Page 1

Electronically Programmable lockstitch Machine

with

Cylinder Arm Profile Sll

Service manual

Page 2

CONTENTS

1.

MECHANISM

4.

STANDARD

ADJUSTMENTS

Needle bar, thread take-up, lower shaft,

D

m

11

m

m

m

fJ

m

m

2. DISASSEMBLY PROCEDURES

shu~tle

and

Work clamp mechanism (1)

Work clamp mechanism (2)

Work clamp mechanism (3)

Feed

mecha.nism

Feed

mechanism

Intermittent-presser

Intermittent-presser

Thread trimming mechanism

Thread

Thread wiper mechanism

Thread winding mechanism

Lubrication

hook mechanism

(X

(Y

release

mechanism

.......................

axis)

..............

axis)

..............

foot

mechanism (1)

foot

mechanism (2)

..............

..........

............

............

............

....

....

............

.............

............

D Covers . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PJ-1

Work clamps (solenoid type) . . . . . . . . . . . 10

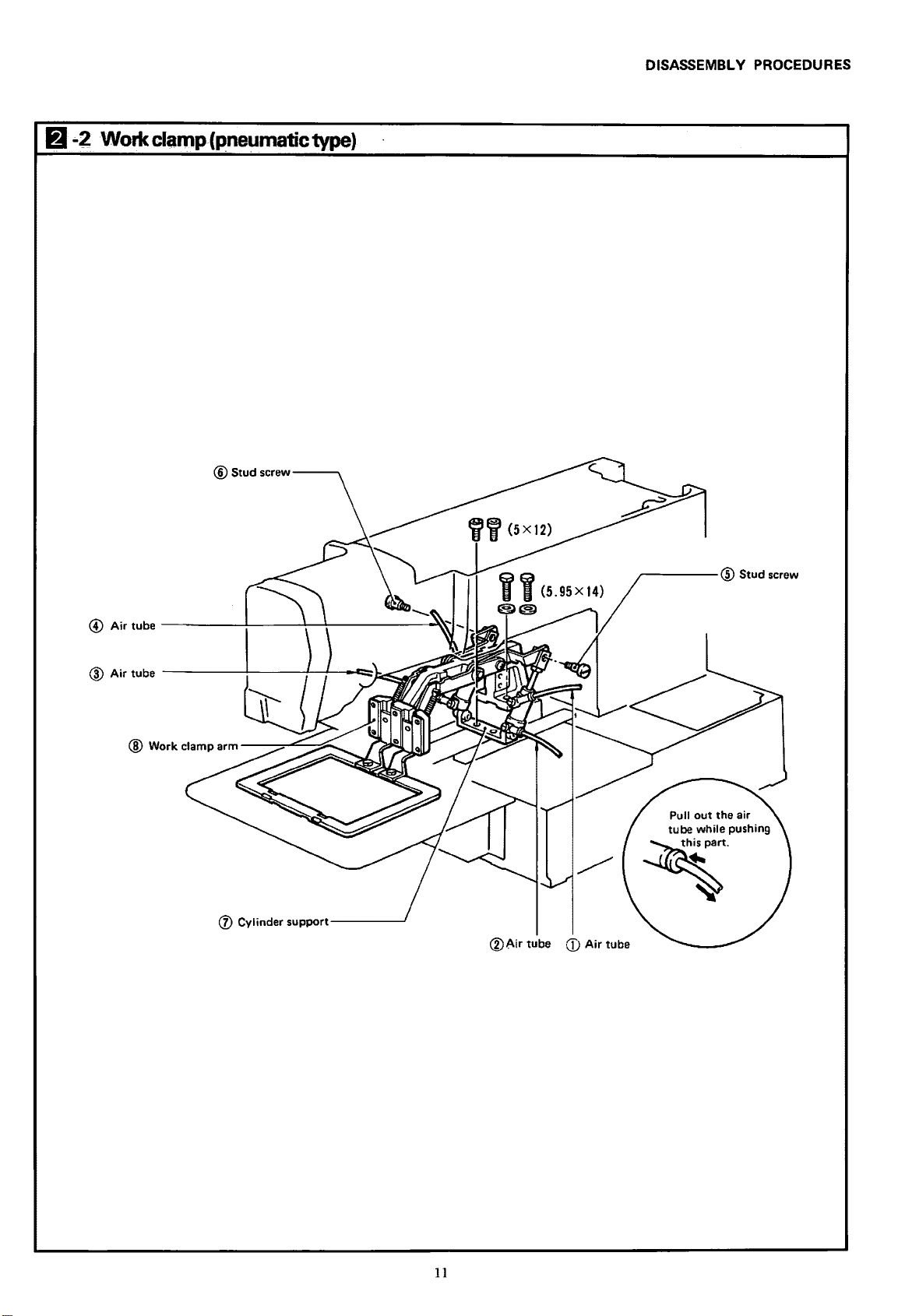

PJ-2

Work clamps (pneumatic type) . . . . . . . . .

11

Lower shaft . . . . . . . . . . . . . . . . . . . . . . .

EJ

Longitudinal feed

D)

Traverse

GJ

Thread wiper . . . . . . . . . . . . . . . . . . . . . . 15

fJ

I nterm

[;]

Needle bar

D)

Work clamp

ml

Thread trimming . . . . . . . . . . . . . . . . . . . 19

feed

itti

nt-presser

m Intermittent-presser

1m

Upper shaft . . . . . . . . . . . . . . . . . . . . . . .

3. ASSEMBLY

PROCEDURES

(Y

axis) . . . . . . . . . . . . . 13

(X axis) . . . . . . . . . . . . . . . . 14

foot

. . . . . . . . . . . . . . 16

........................

lifter

and

thread

release

. . . . . . . 18

foot

lifter.

. . . . . . . . . . 20

AND

ADJUSTMENT

11

12

17

21

D Upper shaft . . . . . . . . . . . . . . . . . . . . . . . 22

PJ

Intermittent-presser

11

Needle bar . . . . . . . . . . . . . . . . . . . . . . . . 24

E)

Intermittent-presser

1!1

Work clamp

G)

Thread

fJ

Traverse feed (X axis) . . . . . . . . . . . . . . . .

[;]

Longitudinal feed (Y axis) . . . . . . . . . . . . . 32

DJ

Lower shaft

1m

Work clamp arm

lifter

trimming

and

m Thread wiper

1m

Intermittent-presser

foot

lifter.

. . . . . . . . . . 23

foot

. . . . . . . . . . . . . . 25

and

thread

release

. . . . . . .

. . . . . . . . . . . . . . . . . . . 29

relevant . . . . . . . . . . . . . . 33

and

relevant . . . . . . . . . . . 34

......................

foot

. . . . . . . . . . . . . . 38

27

30

36

Ill Covers and relevant . . . . . . . . . . . . . . . . . . 39

D Adjustment

of

needle-bar height . . . . . . . . . 42

D

6 Matching the needle

with

the

tip

of

1

11

2

2

3

3

4

4

5

5

6

6

7

Adjustment

needle and the

EJ

Adjustment

the driver . . . . . . . . . . . . . . . . . . . . . . 43

DJ

Adjustment

thread guide

G)

Adjustment

fJ

Adjustment

[;]

Adjustment

D) Adjustment

foot

lift

ml

Adjustment

m Adjustment

and

feed timing . . . . . . . . . . . . . . . . . . 49

16

Adjustment

Ill Adjustment

release

timing . . . . . . . . . . . . . . . . . . . .

Ill Adjustment

mJ

Adjustment

1m

Adjustment

position . . . . . . . . . . . . . . . . . . . . . . . 53

5.

HOW TO

D How

fJ

How

to

make up the clamping type

to

make up the

the shuttle hook . . . . . . . . 42

of

clearance between the

tip

of

the shuttle hook . . . 43

of

the needle receiver

of

the shuttle hook

.....................

of

the

work

clamp

of

the moving blade . . . . . . . . . 45

of

the

presser

of

the intermittent-presser

.......................

of

the thread

of

the needle-stop position

of

the original

of

the upper thread

of

the backlash . . . . . . . . . . . . 52

of

the thread trimming

of

the

work

MAKE

foot

wiper.

clamp

UP

cassette

of

lift

. . . . . . . . 45

. . . . . . . . . . 47

. . . . . . . . . 48

point

. . . . . . . . . 50

cam

lifter

base

THE PRESSER

presser

type

presser

. . . . 53

. . . 56

44

47

51

. . 54

fl

II

II

I

I

I

II

6.

ADJUSTMENT

APPLIANCES

Description on fuse

D

Voltage measurement

PJ

LEOs

on

PCB

11

How

m

m

m

to

Description

Description

7.

TROUBLESHOOTING LIST

......................

use

the DIP switch . . . . . . . . . . . . .

of

each

on

OF ELECTRIC

........•.........

................

connector

control box

..........•

.............

.....

58

59

60

61

63

65

66

I

I

I

8. SPARE PARTS LIST

9.

CONTROL

DIAGRAM

10. TROUBLESHOOTING

FLOW

11. COUNTERMEASURES

CIRCUIT

..................

CHART

...........

BLOCK

..............

..........

69

70

71

78

Page 3

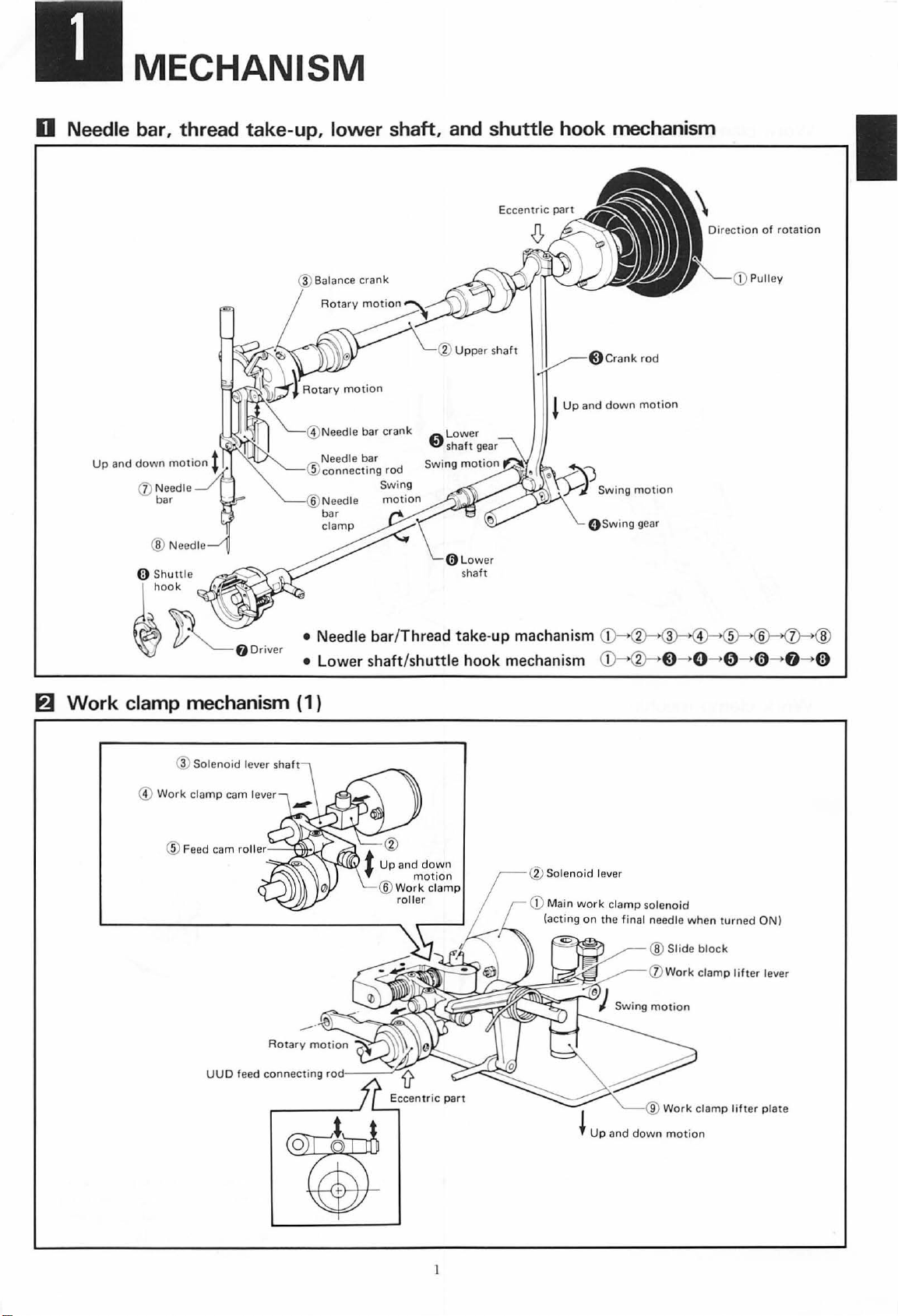

MECHANISM

D Needle bar, thread take-up, lower shaft,

a

W

(j) Needle

bar

and

shuttle hook mechanism

!

Up

and

down

lo

wer

sha

ft

gear

Swing

O Swing gear

motion

motion

Direction

of

Pulley

rotation

fl

Work

•

•

clamp mechanism ( 1 )

®Sol

enoid

lever shaft

@

Work

clamp

cam lever

Needle

Lower

bar/Thread

shaft/shuttle

take-up

hook

machanism

mechanism

@ Sol

enoid

CD

Main

(acting

1 2 3 4 5 6 7 ®

(j)-->®--->

lever

work

clamp solenoid

on

the final needle

~-0-0-0

when

turned

ON)

--+8--+

(l)

I ®

t

Up

and

down motion

Work

clamp

lifter

plate

Page 4

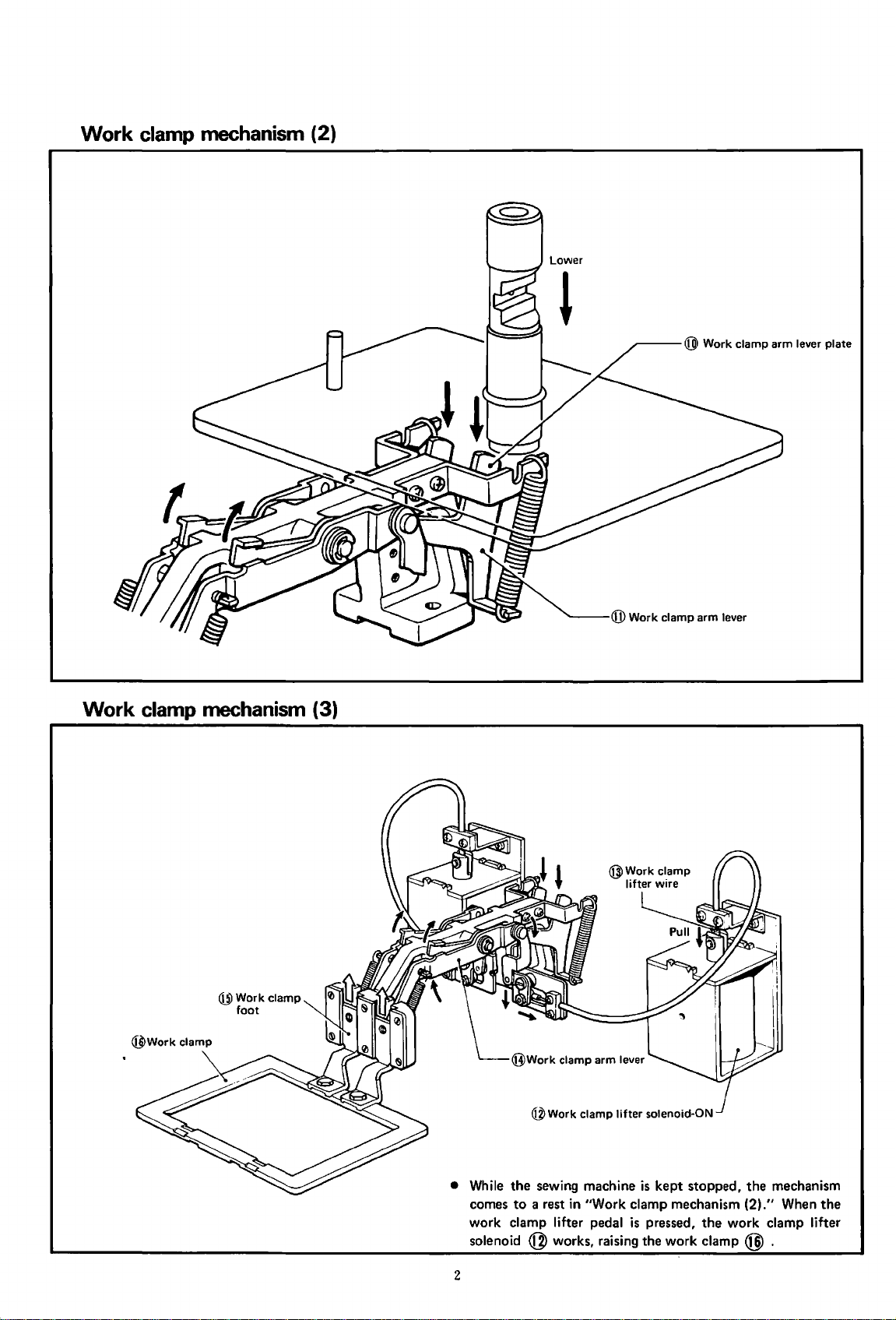

Work

clamp mechanism (2)

Work

clamp mechanism (3)

~--@

Work clamp arm lever plate

@Work

foot

clamp

@Work

• While

the

sewing machine

to

comes

work clamp lifter pedal

solenoid

a rest in "Work clamp mechanism (2)

@works,

2

clamp

lifter

solenoid-ON

is

kept

stopped,

is

pressed,

raising the work clamp @ .

the

work clamp lifter

the

mechanism

."

When

the

Page 5

RJ

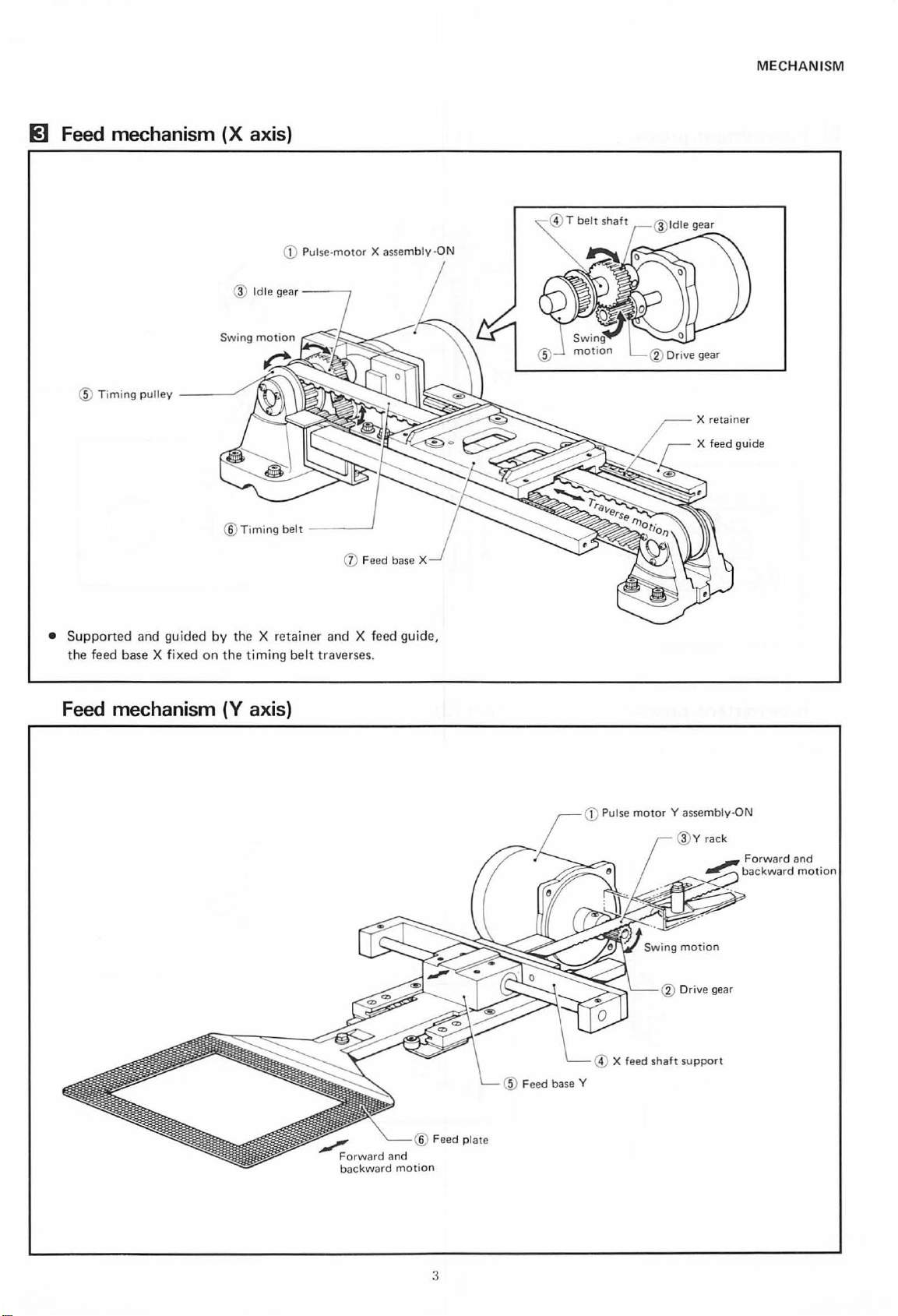

Feed mechanism

@ T imi

ng

pulley

__

_

(X

®

__.,

axis)

Idle

gear--

--,

MECHANISM

T

belt

shaft

X retai

ner

•

Support

the

ed and guid

feed

base

X fixed

Feed mechanism

ed

®

Timing

by

the X reta

on

the

timing belt traverses.

(Y

axis)

belt

--

iner

----'

(j)

and

X feed guid

Feed base X

e,

CD

Pulse

motor

Y assembly·ON

@v

rack

~

F

orwa

backward

rd and

motion

® Feed

pla

te

3

Page 6

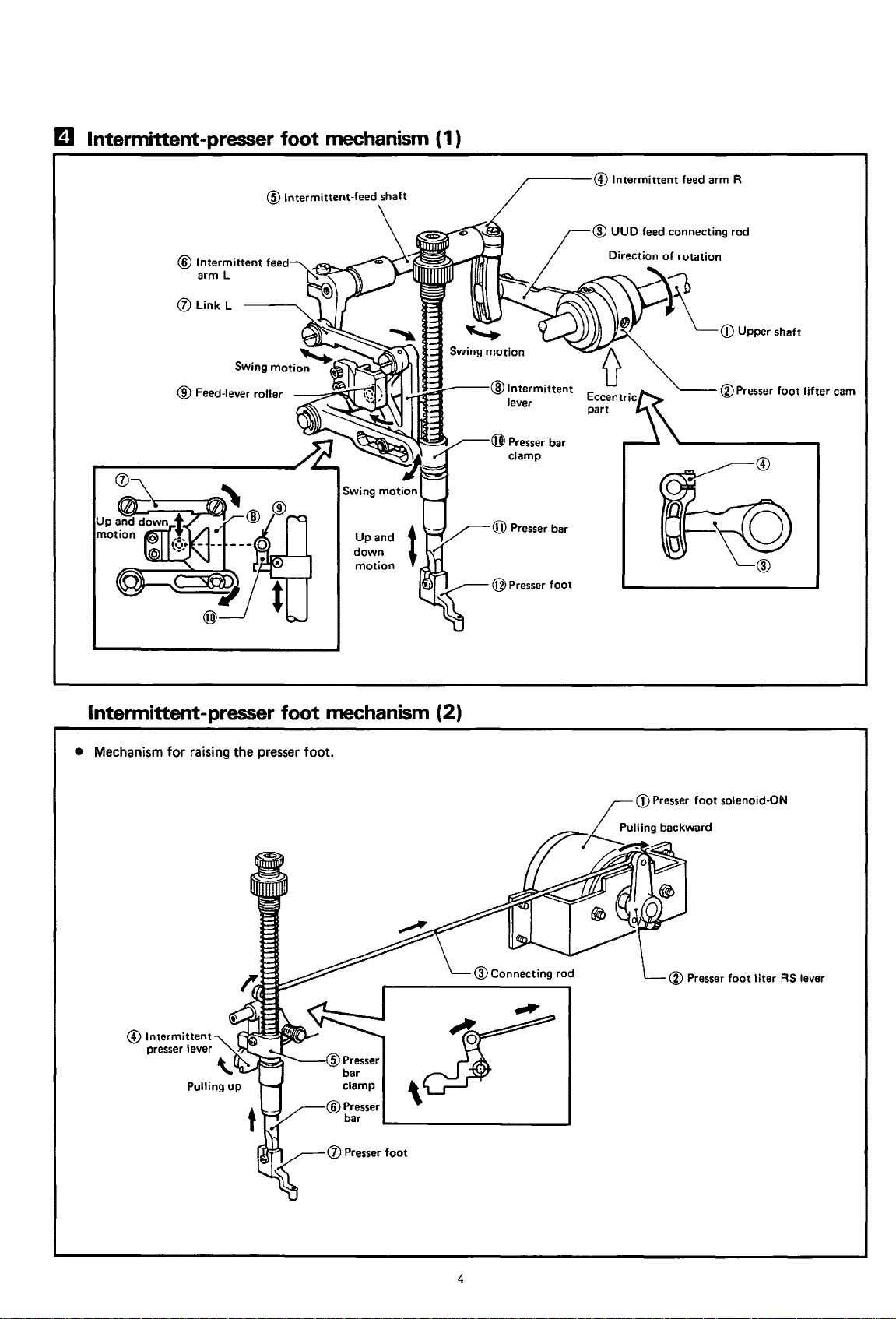

El

Intermittent-presser foot mechanism {1)

®Intermittent

arm L

(j) Link L

@ Feed-lever roller

feed

-----@Intermittent

Direction of rotation

::)~

~-"'----@Intermittent

lever

feed arm R

~CD

Upper shaft

®Presser

foot lifter cam

Intermittent-presser foot mechanism {2)

•

Mechanism

for raising the presser foot.

@ Intermittent

presser lever

\.

4

Page 7

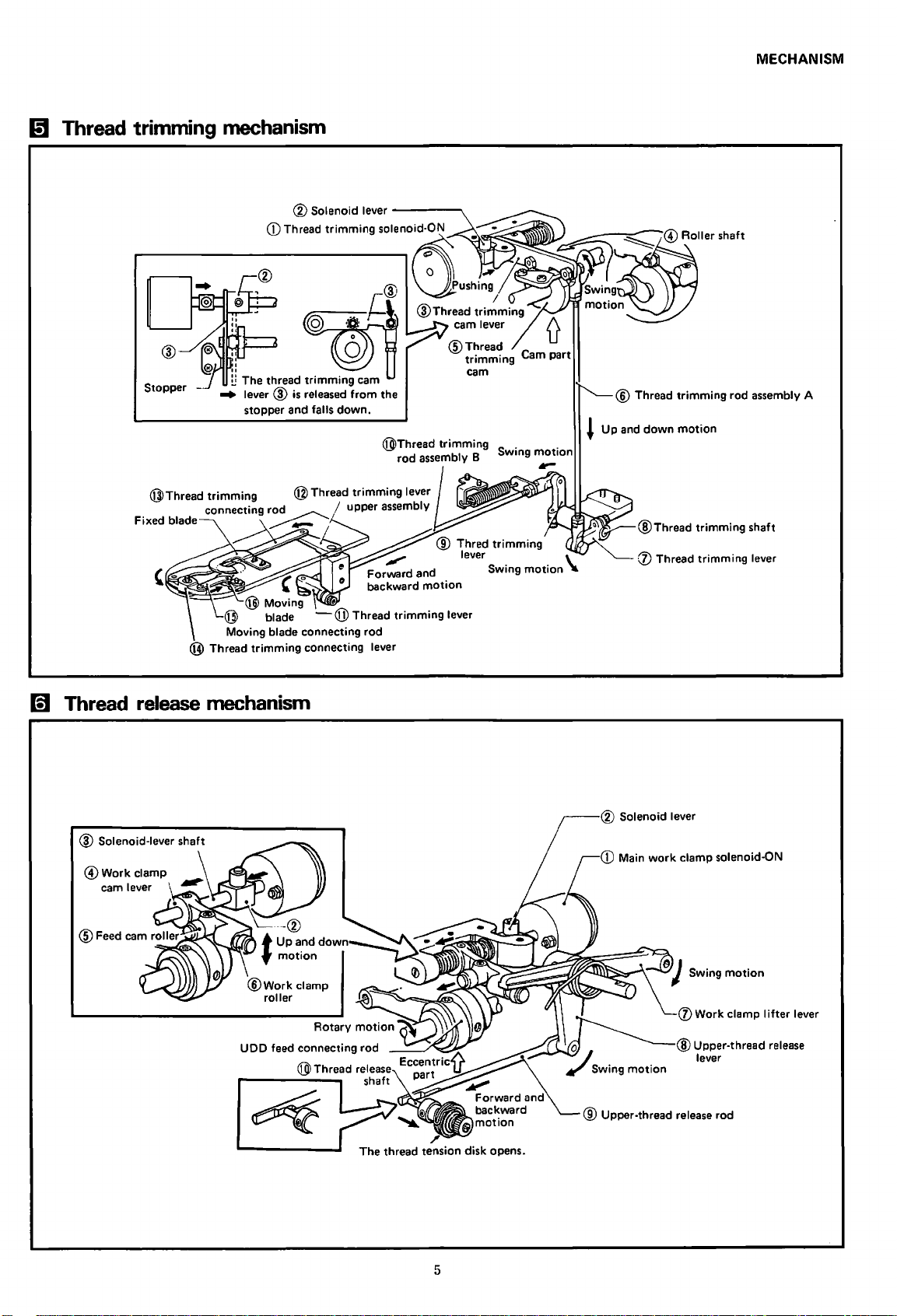

Gt

Thread trimming mechanism

MECHANISM

n

"

Stopper -

Gl

Thread release mechanism

~

~

Moving blade connecting

@ Thread

•

The thread

lever ®

stopper and

is

trimming

~@

0

trimming

released

connecting lever

falls

cam

from

down.

rod

the

@Thread

.tJIIII"""

Forward and

backward

trimming

rod

assembly B Swing

® Thred

lever \

motion

trimming

Swing

motion

motion

~

Up

® Thread

and

down

@Thread

(f) Thread

trimming

motion

trimming

trimming

rod assembly A

shaft

lever

5

CD

Main

work

clamp solenoid-ON

(j)

Work

Upper-thread release

@

lever

clamp I

ifter

lever

Page 8

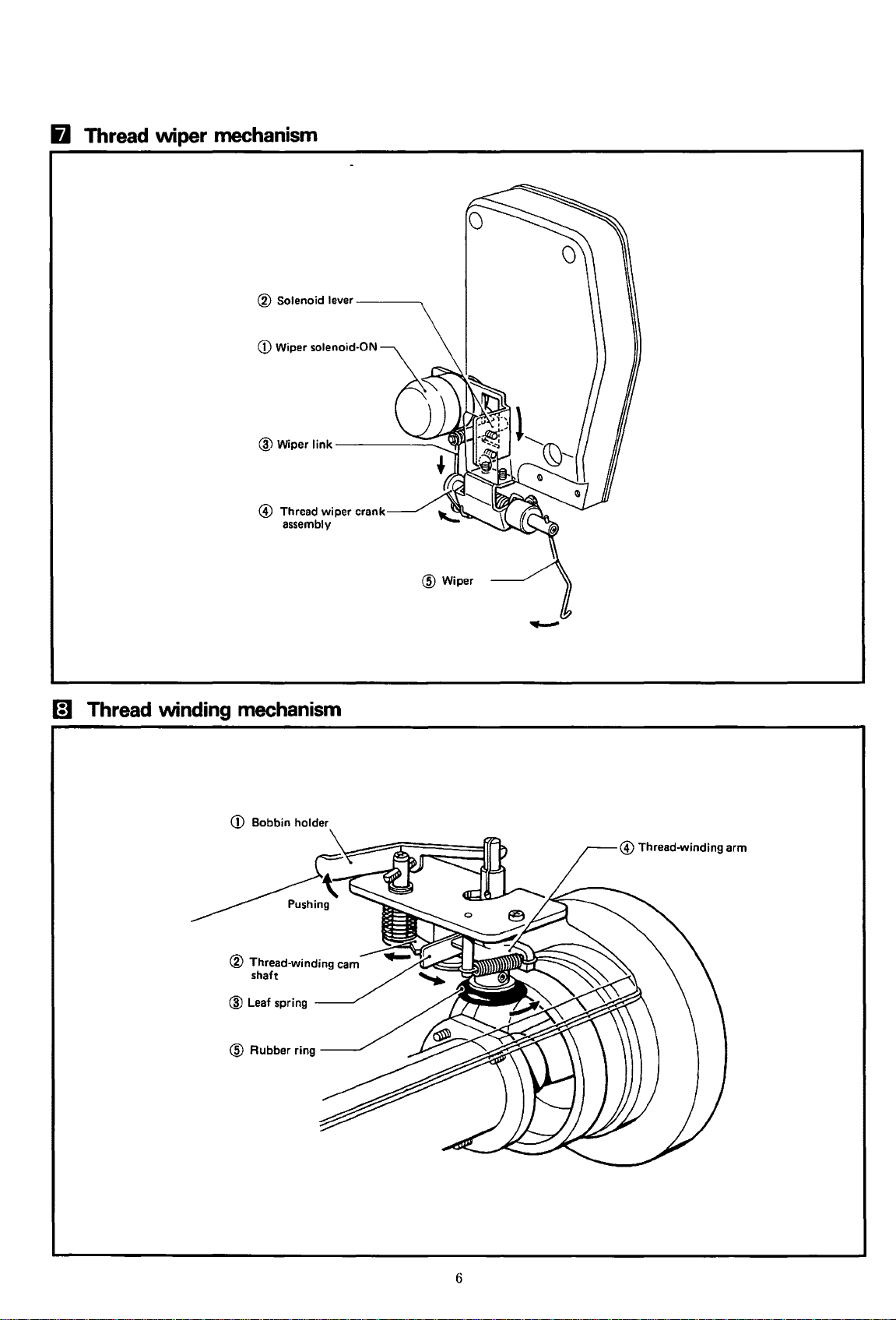

6 Thread wiper mechanism

® Solenoid

CD

@ Thread wiper crank

CJ

Thread winding mechanism

lever----..

Wiper solenoid-ON

assembly

@Wiper

CD

Bobbin holder

® Thread-winding cam

shaft

@ Leaf spring

6

Page 9

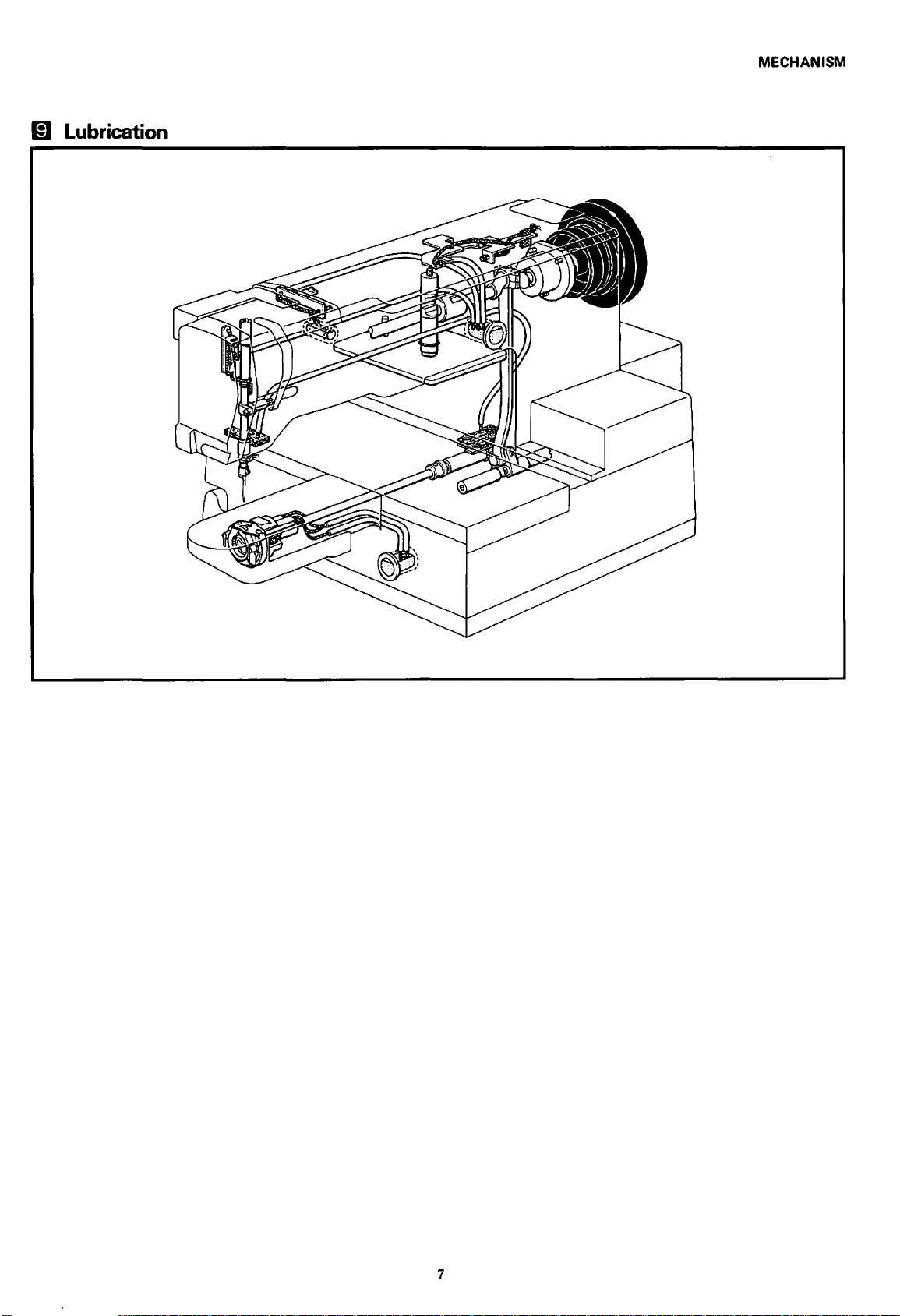

(!] Lubrication

MECHANISM

7

Page 10

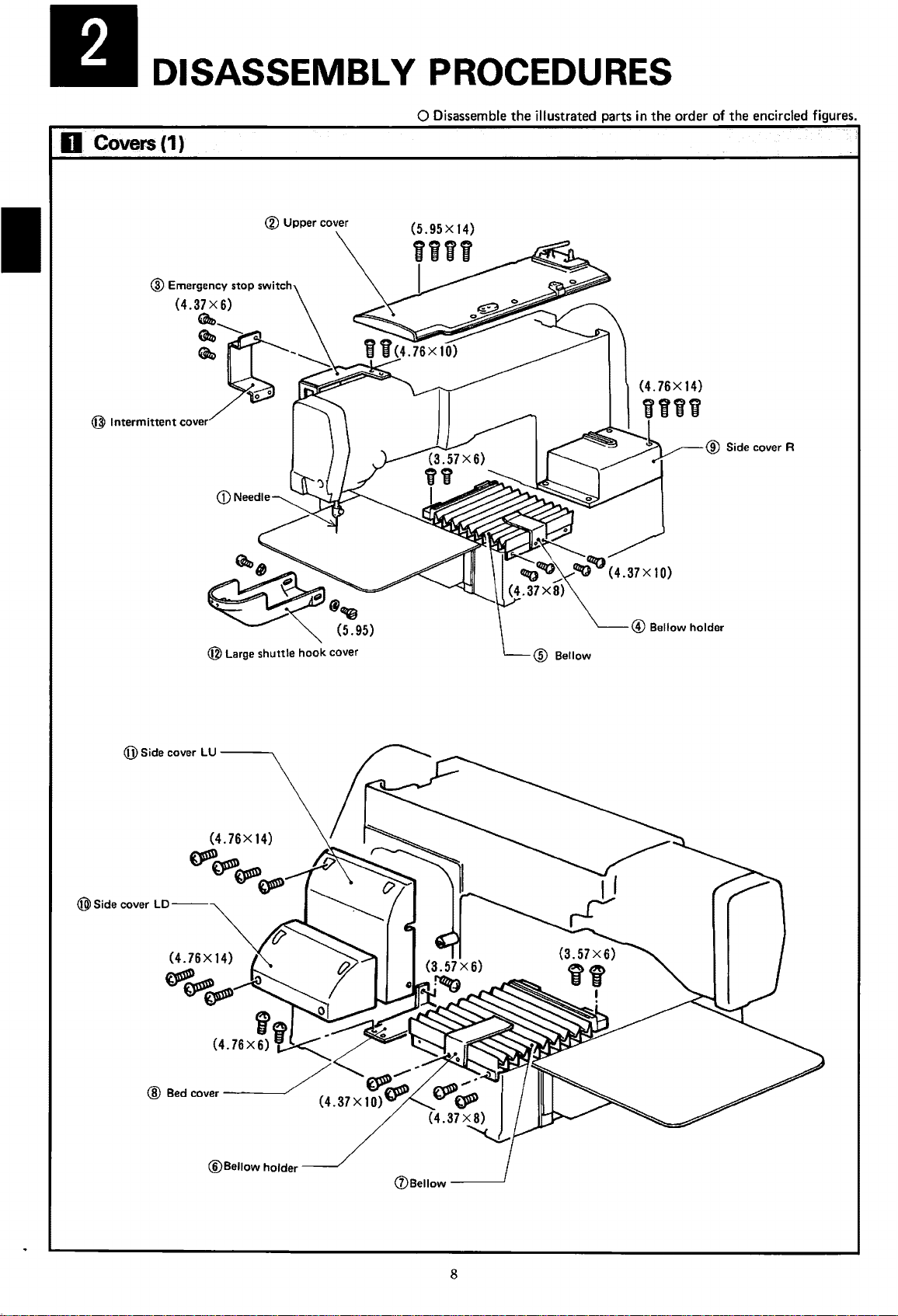

DISASSEMBLY PROCEDURES

D Covers(1)

® Upper cover

0 Disassemble

the

illustrated parts in

the

order of

the

encircled figures.

(jJ)

Side cover LU

® Side cover LD

@ Large shuttle

---...

(4.

76X

~~

~~

14)

hook

cover

@Bellow

holder

Cl)Bellow

-----'

8

Page 11

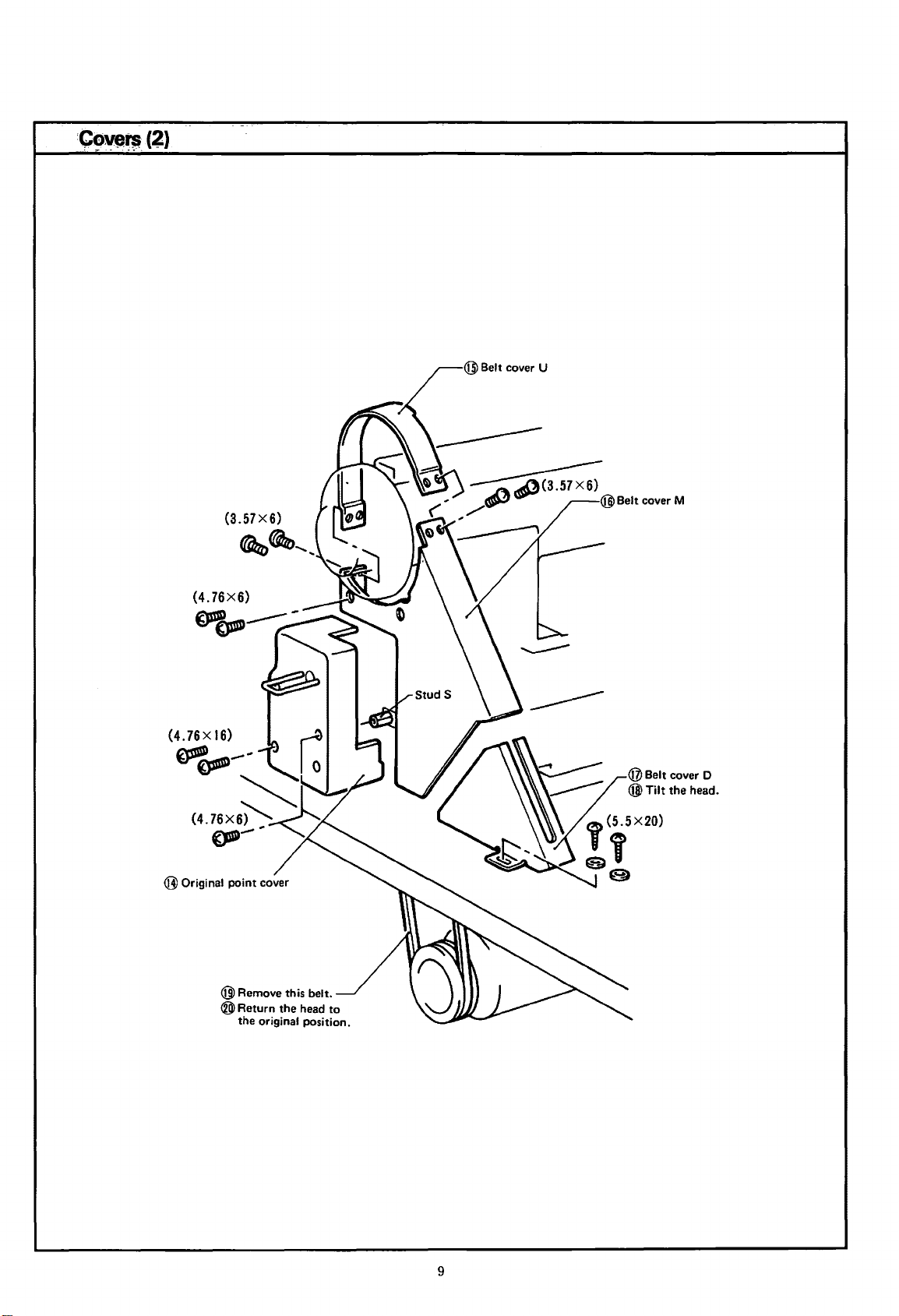

:Cave~(~)

:-·

- -- -

...

-

(3.57X6)

@ Belt cover U

~~'--

(4.76X6)

~~----

@Original

point

cover

@ Remove this belt.

®

Return

the

the original pos1t1on.

hea~

!o

9

Page 12

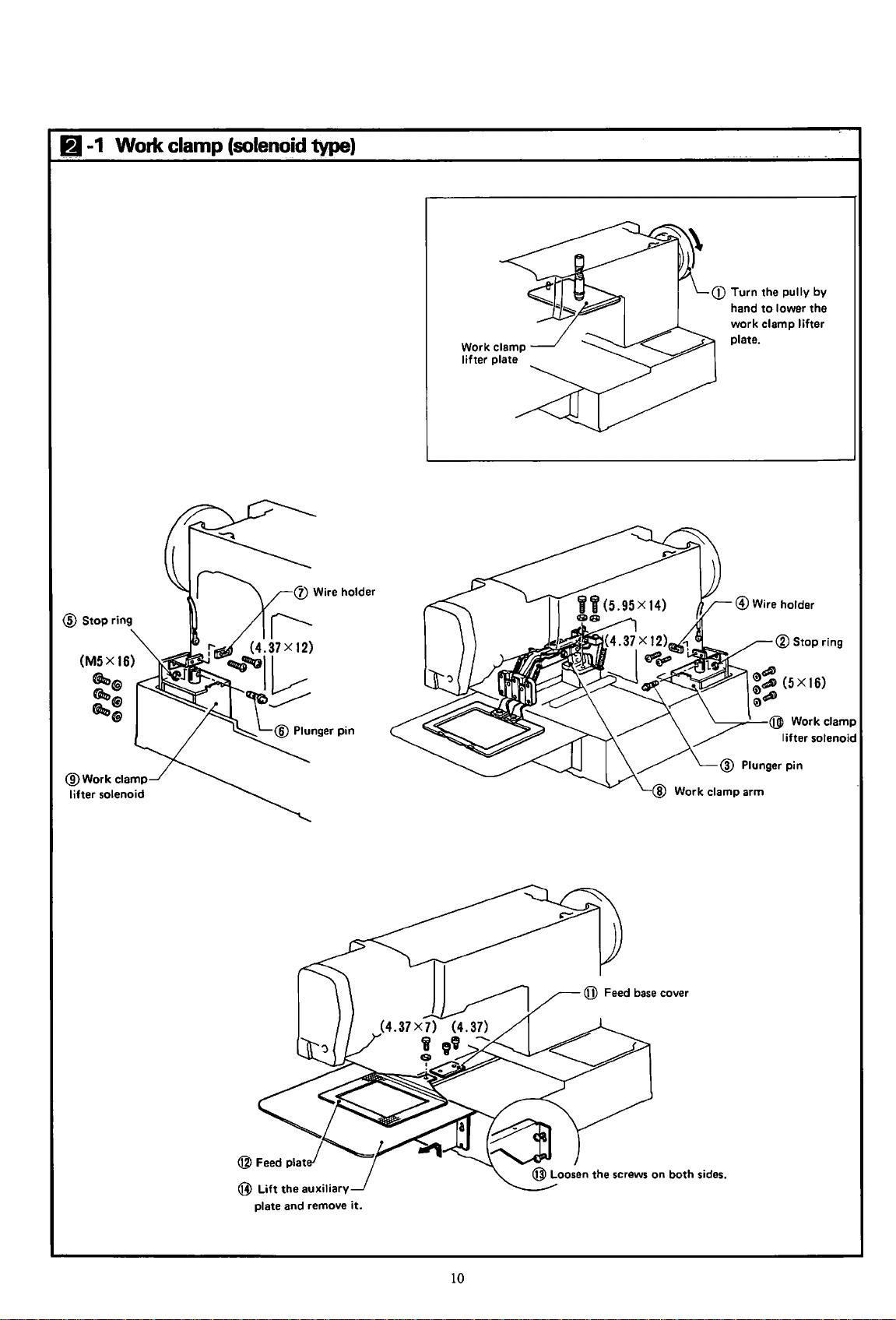

11-1

Work

clamp

(solenoid

type)

Work clamp

lifter

plate

CD

Turn

hand

work

plate.

the

pully

to

lower

clamp

by

the

lifter

@Stop

(M5X

ring

16)

~®

(Az,®

~@

Work

clamp arm

®Stop

'---__,.....-®

lifter

ring

Work clamp

solenoid

@

Lift

the

auxiliary

plate and remove

it.

10

Page 13

6-2 Workclamp(pneumatictype)

®Stud

screw--""'"'

DISASSEMBL V PROCEDURES

(f) Cylinder

support------J

®Air

tube

CD

Air

,.-----@

Pull

tube

~·

tube

Stud screw

out

the air

while pushing

11

Page 14

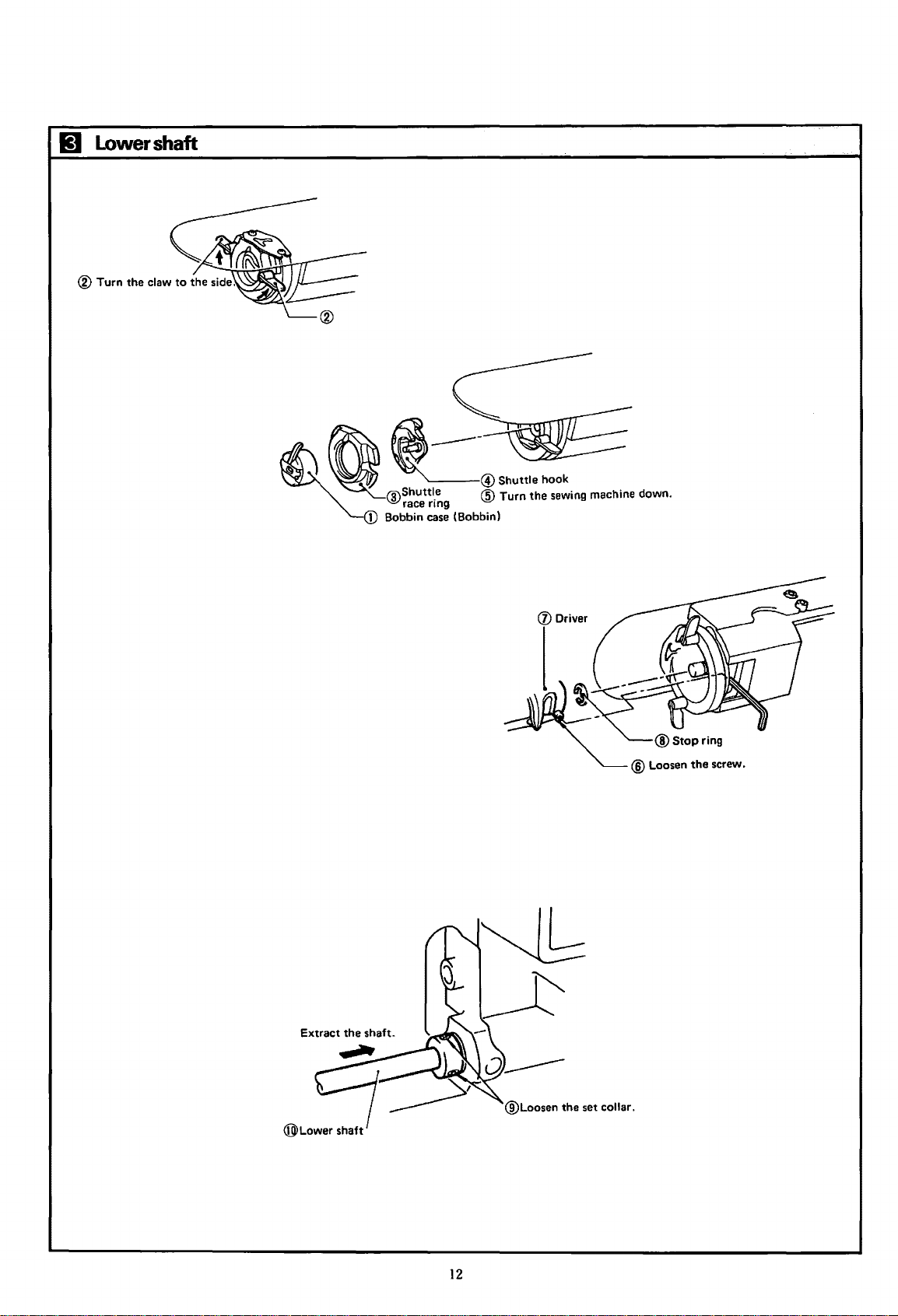

11

Lower

shaft

Extract

the

(j) Driver

shaft.

®Lower

®Loosen

shaft

12

the

set collar.

Page 15

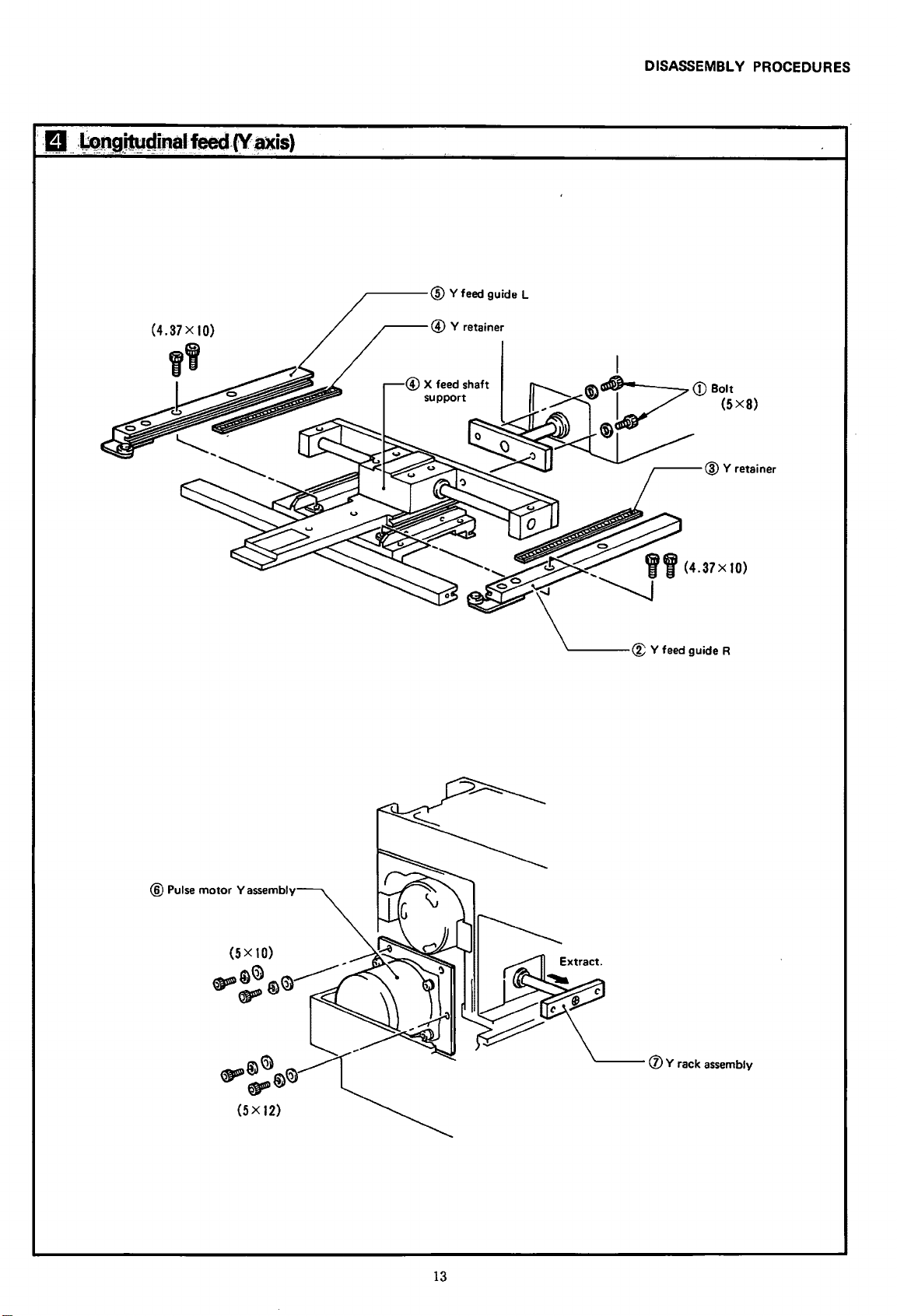

DISASSEMBLY PROCEDURES

,---@

Y feed guide L

®Pulse

motor

Yassembly

13

'---

(J)

Y rack assembly

Page 16

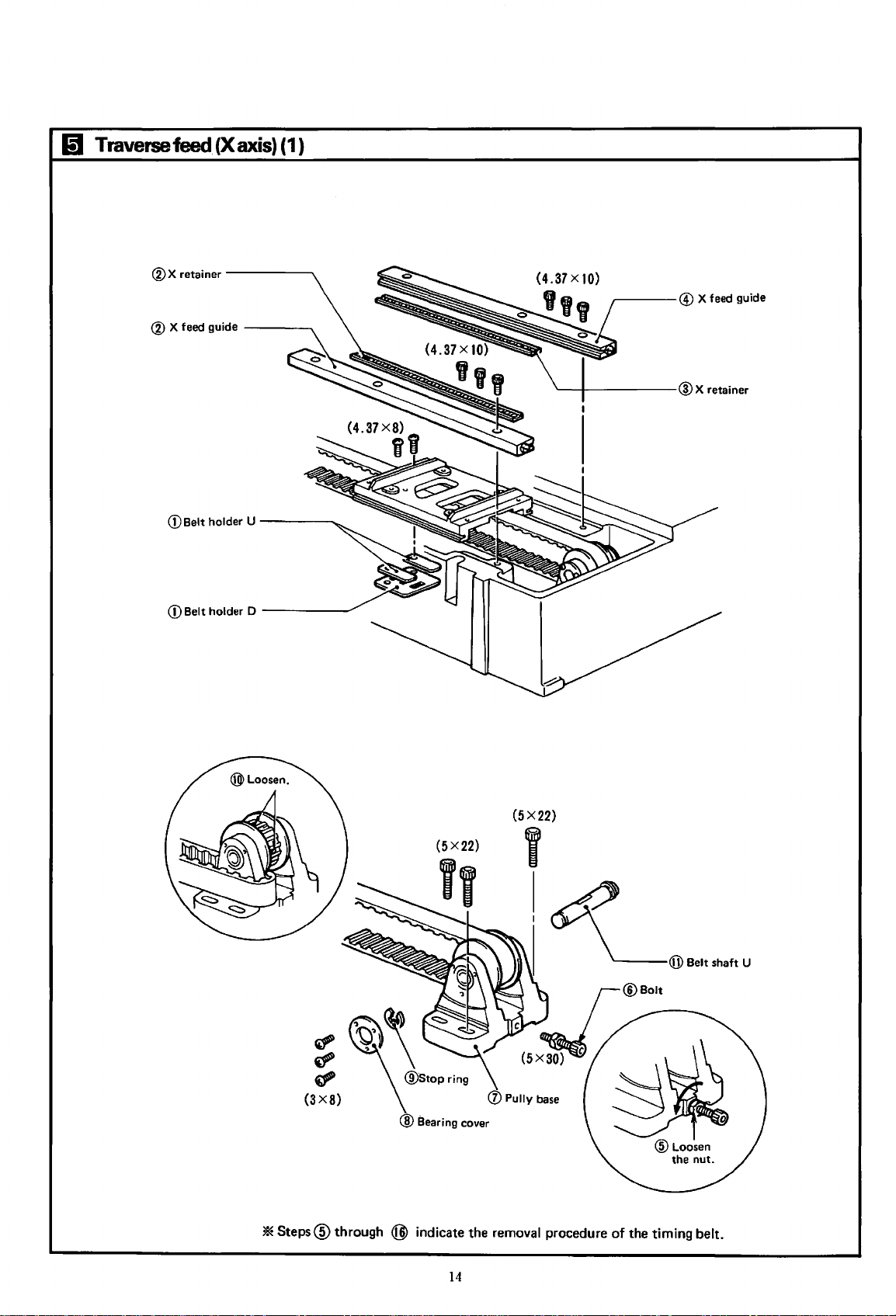

Iii

Traverse

feed (X

®X

retainer----

axis)

(1)

.......

® X feed guide

(DBelt

holder U

CD

Belt holder D

----..

----

------"

(3X8)

'*Steps@

~

d'

d"

through

(5X22)

I

I

(l)

Pully

base

@ Bearing cover

@)

indicate the removal procedure of the timing belt.

14

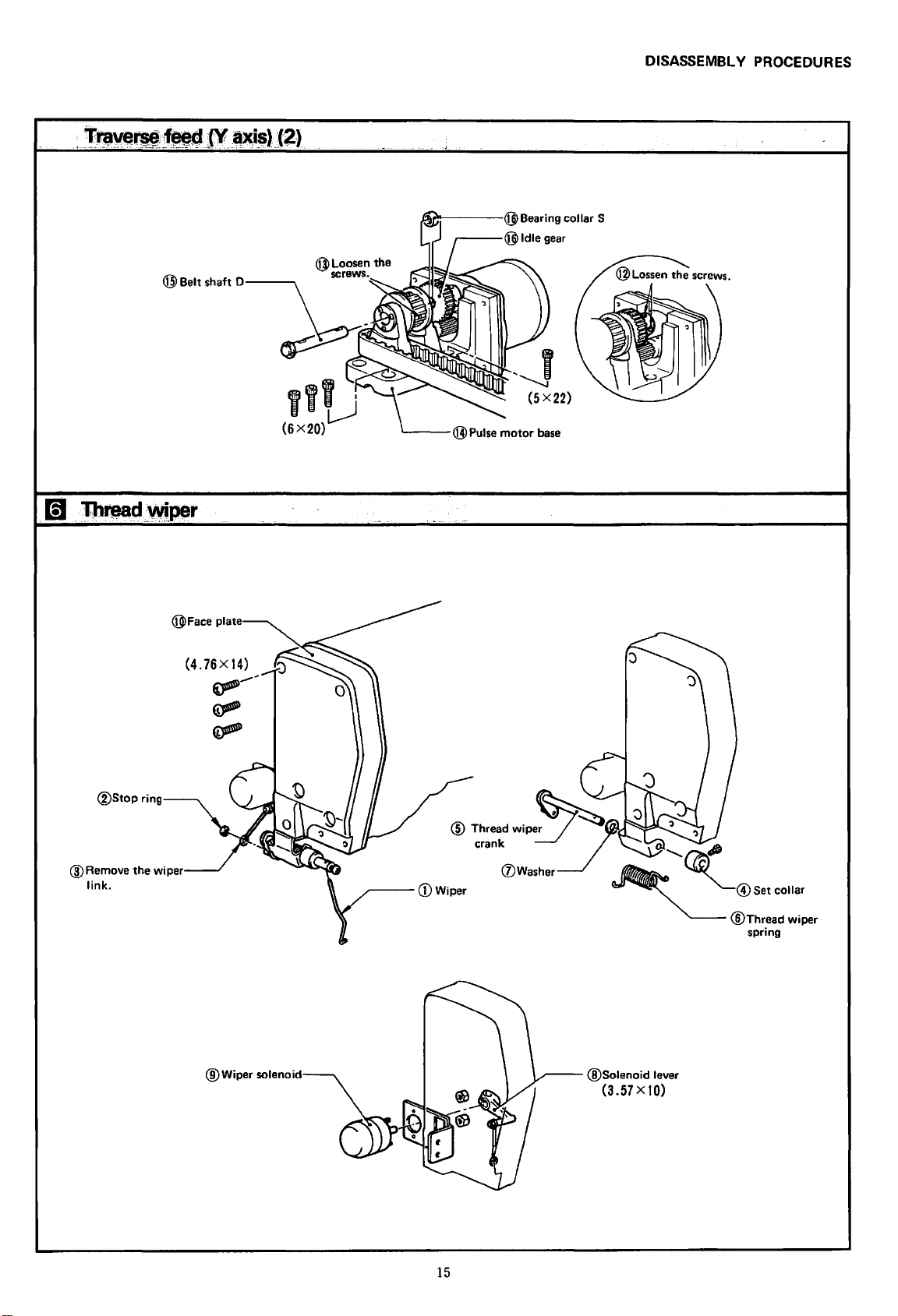

Page 17

DISASSEMBL V PROCEDURES

@Stop

ring

(4.

76 X 14)

~

~

~

___

,,,

(6X20)l)

..

'

1.......---@Pulse

motor

(5X22)

base

@Remove

link.

the

wiper

@Wiper

~--(])Wiper

solenoid~

15

@Solenoid

(3.57X10)

lever

Page 18

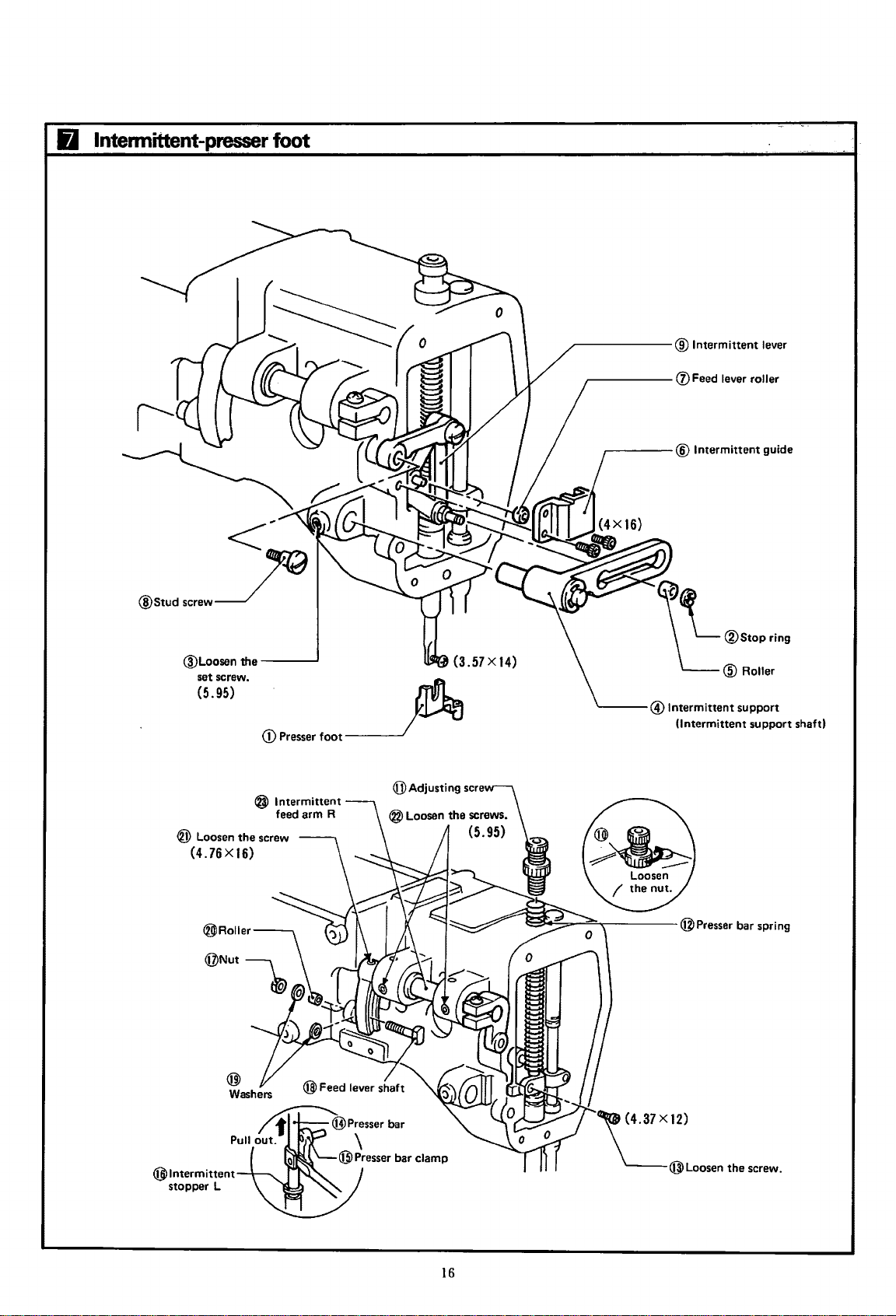

6

lntennittent-presser

foot

@Loosen the

set screw.

(5.95)

CD

Presser foot

@Intermittent

~~

L@Roller

fii\

'--

Intermittent support f )

1.!!.1

(Intermittent sup

lever

®stopring

• port sha t

® Loosen the screw

(4.76X16)

@Intermittent

stopper L

@ Intermittent

feed arm R

"(4.37 X 12)

\___@Loosen

the screw.

16

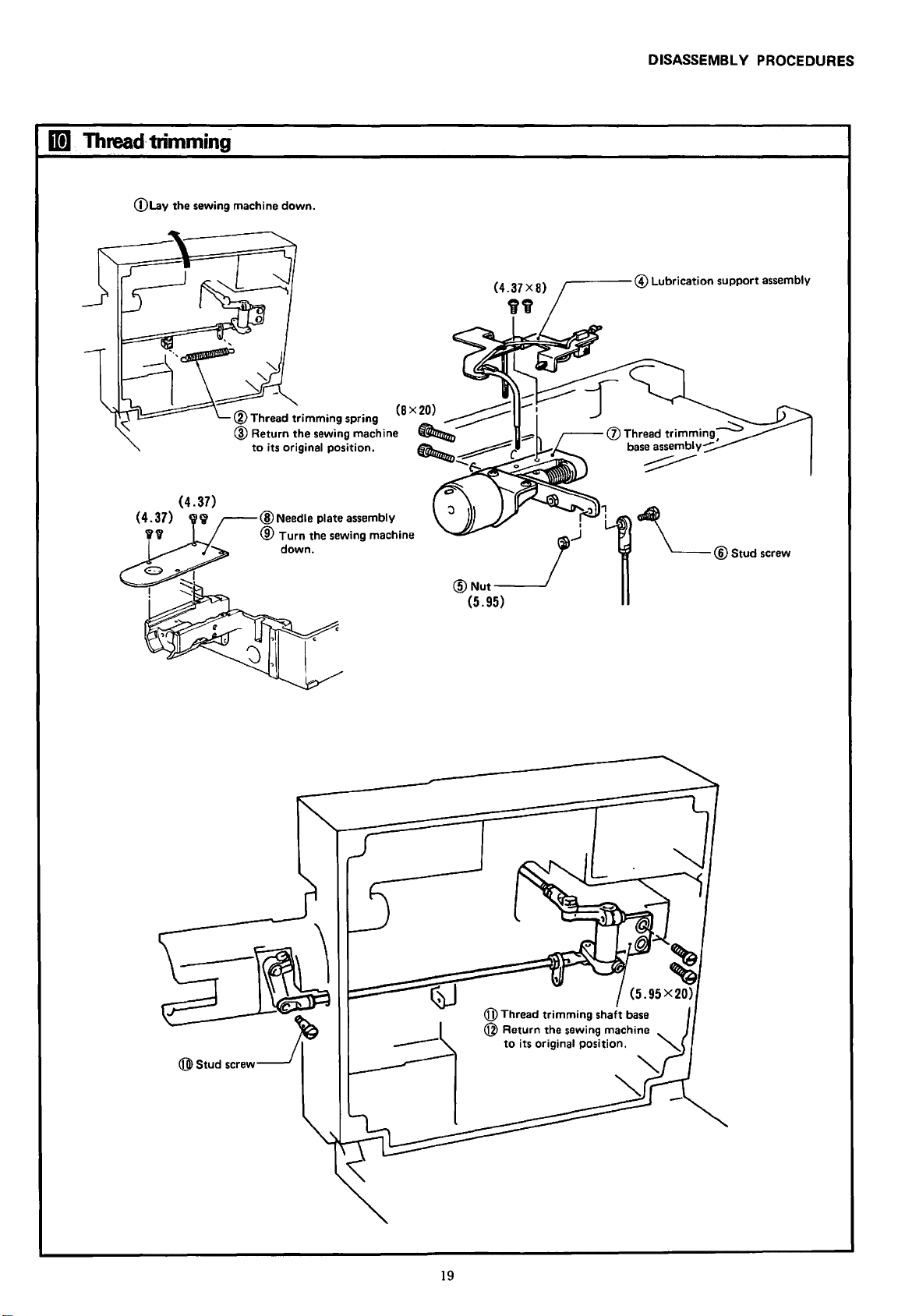

Page 19

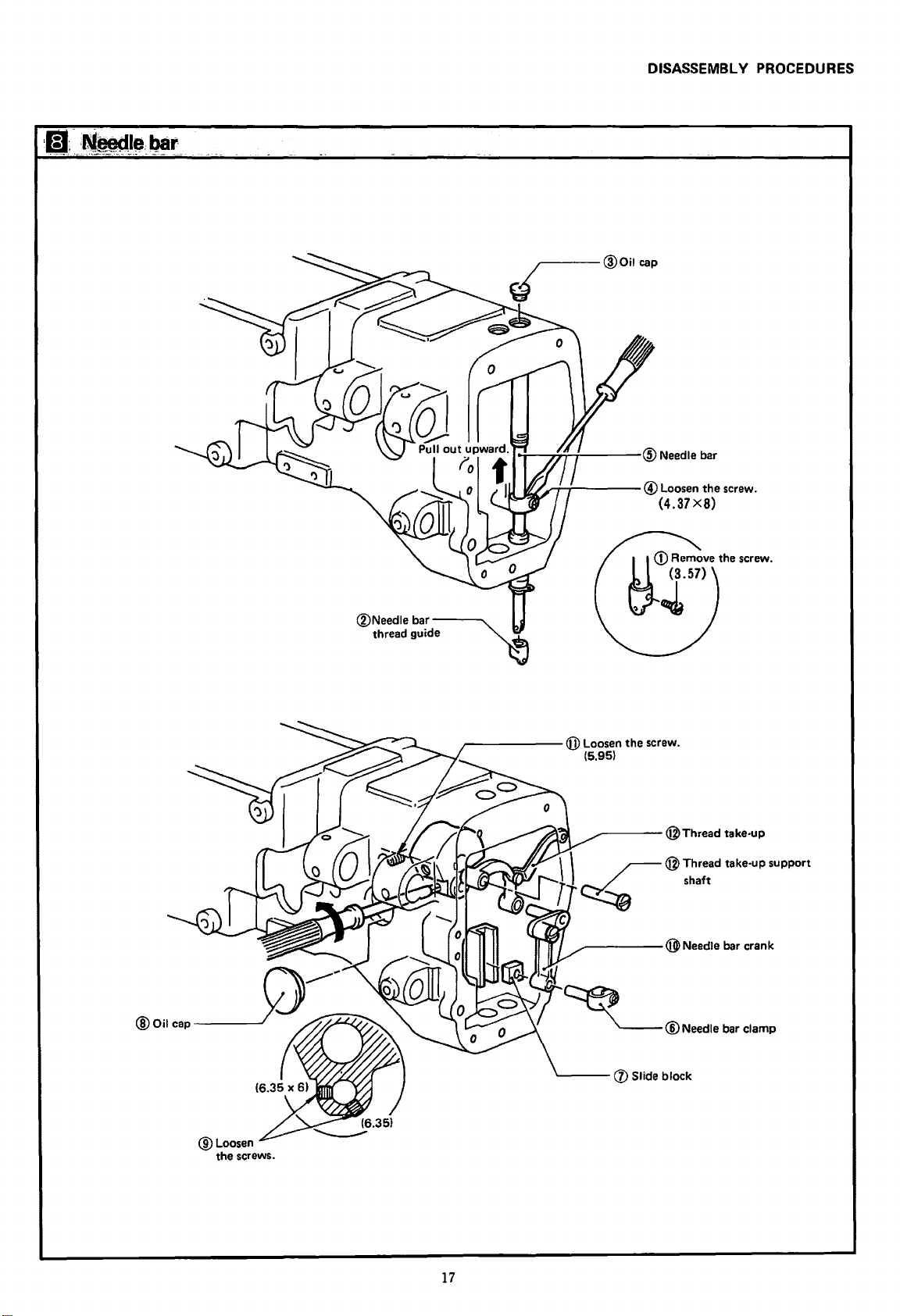

DISASSEMBLy

@Loosen the

(4.37

X8)

screw.

PROCEDURES

@Loosen

the screws.

@Loosen

(5.

) e screw.

95

th

~

®Needle

bar clamp

17

Page 20

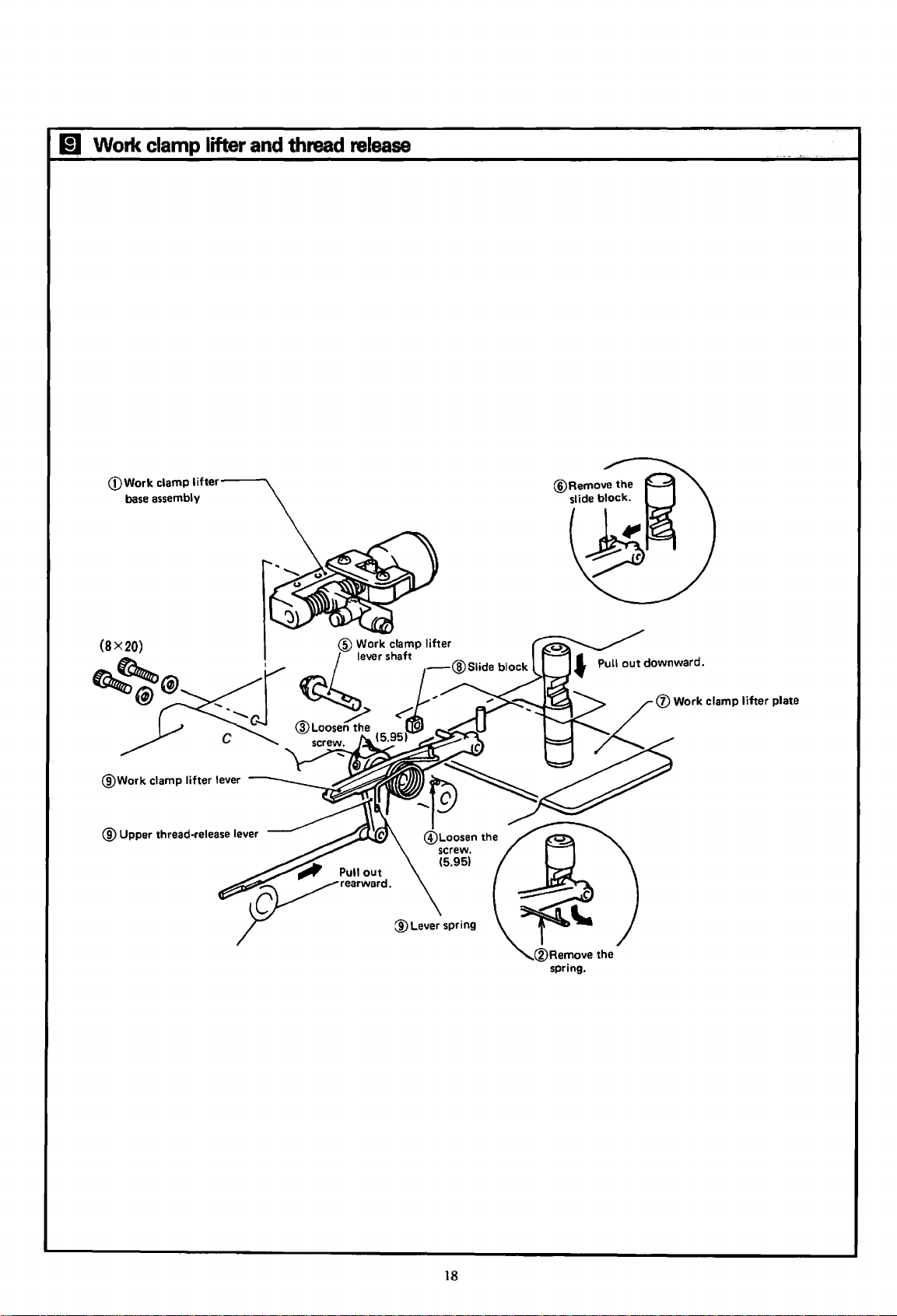

(g

Work

clamp

lifter

and

thread

release

(DWork

@Work

base

clamp

assembly

clamp

lifter

lifter

lever

® Upper thread-release lever

®Remove

spring.

18

the

Page 21

1Dl

Thread·

trimming

(DLay

the sewing machine

DISASSEMBL V PROCEDURES

down.

®Needle

®

Turn

down.

plate assembly

the sewing machine

@Nut__}

(5.95)

r-----@

'f/

Lubrication support assembly

1

1

\__®Stud

screw

@Thread

@ Return the sewing machine

19

trimming

to

its original position.

shaft

"'

base

'-

"-

"

Page 22

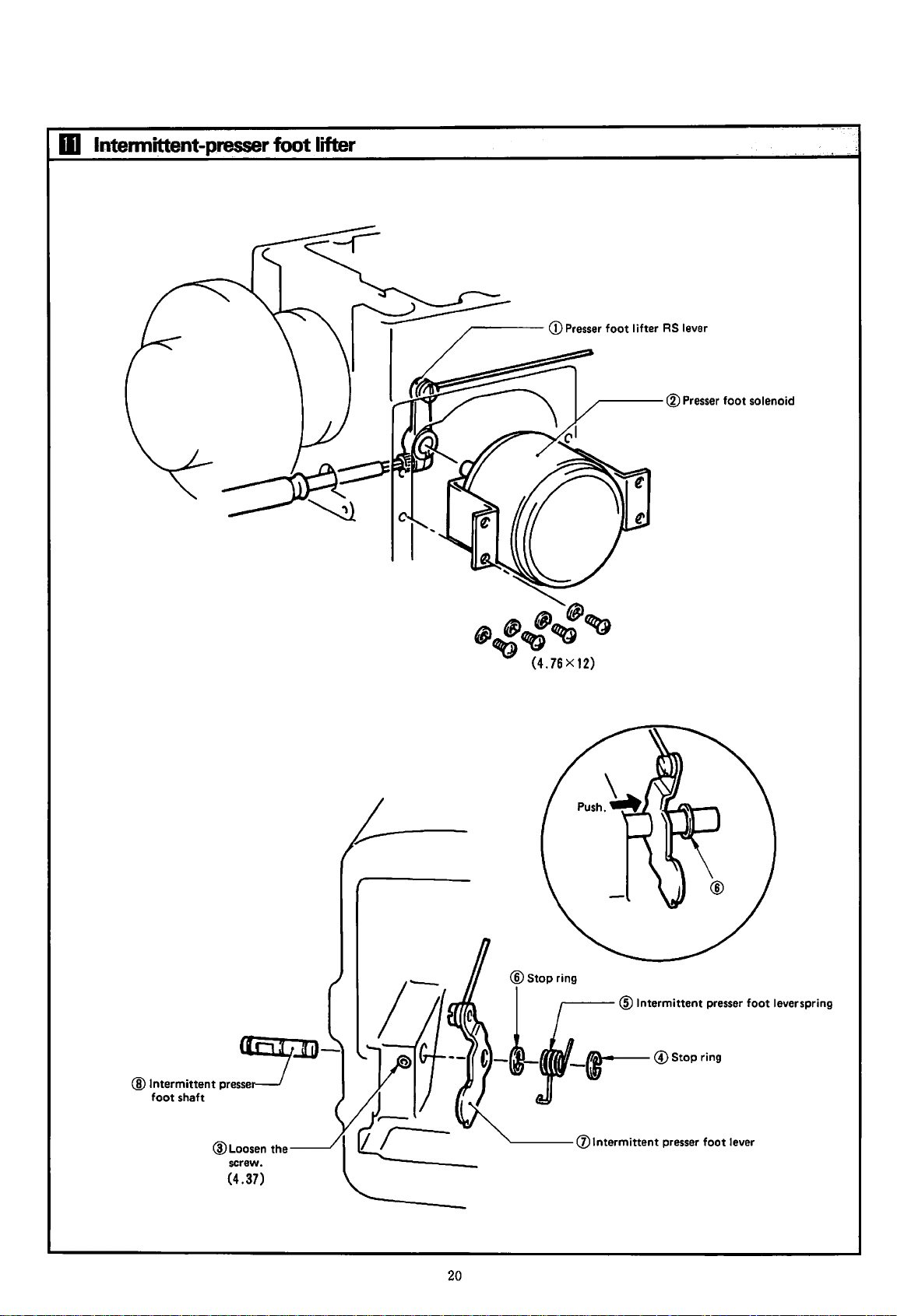

m

lntennittent-presser

foot lifter

~---

®Presser

foot solenoid

-~~

~.:.:~~

(4.

76 X 12)

,..---@Intermittent

®Intermittent

foot shaft

pre~

@Loosen the

screw.

(4.37)

"------(])Intermittent

20

-{1~·---

@Stop

presser foot lever

presser foot leverspring

ring

Page 23

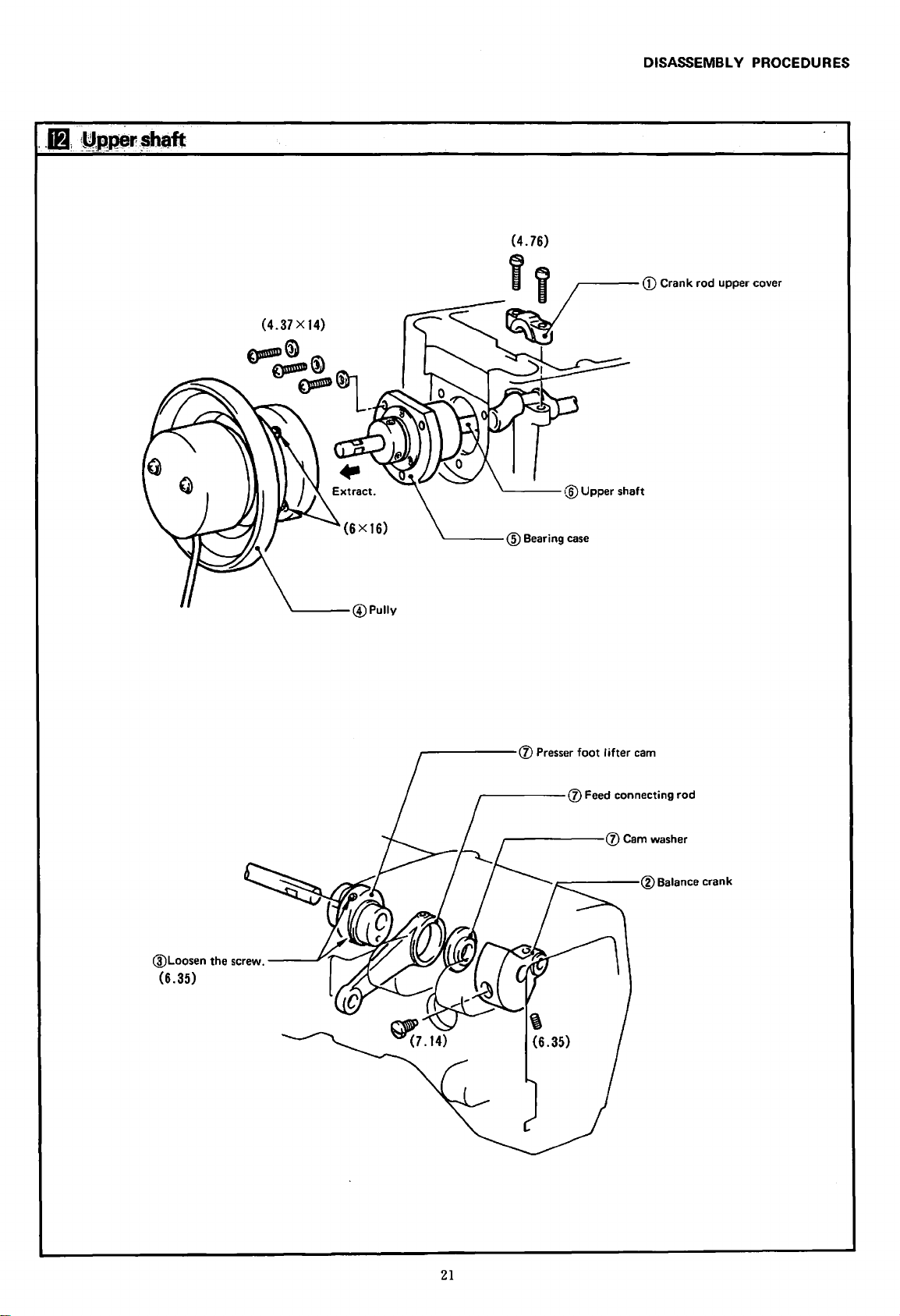

DISASSEMBLY PROCEDURES

@Loosen the

(6.35)

screw.----'

(6X16)

'----@Pully

'------@Bearing

.-----(j)

-----

Presser foot I ifter

------(j)

case

cam

(j) Feed connecting rod

Cam

washer

21

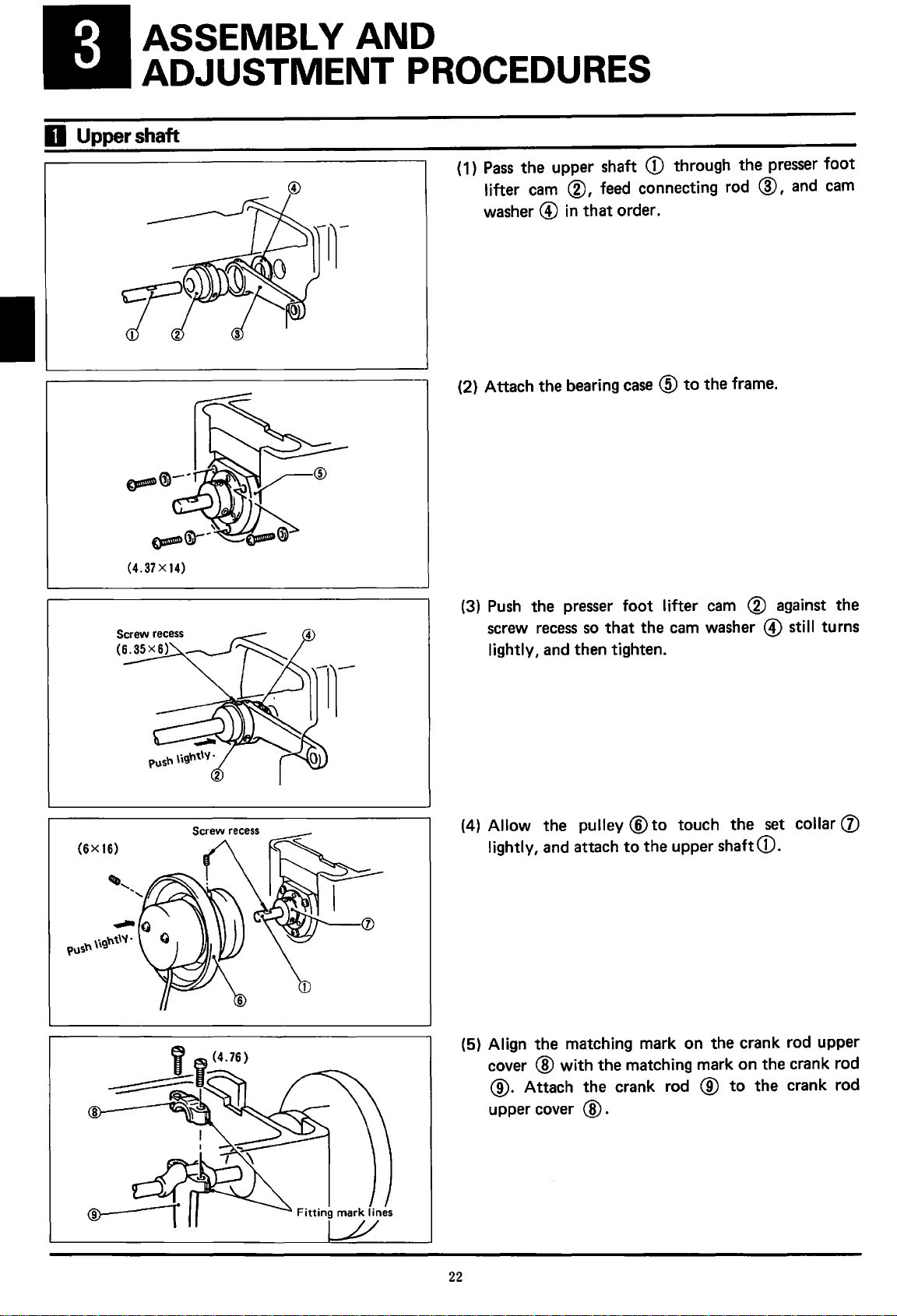

Page 24

ASSEMBLY

AND

D

Upper

ADJUSTMENT

shaft

PROCEDURES

( 1)

Pass

the upper shaft

lifter

cam

@,

washer@

(2} Attach the bearing

in

that

CD

feed connecting rod

order.

case@

through the

to

the frame.

presser

@,

and

foot

cam

Push

the

(3)

screw

lightly,

(4)

Allow

lightly,

(5) Align the matching mark on the crank rod upper

cover

presser

recess

and

then tighten.

the pulley

and

attach

@with

@. Attach the crank rod @

upper cover

foot

lifter

cam

(g)

against the

so

that

the

cam

washer @ sti

®to

to

the matching mark on the crank rod

@ .

touch the

the upper shaft

to

CD.

the crank rod

set

II

collar

turns

(J)

22

Page 25

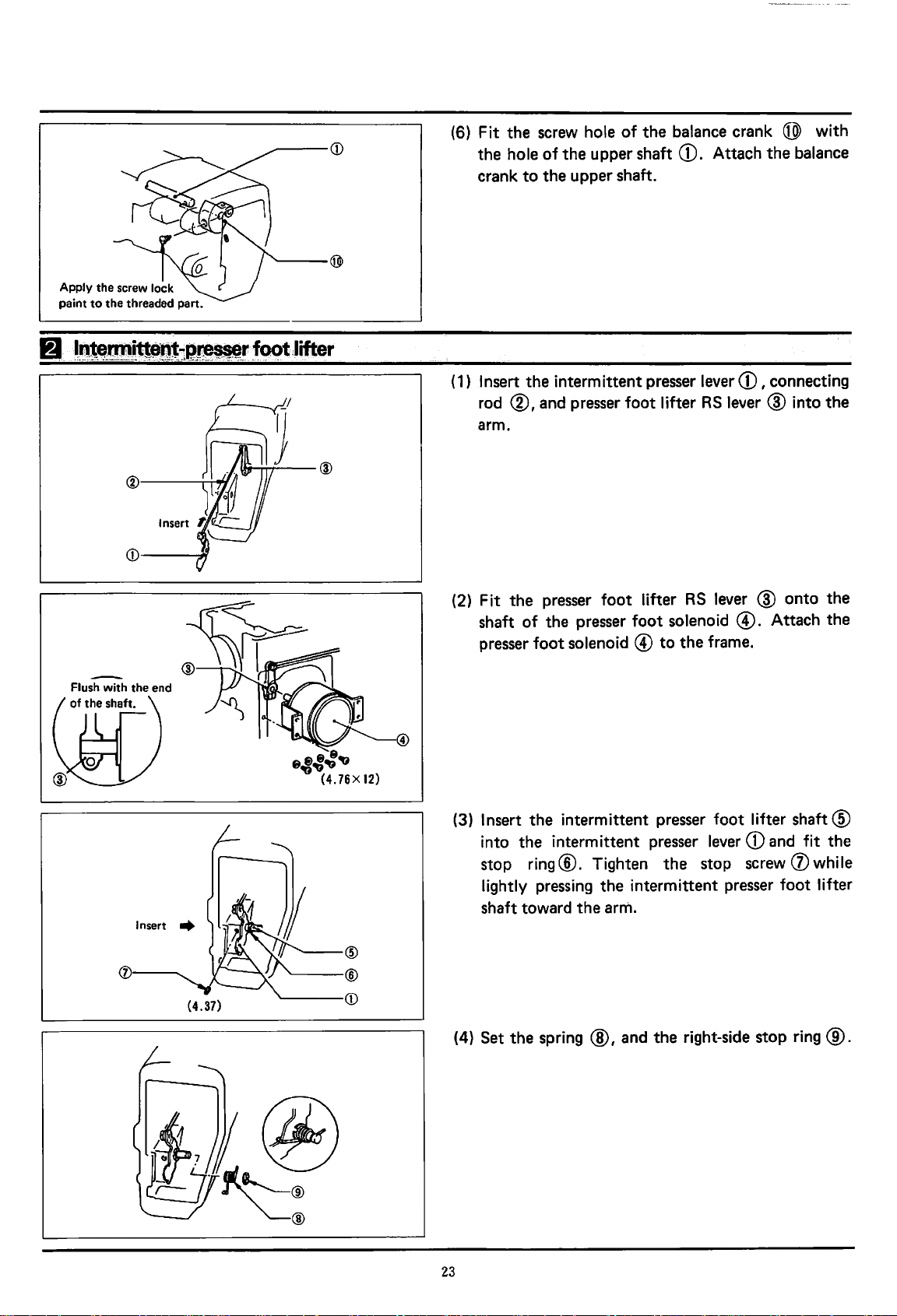

@

(6)

(1)

Fit

the

the

hole

crank

Insert

rod

arm.

screw hole

of

the

to

the

upper shaft.

the

intermittent presser lever

®,and

presser foot lifter

of

upper shaft

the

balance crank @ with

CD.

Attach

RS

the

CD,

connecting

lever@

balance

into

the

(j)l--

Insert

........

'------®

'-----CD

@

(2) Fit

shaft

presser

(3)

Insert

into

stop

lightly

shaft toward

(4) Set

the

presser

of

the presser

foot

the

the

intermittent presser lever

ring®.

pressing

the

spring@,

foot

lifter

foot

solenoid @

intermittent presser foot lifter

Tighten

the

intermittent presser foot lifter

the

arm.

and

RS

lever @

solenoid

to

the

frame.

the

stop screw (j) while

the

right-side stop

@.

CD

onto

Attach

shaft®

and fit

ring@.

the

the

the

23

Page 26

Bl

Needle

bar

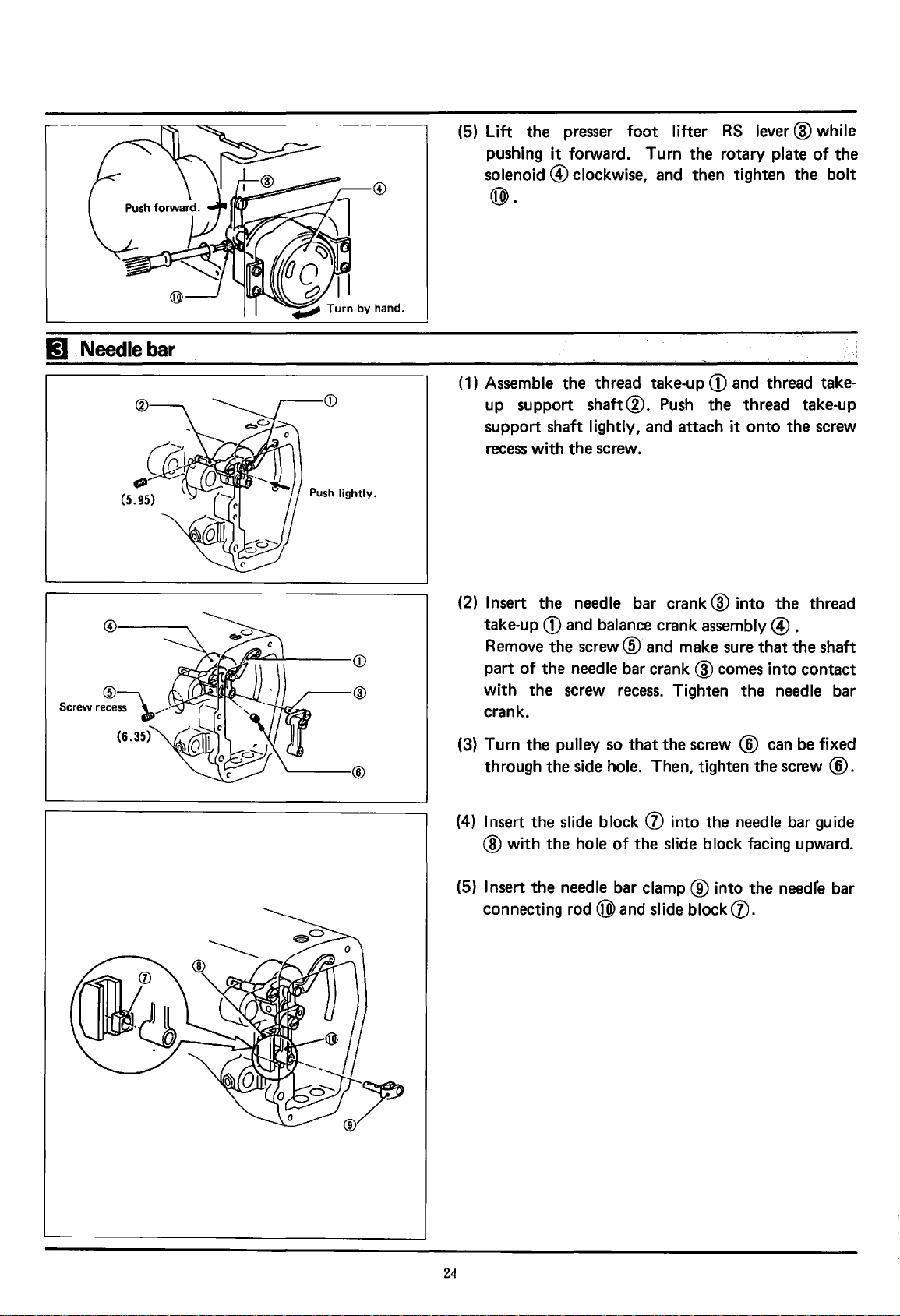

(5)

Lift

pushing

solenoid@

®.

(1)

Assemble

up support

support shaft

recess with

the

presser

it

forward. Turn

clockwise, and then tighten

the

the

foot

lifter

thread take-up

shaft®.

lightly, and attach it

screw.

Push

RS

lever@

the

rotary plate

CD

and thread take-

the

thread take-up

onto

the

the

while

of

the

bolt

screw

Insert

(2)

take-up

Remove

of

part

with

the

crank.

(3) Turn

(4)

the

through

Insert

® with

(5)

Insert

connecting rod

the

needle bar

CD

and balance crank

the

screw@

the

needle bar

screw recess. Tighten

pulley so

the

side hole. Then, tighten

the

slide block (j) into

the

hole

the

needle bar

®and

and make sure

crank@

that

of

the

clamp®

slide block (j).

crank@

the

screw ® can be fixed

slide block facing upward.

into

the

assembly@.

that

comes into

the

needle bar

the

screw ®.

the

needle bar guide

into

the

needfe bar

thread

the

shaft

contact

24

Page 27

ASSEMBL V AND ADJUSTMENT PROCEDURE

DPX5

OPX17

--®

Cutting

part

(6) Insert

(with

toward

(7) Turn

the

the

17). Tighten

(In case of the needle

ence line.)

(8) Fit

bar@.

the

needle

the

oblique

the

operator).

the

pulley so

lowest position. Match

needle bar with

the

needle-bar thread guide @

Attach

@.

(9) Mount

the

oil caps

the

bar@

cut

that

screw

the

@and

from

the

part

of

the

the

needle bar comes

the

reference line

the

second lowest line

of

the

needle bar clamp.

DP

x 5, use

screw@

@on

to

the

top

of

needle

the

on

the

needle bar

frame.

the

top

the

arm

bar@

(DP

refer-

needle

to

of

x

lEI

Intermittent-presser

foot

@

(1) Fit

(2) Insert

(3) Lightly hold

(4) Fit

the

intermittent feed shaft

the

insert

the

@.

Tighten

tent

feed arm R

feed shaft

tighten

the

from

®

(Position

bar@

the

the

guide

groove

the

at

the

toward you.)

intermittent feed arm

CD

screw®.

of

top

same time.

the

(Dto

the

R®.

roller@

the

the

and intermittent feed arm R

part

the

of

screw hole plane part

into

the

feed lever

®at

frame between

of

frame. Insert

the

shaft@

the

center

the

presser bar clamp (j) with

arm, and insert

feed connecting rod

to

of

the

the

the

presser bar @

the

of

frame and

the

intermit-

oval hole.

intermittent

®and

stopper L

the

presser

®

Threaded plane

the presser bar @.

of

25

Page 28

,..----®

(5)

Fit

the

intermittent lever ®

presser bar clamp (j), and tighten

@.

in

the

the

shaft

of

roller shaft

the

r----

Roller

shaft

(6) Attach

(7) Fit

lever

guide

(8) Attach

(9) Try

find a

Tighten

(10)

Fit

(11) Fit

the

the

feed lever

@.

<[4)

the

to

move

point

the

the

roller®

the

intermittent

link@.

roller@

Temporarily secure

to

the

frame.

adjusting

the

where

intermittent

presser

in

the

screw@

there

guide®

roller shaft.

support

.

bar®

is

in

the

intermittent

the

intermittent

up and down and

the

least resistance.

at

this point.

shaft@

in

@ , and fit with the screw recess. Lightly push

the

intermittent

support

shaft

@ and tighten.

the

roller

"'--T-i--@

frJ.JJ~~ef---....;.-i---

(J)

®

(12) Fit

( 13) Remove

the

stop

ring@

the

adjusting screw

presser bar spring

in

@.

again and fix it with

(14) Turn

the

pulley until

lowest position. Loosen

L@.

(15)

Try

to

move

the

link

and find a

tween

clamp (j) and

®

at

ing it

place where

the

bottom

the

stopper L

this point. (Move

at

the

point

indicated by

link L becomes easily movable.)

the

roller shaft. ·

Tighten

the

nut

@.

the

presser bar comes

the

intermittent feed arm

L@

leftward and rightward,

there

surface

of

®.

the

link

@and

the

is

no clearance be-

Tighten

L@

the

insert

adjusting screw

the

presser bar

the

while push-

arrow, and

to

the

the

link

the

26

Page 29

lit

·WGrk

clamp

lifter

aod

thread

ASSEMBLY AND ADJUSTMENT PROCEDURE

release

(1) Assemble the

thread

rod@.

Insert the

(2)

until

shaft@.

(3)

Fit

release

Put the assembly in the arm.

end

it

comes

the lever spring

work

lever®,

clamp

and

of

the upper thread

contact

with

@with

lifter

lever

upper thread

release

the thread

the

boss

of

CD,

upper

release

rod®

release

the frame.

Push lightly.

(4)

Insert the work clamp

lower surface

(5)

Fit

the slide block (j) in the shaft

clamp

(6) Insert the work clamp

with

pushing the

27

lifter

the

plate®.

screw

work

of

the frame.

recess.

clamp

lifter

plate®

lifter

lever shaft @

Tighten the

lifter

lever shaft lightly.

from the

of

the

screw®

work

and

while

fit

Page 30

®

<D

{7)

Raise

the work clamp

lever spring@

(8)

Place

the roller

clamp lifter levereD,

lifter

base@.

0.5 mm between the

and

the

end

of

lifter

plate ®

with

the work clamp lever

of

the

cam

lever®

and

mount the work clamp

Ensure that there

end

of

feed

the work clamp lifter

and

fit

CD.

under the

is

a clearance

roller shaft @

cam

work

@ .

the

of

0.5mm

(9) Turn the pulley until the thread take-up

the lowest position, while pushing the main

clamp solenoid

on the work clamp I ifter

( 1

0)

Push

the thread

upper thread

upper thread

tension disk

@so

release

release

release

loosens.

that the feed roller @

cam

@ .

shaft

rod@,

lever®

®with

and adjust

part ®

until the thread

comes

work

rests

of

using

to

the

the

28

Page 31

ASSEMBLY AND ADJUSTMENT PROCEDURE

(8X20)

~

~®:

®;;:::::::---~-~----CD

0.5mm

®~/])

@~

@

®

(1) Attach

Ensure

the

thread trimming cam @ .

(2) Attach

to

(3)

Lay

(4) Attach

frame.

the

thread trimming base

that

there

end

of

the

roller

the

upper shaft lubrication

the

thread trimming base

the

sewing machine down.

the

thread trimming shaft

is

a clearance

shaft®

of

and

CD.

CD

to

the

0.5

mm between

the

end

support

base@

frame.

of

the

plate@

to

the

(5) Attach

trimming

(6) Attach

trimming cam

@).

the

thread trimming rod B

lever(]).

the

thread trimming rod

lever®,

and tighten with

®to

A®

to

the

the

thread

thread

the

nut

29

Page 32

Return

to

the original

position.

(7) Hook up

(8) Return

the

the

thread trimming

sewing machine

spring@

to

the

.

original position.

16

Traverse

feed

(X

axis)

(9) Attach

thread trimming

trimming connecting

the

(1)

Attach

pulse

the

needle

flat head screw.

the

timing.belt®and

motor

o@.

base

plate@

lever@

CD

by fitting

into hole

rod@ . Start

and

then

the

in

tightening with

timing

attach

pully@to

the

pin

the

belt

on

the

th.read

the

shaft

(2)

Set

the

bearing

at

the

top

of

recess by

them, and then fix with

(3)

Ensure

timing pulley @ are equal. Secure

pulley

recess.

30

that

@with

collarS@

the

belt shaft

lightly holding

the

clearances on both sides

the

screws while adjusting

and idle

D@.

the

the

screws.

gear®

Adjust

belt shaft against

in place

the

the

the

screw

of

the

timing

screw

Page 33

ASSEMBL V AND ADJUSTMENT PROCEDURE

(6X20)

II

~~

I

l.

(6X20)

I

'(5X22)

G9

!

'----CD

(4) Securely attach the pulse-motor

base.

(5)

Attach the timing belt

the pulley

the

reverse

(6) Mount the stop

attach the bearing cover @ .

base

(j). Attach the belt shaft U

side.

ring®

CV

and

on the belt shaft U

base

timing

CD

to

the

pulley®

bed

to

®on

®and

(7)

Ensure

timing

screws pulley ®

recess.

(8) Temporarily tighten the pulley

base.

bolt

tion

CV

applied at the center

base

(9) Fix the adjusting

that the

pulley ®

Adjust the timing belt

@

of

4 mm under a

with

with

the

so

that

3 bolts.

clearances

are

screws

the timing belt produces a deflec-

bolt@

on both

equal. Tighten the timing

while adjusting the screw

CV

load

of

approximately 400 g

of

the belt. Fix the

with

the

base

using

nut@

(j) on the

sides

of

the

bed

the adjusting

pu

I ley

.

Apply

a load

(of

approx.

400

g).

31

Page 34

(1

0) Push

the

X feed

bed base, and tighten.

guide@

against

the

end

of

the

C)

Longitudinal

feed

(V

axis)

,.----@

Attach

(11)

the

( 12) Temporarily tighten

guide

Try

ward while pushing

point

tering and moves smoothly. Fix

this

(13)

Fit

the

and tighten while moving

the X retainer@

X feed guide @ .

the

@

to

the

feed table X ® using

to

move

the

feed table X rightward and left-

the

where

point

the

belt holder D @ . Load 2 belt holders U ®

using

teeth

the

feed table X @ causes no chat-

the

bolts.

of

the

timing belt into

and feed table

X retainer

X feed

the

feed table

@and

guide@.

the

the

X@

X feed

the

bolts.

Find a

feed table

groove

X@.

to

at

of

CD

32

(

1)

(2)

Put

the

original

Attach

raising it

Y rack

point

the

CD

into

dog ® with it parallel

pulse-motor Y @

lightly so

that

the

frame. Insert

to

the

its backlash becomes 0.

the

to

the

axis.

frame while

Y

Page 35

ASSEMBL V AND ADJUSTMENT PROCEDURE

Push lightly for

adjustment.

®

(3) Push

(4) Attach

(5) Attach

(6) Tighten

the

Y feed guide L @ against

feed table X ®, and tighten.

theY

retainer®

the

Y retainer @ and Y feed guide R @

and move

push

where

and moves smoothly, using

the

feed table X ®

theY

feed

guideR®,

the

feed table Y (f) causes no chattering

the

Y rack

@.

and feed table

the

Q)to

the

the

end

of

the

v(f).

to

the

left. Lightly

and tighten

bolts.

X feed shaft support

at

a point

BJ,

Lower

@------..

shaft

and

relevant

(1) Lay

(2) Put

(3) Engage

(4) Mount

(5) Fit

(6) Return

the

sewing machine down.

the

lower shaft

rear side, and fit it

collar®

and tighten

does

rarily tighten it through

not

the

the

facing

the

lower shaft

the

chatter.

stop

driver@

the

sewing machine

CD

to

the

the

bushing side.

set

collar®

ring@

with

in

the

machine from

ground surface

gear®

on

the

the

with

so

that

the

lower shaft

lower shaft

stop

ring@.

to

its original position.

of

the

swing gear,

the

lower shaft

CD.

the

CD

Tempo-

the

set

33

Page 36

1Dl

Work clamp arm and

~levant

Tightening screws

• For electromagnetic types (For pneumatic types,

(1) Attach

tighten while matching

auxiliary plate with

plate®.

(2) Tighten

(3) Attach

@.

start

from item (10).)

(4) Attach

®

to

the

auxiliary plate

the

the

feed plate @

the

feed table

the

work clamp lifter solenoids R

the

frame.

CD

the

upper surface

to

the

cover@

to

the

frame, and

upper surface

of

the

feed table

to

the

feed table Y

CD

of

needle

Y@.

and L

the

,---@

r---(1)

@--

(J)

(5) Remove the presser

® (6) Fit

(7)

@

(8) Put

--

the

work clamp

feed table

Attach the presser

clamp lifter

Y@

the

plunger pin (j)

wire®,

®.

springs@

arm@

and secure.

springs@

and hold it with

at

.

into

again.

the

the

top

groove

of

the

the

stop ring

in

the

work

34

Page 37

ASSEMBLY AND ADJUSTMENT PROCEDURE

• For pneumatic types

(9) Hold the

®

with

(10)

Fit

the work clamp

feed

table

tip

of

the wire

Y@,

the work clamp

presser

and

V ® ,

arm@

secure.

into the groove in the

and

lifter

tighten.

wire fitting

(11) Attach the cylinder

®.

(12) Attach the cylinder

arm lever C

( 13) Connect the air tube

the left.

@ .

support@

joint

as

illustrated in the Figure to

to the

@to

the work clamp

feed

table Y

Viewed

from

the lower rear side

of

the

machine table

35

Page 38

m

Thread

wiper

Face

plate-----r-1..._11_

r-----<D

<D

(1) Attach the wiper solenoid

CD

to

®.

(2) Temporarily tighten the solenoid

wiper

solenoid

(3)

Attach the thread wiper

spring@,

and

CD.

set

collar

CD

as

crank@,

illustrated.

the solenoid

lever®

to

washer@,

base

the

(4) Lightly

screw

the thread wiper crank.

(5) Hook the

(6)

Fit

wiper

(7) Temporarily tighten the thread wiper

thread wiper

(8) Attach the

push

is

aligned

spring®

the wiper

crank@,

face

the thread wiper

with

the

screw

on

the

screw.

link®

and

crank@.

plate

with

mount the stop

(jJ)

.

crank@

recess,

the pin

on

ring®.

until the

and

tighten

the thread

®to

the

~-®

36

Page 39

ASSEMBLY AND ADJUSTMENT PROCEDURE

(9) Attach the

(10) Adjust

thread wiper

where

(

11)

Turn the pulley

19

mm away from the upper surface

plate.

(

12)

Adjust by putting the thread wiper @ in

until there

needle

needle@.

using

it

stops.

and

threed

the solenoid

@

becomes

so

that

is

clearance

wiper®.

lever

horizontal at the point

needle

of 2 mm

®

so

tip

is

positioned

of

the

between the

that the

needle

and

out

Tip

of

the

shuttle

~@

~

hook

DPX17

(13) Turn the pulley by

lowest position. Align the reference line

needle

(In the

highest reference line.)

Insert the shuttle

(14)

the

at the center

bar

case

driver®

with

of

until the

of

hand

until the

the lowest reference line

the

the

needle

hook@

needle.

tip

DP x 5,

into

of

the shuttle hook

needle

use

the arm. Adjust

(DP

the

is

at the

of

x 17).

second

rests

the

(15) Attach the shuttle

set

the claw. Put the bobbin case@ in the shuttle

hook@.

37

race

ring@

to

the arm,

and

Page 40

1m

Intermittent-presser

foot

(1)

Remove

the

oil cap

CD

on

the

face plate.

(2) Turn

(3) Loosen

(4)

(5) Fit

the

position.

Turn

the

position.

the

align with

porarily tighten

pulley until

the

screw on

pulley until

presser

the

top

the

foot@

end

the

presser foot.

the

needle

presser bar

the

needle

in

the presser

of

the

screw

is

at

the lowest

clamp®.

is

at

the

bar@

head@.

highest

and

Tem-

(6)

Turn

the

pulley until

lowest position

the center of

(7) Press lightly

the needle hole plate, and tighten

presser bar

(8) Attach the oil cap (D.

(9) Attach

foot®.

at

while ensuring the needle rests

the

the

clamp®.

the center of the groove of

hole

top

in

of

the

the

the

needle bar rests

presser foot.

presser

foot@

the

screw on the

the

at

the

at

against

presser

38

Page 41

ASSEMBLY AND ADJUSTMENT PROCEDURE

CD-----...

~·

4.37X8

( 1 ) Attach the upper cover

(2)

Attach the bellows R ®

table rightward

to

the

feed

(3)

Attach the bellow holder R

and

table@.

leftward while tightening them

CD.

and

®and

L@.

Move

L@.

the

feed

(4) Attach the

(5)

Attach the

side

cover R (j).

side

cover

LU@.

39

Page 42

(6) Attach the

side

cover

LD@.

(7) Attach the

(8) Mount the emergency stop

(9) Attach the intermittent

(10) Attach the

using the

bed

large

wave

cover®.

shuttle hook

washer @

switch@.

cover@

cover@

and

stud screw ® .

.

to

the

arm

(11) Lay the

return the sewing machine

(12) Attach the belt cover M

40

sewing

machine down.

to

its original position.

®.

Fit

the V-belt

and

Page 43

ASSEMBLY AND ADJUSTMENT PROCEDURE

{3.57X6)

fi,(j,

®,-----,.

(13) Attach the belt cover

( 14) Attach

.the

belt cover D @ with two

U@.

washers.

(15) Attach the original point

cover@.

screws

and

41

Page 44

STANDARD ADJUSTMENTS

g,

Adjustmen~

of

n•le~bar

heigflt

(1)

Remove

the oil

cap

CD.

DPX5

Lowest position

11

Matching the needle with the tip

~---

~--

Needle bar

Needle bar bushing

Needle bar bushing

of

(2) Turn the pully until the

lowest position.

(3)

Loosen

(4)

Align the

lower

DP

x 17). (For a

reference line).

the shuttle hook

(1)

Turn the pulley

lowest position

with the lower

a

DP x 17

second

the

screw®.

second

end

of

needle). (For a

highest reference I i

lowest reference line with the

the

needle

DP

to

raise

and

align the lowest reference line

end

of

needle

bar bushing (the

x 5

needle,

the

the

needle

DP

ne.)

bar

use

needle

bar bushing (for

x 5

needle,

rests

at the

needle

the highest

bar from the

use

of

the

Tip

of

the

shuttle

hook

DPX17

Center

of

needle

(2)

Loosen

®so

the center

the

set

that the

of

the

screw

tip

of

needle.

CD

and

adjust

the shuttle hook

using

the driver

aligns

with

42

Page 45

Tip

of

the shuttle

hook

Center

of

needle

(1) Turn the pulley

hook

to

align

with

to

allow the

the center

tip

of

the needle.

of

the shuttle

E1

Adjustment

Tip

of

the shuttle

of

Center

the

of

needle

I

i

hook

needle

Tip

of

receiver

the shuttle

hook

of

the

(2) Adjust by loosening the

eccentric shaft

the needle

0.01 mm

to

®so

and

the

0.08 mm.

driver

(1) Align the

the

needle

tip

of

the shuttle hook

by

turning the pulley.

screw

CD

and

turning the

that the clearance between

tip

of

the shuttle hook

with

is

the center

from

of

(2) Lay the

(3)

Loosen the

tric

needle

43

sewing

shaft @

receiver

machine down.

screw®.

so

that the

of

the driver

Adjust by turning the

needle

lightly contacts the

CD

.

eccen-

Page 46

(1)

(2)

(3)

Remove

Loosen

Raise

it

the

the

the auxiliary

toward the operator.

feed

plate

screws®

<D.

.

plate@

and

remove

by

sliding

(4)

Remove

(5) Drive the

guide@

Allow

tighten.

the

the

needle

needle

into both

needle

plate®.

groove

to

of

the shuttle hook thread

sides

of

the

needle

lightly touch the bottom

center.

and

44

Page 47

DJ

A,~jJJ$tm,ent

of

tb!3

_wort<

c.laRJp

STANDARD ADJUSTMENTS

lift

(1) Loosen the

@until

work clamp

the arm, when the work clamp lifter plate

<To

set the work clamp

( 1 ) Loosen the

that there

clamp lifter plate

left) when the holder

nut®

there

lifter

screws

is

a clearance

and

adjust the adjusting screw

is

a clearance

plate

CD

and

lift

to

a maximum

@ (right and left)

of

1 mm between the

CD

and

lever

is

lowered.

of

2 mm between the

the lower surface

plate®

is

of

20

and

adjust

(right and

of

raised.

mm:>

so

work

fJ

Adj~stment

of the moving blade

5-6mm

@

(2)

If

the clearance

(3) Loosen the

solenoid

part

(1) Set the

(2) Loosen the screw

trimming connecting lever

groove

CD

side

becomes 5 to

sewing_machine

edge

is

even

is

screws@

until the wire

®

with

the

greater, the

and

6 mm.

in the stop position.

®

and

of

the shuttle hook thread guide

tip

of

lift

is

reduced.

pull the wire tube on the

of

the

presser

adjust using the thread

@

so

the moving

that

the needle

blade®.

arm

lever

45

Page 48

• Replacement

of

the

moving and fixed blades

( 1 ) Remove

the

feed plate

CD

.

(2) Loosen

(3) Raise

(4) Remove

(5) Remove

the

it toward

the

new one.

the

screws®.

auxiliary

the

the

needle

the

plate®

operator.

plate@.

moving

and remove by sliding

blade@

and replace it with

~@

®

~

Do

notpro!QJ@

leftward

from

here.

(6) Remove

new one. Ensure

between

fixed blade

the

leftward from

(7)

Reassemble

ing

46

the

the

tip

of

the

disassembly steps.

fixed

blade®

that

needle hole plate (j) and

®after

the

fixed blade ® does

the

end

the

moving and fixed blades

and replace it with the·

there

is

a clearance

replacement. Make sure

of

the

needle-hole plate (j).

not

of

1

mm

the

new

that

protrude

by

revers-

Page 49

STANDARD ADJUSTMENTS

(1)

Turn the pulley until the presser foot

lowest position.

(2)

Loosen the screw

the

where

lightly contacts the material

(3)

Turn the pulley and make sure

enters

(4)

If

the

presser foot, remove

screw@,

lower surface

the

center of the presser foot.

needle does not enter the center of

and turn

<D.

Retighten it

the

the

presser

of

the presser

to

be sewn:

oil

cap@,

bar@

at

that

to

is

at the

a position

foot®

the

needle

the

loosen

adjust.

the

I]

Adjustment

of

the intermittent-presser foQt

Standard lilt 3.5mm

L~~:ta

®

CD

lift

o The standard I ift

~

t

<To

change the standard lift:>

1)

Loosen the nut

(

the

feed connecting

\lncrea~

S Decrease

lowering the set position decreases

(2)

Remove the face

of

the presser foot

<D.

Raising the set position

rod®

plate@.

is

increases the lift;

the

3.5 mm.

of

lift.

47

Page 50

(3) Turn

the

position. Loosen

pulley until

the

the

presser bar

intermittent feed arm L

is

at

its lowest

@.

1m

Adjustment

--,~~------.'-#---@

'------®

of

the

tbread

wiper

(j)

(4) Ensure that there

bar clamp

bar

kept touching

Tighten

(

1)

Adjust

® so

stop position.

(j) I intermittent

bushing@,

the

the

intermittent feed arm L

the

thread wiper

that

the

is

no clearance among

stopper®

with

the

intermittent

intermittent stopper

CD

with

the

wiper becomes horizontal

the

I and presser

support@

support@.

@.

solenoid lever

presser

at

the

e.:-_;:::-·

\

.\

·~

@____)'-

<D

<D

2mm

®

(2) Actuate

wiper with

of

CD

thread wiper does

At

the

approximately 2 mm from

48

the

the

approximately 2

and the tip

the

same time, ensure

front the tip

thread wiper

screw@

mm

of

the needle. Make sure

not

of

the

CD.

so

that

between

strike

the

that

thread wiper

the

center

Adjust

there

presser

when viewed from

the

is

a clearance

the

thread wiper

foot@.

CD

protrudes

of

the

thread

that

the

needle.

Page 51

m

Adjustment

of the

needle-$top

position

an_~:-~

tifTiing:

STANDARD ADJUSTMENTS

. i

Needle

19mm

top

position

Material

Needle stop

position

raises.

Direction

of

rotation

(1) Remove

(2) Adjust

®so

mm

plate.

stop position; counterclockwise,

the

cover

the

needle-stop position with

that

the

away from

Turning

CD

of

needle tip comes

the

upper surface

the

element®

the

synchronizer.

lowers it.

the

element

to

a stop 19

of

clockwise raises

the

......

20

needle

Needle

_[I

top

position

LBF

Direction

of

rotation

..

...

stop position

lowers.

eeong

d.

No

feed

(3)

Adjust

element @ so

needle has come

and stops before

Note: For thicker material, increasing

timing speed reduces

sewing performance.

the

timing

that

of

the needle and feed with

feed starts working after

out

of

the

material being sewn

the

needle touches

needle flow and improves

the

the

the

material.

the

feed

~atch

The element ® coincides

with

the

magnet@

take-up

thread

tion.

top

at

posi·

the

49

Page 52

J$

Adjustment

of

the original point

(1) Remove the feed plate

(2)

Attach

original

the original -

point

is

in

the center on the operator side.

point

CD

.

reference plate

®.

The

Q)-------

Orig

inal point

(X-O·Y.Q

)

<

Adjustment

(1) Remove

(2) Remove the bellow L ® .

(3) Switch

(4)

Press

(5) Move the

reference plate

(6) Loosen

aligned

by

moving the X original

and

<

Adjustment

(1) Remove the

(2) Switch the sewing machine ON.

(3)

Press

(4) Move

reference plate

(5) Loosen

point

needle

of

X axis>

the bellow

the

sewing machine

the

[E] key on the programmer.

needle

th

e screws ®

with

the original point.

leftward.

of

Y axis>

original-

the [E) key on the programmer.

the

needle

the hexagonal

dog ® forward and backward

tip

aligns

holder LG).

tip

by

turning

point

tip

by

turning

with

the

ON.

toward

the

so

that

point

cover

toward

the

bolt

® . Move

original

the

pulley.

the needle

Adjust

dog @ rightward

eD.

the

pulley.

point

original-point

tip

is

the X axis

original-

the

.

point

original-

until

the

50

Page 53

Tension gauge

Approx.

~mm

e:-

420g

±11

r----®

(3)

Loosen

with

(4)

Ensure

imately 4 mm

imately

STANDARD ADJUSTMENTS

the

nut @ and

the adjusting screw @ .

that the timing belt

at

420

g.

screw@.

the center under a load

Make adjustment

is

deflected

by

of

approxapprox-

Ill

.

Adjustment

<D---

of

the

upper

thread

release

timing

(

1)

Remove

(2) Turn the pulley while pushing the main

clamp solenoid

the

take-up@

with

upper thread

the upper cover

®.

work

clamp

the upper thread

lifter

at the lowest position. Then, adjust

loosens.

Place

cam@

~

CD.

the

feed

release

cam

and

keep the thread

lever®

roller

until the

work

@on

51

Page 54

lEI

Adjustment

of

.the

,backlash

<Lower

(1)

(2) Loosen

shaft>

Lay

the

®

to

0.07 mm

sewing machine down.

the

screw

CD

and turn

adjust

at

the

backlash. Provide a play of

the

top

of

the

the

driver®.

swing gear shaft

0.04-

l.

(5X10) fiP

<Longitudinal

(1)

Loosen the bolts

motor

between the drive gear and theY-rack shaft.

..

~.~:""'llii.,_

Lift

it

up

slightly.

---®

<Traverse feed>

(

1)

Loosen the bolts

motor

between

52

feed>

CD

and slightly raise

® . Adjust so

X®.

Adjust so

the

drive gear ® and the idle gear

that

no backlash remains

CD

and slightly raise the pulse-

that

there

the

is

no backlash

@.

pulse-

Page 55

STANDARD ADJUSTMENTS

lm.~

Adjqstmeqt

Qf

0.5mm

1he

(])~

®---¥

ml

~djt~.~ent

of

the.

thread

work

c_lamp·

..

trirnming,t:aro

CD

lifter

ba~

(

1)

Adjust with the thread trimming

there

shaft

CD

is a clearance

and

the thread trimming

of

0.5

P9'ition

(1) Attach the work clamp lifter

ing

that there

work clamp lifter

@.

is a clearance

cam

®and

cam

mm

between the roller

cam®.

base

CD

while

of

0.5

mm

between the

feed

cam

roller shaft

11

®until

ensur-

53

Page 56

HOW

TO MAKE UP THE PRESSER

e The presser

The

maximum

• Clamping

Type

~

How

to

is

available in

sewing

Work

clamp

two

range

types; clamping

is

100 ( L) x 120

Work

(Single

clamp

type)

type

and cassette type.

(W)

mm.

v~l

Feed plate

make up the clamping type presser

• Cassette

Cl

amp

1.

How

Type

spring~

~

~

to

make up

the

:7

~""

work

-

Cassette clamp

·

~

Cassette cl

clamp blank

<OpPOrt

amp

assembly

Presser

Feed

foot

plate

-----

D/2 +

1-1

.5

D/2

mm

~-

+ 1-1.5

Work

,--

Feed plate

Work

Sewing

clamp

(One-piece

(The

threads along.)

clamp

position

needle

mm

type)

2.

Cut

out the

si

ze

is

presser

D:

How

wor

wider

than a sewing

foot

diameter + 1-1.5 mm

Diameter

to

make up

k clamp blank

of

the

top

end

the

feed plate blank

posit

of

so

that

the

ion

by

(half

).

the presser

cutout

of

the

foot

Cut

out

the feed plate blank 1-1.5

ng

the

case

I

I

I

I

I

I

I

I

L

l...

_-_-_-_-_-_-_-l

~

1-1.5

1-1.5

Sewing

position

mm

mm

the sewi

In

required on

54

position.

of

the

both sid

mm

left

figure, 1-1.5 mm margin

es

of

the

sewing position.

apart

from

is

Page 57

Work

clamp

(Standard) \

OT

clamp

asse mbly

3. How

(

1)

(2) Bond a

to

make

Cut

out

contour

around

material

up

the

the

of

a material

paper

the

cut-out

to

be

plastic presser

plastic pla

to

cushion

part

sewn.

te

according

be

sewn.

material

to

secure ly press a

or

to

the

the

like

fl

How

Feed plate blan k

to

make up the cassette type presser

~

Hin

g e

s

Cassette pl

ate

U

(3) Make

*

Th

e cassette

plate

in

the left

(1)

item

U,

Cut

up

"2.

cassette

figure.

out

the

ting dimensions, refer

make

up

the

* Making up

nately

w

the

feed

plate

How

to

make

type

presser

plate

D,

cassette plates U

clamping

two

cassettes

blank

upthefeedplateblank."

is

composed

and

to

type

by

hinges as illustrated

and

section

presser."

to

use them al

ill increase work efficiency.

referring

of

a cassette

D.

For

"1.

How

to

cut-

to

ter

-

Cassette

\_

clamp

assembly

Cassette

Casse

Lower cassette plate (Plastic plat

tte

plat

plate

e D-A

D-B

(I

ron)

(2) Bond a

aro

material

*

The

cassette

und

paper

the

to

be

plate

cushion

cut-out

part

sewn.

D is available

material

to

or

secure ly press a

in

two

the

like

types; D-A

and D-B.

* Use

the

cassette

the

D-A,

except

must

be

bonded

mounting

a

counters

eter

hinges

countersunk

plastic plate.

unk

plate

that

on

on

screw

hole

D-B

a plastic

the

back

the

cassette

M3 into

prior

with

of

the

plate

the D-B.

plate

the

4.6

to

Co

unt

same

way as

or

the

D-B, insert

mm

bonding

ersunk

screw M3

like

When

diam

the

-

I

~

e)

Lower cassette plate

Bond

55

Page 58

I

Work

clamp

Work clamp blank B·1R

Work chimp blank 8·1 L

Work clamp blank B·3R

Work clamp blank

blank

BolL

I

t3.2

t4

153448-000

153449-000

153470-000

153471-000

DDI·

50+--1

Work clamp blank 1·3R

Work clump blank 1-3L

Work clamp blank 1-4R

Work clamp blank 1-4L

Work clamp blank 1-5R

Work damp blank 1·5L 502826-000

t3.2

t4

t5

502821-000

502822-000

502823-000

502824-000

502825-000

Work clamp blank 2·3R

Work chimp blank

Work clamp blank 2-4R

Work clamp blank

~ork

clamp blank 2·5R

Work clamp blank

2·3L

2-4L

2·5L

t3.2

t4

t5

502827-000

502828-000

502829-000

502830-000

502831-000

502832-000

Work clamp blank 3·3

Work clamp blank 3-4

Work clamp blank 3·5

Back

T

11

....__

___

1--150~

I

Feed

plate

___,

1

blank

Feed

plate blank 1

Work clamp blank 5·3

W~rk

Work clamp blank 5-5

clamp blank 5-4

Work clomp blank 4·3

Work clamp blank 4-4

Work

clamp blank 4·5

r~

l 1

1--170--j

Feed

plate blank 2

Feed

plate blank 3

T

156

I

Feed

plate blank 4

56

I

Feed

plate blank 5

Page 59

Cassette clamp j

Cassette clamp 1 A

Cassette clamp 1 L

[ni

106

Cassette clamp

Cassette

I Clamp spring I

clamp

2R

2L

70-11

82--1

crr·~

10

10-t

1

82~

Cassette clamp

Cassette

clamp

3R

3 L

Cassette clamp

Cassette clamp

Cassette support

assembly(t3.2)

502963-001

Lower cassette plate

A(t1)

502969-000

B (

t2)

502970-000

4R

4L

236~

~\&,

~

t0.4

I Clamp spring 1 I 502853-00 I I I Clamp spring

OTclamp

assembly A

(t0.5)

t2)

503902-001

503904-001

8 ( t 1 ) 503903-001

c (

~~

Cassette plate U-A ( t

-152632-001

1)

B(t2)

Hinge, right

502968-000

502971-000

t 0.6

21

502854-00 I I I Clamp spring 3 I 502855-00 I l

~~~~~~amp

Cossette plate U·A

Hinge, left

Hinge, right

Cassette plate D·A

t 0.8

A

502959-001

502968-000

152633-001

152632-001

502966-001

Cassette plate D-A(t1)

502966-001

I Presser

foot

I

Presser foot L

502469-001

Presser foot R

502441-001

57

~::'~~,,!=lamp

Cassette plate U·B

Hinge, left

Hinge, rigtlt

cassette

B

plate D·A

Presser foot

505667-001

502960-001

502971-000

152633-001

152632-001

502966-001

MM

Page 60

D

Description

ADJUSTMENT

OF

ELECTRIC APPLIANCES

on

fuse

1. Position

Open

the front.

the control box cover.

of

fuse

Control

box

At

the upper left

---f---

is

the

fuse

holder

having

three

fuses,

when viewed from

2. Fuse capacity

No.

1

2

3

I

i

. ®

I®~®

~®~&

&A

~

(4X10)

Type and capacity

Cylindrical fuse:

Glass

tube fuse:

Glass

tube fuse:

of

fuses

5A-500V

15A-125V

15A-125V

For AC

For pulse

For

and brake

input

pulse

Remarks

motor

motor, solenoid,

of

sewing machine

and

motor

clutch

58

Page 61

3. Countermeasures when a fuse blows

For

your

reference, the following table shows phenomena when a fuse blows.

the

same

capacity

as

that

of

the blown

one.

Be

sure

to

use

a fuse

with

Fuse No.

0

No power lamp lights

o The low

o

The

o No presser opens

o

The

of

presser

low

motor.

torque

torque

measurement

6

1

2

3

Voltage

The following figures show where

1. Check

Measure

for

control voltage +5V, + 12V and

voltage

with

a tester· between check pins on the PCB;

CH4

CH3

CH2

0 0 0 0

-12V

+12V ±OV

Trouble encountered when a fuse blows

or

works.

of

pulse

motor

causes the distorted

is

easily moved by hand even when

or

closes.

of

pulse

motor

causes feed malfunction only with noisy sound

to

measure

voltage on the

-12V

CH

1

+5V

the

PCB

or

dislocated patterns.

motor

is

energized.

and

connectors.

CH

1-CH2,

CH2-CH4

Reference page

and

CH2-CH3.

78 (#2)

80 (#7)

79 (#5)

Check list 1

SV

DC±

C H I

C

H4EB-

C H

ffi-

2EB-

C H

C H

C H

28

28

38

12V

59

0.25V, acceptable

DC±

O.SV,

acceptable

Page 62

2. Check

( 1 )

for

drive voltages

Remove

VL

and

the connector P 1 .

VH

I]·

On

(2)

Note:

lffi-38

2®-38

...

LEOs.

the

Measure

wire

side

Use

on

:PCB

PCB

are

drive voltages

of

the connector

a tester probe

Check list 2

Approximately

Approximately 1

eight LED lamps by which the operator

VL

on

and

P1

using a tester.

the

side

44 V DC,

OV

DC, acceptable

VH

on the

of

the lead.

acceptable

lead

can

D

monitor

(Viewed

control

7 6

8 9

from

signals.

3 2 1

5 4

13

In

11

12

10

-

the lead wire side)

1.

Monitoring solenoid

The

LE

Ds

noid

is

turned ON.

LED 1:

LED 2:

LED3:

LED4:

LED 5: Left

output

1 through 6 light when

Right

side

of

presser

Presser

Thread wiper

Main

foot

presser

side

of

presser

o

o o

oD

oD

each

iU

·oooo

sole-

0

CJ

2.

000000

Monitoring

LED 7

LED 8 for brake:

LED7

LEOS

output

for

clutch:

Lights while the

rotating.

Lights momentarily when the sewing

machine

panied by a braking sound.

of

brakes and clutches

sewing

comes

to

a stop, accom-

machine

is

LED6:

Thread trimming

60

Page 63

El

How

1.

Changing

movement

to

use

the

DIP sWitch

selectors 1 through 3

of

the

presser.

of

DIP switch

CD

located on the lower

Turn

the power

then open the

off

and

control

ADJUSTMENT

left

box.

OF

of

the control

ELECTRIC APPLIANCES

PCB

varies

the

The presser

OFF

ON

:~

is

automatically raised after sewing.

····································

OFF

:1

Raise

the presser by pressing the work clamp lifter pedal

after sewing.

Pressing the work

presser@,

ously.

To lower them, turn the switches

low. (The work clamp lifter

stage switch.)

1st stage switch

2nd stage switch 0

1st stage switch

2nd stage switch

clamp lifter pedal ® raises the right

left

presser@,

ON

-the

N-

the right presser @ and presser

foot

ON

-the

ON-

the left presser @ and presser

foot

ON

n

and presser

pedal®

left

presser@

@ lower.

right

@ lower.

foot@

is

presser@

ON

designed

lowers.

simultane-

as

shown

lowers.

be-

as a 2-

1st stage switch

2nd stage switch

61

ON

ON

-the

-the

right presser @ and left pres-

ser@

lower.

presser foot @lowers.

Page 64

2. Selector 4

of

DIP switch

CD

is

used for selecting

the

electromagnetic

type

or

pneumatic type.

3.

Selectors 5 through 8

The

sewing machine

(the thread trimming speed).

The sewing machine turns within a speed range

1500

spm.

OFF

~~

For electromagnetic

of

DIP

OFF

;

7

8

OFF

;

7

8

ON

~;i~i~i~i~i~i

=~=~=~=~=~=~

~=~=~=~=~=~=

turns

at

ON

~==~=~=~{:

·~=r=~=~=~=

=~=~=~=~=~==

:::::~:~::::

type

switch

CD

approximately

serve

as

230

of

the

spm

550-

test

switch for

The sewing machine turns within a speed range of

1200

volume

The

2000

For pneumatic type

the

sewing machine motor.

OFF

:

~;i~i~i~i~i~~

7

8

spm. The speed may be changed

on

the

panel.

OFF

5

6

7

·1

8

sewing machine turns within a speed range

spm.

ON

ON

~=~=~=~:::::

=~=~=~=~::::

with

the

ON

t=~=~=~=i

:f~=~=~=~

r~

:i:~:i:i:i:

of

400--

speed

850-

Selectors 5 through 8 are provided solely for testing

OFF when

the

sewing machine

is

in

normal use.

the

sewing machine controls.

Be

sure

to

set

all

of

them

62

Page 65

II

Deseriptian

Most

of

the sewing machine failures

faulty contact. Check

contact

with

of

,each

each

wire before troubleshooting. For

connector

to

make

resulting from connector failures.

*For

the connector No., refer

to

are

due

to

connector problems

sure

that

each

connector

your

is

properly inserted

reference, the following table

the control circuit block diagram

ADJUSTMENT

such

as

on

page

OF

ELECTRIC APPLIANCES

improperly inserted connectors

and

each

pin

comes

shows

in proper

the symptoms

70.

and

Connector No.

p 1

J 1

P2

J 2

I

J

27

P27

P3

J 3

I

J

28

P28

P4

J 4

I

J

29

P29

Connection

Power

supply

t

PCB

PCB

t

Each

solenoid

PCB

t

X pulse

motor

PCB

t

Y pulse

motor

signal

Main

+ 5

V, + 12V,

Drive

voltage

Solenoid drive power

supply

Pulse-motor

supply

Pulse-motor

supply

+44

+

-12V

V

y

10

drive power

drive power

Phenomenon resulting

Abnormal motion

o

o No motion

o

Malfunction

wiper parts, main

ming parts.

o Disorder in X direction.

Abnormal sound

o

o Disorder in Y direction.

o

Abnormal noise

from

of

presser,

presser,

from

from Y pulse

improper contact

presser

X pulse-motor.

and

foot,

thread

motor

thread

trim-

P5

J 5

I

J

30

P30

P6

J 6

I

J

21

P21

P7

J 7

P8

J 8

I

J

25

P25

PCB

t

Brakes and clutches

PCB

t

Synchronizer

PCB

t

Switch panel

PCB

t

Programmer

Sewing

and

machine starting

stopping currents

+5V

Needle

top

position,

synchronizing, and rotation

signals

+5V

Speed

volume signal

Key switch signal

Display signal

o Abnormal rotation

o Poor stop

o The sewing machine turns at high

stops. (The emergency stop lamp lights.)

o The mechanism does

needle

o The sewing machine turns

mechanism

o The power

o

Even

the sewing machine

stant

o Malfunction

of

top

position.

does

lamp

though the

speed

of

of

sewing machine

sewing machine

not

not

work.

does

not

light.

speed

volume

keeps

2000

spm.

of

programmer

speed

stop

above

but

turning at a con-

and

the

the feed

is

turned,

63

Page 66

Connector No.

Connection Main

signal

Phenomenon resulting from improper

contact

P9

J 9

I

J

26

P26

P10

J

10

I

J

24

P24

Pll

Jll

I

J

23