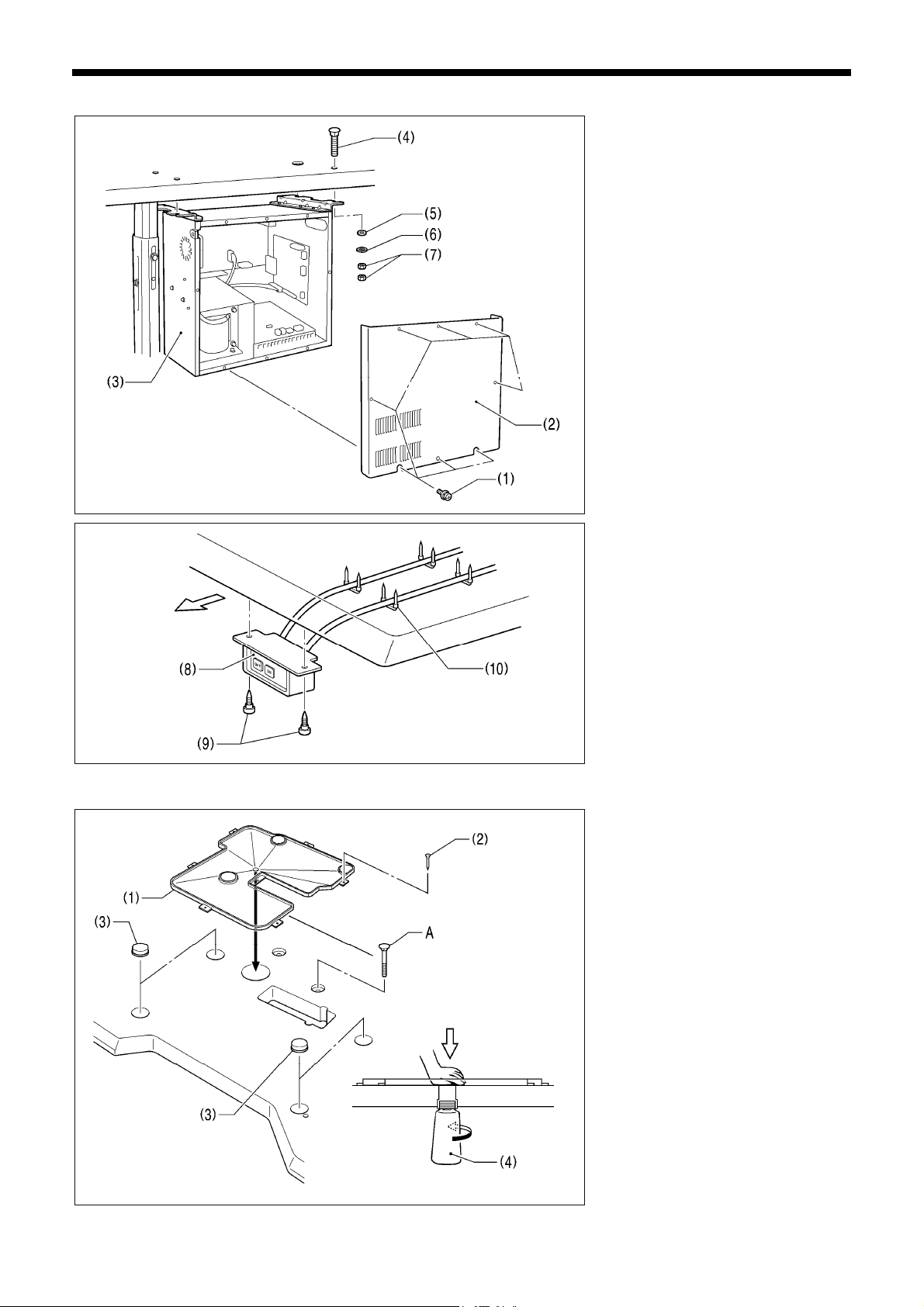

3-2. Installing the control box

Operator

3-3. Installing the oil pan

5

Remove the eight screws (1), and then

remove the control box cover (2).

(3) Control box

(4) Bolts [4 pcs.]

(5) Plain washers [4 pcs.]

(6) Spring washers [4 pcs.]

(7) Nuts [8 pcs.]

1840B

(8) Power switch

(9) Wood screws [2 pcs.]

(10) Staples [4 pcs.]

1841B

For motor-driven work clamp

specifications, install the treadle unit

mounting bolt (A) before installing the

oil pan.

(Refer to "3-7. Installing the treadle unit

(motor-driven work clamp

specifications)".)

(1) Oil pan

(2) Nails [7 pcs.]

(3) Rubber cushions [4 pcs.]

(4) Waste oil tank

4911Q

BAS-300G, BAS-311G, BAS-326G

Page 15

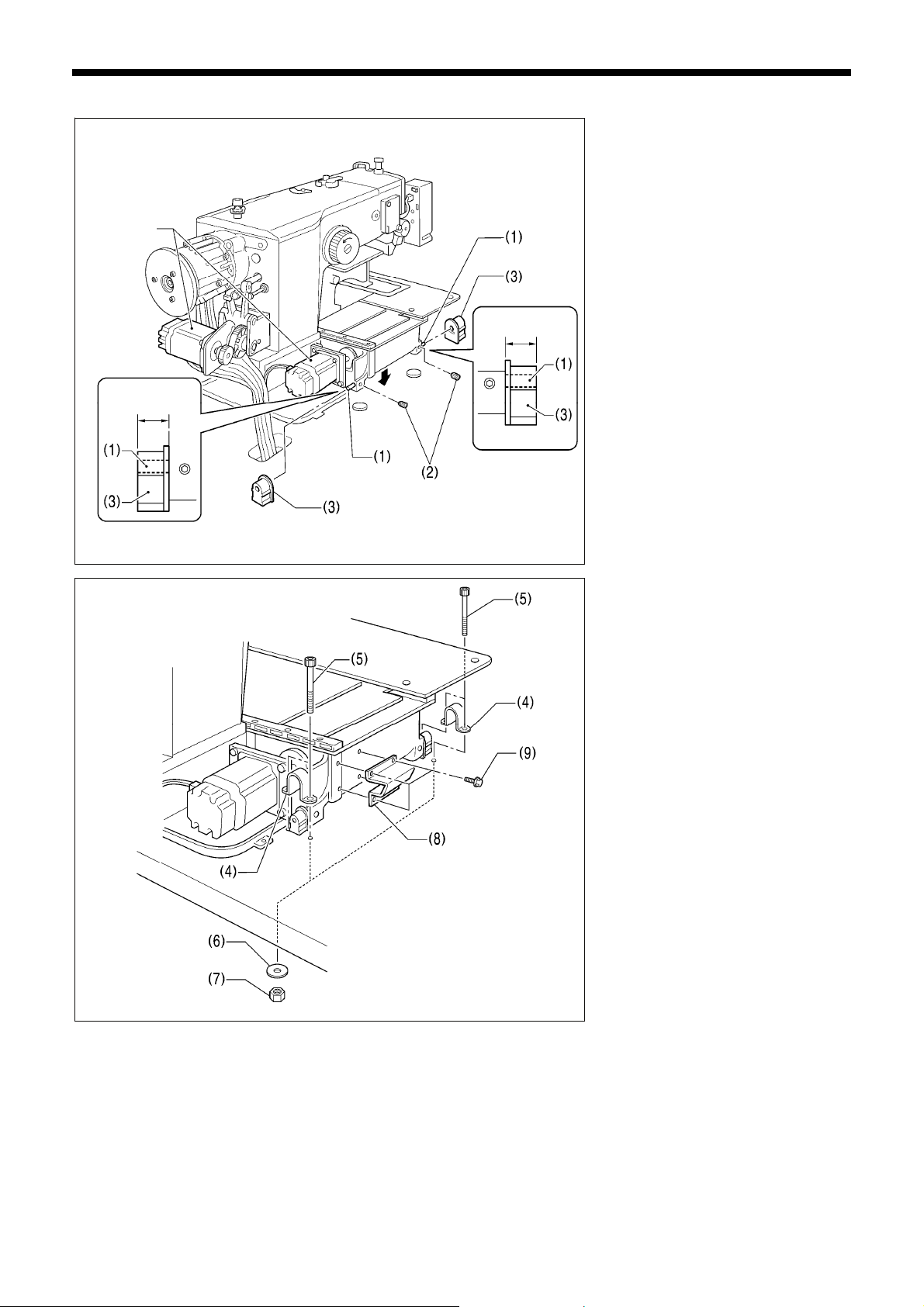

3-4. Installing the machine head

3. INSTALLATION

(1) Pins [2 pcs.]

(2) Set screws [2 pcs.]

(3) Hinge rubber assemblies [2 pcs.]

Place the machine head gently on top of

the oil pan and the rubber cushions.

Pulse motor

Approx. 20 mm

Approx. 20 mm

2966B

NOTE:

• Be careful not to get the cords

clamped between the machine head

and the oil pan.

• When holding the machine head, do

not hold it by the pulse motor. This

may cause problems with operation

of the pulse motor.

(4) Hinge holders [2 pcs.]

(5) Bolts [4 pcs.]

(6) Plain washers [4 pcs.]

(7) Nuts [4 pcs.]

(8) Head rest

(9) Bolts with washer [4 pcs.]

4913Q

BAS-300G, BAS-311G, BAS-326G

6

Page 16

3. INSTALLATION

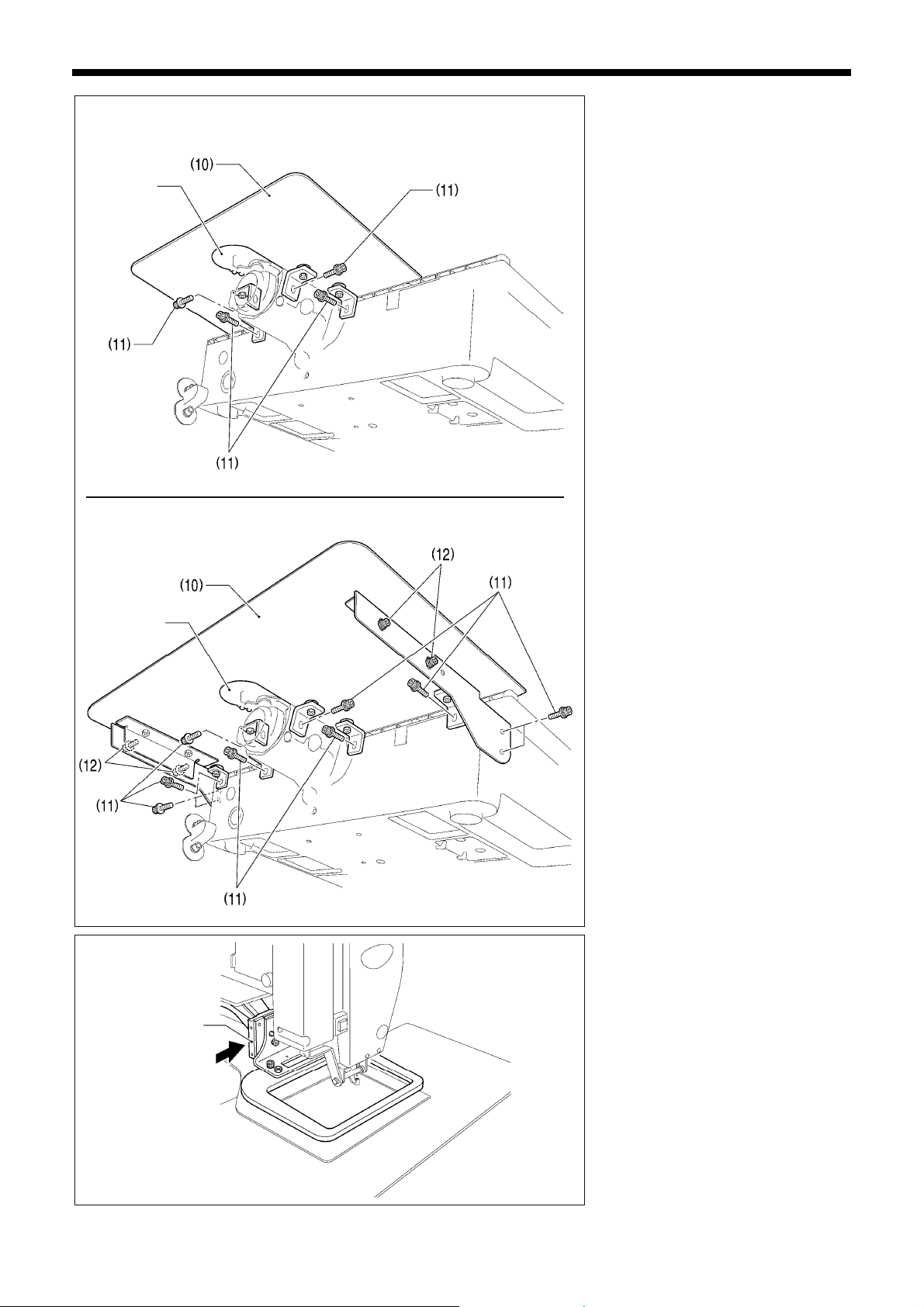

<BAS-300G>

Needle plate

<BAS-311G, 326G>

Needle plate

2698B

<BAS-300G>

(10) Auxiliary plate

(11) Bolts with washer [4 pcs.]

Loosen the four bolts with washer (11),

and adjust so that the auxiliary plate (10)

is 0 to 0.5 mm above the needle plate.

NOTE:

Install the auxiliary plate (10) so that it

is horizontal.

If the auxiliary plate (10) is lower than

the needle plate, the feed plate may

get caught on the needle plate.

<BAS-311G, 326G>

(10) Auxiliary plate

(11) Bolts with washer [10 pcs.]

Loosen the six bolts with washer (11) and

the four bolts with washer (12), and adjust

so that the auxiliary plate (10) is 0 to 0.5

mm above the needle plate.

Work clamp arm

NOTE:

Install the auxiliary plate (10) so that it

is horizontal.

If the auxiliary plate (10) is lower than

the needle plate, the feed plate may

get caught on the needle plate.

2697B

Move the work clamp arm all the way to

the right when looking from the front of

the sewing machine (the direction of the

arrow in the illustration), and then gently

tilt back the machine head.

NOTE:

Two or more people should tilt back the

machine head, and it should be tilted

gently while being held with both

hands.

2969B

7

BAS-300G, BAS-311G, BAS-326G

Page 17

1902B

3. INSTALLATION

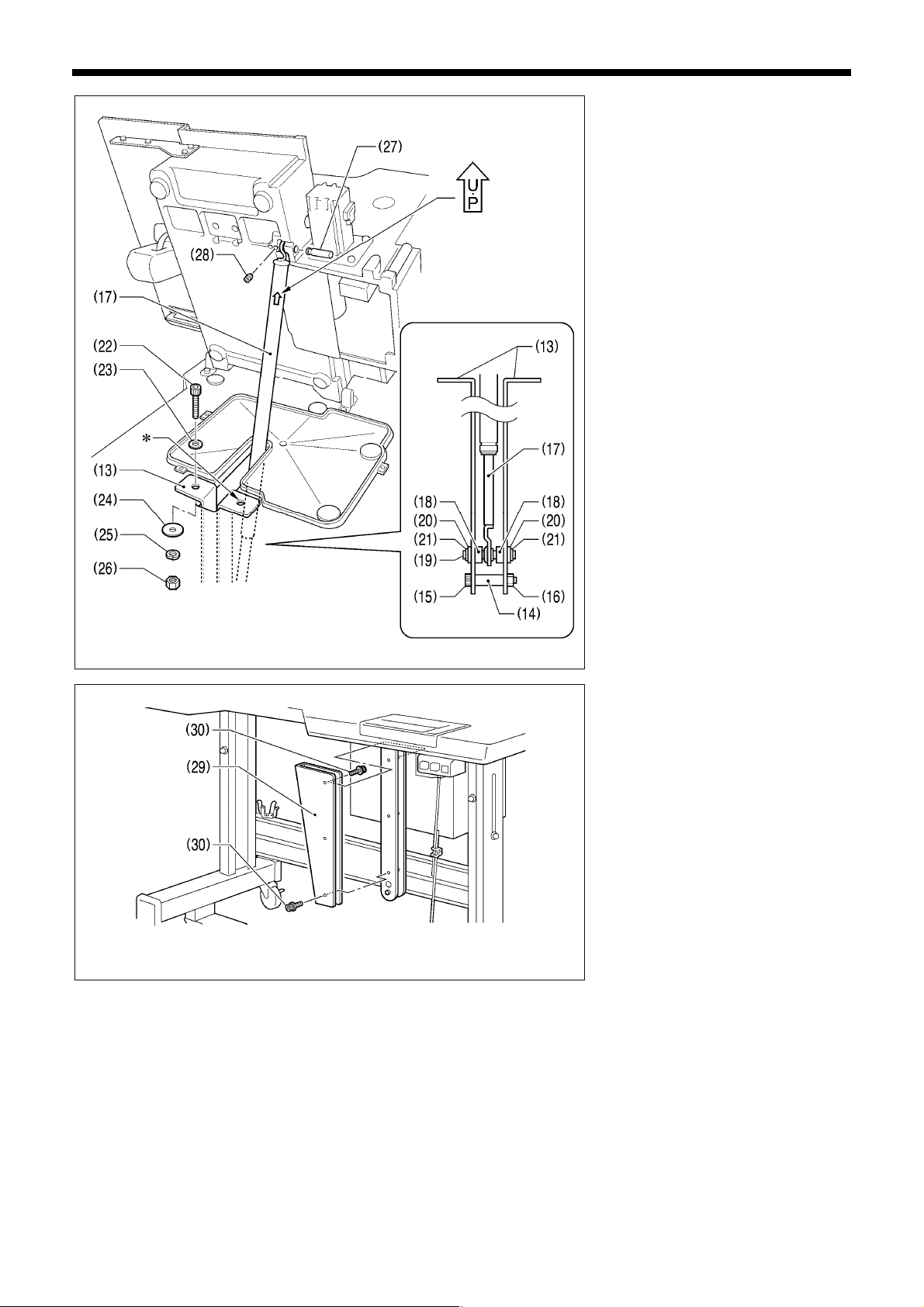

(13) Gas spring holders [2 pcs.]

(14) Spacer

(15) Bolt

(16) Nut

(17) Gas spring

(18) Shaft collars [2 pcs.]

Be sure to install so

that the side with “UP”

on it is facing upward.

(19) Gas spring shaft D

(20) Plain washers [2 pcs.]

(21) Retaining rings E [2 pcs.]

(22) Bolts [2 pcs.]

(23) Plain washers (medium) [2 pcs.]

(24) Plain washers (large) [2 pcs.]

(25) Spring washers [2 pcs.]

(26) Nuts [2 pcs.]

(27) Gas spring shaft U

(28) Set screw

NOTE:

For motor-driven work clamp

specifications, the bolts (22), plain

washers (23), plain washers (24),

spring washers (25) and nuts (26) in

the places marked with * are also used

to install the treadle unit. (Refer to "3-7.

Installing the treadle unit (motor-driven

work clamp specifications)".)

(29) Gas spring support cover

(30) Bolts with washer [6 pcs.]

4916Q

BAS-300G, BAS-311G, BAS-326G

8

Page 18

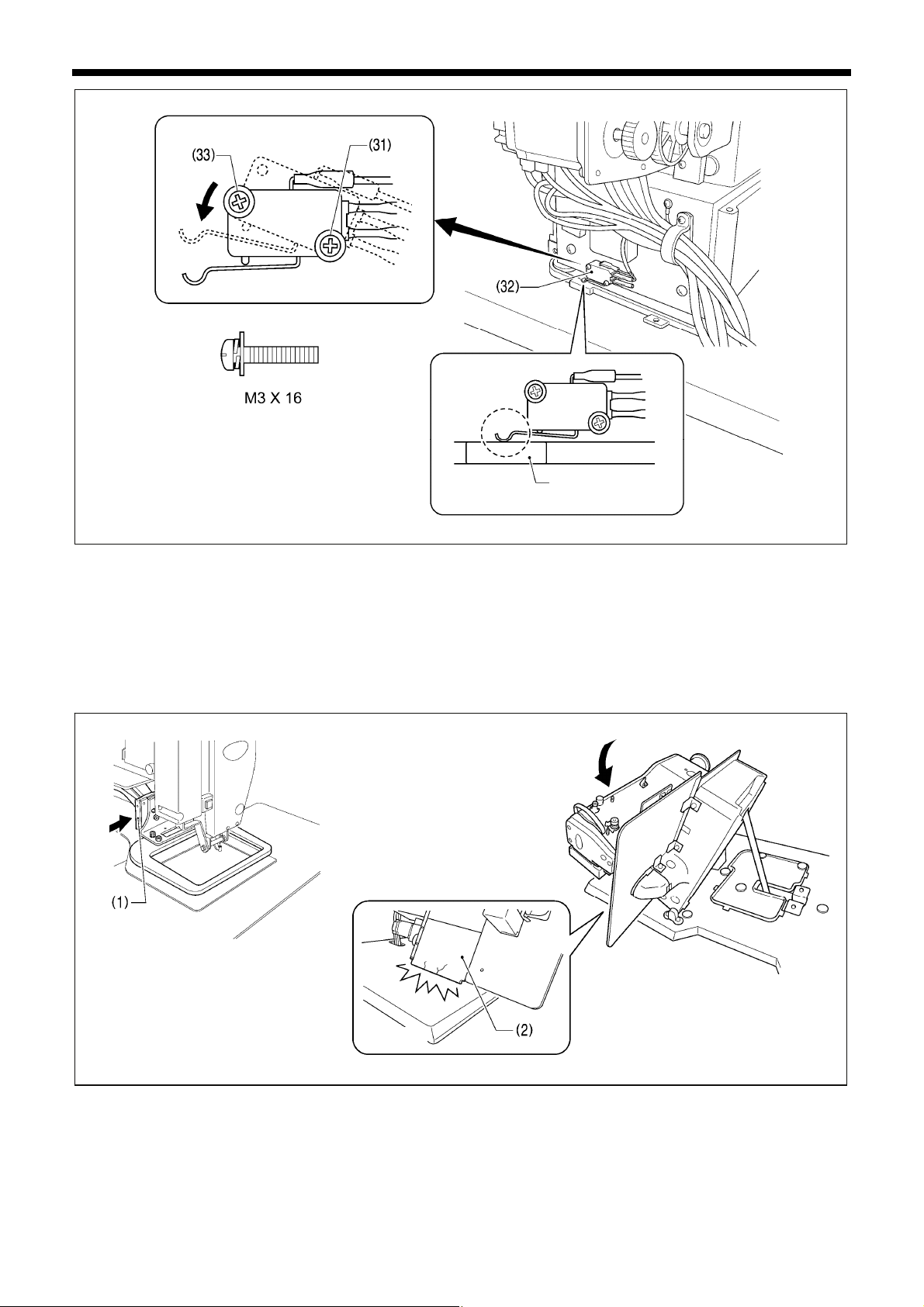

3. INSTALLATION

Figure 1

Oil pan

2365B

• Gently return the machine head to its original position.

• Loosen the screw (31). Move the machine head switch (32) to the position shown in the illustration, and then secure the machine

head switch (32) with the screw (31) and the accessory M3x16 screw (33).

• Check that the machine head switch (32) is turned on as shown in figure 1.

NOTE:

If the machine head switch is not turned on, errors "E050", "E051" and "E055" will be generated.

3-5. Tilting the sewing machine head

2970B 4919Q

1. Move the work clamp arm (1) as far as it will go in the direction of the arrow in the illustration (to the right when looking from the

front of the sewing machine).

2. Stand at the left side of the table, and gently tilt the machine head towards you.

CAUTION

NOTE:

Always be sure to move the work clamp arm (1) all the way to the right before tilting back the machine head. If you try to tilt back

the machine head while the work clamp arm (1) is still on the left side, it may damage the outer cover L (2).

9

BAS-300G, BAS-311G, BAS-326G

Page 19

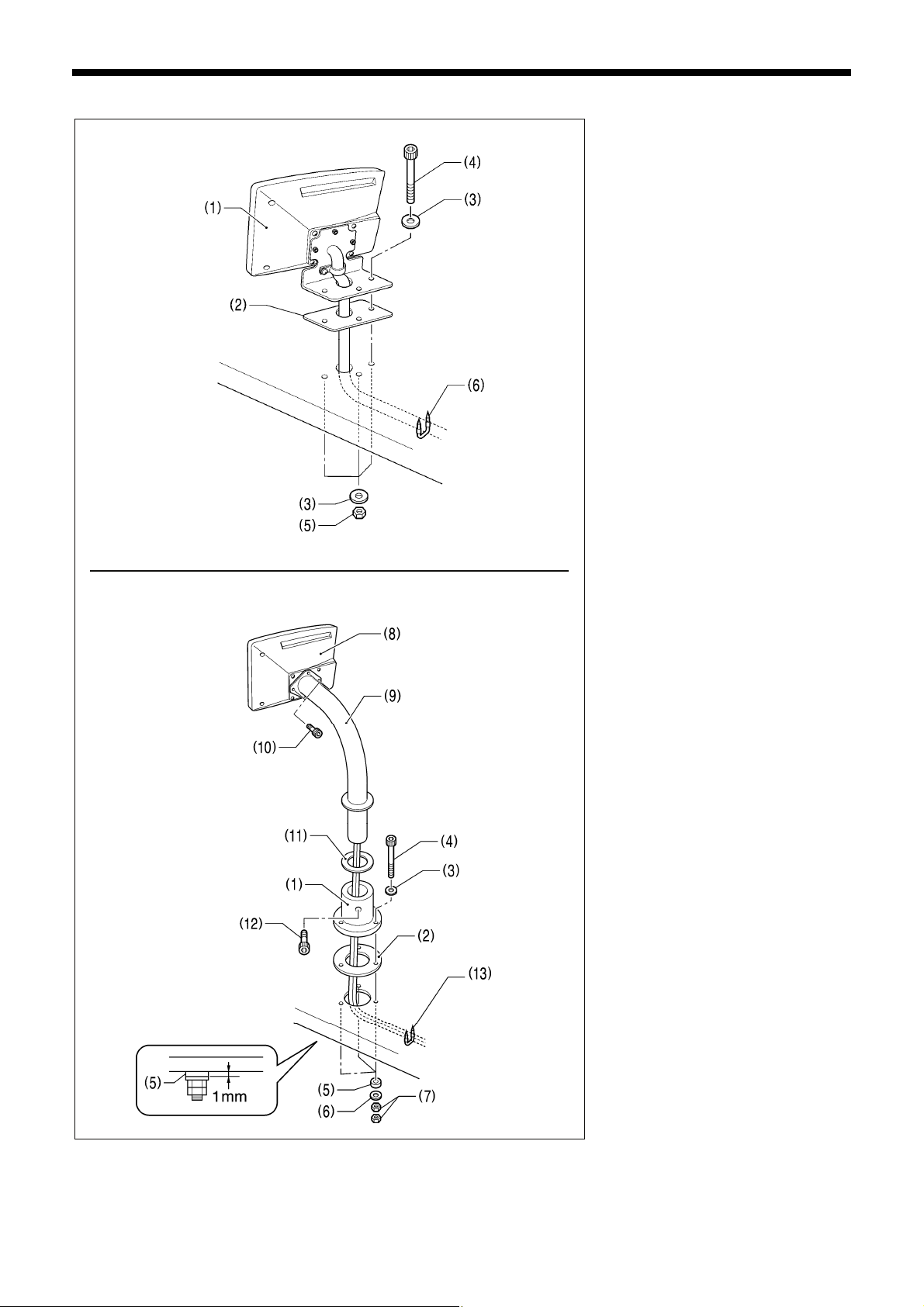

3-6. Installing the operation panel

<BAS-300G>

3. INSTALLATION

2971B

<BAS-300G>

(1) Operation panel set

(2) Panel rubber

(3) Plain washers [6 pcs.]

(4) Bolts [3 pcs.]

(5) Nuts [6 pcs.]

• Insert the cord from the operation

panel (1) which has been passed

through the hole in the table into the

control box through the hole in the side

of the control box.

(6) Staples [3 pcs.]

<BAS-311G, 326G>

<BAS-311G, 326G>

(1) Operation panel base

(2) Cushion A

(3) Plain washers (medium) [3 pcs.]

(4) Bolts [3 pcs.]

(5) Cushions B [3 pcs.]

(6) Plain washers (large) [3 pcs.]

(7) Nuts [6 pcs.]

Tighten until the thickness of cushion B

(5) is about 1 mm.

(8) Operation panel

(9) Operation panel stand

(10) Bolts [3 pcs.]

(11) Rubber seat

(12) Bolt

• Pass the cord from the operation panel

(8) through the operation panel stand

(9) and the rubber seat (11).

• Fit the operation panel stand (9) into

the operation panel base (1), and then

secure it with the bolt (12).

• Pass the cord from the operation panel

(8) through the hole in the table, and

then insert it into the control box

through the hole in the side of the

control box.

(13) Staples [3 pcs.]

BAS-300G, BAS-311G, BAS-326G

4920Q

10

Page 20

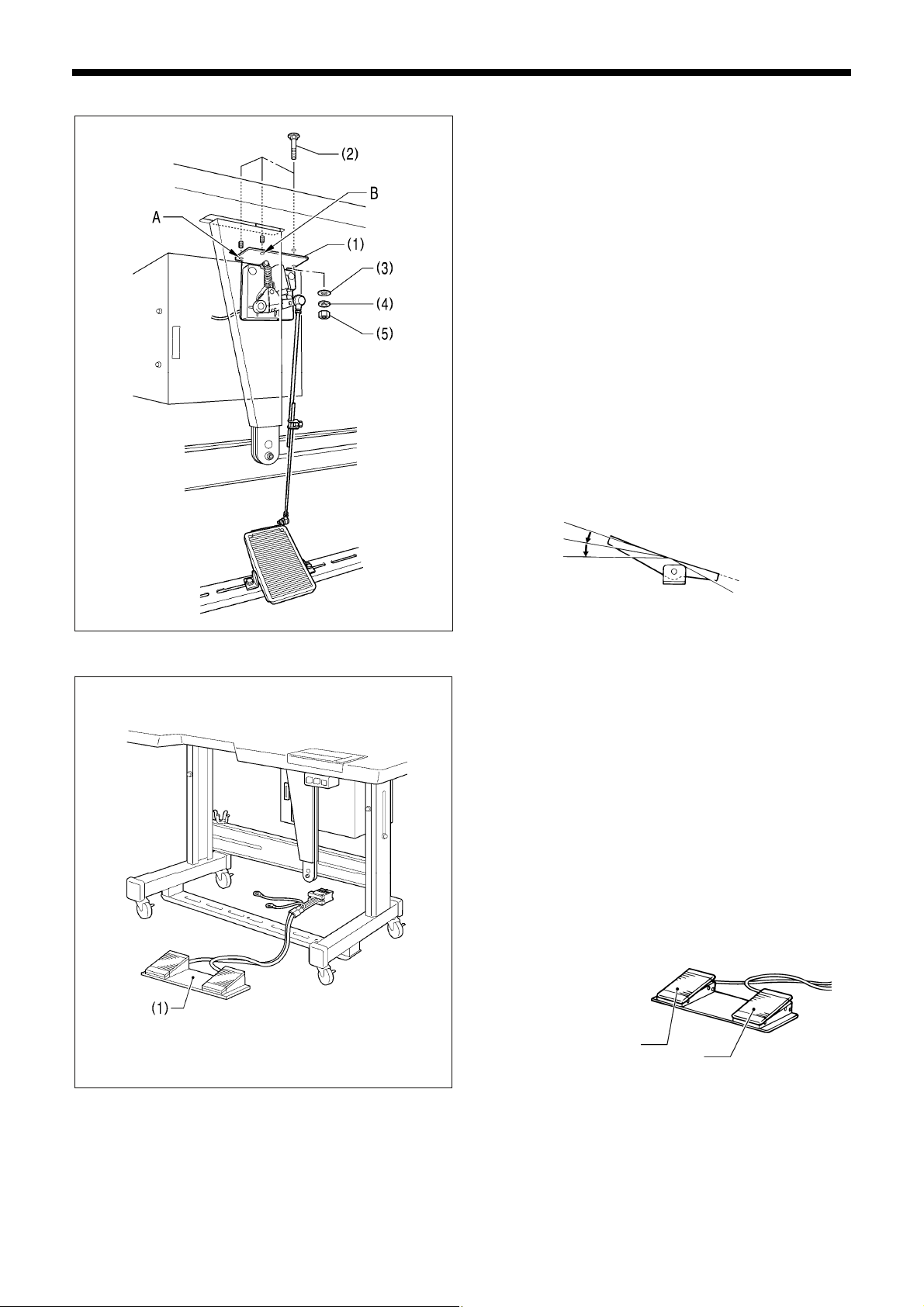

3. INSTALLATION

3-7. Installing the treadle unit (motor-driven work clamp specifications)

(1) Treadle unit

(2) Bolts [3 pcs.]

(3) Plain washers [3 pcs.]

(4) Spring washers [3 pcs.]

(5) Nuts [3 pcs.]

NOTE:

• Install the bolt for mounting hole A before installing the oil

pan. (Refer to “3-3. Installing the oil pan.”)

• Mounting hole B is used to install the gas spring supports

with the bolt, plain washer, spring washer and nut. (Refer

to "3-4. Installing the machine head".)

* Use a commercially-available foot switch and connecting rod.

* If changing the mounting position for the treadle unit, use the

accessory bolts, plain washers, spring washers and nuts.

<Foot switch operating method>

When the foot switch is depressed to the 1st step, the work

clamp is lowered, and when it is depressed to the 2nd step, the

sewing machine starts sewing.

4921Q

1st step

2nd step

4441Q

3-8. Installing the two-pedal foot switch (pneumatic work clamp specifications)

(1) Foot switch

Insert the connector for the foot switch (1) into P6 (FOOT) on

the main PCB. (Refer to "3-9. Connecting the cords".)

* Be sure to make the ground connection. (Refer to “3-10.

Connecting the ground wire”.)

<Foot switch operating method>

When the work clamp switch (left) is depressed, both work

clamps are lowered, and when the start switch (right) is

depressed, the sewing machine starts sewing.

* The work clamp lowering method can be changed using

memory switch No. 002. (Refer to "6-3. List of memory

switch settings.")

2972B

Work clamp switch (2-step)

Star t switch

4923Q

11

BAS-300G, BAS-311G, BAS-326G

Page 21

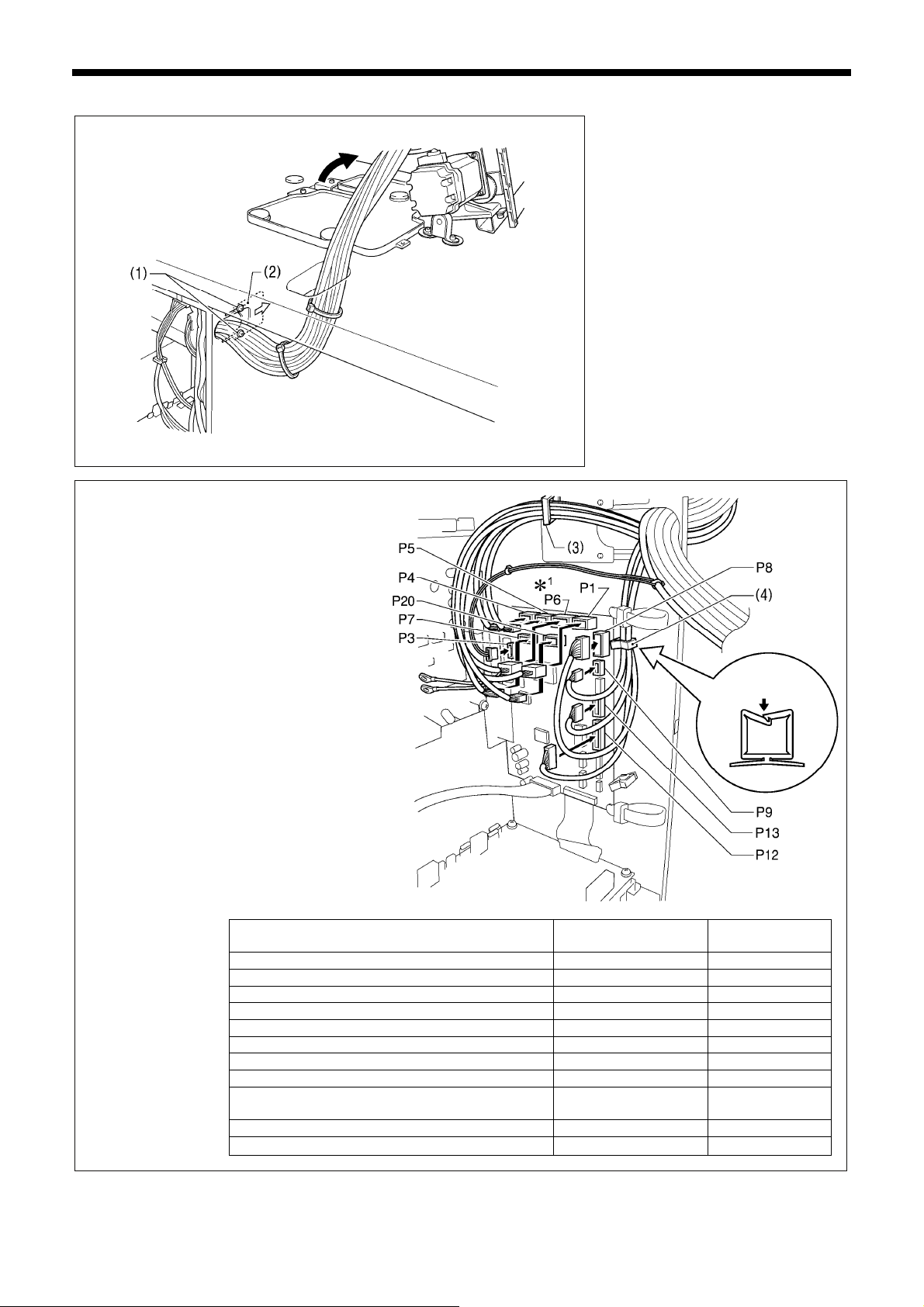

3-9. Connecting the cords

<Main PCB>

3. INSTALLATION

1. Gently tilt back the machine head.

2. Pass the cord bundle through the hole

in the work table.

3. Loosen the two screws (1), and then

open the cord presser plate (2) in the

direction of the right arrow and pass

the cord bundle through the opening.

4. Securely connect the connectors as

indicated in the table below.

NOTE:

• Check that the connector is facing

the correct way, and then insert it

firmly until it locks into place.

• Secure the cables with cable ties

and cord clamps, while being careful

not to pull on the connector.

4924Q

NOTE:

• Check that the connector is facing the correct

way, and then insert it firmly until it locks into

place.

• Secure the cables with cable ties and cord

clamps, while being careful not to pull on the

connector.

*

1

: Be sure to make the ground connection.

(Refer to "3-10. Connecting the ground

wire".)

X pulse motor encoder 5-pin white P20 (X-ENC) (3)

Y pulse motor encoder 5-pin blue P4 (Y-ENC) (3)

Work clamp pulse motor encoder 5-pin black P5 (P-ENC) (3)

Foot switch 10-pin P6 (FOOT) (3)

Operation panel 8-pin P1 (PANEL) (3)

Machine head switch 3-pin P9 (HEAD-SW) (4)

Home position sensor assembly 12-pin P8 (SENSOR1) (4)

STOP switch 6-pin P13 (HEAD) (4)

Valve harness 12-pin (pneumatic work clamp

specifications)

Programmer relay harness 8-pin P7 (PRG) (3)

1842B

Solenoid selection harness 4-pin P3(CUTTER) -

Connector

Lock the cord

clamp securely.

Connection location on

main PCB

Cord clamp

P12 (AIR1) (4)

(Continued on next page)

BAS-300G, BAS-311G, BAS-326G

12

Page 22

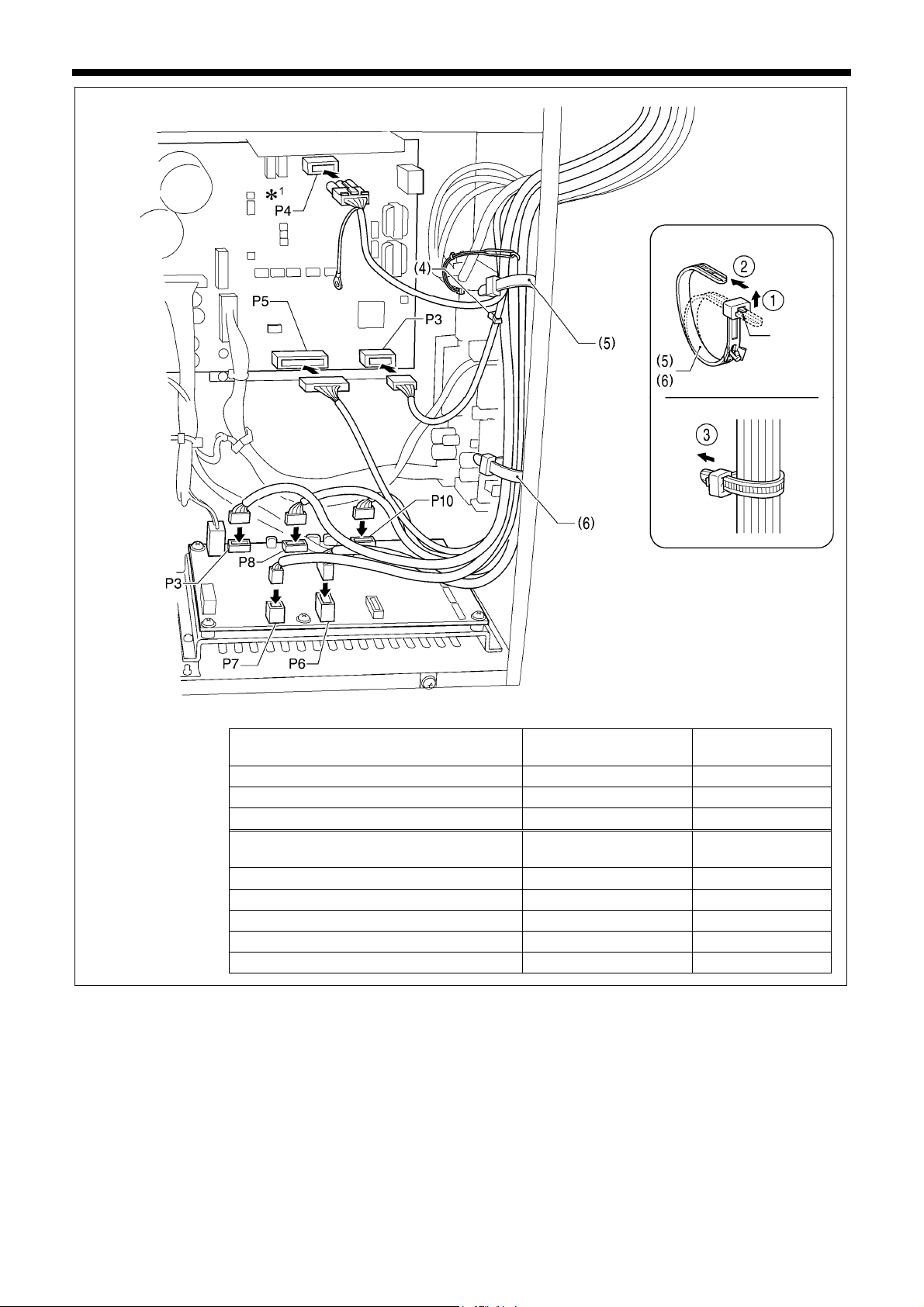

3. INSTALLATION

r

<Power supply motor PCB>

<PMD PCB>

Machine head memory 7-pin P3 (HEAD-M) (4)

Upper shaft motor 3-pin P4 (UVW) (5)

Synchronizer 14-pin P5 (SYNC) (5), (6)

Work clamp pulse motor 4-pin black P3 (PPM) (5), (6)

Thread trimmer solenoid 6-pin P6 (SOL1) (5), (6)

Tension release solenoid 4-pin P7 (SOL2) (5), (6)

Y pulse motor 4-pin blue P8 (YPM) (5), (6)

1843B

X pulse motor 4-pin white P10 (XPM) (5), (6)

Connector

Connector

<Removing>

<Securing>

NOTE:

Route the X, Y and work clamp pulse moto

harnesses so that they do not touch the

PMD PCB.

*

1

: Be sure to make the ground connection.

(Refer to "3-10. Connecting the ground

wire".)

Connection location on

power supply motor PCB

Connection location on

PMD PCB

Cord clamp/cable tie

Cable tie

(Continued on next page)

Press

the tab.

13

BAS-300G, BAS-311G, BAS-326G

Page 23

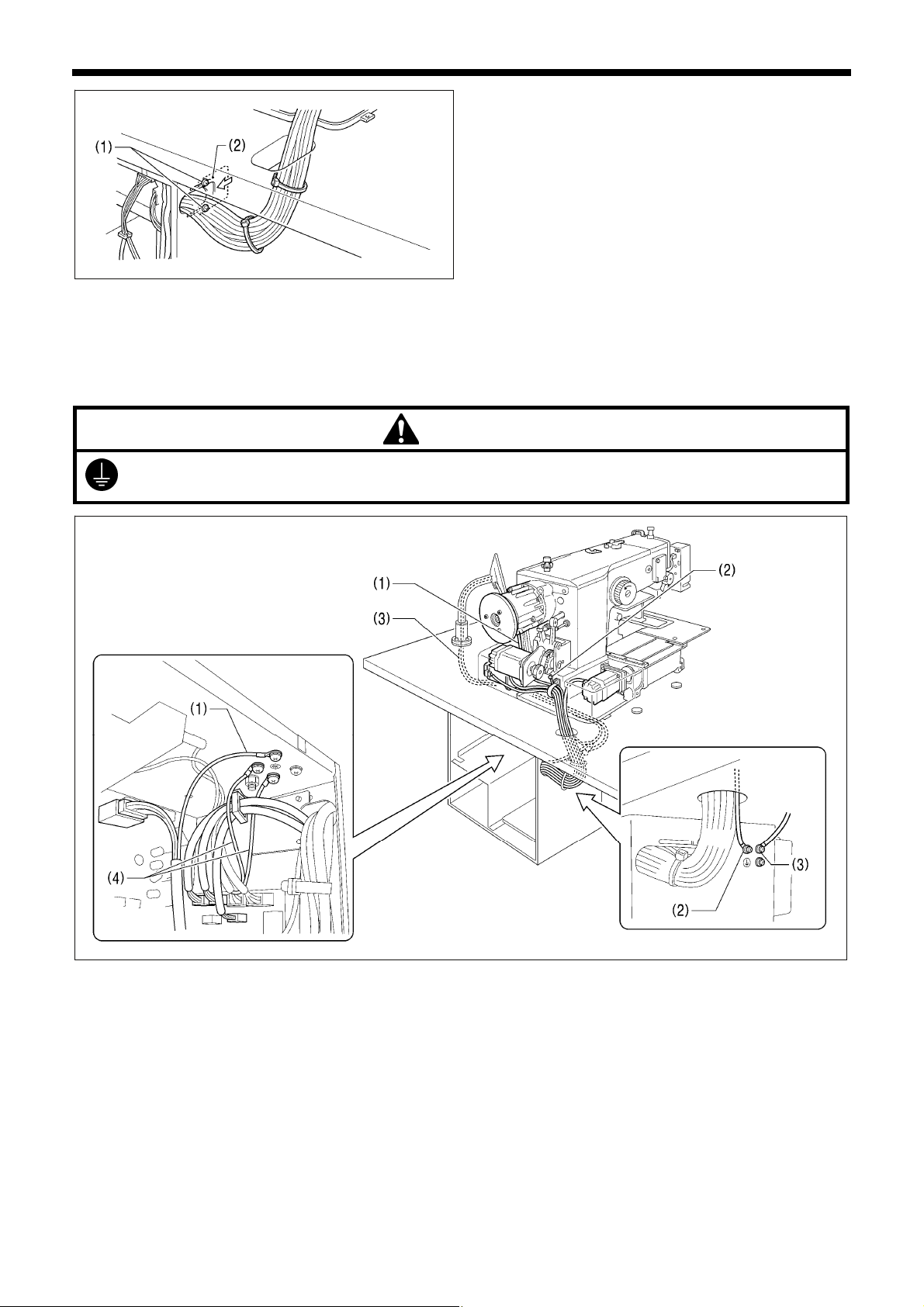

3-10. Connecting the ground wire

CAUTION

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious electric

shock, and problems with correct operation may also occur.

3. INSTALLATION

5. Close the cord presser plate (2) in the direction of the left

arrow, and secure it by tightening the two screws (1).

Note: Close the cord presser plate (2) securely so that no

foreign objects, insects or small animals can get inside

the control box.

6. Check that the cords do not get pulled, and then gently

return the machine head to its original position.

4927Q

(1) Ground wire from upper shaft motor harness

(2) Ground wire from the machine head

(3) Ground wire from operation panel

(4) Ground wires from two-pedal foot switch harnesses (2 wires) [for pneumatic work clamp specifications only]

• Tighten the control box cover with the eight screws. Check that the cords are not clamped by the cover at this time.

2973B

NOTE: Make sure that the ground connections are secure in order to ensure safety.

BAS-300G, BAS-311G, BAS-326G

14

Page 24

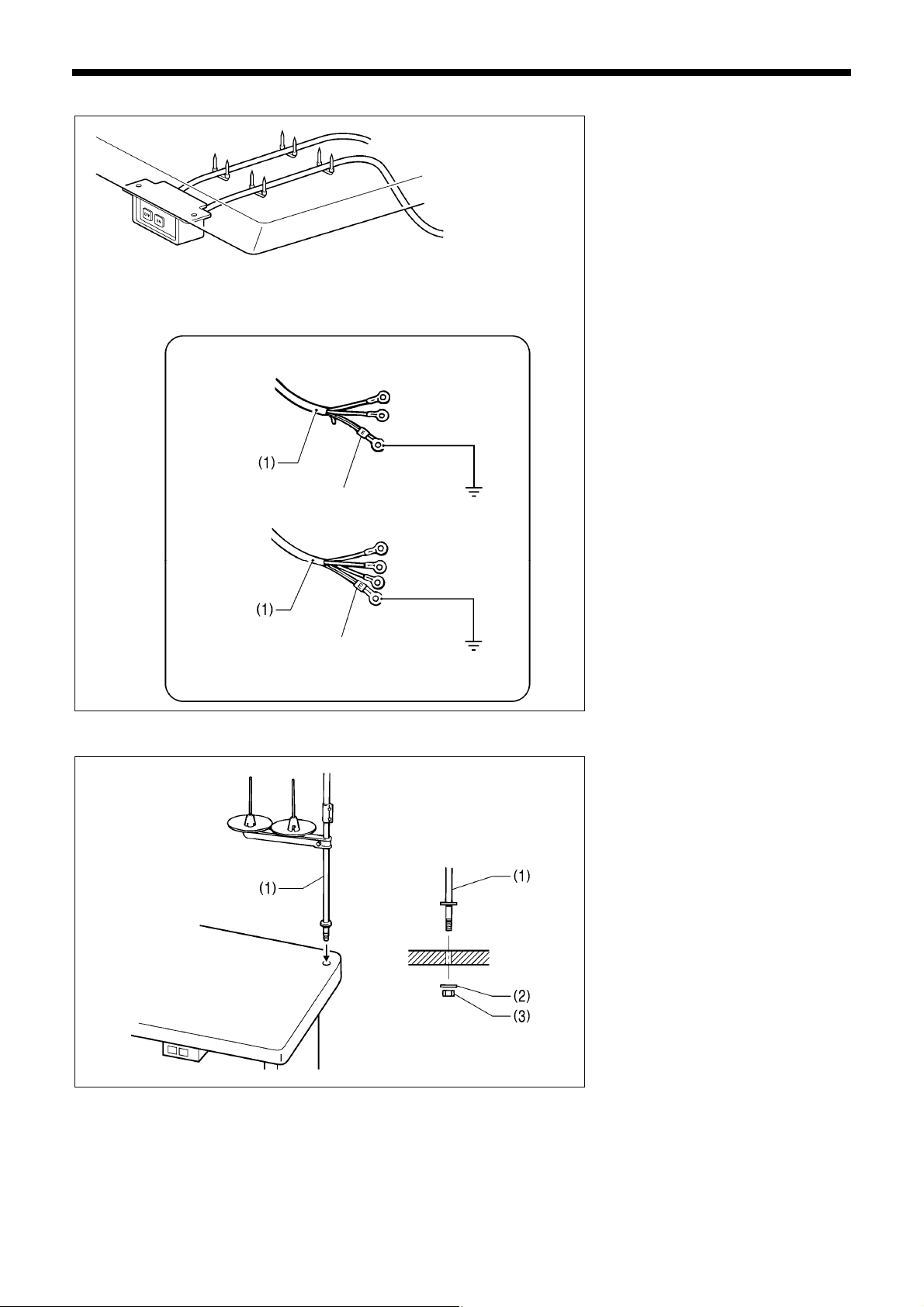

3. INSTALLATION

3-11. Connecting the power cord

<Single-phase

specifications>

<Three-phase

specifications>

Green and yellow wire

(ground wire)

Green and yellow wire

(ground wire)

5239Q

3-12. Installing the cotton stand

2974B

1. Attach an appropriate plug to the

power cord (1). (The green and yellow

wire is the ground wire.)

2. Insert the plug into a

properly-grounded AC power supply.

* The inside of the control box uses

single-phase power.

NOTE:

Do not use an extension cord. If this is

not observed, it may cause problems

with correct operation.

(1) Cotton stand

NOTE:

Fit the washer (2), and then securely

tighten the nut (3) so that the cotton

stand does not move.

15

BAS-300G, BAS-311G, BAS-326G

Page 25

3. INSTALLATION

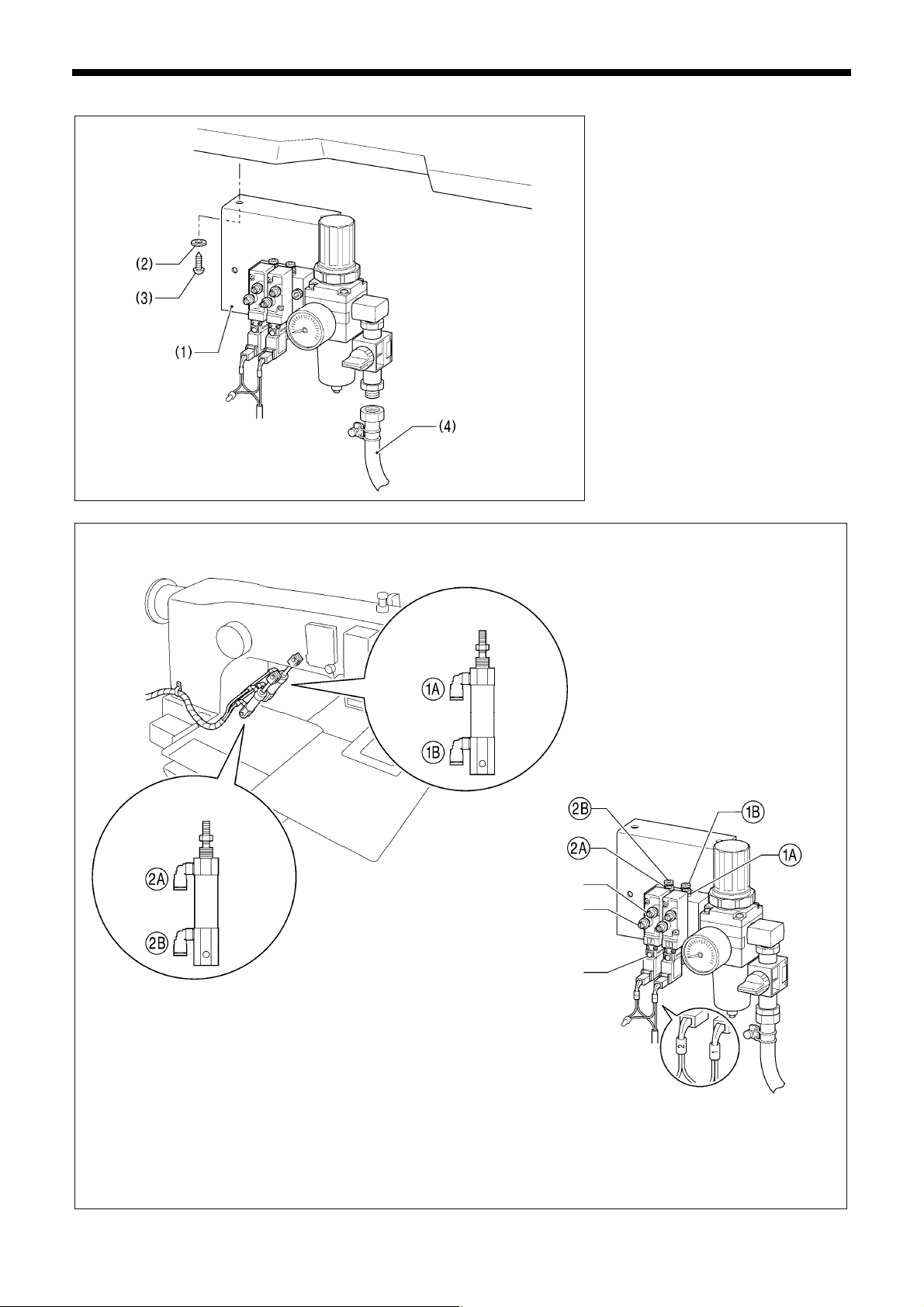

3-13. Installing the pneumatic unit (pneumatic work clamp specifications)

Install underneath the work table.

(1) Solenoid valve assembly

(2) Washers [2 pcs.]

(3) Wood screws [2 pcs.]

(4) Rubber hose

After installing the pneumatic unit, adjust

the air pressure.

(Refer to "10-16. Adjusting the air

pressure".)

NOTE:

Make sure that the pneumatic unit

does not touch the control box or the

work table leg.

1904B

Connect each air tube to the position with the corresponding number.

Cylinder R

Cylinder L

Upper knob

Lower knob

Manual button

<Adjusting the speed controller>

You can use the valve knobs to adjust the lifting and lowering speeds.

The valve knobs should be adjusted so that the left and right sides of the work clamp operate at the same speed.

• When the upper knob is tightened, the lifting speed becomes slower. When it is loosened, the lifting speed becomes faster.

• When the lower knob is tightened, the lowering speed becomes slower. When it is loosened, the lowering speed becomes

faster.

You can operate the work clamp while the power is turned off by pressing the manual button.

BAS-300G, BAS-311G, BAS-326G

5220Q 1905B

16

Page 26

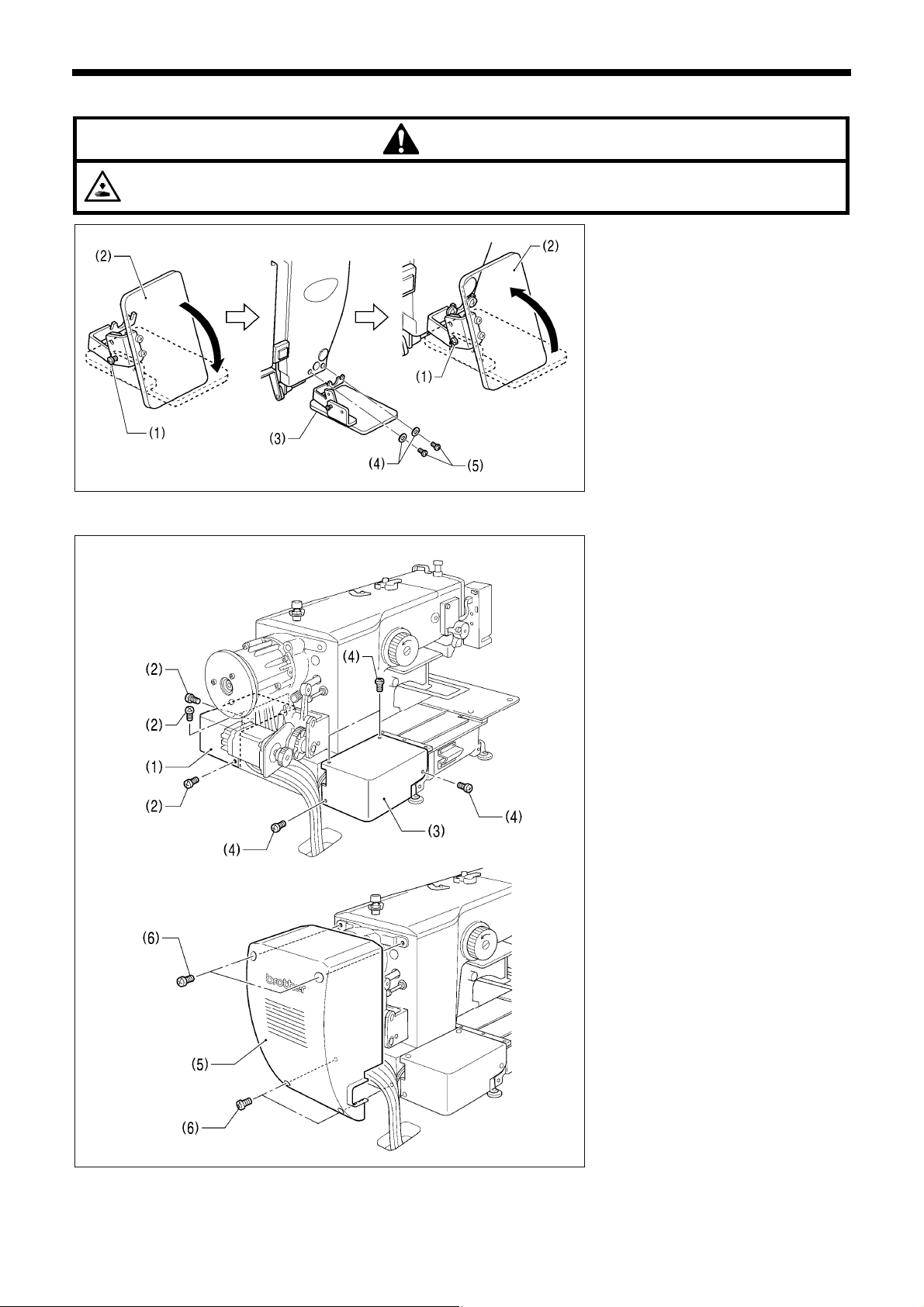

3. INSTALLATION

3-14. Installing the eye guard

CAUTION

Attach all safety devices before using the sewing machine.

If the machine is used without these devices attached, injury may result.

3-15. Installing the motor cover

2367B

2975B

2976B

(1) Screw (loosen)

(2) Eye guard (tilt forward)

(3) Eye guard assembly

(4) Plain washers [2 pcs.]

(5) Screws [2 pcs.]

After installing the eye guard assembly

(3), return the eye guard (2) to its original

angle, and then tighten the screw (1) to

secure it in place

(1) Motor cover R

(2) Screws [4 pcs.]

(3) Motor cover L

(4) Screws [4 pcs.]

(5) Motor cover

(6) Screws [4 pcs.]

NOTE:

Be careful not to clamp the cords when

installing the motor cover.

17

BAS-300G, BAS-311G, BAS-326G

Page 27

3. INSTALLATION

3-16. Lubrication

CAUTION

Do not connect the power cord until lubrication is complete.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do not get into

your eyes or onto your skin. If the oil and grease get into your eyes or onto your skin, inflammation can result.

Furthermore, do not drink or eat the lubricating oil or grease. They may cause diarrhea or vomiting.

Keep the oil out of the reach of children.

The sewing machine should always be lubricated and the oil supply replenished before it is used for the first time, and also after

long periods of non-use.

Use only the lubricating oil <JX Nippon Oil & Energy Corporation Sewing Lube 10N; VG10> specified by Brother.

* If this type of lubricating oil is difficult to obtain, the recommended oil to use is <Exxon Mobil Essotex SM10; VG10>.

5221Q

1. Fill the arm-side oil tank with oil.

2. Move the work clamp arm (1) as far as it will go to the right when looking from the front of the sewing machine, and then slide the

outer cover L (2) into the inner cover L (3) so that the lubrication hole in the bed is visible. Pour oil into the bed side oil tank

through this hole.

NOTE:

Be sure to fill the machine with oil when the oil level is down to about one-third full in the oil sight glass. If the oil drops below the

one-third level, there is the danger that the machine may seize during operation.

1845B 4940Q

3. Pour oil in through the two holes of the shuttle race base assembly so that the felt (4) is lightly moistened.

NOTE:

・ The two pieces of felt (4) should normally project by 0 to 0.5 mm from the hook race. Be careful not to push in the felt (4)

when lubricating.

・ If there is no more oil on the felt (4) of the shuttle race base assembly, problems with sewing may result.

4. If using the needle cooler (5), fill it with silicon oil (100 mm

2

/s). (Refer to “4-2. Threading the upper thread”.)

<Standard parts>

・ BAS-300G-03[]

・ BAS-311G

・ BAS-326G

<Option parts>

・ BAS-300G-01[]

・ BAS-300G-02[]

2368B

BAS-300G, BAS-311G, BAS-326G

18

Page 28

3. INSTALLATION

3-17. Installing the machine head fixing bolt

When transporting the sewing machine, secure the machine head to the table with the machine head fixing bolt.

(1) Plain washer

(2) Machine head fixing bolt

NOTE:

When operating the sewing machine,

remove the machine head fixing bolt.

5021Q

19

BAS-300G, BAS-311G, BAS-326G

Page 29

4. PREPARATION BEFORE SEWING

4. PREPARATION BEFORE SEWING

4-1. Installing the needle

CAUTION

Turn off the power switch before installing the needle.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

1. Loosen the set screw (1).

2. Insert the needle (2) in a straight line as far as it will go,

making sure that the long groove on the needle is at the

front, and then securely tighten the set screw (1).

2369B

4-2. Threading the upper thread

Thread the upper thread correctly as shown in the illustration below.

* When using threading mode for threading, the tension discs (1) will open so that the thread can be threaded more easily.

(Refer to following page.)

[If using cotton thread or spun thread]

2370B

• Turn the machine pulley (2) and raise the thread take-up (3) to its highest position before threading the upper thread.

(This will make threading easier and it will prevent the thread from coming out at the sewing start.)

• When threading the thread through the needle, allow a distance of approximately 40 mm between the needle hole and the

end of the thread.

If the trailing length of the thread is too long, it may cause the thread to become tangled.

2977B

[If using synthetic thread]

<Standard parts>

BAS-300G-03[], BAS-311G, BAS-326G

<Option parts>

BAS-300G-01[], 02[]

Thread the

upper thread

Needle cooler

2978B

BAS-300G, BAS-311G, BAS-326G

20

Page 30

4. PREPARATION BEFORE SEWING

<Threading mode>

Threading mode is safe because the sewing machine will not start even when the foot switch is depressed.

1

2

Threading the thread.

3

• When 5 minutes have passed, the buzzer will sound and the tension discs will close.

Ending threading mode

4

All indicators switch off

THREAD/CLAMP indicator illuminates

MENU indicator switches off

THREAD/CLAMP indicator switches off

Turn on the power switch.

Press the THREAD/CLAMP key.

• The work clamp will drop.

• The tension discs will open.

Press the THREAD/CLAMP key.

• The work clamp will return to where it was before

threading mode was started.

4421Q

4427Q

21

BAS-300G, BAS-311G, BAS-326G

Page 31

4-3. Winding the lower thread

CAUTION

Do not touch any of the moving parts or press any objects against the machine while winding the lower thread.

Injury or damage to the sewing machine may result.

4429Q

4431Q

4432Q

For case A

4430Q

4. PREPARATION BEFORE SEWING

1. Place the bobbin onto the bobbin winder shaft (1).

2. Thread the thread as shown in the illustration, wind the

thread around the bobbin several times, and then press

the bobbin presser arm (2).

3. Turn on the power switch.

4. Depress the foot switch to the 2nd step.

(If using a two-pedal foot switch, lower the work clamp

before depressing the start switch.)

The feed mechanism will move to the home position.

5. Check that the needle does not touch the work clamp,

and then while pressing the TENSION/WIND key (3),

depress the foot switch to the 2nd step.

(If using a two-pedal foot switch, lower the work clamp

before depressing the start switch.)

6. Release the TENSION WIND key (3) after the machine

starts operating, and keep depressing the foot switch

until the lower thread stops being wound onto the

bobbin.

(If you release the foot switch before winding is

complete, and then depress it again while pressing the

TENSION/ WIND key (3), winding will start again.)

7. Once winding of the set amount of lower thread (80 90% of the bobbin capacity) is completed, the bobbin

presser arm (2) will return automatically.

8. Remove the bobbin, hook the thread onto the knife (4),

and then pull the bobbin in the direction of the arrow to

cut the thread.

Adjusting the bobbin winding amount

Loosen the screw (5) and move the bobbin presser (6) to

adjust.

If the thread winds onto the bobbin unevenly

Loosen the set screw (7) and move the bobbin winder

tension assembly (8) up and down to adjust.

* For case A, move the bobbin winder tension assembly

(8) down, and for case B, move it upward.

4471Q

For case B

BAS-300G, BAS-311G, BAS-326G

22

Page 32

4. PREPARATION BEFORE SEWING

4-4. Installing the bobbin case

CAUTION

Turn off the power switch before installing the bobbin case.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

4945Q

1. Pull the shuttle race cover (1) downward to open it.

2. While holding the bobbin so that the thread winds to the right, insert the bobbin into the bobbin case.

3. Pass the thread through the slot (2) and pull it out from the thread hole (3).

4. Check that the bobbin turns in the direction of the arrow when the thread is pulled.

5. Pass the thread through the lever thread hole (4), and then pull out approximately 30 mm of thread.

6. Hold the latch on the bobbin case and insert the bobbin case into the rotary hook.

2534Q

30mm

2535Q

23

BAS-300G, BAS-311G, BAS-326G

Page 33

4-5. Thread tension

[Thread tension reference]

Specifications

Upper thread #20 or similar #50 or similar #4 or similar

Lower thread #20 or similar #50 or similar #4 or similar

Heavy-weight materials

(-01[])

4. PREPARATION BEFORE SEWING

Medium-weight materials

(-02[])

Seatbelt (-03[])

Upper thread tension (N)

Lower thread tension (N)

Pre-tension (N)

1.4 − 1.8 0.8 − 1.2 1.2 − 2.0

0.2 − 0.3 1.0 − 1.5

0.1 − 0.6 0.1 − 0.3 0.3 − 0.6

Needle DP x 17 #19 DP x 5 #16 DP x 17 #25

Normal sewing speed 2,000 sti/min 2,000 sti/min 1,300 sti/min

4-5-1. Lower thread tension

Adjust the thread tension to the weakest possible tension by

turning the thread tension nut (1) until the bobbin case will

not drop by its own weight while the thread end coming out

of the bobbin case is held.

Stronger

Weaker

2536Q

4-5-2. Upper thread tension

1. Turn the tension nut (1) (main tension) to adjust the

tension as appropriate for the material being sewn.

2. Use the tension nut (2) (sub tension) to adjust the upper

thread trailing length to about 40 mm.

Stronger

Weaker

Stronger

Weaker

2153B

BAS-300G, BAS-311G, BAS-326G

24

Page 34

4. PREPARATION BEFORE SEWING

4-6. Home position detection

Aligned

5223Q

4421Q

2979B

Before starting home position detection, check that the

needle bar is at its highest position.

Turn the pulley (1) in the direction of the arrow until the

ridge at the bottom of the thread take-up (2) is aligned with

the processed line on the arm.

1. Turn on the power switch.

The power indicator (3) will illuminate, and the model

number will appear in the PROGRAM No. display (4)

and the specifications class will appear in the menu

display (5).

2nd step

4441Q 4953Q

4952Q

Specifications

Motor-driven work clamp [ELEC]

Pneumatic work clamp [ Air]

After this, the program number will flash in the

PROGRAM No. display (4).

2. Depress the foot switch to the 2nd step.

(If using a two-pedal foot switch, lower the work clamp

before depressing the start switch (6).)

The sewing machine will move to the home position and

the work clamp will rise.

* For programs with a large number of stitches, the

buzzer will sound after the home position is detected,

and then the feed mechanism will move to the sewing

start position.

NOTE:

If error "E110" appears when the foot switch is

depressed, turn the pulley (1) in the direction of

operation to clear the error.

25

BAS-300G, BAS-311G, BAS-326G

Page 35

5. USING THE OPERATION PANEL (BASIC OPERATIONS)

5. USING THE OPERATION PANEL

(BASIC OPERATIONS)

5-1. Name and function of each operation panel item

4435Q

(1) Power indicator

Illuminates when the power is turned on.

(2) CAUTION indicator

Illuminates when an error occurs.

(3) RESET key

Used to reset errors.

(4) TEST key

Used to start test mode.

(5) TEST indicator

Illuminates when the TEST key (4) has been pressed.

(6) THREAD/CLAMP key

Used to start threading mode or work clamp height setting mode.

(7) THREAD/CLAMP indicator

Illuminates when the THREAD/CLAMP key (6) has been pressed.

(8) TENSION/WIND key

Used to wind the lower thread.

(9) TENSION/WIND indicator

Spare

(10) X-SCALE indicator

Illuminates when the SELECT key (15) is pressed to shown the X-scale setting.

(11) Y-SCALE indicator

Illuminates when the SELECT key (15) is pressed to shown the Y-scale setting.

(Continued on next page)

BAS-300G, BAS-311G, BAS-326G

26

Page 36

5. USING THE OPERATION PANEL (BASIC OPERATIONS)

(12) SPEED indicator

Illuminates when the SELECT key (15) is pressed to shown the sewing speed setting.

(13) COUNTER indicator

Illuminates when the SELECT key (15) is pressed to shown the lower thread or production counter setting.

(14) SPLIT No. indicator

Illuminates when the SELECT key (15) is pressed to show the split setting when split data (for specifying a pause while

the program is running) exists.

(15) SELECT key

Used to select a menu (X-scale, Y-scale, sewing speed and counter).

(16) Menu display

Displays information such as menu setting values, memory switch settings and error codes.

(17) Setting keys

Used to change the value which is displayed in the menu display (16).

In addition, it is used to move the needle position forward and back when sewing has been paused.

(18) PROGRAM No. display

Displays information such as program numbers.

(19) Setting keys

Used to change the value which is displayed in the PROGRAM No. display (18).

(20) CF media indicator

Illuminates when a CF card (external media) is inserted while the power is turned on.

(21) FD media indicator

Illuminates when a floppy disk (external media) is inserted while the power is turned on. [Option compatibility]

(22) Function keys [F1, F2, F3, F4]

Used to select user programs and to set and select cycle programs.

(23) R/W key

Used to read data from and write data to external media.

TM

CF

is a trademark of SanDisk Corporation.

4435Q

27

BAS-300G, BAS-311G, BAS-326G

Page 37

5. USING THE OPERATION PANEL (BASIC OPERATIONS)

5-2. Loading sewing data

Refer to "7-1. Notes on handling CF cards (sold separately)" for details on using CF cards.

1

2

CF media indicator illuminates

3

Loading

Loading complete

4

The PROGRAM No. display will change from " P" to the selected program number.

Turn off the power switch, remove the CF card, and then close the cover of the CF slot.

With the power turned off, insert the CF card into the CF

slot.

NOTE:

• Make sure the CF card is facing the correct way

when inserting it.

• Always be sure to keep the cover closed except

when inserting and removing the CF card. If this is

not done, dust may get inside and cause problems

with operation.

Turn on the power switch.

Press the or key to select the program number

(100 − 999).

* The "---" display is used to check the feed home

position.

Press the R/W key.

• The buzzer will sound and the selected sewing data

will be loaded from the CF card and copied into the

sewing machine's internal memory.

4453Q

4457Q4421Q

4498Q

5-3. Setting the program number

2nd step

BAS-300G, BAS-311G, BAS-326G

1. Press the or key (1) to select the program number

that is loaded into the internal memory.

• The program number will flash in the PROGRAM No.

display (2).

• "---" will appear at the time of shipment from the

factory. (For checking feed home position)

2. Depress the foot switch to the 2nd step.

(If using a two-pedal foot switch, lower the work clamp

before depressing the start switch.)

• The feed mechanism will move to the home position

and the program number will be accepted.

• The program number will stop flashing and illuminate

steadily.

NOTE:

After completing the setting, be sure to refer to "5-6.

Checking the sewing pattern" to check that the needle

drop position is correct.

4954Q

28

Page 38

5. USING THE OPERATION PANEL (BASIC OPERATIONS)

5-4. Setting the X-scale and Y-scale

2nd step

4955Q

5-5. Setting the sewing speed

The scales are set to 100 (%) at the time of shipment from

the factory.

1. Press the SELECT key (1) so that the X-SCALE

indicator (2) (for X-scale setting) or the Y-SCALE

indicator (3) (for Y-scale setting) is illuminated.

• The setting value (%) will appear in the menu display

(4).

* When memory switch no. 402 is set to "ON", the

settings will be displayed in units of mm.

2. Press the or key (5) to set the scale (0 − 400).

• The program number will flash in the PROGRAM No.

display (6).

3. Depress the foot switch to the 2nd step.

(If using a two-pedal foot switch, lower the work clamp

before depressing the start switch.)

• The feed mechanism will move to the home position

and the scale will be accepted.

• The program number will stop flashing and illuminate

steadily.

NOTE:

After completing the setting, be sure to refer to "5-6.

Checking the sewing pattern" to check that the needle

drop position is correct.

The sewing speed is set to 2000 (sti/min) at the time of

shipment from the factory.

1. Press the SELECT key (1) until the SPEED indicator (2)

illuminates.

• The setting value (sti/min) will appear in the menu

display (3).

2. Press the

(Sewing speed setting: 400 − 2700)

or key (4) to set the sewing speed.

29

4956Q

BAS-300G, BAS-311G, BAS-326G

Page 39

5. USING THE OPERATION PANEL (BASIC OPERATIONS)

5-6. Checking the sewing pattern

Use test feed mode to check the needle movement with only the feed mechanism operating.

Check that the needle hole does not come out from the frame of the work clamp.

1

TEST indicator illuminates

2

COUNTER indicator illuminates

Starting continuous test feed mode

3

1st step

2nd step

TEST indicator illuminates

TEST indicator switches off

If test feeding continues to the final stitch,

4

it will then stop.

2nd step

Press the TEST key.

Select the program number to be checked, and then set the X-scale and

the Y-scale.

• The program number will flash.

Depress the foot switch to the 2nd step.

(If using a two-pedal foot switch, lower the work clamp before depressing

the start switch.)

• The feed mechanism will move to the home position and the program

number will stop flashing and illuminate steadily.

• The number of stitches will appear in the menu display.

Depress the foot switch to the 2nd step and then release it.

(If using a two-pedal foot switch, lower the work clamp before depressing

the start switch and releasing it.)

• Feed mechanism starts moving continuously one stitch at a time.

[Fast-forward test mode]

If you depress the foot switch to the 1st step while the feed mechanism is

moving, the feeding speed will become faster while the foot switch is being

depressed. (If using a two-pedal foot switch, depress the work clamp

switch.)

2nd step

If you press the

forward one stitch at a time, and if you press the

key, the feed mechanism will move backward one

stitch at a time. (The feed will move quicker if you

keep the key pressed down.)

key, the feed mechanism will move

If you would like sewing to start while test feeding is in

progress, press the TEST key to switch off the TEST

indicator.

When you depress the foot switch to the 2nd step,

sewing will start. (If using a two-pedal foot switch,

depress the start switch.)

Press the TEST key.

TEST indicator switches off

4957Q

4441Q

4441Q

4443Q

4441Q

BAS-300G, BAS-311G, BAS-326G

30

Page 40

5. USING THE OPERATION PANEL (BASIC OPERATIONS)

5-7. Setting the work clamp lift amount

The setting for the work clamp lift amount can be changed using the operation panel.

* For pneumatic work clamp specifications, only threading mode and intermittent presser foot height setting mode will be

available.

1

Motor-driven work clamp specifications only

2

All indicators switch off

THREAD/CLAMP indicator illuminates

MENU indicator switches off

When memory switch No. 003 is set to "2"

Press the THREAD/CLAMP key.

The sewing machine will switch to threading mode.

• " 1" will appear in the PROGRAM No. display, and the work

clamp will drop.

4445Q

Press the key.

The sewing machine will switch to work clamp height setting

mode.

• " 2" will appear in the PROGRAM No. display, and the work

clamp will rise to the setting value that appears in the menu

display.

(Work clamp height setting: 15 − 25)

Press the or key to set the work clamp height.

• The work clamp will rise or drop to the height of the new value

that has been set.

5224Q

Press the key.

The sewing machine will switch to intermediate work clamp

height setting mode.

• " 3" will appear in the PROGRAM No. display, and the

work clamp will move to the setting value that appears in

the menu display.

(Intermediate work clamp height setting: 1 − 15)

Press the

height.

• The work clamp will rise or drop to the height of the new

value that has been set.

or key to set the intermediate work clamp

NOTE:

When setting the work clamp height and the

intermediate presser foot work clamp height, check

that the slider (1) is touching the work clamp lifter

plate assembly (2).

5254Q

31

BAS-300G, BAS-311G, BAS-326G

4959Q

Page 41

5. USING THE OPERATION PANEL (BASIC OPERATIONS)

3

Press the key.

The sewing machine will switch to intermittent presser foot height

setting mode.

• " 4" will appear in the PROGRAM No. display, and the work

clamp will rise to the setting value that appears in the menu

display.

(Intermittent presser foot height setting: 0.0 − 10.0)

Press the

height.

• The intermittent presser foot will rise or drop to the height of

the new value that has been set.

NOTE:

After making the setting, be sure to turn the pulley once by

hand and check that the intermittent presser foot does not

touch the needle bar.

or key to set the intermittent presser foot

5225Q

<Changing modes>

Ending setting mode

4

THREAD/CLAMP indicator switches off

Intermittent presser foot operation

During standby

When lowered

While sewing

Motor-driven work clamp specifications

" 1" Threading mode

↑ ↓

" 2" Work clamp height setting mode

↑ ↓

" 3" Intermediate work clamp height setting mode (*)

↑ ↓

" 4" Intermittent presser foot height setting mode

Pneumatic work clamp specifications

" 1" Threading mode

↑ ↓

" 4" Intermittent presser foot height setting mode

* When memory switch No. 003 is set to “2”

Press the THREAD/CLAMP key.

• The setting values will be memorized.

• The work clamp will return to where it was before setting mode

was started.

1 Intermittent presser foot lift amount

2 Intermittent presser foot height

The settings can be made by the above

operations.

However, set the intermittent presser foot

height to a higher setting than the

intermittent stroke.

* If it is set smaller, the intermittent presser

foot will come into contact with the

needle plate.

3 Intermittent stroke

Refer to “10-14. Changing the intermittent

stroke” when making the adjustment.

4448Q

5033Q

BAS-300G, BAS-311G, BAS-326G

32

Page 42

6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

6. USING THE OPERATION PANEL

(ADVANCED OPERATIONS)

6-1. List of advanced functions

While holding down the TEST key, press the corresponding combination key.

1

2

3

When SPEED indicator is illuminated

4

5

Memory switch setting mode

Refer to "6-2. Setting memory switches".

Lower thread counter setting mode

Refer to "6-4. Using the lower thread counter".

Production counter setting mode

Refer to "6-5. Using the production counter".

Production counter temporary display function

Refer to "6-5. Using the production counter".

User program setting mode

Refer to "6-7. Using user programs".

4488Q

4489Q

4490Q

4491Q

4492Q

4493Q

33

BAS-300G, BAS-311G, BAS-326G

Page 43

6-2. Setting memory switches

6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

1

2

If you would like to display only the numbers of

memory switches that have been changed from

default settings

Ending setting mode

3

All indicators switch off

Menu indicator switches off

TEST indicator illuminates

TEST indicator switches off

• If you would like to return the setting for a single memory switch to the default setting, press the

RESET key while the number for that memory switch is displayed.

• To return the settings for all memory switches to the default settings, keep pressing the RESET key

for two or more seconds until the buzzer makes a long beep.

While pressing the SELECT key, turn on the power

switch.

* Keep pressing the SELECT key until the model name

is displayed and the buzzer beeps once.

or

With the power turned on, press the TEST key and the

TENSION/WIND key simultaneously.

• The memory switch number will appear in the

PROGRAM No. display, and its setting value will

appear in the menu display.

4421Q4449Q

Press the

number.

or key to select the memory switch

Press the or key to change the setting.

4961Q

While pressing the SELECT key, press the

• The numbers of memory switches that have been

changed from default settings will appear in order.

• If no memory switches have been changed from their

default settings, the display will not change and the

buzzer will beep twice.

Press the TEST key.

• The changes will be memorized and the sewing

machine will switch to home position detection standby.

or key.

4452Q

BAS-300G, BAS-311G, BAS-326G

34

Page 44

6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

6-3. List of memory switch settings

No.

001

002

003

100

200

300

400

401

402

403

* The mm display may differ slightly from the actual sewing size.

Setting

range

Work clamp lift timing after sewing is completed

OFF Lifts at the final stitch position.

ON Lifts after moving to the sewing start position.

Separate-type work clamp drop operation (pneumatic work clamp specifications)

0 Left and right work clamp drop at the same time.

1

2

Work clamp drop operation (motor-driven work clamp specifications)

0

1

2

Sewing start speed

OFF

ON

Single-stitch test feed

OFF

ON

Production counter display

OFF Lower thread counter display

ON Production counter display

User programs

OFF Disabled

ON User program mode is enabled.

Cycle programs

OFF Disabled

ON When sewing user programs, the set programs are sewn in numeric order.

Maximum reduction ratio (mm display) (*)

OFF Displayed as %.

ON Displayed as mm.

Split mode selection

0 Continuous split (split menu is disabled before split detection)

1 Continuous split (split menu is always enabled)

2 Independent split

Work clamp drops in the order left → right.

Work clamp drops in the order right → left.

Analog dropping: Work clamp drops in direct proportion to the pedal depression

amount, and sewing starts when the pedal is fully depressed

1st step drop: Work clamp drops when the pedal is depressed to the 1st step, and

sewing starts when the pedal is depressed to the 2nd step

2nd step drop: Work clamp drops to intermediate height when the pedal is

depressed to the 1st step, and work clamp drops and sewing starts when the

pedal is depressed to the 2nd step.

The sewing speed for the first 1 − 5 stitches is set by memory switch numbers 151

− 155.

(Refer to the service manual for details of memory switch Nos. 151 − 155.)

1st stitch at 400 sti/min, 2nd stitch at 400 sti/min, 3rd stitch at 600 sti/min, 4th

stitch at 900 sti/min, 5th stitch at 2,000 sti/min

Test feed starts when the foot switch (start switch) is depressed, and it continues

automatically until the final stitch.

Test feed is carried out one stitch at a time when the foot switch (start switch) is

depressed (feed becomes continuous if the foot switch [start switch] is

continuously depressed).

In addition, when the TEST indicator is illuminated, test feeding will move forward

one stitch at a time when the machine pulley is turned by hand.

Setting items Initial value

ON

0

2

OFF

OFF

OFF

OFF

OFF

OFF

0

35

BAS-300G, BAS-311G, BAS-326G

Page 45

6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

6-4. Using the lower thread counter

If you use the lower thread counter to set the number of articles which can be sewn with the amount of lower thread

available, you can stop the lower thread running out in the middle of sewing a pattern.

<Setting defaults>

1

TEST indicator illuminates, COUNTER indicator flashes

2

Press the

• The initial value can be set from 1 ("0001") to 9999 ("9999").

• If the initial value is set to "0000", the lower thread counter will not operate.

• If you press the RESET key during setting mode, the value will become

"0000".

or key to set the initial value.

If you press the R/W key during setting mode, the initial value for

the program number being displayed will be stored, and you can

set the lower thread counter separately for each item of sewing

data.

4456Q

Ending setting mode

3

TEST indicator switches off

<Lower thread counter operation>

If you press the SELECT key (1) to select the counter display menu when memory switch no. 300 is set to "OFF", the

COUNTER indicator will illuminate and the lower thread counter will appear in the menu display (2).

While pressing the TEST key, press the key.

• The initial value which was set previously will appear in

the menu display.

4455Q

4962Q

Press the TEST key.

• The initial value will be memorized.

1. Each time the sewing of a single article is completed,

the value shown in the menu display (2) is reduced by 1.

2. When the lower thread counter reaches "0000", the

buzzer will sound continuously. The sewing machine will

not operate during this time, even if the foot switch is

depressed.

3. When you press the RESET key (3), the buzzer will stop,

the initial value will appear in the menu display (2) and

sewing will be possible.

• If no initial value has been set, the display will be

"0000".

* You can press the

thread counter to a desired value. However, this value

will not be stored as the initial value.

* If a lower thread counter value is set, the lower thread

counter will operate even if the lower thread counter is

not being displayed.

or key (4) to set the lower

4963Q

BAS-300G, BAS-311G, BAS-326G

36

Page 46

6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

6-5. Using the production counter

<Setting the counter value>

1

TEST indicator and SPEED indicator illuminate

COUNTER indicator flashes

2

Ending setting mode

3

TEST indicator switches off

<Production counter operation>

If you press the SELECT key (1) to select the counter display menu when memory switch no. 300 is set to "ON", the SPEED

and COUNTER indicators will illuminate and the production counter will appear in the menu display (2).

While pressing the TEST key, press the key.

• The counter value that was previously set will appear

as a 7-digit number in the PROGRAM No. display and

the menu display.

4465Q4464Q

Press the or key to set the counter value.

• The counter value can be set to between "000" "0000"

and "999" "9999".

• If you press the RESET key during setting mode, the

value will become "000" "0000".

4466Q

Press the TEST key.

• The counter value will be memorized.

1. Each time the sewing of a single article is completed,

the value shown in the menu display (2) is increased by

1.

2. While the

digits will appear in the PROGRAM No. display (4) so

that the total number of digits displayed will be seven.

3. If you press the RESET key (5) for 2 seconds or more,

the counter value will be reset to [0000].

key (3) is being pressed, the first three

37

Temporary display function

You can display the production counter temporarily while

the lower thread counter is being displayed.

When the SPEED indicator is illuminated, hold down the

TEST key (6) and then press the RESET key (5) to display

the production counter in the menu display (2).

Press the TEST key (6) or the SELECT key (1) to switch the

menu back to the normal menu display.

* You can start sewing while the temporary display still

4468Q

BAS-300G, BAS-311G, BAS-326G

appears.

Page 47

6-6. Setting the split number

If split data (data that causes sewing to pause) exists within a single program,

the numbers that are used to specify the patterns that are separated by split

data are called split numbers.

6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

4964Q

Pattern 1

Pattern 2

Pattern 3

2nd step

Pattern 1: Split No. 1

Pattern 2: Split No. 2

Pattern 3: Split No. 3

1. Press the

2. Depress the foot switch to the 2nd step.

3. Press the SELECT key (3) so that the SPLIT No.

4. Press the

4965Q

or key (1) to select a program number

for a program that contains split data.

• The program number will flash in the PROGRAM No.

display (2).

(If using a two-pedal foot switch, lower the work clamp

before depressing the start switch.)

• The feed mechanism will move to the home position

and the program number will be accepted.

• The program number will stop flashing and illuminate

steadily.

indicator (4) illuminates.

• The split number will appear in the menu display (5).

or key (6) to set the split number.

The setting for memory switch No. 403 lets you select the split mode.

[Continuous split]

Memory switch No. 403 = 0 (Split mode is enabled after split data is detected)

Memory switch No. 403 = 1 (Split mode is always enabled)

• Sewing is carried out each time in the order of steps 1 → 2 → 3 → 1 (for example, if there are two sections of split

data).

[Independent split]

Memory switch No. 403 = 2

• The pattern for the displayed split number is sewn independently.

BAS-300G, BAS-311G, BAS-326G

38

Page 48

6. USING THE OPERATION PANEL (ADVANCED OPERATIONS)

6-7. Using user programs

Up to 50 different combinations of settings including program no., X-scale, Y-scale, sewing speed, work clamp height and

intermittent presser foot height can be memorized as user programs (U1 to U50). (However, the work clamp height setting is

only enabled for motor-driven work clamp specifications.)

If you are sewing certain patterns over and over again, it is useful to record the settings for these patterns into a user

program.

User programs are enabled when memory switch no. 400 is set to "ON".

<Recording user programs>

Select a user program number.

1

TEST indicator illuminates, MENU indicator flashes

First, set the program number.

2

Next, set the X-scale.

3

Next, set the Y-scale.

4

Next, set the sewing speed.

5

X-SCALE indicator flashes

Y-SCALE indicator flashes

SPEED indicator flashes

While pressing the TEST key, press the SELECT key.

• Switch to user program recording mode. Check that

the menu indicators are flashing.

• The user program number will appear in the

PROGRAM No. display, and " P- - - " will appear in the

menu display.

Press the

number.

Press the

to be recorded.

NOTE:

Select a program number that is recorded in the

internal memory. You cannot specify program

numbers on removable media.

or key to select the user program

4469Q

or key to set the user program number

4966Q

Press the SELECT key.

Press the or key to set the X-scale to be recorded.

4470Q